Patents

Literature

358results about How to "Low steam pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Control method for aerosol in flue gas desulfurization by utilizing ammonia method and master desulfurizing tower

InactiveCN102000490ASolve the emission problemSimple processDispersed particle separationThermodynamicsWater vapor

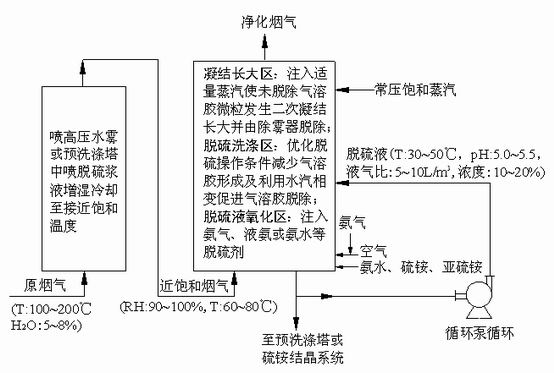

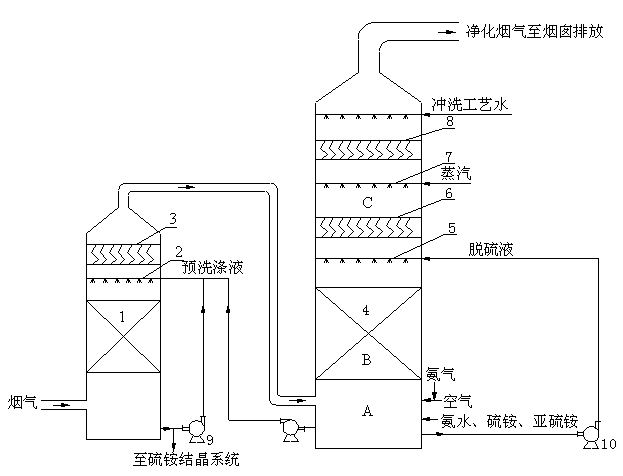

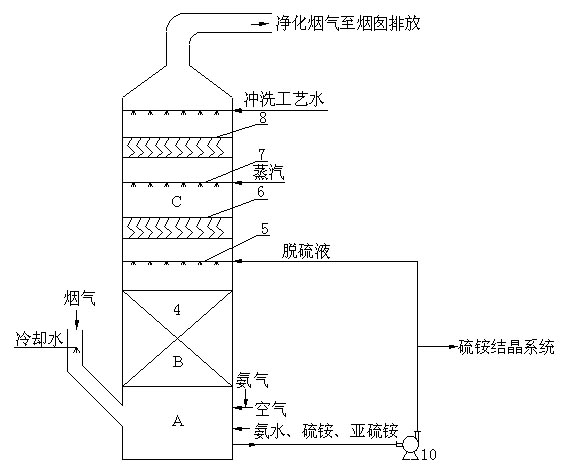

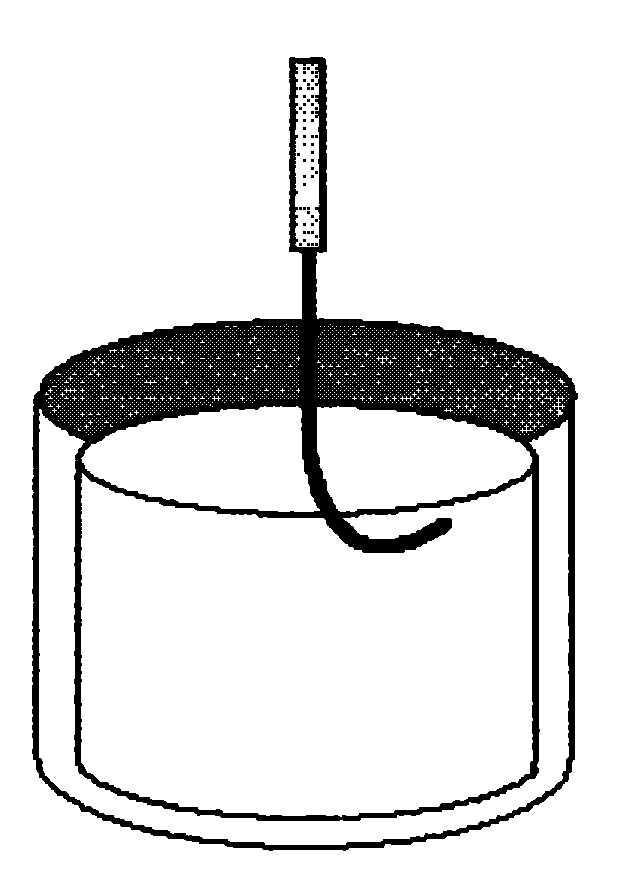

The invention discloses a control method for aerosol in flue gas desulfurization by utilizing an ammonia method and a master desulfurizing tower, and the control method is characterized in that flue gas enters the master desulfurizing tower after being cooled to the relative humidity of 90 to 100% and the temperature of 60 to 80 DEG C through high-pressure waster mist or prewashing temperature reduction; the generation of the aerosol particles in the desulfurization by utilizing the ammonia method is reduced by optimizing desulfurization operating conditions, and the formed aerosol particles are condensed to grow big and are partially washed to be eliminated through a desulfurizing solution; an appropriate amount of steam is injected into the saturated flue gas through desulfurizing and eliminating the partial aerosol particles; the oversaturated water vapor environment required by the secondary condensation and the growth of the aerosol particles is established on the top of the master desulfurizing tower; and the condensed and the grown aerosol particles are eliminated through a high-efficiency demister. The invention combines the formation mechanism of the aerosol in the flue gas desulfurization by utilizing the ammonia method; and the formation of the aerosol is reduced by optimizing the process conditions of the desulfurization operation and the elimination of the formed aerosol is promoted by utilizing a steam phase change principle at the same time so that the exhaust problem of the aerosol in the flue gas desulfurization by utilizing the ammonia method can be effectively solved.

Owner:SOUTHEAST UNIV

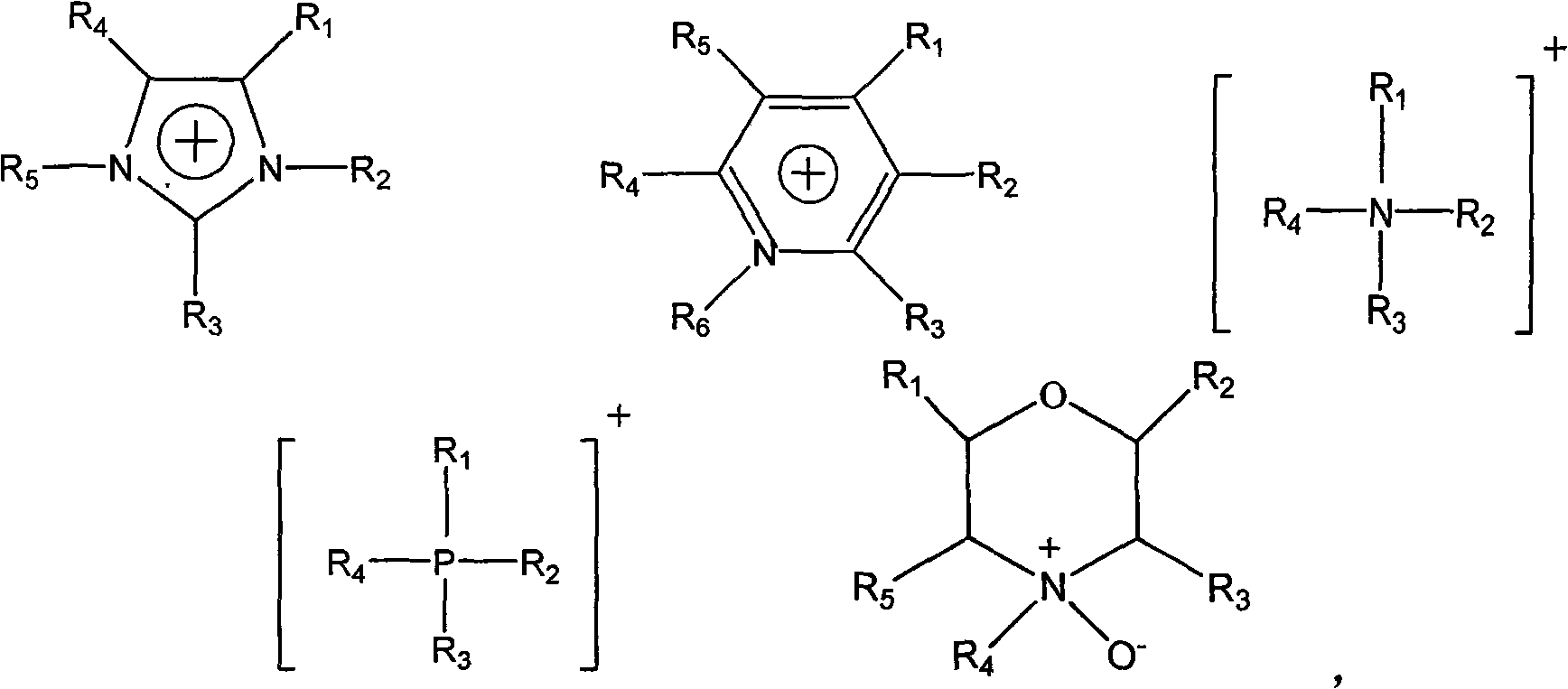

L-sulforamidate type chiral ionic liquid and its prepn

InactiveCN1383920AEasy to getLow priceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSide productIon

The present invention relates to a new type chemical material and its preparation. L-sulforamidate-type chiral ionic liquid is prepared through the full reaction of aqueous L-amino acid solution with98% sulfuric acid. The produced L-sulforamidate-type chiral ionic liquid has the features of both ionic liquid and chiral matter. The reaction has high product purity, low cost, no exhausted pollutant and no side product, and is suitable for application in large scale industrial production. The new material is capable of becoming environmentally friendly important chemical material.

Owner:EAST CHINA NORMAL UNIVERSITY

Method for synthesizing biologic diesel oil based on ion liquid

ActiveCN1696248ASimple processWell mixedLiquid hydrocarbon mixture productionBio-feedstockSolventIon

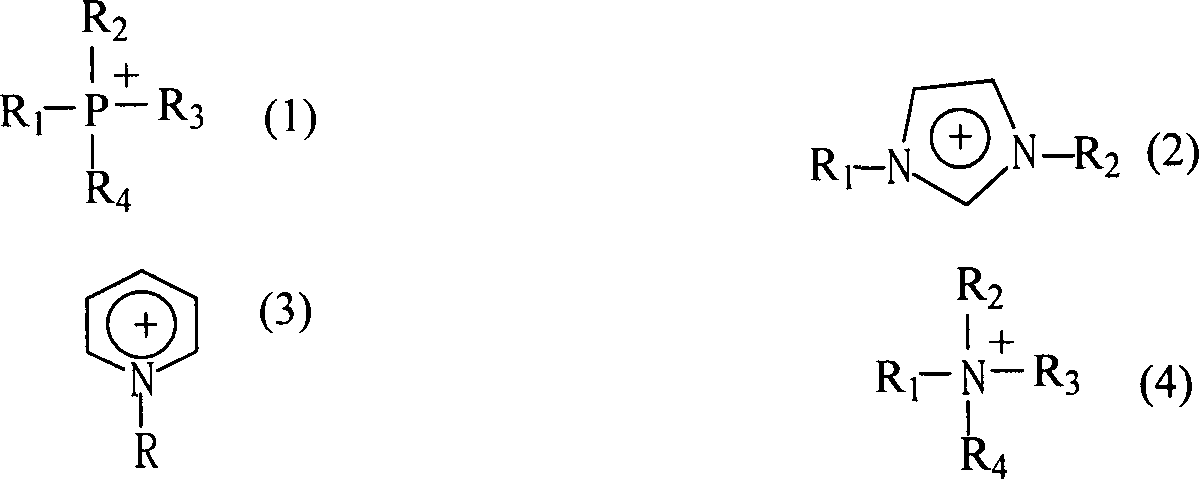

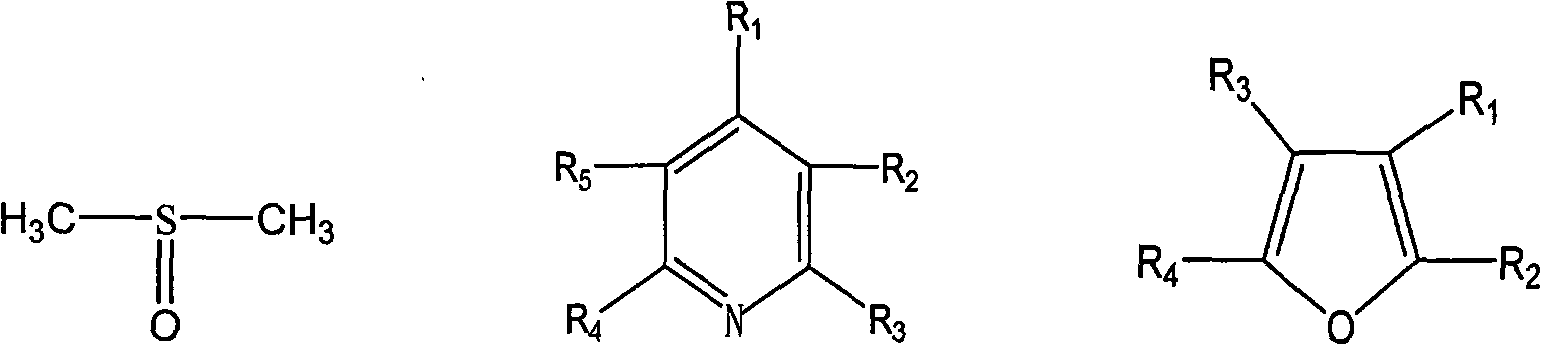

A process based on ionic liquid for synthesizing biologic diesel oil features that the ionic liquid can be used as both catalyst and solvent, so speeding up the reaction. Said ionic liquid is prepared from the N or P contained compound (alkylimidazole, alkylpyredine, quaternary ammonium salt, etc) and the halide (or acidic salt) of metal or non-metal.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

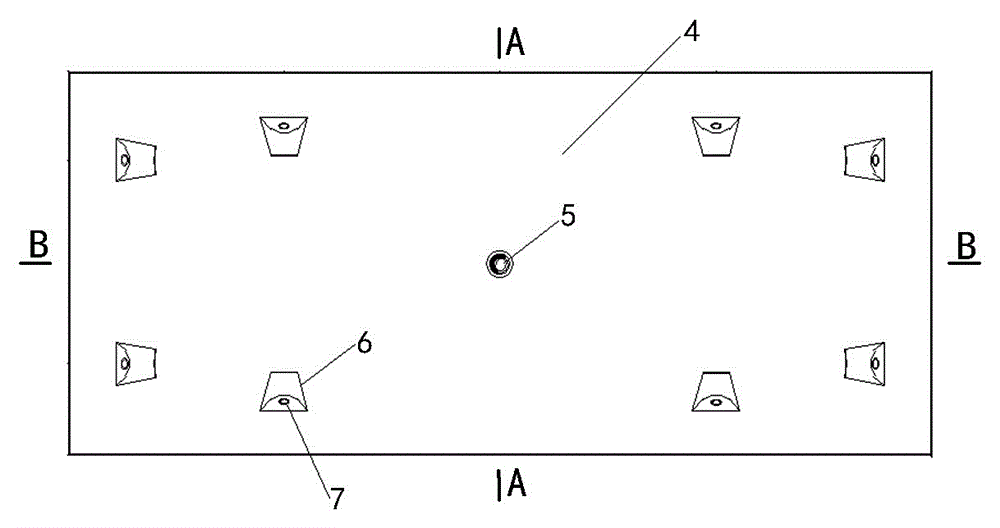

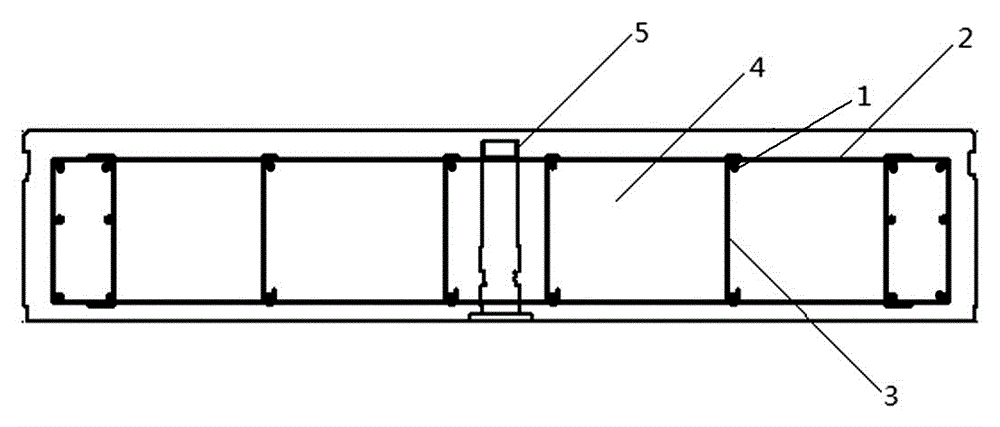

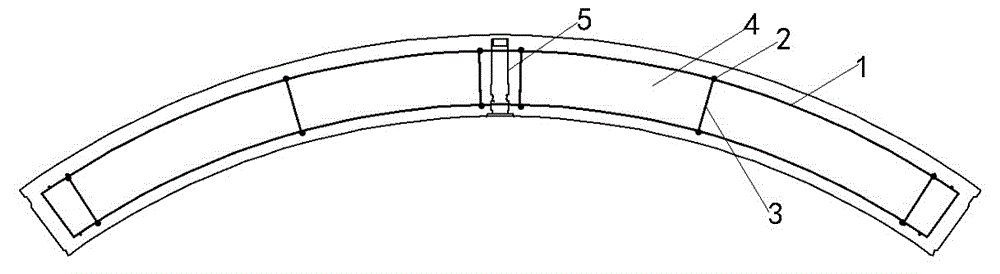

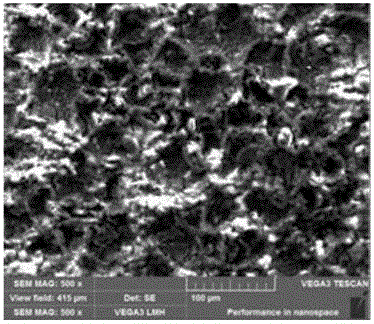

Ultra-high performance hybrid fiber concrete shield segment and preparation method thereof

InactiveCN105041336AReduce dosageReduce consumptionUnderground chambersTunnel liningCrack resistanceReinforced concrete

The invention discloses an ultra-high performance hybrid fiber concrete shield segment and a preparation method thereof. The ultra-high performance hybrid fiber concrete shield segment is of a reinforced concrete structure which consists of a steel skeleton and concrete, wherein the reinforcement ratio of used main reinforcements is 0.5%-1.0%, the distances of the main reinforcements are 150-300mm, the grades of steel reinforcements are not less than three, the smallest steel reinforcement distance of distributed reinforcements is 400mm, the biggest steel reinforcement distance of used distributed reinforcements is 2000mm, and the grades of the steel reinforcements are not less than two. The ultra-high performance hybrid fiber concrete shield segment is made from ultra-high performance hybrid fiber concrete, and comprises cementitious materials, sands, crushed stones, steel fibers, synthetic fibers, water reducer, defoamer and water. The ultra-high performance hybrid fiber concrete shield segment is less in dosage of the steel reinforcements and concrete and high in early strength, can prevent steam preservation, reduces energy consumption, and is green, energy-saving and environmentally friendly. The ultra-high performance hybrid fiber concrete shield segment is strong in anti-burst performance when having a fire, excellent in toughness and crack resistance and excellent in durability, enables edge joints not to easily break, and overcomes the defects of traditional segments.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

