Patents

Literature

1141results about How to "Reduced strength requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

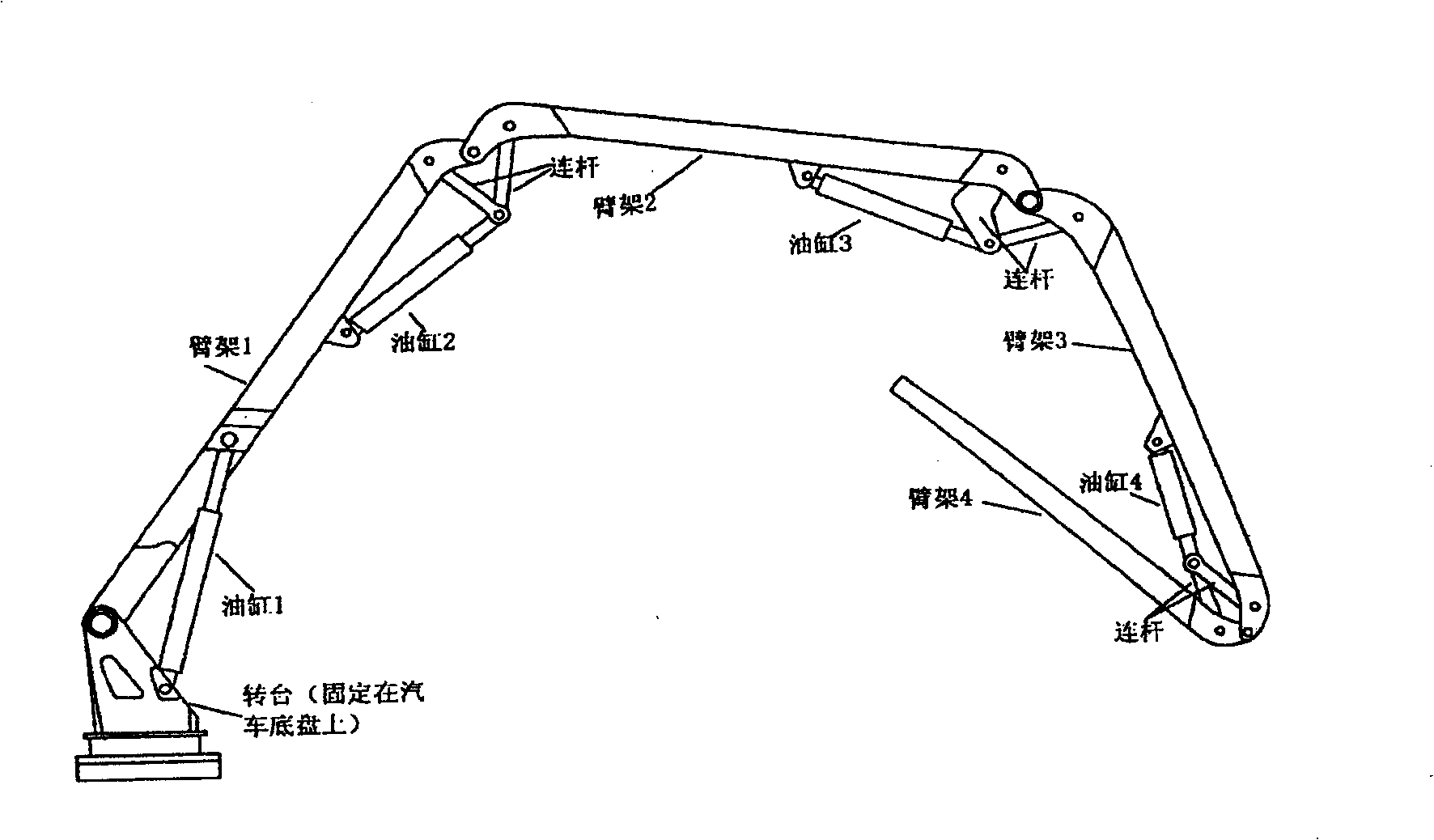

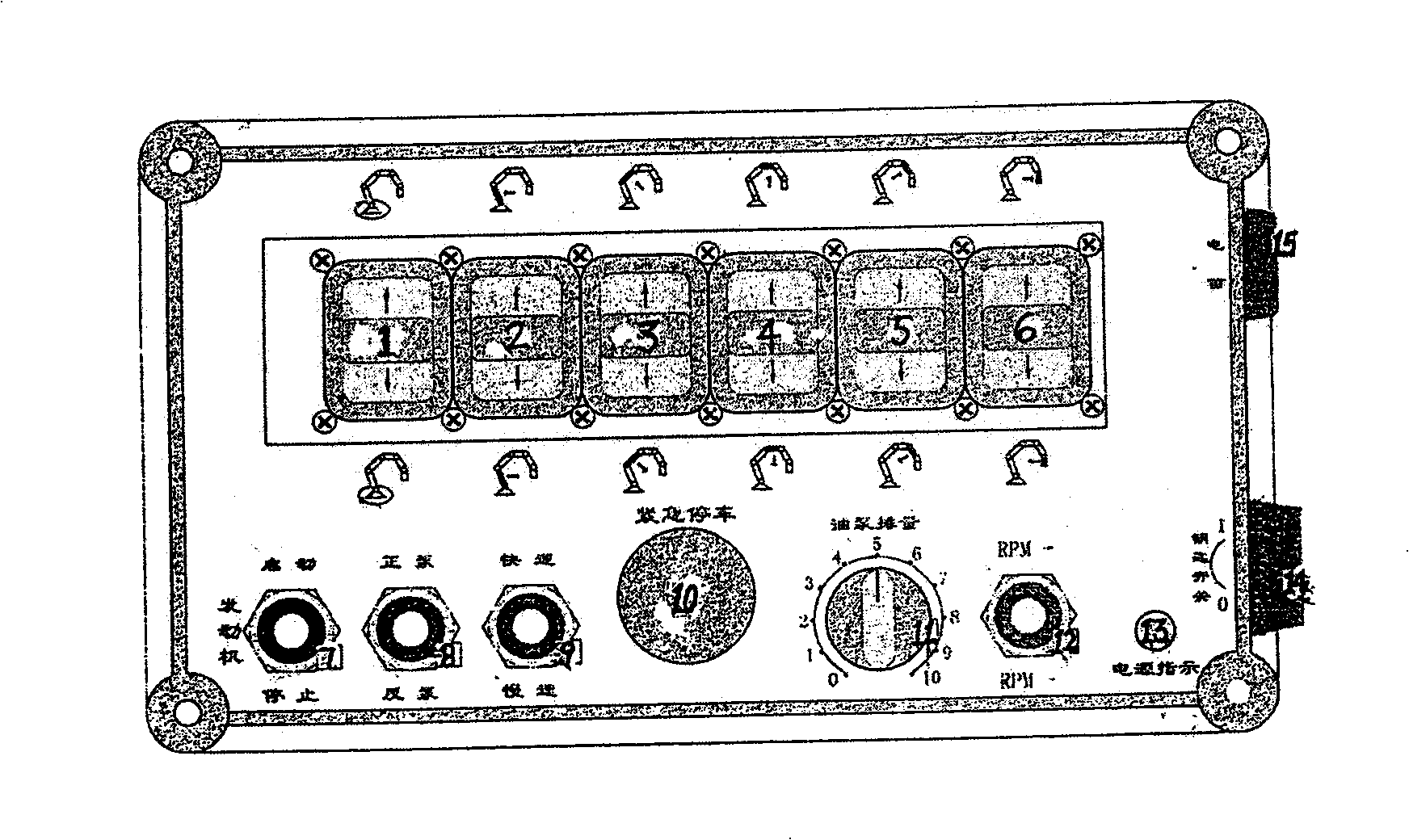

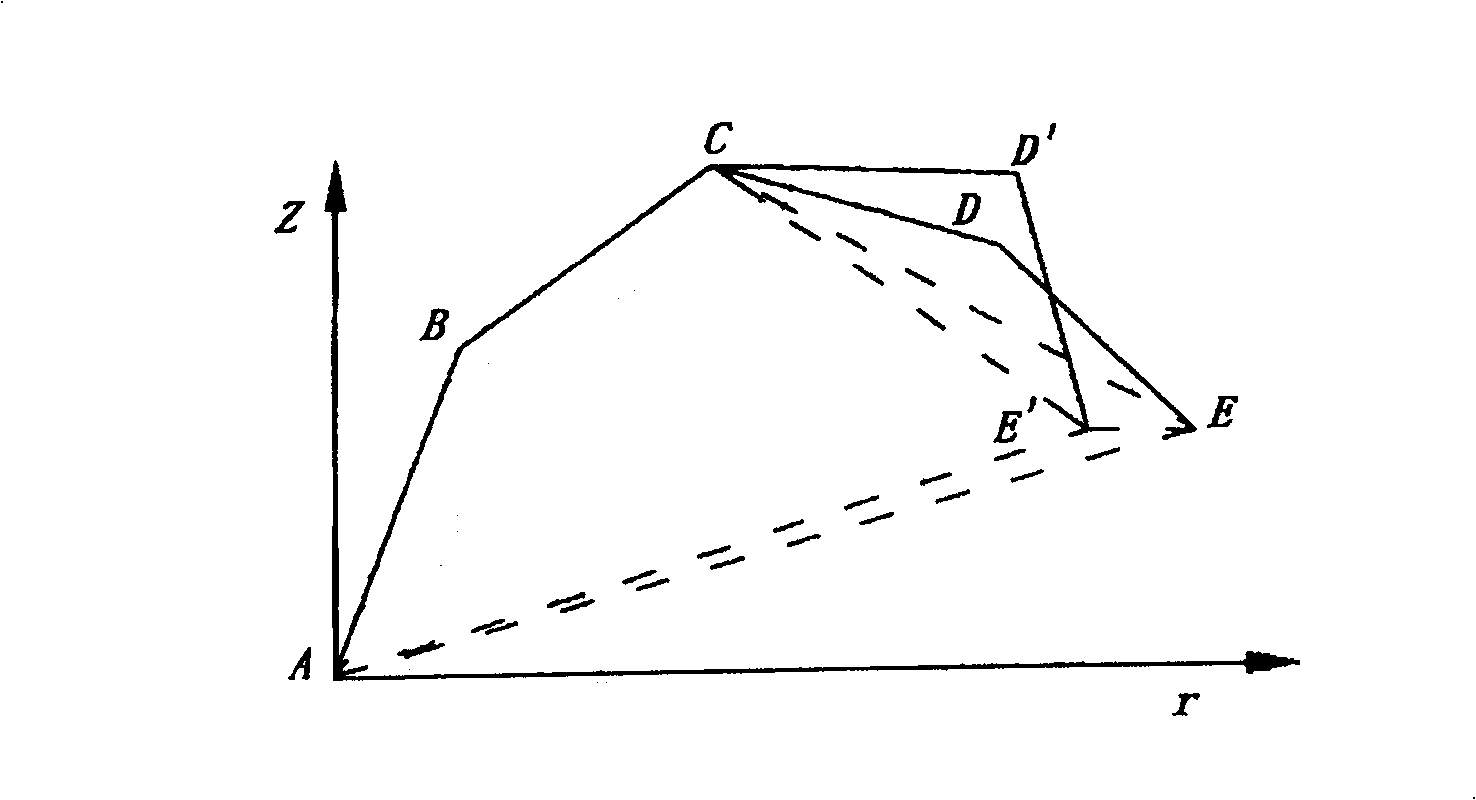

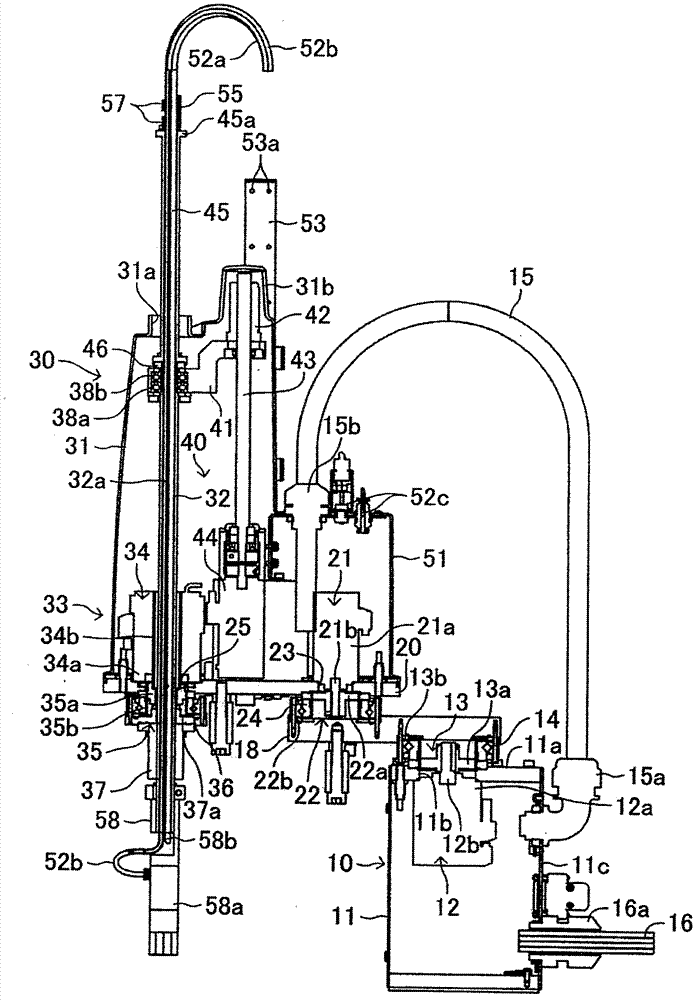

Concrete pump truck intelligent arm support control system and control method thereof

InactiveCN101525944AGuaranteed accuracyGuaranteed reasonablenessBuilding material handlingLocation detectionControl system

The invention provides a concrete pump truck intelligent arm support control system and a control method thereof. The control system comprises an arm support, a controller, an operating device and an actuator. The control system is characterized in that the control system also comprises an arm support detecting device which is used for detecting the spatial location of each segment of the arm support and transmitting detected spatial location signals of each segment of the arm support to the controller. The control method comprises: the construction of an arm support coordinate system; the detection of the current arm support position; the control of the actions of the arm support. In the concrete pump truck intelligent arm support control system, an operator is not required to manually regulate the position the gyratory angle of each segment of the arm support, the pouring accuracy and the operational reasonability are guaranteed, and the construction efficiency and the whole service life of the truck are improved greatly; within the stress impact allowable range and on the basis of the consideration of the concrete fluidity, coordinated actions of a plurality of segments of the arm support are realized; simultaneously, during the controlling process, extreme conditions and unreasonable operations of the movements of a plurality of the segments of the arm support are limited, the labor intensity and the experience requirement of the operator are alleviated greatly, and influences of unreasonable operations on the arm support structure and the service life of a hydraulic system are avoided.

Owner:BEIJING EASYSOLUTION ELECTRONICS

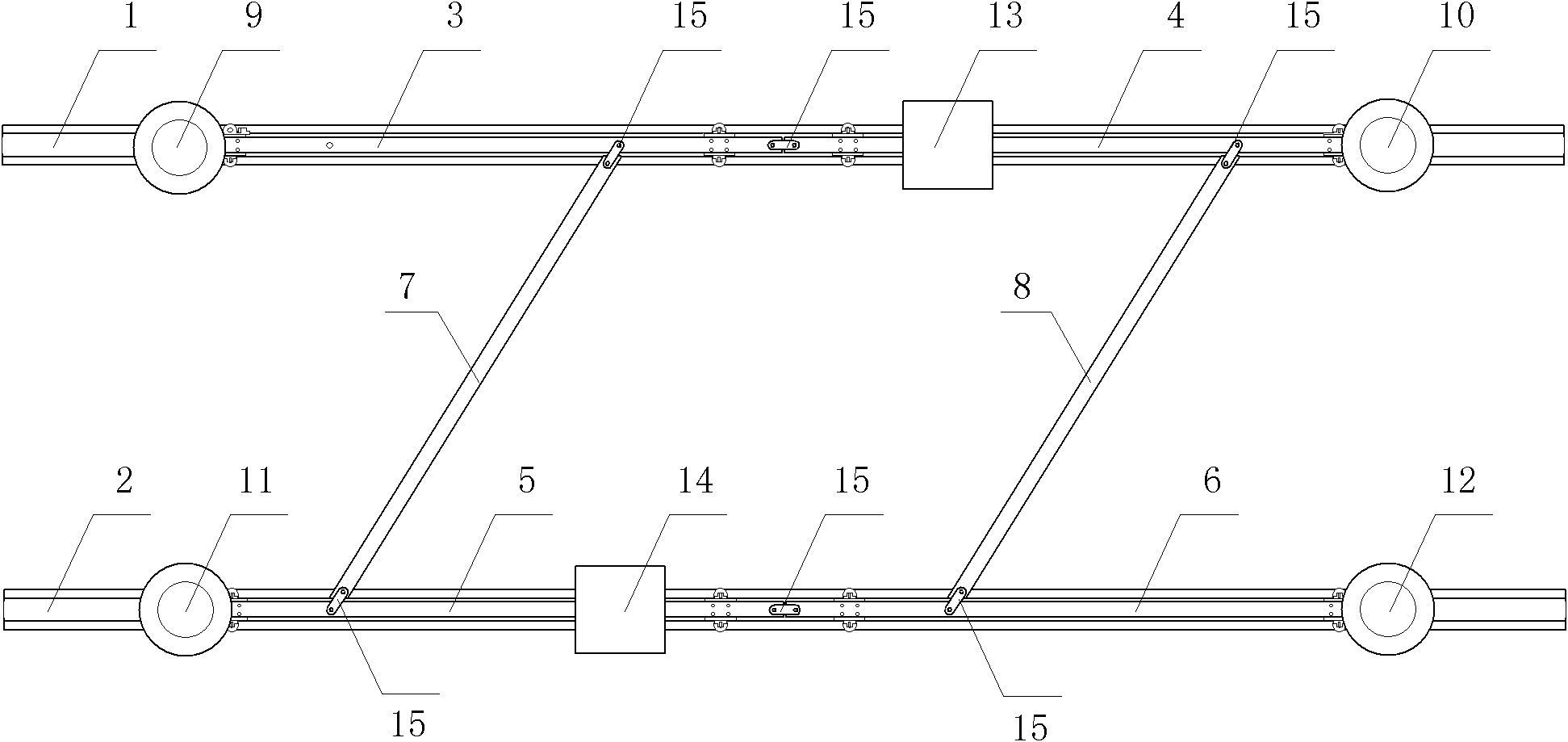

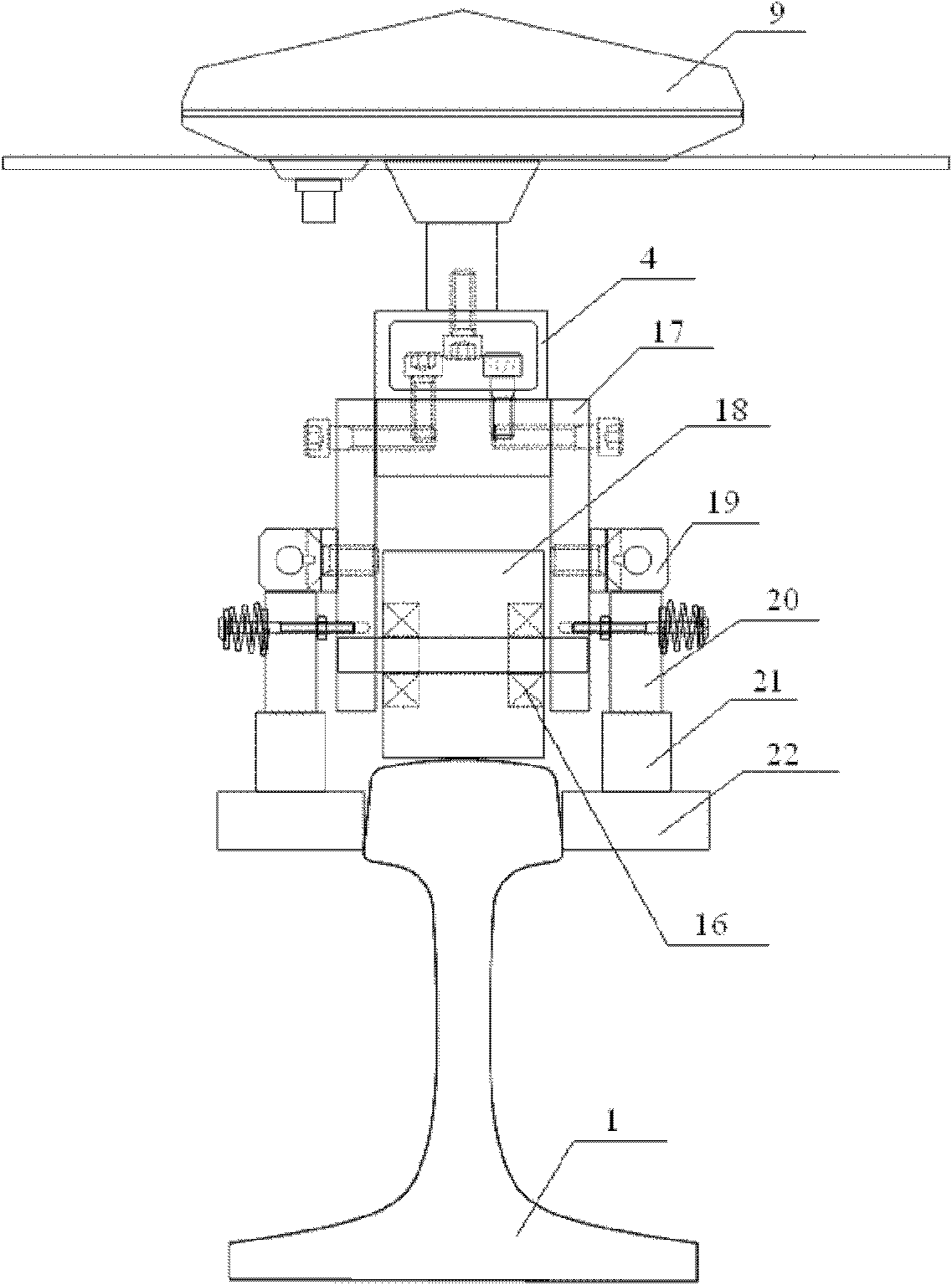

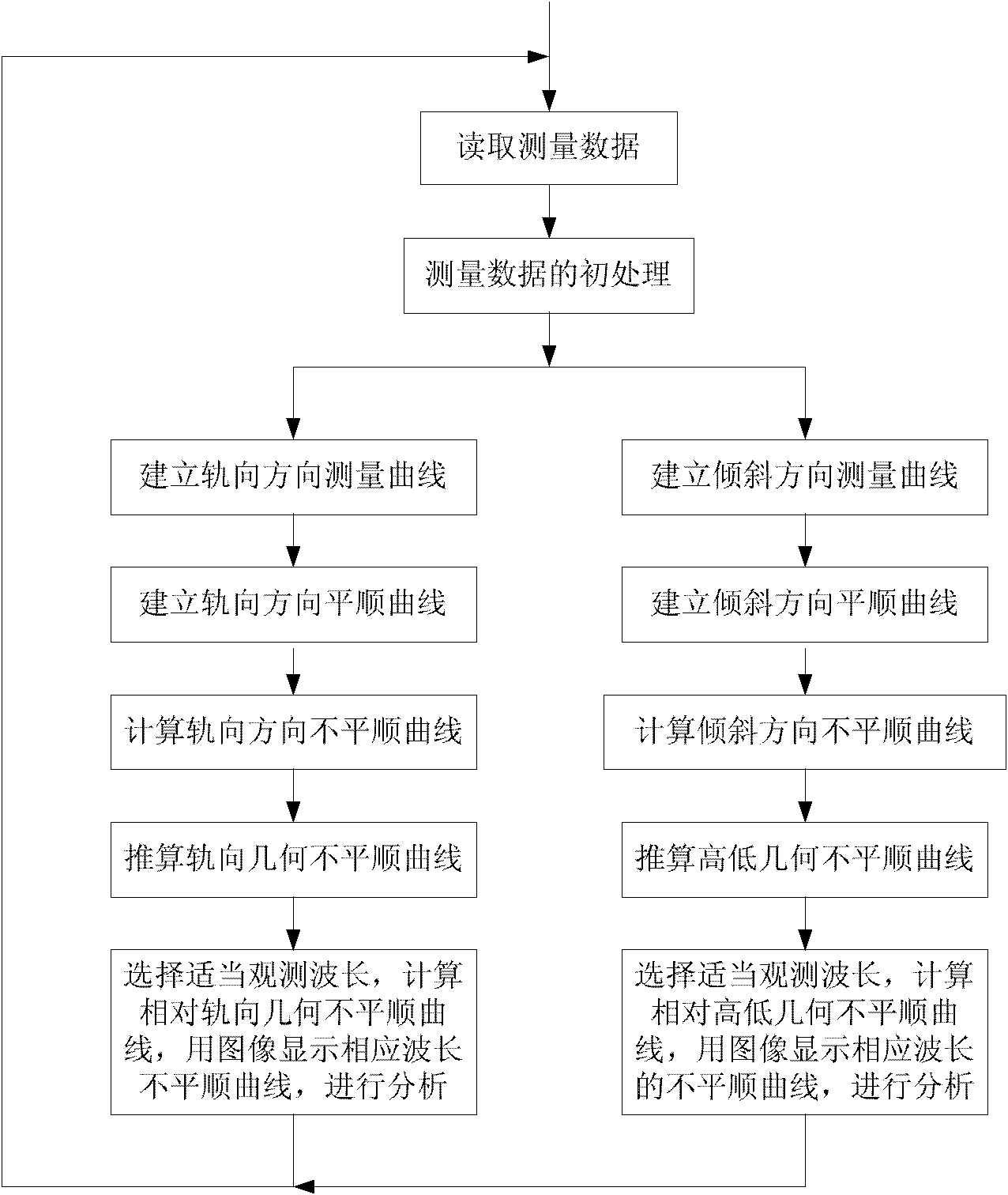

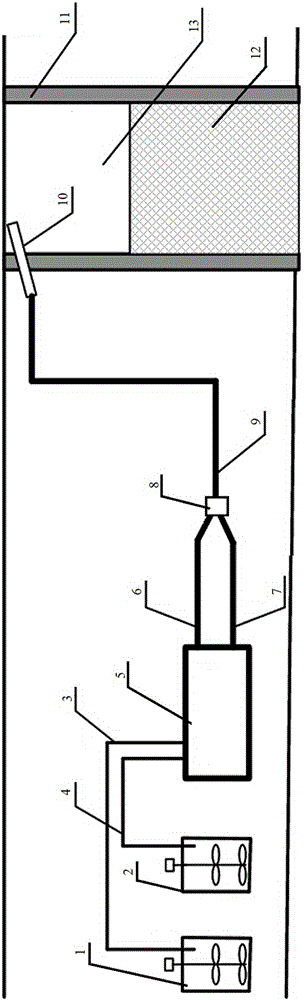

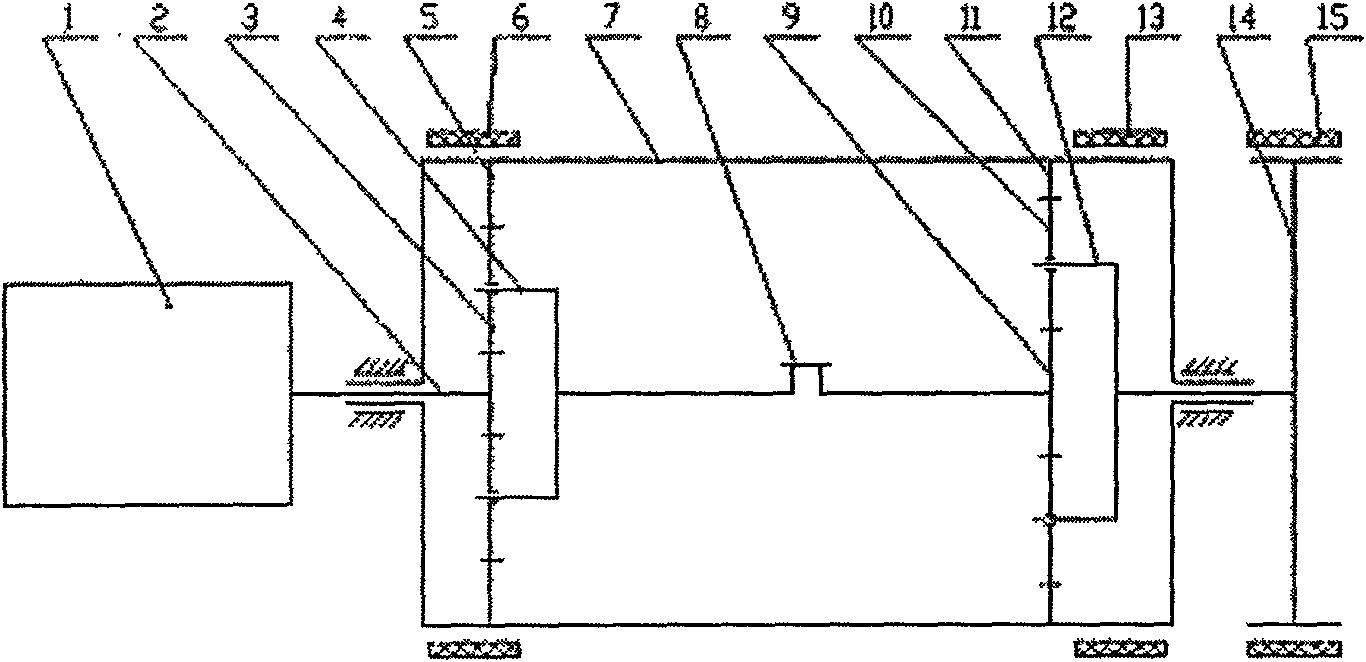

GPS (Global Positioning System) track irregularity detection system and method

ActiveCN102337710AHandling location information is simpleImprove work efficiencyMeasuring apparatusAccuracy and precisionEnvironmental geology

The invention discloses a GPS (Global Positioning System) track irregularity detection system and method. The system comprises a measuring unit and a data postprocessing unit, wherein the measuring unit comprises a moving bracket movably arranged on the surface of a track, and a measuring device; the measuring device is rigidly fixed on the moving bracket and comprises two independently-arranged measured data acquisition recorders; the measured data acquisition recorders are used for measuring state data of the moving bracket in real time and recording the state data measured at every time to a data recording unit according to a time sequence arrangement; and the data postprocessing unit is used for processing the state data recorded in the data recording unit in an off-line way. The GPS (Global Positioning System) track irregularity detection system and method disclosed by the invention have the advantages of high measurement precision, high measurement speed and complete measuring functions.

