Patents

Literature

1181 results about "Carboxymethylcellulose Sodium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cellulose derivative which is a beta-(1,4)-D-glucopyranose polymer. It is used as a bulk laxative and as an emulsifier and thickener in cosmetics and pharmaceuticals and as a stabilizer for reagents.

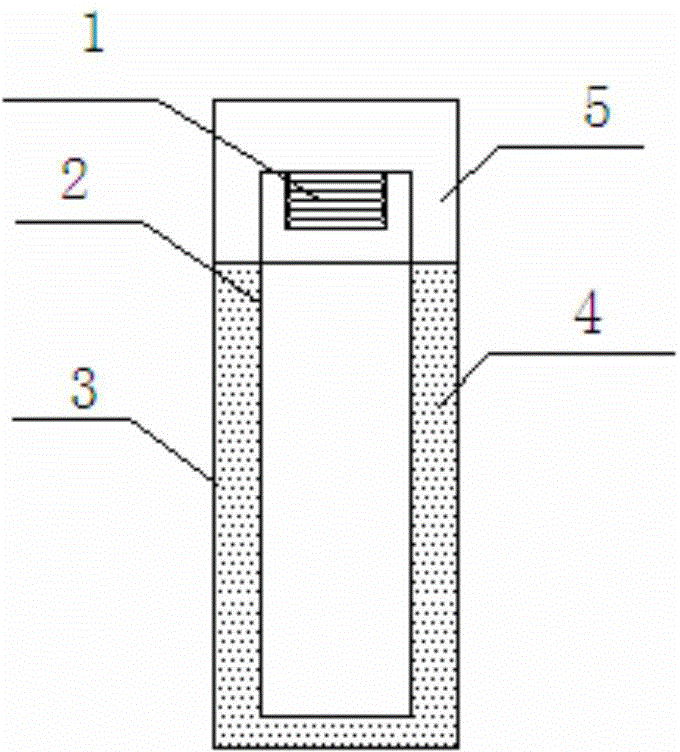

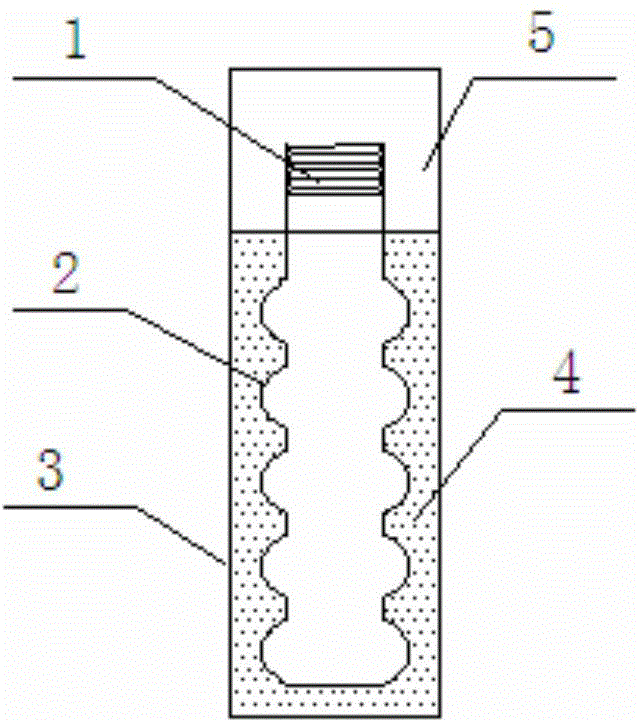

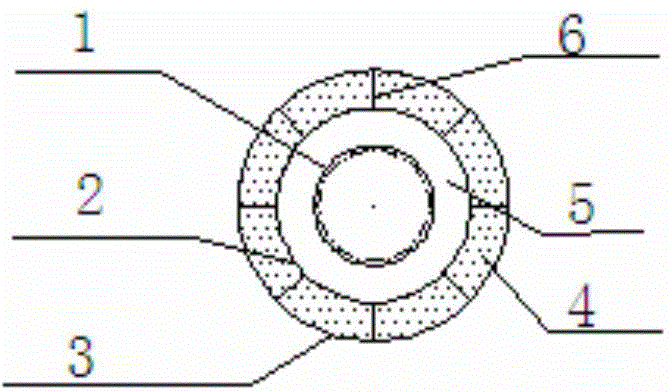

Phase transition temperature adjusting system and phase transition temperature adjusting cup

ActiveCN104887011AHeat absorption and release performance are highly matchedGuaranteed to drink normallyDrinking vesselsCarbon nanotubeSodium Thiosulfate Pentahydrate

Owner:YUTIAN ENERGY CO LTD

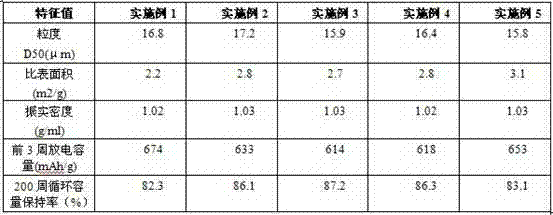

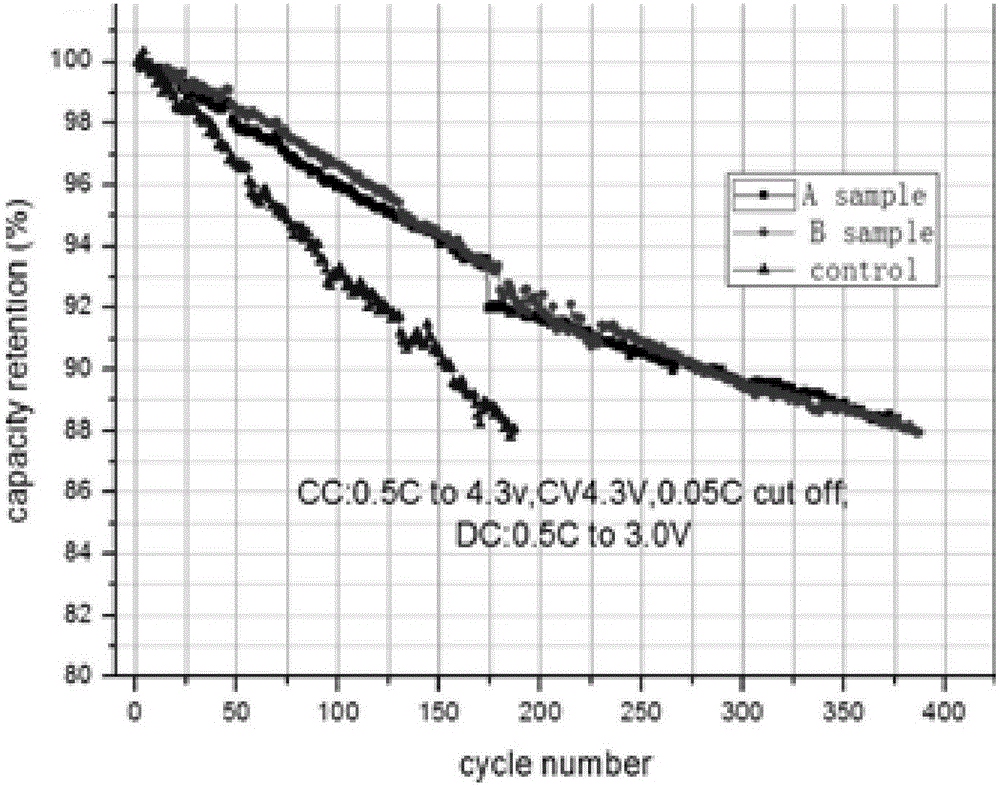

Silicon-carbon composite material for lithium ion battery and preparation method thereof

ActiveCN102891297AImprove cycle performanceIncrease capacityCell electrodesCarbon compositesCarboxymethyl cellulose

The invention discloses a silicon-carbon composite material for a lithium ion battery and a preparation method for the silicon-carbon composite material, and belongs to the field of lithium ion batteries. The silicon-carbon composite material is characterized in that carboxymethylcellulose sodium is used as a bonding agent, a liquid phase coating technology is used for silicon-carbon compounding, and a spray drying technology is used for drying granulation to prepare the silicon-carbon composite material with uniform granularity and excellent performance for the lithium ion battery. The silicon-carbon composite material and the preparation method thereof have the advantages that 1, the composite material for the lithium ion battery is prepared through a silicon-carbon compounding technology, and the capacity of the composite material is higher than that of the conventional graphite cathode material, reaches over 500mAh / g, and can meet requirements on the growing of the market of lithium ion batteries; 2, carboxymethylcellulose is used as a bonding agent which can be effectively coated and bonded on the silicon-carbon material to prevent efflorescence caused by silicon during charging and discharging, so that the cycling performance of the silicon-carbon composite material is effectively improved; and 3, the liquid phase coating and spray drying granulation technologies are adopted, so that the silicon-carbon material can be uniformly coated and bonded, has uniform granules, and is small in specific area, and the cycling performance of the silicon-carbon composite material is further improved.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

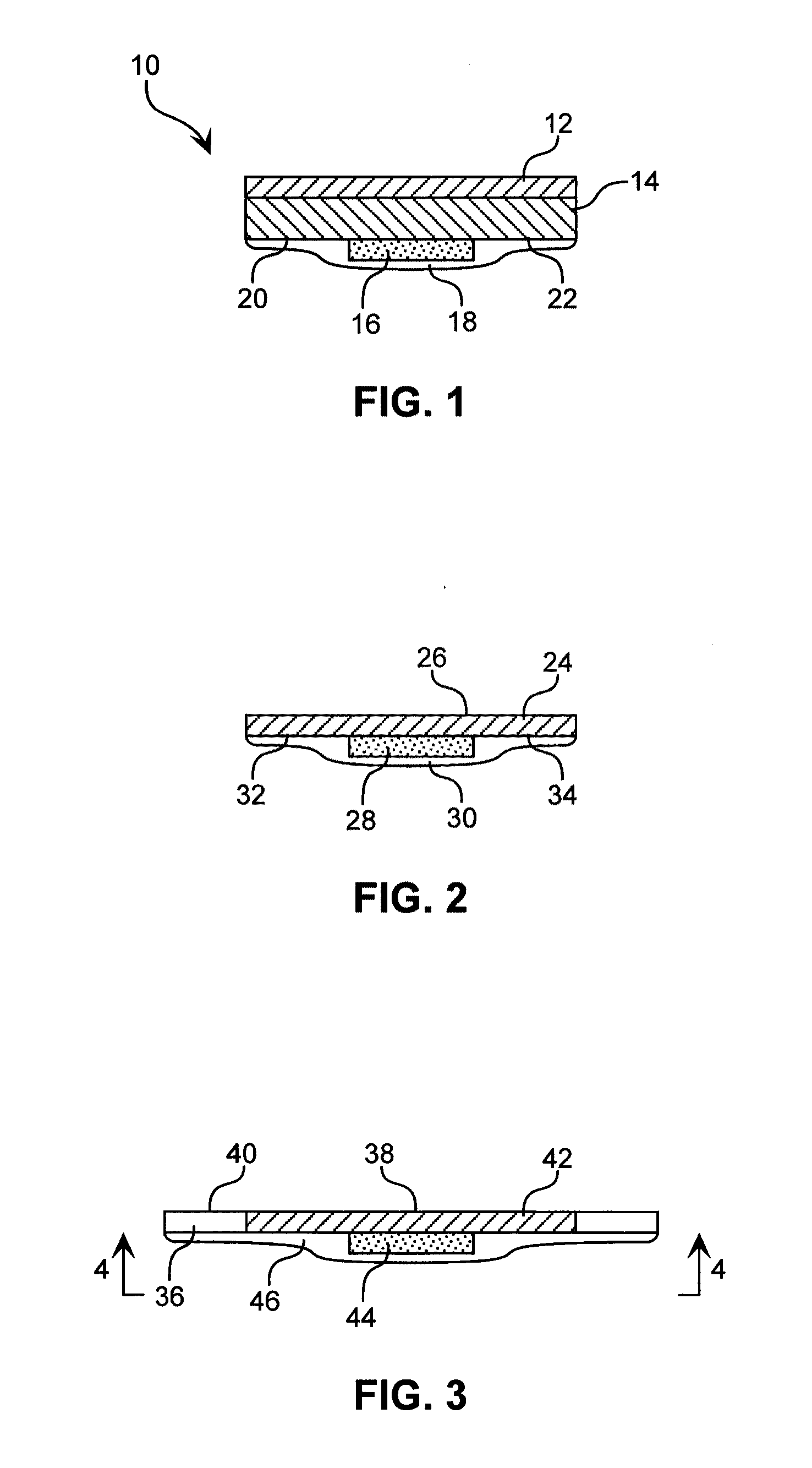

Hydrogel Compositions

InactiveUS20090258060A1Improve attributesLess tackyCosmetic preparationsPowder deliveryElastomerHydrophilic polymers

Hydrogel compositions are provided (a) that have a continuous hydrophobic phase and a discontinuous hydrophilic phase, (b) that have a discontinuous hydrophilic phase and a continuous hydrophilic phase, or (c) that are entirely composed of a continuous hydrophilic phase. The hydrophobic phase, if present, is composed of a hydrophobic polymer, particularly a hydrophobic pressure-sensitive adhesive (PSA), a plasticizing elastomer, a tackifying resin, and an optional antioxidant. The discontinuous hydrophilic phase, if present, is composed of a crosslinked hydrophilic polymer, particularly a crosslinked cellulosic polymer such as crosslinked sodium carboxymethylcellulose. For those hydrogel compositions containing a continuous hydrophilic phase, the components of the phase include a cellulose ester composition or an acrylate polymer or copolymer, and a blend of a hydrophilic polymer and a complementary oligomer capable of hydrogen bonding thereto. Films prepared from hydrogel compositions containing or entirely composed of the aforementioned continuous hydrophilic phase can be made translucent, and may be prepared using either melt extrusion or solution casting. A preferred use of the hydrogel compositions is in wound dressings, although numerous other uses are possible as well.

