Patents

Literature

2322 results about "Wet grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer Delivery in Well Treatment Applications

InactiveUS20090023614A1Reduce solubilityEasy to pumpTransportation and packagingFluid removalActive polymerEmulsion

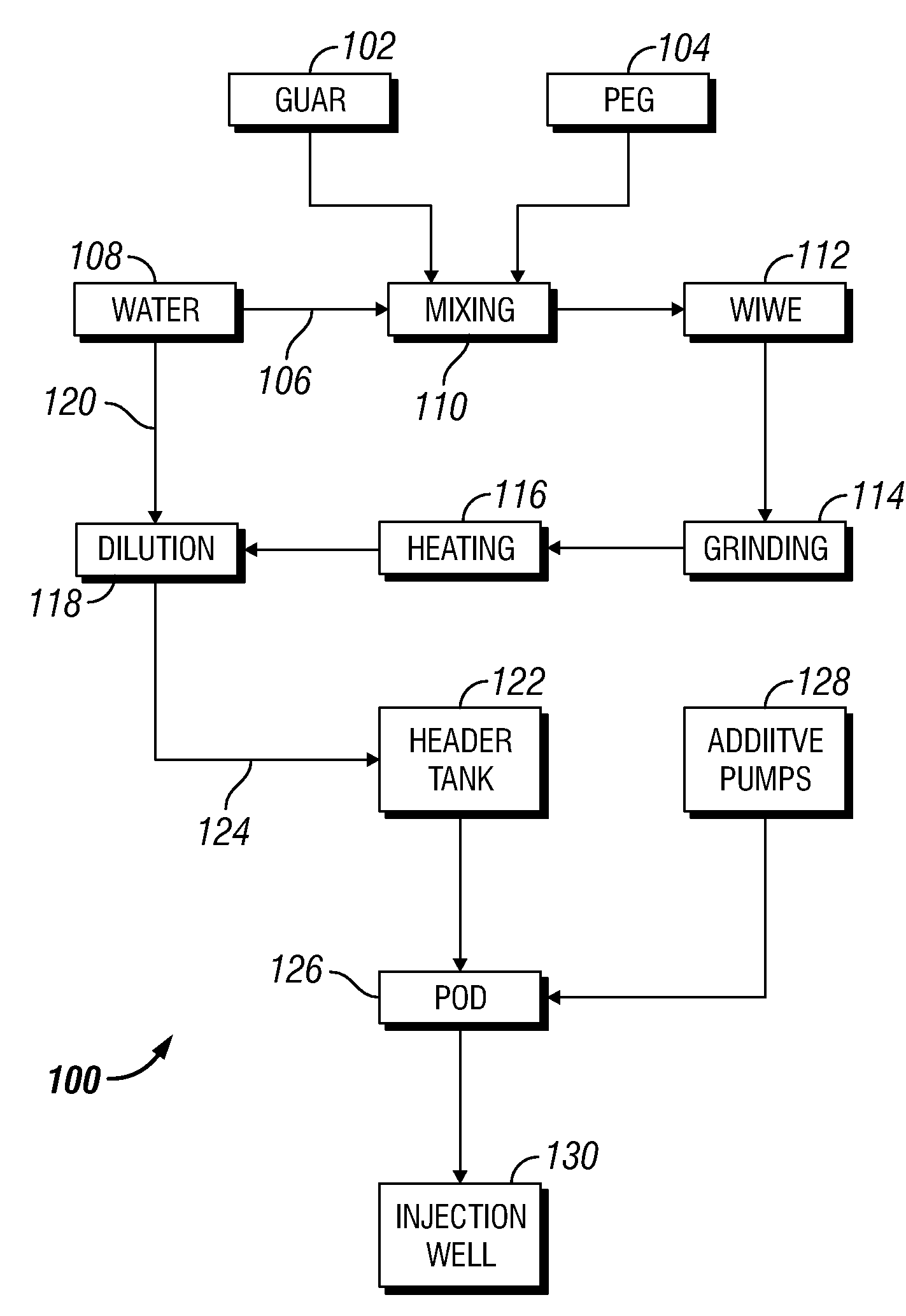

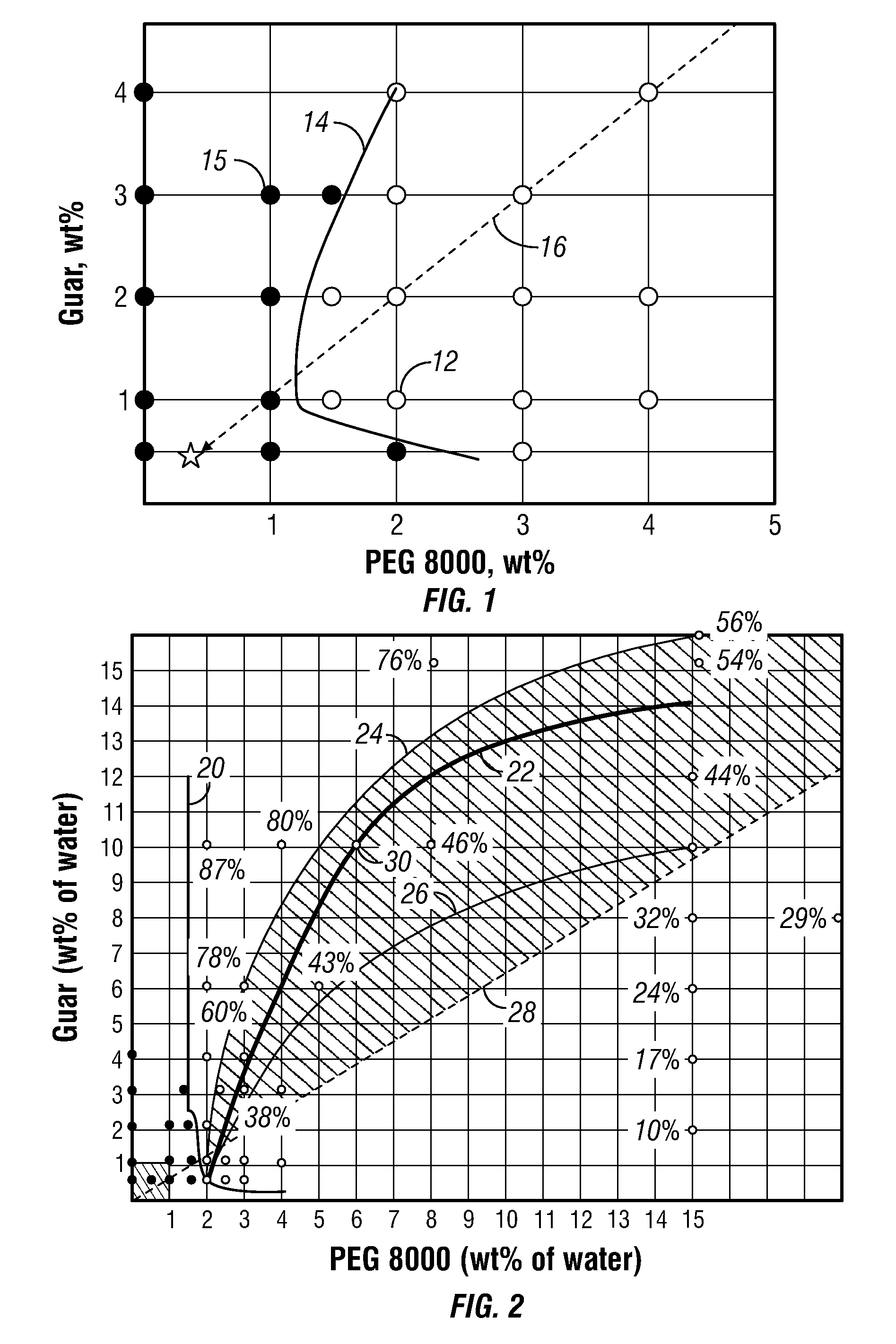

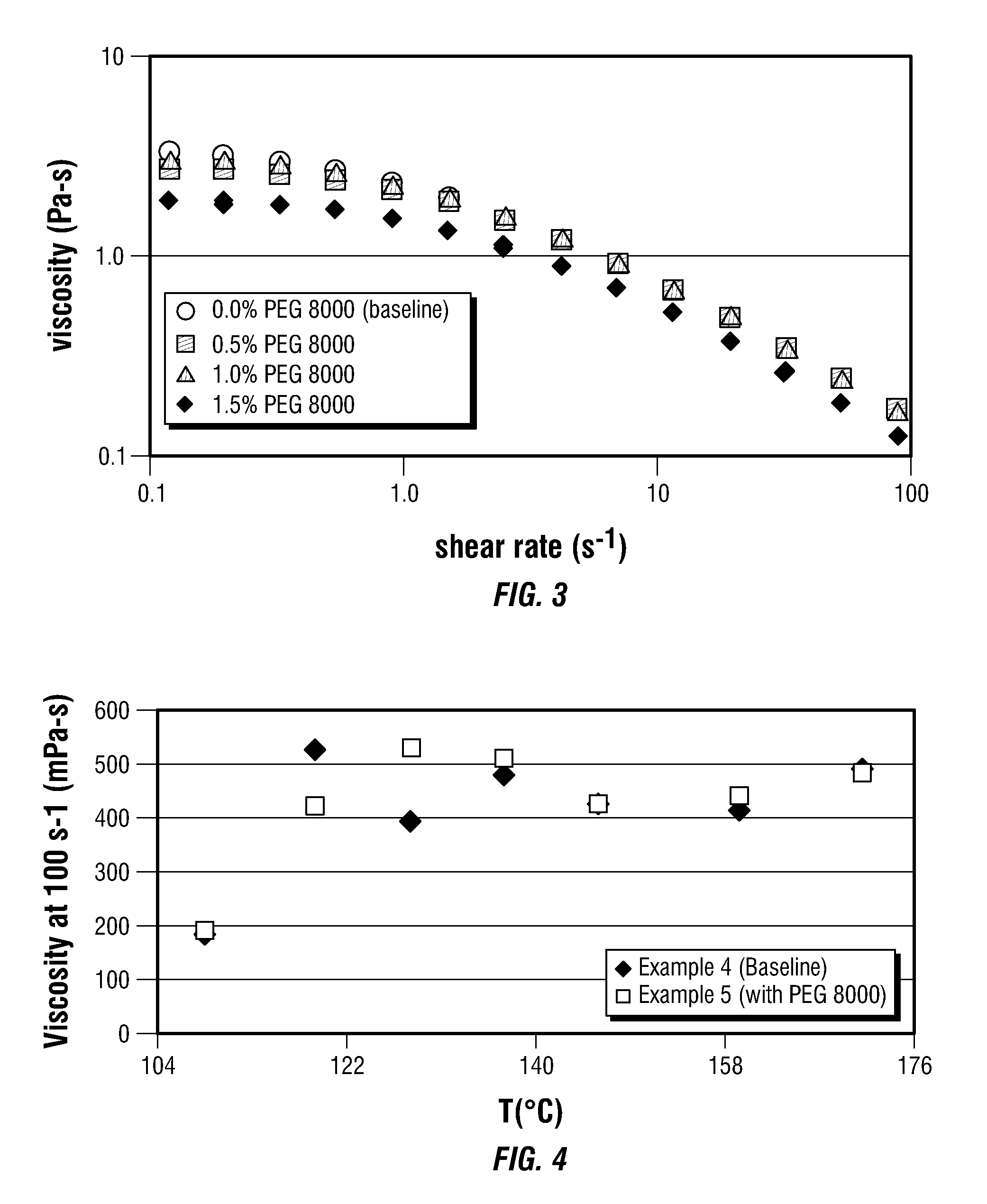

This invention relates to compositions and methods for treating subterranean formations, in particular, oilfield stimulation compositions and methods using water-in-water polymer emulsions to uniformly dissolve a rheologically active polymer, such as a thickener or friction reducer, in the treatment fluid. The emulsions have a low viscosity and are easily pumped for mixing into a treatment fluid, where upon dilution with an aqueous medium, the polymer is easily hydrated without forming fish-eyes. The partitioning agent in the water-in-water emulsion does not generally affect the rheology of the treatment fluid. The invention also relates to further processing of the emulsion by wet grinding, high shear mixing and / or heating to enhance the hydration rate in the preparation of the well treatment fluid.

Owner:SCHLUMBERGER TECH CORP

Manual thermit welding electrode and preparation and using methods thereof

ActiveCN101444876AFirmly connectedEasy to weldWelding/cutting media/materialsAlumino-thermic welding apparatusSlagEngineering

The invention discloses a manual thermit welding electrode and preparation and using method thereof which belong to the technical field of welding. A welding compound of the welding electrode comprises a thermit, a slag forming constituent and an alloying agent. Raw materials are weighed according to the proportion and arranged in a ball mill, a grinding ball and a milling medium are added, and the welding compound is obtained by drying after wet grinding; the welding compound is filled in a cylinder which is made of paper, a lead wire is arranged at one end of the cylinder, and the other end is sealed by a plastic plug, thereby forming the thermit welding electrode; the welding electrode is arranged in a sleeve which is made of paper and sealed for preservation. When in use, the sleeve is fixed on the plug at the back end of the welding electrode, the sleeve is held by a hand, and the lead wire at the front end of the welding electrode is ignited, and then the manual welding or cutting operation can be carried out. The welding electrode is small, lightweight and portable, the welding and the cutting operations are simple, rapid and safe, the welding and the cutting operations can be carried out anytime and anywhere, and the welding electrode can be applied in the welding and the cutting of steels, stainless steels or copper alloy materials.