Owner:SAFEWAY XIAN NAVIGATION TECH

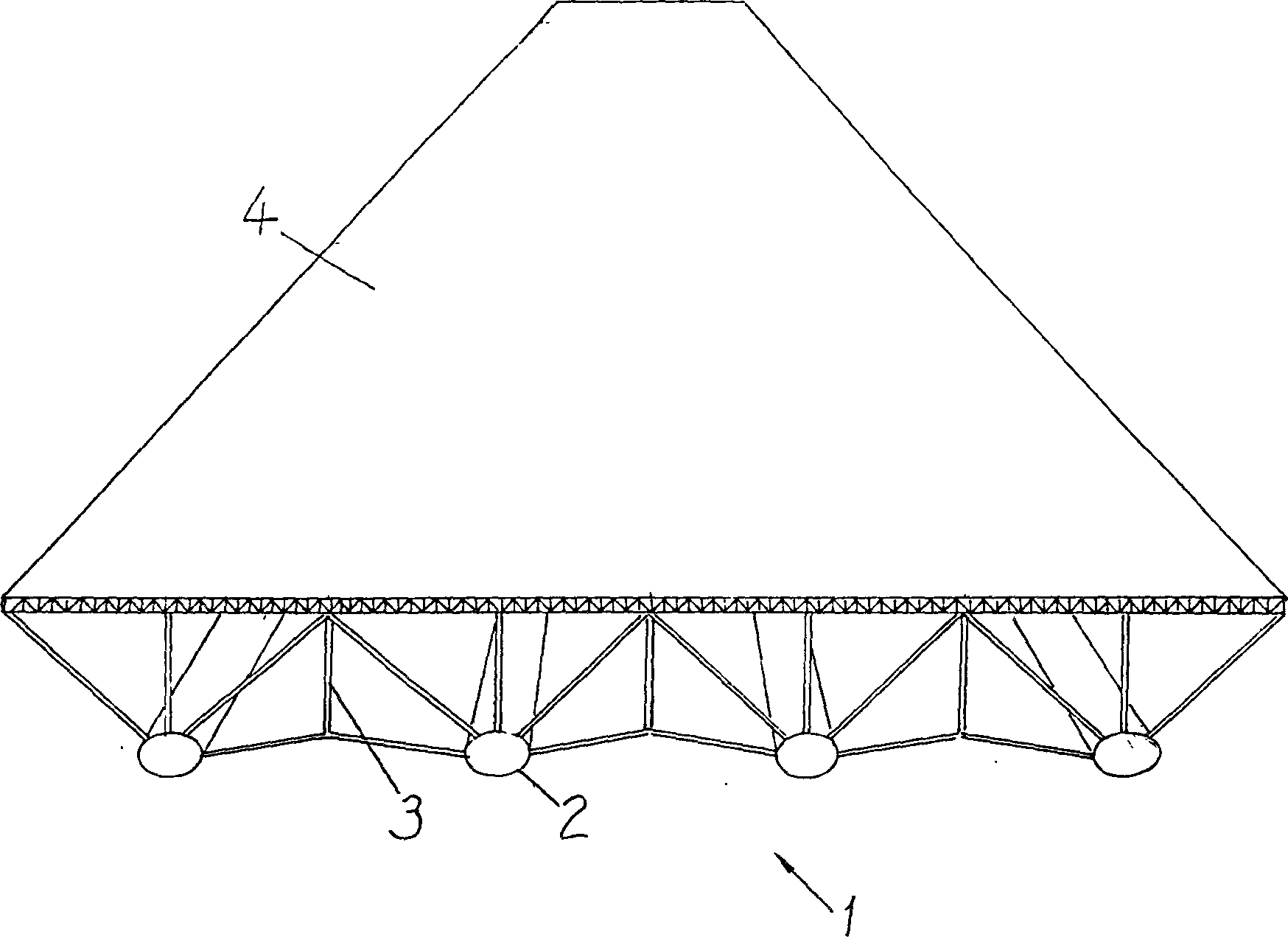

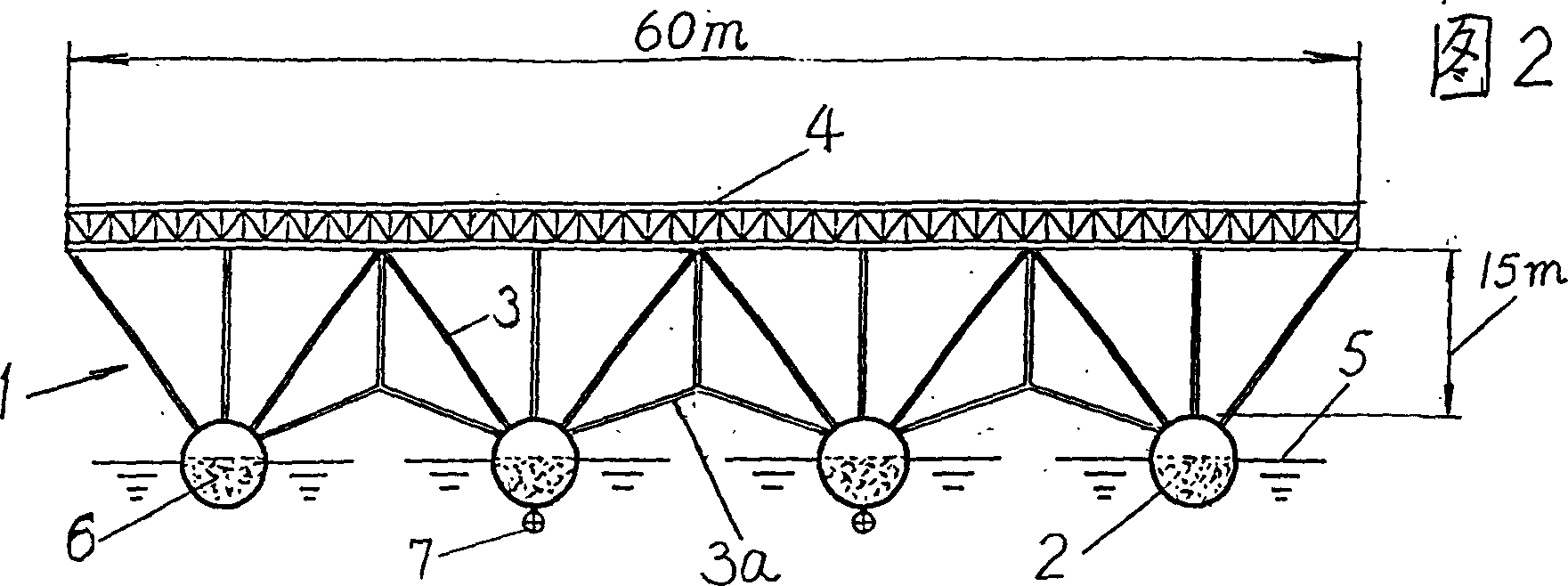

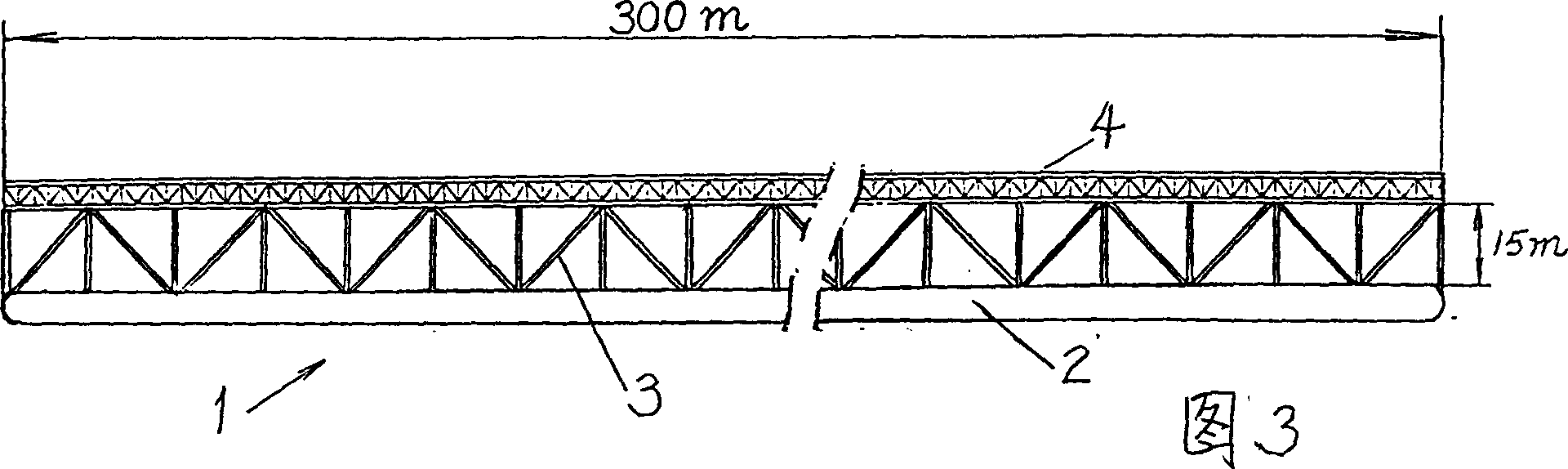

Super large truss type floating maine platform

An ultra-large truss type floating marine platform is composed of floating drums dispersed on water surface, a working platform above water surface, and connecting rods. Its advantage is high stability.

Owner:TANGSHAN REMOVABLE ISLAND MARINE HEAVY IND CO LTD

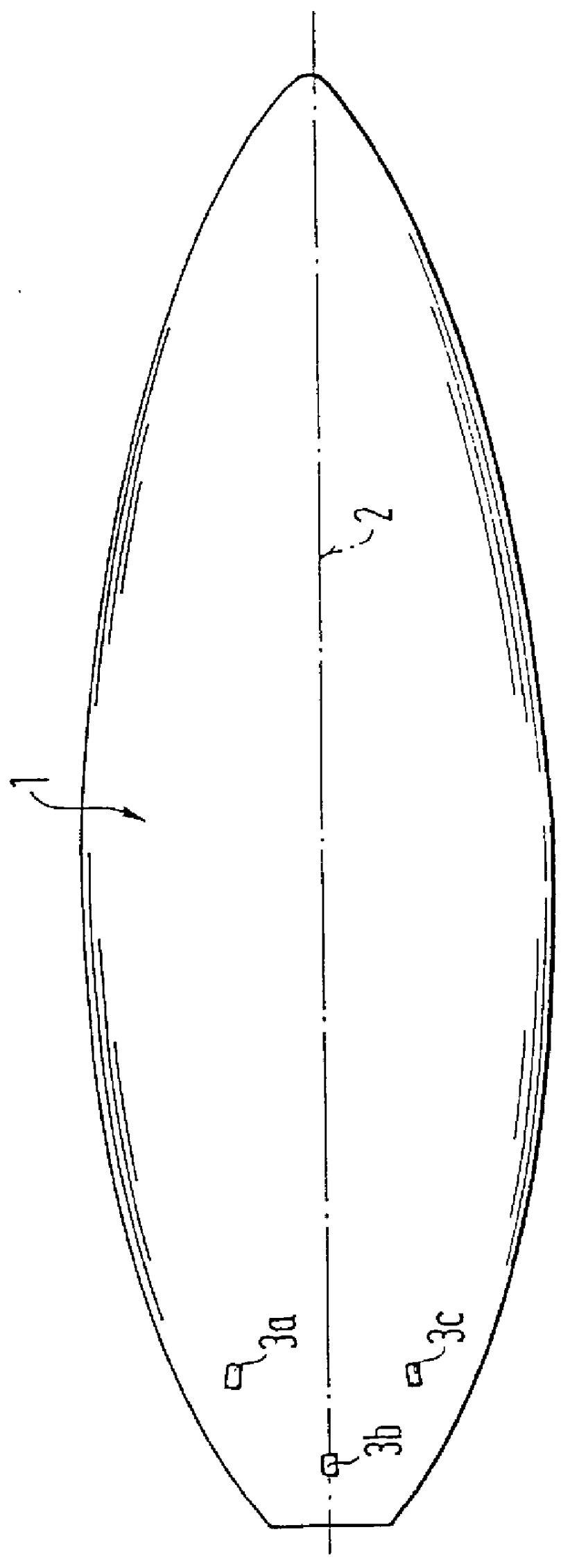

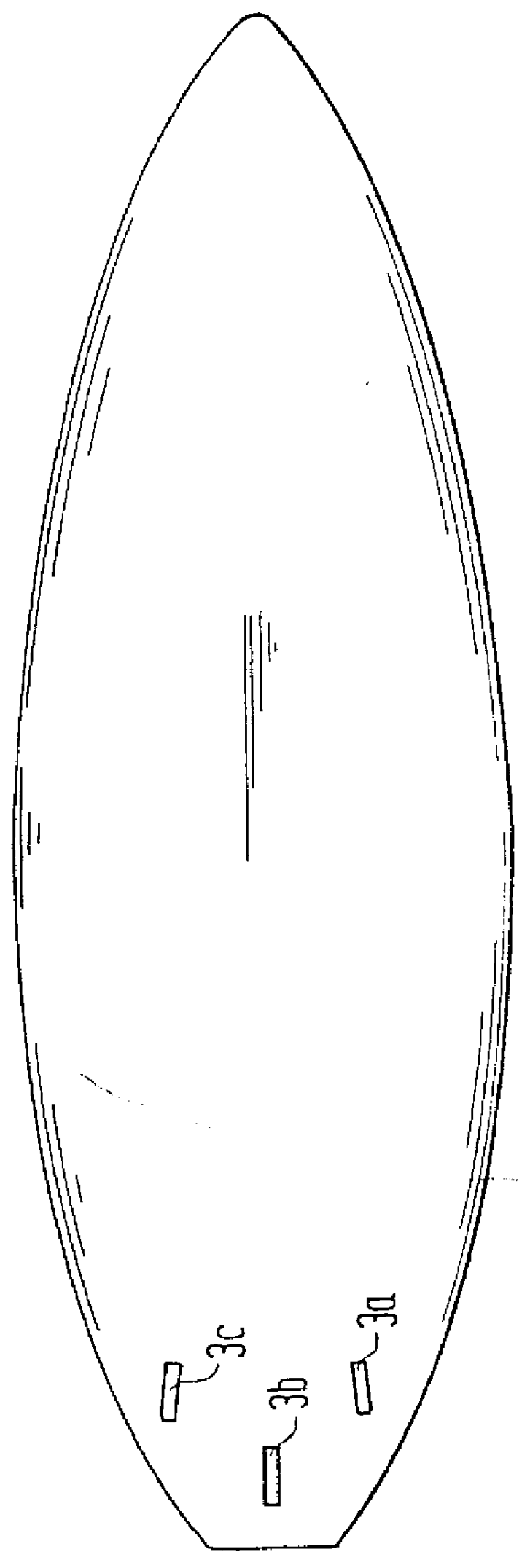

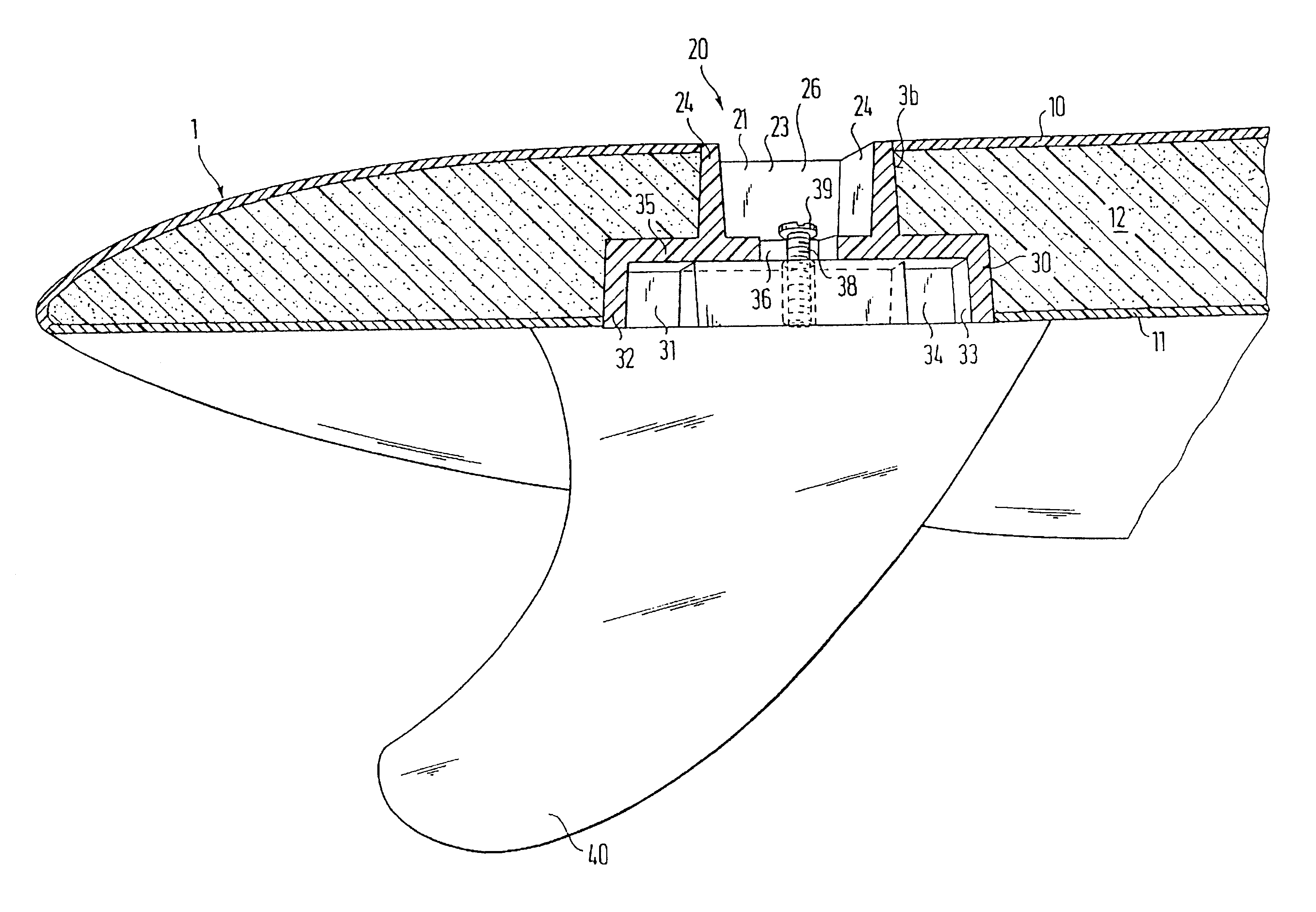

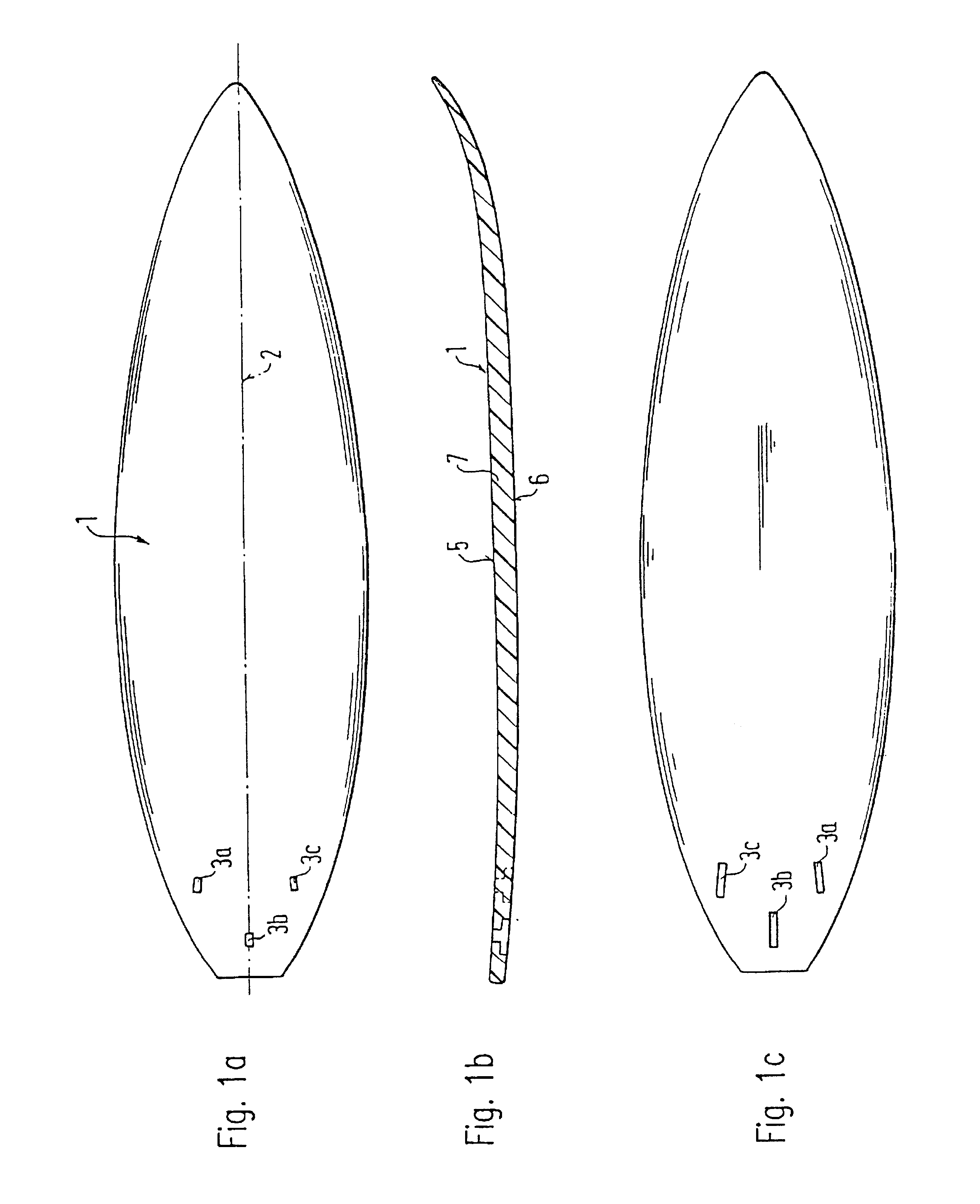

Surf- or sail-board and method of producing the same

Owner:RAPP PETER

Precesion casting method for high temperature alloy complex thin-walled castings

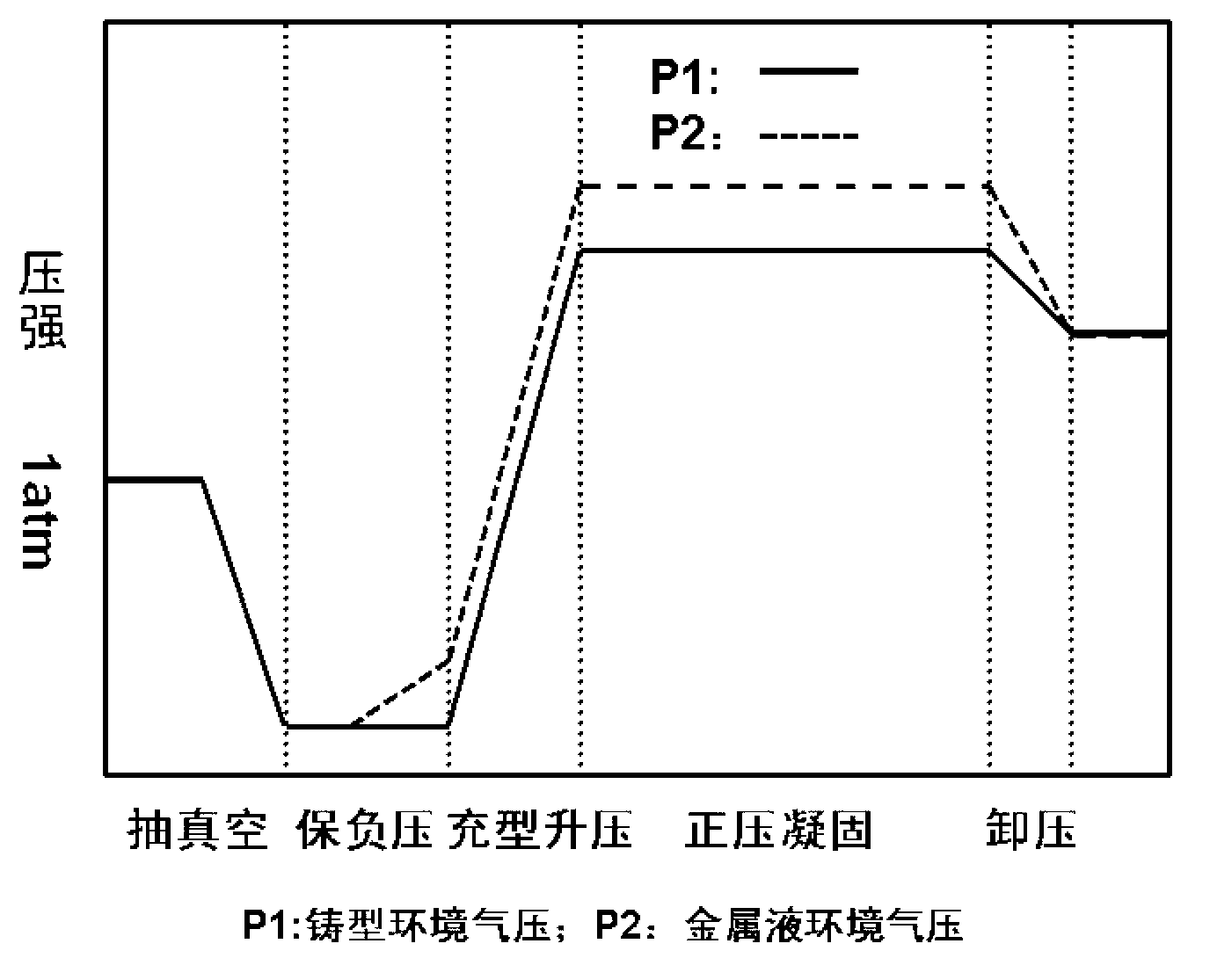

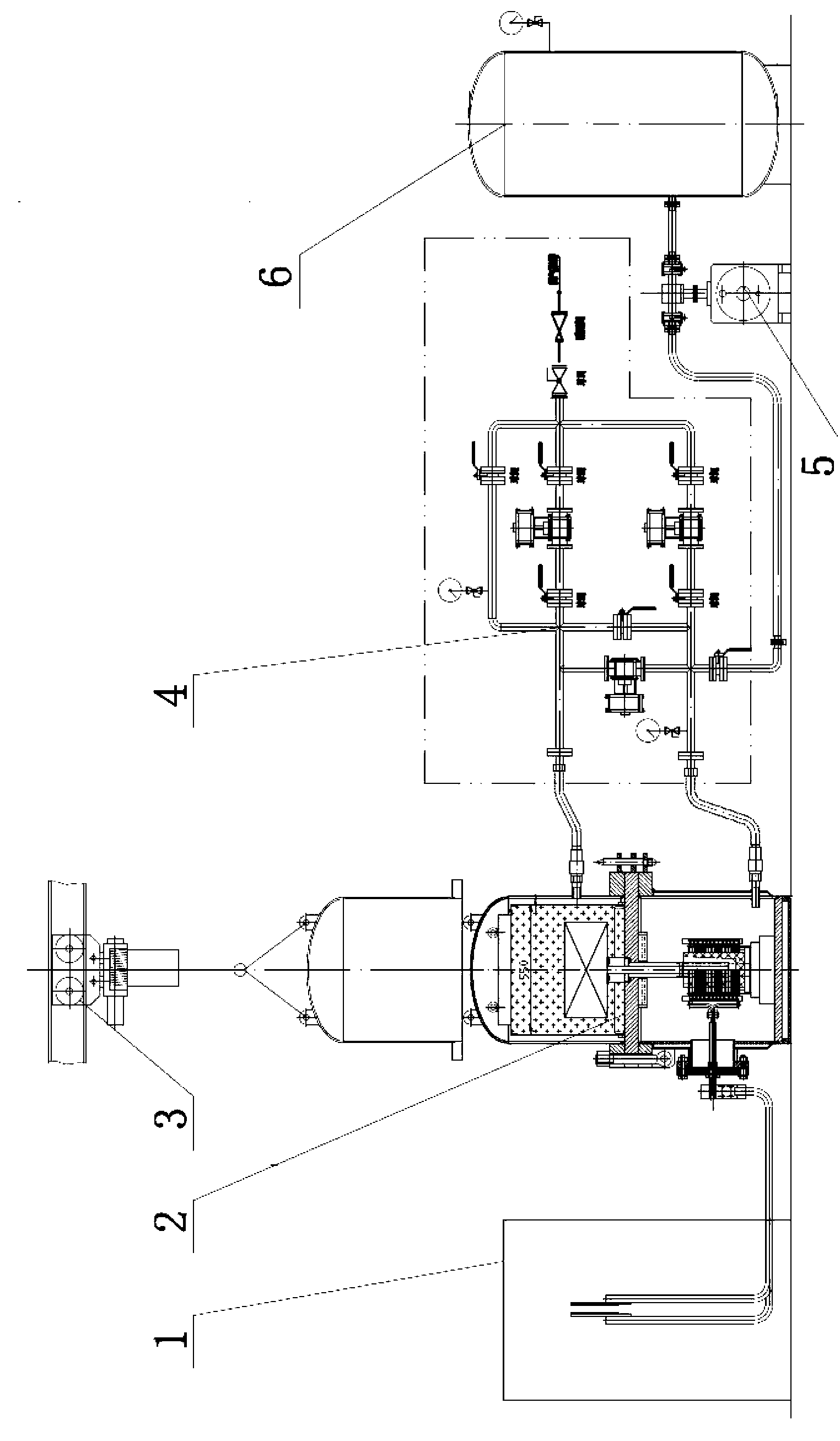

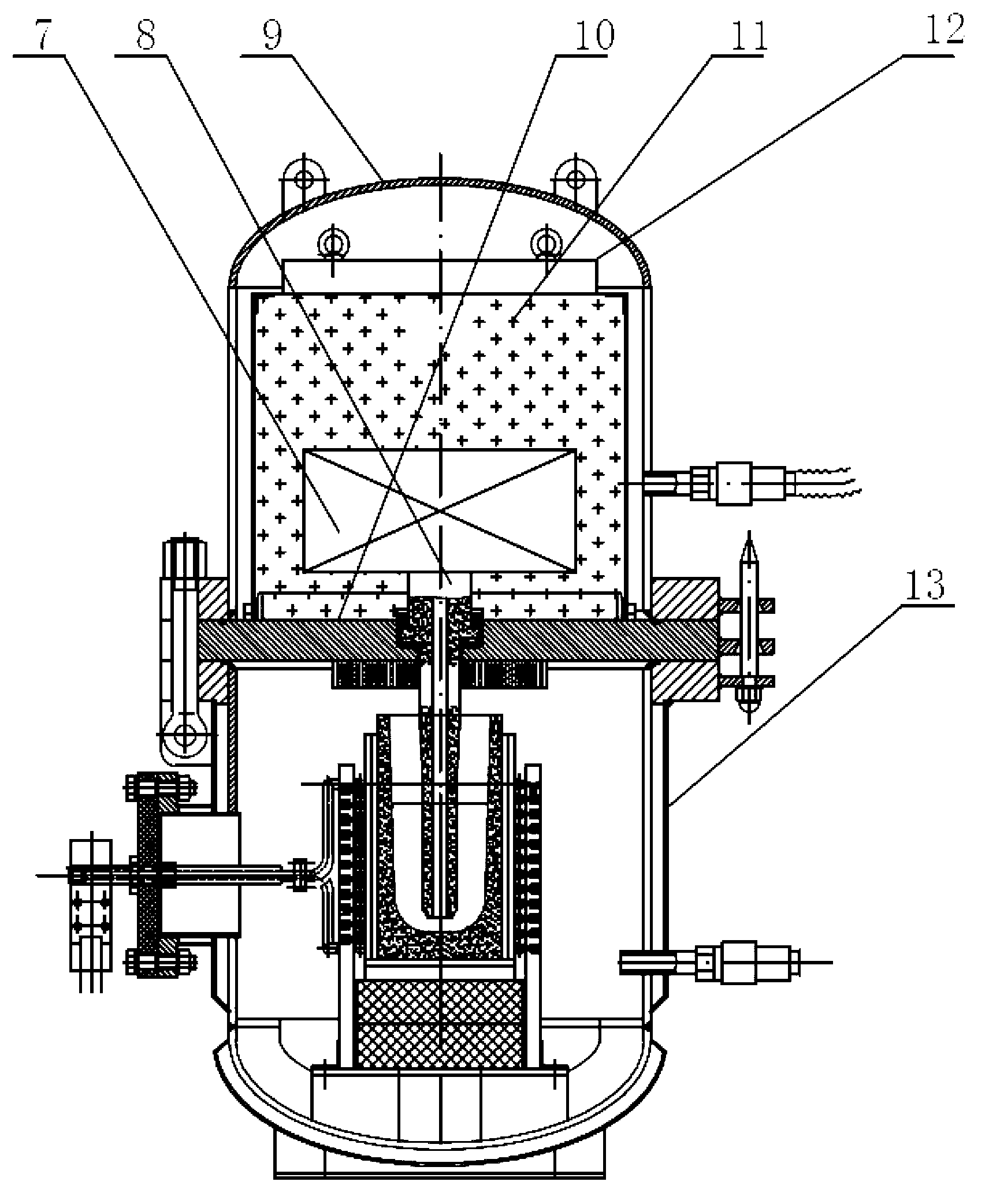

ActiveCN102699311ASolve filling problemsReduce air permeabilityFoundry mouldsFoundry coresIntermediate frequencyMold filling

The invention discloses a precision casting method for high temperature alloy complex thin-walled castings. The method comprises the following steps of: utilizing a medium frequency induction heating power supply to melt the alloy, utilizing a medium baffle to separate an upper tank and a lower tank, and utilizing an electric hoist to elevate the upper tank when a casting mold and a liquid rising tube are installed; after the installation is completed, utilizing a gas circuit control pipeline, a vacuum system and a gas tank to realize vacuum and pressure regulation in a pressure regulating furnace. By adopting the method disclosed by the invention, stable and efficient mold filling is realized, the castings is solidified sequentially, utilization efficiency of the material can be effectively improved, and the space for near-end net shape casting can be supplied; the complex, thin-walled and integral metal castings which are difficult to cast through other molding methods can be produced, so as to solve the filling problem in the pouring process of the complex thin-walled castings, and in particular, the filling capacity for the thin-walled castings with the wall thickness of less than 3mm is greatly improved. Accurate castings with high dimensional accuracy can be obtained through high temperature alloy pressure regulating investment precision casting, and the accuracy of the casting can reach between CT4 and CT6.

