Patents

Literature

3479results about "Vessel walls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

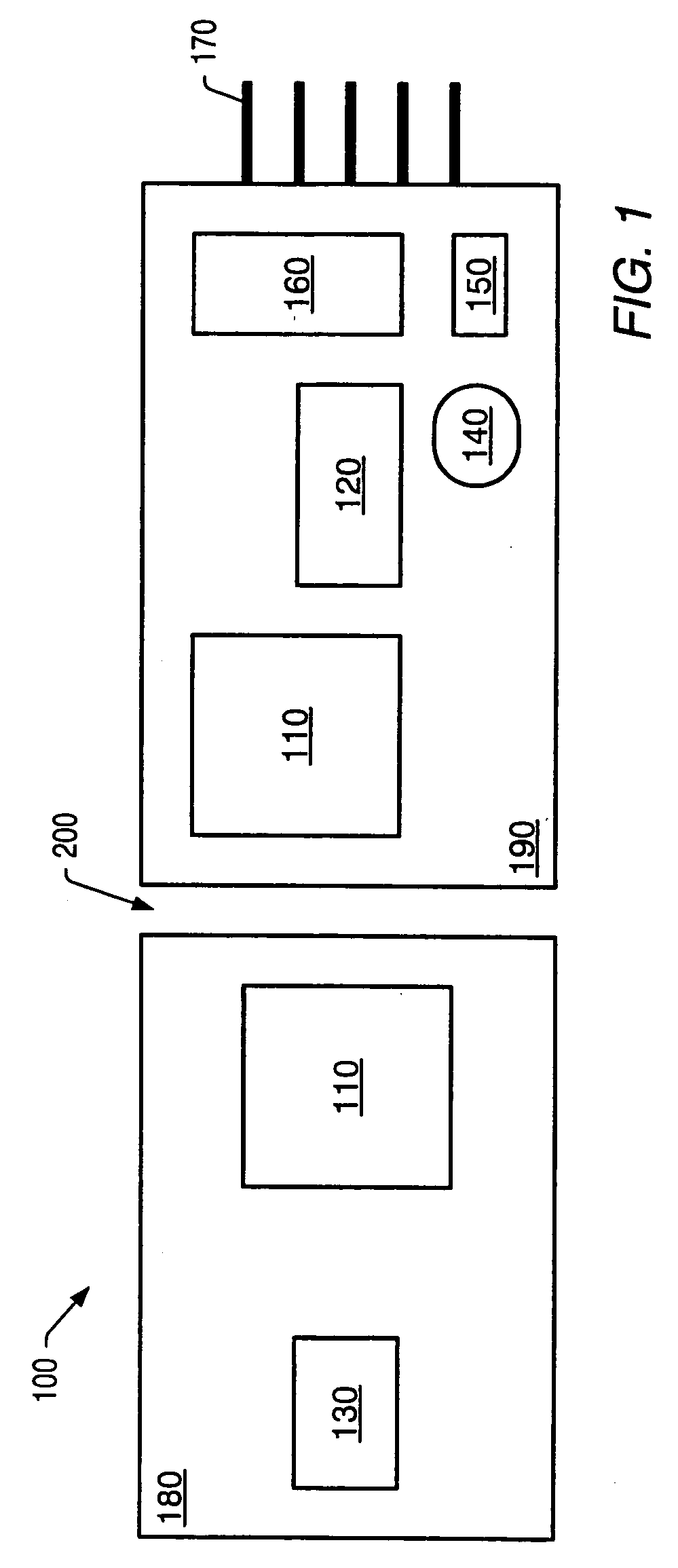

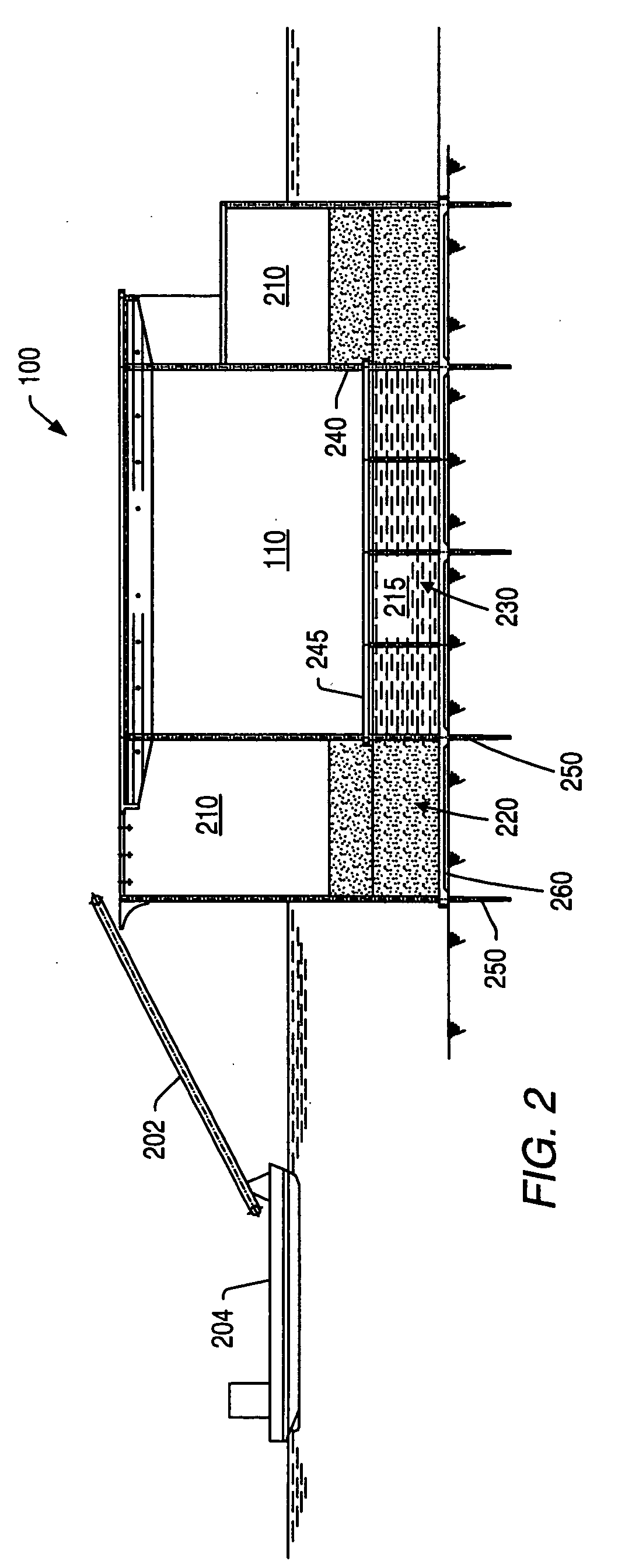

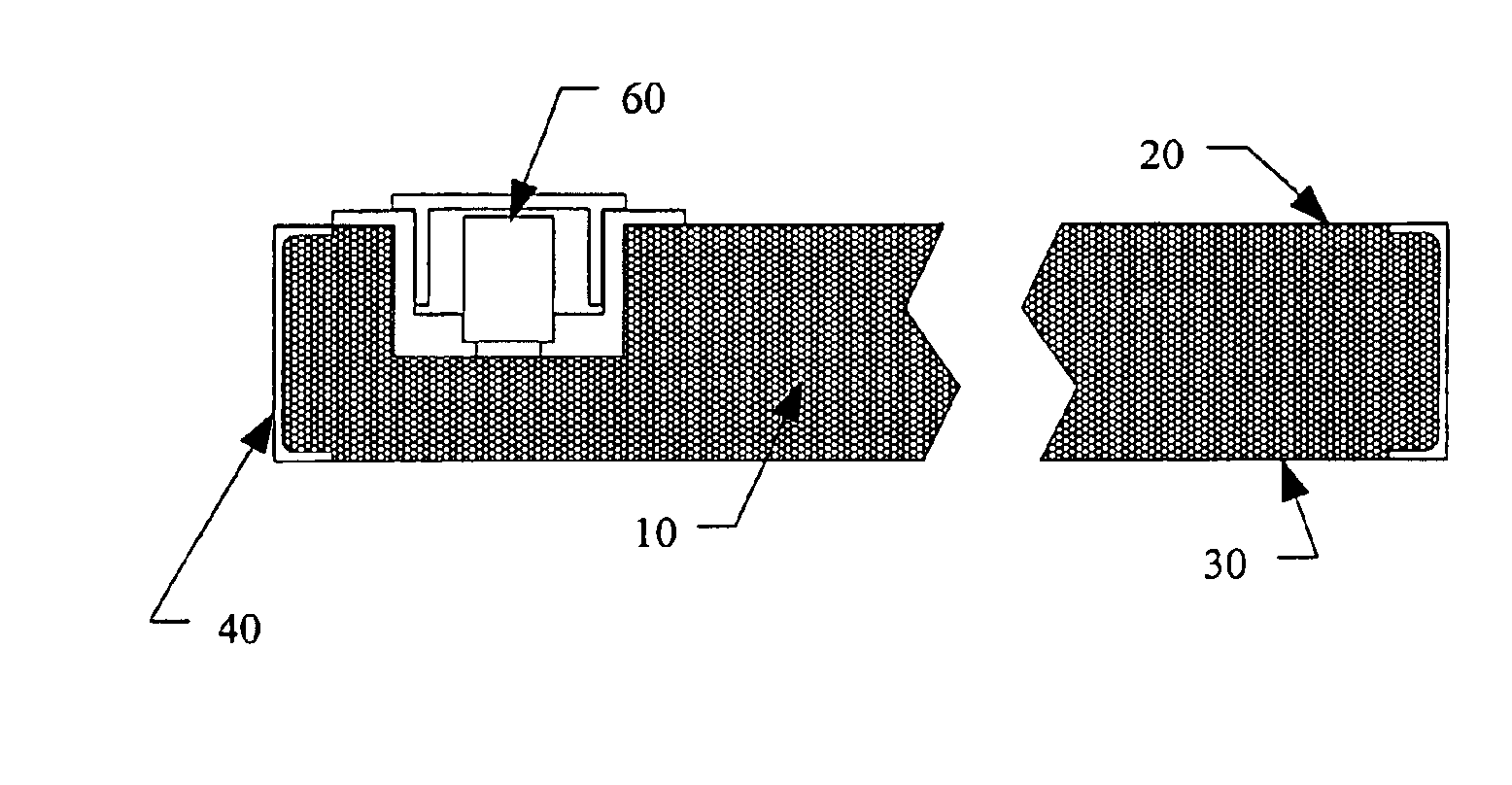

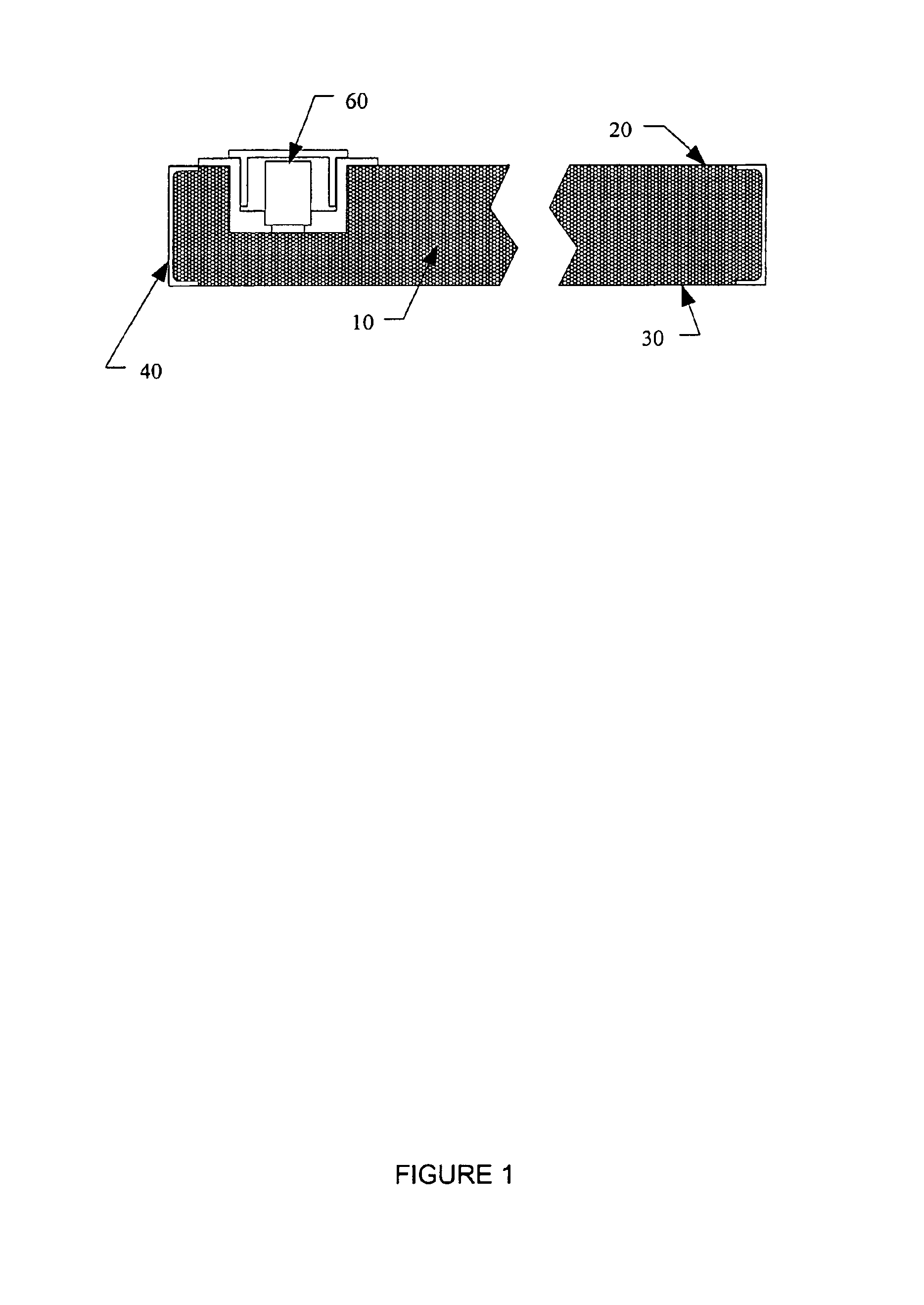

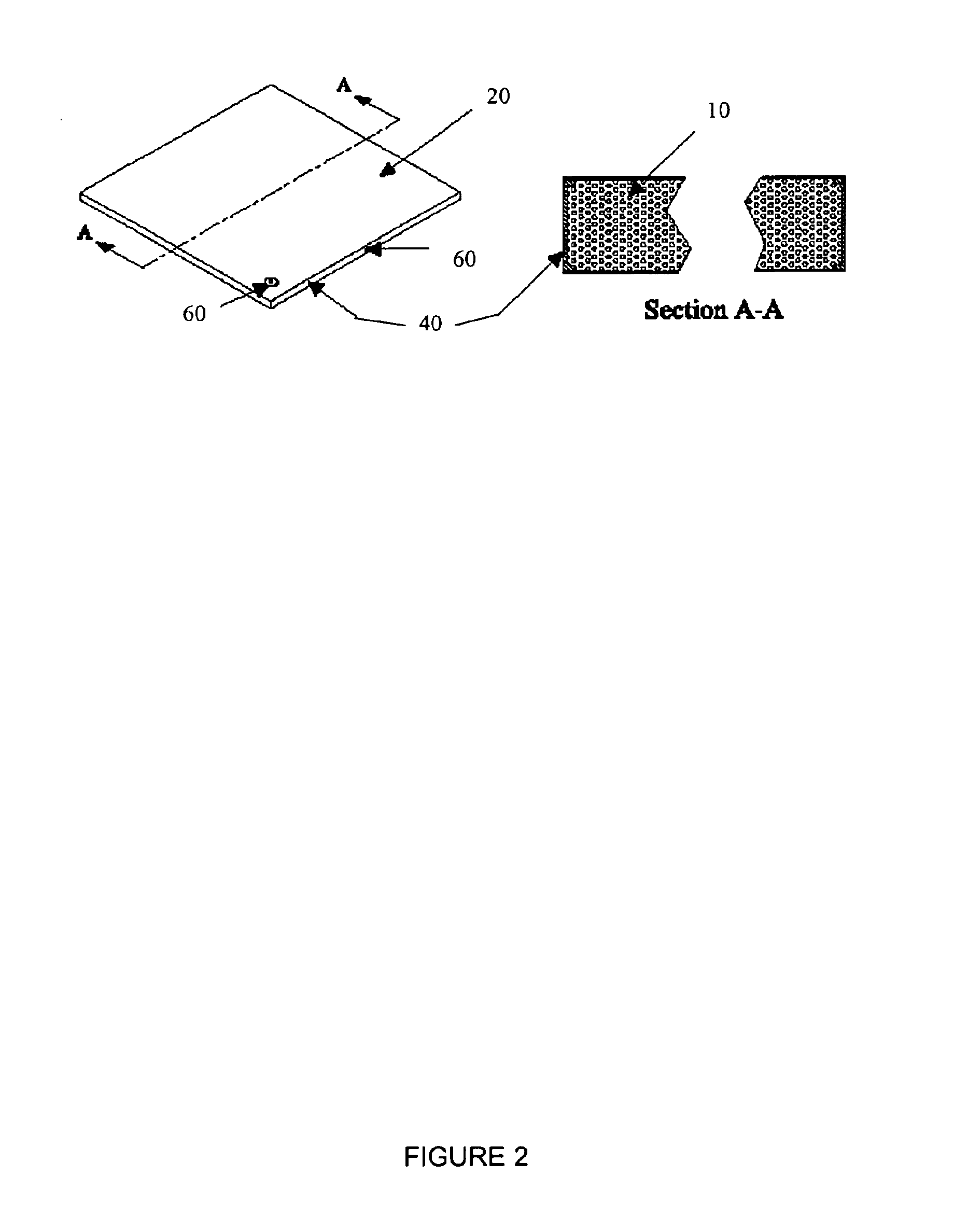

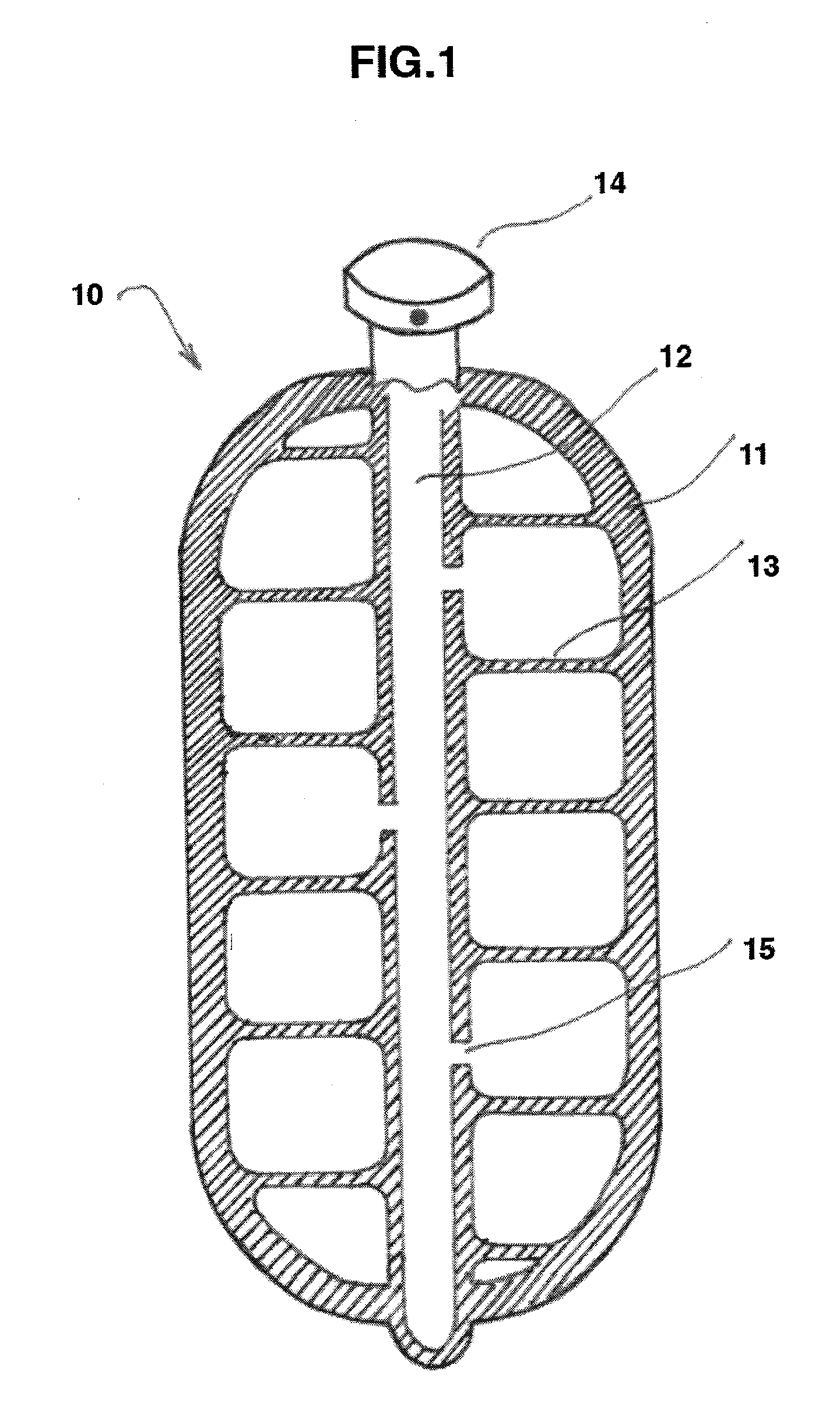

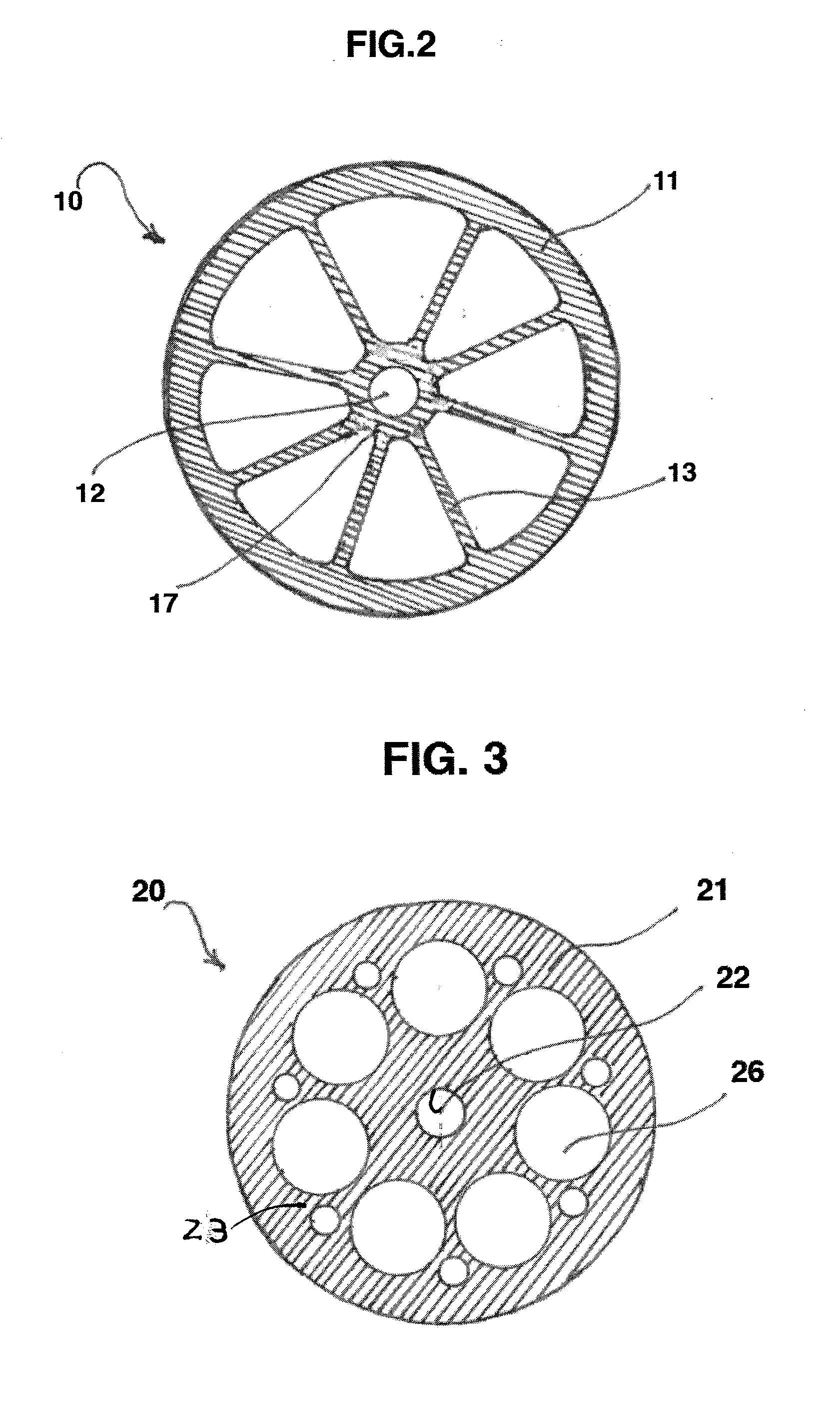

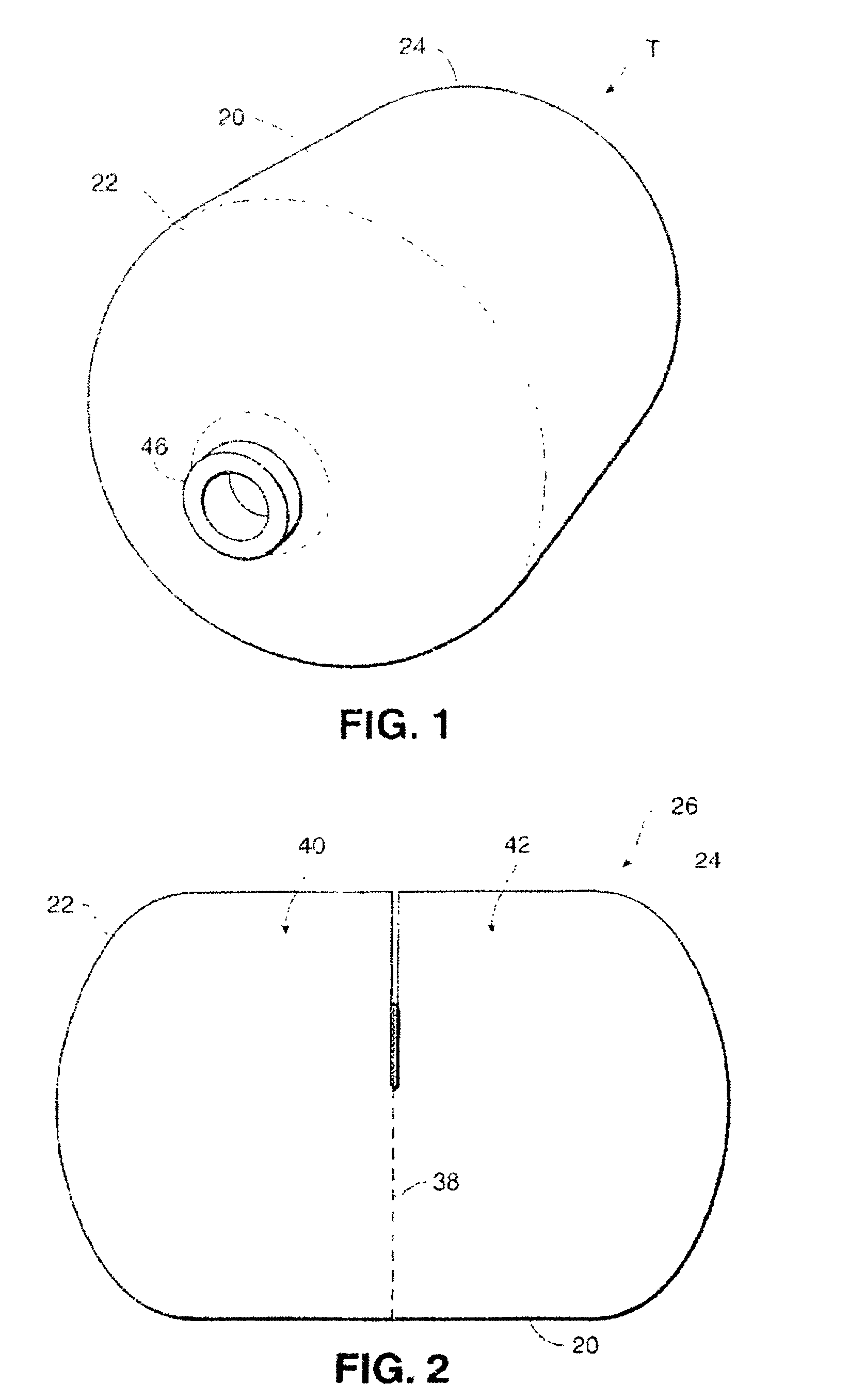

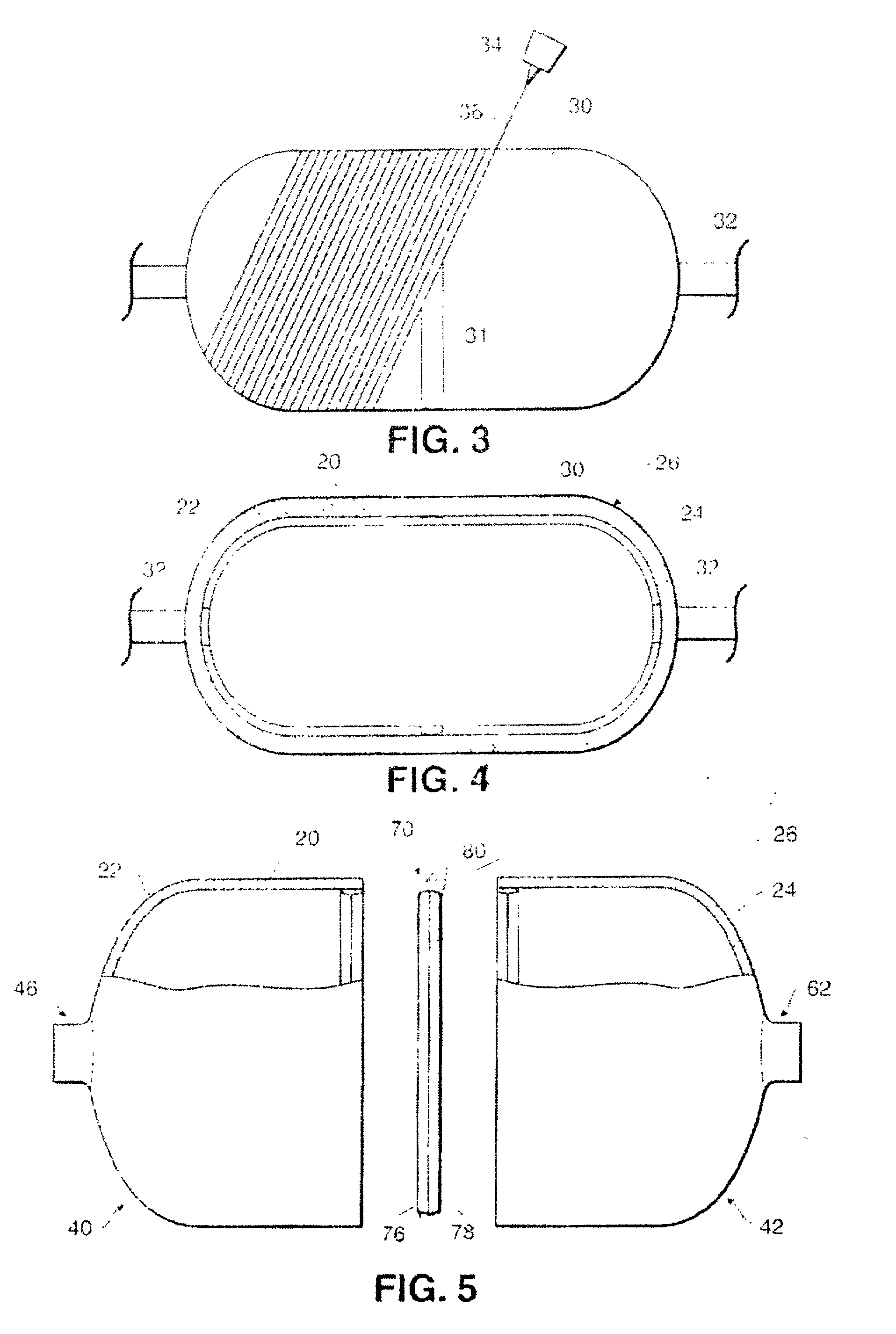

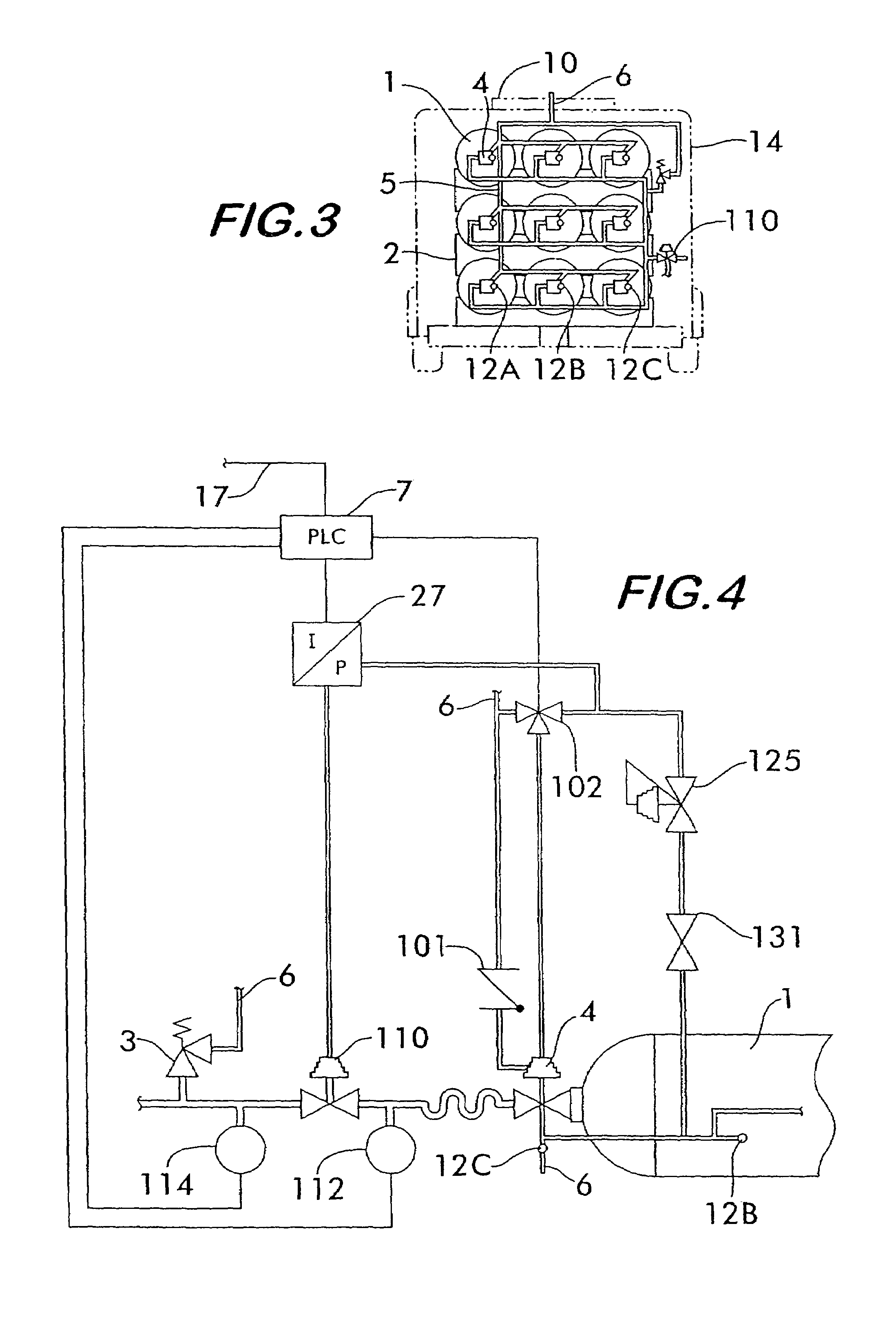

Vaporizer delivery ampoule

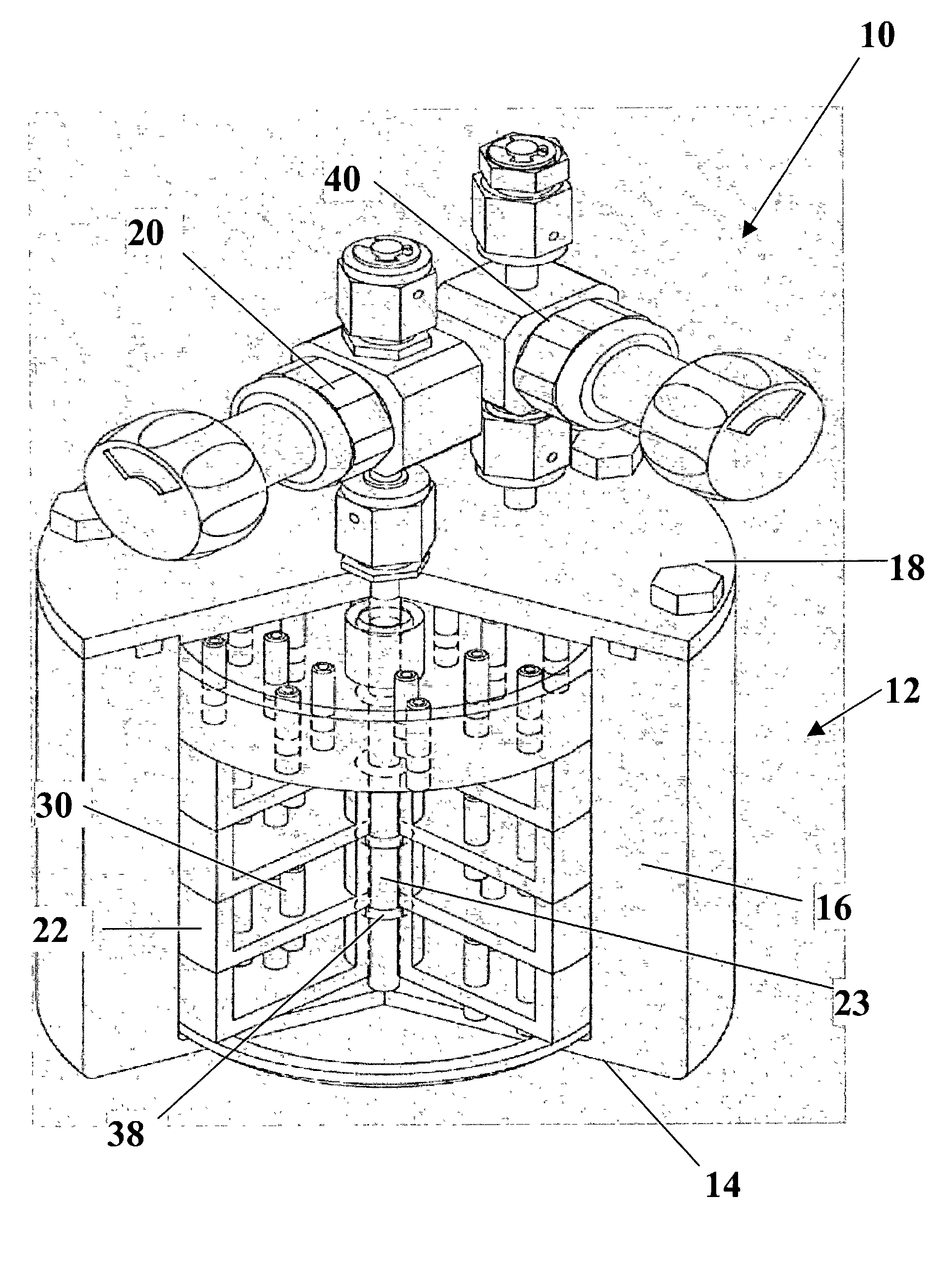

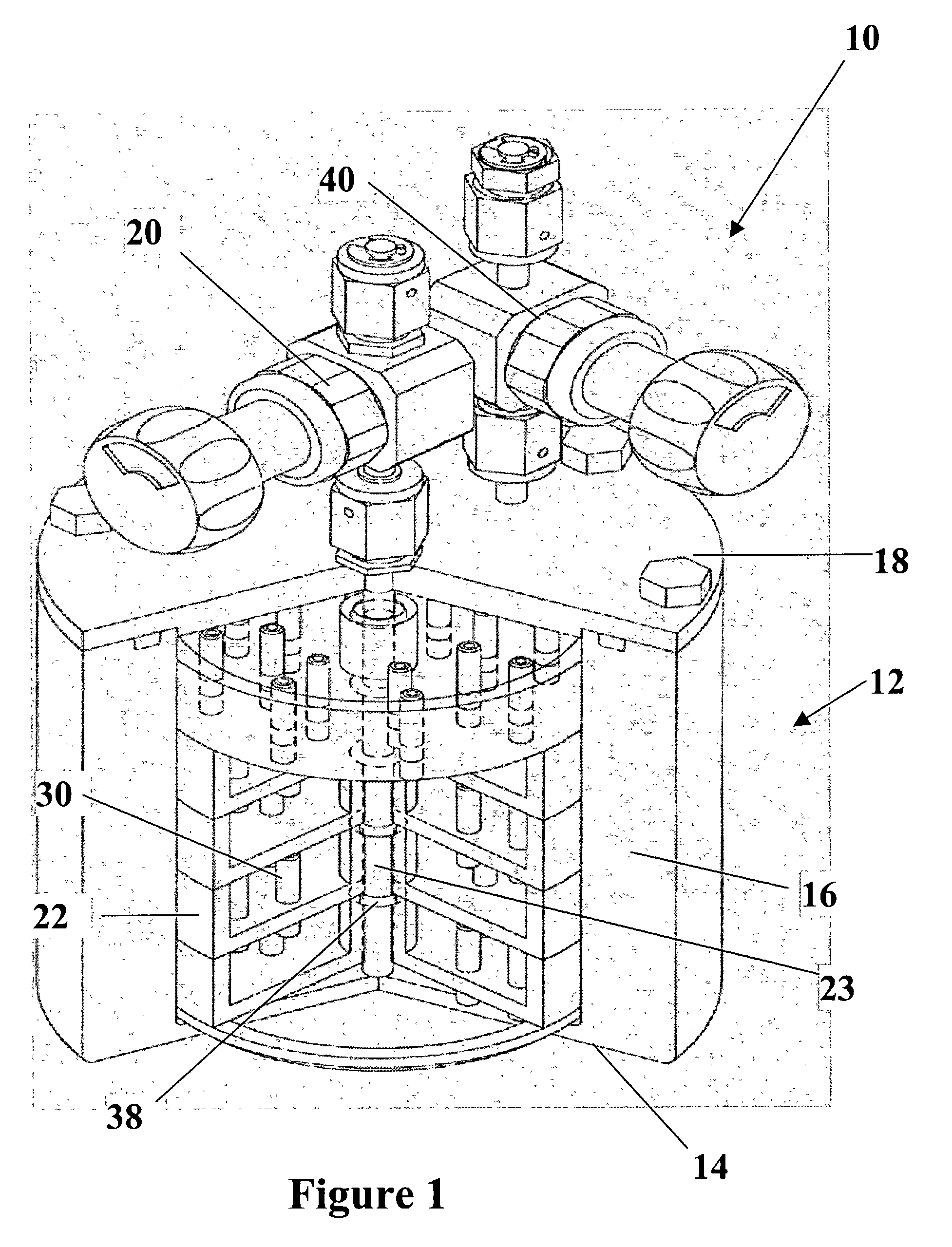

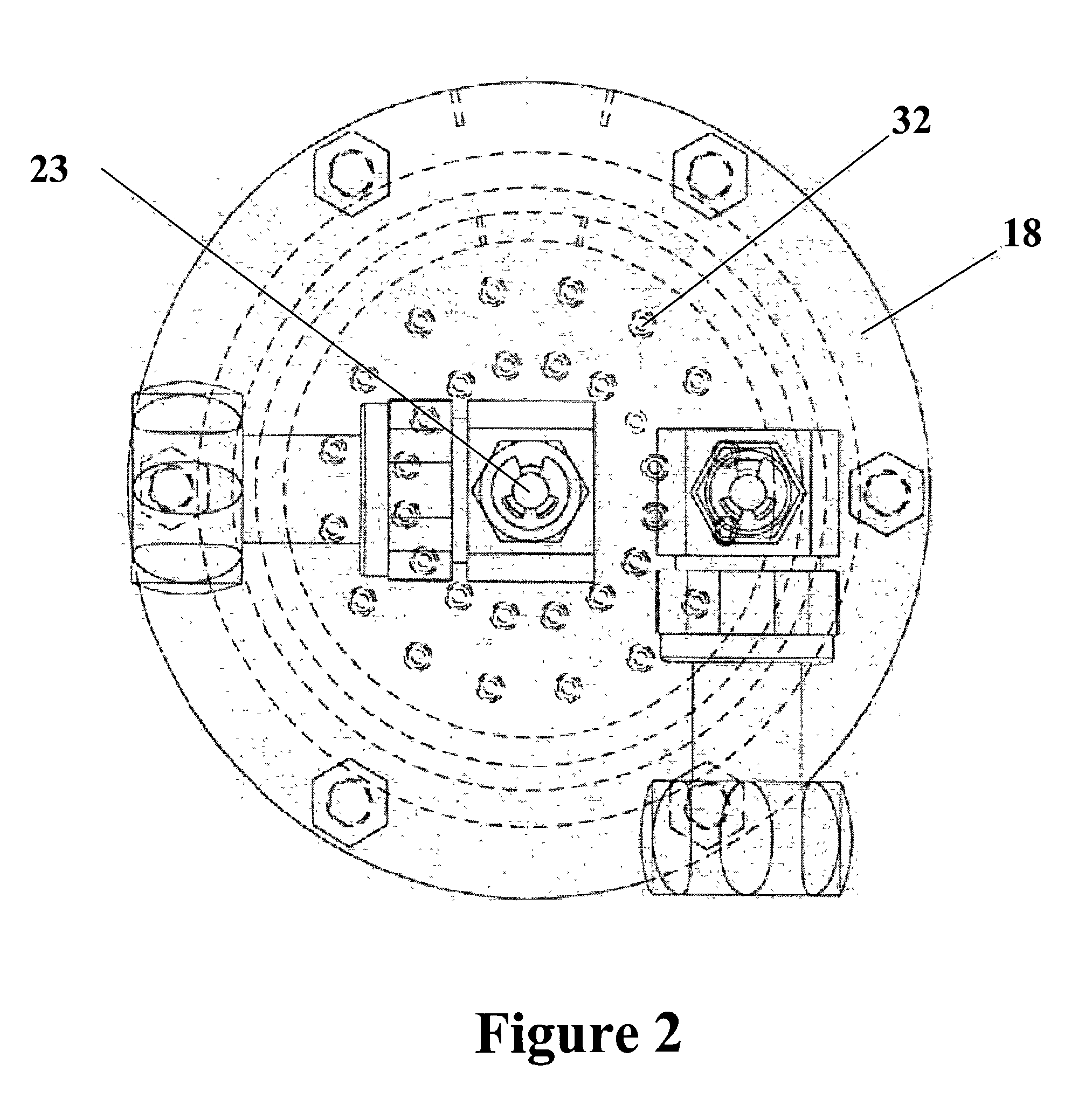

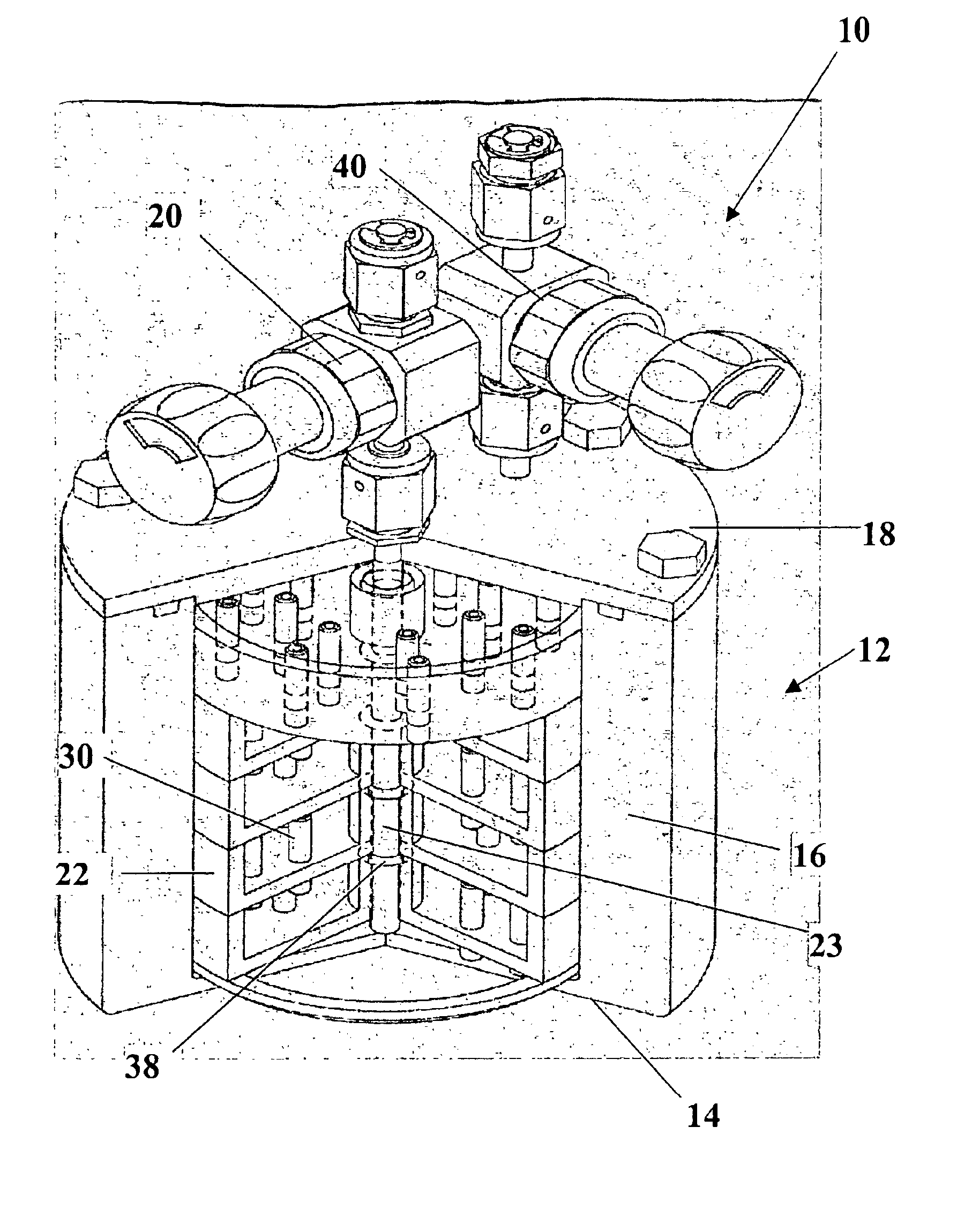

InactiveUS20040016404A1Increase the areaShorten closing timeVessel wallsNon-pressured vesselsSource materialEngineering

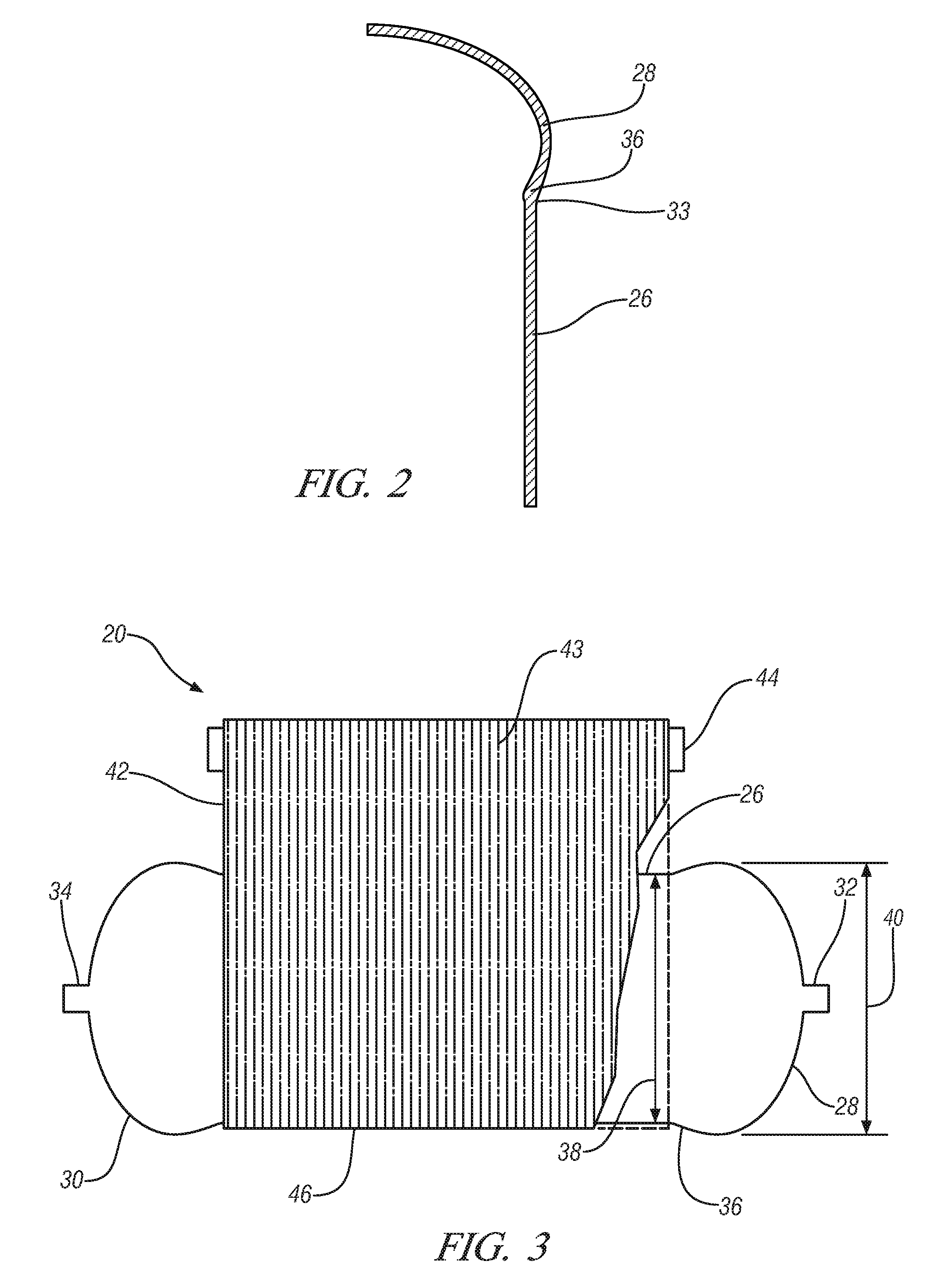

A vaporizer delivery system for use in semiconductor manufacturing processes including a plurality of vertically stacked containers for holding a vaporizable source material. Each of the vertically stacked containers includes a plurality of vented protuberances extending into the interior of the each stacked container thereby providing channels for passage of a carrier gas between adjacent vertically stacked containers.

Owner:ENTEGRIS INC

Vaporizer delivery ampoule

InactiveUS6921062B2Increase the areaShorten closing timeDrying using combination processesDrying solid materials with heatSource materialEngineering

A vaporizer delivery system for use in semiconductor manufacturing processes including a plurality of vertically stacked containers for holding a vaporizable source material. Each of the vertically stacked containers includes a plurality of vented protuberances extending into the interior of the each stacked container thereby providing channels for passage of a carrier gas between adjacent vertically stacked containers.

Owner:ENTEGRIS INC

Method of passivating a gas vessel or component of a gas transfer system using a silicon overlay coating

A method of passivating the interior surface of a gas storage vessel to protect the surface against corrosion. The interior surface of the vessel is first dehydrated and then evacuated. A silicon hydride gas is introduced into the vessel. The vessel and silicon hydride gas contained therein are heated and pressurized to decompose the gase. A layer of silicon is deposited on the interior surface of the vessel. The duration of the silicon depositing step is controlled to prevent the formation of silicon dust in the vessel. The vessel is then purged with an inert gas to remove the silicon hydride gas. The vessel is cycled through the silicon depositing step until the entire interior surface of the vessel is covered with a layer of silicon. The vessel is then evacuated and cooled to room temperature.

