Patents

Literature

45results about How to "Rotary realization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

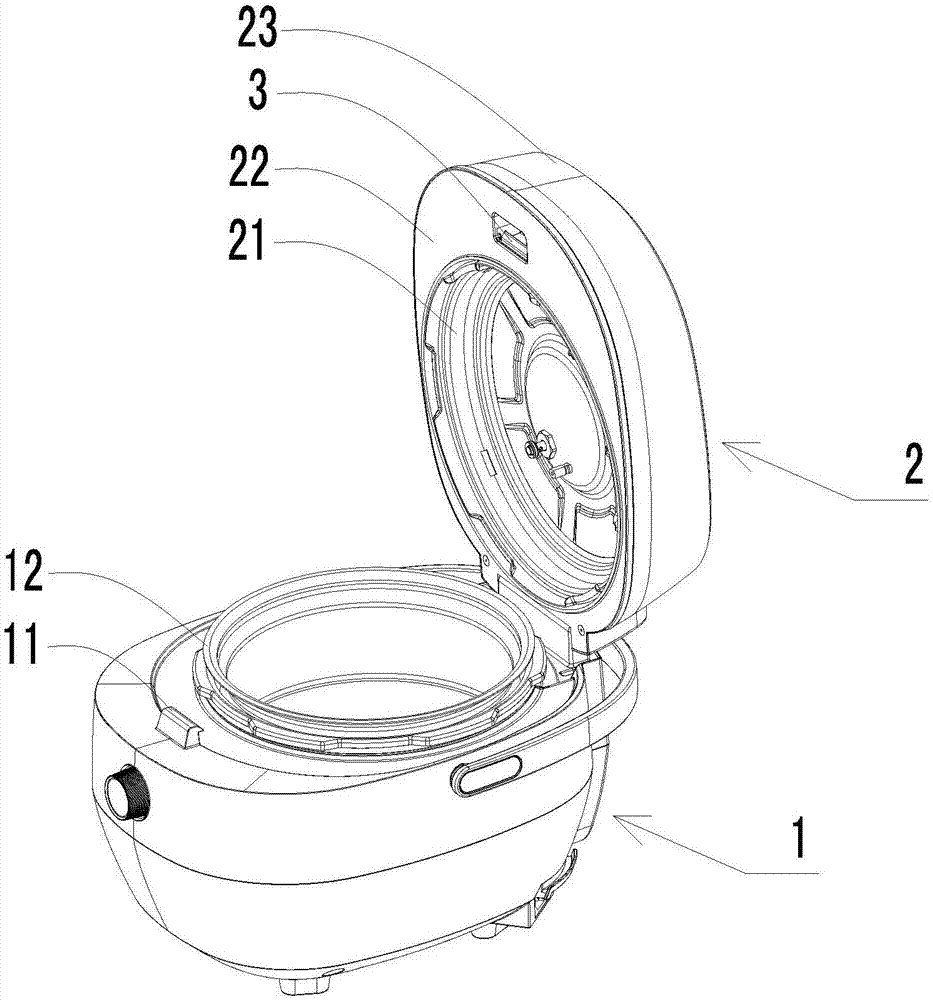

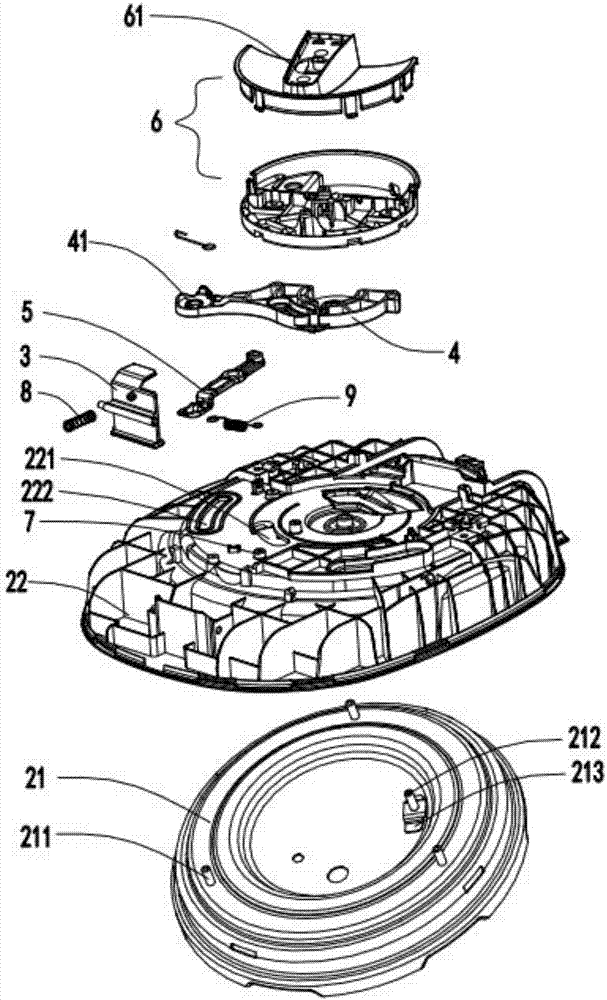

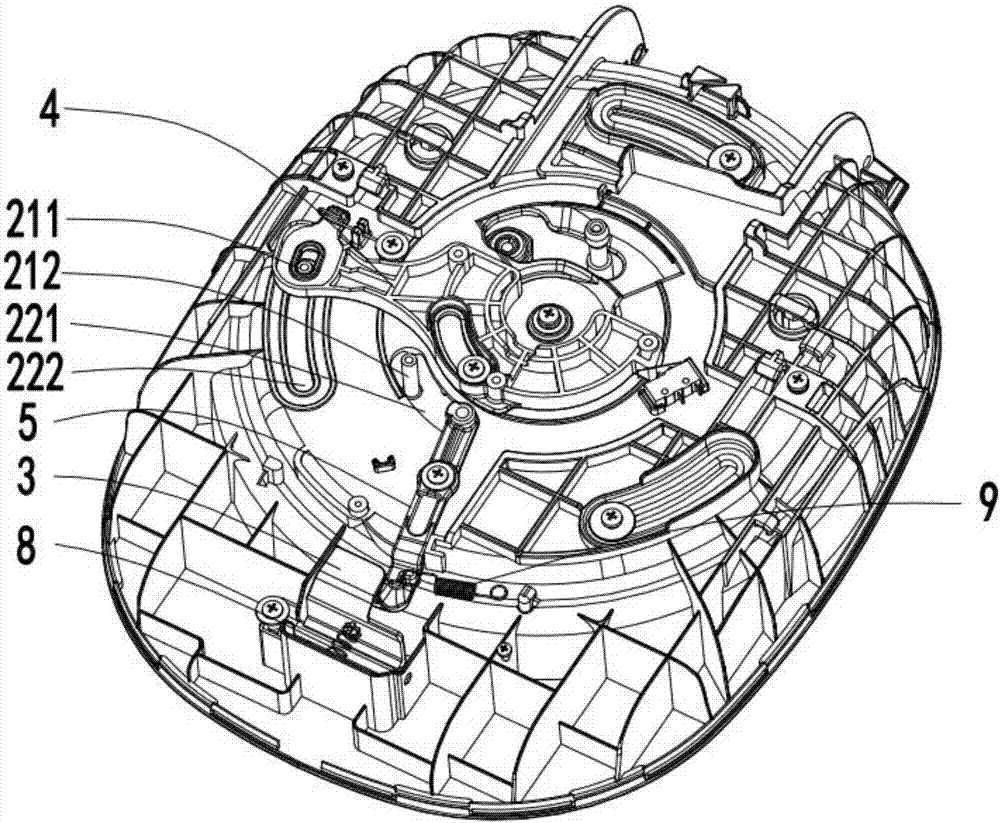

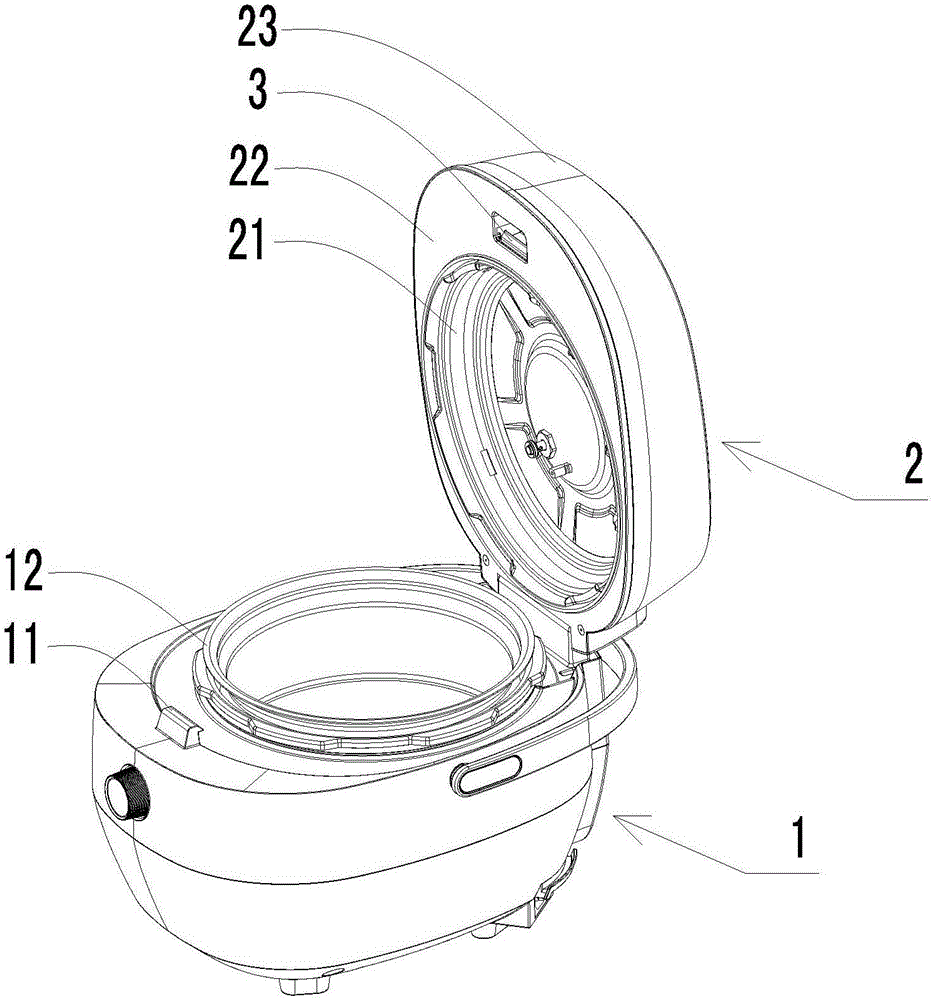

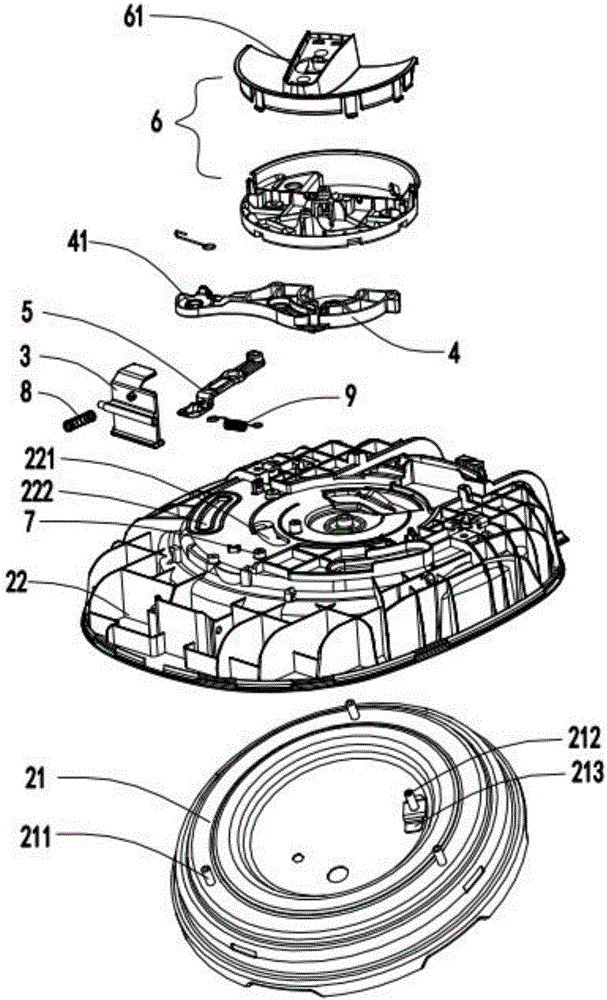

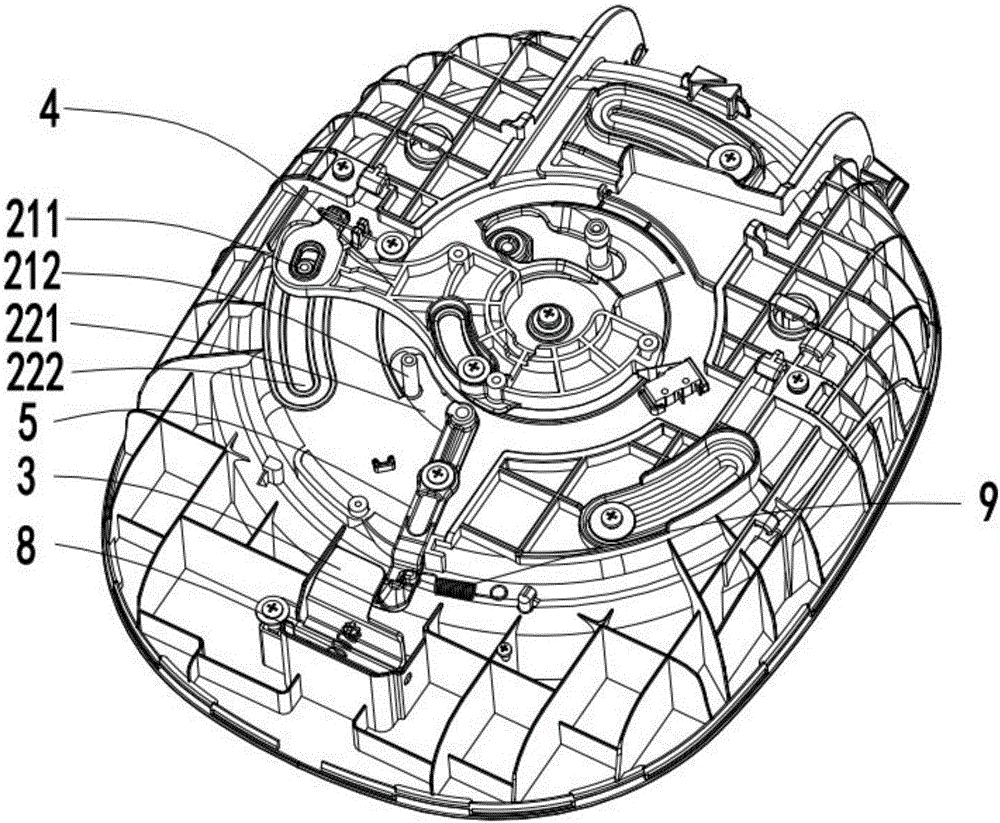

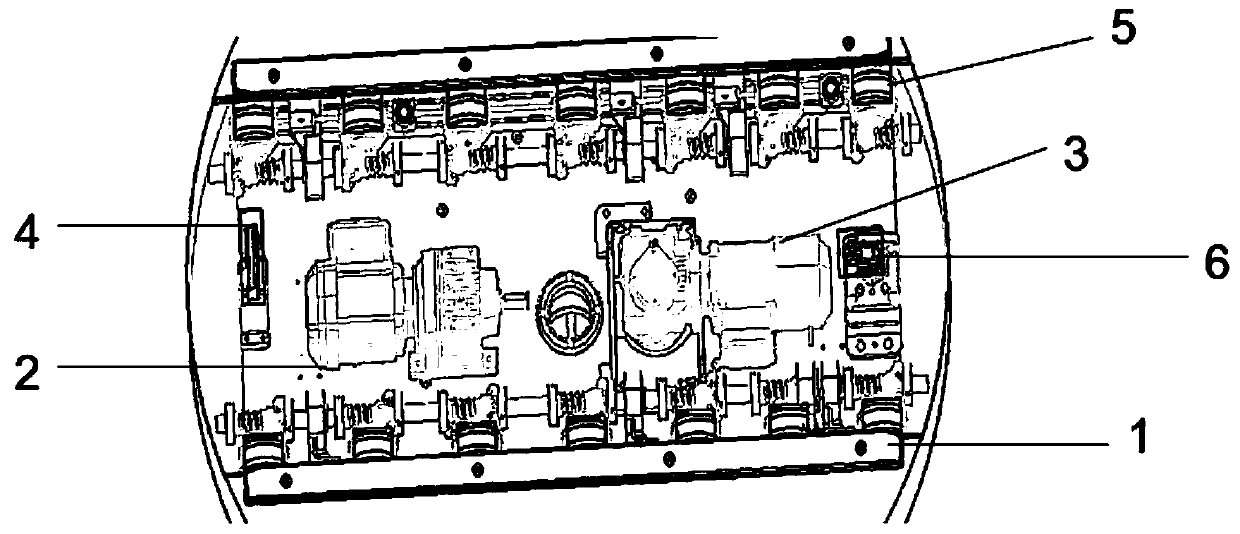

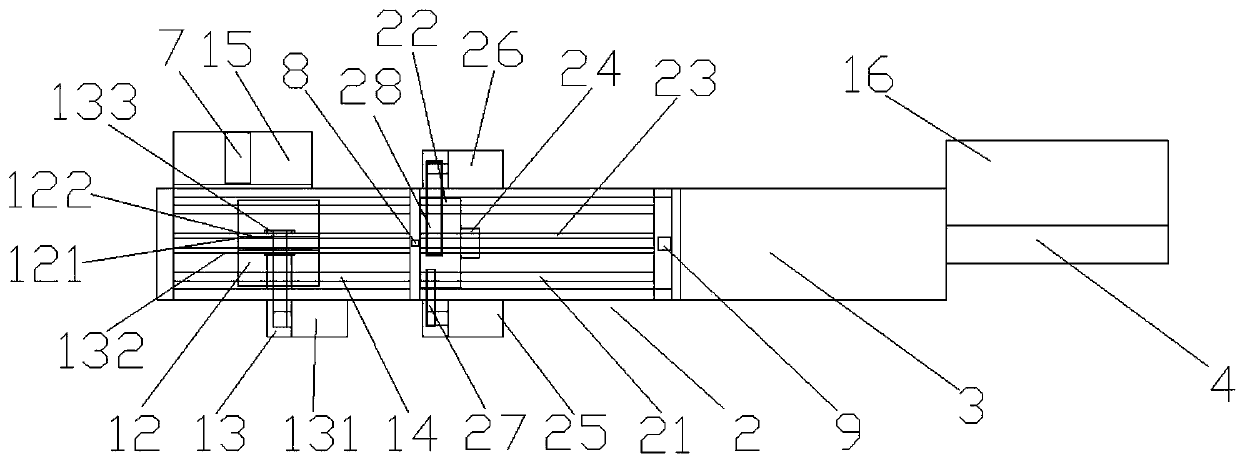

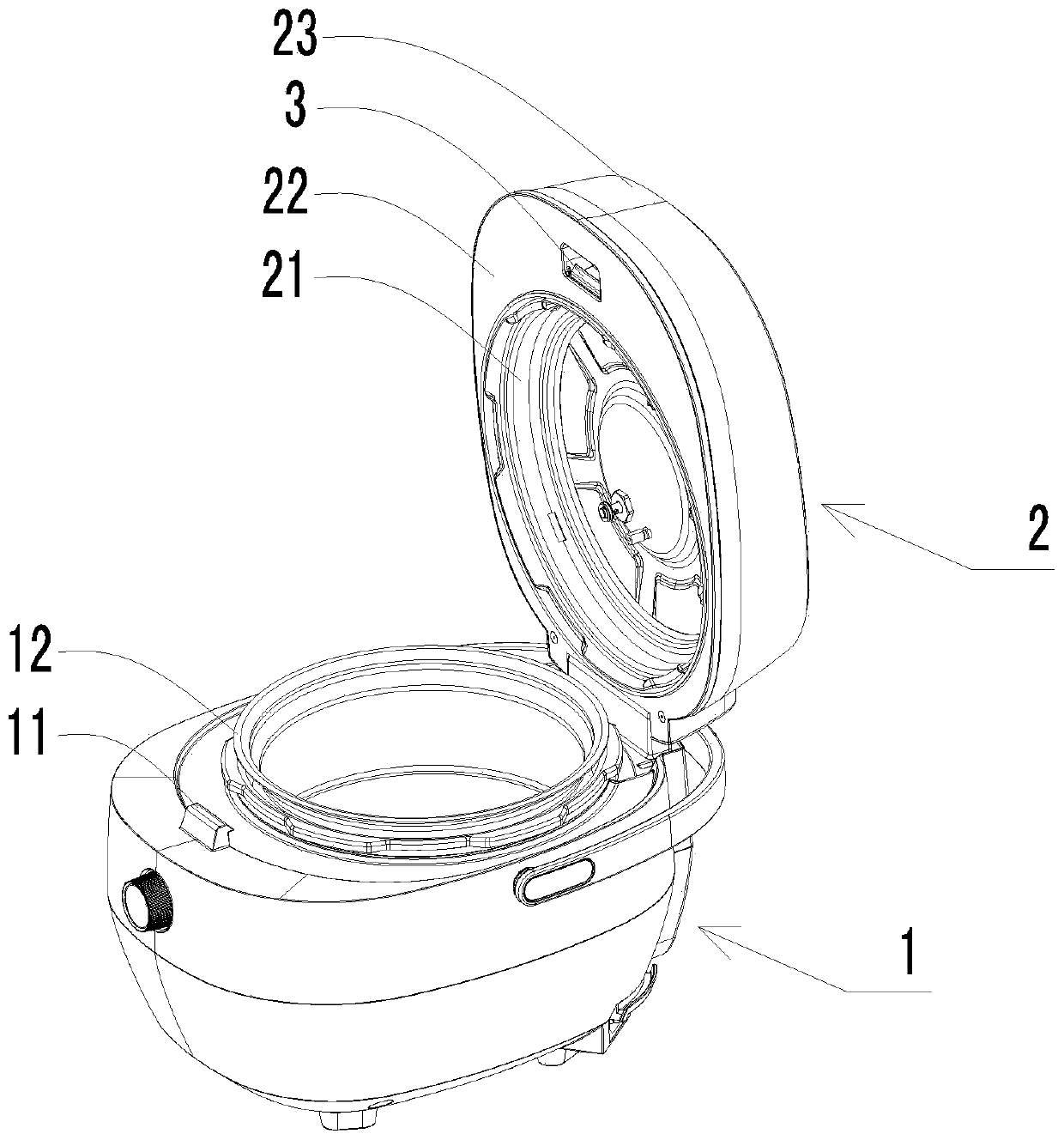

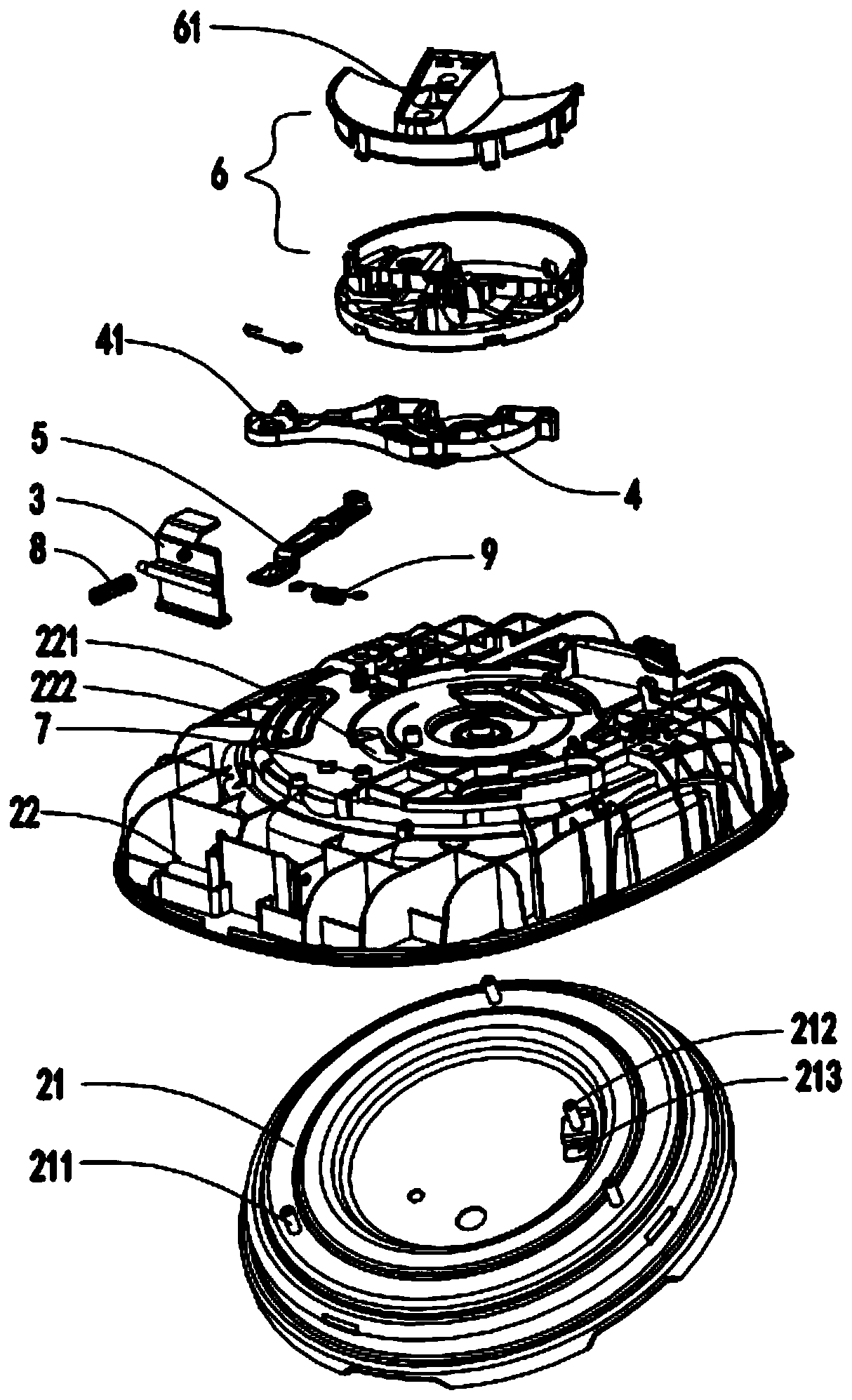

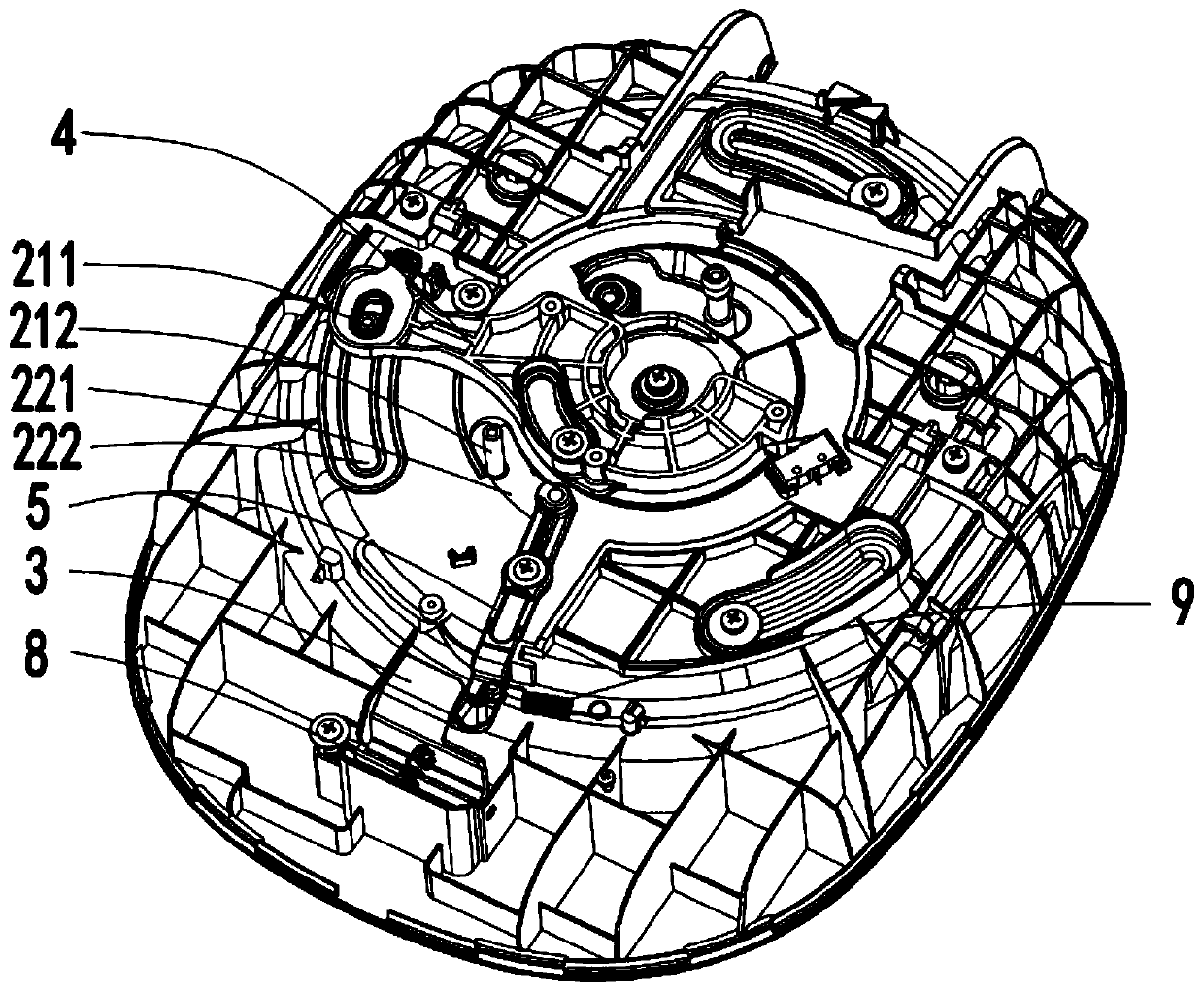

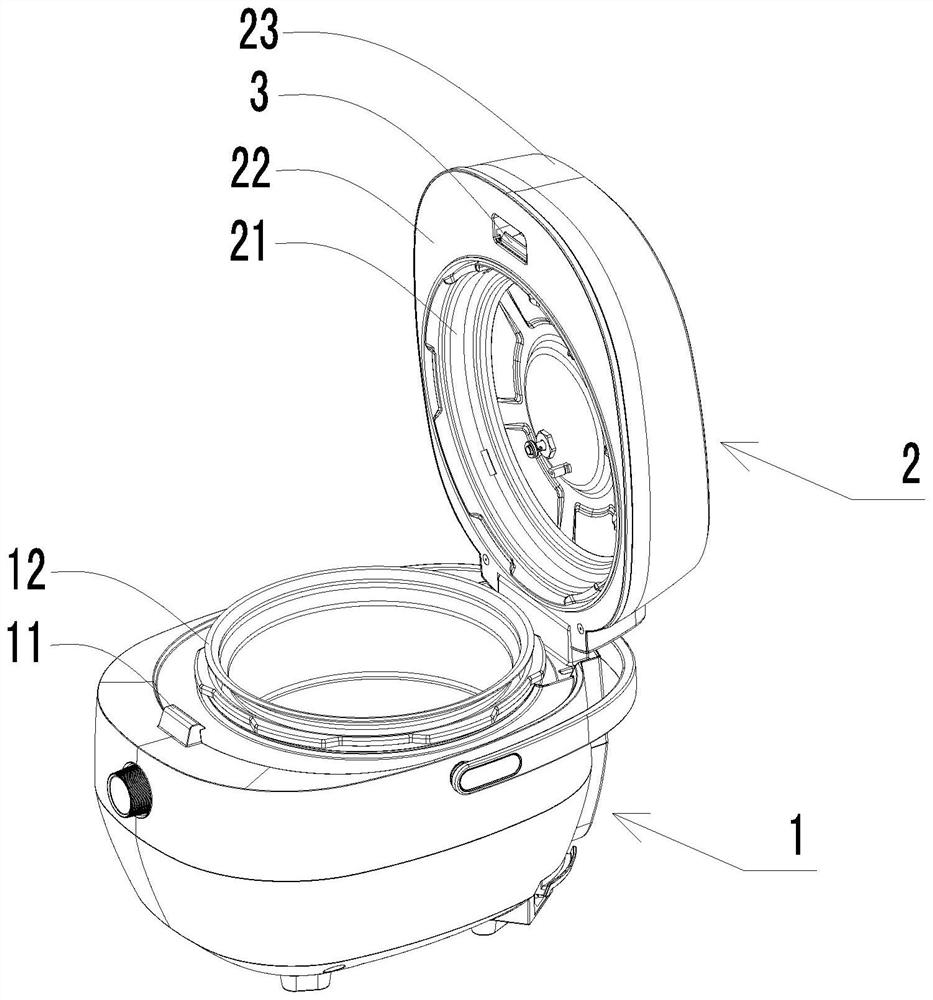

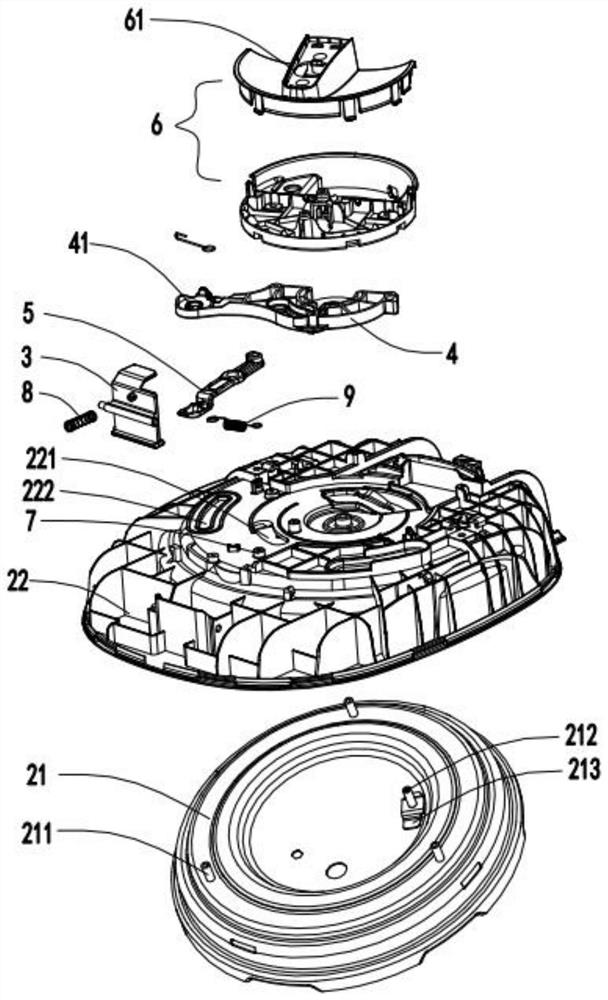

