Lining paper for embossment cigarette and manufacturing method thereof

A technology for lining paper for cigarettes and a manufacturing method, applied in the field of papermaking, can solve the problems of high cost and unenvironmental protection of composite aluminum foil, and achieve the effect of improving the texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

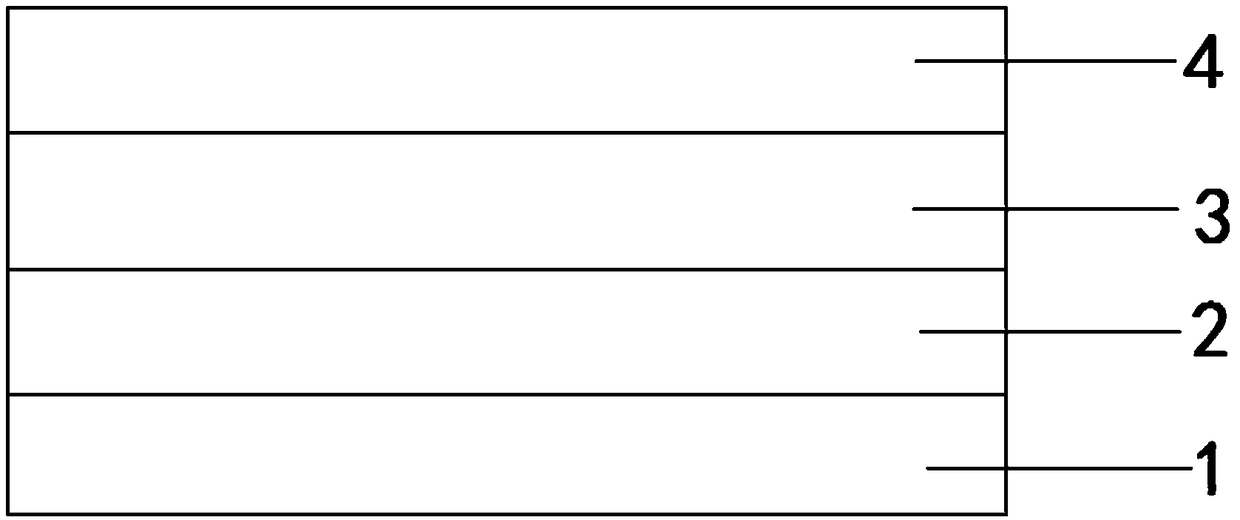

[0028] A kind of embossed inner lining paper for cigarettes, it has such as figure 1 The structure shown includes a base paper layer 1 and a UV embossed ink layer 2 , a vacuum aluminized layer 3 and a water-based ink layer 4 sequentially stacked on the surface of the base paper layer 1 from inside to outside. The preparation steps of the embossed inner liner paper for cigarettes include:

[0029] 1) By means of gravure printing, UV embossed ink is coated on the surface of the base paper layer 1 and irradiated and cured by a UV lamp with a wavelength of 500nm to form a UV embossed ink layer 2, wherein, in the gravure printing process , the graphic height is 15μm, and the roller coating depth is 65μm;

[0030] 2) adopt the mode of vacuum aluminizing, aluminum wire is directly plated on the surface of described UV embossing ink layer 2 by vacuum evaporation to form vacuum aluminized layer 3, wherein, the thickness of described vacuum aluminized layer 3 is

[0031] 3) Apply th...

Embodiment 2

[0033] A kind of embossed inner lining paper for cigarettes, it has such as figure 1 The structure shown includes a base paper layer 1 and a high-viscosity ink layer 2 , a vacuum aluminized layer 3 and a water-based ink layer 4 sequentially stacked on the surface of the base paper layer 1 from inside to outside. The preparation steps of the embossed inner liner paper for cigarettes include:

[0034] 1) Coating high-viscosity ink with a viscosity of 5000mPa·s on the surface of the base paper layer 1 and curing it at 80°C by coating, embossing the graphic on the cured high-viscosity ink forming the high-viscosity ink layer on the viscosity ink, wherein the coating thickness of the high-viscosity ink is 50 μm, and the embossing depth is 100 μm;

[0035] 2) adopt the mode of vacuum aluminizing, aluminum wire is directly plated on the surface of described high-viscosity ink layer 2 by vacuum evaporation to form vacuum aluminized layer 3, wherein, the thickness of described vacuum al...

Embodiment 3

[0038] A kind of embossed inner lining paper for cigarettes, it has such as figure 1 The structure shown includes a base paper layer 1 and a thermoplastic ink 2 , a vacuum aluminized layer 3 and a water-based ink layer 4 sequentially stacked on the surface of the base paper layer 1 from inside to outside. The preparation steps of the embossed inner liner paper for cigarettes include:

[0039] 1) Coating the thermoplastic ink on the surface of the base paper layer 1 by means of coating, embossing the graphics and text on the thermoplastic ink at the same time, and cooling and solidifying at room temperature to obtain the thermoplastic ink Layer 2, wherein the coating amount of the thermoplastic ink is 100g / m 2 , embossing depth is 150μm;

[0040] 2) adopt the mode of vacuum aluminizing, aluminum wire is directly plated on the surface of described UV embossing ink layer 2 by vacuum evaporation to form vacuum aluminized layer 3, wherein, the thickness of described vacuum alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com