Owner:SILCOTEK CORP

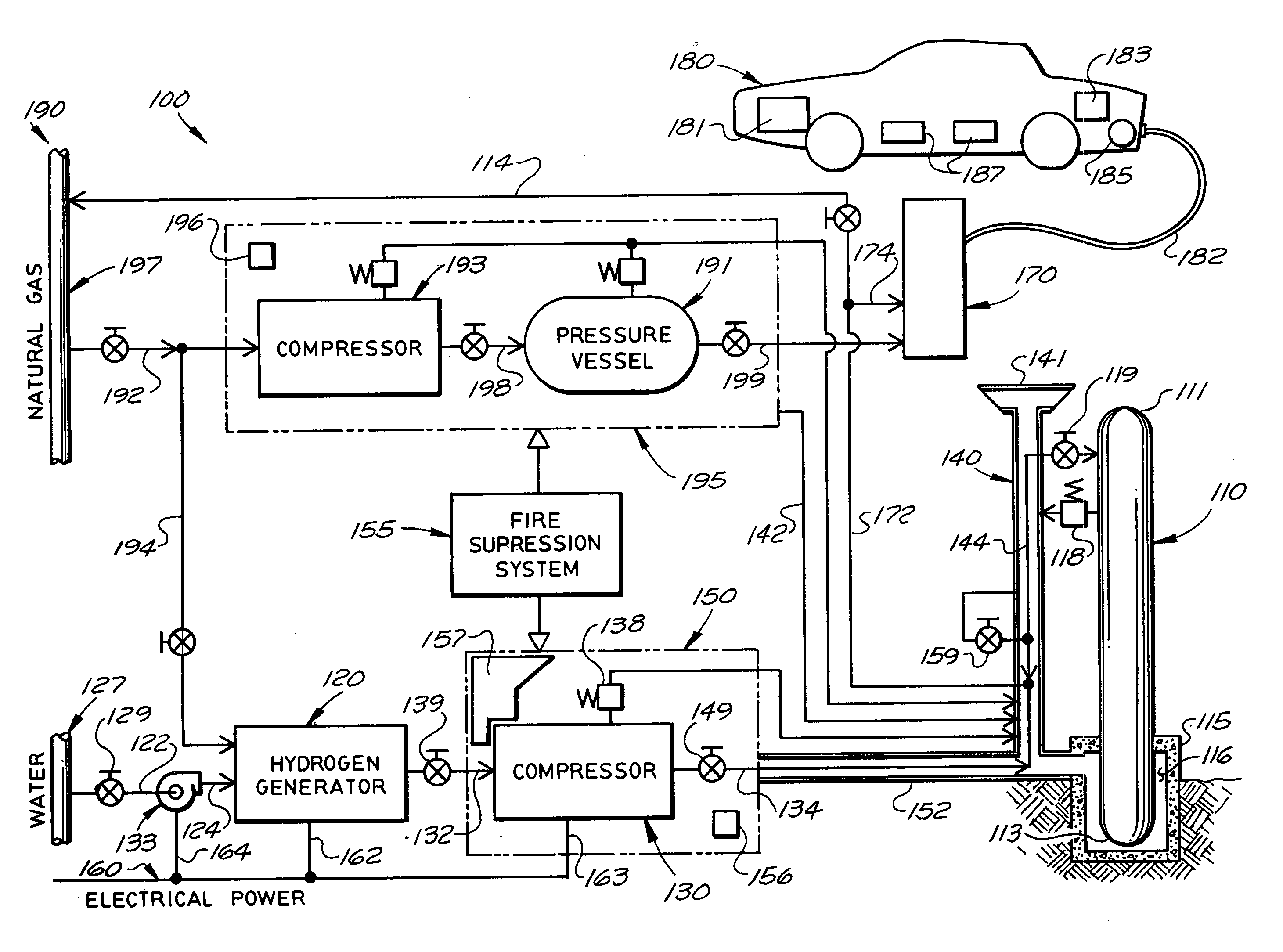

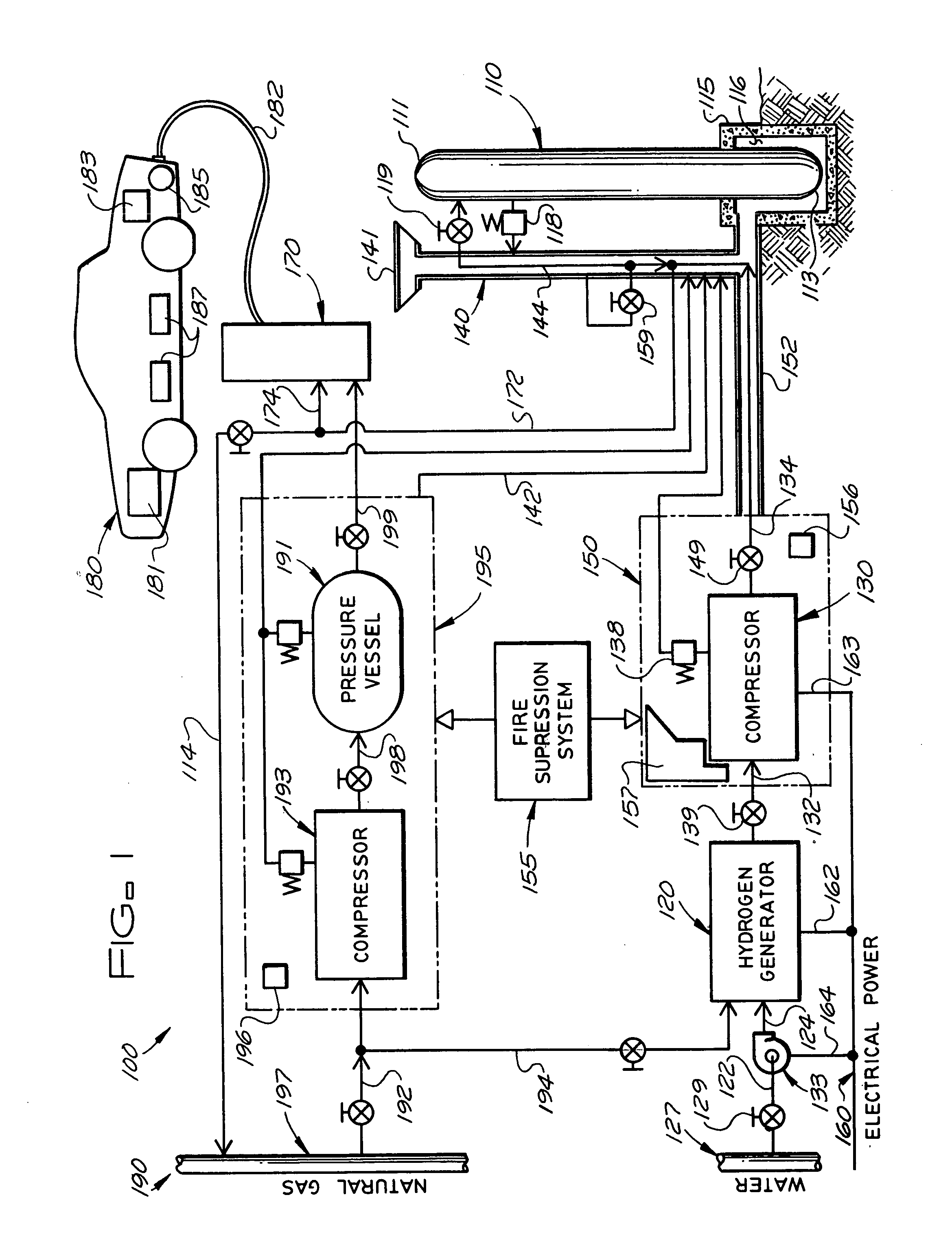

Hydrogen handling or dispensing system

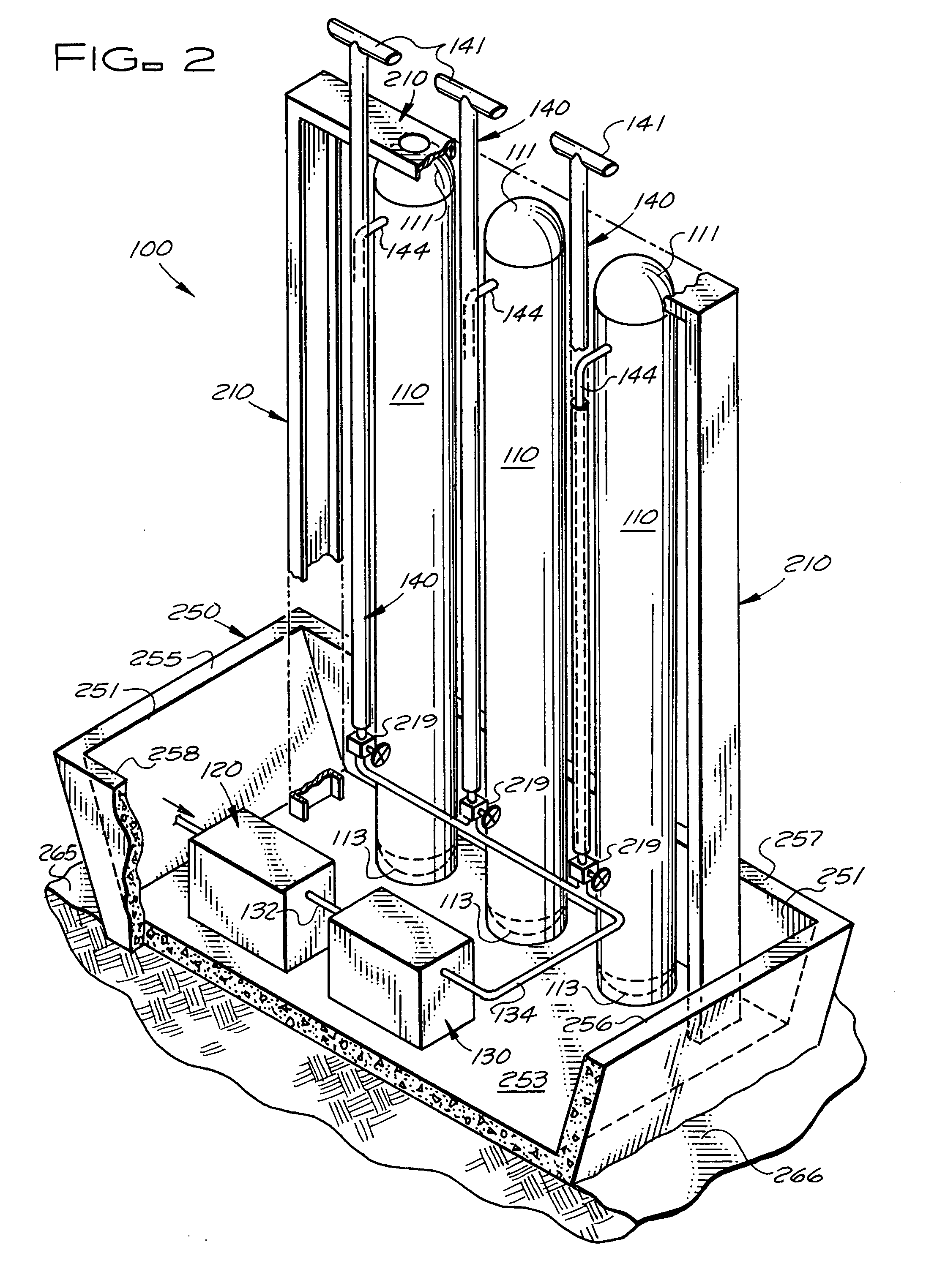

InactiveUS20050000802A1Avoid burnsCheap manufacturingLiquid fillingGas handling applicationsHydrogenHuman life

Systems for handling and / or dispensing hydrogen or a mixture of fuels containing hydrogen gas including refueling stations for hydrogen-powered vehicles. Pure hydrogen or various mixtures ratios of hydrogen and CNG may be dispensed. Hydrogen handling equipment may include a hydrogen generator, a pressurizing apparatus or compressor, pressure vessels, piping, valves, vent pipes, and / or a dispenser. Substantially vertical orientation of pressure vessels may reduce the amount of land required and facilitate installation in urban environments. Pressurization may take place before hydrogen generation to reduce the power required for pressurization. Safety features include enclosures and surrounding walls that lean away from the equipment. Any leaking hydrogen, fires, or explosions may be contained and / or directed upward, protecting human life and property. Systems may be shop assembled and certified.

Owner:ARIZONA PUBLIC SERVICE

Portable fuel cartridge for fuel cells

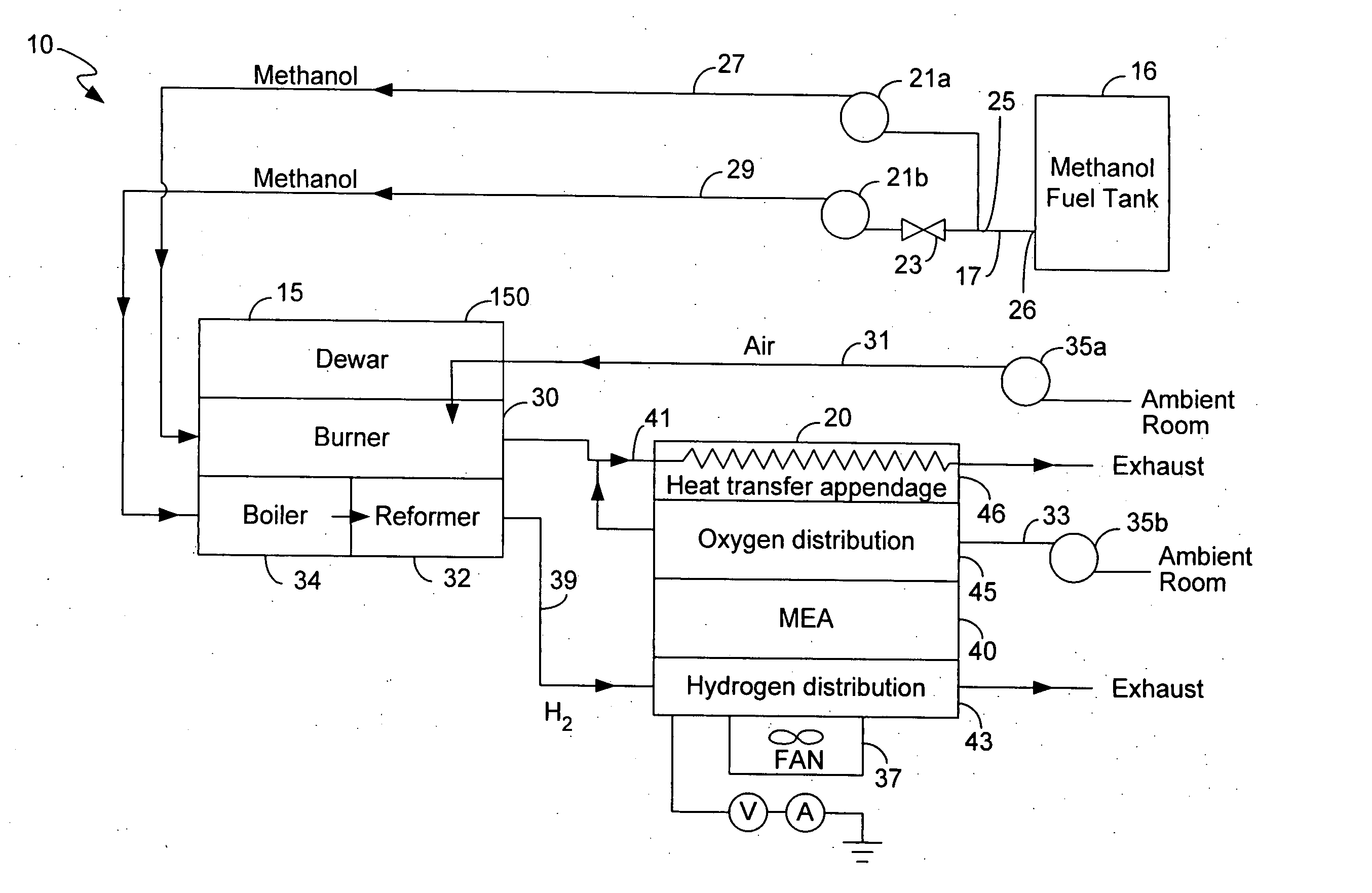

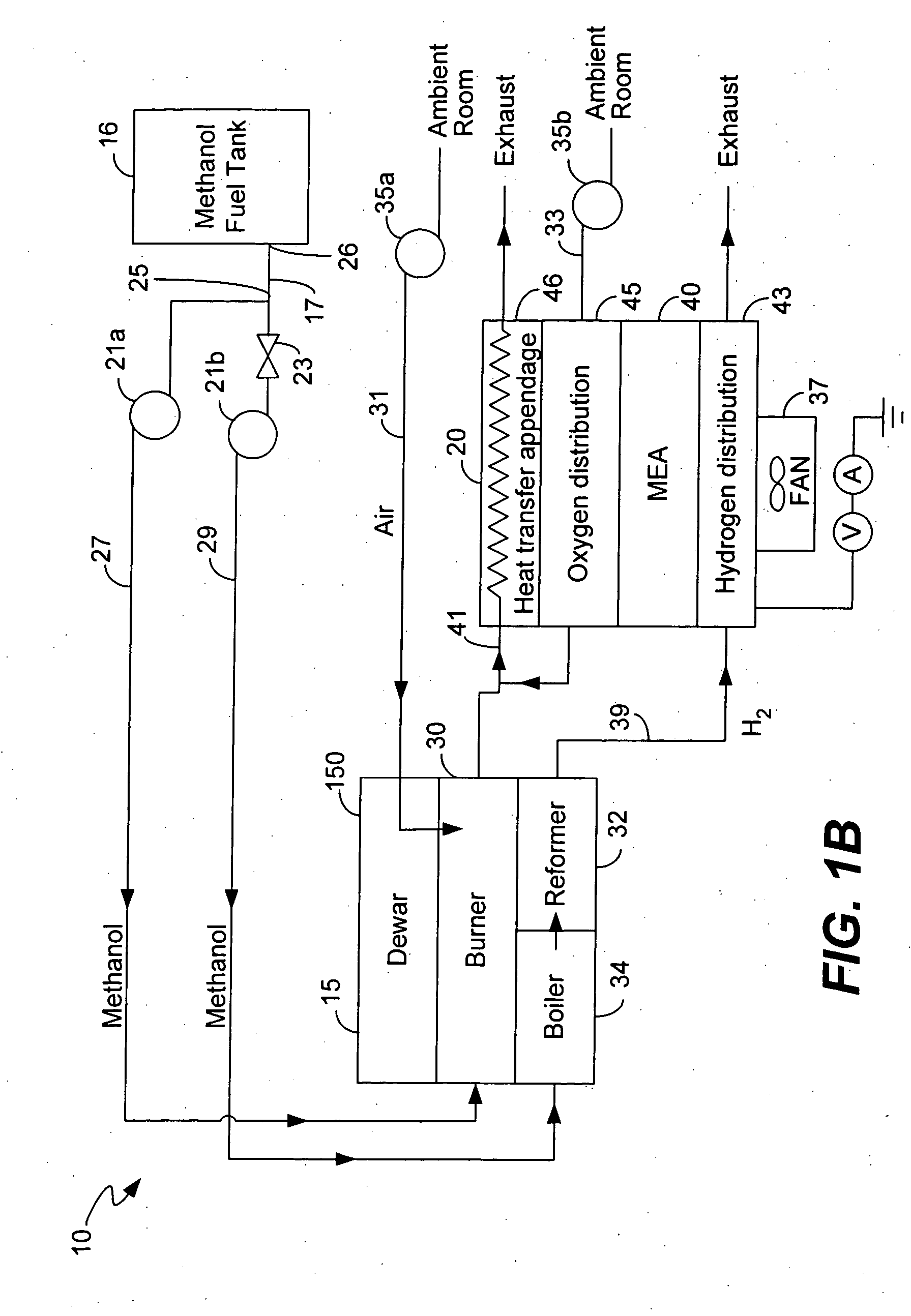

InactiveUS20050008908A1Promote hydrogen productionPromote productionFuel cell heat exchangeReactant parameters controlHydrogen fuelElectron

Described herein is a portable storage device that stores a hydrogen fuel source. The storage device includes a bladder that contains the hydrogen fuel source and conforms to the volume of the hydrogen fuel source. A housing provides mechanical protection for the bladder. The storage device also includes a connector that interfaces with a mating connector to permit transfer of the fuel source between the bladder and a device that includes the mating connector. The device may be a portable electronics device such as a laptop computer. Refillable hydrogen fuel source storage devices and systems are also described. The refillable system comprises a hydrogen fuel source refiner that includes the mating connector and provides the hydrogen fuel source to the storage device. Hot swappable fuel storage systems described herein allow a portable hydrogen fuel source storage device to be removed from a fuel processor or electronics device it provides the hydrogen fuel source to, without shutting down the receiving device or without compromising hydrogen fuel source provision to the receiving device for a limited time.