Owner:CORIUM PHARMA SOLUTIONS INC

Eco-friendly sand stabilization dust depressor and preparation method thereof

InactiveCN102863965AReduce wasteCause harmClimate change adaptationOrganic fertilisersPolyvinyl alcoholPlanting seed

An eco-friendly sand stabilization dust depressor is dark-brown milky liquid prepared by biomass materials, surfactants, water-soluble polymers, moisturizers, preservatives and water through mixing. The viscosity of the dust depressor is 50-80 centipoise at the normal temperature. The biomass materials are solid cake-like residues of plant seeds after a squeezing and oil pressing process or solvent digestion; the water-soluble polymers are carboxymethylcellulose and polyvinyl alcohol; and the moisturizers are magnesium chloride, calcium chloride, sodium sulfate, sodium silicate and the like. The obtained sand stabilization dust depressor is eco-friendly; and the preparation process is simple, short in process and easy to operate. The eco-friendly sand stabilization dust depressor has the advantages of being environment-friendly, non-toxic and free of pollution; and capable of effectively controlling soil wind erosion and land desertification, reducing dust weather, playing roles in sand stabilization, dust proofing and depression, and being widely used in severe wind erosive areas such as suburban farmlands, wastelands, degraded grasslands and deserts.

Owner:NANKAI UNIV

Compound danshen oral disintegrant tablet and its preparation method

The present invention relates to a compound salvia oral disintegrant tablet capable of being disintegrated quickly in oral cavity to release medicine. It composition includes the salvia root extract, notoginseng total saponin, borneol and excipient, and its disintegration time is within 40 sec, in which the excipient includes filling agent, disintegrant, glidant and corrective. Its filling agent is of microcrystalline cellulose, its dose is 40%-90% of total weight of the prescription, and the disintegrant is selected from sodium carboxymethylstarch, cross-linked carboxymethylcellulose sodium, cross-linked polyvinylpyrrolidone and low-substituted hydroxypropyl cellulose, and its dose is 5%-25% of total weight of prescription.

Owner:BEIJING BOERDA BIO TECH DEV

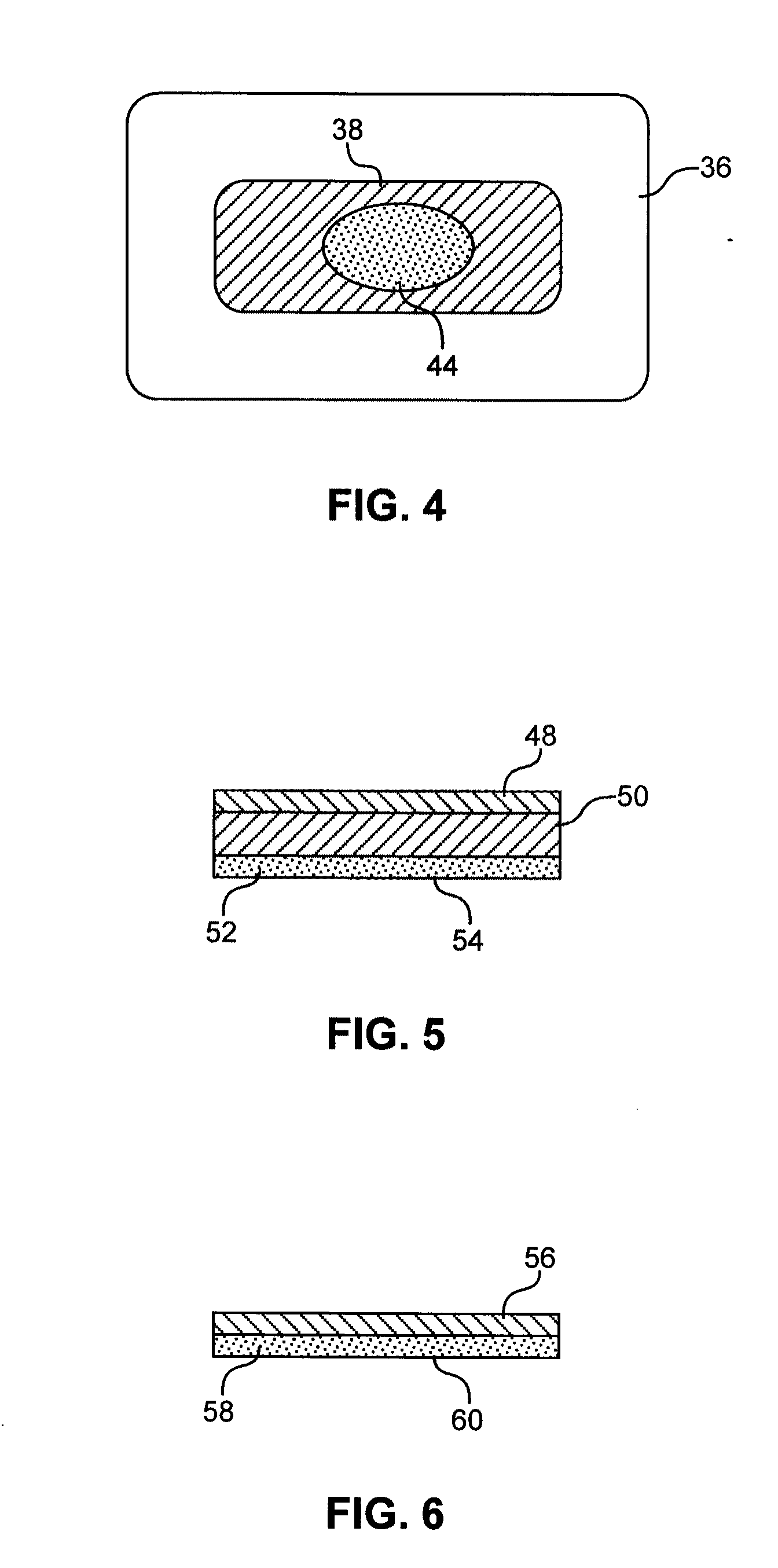

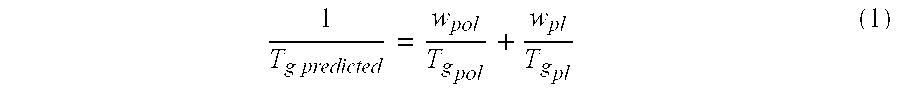

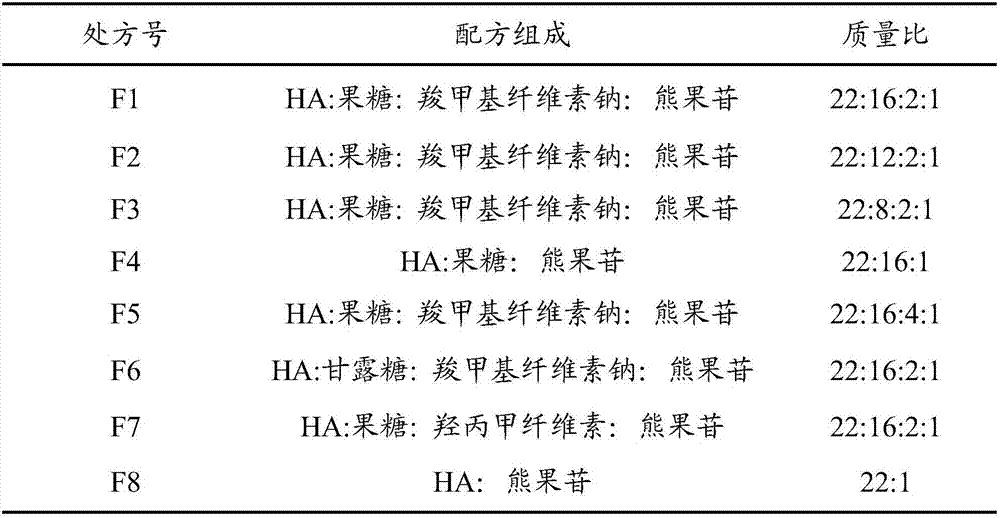

Soluble microneedle patch used for skin whitening and preparation method thereof

ActiveCN107375008AHigh mechanical strengthSolve the lack of hardnessCosmetic preparationsToilet preparationsSolubilitySodium hyaluronate

The invention relates to a soluble microneedle patch used for skin whitening and a preparation method thereof. The soluble microneedle patch comprises a needle point and a substrate, the needle point comprises the following raw materials in parts by weight: 1 part of arbutin, 15-30 parts of hyaluronic acid or its salt, and 5-25 parts of a forming material; wherein the hyaluronic acid or its salt is hyaluronic acid or sodium hyaluronate; and the forming material is selected from at least one of fructose, mannose, carboxymethylcellulose sodium and hydroxypropyl methylcellulose. The soluble microneedle patch has good mechanical strength, hardness and dissolvability, avoids the disadvantage that a traditional skin-caring mode cannot perform arbutin advantage, and has obvious effects for lightning color spots and whitening skin.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD +1

High-specific-capacity silicon-based negative electrode composite binder and preparation method for negative plate containing same

ActiveCN106058259ASolve the technical problem of short cycle lifeCell electrodesSecondary cellsButadiene-styrene rubberPolymerization

The invention discloses a high-specific-capacity silicon-based negative electrode composite binder and a preparation method for a negative plate containing the same, belonging to the field of binders for batteries. The high-specific-capacity silicon-based negative electrode composite binder comprises 5 to 50 wt% of carboxymethylcellulose sodium, 5 to 30 wt% of polyacrylic acid and 20 to 90 wt% of styrene-butadiene rubber. The preparation method for the negative plate comprises the following steps: binder preparation; addition of a conductive agent; addition of a main material; sieving; coating; high temperature polymerization; rolling; and punching. The composite binder provided by the invention can overcome the technical problem of short cycle life of a battery caused by immense volume changes of a conventional silicon-based negative electrode material during intercalation and deintercalation of lithium ions.

