Patents

Literature

683results about How to "No peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

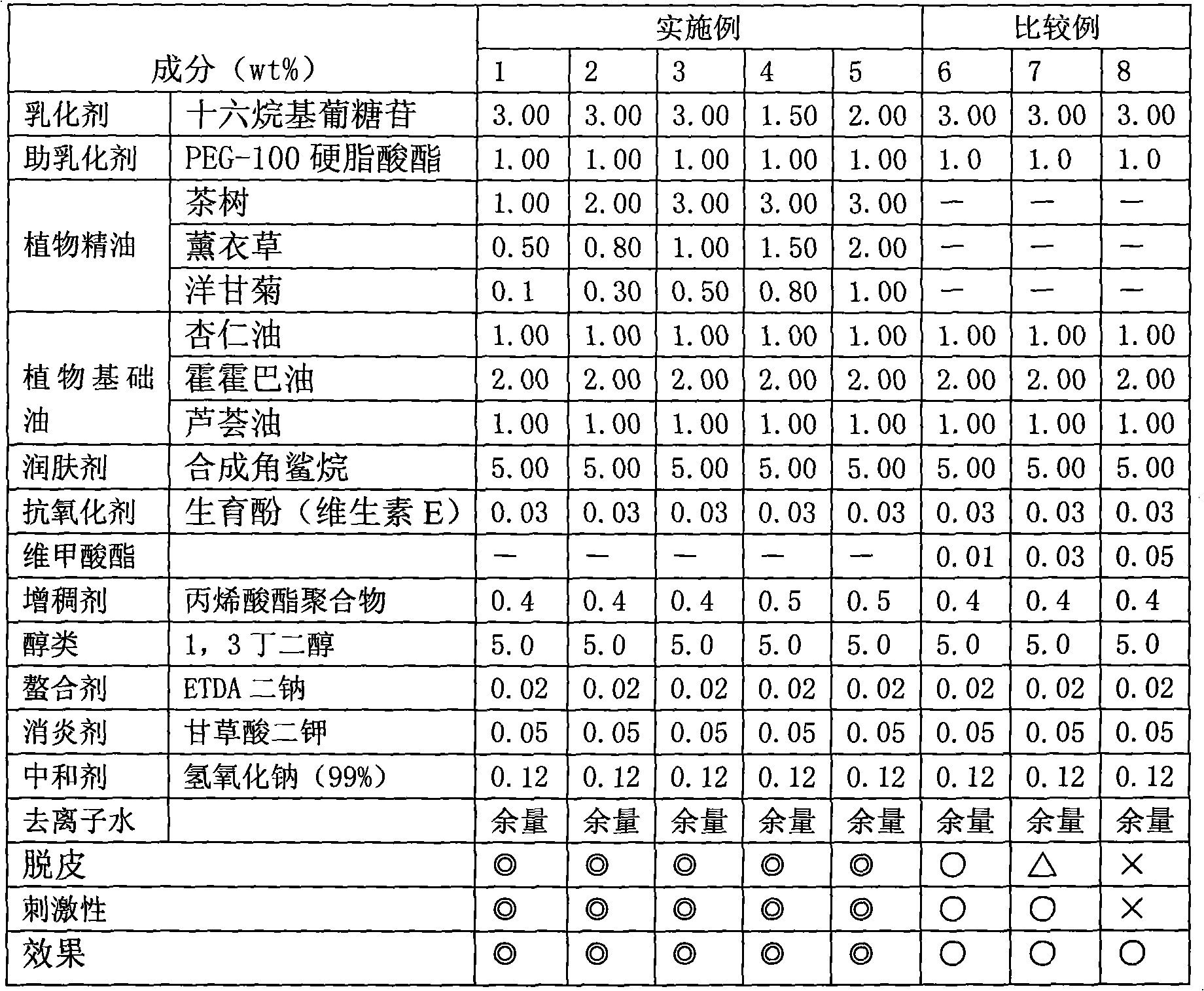

Acne treatment cosmetic composition

InactiveCN101664371AGood effectGood effect on acneCosmetic preparationsToilet preparationsAcne treatmentEssence oil

The invention discloses an acne treatment cosmetic composition. The formula comprises the following components according to weight percentage: 0.01-50.00 percent of essential oil, 0.01-10.00 percent of vegetable base oil, 0.00-6.00 percent of emulsifier, 0.01-10.0 percent of counter irritant, 0.01-0.20 percent of antioxidant, 0-4.00 percent of thickener, 0.10-0.80 percent of preservative and the balance of deionized water. The composition has good acne treatment effect, rapid infiltration, no decrustation and little stimulation, and can be used for skincare products such as mildy wash, cream,skin milk, facial mask, various aqua products (astringent, smoothing toner, toner, nutritive water and acne removing liquor) and the like.

Owner:MINGCHEN HEALTH CO LTD

High-temperature-resisting heat-insulation coating as well as preparation method and application thereof

ActiveCN103725074AEasy to use in constructionPlay the role of saving energy and reducing consumptionReflecting/signal paintsPetroleumEnergy consumption

The invention relates to the field of functional coatings and particularly relates to a high-temperature-resisting heat-insulation coating and a preparation method thereof. The high-temperature-resisting heat-insulation coating is composed of the following raw materials in percentage by mass: 10%-40% of high-reflection paint with a shell-core structure, 10%-40% of heat-insulation powder with the shell-core structure, 1%-5% of a toughening agent, 10%-50% of a high-temperature bonding agent, 1%-10% of a coating auxiliary agent, and the balance of water. The preparation method comprises the following steps: mixing, dispersing and grinding raw materials; carrying out homogenization to enable an average grain diameter to be 325-400 meshes; and filtering and packaging to obtain a finished product. The high-temperature-resisting heat-insulation coating can be applied to high-temperature fields of industrial furnaces, industrial boilers, high-temperature steam pipelines, petroleum cracking equipment, engine parts, high-temperature smelting, sintering furnaces and the like, and can be used under a higher temperature for long time; the energy consumption can be saved and the service life of the furnaces is prolonged.

Owner:武汉双虎涂料股份有限公司

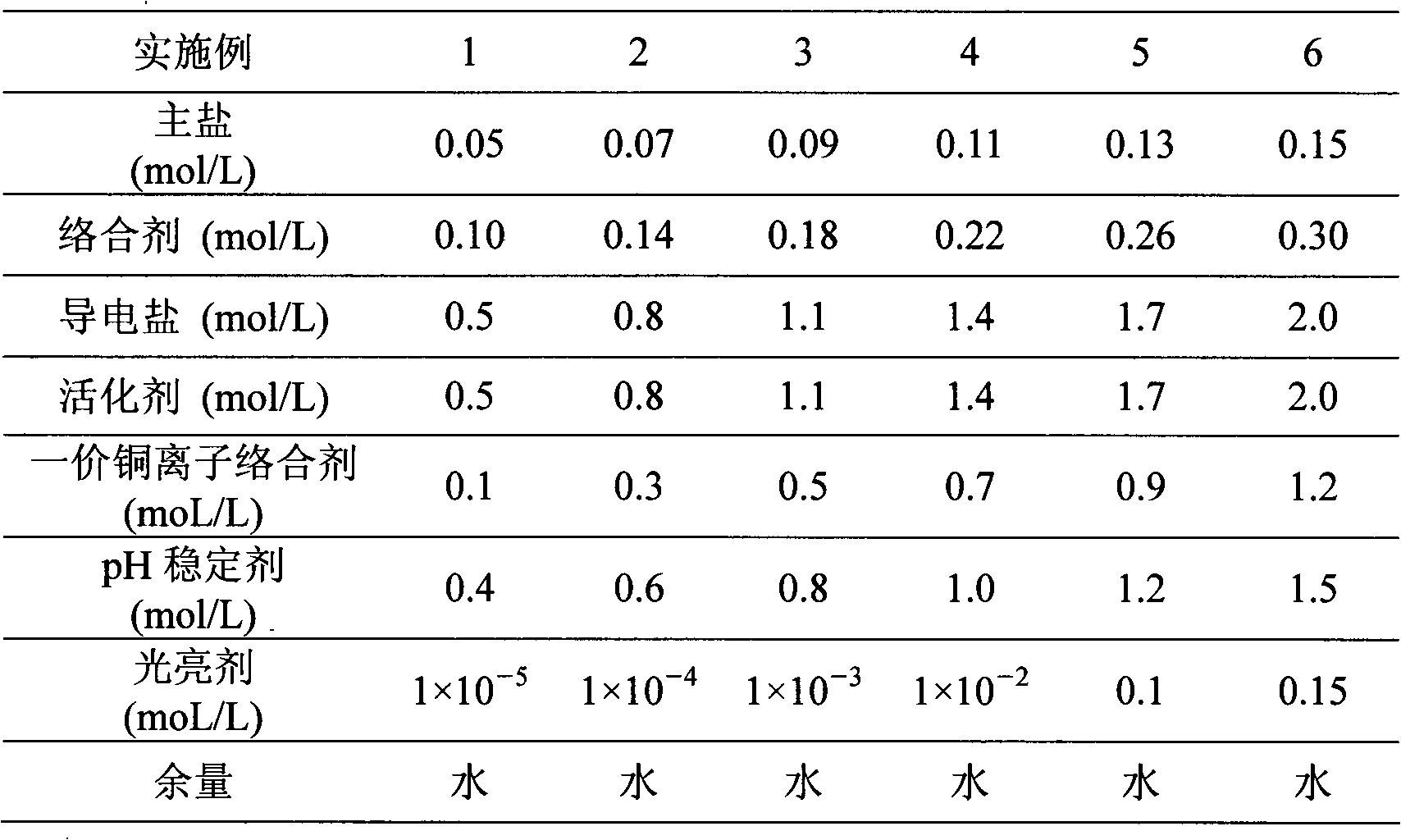

Alkaline non-cyanide plating solution for copper-plating used on iron and steel base and preparation method thereof

An alkaline non-cyanide plating solution for copper-plating used on iron and steel base and a preparation method thereof relate to a kind of plating solution. The invention provides the alkaline non-cyanide plating solution for copper-plating used on iron and steel base and the preparation method thereof. The plating solution comprises the following components: main salt, complexing agent, conductive salt, activator, cuprous ion complexing agent, pH stabilizer and brightening agent. The method comprises the following steps: adding complexing agent in water, stirring to dissolve complexing agent, obtaining a solution A; adding main salt in the solution A, stirring to dissolve main salt, obtaining a solution B; adding conductive salt in water, stirring to dissolve conductive salt, obtaininga solution C; mixing the solution B and solution C, adjusting the pH value to 2.0-4.5 with sulfuric acid or sodium hydroxide, obtaining a solution D; adding additive in the solution D, adding water toperform constant volume process and obtaining the alkaline non-cyanide plating solution for copper-plating in the desired volume for use, wherein the additive is activator, cuprous ion complexing agent, pH stabilizer and brightening agent.

