Patents

Literature

30results about How to "Play a matting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

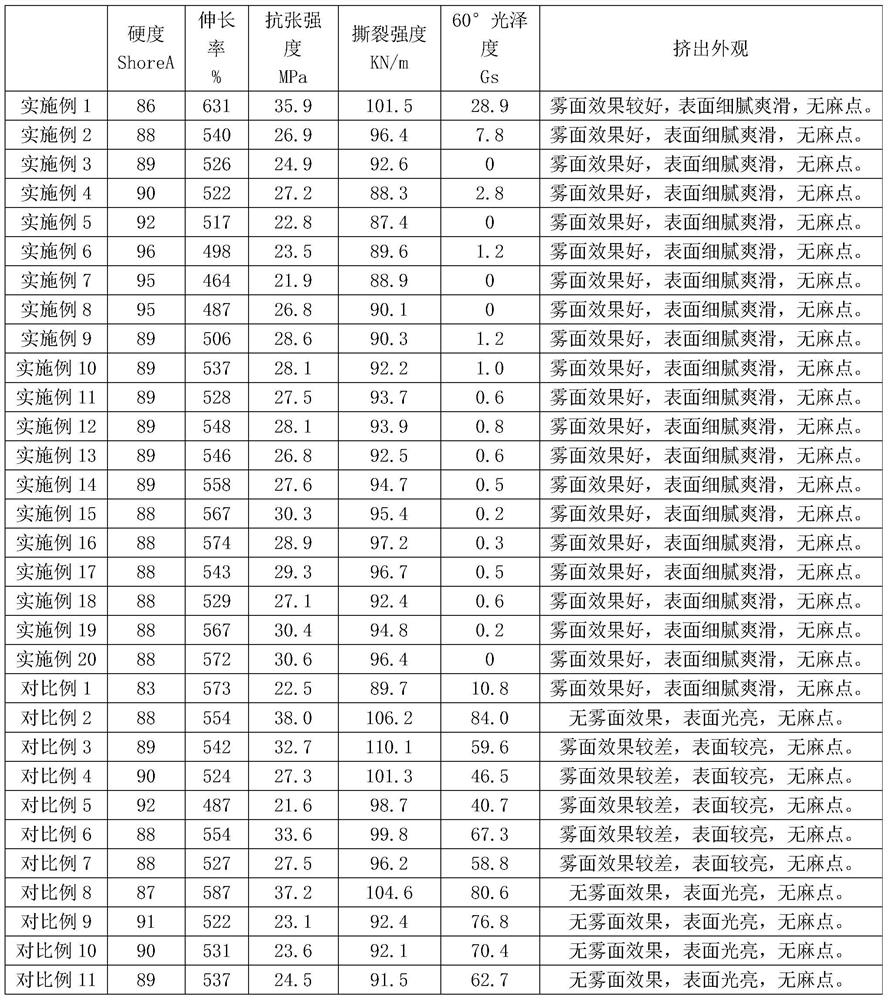

Low-glossiness thermoplastic polyurethane composition and preparation method and application thereof

The invention relates to a low-glossiness thermoplastic polyurethane composition and a preparation method and application thereof. The composition comprises, by weight, (A) 50%-95% of thermoplastic polyurethane elastomer, (B) 3%-45% of thermoplastic polyamide polymer or commixture of thermoplastic polyamide and thermoplastic polyamide polymer; (C) 1%-20% of a third component, wherein the third component is selected from one or more of inorganic filler, polycarbonate powder, PTFE (polytetrafluoroethylene) powder and organic (hypophosphite)phosphate. According to standard ASTM D523 tests, 60-degree surface glossiness is lower than 30Gs, and the composition is great in mechanical property and processability, uniform and delicate in surface matting effect, smooth in handfeel and suitable for preparation of cables, pipes, belts and film products.

Owner:WANHUA CHEM GRP CO LTD

Matte TPO skin material with low processing viscosity as well as preparation method and application of TPO skin material

