Patents

Literature

217results about How to "High bond strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Starch-based wood adhesive and preparation method and application thereof

ActiveCN102031078AImprove storage stabilityHigh bond strengthGraft polymer adhesivesButyl acrylateBonding strength

The invention provides a starch-based wood adhesive and a preparation method and application thereof, and belongs to the technical field of adhesive. In the invention, a starch adhesive for woods with good property is prepared by performing acidolysis and gelatinization on starch serving as raw materials, grafting, copolymerizing and modifying the starch by using two monomers of vinylacetate and butyl acrylate under the condition of adding an emulsifier, and adding an accessory ingredient after lowering the temperature. The adhesive prepared by the preparation method has the advantages of good preservation stability, high bonding strength, milky white and glossy color and the like, and can be applied to decoration of woods and bonding of artificial plates and glued plates.

Owner:JIANGNAN UNIV

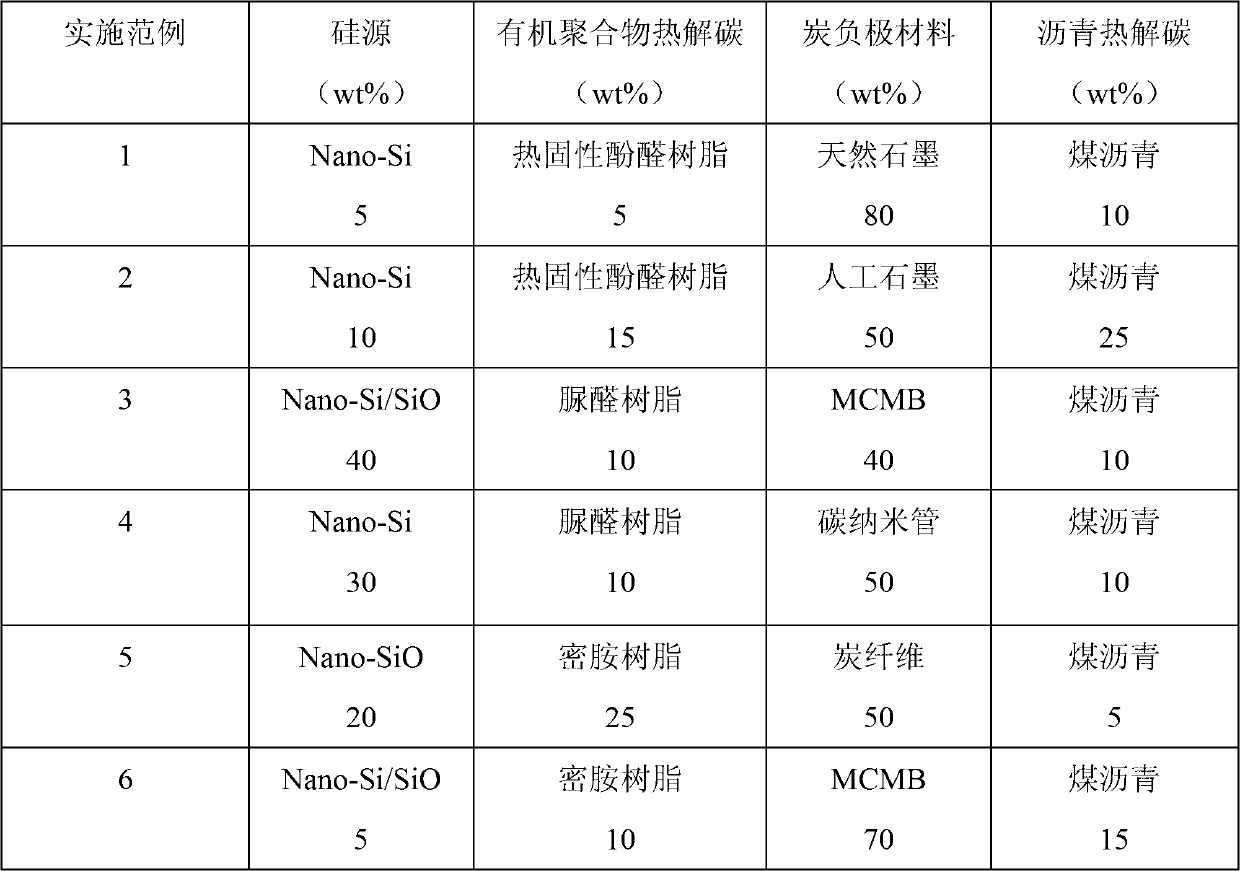

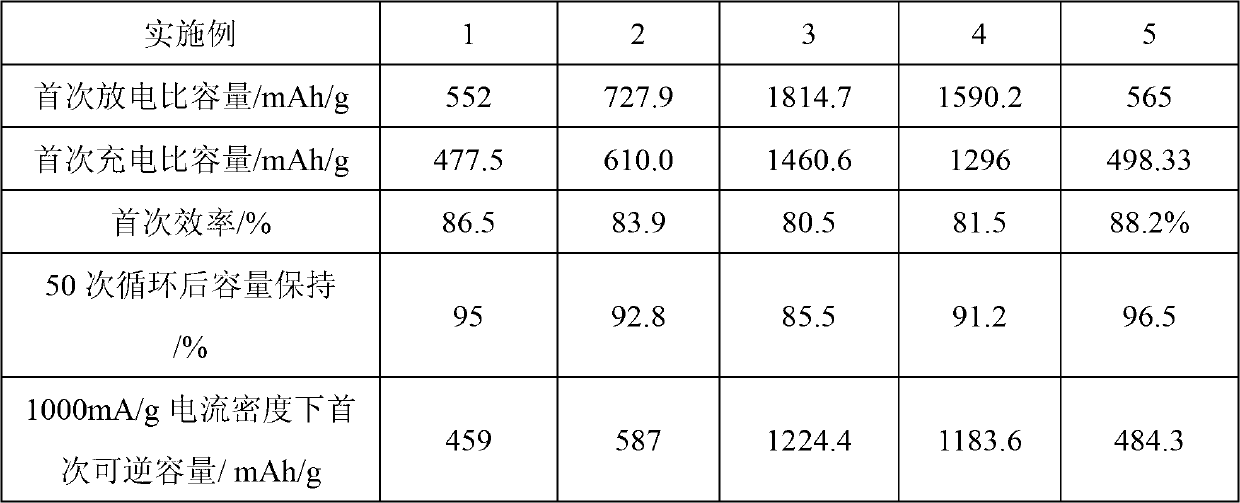

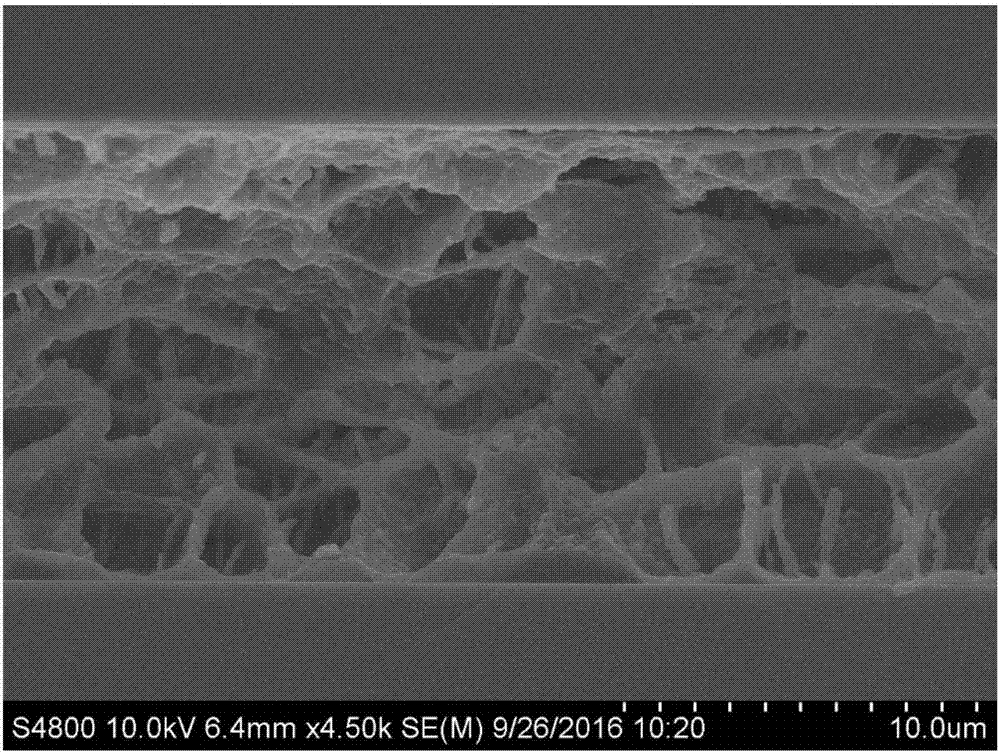

Multi-core core-shell-structure silicon carbon composite negative pole material and preparation method thereof

The invention relates to a multi-core core-shell-structure silicon carbon composite negative pole material and a preparation method thereof. The preparation method comprises the following steps: 1. preparation method of high-dispersivity multi-core porous spheres; 2. preparation of high-dispersivity asphalt suspension; and 3. preparation of multi-core core-shell-structure silicon carbon composite negative pole material: adding the porous spheres prepared in the step 1 into the high-dispersivity asphalt suspension prepared in the step 2, carrying out ultrasonic dispersion, heating and drying by distillation while intensely stirring to remove the solvent, transferring the powder particles into a protective atmosphere, and holding at low temperature so that the asphalt liquid enters the inside of the porous spheres to enhance the binding strength between the silicon source and the conducting carbon mesh, carry out secondary coating on the silicon source, overcome the defects in the coating in the step 1 and enhance the capacity performance of the silicon; and carrying out high-heat treatment. The invention is simple and easy to implement, and has the advantage of high practicality. The prepared silicon carbon composite material has the advantages of high reversible capacity, designable capacity, favorable cycle performance, favorable heavy-current discharge capacity, high tap density and the like.

Owner:CENT SOUTH UNIV

Adhesive, its preparation method and application method

ActiveCN102417804AHigh bond strengthImprove appearance performanceLaminationLamination apparatusSteel platesChemistry

The invention provides an adhesive, its preparation method and an application method. The adhesive contains a resin ingredient and a cured ingredient, wherein the resin ingredient contains a main resin, a flexibilizer and a filling material. The main resin contains a first epoxy resin and a second epoxy resin, wherein epoxy equivalent of the first epoxy resin is 150-300 and softening point of the second epoxy resin is 65-100 DEG C. The cured ingredient contains a normal-temperature curing agent. After the adhesive is coated on the surface of steel plates, the bonding strength between the steel plates is very high without the need of spot welding or riveting.