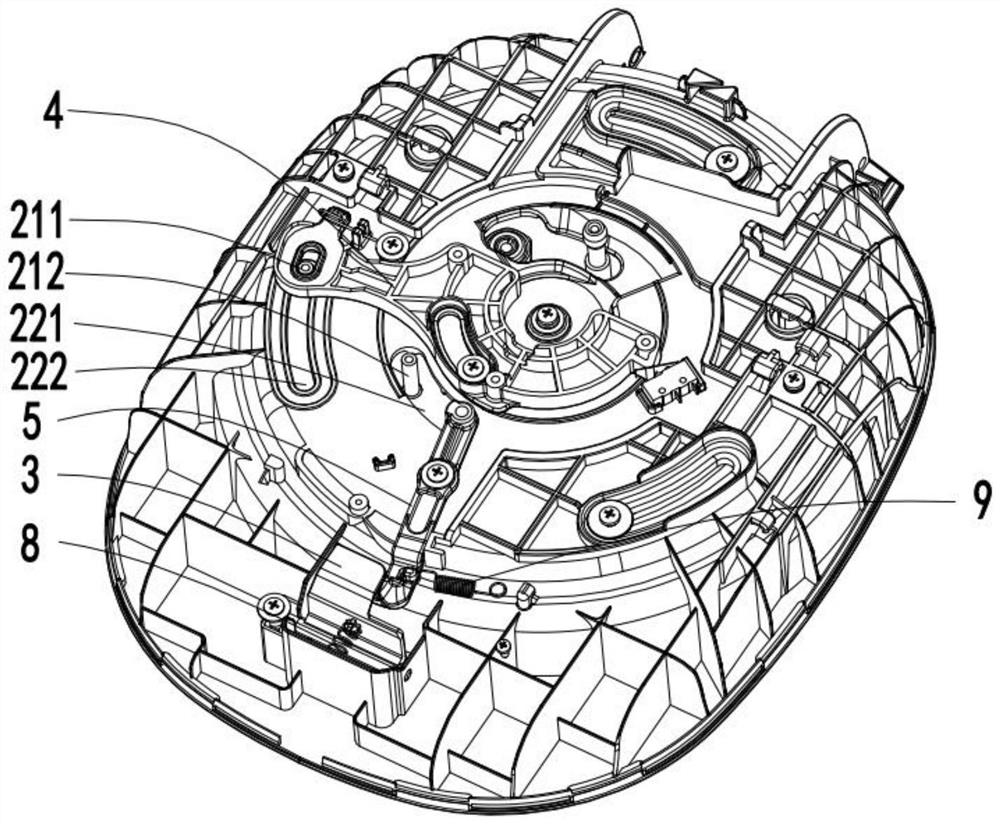

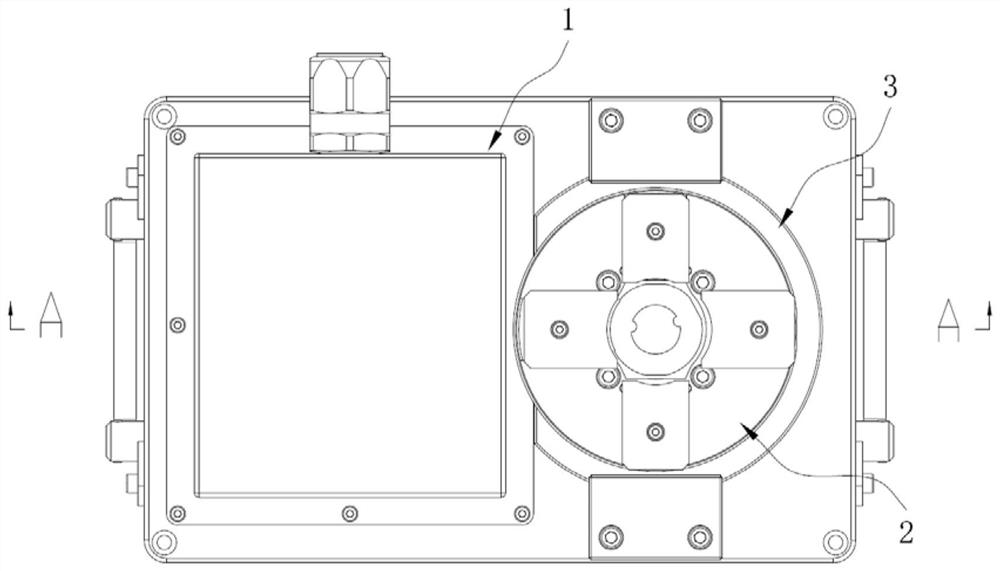

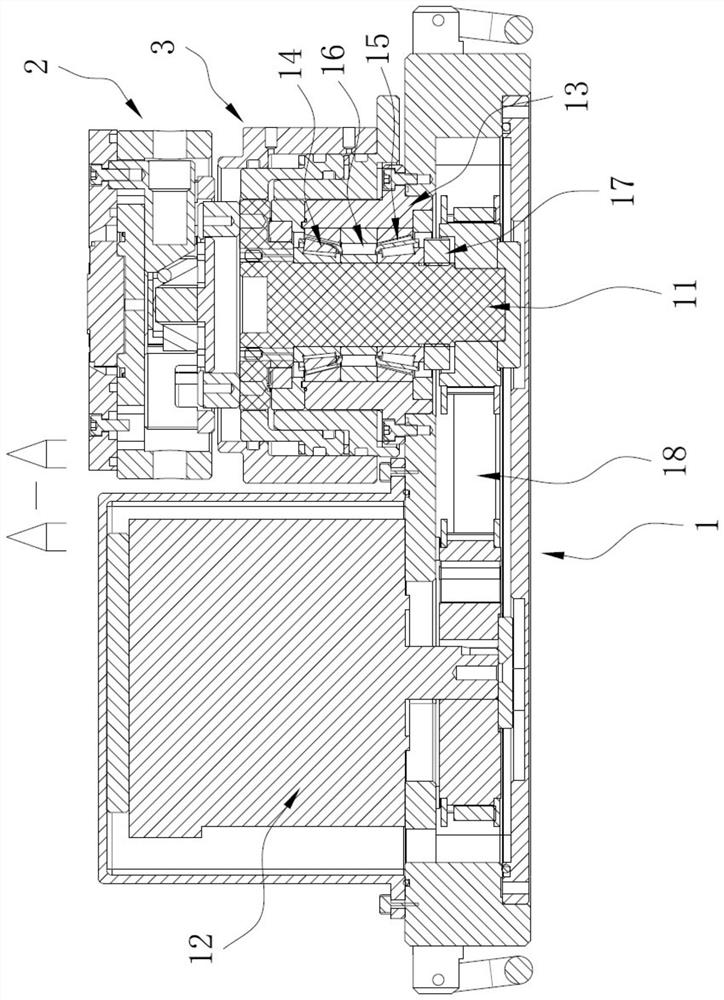

Electric pressure cooker with cover being conveniently opened

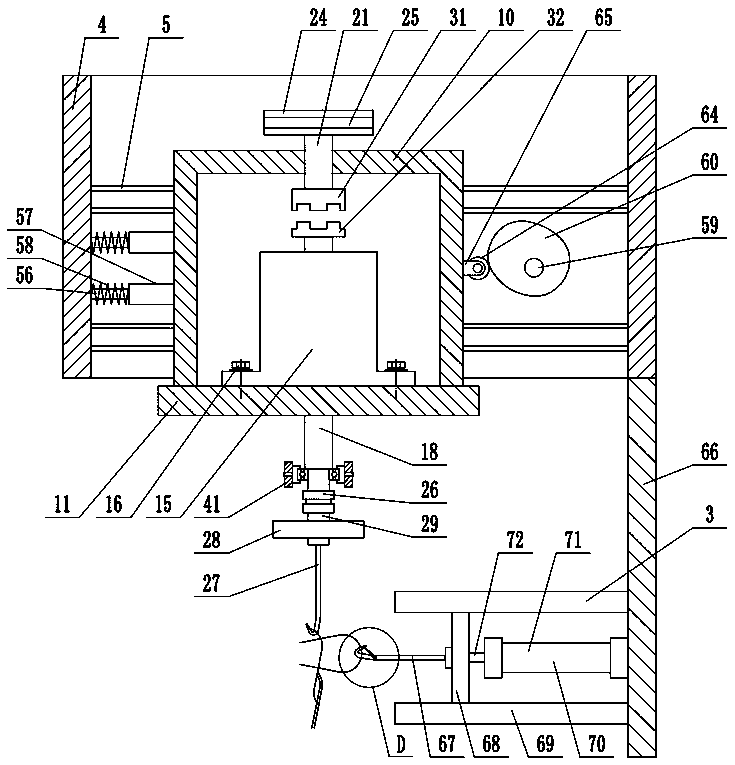

The invention provides an electric pressure cooker with a cover being conveniently opened. The cooker comprises a cooker body, a cooker cover and a buckling part. The buckling part comprises a movable clamping part arranged on the cooker cover and a fastener located on the cooker body. The cooker cover is buckled with the cooker body through the buckling part. The cooker cover comprises a lining and a lock cover