Patents

Literature

1887 results about "Carburetor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A carburetor (American English) or carburettor (British English) is a device that mixes air and fuel for internal combustion engines in the proper air–fuel ratio for combustion. It is sometimes colloquially shortened to carb in the UK and North America or carby in Australia. To carburate or carburet (and thus carburation or carburetion, respectively) means to mix the air and fuel or to equip (an engine) with a carburetor for that purpose.

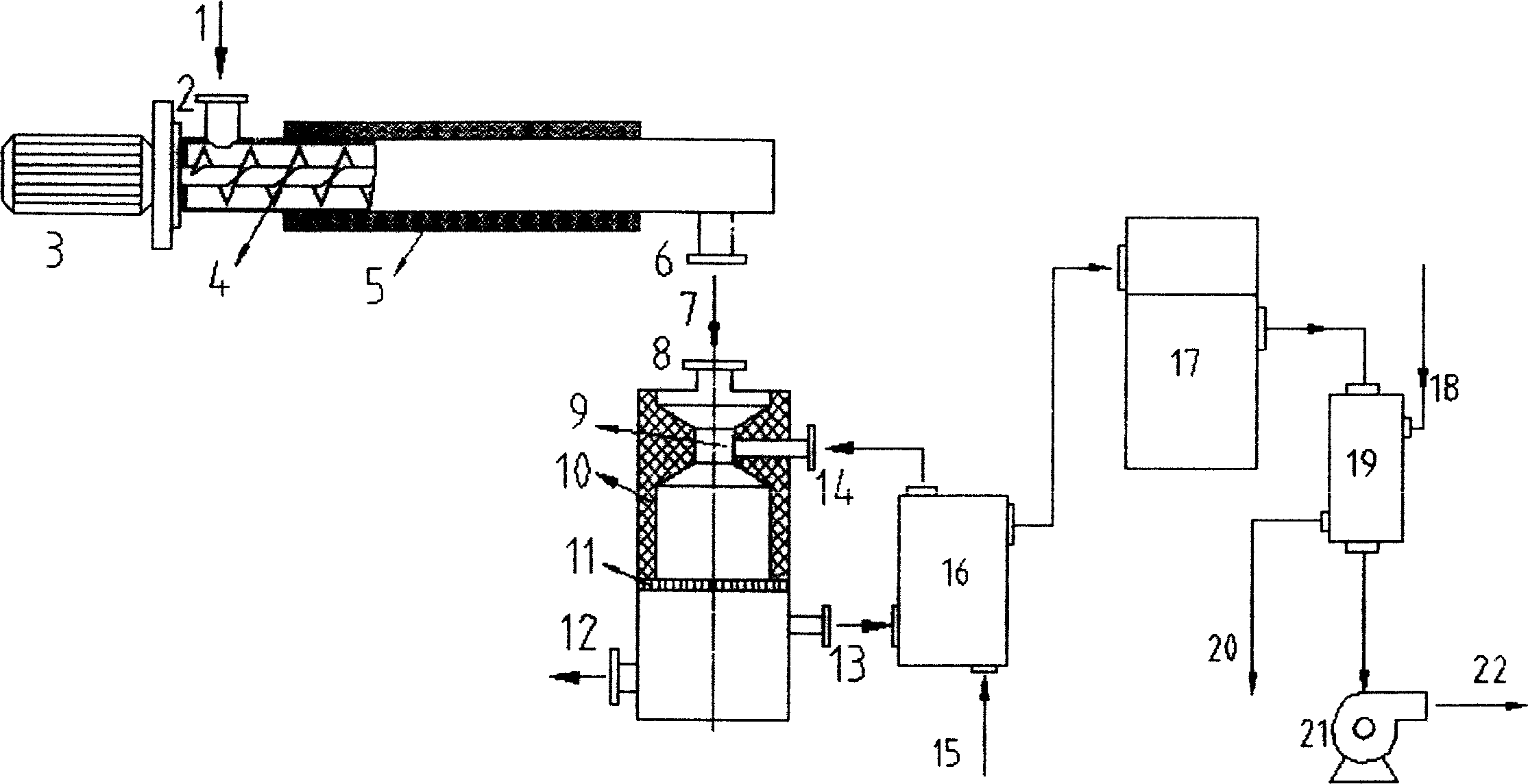

Low-tar biomass gasifying method and apparatus

InactiveCN1710023AWide adaptability of raw materialsSpecial form destructive distillationCarbon layerDecomposition

The invention discloses a kind of biomass gasifying method and device. The technology through separating the two courses of solid biomass pyrogenation and decomposition and gasification of the pyrogenation outcome, then transform the biomass into flammable gas of rather low tar content. Firstly send biomass into the pyrogenation reactor, without oxidant in; have pyrogenation reaction at 400 - 650 Deg. C, the pyrogenation outcome including pyrogenation gas and remaining charcoal gets into pyrogenation carburetor, and have incomplete oxidizing combustion reaction with sent oxidant, to form a high temperature of 900 - 1100 Deg. C. At the time, the heavy hydrocarbon substance of tar decomposes into small molecule gas, and the decomposed gas leaves out of the carburetor after having deoxidizing reaction with the nether blazing carbon layer. The high temperature gas is provided for consumers' use after depurated and cooled. The gas produced by the invention has very low tar content, which makes the following depurating equipment simple, won't produce second pollution and makes the raw materials widely used. The produced fuel gas can be used in civil filed and directly used for generating electricity.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

