Patents

Literature

76 results about "Direct plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direct plating of bacteria is the traditional method used for identification of bacteria in wine. This method is most often used when the winemaker expects low to moderate levels of bacteria in the wine, for example, during barrel aging.

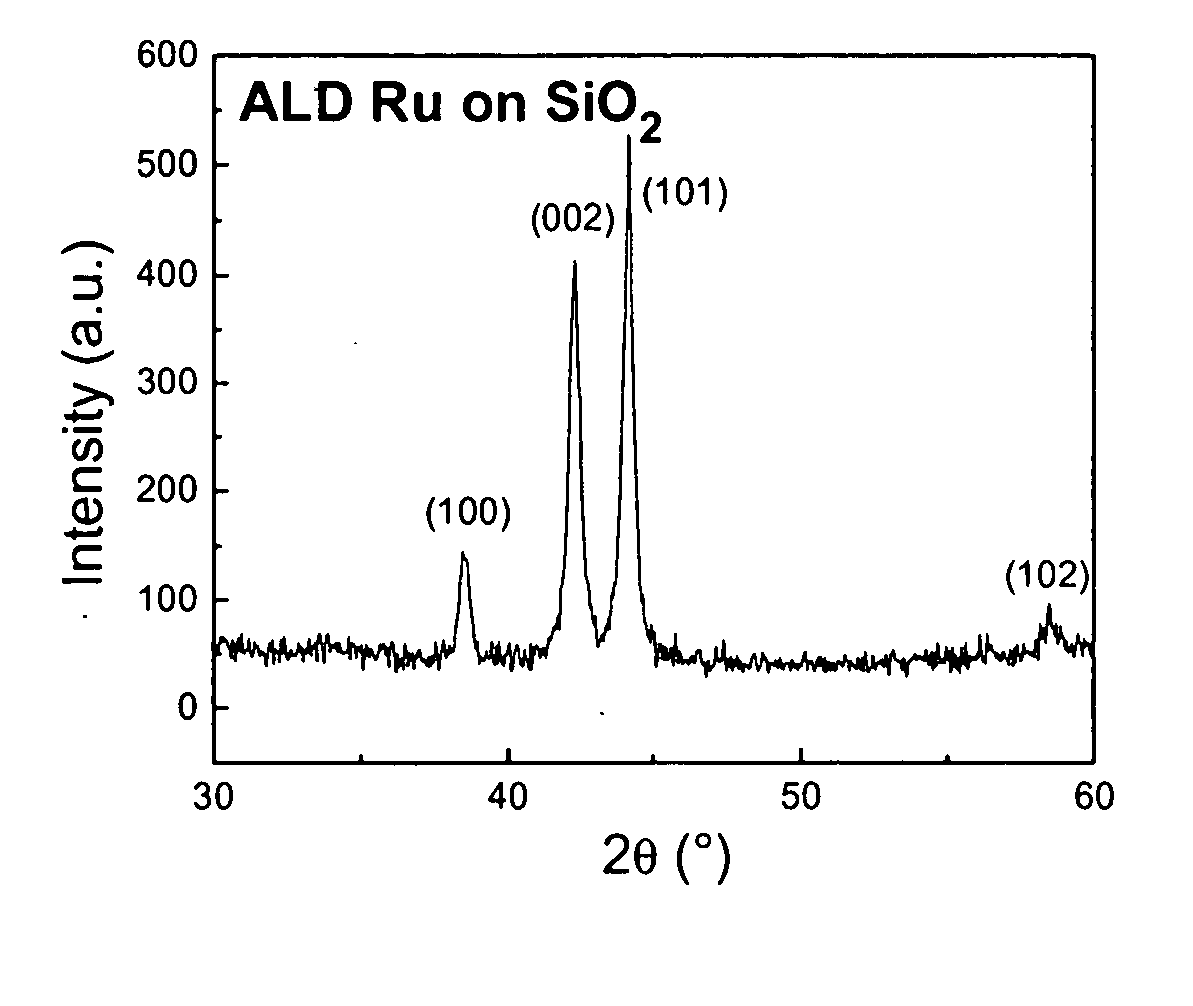

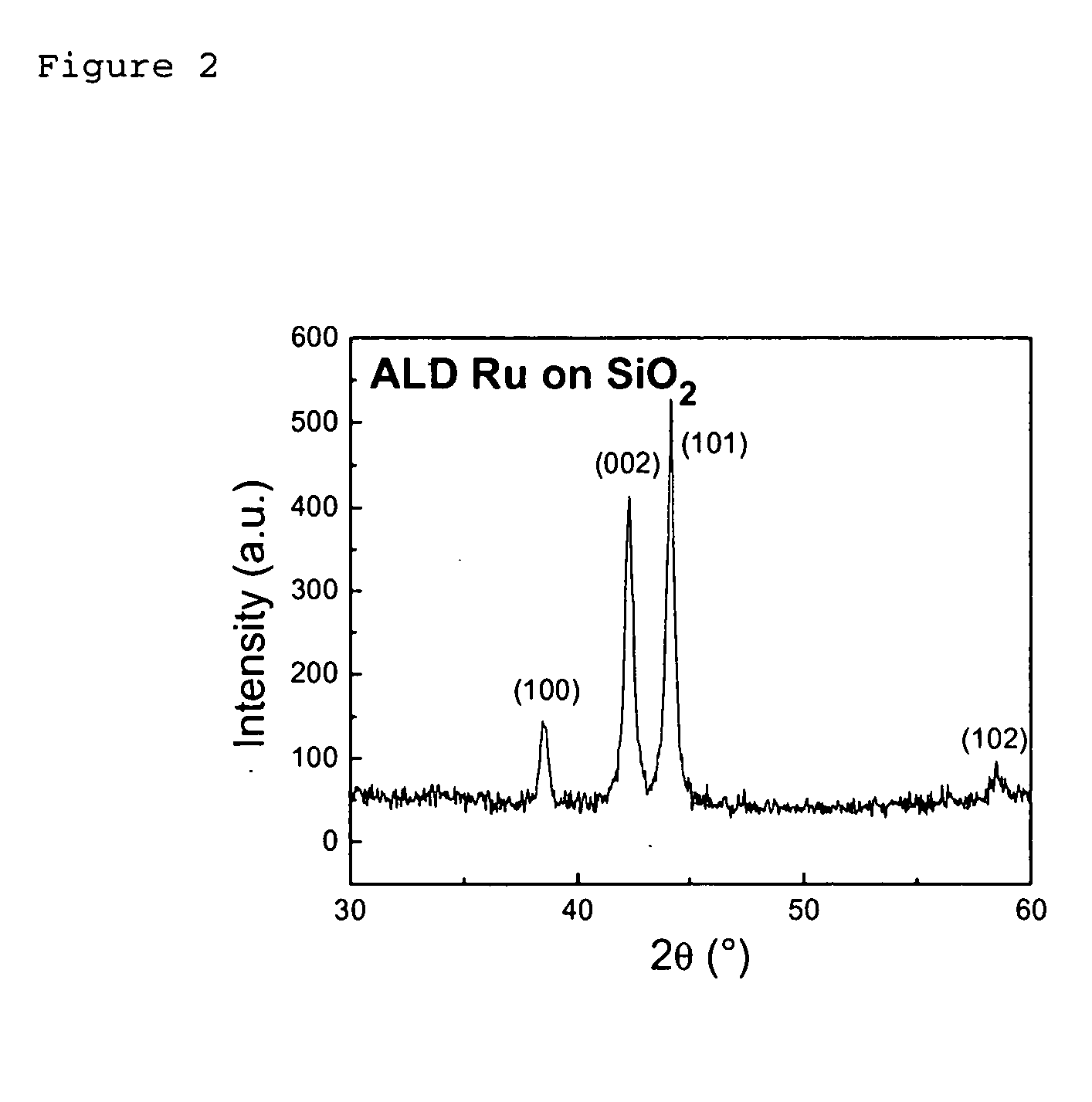

Ald deposition of ruthenium

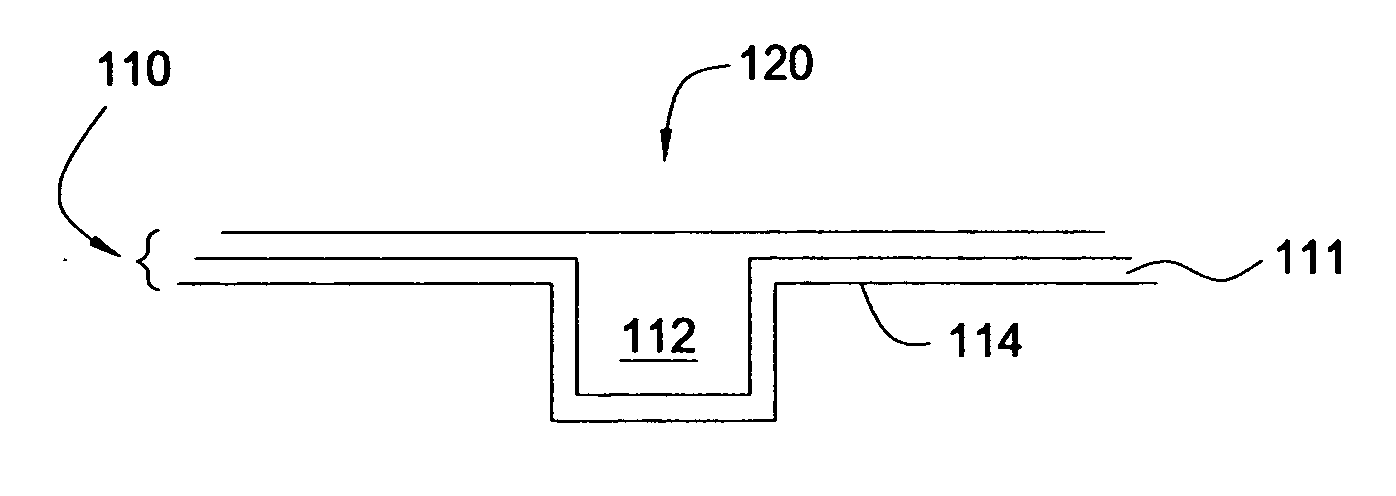

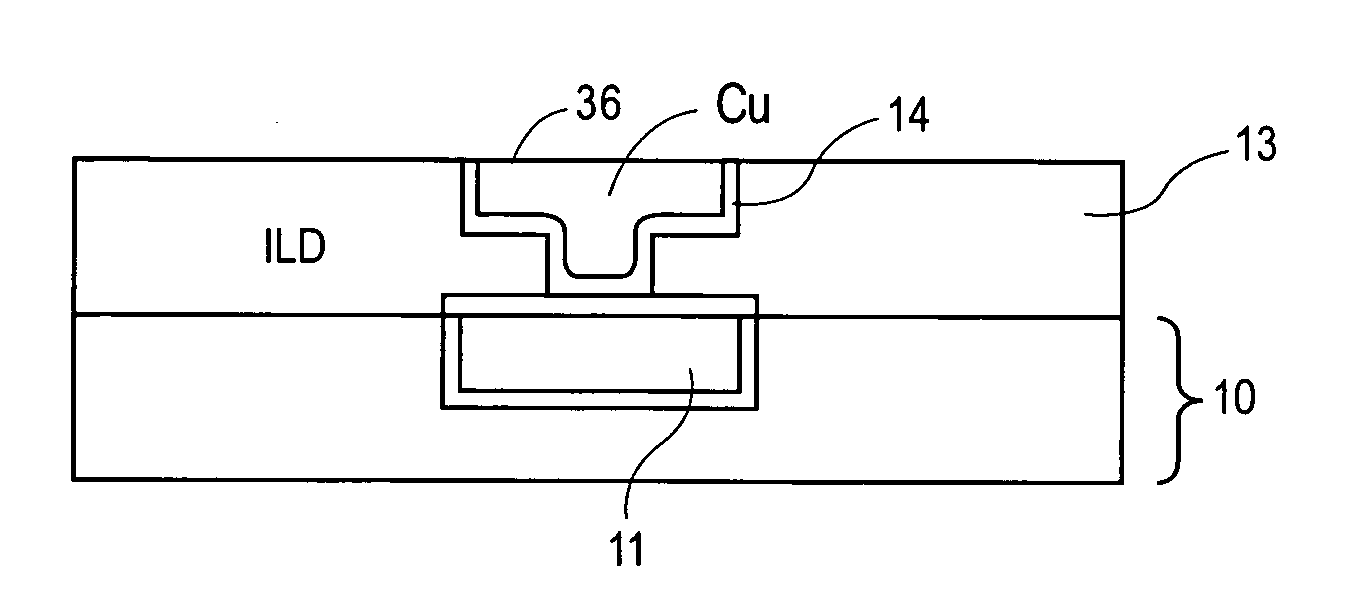

InactiveUS20050118807A1None be problem freeLow impurity contentSemiconductor/solid-state device detailsSolid-state devicesCMOSCopper interconnect

A method to deposit nucleation problem free ruthenium by ALD. The nucleation problem free, relatively smooth ruthenium ALD film is deposited by the use of plasma-enhanced ALD of ruthenium underlay for consequent thermal ruthenium ALD layer. In addition, oxygen or nitrogen plasma treatments of SiO2 or other dielectrics leads to uniform ALD ruthenium deposition. The method has application as a direct plating layer for a copper interconnect or metal gate structure for advanced CMOS devices.

Owner:IBM CORP

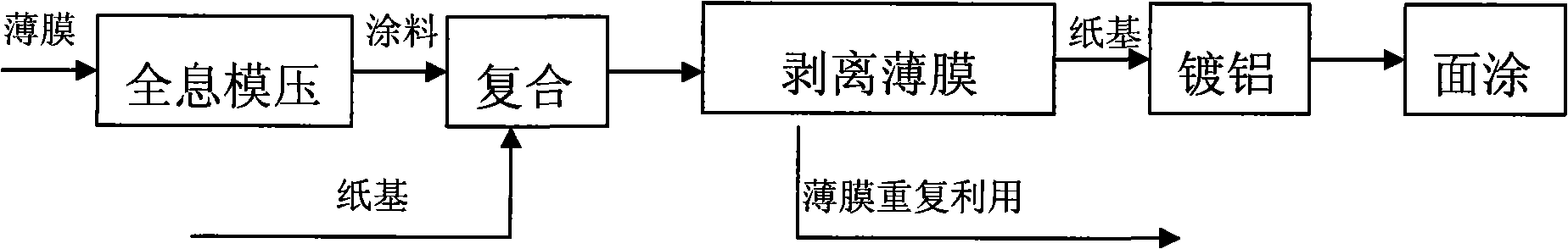

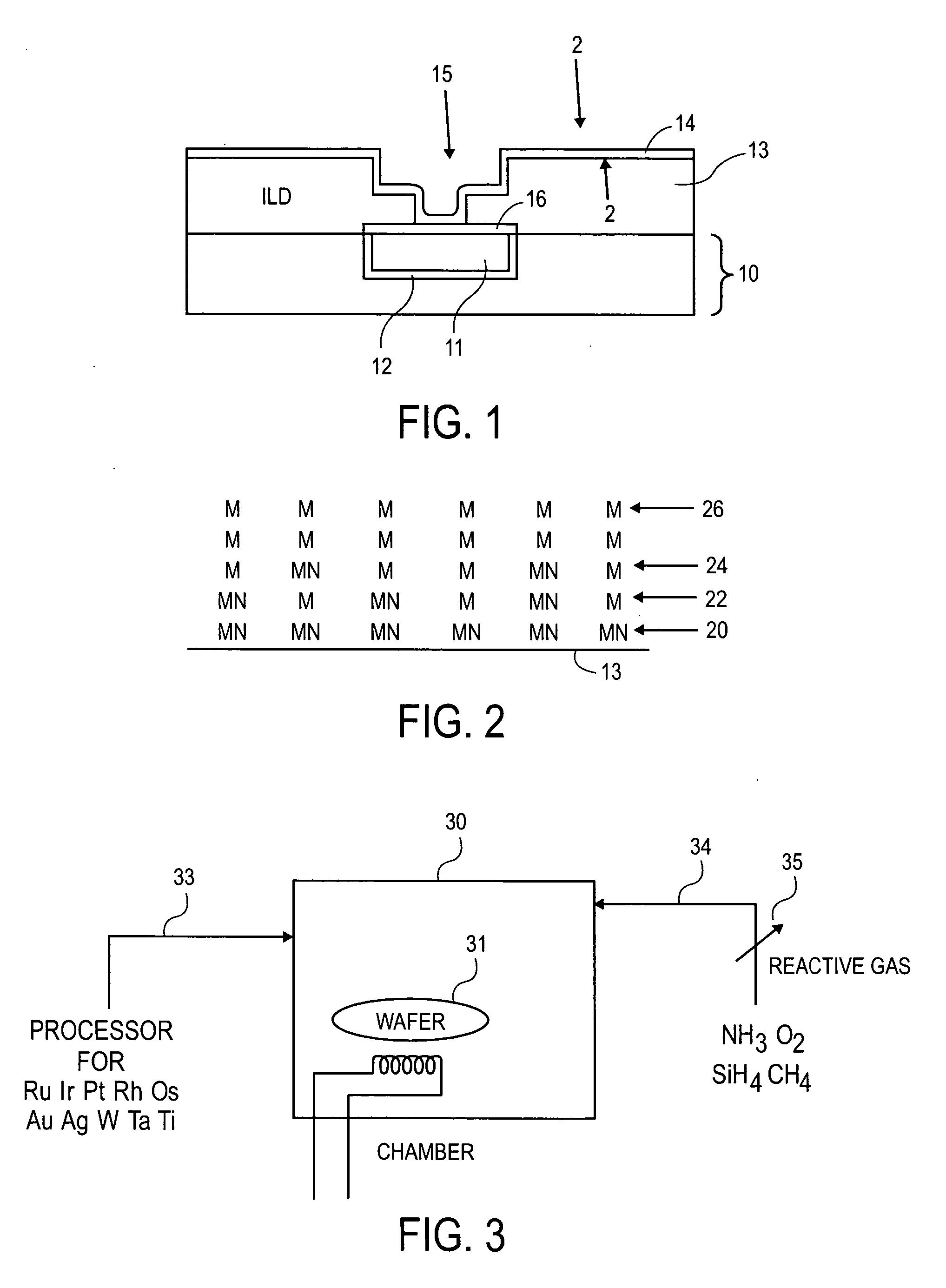

Method of direct plating of copper on a ruthenium alloy

InactiveUS20060283716A1Semiconductor/solid-state device detailsSolid-state devicesAlloyDirect plating

