Patents

Literature

1222results about "Gas purification by liquid washing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

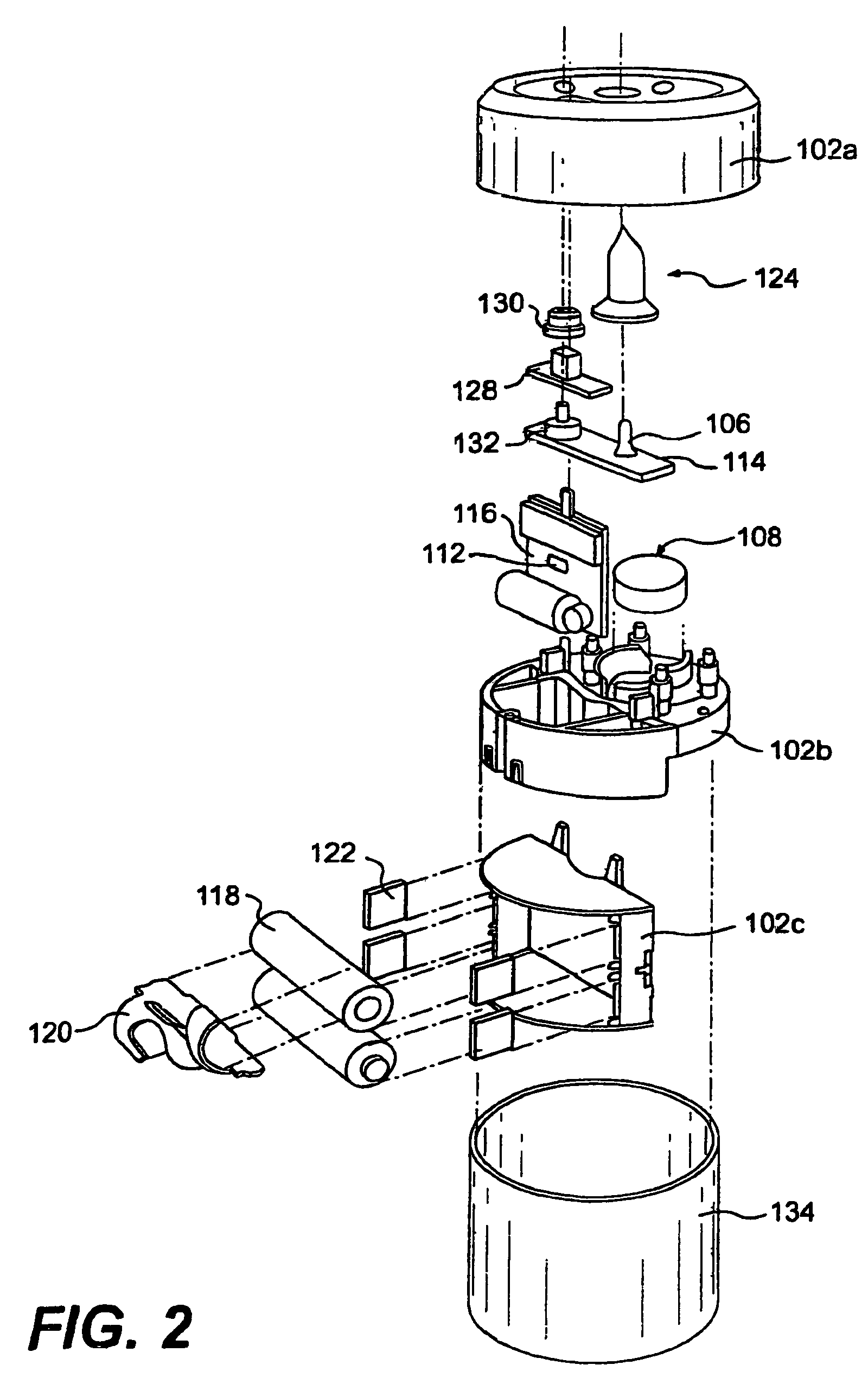

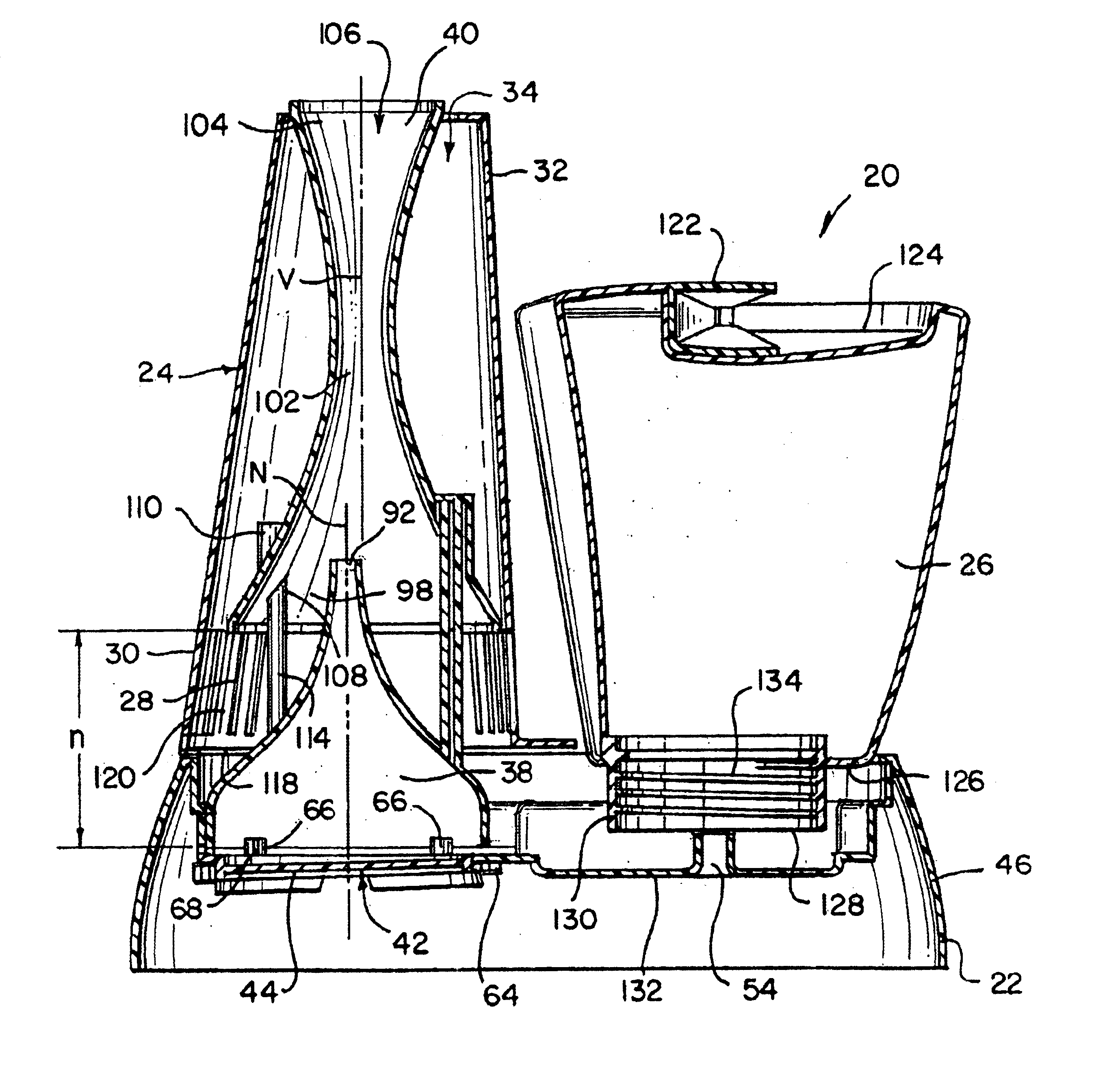

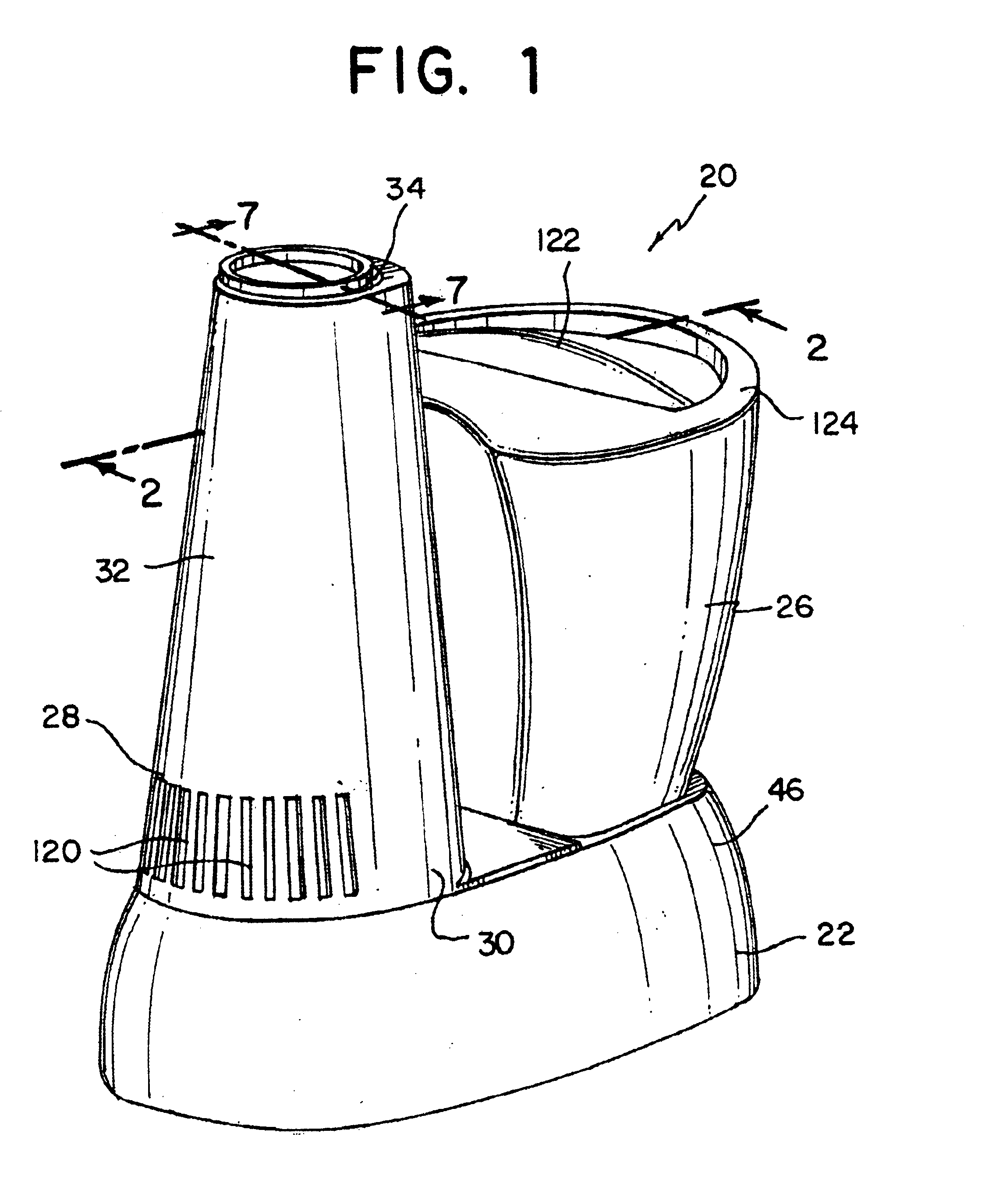

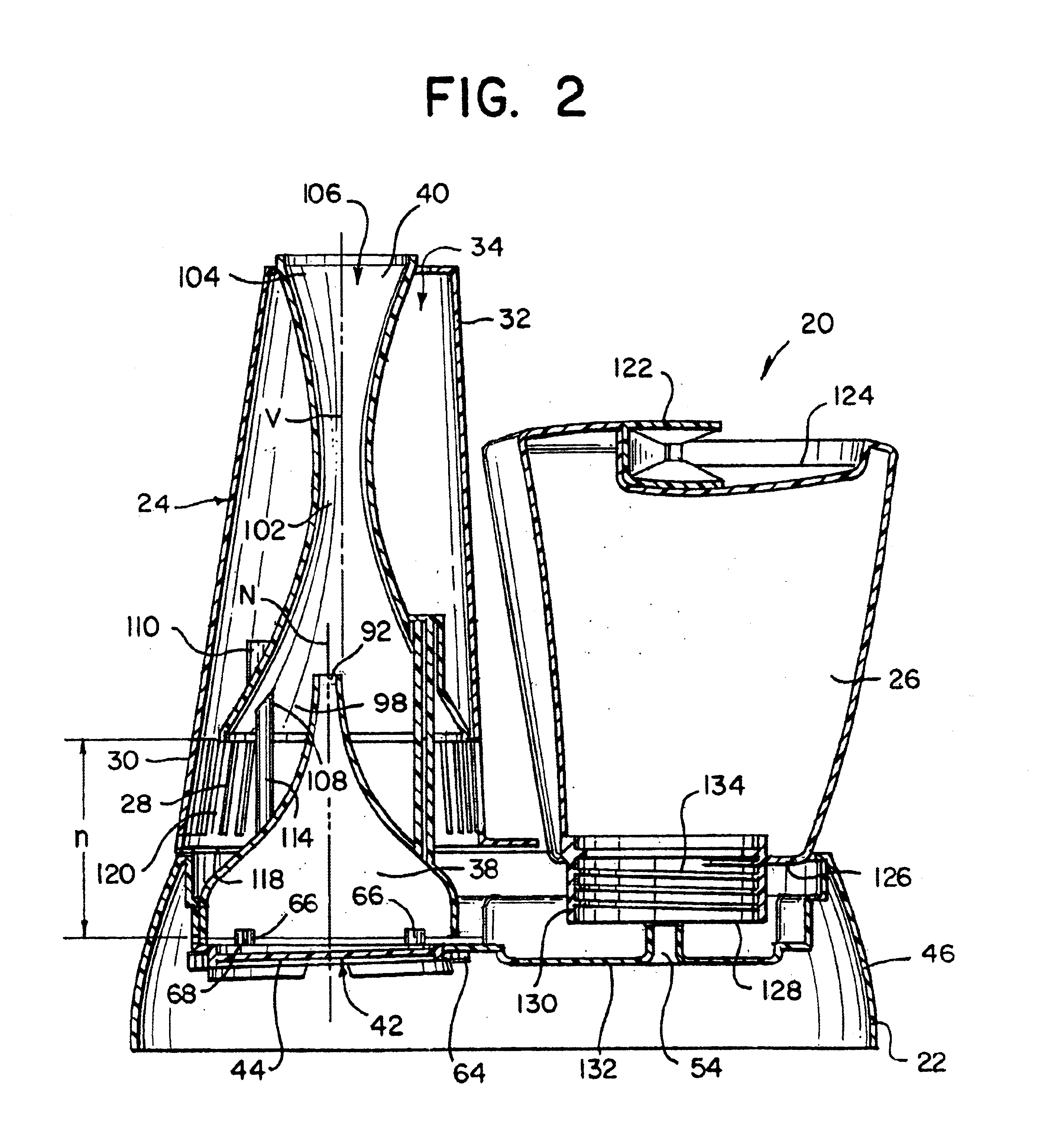

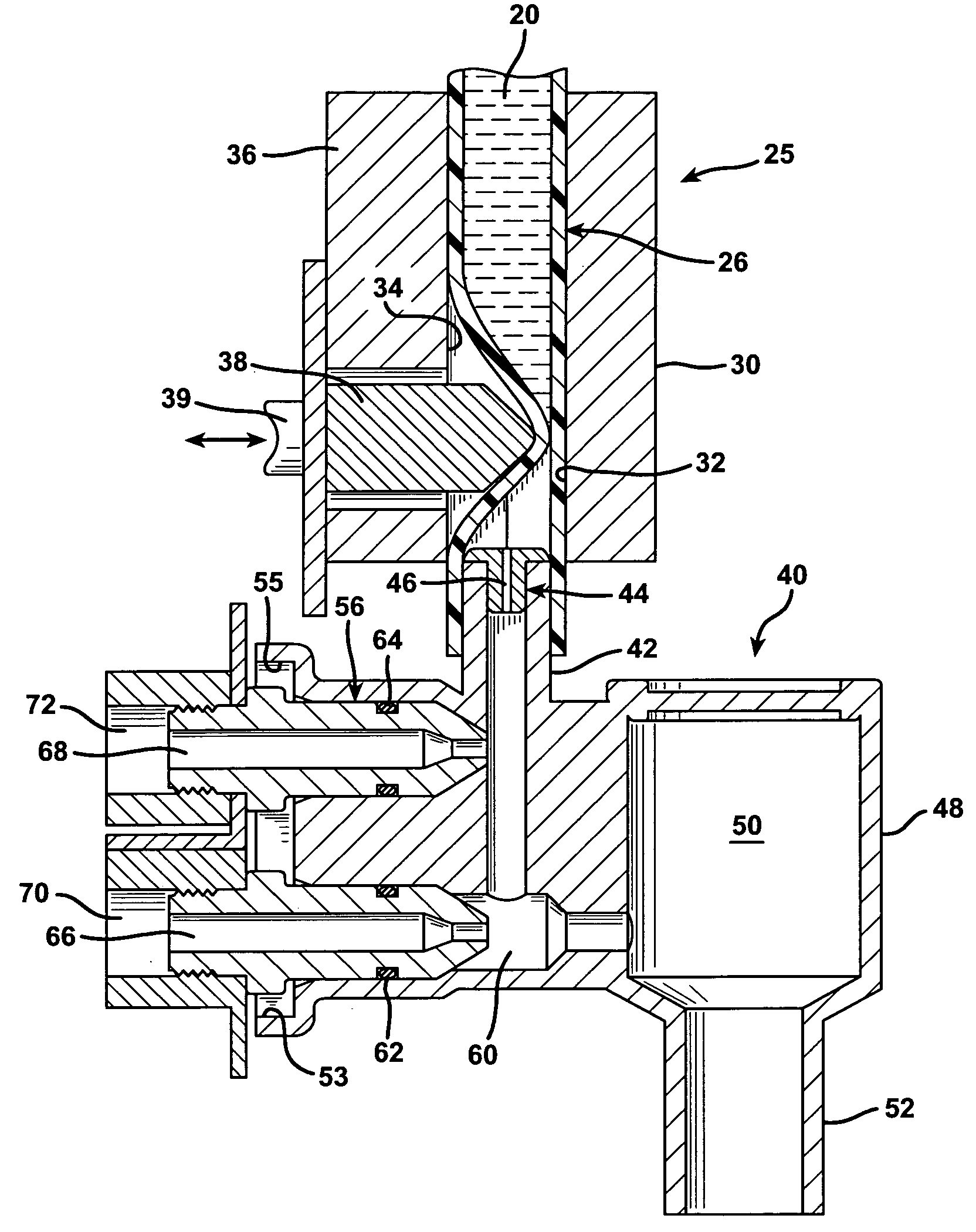

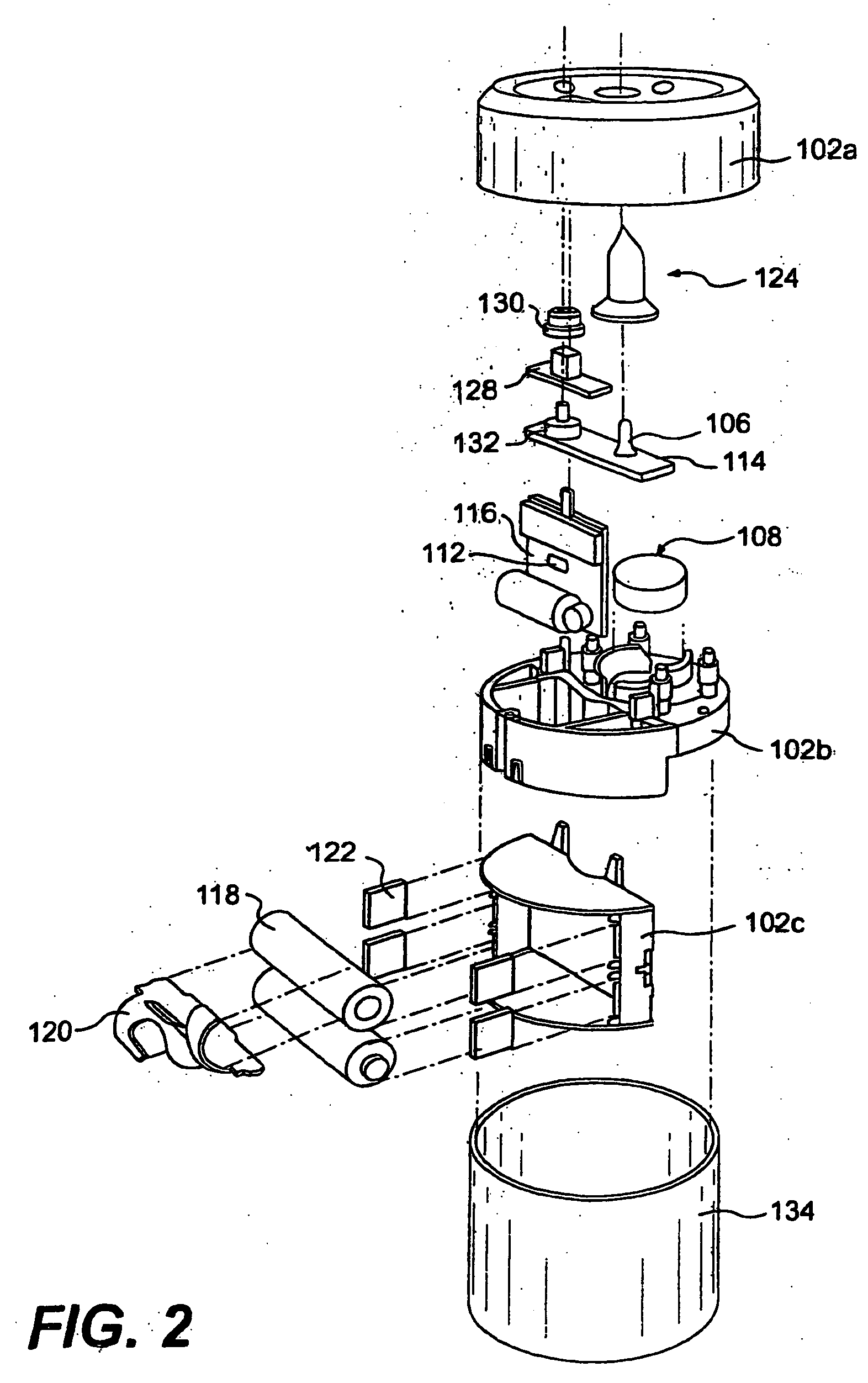

Vaporizer delivery ampoule

InactiveUS6921062B2Increase the areaShorten closing timeDrying using combination processesDrying solid materials with heatSource materialEngineering

A vaporizer delivery system for use in semiconductor manufacturing processes including a plurality of vertically stacked containers for holding a vaporizable source material. Each of the vertically stacked containers includes a plurality of vented protuberances extending into the interior of the each stacked container thereby providing channels for passage of a carrier gas between adjacent vertically stacked containers.

Owner:ENTEGRIS INC

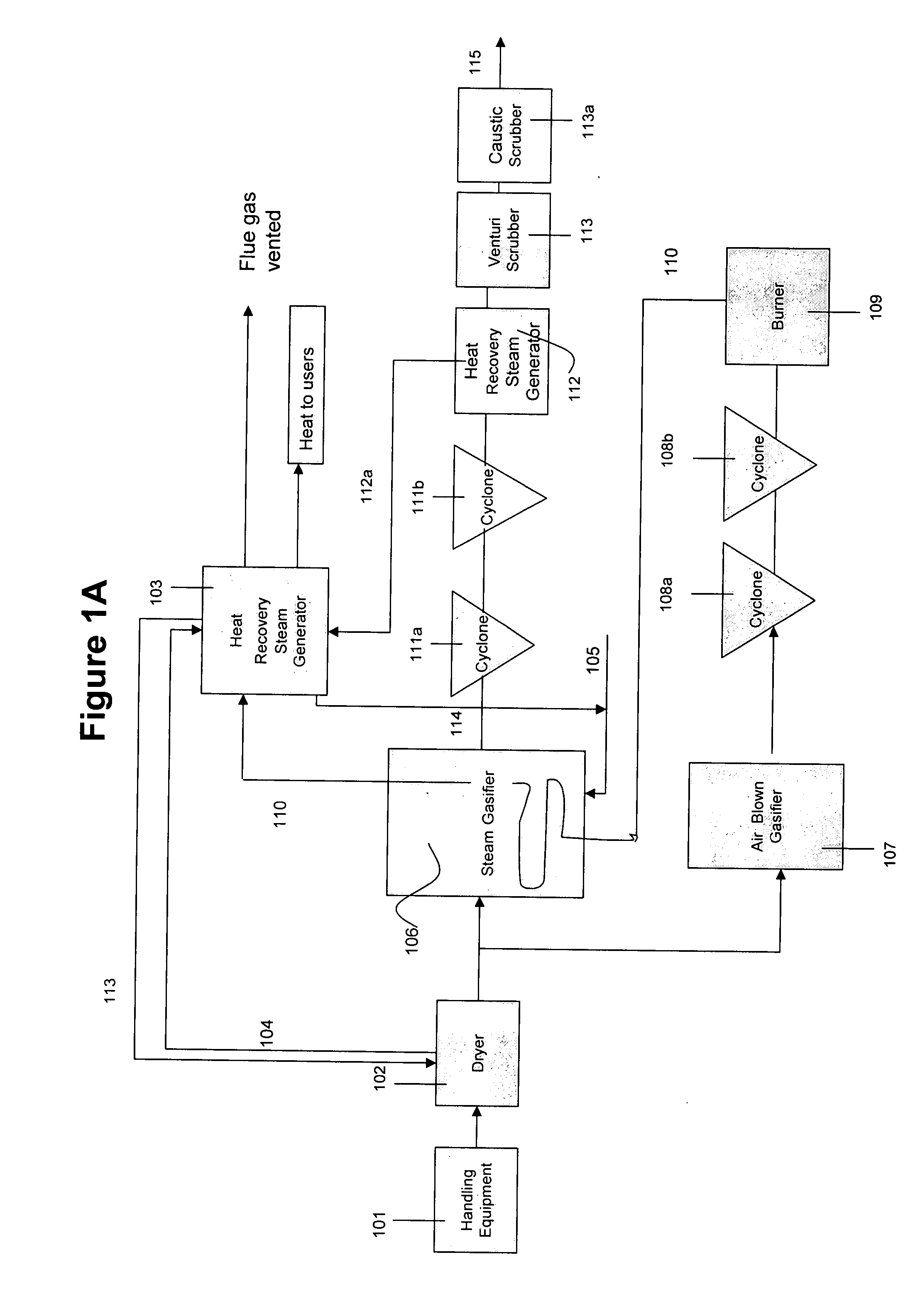

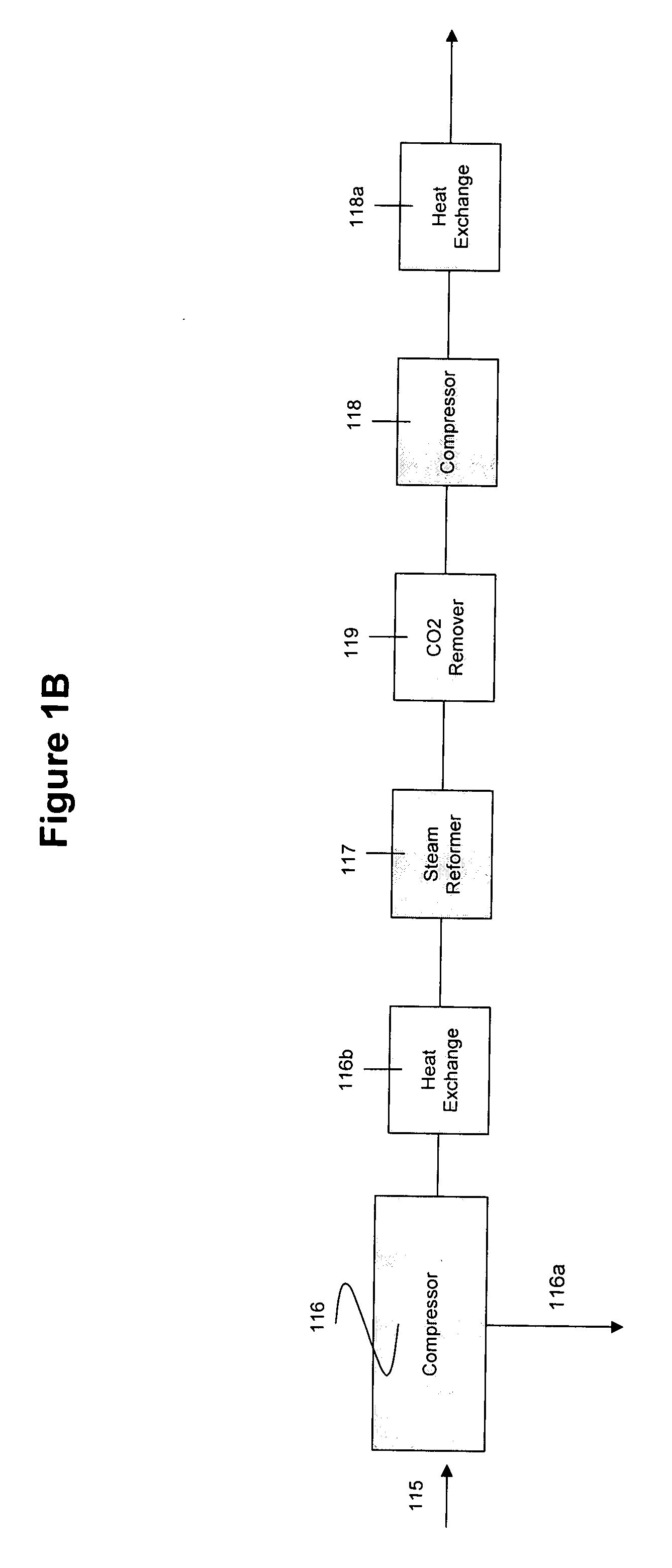

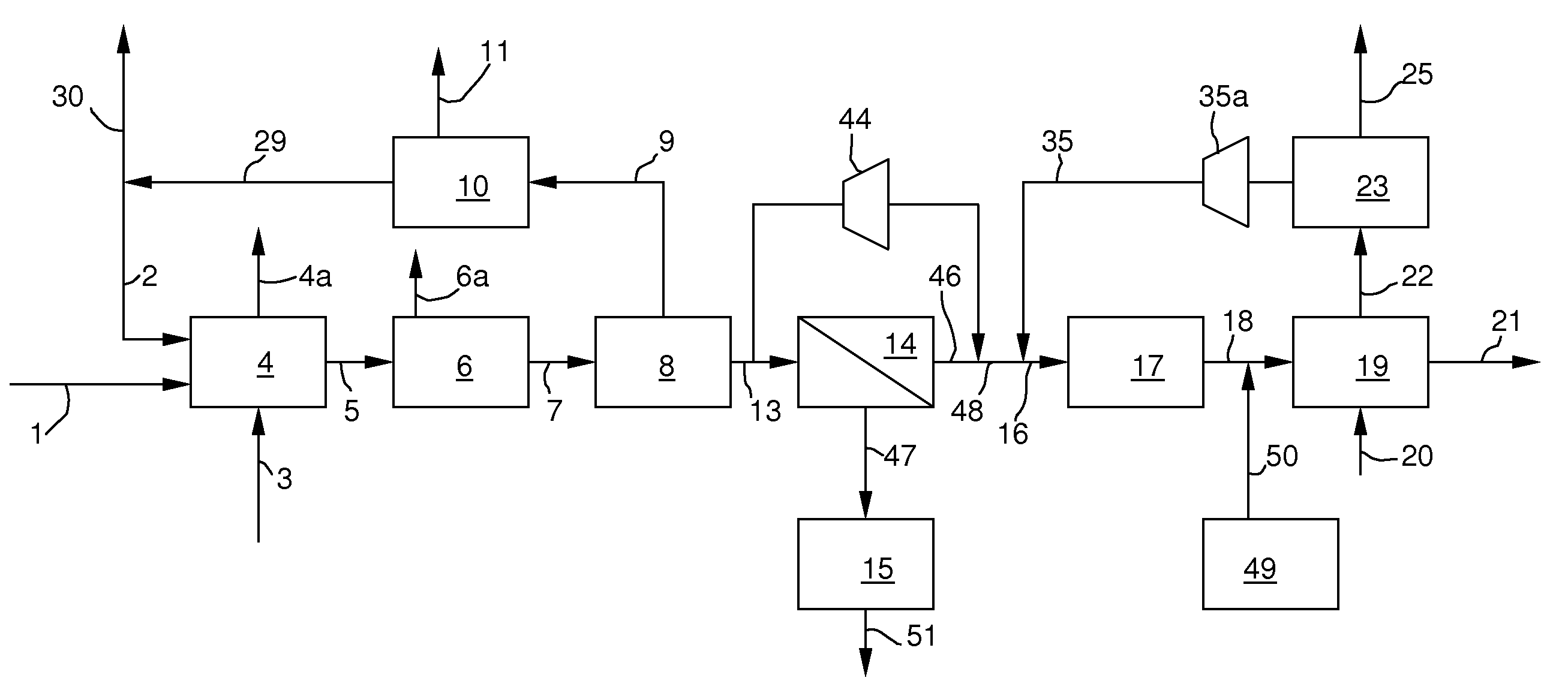

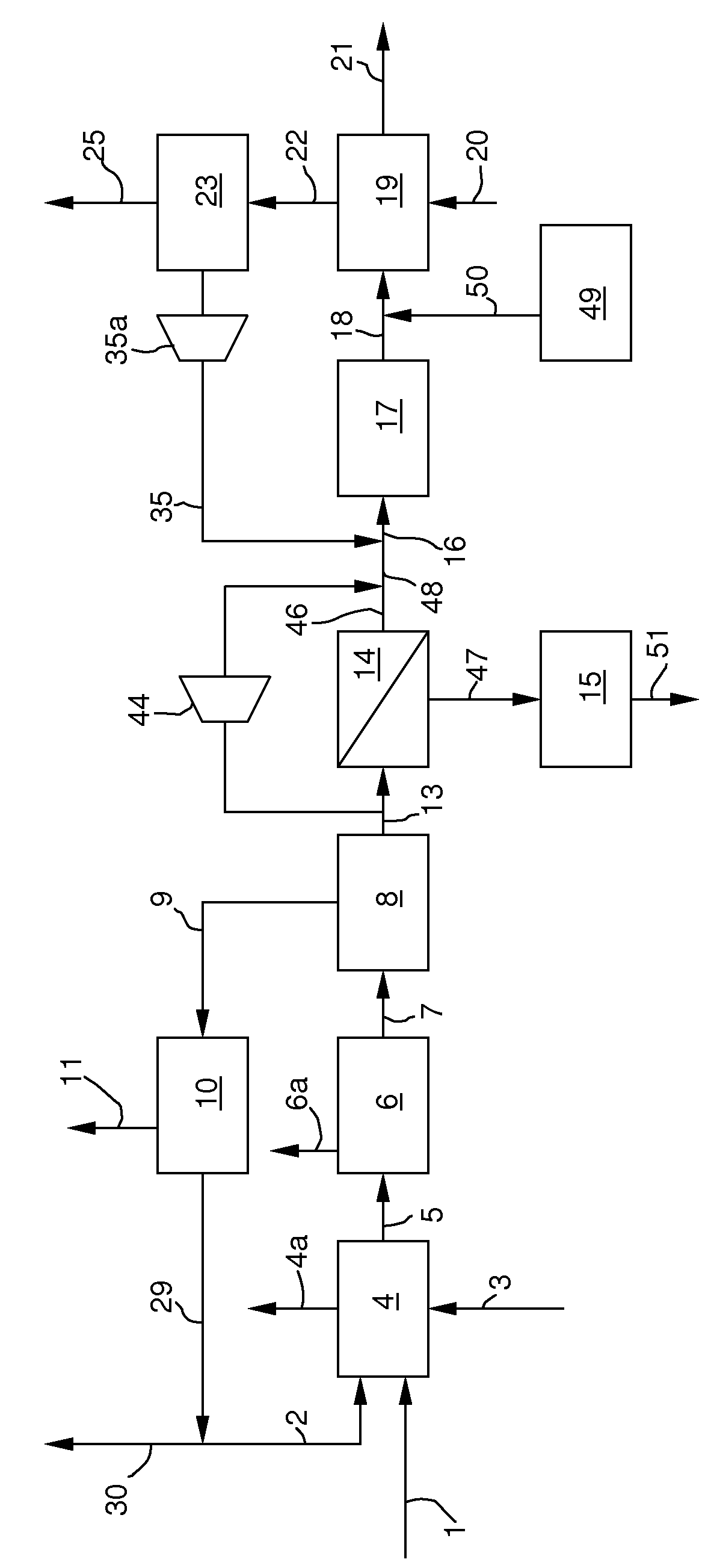

System and method for converting biomass to ethanol via syngas

A method and apparatus for synthesizing ethanol using synthetic routes via synthesis gas are disclosed. A method and apparatus for gasifying biomass, such as biomass, in a steam gasifier that employs a fluidized bed and heating using hot flue gases from the combustion of synthesis gas is described. Methods and apparatus for converting synthesis gas into ethanol are also disclosed, using stepwise catalytic reactions to convert the carbon monoxide and hydrogen into ethanol using catalysts including iridium acetate.