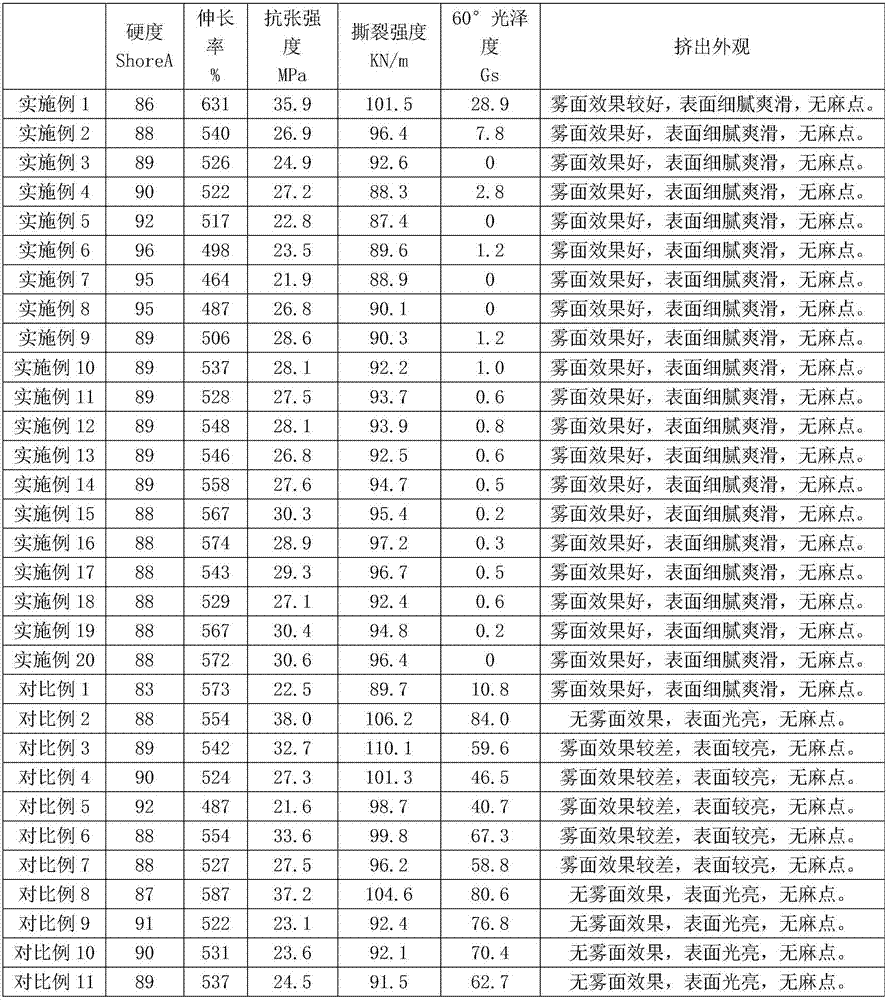

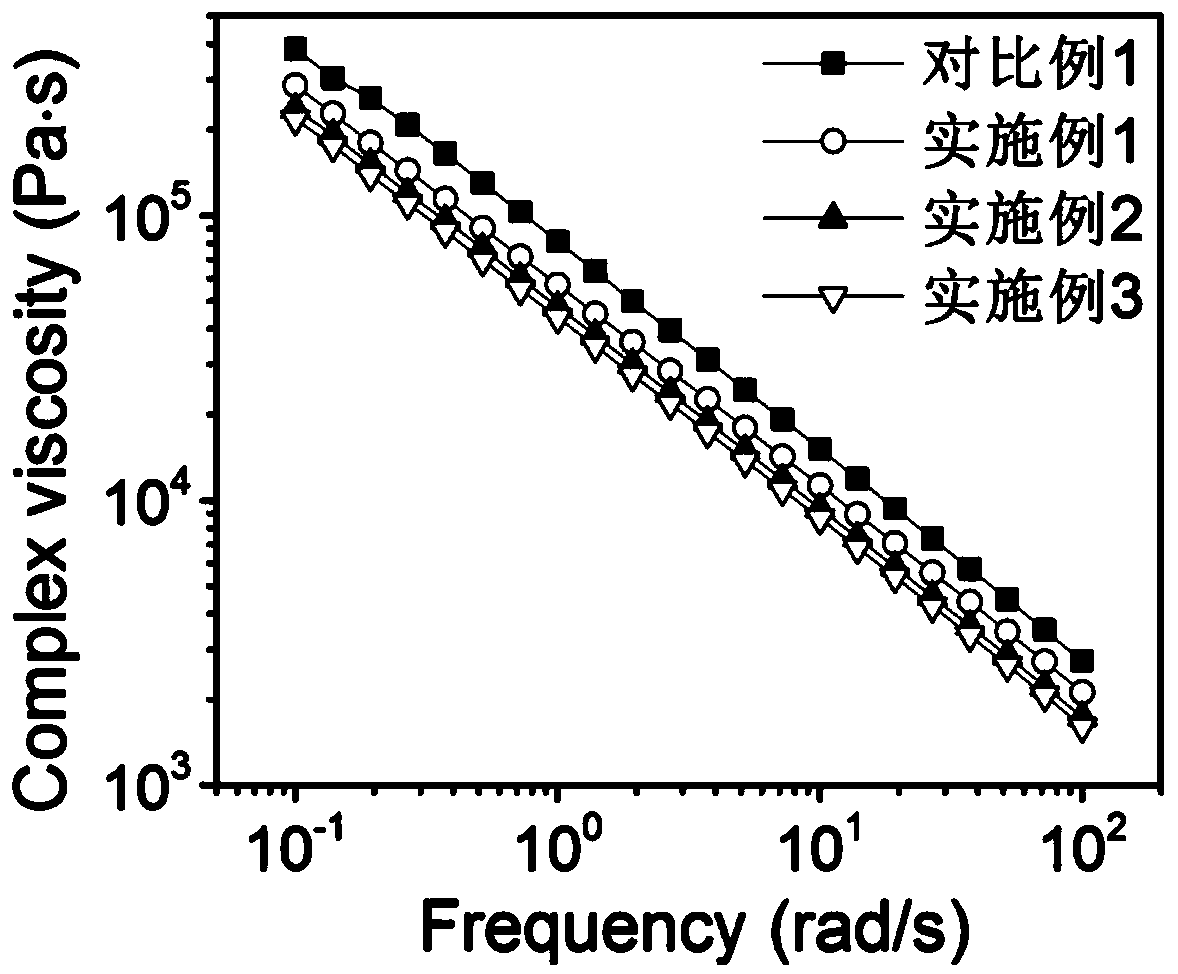

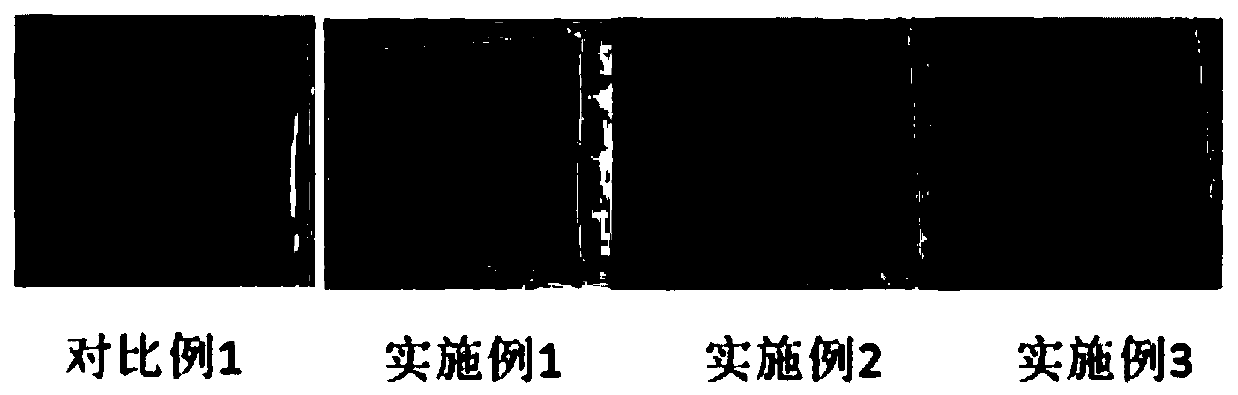

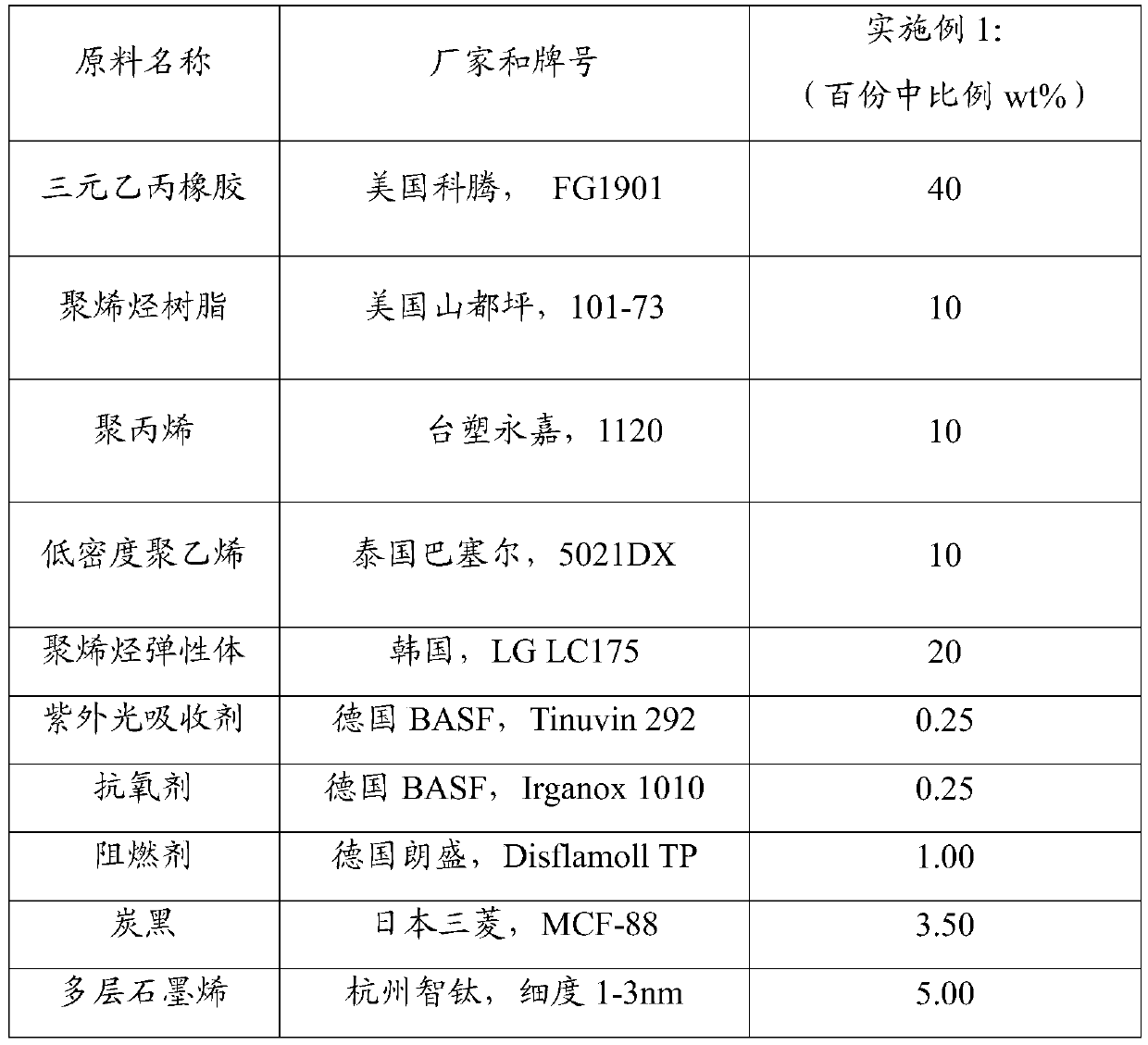

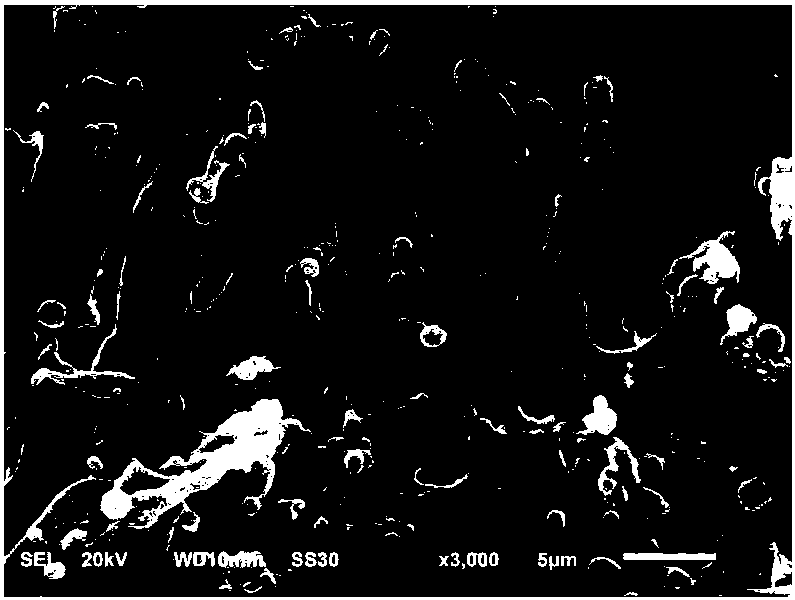

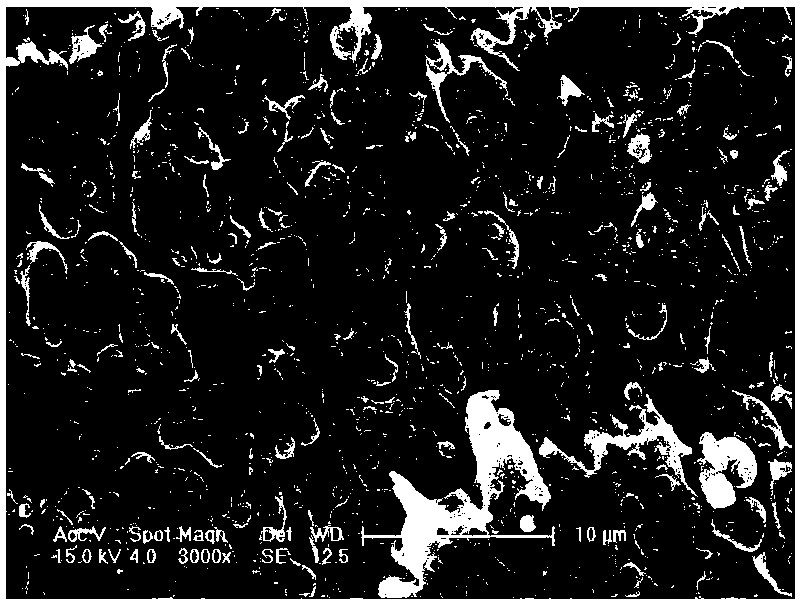

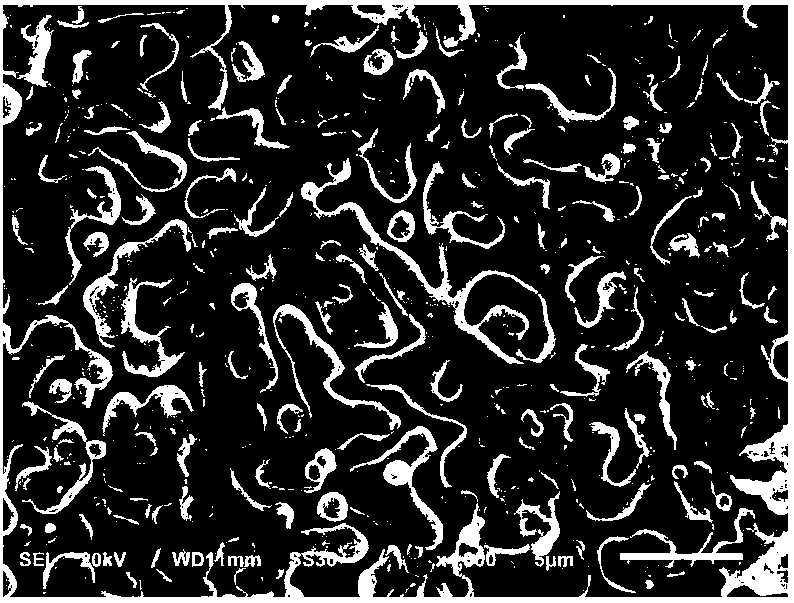

The invention provides a matte TPO skin material with low processing viscosity as well as a preparation method and application of the TPO skin material. The TPO skin material is formed by filling a thermoplastic polyolefin (TPO) with nanoparticles, wherein the mass ratio of the TPO to the nanoparticles is (90-99.5):(0.5-10); and the nanoparticles include one or more selected from the group consisting of multi-layer graphene, carbon nanotubes, monodisperse polystyrene microspheres, manganese oxide nanowires, iron tetroxide nanoparticles, fumed silica, and nano carbon black particles. The nanoparticles are packed in the TPO, so that the free volume of the polymer is increased, and the density of entanglement points is reduced; at the same time, interface slip occurs between the nanoparticlesand the polymer, the interface slip acts as a lubricant to reduce the viscosity of the system, so that the process temperature of operation such as mixing, calendaring and extrusion in the material processing process is reduced; the nanoparticles play a matting effect; the added nanoparticles have little effect on the mechanical properties of the material and improves the friction-resistant coefficient; and the TPO skin material provides guidance for industrial production.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Matt PC/PBT alloy material and preparation method thereof

InactiveCN107586447AIncrease reflective differenceTo achieve the purpose of extinctionAlloyThermal stability

The invention discloses a matt PC / PBT alloy material and a preparation method thereof. Alloy material components comprise bisphenol A PC resin, PBT resin, ABS resin, a flexibilizer, a compatilizer, aflatting agent, and an ester exchange inhibitor; and the PC / PBT alloy material is prepared by mixing of all components, melting, extrusion, and pelletizing. According to the invention, a delustering purpose is realized by utilizing the components, so that the PC / PBT alloy material with low glossiness which a conventional matt PC / PBT alloy cannot achieveis prepared, the thermal stability of the material is not damaged, and the PC / PBT alloy material prepared by the method is suitable for the field which has higher matt requirements.

Owner:ORINKO NEW MATERIAL CO LTD

Matt polycarbonate styrene resin alloy and preparation method thereof

The invention relates to a matt polycarbonate styrene resin alloy. The matt polycarbonate styrene resin alloy contains following raw material constituents of, by weight part, 50-80 parts of polycarbonate resin, 15-48 parts of polycarbonate resin, 2-5 parts of isocyanate chemical compounds, 0.5-2 parts of compatible agent and 0.5-1 part of processing agent. A preparation method of the matt polycarbonate styrene resin alloy includes following steps: mixing the above raw material constituents in a high speed mixer in advance for 3-10min, and then extruding and granulating the premixed materials through a double screw extruder under 230-280 degree centigrade so as to obtain the matt polycarbonate styrene resin alloy. The matt polycarbonate styrene resin alloy has the advantages that compared with the prior art, no matt master particle needs to be prepared, the polycarbonate styrene resin alloy excellent in matt effect can be directly prepared through a one step method, and the preparation method of the matt polycarbonate styrene resin alloy is simple in technical process, solves the technical problems that glossiness distribution is uneven, physical and mechanical properties are deteriorated, preparation technology is complex and the like, and can reduce cost.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Aluminium ware special-purpose noctilucence paint and application

InactiveCN104893492AGood dispersionImprove adhesionLuminescent paintsSpecial surfacesAdditive ingredientLight extinction

The invention discloses an aluminium ware special-purpose noctilucence paint and application, the aluminium ware special-purpose noctilucence paint is characterized by including the following ingredients by weight: 20-80% of resin, 5-60% of a curing agent, 0.1-20% of a levelling agent, 0.01-20% of a gloss enhancer, 1-40% of a pigment, 0.1-10% of a spice, 1-50% of barium sulfate, 0-50% of a light extinction curing agent, and 1-50% of noctilucent powder. Compared with the existing technology, th aluminium ware special-purpose noctilucence paint has low manufacturing cost, strong adhesion, good pigment dispersion and other characteristics, the prepared coating has the characteristics that the surface is smooth, and may not be too bright and blinkering, and is especially suitable for processing of aluminum curtain walls, aluminum doors, aluminum windows and sun room frames.

