Patents

Literature

405results about How to "Soft luster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-count smooth double-faced wool and production process thereof

The invention discloses high-count smooth double-faced wool which is double-layer texture structure cloth with upper portion and lower portion connected. The front texture of the high-count smooth double-faced wool is 2 / 2 twill, and the back texture of the cloth is 2 / 2 herringbone. A production process of the high-count smooth double-faced wool includes: respectively performing loose fiber dying on wool fibers, dacron fibers and modal fibers, then performing full sliver mixing, and spinning the mixed fibers into 20 / 1 and 24 / 1 yarns with an open-end spinning mode; weaving the high-count smooth double-faced wool cloth on a rapier loom through yarns; and performing blank checking, mending, reviewing, hemming, wool washing, dehydration, milling, wool jigging, dehydration, rotary width drying, wool steaming, fluffing, shearing, squeezing, burring galling, rolling, drying, polishing, polishing shearing, wool steaming and finish inspection on the weaved cloth to manufacture finished products. The high-count smooth double-faced wool is full in hand feeling, elastic, natural and gentle in gloss, and smooth and ordered in villus, cannot cause bottom explosion and depilation, and is rich and smooth in hand feeling and suitable for manufacturing high-grade clothing.

Owner:苏州优布纺织科技有限公司

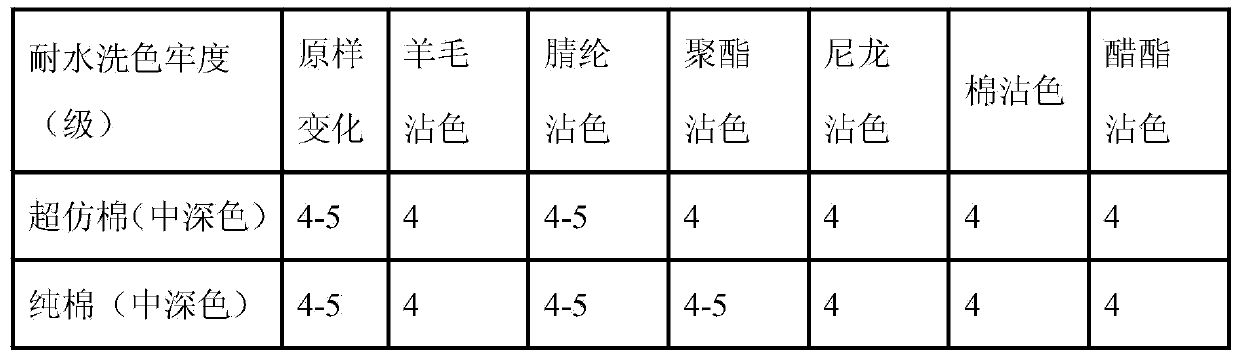

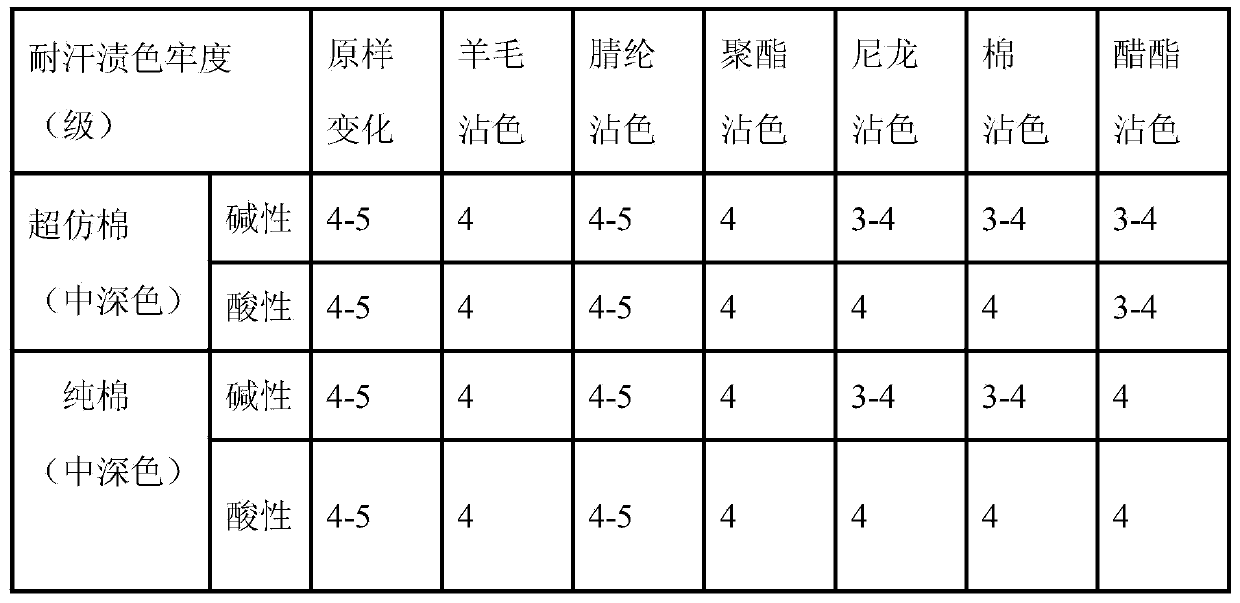

Preparation method of high-imitation cotton printed fabric

InactiveCN103741417AReduce tensionFully swollenSucessive textile treatmentsWoven fabricsPolyesterYarn

The invention discloses a preparation method of a high-imitation cotton printed fabric. The preparation method comprises the following steps: (1) weaving cloth; (2) sizing and oiling; (3) desizing and refining; (4) reducing alkaline amount; (5) shaping; (6) sanding; (7) printing; (8) post-shaping and drying; and (9) absorbing moisture, sweating and finishing. According to the preparation method, superfine denier fiber is used for weaving; warps and wefts adopt high-fischer yarns; compared with normal polyester cotton fabric, the high-imitation cotton printed fabric s better in moisture absorption and air permeability, and smoother in hand feeling; according the preparation method, raw material selection and structure design are used; and the processes of loosing and desizing, shaping, sanding, padding, absorbing moisture, sweating and finishing are used for preparing the high-imitation cotton printed fabric; the preparation method is simple and practical in process and strong in adaptability; the overall process has the characteristics of obviously saving energy and water; test of performances of colour fastness, strength and anti-static property proves that the high-imitation cotton printed fabric completely achieves the effect of the cotton.

Owner:浙江弘晨印染科技股份有限公司

Protein cellulose viscose and preparing method thereof

ActiveCN101298708AGood protein contentImprove spinnabilityConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentSpinningPROTEIN S HEERLEN

The invention relates to a protein viscose fiber and a preparation method thereof, belonging to the textile field and aiming at solving a technical problem about how to provide a method for adopting different animal and plant proteins as materials to prepare the protein viscose fiber. The preparation method of the protein viscose fiber includes the following steps: 1. the animal and plant proteins are degreased, decolored and deodorized to obtain animal-plant protein powder; 2. alkalization: the animal-plant protein powder is dissolved in alkaline liquor to obtain protein alkaline solution; 3. cross-linker is added into the protein alkaline solution to obtain a protein spinning liquor; 4. the protein spinning liquor is blended with a glue to be spun to obtainprotein filaments; 5. the protein filaments are washed by peroxide solution and are oiled, dried and formed into cylinder form to get the protein viscose fiber. The protein viscose fiber preparation method of the invention does not adopt any acetalation treatments to the protein filaments after spinning so as to avoid the remaining of methanal, etc. harmful matters, the technique steps are simple and can be easily operated and the manufacturing can be realized with the existing viscose fiber preparation equipment.

Owner:YIBIN GRACE GROUP CO LTD

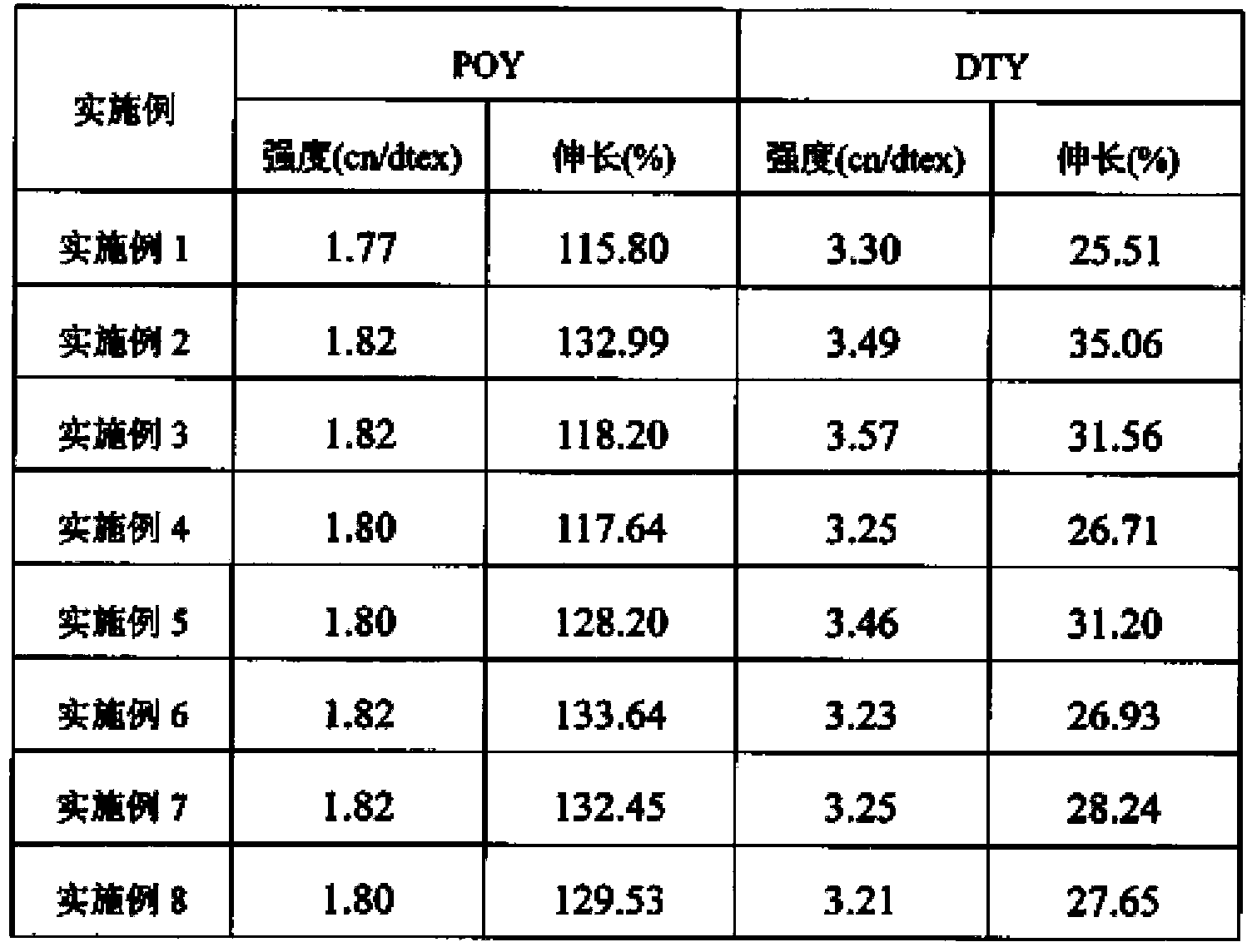

Method for producing terylene fibre with pearly lustre

InactiveCN101381903AImprove performanceAdd lessFilament/thread formingPigment addition to spinning solutionPolyesterLight extinction

The invention relates to a method for preparing polyester fibers with pearly luster. The method comprises the following steps: (1) pearlescent pigment agglomerate and full-dull PET fiber forming resin slice are blended according to the weight ratio of 5-20 to 80-95; and after drying, the water content is less than 100PPM, and the slice is delivered to a feeding port of an extruder and enters an screw extruder for heat fusing and compression; (2) the temperature is controlled to between 290 and 305 DEG C, fusant extruded out by the rotary screw rod enters a metering pump through a distributing pipe and a static mixer, delivered to a spinning component, filtered by a sea sand layer and pressed into a spinning plate to form fusant current which is cooed to form in a spinning cabinet, and the surface of a filament bundle is covered by a spinning finish; and 3. the spinning speed pre-extension is between 2, 500 and 3, 500m / min, the winding carry rate is between 5 and 15 percent for wind-forming, and the full-dull pearlescent polyester fiber POY is obtained. The manufacturing process is easily realized, and is convenient to improve the pearlescent fiber spinning effect and simultaneously provides the fibers with light extinction performance, and the pearlescent pigment has excellent performance and little feed rate.

Owner:DONGHUA UNIV

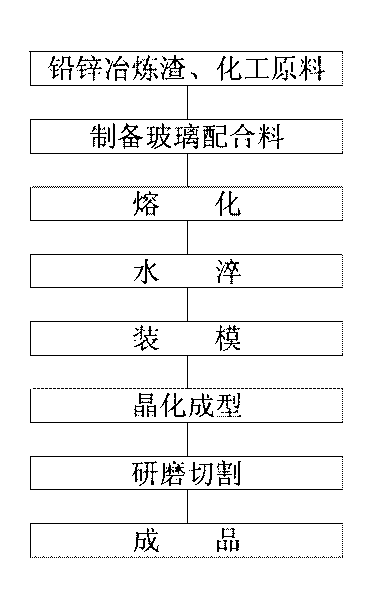

Method for preparing jade type microcrystalline glass with high-temperature furnace slag

The invention discloses a method for preparing jade type microcrystalline glass with high-temperature furnace slag, which comprises the steps of: taking molten furnace slag as main materials; adding auxiliary materials such as fluxing clarifying agent and additive, and the like; further melting and clarifying in a high-temperature furnace to form glass liquid; pouring or calendaring the glass liquid to form basic glass; heat processing the basic glass by means of crystallization to obtain the rough product of the jade type microcrystalline glass; and finish machining to obtain the finished product of the jade type microcrystalline glass. The method not only effectively utilizes the molten high-temperature furnace slag, but also sufficiently utilizes heat energy stored in the high-temperature furnace slag, and prevents the high-temperature furnace slag from generating huge amounts of corrosive hot steam in the process of discharging. The jade type microcrystalline glass prepared by the method is in the status of semitransparent wax, exactly looks like natural jade, has good cutting performance, high intensity and good tenacity, can be used for replacing natural stones in construction industry, and can be used for replacing natural rare jades in machining artware.