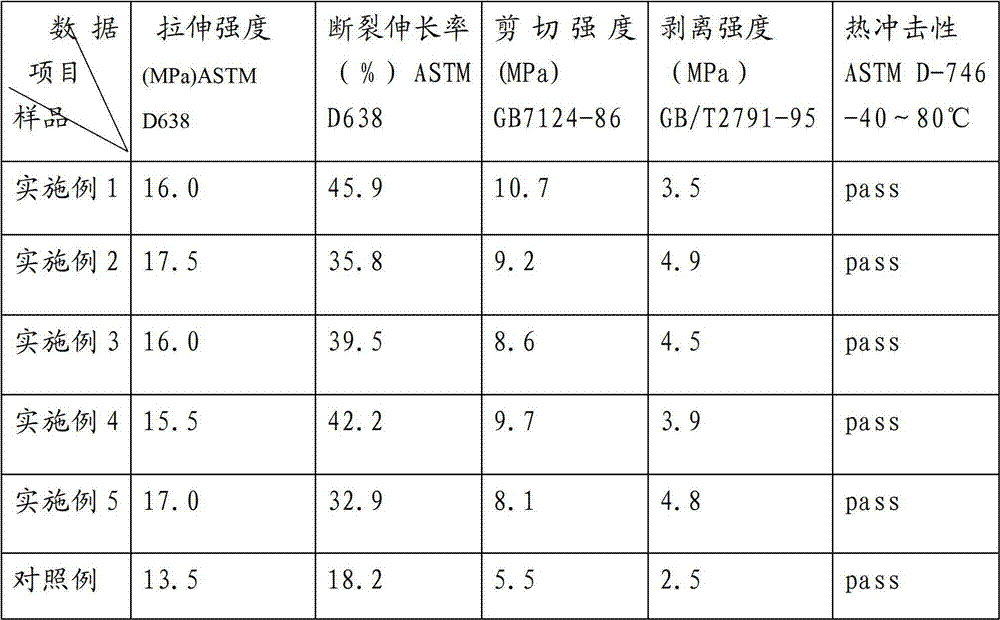

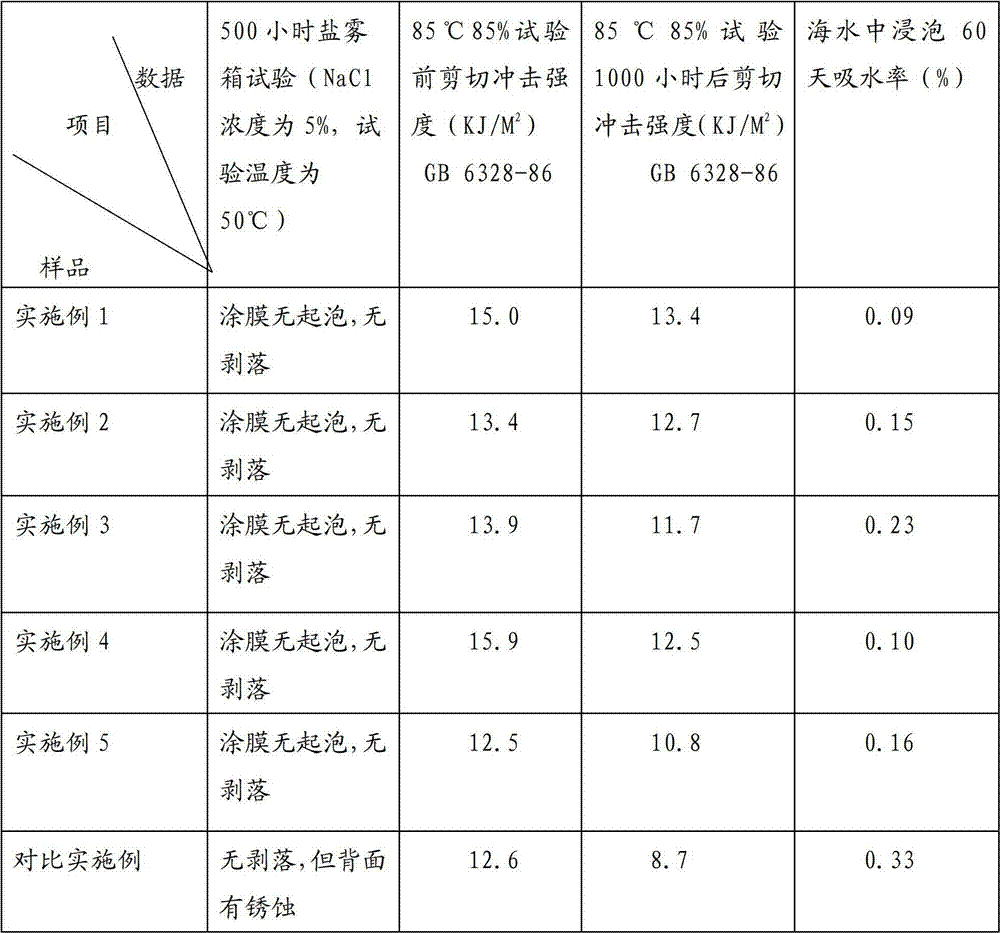

High elastic corrosion resistant epoxy sealant and preparation method thereof

InactiveCN102898988ANo foamingNo peelingNon-macromolecular adhesive additivesOther chemical processesCrack resistanceHigh intensity

The invention relates to a high elastic corrosion resistant epoxy sealant and a preparation method thereof. The epoxy sealant provided by the invention comprises a component A and a component B in a weight ratio of 100:20-100:25. The epoxy sealant provided by the invention has advantages of high strength, high elasticity, low heat release, cracking resistance, good sealing performance and seawater corrosion resistance, is convenient for construction, and greatly improves sealing of key parts of ship stern tube.

Owner:YANTAI DARBOND TECH

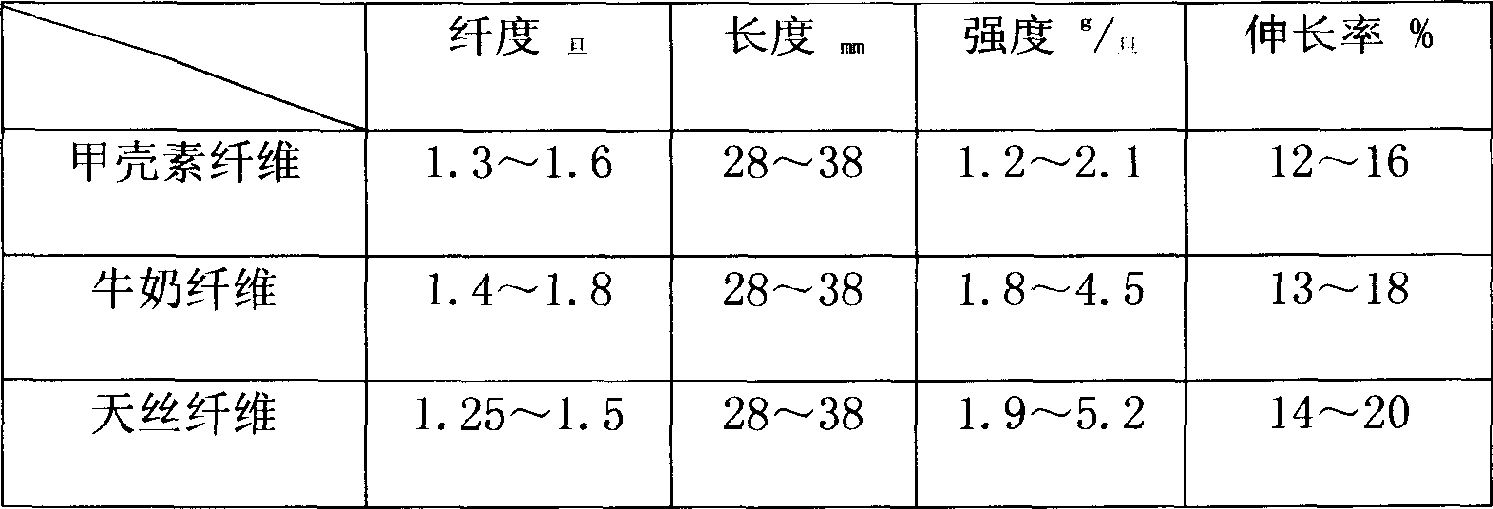

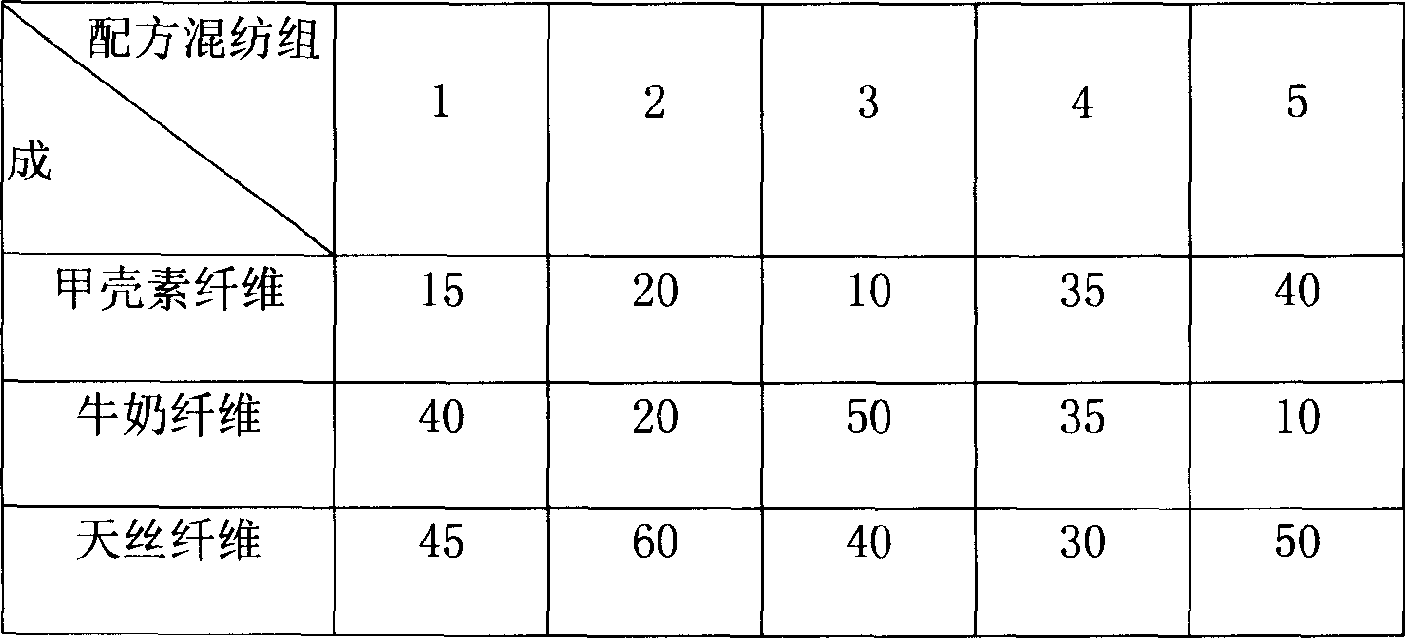

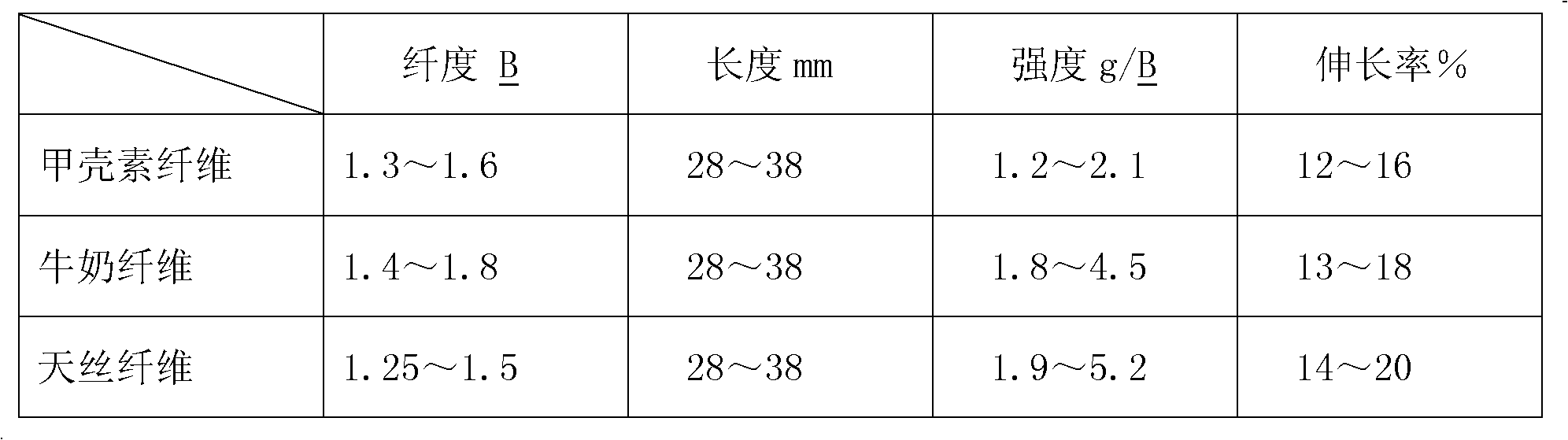

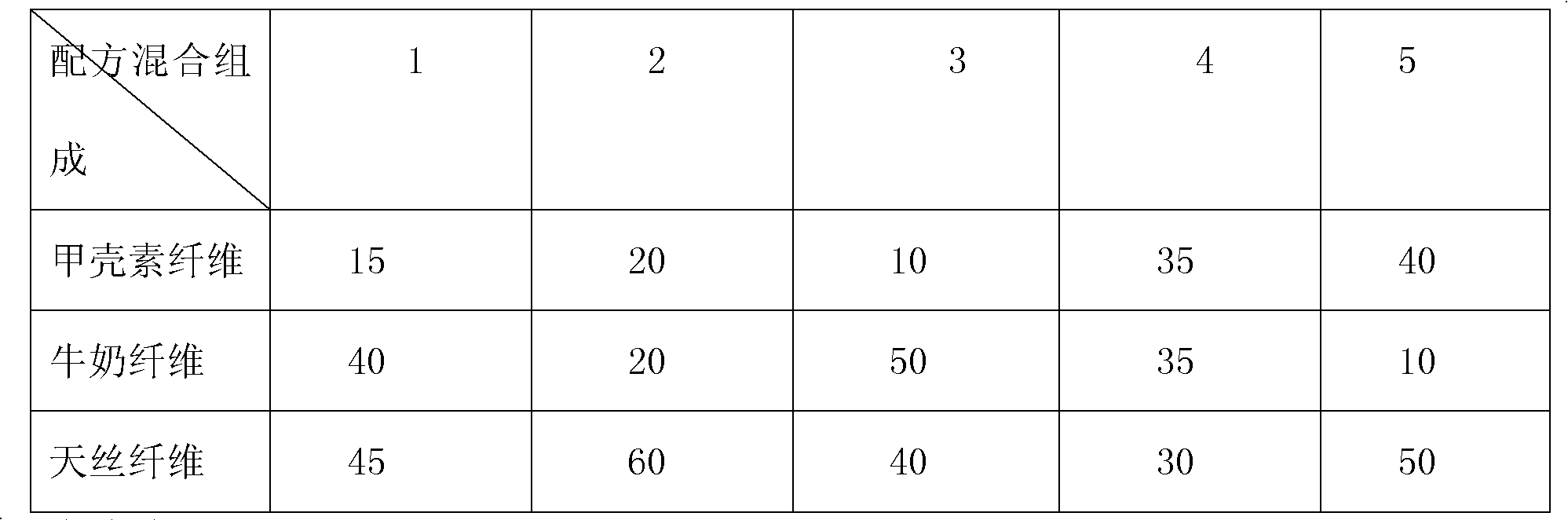

Multe-function skin-protective aromatic spinning material and mfg method thereof

InactiveCN1483874AImprove immunityImprove the quality of living environmentFibre treatmentWoven fabricsYarnEngineering