Owner:何炳贵

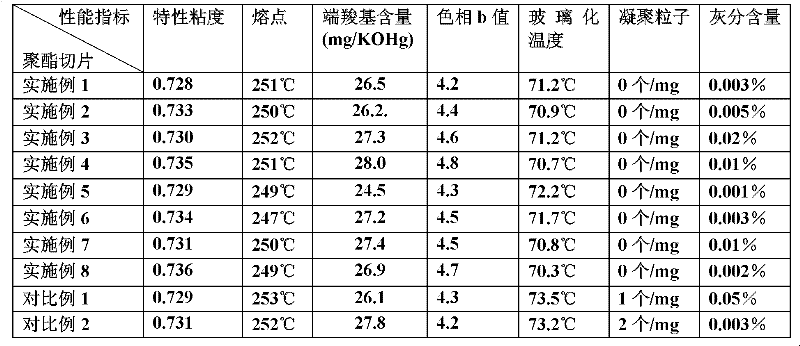

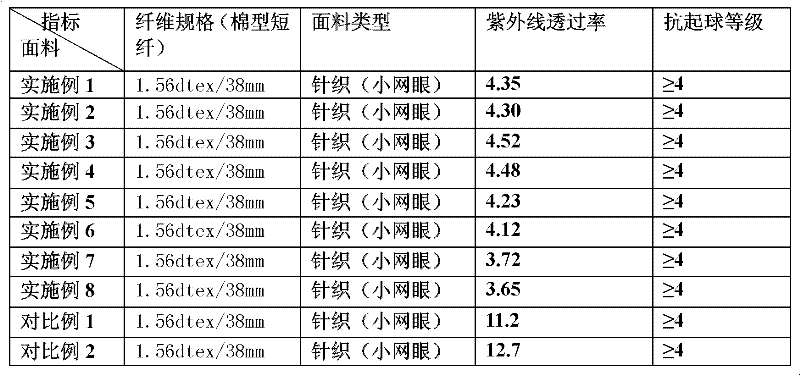

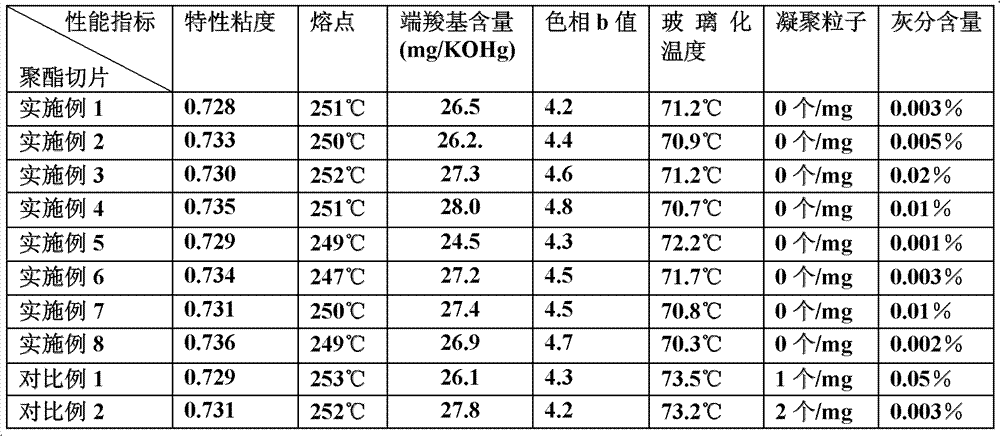

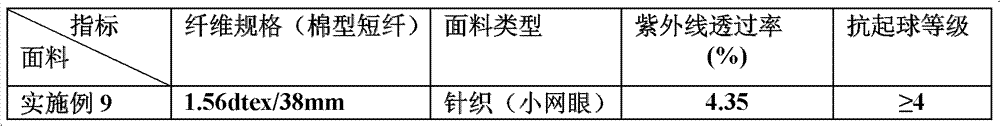

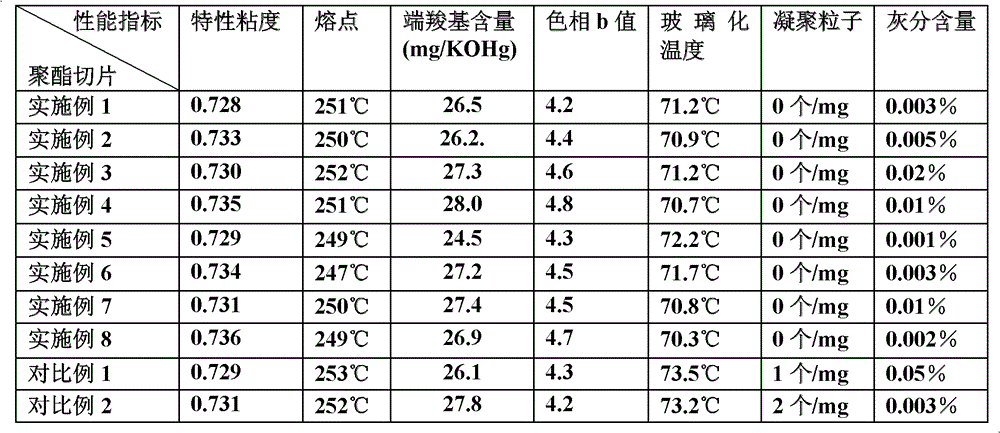

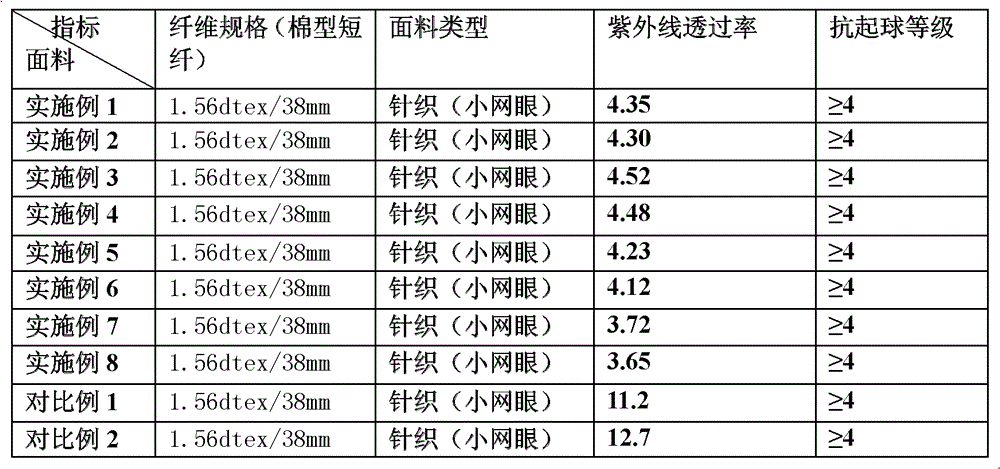

Preparation method of anti-ultraviolet anti-pilling polyester slices

ActiveCN102443153AImprove the diffusion effectReduce transmittanceMonocomponent polyesters artificial filamentPolyesterUltraviolet lights

The invention relates to a preparation method of anti-ultraviolet anti-pilling polyester slices. The preparation method comprises an esterification reaction working procedure and a polymerization reaction working procedure, wherein the esterification reaction working procedure comprises a primary esterification reaction section and a secondary esterification reaction section; in the primary esterification reaction section, aliphatic dicarboxylic acid and / or non-para-aryl dicarboxylic acid are / is introduced to serve as a third monomer; in the secondary esterification reaction section, flexiblepolyethylene glycol is introduced to serve as a fourth monomer; after esterification is completed, a hindered amine light stabilizer and a hindered phenol antioxidant which are respectively prepared from acetic acid and ethylene glycol as a solvent and hydroxy silicone oil are added; and after prepolymerization and before final polymerization in the polymerization reaction working procedure, an ultraviolet absorbent is added. The polyester fibers spun from the polyester slices prepared by the method provided by the invention have excellent anti-ultraviolet and anti-pilling performances; and after the polyester fibers are knitted / woven into knitted / woven fabric, test shows that the fabric has the following correlated technical indexes: the ultraviolet light transmittance is not more than 5.0%, and the anti-pilling performance is not less than 4-level.

Owner:JIANGSU ZHONGLU TECH DEV +1

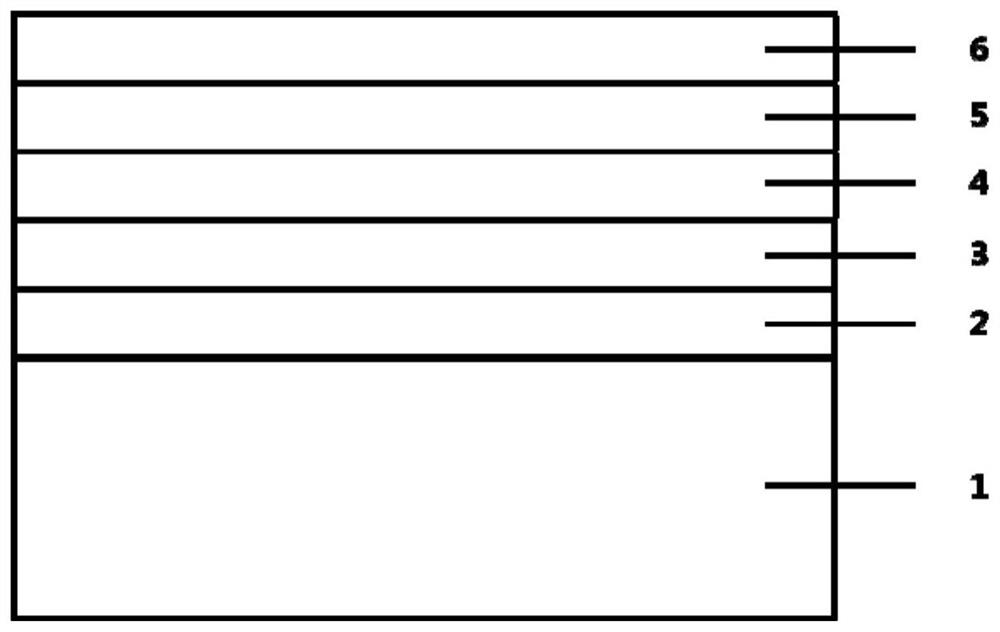

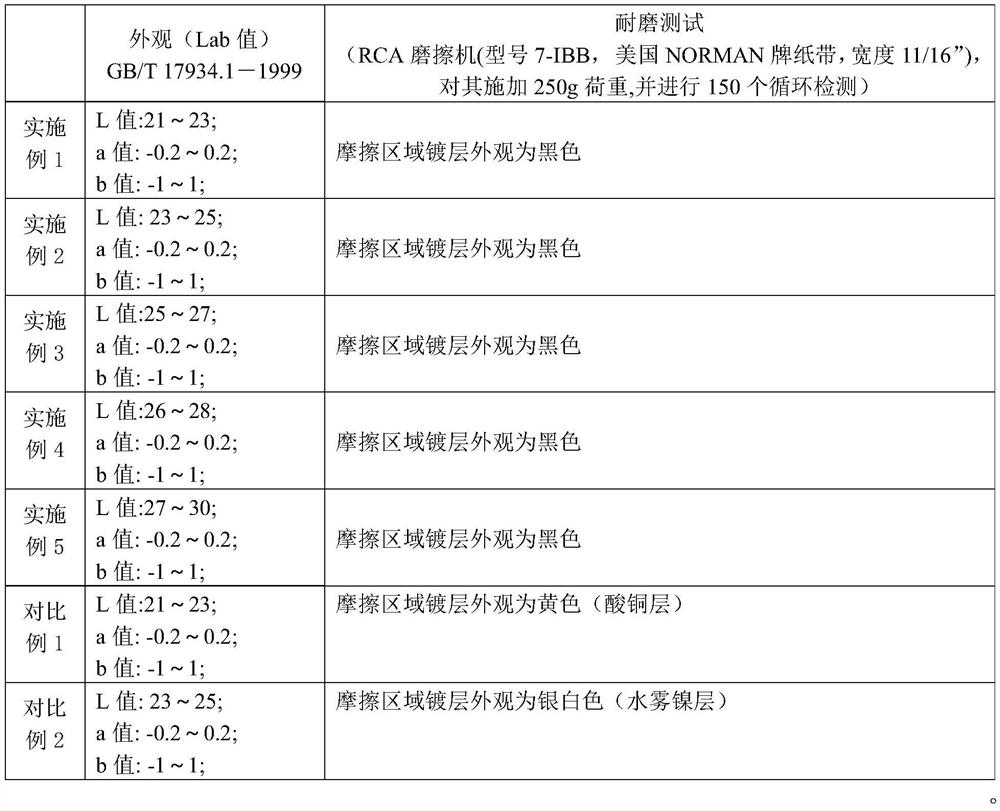

Black surface composite coating and preparation method thereof

The invention discloses a black surface composite coating and a preparation method thereof. The black surface composite coating is formed by sequentially plating an electrocoppering layer, a black nickel layer and a hexavalent black chromium layer on the surface of a base material. The method comprises the following steps of (i), carrying out electroplating pretreatment, specifically, cleaning thesurface of a metal substrate; (ii), electroplating a copper layer, namely plating the copper layer on the clean base material obtained in the step (i); (iii), electroplating the black nickel layer, and carrying out black nickel electroplating treatment on the clean copper layer obtained in the step (ii); and (iv), electroplating the black chromium layer, and carrying out black chromium electroplating treatment on the clean black nickel layer obtained in the step (iii). The black coating prepared by the method not only has matte black color, but also has the advantages of corrosion resistanceand high hardness.