Owner:TSINGHUA UNIV

Wax-containing composition for leather and its product surface coating

ActiveCN1611560AGood miscibilityHigh affinityLiquid surface applicatorsCoatingsSolubilityCarbon chain

The invention relates to a kind of waxy combination for surface coating of leather and its products, which is mainly composed with wax, high molecular polymer cream, long carbon-chain fatty alcohol, fatty amide, surface-active agent, and water, but its components doesn't contain organic solvent, water solubility organic alcohol, and mineral oil. Use fatty amide as cosolvent of coating combination system; fatty amide has fine intersolubility with wax, fatty alcohol, high molecular polymer, and other solid constituents; so it can improve stability of coating combination system, can guarantee continuation and compactness of coating film, and also can avoid the disadvantages of containing mineral oil and low molecular water solubility alcohol in the components. When using for surface coating of leather and its products, it has natural gloss, excellent abilities of water-resistant, antidusting, drying proof, and wet proof, and fine frictional property. So it has convenient usage that is safe, and can decline pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

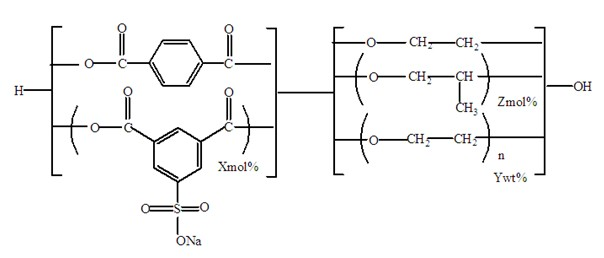

Copolyester section or fiber and preparation method thereof

InactiveCN101357981ASoft touchSoft lusterMonocomponent copolyesters artificial filamentMelt spinning methodsFiberAlcohol

The invention relates to copolyester sheets or a copolyester fiber, which comprises terephthalic acid, m-phthalic acid, glycol and 2-methyl-1, 3-propanediol; the mol ratio of dibasic acids to diatomic alcohols is 1 to 1.7-2.4. The preparation method of the copolyester sheet or fiber comprises the following steps: (1) the terephthalic acid, the m-phthalic acid, the glycol and the 2-methyl-1,3-propanediol are mixed for esterification for 1 to 5 hours together with a catalyzer and a heat stabilizer at 220 to 275 DEG C under the pressure of zero to 0.5MPa; (2) pre-polycondensation follows; the pressure is reduced and the temperature is raised to complete polycondensation, thus getting the copolyester sheets; the copolyester sheets are dried in vacuum, thus getting dry copolyester sheets capable of spinning; and the dry copolyester sheets are spun to get the copolyester fiber. The dyeing behaviour of the copolyester fiber is improved; and the copolyester fiber has the characteristics of resisting roughing and pilling and high contractibility. The preparation method is designed rationally and can be industrialized easily, which is safe for the environment.

Owner:DONGHUA UNIV

Compound protein fiber and preparation method thereof

ActiveCN102174720ASoft touchSoft lusterConjugated cellulose/protein artificial filamentsWet spinning methodsMoisture absorptionPVA - Polyvinyl alcohol

The invention relates to a compound protein fiber and a preparation method thereof. The compound protein fiber comprises the following components in percentage by mass: 10 to 45 percent of collagen, 10 to 45 percent of soybean protein and 10 to 80 percent of polyvinyl alcohol. The preparation method of the compound protein fiber comprises the following steps of: dissolving the collagen and the soybean protein in water, adding the polyvinyl alcohol, dissolving, and performing copolymerization modification to obtain spinning solution; and performing processes such as wet spinning, solidification molding, acetalation treatment and the like to obtain the compound protein fiber. The invention has the characteristics that: the compound protein fiber which has a high mechanical property, a high moisture absorption property, high air permeability, a high dyeing property, smooth handfeel, soft luster, skin intimate performance and health-care performance and is comfortably worn is manufactured by performing blending and copolymerization modification on the polyvinyl alcohol by using the collagen and the soybean protein; and the collagen and the soybean protein have wide raw material resources and low prices, a manufacturing process is relatively simple, and production cost is reduced.

Owner:SHANGHAI QUANYU BIO TECH SUIPING

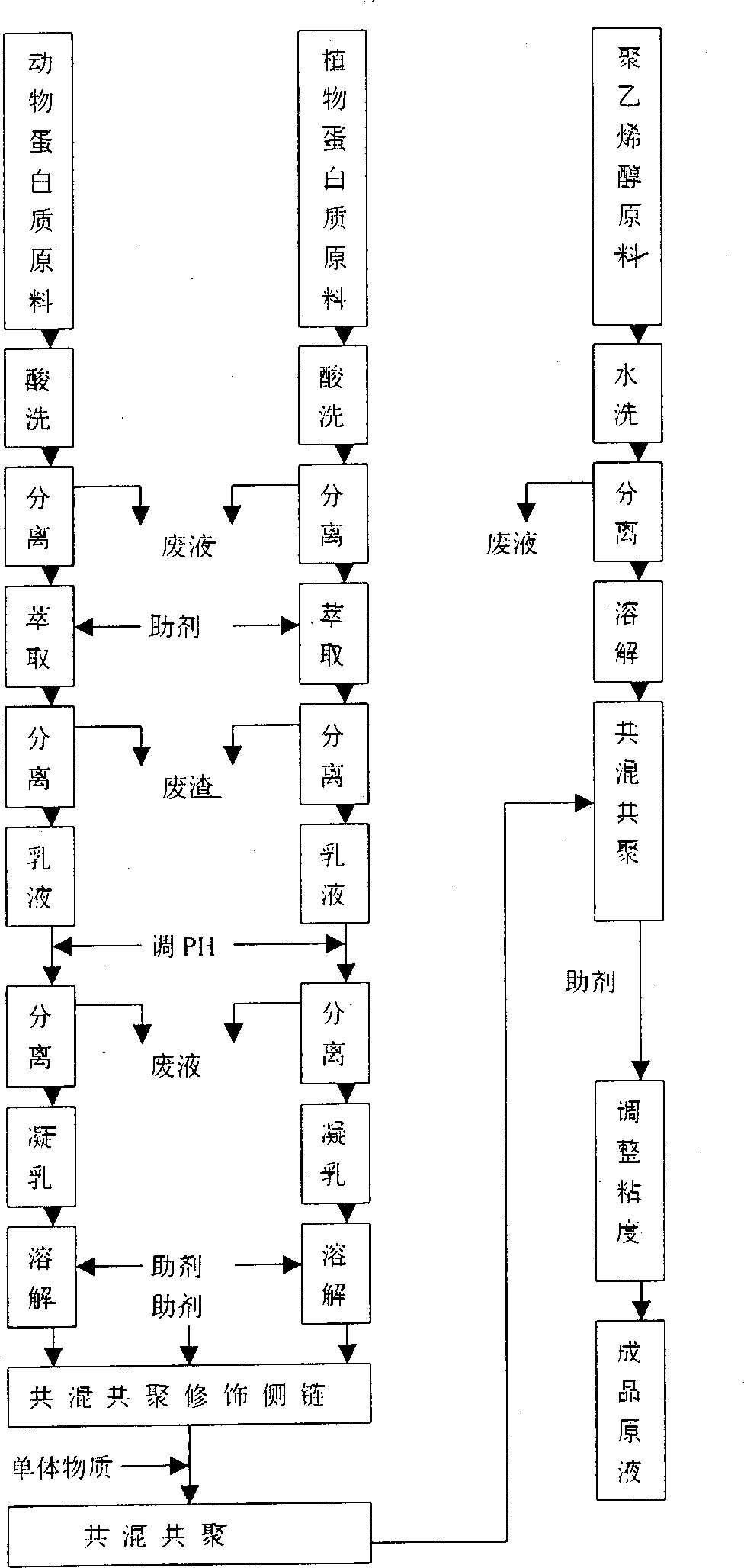

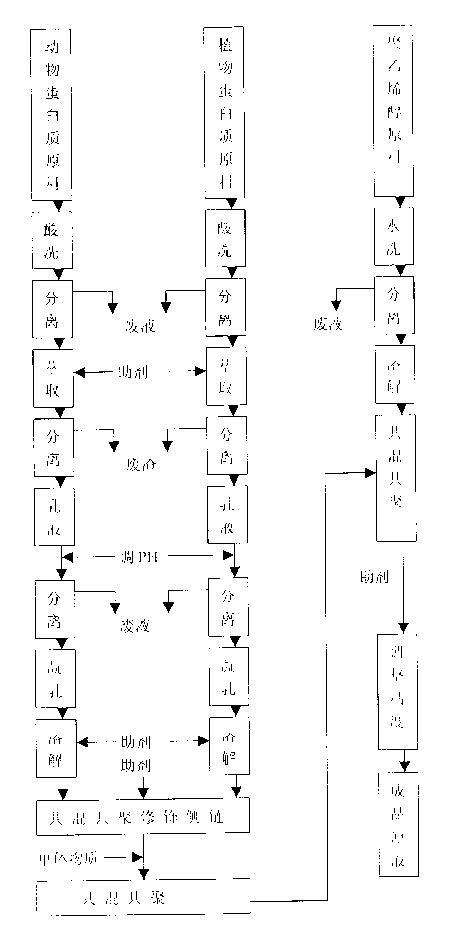

Protein synthetic fibre spinning solution and its producing method

InactiveCN1364948ASkin-friendlyBreathableConjugated cellulose/protein artificial filamentsPolymer scienceAmino acid side chain

The protein fiber spinning solution is produced by using animal and plant material and through the processes of acid pickling, extraction, pH regulation to obtain protein curd, dissolving with cosolvent to form water solution, mixing, modifying side chain of amino acid with modifying agent, copolymerization with coloring monomer, mixing with PVA water solution and addition crosslinking agent to regualte viscosity. It may be used in spinning fiber with the same strengt has chemical fiber, the skin friendship, air penetrability and hygroscopicity the same as natural protein fiber, and improved hot water resistance, shrinkage and color.

