Matte TPO skin material with low processing viscosity as well as preparation method and application of TPO skin material

A technology of skin material and processing viscosity, applied in the field of low processing viscosity matte TPO skin material, can solve the problems of poor wear resistance, decreased mechanical properties, uneven thickness, etc. The effect of increasing free volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The present invention provides a kind of preparation method of TPO skin material described in above-mentioned technical scheme, comprises the following steps:

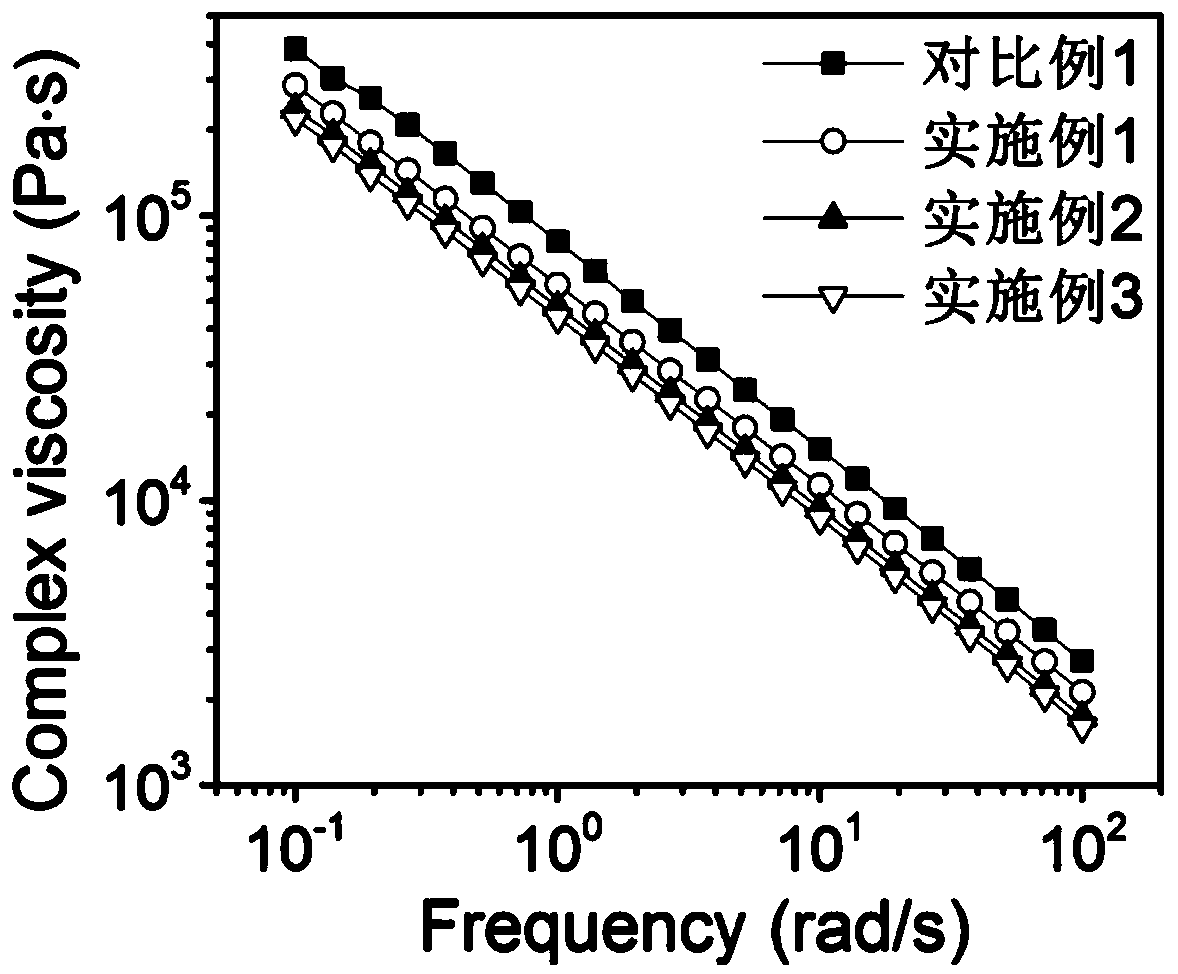

[0062] The thermoplastic polyolefin TPO with a mass ratio of 90-99.5:0.5-10 and nanoparticles are mixed at 180°C-230°C for 7-9 minutes to obtain a low processing viscosity matte TPO skin material.

