Preparation method of emulsion type polyacrylate pressure-sensitive adhesive for reflecting film

A technology of polyacrylate and isooctyl acrylate, which is applied in the field of preparation of emulsion type polyacrylate pressure-sensitive adhesive, can solve the problems of poor water resistance, heat resistance and heat resistance, and achieve strong stickiness and improved resistance. The effect of aging and water resistance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

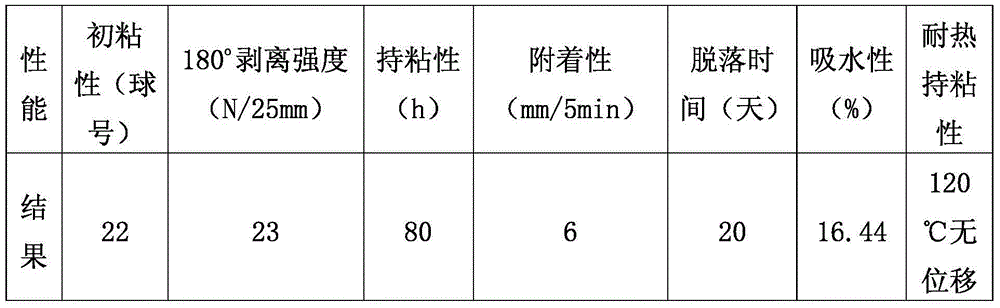

Embodiment 1

[0025] (1) Ingredients: The formula of polyacrylate pressure sensitive adhesive consists of the following components by weight:

[0026] Hard monomer: composed of 5 parts of vinyl acetate and 12 parts of methyl methacrylate;

[0027] Soft monomer: composed of 35 parts of isooctyl acrylate and 25 parts of ethyl acrylate;

[0028] Cross-linking monomer: composed of 2 parts of acrylic acid and 4 parts of methylol acrylamide;

[0029] Emulsifier: composed of 0.4 parts of sodium lauryl sulfate and 2 parts of allyloxy hydroxypropyl sodium sulfonate;

[0030] Initiator: 0.5 parts of ammonium persulfate;

[0031] Dispersant: 68 parts of deionized water.

[0032] (2) Preparation (the following parts are parts by weight):

[0033] First, 0.4 parts of sodium lauryl sulfate, 2 parts of allyloxy hydroxypropyl sodium sulfonate, and 68 parts of deionized water are heated up to 48°C and stirred at 180r / min until clear and transparent, and then 5 parts of vinyl acetate is added. 2 parts, ...

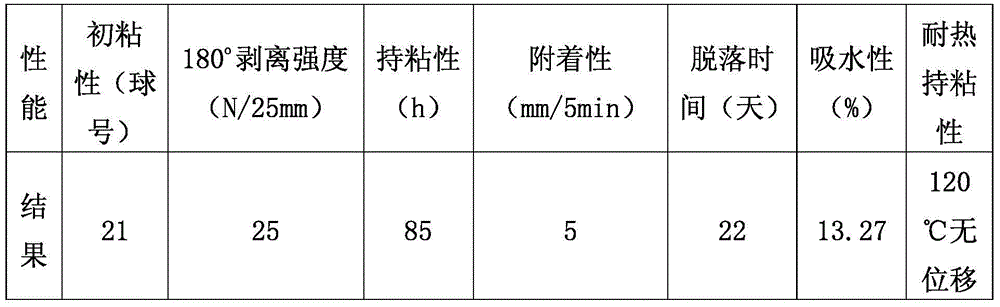

Embodiment 2

[0039] (1) Ingredients: The formula of polyacrylate pressure sensitive adhesive consists of the following components by weight:

[0040] Hard monomer: composed of 10 parts of vinyl acetate and 10 parts of methyl methacrylate;

[0041] Soft monomer: composed of 40 parts of isooctyl acrylate and 20 parts of ethyl acrylate;

[0042] Cross-linking monomer: composed of 4 parts of acrylic acid and 5 parts of methylol acrylamide;

[0043] Emulsifier: composed of 0.6 parts of sodium lauryl sulfate and 1.5 parts of allyloxy hydroxypropyl sodium sulfonate;

[0044] Initiator: 0.6 parts of dibenzoyl peroxide;

[0045] Dispersant: 72 parts of deionized water.

[0046] (2) Preparation (the following parts are parts by weight):

[0047] First, 0.6 parts of sodium lauryl sulfate, 1.5 parts of allyloxy hydroxypropyl sodium sulfonate, and 72 parts of deionized water are heated up to 55 ° C, stirred at 250 r / min until clear and transparent, and then 10 parts of vinyl acetate is added. 10 p...

Embodiment 3

[0053] (1) Ingredients: The formula of polyacrylate pressure sensitive adhesive consists of the following components by weight:

[0054] Hard monomer: composed of 15 parts of vinyl acetate and 8 parts of methyl methacrylate;

[0055] Soft monomer: composed of 45 parts of isooctyl acrylate and 12 parts of ethyl acrylate;

[0056] Cross-linking monomer: composed of 5 parts of acrylic acid and 6 parts of methylol acrylamide;

[0057] Emulsifier: composed of 0.8 parts of sodium lauryl sulfate and 2.6 parts of allyloxy hydroxypropyl sodium sulfonate;

[0058] Initiator: 0.8 parts of sodium bisulfite;

[0059] Dispersant: 76 parts of deionized water.

[0060] (2) Preparation (the following parts are parts by weight):

[0061] First, 0.8 parts of sodium lauryl sulfate, 2.6 parts of allyloxy hydroxypropyl sodium sulfonate, and 76 parts of deionized water were heated up to 45°C, stirred at 200r / min until clear and transparent, and then 15 parts of vinyl acetate was added. 2 parts, 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com