Patents

Literature

43results about How to "Play a heat insulation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resisting heat-insulation coating as well as preparation method and application thereof

ActiveCN103725074AEasy to use in constructionPlay the role of saving energy and reducing consumptionReflecting/signal paintsPetroleumEnergy consumption

The invention relates to the field of functional coatings and particularly relates to a high-temperature-resisting heat-insulation coating and a preparation method thereof. The high-temperature-resisting heat-insulation coating is composed of the following raw materials in percentage by mass: 10%-40% of high-reflection paint with a shell-core structure, 10%-40% of heat-insulation powder with the shell-core structure, 1%-5% of a toughening agent, 10%-50% of a high-temperature bonding agent, 1%-10% of a coating auxiliary agent, and the balance of water. The preparation method comprises the following steps: mixing, dispersing and grinding raw materials; carrying out homogenization to enable an average grain diameter to be 325-400 meshes; and filtering and packaging to obtain a finished product. The high-temperature-resisting heat-insulation coating can be applied to high-temperature fields of industrial furnaces, industrial boilers, high-temperature steam pipelines, petroleum cracking equipment, engine parts, high-temperature smelting, sintering furnaces and the like, and can be used under a higher temperature for long time; the energy consumption can be saved and the service life of the furnaces is prolonged.

Owner:武汉双虎涂料股份有限公司

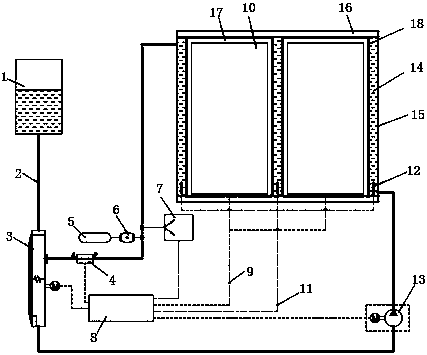

Vacuum liquid-cooled coupling heat management system of power battery and operating method

InactiveCN107706484AInsulate temperature conductionTo achieve heat insulation effectSecondary cellsCell component detailsElectrical batteryHydraulic pump

The invention discloses a vacuum liquid-cooled coupling heat management system of a power battery and an operating method. The vacuum liquid-cooled coupling heat management system comprises a batterypack, hollow cooling plates arranged on two sides of the battery pack, a liquid cooling circuit, with a hydraulic pump, communicating with the cooling plates, and a battery control unit, wherein the liquid cooling circuit is connected with a temperature controller, an electromagnetic valve, an air interchanger and a vacuum pump; the temperature controller is connected with a cooling liquid standbytank; and the air interchanger comprises an air storage tank with a filter screen and an air inlet valve connected with the liquid cooling circuit. The temperature conduction between battery packs isisolated by vacuum plates formed by the cooling plates through the air interchanger and a vacuum pump system, the effects of heat insulation and heat preservation are reached, the hidden danger thatthe temperature of the dense region of the battery pack is increased locally is solved, and the waste of energy sources is reduced, so that the cruising power of a finished automobile power battery system is improved, and the service life of the finished automobile power battery system is prolonged; and when the local temperature is abnormal, liquid can be quickly filled for cooling, so that the temperature of the battery pack and the temperature of the finished automobile system are balanced again.

Owner:DONGGUAN DRN NEW ENERGY

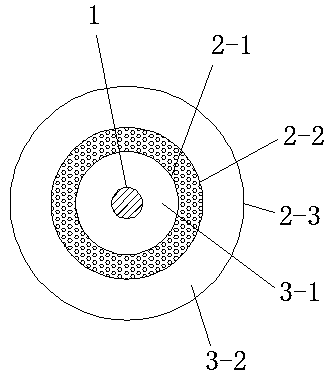

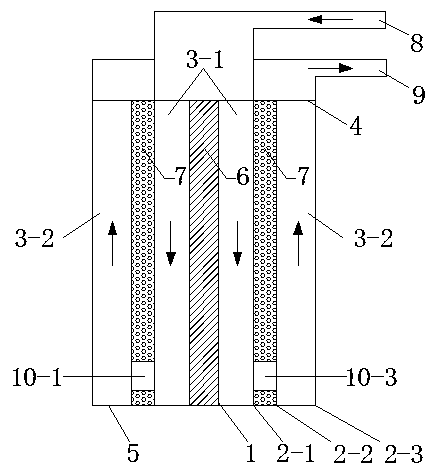

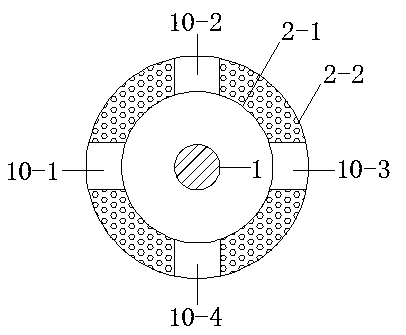

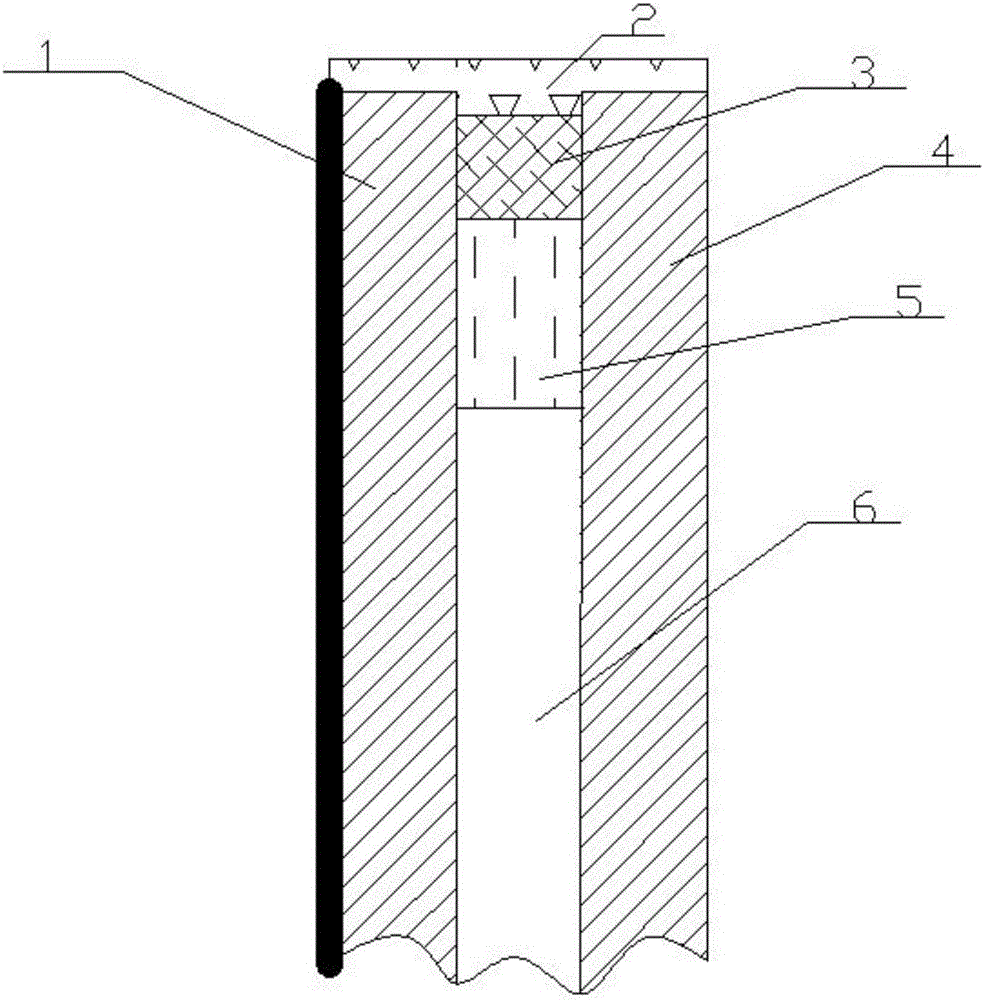

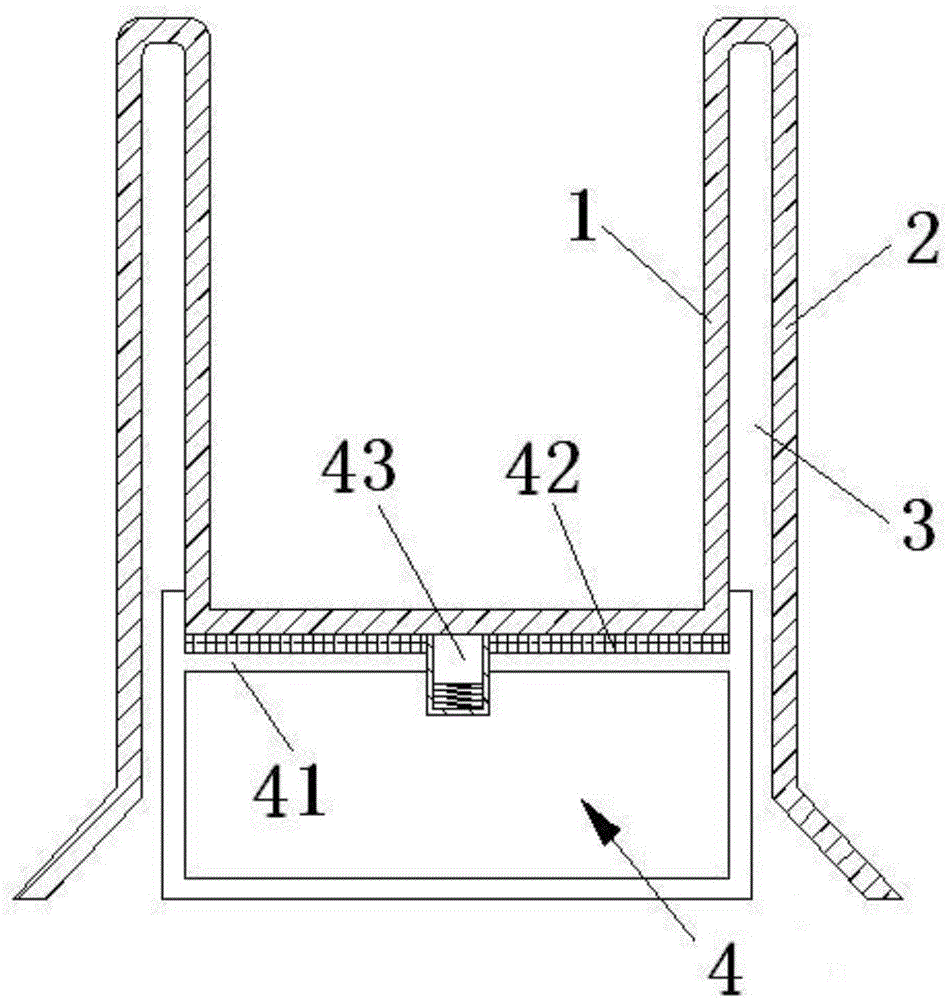

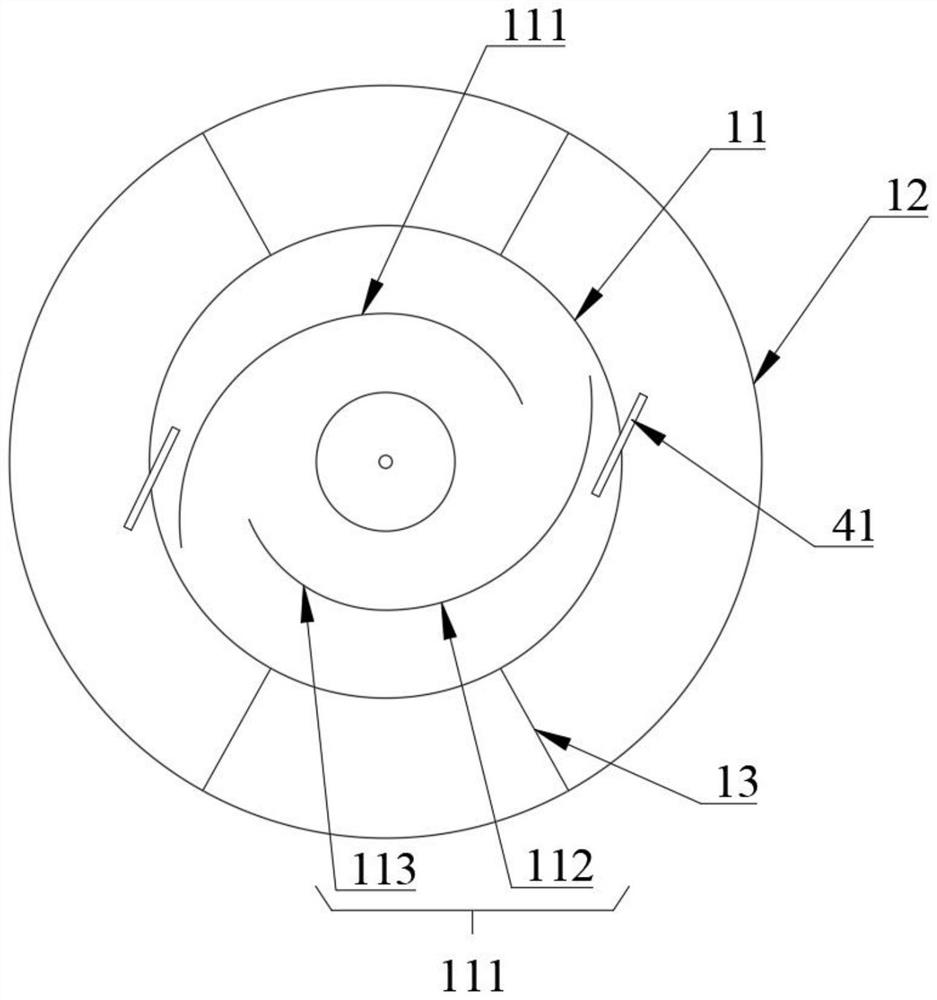

Phase change energy storage sleeve-type geothermal heat exchanger

ActiveCN109405616AShorten the embedding distanceSmall footprintHeat storage plantsHeat-affected zoneEngineering

The invention relates to a phase change energy storage sleeve-type geothermal heat exchanger and belongs to the technical field of ground source heat pump air conditioners. The phase change energy storage sleeve-type geothermal heat exchanger is constituted by a central pipe, a first sleeve, a second sleeve, a third sleeve, a first annular channel, a second annular channel, a top cover plate, a bottom cover plate, summer and winter working condition phase change materials, a water inlet pipe and a water outlet pipe. The first sleeve, the second sleeve and the third sleeve are placed on the outer side of the central pipe in the radius increasing direction with the central pipe as the circle center. The summer working condition phase change materials are packaged into the central pipe, the winter working condition phase change materials are packaged into an annular closed space defined by the second sleeve and the third sleeve. According to the phase change energy storage sleeve-type geothermal heat exchanger, the defects of large soil temperature fluctuation, wide thermal effect zone and large thermal short-circuiting of the water inlet and outlet pipes during operation of an existing geothermal heat exchanger are overcome, through phase change heat absorption and release of the phase change materials, the heat exchange amount of the geothermal heat exchanger can be increased while thermal short-circuiting of the water inlet and outlet pipes is weakened, the thermal effect degree of the soil temperature is reduced, the thermal interference radius is decreased, and the pipe burying area is decreased, so that the heat exchange efficiency of the heat exchanger is improved.

