Preparation and application method for polyurethane modified acrylate water repellent

An acrylic ester and polyurethane modification technology, which is applied in the field of polymers, can solve the problems of reducing fabric light fastness, poor biodegradability, stimulation, etc., and achieve good effect uniformity, small fabric damage, and low finishing temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

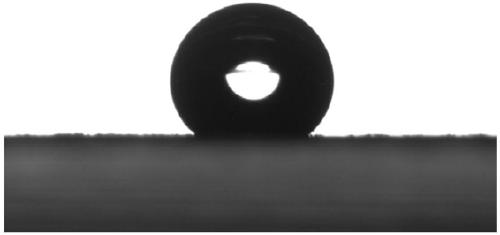

Image

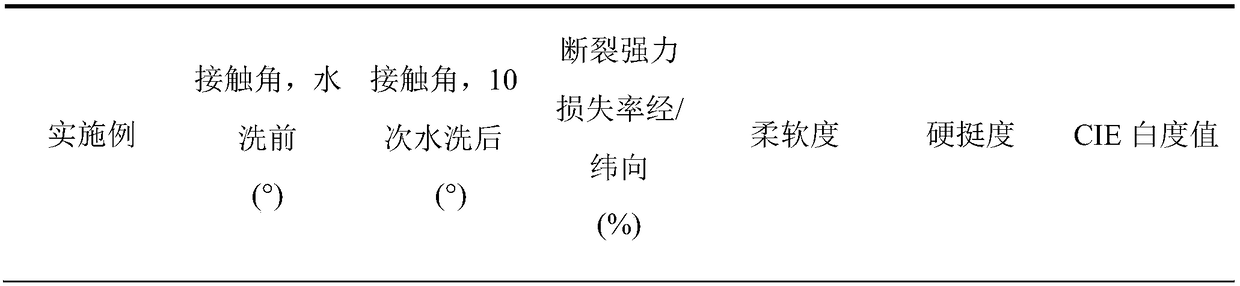

Examples

Embodiment 1

[0028] Prepare the anionic polyurethane modified acrylate water repellent and finish the fabric according to the following steps:

[0029](1) Prepare the water-based polyurethane with double bonds at the end: polyoxypropylene diol (molecular weight 400), 50% dimethylol propionic acid (the total mass of dimethylol propionic acid in this embodiment accounts for diisocyanate, poly Propylene oxide diol, 3% of the total mass of dimethylol propionic acid) and dibutyltin dilaurate (accounting for 0.1% of the total monomer mass participating in the reaction) are vacuum dehydrated and dried and then added toluene diisocyanate under nitrogen protection, -NCO / -OH molar ratio is 1.1:1, keep warm at 50°C for 4h; then add remaining dimethylolpropionic acid and dibutyltin dilaurate dissolved in ethyl acetate, react at 70°C for 1h; add hydroxyethyl acrylate ( Accounting for 6% of the mass of the total monomers participating in the reaction), capping at 50°C for 6h; adding N,N-dimethylethanol...

Embodiment 2

[0033] Prepare the anionic polyurethane modified acrylate water repellent and finish the fabric according to the following steps:

[0034] (1) Preparation of water-based polyurethane with double bonds at the end: polyoxyethylene glycol (molecular weight 200), 20% 1,2-dihydroxy-3-propanesulfonate sodium (accounting for diisocyanate, polyoxyethylene glycol, 1 , 5.4% of the total mass of sodium 2-dihydroxy-3-propanesulfonate) and dibutyltin dilaurate (accounting for 0.1% of the total mass of monomers involved in the reaction) were vacuum dehydrated and dried, and then added 1,6-hexyl Diisocyanate, -NCO / -OH molar ratio is 2:1, keep warm at 65°C for 2.5h; then add the remaining sodium 1,2-dihydroxy-3-propanesulfonate and dibutyltin dilaurate dissolved in butanone , reacted at 50°C for 3h; added hydroxyethyl methacrylate (accounting for 14% of the total monomer mass participating in the reaction), and capped at 60°C for 5h; added triethanolamine (accounting for 2% of the total monom...

Embodiment 3

[0038] Prepare the anionic polyurethane modified acrylate water repellent and finish the fabric according to the following steps:

[0039] (1) Prepare the water-based polyurethane with double bonds at the end: polytetrahydrofuran diol (molecular weight 850), 80% dimethylol butyric acid (accounting for 4.5% of the total mass of diisocyanate, polytetrahydrofuran diol, and dimethylol butyric acid) %) and dibutyltin dilaurate (accounting for 0.1% of the total monomer mass participating in the reaction) are vacuum dehydrated and dried, and then added isophorone diisocyanate under nitrogen protection, the -NCO / -OH molar ratio is 1.3:1, 60°C Insulate for 3h; then add the remaining dimethylolbutyric acid dissolved in acetone (and dibutyltin dilaurate, react at 75°C for 1.5h; add hydroxyethyl acrylate (accounting for 8% of the total monomer mass participating in the reaction), 65 Capping at ℃ for 4 hours; adding triethylamine (accounting for 3% of the total monomer mass involved in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com