Rapid-hardening inorganic filling support material for mine and using method of support material

A mining and inorganic technology, which is applied in the field of fast-hardening inorganic filling and supporting materials for mining, can solve the problems of difficult to play a supporting role, complicated construction process, slow curing speed, etc. The effect of strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

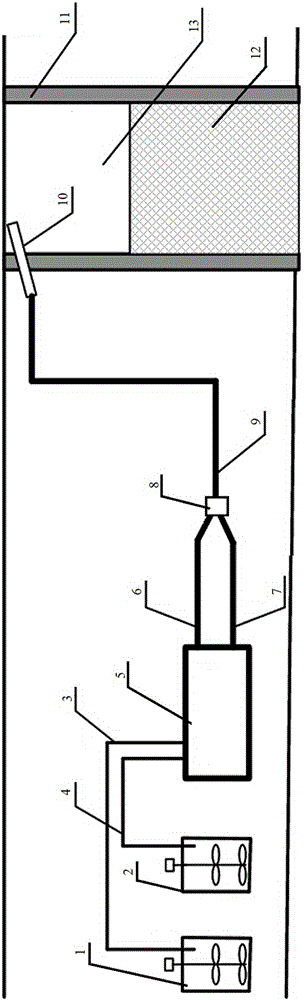

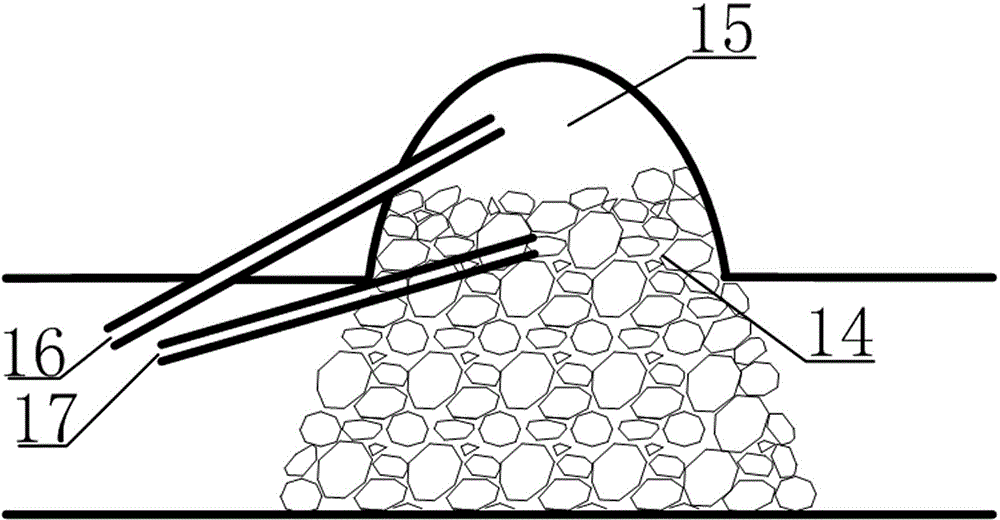

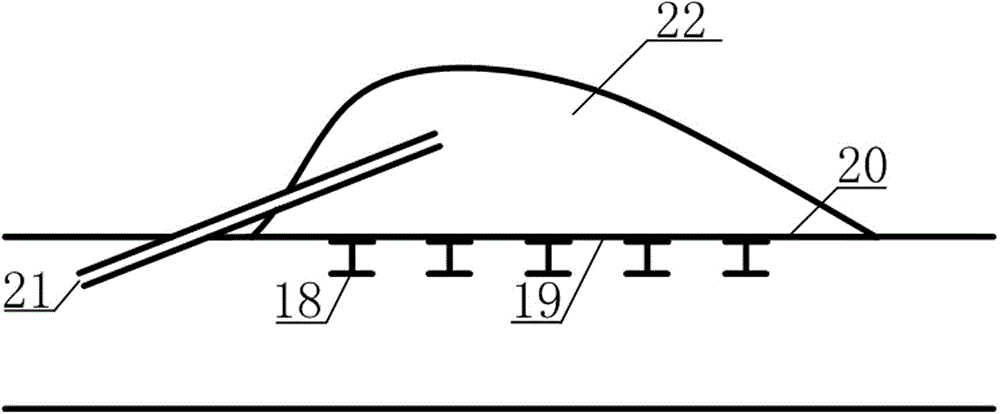

[0029] Such as figure 1 with Figure 4 As shown, the rapid-hardening inorganic filling and supporting material for mines in this embodiment is composed of component A and component B. The component A is composed of the following raw materials: 9700g of sulphoaluminate cement clinker, XWZ-A type Composite admixture 300g, AH-1 type air-entraining agent 3g, aluminum powder 2g, sodium tripolyphosphate 50g, polypropylene fiber 90g, of which XWZ-A type composite admixture includes naphthalene series superplasticizer 45g, sodium metaaluminate 135g, 75g sodium carboxymethyl cellulose, 45g sodium gluconate; component B is composed of the following raw materials: 8000g gypsum, 1700g quicklime, 300g XWZ-B composite admixture, 3g sodium lauryl sulfate, 2g aluminum powder, Sodium hexametaphosphate 50g, alkali-resistant glass fiber 90g, of which XWZ-B type composite admixture includes melamine superplasticizer 36g, citric acid 75g, water-soluble polyvinyl alcohol 24g, sodium sulfate 165g. ...

Embodiment 2

[0037] Such as figure 2 with Figure 4 As shown, the rapid-hardening inorganic filling and supporting material for mines in this embodiment is composed of component A and component B, and the component A is composed of the following raw materials: 9600g of sulphoaluminate cement clinker, XWZ-A type Composite admixture 400g, AH-1 type air-entraining agent 4g, sodium hexametaphosphate 20g, wood fiber 50g, of which XWZ-A type composite admixture includes melamine superplasticizer 60g, sodium sulfate 180g, hydroxypropyl methyl Cellulose 100g, citric acid 60g; component B is composed of the following raw materials: flue gas desulfurization gypsum 8500g, quicklime 1100g, XWZ-B type composite admixture 400g, a-olefin sulfonate sodium 4g, sodium tripolyphosphate 20g, anti-alkali 50g of glass fiber, of which the XWZ-B type composite admixture includes 48g of polycarboxylate superplasticizer, 100g of citric acid, 32g of sodium carboxymethylcellulose, and 220g of sodium carbonate.

[...

Embodiment 3

[0046] Such as image 3 with Figure 4 As shown, the rapid-hardening inorganic filling and supporting material for mines in this embodiment is composed of component A and component B. The component A is composed of the following raw materials: 9500g of sulphoaluminate cement clinker, XWZ-A type Composite admixture 500g, AH-1 air-entraining agent 10g, aluminum powder 5g, sodium hexametaphosphate 100g, polypropylene fiber 200g, of which XWZ-A composite admixture includes melamine superplasticizer 75g, sodium carbonate 225g, Carboxymethylcellulose sodium 125g, borax 75g; Component B consists of the following raw materials: phosphogypsum 7800g, quicklime 1700g, XWZ-B type composite admixture 500g, rosin resin 10g, aluminum powder 5g, sodium hexametaphosphate 100g, 200g of alkali-resistant glass fiber, of which the XWZ-B type composite admixture includes 60g of polycarboxylate superplasticizer, 125g of sodium gluconate, 40g of sodium carboxymethylcellulose, and 275g of sodium carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com