A kind of production technology of Roman cloth

A production process and yarn technology, applied in the production process of Roman cloth, can solve the problems of poor heat resistance and light resistance, affect the quality of Roman cloth, poor heat resistance, etc., achieve soft luster, white color, and good heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

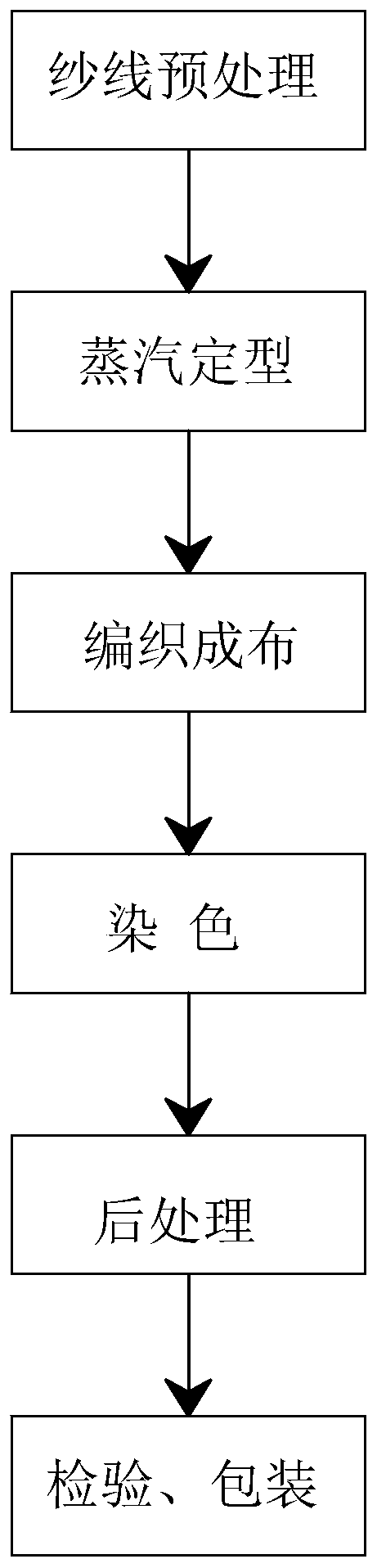

[0042] like figure 1 Shown, a kind of production technique of Roman cloth comprises the following steps:

[0043] (1) Yarn pretreatment: Soak the yarn in the lye for a period of time and then take it out and clean it. The lye includes sodium hydroxide, and the concentration of the lye is 220g / L. Add brucite powder, water The weight ratio of magnesium stone powder to water is: 1:40, the particle size of brucite powder is 5 μm, fatty alcohol polyoxyethylene ether is also added in the soaking tank, and the content of fatty alcohol polyoxyethylene ether is 1%. Put the finished yarn into the soaking tank, heat to 80°C, keep warm for 90 minutes, stir during soaking, the stirring speed is 70 rpm, stir for 5 minutes every 10 minutes, cycle 6 times, rinse with cold water after slow cooling , after rinsing, evenly spray the film-forming spray on the surface of the yarn, the film-forming spray includes film-forming agent and water, the film-forming agent includes acrylic resin, and let ...

Embodiment 2

[0051] A production process of Roman cloth, comprising the following steps:

[0052] (1) Yarn pretreatment: Soak the yarn in the lye for a period of time and then take it out and clean it. The lye is sodium hydroxide and potassium hydroxide. The concentration of the lye is 200g / L, and brucite is added to the soaking tank Powder, the weight ratio of brucite powder to water is: 1:50, the particle size of brucite powder is 15 μm, fatty alcohol polyoxyethylene ether is also added in the soaking tank, and the content of fatty alcohol polyoxyethylene ether is 6%. , put the cleaned yarn into the soaking tank, heat to 120°C, keep warm for 60 minutes, stir during soaking, the stirring speed is 40 rpm, stir for 5 minutes every 10 minutes, cycle 4 times, after slow cooling Rinse with cold water, after rinsing, evenly spray the film-forming spray on the surface of the yarn, the film-forming spray includes film-forming agent and water, the film-forming agent includes polyurethane resin, an...

Embodiment 3

[0060] A production process of Roman cloth, comprising the following steps:

[0061] (1) Yarn pretreatment: Soak the yarn in the lye for a period of time and then take it out and clean it. The lye includes potassium hydroxide, and the concentration of the lye is 210g / L. Add brucite powder, water The weight ratio of magnesium stone powder to water is: 1:60, the particle size of brucite powder is 10 μm, fatty alcohol polyoxyethylene ether is also added in the soaking tank, and the content of fatty alcohol polyoxyethylene ether is 3%, and the cleaning Put the finished yarn into the soaking tank, heat to 90°C, keep warm for 70 minutes, stir during soaking, the stirring speed is 80 rpm, stir for 5 minutes every 10 minutes, cycle 4 times, rinse with cold water after slow cooling , after rinsing, evenly spray the film-forming spray on the surface of the yarn, the film-forming spray includes a film-forming agent and water, the film-forming agent includes casein, and let it stand for 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com