Owner:YANGZHOU UNIV

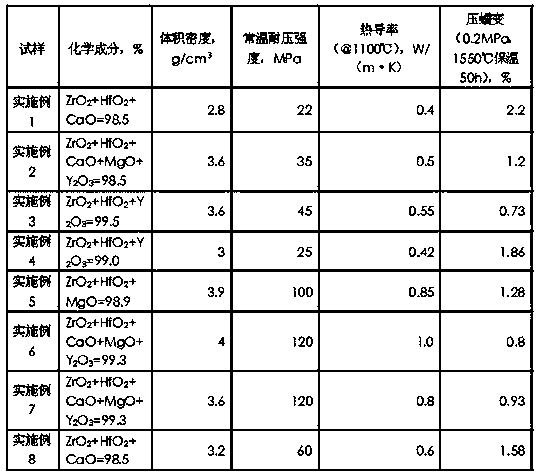

High-purity zirconia insulating refractory product

The invention belongs to the field of refractory materials, and mainly relates to a high-purity zirconia insulating refractory product. The high-purity zirconia insulating refractory product is composed of an aggregate and a matrix; the aggregate is porous zirconia particles prepared by a sintering method and having a volume density of 3.0-5.0 g / cm<3>; the aggregate accounts for 55%-80% of the total mass of the whole refractory product, and the aggregate has a particle size of 0.2-3 mm; the matrix comprises a mixture composed of zirconia fine powder and zirconia fine powder; the high-purity zirconia insulating refractory product is a refractory material having a certain shape at the normal temperature, and is subjected to heat treatment under a high temperature oxidizing atmosphere of which the maximum firing temperature is 1600-1800 DEG C. The high-purity zirconia insulating refractory product has the characteristics of high use temperature, moderate thermal conductivity and high mechanical strength, and has the functions of heat preservation and structural support at the high temperature.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

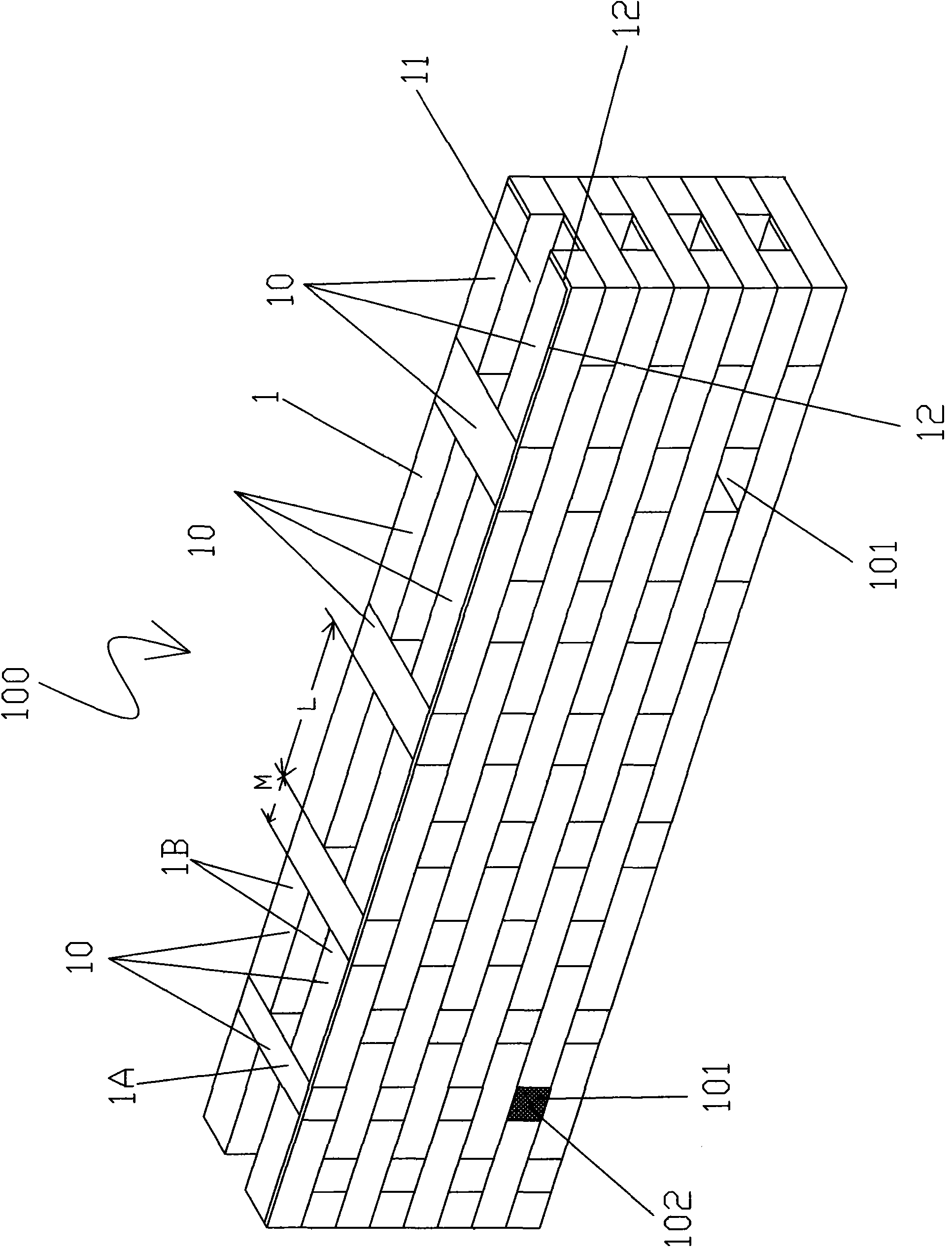

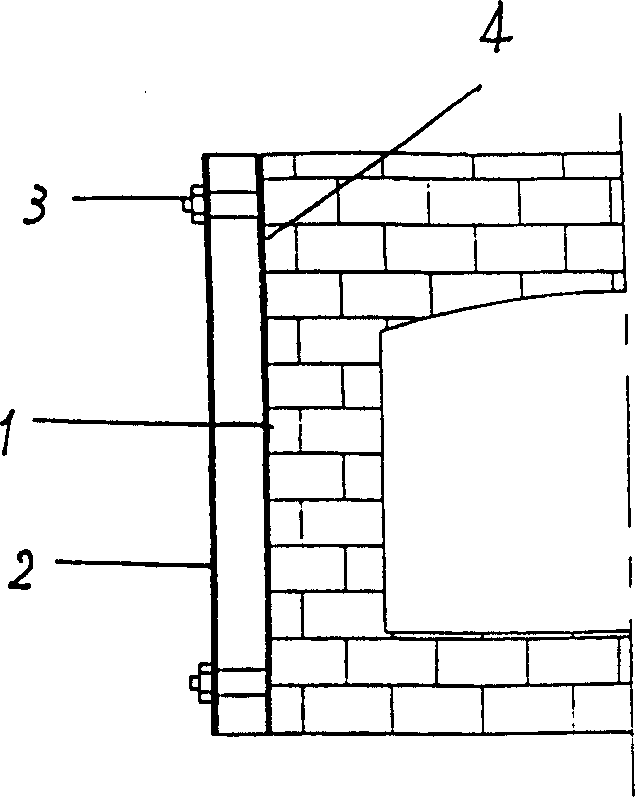

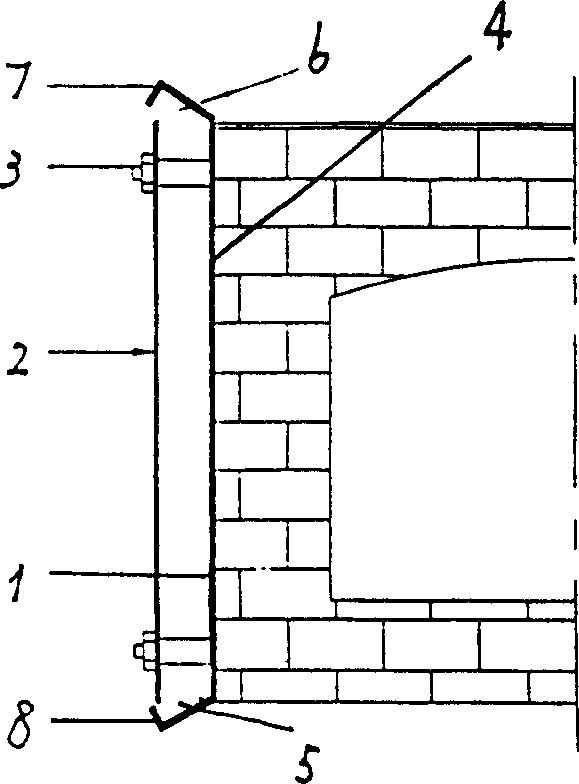

Heat-insulating and heat-preserving wall

InactiveCN101614049APlay a heat insulation effectReduce interior renovation costsWallsBrickSolid wall

The invention discloses a heat-insulating and heat-preserving wall formed by stacking a plurality of layers of bricks layer by layer. Each layer comprises a plurality of assembly units arranged in sequence; wherein, each assembly unit comprises a brick transversely arranged along the wall and two parallel bricks arranged along the length direction of the wall; the length of each brick is larger than twice the width thereof, so that a heat-insulating gap can be left between the two parallel bricks arranged along the length direction of the wall; the adjacent assembly units in an upper and a lower layer are arranged in a staggered manner; and the heat-insulating gaps between layers are communicated, thereby forming the heat-insulating layers in the wall. By forming the heat-insulating layers in the wall, the external heat can hardly be transferred into a room, and the internal heat of the room can hardly be emitted to the external, thereby achieving the heat-insulating and heat-preserving effects; the wall of the invention is applicable in building single-storey houses and high-rise buildings, so that the applicable range is wide; and compared with the existing solid wall, the invention can save a plurality of bricks and ensure the solidness of the wall at the same time.

Owner:广州特镭格科技有限公司

Heating-layer pavement for cold region and construction technology thereof

The invention discloses a heating-layer pavement for a cold region. The heating-layer pavement comprises a pavement structure layer, a roadbed structure layer, a foam light layer and an original frozen soil layer, wherein the pavement structure layer is arranged at the top part of the roadbed structure layer in parallel; the roadbed structure layer covers the top part of the foam light layer; the foam light layer is arranged at the top part of the original frozen soil layer in parallel and is arranged in a position which is 0.8 to 2.0 m apart from the bottom part of the pavement structure layer; the foam standard density of the foam light layer is 50kg / m<3>. According to the heating-layer pavement for the cold region, disclosed by the invention, in foam light soil, the volume percentage of foam is up to 40 to 70 percent, the content of the foam is high, the volume weight is small, the shock absorption performance is good, a heat conductivity coefficient is small, heat insulation and sound insulation effects are good, and the anti-freezing-and-thawing performance is strong; when the heating-layer pavement is used as a heat insulation layer between frozen soil and an earth fill embankment in the cold region, energy exchange between original frozen soil and the exterior can be well switched off, heat insulation and heat preservation effects are achieved, and the problem of frost failures in the cold region can be effectively solved.

Owner:JIANGSU ZHAOTONG ENG TECH CO LTD

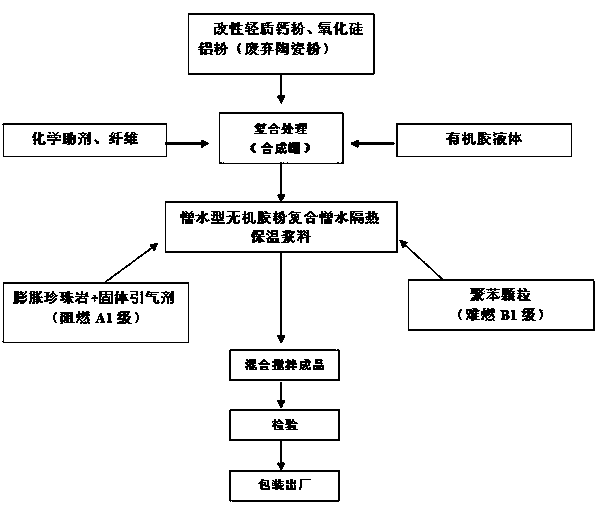

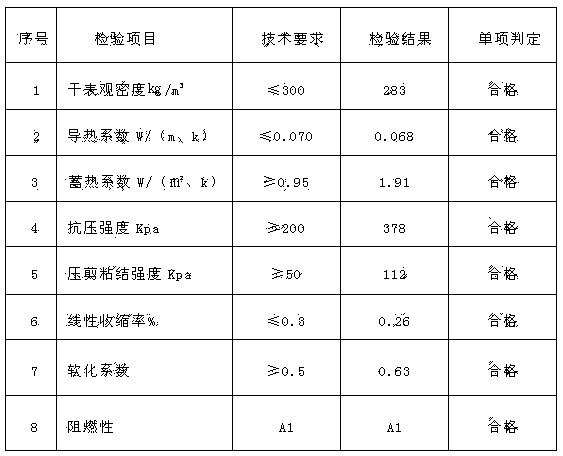

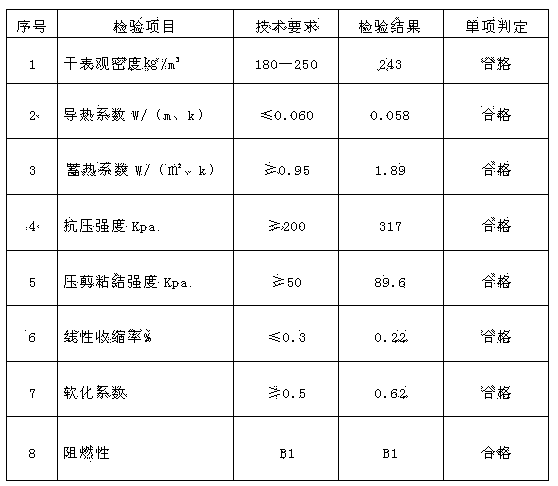

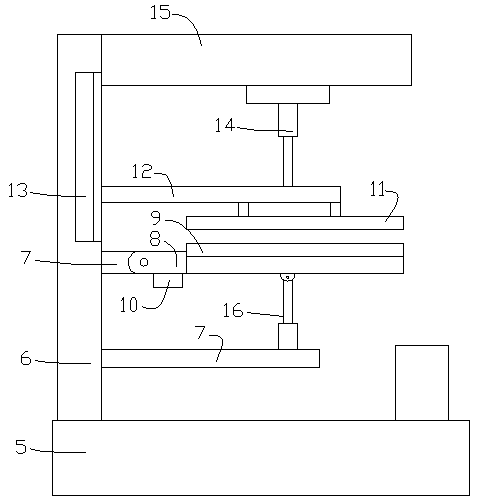

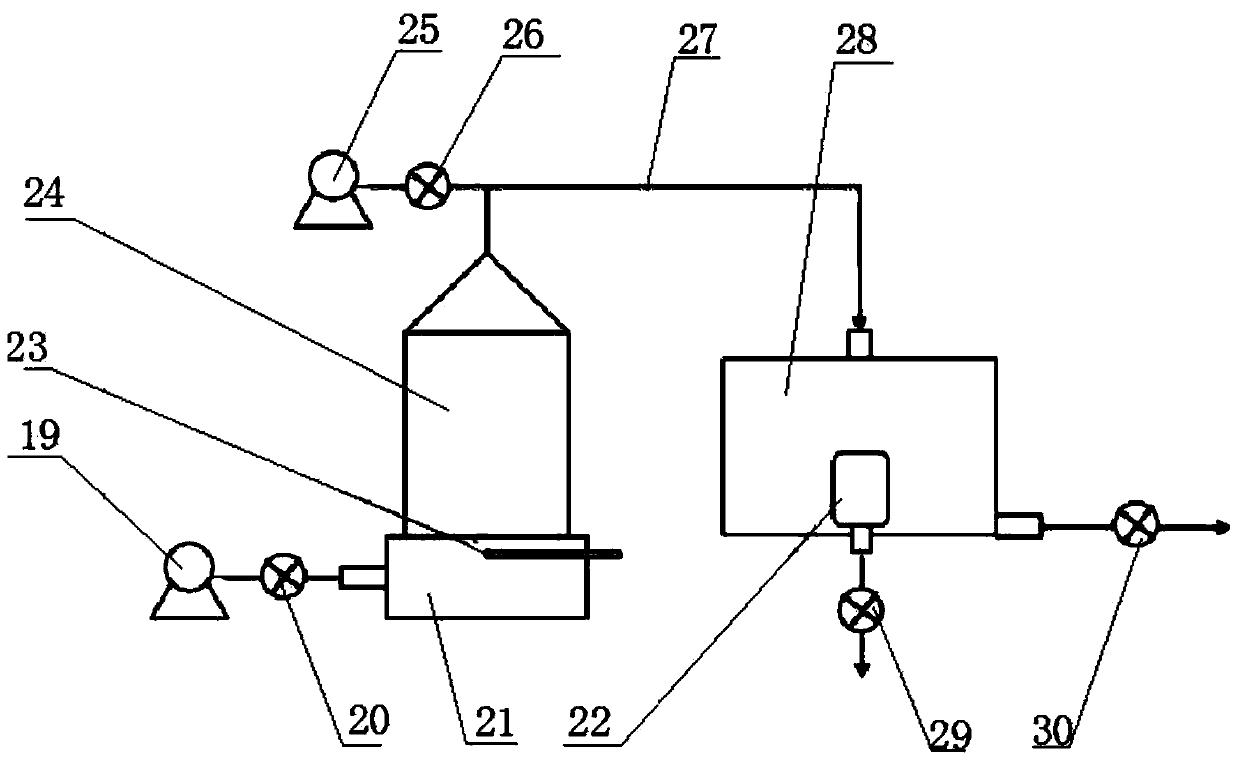

Hydrophobic inorganic gel powder compounded multifunctional insulating mortar, as well as application and preparation method thereof

The invention relates to hydrophobic inorganic gel powder compounded multifunctional insulating mortar, as well as application and a preparation method thereof. The insulating mortar comprises the following raw materials: modified light calcium carbonate powder, monox aluminum powder, an acrylic ester emulsion, an organic polymer cementing material and additives; the raw materials are mixed and prepared to obtain the mortar. The method comprises the following steps: sucking the modified light calcium carbonate powder and the monox aluminum powder into a mixing agitation tank for mixing agitation through vacuum negative-pressure equipment; sucking the acrylic ester emulsion, the organic polymer cementing material and the additives into the mixing agitation tank through the vacuum negative-pressure equipment; finally carrying out mixing agitation at the ordinary temperature to prepare the hydrophobic inorganic gel powder multifunctional insulating mortar. The insulating mortar can be added with different fillers, expanded perlite and polystyrene granules according to the requirements of fire-resistant grades, so as to be compounded into thermal insulation mortar materials for the exterior wall and the roof of a building enclosure. The insulating mortar, the application and the preparation method have the advantages that the energy-saving effect is obvious; the waterproof, air-permeable, fire-resistant and thermal insulation abilities are good; the operation such as mortar and sand pulp production and on-site construction is convenient; the production cost and application cost are low.