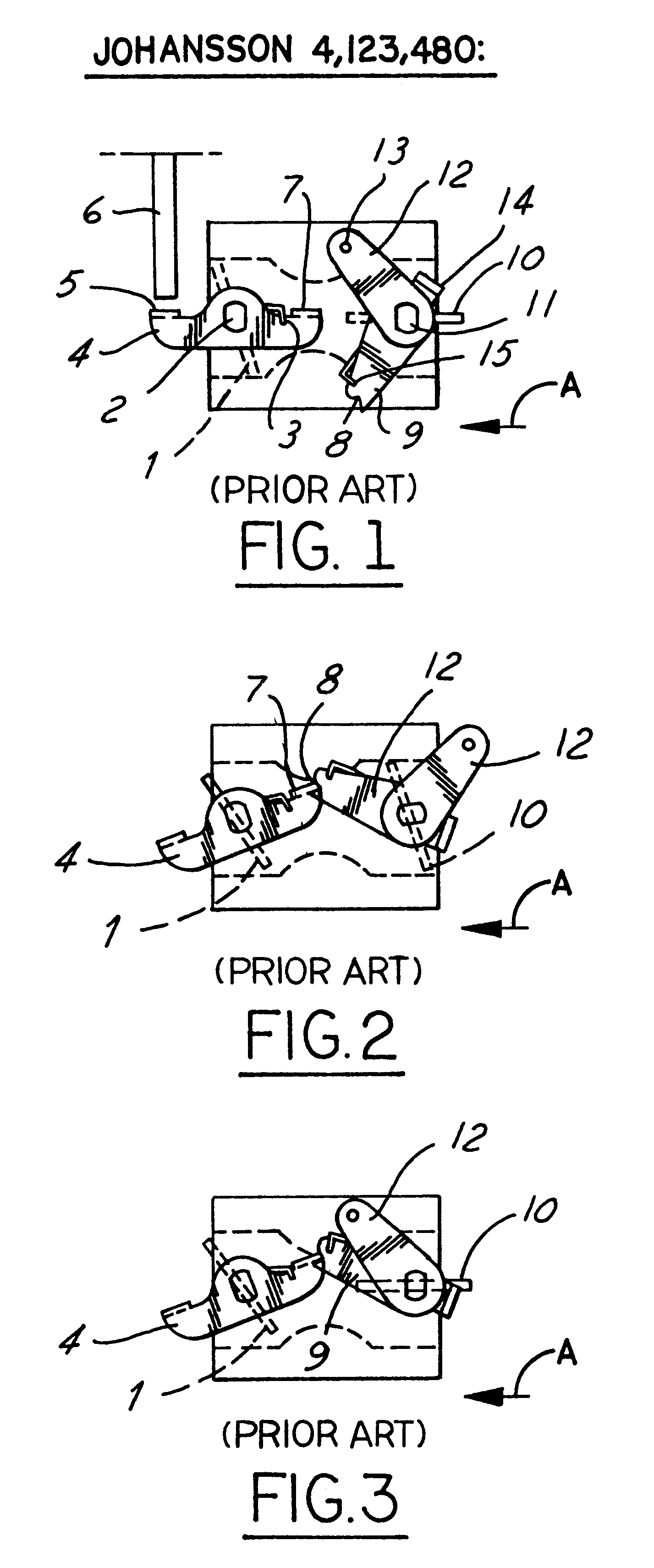

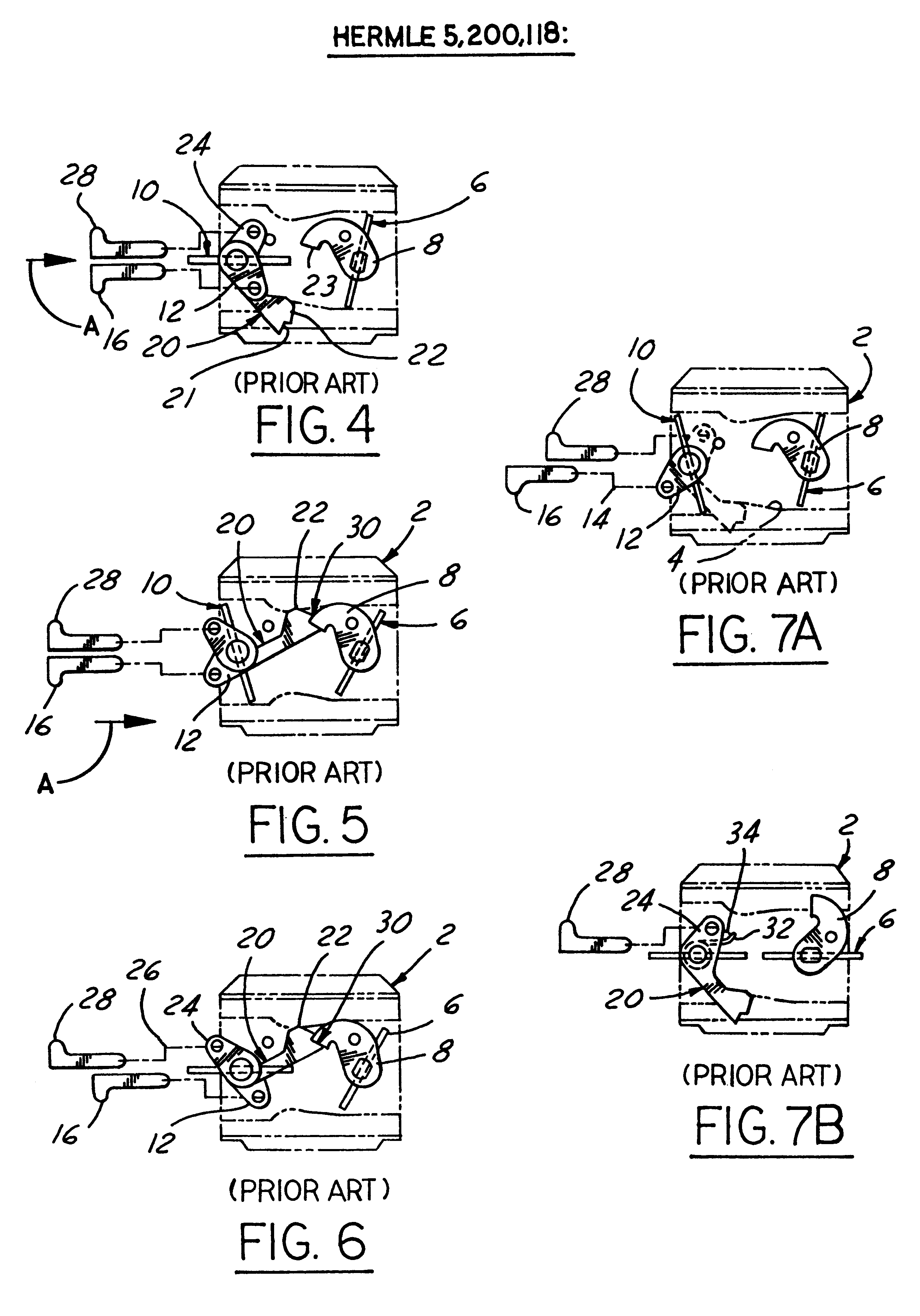

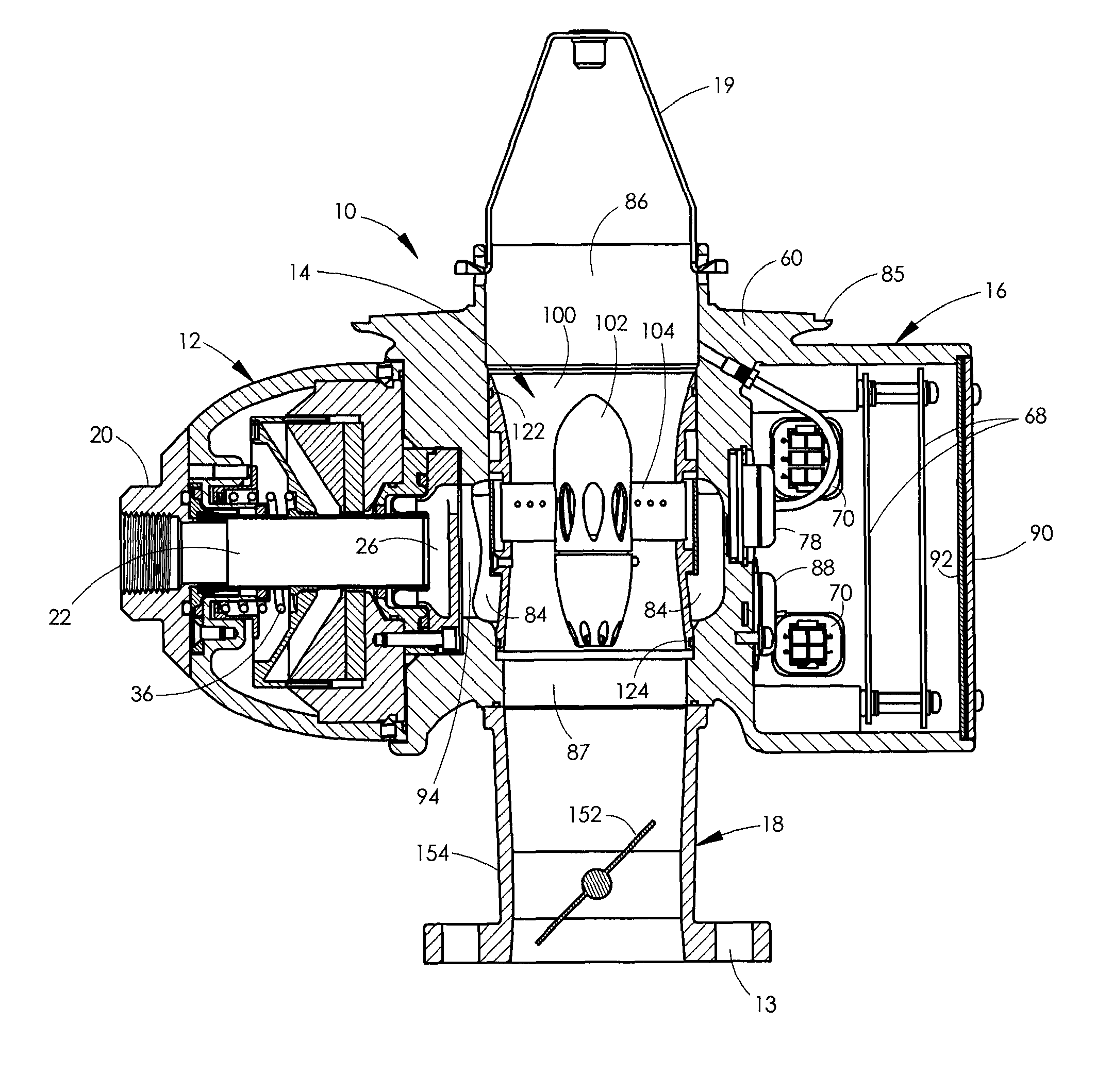

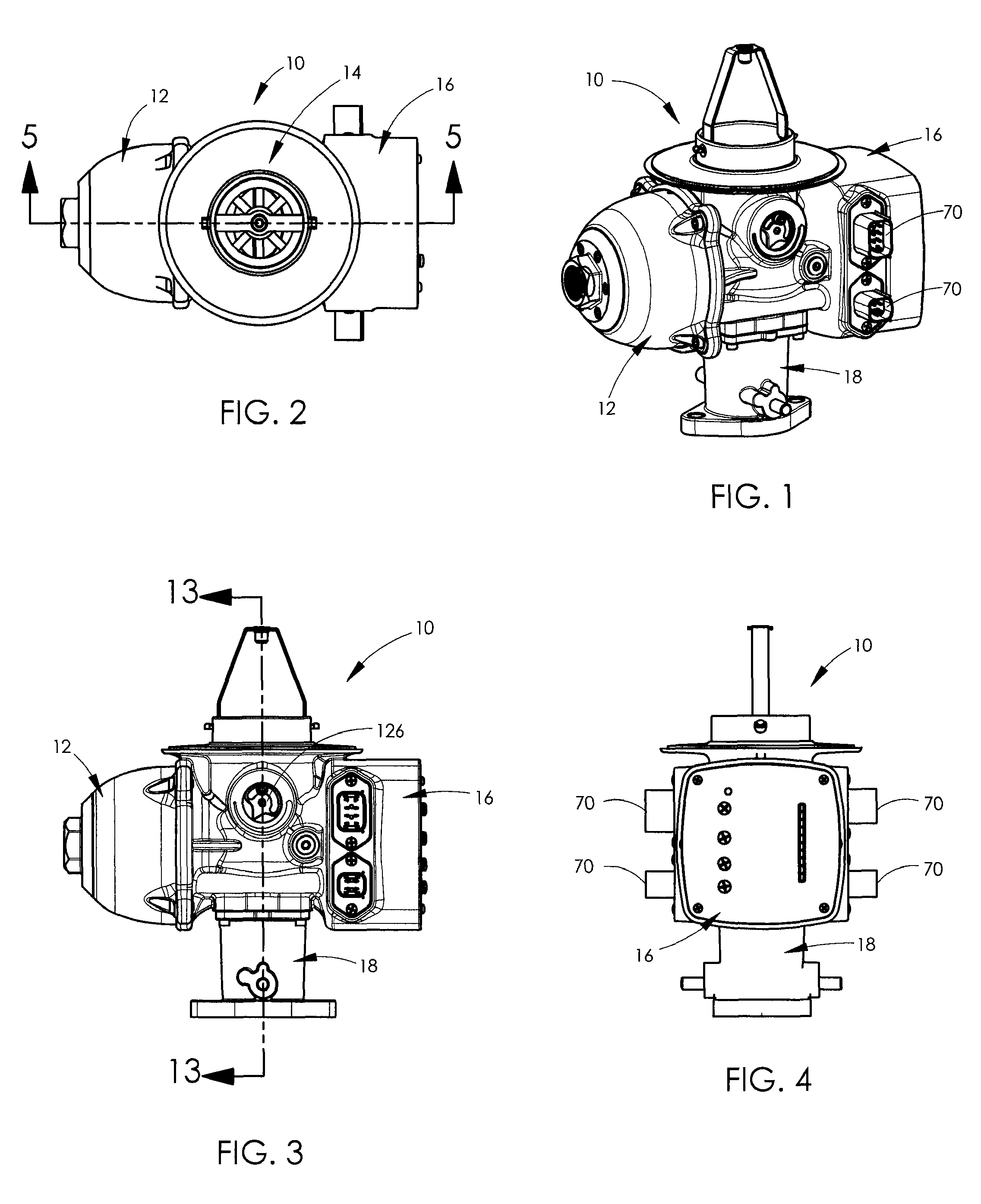

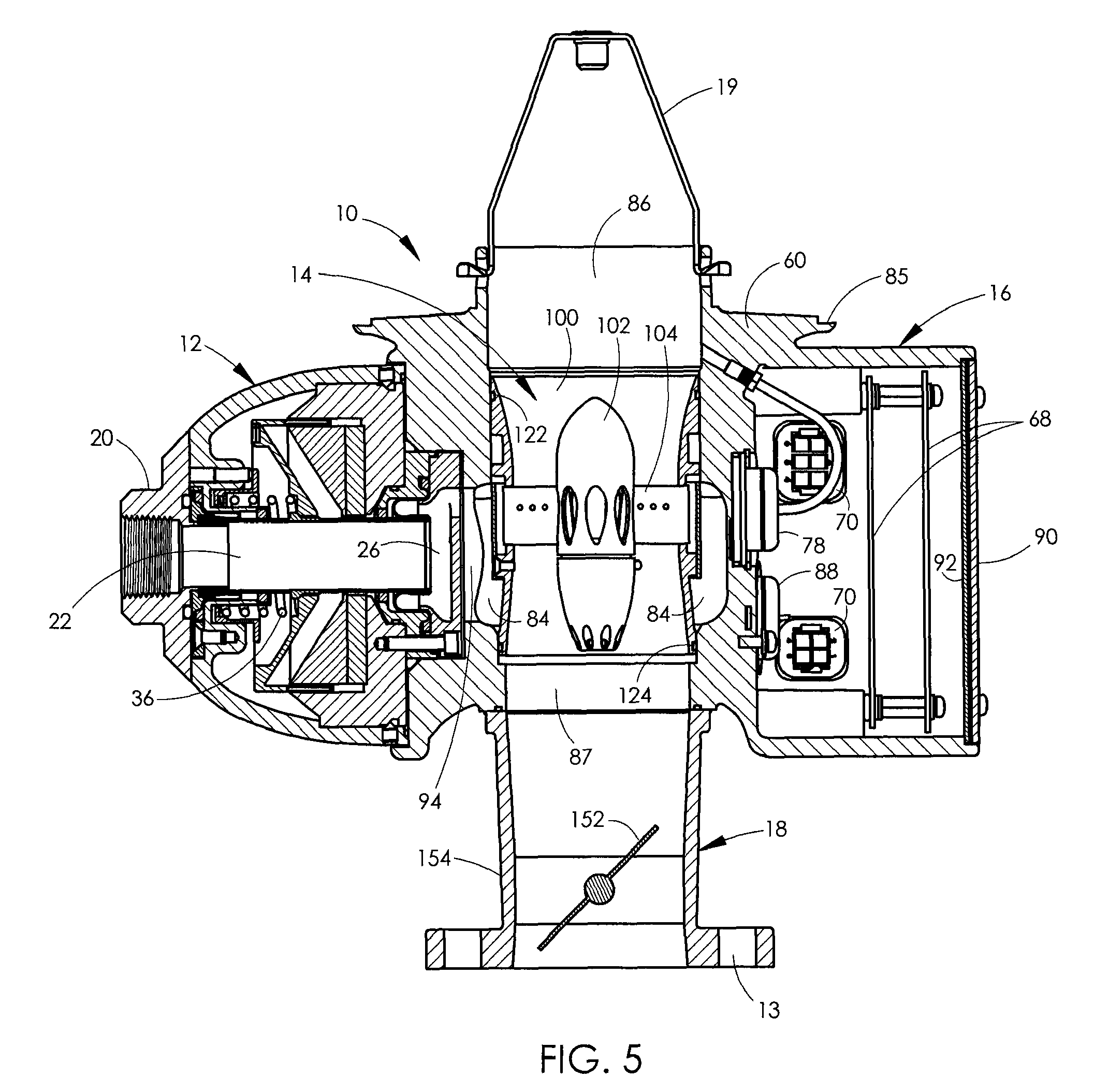

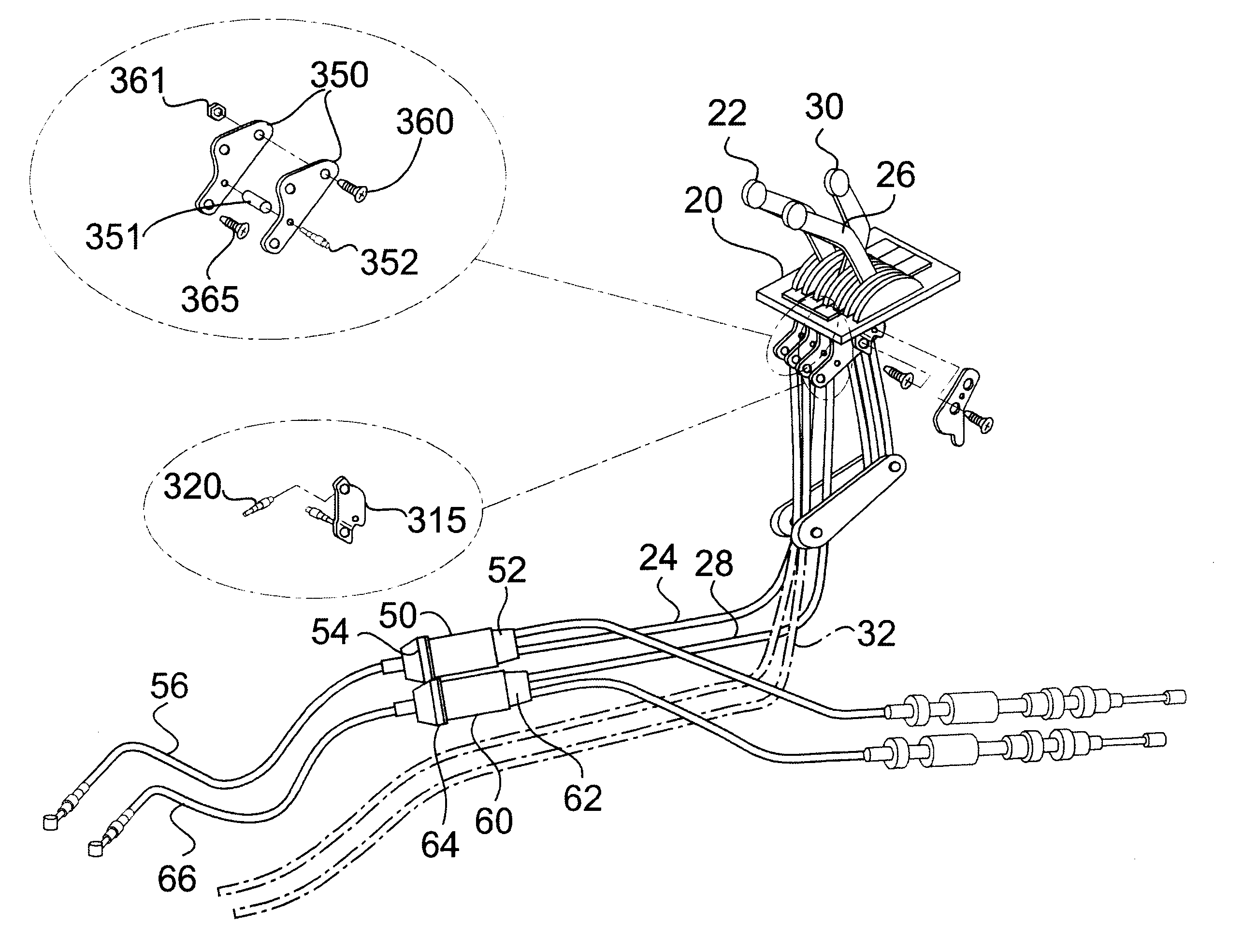

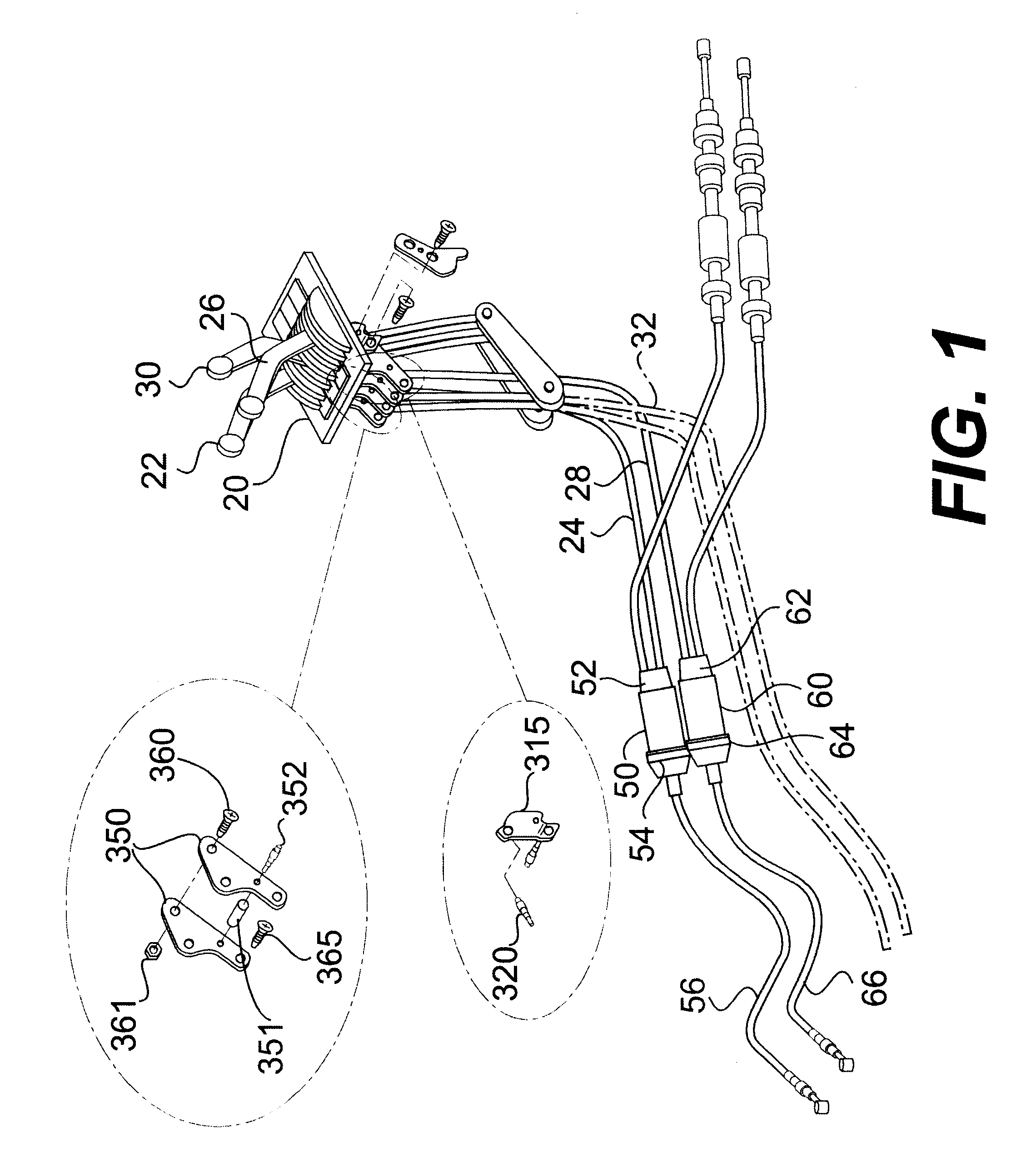

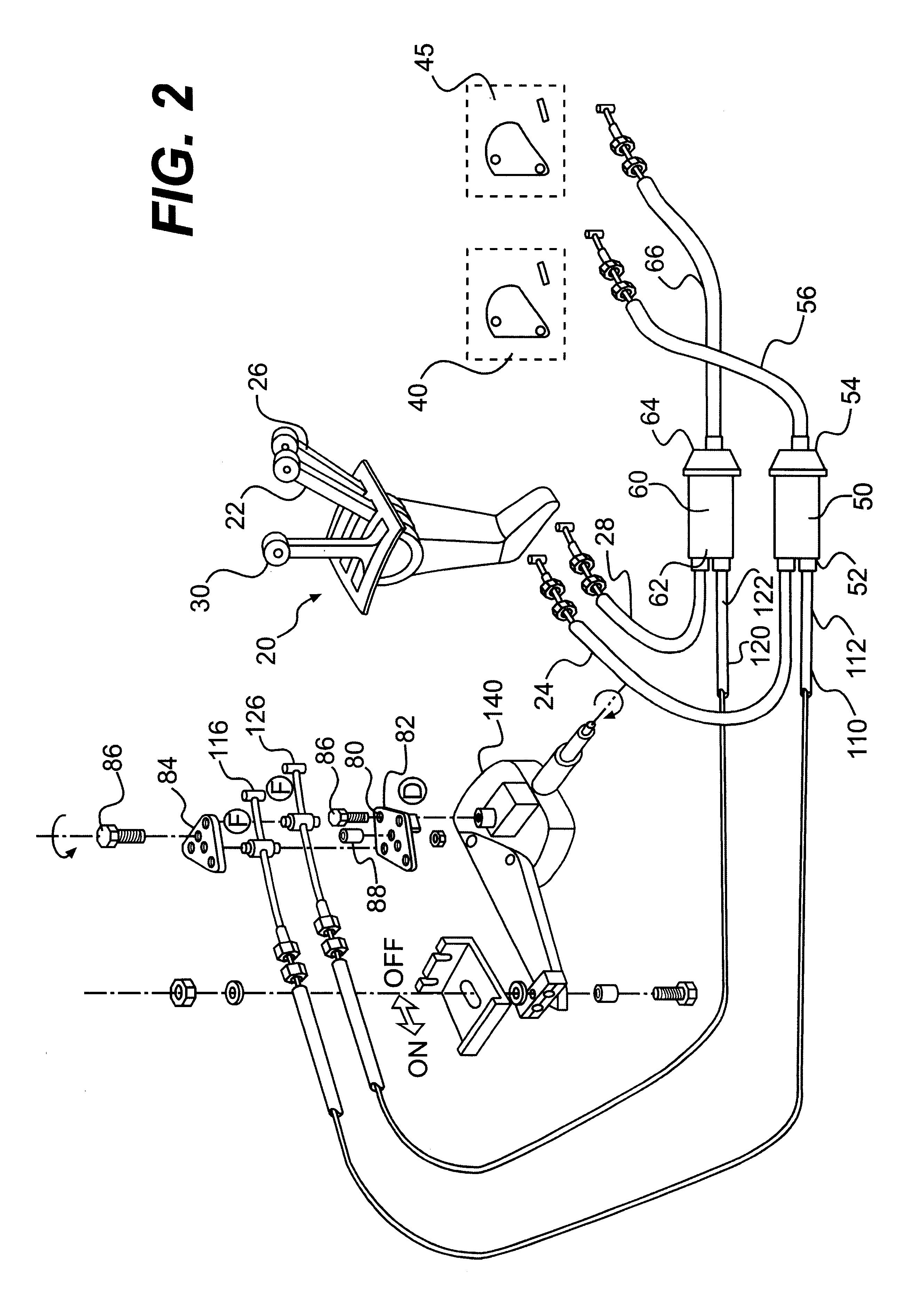

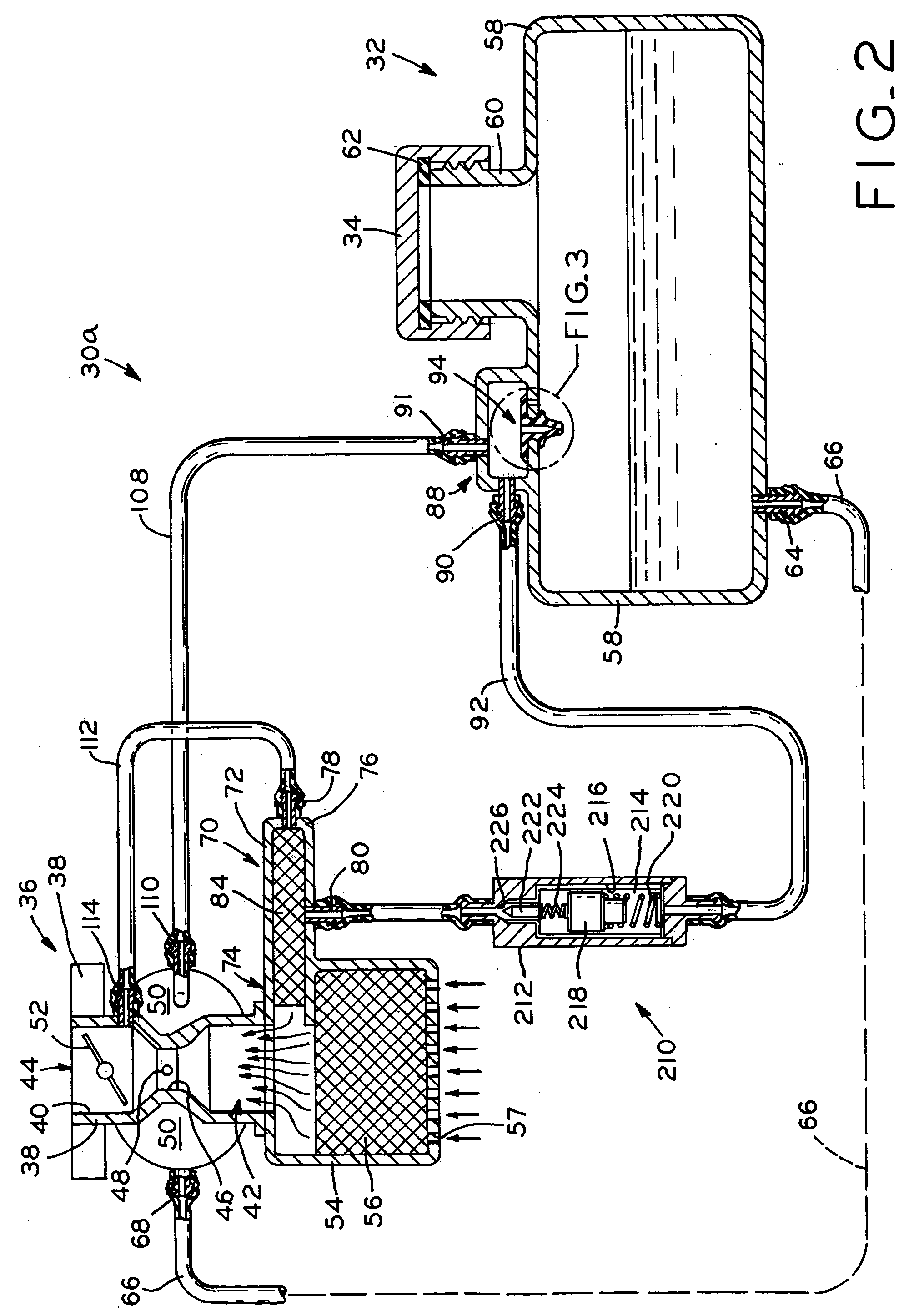

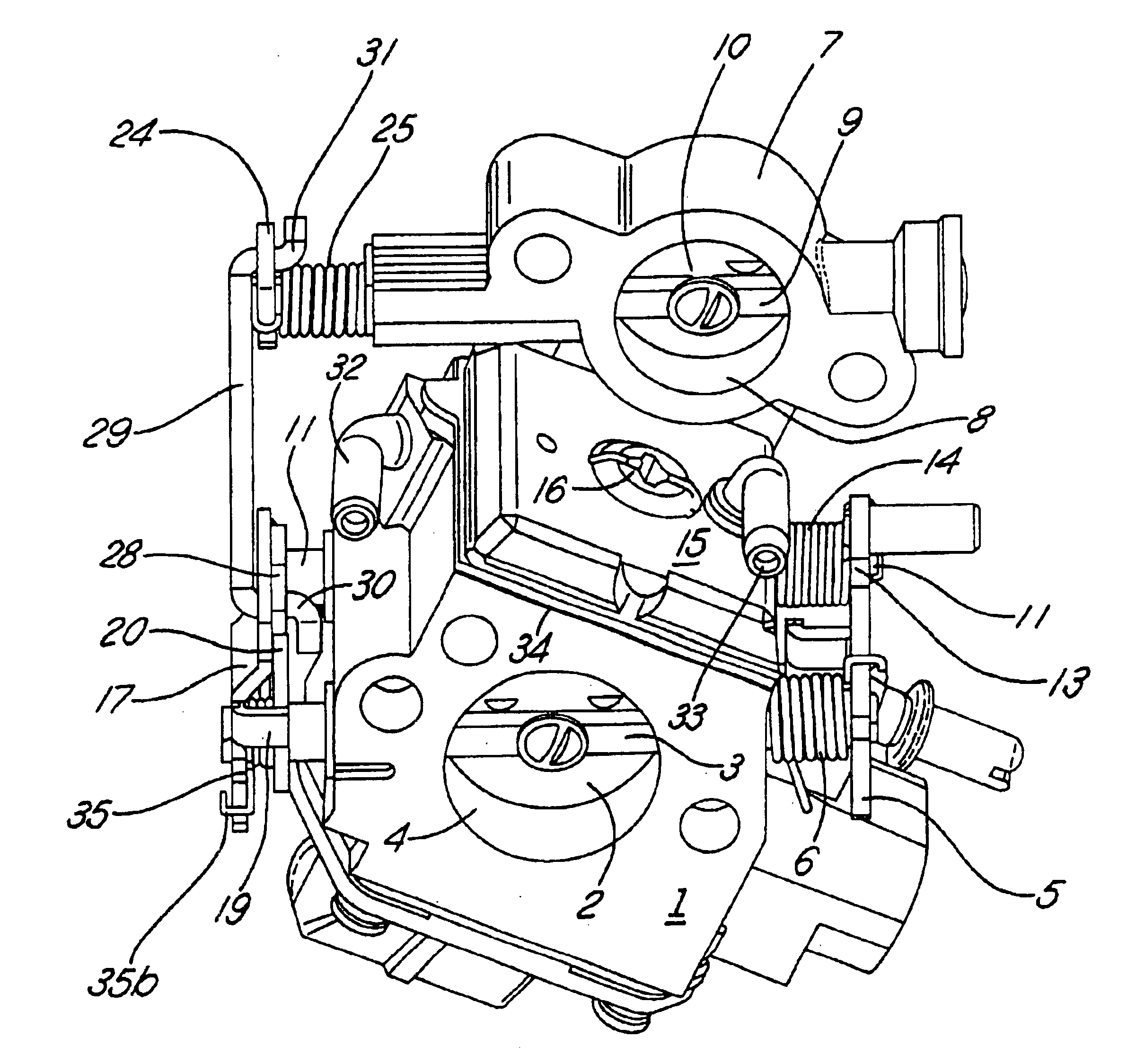

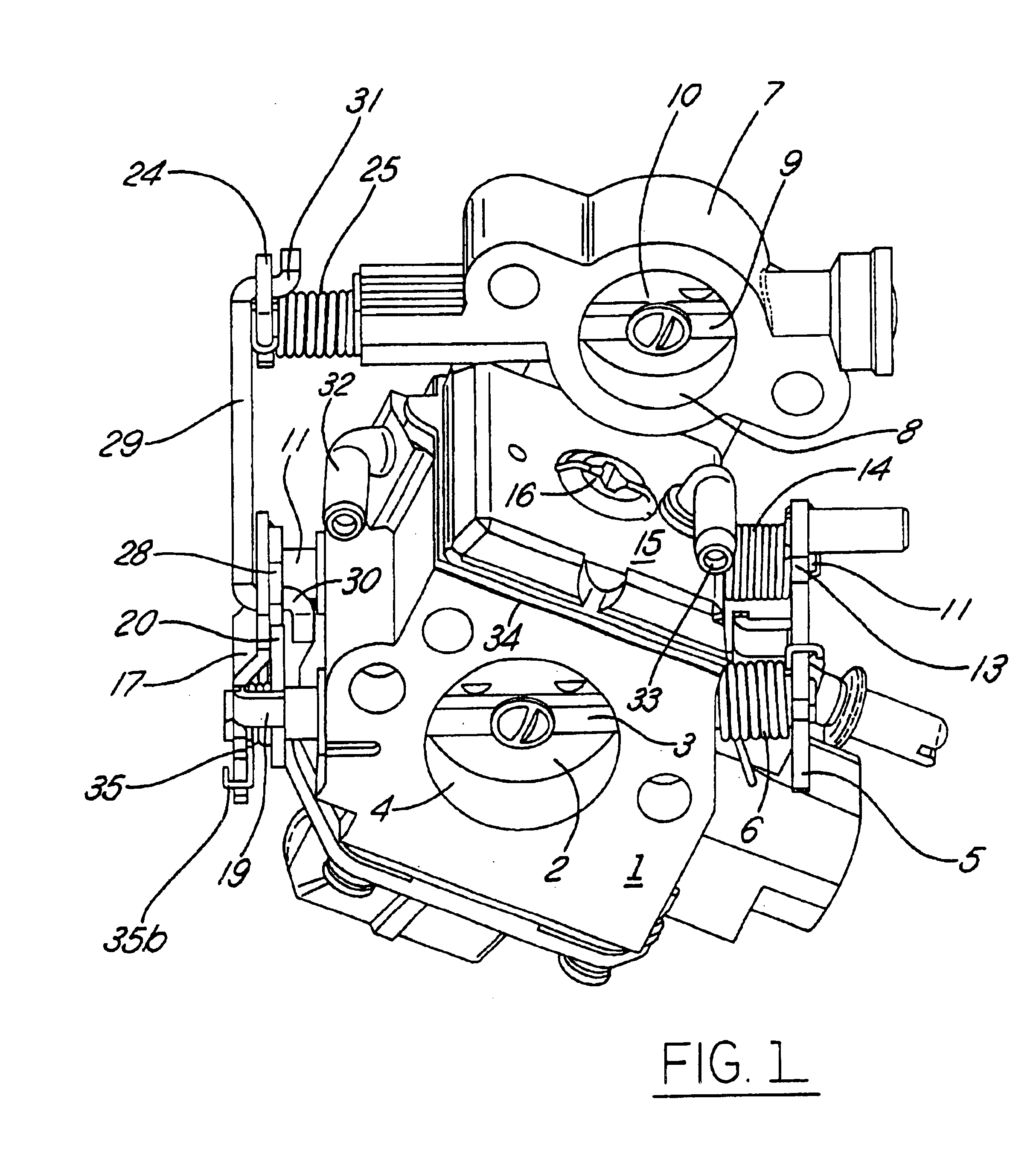

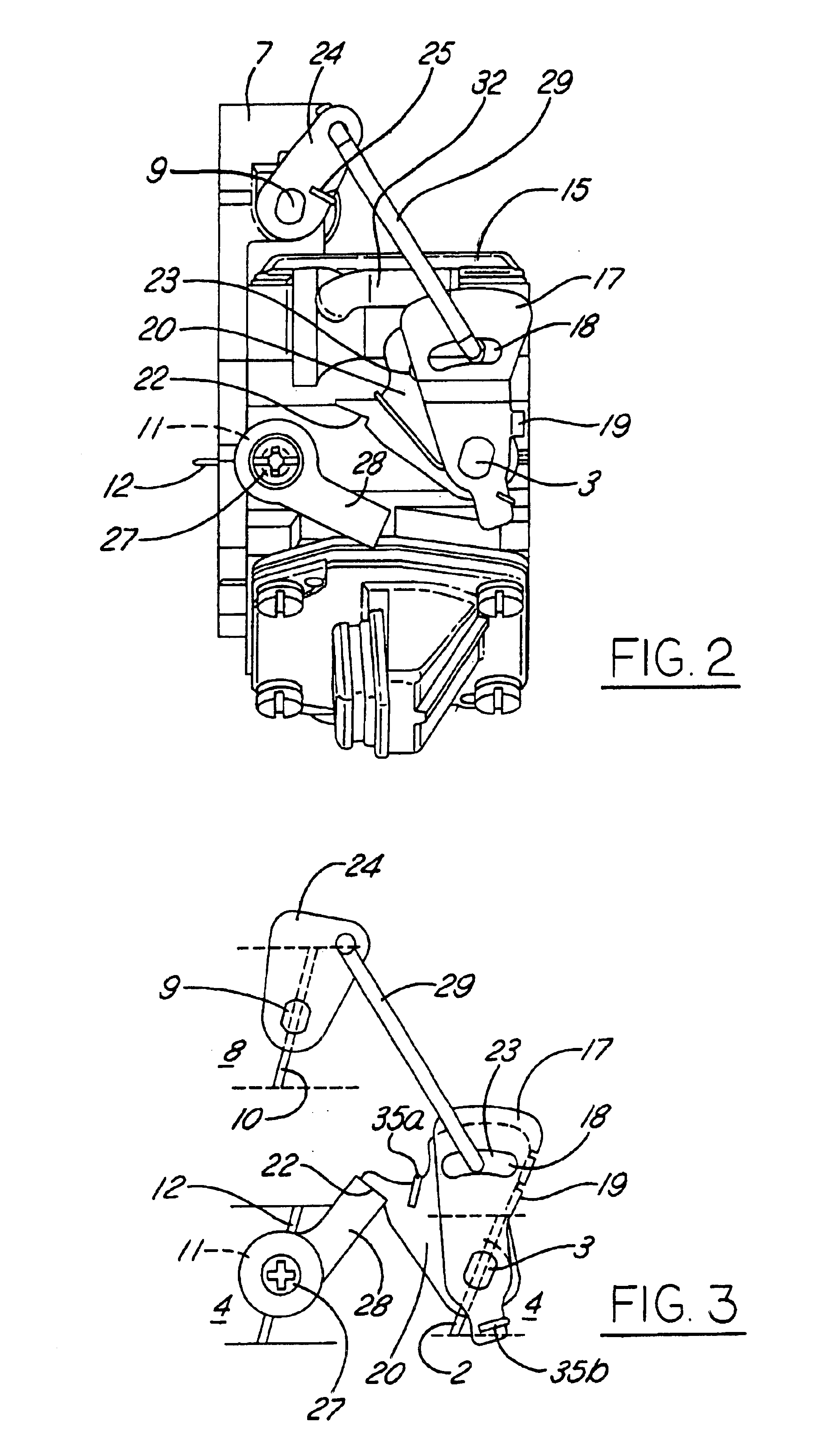

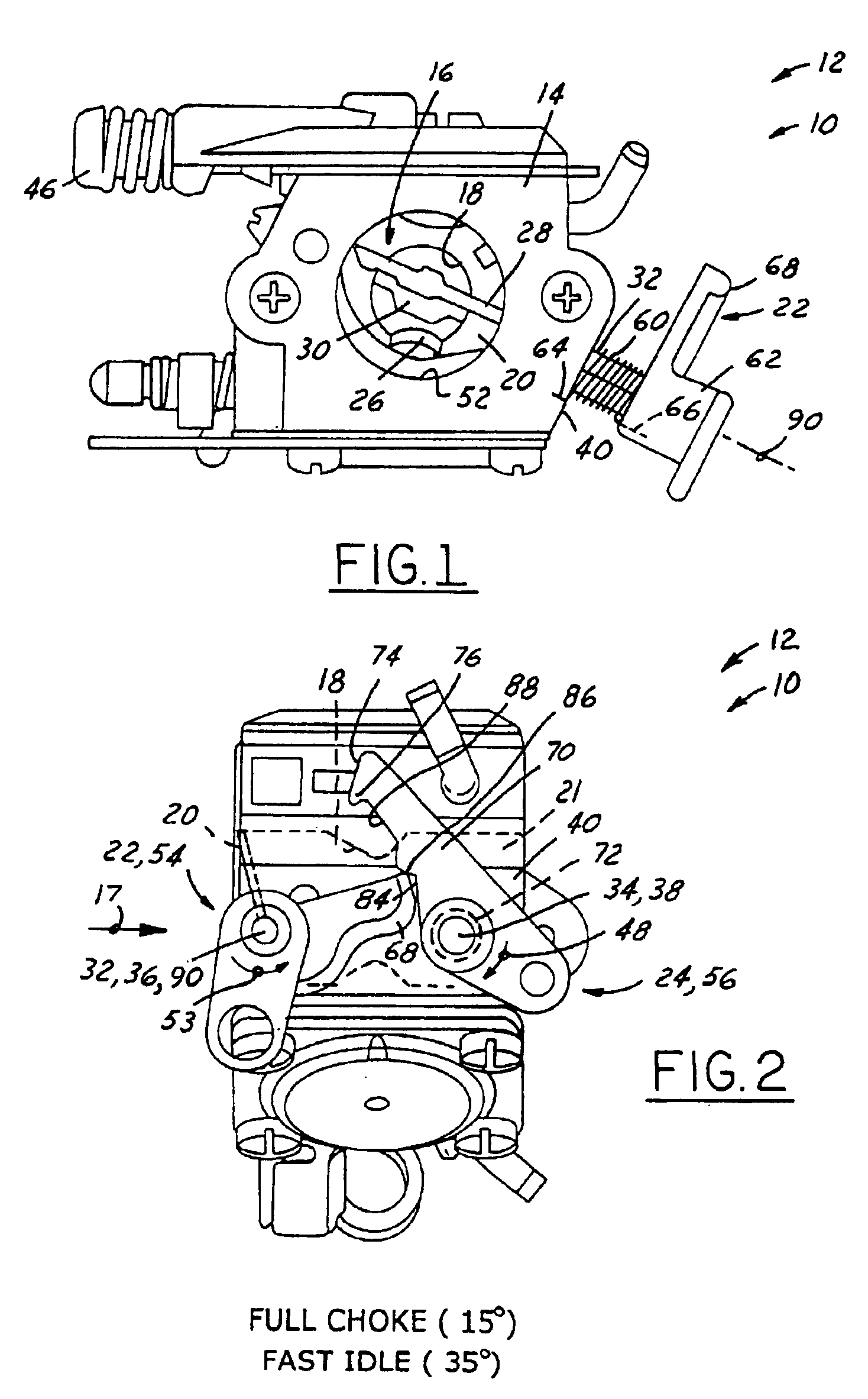

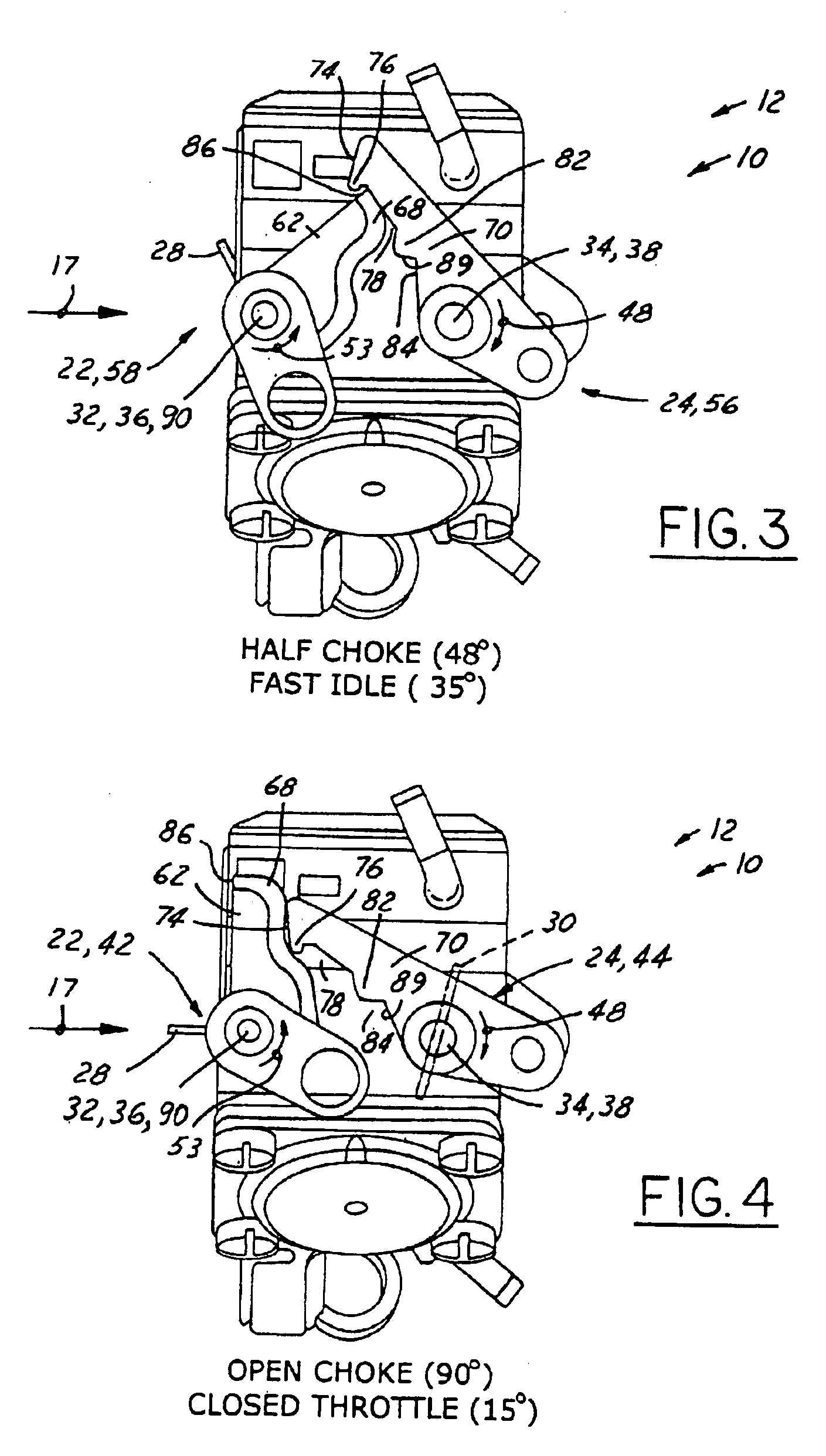

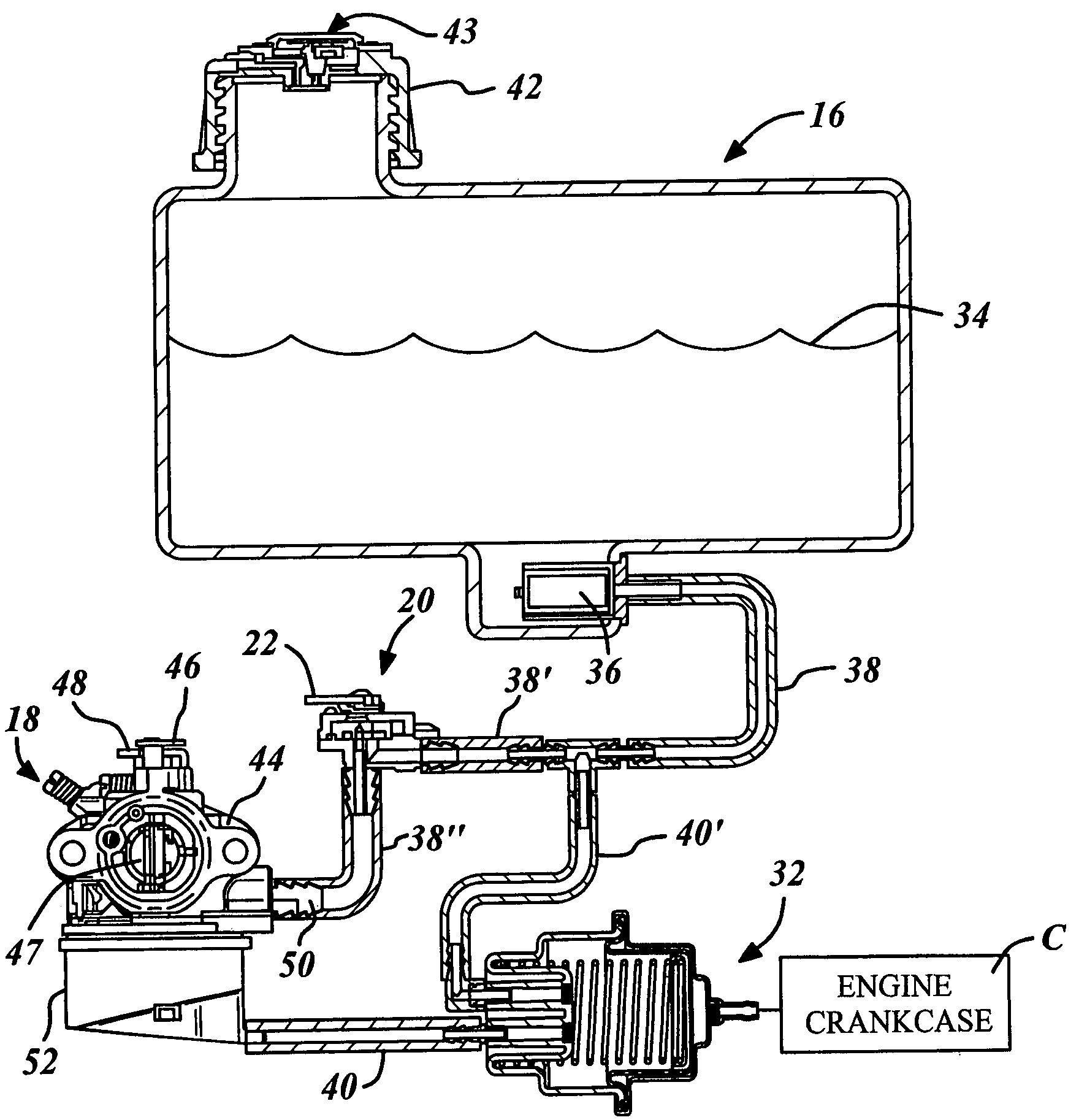

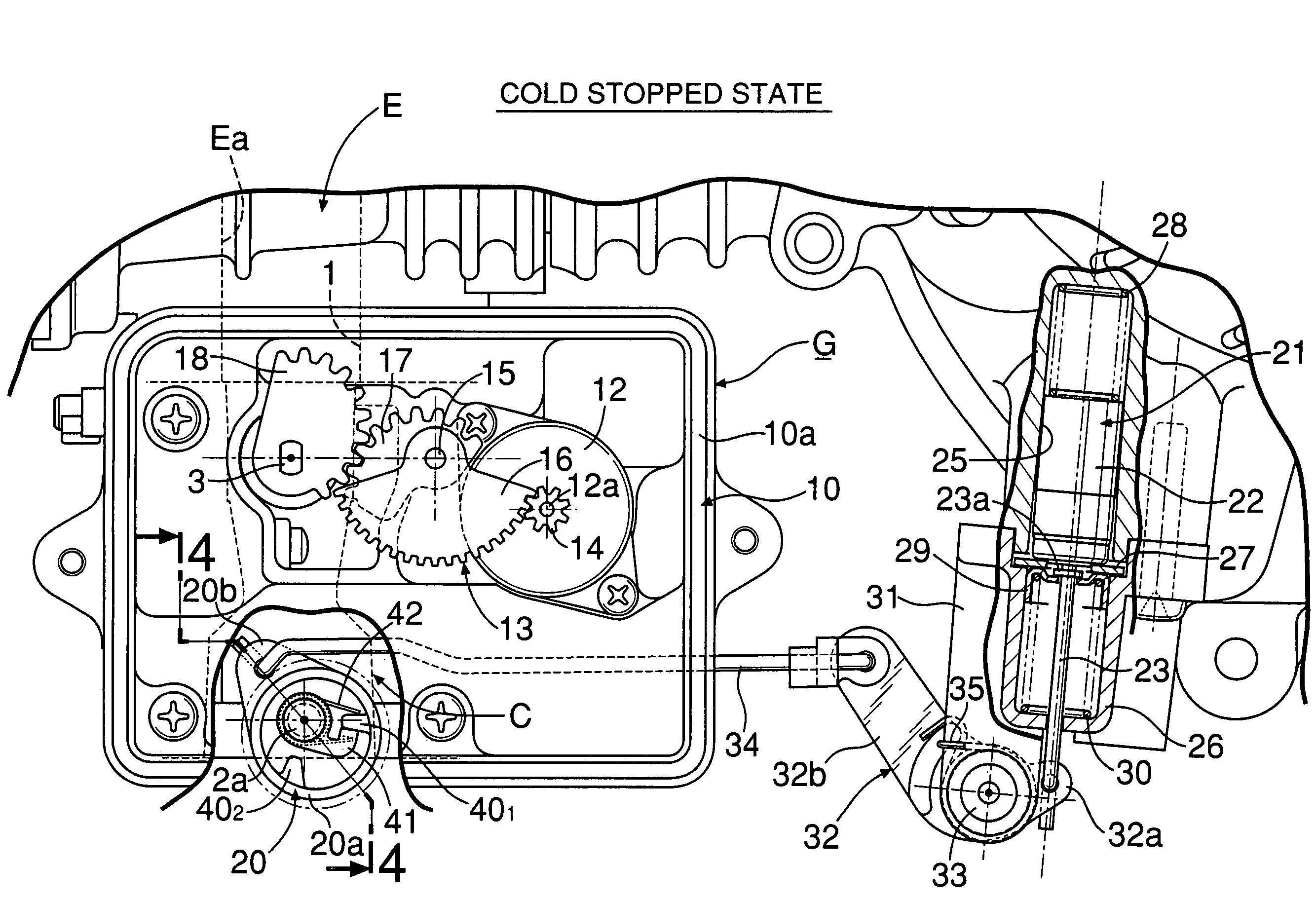

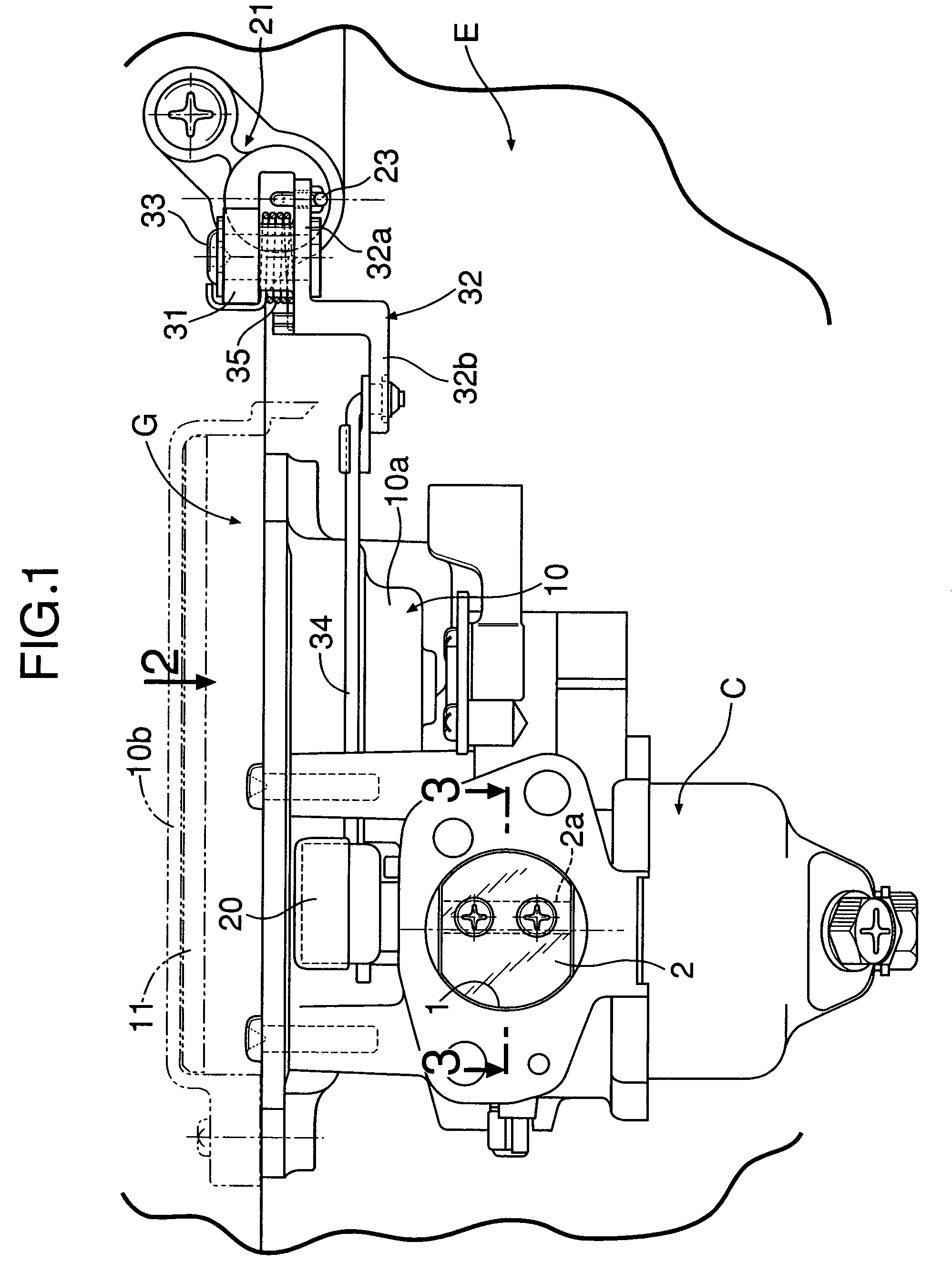

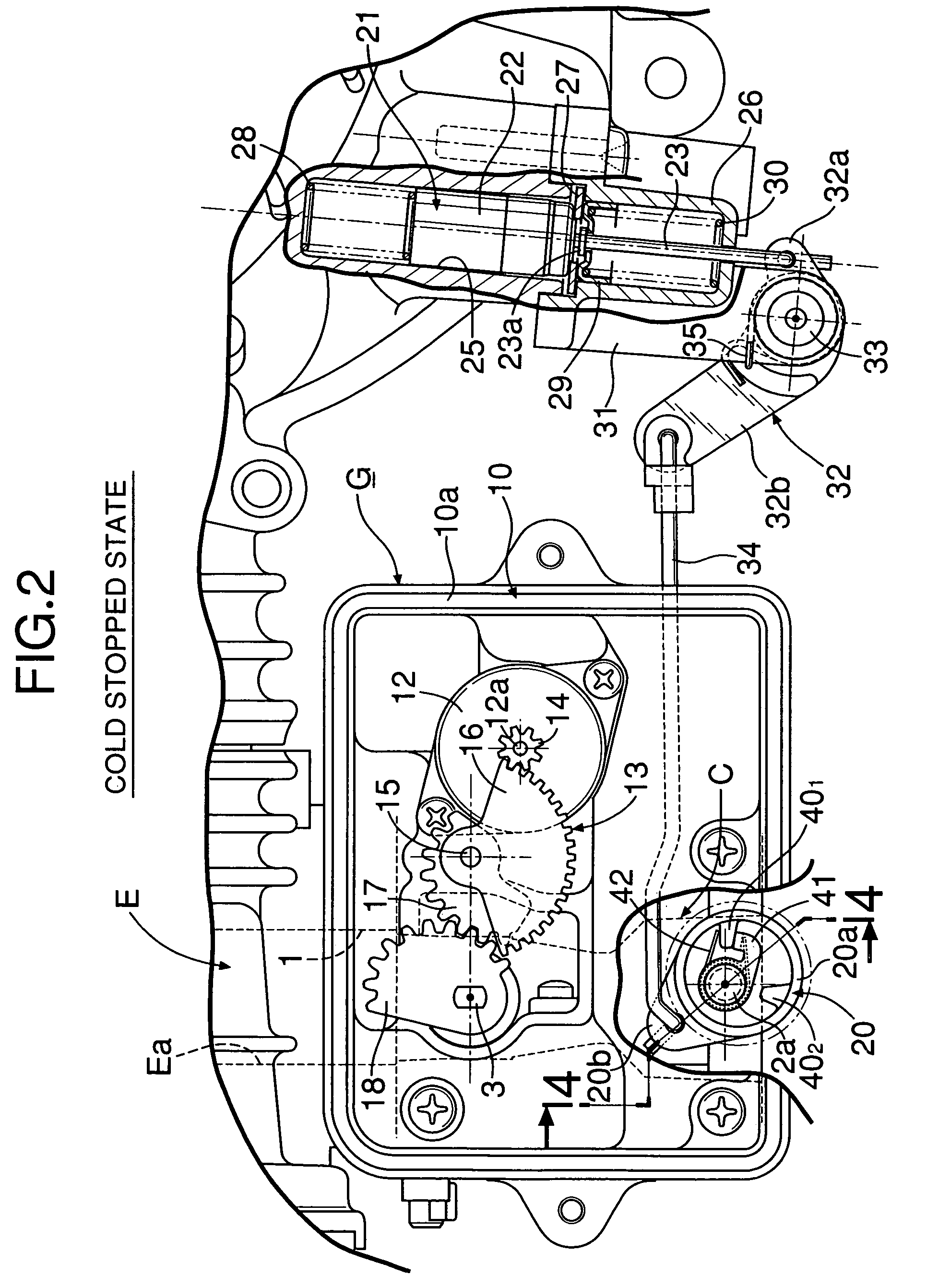

Carburetor throttle and choke control mechanism

InactiveUS6202989B1Low costEasy to modifyElectrical controlLighting and heating apparatusIdle speedCarburetor