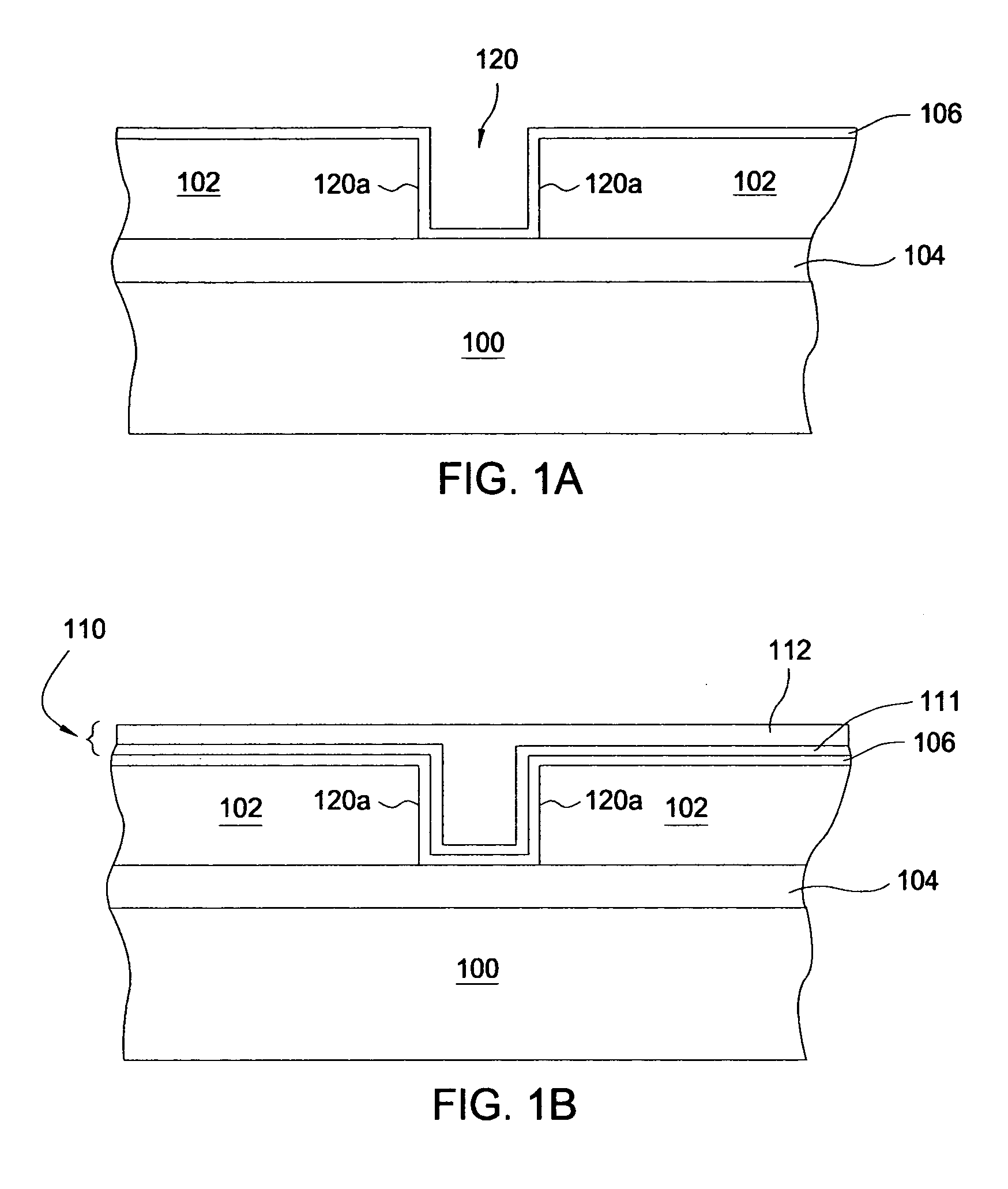

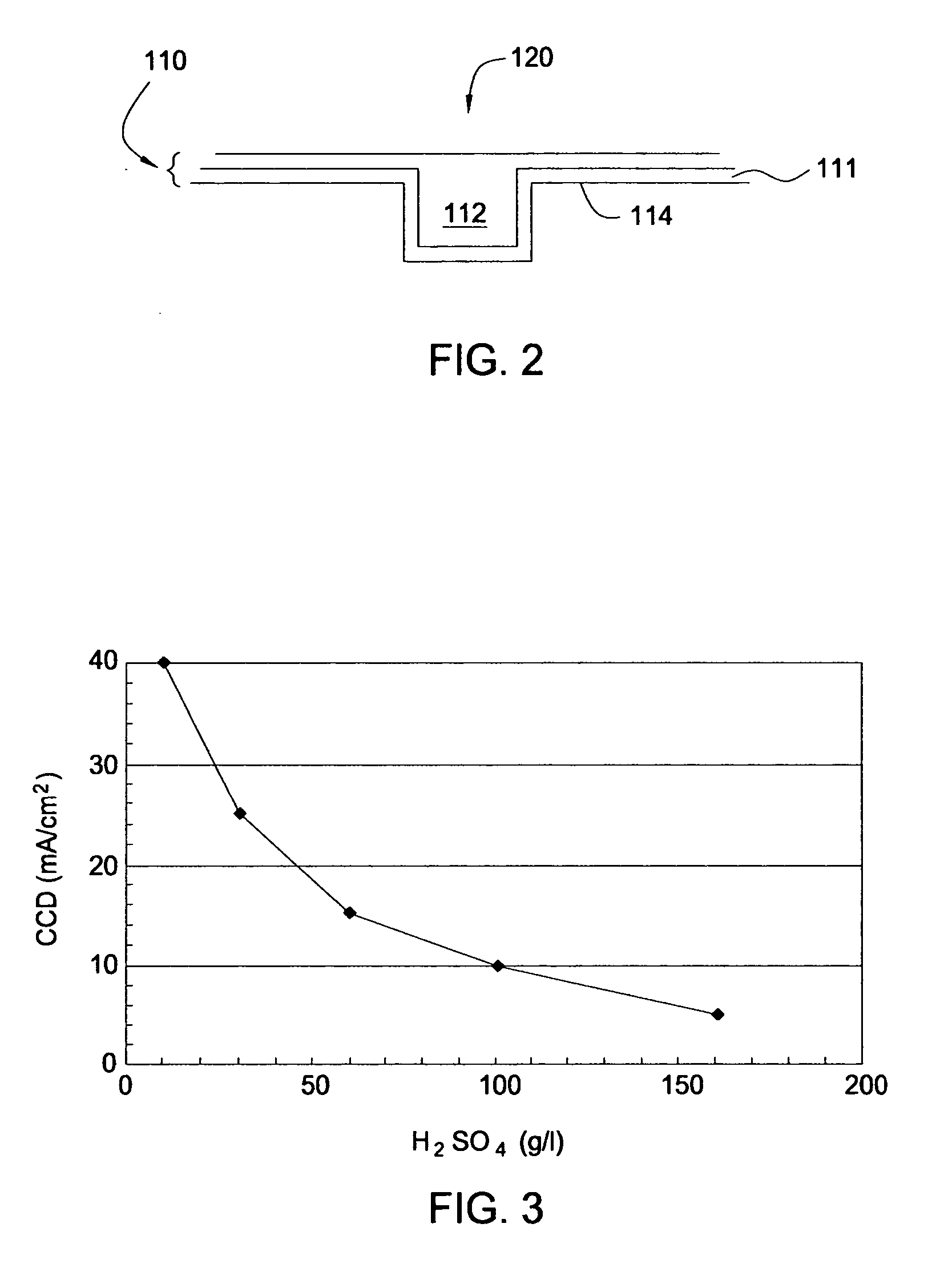

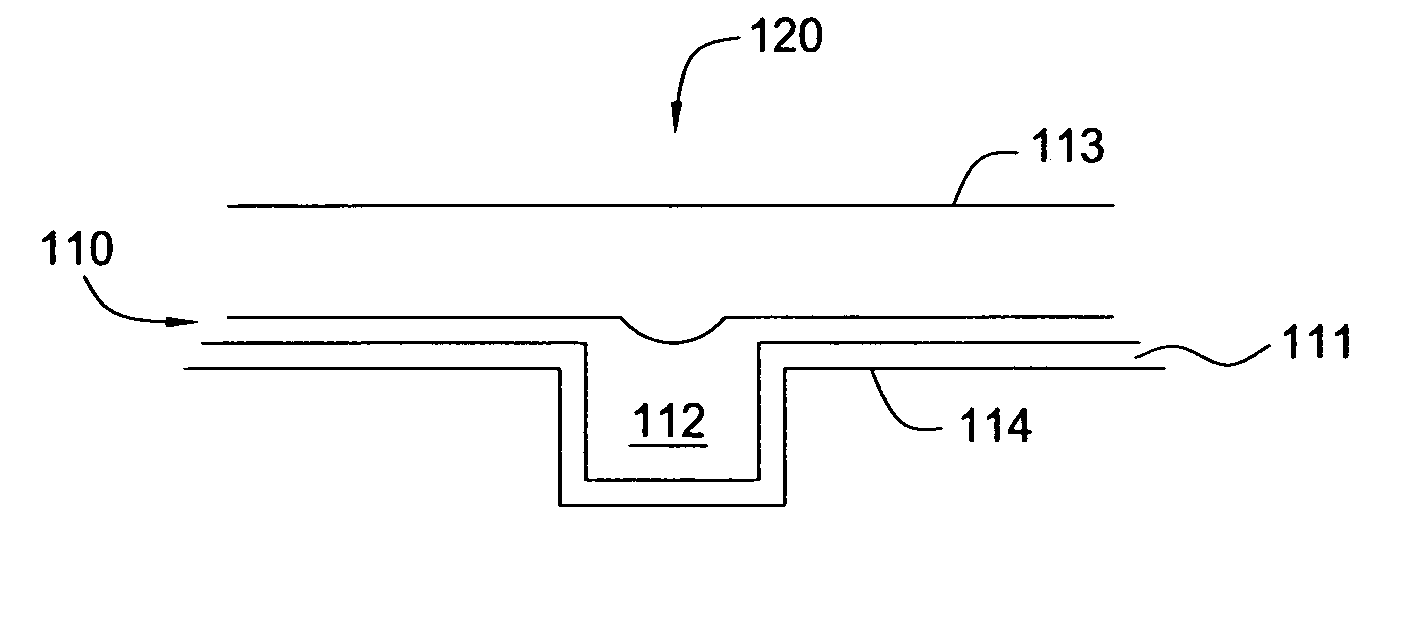

A method is disclosed for depositing a copper seed layer onto a substrate surface, generally onto a barrier layer that is an alloy of a group VIII metal and a refractory metal. In one aspect, the alloy consists of at least 50% ruthenium and the balance a copper diffusion barrier material. A copper layer is electroplated on the alloy directly. In one aspect, the surface of the barrier layer is conditioned prior to plating to improve adhesion and reduce the critical current density for plating on the barrier layer. The conditioning may include cathodic pre-treatment or a plasma pre-treatment in a hydrogen or hydrogen / helium mixture. In one aspect, the substrate surface is immersed in an acidic plating bath and a nucleation waveform is applied to form a seed layer. In another aspect, the substrate is immersed in a neutral or alkaline copper solution that includes complexed copper ions.

Owner:APPLIED MATERIALS INC

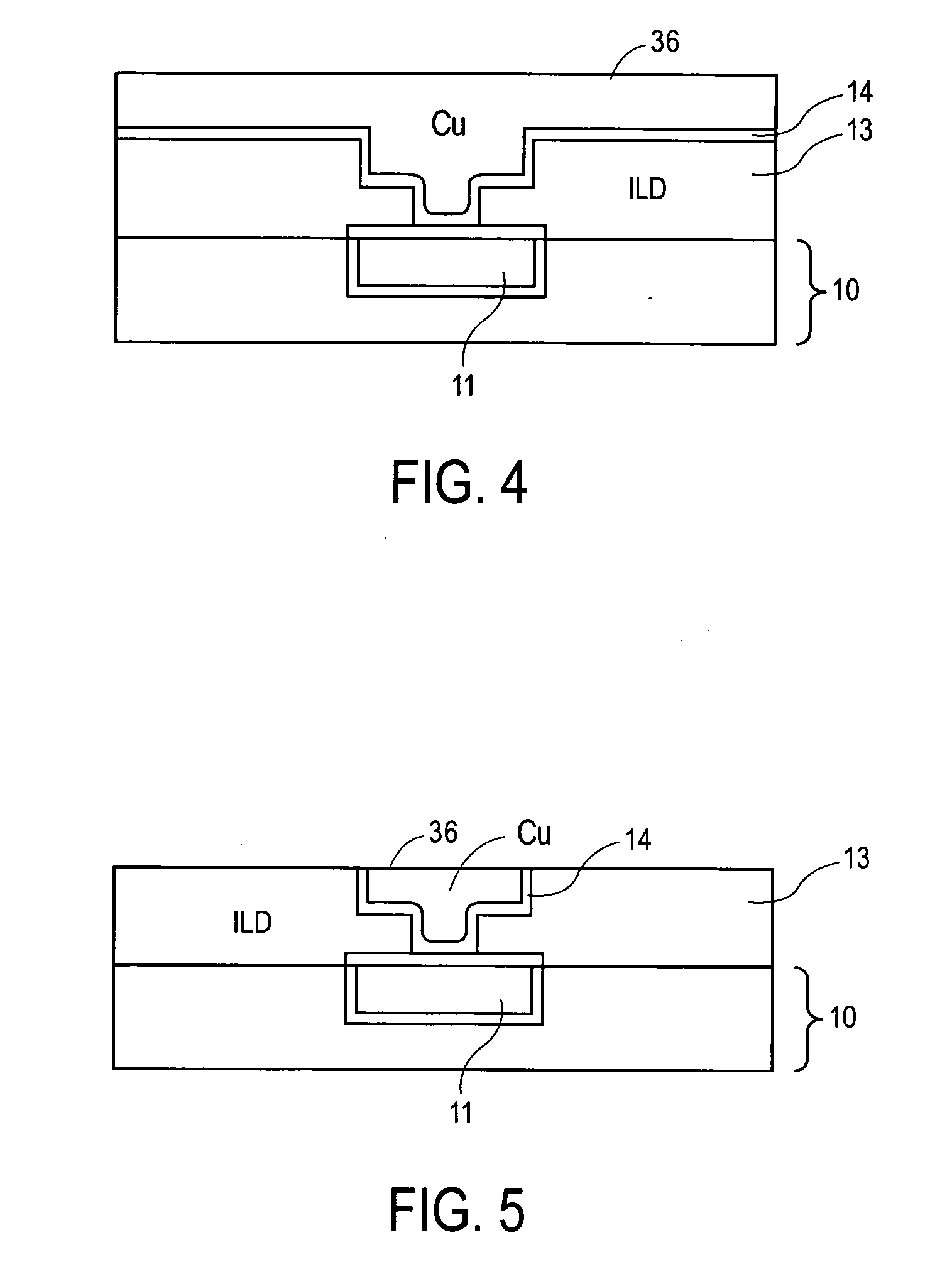

Method of direct plating of copper on a substrate structure

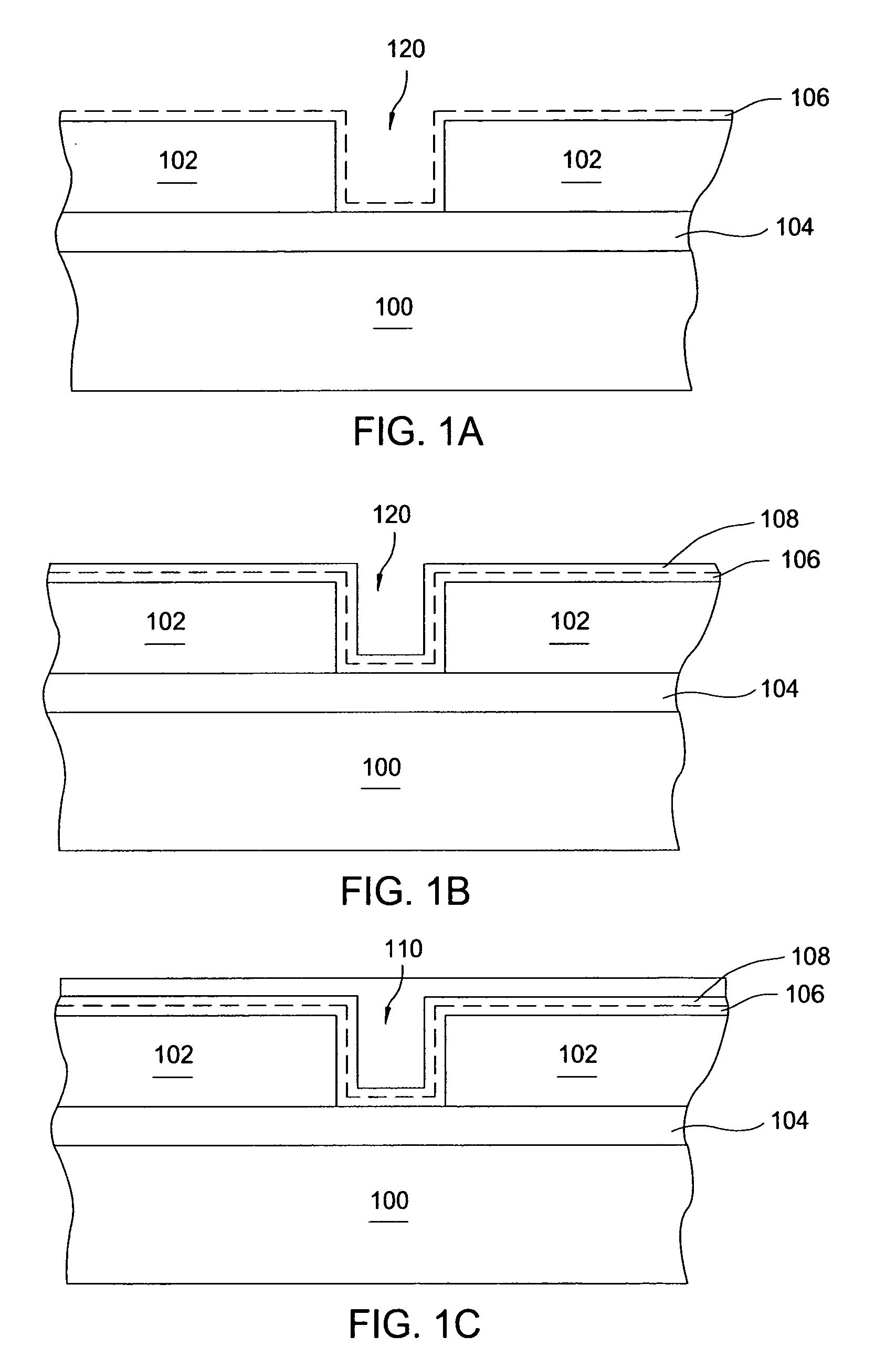

InactiveUS20070125657A1Semiconductor/solid-state device detailsSolid-state devicesCopperSubstrate surface

The present invention teaches a method for depositing a copper seed layer onto a substrate surface, generally onto a barrier layer. The barrier layer may include a refractory metal and / or a group 8, 9 or 10 metal. The method includes cathodically pre-treating the substrate in an acid-containing solution. The substrate is then placed into a copper solution (pH≧7.0) that includes complexed copper ions and a current or bias is applied across the substrate surface. The complexed copper ions are reduced to deposit a copper seed layer onto the barrier layer. In one aspect, a complex alkaline bath is then used to electrochemically plate a gapfill layer on the substrate surface, followed by overfill in the same bath. In another aspect, an acidic bath ECP gapfill process and overfill process follow the alkaline seed layer process.

Owner:APPLIED MATERIALS INC

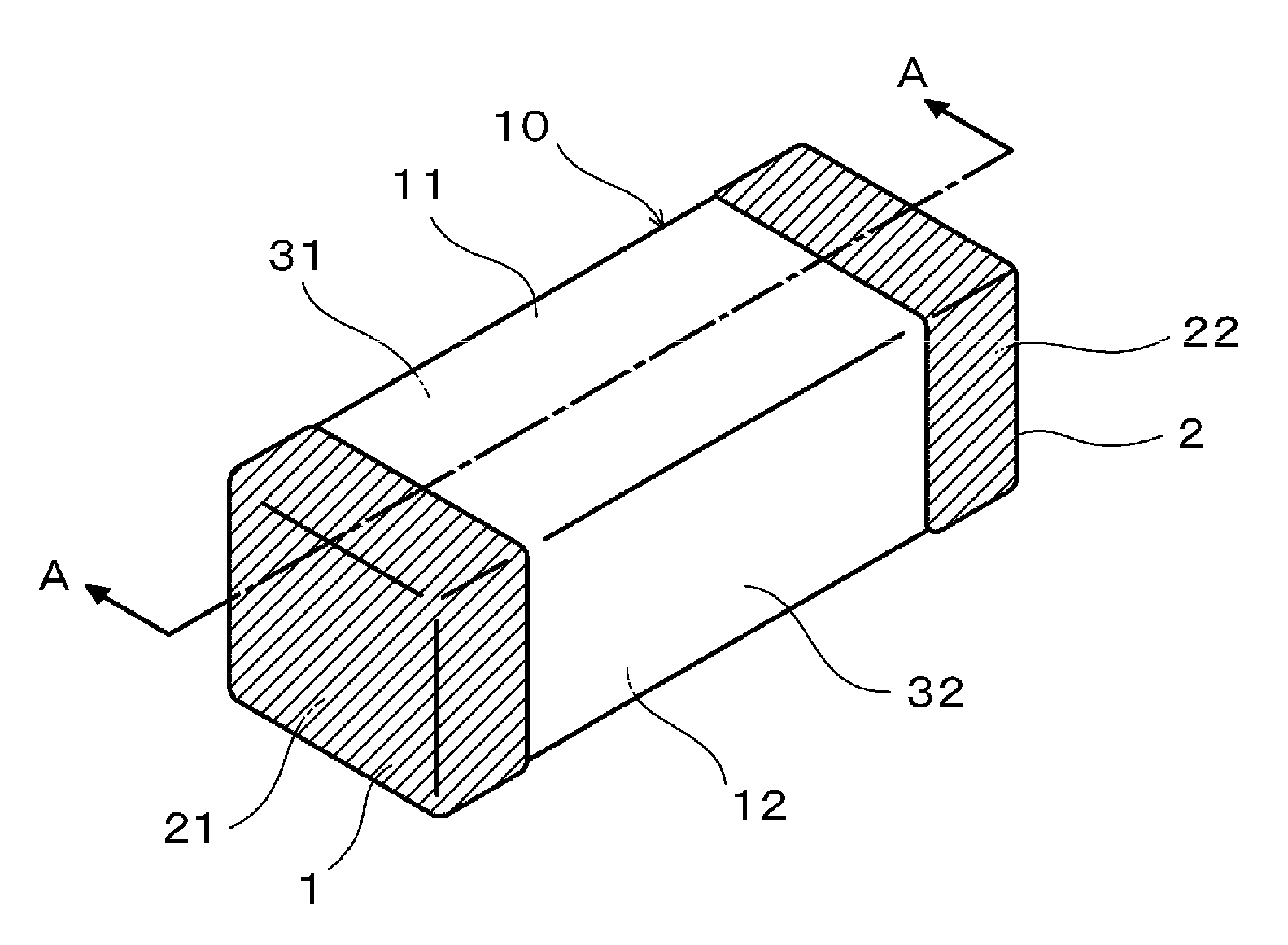

Method for preparing holography sputtering internal lining paper

InactiveCN101270557AImprove product qualityReduce defectsSpecial visual effect coatingsMechanical working/deformationPulp and paper industryWater requirement

The invention relates to a manufacture method for holographic direct plating lining paper which belongs to the technical field of an aluminum-plated paper manufacture method. The working procedures include: (1) providing a film; (2) carrying out laser holographic contour forging treatment on the film; (3) coating a layer of compound glue dope on the surface of the film with the holographic layer and then compounding with a lining paper base; (4) peeling off the film to obtain the paper base with holographic information and meeting the water requirements of aluminum plating; (5) plating aluminum on the coat of the paper base; (6) subsequent treatment of aluminum plating; core: compounding the coat printed with a holographic pattern on the paper base to replace the spreading pre-treatment on the paper base and directly carrying out vacuum aluminum plating on the surface of a dope layer. The invention has the effects that: 1, the quality of the holographic lining paper is high and completely removes various defects of the lining paper manufactured by a common direct plating method; 2 the technique step is simple; besides, as a BOPP film can be repeatedly used, the cost can be reduced, thus being suitable for batch manufacture; 3, compared with the common direct plating lining paper, the holographic pattern is added, thus being beneficial to anti-fake of the product and improving the grade of the product.

