Patents

Literature

358results about How to "Intensity effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

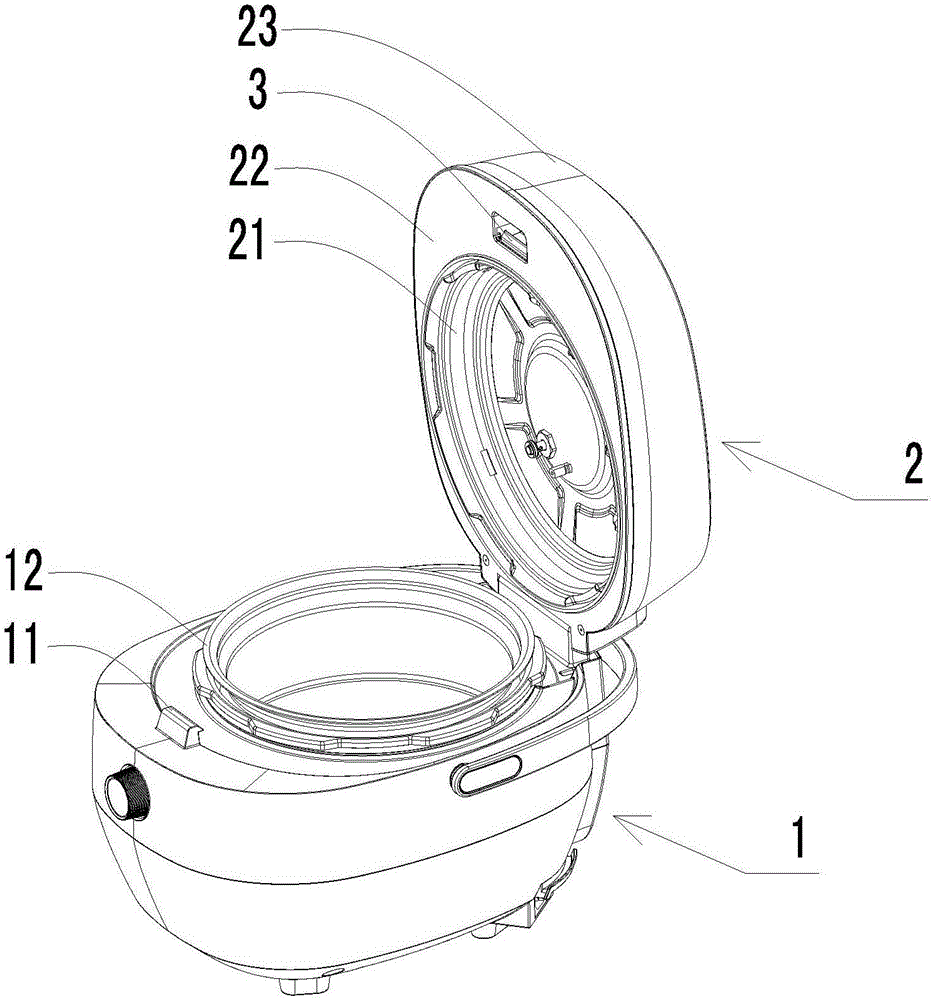

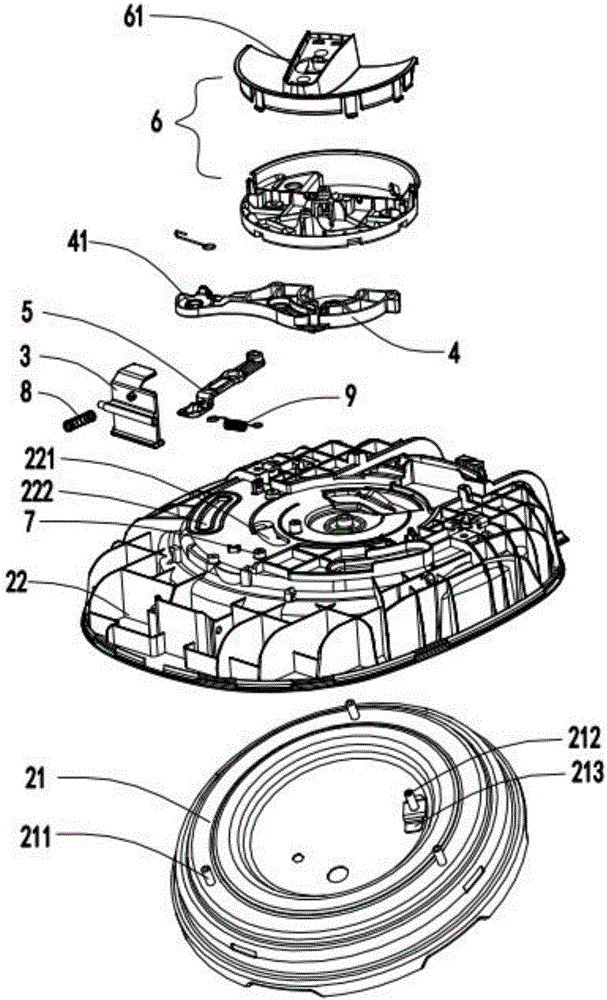

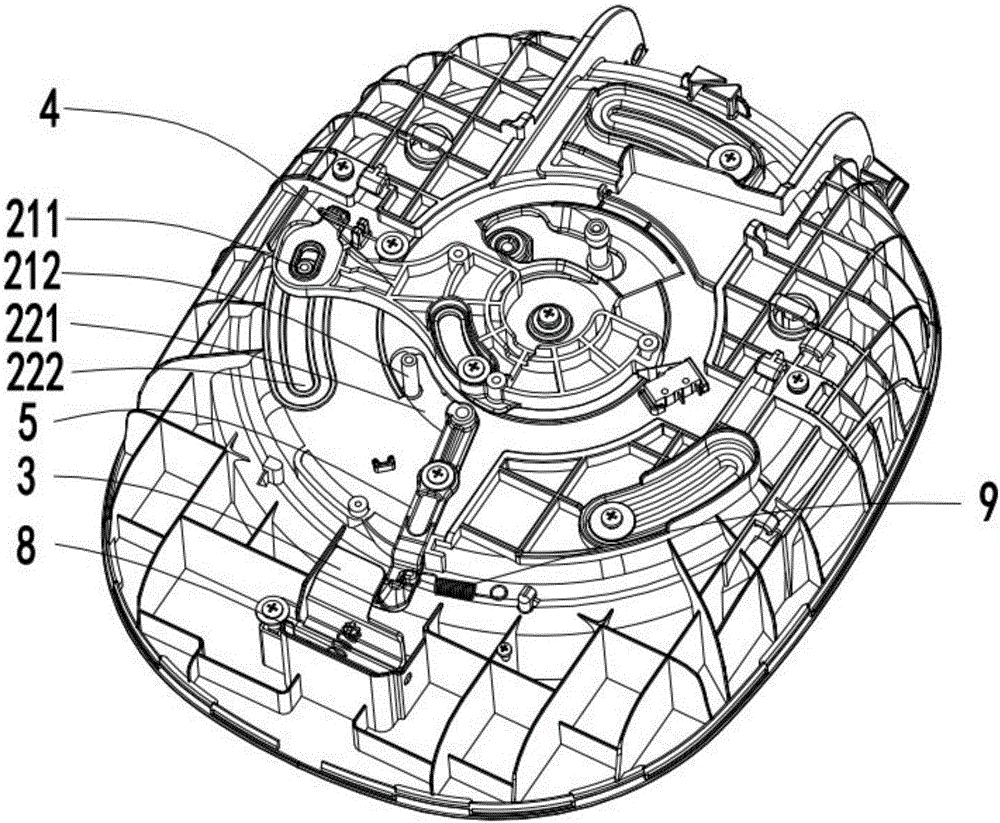

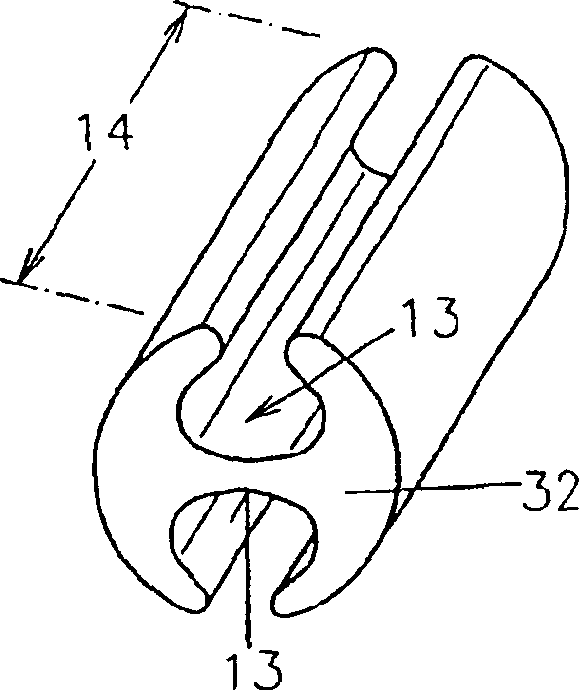

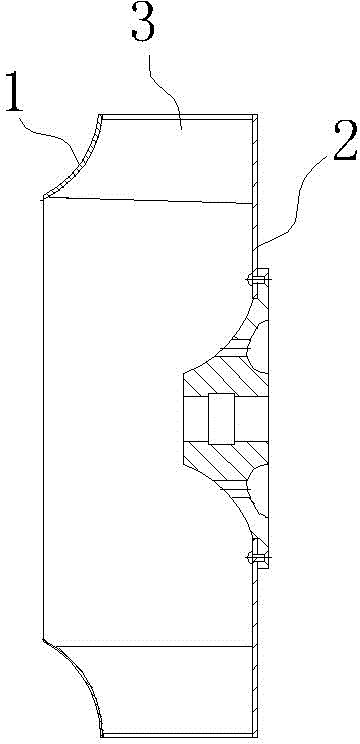

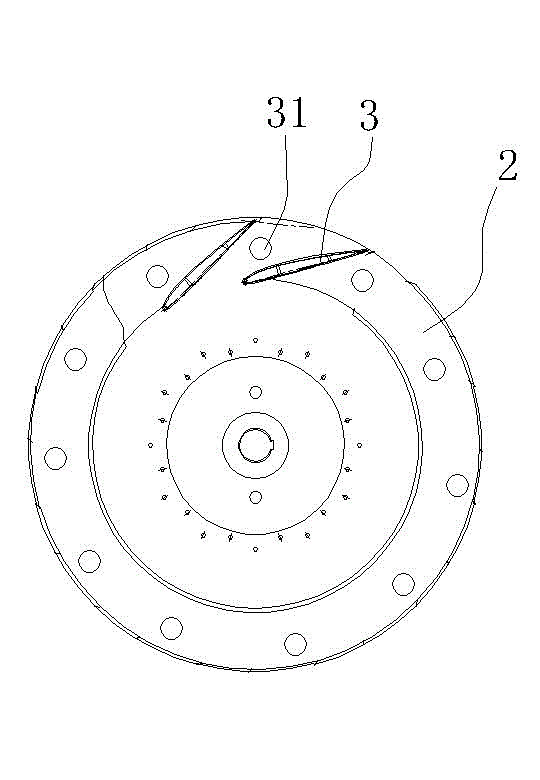

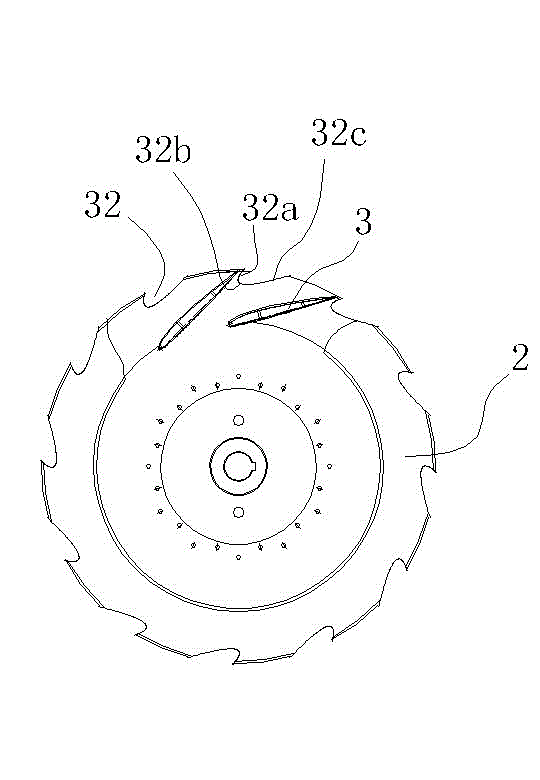

Electric pressure cooker capable of facilitating cover opening

The invention provides an electric pressure cooker capable of facilitating cover opening. The electric pressure cooker comprises a pot body, a pot cover and a clamping buckling component; the pot cover comprises a liner and a lock cover located below the liner; the clamping buckling component comprises a movable clamping component arranged on the liner and a buckling component located on the pot body; the pot cover is buckled to the pot body through the clamping buckling component; the liner is provided with a cover opening assembly; the cover opening assembly drives the lock cover to rotate; the rotation of the lock cover enables the locking and unlocking of the lock cover and the pot body; the lock cover is provided with an unbuckling component; a distance from the unbuckling component to the center of the lock cover is 1 / 5 to 4 / 5 of the radius of the lock cover; a collision avoidance groove is arranged on the liner; the unbuckling component passes through the collision avoidance groove and extends to the upper surface of the liner; and the cover opening assembly drives the lock cover to rotate for unlocking, and the unbuckling component acts, so that the movable clamping component is separated from the buckling component. According to the electric pressure cooker of the invention, the pot cover can be opened just through rotation, and therefore, the electric pressure cooker is convenient for a user to use.

Owner:JOYOUNG CO LTD

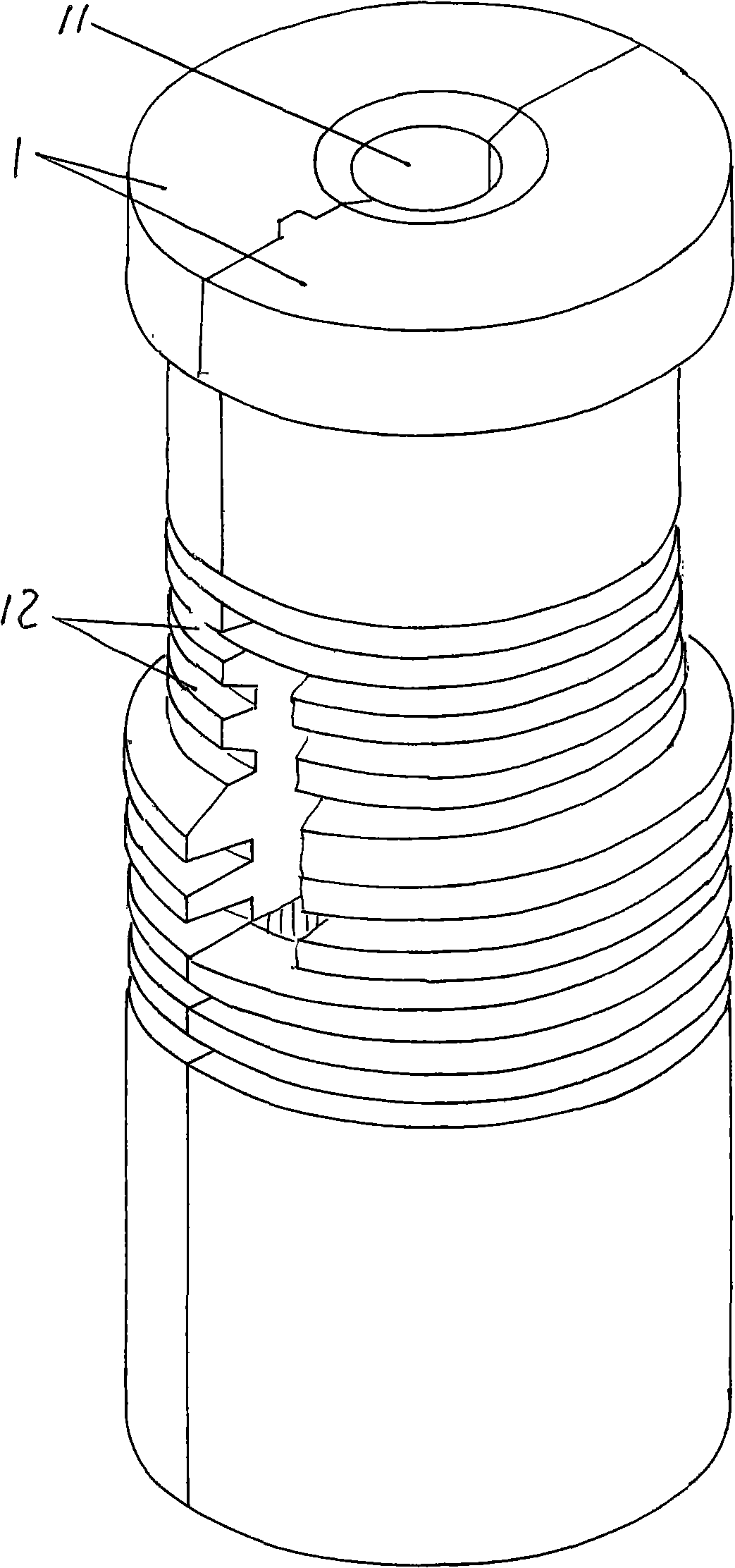

Mould for processing glass container

InactiveCN101298358AAccelerate heat dissipationImprove bottle forming speedGlass shaping apparatusGlass productionGlass containerSoftening point

The invention provides a mold for processing a glass container and belongs to the technical field of mold. The mold includes a pair of half molds that are opposite to each other and have the same shape and a bottle mold cavity, and a heat-radiating groove is opened on the outer wall of the two half molds. The mold has the advantages that the heat-radiating grooves on the outer wall of the two half molds are helpful for heat radiation of the half molds, which leads the temperature of the mold cavity to drop under the softening point rapidly and is favorable for improving the formation speed of the bottle in the mold cavity and the production speed of the bottle; the opening of the heat-radiating groove does not affect the strength of the half molds, thus being capable of ensuring the service life of the mold.