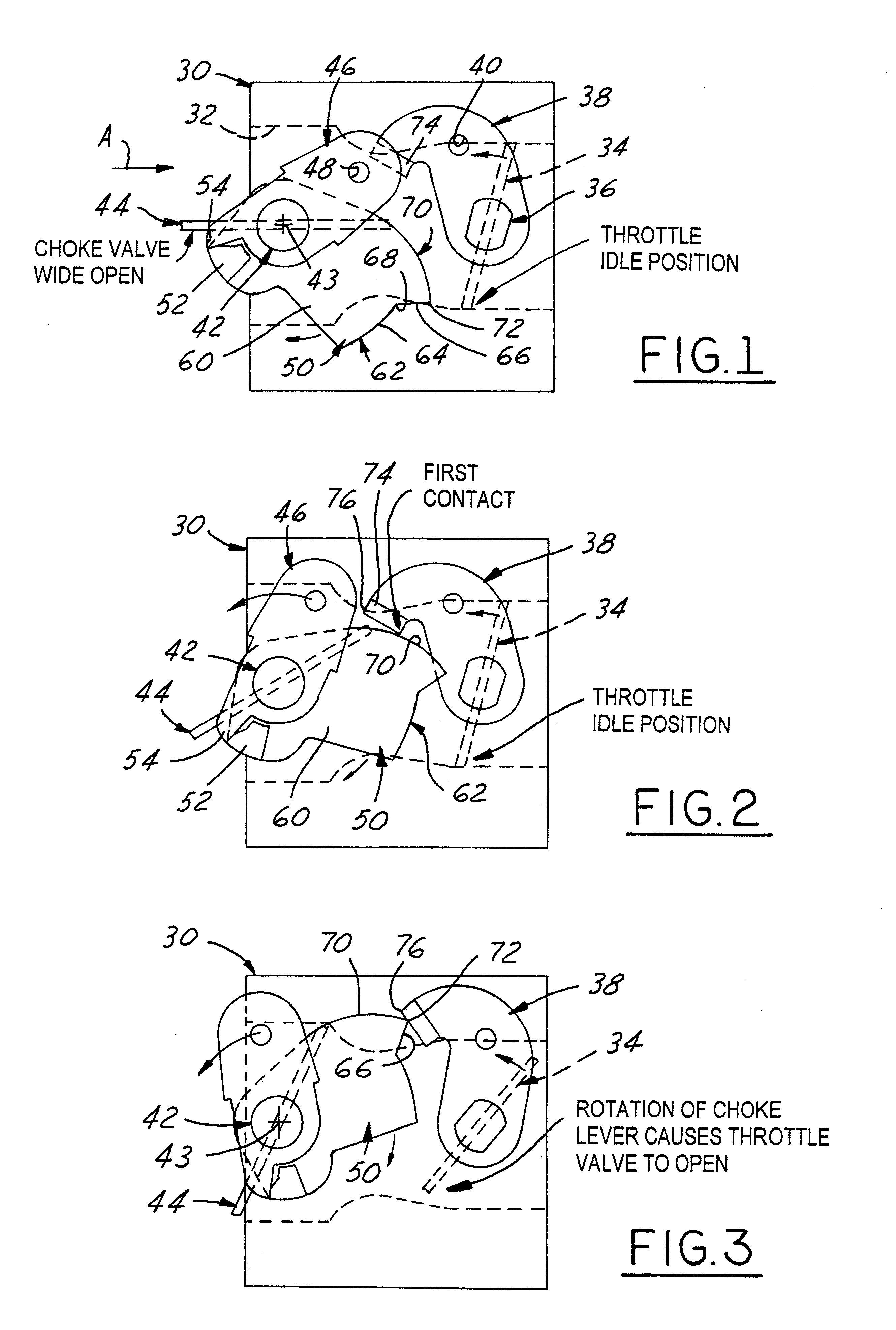

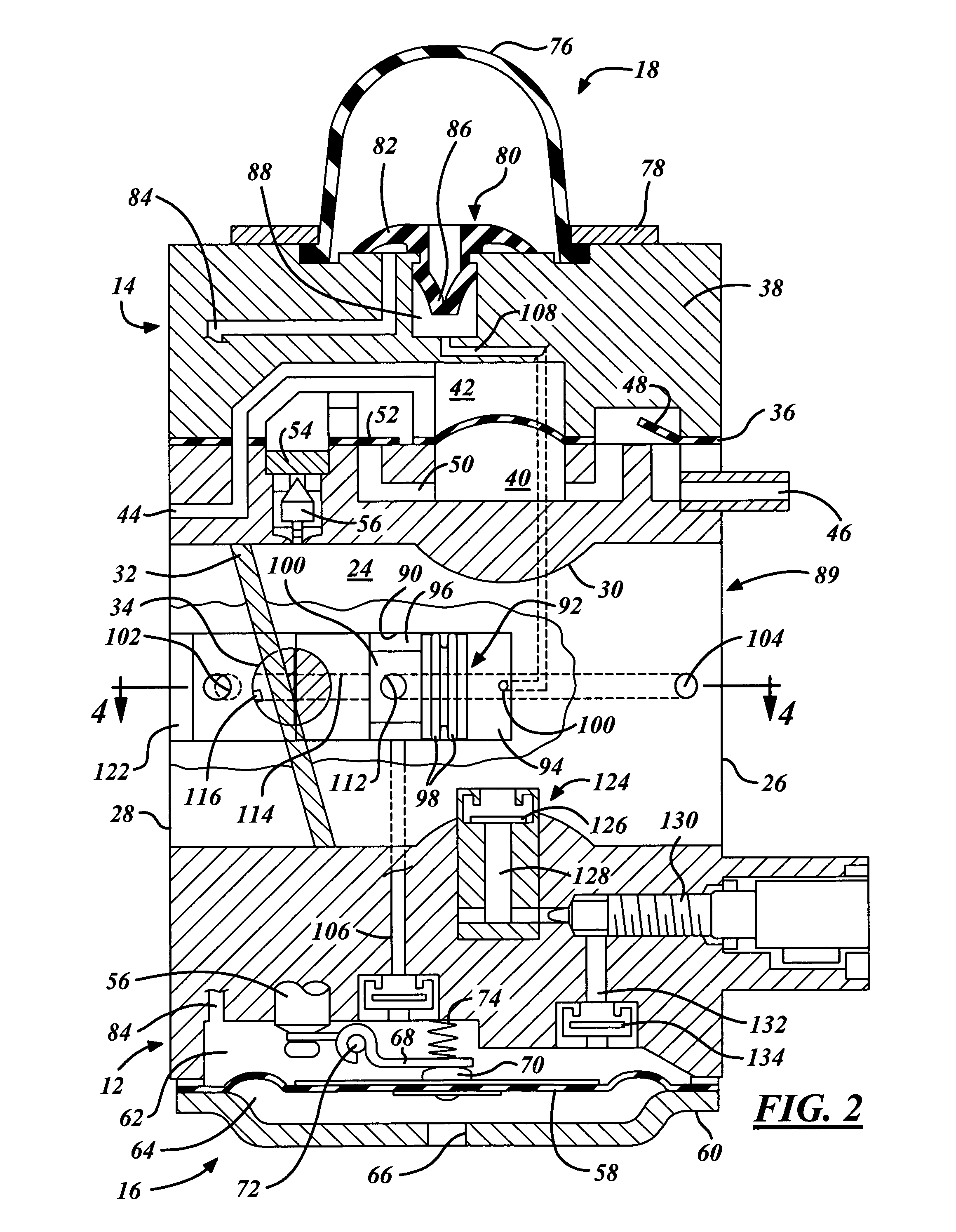

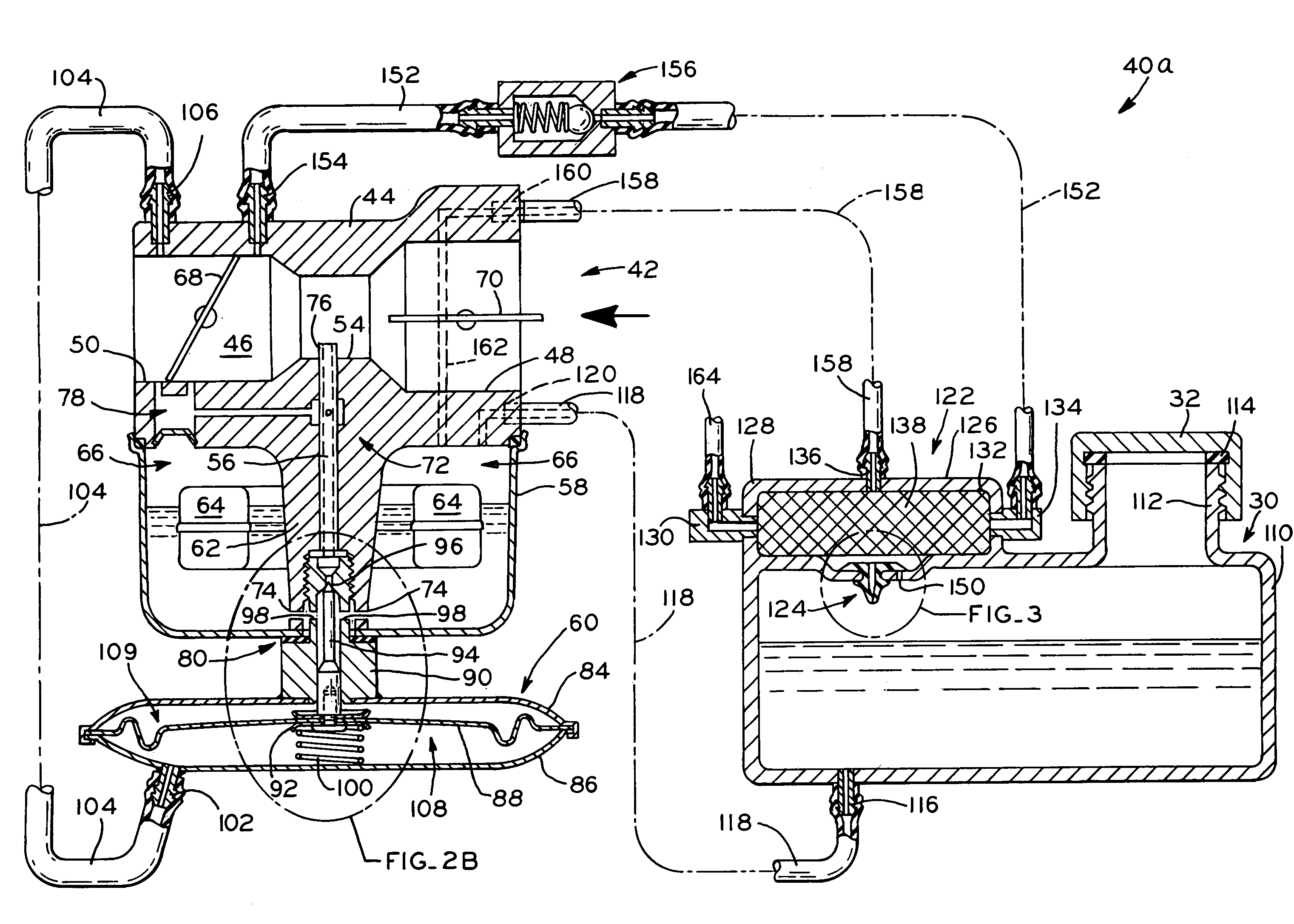

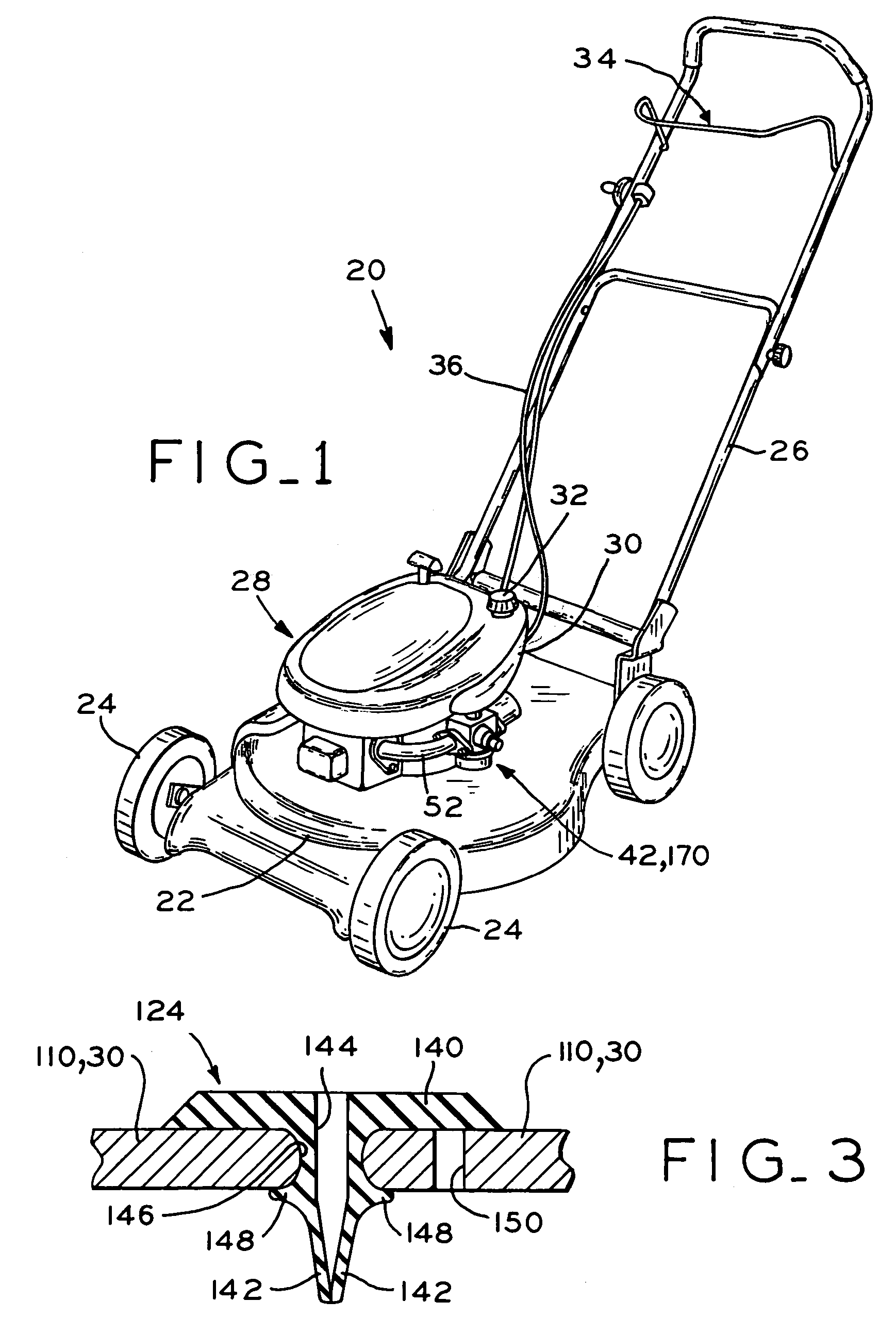

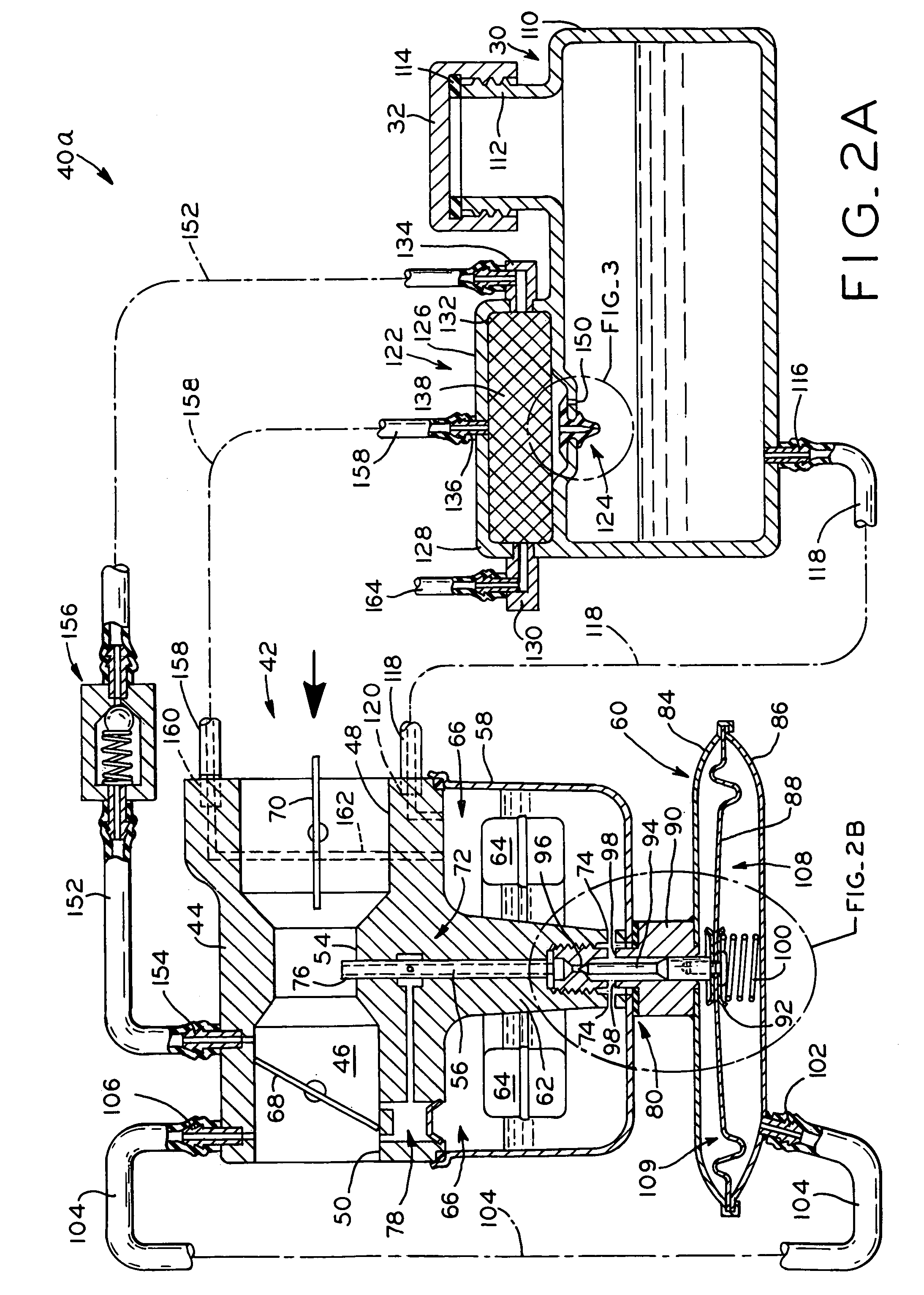

A control mechanism for a carburetor having a throttle valve and a choke valve each having at least a cold-starting position and a full-speed position. The throttle valve is spring biased toward its third, low idle position, and the choke valve is mounted on a choke shaft and is spring biased toward its full-speed open position. When the choke valve is moved by a choke shaft lever from its open position toward its cold start closed position a fast idle lever associated with the choke valve shaft engages, via releasable latch parts, a throttle lever associated with the throttle valve. The interengaging latch parts of these fast idle and throttle levers hold both valves in their respective cold-starting positions in opposition to their respective biasing springs. These latch levers can be released by operator actuation of the throttle valve control, thereby causing the choke valve to be automatically returned to its open position by its biasing spring, or, alternatively, the choke valve can be moved independently to its full-speed position. One of these fast idle and throttle latch levers has a notch, and the other has a pawl selectively engaging the notch when it becomes aligned therewith when the latch levers are operator-actuated to their respective cold start positions. The choke shaft is torsionally resilient so that when the choke shaft lever is forced to override initial-choke-closed position, it thereby twists the choke shaft after the choke valve has been bore-stopped at closed position. Upon release of operator actuating force, this feature prevents most, if not all of the previous retrograde movement of the choke and throttle valves out of their design cold start positions, despite operating slack in the latch system due to manufacturing tolerance stack-up in the various parts of the latch system parts and / or control mechanism in their assembly and operation.

Owner:WALBRO ENGINE MANAGEMENT

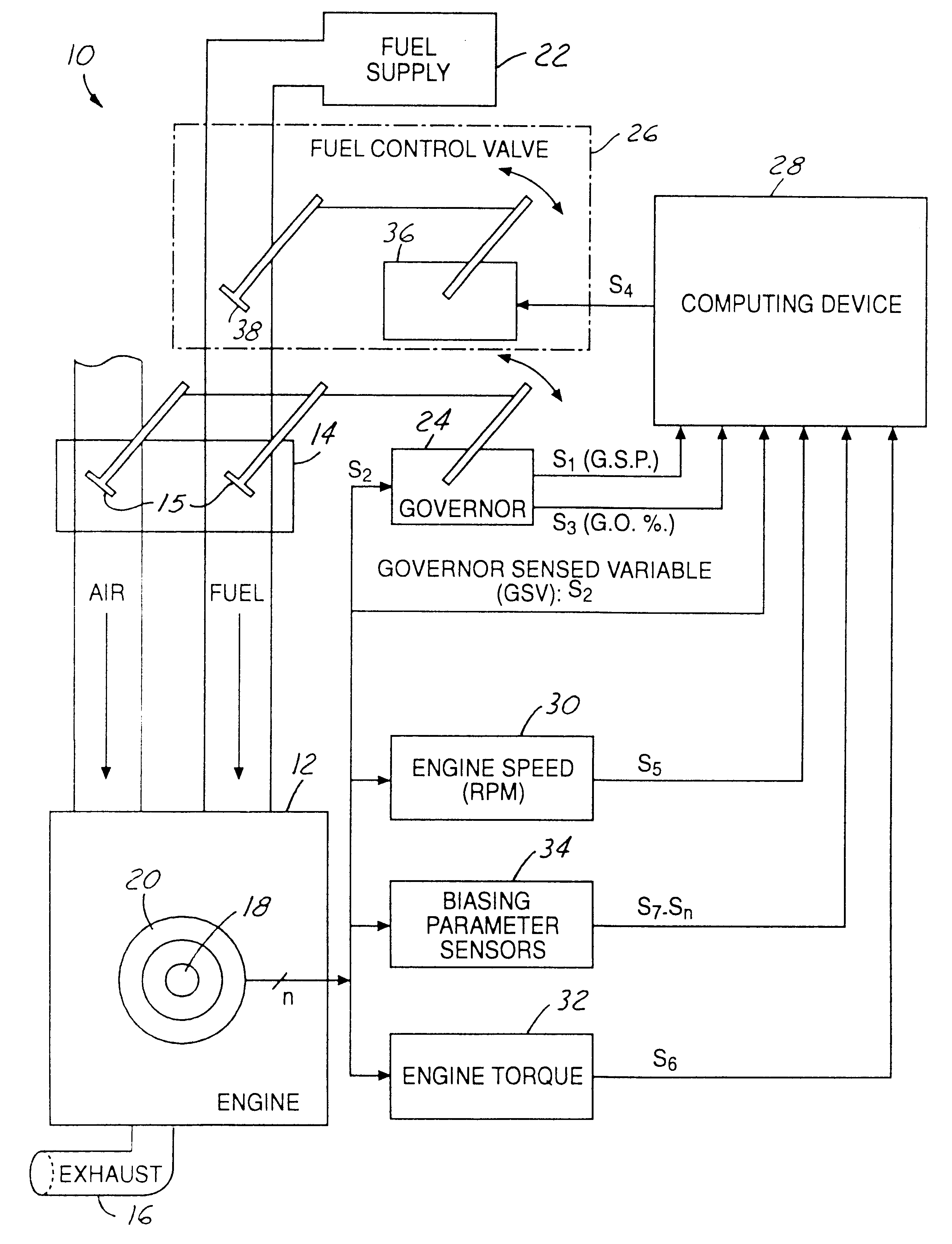

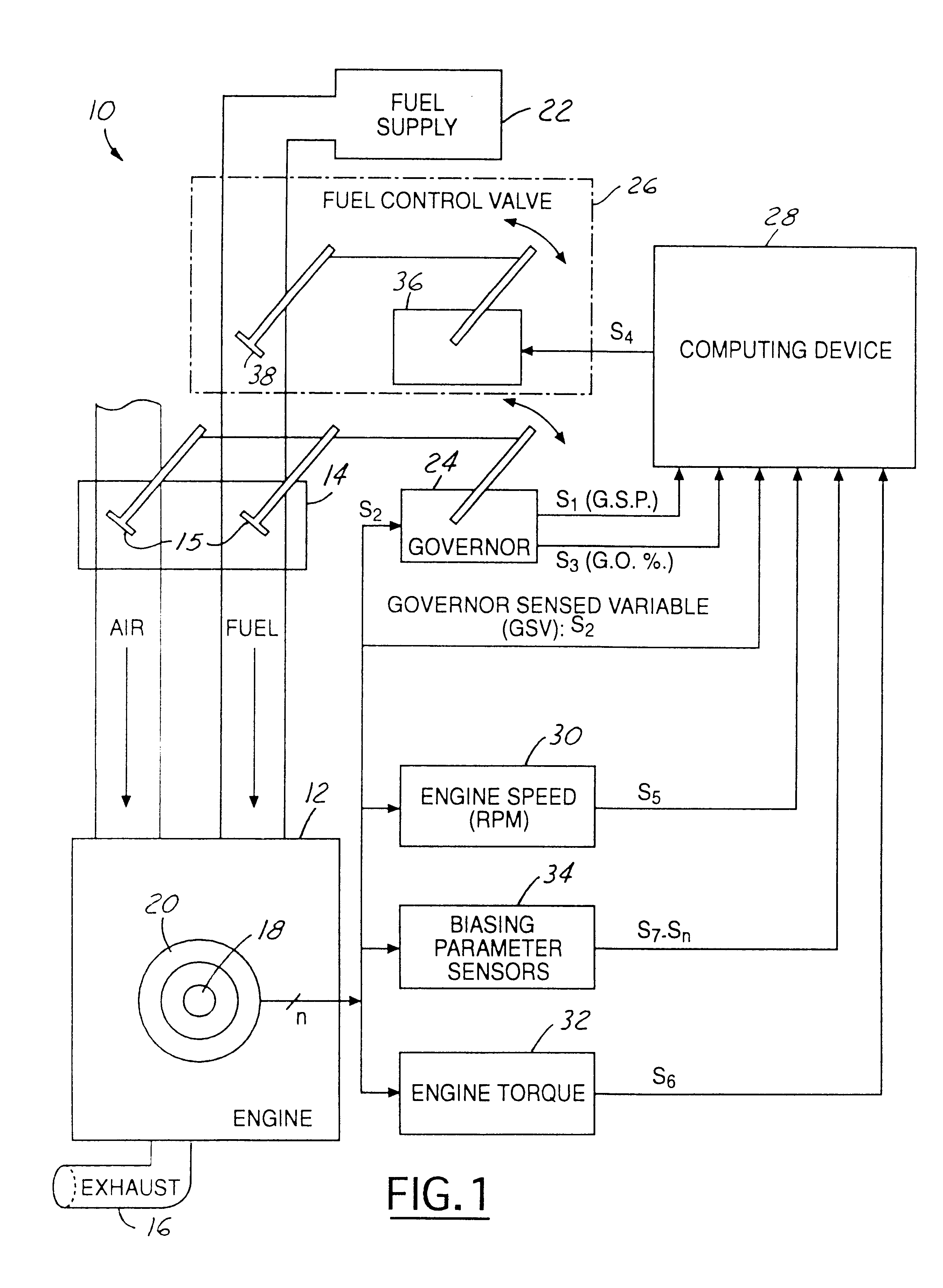

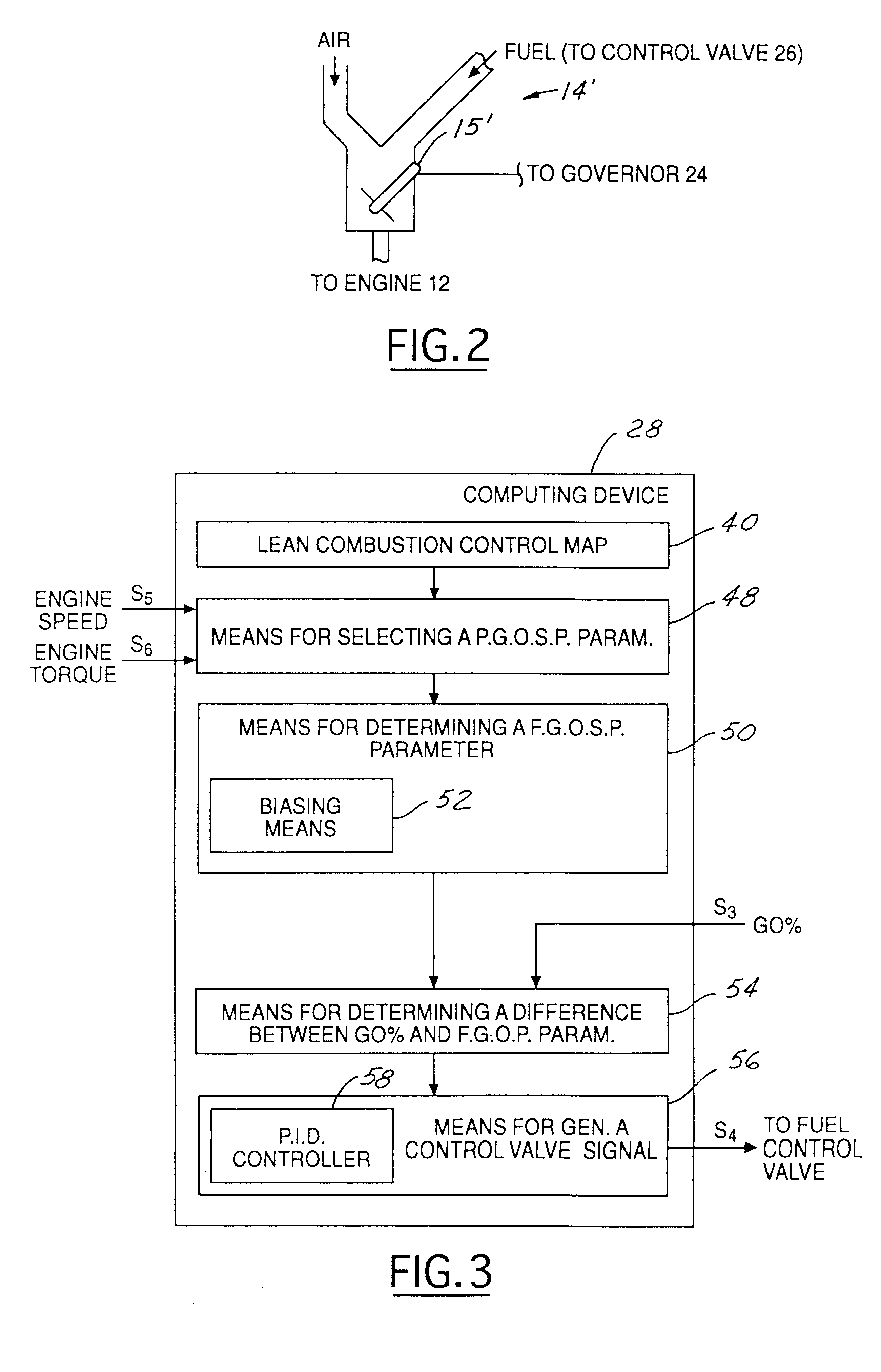

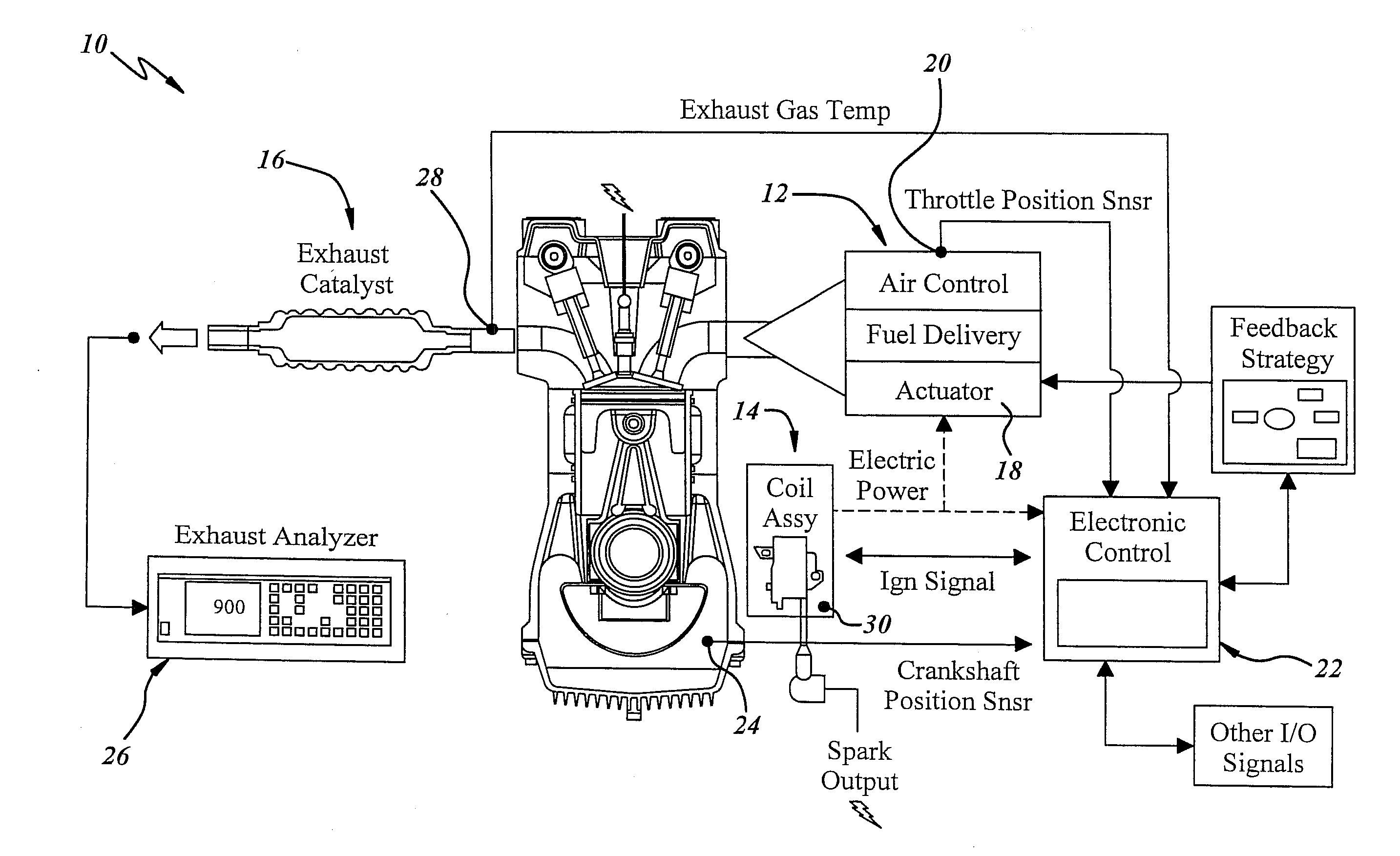

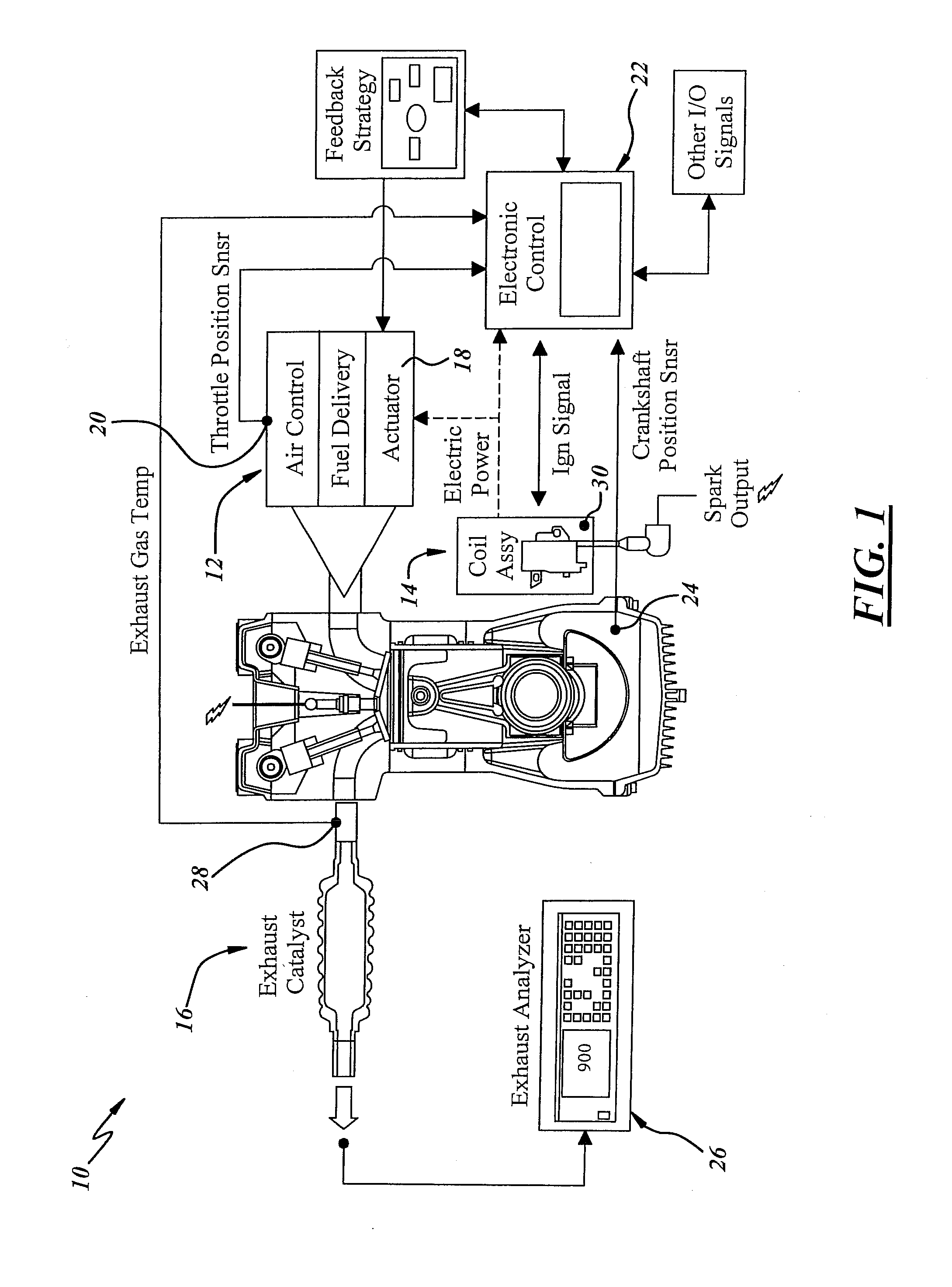

Method and system for controlling an air-to-fuel ratio in a non-stoichiometric power governed gaseous-fueled stationary internal combustion engine

InactiveUS6189523B1Reduces "pumping losses.Less importantAnalogue computers for vehiclesElectrical controlControl signalExhaust fumes

A gaseous-fueled reciprocating internal combustion engine includes a carburetor having a throttle valve that is controlled by a speed governor. A proportional fuel control valve is disposed intermediate a fuel supply and the carburetor, and is controlled by an air fuel computing device. The computing device generates a control signal to adjust the fuel control valve based on a governor sensed variable indicative of engine speed, sensed engine torque, a governor output signal from the governor indicative of an opening position of the throttle valve wherein 100% corresponds to a wide open throttle position, and 0% corresponds to a closed position, and a lean combustion control map containing predetermined set point values stored in memory. During operation, the control valve is responsive to the control signal generated by the computing device for adjustment of a fuel flow therethrough so as to obtain a ratio of air to fuel provided to the engine that is substantially at a lean misfire limit of the engine, thereby reducing fuel consumption, NOx emissions, and reducing exhaust gas temperatures. Alternatively, the control signal is generated using engine speed alone.