Owner:JOMOO KITCHEN & BATHROOM

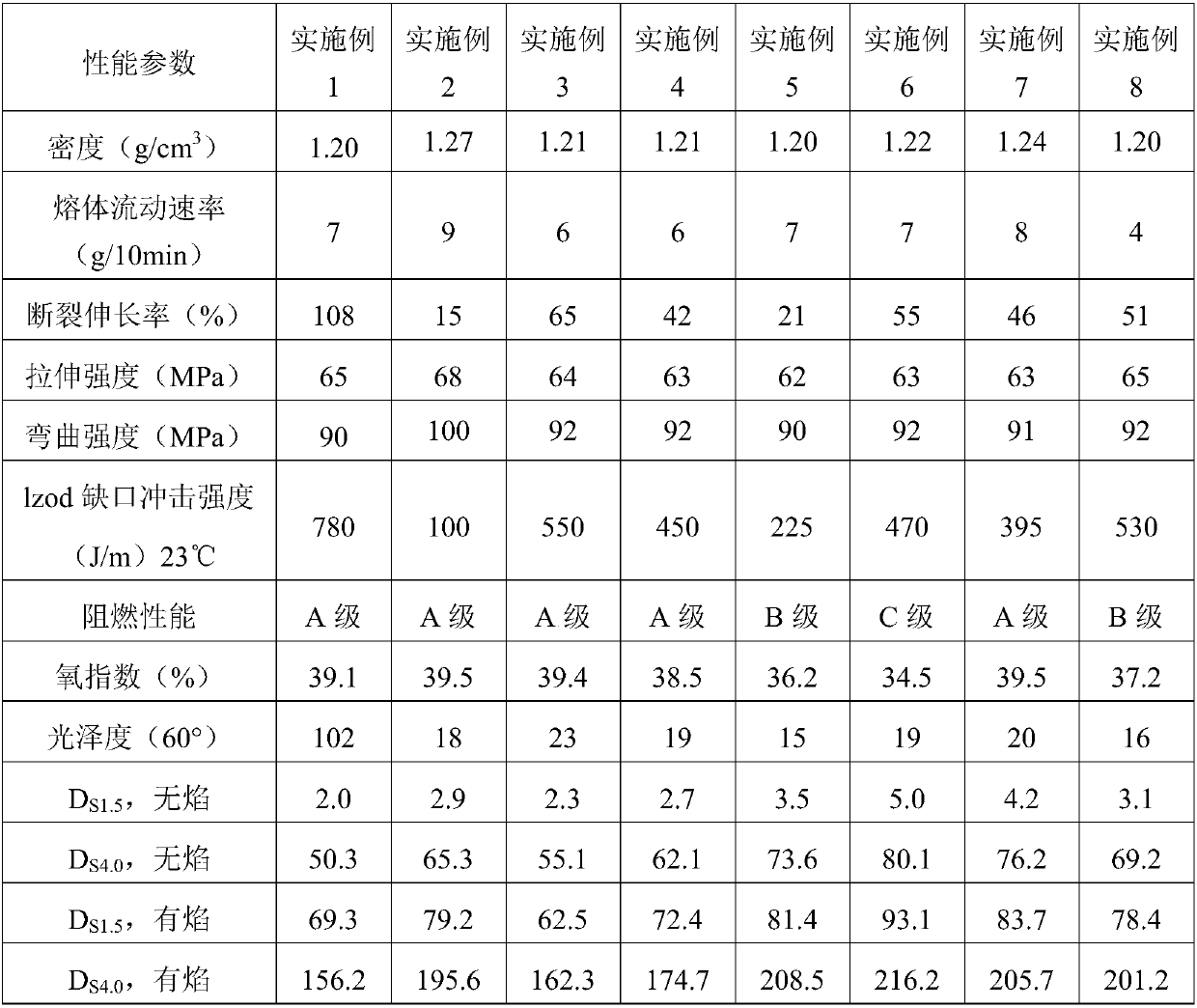

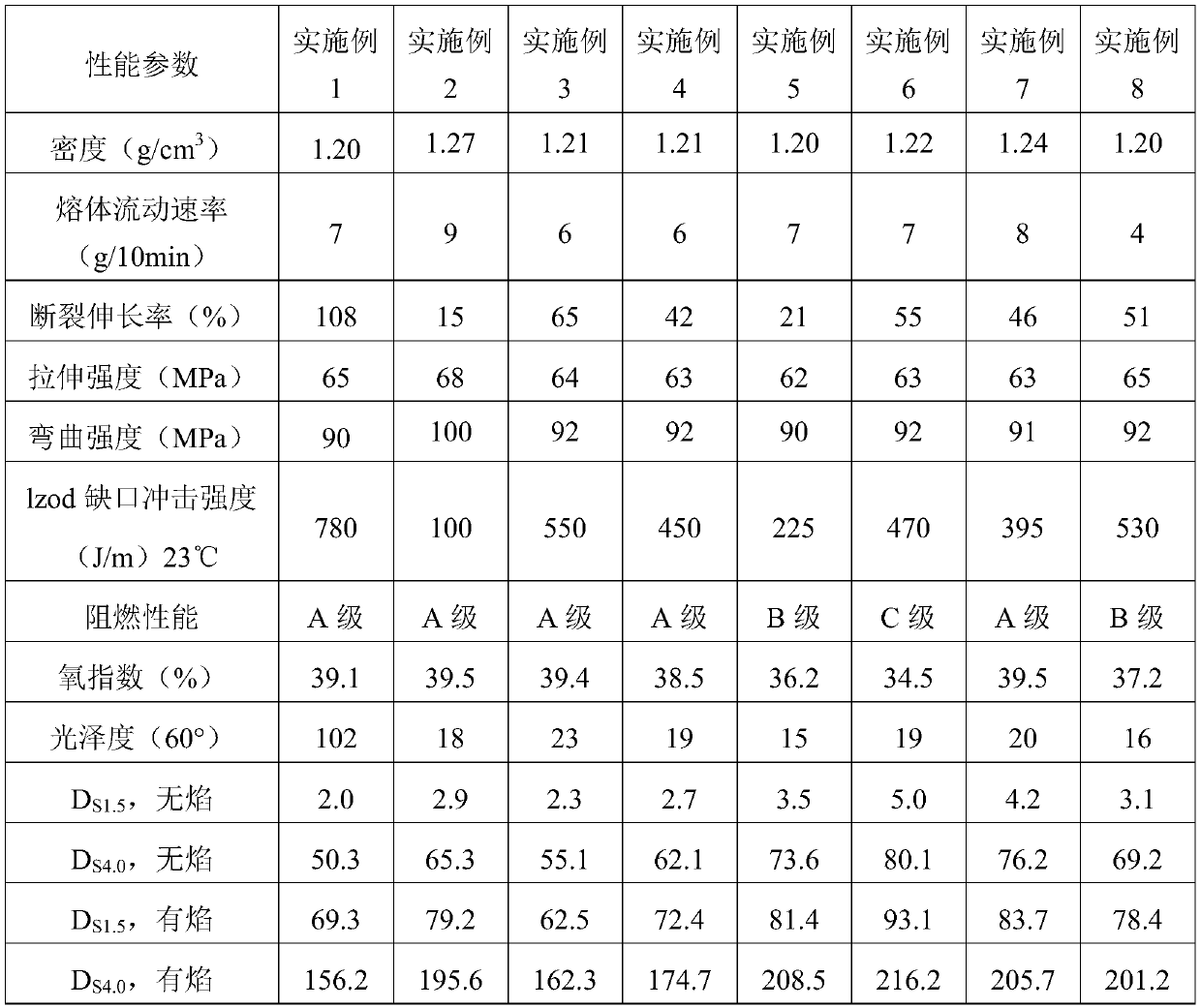

Low-gloss low-smoke halogen-free flame-retardant polycarbonate composite material

The invention specifically relates to a low-gloss low-smoke halogen-free flame-retardant polycarbonate composite material, belonging to the field of polymer composite materials. The polycarbonate composite material comprises the following components by weight: 70-90% of branched polycarbonate resin, 5-20% of PC composite resin, 1-5% of an epoxy-reactive compatilizer, 0.5-2% of a matting agent, 0.1-1% of a sulfonate flame retardant, 0.1-1% of a polysiloxane flame retardant and 0.5-1.5% of an auxiliary agent. The polycarbonate composite material of the invention has the advantages that the PC composite resin, the epoxy-reactive compatilizer and the matting agent have good synergistic effect and ensure low glossiness of the composite material without influence on the flame retardancy and smoke density of the composite material; high-concentration epoxy groups play the roles of chain extension and cross-linking, so certain extinction effect is exerted on the polyester material; and since branched PC is compounded with the sulfonate flame retardant and the polysiloxane flame retardant, the testing smoke density in the combustion process is very low on the basis of ensured flame retardancy.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

Anti-sticking cream and preparation method thereof

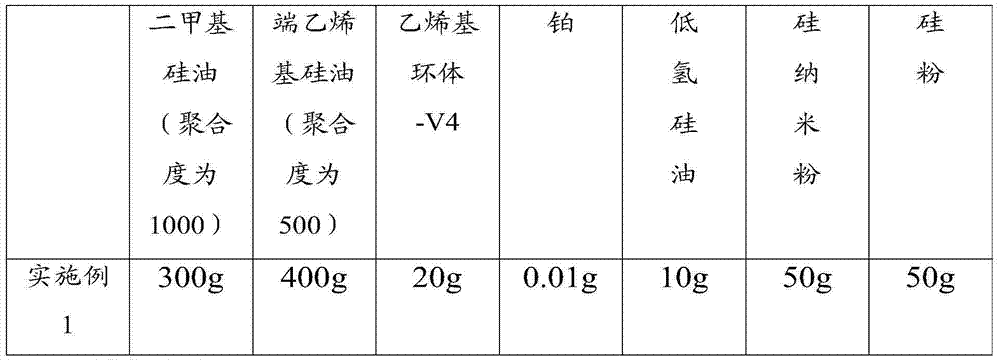

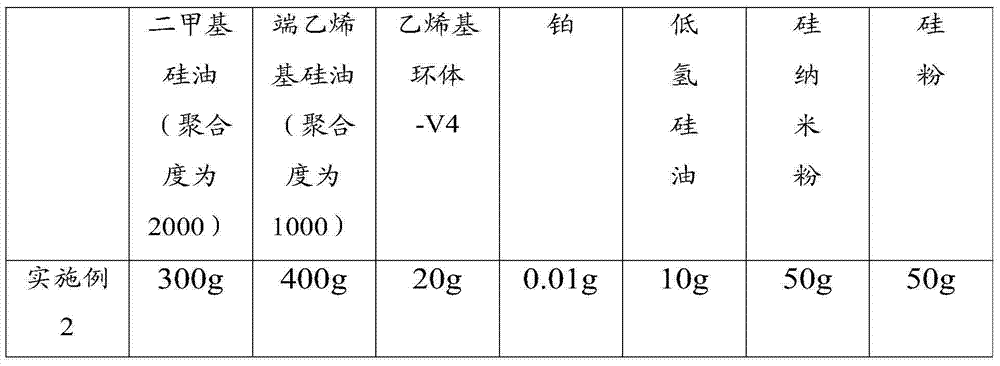

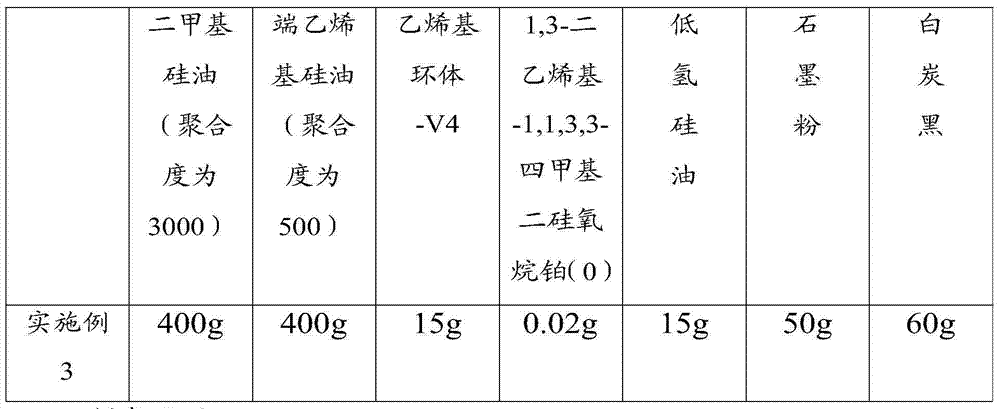

The invention provides anti-sticking cream, which is prepared from the following components in parts by weight: 30-40 parts of simethicone, 40-50 parts of vinyl-terminated silicone oil, 1-2 parts of yetravinyl tetramethyl cyclotetrasiloxane, 0.001-0.005 part of catalyst, 1-2 parts of curing agent, 5-15 parts of lubricant and 5-10 parts of thickening agent. The component raw materials are reacted with one another to prepare the anti-sticking cream which is environment-friendly, toxicity-free and odor-free, flame-retardant, wide in application, prominent in curing property, easy to peel off, and durable in anti-sticking performance, and when the cream is uniformly smeared on the surface of a bridge aperture, a doorway, an electric pole, a news stall, a waiting hall, an information board, an advertisement board, a residence door, a corridor door, a shop door, a security door, a distribution box, an electric meter box, a cable box, a broadband box, a gas box, a mailbox, a garbage box and the like, a soft and bright vision effect can be realized. When an adlet is found to be adhered on the surfaces, the adlet can be removed easily, and no traces or spots are left.