Owner:BYD CO LTD

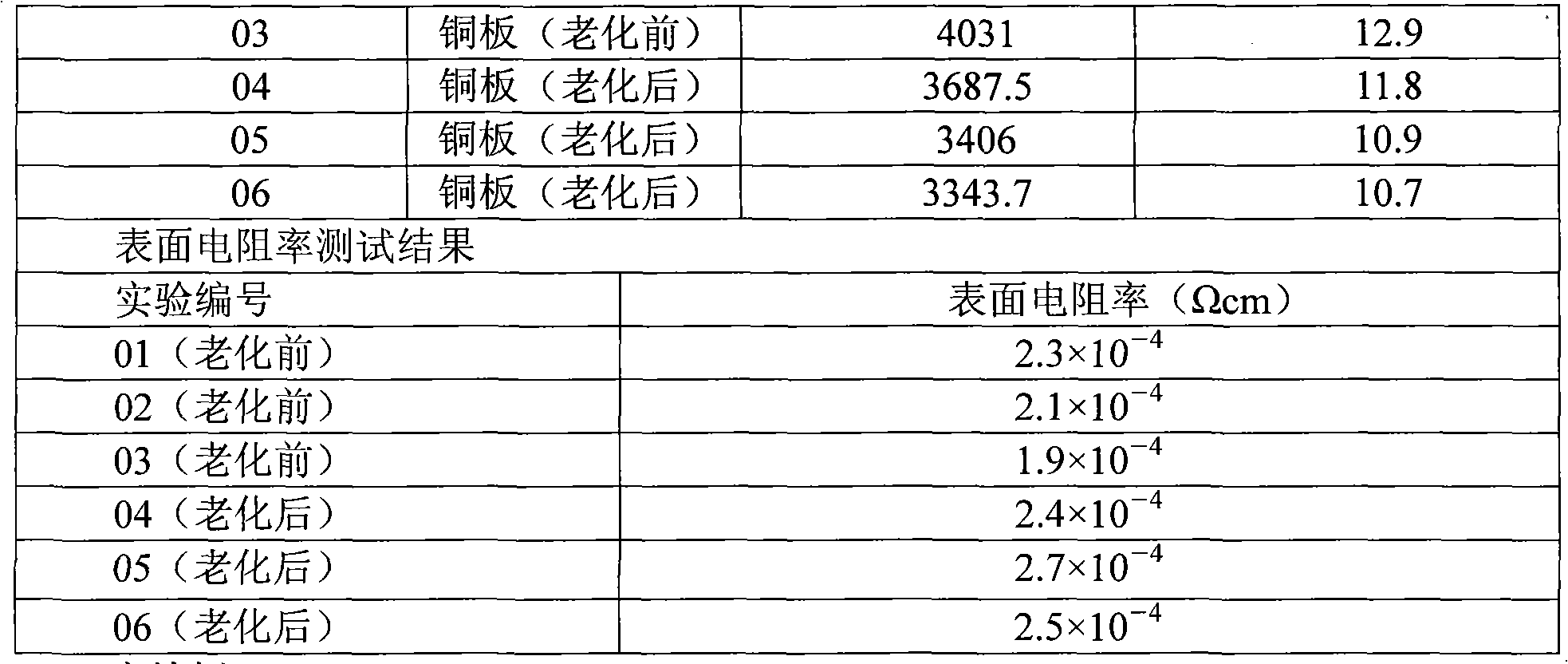

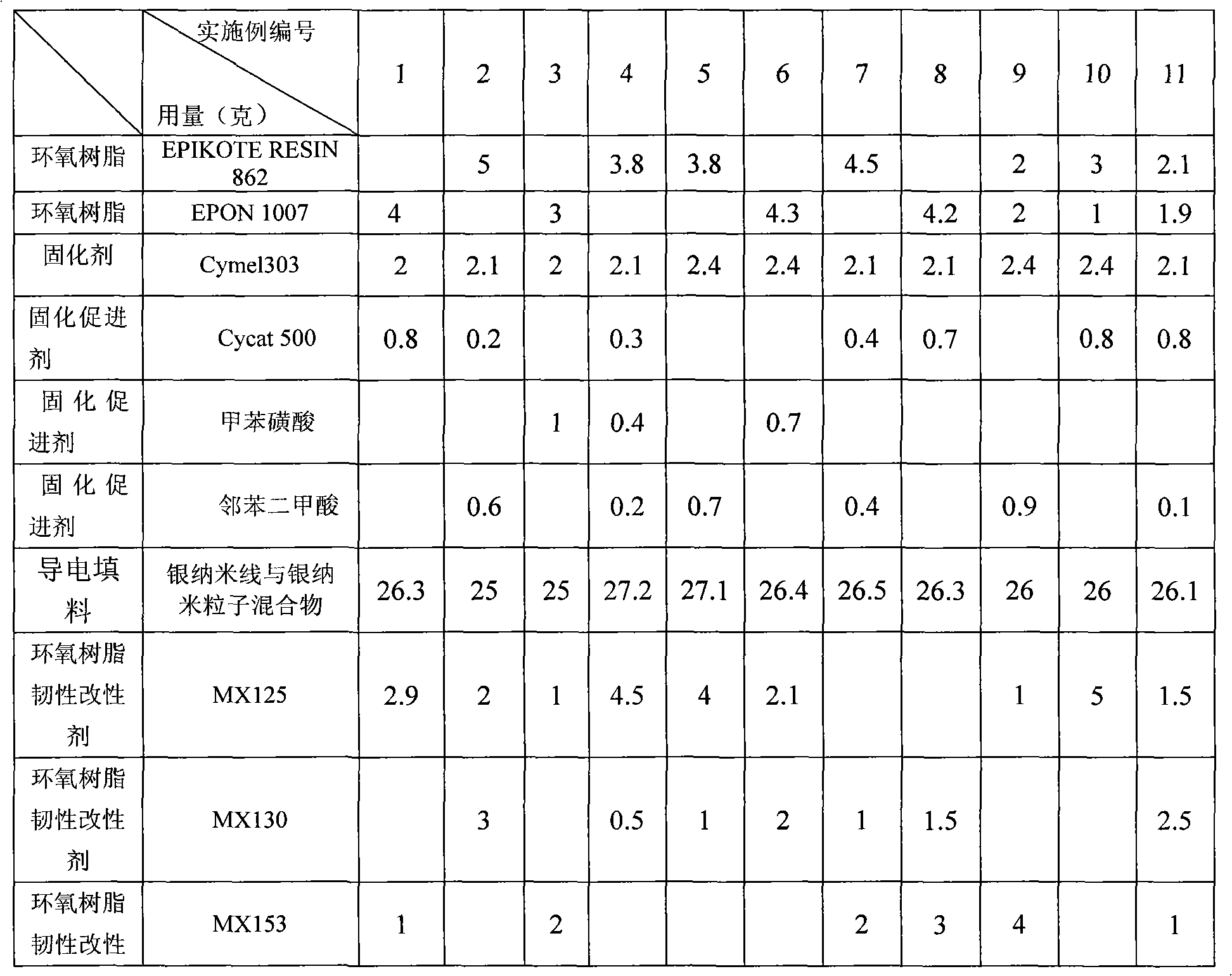

Conductive printing ink composite for printing of wireless radio frequency identification devices (RFID)

Owner:溧阳常大技术转移中心有限公司

Lithium ion battery anode material and lithium ion battery and anode containing the material

ActiveCN101207197AHigh bond strengthImprove conductivityElectrode carriers/collectorsActive material electrodesOxideLithium electrode

The invention relates to positive electrode active material of a lithium ion battery, which comprises a component A, a component B and binding agent. The component A is lithium metal phosphate, the component B is chosen from one or more of lithium transition metal oxide compound, acetylene black, superconductive soot carbon, conducting graphite and conducting carbon fiber; wherein, the grain diameter D50 of the component A is 1-6 microns, the grain diameter D50 of the component B is 4-20 microns, and the grain diameter D50 of the component B is larger than the grain diameter D50 of the component A. The battery of the positive electrode active material provided by the invention has the advantages that the capacity of the battery is large, the discharge performance of high current is strong, the circulation performance is good, the internal resistance is little, and the overall performance of the battery is greatly improved.

Owner:BYD CO LTD

Thermosetting phosphate casting binder as well as preparation method and application method thereof

The invention provides a thermosetting phosphate casting binder. The thermosetting phosphate casting binder is prepared from the following raw materials in percentage by weight: 50 percent to 57 percent of industrial phosphoric acid, 9 percent to 12 percent of aluminum hydroxide, 0.75 percent to 2.18 percent of boric acid, 0.66 percent to 2.48 percent of citric acid, 0.075 percent to 0.57 percentof silicic acid, 0.075 percent to 0.47 percent of a water-soluble high molecular material, 0.75 percent to 3.53 percent of magnesium carbonate, 3.5 percent to 6.5 percent of magnesium chloride, 0.035percent to 0.19 percent of a silane coupling agent and the balance of pure water. According to the thermosetting phosphate casting binder provided by the invention, organic acid, inorganic acid and the water-soluble high molecular material are used for modifying a phosphoric acid binder, so that the aim of remarkably improving the performance of heat-curing sand by the phosphoric acid binder is realized; the thermosetting phosphate casting binder provided by the invention has the advantages of high binding strength, rapid curing speed and good moisture resistance and has a wide application prospect in a casting industry.

Owner:HUBEI UNIV OF TECH

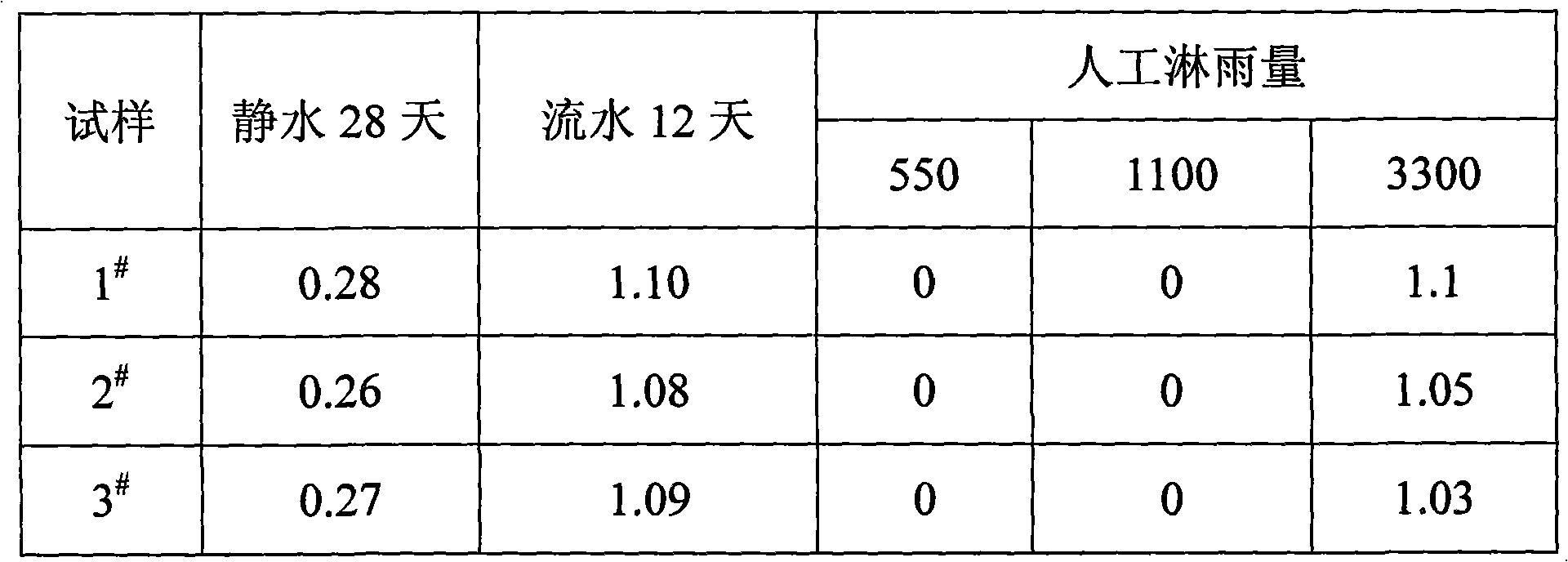

Organic silicon rubber waterproof adhesive and preparation method thereof

InactiveCN103387811AImprove curing depthHigh bond strengthNon-macromolecular adhesive additivesSilane couplingChemistry

The invention discloses an organic silicon rubber waterproof adhesive and a preparation method thereof. The preparation method comprises the steps of: firstly, respectively feeding 20-40 parts by weight of hydroxyl-terminated polysiloxane, 4-7 parts by weight of a reinforcing agent, 41-60 parts of inorganic filler and 2-5 parts of inorganic adsorbent into a stirrer, mixing, and continuously discharging the mixed adhesive material; continuously feeding the mixed adhesive material into a material tank under a reduced pressure state by a pump and continuously degassing in the material tank; continuously feeding the degassed adhesive material into a static mixer, and meanwhile continuously feeding a mixture of 1-3 parts of a crosslinking agent and 0.2-0.8 part of a catalyst into the static mixer by a horizontal closed type continuous kneader; continuously feeding the statically-mixed adhesive material into a double-screw mixing extruder and meanwhile, continuously refilling 0.2-0.8 part of a silane coupling agent and 0.5-3 parts of a curing catalyst through a dropwise filling hole with pressure in the double-screw mixing extruder; mixing the adhesive material in the double-screw mixing extruder, continuously feeding the adhesive material into the mixer for degasing, and finally packaging.