Owner:WANXIANG 123 CO LTD

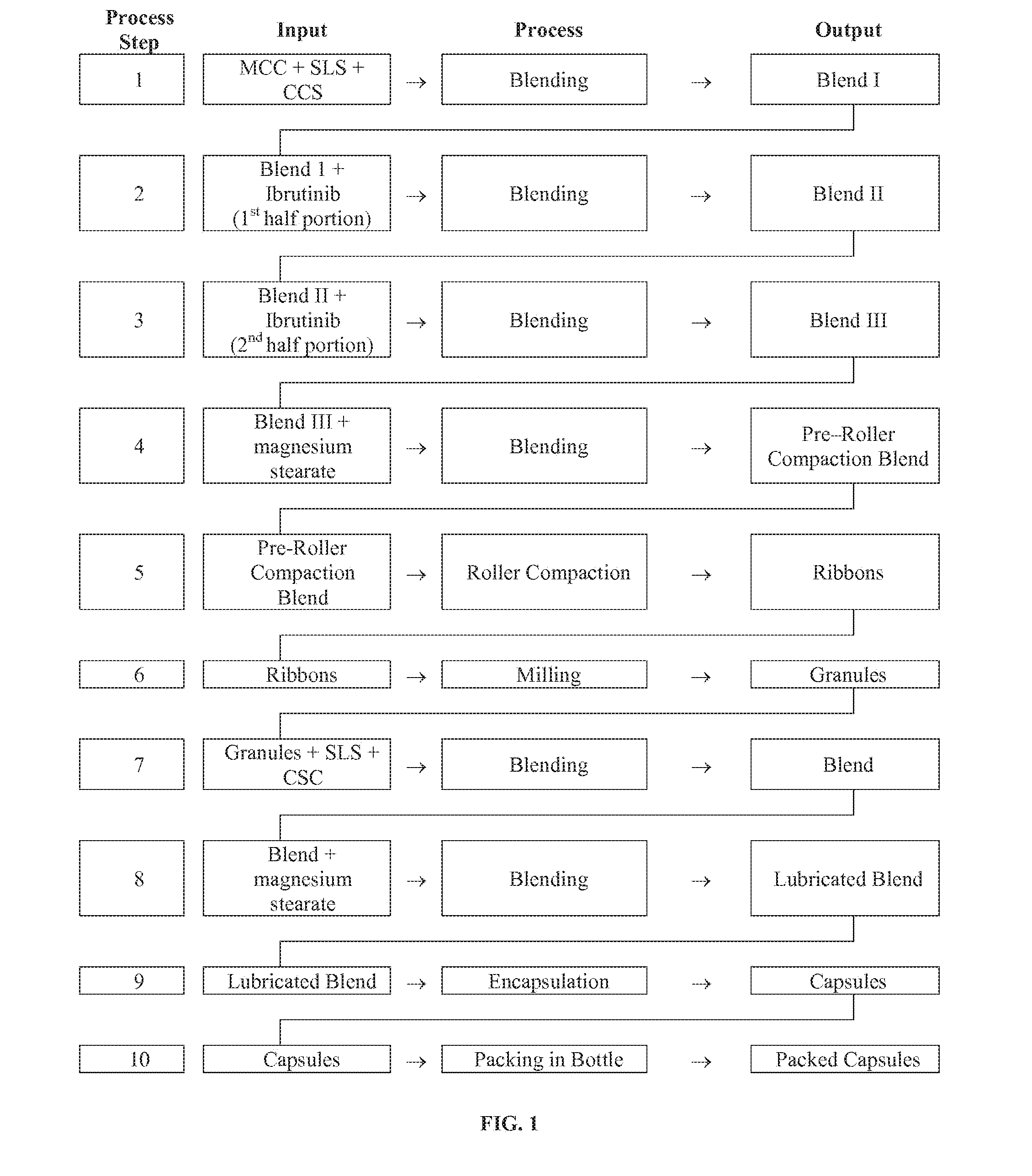

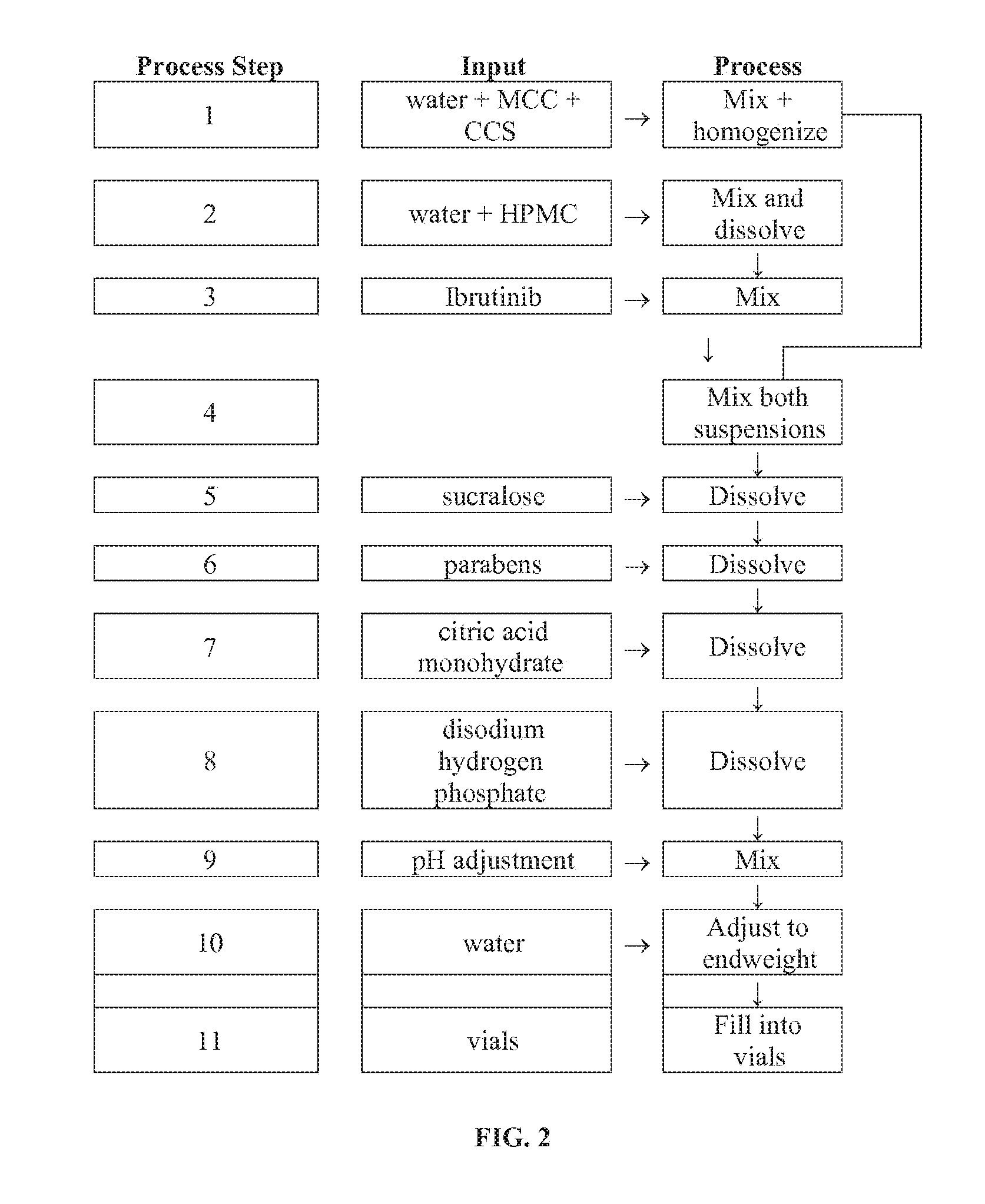

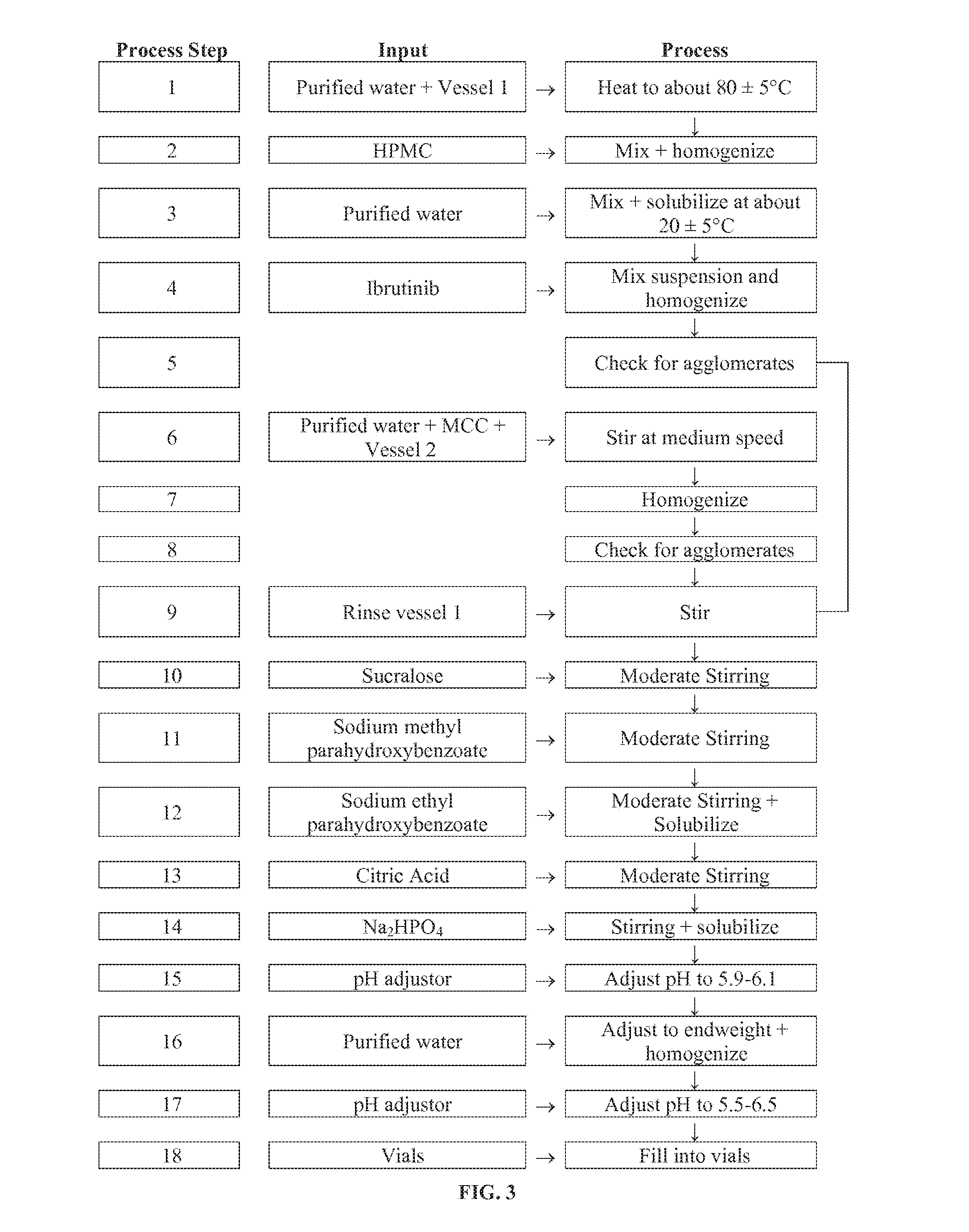

Compositions Containing Ibrutinib

InactiveUS20160287594A1Easy to sprinkleOrganic active ingredientsInorganic non-active ingredientsWaldenstrom macroglobulinemiaMetabolite

Discussed herein are pharmaceutical compositions containing Ibrutinib and processes for preparing them. The compositions may be utilized in the treatment of a variety of conditions including, without limitation, B-cell proliferative disorders such as non-Hodgkin lymphoma (diffuse large B cell lymphoma, follicular lymphoma, mantle cell lymphoma or burkitt lymphoma), Waldenstrom macroglobulinemia, plasma cell myeloma, chronic lymphocytic leukemia, lymphoma, or leukemia. These compositions are designed for oral ingestion. The compositions are contained within a capsule such as a standard or sprinkle or in a liquid formulation such as a suspension. In one embodiment, the pharmaceutical composition contains Ibrutinib, a salt, prodrug, or metabolite thereof, microcrystalline cellulose, croscarmellose sodium, sodium lauryl sulfate, and magnesium stearate. In another embodiment, the pharmaceutical composition contains Ibrutinib, a salt, prodrug, or metabolite thereof, microcrystalline cellulose, carboxymethylcellulose sodium, hydroxypropylmethylcellulose, citric acid monohydrate, disodium hydrogen phosphate, sucralose, sodium methyl parahydroxybenzoate, sodium ethyl parahydroxybenzoate, concentrated hydrochloric acid, sodium hydroxide, and water.

Owner:JANSSEN PHARMA NV

Composition for caries prevention

InactiveUS20050089481A1Excellent composition for preventionInhibition is effectiveCosmetic preparationsImpression capsCementum cariesPhosphopeptide

To obtain a composition for caries prevention, which has effects for efficiently suppressing demineralization and promoting remineralization and stability in keeping for a long time, 0.01 to 10% by weight of sodium carboxymethylcellulose having the etherification degree of 0.7 to 1.0 is used in a composition blended with a casein phosphopeptide-amorphous calcium phosphate complex (CPP-ACP) and / or a casein phosphopeptide-amorphous calcium fluoride phosphate complex (CPP-ACFP), a sodium carboxymethylcellulose, a viscosity regulator and water.

Owner:GC CORP

Method for preparing sludge-based formed magnetic active carbon

ActiveCN103521180AUniform sizeHigh compressive strengthOther chemical processesAlkali metal oxides/hydroxidesMagnetic stabilitySludge

The invention provides a method for preparing sludge-based formed magnetic active carbon. The method comprises the steps as follows: sludge is used as a raw material, an activating agent is added for carbonizing and activating the sludge; nano-sized Fe3O4 is used as a magnetic source for magnetizing the sludge active carbon; and sodium carboxymethylcellulose and aluminum salt are composited to an organic-inorganic binding agent, the binding agent and a p-toluenesulfonhydrazide foaming agent are used for uniformly binding powdery magnetic active carbon into a formed magnetic active carbon precursor with abundant pore structures, and finally, the formed magnetic active carbon precursor is heated to obtain the sludge-based formed magnetic active carbon. According to the method, the sludge is used as a main raw material, the resource utilization of the sludge is achieved, the recycling is convenient, and reutilization can be achieved; and further, the sludge-based formed magnetic active carbon has a stable structure and good magnetic stability, and can be widely used in the fields such as sewage treatment, soil pollution treatment and the like.