Owner:CHANGSHU WEIHENG MOLD MFG

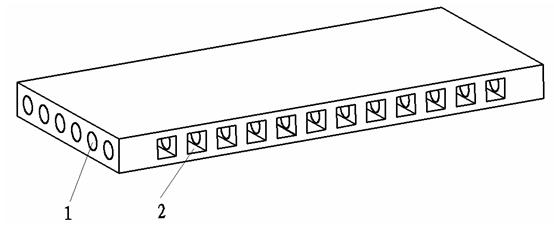

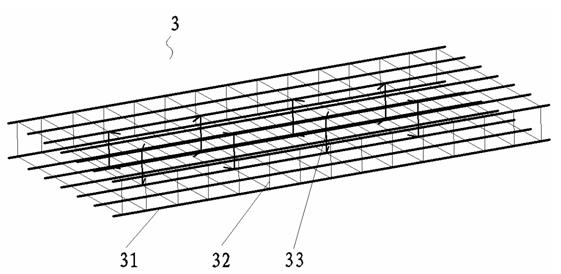

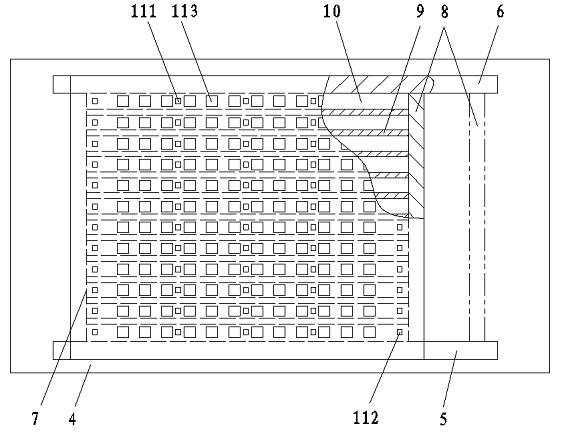

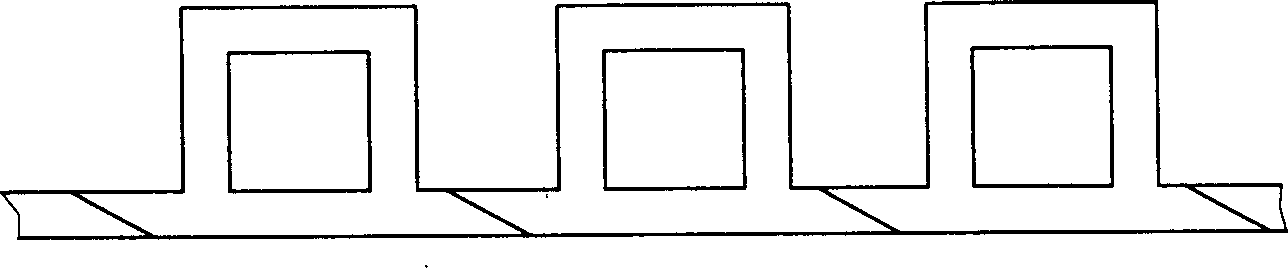

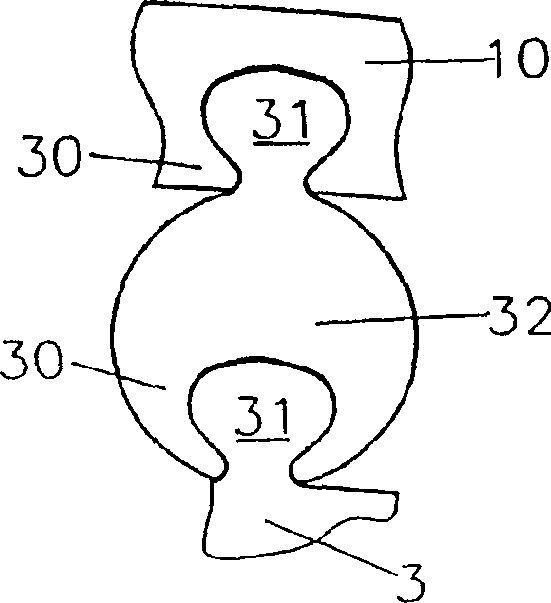

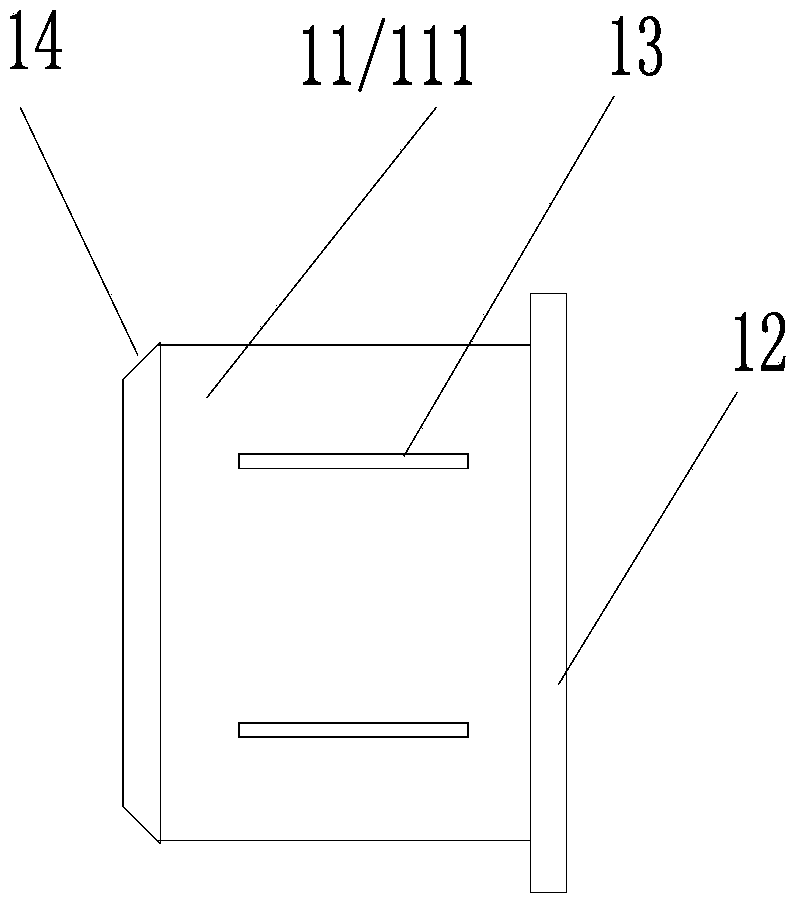

Prefabricated reinforced concrete hollow template internally provided with cross holes and molding and forming device thereof

The invention relates to a prefabricated reinforced concrete hollow template internally provided with cross holes and a molding and forming device of the prefabricated reinforced concrete hollow template. The hollow template is internally provided with longitudinal through holes with round cross sections along the length direction and latitudinal through holes with square cross sections along the width direction, wherein the longitudinal through holes are arrayed parallel one another, the latitudinal through holes are also arrayed parallel one another, and the diameter of each longitudinal through hole is less than the length of the side of each latitudinal through hole. Two large surfaces of the hollow template are flat surfaces formed by molding. A casting mold of the molding and forming device is of a vertical type and provided with one or more mold cavities; each mold cavity is surrounded by a front face plate, a rear face plate, a left side plate and a right side plate; a core tube frame or upper side plate capable of fixing a vertical core tube is arranged on the upper part or above each mold cavity; and the left side plate, the right side plate and the upper side plate are provided with a plurality of horizontal holes and vertical holes respectively. Each surface of the hollow template processed by using the molding and forming device is flat without being polished and subjected to similar treatment. The hollow template is high in strength and good in quality, can be directly used for the construction of a load-bearing wall with few procedures in a short time and can ensure that the load-bearing wall is not easy to shrink and crack.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

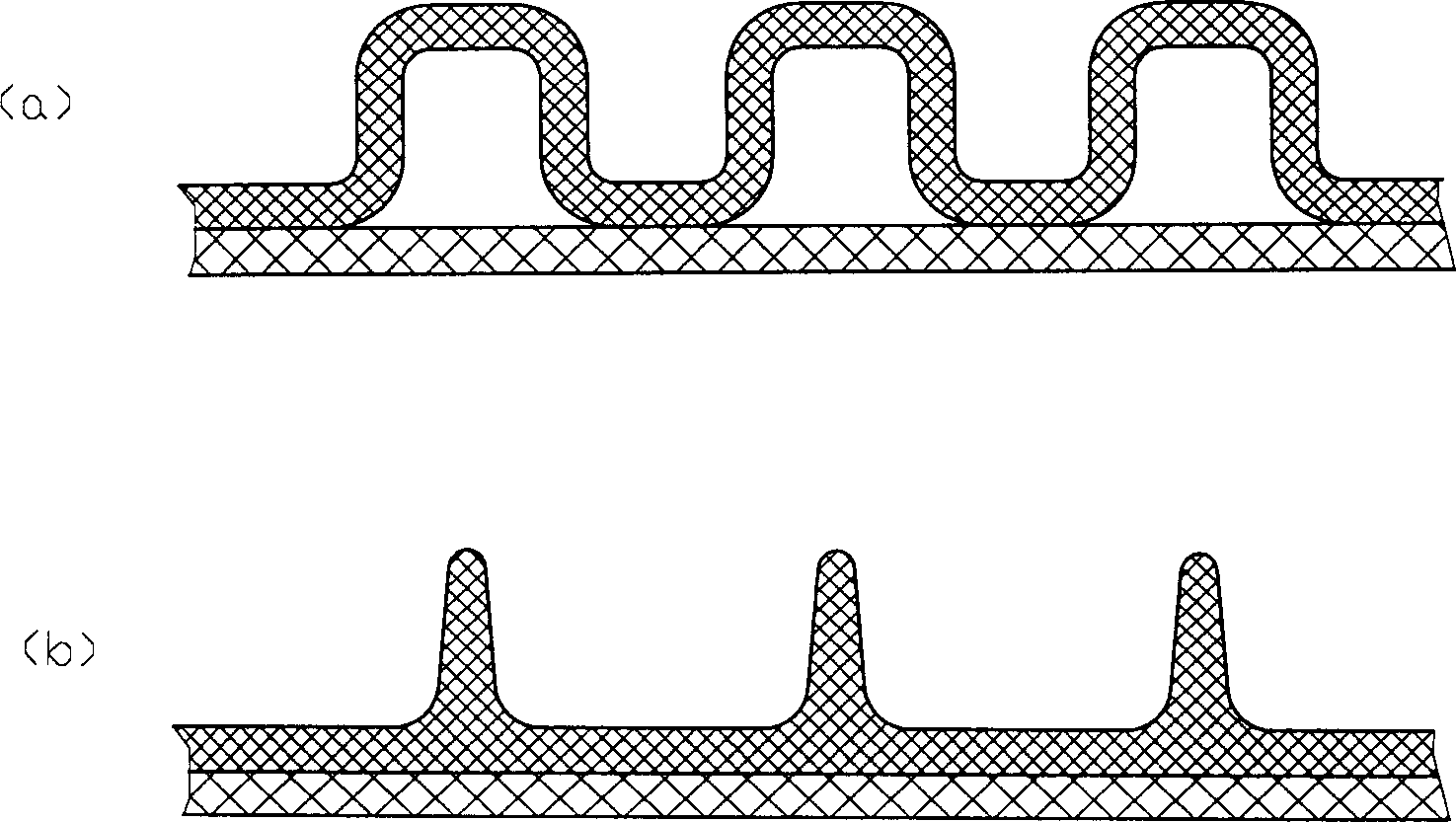

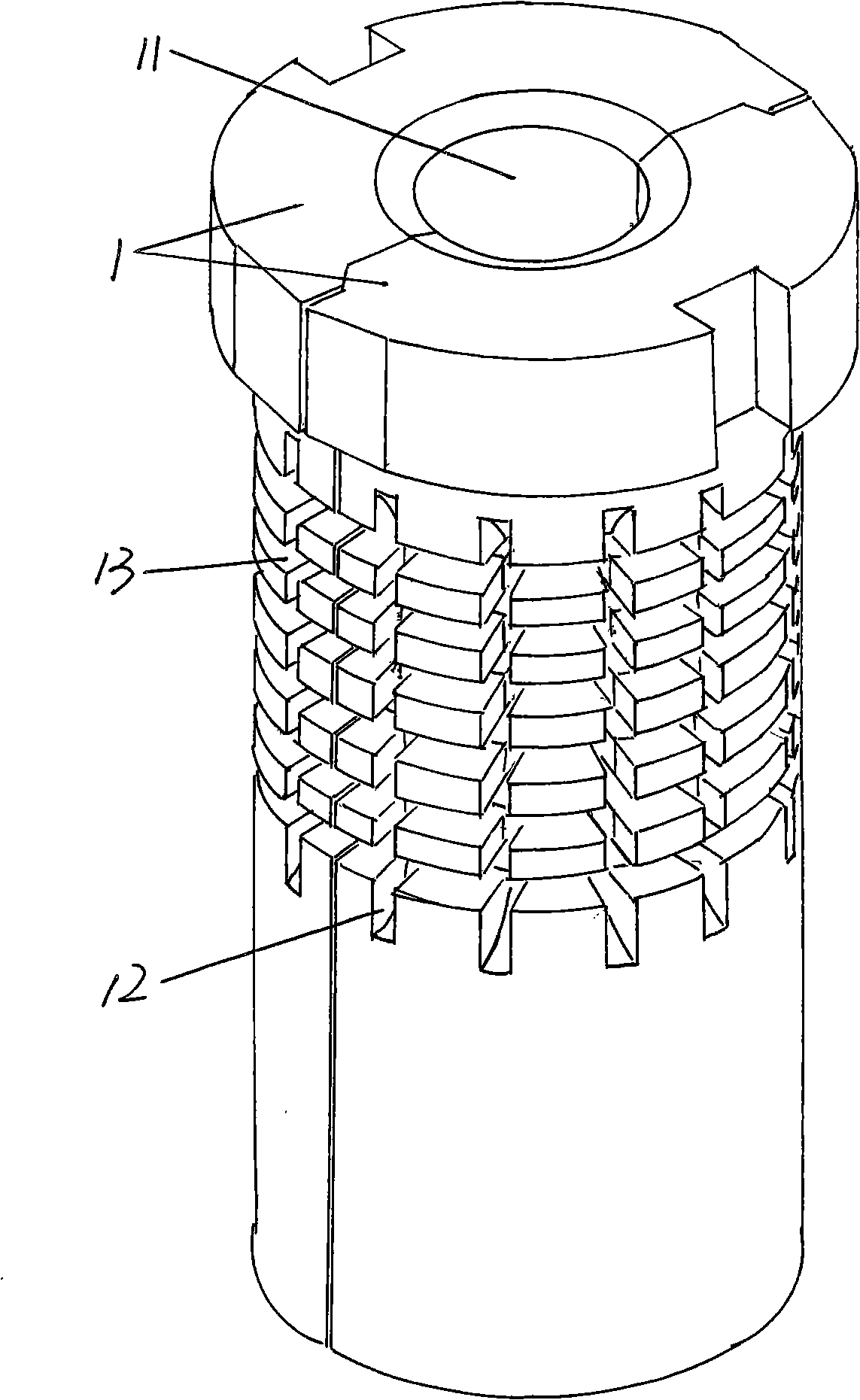

Screw type corrugated plastic pipe material and its manufacturing method

InactiveCN1414277AGuaranteed StrengthGuaranteed lifeRigid pipesTubular articlesPlastic filmConductor Coil

The present invention relates to spiral type corrugated plastic pipe material and its preparation method. The perparation method includes following steps: using a first extrusion mechanism to extrudethe fused bar shaped plastic sheet material used as pipe wall material which is wound around the pipe axis in the form of spiral-joint pipe with adjucent edges mutually lap-fused jointed successively, then using a press roller mechanism tightly press the spirally lap-fused joint to form the spiral-joint plastic pipe; similarly, using another extrusion mechanism extrudes corresponding rib type strengthening trapesoidal plastic tube and using the same spiral winding mode to press the said plastic tube on the spiral-joint of the above-mentioned plastic pipe to obtain the said corrugated plastic pipe.

Owner:SICHUAN GOLDSTONE ORIENT NEW MATERIAL EQUIP

Mould for processing glass container

InactiveCN101298359AImprove cooling effectIntensity effectGlass shaping apparatusGlass productionBottleMaterials science

The invention provides a mold for processing a glass container and belongs to the technical field of mold. The mold includes a pair of half molds that are opposite to each other and have the same shape and a bottle mold cavity, a first heat-radiating groove and a second heat-radiating groove are alternatively opened on the outer wall of the two half molds. The mold has the advantages that the first and the second heat-radiating grooves on the outer wall of the two half molds are helpful for heat radiation of the half molds, which leads the temperature of the mold cavity to drop under the softening point rapidly and is favorable for improving the formation speed of the bottle in the mold cavity and the production speed of the bottle; the opening of the first heat-radiating groove and the second heat-radiating groove does not affect the strength of the half molds, thus being capable of ensuring the service life of the mold.