Owner:ULTRACELL LLC

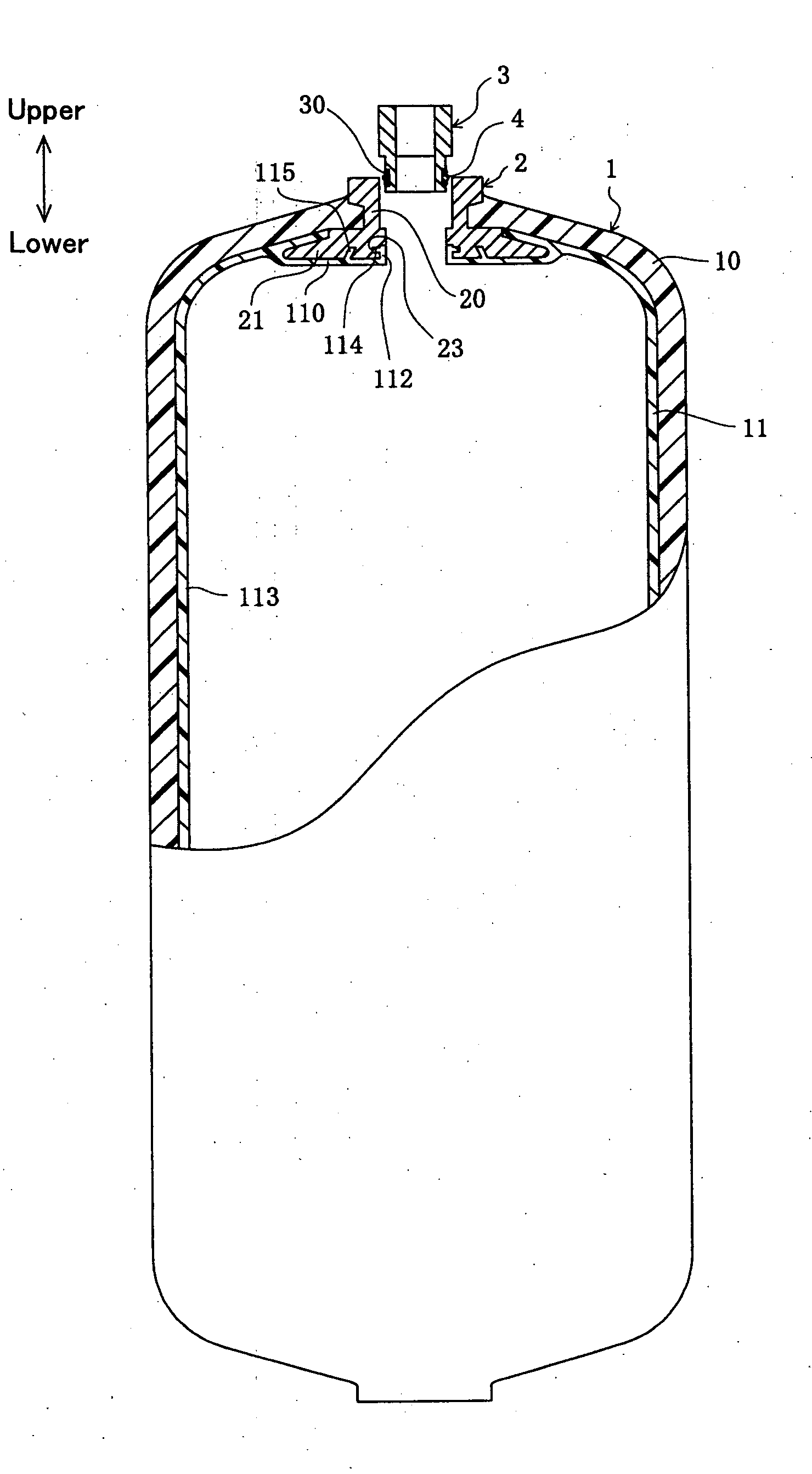

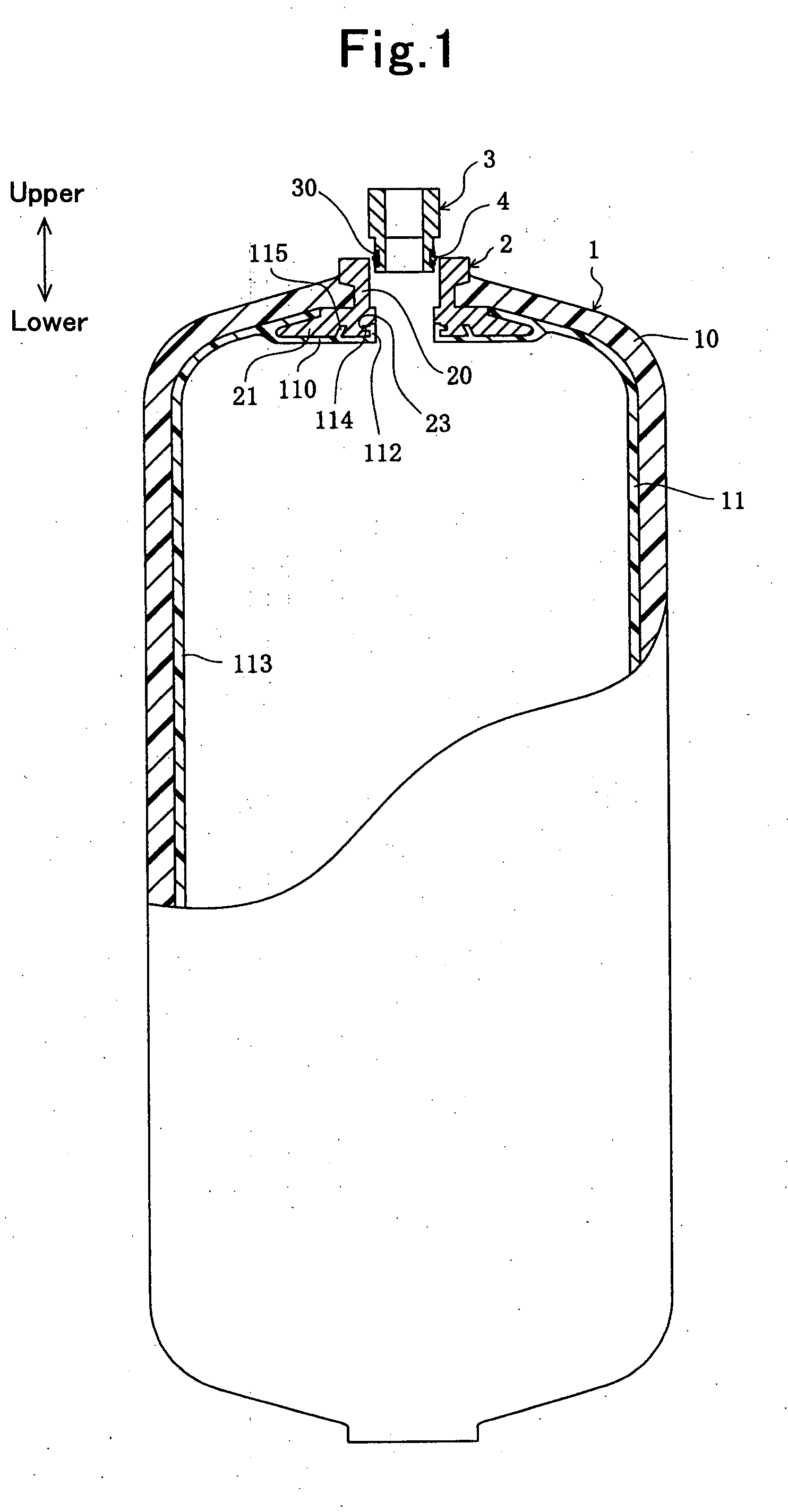

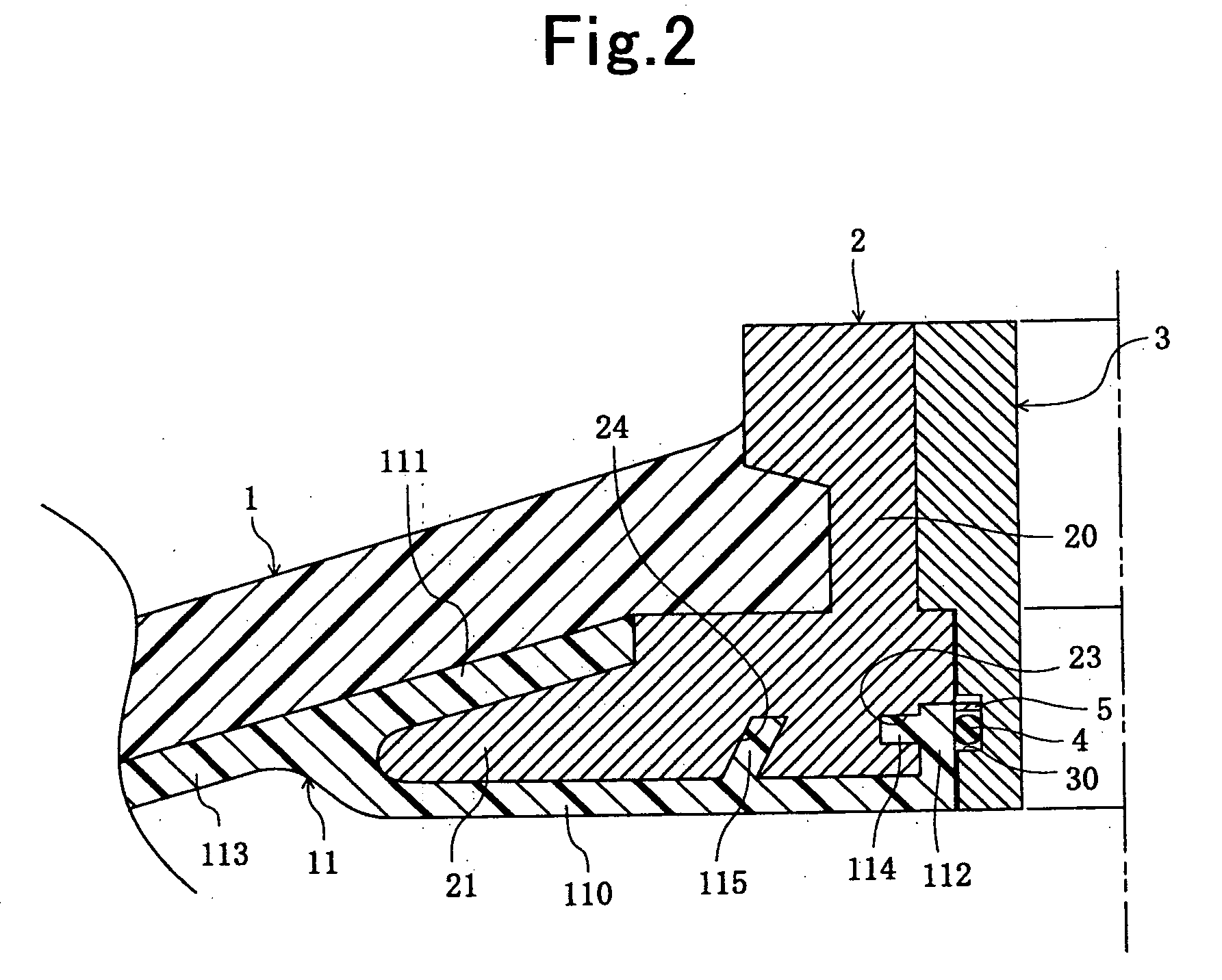

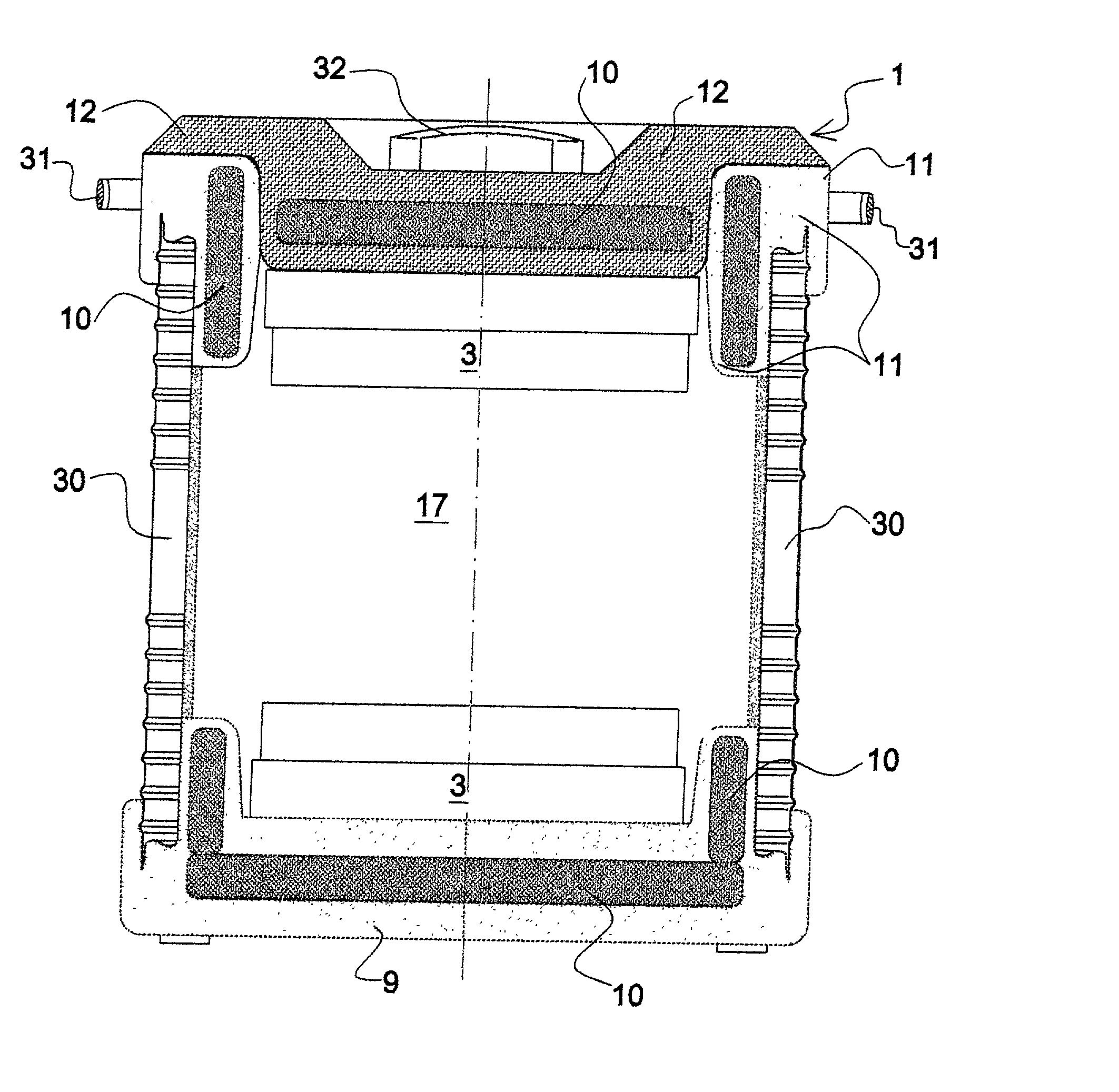

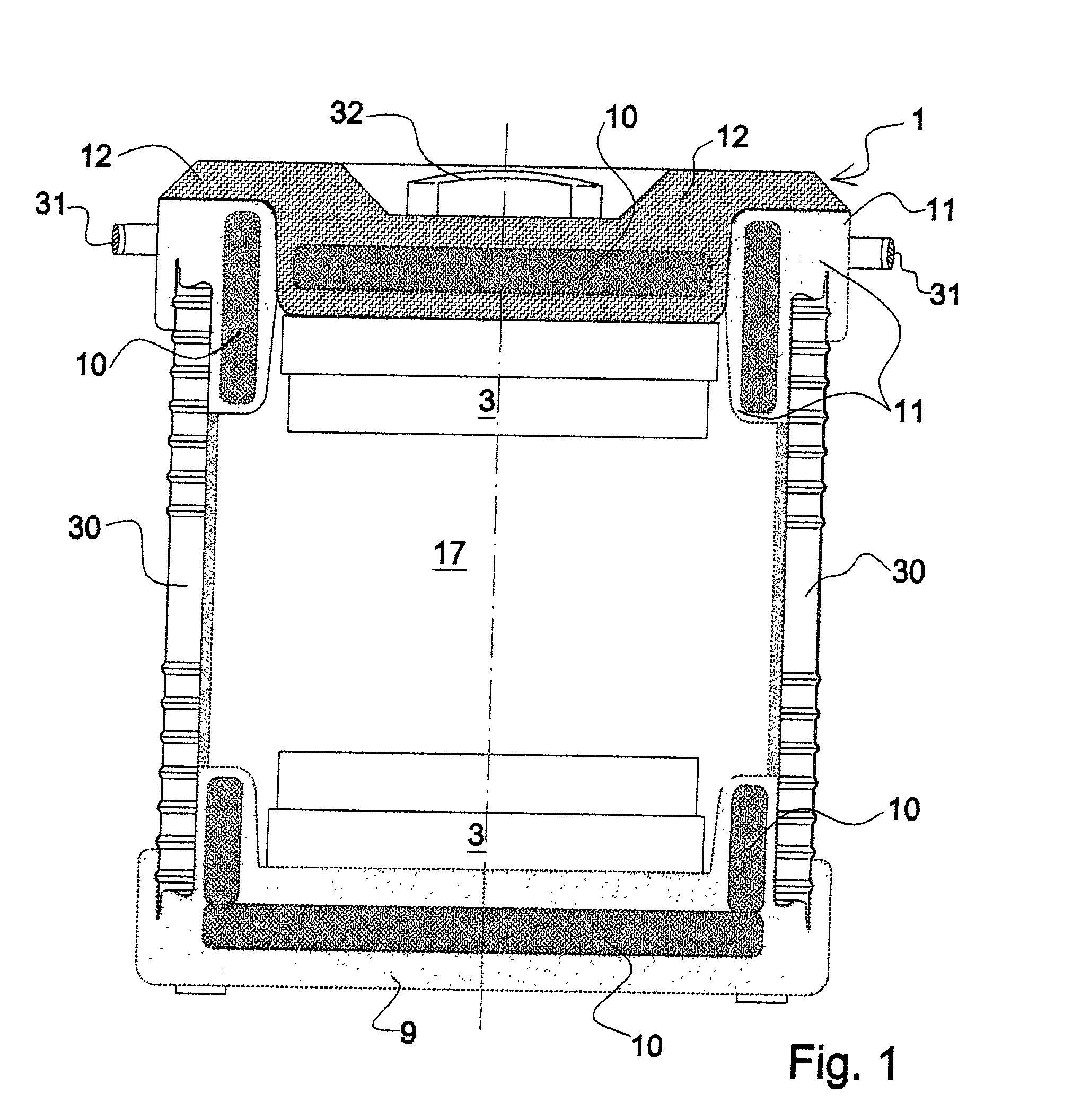

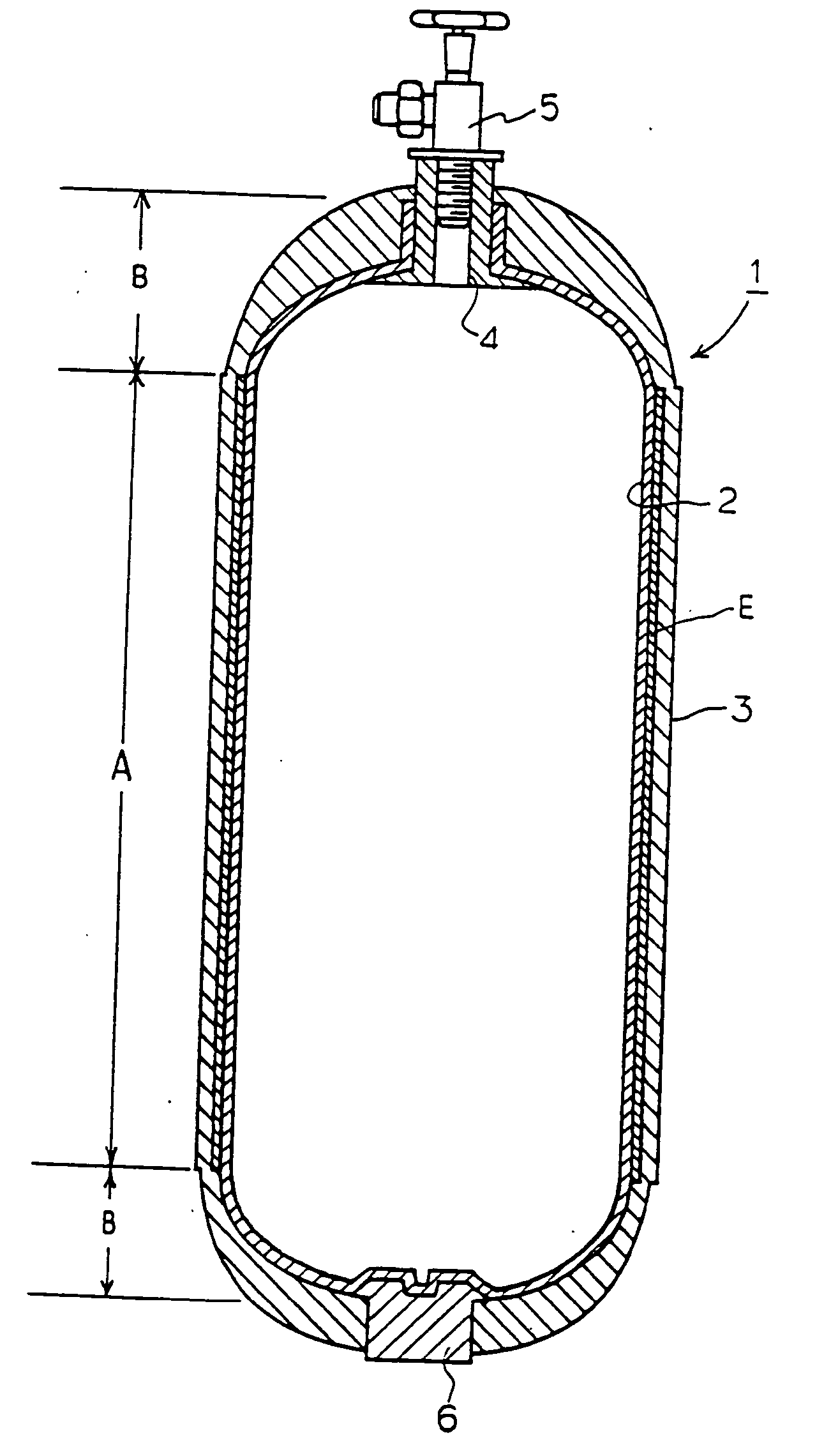

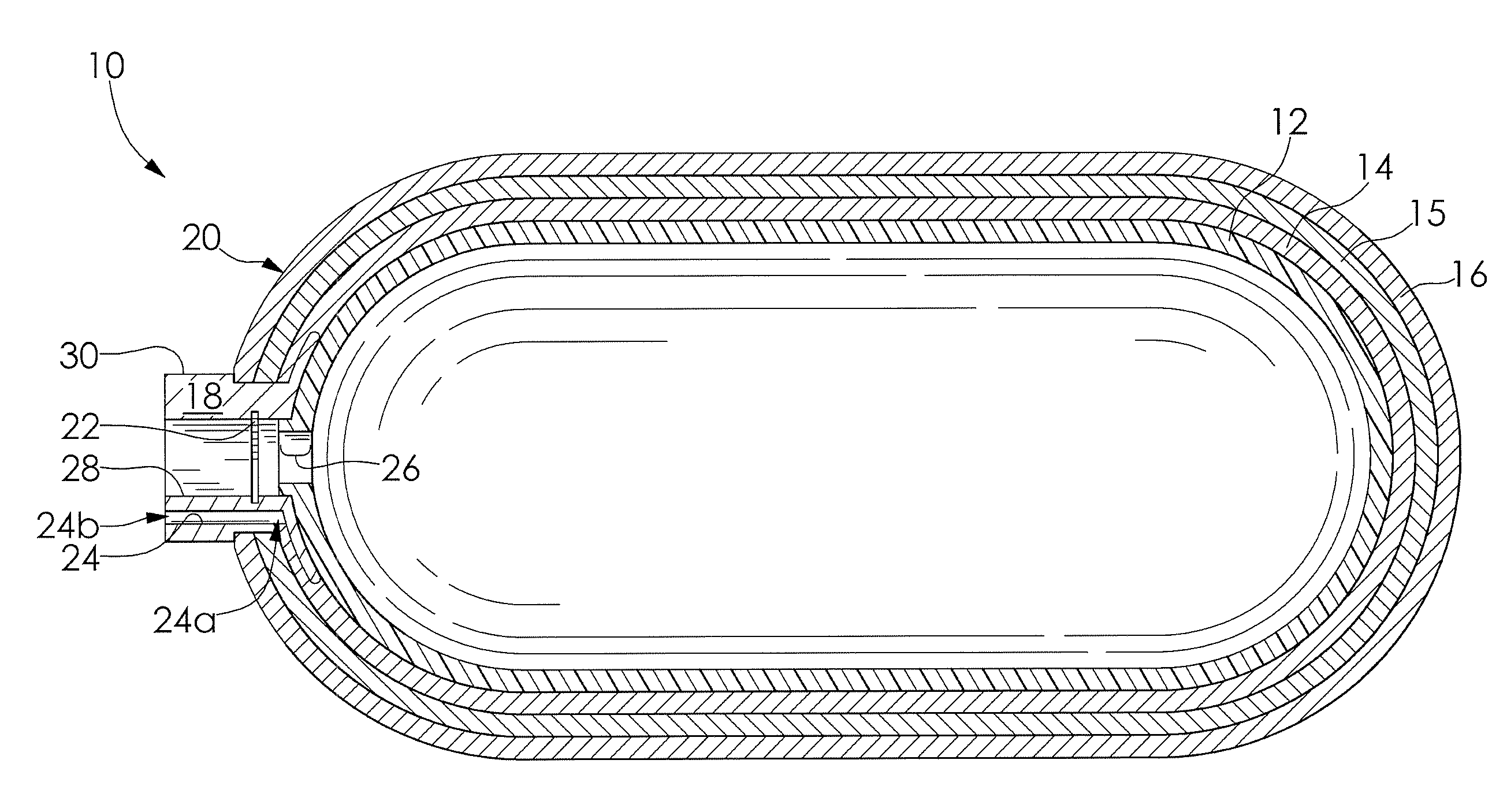

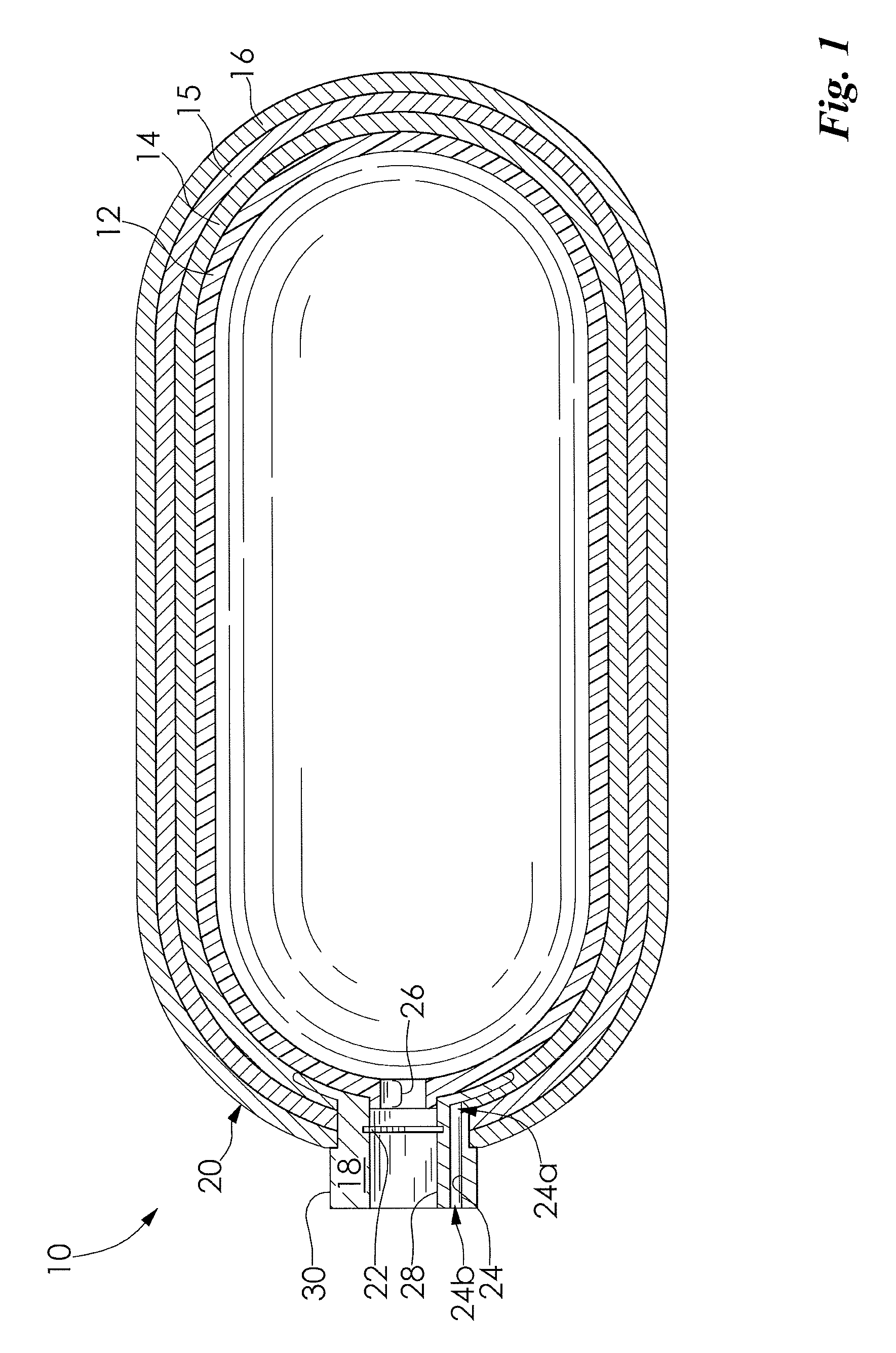

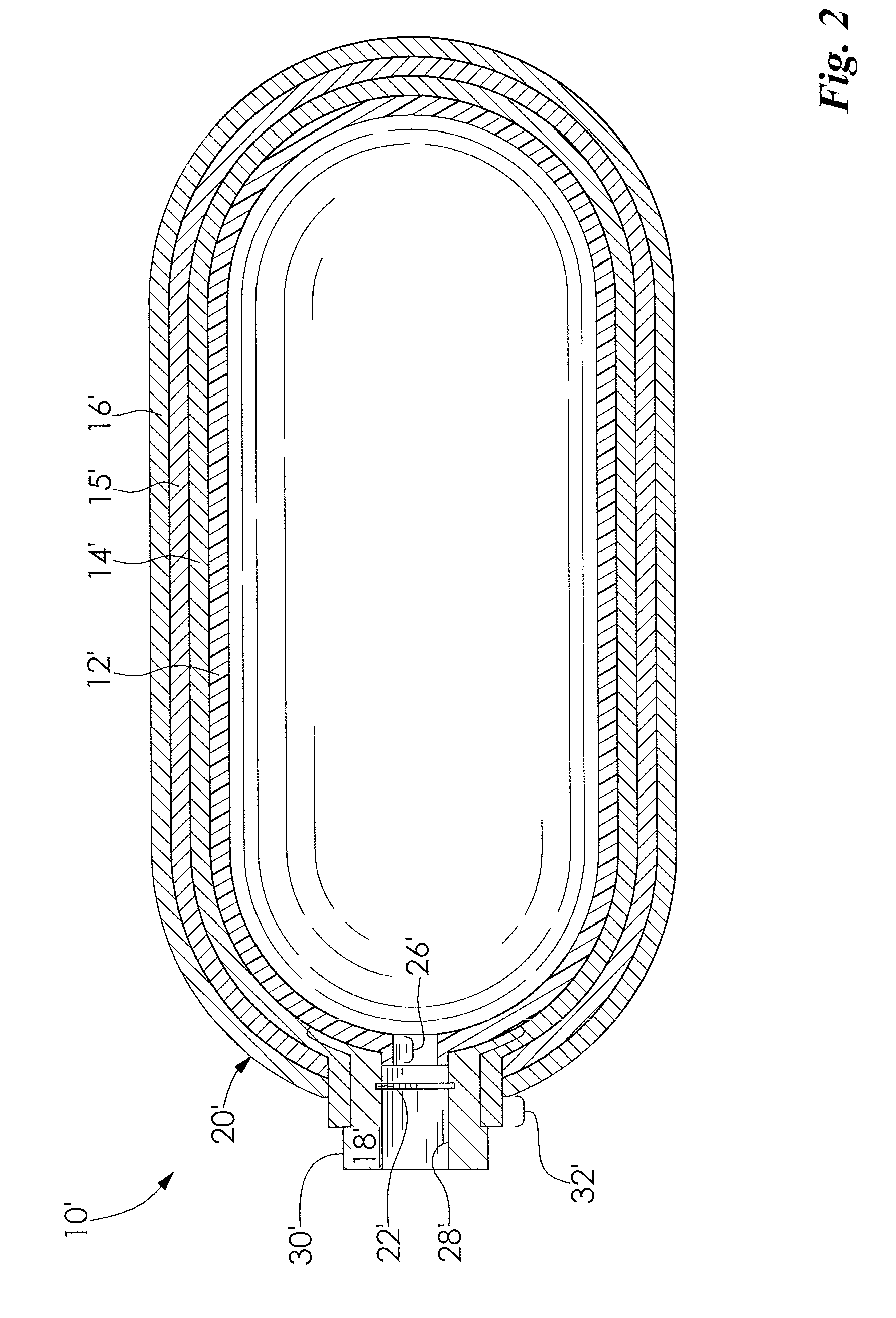

Pressure vessel

A pressure vessel capable of securely sealing a mouth ring with a liner portion, and being manufactured at low costs. A boss seal part 112 is provided in a liner portion 11 of the pressure vessel, and an inner peripheral surface of a boss part 20 of a mouth ring 2 is covered with the boss seal part 112. A boss-side collar part 114 is provided in the boss seal part 112 so as to project outwardly, and a sealing member 4 composed of a resilient body is disposed in a space between an inner peripheral surface of the boss seal part 112 and an outer peripheral surface of the valve 3.

Owner:TOYODA GOSEI CO LTD +1

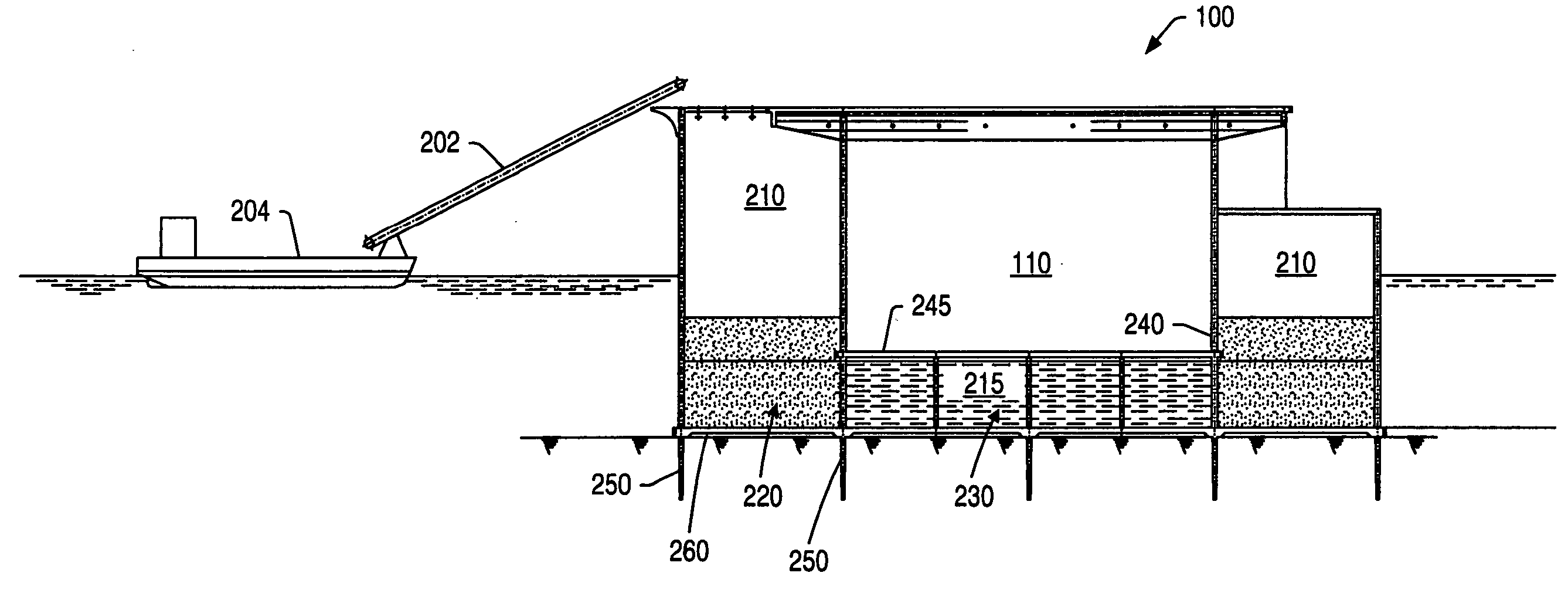

Liquefied natural gas structure

InactiveUS20050115248A1Easy transferProvide protectionGas handling/storage effectsSolid materialMarine engineeringTower

An offshore liquefied natural gas structure may receive, store, and process liquefied natural gas from carriers. A structure may be a gravity base structure. A structure may include a system of ballast storage areas, transfer equipment to offload liquefied natural gas from a carrier, docking equipment to allow direct mooring with carriers, platforms to elevate equipment, water intake systems to provide water to the structure, wave deflectors, and / or projections extending from a bottom of the structure. A portion of the structure may be composed of lightweight concrete. Pipelines may be coupled to the structure to export processed natural gas onshore. Living quarters, flare towers, and export line metering equipment may be included on the structure.