Owner:王祥林 +1

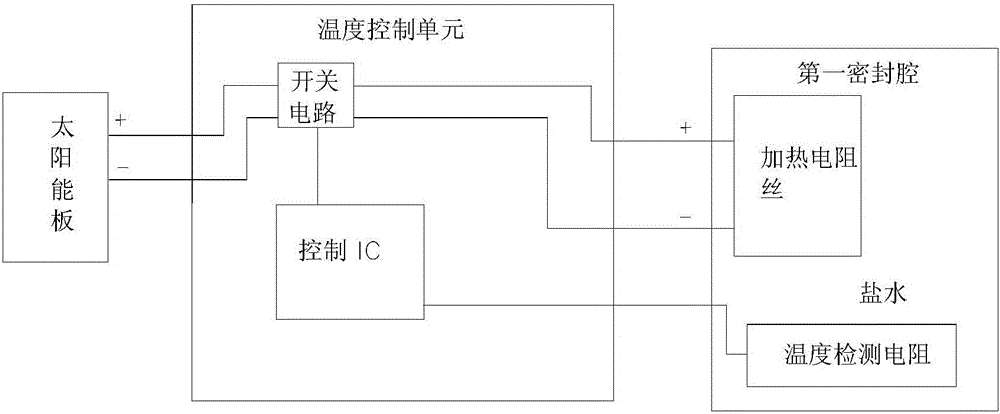

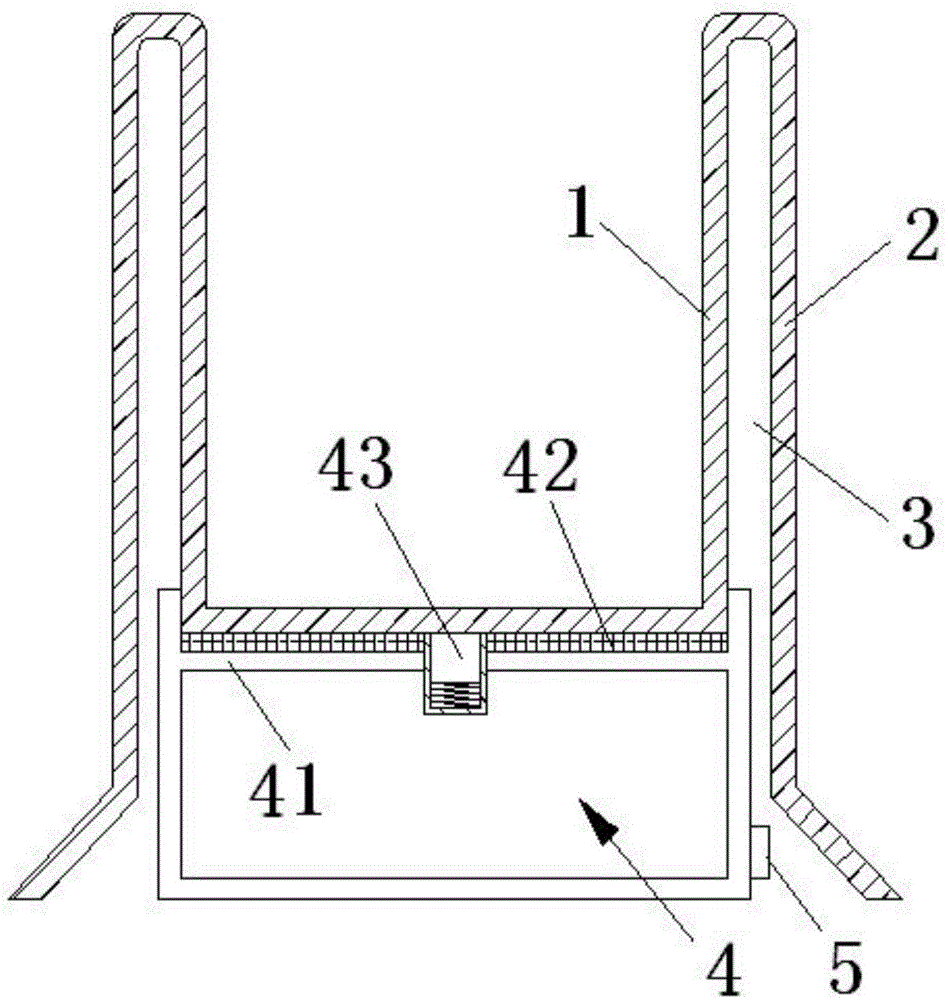

Battery box

InactiveCN106058096AReduce heat convectionPlay a heat insulation effectBattery isolationEngineeringThermal conductivity

The invention discloses a battery box. The battery box comprises a box body. The box body sequentially comprises a battery bin, a first sealing cavity, a second sealing cavity and a third sealing cavity from the center to the exterior. The first sealing cavity is filled with asbestos or saline. The second sealing cavity is filled with water or inert gas. The third sealing cavity is filled with inert gas or vacuumized. Due to multiple sealed spaces, heat convection between the battery bin and air outside the box can be effectively weakened, and the effects of heat insulation and preservation are achieved; by adopting water, saline and asbestos, heat is stored, and the battery bin is further insulated; by means of characteristics of insert gas or vacuum low thermal conductivity, the battery bin is further insulated.

Owner:深圳市优威视讯科技股份有限公司

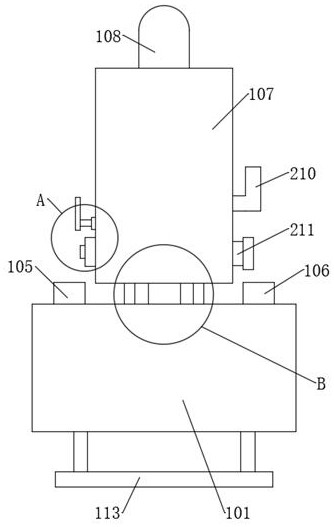

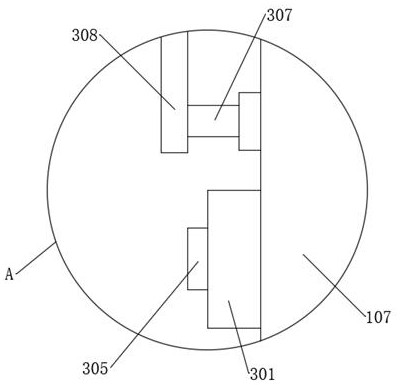

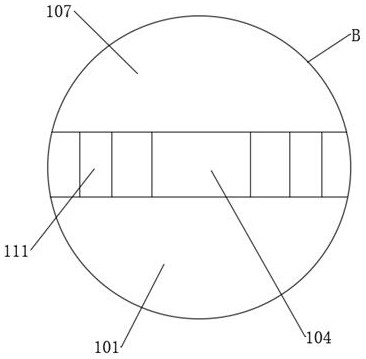

Energy-saving and environment-friendly gas monitor for environmental monitoring

ActiveCN114563538ATimely replacementGuaranteed uptimeWithdrawing sample devicesThermometer applicationsProcess engineeringWater temperature

The invention discloses an energy-saving and environment-friendly gas monitor for environmental monitoring, and belongs to the technical field of environmental monitoring. A driving spring is heated by absorbing solar energy, so that the driving spring is recovered to a high-temperature phase shape, a piston plate is driven to extract gas, then the driving spring is cooled by cooling water, and the energy-saving and environment-friendly gas monitor for environmental monitoring is obtained. Compared with manual driving in the prior art, manual air exhaust and air exhaust are not needed, the air exhaust device is simple and efficient, manpower can be effectively saved, practicability is improved, and compared with automatic driving in the prior art, the air exhaust device has the advantages that manual air exhaust and air exhaust are not needed. The cooling device is simple in structure and low in cost, does not need to consume electric energy, and greatly improves the energy-saving and environment-friendly performance, and the water temperature monitoring reminding piece can remind workers when the temperature of cooling water is high, so that the workers are prompted to replace the cooling water in time.

Owner:南通诺澳电子有限公司

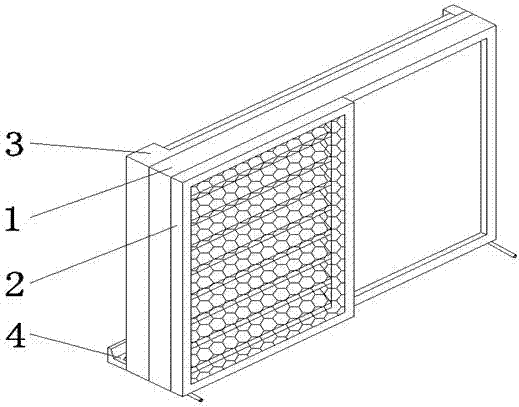

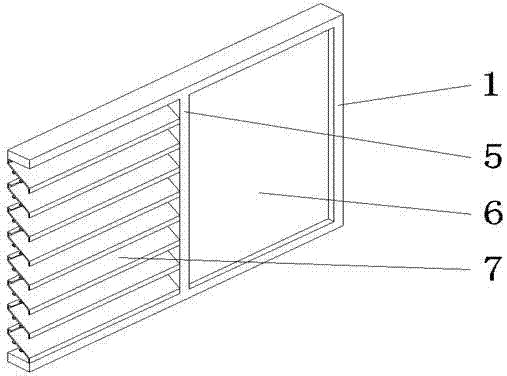

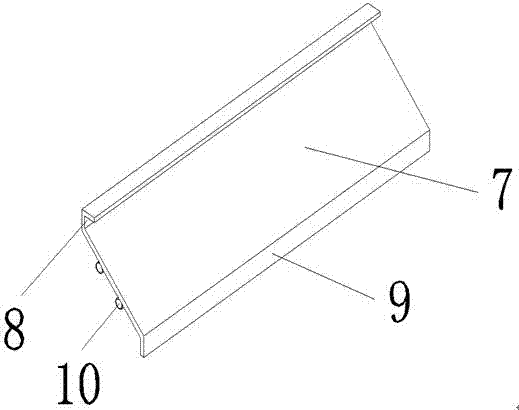

Rainproof and dustproof ventilation and lighting window

InactiveCN107514214AImprove light transmissionEasy to collectFixed grillesVentilation arrangementEngineeringNatural ventilation

The invention discloses a rainproof, dustproof, ventilated and daylighting window, which comprises a main window, a protective window, an invisible screen window and a water retaining platform. A central column is installed and fixed in the middle of the main window by screws, and the left side of the central column is connected to the main body. The right side of the window is inlaid with tempered glass, the right side of the center column and the left side of the main window are perforated with ventilation louvers through screw rods, and the upper water baffle, the lower water baffle and the screw holes are arranged on the ventilation louvers. The protective window is installed and fixed on the front end of the ventilation louver by screws, and the protective mesh is inlaid inside the protective window. The invisible screen window is installed and fixed on the rear end of the main window by screws, and the water retaining platform is pasted behind the main window by sealant Below the end, grooves and drainage pipes are arranged on the water retaining platform. The invention has simple structure and convenient installation, can effectively improve indoor natural ventilation effect, and can effectively prevent birds, dust and rain.

Owner:ZAOZHUANG POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +2

Environment-friendly heat insulation type architectural energy-saving thermal insulation material

InactiveCN107474666AWith heat insulation effectLow toxicityEmulsion paintsEpoxy resin coatingsEpoxyEmulsion

The invention discloses an environment-friendly heat insulation type architectural energy-saving thermal insulation material. The thermal insulation material disclosed by the invention comprises the following components by weight percent: 30-40% of elastic acrylic modified emulsion (waterborne), 5-7% of epoxy resin (waterborne), 3-5% of n-butyl alcohol, 10-15% of hollow glass beads, 8-12% of functional fillers, 15-20% of kaolin, 0.8-1.2% of talcum powder, 0.5-0.7% of a dispersing agent, 0.3-0.5% of a wetting agent, 0.4-0.6%of an antifoaming agent, 0.1-0.3% of an antibacterial agent, 0.2-0.4% of a mildew preventive, 1.5-2.5% of a flatting agent, 0.8-1.2% of a thickening agent and 8-12% of water.

Owner:绵阳旺通科技有限公司

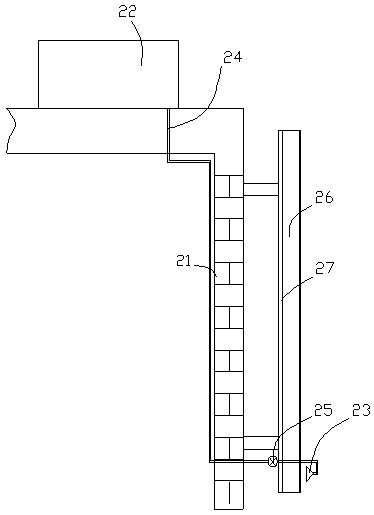

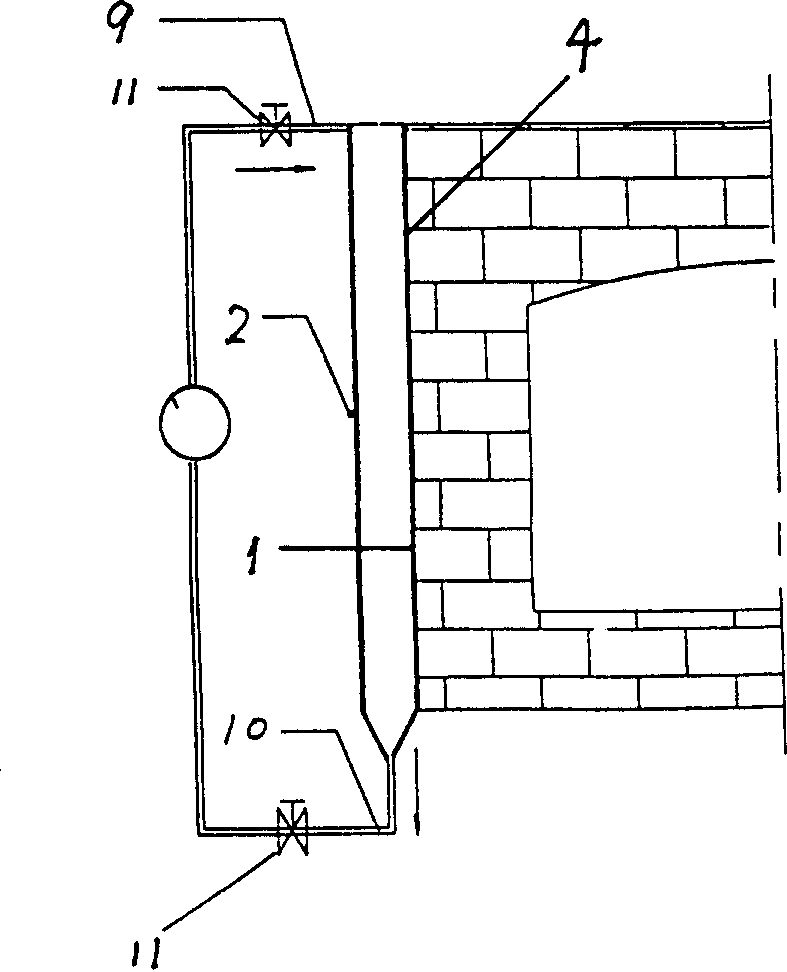

Regression reflection energy-saving outer wall system

ActiveCN109779083AProtect from direct sunlightGood to take awayWallsLighting and heating apparatusWater storage tankControl valves

The invention discloses a regression reflection energy-saving outer wall system. The system comprises a vertically-arranged wall body; a spray head system is arranged on the wall body and comprises awater collection tank arranged on the roof; a water storage tank connected with the water collection tank and a spray head arranged outside the wall body, the spray head is connected with the water storage tank through a water spray pipeline, and a control valve is arranged on the water spray pipeline and connected with a controller; the heat insulation structure is characterized by further comprising an outer retaining wall which is vertically arranged, the outer retaining wall is arranged on the outer side of the wall body at intervals, and a heat insulation space which circumferentially communicates with the outer retaining wall and the wall body outwards is formed between the outer retaining wall and the wall body. The air conditioner has the effects of spraying cooling, heat insulation, heat preservation, convection cooling and the like, so that the cold load of the air conditioner is reduced, and the purposes of energy conservation and emission reduction are achieved.