Owner:ANR PIPELINE

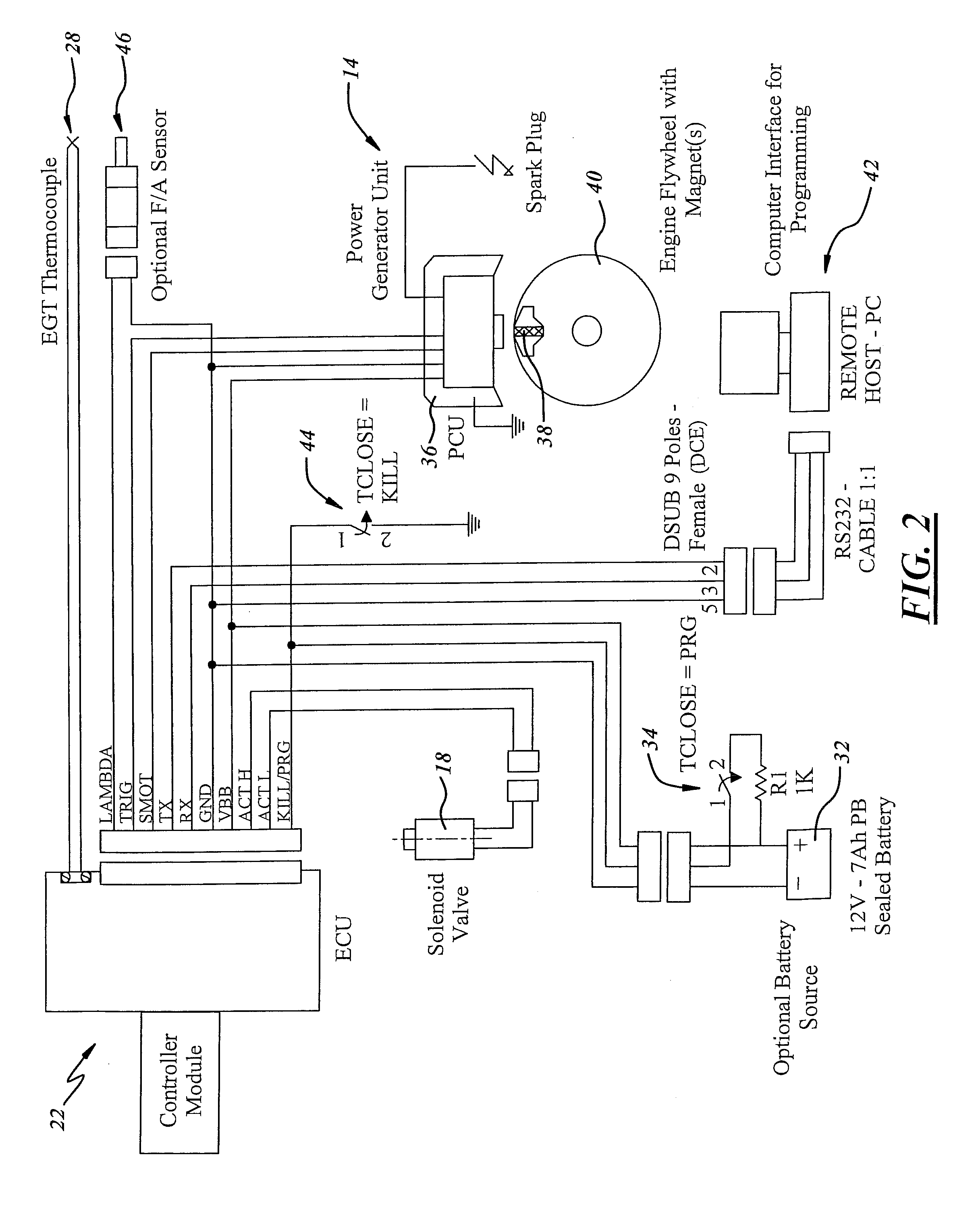

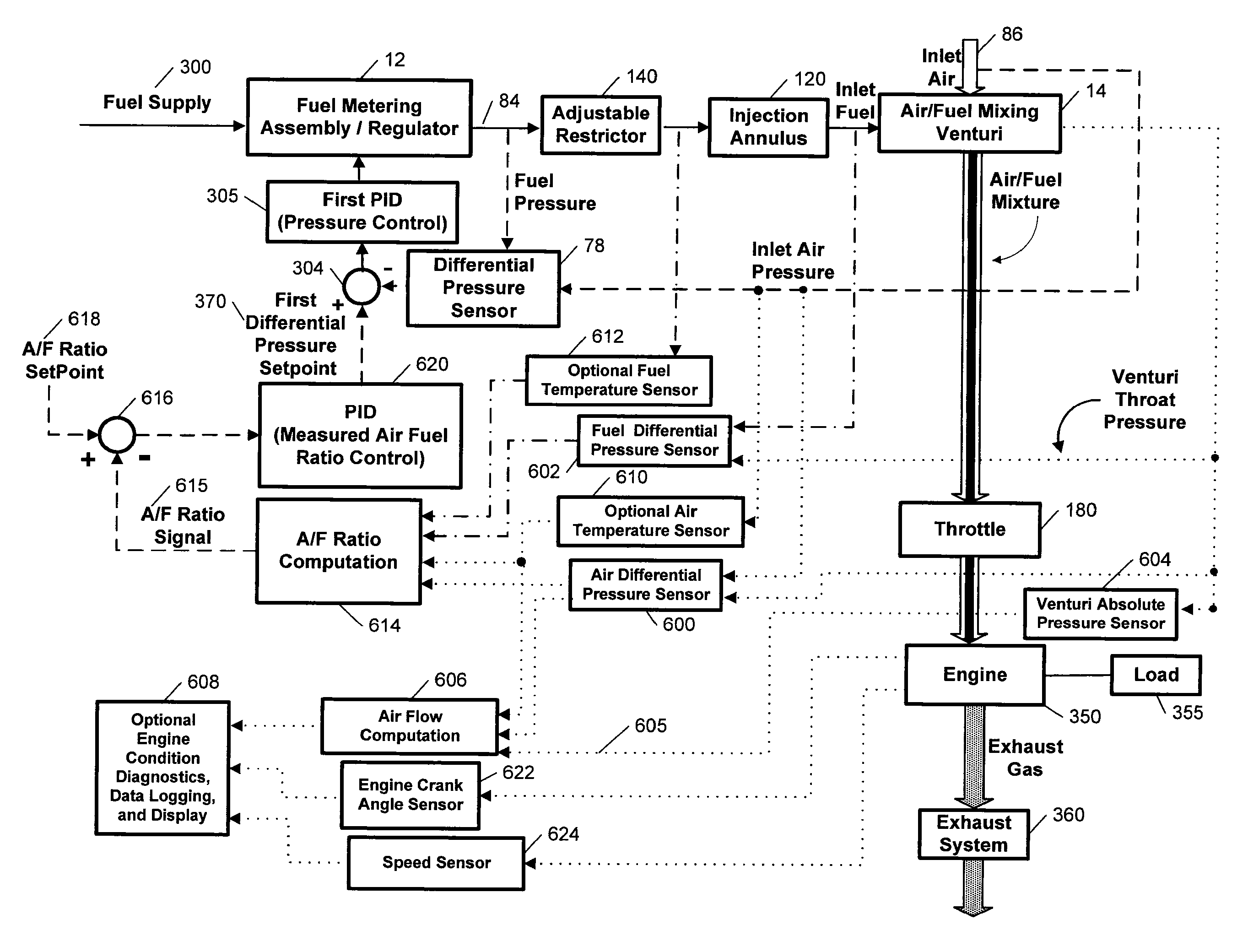

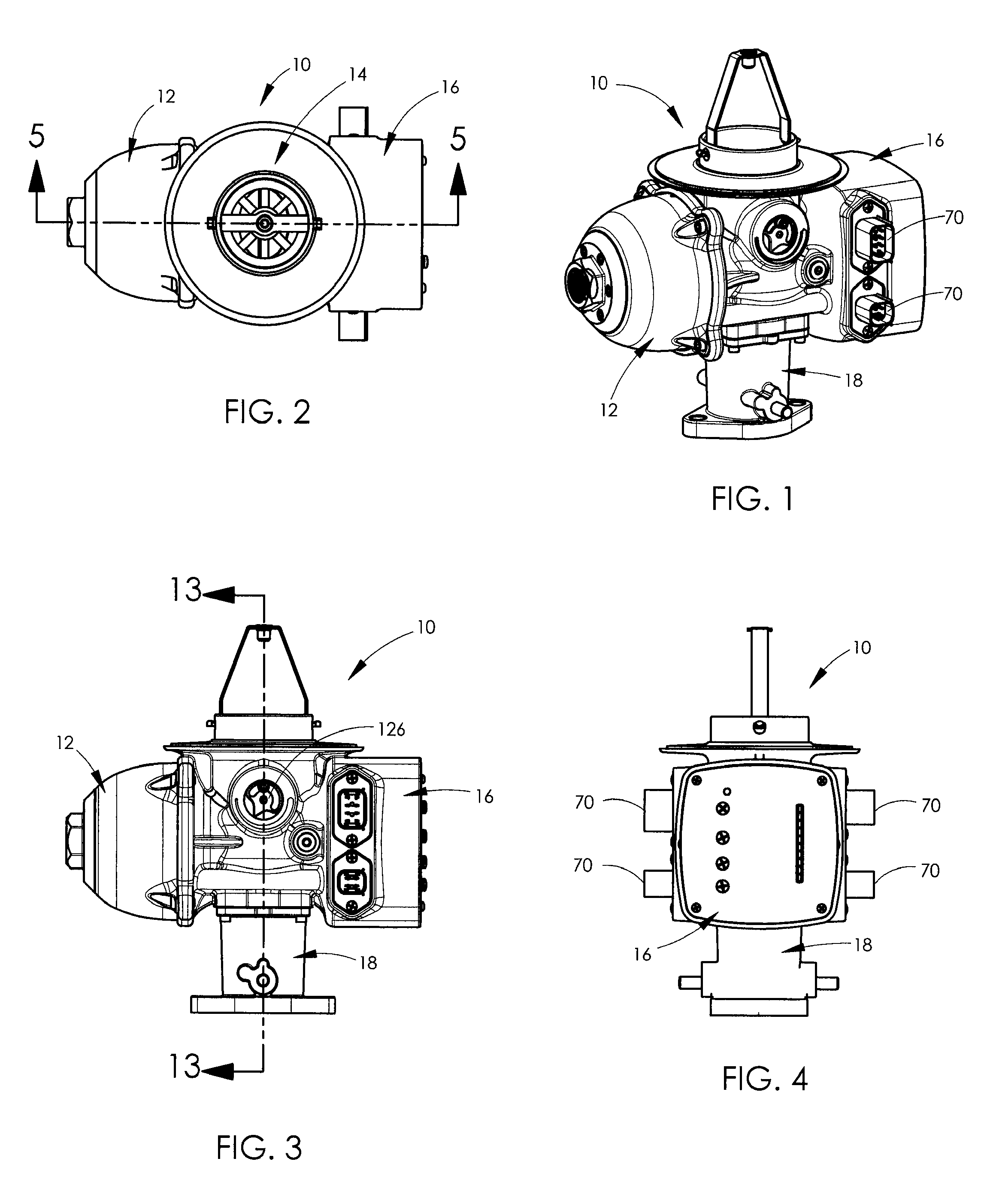

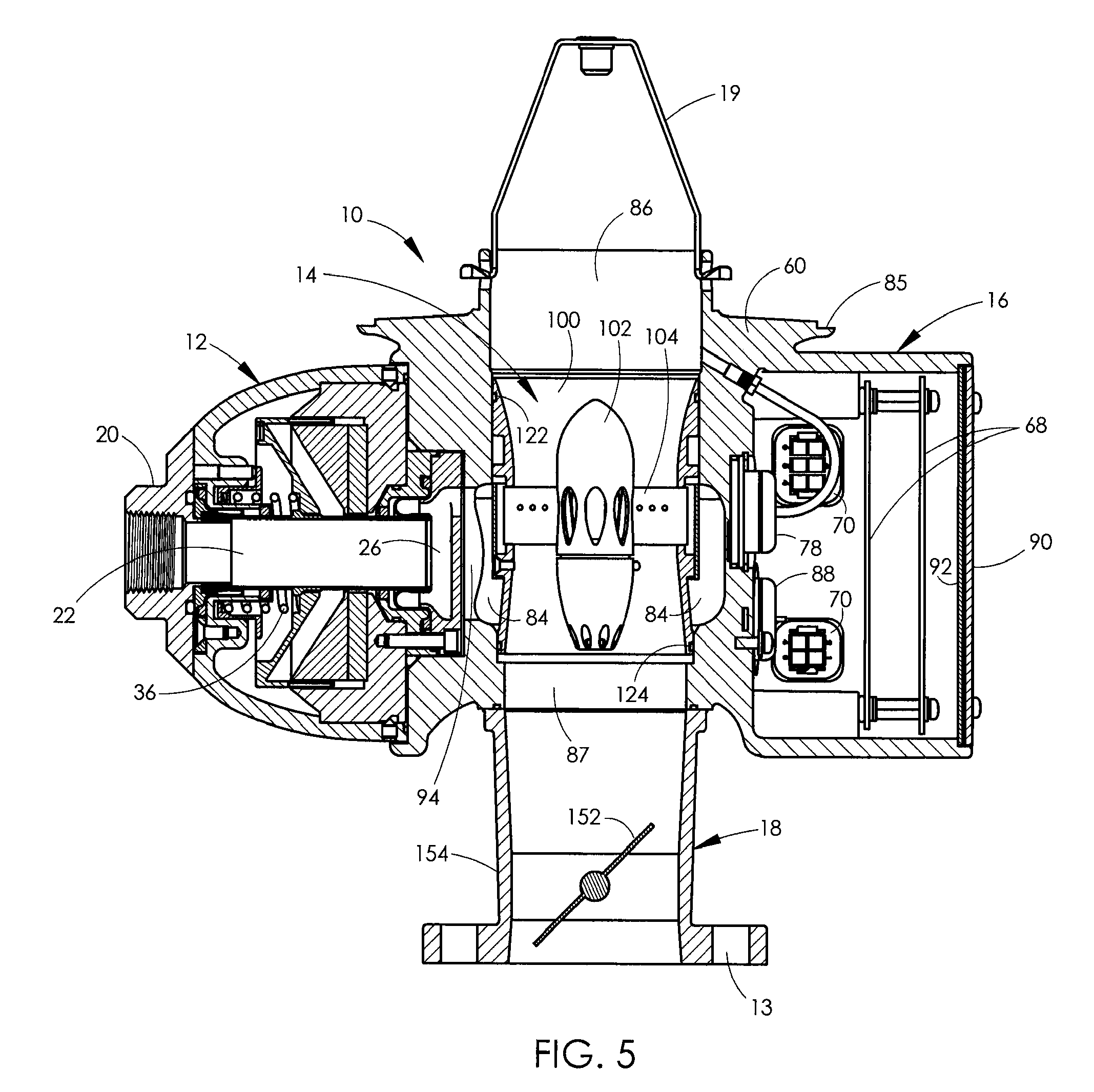

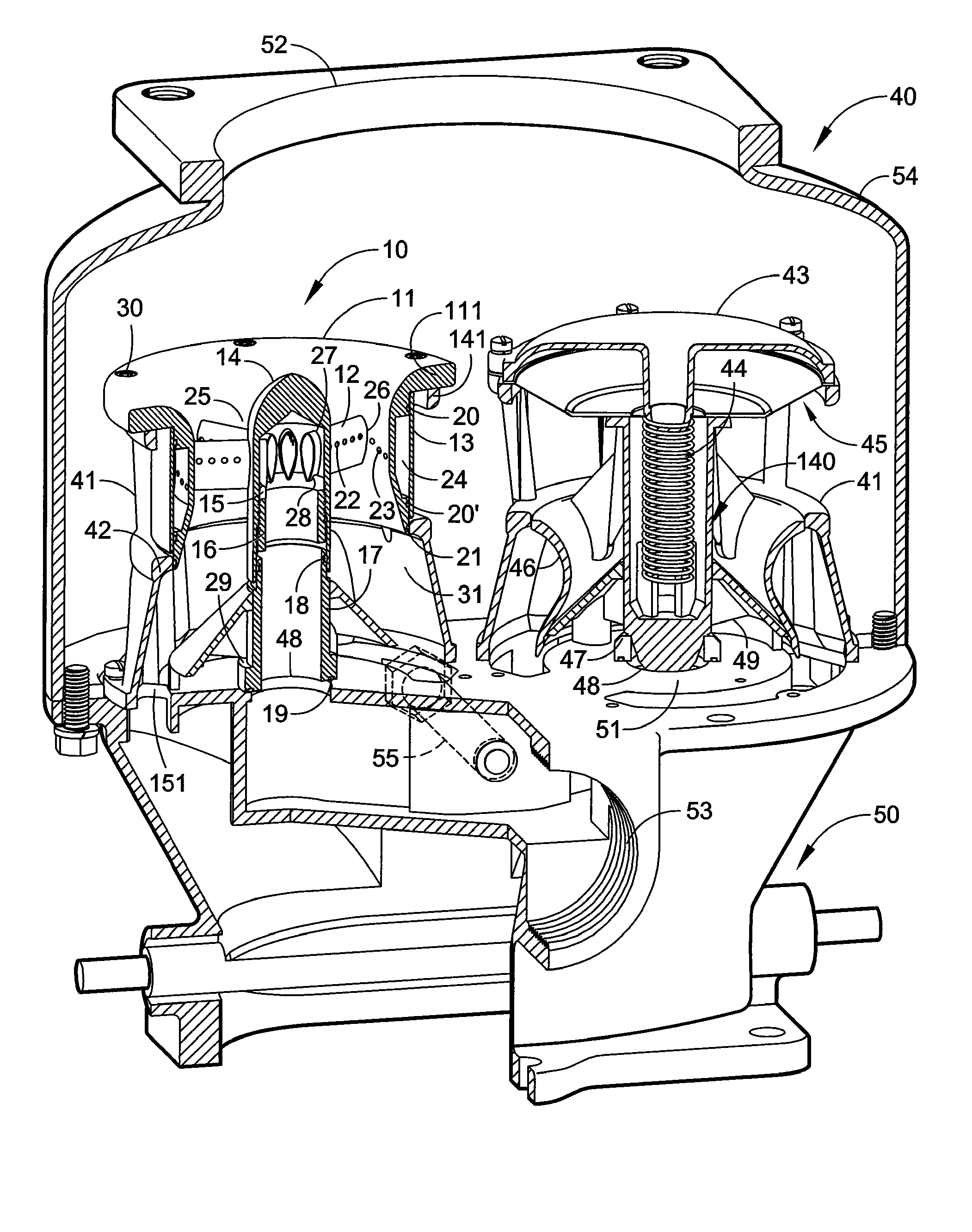

Fuel control system and method for gas engines

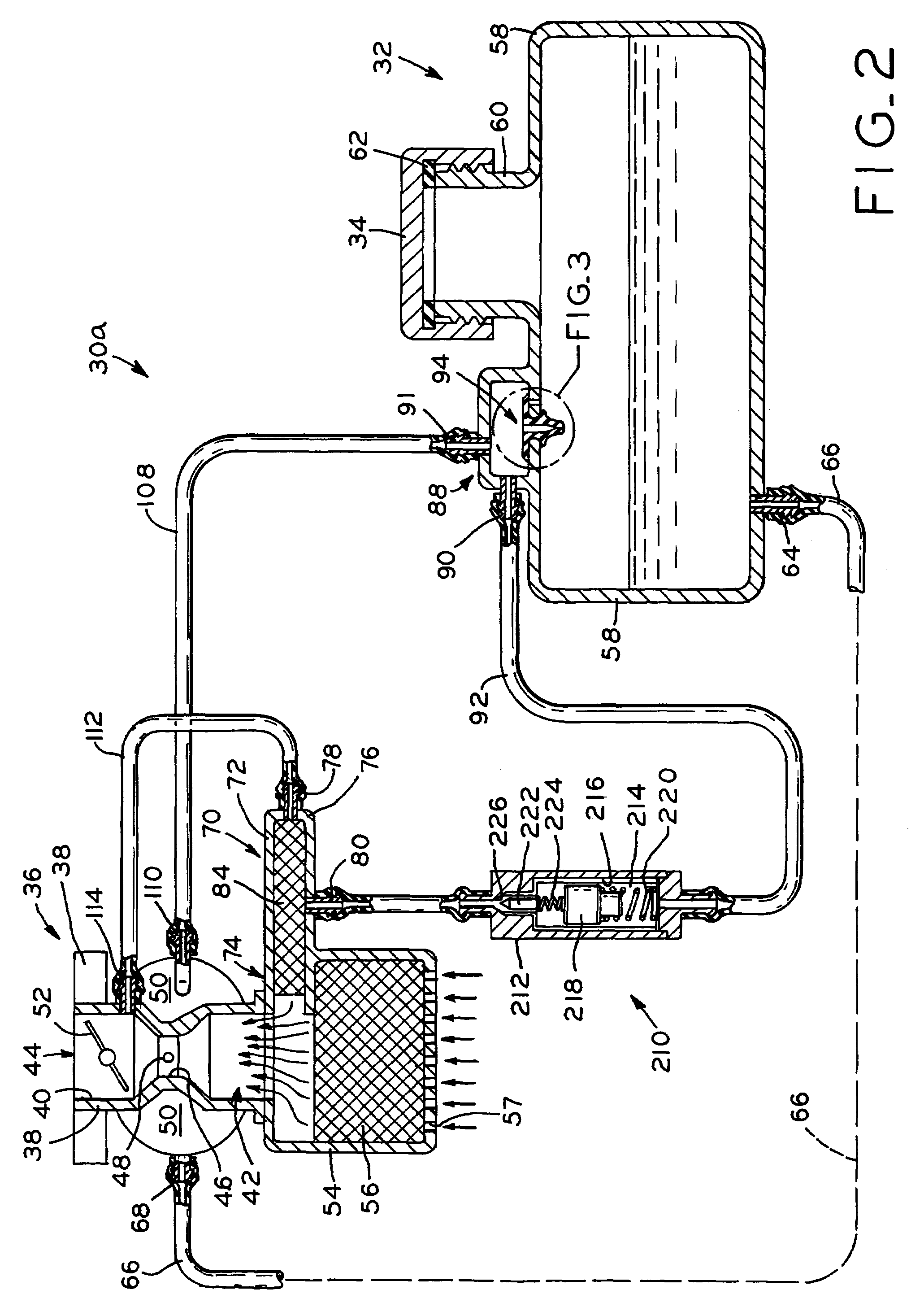

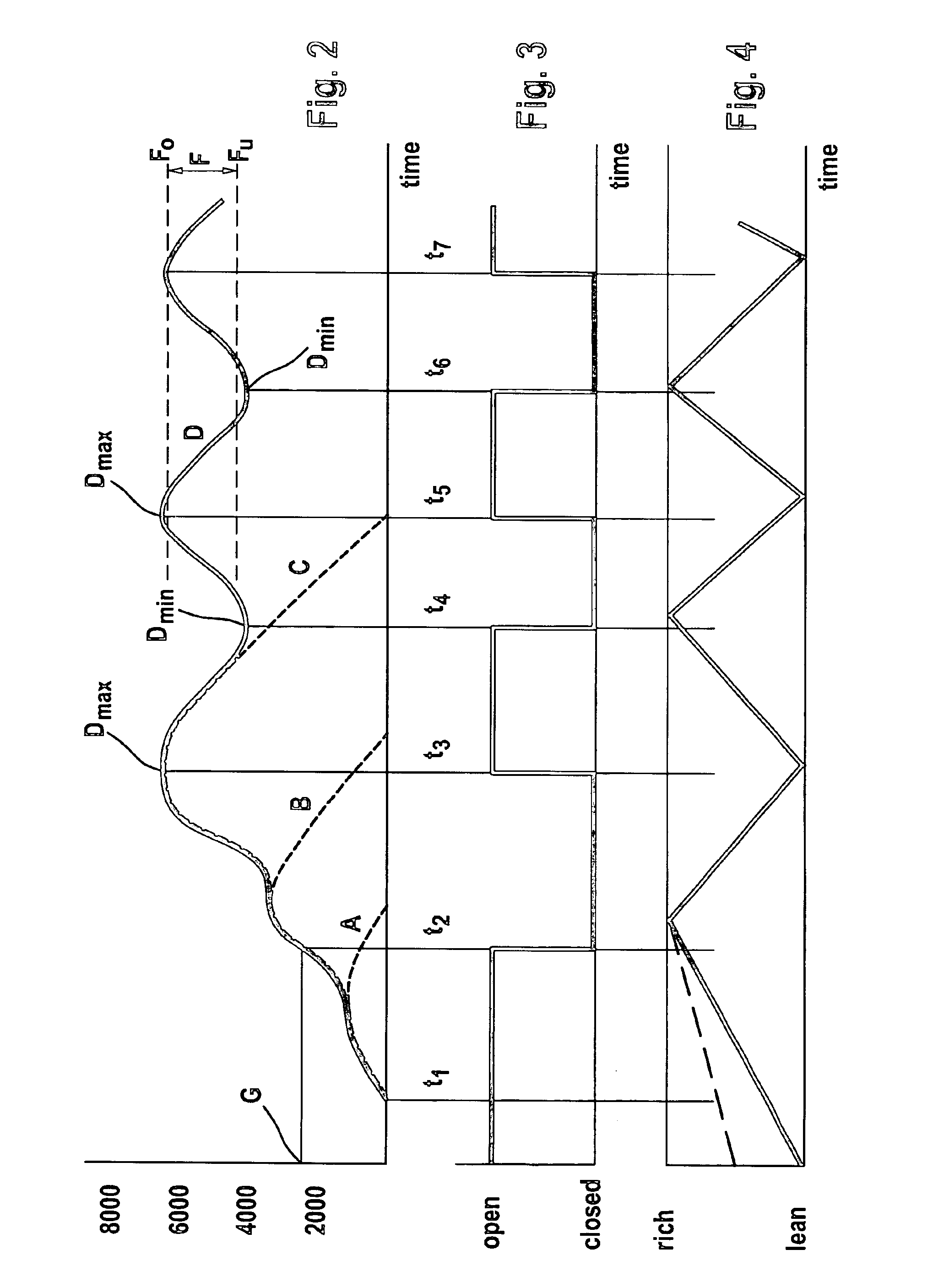

InactiveUS8005603B2Cost effectivePromote recoveryInternal combustion piston enginesSpace heating and ventilationControl systemClosed loop

A gaseous carburetor or fuel control system includes a fuel metering assembly, a venturi mixer assembly, a throttle assembly, and an electronic control unit. The control unit controls the fuel metering assembly in a closed loop manner based on detected gas and air pressure to an air / fuel mixing venturi. An electronic governor which controls the throttle valve may also be controlled by the same control unit which controls the fuel metering assembly, using a separate control loop.

Owner:CONTINENTAL CONTROLS CORP

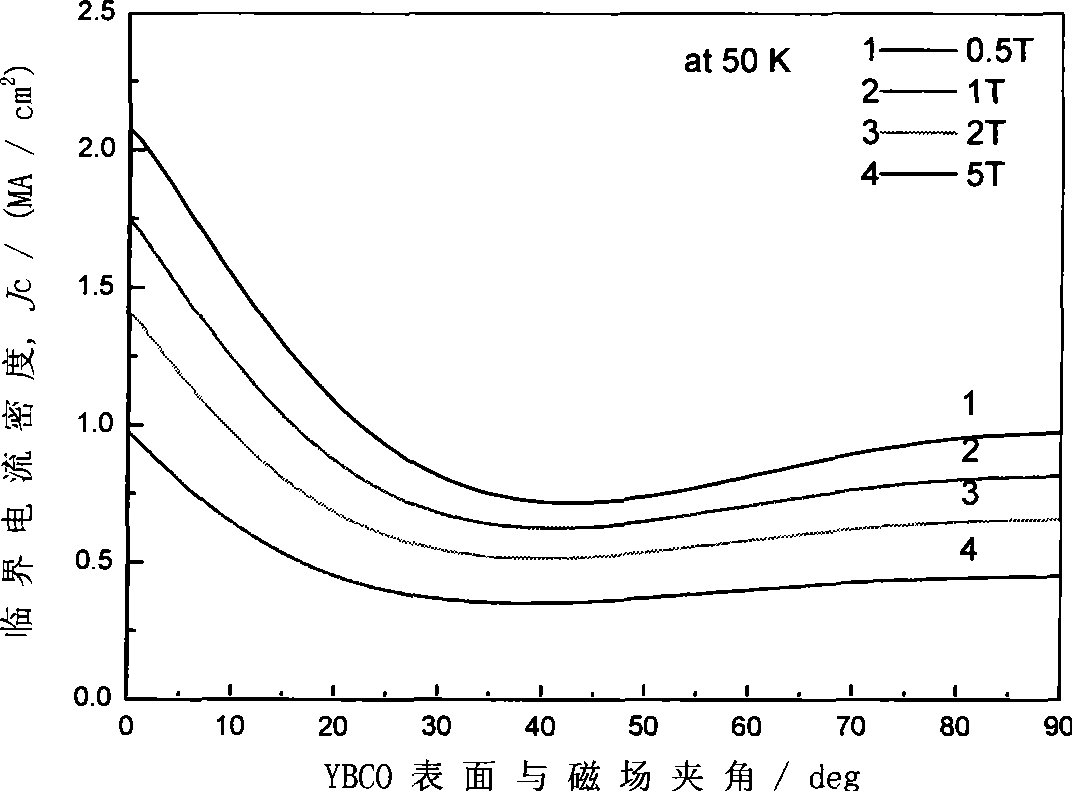

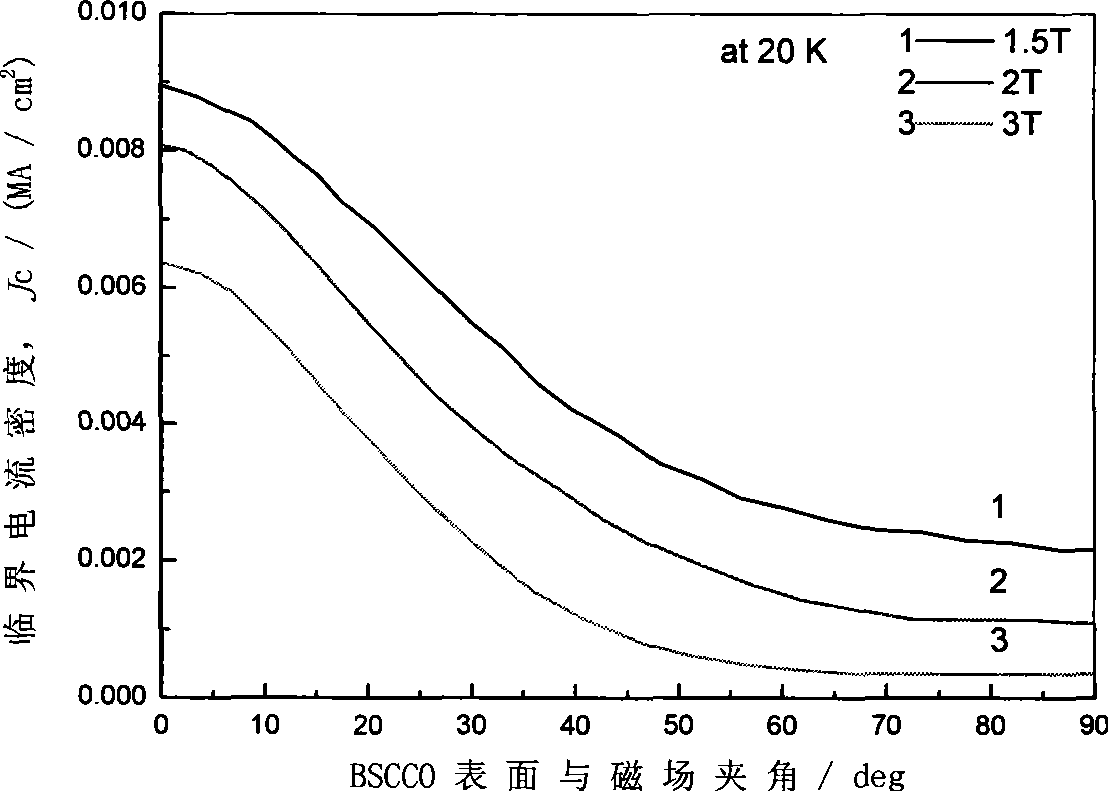

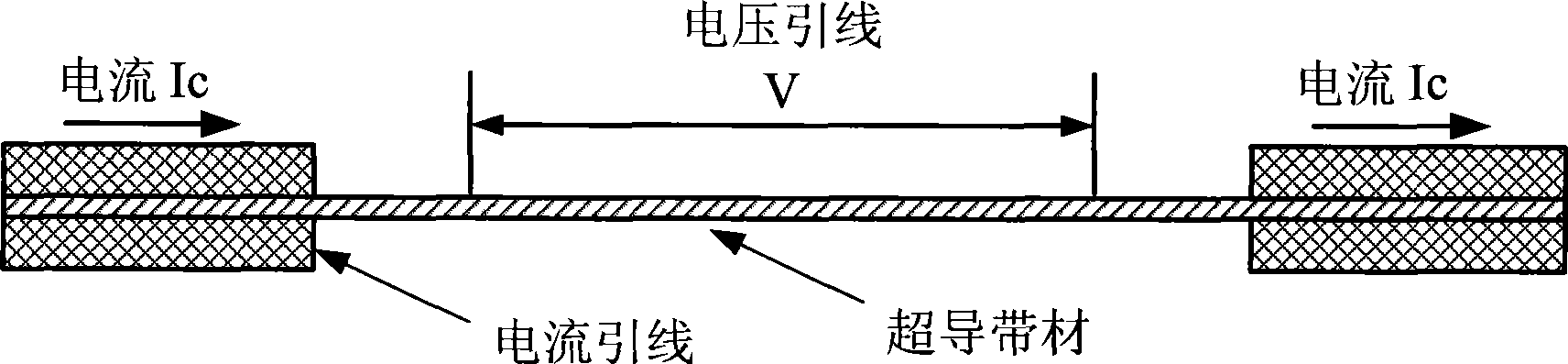

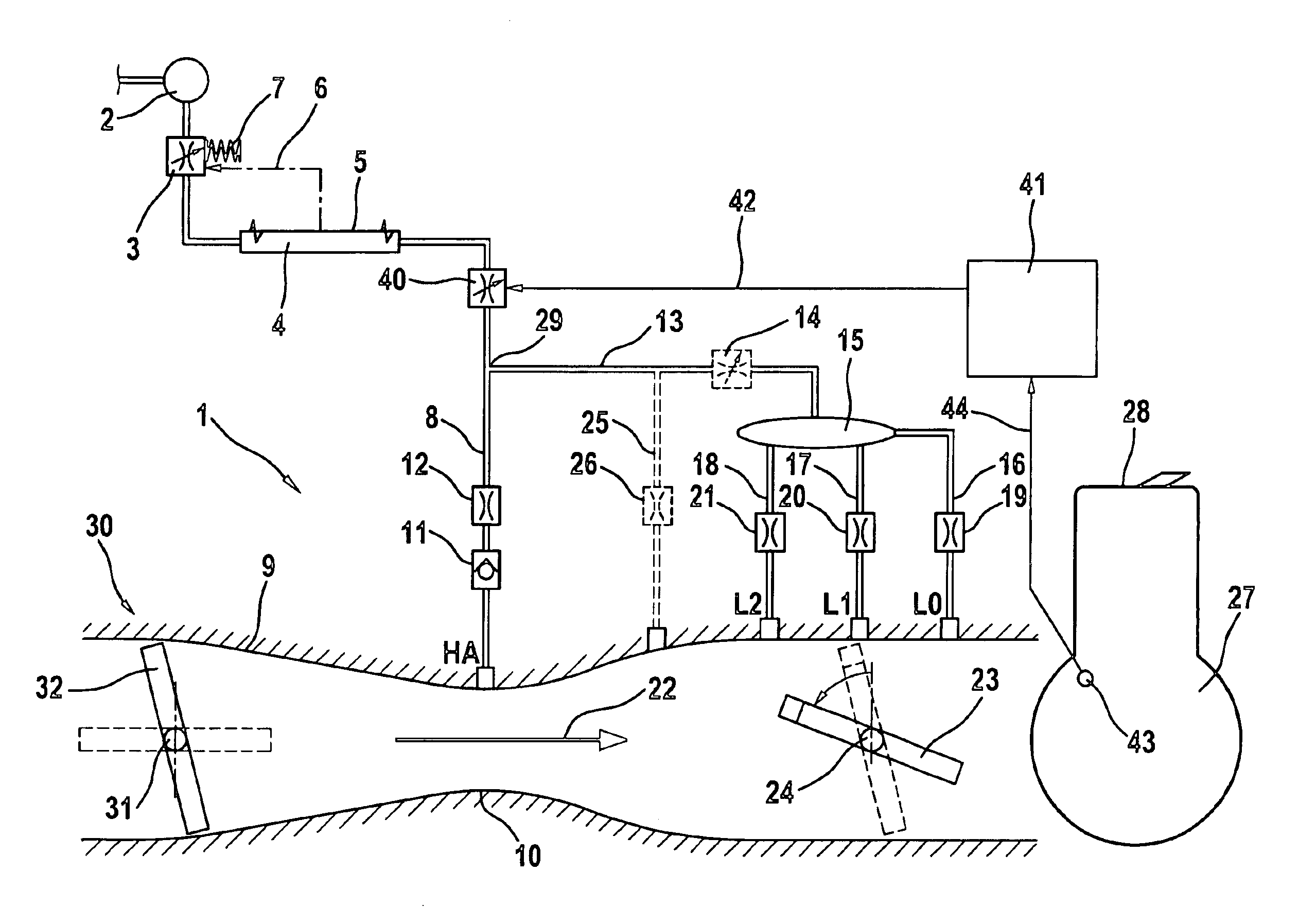

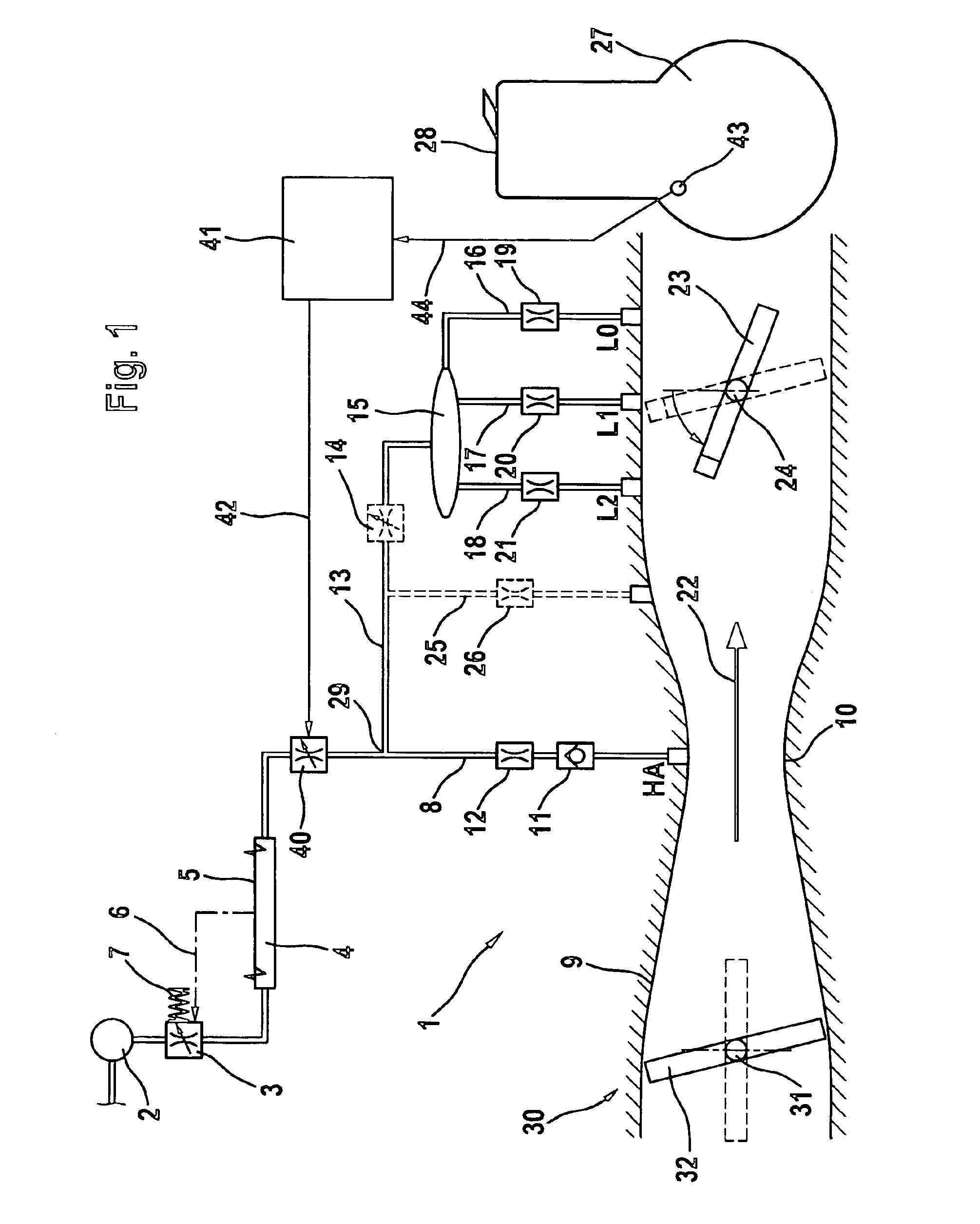

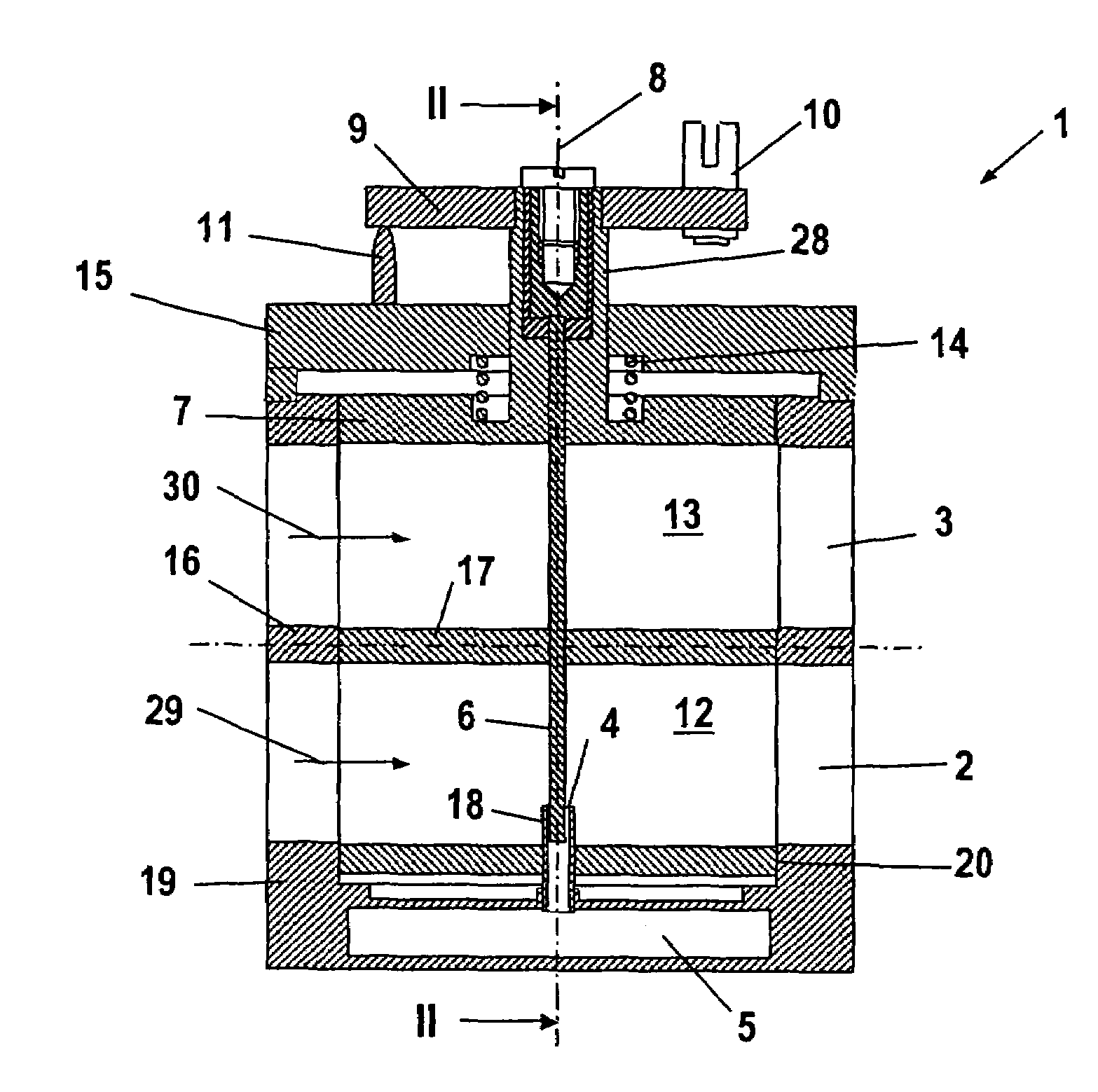

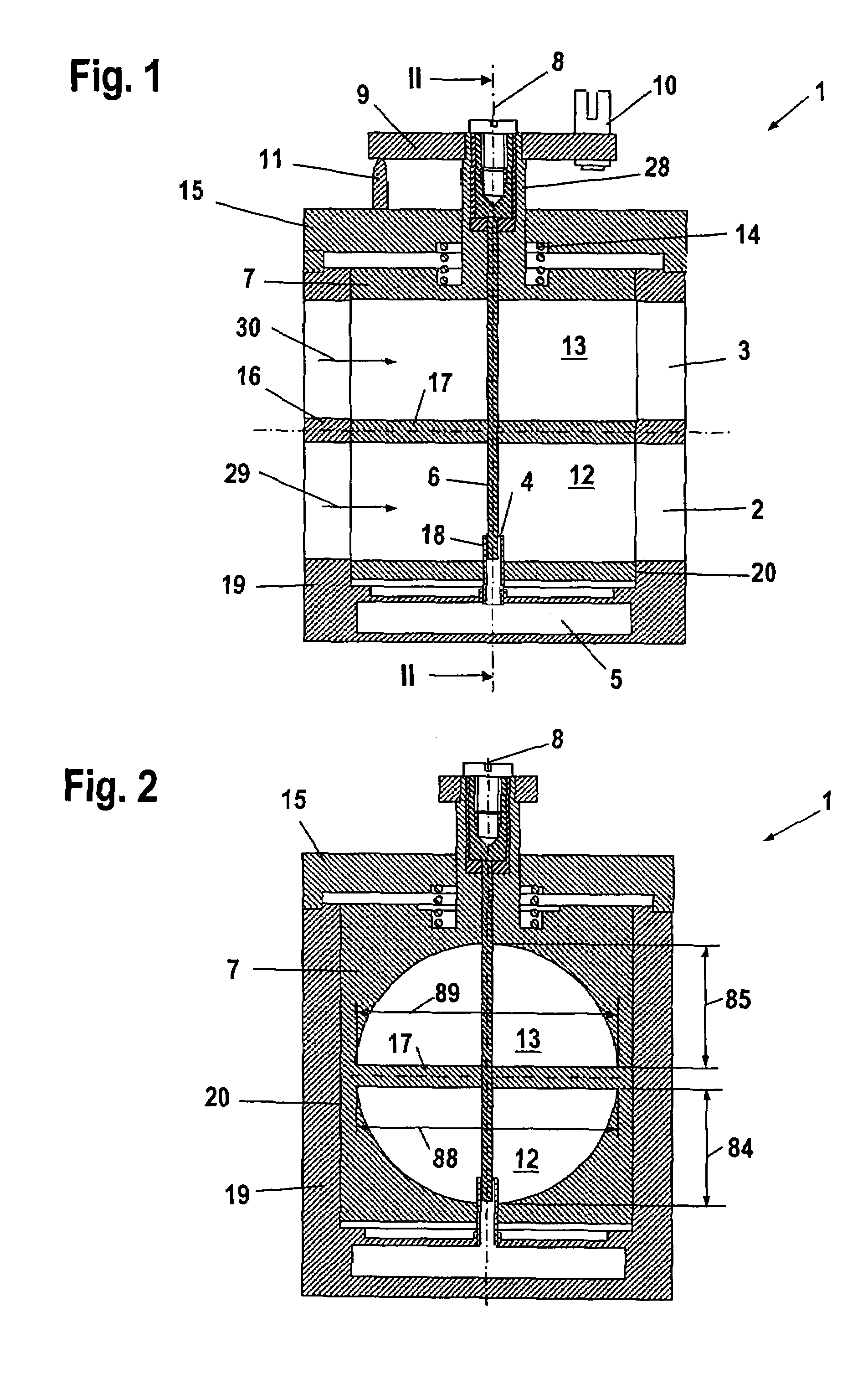

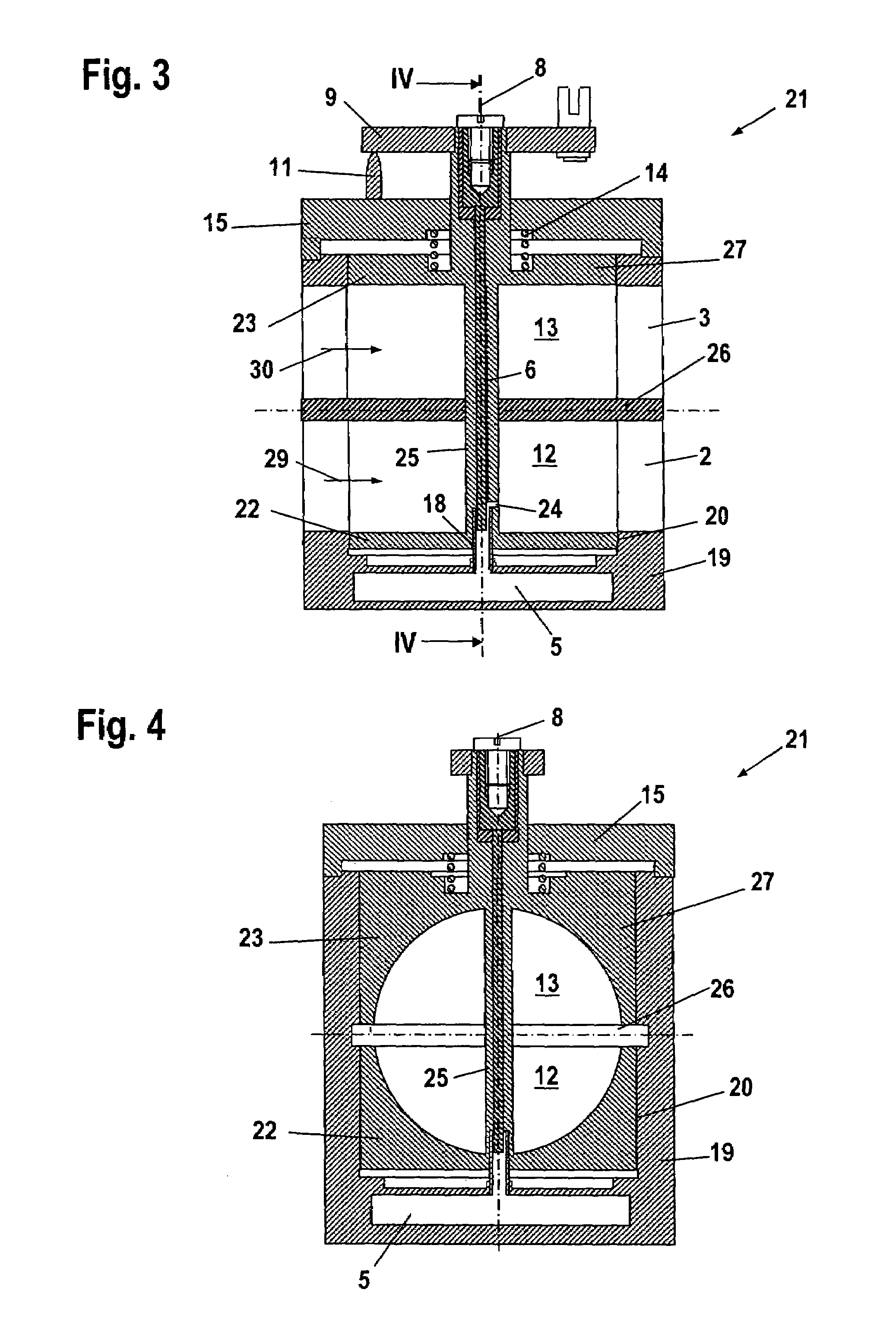

Measurement device of critical current properties of high-temperature superconducting tape

ActiveCN101446609AMeasuring critical current characteristicsRealize critical current characteristic measurementElectrical testingMagnitude/direction of magnetic fieldsYttrium barium copper oxideMeasurement device

The invention provides a measurement device of critical current properties of a high-temperature superconducting tape, and the device comprises a superconducting tape sample rack 1, a Hall magnetic field probe 2, a temperature probe 3, a background magnetic field magnet 4, a rotary rod 5, a rotary handle 6, a superconducting tape current lead wire 7, a background magnetic field magnet current lead wire 8, a low-temperature dewar 9, a cooling medium storage container 10, a low-temperature cooling medium 11, an extraction valve 12, a carburetor 13, a vacuum unit 14, a GM refrigerator 15, a background magnetic field magnet DC power supply 16, a superconducting DC power supply 17 and a system control, data acquisition and processing system 18. The device can simply and rapidly calculate the temperature, the background magnetic field and the impact factors on the change of the direction of the magnetic field thereof, thereby being applicable to the measurement of the critical current properties of yttrium barium copper oxide YBCO high-temperature superconducting tape.

Owner:CHINA ELECTRIC POWER RES INST +1

Engine fuel delivery systems, apparatus and methods

ActiveUS20100258099A1Avoid communicationAnalogue computers for vehiclesElectrical controlControl systemEngineering

A method of operating an engine is disclosed, which includes determining a peak power condition for the engine, measuring a temperature associated with the engine at said peak power condition, comparing the temperature measured with a previously determined temperature associated with a known peak power condition of the engine, determining an offset value based on the comparison made in step, controlling at least one of an air-fuel mixture delivered to the engine or ignition spark timing based on said offset value. Various engine fuel delivery systems, carburetors, fuel injection and control systems also are disclosed.