Owner:杨恩林

Polycarbonate styrene resin alloy and preparation method thereof

The invention relates to a polycarbonate styrene resin alloy and a preparation method thereof. The polycarbonate styrene resin alloy comprises the following raw material components in parts by weight:30-60 parts of polycarbonate resin, 25-60 parts of styrene resin, 5-30 parts of branched polycarbonate, 5-15 parts of assistant crosslinking resin and 0.5-1.0 part of a processing aid. The preparation method comprises the following steps: premixing the raw materials in a high-speed mixer for 3-10 min, and carrying out extrusion granulation on the premix through a double-screw extruder at the temperature of 230-280 DEG C to obtain the ultralow-gloss polycarbonate styrene resin alloy. Compared with the prior art, the polycarbonate styrene resin alloy with ultralow gloss is directly prepared bya one-step method without preparing low gloss master batch, the preparation method and the technological process are simple, the problems of insufficient gloss, uneven gloss distribution, deterioration of physical and mechanical properties, complex process, high cost and the like are solved, and the resin alloy is particularly suitable for the field of automotive interiors.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Film-coated radiation-cured bright abrasive paper and preparation method thereof

PendingCN111270560AStrong combination fastnessHigh brightness and glossSpecial paperPaper/cardboardVolatile organic compoundPrepolymer

The invention discloses film-coated radiation-cured bright abrasive paper and a preparation method of the film-coated radiation-cured bright abrasive paper. The paper comprises a paper base material,an adhesive layer, an evaporation layer, a frosted layer, a film layer and a surface coating, wherein the frosted layer is prepared from a frosted coating added with organic frosted particles; the frosted coating is prepared from the following components in parts by weight: 20-70 parts of a prepolymer, 20-70 parts of an active diluent, 1.0-20.0 parts of organic frosted particles, 0-5.0 parts of aphotoinitiator and 1.0-5.0 parts of an auxiliary agent. By means of the technical scheme, the paper has bright bright crystal effect, strong visual impact effect, visual impression of frosted and gravel, smooth surface, low energy consumption, zero emission of volatile organic compounds in the technological process, and environmental protection.

Owner:YANTAI BOYUAN TECH MATERIALS

Baking varnish composition

The invention discloses a dissolvent type baking lacquer composition comprising polyester resin, amino article, polyester modified polydimethyl siloxane, silicon dioxde and dissolvent by a specific proportion. The composition can overcome the drawbacks of long hardening time of the conventional baking lacquer, it has high glossiness, high ductility, and can lower baking temperature and shorten curing time. íí

Owner:MITAC COMP (SHUN DE) LTD

A kind of matting polypropylene composite material and preparation method thereof

The invention discloses a delustering polypropylene composite material and a preparation method thereof. The dulling polypropylene composite material comprises the following components in mass percent: 60-80% of polypropylene, 2-20% of flexibilizer, 5-20% of compatilizer, 5-25% of organic delustering agent, 0.5-5% of inorganic delustering agent, 0.1-2% of antioxidant and 2-20% of inorganic filler. The dispersion effect of delustering components in the polypropylene is strengthened through preparing master batch, the polypropylene, the delustering agent, the inorganic filler and part of compatilizer are firstly co-blended and then extruded through a dual-screw extruder to prepare the delustering master batch, and then the delustering master batch is co-blended with polypropylene and other components, and then extruded to prepare the delustering polypropylene composite material. The delustering polypropylene composite material is excellent in delustering performance, suitable for injection molding of various delustering products, can be applied to indoor decoration and automotive upholstery and can be used for preventing glare from generating in daily life.

Owner:GUANGDONG KINGFA TECH CO LTD

A low-gloss, low-smoke, halogen-free, flame-retardant polycarbonate composite material

The invention relates to the field of polymer composite materials, in particular to a low-gloss, low-smoke, halogen-free flame-retardant polycarbonate composite material, which comprises the following components by weight percentage: branched polycarbonate resin 70-90%, PC composite Resin 5‑20%, epoxy reactive compatibilizer 1‑5%, matting agent 0.5‑2%, sulfonate flame retardant 0.1‑1%, polysiloxane flame retardant 0.1‑1%, auxiliary agent 0.5‑1.5%. The invention has the advantages that: the PC composite resin, the epoxy-reactive compatibilizer, and the matting agent have a good synergistic effect, which ensures that the composite material has a lower gloss, and does not affect the flame retardancy and smoke density of the material , among them, the high concentration of epoxy groups plays the role of chain extension and crosslinking, which can play a certain extinction effect on polyester materials; branched PC, compound sulfonate flame retardant, polysiloxane flame retardant agent, on the basis of ensuring flame retardancy, the smoke density in the combustion process test is very low.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

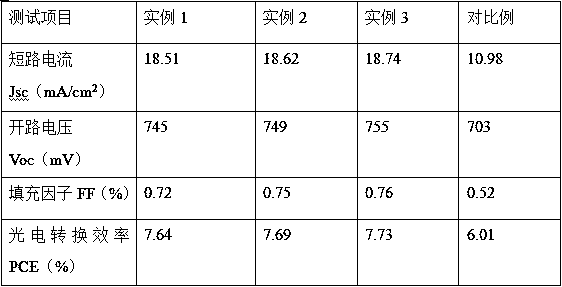

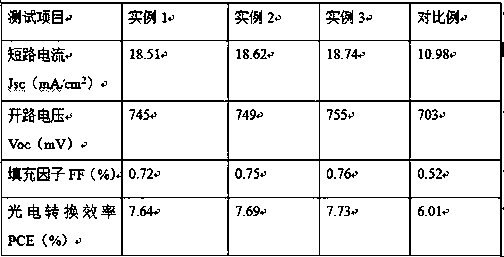

Preparation method of dye-sensitized solar battery counter electrode material

ActiveCN108922785AImprove electrocatalytic efficiencyReduce convection coolingLight-sensitive devicesPhotovoltaic energy generationCarbon nanotubeP-Nitroaniline

The invention belongs to the technical field of renewable clean energy source, and specifically relates to a preparation method of a dye-sensitized solar battery counter electrode material. In the method, emulsifier OP-10, liquid paraffin and other materials are used as raw materials to obtain oil-in-water emulsion, the oil-in-water emulsion is mixed with sodium metasilicate nonahydrate solution for reaction, thus, counter electrode sizing agent is obtained, the counter electrode sizing agent is subjected to refrigerated centrifugation and precipitate is collected, the precipitate is mixed with dispersed gelatinous coating and sprayed on a FTO conducting glass surface, thus, the dye-sensitized solar battery counter electrode material is obtained. According to the method provided by the invention, an outer hole of an organic dispersed carbon nano tube is plugged by tungsten carbide, electrocatalytic efficiency of the counter electrode is improved, the surface of the carbon nano tube ismodified by paranitroaniline diazo salt, convective heat loss of the electrode material is reduced, photoelectric conversion energy storage is also facilitated, titanium dioxide added in the coating plays a role in a flatting effect and a function of increasing specific area of the surface, photoelectric conversion efficiency of the electrode material is improved, thus, the method has wide application foreground.

Owner:温州涌润信息科技有限公司

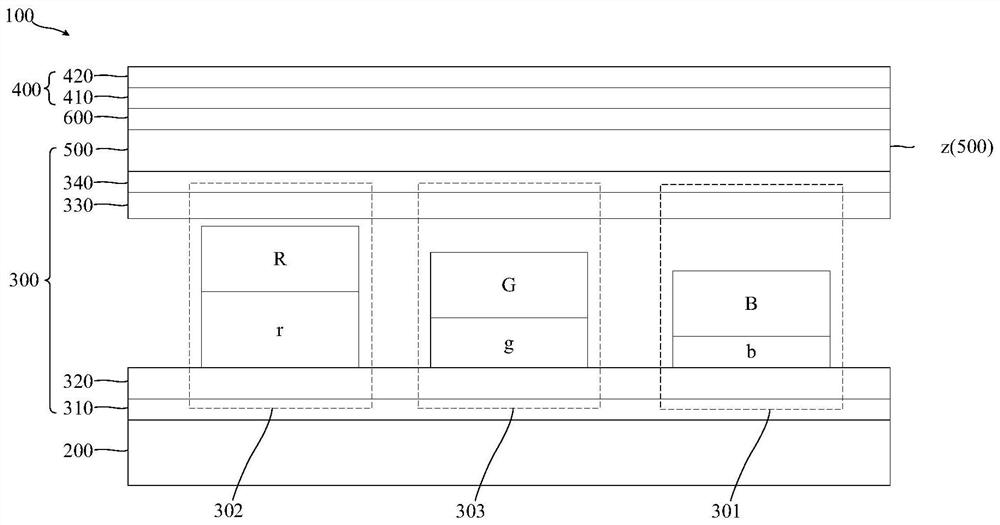

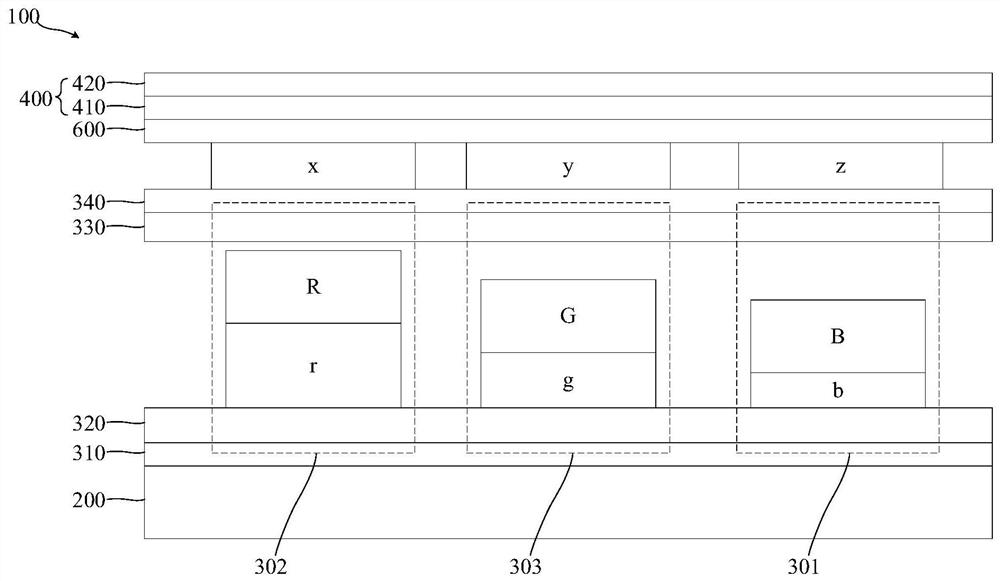

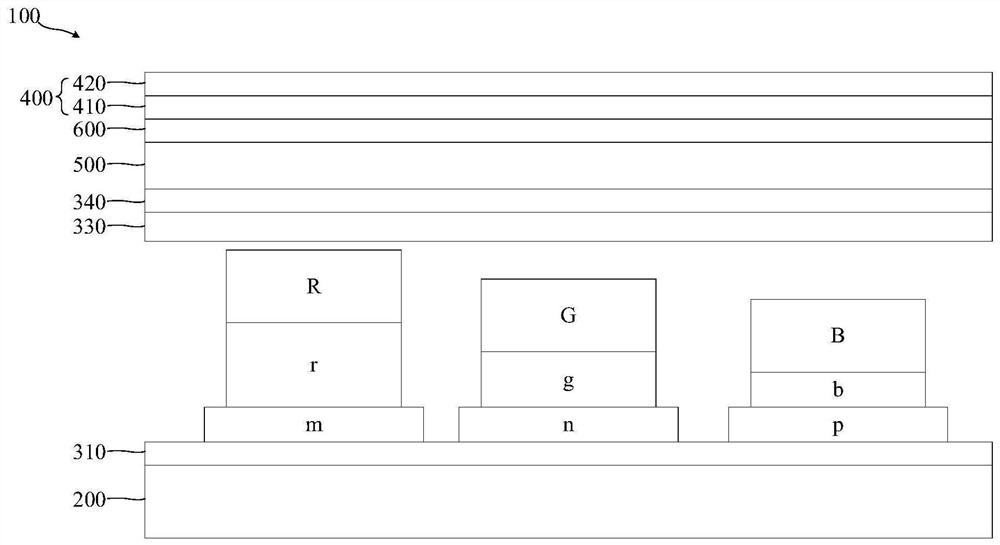

Display panel and mobile terminal

ActiveCN113871547ALow color temperatureImprove the display effectSolid-state devicesSemiconductor/solid-state device manufacturingUltraviolet lightsLight extinction