Owner:WOODLAND BIOFUELS

Active material and light emitting device

InactiveUS7824627B2Point-like light sourceSpace heating and ventilationLight emissionLight-emitting diode

Owner:SC JOHNSON & SON INC

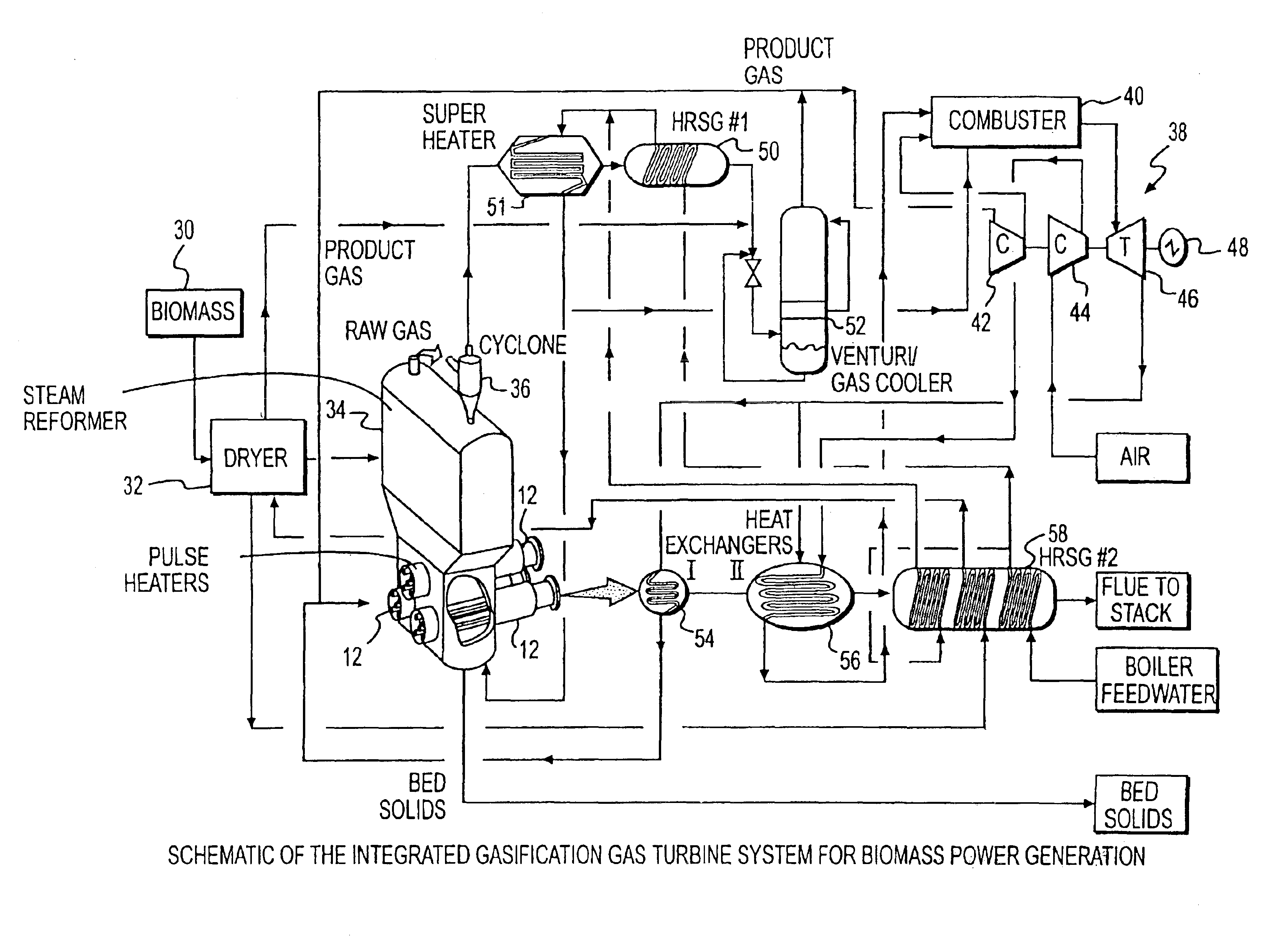

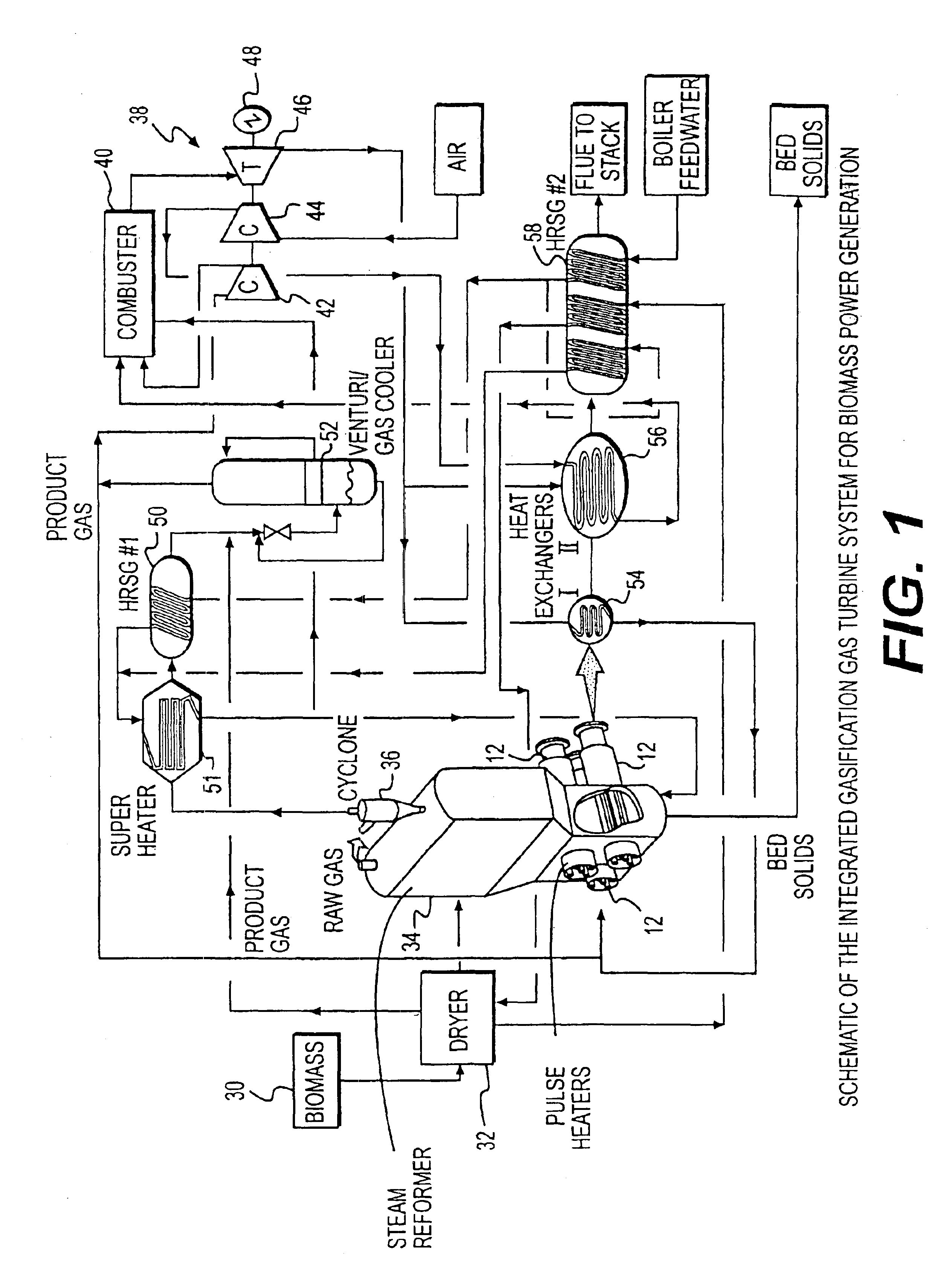

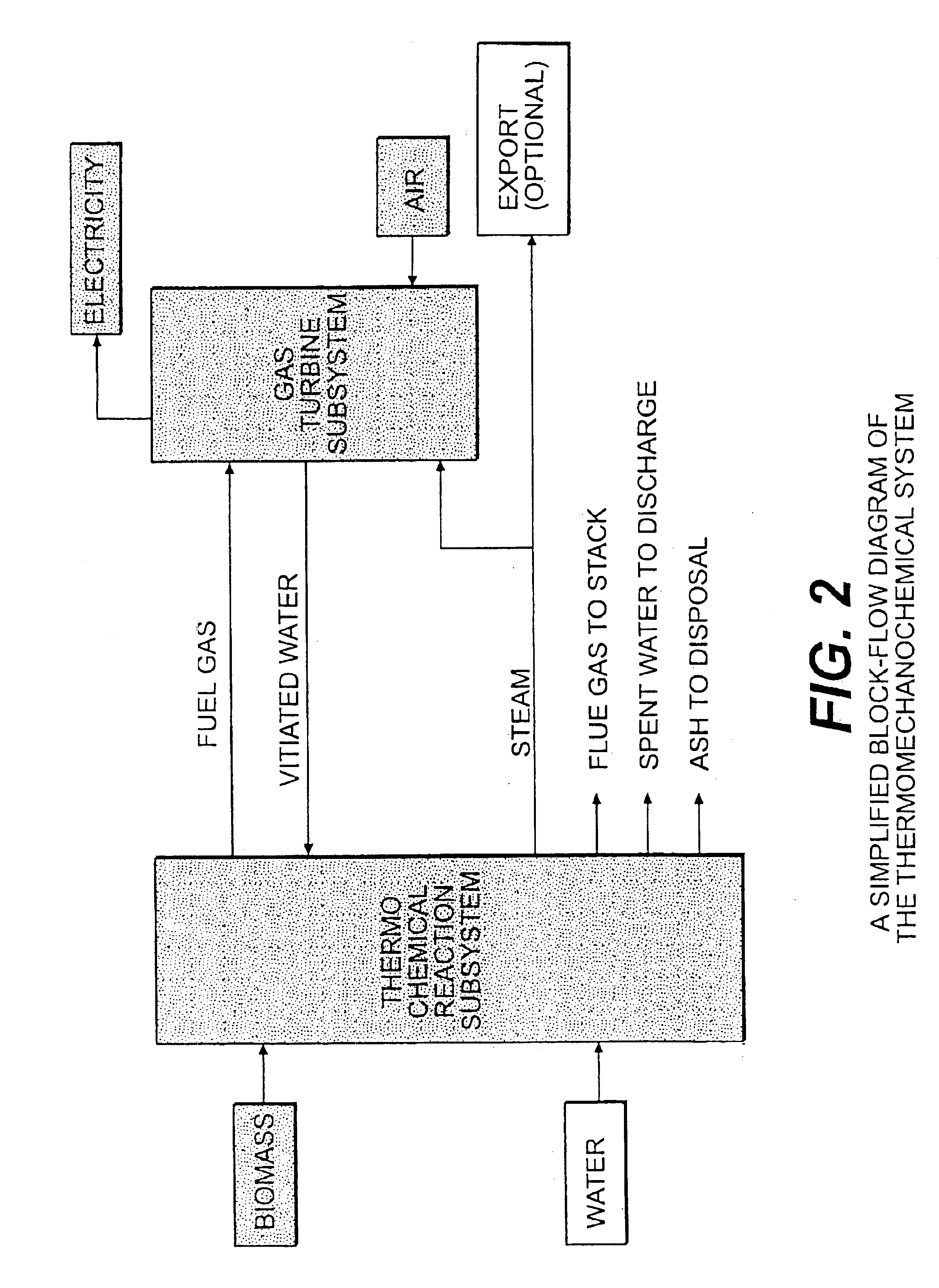

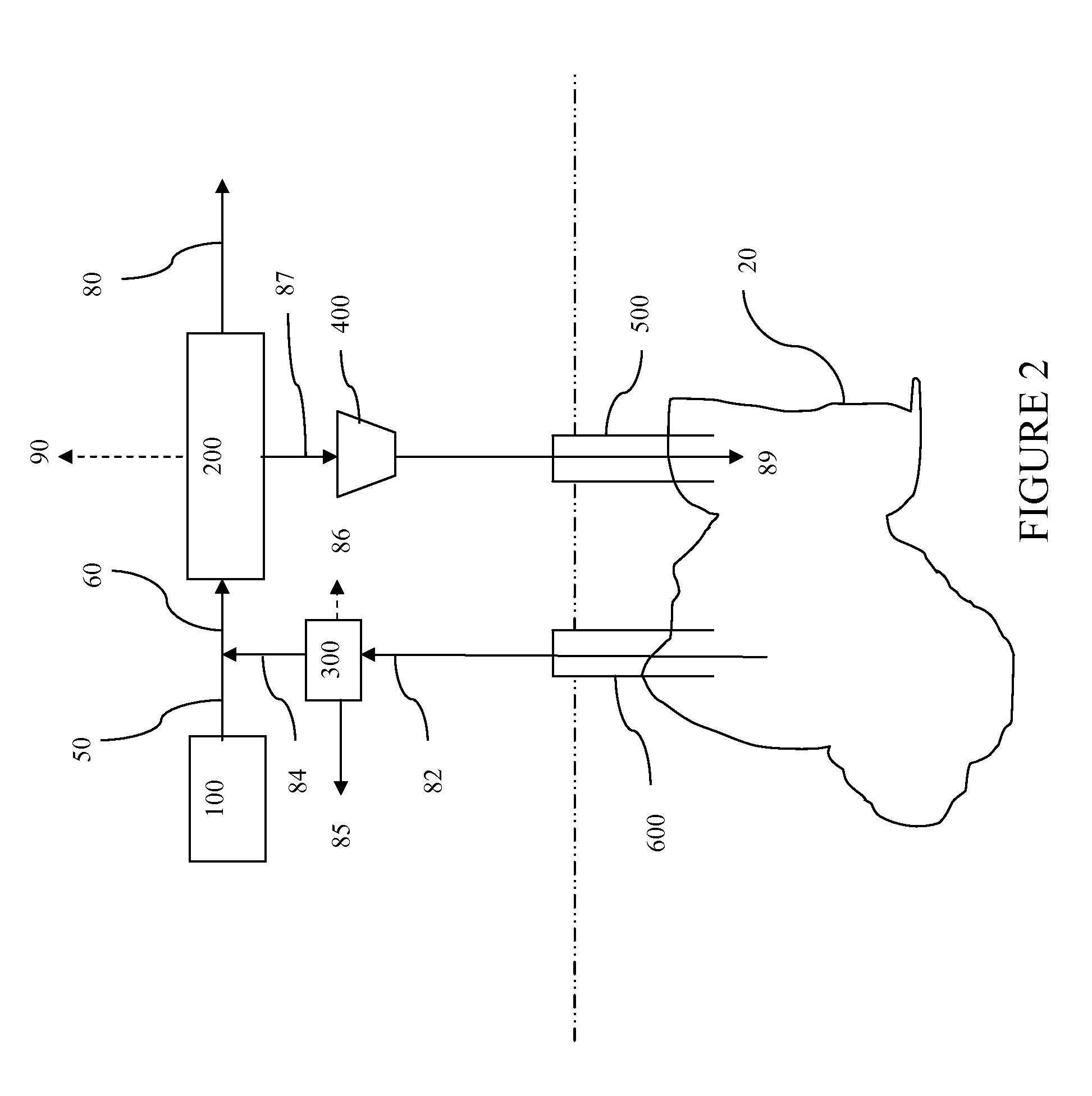

System integration of a steam reformer and gas turbine

A novel process and apparatus for power generation from biomass and other carbonaceous feedstocks are provided. The process integrates a pulse combustor steam reformer with a gas turbine to generate electricity such that (i) efficiency is higher than those of conventional and current advanced power systems, (ii) emissions are lower than those proposed in the new environmental regulations, and (iii) performance is comparable to that of combined cycle, even though a bottoming cycle is not included here. The pulse combustor steam reformer generates a hydrogen-rich, medium-Btu fuel gas that is fired in a gas turbine to generate electricity. The apparatus may be configured to produce only power or combined heat and power.

Owner:THERMOCHEM RECOVERY INT

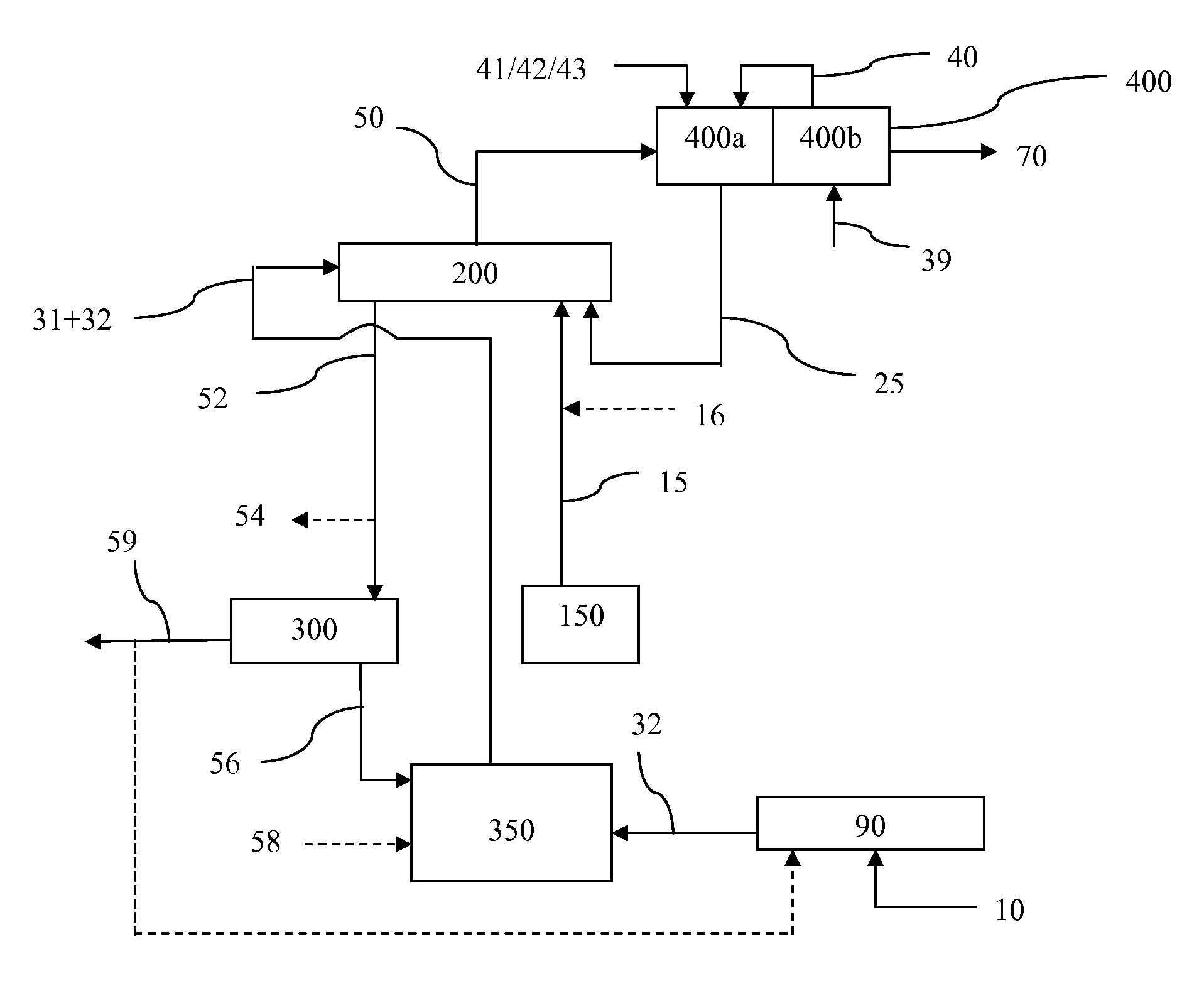

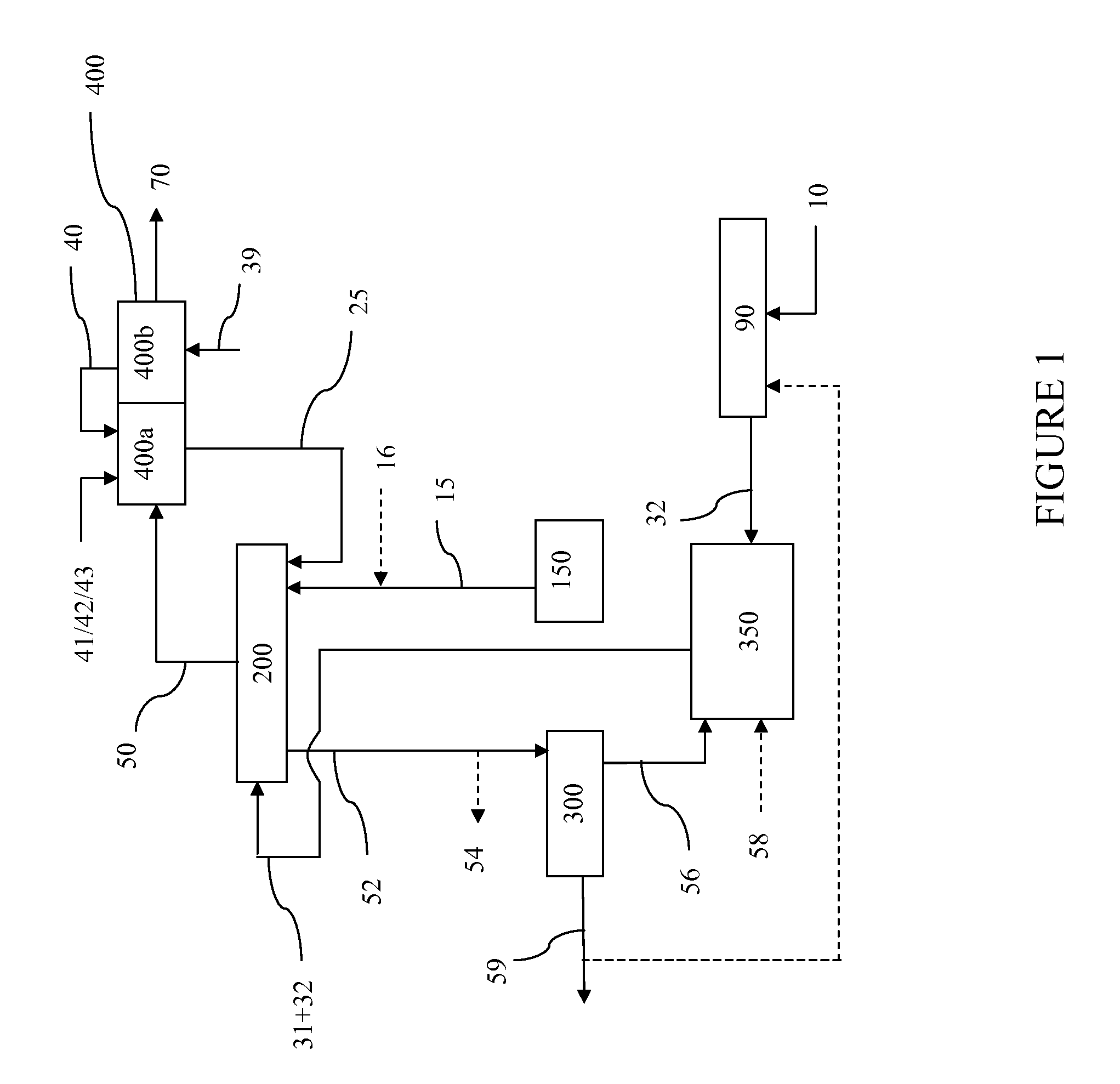

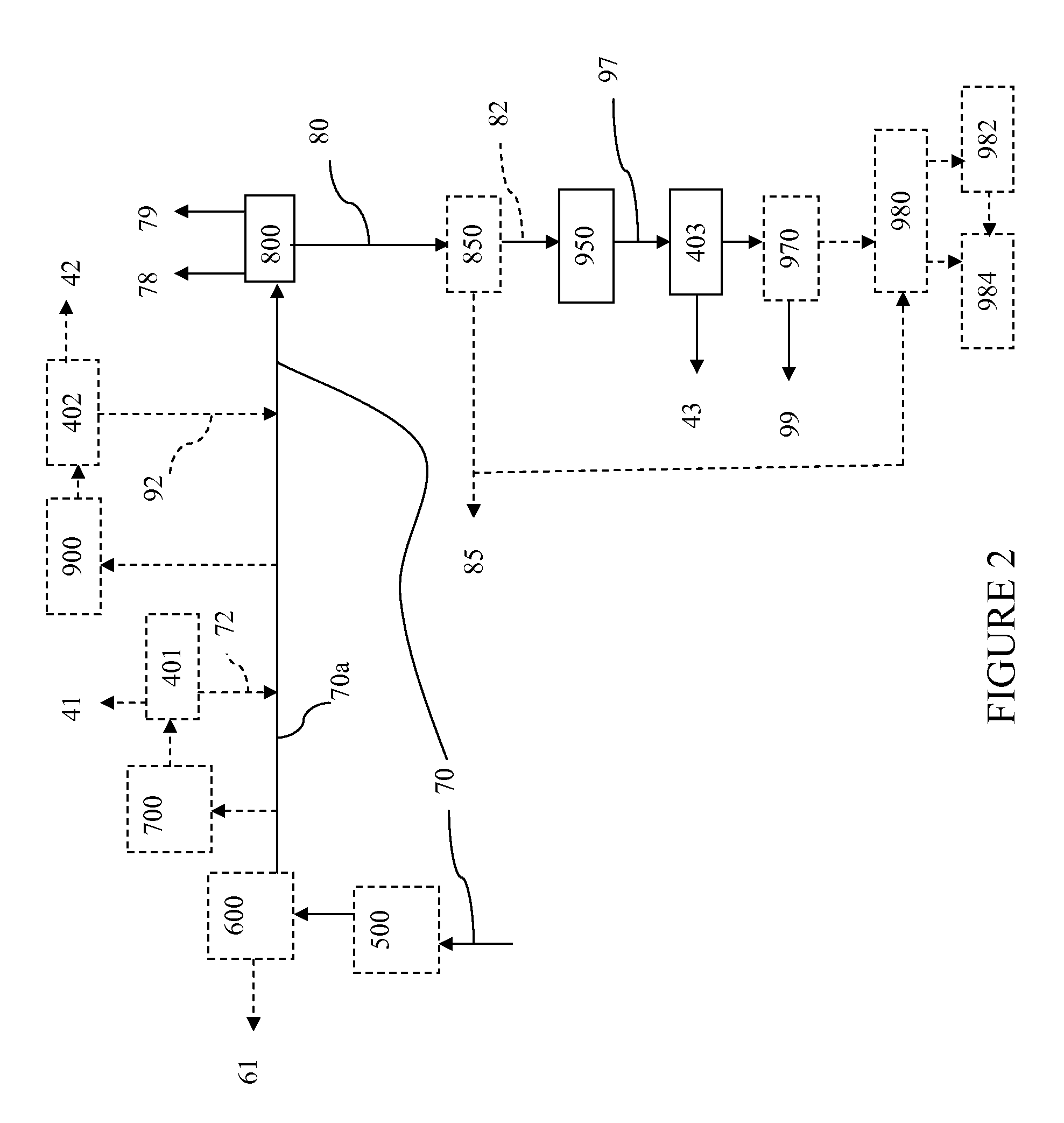

Processes for Hydromethanation of a Carbonaceous Feedstock

ActiveUS20100287835A1Increase the amount of carbonIncrease volumeHydrocarbon by isomerisationHydrogen separationMethanationOrganic chemistry

The present invention relates to processes for preparing gaseous products, and in particular methane, via the hydromethanation of a carbonaceous feedstock in the presence of steam, syngas, a hydromethanation catalyst and an oxygen-rich gas stream.

Owner:SURE CHAMPION INVESTMENT LTD

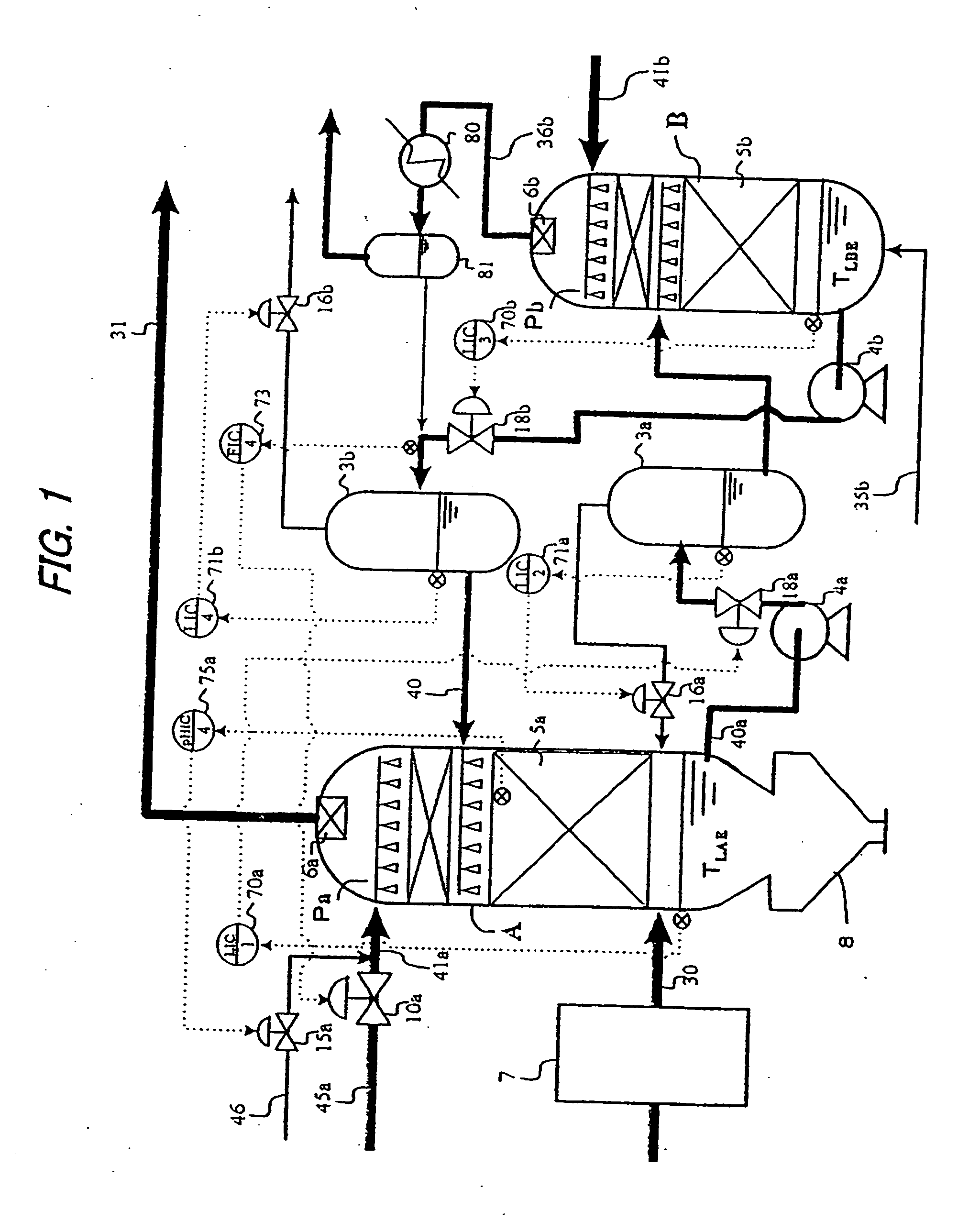

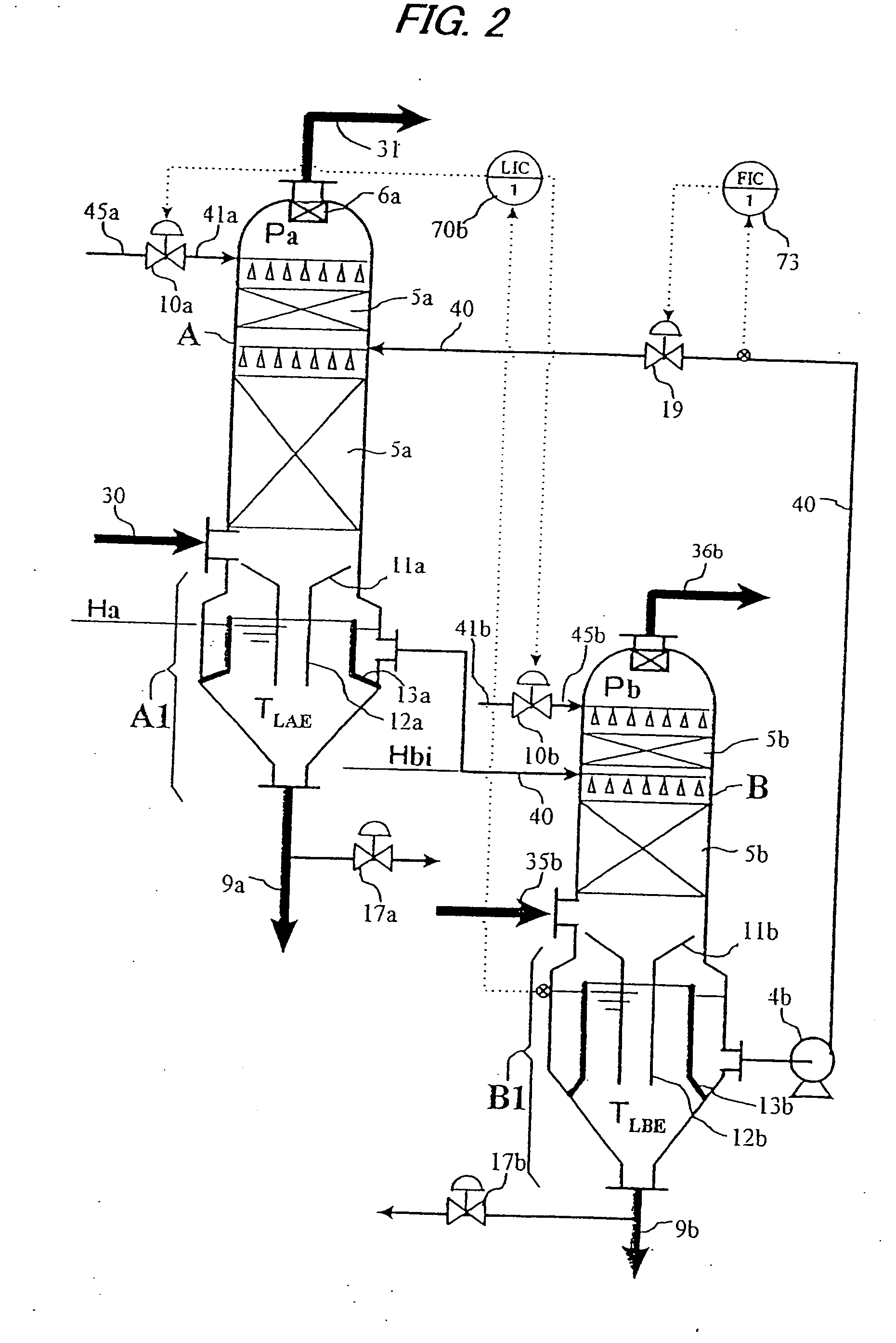

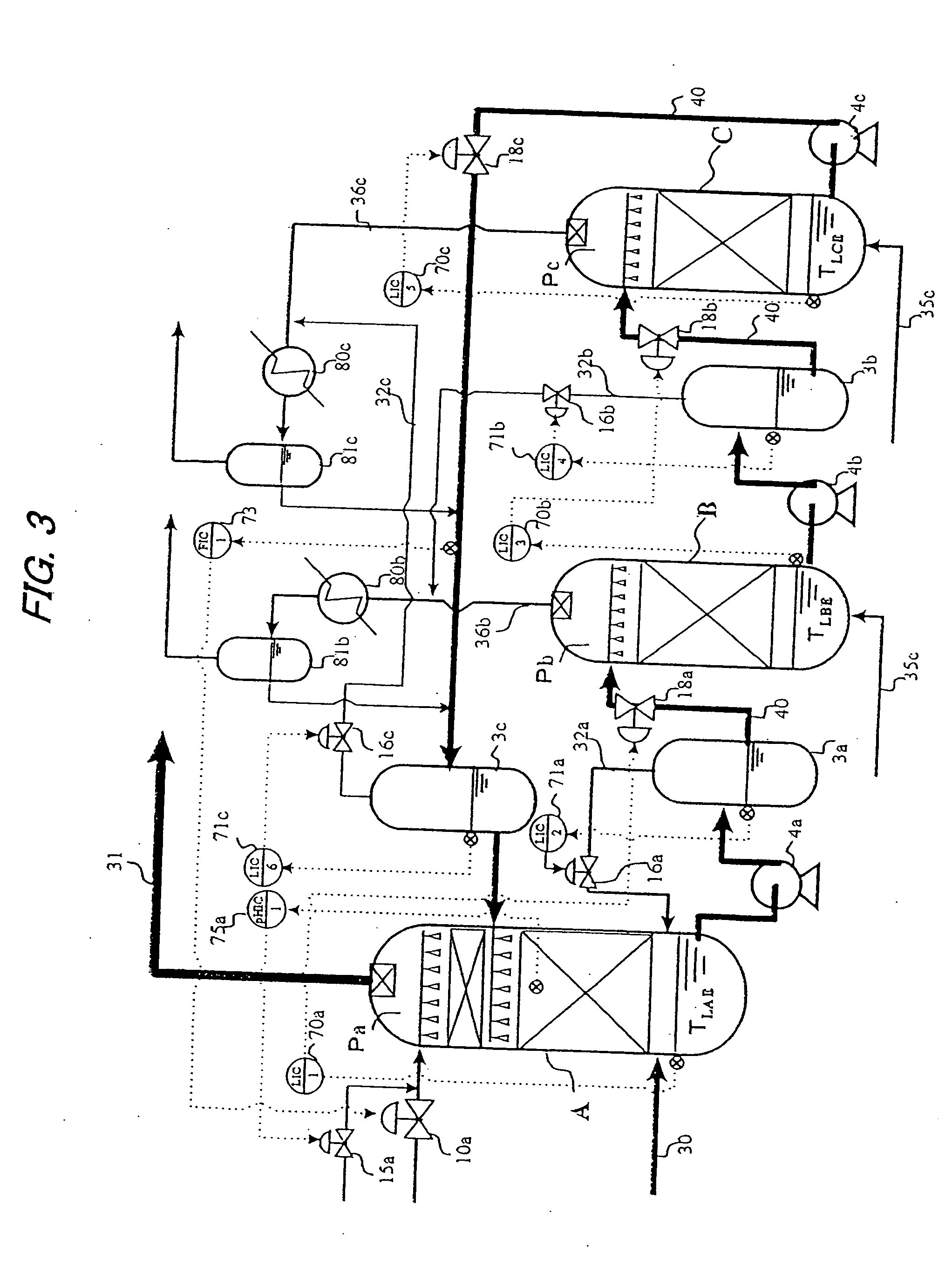

Acid gas scrubbing apparatus and method

InactiveUS20050132883A1Improve energy efficiencyImprove acid gas removal capabilityUsing liquid separation agentCombustible gas catalytic treatmentScrubberCarbon dioxide

An acid gas scrubbing apparatus and method brings a gas, to be scrubbed, containing carbon dioxide into contact with a gas scrubbing liquid containing alkaline agent and cooled, and acid gases in the gas are removed. A gas scrubber removes acid gases in a gas, to be scrubbed, containing carbon dioxide by bringing the gas to be scrubbed into contact with a gas scrubbing liquid containing alkaline agent. A scrubbing liquid regenerator regenerates and cools the gas scrubbing liquid by bringing the gas scrubbing liquid into contact with a regenerating gas having components different from the gas scrubbing liquid and the gas to be scrubbed. A circulating device is provided between the gas scrubber and the scrubbing liquid regenerator for circulating the scrubbing liquid.

Owner:SU QINGQUAN +4

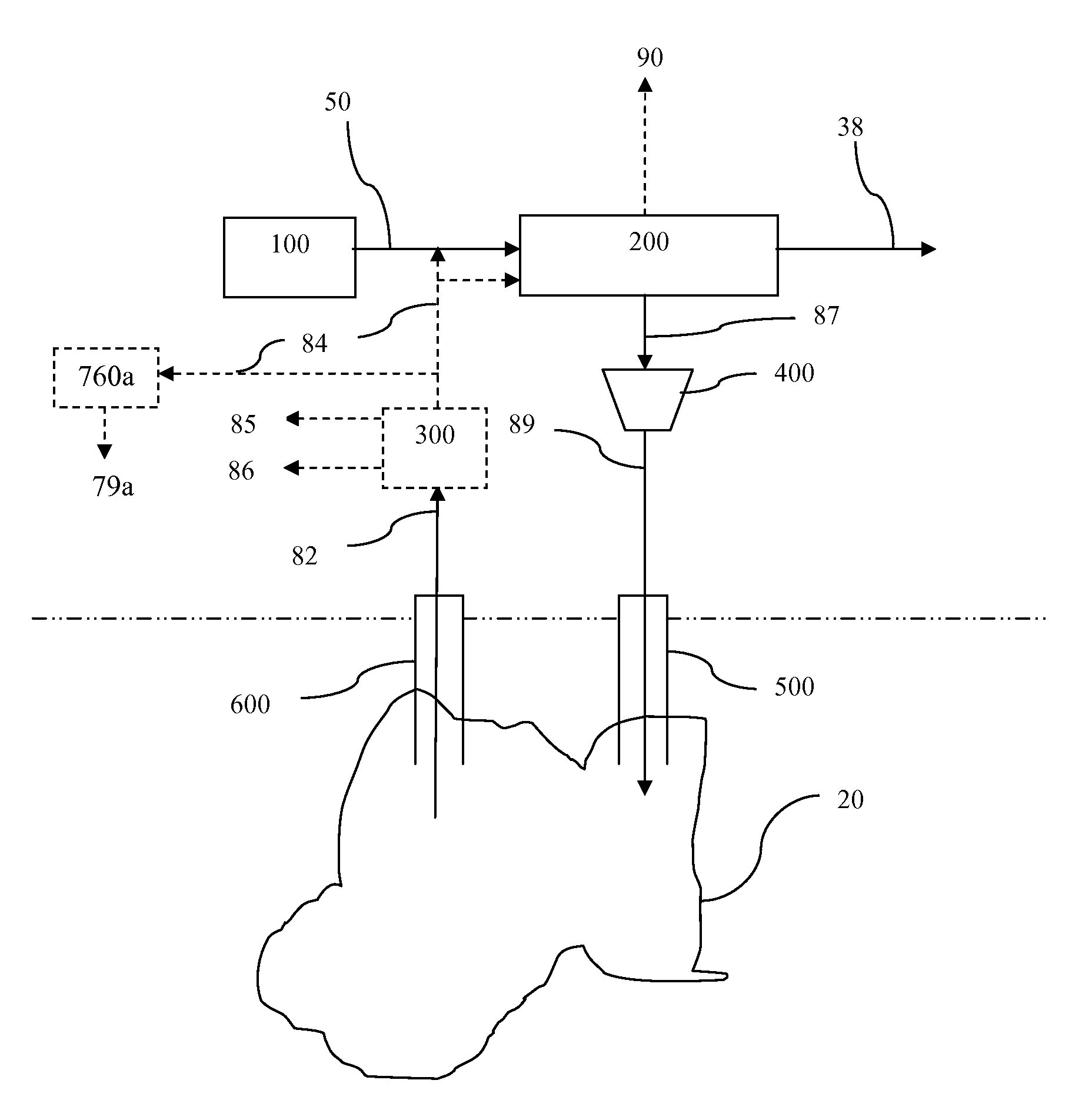

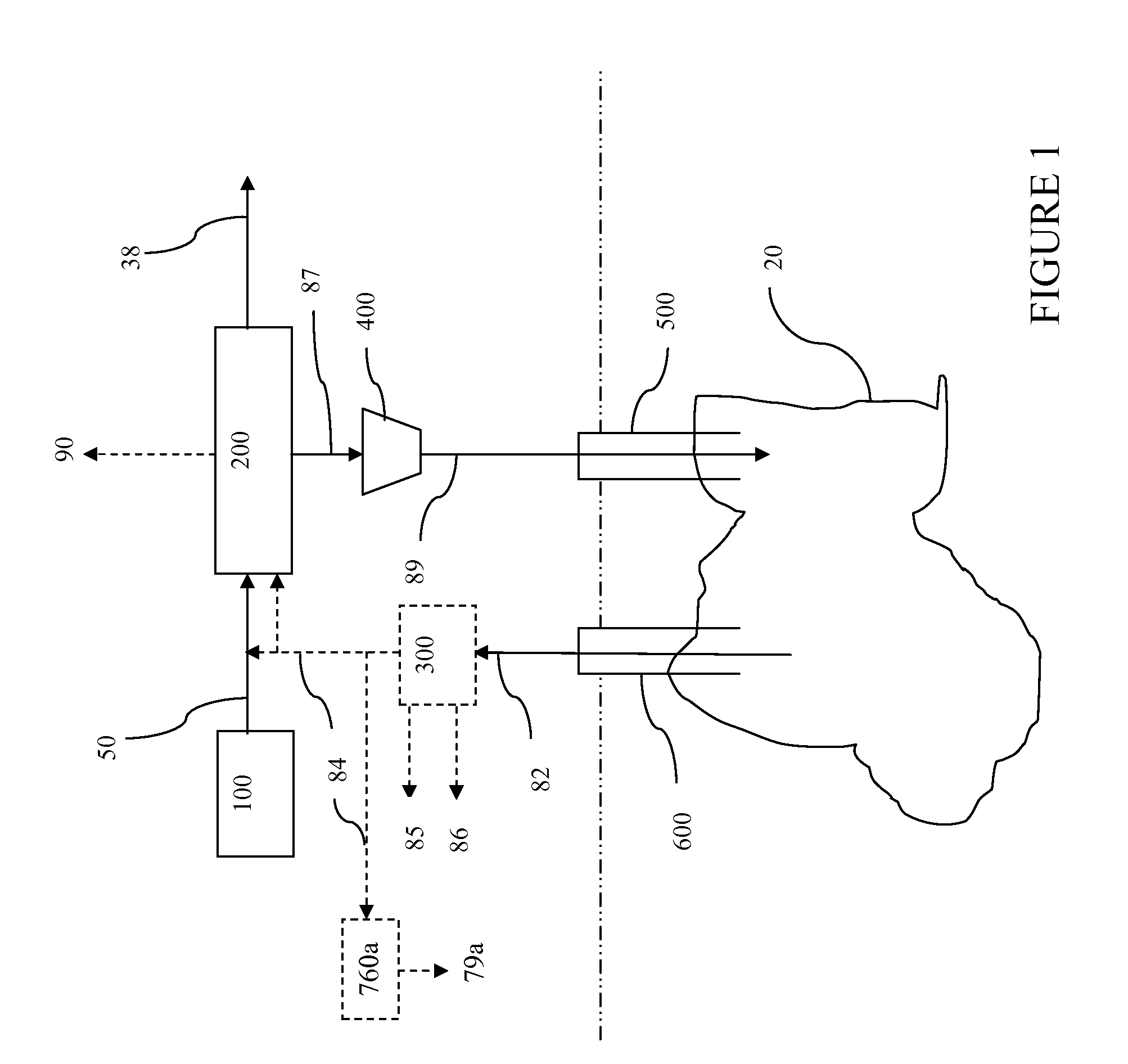

Integrated enhanced oil recovery process

ActiveUS20110146979A1Increase productionEnhanced overall recoveryDrilling rodsOther gas emission reduction technologiesGeneration processCarbon dioxide

The present invention relates to an enhanced oil recovery process that is integrated with a synthesis gas generation process, such as gasification or reforming, involving capture and recycle of a sour carbon dioxide stream for EOR use.