Owner:FUJIAN UNIV OF TECH

Water-based paint for iron casting through lost foam casting die

InactiveCN102921880AHigh temperature strengthSuitable for high temperature breathabilityFoundry mouldsFoundry coresSODIUM METAPHOSPHATECellulose

The invention discloses a water-based paint for an iron casting through a lost foam casting die. The paint comprises refractory aggregate, binders, a suspending agent, additives and a dispersing agent, wherein the refractory aggregate comprises high aluminum powder, zircon powder and pyrophyllite; the binders comprise silica sol or white emulsion, polyvinyl acetate emulsion, bentonite and sodium hexametaphosphate; the suspending agent comprises sodium carboxymethylcellulose; the additives comprise Tween, octanol, sodium carbonate, cryolite and iron oxide powder; and the dispersing agent is water. According to the paint, suitable ingredients are chosen, the content is adjusted, a suitable mixing process is adopted, and therefore performances such as normal temperature and high-temperature strength, suitable high-temperature permeability and good leveling property, suspension property and painting performance of a coating can be satisfied completely. The paint is suitable for gray iron castings with different trademarks and enables the expendable casting die to be stripped with the iron casting easily, particularly for stripping in flakiness of a sintered coating during cleaning, and the possibilities for diverse defect generation on the surface of the iron casting are reduced; and simultaneously, pollution of coating components to the environment is reduced greatly due to the selection of phosphate assistant.

Owner:XUZHOU PENGJU SNAPDRAGON ARTS & CRAFTS

Taxine kind anti-cancer slow release injection

InactiveCN1923189AOrganic active ingredientsPharmaceutical delivery mechanismCelluloseAcetic acid ethenyl ester

The invention relates to a slow-release injection of taxine anti-cancer drug, which comprises anti-cancer drug, slow-release finding, suspension and / or solvent. Wherein, said anti-cancer drug is taxine, 2'-hydroxy Paclitaxel, etc; the slow-release finding is polymer of hydroxyl, glycollic acid and glycolic acid, one of acetic acid ethyenyl ester polymer and polyphony; the suspension is polyphenyl (sodium), and mannite; the solvent is distilled water, injection water, absolute ethyl alcohol, etc. The invention can be injected to reduce the toxicity effect of drug, and improve the density locally to strengthen the treatment effect of chemotherapy and radiation therapy.

Owner:孔庆忠

A kind of capsicum self-isolation method

InactiveCN102273402AEasy to operateReduce labor costsPlant genotype modificationGeitonogamyAfter treatment

Belonging to the technical field of plant breeding, the invention relates to a pepper inbred isolation method, which comprises the steps of: 1) plant selection: obsoleting substandard heterologous strains; 2) blend solution preparation: preparing a blend solution with a sodium alginate concentration of 5-10% and a carboxymethylcellulose sodium concentration of 0.5-2% with deionized water; 3) petal selection: selecting petals about 6-12h before flowering; 4) petal treatment: taking the petals to be treated on one hand lightly and taking the blend solution on the other hand, and soaking the petals in the blend solution till the joint of a calyx and a flower stalk, and making a mark with a color line; 5) management after treatment: identical with the routine field management method of pepperproduction. The pepper inbred isolation method of the invention isolates petals through a flexible film generated by the blend solution, and conducts geitonogamy to a gynoecium and a stamen of a sameflower. Being simple and rapid, the method of the invention can save the labor cost and has high?fruiting rate. Besides, the method in the invention causes no pollution to the environment and agricultural products, and can realize good application effect.

Owner:HANGZHOU ACAD OF AGRI SCI

Method and pharmaceutical to treat spinal discs

Methods for reducing chronic pain caused by a disrupted spinal disc are described. In one method, a physiologically acceptable amount of an injectable is injected into the disc. The injectable is obtained from a stock solution comprising chondroitin sulphate, glucosamine HCl, aqueous solution of dextrose; sodium carboxymethylcellulose, and a buffer substance in quantity to bring the pH of the stock solution to a value above about 6.0. Water is also added to dilute the stock solution. The stock solution may further comprise an anesthetic such as bupivicaine.

Owner:NOTOGEN INC

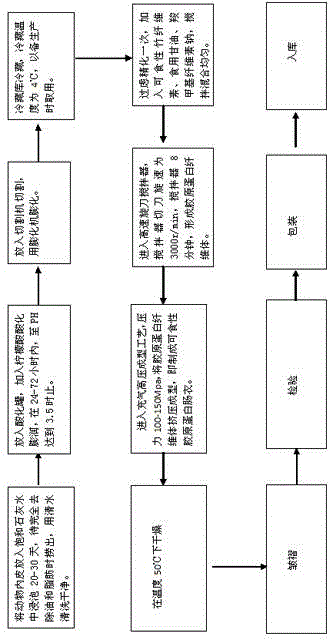

Edible collagen casing and production method thereof

ActiveCN102742862AExquisite materialsFormulation ScienceSausage casingsFood preparationFlavorCellulose fiber

The invention relates to an edible collagen casing and a production method thereof. The raw materials of the casing comprises animal endothelia, edible bamboo cellulose fiber, edible glycerin, carboxymethylcellulose sodium, saturated limewater and citric acid, wherein the mass percentage of citric acid is 99.9%, and the surface of the casing is provided with tubular film skins having micropores. The production method for the casing comprises the steps of removing oil and fat from the animal endothelia; washing clean via clear water; acidifying and swelling; cutting into slices; refrigerating; filtering and refining; adding the edible bamboo cellulose fiber, edible glycerin and carboxymethylcellulose sodium; stirring and mixing evenly; refrigerating for two hours; stirring with high-speed rotary knife stirrer; extrusion forming; and folding, testing, packaging and warehousing after drying. The edible collagen casing has the advantages of flavor and permeability of natural casing, low cost and good mouthfeel, and is not easy to smash.

Owner:HANDAN DIKE CASING

Coating composition for taste masking coating and methods for their application and use

The present invention relates to coating compositions for taste masking and methods for applying the coating compositions to dosage forms to mask the taste of a medicinal substance. The taste masking coating compositions generally include a copolymer of acrylate and methacrylate with a quaternary ammonium group in combination with sodium carboxymethylcellulose and a polyvinyl alcohol-polyethylene glycol copolymer.

Owner:RANBAXY LAB LTD

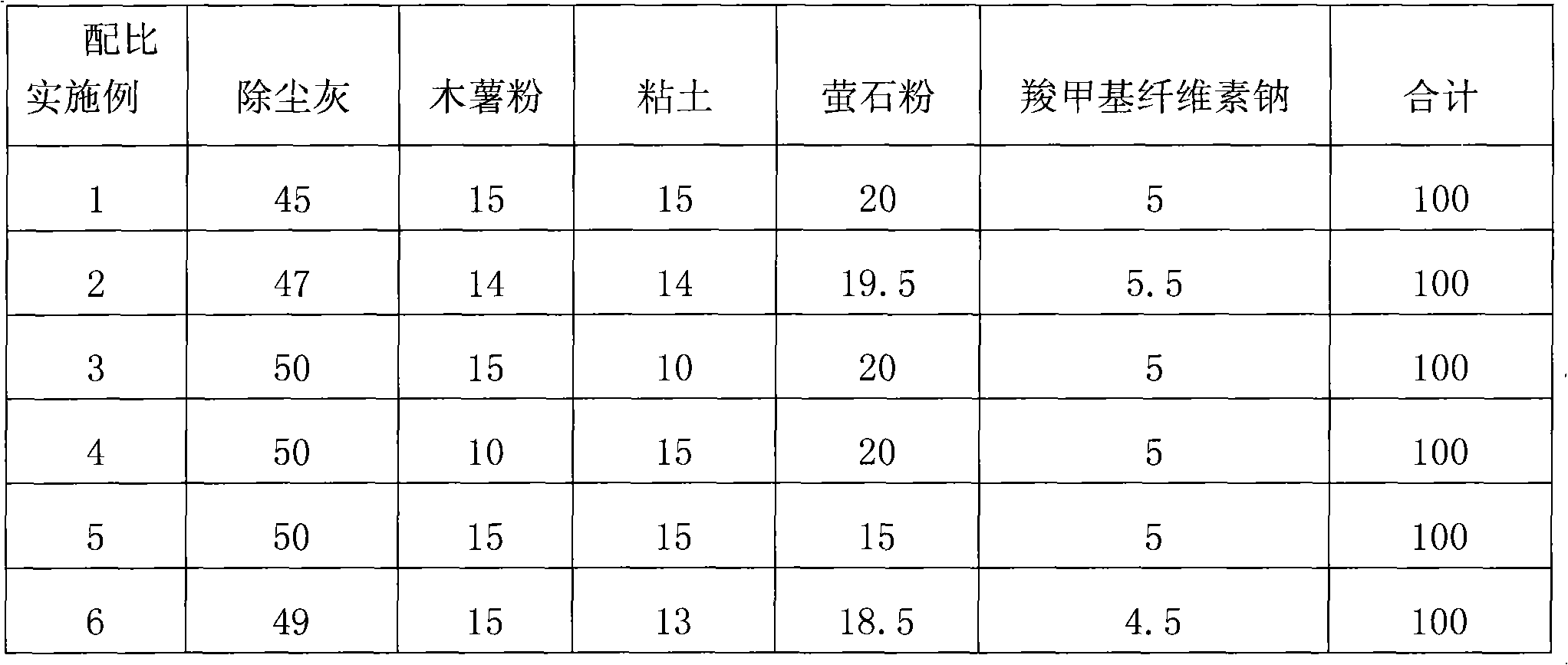

Metallurgical pellet compound binding agent

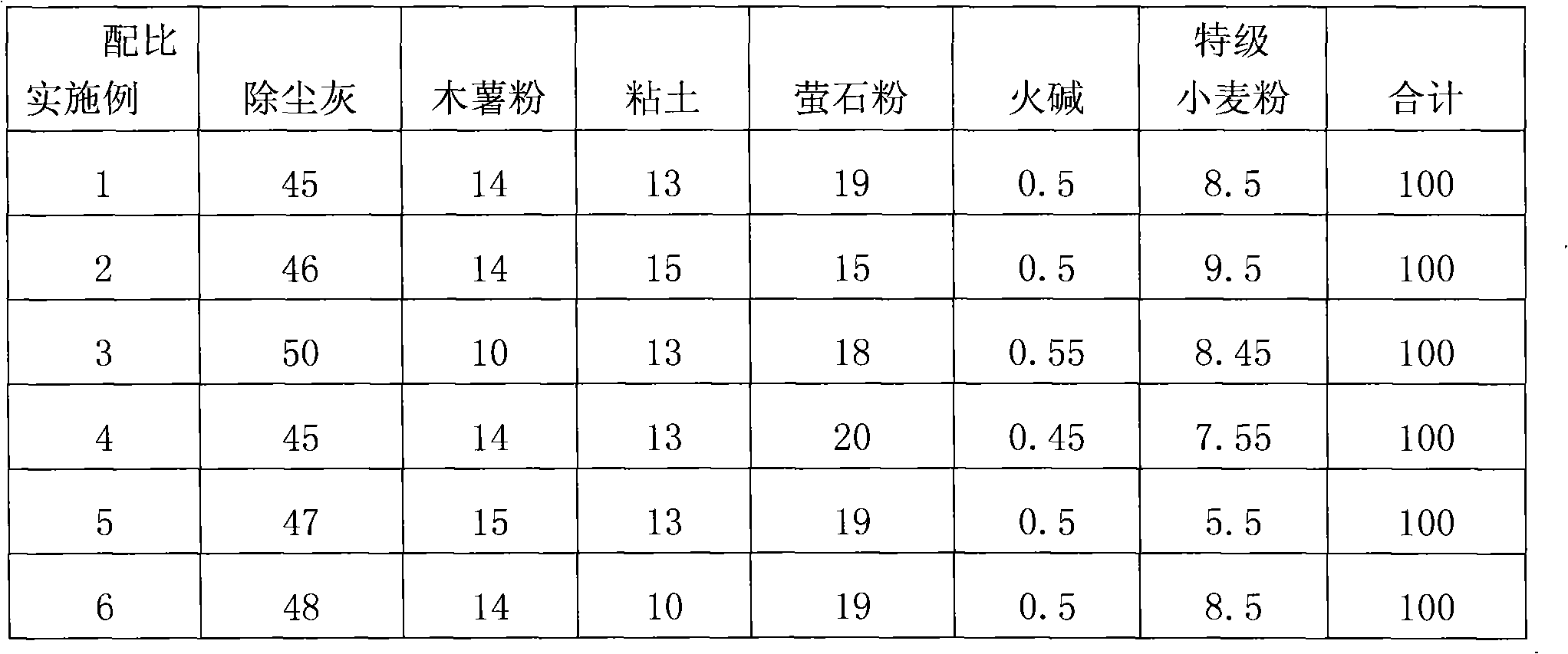

The invention discloses a metallurgical pellet compound binding agent. The compound binding agent comprises the following components in percentage by weight: 45 to 50 percent of dust generated in blast furnace ironmaking and sintering production processes, wherein the dust is grounded to ensure that more than or equal to 80 percent of the dust has the particle size of 0.043 mm, the TFe in the dust is more than or equal to 60 percent, and montmorillonite in the dust is more than or equal to 20 percent; 10 to 15 percent of cassava meal of which more than or equal to 80 percent has the particle size of 0.043 mm; 10 to 15 percent of clay of which more than or equal to 80 percent has the particle size of 0.043 mm; 15 to 20 percent of fluorspar powder of which more than or equal to 80 percent has the particle size of 0.043 mm; and 4.5 to 5.5 percent of carboxymethylcellulose sodium of which more than or equal to 80 percent has the particle size of 0.043 mm. The carboxymethylcellulose sodium of the compound binding agent can be replaced by caustic soda and special-grade wheat flour. The components are uniformly stirred according to the percentage by weight to prepare the pellet compound binding agent; and during the production of pellets, 0.8 to 1.2 percent of 0.5 percent replaceable bentonite is added, and not only a requirement on pellet production can be meet, but also the used amount of the bentonite is reduced, thereby fulfilling the aims of improving the grade of pellet iron ores and simultaneously improving blast furnace coefficients.