Owner:YANTAI BOYUAN TECH MATERIALS

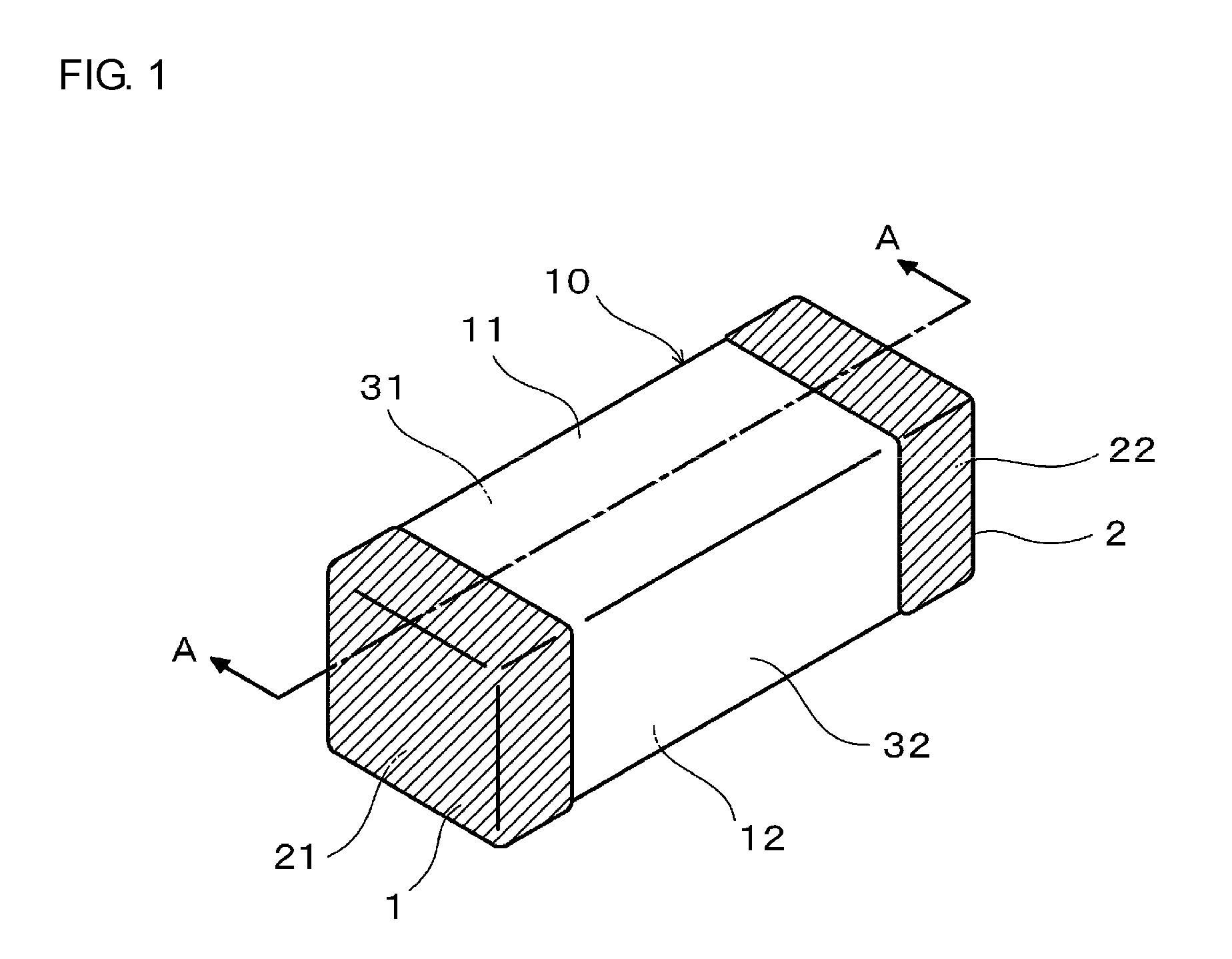

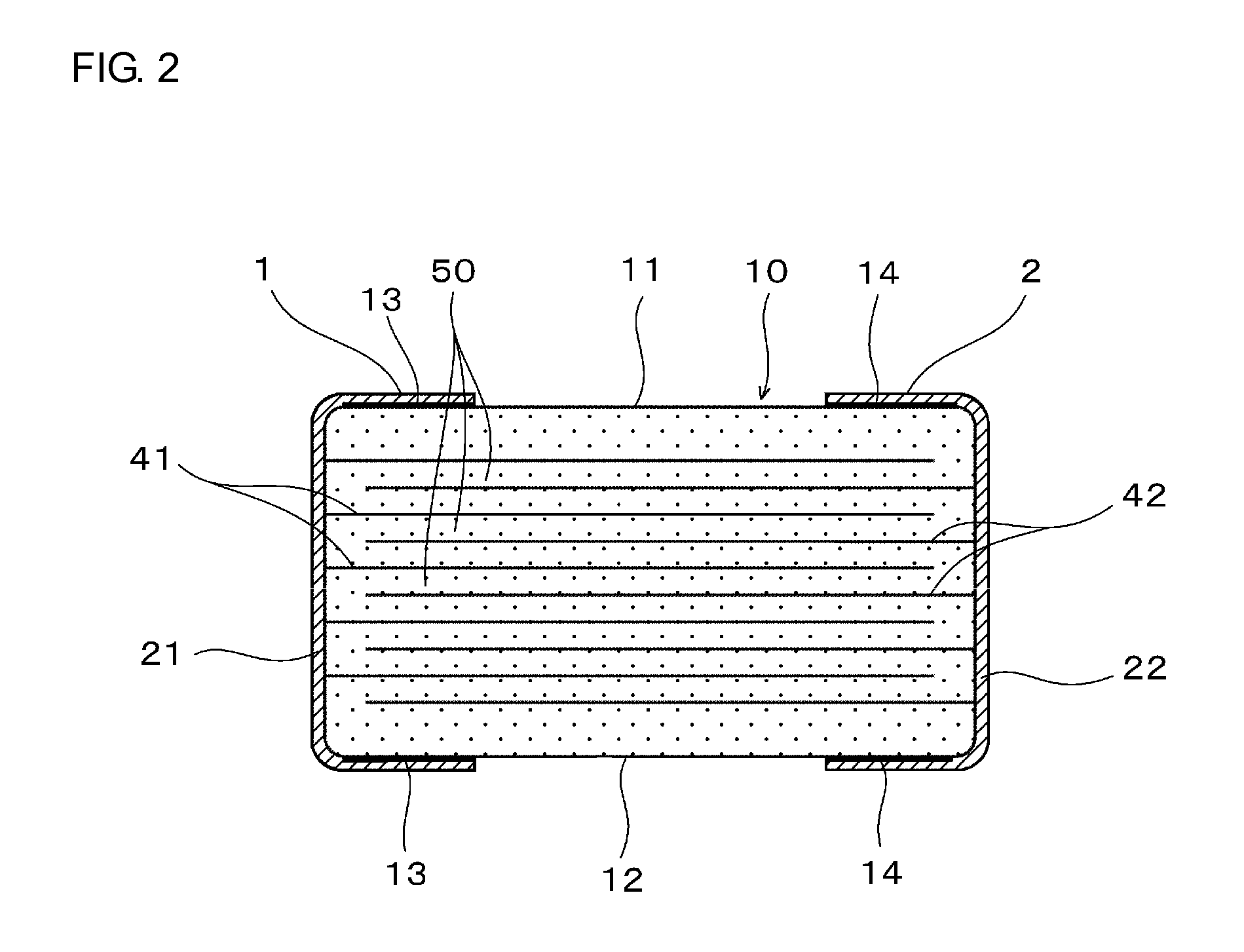

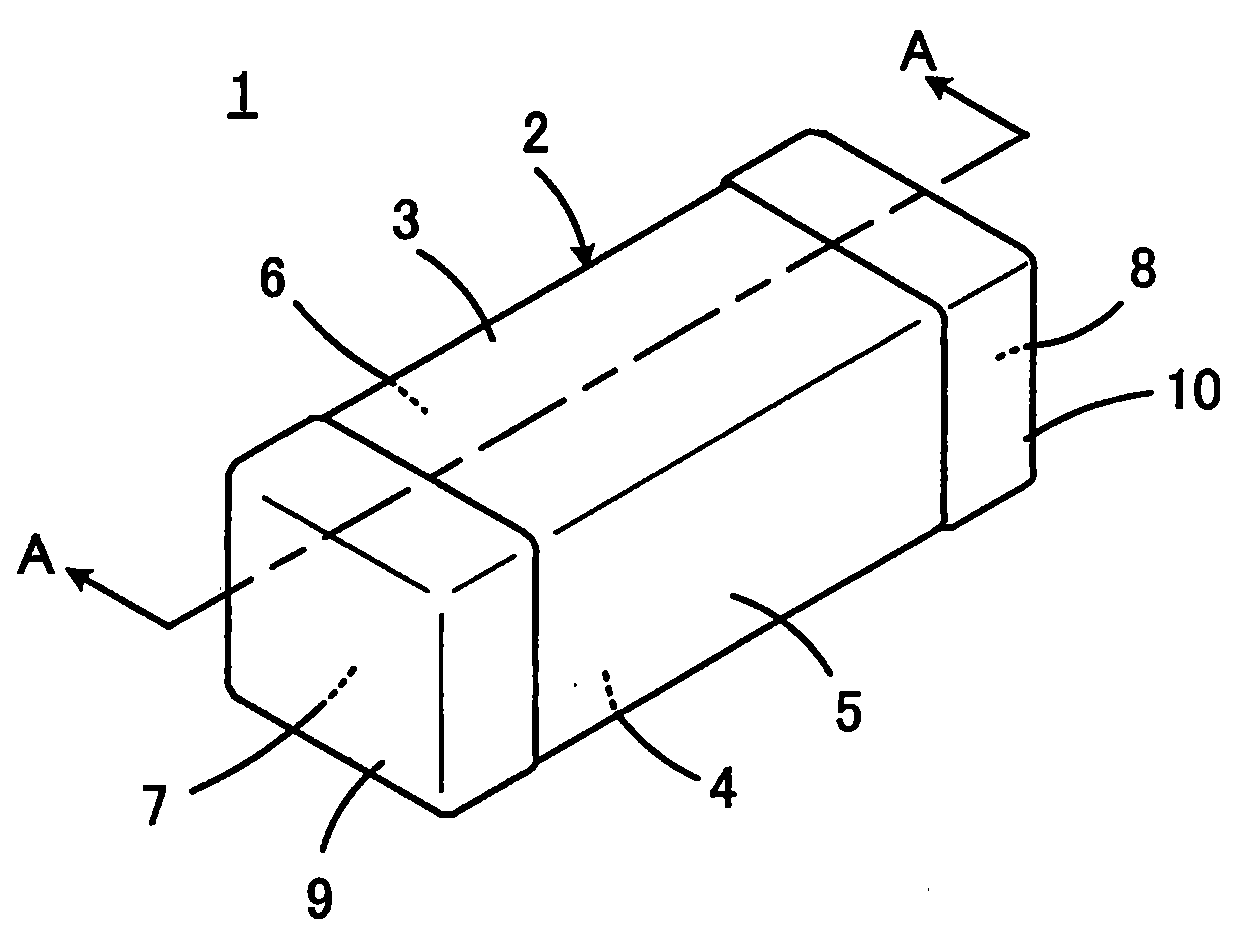

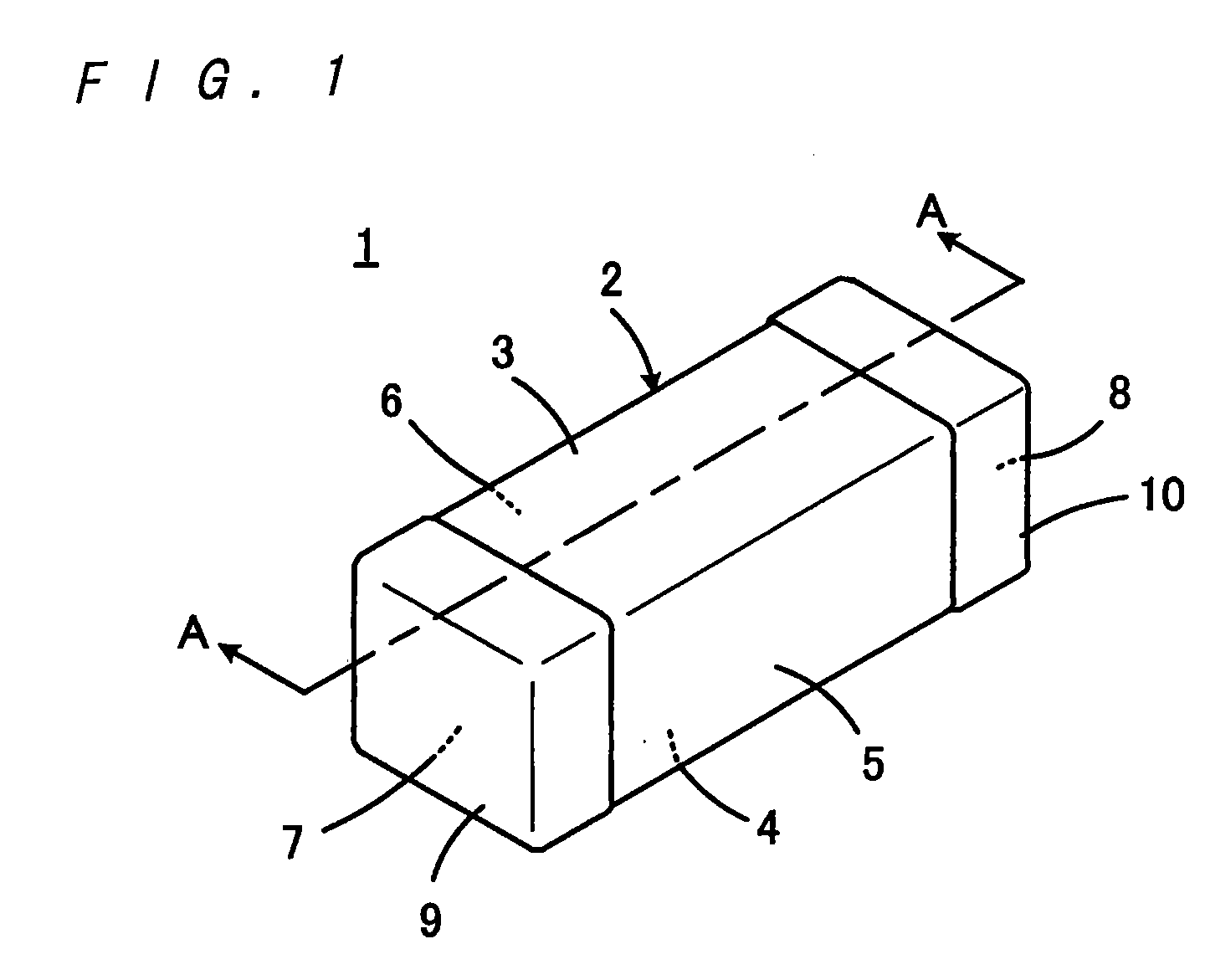

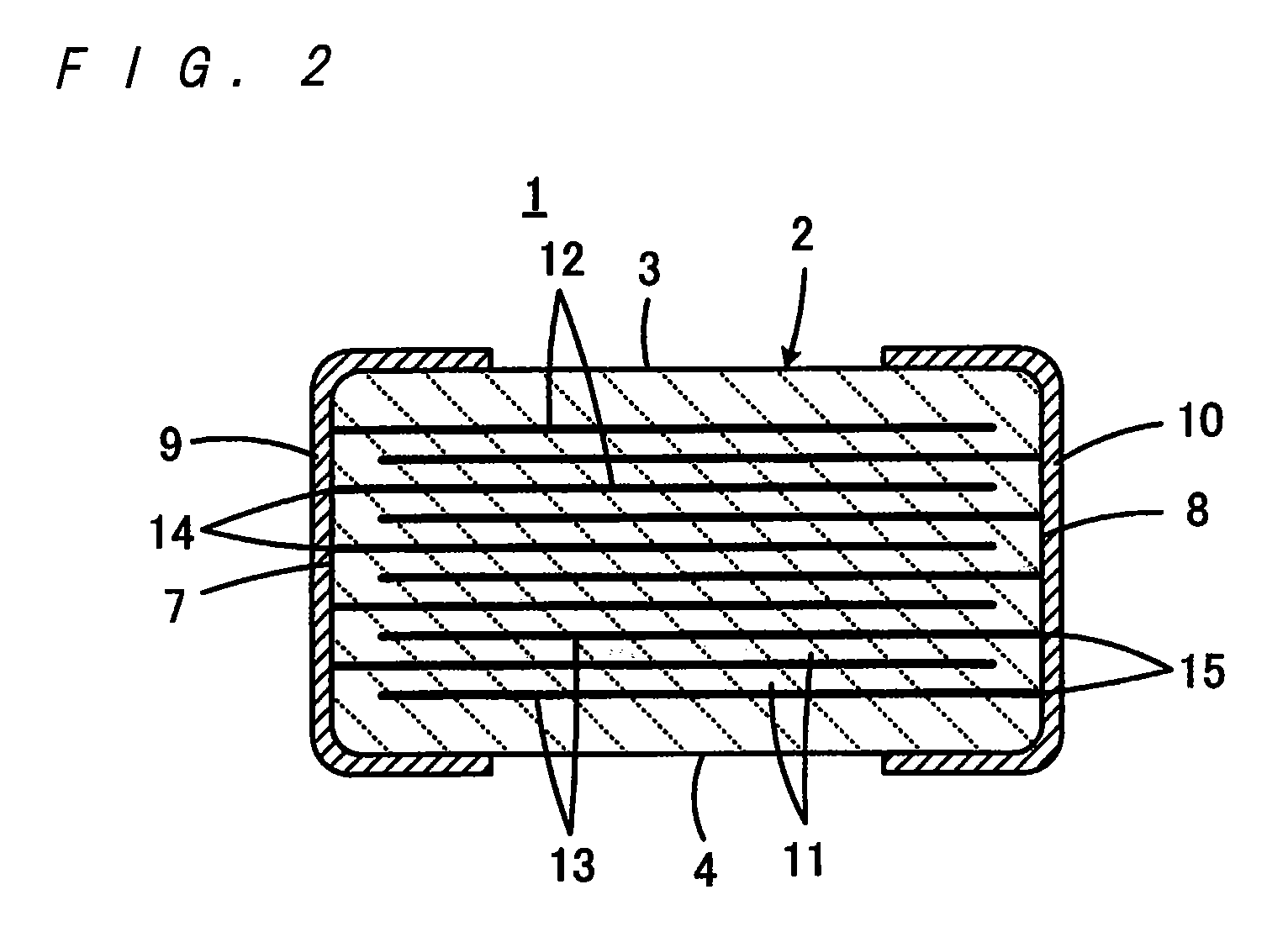

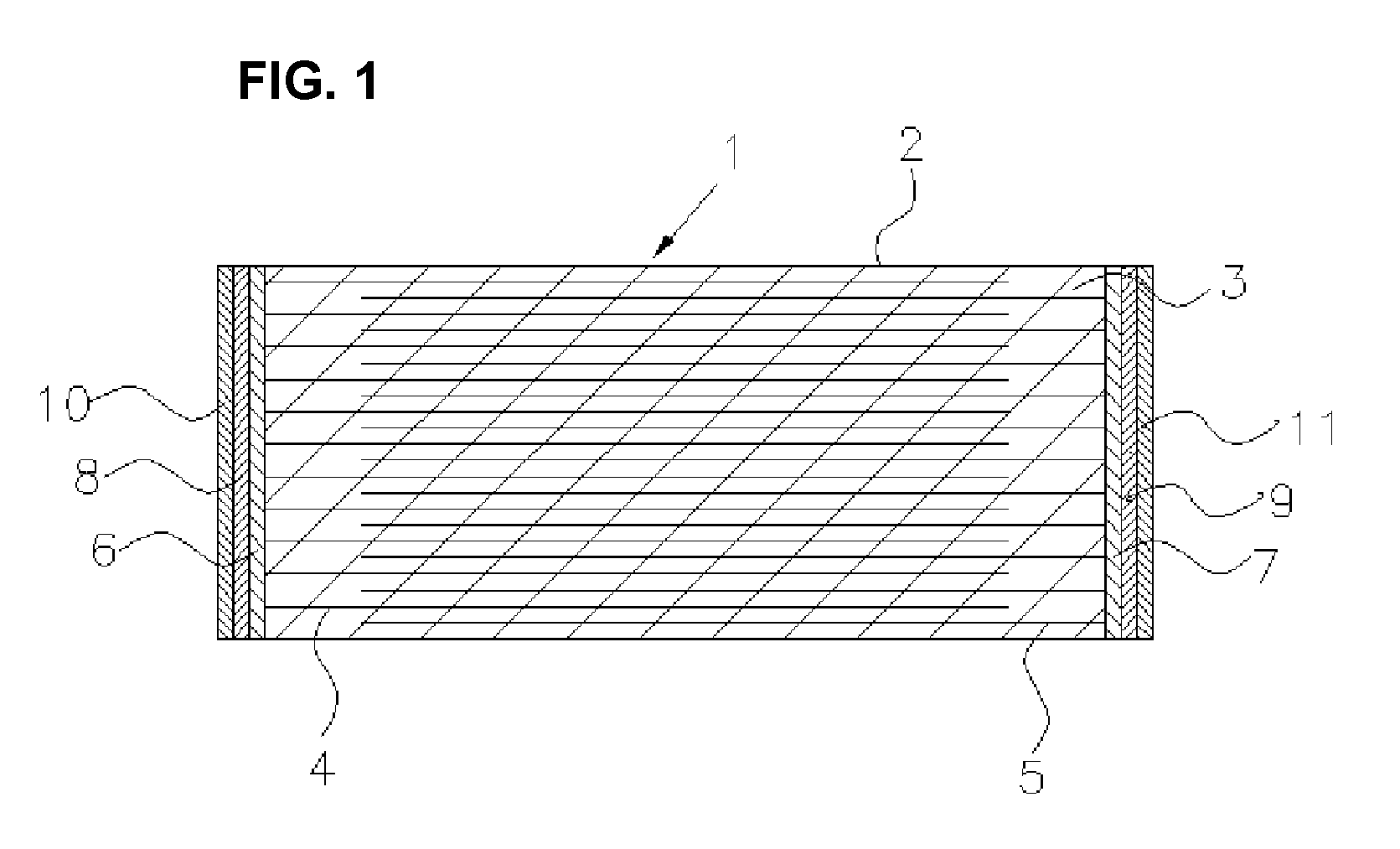

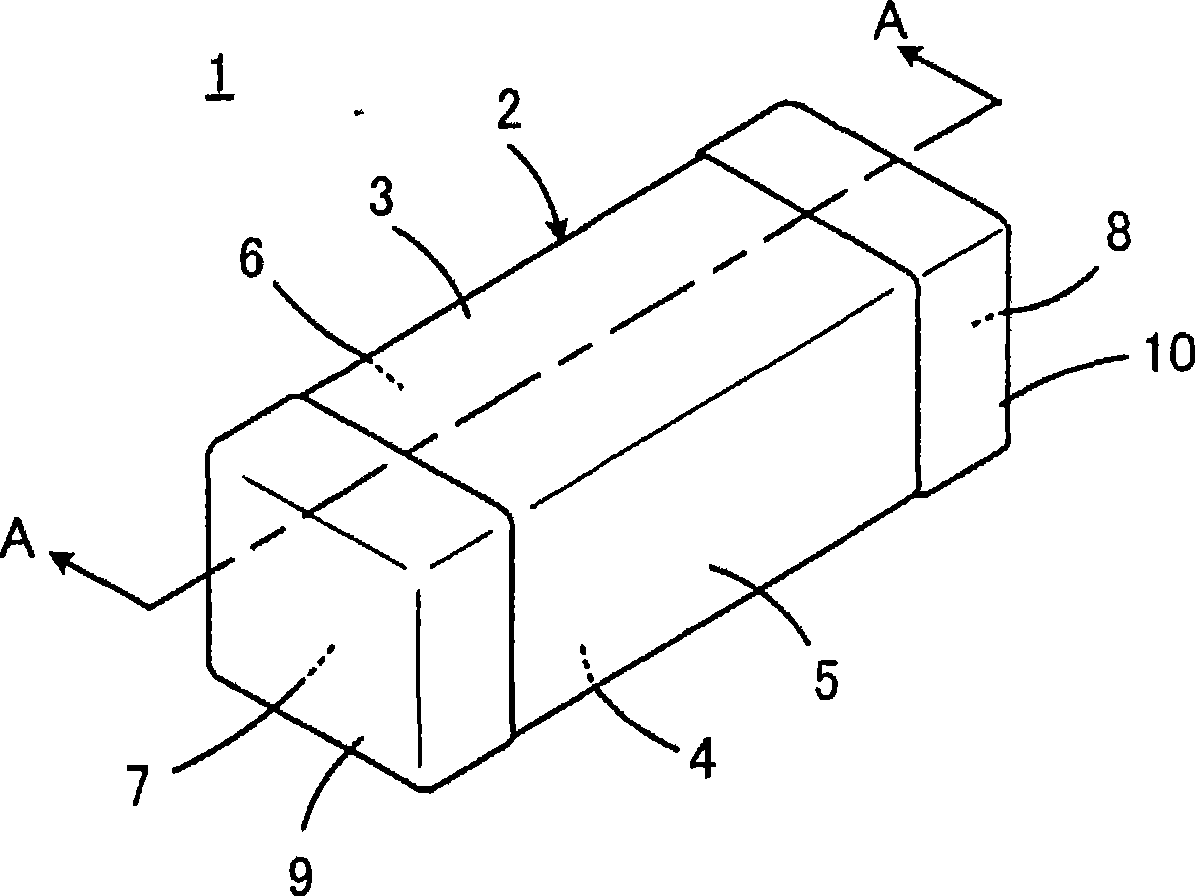

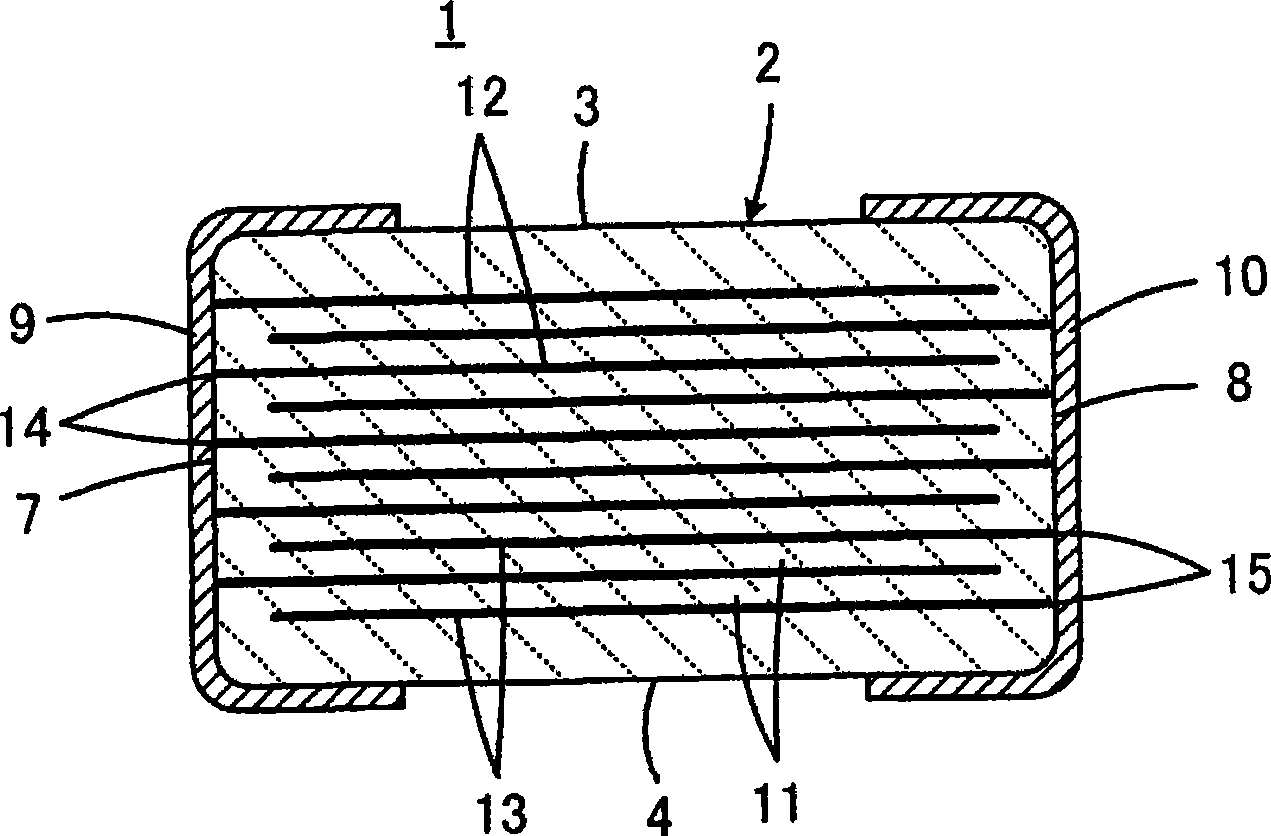

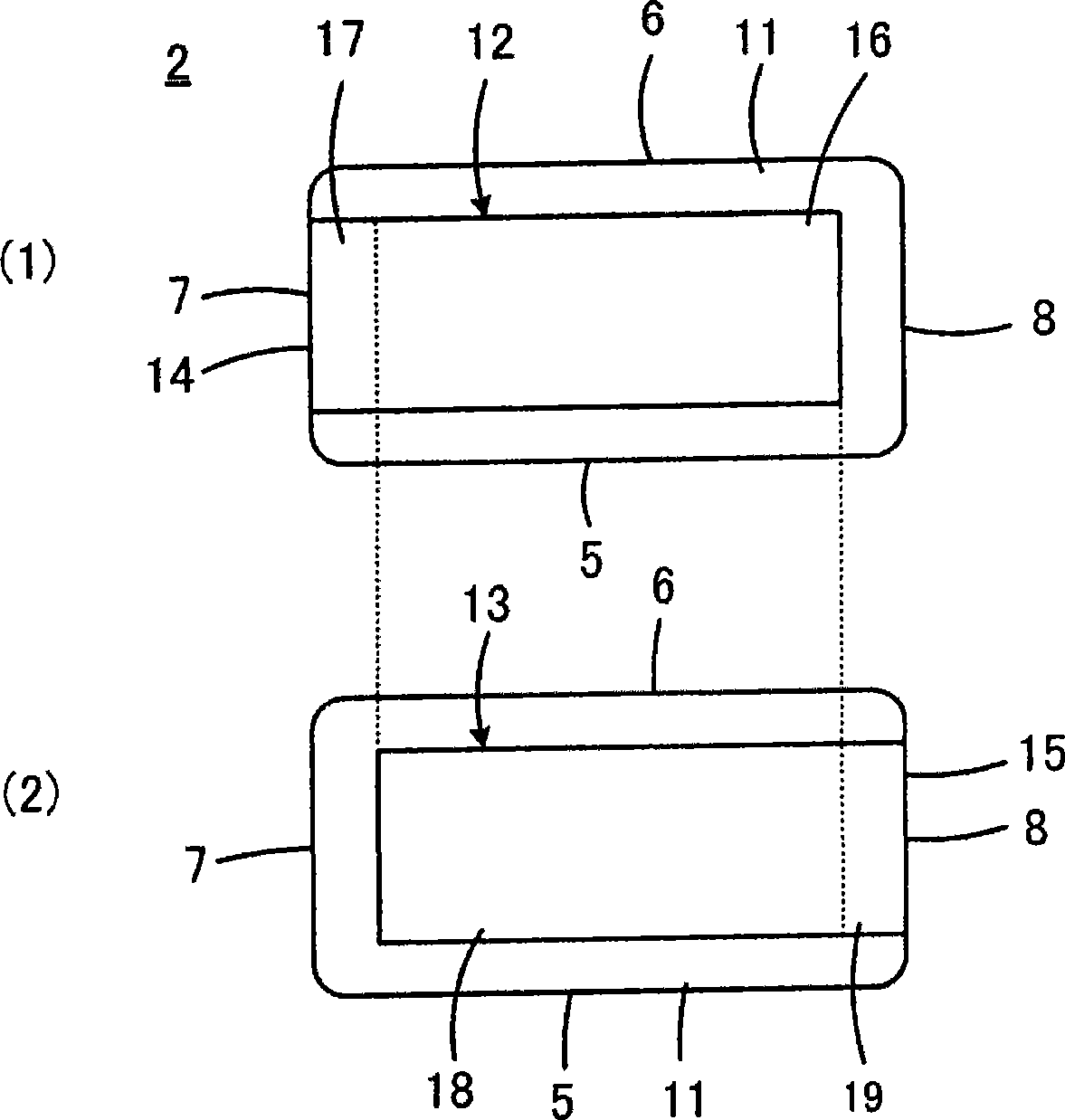

Multilayer ceramic electronic component and method for manufacturing the same

ActiveUS20090310276A1High bonding strengthComponents is relatively effectiveFixed capacitor electrodesFixed capacitor dielectricElectrical conductorElectronic component

A multilayer ceramic electronic component includes external terminal electrodes that are formed by direct plating on the first and second side surfaces of a ceramic body including stacked ceramic layers and inner conductors. The external terminal electrodes include base plating films formed so as to cover the exposed portions of inner conductors. Voids are provided that are open to the side surfaces of the ceramic body so as to be