Owner:XIAMEN UNIV

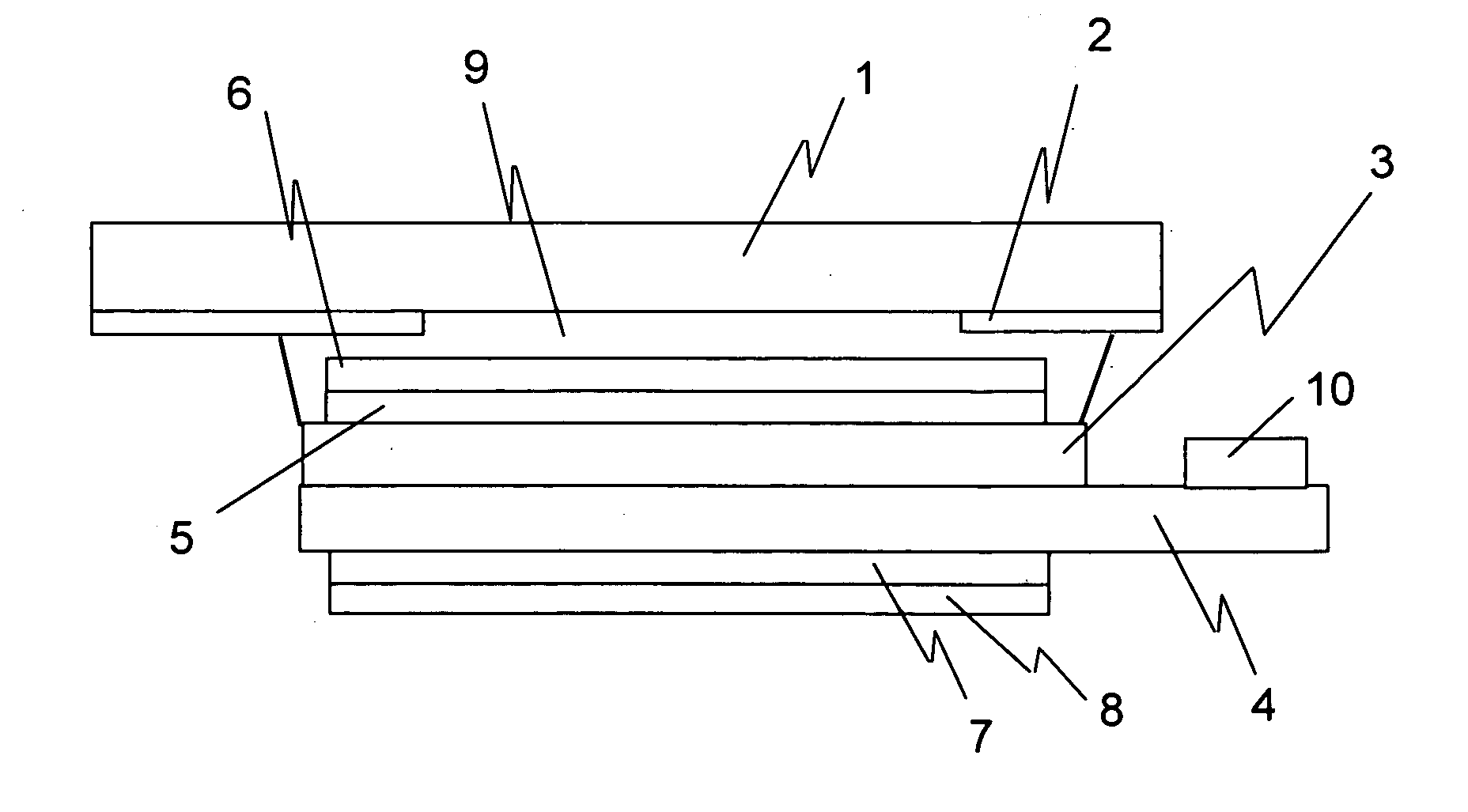

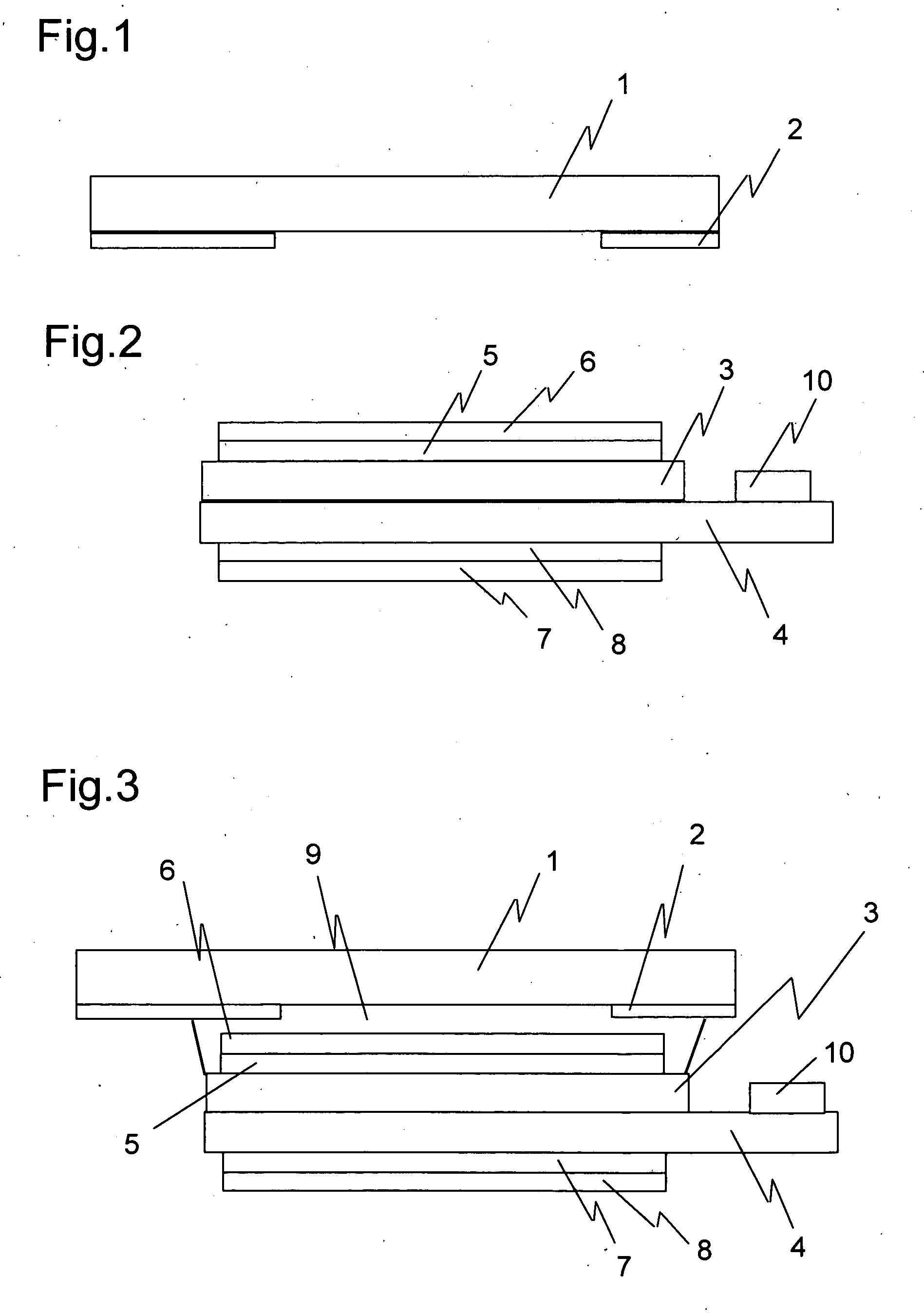

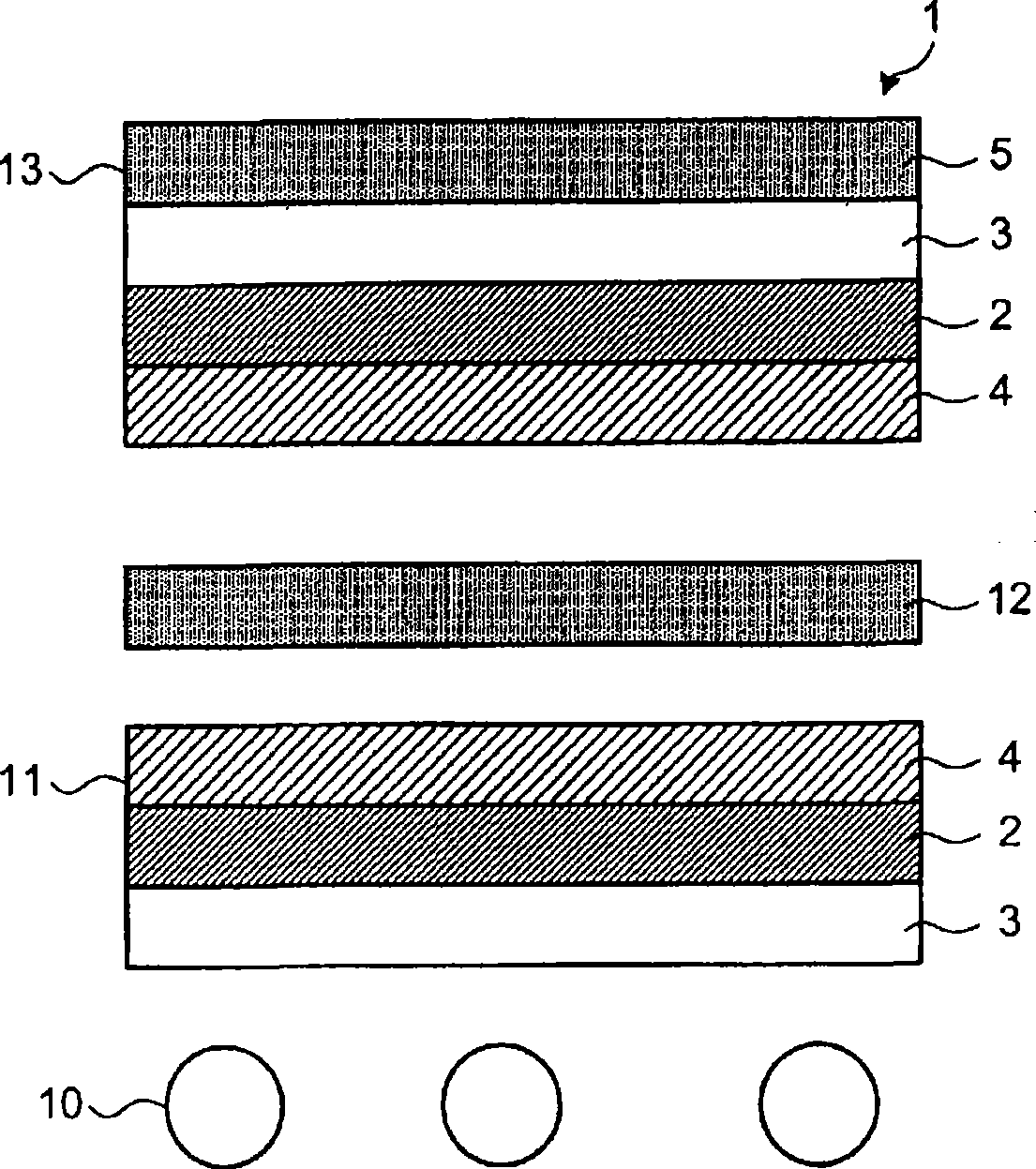

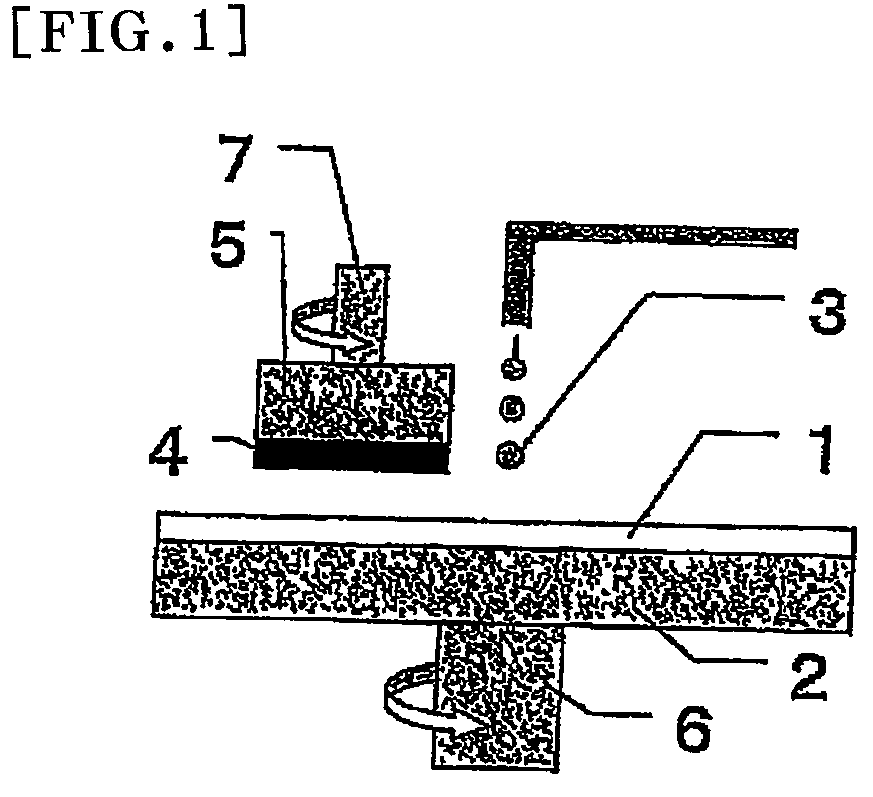

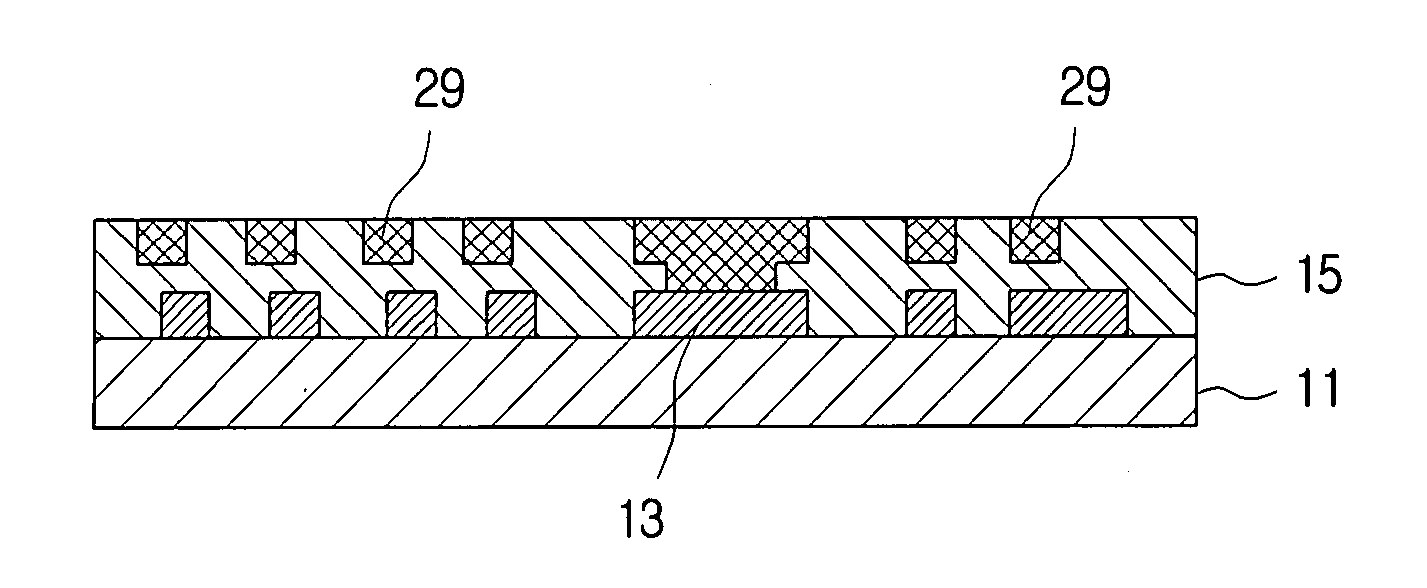

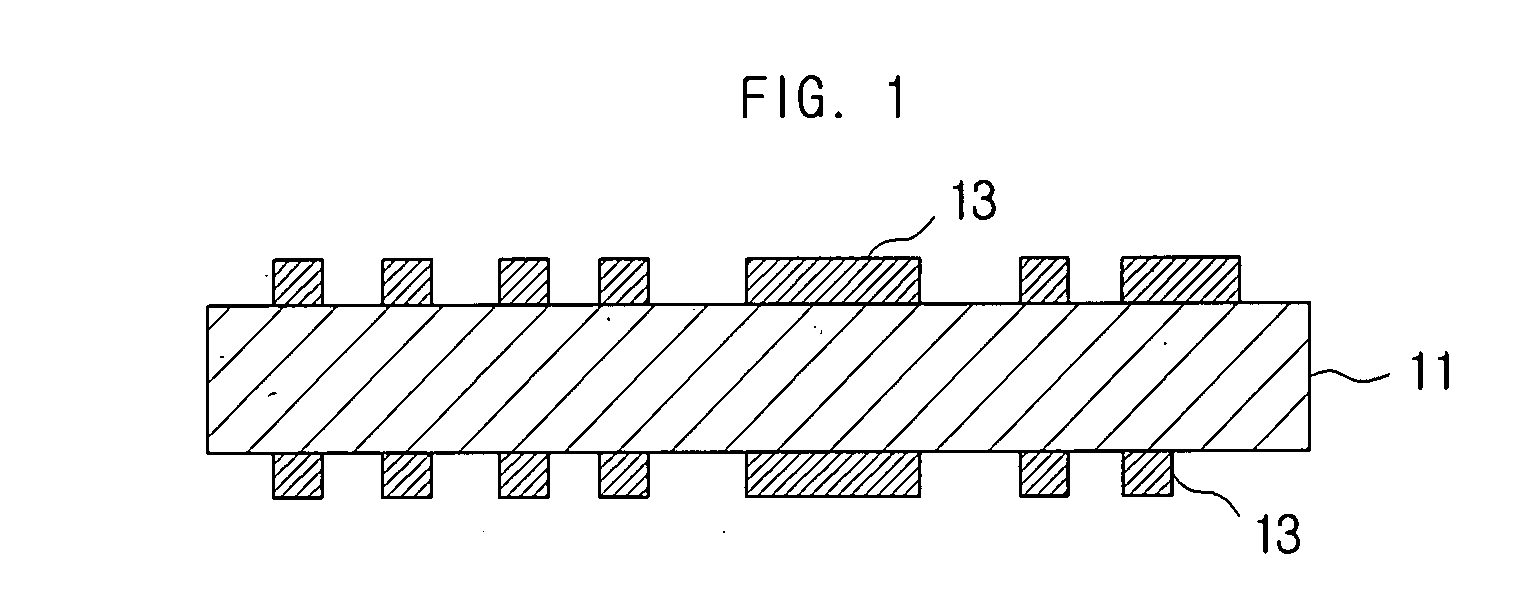

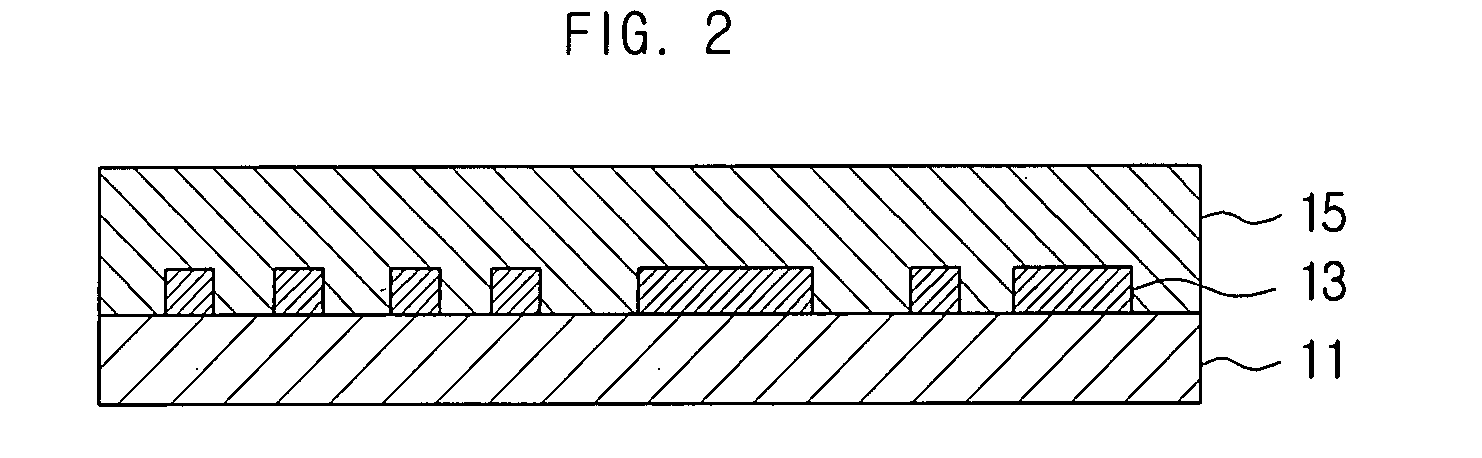

Display Apparatus and Method of Manufacturing a Display Apparatus

InactiveUS20090162645A1Less unevenness in displayed imageNo peelingLamination ancillary operationsLaminationOptical bondingLiquid-crystal display

A display apparatus is provided in which a transparent cover plate or a touch panel is bonded to a liquid crystal display device in a full-surface contact manner and which is free from unevenness in displayed colors and peeling. The transparent cover plate or touch panel and the liquid crystal display device are bonded with an optical adhesive, which is set to a Shore A hardness of 1 or more to 30 or less. The thickness of the adhesive layer is set to 30 to 200 μm.