Owner:WALBRO LLC

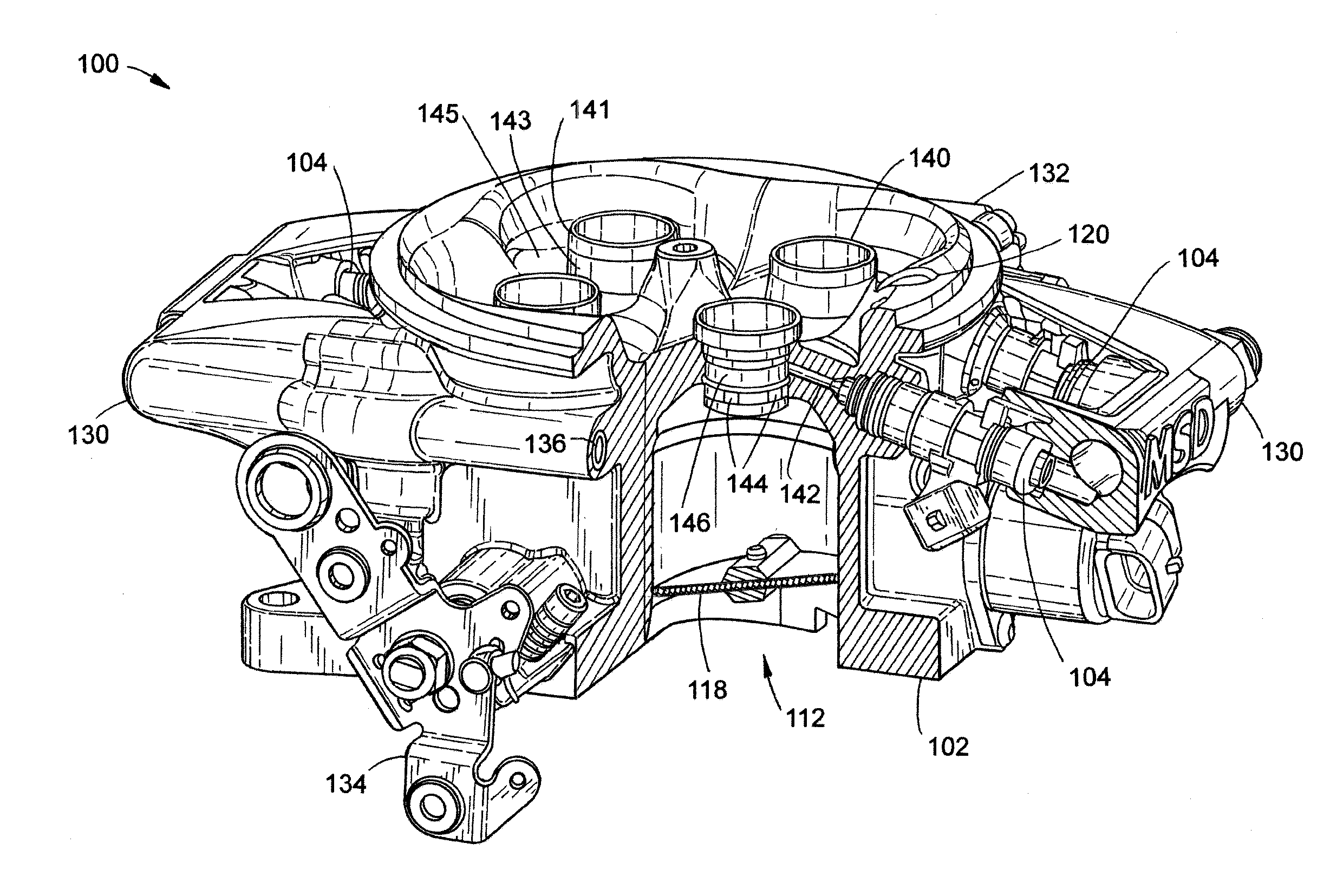

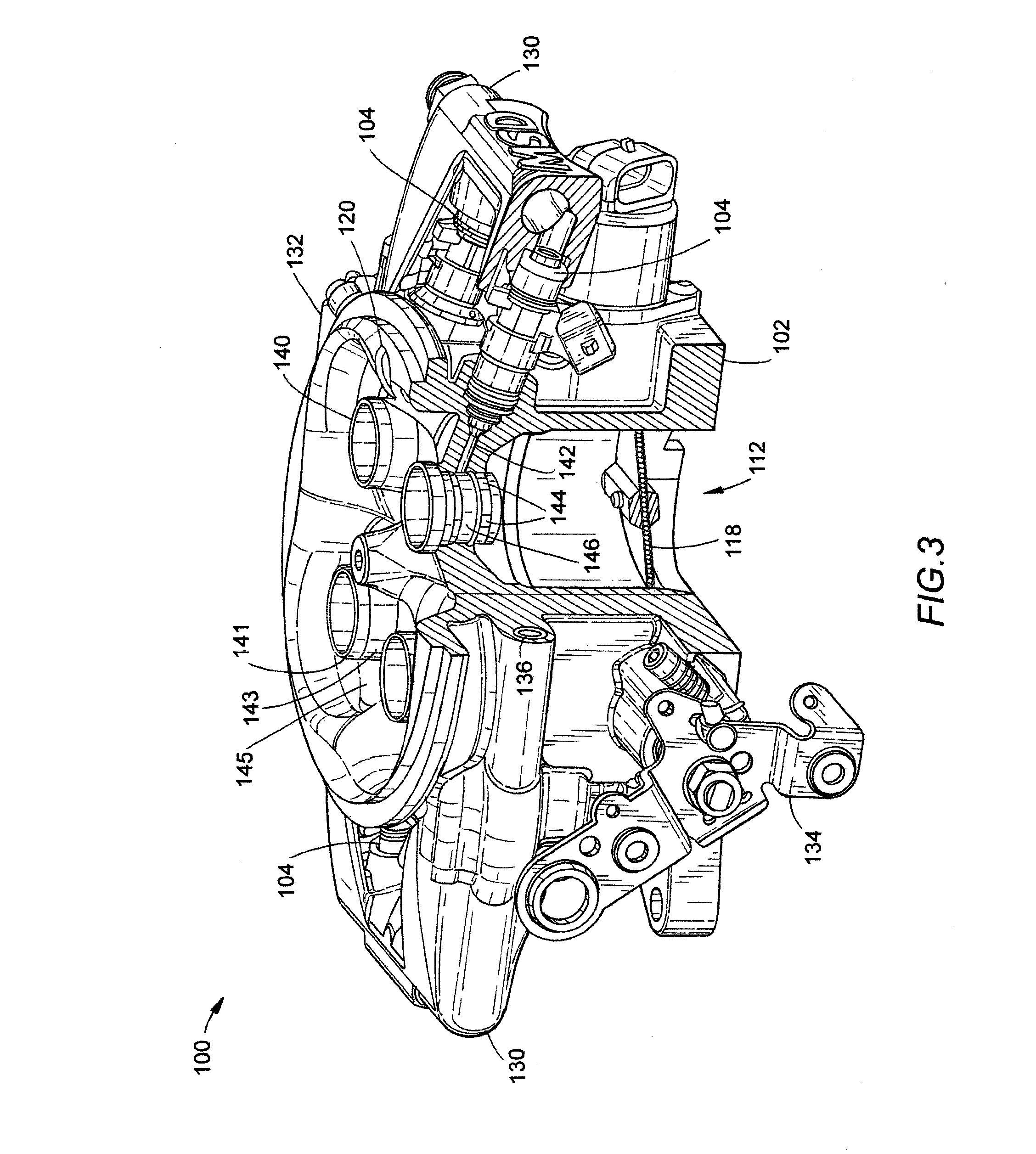

Throttle body fuel injection system with improved fuel distribution

ActiveUS20130298871A1Minimizing any tendencyIncrease the pulse widthElectrical controlInternal combustion piston enginesFuel distributionEngineering

A throttle body fuel injection system and method that is arranged to easily replace four-barrel carburetors includes a throttle body assembly with four main bores, each with a throttle plate and an associated fuel injector. Each injector feeds fuel into a circular fuel distribution ring via a fuel injection conduit, which introduces pressurized fuel into the air stream. The fuel distribution rings and bores have profiles that avoid constrictions for to prevent low pressure zones according to the Venturi effect. Fuel is injected through downward-facing outlets at or near the bottom end of the rings. The fuel injection rings are two-piece, each formed of an insert pressed into an outer housing. The insert includes axial grooves intervaled about its exterior circumference of insert that are joined by a circumferential groove formed about the insert. The grooves are in fluid communication with a conduit that supplies fuel from a fuel injector.

Owner:MSD LLC

Fuel control system and method for gas engines

InactiveUS20090088950A1Cost effectivePromote recoveryInternal combustion piston enginesSpace heating and ventilationControl systemEngineering

A gaseous carburetor or fuel control system includes a fuel metering assembly, a venturi mixer assembly, a throttle assembly, and an electronic control unit. The control unit controls the fuel metering assembly in a closed loop manner based on detected gas and air pressure to an air / fuel mixing venturi. An electronic governor which controls the throttle valve may also be controlled by the same control unit which controls the fuel metering assembly, using a separate control loop.

Owner:CONTINENTAL CONTROLS CORP

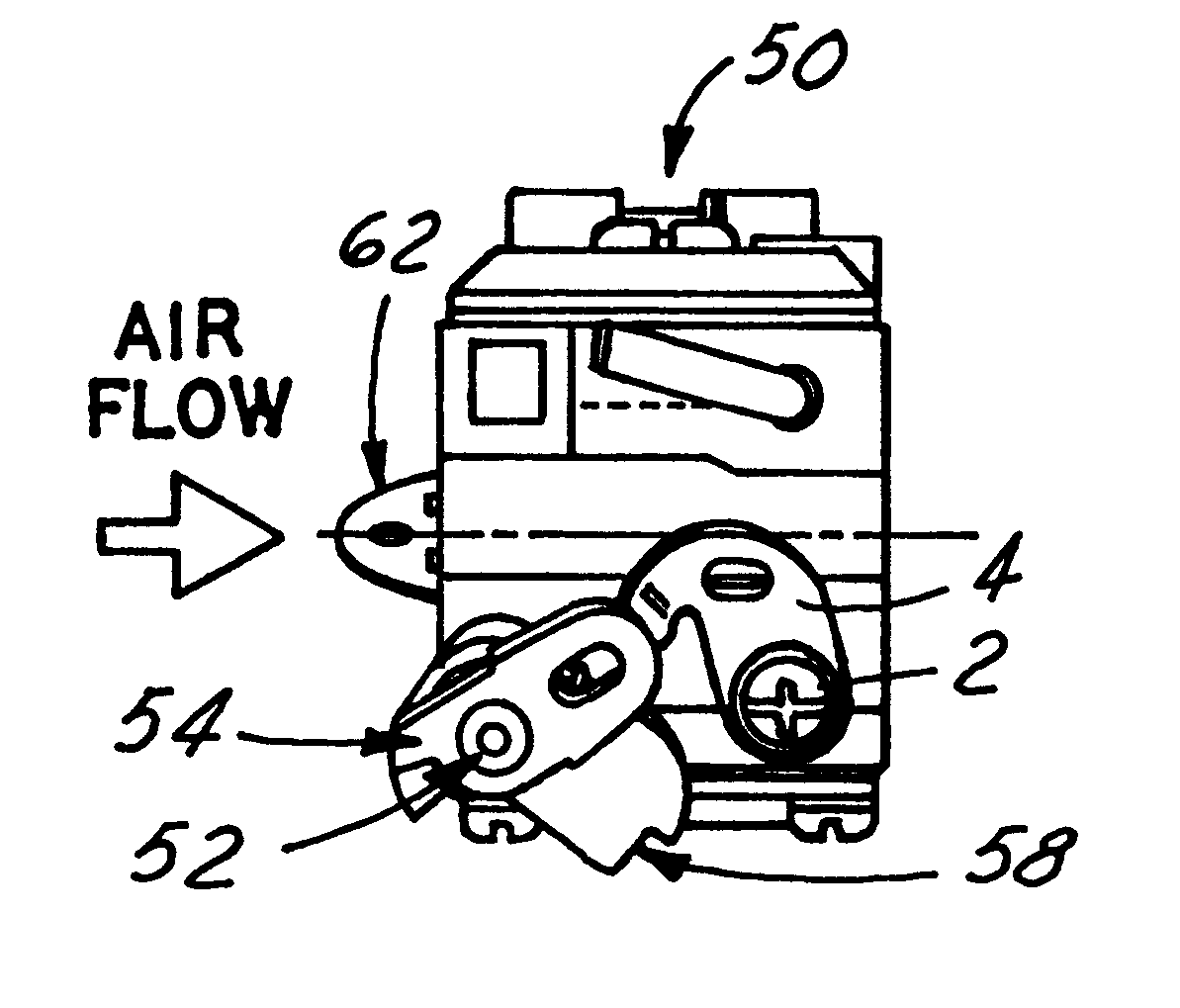

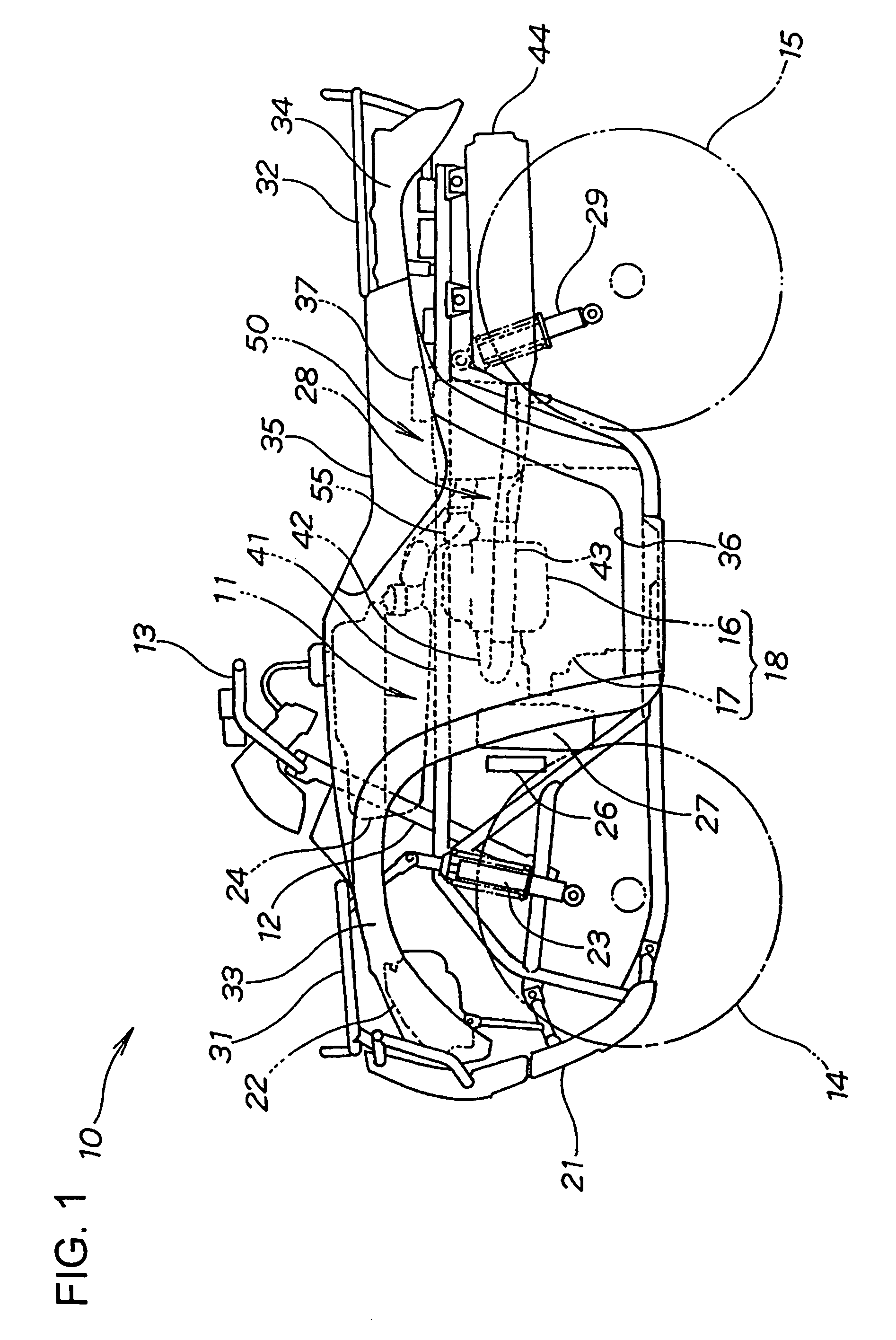

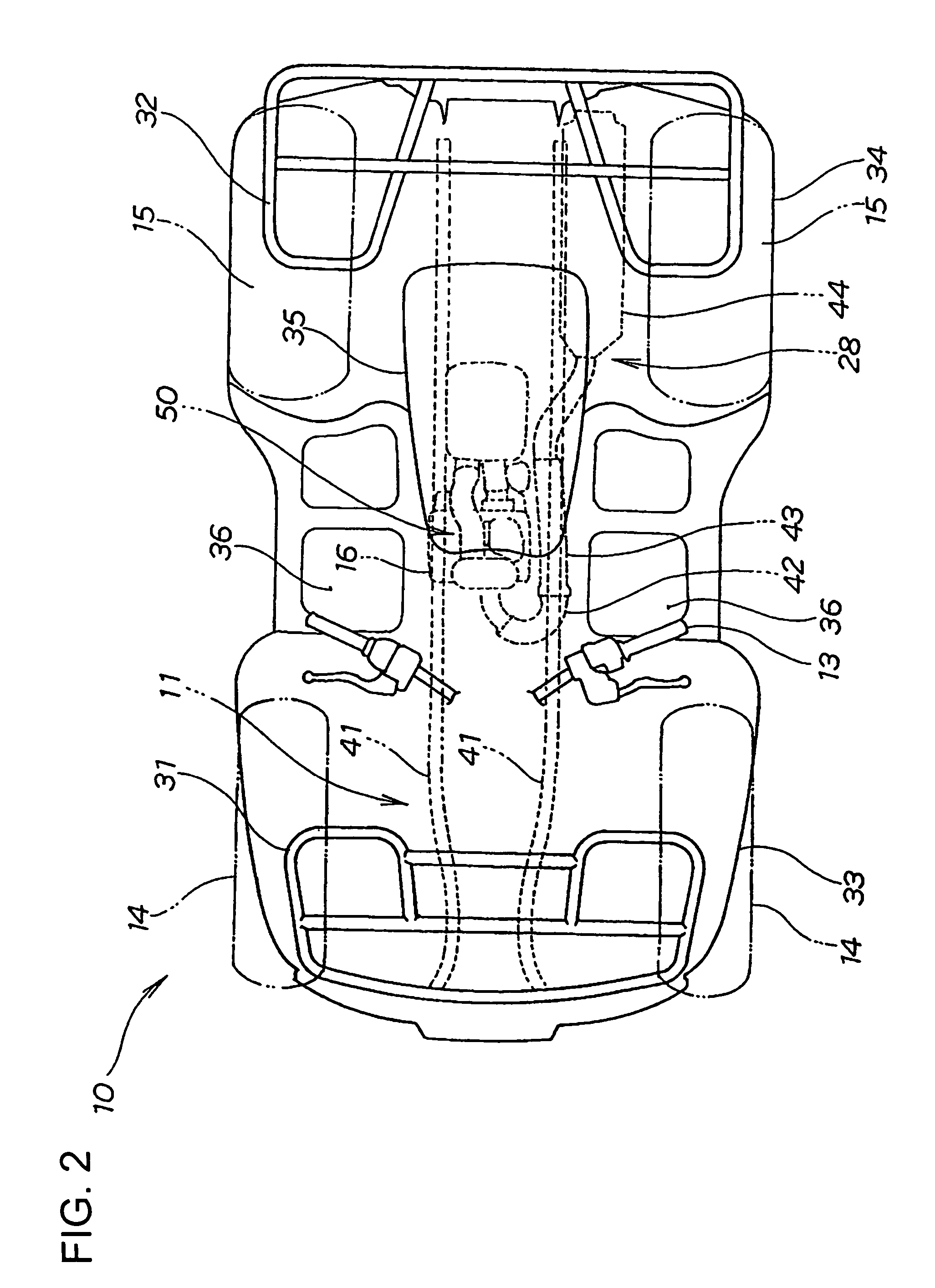

Watercraft with steer-response engine speed controller

InactiveUS6405669B2Enhancing docking and other directional movementEasy to moveSteering ruddersPropulsion power plantsJet propulsionLow speed

A steering control system is provided that provides thrust for steering control in a watercraft that is powered by a propulsion unit. The steering control system is applicable to various types of watercraft, including boats and personal watercraft, that are powered by inboard jet propulsion systems or outboard engines. The steering control system is activated by the steering helm assembly and / or an electronic control mechanism. Thrust is provided by preferably controlling the throttle, or more particularly the air-fuel mixture of the carburetor of the engine. The system is particularly, although not solely, suited for steering while the watercraft is operated at low speeds.

Owner:BRP US

Vacuum shutdown system

InactiveUS7007658B1Easily employedGood adhesionLighting and heating apparatusUsing liquid separation agentCarburetorFuel oil

A device for shutdown of an internal combustion engine which provides for the cessation of fuel and air mixture in a carburetor supplying the cylinders of the engine with fuel for ignition. The device features a conduit in sealed engagement with the fuel supply bowl of the carburetor which may by switched from engagement between the atmosphere or a negative air pressure supply. When switched to communication with negative air pressure the device causes a vacuum in the fuel bowl of the carburator thereby ceasing fuel flow and shutting down the engine due to lack of fuel.

Owner:SMARTPLUGS CORP

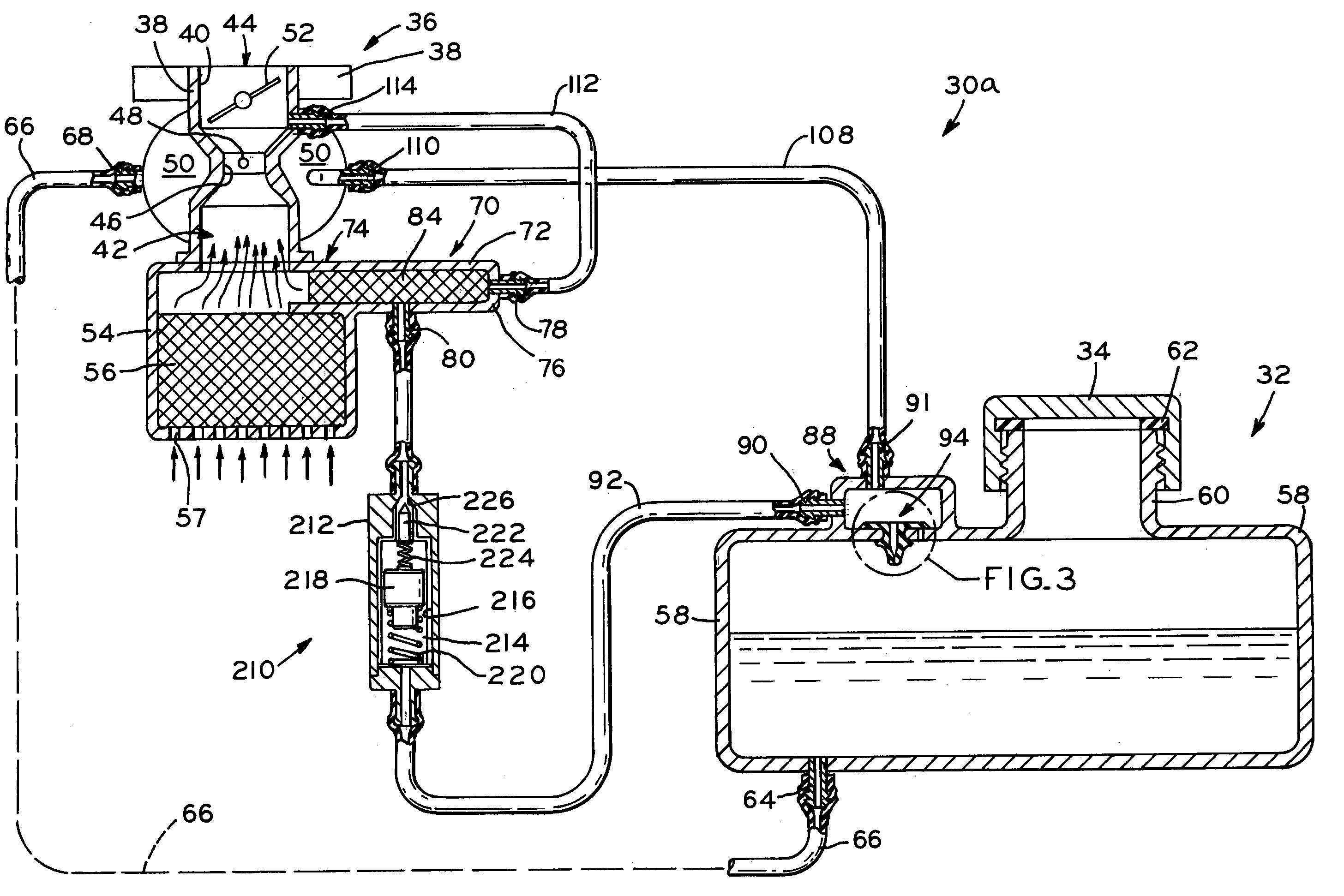

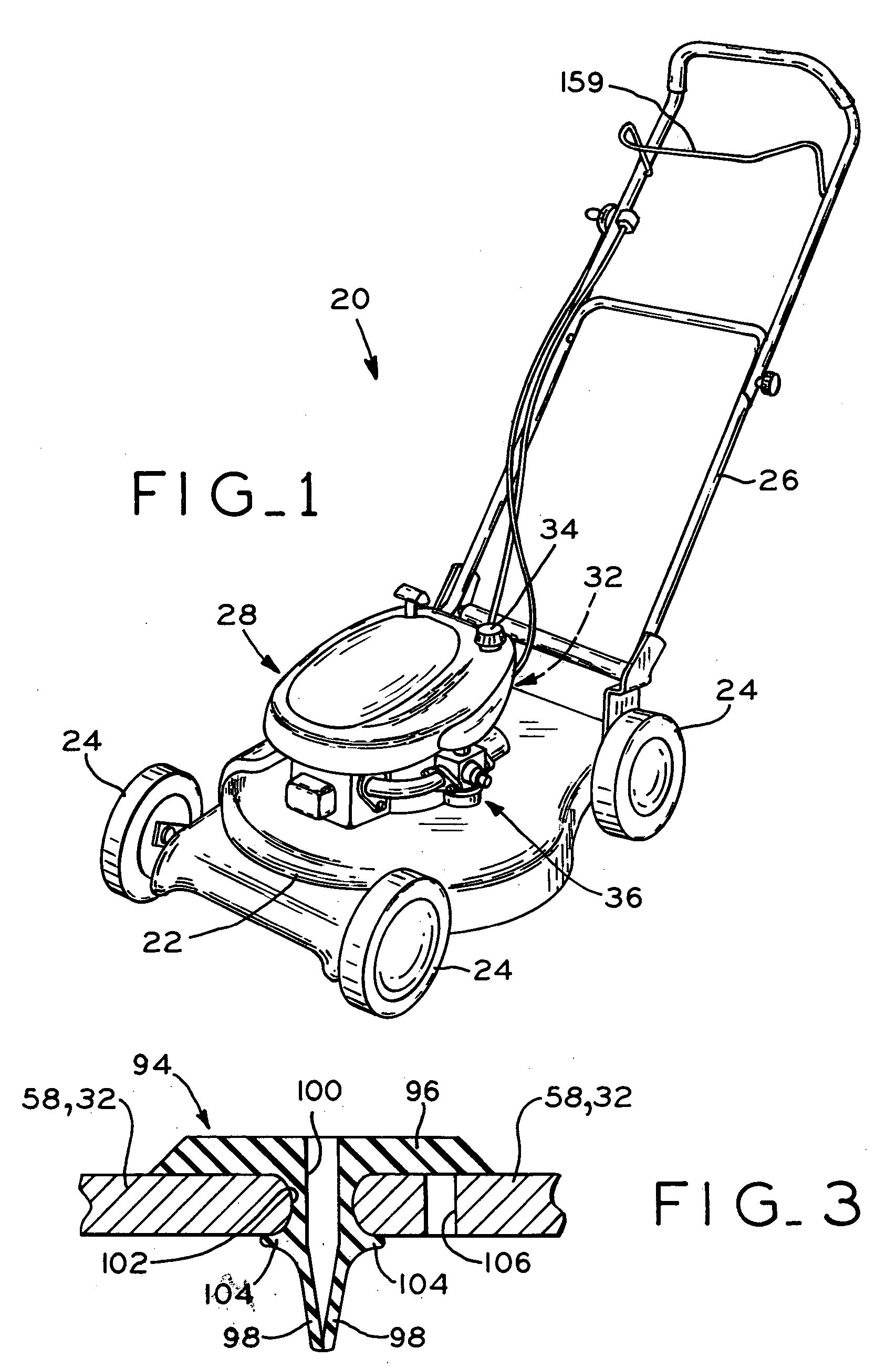

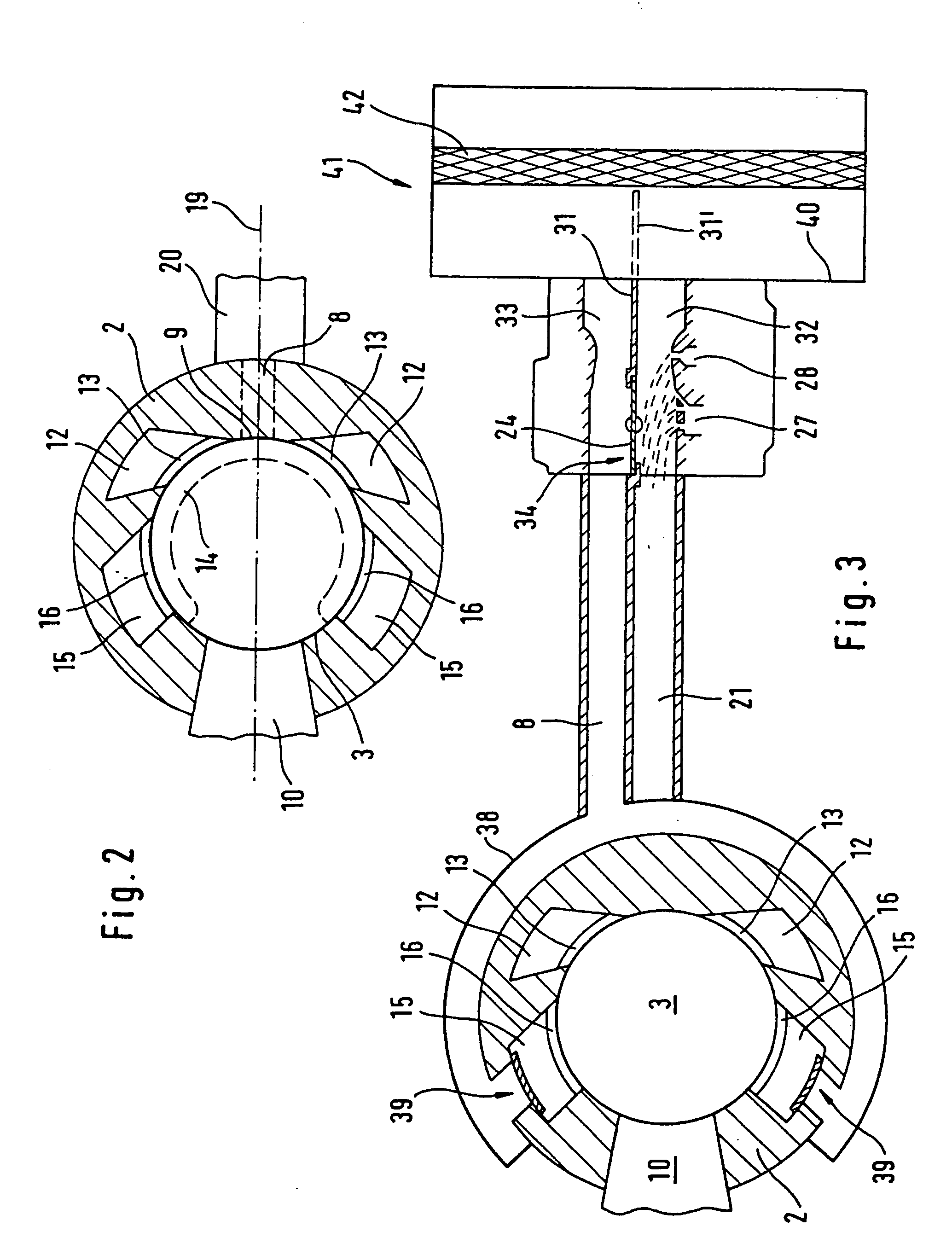

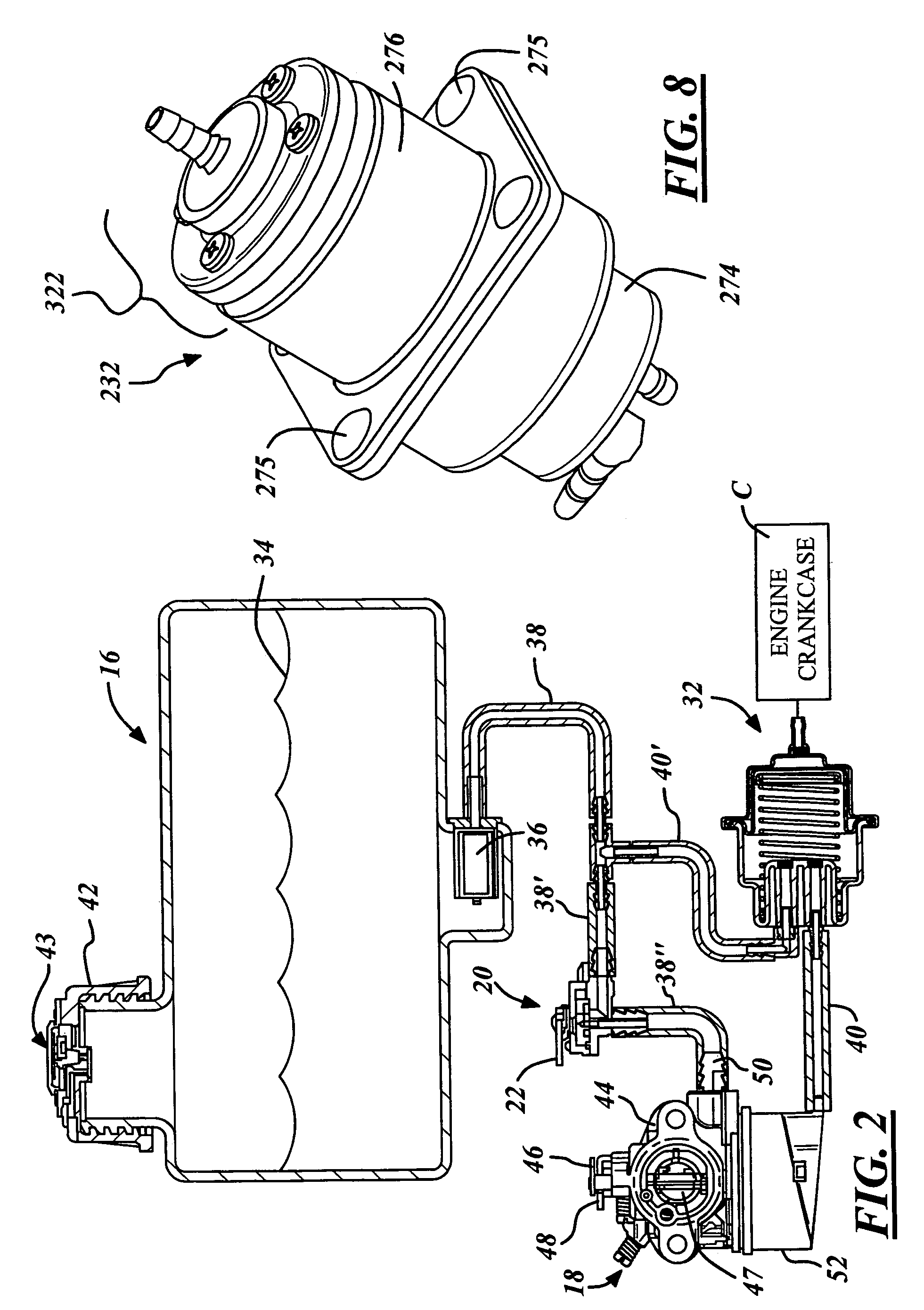

Evaporative emissions control system including a charcoal canister for small internal combustion engines

InactiveUS20050178368A1Easy to collectEasy to trapNon-fuel substance addition to fuelLarge containersAtmospheric airControl system

Owner:TECUMSEH PROD CO +1

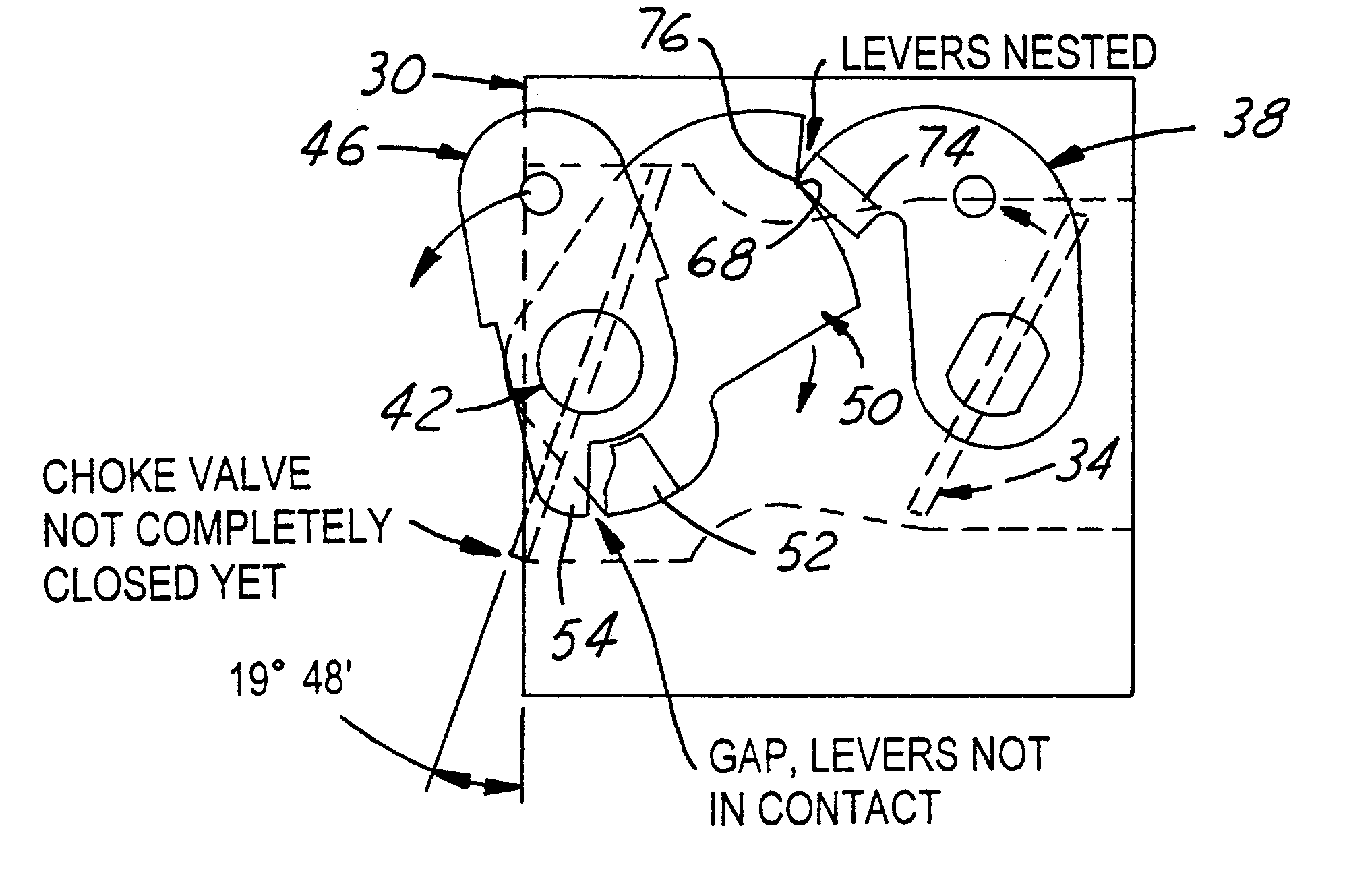

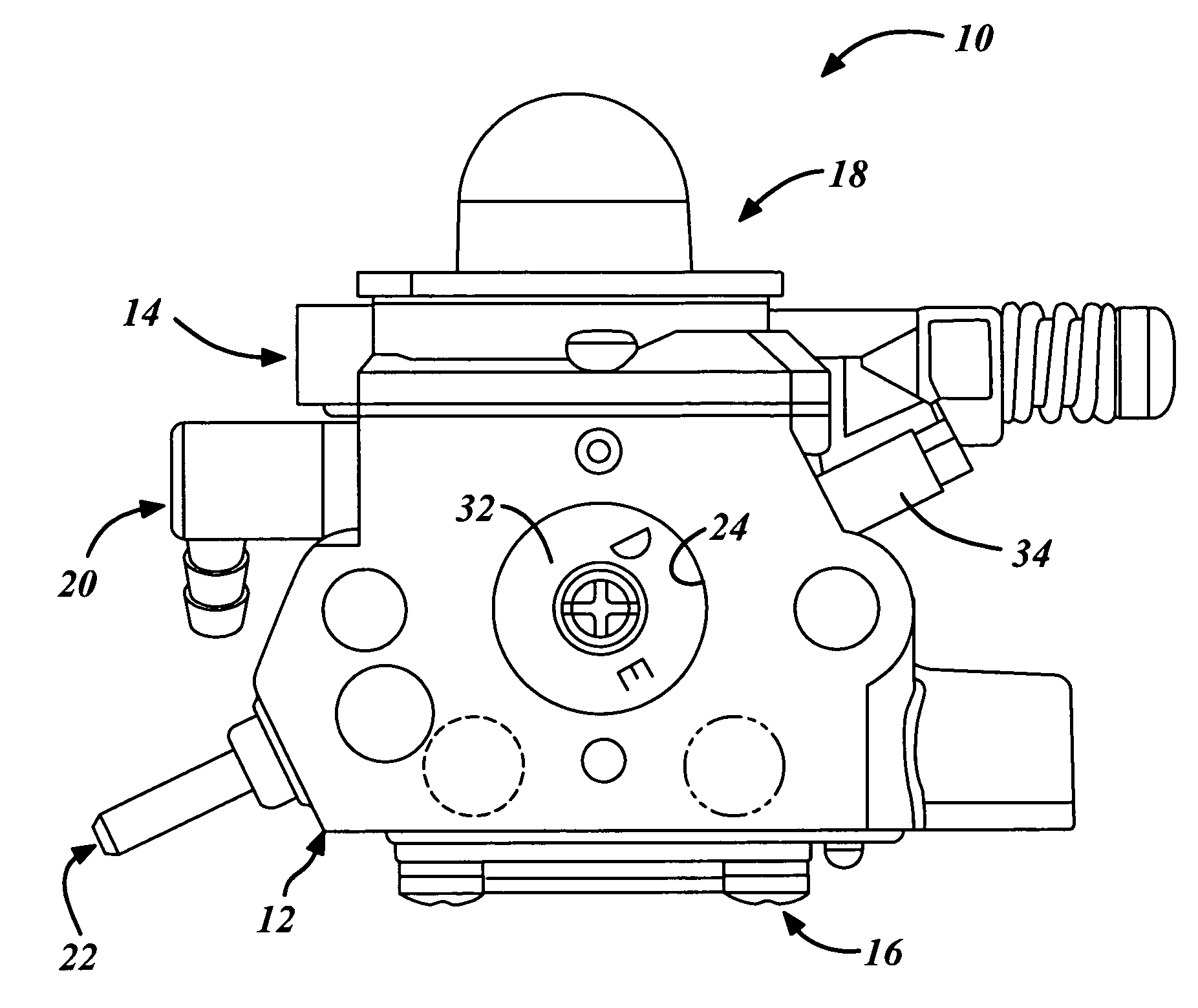

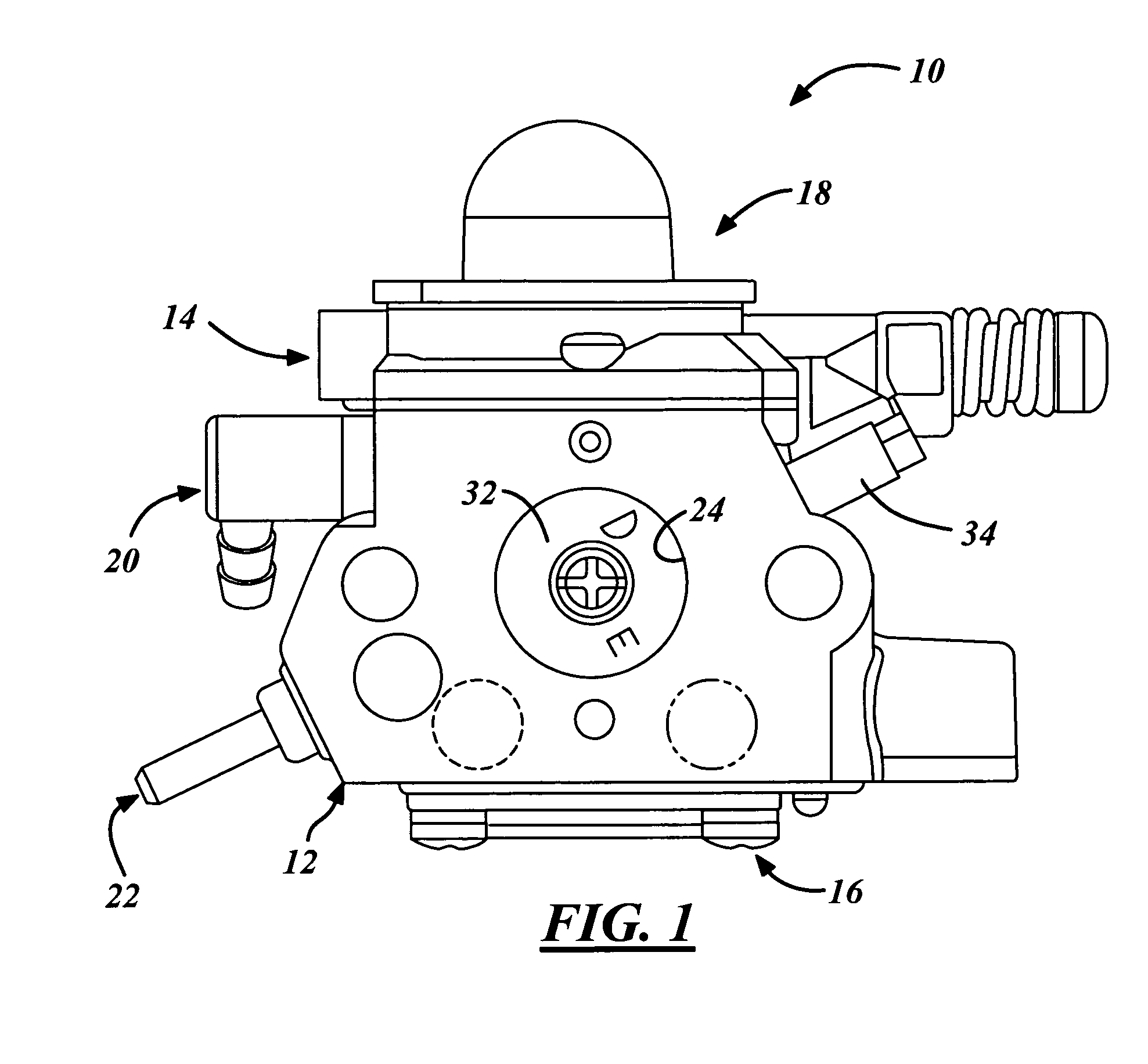

Carburetor throttle and choke control mechanism

InactiveUS6439547B1Low costEasy to modifyElectrical controlLighting and heating apparatusEngineeringAbutment

A carburetor throttle and choke control mechanism incorporating a choke-throttle cold-start fast idle setting latch mechanism having, in a first embodiment, a blade of a fast idle lever specially contoured for creating upon interengagement with a tang on a throttle lever initial torque resistance to co-rotation of the fast idle lever toward latched condition and then effecting force reversal for creating aiding torque to accelerate the fast idle lever relative to choke lever and thereby open a gap in the push coupling that remains in the latched position of the choke and throttle valves. The choke lever has a relatively rigid pusher leg portion adapted for abutment in push relation with a fast idle lever tang. In a second embodiment an extension of the leg portion in the form of a generally U-shaped resilient spring hook portion is adapted to overlap the tang and releasably hook engage the same when the leg portion is brought into full push abutment with said tang. The U-shaped hook portion is resiliently flexible to act as a spring to develop a torque on the choke by pulling the choke valve fully closed when said fast idle lever is moved to fully latched condition while flexing so that the gap remains between the pusher leg portion and the tang.