Owner:TSINGHUA UNIV

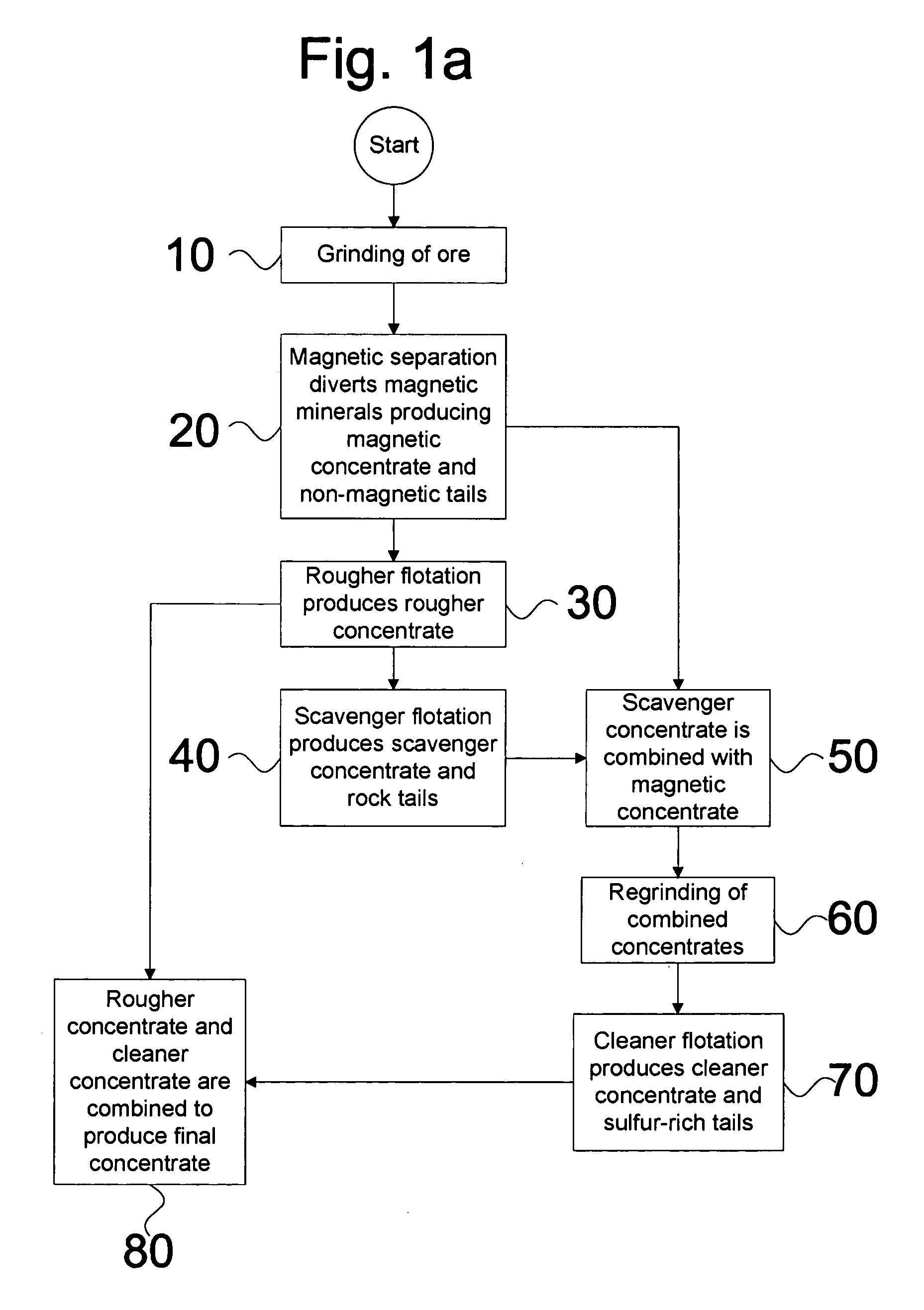

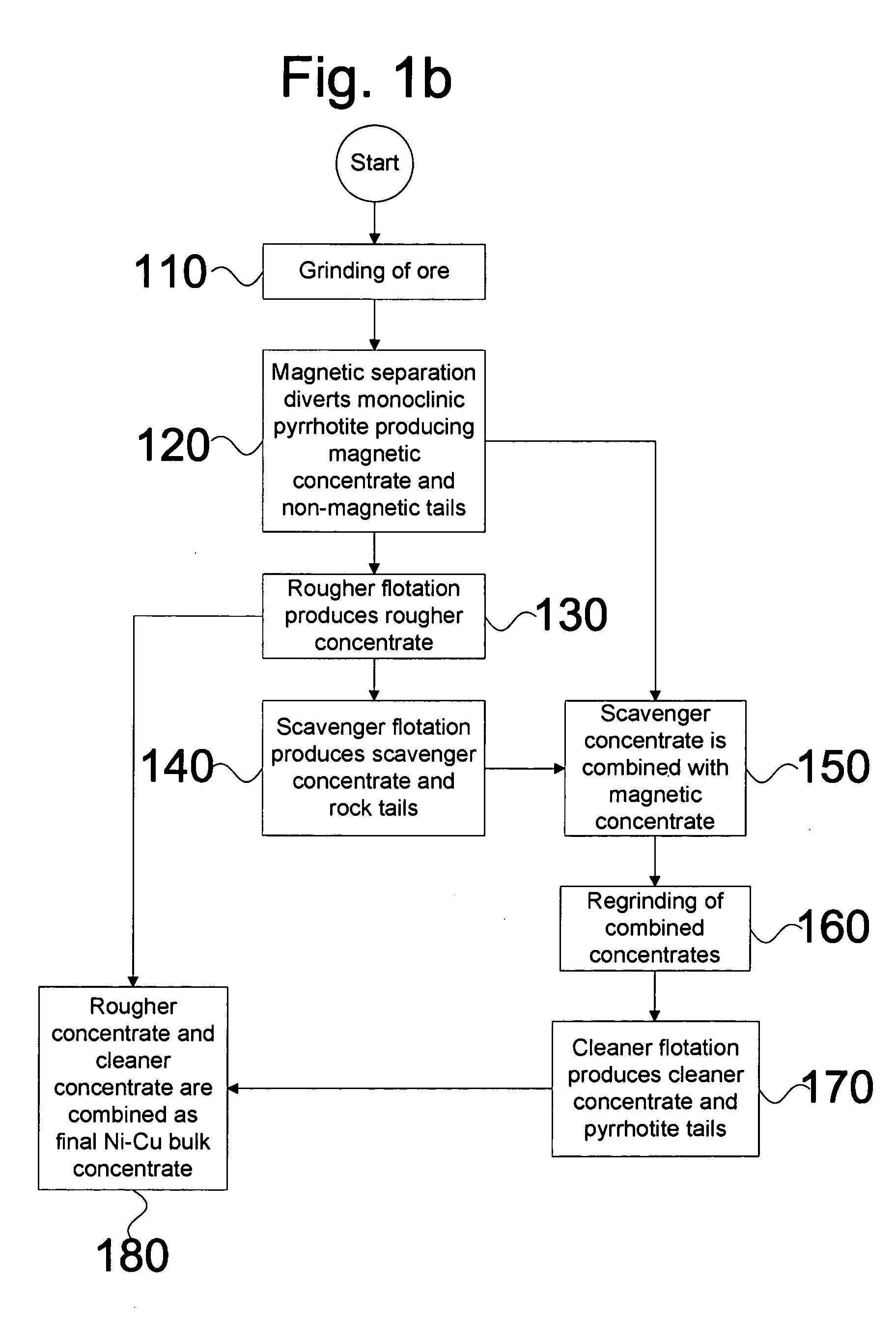

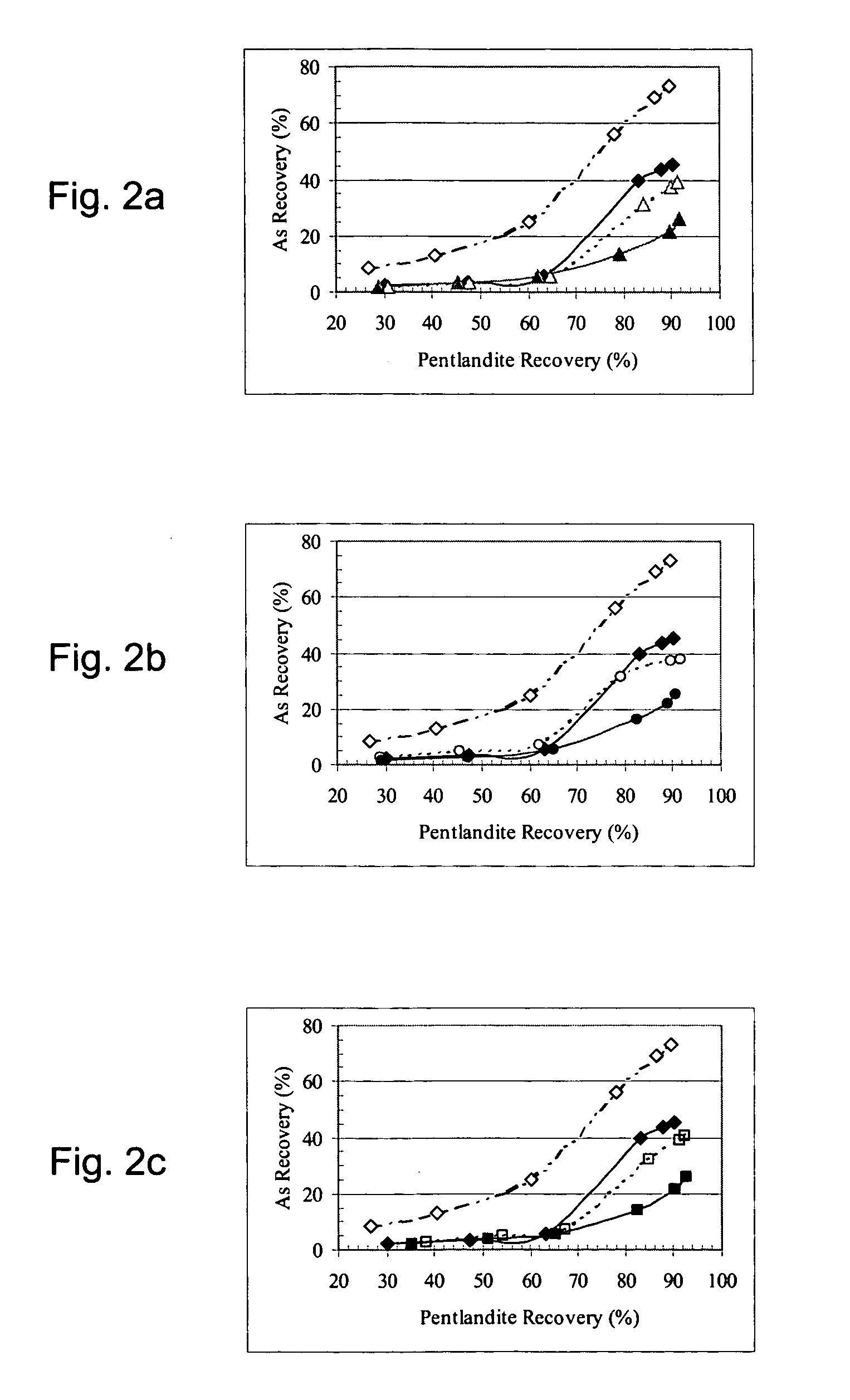

Arsenide depression in flotation of multi-sulfide minerals

A mineral separation process includes wet-grinding the ore to liberation of minerals, oxidizing the slurry using air, hydrogen peroxide or other oxidants and floating the valuable minerals at a pH between about 9.0 and 10.0 with a xanthate as collector, and a combination of a polyamine and a sulfur containing species as depressants for arsenide minerals. This depressant suite effectively depresses the flotation of arsenide minerals with no effect on the flotation of the valuable minerals.

Owner:INCO

Preparation method of ceramic granules

InactiveCN102060562ALow water absorptionHigh compressive strengthCeramicwareSpherical granuleDiiron Trioxide

The invention relates to a preparation method of ceramic granules, which comprises the following steps: drying and crushing coal ash, kaolin, ferric oxide and basic magnesium carbonate into powder after wet grinding; carrying out the biscuit firing treatment on the powder to prepare biscuit-firing granules after spherical granules are prepared; preparing microcrystal glass powder by utilizing an Li-Al-Si system; pouring the prepared microcrystal glass powder into a granulator to be stirred; preparing the biscuit-firing granules packaged by the microcrystal glass powder after the surface of the biscuit-firing granules is completely packaged by the microcrystal glass powder; placing the biscuit-firing granules packaged by the microcrystal glass powder into the granulator; adding the powder;preparing the ceramic granules to be treated through the biscuit firing after the biscuit-firing granules packaged by the microcrystal glass powder are completely packaged by the powder; and preparing the ceramic granules after the ceramic granules to be treated through the biscuit firing are placed into a muffle furnace to be sintered and crushed. In the invention, a packaging method is adopted to prepare the ceramic granules, the inner layer of the prepared ceramic granules is completely packaged by the glass powder, and the gas of the inner layer is prevented from discharging in the sintering course so that the inner layer is in a loose porous structure, thereby greatly reducing the water absorption rate of the ceramic granules and decreasing the specific gravity.

Owner:SHAANXI UNIV OF SCI & TECH +1

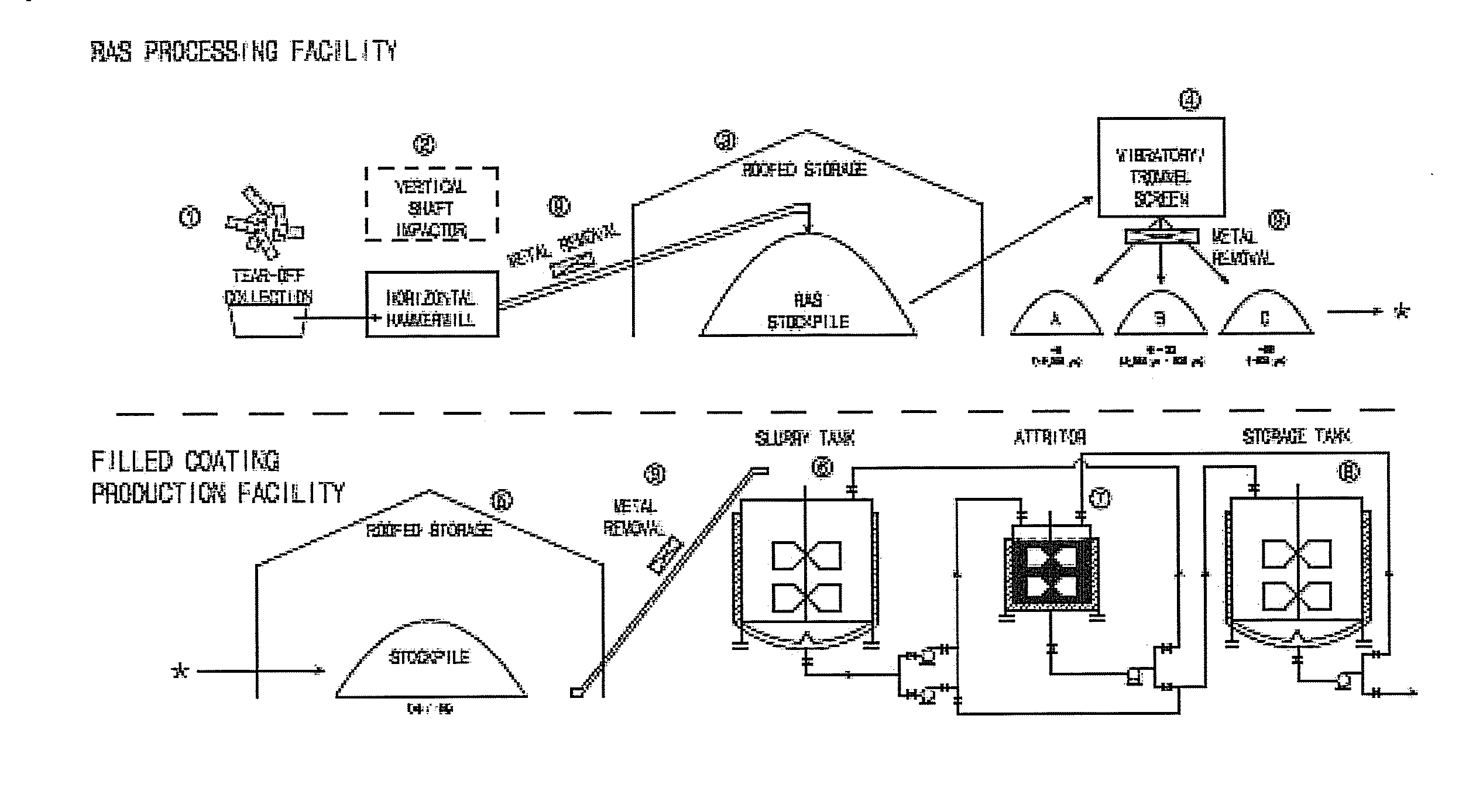

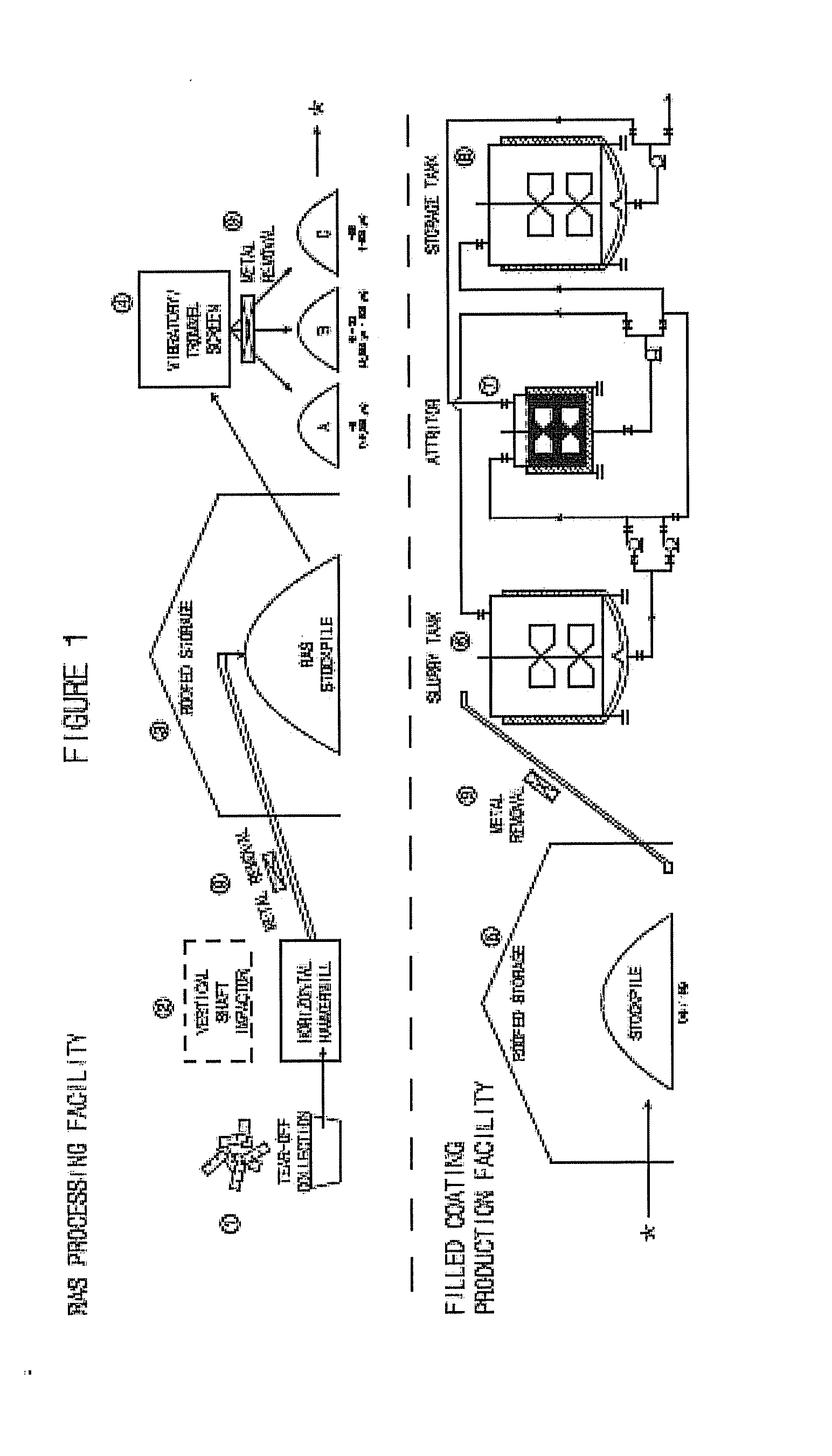

System and method for manufacturing asphalt products with recycled asphalt shingles

InactiveUS20140014000A1Minimize moisturePrevent excessive foamingIn situ pavingsRoof covering using tiles/slatesAsphalt shingleSlurry

A method for manufacturing a processed asphalt suspension is provided. The method includes dry grinding shingle waste material to a particle size of less than 1 cm, forming ground recycled shingle material, introducing virgin asphalt into a heated slurry tank and mixing the ground recycled shingle material with the virgin asphalt in the heated slurry tank, forming a mixed asphalt slurry, introducing the mixed asphalt slurry into a wet grinding machine, and recovering a processed asphalt suspension comprising particles having a size no greater than about 200 microns. Roofing and paving products manufactured from the processed asphalt suspension are also provided.

Owner:HERITAGE ENVIRONMENTAL SERVICES

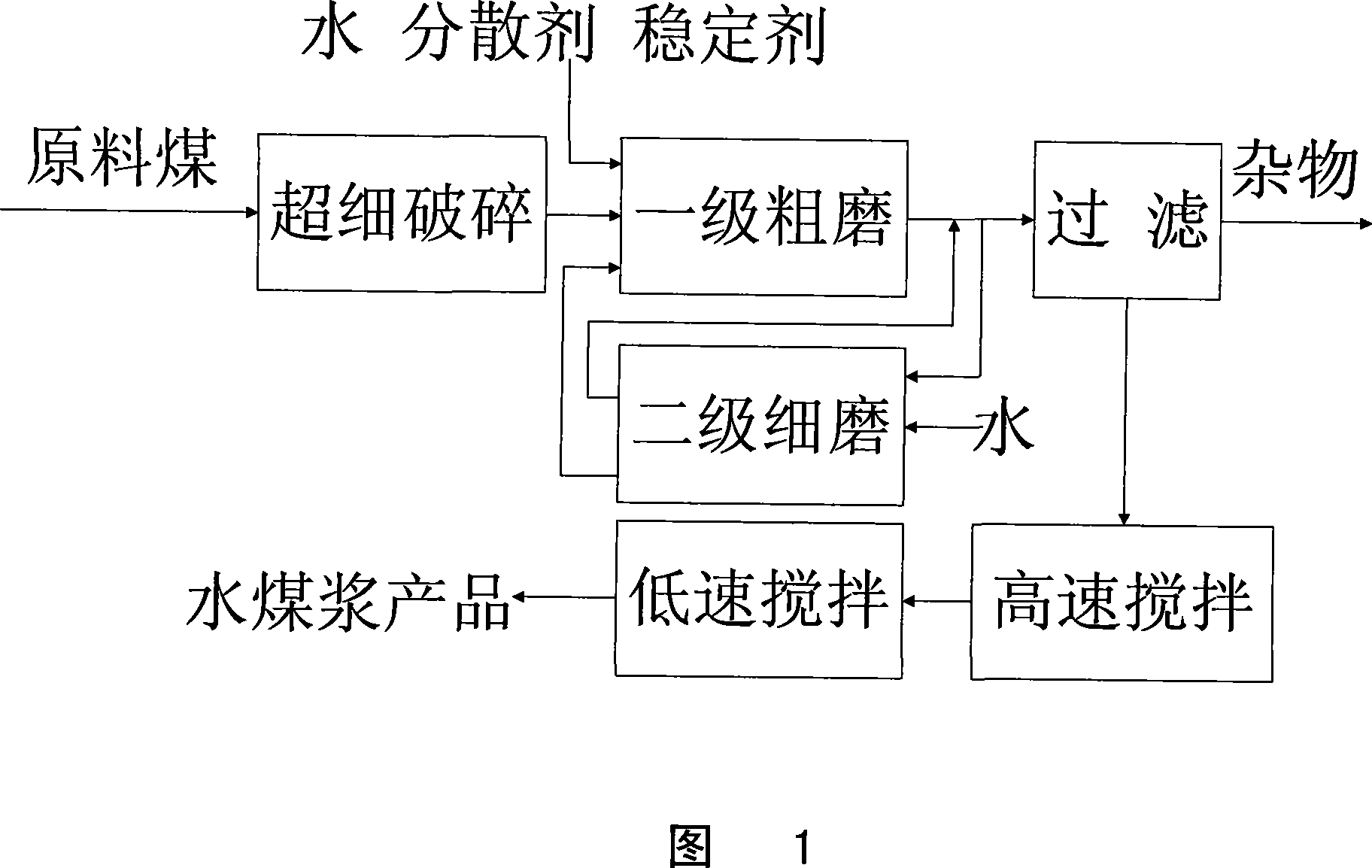

Method for preparing high concentration water-coal-slurry by low-rank coal

ActiveCN101173765AImprove particle size distributionReduce preparation energy consumptionLump/pulverulent fuel preparationHigh concentrationCoal water

The invention relates to a method for preparing high-concentration coal-water slurry by using low-rank coal. The steps include: 1) ultrafine crushing of low-rank coal; 2; 3) wet coarse grinding of the mixture; 4) ① mix 10% to 30% of the total amount of coal slurry after coarse grinding with water in a mass ratio of 5:1 to 2, and then carry out Wet fine grinding; ②The coal slurry after wet coarse grinding other than wet fine grinding is directly sent to the filter device; 5) The coal slurry after step 4) ① fine grinding is processed in the following way: ①Return all the coal slurry to step 3 ) for circulating coarse grinding; or ② return part of the coal slurry to step 3) for circulating coarse grinding, and send another part of finely ground coal slurry directly into the filter device; or ③ directly send all the coal slurry into the filter device; 6) The coal slurry sent to the filter device is filtered through a 18-20 mesh filter, and then stirred at a high speed in the stirring device, left standing, or stirred at a low speed to obtain a high-concentration coal-water slurry product.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

