Patents

Literature

751 results about "Critical current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

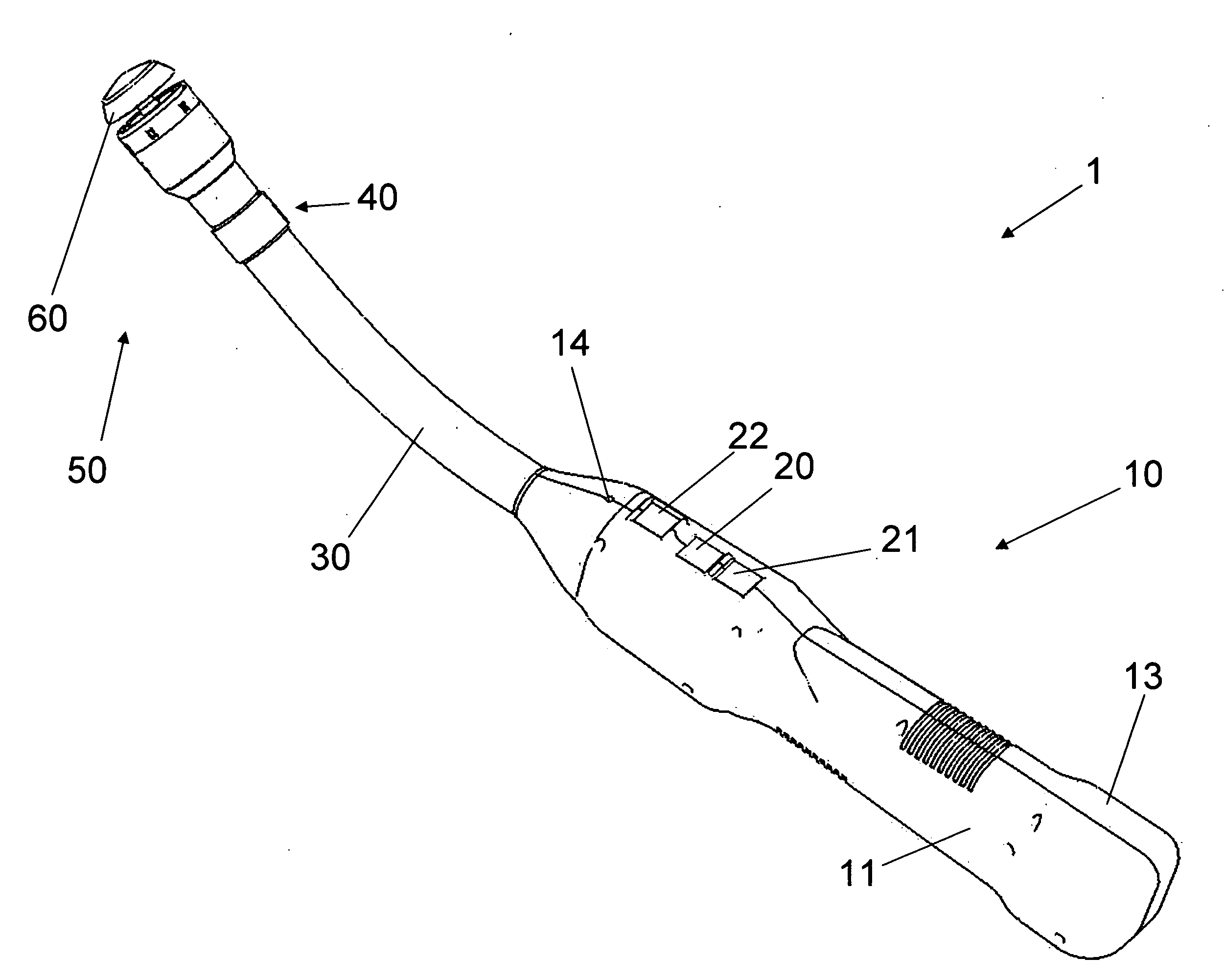

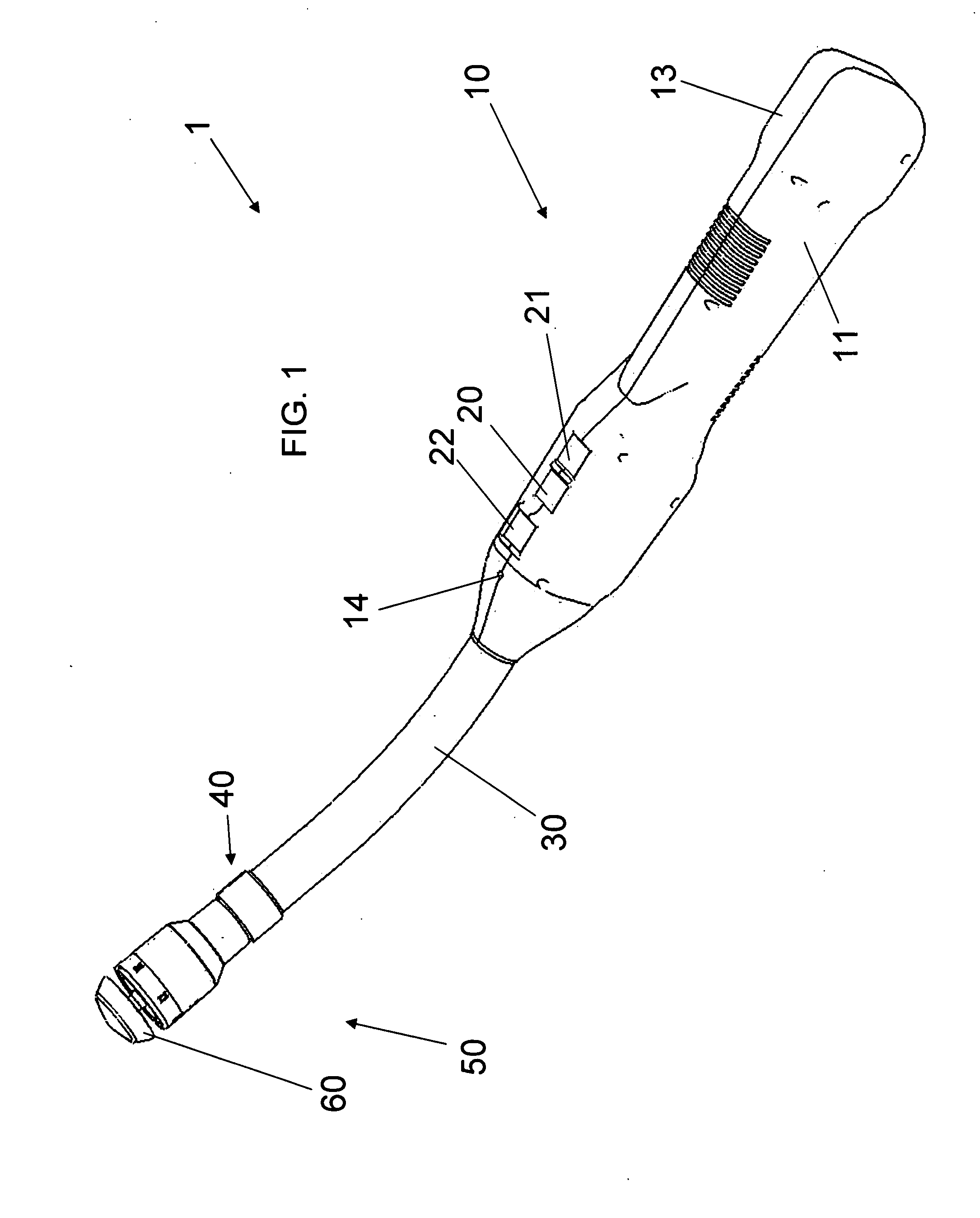

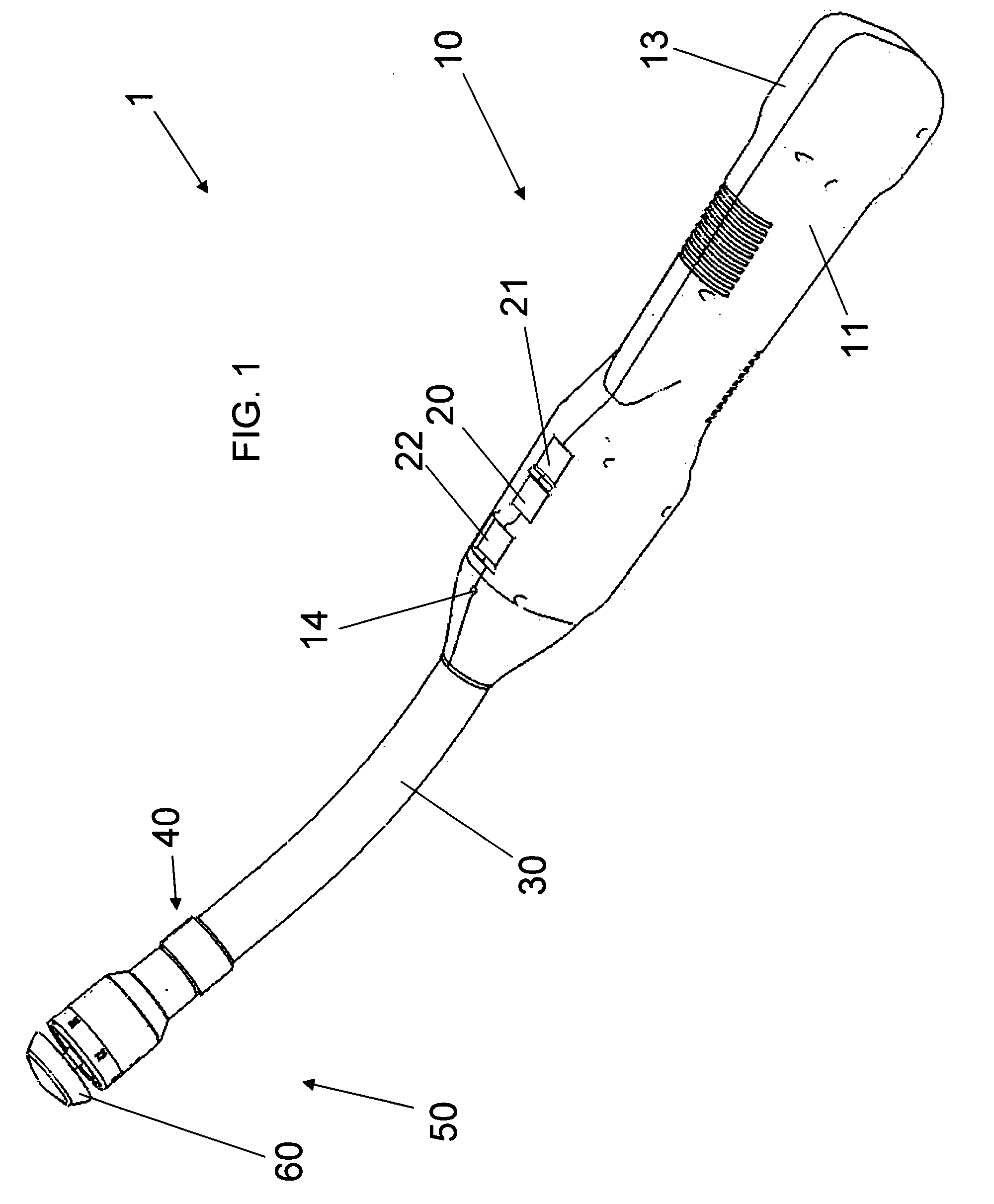

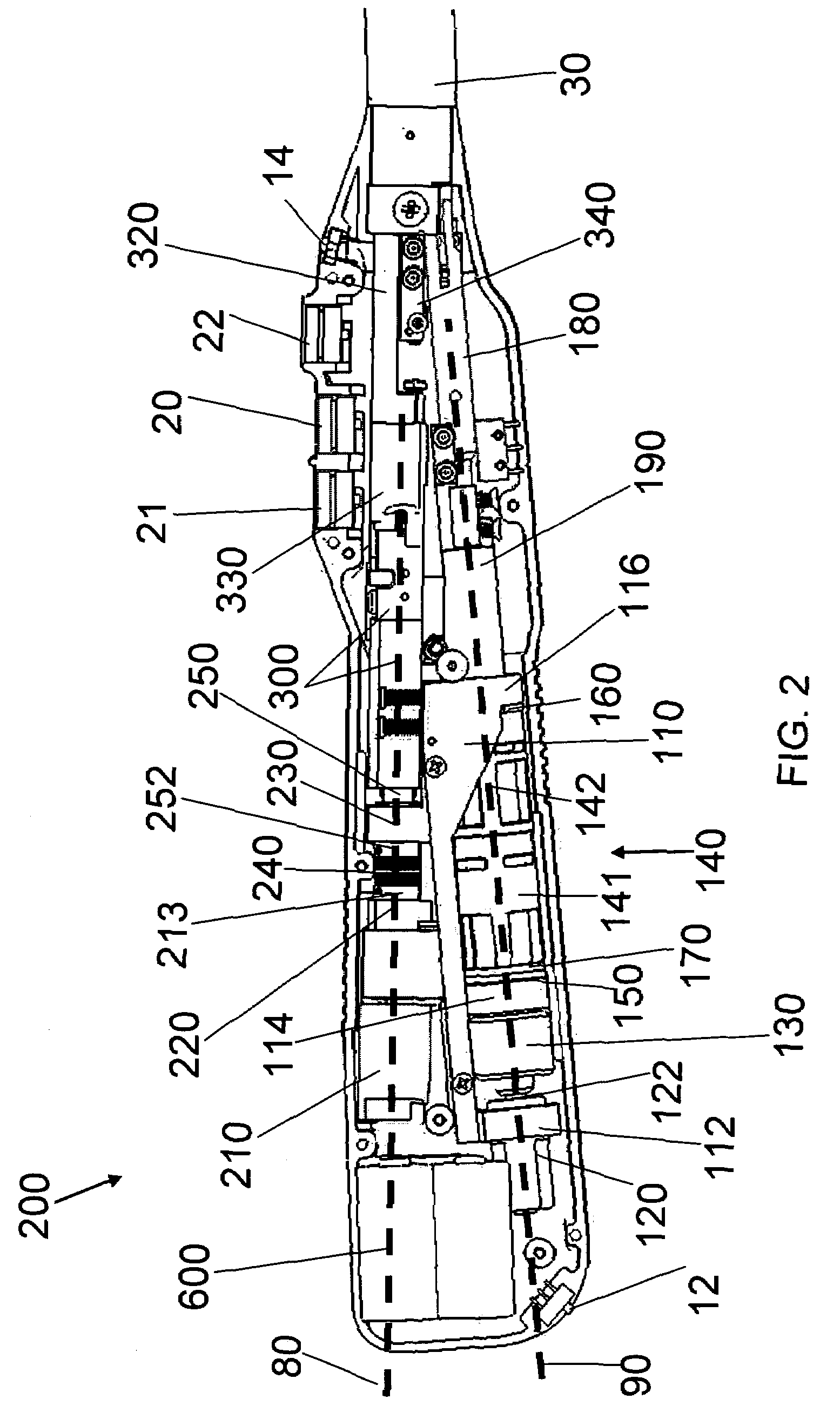

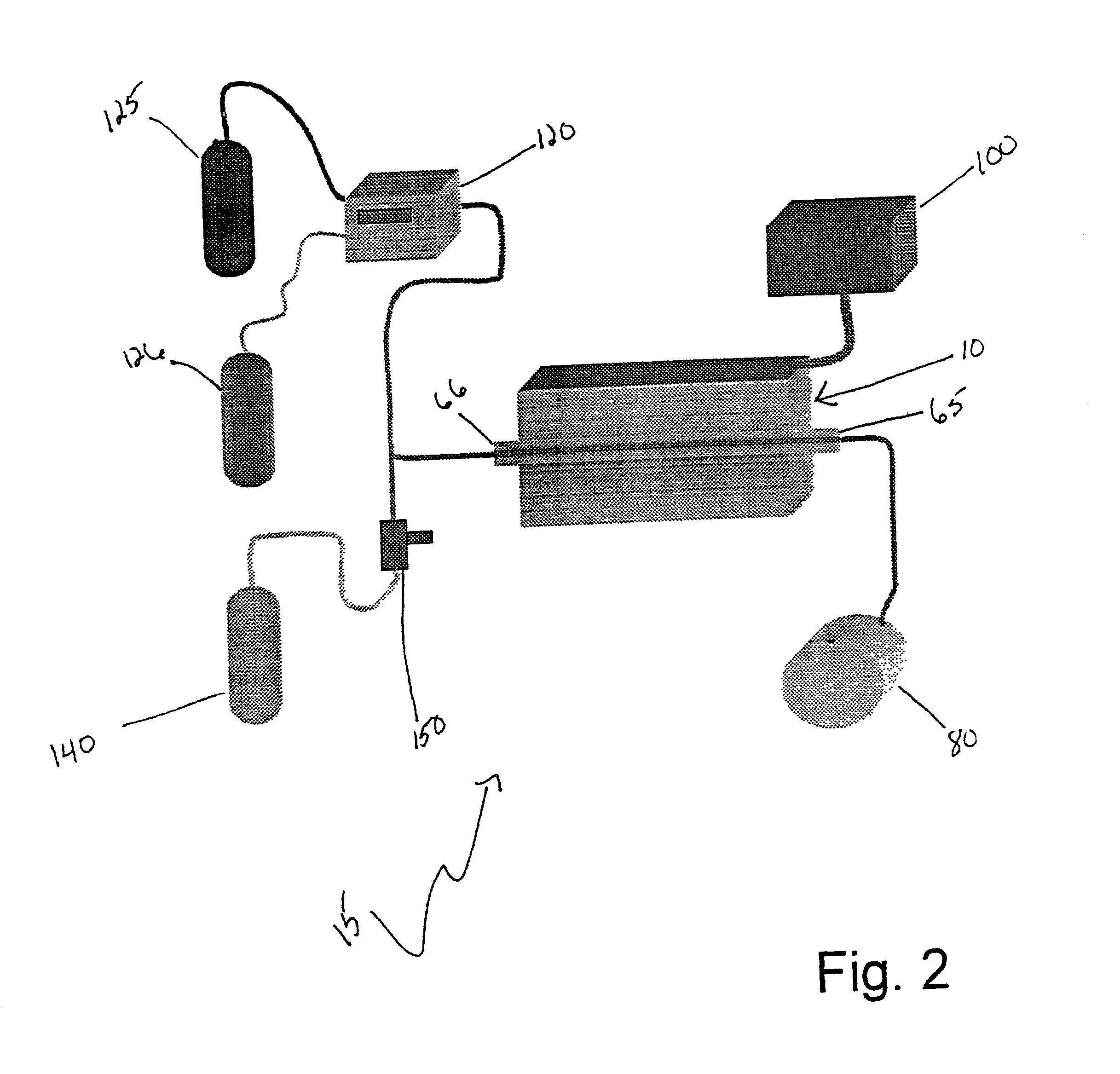

Electric surgical instrument with optimized power supply and drive

ActiveUS20070270784A1Comfortably fit into a user's handReduce manufacturing difficultySuture equipmentsStapling toolsAverage currentActuator

A surgical instrument includes a surgical end effector having at least one actuation assembly to effect a surgical procedure when actuated, an electric motor operationally connected to the end effector to operate the at least one actuation assembly, and a power supply electrically connected to the motor and selectively powering the motor to actuate the actuation assembly. The power supply has a battery cell with a critical current rate and, when activated to power the motor and actuate the actuation assembly, operates the cell at a super-critical current rate or at an average current rate above the critical current rate. The power supply selectively powers the motor to actuate the assembly less than 16 times during a clinical life of at least one of the end effector, the motor, and the power supply. When actuated, the assembly operates only between 0.5 seconds and 16 seconds in duration.

Owner:CILAG GMBH INT

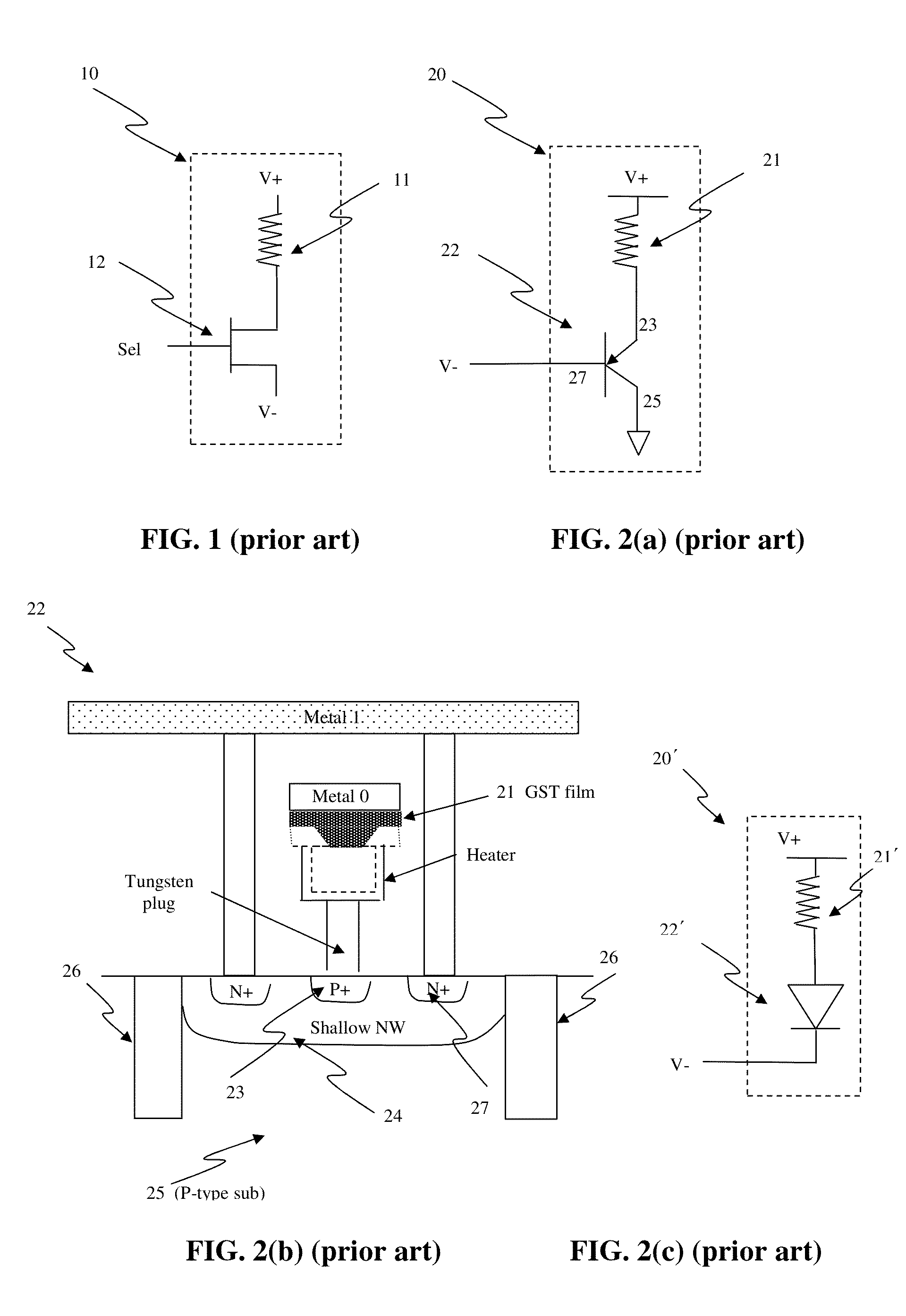

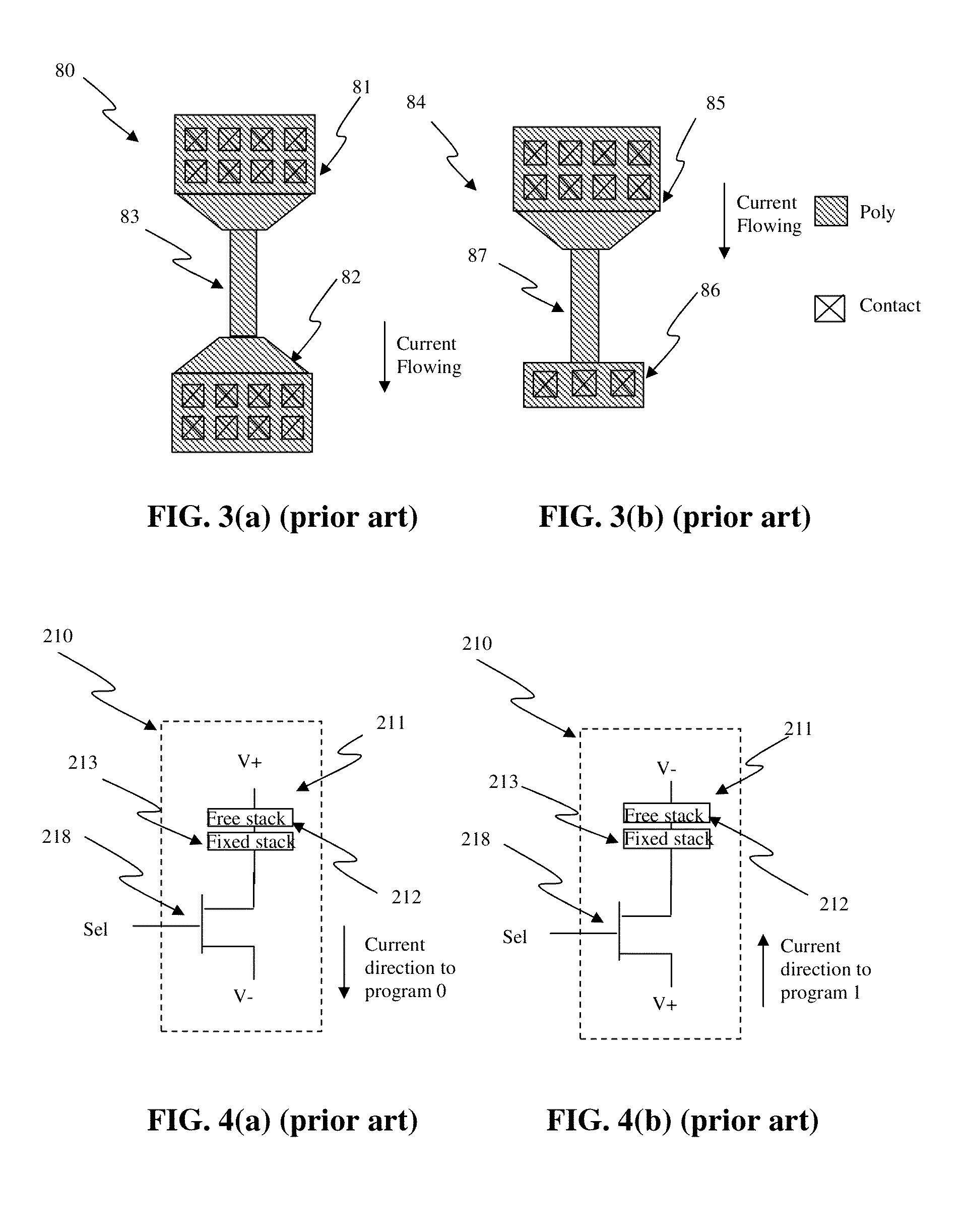

High performance MTJ element for STT-RAM and method for making the same

ActiveUS20090027810A1Low angular dispersionEasy to operateNanomagnetismMagnetic-field-controlled resistorsSpin angular momentum of lightDamping factor

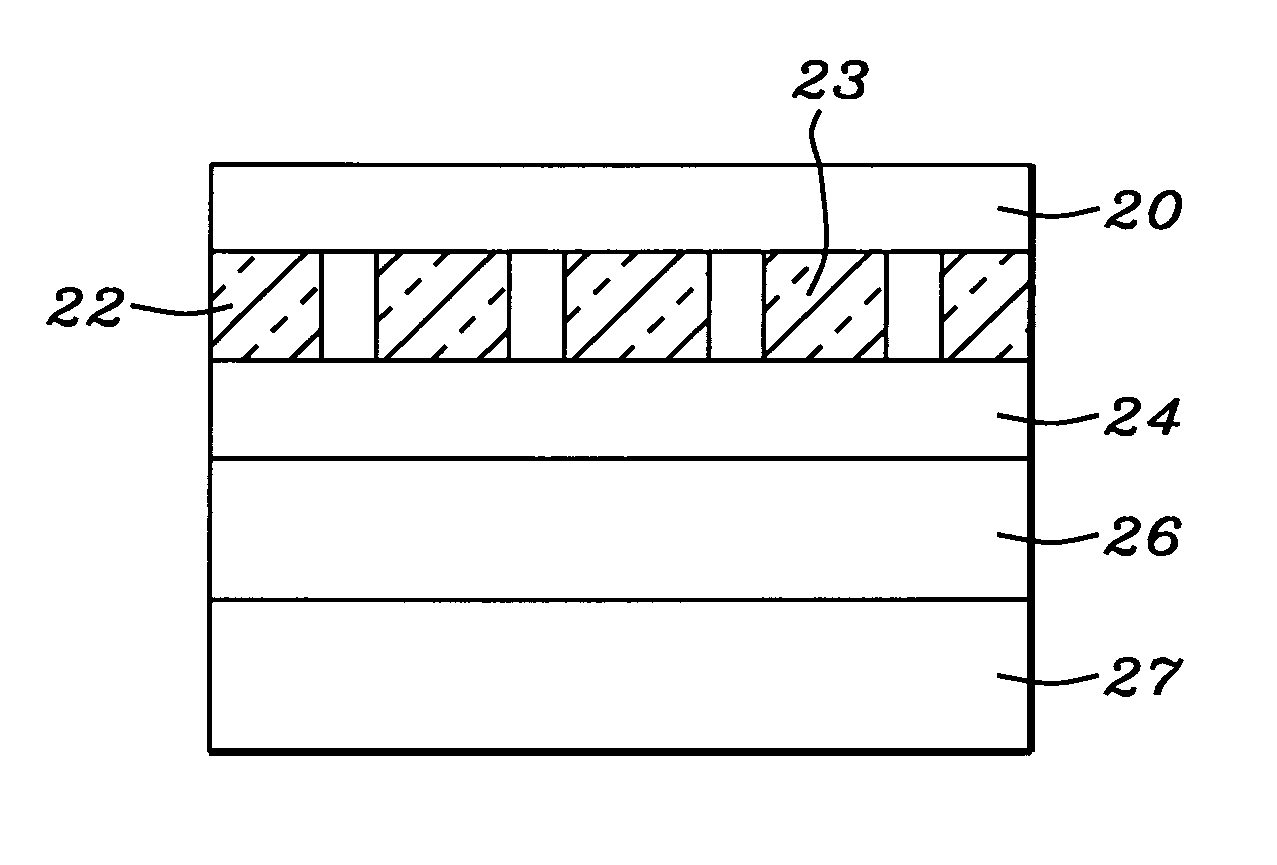

We describe the structure and method of forming a STT-MTJ MRAM cell that utilizes transfer of spin angular momentum as a mechanism for changing the magnetic moment direction of a free layer. The device includes an IrMn pinning layer, a SyAP pinned layer, a naturally oxidized, crystalline MgO tunneling barrier layer that is formed on an Ar-ion plasma smoothed surface of the pinned layer and, in one embodiment, a free layer that comprises an amorphous layer of Co60Fe20B20. of approximately 20 angstroms thickness formed between two crystalline layers of Fe of 3 and 6 angstroms thickness respectively. The free layer is characterized by a low Gilbert damping factor and by very strong polarizing action on conduction electrons. The resulting cell has a low critical current, a high dR / R and a plurality of such cells will exhibit a low variation of both resistance and pinned layer magnetization angular dispersion.