The embodiment of the invention discloses a display panel and a mobile terminal. The display panel comprises a light-emitting functional layer and a thin film packaging layer, the light-emitting functional layer comprises a plurality of first light-emitting units and a plurality of first light extraction units located between the first light-emitting units and the thin film packaging layer, and the extinction coefficient of the first light extraction units to ultraviolet light is larger than that of the thin film packaging layer to ultraviolet light. According to the embodiment of the invention, the first light extraction unit comprising the ultraviolet light absorption material is arranged between the first light emitting unit and the thin film packaging layer, so that when sunlight or ultraviolet light irradiates the display panel, the first light extraction unit plays a role in absorbing or extinction the ultraviolet light. The problem that the color temperature of the display panel is reduced due to the fact that the light-emitting materials in the first light-emitting units are damaged by ultraviolet light is relieved, and the display effect of the display panel is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

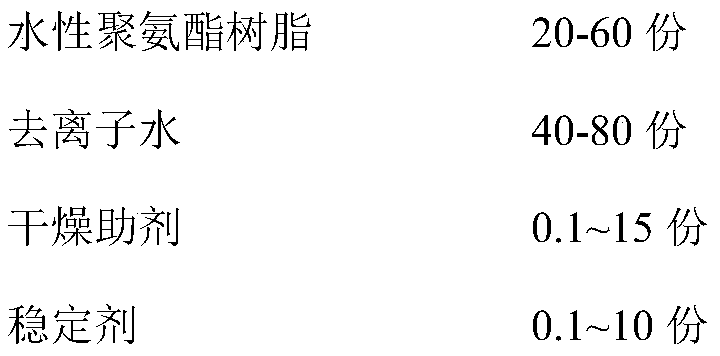

A kind of water-based polyurethane three-proof paint for circuit board anticorrosion

ActiveCN107573831BFree from corrosionImprove insulation performanceAnti-corrosive paintsPolyurea/polyurethane coatingsEngineeringMechanical engineering

Owner:YIK SHING TAT INDUSTRIALCO LTD

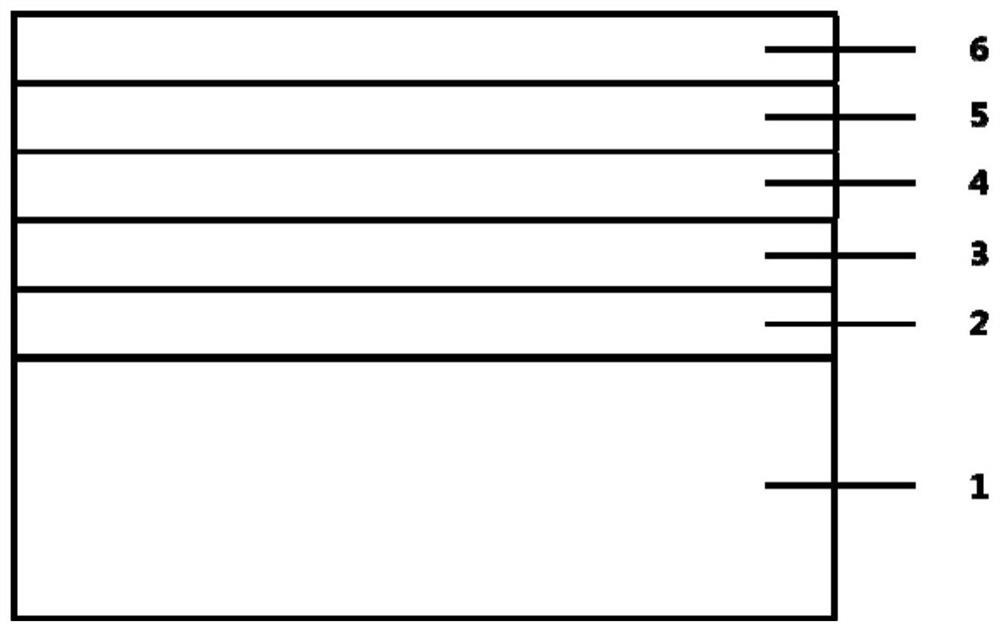

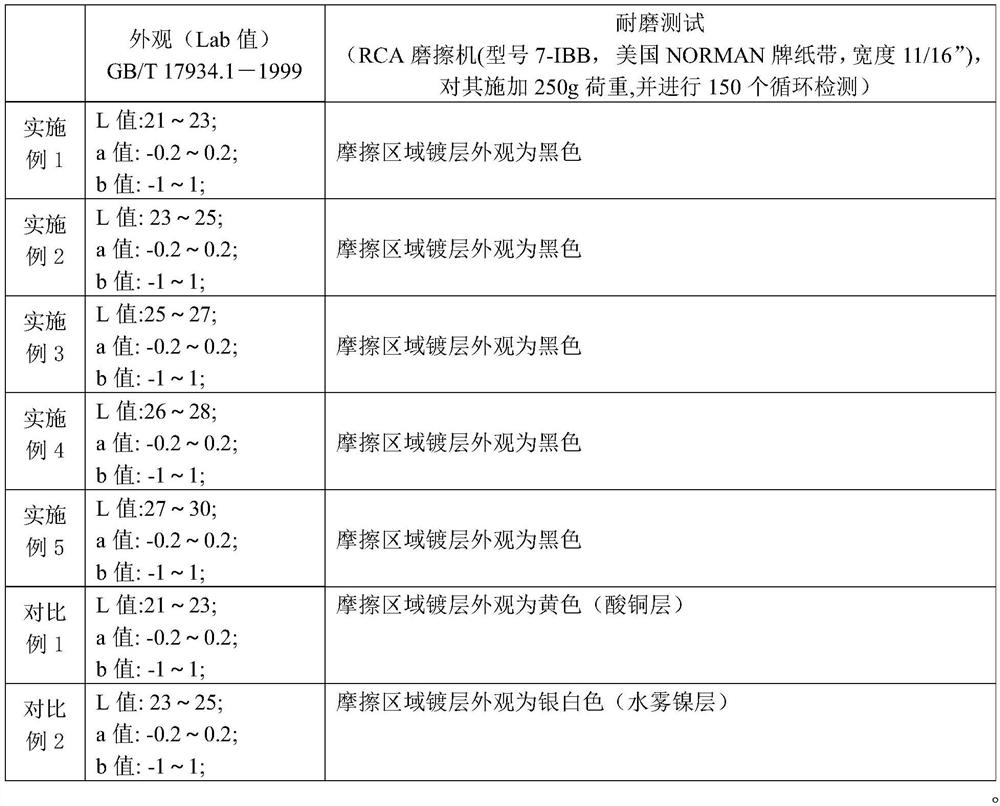

A kind of black surface composite coating and preparation method thereof

The invention discloses a black surface composite coating and a preparation method thereof. The black surface coating is sequentially plated with an electroplated copper layer, a black nickel layer and a hexavalent black chromium layer on the surface of a base material. The method includes the following steps: (i) electroplating pre-treatment, cleaning the surface of the metal substrate; (ii) electroplating a copper layer, electroplating a copper layer on the clean substrate obtained in (i); (iii) electroplating a black nickel layer, Black nickel electroplating is performed on the clean copper layer obtained in (ii); black chromium electroplating is performed on (iv) a black chromium layer, and black chromium electroplating is performed on the clean black nickel layer obtained in (iii). The black coating prepared by the method of the present invention not only has a matte black luster, but also has the advantages of corrosion resistance and high hardness.

Owner:JOMOO KITCHEN & BATHROOM

Degradable matting daily chemical bottle and preparation method thereof

ActiveCN113308101AReduce optical transmissionPlay a matting effectBio-packagingPolyurea/polyurethane coatingsIsocyanateMultiple frequency

The invention relates to a preparation method of a degradable matting daily chemical bottle, which is characterized in that a matting polyurethane paint coating is used to carry out matting treatment on the daily chemical bottle, and the matting polyurethane paint coating comprises 50-60 parts of polyether polyol, 20-30 parts of isocyanate, 1-5 parts of a catalyst, 20-30 parts of a solvent, and 10-20 parts of benzene ring-containing alcohol. The matting polyurethane paint coating contains benzene ring-containing alcohol, and the polyurethane paint coating has certain matting performance due to the addition of the alcohol; in addition, microwaves with multiple frequency bands are used for removal in the polyurethane paint curing process, the extinction effect is further improved, and the daily chemical bottle prepared through the method is high in visual sense.

Owner:威骏(上海)环保包装有限公司

Method for preparing polyester fibers with ultraviolet-resistant and anti-pilling composite function

ActiveCN102443877BImprove the diffusion effectReduce transmittanceArtificial filament heat treatmentMelt spinning methodsPolyesterFiber

The invention relates to a method for preparing polyester fibers with ultraviolet-resistant and anti-pilling composite function. The method comprises an esterification reaction procedure, a polymerization reaction procedure and a spinning procedure, wherein the esterification reaction procedure comprises a primary esterification reaction stage and a secondary esterification reaction stage, and aliphatic dicarboxylic acid or non-p-aryl dicarboxylic acid serving as a third monomer is introduced in the primary esterification reaction stage; flexible polyethylene glycol serving as a fourth monomer is introduced in the secondary esterification reaction stage; a hindered amine light stabilizer and a hindered phenol antioxidant which are respectively prepared by using acetic acid and ethylene glycol as solvents and hydroxy silicone oil are added after the esterification is completed; and after the pre-polymerization of the polymerization reaction procedure is completed and before final polymerization, an ultraviolet absorbent is added. Before the spinning procedure, polyester slices are pre-crystallized and dried. The polyester fibers obtained by the method have excellent ultraviolet-resistant and anti-pilling function; and after the polyester fibers are woven into knitted fabrics and woven fabrics, tests show the related technical indexes that: the ultraviolet transmission rate is less than or equal to 5.0 percent, and the anti-pilling performance is more than or equal to level 4.

Owner:JIANGSU GUOWANG HIGH TECH FIBER CO LTD

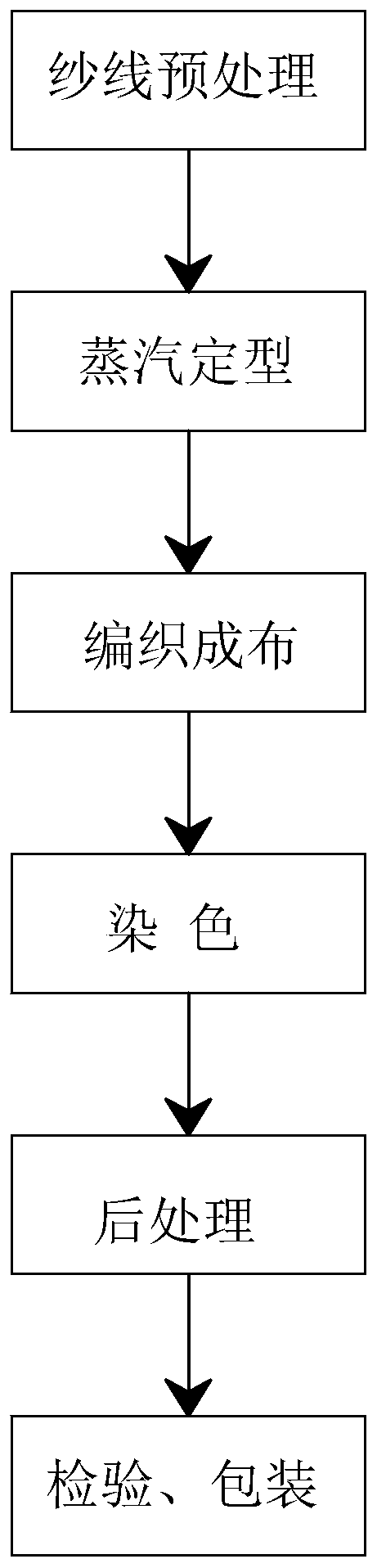

A kind of production technology of Roman cloth

ActiveCN107956029BImprove heat resistanceQuality improvementWeft knittingFibre typesYarnProcess engineering

Owner:绍兴柯桥杰坝针纺科技有限公司

Preparation method of matte hydroxy acrylic resin

The invention discloses a preparation method of matte hydroxy acrylic resin. The preparation method comprises the following steps: adding a solvent and modified grafted polypropylene into a reaction kettle, wherein the modified grafted polypropylene is formed by grafting polypropylene and a grafting monomer, adding a comonomer and a part of a copolymerization initiator into a dropwise adding kettle, and uniformly stirring and mixing to obtain a copolymerization premixed solution; raising the temperature of the reaction kettle to 100 DEG C, dropwise adding the copolymerization premixed liquid into the reaction kettle by utilizing a dropwise adding kettle, and after dropwise adding is completed, carrying out heat preservation reaction for 1-3 hours under the temperature condition of 100 DEG C; supplementing the other part of the copolymerization initiator, and continuously carrying out heat preservation reaction for 2-4 hours; and cooling the reaction kettle to 60-80 DEG C, and discharging to obtain the matte hydroxy acrylic resin. According to the method, the modified grafted polypropylene is introduced into the acrylic resin, so that the glossiness of the acrylic resin is reduced by utilizing the modified grafted polypropylene, and the hydroxy acrylic resin with a relatively good matte effect is obtained.