located below the lining. The lock cover rotates so that the lock cover and the cooker body are locked and unlocked. The cooker cover is further provided with a cover-opening assembly which drives the locking cover to rotate. The lock cover is provided with an unlocking part. When the cover-opening assembly drives the lock cover to rotate at the first set position, the lock cover and the cooker body are unlocked. When the cover-opening assembly drives the lock cover to continuously rotate at the second set position, the fastener is acted upon the movable clamping part. The movable clamping part is separated from the fastener such that the cooker cover is opened. The rotation angle at which the lock cover rotates from the first set position to the second set position is Alfa. The cooker cover is provided with an elastic device driving the lock cover to rotate. After the cooker cover is opened, the elastic device drives the lock cover to rotate at the angle of Beta which is less than Afla. The electric pressure cooker with the cover being conveniently opened facilitates opening the cover.

Owner:JOYOUNG CO LTD

Electric pressure cooker capable of facilitating cover opening

The invention provides an electric pressure cooker capable of facilitating cover opening. The electric pressure cooker comprises a pot body, a pot cover and a clamping buckling component; the pot cover comprises a liner and a lock cover located below the liner; the clamping buckling component comprises a movable clamping component arranged on the liner and a buckling component located on the pot body; the pot cover is buckled to the pot body through the clamping buckling component; the liner is provided with a cover opening assembly; the cover opening assembly drives the lock cover to rotate; the rotation of the lock cover enables the locking and unlocking of the lock cover and the pot body; the lock cover is provided with an unbuckling component; a distance from the unbuckling component to the center of the lock cover is 1 / 5 to 4 / 5 of the radius of the lock cover; a collision avoidance groove is arranged on the liner; the unbuckling component passes through the collision avoidance groove and extends to the upper surface of the liner; and the cover opening assembly drives the lock cover to rotate for unlocking, and the unbuckling component acts, so that the movable clamping component is separated from the buckling component. According to the electric pressure cooker of the invention, the pot cover can be opened just through rotation, and therefore, the electric pressure cooker is convenient for a user to use.