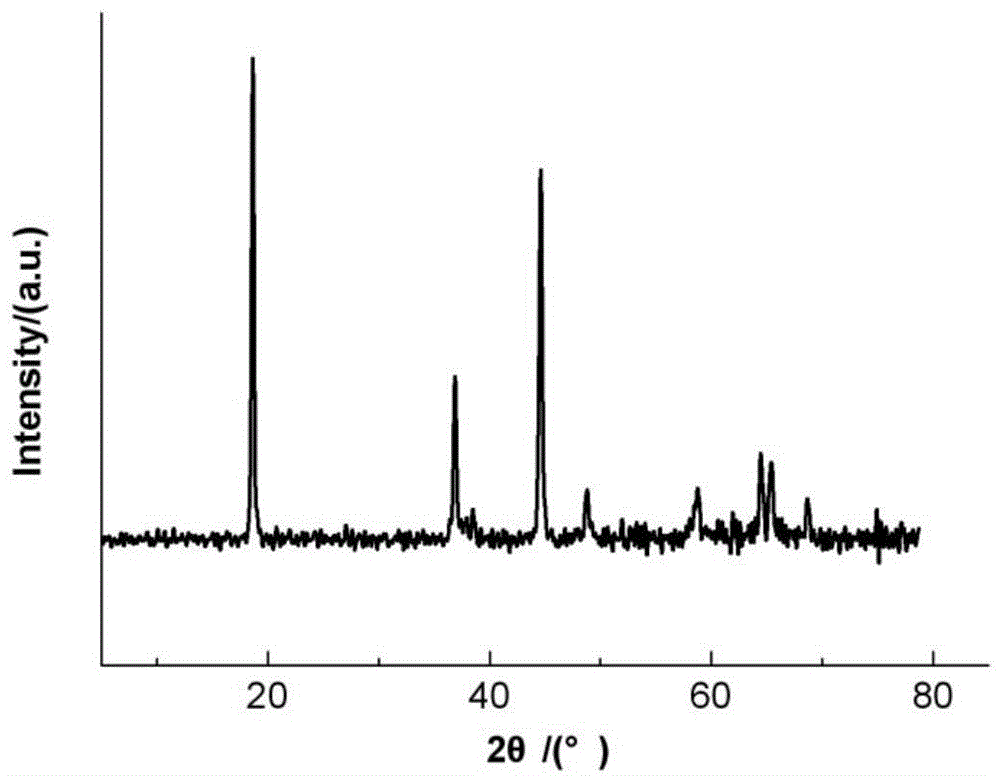

Method for preparing extra-coarse grained carbide alloy

The invention discloses a method for preparing an extra-coarse grained carbide alloy. The method is characterized by comprising the following steps of: pre-mixing extra-coarse tungsten carbide powder having a grinding Fisher particle size of over 6 mu m and cobalt powder; adding molding agents and pressing the mixture to form lumps; pre-sintering the lumps in a degumming furnace having ammonia decomposition gas therein; placing the obtained product, the tungsten carbide powder and the cobalt powder into a ball mill for smashing and wet grinding to prepare a mixture containing 6 to 13 percent cobalt; adding molding agents into the mixture, and pressing to obtain the finished product; after degumming the finished product, sintering the finished product at the high temperature by using a pressurized sintering furnace; and thermally treating the sintered product by using a double-chamber high-pressure gas cooling vacuum furnace, wherein 87 to 94 parts of tungsten carbide, 6 to 13 parts of carbide powder and 0.5 to 2.5 parts of molding agent are pre-mixed. The method avoids the dispersing or grading sieving, and cobalt coating of the tungsten carbide; moreover, the prepared carbide alloy has good compactness, high strength and impact resistance, simple production process and no environment pollution.

Owner:SHANDONG CEMENTED CARBIDE

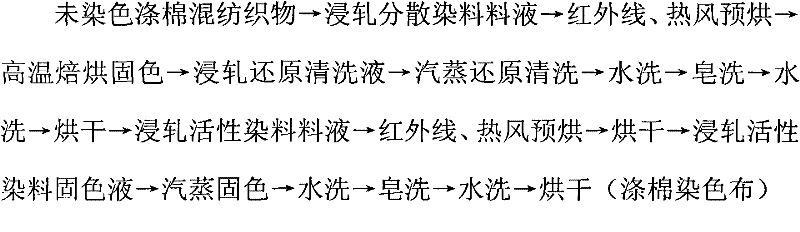

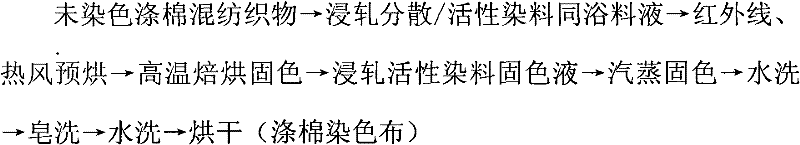

One-bath one-step process for dispersing/reactive dye of cotton-polyester blended fabric

InactiveCN102409565AReduce contentReduce consumptionSolvent-treatmentLiquid/gas/vapor removalFiberPolyester

The invention relates to a one-bath one-step process for a dispersing / reactive dye of a cotton-polyester blended fabric. The one-bath one-step process mainly comprises the following steps performed on the cotton-polyester blended fabric: dispersing / reactive dye one-bath pad dyeing; infrared and hot-air drying in advance; high-temperature baking fixation; padding in a reactive dye fixation solution; steam fixation; water washing; soaping; water washing; drying; terylene dyeing; and obtaining finished cloth. The one-bath one-step process is characterized by fully padding an unstained cotton-polyester blended fabric in a dispersing / reactive dye one-bath solution, introducing infrared and hot air so as to dry 60-70% of water in the fabric in advance, baking at high temperature so as to dye and fix color for polyester fibers, fully padding in the reactive dye fixation solution, performing steam fixation so as to dye and fix color for cotton fibers, and performing the processes of water washing, soaping and water washing so as to fully develop color on the fabric and fully wash off the surface dyeing on the fabric, thereby finishing a dyeing process. The dry and wet grinding fastness can fully meet the customer demand.

Owner:XIANGFAN NEW NO 45 PRINTING & DYEING

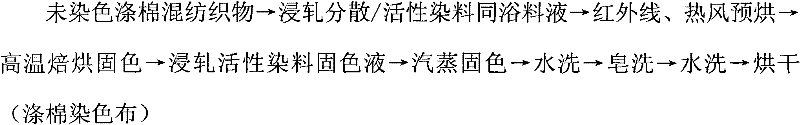

Breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking

A breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking belongs to a coal breaking dissociation flotation process. (1) coal products in a coal preparation plant serve as raw materials, and the coal which is larger than 6mm is rolled and broke into size smaller than 6mm; (2) a desliming screen is used for desliming on middings smaller than 6mm, middings which is 6-0.5mm enters a three-product dense medium cyclone, and dense medium, middings and gangue are obtained after two-stage medium separation is carried out; (3) the middings smaller than 0.5mm is mixed with clean coal magnetic separation gangue, a grading hydrocyclones group is adopted to conduct high frequency screening to obtain high ash fine silt contained slurry water, and coarse particle are mixed with middings on the midding sculping screen to enter a ball mill for wet grinding; and (4) products after grinding enter a flotation column to conduct flotation, foam clean coal and tailing are respectively concentrated, filtered and dewatered to obtain flotation clean coal and tailing products. The breaking grinding dissociation and re-flotation two-stage recovery process has the advantages that the high ash fine silt in fine fraction is pre-selected, pollution of the high ash fine silt is reduced, equipment separation particle size range is reduced, separation accuracy of equipment is improved, and scarce coking coal resources are recovered as far as possible.

Owner:CHINA UNIV OF MINING & TECH

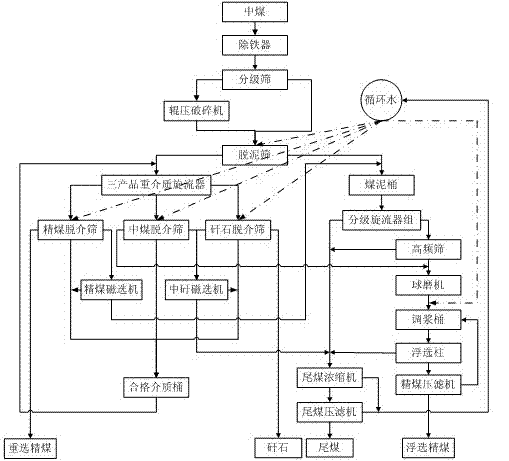

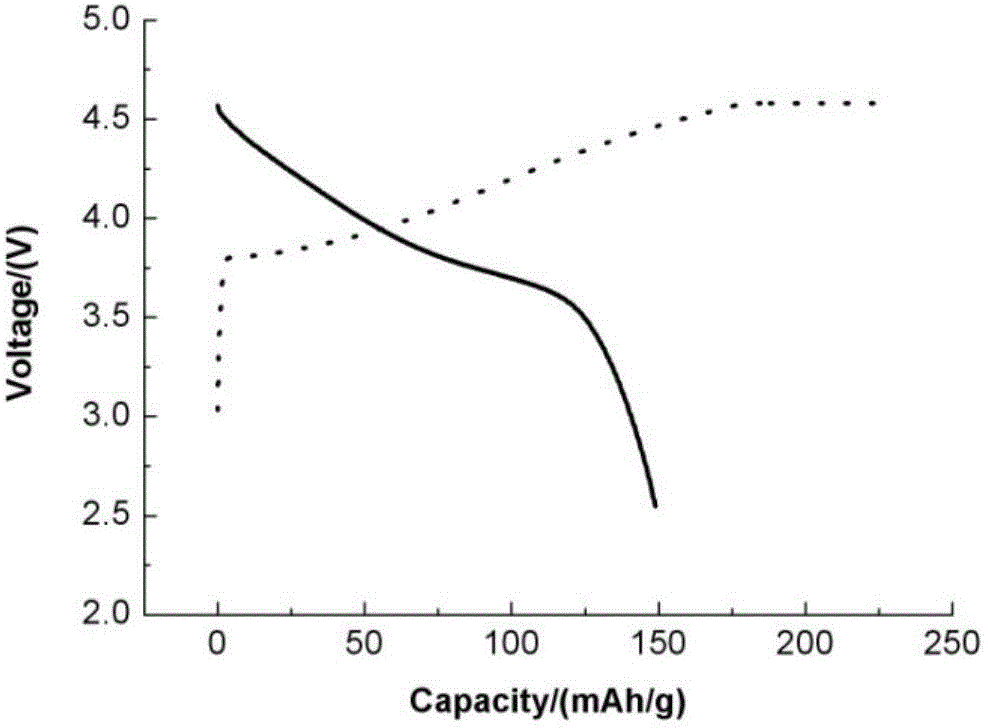

Method for preparing trivalent ion-doped lithium-rich solid solution cathode material

Owner:FUJIAN NORMAL UNIV

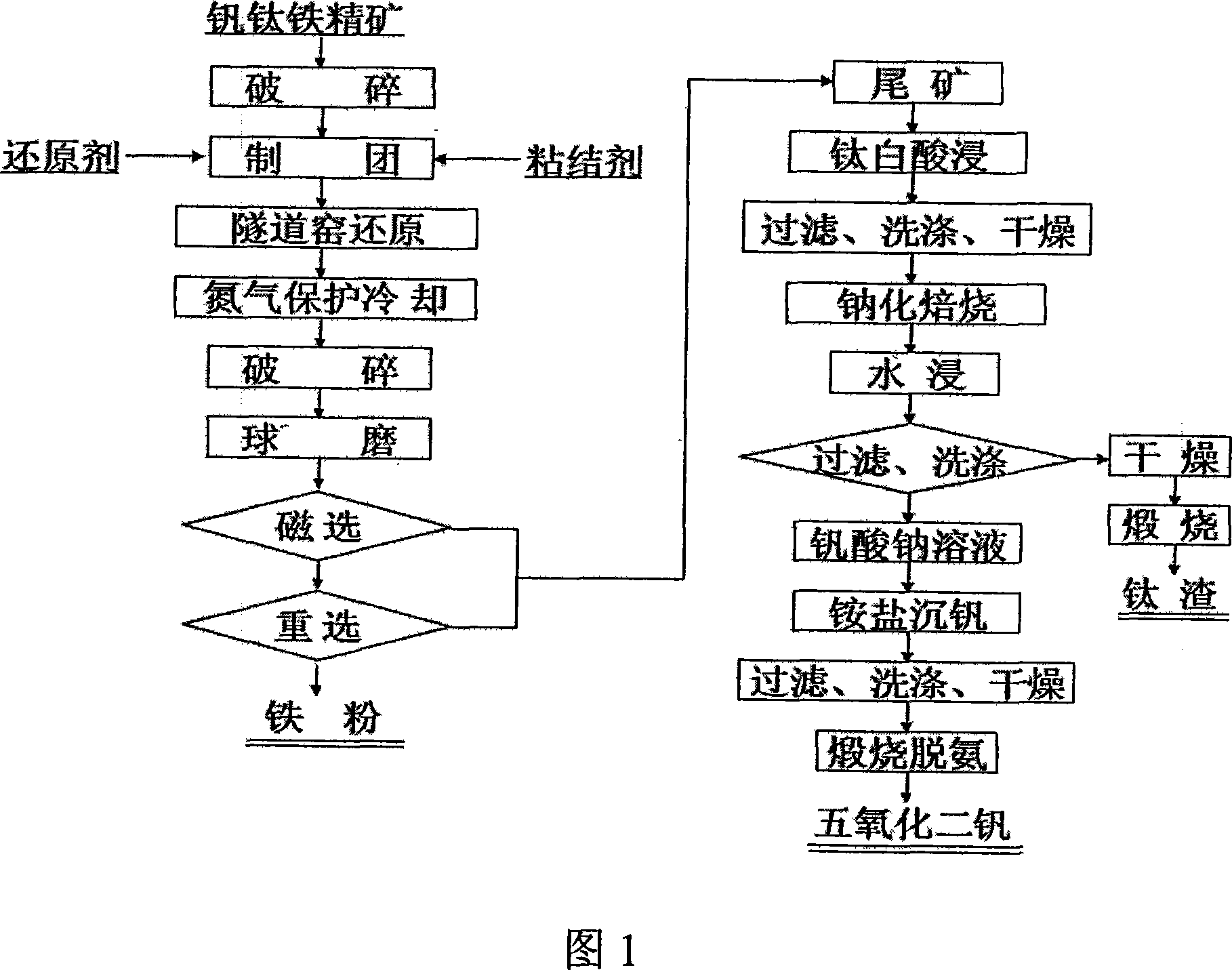

Method for comprehensive utilization of V-Ti-bearing iron ore concentrate by using tunnel kiln reduction-grinding - separation

InactiveCN101113488AAvoid defects such as loopsHigh yieldProcess efficiency improvementTunnel kilnResource utilization

The invention relates to an iron powder production method by using a tunnel kiln to reduce concentrate pellets containing carbon vanadium ferrotitanium with titanium slag and vanadium pentoxide as combined products. Concentrate pellets are made from vanadium-titanium iron concentrate through crashing and damp milling. The iron powder and tailings are obtained by putting the concentrate pellets into the tunnel kiln to be reduced, crashing, wet-grinding, magnetic separation and gravity separation. The tailings are soaked with titania waste acid to eliminate remnants magnesium and iron. Then the tailings are filtrated and dried to obtain a new material. And then the new material is added with sodium salt to do salt roast and then to be soaked by water, then titanium slag and sodium vanadate are obtained respectively after the water soaking. At last, the vanadium pentoxide is obtained by ammonium vanadate precipitating and calcination deaminase to the sodium vanadate liquid. The invention eliminates the disadvantage of high energy consumption by electric furnace smelting and bad separating effect of vanadium and titanium, difficult control of vanadium and titanium trend and low yield rate of extracting vanadium and titanium through converter blowing iron molten, etc. The invention has the advantages of high yield rate of vanadium, titanium and iron and high resources utilization rate and explores a novel practical way for comprehensive utilization of vanadium, titanium and iron concentrate ore.