Owner:CHONGQING UNIV

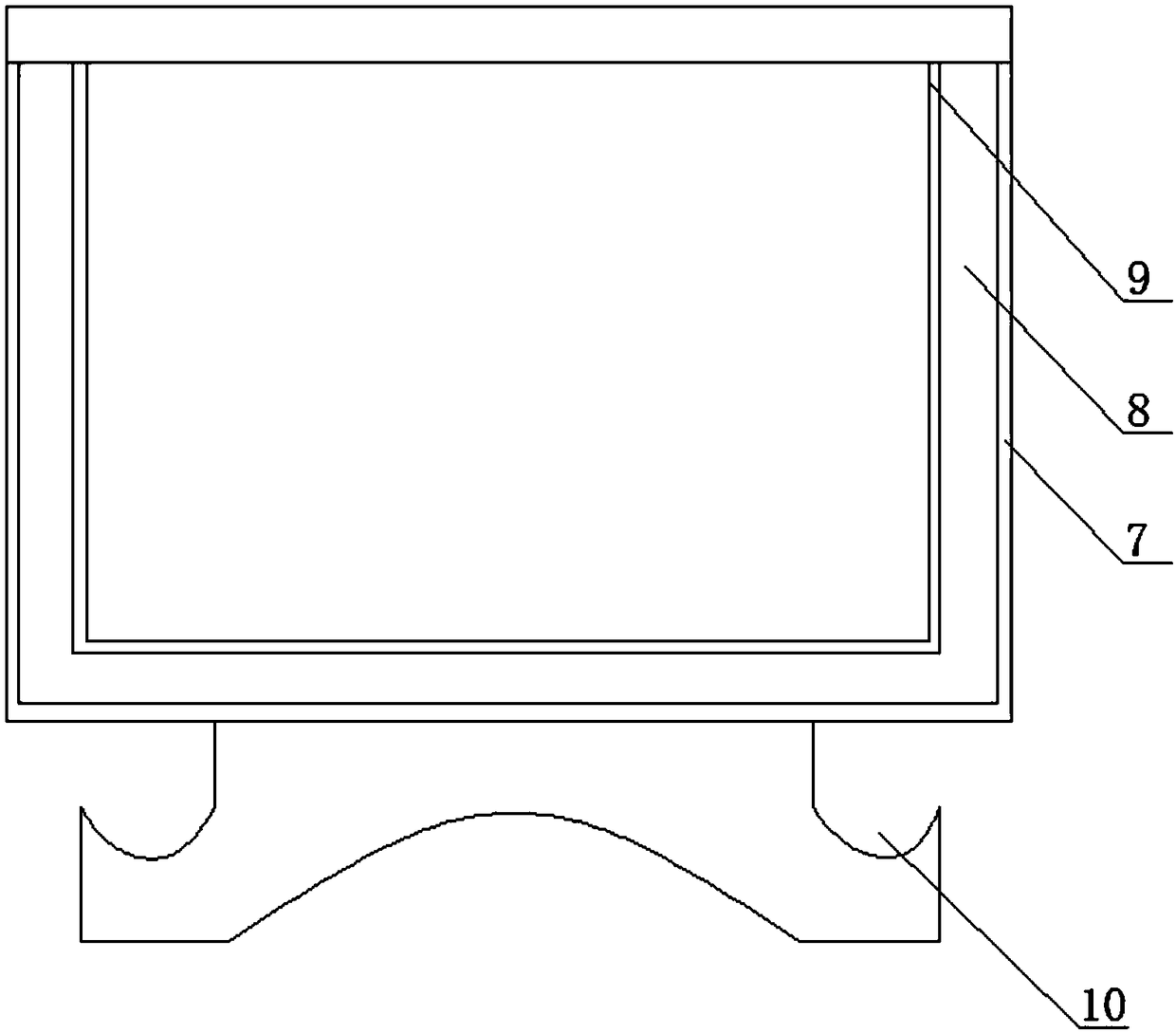

Sealing double-layer heat reflection hollow glass and preparation method thereof

The invention provides a sealing double-layer heat reflection hollow glass. The sealing double-layer heat reflection hollow glass comprises an outer-layer glass body, a sealing adhesive piece, an inner-layer glass body, an aluminum strip and a hollow layer. The hollow layer formed through aluminum strip partition is arranged between the outer-layer glass body and the inner-layer glass body. The outer-layer glass body is mirror glass and stored outside the sealing double-layer heat reflection hollow glass. The sealing adhesive piece is stored outside the aluminum strip and seals the outer-layer glass body and the inner-layer glass body. The aluminum strip is stored between the outer-layer glass body and the inner-layer glass body and inside the sealing adhesive piece. The outer-layer glass body and the inner-layer glass body are connected through the adhesive piece in a sealed mode. According to the sealing double-layer heat reflection hollow glass, metal-plating oxide thin film mirror glass is adopted so that infrared rays can be better reflected; a drying agent is stored in the hollow aluminum strip, so that the large humidity caused due to the fact that the inner and outer temperatures of the double-layer glass are not even is prevented, and a better heat insulation effect is achieved; through the adhesive piece, uneven distribution of traditional glue is solved; and through an outermost sealing protecting bush, airtightness of the double-layer glass is further improved, and the most fragile corners of the double-layer glass are protected.

Owner:泰州市同裕节能门窗有限公司

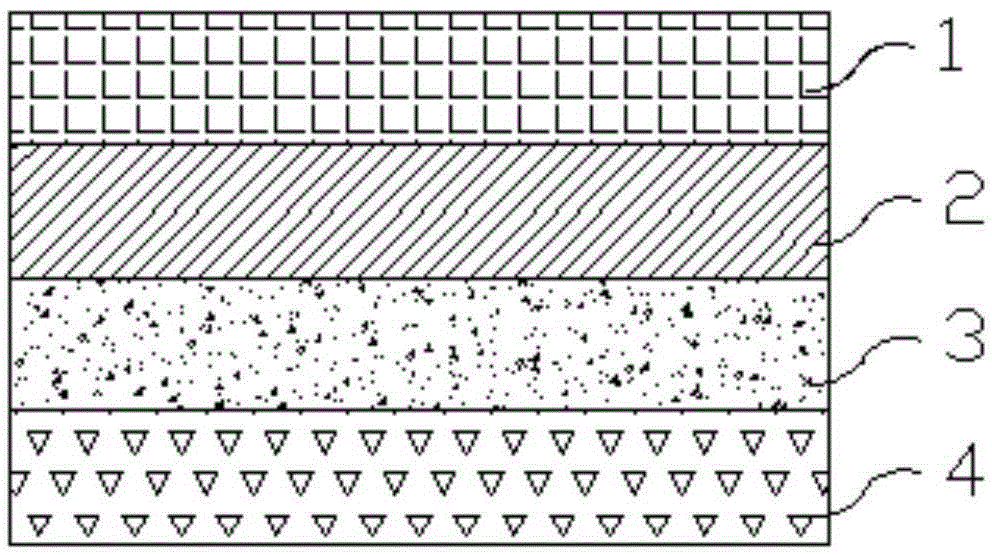

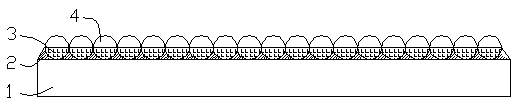

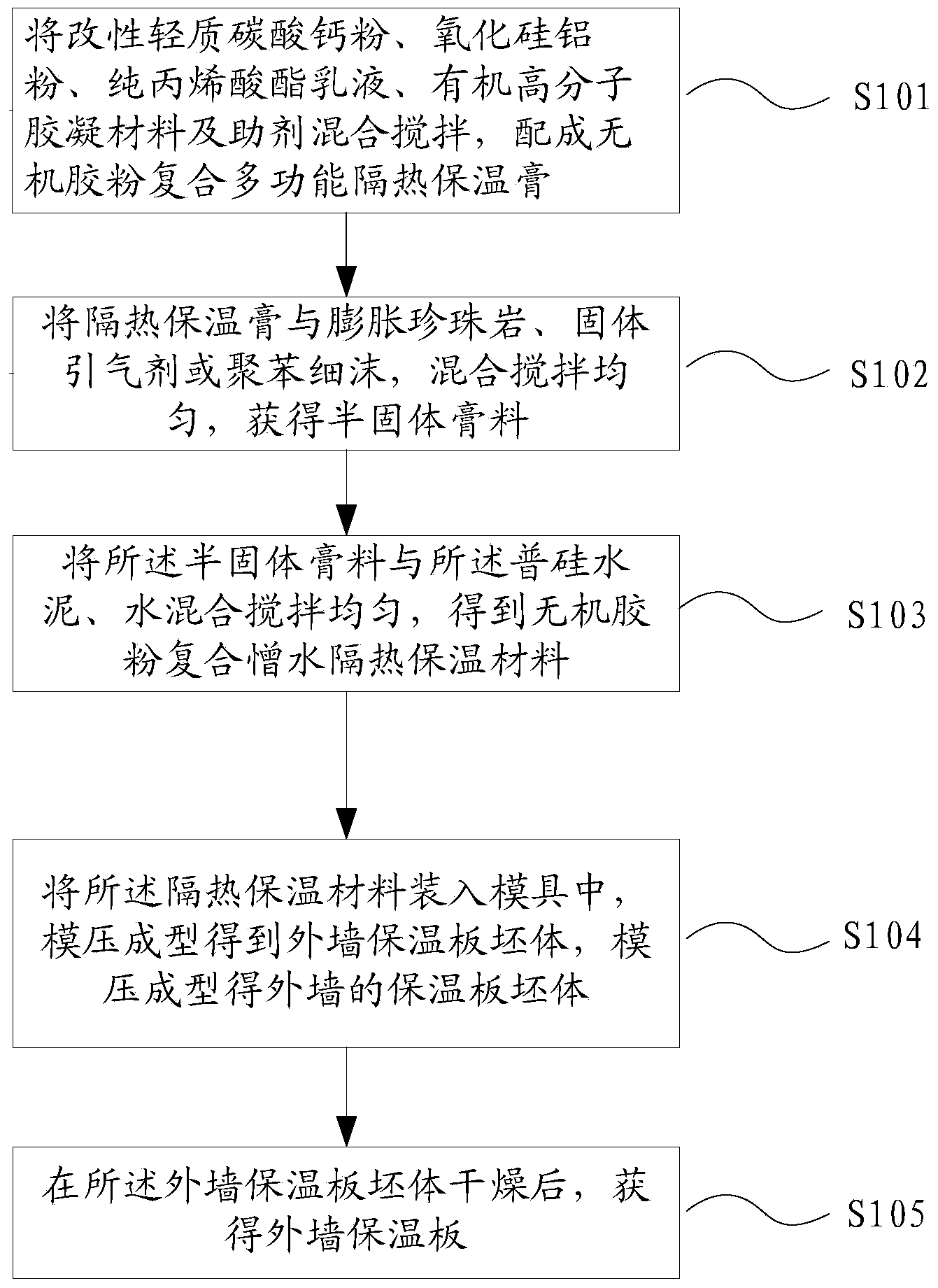

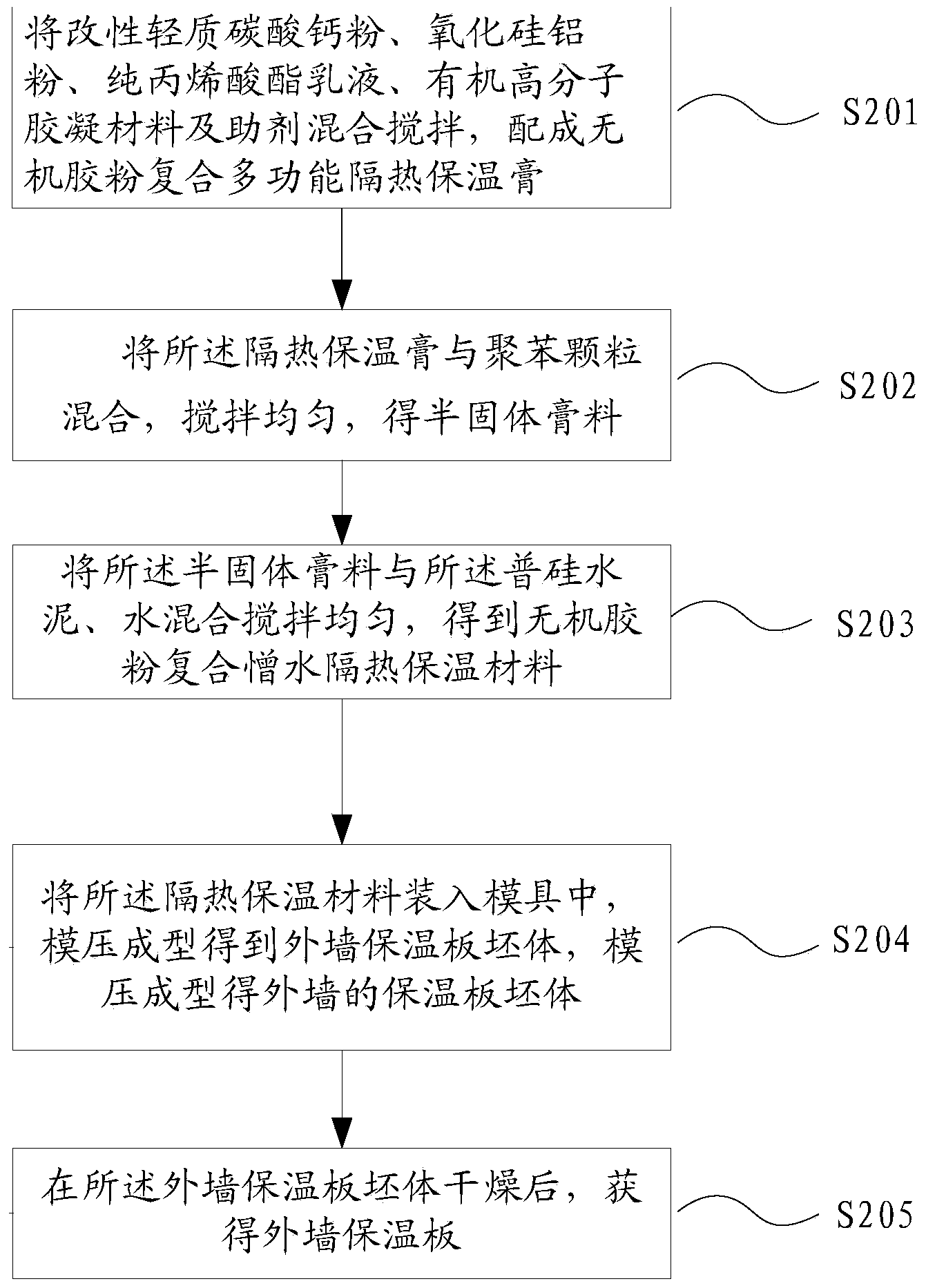

Exterior wall, slope and flat roofing insulation board manufacturing method and insulation board

InactiveCN104163605AImprove breathabilityAvoid pollutionSolid waste managementInsulation layerPortland cement

The invention discloses an exterior wall, slope and flat roofing insulation board manufacturing method and an insulation board; an exterior wall insulation board comprises modified light calcium carbonate powder, silica aluminum powder, pure acrylate emulsion, an organic polymer gel material and additives which are added into the insulation board, and ordinary portland cement, expanded perlite, polyphenyl fine foam, clean water and a solid air entraining agent; a slope and flat roofing insulation board comprises the modified light calcium carbonate powder, the silica aluminum powder, the pure acrylate emulsion, the organic polymer gel material, the additives, the ordinary portland cement, polyphenyl particles and the clean water. The problem of poor hydrophobic performance of building insulation layers in the prior art can be solved, the insulation board has good permeability and can prevent condensation and dew formation, the hydrophobicity reaches more than 98%, the adhesive force is strong, and improves the service life and the thermal insulation performance of building exterior walls.

Owner:HUBEI HUAYULONG ENERGY SAVING MATERIALS TECH CO LTD

Environment-friendly heat-insulating building energy-saving heat-preserving material

InactiveCN109456653AWith heat insulation effectLow toxicityEpoxy resin coatingsReflecting/signal paintsWater basedEpoxy

The invention discloses an environment-friendly heat-insulating building energy-saving heat-preserving material. The environment-friendly heat-insulating building energy-saving heat-preserving material comprises the following raw material components according to a mass percentage: 30-40% of elastic acrylic acid modified emulsion (water-based), 5-7% of epoxy resin (water-based), 3-5% of n-butyl alcohol, 10-15% of hollow glass beads, 8-12% of functional filler, 15-20% of kaolin, 0.8-1.2% of talcum powder, 0.5-0.7% of a dispersing agent, 0.3-0.5% of a wetting agent, 0.4-0.6% of a defoaming agent,0.1-0.3% of an anti-bacterial agent, 0.2-0.4% of a mildew preventive, 1.5-2.5% of a flatting agent, 0.8-1.2% of a thickening agent, and 8-12% of water.