[0063] In the present invention, the mixture is preferably mixed under the condition of stirring, and the stirring speed is preferably 180-220 rpm, more preferably 190-210 rpm; in a specific embodiment, the stirring speed is 200 rpm.

[0064] The thermoplastic polyolefin TPO and nanoparticles are preferably mixed at 185-215° C. for 7.5-8.5 minutes, more preferably at 200° C. for 8 minutes.

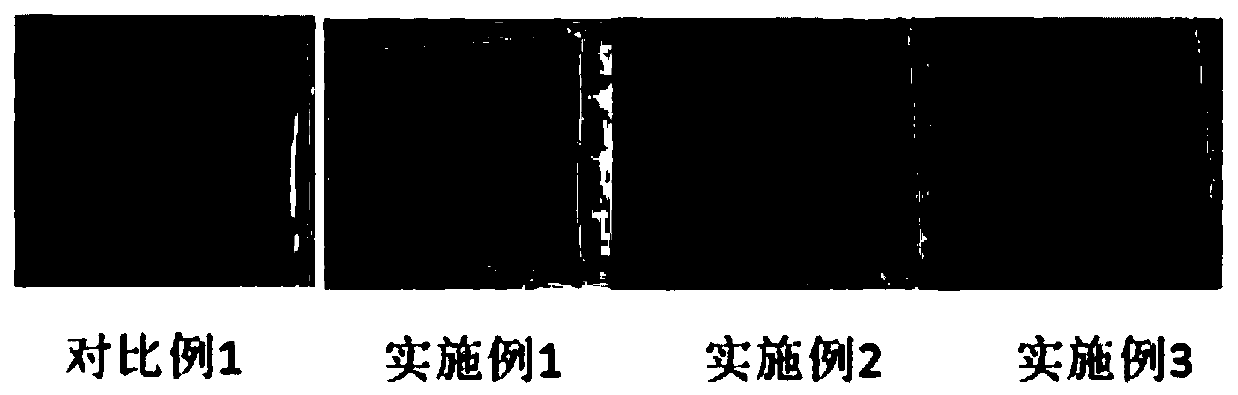

[0065] The present invention provides an application of the low-processing-viscosity matte TPO skin material described in the above technical solution or the low-processing-viscosity matte TPO skin material prepared by the prepar...