Owner:攀枝花锐龙冶化材料开发有限公司

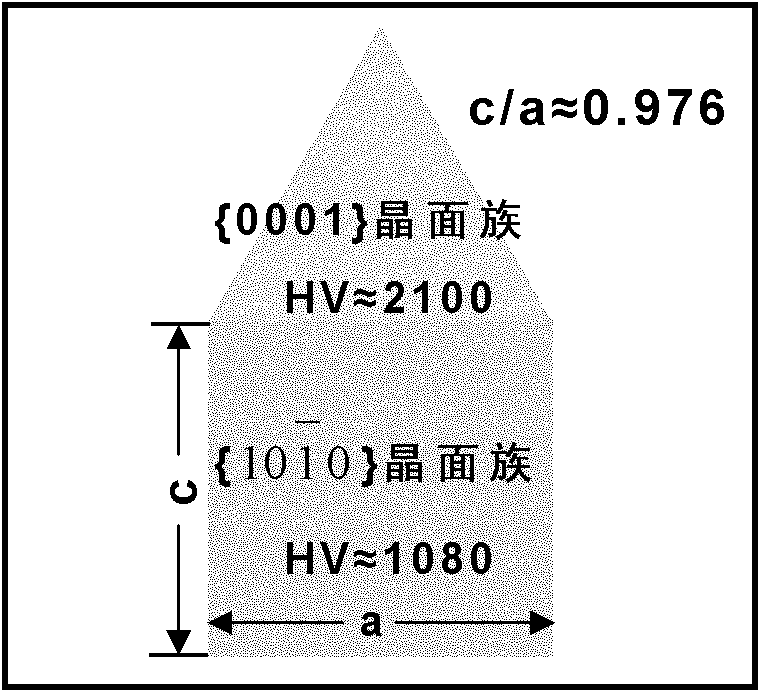

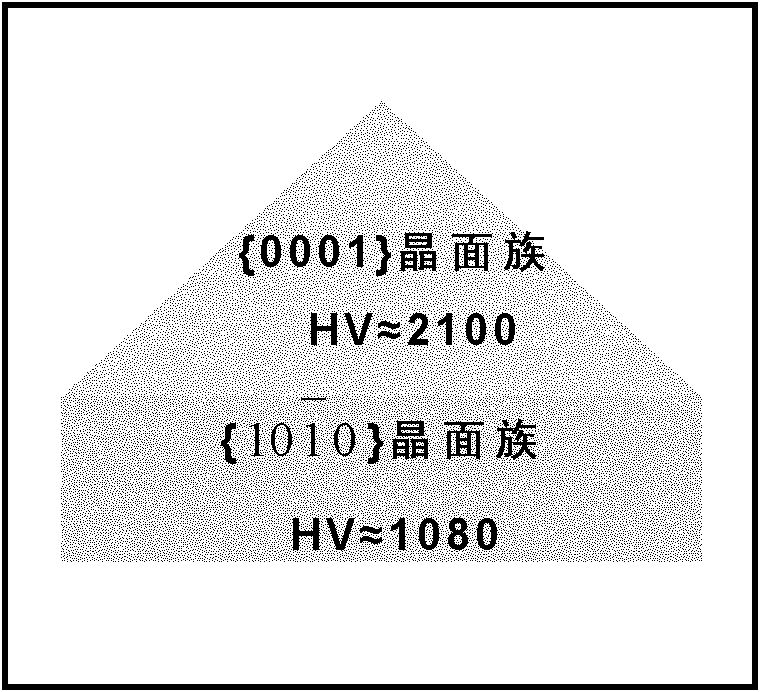

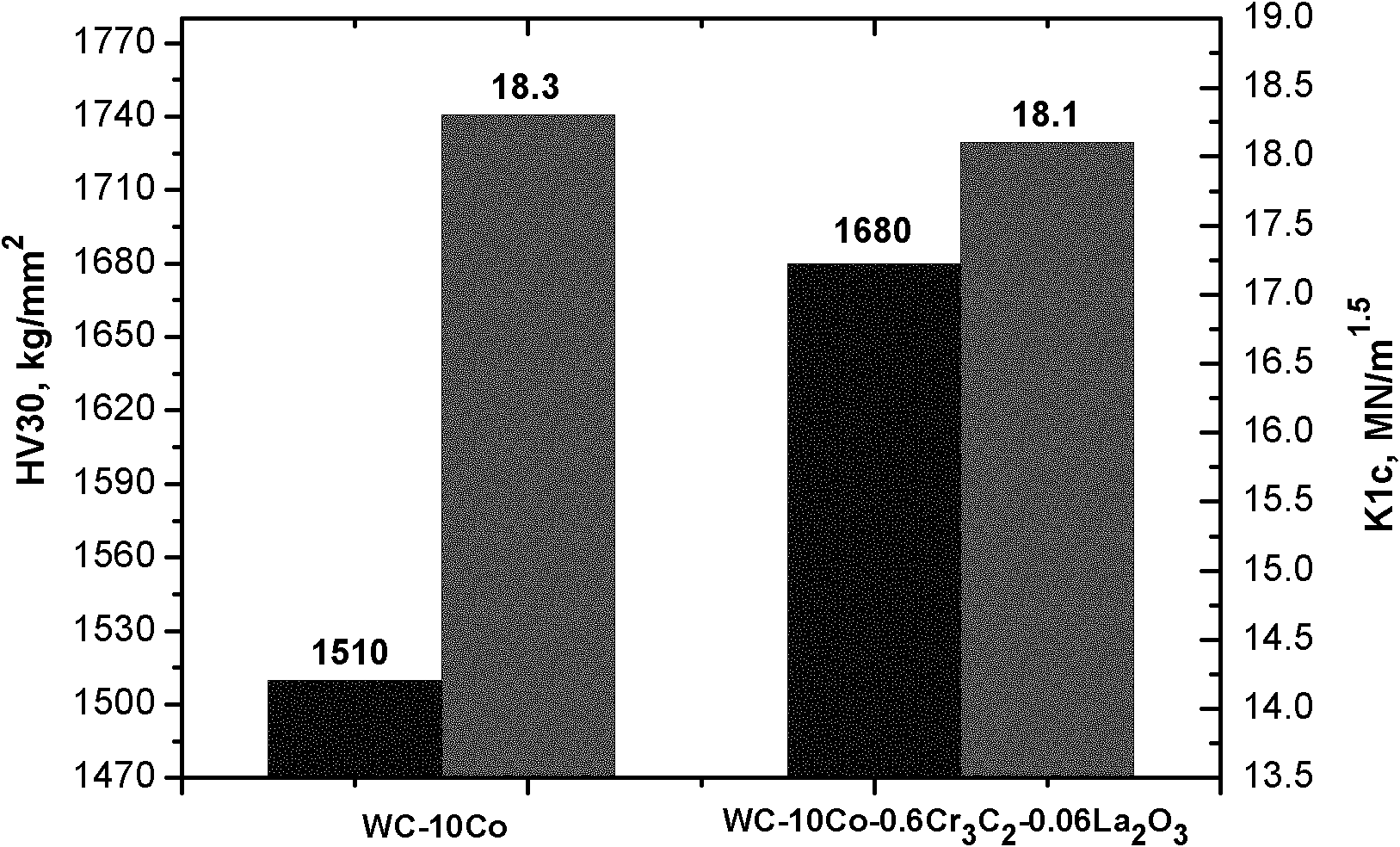

Method for preparing WC base hard alloy with high hardness and high toughness

The invention discloses a method for preparing a WC base hard alloy with high hardness and high toughness. Nano W powder, nano graphite powder and superfine Co powder or superfine Ni powder or superfine Co powder and superfine Ni powder with the specific surface area average granularity of smaller than 0.5 micron are used as raw materials; superfine Cr3C2 and rare earth are used as combined doping agents; the addition amount of the superfine Cr3C2 is controlled to account for 6-8 percent by mass of alloy binding agent; the addition amount of rare earth is controlled to account for 0.3-0.7 percent by mass of alloy binding agent in the terms of oxide; W-Co-C or W-Ni-C or a W-Co-Ni-C mixed material which is combined and doped by superfine Cr3C2 and rare earth is prepared by adopting a wet grinding process; an alloy press blank is prepared by adopting a die forming or hydrostaticisostatic forming process according to the product size and appearance characteristics; alloy is sintered by adopting a vacuum-sintering process or a pressure sintering process; and the alloy sintering temperature is controlled between 1,360 DEG C and 1,420 DEG C. According to the invention, WC base hard alloy with high crystalline perfection, pure plate-shaped crystal structure and isotropy can be prepared and the double-high performance characteristics of the alloy are realized.

Owner:GUANGDONG XIANGLU TUNGSTEN

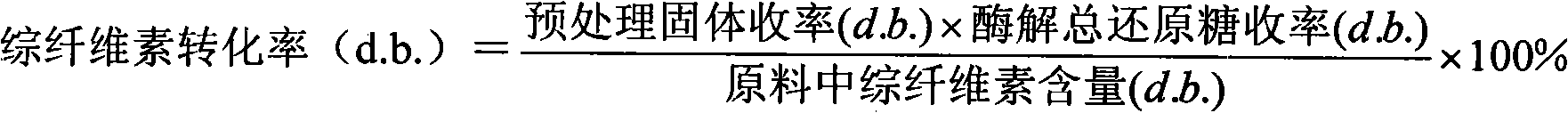

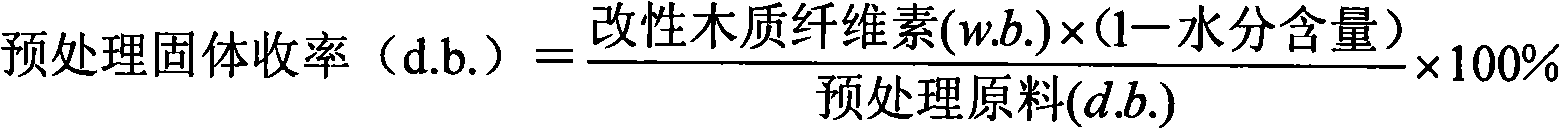

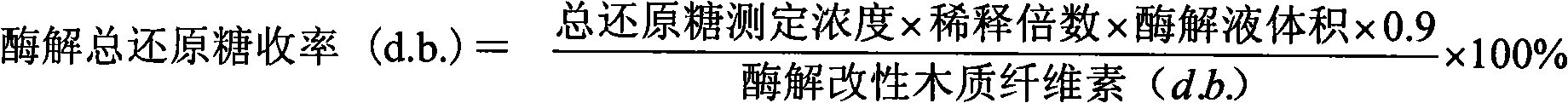

Pre-treatment method for highly-effective saccharification of lignocellulose

InactiveCN101255479AReduce the cost of trainingImprove securitySugar derivativesSugar derivatives preparationCelluloseLiquid glucose

The invention discloses a pretreatment method for effectively saccharifying lignocellulose, particularly discloses a pretreatment method of lignocellulose with room-temperature light-concentration lye, characterized in the method comprises the steps of coarse grinding, lye wetmilling, alkali recovery and enzymolysizing. The ground lignocellulose is mixed with univalent metal lye having a concentration of 0.1% to 3%, solid and liquid are separated under room temperature after wet grinding, wherein the liquid is used for recovering univalent metal lye, and the solid, namely the modified lignocellulose, is used for further enzymolysizing for preparing liquid glucose. According to the invention, lignocellulose is used as the raw material, room temperature condition without external heating can be selected, low-concentration lye is pretreated, the lye can be effectively recovered, the enzymolysis efficiency is improved, the glucose yield is increased, the cost is lowered, the economical efficiency is enhanced, and drawbacks of high energy consumption, low glucose recovery rate, and high equipment requirements in current lignocellulose pretreatment method are made up.

Owner:NANJING TECH UNIV

Method for preparing foamed ceramic insulation board by waste glass ceramic wafer

The invention discloses a method for preparing a foamed ceramic insulation board by a waste glass ceramic wafer, belonging to the field of preparation technology of the foamed ceramic insulation board. The method comprises the steps of: washing the waste glass ceramic wafer with clear water, drying and grinding by ball milling to obtain waste glass ceramic powder with the fineness less than or equal to 100mu m; mixing the waste glass ceramic powder, pulverized fuel ash, furnace slag, coal gangue, ceramic tailings, foaming agent and modifying agent according to the mass ratio of (30-40):(10-15):(5-7):(10-18):(25-35):(1.8-2.2):(1.1-1.5); putting the mixture into a ball grinding mill, carrying out wet grinding and evenly mixing to form mixed slurry; drying by a pressure type spray granulation dryer and putting the dried product into a foaming refractory mould coated with aluminum oxide; heating to 1120-1150 DEG C in a heating furnace; and finally, annealing, cooling and cutting to obtain the foamed ceramic insulation board. The method is low in production cost and simple in technology, and can be used for continuously preparing the porous foamed ceramic insulation board with large size; and the product is good in performances.

Owner:ANSHENG SCI & TECH DEP

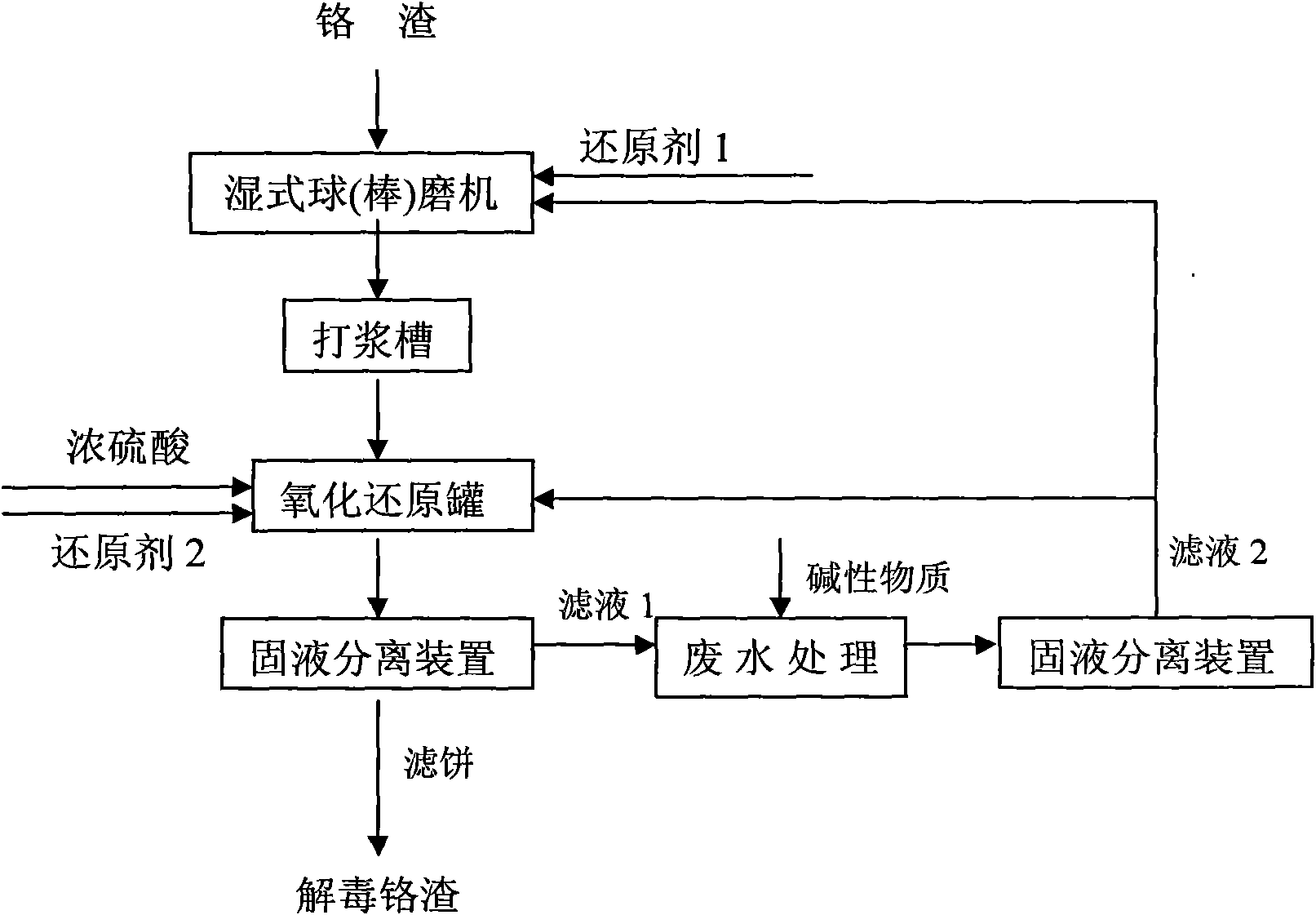

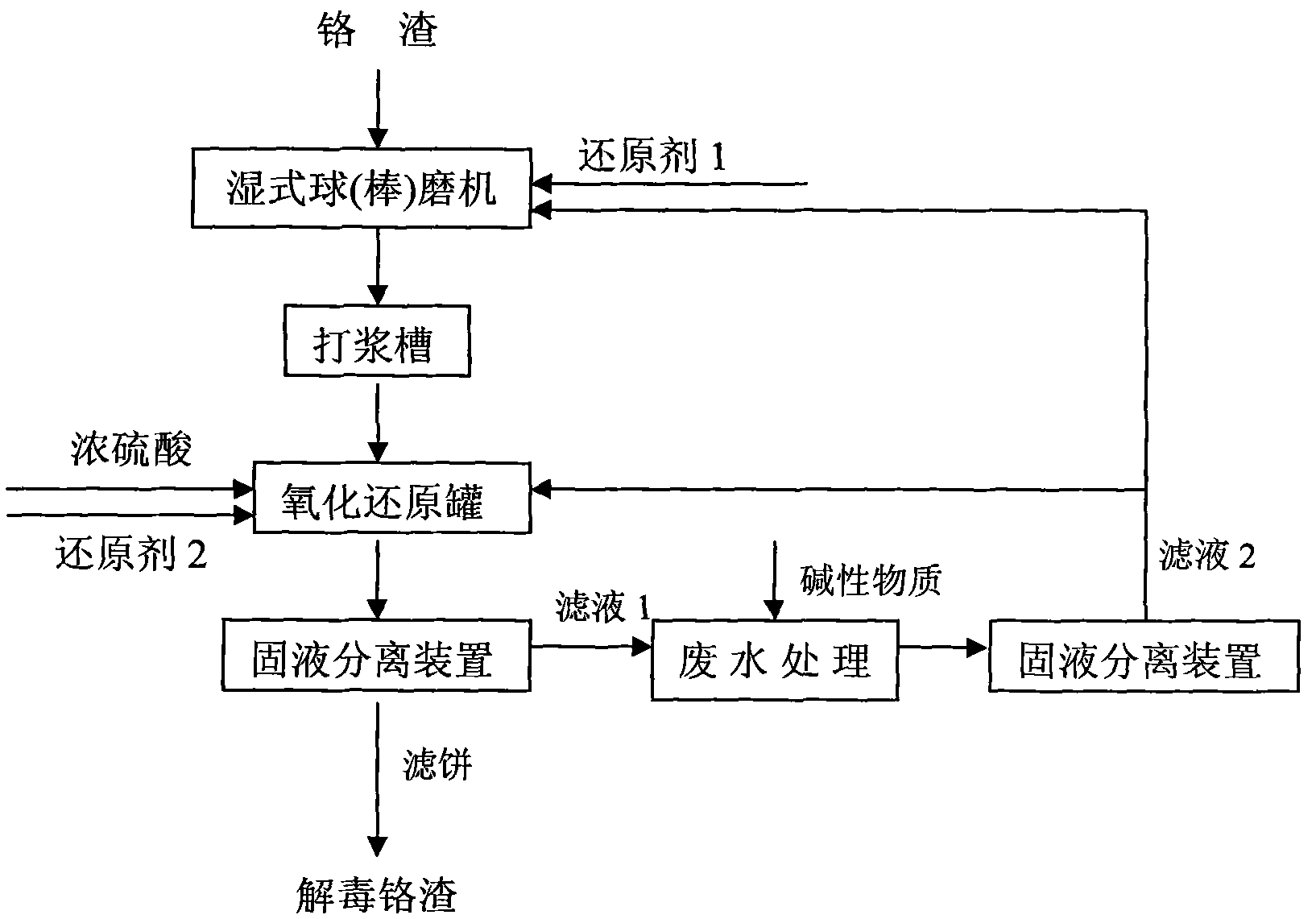

Chromium residue detoxifying process

InactiveCN101816829AReduce dosageImprove mixing uniformityChemical protectionSodium hydrosulfideSlurry

The invention belongs to the technical field of chromium residue detoxifying, and discloses a chromium residue detoxifying process. The process comprises the following steps of: performing wet grinding on chromium residue, adding water into the chromium residue to prepare chromium residue slurry; and after being subjected to acid-leaching reduction reaction, performing solid-liquid separation on the chromium residue slurry to obtain a filter cake, namely the detoxified chromium residue. The process is characterized in that: under the condition of not changing the original alkaline environment of the chromium residue, a reducing agent 1 is added into the chromium residue directly, and then the reducing agent and the chromium residue are subjected to wet grinding to form particles with 100 to 300 meshes; and the water is added to prepare the chromium residue slurry with 30 to 45 baume degrees, wherein the reducing agent 1 is sodium sulphide, sodium bisulfide, sodium thiosulfate or sodium pyrosulfite. The process has simpleness, thorough detoxification, no chromium return phenomenon and easy implementation of mass production; and the process prolongs effective reduction reaction time, improves reaction efficiency, saves the using amount of acid during the acid-leaching reduction, and has low processing cost because Cr6+ in the chromium residue is subjected to two times of dissolution and reduction.