Owner:SHELL OIL CO

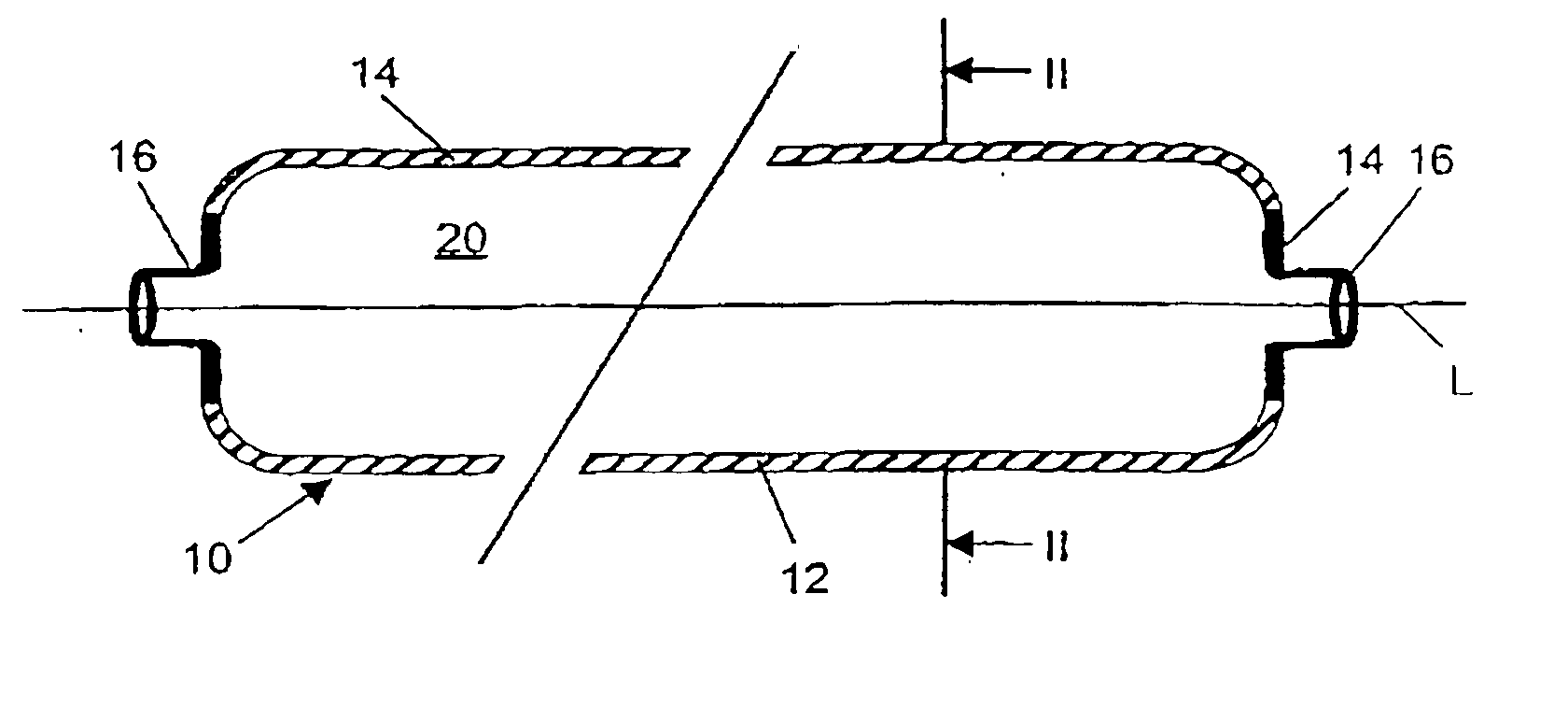

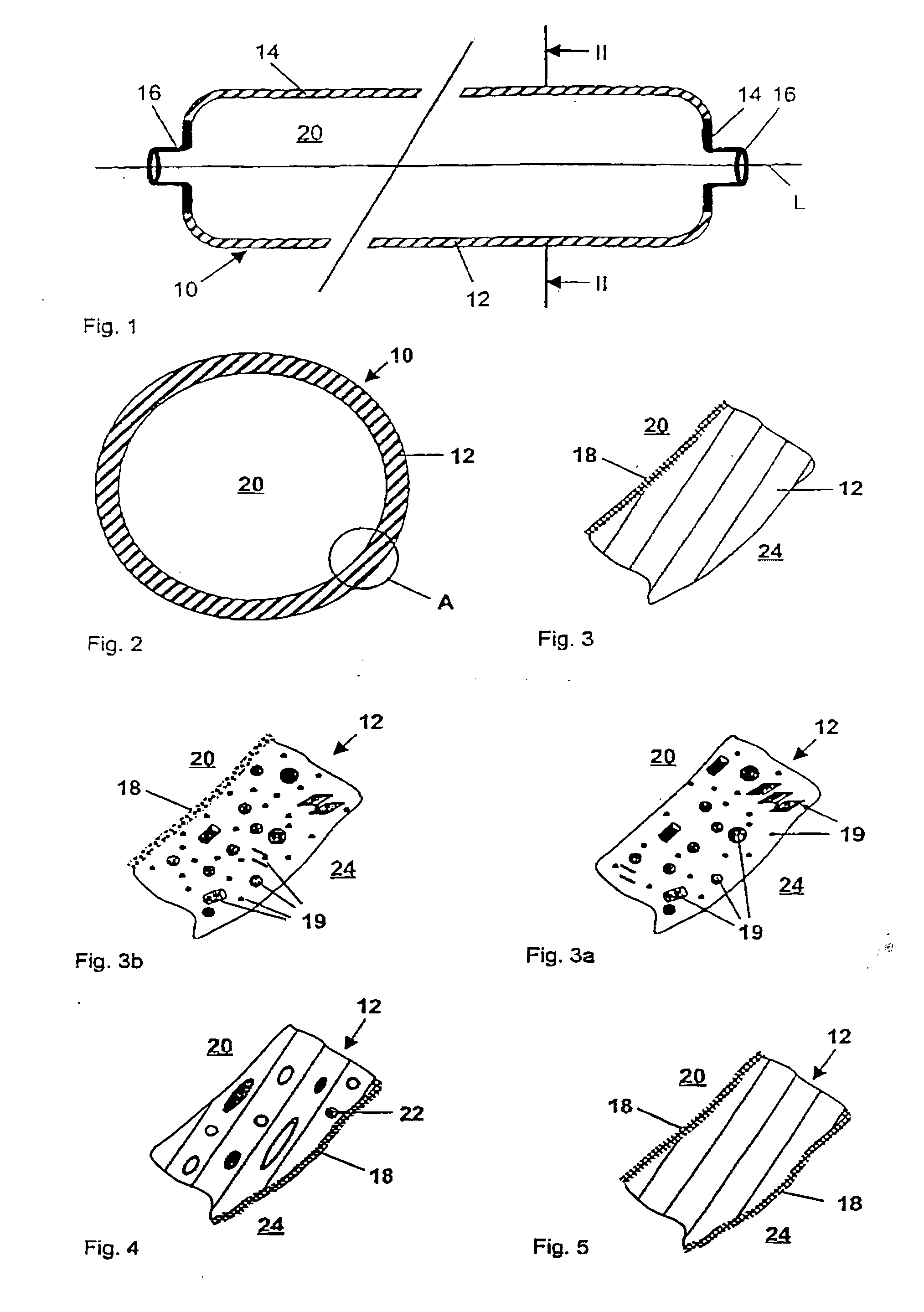

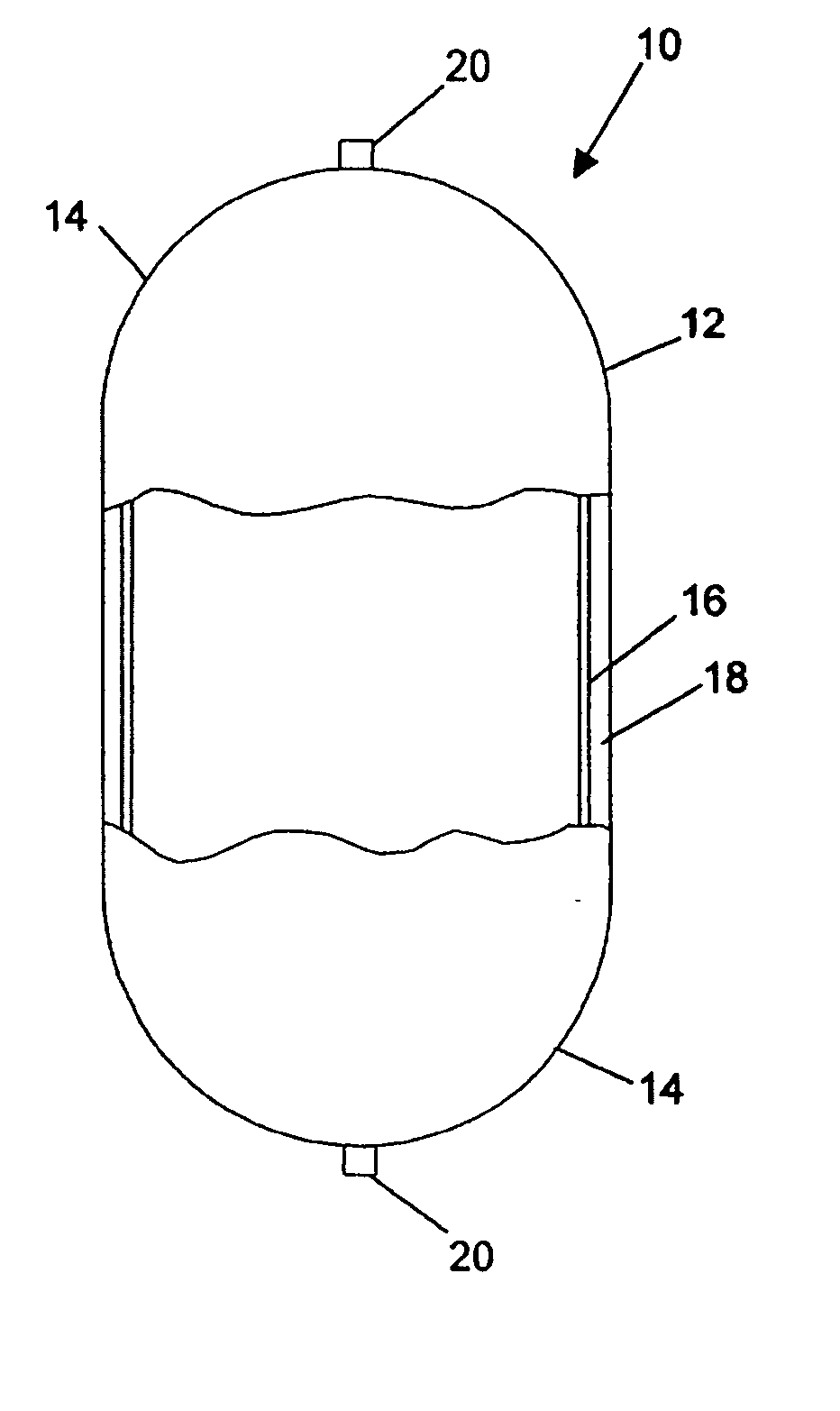

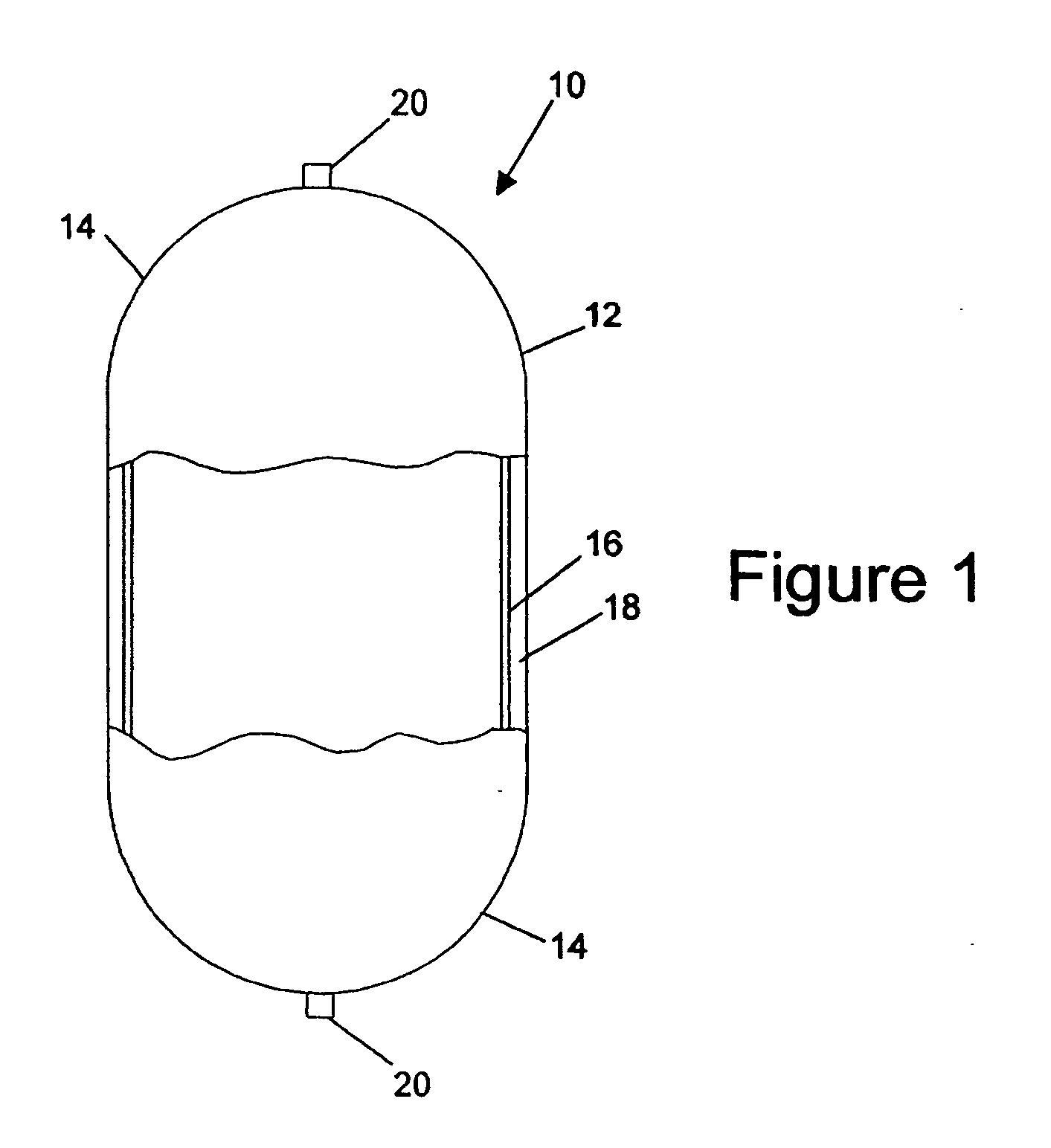

Gastight container

InactiveUS20040149759A1Reduce quality problemsNegligible in recyclingAircraft componentsVessel mounting detailsHydrogenComposite film

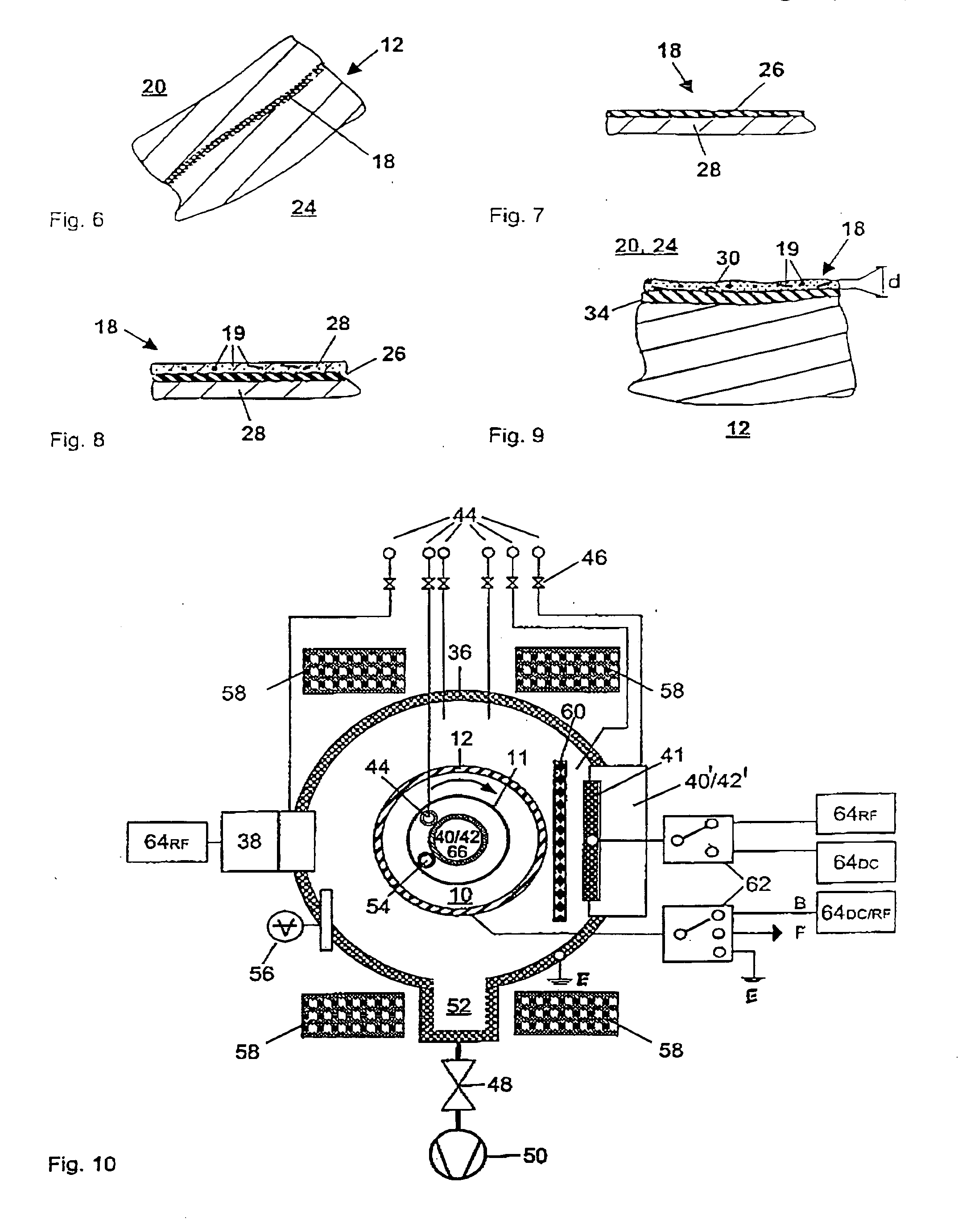

The invention relates to a gastight, pressure-resistant storage and / or transport container (10) for low-molecular, reactive filling media, especially for hydrogen, oxygen, air, methane and / or methanol. Said container has a high filling pressure and is embodied in an essentially rotationally symmetric manner, having at least one connector cap (15) with a sealing device (16). The wall (12) of the container is essentially comprised of a thermoplastic synthetic material having at least one diffusion barrier (18, 19) system and / or a diffusion barrier and anti-corrosion system (18, 19). In order to offer protection for hydrogen and oxygen containers, the diffusion barrier system can be embodied in the form of at least one compact layer and / or can contain finely dispersed, distributed reactive nanoparticles (18) in the wall (12) of the container, in at least one composite film (28) and / or in at least one diffusion barrier layer (18).

Owner:MOSER EVA MARIA +1

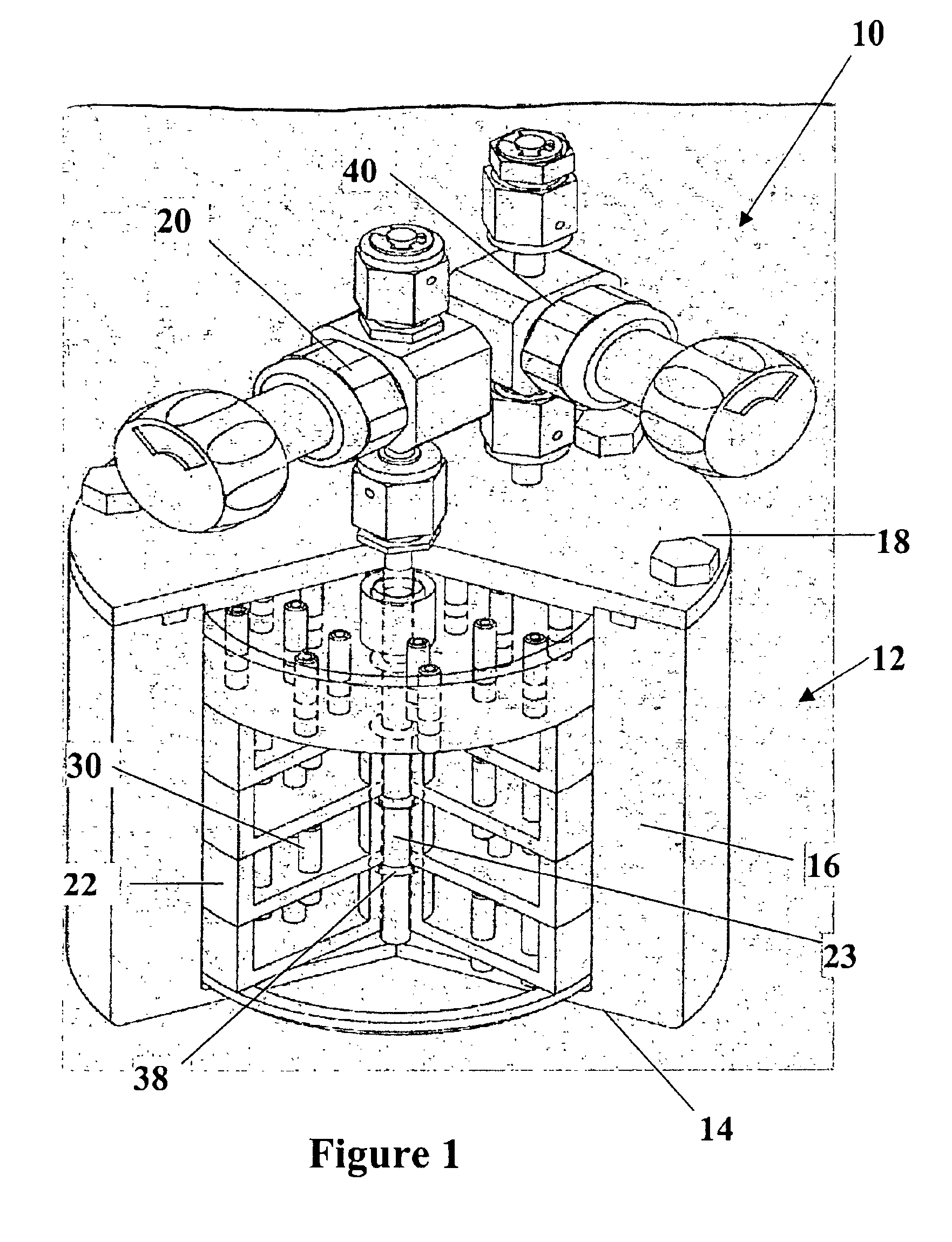

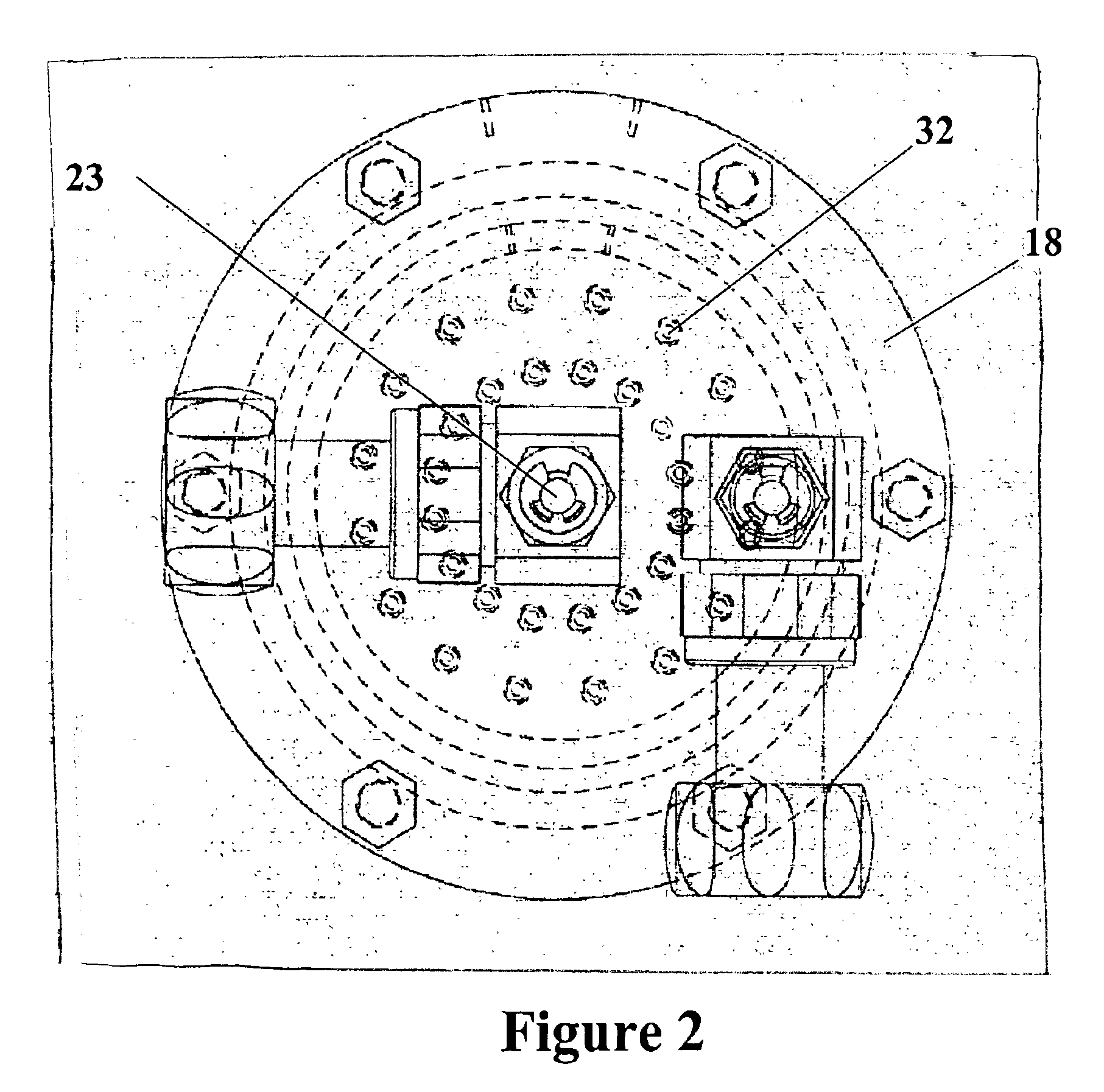

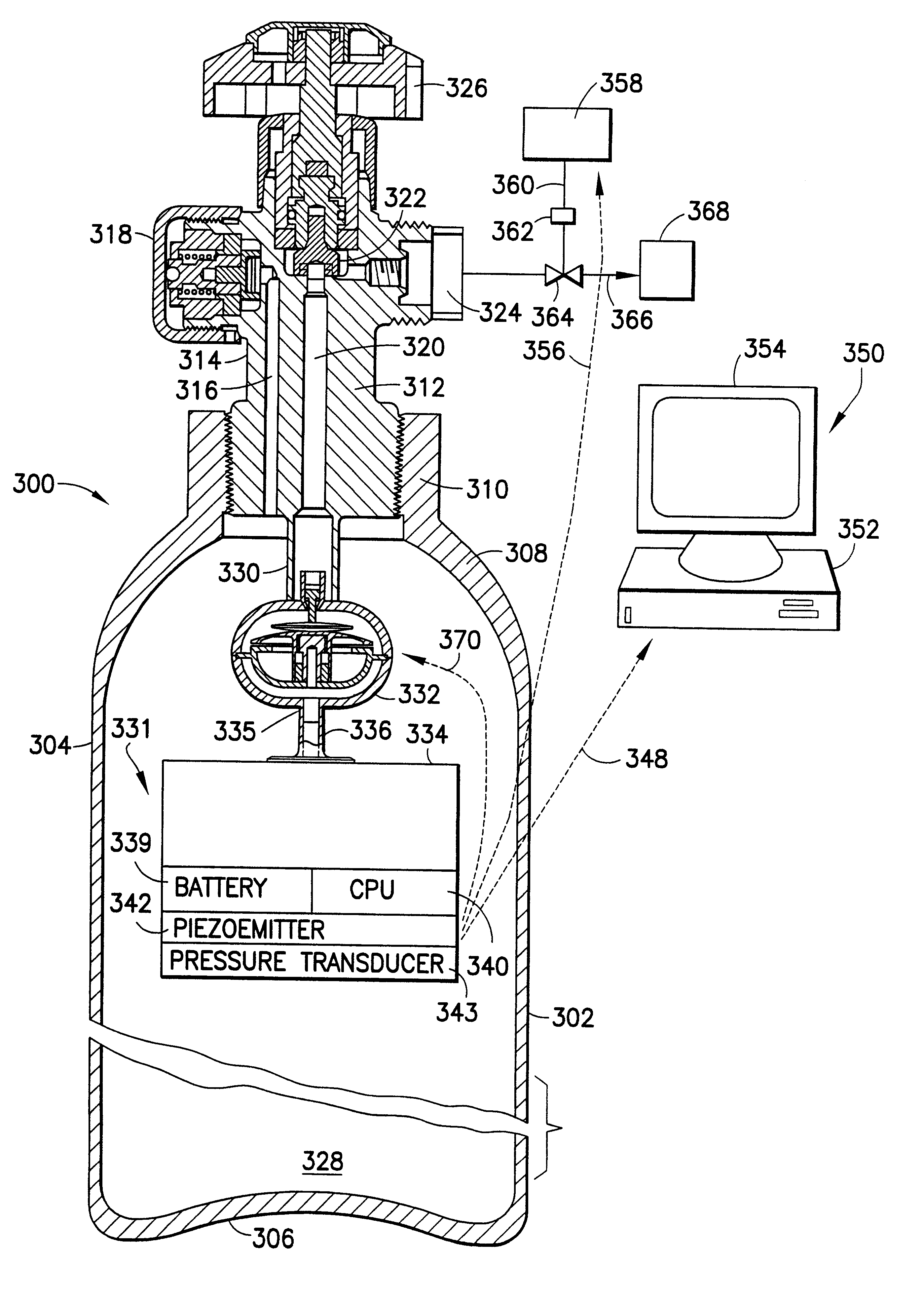

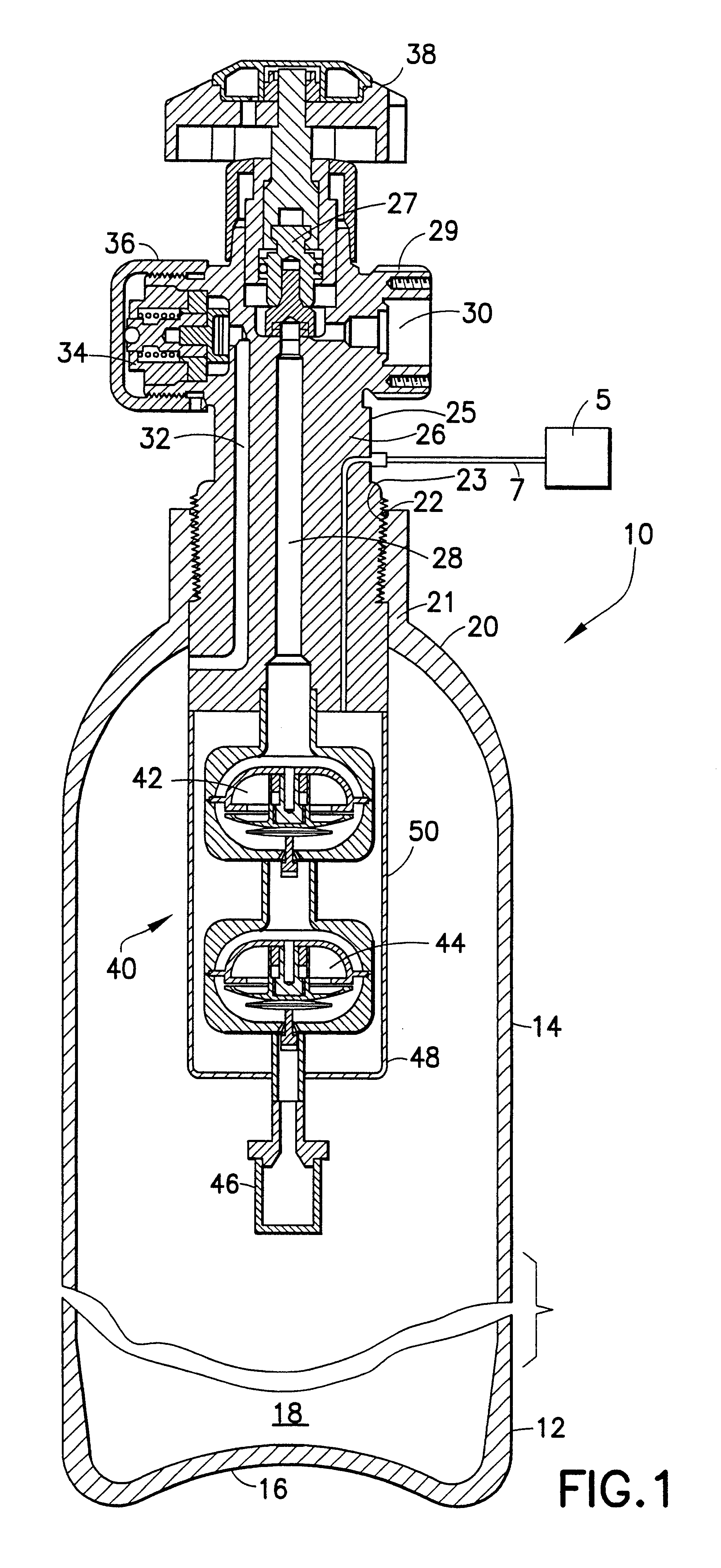

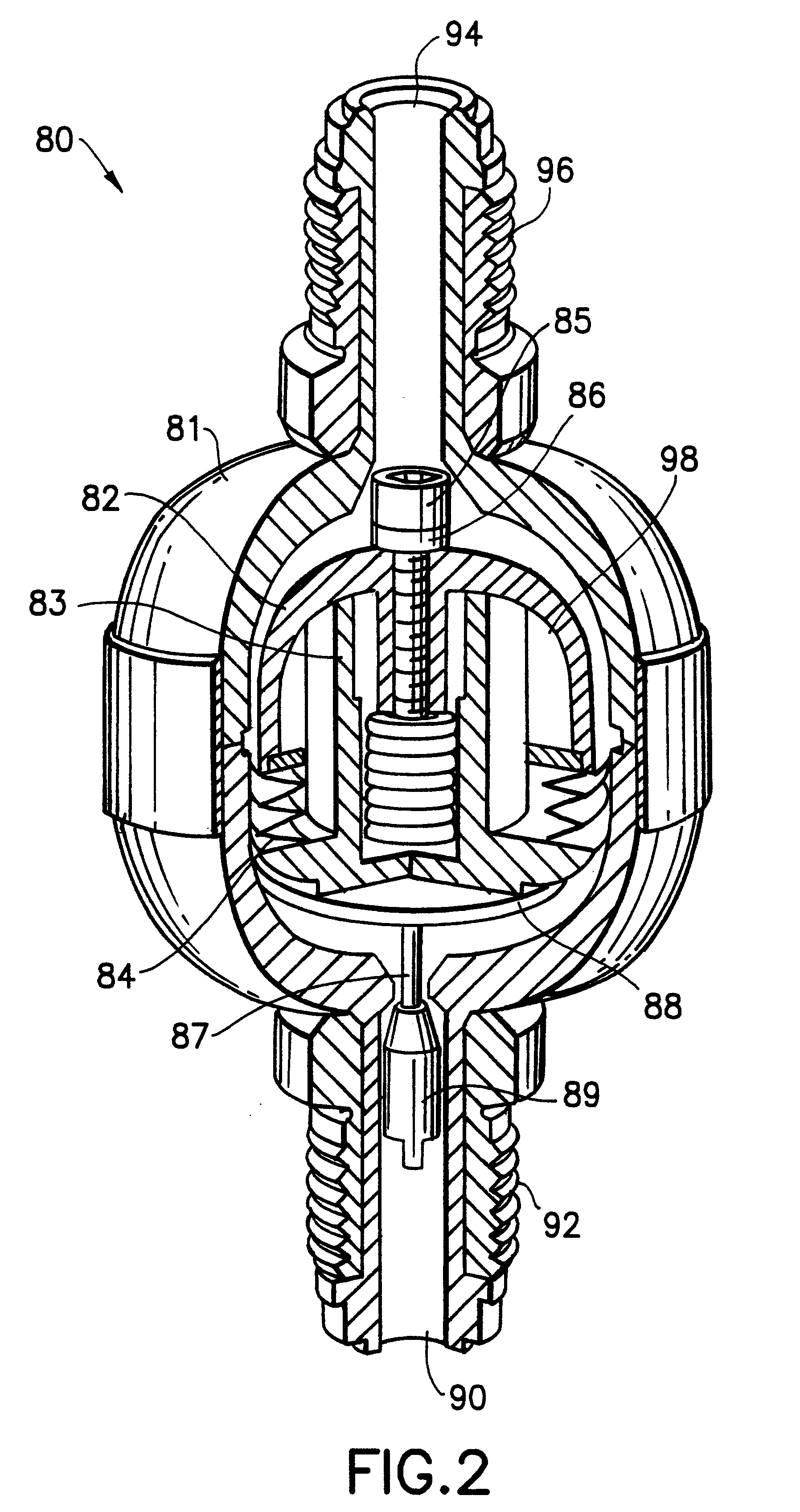

Fluid storage and dispensing system featuring interiorly disposed and exteriorly adjustable regulator for high flow dispensing of gas

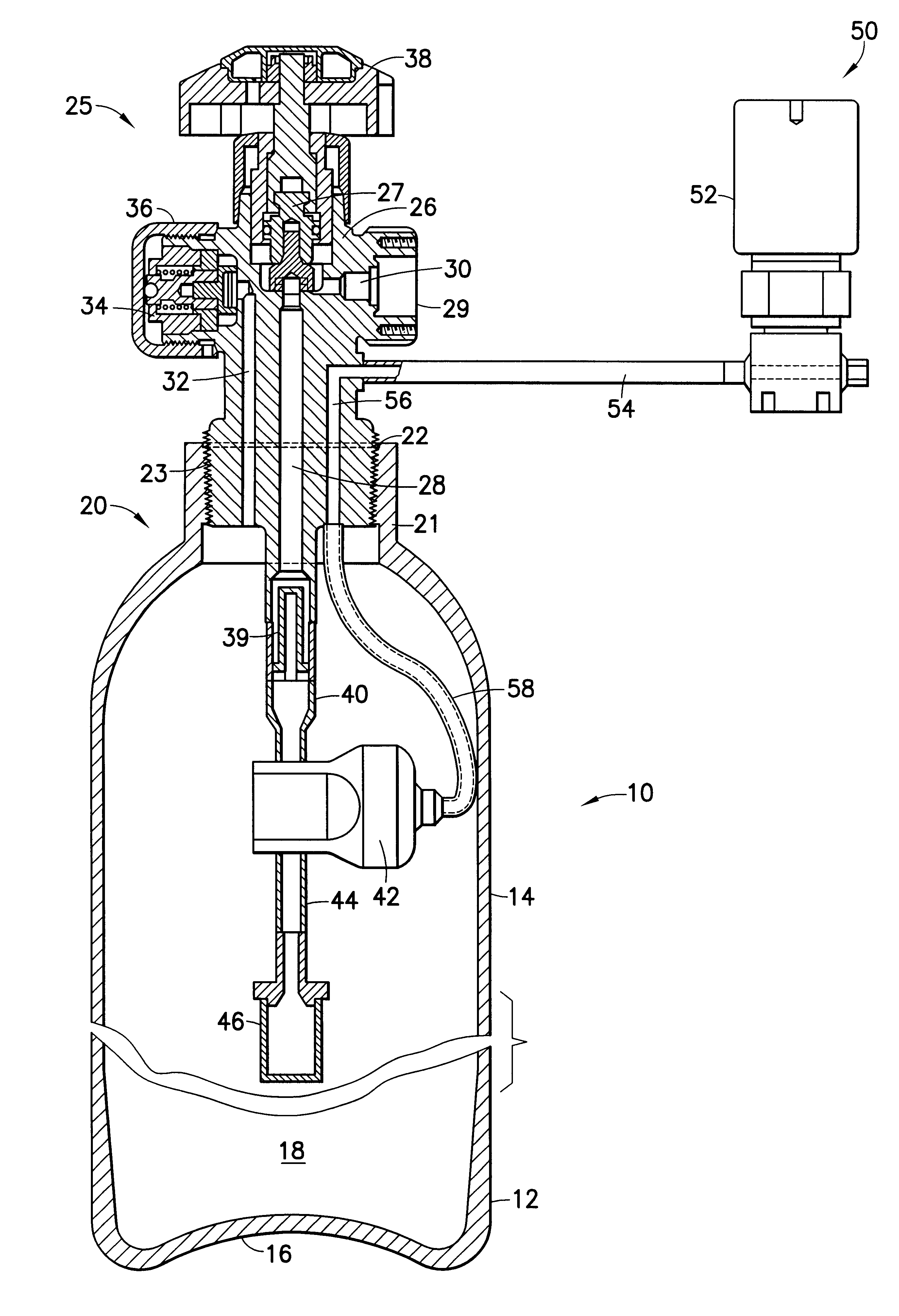

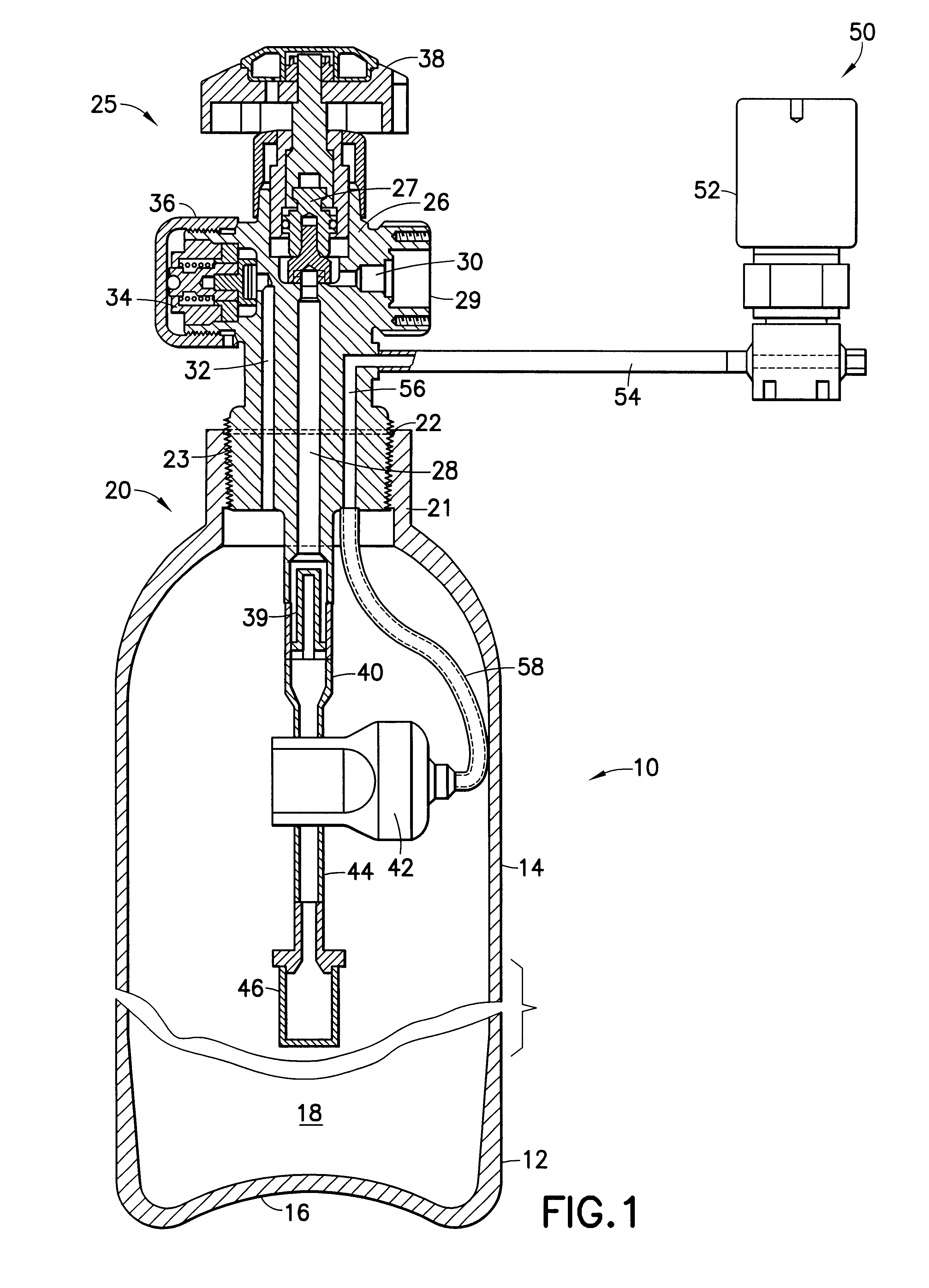

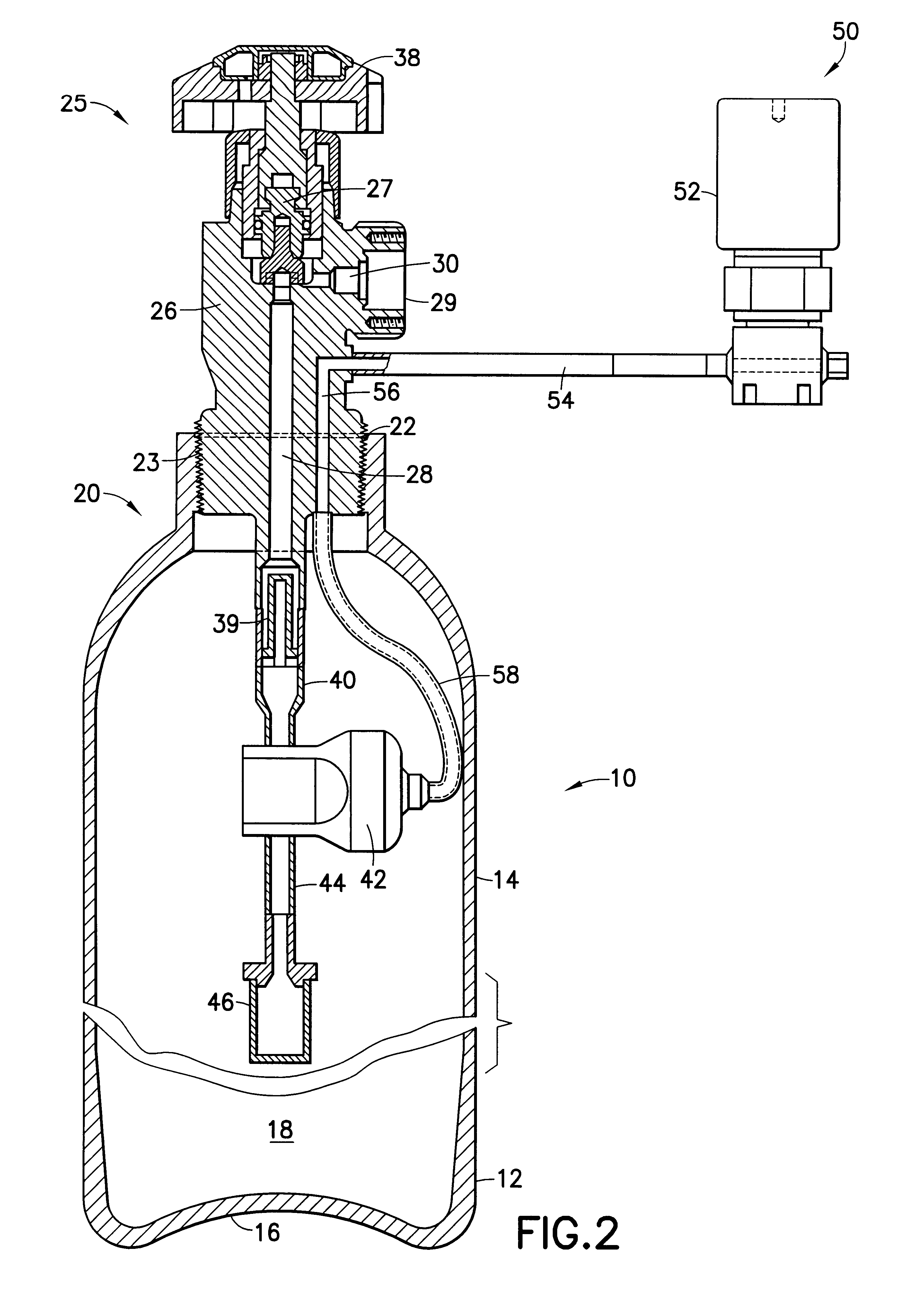

InactiveUS6257000B1CostPerformanceContainer filling methodsSemiconductor devicesEngineeringAtmospheric pressure

A fluid storage and dispensing system including a vessel for holding a fluid, an adjustable set point pressure regulator in the interior volume of the vessel, a dispensing assembly in fluid flow communication with the regulator for dispensing fluid at a pressure determined by the set point of the regulator, and an adjusting assembly exterior to the vessel for in situ adjustment of the set point of the internally disposed regulator. By such arrangement, fluid storage and dispensing operations can have respectively differing regulator set point pressures, as for example a sub-atmospheric pressure set point for storage and a super-atmospheric pressure set point for dispensing.