Owner:SEIKO INSTR INC

Polarizing plate, liquid crystal display and protective film

ActiveCN101460306AImprove scratch resistanceHigh mechanical strengthSynthetic resin layered productsPolarising elementsVisibilityTectorial membrane

Disclosed is a polarizing plate having high mechanical strength, while being excellent in flexibility and abrasion resistance. This polarizing plate is not deteriorated in visibility even under high temperature, high humidity conditions, and hardly suffers from visibility obstacles such as color shading due to dimensional change. Also disclosed is a liquid crystal display using such a polarizing plate. A film mainly containing a thermoplastic resin and composed of a plurality of layers is employed as a first protective film used on the viewer side of the polarizing plate, and at least one surface layer of the first protective film is mainly composed of an acrylic resin. A second protective layer having specific characteristics is arranged on the liquid crystal cell side.

Owner:ZEON CORP

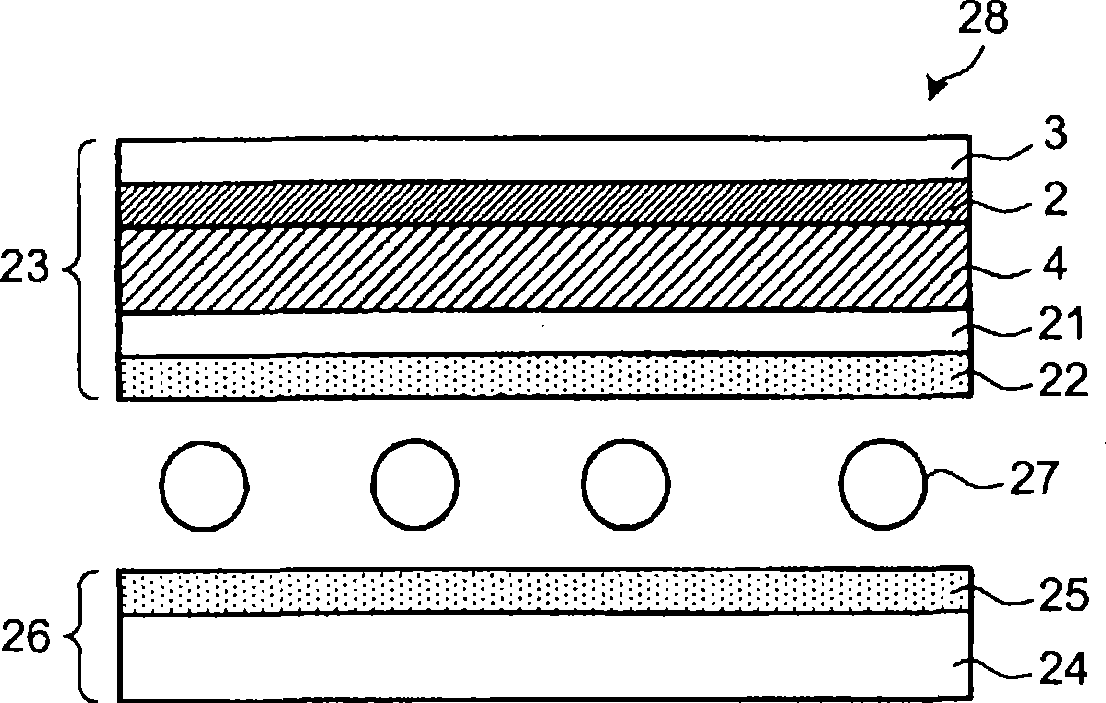

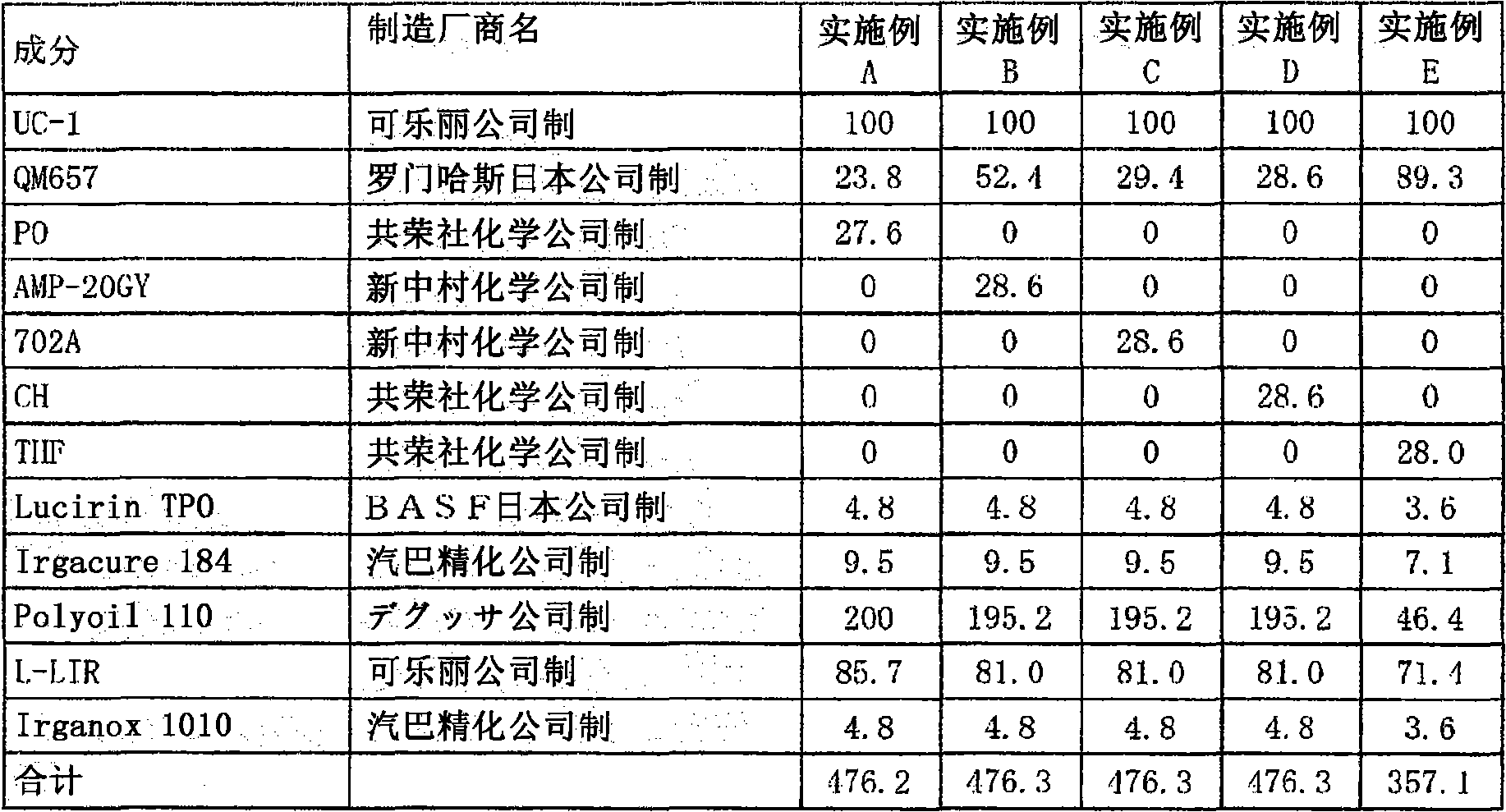

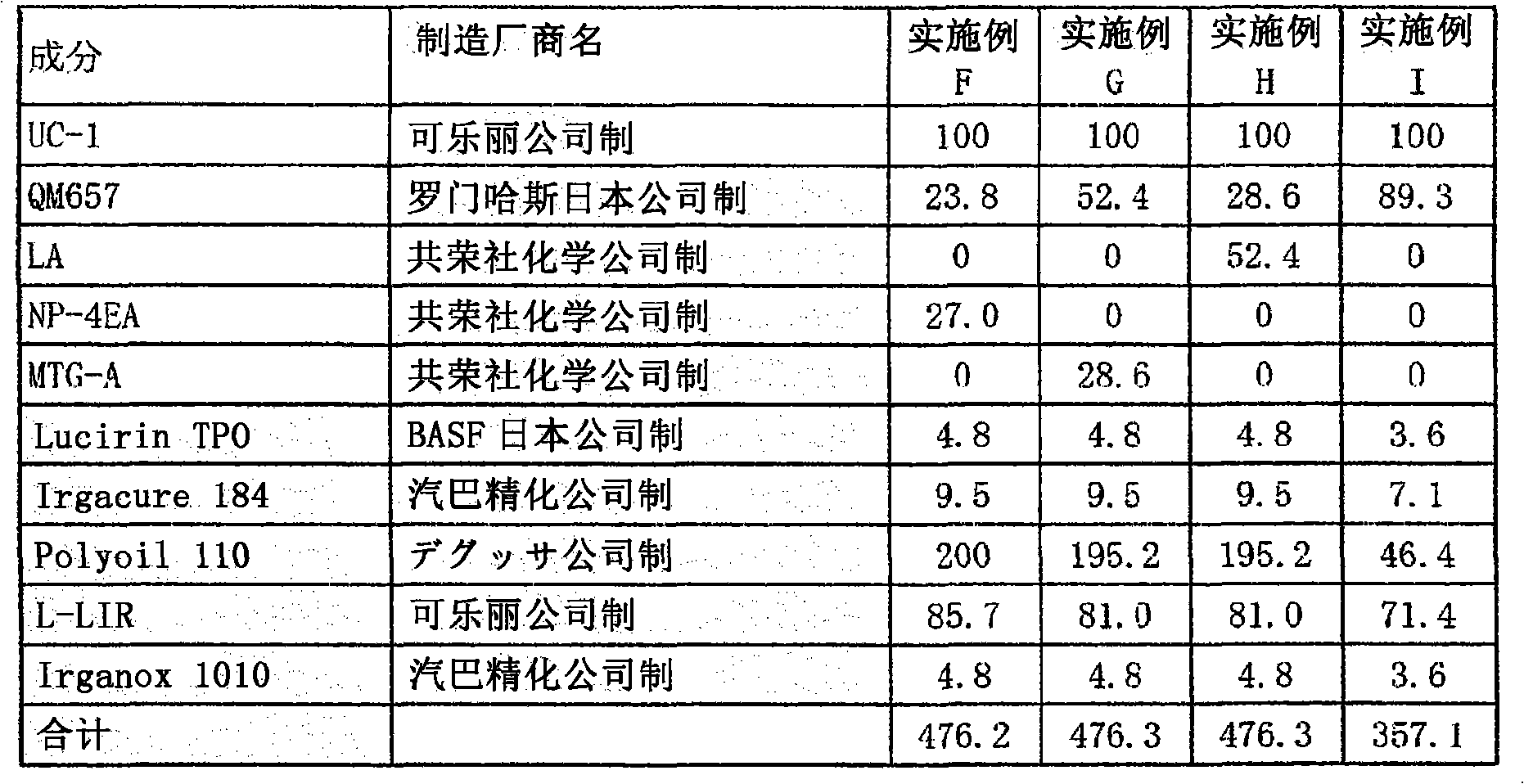

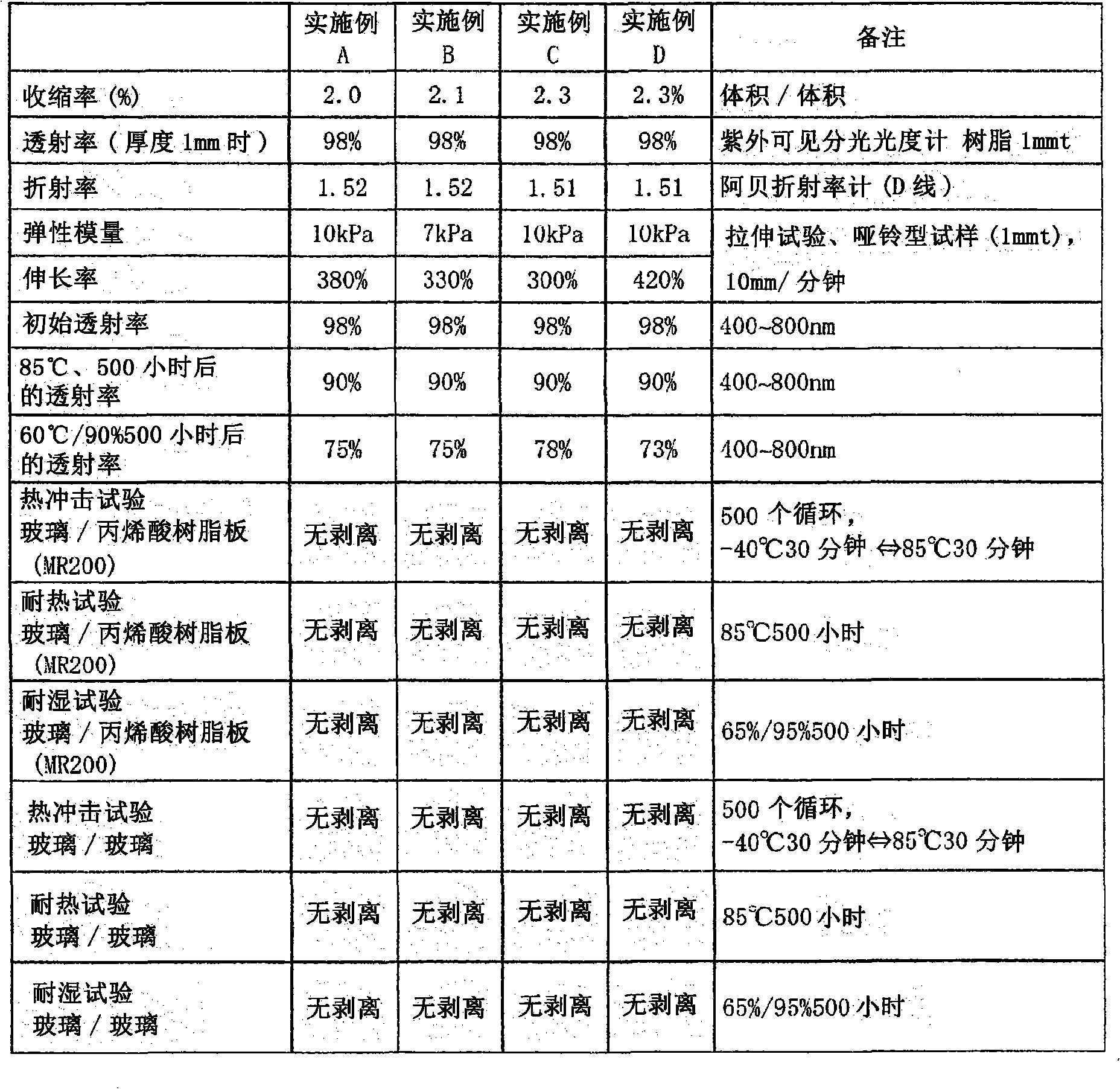

Photocurable resin composition for laminating optically functional material

ActiveCN102144009AAdhesive forceNo peelingNon-macromolecular adhesive additivesMacromolecular adhesive additivesTouch panelChemistry

Disclosed is a photocurable adhesive composition which, in the lamination of a decorated plate or an icon sheet on a touch panel or in the lamination of a transparent substrate with a transparent electrode formed thereon on a transparent plate in an electrostatic capacitive touch panel, can impart satisfactory adhesive properties and can realize the lamination without incorporating air bubbles. Also disclosed is a photocurable resin composition for use in the lamination of a display and an optically functional material on each other, which, when a display is laminated on an optically functional material, does not cause the delamination of a bonded surface or the breaking of a glass in the display. The photocurable adhesive composition comprises (A) a (meth)acrylate oligomer having a polyisoprene, polybutadiene, or polyurethane skeleton, (B) a softening component, and optionally (C) (C1) a (meth)acrylate monomer selected from phenoxyethyl(meth)acrylate, phenoxy polyethylene glycol(meth)acrylate, 2-hydroxy-3-phenoxypropyl(meth)acrylate, and cyclohexyl(meth)acrylate, (C2) or a thiol compound. The photocurable resin composition can provide a cured product having a modulus of elasticity and an elongation at break both of which fall within given ranges.