Owner:SHANGHAI JIAO TONG UNIV

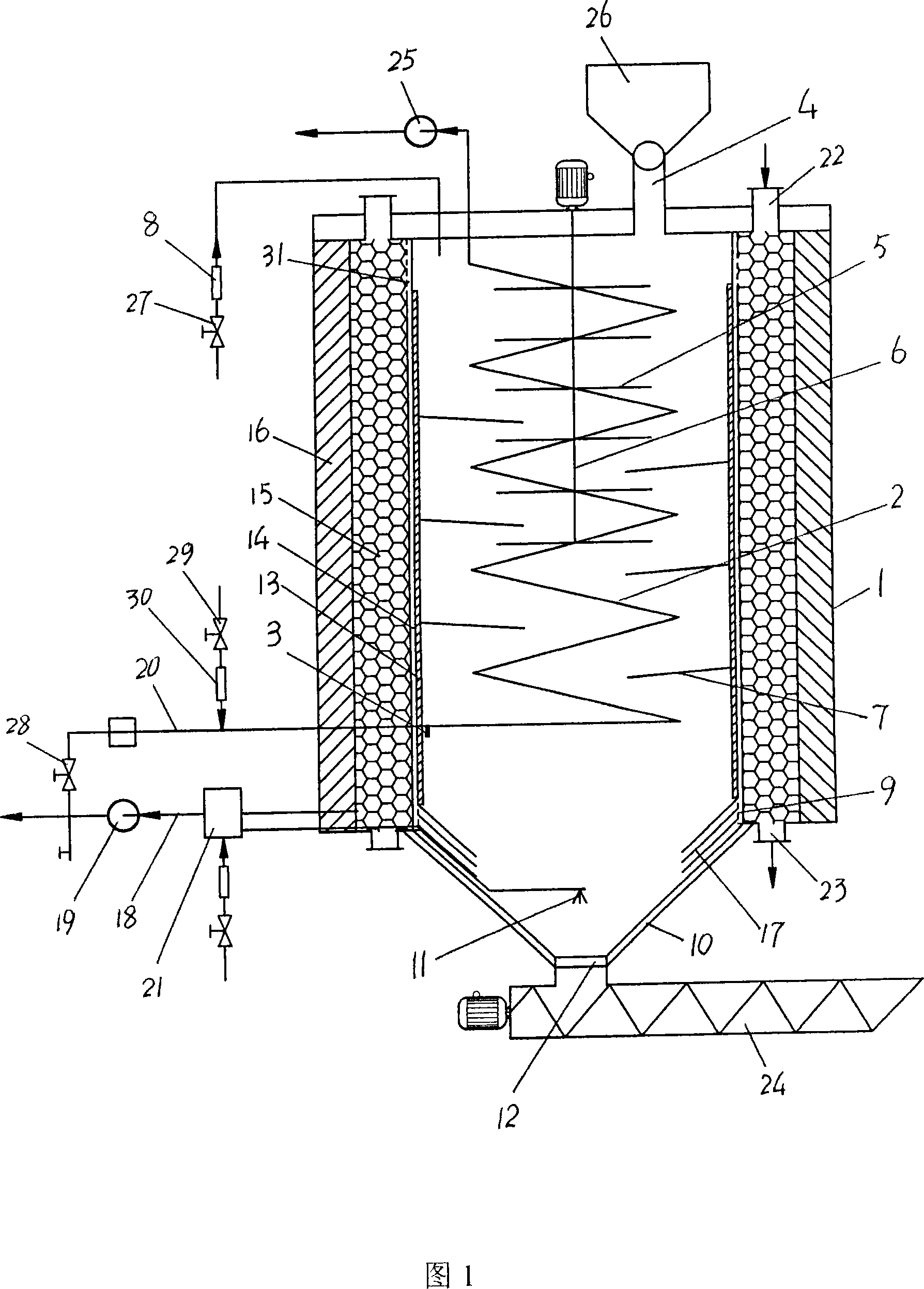

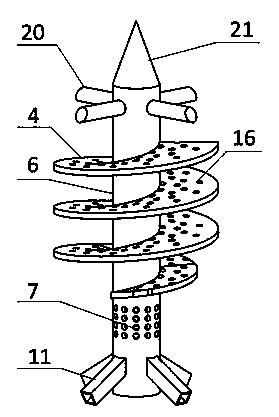

Internal-combustion heating type biomass gasification furnace

ActiveCN101021334AImprove biomass gasification rate and gas calorific valueImprove gasification efficiencyDomestic stoves or rangesLighting and heating apparatusNitrogen gasEngineering

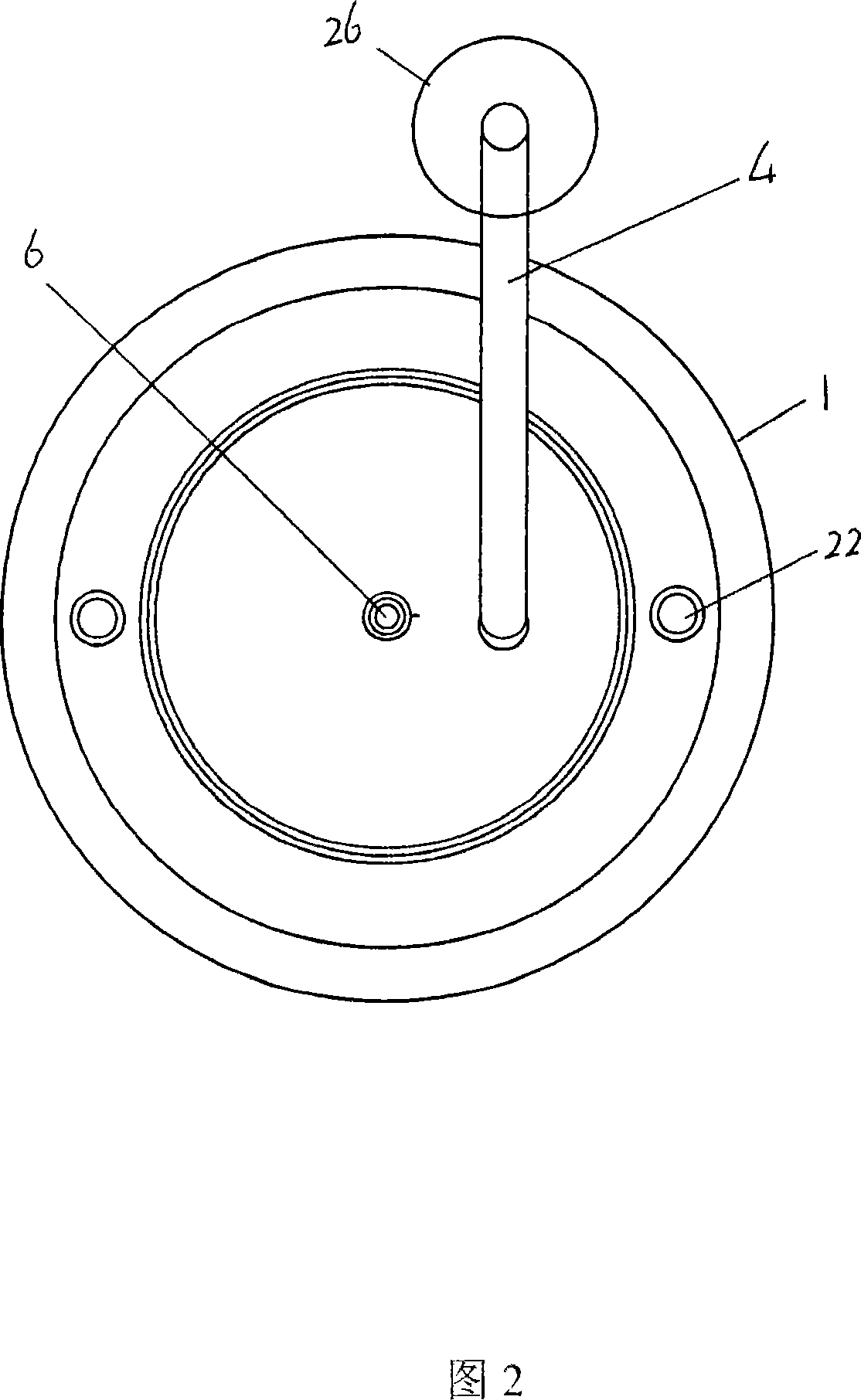

The present invention relates to an internal combustion heated biomass gasification furnace. Its structure is characterized by that it adopts a cylindrical furnace body, in the furnace body interior a coiled internal combustion pipe is set, the internal combustion pipe inlet is positioned in the lower portion of said cylindrical furnace body, and its outlet is extended to the exterior of furnace body from the top portion of cylindrical furnace body, its igniter is positioned in the internal combustion pipe inlet; over the cylindrical furnace body a helical feeding mechanism is set, its helical feeding hole is positioned on the eccentric position of cylindrical furnace body top portion, on the centre axis position of said cylindrical furnace body a stirring shaft with stirring blades is set, on the inside wall of cylindrical furnace body several layers of baffle plates are set, the combustion-supporting air inlet is set in the top portion of said cylindrical furnace body, and the gas outlet in the furnace body is positioned in the lower portion of said furnace body.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

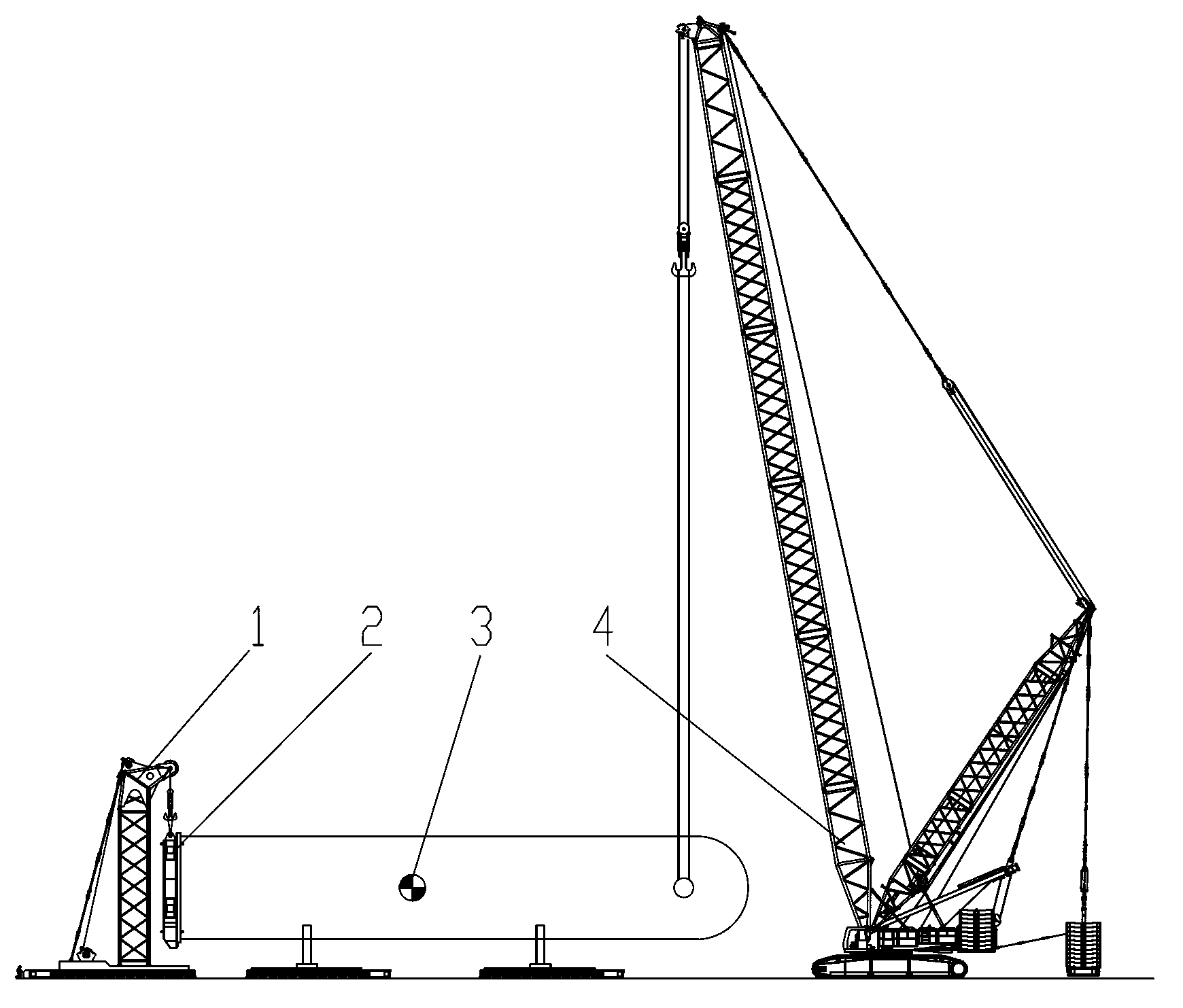

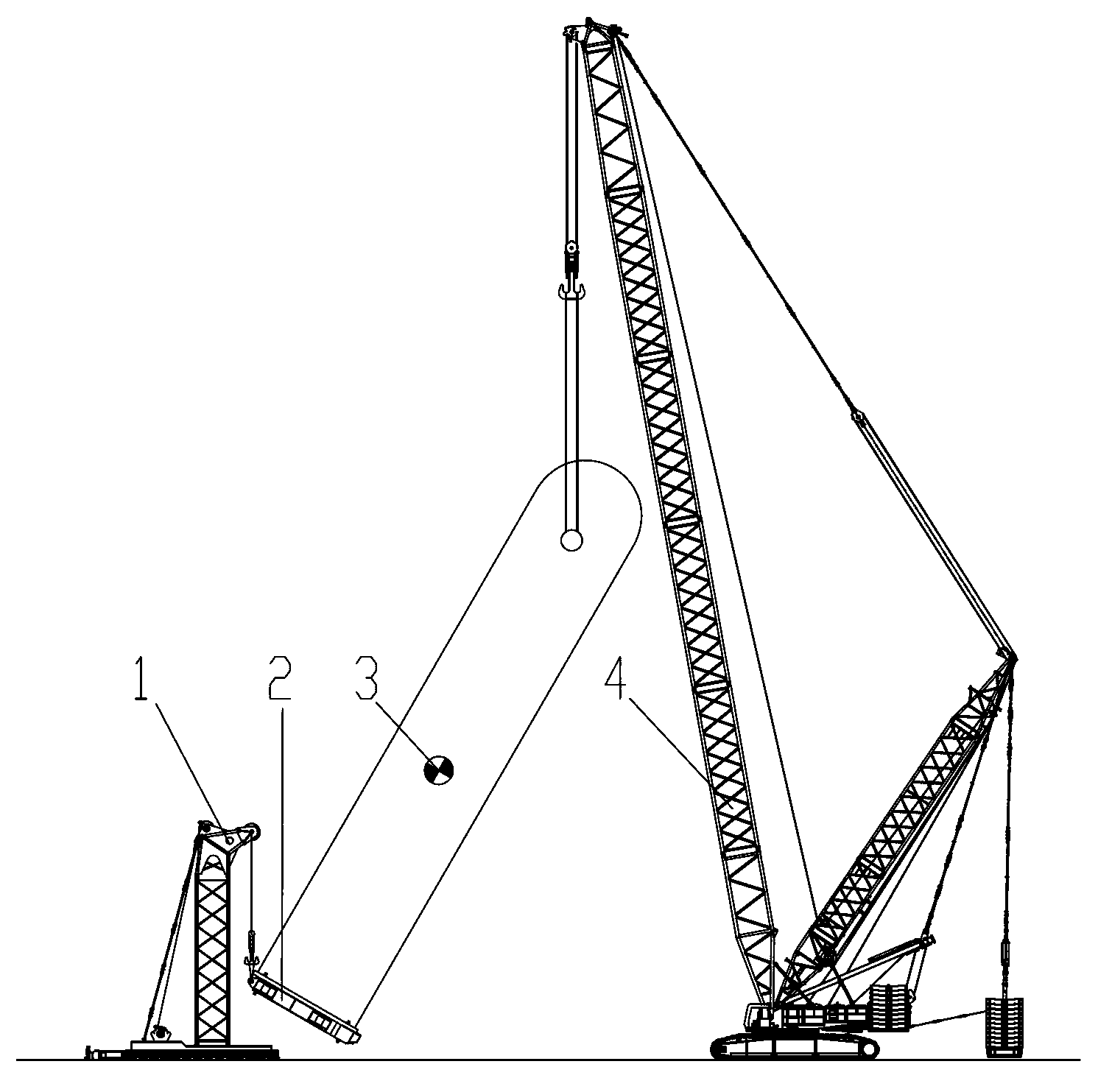

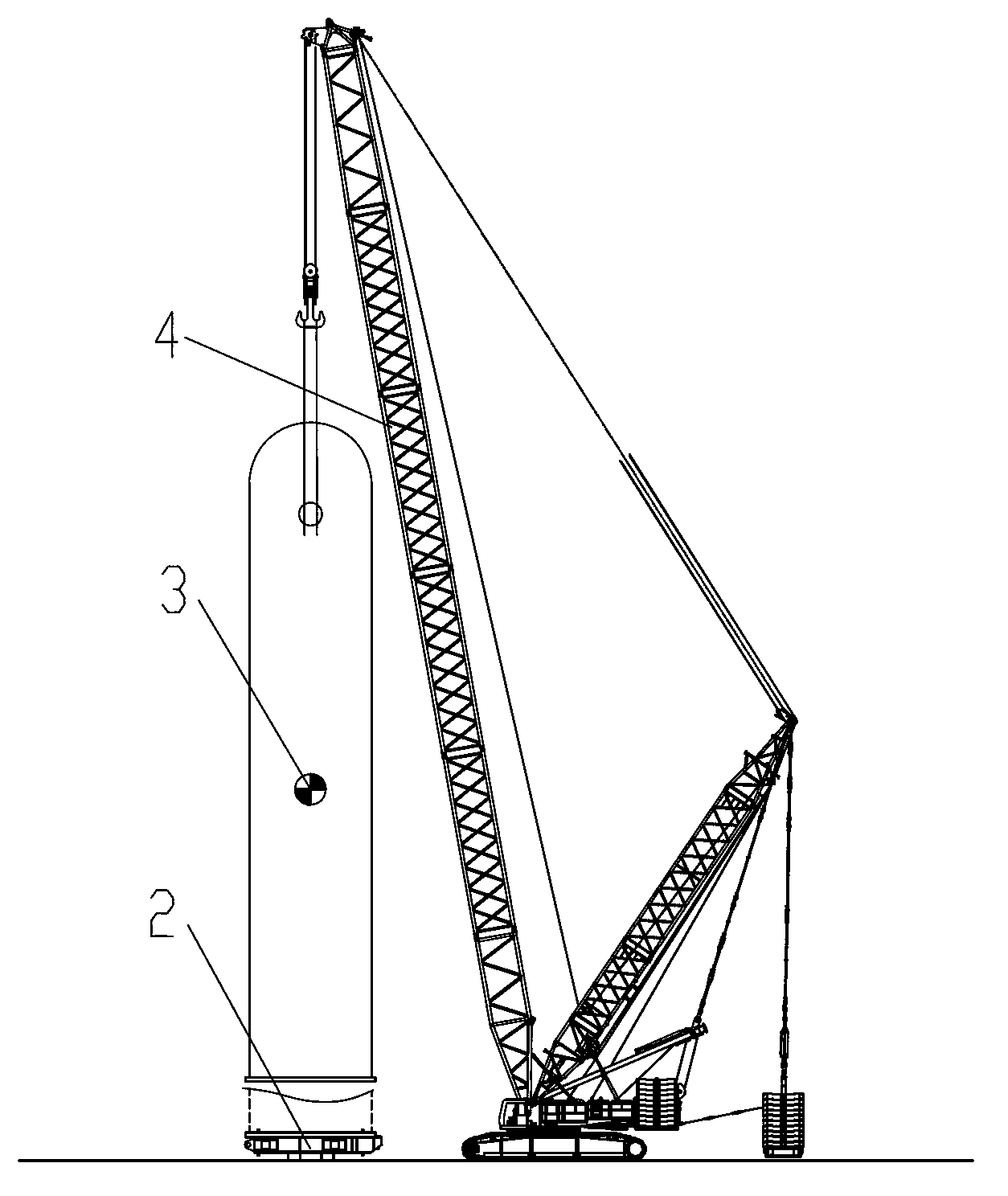

Tail device and tail dragging method

InactiveCN103058054AGuaranteed connectionStable equilibriumLoad-engaging elementsEngineeringGravity center

The present invention discloses a tail device and a tail dragging method. The tail device comprises: a tail end row which at least comprises a boom system, a travelling mechanism and a lifting mechanism, wherein the boom system is provided with a lifting mechanism and is supported on the travelling mechanism; and a tailstock which is used for being removably fixed to the lower part of a lifted device, and is provided with lifting holes. In the process of lifting the lifted device from the ground, the lifting mechanism is in hanging connection with the lifting holes, and the lifting holes are located at the end deviating from the ground. When the tail device is use for lifting a device, the center of gravity of the lifted device can be guaranteed to be always located below a connection line between the lifting point of main lifting equipment and the lifting point or the support point of the tail end row. The tail device has the advantages of good security, small weight borne by the tail end row, low lifting cost, etc.

Owner:SANY HEAVY IND CO LTD (CN)