Owner:河南金谷环保工程设备有限公司

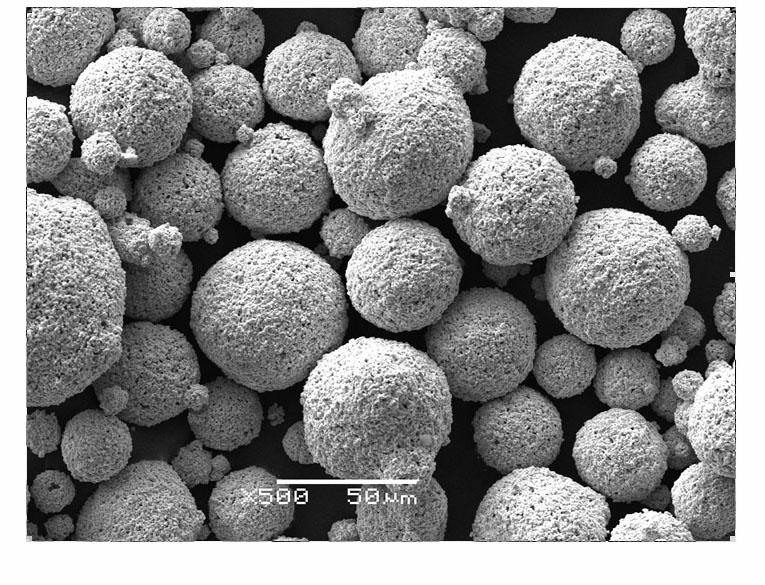

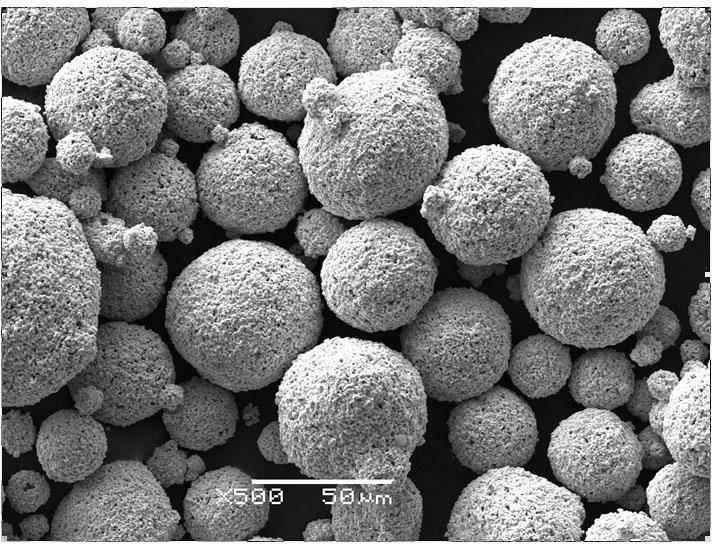

Method for producing spherical thermal-spraying powder

The invention discloses a method for producing spherical thermal-spraying powder. The method sequentially comprises the steps of: A, firstly, adding 55-95% of tungsten carbide powder, 5-33% of metal nickel powder or cobalt powder or iron powder, and 0-22% of chromium carbide powder into a ball grinding mill in terms of mass percentage, meanwhile, adding 15-35% of wet-grinding media and 2-5% of a forming agent in terms of the total mass of raw material powder, and performing wet grinding for 12-40h to obtain mixed slurry; B, centrifuging, atomizing and pelleting to obtain spherical mixed powder; C, placing the spherical mixed powder into a dewaxing and sintering integrated furnace, removing the forming agent, sintering for 20-70min in vacuum at the temperature of 800-1350 DEG C, cooling to below 50 DEG C and discharging out of the furnace; and D, crushing and sieving agglomerate materials obtained in the step C to obtain the spherical thermal-spraying powder. The method disclosed by the invention has wide applicability, and is not only suitable for producing the tungsten-carbide-based spherical thermal-spraying powder but also suitable for producing the thermal-spraying powder of other metal, nonmetal and mixtures of metal and nonmetal; and a production process is nonhazardous, the quality is stable and consistent, and the thermal-spraying powder smaller than 30 micrometers can be produced.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

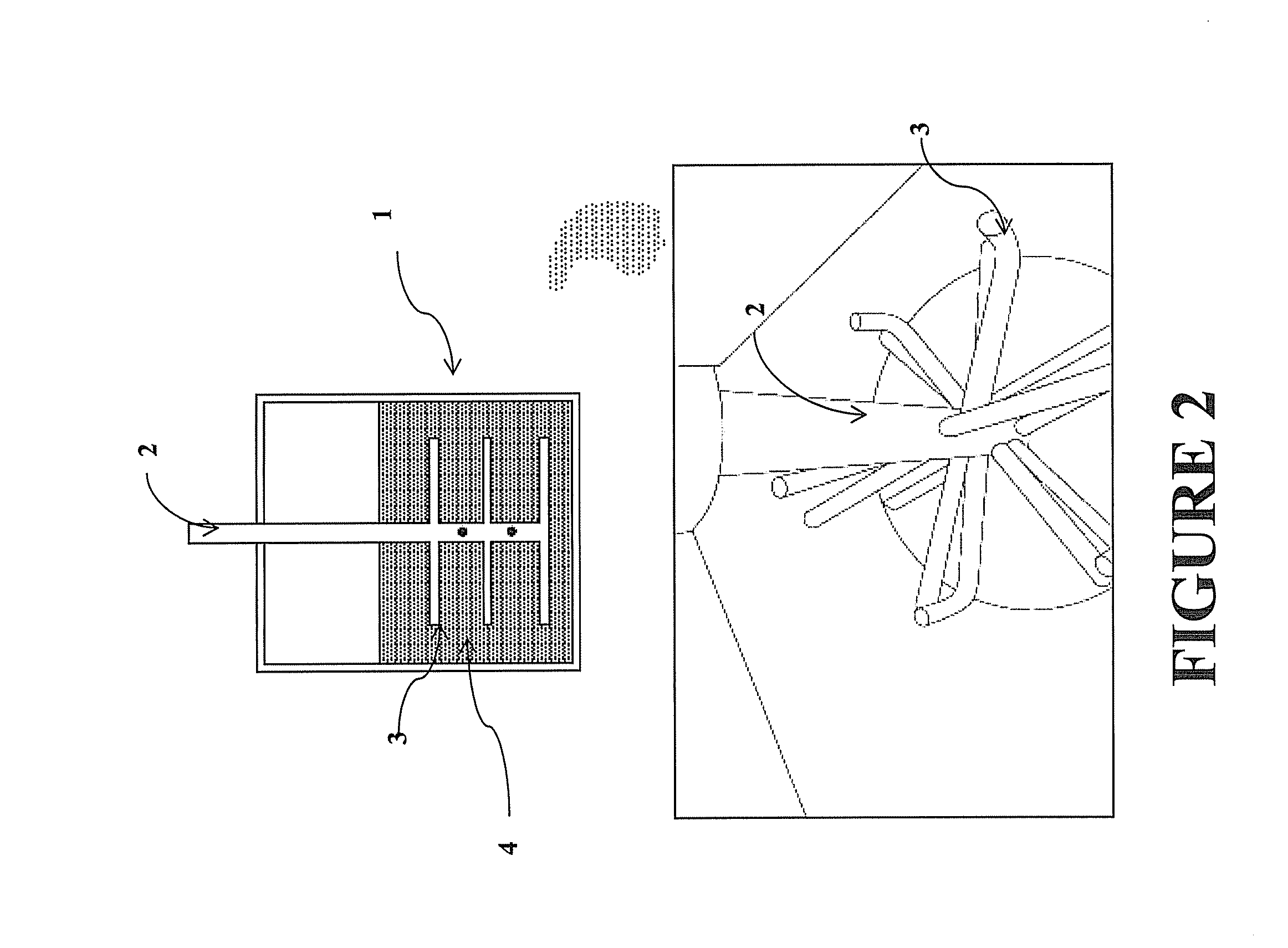

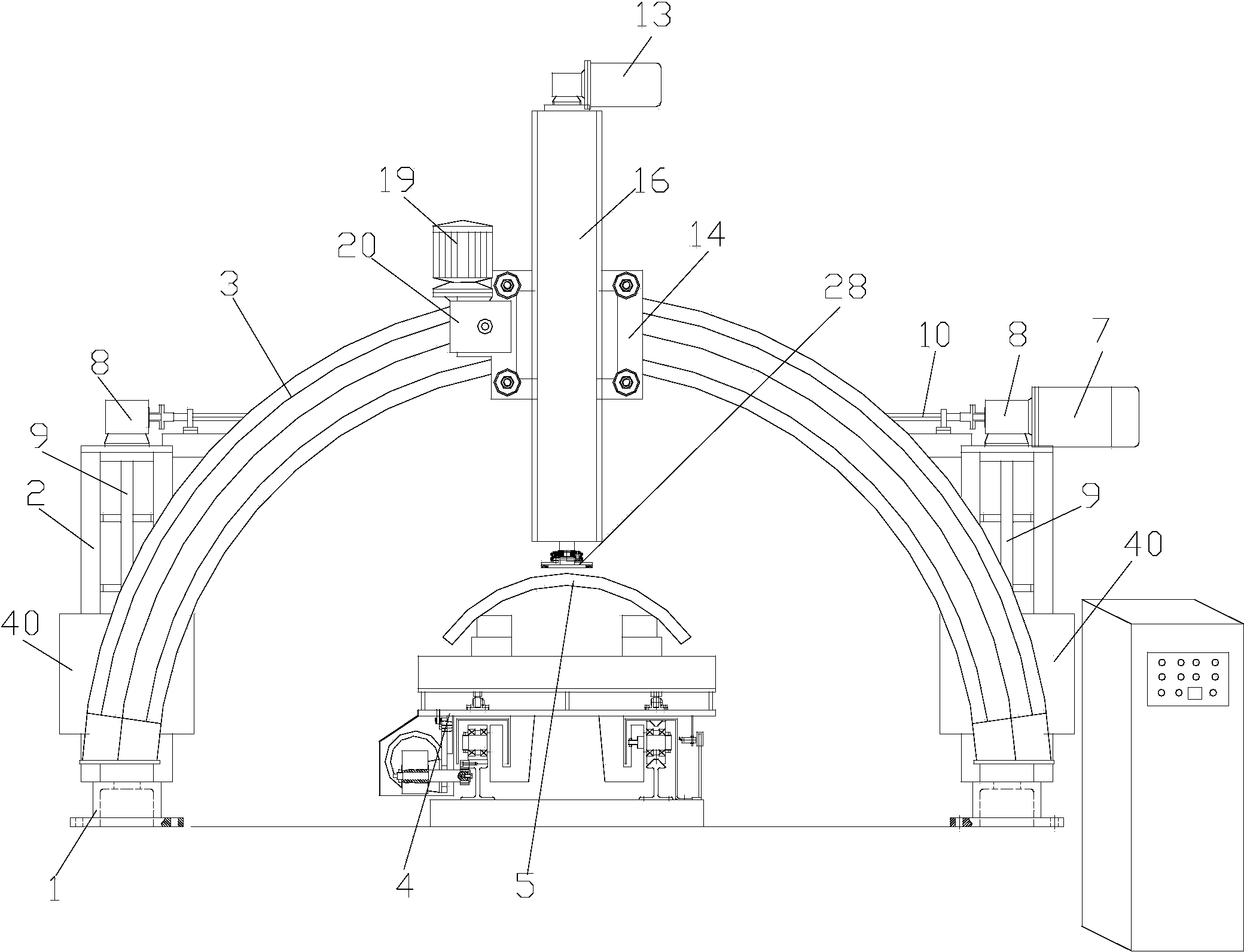

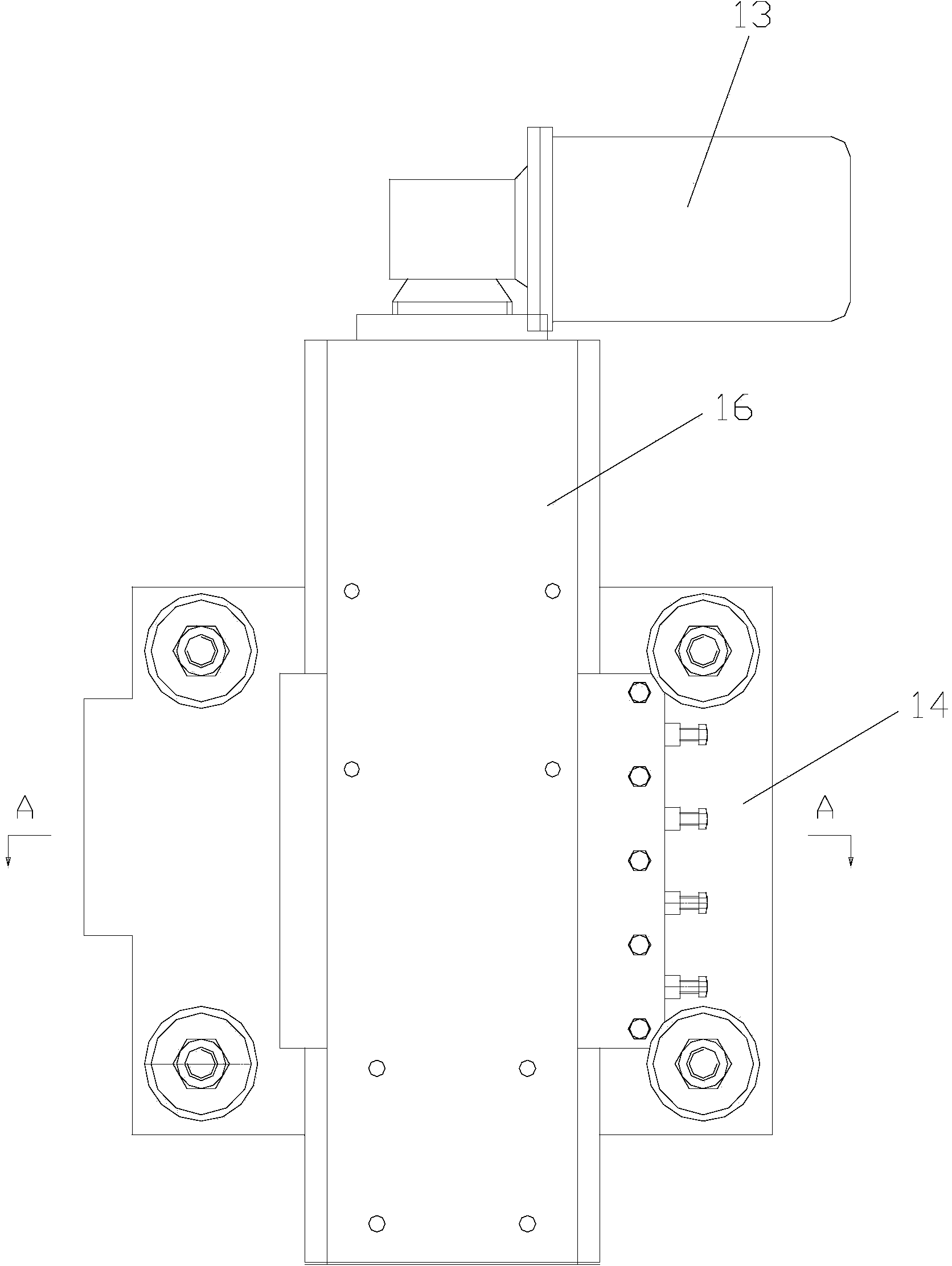

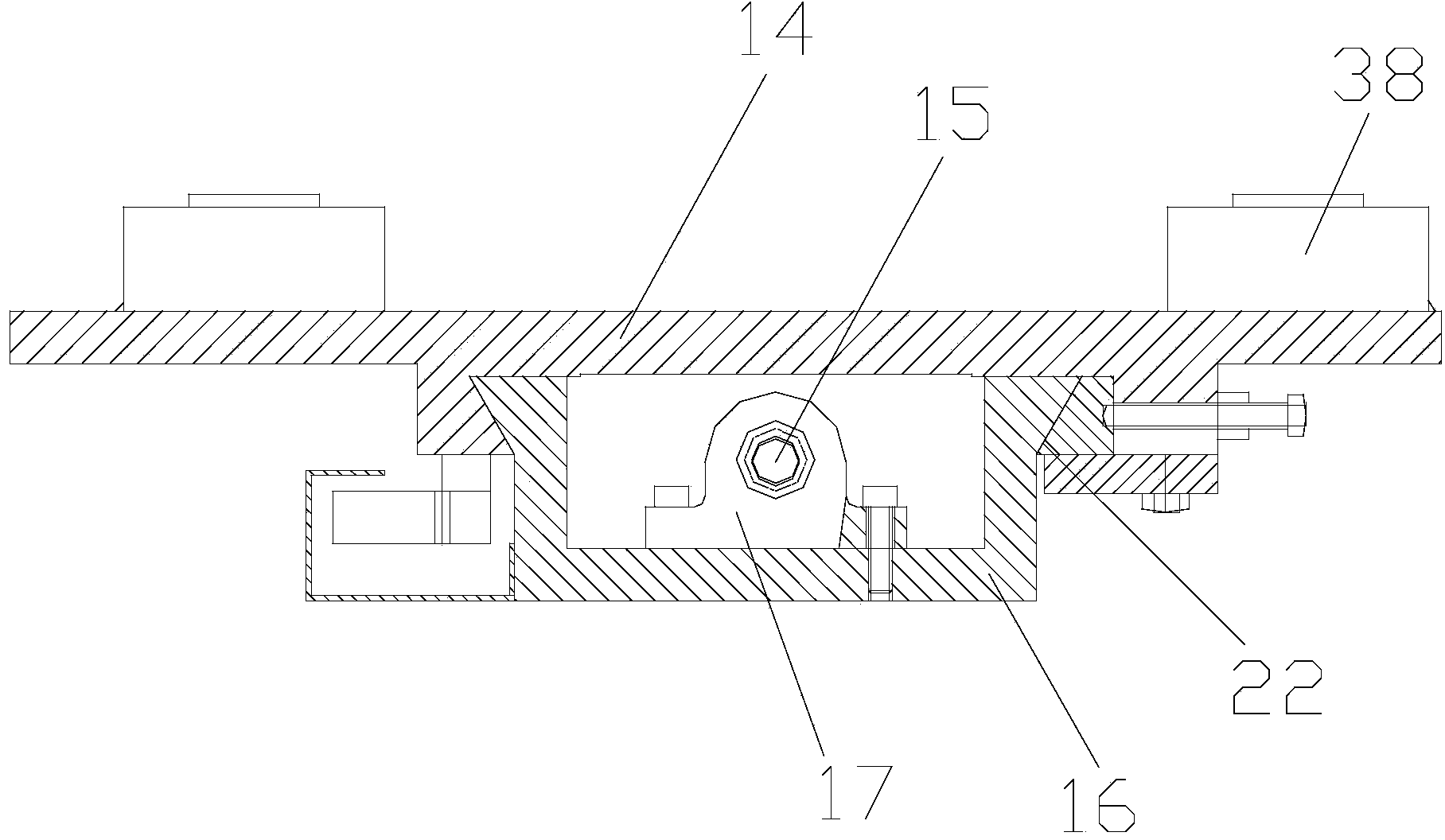

Automatic arc slab rough grinding machine

InactiveCN103978414AReduced strength requirementsLow technical requirementsGrinding machinesGrinding/polishing safety devicesWorking environmentWet grinding

The invention provides an automatic arc slab rough grinding machine which comprises a base, stand columns, an arched girder and an adjustable working platform in the middle of the base. The two ends of the arched girder are fixedly connected with arched girder lifting devices arranged on the stand columns, and the arched girder lifting devices drive the arched girder to slide along the stand columns synchronously in the vertical direction. A grinding head lifting device and a circular motion mechanism are arranged on the arched girder, and the grinding head lifting device is fixed to the circular motion mechanism and drives a grinding head device fixed in the grinding head lifting device to make contact with or be separated from the surface of a workpiece fixed to the adjustable working table. Water is sprayed on the grinding head device so that wet grinding can be conducted between the grinding head device and the workpiece during work. The circular motion mechanism is matched with a long chain fixed to the arched girder, and drives the grinding head lifting device to do the circular motion in a rail direction of an arc-shaped guide rail on the arched girder and to grind the workpiece on the adjustable working table. By means of the automatic arc slab rough grinding machine, accuracy and efficiency of grinding the workpiece are improved, the working environment for workers is improved, and grinding powder is prevented.