Owner:CHANGSHU WEIHENG MOLD MFG

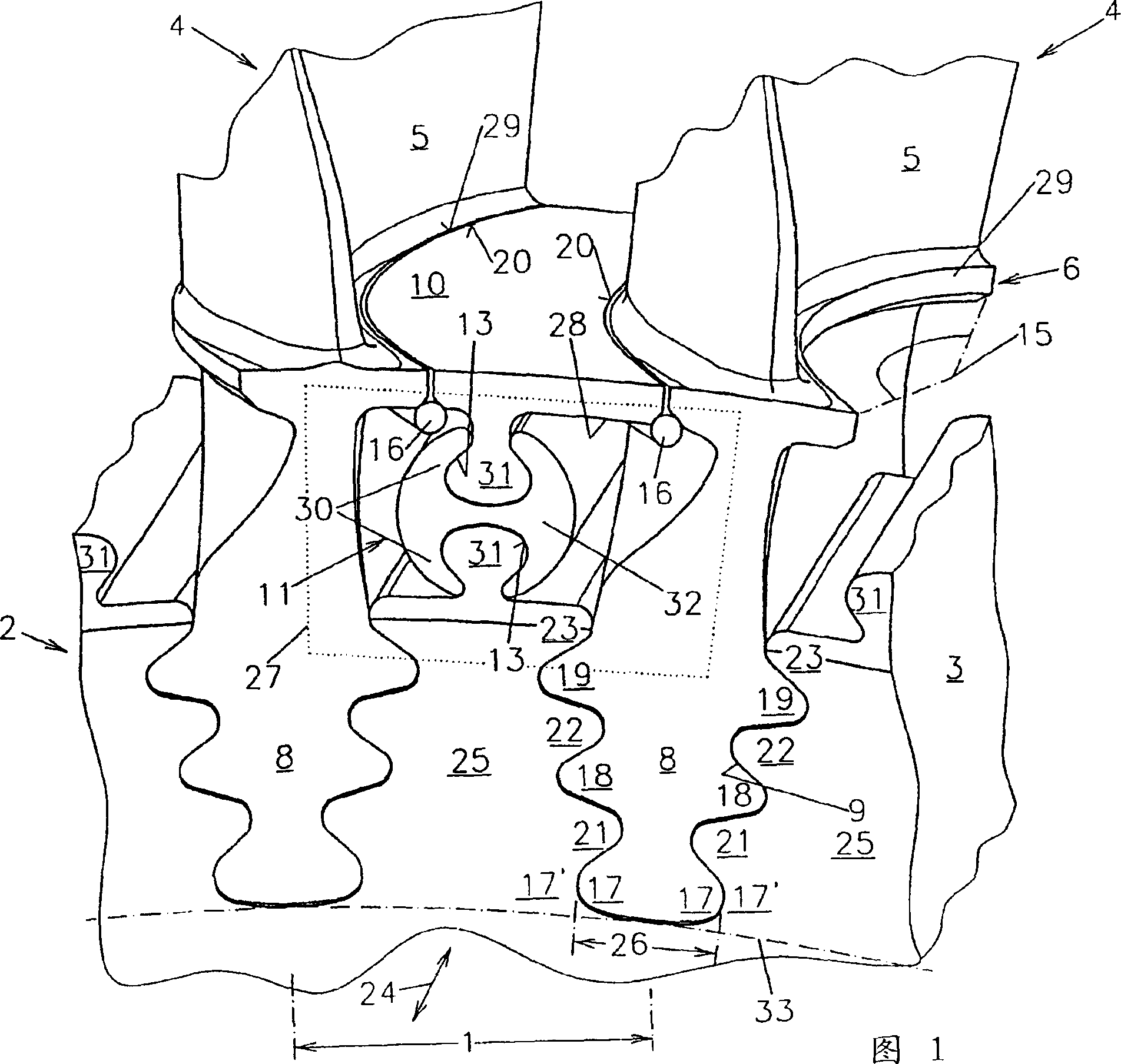

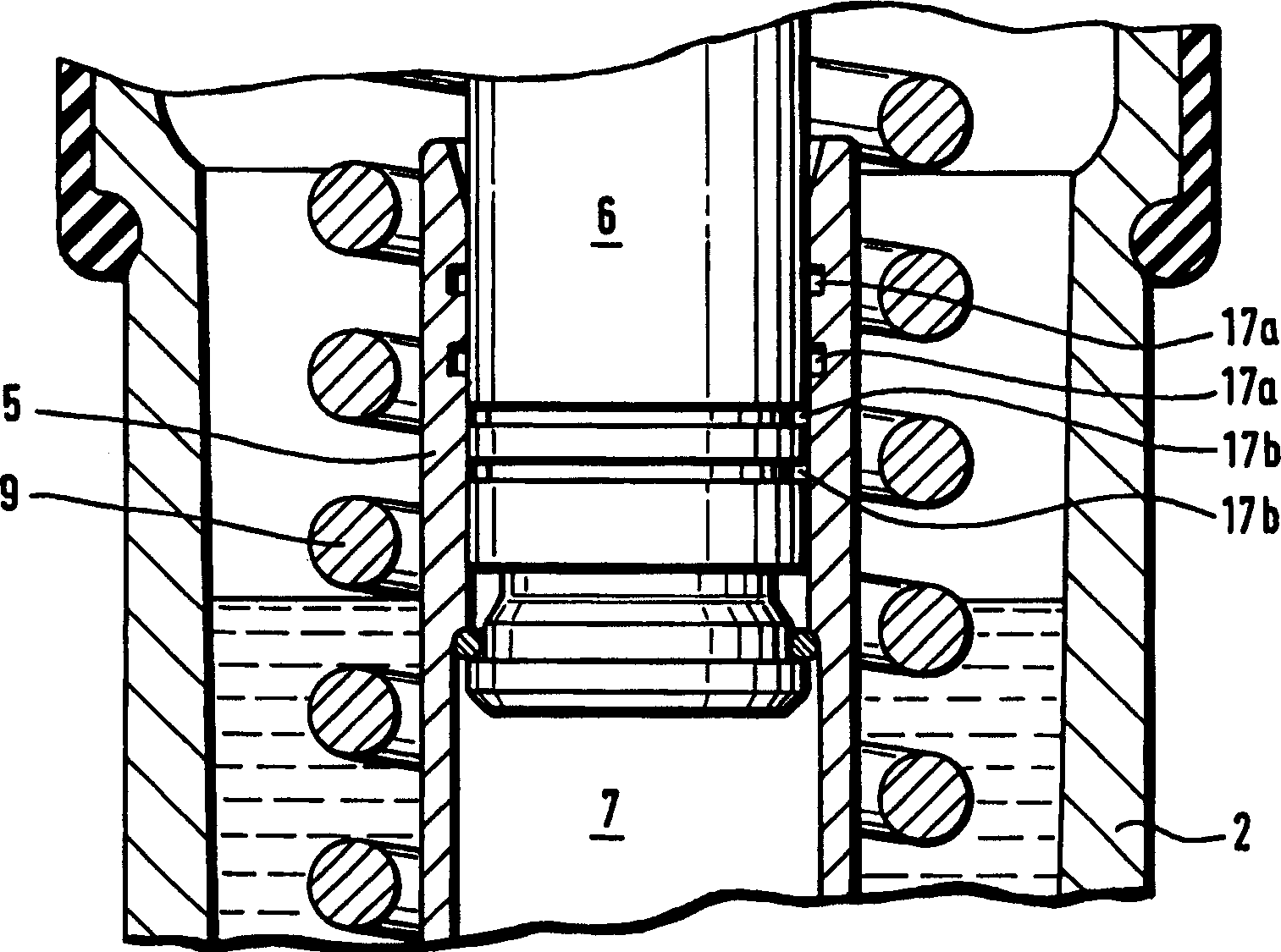

Turbine blade arrangement

The invention relates to a turbine blade arrangement consisting of rotating blades (4) respectively provided with a leg (8) which can be respectively inserted into a groove (9) on the outer circumference (2) of a turbine disk in a radial, positive fit and which are respectively provided with a profiled section (5) which has a lateral platform (6) located in an end area on the side of the disk. According to the invention, at least one part (10) of the platform is joined to the turbine disk by means of a retaining element which is independent from the leg (8) of the blades in order to extend the profiled sections of the rotating blades.

Owner:SIEMENS AG

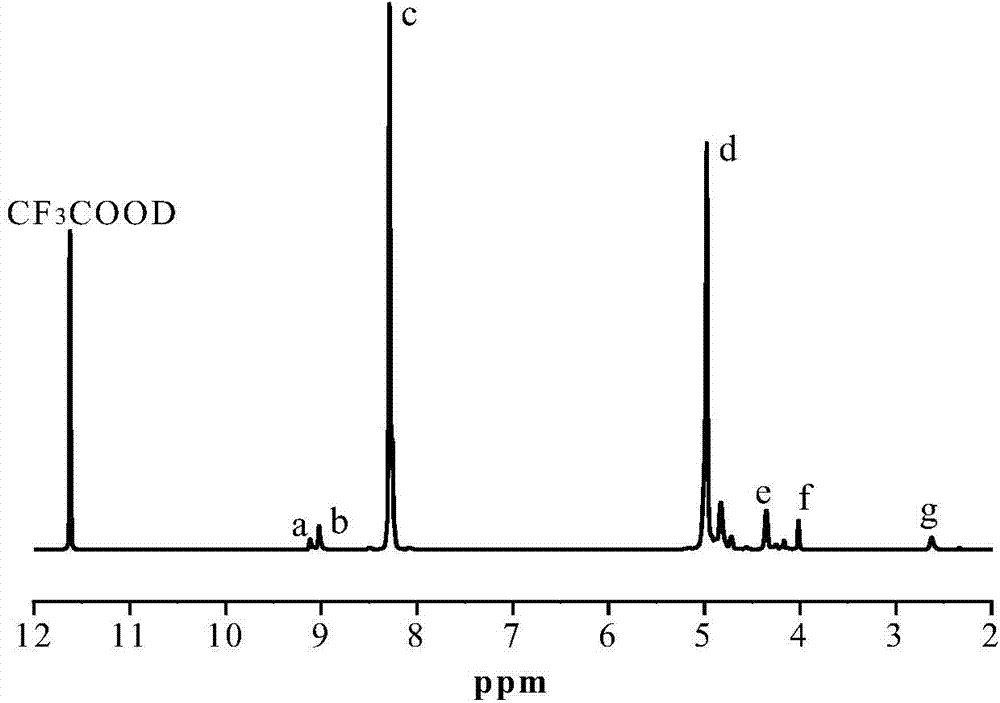

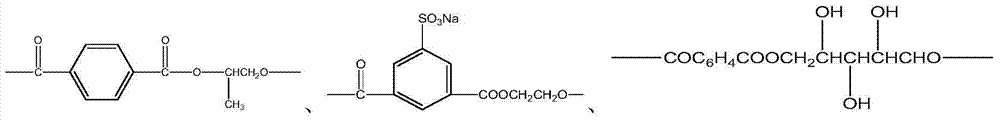

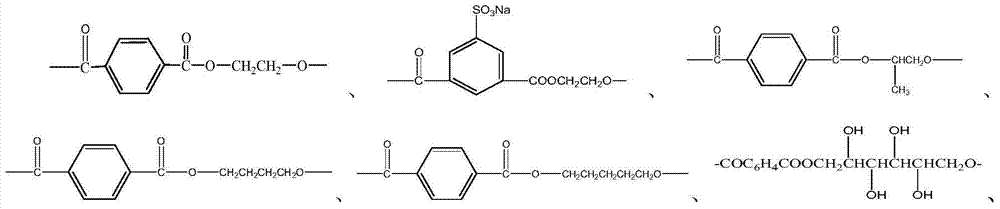

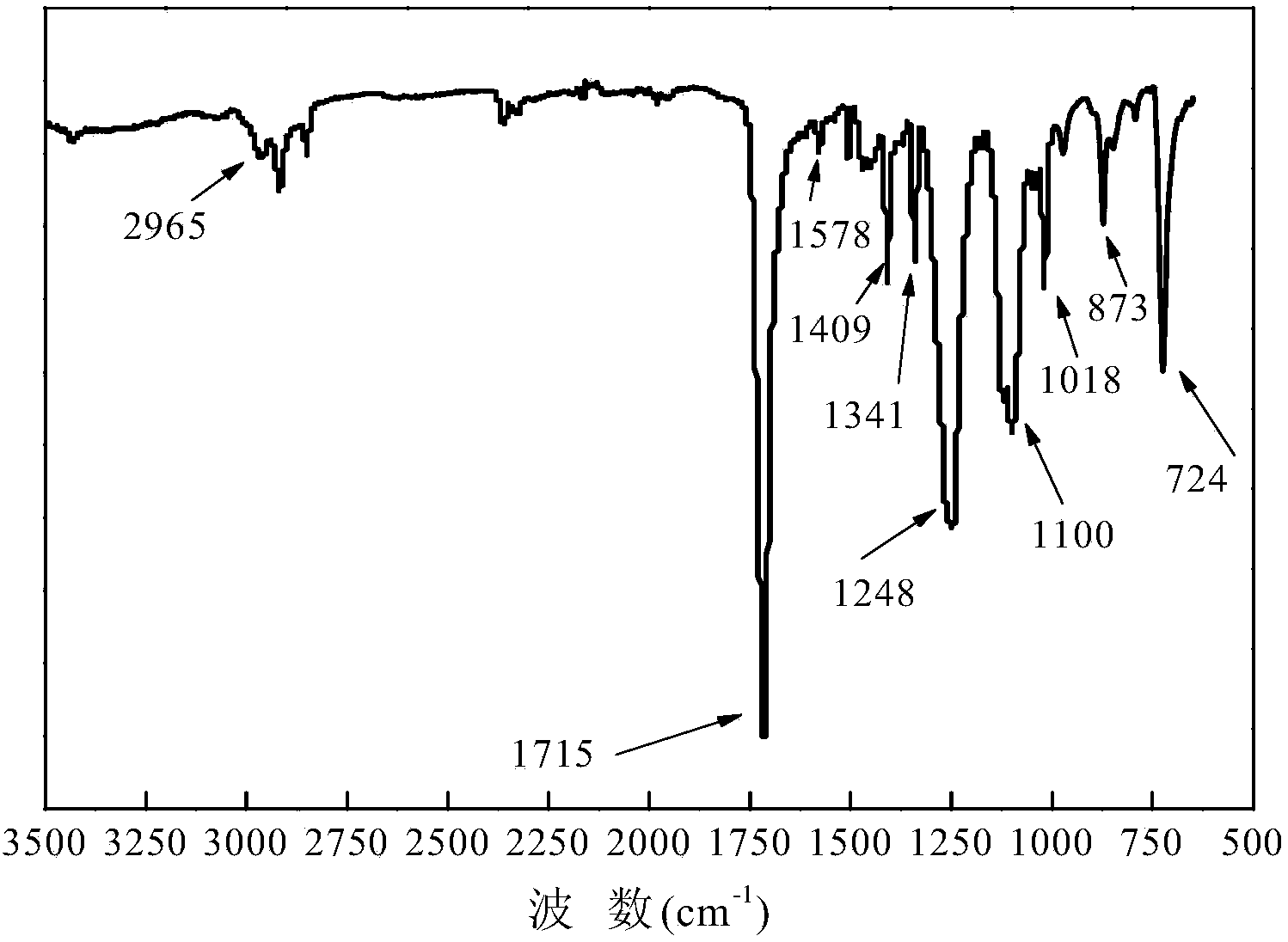

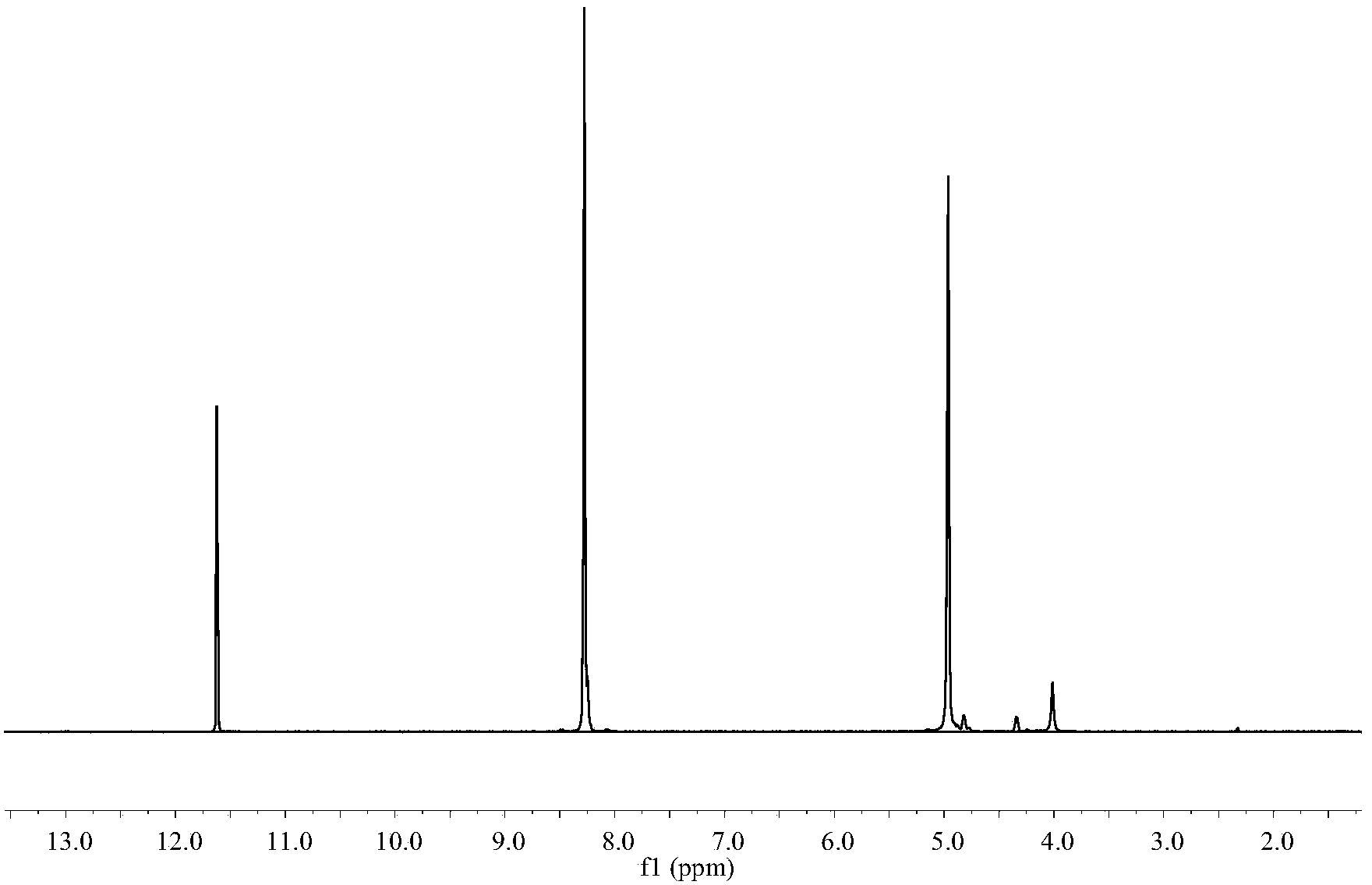

Preparation method of easily dyed polyester fiber with high hydrophilicity

ActiveCN103789865AAdequate responseReduce wasteArtificial filament heat treatmentMonocomponent copolyesters artificial filamentPolymer sciencePolyethylene glycol

The invention relates to a preparation method of an easily dyed polyester fiber with high hydrophilicity. The preparation method comprises the following steps: performing esterification by stages, wherein dihydric alcohols, polyhydric alcohols and polyethylene glycol macromolecules are mixed according to a certain mole ratio, in the first esterification stage, acid is slightly excess to ensure that parts with low capability of participating in esterification reaction in the polyhydric alcohols fully react and are grafted into polyester molecular chains, and in the second esterification stage, the dihydric alcohols are replenished to control the terminal carboxyl group of copolyester; and then performing condensation polymerization to prepare the easily dyed polyester with high hydrophilicity. The preparation method has the advantages that the easily dyed polyester fiber with high hydrophilicity is finally prepared by carrying out melt spinning on easily dyed polyester with high hydrophilicity; polyhydric active sites in the fiber, ether bonds in flexible chain polyethylene glycol and sulfonate groups in binary acid have strong adsorption functions and can endow the fiber with good moisture absorption property and dyeing property; the easily dyed polyester fiber with high hydrophilicity can be widely used for preparing moisture absorbing and sweat releasing antistatic fibers made into fabrics next to the skin; the easily dyed polyester fiber with high hydrophilicity has an obvious modification effect and is especially suitable for the melt direct spinning process.