Owner:KYORITSU KAGAKU SANGYO KK

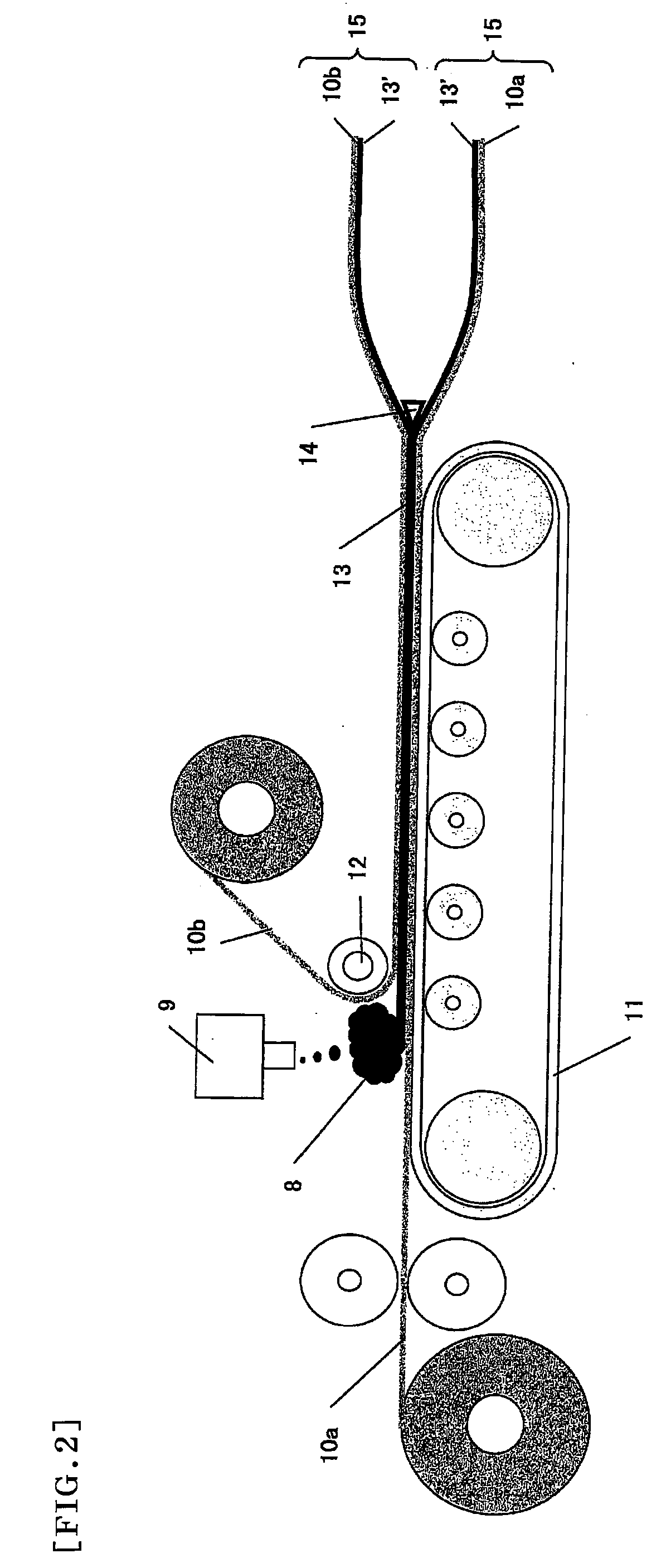

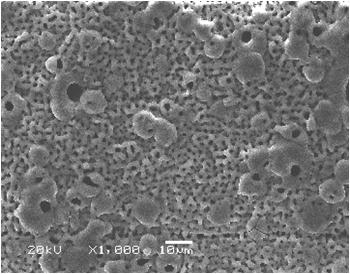

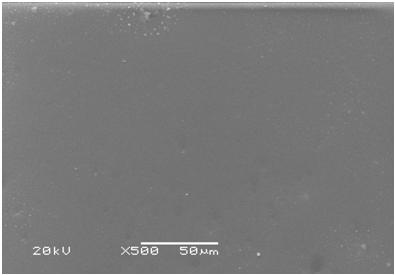

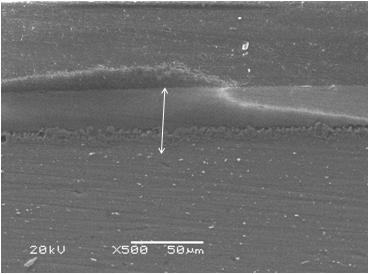

Method for manufacturing polishing pad

InactiveUS20090093202A1Improve productivityHigh thickness accuracyLamination ancillary operationsAbrasion apparatusProduction rateEngineering

A method for manufacturing a polishing pad, which may be laminated, with a small number of manufacturing steps, high productivity and no peeling between a polishing layer and a cushion layer includes preparing a cell-dispersed urethane composition by a mechanical foaming method; continuously discharging the cell-dispersed urethane composition onto a face material, while feeding the face material; laminating another face material on the cell-dispersed urethane composition; curing the cell-dispersed urethane composition, while controlling its thickness to be uniform, so that a polishing layer including a polyurethane foam is formed; cutting the polishing layer parallel to the face into two pieces so that two long polishing layers each including the polishing layer and the face material are simultaneously formed; and cutting the long polishing layers to produce the polishing pad.

Owner:TOYO TIRE & RUBBER CO LTD

Preparation method of magnesium alloy surface micro-arc oxidation/spray coating compound film

ActiveCN101871119AHigh bonding strengthImprove corrosion resistanceAnodisationLiquid surface applicatorsMicro arc oxidationPlasma electrolytic oxidation

The invention provides a preparation method of a magnesium alloy surface micro-arc oxidation / spray coating compound film, which relates to a preparation method of a magnesium alloy surface compound film. The invention solves the problems that film layers obtained by chemical composition coating, anodic oxidation and vapor deposition in the existing magnesium alloy surface treatment method are thin and have poor corrosion resistance performance, the ion injection has high cost and is difficult to realize large-area processing, the combining force between coating layers and the magnesium alloy is poor, and organic coating layers has the defect of easy aging. The preparation method has the following steps: firstly, using micro-arc oxidation for preparing ceramic films on the surface of the magnesium alloy; then, adopting air spray coating for spraying and coating inorganic paint onto the ceramic films; and then, carrying out heat treatment to obtain the micro-arc oxidation / spray coating compound film. The method is simple, and the cost is low. The air spray coating uses porous structures of the micro-arc oxidation ceramic films, so the combination of the inorganic coating layers and the ceramic films is firm, the thickness of the compound films is between 20 and 40 mum, the self corrosion electric potential is positively moved to -1.02 V, the corrosion current density is lowered by 5 orders through being compared with that of the magnesium alloy, the magnesium alloy surface micro-arc oxidation / spray coating compound film has no damage after 72 to 144h of salt spray tests, and the corrosion resistance performance is good.

Owner:HARBIN INST OF TECH

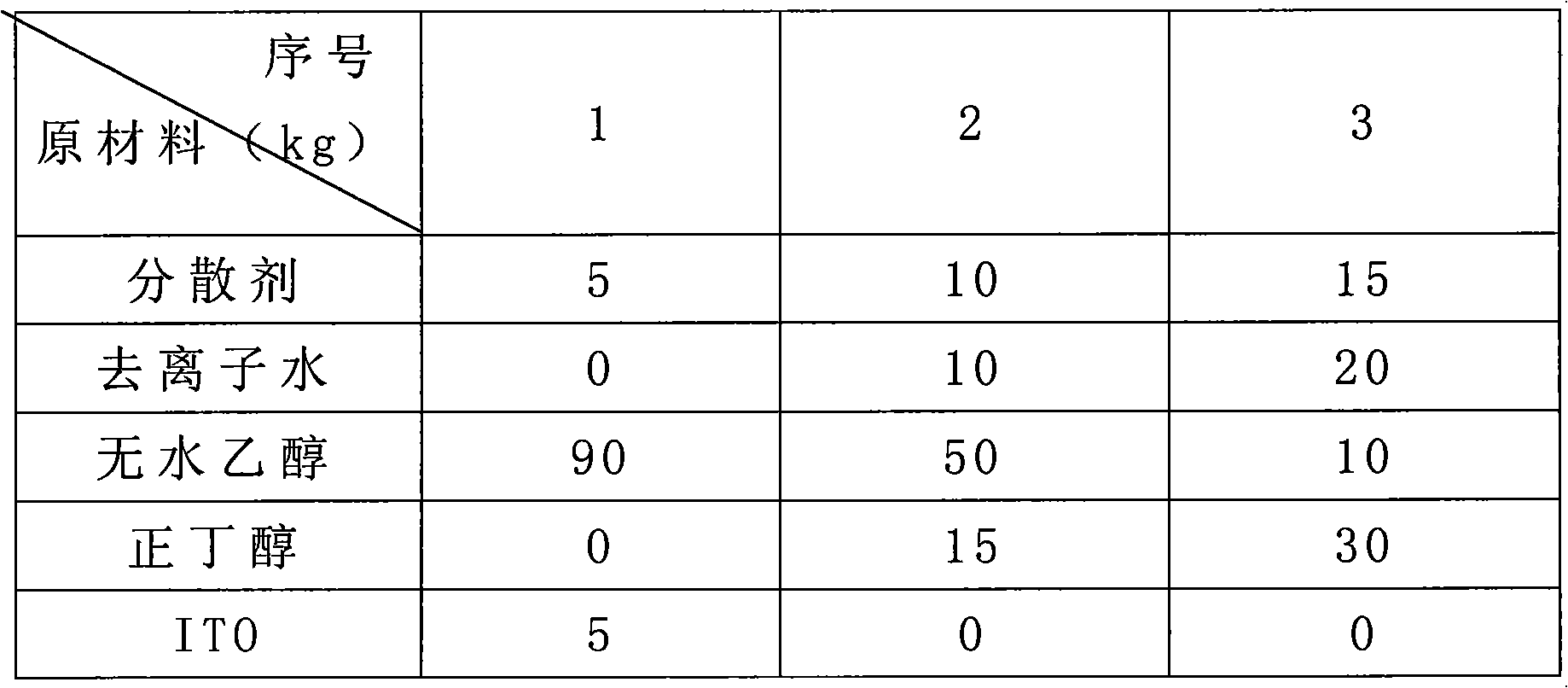

Insulating mould coating, laminated glass intermediate film, heat-protecting glass and laminated glass thereof

The invention relates to an insulating mould coating, a laminated glass intermediate film, a piece of heat-protecting glass and a piece of laminated glass thereof. The transparent insulating mould coating is prepared by dissolving a thermal plastic macromolecule resin into a solvent, then adding a nanometer material body sizing agent and other auxiliary agents and stirring the mixture evenly. Theinsulating mould coating can be coated on glass and transparent resin film materials, and has very strong bonding strength, and refraction coefficients similar to that of the glass and the laminated glass intermediate film; and the insulating laminated glass prepared by using the insulating mould coating has the characteristics of high visible light transmittance, infrared ray shielding, heat insulation, ultraviolet ageing resistance and the like. The insulating mould coating is simple to prepare, needs no large-scale equipment, and is favorable for popularization.

Owner:HUNAN MASHI NANOMETER NEW MATERIAL

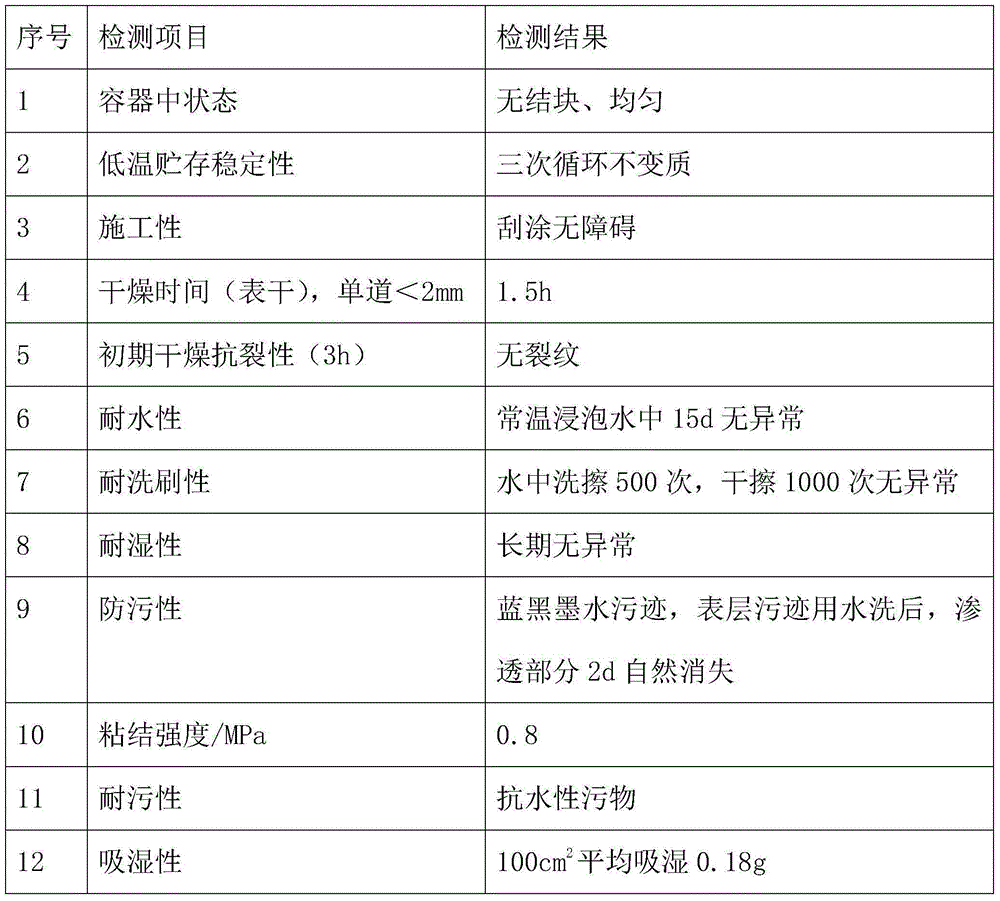

Aqueous texture wallpaper paint and method for making same

The invention relates to a watercraft texture wallpaper paint, characterized in that the invention comprises the following components: 31 percent to 35 percent of styrene-acrylic emulsion, 23.94 percent of superfine weight calcium, 1 percent to 2 percent of nano-titanium dioxide, 10 percent to 18 percent of titanium pigment, 8 percent to 9.8 percent of calcined kaolin, 1.2 percent to 1.8 percent of ethylene glycol, 0.2 percent to 0.5 percent of hydroxyethylcellulose, 0.8 percent to 1.5 percent of film forming additive, 0.15 percent to 0.25 percent of multi-functional additive, 0.3 percent to 0.5 percent of dispersant, 0.1 percent to 0.2 percent of wetting agent, 0.15 percent to 0.21 percent of defoamer, 0.08 percent of anticorrosion and insecticide, 0.8 percent to 2 percent of thickener and 20 percent to 22 percent of water. The invention is the watercraft texture wallpaper paint, is environment-friendly, has strong elastic tension, has good covering and anti-cracking effect on the fine cracking of wall, and has good scrape resistance performance, greatly enhancing the degree of wall surface protection; meanwhile, the invention still has strong waterproof performance, without color-changing and decortication and mildew and can fully solve the common problems existing in wall decoration.