Owner:马鞍山市金鑫建材有限公司

Method for preparing high-substitution and high-viscosity sodium carboxymethyl cellulose from bagasse

InactiveCN102167749AIncrease the amorphous regionHigh reactivityPaper material treatmentFiberCarboxymethyl cellulose

The invention discloses a method for preparing high-substitution and high-viscosity sodium carboxymethyl cellulose from bagasse. The method comprises the following steps of: pretreating bagasse fibers through ball milling; refining activated bagasse fibers; and etherifying the refined bagasse fibers. Since the bagasse fibers are pretreated by the ball milling in the invention, a lignin protectionlayer is damaged and a crystal structure of cellulose is changed, an amorphous region of bagasse cellulose is increased, reaction activity of the bagasse cellulose is improved, high viscosity is realized by adding a crosslinking agent, the substitution of the prepared sodium carboxymethyl cellulose reaches over 1.5 and the viscosity reaches over 1,585mPa.S through a series of subsequent process method and optimization of control parameters, and the method has the advantages of low production cost, simple process and environmental friendliness.

Owner:GUANGXI UNIV

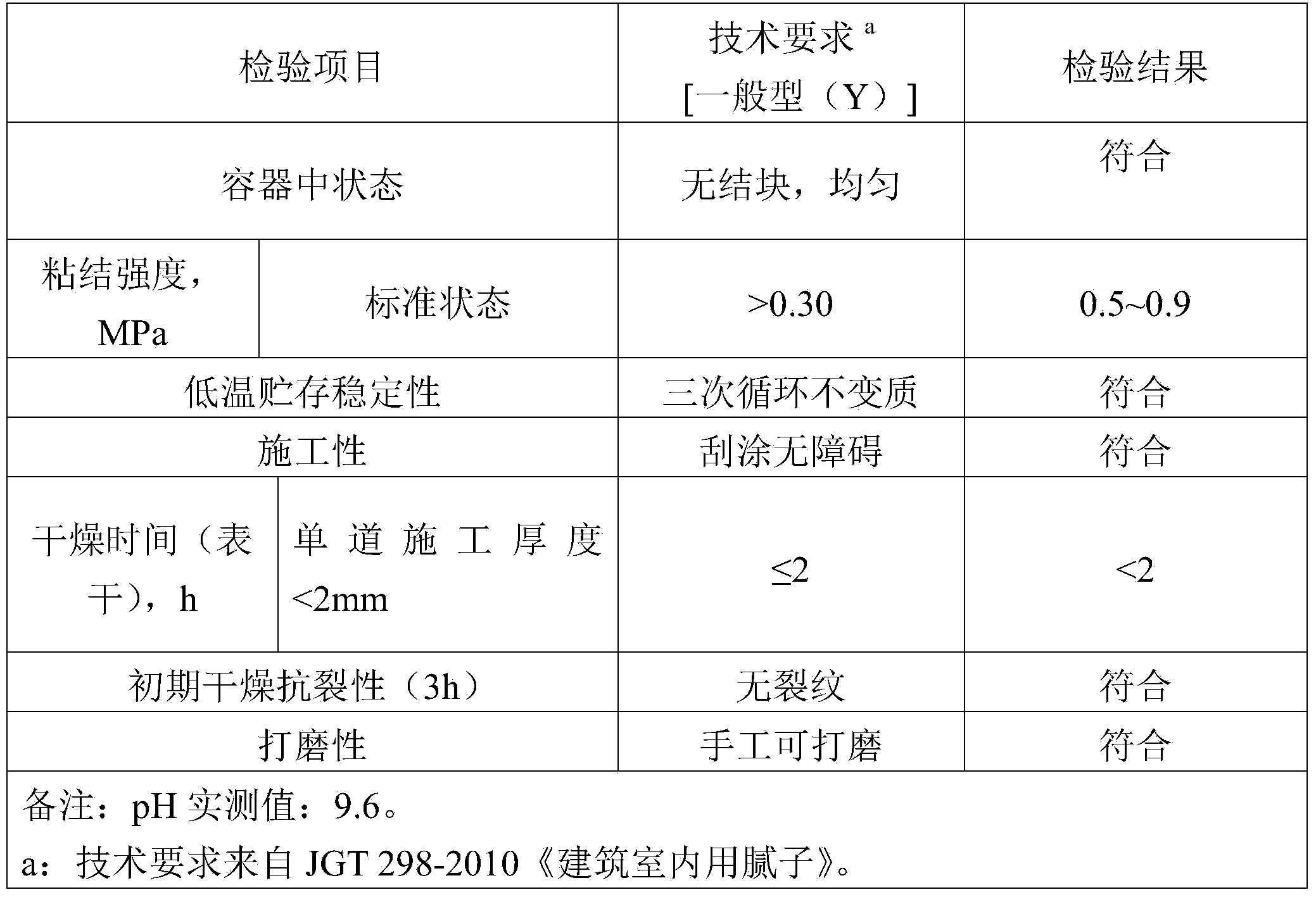

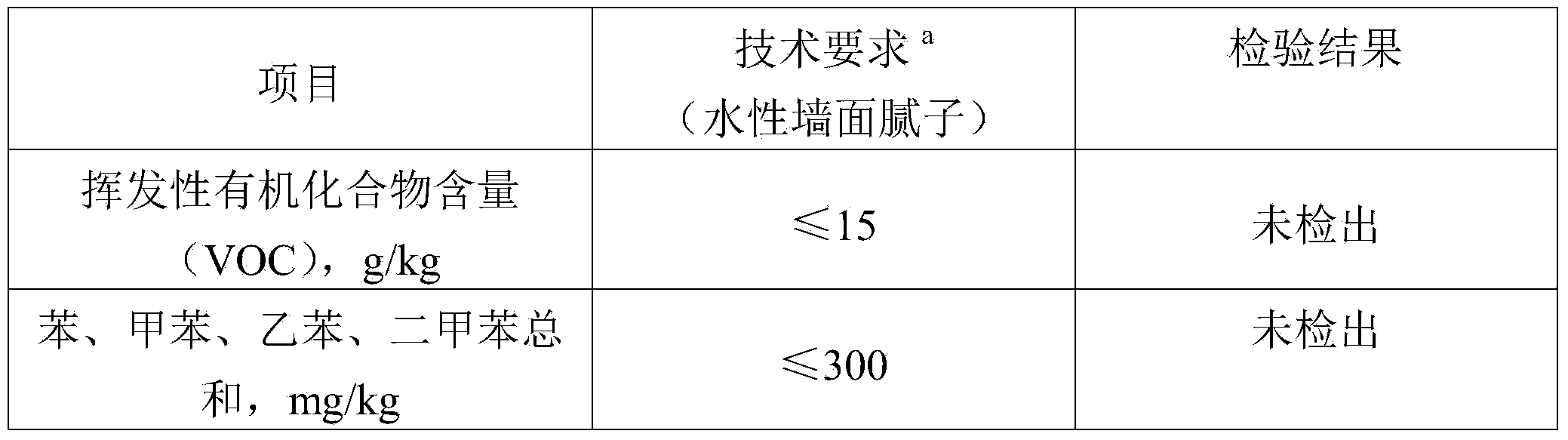

Environmentally-friendly interior wall putty powder, putty paste, and preparation methods of putty powder and putty paste

InactiveCN103525151AReduce the content of heavy metal elementsImprove impact resistanceFilling pastesCrack resistanceHydroxyethyl cellulose

The invention discloses an environmentally-friendly interior wall putty powder, a putty paste, and preparation methods of the putty powder and the putty paste. The putty powder comprises, by weight, 45-72 parts of talcum powder, 18-30 parts of heavy calcium carbonate, 5-10 parts of calcium bentonite, 0.6-1.5 parts of carboxymethylcellulose sodium, 1-5 parts of polyacrylamide, 0.3-1.7 parts of hydroxyethyl cellulose, 0-20 parts of building gypsum powder, 0-0.8 parts of carboxymethyl cellulose, 0-8 parts of alpha-pregelatinized starch, 0-3 parts of hydroxypropyl methyl cellulose and 0-0.5 parts of sodium dodecyl benzene sulfonate. The preparation method of the putty powder comprises the following steps: uniformly mixing the above components, stirring for 10-15min, and discharging the above obtained mixture. The putty paste is obtained by adding water having a weight 0.3-0.5 times the weight of the putty powder and uniformly stirring. The putty powder / putty paste contains no or a tiny amount of formaldehyde and an extremely low content of heavy metal elements, is an environmentally-friendly product, and has the advantages of excellent impact resistance, excellent hydrophobicity and waterproofness, high elasticity, good crack resistance, stable storage and easy construction.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

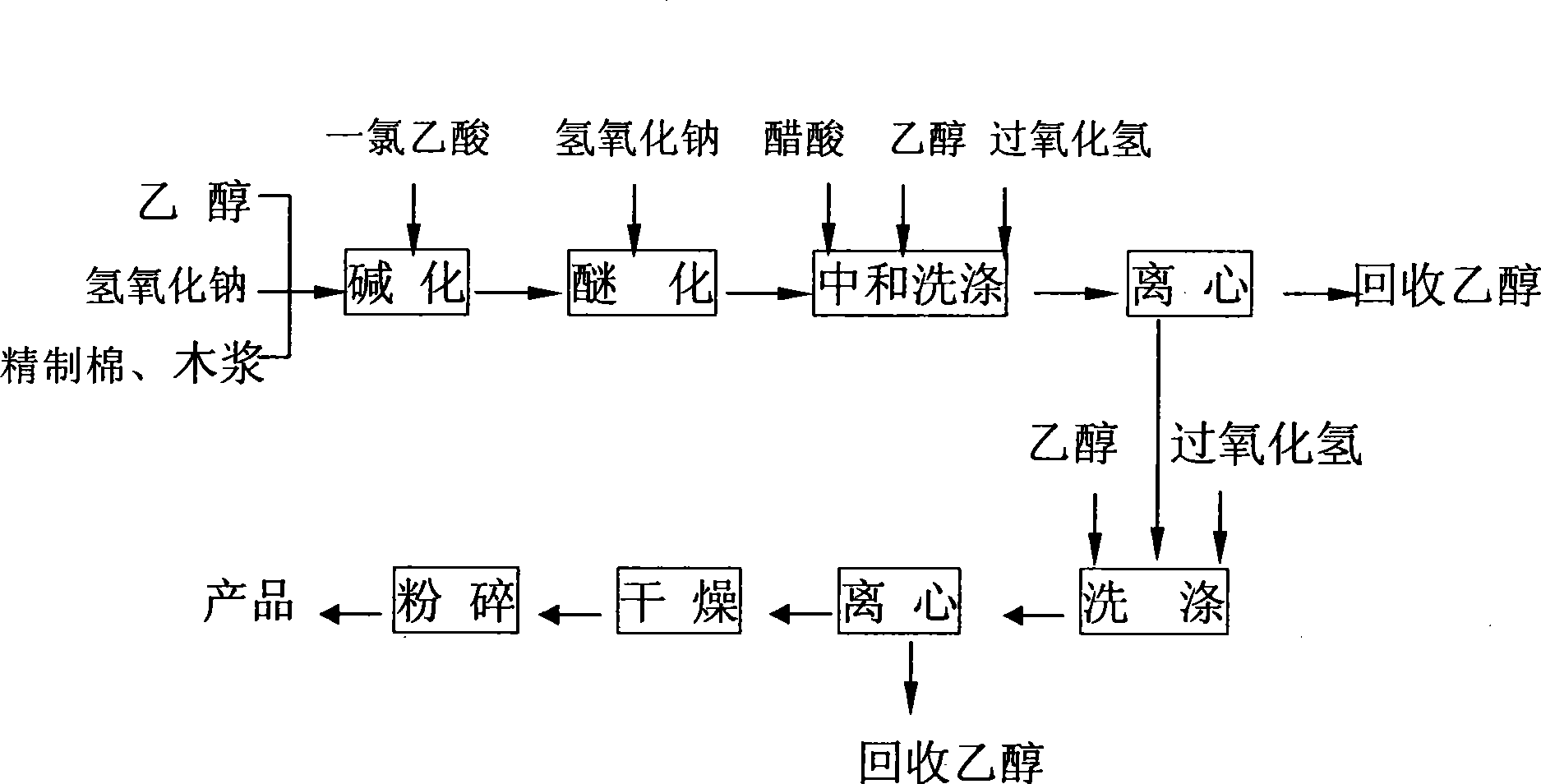

Preparation method of sodium carboxymethyl cellulose for food

The present invention relates to a food sodium carboxymethylcellulose preparation method, which includes: principally adding a mixed cellulosic material composed of 100 parts of wood pulp and purified cotton with a mixing ratio of 0.25-1.5:1, ethanol solvent and sodium hydroxide aqueous solution into a kneader, performing quaternization for 50-100 minutes under the mixing condition of 20-40 EDG C, and then respectively slowly adding chloroacetic acid ethanol solution and sodium hydrate aqueous solution, and performing etherifying response for 40-100 minutes under the mixing condition of 75-80 EDG C, and then cooling down for discharging; preparing sodium carboxymethylcellulose by using acetic acid to neutralize the obtained material, and simultaneously using ethanol aqueous solution for washing twice, adding aqueous hydrogen peroxide solution once or twice at the same time of washing and the other steps. The preparation method has simple method, low-cost, high yield, convenient operation; its products have lower viscosity, low prices, and widely application in various types of food and drinks as a stabilizer of emulsion and suspension, playing a thickening role.