Owner:FUJIAN RUISEN CHEM

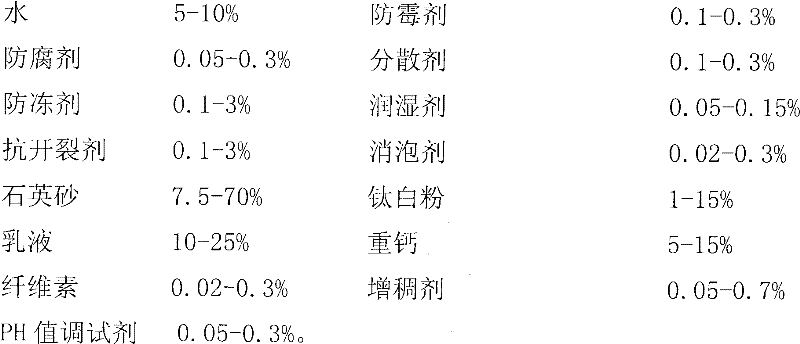

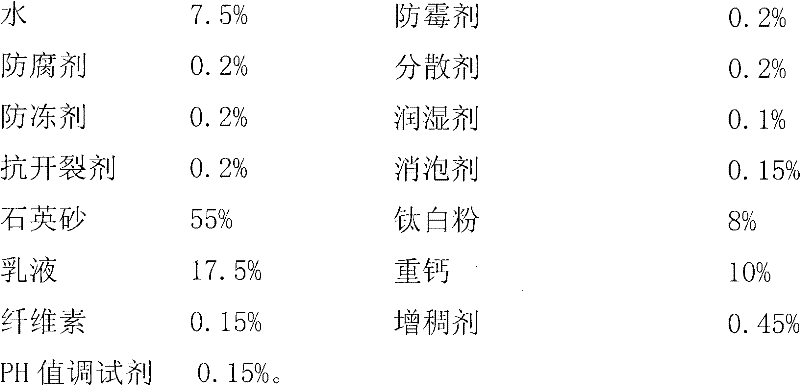

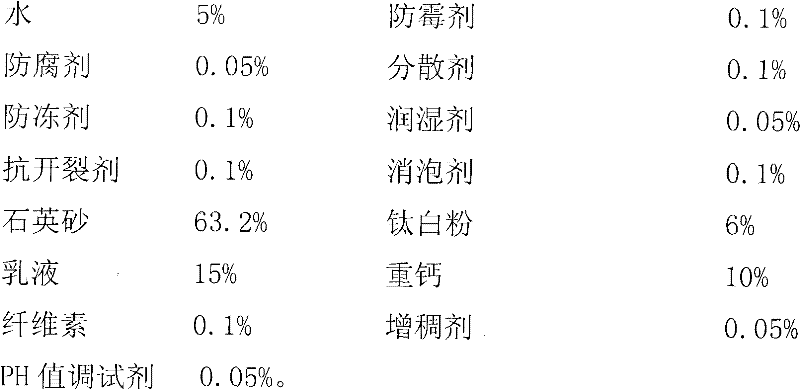

Special flexible texture coating for external heat insulating wall, and preparation method thereof

The invention discloses a special flexible texture coating for an external heat insulating wall. The coating is characterized by: 1) mixing water, an antimildew agent, a preservative, a dispersing agent, a wetting agent, a antifoaming agent, titanium pigment and calcium carbonate according to a mass ratio, followed by carrying out high speed dispersion to provide a spare use; 2) then mixing an emulsion, quartz sand and the antifoaming agent according to a mass ratio, followed by being added to the prepared mixed solution from the step 1), then carrying out medium-speed stirring; 3) mixing cellulose and the water according to a mass ratio, and carrying out stirring to prepare a mixed material of the cellulose to provide a spare use; 4) adding the mixture prepared through medium-speed stirring to the mixed material of the cellulose to carry out stirring, such that the mixed material of the cellulose can provide uniform thickening effect; 5) carrying out a color treatment for the finished product from the step 4). The coating provided by the present invention has characteristics of free of crack, high cohesional strength, effective prevention from coating deterioration, good water resistance, excellent penetration resistance, excellent flexibility. With the coating provided by the present invention, the fine cracks can be filled so as to prolong a service life of the external heat insulating wall and effectively protect buildings.

Owner:SHANDONG QINHENG TECH

Trans electronic control liquid crystal light dimming film and preparation method thereof

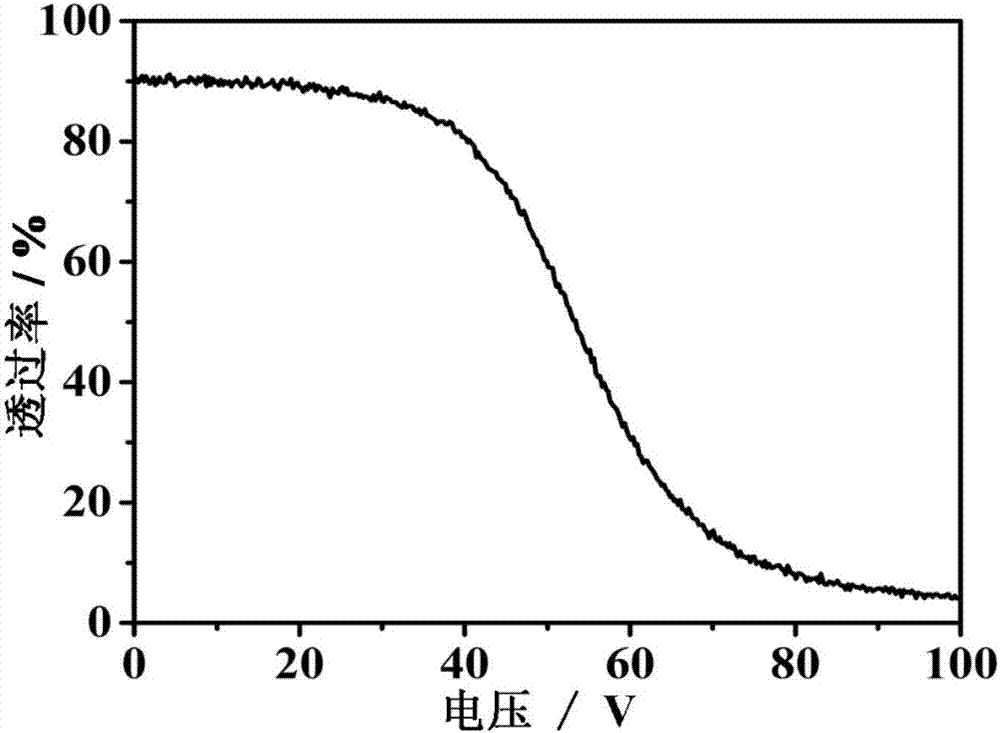

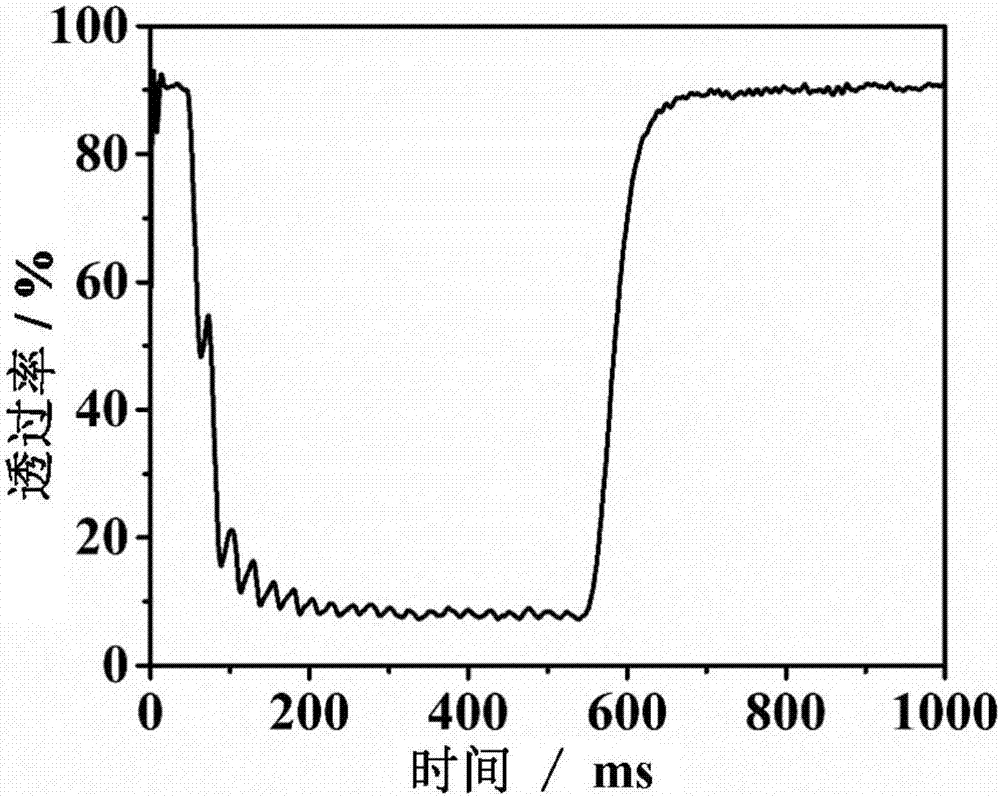

The invention discloses a trans electronic control liquid crystal light dimming film and a preparation method thereof. The liquid crystal light dimming film comprises a macromolecular network skeleton and double-frequency nematic-phase liquid crystal molecules, a polymer dispersed liquid crystal network structure and a polymer stabilized liquid crystal network structure coexist in the macromolecular network skeleton, and the structures particularly comprise macromolecular matrixes containing meshes and macromolecular networks which are perpendicularly arranged in the meshes; the double-frequency nematic-phase liquid crystal molecules are dispersed in the macromolecular network skeleton. According to the trans electronic control liquid crystal light dimming film, the PD-SLC network structure is constructed between two substrates by adopting a stepped polymerization method, the bonding strength between the two substrates is greatly improved and is higher than 8.2 N / cm<2>, and when a voltage is applied to the film at the frequency higher than the liquid crystal material crossover frequency, the state of the film can be changed from a transparent state to a light scattering state; the light transmittance of the film can be adjusted from 0.3% to 82% by adjusting the size of the voltage.