Owner:佛山市顺德区清大润彩涂料有限公司

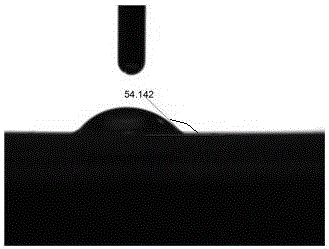

Preparation method of wear-resistant super-hydrophobic nanometer titania coating

InactiveCN105602412AExtended service lifeImprove protectionEpoxy resin coatingsPigment treatment with organosilicon compoundsEpoxyWear resistant

The invention discloses a preparation method of a wear-resistant super-hydrophobic nanometer titania coating. The preparation method includes firstly, dissolving silane coupling agent in ethyl alcohol and then heating and stirring to react to obtain a solution; secondly, adding nanometer titania into the solution and then stirring and drying to obtain hydrophobic nanometer titania powder; thirdly, mixing a certain quantity of epoxy resin with hardener while adding in diluting agent to dilute the resin completely to obtain a diluted liquid, adding the hydrophobic nanometer titania powder into the diluted liquid, then subjecting the mixture to ultrasonic dispersion with complete stirring to allow the nanometer titania to contact with the resin completely so as to obtain a suspension liquid; and finally, coating the suspension liquid on a base material and drying completely so as to obtain the wear-resistant super-hydrophobic nanometer titania coating. Compared with the pure hydrophobic nanometer coating, the wear-resistant super-hydrophobic nanometer titania coating prepared by the method has the advantages that coating hardness is improved greatly, and super-hydrophobic property of the coating is guaranteed while interlayer adhesion and inner binding force of the nanometer coating are improved greatly.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Composite sheet material for brazing

InactiveUS6753094B1Good self-lubricating performanceImprove adhesionLiquid surface applicatorsSynthetic resin layered productsPolyolefinMetal powder

The invention relates to a composite sheet material for brazing, the composite sheet material having a structure comprising an aluminium or aluminium alloy substrate on at least one side coupled to a layer comprising a polyolefin / acrylic acid copolymer as a carrier filled with brazing flux material, and optionally also with a metal powder, in an amount sufficient to achieve brazing. The invention further relates to a method of manufacturing composite sheet material for brazing, which method comprises the steps (a) mixing the polyolefin / acrylic acid copolymer with the brazing flux material and / or metal powder, and (b) applying to at least one surface of the metal substrate a mixture of said copolymer filled with the brazing flux material and / or metal powder, in an amount sufficient to achieve subsequent brazing.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

Downconversion frequency shift infrared radiation enhanced coating and preparation method thereof

InactiveCN101712816AHigh heat conversion efficiencyImprove absorption rateCoatingsEmissivityFrequency shift

The invention relates to an infrared radiation enhanced coating and a preparation method thereof. The downconversion frequency shift infrared radiation enhanced coating is characterized by consisting of the following components in percentage by mass: 20 to 50 percent of radiation synergistic enhancer, 1 to 7 percent of downconversion frequency shift additive, 15 to 45 percent of high-temperature resistant base stock, 32 to 50 percent of high-temperature binder, 1 to 4 percent of flexibilizer and 1 to 4 percent of coating auxiliary agent, and the sum of the mass percentage of the components is 100 percent. The coating not only has high emissivity and good thermal shock resistance, but also can convert visible light into infrared radiation; and the thermal conversion efficiency of the coating is effectively improved.

Owner:WUHAN YINFURUI NEW MATERIAL

Concrete maintenance and reinforcement treatment method

InactiveCN102220813AGood sealingIncreasing the thicknessBuilding repairsBridge erection/assemblyFiberAdhesive

The invention relates to a concrete maintenance and reinforcement treatment method. The method comprises the following steps: (1) carrying out nondestructive treatment on the concrete base surface defects; (2) carrying out rust-proof treatment on reinforcing bars; (3) carrying out concrete alkalinity recovery treatment; (4) carrying out concrete crack repairing treatment; (5) daubing new and old concrete adhesives; (6) daubing inorganic polymer mortar and carrying out curing; (7) sticking carbon fiber cloth; (8) brushing an inorganic water and salt injury resistant concrete protective agent; and (9) brushing a surface self-cleaning material, thus completing construction. The method has the following beneficial effects: rust can be removed or prevented from the reinforcing bars to protect the reinforcing bars and prevent further corrosion; by adopting the carbon fiber cloth for reinforcement, the concrete structure has the characteristics of high strength, light weight, simpleness and convenience in construction and corrosion resistance; the bearing capability of the beam body is improved; the deflection of the structure is reduced; the construction efficiency is greatly improved by adopting the airless spraying and coating operations; the coating is saved by 30%; and by brushing the self-cleaning material, the structure has the self-cleaning capability, thus avoiding cleaning or reducing the cleaning frequency.

Owner:SHANGHAI FAHE BRIDGE & TUNNEL MAINTENANCE ENG TECH

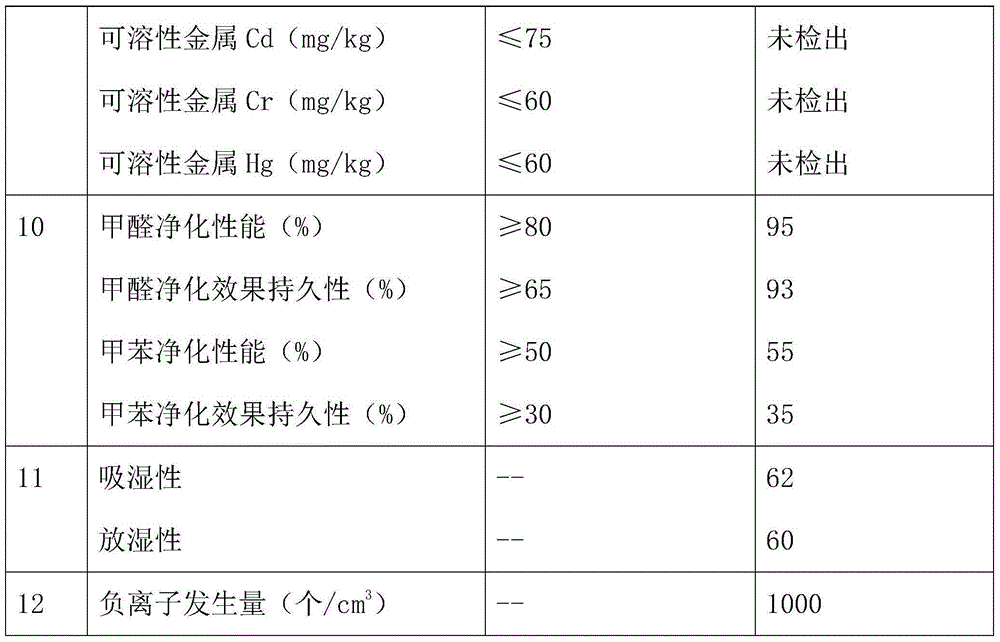

Environment-friendly humidifying diatom ooze coating

InactiveCN105131739AImproved adhesion and moisture absorptionImprove water permeability and breathabilityCoatingsEmulsionChemistry

The invention discloses an environment-friendly humidifying diatom ooze coating. The coating is prepared from silica sol / benzene-acrylic compound emulsion, pure acrylic emulsion, modified diatom ooze, light calcium carbonate, lithopone, anion powder, sodium alginate, dispersing agents SN-5040, ethylene glycol, wetting agents AP-680, alcohol ester-12, propylene glycol monomethyl ether acetate, thickening agents, flatting agents, defoaming agents, sterilization and mildew prevention agents and deionized water. The environment-friendly humidifying diatom ooze coating has the effects of absorbing moisture, releasing moisture, cleaning air and releasing anions, harmful ingredients in indoor air can be absorbed, and the environment protection and healthy effects are achieved.

Owner:TIANCHANG YINHU PAINT

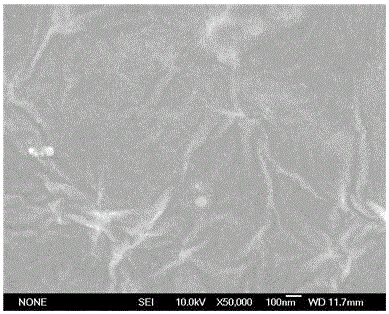

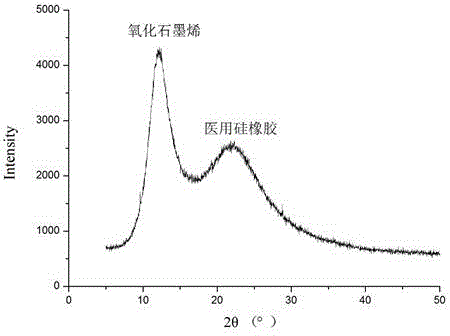

Graphene oxide/polymer composite antibacterial material and preparation method thereof

InactiveCN106178112AImprove antibacterial propertiesGood biocompatibilitySurgeryPharmaceutical delivery mechanismAdditive ingredientMegasonic cleaning

The invention discloses a graphene oxide / polymer composite antibacterial material and a preparation method thereof. The composite antibacterial material is characterized in that a polymer is subjected to surface modification and then is combined with graphene oxide dispersed in water, thus obtaining a graphene oxide antibacterial coating bonded on a polymer matrix, wherein the thickness of the antibacterial coating is 1 to 50nm. The preparation method of the graphene oxide / polymer composite antibacterial material comprises the following steps: firstly, performing ultrasonic cleaning on the polymer; secondly, performing surface modification on the polymer subjected to ultrasonic cleaning; thirdly, immersing an activated polymer matrix into a coupling agent solution and soaking; fourthly, taking out the soaked polymer, leaching with deionized water, then putting into a graphene oxide suspension liquid for 0.2 to 24 hours, taking out, leaching and naturally drying in air to obtain the graphene oxide / polymer composite antibacterial material. The invention designs and prepares the composite antibacterial material by taking graphene oxide as an antibacterial ingredient; the composite antibacterial material has a transparent antibacterial layer, is excellent in antibacterial property and is firmly bonded with the matrix.

Owner:TAIYUAN UNIV OF TECH

Fabricating method for printed circuit board

InactiveUS20080052905A1No peelingFabrication can be reducedPrinted circuit assemblingResist coatingFine lineProduction rate

A method of fabricating a printed circuit board is disclosed. A method of fabricating a printed circuit board that includes: stacking an insulation layer on at least one surface of a core layer, on which an inner circuit is formed, and forming an outer circuit pattern; burying the outer circuit pattern in the insulation layer; removing the outer circuit pattern to form minute grooves and curing the insulation layer; and forming an outer circuit by filling metal in the minute grooves, makes it possible to readily form high-resolution fine-line circuits, as well as to reduce fabrication costs and increase productivity.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Special adhesive for underwater construction and preparation method thereof

InactiveCN103555243AIncrease elasticityGood resistance to cold and heat shockNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesiveActive agent

The invention discloses a special adhesive for underwater construction, and the special adhesive comprises an A component and a B component at a weight ratio of 100:(20-100):25, wherein the A component is prepared from the following raw materials in parts by weight: 30-60 parts of modified epoxy resin, 5-30 parts of tackifier, 2-10 parts of accelerant, 5-15 parts of reactive diluent, 0.1-0.3 parts of surfactant, and 10-35 parts of filler powder; the B component is prepared from the following raw materials in parts by weight: 0-60 parts of ketimine, 0-60 parts of phenalkamine, 30-65 parts of modified polyamide, 1-6 parts of curing accelerator, and 2-15 parts of moisture repellent. The special adhesive for underwater construction has the advantages of being good in bonding strength in water, good in toughness, water-resistant, capable of resisting chemical attack, strong in initial viscous force and convenient to construct, and great improvement is brought for the underwater construction field.