adjacent to the ends in the width direction of the exposed portions of the inner conductors. A plating metal defining the base plating films enters the voids and is electrically connected to the inner conductors in the ceramic body.

Owner:MURATA MFG CO LTD

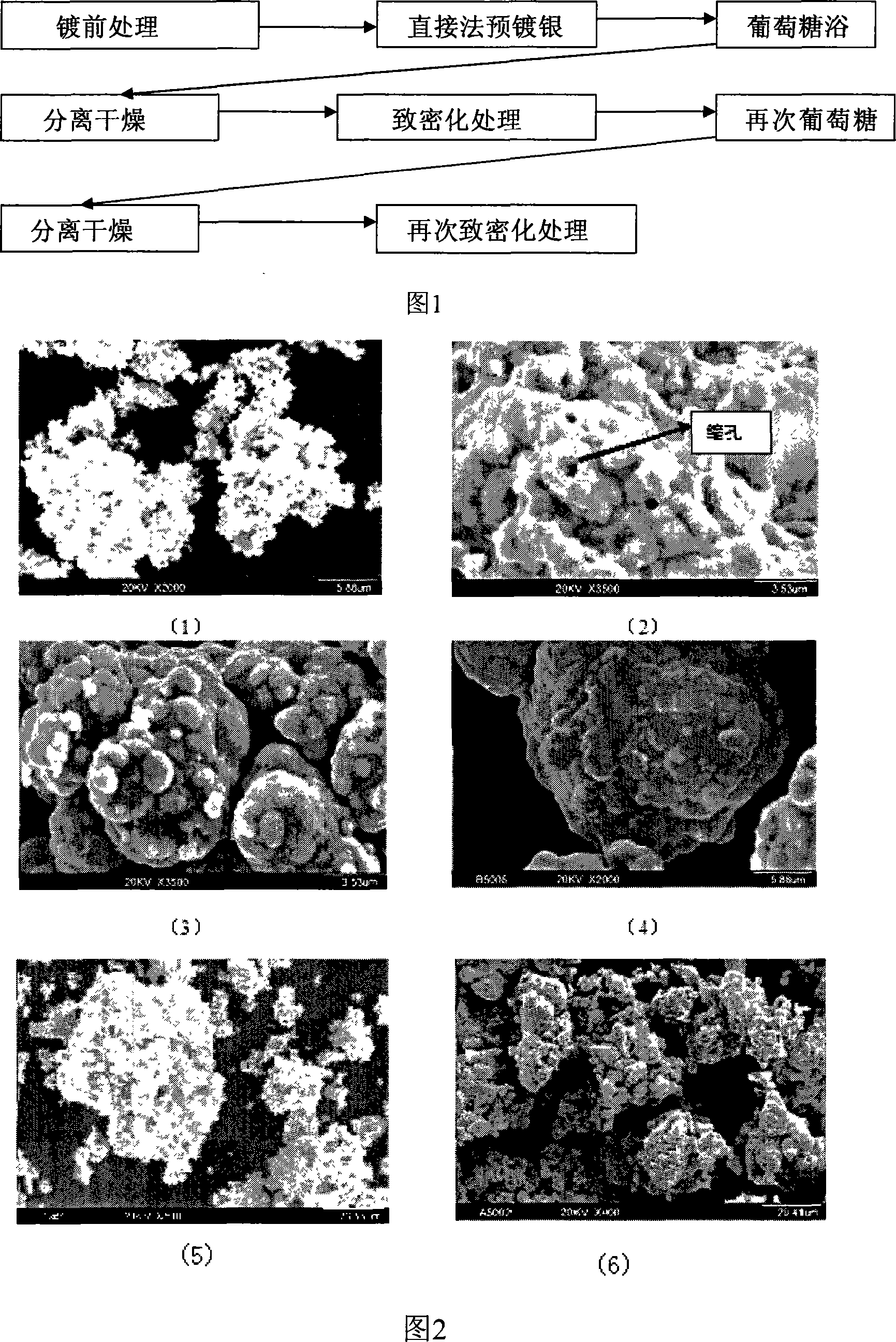

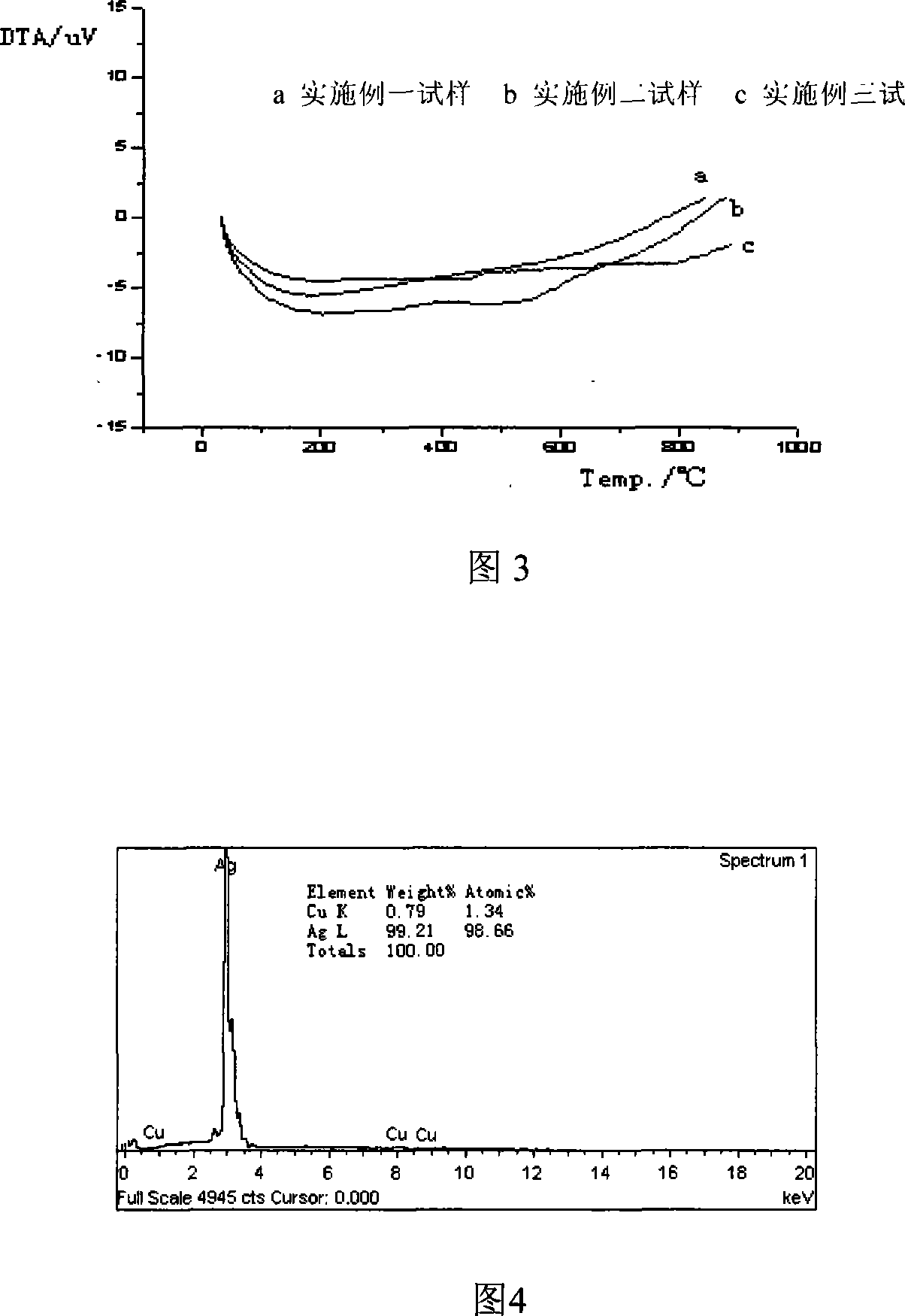

Prepn process of composite Cu-Ag metal powder in core-shell structure

InactiveCN101088670AImprove antioxidant capacityNot easily oxidizedCoatingsChemical reactionGlucose polymers

The present invention relates to preparation process of composite Cu-Ag metal powder in core-shell structure. Cu powder is pre-plated in a direct plating process for Ag to crystallize and grow in the surface of Cu well, and through twice chemical reactions in glucose bath and twice densifying treatments, micron level Cu powder is clad with a complete compact Ag layer with greatly reduced gaps. The Ag plated Cu powder has improved high temperature oxidation resistance in the temperature up to 790 deg.c, and high binding strength between the Cu core and the Ag shell.