Owner:PEKING UNIV

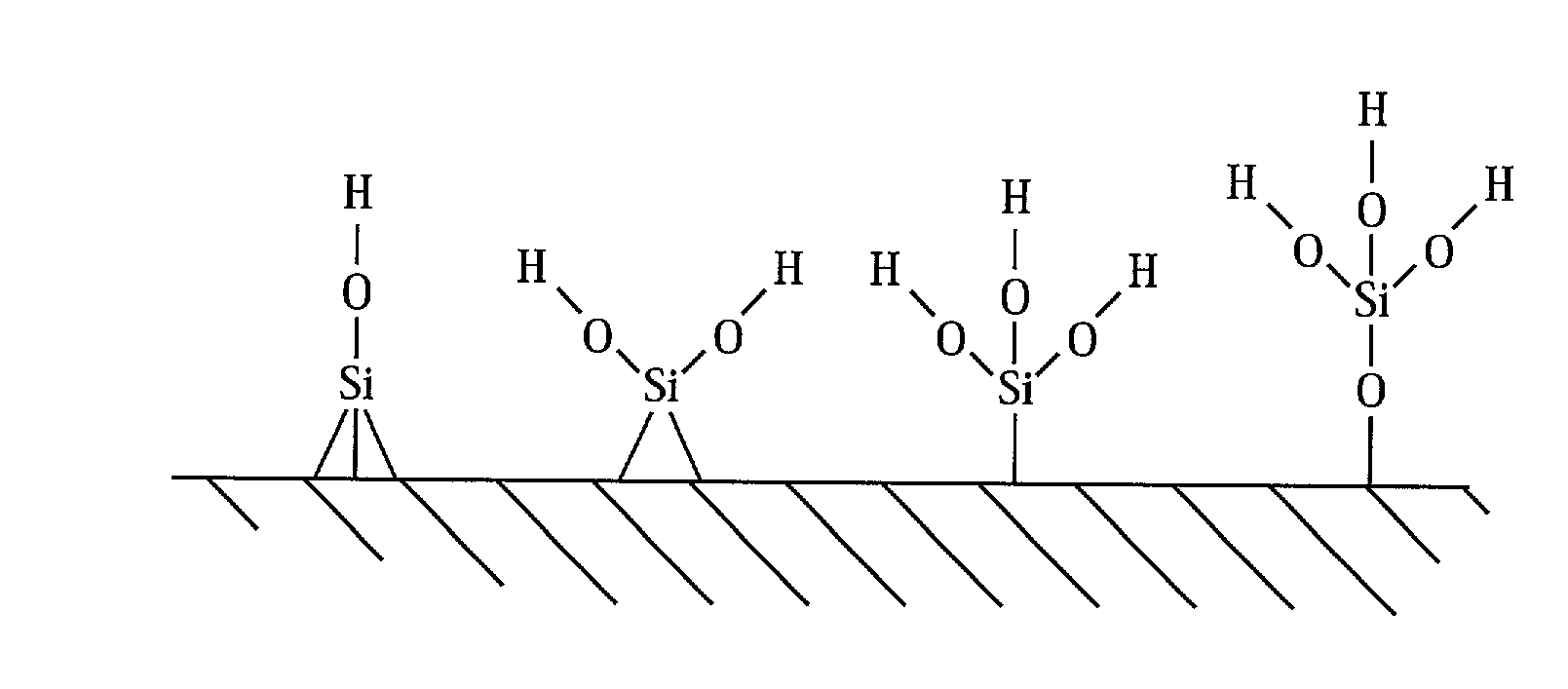

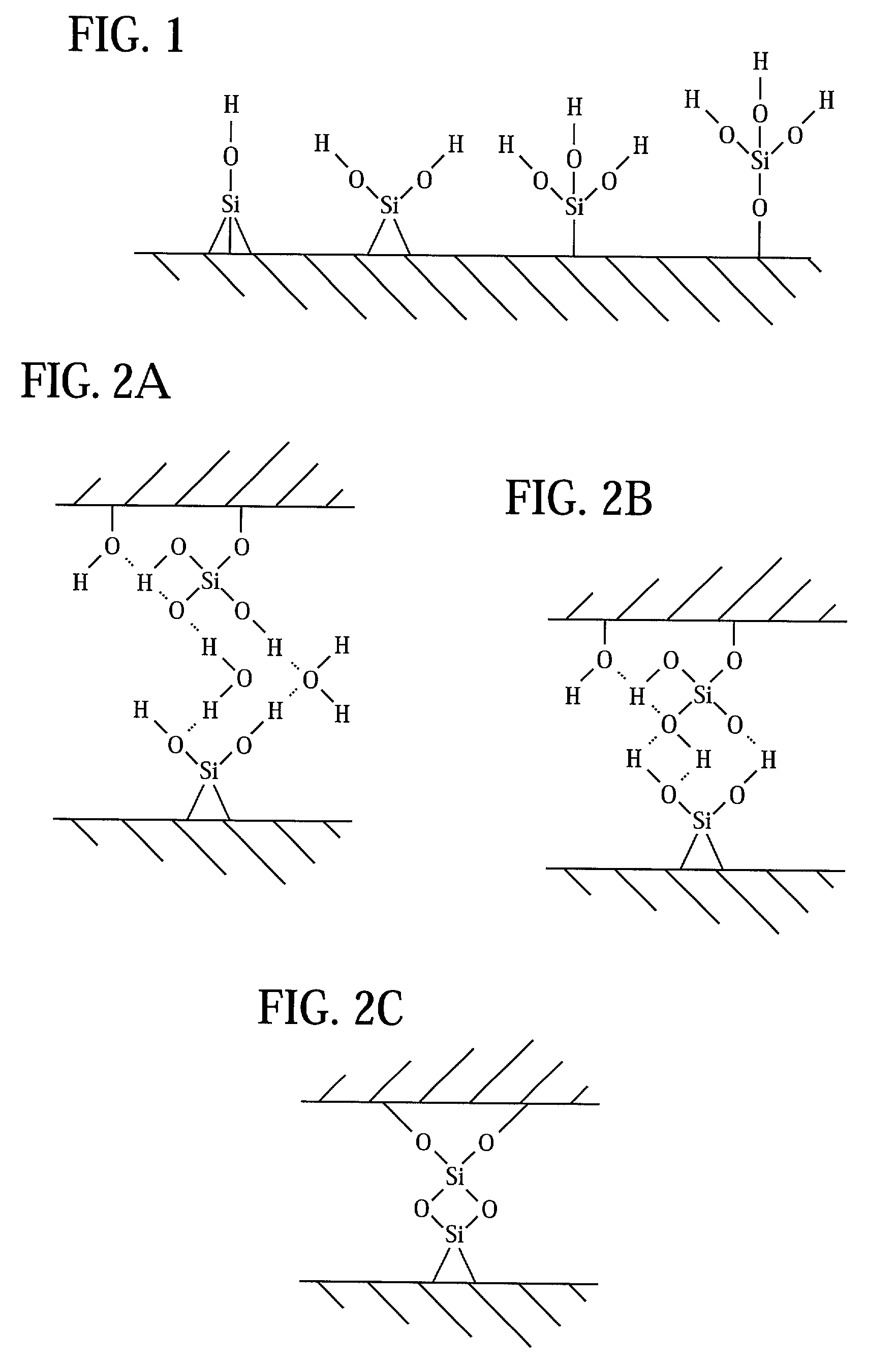

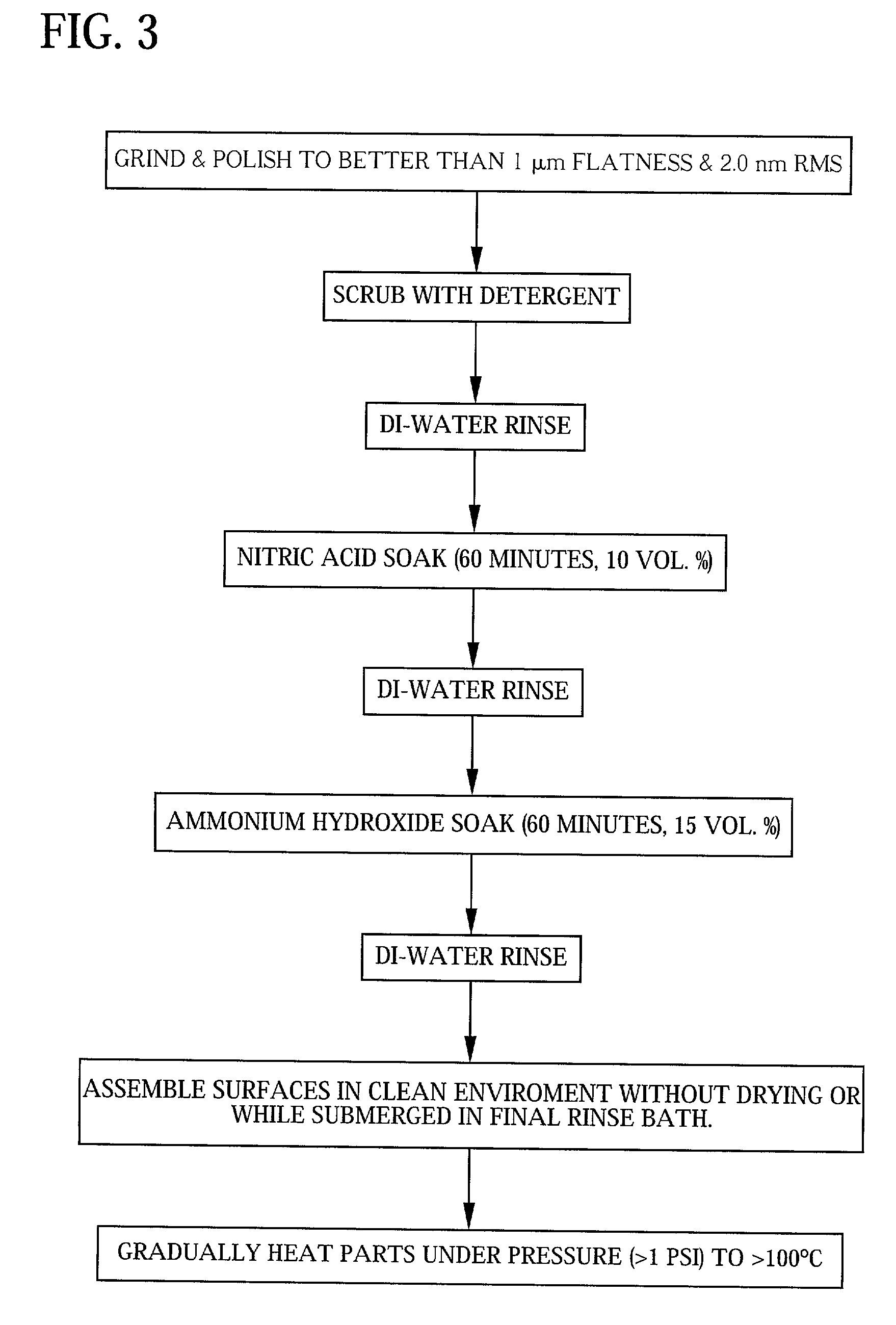

Direct bonding of articles containing silicon

InactiveUS20030079822A1High bond strengthImproves seal integrityLamination ancillary operationsDecorative surface effectsPolymer scienceAdhesive

Owner:CORNING INC

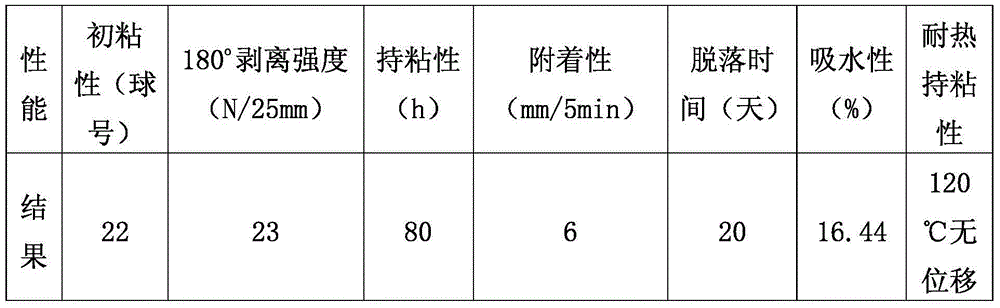

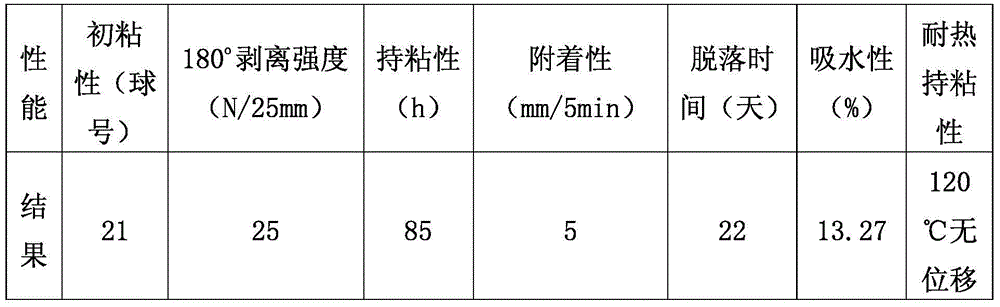

Preparation method of emulsion type polyacrylate pressure-sensitive adhesive for reflecting film

ActiveCN104449485AHigh bond strengthImprove aging resistanceFilm/foil adhesivesEster polymer adhesivesChemistryEmulsion

The invention relates to a preparation method of an emulsion type polyacrylate pressure-sensitive adhesive for a reflecting film. Hard monomers (5-15 parts of vinyl acetate and 5-15 parts of methyl methacrylate) and soft monomers (30-50 parts of ethylhexyl acrylate and 10-30 parts of ethyl acrylate) are subjected to quaternary monomer copolymerization, and consequently, the bonding strength of the pressure-sensitive adhesive is improved obviously. In addition, 0.3-1 part of lauryl sodium sulfate and 1-3 parts of sodium allyloxyhydroxypropyl sulfonate are taken as emulsifying agents; a substance with a surfactant is polymerized to a macromolecular chain to take the place of a part of the micromolecular emulsifying agent lauryl sodium sulfate, and therefore, the aging resistance and the water resistance of the pressure-sensitive adhesive are improved. The emulsion type pressure-sensitive adhesive prepared by use of the preparation method is high in permanent adhesion, high in peel strength, and high in combination properties such as aging resistance, high temperature resistance, water resistance and acid rain resistance, and capable of meeting the requirement on long-term use of the reflecting film. In addition, the preparation method is simple in process, free from environment pollution, low in cost, and suitable for large-scale industrial production.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