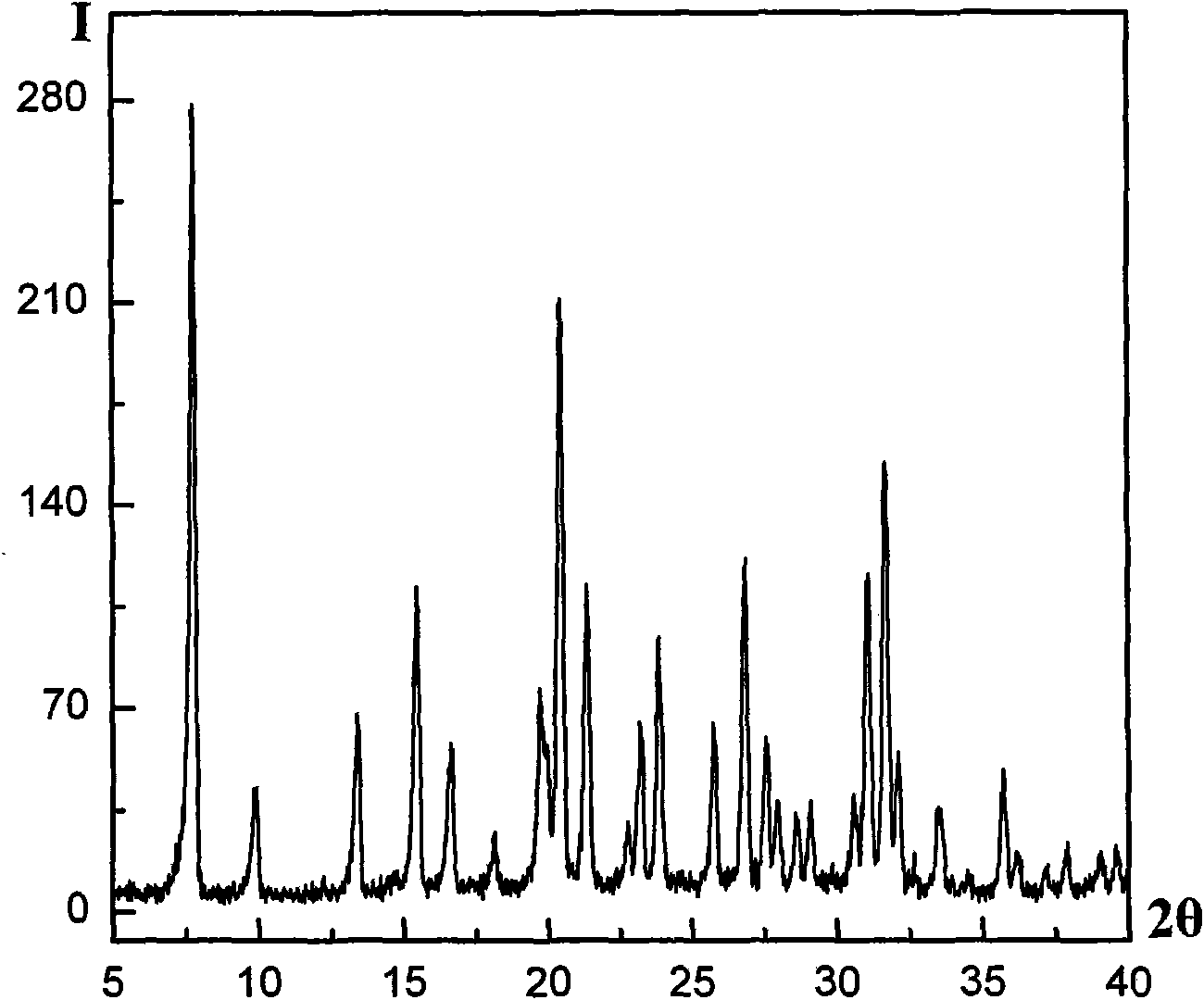

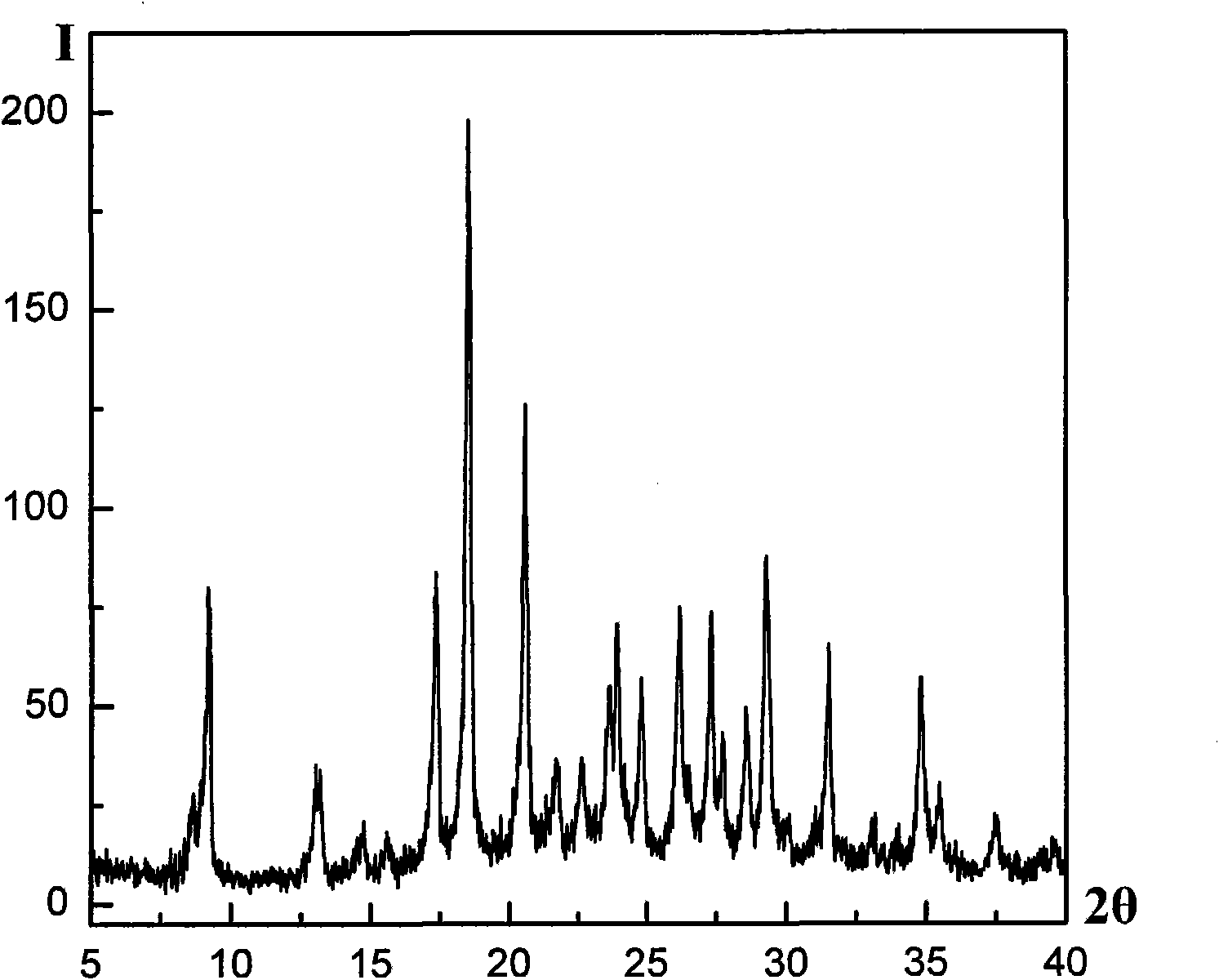

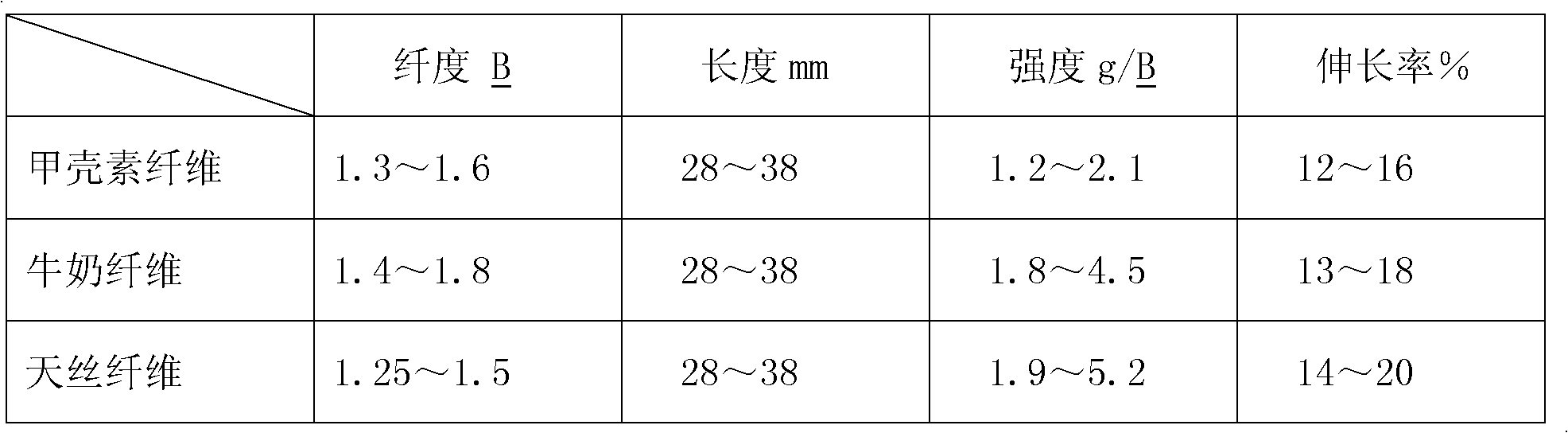

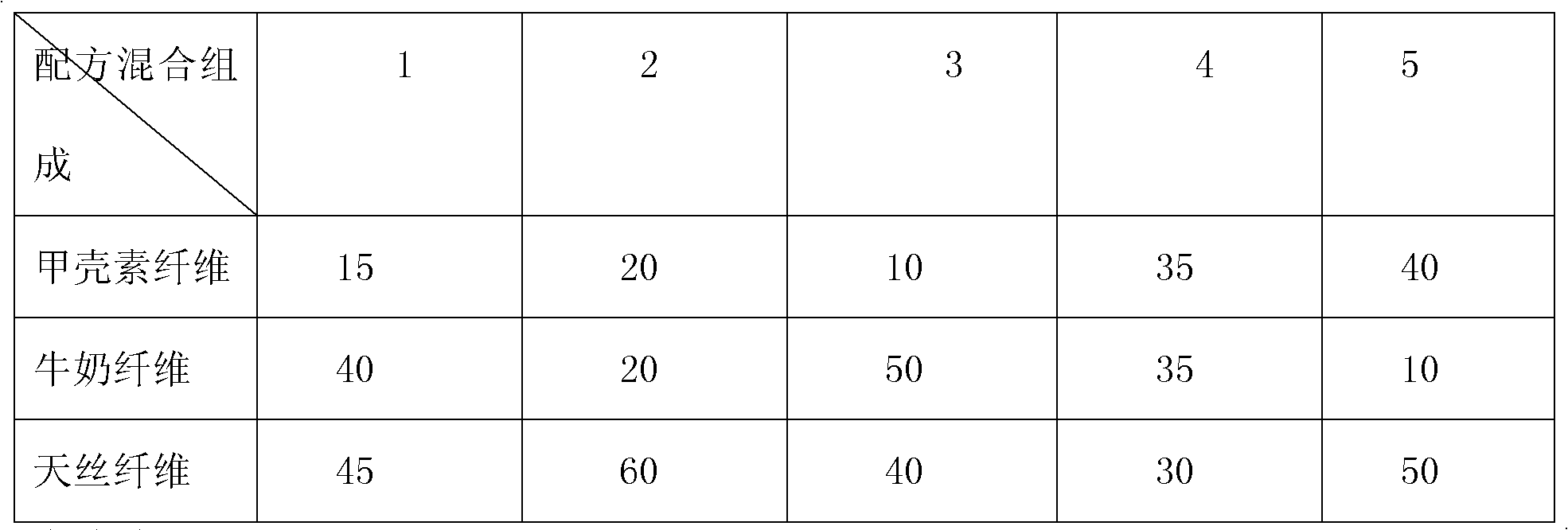

The present invention relates to a multifunctional skin-protecting aromatic spinning material and its making method. Said multifunctional spinning material is made from chitin fibre, milk protein fibre and tencel fibre, and blended spinning them into yarn according to blending ratio of 10-40:10-50:40-60, then knitting or weaving said material into face fabric, and making the face fabric undergo the process of micapsule aromatic after-finishing treatment to obtain the invented product.

Owner:SHANGHAI JIERUNSI TEXTILE

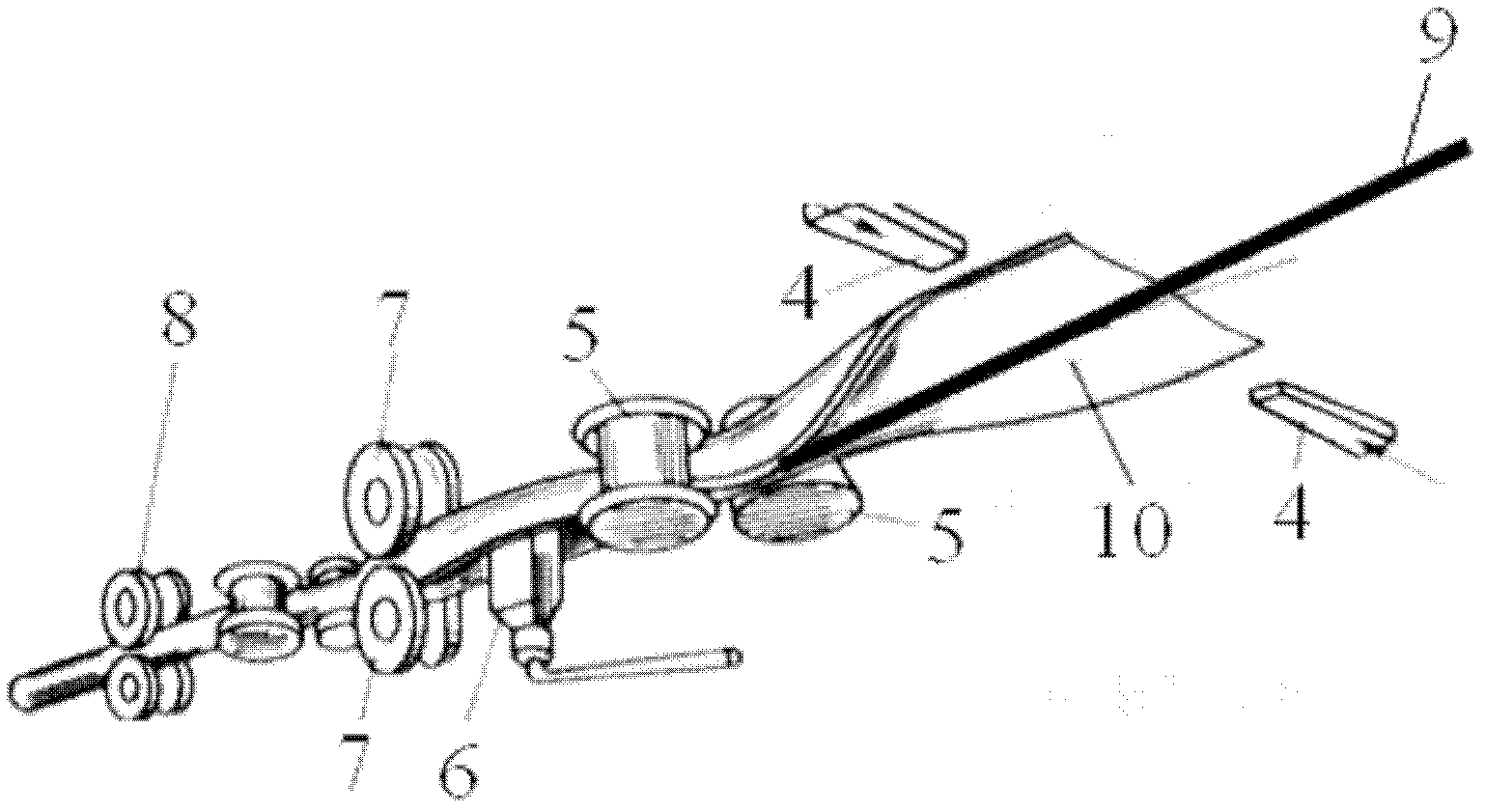

Electrodeposition method, electrodeposition solution and method for preparation of rare earth permanent magnetic material by electrodeposition

InactiveCN105839152AFast depositionSave time in electrodeposition processInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementTetrafluoroborate

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Metallurgical pellet compound binding agent