Owner:BAOJI YINKANG MACHINERY EQUIP

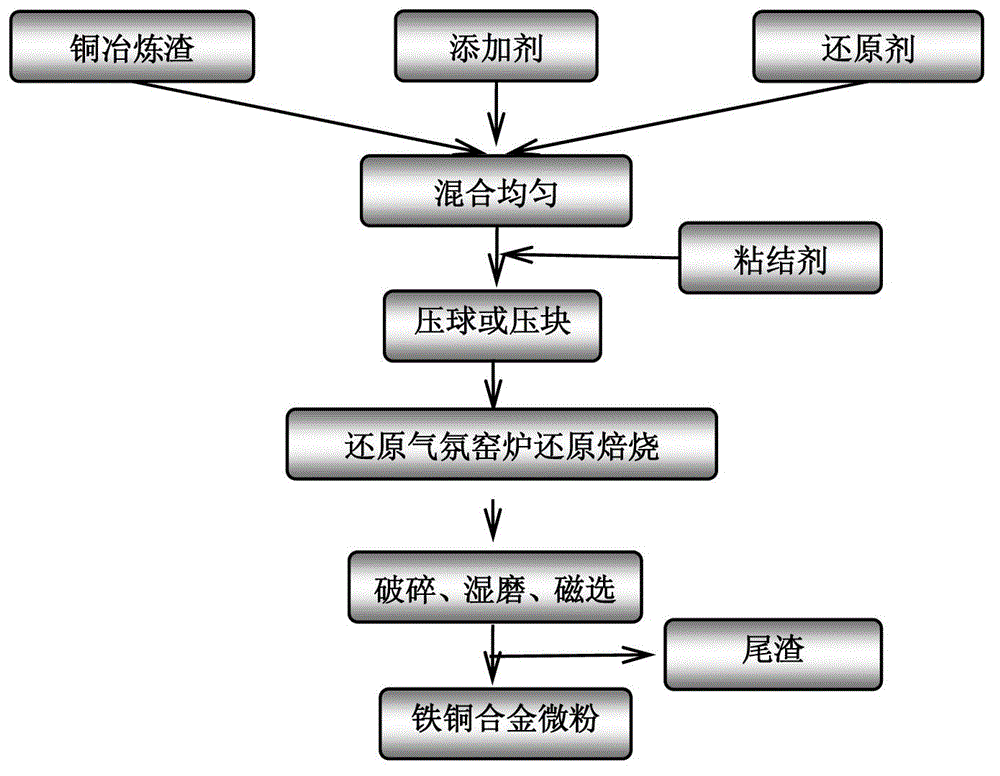

Method for rapidly reducing copper slags to produce iron-copper alloys in kiln in reducing atmosphere

ActiveCN102719676AIncrease added valueAchieve restorationProcess efficiency improvementSilicic acidReducing atmosphere

A method for rapidly reducing copper slags to produce iron-copper alloys in a kiln in a reducing atmosphere is characterized by including the steps: proportionally mixing the copper slags, reducing agents and additives, crushing or levigating the mixture to 200 meshes to obtain 20%-40% of residues on sieve; doping agglomerants and water occupying 5-20% of all materials on a dry mass basis, uniformly mixing, producing the uniformly mixed mixture to pellets with the diameters ranging from 15mm to 30mm and small cylindrical briquettes with all the heights ranging from 15mm to 30mm by a pellet press or a briquetting machine, and drying the pellets or small cylindrical briquettes; flatly laying the dried pellets or small cylindrical briquettes at the bottom of the kiln, wherein the material layer thickness ranges from 20mm to 45mm, the material layer reducing temperature ranges from 1250 DEG C to 1450 DEG C, and the reducing time is 10-40min; and subjecting the reduced pellets or the briquettes to cooling, crushing, wet grinding and wet separation so that iron-copper alloy powder with the iron recovery rate of 85%-99% is obtained. According to the method, iron in a great quantity of silicate iron in the copper slags, which cannot be separated out by the traditional technology, is extracted and turns into the iron-copper alloy micro powder with high added value so that iron and copper in the copper slags are extracted and used simultaneously, and physical and chemical heat energy in strong reducing waste gas can be completely recovered during rapid depth reduction.

Owner:TONGLING NON FERROUS METAL GROUP CORP +1

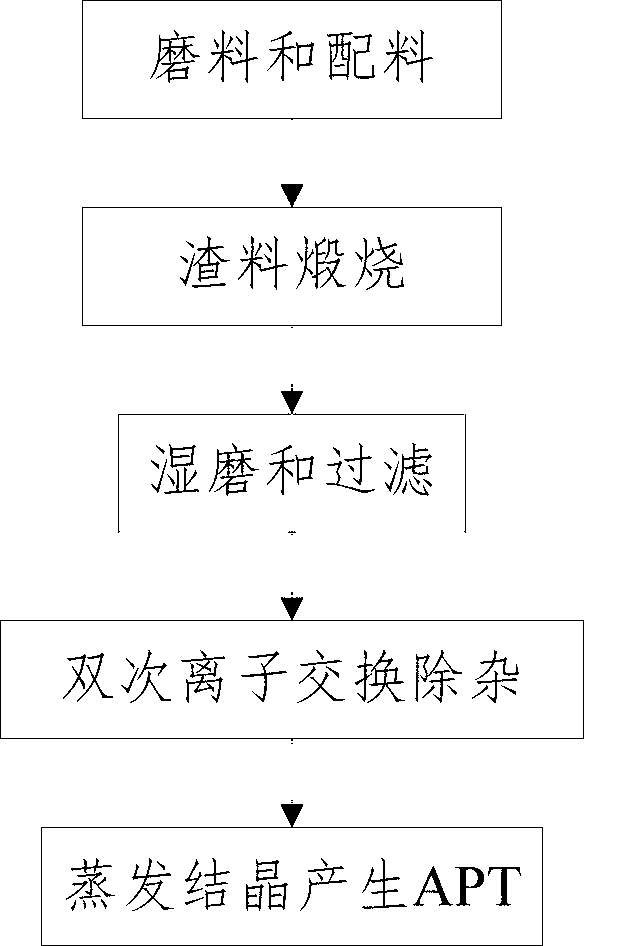

Method for regenerating APT (ammonium paratungstate) by use of APT waste low-grade tungsten slag

InactiveCN103103359AHigh recovery rateEasy to useProcess efficiency improvementAmmonium paratungstateSlag

The invention belongs to the field of tungsten resource recycling, and particularly relates to a method for regenerating APT (ammonium paratungstate) by the use of waste low-grade tungsten slag in an APT production process. The invention discloses a method for regenerating APT by use of APT waste low-grade tungsten slag, which is realized by improving the technological parameters of the traditional soda sintering method and comprises the following steps of: (a) grinding and dosing; (b) slag calcining; (c) wet grinding and filtering; (d) two-secondary ion exchange and impurity removal; and (e) evaporating and crystallizing to generate APT. The method provided by the invention can reduce resource waste, improve the utilization rate of resources, and can increase the economic benefits of an enterprise by recycling the APT waste low-grade tungsten slag; the method is suitable for treating the waste low-grade tungsten slag of which the WO3 grade is 2-10%, overcomes the shortcomings of the technology matching the waste and the tungsten concentrate raw material, and can effectively improve the recovery rate of tungsten and reduce environmental pollution; and through the invention, the service life of the tungsten resource of the country can be prolonged, the current situation of shortage in tungsten resource is relieved, the emission of waste can be effectively reduced, and environmental pollution is reduced.

Owner:陈泉兴

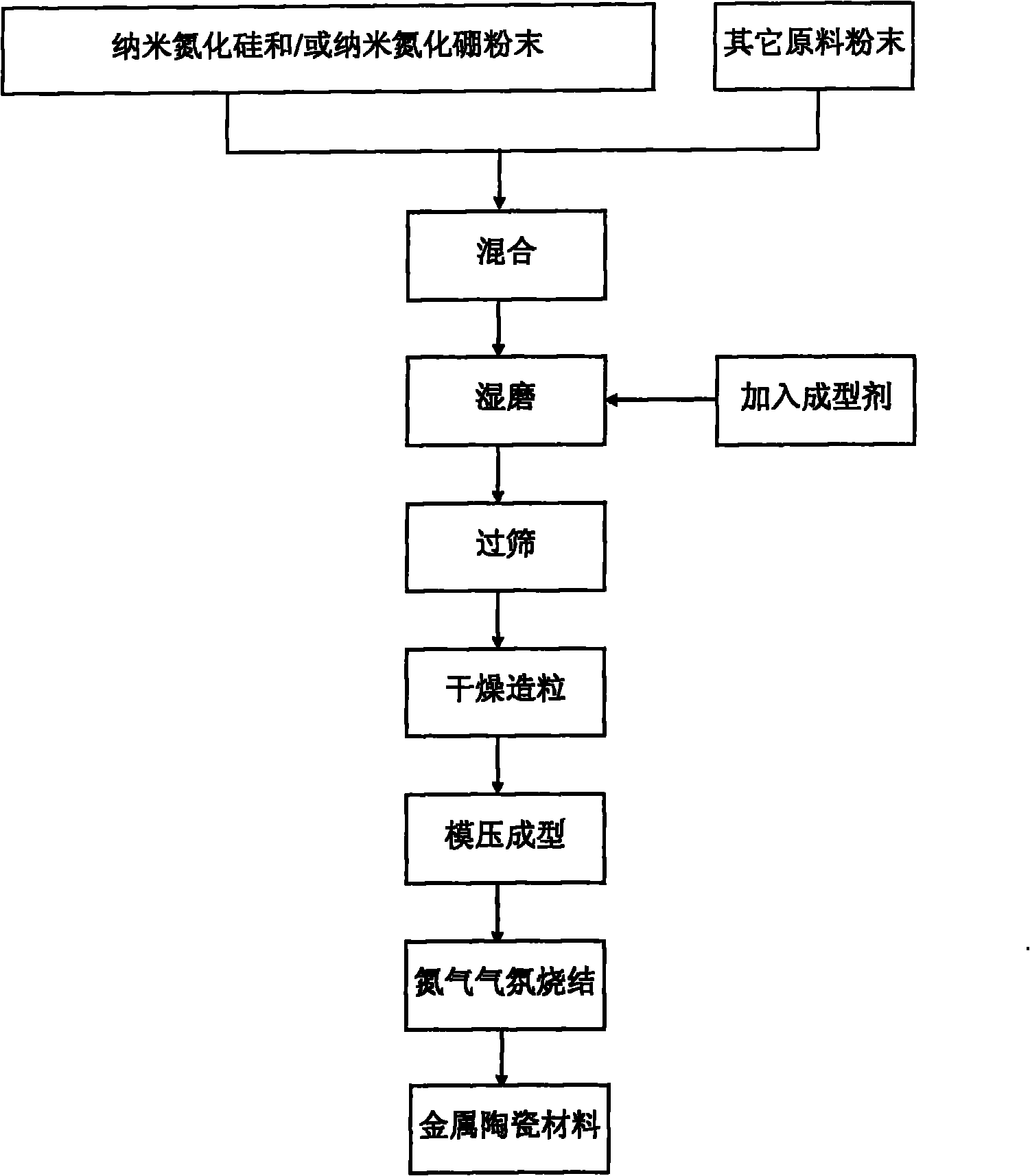

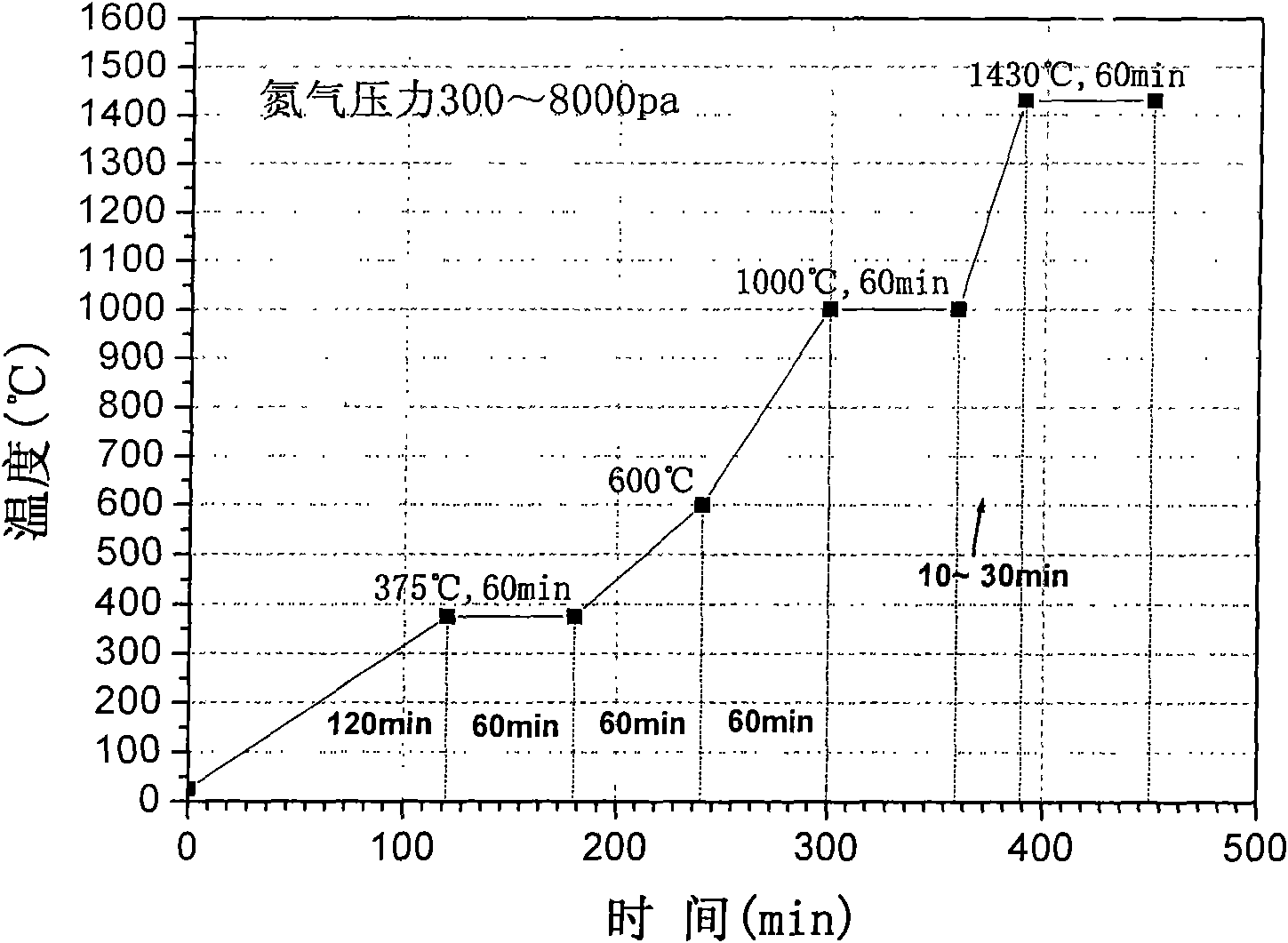

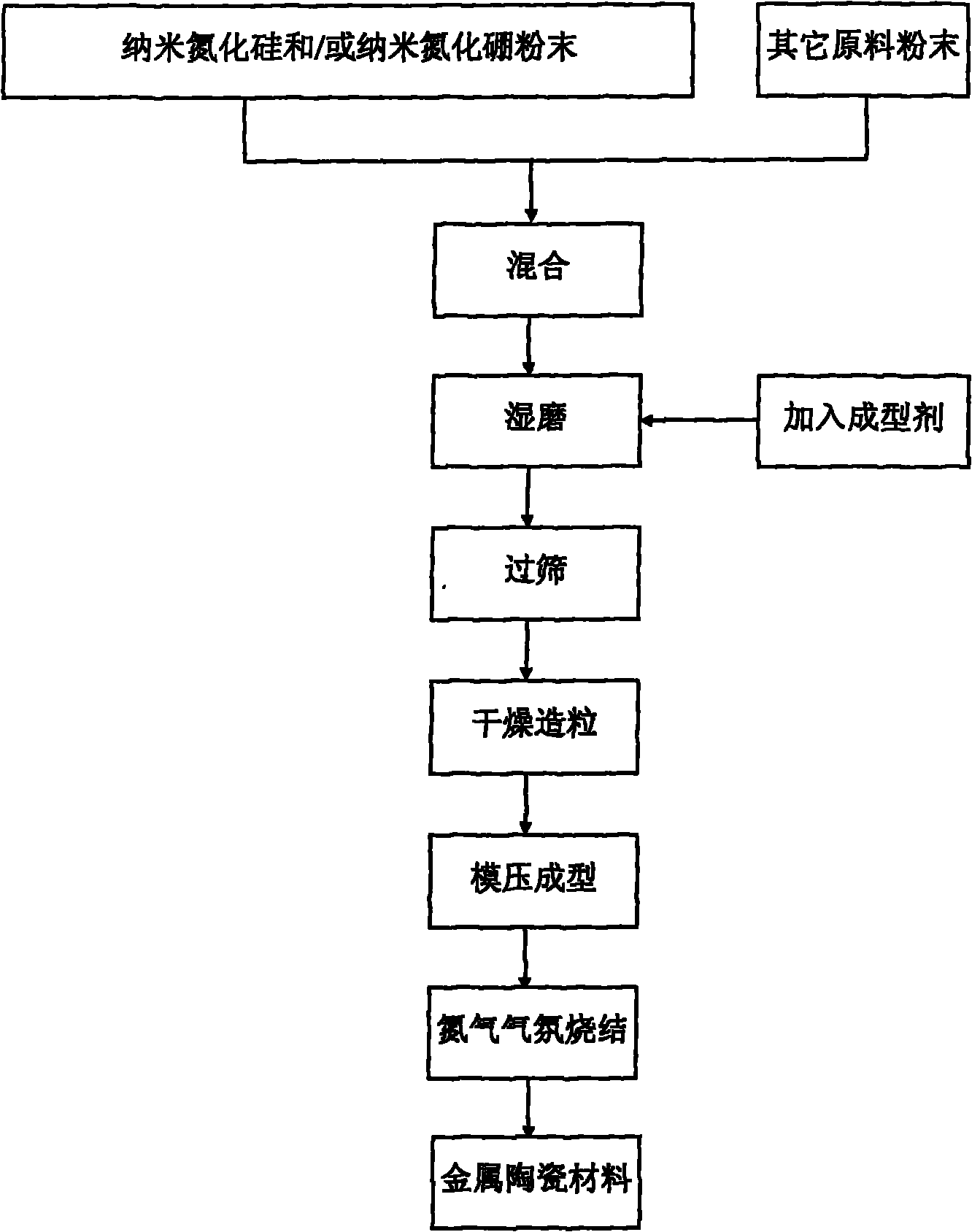

Nano silicon nitride and boron nitride reinforced titanium carbonitride based cermet

The invention discloses a nano silicon nitride and boron nitride reinforced titanium carbonitride based cermet. A reinforced phase is added into a base material having a main phase of titanium carbonitride Ti(C, N) and a binder phase of nickel and cobalt metals, is at least one of nano silicon nitride and nano boron nitride, and is 0.5 to 2.5 volume percent of the base material. The preparation method comprises the following process flows: preparing raw material powder containing the nano silicon nitride and / or nano boron nitride; mixing; adding a forming agent; performing wet grinding; sieving; drying and granulating; performing compression molding; sintering in nitrogen; and obtaining the cermet. The cermet has the advantages of high hardness, high strength and high toughness, and can be widely applied to middle and low carbon steel and low alloy steel high-speed cutting tool materials; and the preparation process is easy to control and is suitable for large-scale industrial production.