Owner:SURE CHAMPION INVESTMENT LTD

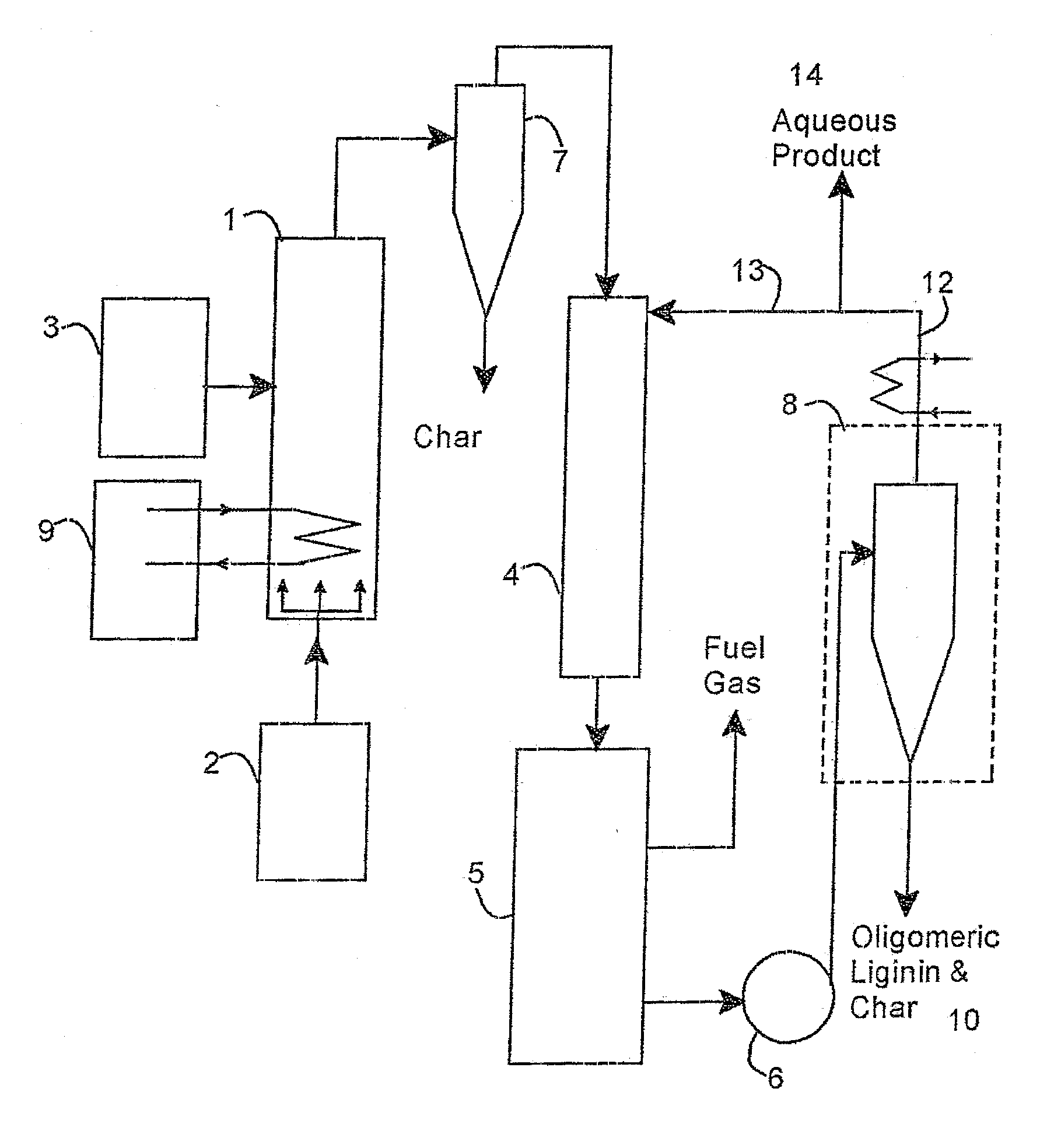

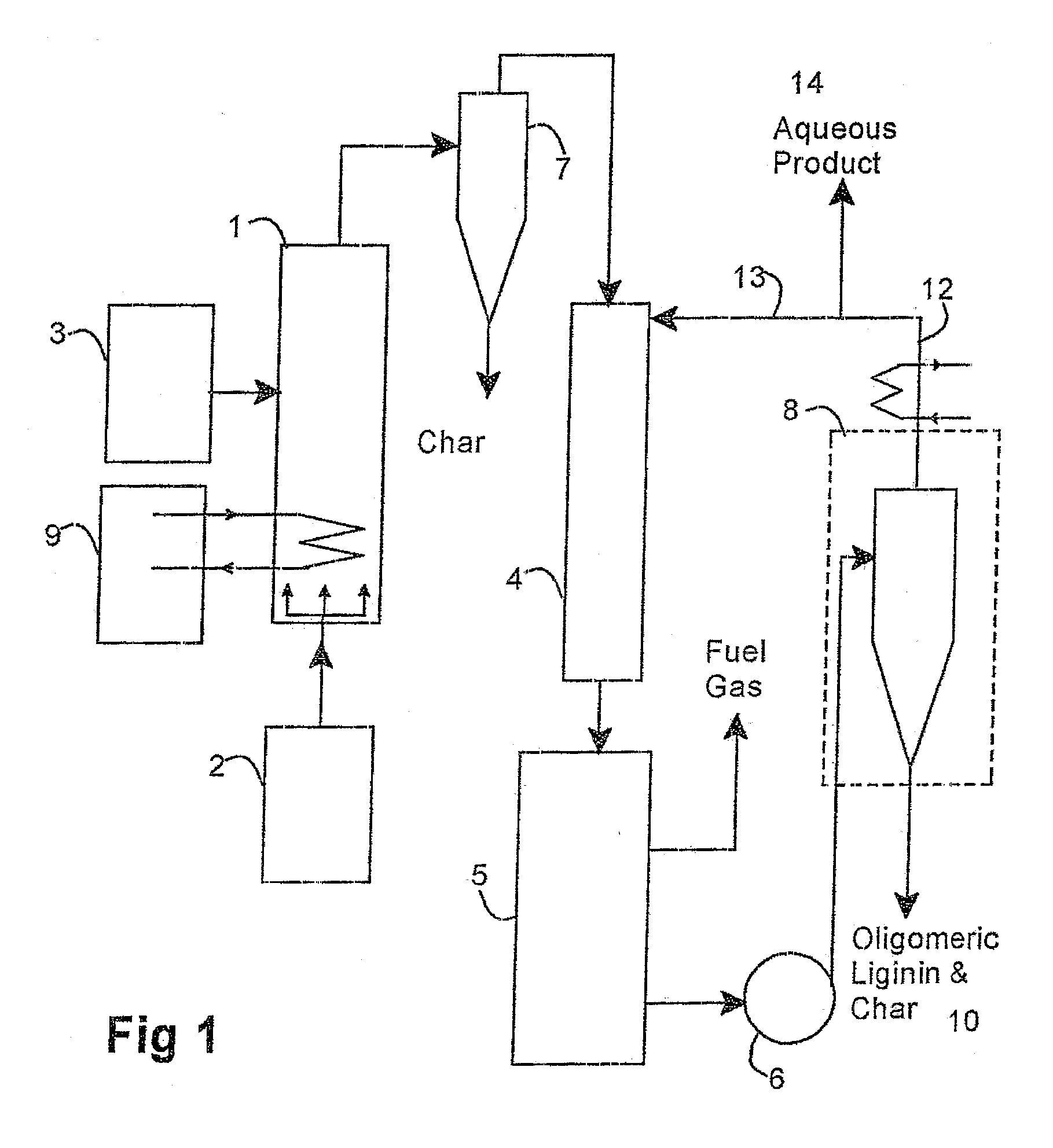

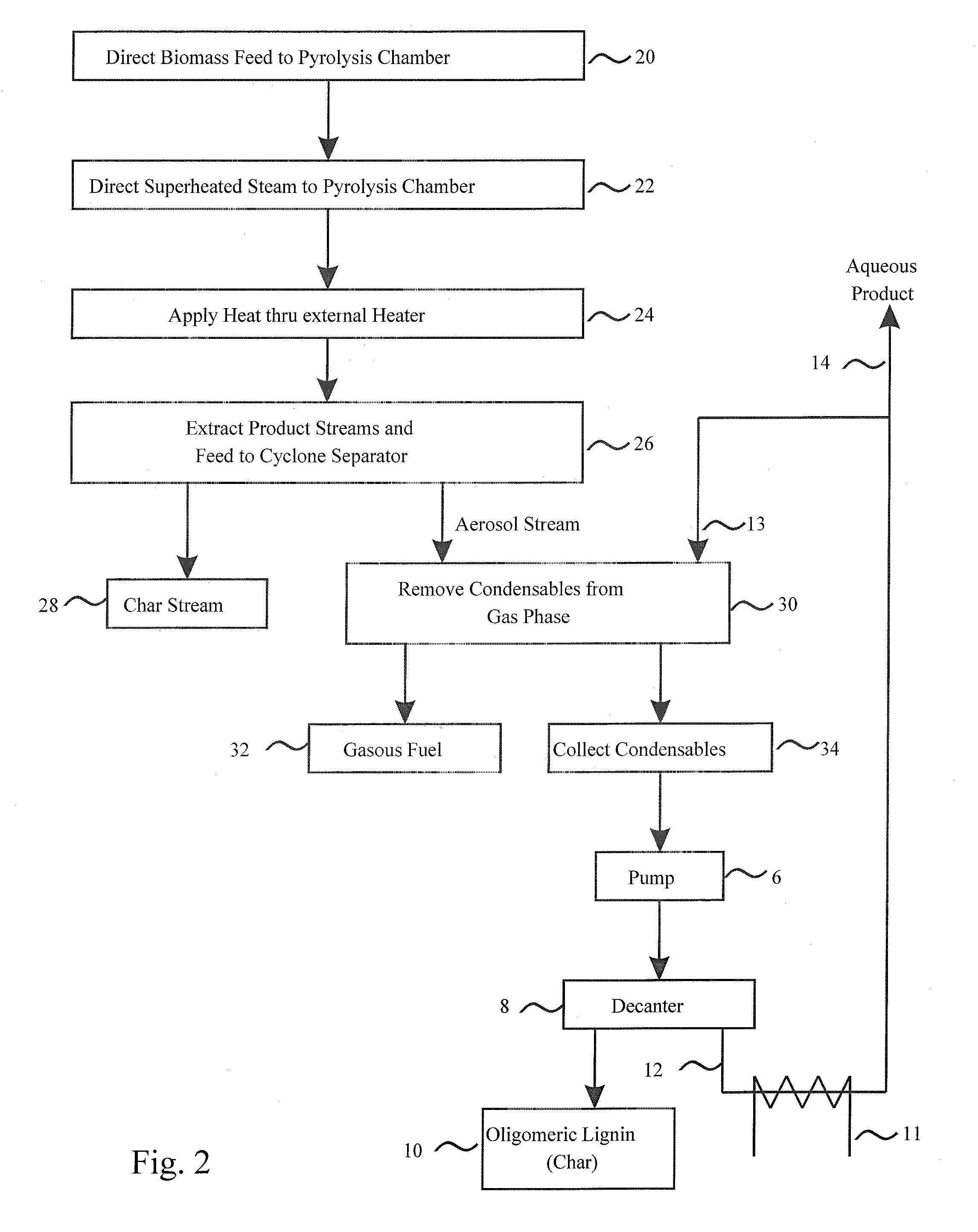

Method of producing hodge carbonyls and oligomeric lignin

ActiveUS20090126433A1Low lignin contentBiofuelsIndirect and direct heating destructive distillationSufficient timeProcess engineering

A method of treating biomass feed by pyrolyzing it in the presence of superheated steam at a selected temperature for a sufficient time to produce at least one product stream.

Owner:KERRY GRP SERVICES INT

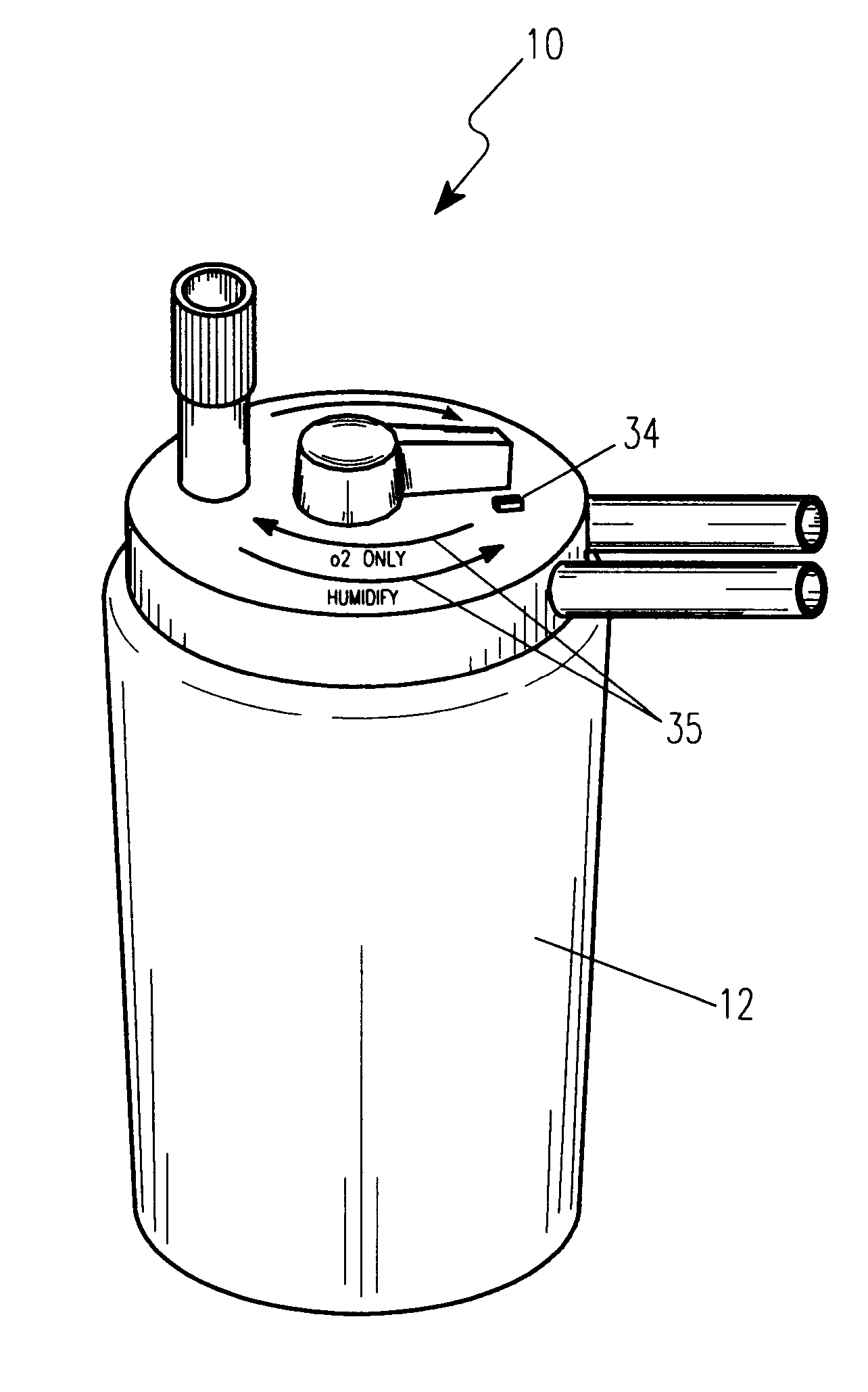

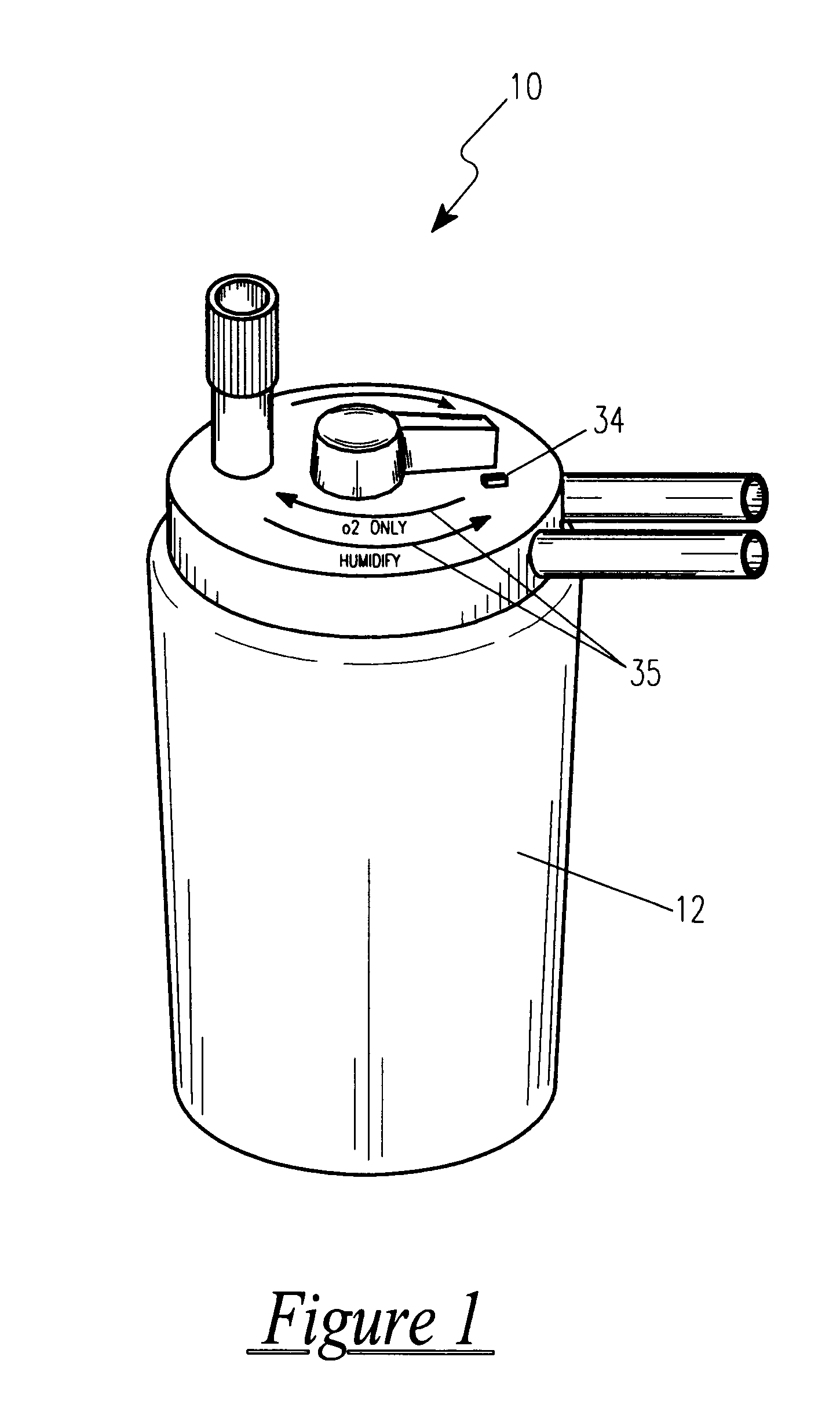

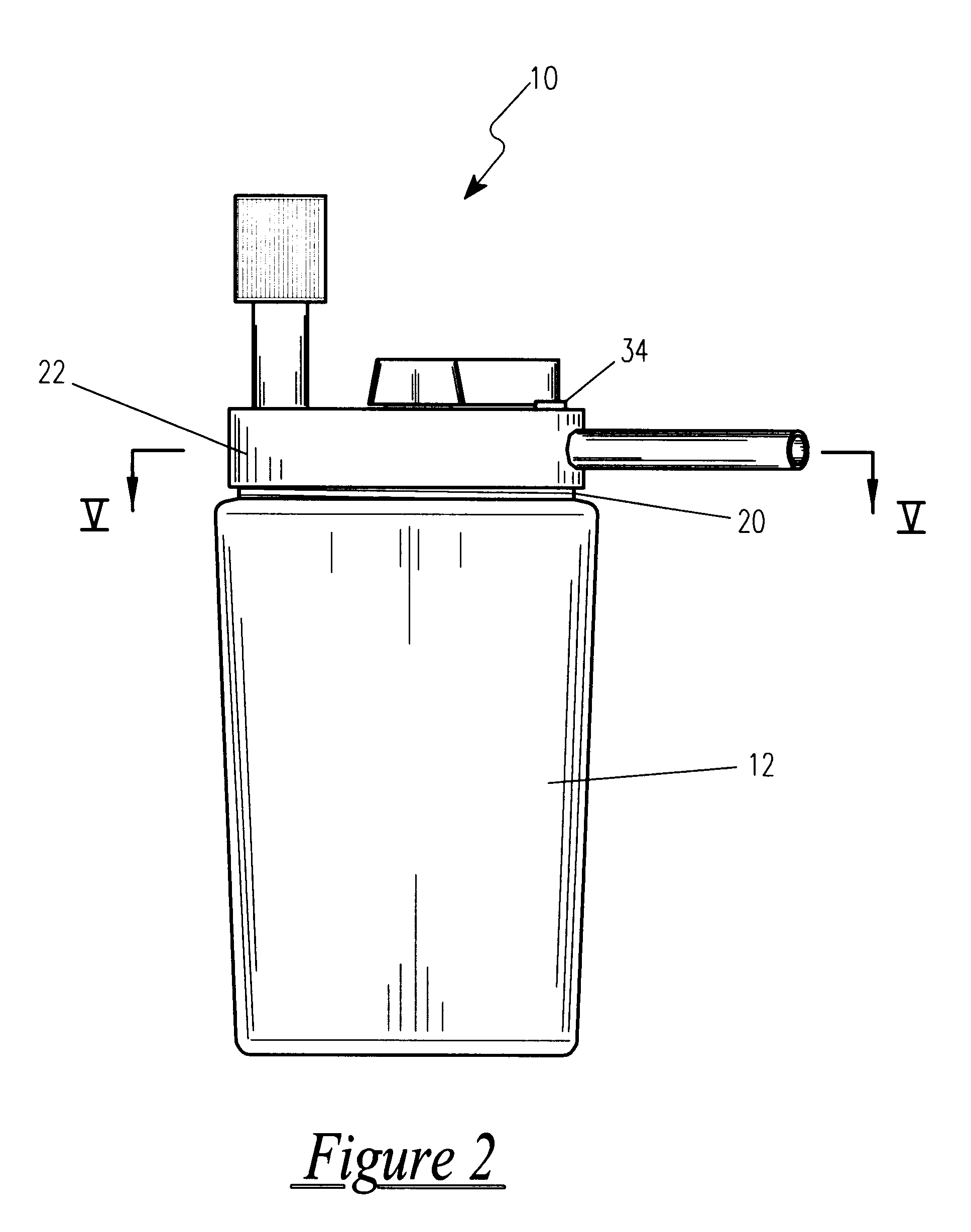

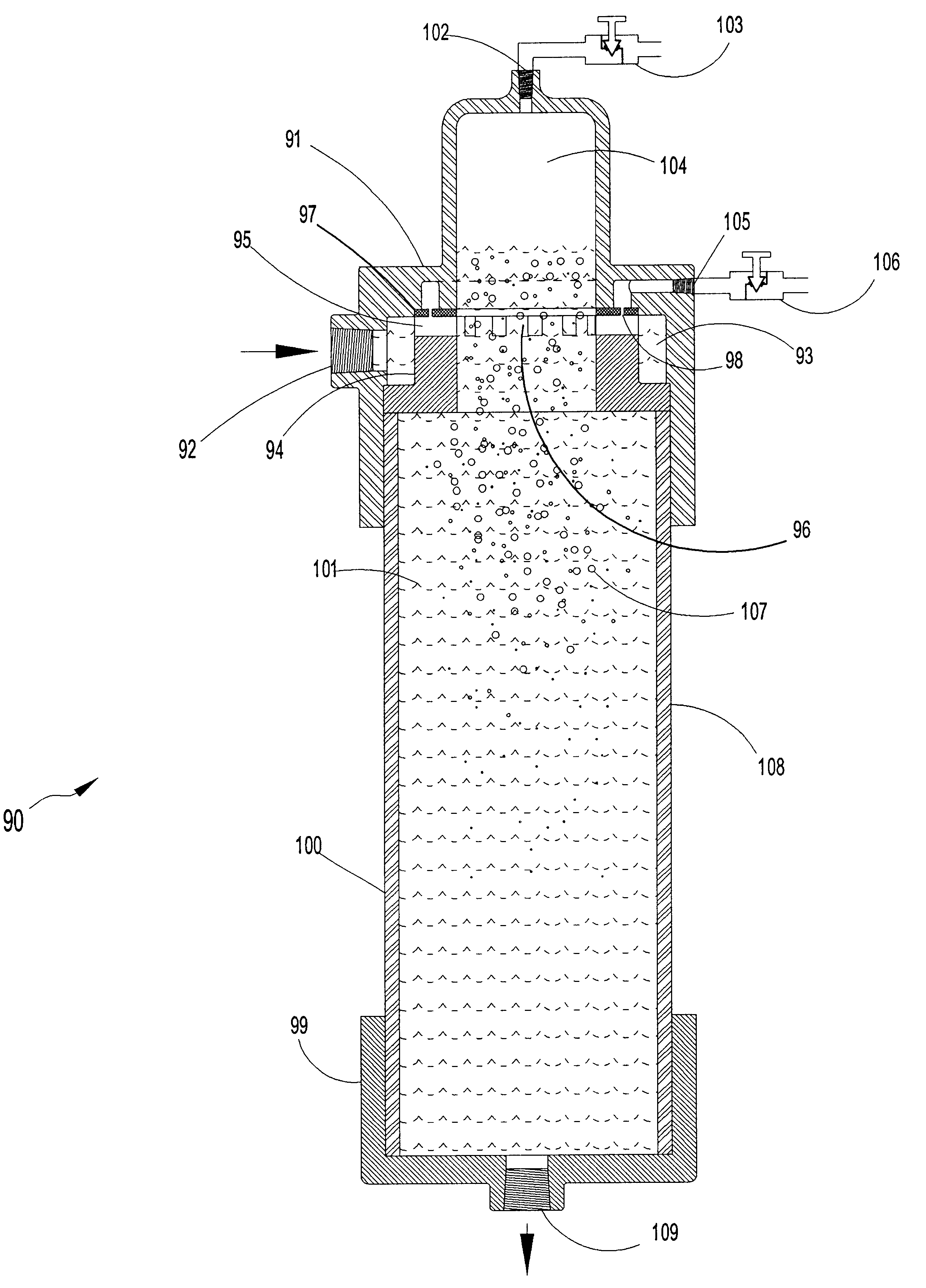

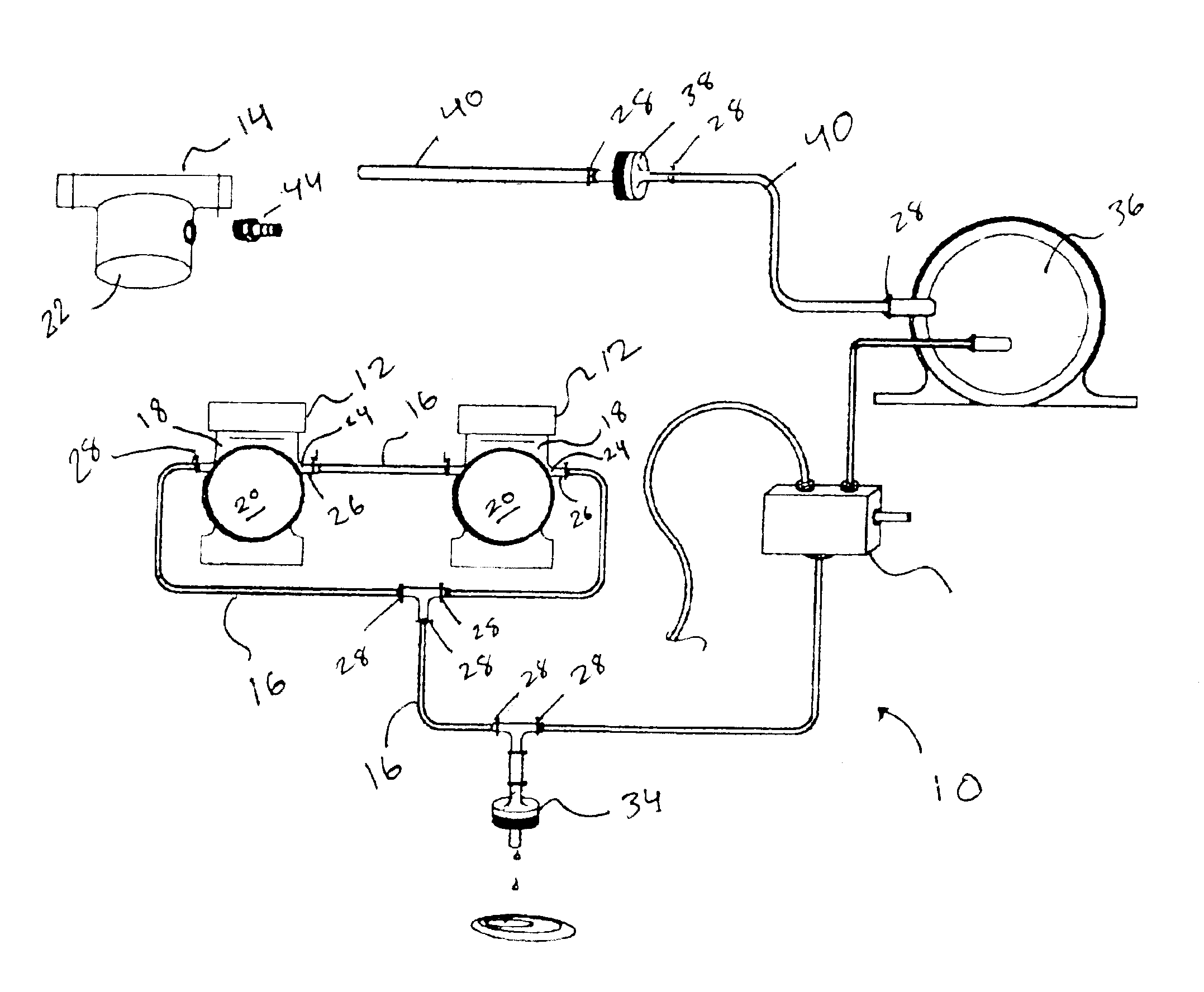

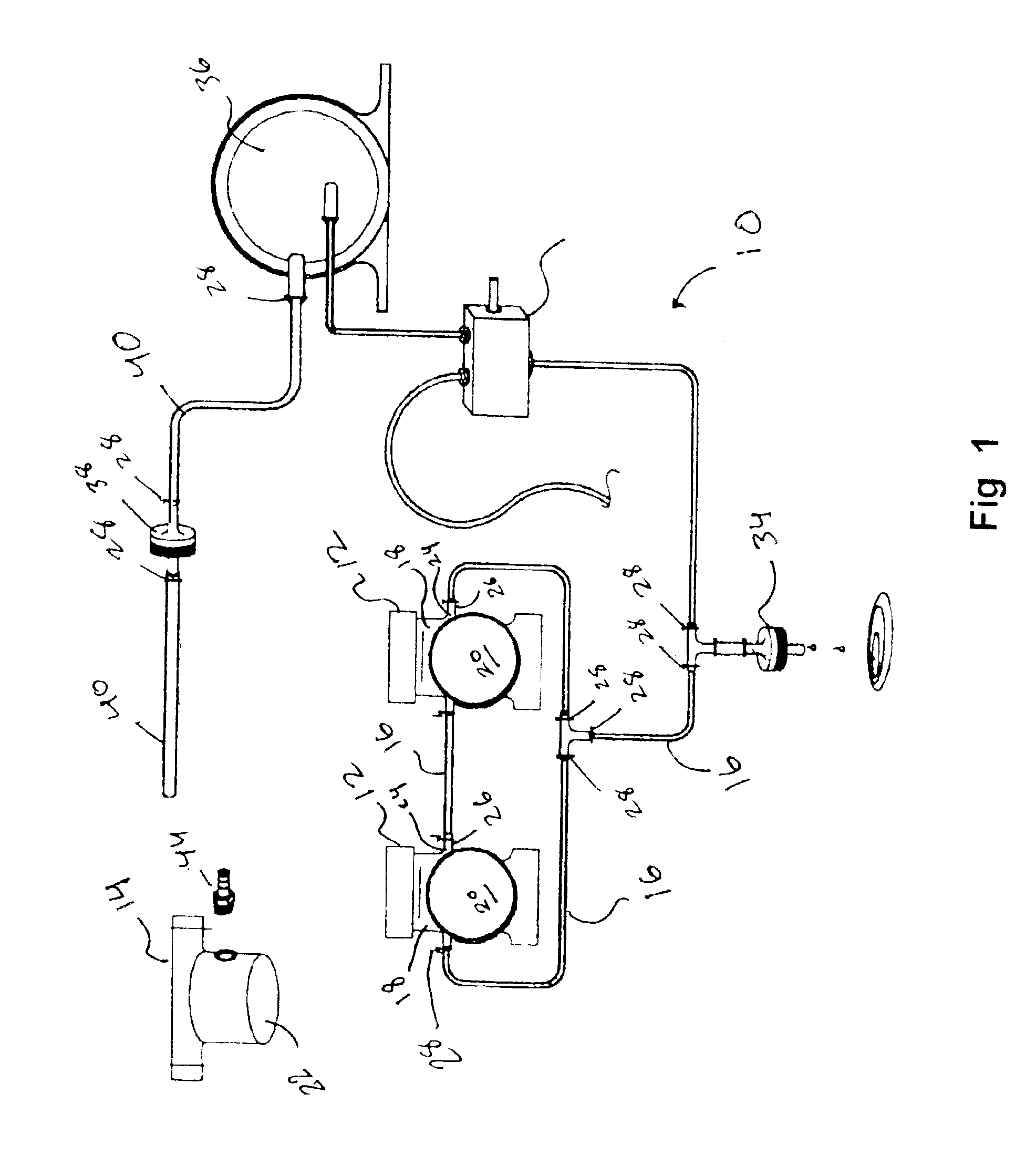

Dual port medical oxygen humidifier

InactiveUS6189870B1Easy to switchReduces and eliminates possibilityLighting and heating apparatusTransportation and packagingEngineeringMoisture

An improved disposable bubble oxygen humidifier is provided having a humidifying chamber included for the blending of oxygen and moisture. A slide switch on the top of the humidifier directs pure oxygen to the patient, or alternately, routes the oxygen through the humidifier and on to the patient. Hoses are attached at an inlet supply port and an outlet discharge port.