Owner:TAIWAN SEMICON MFG CO LTD

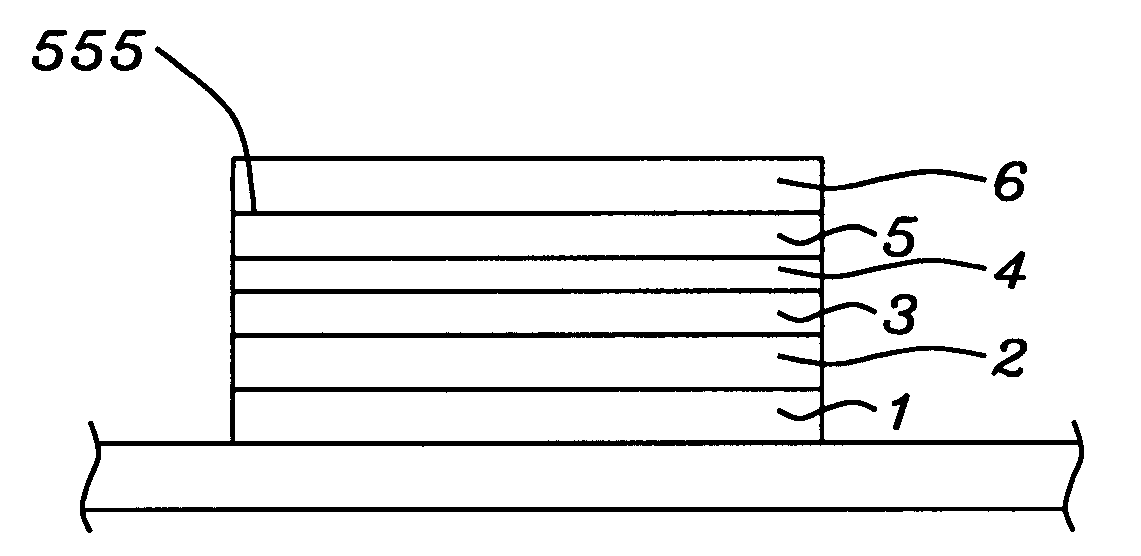

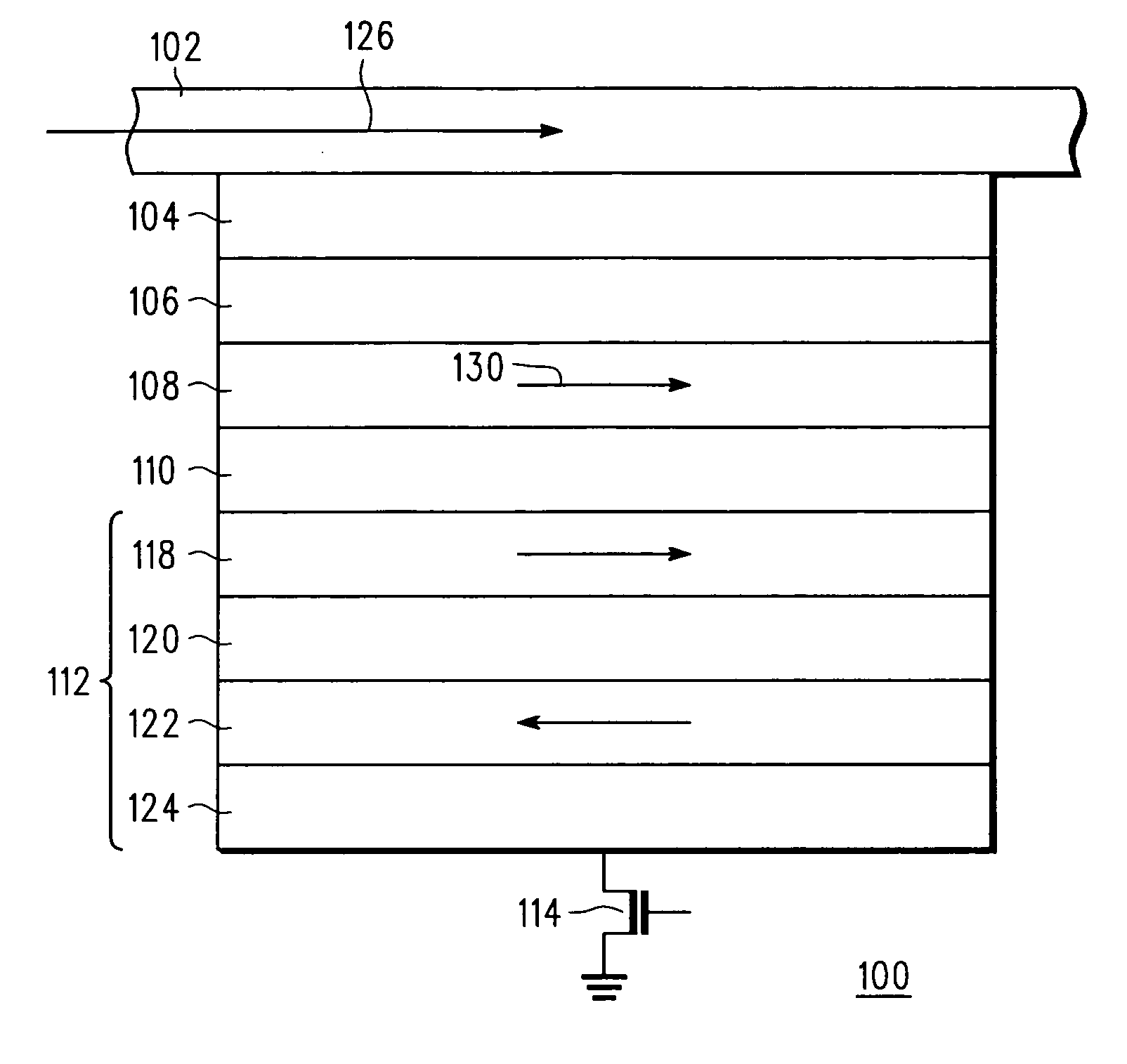

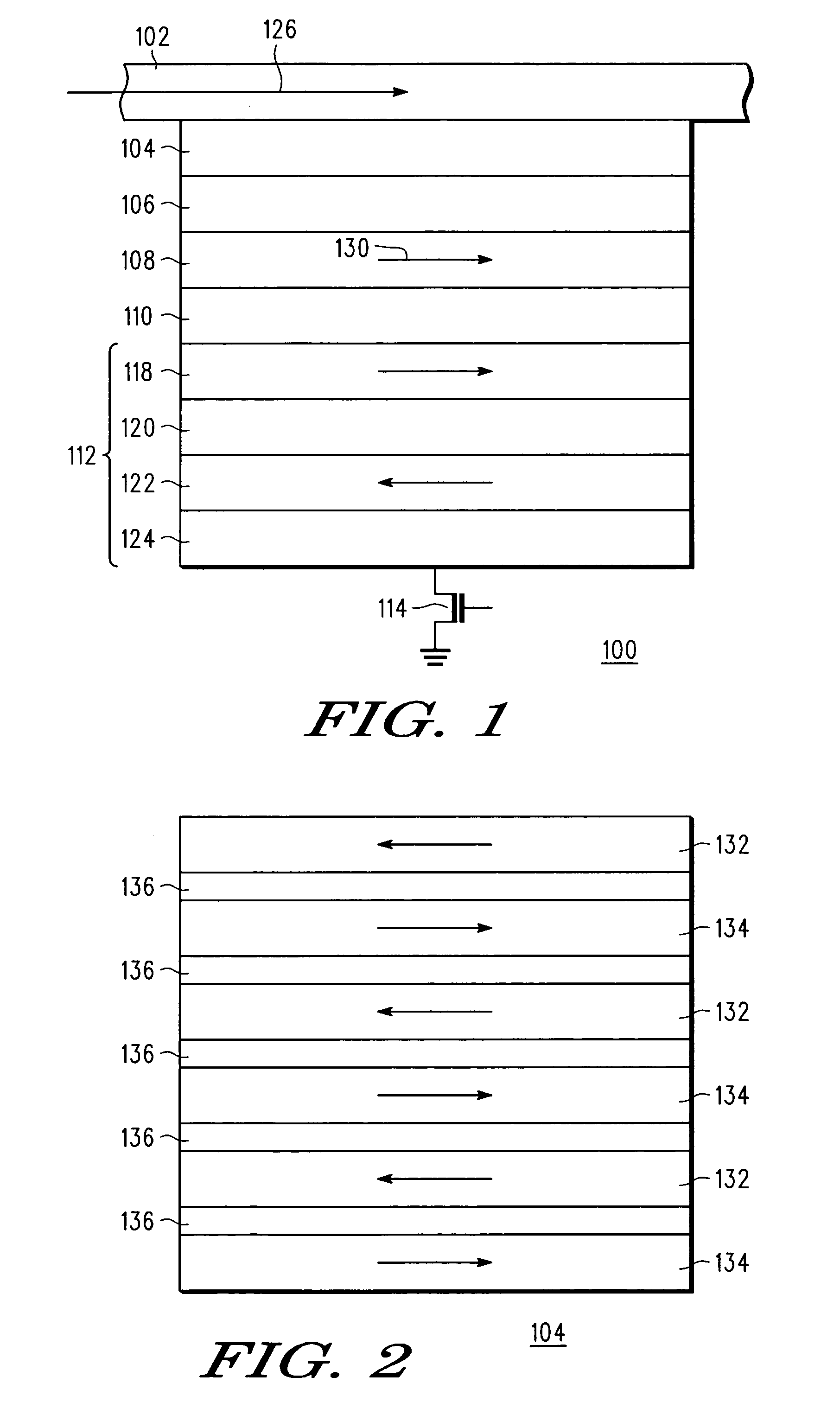

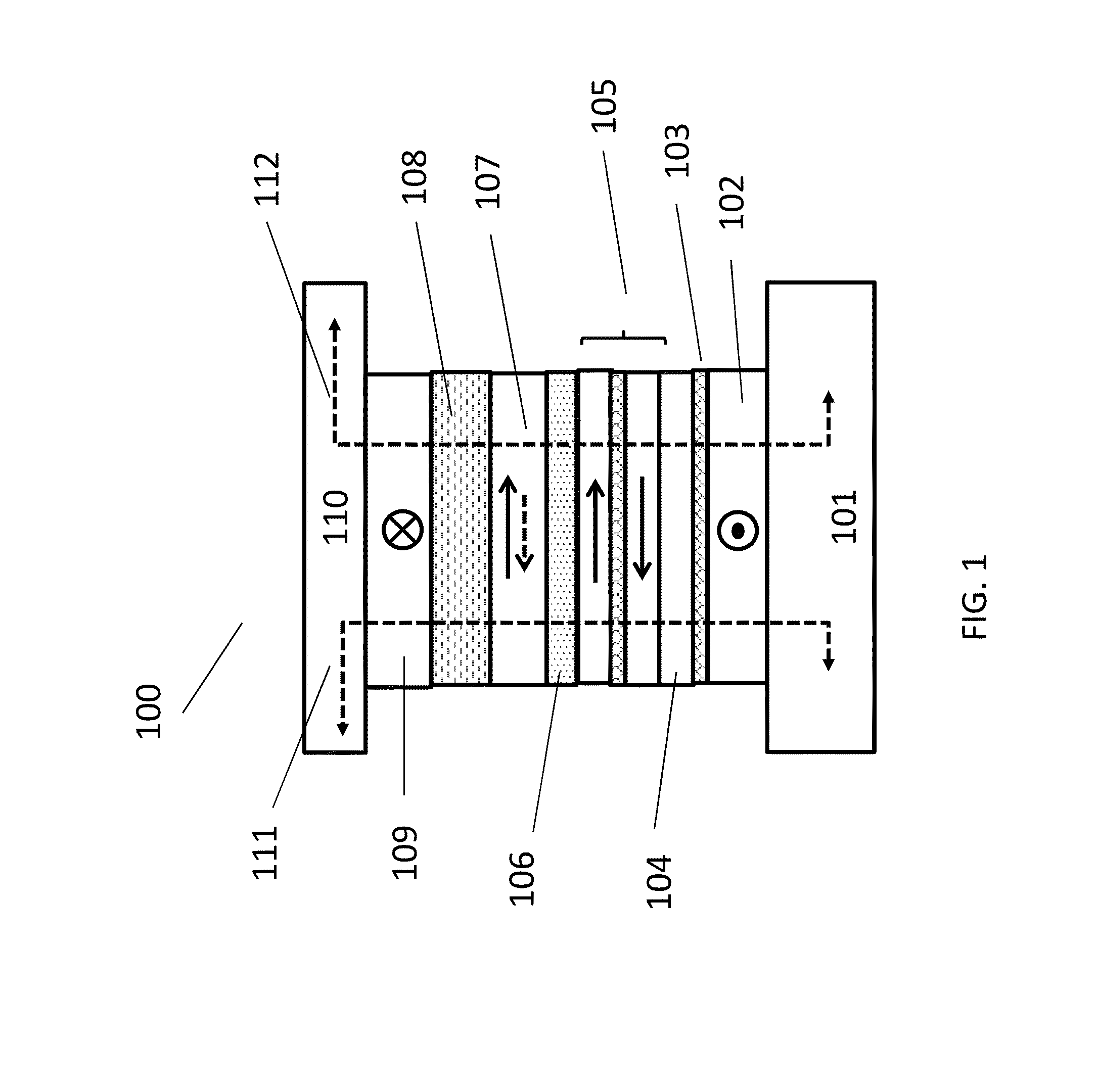

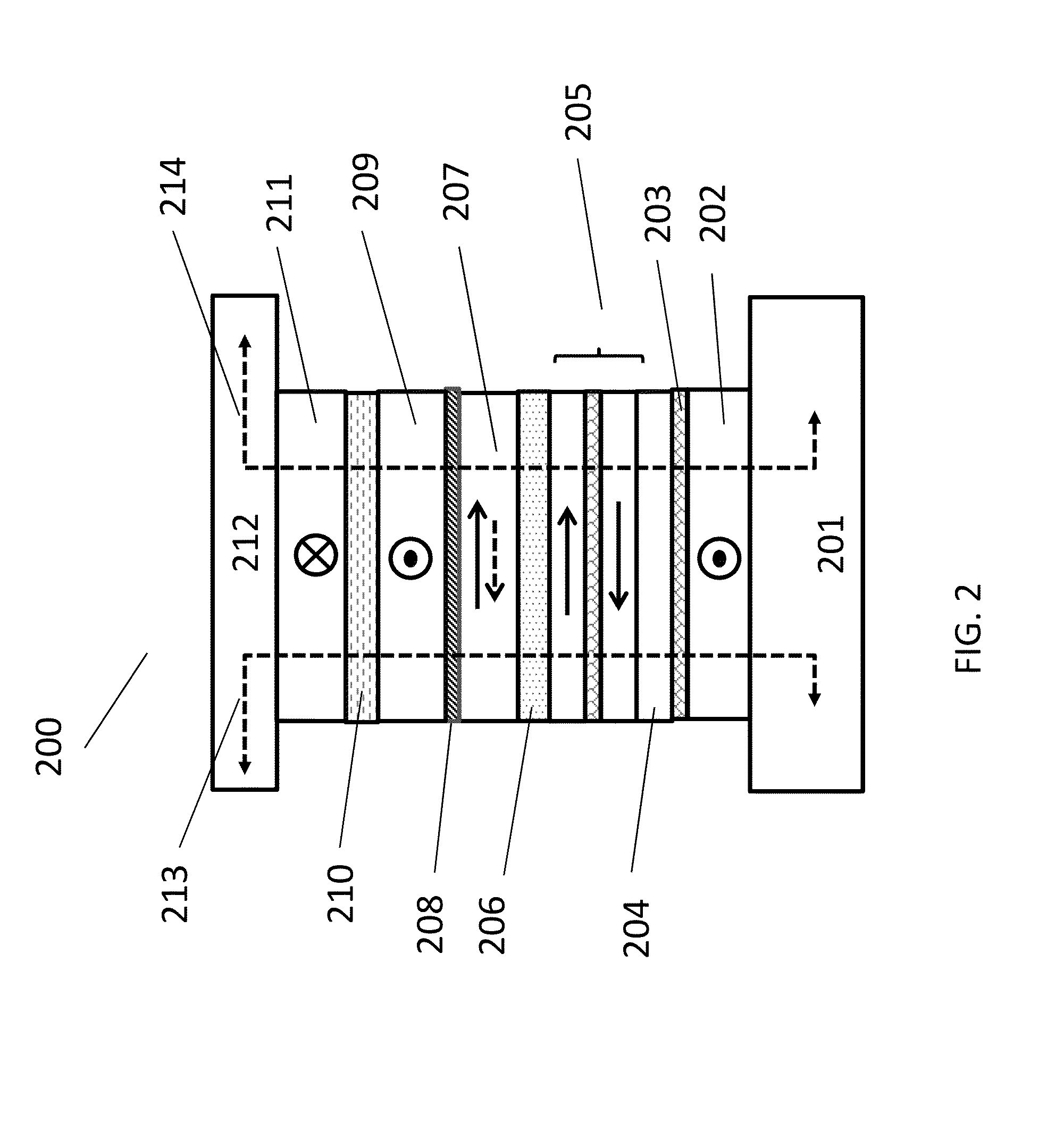

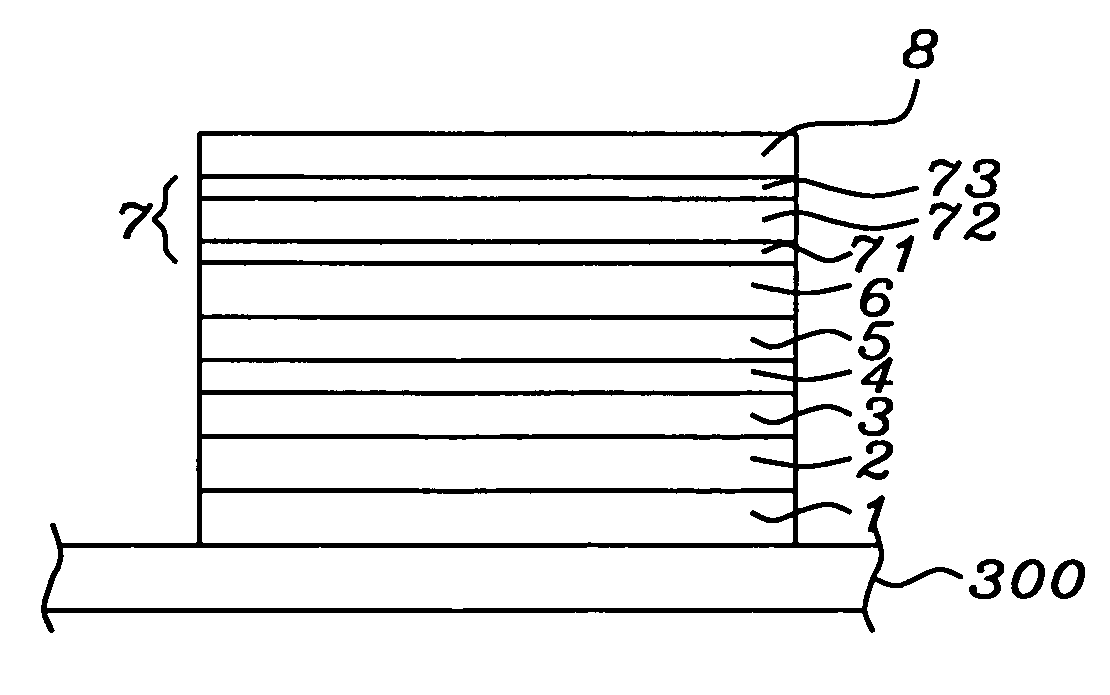

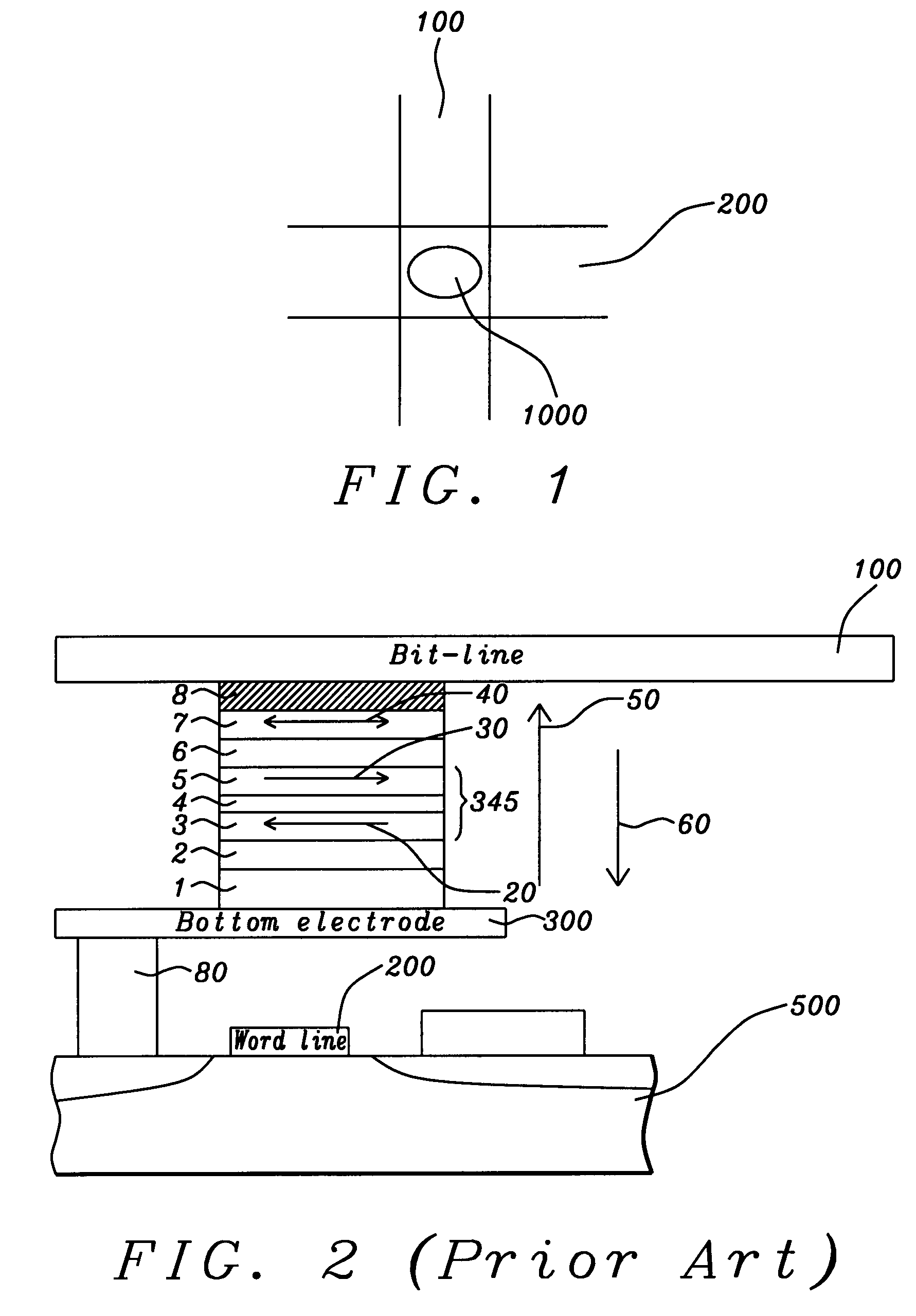

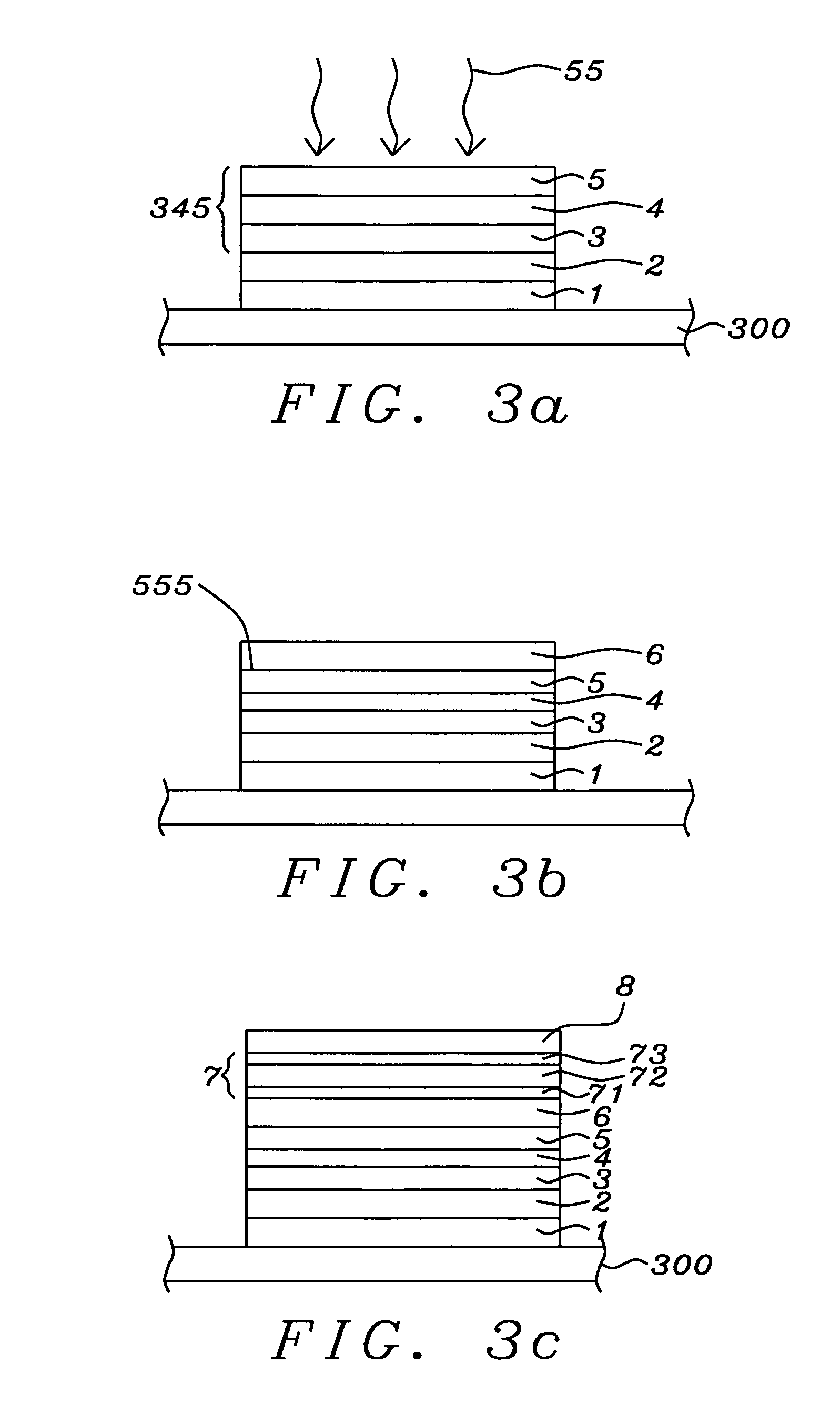

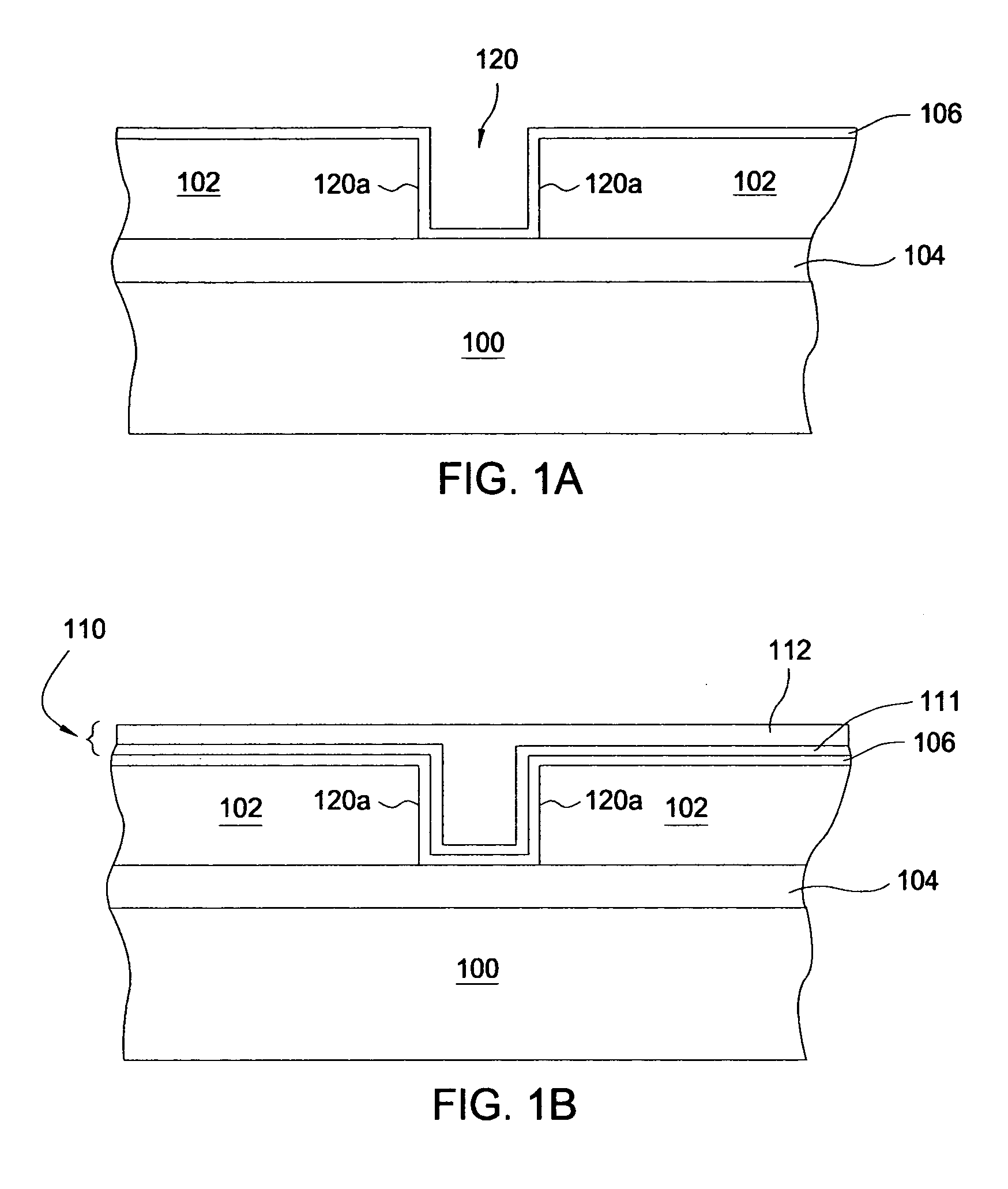

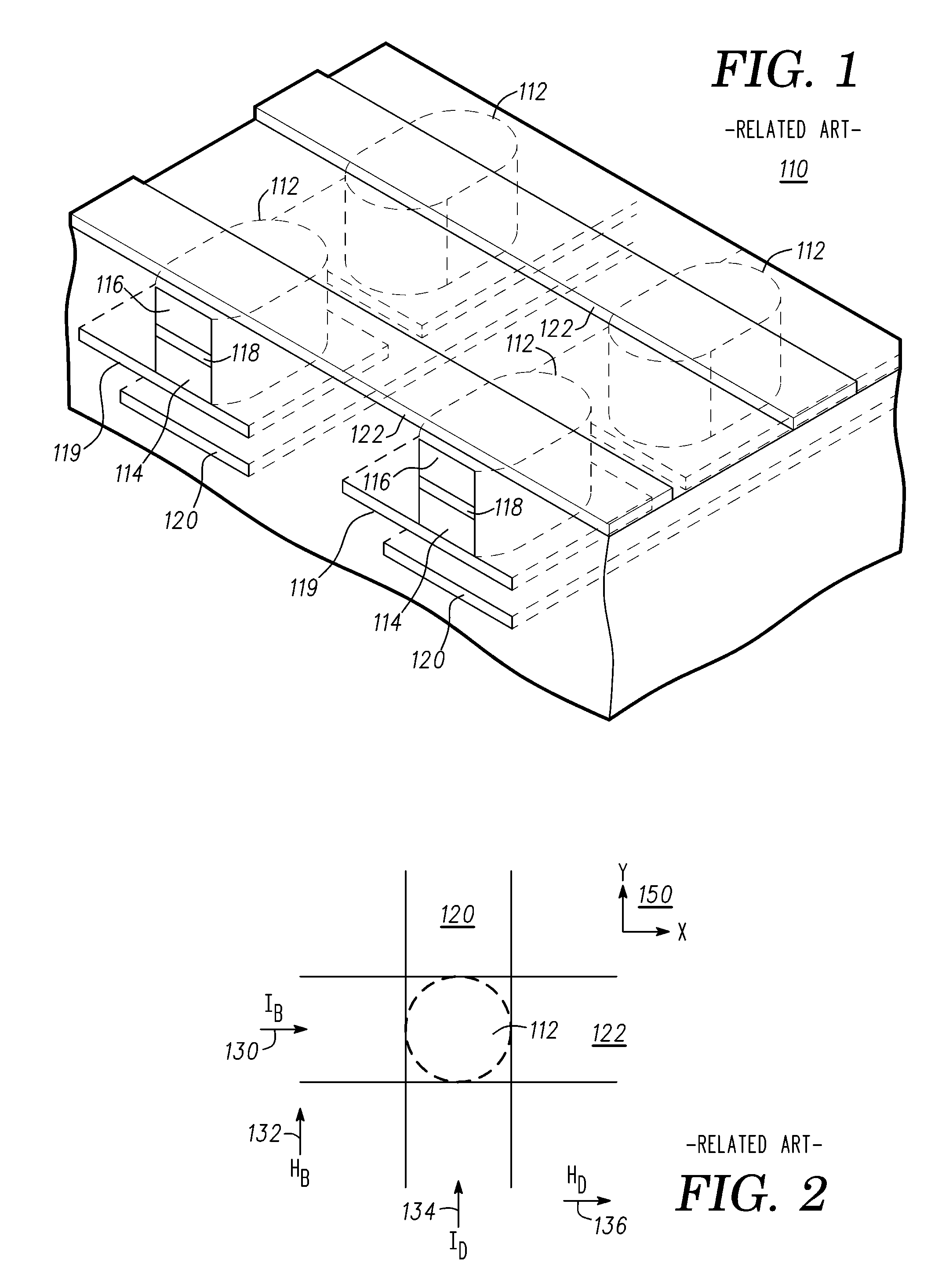

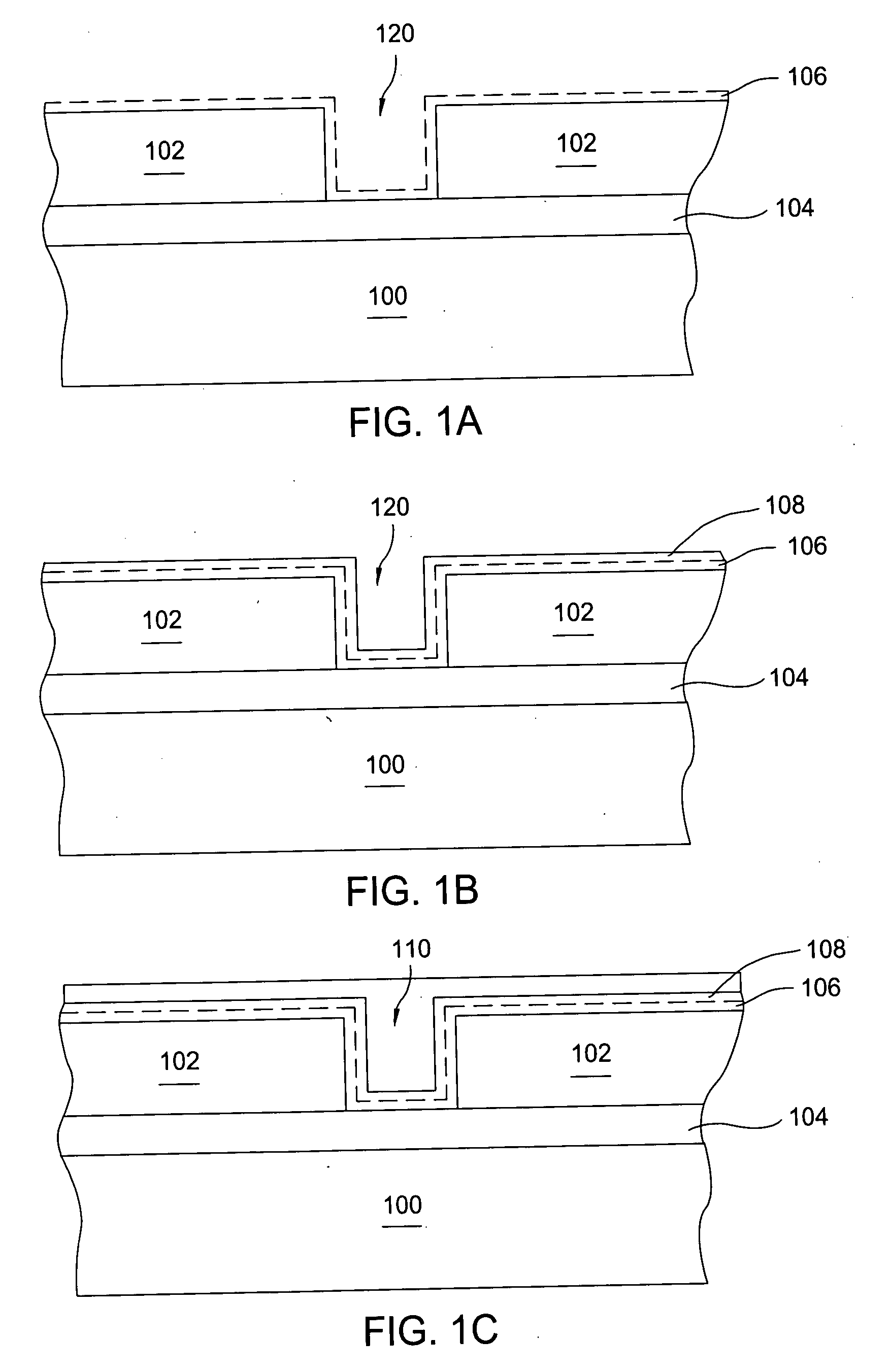

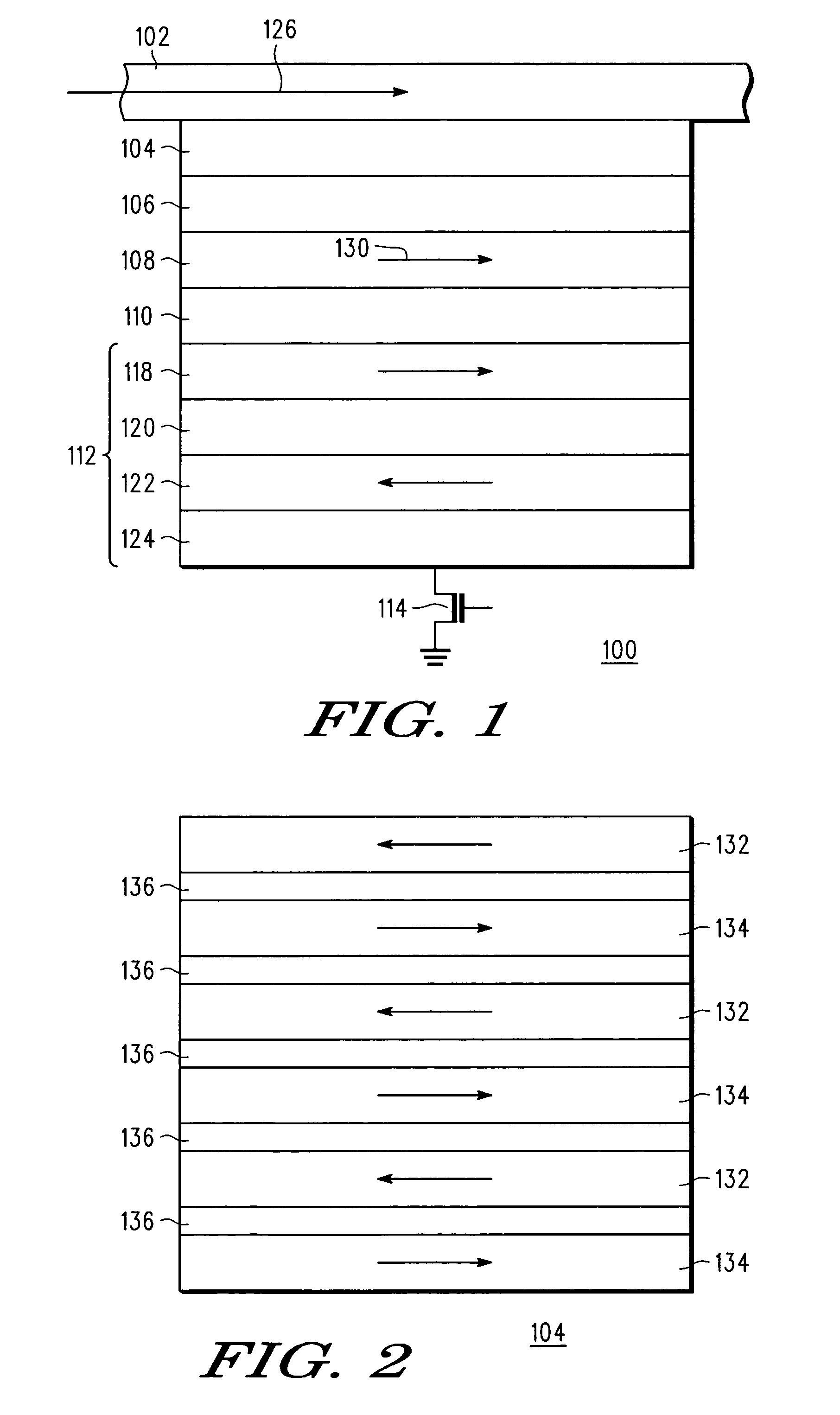

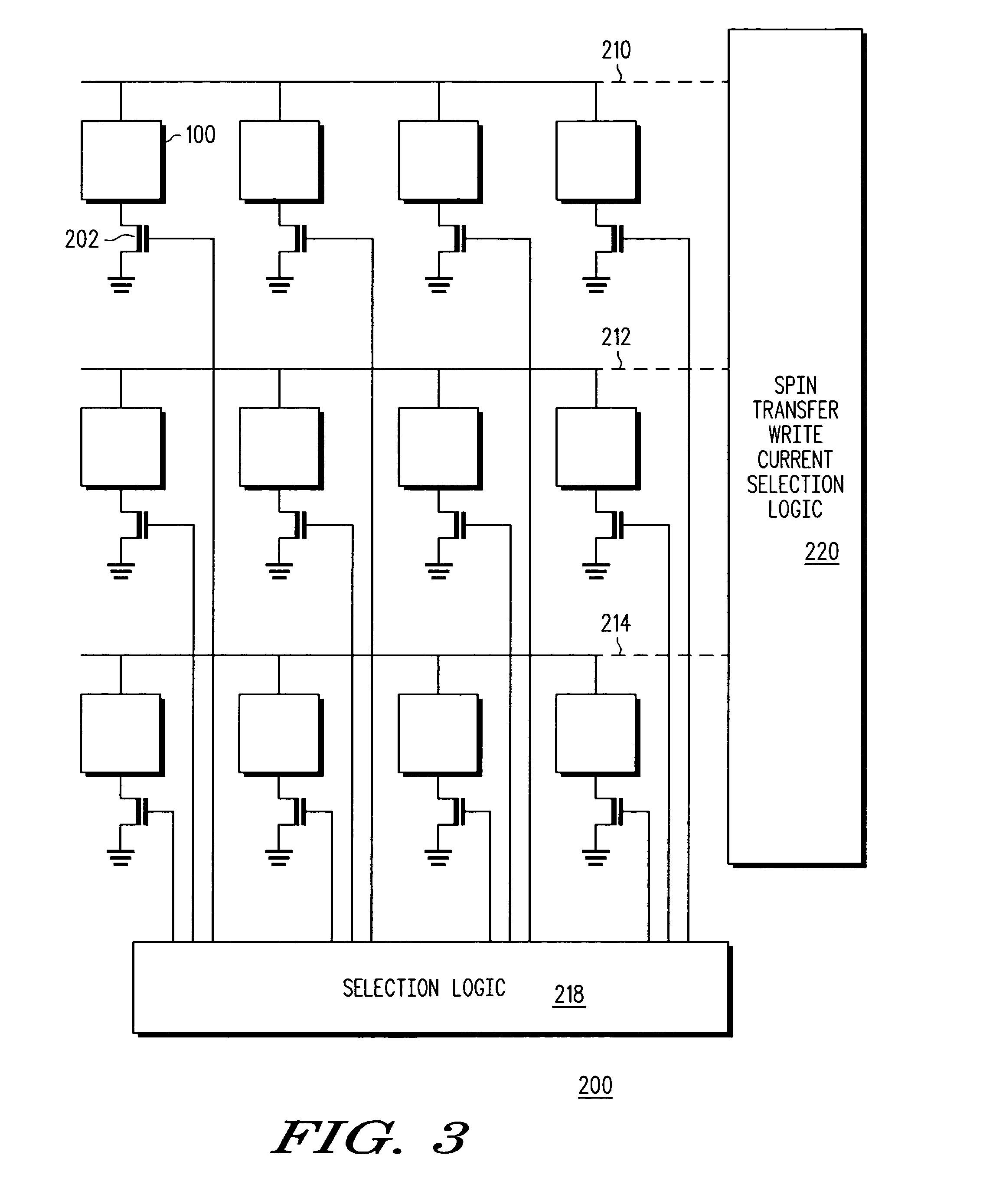

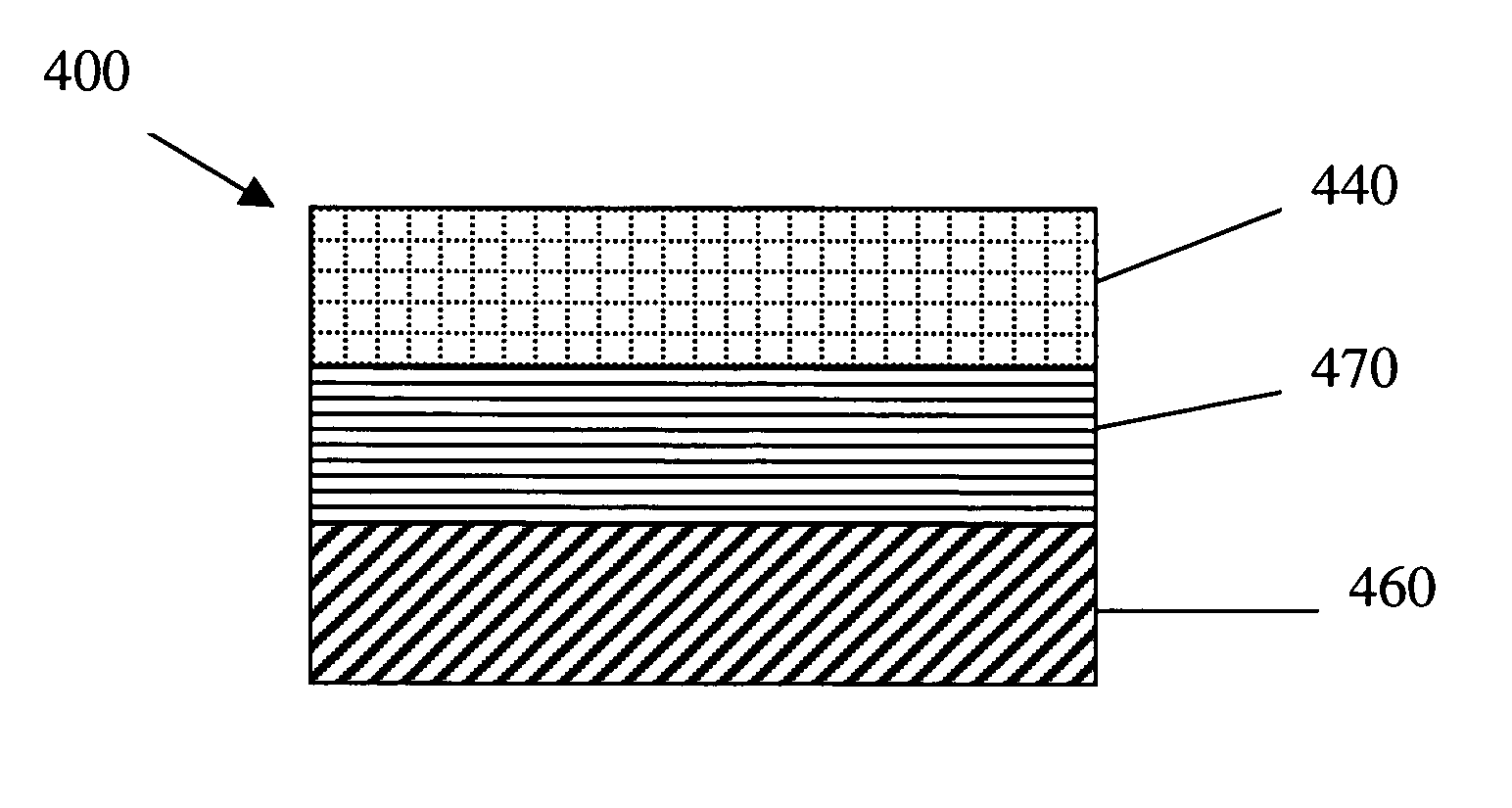

Spin-transfer based MRAM with reduced critical current density

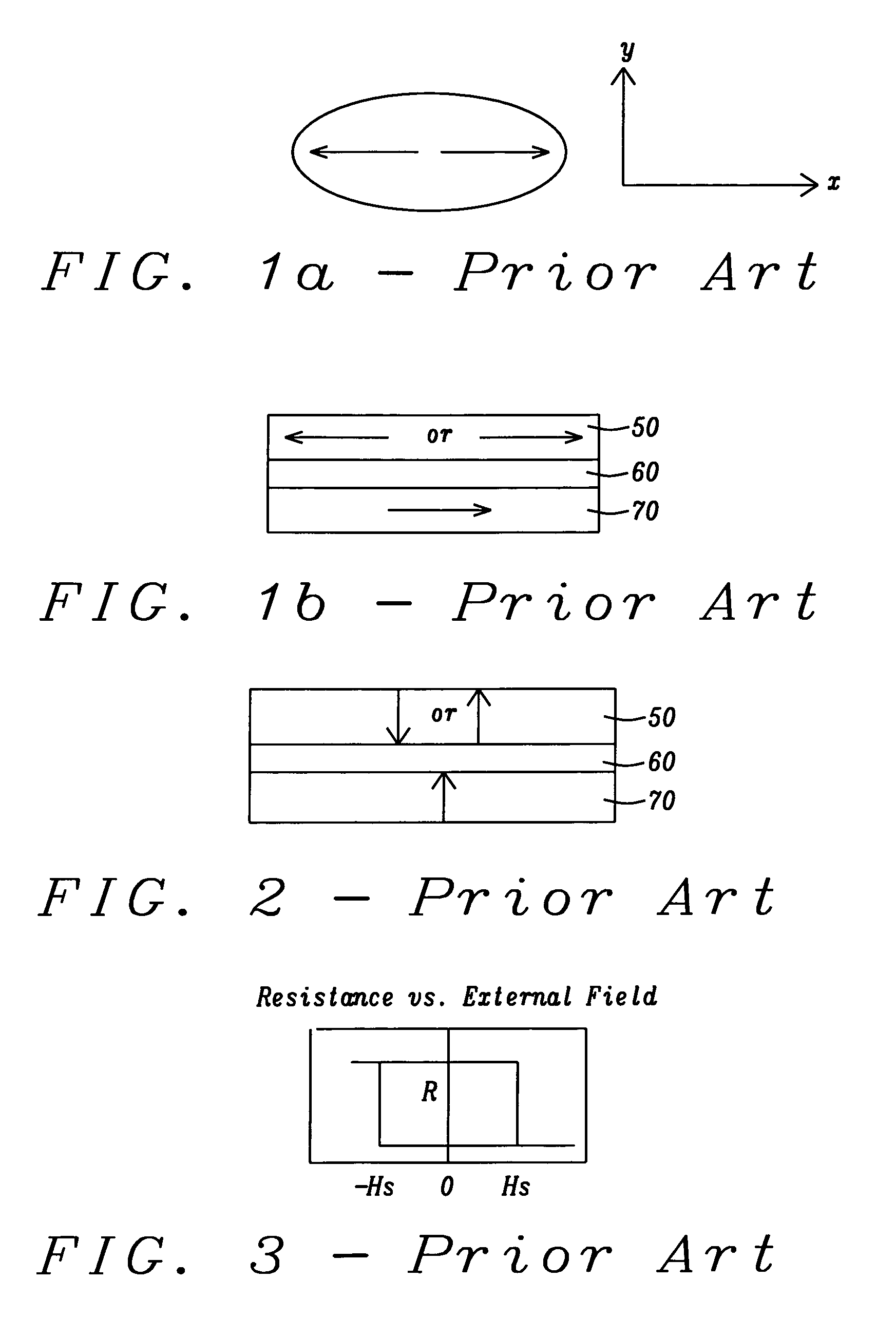

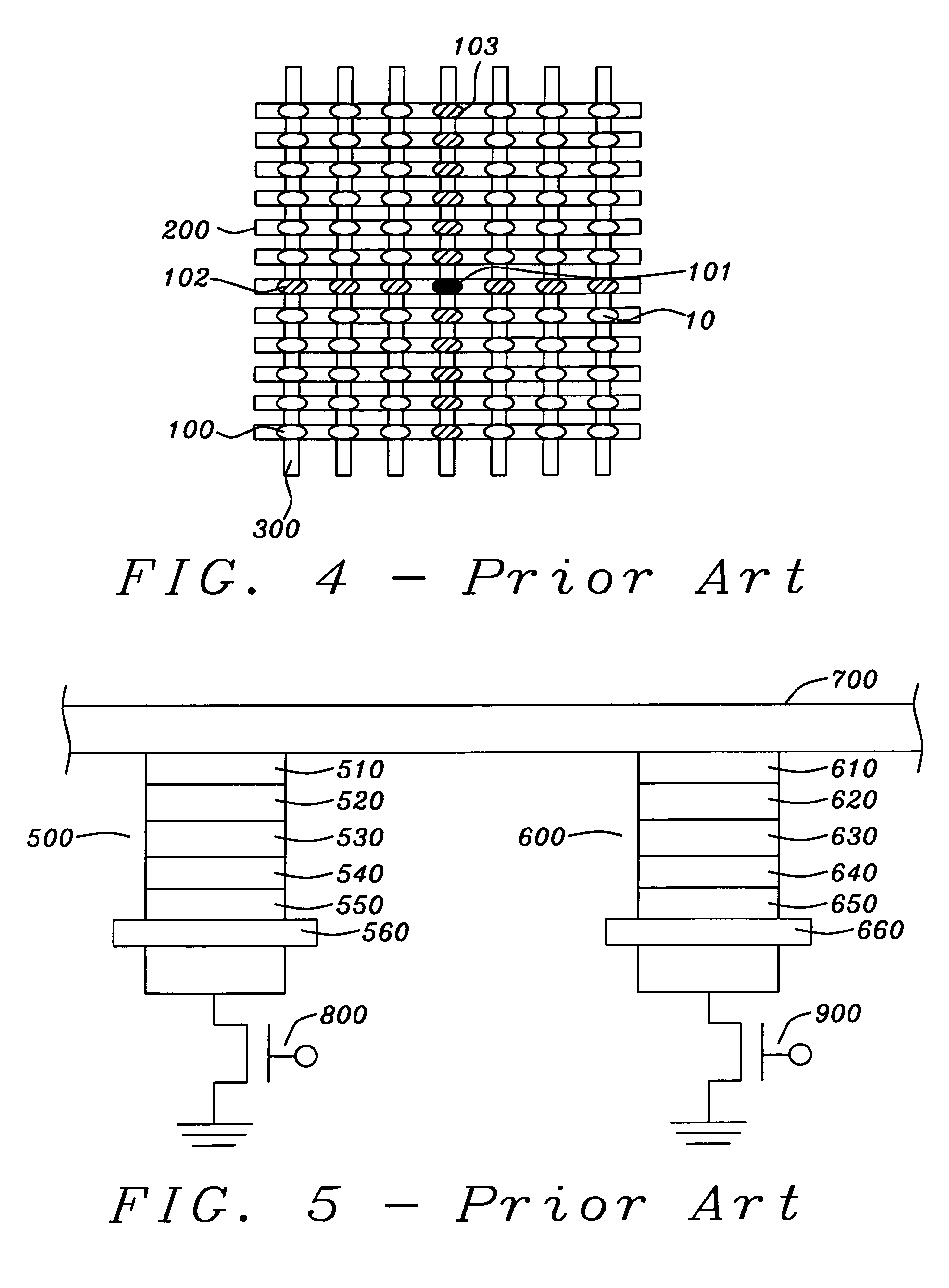

A magnetic random access memory device comprises a spin torque MRAM cell (100) having a reduced switching current (Ic) wherein standard materials may be used for a free layer (108). A fixed magnetic element (112) polarizes electrons passing therethrough, and the free magnetic element (108) having a first plane anisotropy comprises a first magnetization (130) whose direction is varied by the spin torque of the polarized electrons. An insulator (110) is positioned between the fixed magnetic element (112) and the free magnetic element (108), and a keeper layer (104) positioned contiguous to the free magnetic element (108) and having a second plane anisotropy orthogonal to the first plane anisotropy, reduces the first plane anisotropy and hence reduces the spin torque switching current (Ic). The keeper layer (104) may comprise alternating synthetic antiferromagnetic layers (132, 134) of magnetization approximately equal in magnitude and opposite in direction.

Owner:EVERSPIN TECHNOLOGIES

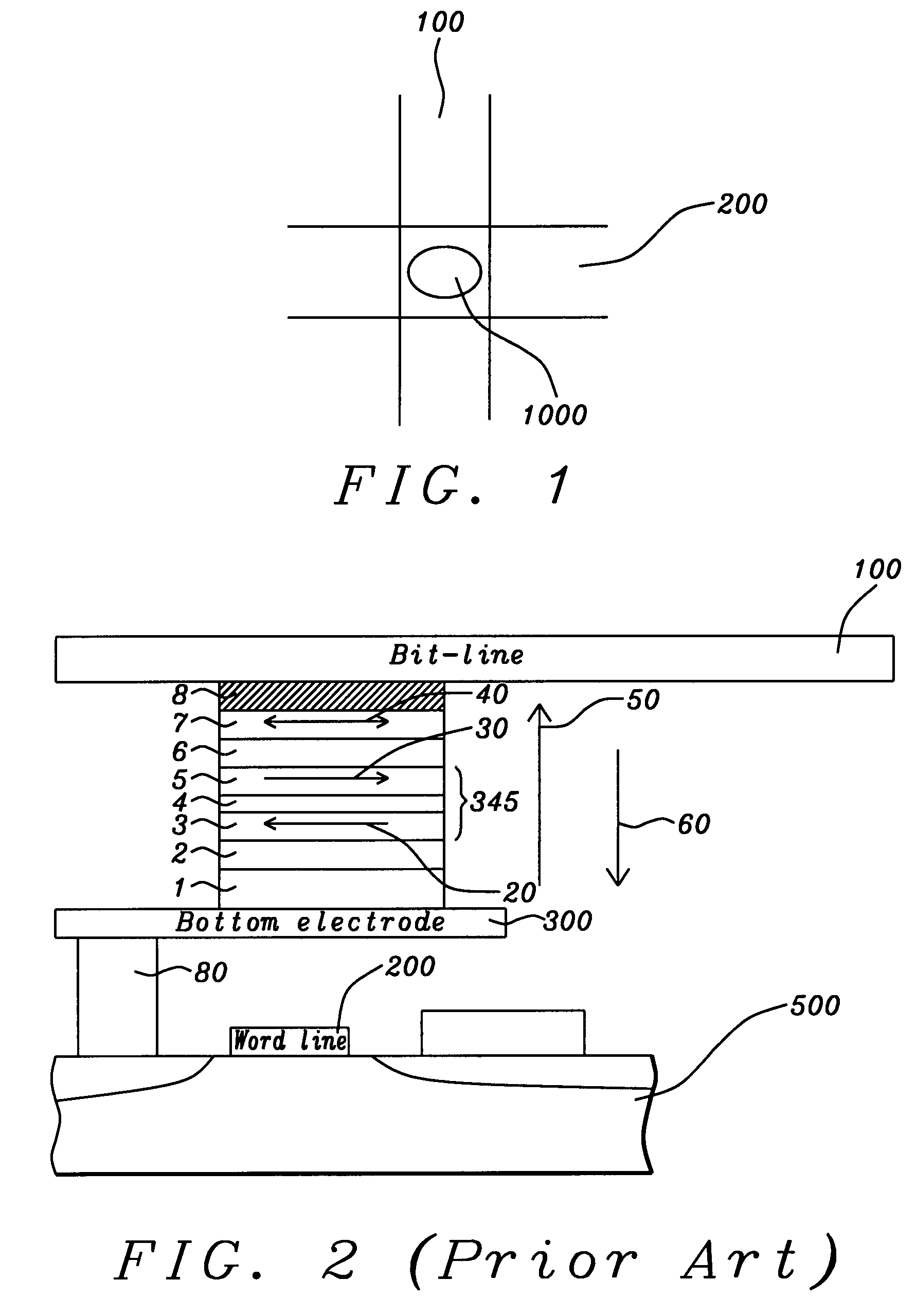

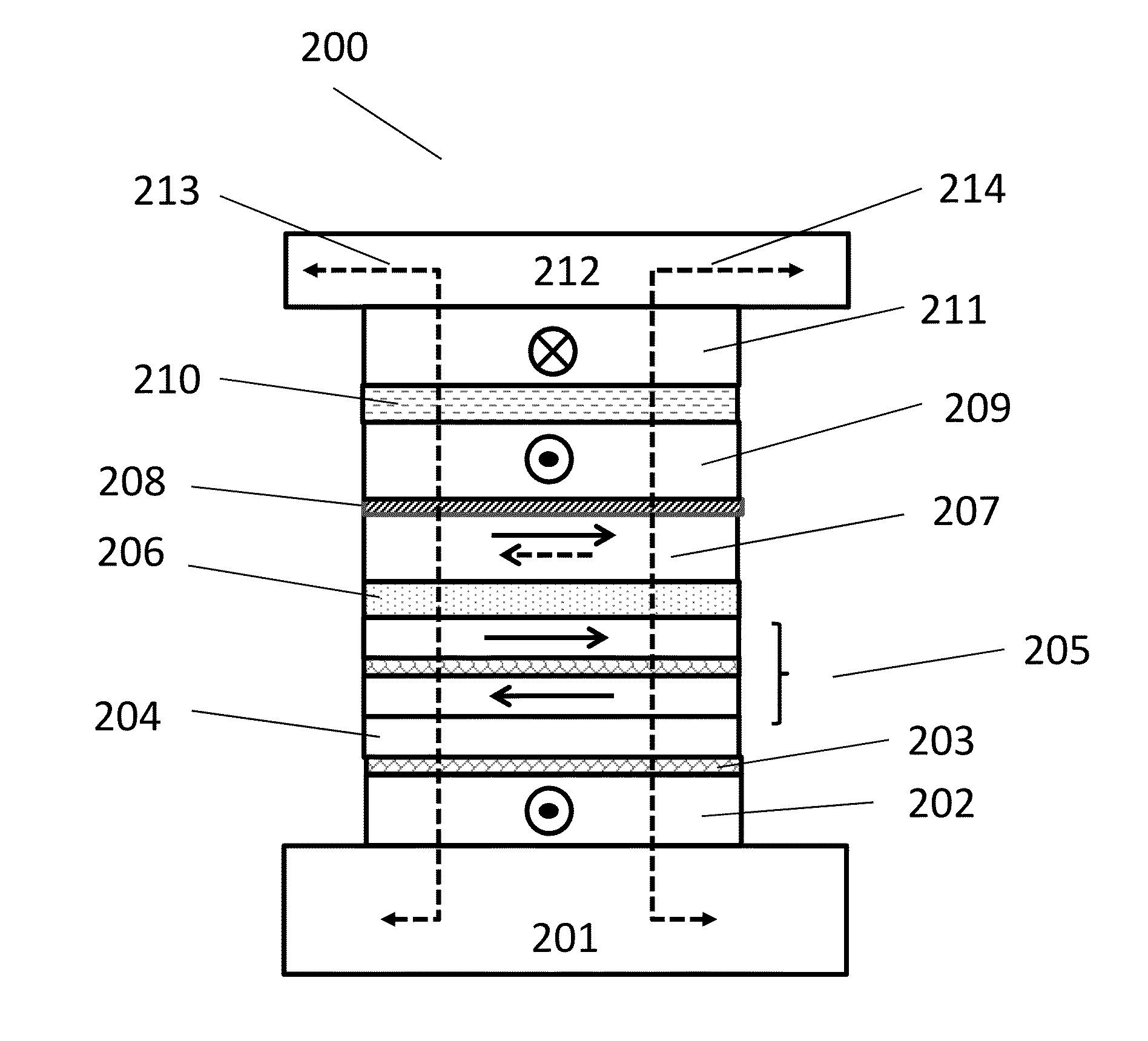

Magnetoresistive random access memory cell design

InactiveUS20130307097A1Improve thermal stabilityLow switching currentSemiconductor devicesIn planeComputer architecture

