Hydraulic tensioner

A tensioning device, hydraulic technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem that the tensioning device and the tensioning wheel cannot guarantee the positioning state, the noise of the tensioning device, etc., to avoid unfavorable , to avoid the effect of empty stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

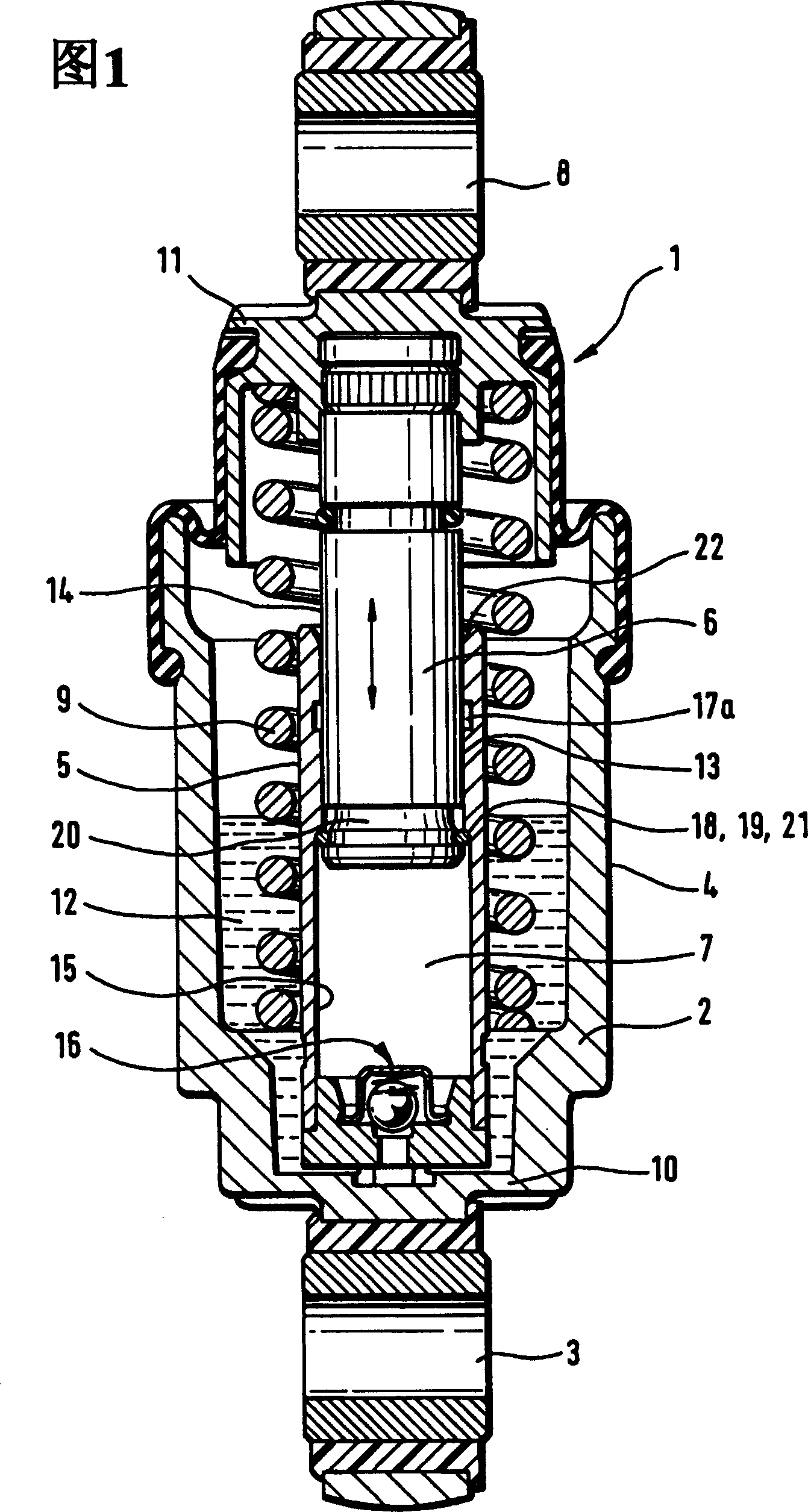

[0026] FIG. 1 shows a hydromechanically acting tensioning device 1 comprising a rotationally symmetrical pot-shaped housing 2 which is fixed but pivotable by means of fastening lugs 3 to, for example, an internal combustion engine not shown in FIG. 1 . Radially spaced from the outer wall 4, a cylinder 5 in which a longitudinally displaceable guiding piston 6 is housed concentrically within the housing. The piston 6 of the pressure chamber 7 in the end-side delimiting cylinder 5 has, on the end remote from the pressure chamber 7, a fastening lug 8 which interacts indirectly or directly with a tensioning pulley which pretensions the traction drive Traction devices, especially belts. The reasonable power supply of the tensioning wheel is completed by means of the helical compression spring 9. The helical compression spring 9 is supported on the bottom 10 of the housing 2 by the first spring end, and is supported by the second spring end on the fixed lifting lug 8 or on the opposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com