Owner:泰兴盛嘉树脂有限公司

A kind of matte polycarbonate styrenic resin alloy and preparation method thereof

The invention relates to a matt polycarbonate styrene resin alloy. The matt polycarbonate styrene resin alloy contains following raw material constituents of, by weight part, 50-80 parts of polycarbonate resin, 15-48 parts of polycarbonate resin, 2-5 parts of isocyanate chemical compounds, 0.5-2 parts of compatible agent and 0.5-1 part of processing agent. A preparation method of the matt polycarbonate styrene resin alloy includes following steps: mixing the above raw material constituents in a high speed mixer in advance for 3-10min, and then extruding and granulating the premixed materials through a double screw extruder under 230-280 degree centigrade so as to obtain the matt polycarbonate styrene resin alloy. The matt polycarbonate styrene resin alloy has the advantages that compared with the prior art, no matt master particle needs to be prepared, the polycarbonate styrene resin alloy excellent in matt effect can be directly prepared through a one step method, and the preparation method of the matt polycarbonate styrene resin alloy is simple in technical process, solves the technical problems that glossiness distribution is uneven, physical and mechanical properties are deteriorated, preparation technology is complex and the like, and can reduce cost.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

A kind of preparation method of counter electrode material of dye-sensitized solar cell

ActiveCN108922785BImprove electrocatalytic efficiencyReduce convection coolingLight-sensitive devicesPhotovoltaic energy generationSodium metasilicateElectrical battery

The invention belongs to the technical field of renewable clean energy source, and specifically relates to a preparation method of a dye-sensitized solar battery counter electrode material. In the method, emulsifier OP-10, liquid paraffin and other materials are used as raw materials to obtain oil-in-water emulsion, the oil-in-water emulsion is mixed with sodium metasilicate nonahydrate solution for reaction, thus, counter electrode sizing agent is obtained, the counter electrode sizing agent is subjected to refrigerated centrifugation and precipitate is collected, the precipitate is mixed with dispersed gelatinous coating and sprayed on a FTO conducting glass surface, thus, the dye-sensitized solar battery counter electrode material is obtained. According to the method provided by the invention, an outer hole of an organic dispersed carbon nano tube is plugged by tungsten carbide, electrocatalytic efficiency of the counter electrode is improved, the surface of the carbon nano tube ismodified by paranitroaniline diazo salt, convective heat loss of the electrode material is reduced, photoelectric conversion energy storage is also facilitated, titanium dioxide added in the coating plays a role in a flatting effect and a function of increasing specific area of the surface, photoelectric conversion efficiency of the electrode material is improved, thus, the method has wide application foreground.

Owner:温州涌润信息科技有限公司

A kind of luminous paint specially used for aluminum products and its application

InactiveCN104893492BGood dispersionImprove adhesionLuminescent paintsSpecial surfacesBarium sulfateMaterials science

The invention discloses a luminous paint specially used for aluminum products, which is characterized in that it comprises the following raw materials by weight percentage: resin: 20-80%, curing agent: 5-60%, leveling agent: 0.1-20%, brightening agent : 0.01‑20%, pigment: 1‑40%, fragrance: 0.1‑10%, barium sulfate: 1‑50%, matting curing agent: 0‑50%, luminous powder: 1‑50%. Compared with the prior art, the luminous paint specially used for aluminum products provided by the present invention has the characteristics of low manufacturing cost, strong adhesion and good dispersibility of pigments, and the prepared coating has smooth surface without being too dark. The bright and dazzling features are especially suitable for the processing of aluminum curtain walls, aluminum doors, aluminum windows and sun room frames.

Owner:何炳贵

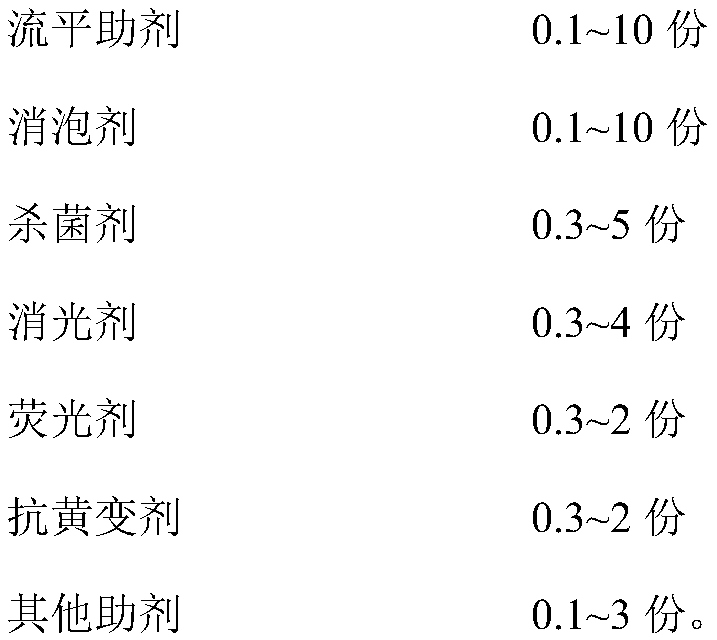

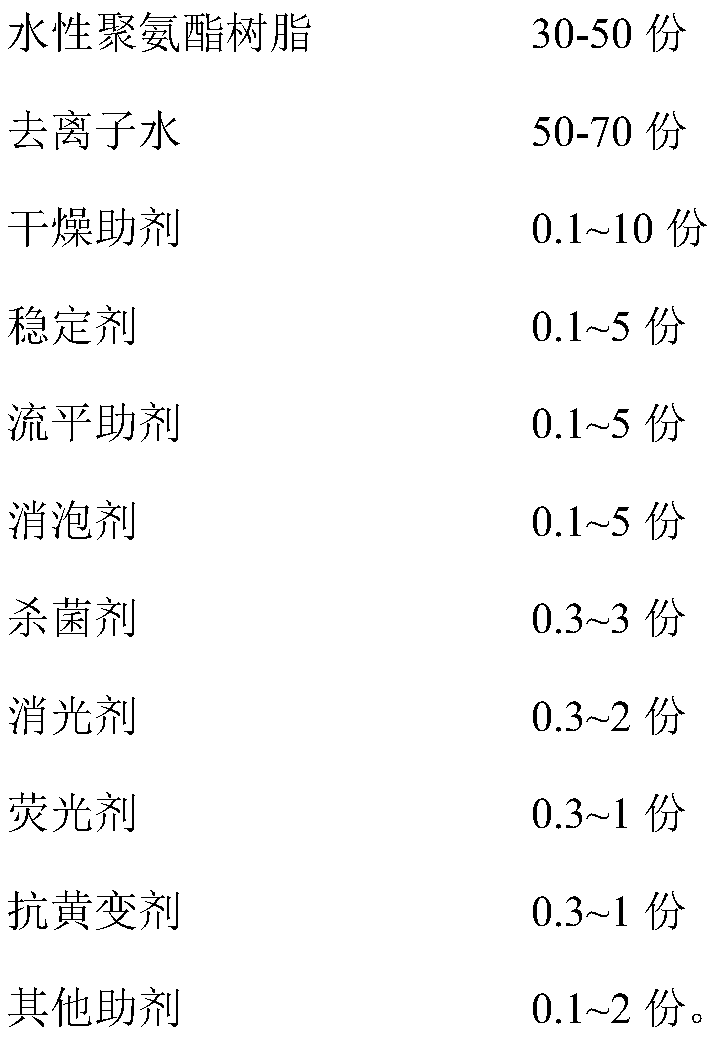

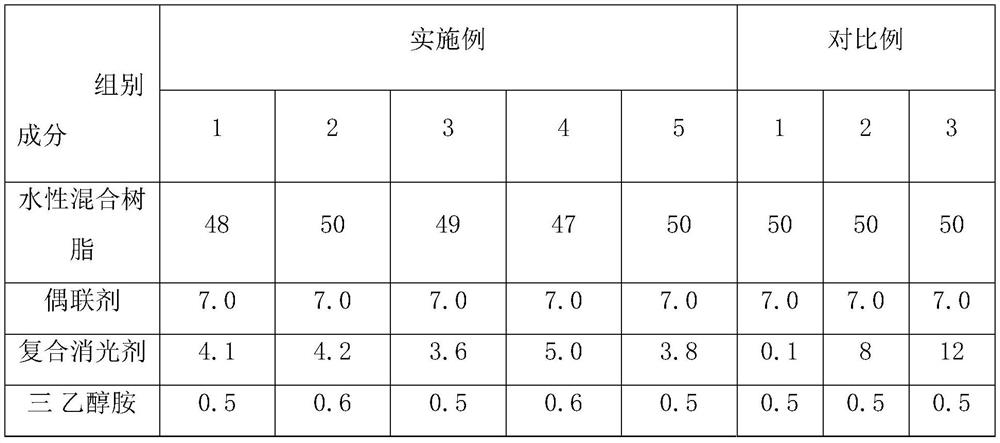

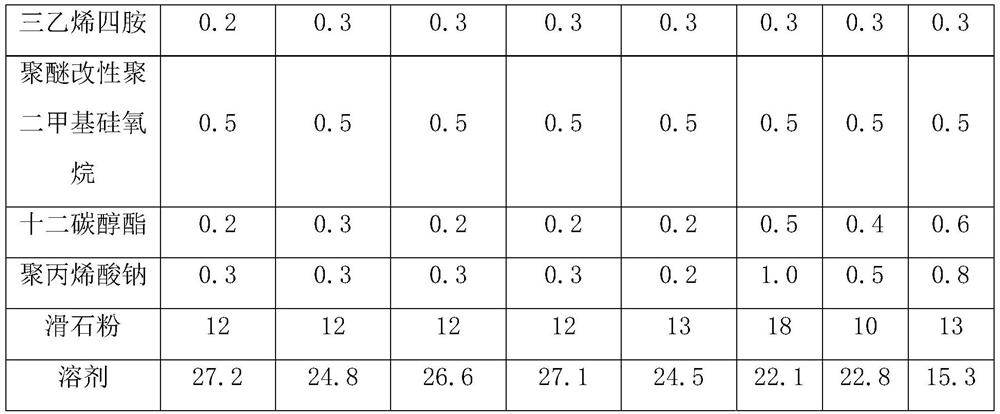

Metal printing soft paint and preparation method thereof

ActiveCN114231102AImprove stabilityGood dispersionPolyurea/polyurethane coatingsPolycarbonate coatingsPolymer scienceWeather resistance

The invention provides a soft coating for metal printing and a preparation method thereof, and the soft coating for metal printing comprises the following preparation raw materials in percentage by mass: water-based mixed resin, a coupling agent, a composite delustering agent, a dispersing agent, a curing agent, a flatting agent, a film-forming agent, a defoaming agent, a filling agent and a solvent, the composite delustering agent is prepared by compounding porous silicon dioxide, an emulsifier, polyurethane and polytetrafluoroethylene, and the mass ratio of the porous silicon dioxide to the emulsifier to the polyurethane to the polytetrafluoroethylene is (10-15): (1-8): (2-7): (1-5). By optimizing the formula of the soft paint for metal printing, the formula system is more stable, the storage and use stability of the paint are facilitated, and the dispersity of the components of the formula system can be promoted by compounding the porous silicon dioxide, the emulsifier, the polyurethane and the polytetrafluoroethylene as a composite delustering agent, so that a coating film is more uniform and has a soft hand feeling; the wear resistance, the scratch resistance and the weather resistance are excellent.