Owner:XI AN JIAOTONG UNIV

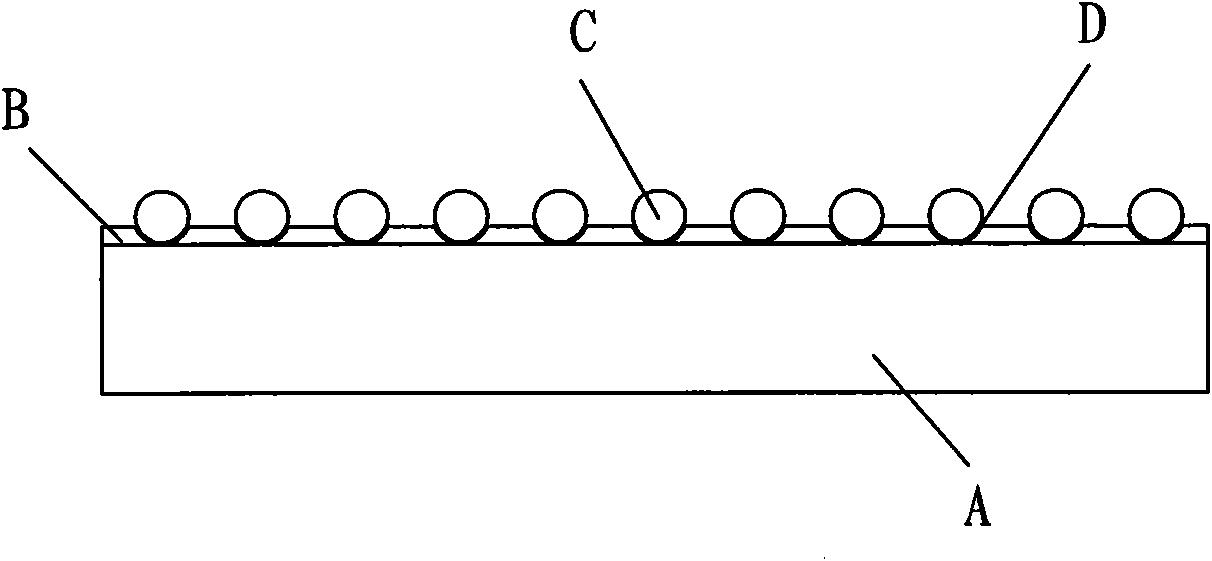

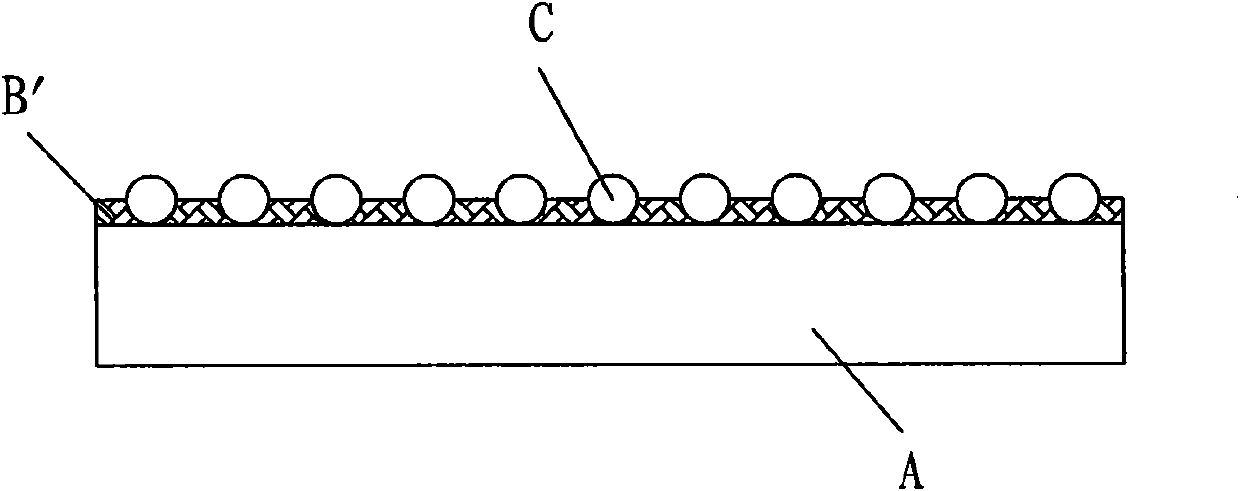

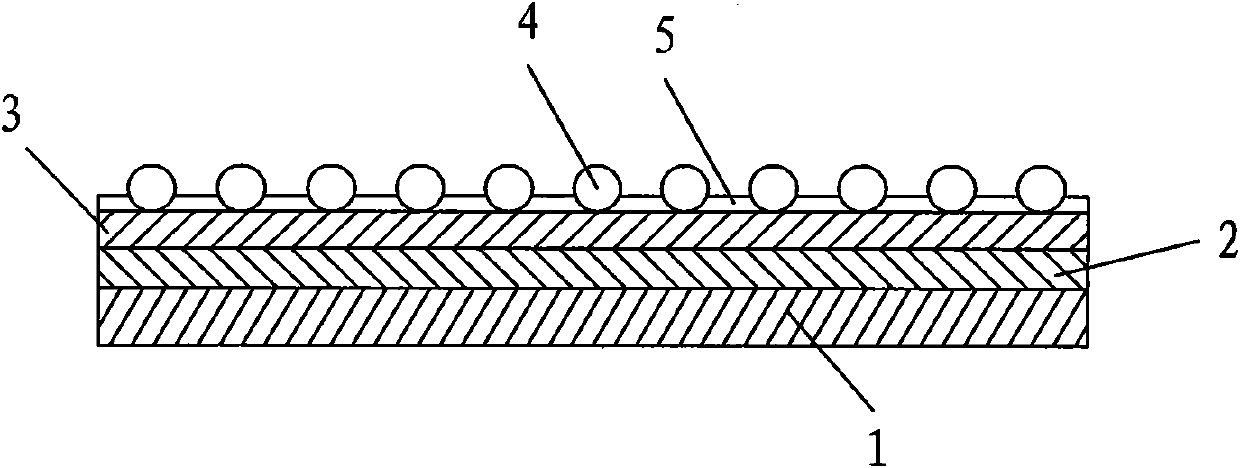

Exposed glass bead reflecting film capable of reflecting colored light and manufacturing method thereof

ActiveCN101995596AReduce nighttime accidentsImprove night work managementOptical elementsLaser patterningReflective layer

The invention discloses an exposed glass bead reflecting film capable of reflecting colored light and a manufacturing method thereof. The exposed glass bead reflecting film comprises a base material, a reflecting layer, a transparent color layer and a plurality of glass bead convex lenses; the reflecting layer and the transparent color layer are arranged on the base material in turn; the plurality of glass bead convex lenses are planted on the transparent color layer through a transparent adhesive layer; each glass bead convex lens penetrates the transparent adhesive layer and is in point contact with the upper plane of the transparent color layer; and a laser pattern can be pressed on the transparent color layer according to requirements. The manufacturing method for the reflecting material comprises a reflecting layer direct plating method and a reflecting layer reverse adhesion method. Compared with the conventional exposed reflecting material, when applied to a night reflecting device, the exposed glass bead reflecting film can reflect the colored light, also has the laser effect, and has positive effects of reducing accidents at night, improving night work management and beautifying some wearing products and daily products.

Owner:晋江市夜视明反光材料有限公司

Multilayer ceramic electronic component and manufacturing method thereof

ActiveUS20090161293A1Small sizeIncrease volumeFixed capacitor electrodesFixed capacitor dielectricAdhesiveElectronic component

A multilayer ceramic electronic component including thin external terminal electrodes each having a superior bonding force to a ceramic base body is provided. In order to form the external terminal electrodes, after Cu plating films are deposited on exposed portions of internal electrodes by direct plating on a ceramic base body, a Cu liquid phase, an O2-containing liquid phase, and a Cu solid phase are generated between the Cu plating film and the ceramic base body by a heat treatment, so that Cu oxides are dispersed in the Cu plating film, at least near an interface with the ceramic base body. Since the Cu oxides function as an adhesive, a bonding force of the Cu plating film to the ceramic base body can be increased, and hence the external terminal electrode having a superior bonding force to the ceramic base body can be obtained.

Owner:MURATA MFG CO LTD

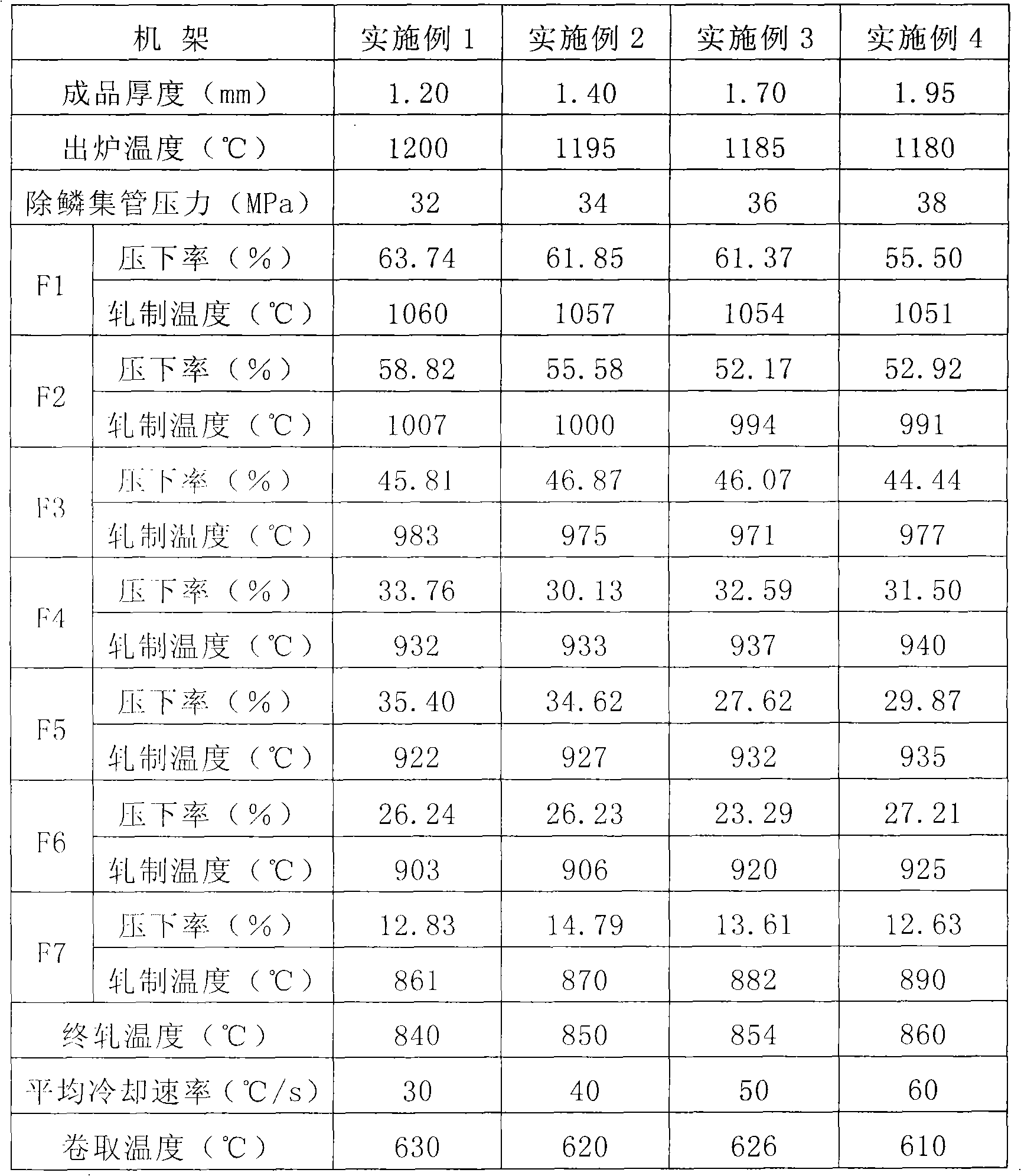

High-strength thin-specification direct-plating steel based on thin slab casting and rolling process and making method thereof

InactiveCN101818299AImprove hot-dip galvanizing performanceImprove surface qualityTemperature control deviceMetal rolling arrangementsLiquid coreChemical composition

The invention provides high-strength thin-specification direct-plating steel based on a thin slab casting and rolling process and a making method thereof. The steel comprises the following chemical components in percentage by weight: C, 0.17-0.20%, Si, 0.09-0.25%, Mn, 0.90-1.40%, P, not more than 0.020%, S, not more than 0.010%, Als, 0.015-0.060%, and the balance of Fe and inevitable impurities. The process comprises the steps of molten iron desulfuration, bessemerize, argon blowing, LE furnace refining, continuous casting, descaling in a rotating way, soaking pit treatment, hydraulic jet descaling, seven-rack finish rolling, laminar cooling and reeling, wherein liquid core downward pressing is adopted in the step of continuous casting and the casting blank thickness is decreased to 50-55mm from 70-90mm; the discharging temperature of a soaking pit is 180-1200 DEG C to ensure that the temperature of blanks during the hydraulic jet descaling is between 1175-1190 DEG C and the temperature of a hydraulic jet descaling collecting pipe is 32-38 MPa; and the average cooling speed of laminar cooling after the seven-rack finish rolling is 30-60 DEG C / s.

Owner:武钢集团有限公司

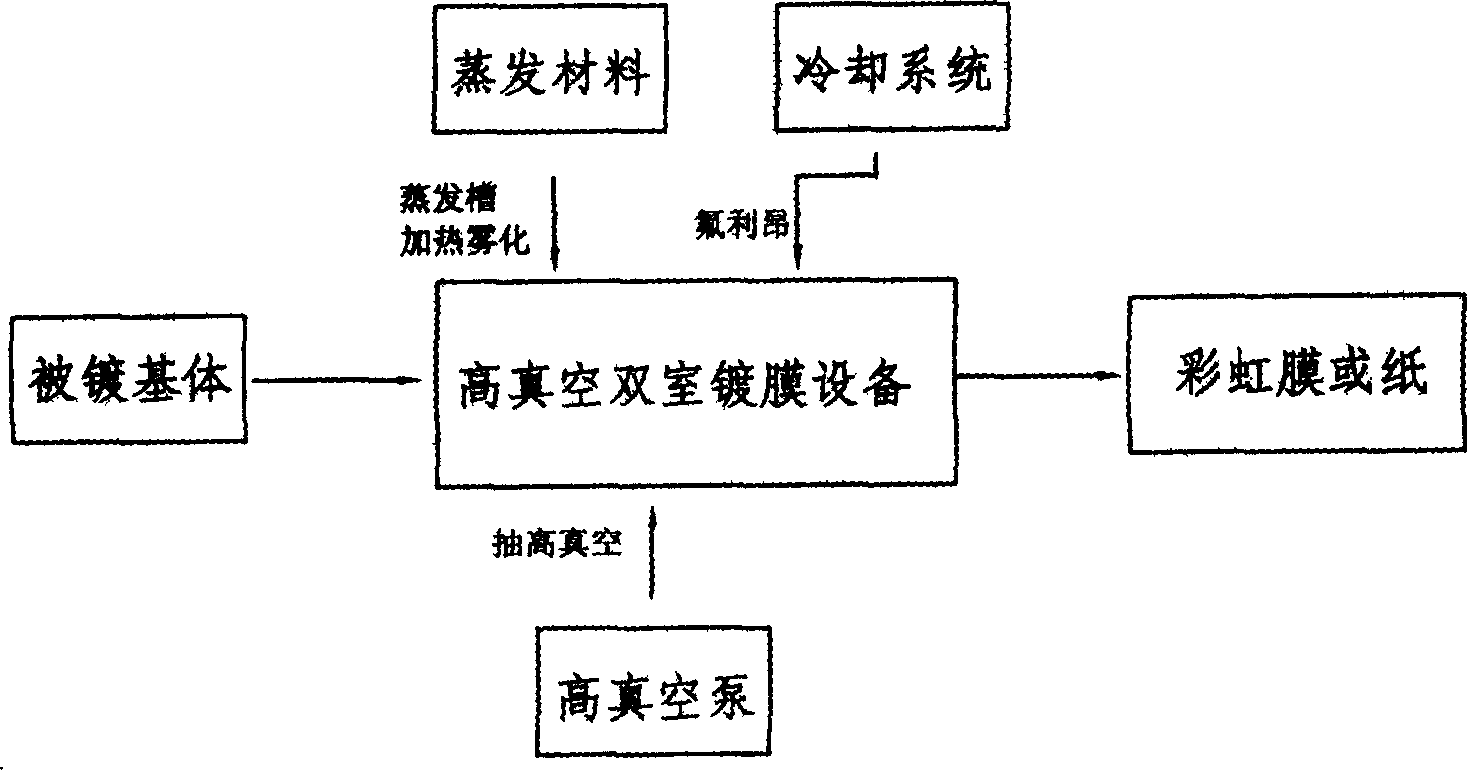

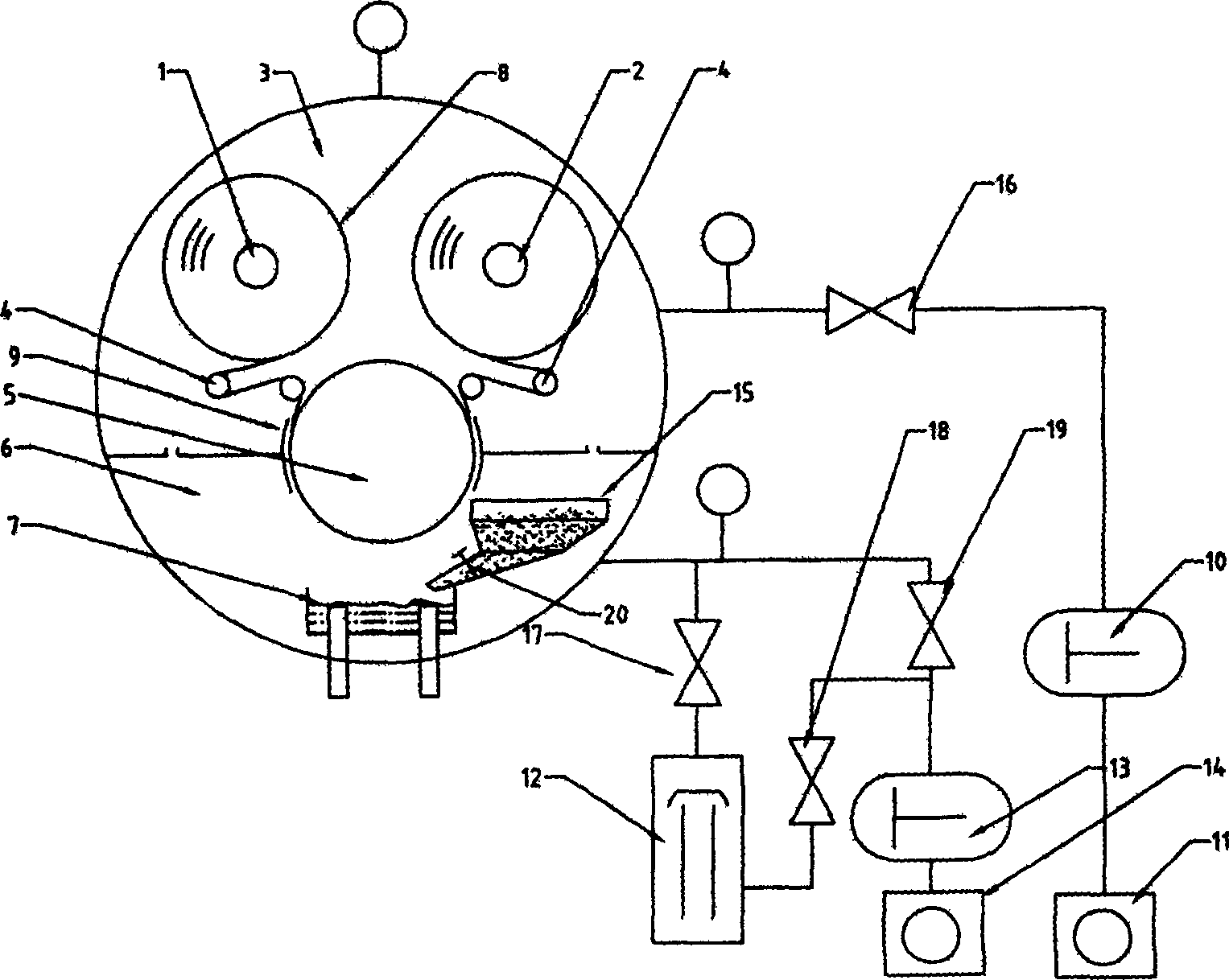

Method for fabricating rainbow film or paper through direct plating

InactiveCN1696331AEasy to processGood rainbow effectVacuum evaporation coatingSputtering coatingRainbowBoiling point

A method for directly evaporating rainbow film (or paper) includes reforming the existing high-vacuum dual-chamber film plating equipment in such manner that the water cooling pipeline of central cooling drum is replaced by the force fereon refrigerating system and a evaporator and a hopper container for regulating the material feeding are installed at bottom of high-vacuum evaporating chamber, loading the evaporation material in the evaporator, heating it until it is boiling or atomizing and direct evaporation plating.