Owner:WITHALL GORDON

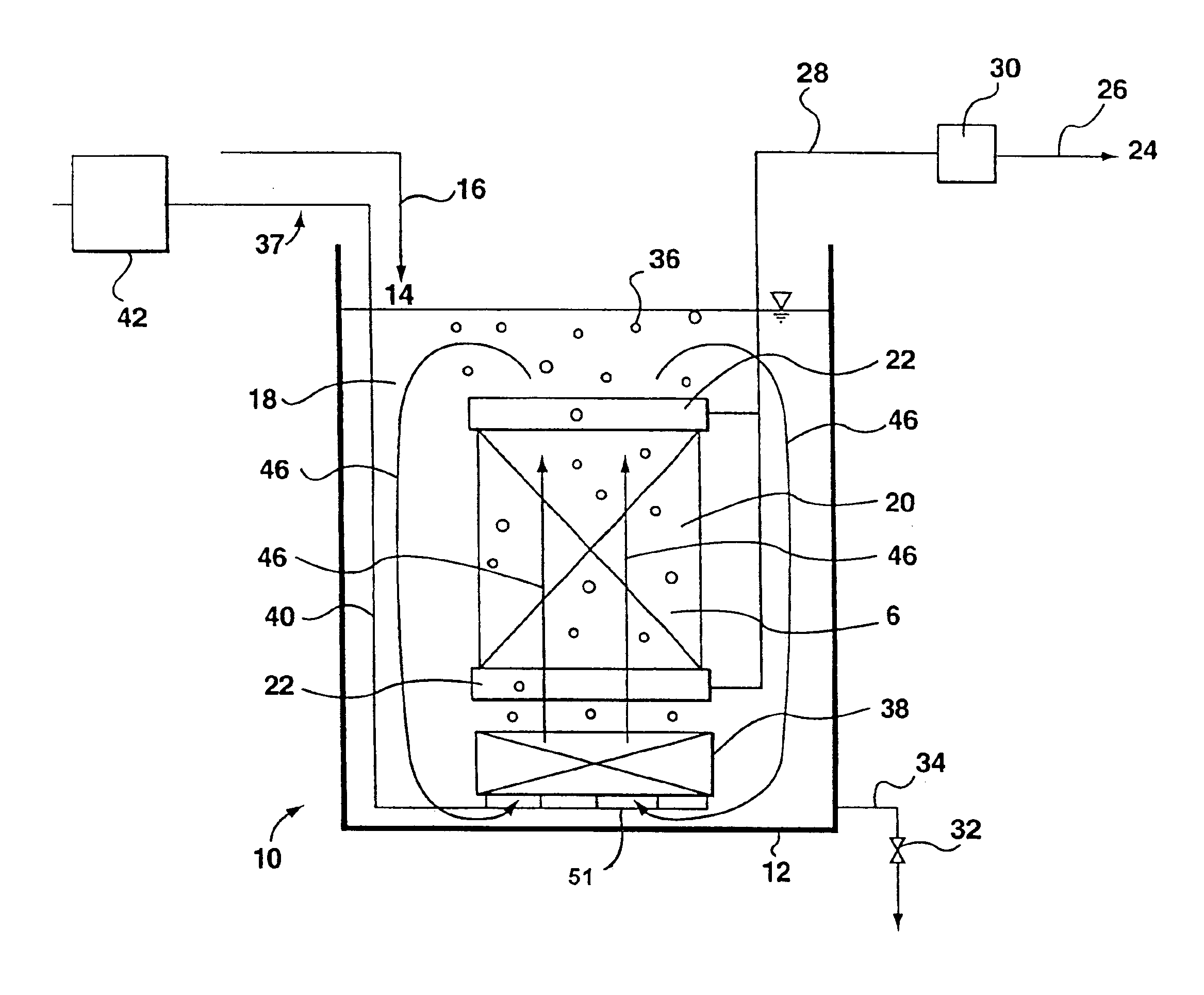

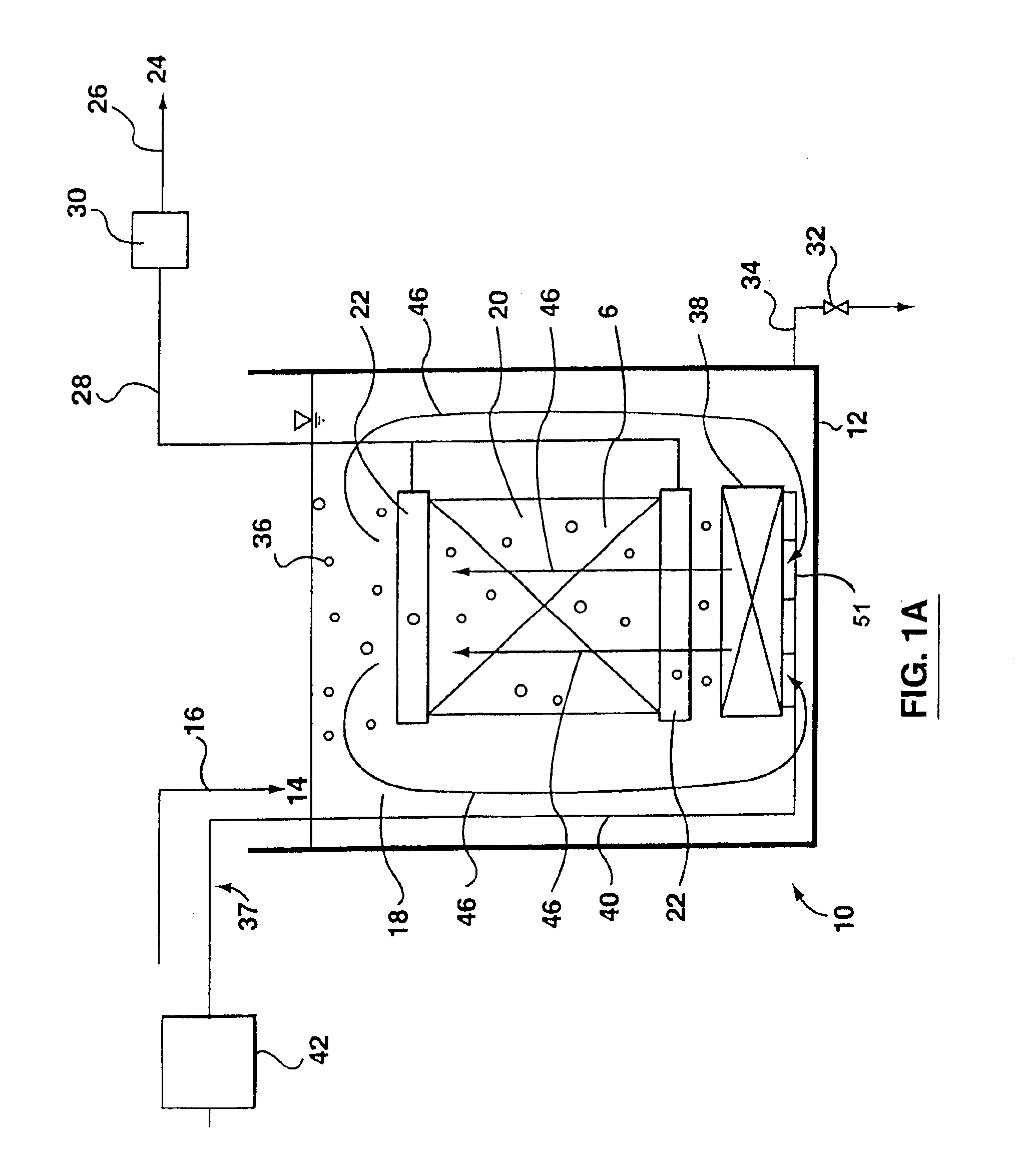

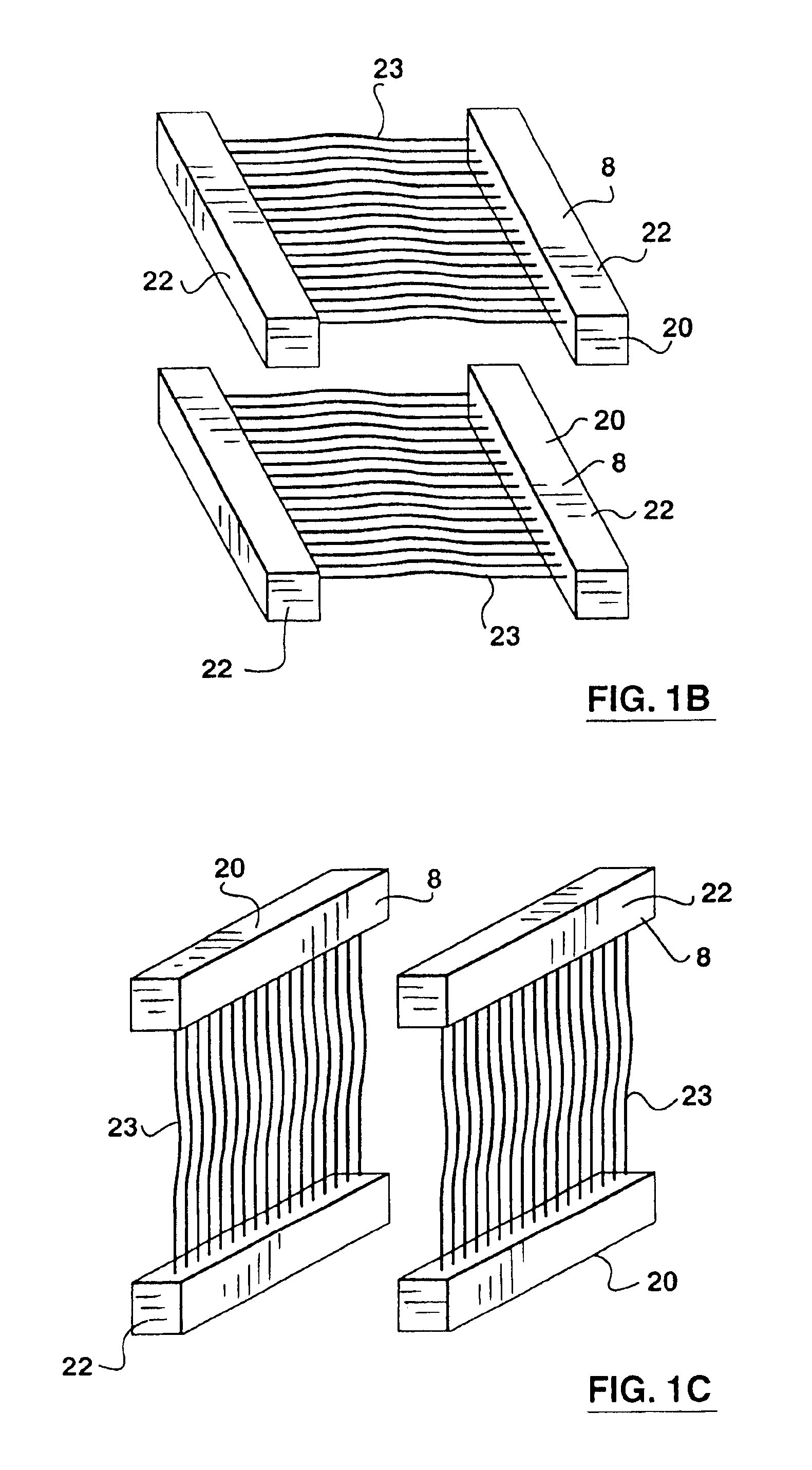

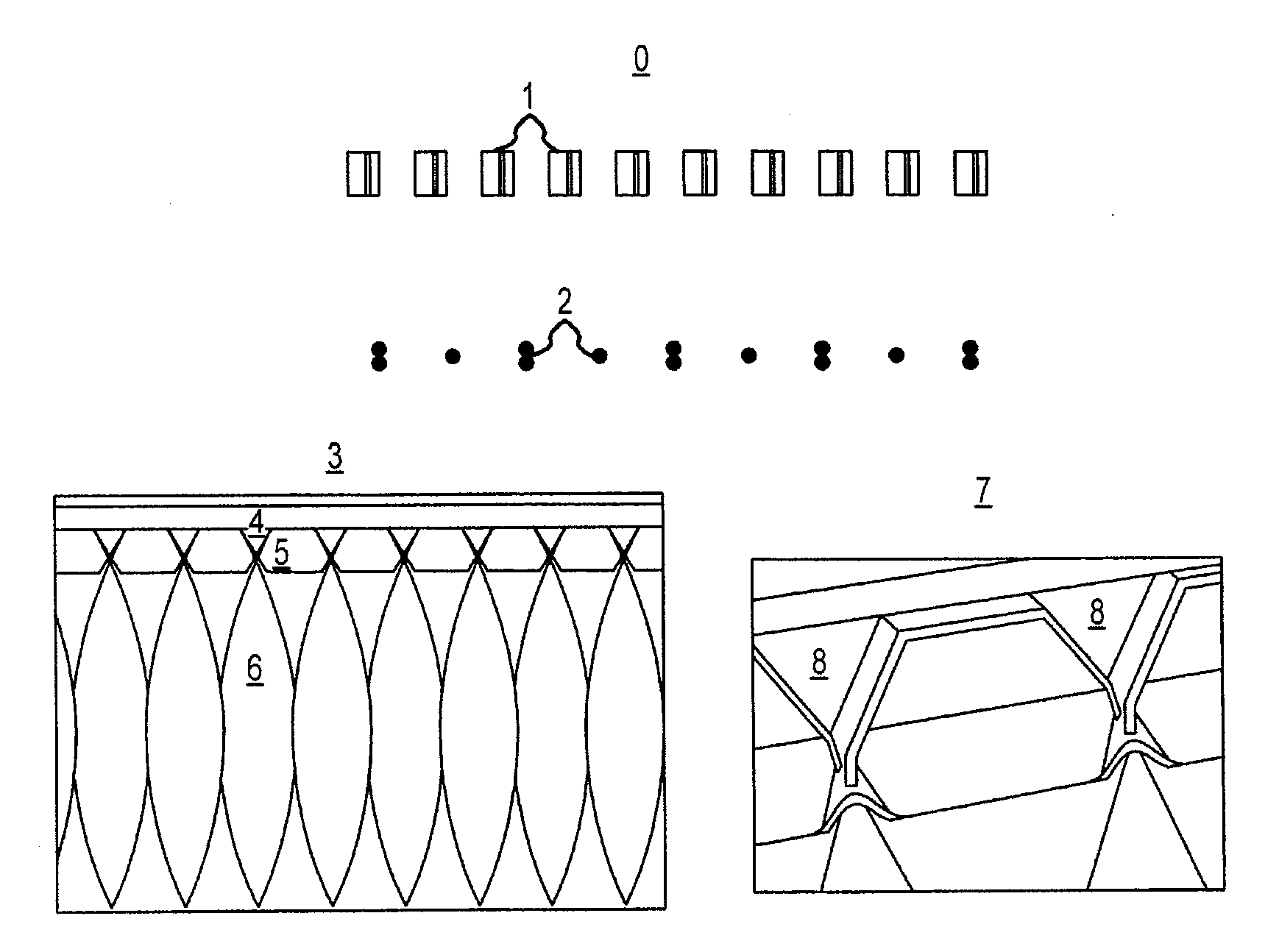

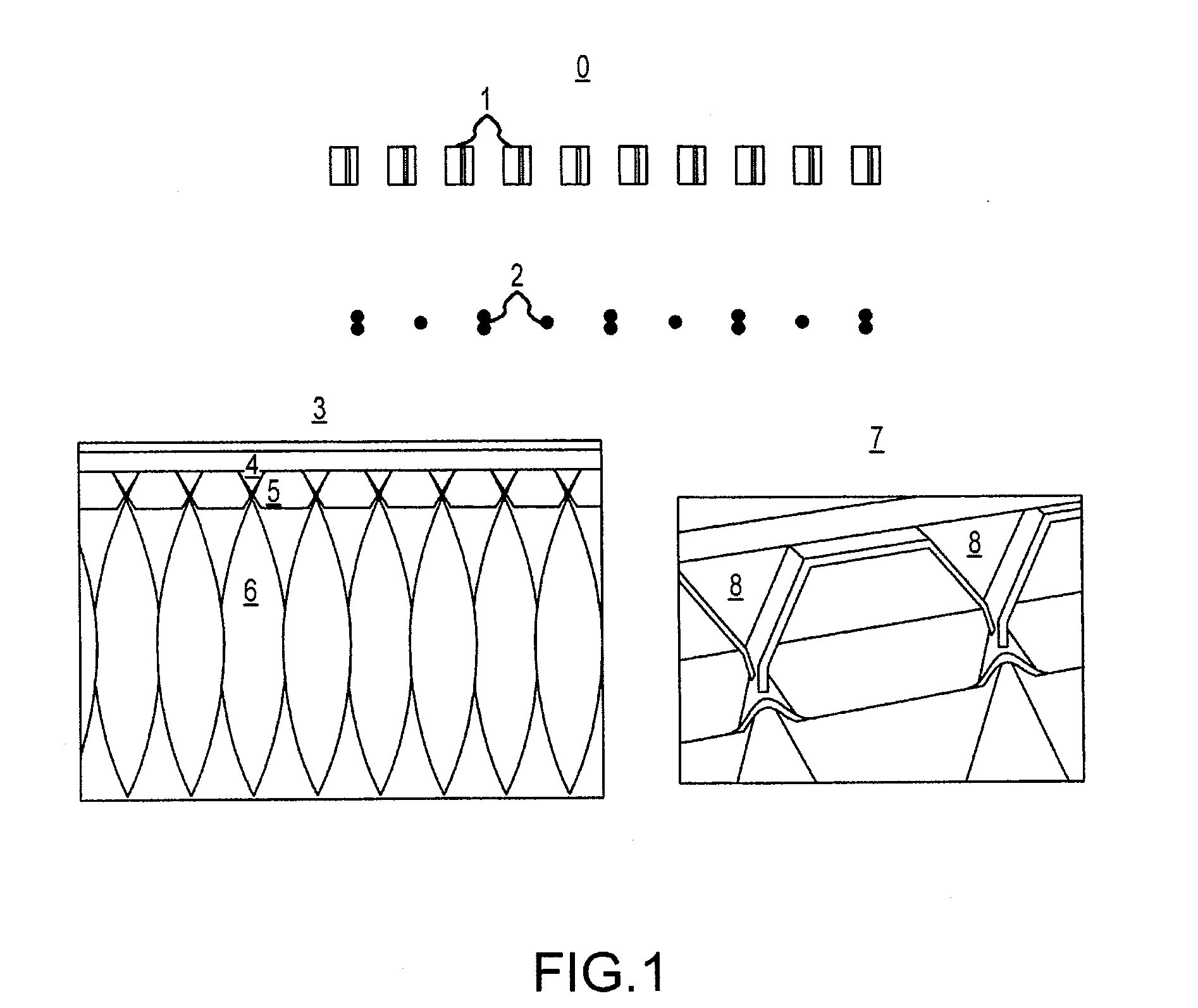

Cyclic aeration system for submerged membrane modules

InactiveUS6881343B2Easy illustrationSmall sizeTreatment using aerobic processesLighting and heating apparatusAeration systemEnvironmental engineering

An aeration system for a submerged membrane module has a set of aerators connected to an air blower, valves and a controller adapted to alternately provide a higher rate or air flow and a lower rate of air flow in repeated cycles. In an embodiment, the air blower, valves and controller, simultaneously provide the alternating air flow to two or more sets of aerators such that the total air flow is constant, allowing the blower to be operated at a constant speed. In another embodiment, the repeated cycles are of short duration. Transient flow conditions result in the tank water which helps avoid dead spaces and assists in agitating the membranes.

Owner:ZENON TECH PARTNERSHIP

Process for production of elemental iron

InactiveUS7931731B2Easy to processIsotope separationHydrogen/synthetic gas productionPartial oxidationFerric

A process to prepare elemental iron by contacting an iron ore feed with a reducing gas at a pressure of between 1 and 10 bar to obtain iron and an off-gas includes preparing the reducing gas by performing the following steps: (a) partially oxidizing a mixture comprising a solid or liquid carbonaceous fuel and oxygen at a pressure of between 10 and 80 bar, thereby obtaining a gas comprising H2 and CO; (b) removing CO2 and H2S from the gas obtained in step (a) to obtain an intermediate gas comprising H2 and CO; (c) supplying the intermediate gas obtained in step (b) to a H2-selective membrane to obtain a H2-rich permeate gas and a CO-rich retentate; and (d) heating H2-rich permeate to obtain a heated H2-rich permeate as the reducing gas.

Owner:SHELL OIL CO

Humidifier with a heating disc

InactiveUS6874771B2Lighting and heating apparatusMixing methodsLiquid storage tankMechanical engineering

A humidifier includes a base defining a reservoir for retaining liquid, a humidification device for inducing dispersion of liquid withdrawn from the reservoir into the environment and a liquid storage tank having an outlet for feeding liquid into the reservoir. The humidification device includes a heated disc for evaporating a stream of liquid delivered from the reservoir to the heated disc by a delivery mechanism. The delivery mechanism may deliver the stream of liquid as a mist, a thin film or a controlled stream of liquid onto the disc.

Owner:HELEN OF TROY LIMITED

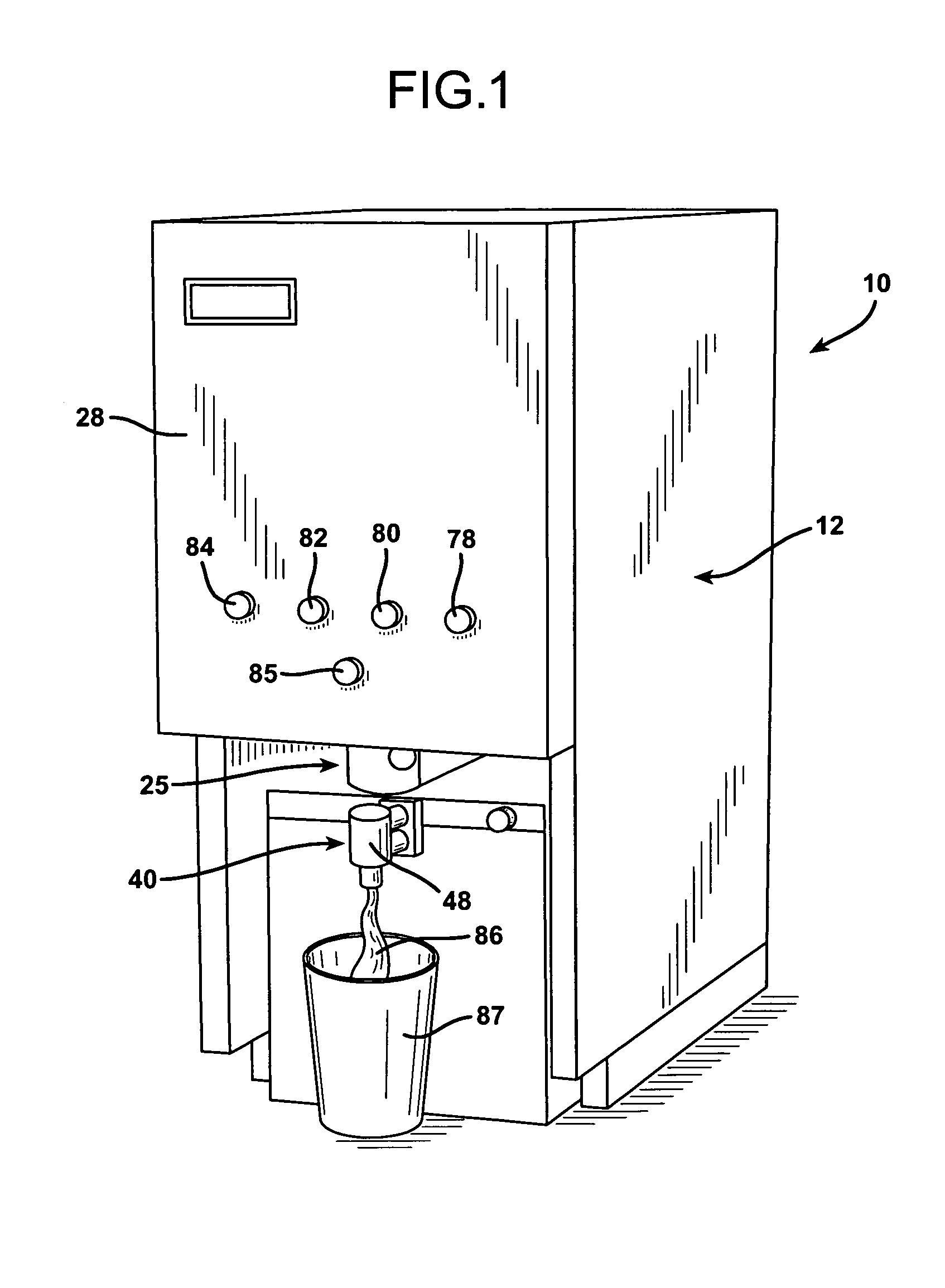

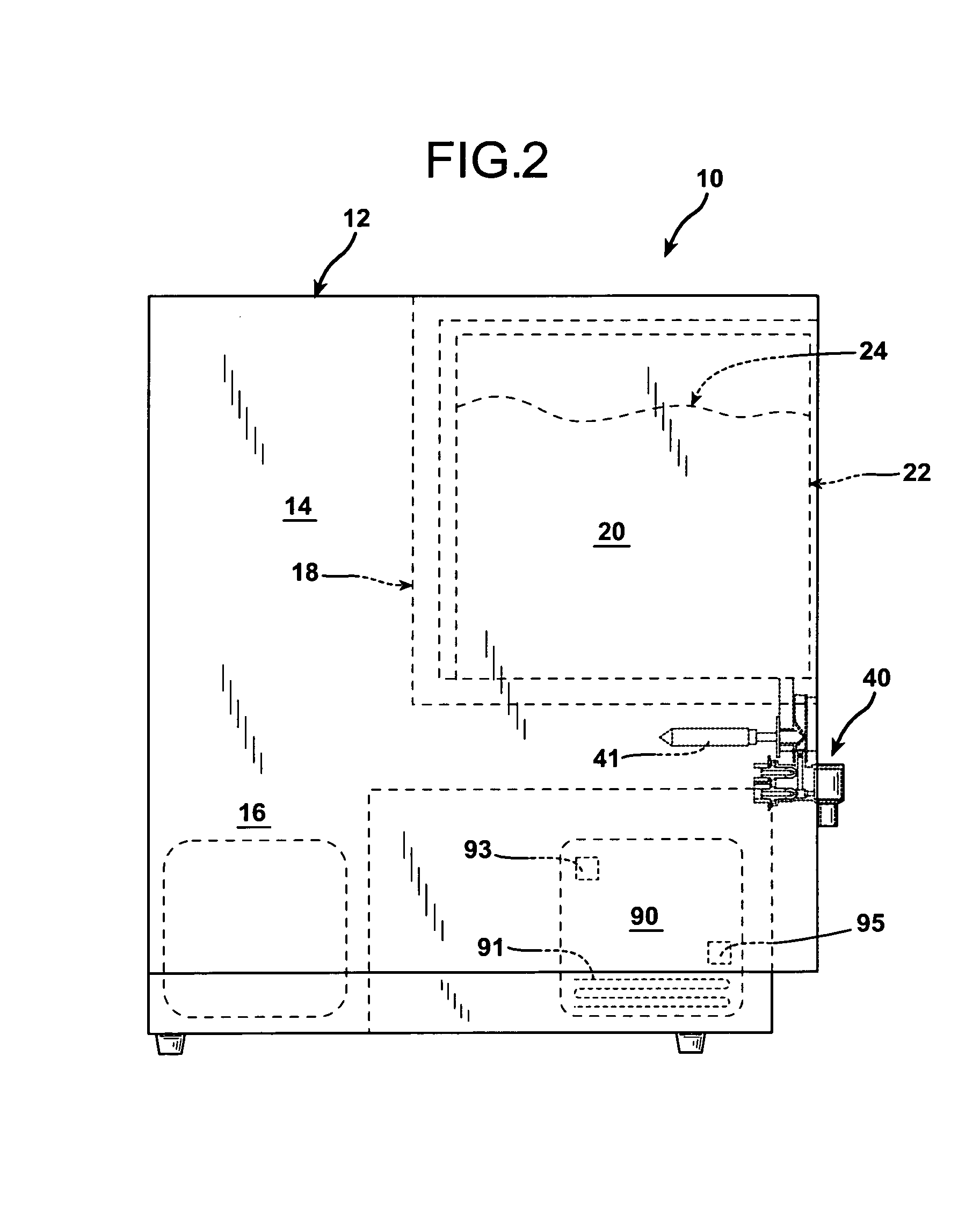

Hot dairy-based beverage dispenser

InactiveUS7021206B2Reduce eliminateConstant flowLighting and heating apparatusUsing liquid separation agentPinch valveEngineering

A dispensing unit for dispensing hot, dairy-based beverages has a self-contained refrigerated unit located above a venturi-type emulsification foaming head. The dispensing unit has particular applicability to the dispensation of foamy, hot milk for use in beverages such as cappuccino and nonfoamy, hot milk for use in beverages such as coffee latte, hot chocolate, and other hot dairy-based beverages. The refrigeration unit accommodates a “bag in box” cold milk storage container of the type widely used in food service establishments. The dispensing unit employs a pinch valve that avoids direct contact between the milk and the valve components. The refrigerated milk is stored above the level of the foamer head so that the flow of milk results partially from gravitational force on the milk, and is not totally dependent upon venturi suction created in the foamer head.

Owner:ECKENHAUSEN ROLAND B +1

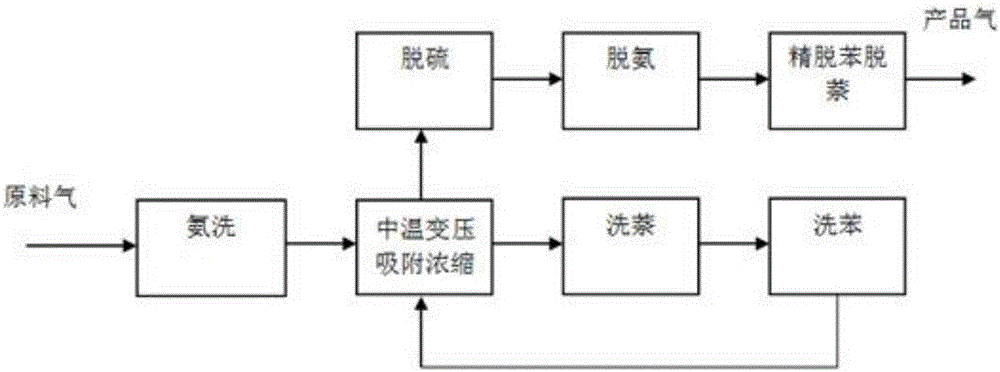

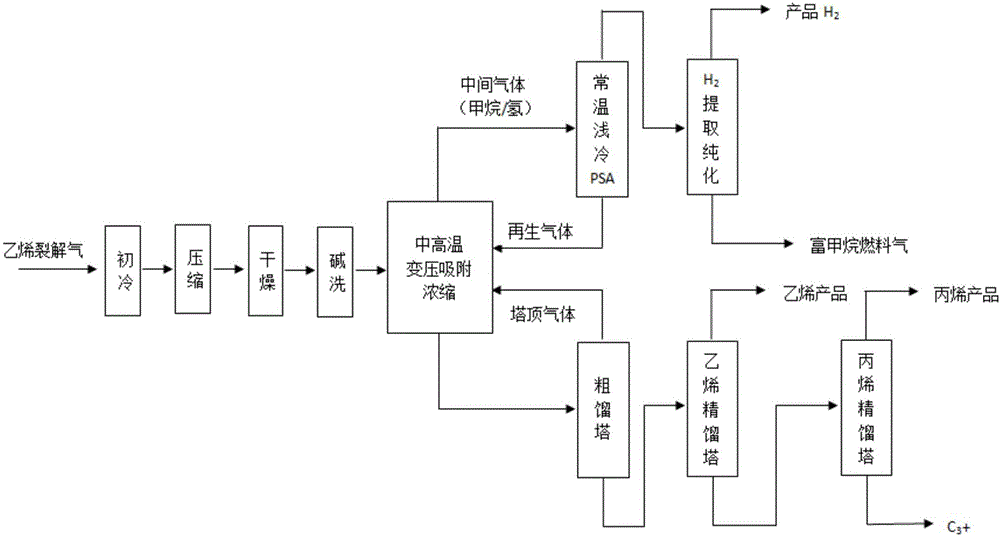

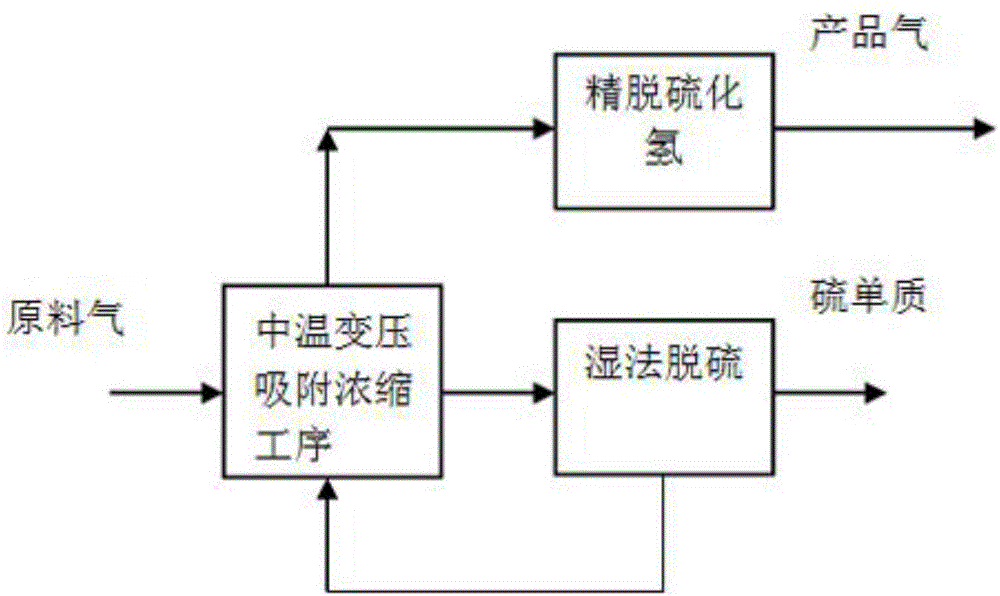

Full-temperature-range pressure swing adsorption gas separation, refinement and purification method

ActiveCN105749699AReduce energy consumptionBroaden the scope of adsorption separation applicationsSolidificationLiquefactionEnergy gradientPurification methods

The invention discloses a full-temperature-range pressure swing adsorption gas separation, refinement and purification method.By means of the difference of the temperatures and pressures of different raw material gases and the difference of the adsorption separation coefficients and physical chemistry properties of all components in the raw material gases in the temperature range of 80-200 DEG C and the pressure range of 0.03-4.0 MPa, the adsorption or desorption regeneration operation of the pressure swing adsorption circulation process is adjusted by coupling all separation methods, the adsorption theory that the pressure or temperature swing adsorption separation process is only limited to the adsorption and desorption regeneration circulation operation through pressure or temperature changes is expanded, and therefore all raw material gases are separated, refined and purified by achieving the energy gradient utilization in the gas separation, refinement and purification process and achieving the circulation operation, where adsorption, desorption and regeneration are easily matched and balanced, in the moderate to low cold and moderate to high temperature pressure swing adsorption separation process, and it is changed that a traditional adsorption method is only limited to the auxiliary effect of refinement and purification, and adsorption becomes the basic separation unit operation just as important as refinement, absorption and extraction separation.

Owner:SICHUAN TECHAIRS

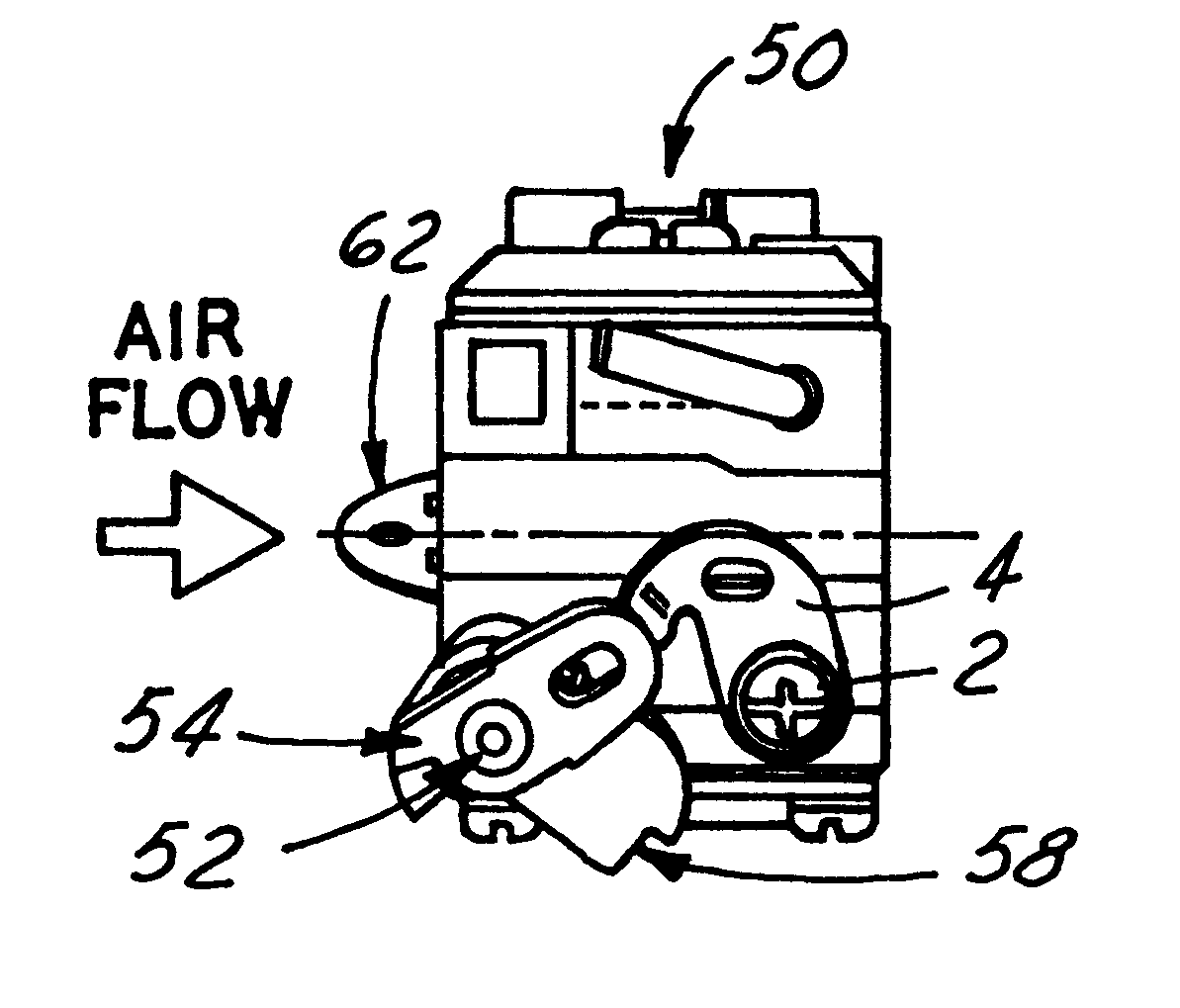

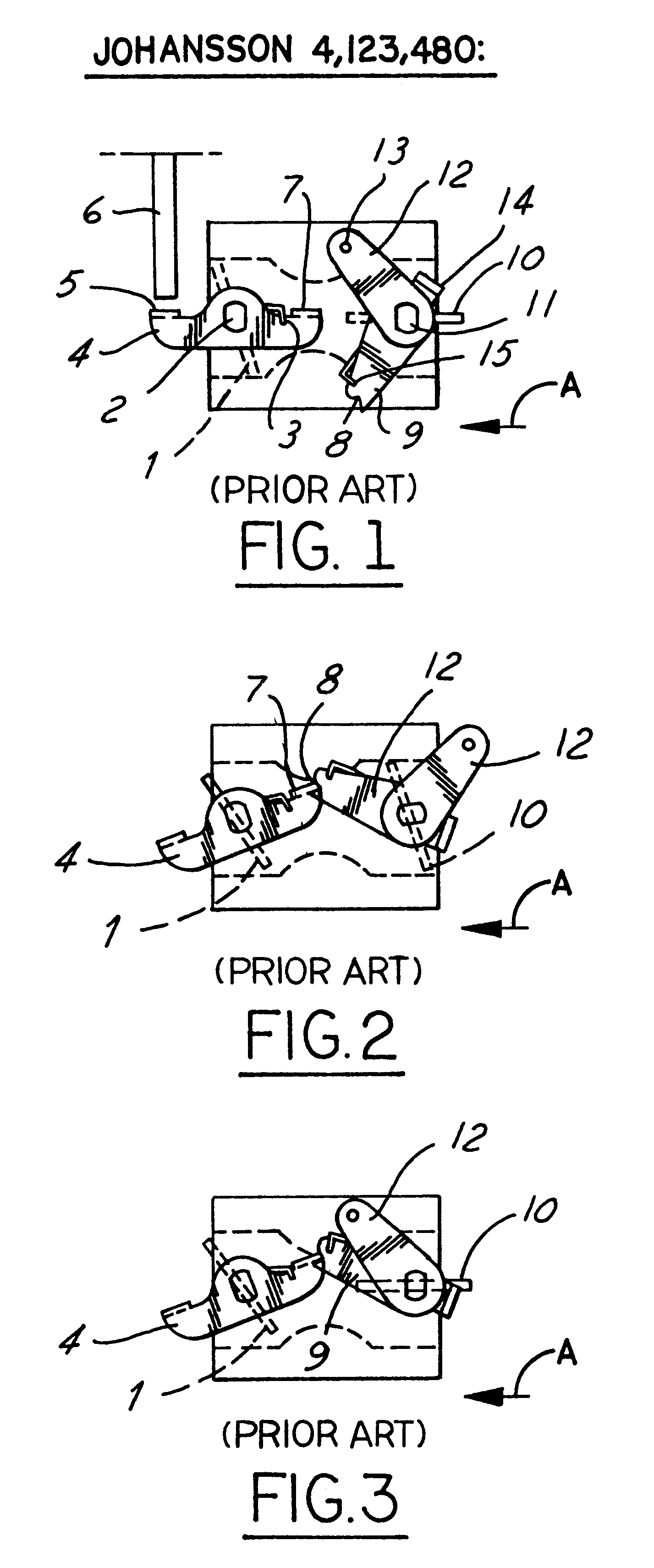

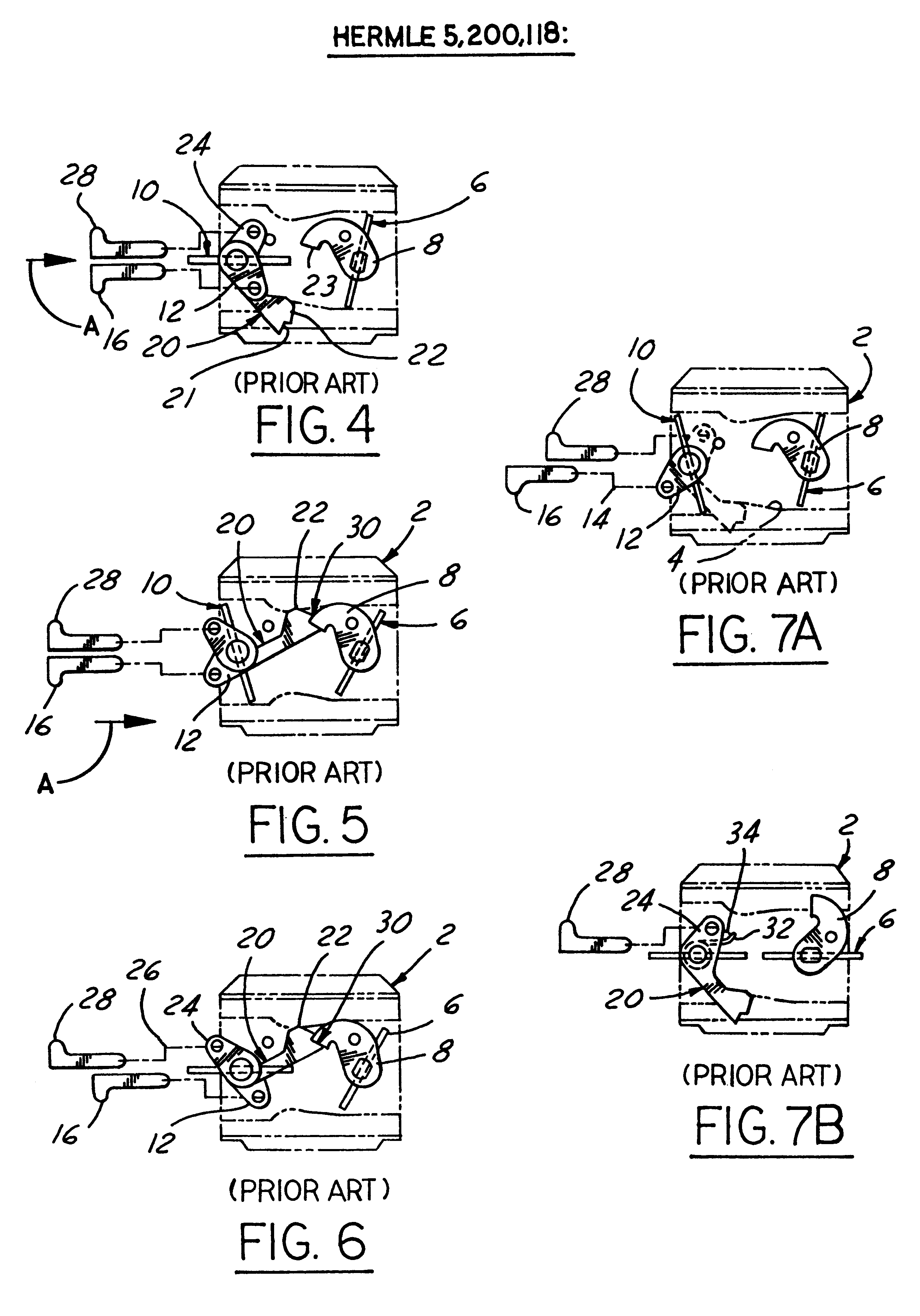

Carburetor throttle and choke control mechanism

InactiveUS6202989B1Low costEasy to modifyElectrical controlLighting and heating apparatusIdle speedCarburetor

A control mechanism for a carburetor having a throttle valve and a choke valve each having at least a cold-starting position and a full-speed position. The throttle valve is spring biased toward its third, low idle position, and the choke valve is mounted on a choke shaft and is spring biased toward its full-speed open position. When the choke valve is moved by a choke shaft lever from its open position toward its cold start closed position a fast idle lever associated with the choke valve shaft engages, via releasable latch parts, a throttle lever associated with the throttle valve. The interengaging latch parts of these fast idle and throttle levers hold both valves in their respective cold-starting positions in opposition to their respective biasing springs. These latch levers can be released by operator actuation of the throttle valve control, thereby causing the choke valve to be automatically returned to its open position by its biasing spring, or, alternatively, the choke valve can be moved independently to its full-speed position. One of these fast idle and throttle latch levers has a notch, and the other has a pawl selectively engaging the notch when it becomes aligned therewith when the latch levers are operator-actuated to their respective cold start positions. The choke shaft is torsionally resilient so that when the choke shaft lever is forced to override initial-choke-closed position, it thereby twists the choke shaft after the choke valve has been bore-stopped at closed position. Upon release of operator actuating force, this feature prevents most, if not all of the previous retrograde movement of the choke and throttle valves out of their design cold start positions, despite operating slack in the latch system due to manufacturing tolerance stack-up in the various parts of the latch system parts and / or control mechanism in their assembly and operation.