Owner:广东鑫皇冠新材料有限公司

Preparation method of anti-ultraviolet anti-pilling polyester slices

ActiveCN102443153BImprove the diffusion effectReduce transmittanceMonocomponent polyesters artificial filamentPolyesterPolyethylene glycol

The invention relates to a preparation method of anti-ultraviolet anti-pilling polyester slices. The preparation method comprises an esterification reaction working procedure and a polymerization reaction working procedure, wherein the esterification reaction working procedure comprises a primary esterification reaction section and a secondary esterification reaction section; in the primary esterification reaction section, aliphatic dicarboxylic acid and / or non-para-aryl dicarboxylic acid are / is introduced to serve as a third monomer; in the secondary esterification reaction section, flexible polyethylene glycol is introduced to serve as a fourth monomer; after esterification is completed, a hindered amine light stabilizer and a hindered phenol antioxidant which are respectively prepared from acetic acid and ethylene glycol as a solvent and hydroxy silicone oil are added; and after prepolymerization and before final polymerization in the polymerization reaction working procedure, an ultraviolet absorbent is added. The polyester fibers spun from the polyester slices prepared by the method provided by the invention have excellent anti-ultraviolet and anti-pilling performances; and after the polyester fibers are knitted / woven into knitted / woven fabric, test shows that the fabric has the following correlated technical indexes: the ultraviolet light transmittance is not more than 5.0%, and the anti-pilling performance is not less than 4-level.

Owner:JIANGSU ZHONGLU TECH DEV +1

A low-gloss thermoplastic polyurethane composition and its preparation method and application

The invention relates to a thermoplastic polyurethane composition with low gloss and its preparation method and application. The composition comprises the following components in mass percentage, (A) 50%-95% thermoplastic polyurethane elastomer; (B) 3%-45% thermoplastic polyamide polymer or thermoplastic polyamide and thermoplastic polyester polymer Blend; (C) 1%-20% of the third component, the third component is selected from one or more of inorganic filler, polycarbonate powder, PTFE powder, organic (hypo)phosphate. According to the standard ASTM D523 test, the composition of the present invention has a 60° surface gloss of less than 30Gs, and the material has good mechanical properties and processing properties, the surface matting effect is uniform and delicate, and the hand feels smooth. It is suitable for preparing cables, pipes, belts and films. product.

Owner:WANHUA CHEM GRP CO LTD

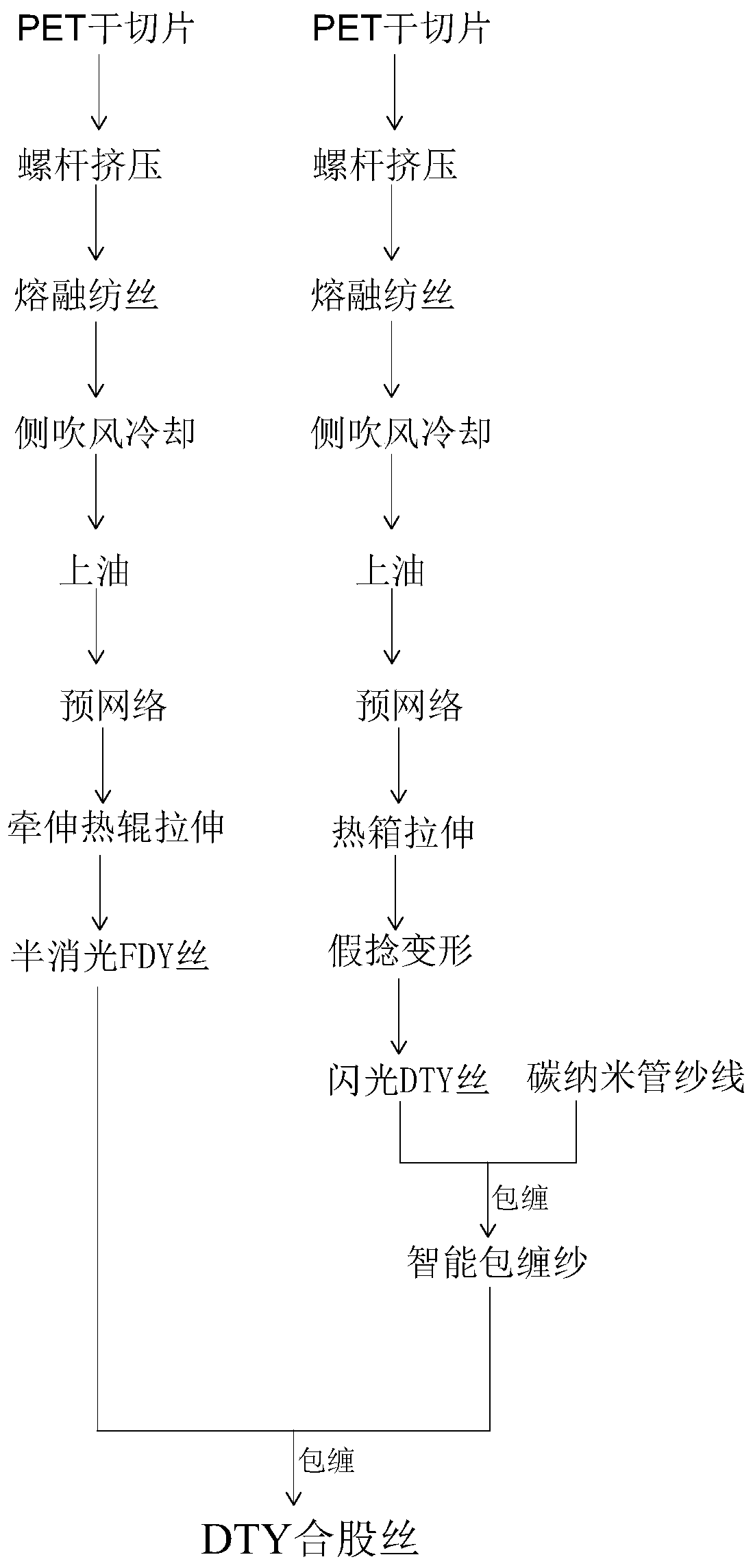

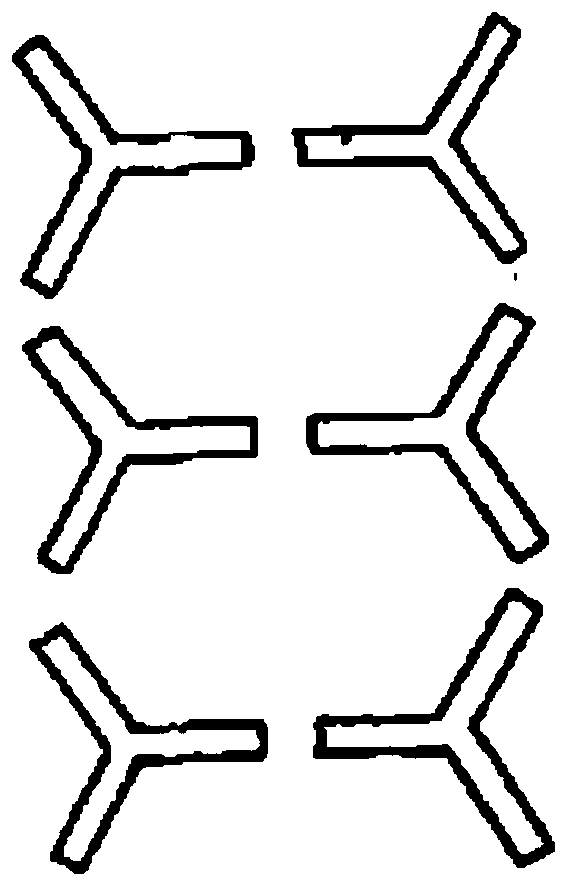

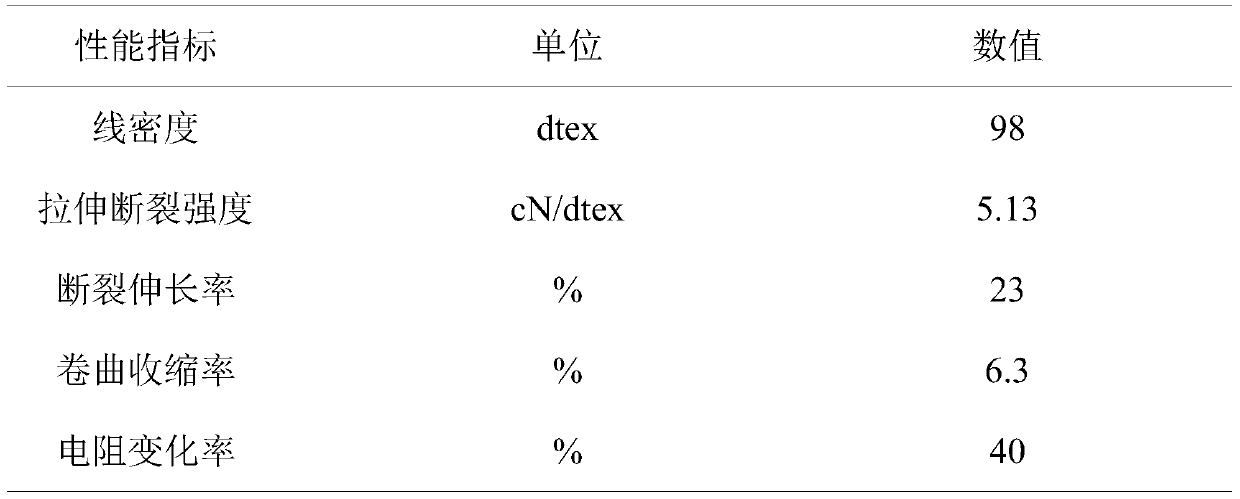

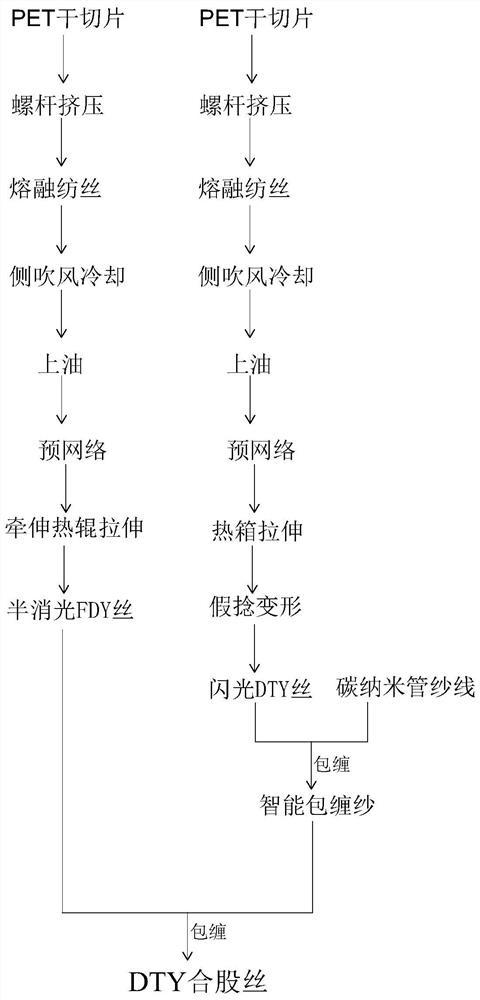

Preparation process of multi-ply DTY with special gloss

ActiveCN111218741AGood hygroscopicityImprove fluffinessArtificial thread manufacturing machinesMelt spinning methodsCarbon nanotube yarnProcess engineering

The present invention discloses a preparation process of a multi-ply DTY with special gloss. The process comprises the following steps of preparing a semi-dull FDY; preparing a flash DTY; by taking adull FDY as a core yarn and taking a carbon nanotube yarn as a skin yarn, performing wrapping to obtain an intelligent wrapped yarn; and by taking the flash DTY as a core yarn and taking the intelligent wrapped yarn as a skin yarn, performing wrapping to obtain the multi-ply DTY with the special gloss. The multi-ply DTY prepared by the process has the relatively special gloss, fluffy and soft handfeeling, certain elasticity and relatively good moisture absorption, and can be used as an intelligent yarn.

Owner:苏州萧然新材料有限公司

A preparation process of dty plied yarn with special luster

ActiveCN111218741BGood hygroscopicityImprove fluffinessArtificial thread manufacturing machinesMelt spinning methodsPolymer scienceCarbon nanotube yarn

The present invention discloses a preparation process of a multi-ply DTY with special gloss. The process comprises the following steps of preparing a semi-dull FDY; preparing a flash DTY; by taking adull FDY as a core yarn and taking a carbon nanotube yarn as a skin yarn, performing wrapping to obtain an intelligent wrapped yarn; and by taking the flash DTY as a core yarn and taking the intelligent wrapped yarn as a skin yarn, performing wrapping to obtain the multi-ply DTY with the special gloss. The multi-ply DTY prepared by the process has the relatively special gloss, fluffy and soft handfeeling, certain elasticity and relatively good moisture absorption, and can be used as an intelligent yarn.

Owner:苏州萧然新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com