Owner:JIANGSU DELI CHEM FIBER CO LTD

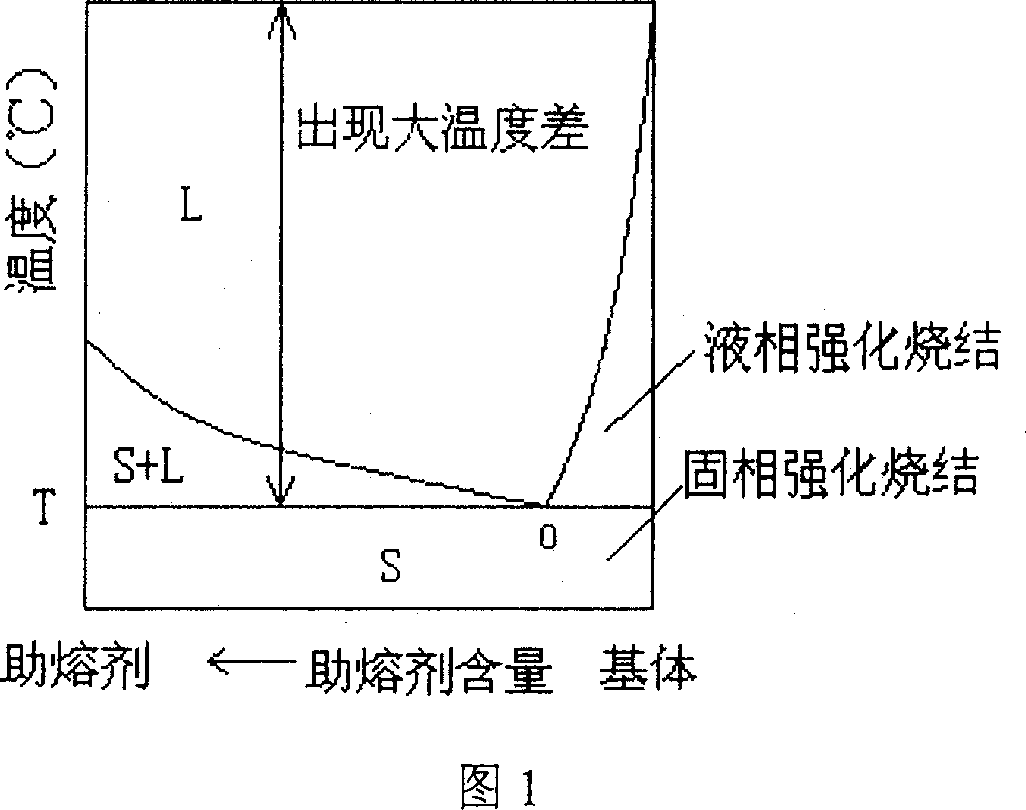

Ceramic sintering fluxing agent

InactiveCN1974487ANo significant requirement on particle sizeLow priceCeramic sinteringSolid solution

The present invention is ceramic sintering fluxing agent, and belongs to the field of building material technology. The method of the present invention is that the first level fluxing agent capable of generating solid solution of lower smelting point is used in fluxing the second level fluxing agent capable of generating solid solution of higher smelting point, the second level fluxing agent is used in fluxing the third level fluxing agent, and so on to complete the sintering of the material at relatively low temperature and lowered power consumption. The ceramic sintering fluxing agent of the present invention is a composite fluxing agent comprising B2O3, K2O+Na2O and CaF2 separately as the first level, the second level and the third level fluxing agent, or comprising Bi2O3, PbO and CaF2, or comprising V2O5, Bi2O3 and LiF+AlF3. It is added into sintering process in the amount of 0.01-0.5 % to lower the sintering temperature by 100 -170 deg.c.

Owner:UNIV OF SCI & TECH BEIJING

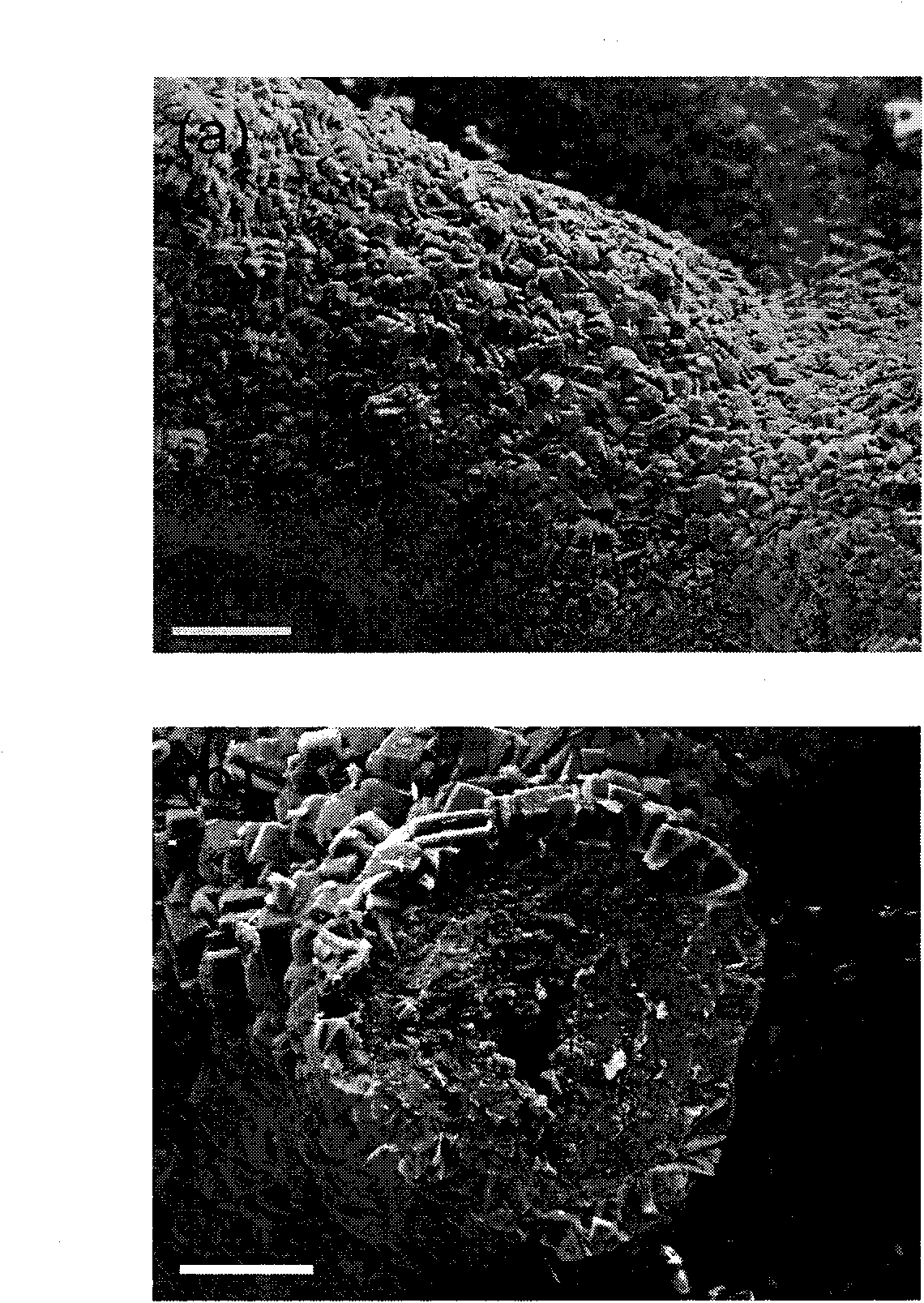

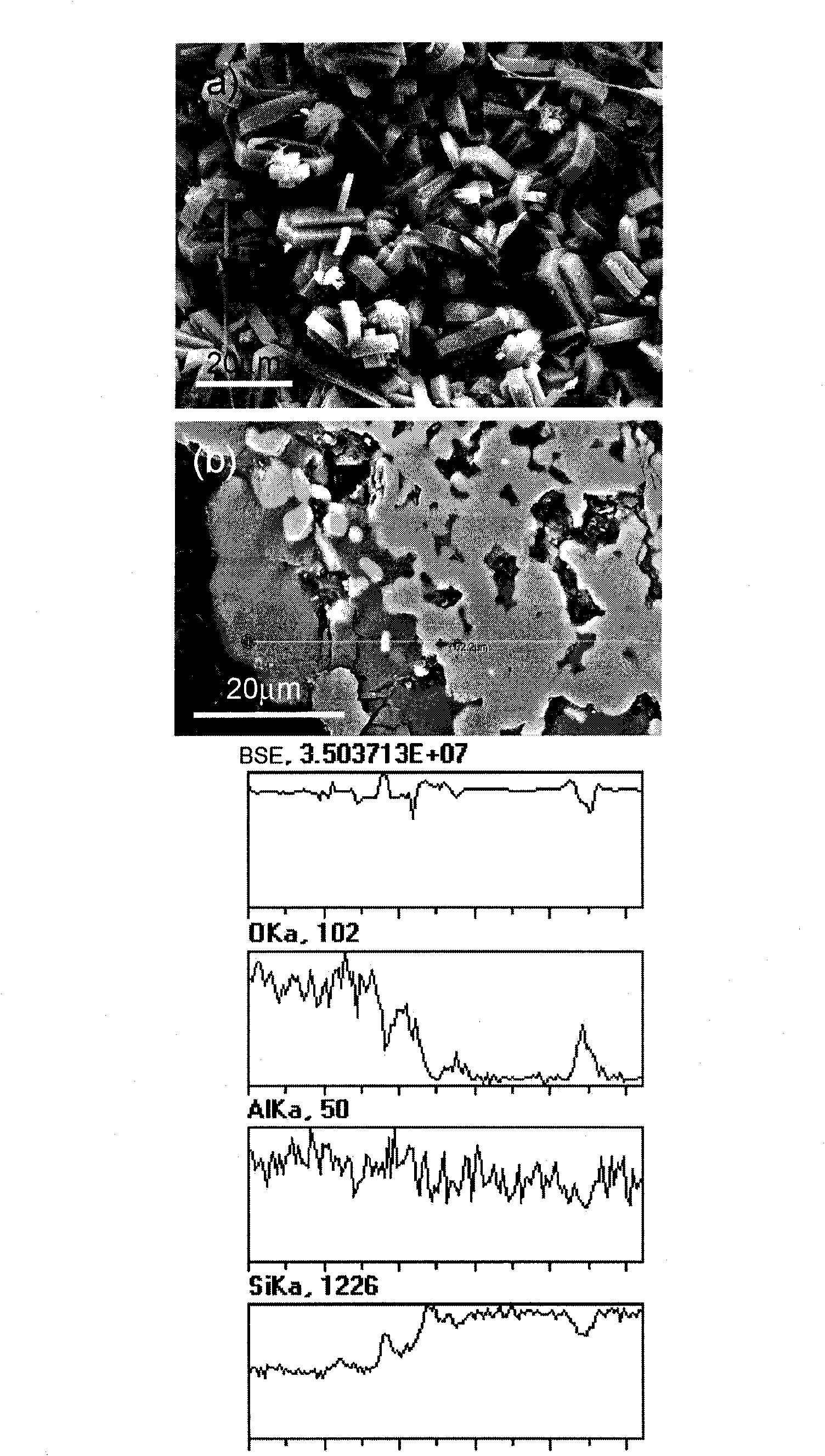

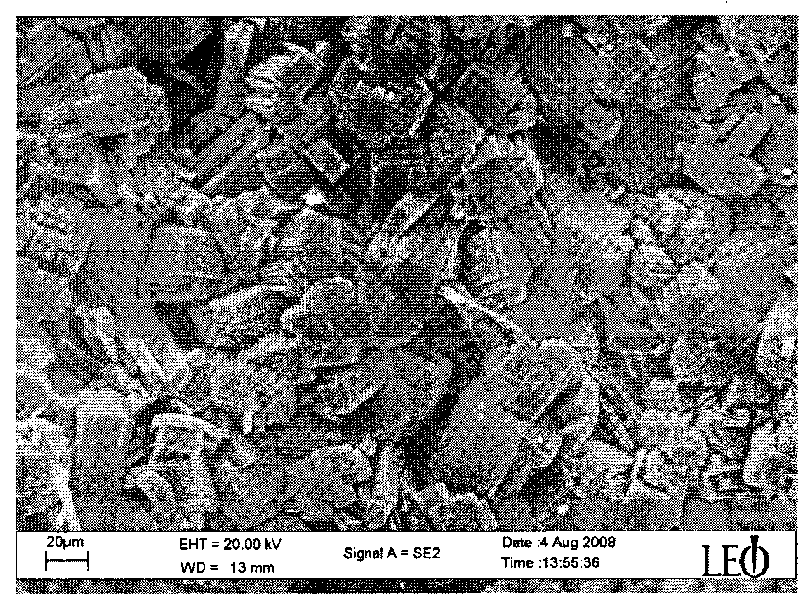

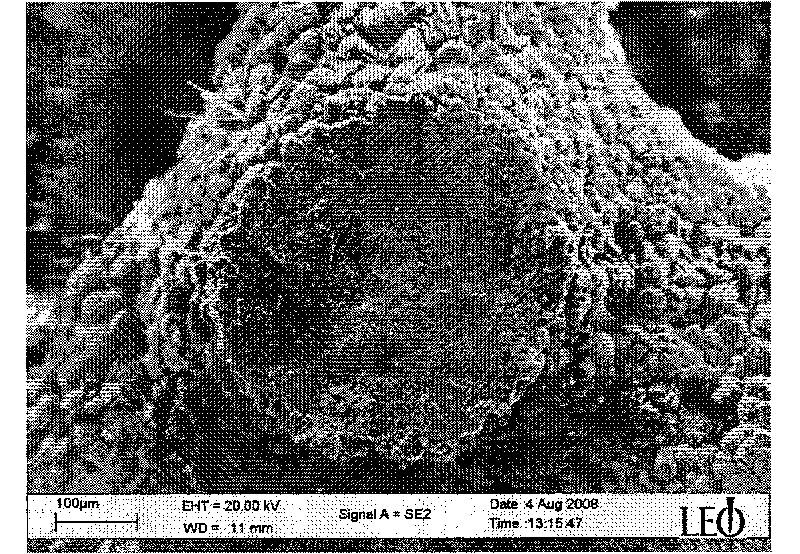

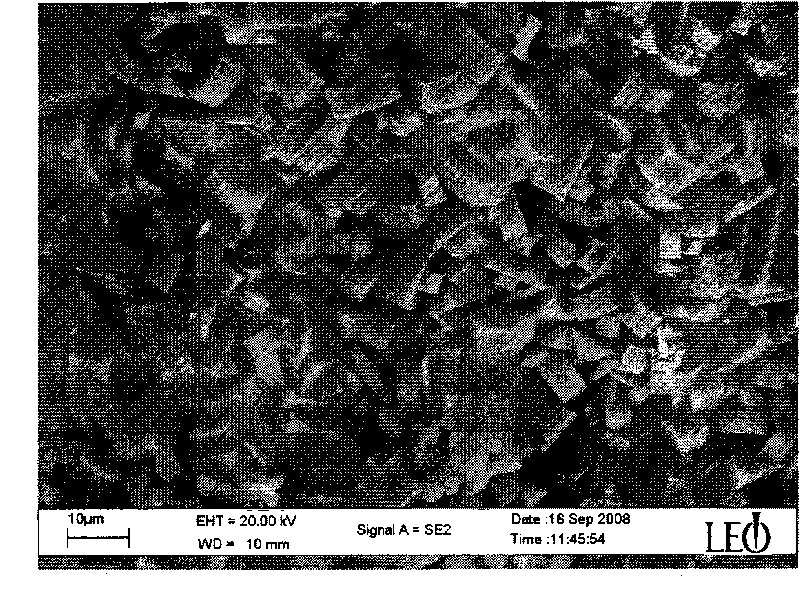

Preparation method for molecular sieve coating material on porous silicon carbide ceramic surface

InactiveCN101857462AIntensity effectImprove the bonding strength of the interfaceMolecular sieve catalystsCrystalline aluminosilicate zeolitesInterfacial bondingRaw material

The invention relates to a preparation technique for a molecular sieve coating material, in particular to a preparation method for a molecular sieve coating material on a porous silicon carbide ceramic surface. Porous silicon carbide ceramic is used as a carrier, solid raw materials such as silicon blocks, quartz, silicon-aluminum composite oxide sintered powder with adjustable silicon-aluminum atomic ratio and the like are used as a silicon source or a silicon-aluminum source, and the raw materials are synthesized through in-situ hydrothermal reaction. The porous silicon carbide ceramic surface is provided with microporous structures. The use of the solid silicon source or silicon-aluminum source can enable the release speed of the silicon source or silicon-aluminum source for the growth of crystal nucleus to be controllable. Thereby, the prepared molecular sieve coating is evenly loaded on the surface of the silicon carbide ceramic carrier, the silicon-to-aluminum ratio can be accurately controlled, and the composite material formed by the molecular sieve and the porous silicon carbide ceramic has unique microporous / macroporous structures; and the chemical bonding between the molecular sieve and the porous silicon carbide ceramic is realized and the interfacial bonding strength is high. The invention has the advantages that the technology of the method is simple, the operation is convenient, the complex equipment is not required, the preparation cost is low and the method is more suitable for industrialized mass production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of molecular sieve coating material on surface of porous silicon carbide ceramic with surface rich in silicon

InactiveCN101723709AIntensity effectImprove the bonding strength of the interfaceMolecular-sieve and base-exchange compoundsComposite oxideMaterials science

The invention relates to a preparation method of a molecular sieve coating material on the surface of porous silicon carbide ceramic with the surface rich in silicon, and the molecular sieve coating material is prepared by using the porous silicon carbide ceramic with the surface rich in silicon as a carrier; using solid materials, such as silicon blocks, quartz, sliicon-alumininm composite oxide sintering powder with adjustable sliicon-alumininm atomic ratio, and the like as a silicon source or a sliicon-alumininm source, and adopting a in situ hydrothermally synthesizing method. Molecular sieve crystals preferentially nucleate on the surface of the porous silicon carbide ceramic due to a surface silicon layer of the porous silicon carbide ceramic, the solid silicon source or the sliicon-alumininm source are used so that the release speed of the silicon source or sliicon-alumininm source for the growth of crystal nucleus is controllable. Therefore, prepared molecular sieve coating is uniformly loaded on the surface of the silicon carbide ceramic carrier; the composite material formed by a molecular sieve and the porous silicon carbide ceramic has a unique micropore / macropore structure; chemical combination is realized between the molecular sieve and the porous silicon carbide ceramic, and the molecular sieve and the porous silicon carbide ceramic have high interface combination strength. The preparation method has simple technology, convenient operation without complex equipment and low manufacturing cost and is more suitable for industrialized and mass production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

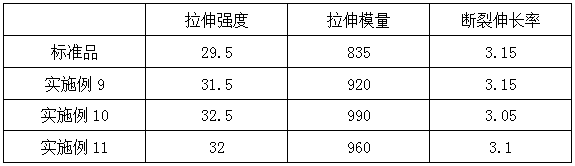

Multistage stretching technology for manufacture aramid fiber III

ActiveCN102797061AImprove mechanical propertiesImprove product qualityArtificial filament washing/dryingArtificial filament heat treatmentPolymer scienceAramid

The invention relates to a multistage stretching technology for manufacture aramid fiber III, which belongs to the technical field of chemical fiber. The multistage stretching technology comprises a negative stretching technology, plasticizing stretching treatment, water washing and plasticizing stretching treatment again to obtain final products. The multistage stretching technology can obviously improve the mechanical property of aramid fiber III, the multifilament stretching strength is increased to 32cN / dtex from 30cN / dtex, and the stretching modulus is increased to 950cN / dtex from 850cN / dtex. High-strength and high-modulus fiber obtained can be applied to applicable fields with higher market requirements.