Owner:WALBRO ENGINE MANAGEMENT

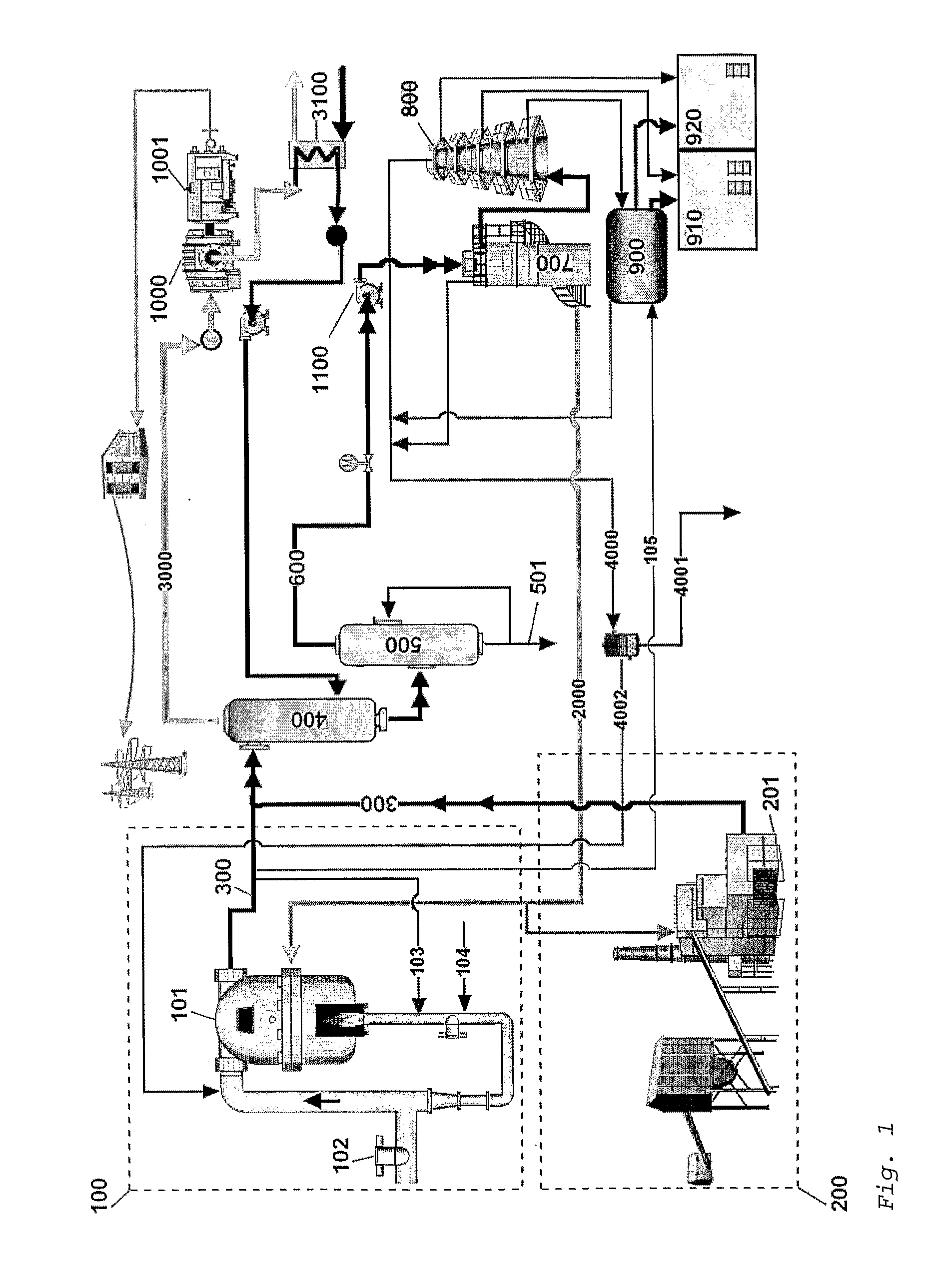

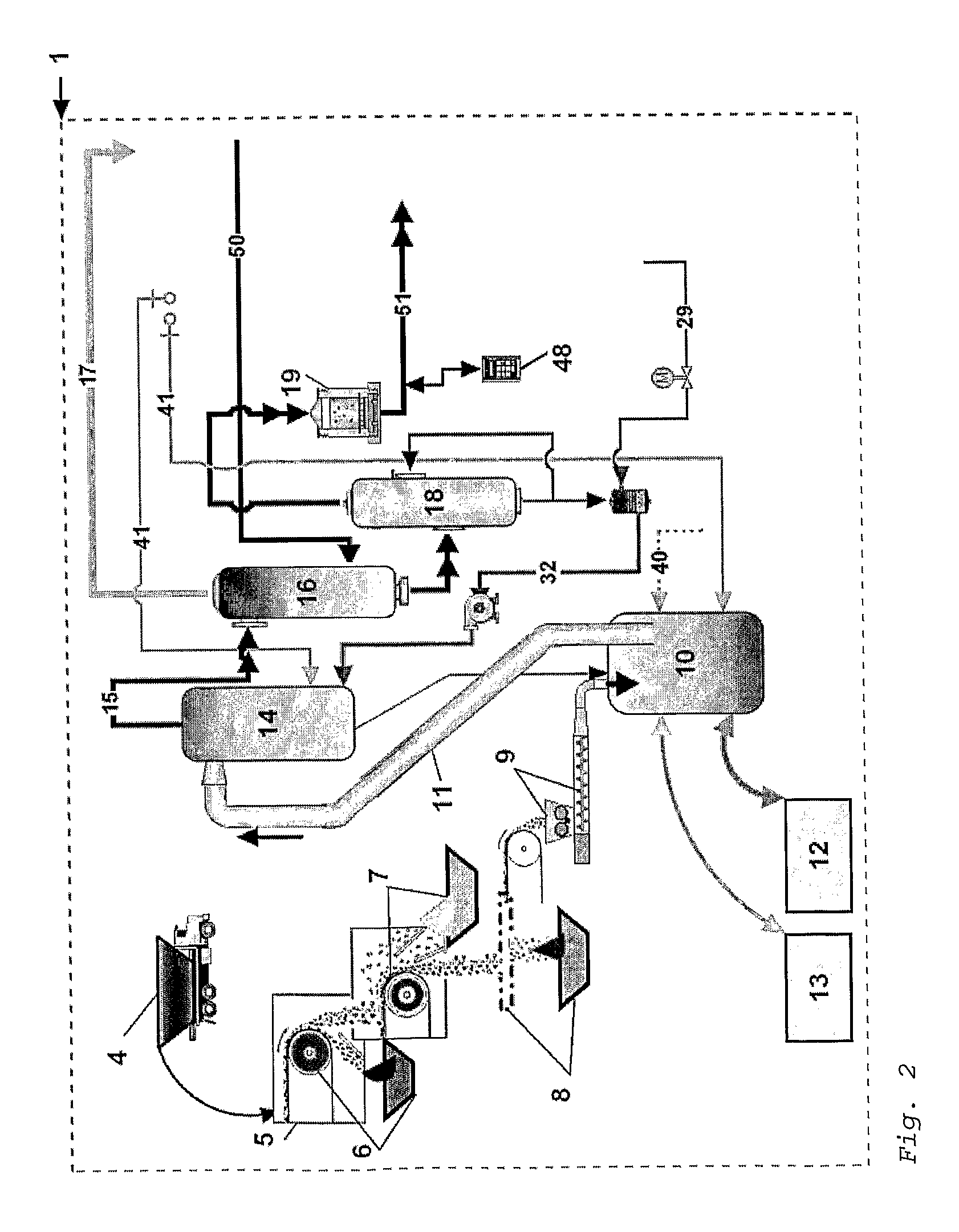

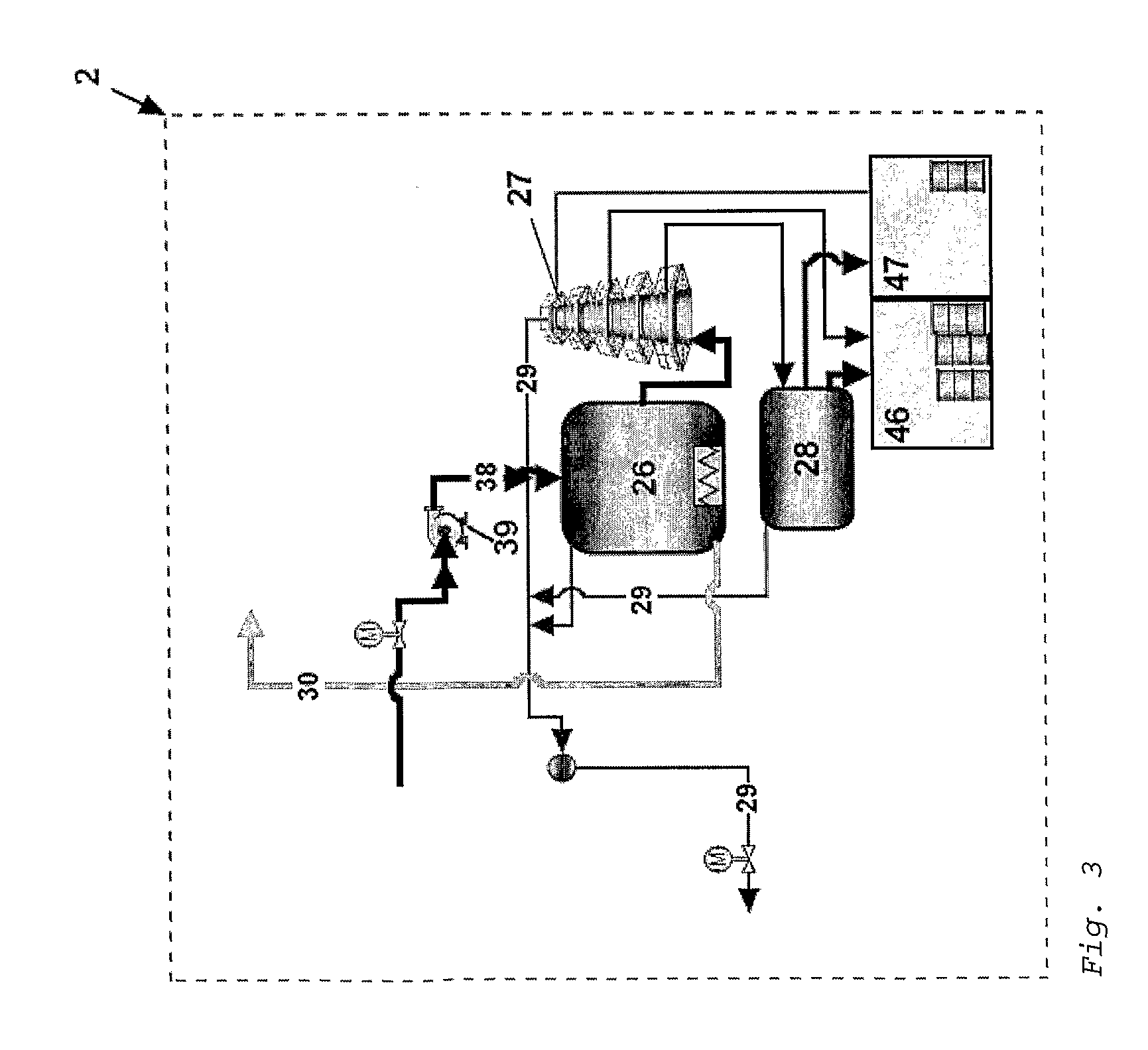

Waste to liquid hydrocarbon refinery system

InactiveUS20110158858A1Eliminate concernsReduce dependenceDirect heating destructive distillationCombustible gas catalytic treatmentLiquid wasteCogeneration

A Waste to Liquid Hydrocarbon Refinery System that transforms any municipal solid wastes and hazardous industrial wastes, Biomass or any carbon containing feedstock into synthetic hydrocarbon, particularly, but not exclusively, diesel and gasoline and / or electricity and co-generated heat, comprising three major subsystems: i) the Pyro-Electric Thermal Converter (PETC) (10) and Plasma Arc (PA) waste and biomass gasification subsystem (1); ii) the hydrocarbon synthesis subsystem (2); and iii) the electricity generation and heat co-generation subsystem (3).

Owner:ALVES RAMALHO GOMES MARIO LUIS

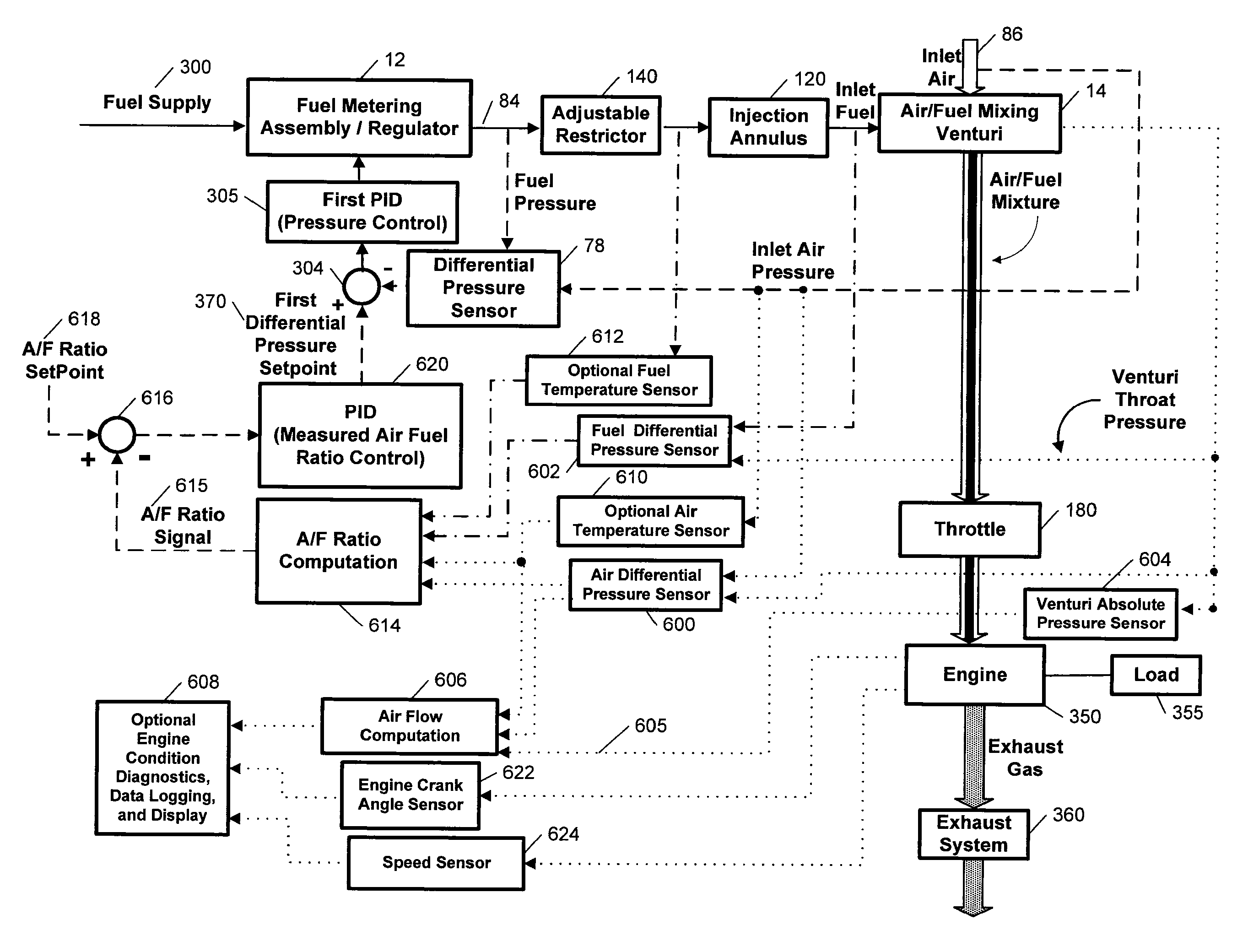

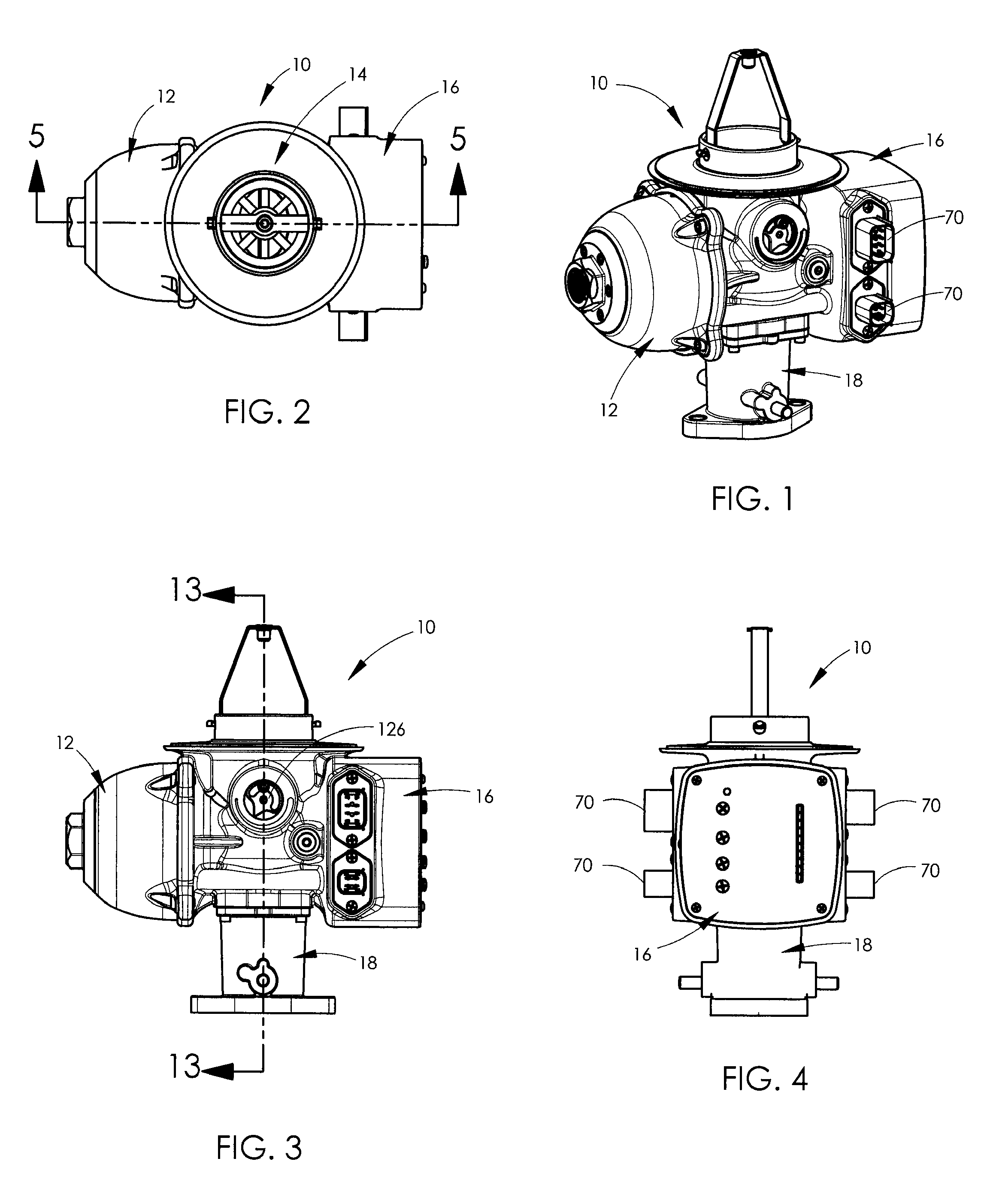

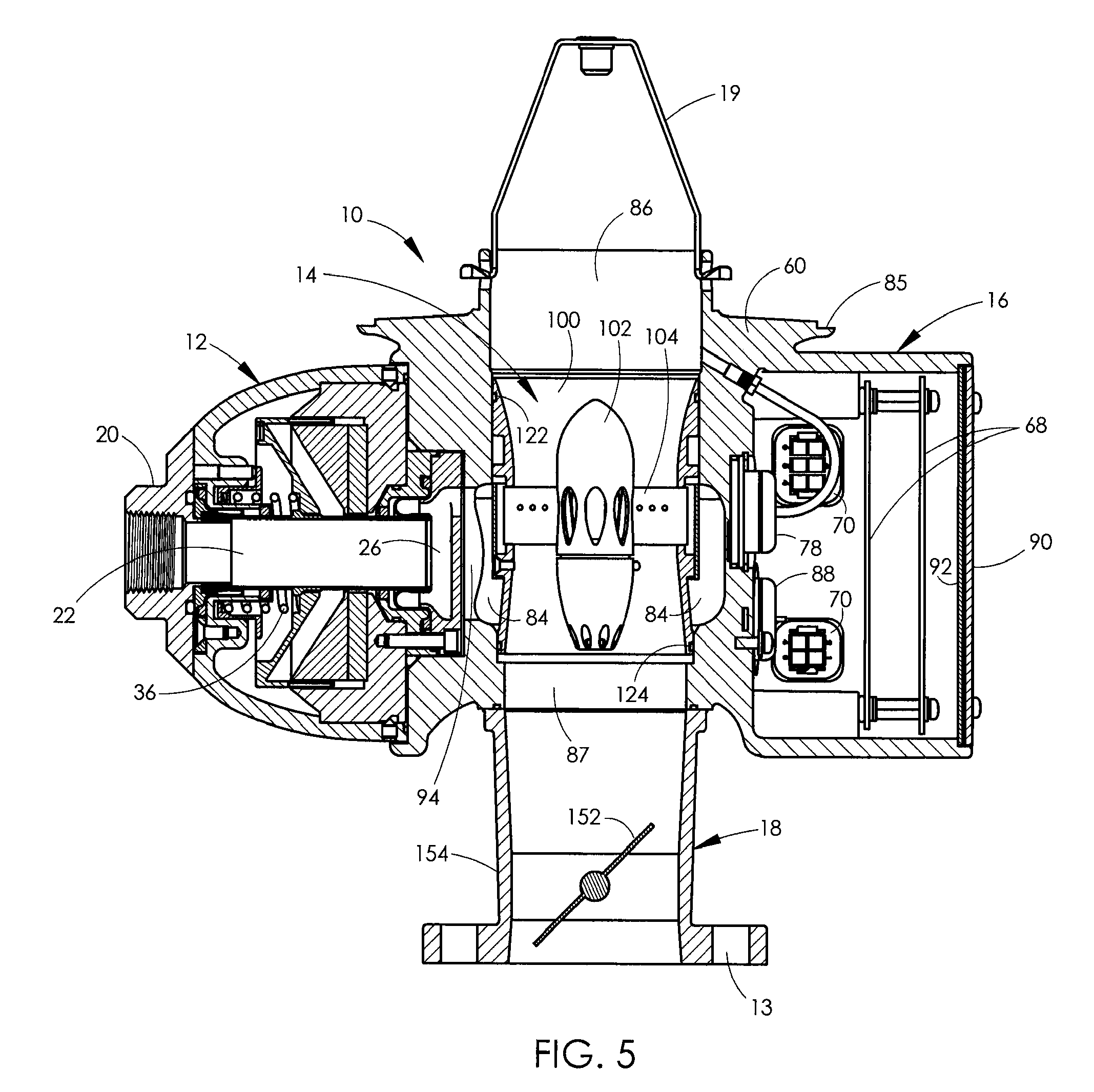

Fuel control system and method for gas engines

InactiveUS8005603B2Cost effectivePromote recoveryInternal combustion piston enginesSpace heating and ventilationControl systemClosed loop

A gaseous carburetor or fuel control system includes a fuel metering assembly, a venturi mixer assembly, a throttle assembly, and an electronic control unit. The control unit controls the fuel metering assembly in a closed loop manner based on detected gas and air pressure to an air / fuel mixing venturi. An electronic governor which controls the throttle valve may also be controlled by the same control unit which controls the fuel metering assembly, using a separate control loop.

Owner:CONTINENTAL CONTROLS CORP

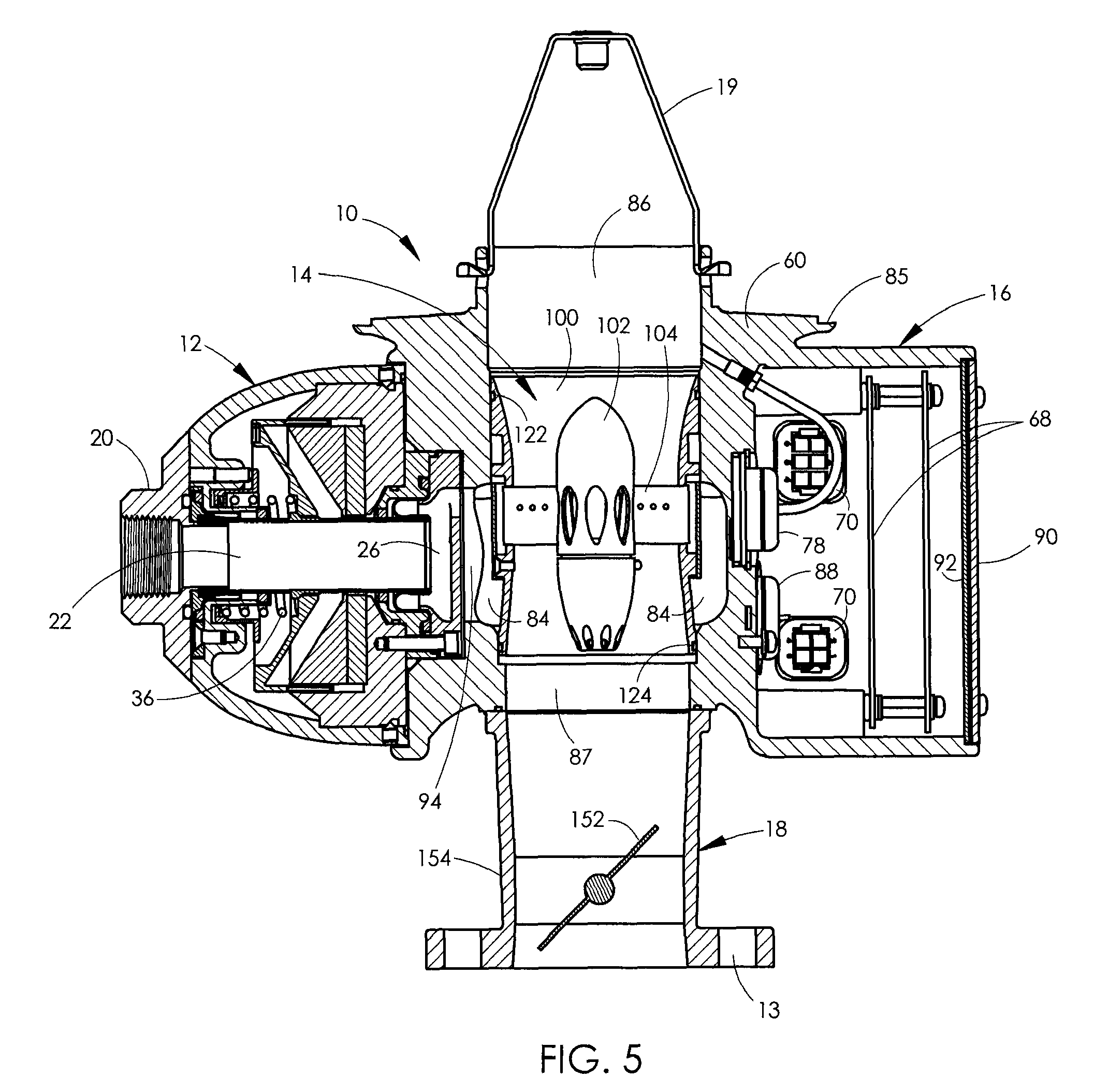

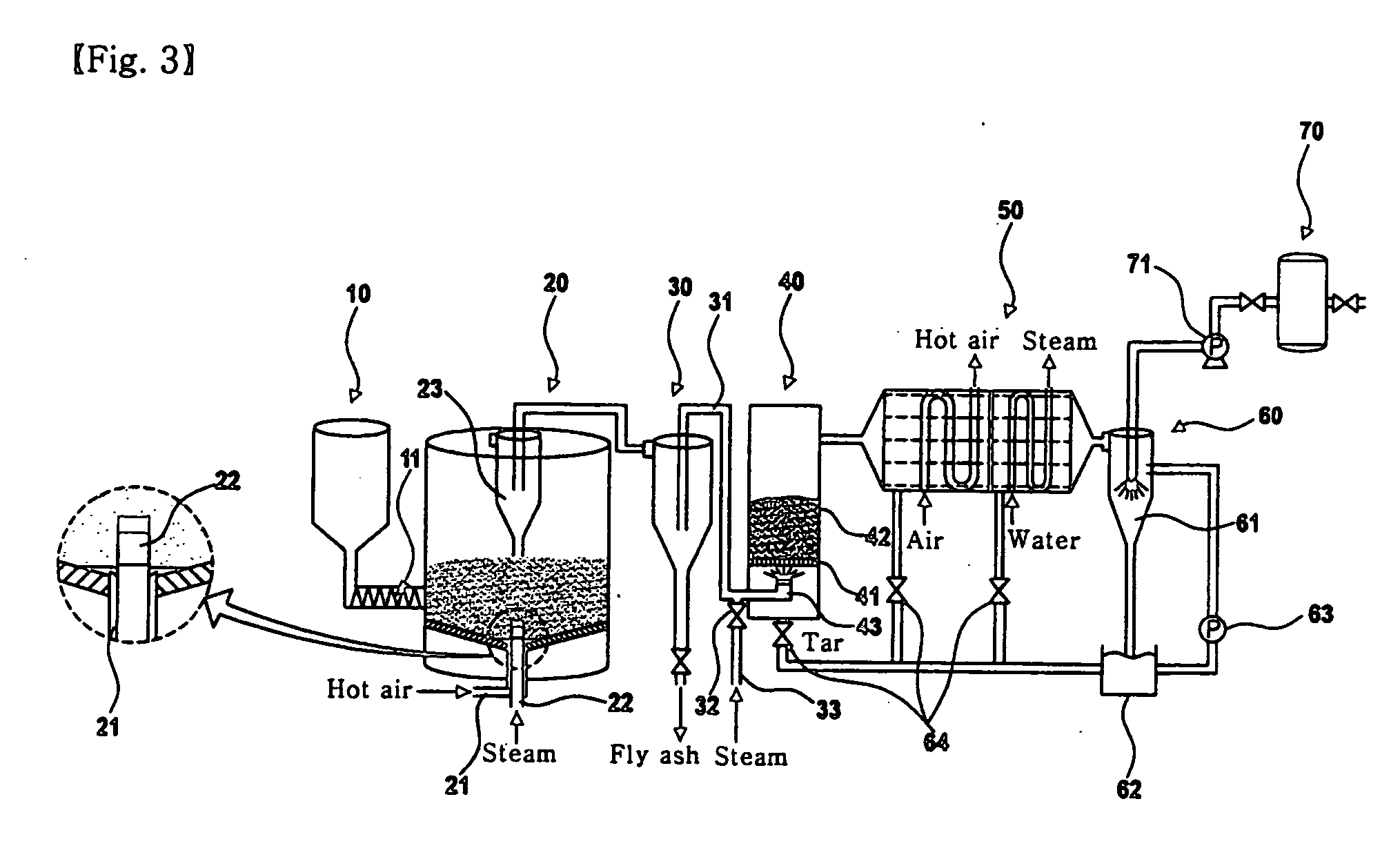

Apparatus of catalytic gasification for refined biomass fuel at low temperature and the method thereof

InactiveUS20070094929A1Low production costCompactCombustible gas catalytic treatmentLiquid hydrocarbon mixture productionCatalytic reformingFluidized bed

Disclosed is a gasification technique for converting biomass, which is difficult to treat, into clean gas fuel able to be burned in a cogeneration system. The gasification technique includes first stage fluidized-bed catalytic gasification, and second stage gasification of tar and catalytic reforming to convert nitrogen in tar, and HCN in a flammable gas into NH3, unlike conventional gasification techniques. In addition, since the temperature of a total gasification process is lower than a melting point of ash, powdery ash is generated and thus easily treated. Also, little heat is released due to the low process temperature, and therefore, a compact reactor may be designed to produce gas having a high caloric value. Further, the generated tar is recovered and reused in other processes, and the gas fuel contains a small amount of ammonia.

Owner:KOREA INST OF ENERGY RES

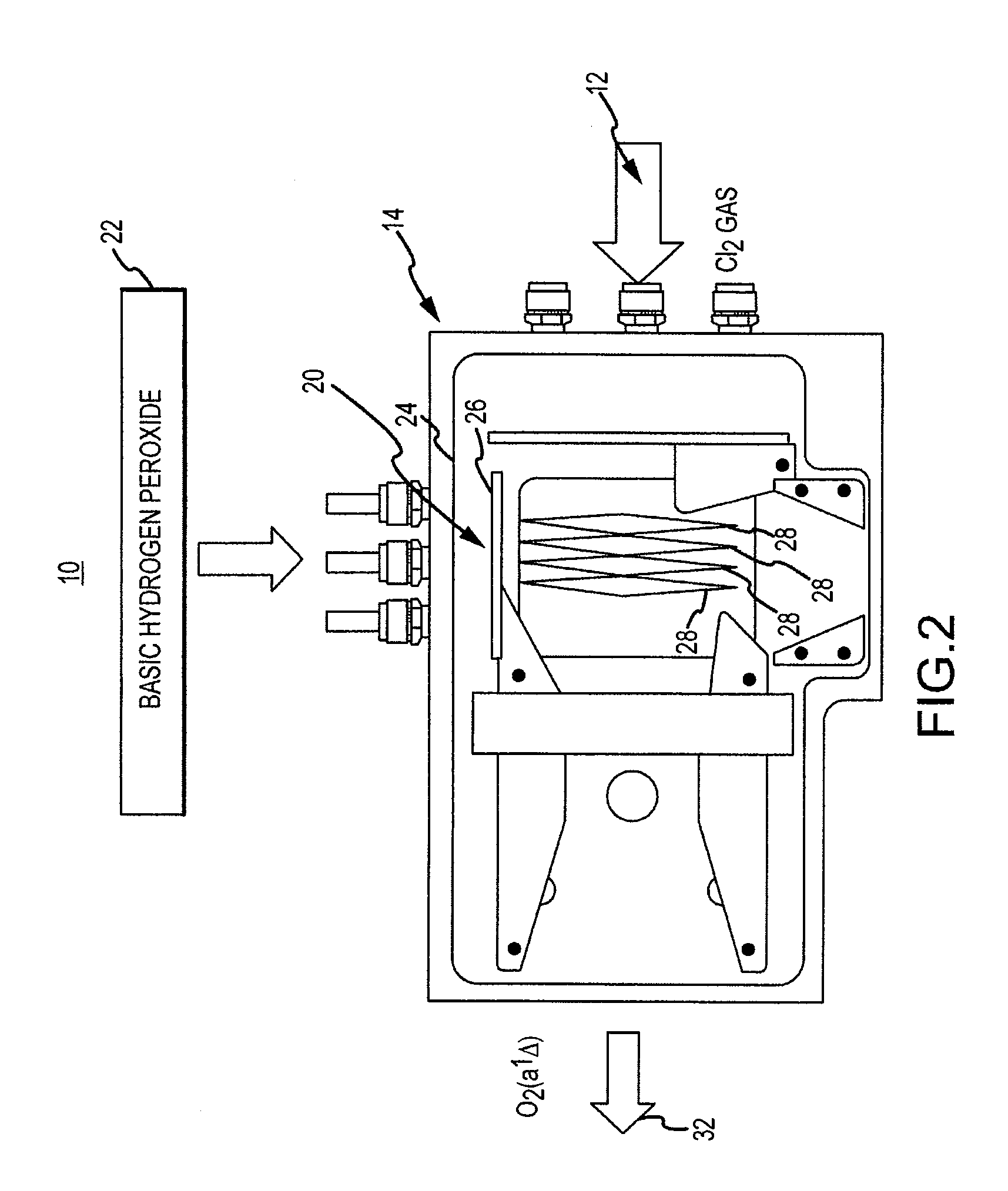

Gas liquid contactor and effluent cleaning system and method

InactiveUS20100011956A1Large volumetric mass transport coefficientSmall sizeLaser detailsFlow mixersLiquid jetEngineering

The invention relates to a gas liquid contactor and effluent cleaning system and method and more particularly to an array of nozzles configured to produce uniformly spaced flat liquid jets shaped to minimize disruption from a gas. An embodiment of the invention is directed towards a gas liquid contactor module including a liquid inlet and outlet and a gas inlet and outlet. An array of nozzles is in communication with the liquid inlet and the gas inlet. The array of nozzles is configured to produce uniformly spaced flat liquid jets shaped to minimize disruption from a gas flow and maximize gas flow and liquid flow interactions while rapidly replenishing the liquid.