Owner:卓宝松 +1

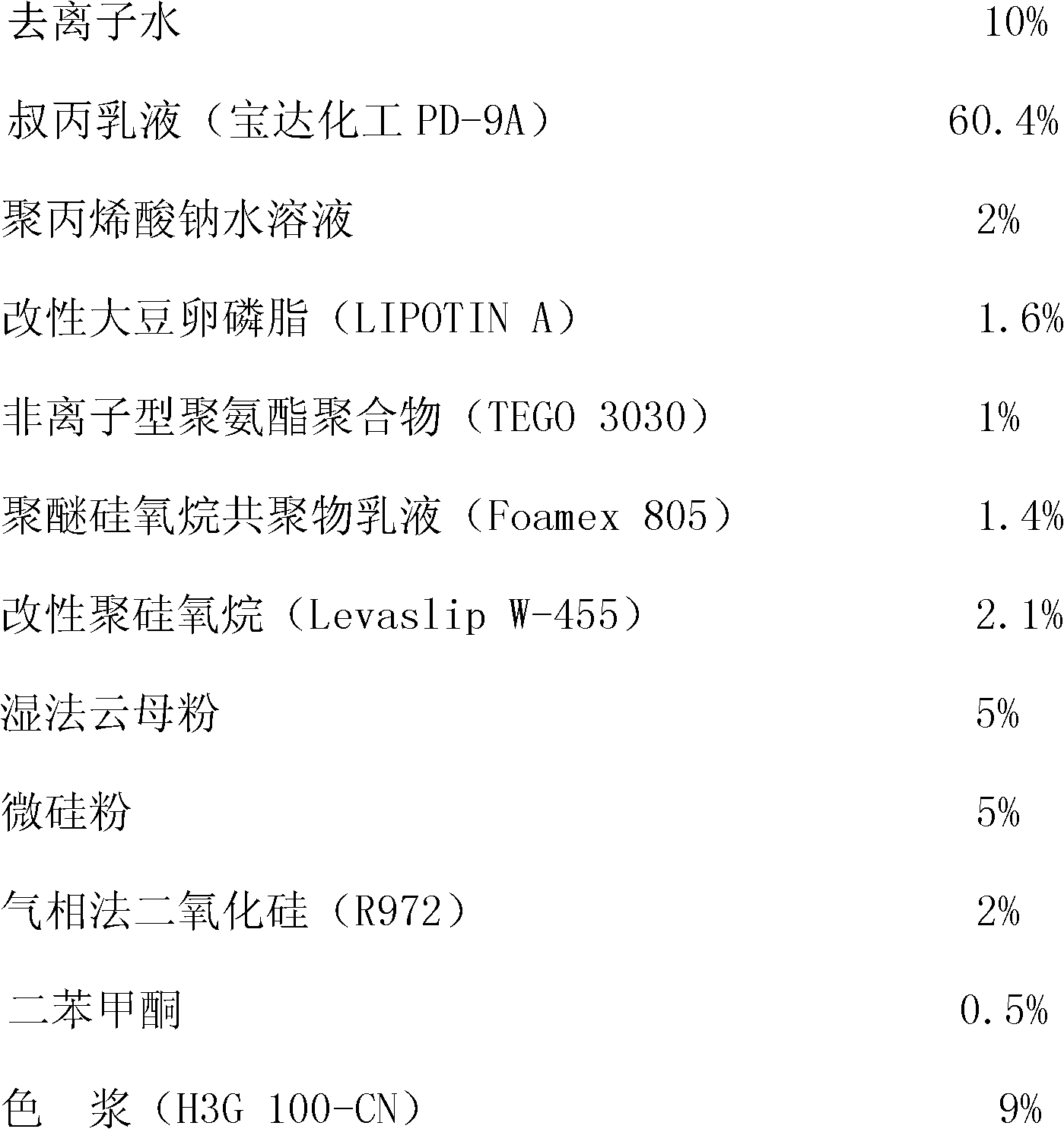

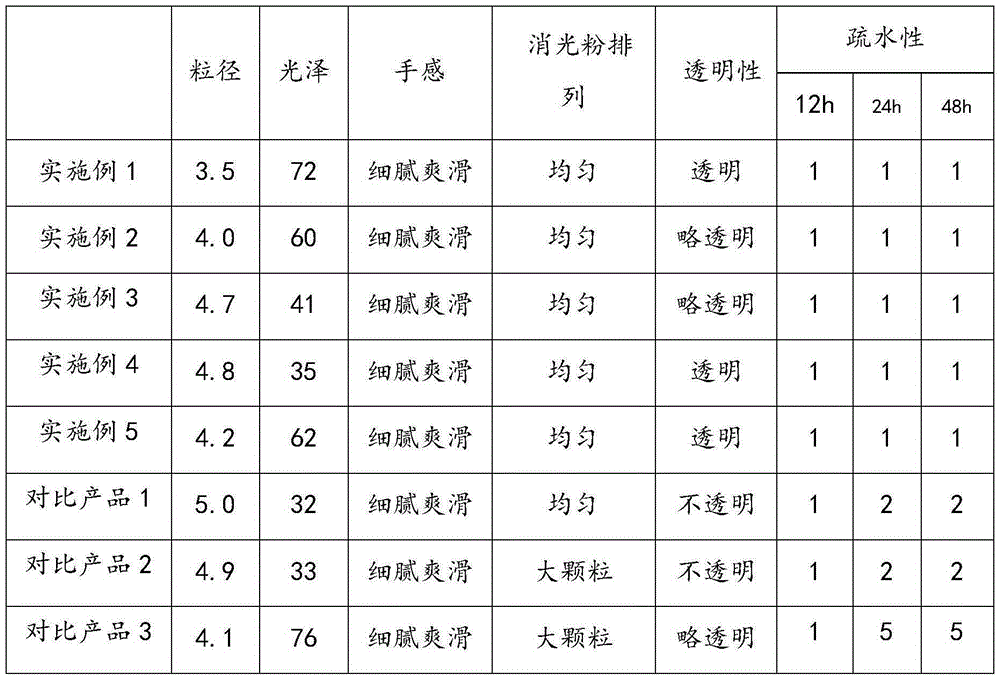

Aqueous flexible plate printing ink and preparation thereof

InactiveCN101328329AReduce pollutionFine inkInksOther printing apparatusSolubilityAtmospheric contamination

A water-basedsoft printing ink comprises the following compositions: 30 to 35 percent of pigment, 25 to 32 percent of acrylic resin, 0.2 to 0.5 percent of antifoaming agent, 2 to 5 percent of ethylene glycol monomethyl ether, 1.0 to 2.5 percent of wax slurry, 0.9 to 1.5 percent of leveling agent, and 23 to 30 percent of water. A preparation method comprises the three working procedures of colored slurry grinding, aquosity treatment and printing ink preparation in turn. The water-basedsoft printing ink has novel compositions, scientific blending, simple preparation, lower cost, fine ink quality, mellow brightness, high color saturation, brilliant color, high drying speed, grid point superimposition and overprinting, good water solubility, easy cleaning, corrosiveness free on printing rollers, low viscosity, high color content, good penetrability and printing adaptability, suitability for multicolor machine high-speed printing, high abrasion resistance, difficult decolorization, wide color range, closeness to a normal color sample, and consistency to the requirements on top-grade printing; and the printing ink also meets EU ROHS standards, and facilitates safe production and environmental protection with low air pollution and without any noxious solvent residual.

Owner:广东佳景科技股份有限公司

Preparation method of easily dyed polyester fiber with high hydrophilicity

ActiveCN103789865AAdequate responseReduce wasteArtificial filament heat treatmentMonocomponent copolyesters artificial filamentPolymer sciencePolyethylene glycol

The invention relates to a preparation method of an easily dyed polyester fiber with high hydrophilicity. The preparation method comprises the following steps: performing esterification by stages, wherein dihydric alcohols, polyhydric alcohols and polyethylene glycol macromolecules are mixed according to a certain mole ratio, in the first esterification stage, acid is slightly excess to ensure that parts with low capability of participating in esterification reaction in the polyhydric alcohols fully react and are grafted into polyester molecular chains, and in the second esterification stage, the dihydric alcohols are replenished to control the terminal carboxyl group of copolyester; and then performing condensation polymerization to prepare the easily dyed polyester with high hydrophilicity. The preparation method has the advantages that the easily dyed polyester fiber with high hydrophilicity is finally prepared by carrying out melt spinning on easily dyed polyester with high hydrophilicity; polyhydric active sites in the fiber, ether bonds in flexible chain polyethylene glycol and sulfonate groups in binary acid have strong adsorption functions and can endow the fiber with good moisture absorption property and dyeing property; the easily dyed polyester fiber with high hydrophilicity can be widely used for preparing moisture absorbing and sweat releasing antistatic fibers made into fabrics next to the skin; the easily dyed polyester fiber with high hydrophilicity has an obvious modification effect and is especially suitable for the melt direct spinning process.

Owner:JIANGSU DELI CHEM FIBER CO LTD

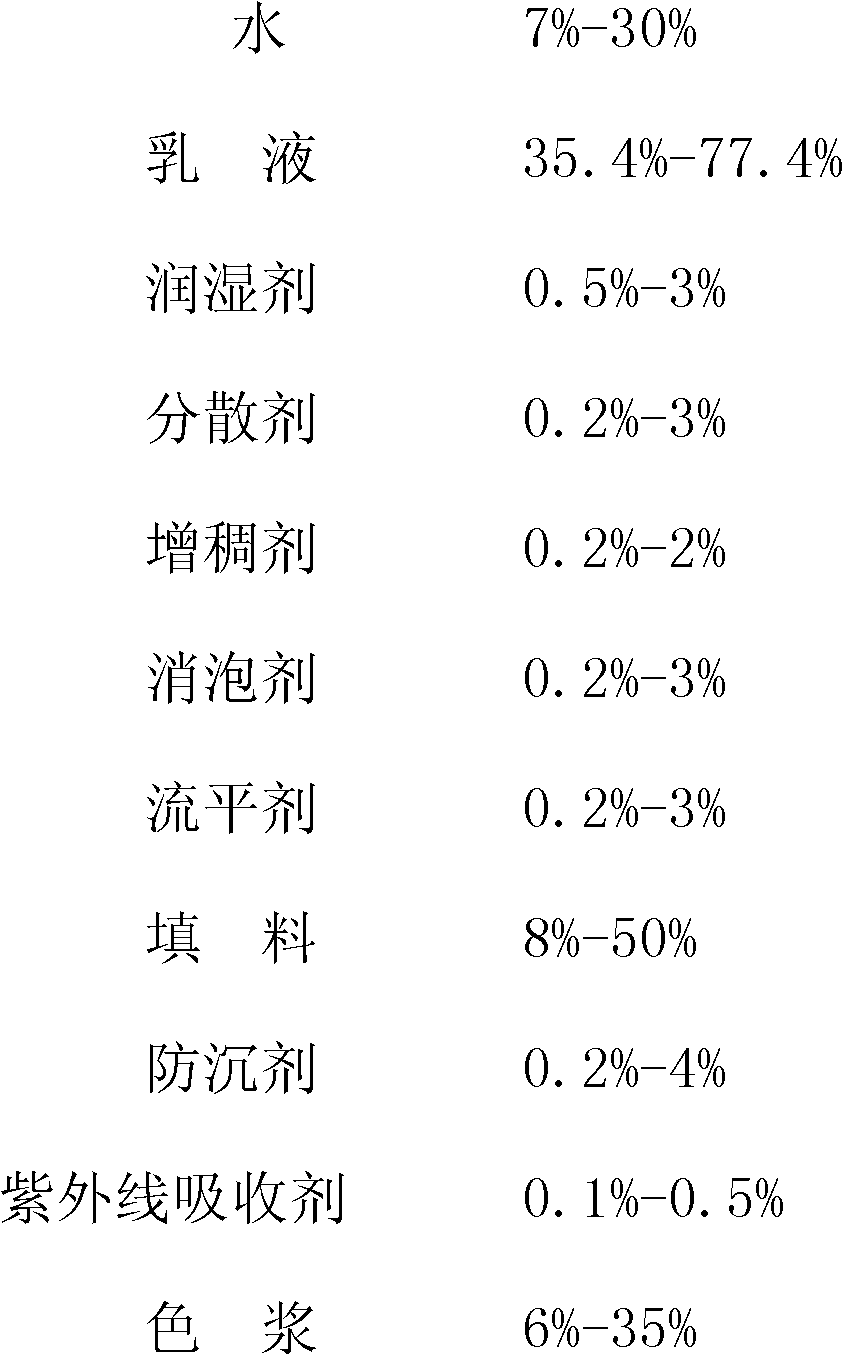

Aqueous environment-friendly anti-aging floor coating and preparation method thereof

InactiveCN102533082AImprove stain resistanceGood alkali resistancePolyurea/polyurethane coatingsEmulsionAging resistance

The invention provides an aqueous environment-friendly anti-aging floor coating and a preparation method of the floor coating. The floor coating comprises components A and B in weight ratio of 4:1, wherein the component A comprises water, modified polyalcohol emulsion, wetting agent, dispersing agent, thickening agent, defoaming agent, flatting agent, filler and anti-settling agent and the component B comprises aqueous curing agent and drier. The preparation method of the invention comprises the steps of putting water, the thickening agent, the wetting agent, the dispersing agent, the defoaming agent and the filler in a dispersing vat to disperse at a high speed, adding the emulsion, a color paste, the anti-settling agent, an ultraviolet absorbent and the flatting agent, uniformly mixing and packaging to obtain the component A; and putting the aqueous curing agent and the drier in the dispersing vat to disperse for 10-20min, uniformly mixing and packaging to obtain the component B. The floor coating of the invention has the advantages of environmental friendliness, soft gloss, wear and shock resistance, simpleness and convenience for construction, ultraviolet and aging resistance, long service life and suitability of being used indoors and outdoors.

Owner:武汉菲凡士建材有限公司

Preparation method of modified silicon dioxide obtained via super-hydrophobic modification

ActiveCN105400239AReduce post-processing stepsReduce energy consumptionCoatingsPigment treatment with macromolecular organic compoundsAcetic acidMixed states

The invention discloses a preparation method of modified silicon dioxide obtained via super-hydrophobic modification. The preparation method comprises following steps: 1) a raw material A (a silicon dioxide base material, dry powder) is delivered into a mixer, a mixed state is maintained, a raw material C (a super-hydrophobic modification accessory ingredient prepared via mixing of 1.5% acetic acid aqueous solution and isopropanol at a mass ratio of 1-3:4-10) is atomized, and is sprayed into the mixed uniformly, and stirring is kept; 2) a raw material B (a hydrophobic modification agent organic silane coupling agent) is atomized, and is sprayed into the mixer uniformly, and stirring is kept; 3) aging is carried out; and 4) ultrafine grinding is carried out so as to obtain a finished product. Fewer processing steps are needed; energy consumption is low; requirements of industrialized large-scale production can be satisfied; particle size distribution of the modified silicon dioxide obtained via super-hydrophobic modification is uniform; pore structures are stable; and hydrophobic performance is stable. The prepared super-hydrophobic silicon dioxide prepared via the preparation method is taken as a flatting agent, and can be used for providing paint with super hydrophobic performance; film forming coating particle arrangement is uniform; and luster is soft.

Owner:北京航天赛德科技发展有限公司

Method for preparing cotton-like fabric through alkali decrement

InactiveCN102433729AThe texture of the cloth surface is dense and smoothSofter and fluffier than ultra cottonFibre typesFiberThermal insulation

The invention discloses a method for preparing cotton-like fabric through alkali decrement. The method comprises the steps of: a. first conducting unwinding treatment to polyester grey fabric, then carrying out sanding treatment; b. performing high temperature alkali decrement treatment in a high-temperature high-pressure overflow dyeing machine; c. dyeing and bleaching the treated fabric; d. carrying out shaping treatment to the dyed fabric for stabilizing the dimension; e. examining and packing a finished product. The high temperature alkali decrement technology consists of: with 10-15g / L of sodium hydroxide and 1g / L of a detergent, controlling the bath ratio at 1:15, first raising the temperature to 120-130DEG C at a speed of 2-5DEG C / min, conducting thermal insulation for 20-30min, then lowering the temperature to 50-80DEG C at a speed of 2-4DEG C / min, carrying out thermal insulation for 30-60min, and then lowering the temperature to normal temperature at a speed of 0.5-2.5DEG C / min. The fabric prepared by the method of the invention has the advantages that: 1. the fabric surface has dense and flat lines, the handfeel is soft and fluffy and surpasses cotton; 2. fibers have a strong fluffy feel, the luster is gentle, and the fabric surface can generates diffuse reflection to light and has gentle luster; 3. the fabric surface is smooth, has good permeability, and can improve chemical fibers, static resistance and stuffy feeling; the product can compare favorably with cotton fabric in terms of performances, and has lower price.