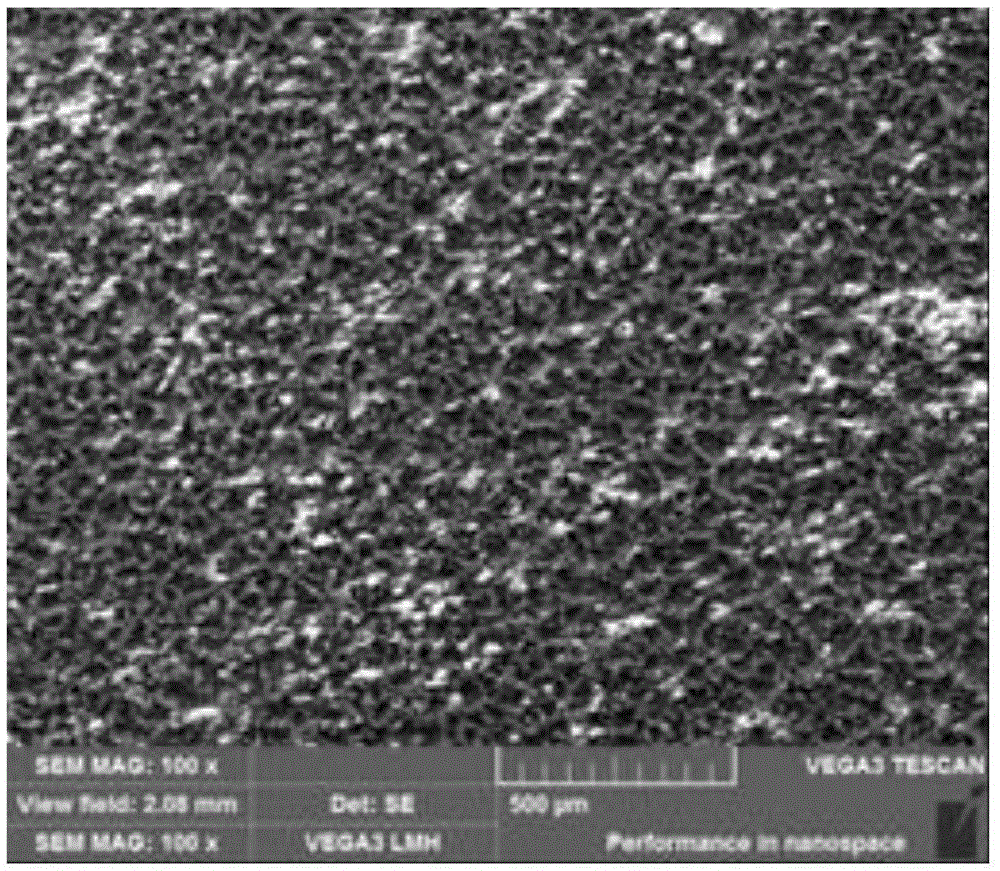

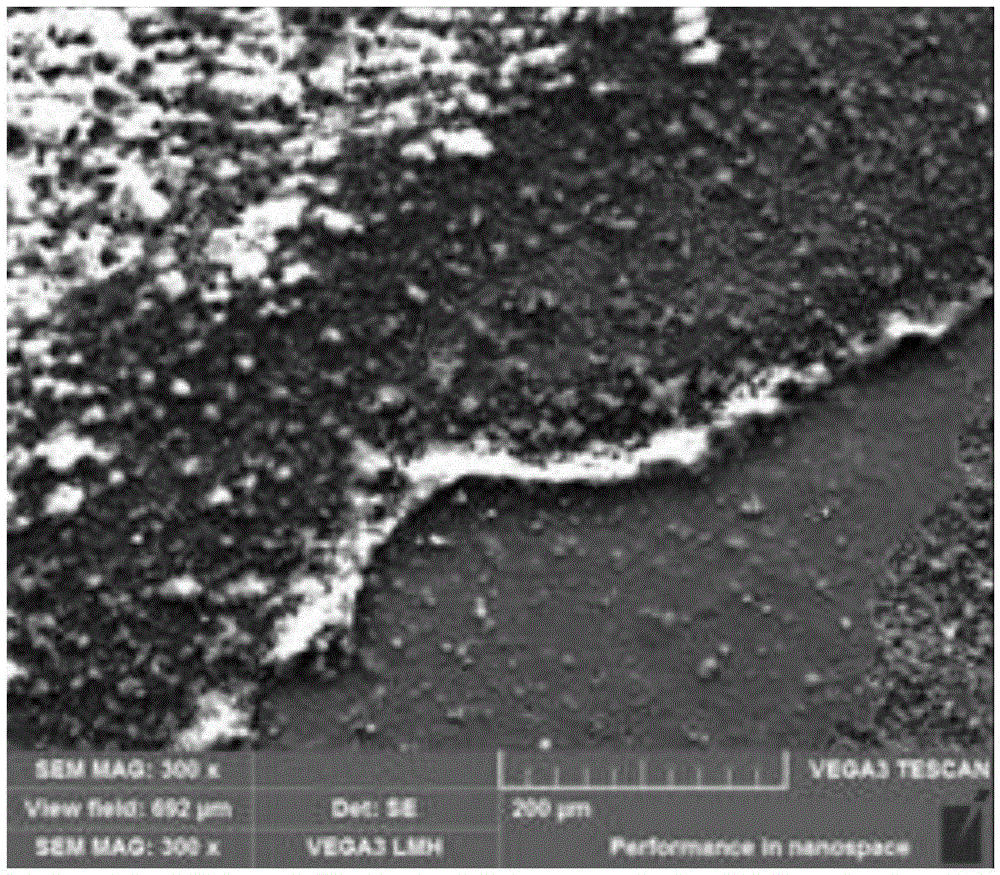

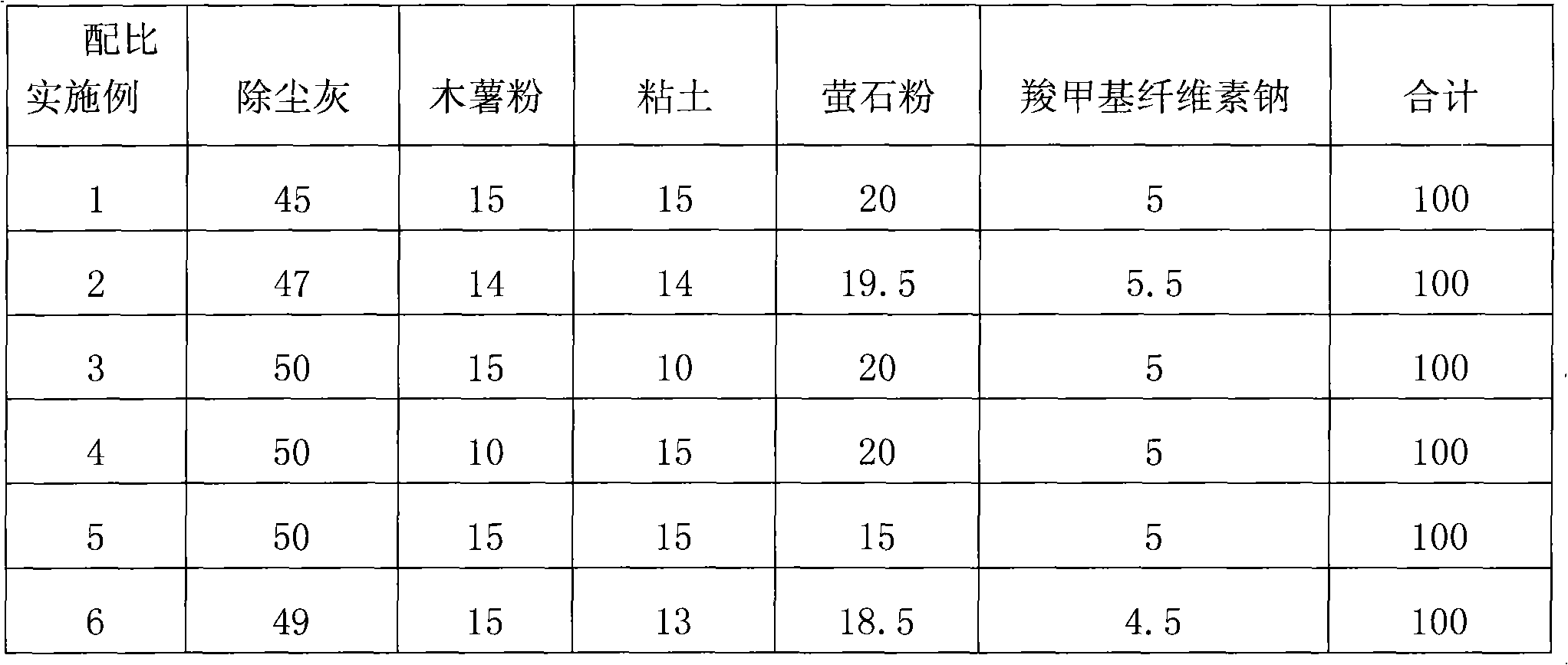

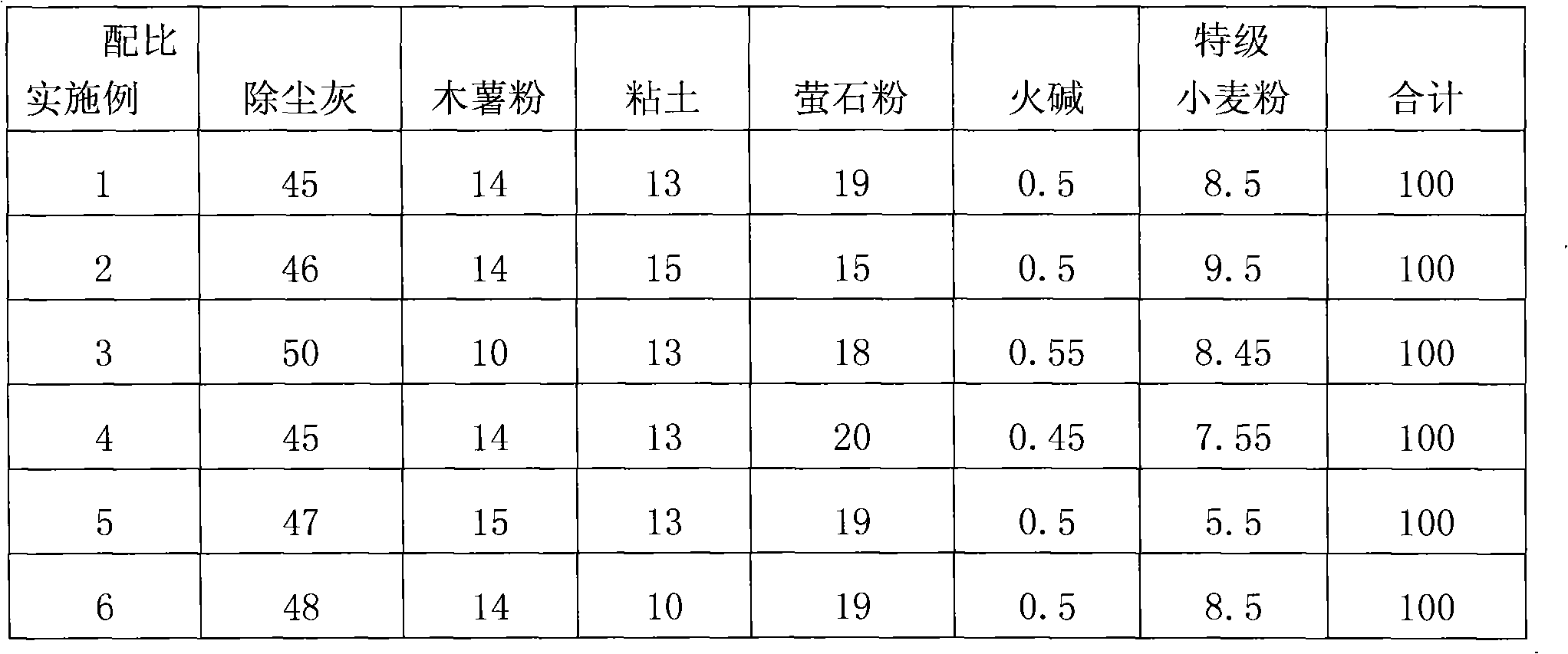

The invention discloses a metallurgical pellet compound binding agent. The compound binding agent comprises the following components in percentage by weight: 45 to 50 percent of dust generated in blast furnace ironmaking and sintering production processes, wherein the dust is grounded to ensure that more than or equal to 80 percent of the dust has the particle size of 0.043 mm, the TFe in the dust is more than or equal to 60 percent, and montmorillonite in the dust is more than or equal to 20 percent; 10 to 15 percent of cassava meal of which more than or equal to 80 percent has the particle size of 0.043 mm; 10 to 15 percent of clay of which more than or equal to 80 percent has the particle size of 0.043 mm; 15 to 20 percent of fluorspar powder of which more than or equal to 80 percent has the particle size of 0.043 mm; and 4.5 to 5.5 percent of carboxymethylcellulose sodium of which more than or equal to 80 percent has the particle size of 0.043 mm. The carboxymethylcellulose sodium of the compound binding agent can be replaced by caustic soda and special-grade wheat flour. The components are uniformly stirred according to the percentage by weight to prepare the pellet compound binding agent; and during the production of pellets, 0.8 to 1.2 percent of 0.5 percent replaceable bentonite is added, and not only a requirement on pellet production can be meet, but also the used amount of the bentonite is reduced, thereby fulfilling the aims of improving the grade of pellet iron ores and simultaneously improving blast furnace coefficients.

Owner:马鞍山市金鑫建材有限公司

L-hydrosulformidate type chiral ionic liquid and its prepn

InactiveCN1383921AEasy to getLow priceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAqueous solutionIonic liquid

The present invention relates to a new type chemical material and its preparation. L-hydrosulforamidate-type chiral ionic liquid is prepared through the full reaction of aqueous L-amino acid solutionwith 98% sulfuric acid. The produced L-hydrosulforamidate-type chiral ionic liquid has the features of both ionic liquid and chiral matter. The reaction has high product purity, low cost, no exhausted pollutant and no side product, and is suitable for application in large scale industrial production. The new material is capable of becoming environmentally friendly important chemical material.

Owner:EAST CHINA NORMAL UNIV

Method for catalyzing ethyne hydrochlorination reaction by utilizing metal nanoparticle/ionic liquid system

ActiveCN105001040AAvoid pollutionInhibitory activityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenProduct gas

The invention discloses a method for catalyzing ethyne hydrochlorination reaction by utilizing a metal nanoparticle / ionic liquid system. The method comprises the steps that a metal nanoparticle / ionic liquid phase catalytic system is prepared, ionic liquid is surface activity ionic liquid, under the temperature ranging from 60 DEG C to 120 DEG C, hydrogen chloride is pumped into the metal nanoparticle / ionic liquid phase catalytic system, activation is carried out, warming is carried out until the temperature ranges from 140 DEG C to 220 DEG C, ethyne and the hydrogen chloride are pumped, the reaction is carried out, and after processing is carried out, a chloroethylene product gas is obtained. The special surface activity ionic liquid and a metal nanoparticle are subjected to in-situ reaction or compounding, the metal nanoparticle / ionic liquid system is obtained, the metal nanoparticle / ionic liquid system is utilized to catalyze the ethyne hydrochlorination reaction, the ethyne converting rate can reach up to 99% in a maximum mode, the chloroethylene selectivity is larger than 99.5%, and the catalytic system has the best cycling stability.

Owner:ZHEJIANG UNIV

Skincare aromatic textile material and manufacturing method thereof

InactiveCN103147195AImprove immunityImprove the quality of living environmentFibre treatmentYarnAromatherapyHuman body

The invention provides a skincare aromatic textile material, which is characterized in that the skincare aromatic textile material is formed by blending chitosan fibers, milk protein fibers and tencel fibers, wherein the weight percent of the blended fibers is (10-40): (50-40):(40-60), and the blended fiber at least comprises fragrance. The skincare aromatic textile material has the advantages that after the three fibers are blended, the advantages of the three kinds of fibers can be adequately played, so that a product can have functions of bacteriostasis, deodorization, skin moistening, skin nourishing, humidity absorption, softness and comfort. Meanwhile, through post-treatment of microcapsules containing the fragrance, fabric becomes a best carrier of the microcapsules containing the fragrance, and the aromatherapy can be realized by slowly releasing the fragrance of the microcapsules by the fabric, so that the immunity of the human body can be enhanced, the quality of a living environment of people is improved, and a certain auxiliary treatment effect can be realized for the health of the human body.

Owner:青岛同盈家纺有限公司

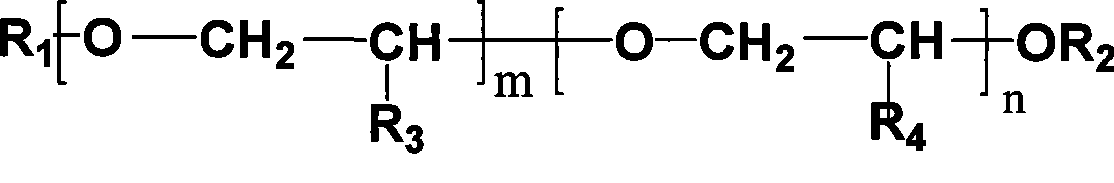

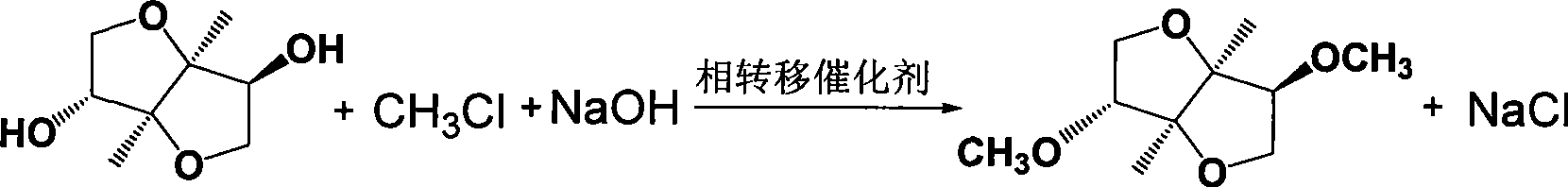

Method for synthesizing isosorbide dimethyl ether

ActiveCN101445508ANo pollution in the processAchieving zero emissionsOrganic chemistryHydrogenHydrogen atom

A method for synthesizing isosorbide dimethyl ether comprises the following steps: (1) adding solvent, isosorbide, alkali and phase transfer catalyst in a reaction vessel; (2) stirring and raising the temperature to 80 to 100 DEG C, reducing the pressure until the gauge pressure is minus 0.095 MPa, and dewatering; (3) leading into chloromethane under the condition of the phase transfer catalyst, and complete the etherification reaction with the pressure 0.1 to 1.0 MPa and the temperature 50 to 90 DEG C; (4) carrying out acid neutralization; (5) filtering and desalting; (6) and carrying out reduced pressure distillation, and collecting fraction with the temperature of 92 to 93 DEG C to get isosorbide dimethyl ether and recovering the solvent. The solvent adopts low molecular polyether with alkyl sealing the ends, in the formulae, R1 and R2 are hydrogen atoms or alkyl; the adopted alkyl comprises 1 to 15 carbon atoms; R3 and R4 are hydrogen atoms or methyl, or other lower alkyl; and m plus n is an integer between 4 to 15. The invention realizes zero discharge, reduces cost and increases production efficiency.

Owner:南京威尔药业科技有限公司

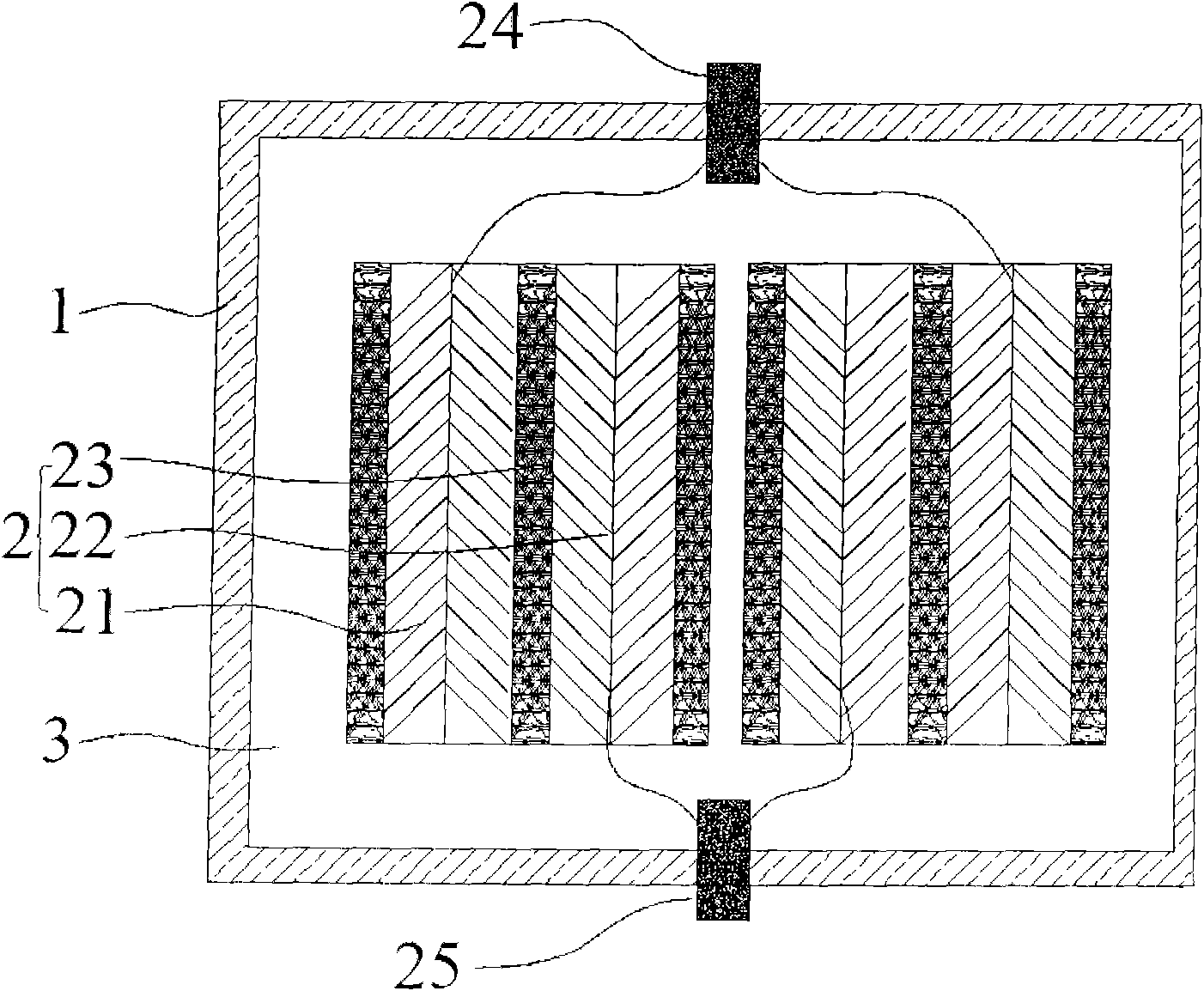

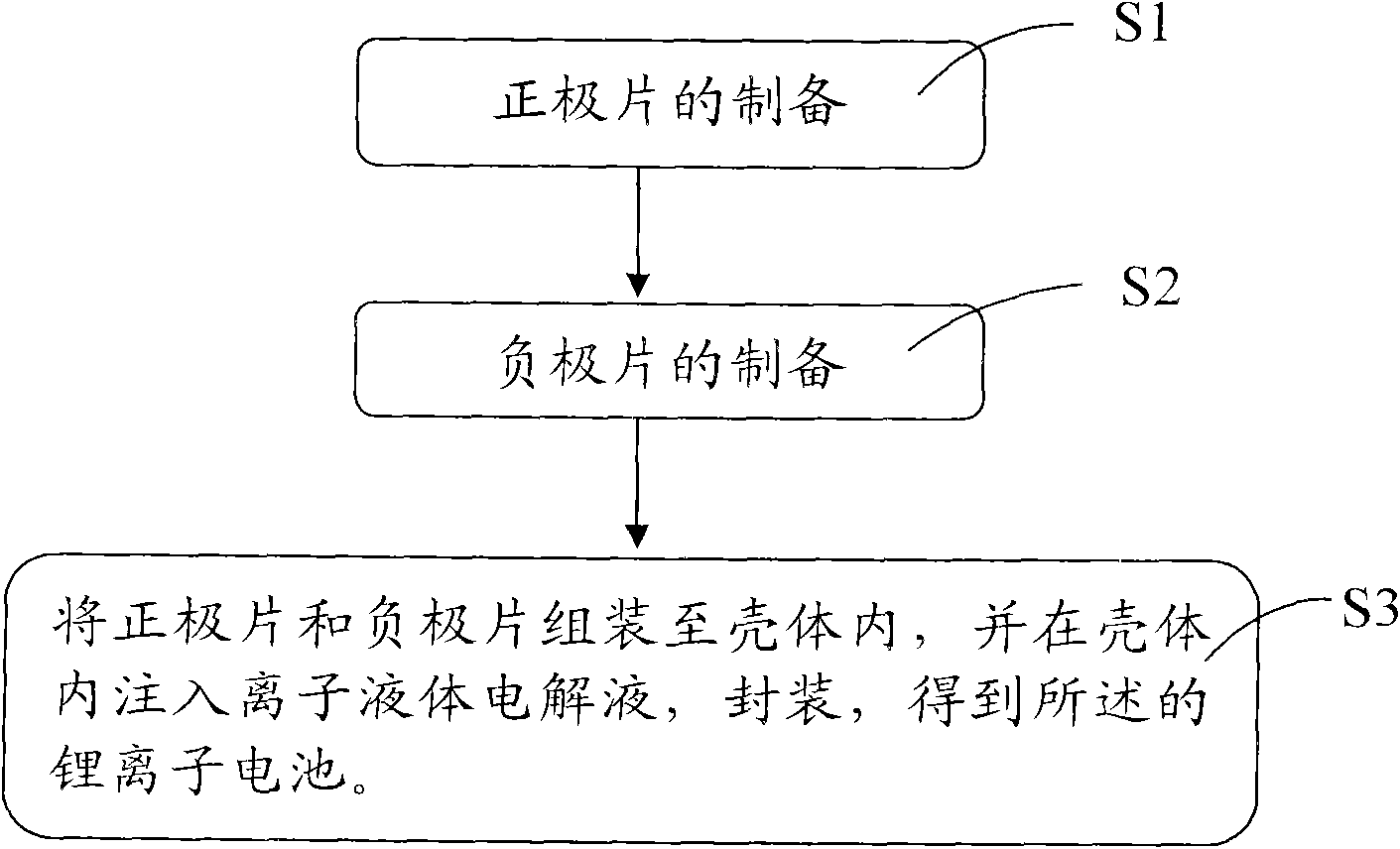

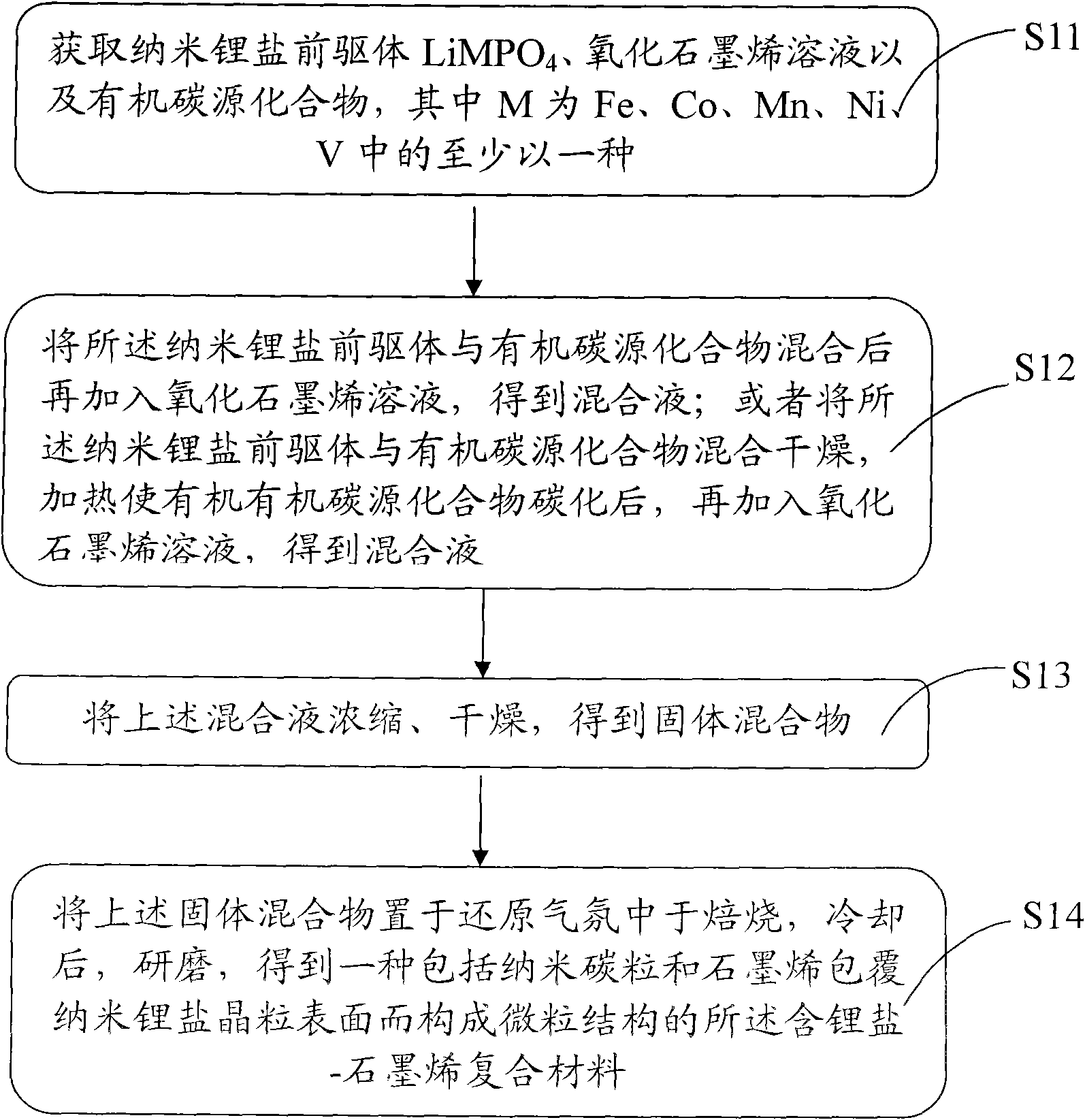

Lithium ion battery and preparation method thereof

ActiveCN102468515APromote circulationImprove performanceFinal product manufactureNon-aqueous electrolyte accumulator electrodesHigh energyPhysical chemistry