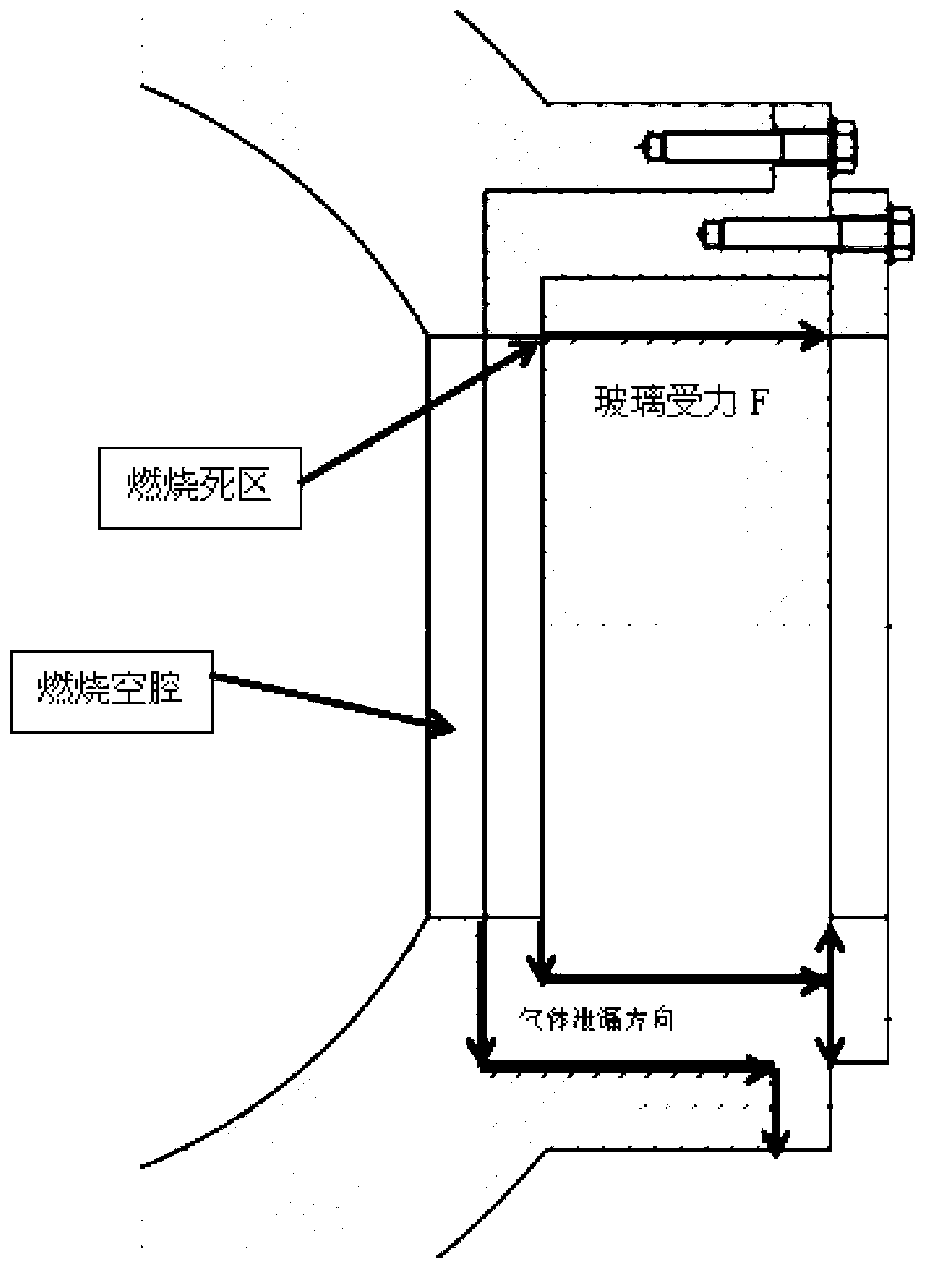

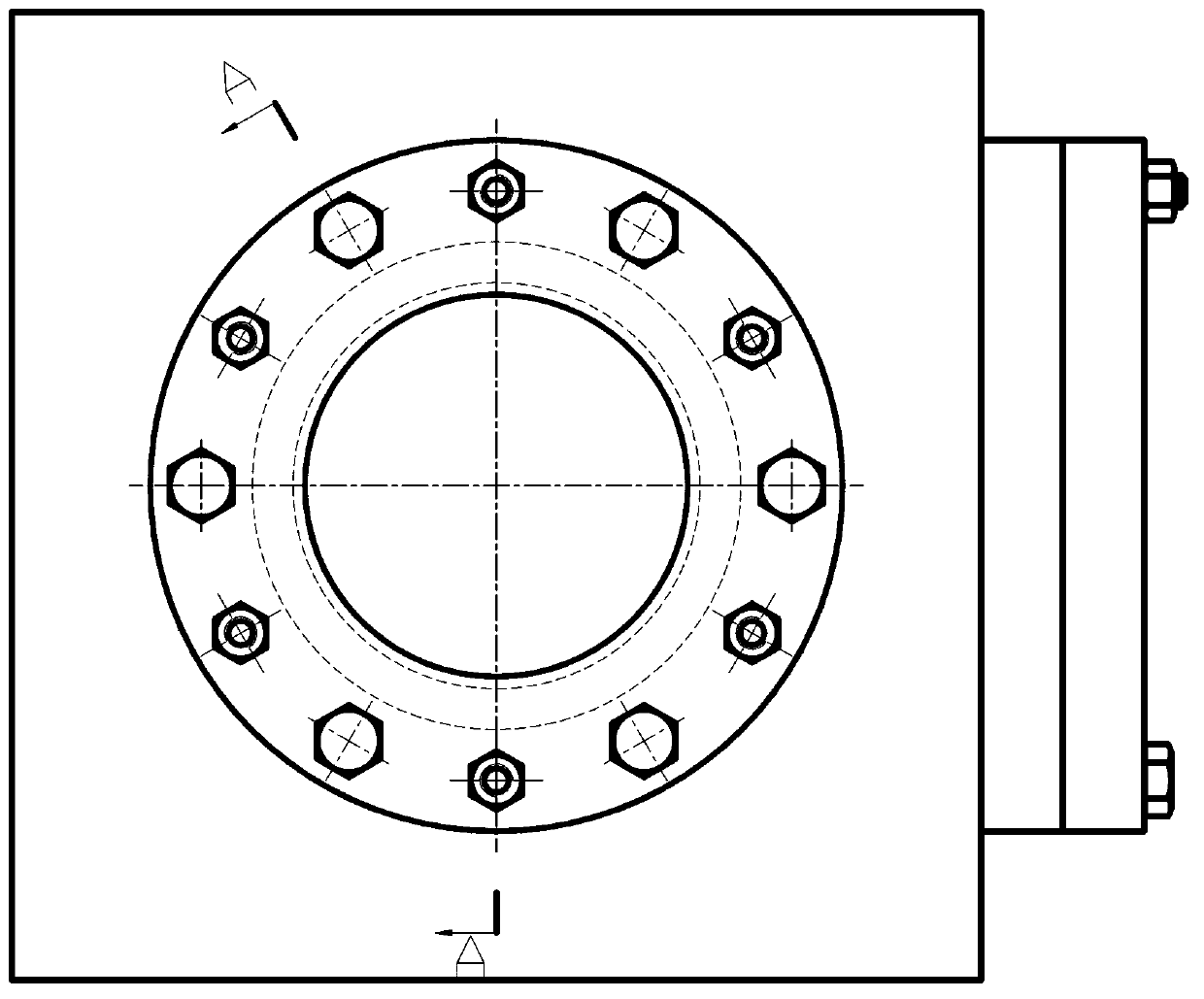

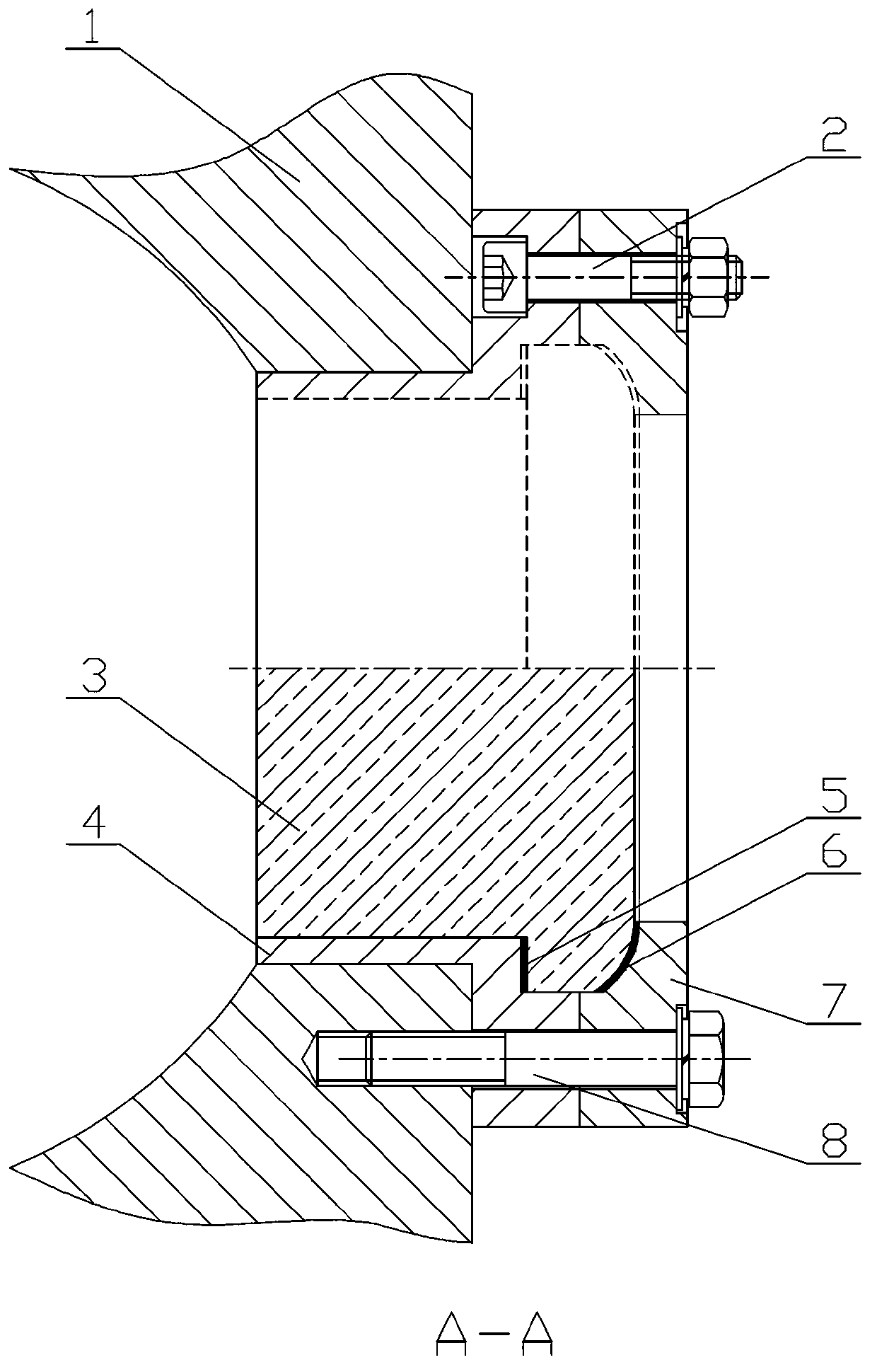

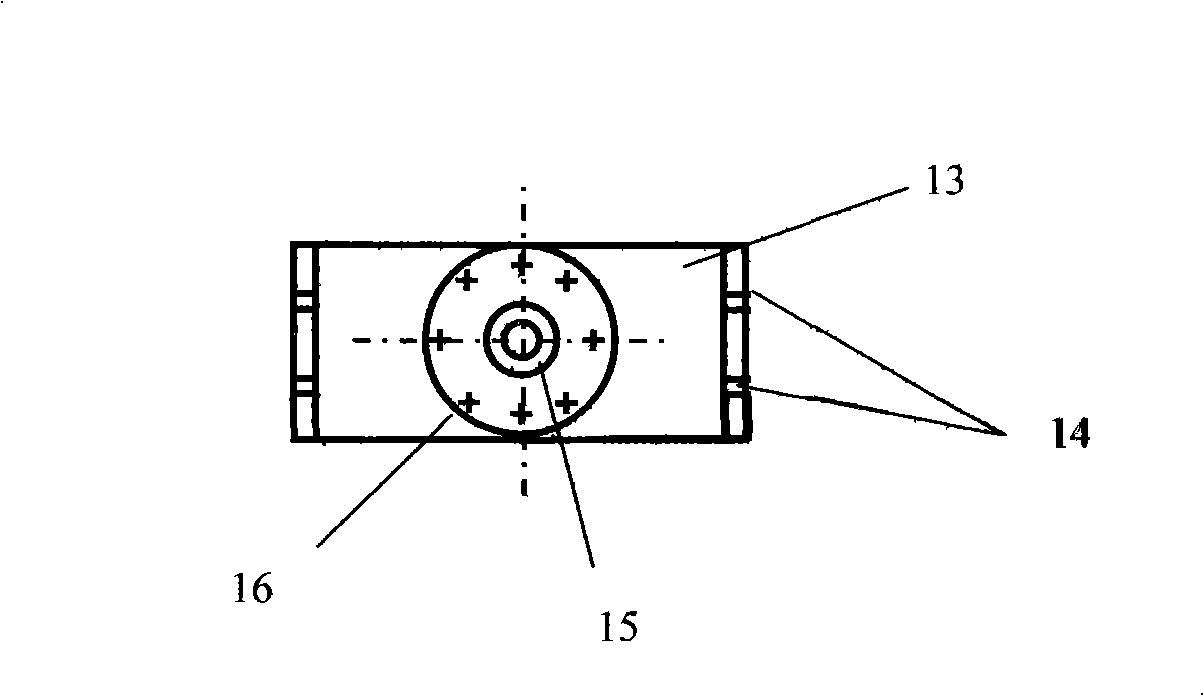

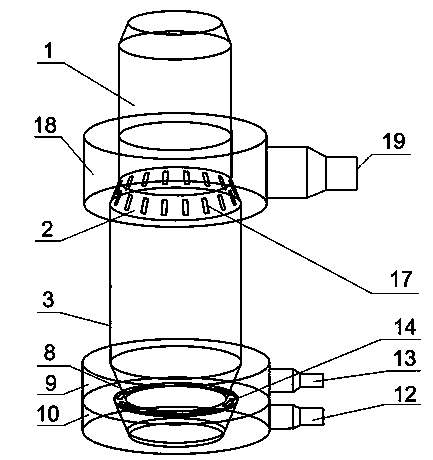

Constant volume combustion device for observing mutual effect of flame and pressure wave

InactiveCN103278331ASmooth structureReduce interlacingInternal-combustion engine testingCombustionEngineering

The invention discloses a constant volume combustion device for observing the mutual effect of a flame and a pressure wave. A combustion bomb body is provided with an observation hole provided with an optical observation window; the optical observation window comprises optical glass provided with an annular boss on the outer side; the inner side and the outer side of the optical glass are respectively provided with an embedding end cover and a compressing end cover which are mutually connected through a bolt; the embedding end cover and the compressing end cover are arranged on the combustion bomb body through bolts; and high-temperature resistant gaskets are respectively arranged among the embedding end cover, the compressing end cover and the optical glass. According to the constant volume combustion device, the influence of the installation of the optical observation window of the combustion bomb body to the regularity of the inner cavity shape of the optical observation window is reduced, and the inner cavity smoothness is improved, so that the reflection effects of an inner flow field and a wall pressure wave are improved; and meanwhile, the stress manner of glass in the traditional optical observation window is changed, the thickness of the glass is reduced, and the device is beneficial to observation and shooting effects of experiments.

Owner:TIANJIN UNIV

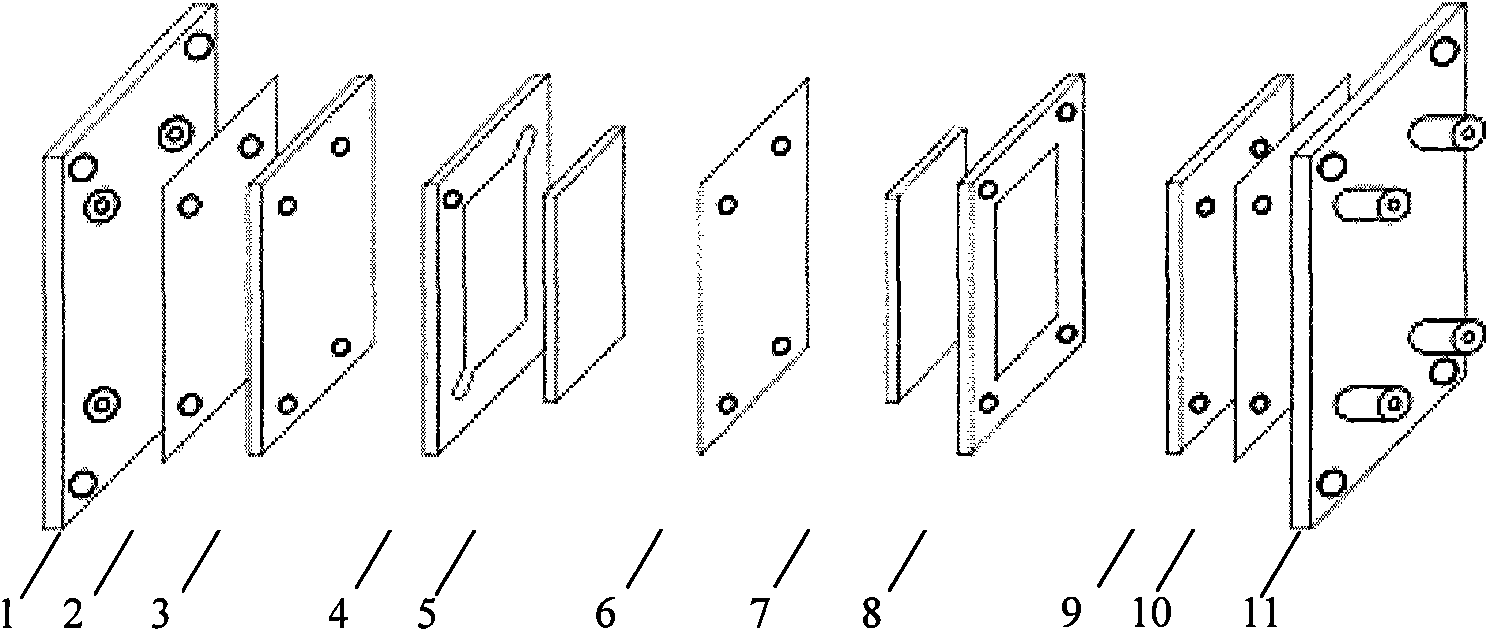

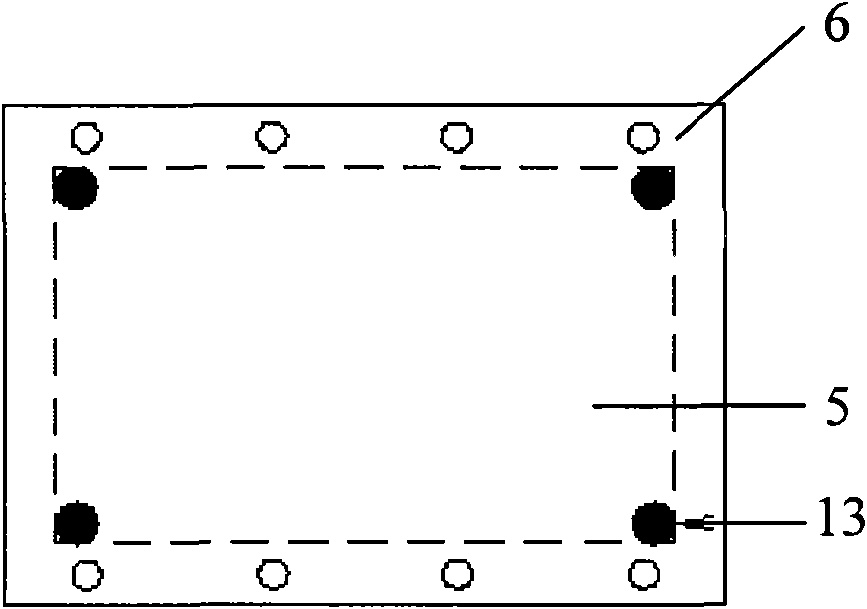

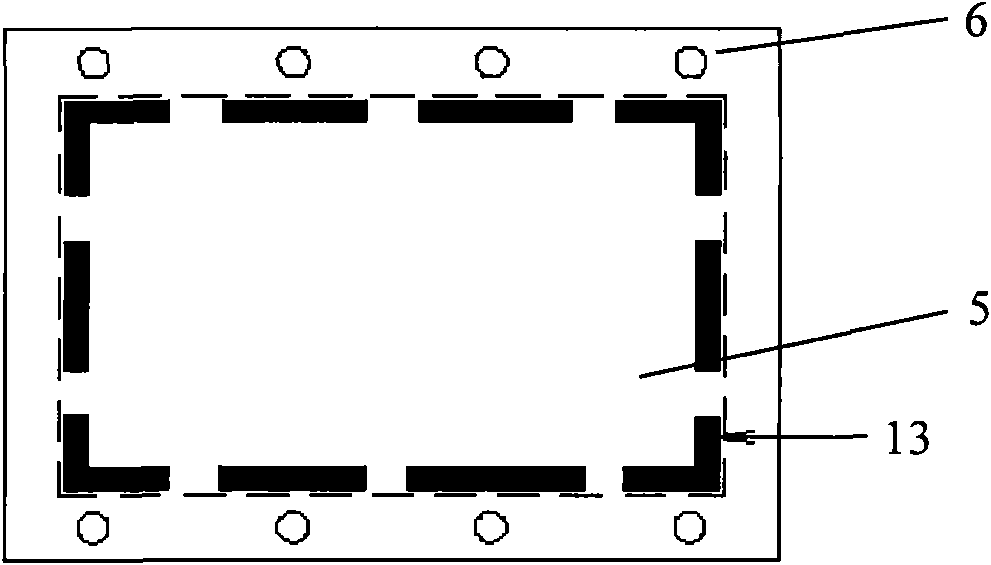

High-tightness flow battery

InactiveCN101651220ALower internal resistanceImprove voltage efficiencyRegenerative fuel cellsSecondary cellsInternal resistanceAdhesive

The invention provides a flow battery integrating device which comprises a negative electrode flow frame, a negative electrode, a proton exchange membrane, a positive electrode and a positive electrode flow frame which are sequentially connected with each other. The proton exchange membrane and the flow frames are spliced by acid-resistant binding agent, and the positive electrode and the proton exchange membrane, and the negative electrode and the proton exchange membrane are splice by conductive adhesive. Because the proton exchange membrane, and the flow frames and the electrodes on both sides are integrated in a bonding method, the invention simplifies the battery assembling process and enhances the tightness of the battery, and meanwhile, the integrating device reduces contact resistance between the membrane and the electrodes due to the integration of the membrane and the electrodes so as to reduce the internal resistance of the battery and enhance the efficiency of the battery.

Owner:CENT SOUTH UNIV +1

Three-cylinder coal cutter

InactiveCN101302930AImprove adaptabilityMeet mining requirementsCutting machinesManufacturing technologySimultaneity

The invention discloses a three-roller coal cutter, pertaining to the multi-roller coal cutter field. The coal cutter of the invention is additionally provided with a sectional cutting roller on a same coal mining workface at the middle on the basis of a two-roller coal cutter. As three sectional cutting rollers simultaneity work on the coal mining workface, the roller can be designed into the one with smaller diameter under the situation of the same coal mining height so as to make obvious progress on aspects such as manufacturing technology and cost, etc. Meanwhile, due to a shortened rocker arm, the three-roller coal cutter has more flexibility on the aspect of adaption to mining height.

Owner:卫建清 +1

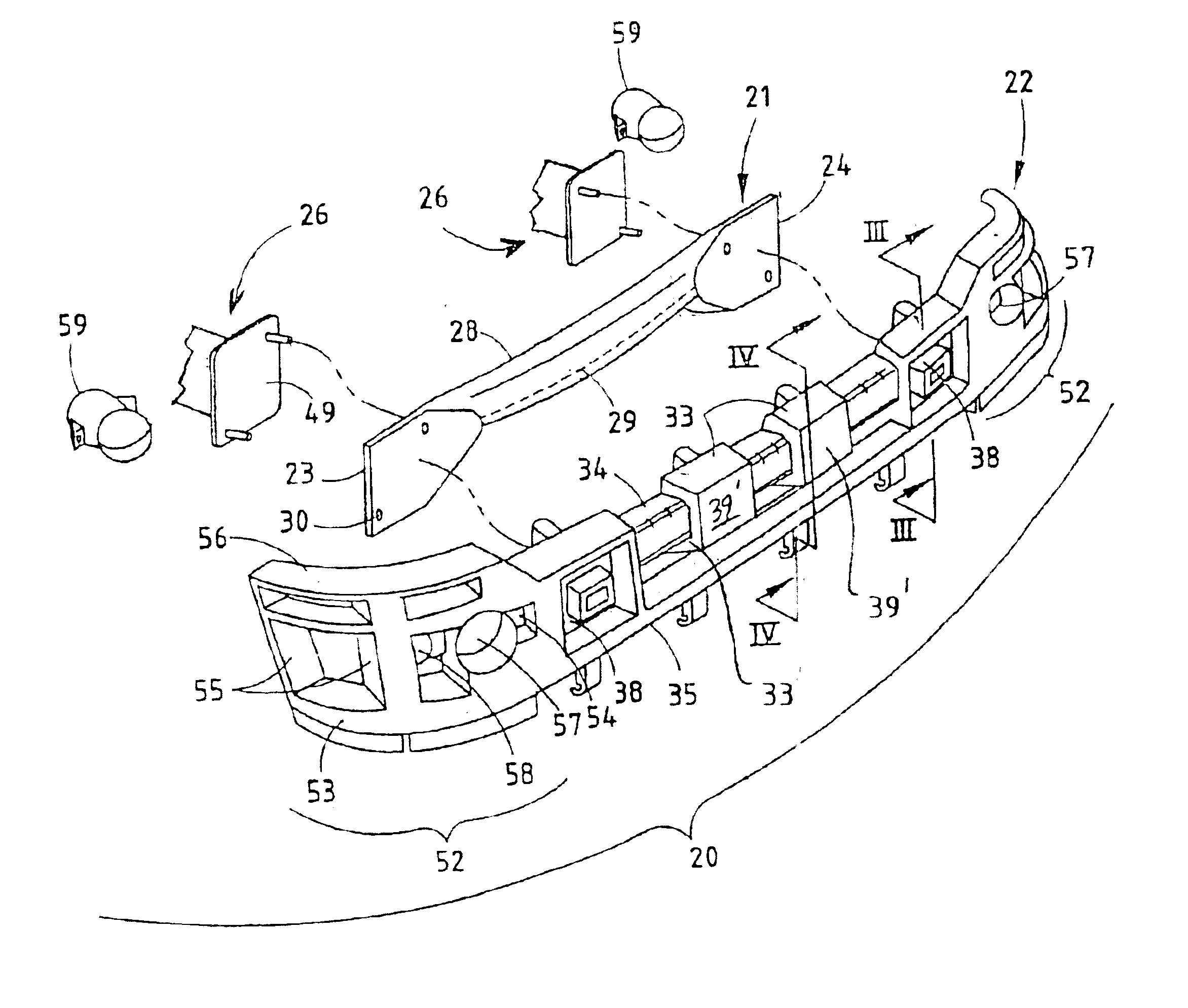

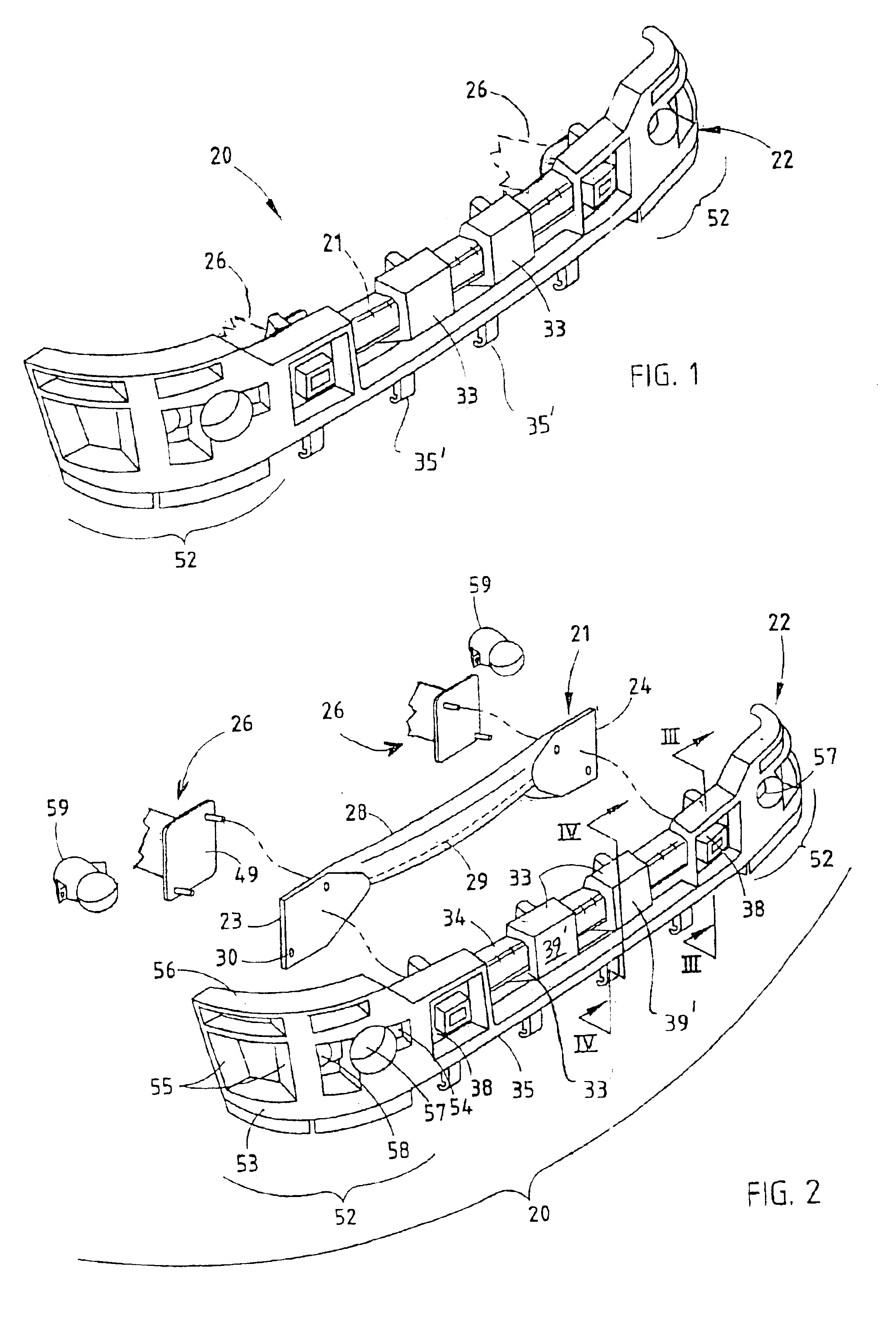

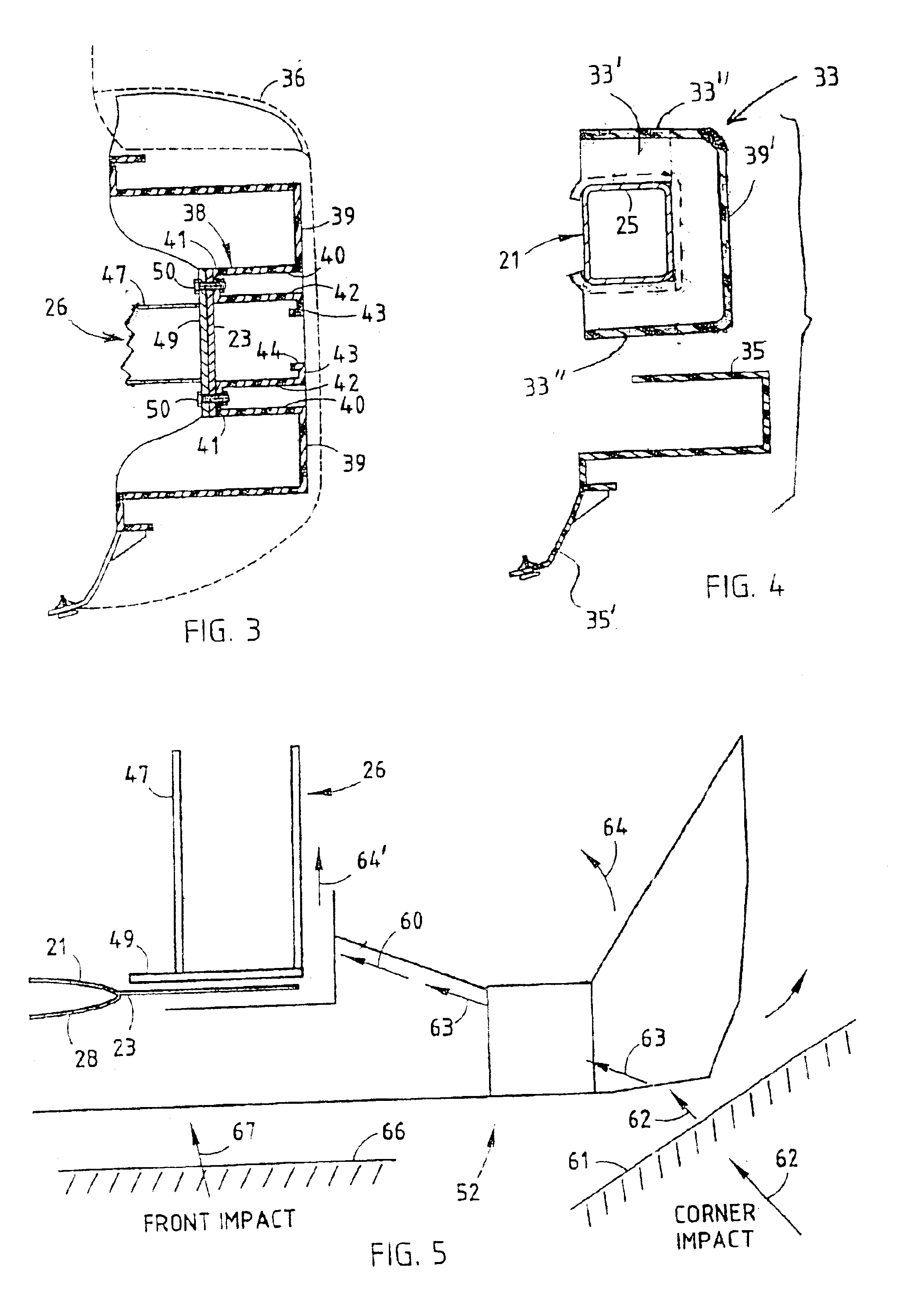

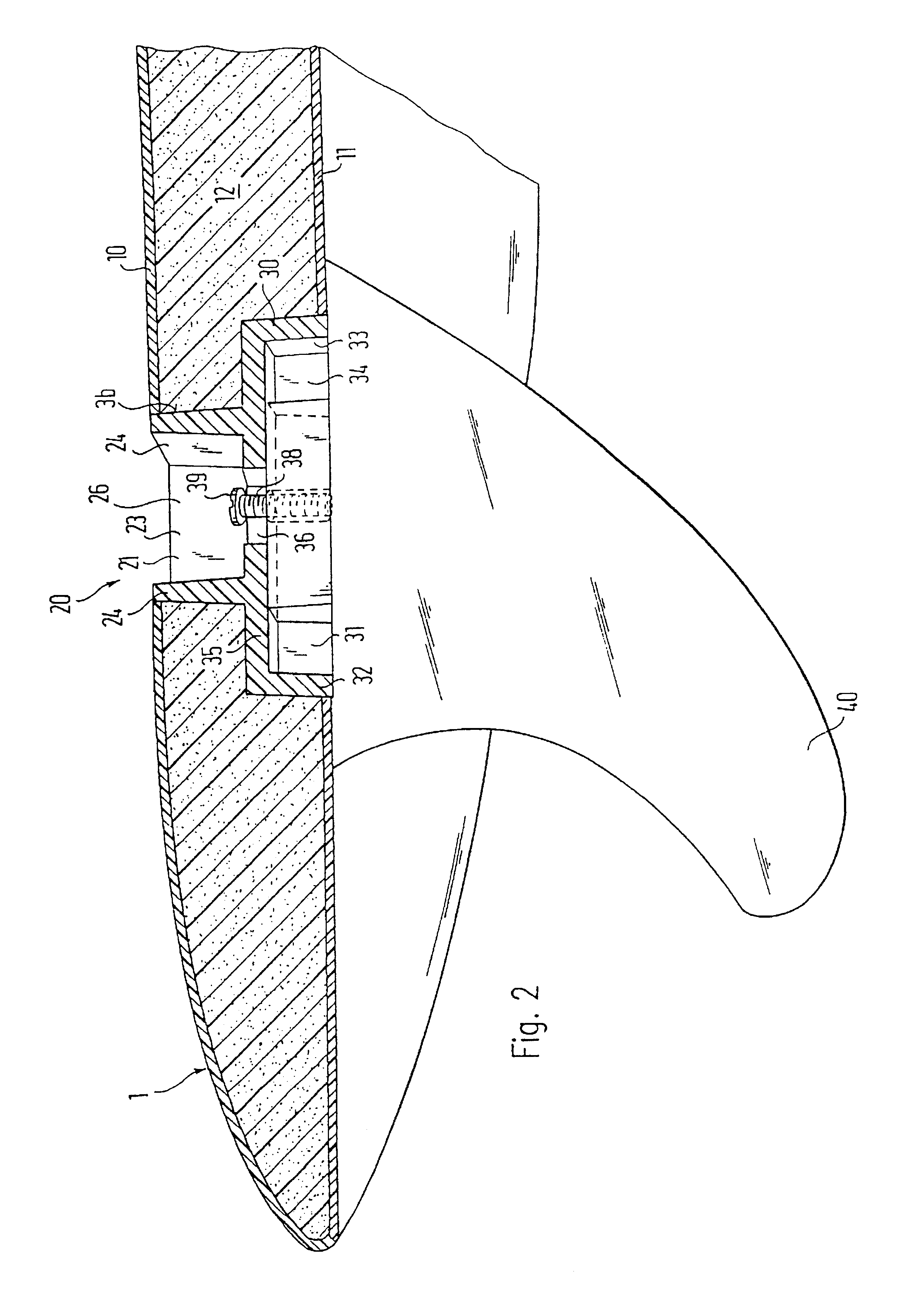

Bumper with integrally formed energy absorber

InactiveUS6908127B2Traditional front-end support structure can be simplified or eliminatedSimple supportMechanical machines/dredgersTowing devicesEngineeringImpact energy

A bumper system comprising a metal tubular beam, an energy absorber and mounts. The metal tubular beam has a center section having front, rear, top, and bottom walls. The energy absorber includes a rail having a rear surface with a rearwardly-facing C-shaped recess mateably receiving the tubular beam therein, with the energy absorber being configured to crush and absorb impact energy prior to collapse of the tubular beam. The mounts engage a rear of the metal tubular beam.

