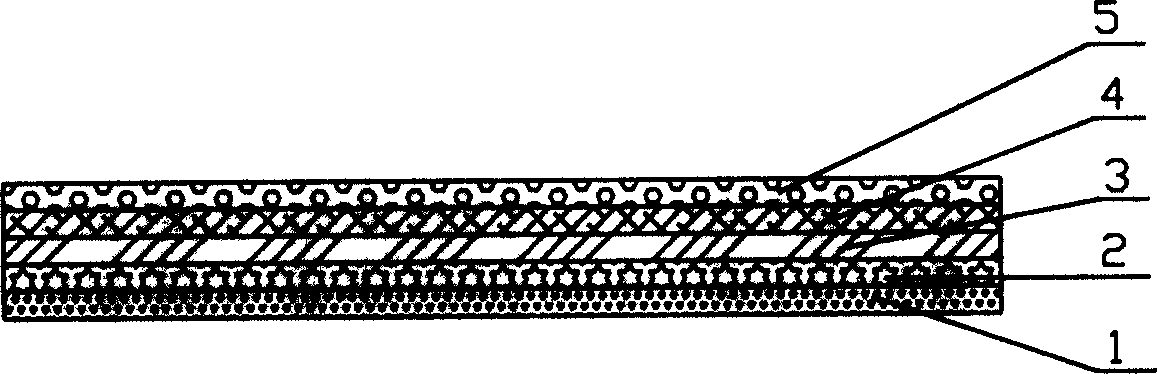

Composite water-proof coiled material and construction method by employing same

A waterproofing membrane and construction method technology, applied in chemical instruments and methods, building insulation materials, building components, etc., can solve the problems of construction period, construction cost impact, invisible damage of waterproof layer, wet base surface and other problems, and achieve Low flatness and dryness requirements, good elasticity and deformation ability, and the effect of simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method for constructing a roof waterproof layer using the composite waterproof coiled material provided by the present invention adopts a wet laying method, and its specific construction steps are:

[0064] 1) laying the base, the steps of laying the base include: a, concrete roof cushion; b, construction preparation; c, base inspection, acceptance;

[0065] 2) Wet paving pretreatment on the base surface, that is, plastering cement mortar or pouring concrete, and leveling;

[0066] 3) Wet-laying the composite waterproof membrane, the step of laying the composite waterproof membrane is wet-laying the large-surface membrane, and rolling while laying is flat;

[0067] 4) After the initial setting of the wet cement mortar or concrete, uncover the release paper on the edge of the composite waterproof membrane to expose the self-adhesive layer;

[0068] 5) Paste the pre-prepared lapping tape on the interface of the two coils, and seal the seams of the butt joint coils.

...

Embodiment 2

[0077] A construction method for the basement floor waterproof layer using the composite waterproof coiled material provided by the present invention adopts the pre-paving method, and its specific construction steps are:

[0078] 1) laying the base layer, the steps of laying the base layer include: a, concrete cushion; b, construction preparation; c, base inspection, acceptance;

[0079] 2) The surface of the base layer is pre-paved, that is, first apply the base treatment agent, and then paste the additional layer on the nodes and special parts, or directly paste the additional layer without applying the base treatment agent;

[0080] 3) pre-laying the composite waterproof membrane, the steps of laying the composite waterproof membrane are firstly positioning, springing the thread, and then sticking and laying the large-surface membrane, while laying and rolling to make it flat;

[0081] 4) Laying the structural waterproof layer means pouring concrete after binding steel bars...

Embodiment 3

[0090] A construction method for the basement side wall waterproof layer using the composite waterproof coiled material provided by the present invention, using the pre-paving method:

[0091] 1) Cut the coiled material to be the same size as the wooden formwork used for construction;

[0092] 2) Fix the coiled material (or the coiled material pre-cut in the factory according to the size) to the formwork with double-capped nails as the fixing parts, so that the bonding layer of the coiled material faces the concrete surface;

[0093] 3) Install formwork and pour concrete;

[0094] 4) Remove the formwork;

[0095] 5) Uncover the release paper at the seam of the coil, apply hot-melt sealant, and then seal the nail hole;

[0096] 6) Post-processing, that is, laying a protective layer.

[0097] The construction points are:

[0098] 1) The waterproof layer construction of the side wall of the basement shall be constructed by a waterproof professional team;

[0099] 2) The coil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com