Owner:JOYOUNG CO LTD

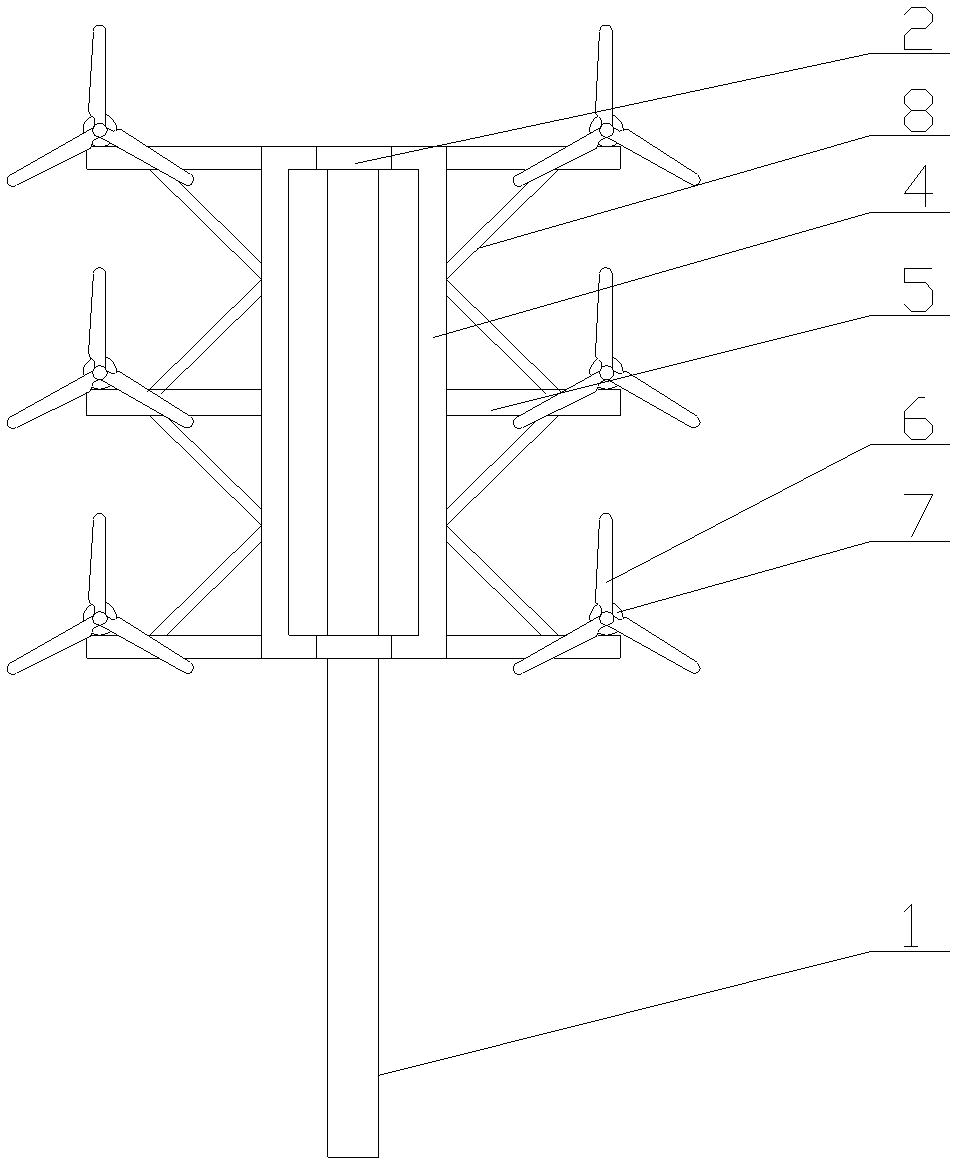

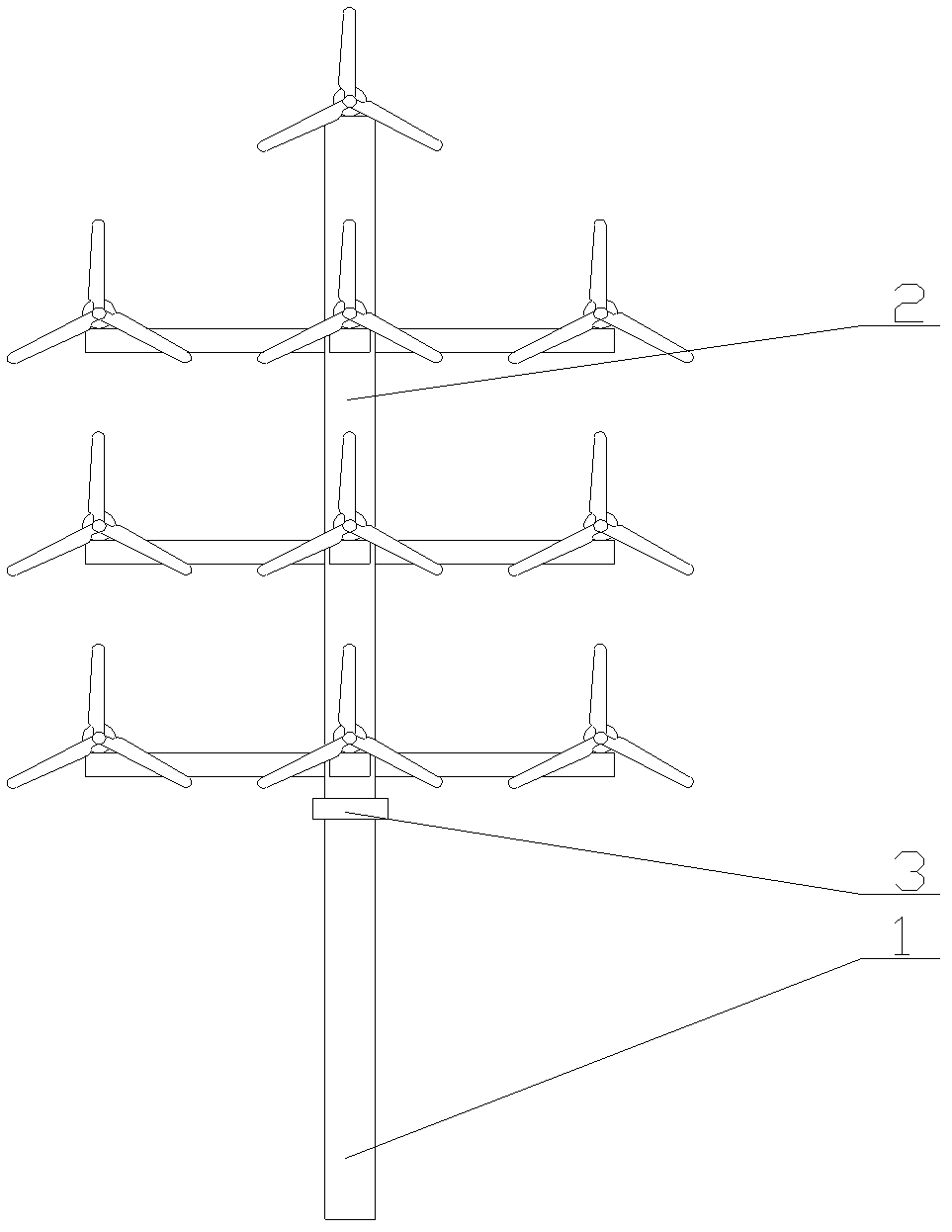