Owner:ENTEGRIS INC

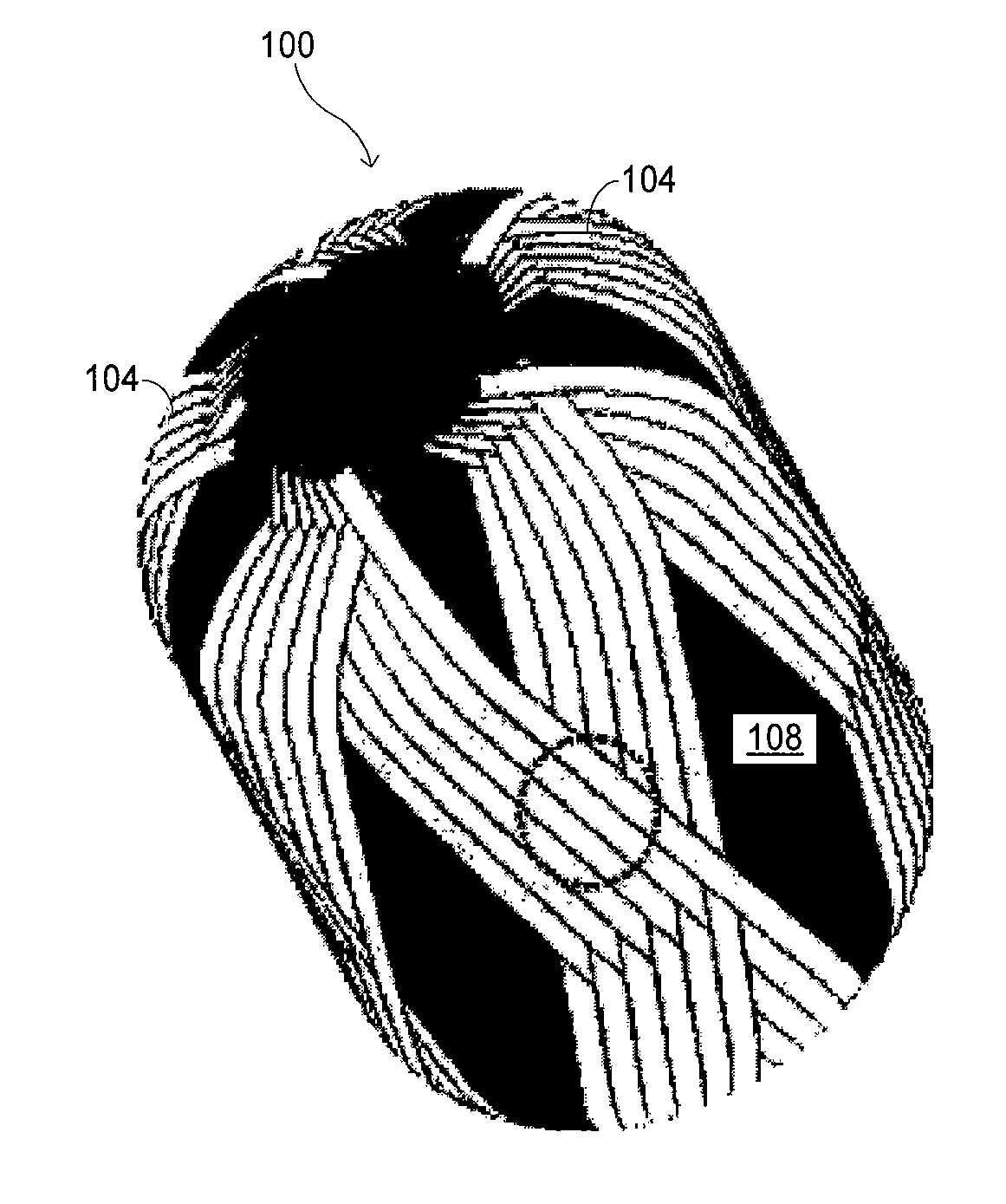

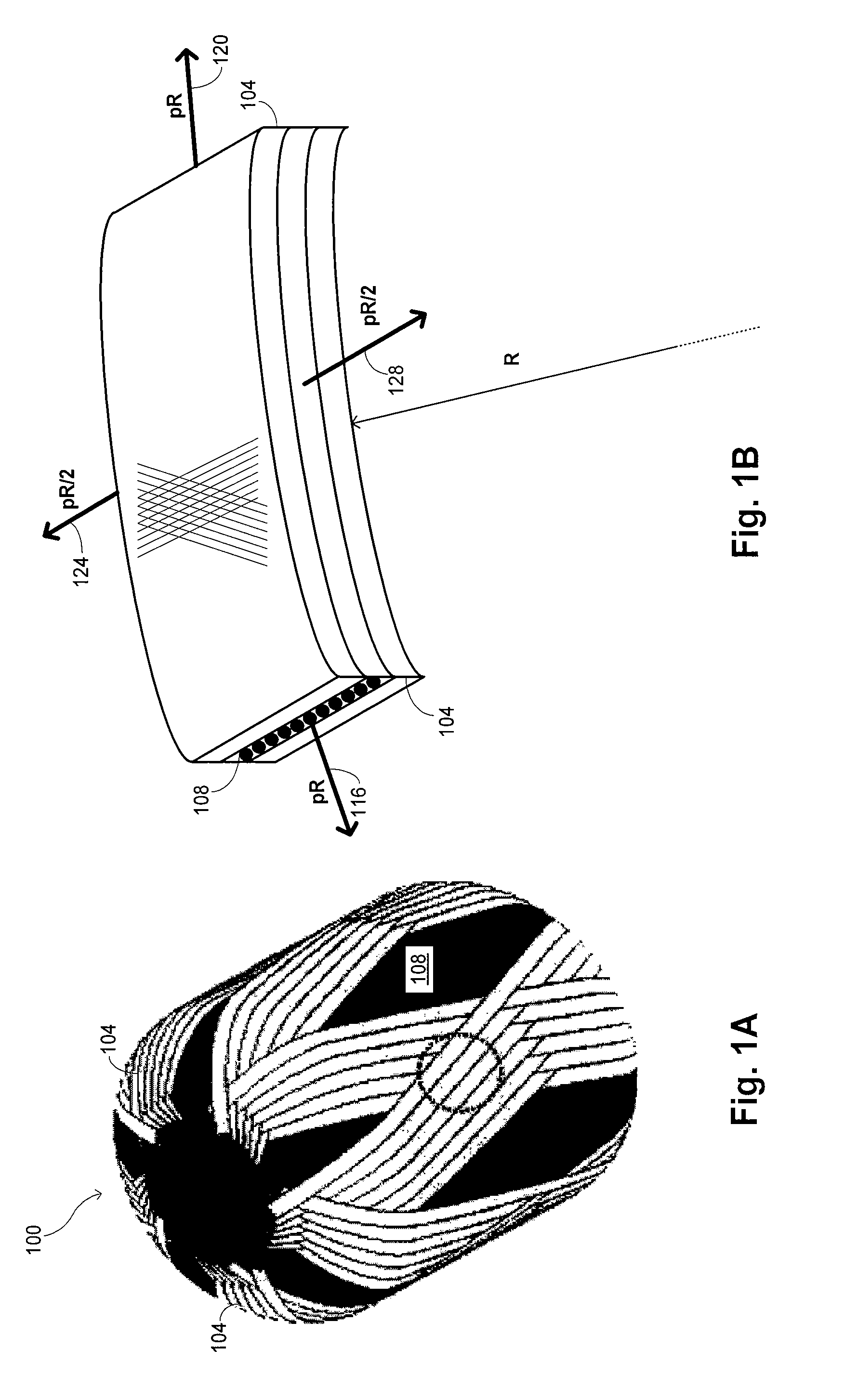

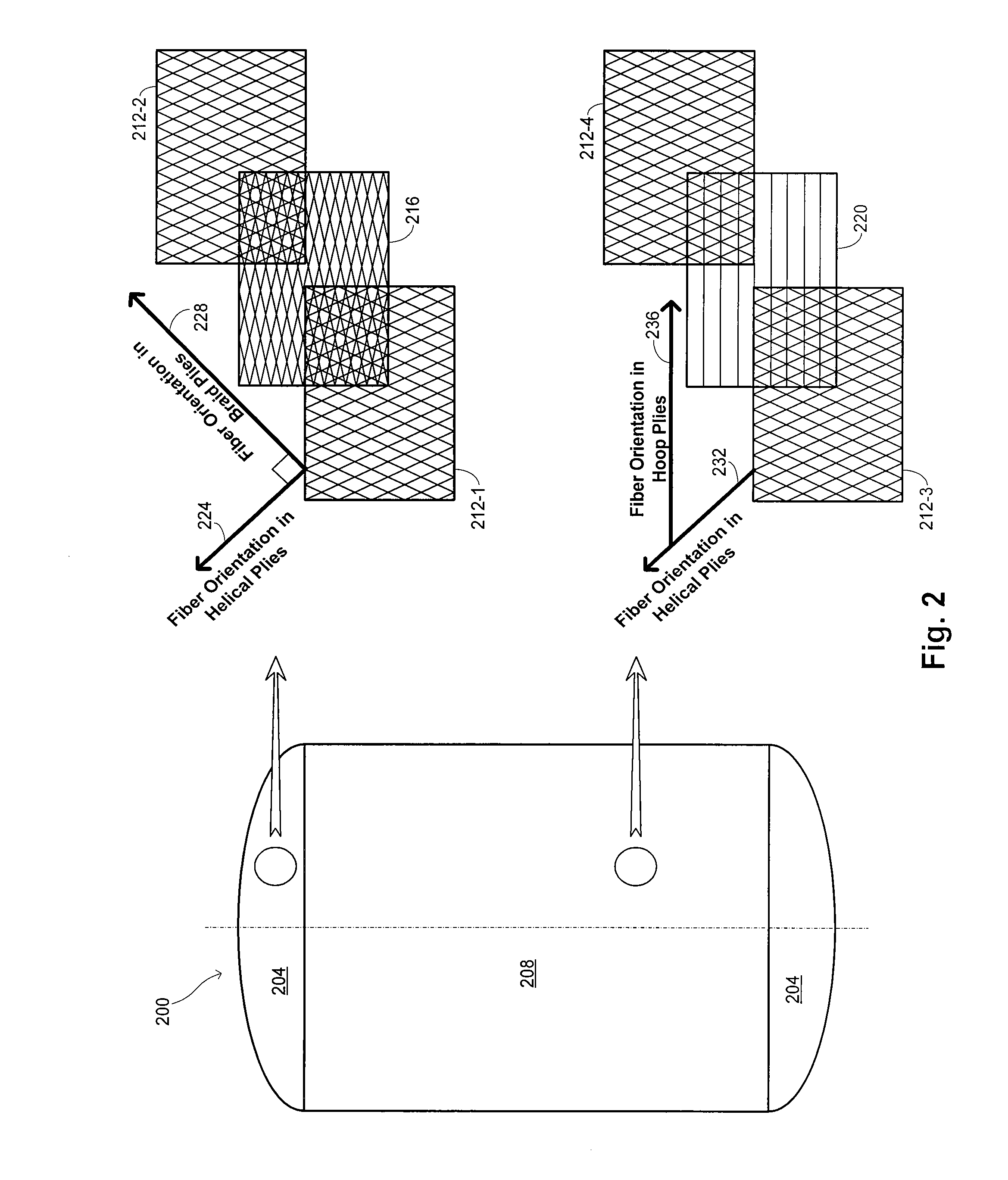

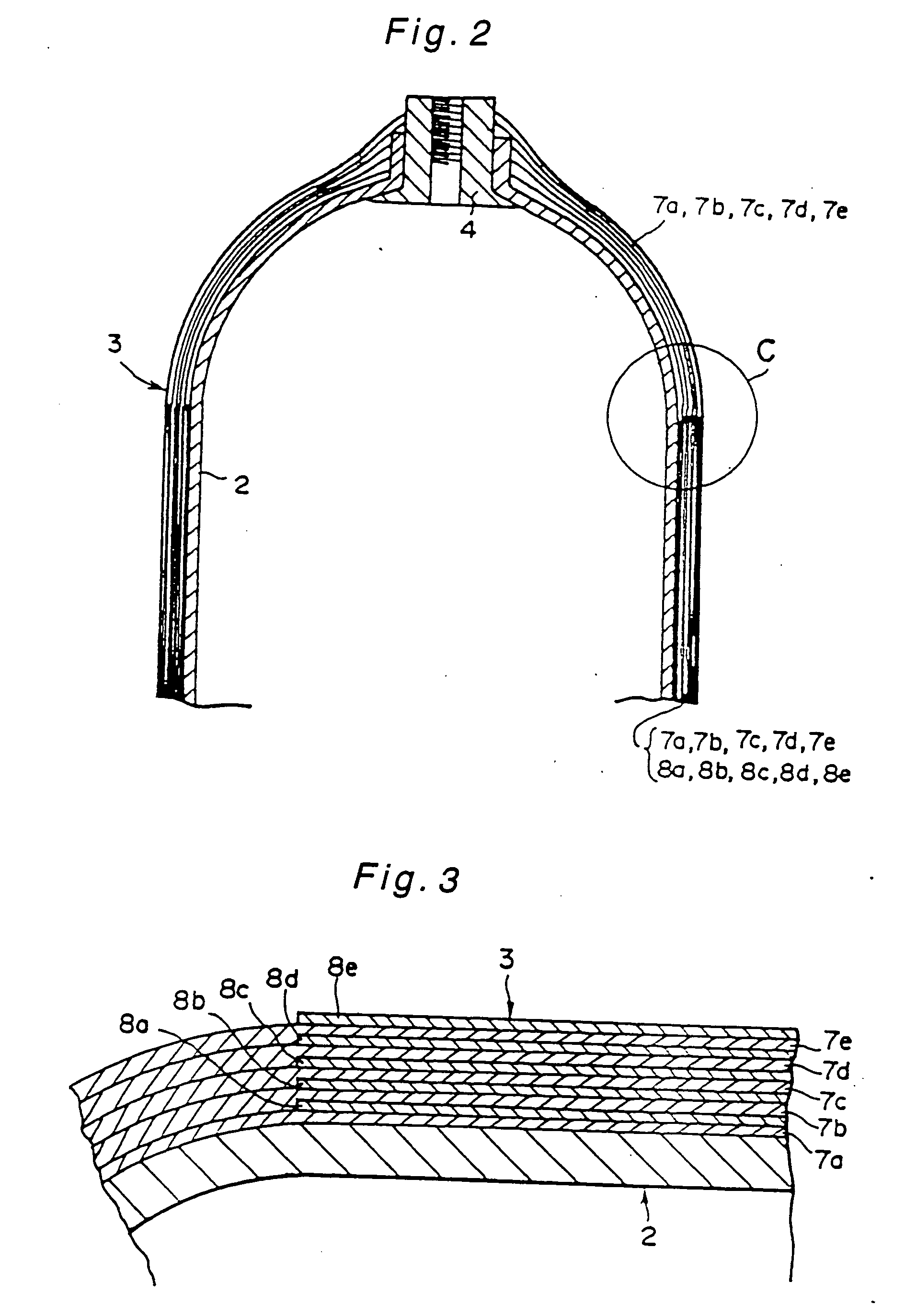

Damage and leakage barrier in all-composite pressure vessels and storage tanks

ActiveUS20090314785A1Superior barrier against leakageStrengthAdhesive processesGas handling applicationsFiberAxis of symmetry

A linerless tank structure has a body that defines an enclosed interior volume. The body has a cylindrical section having an axis of symmetry and a dome section coupled with the cylindrical section. The construction of the pressure vessel includes multiple fiber plies. At least one of the fiber plies is a helical ply having fibers traversing the dome helically about the axis of symmetry. At least a second of the fiber plies is a braided or woven ply.

Owner:COMPOSITE TECH DEV

Microsphere insulation systems

InactiveUS6858280B2Reduce the impactIncreases insulation valueLayered productsContainer filling methodsMicrosphereEngineering

A new insulation system is provided that contains microspheres. This insulation system can be used to provide insulated panels and clamshells, and to insulate annular spaces around objects used to transfer, store, or transport cryogens and other temperature-sensitive materials. This insulation system provides better performance with reduced maintenance than current insulation systems.

Owner:TECH APPL

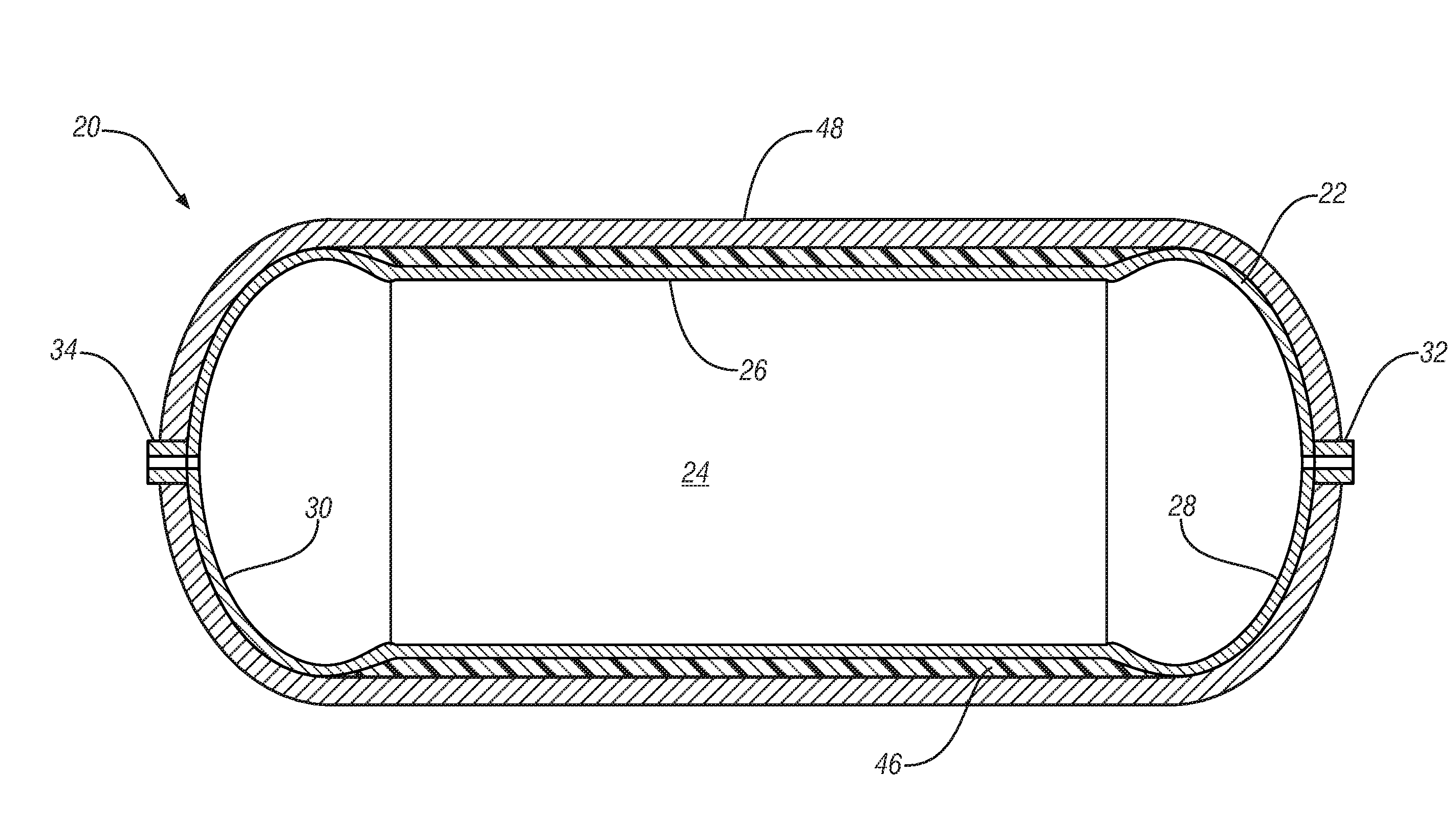

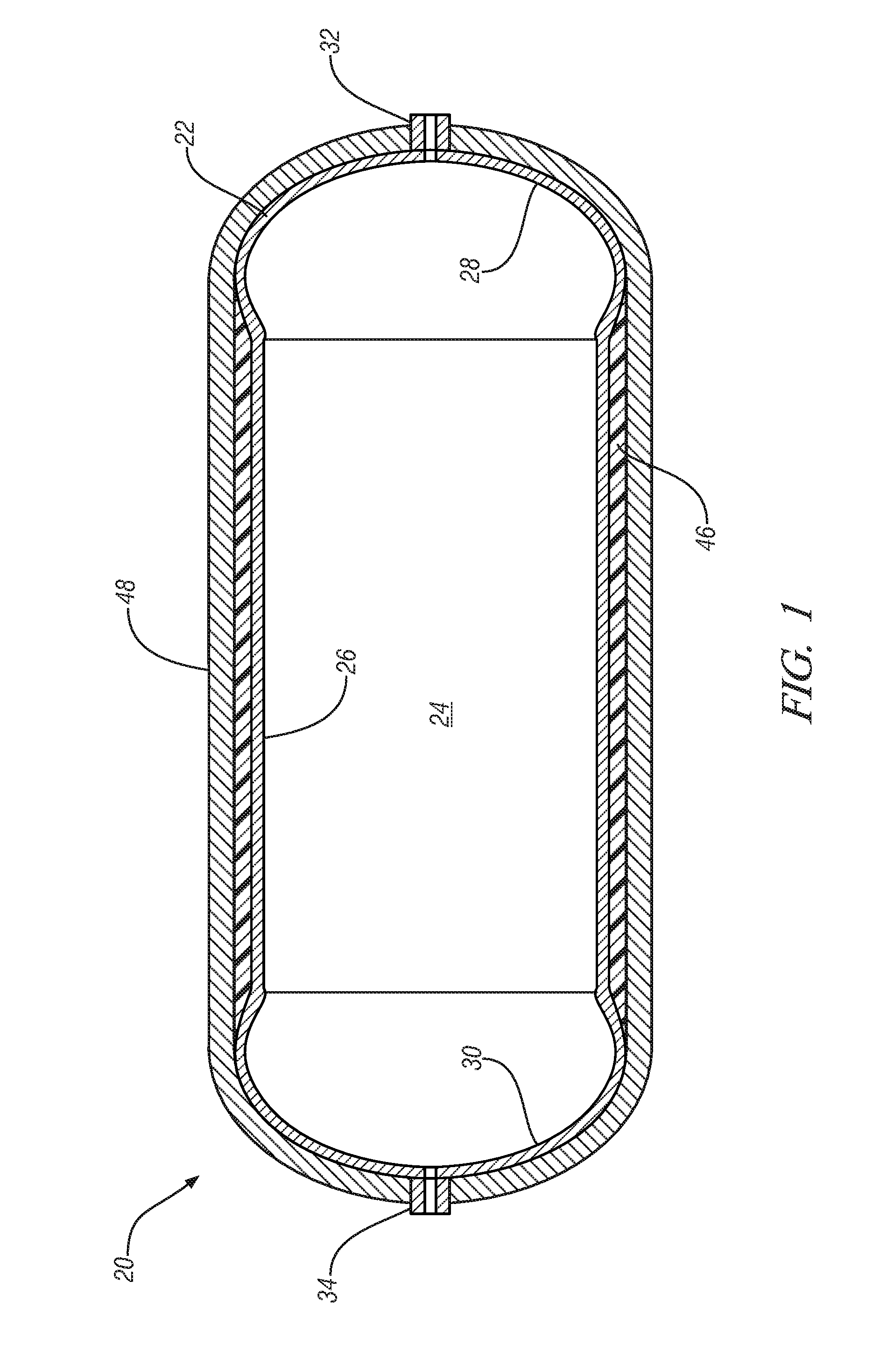

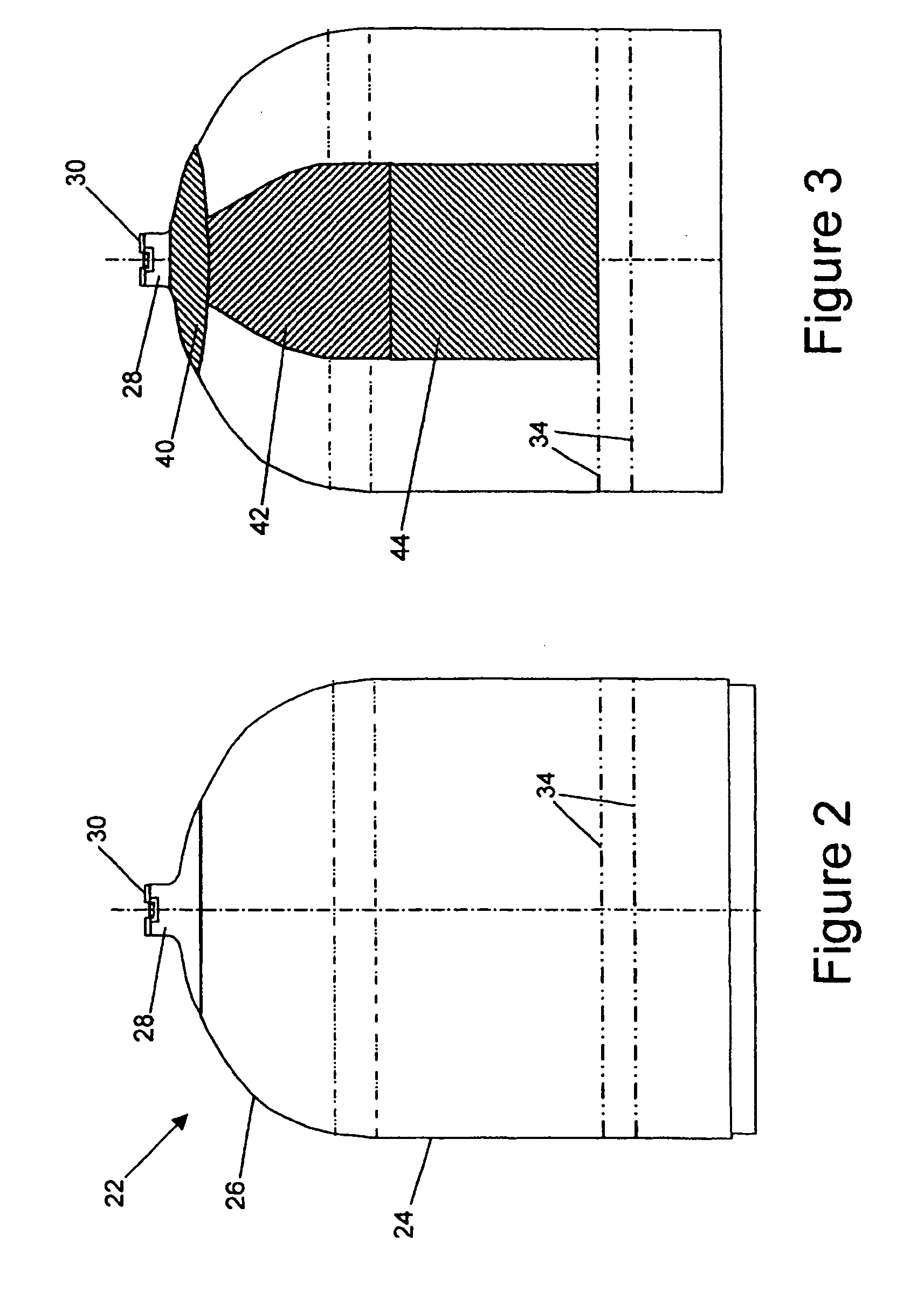

Storage vessel and method of forming

A storage vessel, such as vessels used in storing high pressure gas is provided. The storage vessel includes a liner having a center portion and a first and second end dome. A first composite layer is disposed circumferentially about the center portion. A second composite layer is disposed about said first composite layer and the first and second end dome. In some embodiments, the second composite layer is formed from a knitted or braided sleeve that is tightened over the liner and first composite layer by pulling the sleeve.

Owner:GM GLOBAL TECH OPERATIONS LLC

Thermal container

InactiveUS20020130131A1Easy to manufactureLight weightLighting and heating apparatusVessel wallsThermal energyElectrical conductor

A thermal insulation container for storing materials at predetermined temperatures over extended periods including thermal energy storage units and means for substantially eliminating thermal conductors and providing improved insulation properties by mechanically absorbing temperature induced frictional forces. Highly efficient vacuum thermal insulators embedded within components of the container contribute significantly to its superior temperature maintaining characteristics.

Owner:ZUCKER HANS +2

Compressor

InactiveUS20080008602A1Reduce consumptionSmall sizeAuxillariesContainer filling methodsEngineeringControl valves

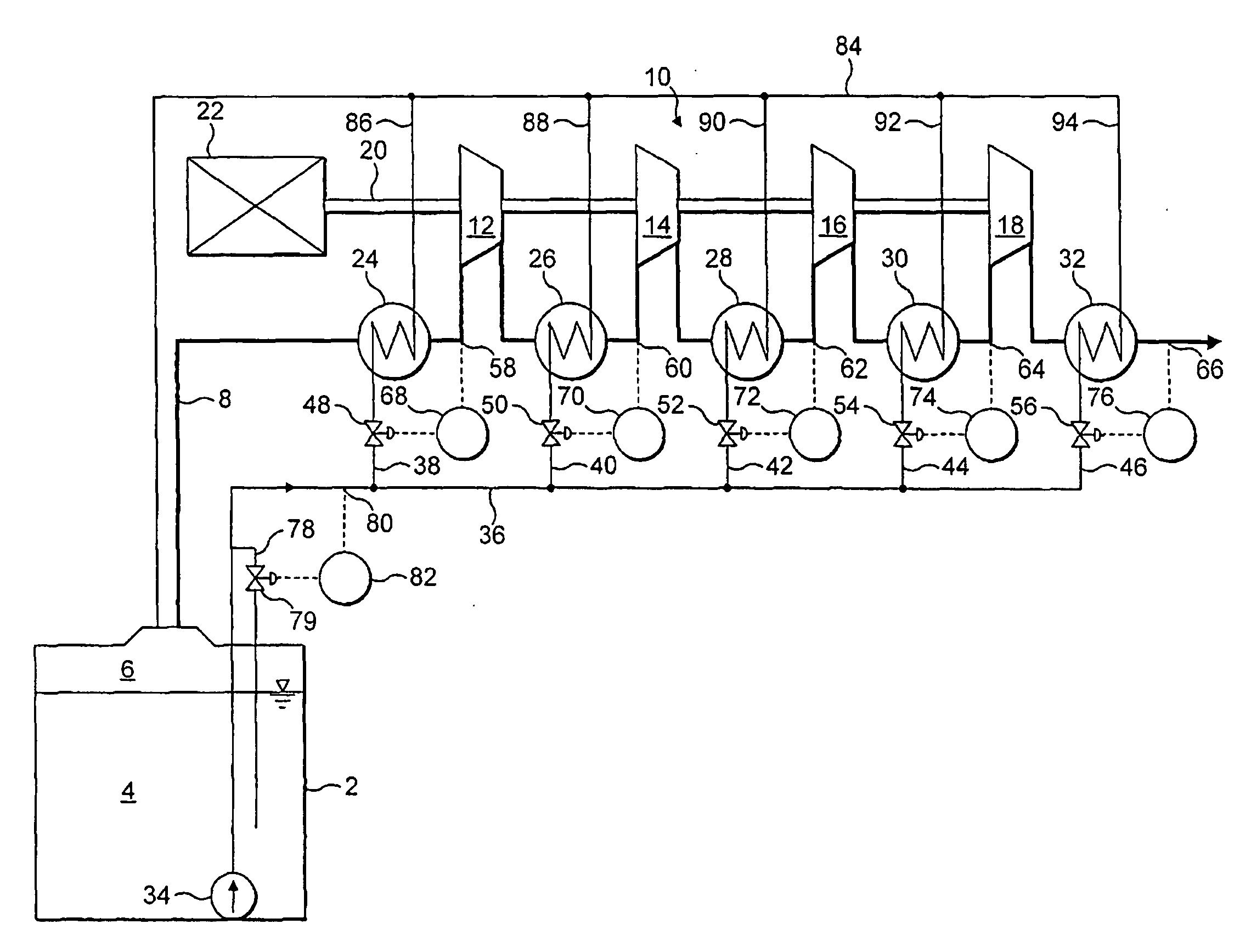

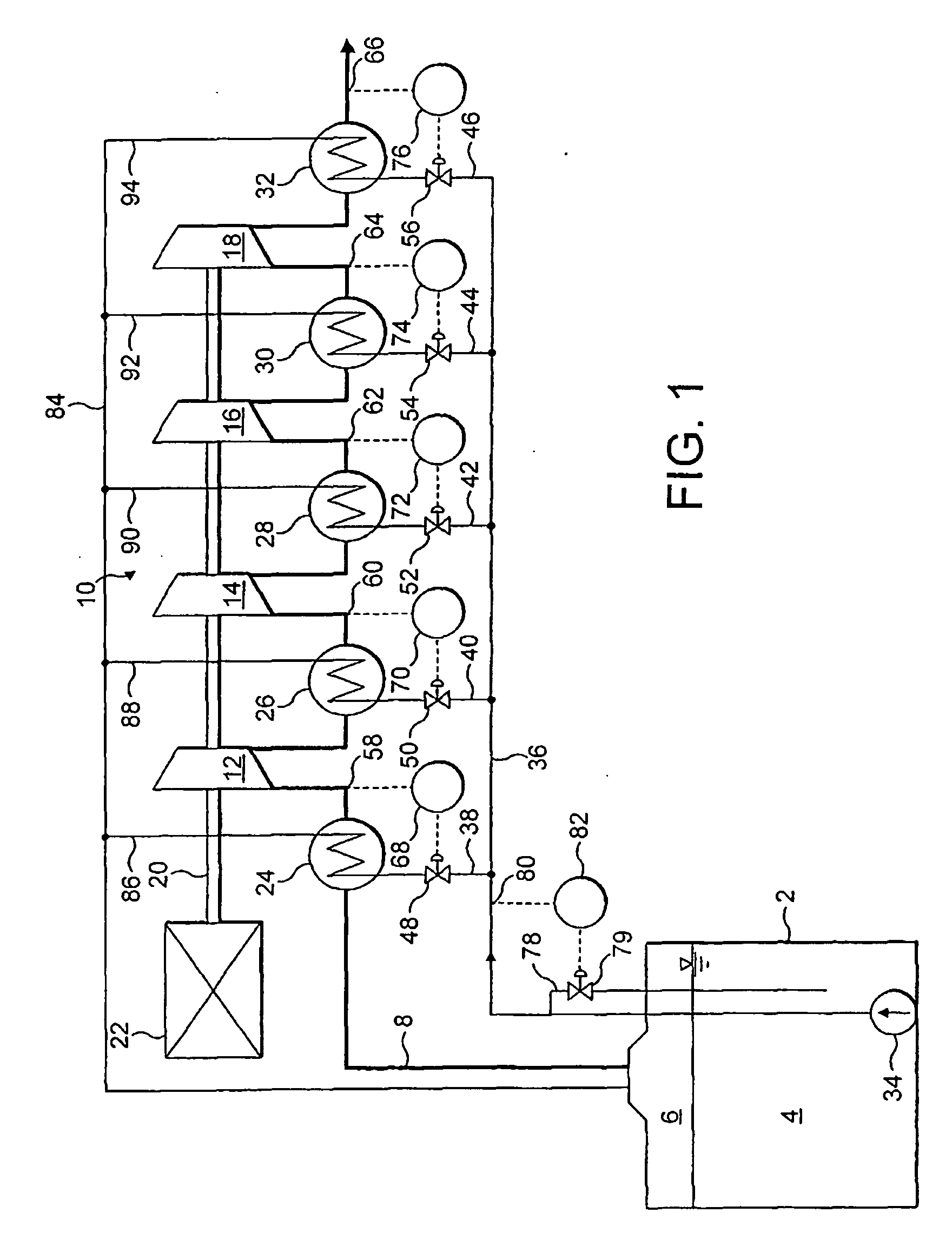

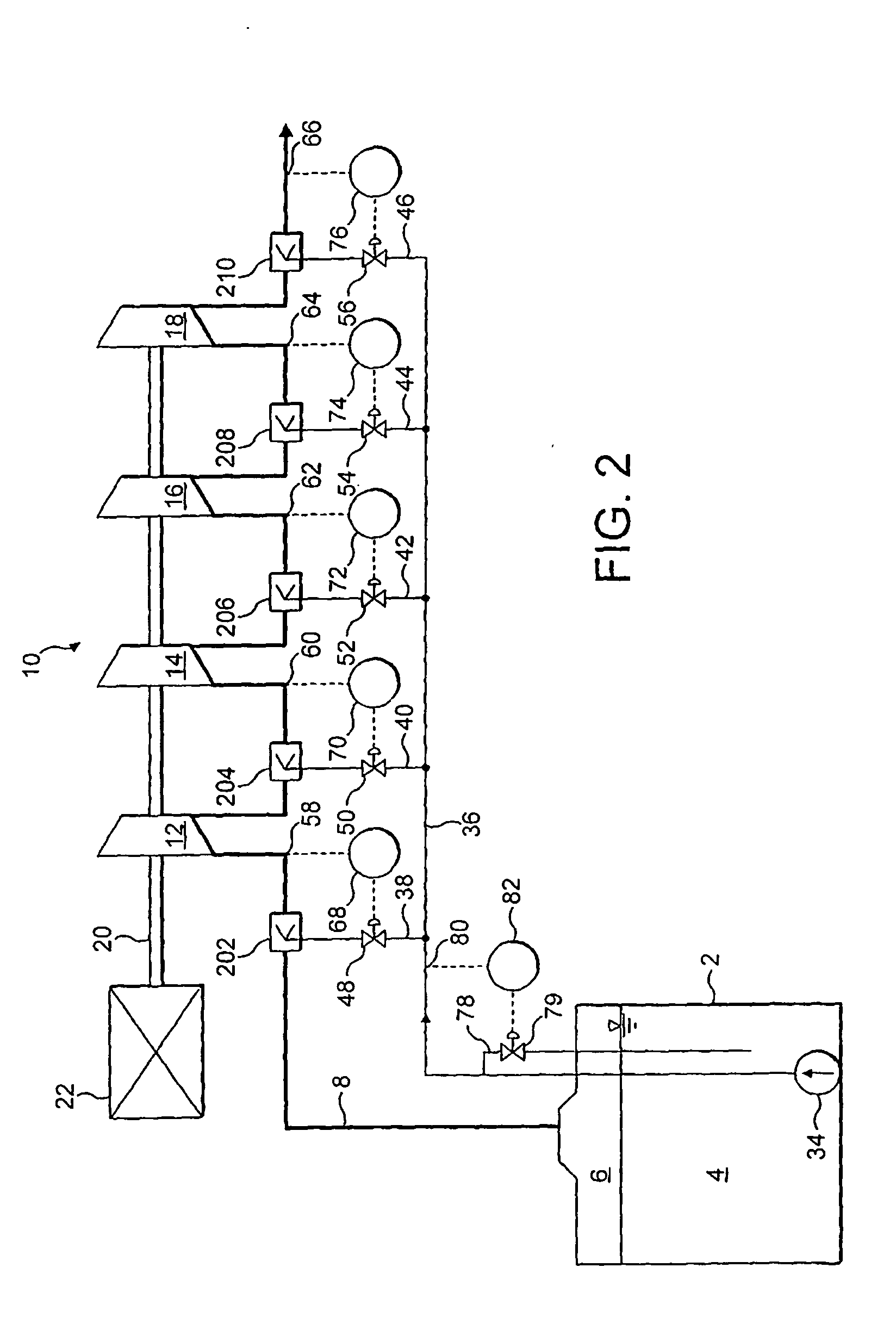

A rotary liquefied natural gas boil-off compressor has a series of compression stages. A gas passage passes through the series of compression stages. The gas passage extends through and is in heat exchange relationship with cooling means in the form of indirect heat exchangers. Each of the heat exchangers is cooled by LNG supplied from a pipeline. Flow control valves are provided for controlling the flow of LNG to the heat exchangers respectively. The valves are controlled in response to temperature sensors respectively, so as to maintain the inlet temperature of each of the compression stages at a chosen sub-ambient temperature or between chosen sub-ambient temperature limits.