Owner:上海长光企业发展有限公司

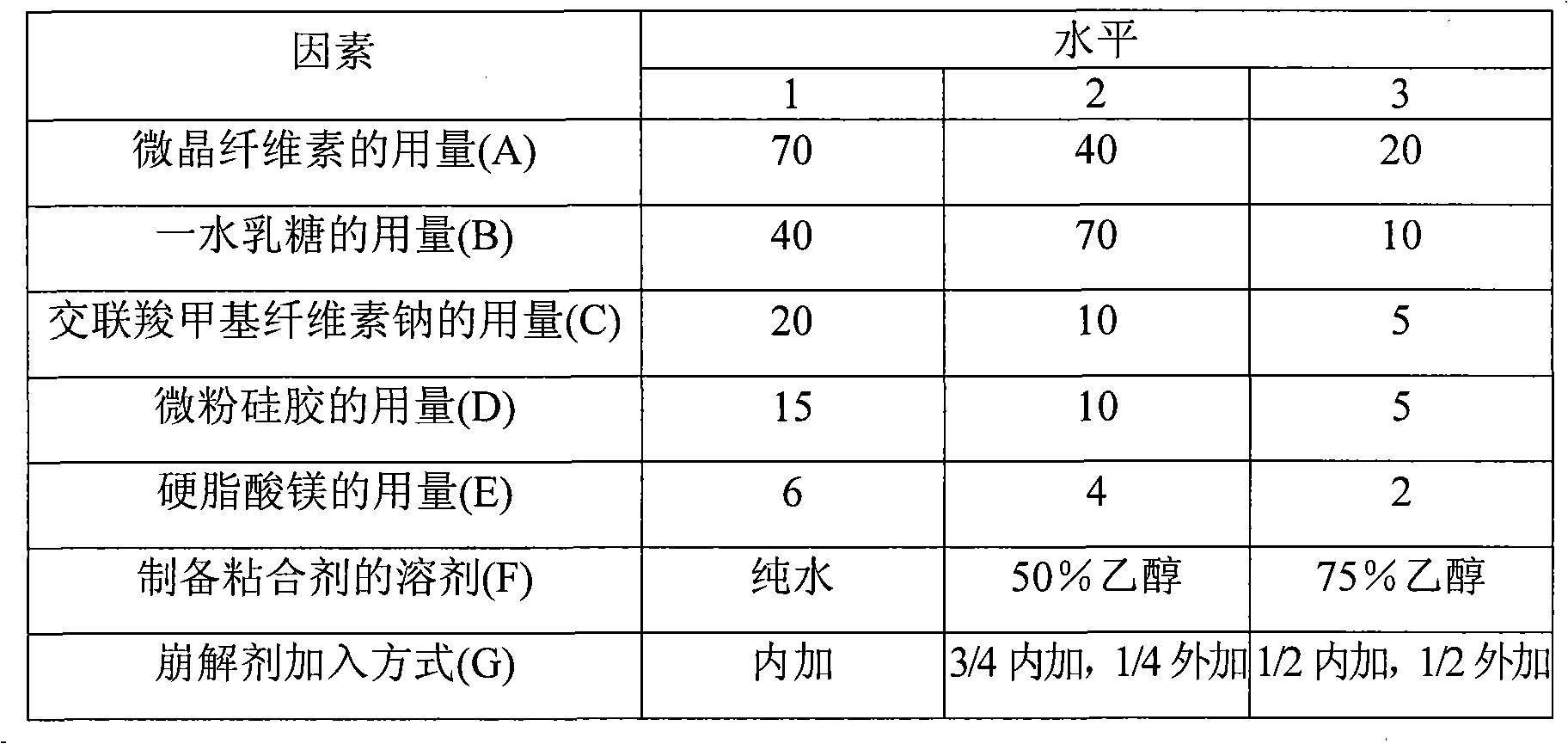

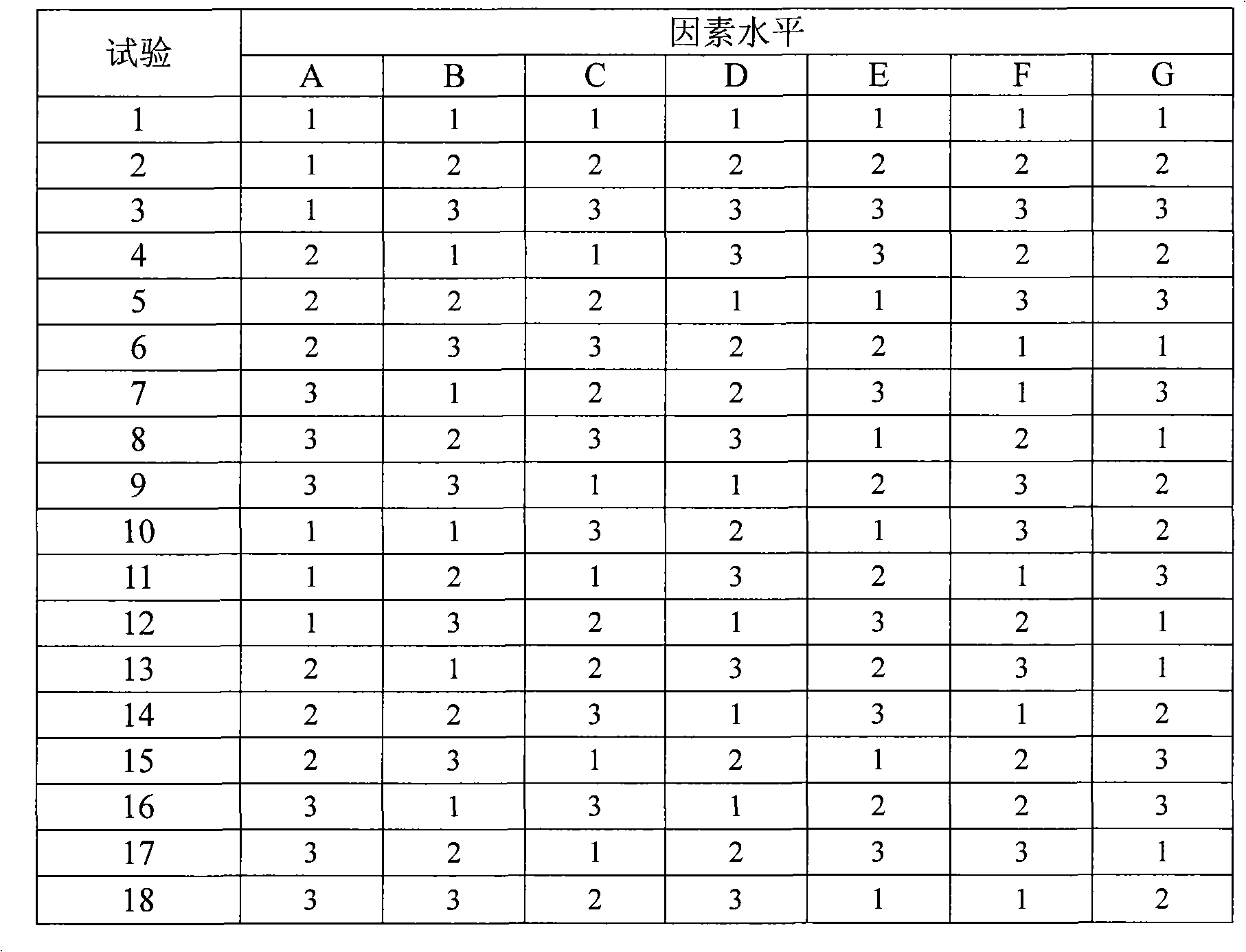

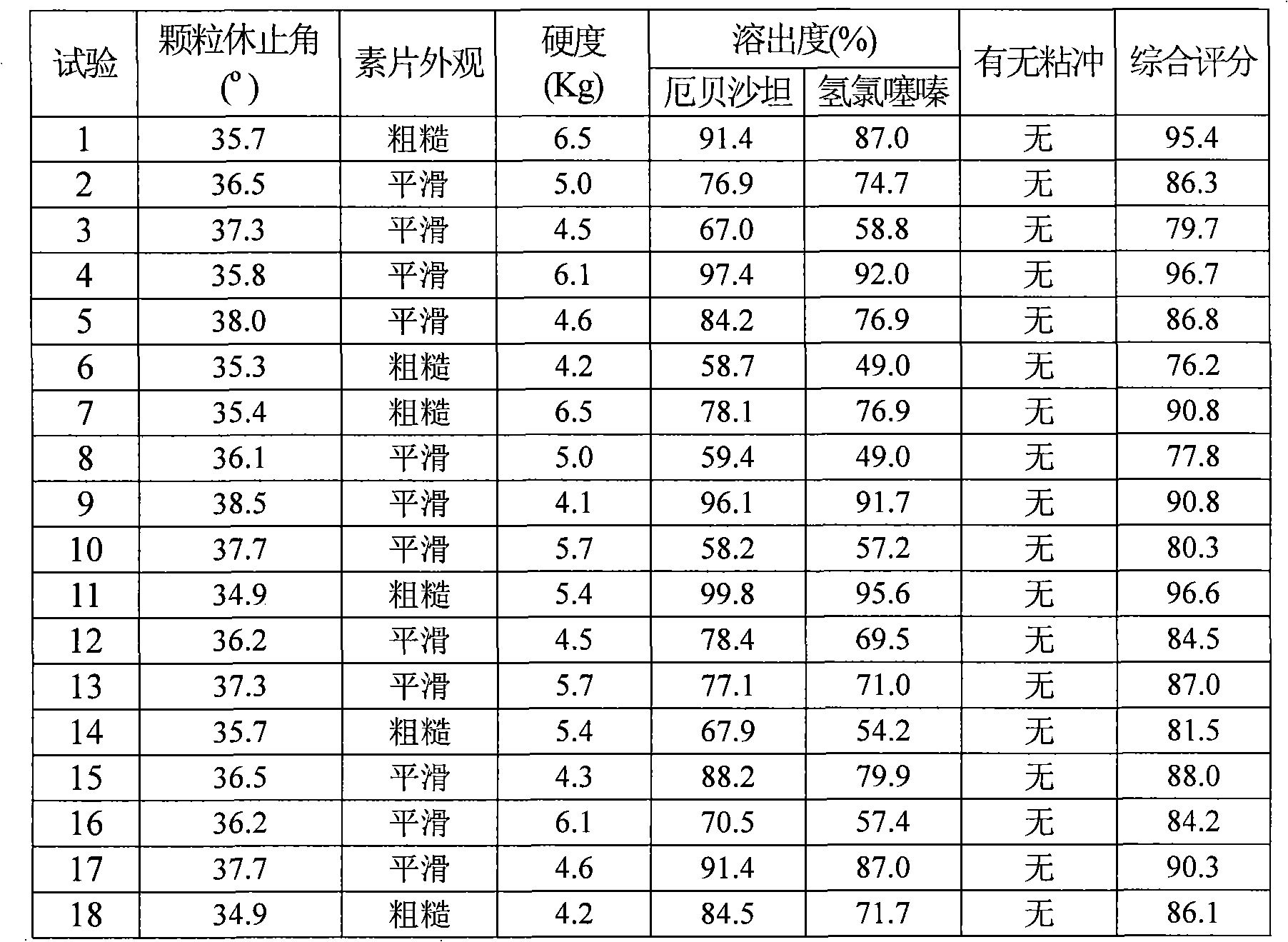

Irbesartan and hydrochlorothiazide pharmaceutical composition and preparation method thereof

ActiveCN101327213AGood auxiliary effectGood quality and stabilityOrganic active ingredientsPharmaceutical non-active ingredientsLACTITOL MONOHYDRATEAdditive ingredient

The invention relates to a medicinal composite of Irbesartan hydrochlorothiazide. The medicinal composite is composed of 150 portions of Irbesartan, 12.5 portions of hydrochlorothiazide, 20 portions to 60 portions of microcrystalline cellulose, 20 portions to 60 portions of lactose monohydrate, 15 portions to 25 portions of crosslinked sodium carboxymethyl cellulose, 1 portion to 10 portions of hydroxypropylmethyl cellulose, 2 portions to 7 portions of SiliciiDoxydum, 1 portion to 3 portions of magnesium stearate. The major medicinal ingredients are mixed with part of the crosslinked sodium carboxymethyl cellulose and the microcrystalline cellulose, and the mixture is crushed down and then added with the lactose monohydrate for mixing; the mixture obtained from the former step is added with 50 percent of ethanol solvent containing 2 percent of hydroxypropylmethyl cellulose for even mixing, then the mixture is screened, made into integral grains which are then dried; the dry grains are mixed with the SiliciiDoxydum, the magnesium stearate and the residual crosslinked sodium carboxymethyl cellulose, and the mixture then undergoes tabletting and coating so as to obtain the medicinal composite. The prescription of the medicinal composite of the invention is reasonable, the quality is stable and reliable, and the medicinal composite has a satisfactory dissolution rate.