Owner:YANTAI DARBOND TECH

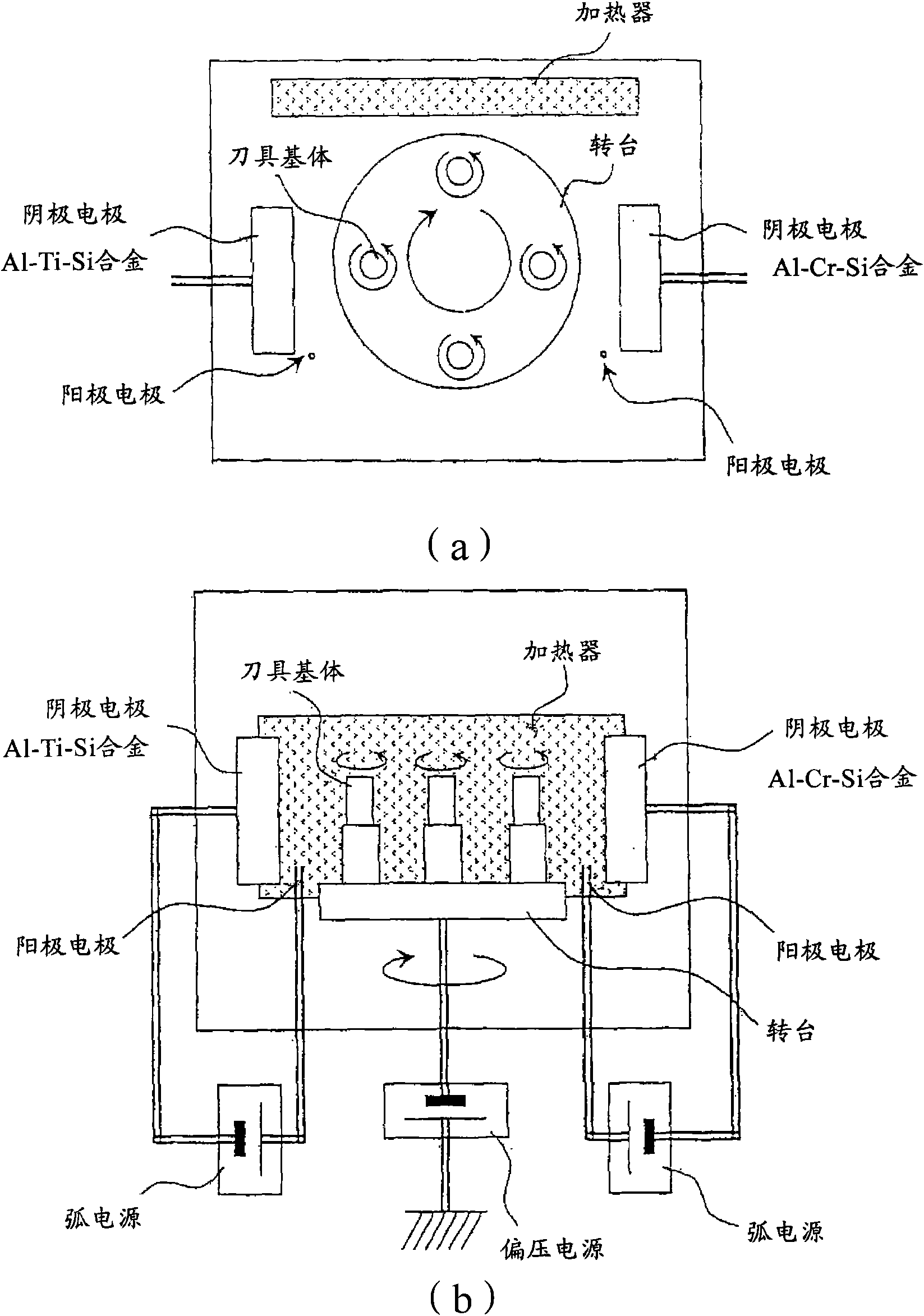

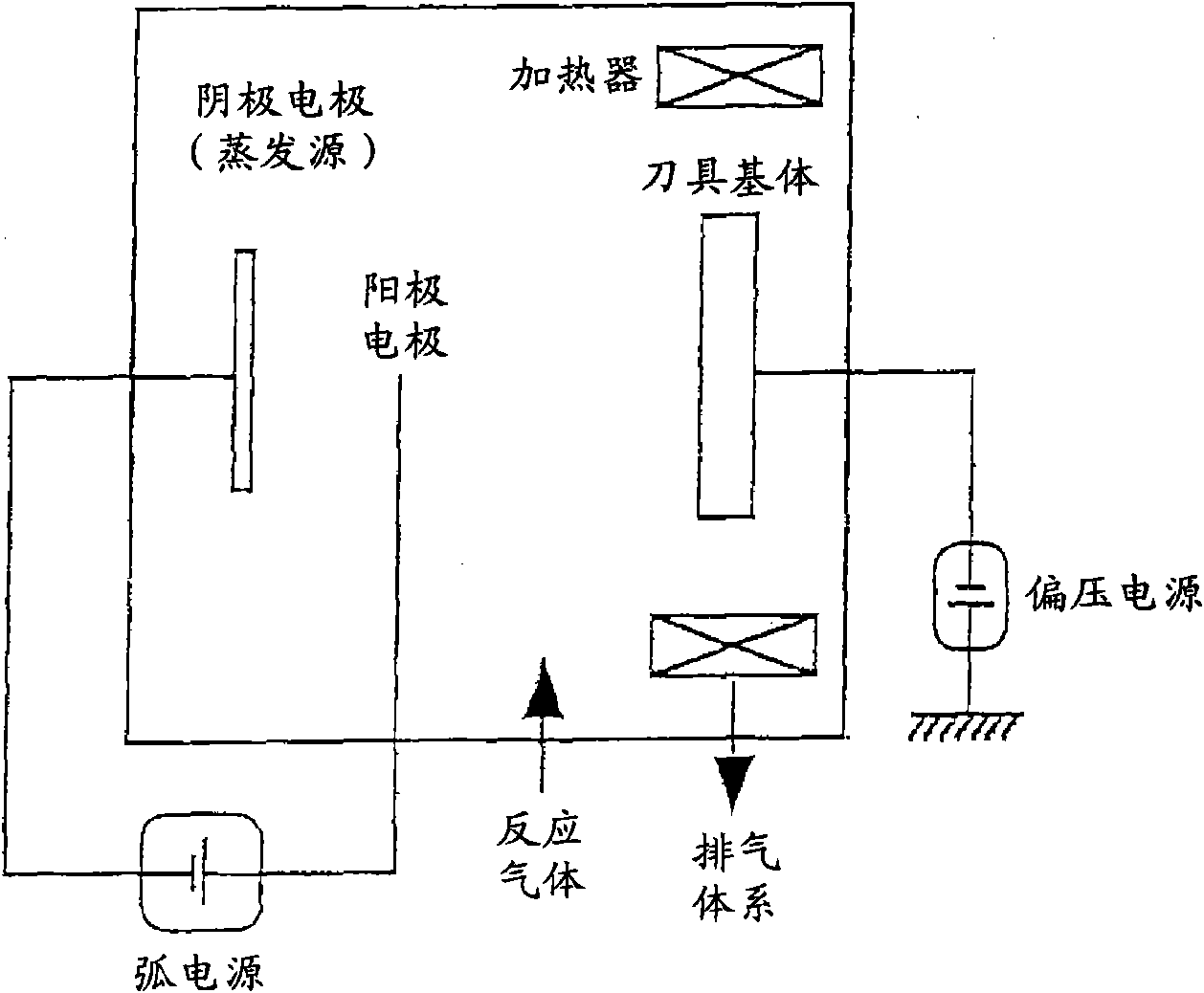

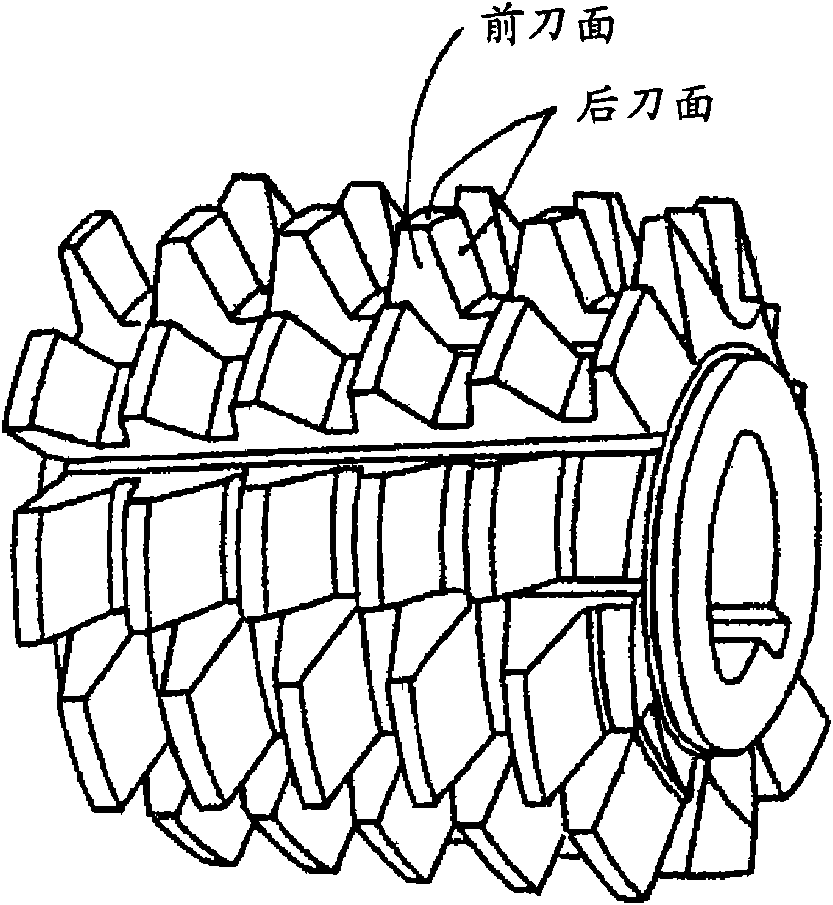

Surface-coated cutting tool

ActiveCN101678467AExcellent high temperature hardnessExcellent high temperature toughnessMilling cuttersVacuum evaporation coatingThin layerCemented carbide

A surface-coated cutting tool which has excellent chipping resistance and wearing resistance in high-speed cutting processing such as high-speed gear cutting processing, high-speed milling processing,and high-speed drilling processing. The surface-coated cutting tool comprises a tool base, e.g., a cemented carbide base, cermet base, or high-speed tool steel base, and at least a hard coating layerformed on a surface of the tool base and having a multilayer structure composed of a thin layer (A) and a thin layer (B) alternating therewith. The thin layer (A) is constituted of an (Al,Cr,Si)N layer satisfying the empirical formula ¢AlXCrYSiZ!N (wherein 0.2 <= X <= 0.45, 0.4 <= Y <= 0.75, 0.01 <=Z <= 0.2, and X+Y+Z=1 in terms of atomic ratio), and the thin layer (B) is constituted of an (Al,Ti,Si)N layer satisfying the empirical formula ¢AlUTiVSiW!N (wherein 0.05 <= U <= 0.75, 0.15 <= V <= 0.94, 0.01 <= W <= 0.1, and U+V+W=1 in terms of atomic ratio).

Owner:MITSUBISHI MATERIALS CORP

High chromium abrasion-proof cast iron abrasive disc and manufacturing method thereof

InactiveCN101195890ASimple production processReduce manufacturing costPulp beating/refining methodsSlagAlloy

The invention relates to a high chromium abrasion-resistant cast iron grinding plate and the manufacturing method, which belongs to the paper making technology field. The invention comprises the following chemical compositions (weight percent): C is 2.0-3.5 percent, Cr is 22.0-28.0 percent, Mn is1.5-2.5 percent, Si is lower than 1.0 percent, W is0.25-0.60 percent, Nb is 0.03-0.12 percent, Ta is 0.01-0.04 percent, V is 0.10-0.25 percent, Ti is 0.08-0.15 percent, RE is 0.05-0.20 percent, B is 0.02-0.10 percent, Mg is 0.04-0.10 percent, and the residual is Fe and inevitable trace impurity. The grinding plate of the invention can be manufactured by adopting an electric furnace, the precoated sand mold casting is operated, the texture of the grinding plate is fine, the intensity is high, toughness is good, and the abrasion resistance and the corrosion resistance are good. The production process of the grinding plate is simple, the cost is low, the main raw material is chromium iron, and inexpensive tungsten slag ferro alloy and vanadium slag ferro alloy are added to be used as auxiliary alloying elements. The grinding plate of the invention is used, production efficiency of a pulp grinder can be improved, the pulp grinding cost is reduced, the physical property of finished paper is bettered, and the grinding plate has good economic and social efficiency.

Owner:BEIJING UNIV OF TECH

Method for preparing porous ceramics supported high activity nano titanium dioxide

InactiveCN1511630ASolve the shortcomings of poor firmness and uneven distributionSolve the shortcomings of easy crackingCatalyst activation/preparationWater vaporAdhesive

The present invention relates to the preparation of high activity TiO2 photocatalyst with porous ceramic base, and is especially the nano titania powder and titania sol combining process of preparing regenerable high activity nano titania carried in porous ceramic. The present invention prepares the high activity nano titania carried in porous ceramic through the combination of two carrying processes, titania powder sintering process and sol-gel process. The process includes preparing titania sol via sol-gel process, mixing titania sol and titania powder in certain ratio while stirring and adding dispersant and adhesive to form new solution, carrying the solution to the surface of porous ceramic, fumigating the carrying ceramic in water vapor atmosphere to eliminate most of the organic matters, and final sintering at high temperature for strong combination between nano titania and carrier and raised activity of titania.

Owner:HUABENGUANG CATALYTIC TECH BEIJING

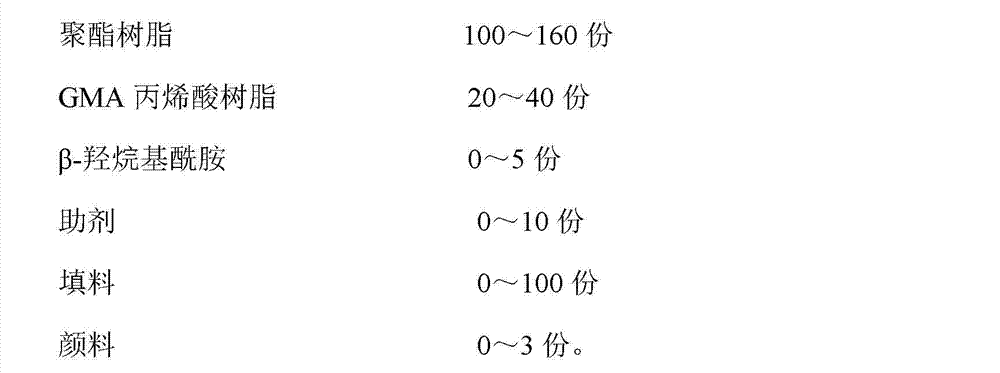

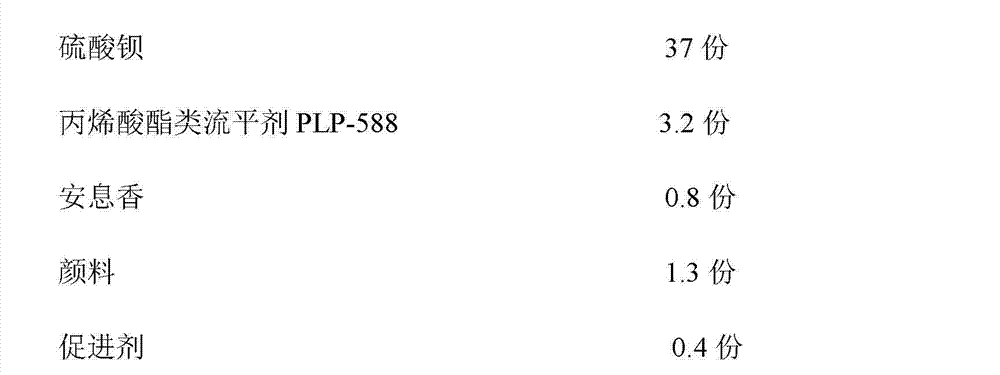

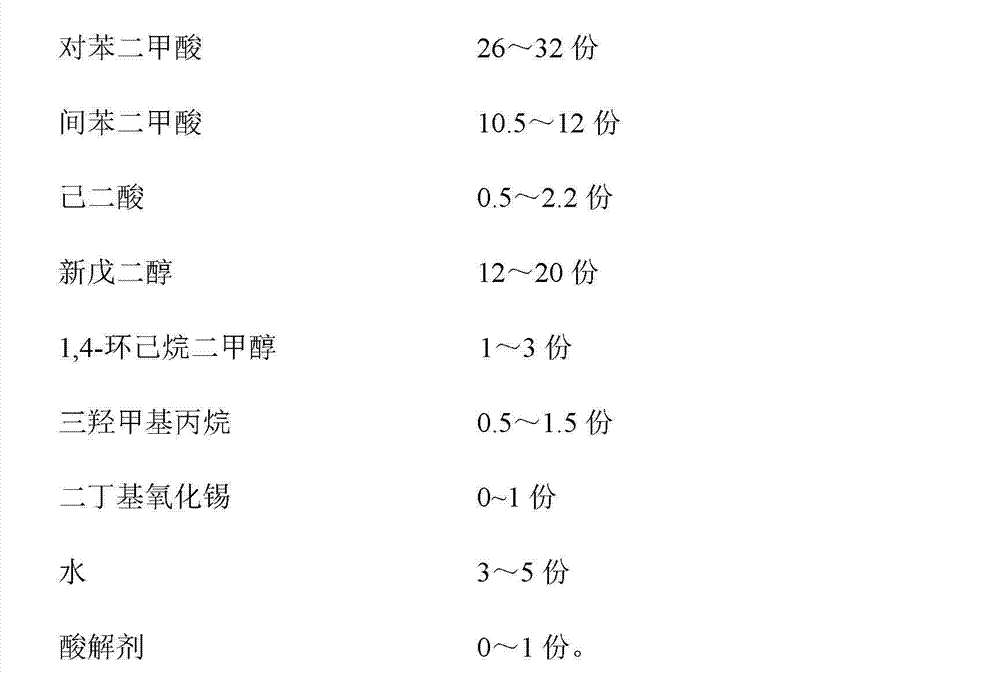

High weather-proof and corrosion-resistant powder paint for satellite earth antenna and preparation method thereof

ActiveCN102898933AGood electrificationShort curing timePowdery paintsPolyester coatingsAcrylic resinPolyester resin

The invention discloses a high weather-proof and corrosion-resistant powder paint for a satellite earth antenna. The paint comprises, by weight, 100-150 parts of polyester resin, 20-40 parts of GMA acrylic resin, 0-5 parts of beta-hydroxyalkylamide, 0-10 parts of assistants, 0-100 parts of paddings and 0-3 parts of pigments. The invention further discloses a preparation method for the powder paint. A coating after being coated by the paint and curing is good in mechanical properties, super-weather-proof, salt mist resistant, and provided with stable low gloss area.