Owner:潘润华

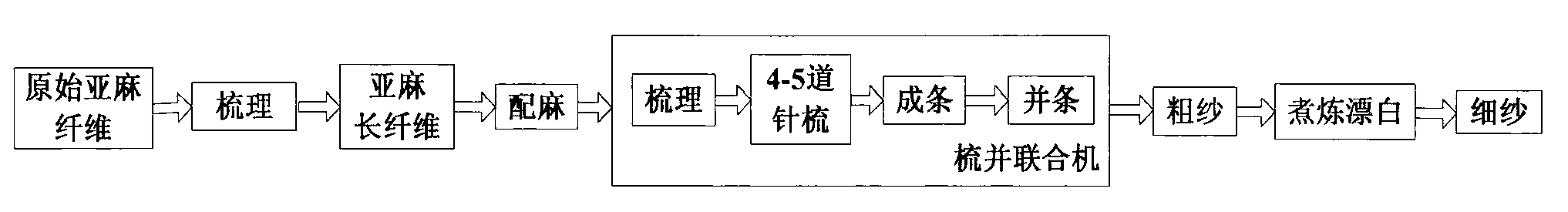

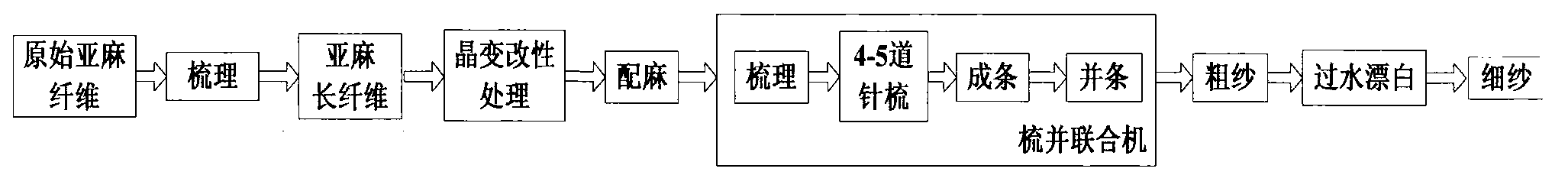

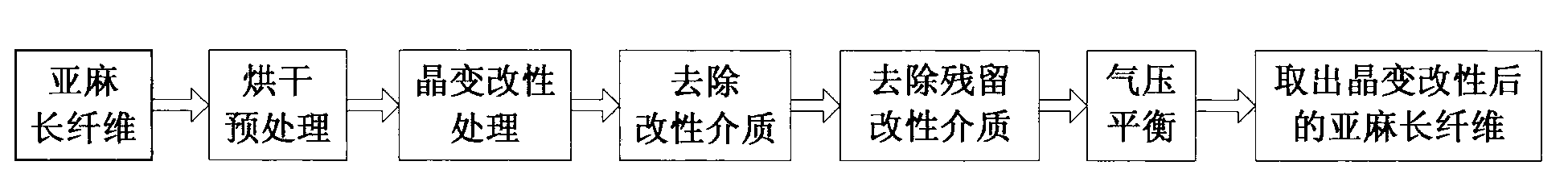

Wet spinning method of low-proportion high-spun flax macrofiber

The invention provides a wet spinning method of low-proportion high-spun flax macrofiber, which comprises the steps of: a first step, combing original flax fiber to obtain flax macrofiber; a third step, carrying out hemp proportioning on the flax macrofiber obtained after crystal transition modification in a former step, gilling, paralleling and spinning by a roving process to obtain flax roving; and a fifth step, carrying out wet spinning on the flax roving obtained after water blanching in a former step by a wet spinning frame to obtain the flax yarn. The wet spinning method is characterized in that a second step of carrying out crystal transition modification treatment on the flax macrofiber is performed between the first step and the third step, and a fourth step of carrying out water blanching on the flax roving is performed between the third step and the fifth step. The method has the advantages that the utilization ratio of the flax macrofiber is greatly improved and reaches more than 70%, and the material resources are saved; high-count linen yarn can be spun according to the fiber proportion of the traditional wet spinning method; and the water blanching replaces the scouring blanching in the traditional wet spinning method, so that the process is simplified, the energy sources are saved and the cost is lowered.

Owner:DONGHUA UNIV +1

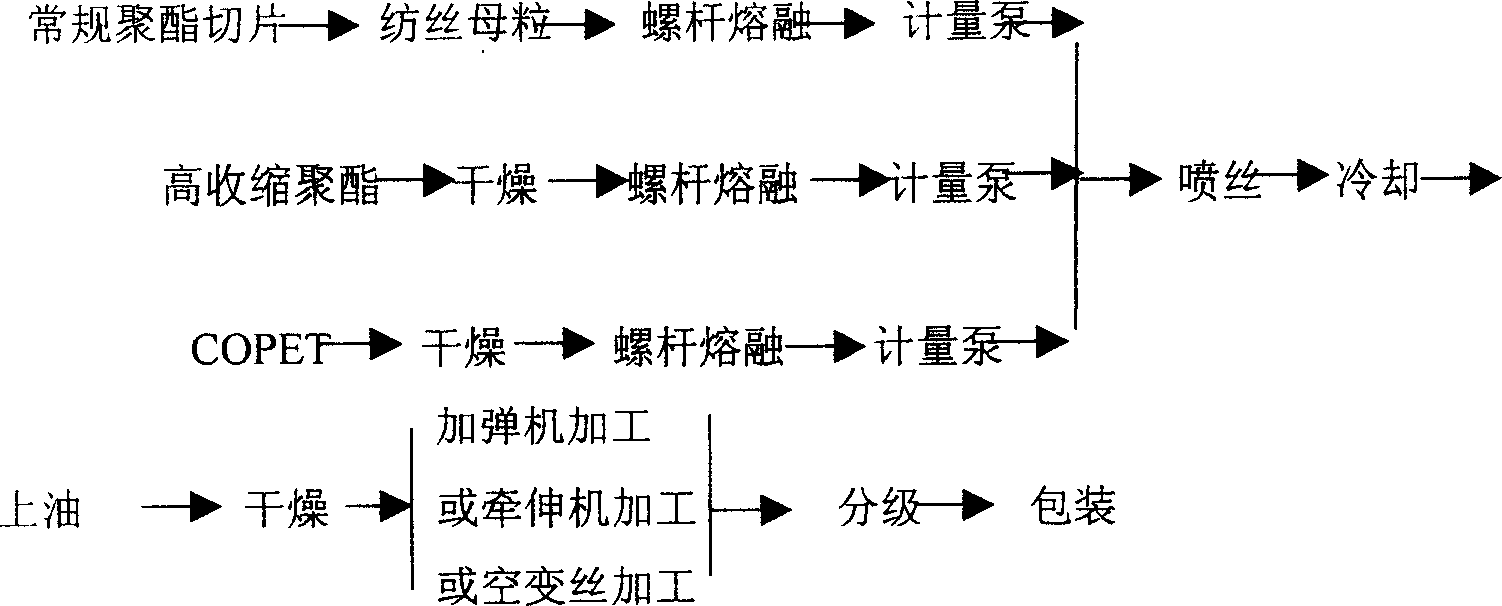

Ultrafine hetero composite elastic fibre and its manufacturing method

InactiveCN1693546ASoft touchComfortable to wearMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterTextile technology

The invention relates to a superfine hetero composite elasticized fiber and its manufacturing method, special spinning equipment, spinning art and the related technique, uses routine polyester slice, highly contractive polyester, and so on as raw materials to prepare spinning solution, makes multicomponent composite spinning on the spinning solution and water soluble polyester, and then elasticizes to make a superfine isomeric composite elasticized fiber finished product, where single silks of the fiber are distributed like an island, and by post processing, the fineness of the fiber is up to 0.01-0.001 dan, and besides, the fiber has the superfine, different-contractive and different section properties. The fabric produced by this fiber has handwriting effect, especially soft handing, and humidity absorbing property up to and even over that of natural fiber, full, comfortable and good-air permeability; and the surface of the fabric has a shine like silk and good dyeing property. This fiber can be widely applied to the industries of machine weaving, knitting, silk manufacturing, etc., to manufacture minic, high grade clothing, blood filtering material, etc.