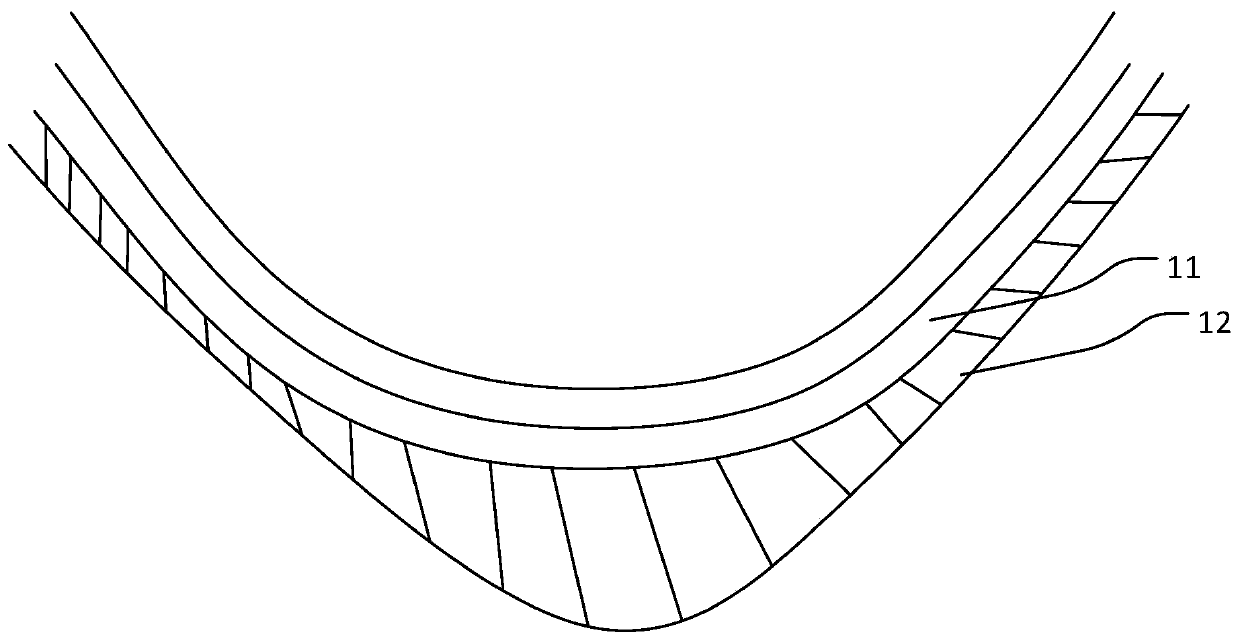

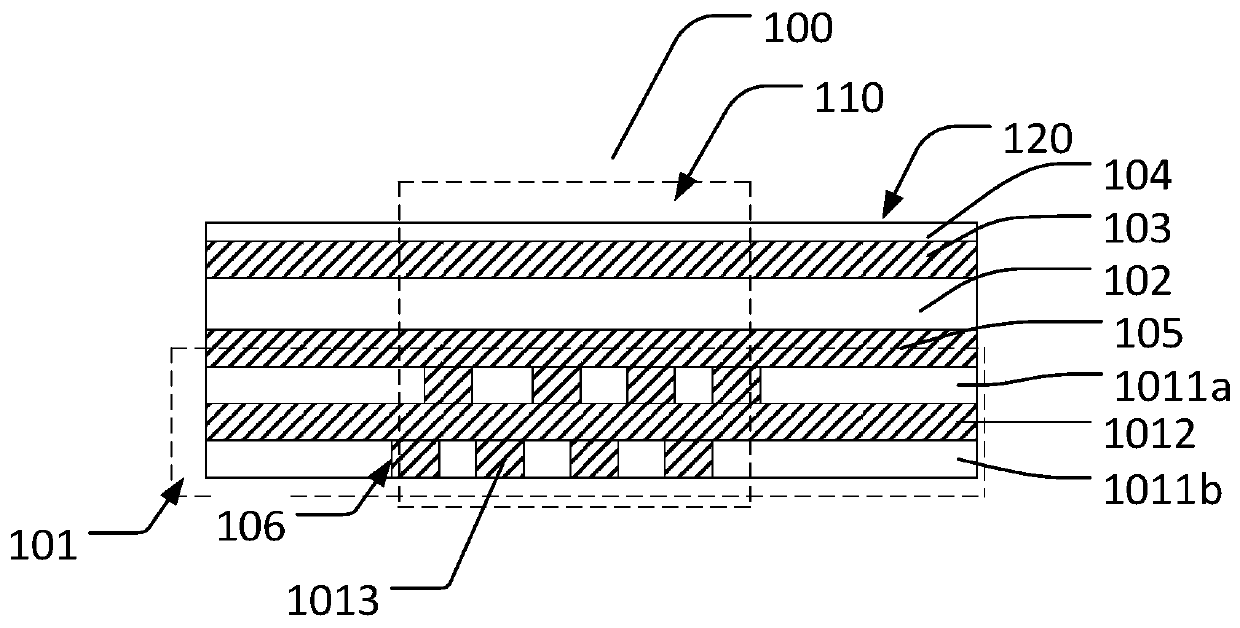

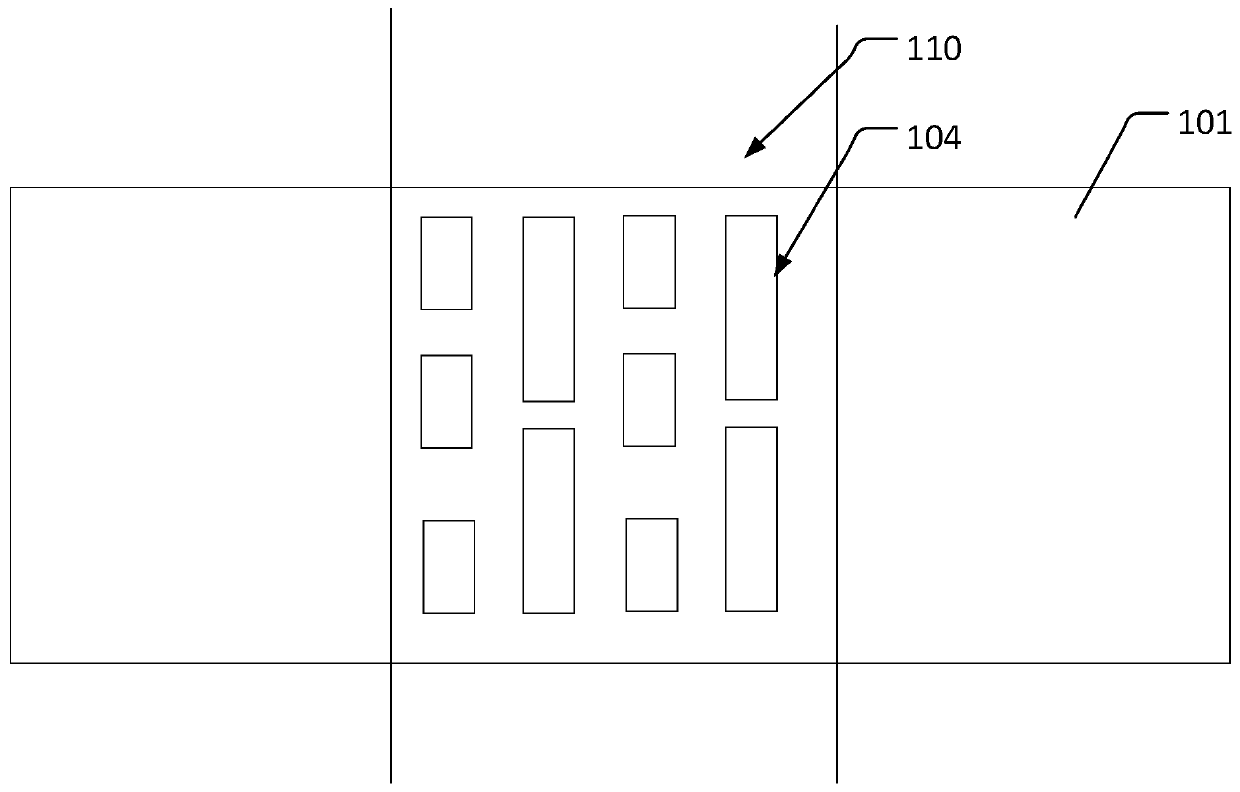

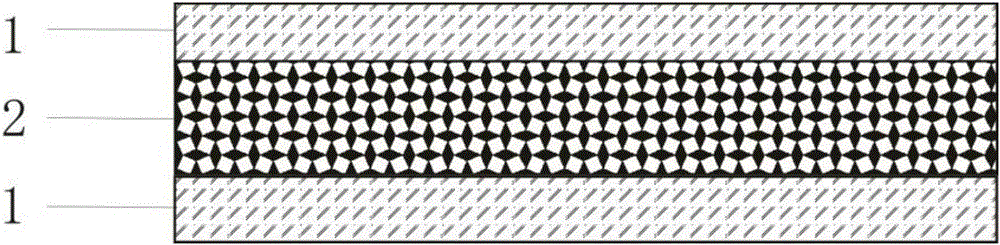

Display device

InactiveCN111312794AGood curl performanceHigh bond strengthSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringBonding strength

The invention provides a display device. The display device comprises a supporting layer, a first adhesive layer, a display panel, a fourth adhesive layer and cover plate glass. The supporting layer is designed into a sandwich structure; the supporting layer comprises at least two layers of metal sheets and a second adhesive layer clamped between the two layers of metal sheets; holes are dug in the two layers of metal sheets, and the two layers of metal sheets are filled with a third adhesive layer, so that the supporting layer has better curling performance and higher bonding strength, and the adhesive layer is effectively prevented from falling off in the bending process. The display panel can be well supported, and flexibility and rigidity are integrated.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Novel heat-insulation dry powder mortar

InactiveCN101723639AHigh bond strengthEarly strength fastSolid waste managementBuilding materialCellulose

The invention belongs to the technical field of building materials, and discloses novel heat-insulation dry powder mortar. The mortar consists of portland cement, fly ash, vitrified beads, floating beads, heavy calcium, cellulose, latex powder and the like. Compared with conventional heat-insulation mortar, the novel heat-insulation dry powder mortar provided by the invention has the advantages of high strength, light weight, high bond strength and the like.

Owner:何林道 +1

Acrylate emulsion modified cement-base repair mortar

The invention discloses acrylate emulsion modified cement-base repair mortar, which consists of the following components in part by weight: 100 parts of portland cement, 50 to 220 parts of 0.50 to 2.0 millimeters of quartz sand, 10 to 100 parts of less than 0.50 millimeter of quartz sand, 5 to 80 parts of acrylate emulsion, 0 to 1.0 part of water reducing agent, 0.5 to 5.0 parts of polypropylene fiber, 0 to 1 part of cellulose ether, 0 to 1.2 parts of defoaming agent and 0 to 60 parts of water. The acrylate emulsion modified cement-base repair mortar has high breaking strength, bonding strength, volume stability, durability and compatibility with cement-base materials, has the high flowability and water-retaining property in the aspect of construction performance, can meet the requirements of different engineering constructions, and can be widely applied to the repair in fields of municipal administration, road surfaces, airports, ports, bridges, dams and the like.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD +1