Owner:NETSHAPE INT LLC

Translational energy-absorbing seat for protecting neck during rear-end collision

The invention discloses a translational energy-absorbing seat for protecting the neck during rear-end collision and belongs to the technical field of automotive passive safety. A seat translational energy-absorbing mechanism is arranged on a slideway of a conventional automobile seat; and the mechanism is arranged under a seat cushion and symmetrically arranged on two sides of the seat. During rear-end collision, the provided translational energy-absorbing mechanism can make the seat and the passenger translate a certain distance backward under the action of a certain constraint force, and reduce relative motion of the trunk and the head of the passenger. Therefore, the neck injury to the automobile passenger during rear-end collision is effectively reduced. Meanwhile, the translational energy-absorbing seat overcomes the defect that the conventional passenger neck protecting seat during rear-end collision has heavy weight, high cost, narrow rear-end collision speed range, and the like, and has better application prospects.

Owner:TSINGHUA UNIV

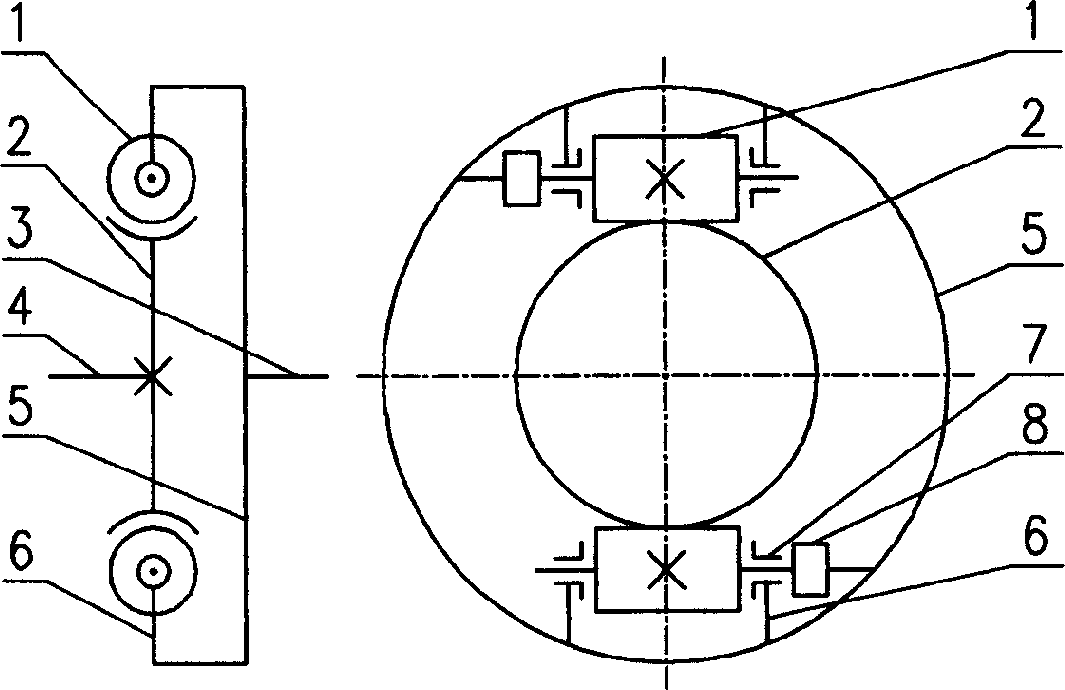

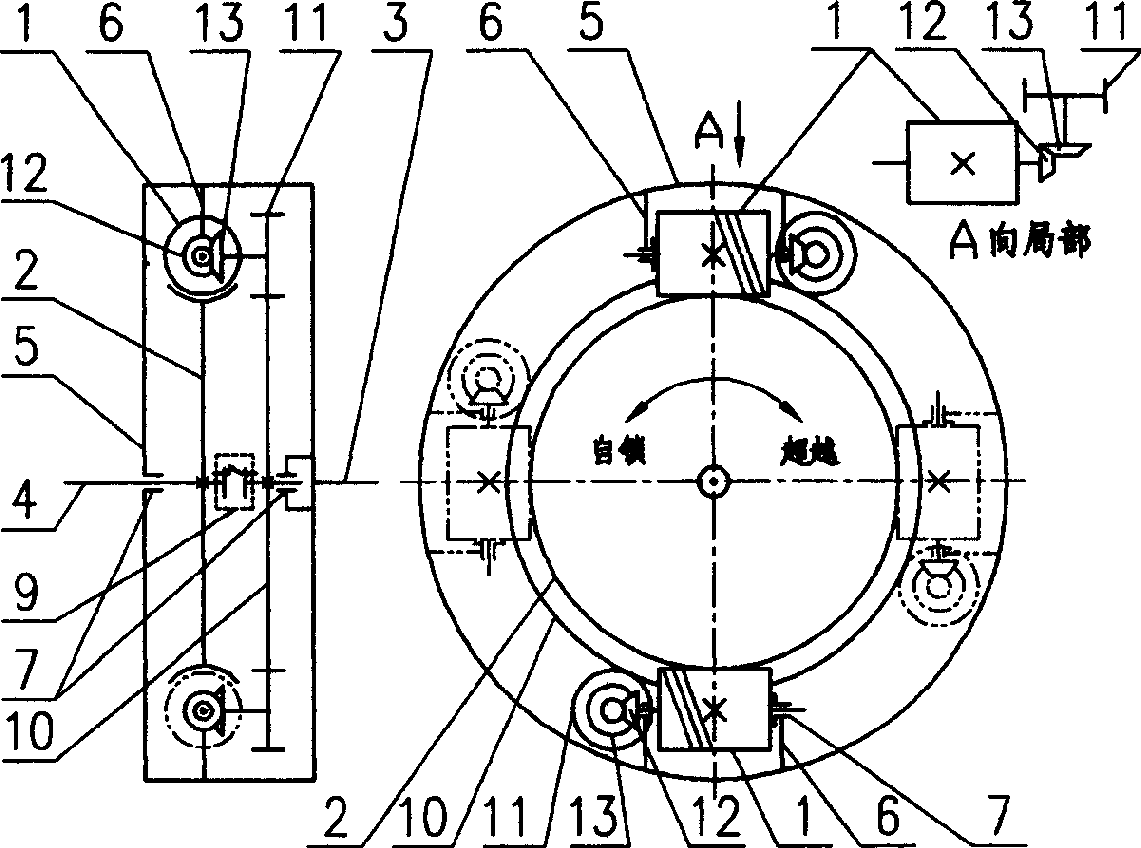

Stepless tooth engagement control type high efficiency and high power clutch

InactiveCN1629508AImprove efficiencyDoes not affect transmission efficiencyFreewheel clutchesAutomatic transmissionMachine tool

Owner:王国斌

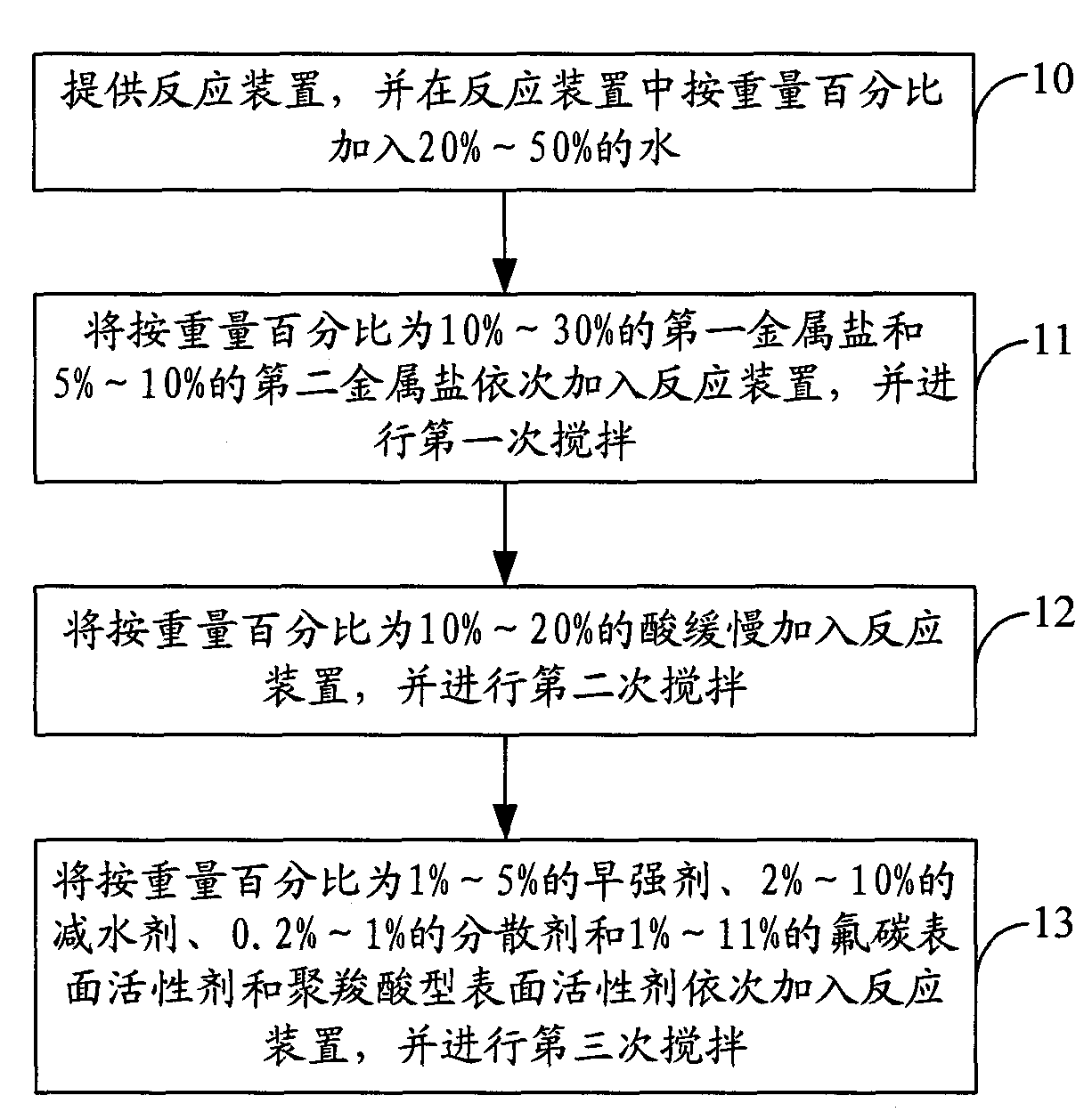

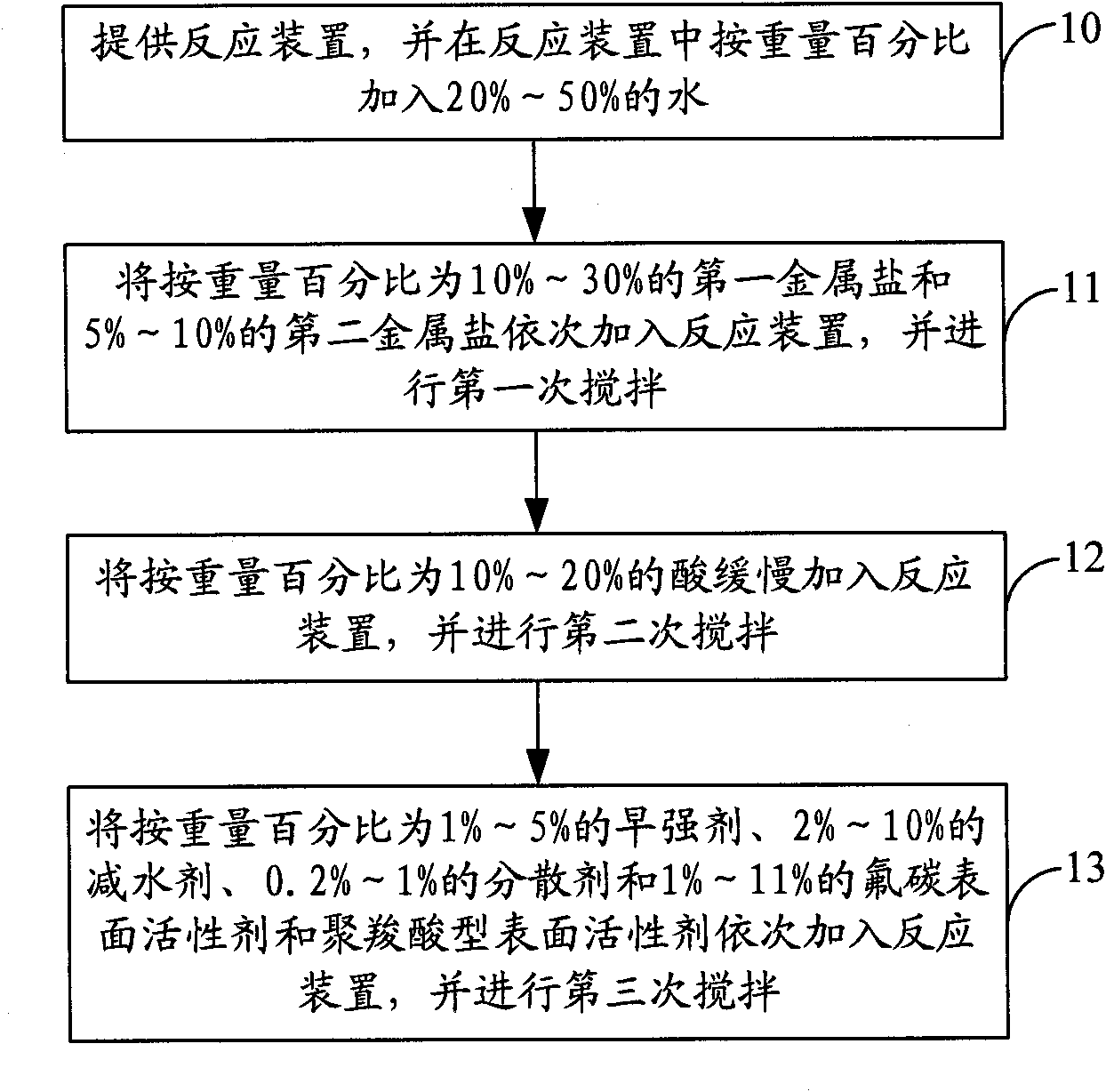

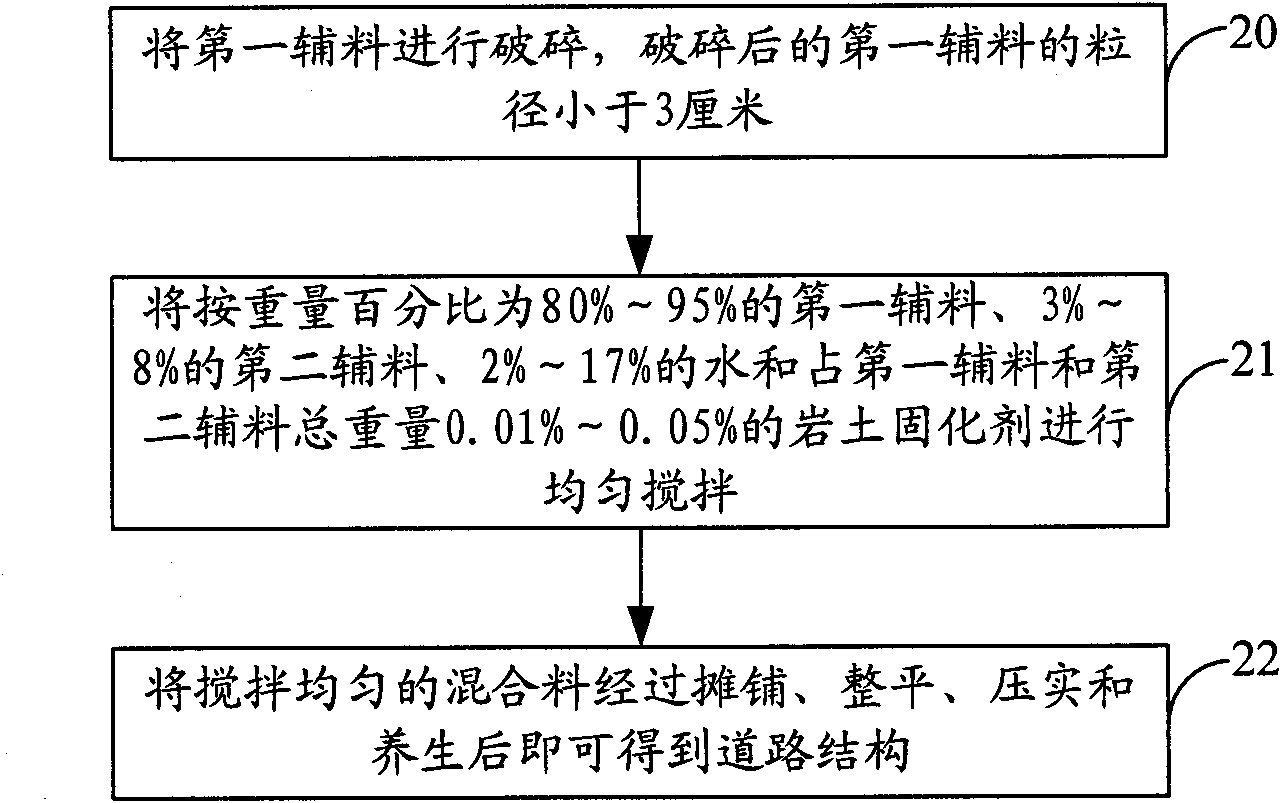

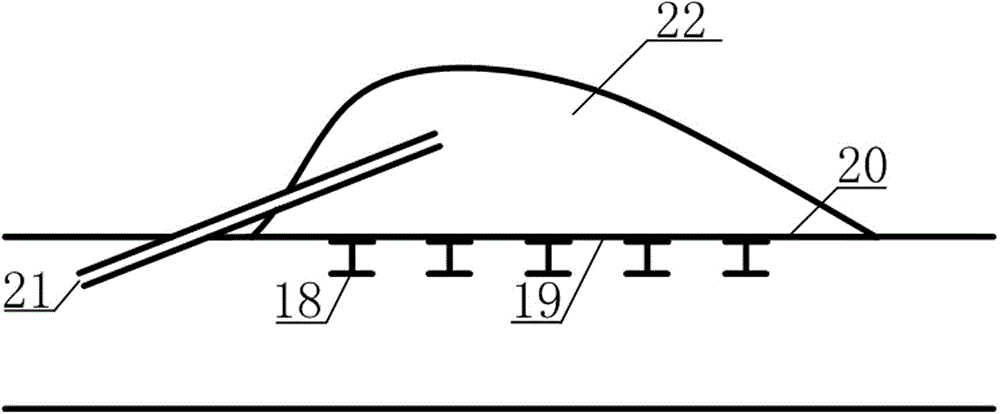

Soil and rock curing agent and manufacturing method thereof and road structure and manufacturing method thereof

InactiveCN101812300AReduced strength requirementsMeet strength requirementsIn situ pavingsRoads maintainenceWater resourcesCompressive strength

The invention relates to a soil and rock curing agent and a manufacturing method thereof and a road structure and a manufacturing method thereof. The soil and rock curing agent comprises a first metal salt, a second metal salt, water, acid, an early strength agent, a water reducing agent, a dispering agent, a fluorocarbon surfactant and a polycarboxylate surfactant. Widely distributed soil, decayed rock, building rubbish and tailing resource are main materials and the soil and rock curing agent is added, thereby being capable of reducing road cost; road roadbed, airport foundation, port foundation and water resource facilities built with the soil and rock curing agent have the advantages of short curing period, water resistance, cold resistance and hairline crack prevention, thereby improving compression strength and bending strength and greatly reducing construction cost.