Owner:JIANGNAN UNIV

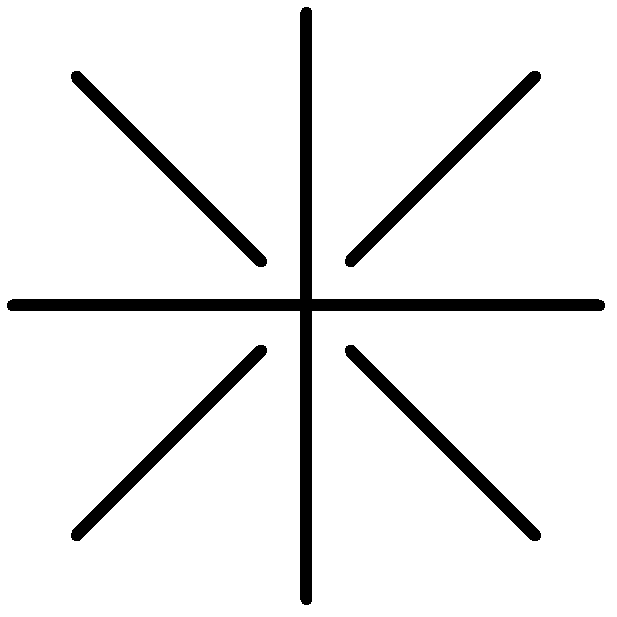

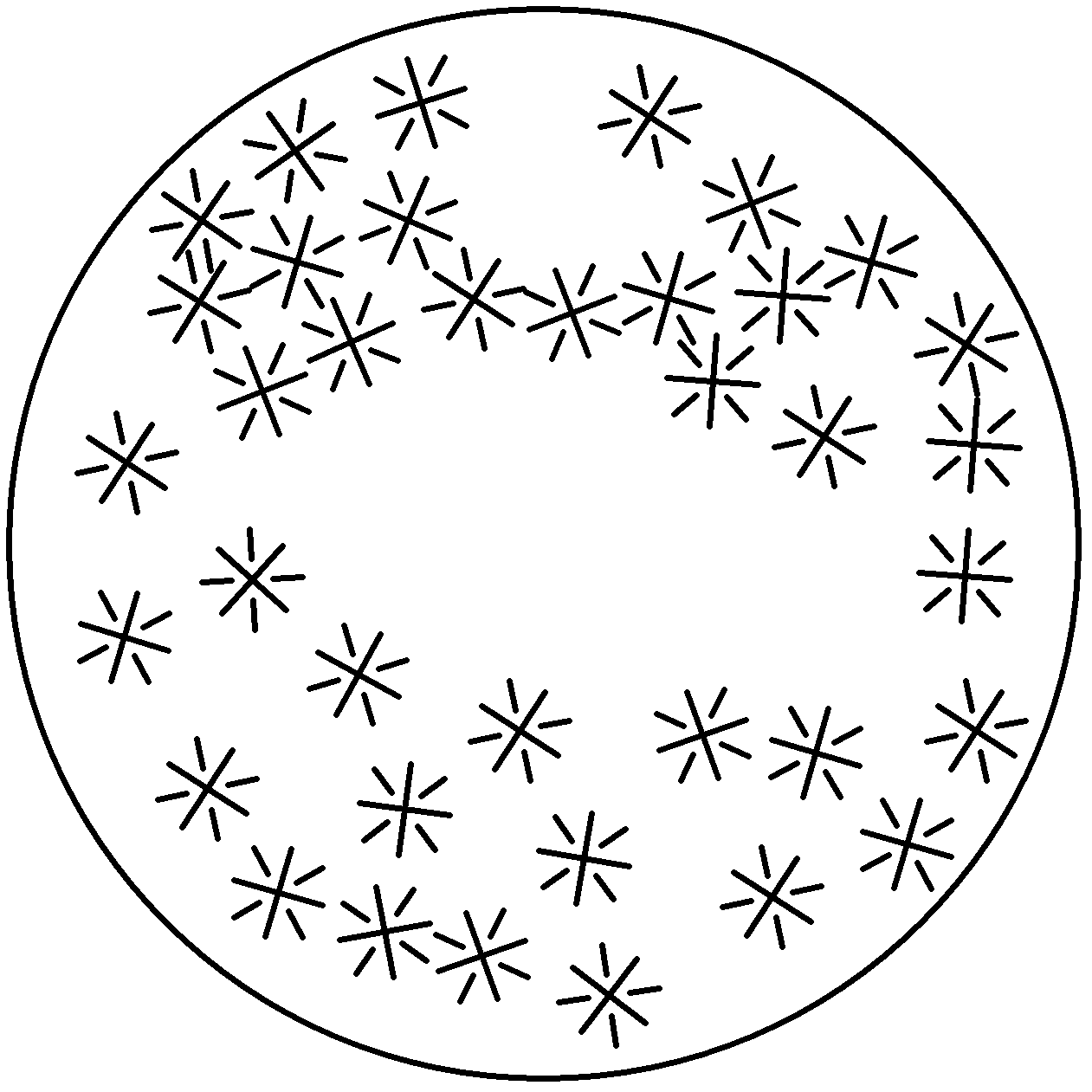

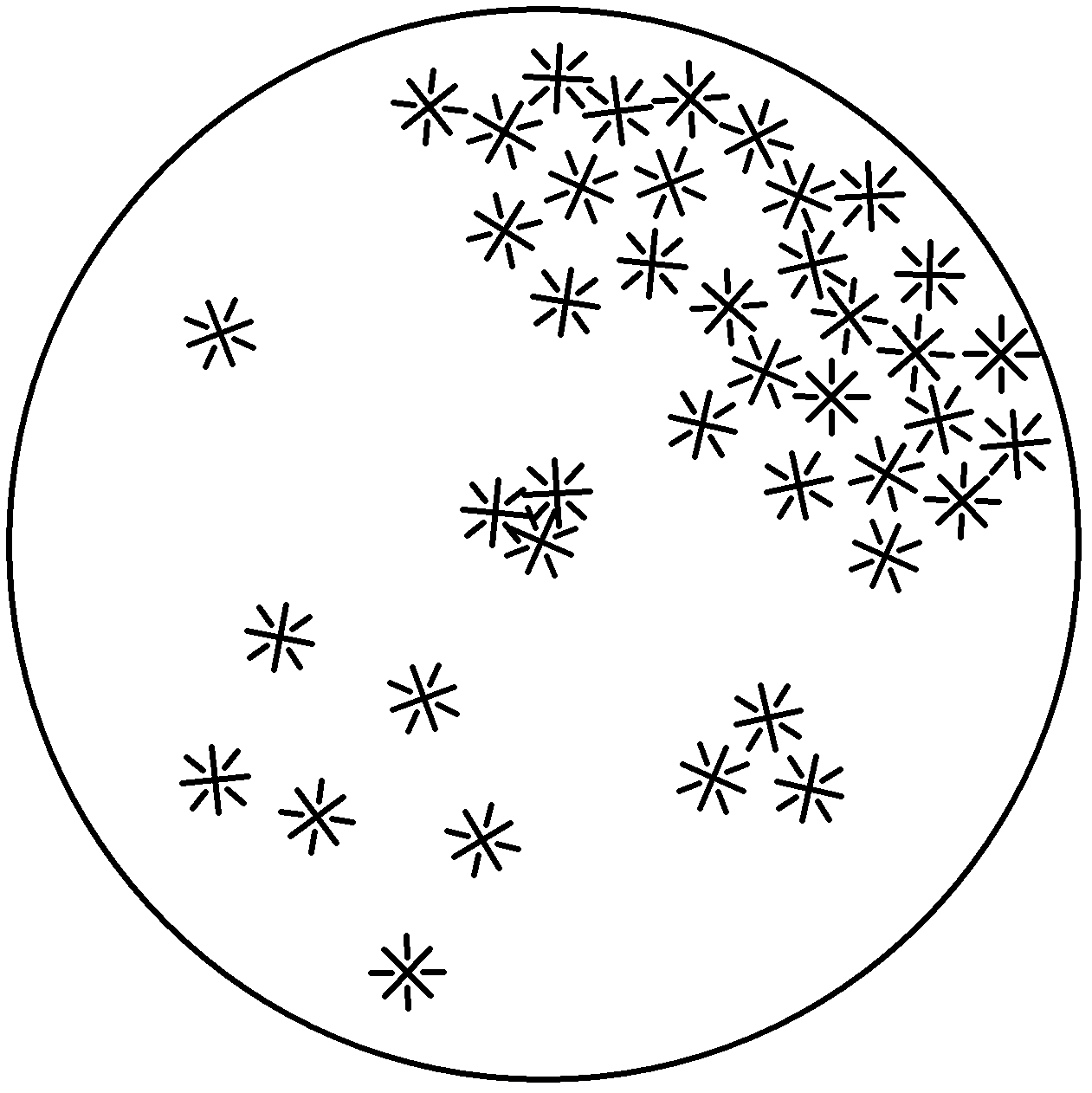

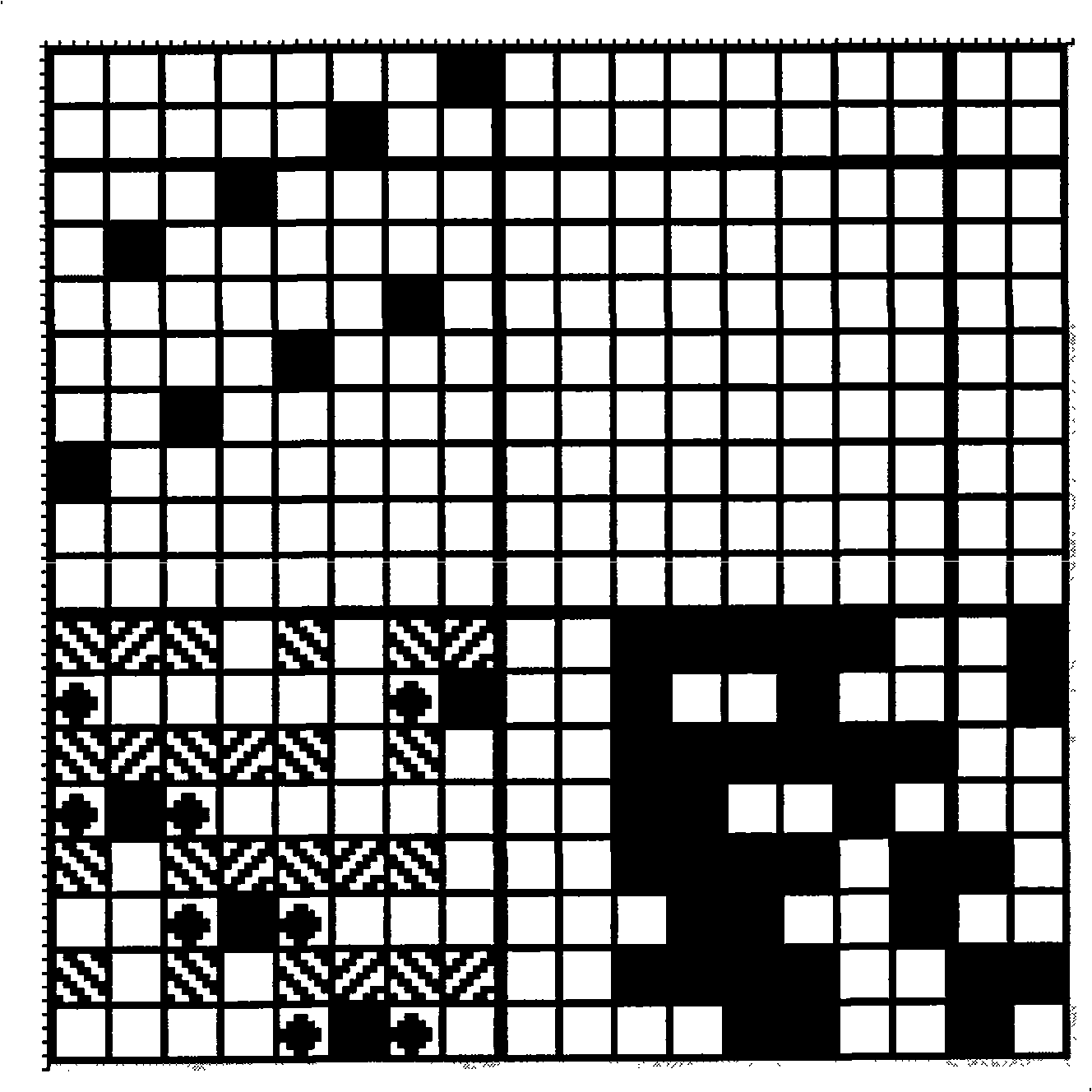

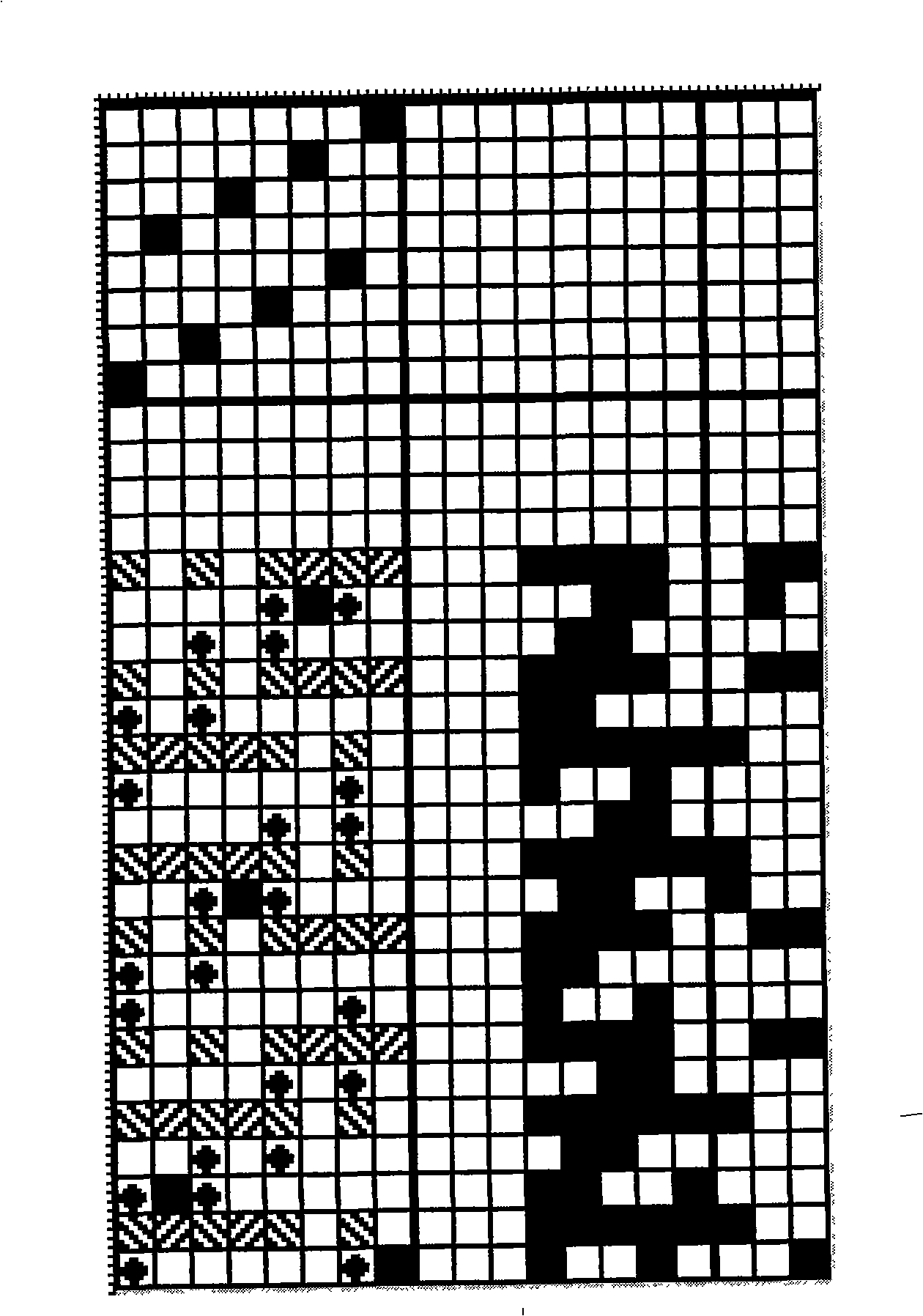

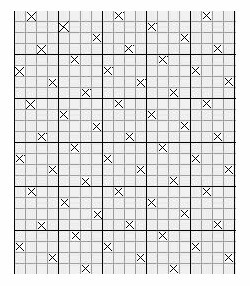

*-shaped knitting method and embroidery method for embroidery

ActiveCN102619039AAvoid concentrated reflectionsSoft lusterEmbroidering machines apparatusYarnEngineering

The invention provides a *-shaped knitting method and embroidery method for embroideries. At least three layers of embroidery stitches overlapped with each other are embroidered at the front face of an embroidered fabric from bottom to top by using embroidery needles and embroider lines layer by layer, wherein each layer of embroidery stitches is formed in such a way that one group of *-shaped units with substantially same stitch lengths are adjacently placed at the front face of the embroidered fabric; with any *-shaped unit as center, the surrounding adjacent *-shaped units in each layer of embroidery stitches rotate at angles on the embroidery face relative to the * shape at the center; the stitch lengths of the *-shaped units in each layer of embroidery stitches are gradually reduced from bottom to top; the *-shaped units are embroidered by using *-shaped knitting method; the knitting method comprises six stitches; and silk yarn embroidery stitches formed on the embroidery fabric by the six stitches are similar to the *-shape. According to the invention, the problem that concentrated light reflection is easy to generate in the embroidery face is solved.

Owner:郁丽勤 +1

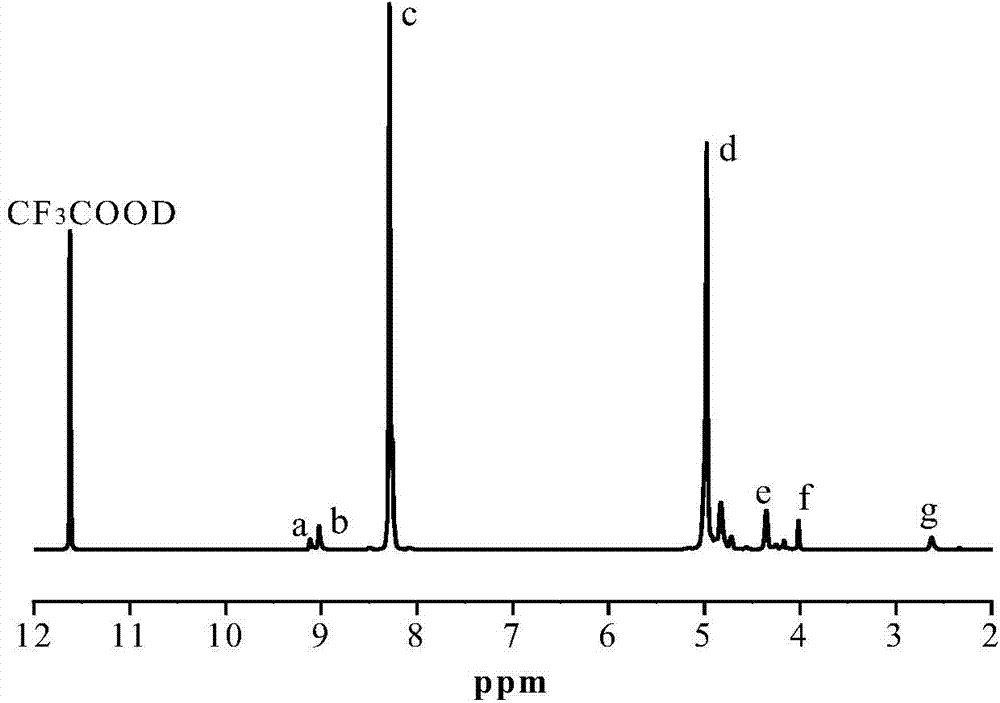

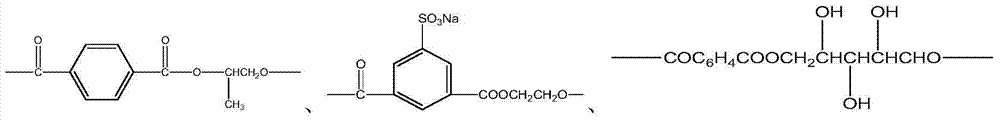

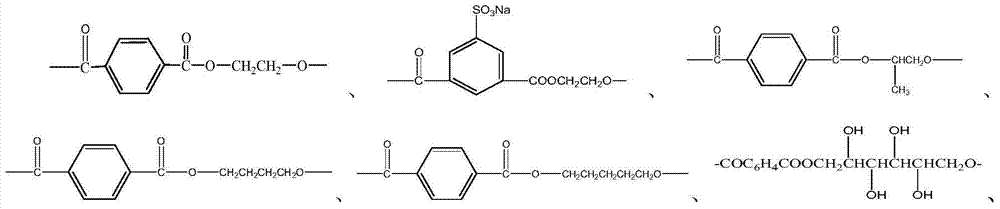

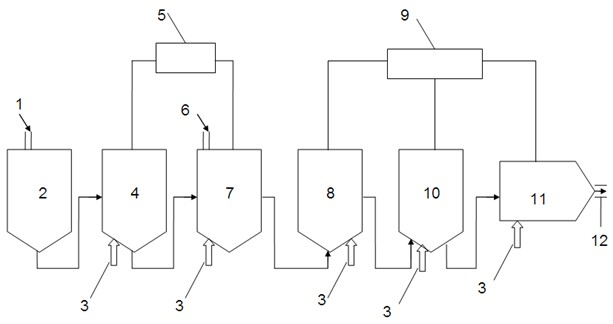

Hydrophilic copolyester slices prepared by continuous method and preparation method thereof