Owner:HAINAN JINRUI PHARMA

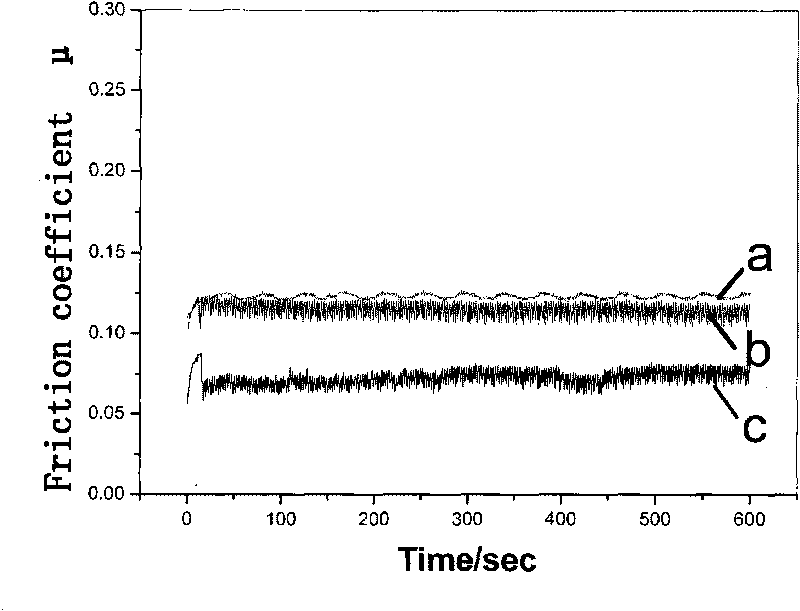

Compound type vegetable oil lubricating agent for drilling fluid and preparation method thereof

InactiveCN101760186ANon-toxicInhibits hydration swellingDrilling compositionVegetable oilFluorescence

The invention discloses a compound type vegetable oil lubricating agent for a drilling fluid and a preparation method thereof. The compound type vegetable oil lubricating agent for the drilling fluid with favorable oiliness, no toxicity, low fluorescent level and favorable bearing and thermostabilized performance is prepared by taking a vegetable oil leftover which is low in price and easy to obtain, lauryl sodium sulfate, sbane 80, sodium carboxymethylcellulose, polyvinylpyrrolidone and the like as main raw materials, adding a solid lubricating agent which is graphite or serpentine and usinga simple and environment-friendly production method, so that not only the production cost is greatly reduced, but also any toxic and harmful action on the environment is not generated in the production process. The compound type vegetable oil lubricating agent for the drilling fluid is not only applied to drilling, but also can be applied to producing wells, can effectively inhibit the hydrous expansion of mud shale, consolidate the well wall and prevent the sticking accidents and is especially suitable for industrial production on a large scale.