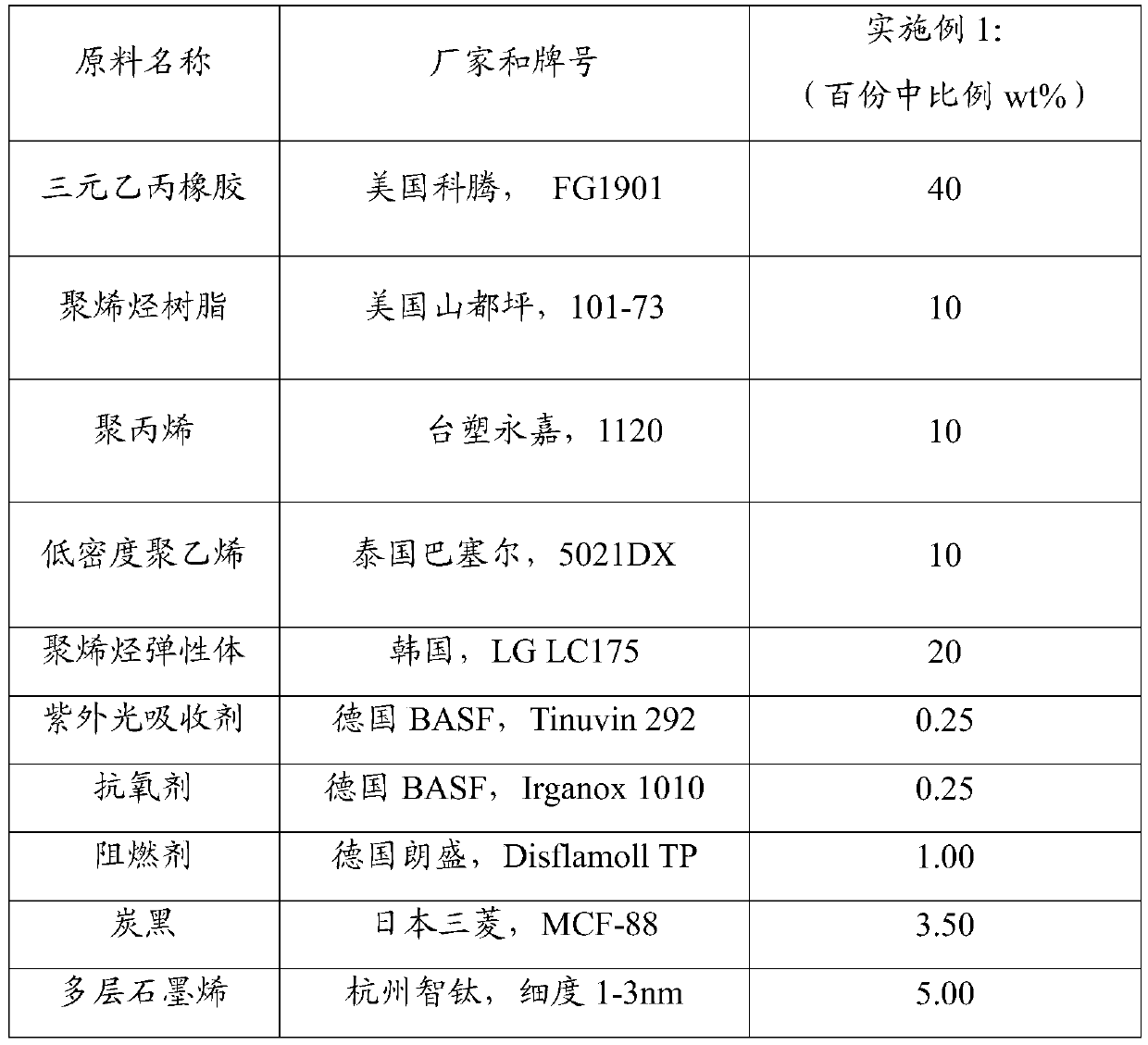

Embodiment 1

[0068] Step 1. Accurately weigh the raw materials of each component according to the formula in Table 1 below

[0069] Table 1: the raw material formula of embodiment 1

[0070]

[0071] The above-mentioned EPDM rubber has an ethylene-propylene ratio of 80 / 20 and a Mooney viscosity of ML1+4 32 125°C. This rubber has the characteristics of rapid vulcanization, high tensile strength, low glass transition temperature, and low permanent deformation.

[0072] The above-mentioned polyolefin resin is an α-olefin copolymer, an olefin copolymer monomer, or a mixture of the above two.

[0073] The melt index of the above-mentioned polypropylene is 20 g / 10 min, and the α-olefin monomers in the polypropylene include: free radical ethylene, 1-butene, 1-pentene and 1-hexene. Polypropylene has low volatility, high viscosity index, low pour point, high flash point, good high-temperature oxidation performance, and long service life.

[0074] The above-mentioned polyolefin elastomer POE is...

Embodiment 2

[0087] Step 1. Accurately weigh the raw materials of each component according to the formula in Table 3 below

[0088] Table 3: the raw material formula of embodiment 2

[0089]

[0090]

[0091] The above-mentioned thermoplastic rubber is thermoplastic dynamic fully vulcanized rubber (TPV), which has excellent tensile strength, high toughness and high resilience; excellent environmental performance and reusability, easy to process and shape; , PS, PBT, PET and other materials co-injection or extrusion molding.

[0092] The above-mentioned polyolefin resin is an α-olefin copolymer, an olefin copolymer monomer, or a mixture of the above two.

[0093] The melt index of the above-mentioned polypropylene is 20g / 10min, and the α-olefin monomers in the polypropylene include: free radical ethylene, 1-butene, 1-pentene and 1-hexene. It has low volatility, high viscosity index, low pour point, high flash point and good high temperature oxidation performance.

[0094] The above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com