Owner:WALBRO LLC

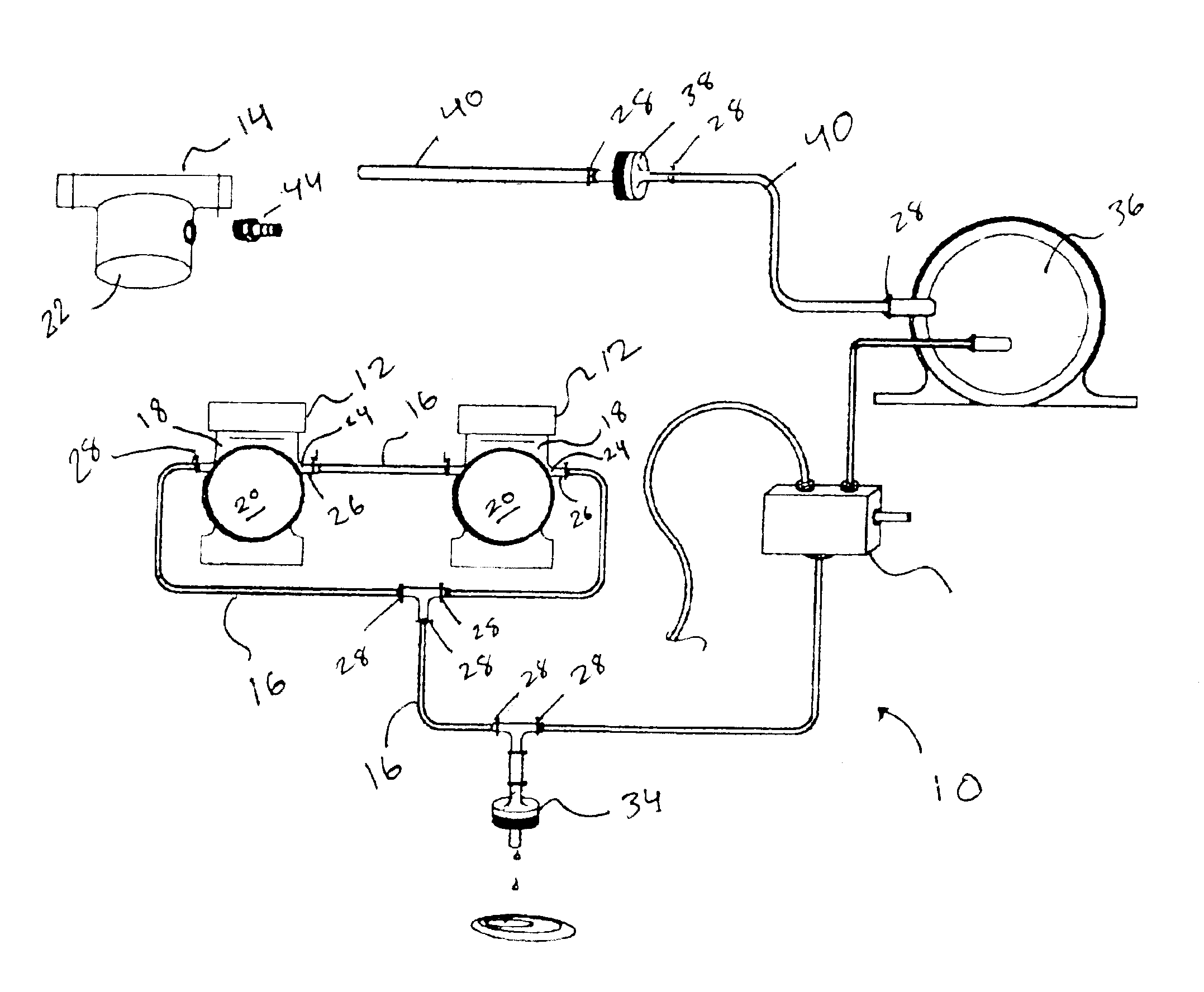

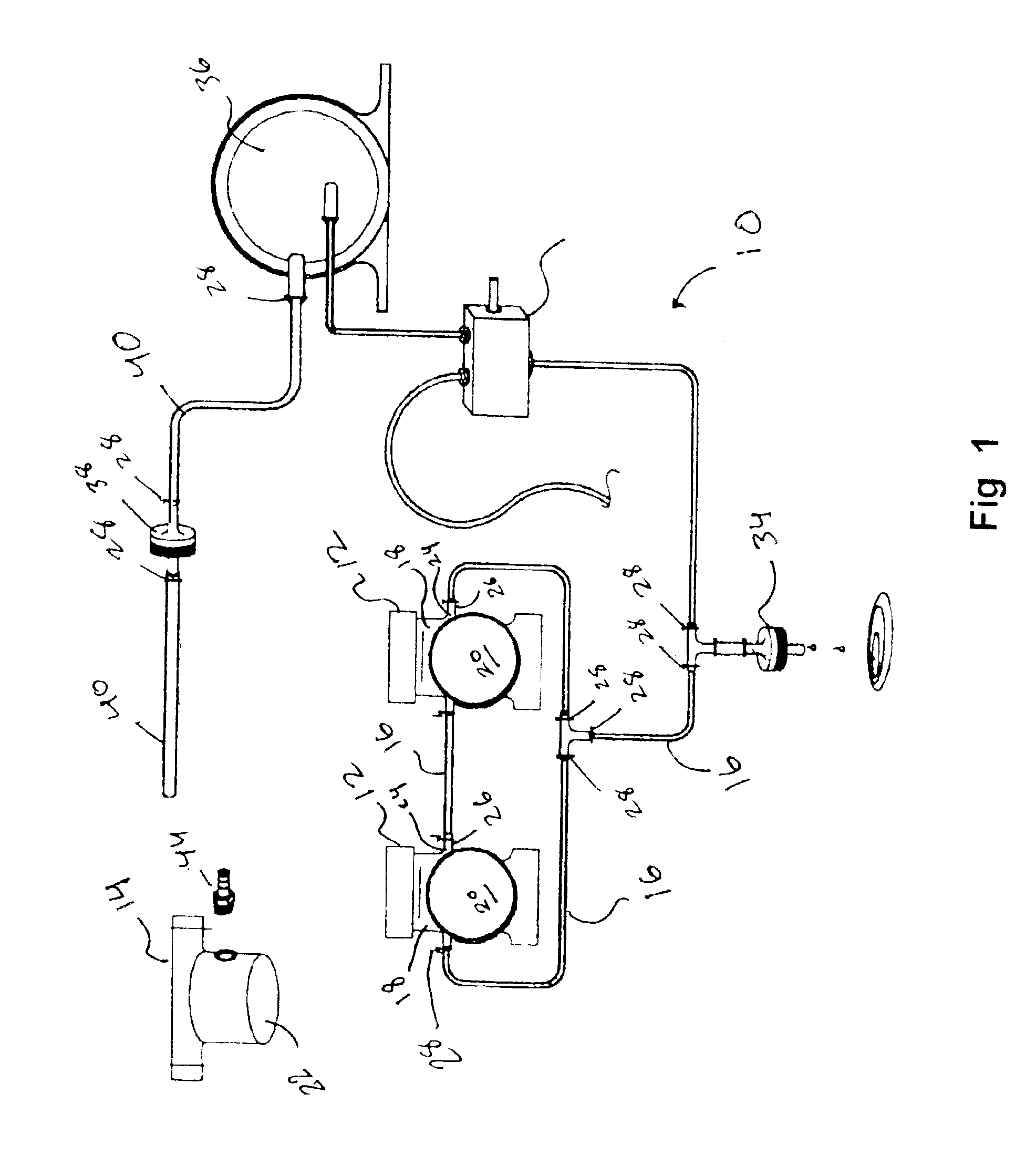

Evaporative emissions control system including a charcoal canister for small internal combustion engines

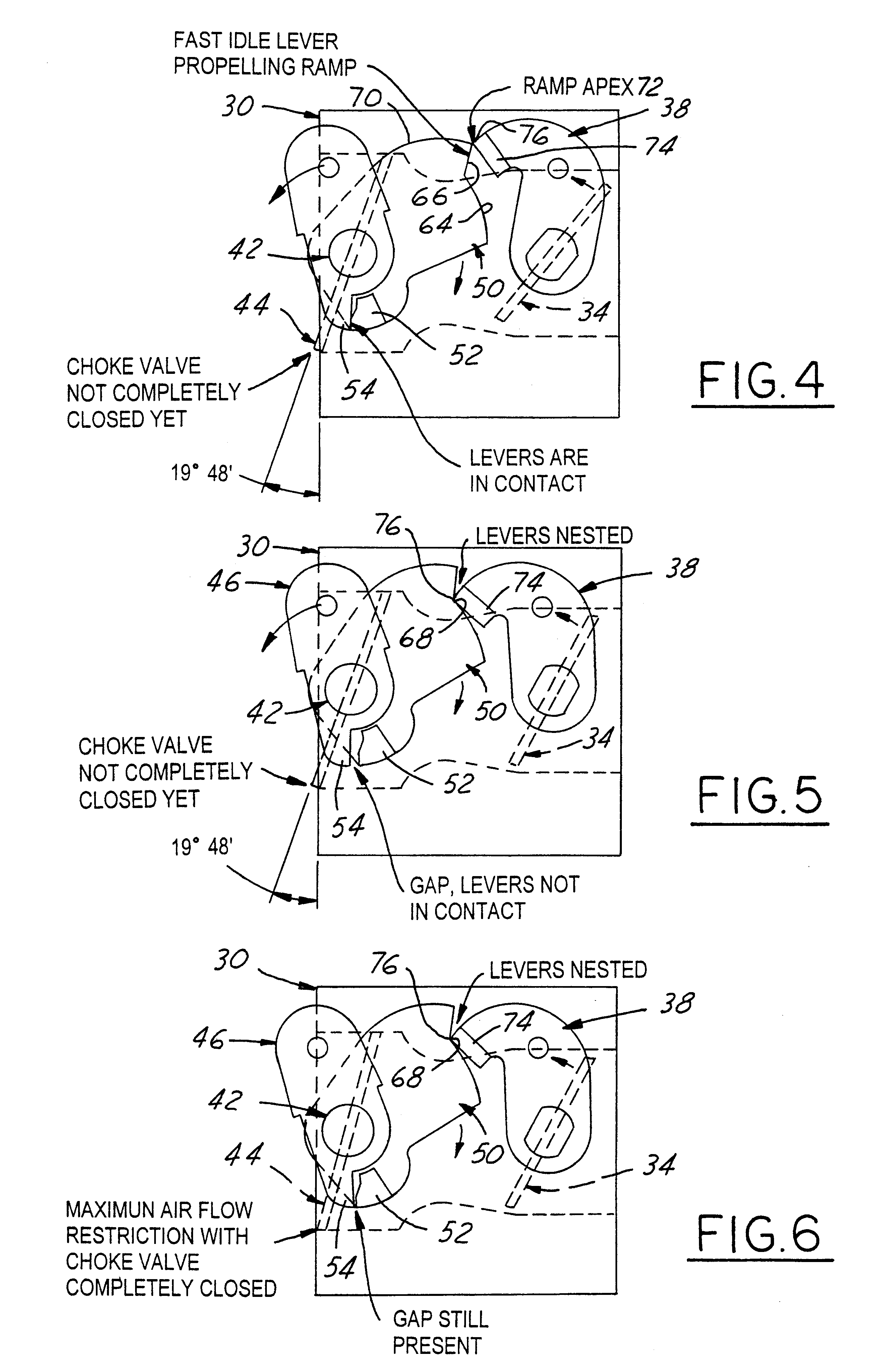

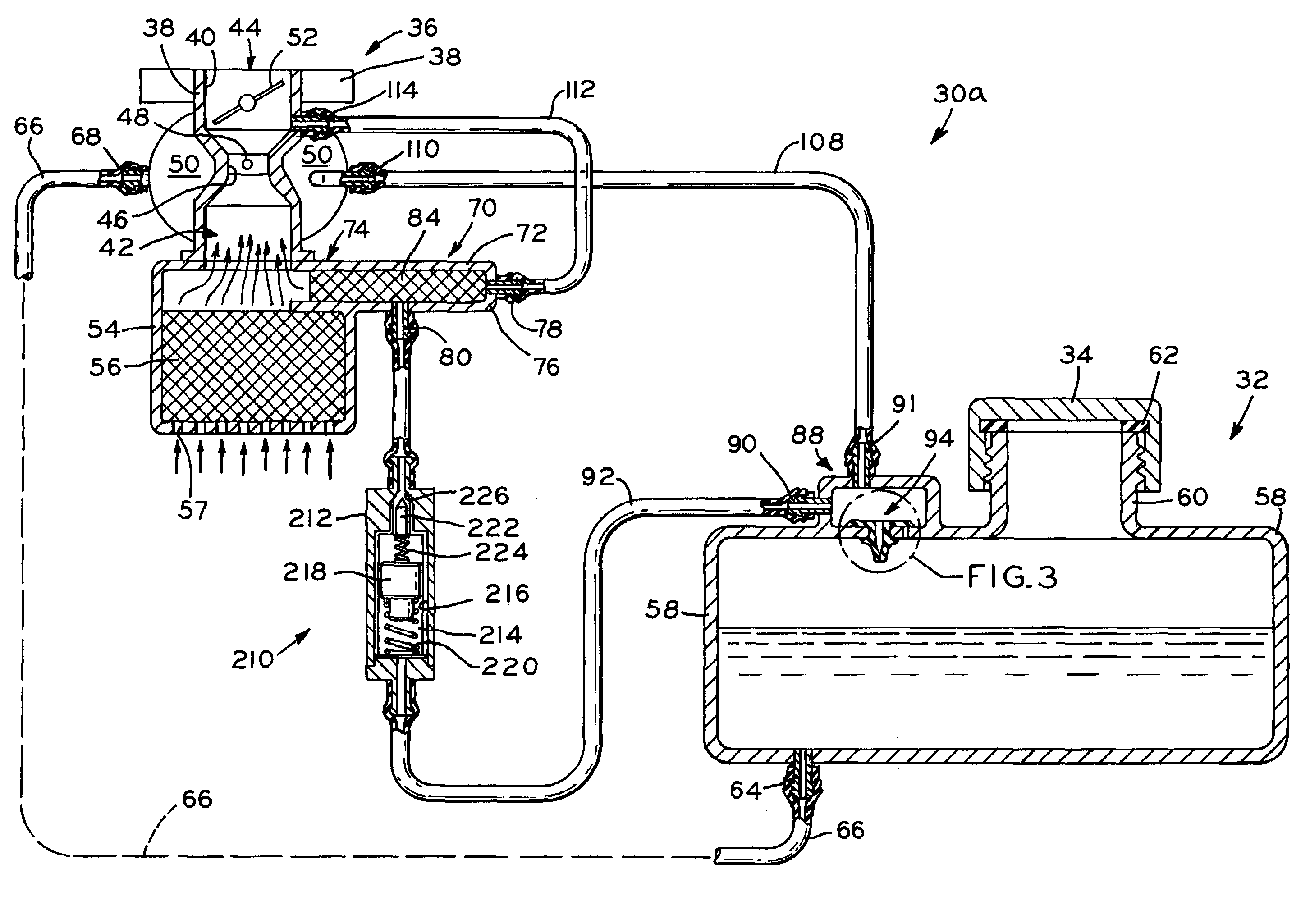

InactiveUS7267112B2Facilitates collection and trappingNon-fuel substance addition to fuelLarge containersAtmospheric airControl system

An evaporative emissions control system for small internal combustion engines, including a charcoal canister which is in fluid communication with the air space above the liquid fuel within the carburetor of the engine and the air space above the liquid fuel within the fuel tank of the engine. The charcoal canister contains charcoal media, and when the engine is not running, fuel vapors from the carburetor and the fuel tank migrate to, and are trapped within, the charcoal media of the charcoal canister. The charcoal canister may comprise a separate component, or may be integrally formed with an engine component such as the air cleaner, the carburetor, or the body of the fuel tank, for example. During running of the engine, vacuum within the carburetor induces a flow of atmospheric air through the charcoal canister to purge the collected fuel vapors from the charcoal media, and the fuel vapors pass into the engine for consumption. In another embodiment, an evaporative emissions control system including a charcoal canister is provided for an engine which includes a fuel injection system.

Owner:TECUMSEH PROD CO +1

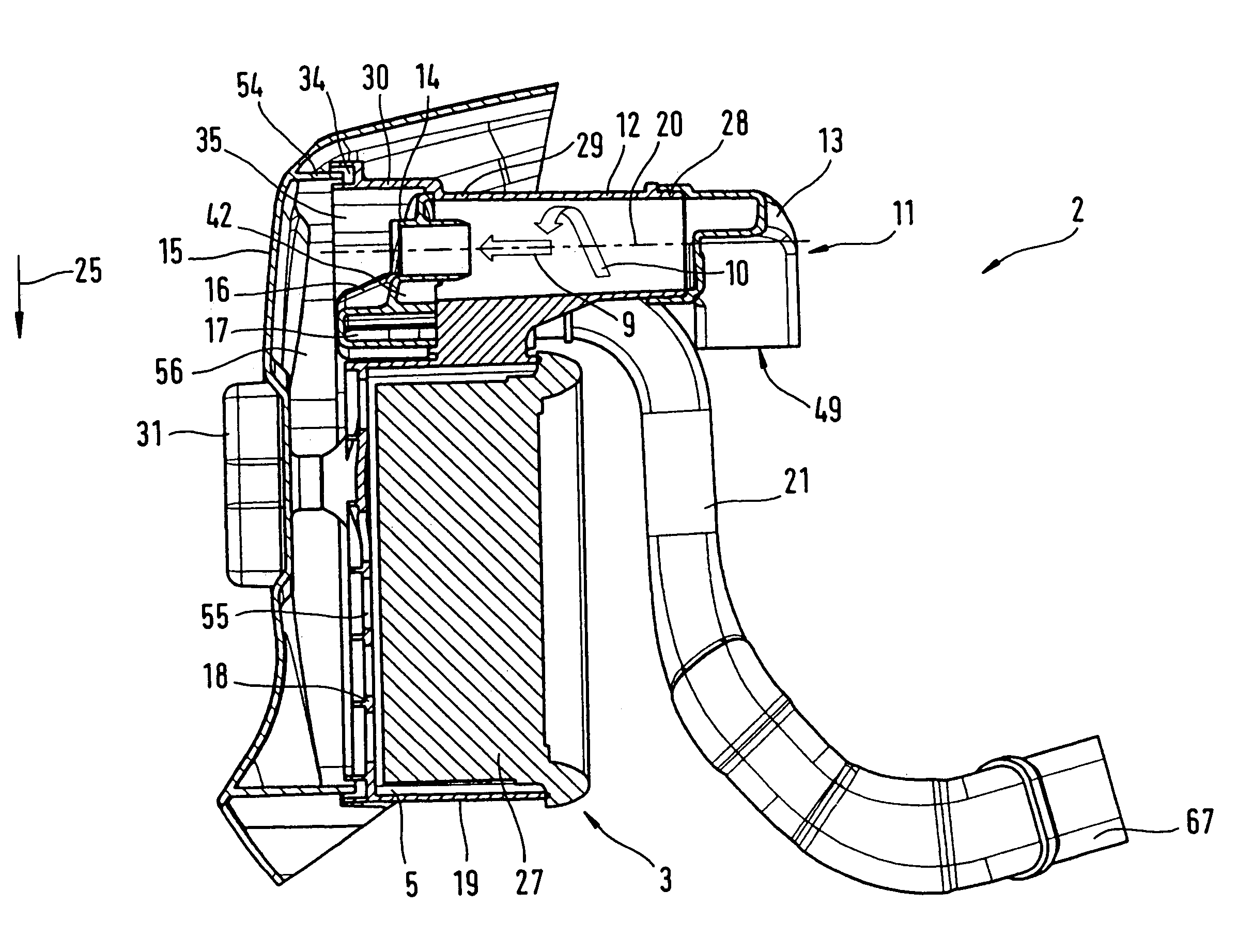

Air intake device

ActiveUS7159557B2Reducing intake sound levelReduce sound levelMachines/enginesAir intakes for fuelCarburetorEngineering

The present invention relates to a vehicle's air intake device. In an embodiment, the intake device comprises an intake pipe, an air cleaner case in fluid communication with the intake pipe, a connection pipe in fluid communication with the air cleaner case, a carburetor attached to the connection pipe, and a plurality of resonators. In an embodiment, the intake device comprises an intake pipe, an air cleaner case in fluid communication with the intake pipe, a connection pipe in fluid communication with the air cleaner case, a carburetor attached to the connection pipe, and means for reducing intake sound levels.

Owner:HONDA MOTOR CO LTD

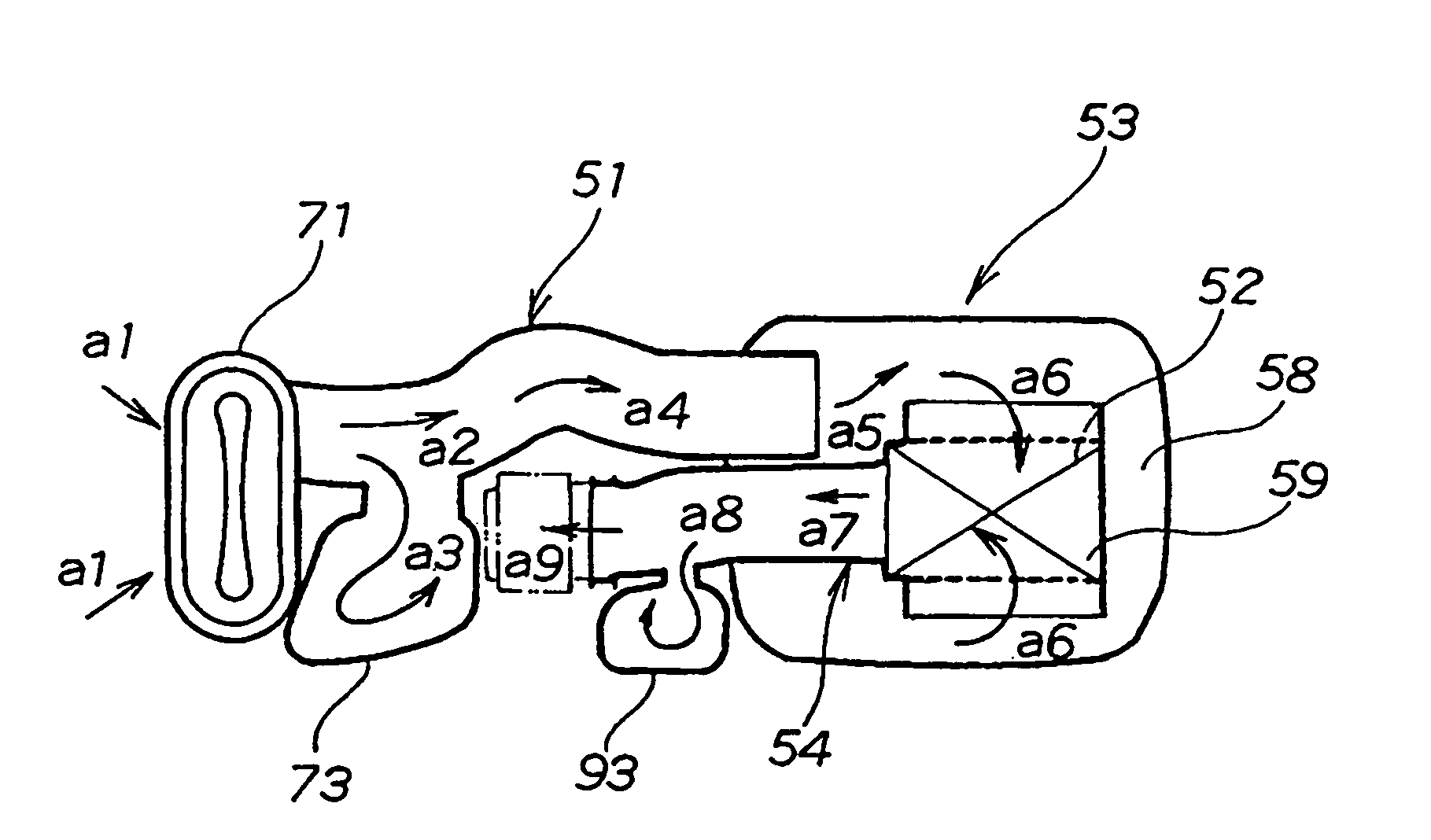

Stratified scavenging carburetor

A stratified scavenging carburetor with a lost motion coupling permits limited relative movement of a throttle valve relative to an air valve so that initial opening of the throttle valve off idle does not open the air valve to avoid diluting with scavenging air the fuel and air mixture delivered to an engine. Rotation of the throttle valve beyond a predetermined amount from idle causes a corresponding opening of the air valve to provide scavenging air to the engine. Closing a choke valve engages a lock lever with the throttle valve to move the throttle valve off idle to a start position without opening the air valve. In another embodiment, closing the choke valve prevents the air valve from opening even if the throttle valve is moved beyond where the throttle valve would cause the air valve to open if the choke valve were open. Thus, a richer than normal fuel and air mixture can be supplied to the engine during a choke-assisted start and warm-up of the engine.

Owner:NIPPON WALBRO KK

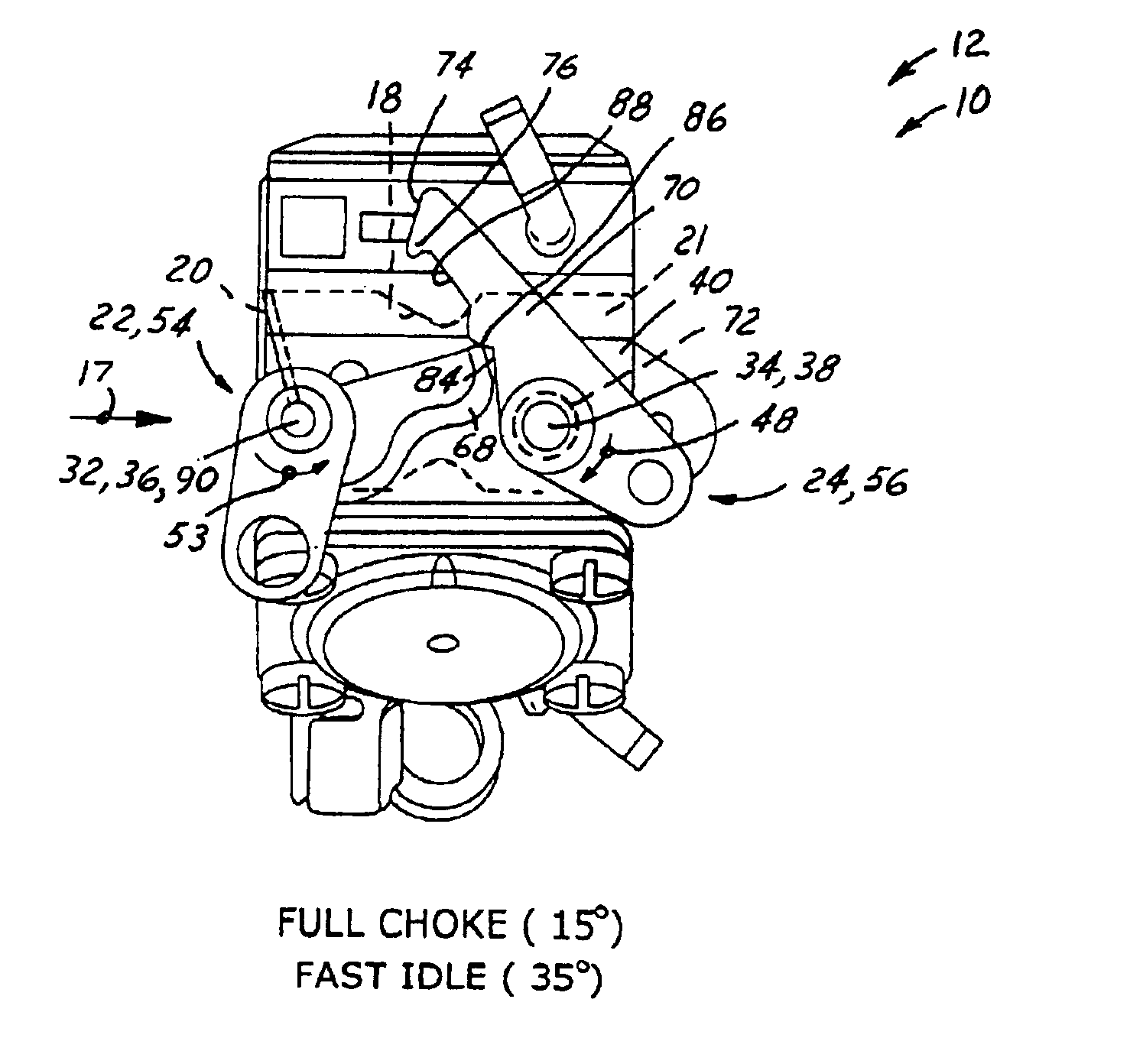

Self-relieving choke starting system for a combustion engine carburetor

InactiveUS6848405B1Improves engine start-upAvoids engine stallingElectrical controlLighting and heating apparatusCombustion chamberEngineering

A self-relieving choke starting system for a carburetor of a combustion engine has an elongated cammed latch which projects radially outward from a rotating shaft of a choke valve located in an upstream region of a fuel-and-air mixing passage carried by a body of the carburetor. During a first attempt at starting a cold engine, the user manually rotates the choke valve from a spring biased open to a full choke position whereupon a cam end of the latch contacts a follower arm, which projects radially outward from a rotating shaft of a throttle valve located downstream of a venturi of the mixing passage. As the choke valve manually rotates closed, the throttle valve automatically rotates in an open direction against the biasing force of a throttle spring from a slow idle state, for normal engine operation, to a fast idle state for engine starting. Once the choke valve is in the full choke position and the throttle valve is in the fast idle position, a rich mixture of fuel-and-air will flow into the combustion chamber of the engine during the first attempt at starting the cold engine. If the first attempt should fail, the user can manually rotate the choke valve in an open direction to a half-choke position while the throttle valve is automatically maintained in the fast idle position to provide a slightly leaner mixture of the fuel-and-air to the engine for following attempts at cold starting.

Owner:WALBRO ENGINE MANAGEMENT

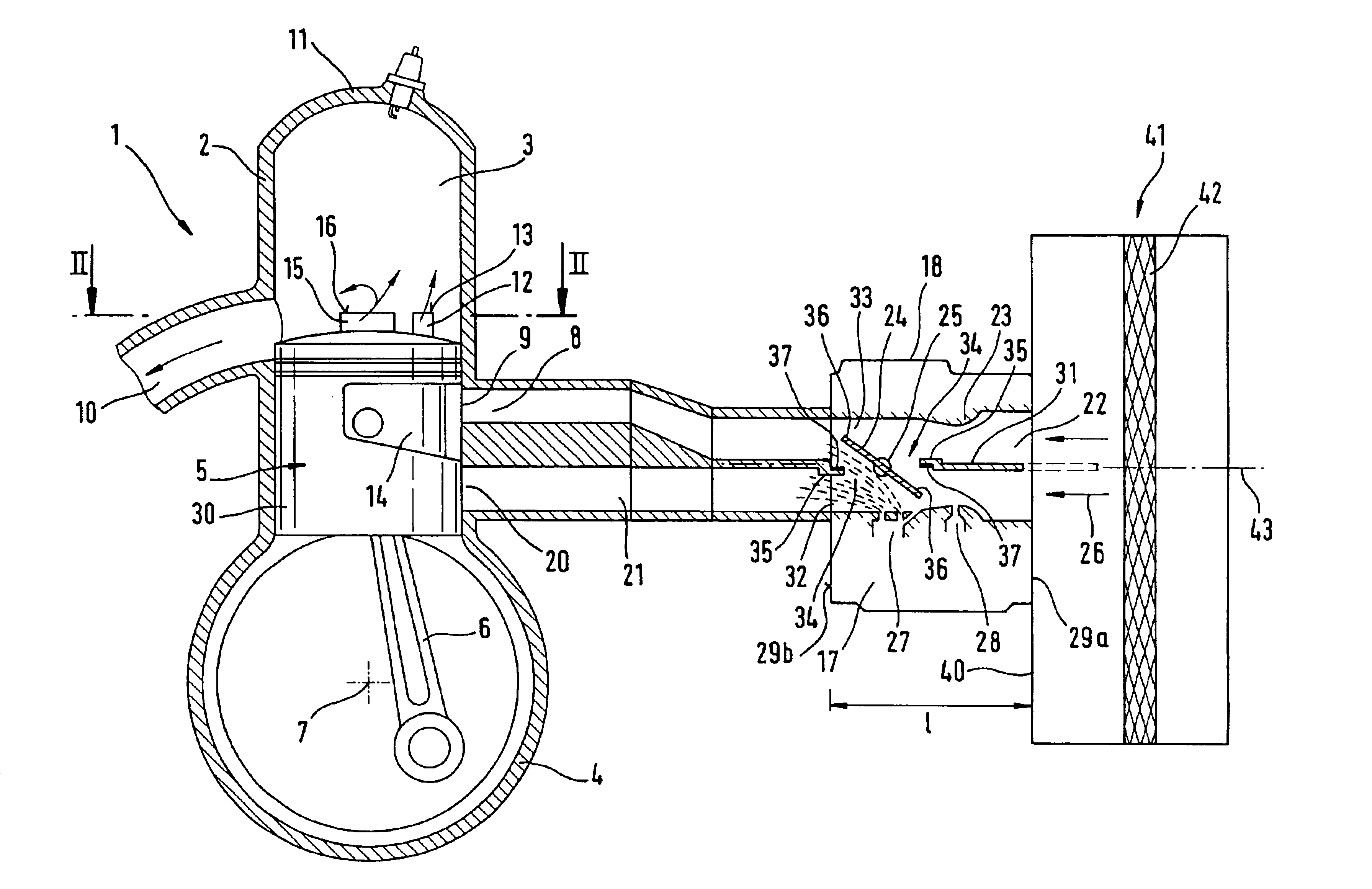

Carburetor arrangement for an internal combustion engine

ActiveUS6932058B2Increase speedDrop in speed is checkedElectrical controlFuel injection apparatusEngineeringCarburetor

A carburetor arrangement is provided for an internal combustion engine that is to be started with a pull cord. A fuel channel that is connected with a fuel-filled storage space opens into and supplies fuel to an intake channel portion as a function of the underpressure in the intake channel portion. The underpressure in the intake channel portion is increased during the start-up process via a start-up mechanism. To keep the engine ready to run with the start-up mechanism engaged, a control valve is disposed between the storage space and where the fuel channel opens into the intake channel portion. The control valve is opened or closed by a control unit as a function of the speed of the internal combustion engine.