Owner:无锡润鹏复合新材料有限公司

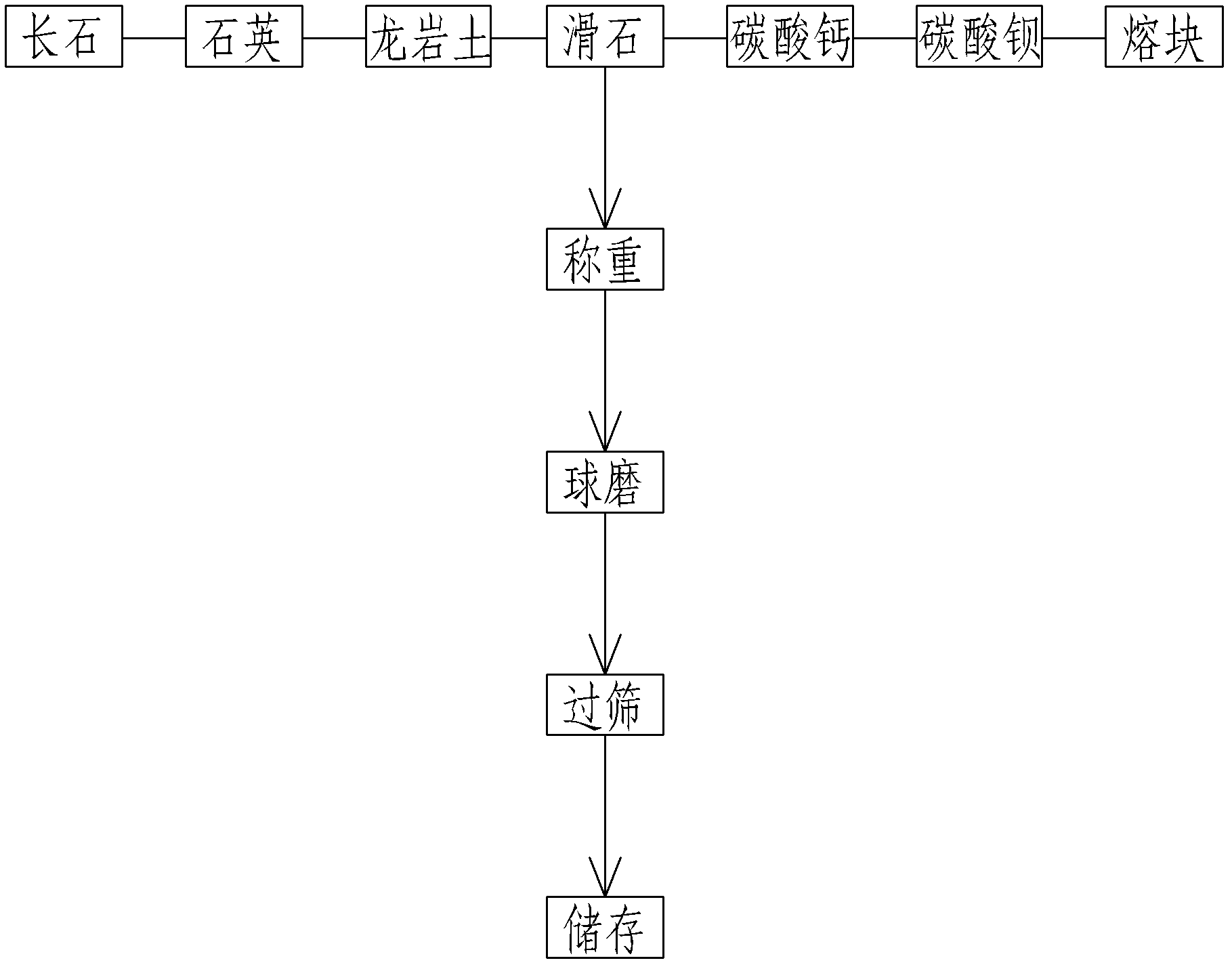

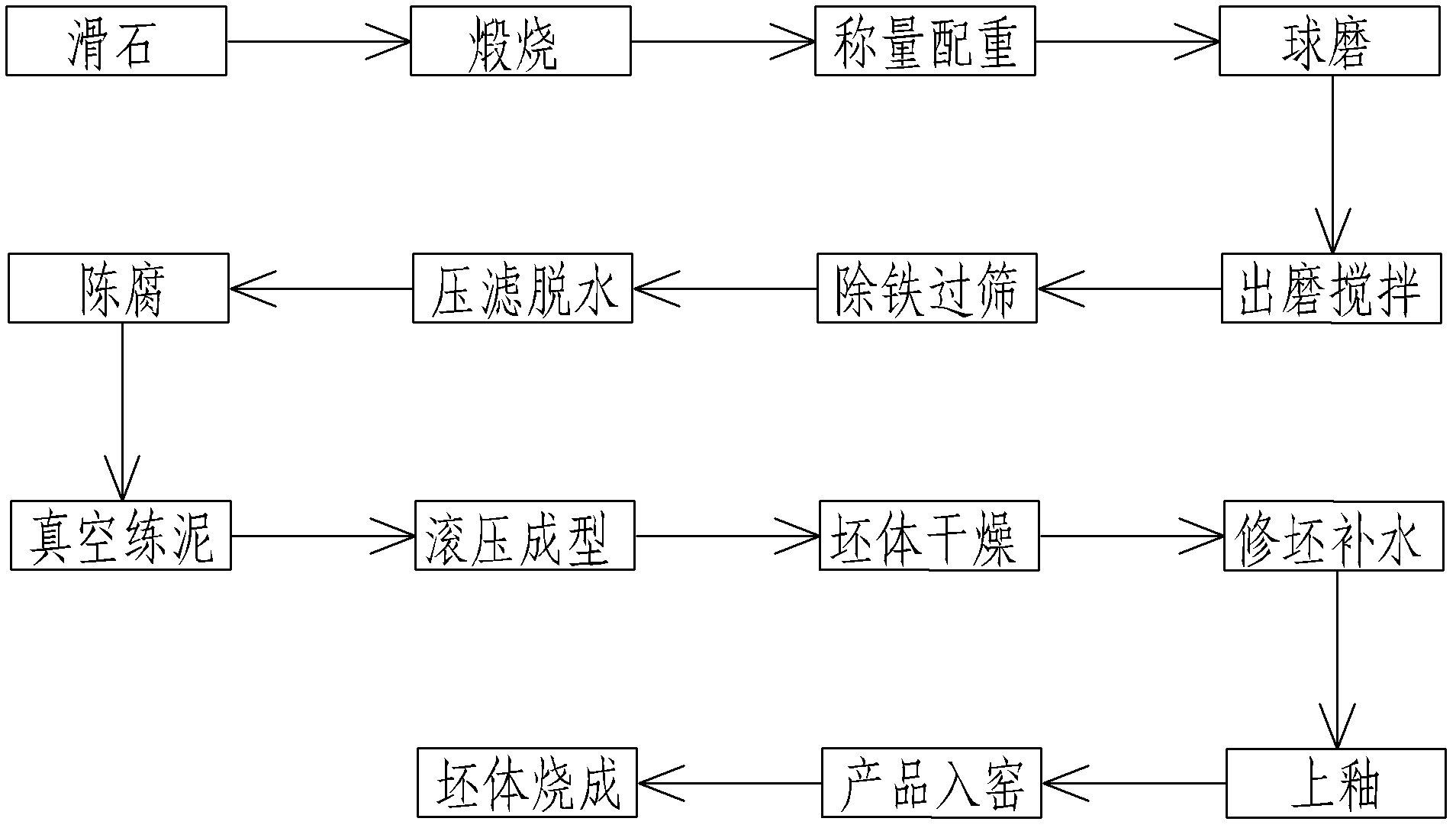

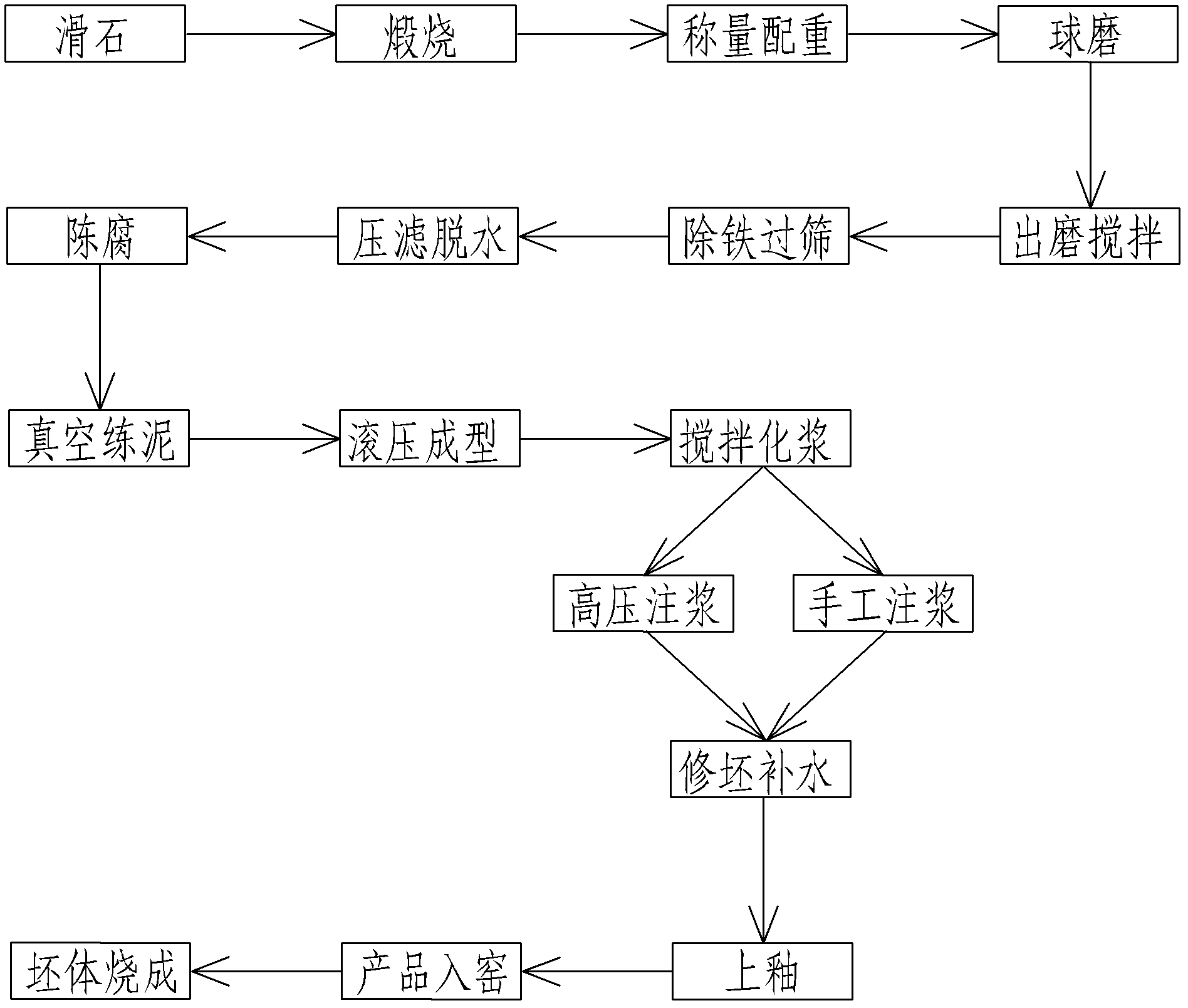

Magnesium jade porcelain formula and one-time calcining manufacture method

The invention relates to a magnesium jade porcelain formula and one-time calcining manufacture method, the raw materials are weighted according to the formula of a blank material and glaze, the method comprise the following steps: calcining a talcum raw material at the temperature of 1150-1250 DEG C; mixing 75-85% of calcined talcum, 5-15% of magnesian clay, 1-5% of feldspar, 1-5% of bentonite, 2-6% of kaolin, 0.1-0.3% of carboxymethylcellulose sodium for ball milling; stirring the clay after mixing and ball milling, deironing and sieving and controlling the particles in the clay less than 30 mum; carrying out press filtration, on the clay after deironing and sieving, dehydrating, aging, vacuum mixing and roll forming; preparing the clay after roll forming into biscuit, glazing, entering into a kiln and calcining a base substrate. One-time calcining of magnesium jade porcelain can be realized, and the problems of poor product regularity and thermal shock resistance performance generated by calcining temperature by using a lot of talcum material can be overcome and enhanced.

Owner:FUJIAN GUANFU IND CO LTD

Flame-retarding paint for casting Mg-alloy and its preparing process

InactiveCN1381321AStrong coatingStrong thixotropyFoundry mouldsFoundry coresPorosityCarboxymethylcellulose Sodium

A fire-retarding paint for casting Mg-alloy with lost mould is prepared from magnesia sand powder, perlite powder, mica powder silica sol, white emulsoid, polyacrylamide, carboxymethylcellulose sodium, adsorbent and flame-retarding agent through preparing solution from adsorbent, carboxymethylcellulose sodium, polyacrylamide and water, and mixing with others. It can make the Mg-alloy casting havesmooth surface.

Owner:SHANGHAI AIERSI LIGHT ALLOY

Moistening mask liquid without emulsifier and preparation method thereof

ActiveCN105395423AImprove performanceIncrease nutritionCosmetic preparationsToilet preparationsJojoba oilPorous particle

The invention provides a moistening mask liquid without an emulsifier. The moistening mask liquid comprises, by weight, 5 to 12% of a humectant, 0.5 to 3.0% of a suspension stabilizing agent, 1 to 10% of grease, 1.0 to 5.0% of a water-soluble active substance, 0.5 to 5.0% of a fat-soluble active substance, 1.0 to 10% of plant extract and 0.01 to 0.3% of a pH value conditioning agent, with the balance being deionized water, wherein the grease is one or more selected from the group consisting of sunflower oil, jojoba oil, avocado oil, olive oil, aloe oil and sweet almond oil, and the suspension stabilizing agent is a three-dimensional stabilizing agent prepared by coating a microcrystalline cellulose porous particle with a particle size of 0.1 to 20 [mu]m with xanthan gum or carboxymethylcellulose sodium. The mask liquid provided by the invention employs the microcrystalline cellulose porous particle in the suspension stabilizing agent to absorb grease with the dissolved fat-soluble active substance and uses xanthan gum or carboxymethylcellulose sodium for suspension adsorption of the porous particle with grease, so the stable mask liquid without any emulsifier is formed; and the mask liquid has no irritation to the skin, and supplements water to the skin and moistens the skin when used, and microcrystalline cellulose particles in a specific particle size range can provide the skin with slippery sensation.

Owner:广东龙湖科技股份有限公司

Slow-release preparation containing beta-lactamase inhibitor and cephalosporin and its use

The present invention relates to a slow-released preparation containing beta-lactamase inhibitor and cephalosporin. Said slow-released preparation can be made into antibiotic slow-released injection or slow-released implant preparation. Said injection is formed from slow-released microsphere and solvent, the slow-released microsphere contains slow-released auxiliary material and beta-lactamase inhibitor with antibacterial effective dose and cephalosporin, the solvent is special one containing suspension adjuvant of carboxymethyl cellulose sodium, etc. and its viscosity is 100 cp-3000 cp (20 deg.C-30 deg.C). The slow-released auxiliary material is selected from EVAc, polylactic acid copolymer, sebacic acid copolymer, albumin glue and gelatin, etc. The slow-released implant preparation is prepared by using slow-released microsphere or adopting melting process. Said invention also provides its application method. and can obtain obvious therapeutic effect for curing various infective diseases.

Owner:JINAN SHUAIHUA PHARMA TECH

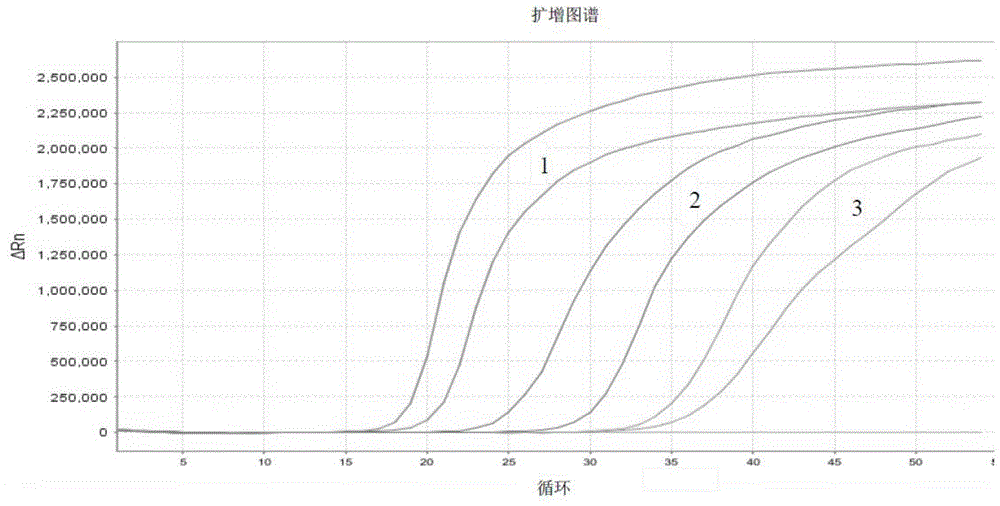

Nucleic acid amplification reaction mixture particle and application thereof

InactiveCN105274192AReduce moisture contentGuaranteed reactivityBioreactor/fermenter combinationsBiological substance pretreatmentsSucroseFreeze-drying

The invention discloses a nucleic acid amplification reaction mixture. The nucleic acid amplification reaction mixed liquor is prepared by freeze drying and is in freeze-drying granular shape, and the water content is 0.1-3%; the nucleic acid amplification reaction mixed liquor at least contains necessary components for a nucleic acid amplification reaction and a freeze-drying protective agent; the freeze-drying protective agent is a mixture containing one or more substances from sucrose, trehalose, glucose, glucan, saccharosan, bovine serum albumin, collagen, polyvinyl pyrrolidone, polyethylene glycol and carboxymethylcellulose sodium, and the weight volume ratio concentration of the freeze-drying protective agent and the nucleic acid amplification reaction mixed liquor is 5%-20%. The nucleic acid amplification reaction mixture freeze-drying particles have compact and tight particle and smooth appearance, and fine apertures are contained in the particles and can be observed under microscopic amplification state; the freeze-drying particles can be stored at room temperature for more than one year with unchanged reaction activity, the biological reaction activity is not changed at 40-45 DEG C, and during usage, a reconstitution fluid is added for rapidly dissolving the particles and recovering the reaction activity.

Owner:GUANGZHOU HUAFENG BIOTECH

Resin sand type casting coating and preparation method thereof

InactiveCN102836952AGood suspensionHigh strengthFoundry mouldsFoundry coresSodium BentoniteFatty alcohol

The invention relates to a resin sand type casting coating and a preparation method thereof, wherein the coating consists of the following components: graphite powder, zircon sand, porzite powder, spodumene powder, sodium bentonite, alkali phenolic resin, silica sol, polyvinyl acetate, carboxymethylcellulose sodium, sodium alkylbenzenesulfonate, fatty alcohol-polyoxyethylene ether and water. The resin sand type casting coating provided by the invention has the advantages of good suspension property, high strength, uniform coating layer and good leveling property. The surface of the dried coating is bright and clean and is free of cavities, bubbles, cracks and the like. After the resin sand type casting coating is used, the cast casting is very high in surface smoothness.

Owner:TAICANG KEBOER PRECISION CASTING

Chitosan gel and preparation method thereof

ActiveCN104027448AImprove utilizationEffective treatmentHydroxy compound active ingredientsAerosol deliveryCelluloseBiocompatibility

The invention relates to the technical field of biogel, specifically to chitosan gel and a preparation method thereof. The gel comprises the following raw materials by weight: 0.5 to 4.5% of modified chitosan, 0.5 to 15% of glycerin, 0.5 to 5% of alum, 0.01 to 0.13% of menthol, 0.2 to 5% of carboxymethylcellulose sodium and 0.2 to 1% of carbomer. The gel is a drug delivery system with a controlled-release function, can improve availability of effective substances, can be tightly applied on an uneven wound without adhesion, avoids secondary harm, has good biocompatibility and strong antibiosis and antiphlogosis effects, incurs no local irritation and no adverse reaction, is capable of rapidly promoting wound healing and effectively treating hemorrhoids, enables hemorrhoids not to recur and is applicable to improvement of symptoms like hemorrhoidal bleeding, hyperemia and oedema of the mucous membranes of hemorrhoids, bearing-down swelling of the anus, constipation, prolapsus of hemorrhoid nuclear and the like caused by internal hemorrhoids, external piles and mixed hemorrhoids and control, nursing and the like after anal fissure and anorectal operations.

Owner:DONGGUAN DAQING MEDICAL DEVICES CO LTD +1

Machinery equipment cleaning compound

InactiveCN103834483AReduce corrosionWith sterilizationNon-ionic surface-active compoundsDetergent compounding agentsSodium metasilicateMass ratio

The invention discloses an industrial level machinery equipment cleaning compound comprising 20-35% of waterless sodium metasilicate in mass, 10-25% of cosolvent in mass, 10-25% of surfactant in mass, 3-5% of antiseptic in mass, 2-4% of corrosion inhibitor in mass, 1.2% of thickening agent in mass and remaining deionized water; the surfactant is a mixture composited by RF-25-1 surfactant, aliphatic acid methyl esters ethoxylate (FMEE) and alkyl glucosides FC-41 according to mass ratio of 1:2:1; the cosolvent comprises at least two from a group formed by isopropanol, glycerol, dichloromethane and tetrachloroethylene; the antiseptic is chlorothalonil powder; the corrosion inhibitor is methyl benzotriazole TTA; the thickening agent is carboxymethylcellulose sodium. Through the said mode, the machinery equipment cleaning compound is anti-bacterium, environmental protection, and can clean the machine equipment with high efficiency.

Owner:SUZHOU LOTTE CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com