A magnetic memory cell comprises in-plane anisotropy tunneling magnetic junction (TMJ) and two fixed in-plane storage-stabilized layers, which splits on the both side of the data storage layer of the TMJ. The magnetizations of the said fixed in-plane storage-stabilized layers are all normal to that of the reference layer of TMJ but point to opposite direction. The existing of the storage-stabilized layers not only enhances the stability of the data storage, but also can reduce the critical current needed to flip the data storage layer via some specially added features.

Owner:GE YI +4

High performance MTJ element for STT-RAM and method for making the same

ActiveUS7750421B2Easy to operateLow dispersionNanomagnetismMagnetic-field-controlled resistorsSpin angular momentum of lightDamping factor

A STT-MTJ MRAM cell that utilizes transfer of spin angular momentum as a mechanism for changing the magnetic moment direction of a free layer includes an IrMn pinning layer, a SyAP pinned layer, a naturally oxidized, crystalline MgO tunneling barrier layer that is formed on an Ar-ion plasma smoothed surface of the pinned layer and, in one embodiment, a free layer that comprises an amorphous layer of Co60Fe20B20 of approximately 20 angstroms thickness formed between two crystalline layers of Fe of 3 and 6 angstroms thickness respectively or on a single such layer. The free layer is characterized by a low Gilbert damping factor and by very strong polarizing action on conduction electrons. The resulting cell has a low critical current, a high dR / R and a plurality of such cells will exhibit a low variation of both resistance and pinned layer magnetization angular dispersion.

Owner:TAIWAN SEMICON MFG CO LTD

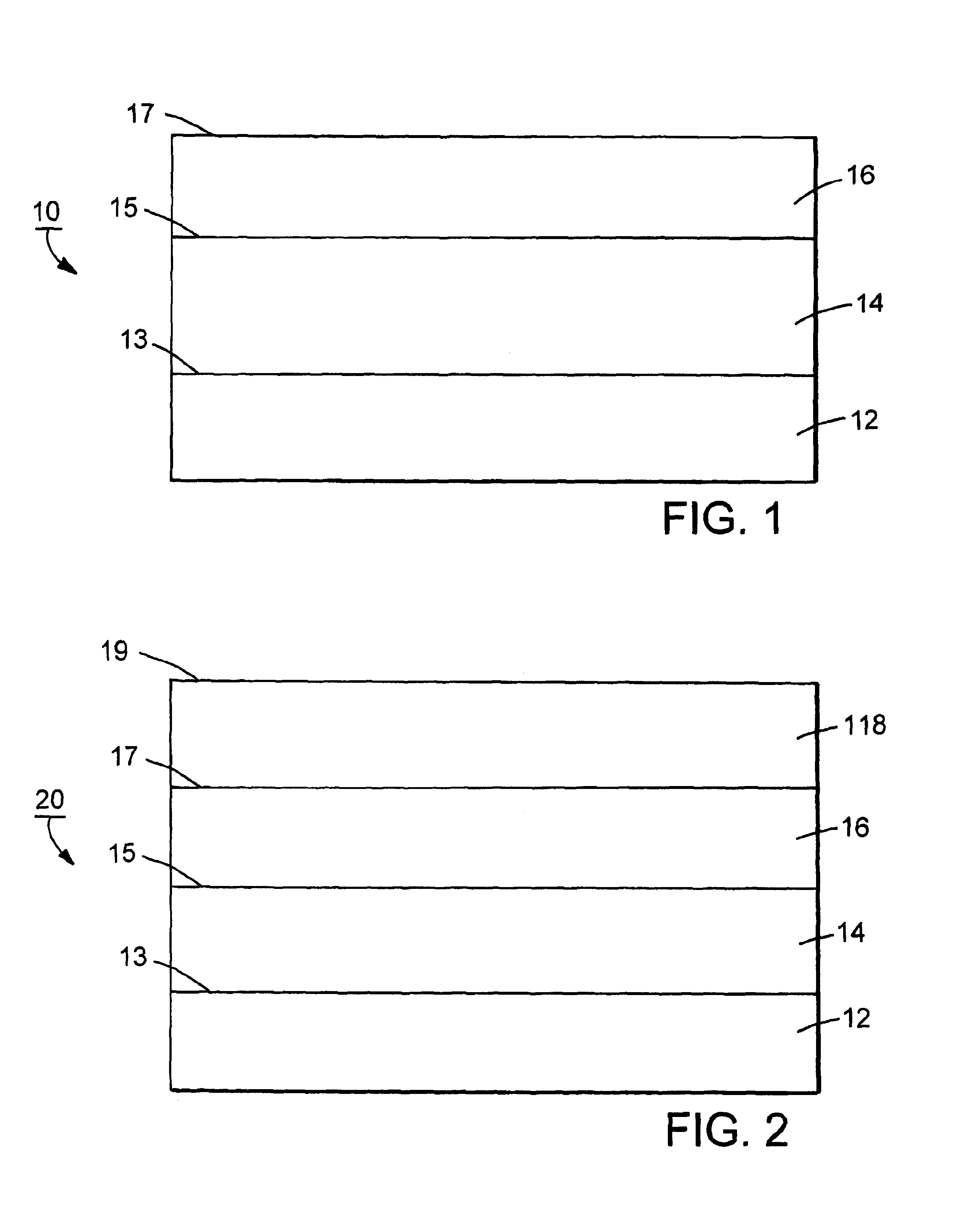

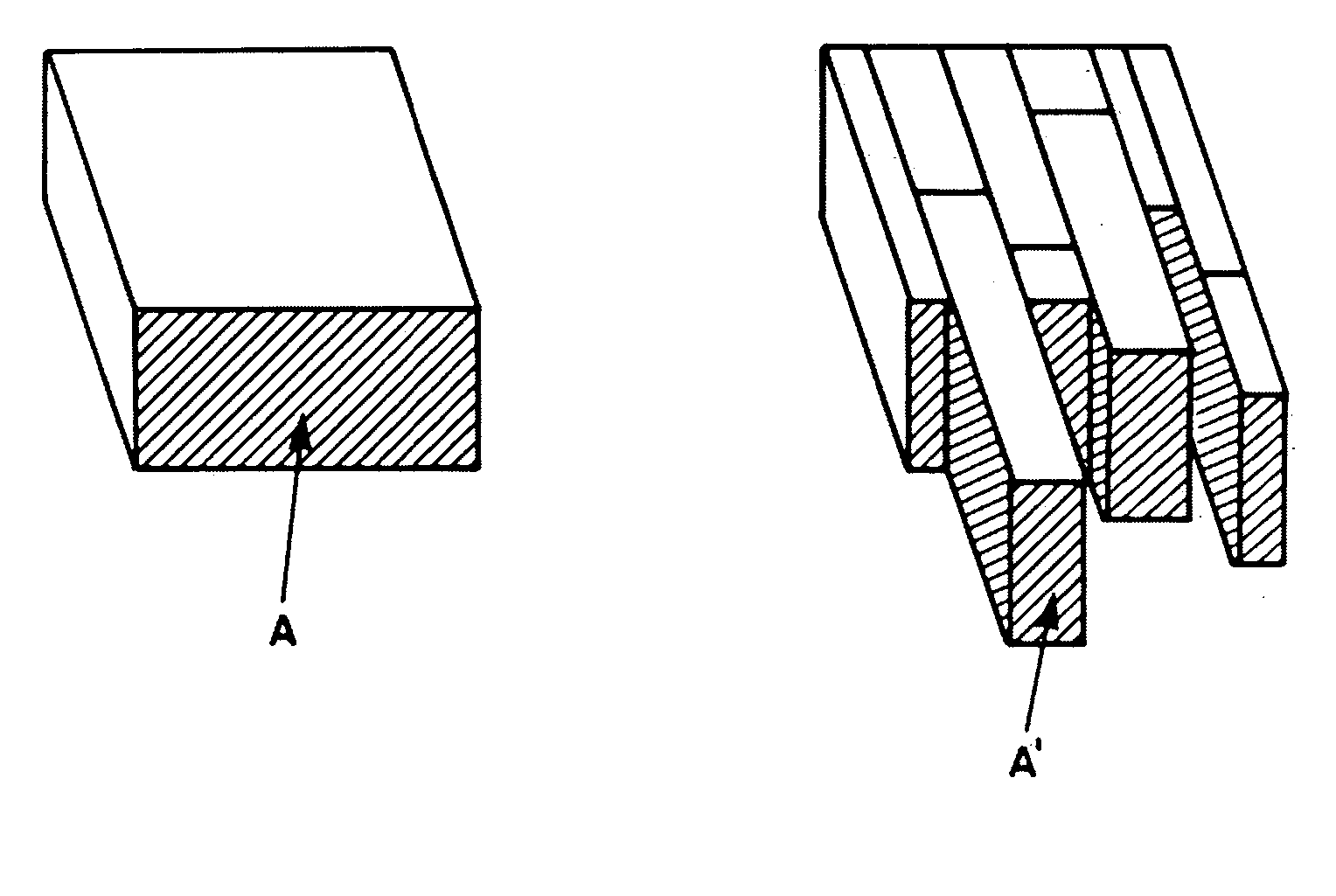

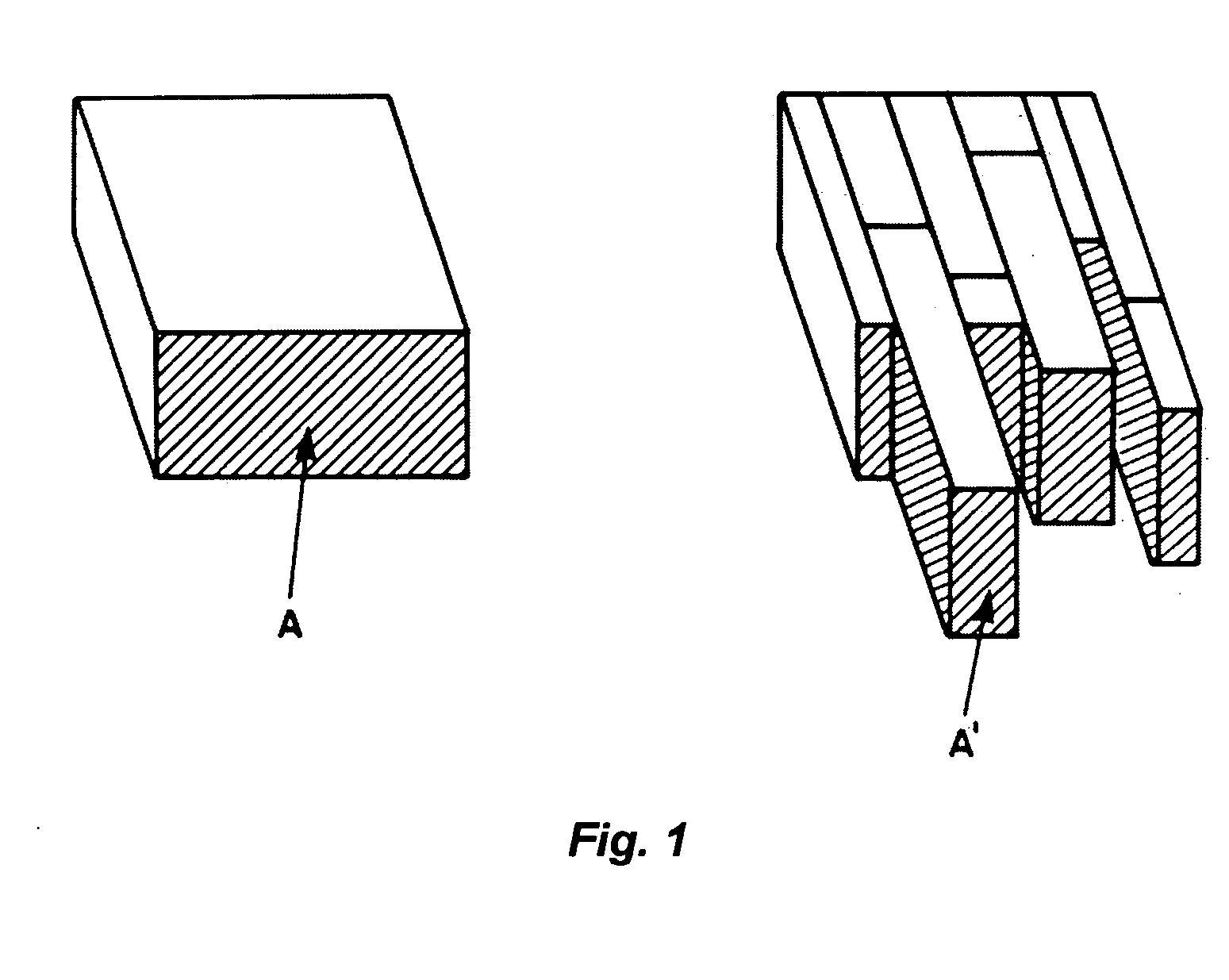

Multi-layer articles and methods of making same

InactiveUS6974501B1High critical current densityHigh densityPolycrystalline material growthFrom normal temperature solutionsPolymer scienceVolumetric Mass Density

The invention relates to multi-layer articles and methods of making such articles. The methods include first conditioning the surface of an underlying layer, such as a buffer layer or a superconductor layer, then disposing a layer of material on the conditioned surface. The conditioned surface can be a high quality surface. Superconductor articles formed by these methods can exhibit relatively high critical current densities.