Owner:田文利

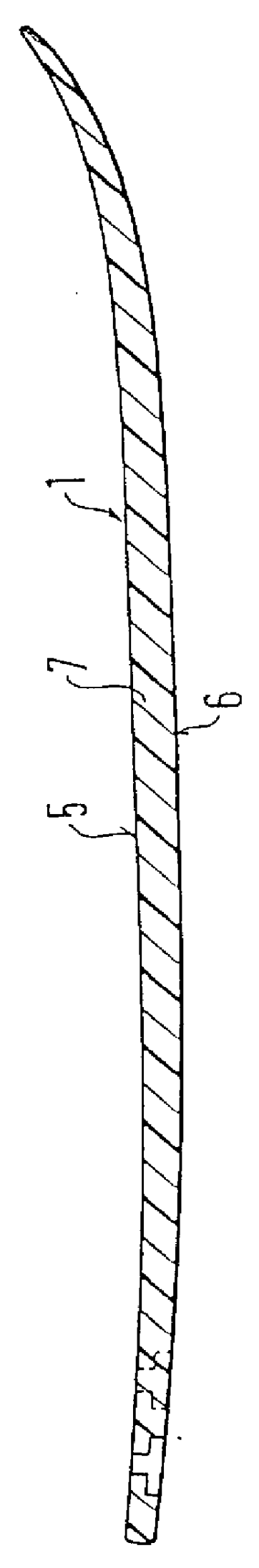

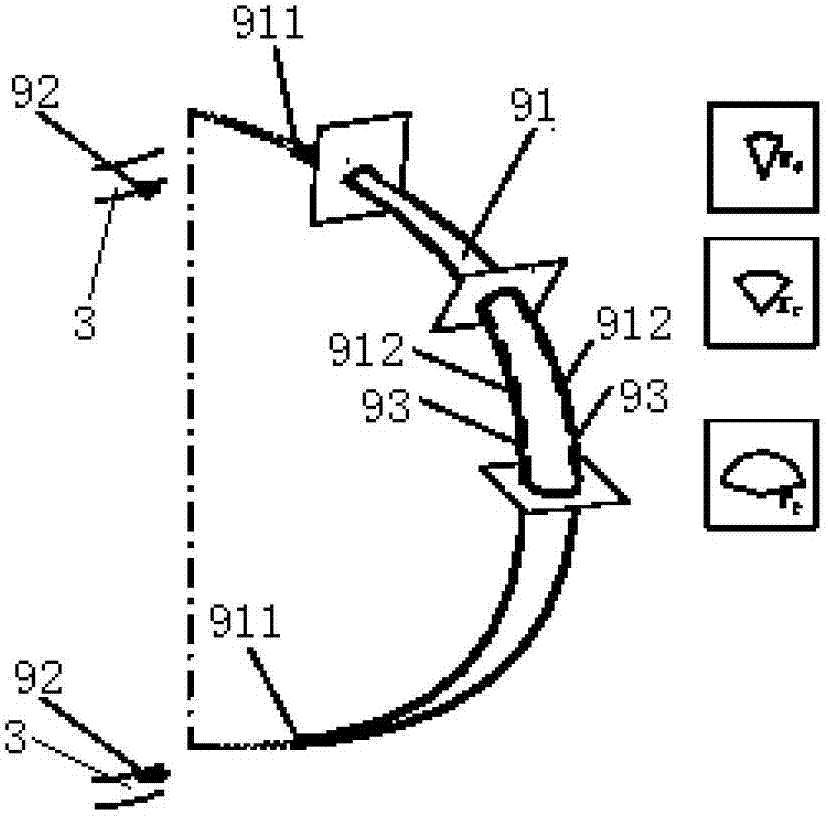

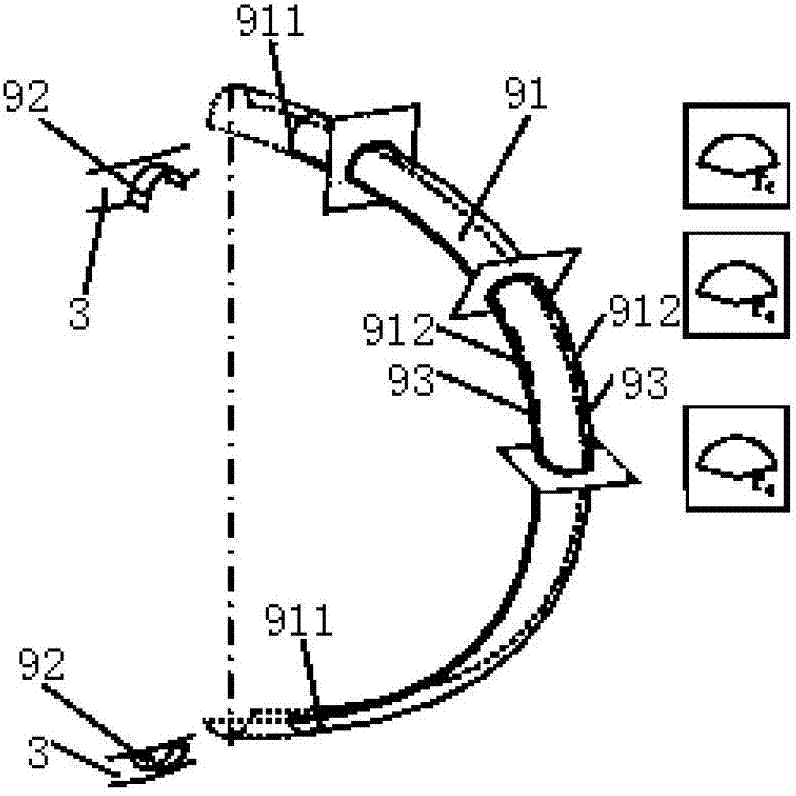

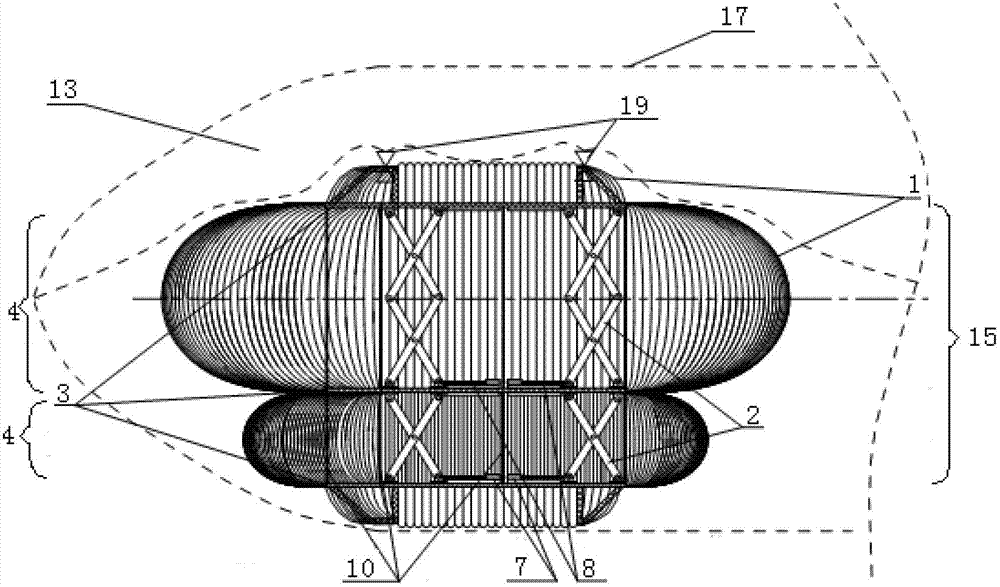

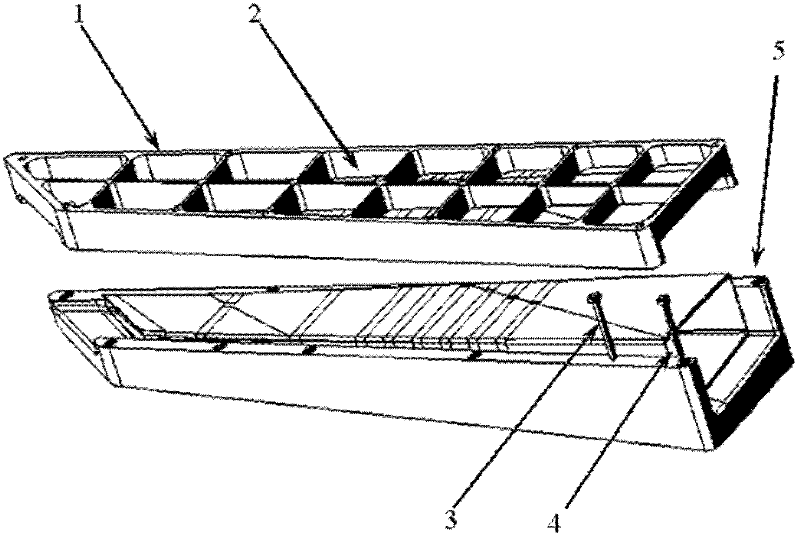

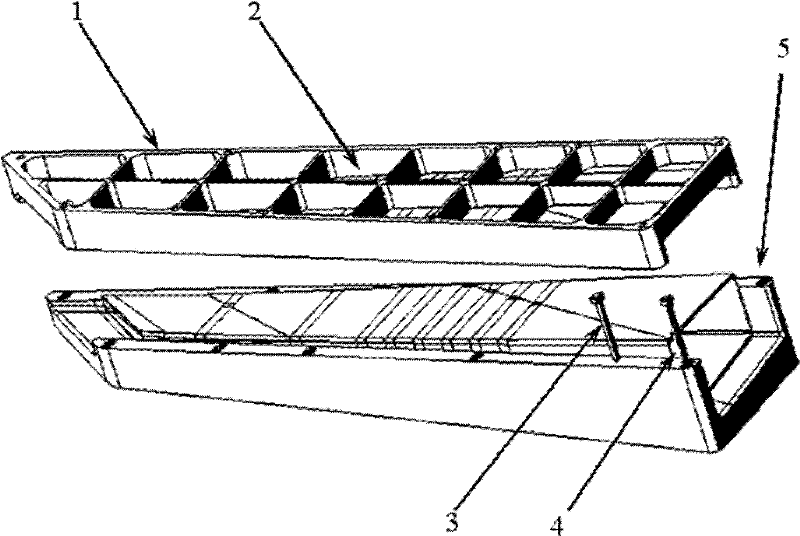

Airship airbag with shape-control frames

The invention relates to an airship airbag with shape-control frames. The airship airbag with the shape-control frames comprises an airbag casing (1) and the shape-control frames; the airtight flexible airbag casing (1) is arranged on the outer layer of the air bag, is of a laminated structure on the whole and consists of a plurality of layered structures; the inside of every layered structure is fixedly connected with the shape-control frames which comprises a plurality of pairs of vertically-arranged folding frames (2) and two pairs of shaping frames (3) respectively hinged to two ends of the folding frames (2); the airbag casing (1) of every layered structure (4) is formed by splicing the airtight film covering pieces (91) of a plurality of convex curved surface unit (9), and every convex curved surface unit (9) not only comprises one elongated airtight film covering piece (91) but also comprises a pair of end-edge fixing parts (92) on the shaping frames (3) and a pair of pulling-resistant straps (93). The airship airbag with the shape-control frames can make full use of the space inside an airship, is good in regularity of expansion and shrinkage deformation and good in repeatability and stability, and can bear relative large overpressure when being inflated and expanded fully.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

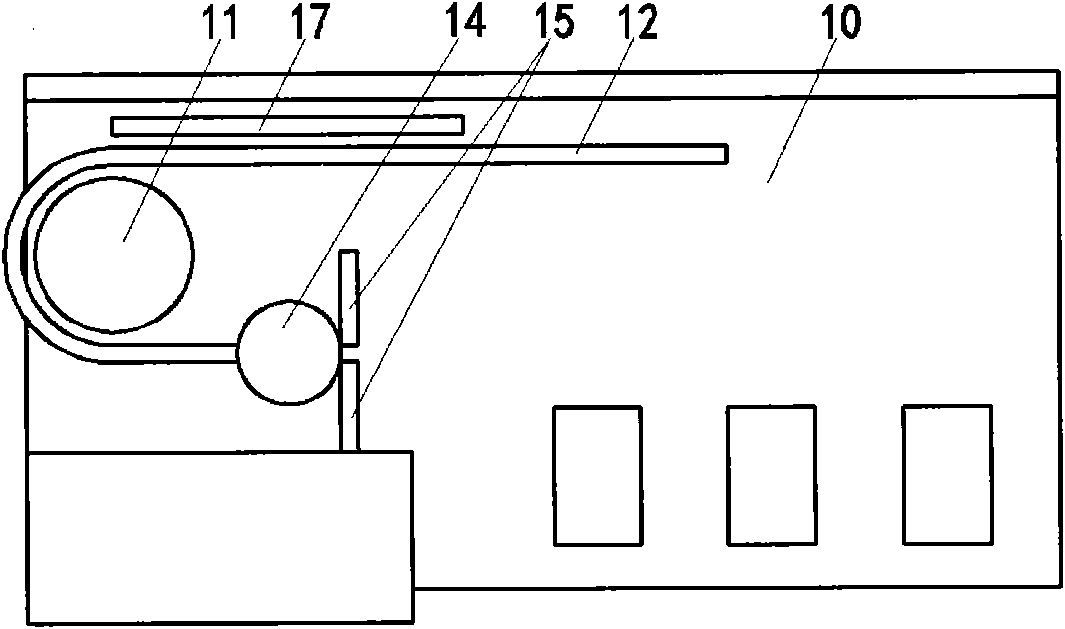

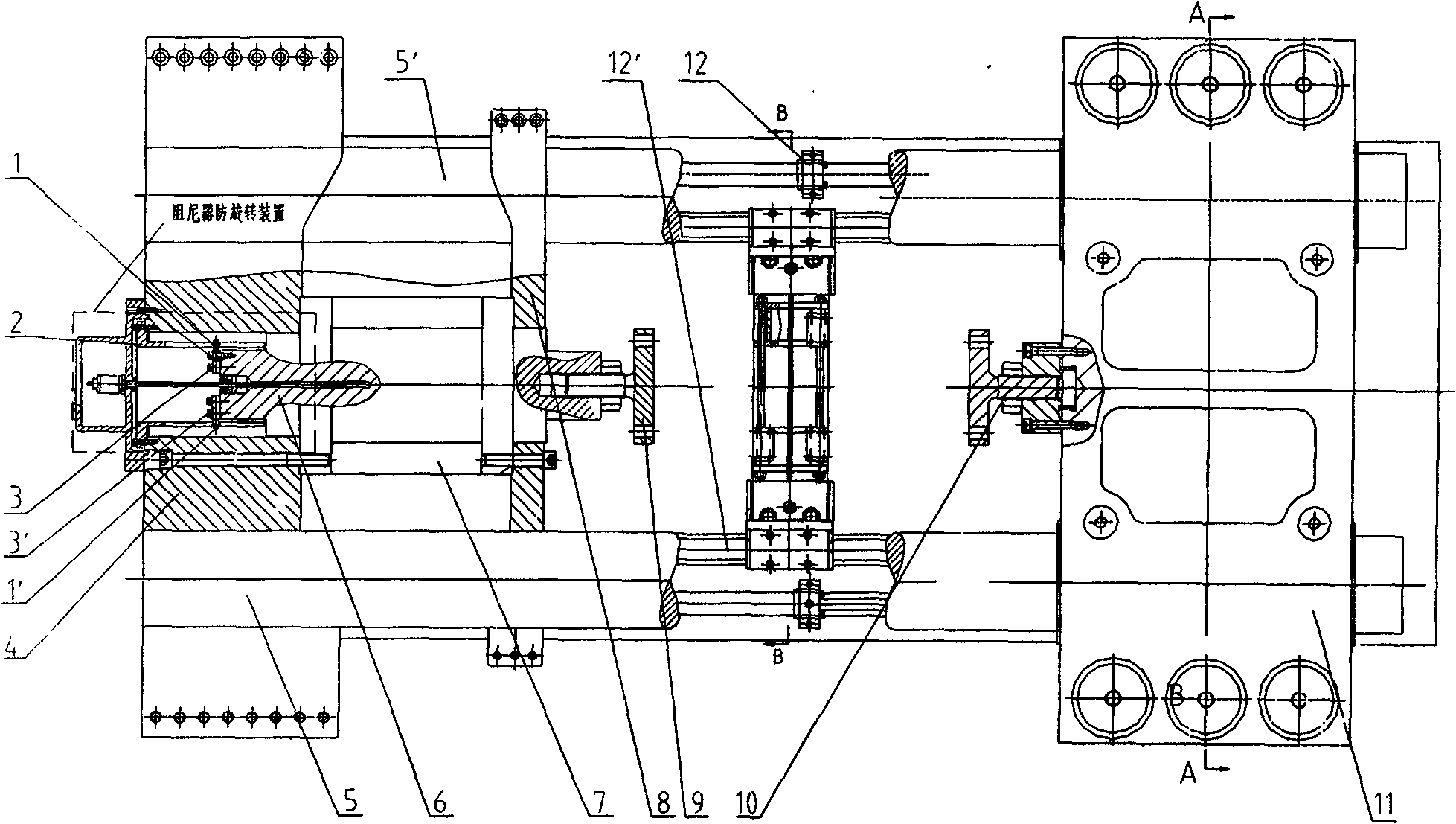

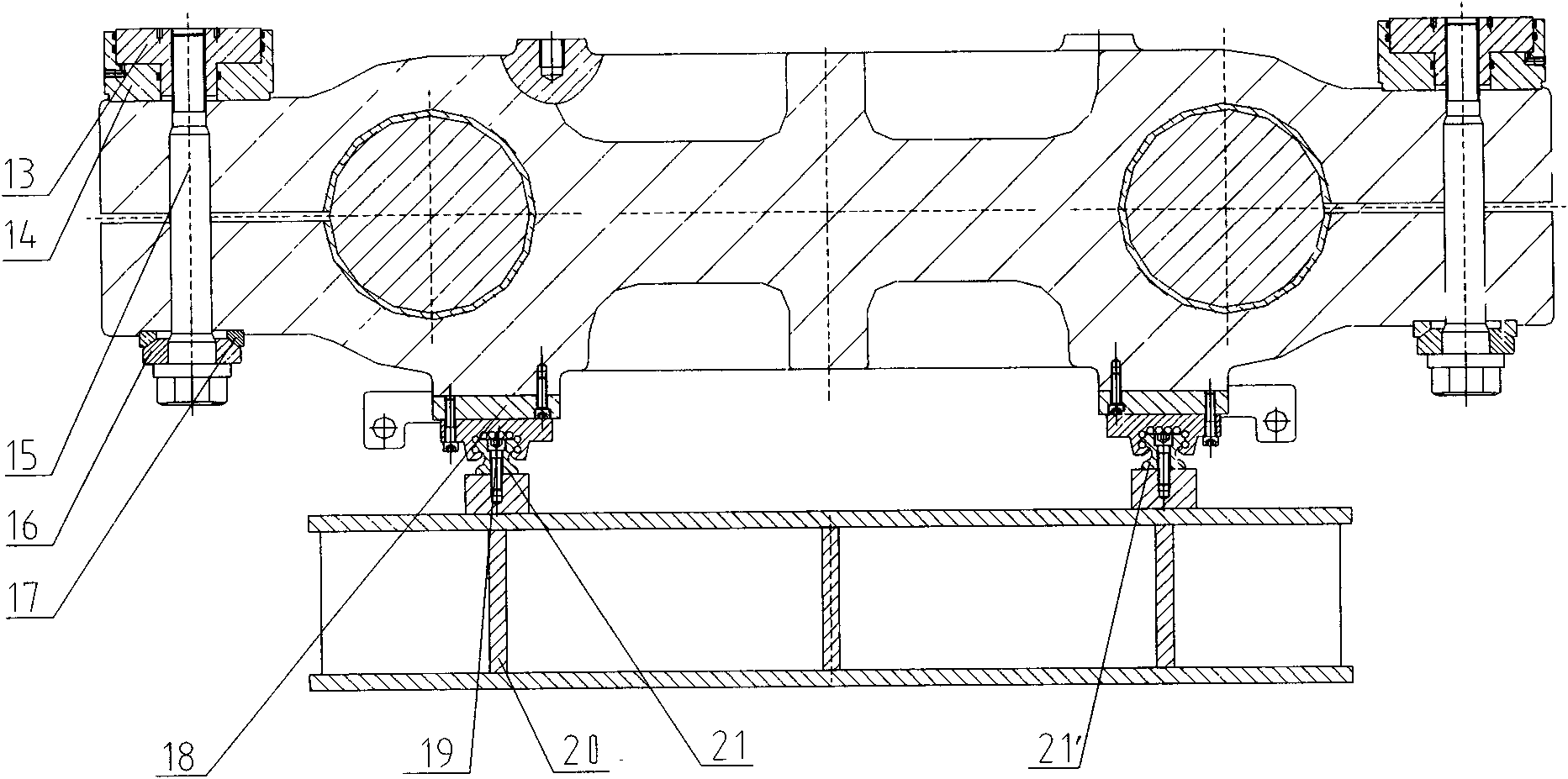

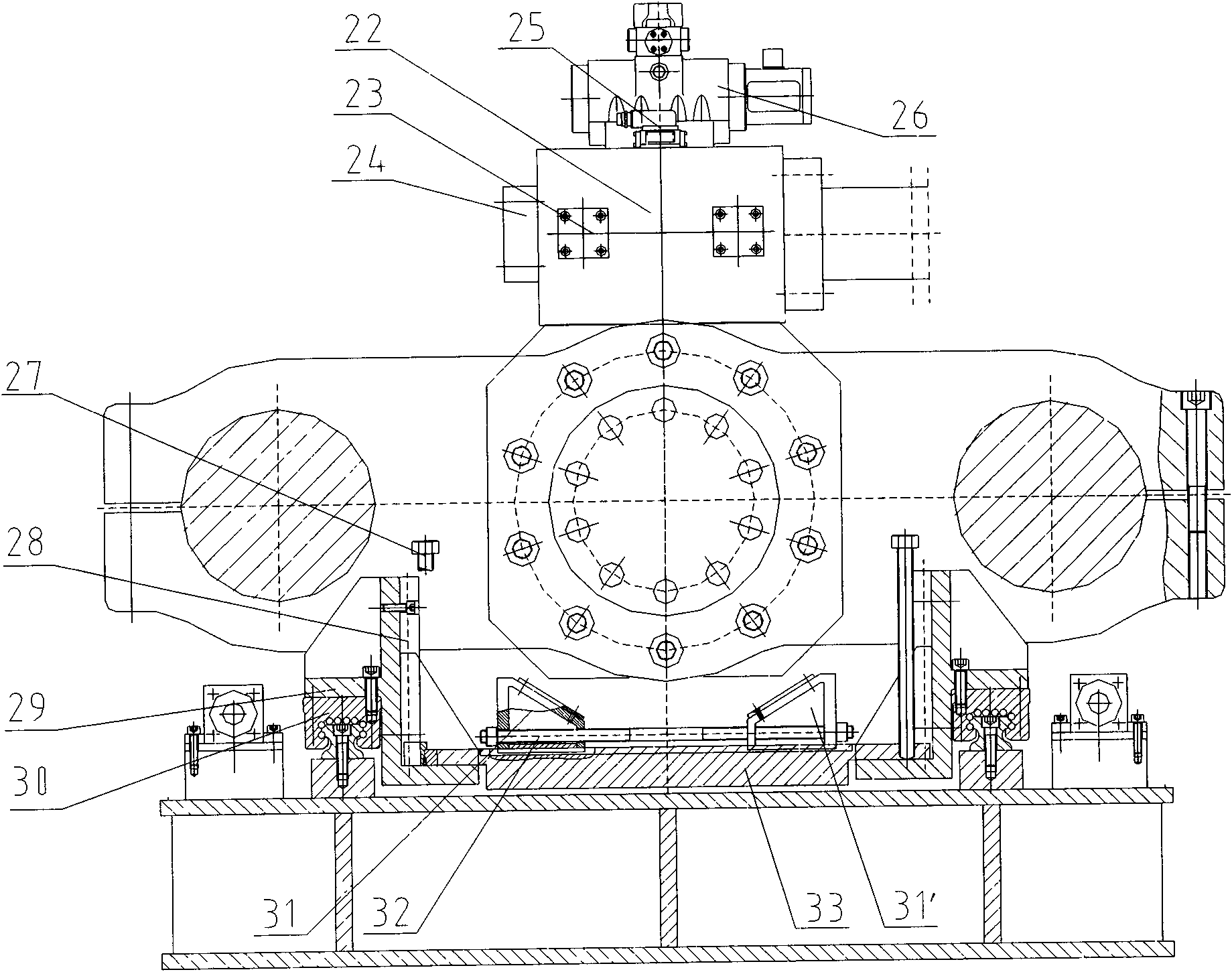

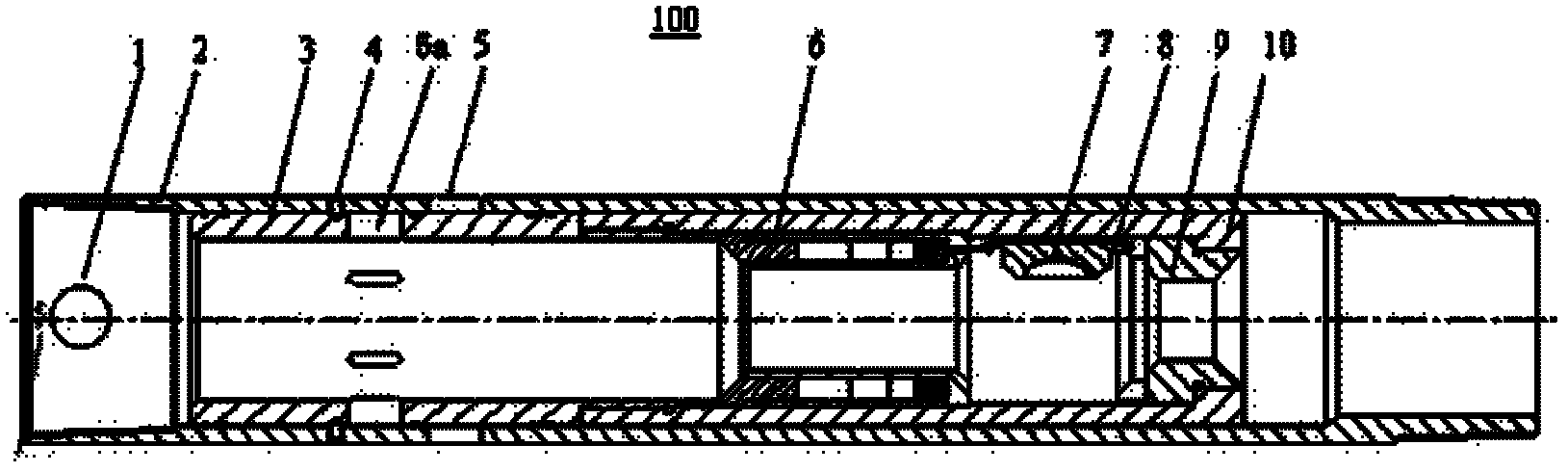

Comprehensive performance testing device for damper

InactiveCN101660979AImprove rigidityReduce shockStructural/machines measurementTest fixtureRigid frame

The invention provides a comprehensive performance testing device for a damper. A platform is provided with two guide rails; the upper sides of the two guide rails are provided with a guide post respectively; one end of each guide post is fixed on the guide rail through a front support and a rear support, while the other end is fixed on the guide rail through a movable cross beam capable of sliding on the guide rail; a servo hydraulic cylinder is arranged between the front support and the rear support; a piston rod of the servo hydraulic cylinder is connected with a left flange through the front support; one side of the movable cross beam facing the left flange is provided with a right flange; front ends of two push-and-pull hydraulic cylinders are connected with the movable cross beam, rear ends of the two push-and-pull hydraulic cylinders are connected with the front support; a servo hydraulic cylinder is provided with an integrated valve block; the integrated valve block is providedwith a large-flow servo valve and a small-flow servo valve which are communicated with the servo hydraulic cylinder; and inlets and outlets of the two flow servo valves are provided insert type stopvalves. The device realizes measurement on dynamic and static performance of the damper through switching among cartridge valves, leads the front support, the rear support, the movable cross beam andthe guide posts to form a rigid frame, and reduces influence of deformation of the device on testing accuracy.

Owner:HUAZHONG UNIV OF SCI & TECH

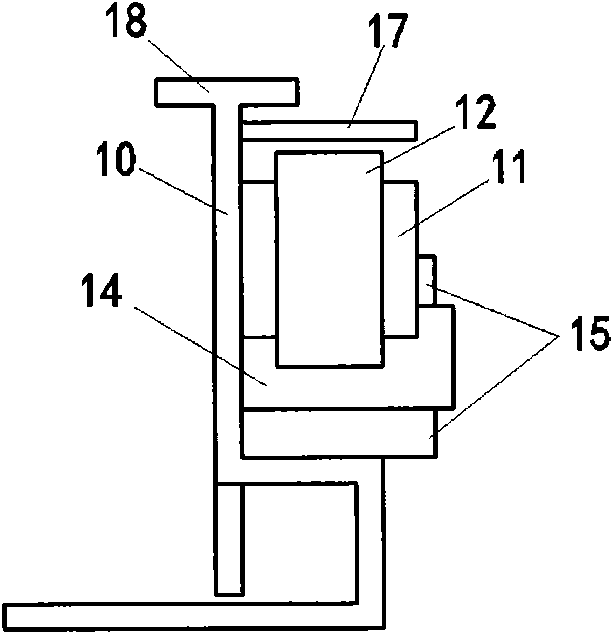

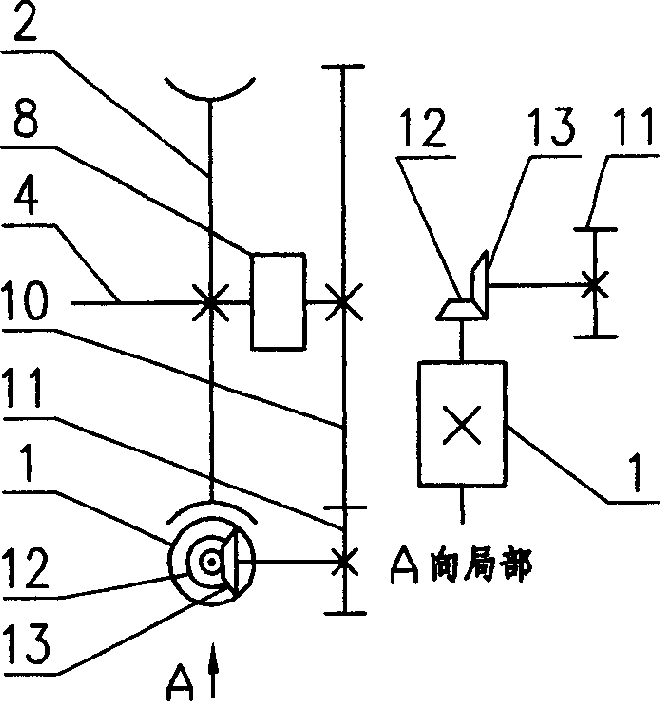

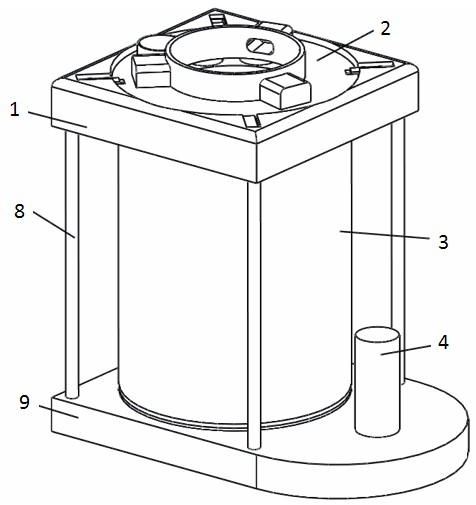

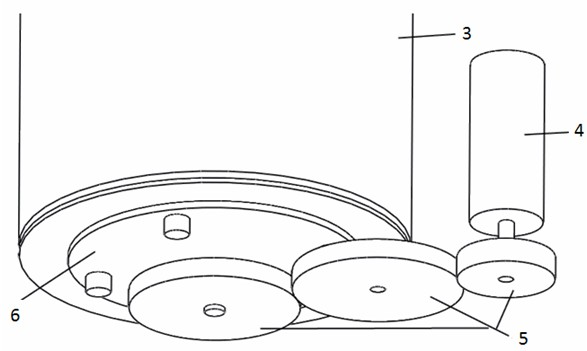

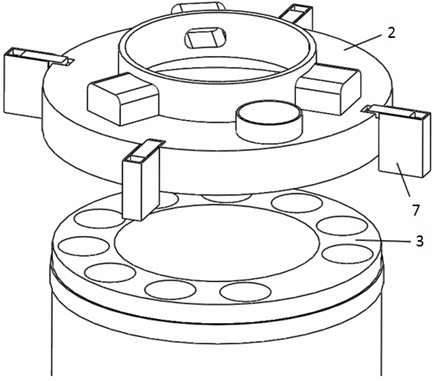

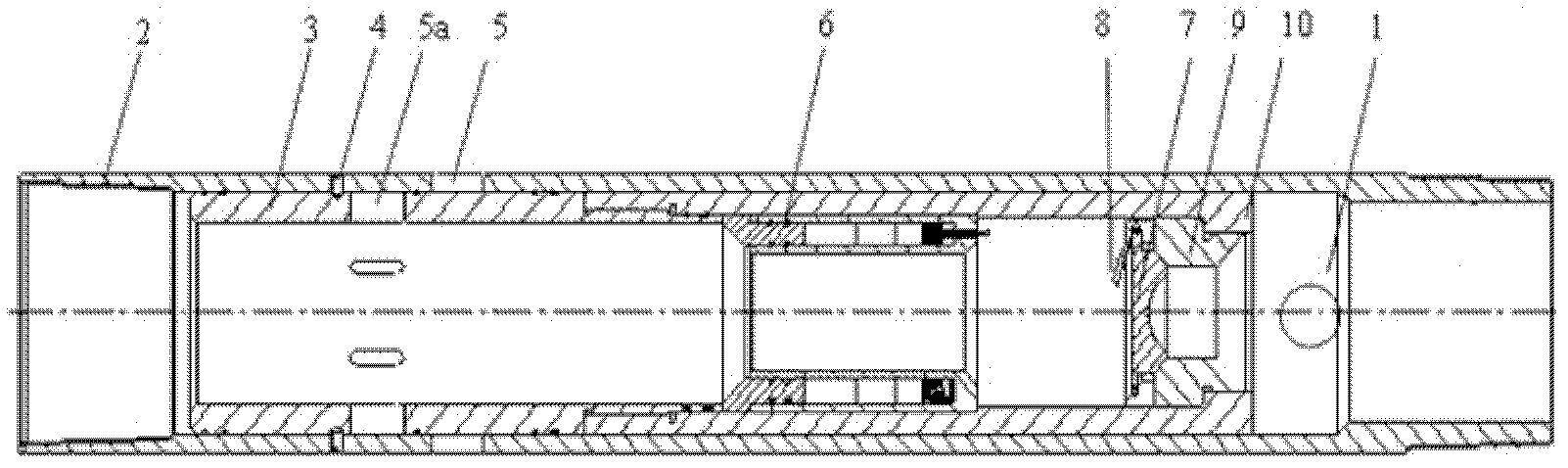

Recovery device of lunar deep soil collector

ActiveCN102359889AEasy maintenanceReduced strength requirementsWithdrawing sample devicesGear driveLunar soil

The invention discloses a recovery device of a lunar deep soil collector, which is composed of an upper and a lower frame. A recovery box driving motor is installed on the lower frame, inside which a gear train is mounted. A first level driven gear meshes with a driving gear on the shaft of the recovery box driving motor, and a last level driven gear is mounted on the recovery box driving disk onthe same shaft. A recovery box cover is disposed in a central hole of the upper frame, the four corners of which are respectively provided with a linear motor. And the movement end of each linear motor is aligned to respective clamping slots uniformly distributed on the circumferential peripheries of the recovery box cover. The recovery box is arranged between the upper and lower frames. A bolt on the lower end surface of the recovery box is inserted into a corresponding through hole on the driving disk. An external thread on the upper end of the external cylindrical surface of the recovery box cooperates with an internal thread on the internal cylindrical surface of the recovery box cover. Therefore, the device of the invention has the advantages of concise and compact structure, space saving, small recovery mass, high driving mode reliability, easy and reliable sample sealing and transfer, and can be used for lunar soil transfer, sealing and recovery after the sampling of a lunar soil multi-rod drill.