Owner:ANDREAS STIHL AG & CO KG

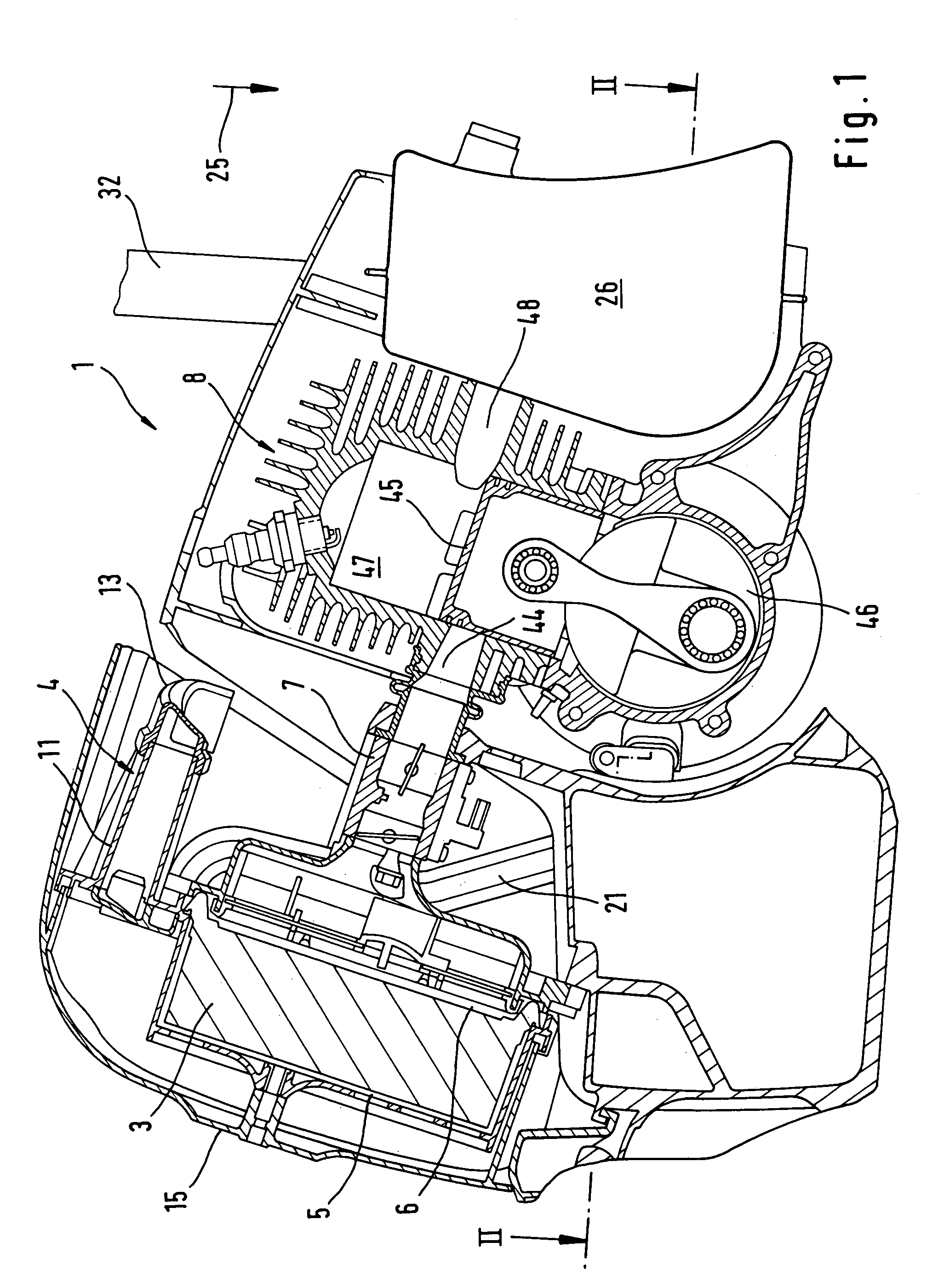

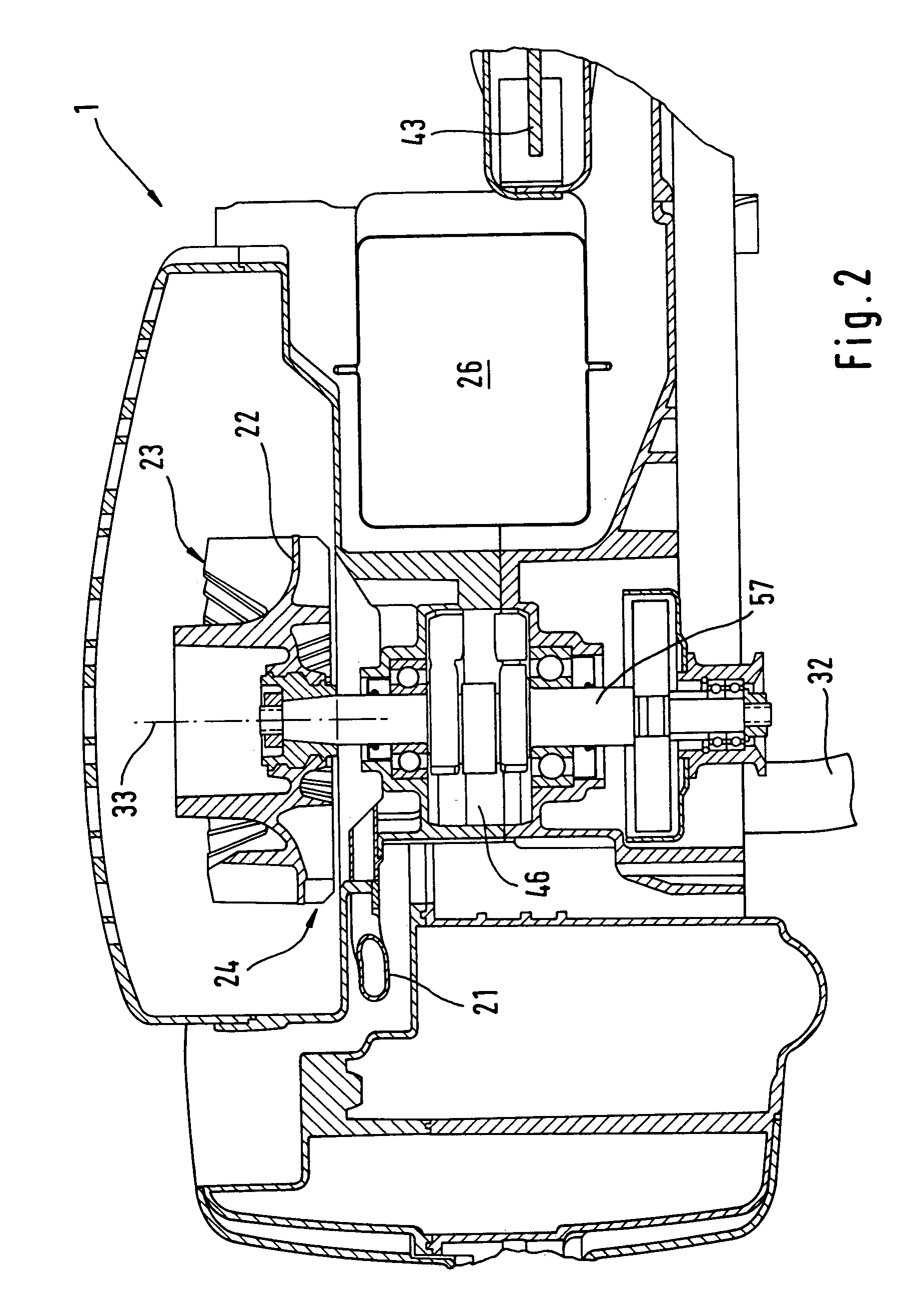

Intake system

An intake system for the combustion air of a motor of a hand held implement is provided. The system includes an air filter and a centrifugal separator. The air filter has a dirt chamber and a clean chamber that is separated therefrom by a filter medium. The clean chamber is fluidically connected with a carburetor of the motor to convey combustion air to the motor. The centrifugal separator splits the air stream into a core flow having low particle density and a peripheral flow having high particle density. The centrifugal separator includes at least two cyclones, wherein the discharged flows from the cyclones are respectively combined in pairs and open out into a common suction tube.

Owner:ANDREAS STIHL AG & CO KG

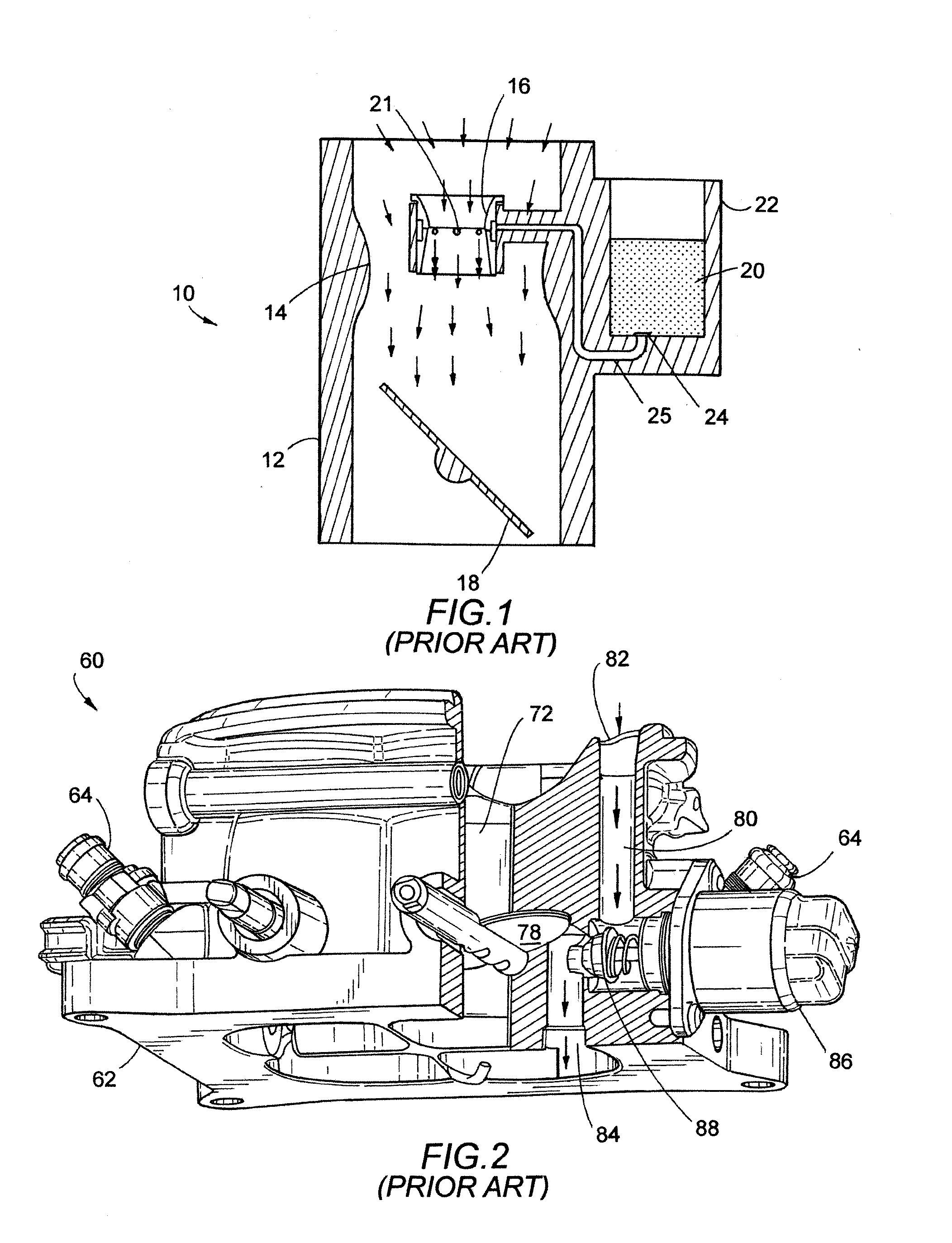

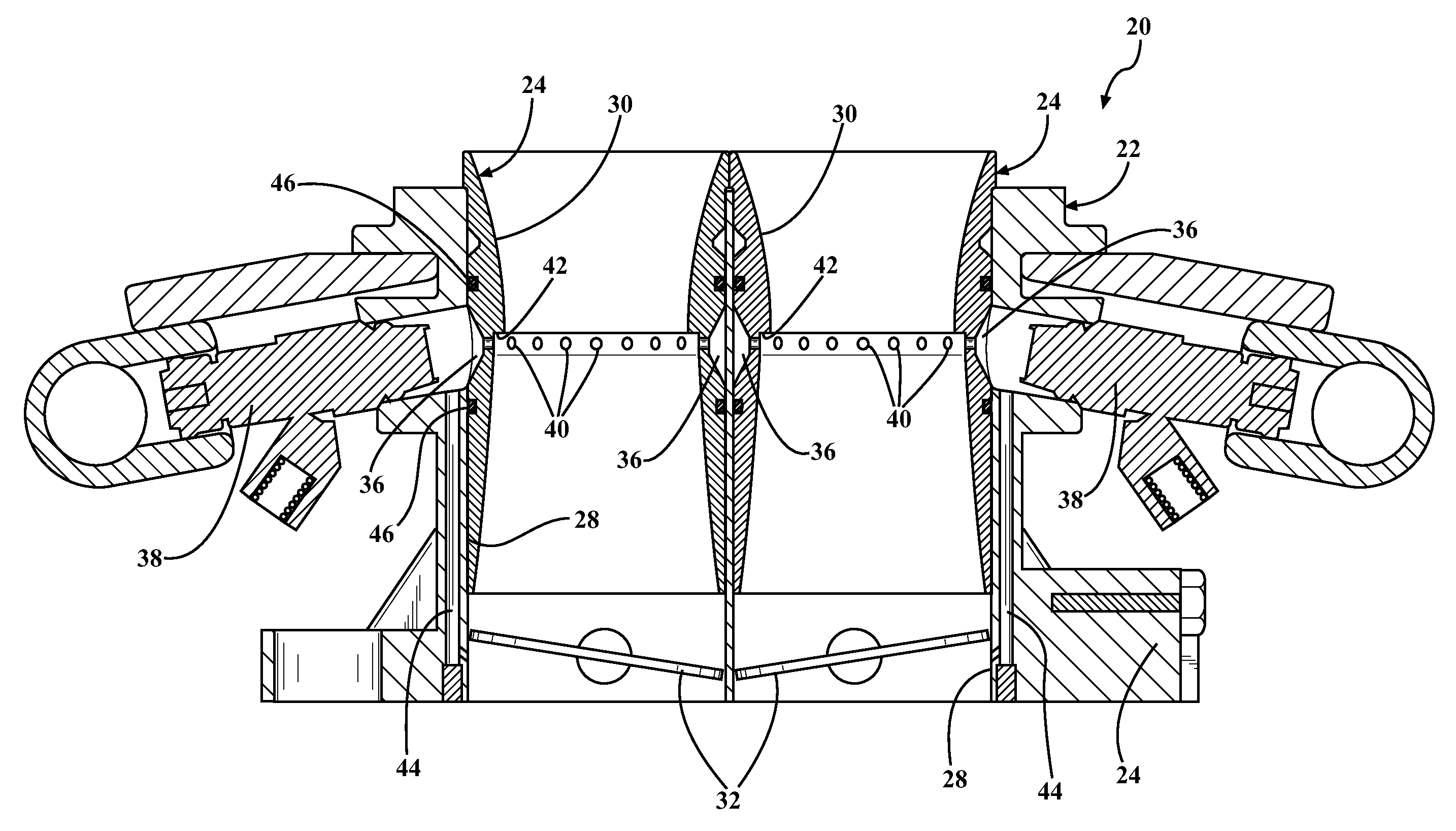

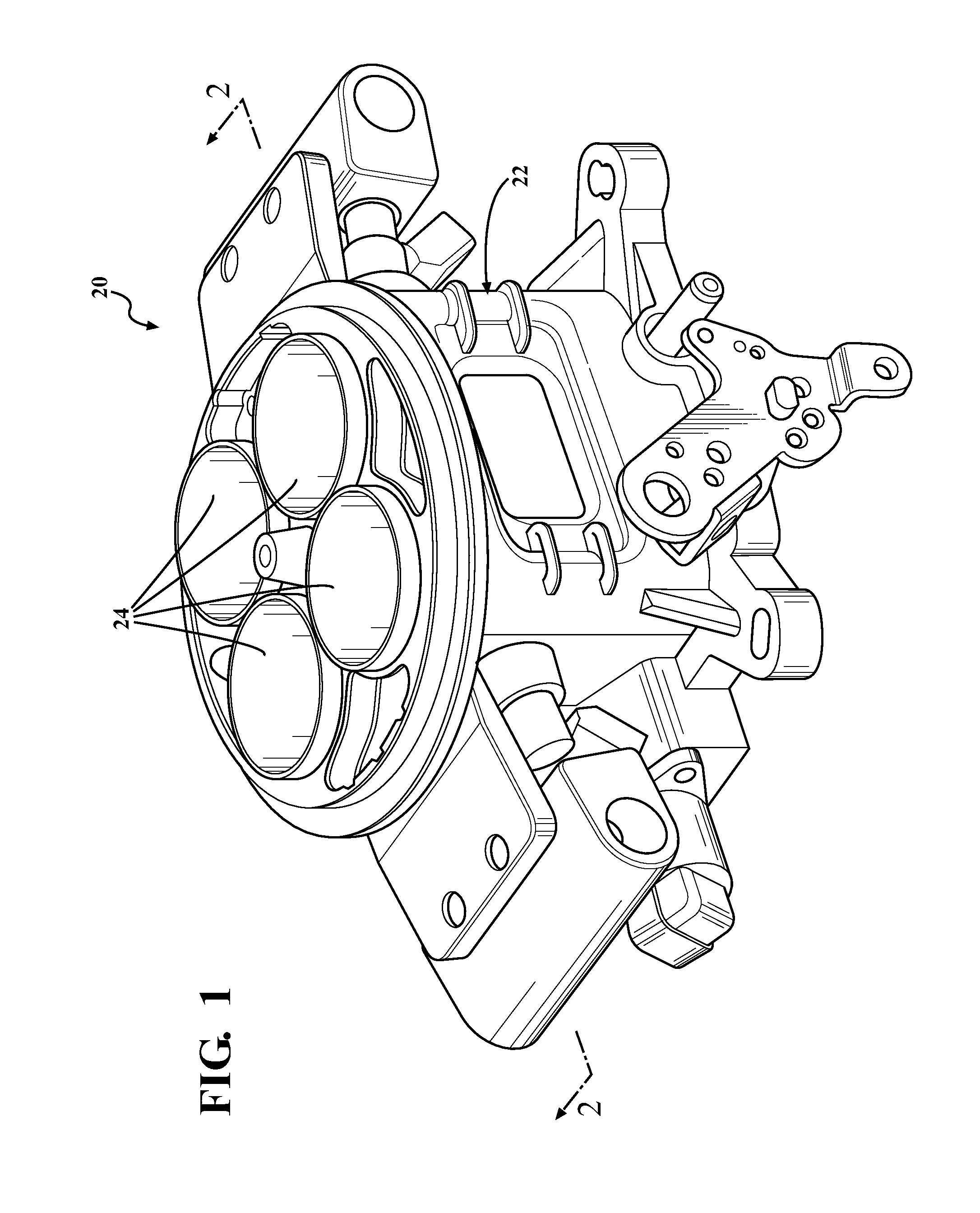

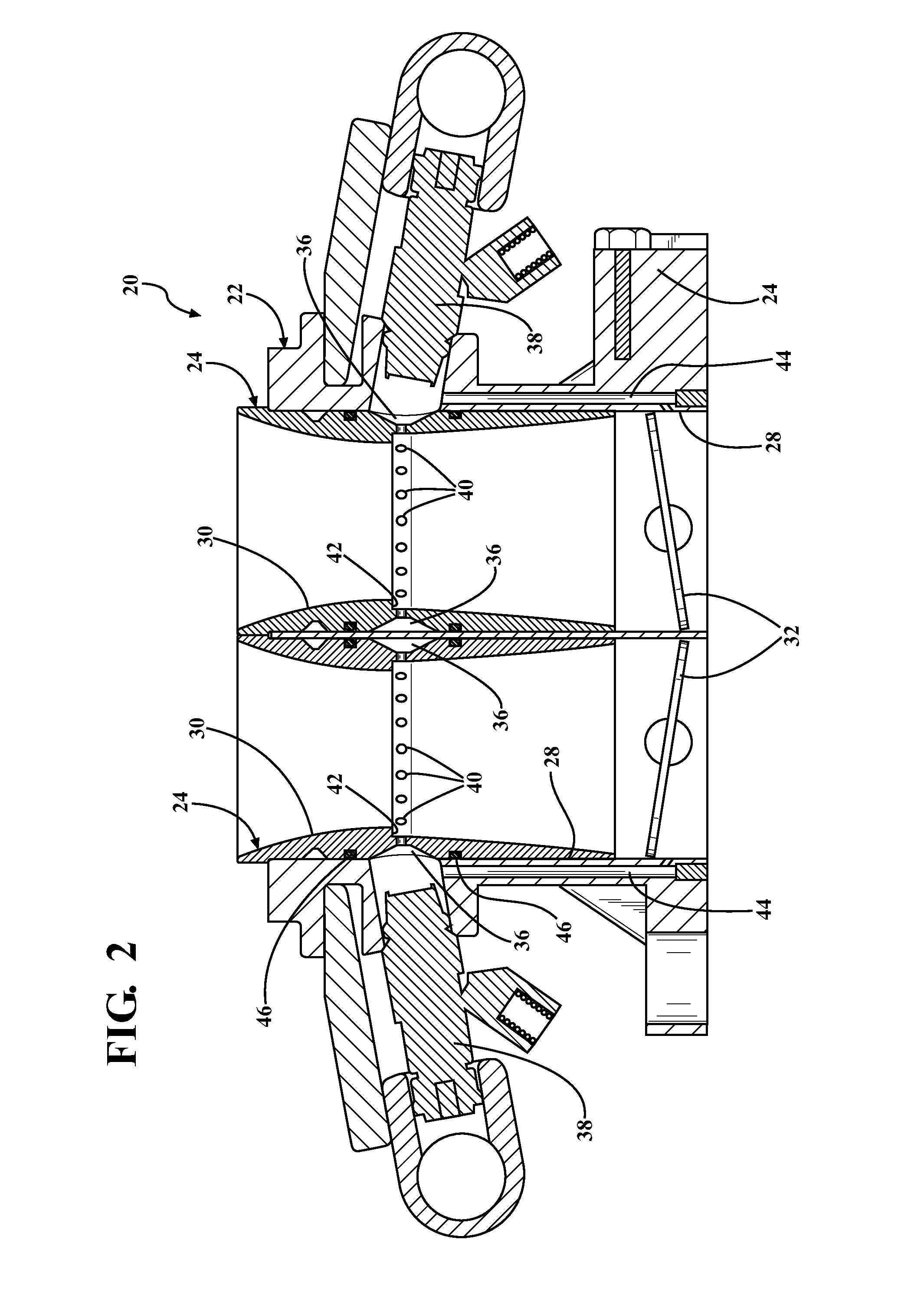

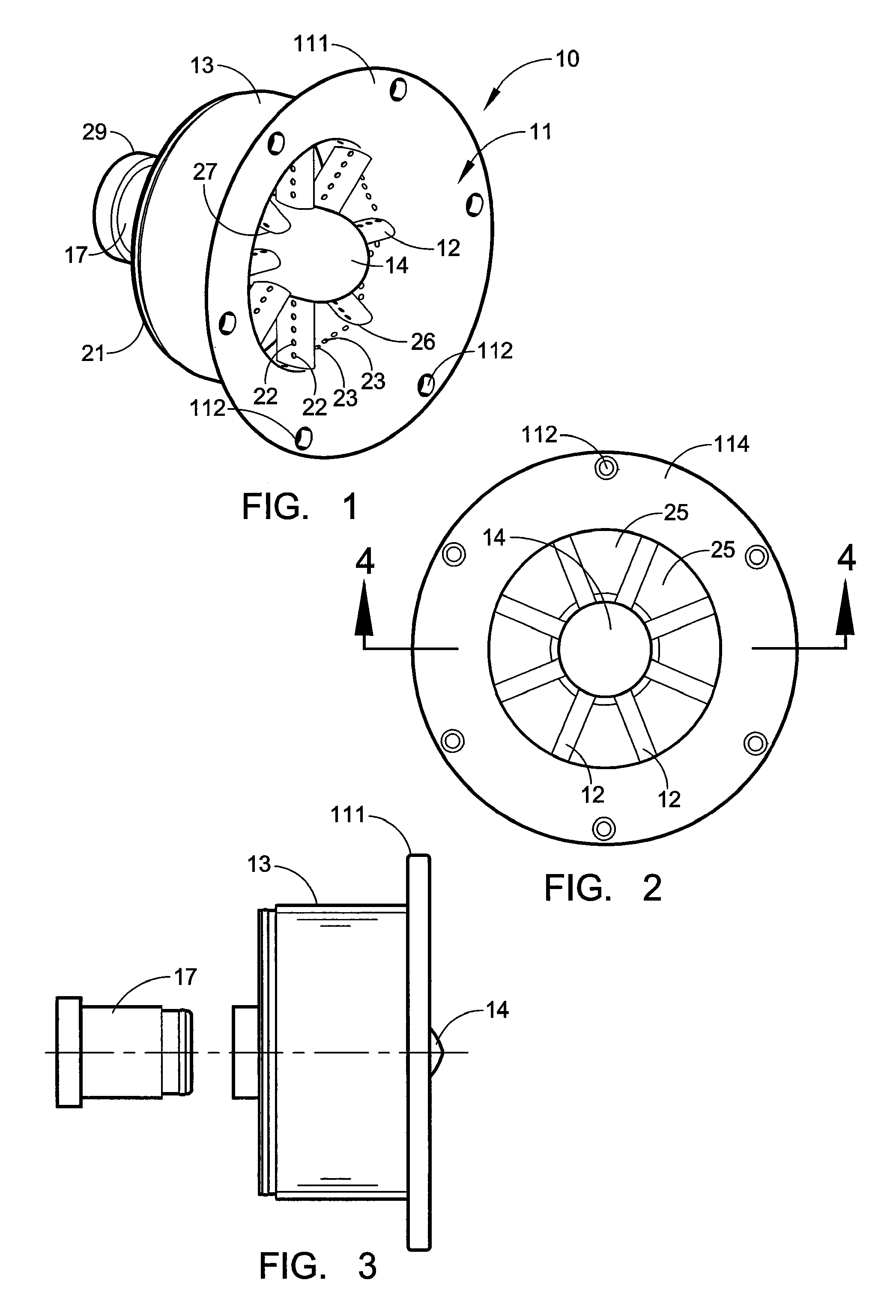

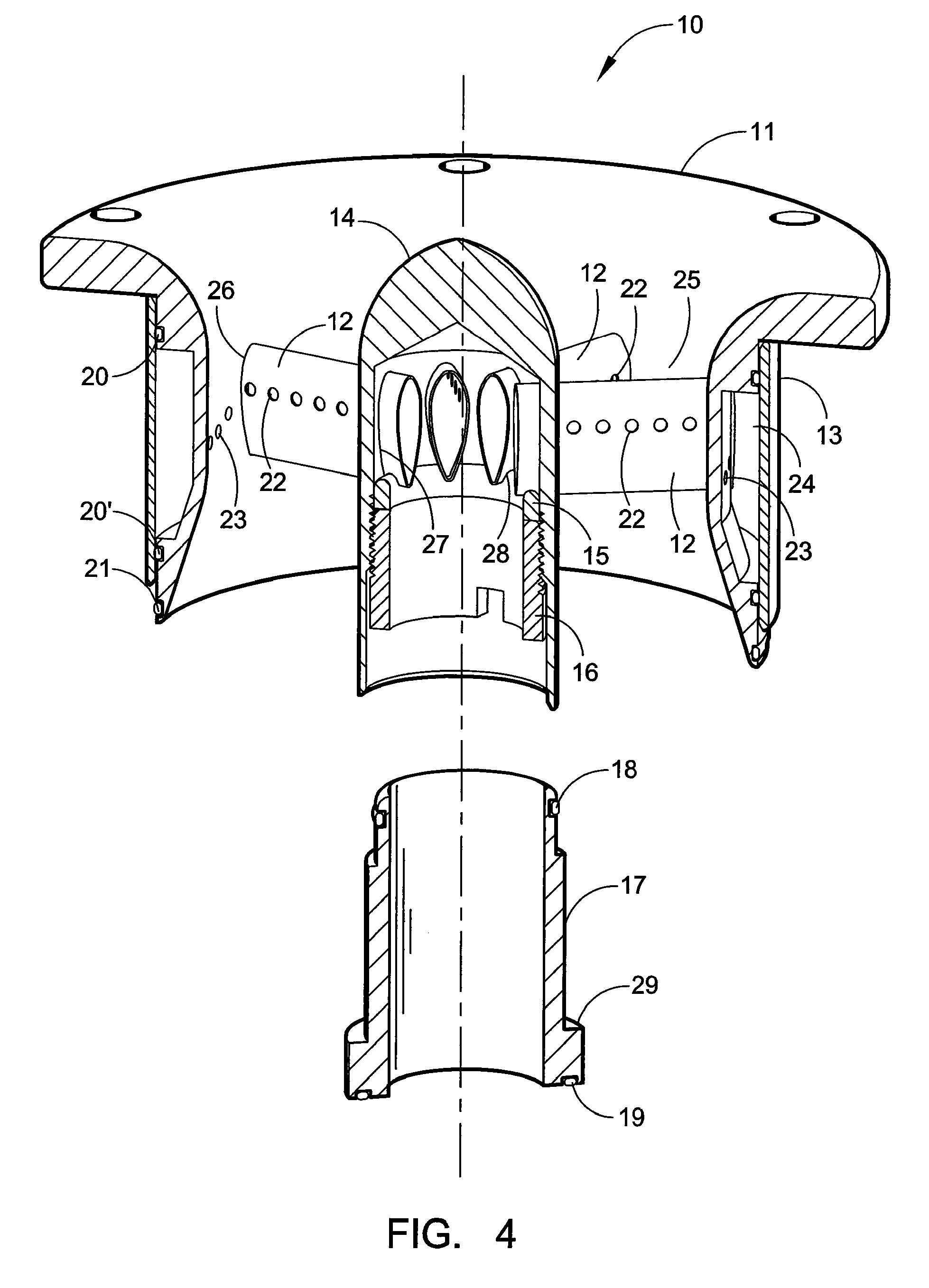

Hybrid carburetor and fuel injection assembly for an internal combustion engine

ActiveUS9115671B2Efficient combustionCheap to createLow pressure fuel injectionMachines/enginesCarburetorHybrid fuel

A hybrid fuel injection and carburetor assembly for delivering a fuel and air mixture into an intake manifold of an engine is provided. The assembly includes a housing and a plurality of inserts with Venturi-shaped bores to establish low pressure regions in the flow of air. The housing and inserts cooperate with one another to present cavities, and the inserts include apertures extending between the cavities and the low-pressure regions. The assembly also includes fuel injectors in fluid communication with the cavities. In operation, fuel is injected at a high pressure into the cavities to the point, and the pressurized fuel is delivered into the low pressure air via the apertures. Because of the large pressure difference between the pressurized fuel in the cavities and the low pressure air, the fuel becomes very atomized.

Owner:HOLLEY PERFORMANCE PRODUCTS

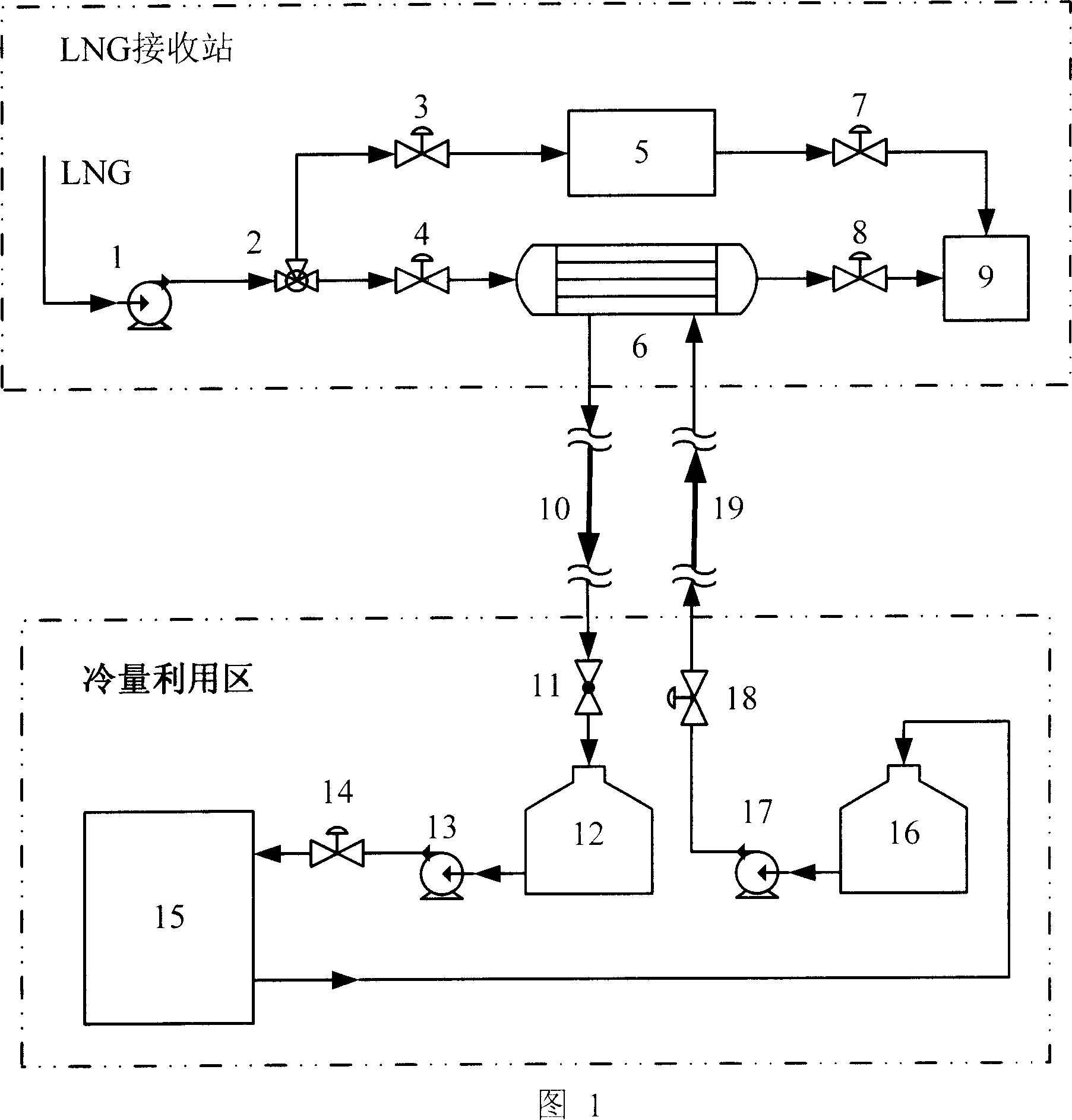

Method for using cooling capacity of LNG with cooling media as medium and apparatus thereof

InactiveCN1963347AGuarantee gas demandNot affected by cooling utilizationDomestic cooling apparatusLighting and heating apparatusNuclear engineeringCarburetor

The utilization of liquefied natural gas with coolant as medium mainly refers to the coolant as the medium to exchange heat with liquefied natural gas in the receiving station, and sending cooled coolant through coolant heat insulation pipe to the cooled energy utilization zone outside the receiving station for customer's use. The equipment applying this method comprises a liquefied natural gas pump, a sea water carburetor, a low temperature heat exchanger, a coolant low temperature reserving tank, a low temperature coolant pump, a coolant normal temperature reserving tank and normal temperature coolant pump. It is simple in operation, convenient to control, feasible to set multi big scale cooled energy utilization to make the best of it.

Owner:SOUTH CHINA UNIV OF TECH

Auxiliary fuel and air supply in a carburetor

InactiveUS7467785B2Exemption stepsEnhances starting and warmUsing liquid separation agentLow pressure fuel injectionEngineeringCarburetor