Owner:THE BOC GRP PLC

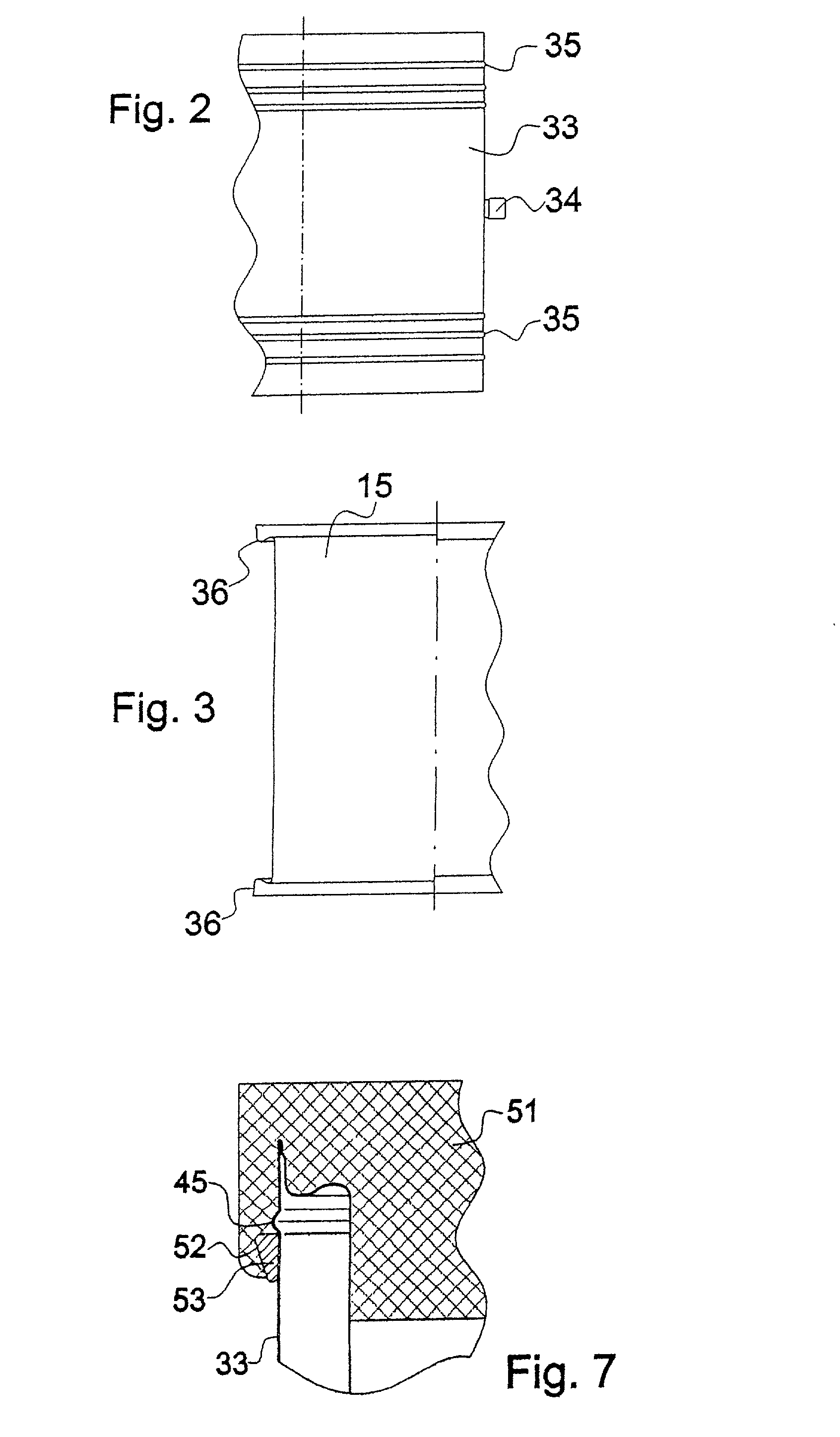

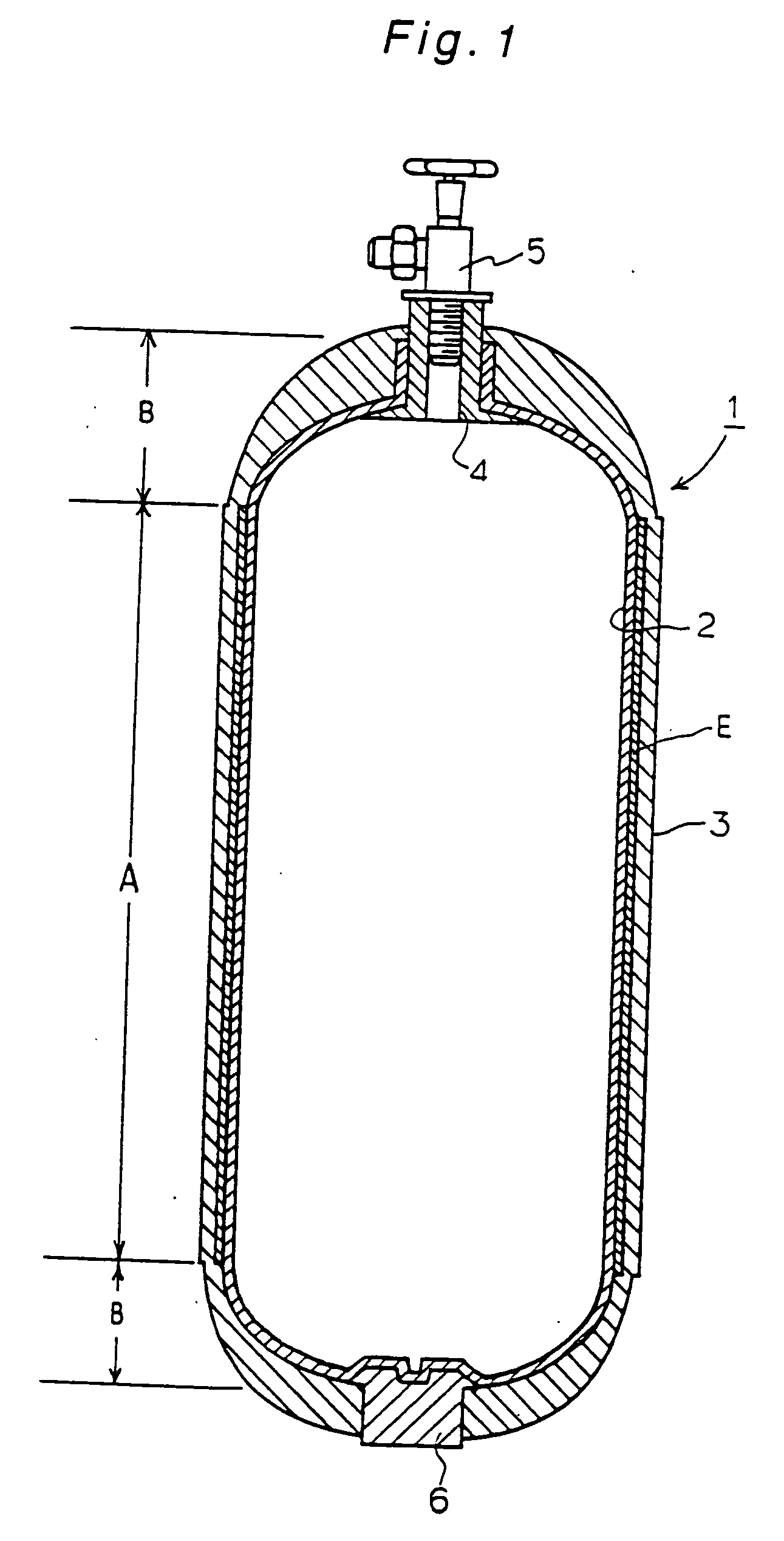

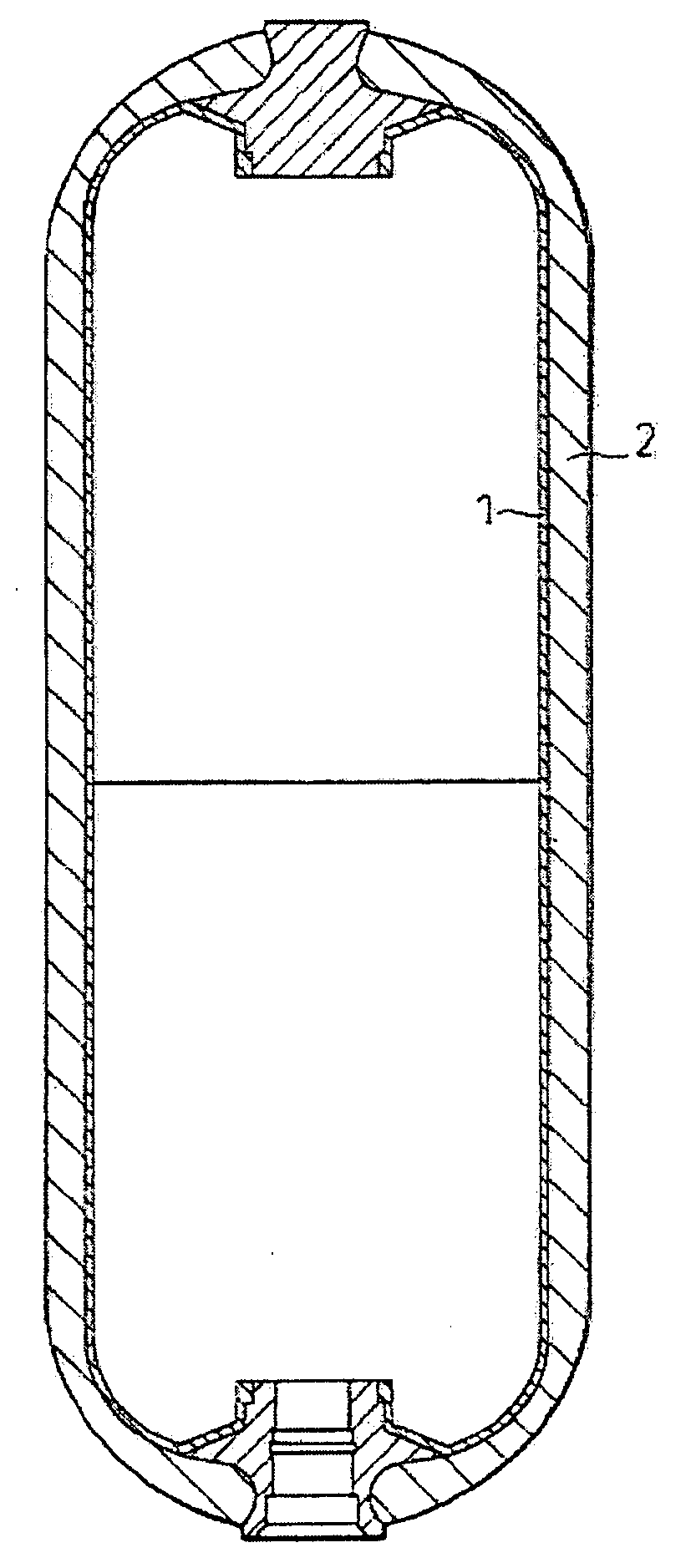

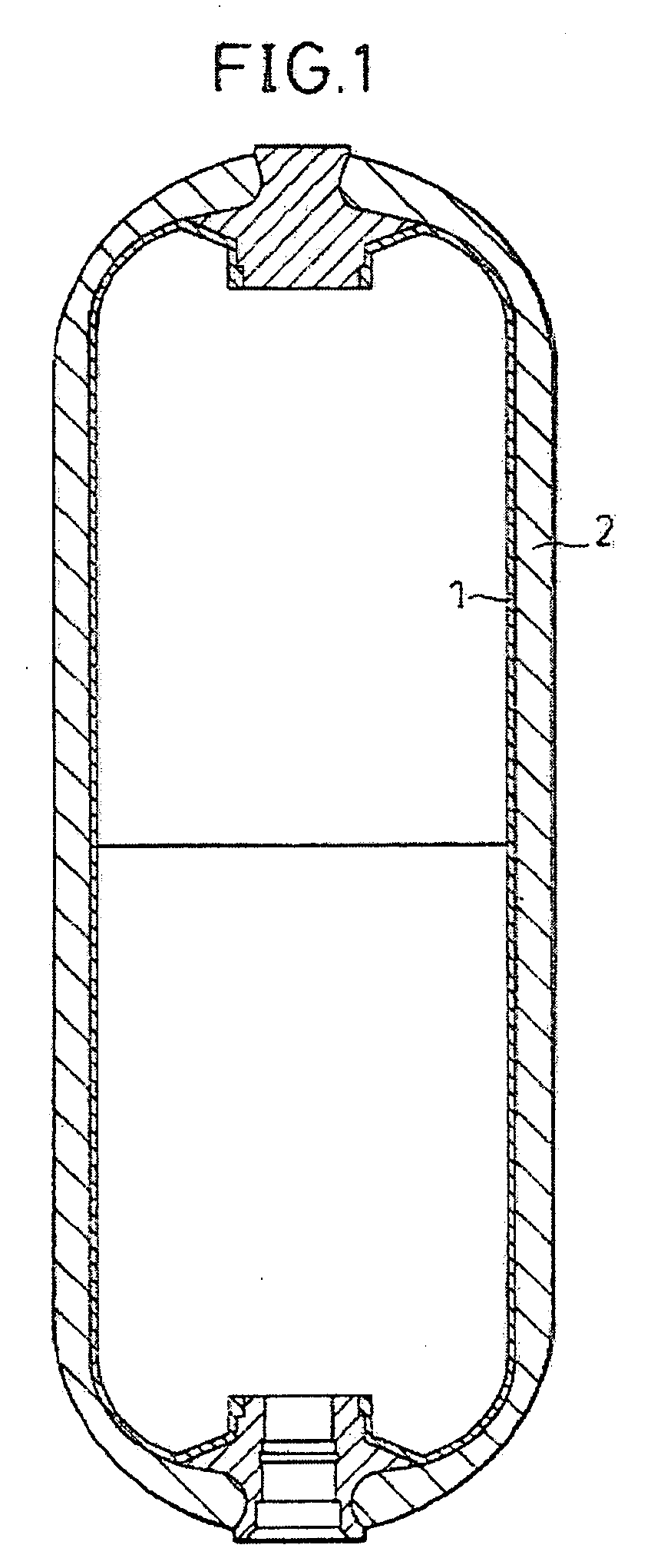

Pressure vessel and process for producing the same

InactiveUS20040206762A1Light weightIncrease pressureVessel mounting detailsVessel manufacturingInternal pressureEngineering

The pressure vessel of the present invention comprises an inner shell capable of serving as a gas barrier and a pressure resistant outer shell provided to cover the inner shell, said outer shell being made of an FRP comprising reinforcing fibers and a resin and is 35 GPa or more in tensile modulus and 1.5% or more in tensile breaking strain. The present invention can provide a pressure vessel not only light in weight,.but also excellent in retaining its internal pressure against repetitive impacts and also excellent in reliability. The process for producing a pressure vessel of the present invention comprises the step of forming a pressure resistant outer shell made of an FRP comprising reinforcing fibers and a resin and is 35 GPa or more in tensile modulus and 1.5% or more in tensile breaking strain, around an inner shell capable of serving as a gas barrier, by a filament winding method or a tape winding method. The present invention can produce a pressure vessel excellent in retaining its internal pressure, excellent in reliability, and light in weight at a low cost.

Owner:TORAY IND INC

Fluid storage and dispensing system featuring externally adjustable regulator assembly for high flow dispensing

InactiveUS6360546B1CostPerformanceContainer filling methodsGas handling applicationsEngineeringAtmospheric pressure

A fluid storage and dispensing system including a fluid storage and dispensing vessel enclosing an interior volume for holding a fluid. The vessel includes a fluid discharge port for discharging fluid from the vessel. A pressure regulating element in the interior volume of the fluid storage and dispensing vessel is arranged to flow fluid therethrough to the fluid discharge port at a set pressure for dispensing thereof. A controller external of the fluid storage and dispensing vessel is arranged to transmit a control input into the vessel to cause the pressure regulating element to change the set pressure of the fluid flowed from the pressure regulating element to the fluid discharge port. By such arrangement, the respective storage and dispensing operations can have differing regulator set point pressures, as for example a subatmospheric pressure set point for storage and a super atmospheric pressure set point for dispensing.

Owner:ADVANCED TECH MATERIALS INC

Composite pressure tank and process for its manufacture

InactiveUS20070205201A1Reduce weightLow costVessel mounting detailsVessel manufacturingBody shapeMaterials science

A pressure vessel and method for producing a pressure vessel is disclosed. The pressure vessel comprises a liner shell fabricated from composite material applied to a soluble mandrel having a body shaped to pattern an interior of the pressure vessel, the liner shell having an opening, a boss having an aperture therethrough, the boss sealingly bonded to the liner shell with the aperture adjacent the opening, and an outer shell fabricated from plies of composite material filament impregnated with matrix material wound over the liner shell and the boss, but not over the aperture.

Owner:MICROCOSM INC

Pressure Vessels, Design and Method of Manufacturing Using Additive Printing

InactiveUS20160061381A1Less materialNo wasteLarge containersArc welding apparatusManufacturing technologyEngineering

Method and design of a pressure vessel having an internal supportive structure that reduces pressure forces applied to the external shell of the vessel by distributing such forces via internal bonds mostly connected to a central supporting element. The method and design allow making much lighter and stronger pressure vessels and containers using additive manufacturing technology, known as 3D printing.

Owner:KOTLIAR IGOR K

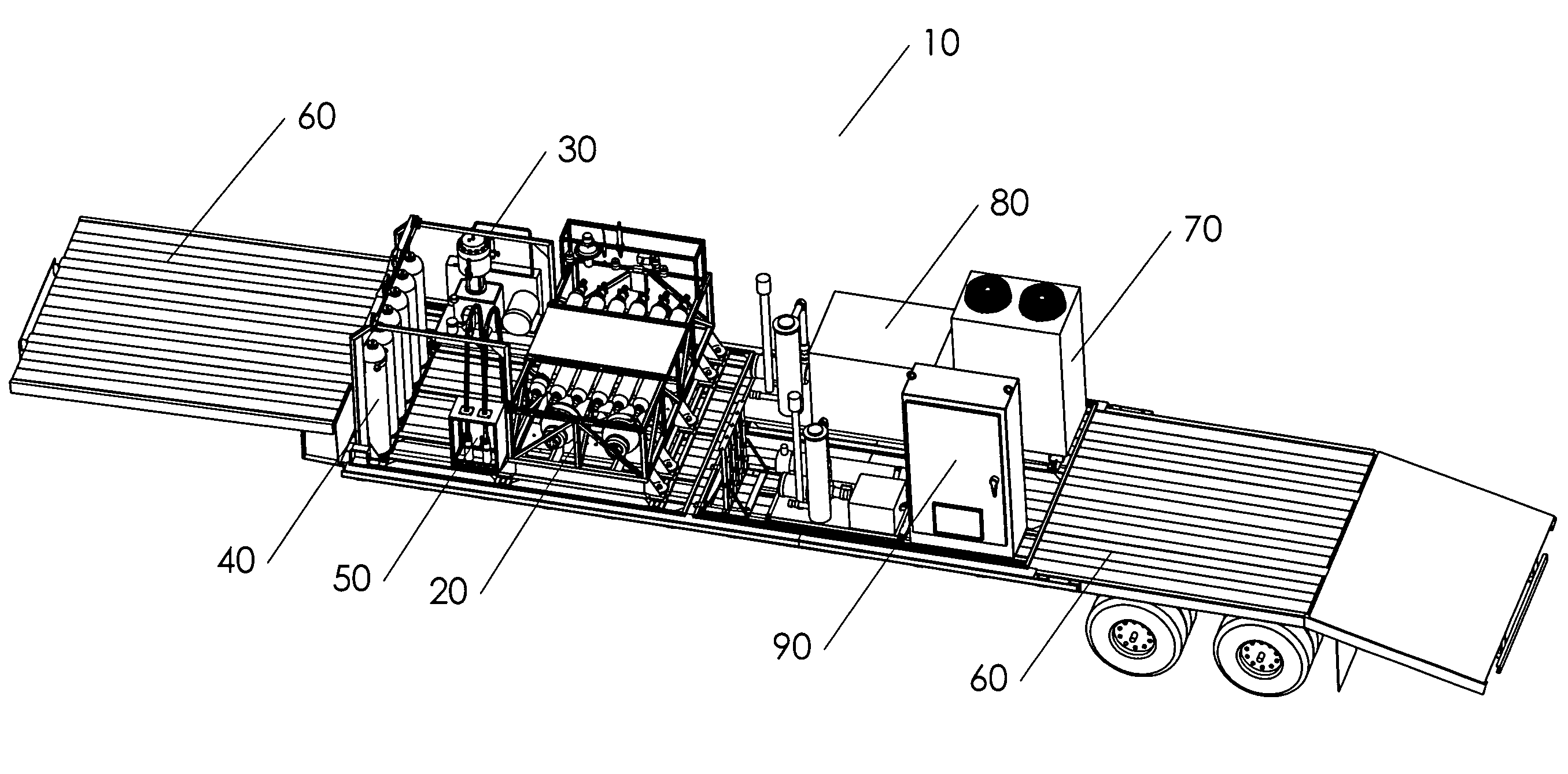

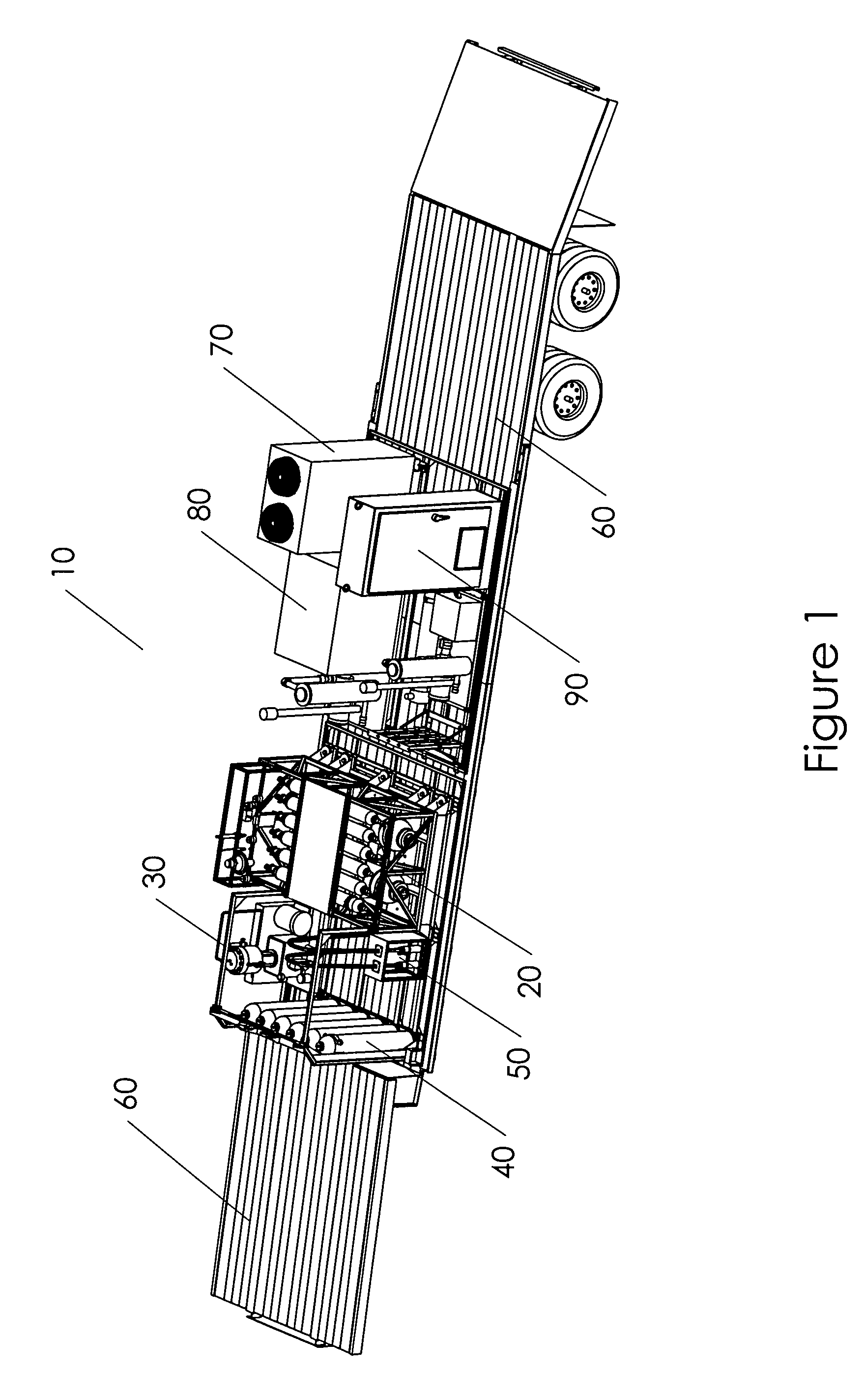

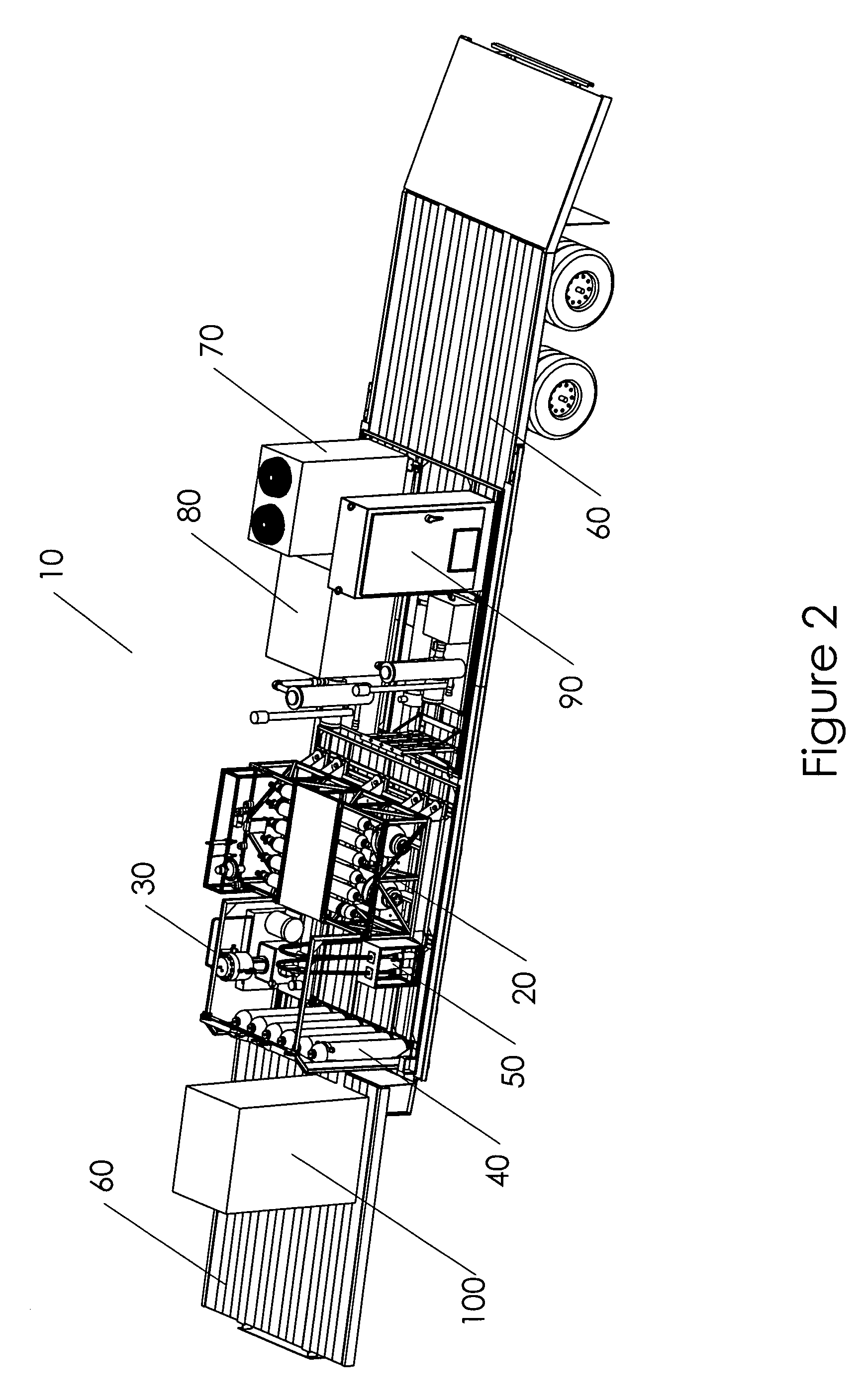

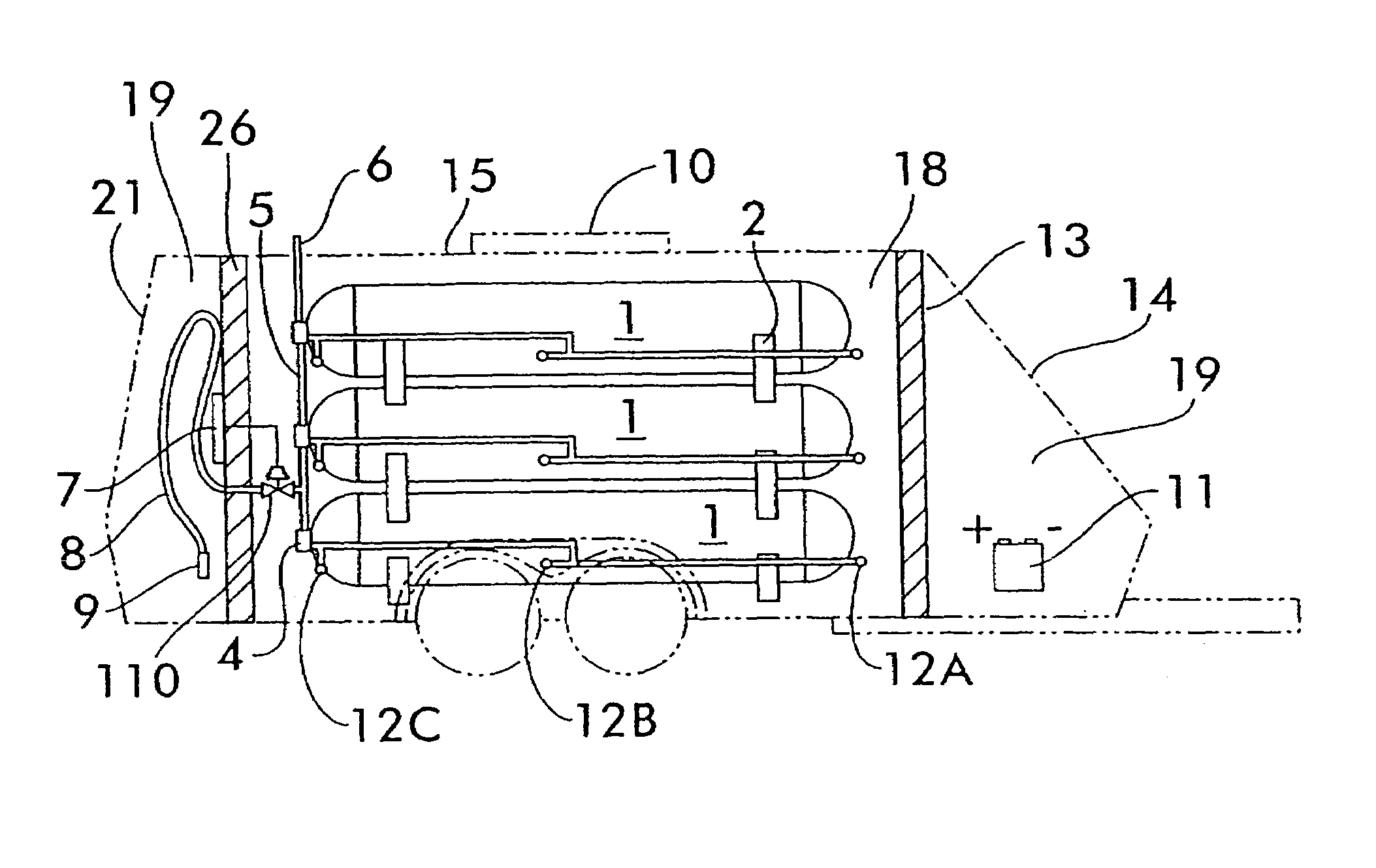

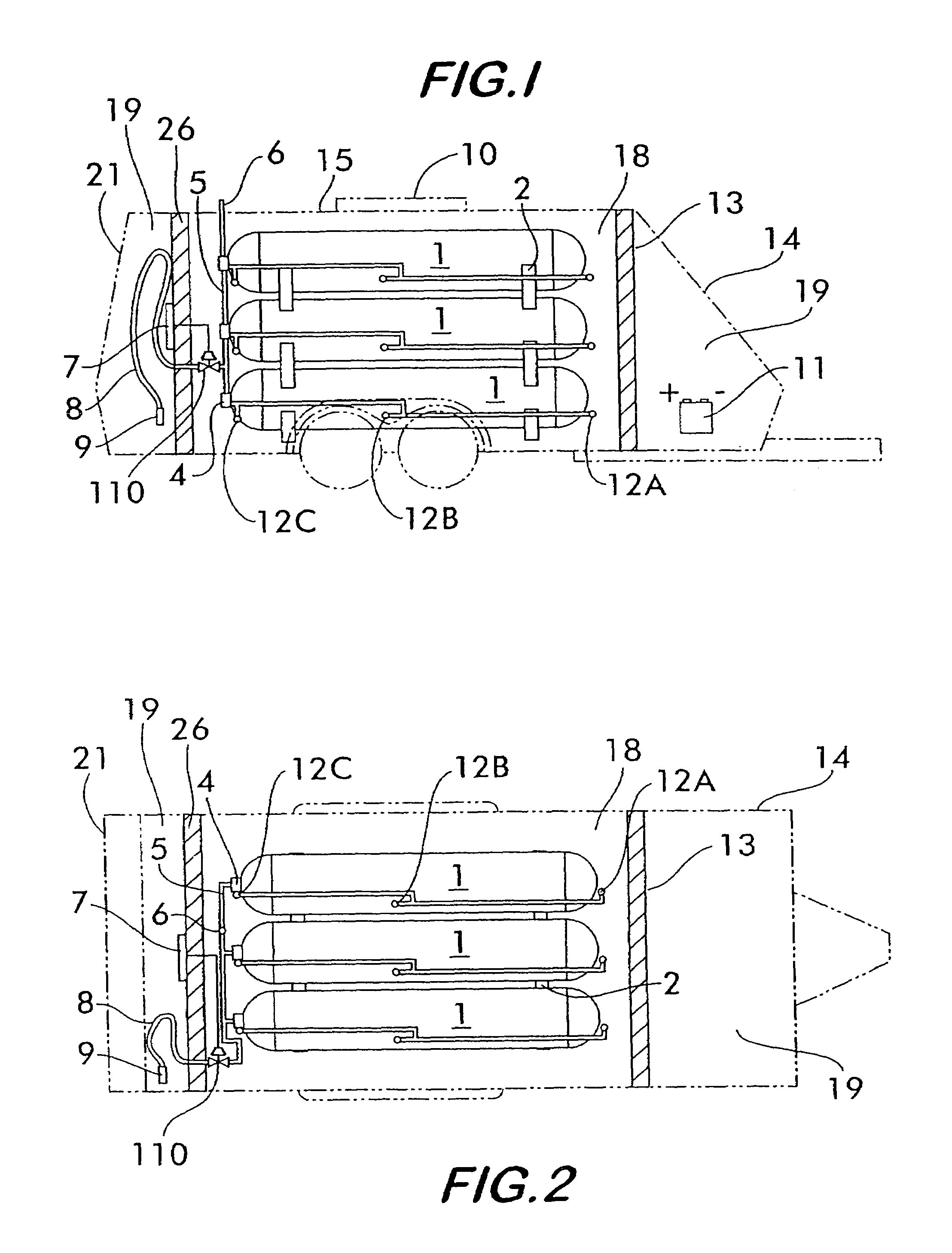

Mobile hydrogen delivery system

A mobile hydrogen delivery system for delivering a compressed stream of hydrogen at pressures up to 15000 psig. The mobile hydrogen delivery system includes a hydrogen compression system, a gaseous hydrogen storage system, and a delivery system for supplying hydrogen to end users. A mobile platform supports the hydrogen compression system, the gaseous hydrogen storage system, and the dispensing system. The mobile platform may be any platform, such as a trailer, capable of being pulled, pushed, or supported by any type of vehicle, such a truck, train, boat, tractor, etc.