InactiveCN102504224AChange molecular structureImprove hydrophilicityMonocomponent polyesters artificial filamentArtifical filament manufactureCopolyesterDibasic acid

The invention discloses a continuous method for preparing hydrophilic copolyester slices and the hydrophilic copolyester slices prepared by the preparation method. The preparation method of the hydrophilic copolyester slices prepared by the continuous method comprises the following steps: continuously and uniformly adding pure terephthalic acid, ethylene glycol, benzene dibasic acid binary alcohol ester-5-sodium sulfonate, polydibasic alcohol, other dibasic alcohols, a delustering agent and the like into a beating kettle in proportion, performing esterification, prepolycondensation and polycondensation reactions, discharging, pelletizing and drying to get the hydrophilic copolyester slices. A continuous polymerization device is adopted for synthesis; and in the prepared hydrophilic copolyester slices, the molecular structure of polyester is changed by adding hydroxyl-containing components and inorganic powder into copolyester slices, thus the hydrophilic property is good. The preparation method is simple, the manufacturing process has no special requirements on the polymerization device, and the hydrophilic copolyester slices can be produced on existing domestic or imported equipment, so that the production cost is slow and industrial production is easy to realize.

Owner:DONGHUA UNIV

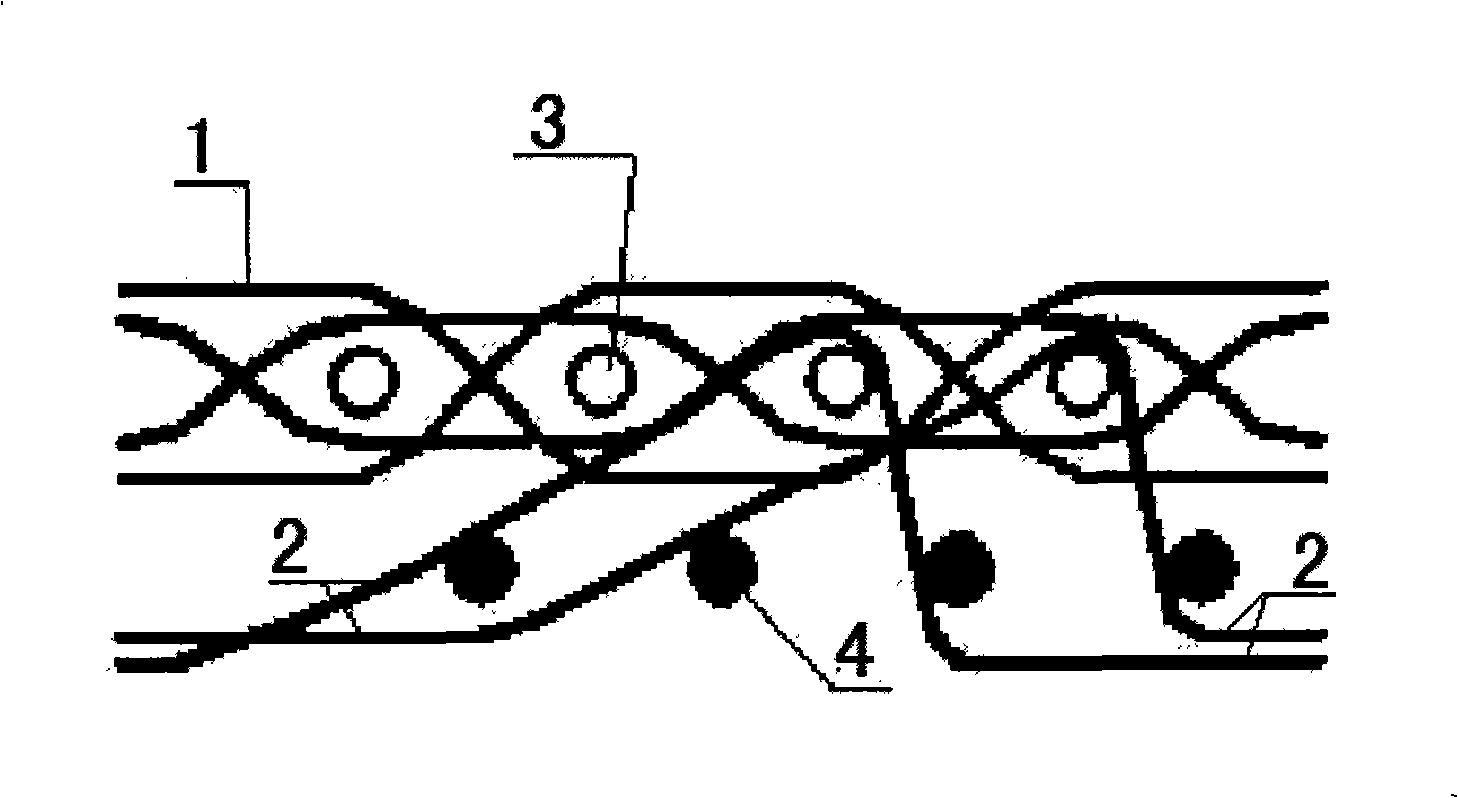

Ramie / terylene double fabric for textile wall cloth and curtain cloth and preparing method thereof

The invention relates to a ramee / terylene double woven fabric used for wall cloth and window blind fabrics, which comprises a surface layer and an inner layer, wherein, the surface layer is weaved by ramee yarns and the inner layer is weaved by terylene yarns, or the surface layer is weaved by terylene yarns and the inner layer is weaved by ramee yarns, and the surface layer and the inner layer are bond into a whole by binding joints which are not exposed on the right side and the reverse side of the fabric. The preparation method of the ramee / terylene double woven fabric adopts the ramee yarns and the terylene yarns as raw materials, and comprises a preparation procedure and a weaving procedure, and the fabric is prepared by adopting a shuttleless loom or loom with shuttles according to selected structure. When weaving by adopting the shuttleless loom, the preparation procedures of the warp comprise the steps of twist setting, winding, warping, warp sizing and warp gaiting, and the preparation procedures of the weft comprise the steps of twist setting and winding; and when weaving by adopting the loom with shuttles, the preparation procedures of the warp comprise the steps of twist setting, winding, warping, warp sizing and warp gaiting, and the preparation procedures of the weft comprise the steps of twist setting, winding and weft winding.

Owner:北京青山绿水苎麻制品有限公司 +1

Production method of full-dull polyester fiber

InactiveCN103451768AAbsolute Addition ReductionIncrease drapeFilament/thread formingMonocomponent polyesters artificial filamentPolyesterMaterials science

The invention provides a production method of a full-dull polyester fiber. According to the production method, common semi-dull polyester chips are taken as a main producing material, and melt spinning is performed by adding full-dull master batch so as to produce the full-dull polyester fiber. A composite spinning component is used in the melt spinning process, correspondingly, the material chips are divided into two or more components, the full-dull master batch is added into one component in the feeding process, and the content of titanium dioxide particles accounts for 1wt%-5wt% of the total weight parts of the fiber.

Owner:SUZHOU LONGJIE SPECIAL FIBER

Production method of cotton polyester interwoven spandex core-spun elastic fabric

InactiveCN103556368ADrop high temperature damageLittle strengthBleaching apparatusDyeing processPolyesterYarn

The invention relates to a production method of textiles, in particular a production method of cotton polyester interwoven spandex core-spun elastic fabric. The cotton polyester interwoven spandex core-spun elastic fabric comprises cotton, polyester and spandex. Sixteen threads of cotton are woven in the warp direction, and 150D low-elasticity interlaced yarn and 70D spandex coated yarn are woven in the weft direction. The dyeing process of the cotton polyester interwoven spandex core-spun elastic fabric sequentially includes the steps of fabric turnover, scouring retreating, single-surface singeing, oxygen bleaching, shaping, mercerizing, double dyeing of pad dyeing and dyeing in the same color and finishing. A scouring and bleaching combined production line is adopted in the steps of scouring retreating and oxygen bleaching, the fabric is subjected to six-latticed countercurrent flattening washing prior to rolling pressure so as to control the moisture content to be 45-55% and subjected to padding in oxygen-bleaching liquid for fabric bleaching; the dyeing process further includes dipping flame-retardant treatment after the finishing process, namely putting the fabric into a vacuum pressure tank to be vacuumized and enabling vacuum degree of the vacuum pressure tank to be from -0.015MPa to -0.025Mpa, and adding a fire retardant into the tank and enabling the pressure to be increased to from 0.1MPa to 0.8Mpa. The fabric is stable in size after being washed, needless of ironing and energy saving in production, and flame-retardant safety is achieved.

Owner:ZHEJIANG DAGANG PRINTING & DYEING

Doping pearlescent pigment and preparation thereof

The invention discloses a doped pearlescent pigment and a preparation method thereof. The pigment uses a glass flake as a substrate; the surface of the glass flake is coated with a SiO2 or SnO2 coating; the surface of the SiO2 or SnO2 coating is coated with a doped metallic oxide coating; the doped metallic oxide coating is a coating of metallic oxide doped with at least one metallic element compound, nonmetallic element compound or the combination of the two. The glass flake after SiO2 or SnO2 coating treatment is directly coated with the doped metallic oxide coating and then calcined once so as to form the doped pearlescent pigment. The invention relates to the pearlescent pigment containing the doped metallic oxide coating. By doping the metallic oxide with different metallic element compounds and / or nonmetallic compounds, the color and glossiness of the doped pigment are adjusted; therefore, both a high-glossiness colorful twinkling effect and a soft-glossiness effect can be obtained. Moreover, the pearlescent pigment has good hiding rate as well.