Owner:WALBRO ENGINE MANAGEMENT

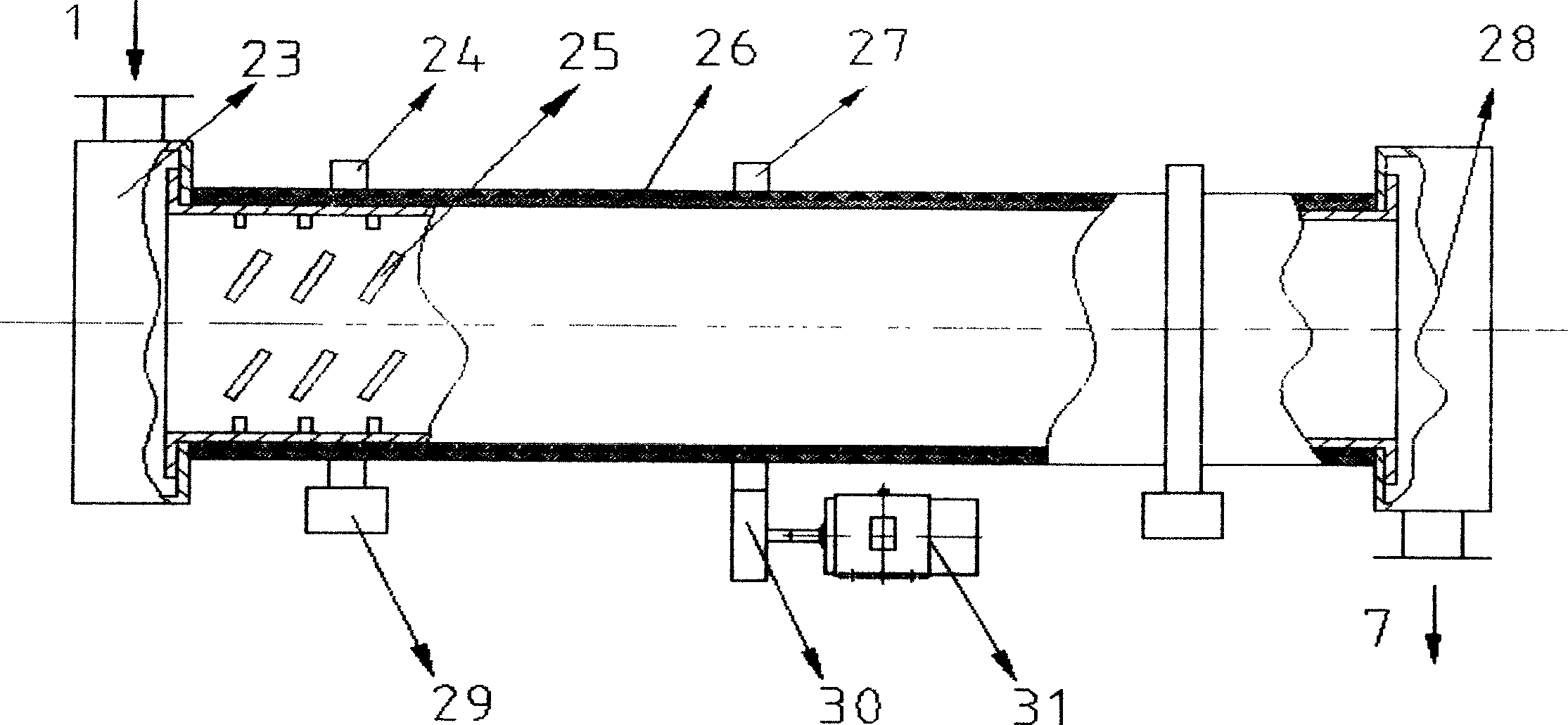

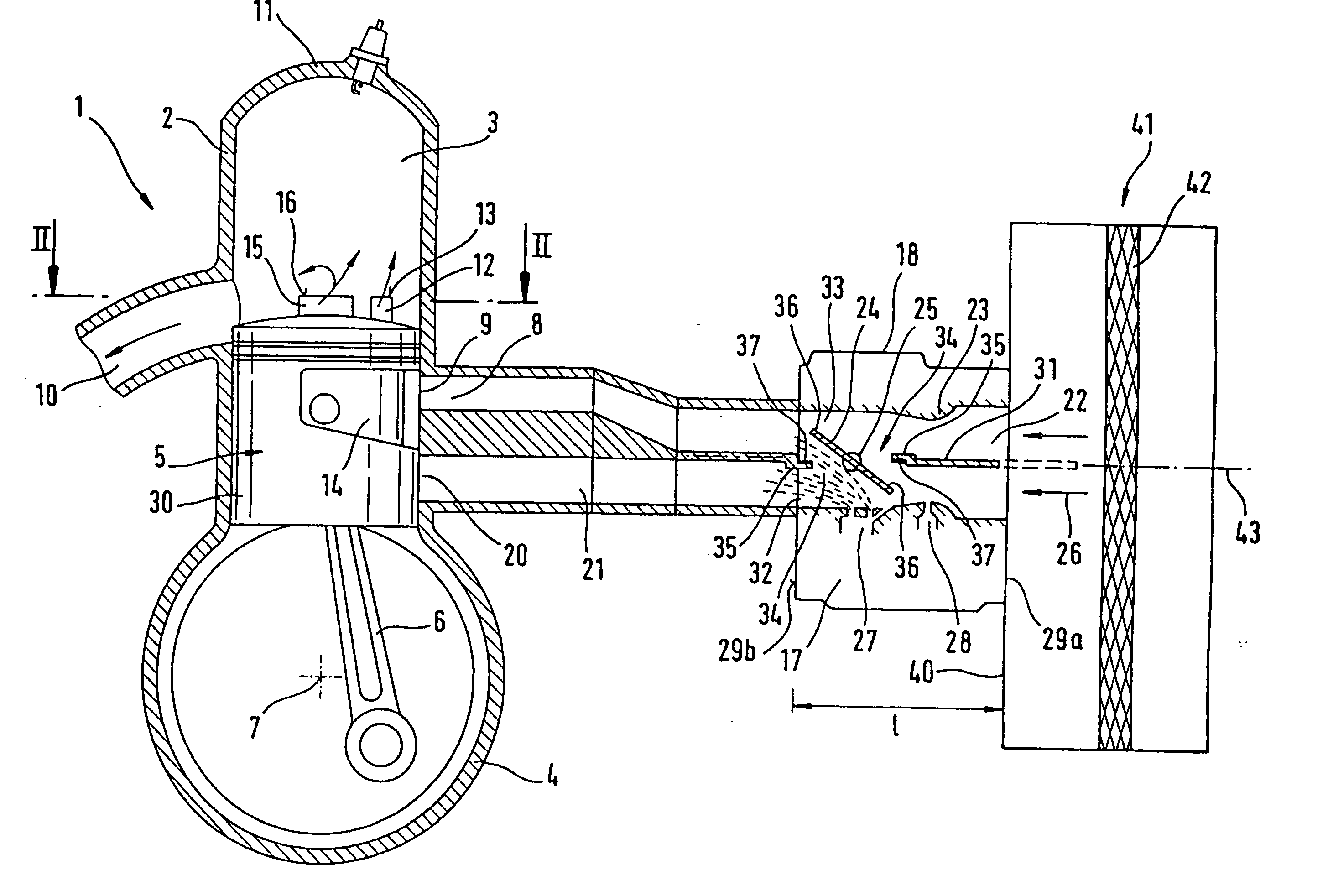

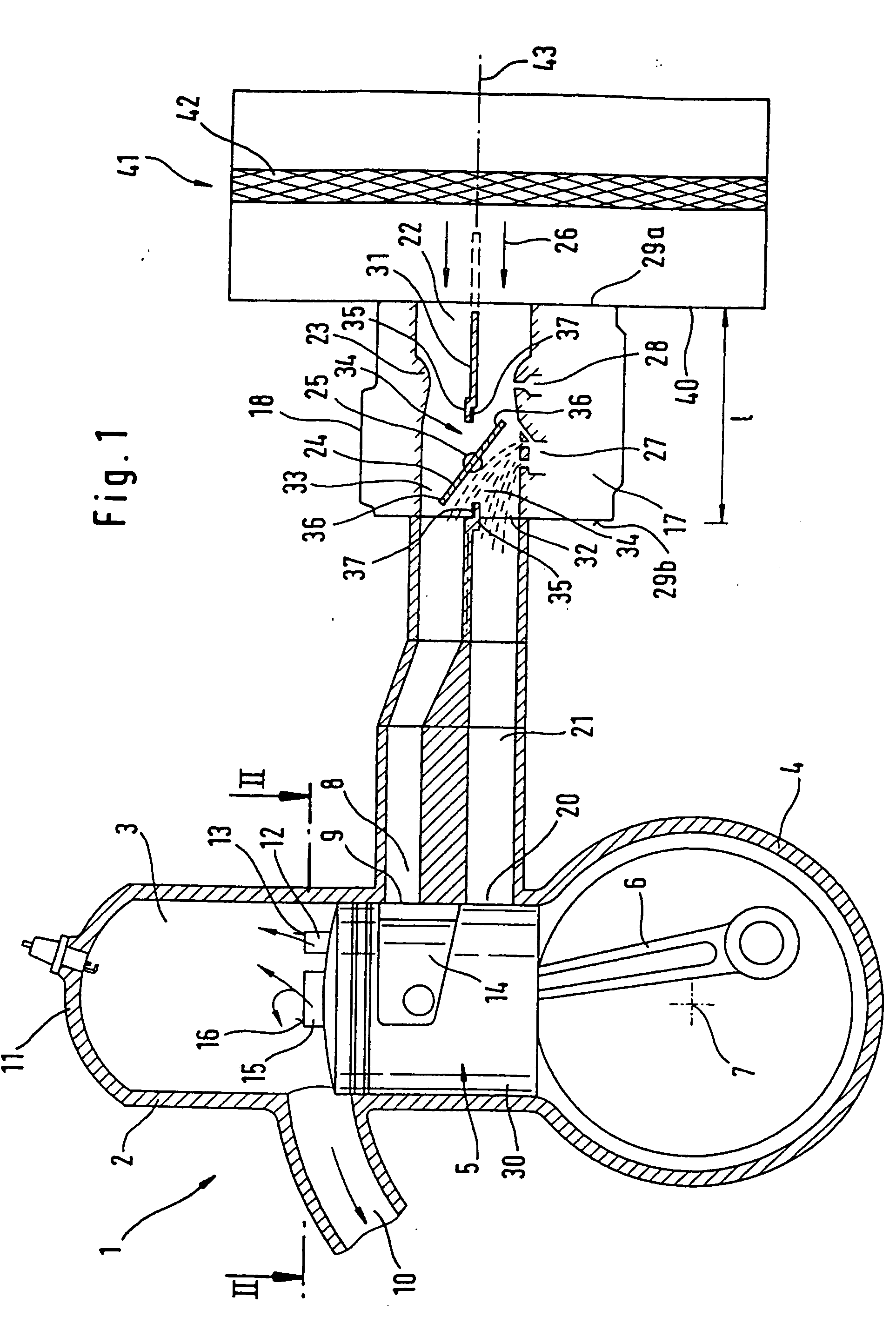

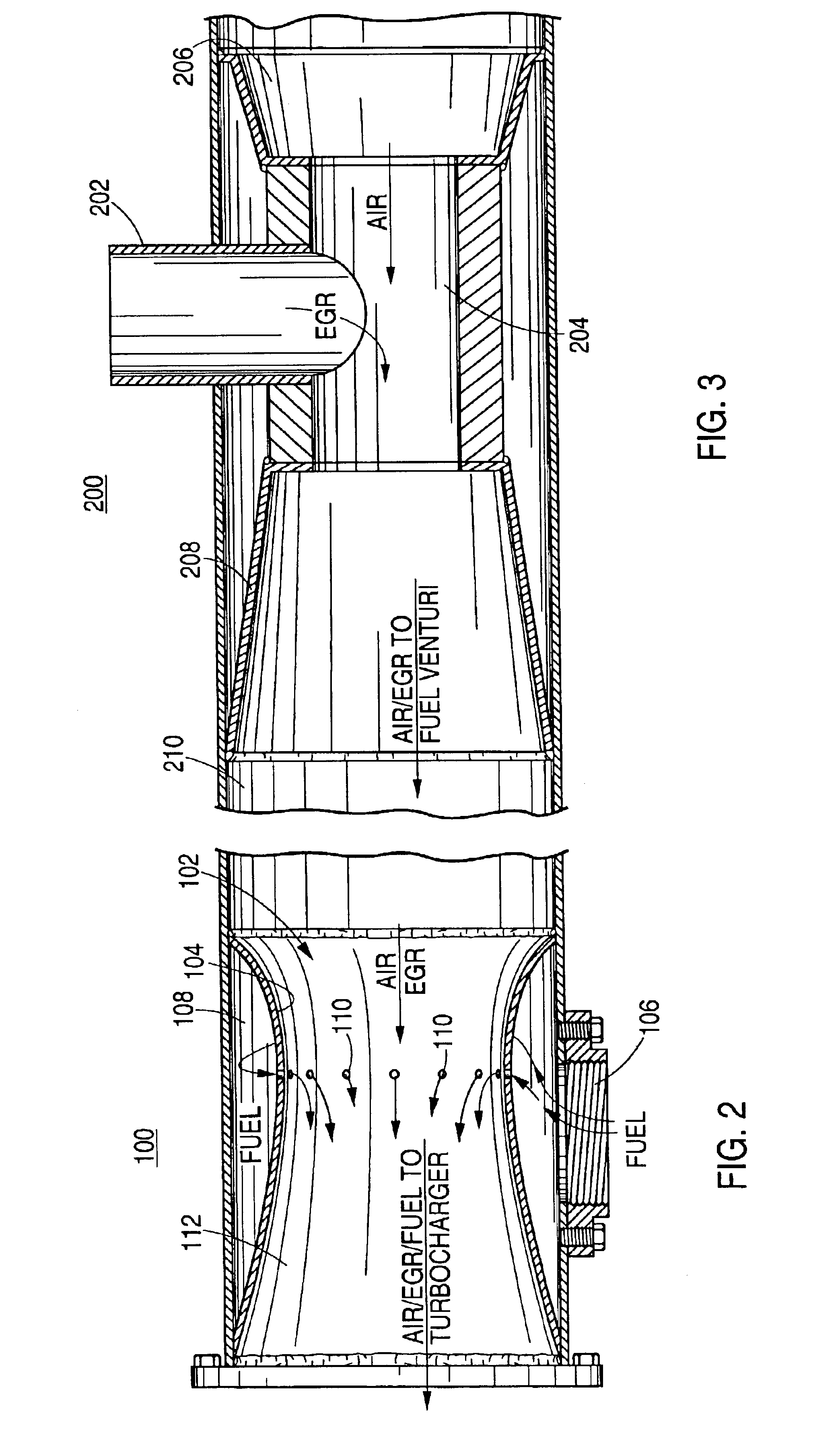

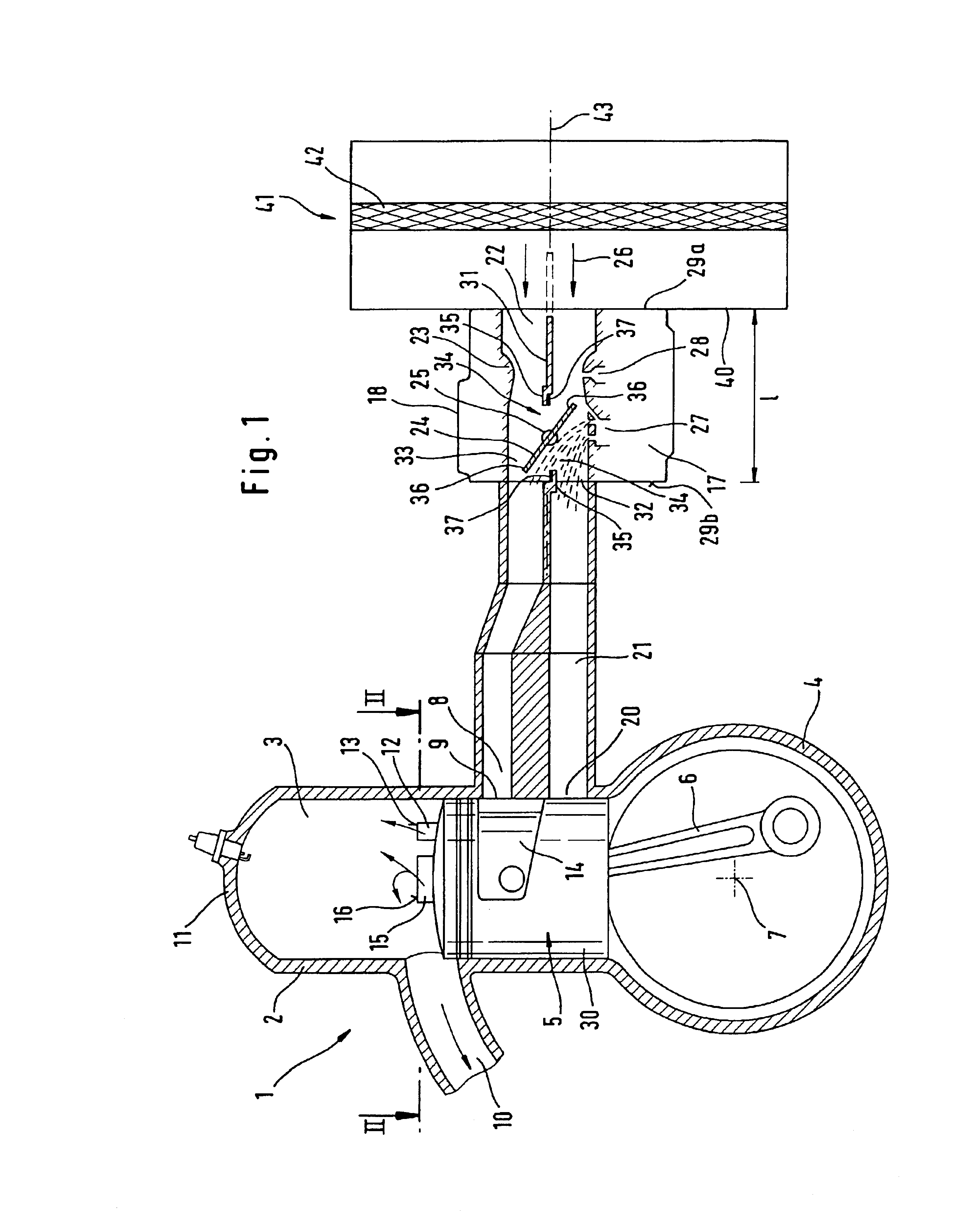

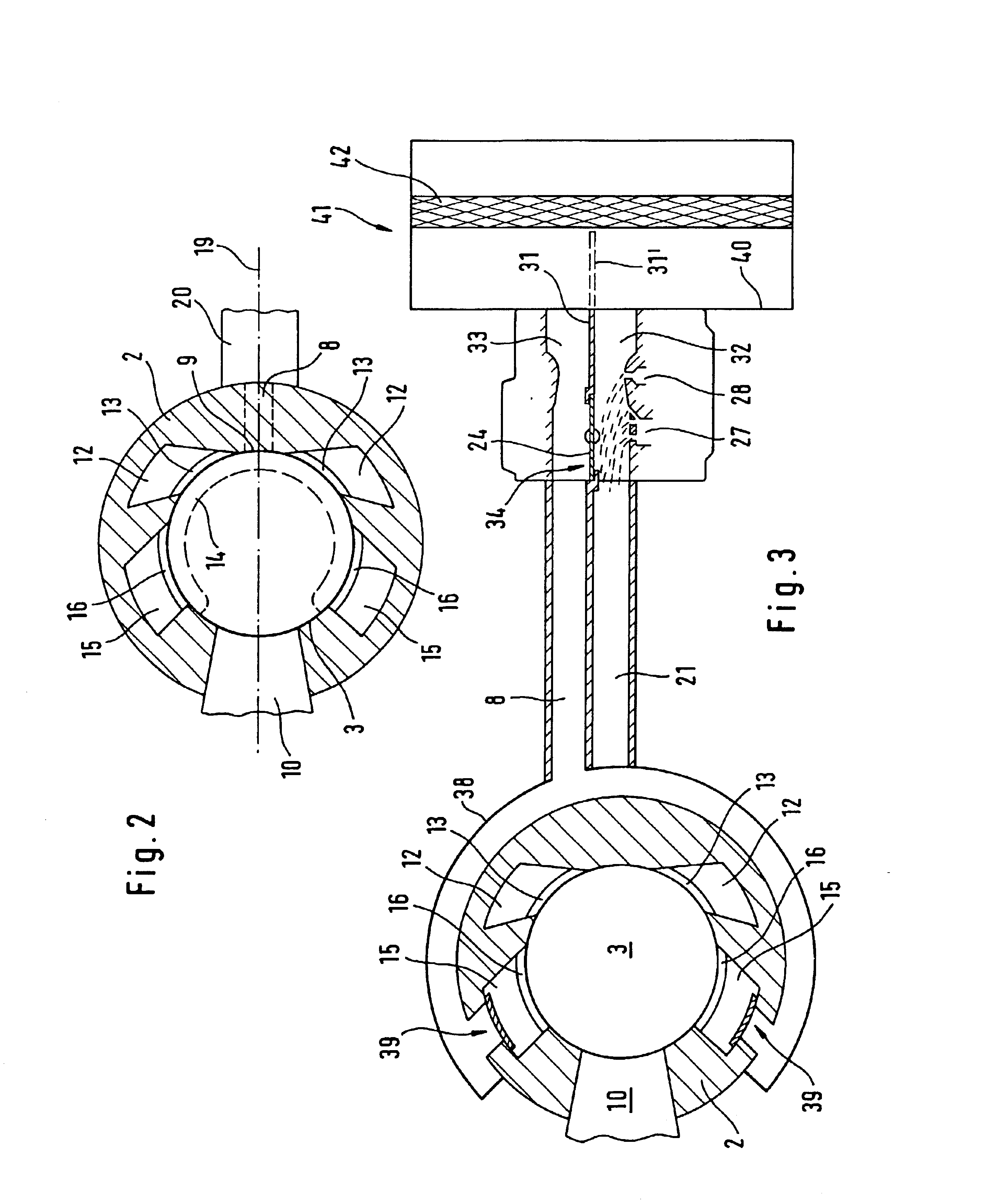

Two-cycle engine with forward scavenging air positioning and single-flow carburetor

InactiveUS20050120985A1Avoid burnsGood effectInternal combustion piston enginesCombustion-air/fuel-air treatmentCombustion chamberEngineering

A two-cycle engine 1 is provided and has a cylinder in which is formed a combustion chamber that is delimited by a piston which, via a connecting rod, drives a crankshaft rotatably mounted in a crankcase. The engine has an air duct that communicates with a transfer channel, and a mixture channel via which fuel / air mixture is drawn into the crankcase. At least a portion of the length of the mixture channel is separated from the air duct by a dividing wall that extends in a direction of flow of the air. The dividing wall separates the channels from one another in such a way that the ratio of the cross-sectional area of the mixture channel to the cross-sectional area of the air duct is approximately in the range of 0.5 to 1.9.

Owner:ANDREAS STIHL AG & CO KG

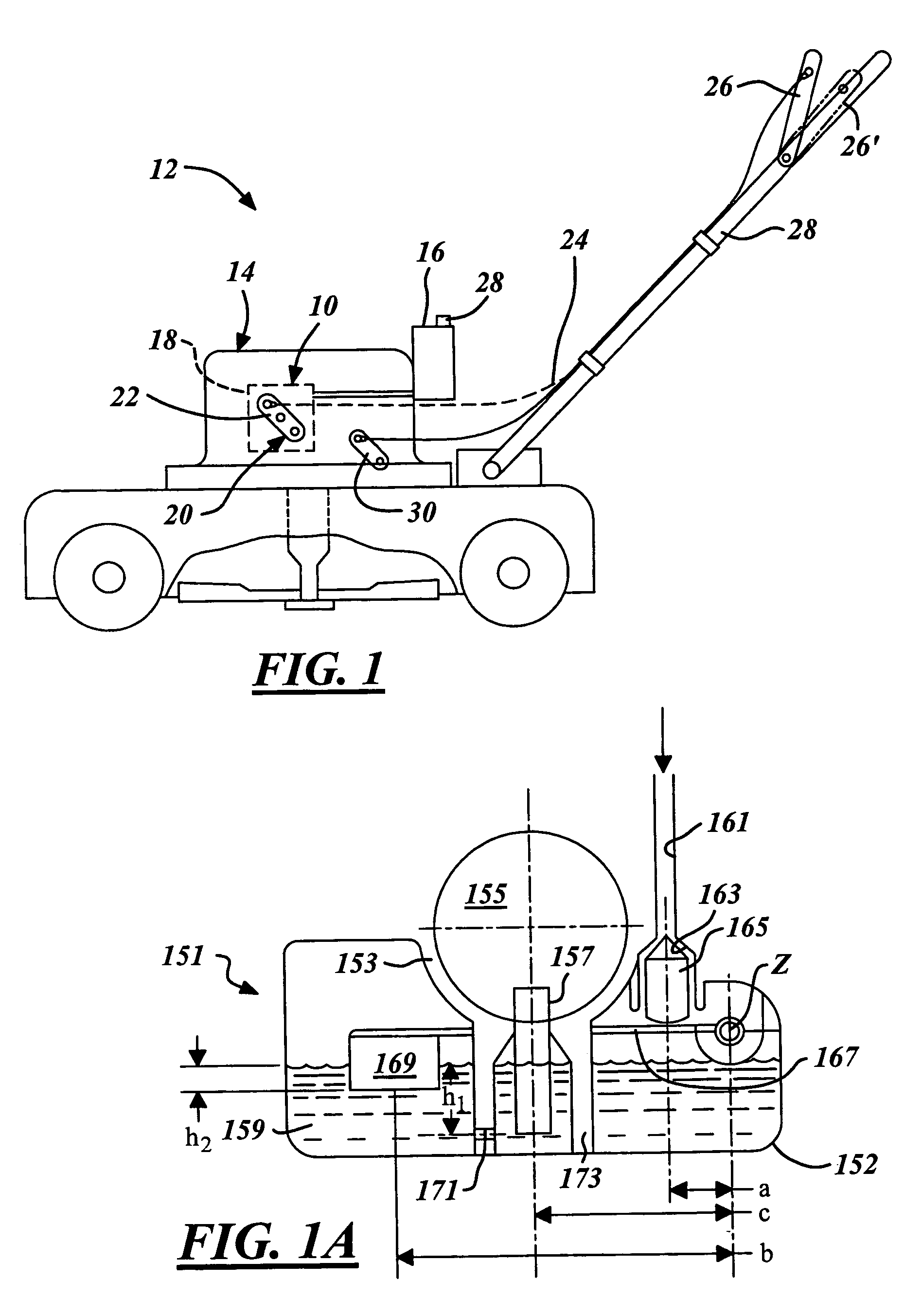

Controlling evaporative emissions in a fuel system

InactiveUS7263981B2Reduce and prevent emissionEmission controlNon-fuel substance addition to fuelFloat-controlled apparatusFuel tankCarburetor

Methods and fuel systems to reduce evaporative emissions of a volatile fuel. A fuel tank contains fuel, a carburetor mixes air with the fuel from the fuel tank, and a plurality of fluid paths route fuel amongst and / or between the fuel tank and the carburetor. A valve actuation device stops flow of fuel in one or more of the plurality of fluid paths and the carburetor is adapted to be drained of fuel during engine shutdown to reduce or prevent evaporative emissions from the fuel system. The carburetor is preferably designed so as to minimize a volume of fuel contained therein.

Owner:WALBRO ENGINE MANAGEMENT

Carburetor

ActiveUS7261281B2Easy to useSmall sizeLighting and heating apparatusUsing liquid separation agentCarburetorThrottle

Owner:ANDREAS STIHL AG & CO KG

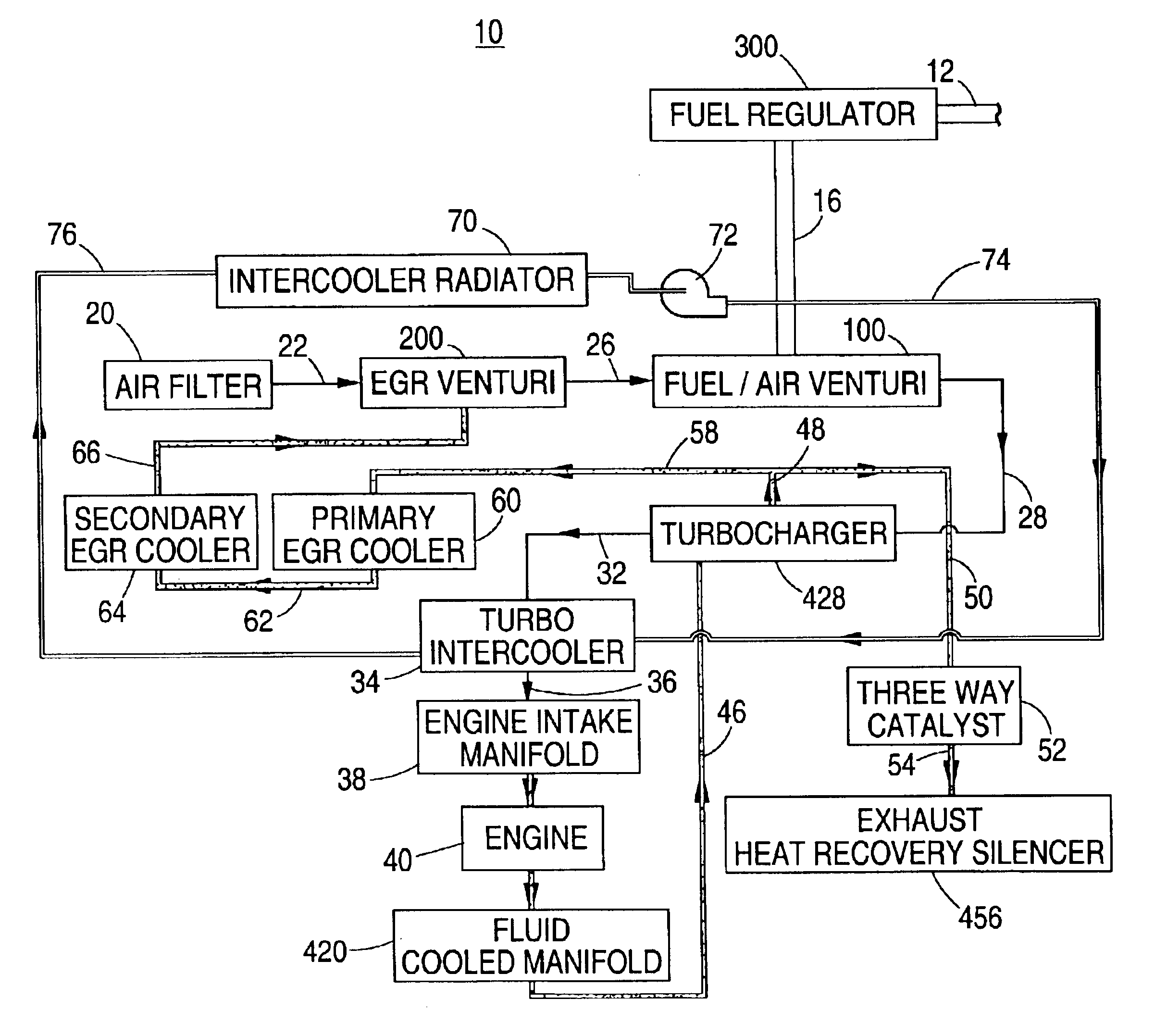

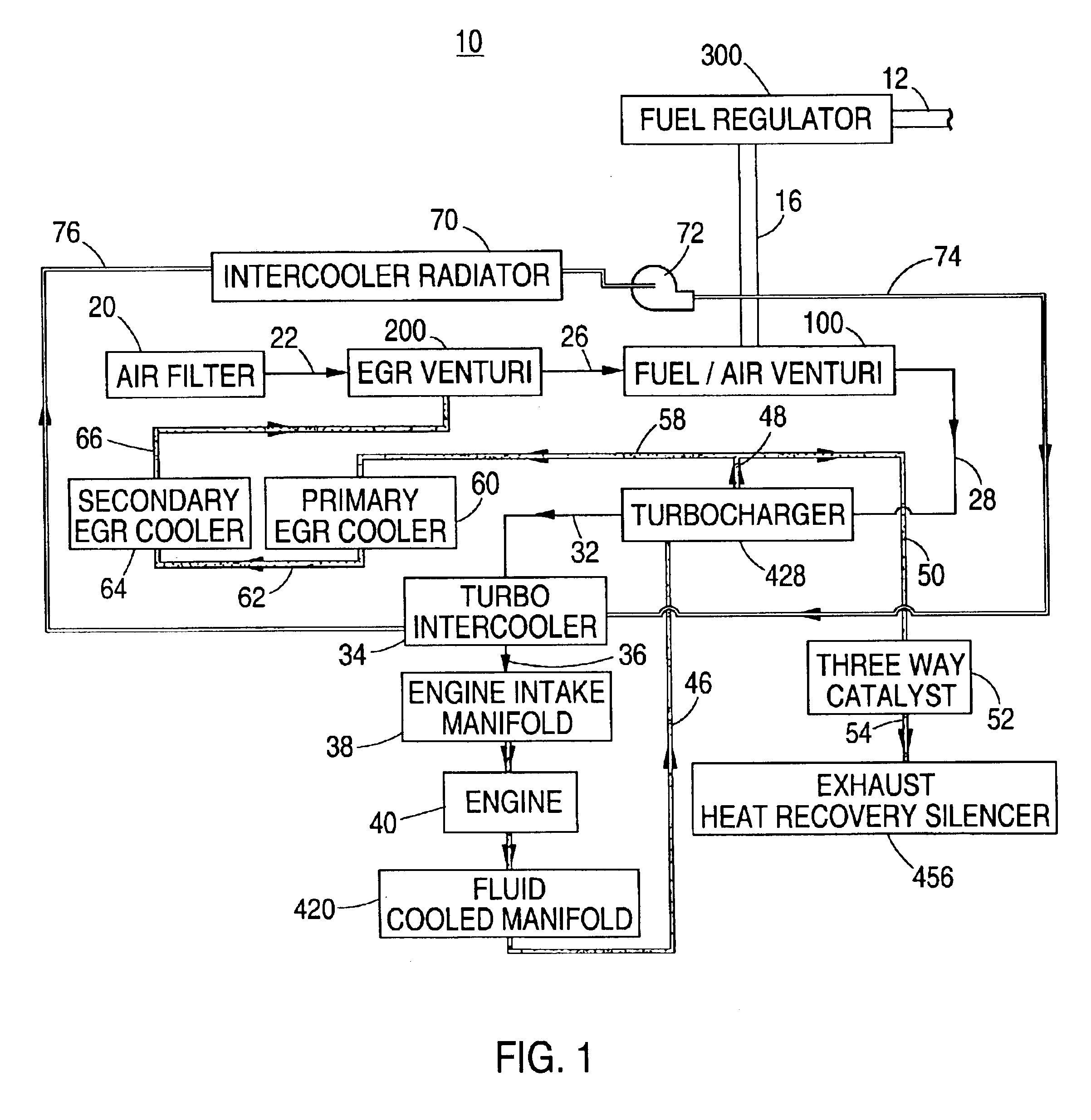

Carburetion for natural gas fueled internal combustion engine using recycled exhaust gas

InactiveUS6880535B2Efficient stable engine performanceLower head temperatureInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerExternal combustion engine

A carburetion system, without complicated control systems, functions uniformly throughout the range of engine load and incremental increases of power demand to provide efficient stable engine performance for a natural gas fired, internal combustion engine using EGR. A cogeneration system for supplying distributed generation of electricity and process / utility heat, employs a system for engine cooling and effective heat transfer to a cogeneration client, reduces engine head temperature, thereby reducing fuel consumption and reducing pollutants, as well as delivering substantially increased heat to a cogeneration process / utility heat facility by use of a carburetion system which employs at least a pair of spaced apart venturi positioned in series proximate one to another such that a first exhaust recycled gas venturi is upstream of a fuel venturi where fuel and air / exhaust gas are admixed prior to the resultant gas being introduced into a turbocharger. The distance between the exhaust venturi and fuel venturi is affective to provide a given amount of exhaust gas to air ratio prior to entering the fuel venturi inlet. Unexpectedly the spatial relationship between the two venturi, one to the other, affectively regulates exhaust gas air mixture, as well as the air / fuel / exhaust gas mixture to the engine by means solely of pressure increase and decrease (vacuum) of the engine intake system.

Owner:CHAPEAU

Two-cycle engine with forward scavenging air positioning and single-flow carburetor

InactiveUS6889637B2Avoid burnsGood effectMixing methodsCombustion-air/fuel-air treatmentCombustion chamberCarburetor

A two-cycle engine having forward scavenging is provided. Mixture drawn into the crankcase via a butterfly valve carburetor is conveyed into a combustion chamber via transfer channels in the cylinder. An air duct is connected via a controllable connection with a transfer channel to supply essentially fuel-free air thereto during a load state of the engine. To convey a fuel quantity adapted to drawn-in air during idling and partial load, yet during full throttle to achieve separated supply of air and mixture, a dividing wall extends in the direction of flow of air in the carburetor intake duct. In the pivot region of the butterfly valve, a connecting aperture in the dividing wall is closed in full throttle by a completely open butterfly valve. During idling and partial load the connecting aperture is open so that a uniform pressure can form in the intake duct in conformity with drawn-in air.

Owner:ANDREAS STIHL AG & CO KG

Carburetor automatic control system in engine

ActiveUS7331326B2Increase fuel consumptionElectrical controlLighting and heating apparatusAutomatic controlVacuum pressure

Owner:HONDA MOTOR CO LTD

Gaseous fuel and air mixing venturi device and method for carburetor

InactiveUS7410152B2Evenly dispersedEqually distributedThermal non-catalytic crackingInternal combustion piston enginesEngineeringCarburetor

A gaseous fuel and air mixing venturi device adapted for retrofitting in a carburetor has a venturi body with a passage for air flow through the body, the passage having a throat of reduced cross-sectional area. The body has an axial fuel inlet port at a first end and fuel supply ports connected to the fuel inlet port and spaced around the throat for supplying fuel to the air flow passage for mixing with air flowing through the passage. The first end of the venturi body has mating seating formations for seating against corresponding seating surfaces of a gaseous fuel carburetor after removal of a spring mass air / fuel mixing section, and a fastener mechanism for releasably securing the venturi body in the carburetor, with the fuel supply port of the carburetor connected to the fuel inlet port of the venturi body.

Owner:CONTINENTAL CONTROLS CORP

Evaporative emissions control system for small internal combustion engines

InactiveUS7165536B2Prevent escapeQuantity minimizationNon-fuel substance addition to fuelMulti-stage carburettorsExternal combustion engineAtmospheric air

An evaporative emissions control system for small internal combustion engines. The system generally includes a charcoal canister and a carburetor with a fuel circuit shutoff valve. The charcoal canister is in fluid communication with the air space above the liquid fuel within the engine fuel tank, and optionally, with the air space above the liquid fuel within the fuel bowl of a fuel bowl-type carburetor. The charcoal canister contains charcoal media which absorbs fuel vapors when the engine is not running. During running of the engine, vacuum within the carburetor induces a flow of atmospheric air through the charcoal canister to purge the collected fuel vapors from the charcoal media, and the fuel vapors pass into the engine for consumption. The carburetor of the engine, which may be either a fuel bowl-type carburetor or a diaphragm carburetor, includes a fuel circuit shutoff valve controlled either by a vacuum signal produced within the engine or by a user-actuated mechanical linkage. The fuel circuit shutoff valve closes the fuel circuit of the carburetor upon engine shutdown to prevent escape of fuel vapors from the carburetor to the atmosphere. In another embodiment, a weir-type carburetor is disclosed which contains a minimal amount of fuel when the engine is not running to reduce or eliminate evaporative emissions.

Owner:CERTIFIED PARTS

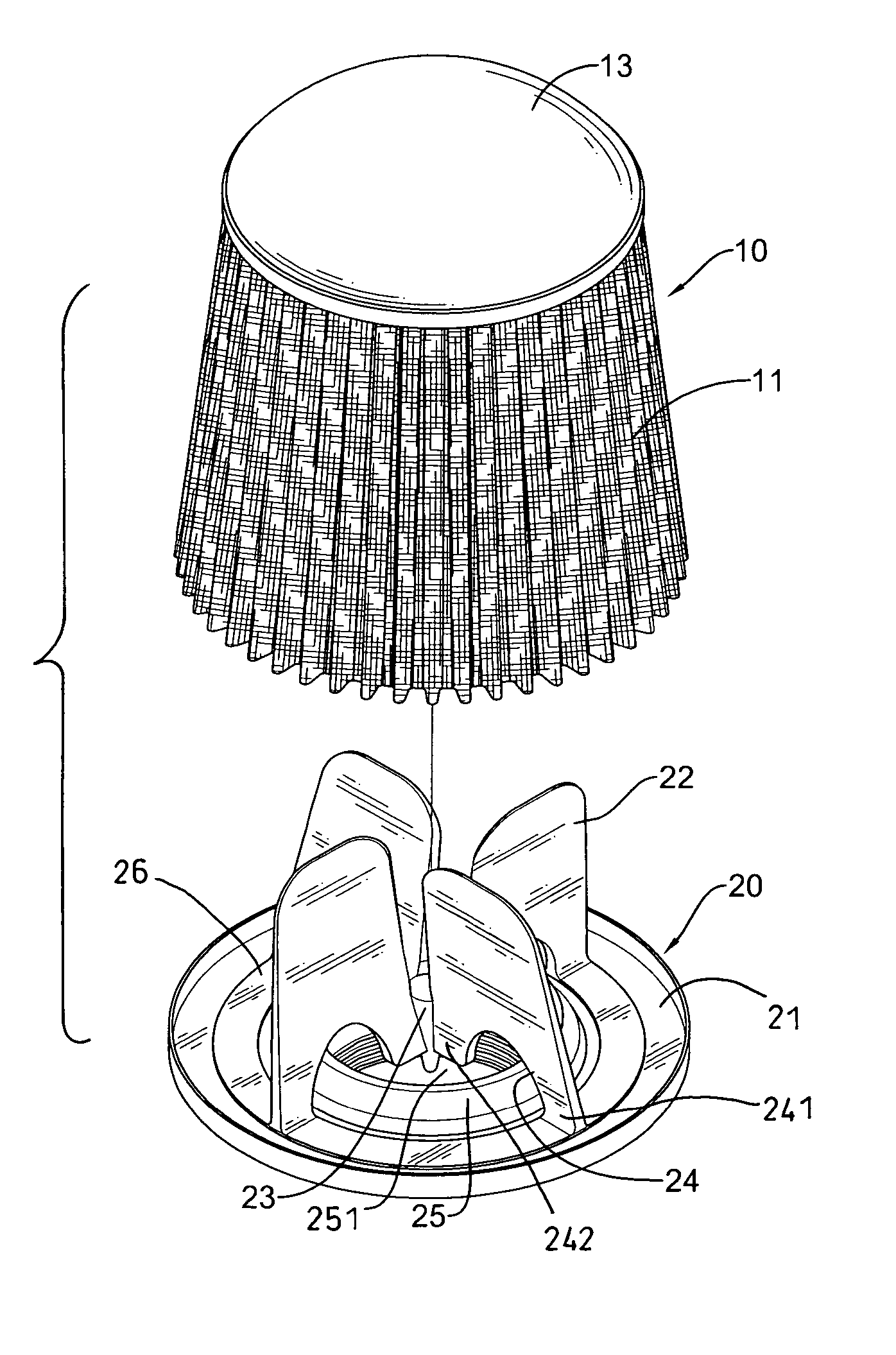

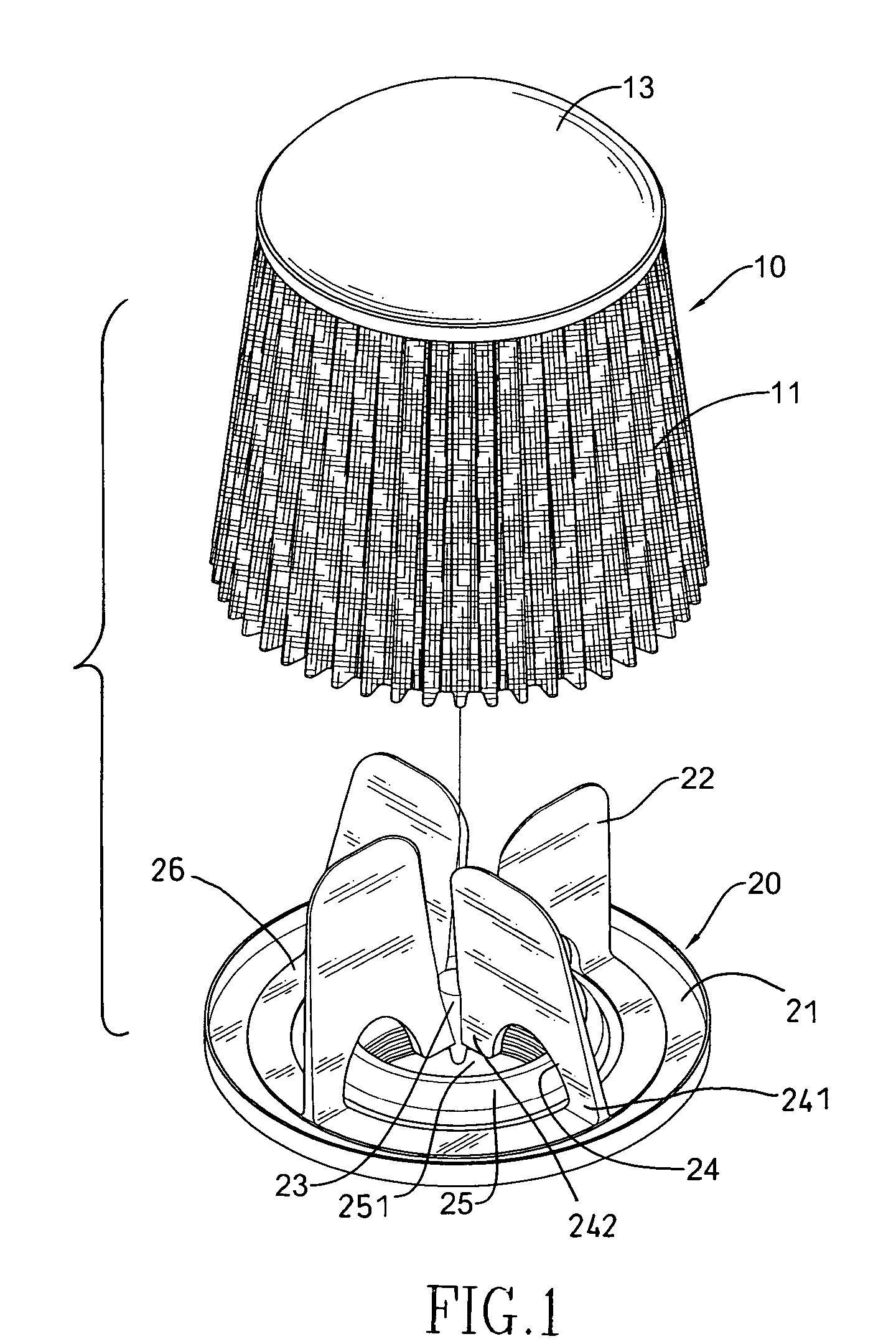

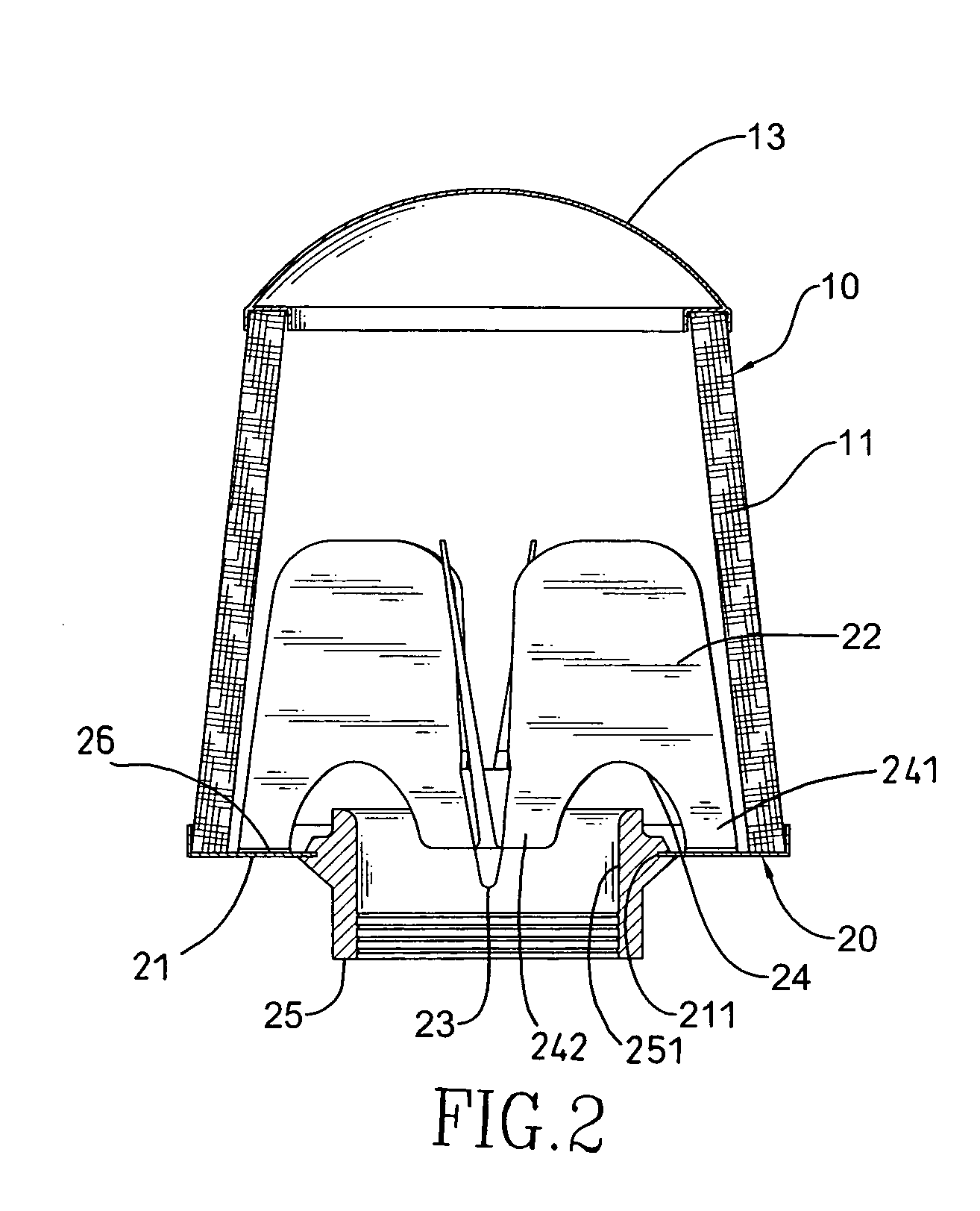

Air filter for an internal combustion engine

An air filter includes a filter assembly and a base frame assembly. The filter assembly connects to the base frame assembly and filters particles from air prior to the air entering an internal combustion engine. The base frame assembly includes a base ring, a connecting bracket and an inner frame. The base ring has a ring configuration with a central through hole. The connecting bracket is mounted and held in the central through hole and has a clean air outlet, such as a through hole. The inner frame is mounted on the base ring over the through hole of the connecting bracket to spin clean air with powerful spinning currents to mix the clean air coming out of the clean air outlet with atomized fuel sprayed into the carburetor. Therefore, the well mixed air-fuel mixture will increase the gasoline engine performance.

Owner:CHANG YUNG YU

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com