Owner:成都乐沸科技有限责任公司

Processing method of polyurethane finishing coat for chemical storage tank

ActiveCN103756543AGood foaming effectGood weather resistancePolyurea/polyurethane coatingsChemical storageOrganic solvent

The invention relates to a processing method of a polyurethane finishing coat for a chemical storage tank. The method comprises the following steps: 1) sequentially adding weather-resistant polyester resin, rutile titanium dioxide, inorganic filler, vacuum beads, a weather-resistant assistant, a pollution-preventing assistant, a nano additive, a dispersant, a defoamer, a rheological assistant, an anti-settling agent, a foaming catalyst and a flatting agent capable of being reacted with -NCO into a stirring vat, and dispersing and grinding to below 50 microns; 2) adjusting the viscosity of the matter obtained by the step 1) by an environment-friendly organic solvent, and then modulating color by a color paste to obtain a preparation component; 3) after mixing a highly weather-resistant polyurethane curing agent and a high flexibility polyurethane curing agent and placing for 1-5 hours at normal temperature, diluting to 60-90% by the environment-friendly organic solvent to obtain a curing agent component; and 4) mixing the preparation component and the curing agent component in a proportion of (1-3):1. The polyurethane finishing coat produced by the method provided by the invention has better foaming property, weather ability and heat-isolating and preserving effect.

Owner:MEGA P&C ADVANCED MATERIALS SHANGHAI CO LTD

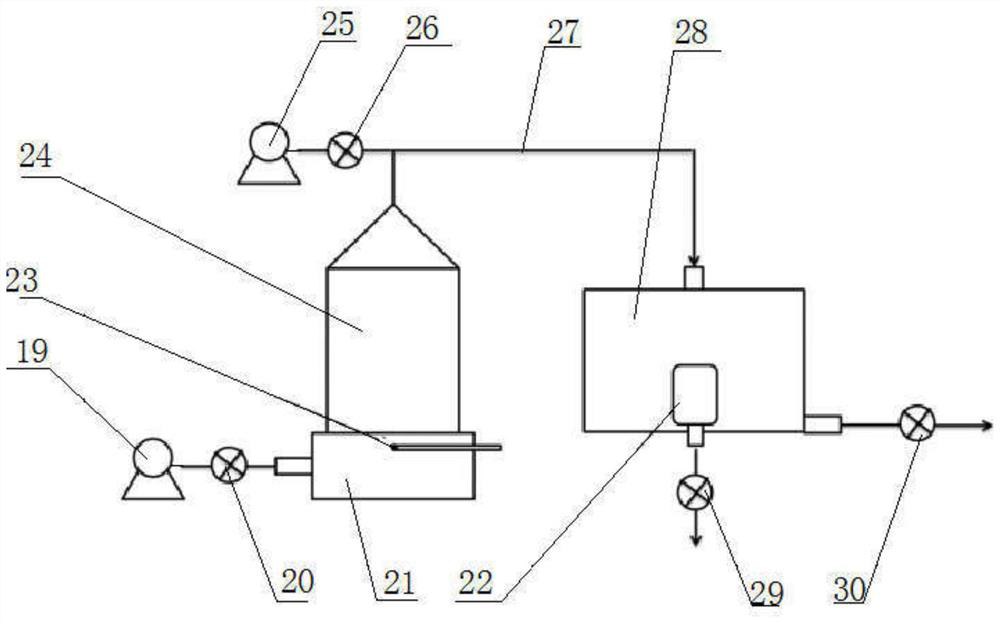

Extraction and separation device for brown carbon

ActiveCN110040715AEasy to analyzeEasy to measureCarbon preparation/purificationSolubilityWater soluble

The invention discloses an extraction and separation device for brown carbon and relates to the technical field of brown carbon extraction and separation devices. The extraction and separation devicecomprises a brown carbon generation assembly, a collection assembly and an extraction and separation assembly, wherein the collection assembly is detachably arranged in the brown carbon generation assembly and the brown carbon is convenient to collect; the collection assembly also can be arranged in the extraction and separation assembly and the brown carbon on the collection assembly is convenient to extract and separate; the extraction and separation assembly at least can be used for carrying out water-soluble brown carbon extraction and separation, alkali-soluble brown carbon extraction andseparation and methanol brown carbon extraction and separation on the brown carbon at one time. The extraction and separation device can be used for generating and separating the brown carbon very well, and 7 types of dissolved-state brown carbon such as water-soluble brown carbon, alkali-soluble brown carbon, methanol-soluble brown carbon, hydrophilic brown carbon and hydrophobic brown carbon are finally obtained; various types of brown carbon are conveniently subjected to analysis and chromatographic scanning and are convenient to determine and analyze.

Owner:ANHUI SCI & TECH UNIV

Method for reducing heat loss of industrial furnace shell

InactiveCN1139779CImprove use valueImprove energy saving effectFurnace componentsSheet steelAluminium

A mehod for decreasing the heat loss of industrial furnace shell features use of dual-layer furnace shell, that is, an additional shell made of thin steel or aluminium sheet is used outside exisiting shell to form an enclosed air layer, so increasing thermal resistance. A layer of refractory fibres is attached to internal or external surface of dual-layer furnace shell.