Owner:中蓝晨光化工有限公司

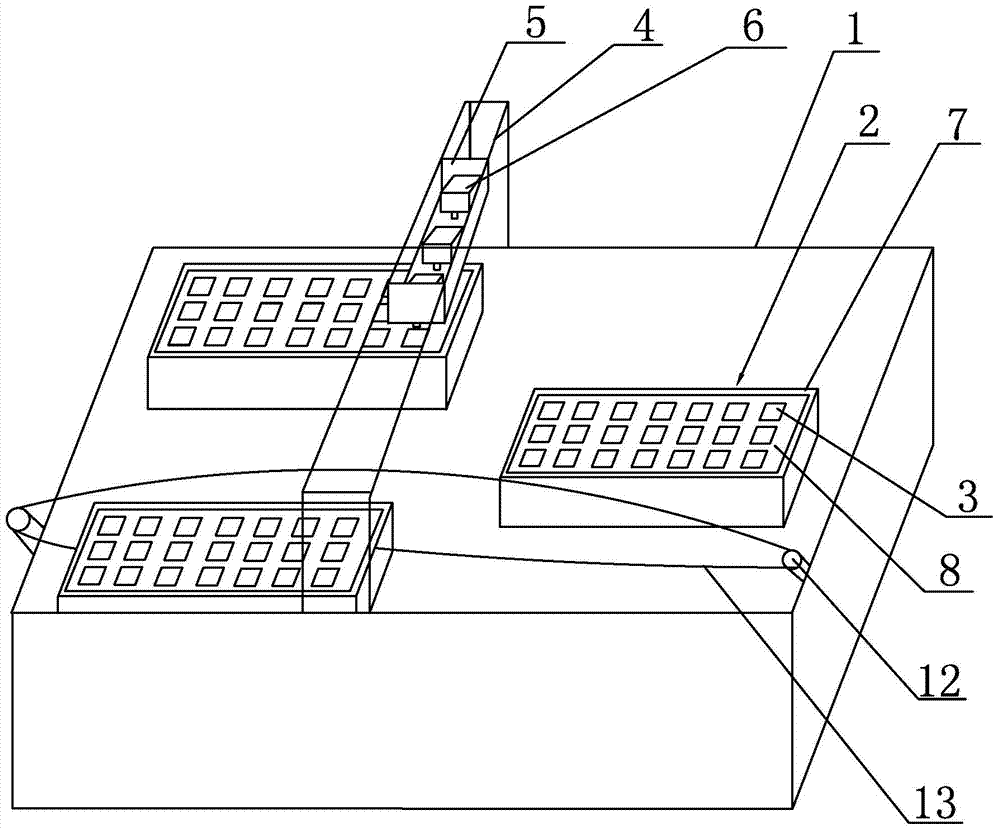

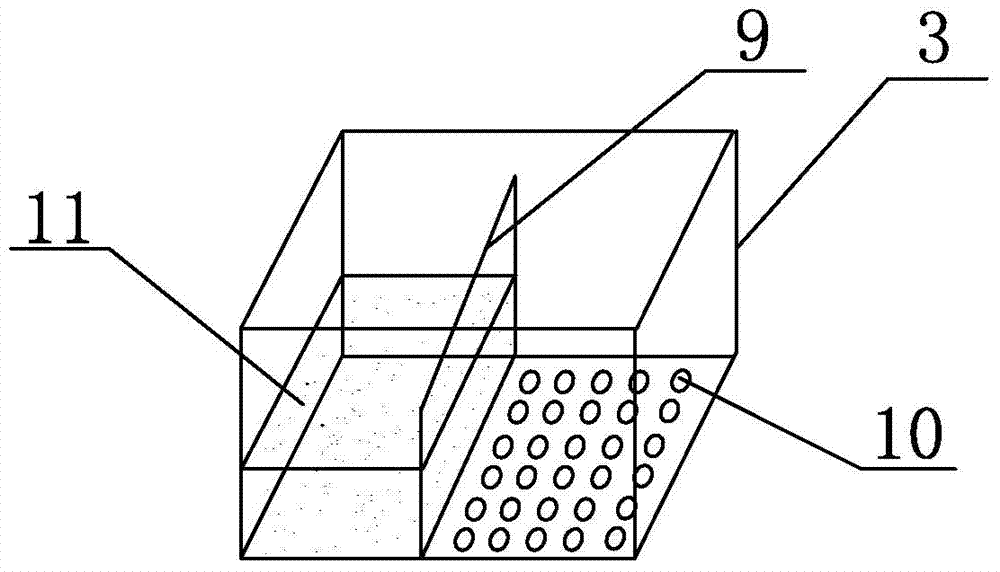

Fodder feeding system for culturing aquatic organisms in baskets on water surface

The invention discloses a fodder feeding system for culturing aquatic organisms in baskets on a water surface. The fodder feeding system comprises a rectangular aquaculture pond, and is characterized in that a plurality of rectangular aquaculture unit blocks capable of floating in water are arranged in the aquaculture pond, a plurality of aquaculture baskets are longitudinally and transversely uniformly arranged in each aquaculture unit block, overhead rails which are higher than the water surface are arranged in the middle of the aquaculture pond along the width direction of the aquaculture pond, a rectangular support capable of moving along the overhead rails back and forth is arranged on the overhead rails, a plurality of feeding machines are arranged in the rectangular support, the quantity of the feeding machines is identical to the quantity of rows of the aquaculture baskets in each aquaculture unit block, and shifting mechanisms for shifting the integral aquaculture unit blocks along the length direction of the aquaculture pond back and forth are arranged on two sides of the aquaculture pond, and can drag the aquaculture unit blocks to be slowly shifted while the feeding machines feed fodder into the aquaculture baskets column by column. The fodder feeding system has the advantage that the fodder feeding system is suitable for accurately, quickly, efficiently and conveniently feeding the fodder into the aquaculture baskets on the large-area water surface.

Owner:NINGBO UNIV

Color pencil lead with high flexural strength and preparation method thereof

ActiveCN108129914AImprove erasabilityHigh flexural strengthPencil leadsNon-propelling pencilsFlexural strengthSolvent

The invention discloses a color pencil lead with high flexural strength and a preparation method thereof. The preparation method comprises blending 20-40 parts by mass of a thermosetting resin, 10-30parts by mass of a thermoplastic resin, 30-50 parts by mass of base raw materials, 10-20 parts by mass of pigment powder, 3-7 parts by mass of an enhancing filler and a solvent under heating, removinga part of the solvent, carrying out roller mixing at 100-120 DEG C until uniform dispersion, extruding the mixture through a bar extruding machine to obtain bars, extruding the bars to obtain pencilleads, and then cutting the pencil leads to obtain color pencil leads with high flexural strength. The preparation method can produce a color pencil lead with high flexural strength, high writing markscrubbability and bright color, has simple processes, realizes a low cost and has high efficiency. The method is suitable for direct large-scale production of color pencil leads with various specifications in the traditional large-scale production factory without new equipment.

Owner:烟台好前程文具有限公司

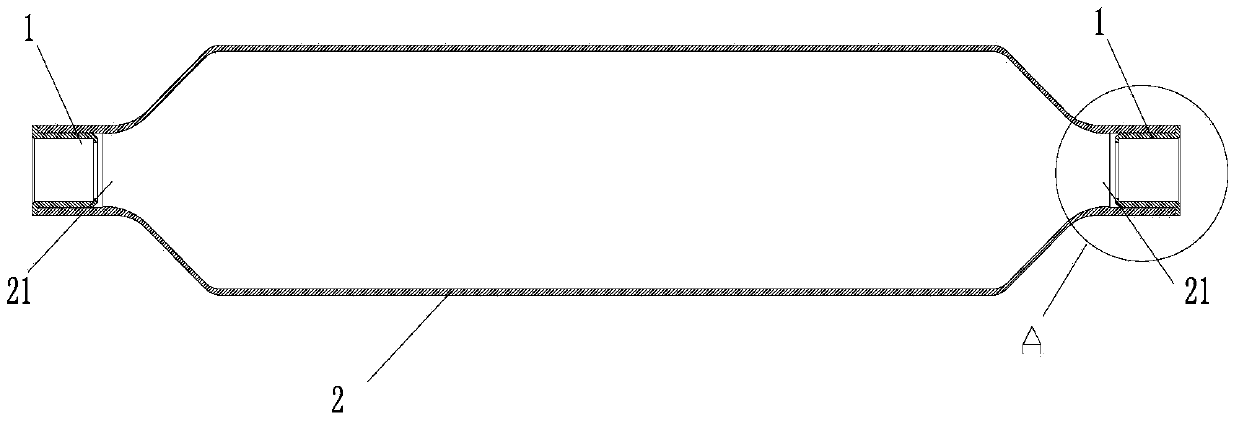

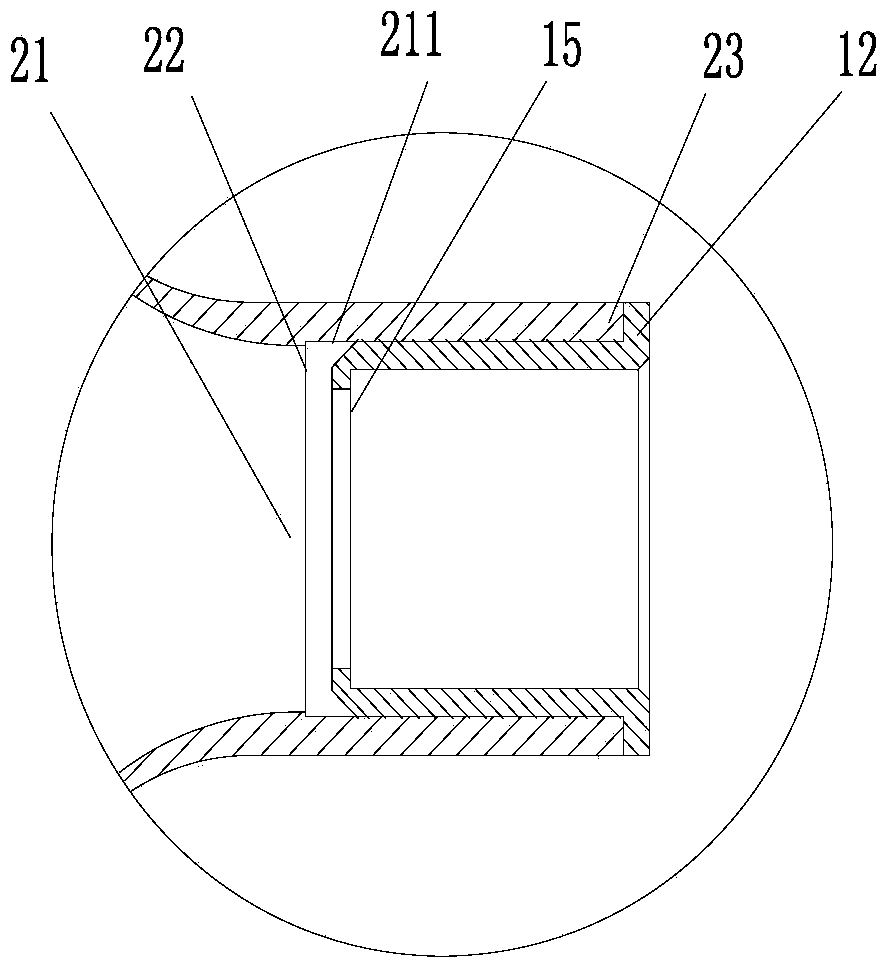

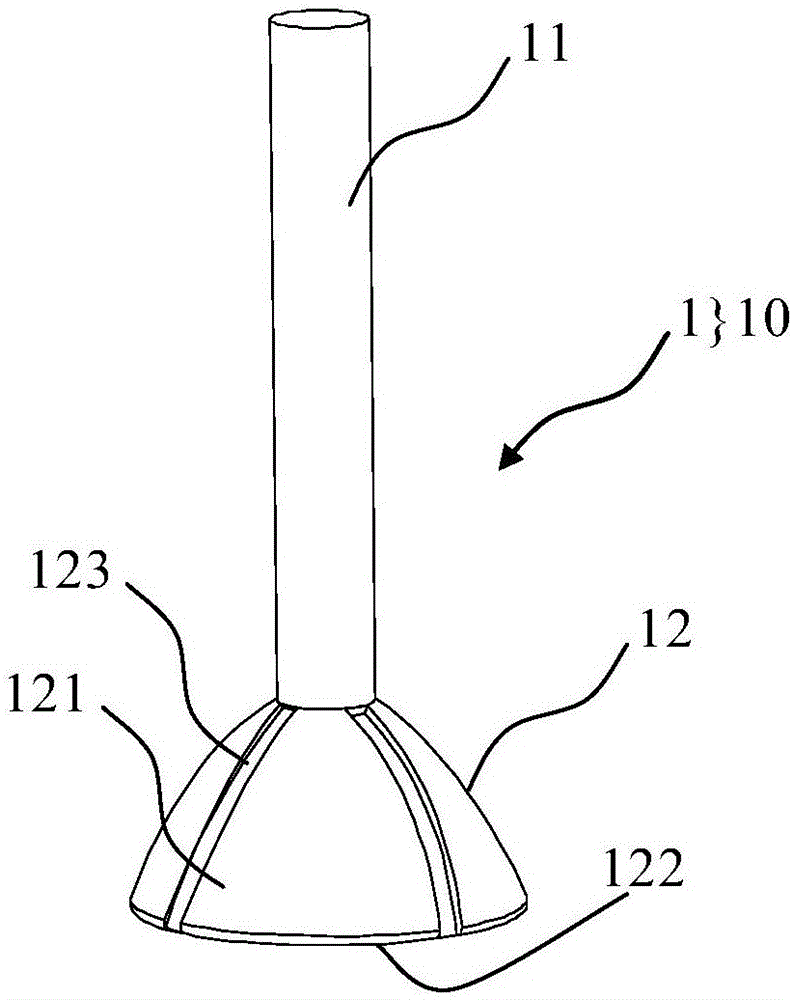

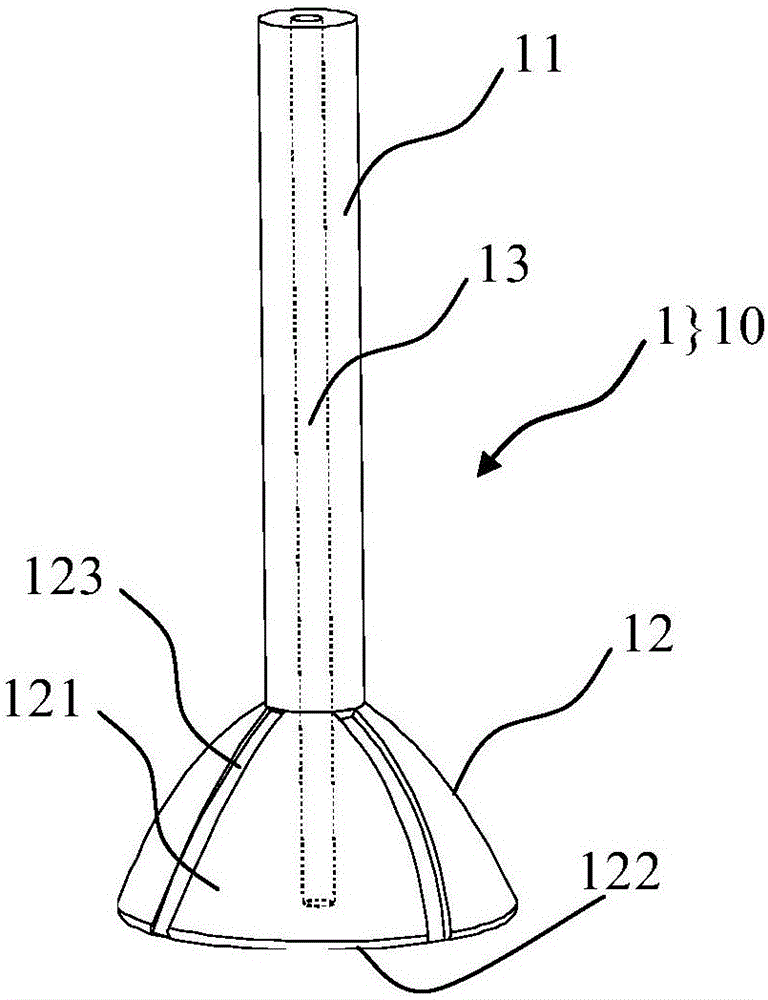

Fluid storage muffler

ActiveCN103791196AIntensity effectReduce contact surfacePipe elementsNon-disconnectible pipe-jointsEngineeringCopper

The invention relates to a fluid storage muffler, and belongs to the technical field of refrigeration. The fluid storage muffler comprises a body (2) made of stainless steel, and connection ports (21) allowing fluid to flow in and flow out are formed in the body (2). The fluid storage muffler is characterized in that a connecting sleeve (1) made of a copper material is welded and fixed in at least one of the connection ports (21), each connecting sleeve (1) comprises a barrel portion (11) and a protruding end portion (12) formed by flanging outwards from the barrel portion (11), an outer wall (111) of each barrel portion (11) is matched with an inner wall (211) of the corresponding connection port (21), and each protruding end portion (12) is matched with an end portion (23) of the corresponding connection port (21). The fluid storage muffler is high in working reliability, products of manufacturers can realize universality, cost is lowered on the premise that welding reliability of the products is guaranteed, and environmental pollution in the manufacturing process and copper pipe deformation in the transportation process are reduced.