The invention discloses a lithium ion battery and a preparation method thereof. The lithium ion battery comprises a shell, ionic liquid electrolyte, positive plates, negative plates and diaphragms, wherein the ionic liquid electrolyte, the positive plates, the negative plates and the diaphragms are coated in the shell; the diaphragms are used for dividing the positive plates from the negative plates; each positive plate comprises a positive substrate and a positive coating which is combined on the surface of the positive substrate; the positive coating comprises a LiMPO4-graphene composite, wherein M is at least one of Fe, Co, Mn, Ni and V; each negative plate comprises a negative substrate and a negative coating which is combined on the surface of the negative substrate; and the negative coating comprises a Li4Ti5O12-graphene composite. The invention also discloses a preparation method for the Li4Ti5O12-graphene composite. The lithium ion battery has high energy density, high power density, better circulation performance and stable performance. The preparation method for the Li4Ti5O12-graphene composite is a simple in process and has high production efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

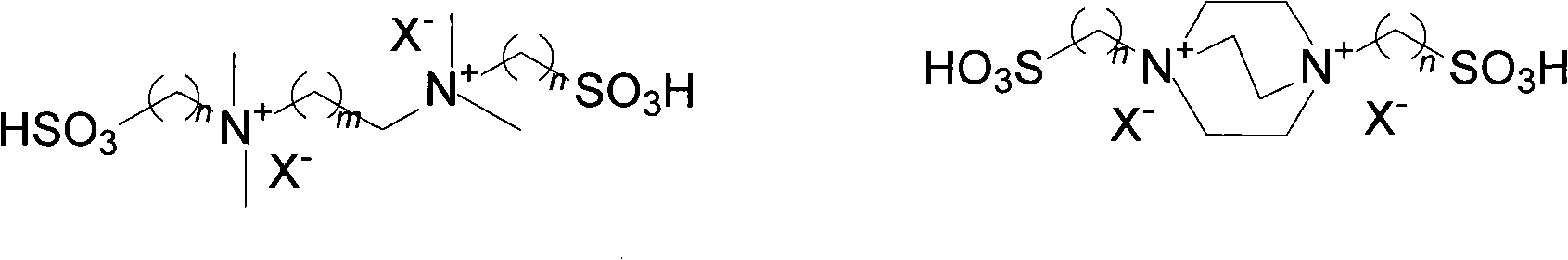

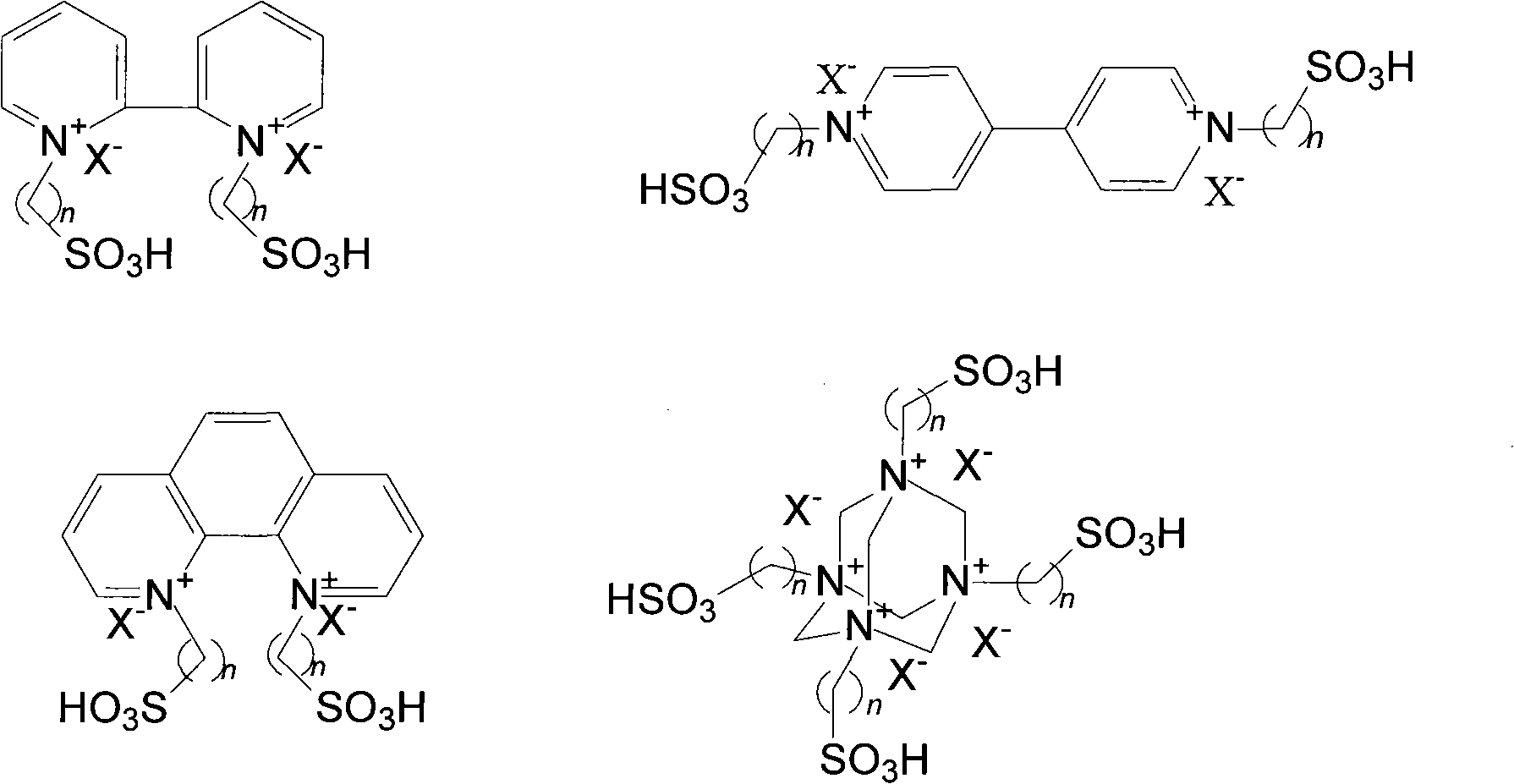

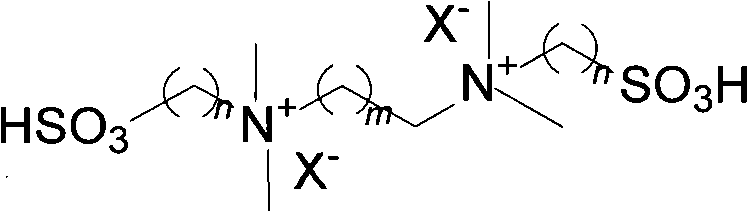

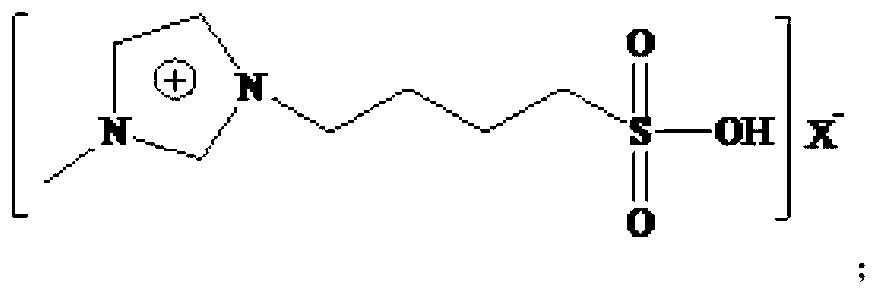

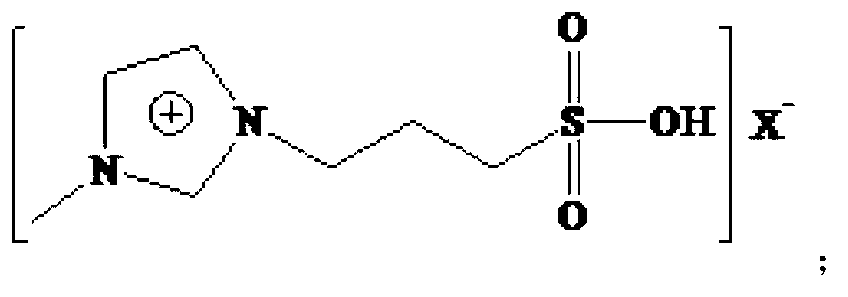

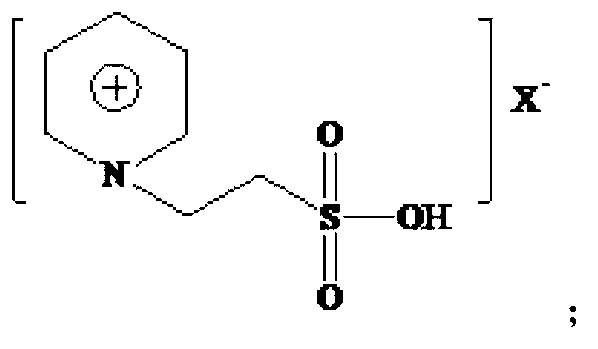

Biodiesel catalyst and method for preparing biodiesel by using same

InactiveCN101927182ACatalytic activity doubledWell mixedFatty acid chemical modificationOrganic compound preparationBiodieselAlcohol

The invention relates to a method for synthesizing biodiesel based on multi-sulfoacid functional ion liquid. The method is characterized by synthesizing the biodiesel through esterification reaction by using fatty acid and alcohol as standard reactants and selecting the multi-sulfoacid functional ion liquid as a catalyst. The method has the advantages of low corrosivity, high catalyst activity, clean reaction process and simple and convenient post-treatment; and the catalyst has the characteristics of high-density reactive site of liquid acid, non-volatility of solid acid and easy separation property and reusability, and waste oils contain a large amount of fatty acid, so the method of the invention can be taken as an important method for industrial use of the waste oils.

Owner:BEIJING FORESTRY UNIVERSITY

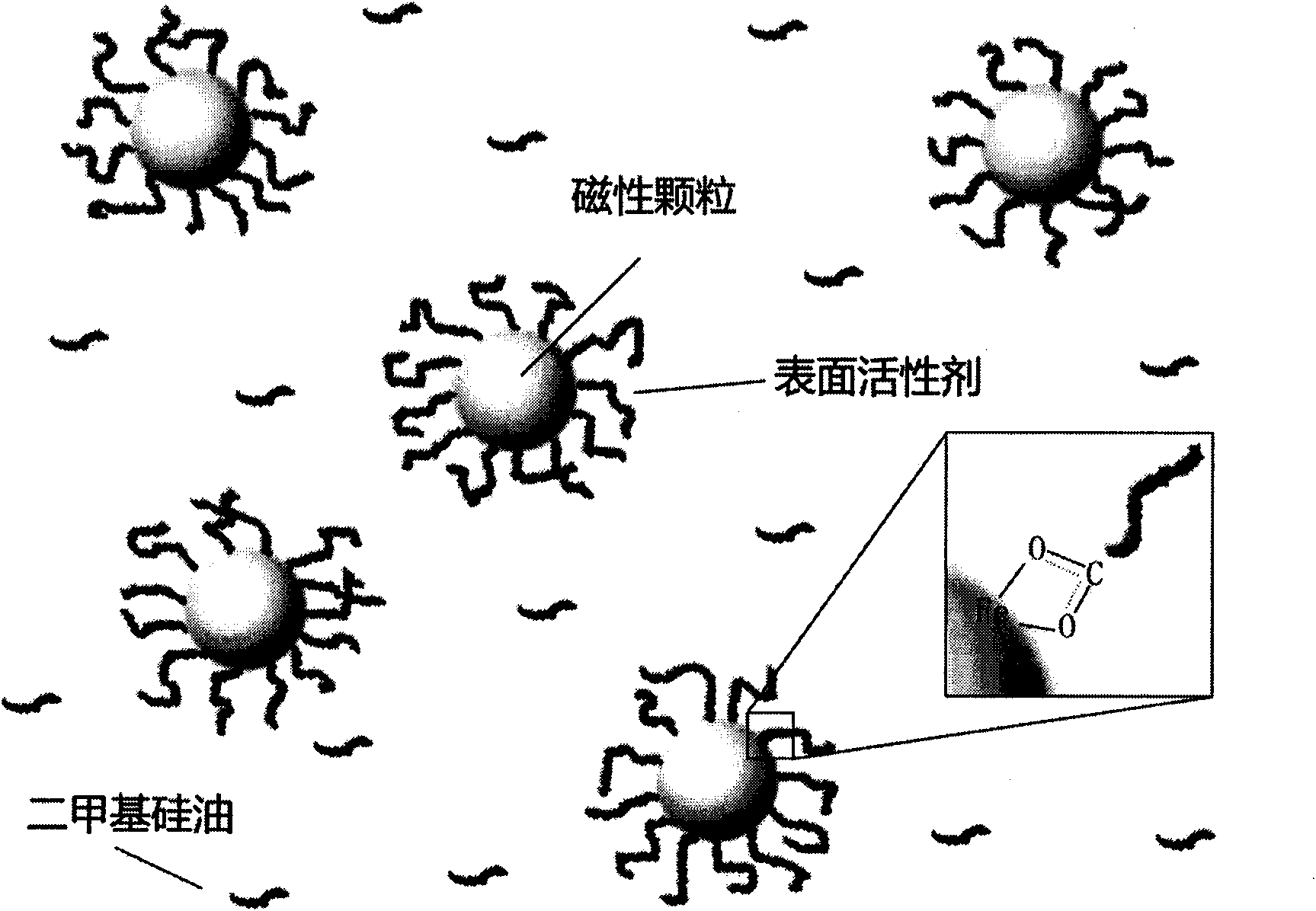

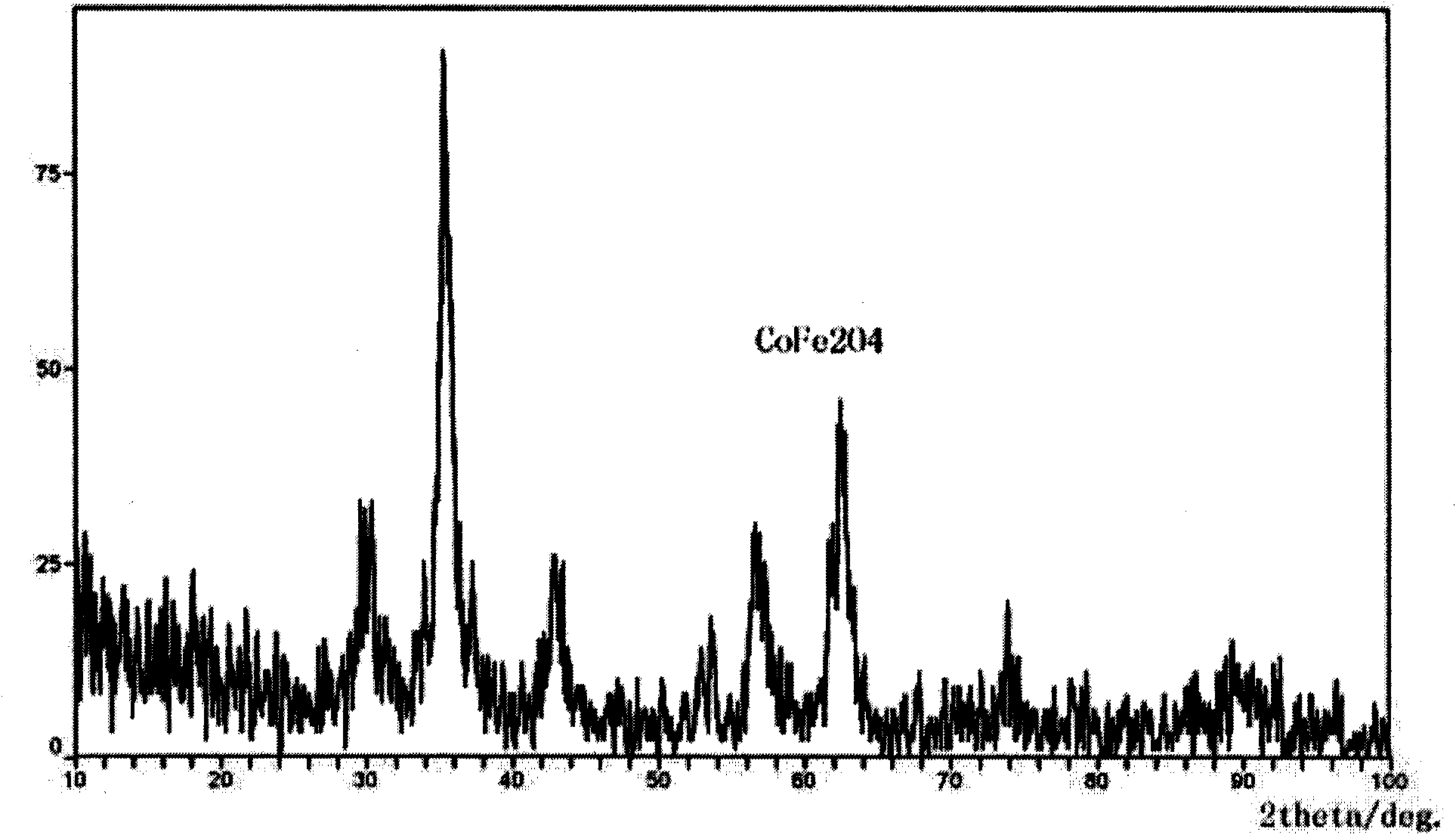

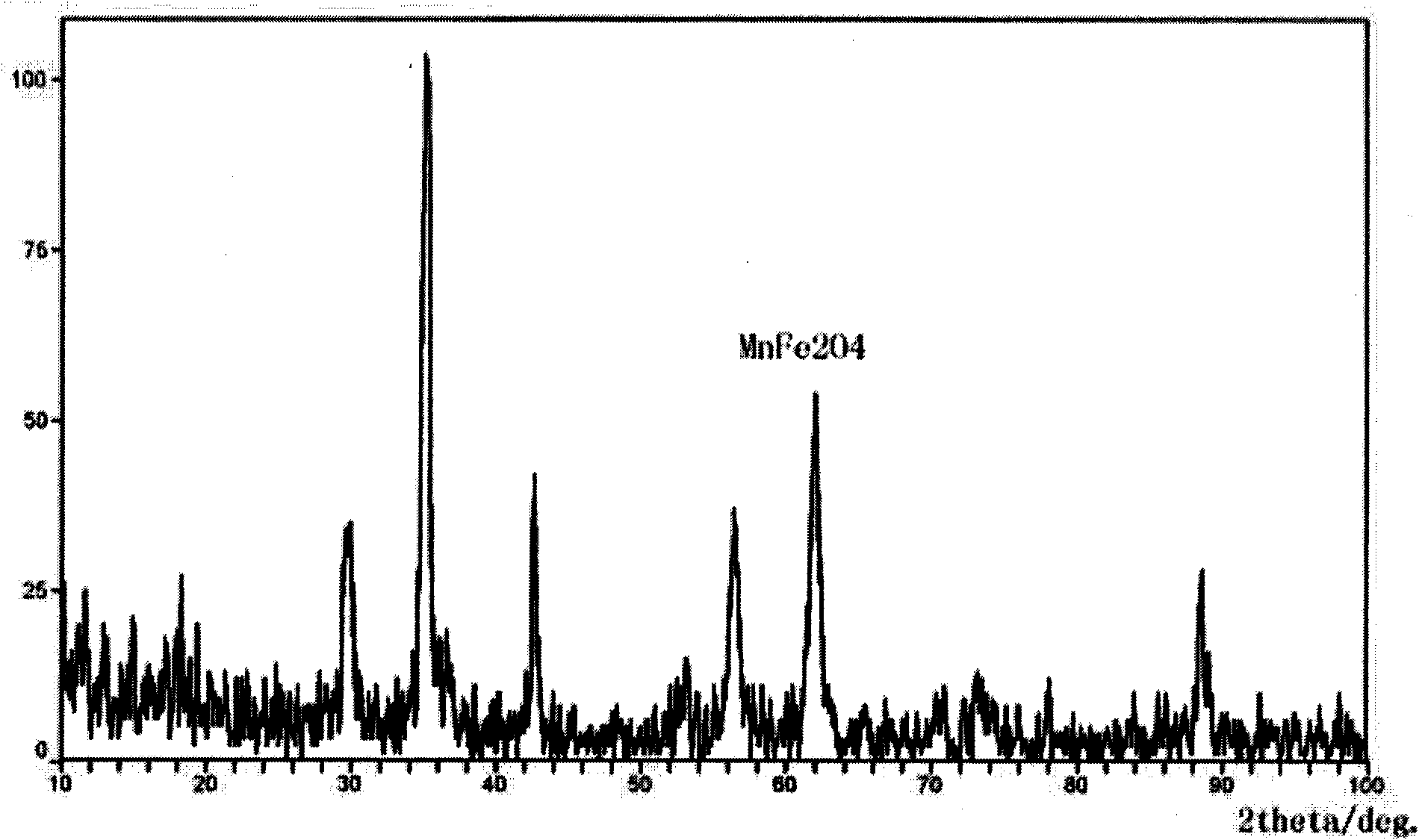

Oxidation resistant dimethyl silicon oil based magnetic fluid and preparation method thereof

InactiveCN101599335ASmall viscosity-temperature coefficientLow compression resistanceMagnetic liquidsOrganic/organic-metallic materials magnetismMethylene DichlorideMagnetic liquids

The invention provides oxidation resistant dimethyl silicon oil based magnetic fluid and a preparation method thereof; the dimethyl silicon oil based magnetic fluid is prepared by nano-magnetic particles, a surface modifier and carrier fluid, and the carrier fluid is the dimethyl silicon oil. The preparation method of the dimethyl silicon oil based magnetic fluid comprises the following steps: preparing the nano-magnetic particles; treating the nano-magnetic particles in an activated way; preparing the nano-magnetic particles which are modified by the surface modifier; adding the modified nano-magnetic particles which are purified into methylene dichloride, dispersing and filtering the mixture to obtain the methylene dichloride based magnetic fluid; adding the magnetic fluid into the dimethyl silicon oil to be stirred and dispersed, heating the mixture and maintaining the temperature between 50 and 90 DEG C, separating and precipitating the mixture to obtain the dimethyl silicon oil based magnetic fluid. The dimethyl silicon oil based magnetic fluid in the invention has the advantages of high stability, low temperature resistance and high temperature resistance. The preparation method is simple, high in efficiency and low in requirement on equipments, thus being easy to be applied in various fields and having wide application prospect.