Owner:XIAMEN UNIV OF TECH

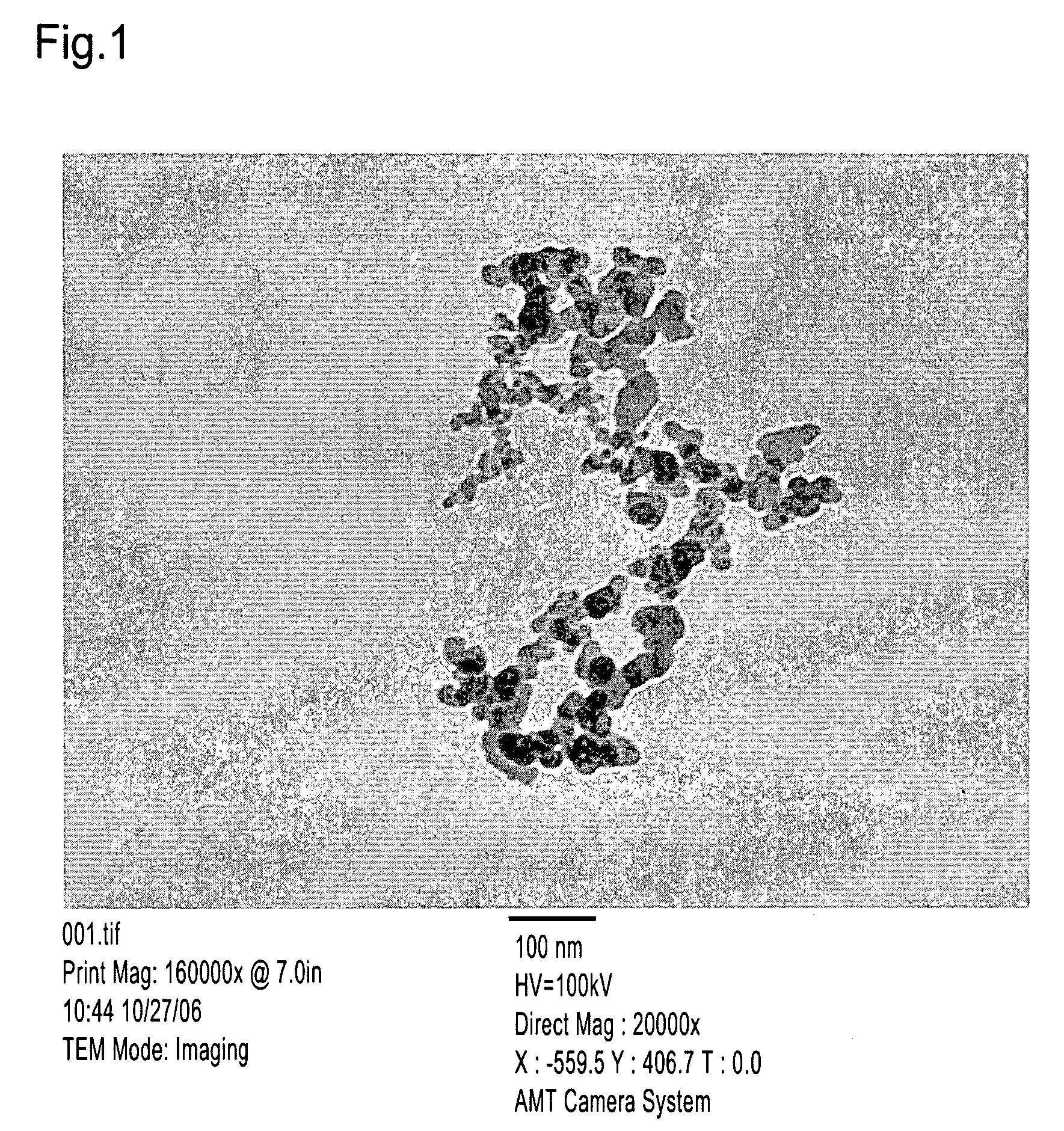

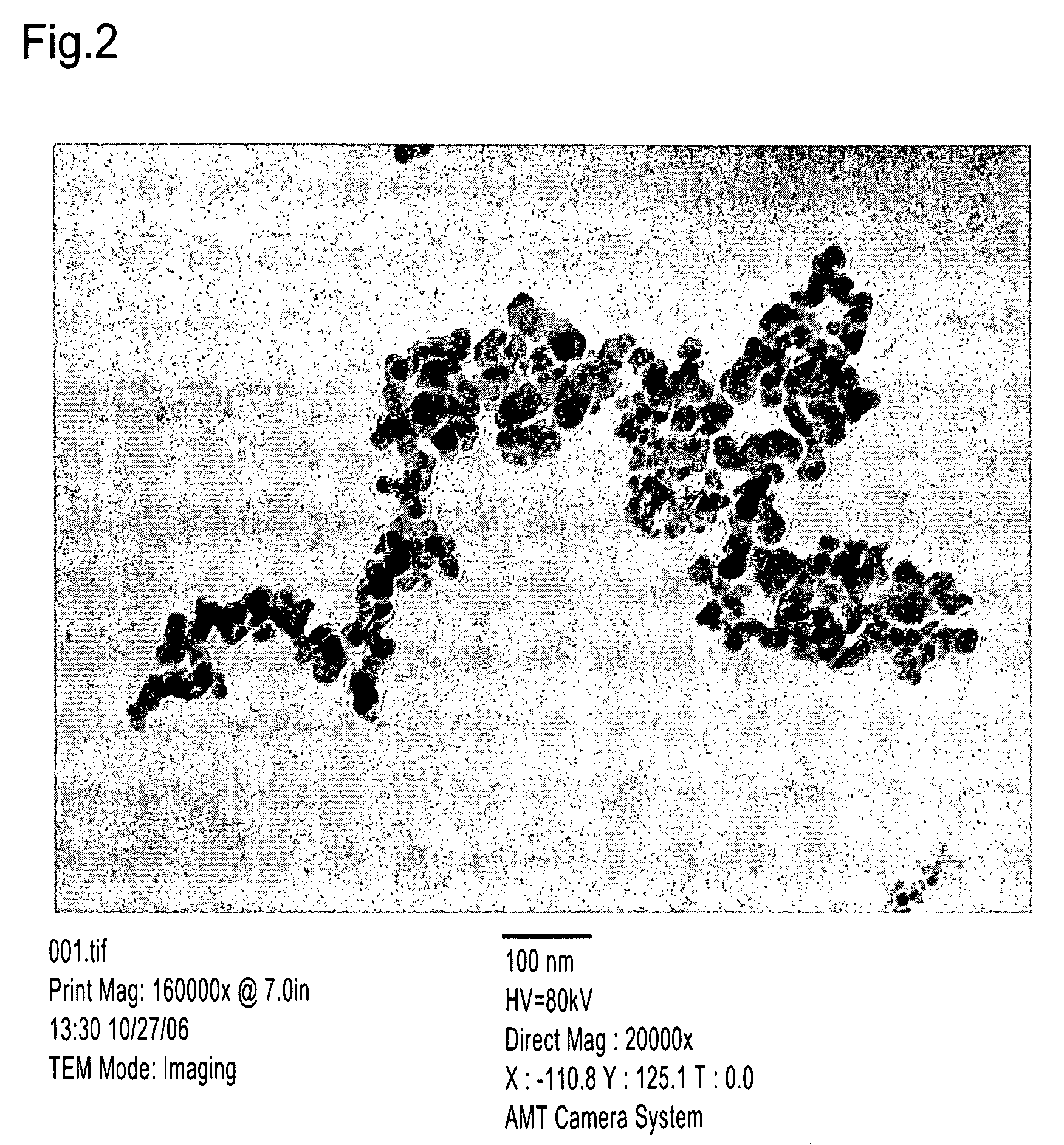

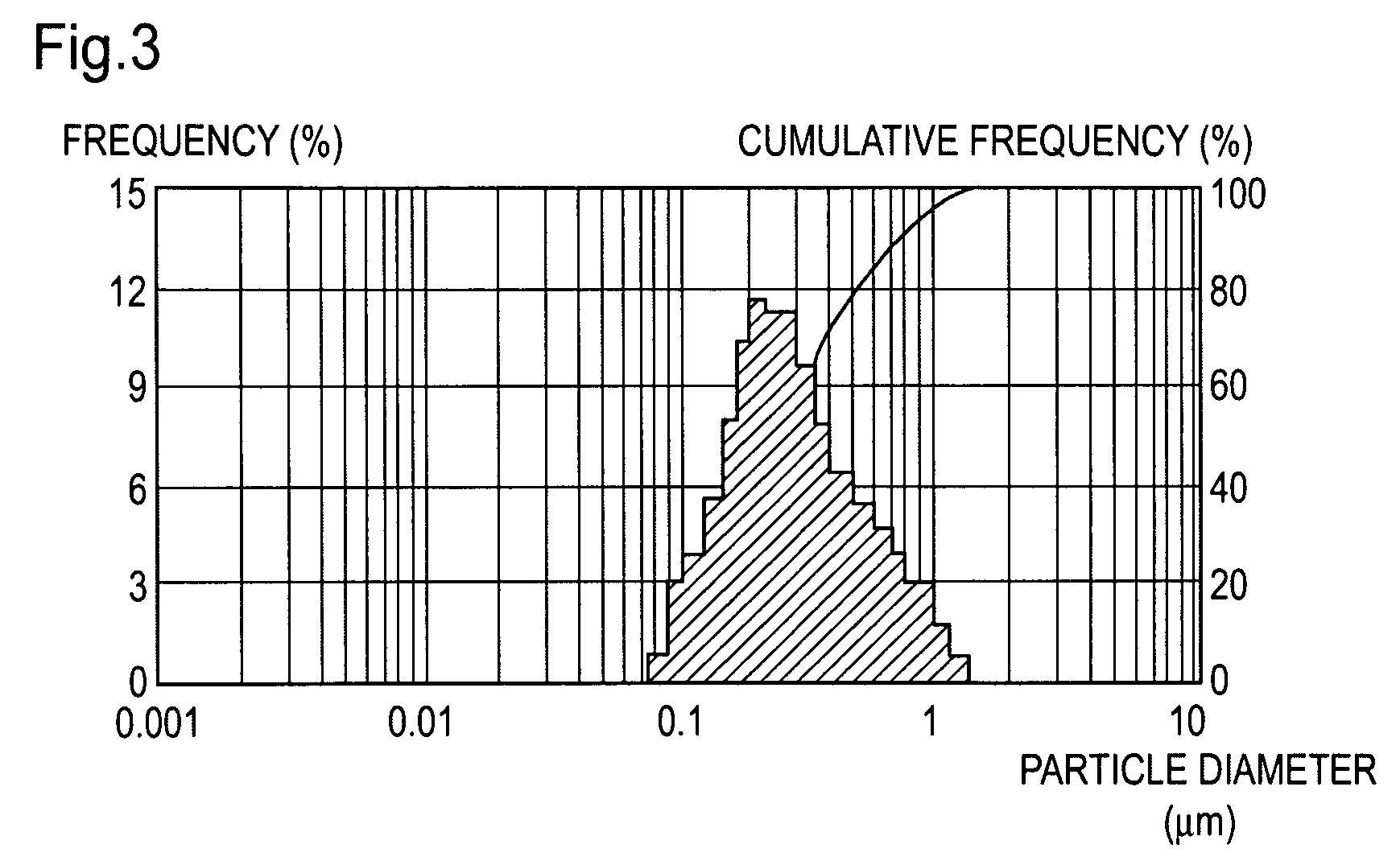

Composition for polishing semiconductor wafer, and method of producing the same

InactiveUS20080237535A1Improve polishing effectBig advantagePigmenting treatmentOther chemical processesSilica particleGas phase

A composition for polishing a semiconductor wafer contains fumed silica particles that are produced by wet grinding using a grinding medium and that have characteristics (A) to (C):(A) a specific surface area in the range of 50 to 200 m2 / g measured by a BET method;(B) an average particle diameter in the range of 10 to 50 nm measured by a laser light-scattering method; and(C) an average ratio A / B of the major axis A to the minor axis B of the fumed silica particles in the range of 1.2 to 2.0 measured by TEM observation,wherein the concentration of silica particles containing the fumed silica particles is in the range of 0.5 to 50 weight percent relative to the total weight of an aqueous dispersion.

Owner:NIPPON CHECMICAL IND CO LTD +1

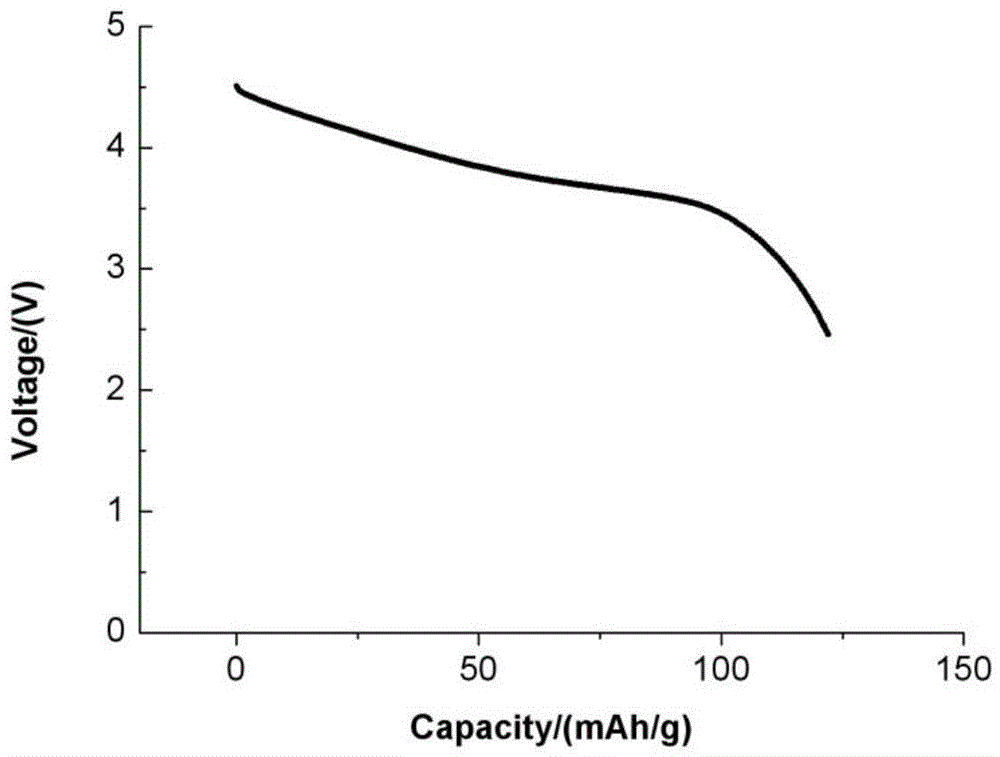

Method for preparing lithium-rich solid solution cathode material through reduction co-precipitation

ActiveCN102881876ALow costWide variety of sourcesHybrid capacitor electrodesCell electrodesManganeseLithium compound

The invention relates to a method for preparing a lithium-rich solid solution cathode material through reduction co-precipitation. The method comprises the following steps of: weighing lithium, nickel, manganese, cobalt and a reducing agent in a molar ratio of (1+x):(1-x).y:(x+z-x.z):(1-x).k:q; and mixing a measured wet grinding medium, the nickel, the manganese and the cobalt, adding the reducing agent, stirring, mixing, adding alkali liquor, performing wet grinding, aging, filtering, washing, adding the wet grinding medium and a lithium compound, performing wet grinding, drying to prepare a precursor, putting the precursor in air, oxygen-rich gas or pure oxygen atmosphere, and sintering to prepare the lithium-rich solid solution cathode material. The electrode material prepared by the method has uniform composition, high discharge performance, and high discharge cycle performance particularly under the high-current condition.