Owner:XINCHANG COUNTY SITONG ELECTRICAL CO LTD

Preparation method of flexible polyhydroxyl polyester fibers

ActiveCN103774267AAdequate responseReduce wasteArtificial thread manufacturing machinesFilament/thread formingPolyethylene glycolMoisture absorption

The invention relates to a preparation method of flexible polyhydroxyl polyester fibers. The preparation method comprises the steps of mixing dihydric alcohol, polyhydroxyl and polyethylene glycol macromolecules according to certain molar ratio, esterfying in different stages, wherein slightly excessive acid is used in a first esterfying stage to ensure that parts of polyhydric alcohol, which has low ability to be involved esterification reaction, can be fully reacted and grafted into a polyester molecular chain; supplementing dihydric alcohol to regulate terminal carboxyl group of copolyester in a second esterfying stage, and then carrying out condensation polymerization to prepare flexible polyhydroxyl polyester; and performing melt spinning to the flexible polyhydroxyl polyester to prepare the flexible polyhydroxyl polyester fiber. The flexible polyhydroxyl polyester fiber has good moisture absorption performance and softening property, and the fiber can be dyed in a mild condition and has good dyeing performance due to the polyhydroxyl active sites in fiber and ether bonds in flexible chain polyethylene glycol; the flexible polyhydroxyl polyester fiber can be widely applied to preparation of antistatic moisture-absorption and sweat-releasing fibers and used as a closed-fit fabric. The modification effect is remarkable and the method is particularly suitable for melt direct-spinning process.

Owner:JIANGSU DELI CHEM FIBER CO LTD

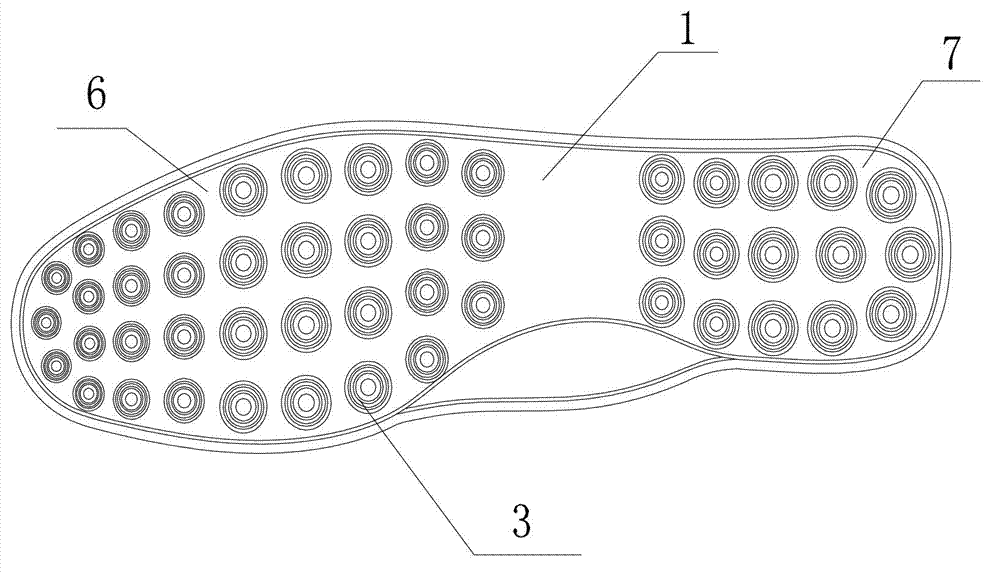

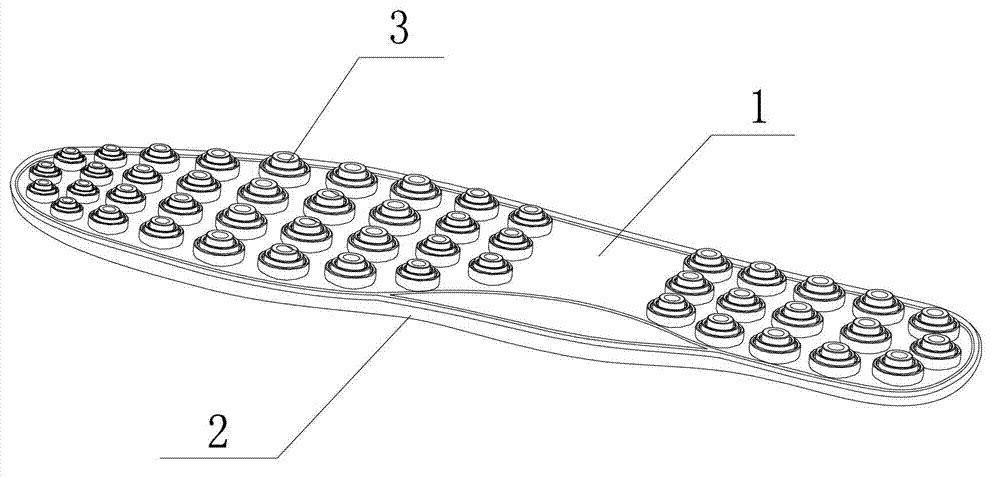

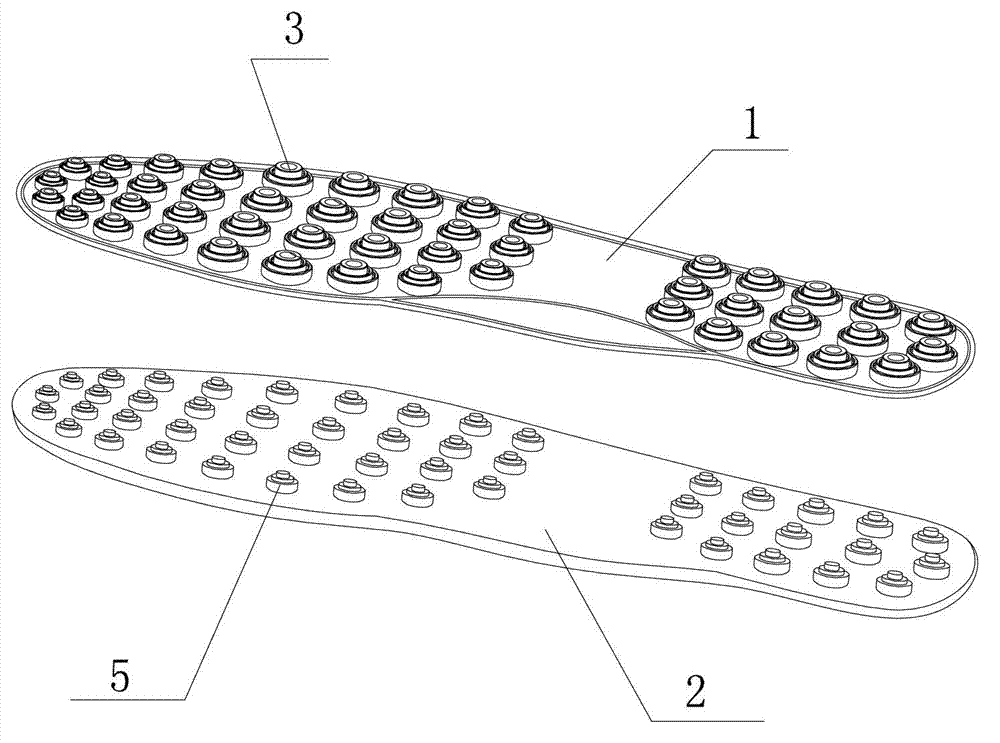

Shock-absorbing sole

The invention relates to a shock-absorbing sole which comprises a sole body. The sole body is used for contacting with the ground, a plurality of shock-absorbing elements which are protruded towards the ground are arranged on the sole body and are hollow, and an opening is arranged at one end, which is far away from the ground, of each shock-absorbing element. The shock-absorbing sole overcomes the shortcoming that an existing shoe is poor in shock-absorbing effect, and the shock-absorbing effect of the shock-absorbing sole is remarkably improved.

Owner:MAOTAI FUJIAN SOLES CO LTD

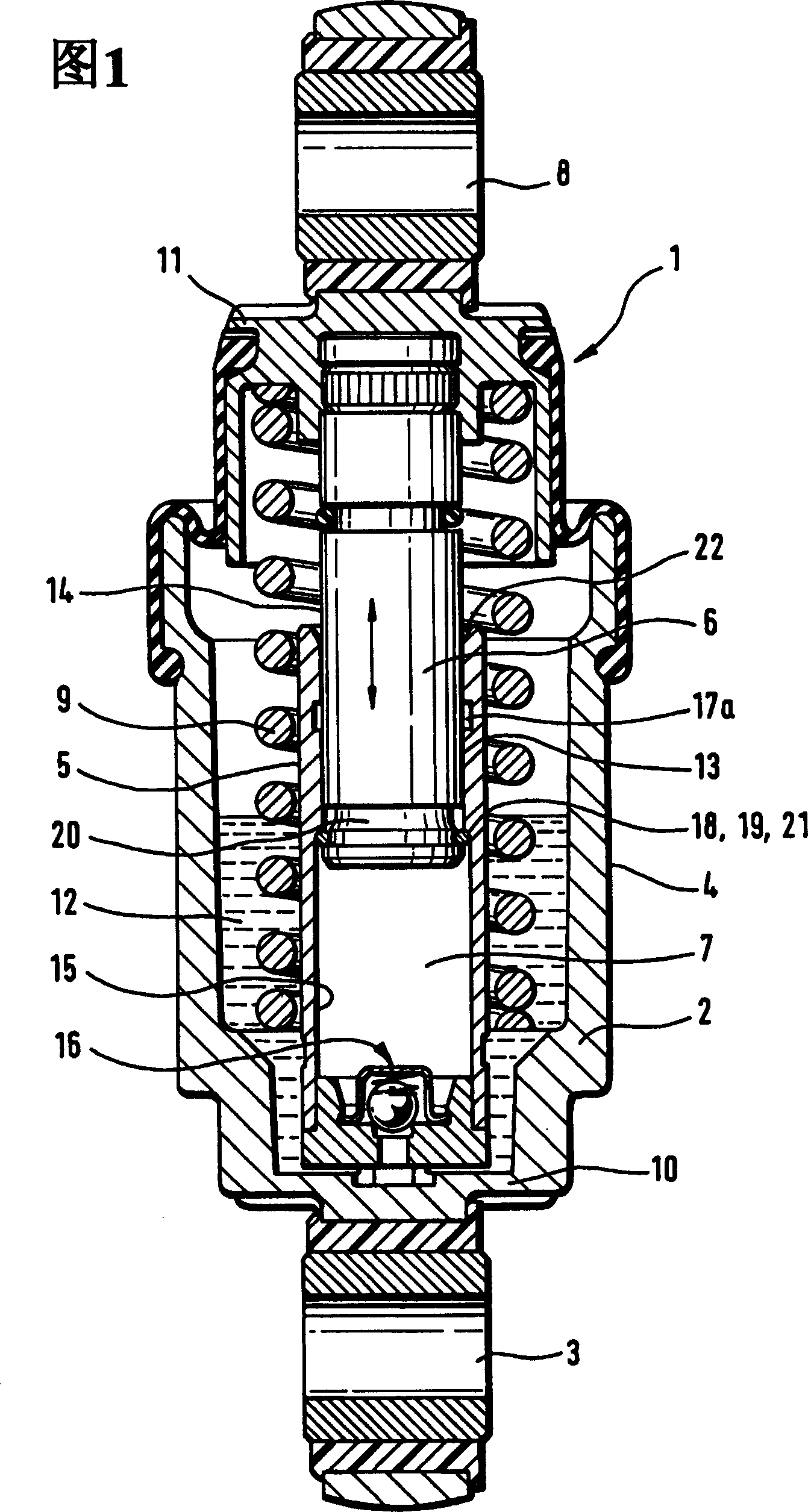

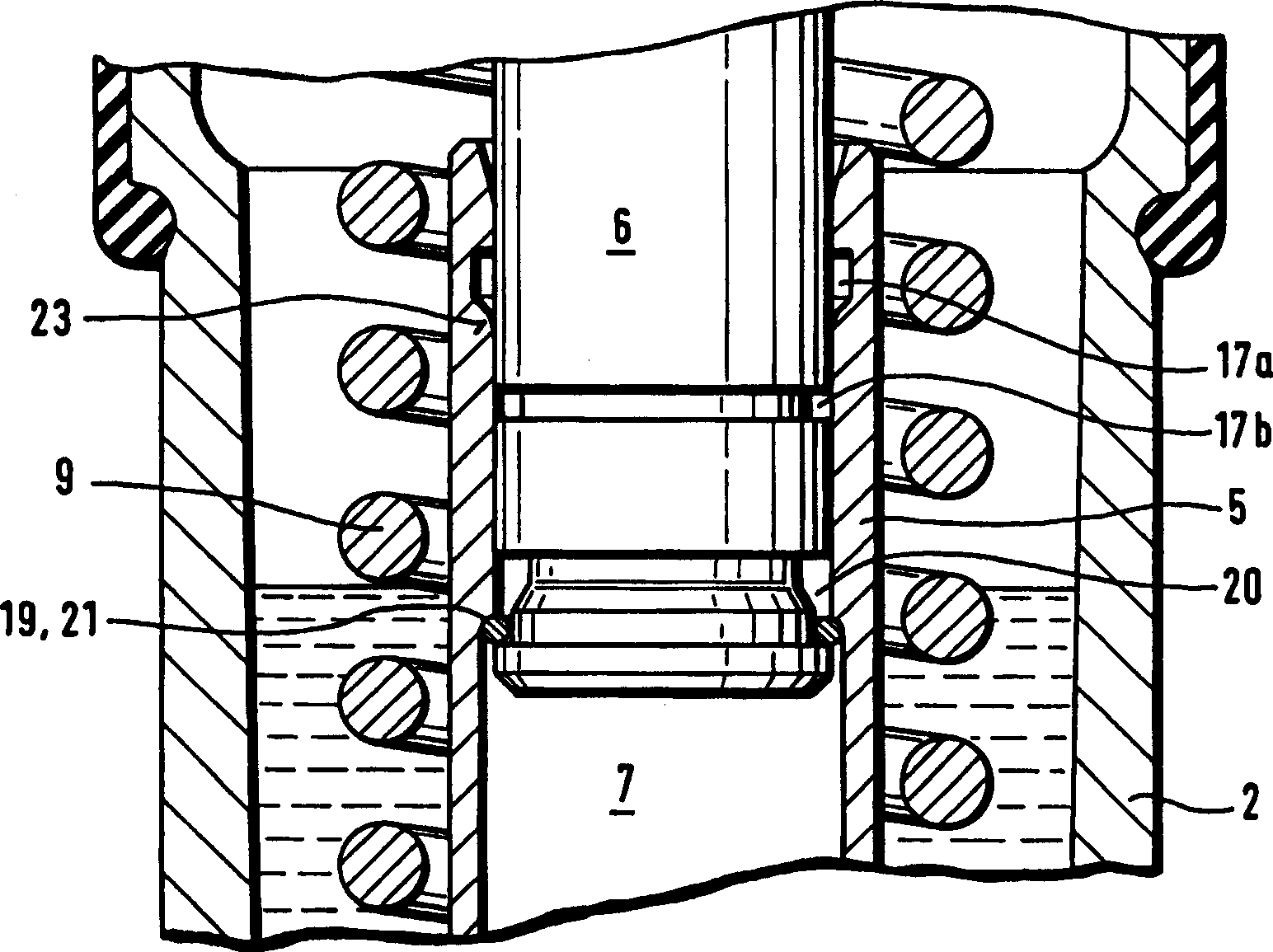

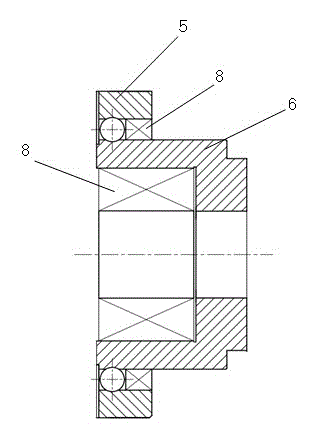

Hydraulic tensioner

A tensioner for a traction drive includes a cylinder arranged in a housing at a distance to a housing wall to thereby define an interior space which contains hydraulic fluid. A piston is received in the cylinder for back-and-forth movement and bounds a pressure chamber containing hydraulic fluid. The piston has a cylinder-distal end which is operatively connected to a spring-biased tension roller supported on a traction member. Formed between the piston and the cylinder is a leakage gap, and a reservoir for hydraulic fluid is provided in an area of the leakage gap to prevent ingress of air into the pressure chamber, when the traction drive is at a rest.