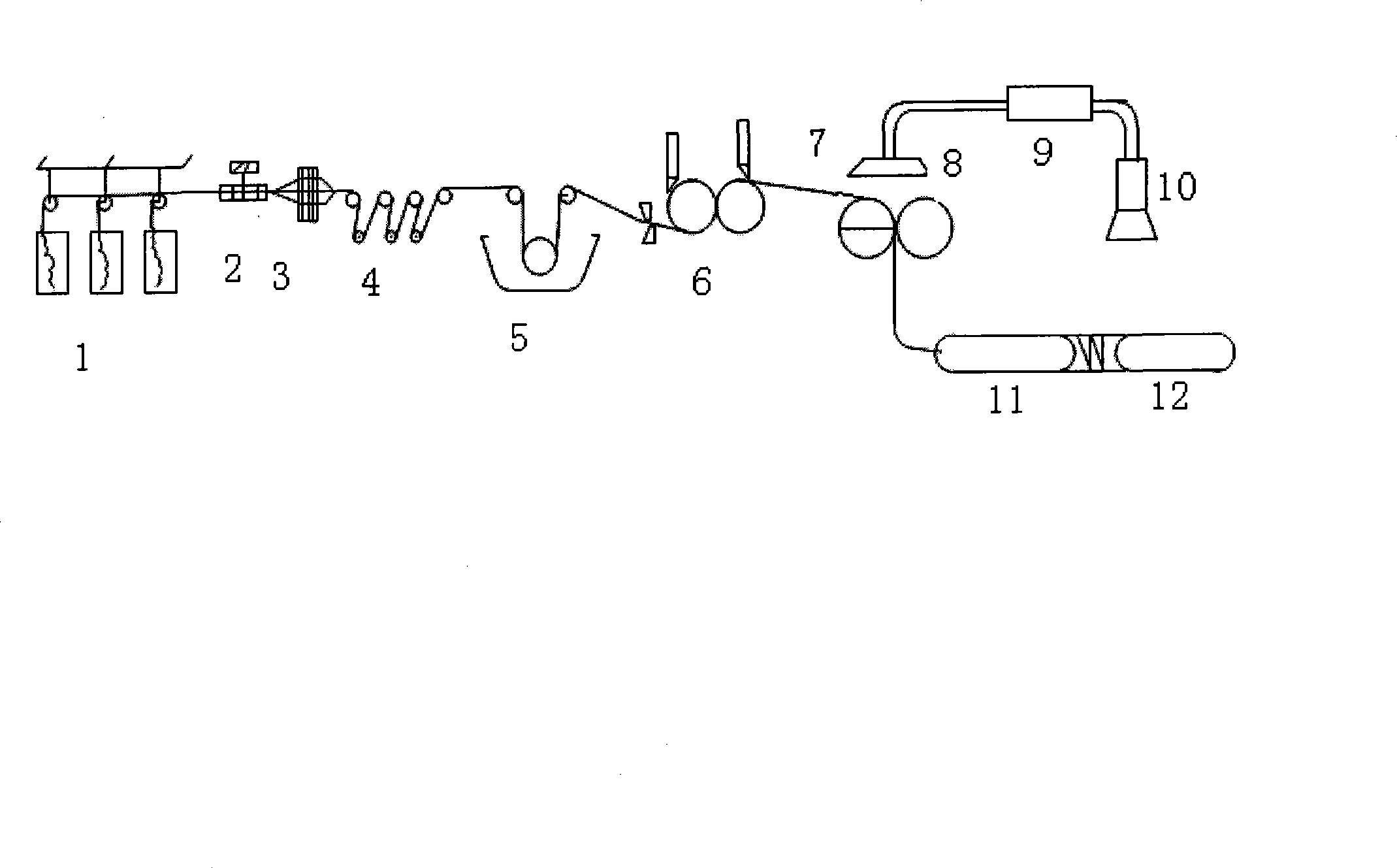

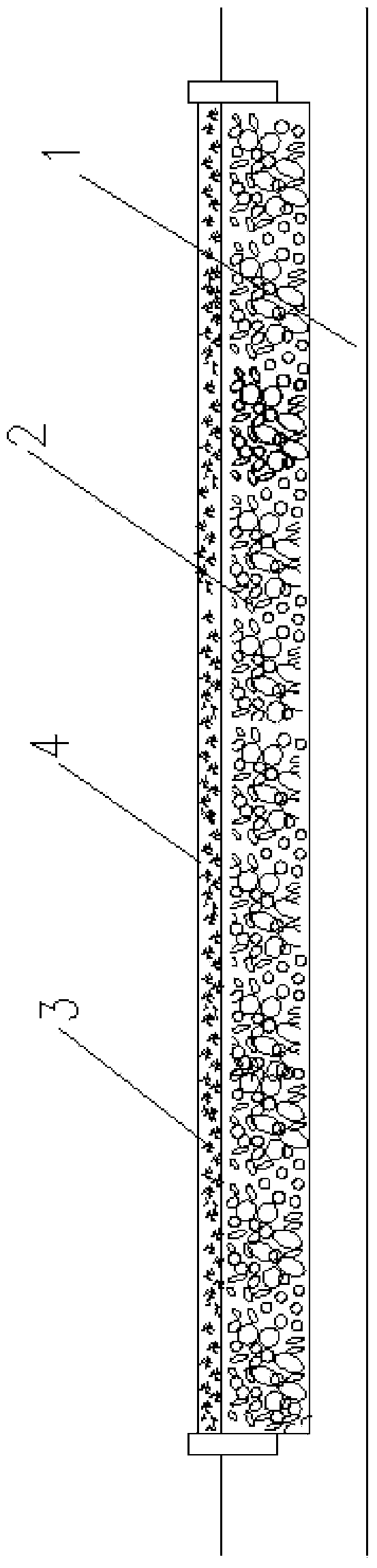

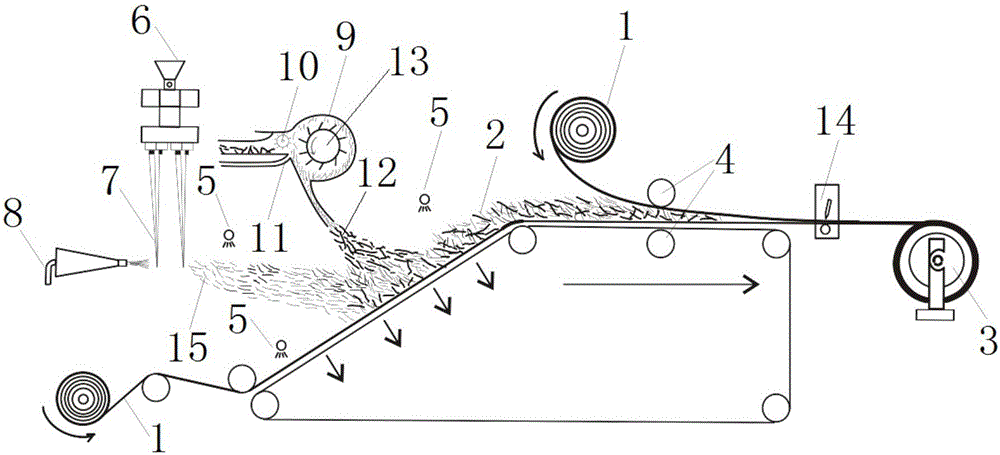

Method for preparing novel welfless cloth and composite UD profile

InactiveCN101177846AHigh bond strengthGuaranteed overall uniformitySheets/panelsPersonal protection gearSizingEngineering

The invention relates to a preparation method of a novel weftless cloth and composite UD material, including the steps: (1) a feeding tension box of a tow frame is provided with a constant static generator; (2) the tow is parallel laid and is put into a steeping vat, then the weftless cloth is topped with gum at the face and the back on a roller and by an atomizing and spraying device; (3) gum at both the face and the back of the weftless cloth is scraped in parallel; (4) the formed weftless cloth is hauled by a chain and parallel conveying way, parallel cut or conversely folded to form an UD composite board of multi-layer structure. The method of the invention is a continuous production method of stable quality and requires low cost, and the prepared UD material is characterized by even quality, fiber being evenly stressed, even sizing rate, etc.

Owner:DONGHUA UNIV +1

Interface mortar

The present invention discloses interface sand pulp, the constitutional materials of which comprises inorganic cementing compound, organic cementing compound tylose ether MC and hydrophobe redispersionable rubber powder, skeletal material and solidification setting accelerator; the ingredients with the following weight percent: 40 to 50 percent of inorganic cementing compound, 0.05 to 1.0 percent of tylose ether MC, 1.0 to 2.5 percent of hydrophobe redispersionable rubber powder, 48 to 60 percent of skeletal material, and 0 to 6 percent of solidification setting accelerator. The interface sand pulp of the present invention has strong adhesive strength, good water-resistant performance, small modulus and good climate-resistant performance, and is free from aging and is free from shrinking during the hardening, and has good flexibility, and is free from producing the interface stress. The interface sand pulp is particularly suitable to be used as the processing agent for the surface of the aeroconcrete and the smooth concrete, and is also applicable to be used as the transitional layer between the substrate and the coating layer, and can also be used for bonding the ceramic tile.

Owner:长沙归一新材料科技股份有限公司

Formula of hydrolysis-resistant waterborne polyurethane artificial leather and method for manufacturing same

InactiveCN101812808AGood cold resistanceHigh bond strengthSynthetic resin layered productsTextiles and paperChemistryFiber

The invention discloses a formula of hydrolysis-resistant waterborne polyurethane artificial leather and a method for manufacturing the same and relates to waterborne polyurethane adhered with ultrafine fiber base. The method comprises the following steps of: preparing surface material resin solution and bottom material resin solution according to a formula proportion by adopting hydrolysis-resistant and cold-resistant waterborne PU resin, standing the solution for defoaming; opening release paper, coating surface material resin on the release paper, sending the release paper to an oven for drying, and winding; and opening the release paper coated with the surface layer, coating bottom material resin on the release paper, sending the release paper to the oven again until the release paper is semi-dried, rapidly adhering the ultrafine fiber base with the release paper, performing roll extrusion and drying, and finally winding and packaging.

Owner:QINGDAO XINYUTIAN CHEM CO LTD +1

Straw added fireproof high-density fiberboard and preparation method thereof

InactiveCN105082308AEliminate internal stressHigh bond strengthFlat articlesDomestic articlesScrapEmulsion

The invention discloses a straw added fireproof high-density fiberboard. The straw added fireproof high-density fiberboard is characterized by being composed of, by weight, 42-45 parts of crop straw, an appropriate amount of sodium hydroxide with the concentration being 2%, an appropriate amount of water, 1.5-2 parts of a silane coupling agent kh450, 66-70 parts of ethyl alcohol with the concentration being 95%, 30-32 parts of wood scraps, 4-6 parts of aluminum hydroxide, 2-3 parts of zinc borate, 7-8 parts of waterborne polyurethane adhesives, 1.5-2 parts of emulsion paraffin and 1-2 parts of pure acrylic emulsion. According to the straw added fireproof high-density fiberboard, while fibers are modified, the aluminum hydroxide, the zinc borate and other flame retardant components are added and attached to the surfaces of the fibers and in gaps, and the fireproof performance of the product is greatly improved. The straw added fireproof high-density fiberboard is simple and scientific in component matching, the technology is easy to industrially control, forming speed is high, and the manufactured fiberboard is good in waterproof and fireproof performance, uniform in density, free of deformation and suitable for application in the industries of furniture, building materials, packaging, decoration and the like.