Owner:林杨

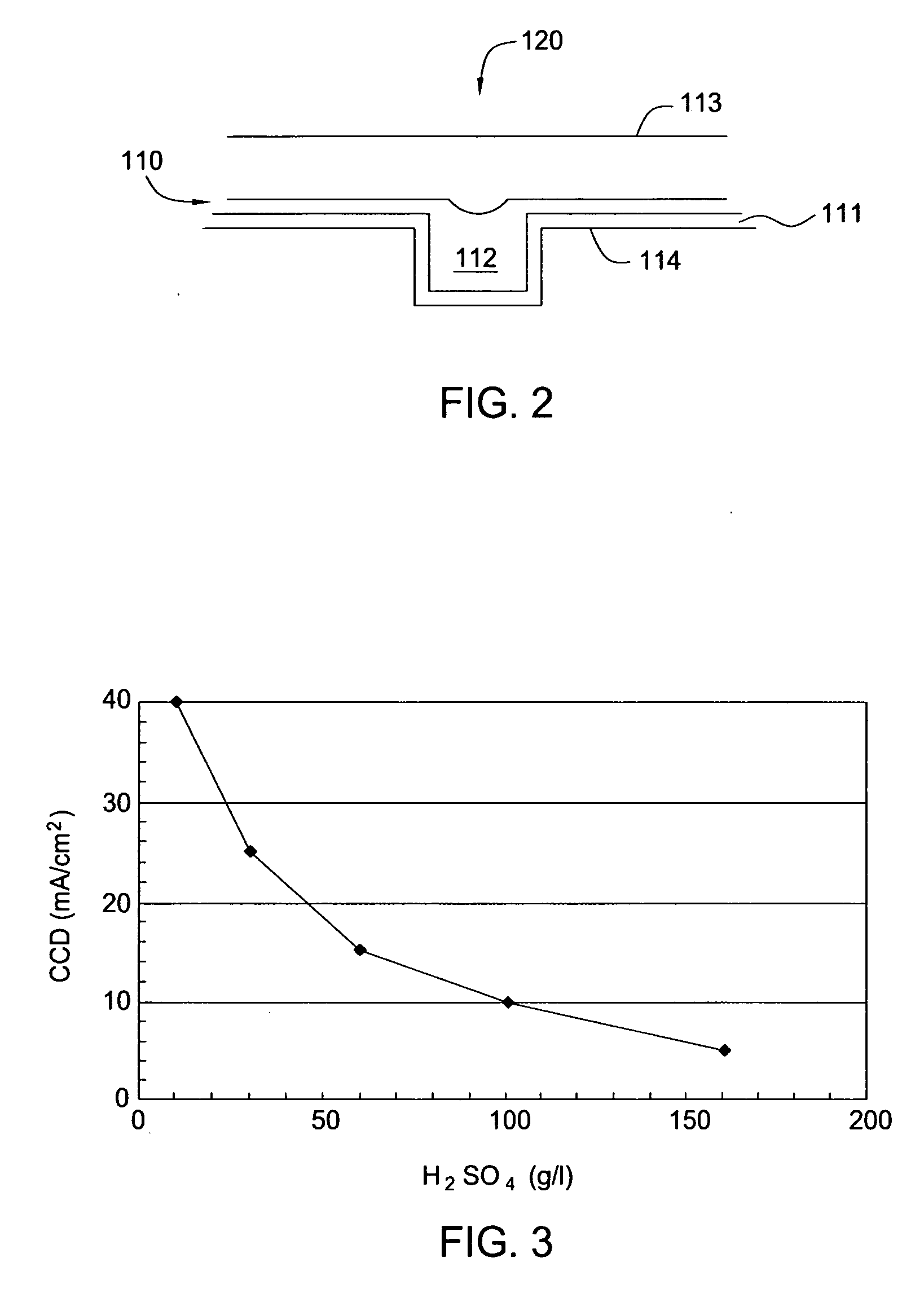

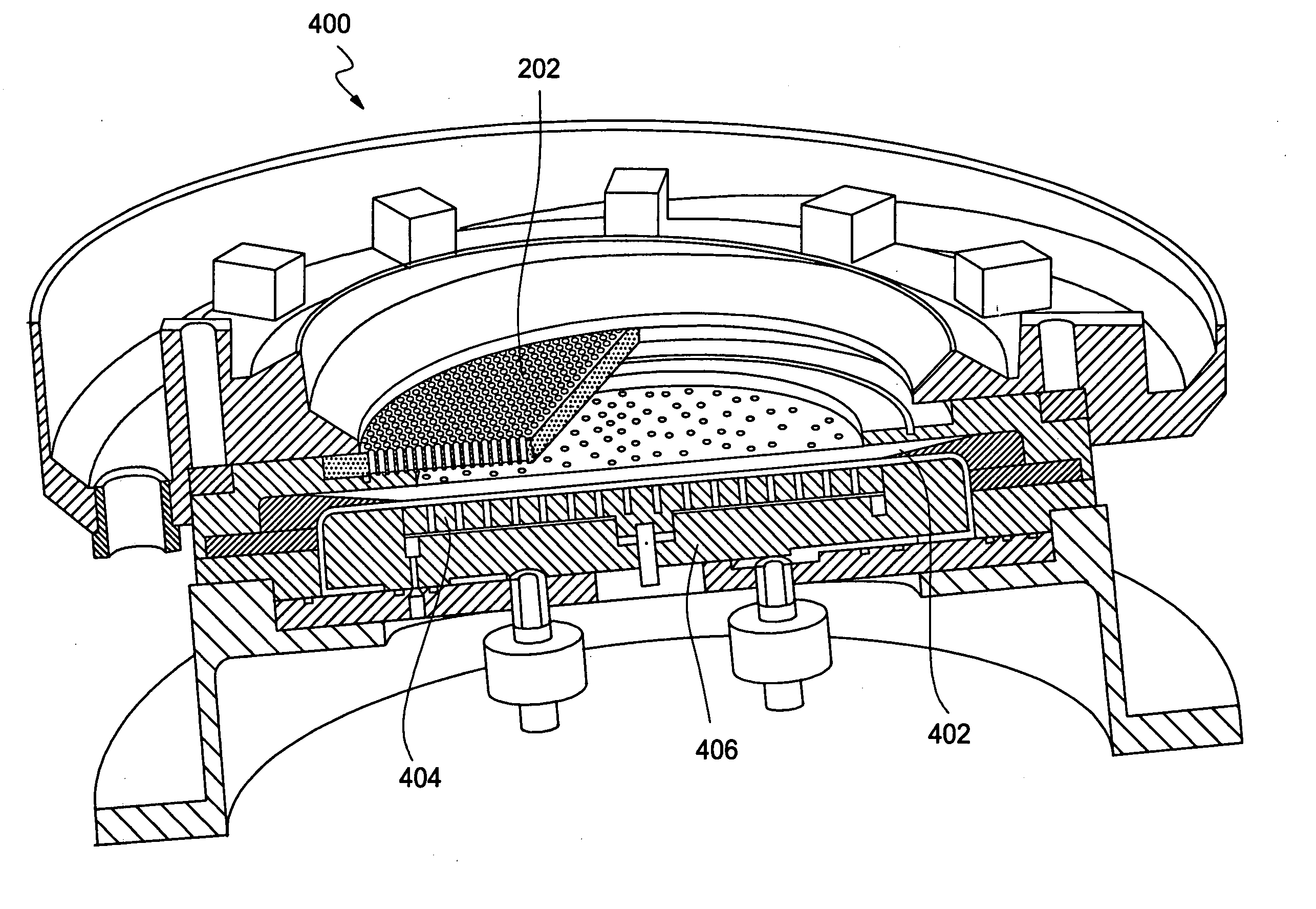

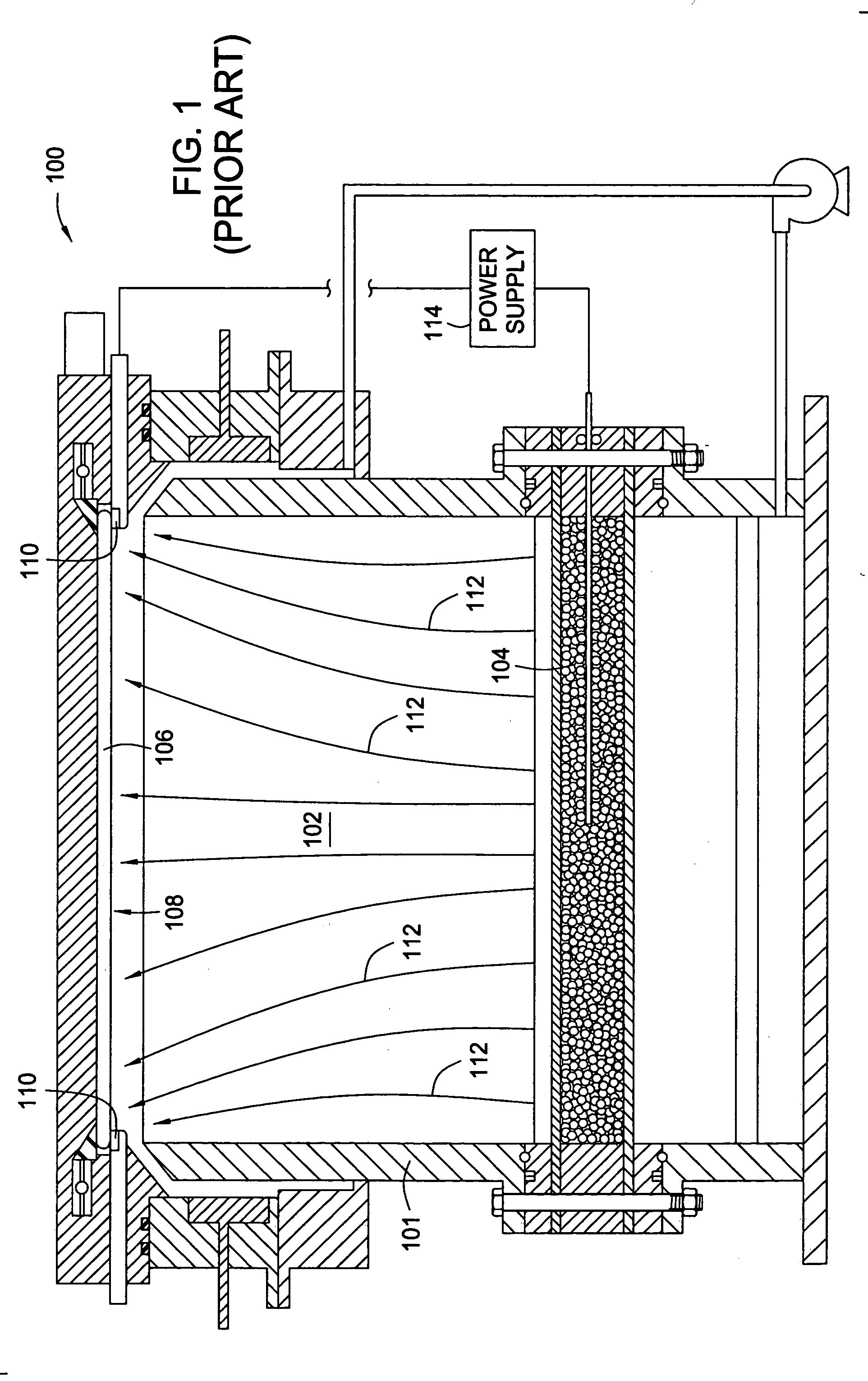

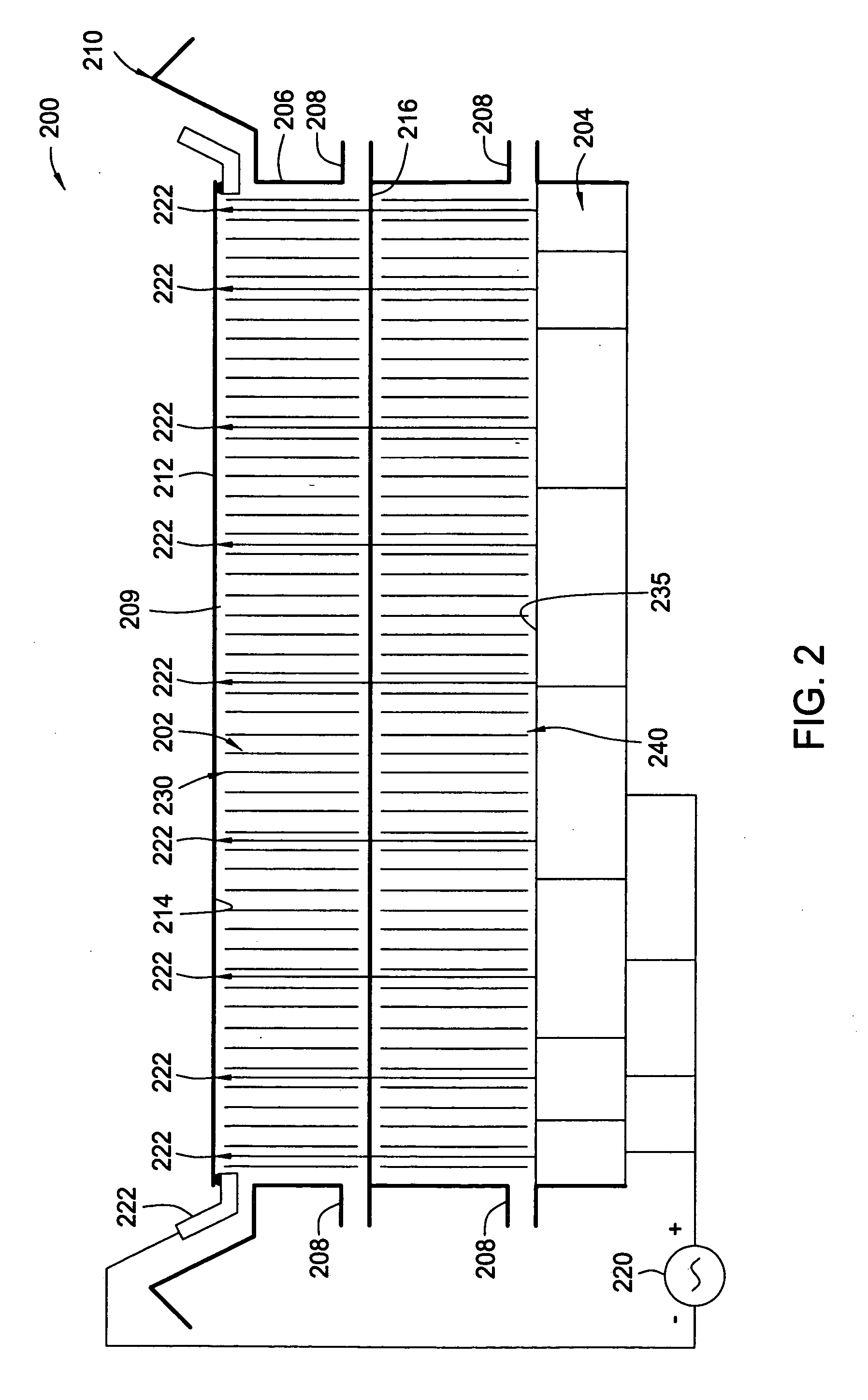

Current collimation for thin seed and direct plating

A method and apparatus for plating a conductive material onto a substrate is provided. The apparatus includes a fluid processing cell having a fluid basin configured to contain an electrolyte solution and having an opening configured to receive a substrate for processing, an anode assembly positioned in the fluid basin, and a collimator positioned in the fluid basin between the anode assembly and the opening.

Owner:APPLIED MATERIALS INC

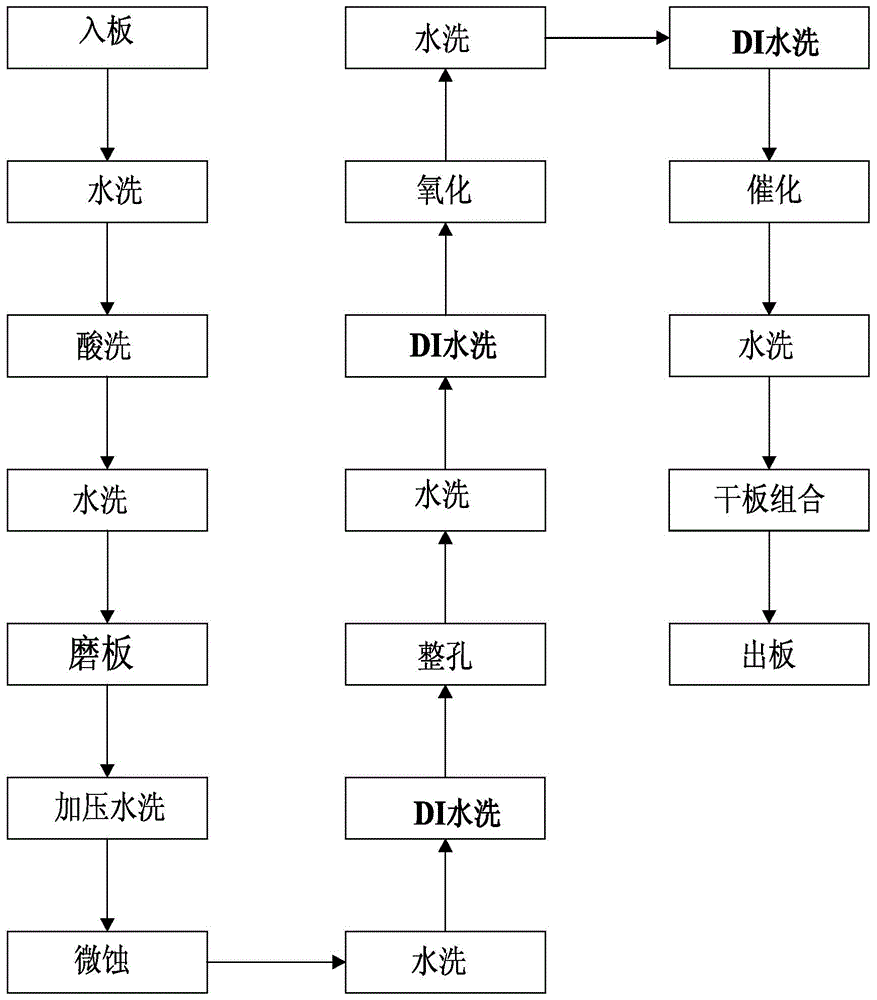

Direct plating technology of circuit board

InactiveCN103957670AShort direct plating processEasy to handlePrinted circuit manufactureWastewaterAcid washing

The invention discloses a direct plating technology of a circuit board. According to the technical scheme, the direct plating technology of the circuit board is characterized in that copper board covering after drilling, board inputting, water washing and acid washing, board grinding, water washing under pressure, tiny corrosion, DI water washing, hole adjusting, oxidation, catalyzing, dry board combination and the like are conducted, and an oxide film conductive layer is formed on a hole wall of the circuit board through a conductive membrane technology to replace chemical deposited copper. The direct plating technology of the circuit board is short in technological process, small in equipment investment, free of formaldehyde, EDTA and other clathrate, small in pollution, easy to control, high in rate of finished products and simple in wastewater treatment.

Owner:广东达进电子科技有限公司

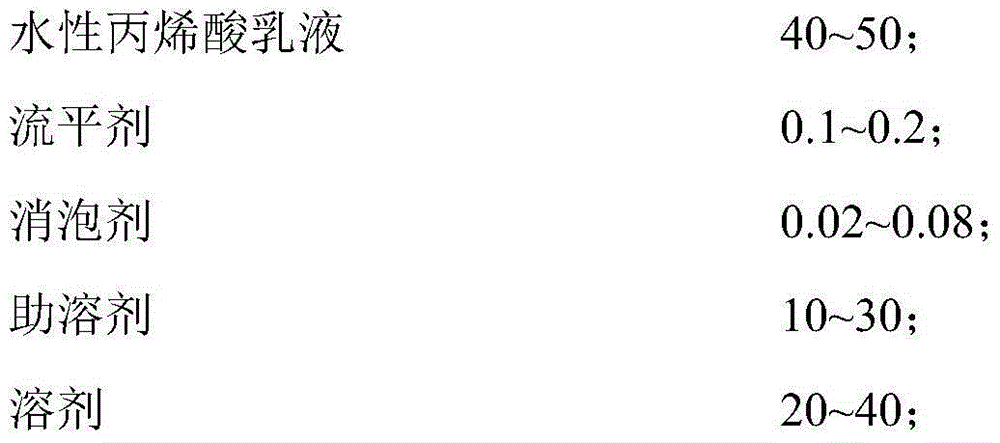

High-gloss direct plating method binding layer coating as well as preparation method and application thereof

ActiveCN101671510AReduce contentReduce manufacturing costSpecial visual effect coatingsCellulose coatingsOrganic solventSolvent

The invention discloses a direct plating method binding layer coating as well as a preparation method and an application thereof. The existing transferring method has higher cost of spray aluminium paper, uses a great amount of organic solvent, and does not accord with related requirements; and the direct plating method has low cost of spray aluminium paper and environmental protection, while is rough in surface effect, thus only being suitable for low-end package. The invention is characterized in that: the coating is prepared by the following materials by weight parts: 30-50 parts of waterborne resin, 13-30 parts of cosolvent, 36-40 parts of deionized water, 0.1-2 parts of pH value conditioning agent, 0.2-0.3 parts of leveling agent, and 0.05-0.1 parts of defoaming agent. The direct plating method binding layer coating takes water as main dispersing medium, does not contain organic solvent substantially, has extremely low content of volatile organic compounds and low production cost, and can achieve mirror effect in the finished paper prepared by using the coating due to high glossiness.

Owner:ZHEJIANG JINGHUA LASER TECH CO LTD

Method for adhesion and deposition of metal films which provide a barrier and permit direct plating

A method for fabricating a barrier layer and a barrier layer is described which employs a metal selected from the group of Ru, Ir, Pd, Pt, Rh, Os, Au, Ag, W, Ta and Ti. A graded region is formed to cause the metal to adhere to an underlying substrate. Direct plating is enabled without a seed layer.

Owner:INTEL CORP

Manufacturing method of cigarette inside lining direct plating laser paper

InactiveCN101037852AReduce dosageEliminate hazardsPaper coatingPhysical paper treatmentLymphatic SpreadEngineering

A method for manufacturing a direct plating lined laser paper of cigarettes is disclosed, which main technological process comprises the steps of coating the base paper surface with a coating layer, laser molding the base paper after the coating, then aluminum plating the base paper, and then brushing and coating a layer to obtain said direct plating lined laser paper of cigarettes. The present invention simplifies the technological process by taking out adhesive and thin film in a metastasis process, and then saves the using amount of metal aluminum in contrast to aluminum foil compound, and lowers the energy consumption and manufacturing cost; furthermore, eliminates the potential harm of residual additive of the original paint to environment and human, by utilizing waterborne coatings.

Owner:湖北盟科纸业有限公司

Ceramic electronic component and method for manufacturing the same

ActiveUS20090268372A1Increase effective volumeImprove reliabilityLamination ancillary operationsElectrolytic coatingsMetallurgyCeramic capacitor

When external electrodes of a multilayer ceramic capacitor are formed by performing direct plating on surfaces at which internal electrodes are exposed without forming paste electrode layers, bonding forces of plating layers are relatively weak, and in addition, when glass particles are included in the plating layers, blisters are often generated. To overcome these problems, a multilayer ceramic capacitor is formed by performing electrolytic plating using a plating bath including glass particles, electrolytic plating layers including glass particles dispersed therein are formed as the external electrodes.