Owner:DYNABAT NEW ENERGY SCI & TECH CO CLD FUJIAN

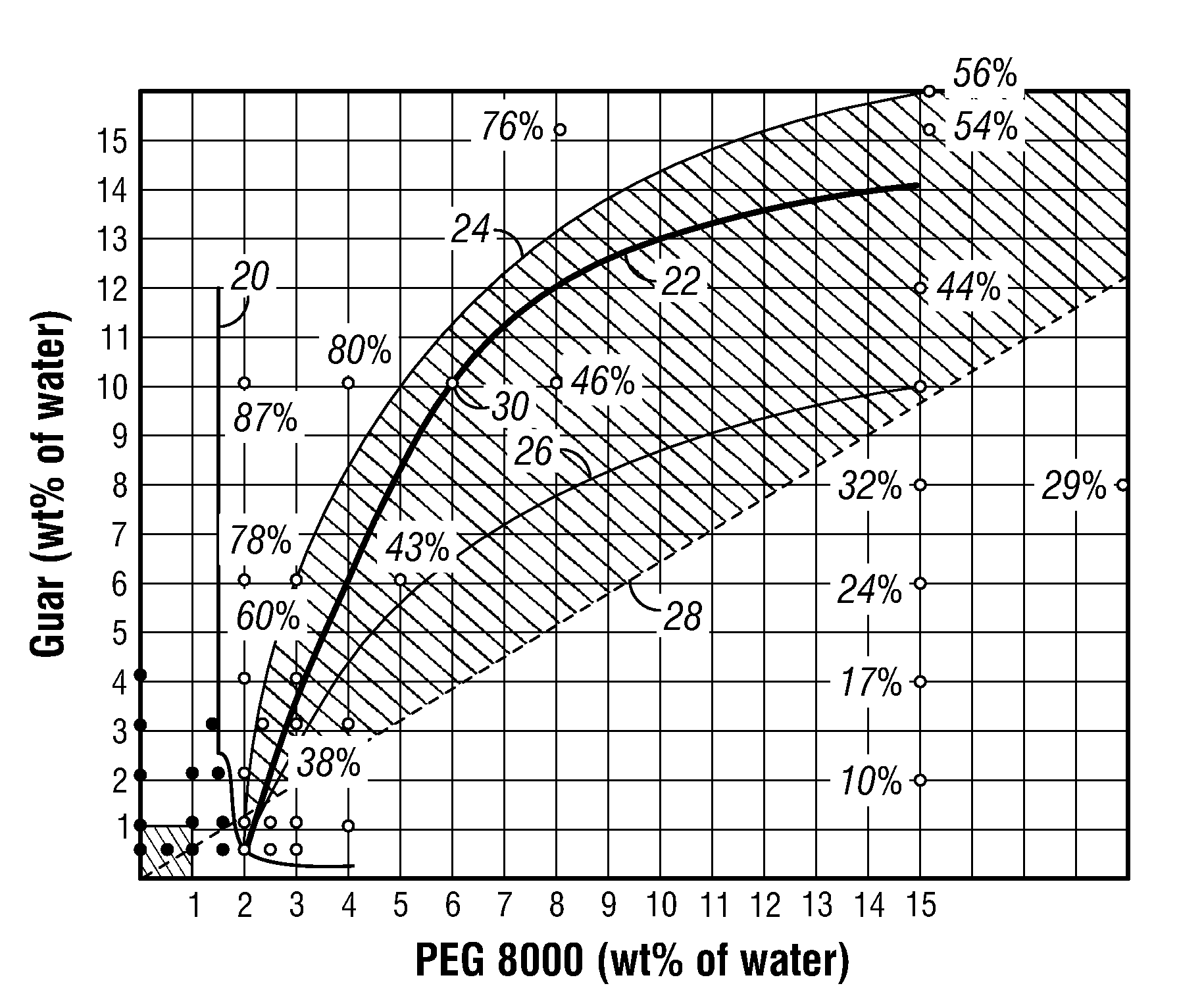

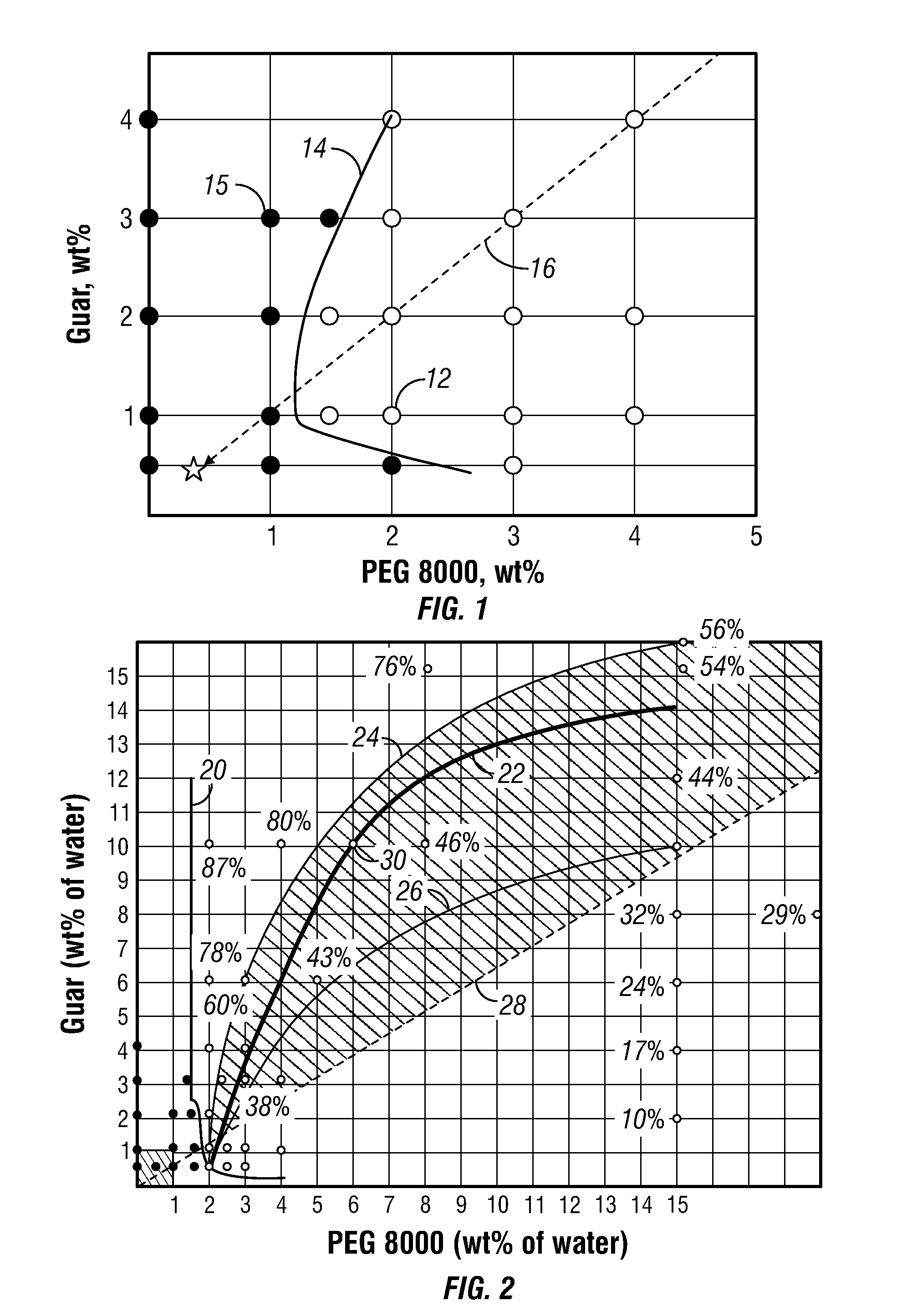

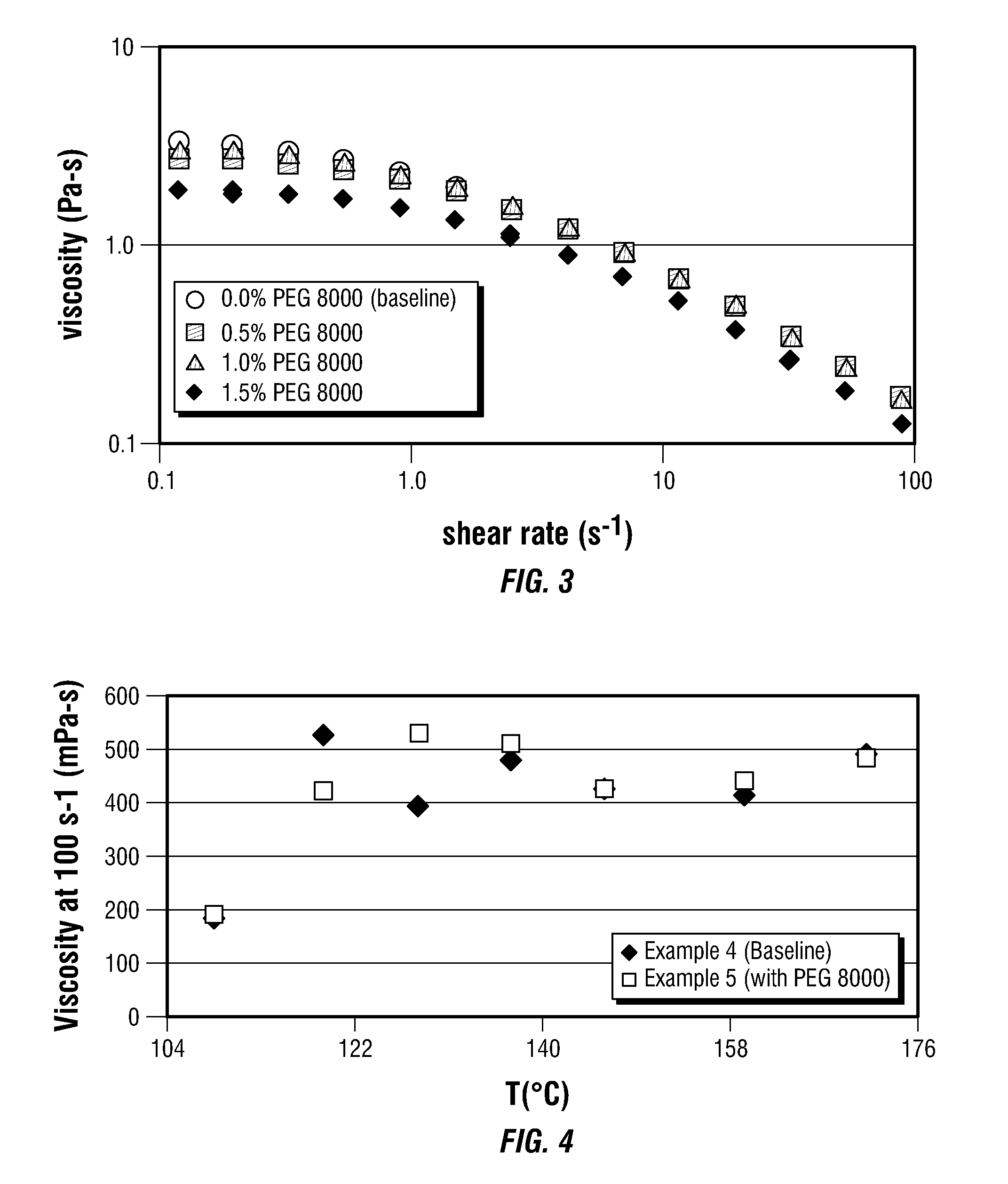

Polymer Delivery In Well Treatment Applications

InactiveUS20090023615A1Reduce solubilityLow viscosityTransportation and packagingMixer accessoriesActive polymerEmulsion

This invention relates to compositions and methods for treating subterranean formations, in particular, oilfield stimulation compositions and methods using water-in-water polymer emulsions to uniformly dissolve a rheologically active polymer, such as a thickener or friction reducer, in the treatment fluid. The emulsions have a low viscosity and are easily pumped for mixing into a treatment fluid, where upon dilution with an aqueous medium, the polymer is easily hydrated without forming fish-eyes. The partitioning agent in the water-in-water emulsion does not generally affect the rheology of the treatment fluid. The invention also relates to further processing of the emulsion by wet grinding, high shear mixing and / or heating to enhance the hydration rate in the preparation of the well treatment fluid.

Owner:SCHLUMBERGER TECH CORP

Preparation method of Li2FeSiO4 cathode material used for controlling Fe3P

InactiveCN101734675ALow costWide variety of sourcesCell electrodesAlkali metal silicatesPhosphorous acidWater baths

The invention relates to a preparation method of Li2FeSiO4 cathode material used for controlling Fe3P. The technical scheme comprises the following steps: weighting lithium salt or hydrate of lithium salt, ferrous salt or hydrate of ferrous salt, silicon compound and phosphorous acid or aqueous solution of phosphorous acid according to a molar ratio of the reactants that Li<+>:Fe<2+>:Si:H3PO3=0.95-1.10:0.95-1.10:0.70-0.999:0.001-0.429, mixing the reactants, then adding carbon-containing compound which accounts for 1wt%-20wt% of anhydrous reactants and wet grinding medium which accounts for 0.10-10 times of anhydrous reactants by volume, mixing with a ball mill, heating with water bath, mixing with a ball mill again, heating and drying in vacuum, and then using the two-stage sintering process or temperature programmed two-stage sintering process to prepare Li2FeSiO4 with controllable Fe3P under inert atmosphere or weak reduction atmosphere. The material prepared by the method of the invention has better discharge performance, the discharge capacity is significantly increased in 2.9V zone and the cycle performance is good under 0.3C current.

Owner:FUJIAN NORMAL UNIV

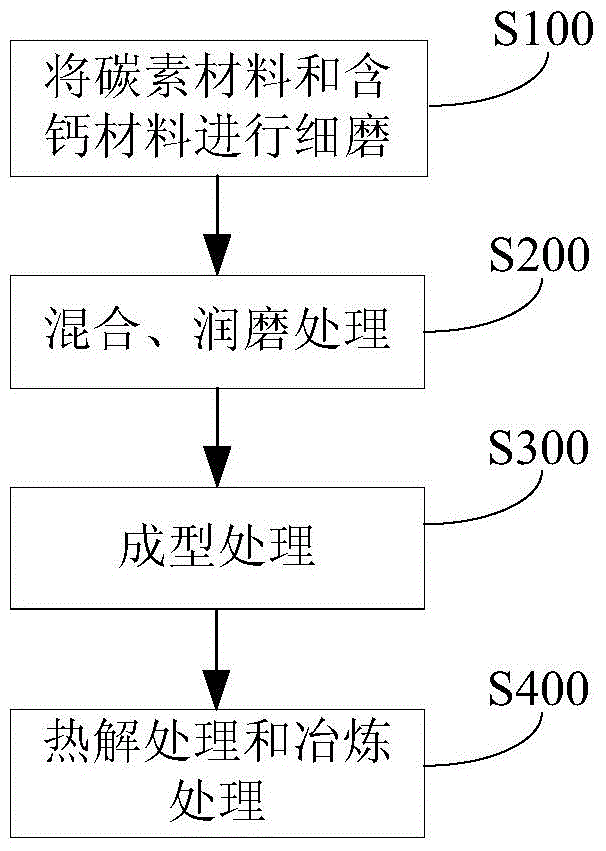

Method for preparing solid calcium carbide

ActiveCN104556036AIncrease productivityReduce manufacturing costCalcium carbideMixed materialsWet grinding

The invention discloses a method for preparing solid calcium carbide. The method comprises the following steps: (1), finely grinding a carbon material and a calcareous material so as to respectively obtain a carbon material powder and a calcareous material powder; (2), mixing and then wet-grinding a mixture containing the carbon material powder and the calcareous material powder, and a bonding agent so as to obtain a mixed material; (3), performing molding on the mixed material so as to obtain material balls; (4), successively distributing the material balls in a rotary hearth furnace, successively pyrolyzing the material balls in a pyrolysis furnace chamber of a radiant tube with the rotation of the bottom of the rotary hearth furnace, and smelting the pyrolyzed material balls in the chamber of a smelting furnace under a temperature of 1200-1380 DEG C, so as to finally obtain solid calcium carbide, coal gas and coal tar. The method disclosed by the invention can be used for preparing solid calcium carbide, the coal gas and the coal tar at the same time, and the production cost of the calcium carbide is obviously lowered.

Owner:SHENWU TECH GRP CO LTD

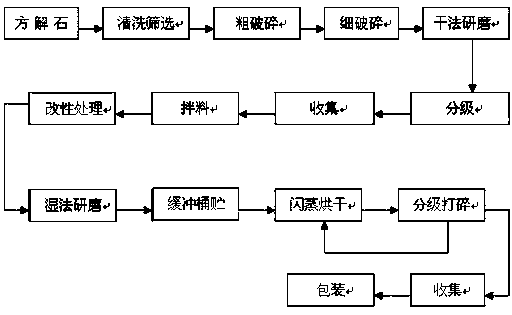

Preparation process of wet-process superfine modified calcium carbonate

InactiveCN104744971AIncrease productivityHigh activityInorganic compound additionPigment treatment with macromolecular organic compoundsSodium stearateMicrosphere

The invention discloses a preparation process of wet-process superfine modified calcium carbonate. The preparation process comprises the following steps: performing cleaning and screening, rough crushing, fine crushing, dry grinding and grading on calcite ores; collecting fine powder of 600 meshes and preparing slurry with water in such a manner that the solid content is 70%-80%; adding a modifier sodium stearate to the slurry for modification treatment and then performing wet grinding, and adding a grinding medium zirconium oxide microspheres and a dispersant sodium polyacrylate during grinding, wherein the volume ratio of the grinding medium to the slurry is 1: 1.5, and the dosage of the modifier is 0.6%-1.2% of the solid content; and putting the slurry obtained after the wet grinding through a vibrating screen, collecting the obtained wet-process superfine modified calcium carbonate slurry into a slurry barrel for flashing drying, collecting the finished product and packaging. The new preparation process is adopted; the wet grinding-modifying integrated technique and the flashing drying technique are adopted so that the production efficiency is high and the production cost is low; the product has the advantages of small particle size, low oil absorption value, high activity and the like; and the major product quality indices are at the international leading level.

Owner:江西科越科技有限公司

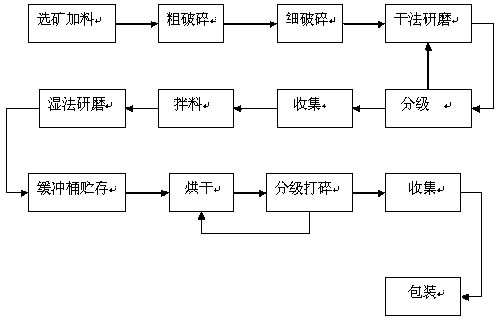

Preparation and purification process for arenaceous quartz and quartz powder, and products produced thereby

InactiveCN101367609AGood effectAvoid pollutionSilicaGlass shaping apparatusWet grindingMonocrystalline silicon

The invention discloses a preparation and purification process of quartz sand and quartz powder and products thereof. The preparation and purification process of quartz sand comprises raw quartz ore, rough separation, fragmentation, water separation, roasting, water fragmentation, soaking in oxalic acid or citric acid, dry grinding or wet grinding, high-gradient magnetic separation, classification, combined process washing, floatation, deionized water washing, special drying. The preparation and purification process of quartz powder comprises quartz sand flotation, ultra fine grinding (dry grinding or wet grinding ), combined process washing, high-gradient magnetic separation, electrostatic separation, deionized water washing, classification, special drying, and vacuum packing. The quartz sand and quartz powder produced with the process of the invention can not foam in the production of glass and chips, an optical fibre and an optical cable can not be broken, the glass does not have water streaks, and the application area is widened. The quartz sand and the quartz powder is suitable for being applied in the fields of monocrystal line silicon, chips, optical fibre and optical cables, war industry, fine chemistry industry and micro-electronics.

Owner:刘少云

Method for chrome-free tanning beach woolfell by adopting chrome-free tanning agent

InactiveCN102758029AHigh whitenessLow free formaldehyde contentTanning treatmentPre-tanning chemical treatmentSewageSewage treatment

The invention discloses a processing method for chrome-free tanning a beach woolfell by adopting a chrome-free tanning agent DESOTAN H30, which comprises the following steps: soaking, fleshing, degreasing, softening, pickling, tanning, extracting alkali, wet grinding, re-tanning, drying, wetting back, dry cleaning, staking, conditioning, reducing, oxidizing, drying, wetting back, staking, dry grinding, dedusting, and obtaining the finished product. The method is the technology for preparing the beach white woolfell, adopts the chrome-free tanning agent to process the beach white woolfell, uses no chrome during the tanning process, and obtains the finished product, which is pure white, slightly curled and distinctive in style, keeps the natural property, contains less than 150ppm of free formaldehyde, has a shrinkage temperature higher than 75 DEG C and has practical production significances. The technology can not only realize zero emission of waste chrome and lower the sewage treatment cost for an enterprise, but also obtain the finished product which is pure white, slightly curled and artistic in appearance, feels plump and soft, contains 130mg / kg of formaldehyde and has a shrinkage temperature of 75 DEG C.

Owner:SHAANXI UNIV OF SCI & TECH +1

Circularly-tanning technology for chrome tanning liquor of sheep garment leather

InactiveCN102586505APure white coatFull coatTanning treatmentPre-tanning chemical treatmentLeather industryFlocculation

The invention discloses a circularly-tanning technology for chrome tanning liquor of sheep garment leather. The circularly-tanning technology comprises the following steps: conditioning, drying, shearing, main-soaking, fleshing, degreasing, pickling, softening, disacidifying, softening, pickling, tanning, wet grinding, retanning, neutralizing, adding grease, retanning, dyeing hair, and dyeing plates. According to the circularly-tanning technology for chrome tanning liquor of sheep garment leather, the formation of hexavalent chromium can be effectively reduced, and the chrome waste liquor flocculation is omitted. According to the test on the chrome content after the chrome tanning liquor is utilized, the chrome waste liquor can be recycled repeatedly by supplementing corresponding chrome powder during next-time recycling, thereby realizing the clean production of tanned leather industry. According to the circularly-tanning technology, the sealed no-emission utilization of a chrome resource can be guaranteed so as to greatly reduce environmental pollution, effectively lower waste water emission and save enterprise waste treatment and production cost. In addition, the quality of the produced leather is consistent with that of the common chrome tanned leather, the shrinkage temperature is above 100DEG C, and a leather body is soft, plump and flexible, is colorful, has pure white hair and has no effect on the dyed hair and the dyed plates.

Owner:ZHEJIANG ZHONGHUI FUR & LEATHER +2

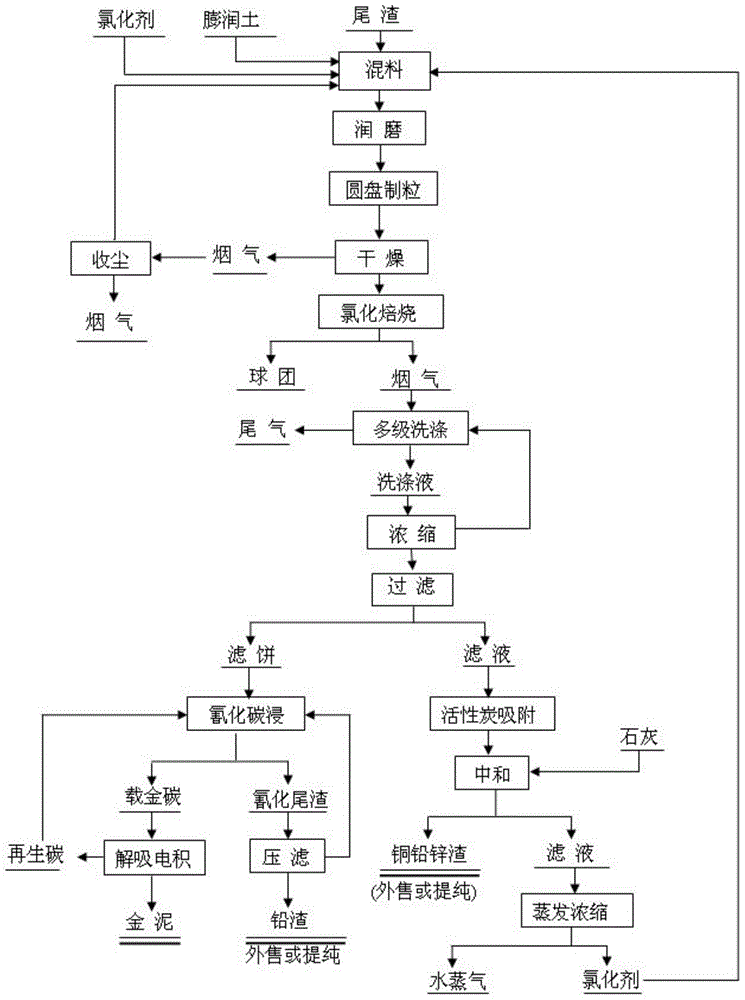

Recovery method for valuable metals in tailings

InactiveCN104164572ALow raw material requirementLow costProcess efficiency improvementRecovery methodMaterials science

The invention discloses a recovery method for valuable metals in tailings, and belongs to the field of treatment for tailings of nonferrous metallurgy. The method comprises the following steps of: mixing the tailings, bentonite and a chlorinating agent, then wet-grinding to generate green balls, drying the green balls and then carrying out chloridizing roasting in a rotary kiln, cooling the roasted balls to obtain qualified pellets, discharging the smoke generated during roasting through multi-stage washing, and conveying smoke dust containing the valuable metals in solution to form recovery solution; filtering the recovery solution to obtain a filter cake, that is, gold-silver-lead residues, and treating the gold-silver-lead residues to recover gold, silver and lead; adsorbing the filtrate after filtering through active carbon, and neutralizing by lime to obtain neutralized filter residue, that is, copper-lead-zinc residues, and treating the copper-lead-zinc residues to recovery copper, zinc and lead; and evaporating and concentrating the filtrate after neutralization, and then recovering the chlorinating agent. The method has the advantages of being low in requirements on the treated raw materials, high in adaptability, short in process flow, low in cost, simple to operate, high in recovery rate, and the like.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com