Owner:ZHEJIANG UNIV

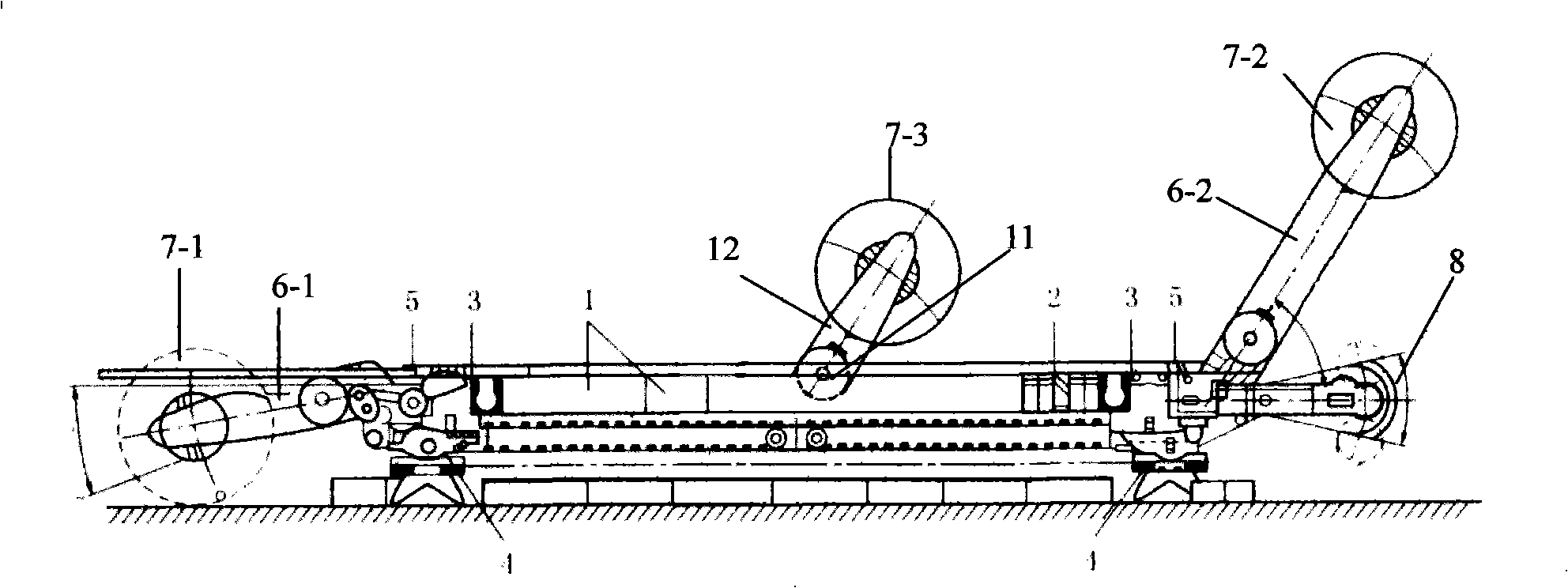

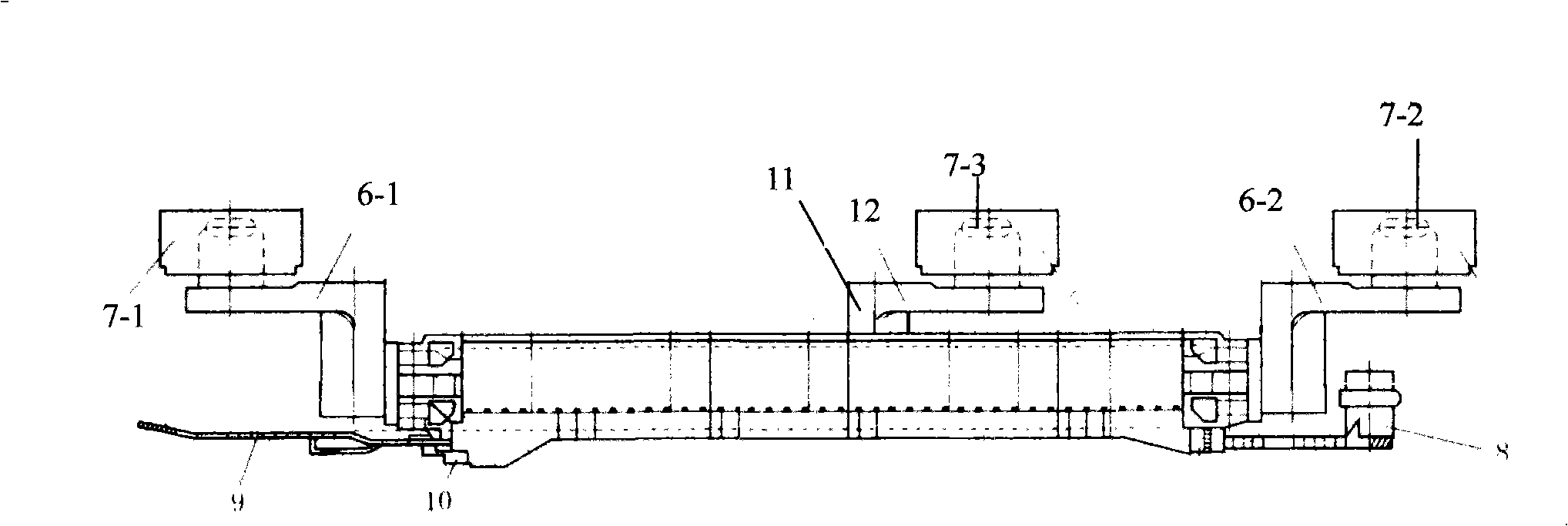

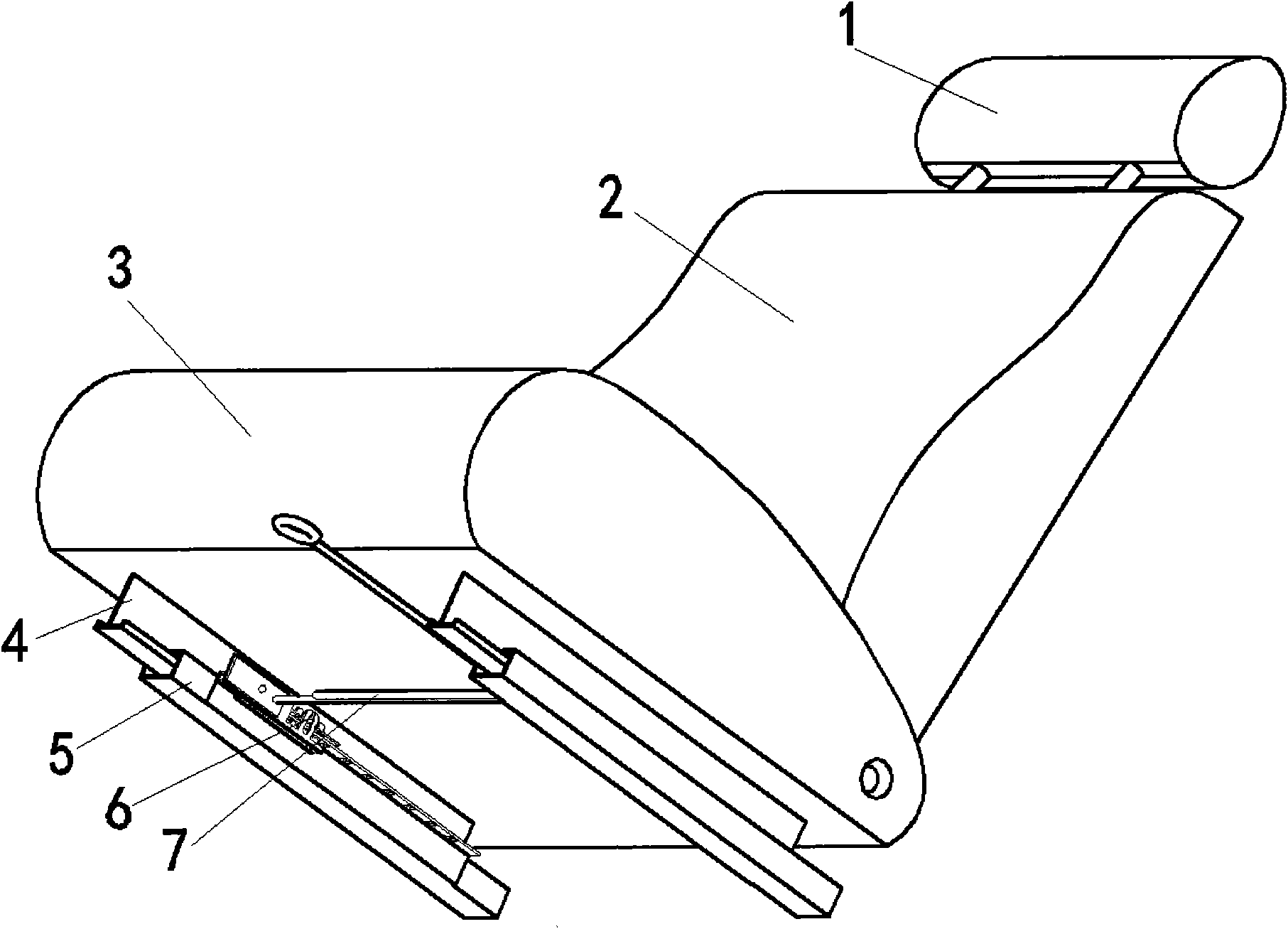

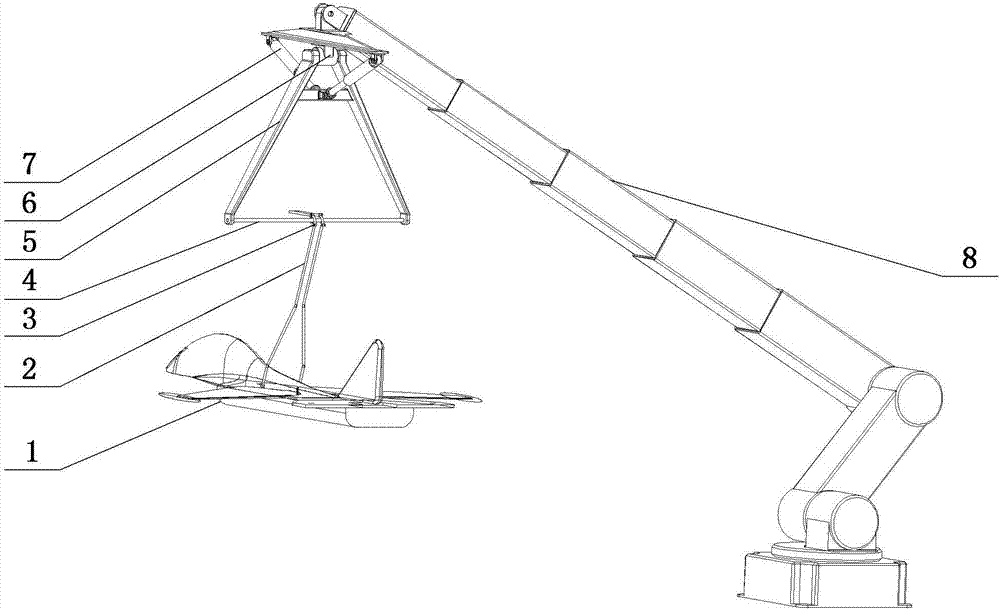

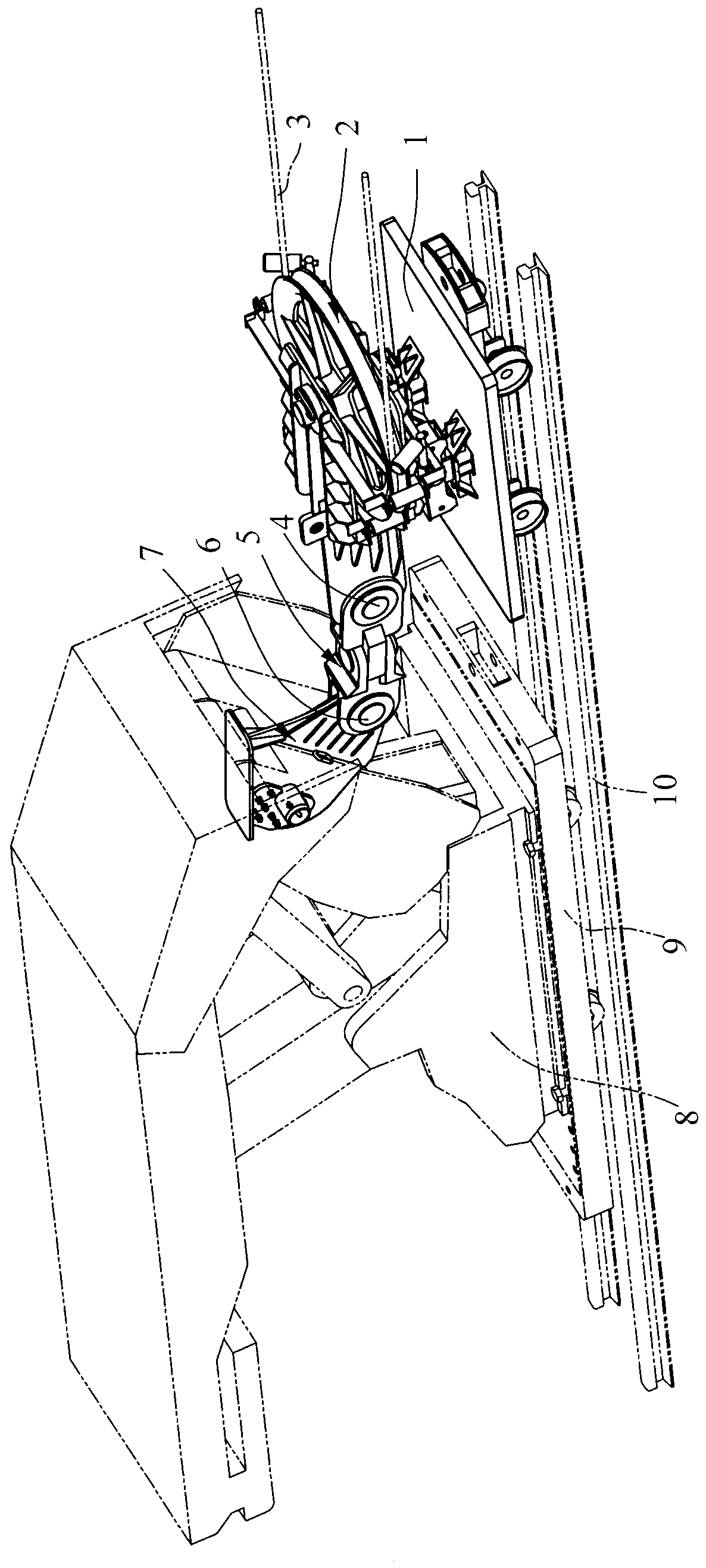

Recovery system for small-sized fixed-wing unmanned aerial vehicle

InactiveCN106892129AAvoid damageAvoid entanglementArresting gearLaunching/towing gearSkyConfined space

The invention provides a recovery system, with the characteristics of accurate site directed recovery, small recovery field, damage prevention of sensitive equipment at the front end of an unmanned aerial vehicle (UAV) and low requirement of the wing strength, for a small-sized fixed-wing UAV and belongs to the field of small-sized fixed-wing UAV recovery system. The recovery system for the small-sized fixed-wing UAV comprises a foldable sky hook, a block device, a buffering energy-absorbing device and a manipulator-arm-type recovery bracket, wherein the foldable sky hook is fixed to the small-sized fixed-wing UAV, and when detecting the block device, the small-sized fixed-wing UAV controls the foldable sky hook to bounce to hook on the block device to realize the blocking of the small-sized fixed-wing UAV; the buffering energy-absorbing device is used to damp the impact kinetic energy of the block device; and the manipulator-arm-type recovery bracket is used to place the small-sized fixed-wing UAV which is blocked to a designated parking position. The recovery system for the small-sized fixed-wing UAV is suitable for recovery environment with confined space such as ground, ships and the like.

Owner:HARBIN INST OF TECH

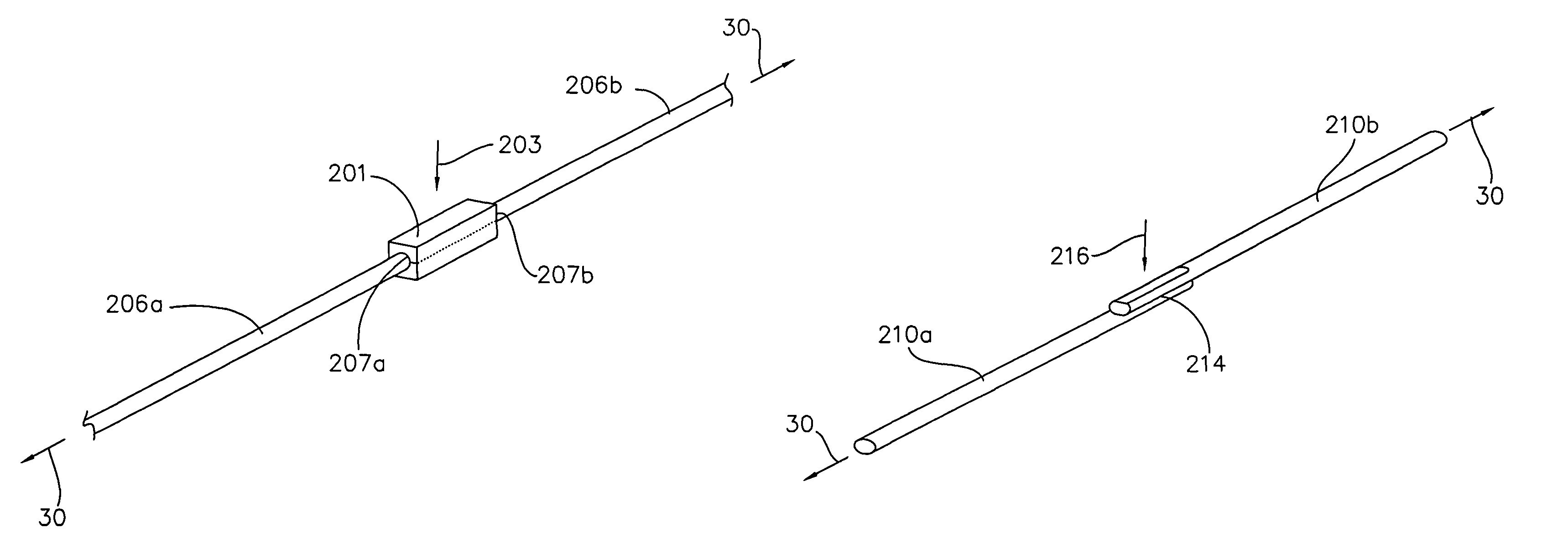

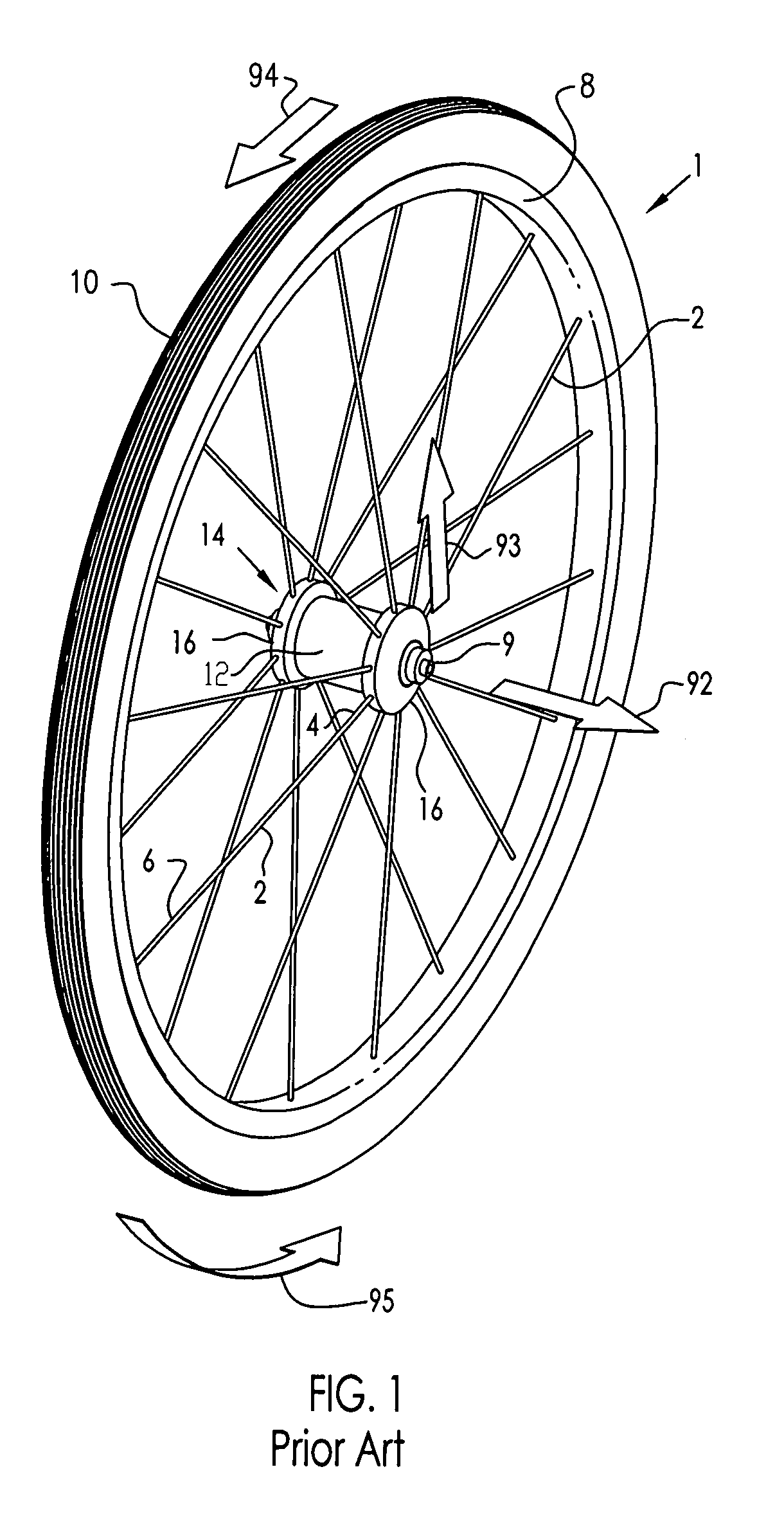

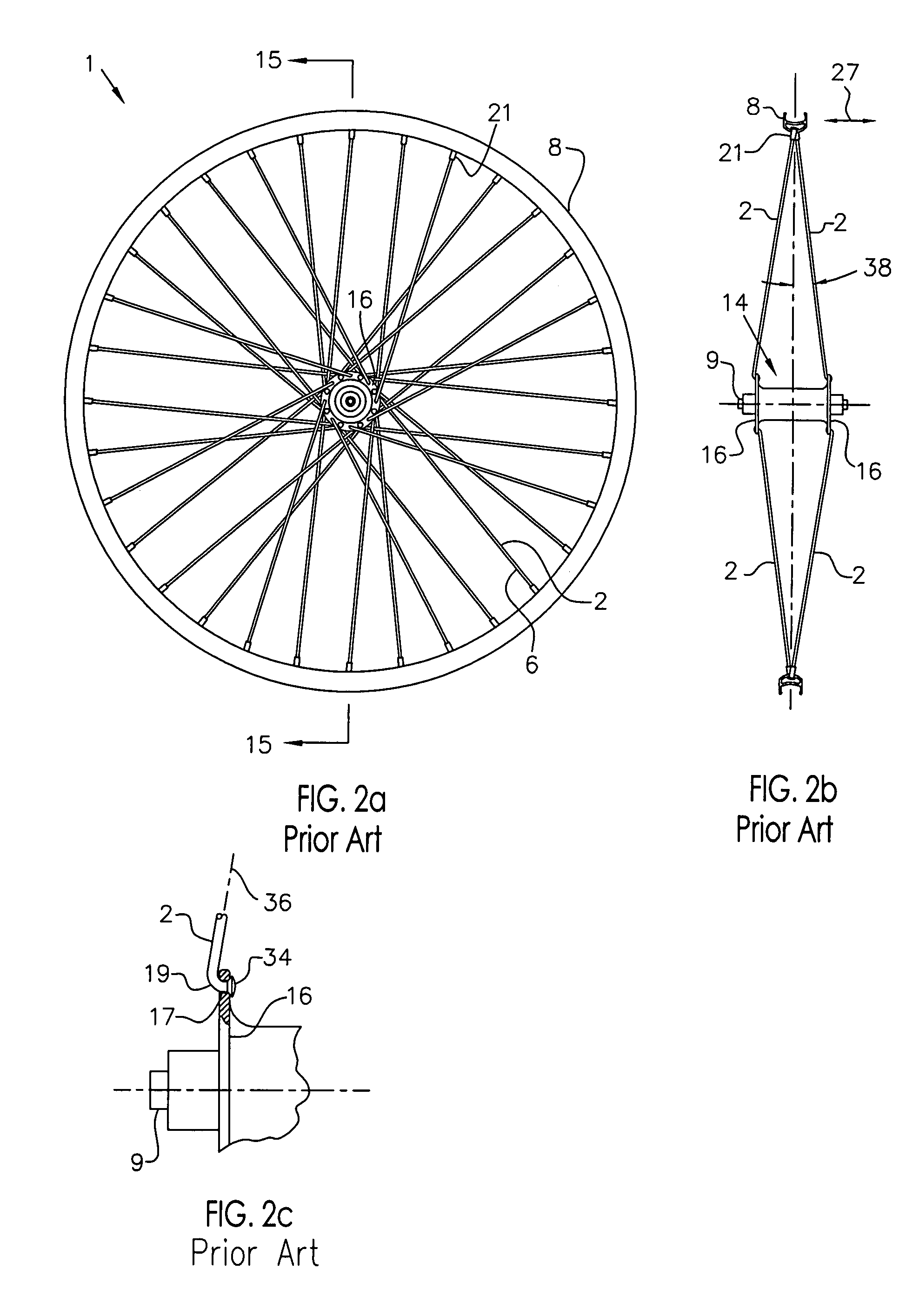

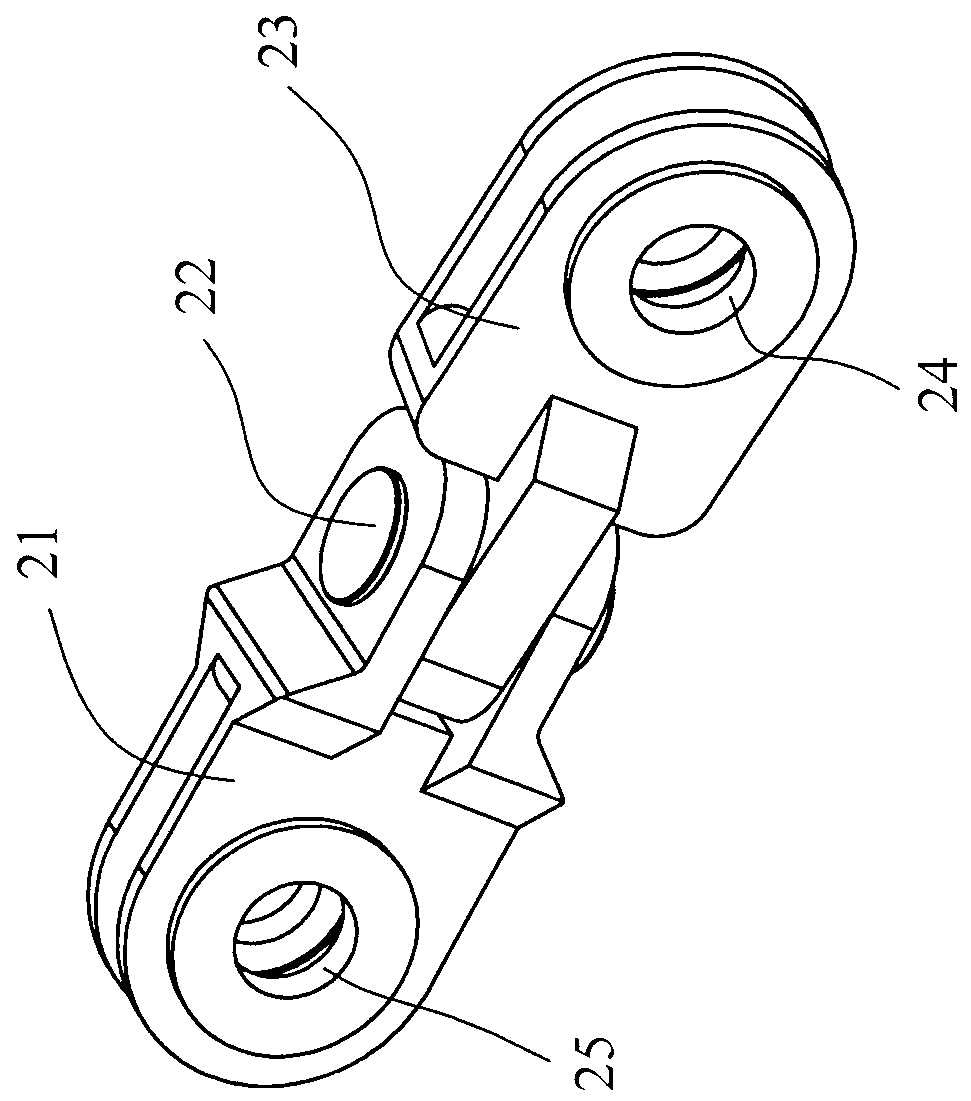

Connecting system for tensile elements such as spokes

ActiveUS7784878B2Lower performance requirementsLow costRimsRopes and cables for vehicles/pulleyEngineeringSpoke

A tensile connector assembly comprising a longitudinal tensile element having a longitudinal axis, an end portion and a cross-section, a connecting element connected to the longitudinal tensile element, and a bracing element connected to the longitudinal tensile element. With a tensile axis of applied tensile load along said longitudinal tensile element. Where the longitudinal tensile element is anchored to the bracing element and the connecting element is connected to the longitudinal tensile element via a welded connection at a welded interface. Where the connections permit the longitudinal tensile element to support said tensile load along the tensile axis.