Owner:SUN YAT SEN UNIV

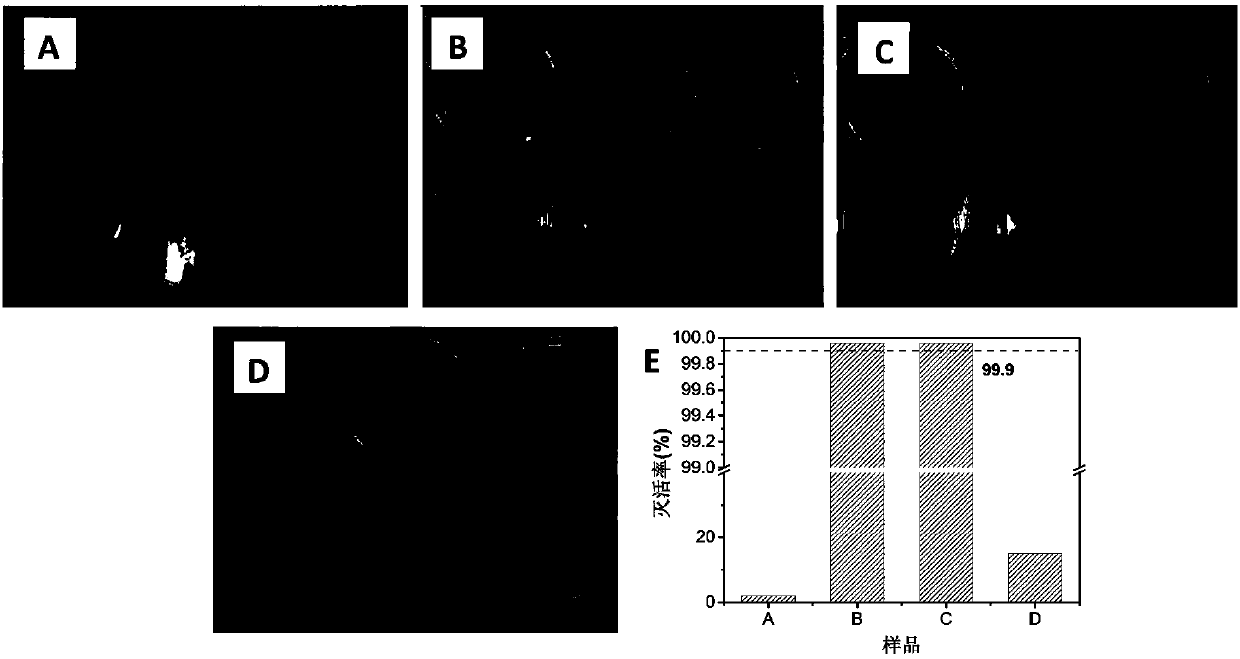

Permanent antibacterial polymer composite material and preparation method thereof

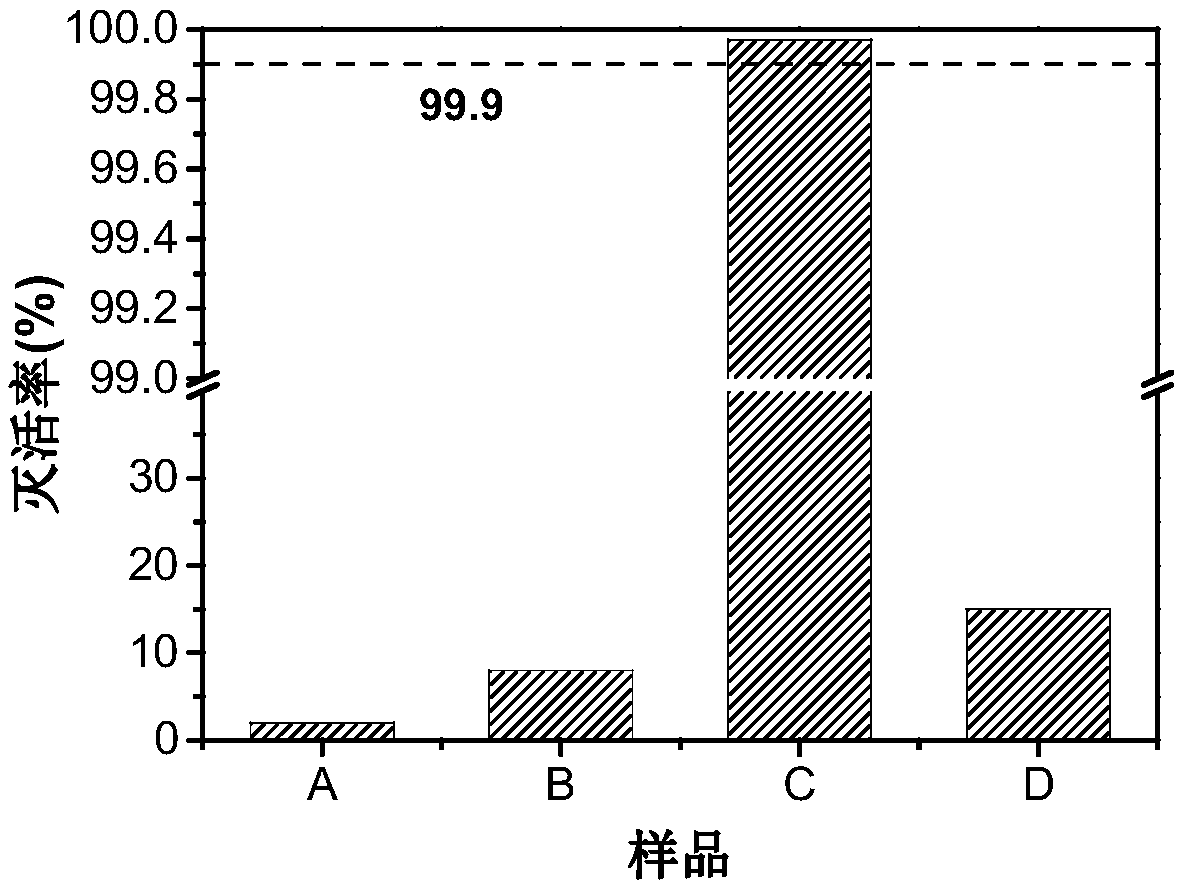

ActiveCN107903561AImprove antibacterial propertiesImprove electrochemical stabilityHollow filament manufactureMonocomponent synthetic polymer artificial filamentPolymer scienceNonwoven fabric

The invention discloses a permanent antibacterial polymer composite material and a preparation method thereof. According to the present invention, various materials such as polymer films, fibers, non-woven fabrics and the like are prepared by selecting different polymer molding technologies while an ion liquid is uniformly distributed and chemically bonded on the material surface, such that the material has good antibacterial effect; and the ion liquid and the polymer molecule are linked through the chemical bond, such that the loss of the ion liquid (antibacterial agent) due to migration andother causes during the long-term use can be avoided so as to maintain the permanent antibacterial performance.

Owner:HANGZHOU NORMAL UNIVERSITY

Capacitor battery with high safety

InactiveCN102881951AImprove securityLow steam pressureCell electrodesSecondary cells servicing/maintenanceActivated carbonLithium vanadium phosphate battery

Relating to novel chemical energy storage technologies, the invention provides a capacitor battery with high safety. The battery positive electrode is composed of a positive active material layer and a protective coating. The battery negative electrode consists of a negative active material layer and the protective coating, which is composed of aluminum oxide of 0.1micrometer-8micrometers. The battery positive electrode material is one or more of ferrate, lithium manganate, lithium iron phosphate, lithium manganese phosphate, lithium vanadium phosphate and lithium ferrous silicate. The battery negative electrode material is one or more of graphite, lithium titanate, a carbon-silicon composite material and a carbon-tin composite material. The capacitor material is one or more of nano-sized graphene, graphene oxide, carbon nanotubes and activated carbon. PP, PE or a composite film of the two can be selected as a diaphragm. An electrolyte is formed by dissolving a lithium salt in an organic solution and adding an ionic liquid. The capacitor battery has the characteristics that: its energy density is large and is similar to that of lithium batteries, and its large current charge-discharge characteristics and recycling service life are similar to those of supercapacitors, so that the capacitor battery can meet the requirements of being used as a high performance energy storage and power battery.

Owner:张宝生

Technology for producing sponge from plant oil polyether

InactiveCN102453224AAlleviate production cost pressureReduce production stepsTemperature controlPolyol

The invention relates to the field of sponge products, and specially, relates to a technology for producing sponge from a plant oil polyether. The technology comprises a raw material supply process section, a mixing process section and a foaming process section. The technology is characterized in that through extraction and synthesis, a plant oil polyether polyol is prepared from plant oil raw materials; raw materials adopted by the raw material supply process section comprise a polyol component and an isocyanate component; the polyol component comprises the plant oil polyether polyol, a chain extender, a foaming agent, a catalyst and a foam stabilizer; the isocyanate component comprises isocyanate; the raw materials are respectively input into a work storage tank; and a work storage tank temperature is controlled in a range of 20 to 25 DEG C by a temperature control system, wherein the temperature error is less than 1DEG C. The technology has the advantages that a plant oil polyether replaces a traditional petroleum polyether to be utilized for production of sponge (comprising common sponge and slow-rebound sponge), and thus waste sponge degradation is realized; environmental pollution is reduced; and environmental protection and sustainable development can be promoted.

Owner:SHANGHAI GLORY HOME TECH CO LTD

Environment-friendly polyurethane water shutoff material and preparation method thereof

The invention belongs to the field of high polymer materials and particularly relates to an environment-friendly polyurethane water shutoff material. The environment-friendly polyurethane water shutoff material is prepared from a polyurethane prepolymer and an additive, wherein the polyurethane prepolymer is prepared from the following raw materials: polyethylene-polypropylene glycol a (functionality: 3-4 and hydroxyl value: 300-500), polyethylene-polypropylene glycol b (functionality: 2-3 and hydroxyl value: 200-400), polyethylene-polypropylene glycol c (functionality: 2-3 and hydroxyl value: 100-200), a water remover and isocyanate; the additive is prepared from the following raw materials: a plasticizing agent, a diluent, a flame retardant, a catalyst and a surfactant. When being injected to a hole or crack, the polyurethane water shutoff material is diffused and solidified in the crack to generate foam with certain strength; molecules of a gel contain a great number of polar groups, so that the environment-friendly polyurethane water shutoff material is high in bonding strength and capable of shutting off the crack, thus playing the water shutoff and consolidation effects. The invention also provides a preparation method of the environment-friendly polyurethane water shutoff material. The preparation method is reasonable in process and easy for industrial production.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

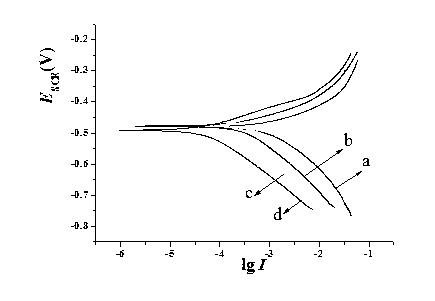

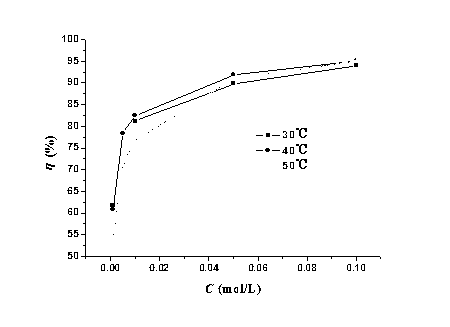

Imidazolyl lysine salt ionic liquid steel corrosion inhibitor and application thereof

The invention discloses an application of ionic liquid which serves as a steel corrosion inhibitor. The imidazolyl lysine salt ionic liquid serves as a corrosion inhibitor, only the corrosion inhibitor is required to be added into a solution contacted with steel, and the corrosion inhibitor is easy to operate and good in corrosion inhibition effect. The corrosion inhibitor is environment-friendly, high in solubility and biodegradability and good in corrosion inhibition effect, and solves the problems that the conventional corrosion inhibitor has large toxic and side effects, low biodegradation, poor environment friendliness and the like.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

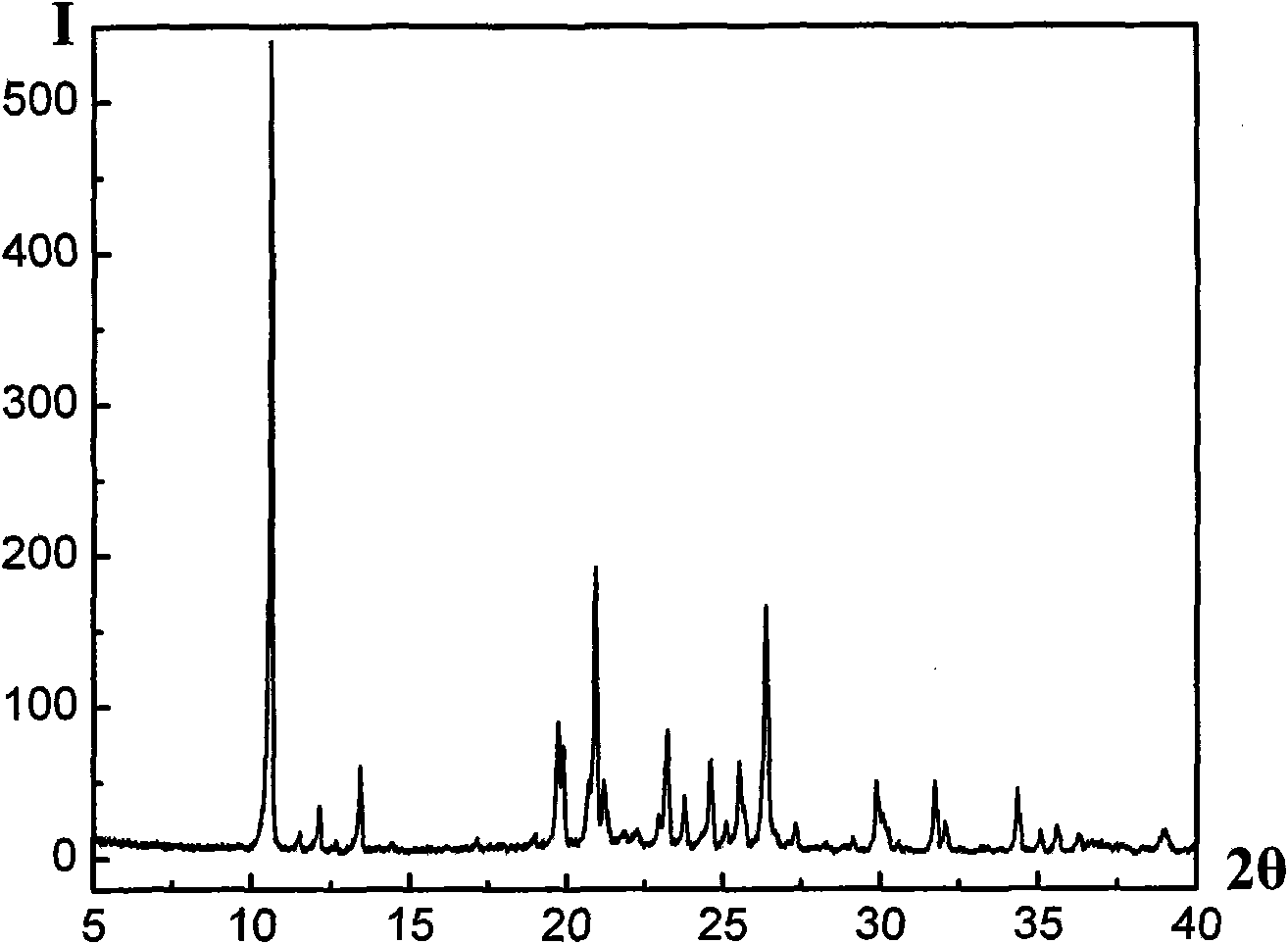

Method for preparing aluminum phosphate molecular screen in eutectic mixture

InactiveCN101602513AEasy to makeNot easy to deliquescenceMolecular-sieve aluminophosphatesMolecular-sieve and base-exchange phosphatesAlcoholInorganic Chemical

The invention provides a method for preparing an aluminum phosphate molecular screen in a eutectic mixture, and belongs to the field of inorganic chemical synthesis. In particular, the invention relates to a method for an aluminum phosphate molecular screen by the eutectic mixture as a reaction solvent and a template. The method is characterized by using the eutectic mixture prepared by combining alcohol and quaternary ammonium salt as the reaction solvent and the template to prepare the aluminum phosphate molecular screen. In the ion thermal reaction, the eutectic mixture has proper acidity and alkaline, the alcohol organic matters are not decomposed to release extra organic amine in the crystallization reaction process when being heated, and the quaternary ammonium salt in the system can fully complete the structure guide action. Compared with the imidazole ionic liquid, the used eutectic mixture material has the advantages of low price, easy purchase and preparation, hard deliquescence and convenient use.

Owner:TAIYUAN UNIV OF TECH

Method for preparing cellulose composite sodium filter membrane

The invention discloses a method for preparing a cellulose composite sodium filter membrane, which comprises the following steps of: (1) dissolving cellulose or cellulose derivates into ionic liquid under a heating condition to obtain solution for preparing the membrane; (2) uniformly coating the solution for preparing the membrane on a non-woven fabric support and then soaking the support into a coagulating bath for coagulation to obtain a cellulose composite membrane; and (3) placing the obtained cellulose composite membrane into the solution of polyacid, poly-acyl chloride or poly-anhydride to perform crosslinking to prepare the cellulose composite sodium filter membrane. In the invention, the ionic liquid has high cellulose and cellulose derivates dissolving capability is used as the membrane-preparing solvent, so the membrane formation performance is high; and the ionic liquid can be recycled and repeatedly used. The crosslinked cellulose selective zone has high hydrophilism and selectivity, and the composite sodium filter membrane has a high flux and a high rejection ratio and can be widely applied in the separation and concentration of dyes, neutral particles, medicaments, food additives and the like.

Owner:ZHEJIANG UNIV

Skin care natural textile material and manufacturing method thereof

InactiveCN103103665AImprove immunityImprove the quality of living environmentFibre treatmentYarnHuman bodyFiber

The invention provides a skin care natural textile material and a manufacturing method of the skin care natural textile material. The skin care natural textile material and the manufacturing method thereof is characterized in that chitin fiber, milk protein fiber, and tencel fiber are blended to form the skin care natural textile material and weight percentage of blending is 10-40 : 10-50 : 40-60, and the blending fiber at least contains aromatic. The skin care natural textile material and the manufacturing method thereof have the advantages that the three kinds of fiber are blended, the advantages of three kinds of fiber can be fully played, and thus products have functions of being anti-bacterial, moistening and caring skin, absorbing moisture, soft, and comfortable. At the same time, with processing of microcapsules containing aromatic, the fabric becomes the best carrier of microcapsules containing aromatic, fabric with slow release of microcapsule aromatic can conduct an aromatic function therapy, an immune ability of a human body is strengthened, quality of the human living environment is improved, and certain supportive therapeutic effect on human body health is realized.