Owner:NEUMANN SYST GROUP

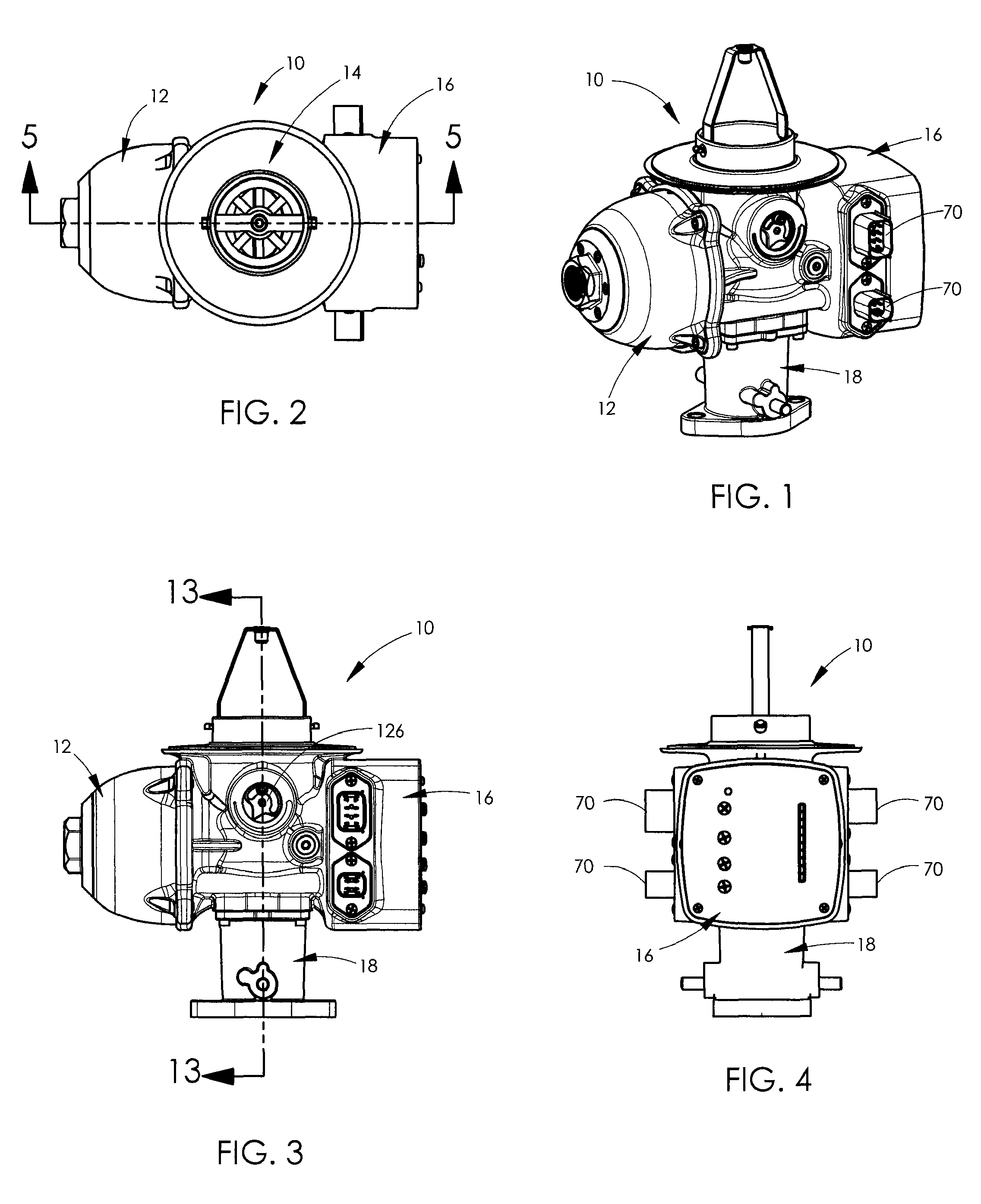

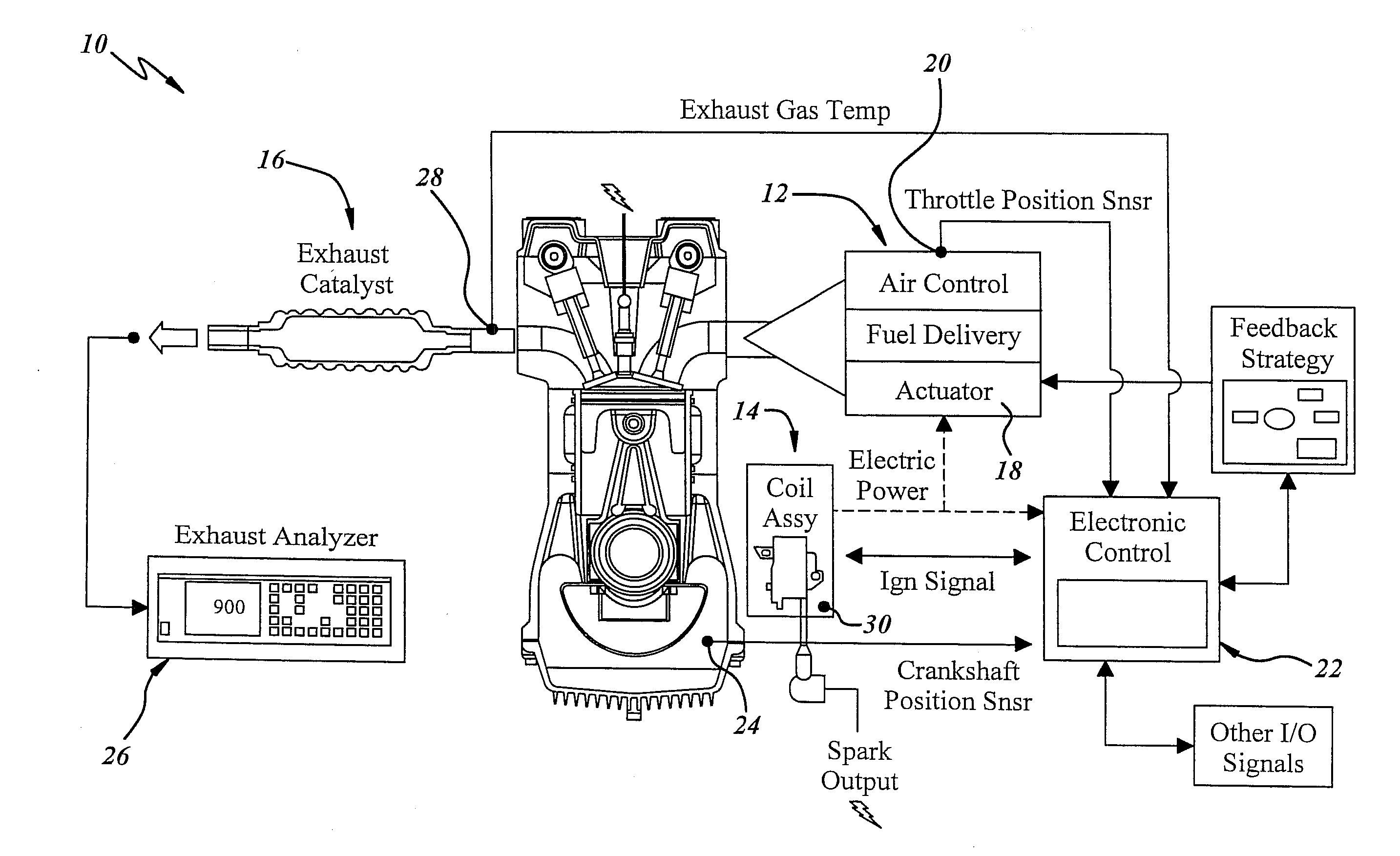

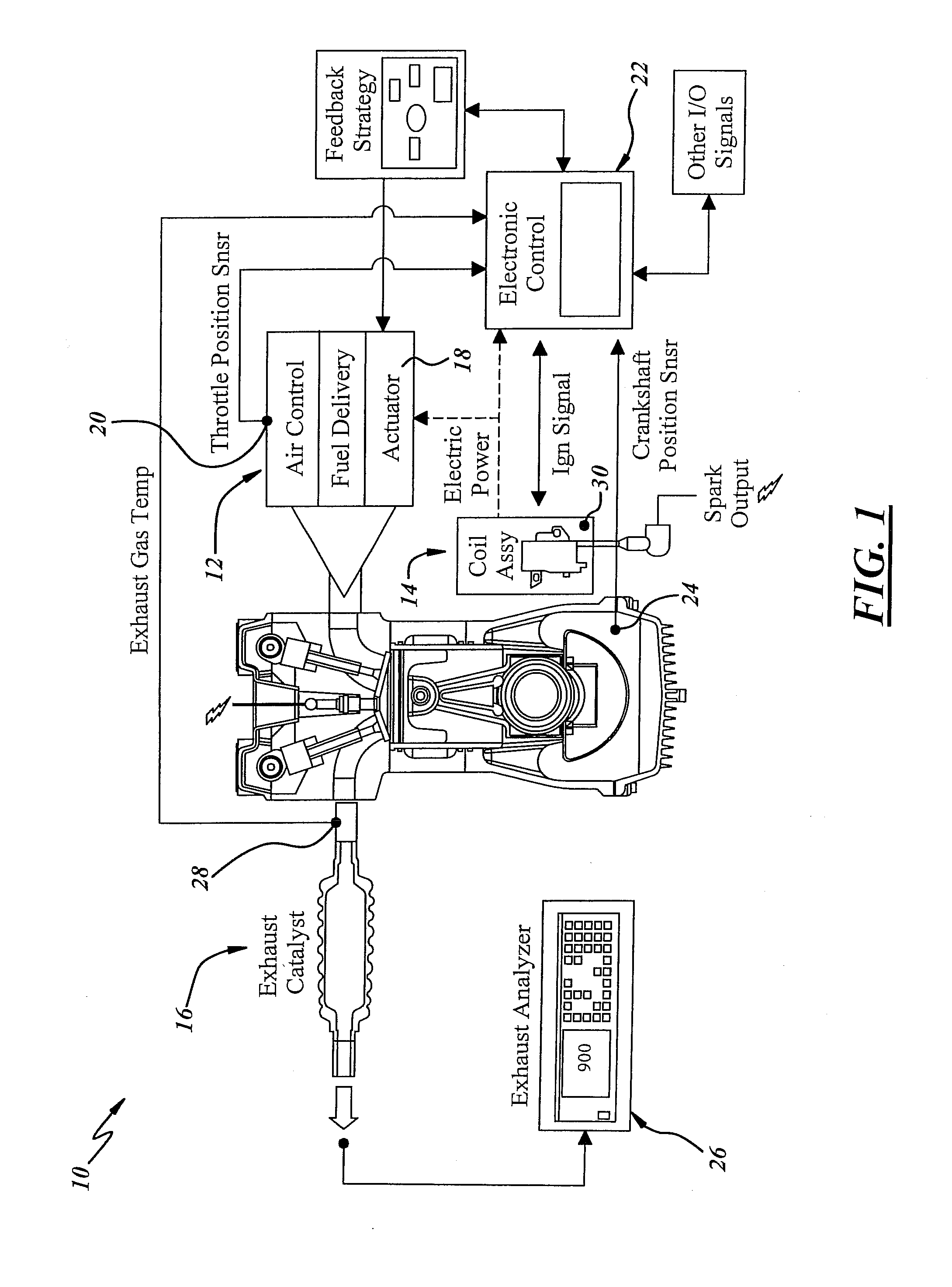

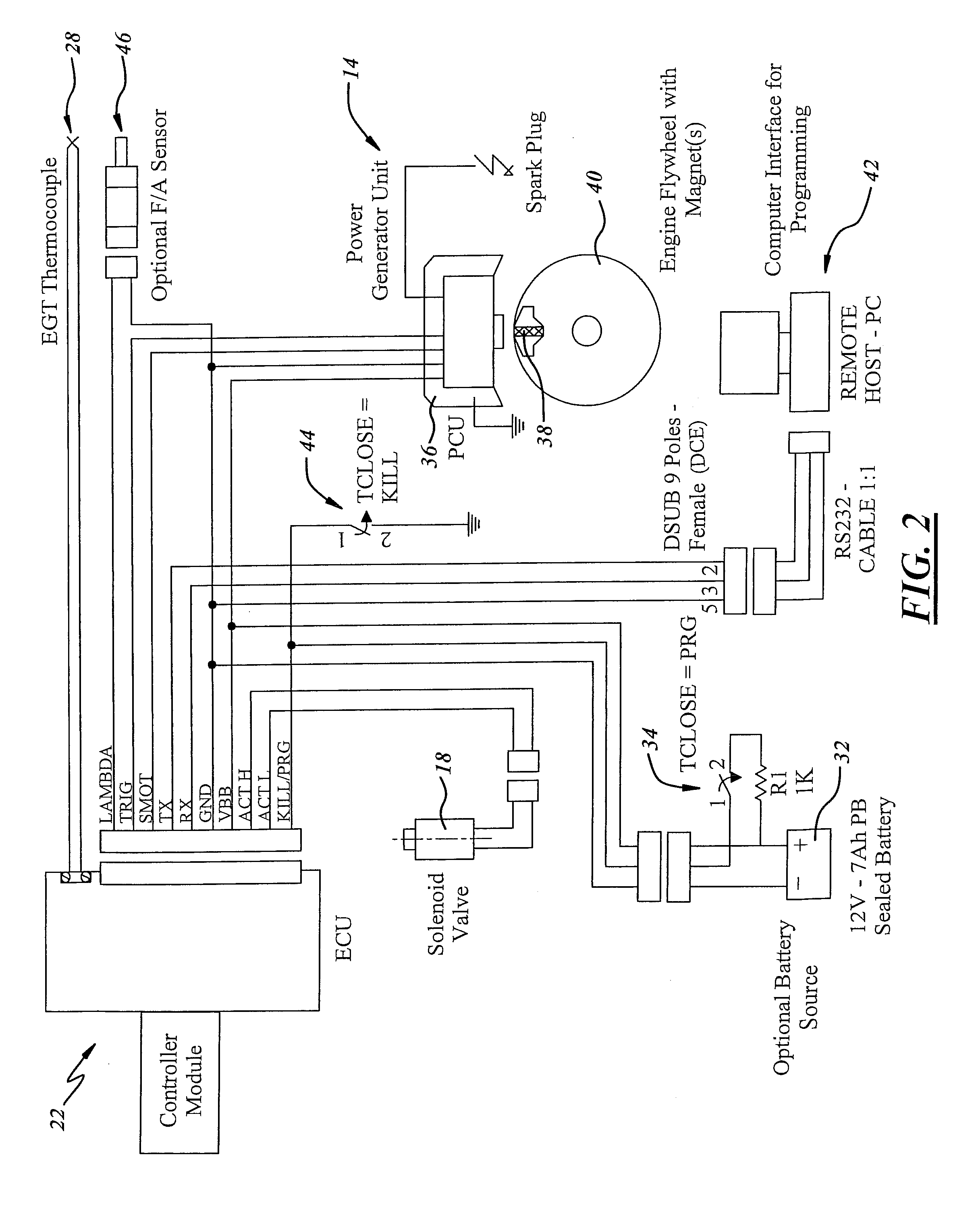

Engine fuel delivery systems, apparatus and methods

ActiveUS20100258099A1Avoid communicationAnalogue computers for vehiclesElectrical controlControl systemEngineering

A method of operating an engine is disclosed, which includes determining a peak power condition for the engine, measuring a temperature associated with the engine at said peak power condition, comparing the temperature measured with a previously determined temperature associated with a known peak power condition of the engine, determining an offset value based on the comparison made in step, controlling at least one of an air-fuel mixture delivered to the engine or ignition spark timing based on said offset value. Various engine fuel delivery systems, carburetors, fuel injection and control systems also are disclosed.

Owner:WALBRO LLC

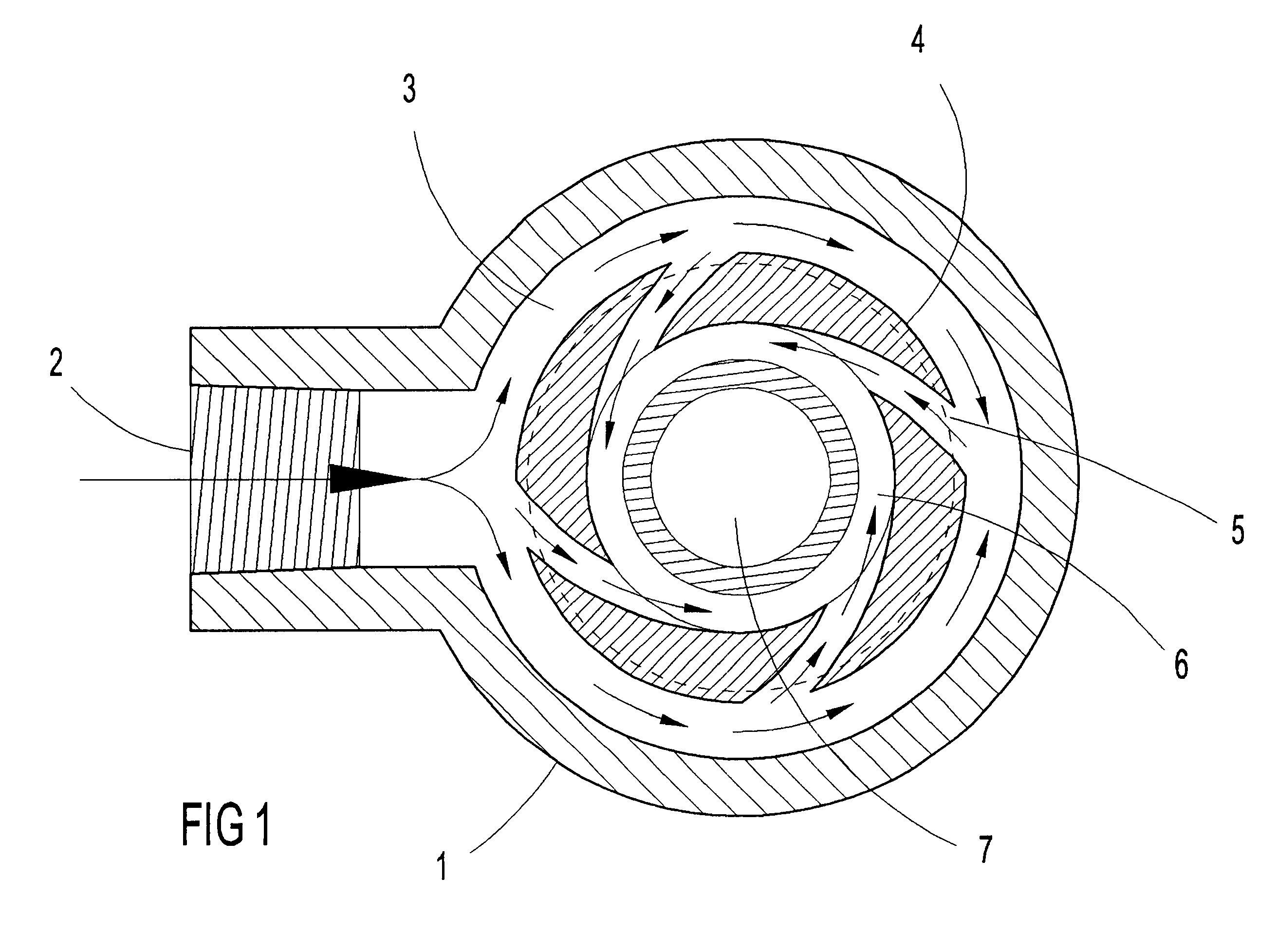

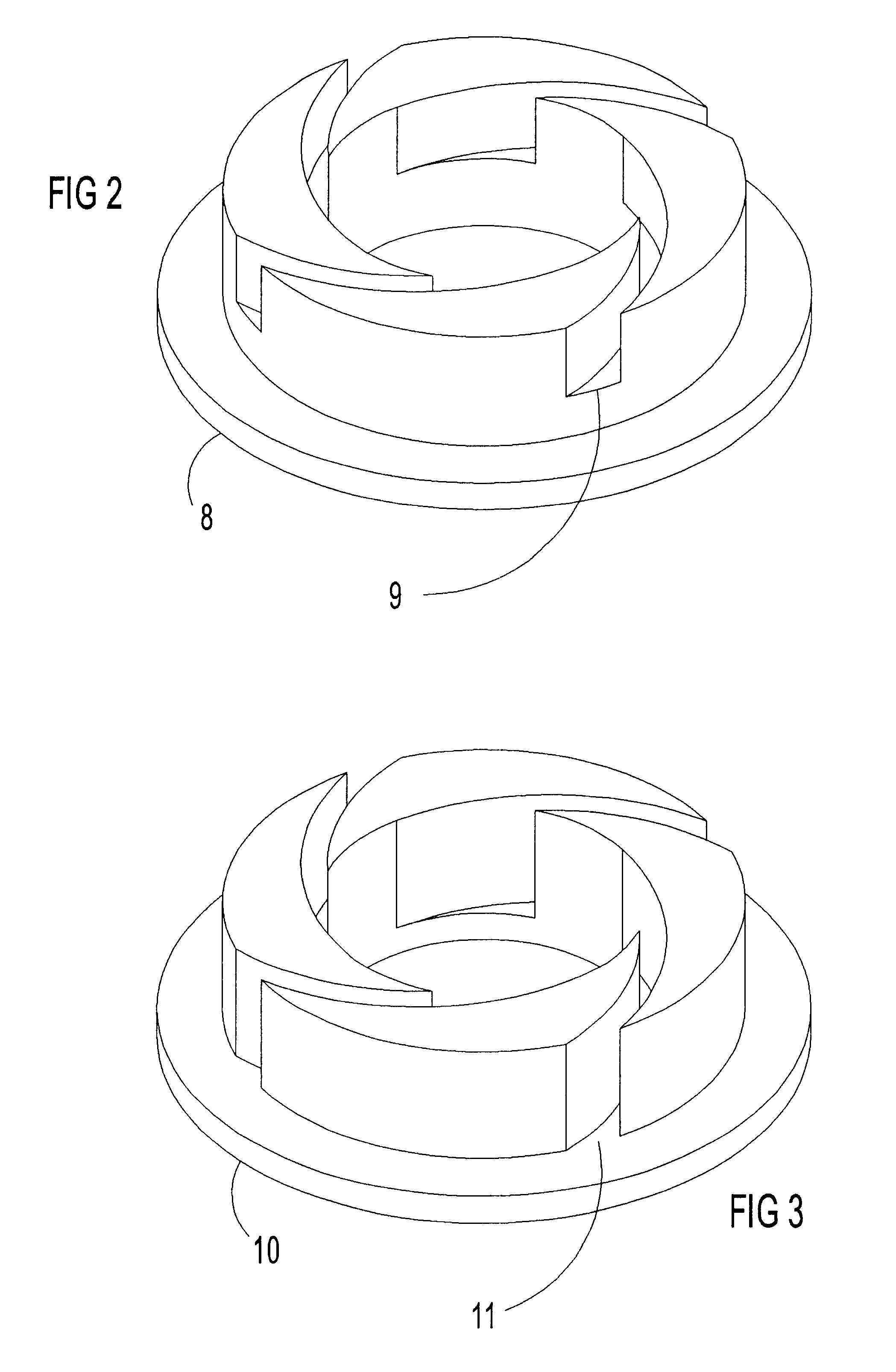

Apparatus for mixing fluids

InactiveUS6669843B2Eliminate needLiquid separation auxillary apparatusSpace heating and ventilationGas passingSolid particle

Owner:HYDROTREAT

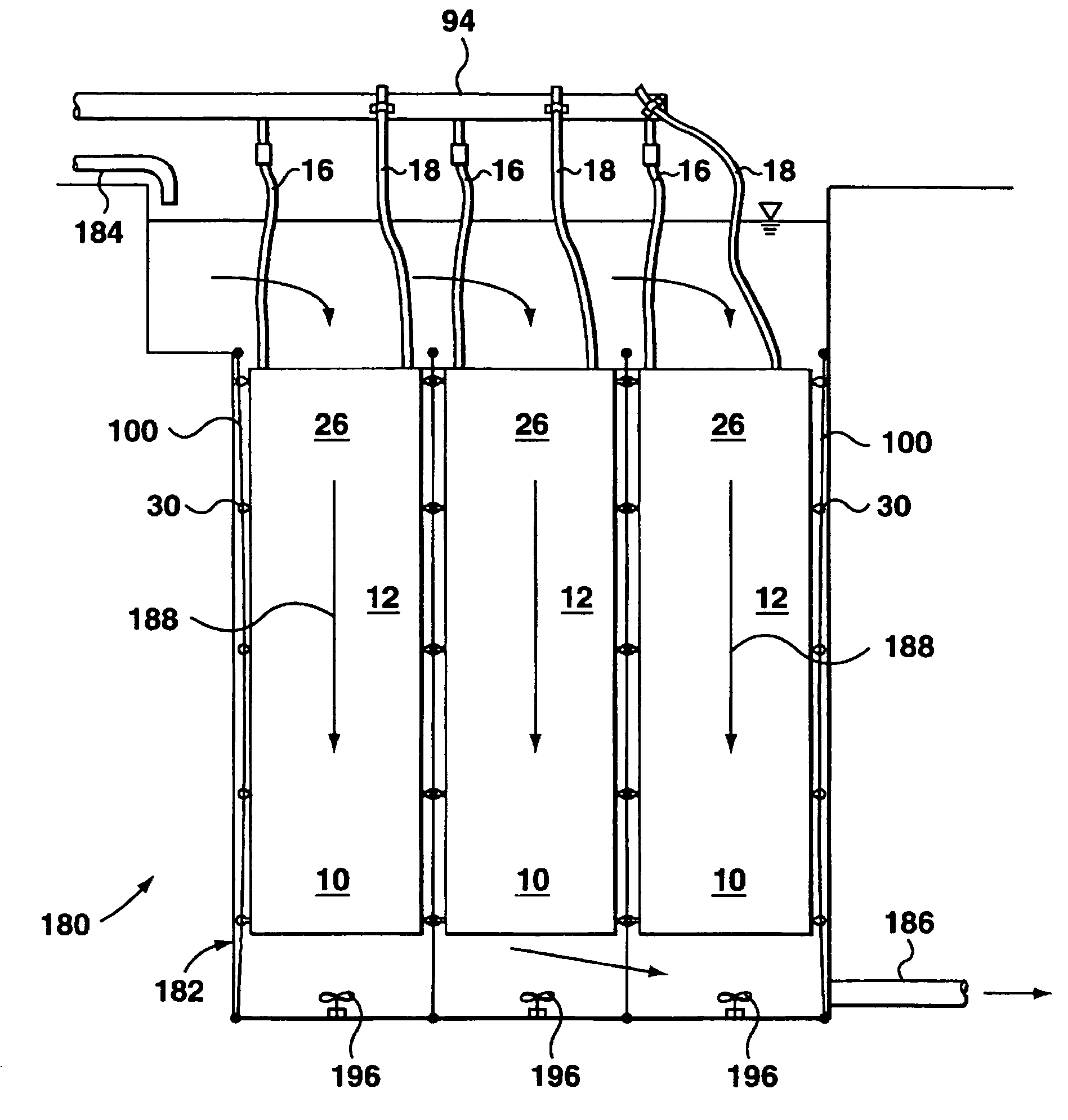

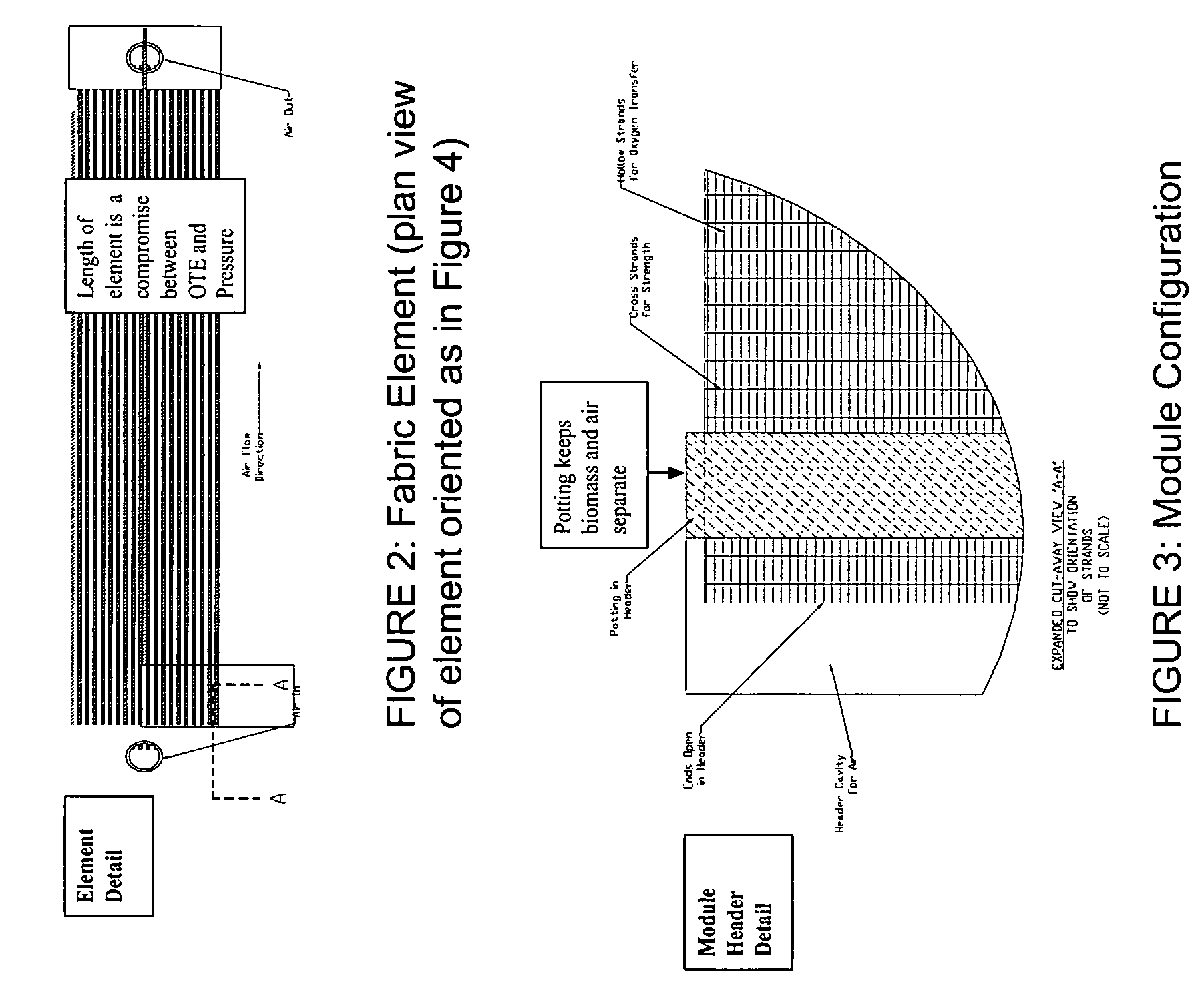

Membrane supported bioreactor for municipal and industrial wastewater treatment

ActiveUS7118672B2Reduce operating costsIncrease surface areaCarburetting airSemi-permeable membranesBiofilmFiber

A membrane supported biofilm reactor uses modules having fine, dense, non-porous hollow fibers made from Polymethyl pentene (PMP) formed into a fabric with the PMP as the weft. One or more sheets of the fabric are potted into a module to enable oxygen containing gas to be supplied to the lumens of the hollow fibers. Various reactors using such modules are described.

Owner:ZENON TECH PARTNERSHIP

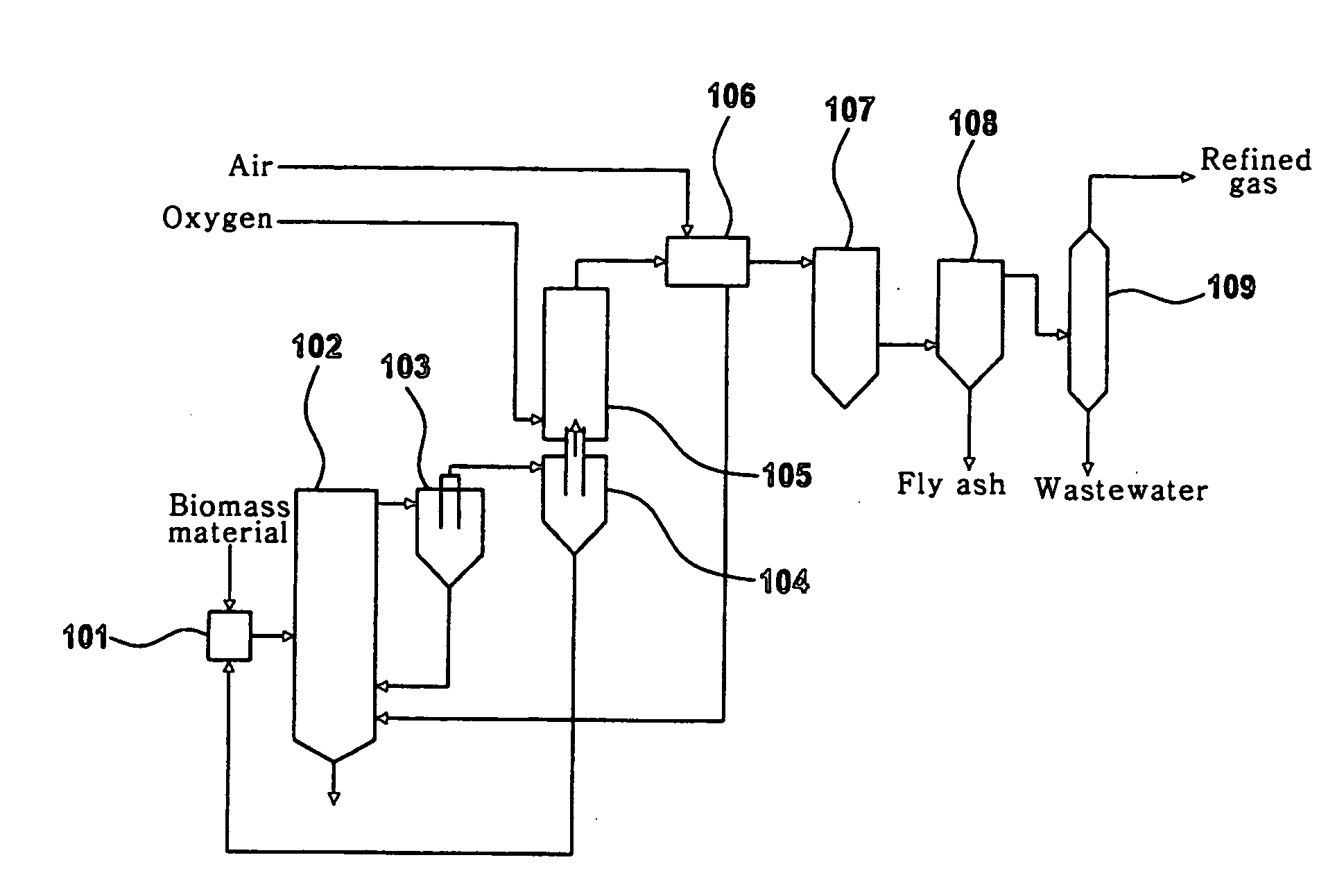

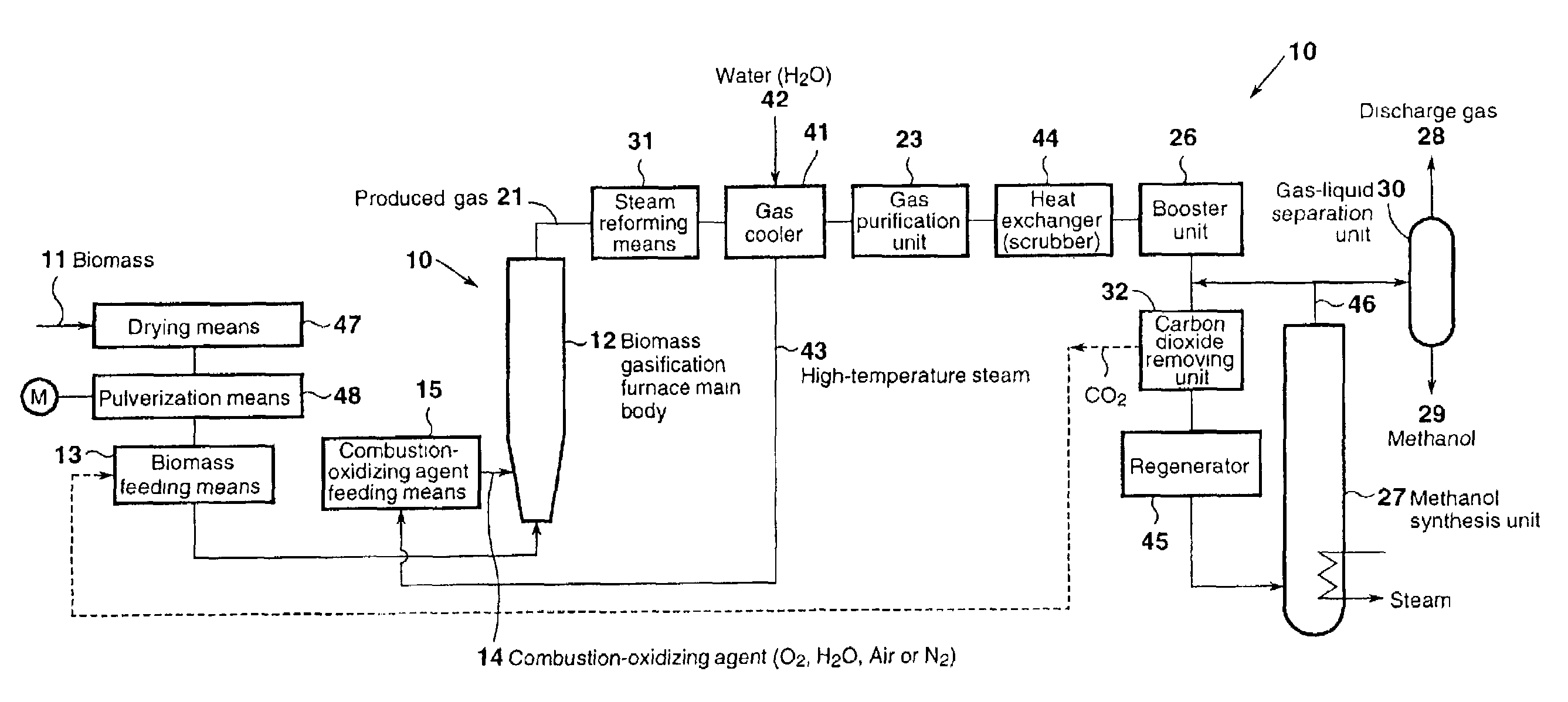

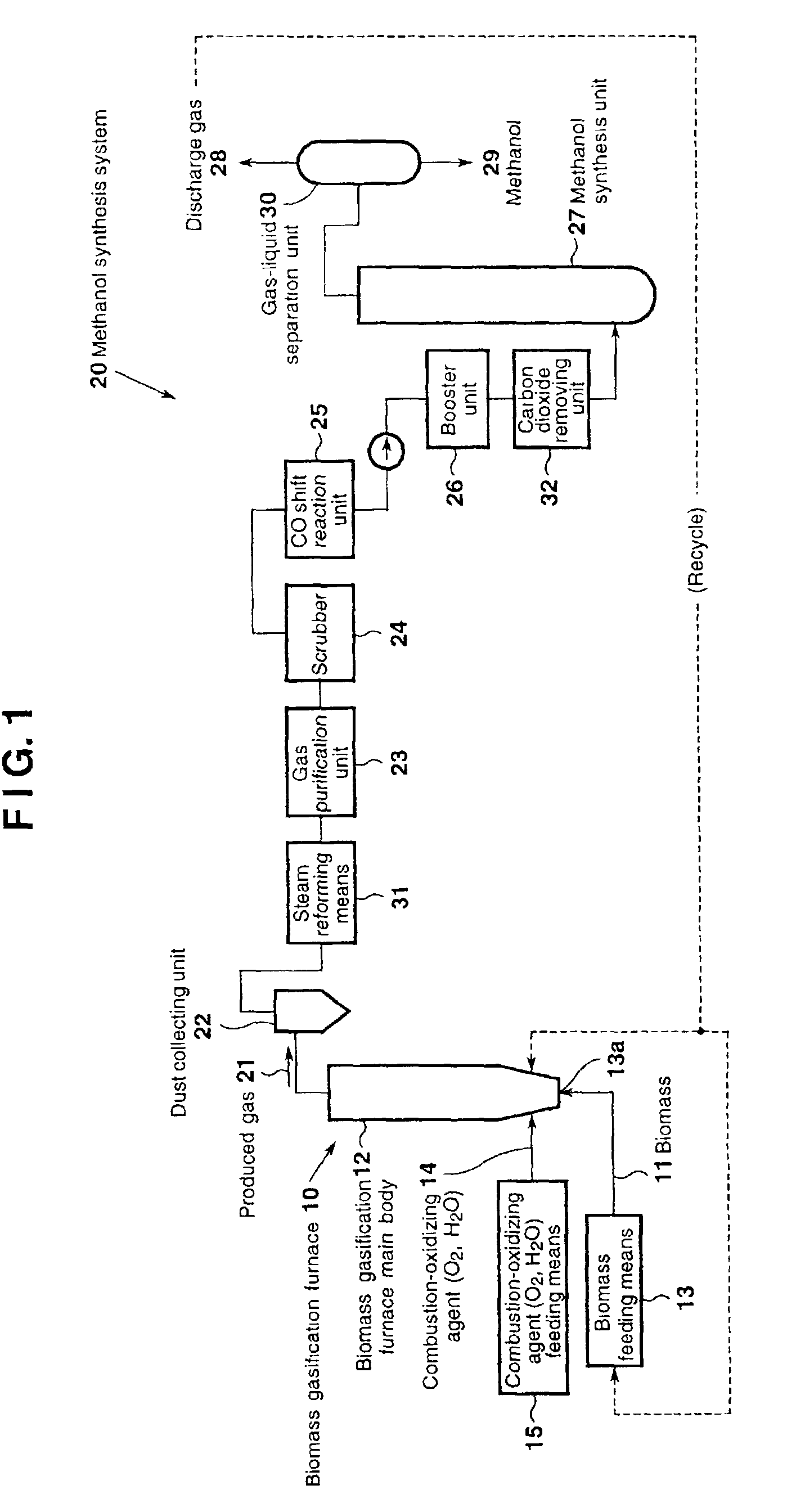

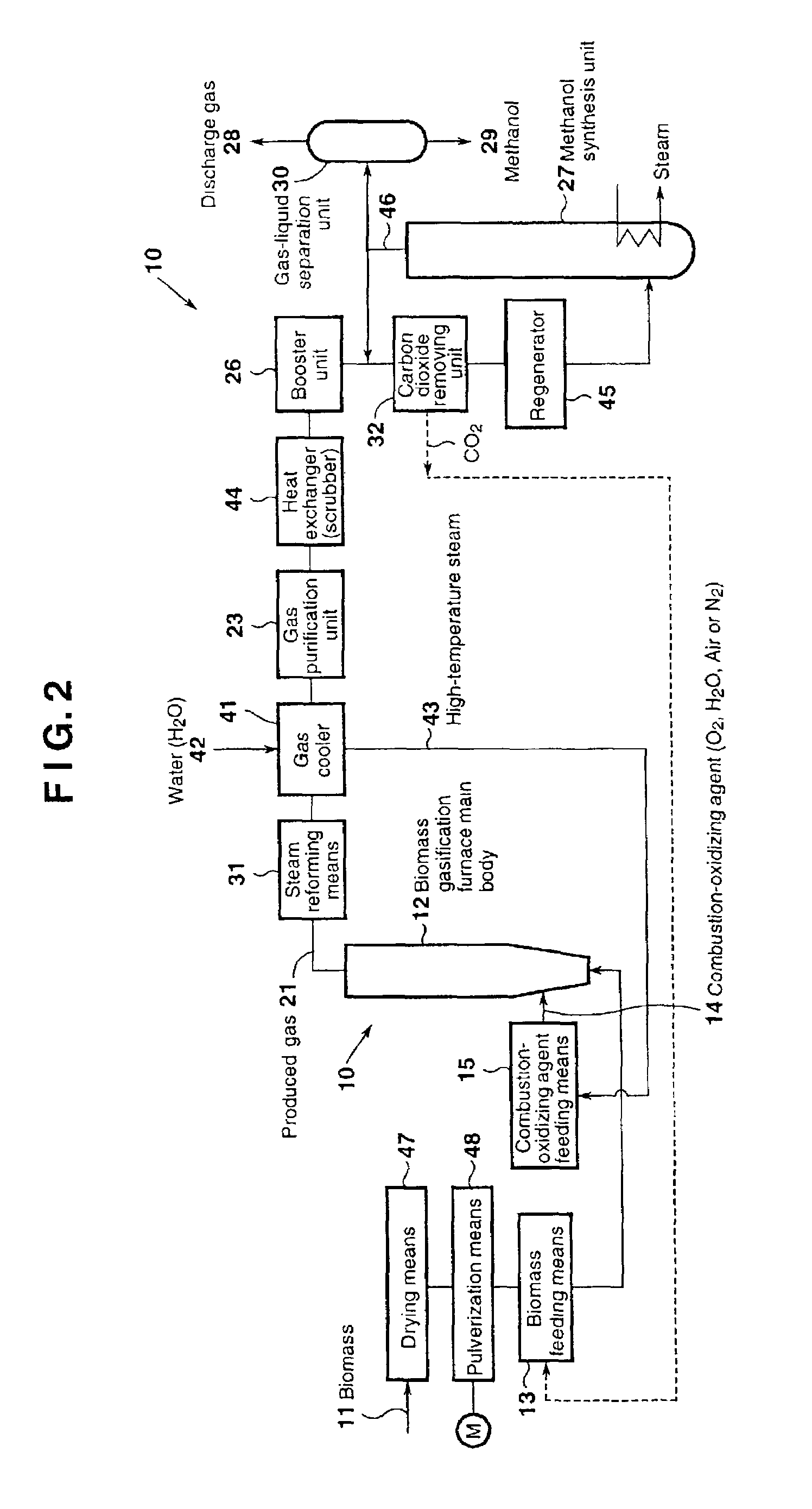

Biomass gasifycation furnace and system for methanol synthesis using gas produced by gasifying biomass

InactiveUS6991769B2Eliminate compression and entanglementCombustible gas catalytic treatmentBiofuelsCombustionProcess engineering

Methanol is synthesized from a gas produced through gasification of biomass serving as a raw material, making use of a biomass feeding means for feeding biomass into a furnace main body and, located above the biomass feeding means, combustion-oxidizing-agent-feeding means for feeding into the furnace main body a combustion-oxidizing agent containing oxygen or a mixture of oxygen and steam.