Owner:HARNYSS IP LLC +1

Diffusion layer for pressure vessels

ActiveUS20090057319A1Improve fluid flowVessel mounting detailsVessel manufacturingEngineeringDiffusion layer

Owner:GM GLOBAL TECH OPERATIONS LLC

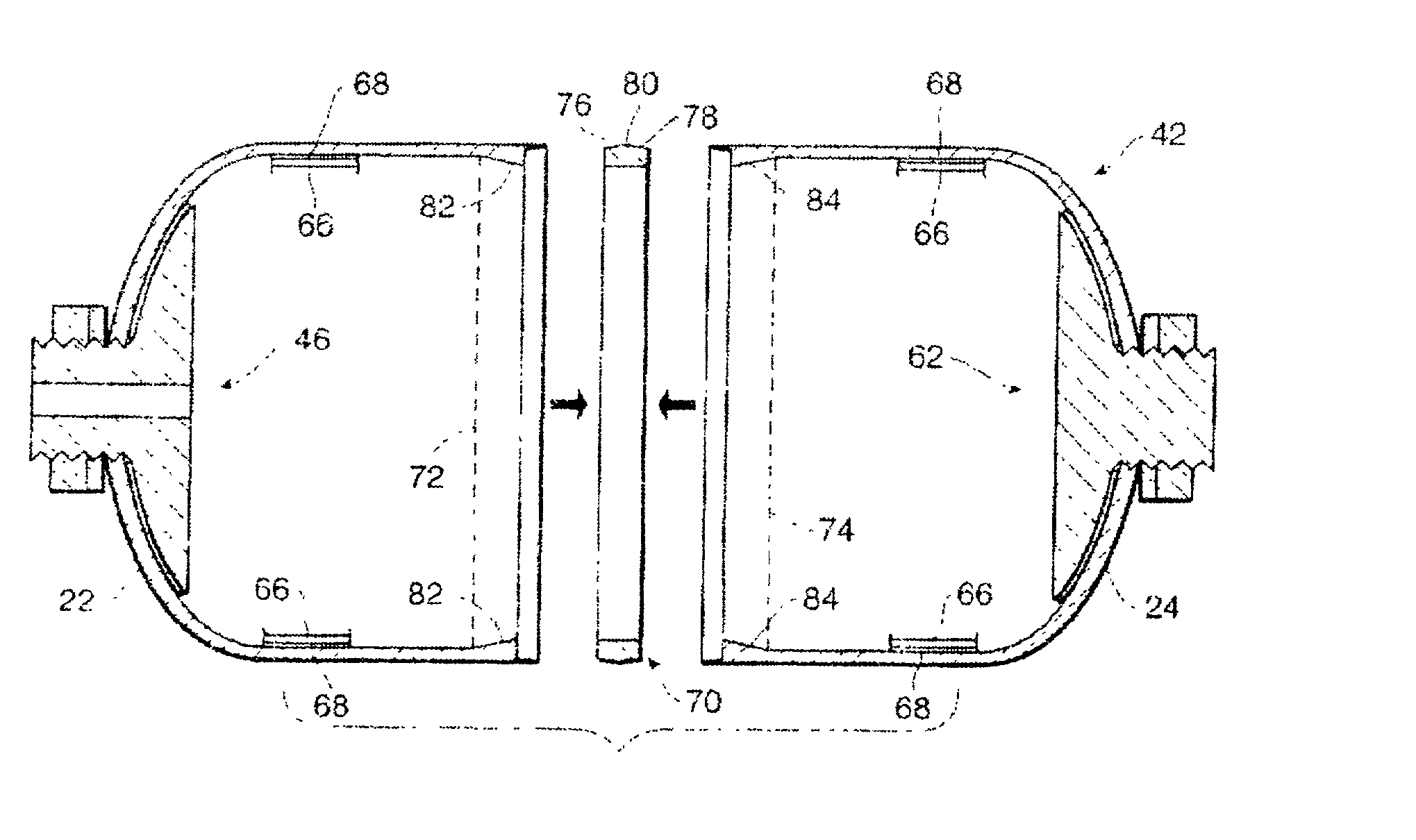

Cryogenic storage system

ActiveUS7278278B2Improve temperature stabilityNon-uniform temperatureVessel mounting detailsDomestic cooling apparatusThermal insulationEngineering

Owner:21ST CENTURY MEDICINE

Low weight high performance composite vessel and method of making same

InactiveUS20040026431A1Light weightSignificant portionVessel mounting detailsVessel manufacturingMechanical engineeringComposite material

Owner:KAISER COMPOSITEK

Self-contained mobile fueling station

A mobile self-contained self-powered station having a plurality of vessels delivers a pressurized fluid to a receiving tank (e.g., a fuel tank of a hydrogen-powered vehicle) without using mechanical compression, external electric power, or other external utilities. The station includes first and second vessels, a conduit in fluid communication with the receiving tank and each of the first and second vessels, means for transferring at least a portion of a quantity of the pressurized fluid from the first vessel to the receiving tank, means for measuring continuously a pressure differential between the increasing pressure in the receiving tank and the decreasing pressure in the first vessel, means for discontinuing the transfer from the first vessel when a predetermined limit value is reached, and means for transferring at least a portion of a quantity of the pressurized fluid from the second vessel to the receiving tank.

Owner:AIR PROD & CHEM INC

Hydrogen tank liner material and hydrogen tank liner

ActiveUS20090203845A1Improve impact resistanceSuitable for useVessel mounting detailsVessel manufacturingAlpha-olefinHydrogen tank

A hydrogen tank liner material comprises a polyamide resin composition which comprises (A) a polyamide resin at 85-40 wt %, (B) a copolyamide at 5-30 wt % and (C) an impact-resistant material at 10-30 wt % with respect to the total weight of the polyamide resin composition. Preferably, the (B) copolyamide is PA6 / 66 and the (C) impact-resistant material is an acid-modified ethylene / α-olefin-based copolymer. A hydrogen tank liner material with excellent gas barrier properties and superior impact resistance even at low temperatures is obtained.

Owner:UBE CORP +1

Methods of reducing the risk of occurrence of pulmonary edema in children in need of treatment with inhaled nitric oxide

ActiveUS8282966B2Reduces occurrenceReduces riskNitrogen compoundsInorganic active ingredientsInhalationNitric oxide

The invention relates methods of reducing the risk or preventing the occurrence of an adverse event (AE) or a serious adverse event (SAE) associated with a medical treatment comprising inhalation of nitric oxide.

Owner:MALLINCKRODT HOSPITAL PRODUCTS IP LTD

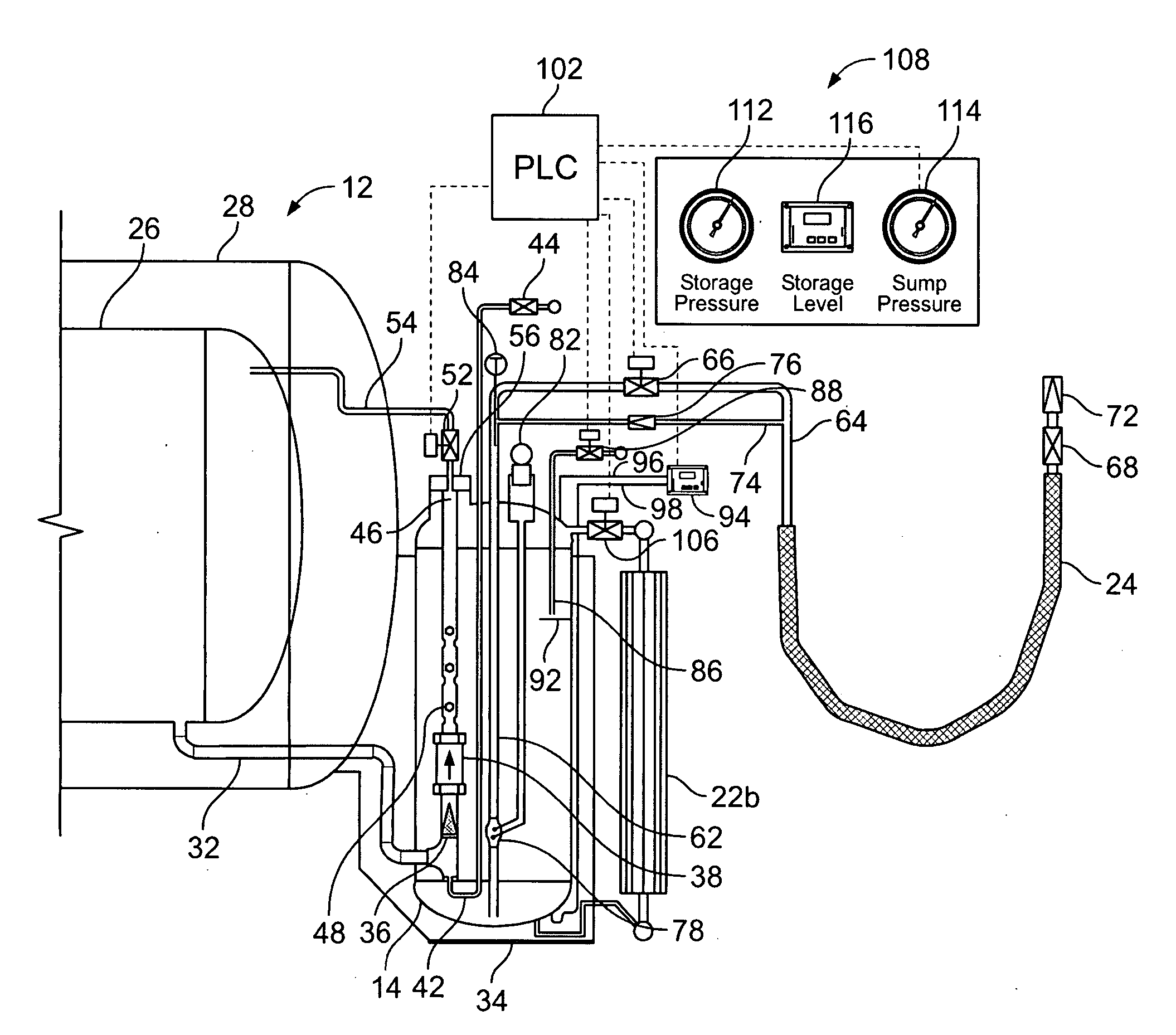

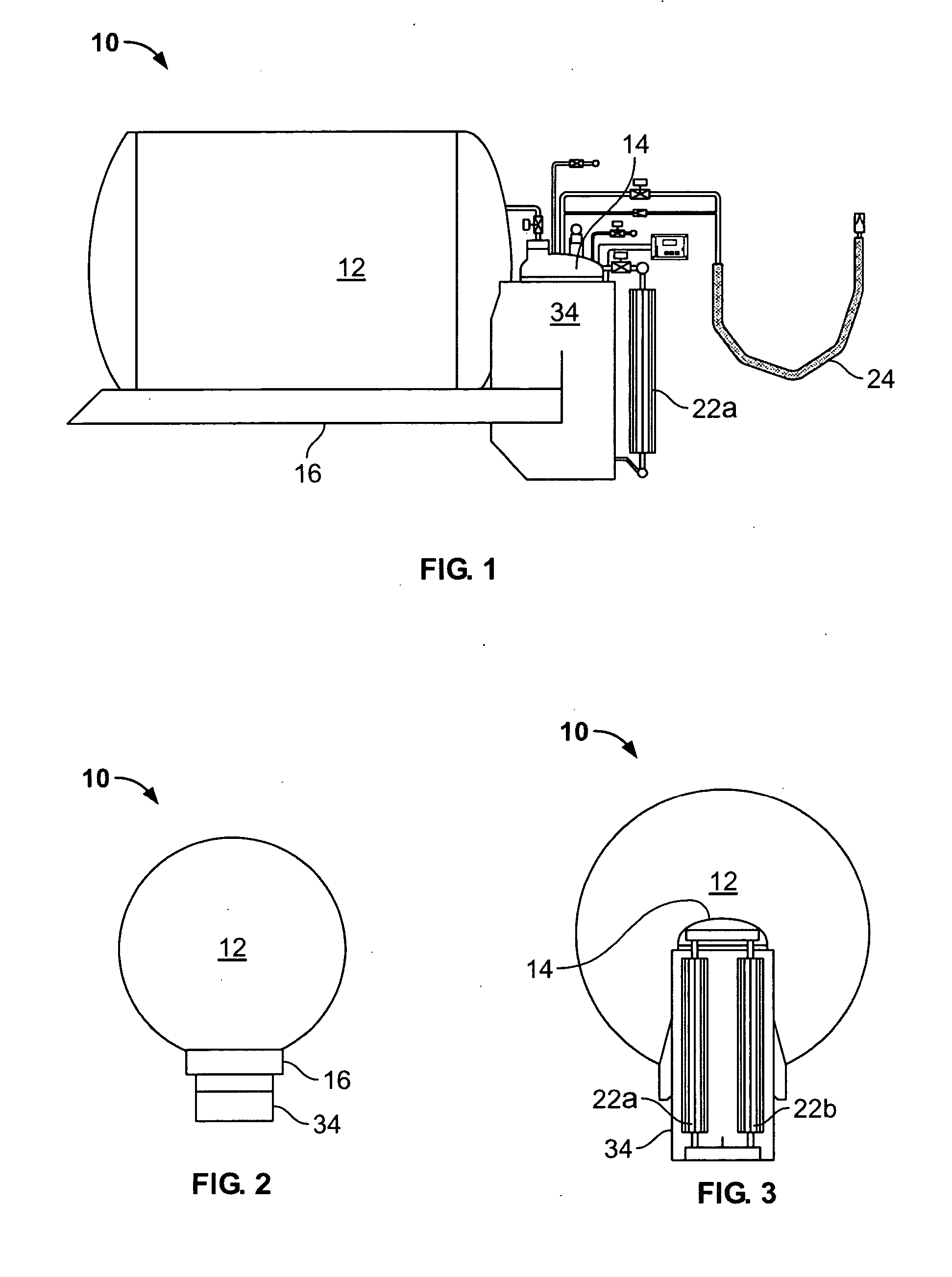

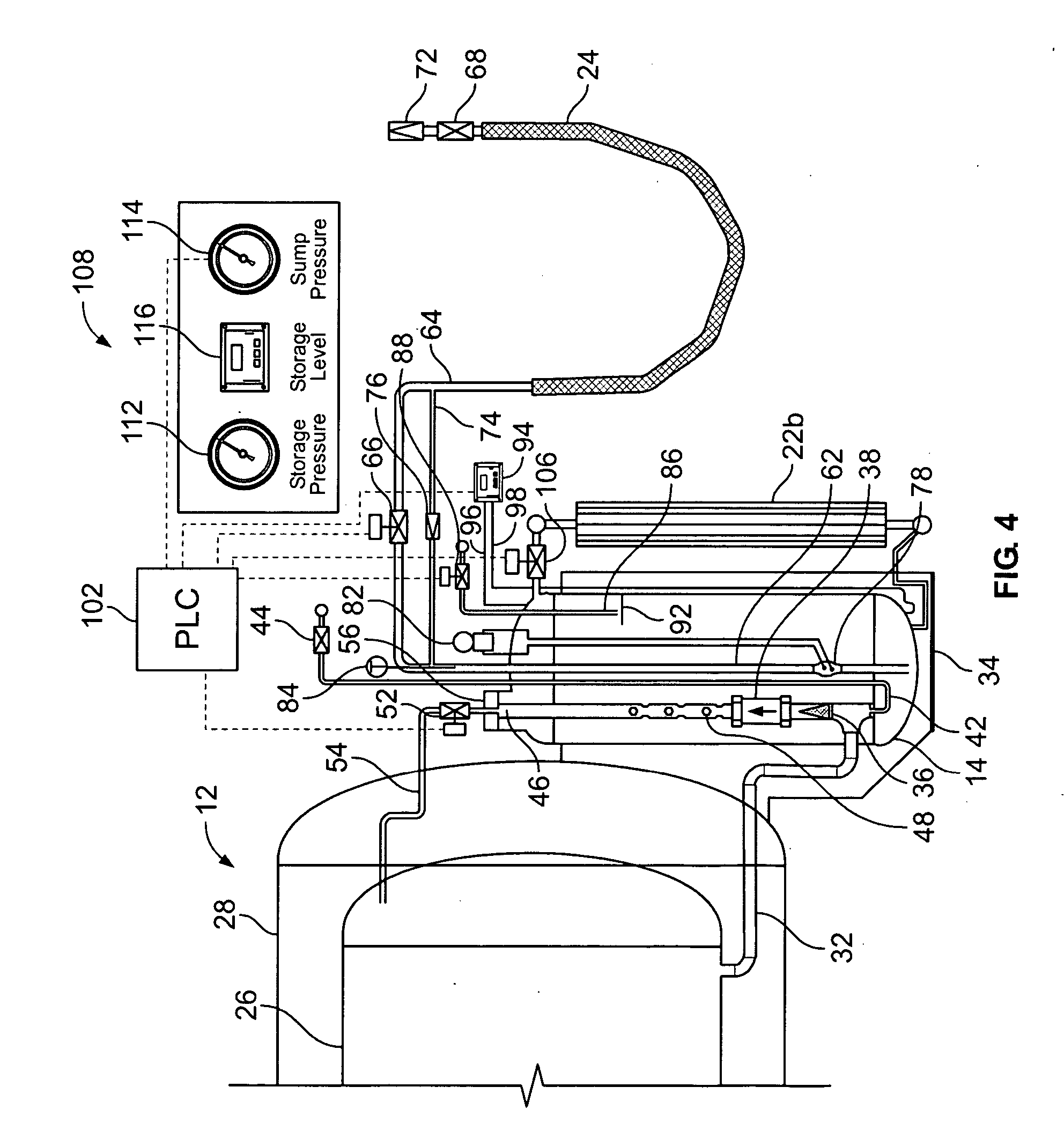

Cryogenic fluid dispensing system

InactiveUS20060218941A1Vessel mounting detailsVessel geometry/arrangement/sizeProcess engineeringHigh pressure

A mobile system for dispensing cryogenic liquid to a use point includes a low pressure bulk tank containing a supply of cryogenic liquid and a high pressure sump in communication with the bulk tank so as to receive cryogenic liquid therefrom. A heat exchanger is in communication with the sump and selectively receives and vaporizes a portion of cryogenic liquid from the sump. The resulting vapor is directed to the sump so as to increase the pressure therein. A pressure builder is in circuit between the sump and the bulk tank. The pressurized cryogenic liquid may be dispensed from the sump via a dispensing hose or directed to the pressure builder so as to pressurize the bulk tank. If the latter is selected, pressurized cryogenic liquid is dispensed from the bulk tank via a second dispensing hose. Operation of the system valves is automated by a controller.

Owner:CHART INDS

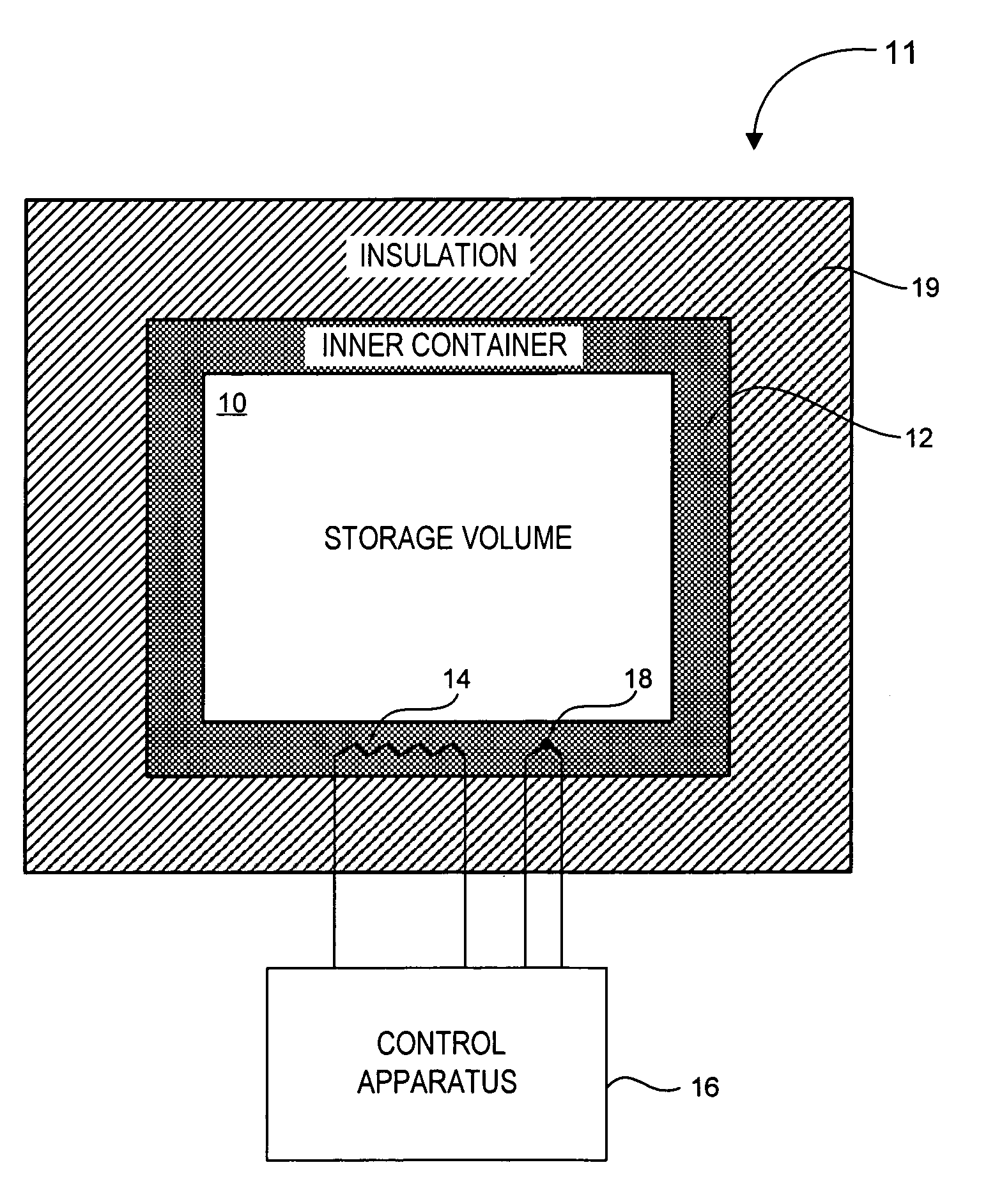

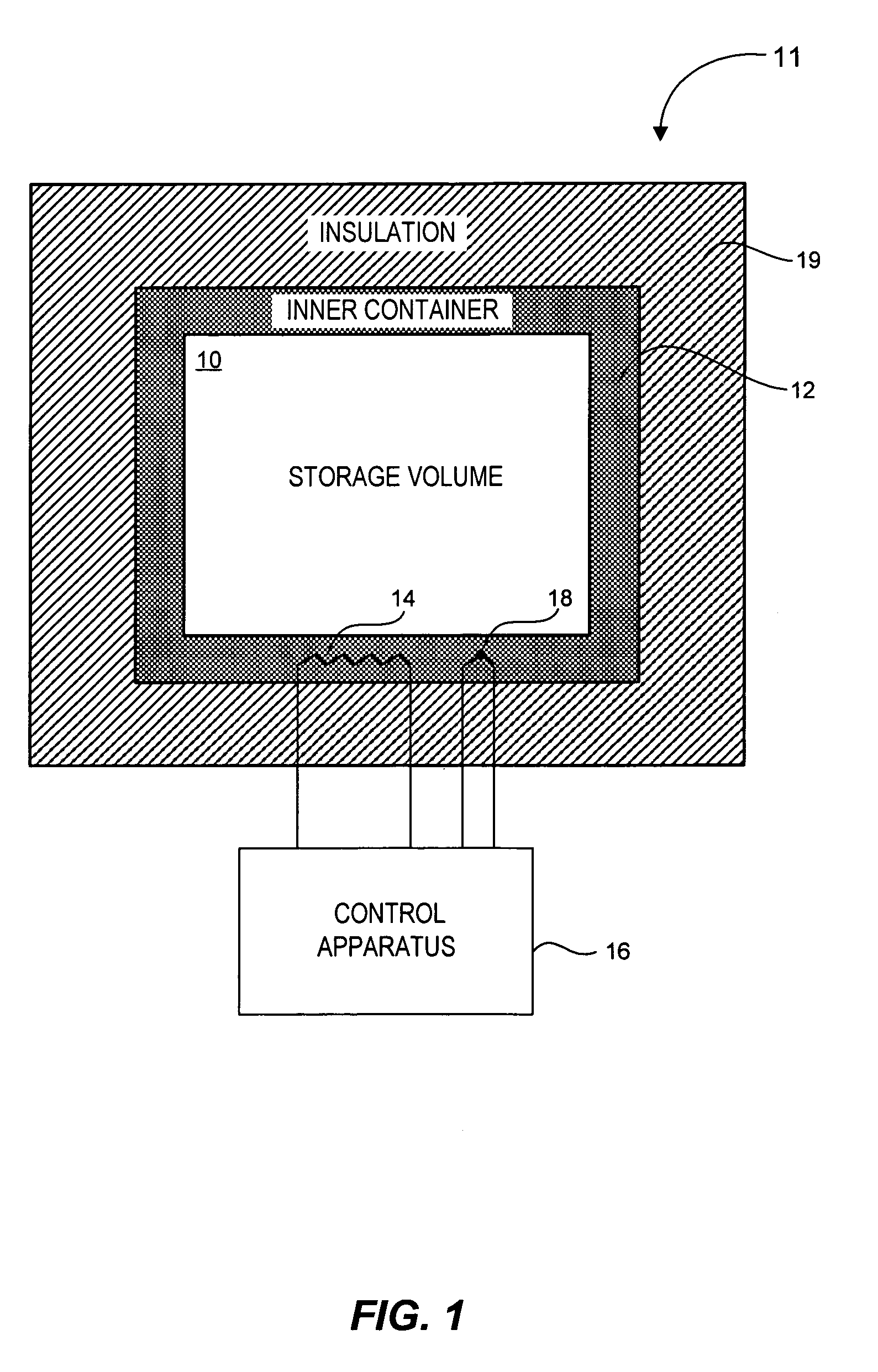

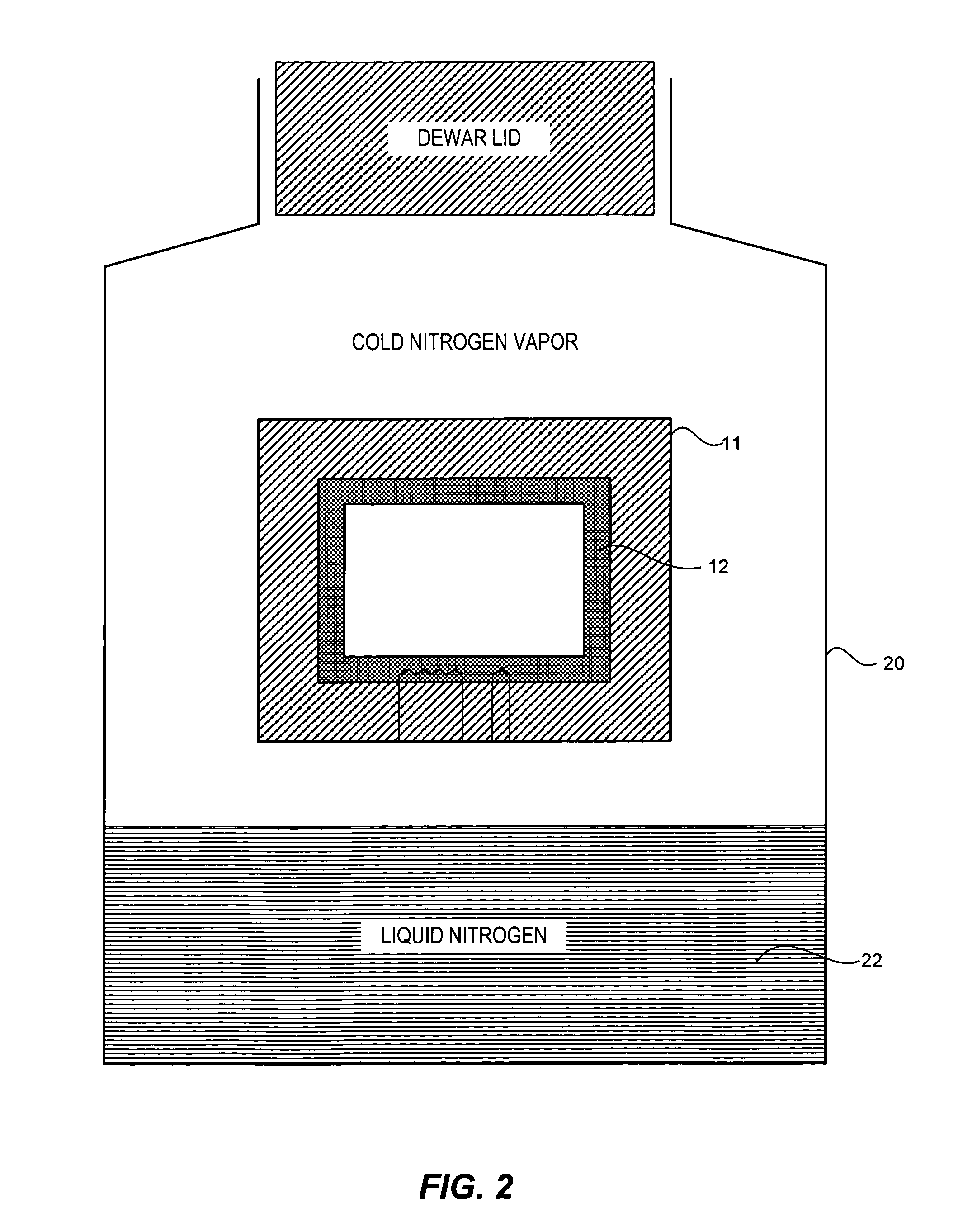

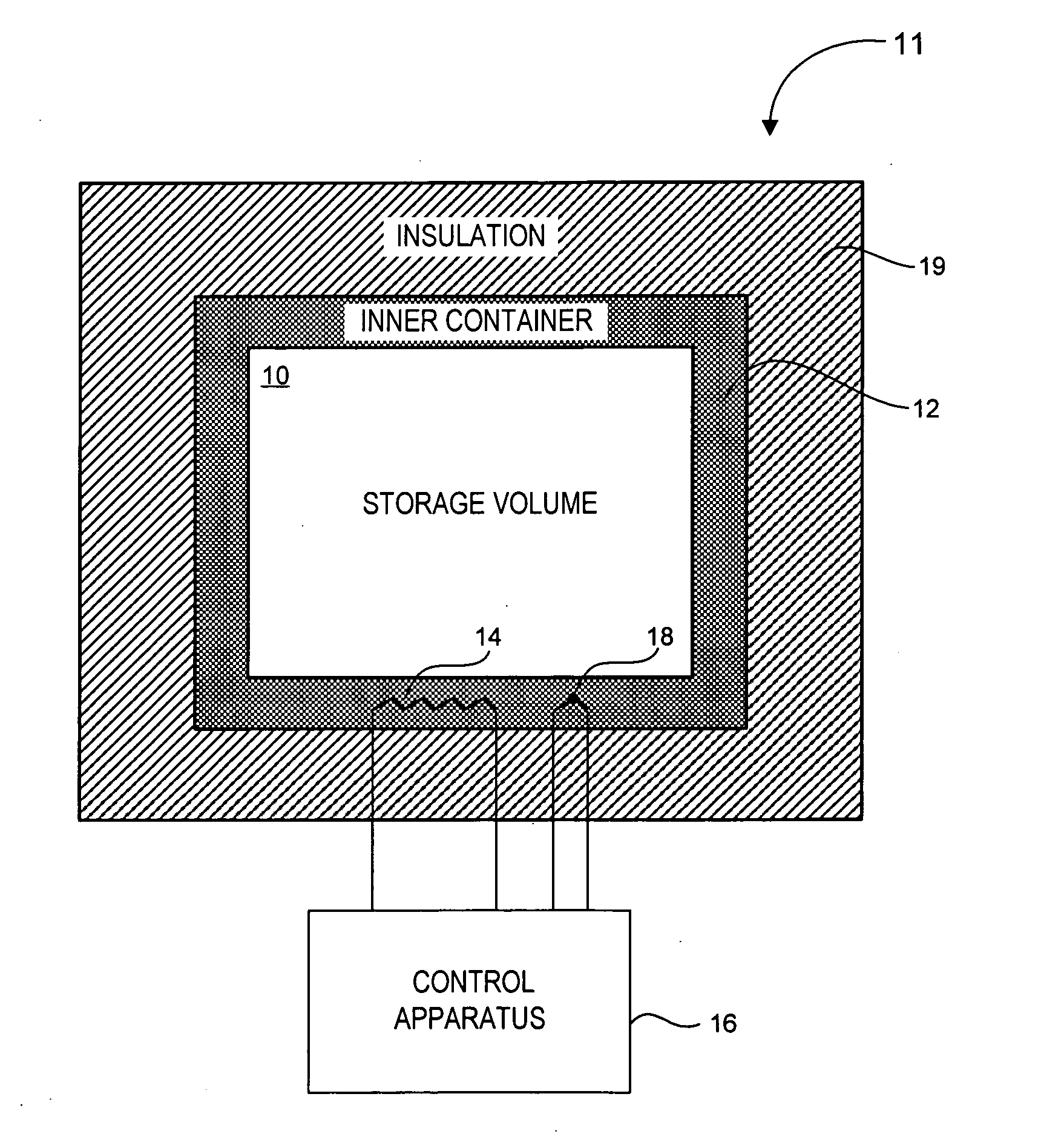

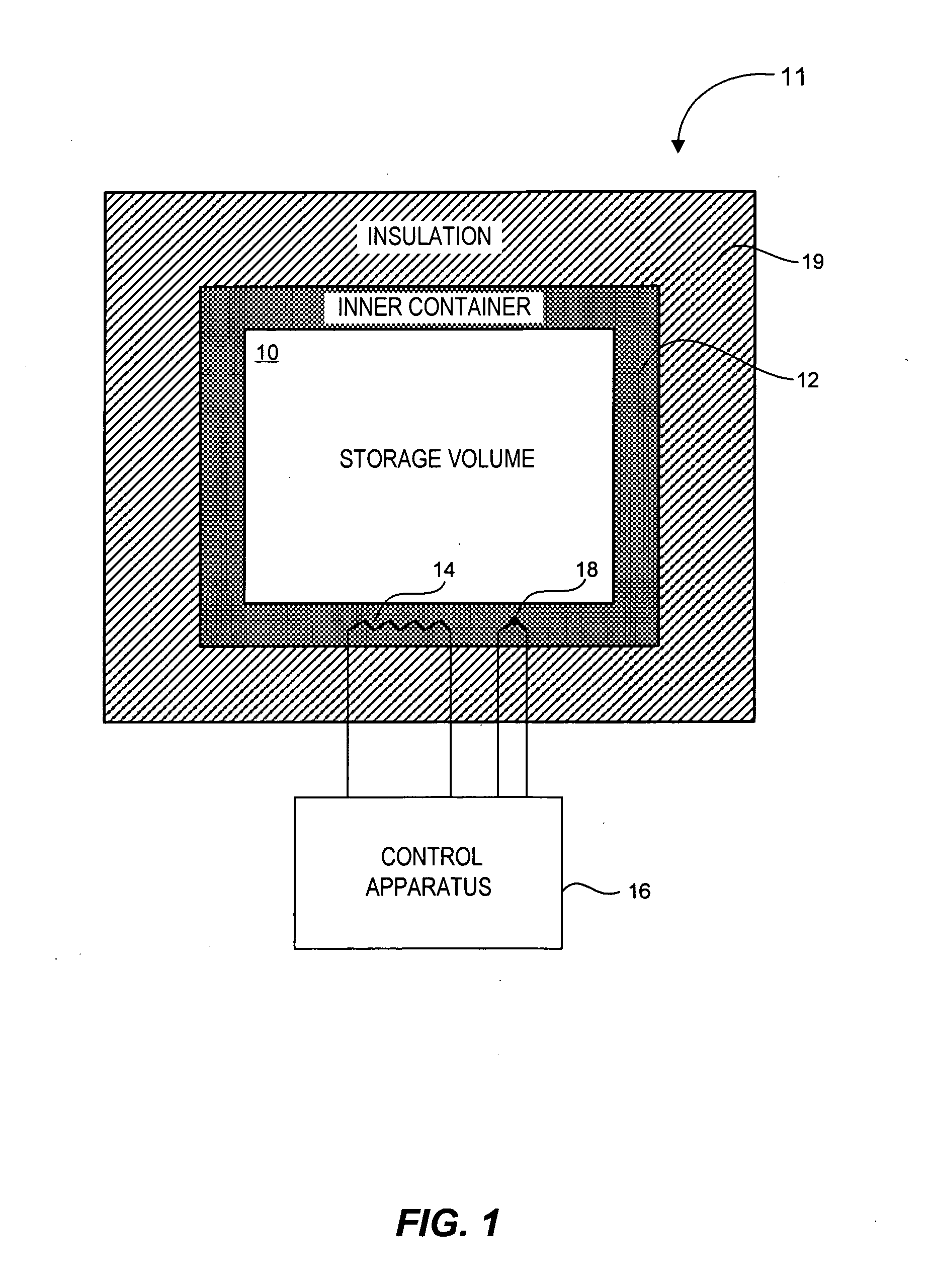

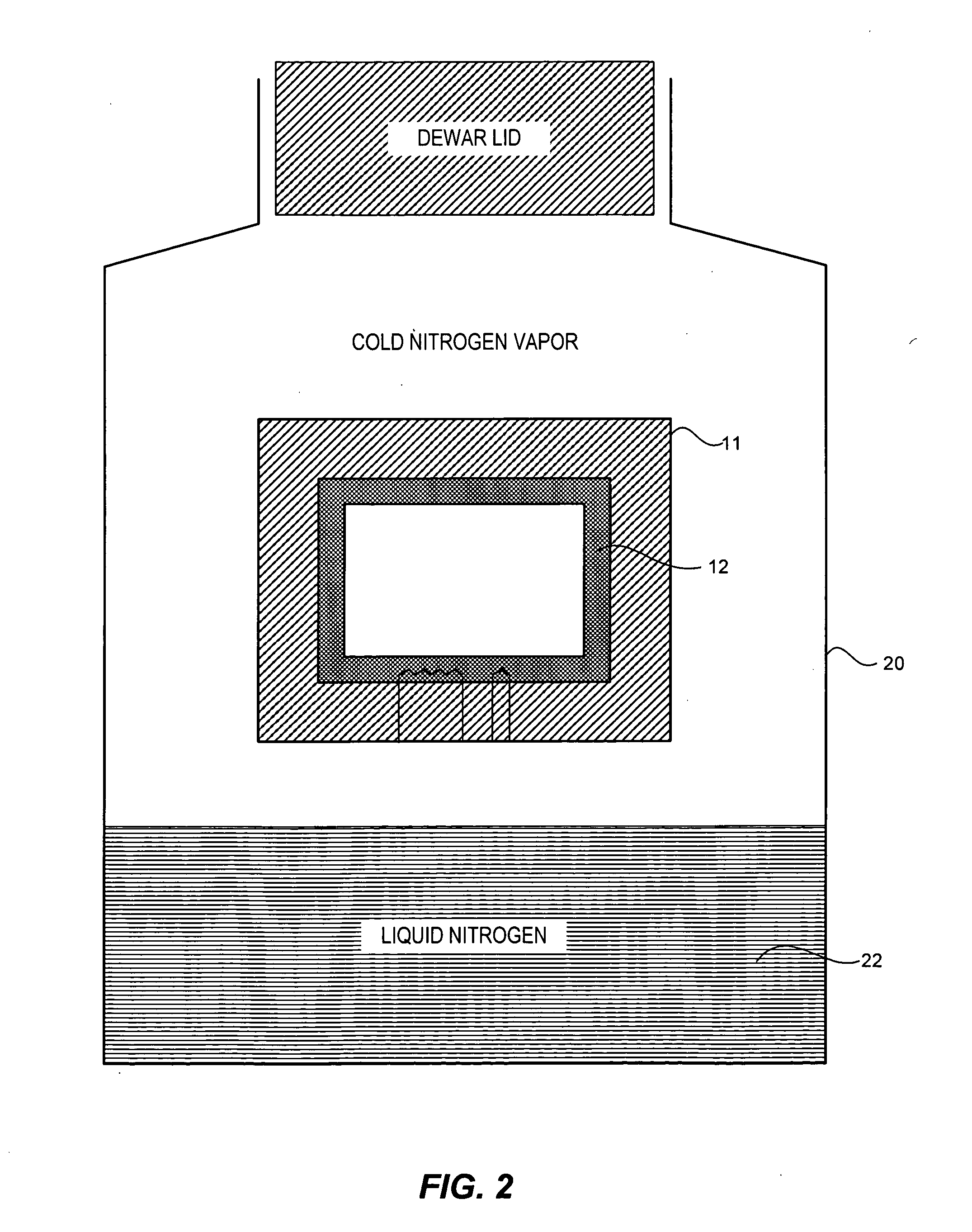

Cryogenic storage system

ActiveUS20050016198A1Improve temperature stabilityNon-uniform temperatureVessel mounting detailsDomestic cooling apparatusThermal insulationEngineering

The present invention provides devices and methods for the cryogenic storage of biological material. Devices of the invention are useful for storing material at a cryogenic temperature. The devices include a temperature chamber defined by a thermally-conductive container and at least one layer of thermal insulation surrounding the thermally-conductive container. Some embodiments utilize one or more heat sources thermally connected to the thermally conductive container. Other embodiments are arranged so that no net flow of heat occurs from the temperature chamber when the temperature chamber is at a set target temperature. Also provided are methods of using the devices.

