Focusing mirror active unordered device and method for roller laser-texturing lathe

A laser texturing and focusing mirror technology, applied in laser welding equipment, optics, optical components, etc., can solve problems such as unsatisfactory disorder effect, and achieve high reliability and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

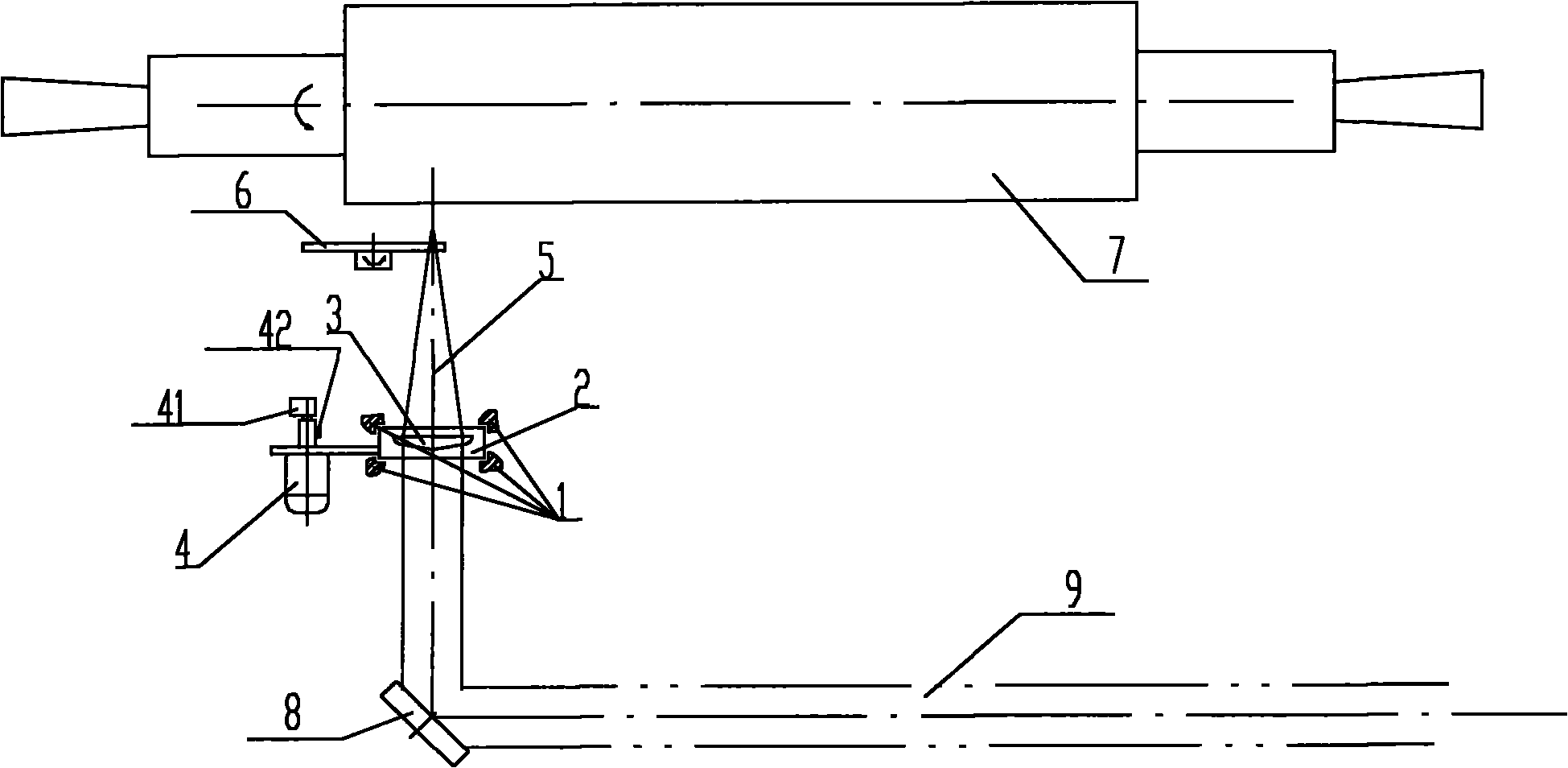

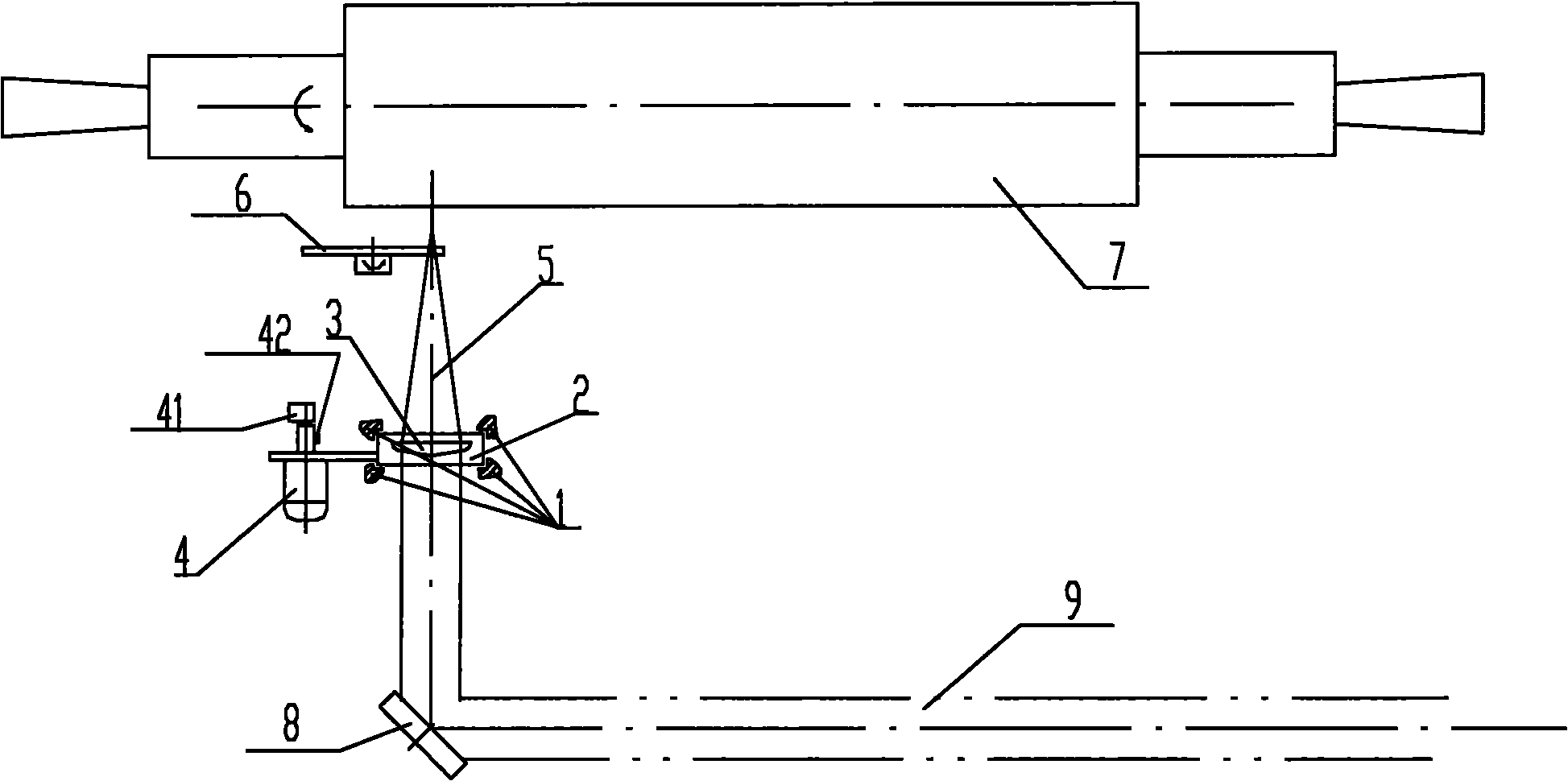

[0034] Fig. 1 is a schematic structural diagram of an active disordered device for a focusing mirror according to an embodiment of the present invention, as shown in Fig. 1 ,

[0035] The focusing mirror active disorder device for roll laser texturing machine tools includes a machine tool support 1, a focusing mirror base 2, a focusing mirror 3, a perturbator 4, a chopping disc 6, a roll 7 and a reflector 8; wherein, the perturbator 4. A disturbance force can be generated. Under the action of the disturbance force, the angle of the focusing mirror base 2 and the focusing mirror 3 can be changed within the constraint range of the machine tool support 1. At the same time, the laser beam passing through the focusing mirror 3 can be compared with the theoretical laser beam. The center line 5 makes an angle ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com