Owner:MURATA MFG CO LTD

Direct plating method for printed circuit board free of chemical plating

InactiveCN104018196AAvoid pollutionDirect Plating RealizationPrinted element electric connection formationChemical treatmentChemical plating

The invention discloses a direct plating method for a printed circuit board free of chemical plating. Formaldehyde pollution is avoided, and metal copper and precious metal palladium are saved. A prefabrication method for additionally fabricating a conductive polymer is not adopted while oxidization and polymerization reactions are carried out in the fabrication flow of the printed circuit board; a hole site of the printed circuit board generates a conductive polymer in the flow; the electrical conductivity in the hole can be obtained without electroless copper plating, so that the hole site of the printed circuit board is well directly copperized. The main points of adopting the novel method are as follows: the processing mode of horizontally placing the printed circuit board is adopted when a conductive high-molecular polymer for replacing electroless copper plating is adopted. Thus, the hole site can be effectively subjected to chemical processing and cleaning. The water consumption is reduced, so that the production efficiency is improved, and the resources are saved.

Owner:武汉中环泽科技有限公司

Directly plating printing method for cigarette package paper

The invention relates to a processing technique for cigarette packaging materials, in particular to a direct plating printing method for a cigarette wrapping paper, which is realized through the following steps: firstly, surface treatment of a wrapping base paper is performed, and direct plating paints are used for coating the surface of the paper; secondly, the wrapping paper after coating is kept for 20 to 40 minutes under room temperature and then sent to a vacuum aluminum plating machine for aluminum plating; thirdly, the aluminized wrapping paper is sent back to a coating machine, and aluminum-foil coating printing inks are adopted for coating a protective layer; fourthly, after the protective layer is coated, the wrapping paper is printed through a printing machine. The invention overcomes the defect that a pearly tipping paper contains poisonous substances and has the advantages of improvement on the basis of development of directly aluminized wrapping papers, stable attachment and conservation of the printing inks.

Owner:QINGDAO XIYINGMEN GRP +1

Catalyst application solution, electroless plating method using same, and direct plating method

ActiveUS20120171363A1Simple treatmentReducing treatmentPretreated surfacesAnti-corrosive paintsAntioxidantDisplacement reactions

Disclosed is a catalyst application solution for plating an insulating portion of an object to be plated that comprises the insulating portion. The catalyst application solution is characterized by containing a water-soluble palladium compound, a reducer, a dispersant, catechol, a copper antioxidant and a buffering agent, and by having a pH of not less than 4. When the catalyst application solution is compared with a Pd—Sn colloidal solution, the catalyst application solution has the following advantages: since the catalyst application solution is a colloidal solution of Pd only that does not contain Sn, a pre-dip process and an Sn removal process are unnecessary and thus the catalyst application process can be simplified; since the catalyst application solution has a pH of not less than 4, haloing does not occur; and since the catalyst application solution is in a reducing atmosphere due to the reducer contained therein, a copper surface is not oxidized and no copper dissolution occurs, thereby causing no palladium displacement reaction.

Owner:C UYEMURA & CO LTD

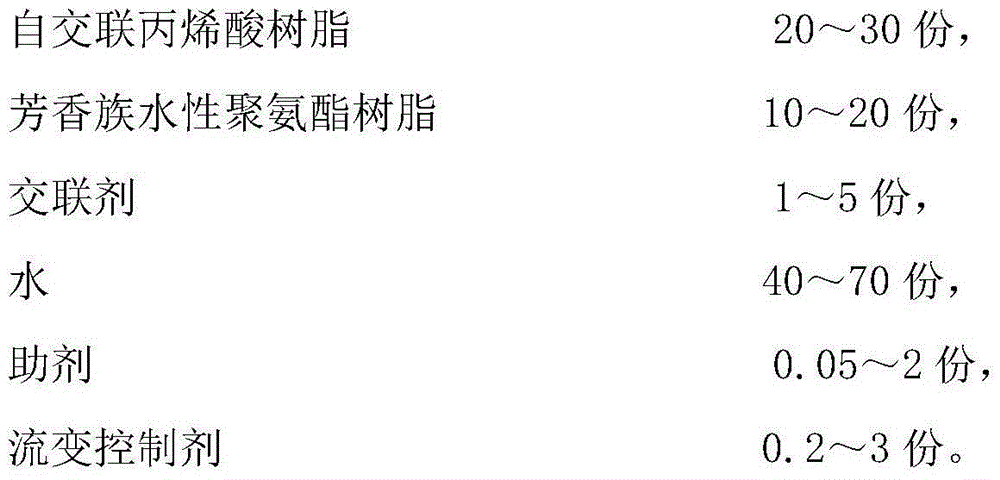

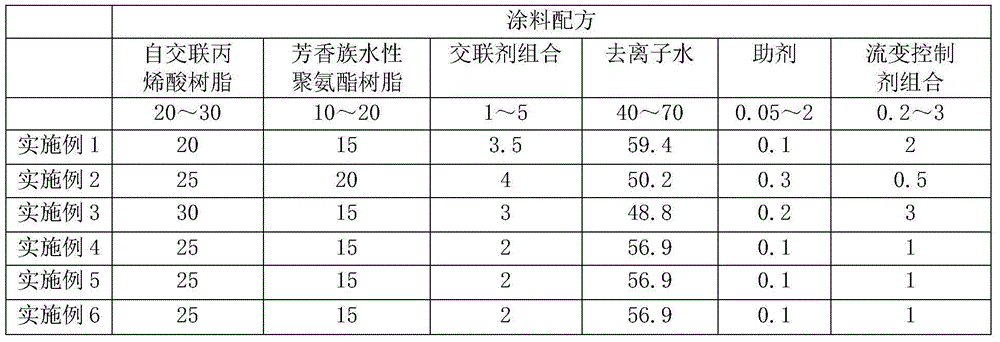

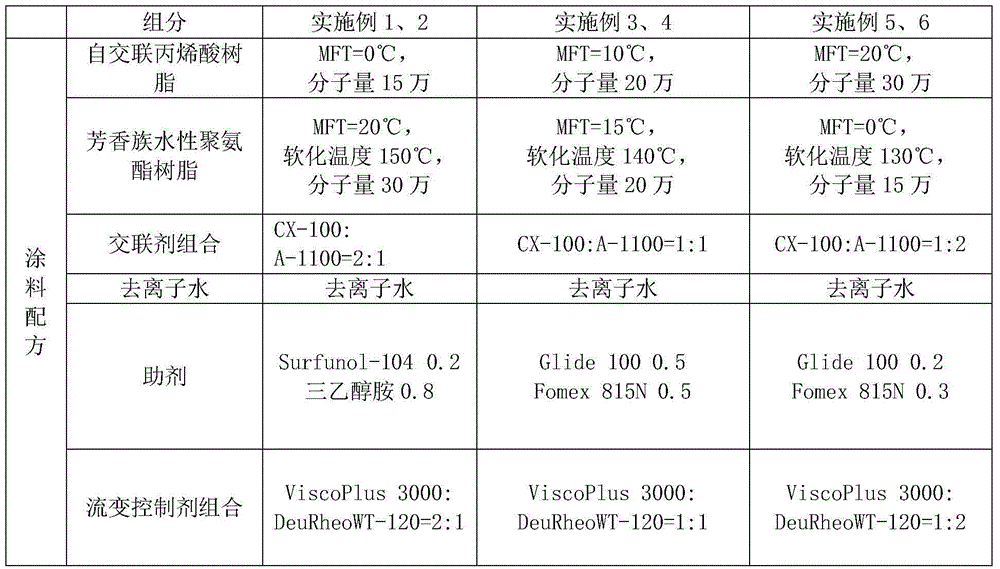

Direct vacuum aluminum plating water-based under-coating paint composition and preparation method thereof

ActiveCN104594119ASolve the main problem of loss of light and whiteningReduce manufacturing costDefoamers additionPaper coatingWater basedCross-link

The invention provides a direct vacuum aluminum plating water-based under-coating paint composition and a preparation method thereof. The paint comprises the following components in parts by weight: 20-30 parts of a self-cross-linking acrylic resin, 10-20 parts of an aromatic water-based polyurethane resin, 1-5 parts of a cross-linking agent, 40-70 parts of water, 0.05-2 parts of aids and 0.2-3 parts of a rheology controller. The problems that the plated aluminum is dazzled and the stiffness is insufficient because the common direct plating coating used for common transfer paper is not subjected to overpressure treatment are solved. Compared with the prior art, the composition disclosed by the invention can be directly used for common transfer paper with obvious cost advantage, imported direct plating special paper with high price does not need to be used, and the production cost of direct plating paper is greatly reduced. In addition, by virtue of the good film-forming property of the formula system, any extra coalescing agent or cosolvent does not need to be added, and the composition has the environment-friendly attributes such as low smell, low VOC content, safety, non-toxicity and the like.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

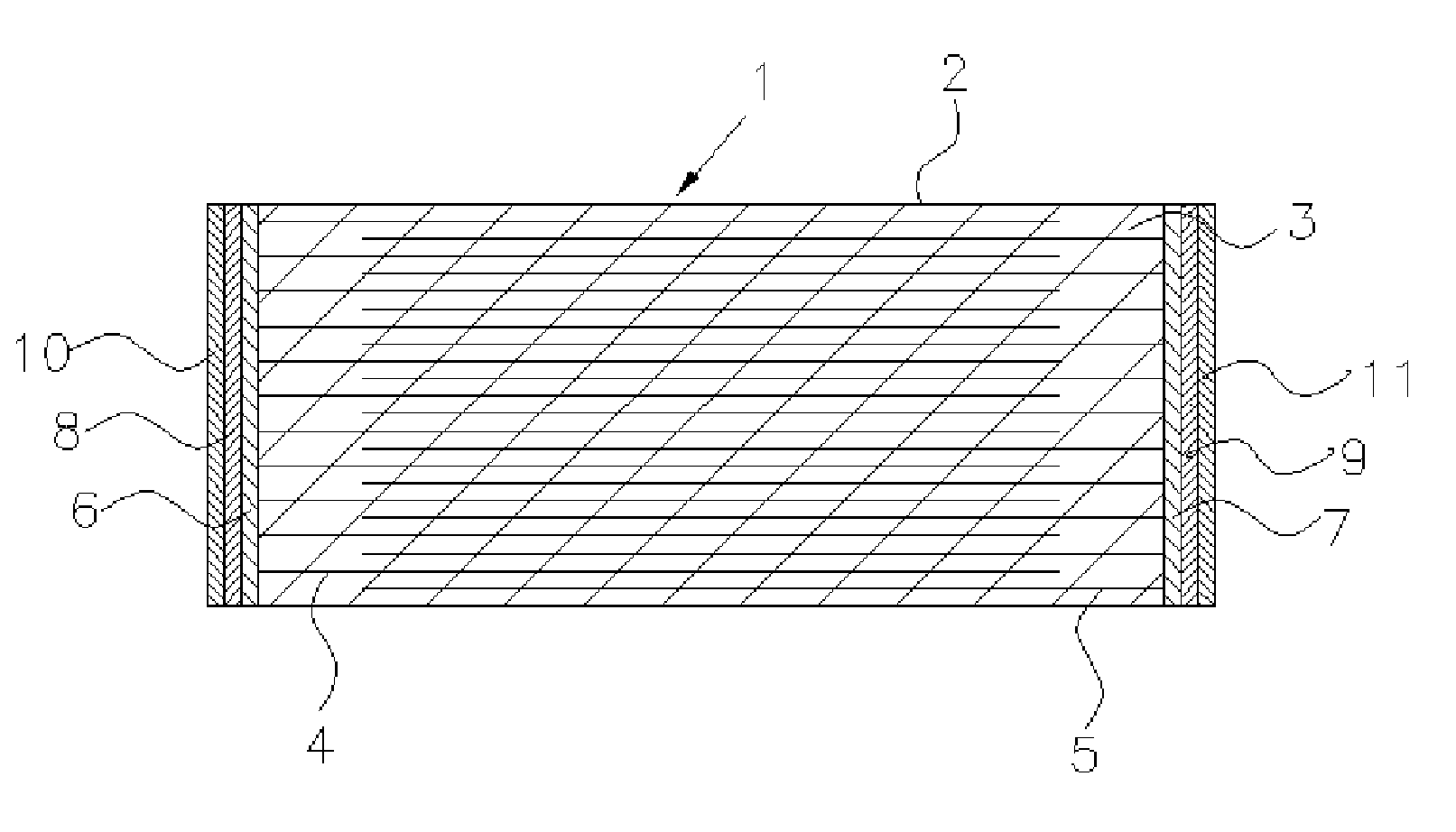

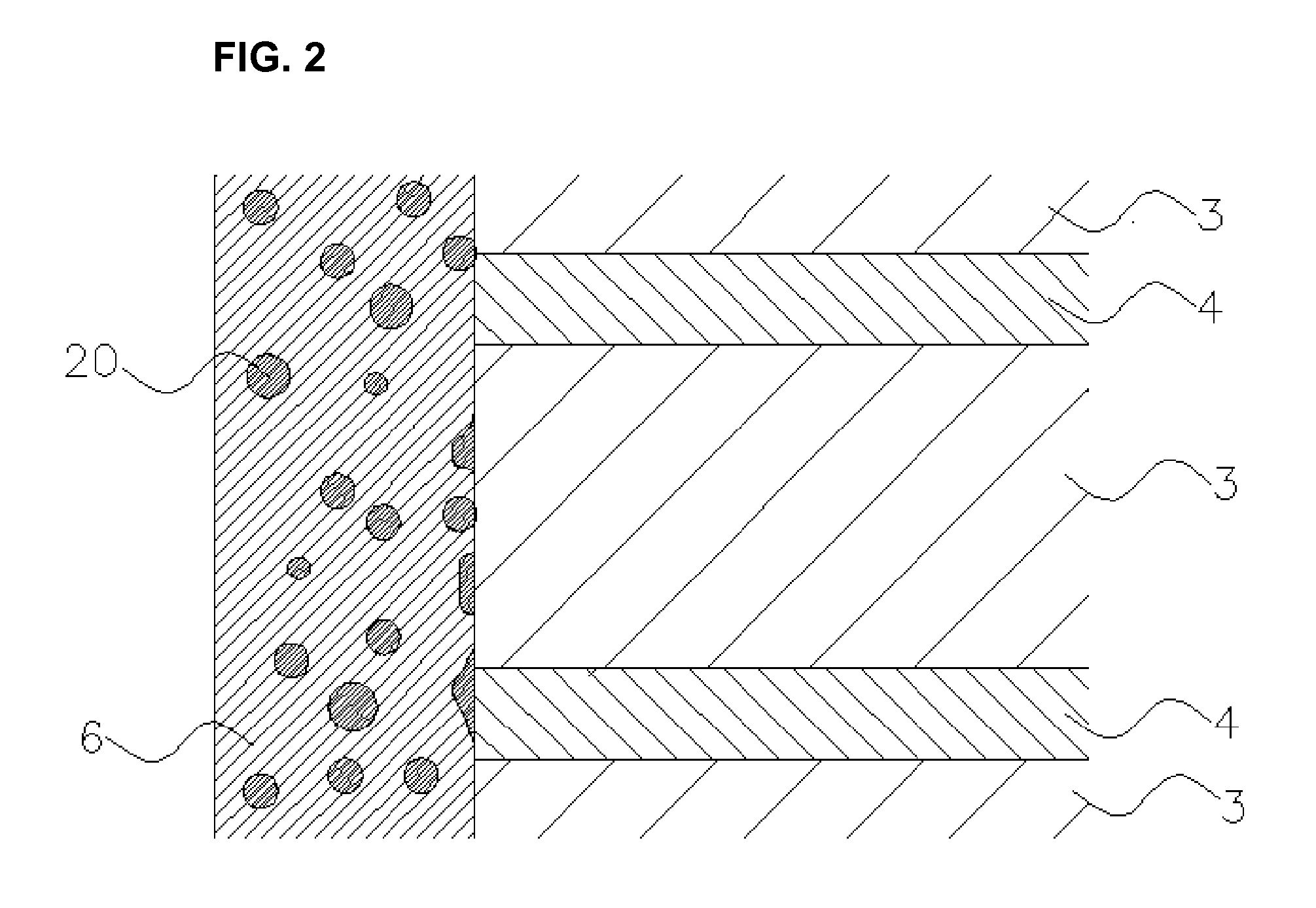

Multilayer ceramic electronic component and manufacturing method thereof

ActiveCN101465206AMiniaturizationPromote high performanceStacked capacitorsFixed capacitor terminalsAdhesiveElectronic component

A multilayer ceramic electronic component including thin external terminal electrodes each having a superior bonding force to a ceramic base body is provided. In order to form the external terminal electrodes (9), after Cu plating films (20) are deposited on exposed portions (14) of internal electrodes (12) by direct plating on a ceramic base body (2), a Cu liquid phase, an O2-containing liquid phase, and a Cu solid phase are generated between the Cu plating film (20) and the ceramic base body (2) by a heat treatment, so that Cu oxides (21) are dispersed in the Cu plating film (20), at least near an interface with the ceramic base body (2). Since the Cu oxides (21) function as an adhesive, a bonding force of the Cu plating film (20) to the ceramic base body (2) can be increased, and hence the external terminal electrode (9) having a superior bonding force to the ceramic base body can be obtained.

Owner:MURATA MFG CO LTD

Method for manufacturing laser direct plating tipping paper

InactiveCN101100833AAdvanced and reasonable technologySolve environmental problemsSpecial paperPaper/cardboardPaper manufacturingCinnamic acid

The invention discloses radium irradiating direct plating Chinese water pine paper manufacturing method. It includes the following steps: mixing cinnamic acid latex with hydrophilic thickening agent in weight percentage of 97%-99% and 1%-3%, standing more then 12 hours to form hydrophilic paint; coating hydrophilic paint on BOPP film with 8-10g / sq m wet coating weight; jointing the base paper with the coating surface; mill finish; drying to make the water content be 5%-8%; peeling off the BOPP film; aluminum plating in vacuum to obtain the finished product. The invention has the advantages of simple, reasonable, scientific select material, good for increasing cigarette grade, reducing its influence for people's health.

Owner:扬州海克赛尔新材料有限公司

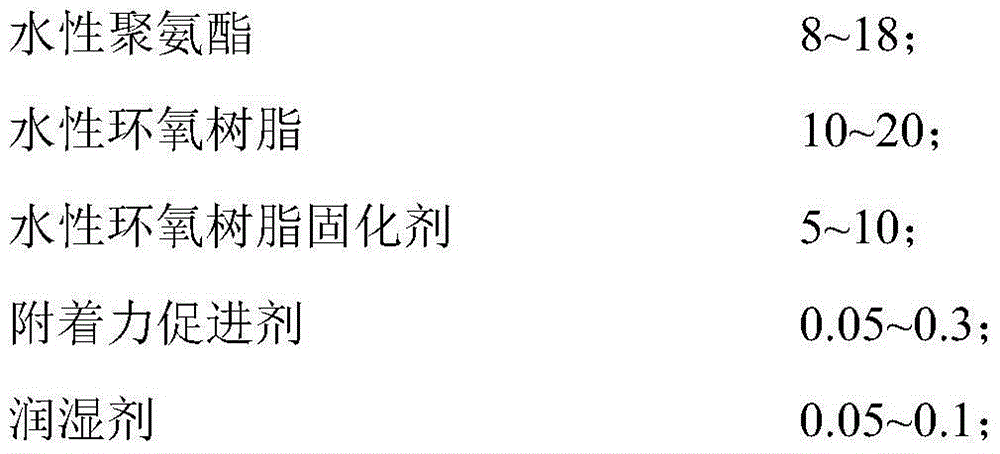

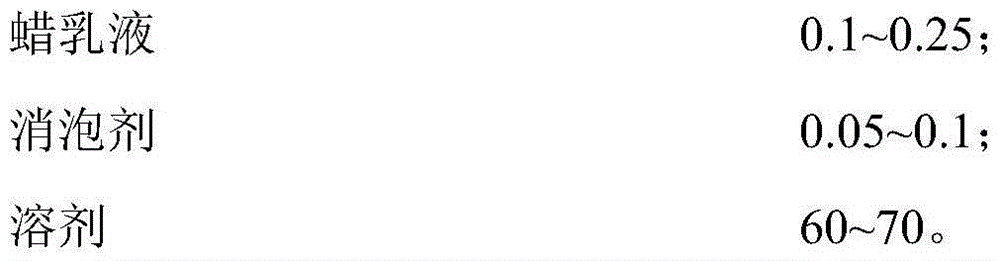

Waterborne environment-friendly direct-plating beer bottle label base and surface paint with ink retaining performance

ActiveCN104562841ASmall smellImprove retentionNon-fibrous pulp additionPaper coatingEpoxySurface level

The invention discloses waterborne environment-friendly direct-plating beer bottle label base and surface paint with ink retaining performance. The paint comprises a base paint component and a surface paint component, wherein the base paint component comprises 40-60 parts of a waterborne acrylic emulsion, 0.1-0.2 parts of a leveling agent, 0.02-0.08 parts of an antifoaming agent, 10-30 parts of a cosolvent and 20-40 parts of a solvent; the surface paint component comprises 8-18 parts of waterborne polyurethane, 10-20 parts of waterborne epoxy resin, 5-10 parts of a waterborne epoxy resin curing agent, 0.05-0.3 parts of an adhesion promoter, 0.05-0.1 parts of a wetting agent, 0.1-0.25 parts of a wax emulsion, 0.05-0.1 parts of an antifoaming agent and 60-70 parts of a solvent. Compared with the prior art, the paint belongs to environment-friendly waterborne paint, is low in odor, low in volatile organic matter content, high in aluminizing brightness, good in surface leveling property and excellent in ink adhesive force, and has the excellent ink retaining effect, the label removing time is less than 300 s, and an aluminized coating is completely cleaned up.