Owner:SHANGHAI JIAO TONG UNIV

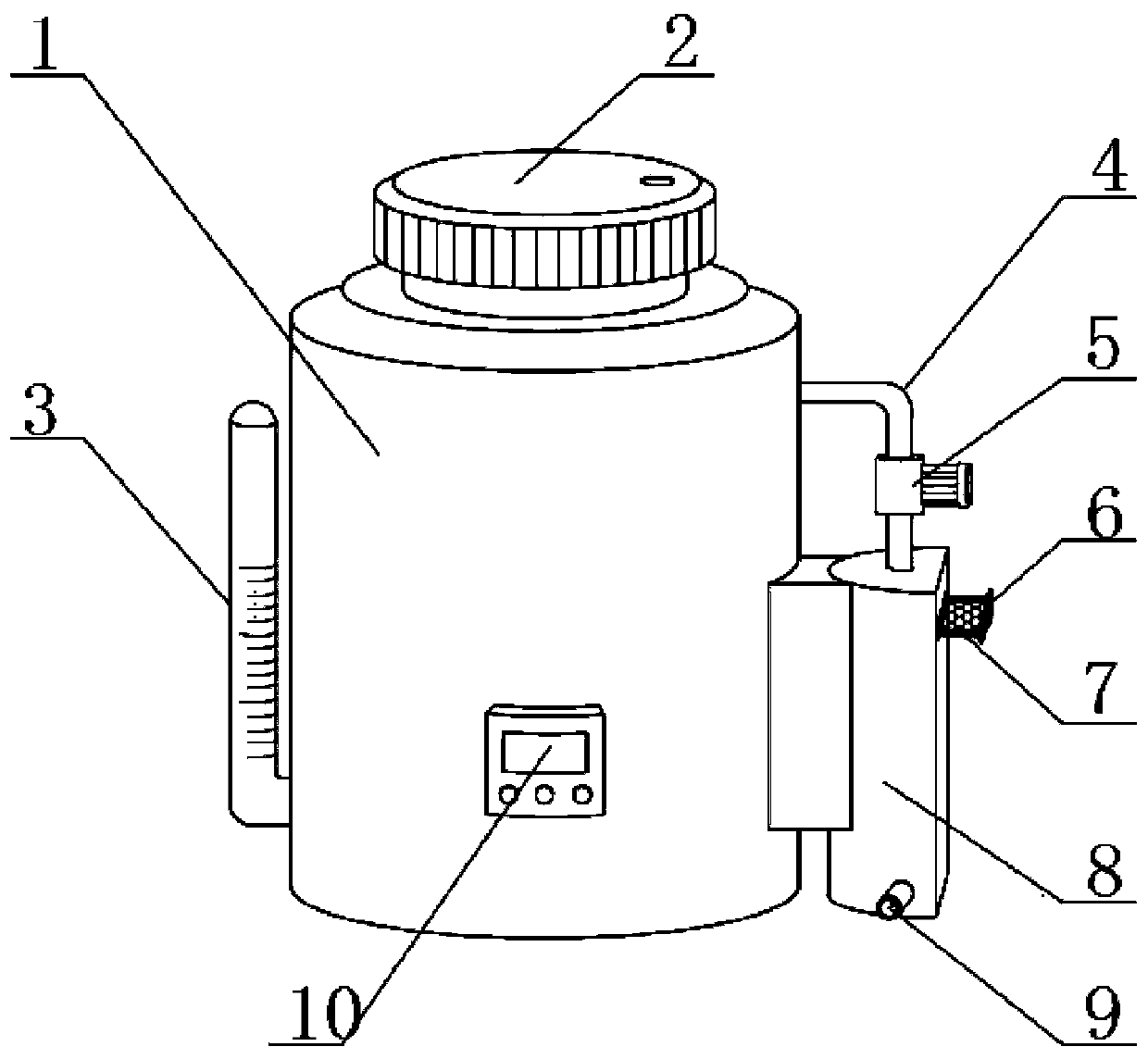

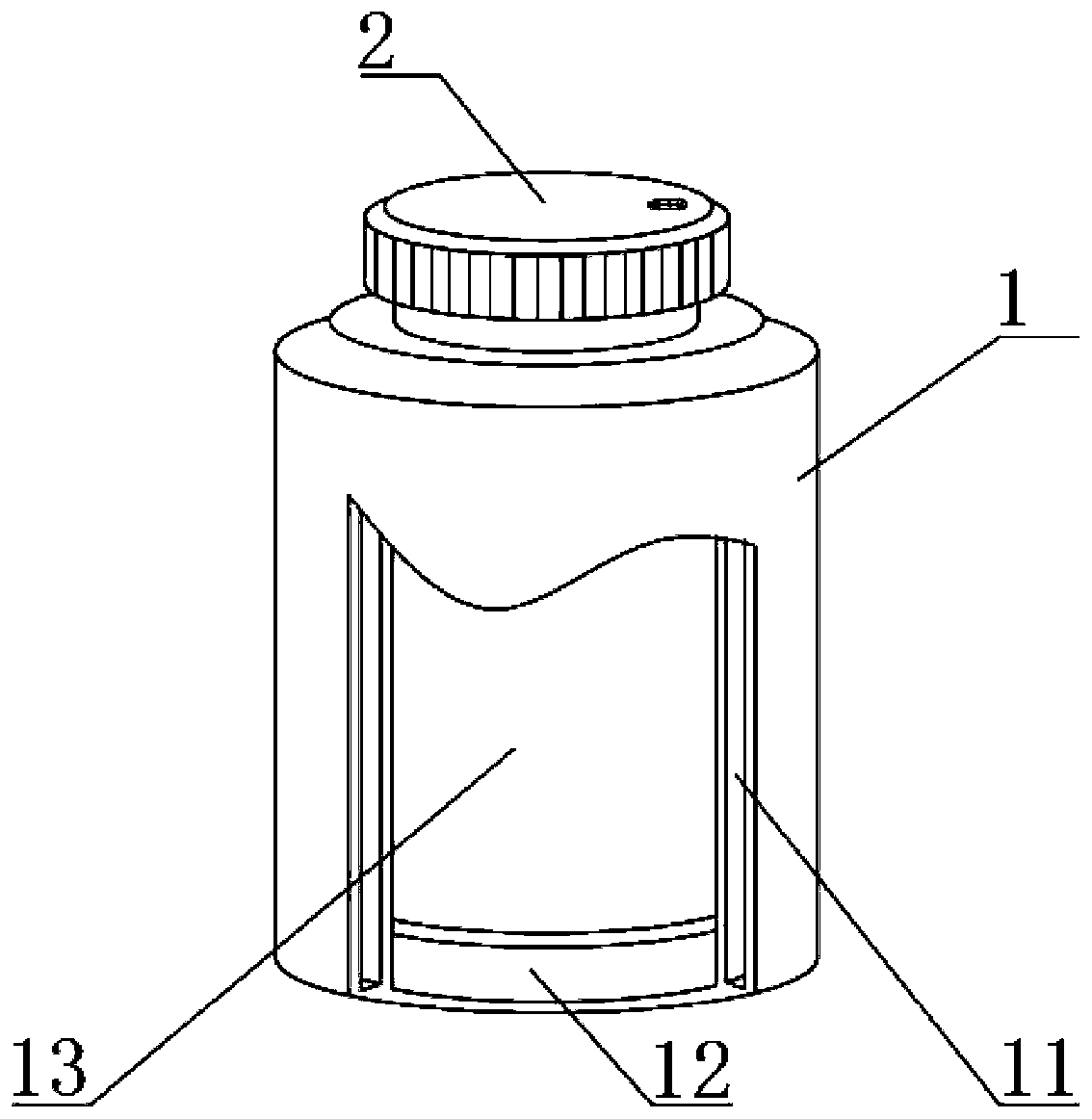

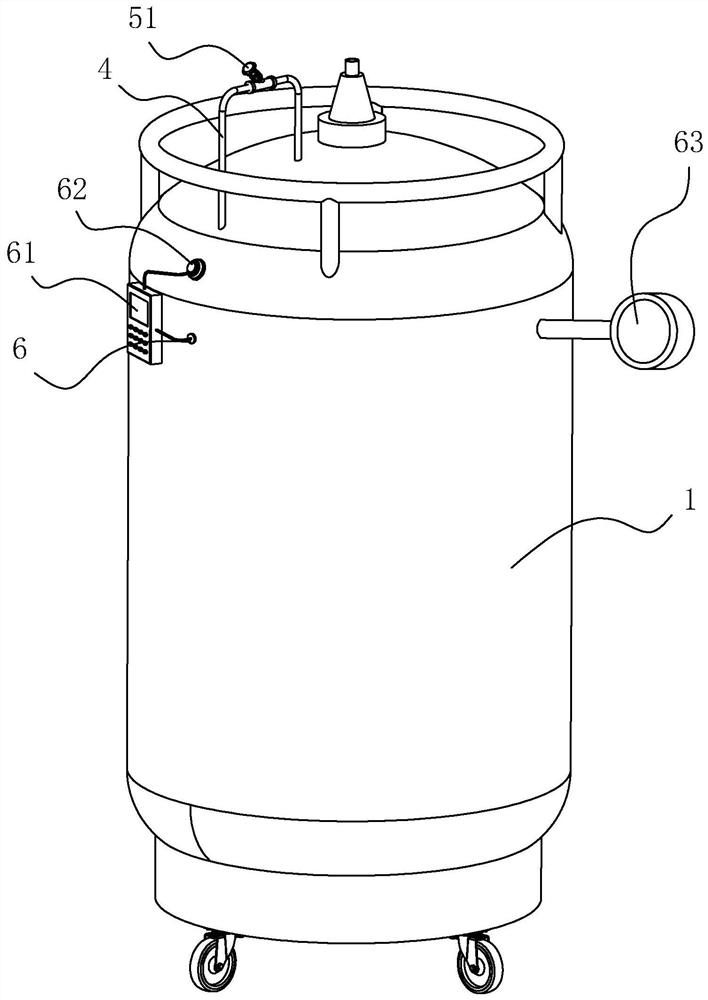

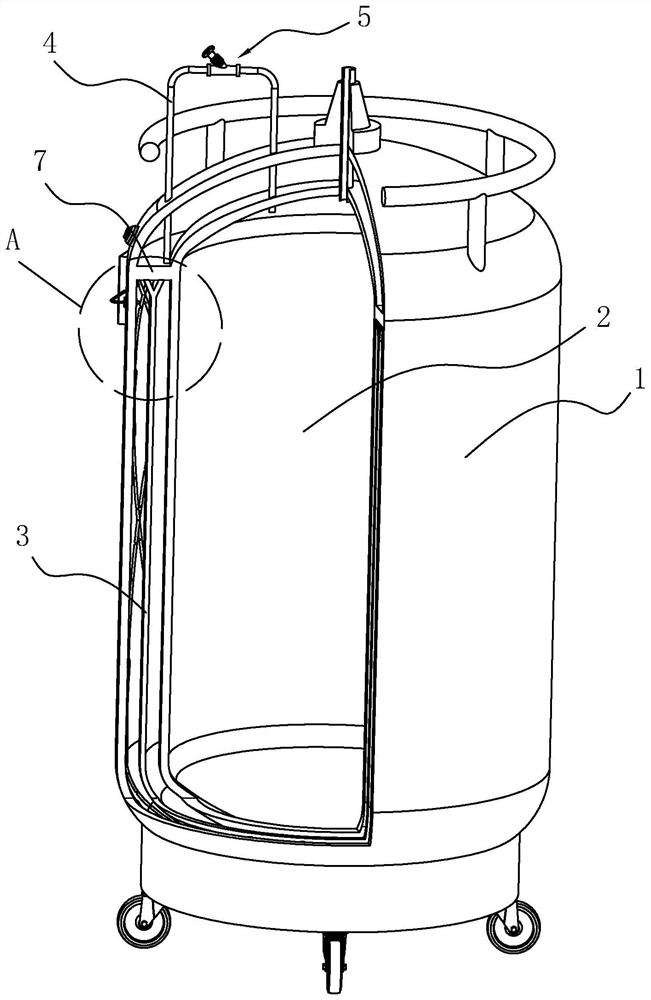

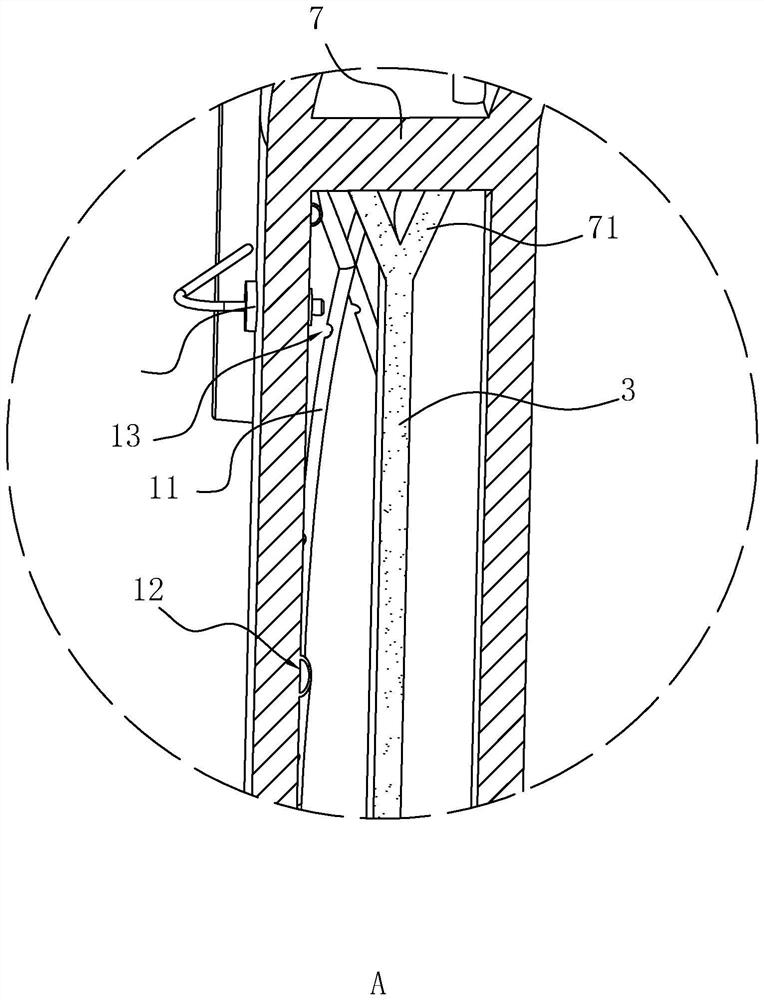

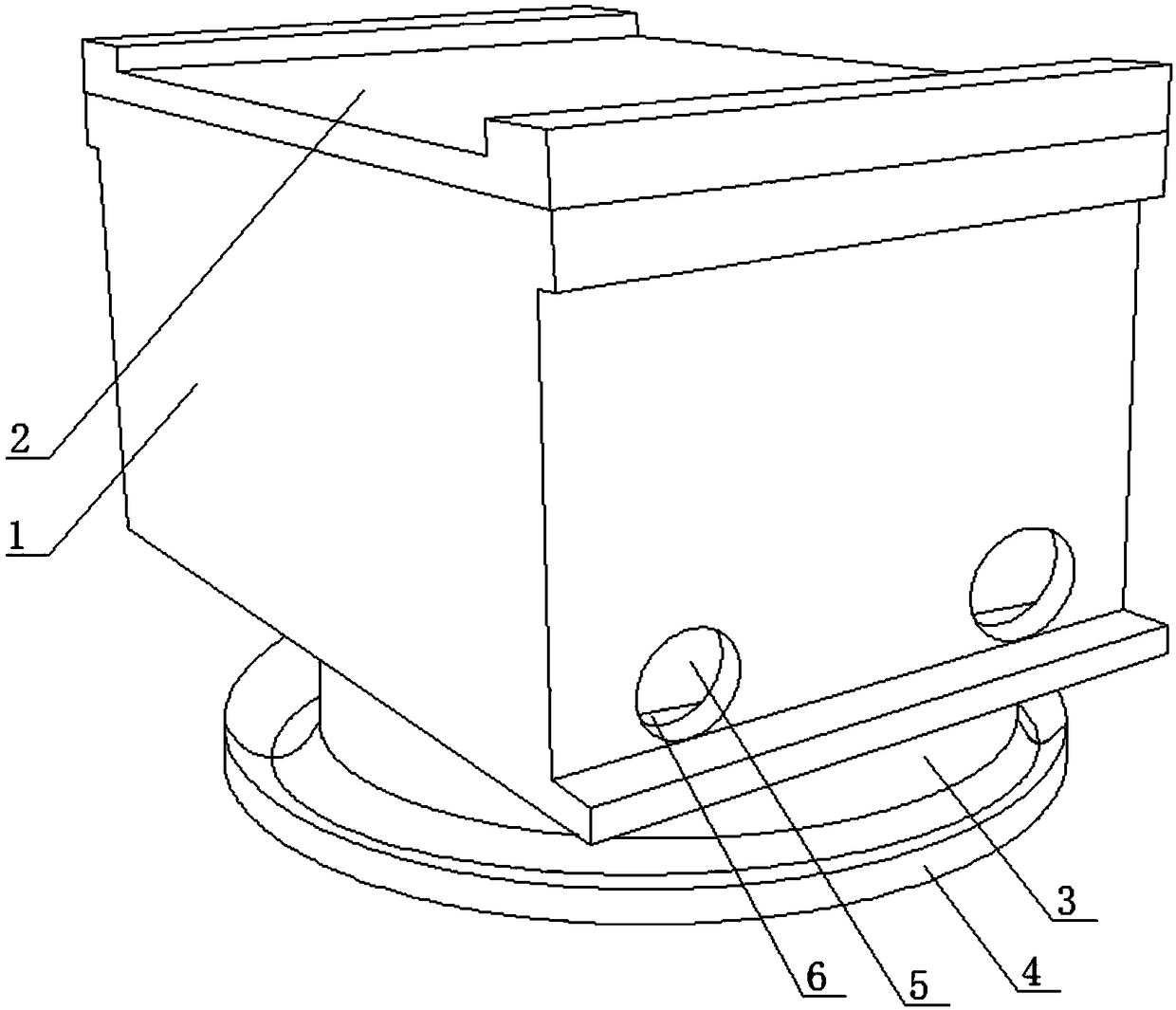

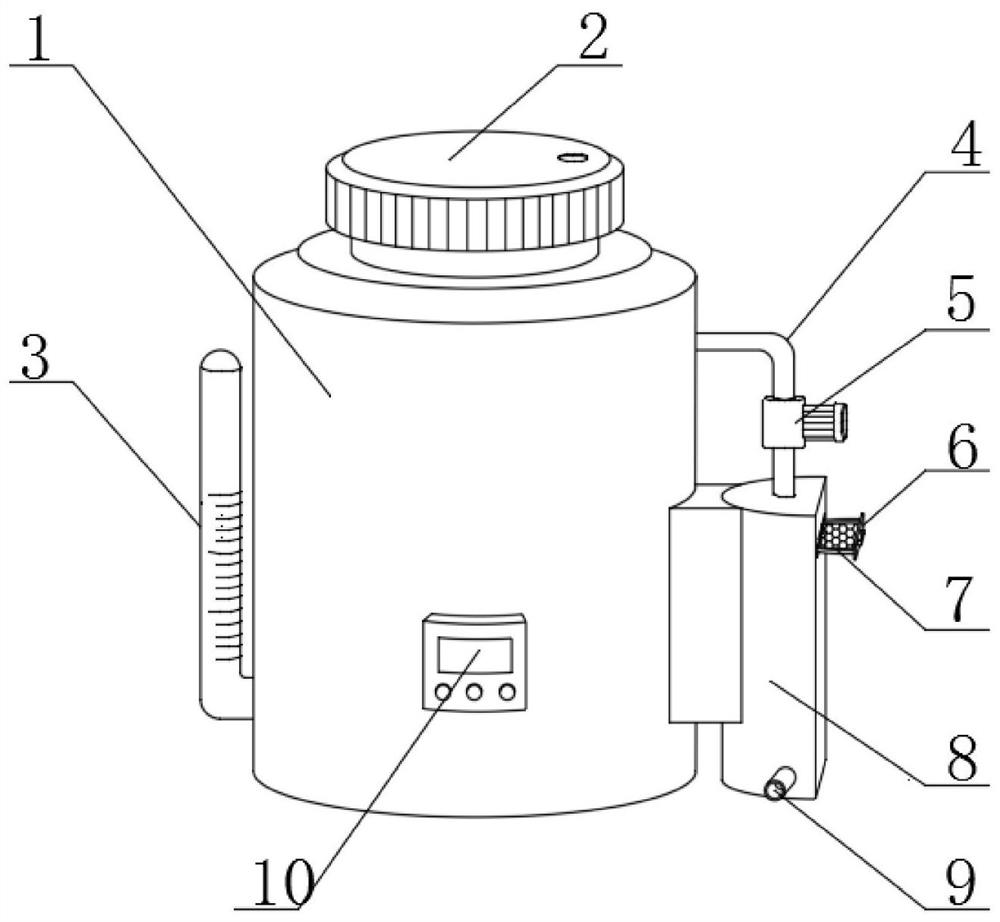

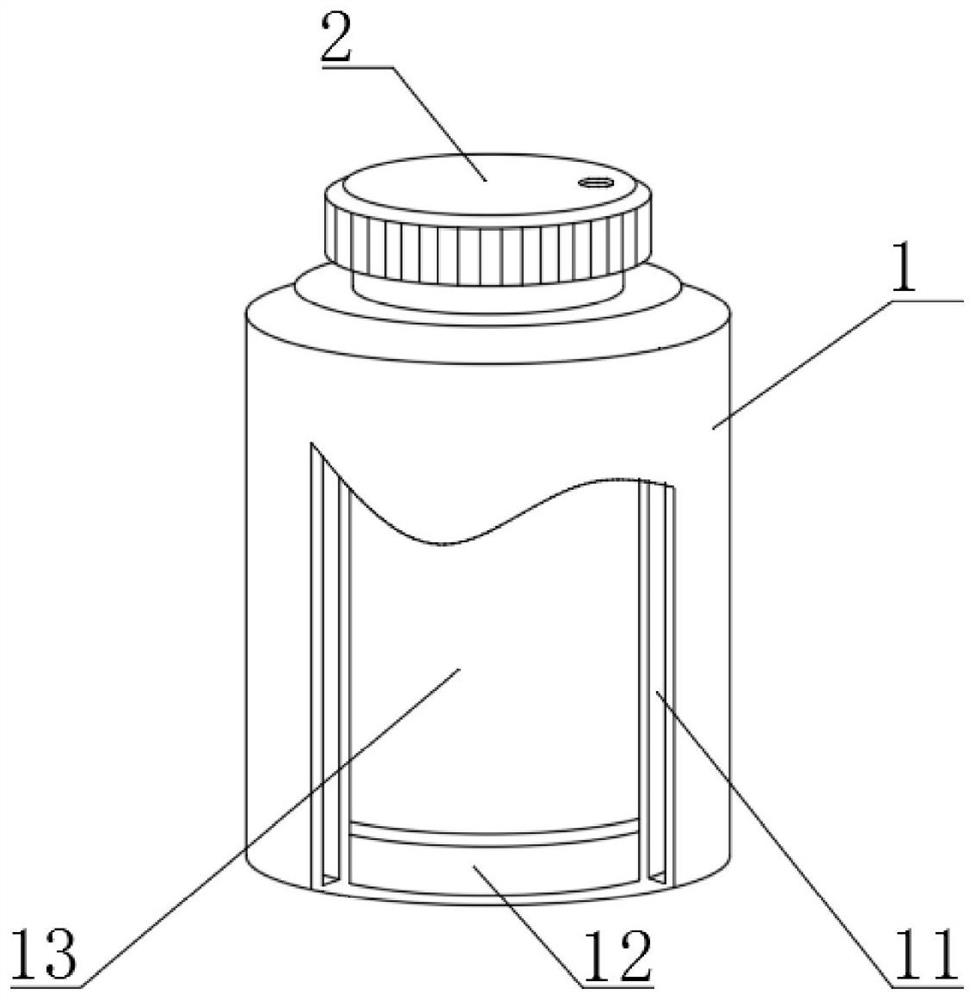

Liquid nitrogen storage tank with air pressure type safety protection function

ActiveCN113418134APlay a heat insulation effectIncrease storage capacityVessel geometry/arrangement/sizeVessel wallsEngineeringHeat conservation

The invention relates to a liquid nitrogen storage tank with an air pressure type safety protection function, which comprises a shell and an inner container; the inner container is fixedly arranged in the shell; a hollow structure is formed between the shell and the inner container; a protective sleeve is arranged between the shell and the inner container; the space between the protective sleeve and the shell is filled with high-pressure gas; a communicating pipe is fixedly arranged on the shell; one end of the communicating pipe is communicated with a gap between the protective sleeve and the inner container, and the other end of the communicating pipe is communicated with an inner cavity of the inner container; and the communicating pipe is provided with a valve assembly used for opening the communicating pipe when air pressure between the shell and the protective sleeve is reduced. When the shell of the storage tank is cracked, high-pressure gas between the shell and the protective sleeve escapes, and the communicating pipe is opened, so that liquid nitrogen stored in the inner container under pressure volatilizes nitrogen and enters the space between the inner container and the protective sleeve, and the protective sleeve is pushed to be in close contact with the inner wall of the shell. The liquid nitrogen storage tank with the air pressure type safety protection function provided by the invention has the effects of improving the safety protection performance of the storage tank and achieving heat insulation and heat preservation on liquid nitrogen in the inner container.