Owner:ZHONGDI HOME TEXTILES

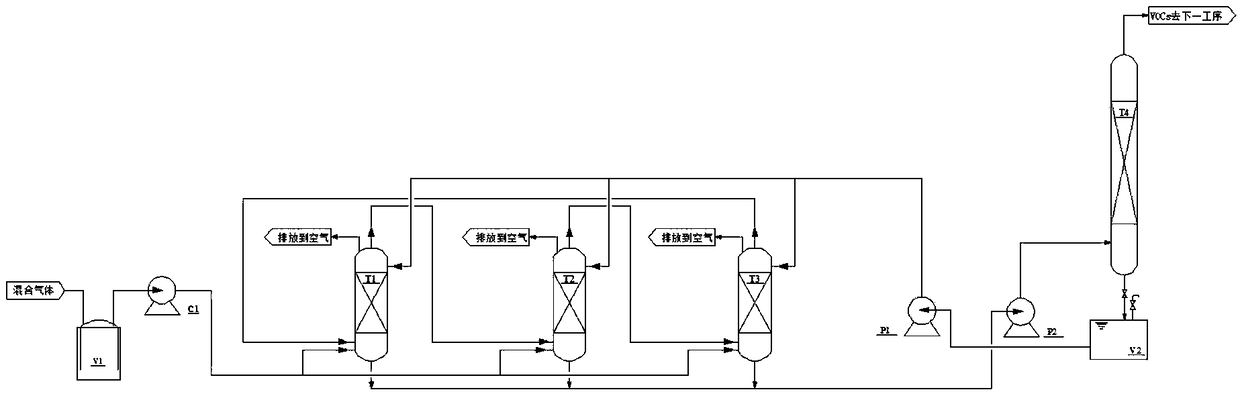

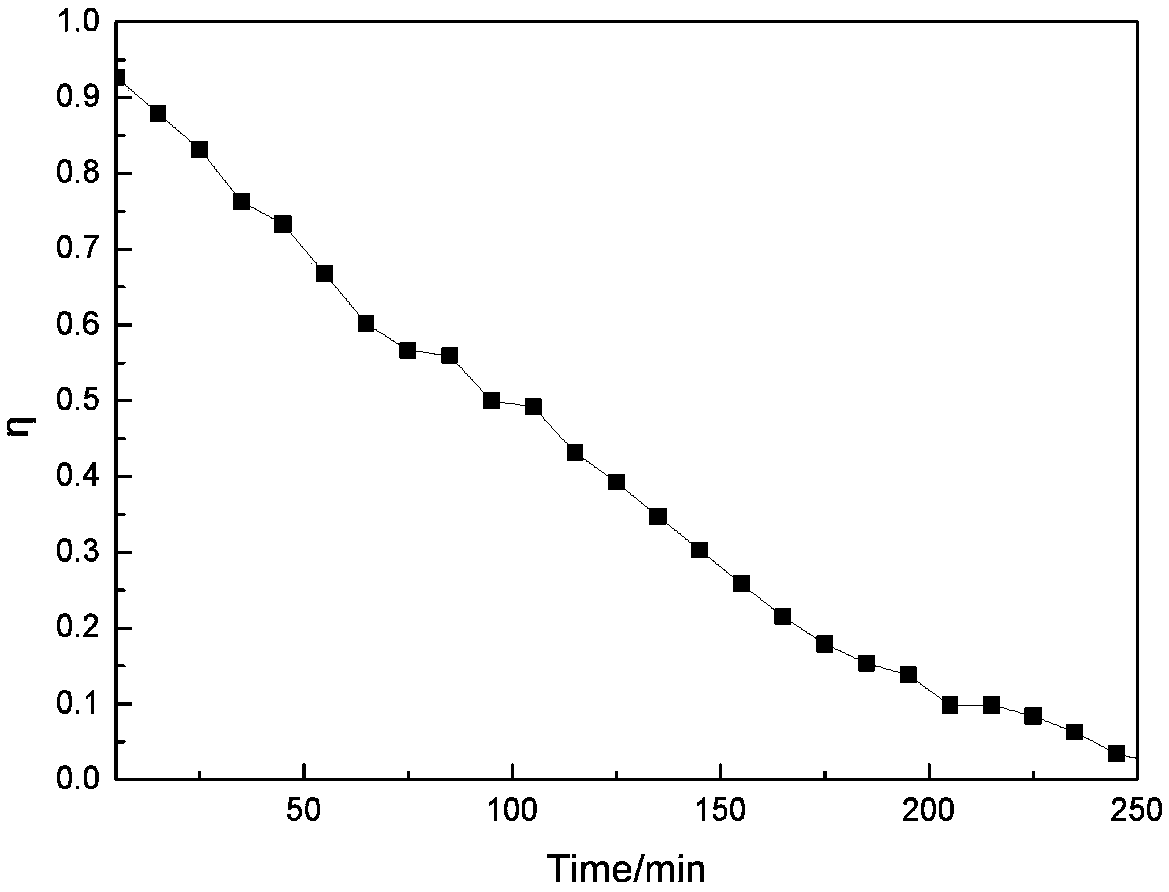

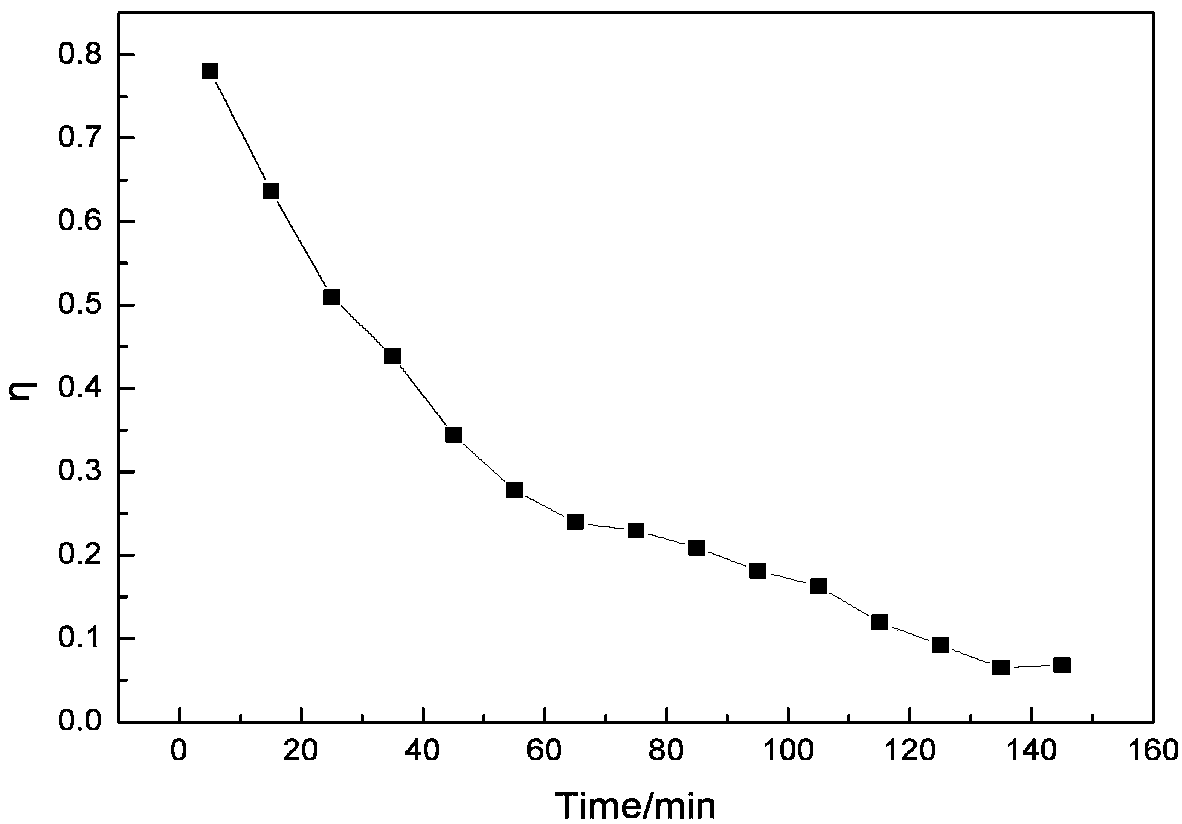

VOCs absorbent and application thereof

ActiveCN108786383AOptimal Intake ConcentrationLow mass transfer efficiencyGas treatmentDispersed particle separationSolubilityBiodiesel

The invention provides a VOCs absorbent and application thereof. The absorbent uses ionic liquid as a polarity phase, a small amount of ion liquid is evenly dispersed in a large amount of water or biodiesel to obtain a microemulsion under the effects of a non-ionic surface active agent and a cosurfactant. The microemulsion has very high VOCs solubleness, and the problems of inorganized VOCs discharge treatment and VOCs recycle of sewage treatment plants are solved.

Owner:HEBEI UNIV OF TECH

Anti-degradable solvent for dissolving cellulose and preparation method of spinning dope thereof

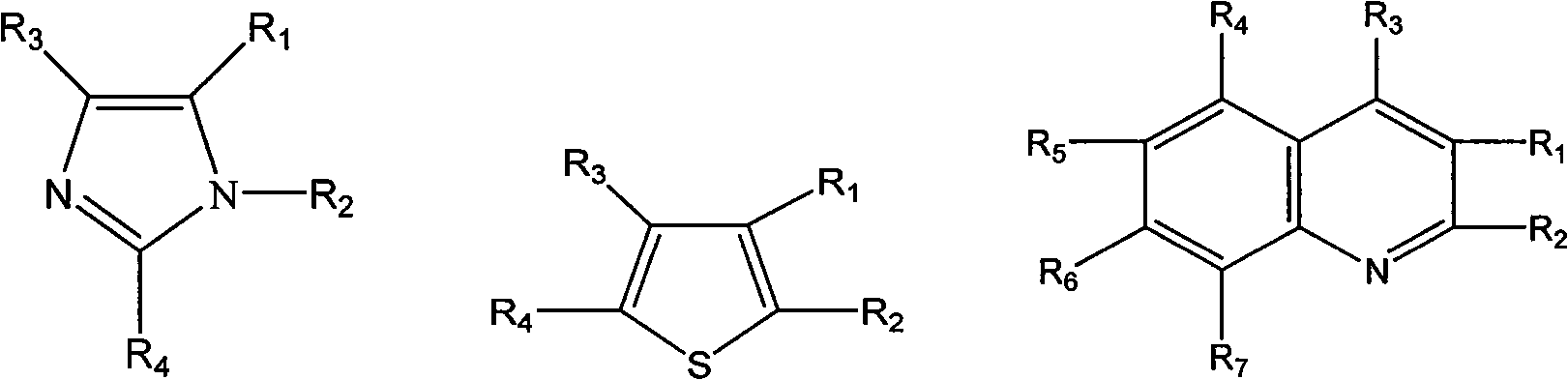

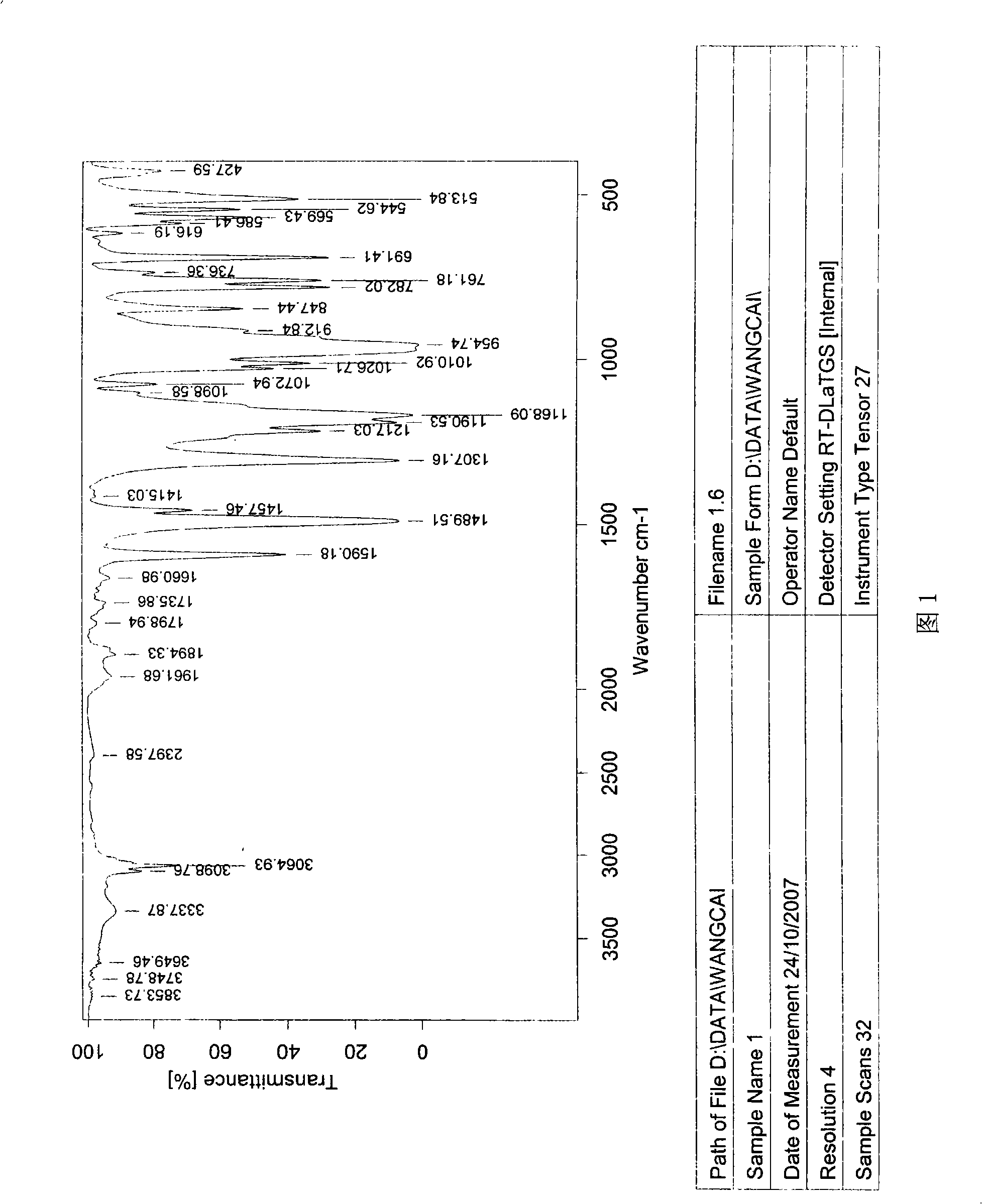

InactiveCN101654522AHigh degree of polymerizationLow steam pressureArtificial filaments from viscoseBulk chemical productionBoiling pointSolvent

The invention relates to an anti-degradable solvent for dissolving cellulose and a preparation method of spinning dope thereof. The solvent dissolves the cellulose by adding an organic substance to the ionic liquid. The ionic liquid has excellent dissolvability to the cellulose, seriously degrades the regenerated cellulose and is hard to spin filament; the addition of the organic substance can obviously improve polymerization degree of cellulose, and reduce viscosity of the spinning solution. Simultaneously, the compound liquid formed by the ionic liquid and the organic substance has the characteristics of extremely low vapor pressure and high boiling point, and is beneficial to recovering and recycling the compound solvent. Compared with the traditional adhesion method, the method has thecharacteristics of no pollution, simple process, low cost, and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

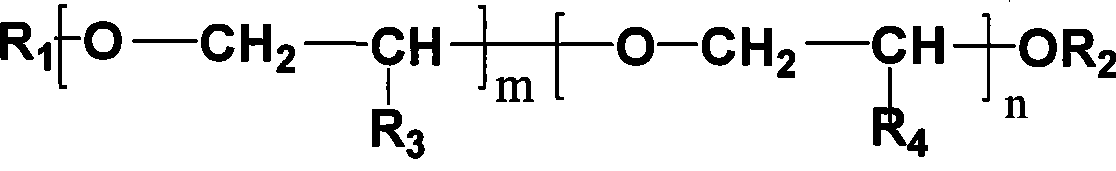

Non-halogen phosphoric acid ester combustion inhibitor for engineering plastic and method of preparing the same

ActiveCN101319057ASufficient supplyReduce investmentFireproof paintsPhosphoric Acid EstersManufacturing cost reduction

The invention relates to a halogen-free phosphate fire retardant used for engineering plastics and a method for producing the same, belonging to the engineering plastic fire retardant and the method for synthesizing the engineering plastic fire retardant technical field. The chemical name of the fire retardant is hydroquinone double phenyl bisphosphate oligomer, and the chemical structural formula is shown on the bottom right. The method comprises the following processing steps: firstly, the method adopts hydroquinone and phosphorus oxychloride as raw materials and a lewis acid as a catalyst for heating reaction; and secondly, the reaction mixture is heated up and dripped with phenol for reaction by taking the lewis acid as the catalyst. The production method has sufficient supply of the raw materials and simple reaction conditions, can reduce the manufacturing cost, and makes products have obvious price advantage; and simultaneously the material has the characteristics of zero halogen, low smoke, low toxity, low corrosiveness, high heat distortion temperature, good fire resistance, good processability, capability of being recycled, etc., and can be widely used as the fire retardant of various engineering plastics.