Owner:SHANGHAI WEIKAI CHEM +1

A kind of method for directly plating conductive metal on polyethylene surface

The invention discloses a method for directly plating conductive metal on the surface of polyethylene. Polyethylene microparticles are placed in a degreasing solution at 30-70°C for 3-8 minutes; after degreasing, they are placed in a roughening solution at 62-80°C. React for 5-15 minutes; put it in the reducing solution after coarsening, and react for 1-3 minutes at 20-50°C; 100ml / LPd / Sn colloid, 20~40℃, react for 5~20min; after activation, put it in the metal replacement solution, 20~60℃, react for 5~10min; after metal replacement, put it in the electroplating solution, 20~50℃ , Current density 0.5 ~ 8A / dm2 for electroplating. The invention avoids the disadvantages of time-consuming, high cost and non-environmental protection of traditional electroless plating, and successfully realizes direct electroplating on the surface of polyethylene.

Owner:XIAMEN HUARONG ENERGY TECH

Hole metallization process of circuit board

ActiveCN108471680AImprove the problem of missing platingHigh bonding strengthPrinted element electric connection formationEtchingCopper plating

The invention provides a hole metallization process of a circuit board. The hole metallization process is a chemical copper plating process or a direct plating process and comprises the step of bakingthe circuit board before oil removal, and the chemical copper plating process comprises the following steps of sequentially performing drilling dirt removal, baking, oil removal, slight etching, pre-impregnation, activation, activation and reduction / acceleration and chemical copper plating on the circuit board. With the hole metallization process provided by the invention, plating leakage occurring in a hole wall of the circuit board can be effectively prevented, the bonding strength between a conductive material and the hole wall is improved, the conductive material and the hole wall are prevented from being separated, the hole wall can be completely covered only by hole metallization in one time and electroplating in one time, and the process required by hole metallization is reduced.

Owner:GUANGDONG SKYCHEM TECH LTD

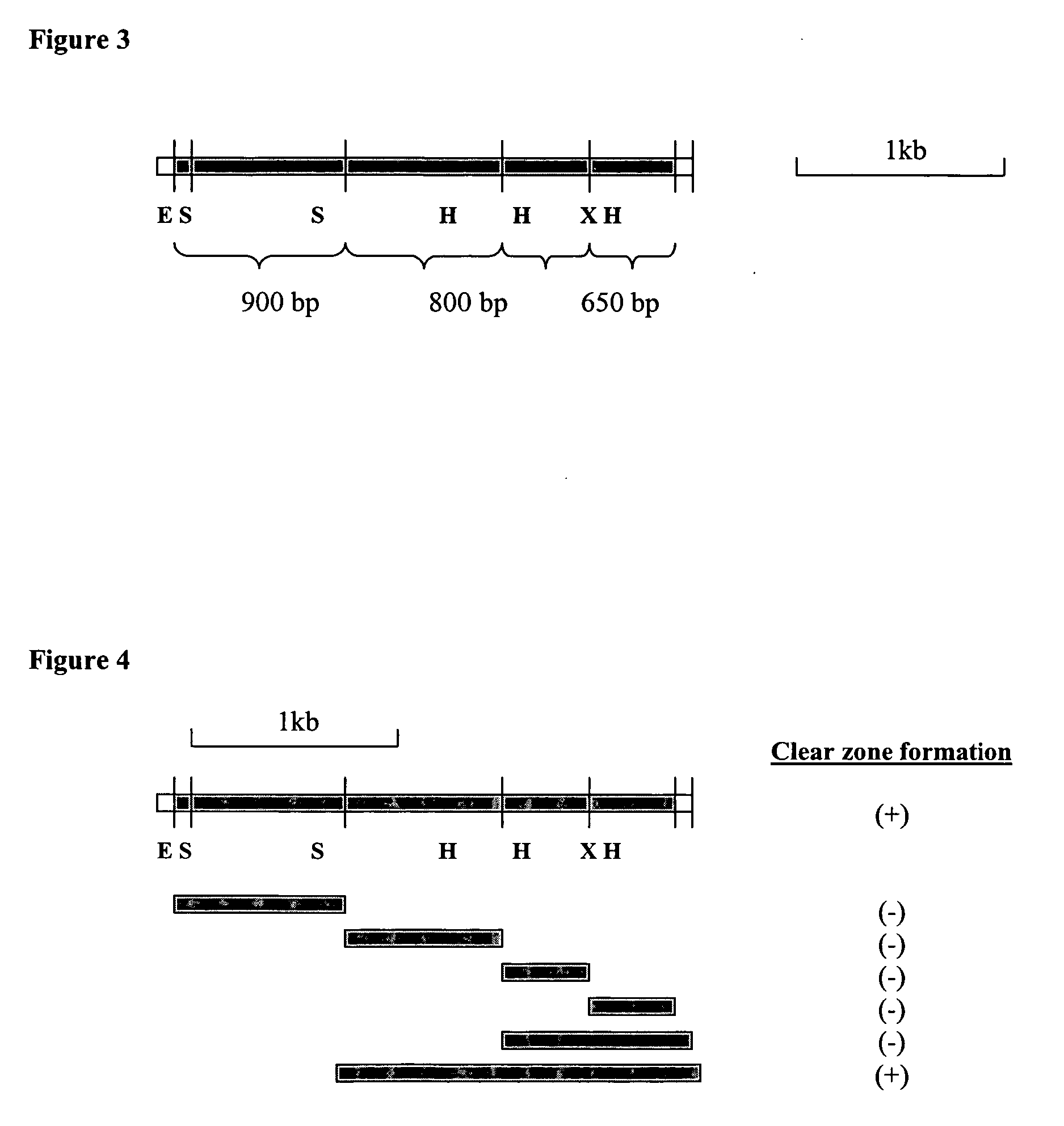

Novel lipase gene from Bacillus sphaericus 205y.

A biologically pure culture of Bacillus sphaericus strain 205y capable of producing an organic solvent-tolerant lipase was isolated from soil samples via direct plating method using 1% (v / v) of either benzene, toluene, or mixture of benzene and toluene as their sole carbon source, ethyl benzene and ρ-xylene. The lipase gene was isolated via genomic library and sequenced. The production of lipase gene from Bacillus sphaericus strain 205y is a novel gene. The lipase gene was cloned from Bacillus sphaericus strain 205y and the recombinant lipase was efficiently excreted into the culture medium using expression vectors bearing the lipase gene.

Owner:UNIVERSITI PUTRA MALAYSIA

Direct plating method and solution for palladium conductor layer formation

ActiveUS20100059386A1Improve adhesionImprove corrosion resistancePrinted circuit aspectsAnti-corrosive paintsCopper platingElectrical conductor

A surface of an object to be plated is subjected to a treatment for palladium catalyst impartation to impart a palladium catalyst to the surface of an insulating part thereof. A palladium conductor layer is formed on the insulating part from a solution for palladium conductor layer formation which contains a palladium compound, an amine compound, and a reducing agent. On the palladium conductor layer is then directly formed a copper deposit by electroplating. Thus, the work is converted to a conductor with the solution for palladium conductor layer formation, which is neutral, without using an electroless copper plating solution which is highly alkaline. Consequently, the polyimide is prevented from being attacked and no adverse influence is exerted on adhesion. By adding an azole compound to the solution for palladium conductor layer formation, a palladium conductor layer is prevented from depositing on copper. Thus, the reliability of connection between the copper part present on a substrate and the copper deposit formed by electroplating is significantly high.

Owner:C UYEMURA & CO LTD

Process for producing partial vacuum metalized paper by direct plating method

The invention provides vacuum metalized paper, in particular a process for producing partial vacuum metalized paper by adopting a direct plating method. The process comprises the following steps of: pretreating the surface of raw paper; preparing a pattern resin roll; applying fluorocarbon oil on the resin roll; applying the fluorocarbon oil on the paper surface; metalizing aluminum in vacuum; and applying a top coat on the partial vacuum metalized paper. The production process does not require film auxiliary materials, metalizes in partial vacuum, and saves materials and energy.

Owner:浙江爱迪尔包装股份有限公司

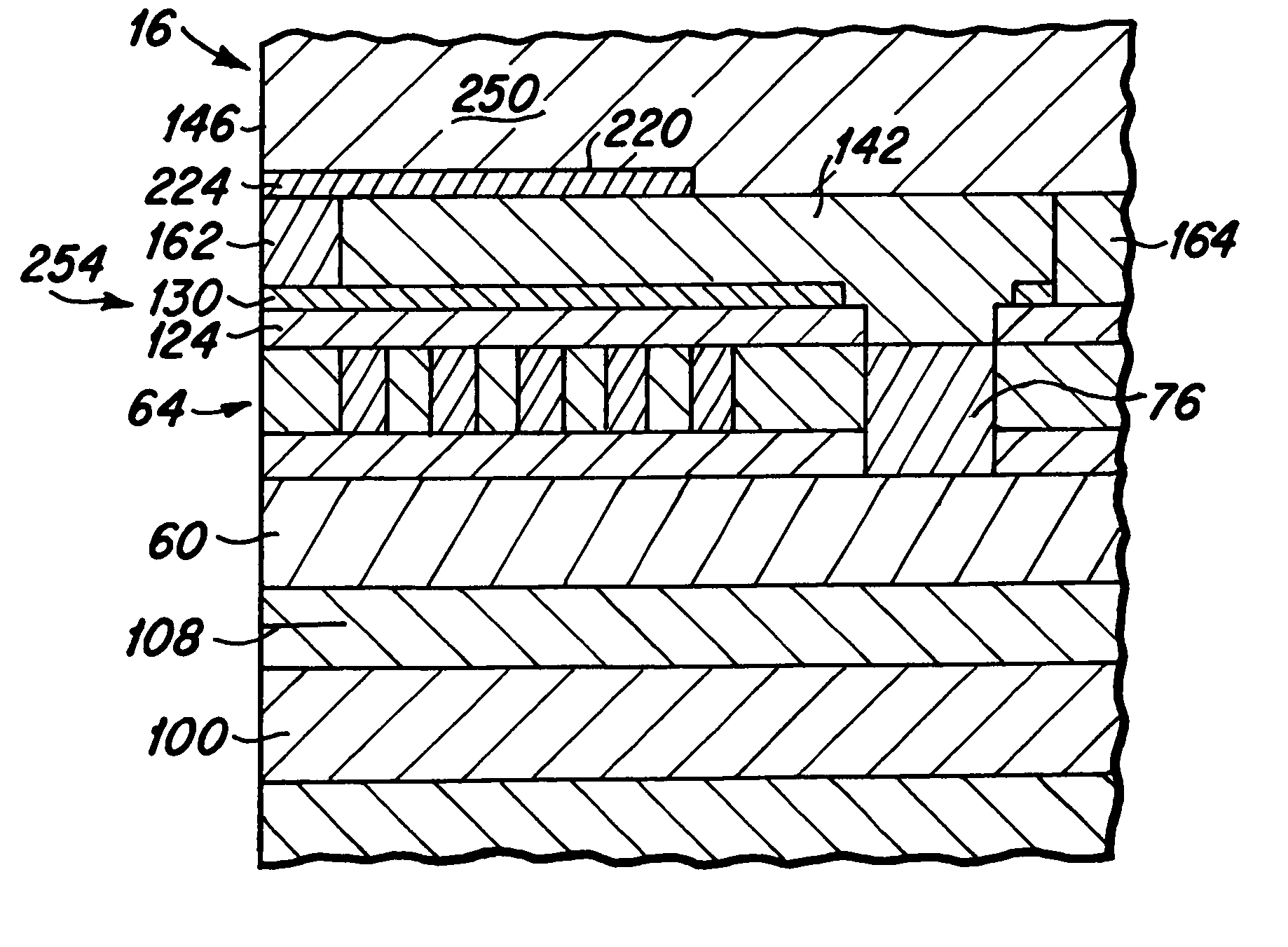

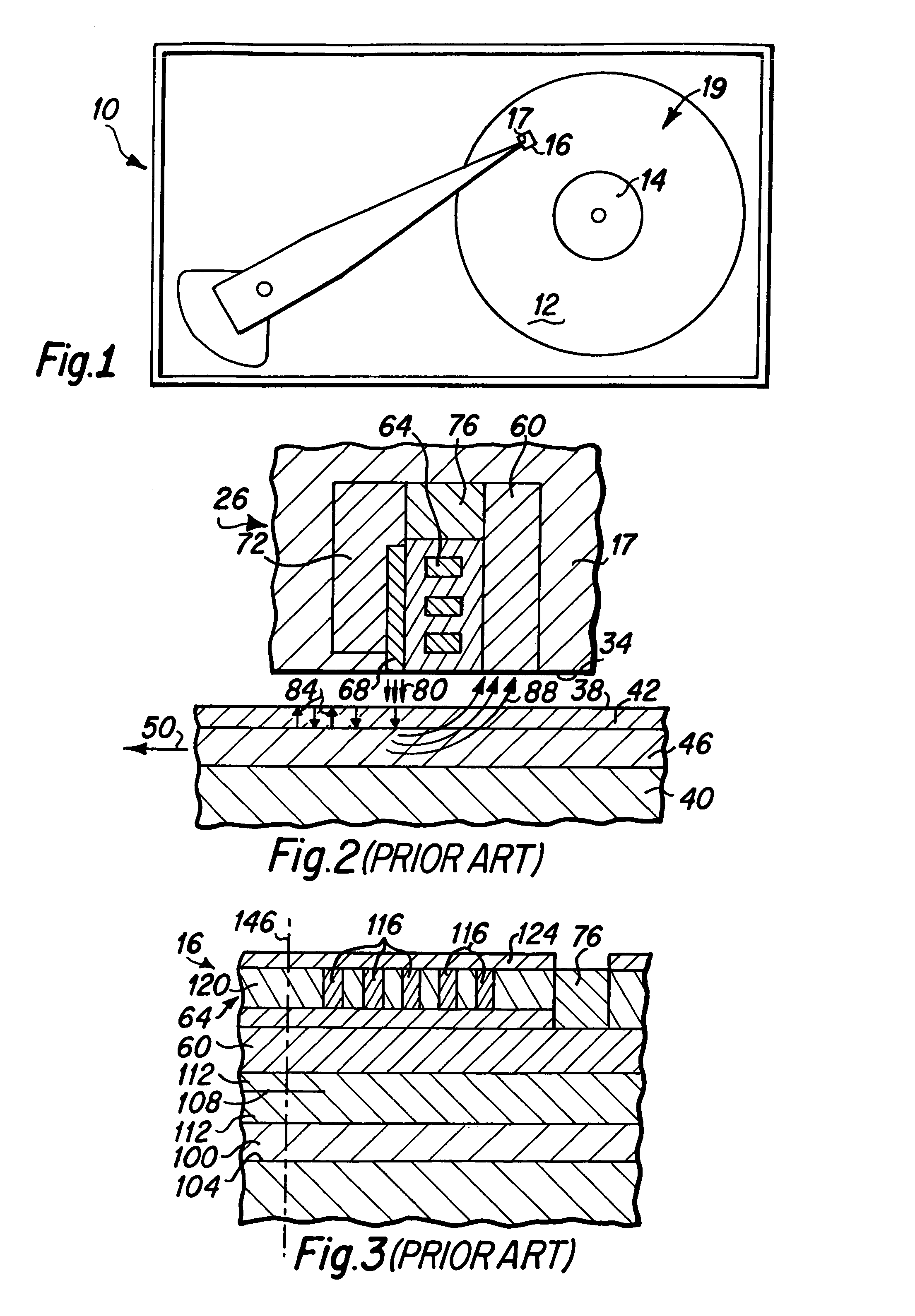

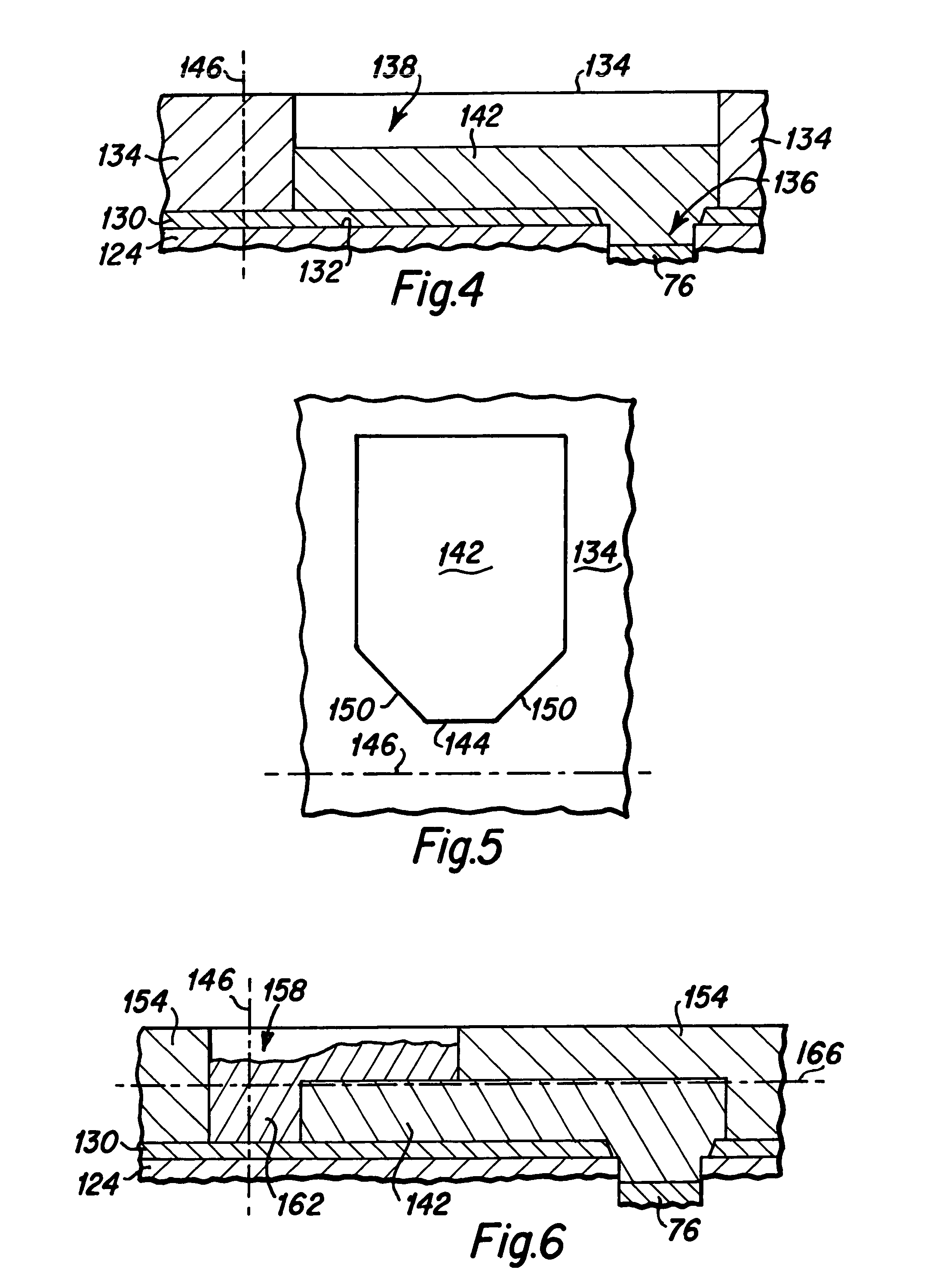

Perpendicular magnetic head having modified shaping layer for direct plating of magnetic pole piece

InactiveUS7119988B2Reduce the possibilityReduce harmManufacture head surfaceHeads using thin filmsMagnetic polesEngineering

A magnetic head of the present invention includes a first magnetic pole that is exposed at the air bearing surface of the magnetic head and a second magnetic pole shaping layer that is not exposed at the air bearing surface. A layer of non-magnetic material is fabricated between the air bearing surface and the shaping layer, where the non-magnetic material is also electrically conductive. The pole tip of the magnetic head is electroplated on top of the non-magnetic electrically conductive material subsequent to the fabrication of the shaping layer, and in magnetic flux communication with the shaping layer.

Owner:WESTERN DIGITAL TECH INC

Lining paper for embossment cigarette and manufacturing method thereof

PendingCN109403151ARich texture effectExquisite appearanceSpecial paperPaper/cardboardWater basedPulp and paper industry

The invention discloses lining paper for an embossment cigarette. The lining paper comprises a body paper layer and a forming layer, a vacuum aluminum plating layer and a water-based ink layer which are sequentially stacked on the surface of the body paper layer from interior to exterior. The invention further discloses a manufacturing method of the lining paper. The method comprises the steps of1, utilizing UV embossed ink, 3D ink, high-viscosity ink or thermal plastic ink to form the forming layer on the surface of the body paper layer; 2, adopting the vacuum aluminum plating mode, directlyplating an aluminum wire to the surface of the forming layer through vacuum steam plating to form a vacuum aluminum plating layer; 3, adopting a roll coating or spraying mode for coating the surfaceof the vacuum aluminum plating layer with the water-based ink and performing curing to form the water-based ink layer. According to the lining paper for the embossment cigarette, the vacuum direct plating mode is adopted for direct aluminum plating on the forming layer, the aluminum atom structure under the gasification state is used for enabling the forming layer to be reduced by 100%, the ultrathin substrate image-text embossment effect is achieved, and the appearance of the lining paper is more delicate.

Owner:GUANGZHOU HUADU LIANHUA PACKING MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com