Owner:SCHLANGER RAPHAEL

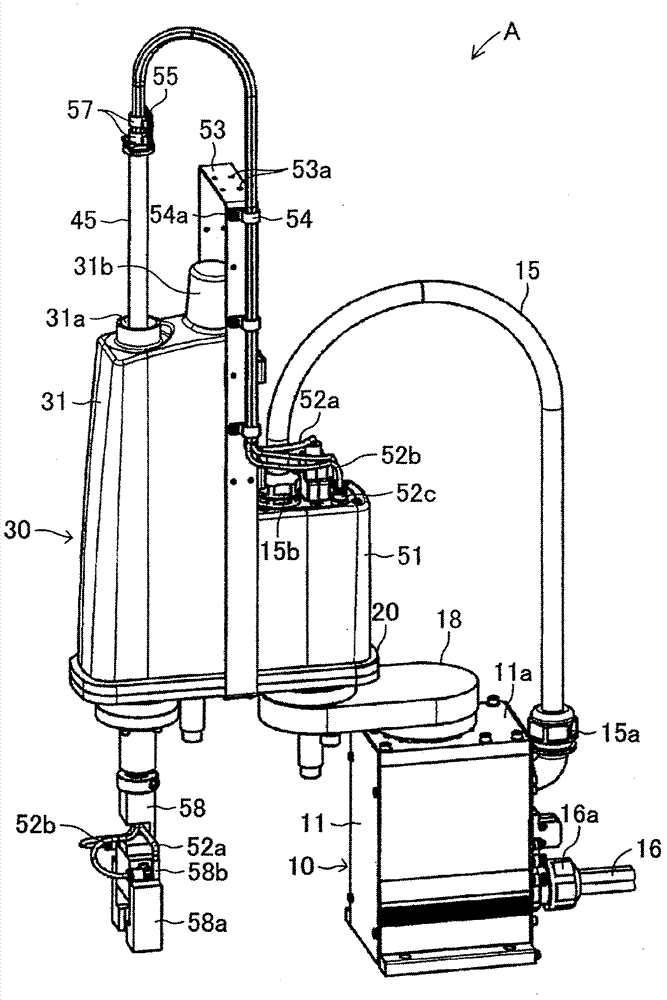

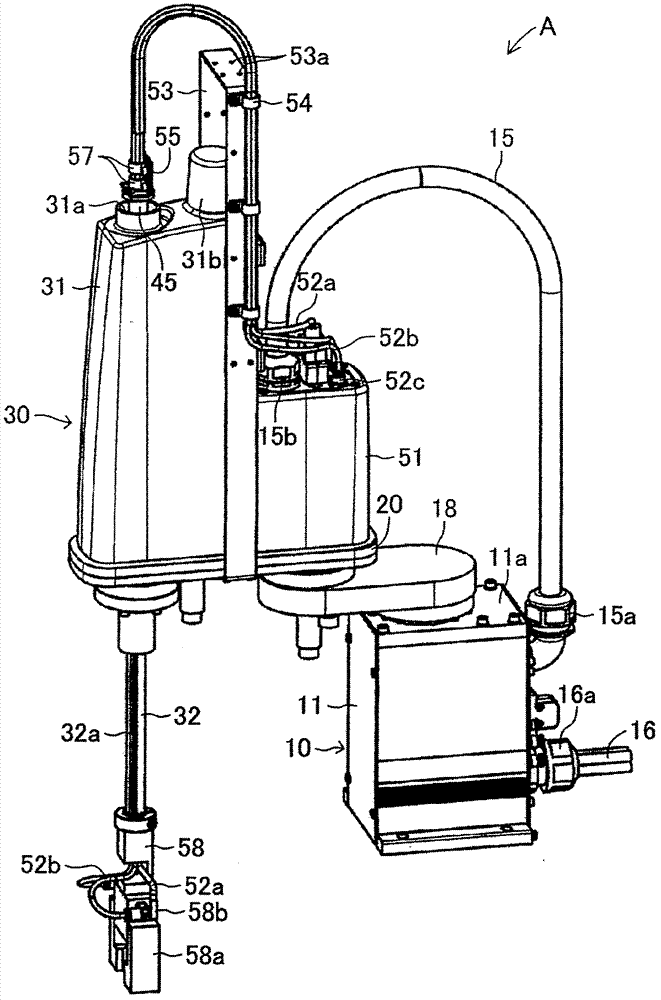

Robot

ActiveCN102729247AReduced strength requirementsReduced precision requirementsProgramme-controlled manipulatorArmsEngineeringMechanical engineering

The invention provides a robot. The robot comprises a root part; arms capable of rotating on the horizontal direction with the root part as the center; a hollow working shaft extending along the vertical direction and supported on the arms in a way to be capable of moving axially and rotating around the axis; a driving part driving the working shaft vertically; a hollow shaft connected on the upper end of the working shaft in a way to have the inner side communicated with the inner side of the working shaft; a linear part equipped in a way to pass through the inner sides of the working shaft and the hollow shaft; and a hood equipped on the arms, covering the working shaft and having a through hole for the hollow shaft to pass through in a way to protrude upwards. Thus, the robot provided in the invention is low in price.

Owner:YAMAHA MOTOR CO LTD

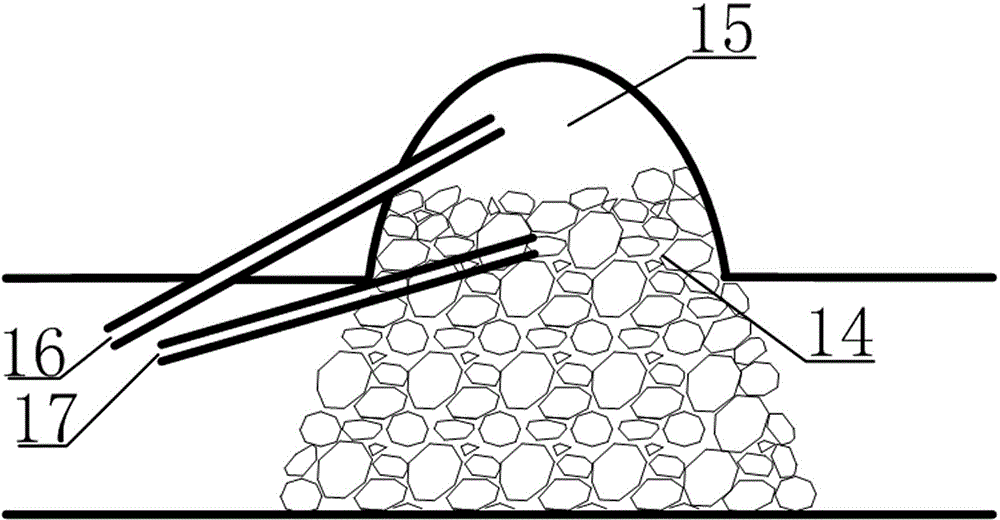

Rapid-hardening inorganic filling support material for mine and using method of support material

The invention discloses a rapid-hardening inorganic filling support material for mine. The support material consists of a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 93-97 parts of sulphoaluminate cement clinker, 2-5 parts of an XWZ-A type compound admixture, 0.01-0.1 part of an air entraining agent, 0.0-0.05 part of an air entraining admixture, 0.2-1.0 part of a foam stabilizer and 0.25-2 parts of fibers; and the component B comprises the following raw materials in parts by weight: 75-88 parts of gypsum, 10-25 parts of lime, 2-5 parts of an XWZ-A type compound admixture, 0.01-0.1 part of an air entraining agent, 0.0-0.05 part of an air entraining admixture, 0.2-1.0 part of a foam stabilizer and 0.25-2 parts of fibers. The prepared filling support material disclosed by the invention has the characteristics of quick setting property, lightweight, rapid hardening property, early strength, high compressibility, high residual strength, good gas tightness and the like, and is particularly suitable for the mine filling support aspect.

Owner:HENAN POLYTECHNIC UNIV

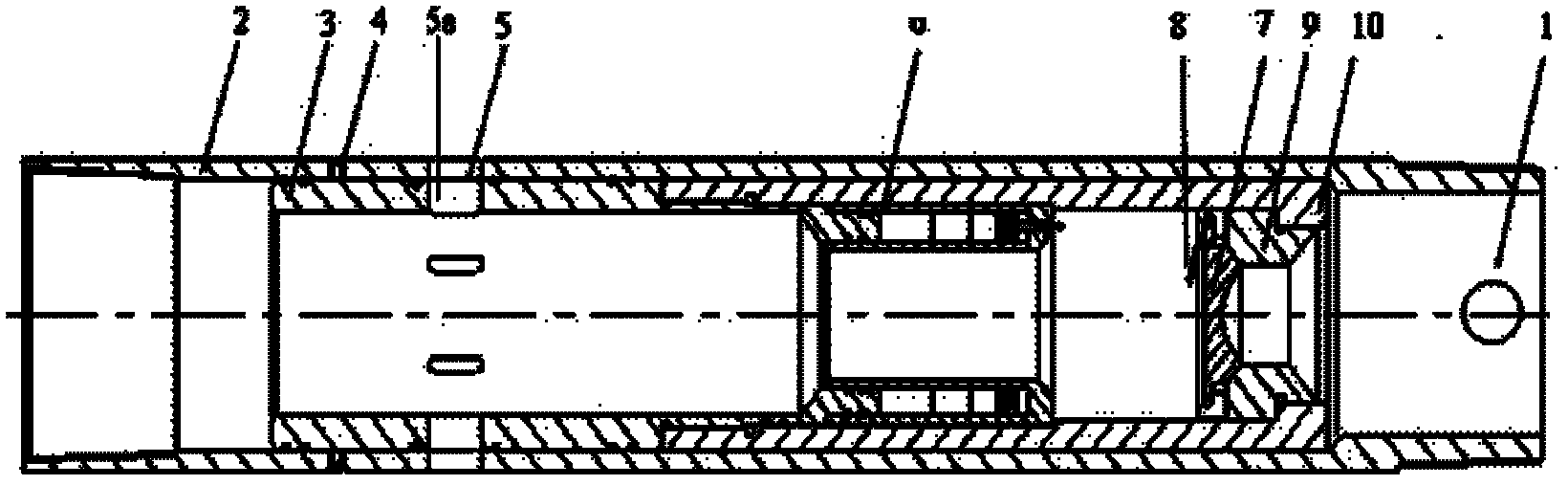

Staged fracturing sliding sleeve used for oil well and device and usage method thereof

ActiveCN103132969AEfficient miningImprove the effective oil passing areaFluid removalWell/borehole valve arrangementsEngineeringPressure controlled ventilation

A staged fracturing sliding sleeve used for an oil well comprises a sliding sleeve outer shell, an inner sliding sleeve, a blocking piece and a suppressing pressure control device. The sliding sleeve outer shell is used for being connected to an oil casing pipe, and a first fracturing hole is formed in the side wall of the outer shell. The inner sliding sleeve is fixed in the outer shell through a pin which penetrates through the side wall of the outer shell and the side wall of the inner sliding sleeve, and a second fracturing hole is formed in the side wall of the inner sliding sleeve, wherein the first fracturing hole and the second fracturing hole are staggered in a radial direction. The blocking piece and the suppressing pressure control device are arranged in the inner sliding sleeve. The suppressing pressure device comprises an actuating mechanism which is used for forcing the blocking piece to keep in an opened position, wherein the actuating mechanism enables the blocking piece to move to a closed position when the suppressing pressure control device receives a preset signal, seals an inner cavity of the inner sliding sleeve and forms pressure accumulation. When the pressure is increased to overcome shear force of the pin, the pin is sheared, and the inner sliding sleeve slides along the axial direction until the first fracturing hole aligns at the second fracturing hole in the axial direction of the sliding sleeve.

Owner:CHINA PETROLEUM & CHEM CORP +1

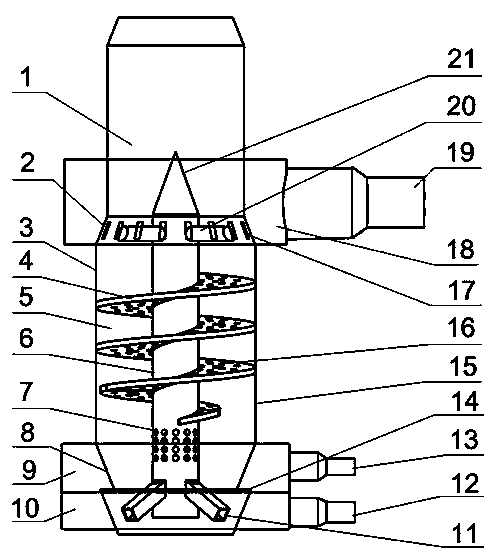

Vertical-type spiral particle waste heat recycling device and method for sintering waste heat power generation system

InactiveCN104048516AAvoid increased resistanceReduce compressive stressEnergy industryIncreasing energy efficiencyControllabilityFlat panel

The invention discloses a vertical-type spiral particle waste heat recycling device and method for sintering waste heat generation. A device body is sequentially provided with a prestoring segment, a chute segment, a cooling segment and a lower conical segment from top to bottom. The device body is internally provided with an air supply body. The air supply body is a cylinder and is hollow. The top of the air supply body is provided with a pointed cone. The upper portion of the air supply body is provided with four cross-shaped supporting rods. The outer ends of the four supporting rods are fixedly connected with the chute segment. A heat exchange cavity is formed between the air supply body and a tank body of the cooling segment. The outer side of the middle of the air supply body is provided with a spiral discharging channel. The periphery of the upper portion of the spiral discharging channel is connected with the cooling segment. The lower portion of the air supply body is provided with an upward-inclined cross-shaped air channel. The cross-shaped air channel is connected with the lower portion of the lower conical segment. The bottom of the lower conical segment is provided with a bulkhead gate. A closed-type vibrating feeder is arranged below the bulkhead gate. The vertical-type spiral particle waste heat recycling device meets the specific requirement of sintering ore for a cooling device and is high in controllability, the service life of the vertical-type spiral particle waste heat recycling device is prolonged, gas resistance is reduced, flow and temperature uniformity are improved, and the waste heat utilization rate is improved.

Owner:ZHEJIANG UNIV

Casting method combining investment precise shell-making process with vacuum suction molding technology

InactiveCN104399891AEasy to makeLow production costFoundry mouldsFoundry coresProcess engineeringUltimate tensile strength

The invention discloses a casting method combining an investment precise shell-making process with a vacuum suction molding technology. The casting method comprises the following steps: manufacturing a wax pattern, assembling the wax pattern, coating the surface of a wax pattern cluster with coating, drying, dewaxing and recovering a molding shell, performing low-temperature roasting on the molding shell, binning and moulding the shell, and performing negative pressure pouring. The casting method has the advantages that the manufacturing process of the molding shell is simplified, the manufacturing cost of the molding shell is reduced, the waste discharging volume is reduced, the low-temperature roasting is adopted, energy consumption is reduced greatly, and the problem of insufficient strength of the molding shell is solved through negative pressure pouring.

Owner:温州兰理工科技园有限公司 +2

Surf- or sail-board and method of producing the same

Owner:RAPP PETER

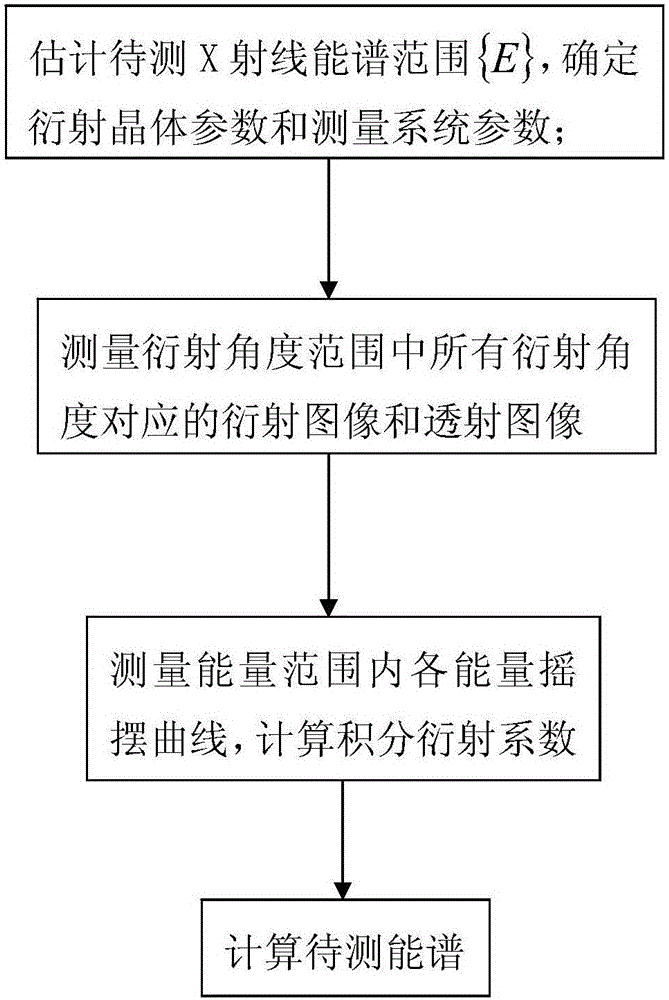

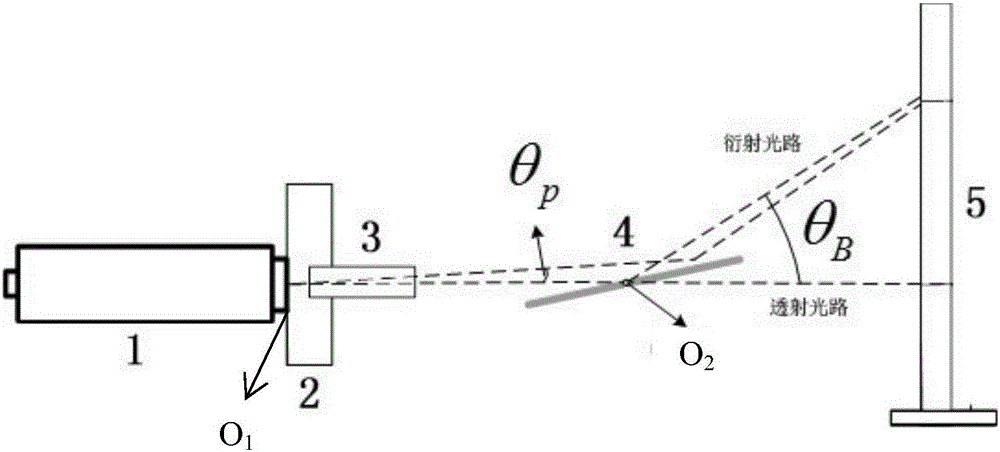

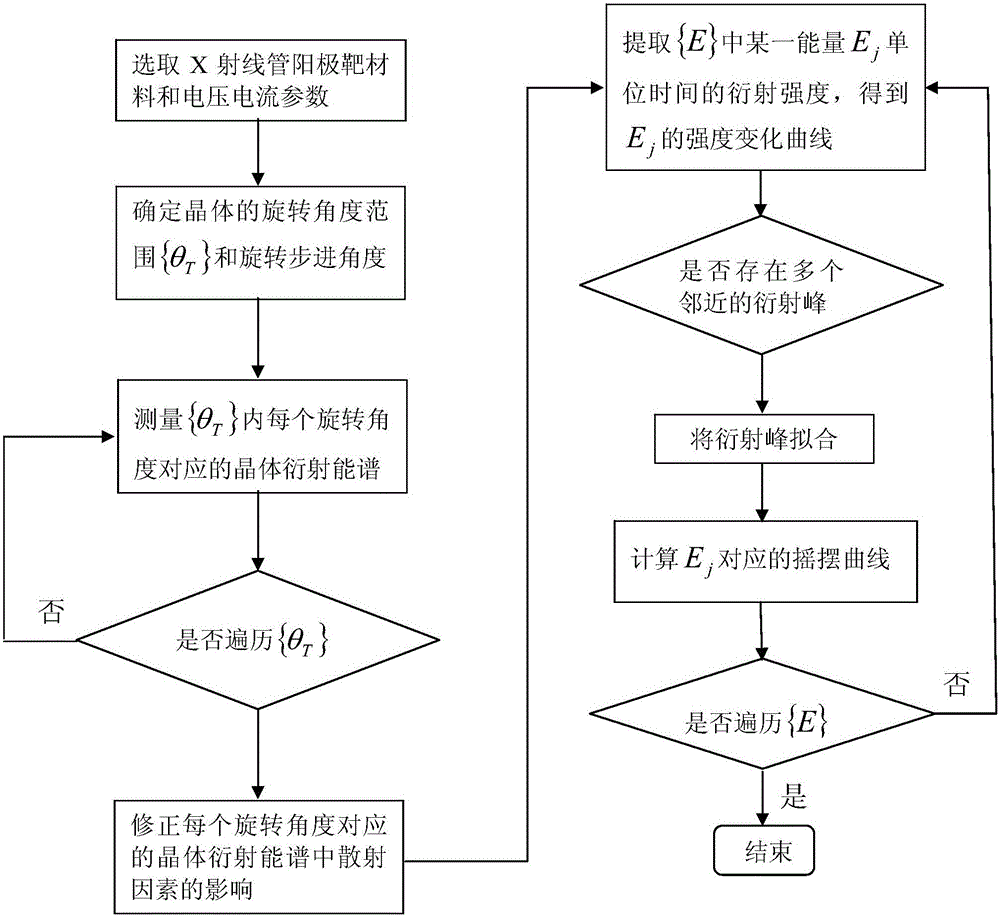

X-ray energy spectrum measurement method based on flat crystal diffraction imaging

InactiveCN105759304AImprove measurement efficiencySimple light pathX-ray spectral distribution measurementPhysicsImage resolution

The invention relates to an X-ray energy spectrum measurement method based on flat crystal diffraction imaging. By using the method, disadvantages that energy spectrum resolution is poor and measurement efficiency is low in an existing method are overcome. The method is suitable for multi-energy X-ray continuous energy spectrum measurement below 100keV. The method comprises the following steps of 1, estimating an energy spectrum scope of an X ray to be measured and determining a diffraction crystal parameter and a measurement system parameter; 2, carrying out imaging on all the diffraction angles in a diffraction angle scope and recording a diffraction image and a transmission image; 3, for a crystal determined in the step1, using a direct current X-ray source and an energy distinguishing detector to measure a rocking curve of each energy X ray to a diffraction crystal in the energy spectrum scope to be measured and calculating an integral diffraction coefficient; 4, according to the transmission image in the step2, calculating diffraction energy corresponding to each pixel of the diffraction image in the step2 so as to acquire an X-ray diffraction energy spectrum; and combining the integral diffraction coefficient of each energy to be measured in the step3 to calculate an incident X ray energy spectrum.

Owner:NORTHWEST INST OF NUCLEAR TECH

Endless rope speed regulation mechanical winch driving device used for mine

InactiveCN101648683AImprove work efficiencyCompact structureWinding mechanismsElectric machineryTraction system

The invention discloses an endless rope speed regulation mechanical winch driving device used for a mine, belonging to a mine transporting device which mainly serves as an underground roadway wire rope traction system. Equal-power double-speed electromotor speed regulation is used for replacing traditional mechanical speed regulation and variable frequency motor speed regulation. The speed regulation device of the invention adopts simultaneously float of high-velocity planet carrier and low-velocity sun gear; a high-speed internal gear and a low-speed internal gear are connected with a rollerinto a whole to realize power division, an electro hydraulic control system is combined for carrying out friction machinery soft start and remote operation control of the drive device. At working time, the invention can arbitrarily switch high speed and low speed without halting. The invention has the advantages of low cost, small noise, compact structure, convenient operation, safety and reliability.

Owner:SHANGHAI DATUN ENERGY

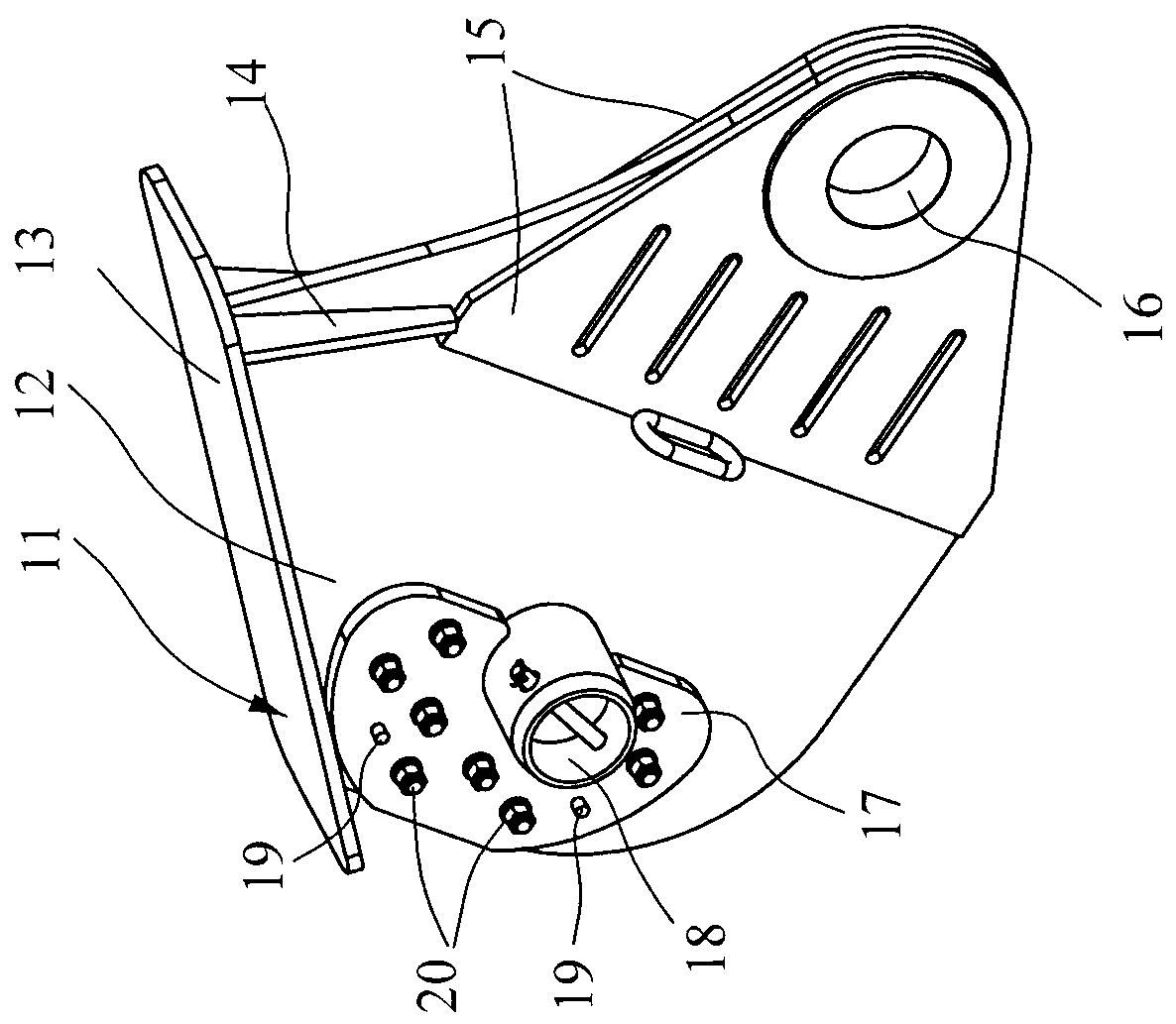

Movable pulley traction connecting device of inclined roadway winch used for transportation of hydraulic support

ActiveCN103334782AHigh strengthEnsure transportation safetyEarth drilling and miningUnderground transportTransportation capacityEngineering

The invention discloses a movable pulley traction connecting device of an inclined roadway winch used for transportation of a hydraulic support. The movable pulley traction connecting device comprises an auxiliary transport cart and a movable pulley unit, and is characterized in that a support connecting plate of a support connecting seat is vertically formed by welding a transverse plate to a vertical plate, a connecting hole is formed in the front end of the support connecting plate, and a limiting pin shaft hole is formed in the back end of the support connecting plate; the transverse plate is inserted into a gap between support connecting rods and a top beam, the vertical plate is inserted into a gap between two support connecting rods at the back part of the hydraulic support, the limiting pin shaft hole is exposed on the inner sides of the support connecting rods, a connecting rod spacer pin is arranged in the limiting pin shaft hole, so that the support connecting seat is connected to the support connecting rods; a middle connector is formed by hinging a front connecting piece to a back connecting piece through a middle pin shaft, the front connecting piece is connected to the connecting hole at the back end of the movable pulley unit, and the back connecting piece is connected with the support connecting seat; when the support is transported, a wire rope surrounds the movable pulley unit, and the end of the rope is fixed nearby the winch, so that the transportation capacity of the winch is doubled to meet overall transportation requirements of some heavy supports.

Owner:CHINA UNIV OF MINING & TECH +2

Solid-base monolithic catalyst with regular porous channels and preparation method of solid-base monolithic catalyst

InactiveCN102039202AReduced strength requirementsExtended service lifePhysical/chemical process catalystsFatty acid esterificationPtru catalystBiodiesel

The invention relates to a solid-base monolithic catalyst with regular porous channels and a preparation method of the solid-base monolithic catalyst as well as an application of the solid-base monolithic catalyst in preparing biodiesel continuously. In the solid-base monolithic catalyst, a honeycomb ceramic with regular straight porous channels is taken as a carrier, and load-type hydrotalcite and hydrotalcite-like solid base which have high activities are loaded on the carrier, so that the solid-base monolithic catalyst with the regular porous channels is prepared. By utilizing the solid-base monolithic catalyst with the regular porous channels provided by the invention, the bed pressure drop in a fixed bed reactor can be greatly reduced. The solid-base monolithic catalyst with the regular porous channels can be applied to continuous fixed bed for biodiesel, has the characteristics of high production efficiency and long service life and is friendly on environment, the cost of the equipment is low, and the energy consumption is low.

Owner:SOUTHEAST UNIV

Method for manufacturing hollow box type element with non-circular section from carbon fiber composite

InactiveCN102555231AReduce pressure and strength requirementsLess investment in equipmentCarbon fiber compositeCircular section

The invention relates to a method for manufacturing hollow box type element with non-circular section from carbon fiber composite, mainly comprising the following steps: preparing a female die outer shape mold for solidification of parts, a female die inner shape mold, a male die for the lay-up, and a soft mold for solidification; laying up the composite on the male die; placing vacuum bags into the inner space of the part and packaging the mold with vacuum bags; applying vacuum to the inner and outer vacuum bags so that the part billet can fit to the cavity of the mold; pre-pressing the mold at a mediate temperature, during which the solidifying pressure and the temperature point for application of the pressure are determined by calculation and experiment. By applying pressure from both inside and outside, applying pressure for molding solidification from the cavity of the mold, and applying completely same pressure to the surface of the mold at the same time to balance the internal pressure of the mold, the method of invention solves the defect that the method in the prior art cannot apply pressure to complex sections, variable sections and angles, and also solves the problems of angle layering and difficult mold releasing of light hollow elements with irregular sections like rectangular tubes.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com