Owner:SUZHOU TAIZHU TECH DEV

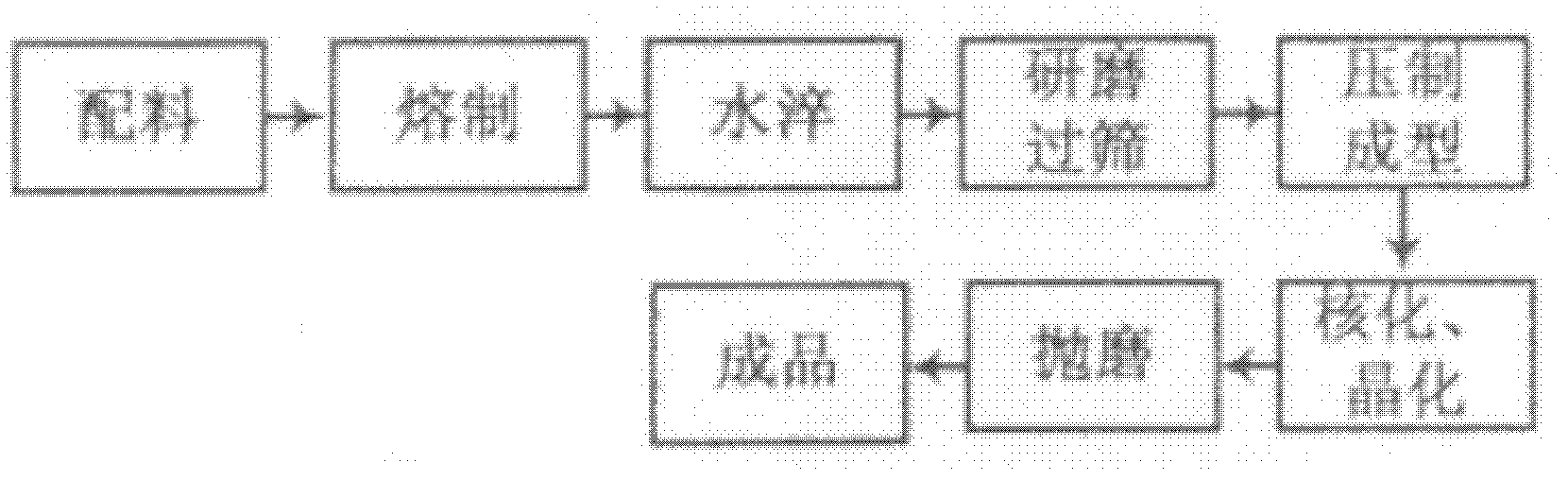

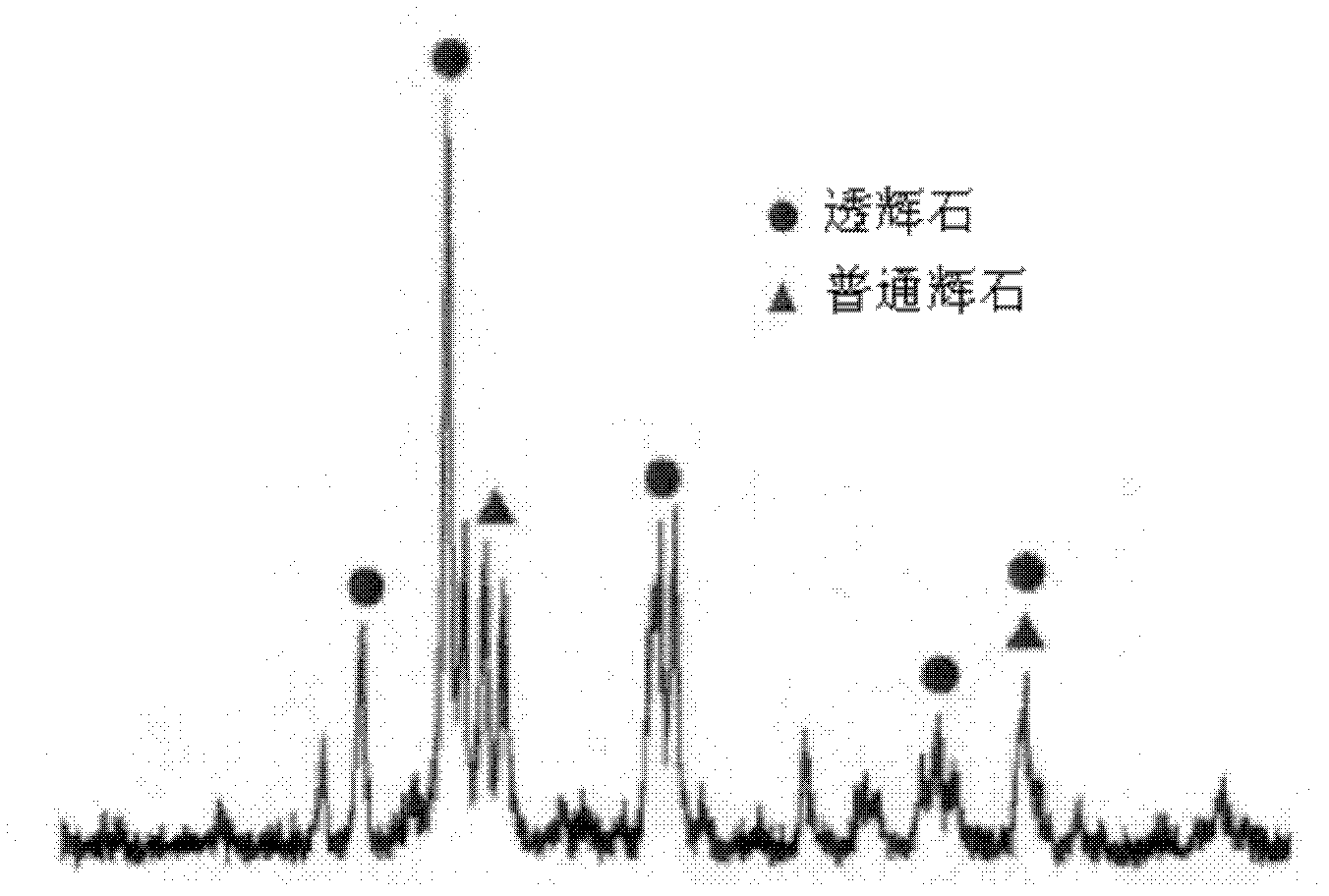

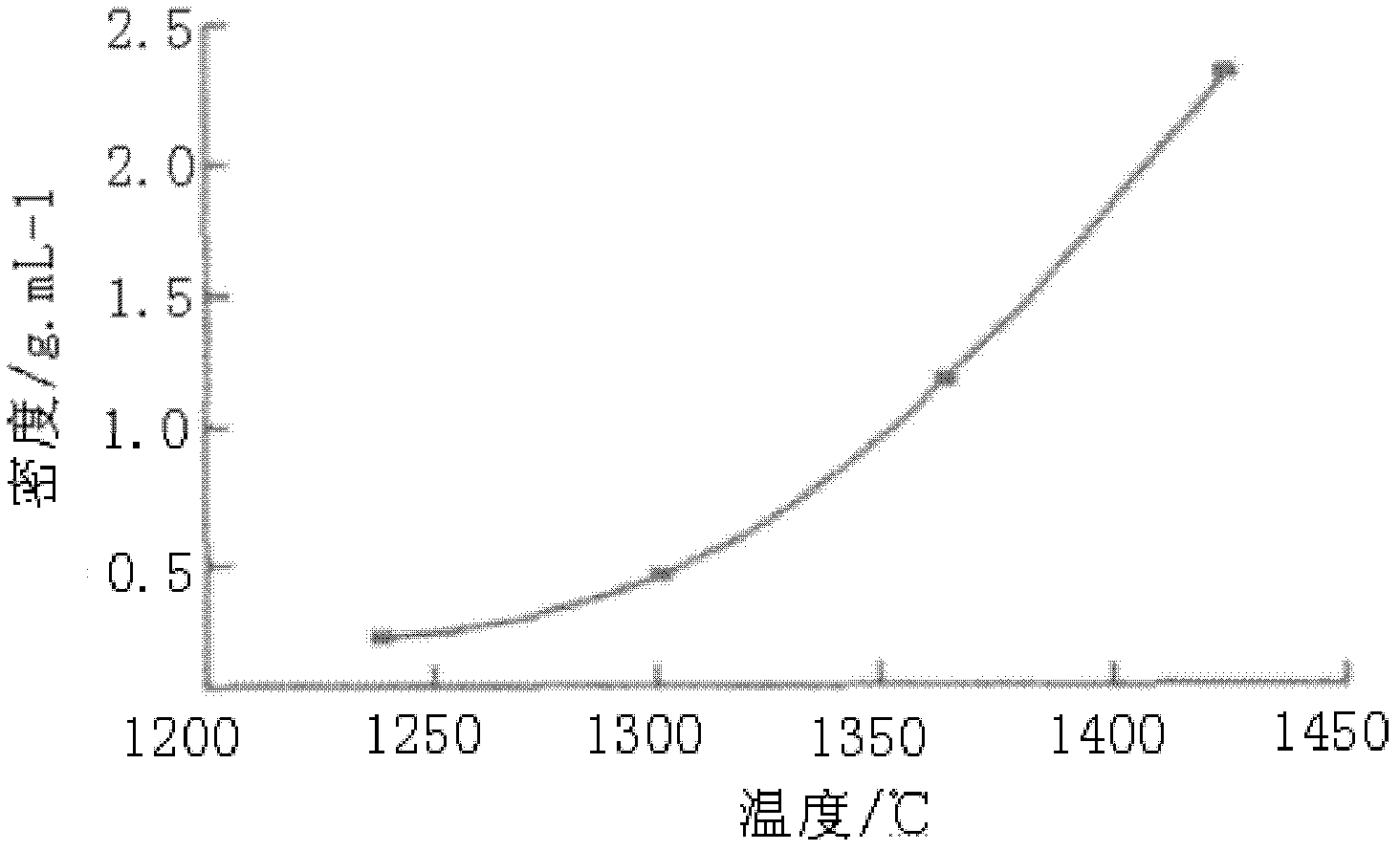

Wear-resistant crystallized glass plate and preparation method thereof

The invention discloses a wear-resistant crystallized glass plate and a preparation method thereof. The wear-resistant crystallized glass plate consists of the following components in parts by weight: 65-85 parts of steel and iron furnace slag, 20-30 parts of quartz sand, 6-10 parts of magnesium oxide, 5-10 parts of titanium dioxide and 1-3 parts of calcium fluoride, wherein the steel and iron furnace slag comprises the following components in percentage by weight: 13-20 percent of SiO2, 10-15 percent of FeO, 40-50 percent of CaO, 5-10 percent of MgO, 2-5 percent of Al2O3, 10-20 percent of TFe, 2-5 percent of MnO2, 0.1-0.5 percent of P2O3 and 0.5-1.5 percent of MFe. The method comprises burdening, melting, water quenching, grinding, sieving, press molding, nucleating, crystallizing and rubbing down, wherein melting is performed at the temperature of 1,380-1,450 DEG C for 1-3 hours; and crystallizing is performed at the temperature of 900-920 DEG C for 1-2 hours. Compared with the prior art, the wear-resistant crystallized glass plate has the advantages of low raw material cost, excellent melting performance, excellent crystallizabitity, high plate hardness, high bending strength, soft and bright surface gloss, denseness, immaculacy and wide product market prospect.

Owner:水经(上海)生物科技有限公司

Artificial hair made from animal protein and process for producing same

InactiveCN1699646AHigh tide rateSpeed up the flowMonocomponent protein artificial filamentWigsCross-linkHair streams

The present invention discloses a kind of artificial hair made of animal protein and its method of production, which essentially consists of blended protein of cross-linking agent and chemical modification, wherein the blended protein of chemical modification is made by taking keratin and albumen protein as the protein materials with its production steps comprising compound of spinning silk original liquid, wet spinning, solidification, de-dissolvent, drawing and chemical cross-linking. The invention has overcome the defects like hard skin and scanty and hollow core existing in the original products of the same and the hair of its product is soft, non-inflammable, and good to the touch with high wet returning rate, gentle luster, long lifespan and low cost.

Owner:POLY WELL NANTONG IND

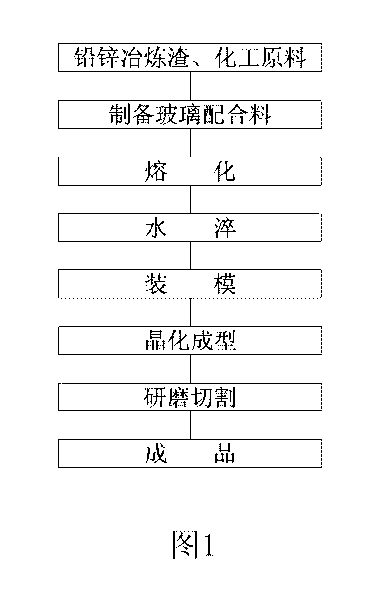

Green glass-ceramic plate made from lead-zinc smelting slag and manufacturing method thereof

The invention relates to a green glass-ceramic plate made from lead-zinc smelting slag and a manufacturing method thereof. The glass raw material is prepared from the following components in parts by weight: 40 to 60 parts of lead-zinc smelting slag, 26 to 38 parts of quartz, 15 to 24 parts of lithium feldspar, 2 to 4 parts of soda ash, 2 to 3 parts of zinc oxide, 2 to 5 parts of barium carbonate, 1 to 3 parts of borax, 2 to 2.5 parts of chromium oxide, 0 to 0.2 part of copper oxide and 0.04 to 0.2 part of carbon powder. The invention is not only in line with the common glass-ceramic produced by completely adopting industrial materials on the aspect of the performance, but also can realize waste utilization, reduce the environmental pollution, the product cost and the melting temperature of glass, improve the melting speed and the melting furnace efficiency of the glass, decrease the energy consumption and can be widely applied to building decoration materials, especially applied in various building decoration engineering, such as inside and outer walls, floors, pillars, table boards of the building, and the like.