Owner:GUANGZHOU KINTE IND

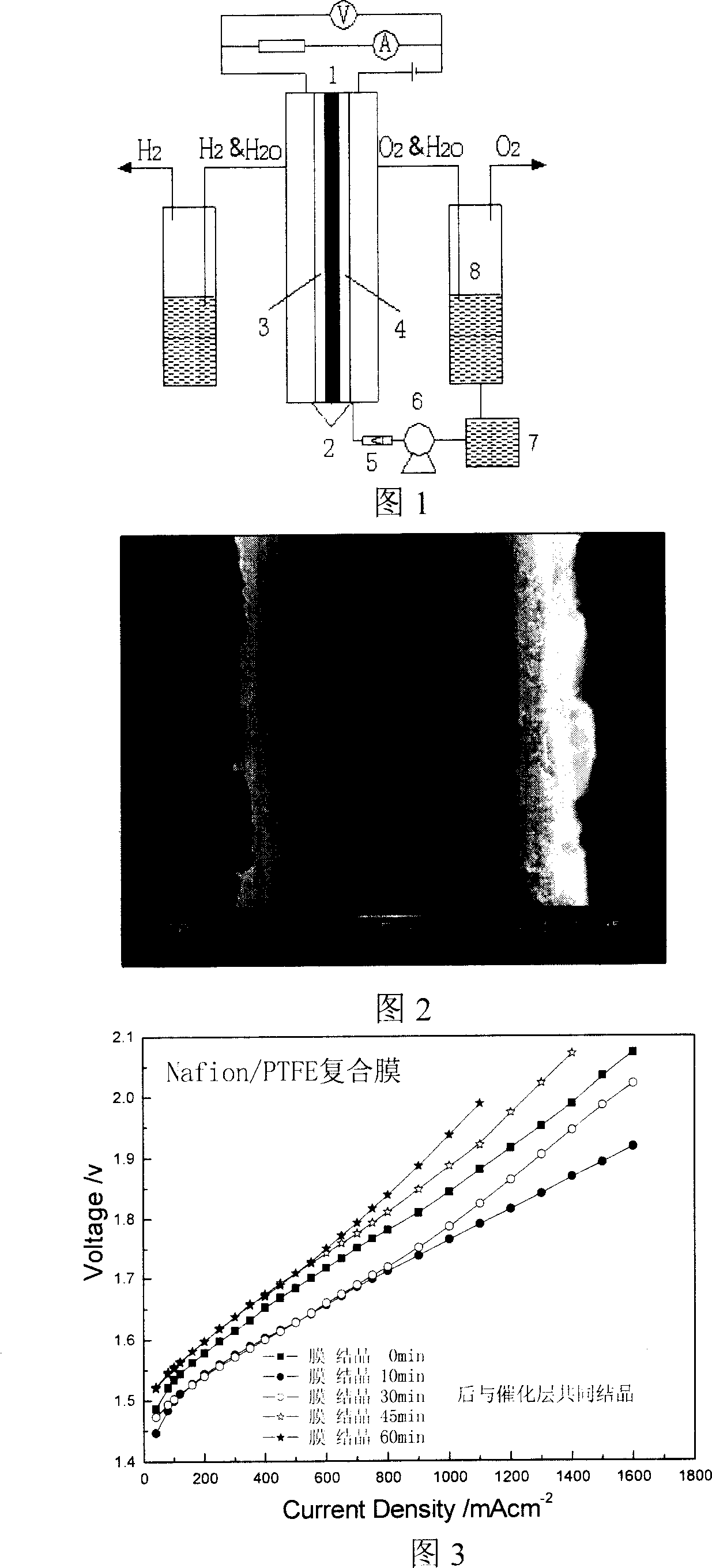

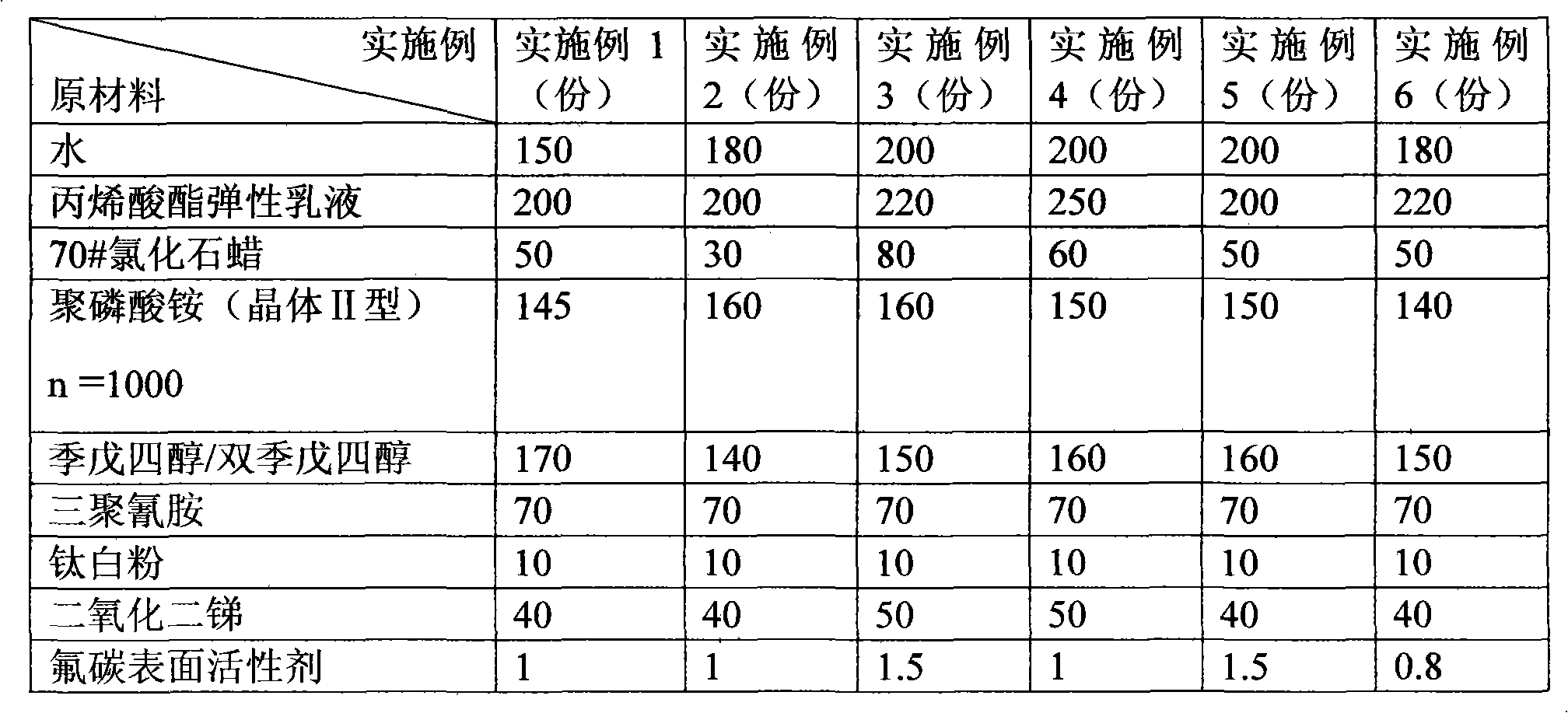

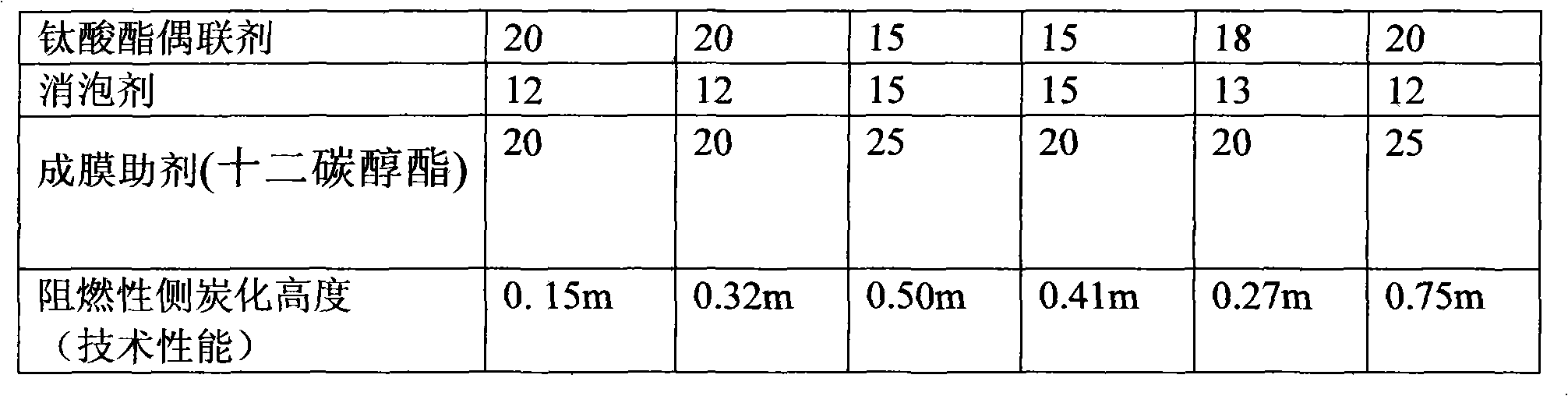

Preparation method of film electrode for solid polymer electrolyte water electrolysis

The invention relates to a method for preparing membrane electrode for solid polymer water electrolyte. It evaporates solid polymer electrolyte solution and forms film, couples catalytic layer composed of catalyst and solid polymer electrolyte on two sides to form integrated membrane electrode, then crystalizes membrane electrode to realize co-crystallization for solid polymer electrolyte. The combination between membrane and catalytic layer is tight and the stratification between membrane and electrode caused by gas evolution and wahsing during water electrolysis process is solved. The invention can produce solid polymer water electrolyte with high performance, high stability and high durability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High weather resistance environment-friendly cable fire-refractory coating and preparation process thereof

InactiveCN101597454AGood film forming effectGood water resistanceFireproof paintsSolventAmmonium polyphosphate

The invention discloses high weather resistance environment-friendly cable fire-refractory coating and a preparation process thereof, belonging to the technical field of coating. The process adopts a base material, namely acrylic ester elastic emulsion, as a main film-forming substance, dopes high polymerization degree ammonium polyphosphate into the base material, has good film-forming effect and water resistance. The method particularly selects Number 70 chlorcosane and diantimony trioxide as synergistic flame-retardant to greatly improve the fire retardant performance, has low proportion of pigment and the base material, optimizes compatibility of a fire retardant system; the coating has weather resistance and has oil resistance for selecting fluorocarbon surfactant. The process improves water resistance and weather resistance of the coating, and adopts titanate coupling agent to improve the combining firmness of the pigment, the base material and cable base materials, and the weather resistance of the coating is further improved. Green and environment-friendly water is used as solvent to reduce cost, and as the solvent is removed in preparation or construction, the coating does not pollute the environment and not hurt the health of operators.

Owner:ZHEJIANG TIANHUA FIREPROOF MATERIAL

Water-based fluorocarbon top coat for wind-powered blades and method for preparing water-based fluorocarbon top coat

ActiveCN102675998AImprove adhesionGood flexibilityAntifouling/underwater paintsPaints with biocidesWater basedLow speed

The invention discloses a water-based fluorocarbon top coat for wind-powered blades and a method for preparing the water-based fluorocarbon top coat and relates to the field of protective paint. According to the water-based fluorocarbon topcoat for wind powered blades, through compounding an hydroxyl acrylic emulsion and a water-based fluorocarbon emulsion and crosslinking hydroxyl acyclic acid with isocyanate so as to form a netted film, thus the coating adhesion, flexibility, chemical medium resistance, wear resistance of a coating are increased; due to the addition of the water-based fluorocarbon emulsion, the weather fastness of the coating is improved, and the gloss retention, color retention and chalking resistance of the coating are excellent; under the condition of stirring a water-dispersed isocyanate curing agent at a lower speed, an ideal emulsion is formed easily through mixing, thereby ensuring the performance of paint; and because of the introduction of a light stabilizer, the lightfastness, color retention and chalking resistance of the coating are improved.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Single-component under-filler with favorable repairing property and preparation method thereof

ActiveCN101880514AFirmly connectedImprove curing effectSemiconductor/solid-state device detailsSolid-state devicesChemistryTO-18

The invention discloses a single-component under-filler with the favorable repairing property, which is prepared by the following raw materials in percentage by weight: 11.8-69 percent of liquid-state epoxy resin, 2-10 percent of epoxy polybutadiene, 11.8-69 percent of polyurethane-modified epoxy resin, 0.5-14.8 percent of alicyclic epoxy resin, 1.5 to 18.5 percent of epoxy diluting agent, 0.5-14.8 percent of latency curing agent, 1.1-30.8 percent of accelerating agent, 0-39 percent of spherical silica micropowder and 0-6 percent of pigment. The invention also discloses a preparation method of the single-component under-filler with the favorable repairing property. The invention has the advantages of low viscosity, rapid curing for 40 seconds at 150 DEG C, high adhesive force, favorable heat-resistant impact-resistant performance and simple manufacture process, and can keep favorable adhesion reliability and solidifiability during heat circulation treatment, can improve the repairing performance of the single-component under-filler at the same time, and can be widely applied to the technical field of backbonded chip package.