Owner:MITSUBISHI HEAVY IND LTD

Fuel control system and method for gas engines

InactiveUS20090088950A1Cost effectivePromote recoveryInternal combustion piston enginesSpace heating and ventilationControl systemEngineering

A gaseous carburetor or fuel control system includes a fuel metering assembly, a venturi mixer assembly, a throttle assembly, and an electronic control unit. The control unit controls the fuel metering assembly in a closed loop manner based on detected gas and air pressure to an air / fuel mixing venturi. An electronic governor which controls the throttle valve may also be controlled by the same control unit which controls the fuel metering assembly, using a separate control loop.

Owner:CONTINENTAL CONTROLS CORP

Vacuum shutdown system

InactiveUS7007658B1Easily employedGood adhesionLighting and heating apparatusUsing liquid separation agentCarburetorFuel oil

A device for shutdown of an internal combustion engine which provides for the cessation of fuel and air mixture in a carburetor supplying the cylinders of the engine with fuel for ignition. The device features a conduit in sealed engagement with the fuel supply bowl of the carburetor which may by switched from engagement between the atmosphere or a negative air pressure supply. When switched to communication with negative air pressure the device causes a vacuum in the fuel bowl of the carburator thereby ceasing fuel flow and shutting down the engine due to lack of fuel.

Owner:SMARTPLUGS CORP

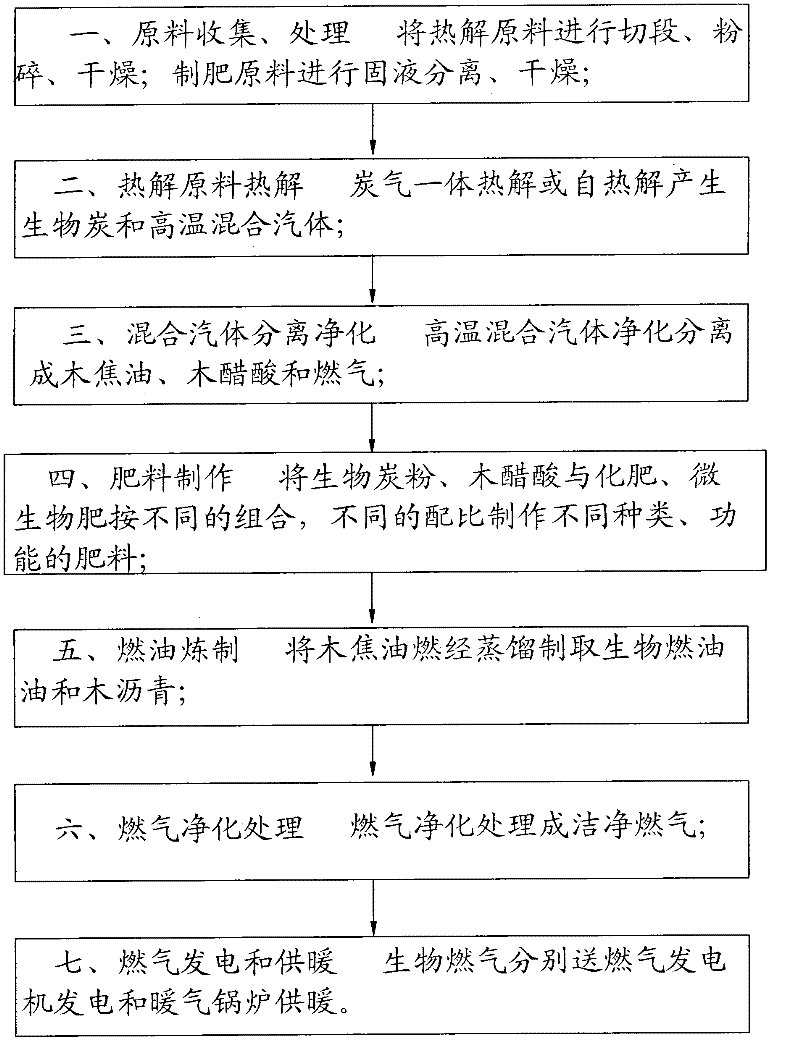

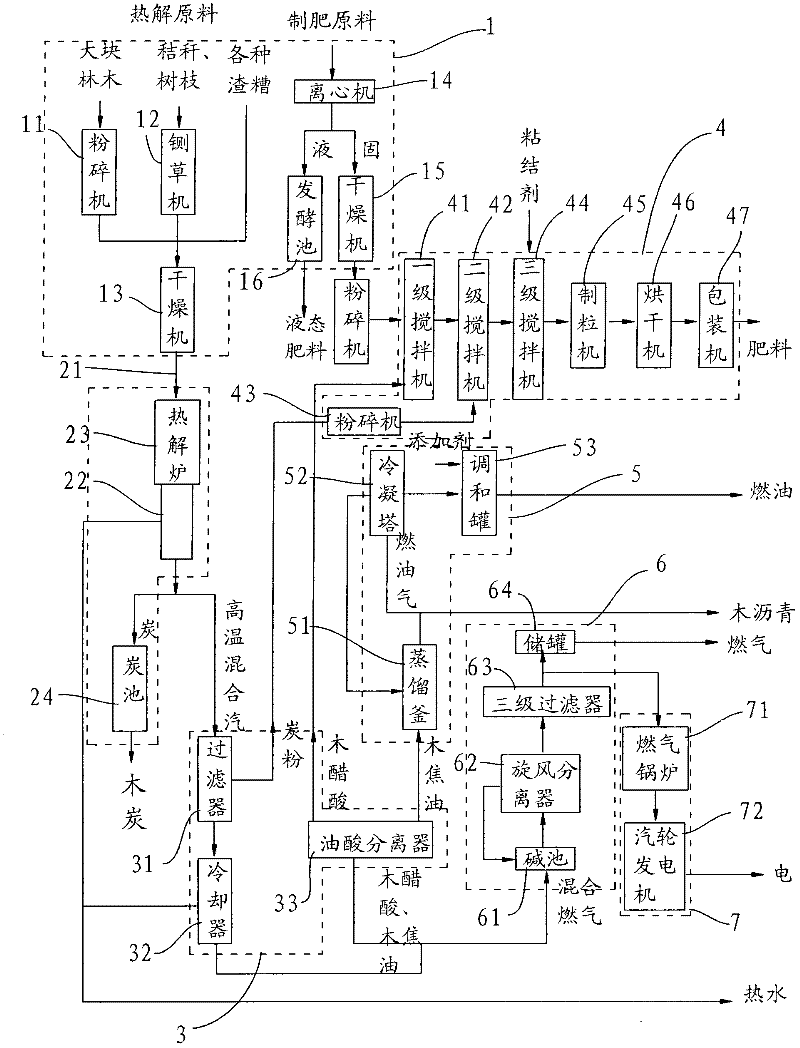

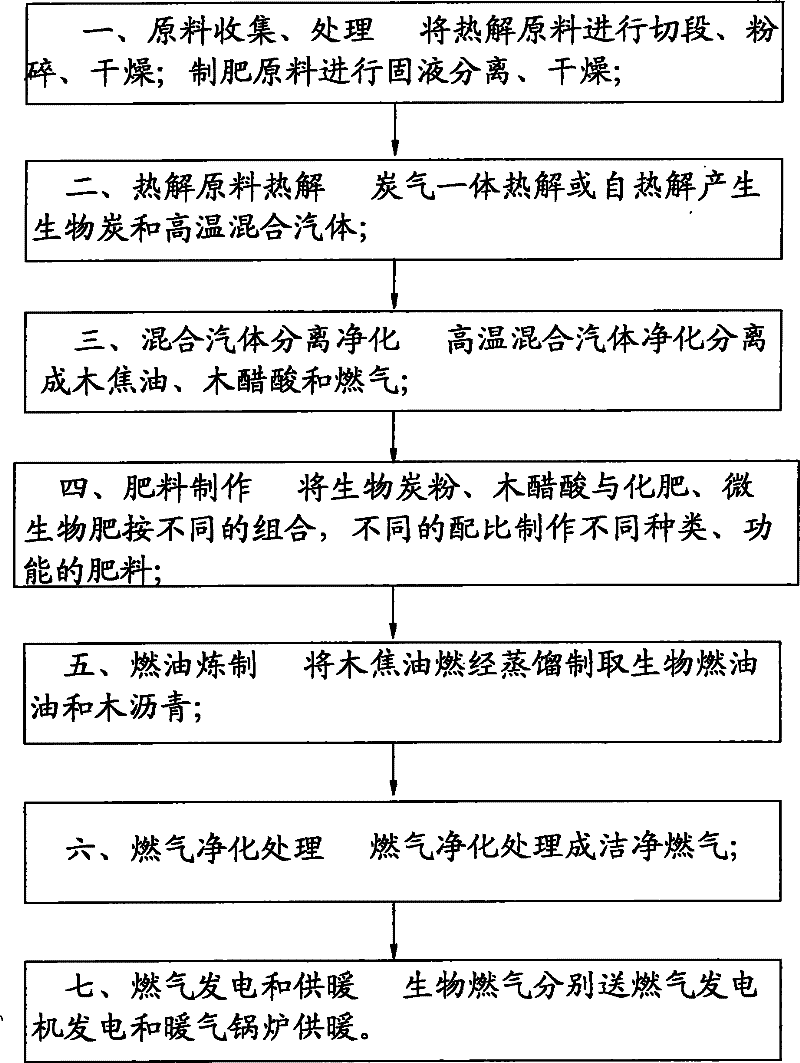

Integrated converting and utilizing co-production method for agricultural waste

InactiveCN102476129AWidely used valueAvoid secondary pollutionSolid waste disposalBiofuelsBiofuelFuel oil

The invention relates to an integrated utilizing technology for agricultural waste and in particular relates to an integrated converting and utilizing co-production method for agricultural waste. The integrated converting and utilizing co-production method comprises the following steps: 1. collecting and processing raw materials; 2. carrying out pyrolysis on the raw materials: generating biochar and high-temperature mixed gas; 3. converting the high-temperature mixed gas: converting the high-temperature mixed gas into wood tar, wood vinegar and fuel gas; 4. manufacturing fertilizers; 5. refining fuel oil: converting the wood tar into biofuel oil and wood pitch; 6. purifying the fuel gas: purifying the fuel gas into clean fuel gas; and 7. converting the fuel gas: respectively sending the biofuel gas into a gas generator, a gas supply pipe network and a heat boiler to covert the biofuel gas into heat energy and electricity energy. The agricultural waste can be converted by multiple levels and are combined to be utilized to obtain straw carbon, fuel gas, heat energy, electricity energy, fertilizers, fuel gas and the like. The use ratio of the agricultural waste reaches 100%. The problem that the agricultural waste is stacked and burnt disorderly can be solved, the pollution problem caused by using chemical fertilizers and pesticides for a long time can be solved, and the problem of utilizing energy, fertilizer and oil in rural areas also can be solved.

Owner:周仁福 +2

Refractory armored quench ring

InactiveUS20050132647A1Minimize thermal stressAvoid exposureMuffle furnacesGasifier mechanical detailsFiberBrick

An improved quench ring in combination with a reactor vessel having a refractory lined reaction chamber with a bottom outlet and a floor to support the refractory lined reaction chamber, wherein the quench ring is protected by a protective barrier comprising dense refractory brick, dense refractory ramming mix, refractory ceramic fiber, and a metal apron support. The protective barrier is removably attached to a portion of the quench ring hotface and protects the quench ring from the high temperature of the effluent exiting the reaction chamber.

Owner:TEXACO INC +1

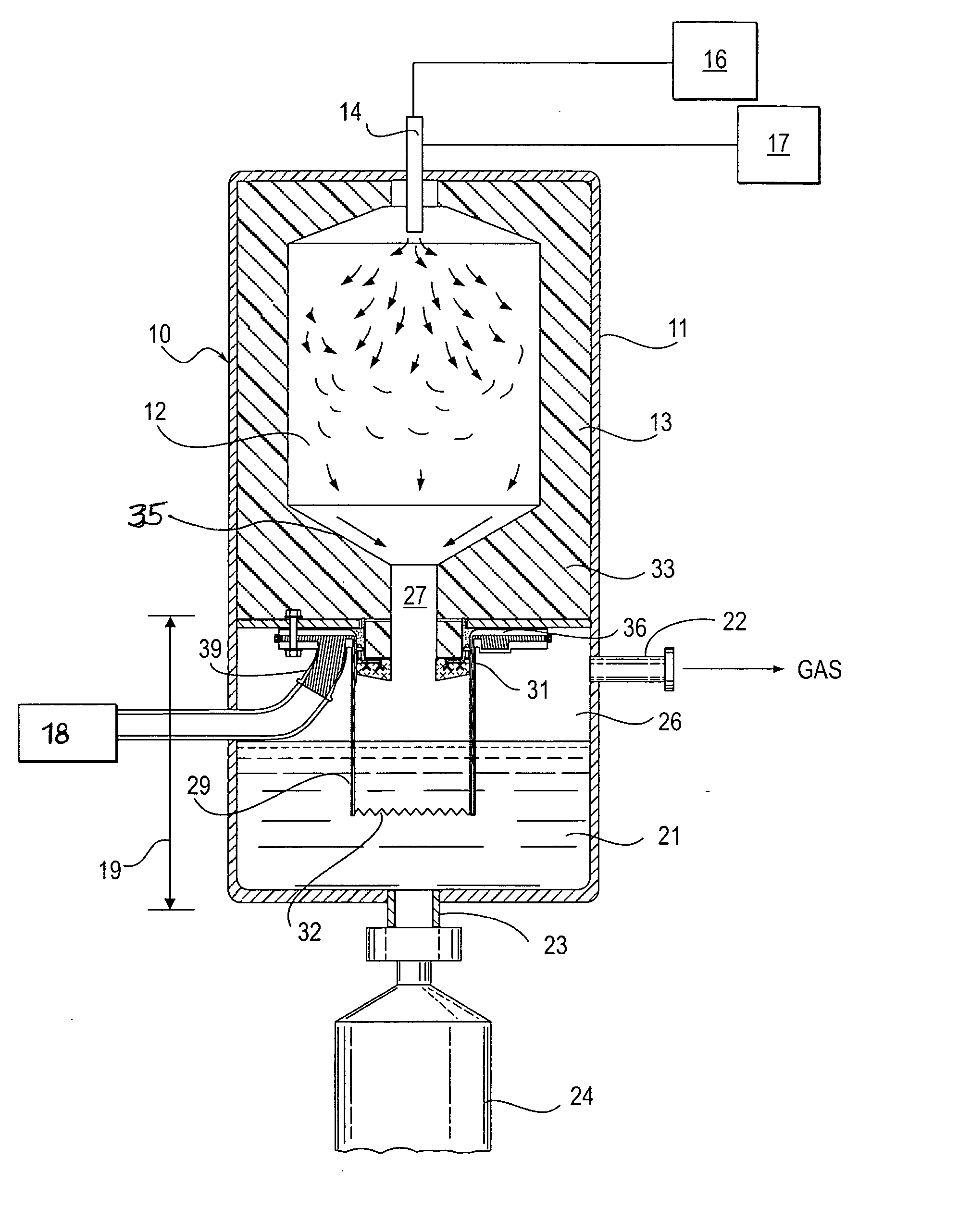

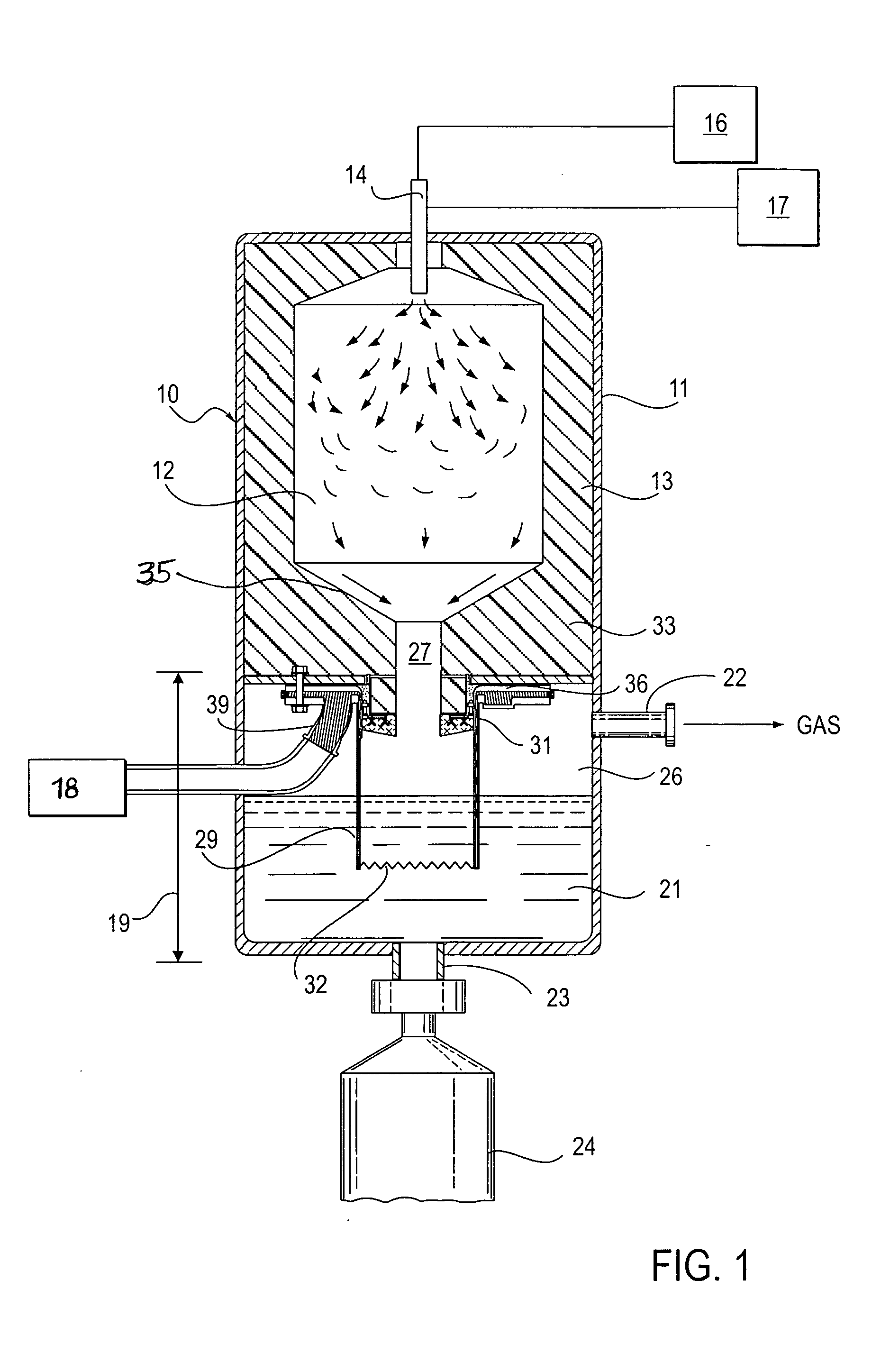

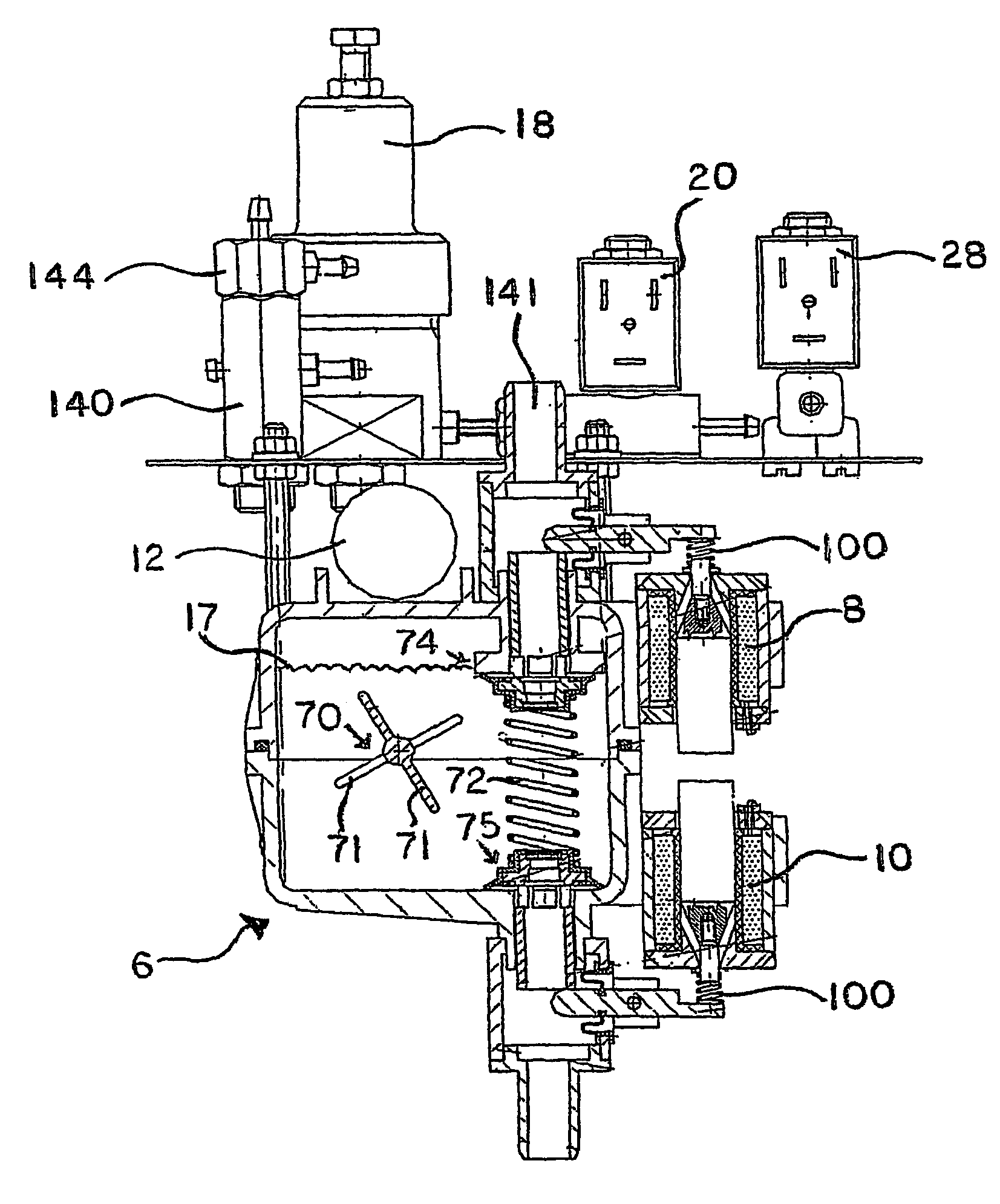

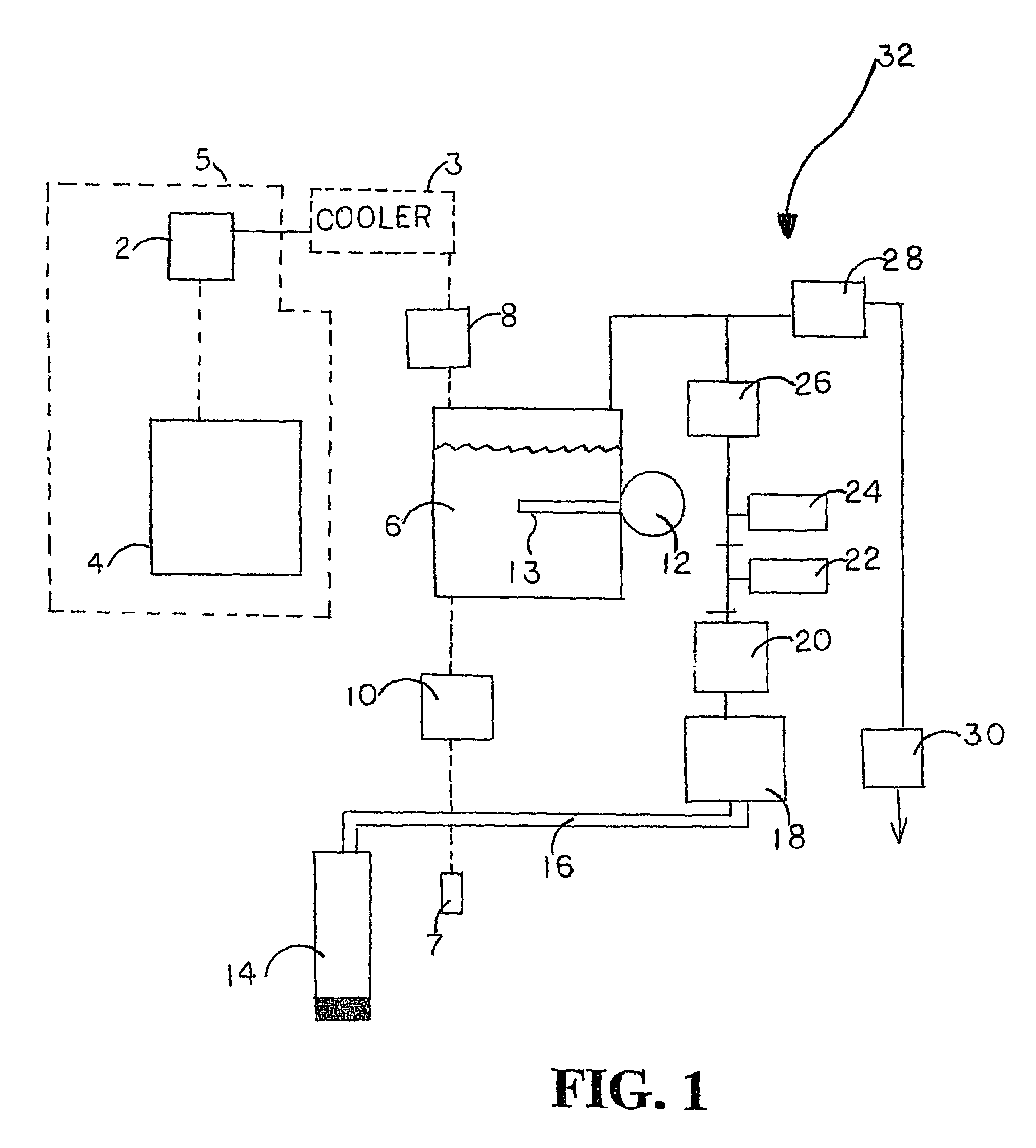

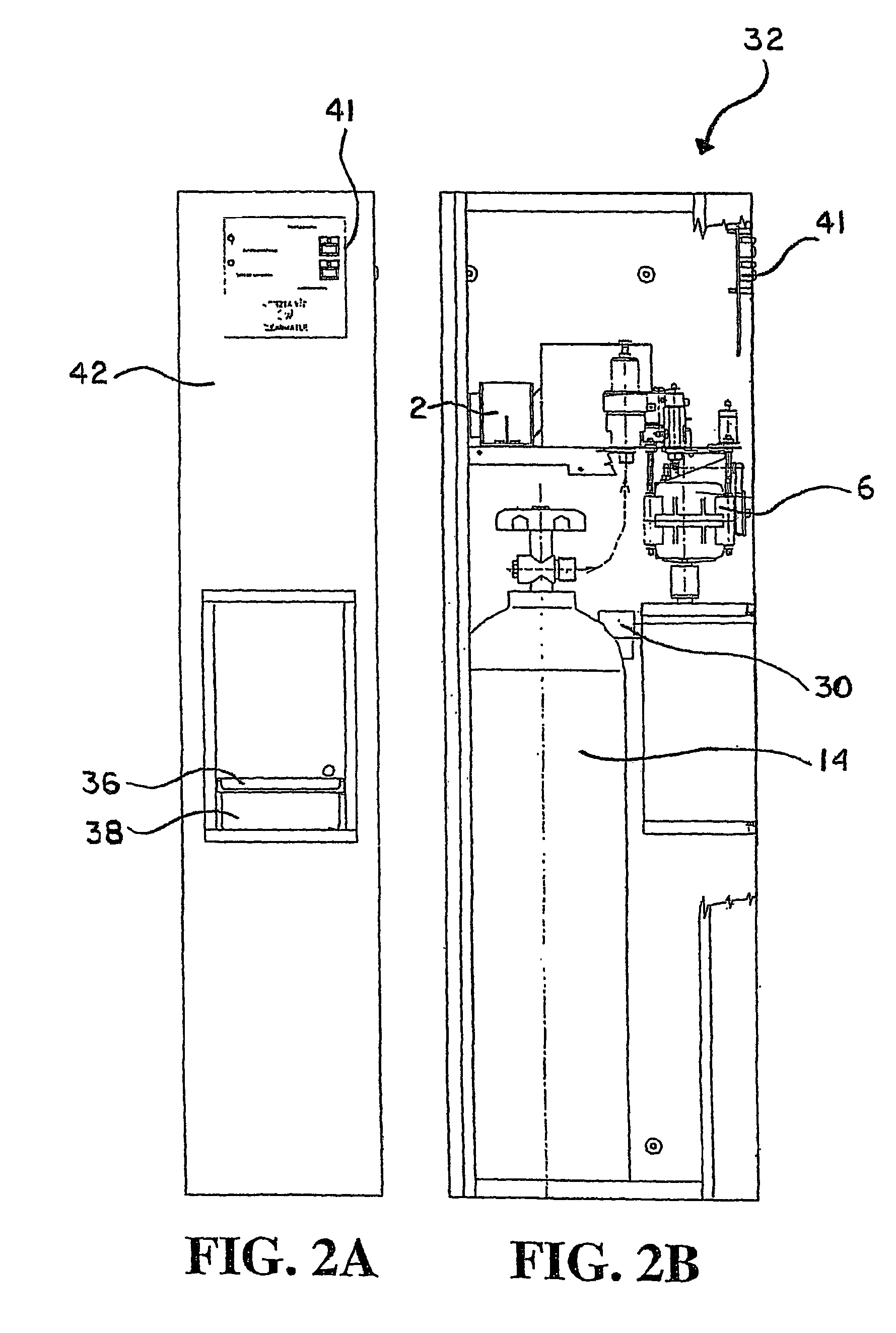

Carbonation system and method

The water carbonation method and apparatus of the present invention consists of a square mixer within a carbonated chamber. The mixer is partially filled with water. Carbon dioxide is then added above the level of water. A rotating member attached to the mixing motor then mixes the water and carbon dioxide to from a carbonated solution. Varying the time for which the carbonation operation is carried on may vary the degree of carbonation. After the specified carbonation cycle, excess carbon dioxide is then relieved through an exhaust solenoid and the remaining carbonated solution is released through the dispensing solenoid into a cup.