Owner:AMERICAN SUPERCONDUCTOR

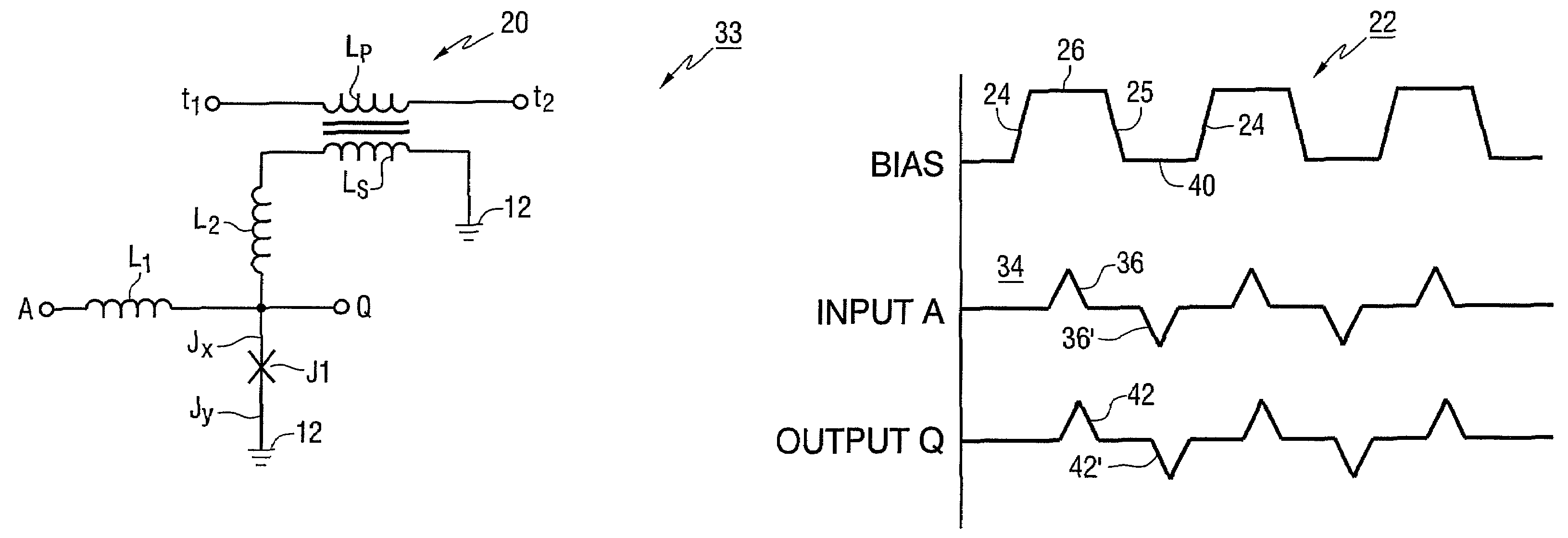

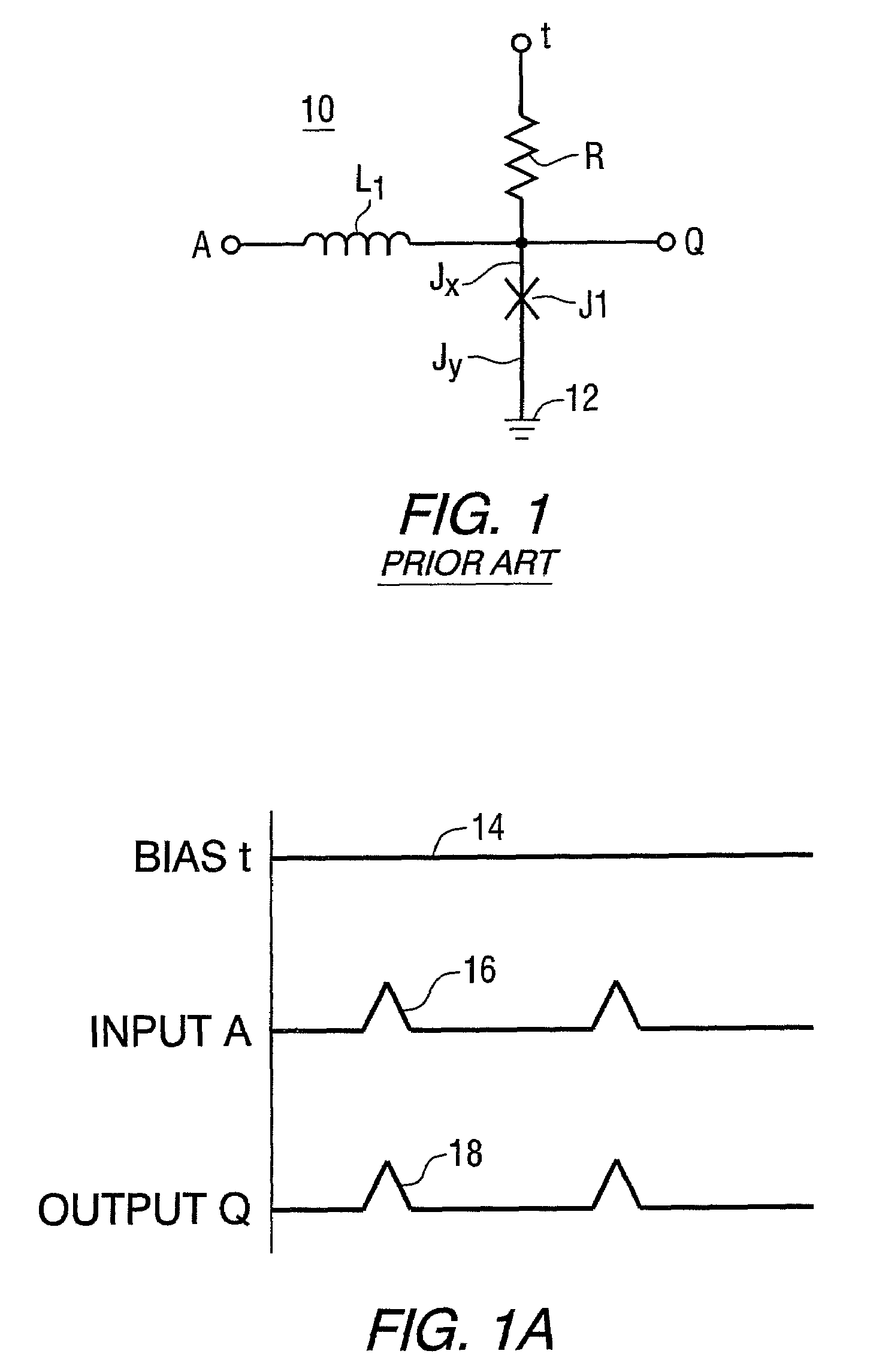

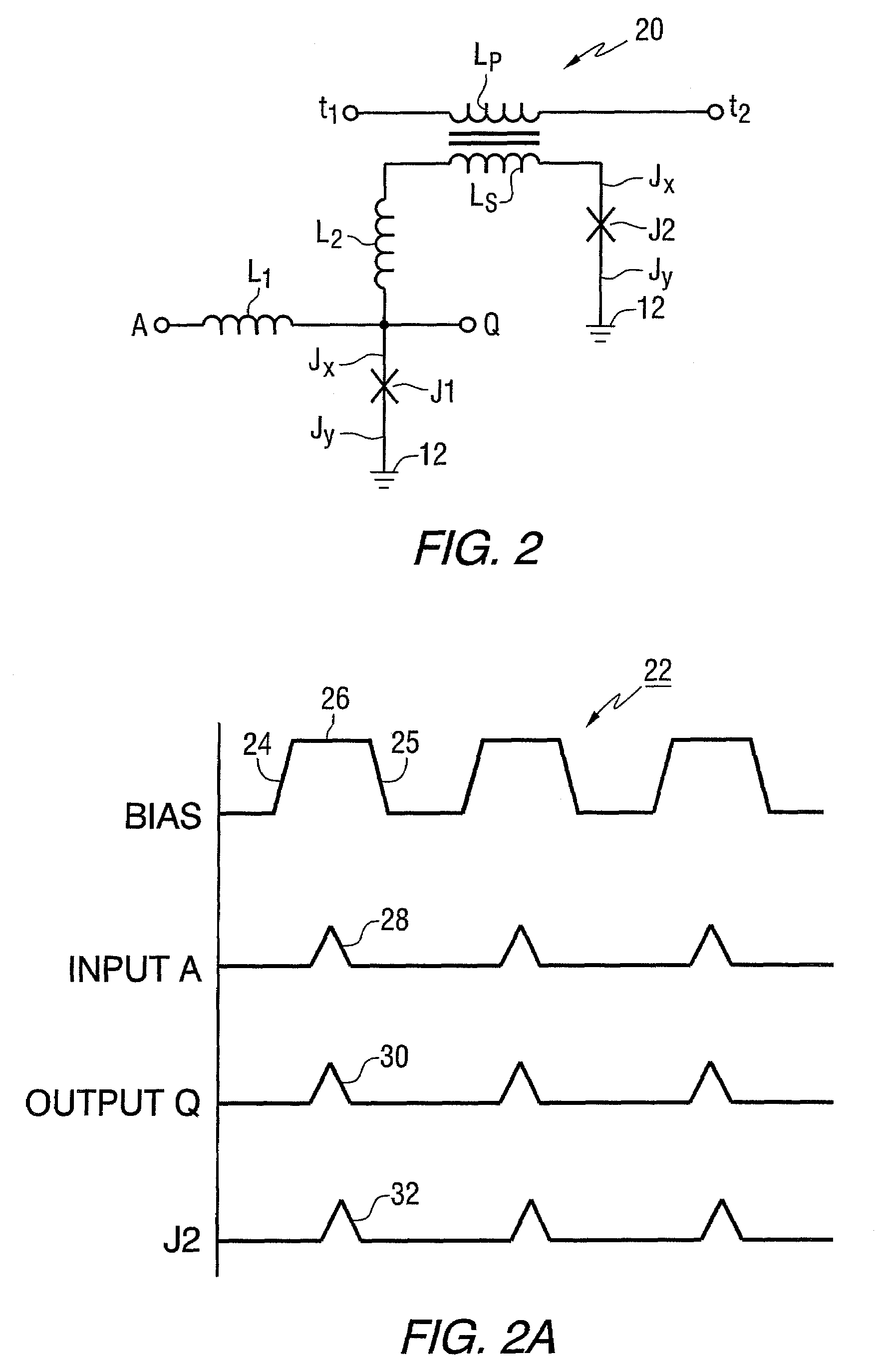

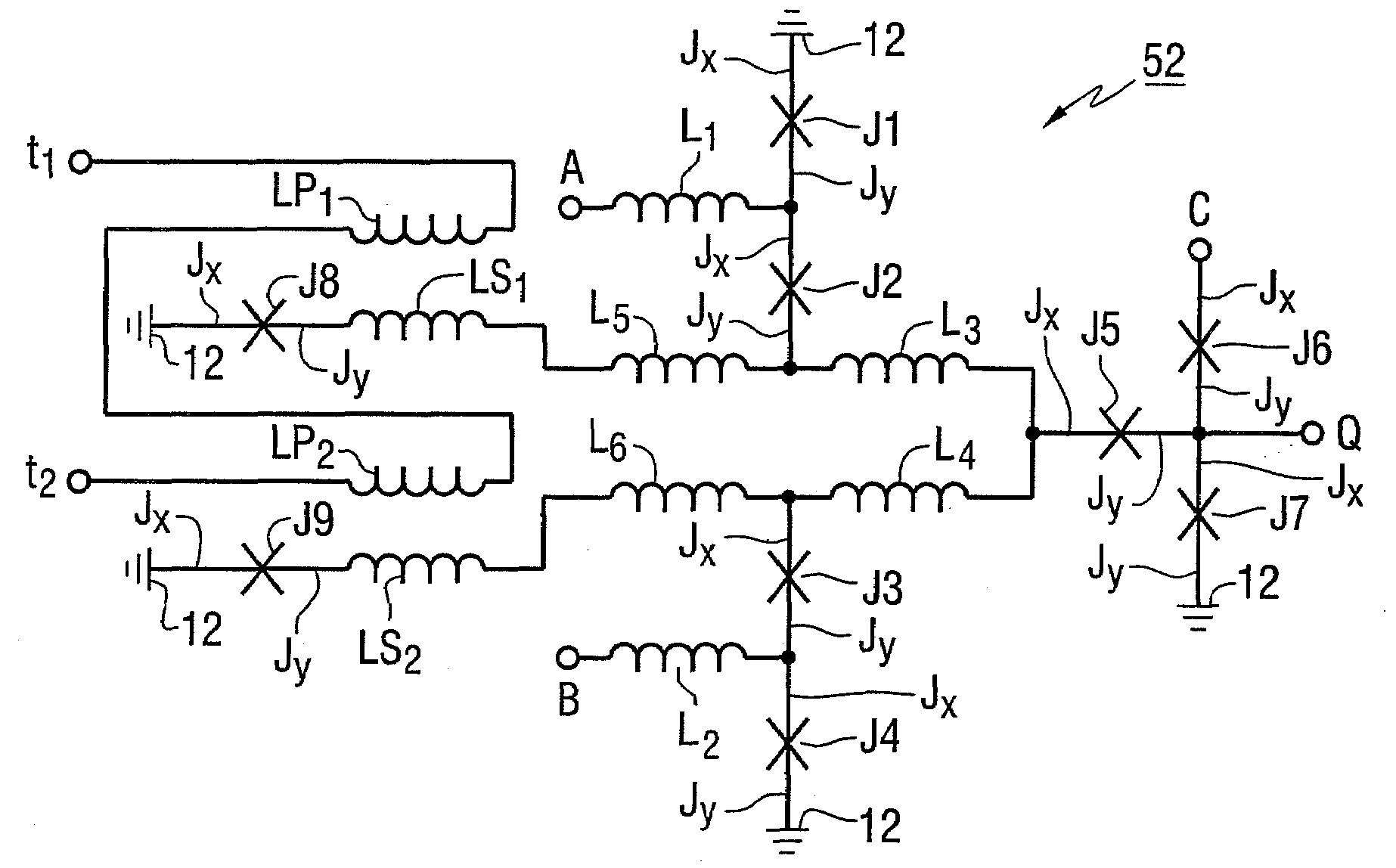

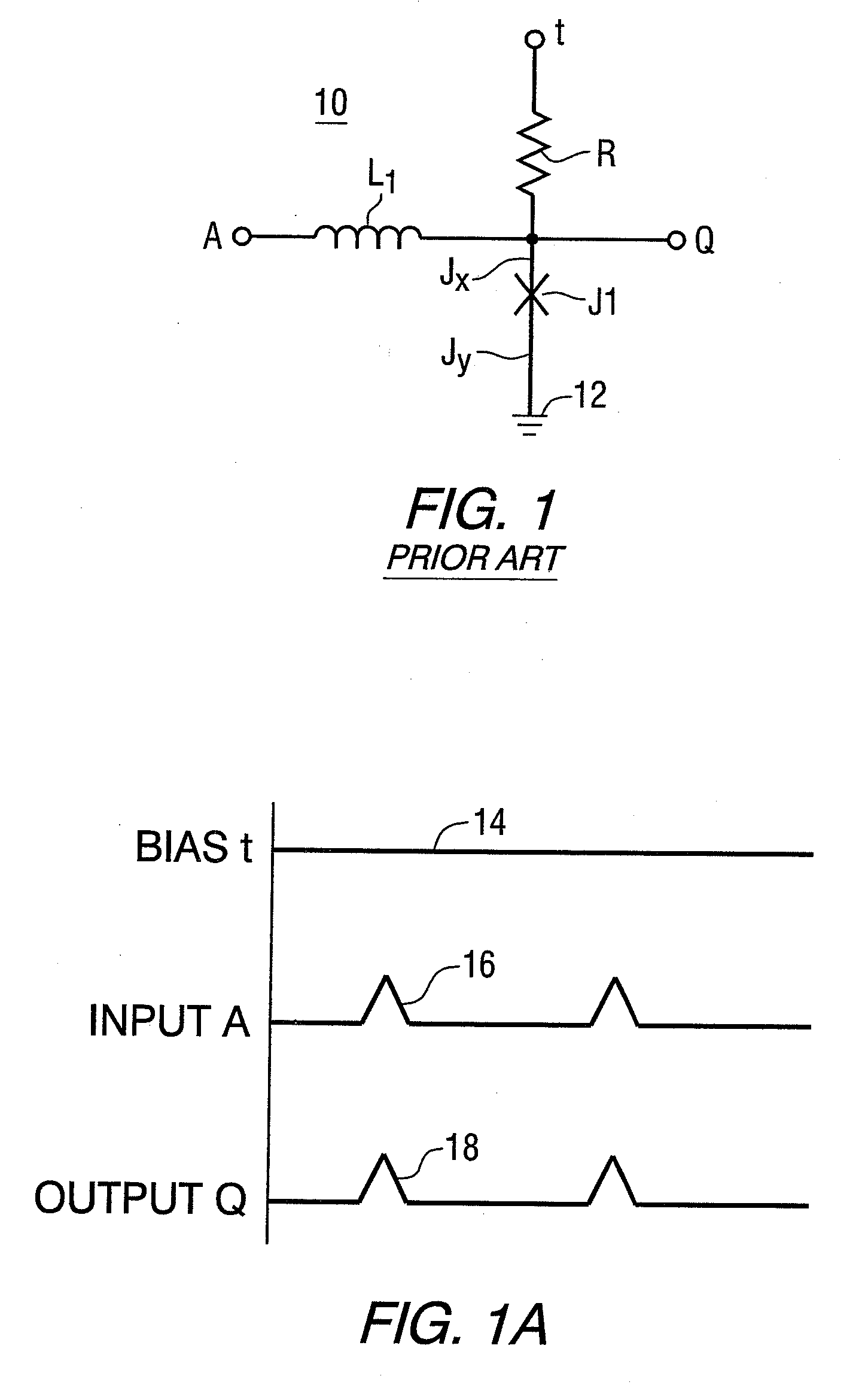

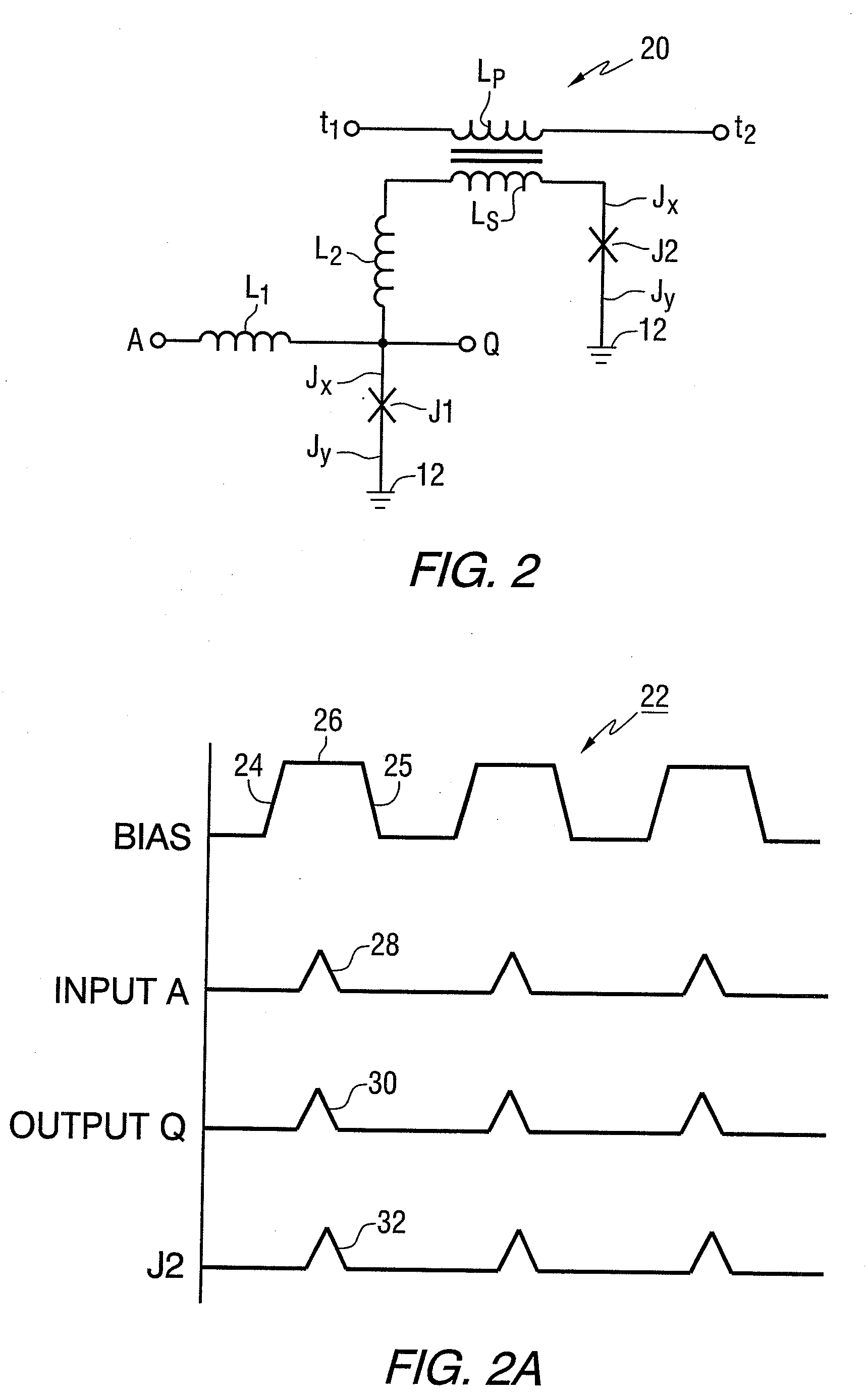

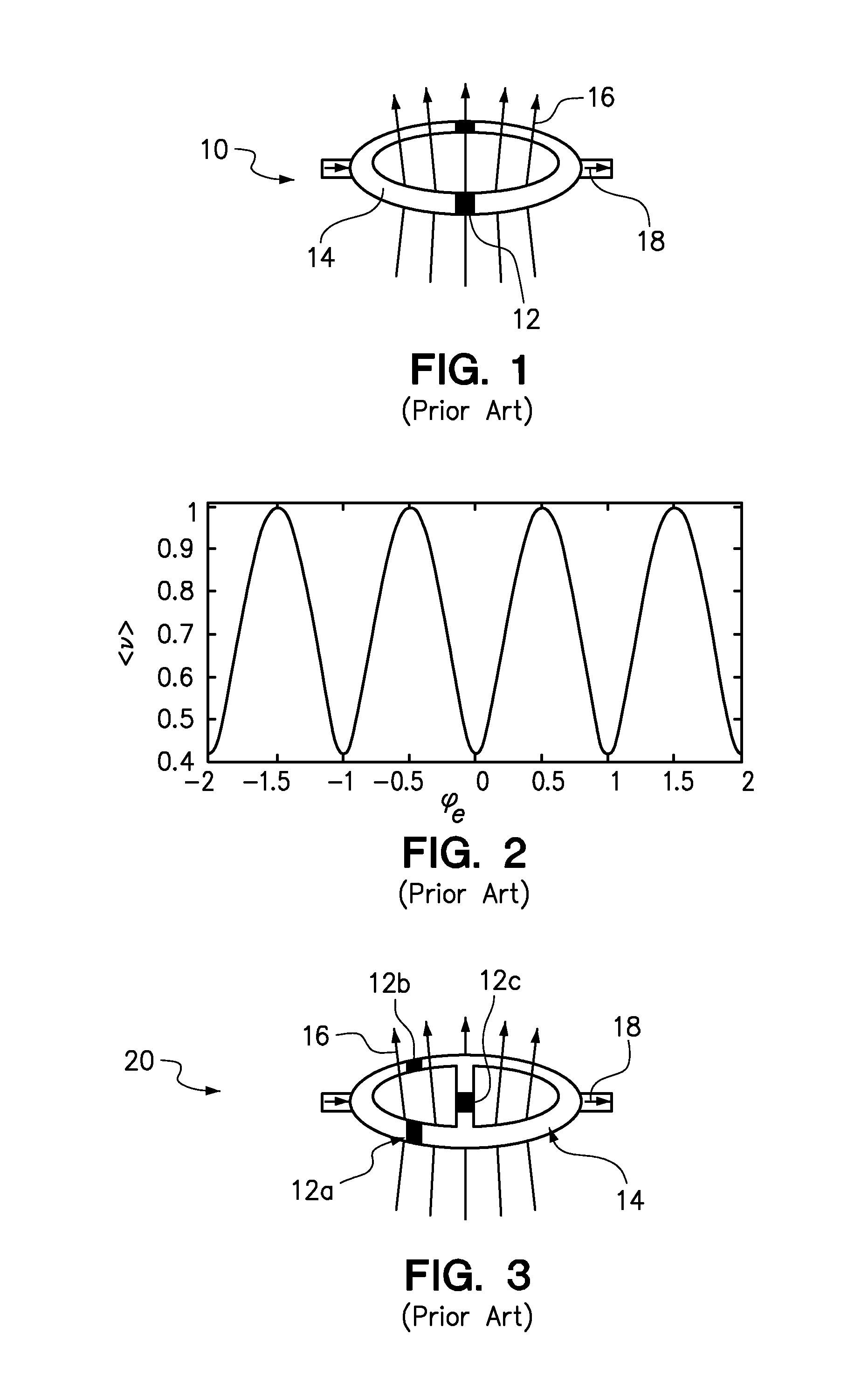

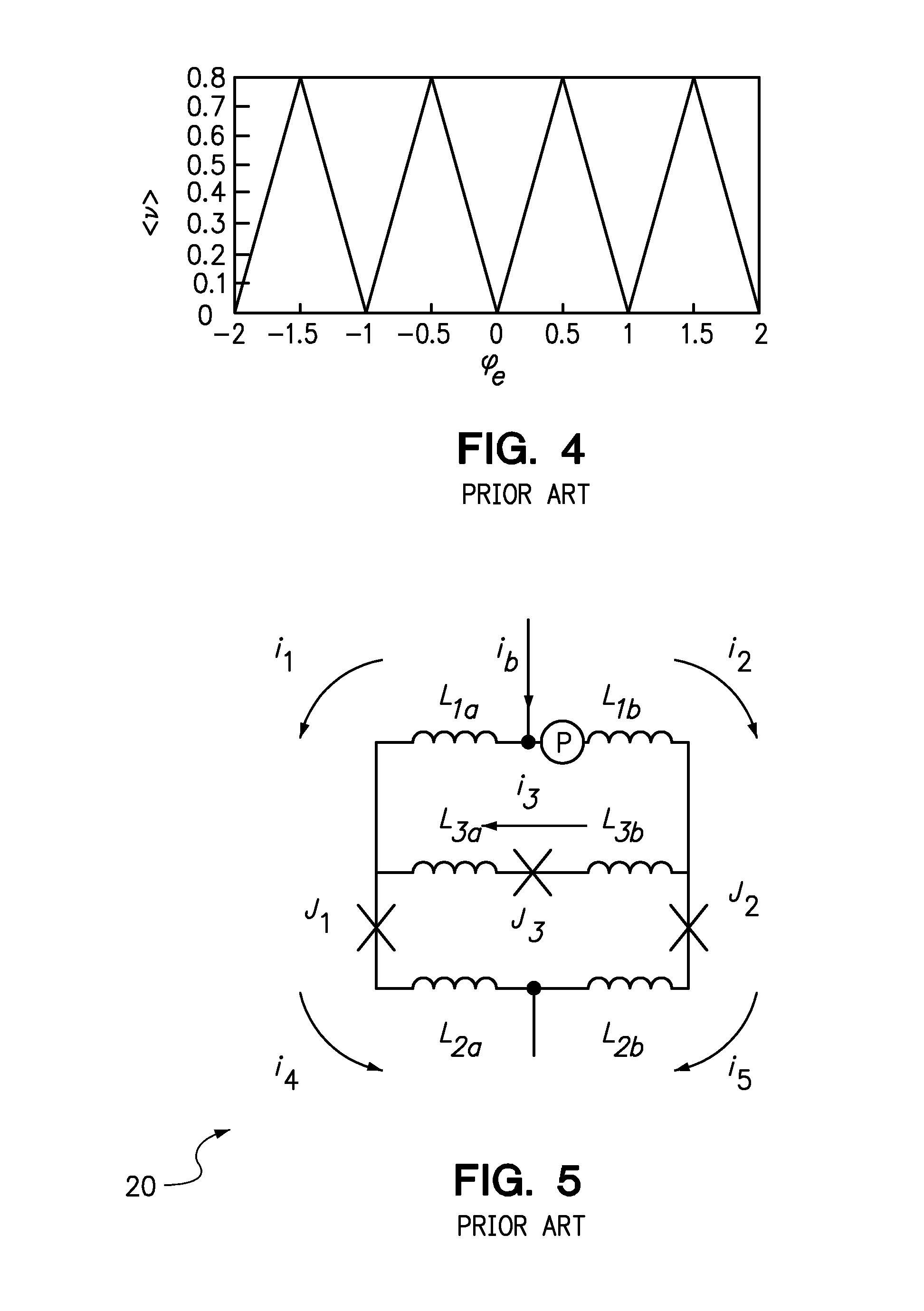

Single flux quantum circuits

ActiveUS7724020B2Reduce and eliminate unnecessary power dissipationQuantum computersPower consumption reductionQuantum circuitTransformer

Superconducting single flux quantum circuits are disclosed herein, each having at least one Josephson junction which will flip when the current through it exceeds a critical current. Bias current for the Josephson junction is provided by a biasing transformer instead of a resistor. The lack of any bias resistors ensures that unwanted power dissipation is eliminated.

Owner:NORTHROP GRUMMAN SYST CORP

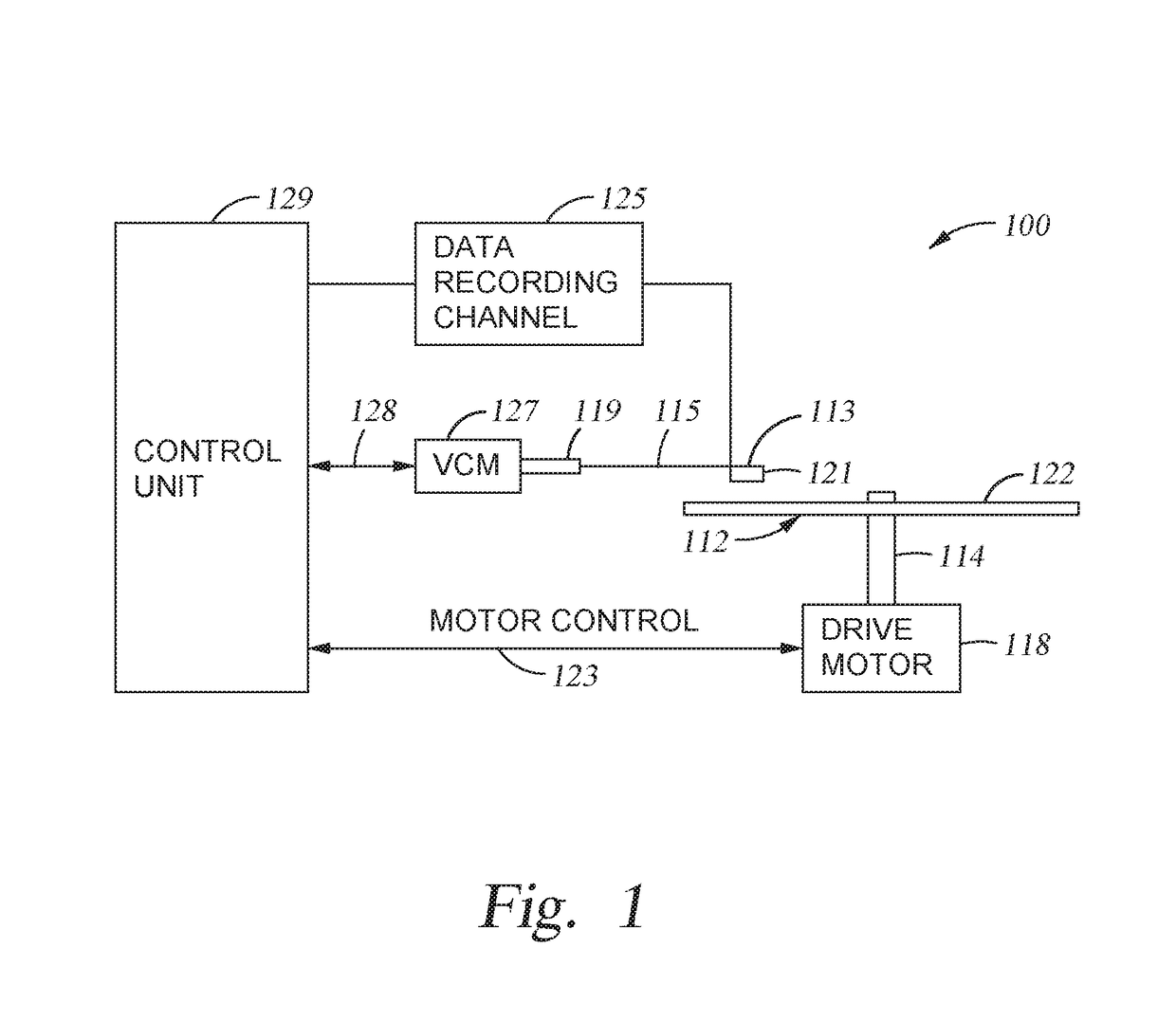

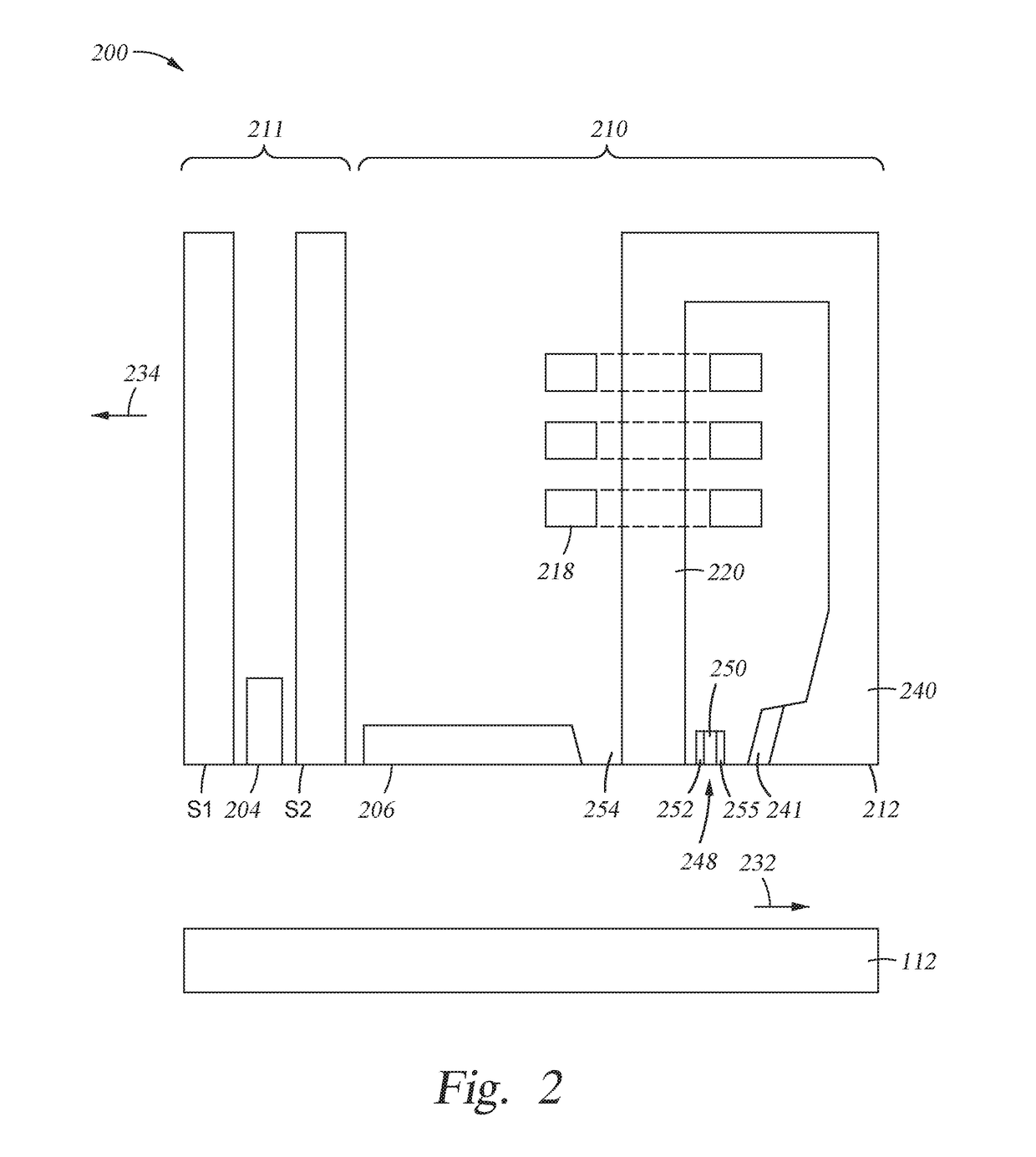

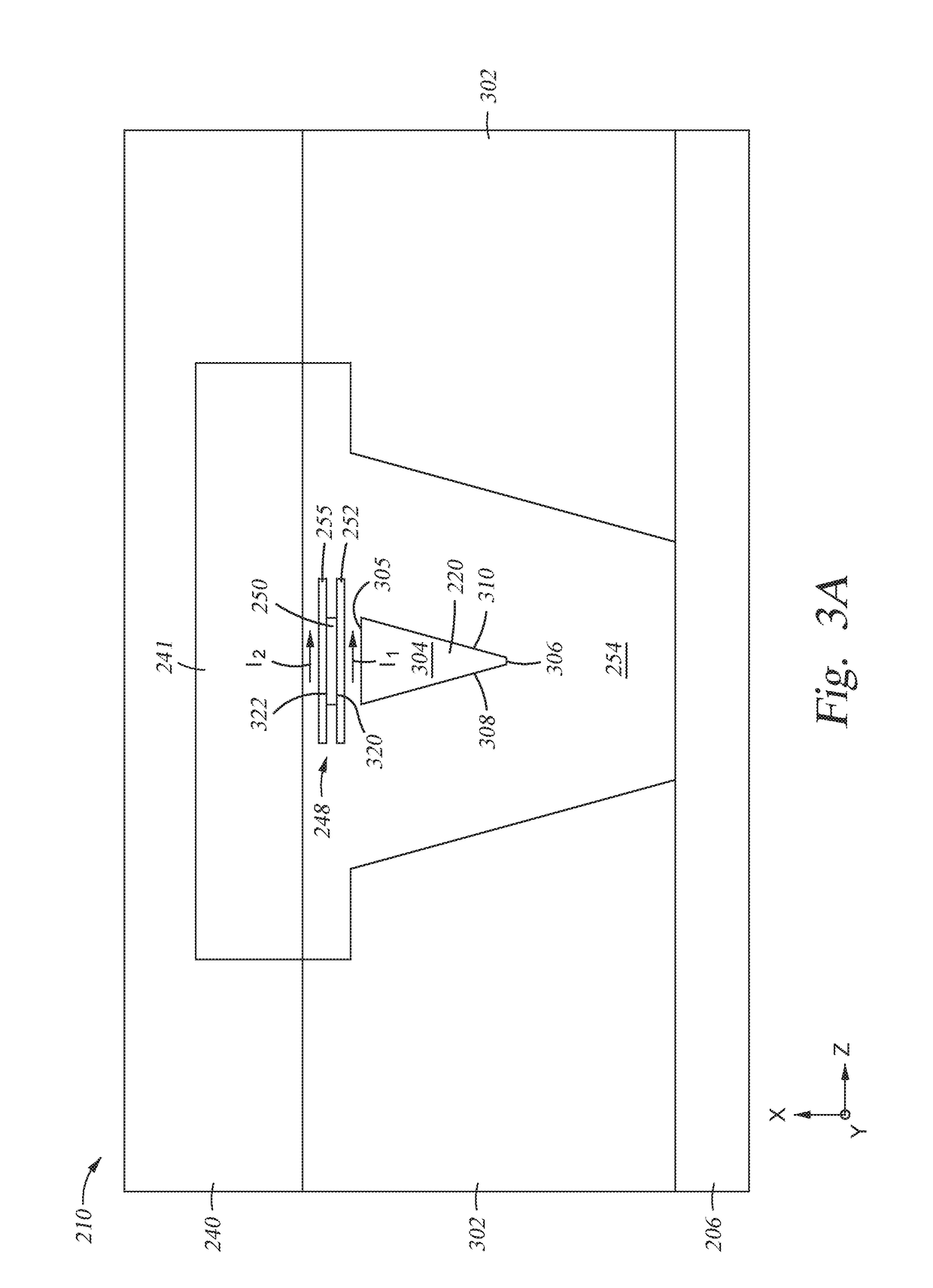

Dual spin-orbit torque oscillator in magnetic recording

ActiveUS10210888B1Reduce critical currentQuality improvementMagnetic-field-controlled resistorsHeads using thin filmsIn planeMagnetic media

The present disclosure generally relates to data storage devices, and more specifically, to a magnetic media drive employing a magnetic recording head. The head includes a main pole, a trailing shield, and an oscillator located between the main pole and the trailing shield. The oscillator is disposed at a media facing surface (MFS). The oscillator includes a spin-torque layer sandwiched between two distinct spin Hall layers. The two distinct spin Hall layers generate spin-orbit torque (SOT) that induces in-plane precessions on opposite surfaces of the spin-torque layer, and both in-plane precessions are in the same direction. The same-direction in-plane precessions on opposite surfaces of the spin-torque layer reduce the critical current of the oscillation of the oscillator, leading to high quality recording.

Owner:WESTERN DIGITAL TECH INC

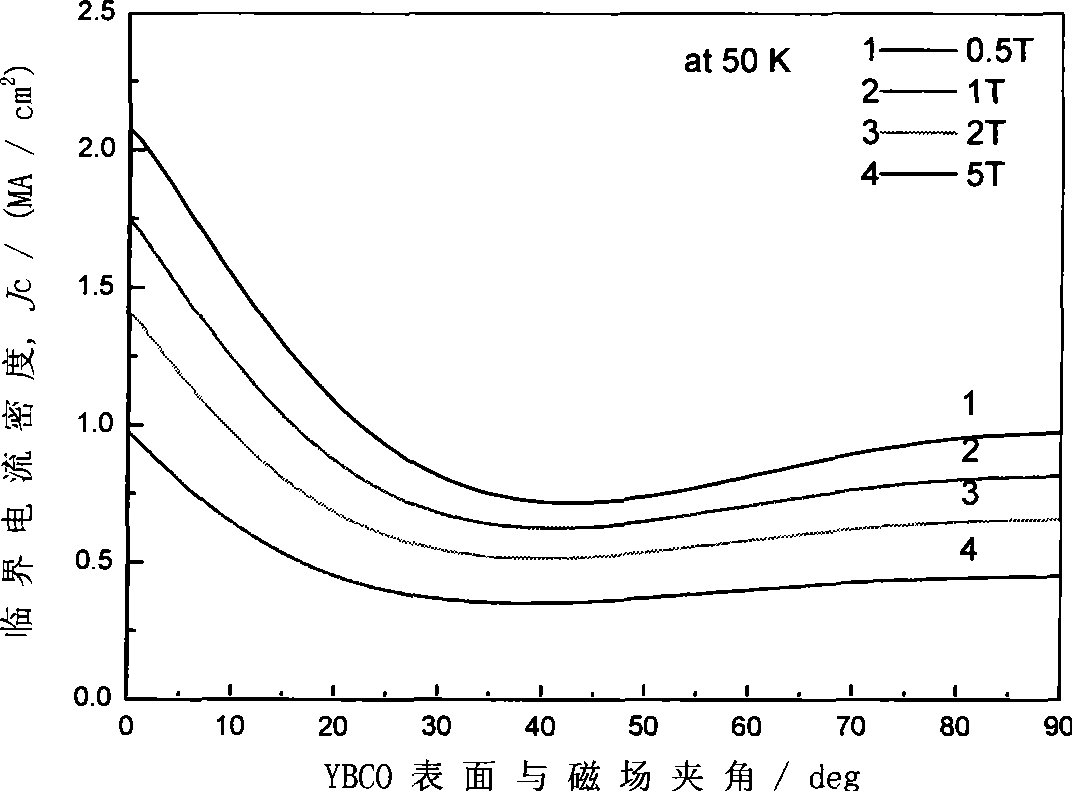

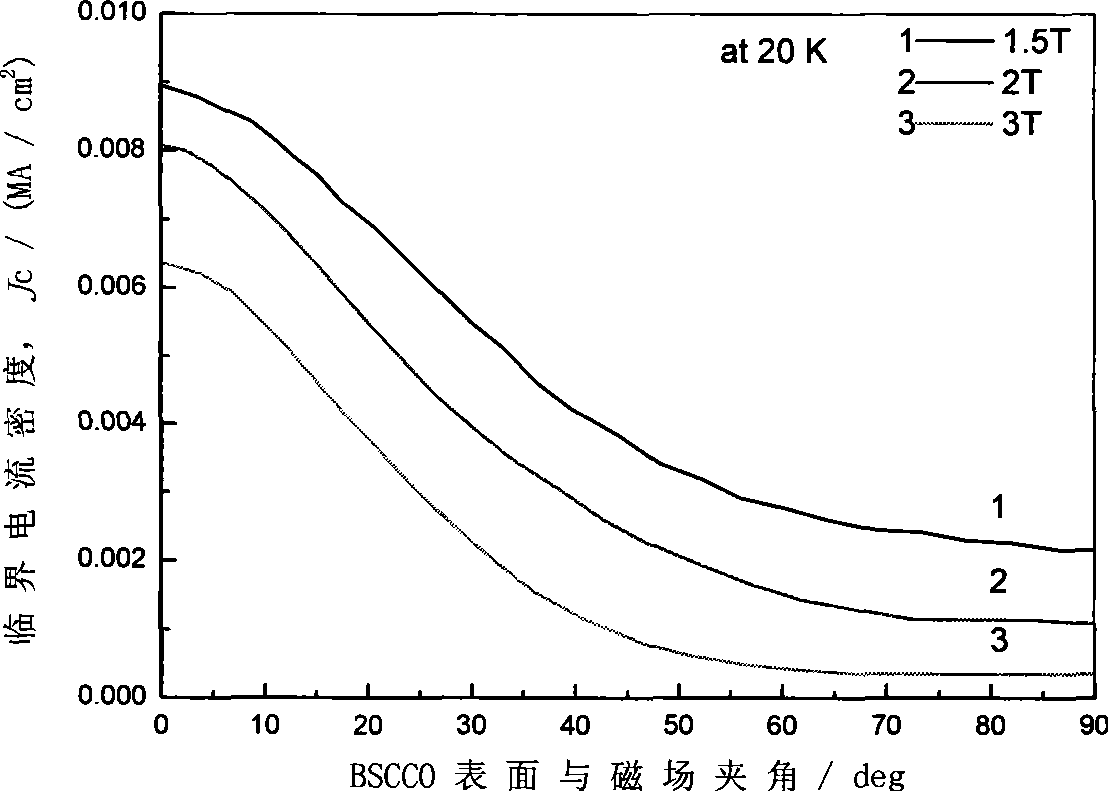

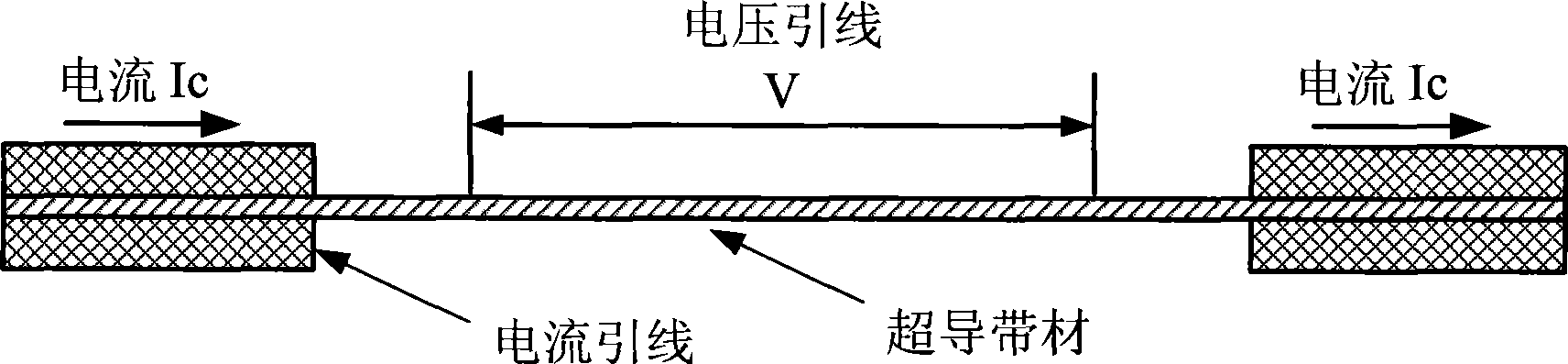

Measurement device of critical current properties of high-temperature superconducting tape

ActiveCN101446609AMeasuring critical current characteristicsRealize critical current characteristic measurementElectrical testingMagnitude/direction of magnetic fieldsYttrium barium copper oxideMeasurement device

The invention provides a measurement device of critical current properties of a high-temperature superconducting tape, and the device comprises a superconducting tape sample rack 1, a Hall magnetic field probe 2, a temperature probe 3, a background magnetic field magnet 4, a rotary rod 5, a rotary handle 6, a superconducting tape current lead wire 7, a background magnetic field magnet current lead wire 8, a low-temperature dewar 9, a cooling medium storage container 10, a low-temperature cooling medium 11, an extraction valve 12, a carburetor 13, a vacuum unit 14, a GM refrigerator 15, a background magnetic field magnet DC power supply 16, a superconducting DC power supply 17 and a system control, data acquisition and processing system 18. The device can simply and rapidly calculate the temperature, the background magnetic field and the impact factors on the change of the direction of the magnetic field thereof, thereby being applicable to the measurement of the critical current properties of yttrium barium copper oxide YBCO high-temperature superconducting tape.