Owner:长沙中益气体有限公司

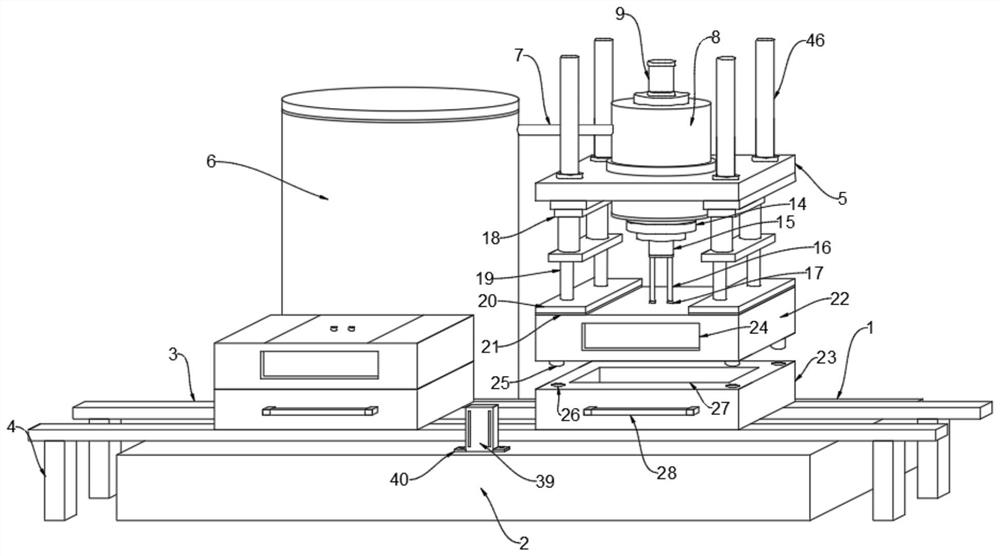

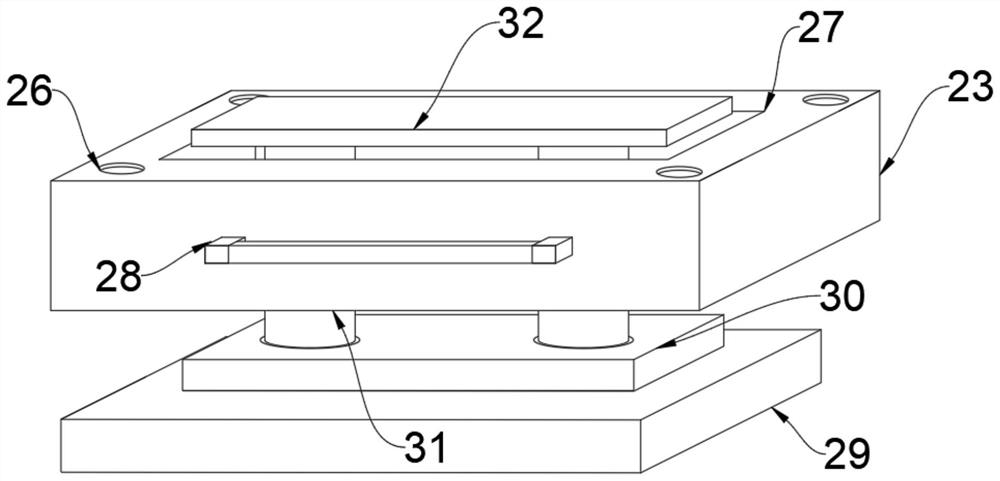

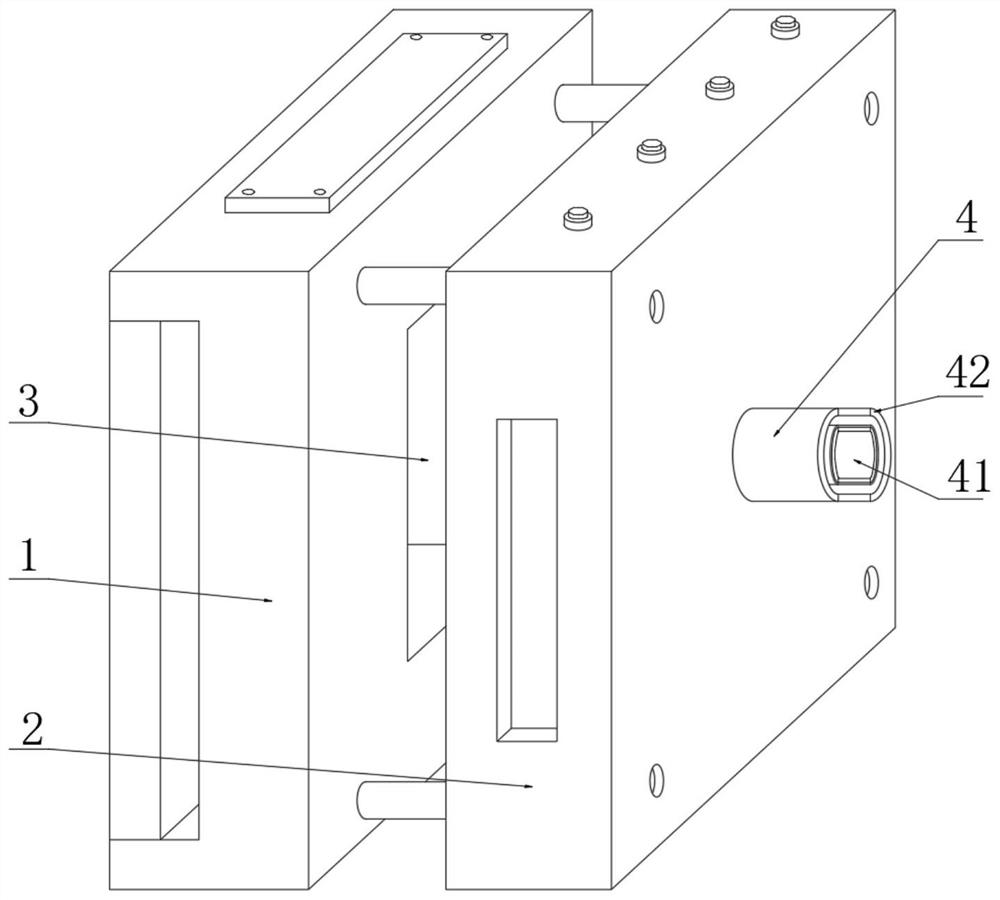

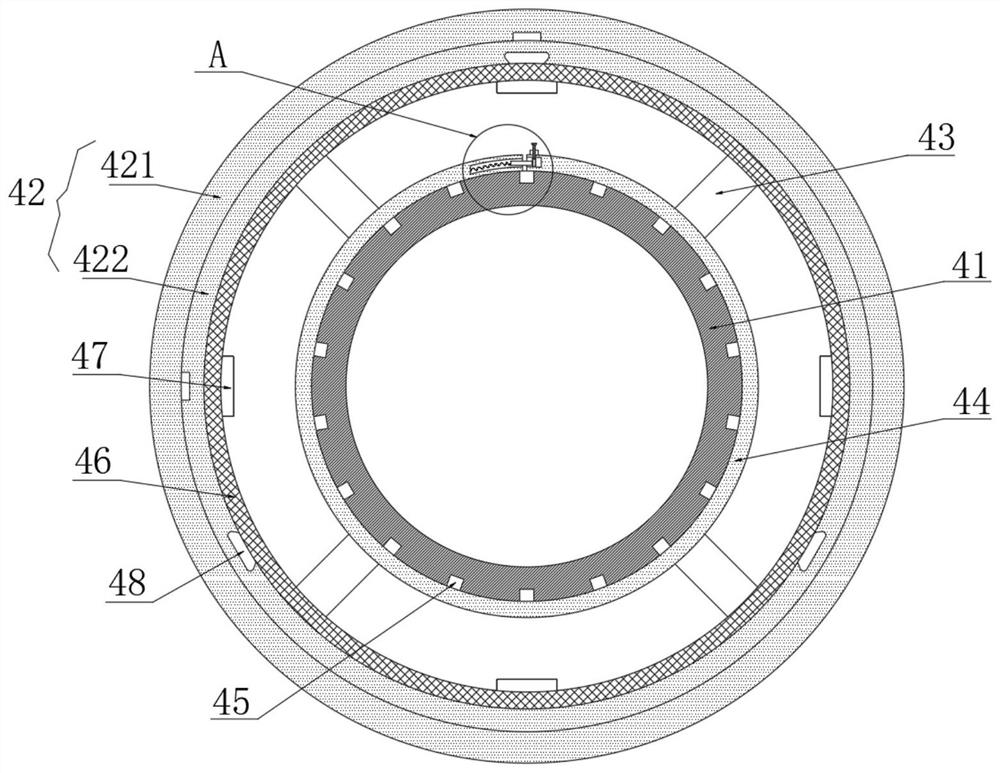

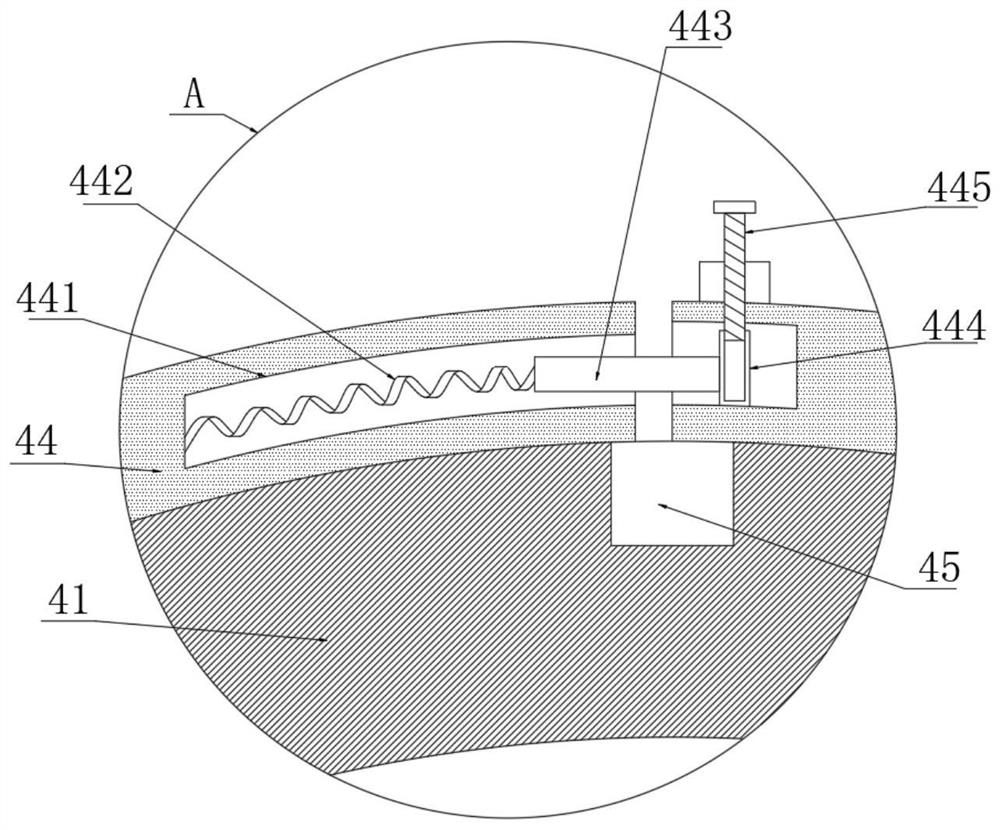

Casting equipment for steel rail pull rod production and machining method thereof

InactiveCN113664192ASolve the problem of fragile moldsEasy to useMelt-holding vesselsMolten metal pouring equipmentsButt jointCasting mold

The invention discloses casting equipment for steel rail pull rod production and a machining method thereof, relates to the technical field of steel rail pull rod production, and aims to solve the problems that existing casting equipment for steel rail pull rod production is generally of a molten iron pouring injection type, a casting mold is prone to being damaged, the overflow waste phenomenon exists, and the equipment is not suitable for being used in a product conveying line. And the device is not suitable for being used in a product conveying line. A casting equipment body is installed above a steel rail pull rod casting conveying table body, a pre-adding tank is installed above the casting equipment body, an electric control discharging opening is formed in the lower end of the pre-adding tank, a liquid discharging disc is installed below the electric control discharging opening, air cylinders are installed on the two sides of the liquid discharging disc, pneumatic rods are installed at the output ends of the air cylinders, pneumatic blocks are installed at the lower ends of the pneumatic rods, electromagnetic iron sheets are installed below the pneumatic blocks, an injection pipe is installed at the lower end of the liquid discharging disc, a pipe body butt joint block is installed at the lower end of the injection pipe, and an upper die body is installed below the pipe body butt joint block.

Owner:马鞍山市莱能节能科技有限公司

A kind of processing method of the polyurethane finish paint that is used for chemical storage tank

ActiveCN103756543BGood foaming effectGood weather resistancePolyurea/polyurethane coatingsChemical storageOrganic solvent

The invention relates to a processing method of a polyurethane finishing coat for a chemical storage tank. The method comprises the following steps: 1) sequentially adding weather-resistant polyester resin, rutile titanium dioxide, inorganic filler, vacuum beads, a weather-resistant assistant, a pollution-preventing assistant, a nano additive, a dispersant, a defoamer, a rheological assistant, an anti-settling agent, a foaming catalyst and a flatting agent capable of being reacted with -NCO into a stirring vat, and dispersing and grinding to below 50 microns; 2) adjusting the viscosity of the matter obtained by the step 1) by an environment-friendly organic solvent, and then modulating color by a color paste to obtain a preparation component; 3) after mixing a highly weather-resistant polyurethane curing agent and a high flexibility polyurethane curing agent and placing for 1-5 hours at normal temperature, diluting to 60-90% by the environment-friendly organic solvent to obtain a curing agent component; and 4) mixing the preparation component and the curing agent component in a proportion of (1-3):1. The polyurethane finishing coat produced by the method provided by the invention has better foaming property, weather ability and heat-isolating and preserving effect.

Owner:MEGA P&C ADVANCED MATERIALS SHANGHAI CO LTD

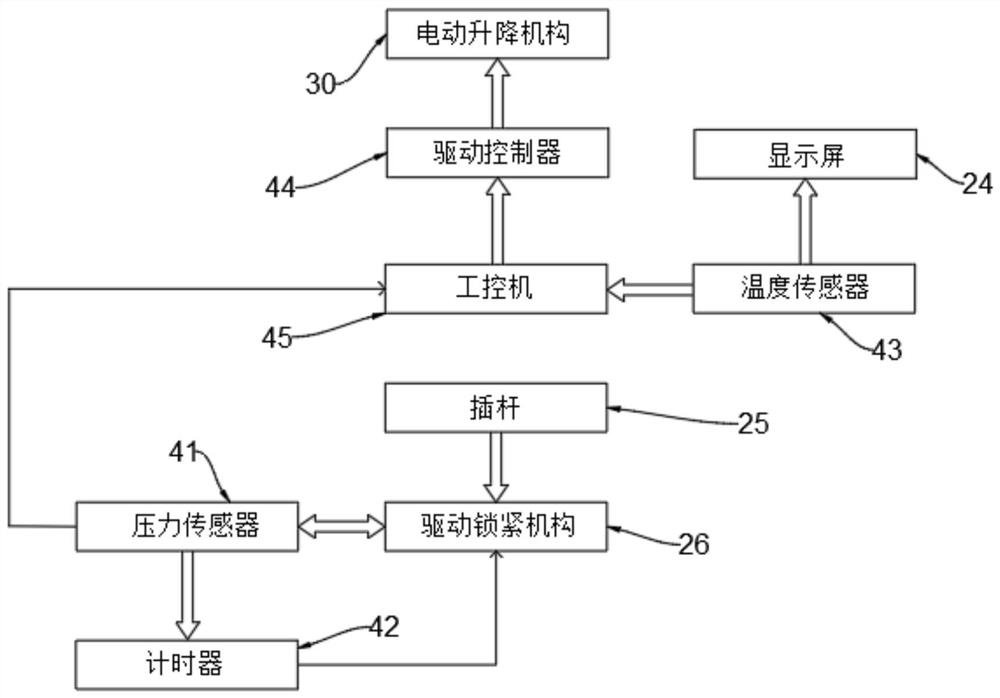

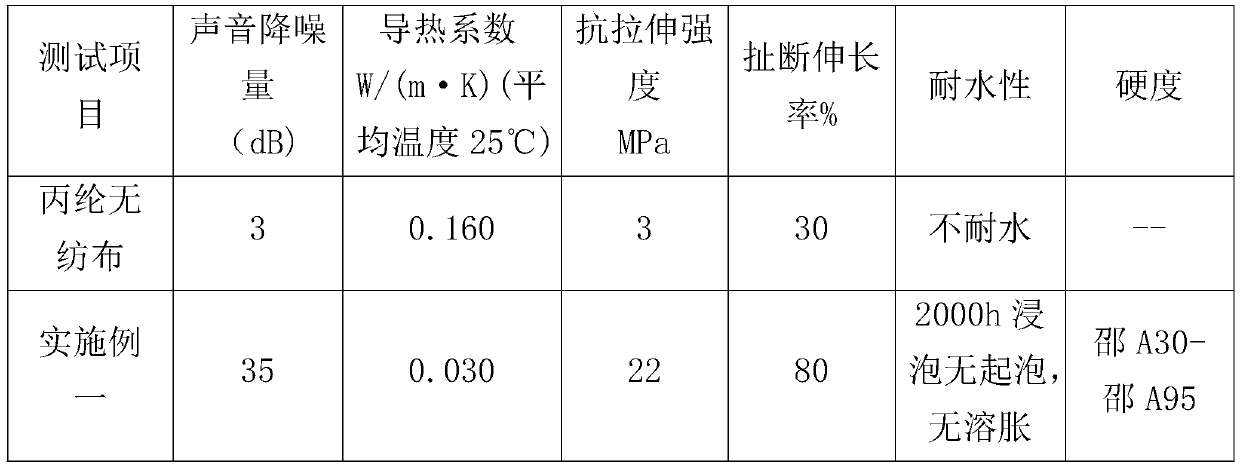

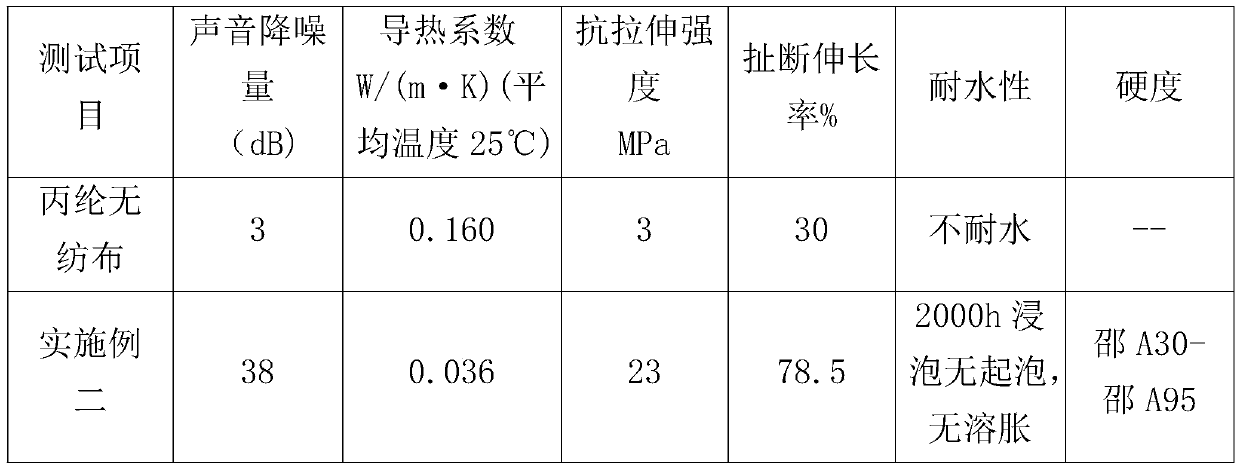

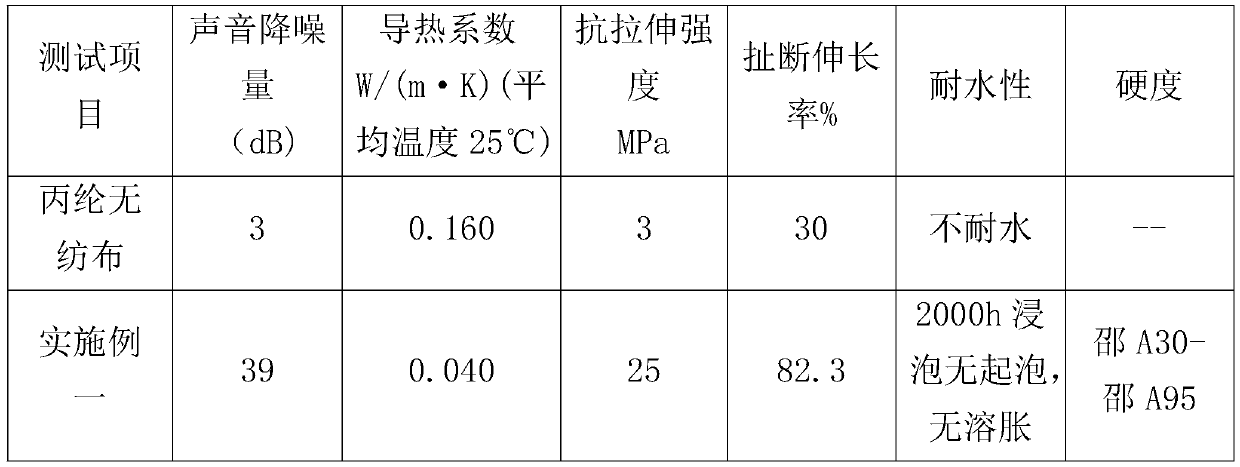

Environment-friendly heat-insulation and noise-reduction polyurea composite material and manufacturing method thereof

