Preparation method of easily dyed polyester fiber with high hydrophilicity

A polyester fiber, high hydrophilic technology, applied in the polyester field, can solve the problems of the influence of subsequent spinning, unreasonable product structure, fierce homogeneity competition, etc., to increase moisture conductivity, less cost increase, The effect of maintaining comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

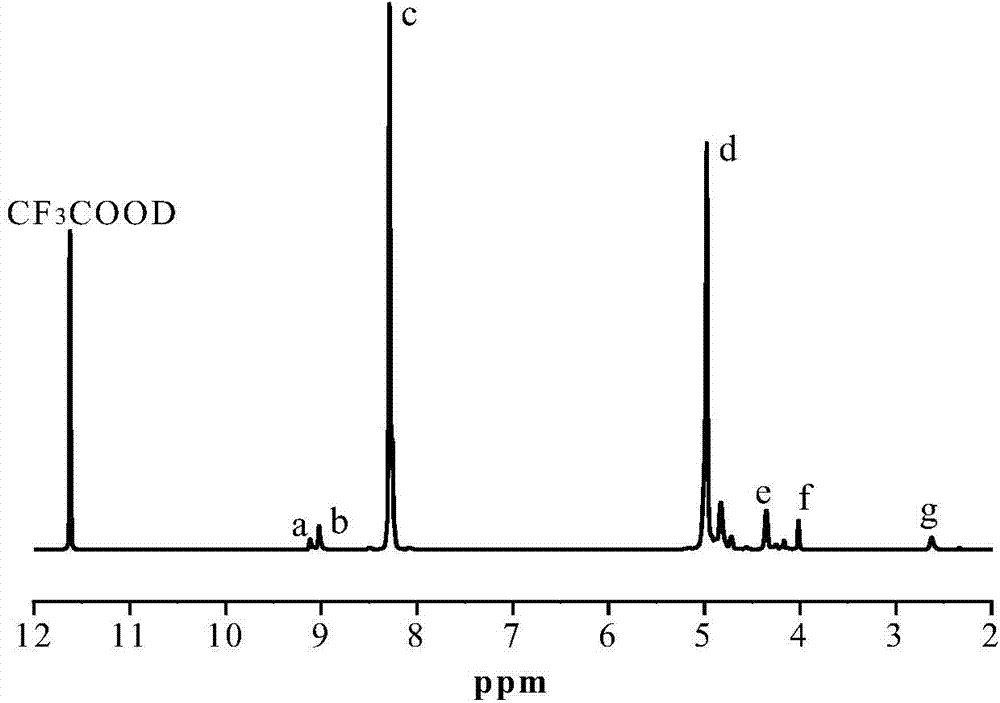

Image

Examples

Embodiment 1

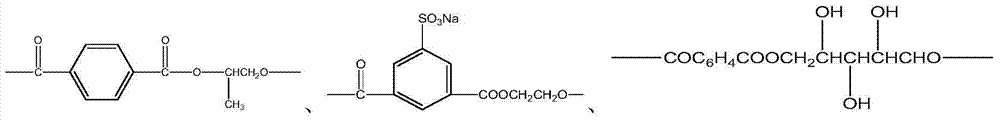

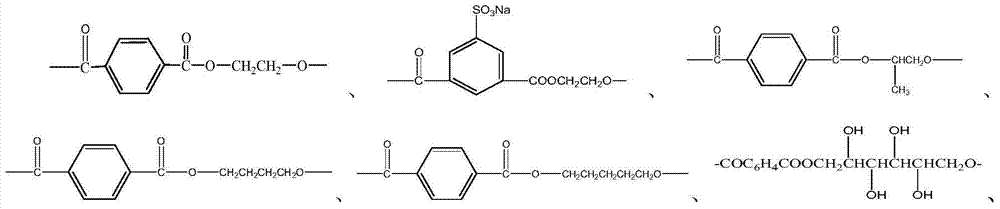

[0054] A method for preparing highly hydrophilic and easy-dyeing polyester fiber includes the first esterification reaction, the second esterification reaction, the polycondensation reaction and the melt spinning forming in sequence. The specific steps are:

[0055] (1) The first esterification reaction:

[0056] Mix ethylene glycol, sorbitol and polyethylene glycol in a molar ratio of 90:0.5:9.5;

[0057] Adding terephthalic acid and 5-sodium sulfonate-diethanol isophthalate according to the molar ratio of the dibasic acid carboxyl functional group to the hydroxyl functional group of the mixed polyol of 1.1:1;

[0058] The terephthalic acid and 5-sodium sulfonate-diethanol isophthalate are mixed in a molar ratio of 90:10;

[0059] The relative number average molecular weight of the polyethylene glycol is 400 g / mol;

[0060] The mixed polyol, polyethylene glycol and the dibasic acid are added to the esterification reactor to perform the first esterification reaction. The pressure of the ...

Embodiment 2

[0074] A preparation method of highly hydrophilic and easy-dyeing polyester fiber includes the first esterification reaction, the second esterification reaction, the polycondensation reaction and the melt spinning forming in sequence, and the specific steps are:

[0075] (1) The first esterification reaction:

[0076] Mixing propylene glycol, sorbitol and polyethylene glycol in a molar ratio of 90:0.5:9.5;

[0077] Adding terephthalic acid at a molar ratio of 1.02:1 between the carboxyl functional groups of the dibasic acid and the hydroxyl functional groups of the mixed polyol;

[0078] The terephthalic acid and 5-sodium sulfonate-diethanol isophthalate are mixed in a molar ratio of 95:5;

[0079] The relative number average molecular weight of the polyethylene glycol is 400 g / mol;

[0080] Adding the mixed polyol and the dibasic acid to the esterification reactor to perform the first esterification reaction, the pressure of the first esterification reaction is 0.01 MPa, the reaction te...

Embodiment 3

[0093] A preparation method of highly hydrophilic and easy-dyeing polyester fiber includes the first esterification reaction, the second esterification reaction, the polycondensation reaction and the melt spinning forming in sequence, and the specific steps are:

[0094] (1) The first esterification reaction:

[0095] Mix butylene glycol, sorbitol and polyethylene glycol according to a molar ratio of 90:0.5:9.5;

[0096] Adding terephthalic acid and 5-sodium sulfonate-diethanol isophthalate according to the molar ratio of the dibasic acid carboxyl functional group to the hydroxyl functional group of the mixed polyol of 1.10:1;

[0097] The terephthalic acid and 5-sodium sulfonate-diethanol isophthalate are mixed in a molar ratio of 90:10;

[0098] The relative number average molecular weight of the polyethylene glycol is 400 g / mol;

[0099] Adding the mixed polyol and the dibasic acid to the esterification reactor to perform the first esterification reaction, the pressure of the first es...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com