Owner:CHINA ELECTRIC POWER RES INST +1

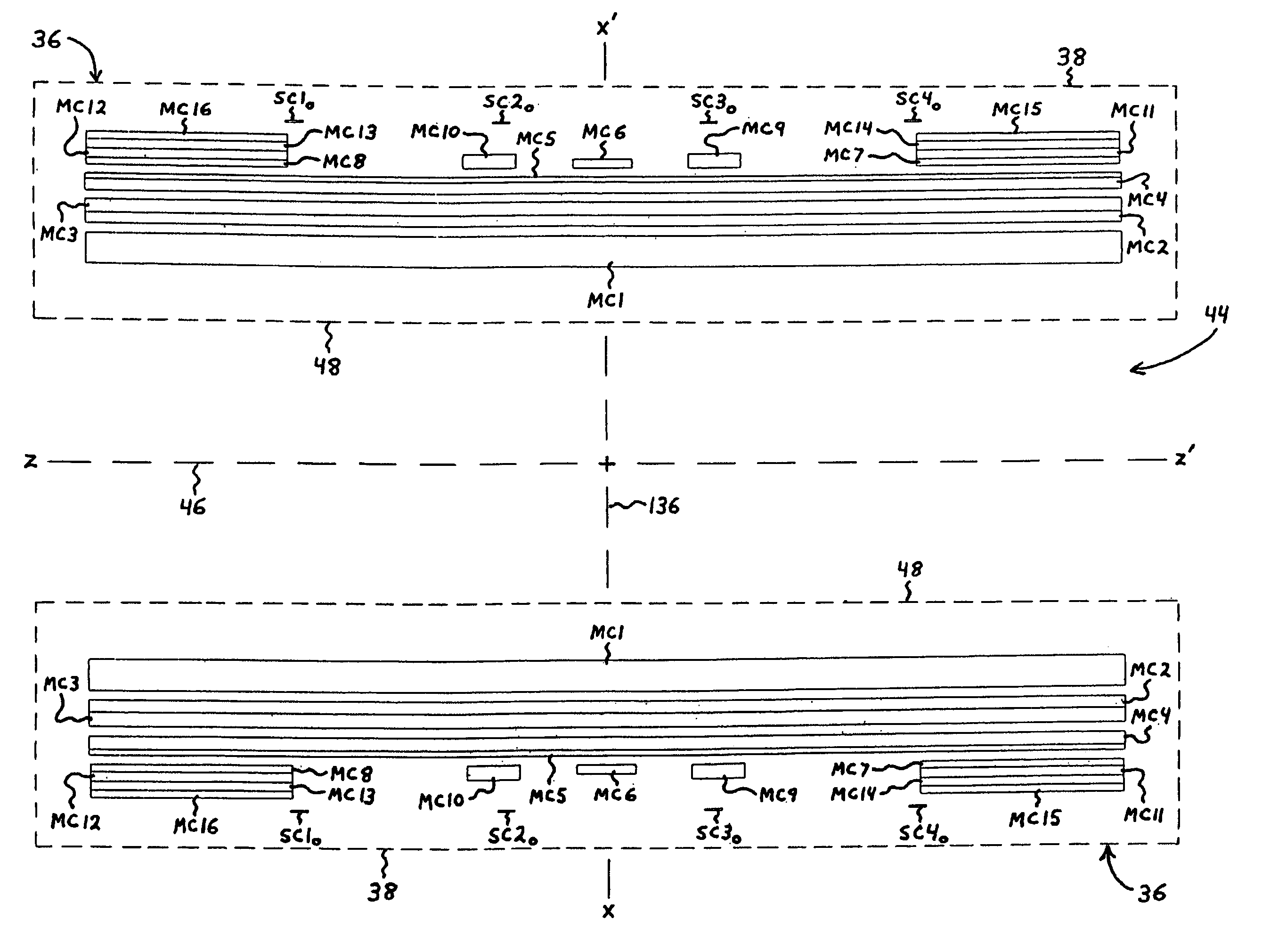

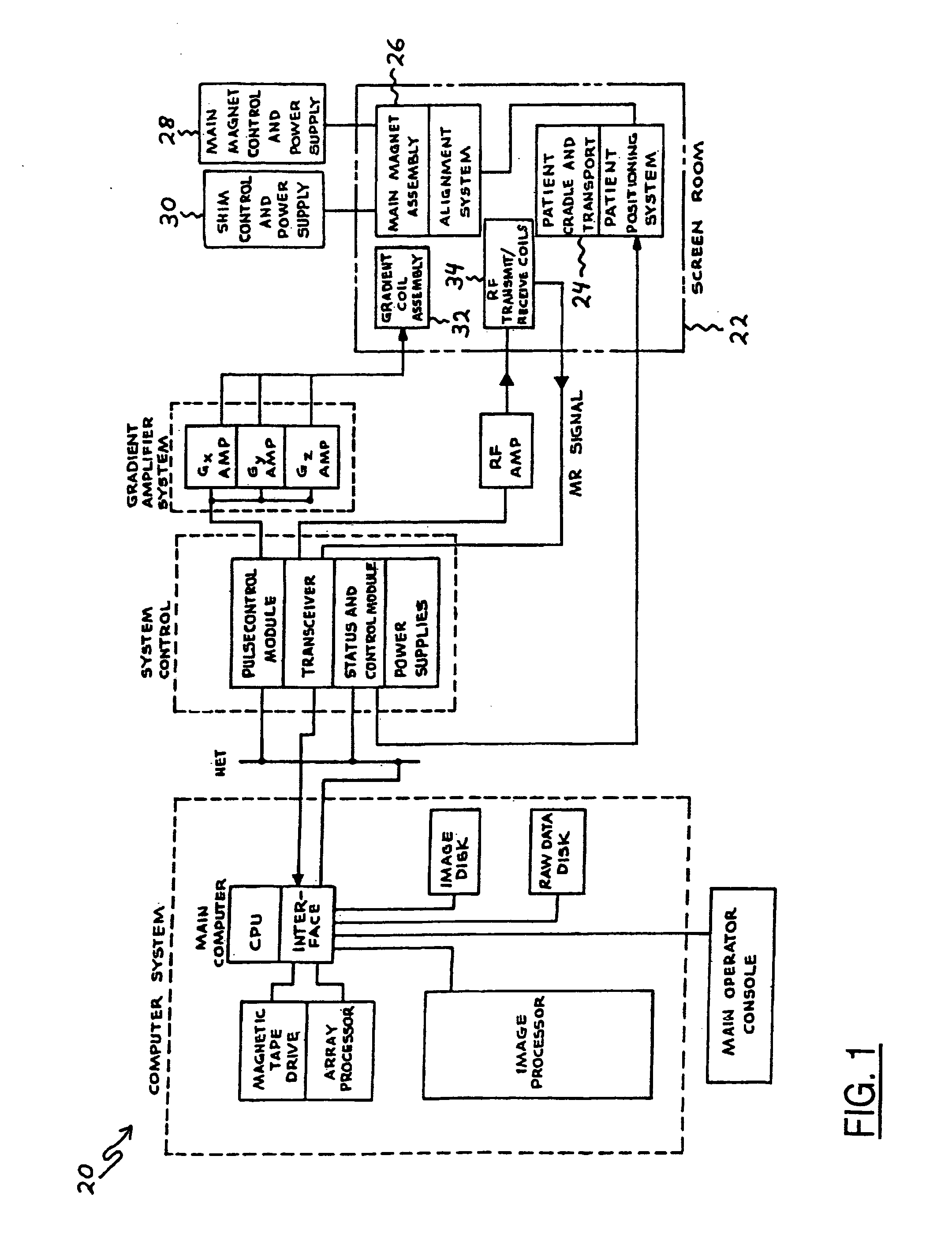

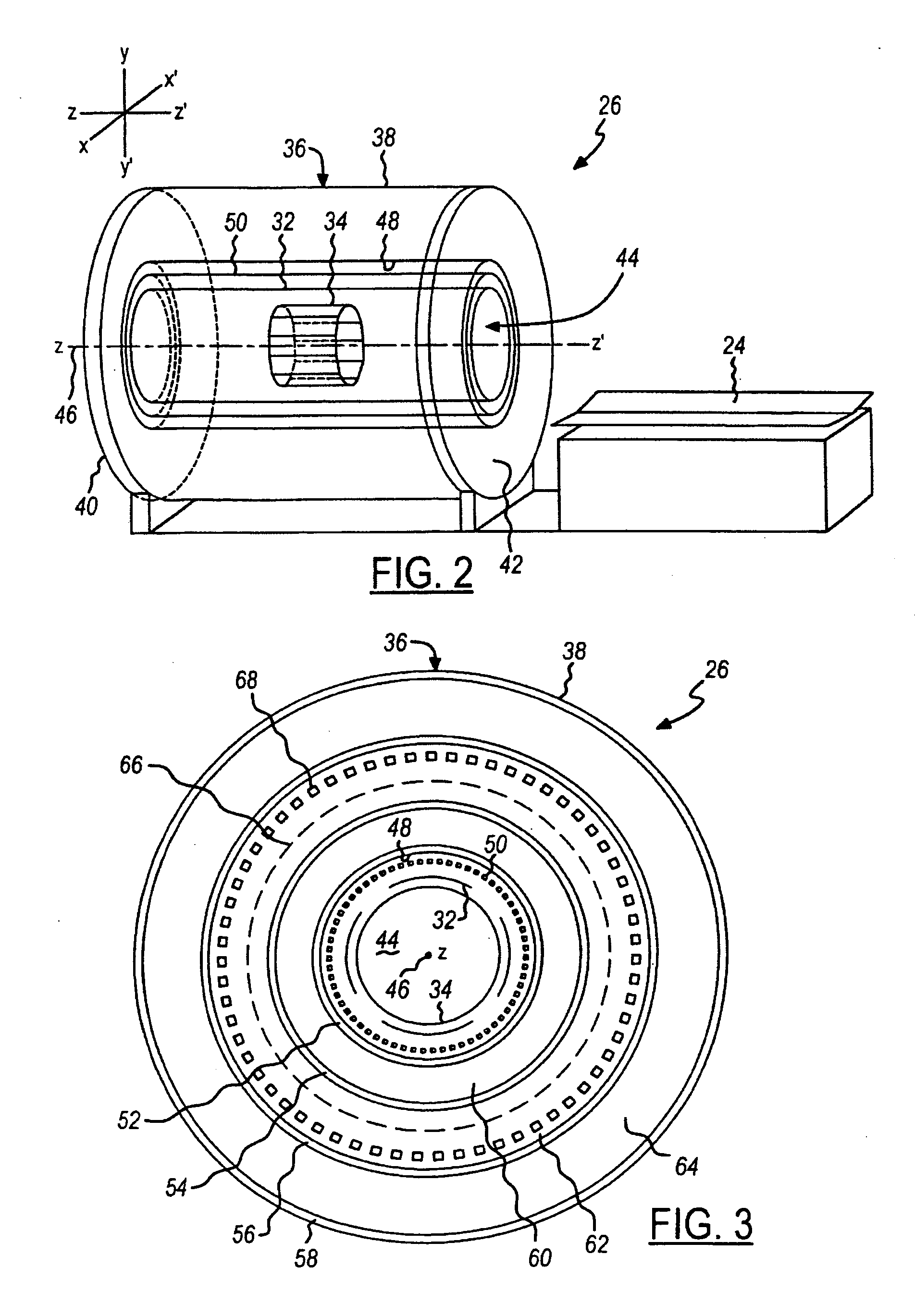

Secondary coil circuit for use with a multi-section protected superconductive magnet coil circuit

A secondary coil circuit for use with a multi-section protected superconductive magnet coil circuit is disclosed herein. The secondary coil circuit includes two circuit nodes, a ramping switch electrically connected between the two circuit nodes, and a number of secondary coils electrically connected between the two circuit nodes. The secondary coils are made of wire having substantially superconductive capability when cooled below a characteristic critical temperature level and conducting electric current below a characteristic critical current level. The secondary coils are sized and positioned relative to the superconductive magnet coils situated in the individual sections of the multi-section protected superconductive magnet coil circuit so as to functionally cooperate with the multi-section protected superconductive magnet coil circuit in producing and maintaining a magnetic field that is substantially homogeneous. In one embodiment, the secondary coil circuit is inductively decoupled from each individual section of the multi-section protected superconductive magnet coil circuit.

Owner:GENERAL ELECTRIC CO

Electrical surgical instrument with optimized power supply and drive

ActiveUS20070270790A1Comfortably fit into a user's handReduce manufacturing difficultySuture equipmentsStapling toolsElectricityElectric machine

A surgical instrument includes an end effector having an actuation assembly to effect a surgical procedure when actuated. An electric motor has a rated operating voltage and is operationally connected to the end effector to operate the actuation assembly. A power supply is electrically connected to the motor and selectively powers the motor to actuate the actuation assembly at least 1 and less than 16 times during a clinical life of at least one of the end effector, the motor, or the power supply. The power supply has a battery cell with a critical current rate. When activated to power the motor and actuate the actuation assembly, the power supply operates the battery cell at a super-critical current rate during a non-zero super-critical pulse discharge period lasting less than approximately 16 seconds. The power supply operates the motor above the rated operating voltage during the super-critical pulse discharge period.

Owner:CILAG GMBH INT

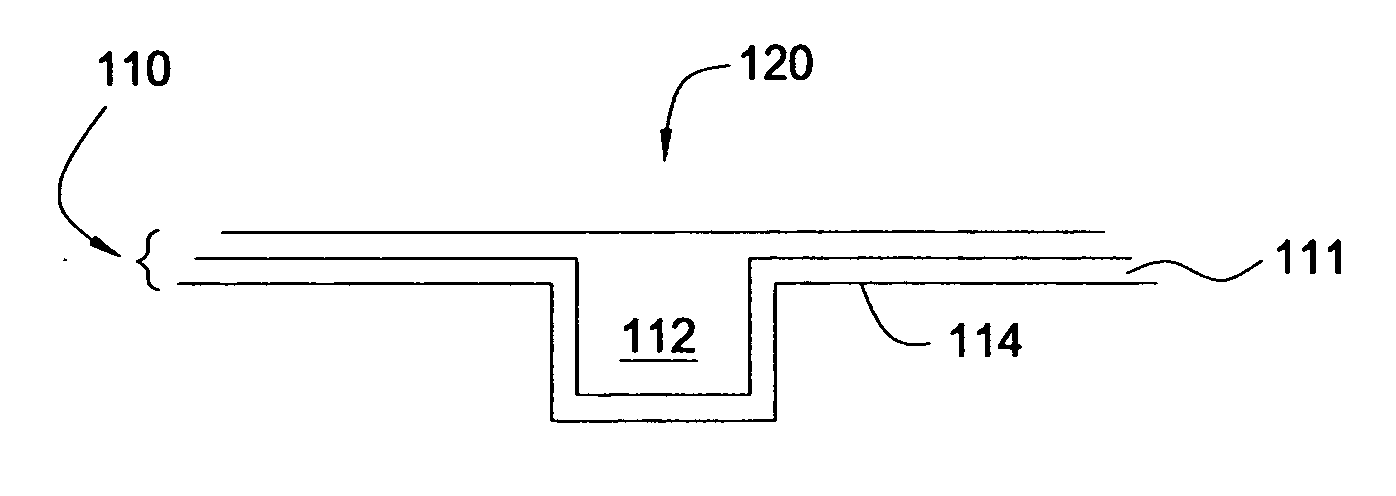

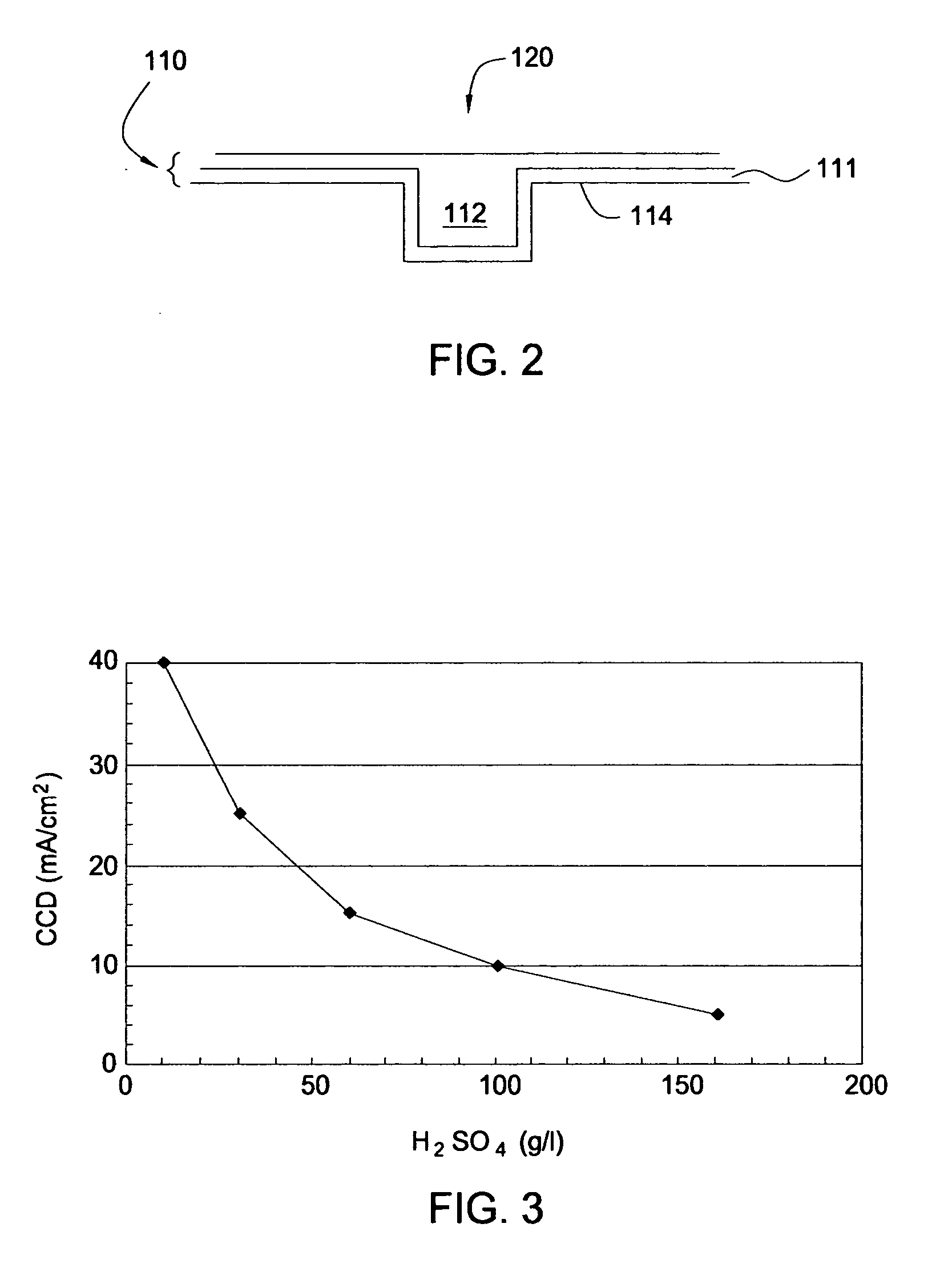

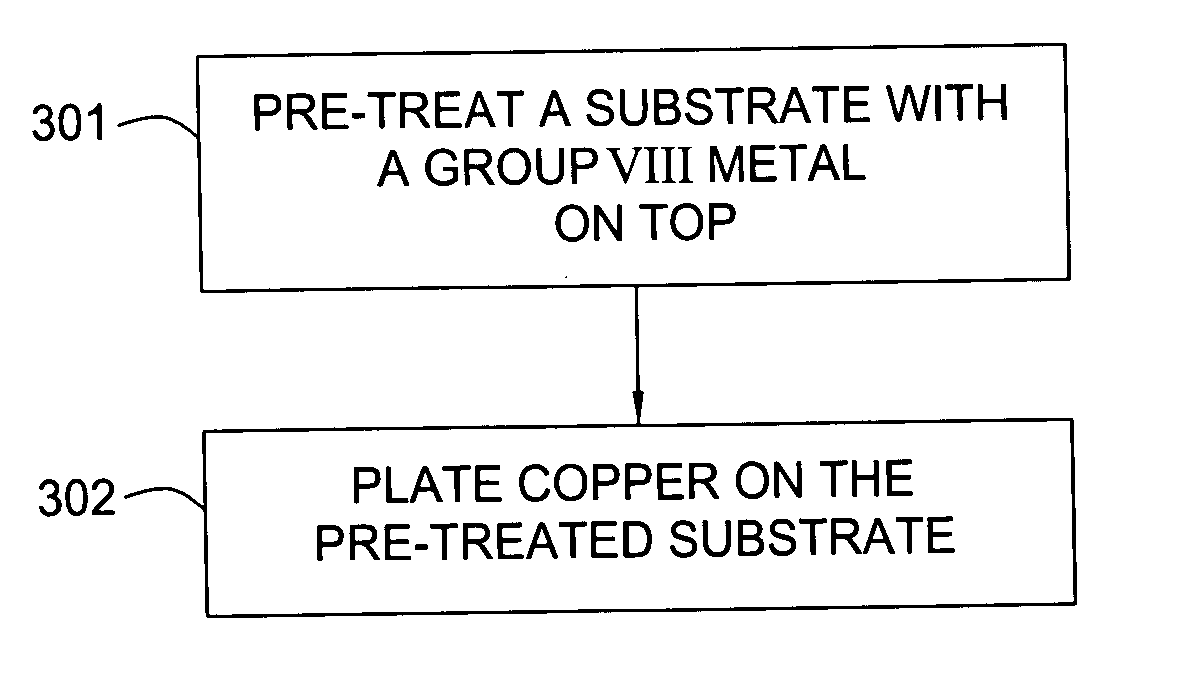

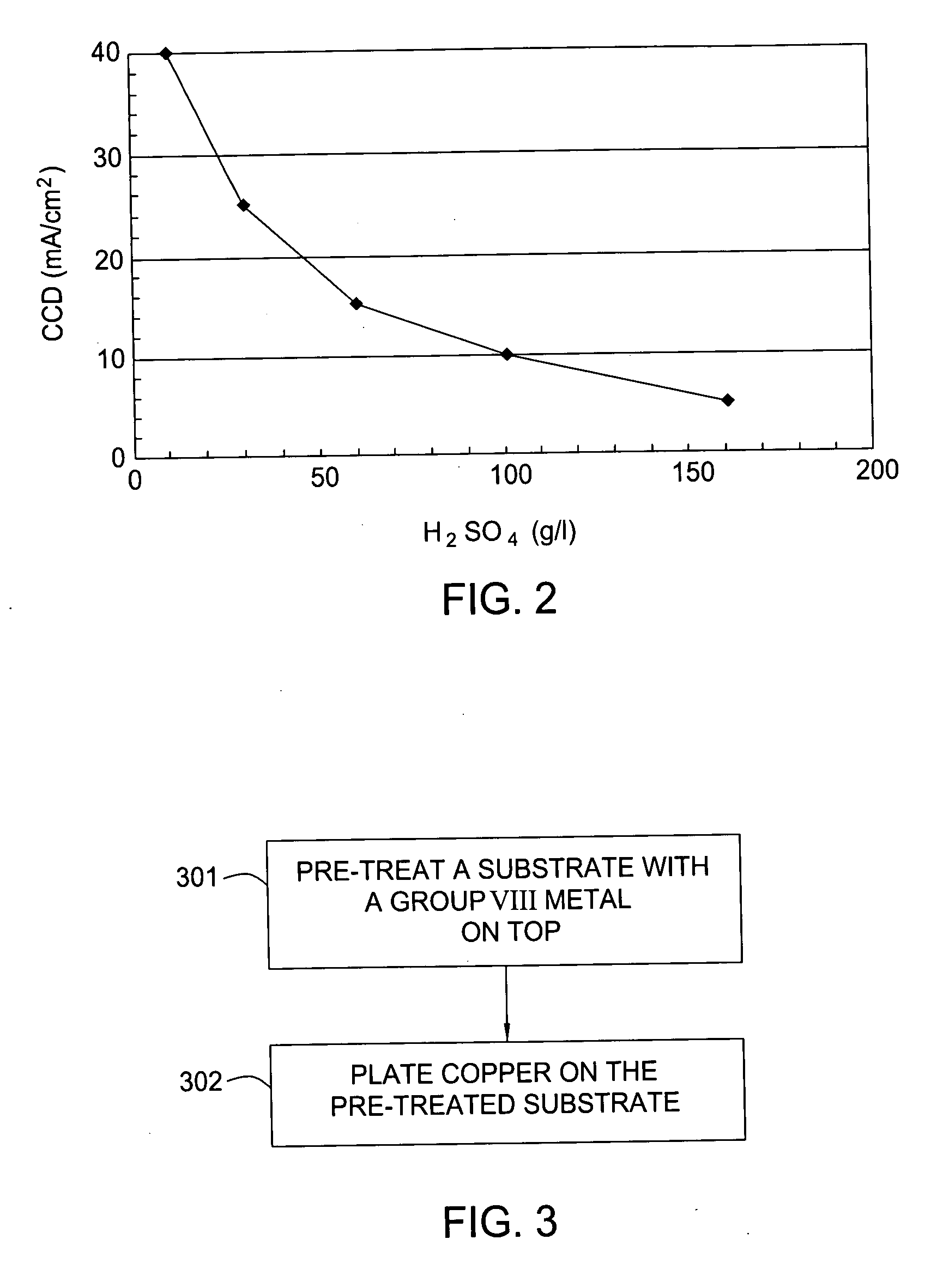

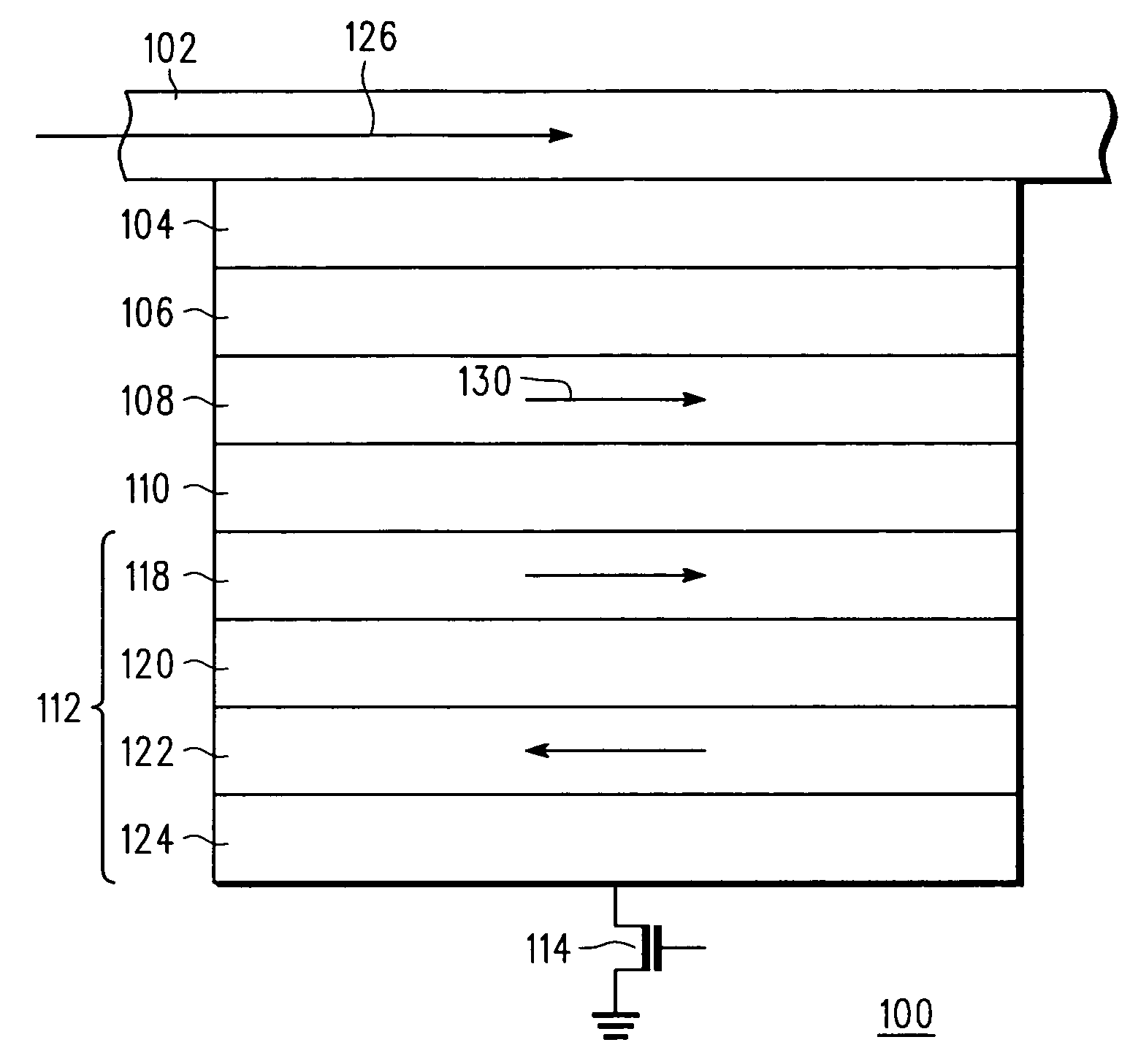

Method of direct plating of copper on a ruthenium alloy

InactiveUS20060283716A1Semiconductor/solid-state device detailsSolid-state devicesAlloyDirect plating

A method is disclosed for depositing a copper seed layer onto a substrate surface, generally onto a barrier layer that is an alloy of a group VIII metal and a refractory metal. In one aspect, the alloy consists of at least 50% ruthenium and the balance a copper diffusion barrier material. A copper layer is electroplated on the alloy directly. In one aspect, the surface of the barrier layer is conditioned prior to plating to improve adhesion and reduce the critical current density for plating on the barrier layer. The conditioning may include cathodic pre-treatment or a plasma pre-treatment in a hydrogen or hydrogen / helium mixture. In one aspect, the substrate surface is immersed in an acidic plating bath and a nucleation waveform is applied to form a seed layer. In another aspect, the substrate is immersed in a neutral or alkaline copper solution that includes complexed copper ions.

Owner:APPLIED MATERIALS INC

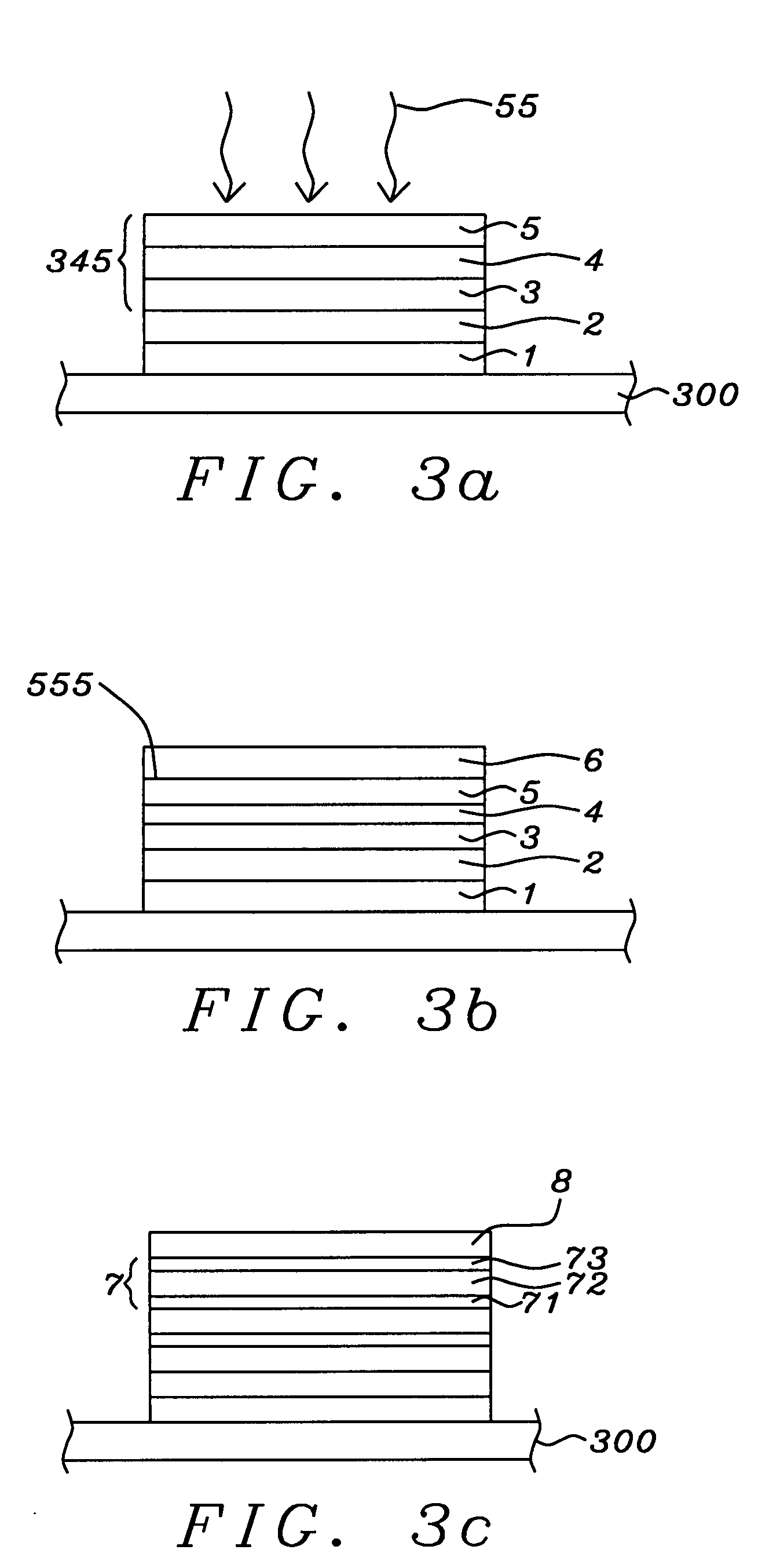

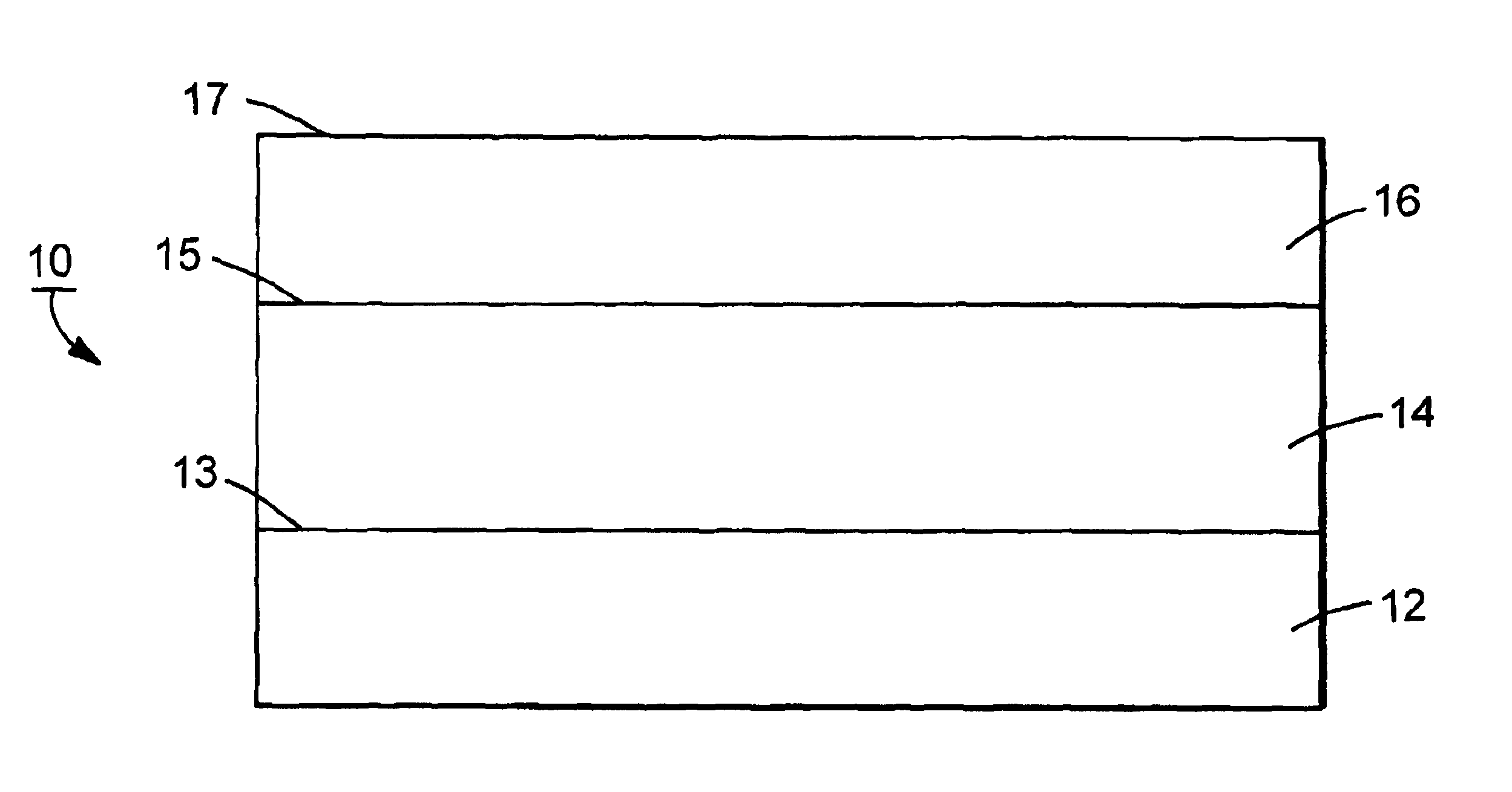

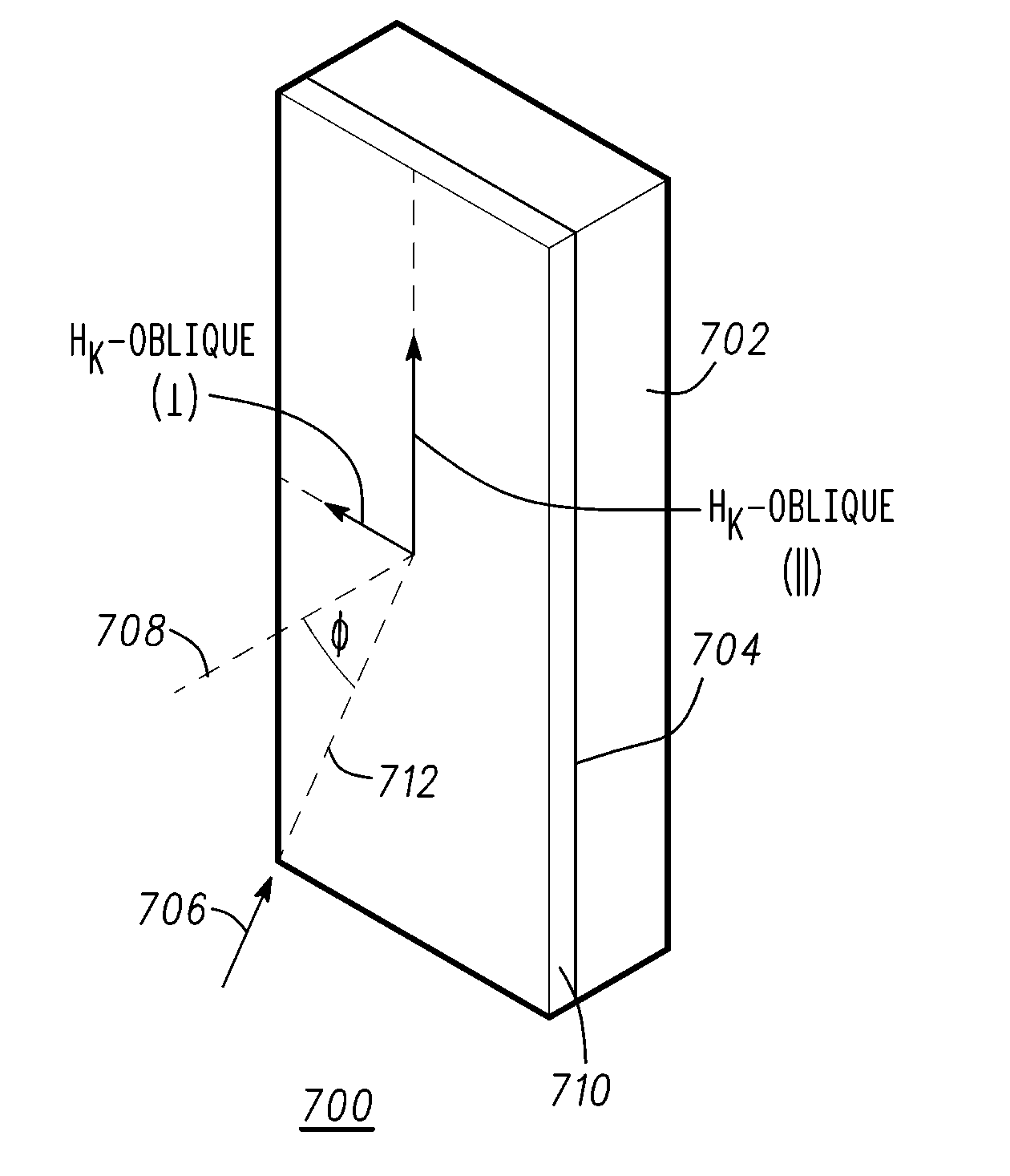

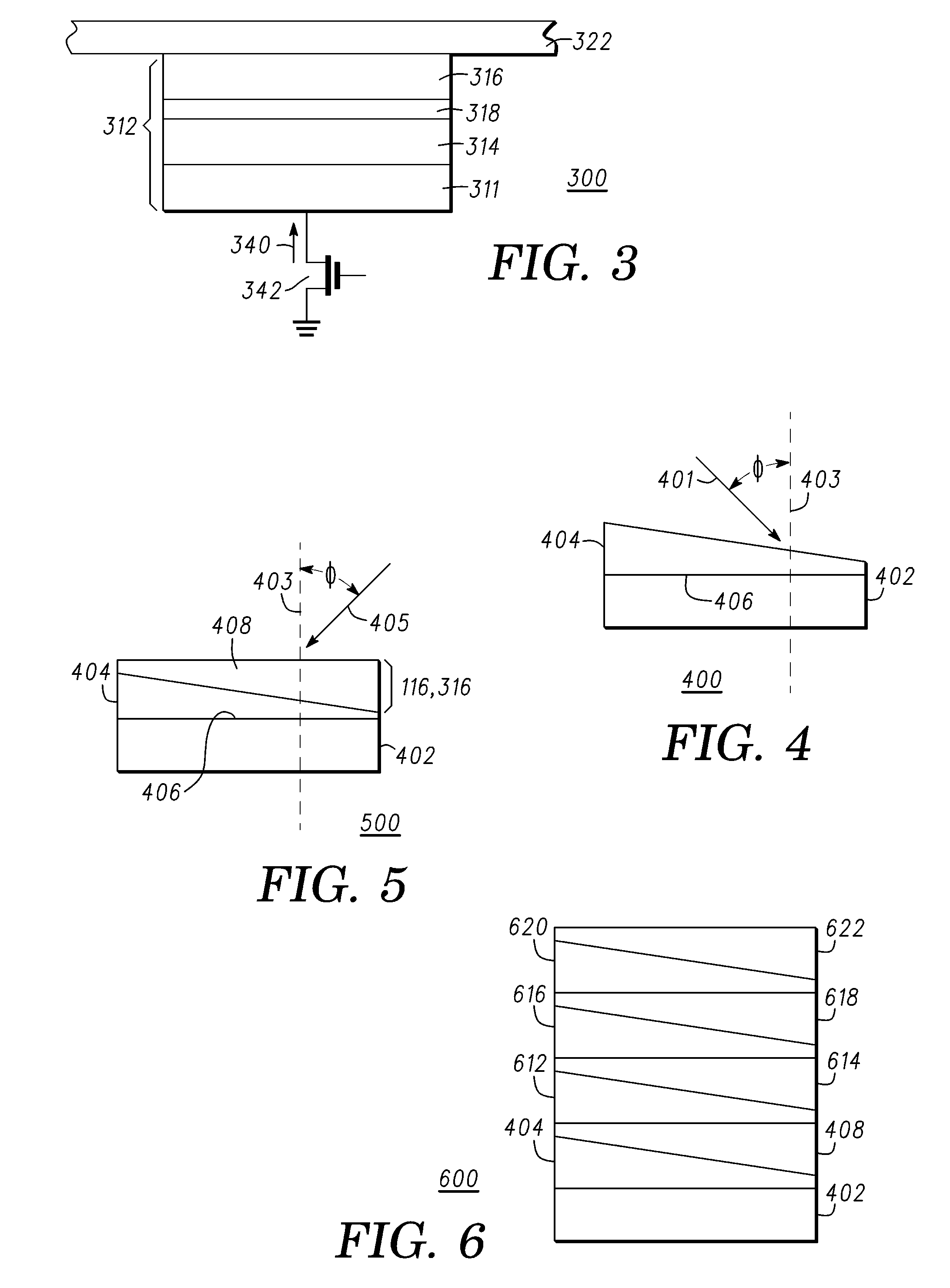

Structure and method for fabricating a magnetic thin film memory having a high field anisotropy

InactiveUS20120015099A1High magnetic materialLow critical currentNanomagnetismInductances/transformers/magnets manufactureDiffusionHigh energy

A method for depositing uniform and smooth ferromagnetic thin films with high deposition-induced microstructural anisotropy includes a magnetic material deposited in two or more static oblique deposition steps from opposed directions to form a free layer having a high kink Hk, a high energy barrier to thermal reversal, a low critical current in spin-torque switching embodiments, and improved resistance to diffusion of material from adjacent layers in the device. Nonmagnetic layers deposited by the static oblique deposition technique may be used as seed layers for a ferromagnetic free layer or to generate other types of anisotropy determined by the deposition-induced microstructural anisotropy. Additional magnetic or non-magnetic layers may be deposited by conventional methods adjacent to oblique layer to provide magnetic coupling control, reduction of surface roughness, and barriers to diffusion from additional adjacent layers in the device.