Owner:PRIMO WATER HLDG INC

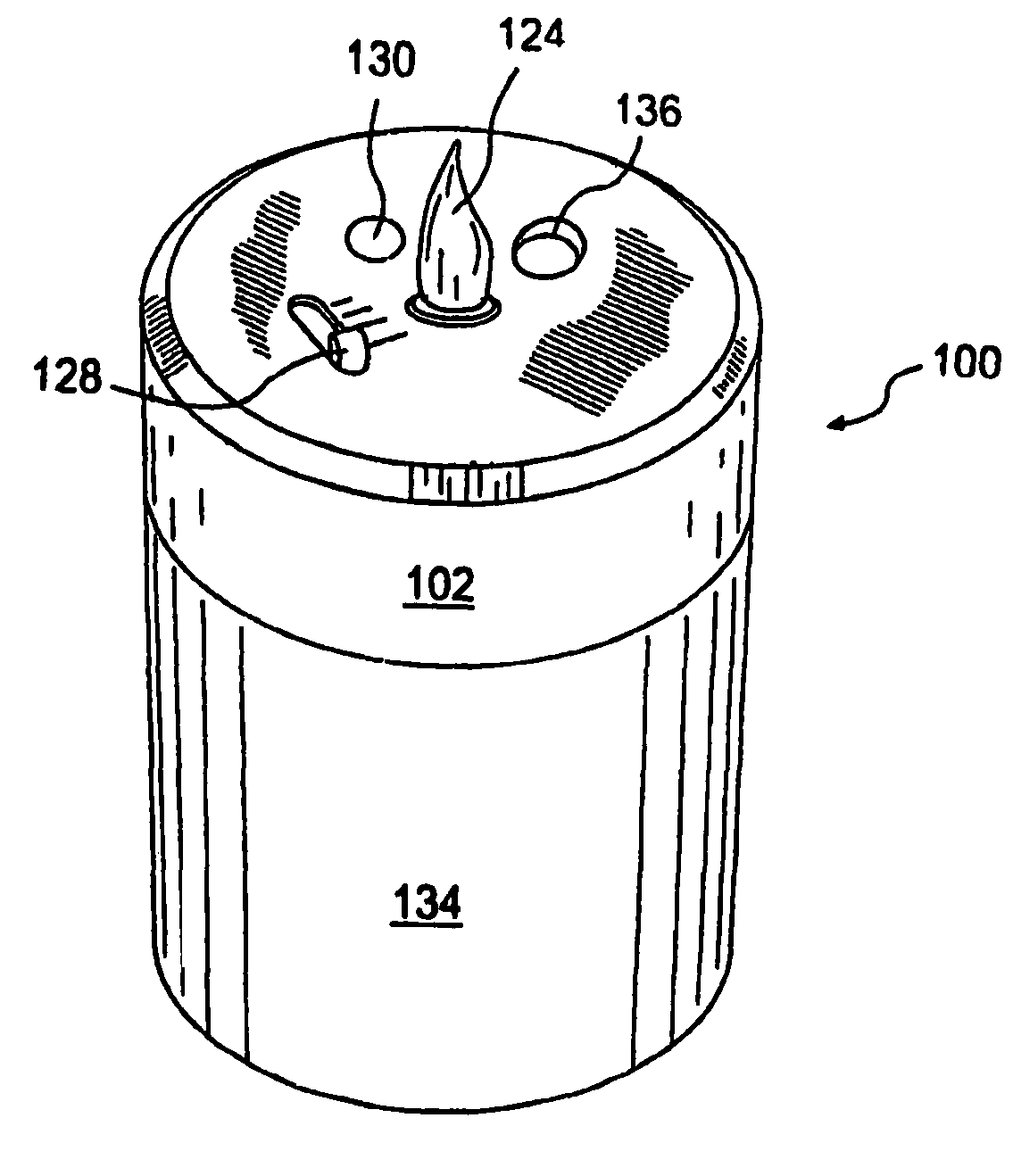

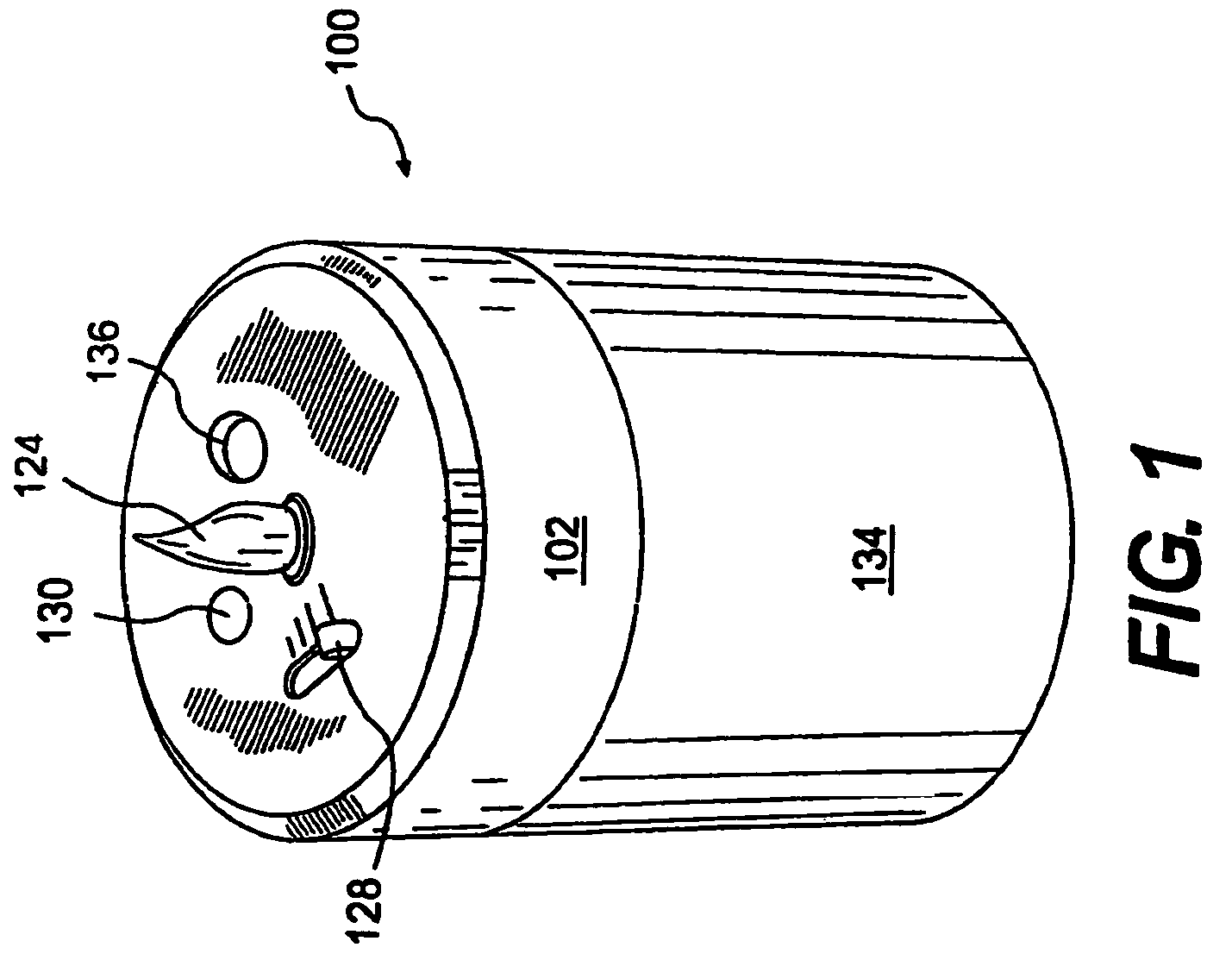

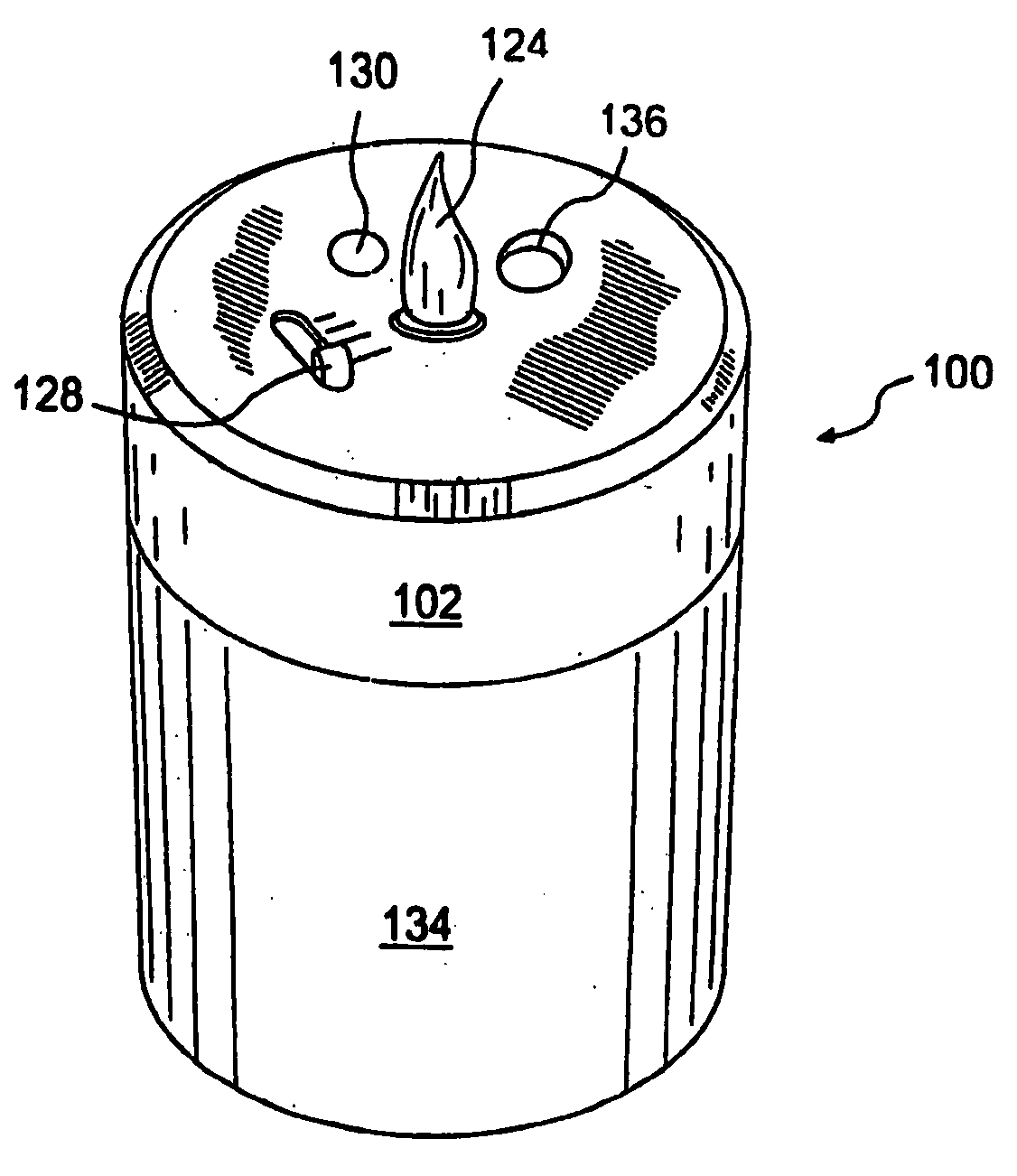

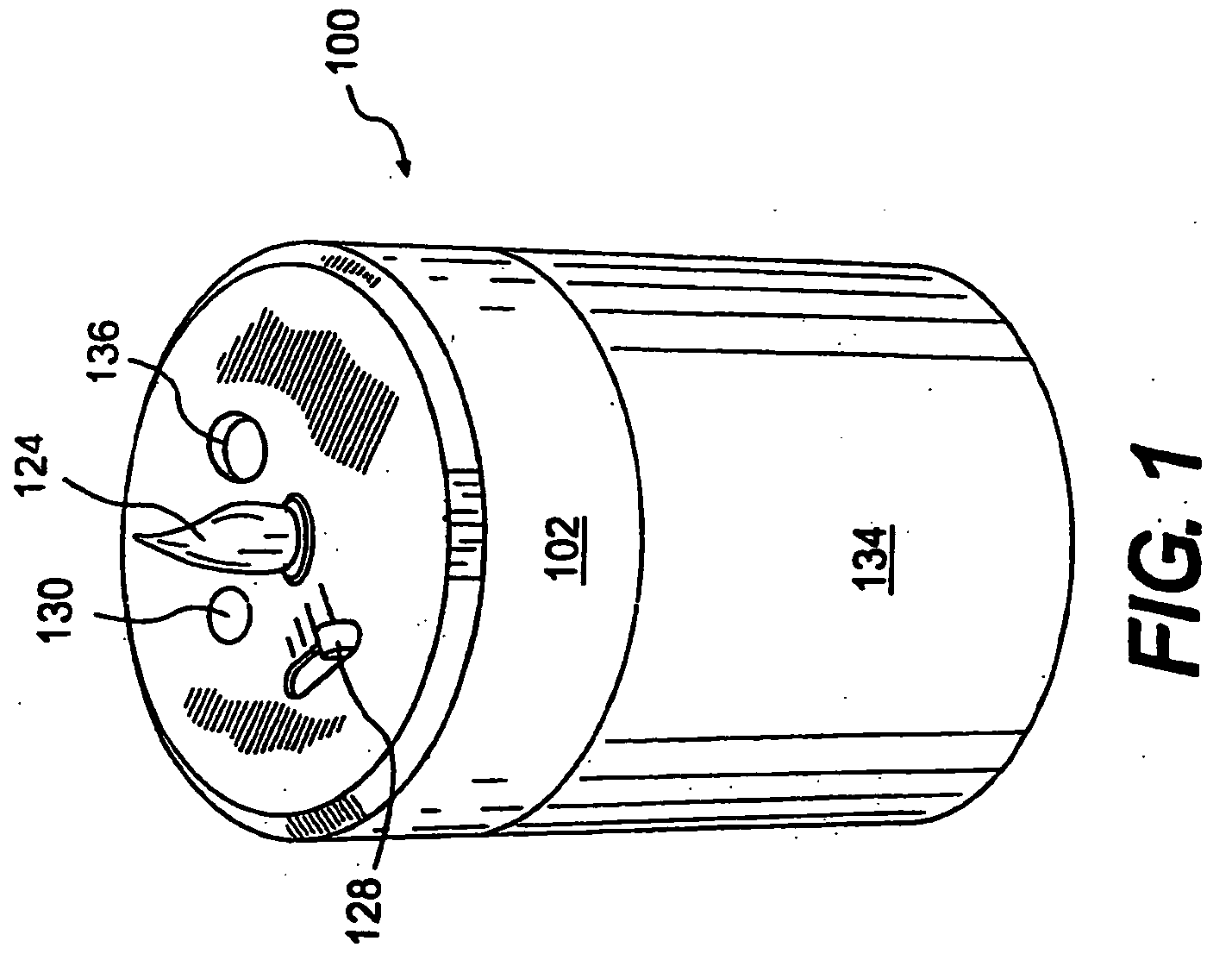

Active material and light emitting device

InactiveUS20060115386A1Point-like light sourceSpace heating and ventilationLight emissionLight emitting device

An active material and light emitting device comprises an ultrasonic atomizer assembly and a light emission device. The active material and light emitting device further includes a housing containing the atomizer assembly and the light emission device such that the atomizer assembly is disposed above the light emission device. The light emission device emits light that is transmitted through a medial portion of the housing.

Owner:SC JOHNSON & SON INC

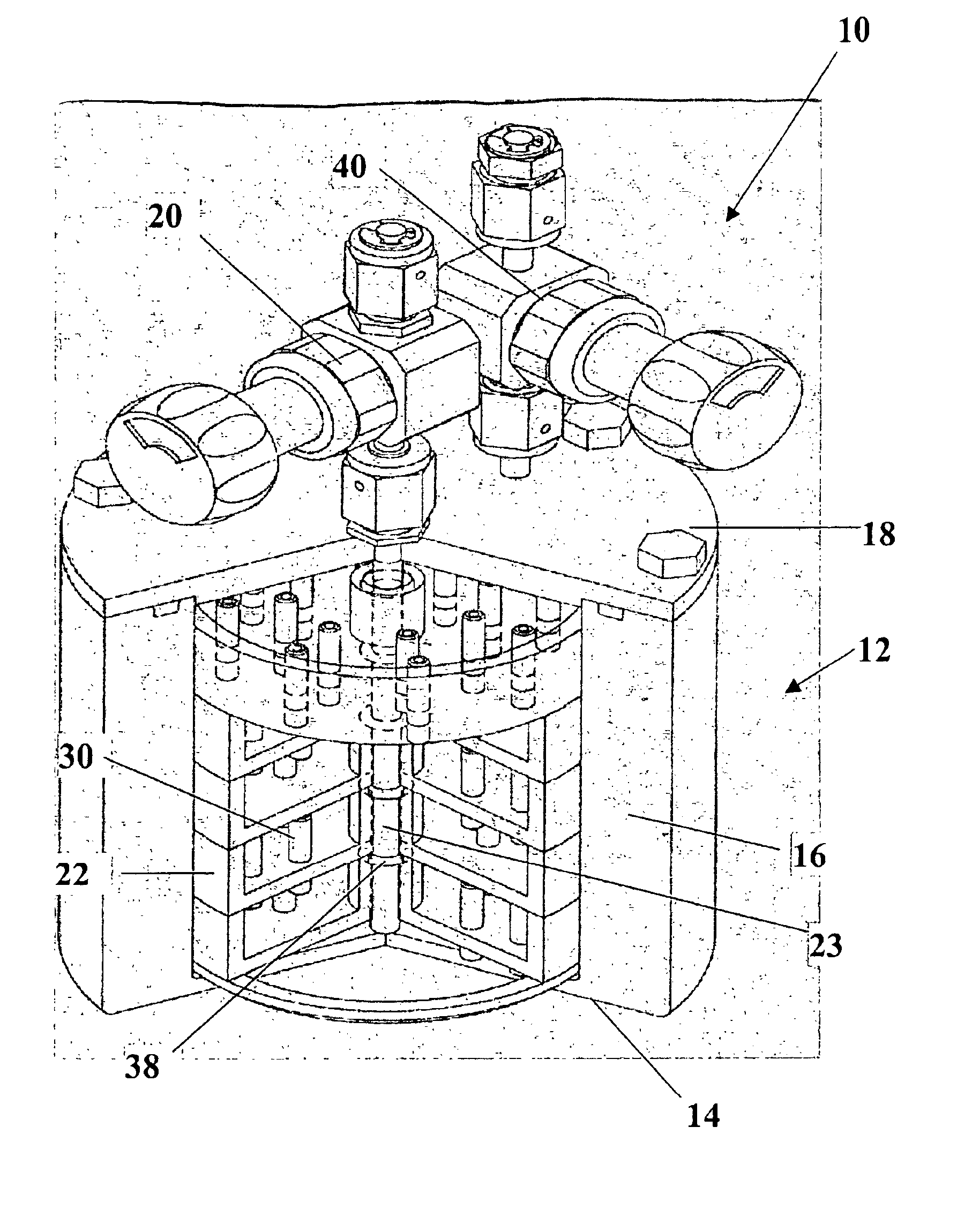

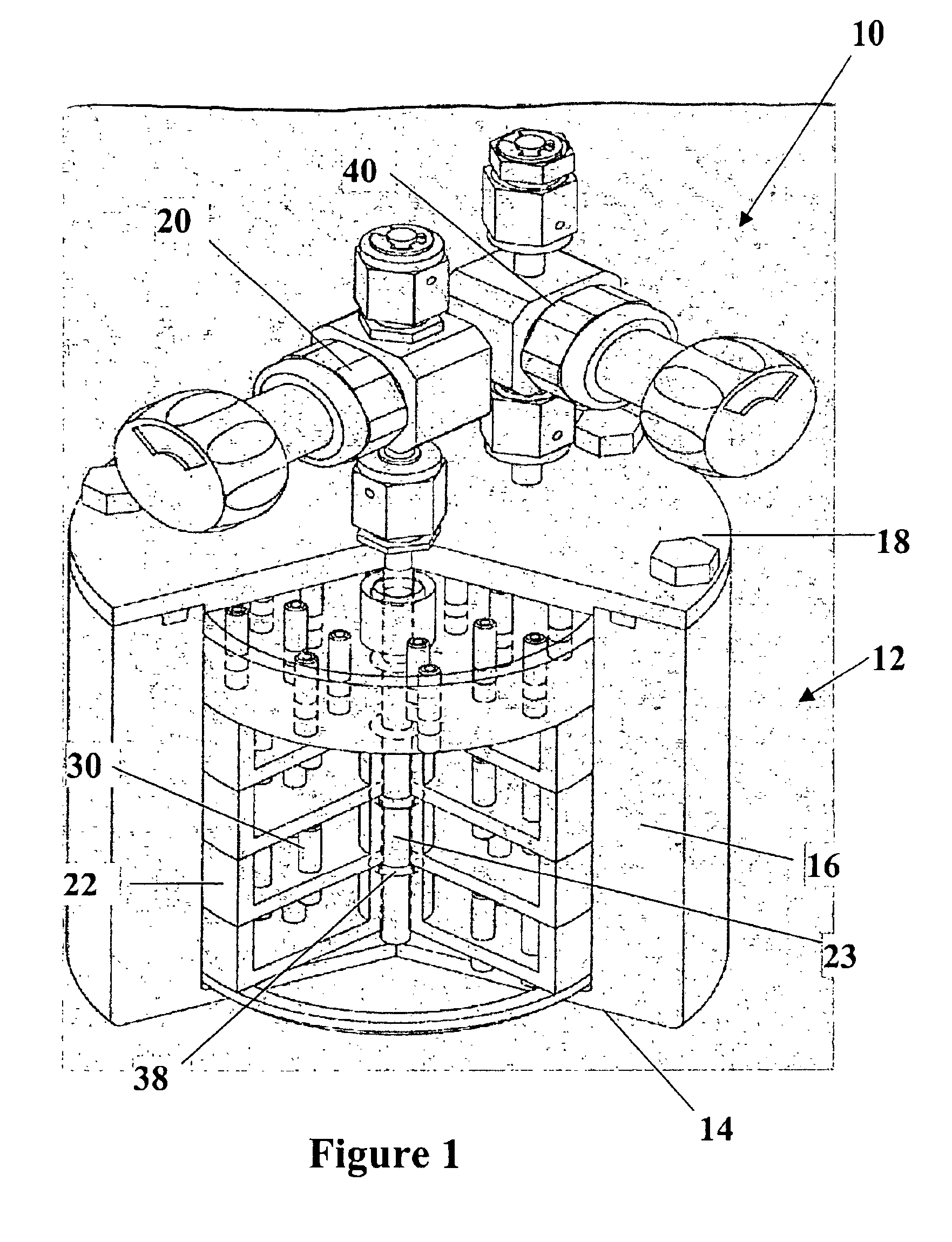

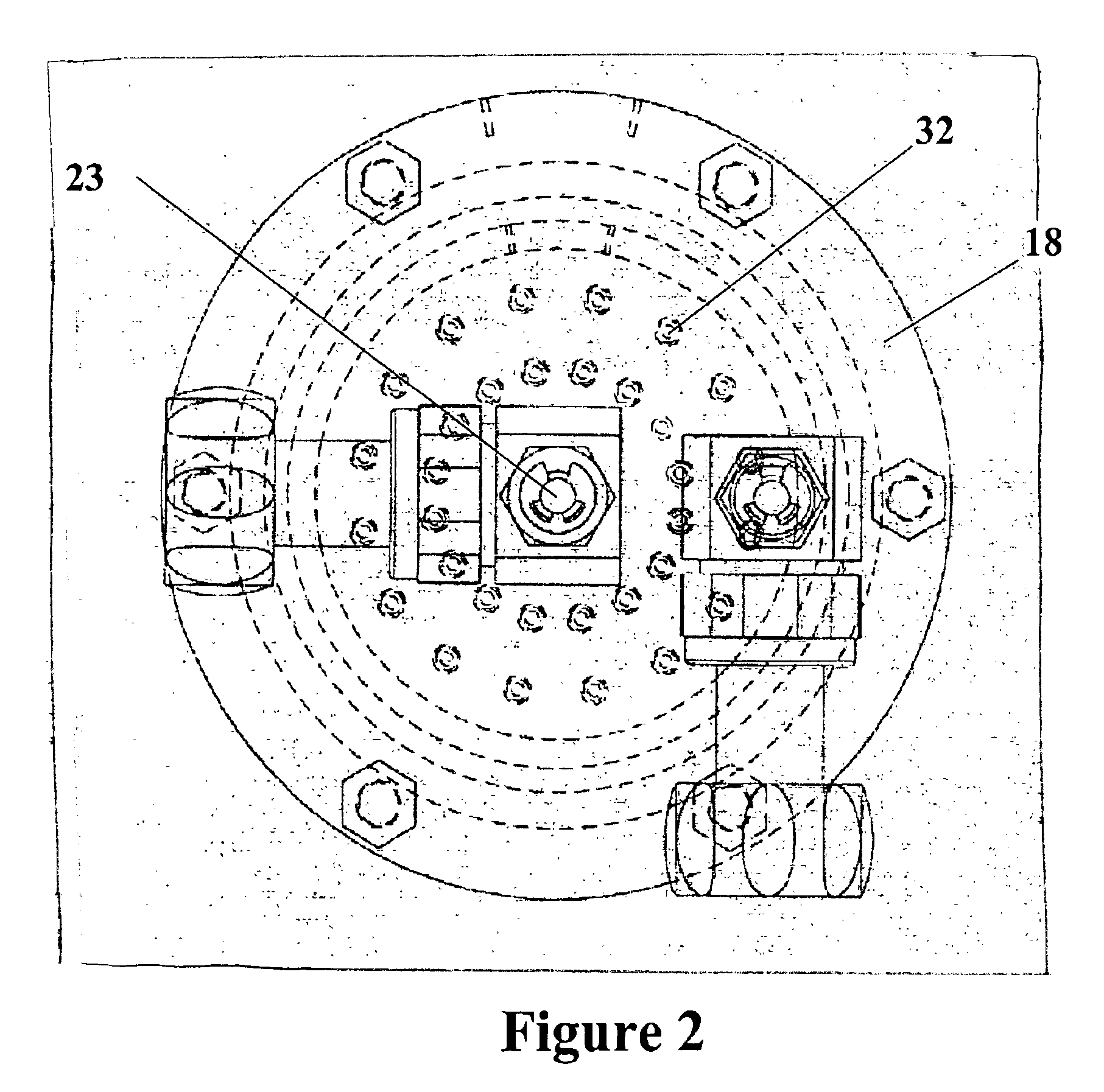

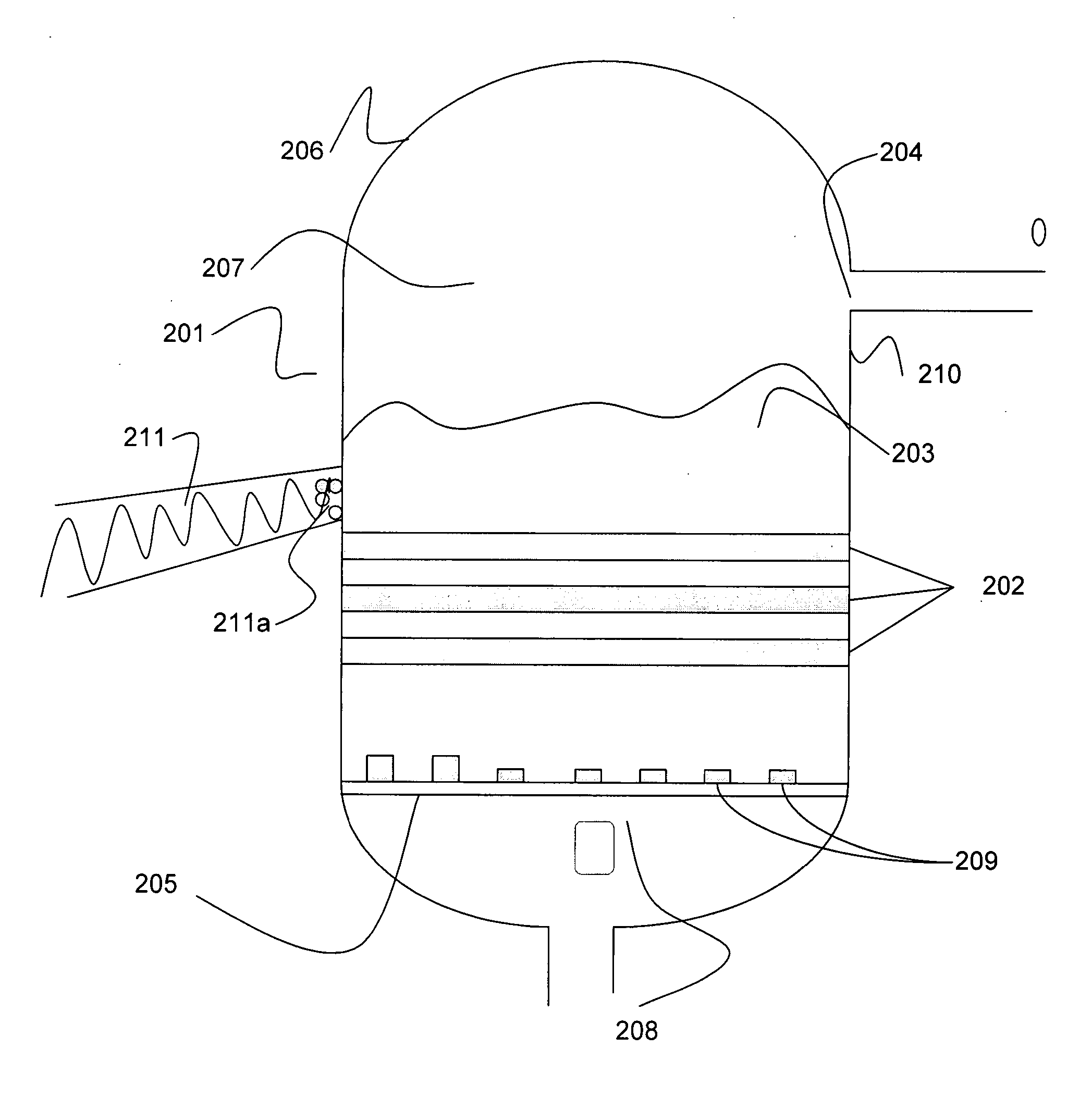

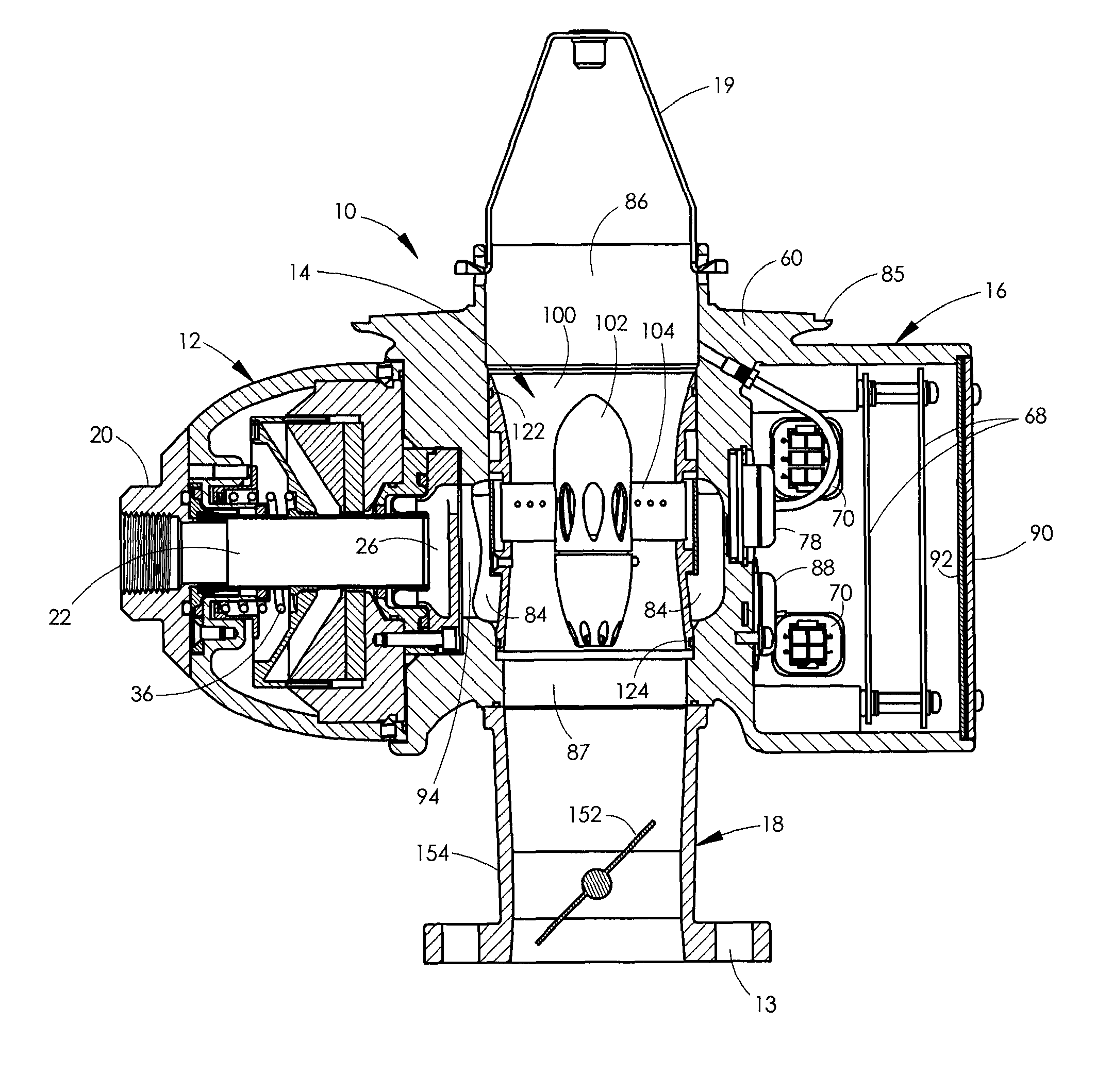

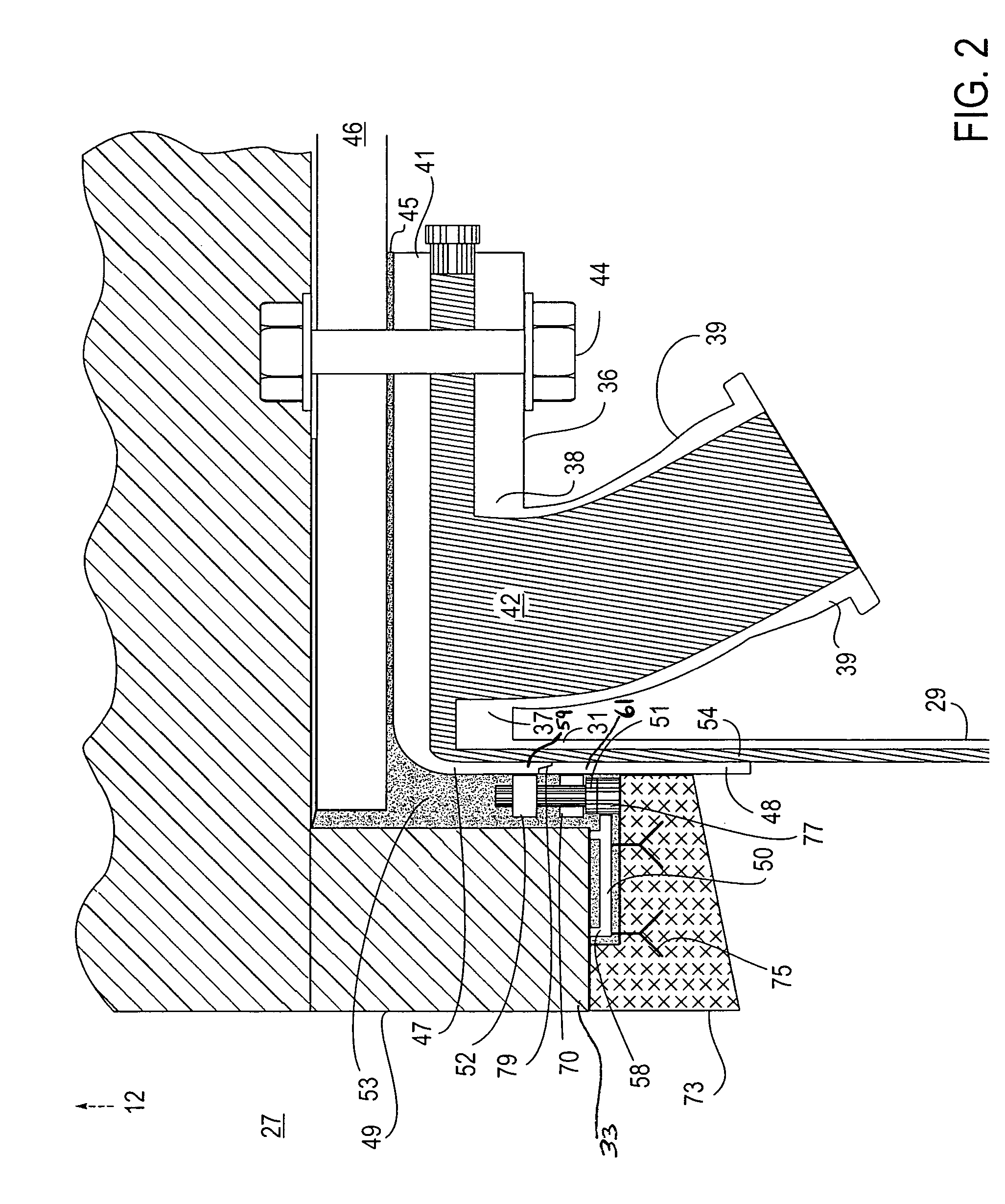

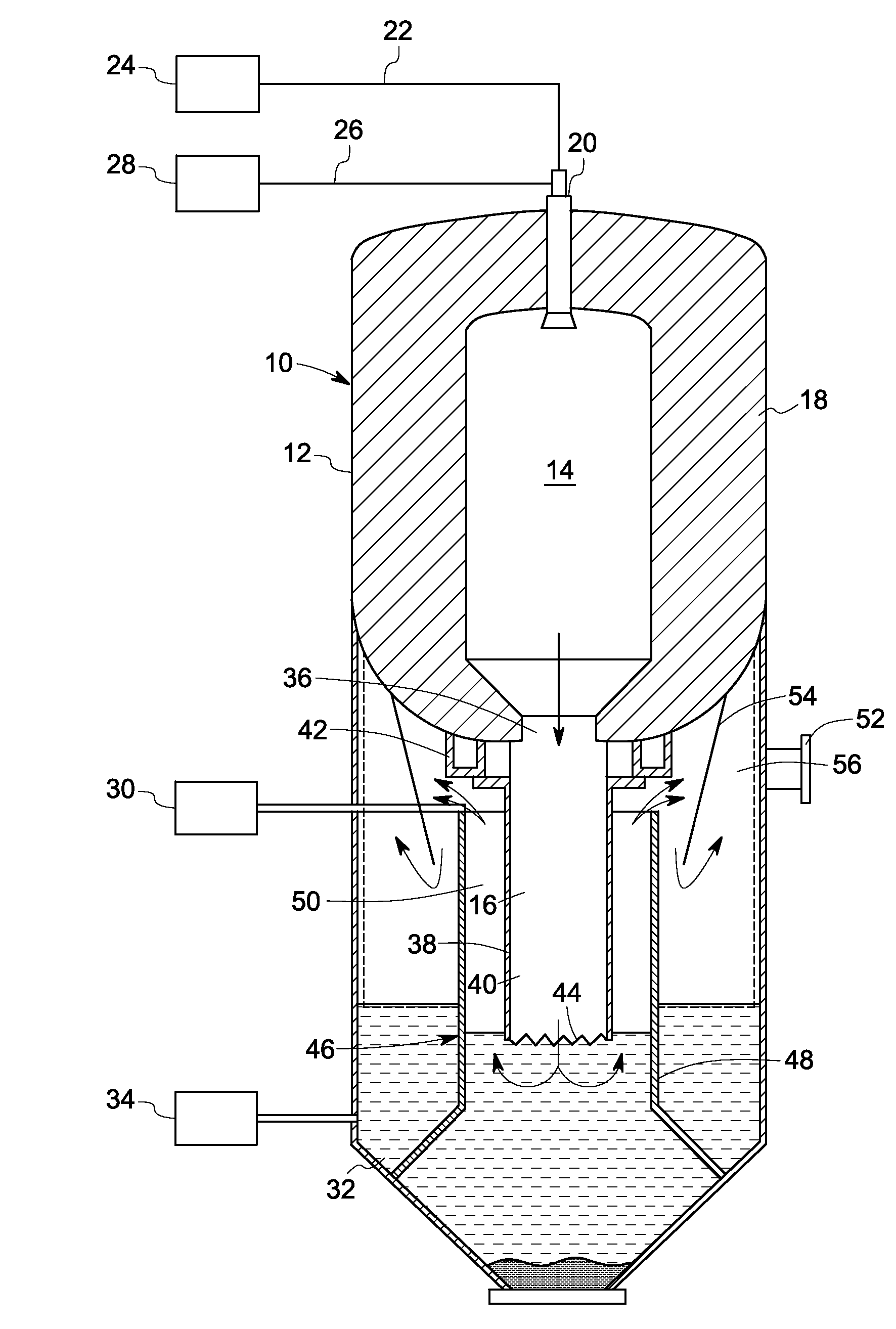

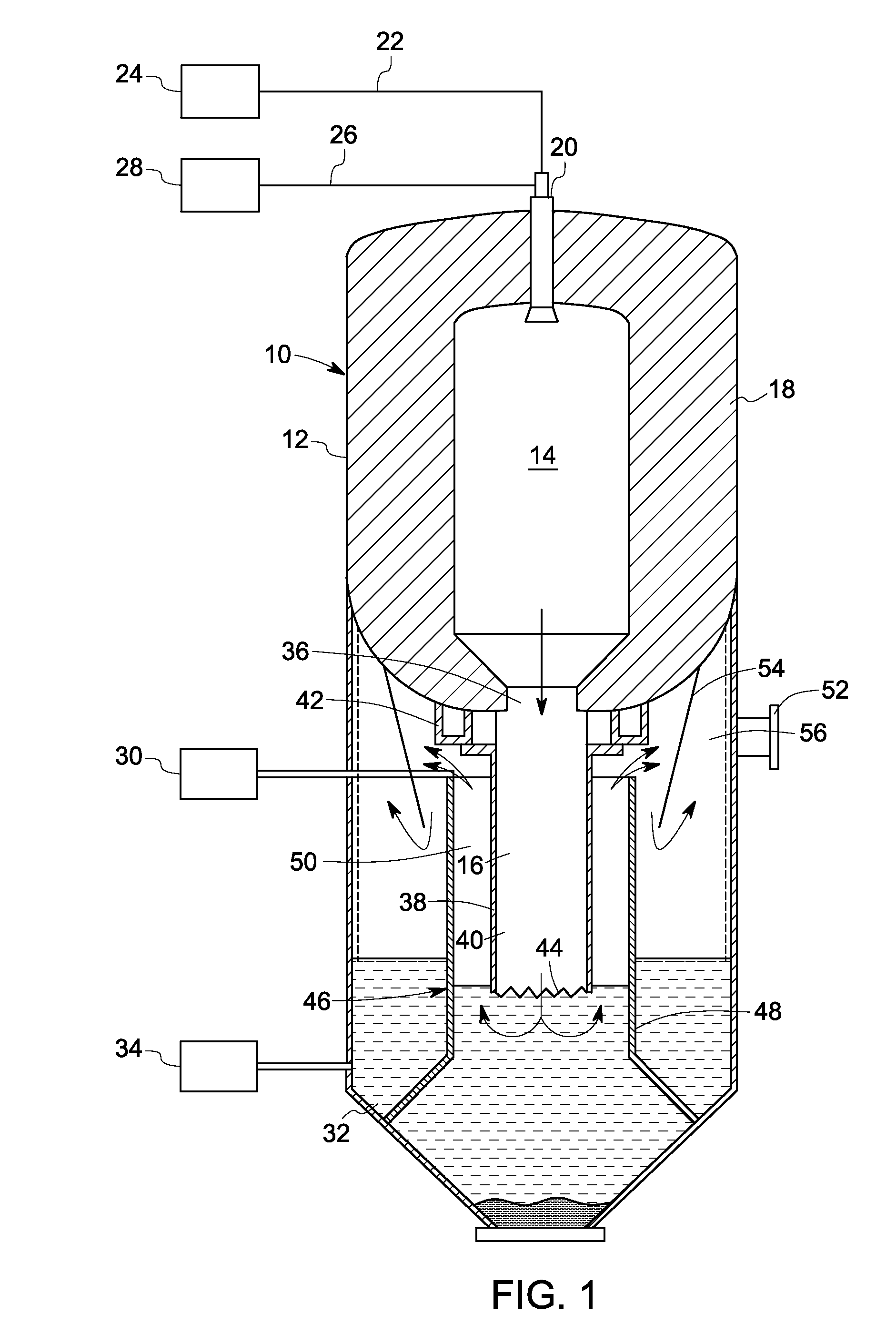

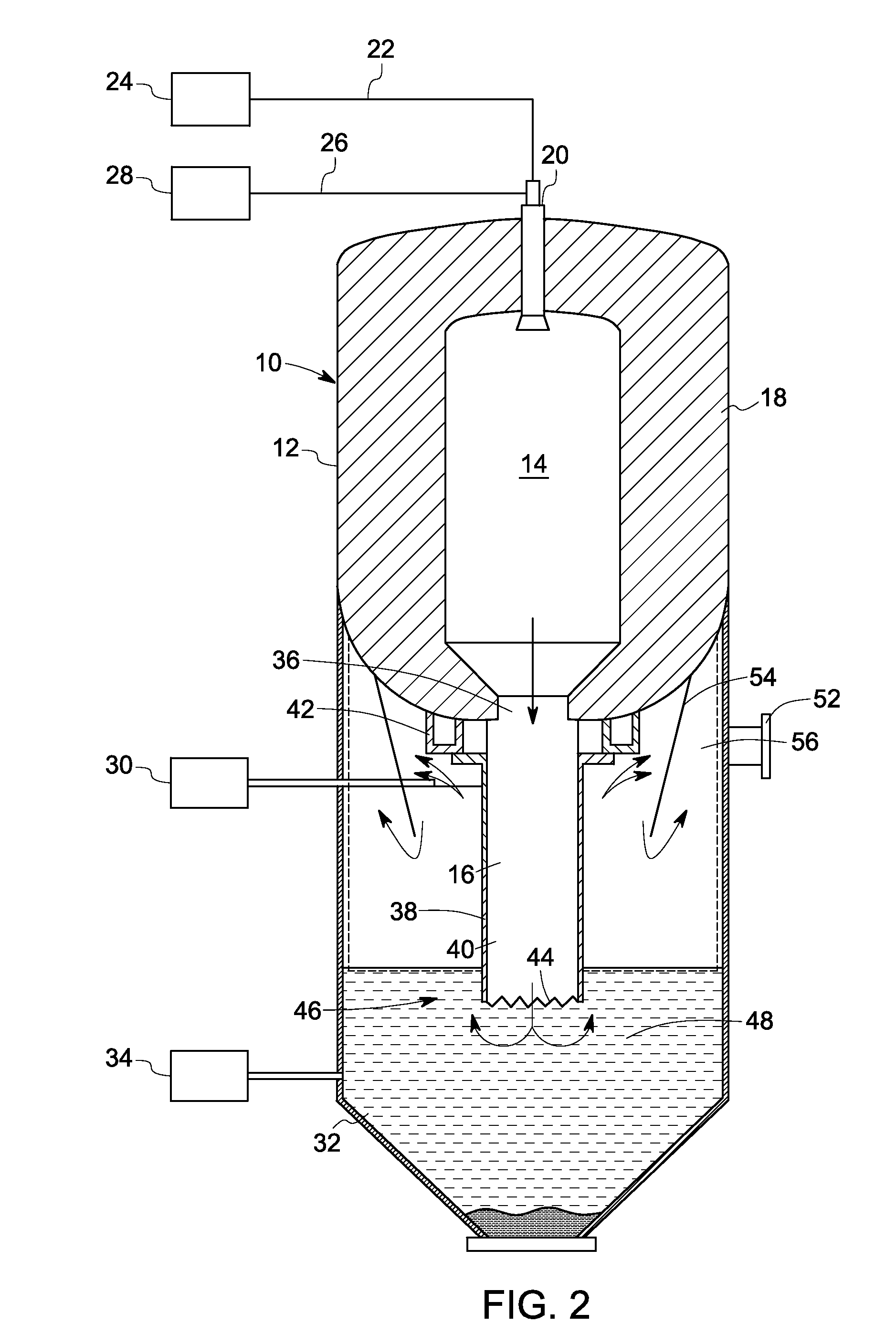

Quench chamber assembly for a gasifier

InactiveUS20100325954A1Avoid shakingGasifier mechanical detailsGas purification by liquid washingSyngasCombustion chamber

A gasifier includes a combustion chamber in which a combustible fuel is burned to produce a syngas and a particulated solid residue. A quench chamber having a liquid coolant is disposed downstream of the combustion chamber. A dip tube is disposed coupling the combustion chamber to the quench chamber. The syngas is directed from the combustion chamber to the quench chamber via the dip tube to contact the liquid coolant and produce a cooled syngas. A draft tube is disposed surrounding the dip tube such that an annular passage is formed between the draft tube and the dip tube. An asymmetric or symmetric baffle is disposed proximate to an exit path of the quench chamber. The cooled syngas is directed through the annular passage and impacted against the asymmetric or symmetric baffle so as to remove entrained liquid content from the cooled syngas before the cooled syngas is directed through the exit path.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com