Owner:ANHUI BAIYI FURNITURE

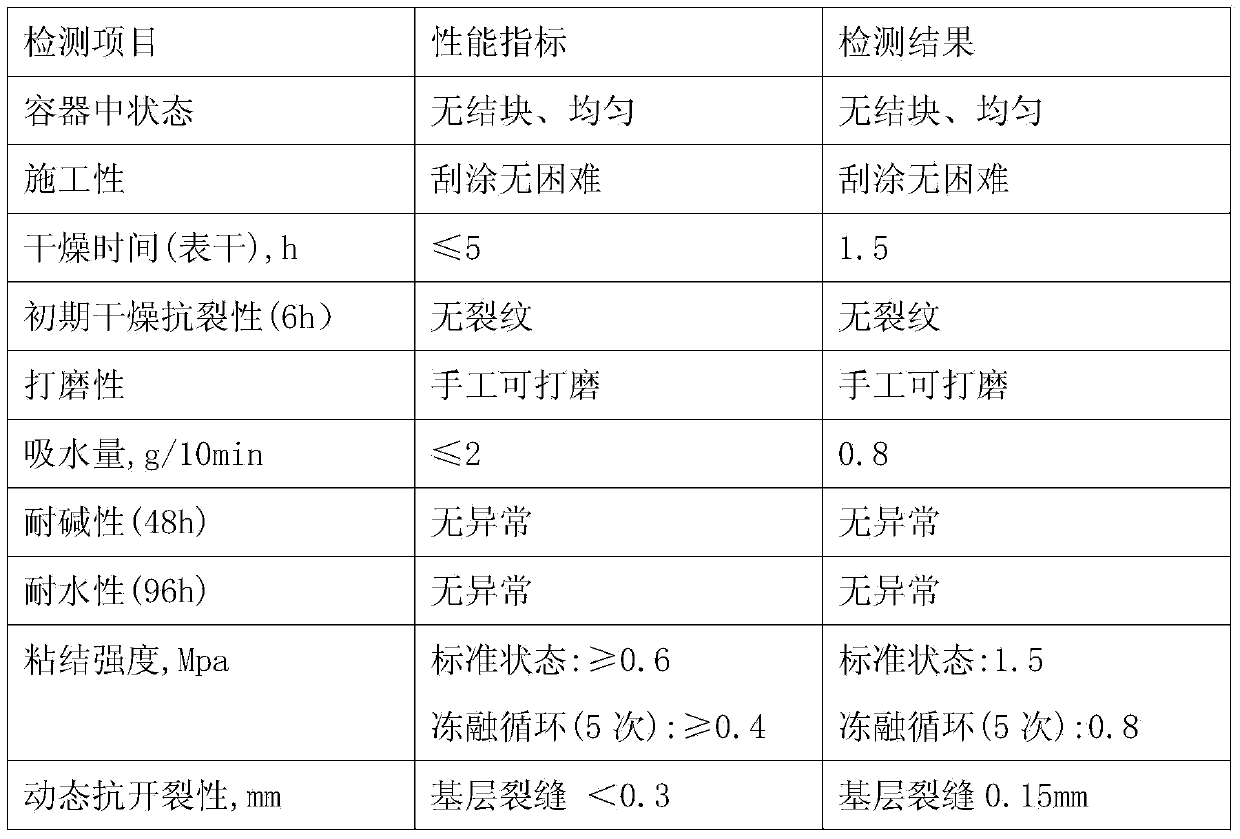

Exterior wall crack resistant elastic putty powder

The invention discloses exterior wall crack resistant elastic putty powder comprising the following raw materials: by weight, 20-30 parts of ash calcium powder, 10-15 parts of white cement powder, 10-20 parts of calcium carbonate powder, 10-15 parts of quartz powder, 40-50 parts of modified talcum powder, 1-1.5 parts of carboxymethyl cellulose, 2-3 parts of carboxymethyl starch ether, 3-4 parts of redispersible latex powder, 2-3 parts of polypropylene staple fiber, 1-2 parts of aluminum silicate fiber and 0.5-1 part of NSJF-2 latex powder. The powder putty has crack resistance, frost resistance, heat resistance, alkali resistance, water resistance and other functions, can greatly improve the bonding strength of a wall body paint substrate, improves the service life of a wall body paint, overcomes the defects of easy falling, peeling and cracking of traditional putty powder, is completely environmentally friendly, may not pollute the environment, is harmless to human body, easy to use, simple to construct, durable and reliable, and has obvious social benefits and environmental benefits.

Owner:岑其挺

Targeted drug release intervened medical appliance and preparation method thereof

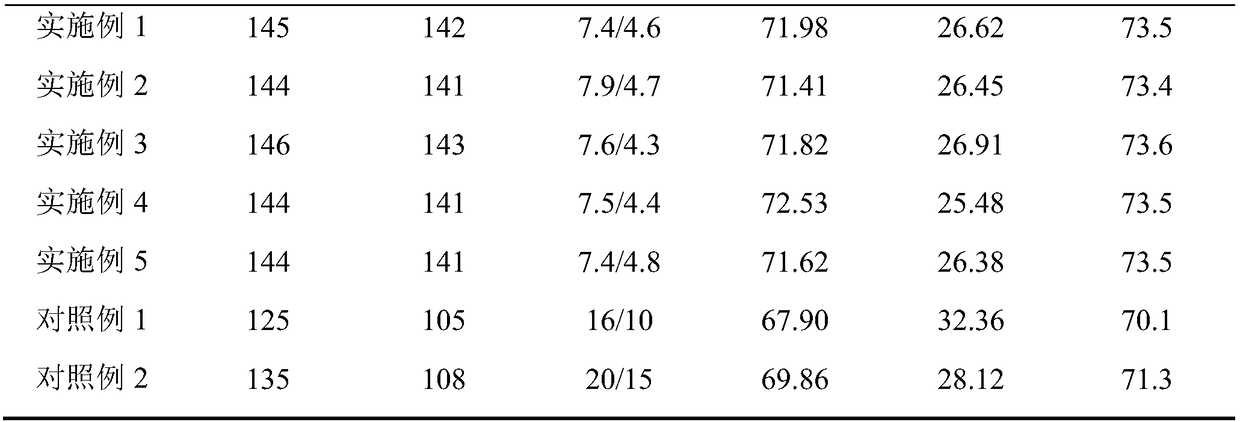

The invention provides a targeted drug release intervened medical appliance and a preparation method thereof. The medical appliance is characterized by comprising an intervening medical appliance and a sustained-release drug coating, wherein the sustained-release drug coating is applied to the surface of the intervening medical appliance. The preparation method comprises a step of applying drugs to the intervening medical appliance to form the targeted drug release intervened medical appliance, wherein the sustained-release drug coating consists of a medicinal material, a medicinal carrier material, antioxidant and adhesive, and the drug application to the intervening medical appliance sequentially comprises the following steps: (1) preparing the sustained-release drug coating; (2) applying the sustained-release drug coating; (3) drying. According to the targeted drug release intervened medical appliance, the binding strength between the sustained-release drug coating and the surface of the intervening medical appliance is high, the medicinal material is prevented from being lost in the subsequent processing process, and the targeted drug release intervened medical appliance has a good drug treatment effect.

Owner:上海赢生医疗科技有限公司

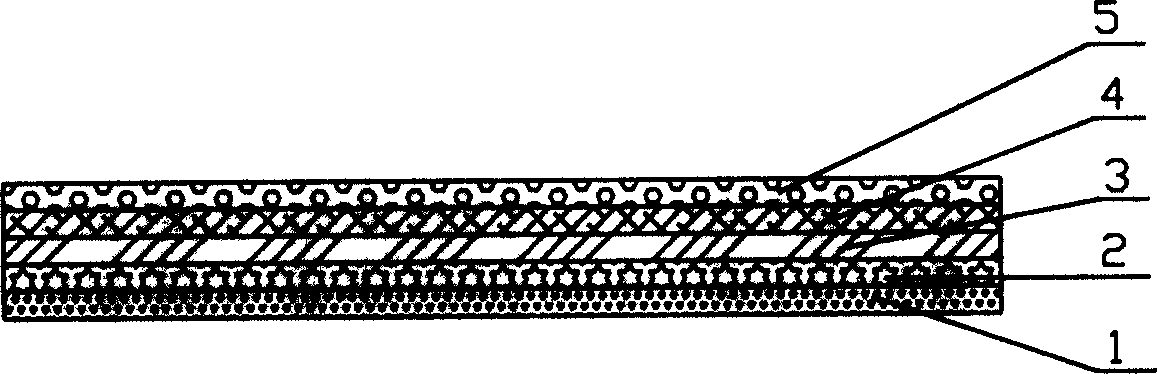

Composite water-proof coiled material and construction method by employing same

ActiveCN1544769AGood elasticity and deformation abilityHigh bond strengthBuilding insulationsBituminous layered productsWaterproofingSizing

The invention discloses a composite waterproof coiled material, from top to bottom, in turn including isolating layer, sizing material layer A, enhanced layer, sizing material layer B and close binder. The close binder can be bond closely with the structural layer of a building and set with particle layer. The invention discloses the constructing methods of pre-laying method and wet-laying method of this coiled material, where the pre-laying method can eliminate the procedure of laying protective layer in traditional construction and the wet-laying method can eliminate the procedure of making primary level making layer and has a few requirements for base level and can make waterproof construction. With respect to the existing techniques, it has the characters of simple structure, good waterproofing effect, strong anti-piercing ability, convenient use and maintenance, simple constructing method, etc.

Owner:SHENZHEN ZHUOBAO TECH

Low agglomerate waterproof emulsion and preparation method thereof

The invention discloses a low agglomerate waterproof emulsion. The emulsion comprises the following components, by mass, styrene 10-18%, methyl methacrylate 2-8%, n-butyl acrylate 8-20%, 2-ethylhexyl acrylate 10-20%, organic acid 0.5-1.5%, functional monomer 0.6-2%, emulsifier 2-3%, pH buffer 0.2-0.4%, redox initiator 0.4-0.8%, and the balance of deionized water. The waterproof emulsion does not contain APEO, and the components scientifically cooperate with each other and have a synergistic effect. Thus the temperature of the emulsion application is suitable for a wide range. The coating film has high bonding strength with base surfaces such as cement, asphalt and polyurethane, and has good water resistance, alkali resistance and weather resistance. Meanwhile, the emulsion has excellent resilience, high practicability, and extremely high promotional value. By optimizing the ratio and the adding method of the emulsifier in a polymerization reaction stage, the preparation method of the waterproof emulsion generates a low amount of aggregates (& lt; 20 ppm), and greatly saves the cost of materials and construction.

Owner:北京宝辰联合科技股份有限公司

Temporary road pavement technology

InactiveCN104631274AHigh bond strengthGuaranteed strength and toughnessIn situ pavingsTemporary pavingsRoad roughnessSurface layer

The invention discloses a temporary road pavement technology which comprises the following steps: I. paving a cushion, namely selecting rubbles with grain size of 150mm below according to the needed amount, paving the rubbles onto a selected and compacted road surface to form a rubber layer; crushing the rubble layer through a press until rubbles in the rubble layer cannot be loosened; II. paving a surface layer, namely selecting fine rubbles with the particle size of 5-10mm according to the needed amount; blending the fine rubbles with dry soil, spraying water while blending until dry soil is formed into clay which is adhered to fine rubbles to form a clay-bound rubble layer; paving the clay-bound rubble layer on the cushion, leveling, milling through the press until the surface of the clay-bound rubble layer has no obvious wheel trace; and III. paving a wear layer. The temporary road pavement technology has the beneficial effects of good road flatness, difficulty offlying of dust and sand, and incapability of enabling the road surface to be muddy in rainy days.

Owner:SHANGHAI INTELLIGENCE POWER ENG CO LTD

High temperature resistant air filtering material and preparation method thereof

ActiveCN106757775AIncrease bulkiness and resistance to deformationHigh bond strengthLaminationLamination apparatusWoven fabricMetallurgy

The invention discloses a high temperature resistant air filtering material and a preparation method thereof. The filtering material comprises three layers, the upper and lower layers are high temperature resistant non-woven fabric layers, the middle layer is a high temperature resistant staple fiber inserted ultra-fine glass fiber non-woven fabric layer. According to the filtering material, in the production process of the glass fiber, the air flow is used for transmitting the high temperature resistant staple and distributing the staple into the ultra-fine glass fiber. After the mixing of the high temperature resistant staple and the ultra-fine glass fiber, sand blasting is used for making the two materials bonded to form a multi-dimensional, multi-sizeable and fluffy high temperature resistant staple inserted ultra-fine glass fiber non-woven fabric layer, then the ultrasonic adhesion technology is used for compounding the upper and lower surfaces of the high temperature resistant staple inserted ultra-fine glass fiber non-woven fabric layer with the high temperature resistant non-woven fabric layer. The high temperature resistant air filtering material has the advantages of being fluffy and soft, good in elasticity, high in porosity, and good in uniformity. The material prepared by using the method has good air permeability, good filtering performance, pressure resistance performance and high temperature performance, can resist ash removal vibration, is not prone to breaking which can invalidate the filtering material.

Owner:榆林天盛缘玻璃纤维科技有限公司

Waterborne polyurethane synthesized by waterborne polyester and preparation method of waterborne polyurethane

The invention discloses waterborne polyurethane synthesized by waterborne polyester. The waterborne polyurethane comprises the following components in a formula in parts by weight: 30-100 parts of polyalcohol, 5-60 parts of polybasic acid, 10-20 parts of polyalcohols, 10-20 parts of hydrophilic monomer, 0-40 parts of solvent, 20-40 parts of polyisocyanates, 4-10 parts of alkali binding agent and 220-280 parts of water. Water-soluble or water-dispersible polyester is used as soft-segment synthesized polyurethane of the waterborne polyester, so that the proportion of the polyester in the waterborne polyurethane is improved. The invention also discloses a preparation method of the waterborne polyurethane. The waterborne polyurethane prepared by the invention has the advantages of uniformity in distribution of a hydrophilic functional group, high molecular weight, high bonding strength and high film strength and can be separately used or mixed with other polymer latex and the like to use.