Owner:EVERSPIN TECHNOLOGIES

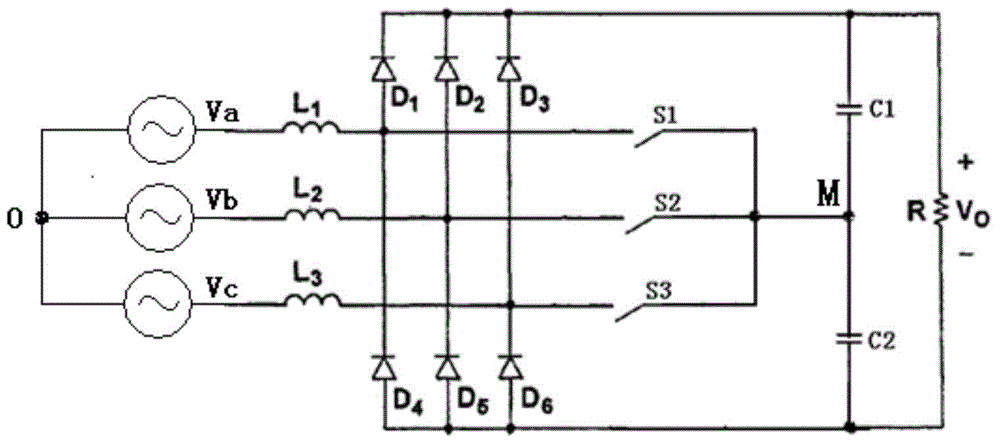

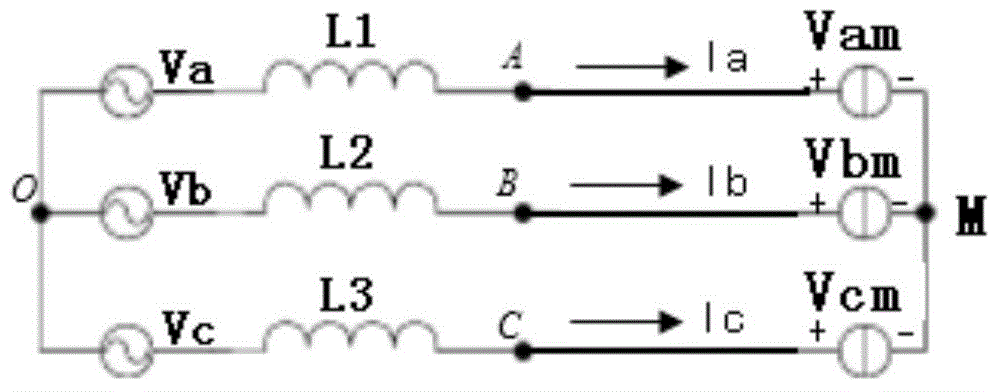

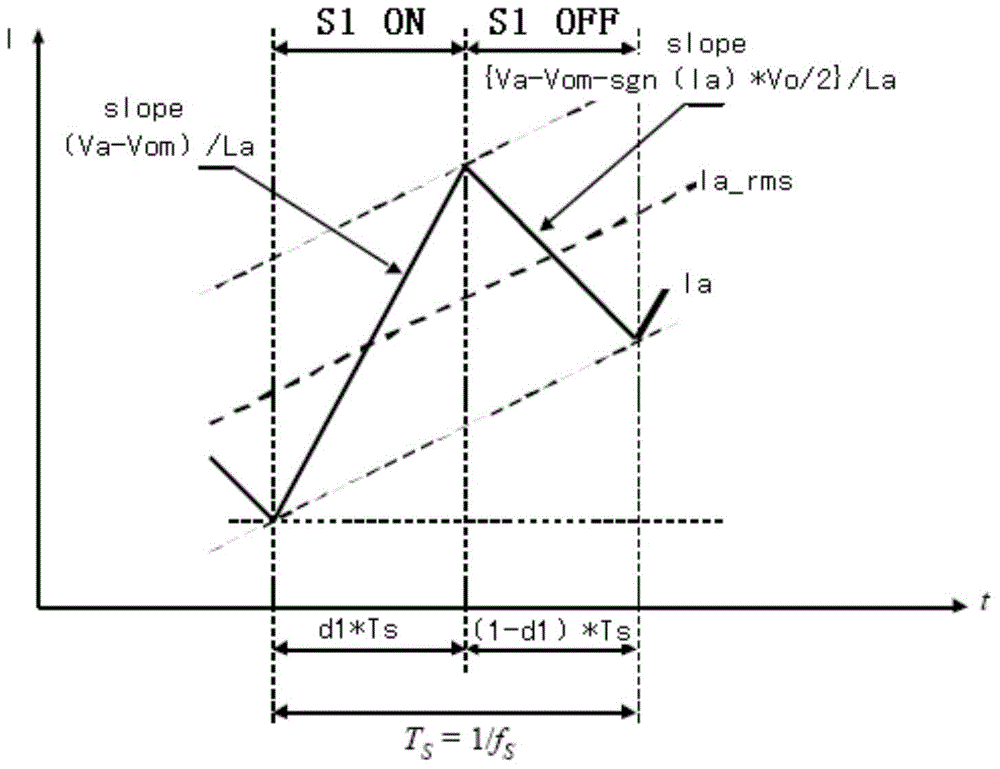

Novel three-phase PFC (power factor correction) rectifier

InactiveCN104811061AMeeting the Needs of High Power DensityImprove efficiencyAc-dc conversion without reversalEfficient power electronics conversionCapacitanceActive power factor correction

The invention provides a novel three-phase PFC (power factor correction) rectifier. The novel three-phase PFC rectifier is characterized in that three-phase input currents are respectively rectified by a full-wave rectifier circuit in a full-bridge mode after input voltages of three-phase alternating-current input ends are transmitted through respective boost inductors, switch circuits are respectively arranged between the boost inductors and middle points M of output voltages of output ends in a connected manner, voltages of output capacitors C1 and C2 of the output ends are boosted and stabilized by the switch circuits by means of PWM (Pulse width modulation) required by corresponding phases, and accordingly constant voltages V<o> can be outputted even under the condition of variation of loads R of the output ends in design ranges; magnet excitation and demagnetization circuits which comprise capacitors are formed between the middle points M of the output voltages of the output ends and nodes of the input voltages of the three-phase alternating-current input ends, so that the boost inductors can be decoupled under working conditions and can work in critical current modes. The novel three-phase PFC rectifier has the advantages that the novel three-phase PFC rectifier can work in the critical current modes (CRM) and also can work in CCM (continuous current mode) or DCM (discontinuous current mode) states according to requirements, and accordingly requirements on high power density and high efficiency can be met.

Owner:ANHUI DYNAMIC POWER

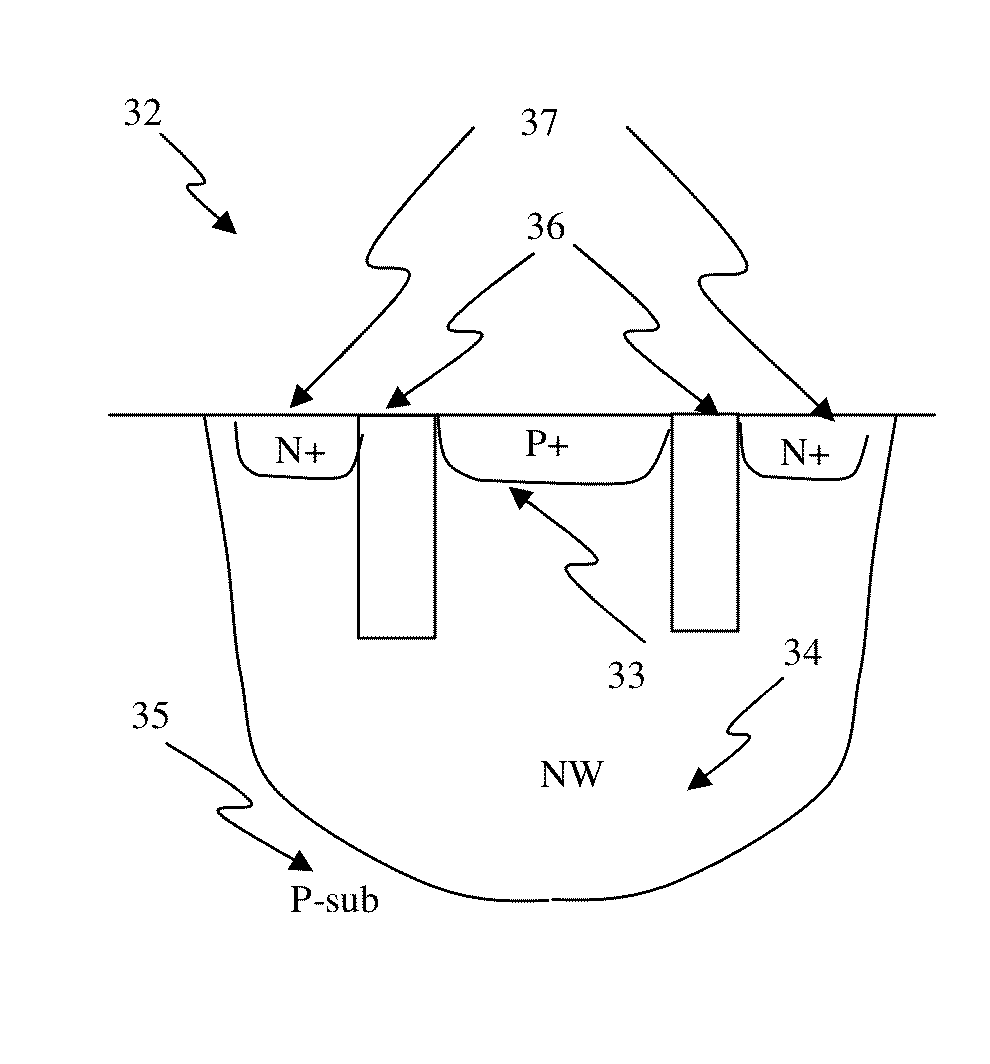

Method and structure for reliable electrical fuse programming

ActiveUS20150003142A1Small cell sizeLow costMagnetic-field-controlled resistorsSolid-state devicesElectrical resistance and conductanceAlgorithm

A method of programming electrical fuses reliably is disclosed. If a programming current exceeds a critical current, disruptive mechanisms such as rupture, thermal runaway, decomposition, or melt, can be a dominant programming mechanism such that programming is not be very reliable. Advantageously, by controlled programming where programming current is maintained below the critical current, electromigration can be the sole programming mechanism and, as a result, programming can be deterministic and very reliable. In this method, fuses can be programmed in multiple shots with progressive resistance changes to determine a lower bound that all fuses can be programmed satisfactorily and an upper bound that at least one fuse can be determined failed. If programming within the lower and upper bounds, defects due to programming can be almost zero and, therefore, defects are essentially determined by pre-program defects.

Owner:ATTOPSEMI TECH CO LTD

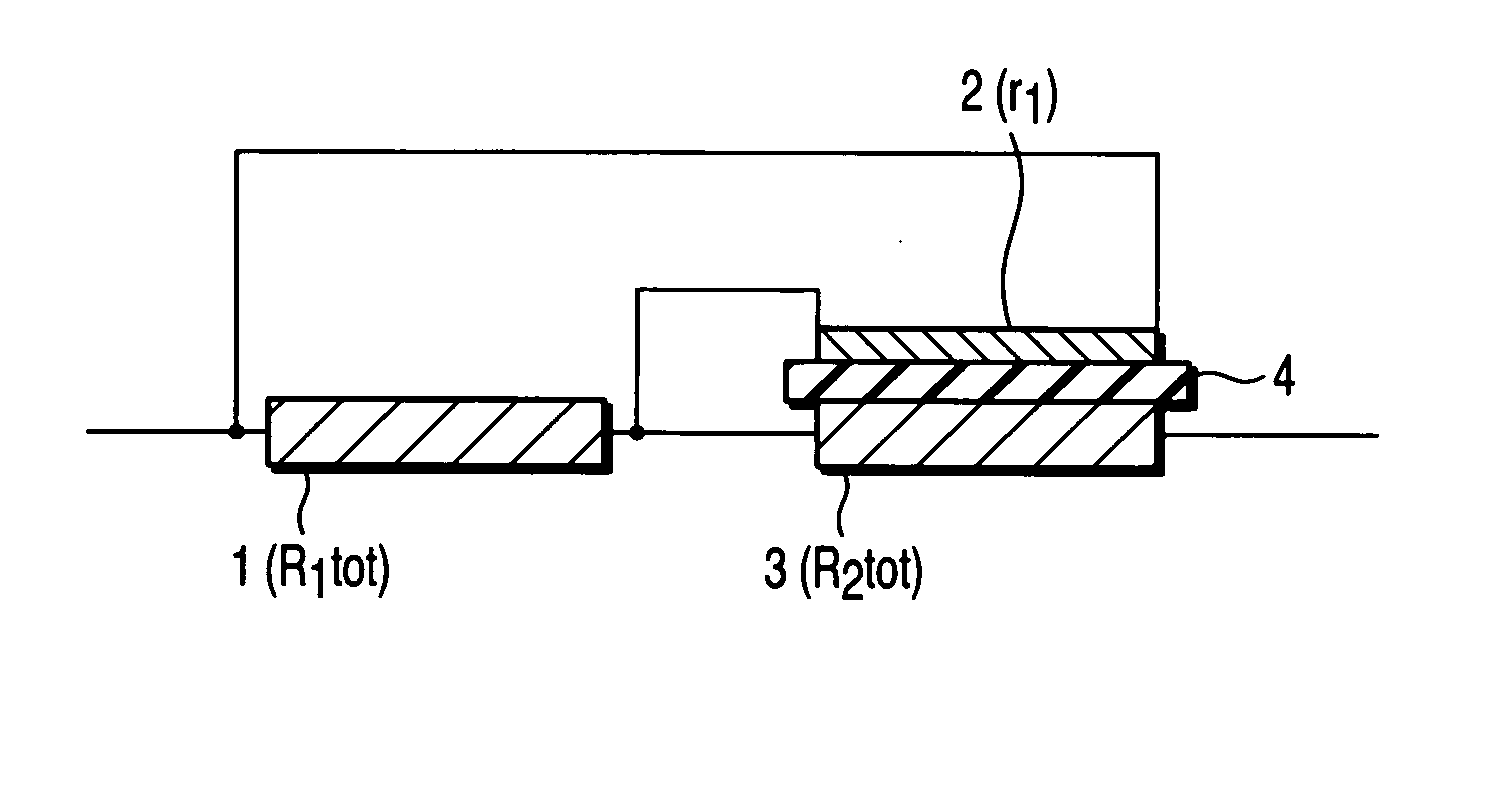

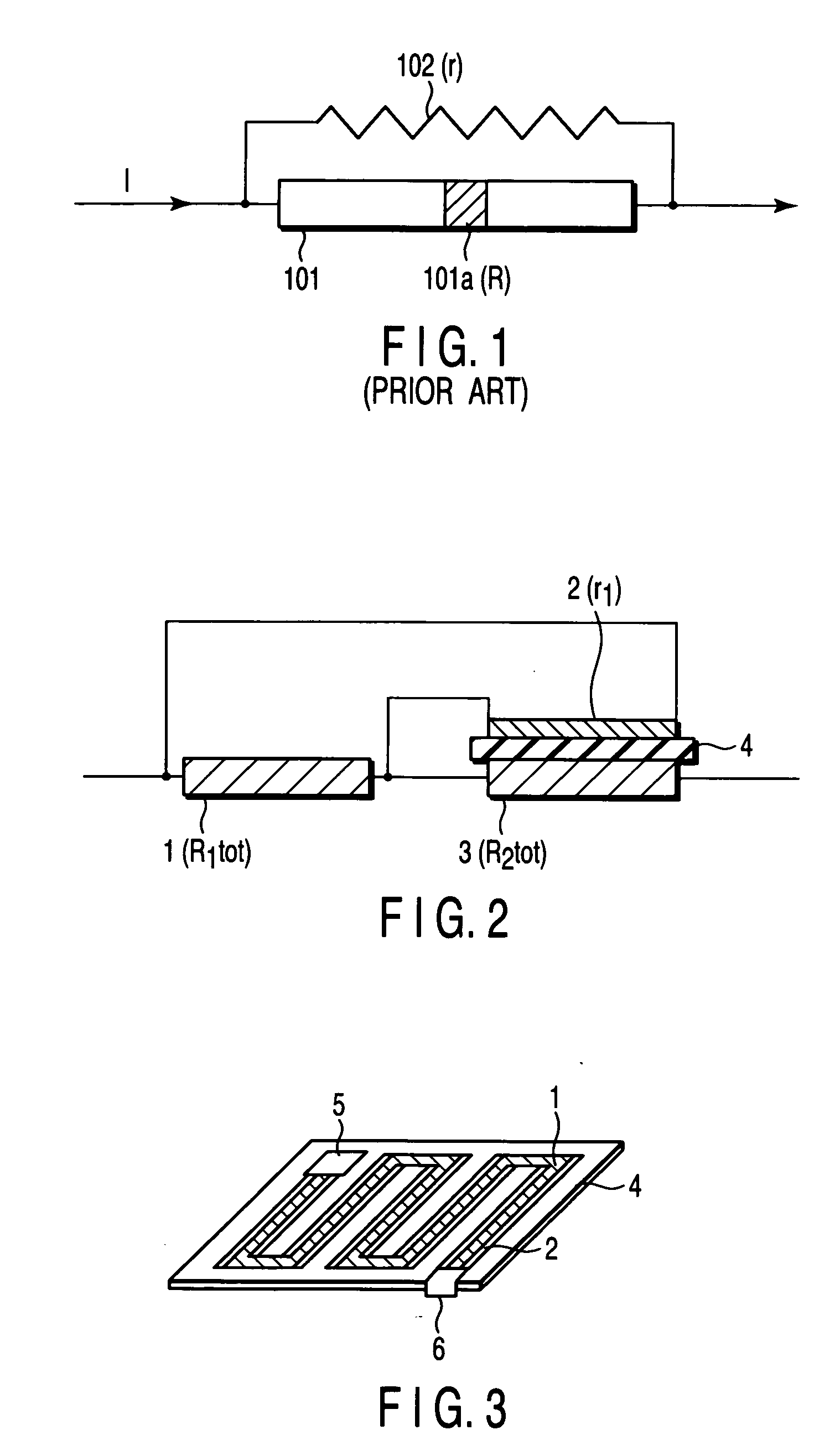

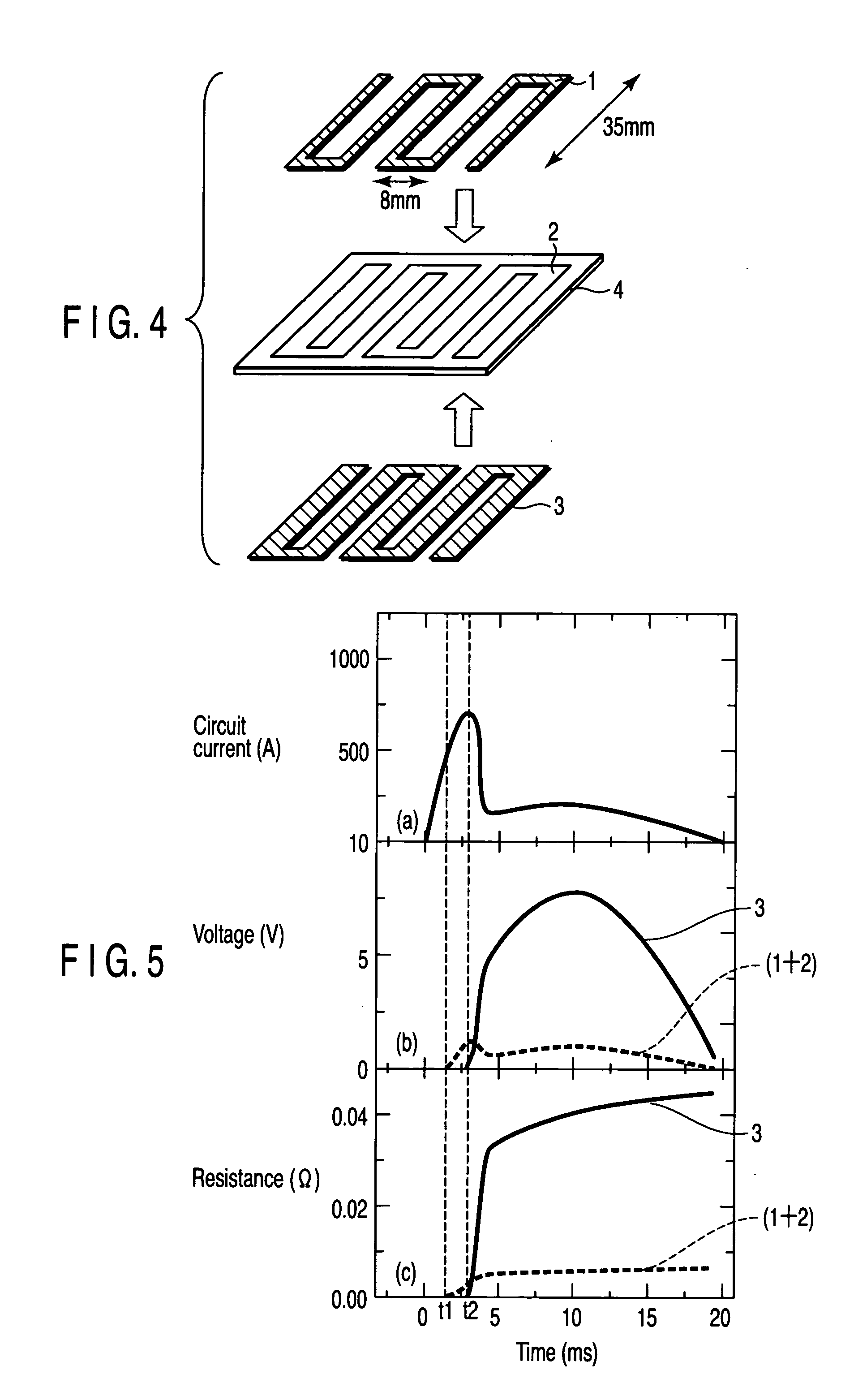

Superconducting current limiting element

InactiveUS20050153843A1Increase valueSuperconductors/hyperconductorsConductive materialCurrent limitingElectrical conductor

A superconducting current limiting element has a parallel circuit including a first superconductor and a normal conductor connected in parallel, and a second superconductor connected in series to the parallel circuit and having a critical current value higher than that of the first superconductor. Further, at least one of the normal conductor and the first superconductor, and the second superconductor are disposed on the same insulating substrate.

Owner:KK TOSHIBA

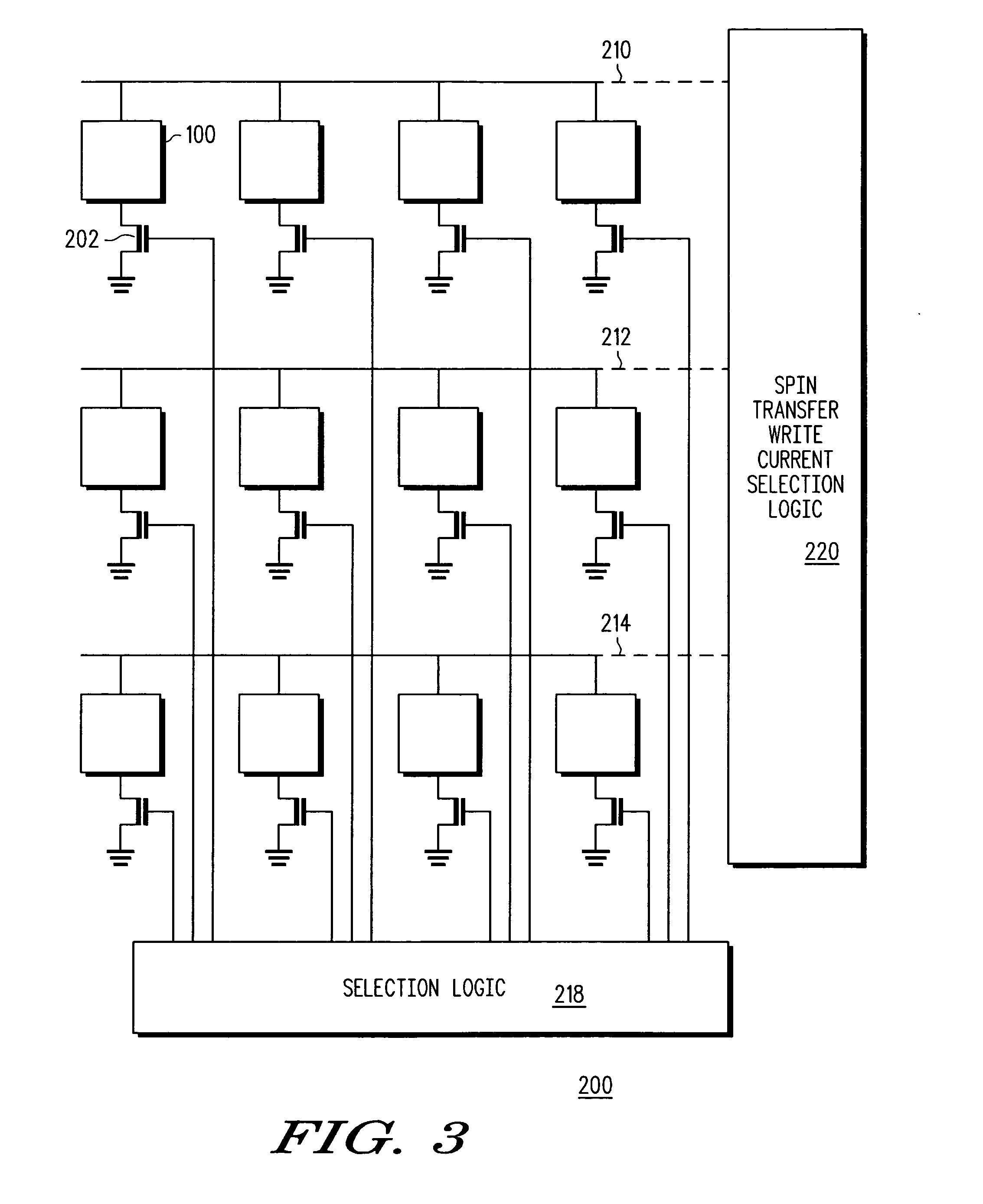

Spin momentum transfer MRAM design

We describe the structure and method of formation of a STT MTJ or GMR MRAM cell element that utilizes transfer of spin torque as a mechanism for changing the magnetization direction of a free layer. The critical current is reduced by constructing the free layer as a lamination comprising two ferromagnetic layers sandwiching a coupling valve layer. When the Curie temperature of the coupling valve layer is above the temperature of the cell, the two ferromagnetic layers are exchange coupled in parallel directions of their magnetization. When the coupling valve layer is above its Curie temperature, it no longer exchange couples the layers and they are magnetostatically coupled. In the exchange coupled configuration, the free layer serves to store data and the cell can be read. In its magnetostatically coupled configuration, the cell can be more easily written upon because one of the layers can assist the spin torque transfer by its magnetostatic coupling. If the free layer is formed as a multi-layered lamination of N periodically repeating combinations of a ferromagnetic layer and a coupling valve layer, the critical current can be reduced by a factor of N.

Owner:TAIWAN SEMICON MFG CO LTD

Plating chemistry and method of single-step electroplating of copper on a barrier metal

InactiveUS20050274622A1Semiconductor/solid-state device manufacturingSemiconductor devicesCopper platingHydrogen

Embodiments of a method of copper plating a substrate surface with a group VIII metal layer have been described. In one embodiment, a method of plating copper on a substrate surface with a group VIII metal layer comprises pre-treating the substrate surface by removing a group VIII metal surface oxide layer and / or surface contaminants and plating the substrate in a copper plating solution comprising about 50 g / l to about 300 g / l of sulfuric acid at an initial plating current higher than the critical current density to deposit a continuous copper layer on the substrate surface. The Pre-treating the substrate can be accomplished by annealing the substrate in an environment with a hydrogen-containing gas environment and / or a non-reactive gas(es) to Ru, by a cathodic treatment in an acid-containing bath, or by immersing the substrate in an acid-containing bath.

Owner:APPLIED MATERIALS INC

Spin-transfer based MRAM with reduced critical current density

A magnetic random access memory device include a spin torque MRAM cell (100) having a reduced switching current (Ic) wherein standard materials may be used for a free layer (108). A fixed magnetic element (112) polarizes electrons passing therethrough, and the free magnetic element (108) having a first plane anisotropy comprises a first magnetization (130) whose direction is varied by the spin torque of the polarized electrons. An insulator (110) is positioned between the fixed magnetic element (112) and the free magnetic element (108), and a keeper layer (104) positioned contiguous to the free magnetic element (108) and having a second plane anisotropy orthogonal to the first plane anisotropy, reduces the first plane anisotropy and hence reduces the spin torque switching current (Ic). The keeper layer (104) may include alternating synthetic antiferromagnetic layers (132, 134) of magnetization approximately equal in magnitude and opposite in direction.

Owner:EVERSPIN TECHNOLOGIES

Single flux quantum circuits

ActiveUS20090153180A1Reduce and eliminate unnecessary power dissipationQuantum computersPower consumption reductionQuantum circuitTransformer

Superconducting single flux quantum circuits are disclosed herein, each having at least one Josephson junction which will flip when the current through it exceeds a critical current. Bias current for the Josephson junction is provided by a biasing transformer instead of a resistor. The lack of any bias resistors ensures that unwanted power dissipation is eliminated.

Owner:NORTHROP GRUMMAN SYST CORP

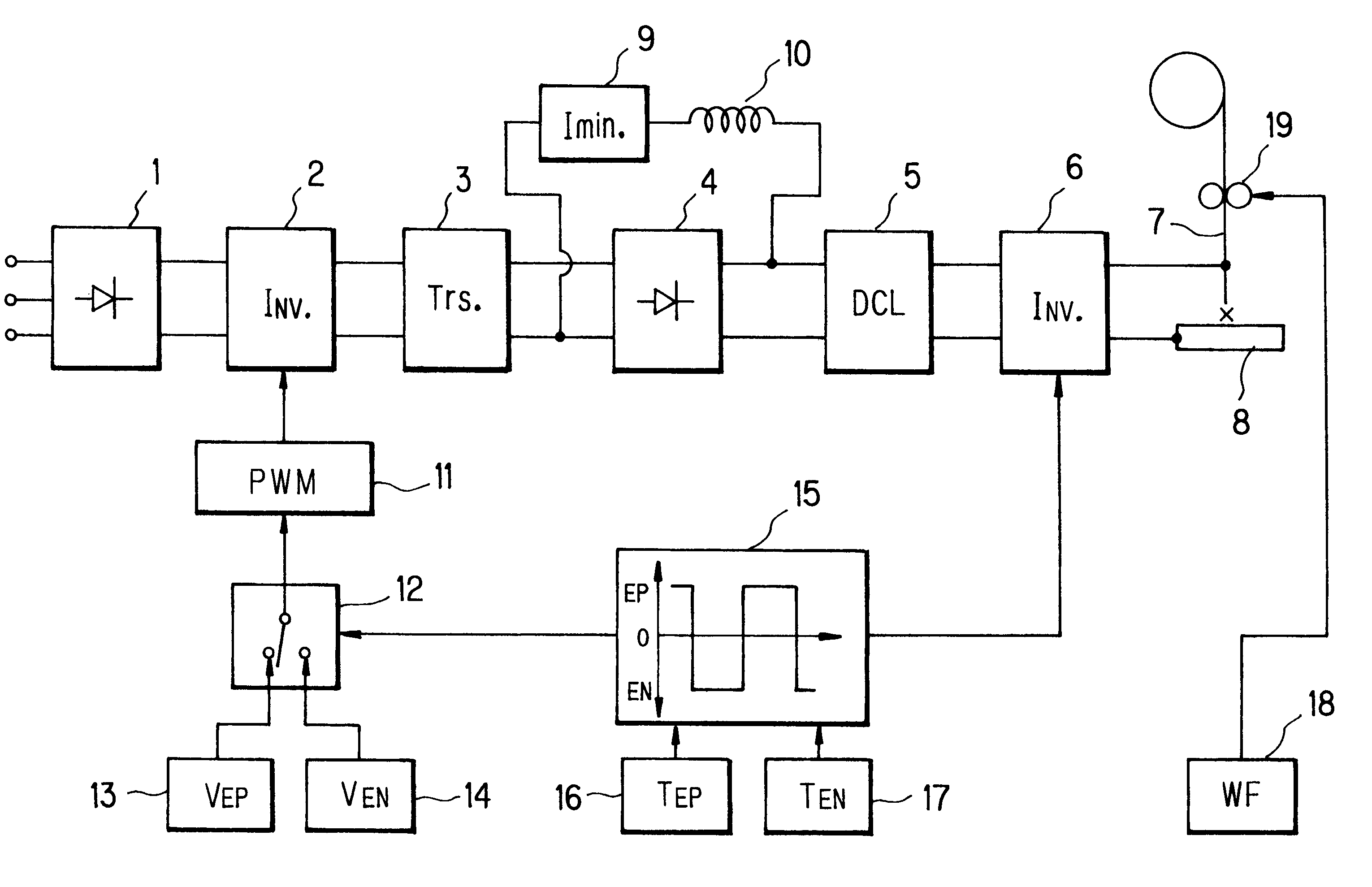

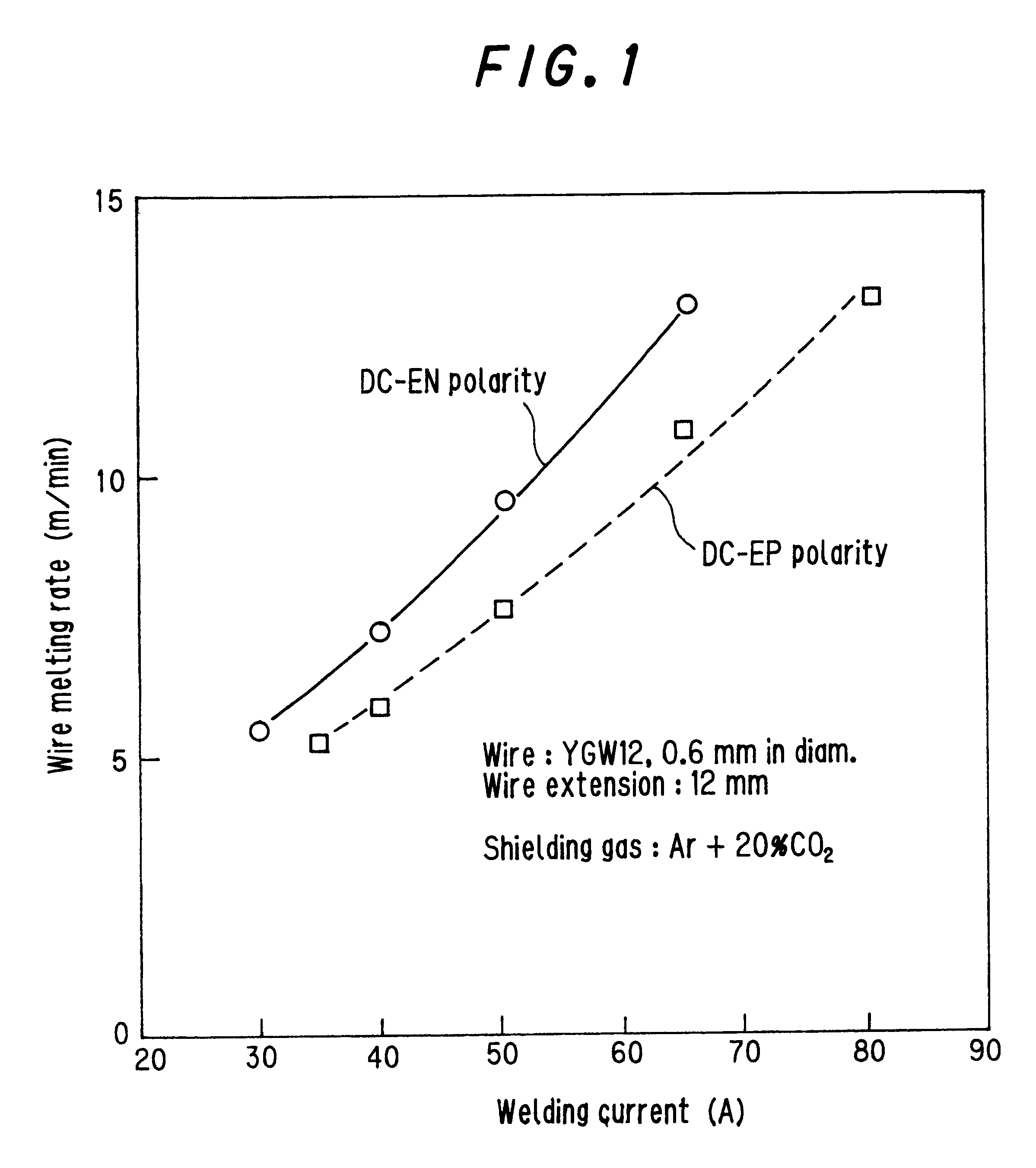

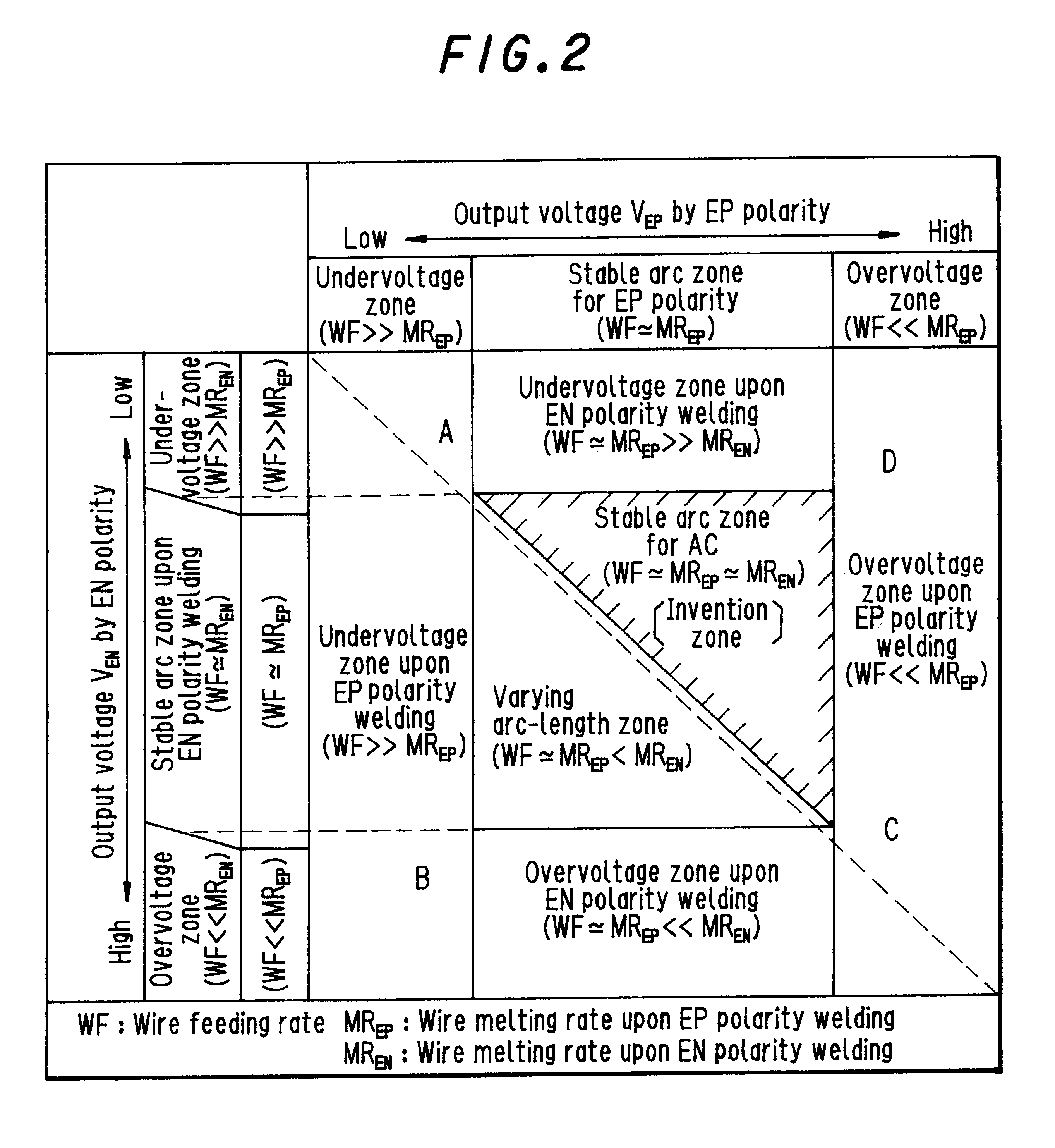

Gas-shielded AC arc welding method and machine making use of consumable electrode

An EP output voltage to be outputted during a period of EP polarity is set so that a welding current becomes equal to or lower than a critical current level, and an EN output voltage to be outputted during a period of EN polarity is set at a level lower than the EP output voltage. This makes it possible to substantially equalize a wire melting rate in the period of EN polarity and that in the period of EP polarity with each other. Even at such a short arc length as causing frequent short circuiting, gas-shielded AC arc welding making use of a consumable wire can be still performed stably so that high wire melting rate, shallow penetration, convex weld reinforcement and the like, which are characteristic features of AC welding, can each be set selectively at a desired level or in a desired shape depending on the application.