Owner:SCHAEFFLER TECH AG & CO KG

Quake-proof construction steel with yield strength of 160MPa and production method thereof

InactiveCN101775541AImprove purityHigh strengthTemperature control deviceFurnace typesProof constructionChemical composition

The invention discloses quake-proof construction steel with the yield strength of 160MPa and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.002 to 0.005 percent of C, less than or equal to 0.03 percent of Si, 0.10 to 0.50 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, 0.002 to 0.007 percent of Mg, 0.020 to 0.070 percent of Ti, 0.010 to 0.030 percent of Nb, 0.001 to 0.003 percent of N, less than or equal to 0.050 percent of Al, and the balance of Fe and inevitable impurities. The production method thereof comprises the steps of desulfuration of molten iron, converter blowing, vacuum treatment, continuous casting, hot rolling, cooling and the like. When the yield strength of steel products exceeds 180Mpa, an annealing treatment step is added after the cooling step. Experiments prove that the quake-proof construction steel with the yield strength of 160MPa has the characteristics of low yield strength, high elongation and excellent impact toughness; and the production method of the steel has the advantages of simple process flow and low production cost.

Owner:武钢集团有限公司

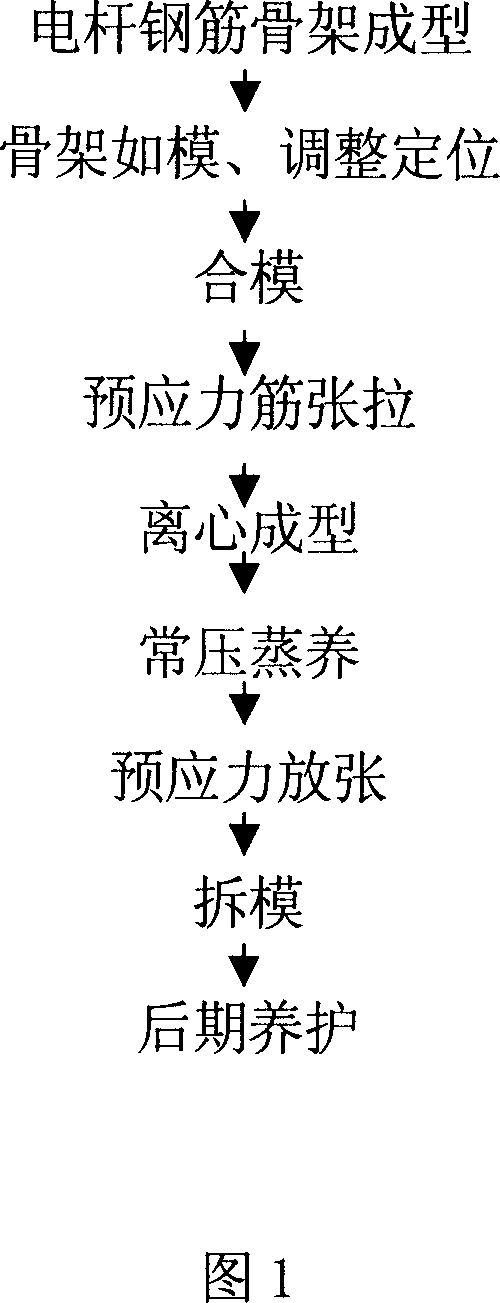

Method for manufacturing wire pole from steel fiber concrete with no bracing wire

InactiveCN1958261AImprove crack resistancePrevent sudden increase in centrifugal forceMixing operation control apparatusCeramic shaping apparatusRebarEmulsion

A method for manufacturing the electric transmission line post without pull cable A high-strength antiwear composite wood-plastics board is composed of an artificial core board with two adhesive layers on its both surface, and two veneers adhered respectively onto said two adhesive layers. Said veneer is chosen from high-density plywood, polyhydroamine solution immersed paperboard, and PCC plate. Said adhesive is chosen from MVF adhesive, high-adhesion emulsion adhesive and universal adhesive. Proportionally mixing cement, water, sand, broken stone and steel fibers, binding a skeleton with reinforcing bars, loading the skeleton in a mould, pouring said mixture in said mould, closing the mould, centrifugal shaping at a gradually increased rotation speed, and ordinary-pressure steam curing. Its product has no cracking.

Owner:HENNAN ELECTRIC POWER SURVEY & DESIGN INST

Manufacturing method of ceramic sheet with infiltration layer

The invention provides a manufacturing method of a ceramic sheet with an infiltration layer. The manufacturing method comprises the following steps: A, sending an unfired brick, with thickness not more than 6.5mm, of a ceramic sheet to a kiln and performing first firing at 600-1050 DEG C; B, applying organic infiltrated glaze ink and organic infiltration aid ink to the green body subjected to first firing; C, carrying out second firing at 1150-1250 DEG C; and D, carrying out polishing and edging to obtain the ceramic sheet product. The ceramic sheet manufactured by adopting the method has the beneficial effects that an infiltration layer formed by infiltrated glaze ink has certain thickness and infiltrates into a precoat, so that the decorative patterns are resistant to wear, thus solving the problems in the prior art that printed decoration layers formed by conventional ink-jet printing do not have a stereoscopic sense of layering and are not resistant to wear.

Owner:FOSHAN DONGPENG CERAMIC +2

Concrete cracking resisting waterproofing agent

The invention relates to a novel concrete cracking resisting waterproofing agent and particularly relates to an aluminum-slag-powder concrete cracking resisting waterproofing agent which is prepared from aluminum slag powder, steel slag powder, mineral slag, fly ash and a small amount of admixture, wherein the aluminum slag powder, the steel slag powder, the mineral slag and the fly ash serve as the raw materials. The aluminum slag powder accounts for 0.3-0.7%, the steel slag powder accounts for 10-30%, the mineral slag accounts for 20-70%, the fly ash accounts for 5-20% and the admixture accounts for 1-3%, wherein the total percent by weight of the components is 100%. The concrete cracking resisting waterproofing agent is low in construction cost and can be used to maintain easily, and the mixing amount of components of the concrete cracking resisting waterproofing agent is easy to control.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

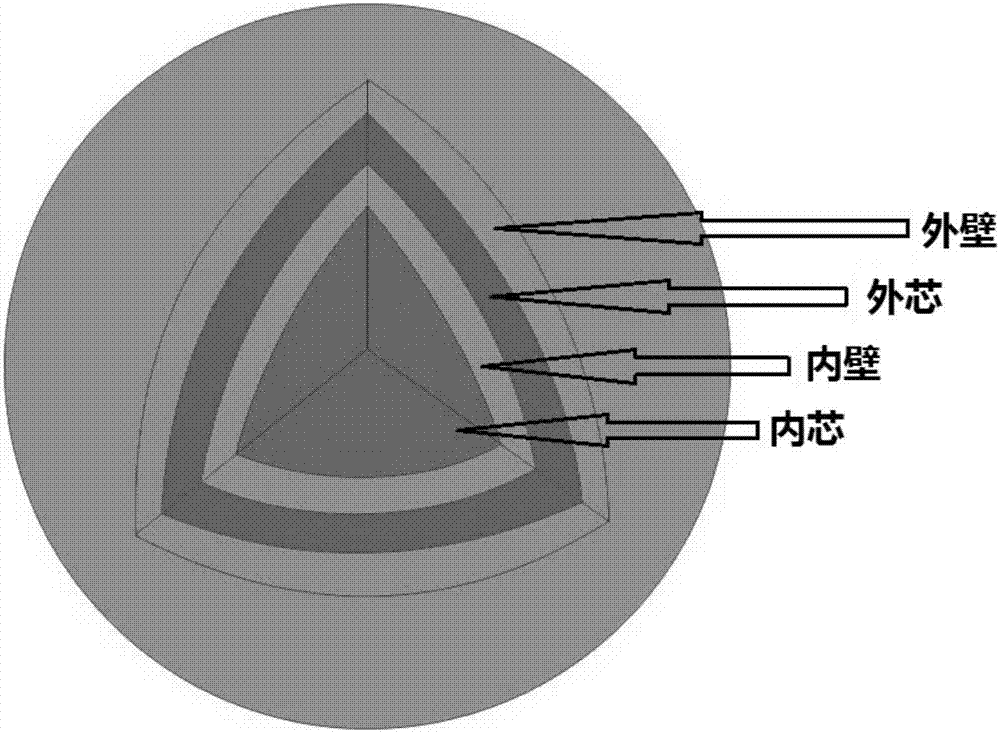

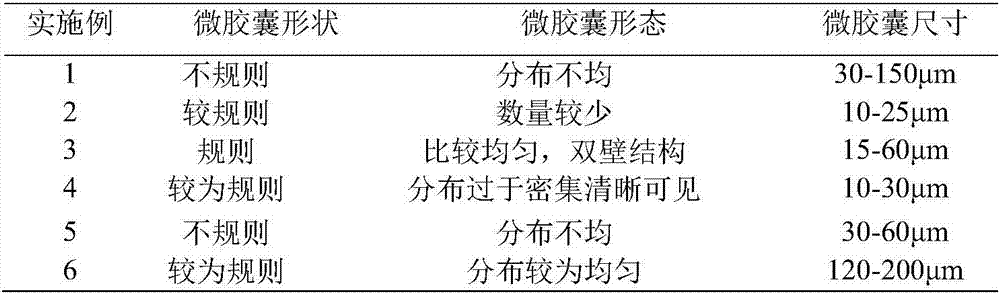

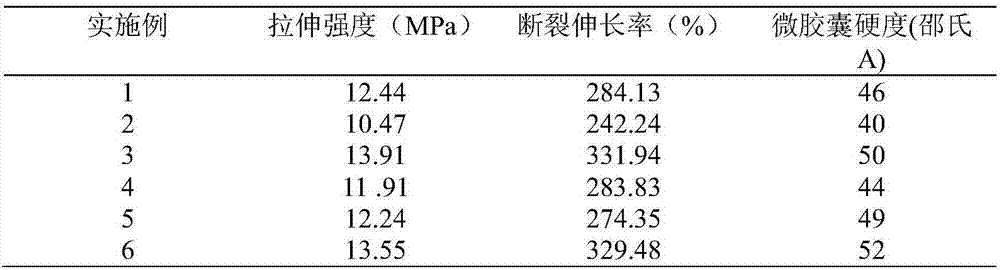

External repairing internal fixing type polyurea-based dual-wall self-repairing microcapsule and preparation method thereof

ActiveCN107970868AExcellent physical and chemical propertiesExtend service lifeCoatingsMicroballoon preparationPrepolymerEmulsion

The invention provides a dual-wall microcapsule system which takes aliphatic isocyanate-amine-terminated polyether polymer as a repair agent and takes an amine group chain extender as a curing agent.The external repairing internal fixing type polyurea-based dual-wall self-repairing microcapsule comprises an inner-layer capsule wall and an outer-layer capsule wall, wherein the inner-layer capsulewall coats the amine group chain extender emulsion, and the outer-layer capsule wall coats prepolymer emulsion; the inner-layer capsule wall and the outer-layer capsule wall are both polyurea preparedwith an interfacial polymerization method; the polyurea of the inner-layer capsule wall is obtained in a way that the amine group chain extender emulsion coated with the inner-layer capsule wall andthe prepolymer emulsion coated with the outer-layer capsule wall react; the polyurea of the outer-layer capsule wall is obtained in a way that the amine group chain extender emulsion and the prepolymer emulsion coated with the outer-layer capsule wall react; the repairing agent and the curing agent are respectively stored in an inner-layer capsule core and an outer-layer capsule core. Therefore, the problem that the contact rate of the repairing agent and the curing agent is low is solved, and in addition, the repairing agent and the curing agent quickly react so the quick repair of cracks isrealized and the external repairing internal fixing type polturea-based dual-wall self-repairing microcapsule also has a wide application prospect.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

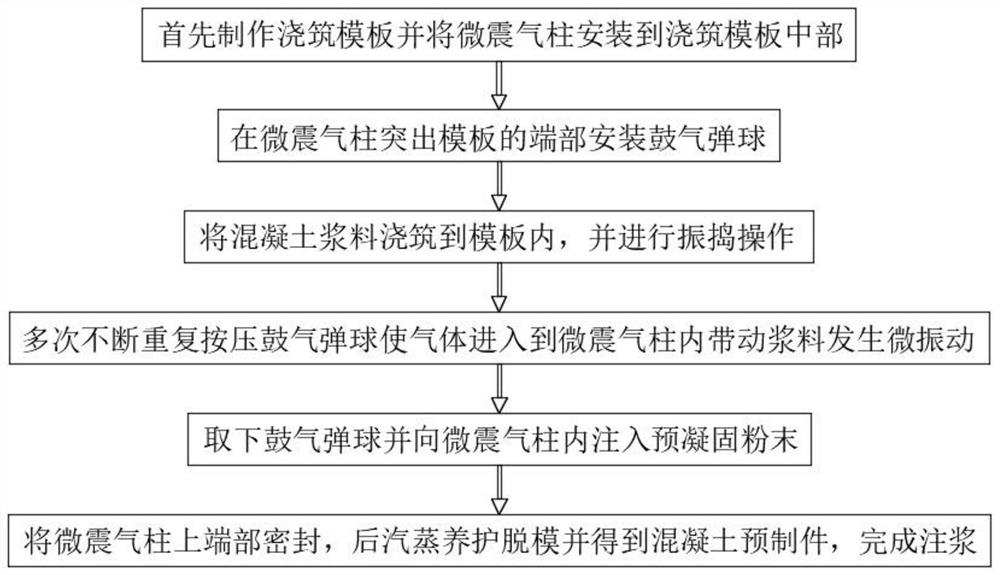

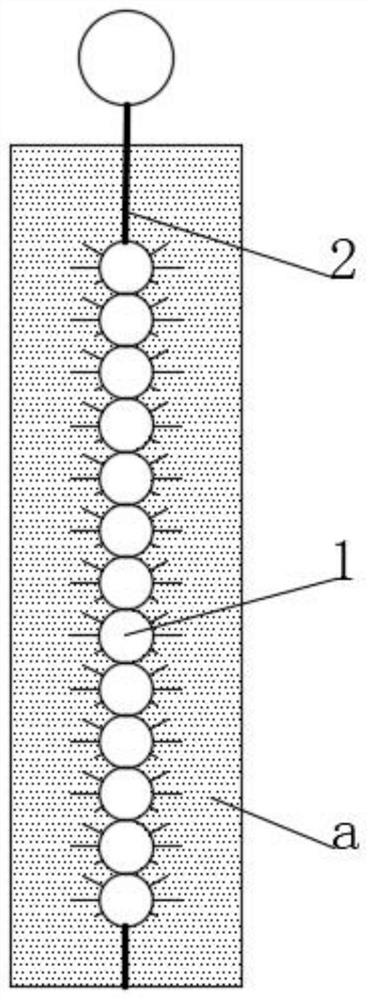

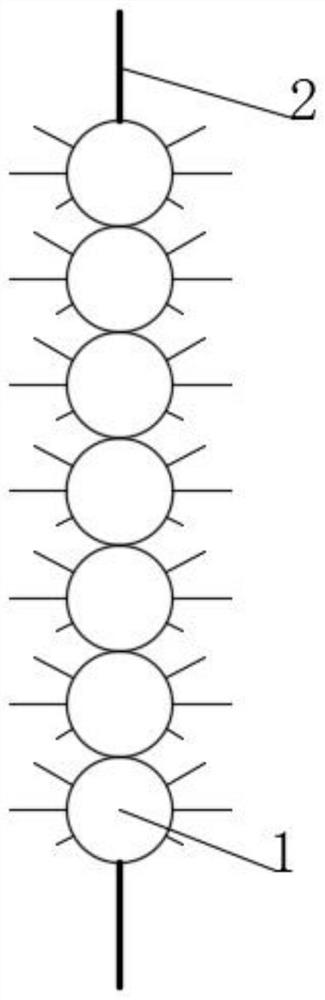

Low voidage grouting process of concrete pouring

InactiveCN111791336AEffective looseningHigh strengthCeramic shaping apparatusArchitectural engineeringStructural engineering

The invention discloses a low voidage grouting process of concrete pouring, and belongs to the field of concrete pouring. According to the low voidage grouting process of concrete pouring, a micro-vibration air column is arranged in a mold plate; after grouting, an inflated ball is squeezed to transfer the position of inert gas inside the pinball, so the micro-vibration air column continuously generates outward expansion vibration and the location of a micro-vibration rod is continuously moved; therefore, surrounding concrete slurry can be effectively loosened, the porosity volume inside the micro-vibration air column can be effectively lowered, and the strength and quality of concrete is significantly improved; and at the same time, pre-solidified powder is injected into the inside of themicro-vibration air column after grouting, so on the one hand, voids in the micro-vibration air column can be effectively filled and influence of the voids on a concrete prefabricated member is effectively avoided, and on the other hand, an operator can open a sealed opening part of the micro-vibration air column to detect the phenomenon of the pre-solidified powder so as to judge the water seepage condition of the concrete prefabricated member, so timely maintenance is convenient and safety is improved.

Owner:百汇环境工程有限公司

Fan impeller

The invention discloses a fan impeller which comprises an impeller cover and an impeller dish, wherein the impeller cover and the impeller dish are connected together through vanes and the impeller dish is provided with a plurality of openings which are arranged uniformly and used for reducing the weight of the impeller dish. Compared with the prior art, the openings which are arranged uniformly on the impeller dish can effectively reduce the weight of the impeller dish, so that the power of a motor can be reduced to achieve the purpose of energy saving, meanwhile, the strength of the impeller dish cannot be affected due to the thickness of the impeller dish is not changed, if the number and size of the openings can be under effective control.

Owner:宁风科技(宁波)有限公司

Pulping process of high-cleanliness primary-color bamboo pulp

InactiveCN109706773AFully soakedIncrease concentrationCellulosic pulp after-treatmentPulp beating methodsFiberHigh concentration

The invention relates to the technical field of household paper, in particular to a pulping process of high-cleanliness primary-color bamboo pulp, the process comprises the following steps: fully soaking and moistening bamboo pulp, carrying out high-concentration pulping by using a high-concentration pulping machine, carrying out low-concentration grinding by using a low-concentration grinding machine, carrying out coarse screening, two-section pressure screen fine screening and grading screening treatment to obtain long-fiber pulp and short-fiber pulp, and finally, mixing 50-90% of the long-fiber pulp and 10-50% of the short-fiber pulp to prepare pulp, adding a certain amount of a softening agent and a wet strength agent, and uniformly mixing to obtain the high-cleanliness primary- colorbamboo pulp. According to the process, redundant fibrous impurities can be removed so as to ensure the paper surface cleanliness, the pulping uniformity is good, and the strength, the softness and thehand feeling of domestic paper are improved.