Owner:广州市才德化学制品有限公司

Preparation method of metal coated PVC (Polyvinyl Chloride) sectional material for improving plasticity

The invention relates to a preparation method of a metal coated PVC (Polyvinyl Chloride) sectional material for improving plasticity. The PVC sectional material with the surface coated with a metal film is prepared by material mixing, extrusion, vacuum cooling and sizing of the PVC sectional material, coating of hot melt adhesive on the surface of the metal film, coating of the metal film on the surface of the PVC sectional material, cutting and molding. According to the preparation method provided by the invention, a PVC raw material and the hot melt adhesive are respectively treated by a separate extruder, so that the bonding strength of the hot melt adhesive is high, the bonding of the metal film is uniform and strong, the bonding strength is high, delamination is unlikely to occur, and the continuous production of the hot melt adhesive, PVC raw material powder and PVC sectional material products with the surfaces coated with the metal films can be realized.

Owner:山东华信塑胶股份有限公司

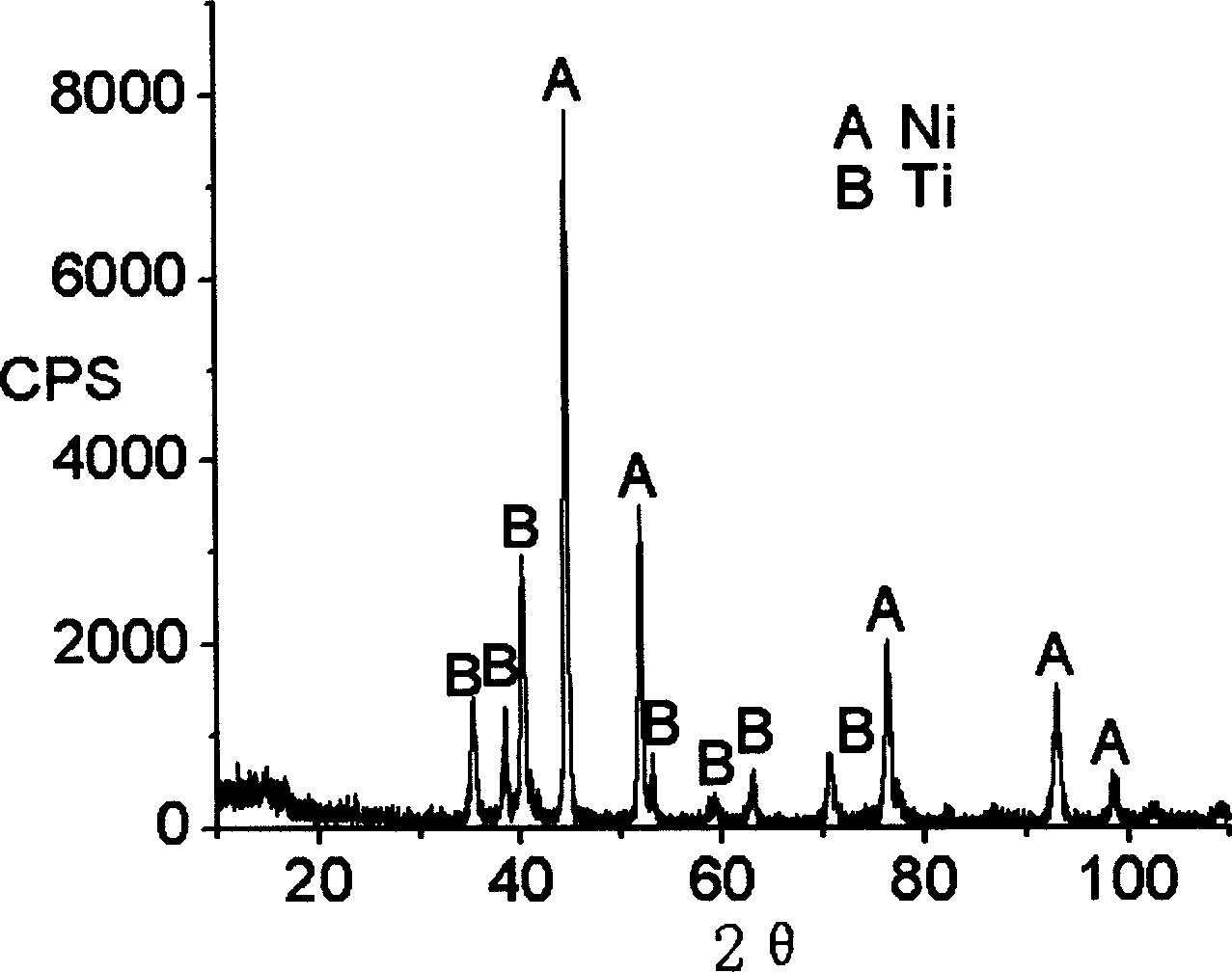

Titanium-nickel-carbon reacting spraying composite powder and preparation thereof

The invention was involved in Ti-Ni-C alloys response spray coating complex powder and its preparation method, which belonged to the powder manufacturing craft of metal ceramic complex coating technology. Cane sugar was used as precursor of carbon and it was carbonized under definite temperature to form Ti-Ni-C alloys response spray coating complex powder, which was enclosed by material powder. The technology was: mixing the Ti and Ni power with mixture ratio ->wet grinding->drying the slurry ->carbonization step by step->breaking and screening. The method not only settled the separation of response component during the response spray powder but also the cane sugar was used as precursor of carbon so it had low carbonization temperature, high carbon purity, small pollution of process of carbonization and the high industrial feasibility. To select Ni as the metal base to reduce rather large grain TiC conglobation and increase the wear-resisting property of coating.

Owner:UNIV OF SCI & TECH BEIJING

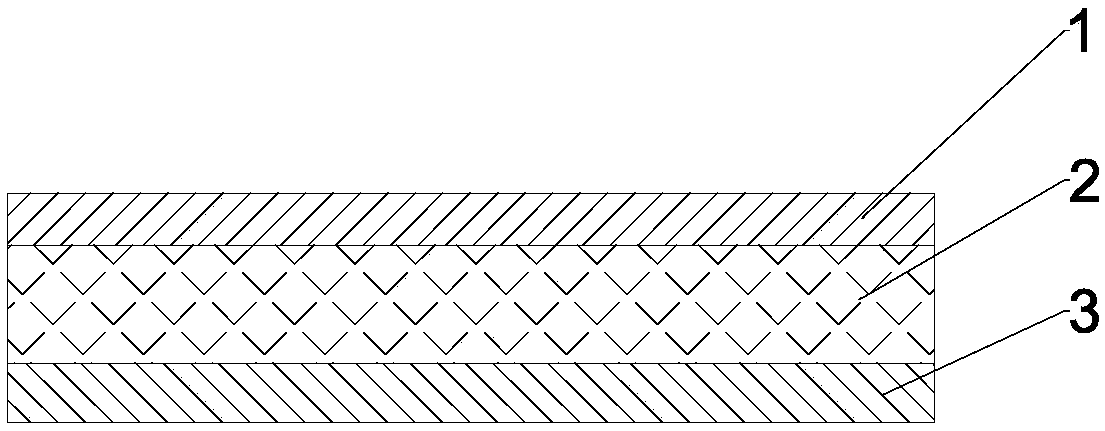

Three-layer composite hot melt adhesive film for bonding metal and polar functional plastic and processing technique thereof

InactiveCN109207073AHigh bond strengthEasy constructionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSteel platesChemistry

Disclosed are a three-layer composite hot melt adhesive film for bonding a metal and a polar functional plastic and a preparation process therefor, wherein the three-layer composite hot melt adhesivefilm comprises an inner layer adhesive bonded to the metal, an outer layer adhesive bonded to the polar functional plastic, and a transition adhesive connecting the inner layer adhesive and the outerlayer adhesive; the inner layer adhesive, the outer layer adhesive and the transition adhesive with different functionalities are modified and then compounded effectively by means of co-extrusion filmblowing or casting, the three-layer composite hot melt adhesive film is used for bonding polar functional materials with metals such as aluminum, galvanized steel plates and the like, and is high inbonding strength and convenient to construct, and can effectively solve the problems of low bonding strength or large odor, serious environmental pollution and the like of an adhesive used for bondingthe polar functional plastic and the metal at present. The three-layer composite hot melt adhesive film can effectively bond the metal and the polar functional plastic at a relatively low temperatureby means of a laminating machine or a stamping machine device, the bonding is convenient, and the plastic is not damaged.

Owner:SHANGHAI BANZAN MACROMOLECULE MATERIAL

Light leveling dry-mixed mortar

The invention discloses light leveling dry-mixed mortar which comprises, by weight percentage, 20-80% of desulfurized gypsum, 0-20% of fly ash, 20-80% of calcium carbonate, 0-20% of cement, 0-30% of sand, 1-12% of lightweight aggregate, 0-0.1% of starch ether, 0-0.5% of magnesium aluminosilicate, 0-3% of redispersible latex powder, 0.1-0.5% of cellulose ether, 0.02-0.15 part of retarder and 0-0.8 part of water reducing agent. The light leveling dry-mixed mortar has the advantages of not cracking, being firmly bonded to a base material, regulating air humidity, having an excellent sound insulation function, being green and environmentally friendly, saving energy and being safe and the like, and conforms to application requirements in modern construction engineering.

Owner:关建光

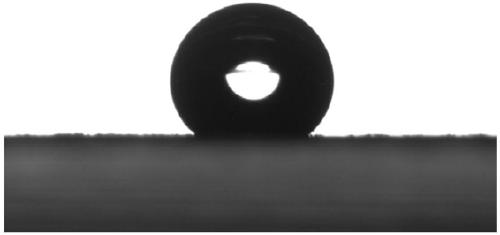

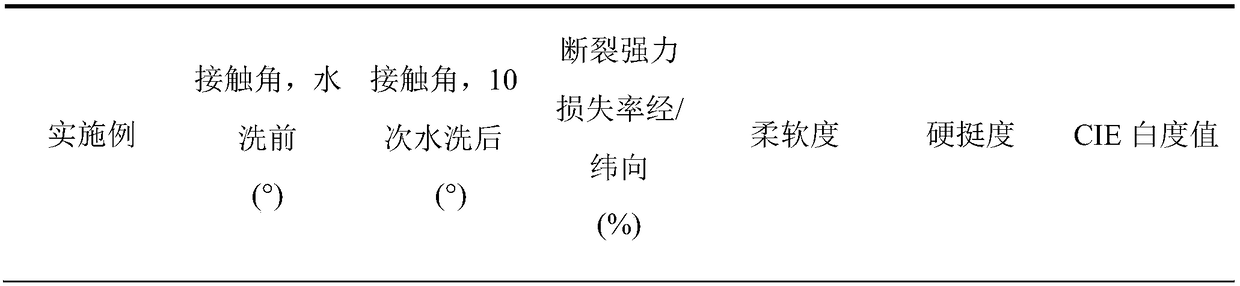

Preparation and application method for polyurethane modified acrylate water repellent

ActiveCN108978226AHigh bond strengthAvoid cold crispy hot stickyLiquid repellent fibresIsocyanateEmulsion

The invention discloses a preparation and application method for a polyurethane modified acrylate water repellent, and belongs to the technical field of macromolecules. According to the preparation and application method, an emulsion polymerization technology is adopted, diisocyanate, polymer dihydric alcohol and a hydrophilic chain extender are subjected to pre-polymerization and chain extension,an end-capping reagent is added for end-capping, then neutralization is carried out, water is added for emulsification, in the absence of an emulsifier, a product and an aliphatic acrylate monomer are subjected to copolymerization so as to prepare an anionic polyurethane modified acrylate composite emulsion, and the anionic polyurethane modified acrylate composite emulsion is used for textile finishing. The preparation and application method has the advantages that a long alkane chain endows fabric with the water repellent property, after the fabric is treated, a layer of water repellent filmis formed on the surface of the fabric, so that the water repellent capacity of the fabric is greatly improved, and polyurethane is added, the fabric can be endowed with the soft and full hand feeling; and in addition, the VOC emission amount is extremely low, and the method is suitable for environmental protection requirements.

Owner:高青如意纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com