Owner:HITACHI SEIKO LTD +1

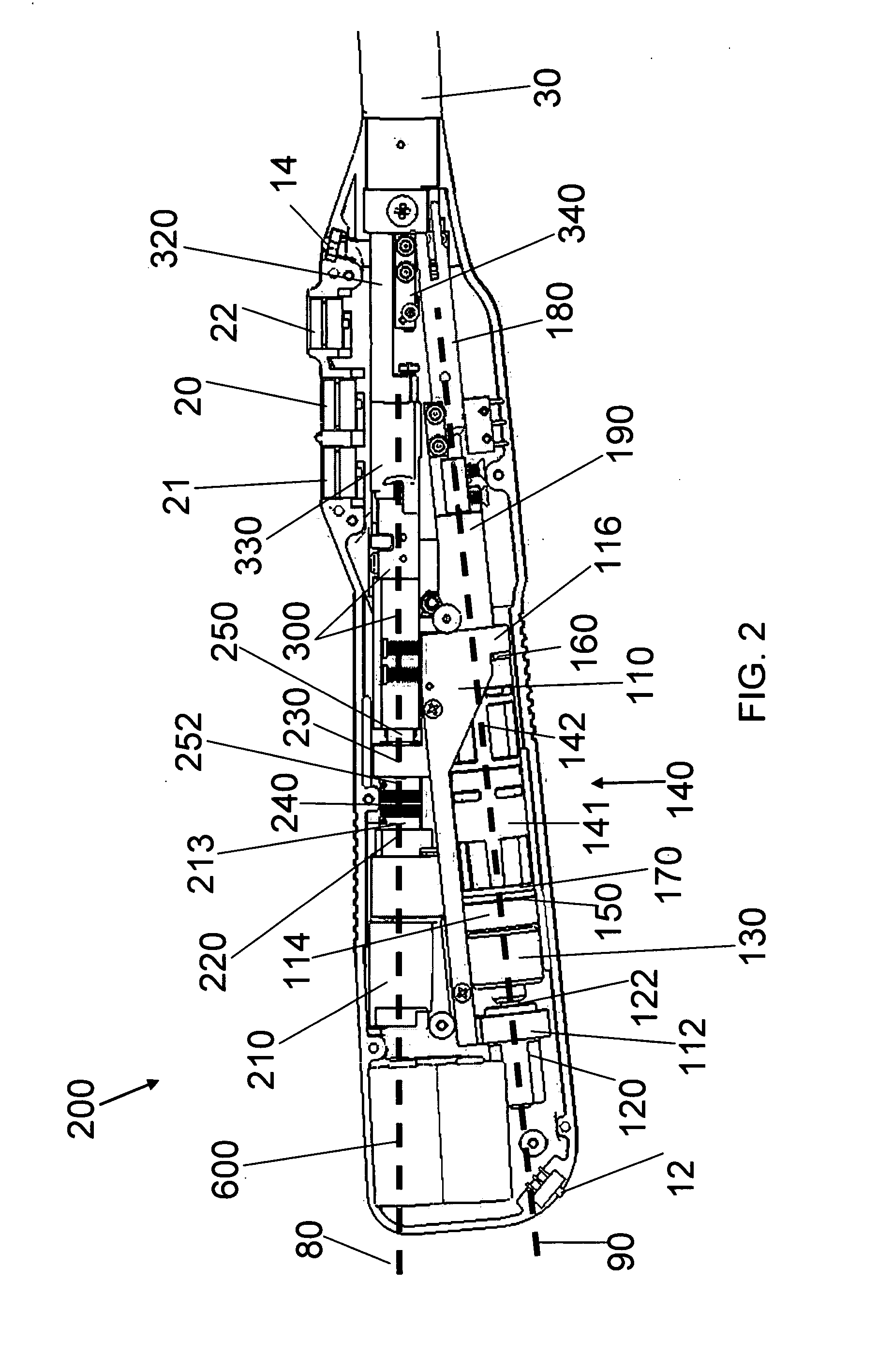

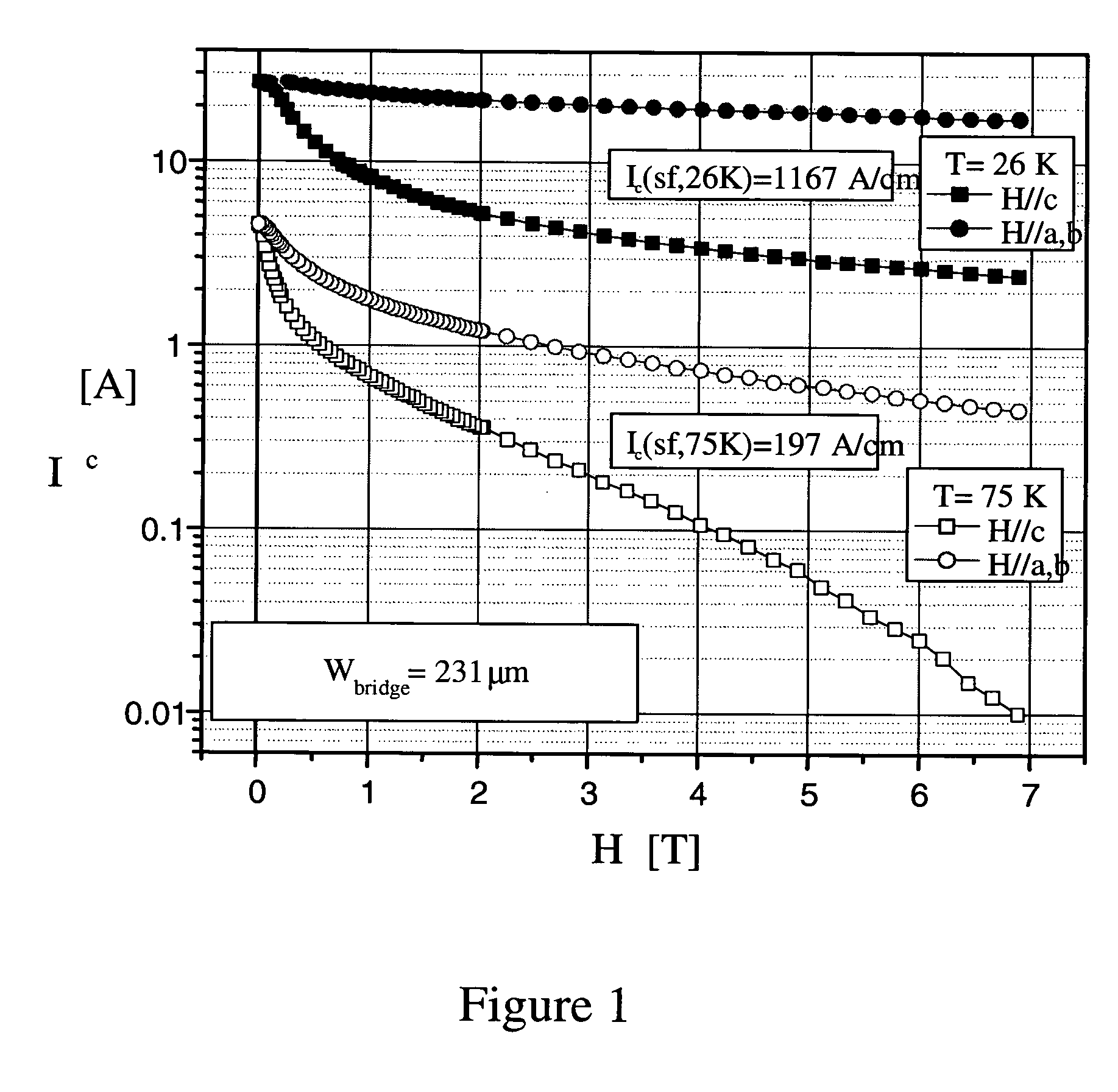

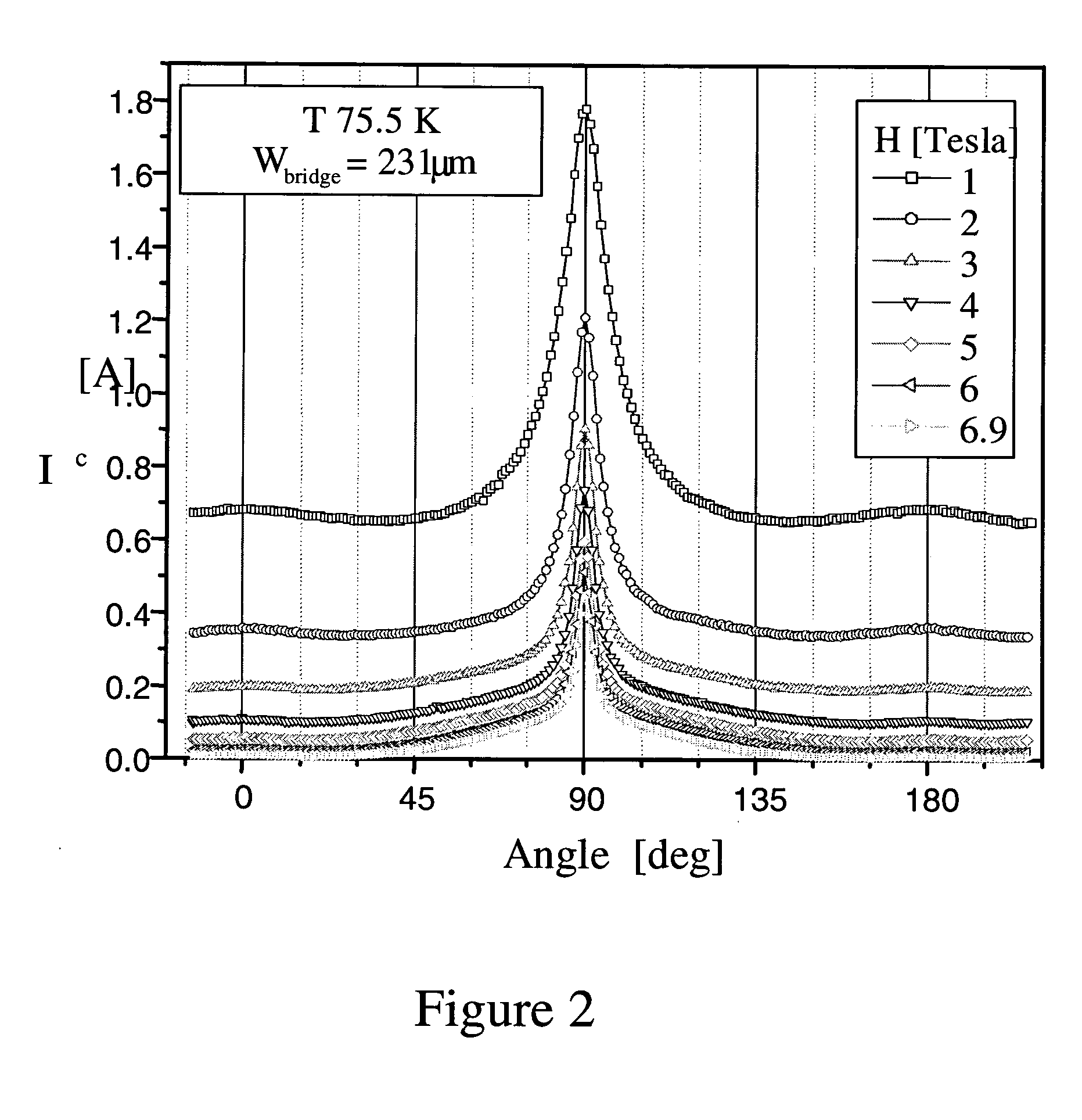

High temperature superconducting wires and coils

ActiveUS20070111893A1Enhance critical current densityHigh densitySuperconductors/hyperconductorsMagnetsElectrical conductorHigh-temperature superconductivity

A superconducting wire includes first and second superconducting layers disposed on one or more substrates in stacked relationship, the first superconducting layer comprising a high temperature superconducting oxide of a first composition and the second superconducting layer comprising a high temperature superconducting layer of a second composition, wherein the first and second compositions are different. The first superconductor layer optionally includes a high temperature superconductor composition selected to provide enhanced critical current (Ic(c)) in the presence of magnetic fields perpendicular to surface of the superconducting layer (H / / c). The second superconductor layer optionally includes a high temperature superconductor composition selected to provide enhanced critical current (Ic) in the presence of magnetic fields parallel to surface of the superconducting layer (H / / ab).

Owner:AMERICAN SUPERCONDUCTOR

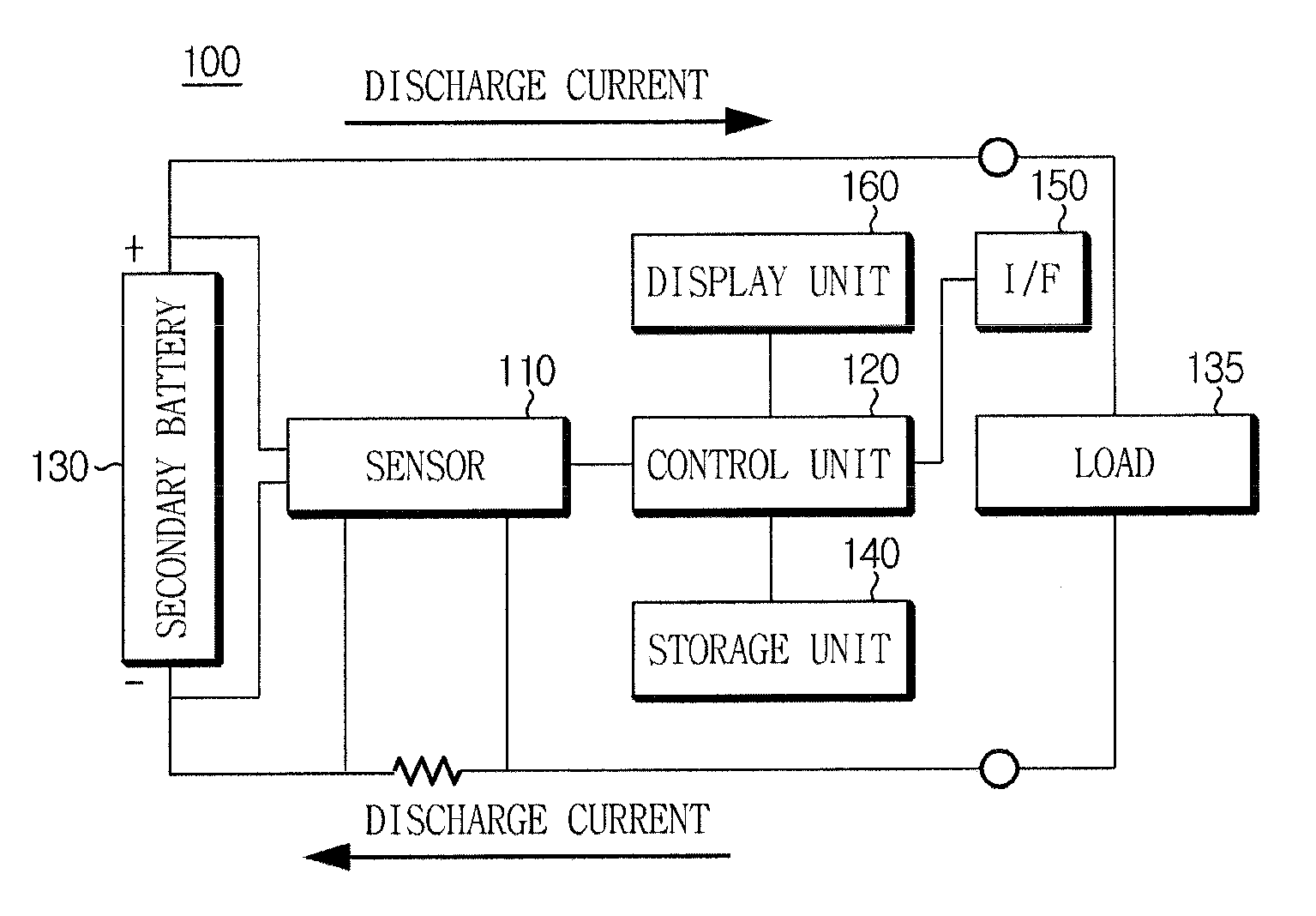

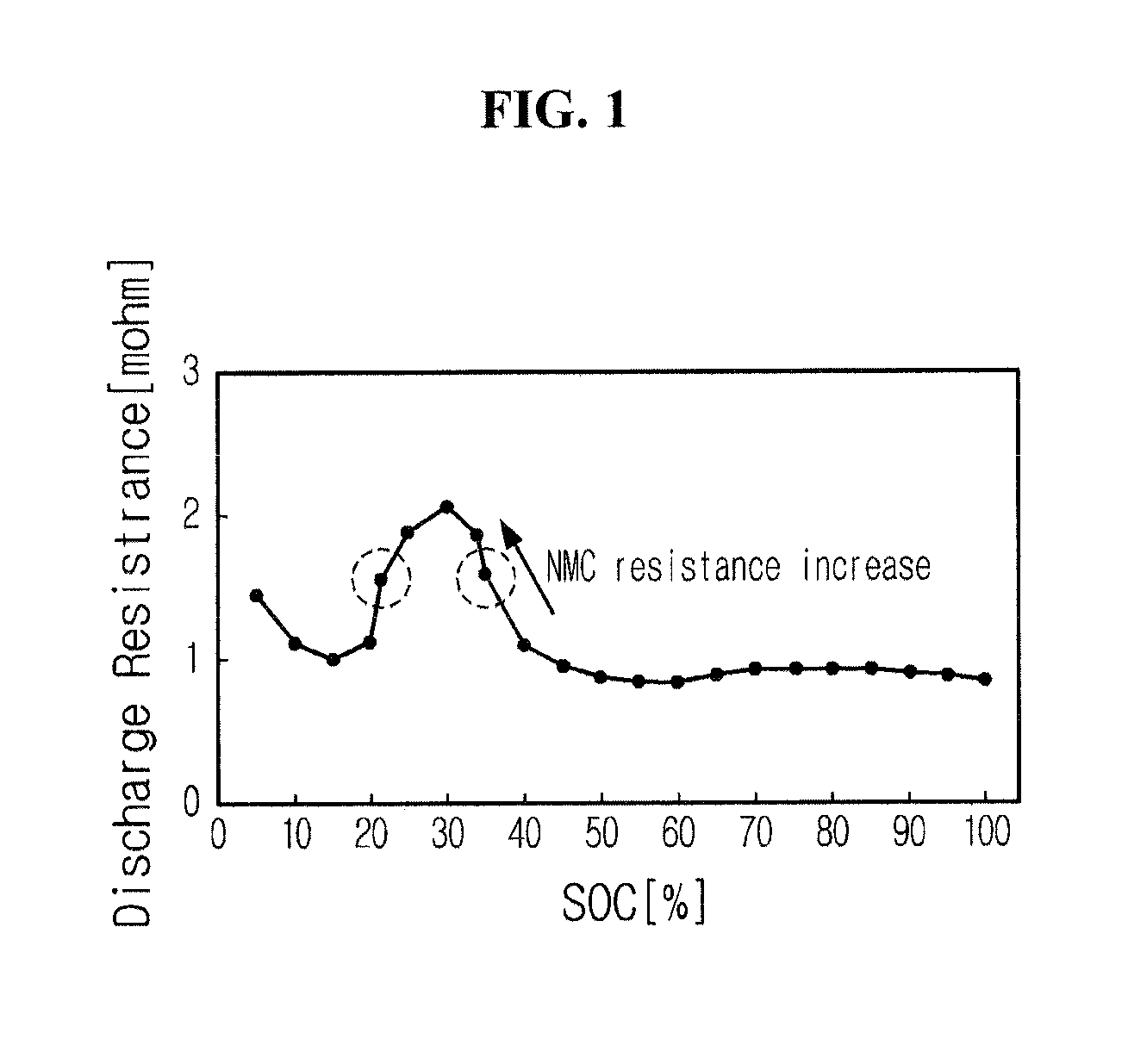

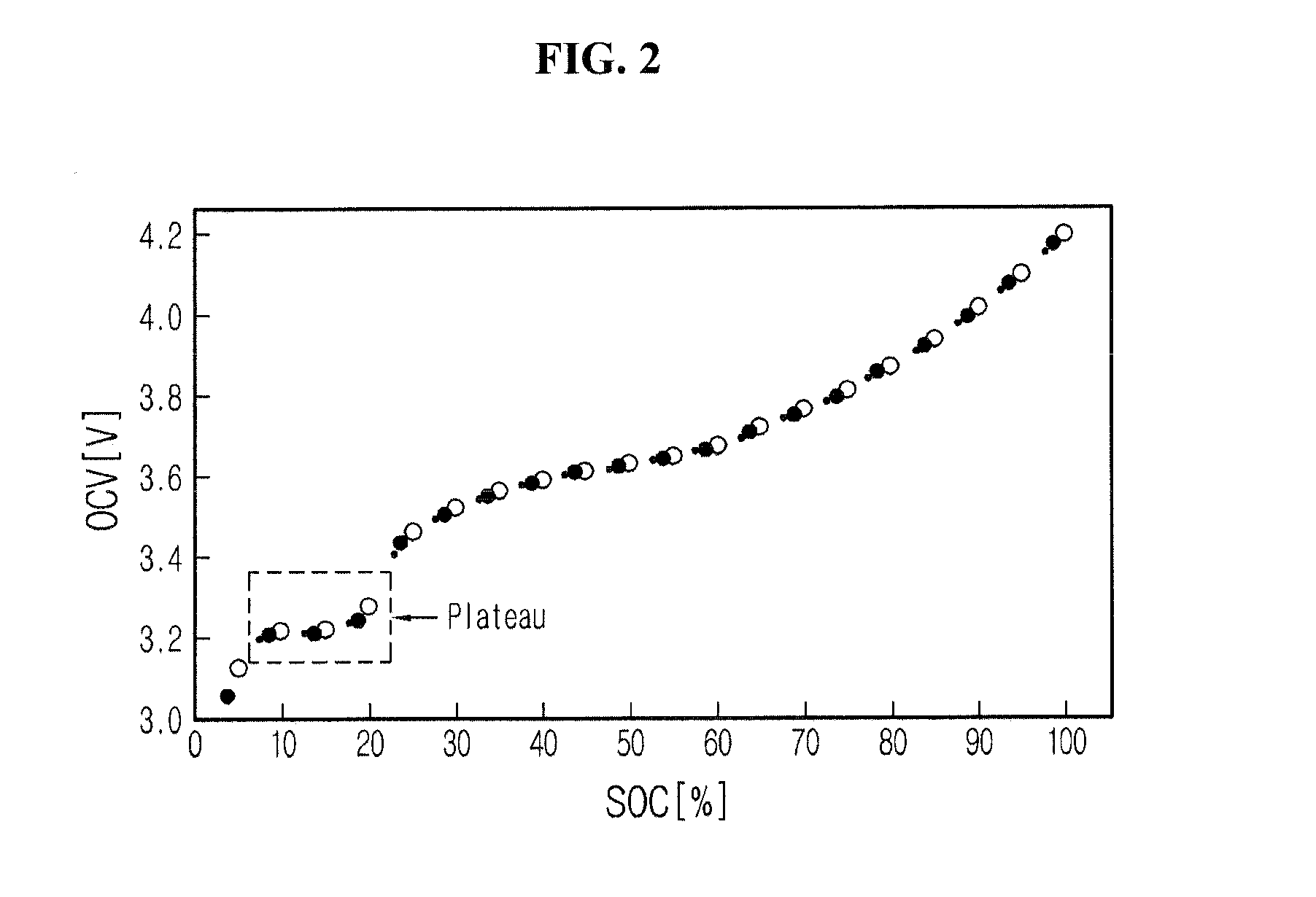

Apparatus of estimating power of secondary battery including blended cathode material and method thereof

ActiveUS20150046110A1Estimated easily and simplyCell electrodesElectrical testingElectrical resistance and conductanceState of charge

Disclosed are an apparatus and method for estimating the power of a secondary battery including a blended cathode material. The apparatus according to the present disclosure includes a sensor configured to measure a discharge current of a secondary battery comprising a cathode including a blended cathode material, and a control unit configured to estimate a state of charge of the secondary battery, determine a discharge voltage of the secondary battery using a first resistance predefined corresponding to the state of charge under a first condition in which a magnitude of the discharge current is smaller than a magnitude of a critical current and a second resistance predefined corresponding to the state of charge under a second condition in which the magnitude of the discharge current is larger than the magnitude of the critical current, and determine the power of the secondary battery from the determined discharge voltage and the measured discharge current.

Owner:LG ENERGY SOLUTION LTD

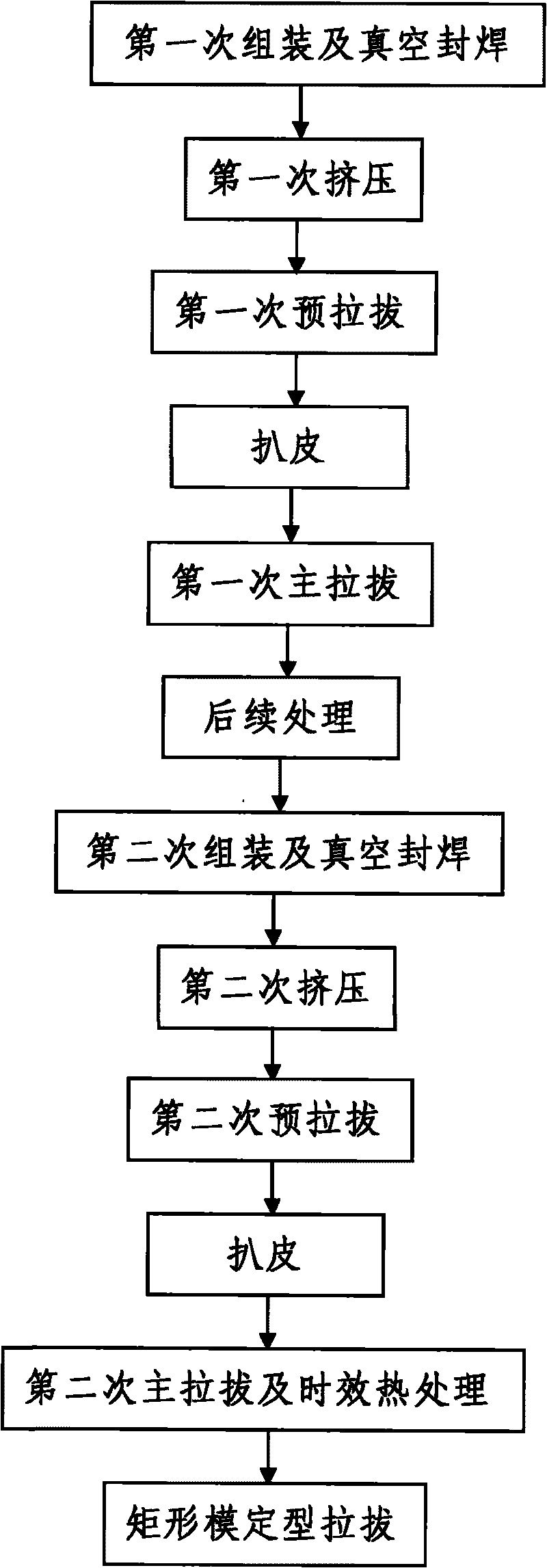

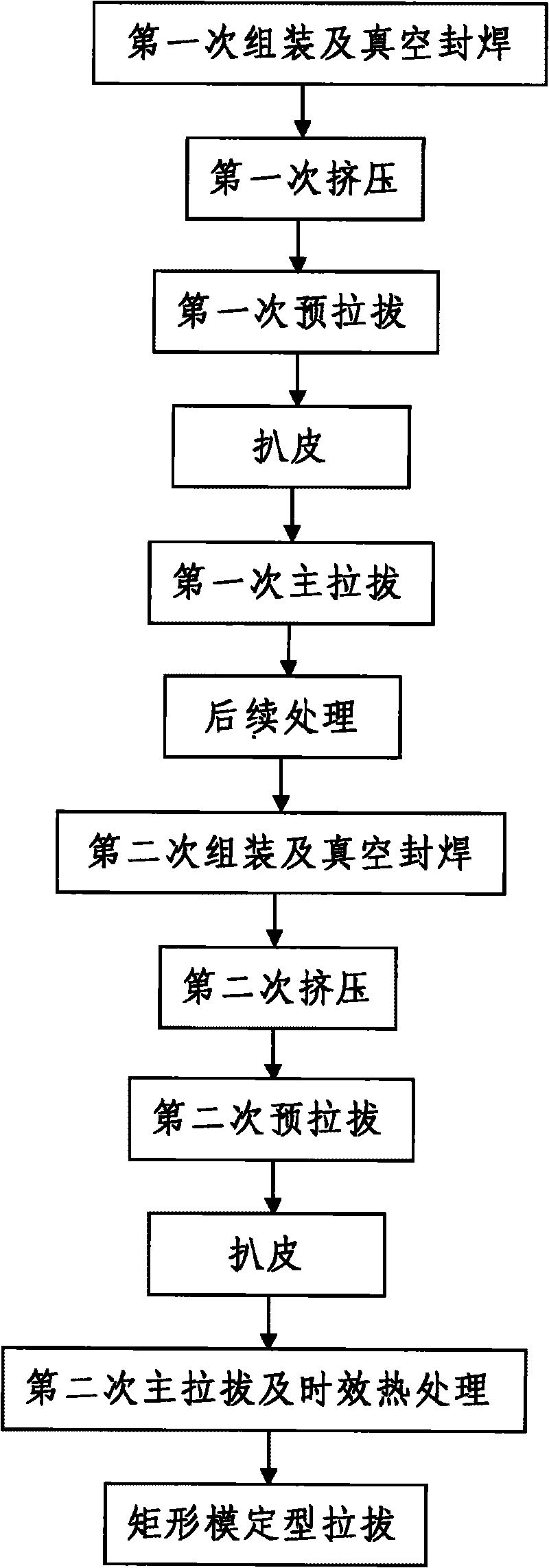

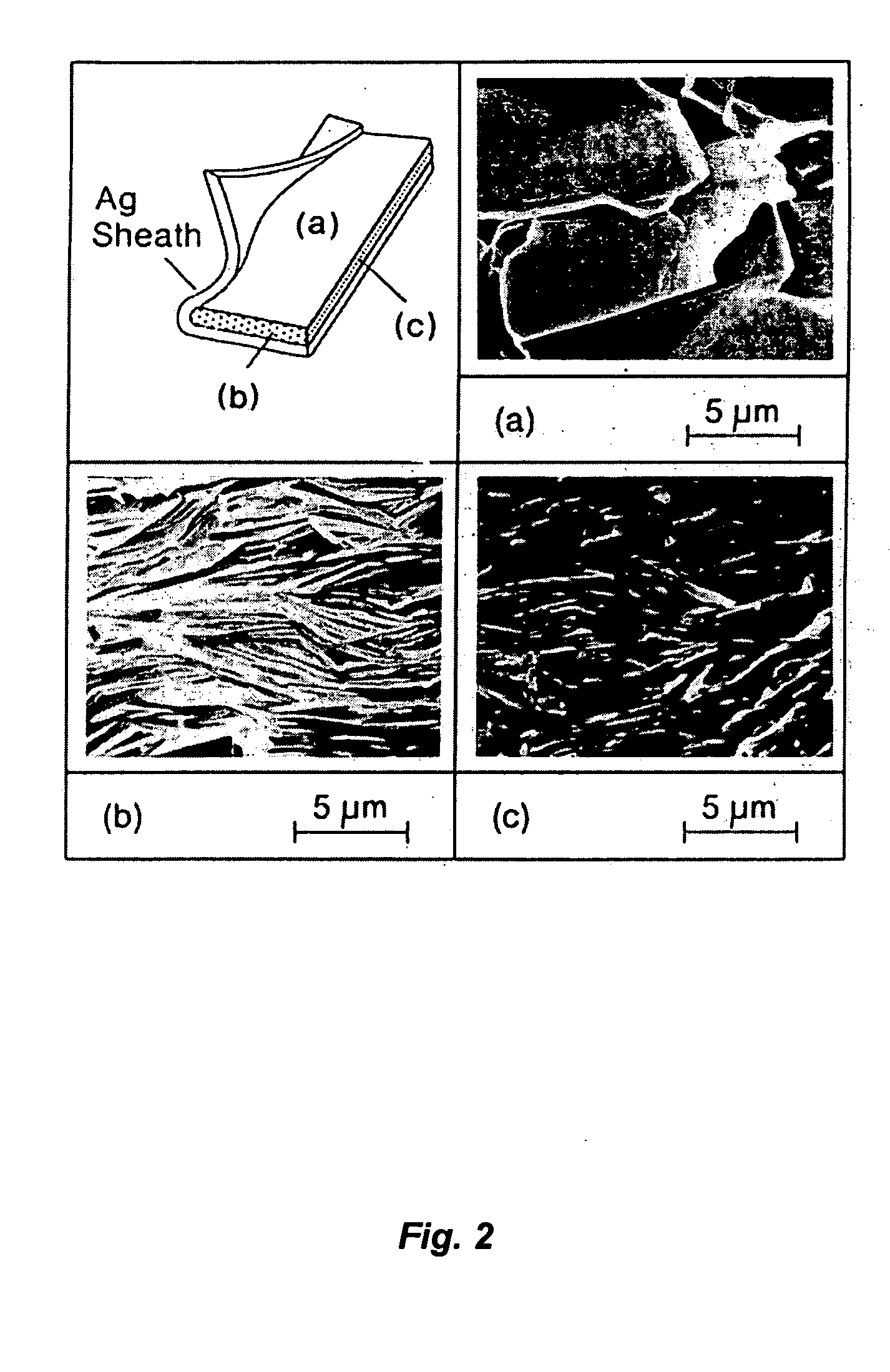

Preparation method for NbTi/Cu multi-core composite superconducting wire with rectangular section

InactiveCN101728029AThe process steps are simpleShort processSuperconductors/hyperconductorsSuperconductor devicesConductor CoilMaterials science

The invention discloses a preparation method for an NbTi / Cu multi-core composite superconducting wire with a rectangular section, which comprises the following steps of: firstly, assembling an NbTi bar, a pure Nb inner pipe and an oxygen-free copper sheath in turn to form an NbTi / Cu composite sheath, sealing an upper end cap and a lower end cap of the NbTi / Cu composite sheath through vacuum welding, and then performing primary extrusion to obtain an NbTi / Cu composite bar; secondly, drawing and scaling the composite bar, and keeping on drawing the composite bar to obtain a hexagonal core rod, and performing assembling for the second time; and thirdly, performing vacuum solder sealing, hot isostatic pressing, secondary extrusion, bar drawing and scaling on the sheath which is assembled in the second time to finally obtain the NbTi / Cu multi-core composite superconducting wire with the rectangular section. The preparation method has the advantages of simple process flow, low preparation cost and good preparation effect, improves the fill factor among windings in the process of coiling a superconducting magnet but simultaneously keeps high critical current density for the wire, and overcomes the defects that the conventional four-high mill or forming roll mill is unevenly stressed, is difficult to process and the like in the rolling process.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

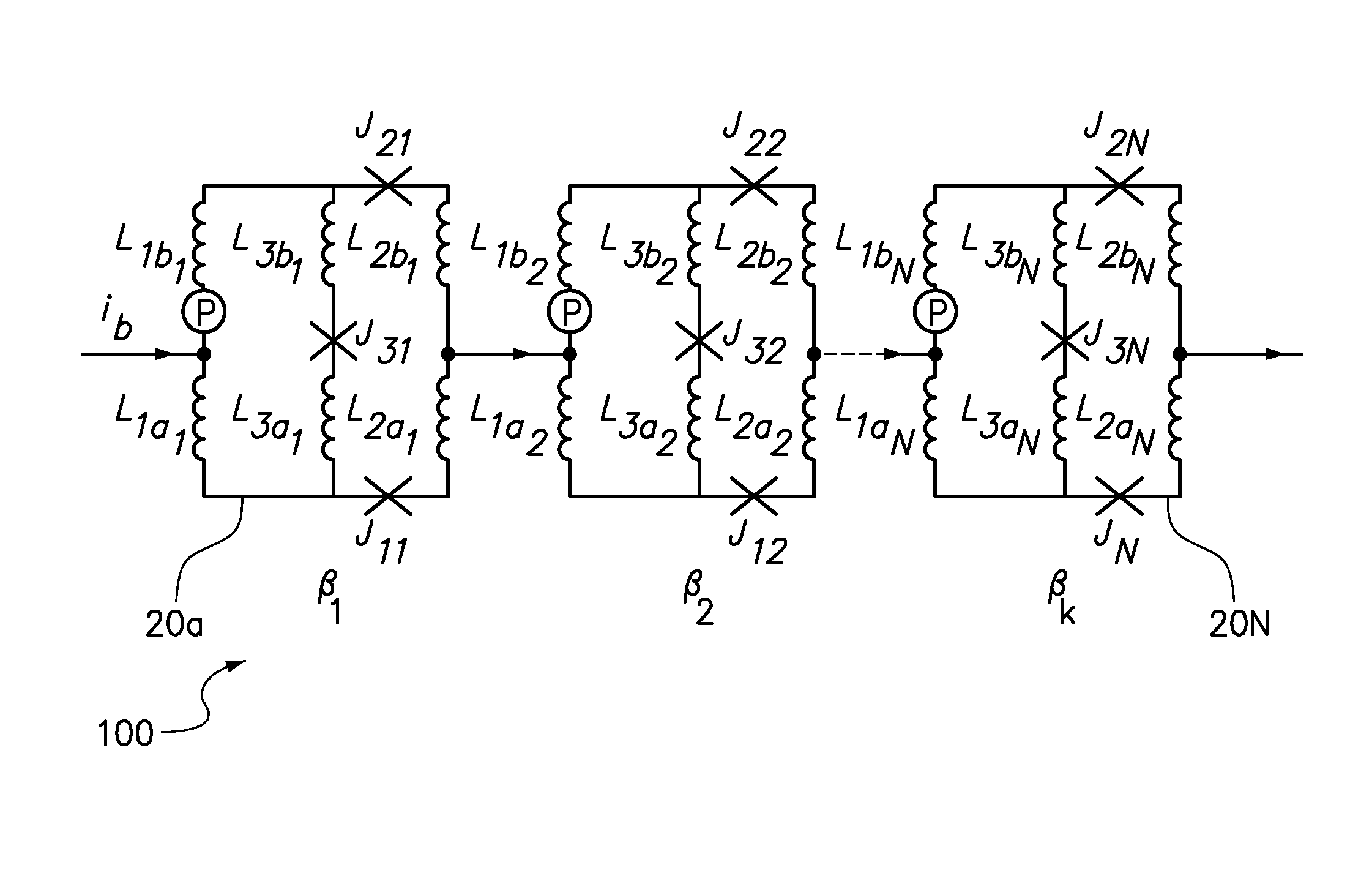

Linear voltage response of non-uniform arrays of bi-SQUIDs

InactiveUS9097751B1Magnetic field measurement using superconductive devicesVoltage responseLinearity

An amplifier and method for improving linear response includes a plurality of N bi-SQUIDs. Each bi-SQUID has a non-uniform bi-SQUID parameter βi, described by βi=2πLiIciΦ0 can be defined for each bi-SQUIDs from i=1 to N, where Li is the loop inductance, ic is the critical current, and Φ0 is a flux quantum for each bi-SQUID. The non-uniform bi-SQUIDs can be connected in series or in parallel to establish a Superconducting Quantum Interference Filter (SQIF) array of bi-SQUIDs. Once connected, a mutual inductance between the connected bi-SQUIDs can be established. If the mutual inductance between connected bi-SQUIDs is accounted for, careful manipulation of the critical current or the loop size, or both, of each bi-SQUID can result in extremely uniform behavior (linear response) of the SQIF when considered as a whole, even though the behavior of the element bi-SQUIDs is non-uniform (different βi, parameters).