Owner:FENGXIAN SANLIAN BUILDING MATERIALS

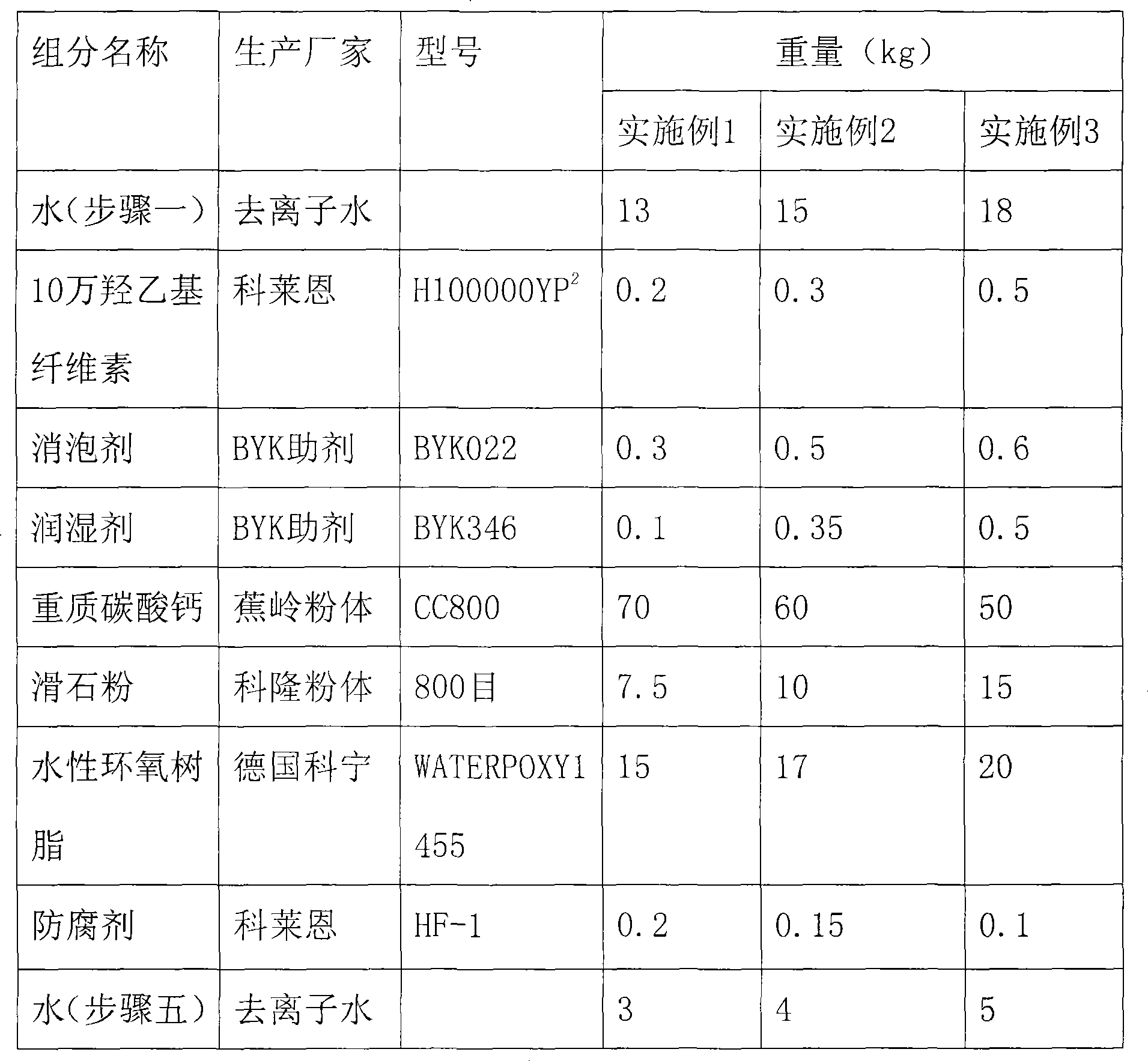

Aqueous epoxy putty, and preparation and use method thereof

The invention relates to an aqueous epoxy putty and a preparation method thereof. The preparation method comprises the following steps: 1. 13 to 18 weight portions of water is added with 0.2 to 0.5 weight portion of thickening agent under the stirring at the speed of 500 to 800 revolutions / minutes, is stirred and is fully dissolved; 2. 0.3 to 0.6 weight portion of a defoaming agent and 0.1 to 0.5 weight portion of wetting agent are sequentially added into the mixture and are evenly stirred; 3. 50 to 70 weight portions of powdered whiting and 7.5 to 15 weight portions of talcum powder are added into the mixture; under the rotational speed of 500 to 800 revolutions / minute, all composition are mixed; and if water is too little to stir the compositions evenly, 3 to 5 weight portions of an aqueous epoxy resin is added into the mixture, is stirred for 5 to 8 minutes till the fineness is between 30 and 40 microns at the rotational speed of 1,200 to1,500 revolutions / minute; 4. at the middle rotational speed, the residual amount of the aqueous epoxy resin is fully replenished to 15 to 20 weight portions totally and is evenly stirred; and 5. the mixture is continuously added with 0.1 to 0.2 weight portion of antiseptic and 3 to 5 weight portions of water, is stirred for 7 to 19 minutes at low speed, and is filtered to obtain the aqueous epoxy putty. According to weight ratio of 6 to 4, an aqueous epoxy curing agent and water are mixed to obtain a special matched curing agent; and according to weight ratio of 20 to 1, the aqueous epoxy putty and the curing agent are mixed for use. The aqueous epoxy putty can solve the problem that oily paint dissolves a polystyrene plate due to the fact that an aqueous epoxy primer is leaked to paint or the thickness of the painted primer does not meet the requirement, and can well decorate and protect a coating layer.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Pure-wool elastic smooth double-side wool and preparation method thereof

The invention relates to a pure-wool elastic smooth double-side wool which is characterized in that the slubbed core yarn of cashmere spandex is taken as abbs, the single yarns of cashmeres are taken as warps, and dual-layer 2 / 1 twill organization is taken as the basic stitch. The weight percentages of the cashmere and the spandex in the abbs are 96.8% and 3.2% respectively; and the cashmere of 15.5 microns and the spandex of 40D are also adopted. In the invention, the double-side wool prepared by the method has the advantages of traditional smooth double-side wool, such as rich hand-feeling, plump and flush floss, and has the downy unique characteristics of the cashmere, such as soft luster, excellent overhanging performance, air-permeability and humidity-absorption, moreover the wrinkle resistance and elastic extension performance of the fabric are increased, thus leading the wool to be soft, with more body, natural in luster, good at handle, with elasticity, and is a high-class sport fabric.

Owner:JIANGSU SUNSHINE +1

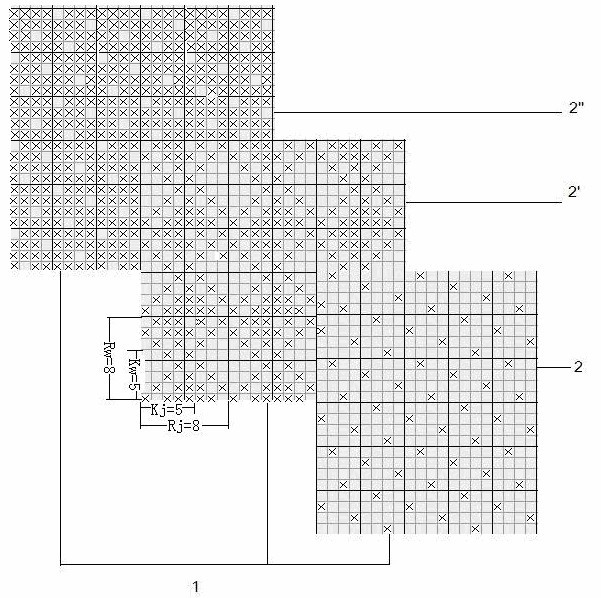

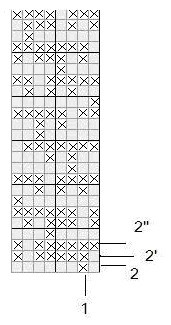

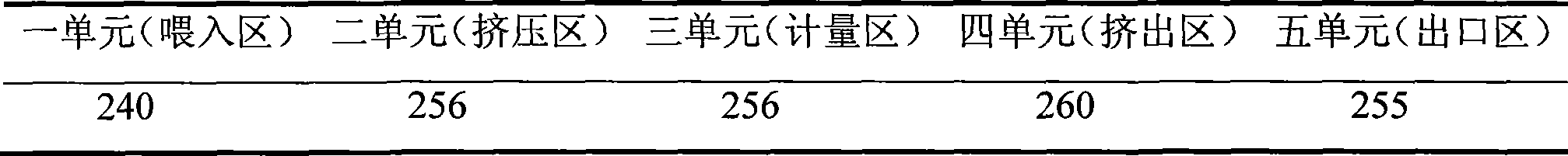

Method for preparing warm composite woven fabric

InactiveCN102181986AElasticIncreased warmth and bulkinessMulti-ply fabricsSwivel-woven fabricsYarnSurface layer

The invention relates to a method for preparing warm composite woven fabric. The warm composite woven fabric is prepared by interweaving a group of warp yarns (1) and three groups of filling yarns in an overlapped way, wherein the three groups of filling yarns are respectively face weft (2), intermediate weft (2') and back weft (2''), the face weft (2), the intermediate weft (2') and the back weft (2'') are arranged according to the proportion of 1:1:1, the warp yarn (1) and the face weft (2) are woven into satin weave which has 8 lines and 5 step weft faces and serves as a surface layer according to a mode of an upper needle and seven lower needles and 5 weft step numbers, the warp yarn (1) and the back weft (2'') are woven into satin weave which has 8 lines and 5 step weft faces and serves as a lining according to a mode of an upper needle and seven lower needles and 5 weft step numbers, the warp yarn (1) and the intermediate weft (2') take honeycomb weave as an intermediate layer in terms of Rj equal to Rw and equal to 8, and the Rj and the Rw are respectively the circulated yarn numbers of warp weave and weft weave. The warm composite woven fabric prepared by the method integrates the characteristics of light weight, super warm property, softness, comfortableness, moisture absorption, air permeability, bacterial resistance and bacterial restraint, and the production is simple and easy to implement.

Owner:江苏保丹服饰有限公司

High-strength wear-resisting TPU compound fabric and preparation method thereof

ActiveCN109501401AImprove wear resistanceGood drapabilitySynthetic resin layered productsLaminationFiberYarn

The invention discloses a high-strength wear-resisting TPU compound fabric which comprises a piece of base cloth and a TPU film coated on the surface of base cloth; bamboo pulp fibers and terylene low-stretch yarns are knitted on a double-side big circular knitting machine in the form of interlock stitch and are weaved into the base cloth; the TPU film is prepared from the following raw materialsin parts by weight: 50-60 parts of modified polyurethane, 6-8 parts of modified attapulgite, 70-80 parts of N,N-dimethyl formamide, 8-11 parts of filler and 10-14 parts of modified polytetrafluoroethylene; the TPU film is compounded on the surface of the base cloth in an unstressing manner, so as to acquire the high-strength wear-resisting TPU compound fabric. According to the invention, bamboo pulp fibers and terylene low-stretch yarns are used for developing the base cloth with an anti-bacterial function, and then a high-strength wear-resisting environment-friendly polyurethane film is compounded, so that the problem of inferior abrasive resistance of fabric is solved; the product is endowed with the advantages of wear resistance, soft luster, moisture absorption, wet permeability, waterproof property, air permeability, antibiosis, deodorization, healthcare, and the like; production cost is greatly lowered.

Owner:上海沙驰服饰有限公司

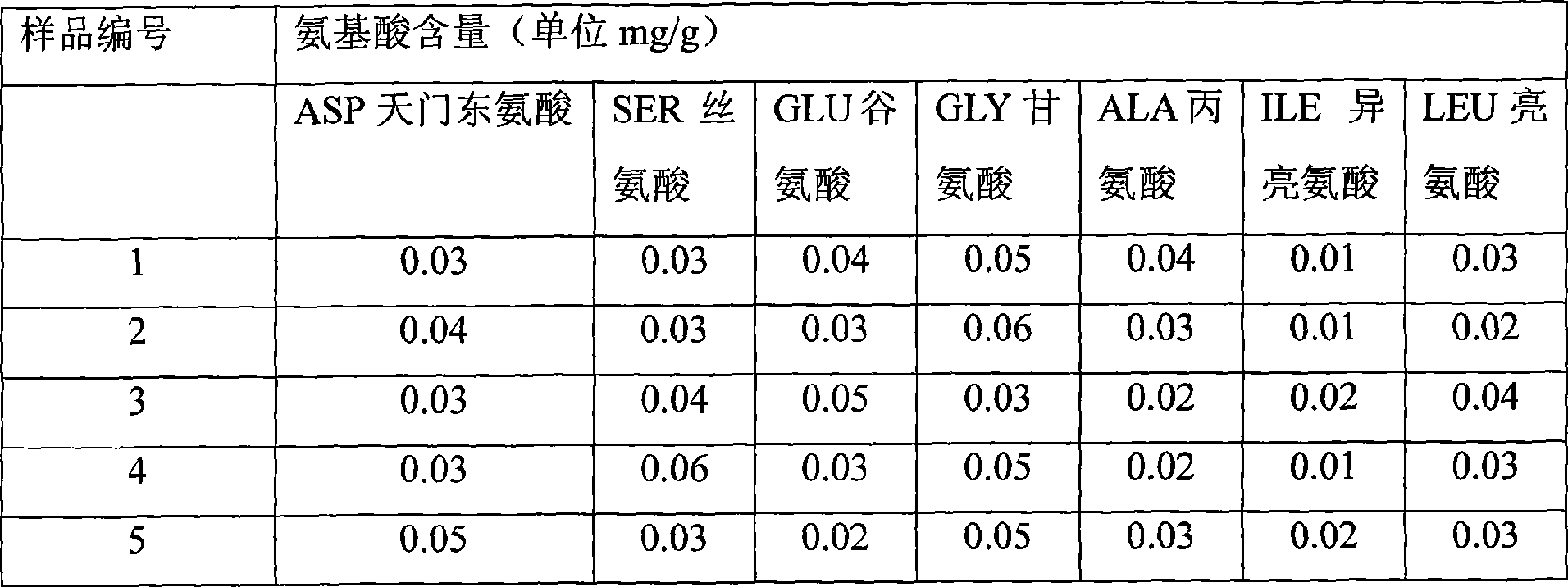

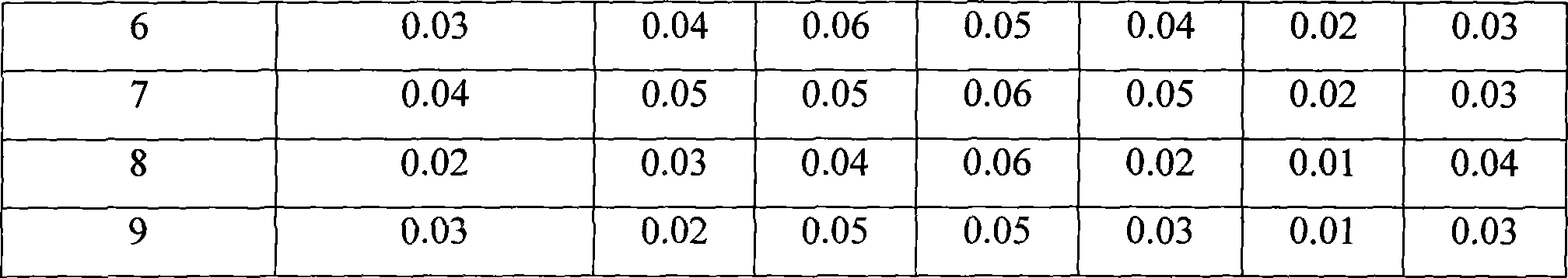

Method for preparing nano-pearl colored polyester fiber

InactiveCN101519808ASmall fluctuationInhibit unstable factorsHollow filament manufactureFilament/thread formingPolyesterFiber

The invention relates to a method for preparing nano-pearl colored polyester fiber, which comprises the following steps that: (1) pearls are sheared and ground to obtain crude pearl powder, then the crude pearl powder is mixed with water, a water dispersion of the pearl powder with a grain diameter of between 50 and 100 nm is obtained through high-pressure crushing, a thermal stabilizer, an antioxidant and an emulsifying agent are added into the water dispersion of the pearl powder, and the drying treatment is performed; (2) the obtained product is mixed evenly with a compatilizer at normal temperature, then the mixture is added into polyester chips, and granulation is performed on the mixture by a double screw extruder; and (3) nano-pearl polyester chips, the polyester chips and color master batch are blended for spinning. The method can be finished on the prior spinning equipment, tows are even and have evenly distributed color and luster; fabric is smooth, and has the characteristic of soft luster; the method is widely applied in the fields of apparel, decoration and industry; and at the same time, the blended color master batch can be used for preparing fibers with various lusters, and the prepared fibers have good nutrition and health care effects on human bodies.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com