Owner:ZHEJIANG WANSHENG

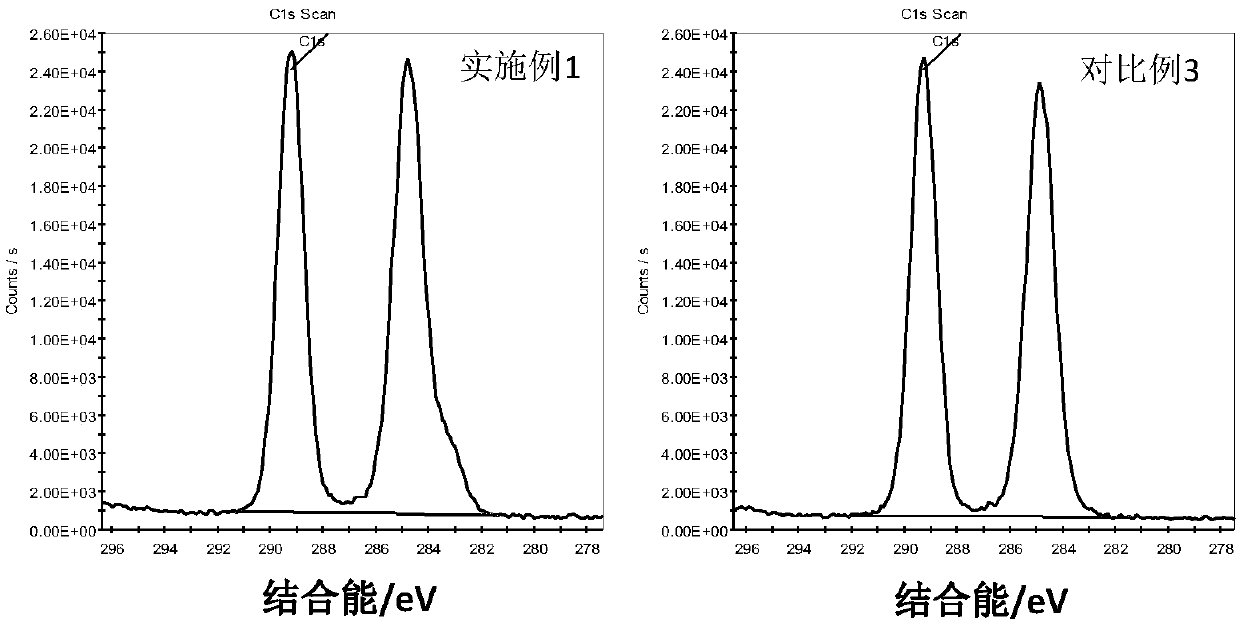

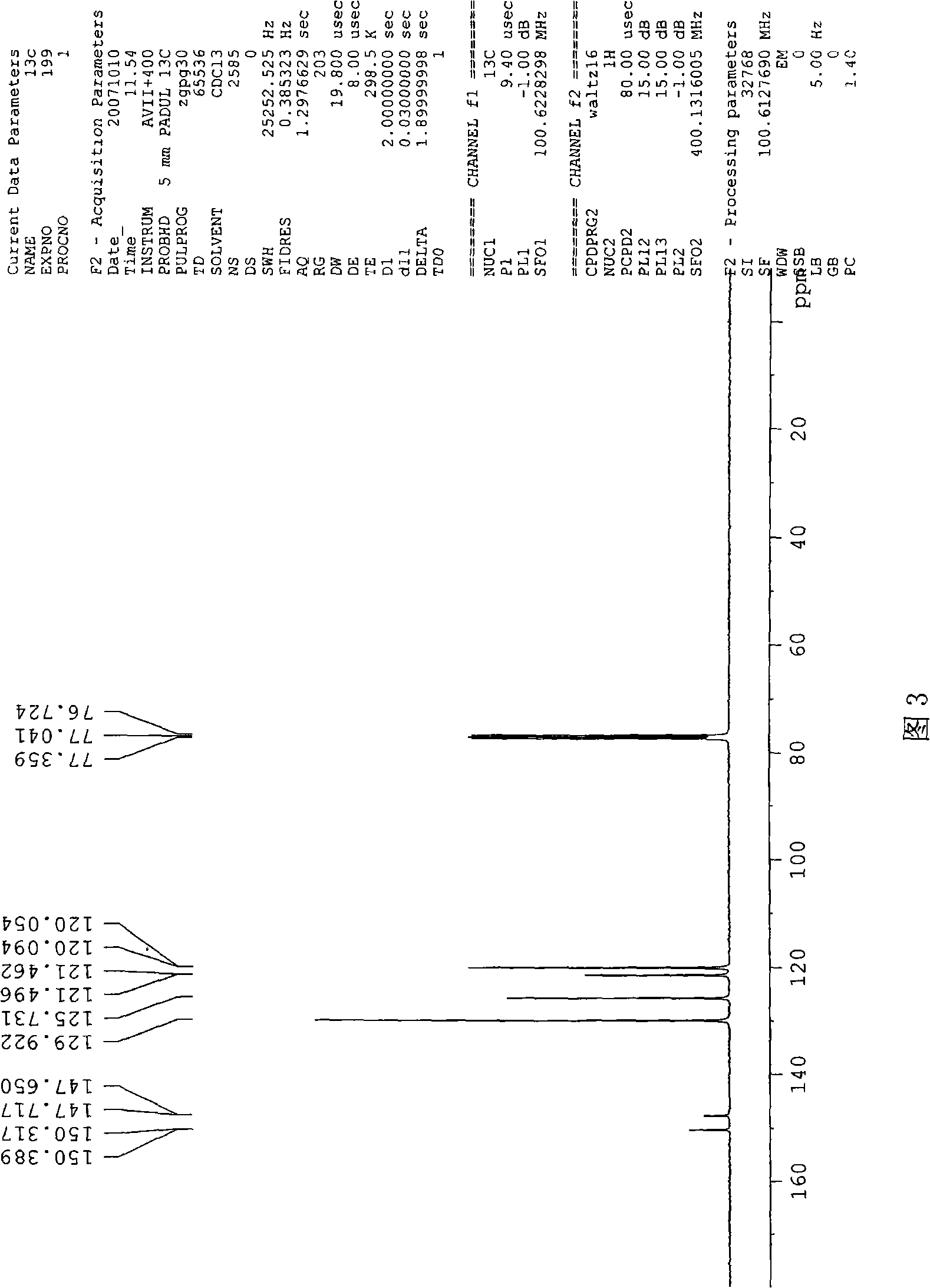

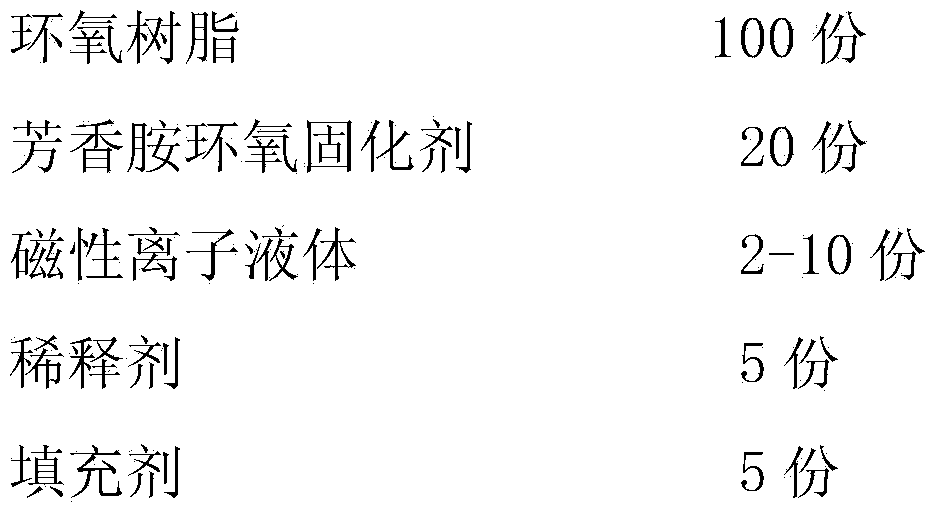

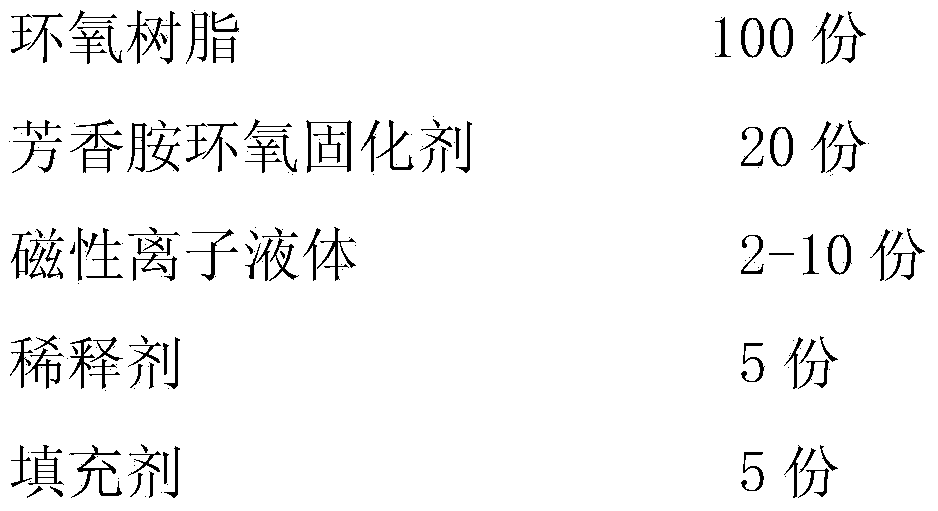

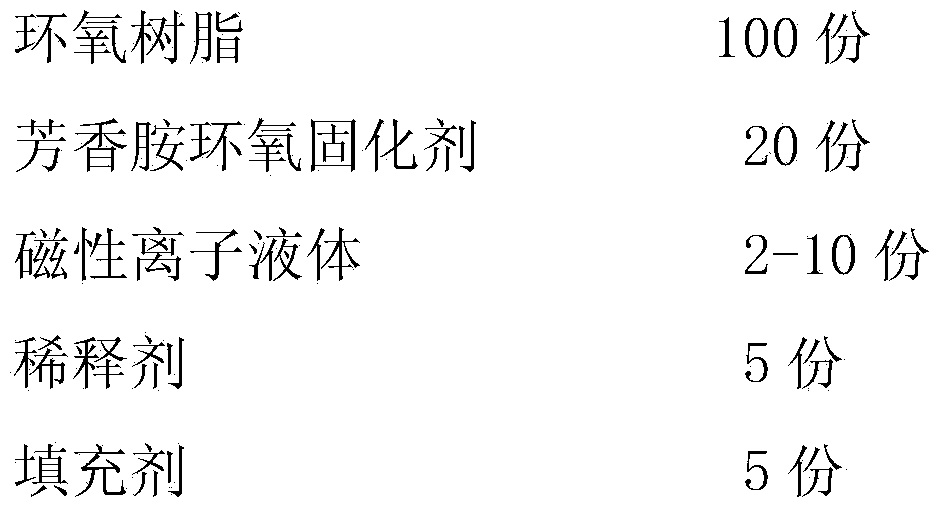

Room-temperature curing epoxy resin adhesive and preparation method thereof

ActiveCN104212394AImprove mechanical propertiesImprove thermal performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesive cementPolymer science

The invention provides a room-temperature curing epoxy resin adhesive and a preparation method thereof and belongs to the technical field of adhesives, solving the problem of relatively high curing temperature of an existing epoxy resin adhesive. The room-temperature curing epoxy resin adhesive comprises the following raw materials in parts by weight: 100 parts of epoxy resin, 20 parts of an aromatic amine epoxy curing agent, 2-10 parts of magnetic ion liquid, 5 parts of a diluent and 5 parts of a filling agent. According to the room-temperature curing epoxy resin adhesive, the structure of the magnetic ion liquid in the room-temperature curing epoxy resin adhesive comprises tertiary amine and quaternary ammonium salt structures due to the existence of the magnetic ion liquid, so that epoxy groups can be cured and catalyzed; when the magnetic ion liquid cooperates with the aromatic amine epoxy curing agent to cure the epoxy resin, the defect of high-temperature use under the high-temperature curing condition in a conventional curing process of the aromatic amine curing agent can be effectively overcome, the epoxy resin can be quickly cured at the room temperature, and a cured material is excellent in mechanical property and heat performance.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

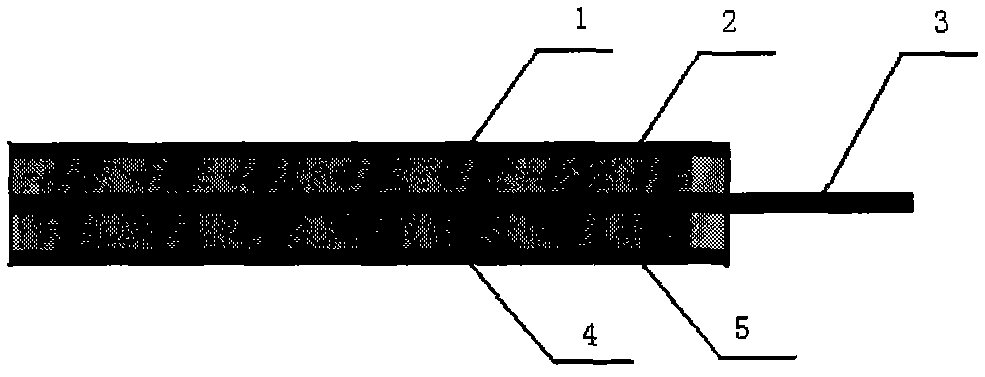

Seamless solid metal calcium cored wire for steelmaking and deoxidation and preparation method thereof

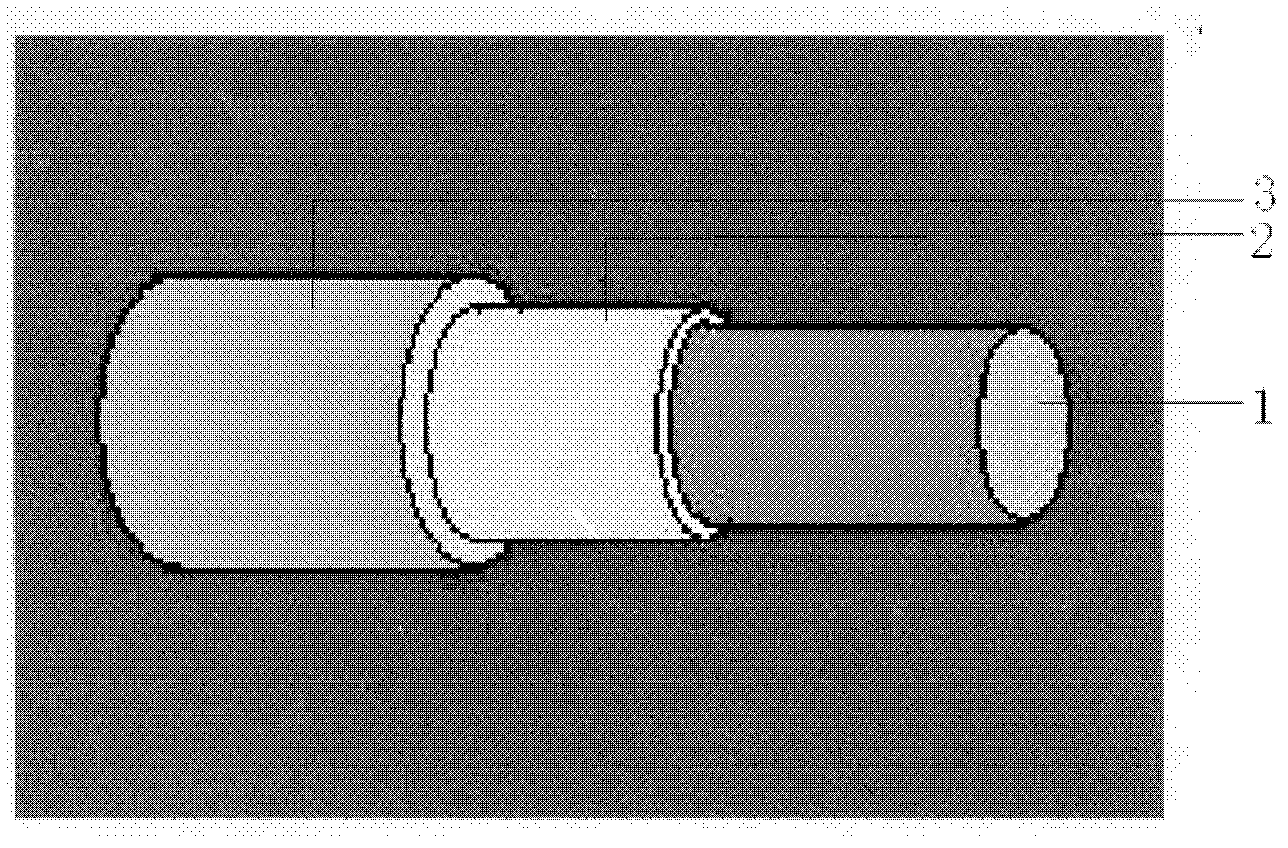

The invention discloses a seamless solid metal calcium cored wire for steelmaking and deoxidation and a preparation method thereof. The seamless solid metal calcium cored wire consists of an outer-layer steel tube, a middle coating layer and an inner core, wherein the inner core is a solid metal calcium (pure calcium) wire. The seamless solid metal calcium cored wire disclosed by the utility model has the beneficial effects that vapor pressure and the gasification rate of metal calcium can be reduced, the depth of the seamless solid metal calcium cored wire inserted in molten steel is increased, the boiling of the molten steel is reduced, the time that the metal calcium is adsorbed by metal is reduced, the boiling phenomenon of the existing seamed solid calcium cored wire inserted in the molten steel is overcome, the phenomenon that the wire feeding is affected due to hollow powder calcium cored wire and non-uniform core powder weigh is reduced, and the bring-in of harmful elements (S, P, C and Si) in the powder calcium cored wire is avoided, so that the yield and the stability of metal calcium are greatly improved.

Owner:周海涛 +1

Technical method for preparing 2-ethyl-2-hexenal by catalyzing self-condensation of n-butyraldehyde with acidic ionic liquid

ActiveCN102701926AGood solubilityLow steam pressureOrganic compound preparationCarbonyl compound preparationSelf-condensationEthyl phosphate

The invention relates to a technical method for preparing 2-ethyl-2-hexenal by catalyzing self-condensation of n-butyraldehyde with an acidic ionic liquid. The technical method comprises the following steps: adding the n-butyraldehyde and an acidic ionic liquid catalyst into a high-pressure autoclave, wherein the using amount of the acidic ionic liquid catalyst is 1-50 percent of the mass of the n-butyraldehyde; and magnetically stirring at 50-150 DEG C and reacting for 0.5-12h, wherein after self-condensation reaction of the n-butyraldehyde, the 2-ethyl-2-hexenal is obtained and the acidic ionic liquid catalyst is a Bronsted acidic ionic liquid or a Lewis acidic ionic liquid. The Bronsted acidic ionic liquid catalyst and the Lewis acidic ionic liquid catalyst are high in catalytic activity, good in selectivity, mild in reaction conditions and reusable; the conversion rate of the n-butyraldehyde is as high as 94.5%; the highest selectivity of the 2-ethyl-2-hexenal is 99.3%; and the acidic ionic liquid catalyst has higher catalytic performance than the traditional industrial liquid alkali catalyst and has a good prospect for industrial application.

Owner:HEBEI UNIV OF TECH

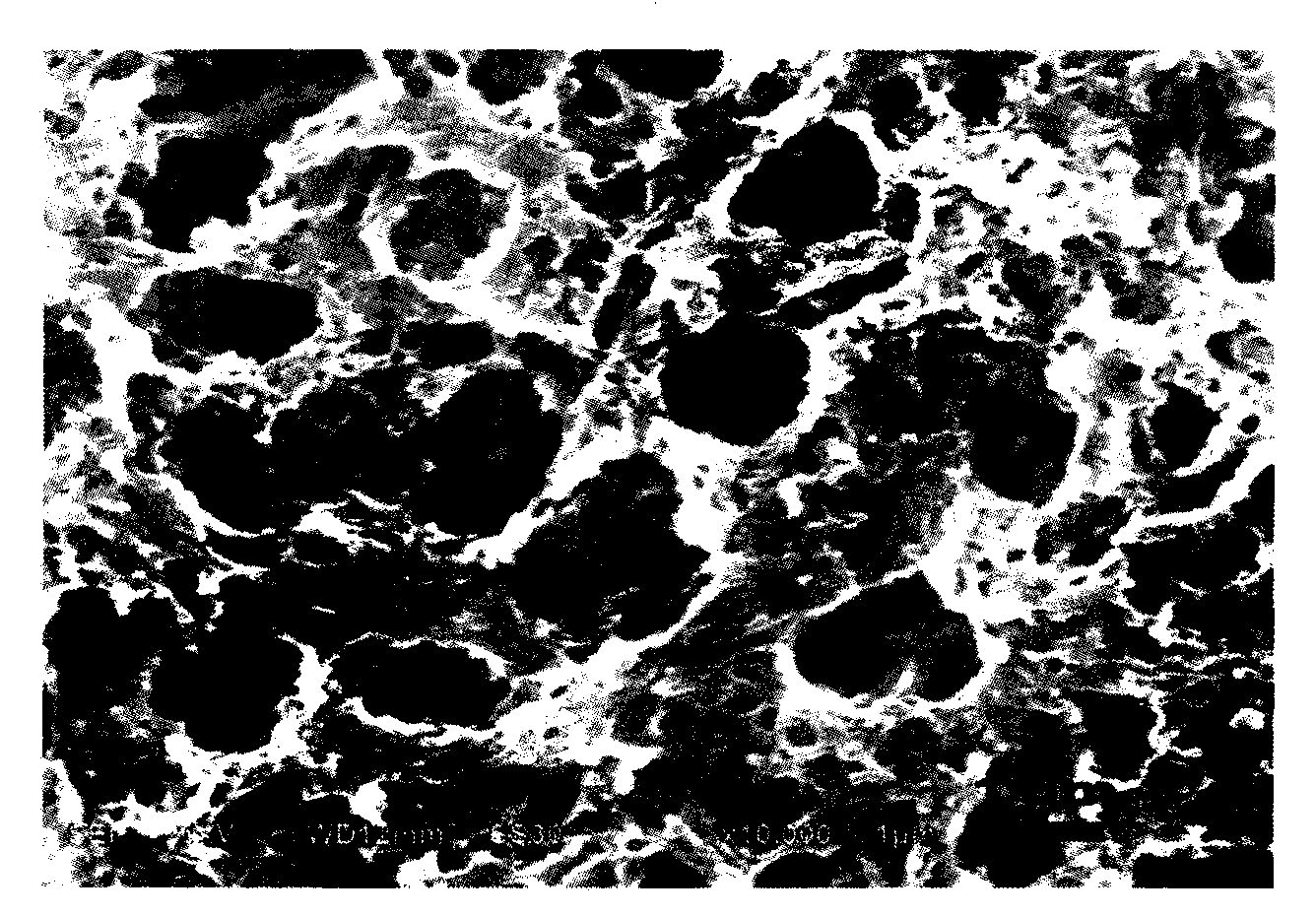

Method for preparing three-dimensional porous polymer electrolyte film

InactiveCN103545548AGood compatibilityEasy to operateSecondary cellsNanotechnologyPorosityPolymer science

The invention provides a method for preparing a three-dimensional porous polymer electrolyte film. The method comprises the following steps of synthesizing sodium carbonate and calcium chloride in water to form nanometer CaCO3 by using an oleic acid and ethanol as dispersing agents; modifying the nanometer CaCO3 by using a titanate coupling agent to synthesize modified nanometer CaCO3; ultrasonically dispersing the modified nanometer CaCO3 into a first organic solvent, adding and dissolving polymer powder to obtain a polymer solution in which the modified nanometer CaCO3 is suspended, casting the polymer solution on the surface of a smooth substrate after room-temperature vacuum defoaming, and drying the substrate at constant temperature to form a polymer film; impregnating the polymer film in an aqueous solution of HCl until no foams are formed, washing the polymer film for many times by using distilled water until the pH is 7, and performing vacuum drying to obtain a three-dimensional porous polymer film; and impregnating the three-dimensional porous polymer film in a liquid electrolyte solution in a water-free and oxygen-free glove box to obtain the three-dimensional porous polymer electrolyte film. The method has the advantages of simplicity, easiness, environmental friendliness and the like, and porosity, aperture distribution and the like in the polymer electrolyte film are easy to control.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com