Owner:21ST CENTURY MEDICINE

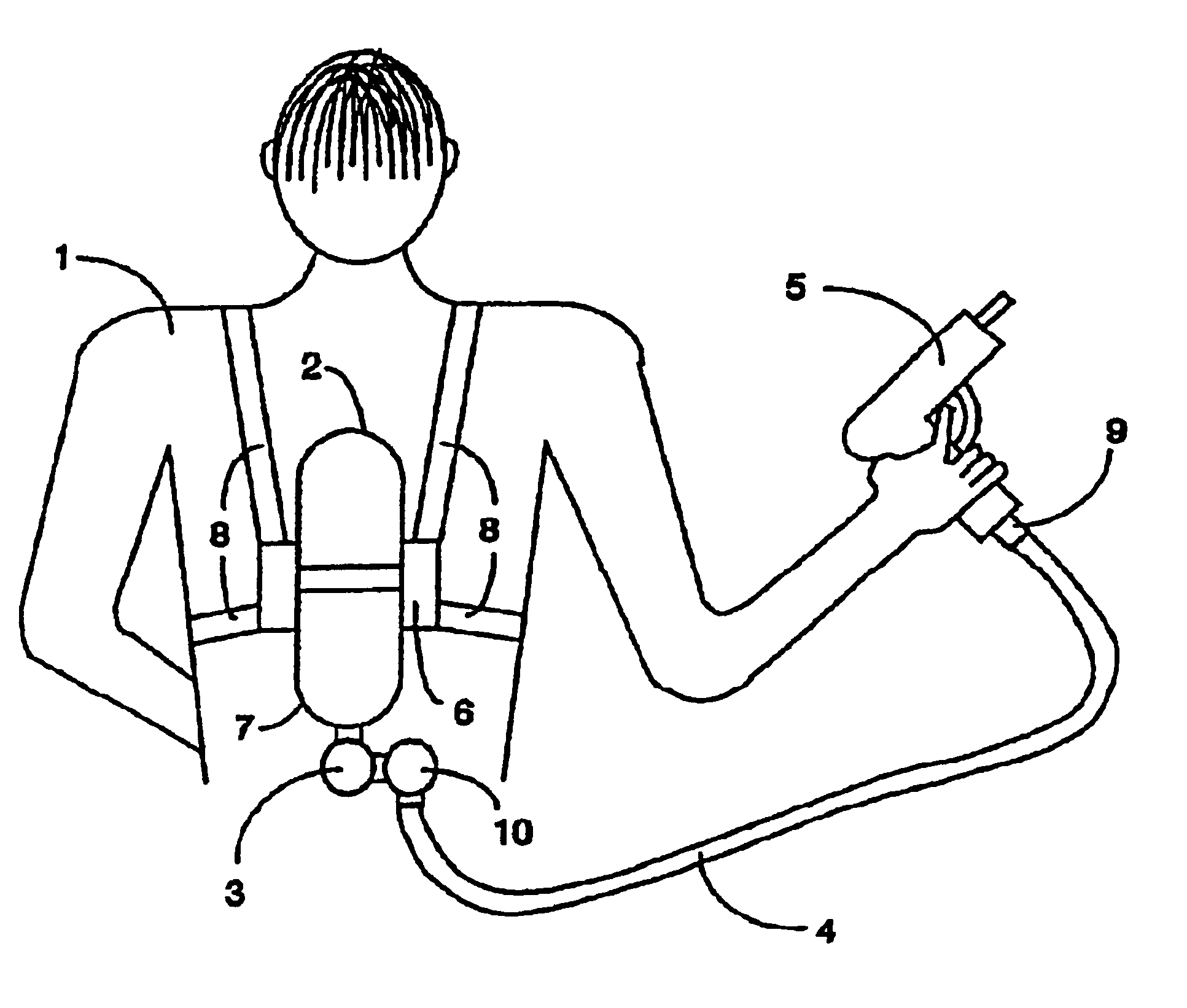

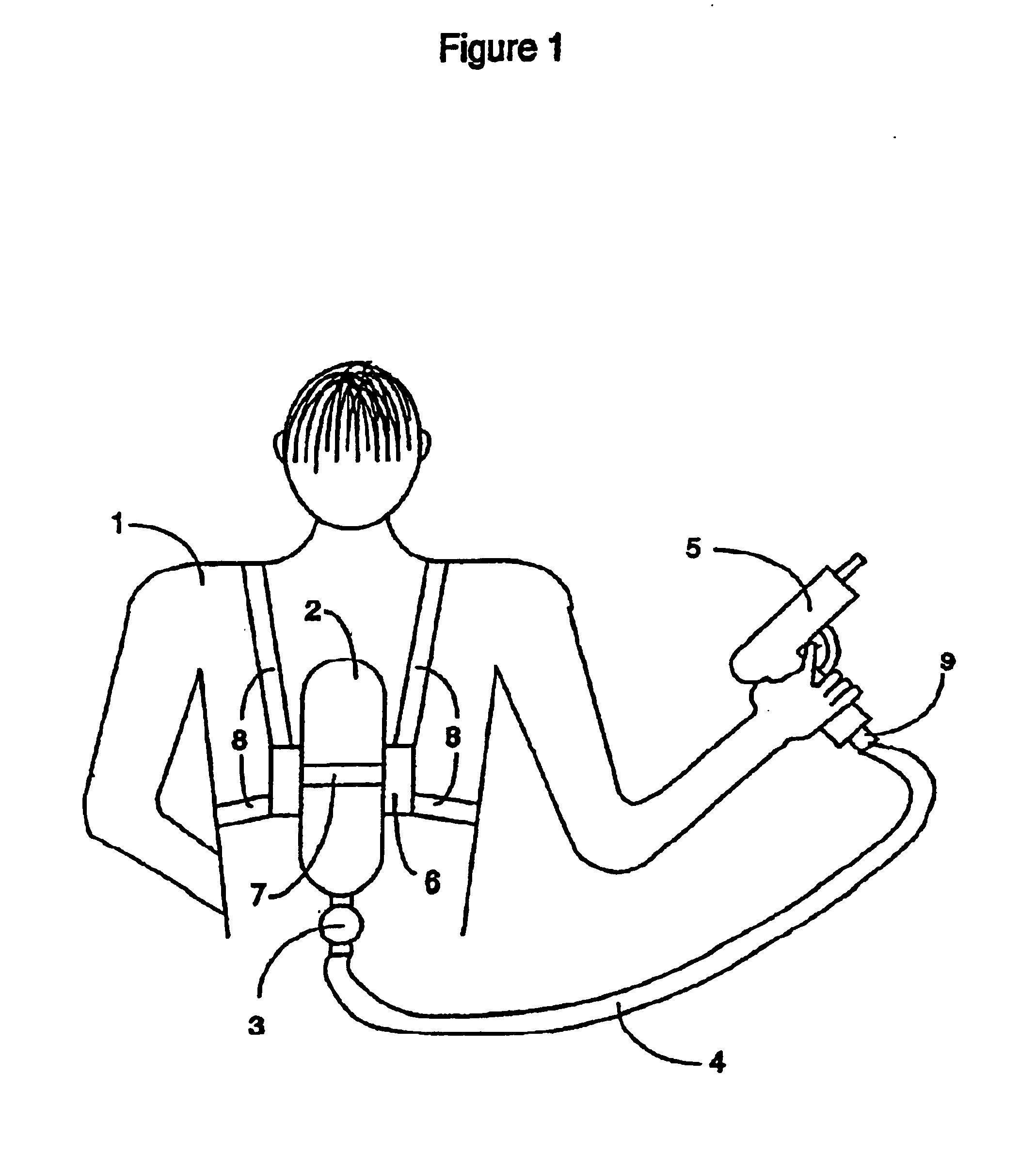

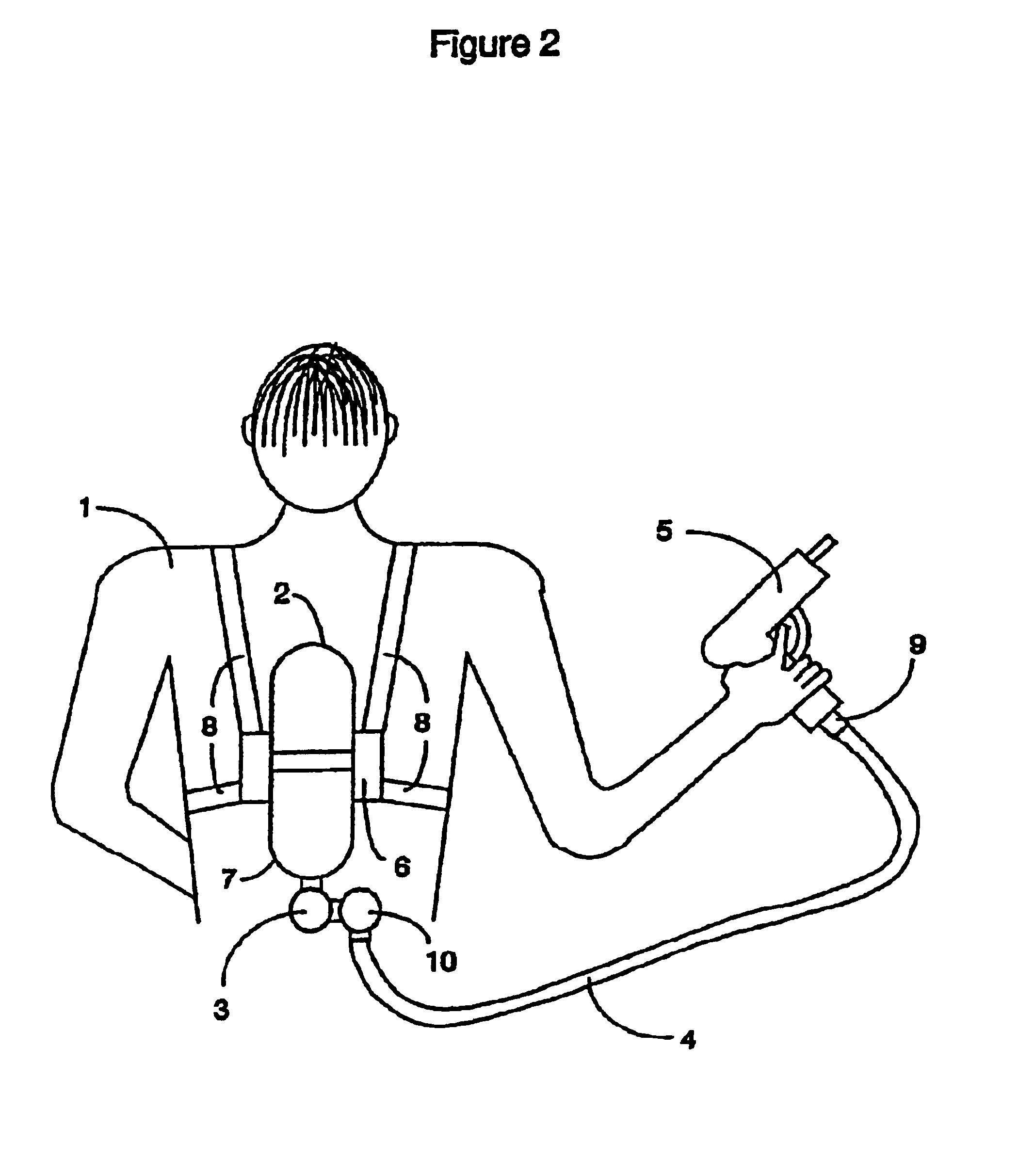

Apparatus and method for using a lightweight portable air/gas power supply

ActiveUS6932128B2Easily and quickly refilledHigh pressure levelTravelling sacksLiquid fillingFiberMulti-valve

A lightweight carbon fiber air / gas supply vessel storing high pressure air / gas. The air / gas supply vessel output is controlled by an adjustable pressure reduction valve which varies output pressure from very high to low pressure levels. An alternative multi-valve system uses a first pressure reduction valve to reduce output pressure from the very high levels in the air / gas supply vessel to an intermediate pressure level, and a second pressure reduction valve that reduces the air / gas pressure from the intermediate level to a fine tunable low pressure level. In both embodiments, the output of the last pressure reduction valve used is connected to a high pressure cable which in turn uses a standard universal fitting which can be coupled to most pneumatically powered equipment. Additional high pressure reservoir vessels can be used to replenish the lightweight air / gas supply vessel when its supply of air / gas is depleted.

Owner:SPEED AIR SYST

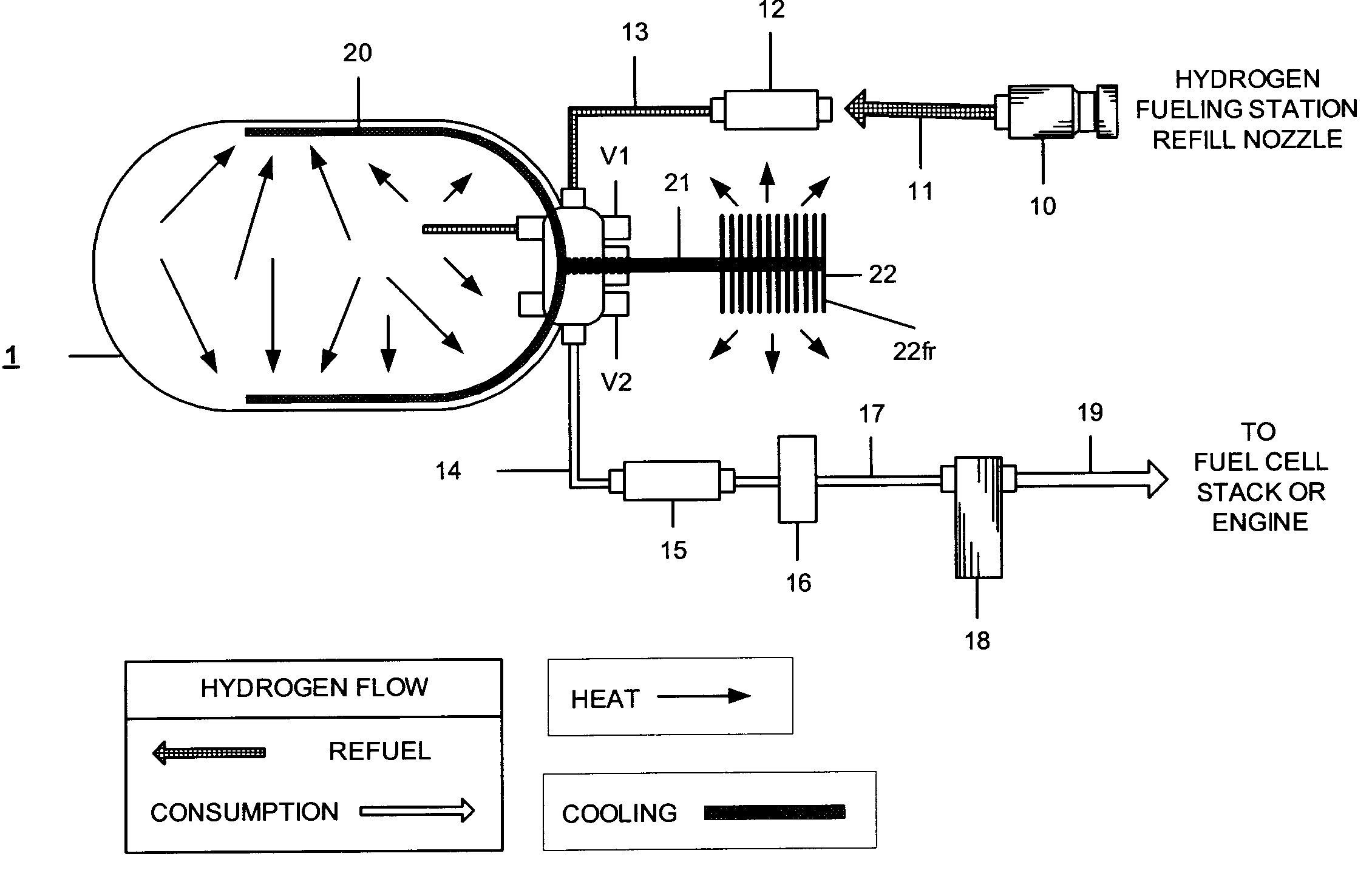

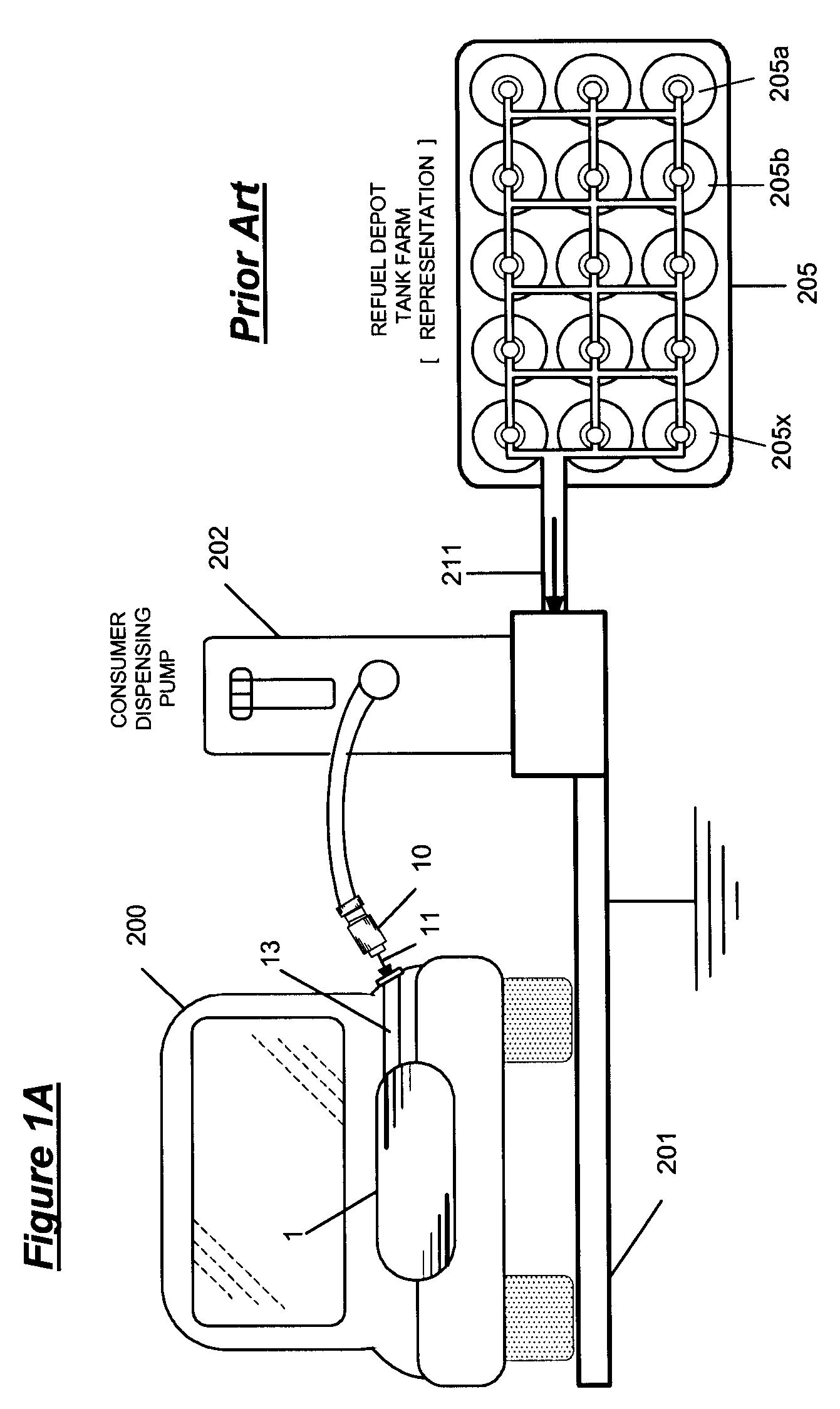

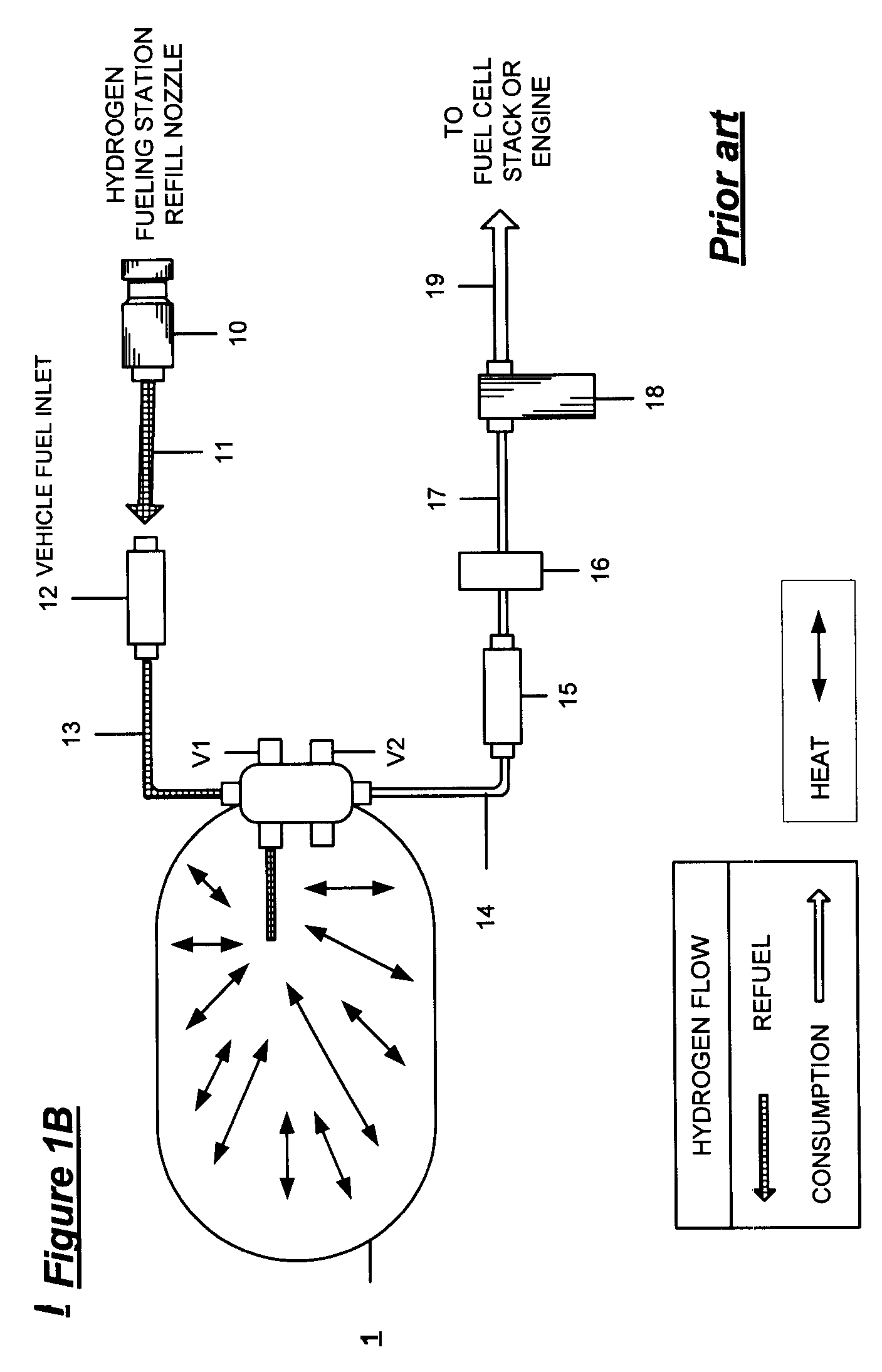

Gas cooling methods for high pressure fuel storage tanks on vehicles powered by compressed natural gas or hydrogen

ActiveUS7377294B2Improve refueling efficiencyIncrease efficiency and refueling capacityGlovesGas handling applicationsThermal energyCompressed natural gas

At a high pressure refuel depot that dispenses high pressure hydrogen or compressed natural gas to vehicles, the thermal energy (heat) generated by the high flow rate of the high pressure refueling gas is evacuated from the on board fuel tank[s] of vehicles eliminating the need for refueling pre treatments such as a slow fill, secondary precooling, and pressure overfill otherwise used to achieve a full vehicle tank refill. In an example, a high pressure fuel depot refilling line is operatively interconnected to an on board vehicle tank having a gas flow circuit wherein the refuel gas itself is circulated within the on board tank to absorb the compression heat of refueling and then to an external radiator before being released into the tank.

Owner:HONDA MOTOR CO LTD

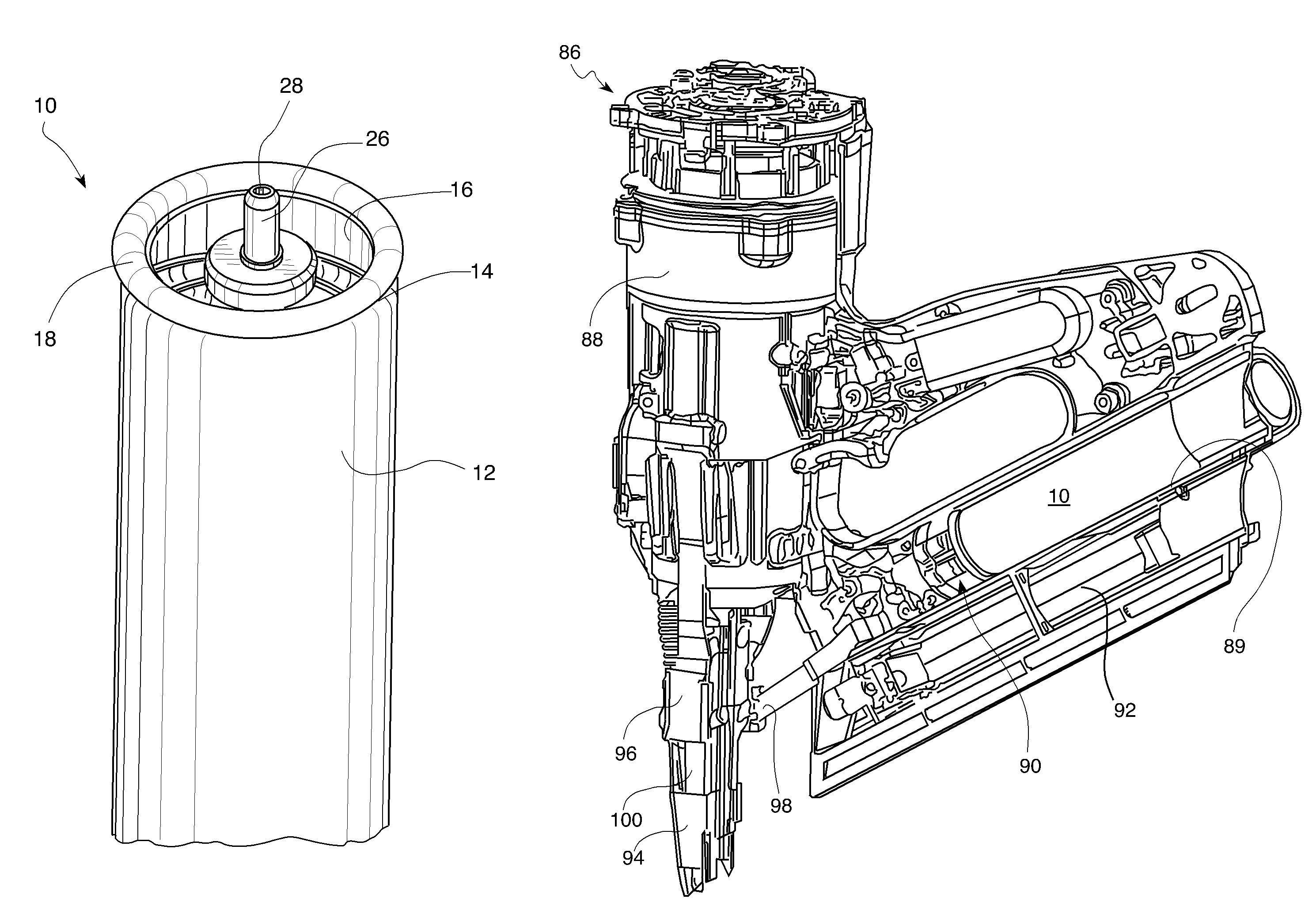

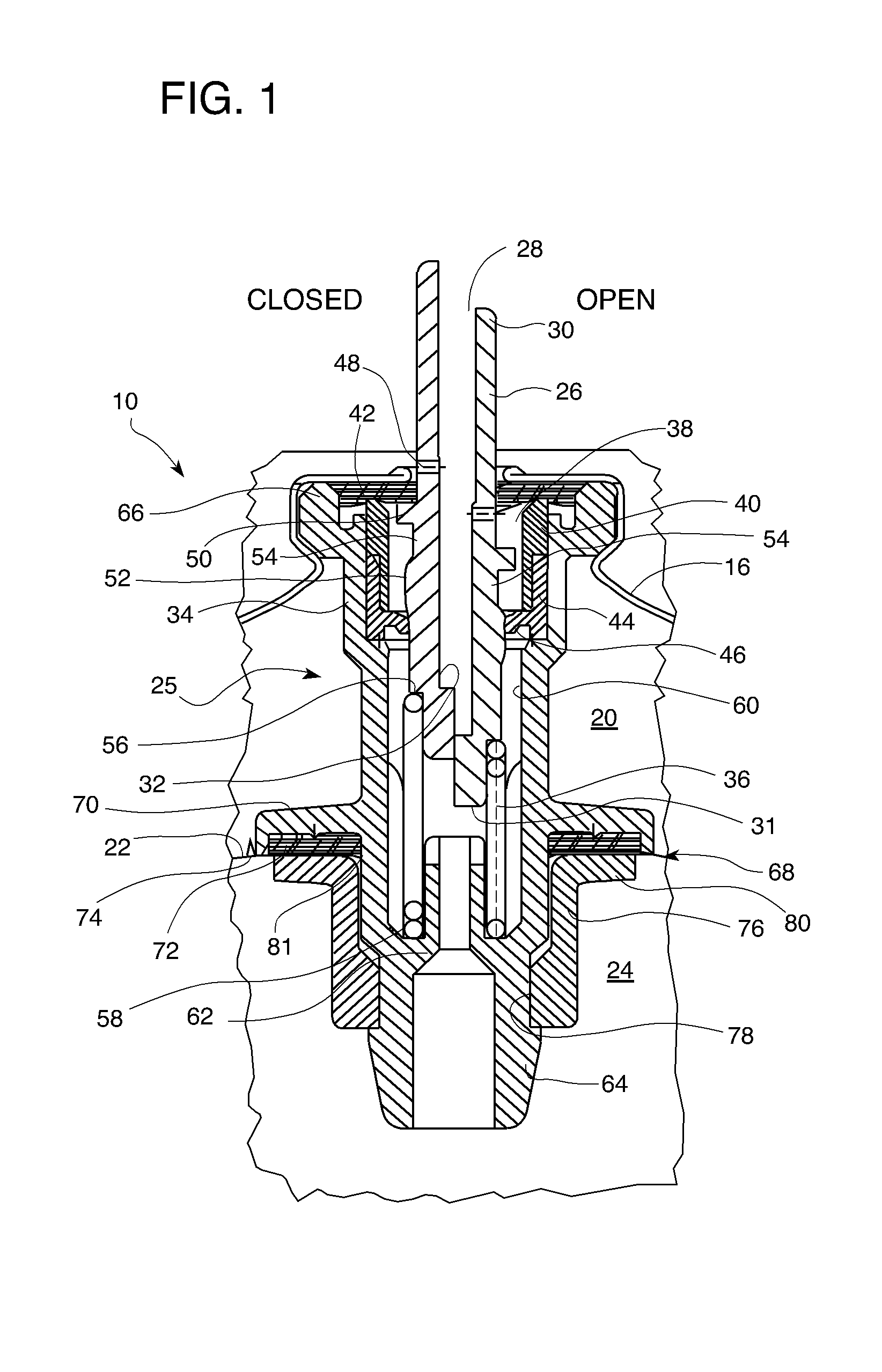

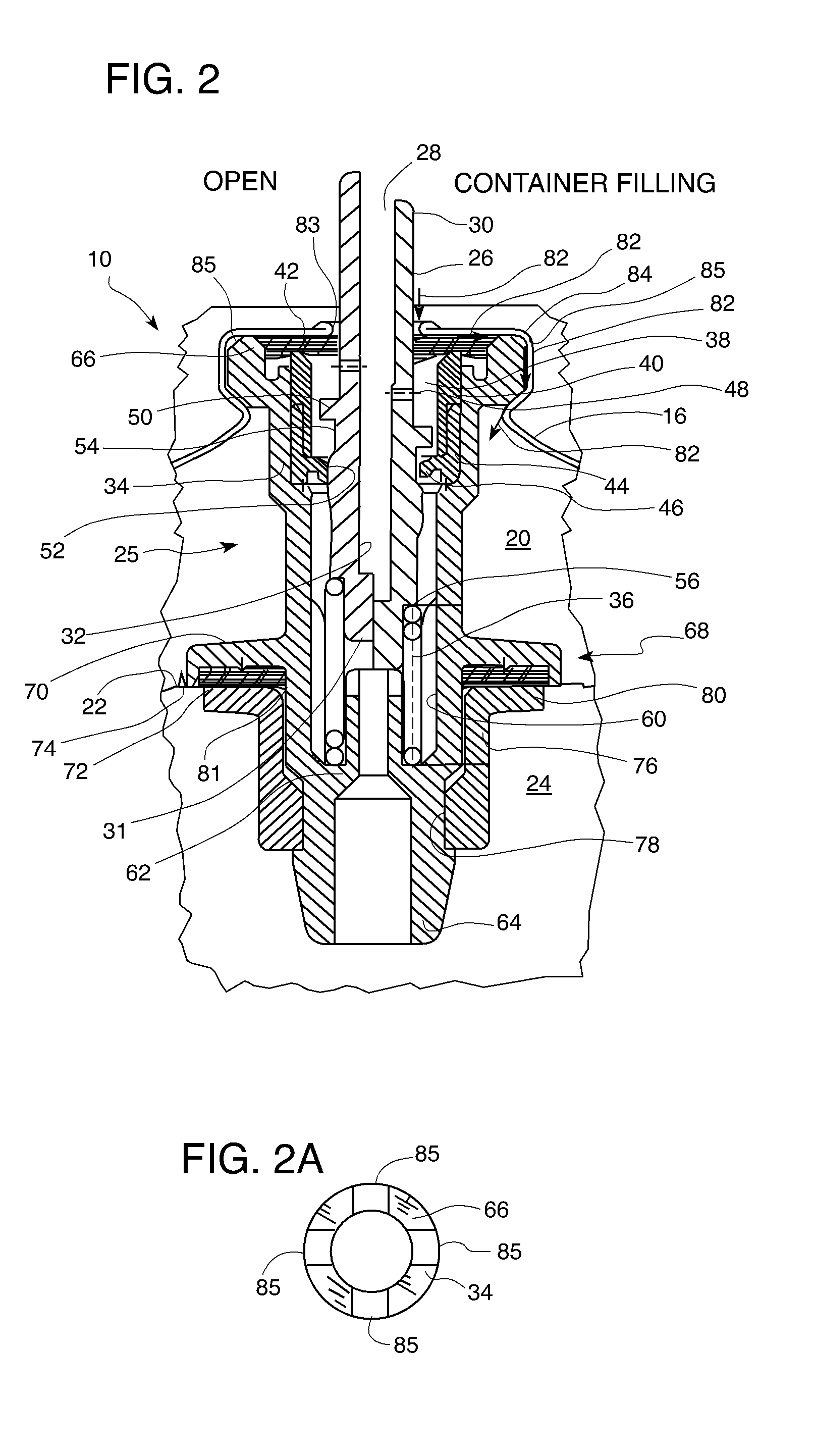

In-can fuel cell metering valve

ActiveUS7392922B2Extended service lifeReduce system costStapling toolsContainer filling methodsFuel cellsCombustion

A fuel cell for use with a combustion tool for delivery of a predetermined amount of fuel with each stem actuation is provided and includes a housing defining an open end enclosed by a closure. A main valve stem has an outlet, disposed in operational relationship to the open end and reciprocating relative to the housing at least between a closed position wherein the stem is relatively extended, and an open position wherein the stem is relatively retracted. A fuel metering valve is located within the housing, associated with the main valve stem, including a fuel metering chamber disposed in close proximity to the closure and configured so that when the stem is in the open position, only a measured amount of fuel is dispensed through the outlet. In a preferred embodiment, the fuel cell housing includes a separate fuel container, and the fuel metering valve includes a valve body having a second end opposite the fuel metering chamber located within the container.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com