Owner:深圳市库泰克电子材料技术有限公司

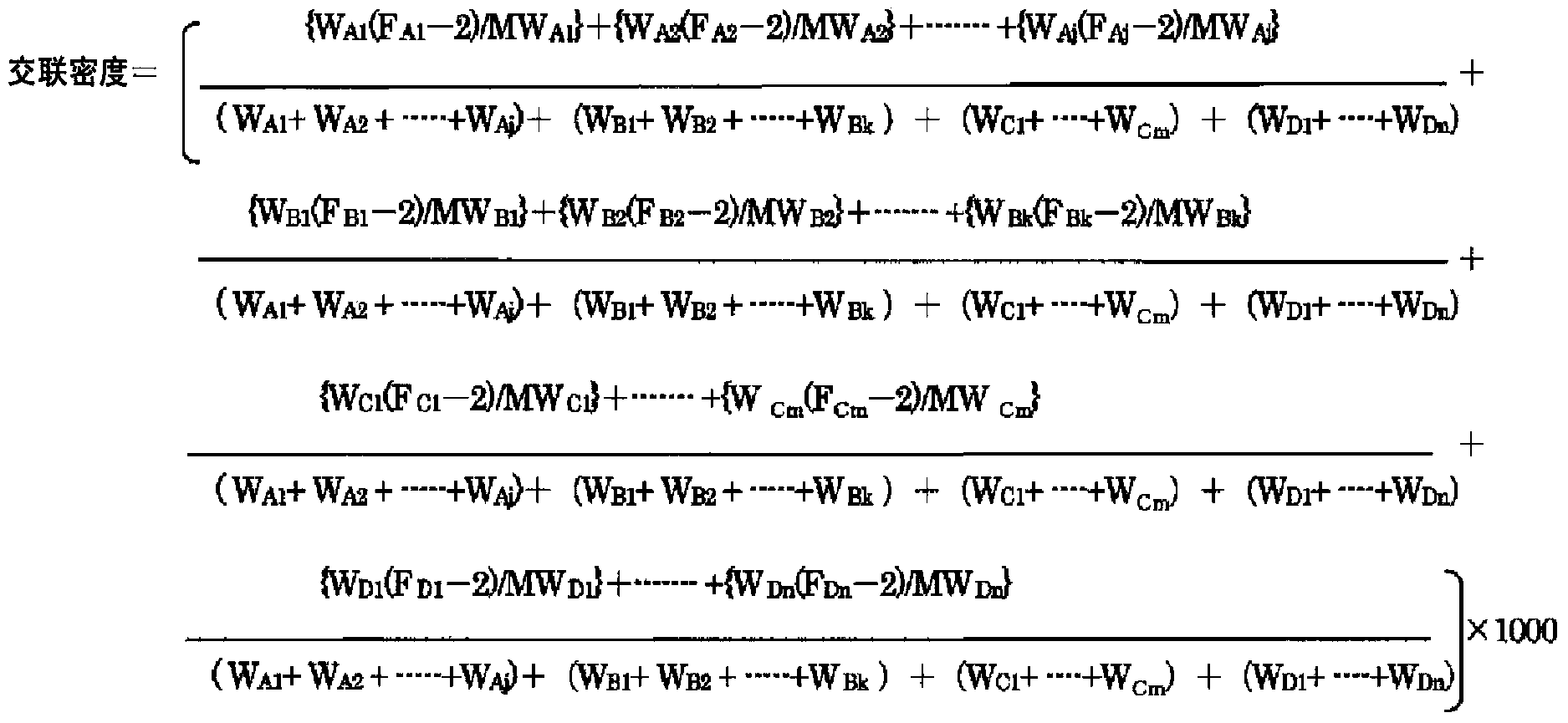

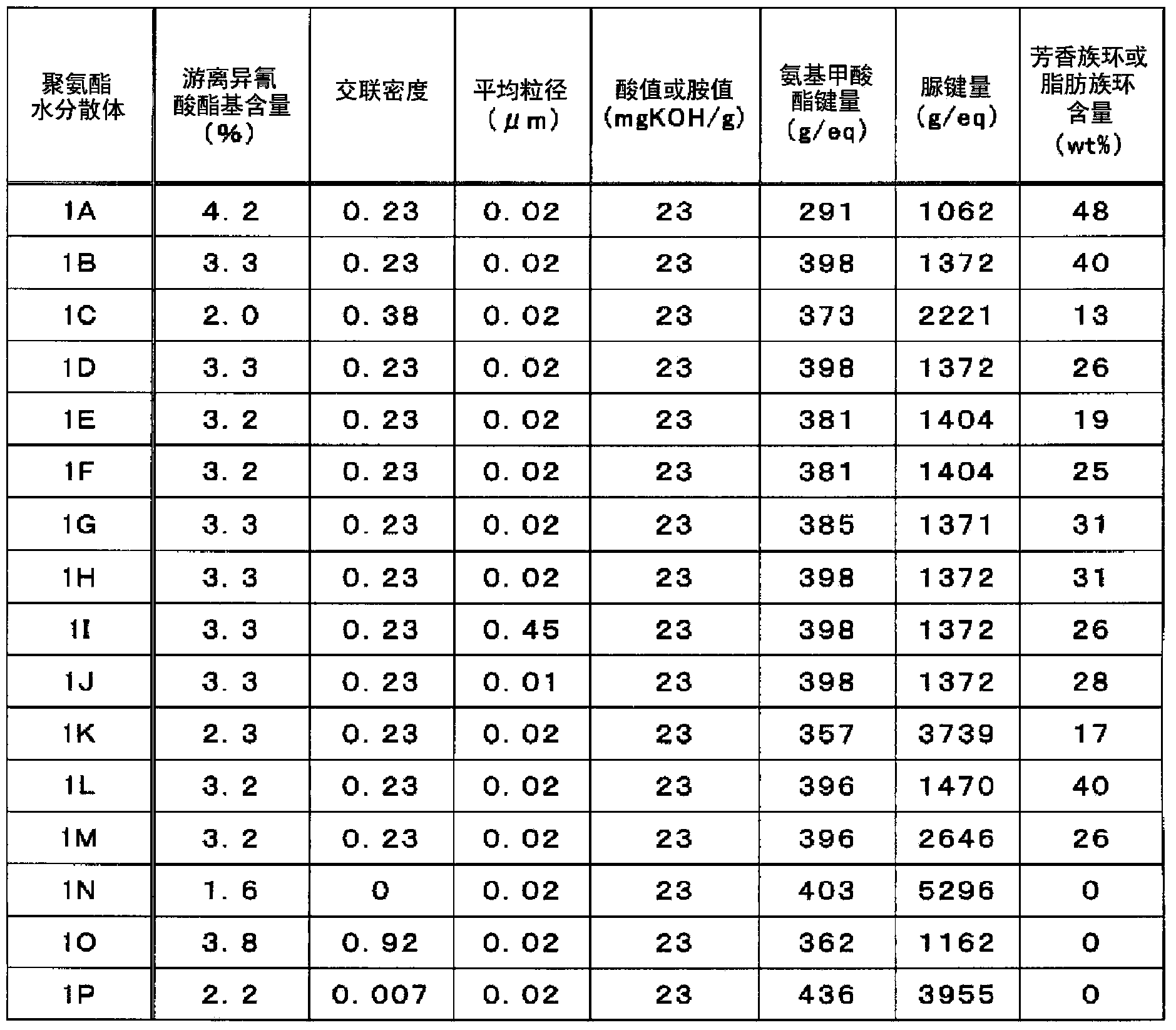

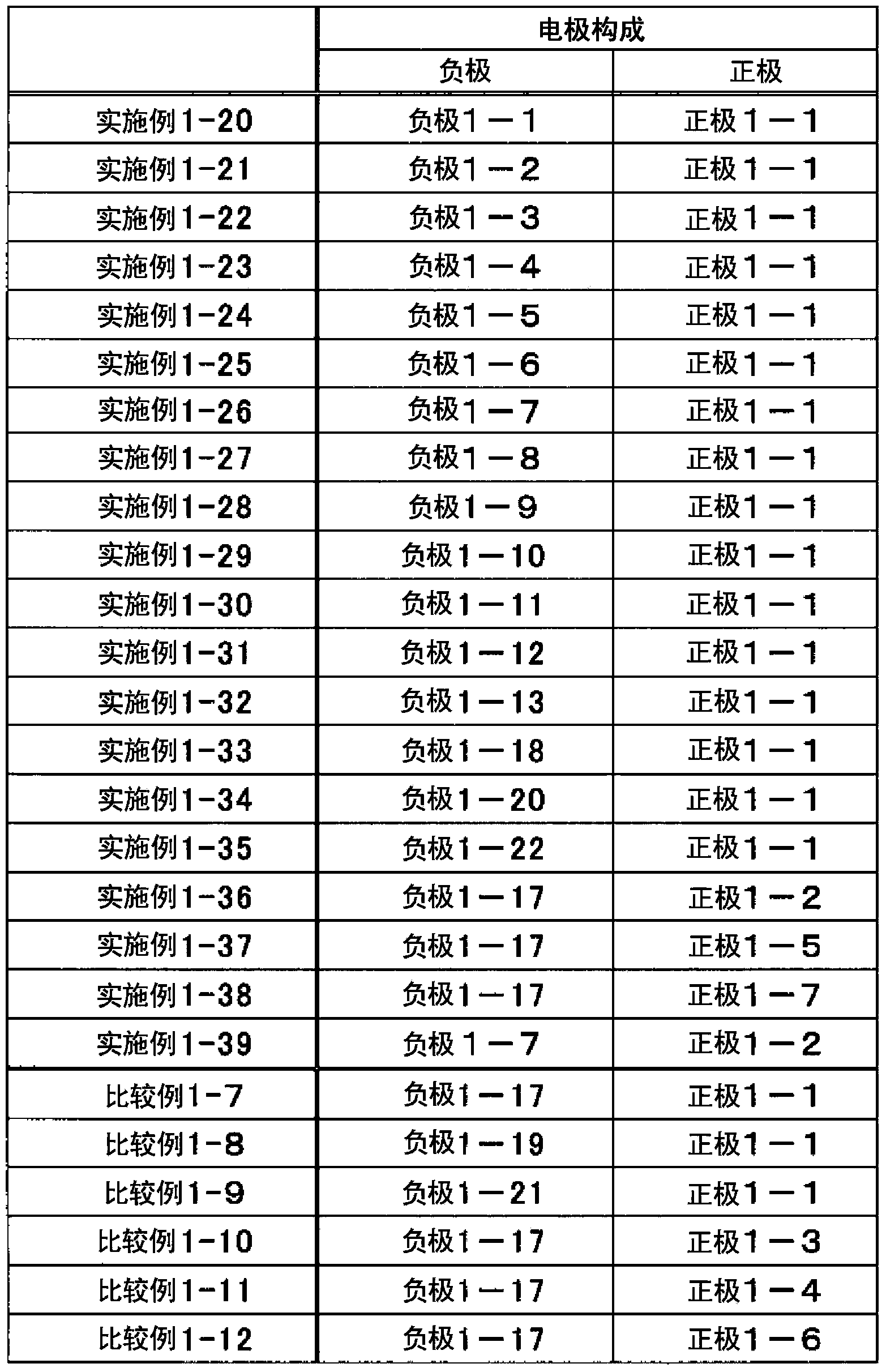

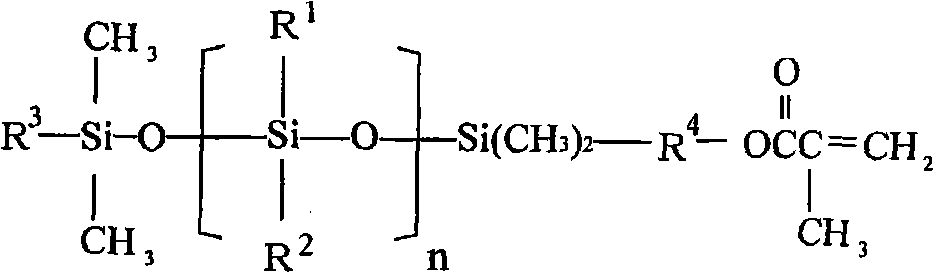

Binder for electrodes of lithium secondary batteries, and lithium secondary battery which uses electrode produced using binder for electrodes of lithium secondary batteries

ActiveCN104115316AExcellent charge and discharge characteristicsExcellent adhesionCell electrodesLi-accumulatorsLithiumHydrogen

Provided are: a binder which exhibits high adhesion to a collector and is not separated during pressing, and has high flexibility, excellent binding properties and excellent electrolyte solution resistance; and a lithium secondary battery which uses an electrode that is produced using the binder, and has excellent charge / discharge characteristics. There is used a binder for electrodes, which contains (A) a polyisocyanate, (B) a compound having two or more active hydrogen groups, (C) a compound having one or more active hydrogen groups and one or more hydrophilic groups, and (D) an aqueous resin composition that contains, as an aqueous dispersion, a hydrophilic group-containing polyurethane that is formed of a chain extender, or an aqueous resin composition that is obtained by emulsifying an unsaturated polymerizable monomer polymer by means of the above-mentioned hydrophilic group-containing polyurethane.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Film base material for adhesive skin patch and adhesive skin patch

InactiveUS20050169975A1Change physical propertiesFailure in characteristicAdhesive dressingsAbsorbent padsFilm basePolypropylene glycol

To have acceptable moisture permeability and enable prevention of deformation due to swelling, the film base material for an adhesive skin patch includes an ether-based urethane resin obtained from at least one member selected from the group consisting of polyoxytetramethylene glycol, butanediol, polyethylene glycol, and polypropylene glycol as a diol component, and methylene diphenyl-diisocyanate as an isocyanate component. The film base material for an adhesive skin patch has a moisture permeability of preferably 800 to 4,000 g / m2·24 hrs. The adhesive skin patch can be produced by forming a pressure-sensitive adhesive layer on one side of the film base material for an adhesive skin patch.

Owner:NITTO DENKO CORP

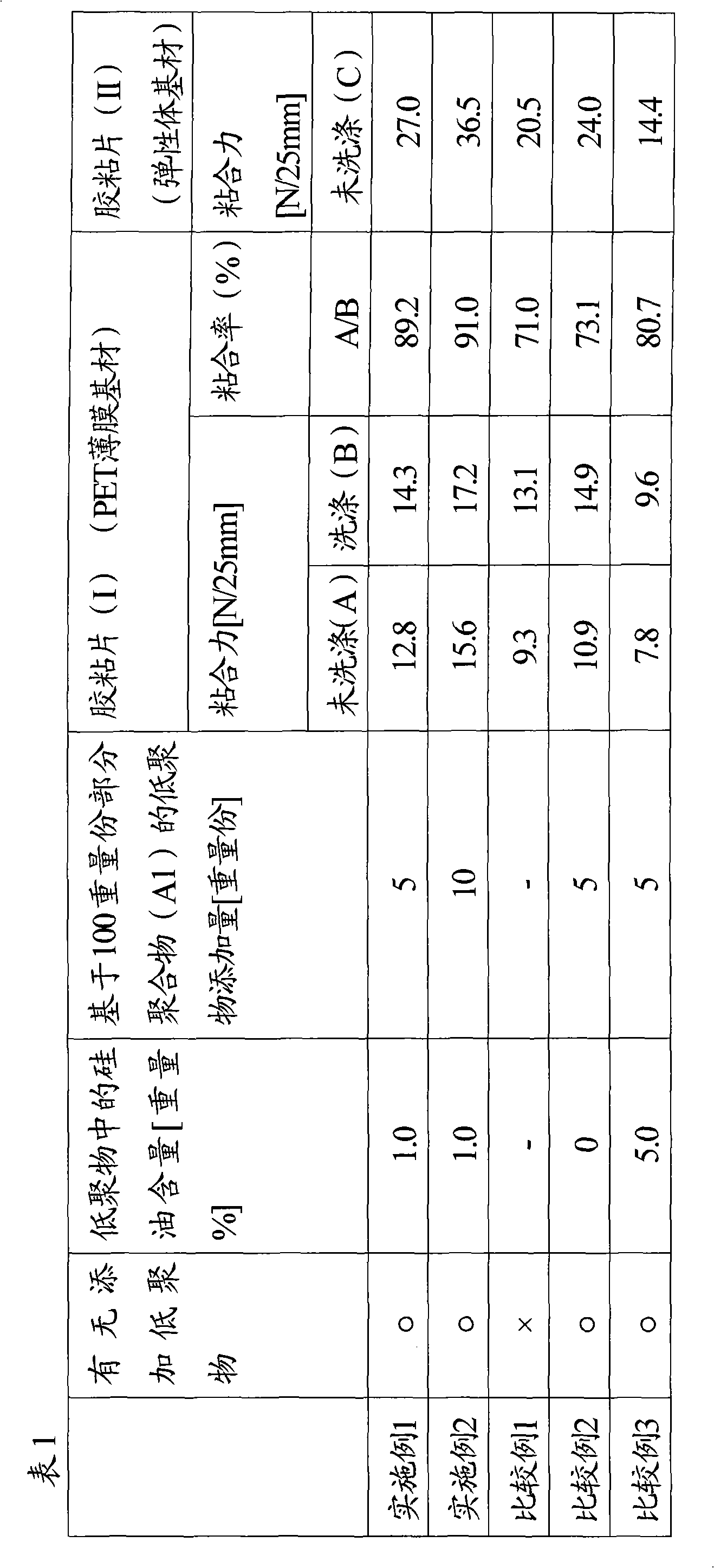

Acrylic adhesive composition, acrylic adhesive sheet, and method for bonding the adhesive sheet to coated surface of automobile

InactiveCN101652447AImprove adhesionNo peelingAdhesive processesNon-macromolecular adhesive additivesCoated surfaceMeth-

Disclosed is an acrylic adhesive composition which enables to form an adhesive layer exhibiting excellent adhesion to a coating film, which is likely to cause adhesion failure due to bleeding of a surface modifying agent or the like, without requiring a cleaning process or the like. Specifically disclosed is an acrylic adhesive composition characterized by containing (a) a vinyl monomer mainly composed of a (meth)acrylic acid alkyl ester monomer (a1) having an alkyl group with 2-14 carbon atoms or a partially polymerized product thereof, and (b) a (meth)acrylic acid ester copolymerized oligomer having a weight average molecular weight of 1,000-30,000, which contains, as monomer components, 96-99.5% by weight of a (meth)acrylic acid alkyl ester (b1) and 0.1-4% by weight of a silicone oil (b2) having a (meth)acryloyl group.

Owner:NITTO DENKO CORP

Self-cleaning antifouling inter wall paint

InactiveCN105131772AImprove water resistanceGood weather resistanceAntifouling/underwater paintsPaints with biocidesEmulsionFluorocarbon

The invention discloses a self-cleaning antifouling inter wall paint. The inner wall paint comprises raw materials: modified fluorocarbon emulsion, pure acrylic emulsion, light calcium carbonate, calcined kaolin, diatomite powder, forsterite powder, nano-stannic oxide, magnesium sulfate, hydroxyethyl cellulose, a dispersant SN-5040, a multifunctional auxiliary agent AMP-95, 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, an antifoaming agent CF-16, negative ion-anti-microbial additives, sodium hexametaphosphate, a leveling agent L-150, a stain resistant agent JZM-1, glycol, mildew inhibitors, wetting agents and deionized water. The coating film of the inter wall paint is compact, and the inter wall paint is hydrophobic and oleophobic and has strong antifouling performance and self-cleaning capability. The coating effect is good and construction is convenient.

Owner:TIANCHANG YINHU PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com