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Superconductors and methods for making such superconductors

InactiveUS20050173679A1Simple manufacturing processInexpensive mass productionConductive materialOrganic conductorsElectrical conductorVolumetric Mass Density

This invention concerns an improvement of the supercurrent carrying capabilities, i.e. the increase of critical current densities, of polycrystalline superconductor structures, especially of high-Tc superconductors fabricated with a coated conductor technique to provide superconducting layers containing flat grains. A superconductor with superior critical current density is obtained by joining, i.e. pressing or otherwise bringing into intensive facial contact, preferably superconducting contact, two or more such superconducting layers.

Owner:MANNHART JOCHEN DIETER +4

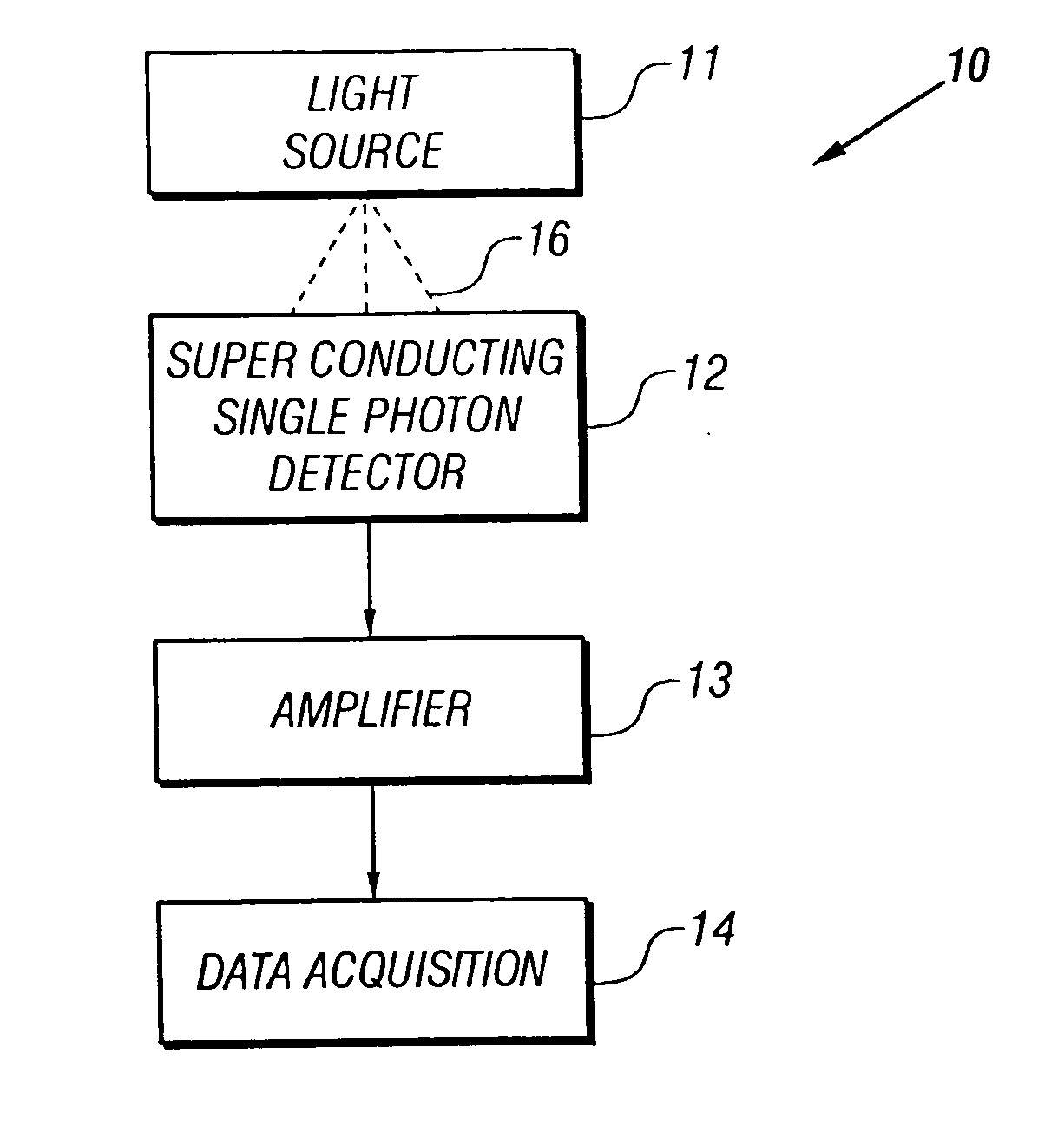

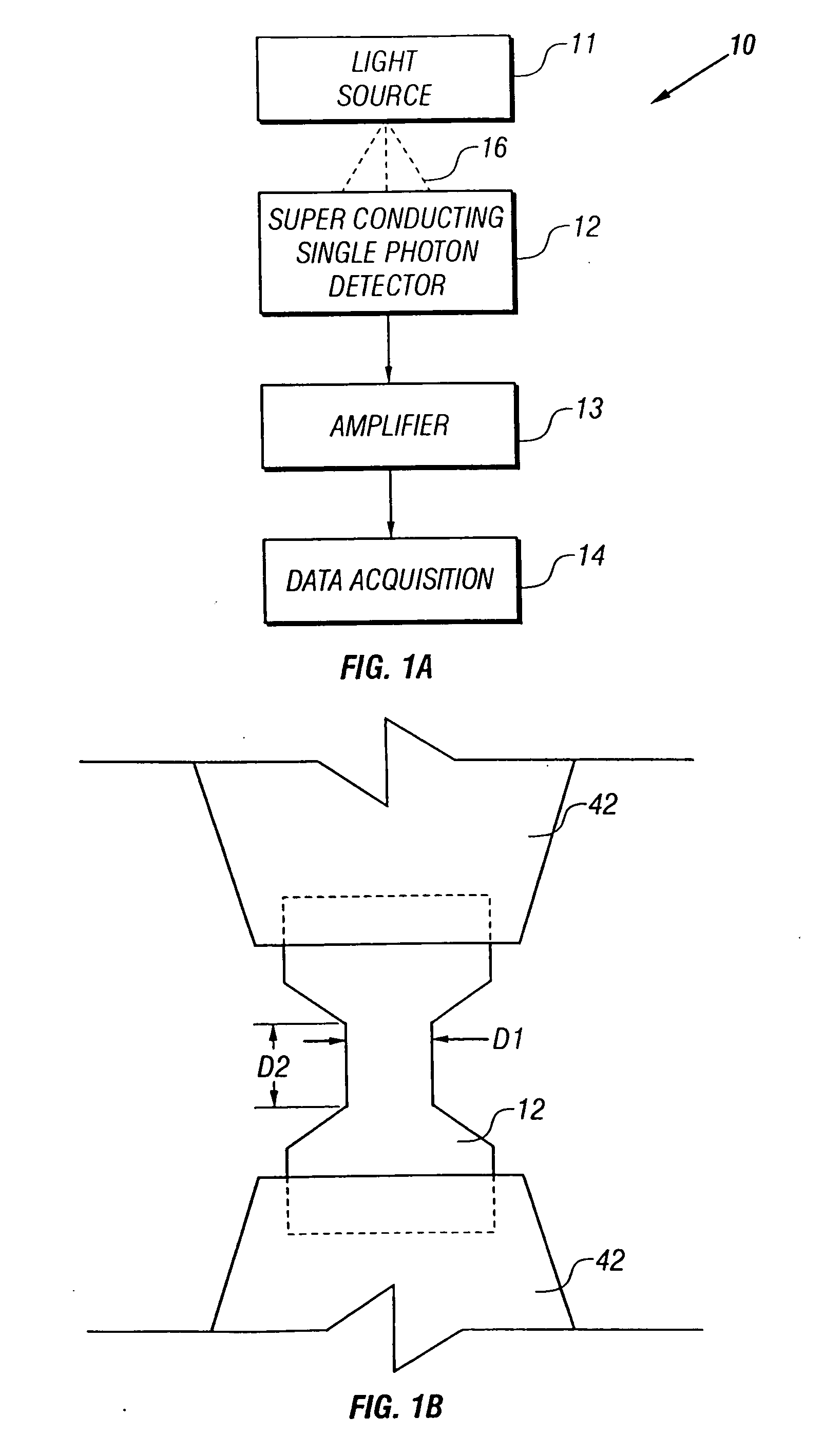

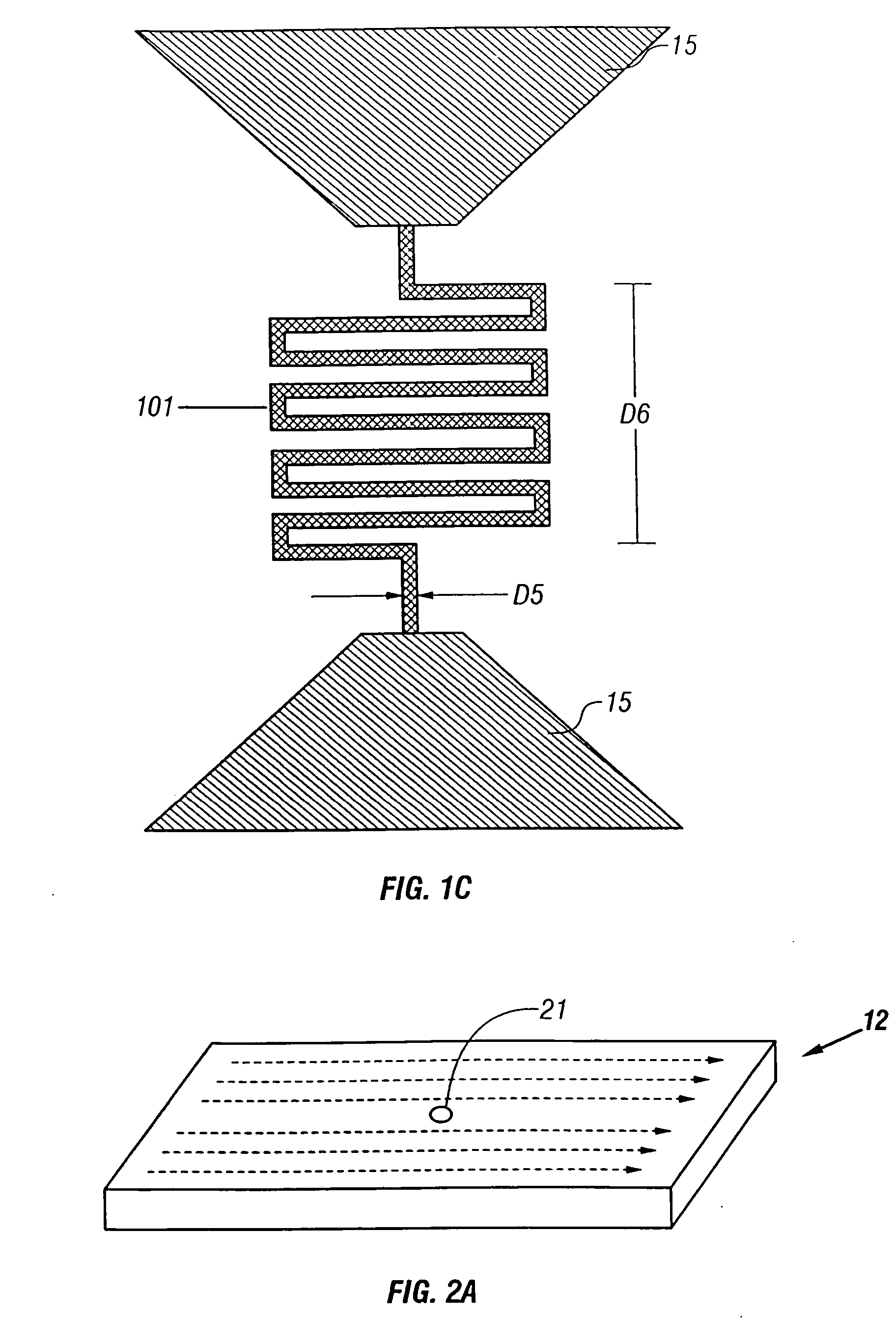

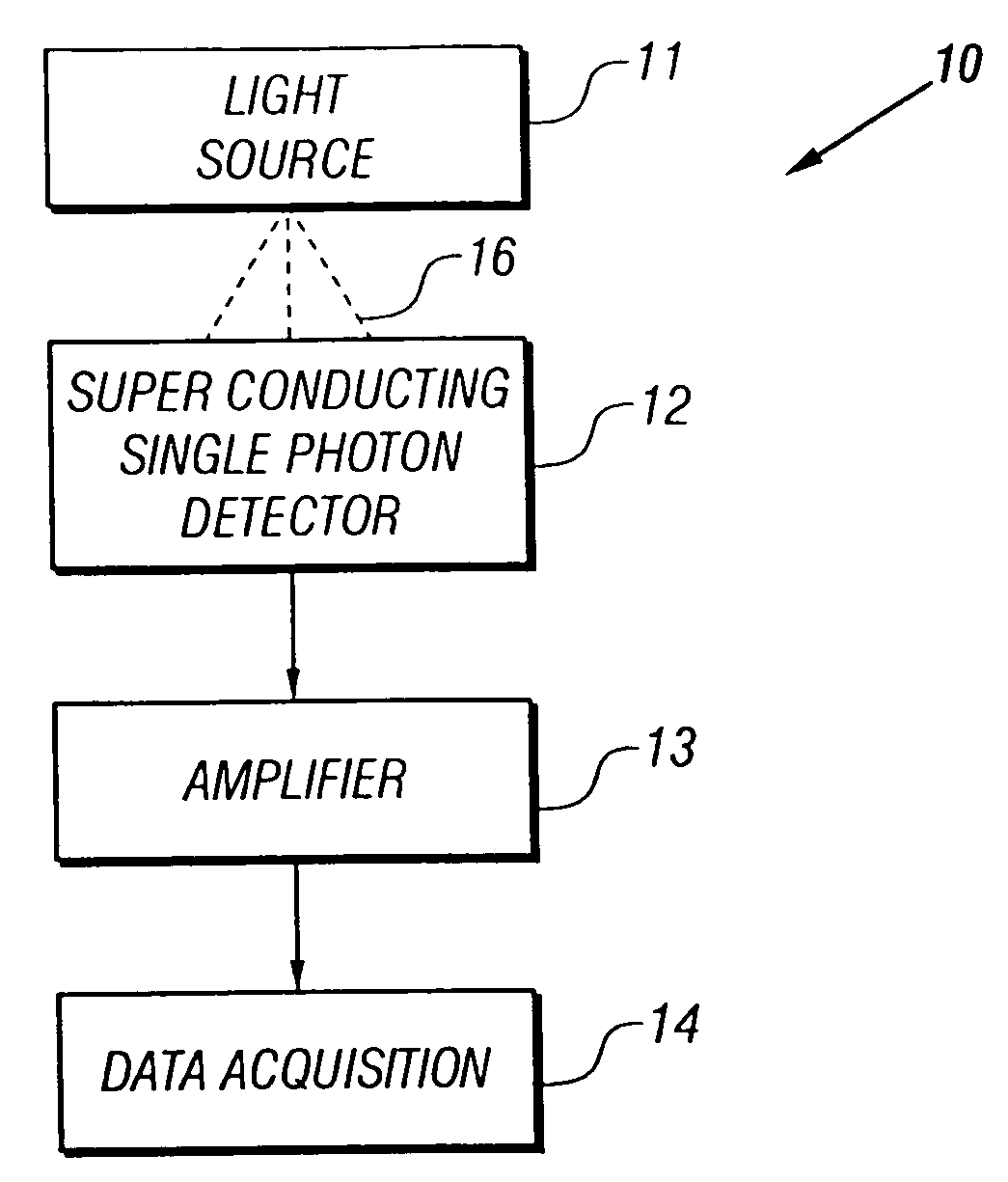

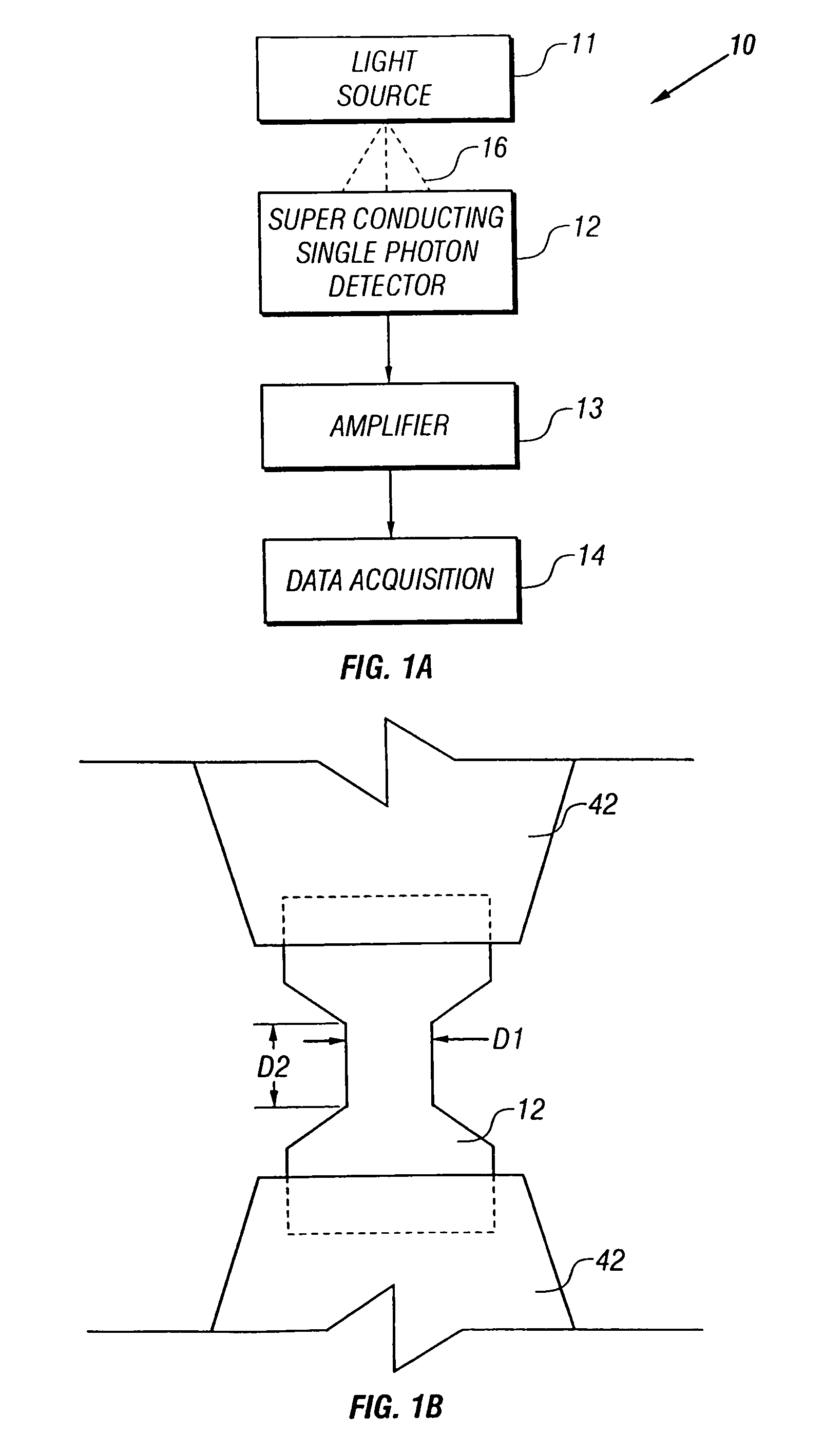

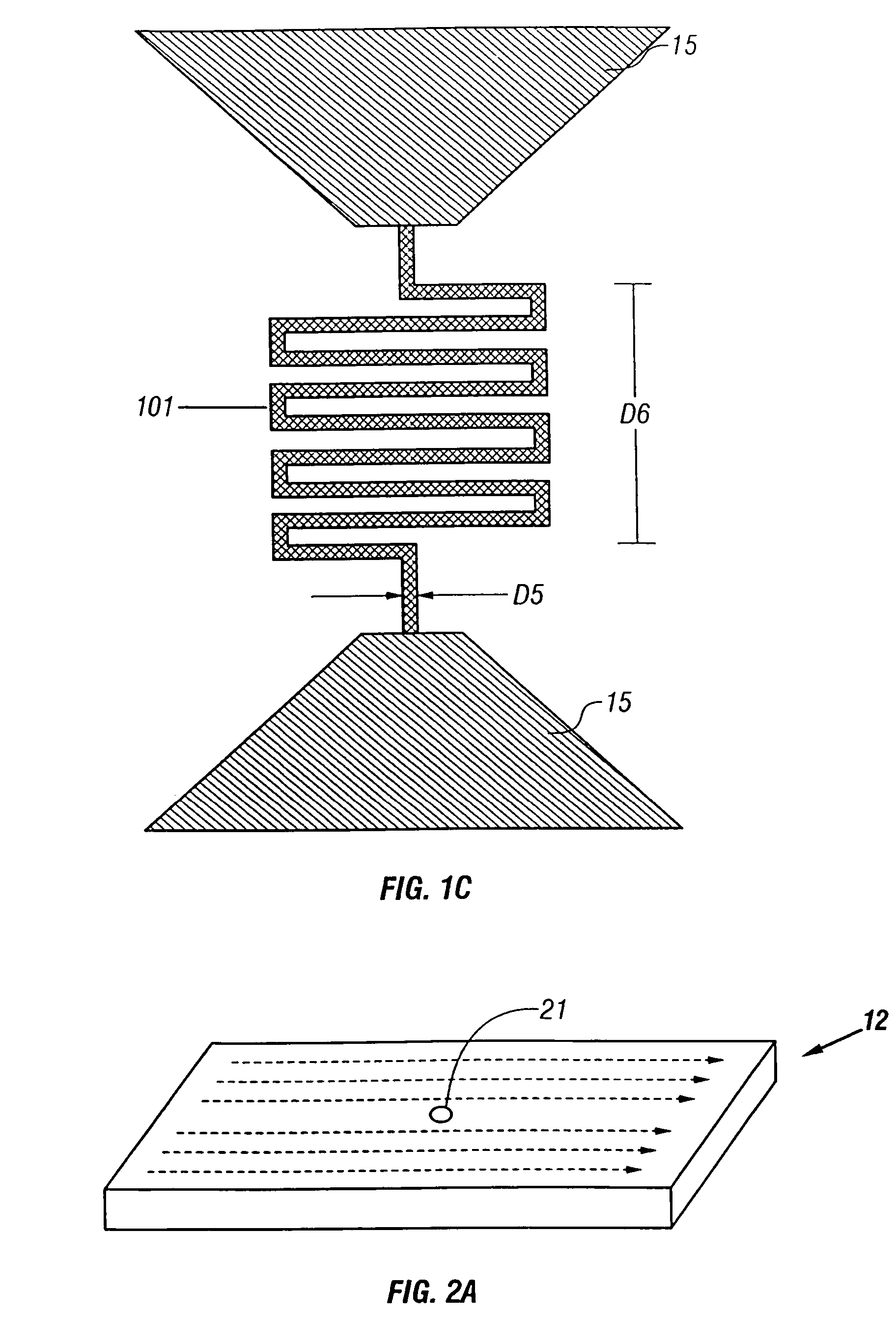

Superconducting single photon detector

InactiveUS20050051726A1Improve quantum efficiencyIncrease surface areaSolid-state devicesMaterial analysis by optical meansDevice materialSuperconductor classification

A single-photon detector includes a superconductor strip biased near its critical current. The superconductor strip provides a discernible output signal upon absorption of a single incident photon. In one example, the superconductor is a strip of NbN (niobium nitride). In another example, the superconductor strip meanders to increase its probability of receiving a photon from a light source. The single-photon detector is suitable for a variety of applications including free-space and satellite communications, quantum communications, quantum cryptography, weak luminescence, and semiconductor device testing.

Owner:DCG SYST +1

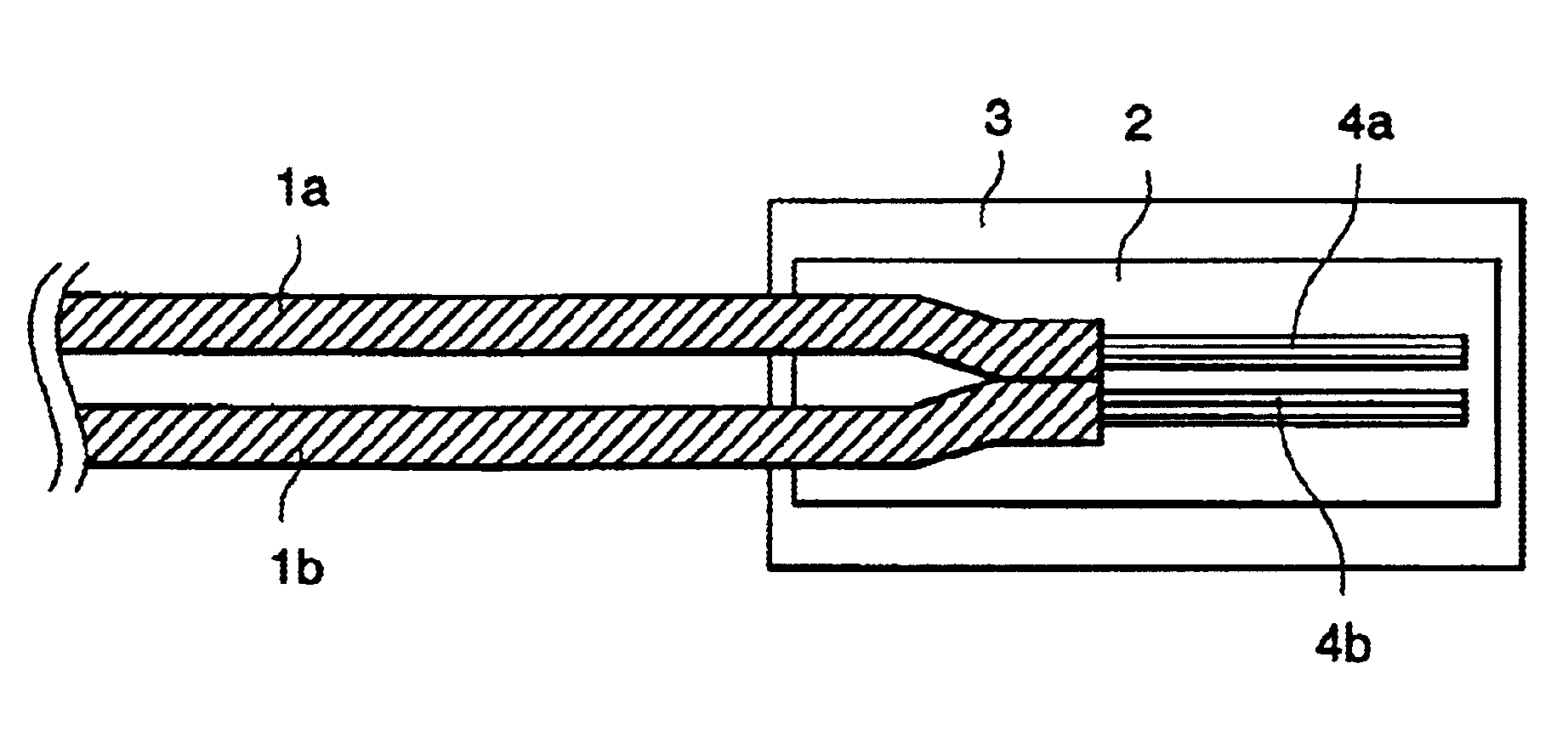

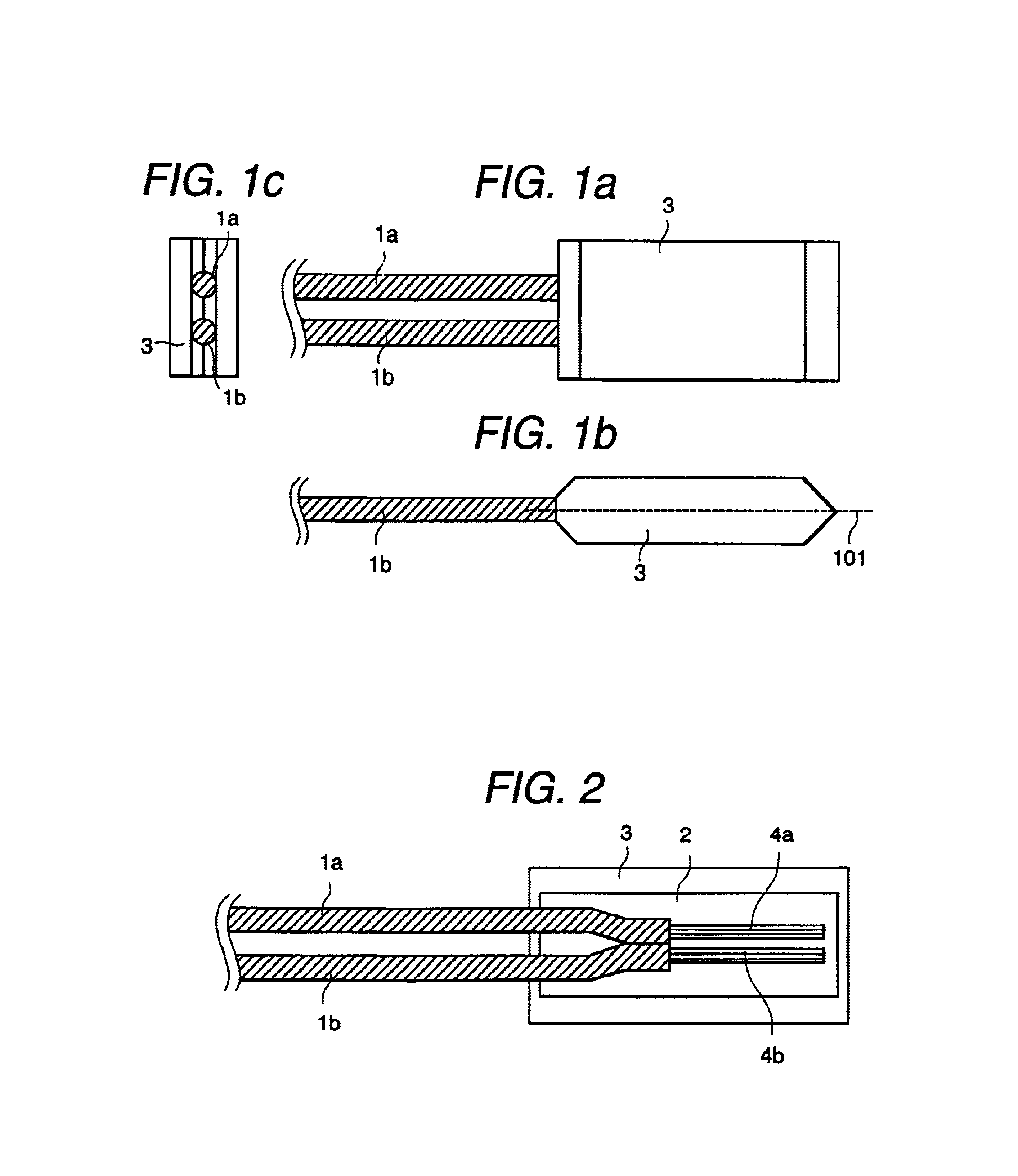

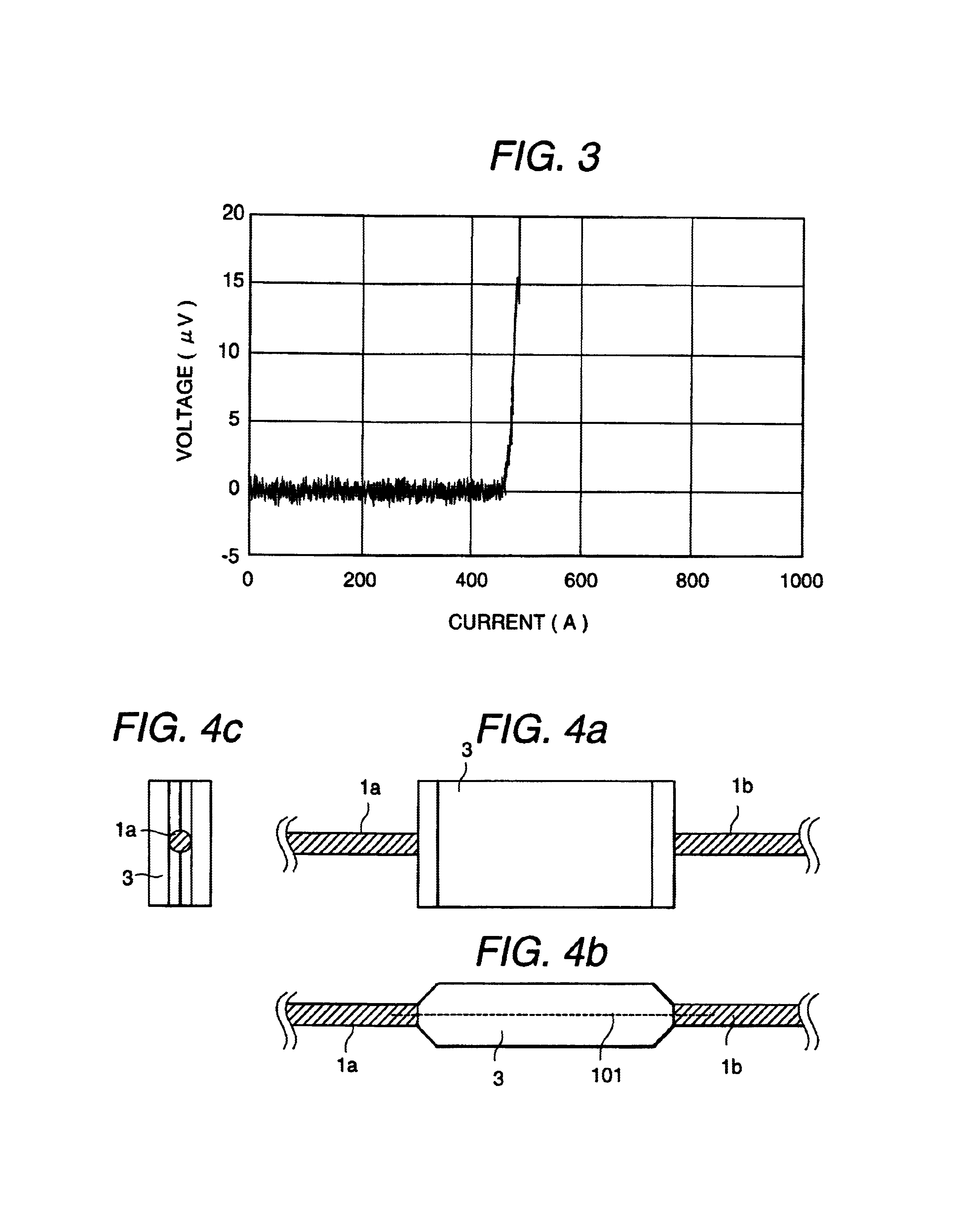

Superconductor connection structure

InactiveUS6921865B2Reduce power consumptionSimple connection structureSuperconductors/hyperconductorsSuperconductor detailsElectricityElectrical connection

Electrical connection of superconducting lines can be achieved by using a low-melting point metal, by mechanical contact of superconducting lines or by welding. According to these methods, however, critical current and critical magnetic field at the connection point are low, and stable connection in a superconducting state has been difficult. The present invention solves these problems and provides a structure and method for connecting superconducting lines. The present invention provides high-performance, high-stability connection of superconducting lines through magnesium diboride (MgB2) powder arranged between superconducting lines.

Owner:HITACHI LTD

Superconducting single photon detector

InactiveUS7049593B2Improve quantum efficiencyIncrease surface areaRadiation pyrometrySolid-state devicesSuperconductor classificationLuminescence

A single-photon detector includes a superconductor strip biased near its critical current. The superconductor strip provides a discernible output signal upon absorption of a single incident photon. In one example, the superconductor is a strip of NbN (niobium nitride). In another example, the superconductor strip meanders to increase its probability of receiving a photon from a light source. The single-photon detector is suitable for a variety of applications including free-space and satellite communications, quantum communications, quantum cryptography, weak luminescence, and semiconductor device testing.

Owner:DCG SYST +1

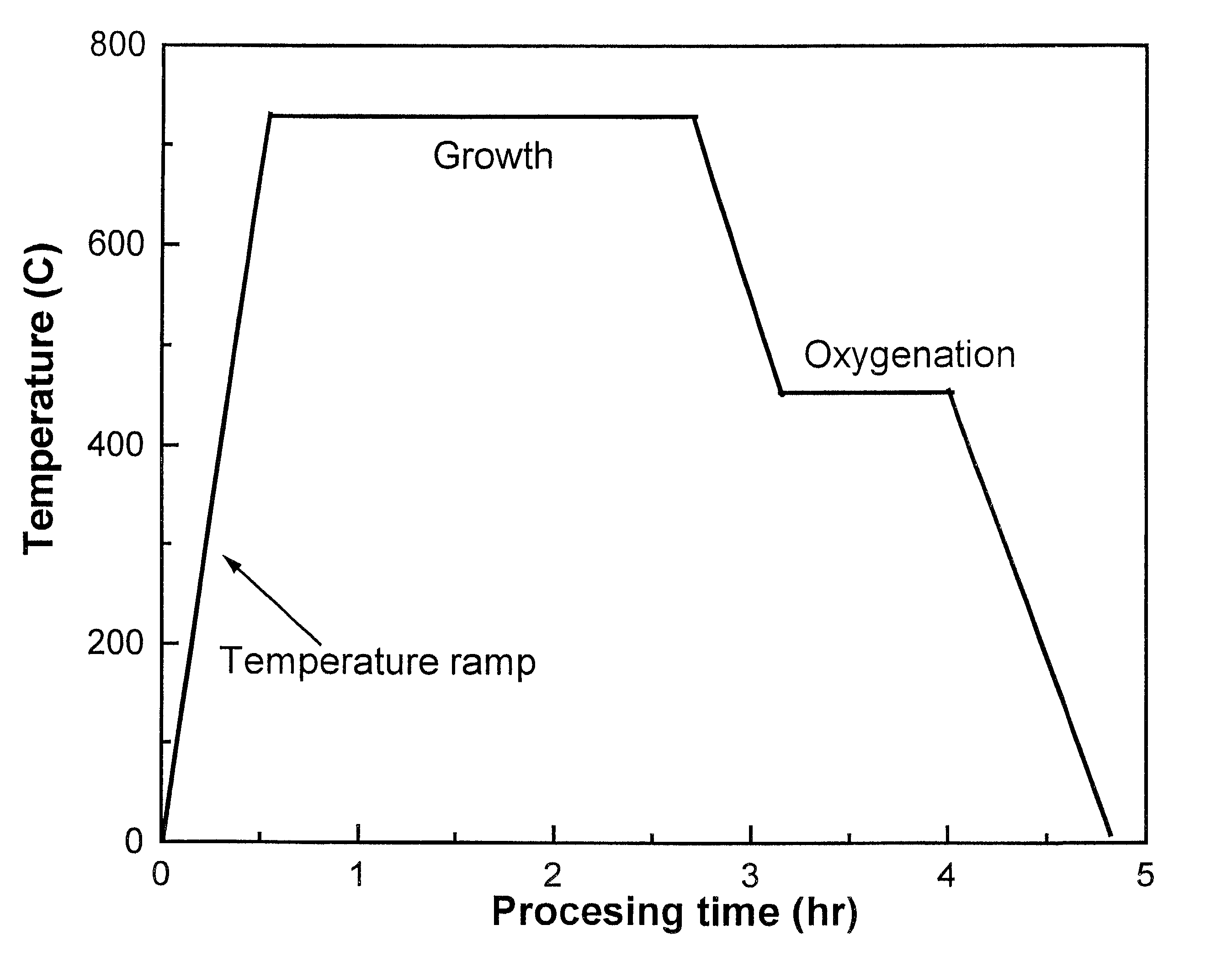

Synthesis of YBa2Cu3O7 using sub-atmospheric processing

InactiveUS20030050195A1Conductive materialVacuum evaporation coatingWater vaporVolumetric Mass Density

The present invention is a method of forming thick films of crystalline YBa2Cu3O7 that includes forming a precursor film comprising barium fluoride (BaF2), yttrium (Y) and copper (Cu). The precursor film is heat-treated at a temperature above 500° C. in the presence of oxygen, nitrogen and water vapor at sub-atmospheric pressure to form a crystalline structure. The crystalline structure is then annealed at about 500° C. in the presence of oxygen to form the crystalline YBa2Cu3O7 film. The YBa2Cu3O7 film formed by this method has a resistivity of from about 100 to about 600 muOhm-cm at room temperature and a critical current density measured at 77 K in a magnetic field of 1 Tesla of about 1.0x105 Ampere per square centimeter (0.1 MA / cm2) or greater.

Owner:BROOKHAVEN SCI ASSOCS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com