InactiveCN111535045AHigh solid contentEasy to makeChemical industryTextiles and paperFiberDimethyl methylphosphonate

The invention relates to the technical field of composite materials, and specifically discloses an environment-friendly heat-insulation and noise-reduction polyurea composite material. The environment-friendly heat-insulation and noise-reduction polyurea composite material comprises polyether polyol, tri(hydroxymethyl)propane, butyl acetate, isophorone diisocyanate, dimethyl methylphosphonate, a light stabilizer, polyaspartic acid resin, cellulose acetate butyrate, siloxane pigment, mica balls, silicate particles and a defoamer; a fiber texture is heated to 40 DEG C; the surface of the fiber texture is dried; the fiber texture is fixed on conveying rollers; one section of the fiber texture is placed on a fixing clamp; the fixing clamp draws the fiber texture to move forwards through a variable frequency motor under control of a PLC; relative positions of a rolling brush and a scraper to the fiber texture are controlled through sensors; a component A is mixed with a pre-mixed material to form slurry, and the slurry is pumped into a paint box by using a diaphragm pump; paint is extracted into a paint container, which is directly connected to the rolling brush, from the paint box according to a using amount; the slurry is painted on the fiber texture in a rolling manner by using the rolling brush; the slurry is slicked with the scraper and is dried; and then the environment-friendly heat-insulation and noise-reduction polyurea composite material is obtained.

Owner:青岛青材科技有限公司

Novel electric heating cup

InactiveCN104367107AVersatileIncrease water temperatureWater-boiling vesselsDrinking vesselsChinese charactersEngineering

The invention provides a novel electric heating cup. The novel electric heating cup is characterized in that a cup body of the electric heating cup is provided with an inner layer, an outer layer formed by bending a cup opening of the inner layer, and an air layer formed by separating the inner layer from the outer layer. The height of the outer layer relative to the cup body is larger than that of the inner layer. The cross section of the cup body is shaped like a Chinese character 'ao' without the bottom edge. A separable electric heating device is arranged under the concaved position of the inner layer. The air layer of the cup body structure can prevent heat of water from being conducted to the outer layer from the inner layer, play a role in heat insulation and heat preservation, and effectively prevent the hands from being scalded. Meanwhile, the inner layer of the cup body is heated through the electric heating device, water temperature rises, and the functions of the cup are enriched.

Owner:韦江华

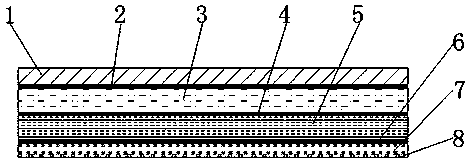

A food-grade high temperature resistant anti-sticking and anti-seepage coated silicon paper

ActiveCN107435277BLow temperature resistanceNon-adhesiveFlexible coversWrappersInsulation layerThermal insulation

The invention discloses food-grade high-temperature-resistant anti-sticking anti-seepage silicon coated paper which comprises a polytetrafluoroethylene layer, a first natural edible glue layer, a first parchment layer, a second natural edible glue layer, a heat insulation layer, a third natural edible glue layer, a second parchment layer and a groove. The first natural edible glue layer is arranged below the polytetrafluoroethylene layer, the first parchment layer is arranged below the first natural edible glue layer, the second natural edible glue layer is arranged below the first parchment layer, and the heat insulation layer is arranged below the second natural edible glue layer. The food-grade high-temperature-resistant anti-sticking anti-seepage silicon coated paper is scientific and reasonable in structure and safe and convenient to use, components such as the heat insulation layer can function in heat insulation and preservation, and anti-sticking and anti-seepage effects can be achieved by the aid of polytetrafluoroethylene with high temperature resistance, low temperature resistance, non-sticking property, corrosion resistance, non-hazardous property and the like.

Owner:枣庄市恒宇纸业有限公司

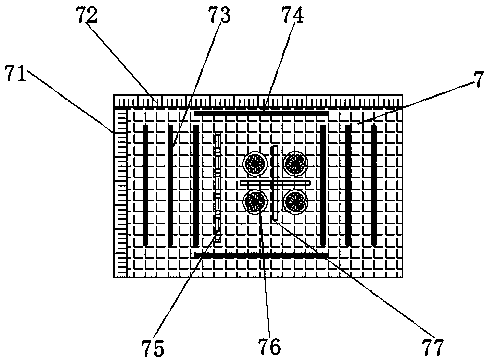

New foam material multi-functional beehive

InactiveCN108739524AAvoid enteringAvoid destructionAnimal repellantsBeehivesWater storage tankPolyethylene glycol

The invention belongs to the technical field of bee-keeping devices, and discloses a new foam material multi-functional beehive. The new foam material multi-functional beehive comprises a box body, abox cover, a support column and a base. The bottom of the box body is provided with the support column. The bottom of the support column is provided with the base. The support column and the base arecylindrical structures. A diameter of the base is greater than a diameter of the support column. A faceplate at the top of the base of the outer side of the support column is provided with an annularwater storage tank. In use, after the beehive is horizontally placed on the ground, water is added to the water storage tank, so the water storage tank forms a circle of a barrier for preventing insects and ants from creeping. Living beings, such as the insects and the ants, who feed on honeybees or honey can be effectively prevented from entering the box body. A foam plate is installed in an interlayer between an outer housing and an inner housing of the box body, and the foam plate is supported by polyethylene glycol terephthalate, so the beehive has the better shearing resistance, heat-insulating property and environmental protection property, an internal honeycomb is prevented from being damaged in a conveying process of the beehive, and heat-insulating and heat-preserving effects canbe achieved.

Owner:芜湖杰汇环保科技有限公司

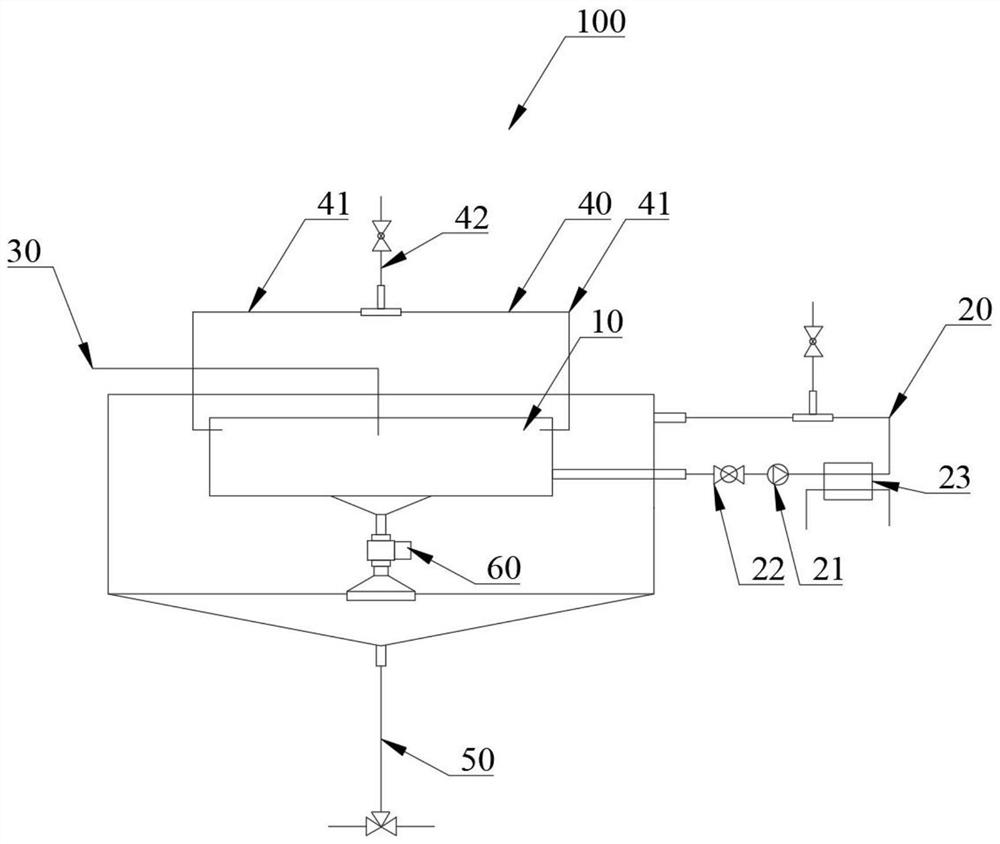

Housing and building integrated sewage treatment system

PendingCN114251967AHigh recovery ratePlay a heat insulation effectRecuperative heat exchangersFlush cleaningWater treatment systemSewage

The invention relates to a housing building integrated sewage treatment system which comprises a water collection tank, a heat exchange pipeline, a first water pump, a first valve, a heat exchanger, a high-temperature sewage recovery pipeline, a cleaning pipeline, a water outlet pipeline and an electromagnetic valve, the first water pump and the first valve are arranged on the heat exchange pipeline; the heat exchange pipeline penetrates through the heat exchanger to exchange heat with the water heater water supply pipeline; the water collecting tank comprises an inner tank and an outer tank; the inner box is fixedly arranged in the outer box; the high-temperature sewage recovery pipeline is communicated to the inner box; an inner box water outlet is formed in the bottom of the inner box; the water outlet of the inner box is communicated with the outer box through an electromagnetic valve; the heat exchange pipeline is communicated with the inner box and the outer box; the water outlet pipeline is communicated to the outer box and is used for discharging water in the outer box; a valve is arranged on the water outlet pipeline; the cleaning pipeline comprises two cleaning water inlet pipes for guiding water into the inner box; and two arc-shaped spacers for guiding water entering from the clean water inlet pipe to generate rotational flow in the inner box are arranged in the inner box. The device has the beneficial effect that the heat recovery rate is high.

Owner:绍兴高新技术产业开发区投资发展集团有限公司

Vacuum cup with USB interface

InactiveCN104367105AVersatileIncrease water temperatureDrinking vesselsWarming devicesChinese charactersThermal insulation

The invention provides a vacuum cup with a USB interface. The vacuum cup with the USB interface is characterized in that the cup body of the vacuum cup is provided with an inner layer, an outer layer formed by bending the cup opening of the inner layer, and an air layer formed by the inner layer and the outer layer in a spaced mode; the height, relative to the cup body, of the outer layer is larger than the height, relative to the cup body, of the inner layer; the cross section of the cup body is shaped like a Chinese character 'ao' without a bottom side; a separable electric heating device is arranged below the concave position of the inner layer and provided with the USB interface. According to the vacuum cup, due to the air layer of the cup body structure, heat of water can be isolated and prevented from being transmitted to the outer layer from the inner layer, the thermal insulation effect and the heat preservation effect are achieved, and the cup can be effectively prevented from scalding a hand; because the electric heating device is used for heating the inner layer of the cup body, the temperature of water is raised, and the functions of the cup are enriched; due to the USB interface, more convenience is provided for office workers.

Owner:韦江华

Chemical storage tank polyurethane paint with weather resistance and heat insulation and preservation performance

InactiveCN109777279AGood foaming effectGood weather resistancePolyurea/polyurethane coatingsChemical storagePolyester

The invention provides chemical storage tank polyurethane paint with weather resistance and heat insulation and preservation performance. The chemical storage tank polyurethane paint with the weatherresistance and the heat insulation and preservation performance is prepared from the following steps: (1) successively adding the following components in parts by weight into a mixing tank: 20 to 50 parts of weather-resisting polyester thermosetting resin which can react with NCO, 20 to 70 parts of carboxymethylcellulose, 40 to 60 parts of inorganic fillers, 20 to 60 parts of vacuum microbeads, 0.02 to 1.5 parts of weather-resisting aids, 11 to 18 parts of antipollution aids, 13 to 20 parts of nano additives, 0.2 to 1.5 parts of dispersing agents, 0.2 to 0.5 part of defoaming agents, 0.5 to 1.5 parts of rheological aids, 0.5 to 1.5 parts of anti-settling agents, 0.5 to 3.0 parts of foaming catalysts, and 0.5 to 1.5 parts of flatting agents, and dispersing and grinding to a size lower thanor equal to 50 micrometers; and (2) adjusting the viscosity of a substance obtained in the step (1) by using 10 to 25 parts of environment-friendly organic solvents, and adjusting the color by using color paste to obtain a preparation component. The chemical storage tank polyurethane paint with weather resistance and heat insulation and preservation performance has the beneficial effects that thepolyurethane finishing paint has good foaming performance and weather resistance, and five years or above of heat insulation and preservation effect can be achieved when the chemical storage tank polyurethane paint is smeared on the surface of a chemical storage tank.

Owner:吕秀梅

Die-casting die of horizontal cold chamber die-casting machine and process thereof

InactiveCN112589070AThe temperature drop is reducedAvoid rapid coolingEngineeringMechanical engineering

The invention discloses a die-casting die of a horizontal cold chamber die-casting machine. The die comprises a movable die and a fixed die, wherein the movable die is arranged on the left side of thefixed die, a cavity is formed in the outer wall of the right side of the movable die, the outer wall of the right side of the fixed die communicates with a pouring pipeline, and the pouring pipelinecomprises an inner pipe communicating with the outer wall of the right side of the fixed die; the outer wall of the inner pipe is sleeved with an outer pipe, supporting rods are evenly arranged between the outer wall of the inner pipe and the inner wall of the outer pipe, a filling pipeline in the device is composed of the outer pipe and the inner pipe, a cavity is formed by separating the supporting rods to have an heat insulation effect, and the temperature drop amplitude of a metal liquid raw material added into the filling pipeline is reduced, so that the metal liquid raw material in the pouring pipeline is prevented from being cooled rapidly, and the use performance of the die-casting die is improved. The temperature in the pouring pipeline cannot be too low through an heat insulationlayer and a heating piece, and the probability that the metal liquid raw material is cooled in the pouring pipeline is further reduced.

Owner:诸暨市旭祥弹簧有限公司

A brown carbon extraction and separation device

ActiveCN110040715BEasy to analyzeEasy to measureCarbon preparation/purificationEnvironmental engineeringAqueous solubility

The invention discloses an extraction and separation device for brown carbon and relates to the technical field of brown carbon extraction and separation devices. The extraction and separation devicecomprises a brown carbon generation assembly, a collection assembly and an extraction and separation assembly, wherein the collection assembly is detachably arranged in the brown carbon generation assembly and the brown carbon is convenient to collect; the collection assembly also can be arranged in the extraction and separation assembly and the brown carbon on the collection assembly is convenient to extract and separate; the extraction and separation assembly at least can be used for carrying out water-soluble brown carbon extraction and separation, alkali-soluble brown carbon extraction andseparation and methanol brown carbon extraction and separation on the brown carbon at one time. The extraction and separation device can be used for generating and separating the brown carbon very well, and 7 types of dissolved-state brown carbon such as water-soluble brown carbon, alkali-soluble brown carbon, methanol-soluble brown carbon, hydrophilic brown carbon and hydrophobic brown carbon are finally obtained; various types of brown carbon are conveniently subjected to analysis and chromatographic scanning and are convenient to determine and analyze.

Owner:ANHUI SCI & TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com