Owner:CHONGQING LIWEN SANITARY PAPER MFG CO LTD

Preparation method of vanadium phosphorus oxide catalyst

ActiveCN106938197AIntensity effectAffect reactivityOrganic chemistryPhysical/chemical process catalystsChemistryCarbon nanotube

The invention relates to the technical field of industrial catalysis, and provides a preparation method of a vanadium phosphorus oxide catalyst. The method comprises the following steps: preparing a metal assistant-doped oxovanadium hydrogenphosphate hemihydrate catalyst precursor powder, wherein the metal assistant is at least one of Fe, Mo, Co, Ce, Zr, Nb, and Ni, and a molar ratio of the metal assistant to vanadium is 0.06 to 0.15; and mixing the catalyst precursor powder with a binder and an auxiliary material, and carrying out strip extrusion or tabletting molding to obtain the vanadium phosphorus oxide catalyst, wherein the binder is at least one of phosphoric acid, pyrophosphoric acid, trimethyl phosphate, triethyl phosphate, aluminum dihydrogen phosphate, potassium dihydrogen phosphate, dipotassium hydrogen phosphate, zinc phosphate, tricalcium phosphate, ammonium phosphate, ammonium pyrophosphate and ammonium hexametaphosphate, the auxiliary material is at least one of graphite, carbon nanotubes, graphene and carbon powder, and a mass ratio of the catalyst precursor powder to the binder to the auxiliary material is 100:(0.1-15):(0.1-10). The preparation method of vanadium phosphorus oxide catalyst is simple and has no special requirements of production devices, and the obtained catalyst has the advantages of high strength, good catalytic effect, and facilitation of industrial production and application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing compositey sealed polyisocyanates coating

InactiveCN104311792AIncrease the degree of cross-linkingExcellent performancePolyurea/polyurethane coatingsPrepolymerIsocyanate

The invention discloses a method for preparing a compositely sealed polyisocyanates coating. The method comprises the following steps: heating and stirring polyether polyol and 4,4-diphenylmethane diisocyanate, reacting to obtain a 4,4-diphenylmethane diisocyanate-polyether polyol prepolymer, performing composite sealing on the 4,4-diphenylmethane diisocyanate-polyether polyol prepolymer by using malonic acid diethyl ester, ethyl acetoacetate and 3,5-lutidine so as to obtain a polyisocyanates curing agent, and finally adding an amino chain expanding agent and a powder filling material into the compositely sealed polyisocyanates curing agent, thereby obtaining the compositely sealed polyisocyanates coating. When heated, the compositely sealed polyisocyanates coating prepared by using the method can be gradually unsealed and cured in different periods, the phenomenon of edge curtain coating of conventional singly sealed polyisocyanates in the baking process because of too high unsealing temperature is avoided, the filming property of the compositely sealed polyisocyanates coating is improved, a prepared film is relatively high in cross-linking degree, and thus good mechanical property is achieved.

Owner:FOSHAN GAOMING FULITE CHEM CO LTD

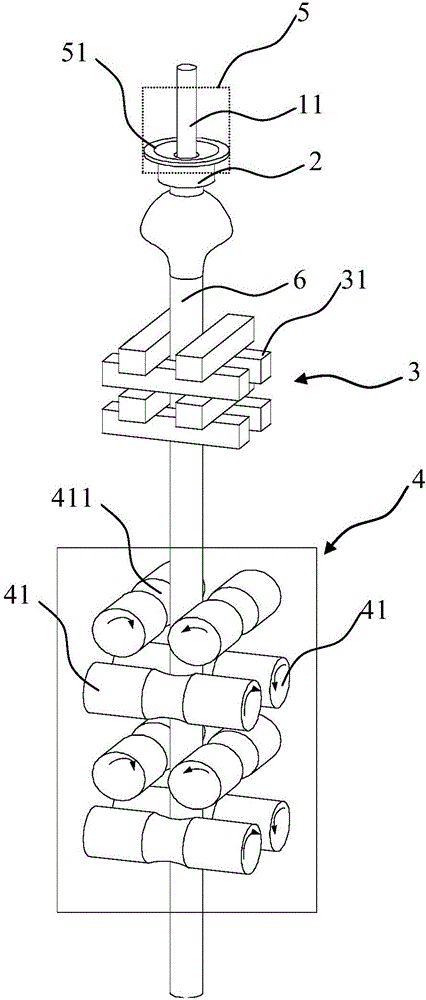

Centrally-mounted drive system of electric bicycle

ActiveCN102745298ALittle impact on appearanceIntensity effectWheel based transmissionChain/belt transmissionSingle stageVehicle frame

A centrally-mounted drive system of an electric bicycle comprises a chain wheel, a motor, a middle shaft and a reduction box, wherein the chain wheel has a disc-shaped structure; a concave circular mounting part is arranged in the middle position of the chain wheel; a housing of the reduction box is arranged in the concave mounting part and matched with the chain wheel; a reducing mechanism in the reduction box is a composite dual-overrun clutch, wherein the inner ring of an outer clutch and the outer ring of an inner clutch share the same component which serves as the output end of a hybrid power source; and the inner ring of the outer clutch is coaxially fixed to the chain wheel. The centrally-mounted drive system of the electric bicycle employs coaxial mounting, coaxial output and single-stage helical gear parallel transmission manners and successfully avoids great change of a frame caused by lift mounting; the single-stage reducing mechanism is employed to realize coaxial output; the volume of the motor is effectively reduced, which has little influence on the appearance of the entire bicycle; and viewed from the angle of the appearance of the entire bicycle, the similarity of the electric bicycle to the bicycle is very high.

Owner:广东广天机电工业研究院有限公司

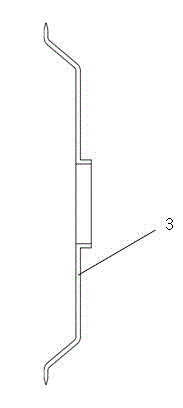

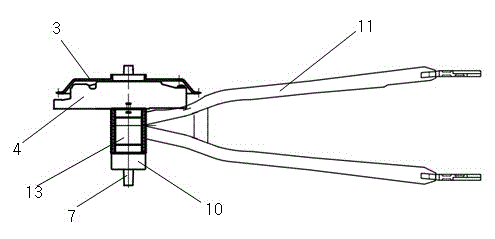

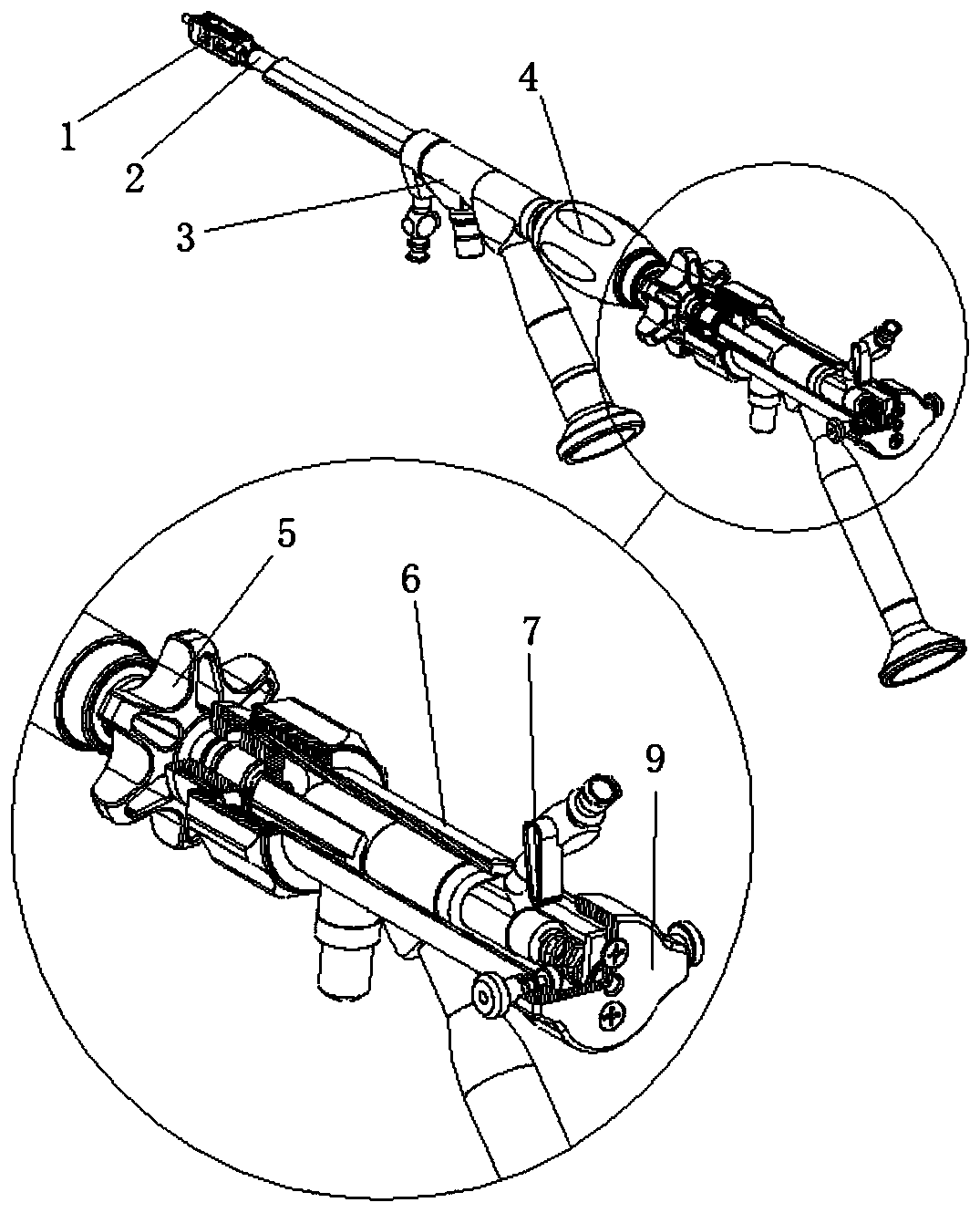

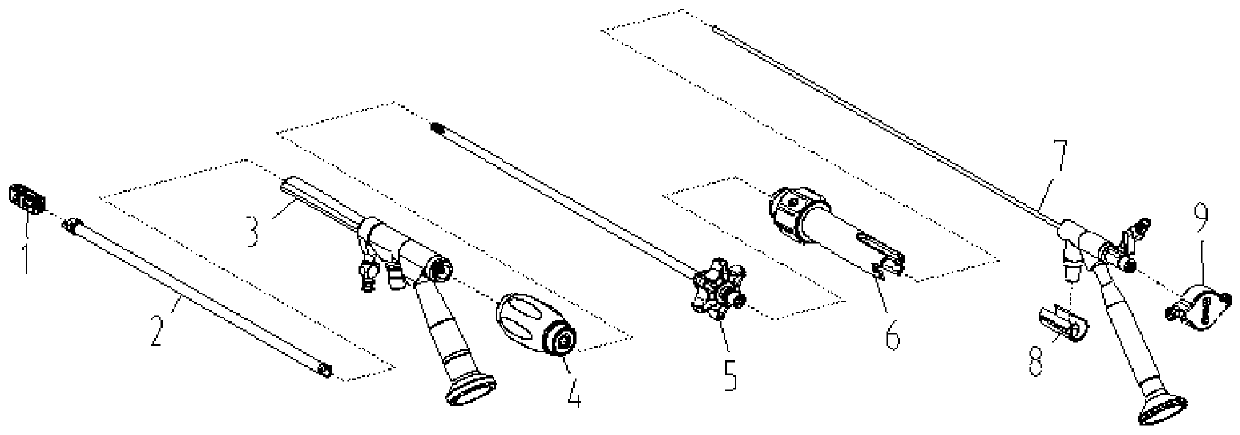

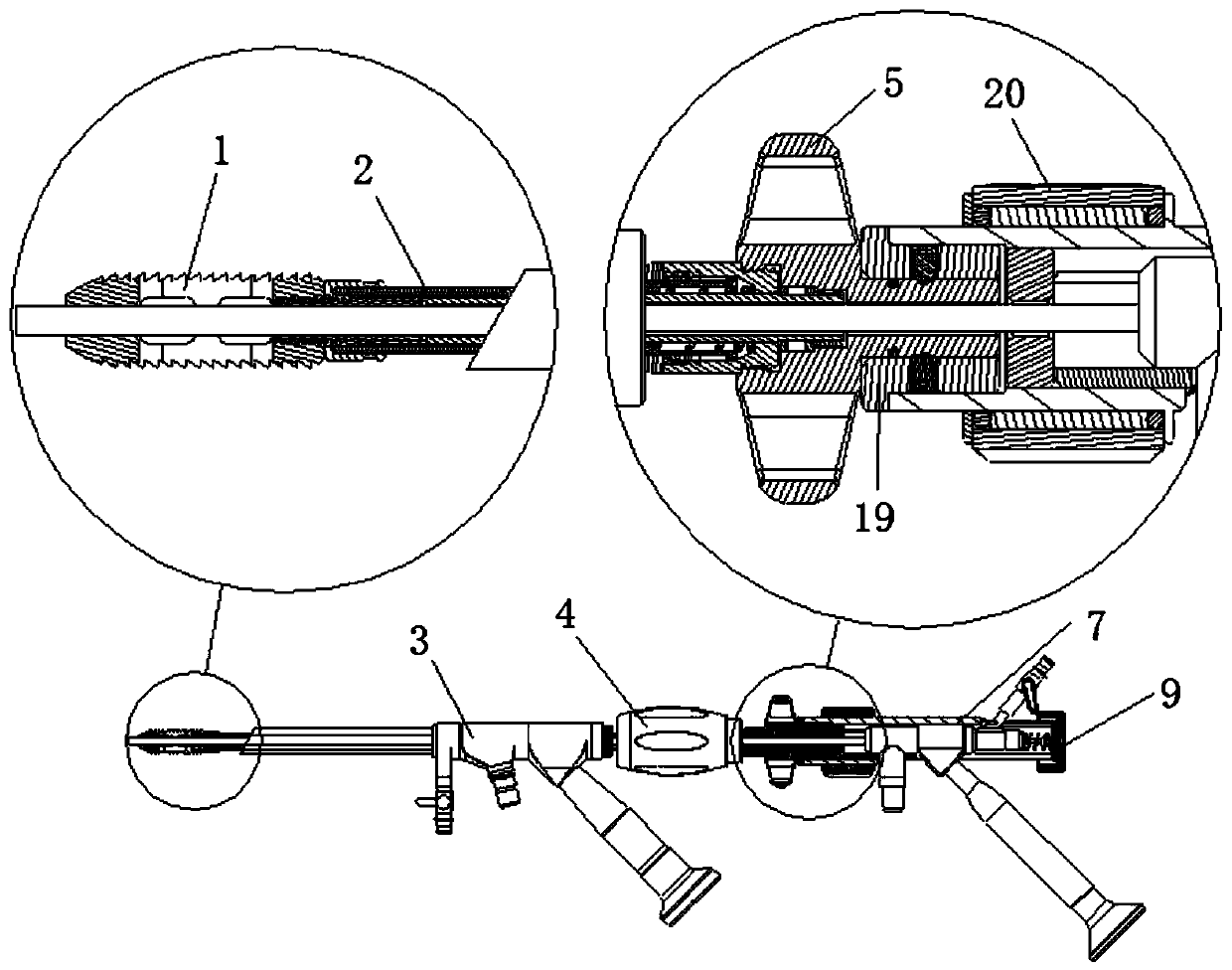

Novel spine full-endoscope fusion implantation system

ActiveCN111053631AAvoid oppressionAvoid mechanical propertiesLaproscopesEndoscopesSpinal columnAnatomy

The invention provides a novel spine full-endoscope fusion implantation system. The system comprises a front-view endoscope, a rearview endoscope, a fusion cage and a fusion cage implantation tool assembly, a clamping tube and the rearview endoscope are connected in a nested mode and then serve as a whole to be fixedly provided with a clamping tube handle, a fusion cage locker penetrates through the interior of the clamping tube and is fixedly connected with the fusion cage through a thread, a front-view endoscope regulator is connected with a combination body of a fore-view endoscope and a buckling seat in a nested manner, a knocking end cover is sleeved on the front-view endoscope regulator, and a combination body formed by the front-view endoscope regulator, the front-view endoscope, the buckling seat and the knocking end cover penetrates into the tail part of the fusion cage locker to make the forefront of the front-view endoscope reach the forefront of the fusion cage. The systemcombines one endoscope or two endoscopes with different specifications with a special tool according to different operations, monitors peripheral tissues under direct view of the endoscope in the whole process, and maximally avoids compression and tractive mechanical damage of the fusion cage to the peripheral important tissues.

Owner:ZHUHAI WEIERKANG BIOTECH

Glass tube molding mold, device and method

ActiveCN106495449AIntensity effectEasy to form internal ribsBioreactor/fermenter combinationsBiological substance pretreatmentsSurface modeManufacturing technology

The invention discloses a glass tube molding mold, device and method. The mold is installed at a discharge port of a molten glass material supply device and comprises an inner mold body, and the inner mold body is installed at the discharge port of the material supply device and comprises a connecting rod and a molding part; the molding part comprises a molding surface, the molding surface is the surface, facing the discharge port, of the molding part and is a spherical surface or conical surface or curved surface which protrudes towards the connecting rod, and at least one material groove is formed in the molding surface in a concaved mode and extends to the bottom of the molding surface from the corresponding joints. In the manufacturing technology, molten glass flows to the molding surface of the inner mold body through flow channel clearances formed in the discharge port, the molding surface guides the molten glass to be diffused in a curved surface mode to form a tube in the initial stage that the molten glass is converted from the flow state to the solidified state, inner ribs are formed by the molten glass flowing along the material grooves on the inner side of the tube, and then the glass tube is driven by a traction device to rotate, so that the inner ribs are in a spiral shape. Accordingly, the production problems in the prior art are solved, and the glass tube with the spiral ribs on the inner wall is produced.

Owner:GUOTOU BIO TECH INVESTMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com