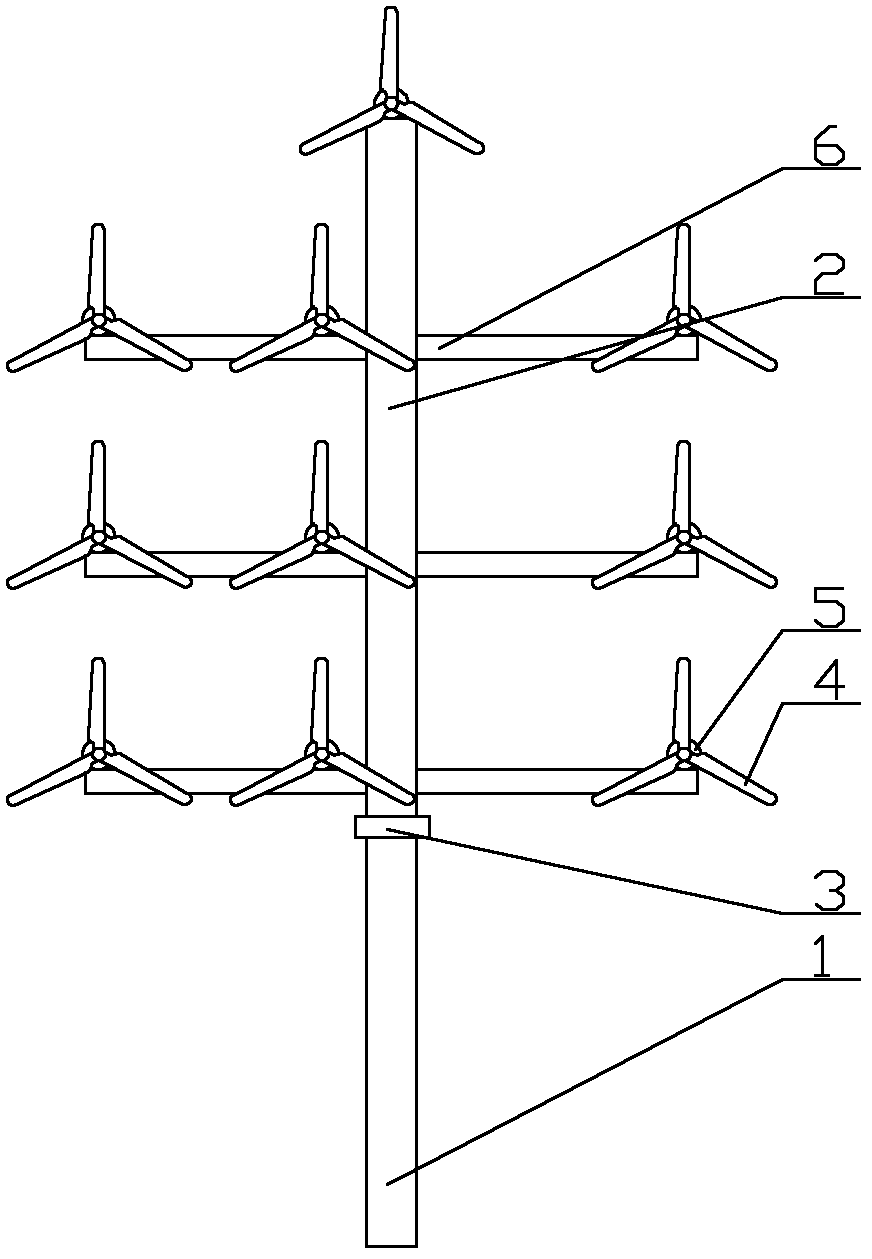

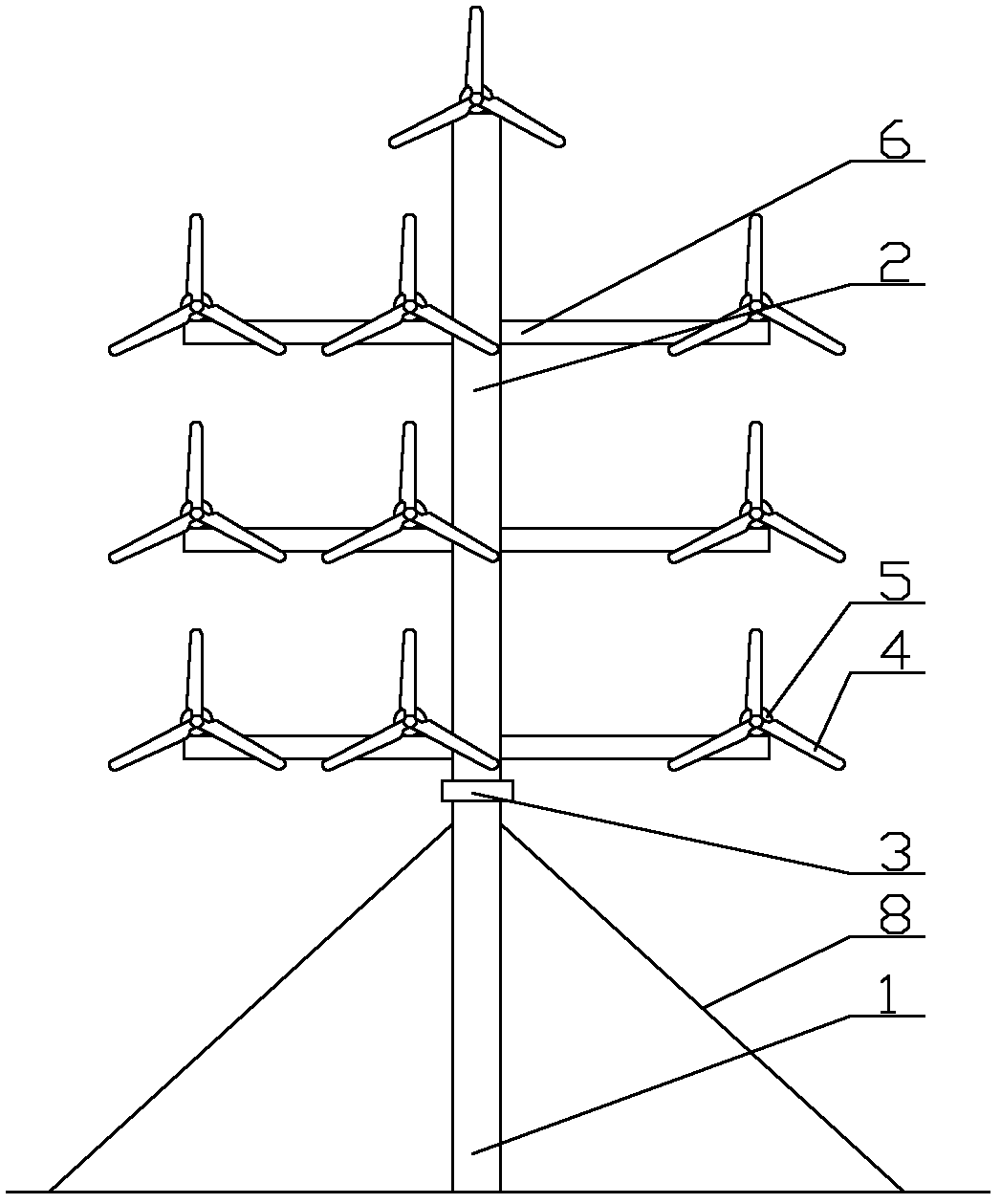

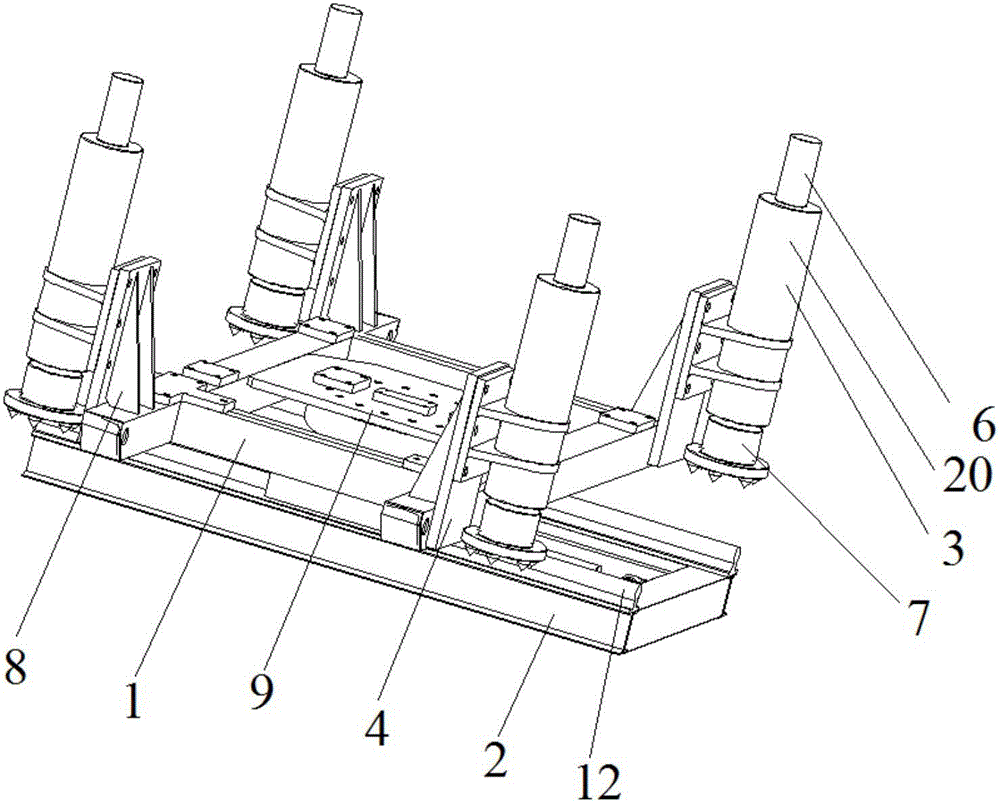

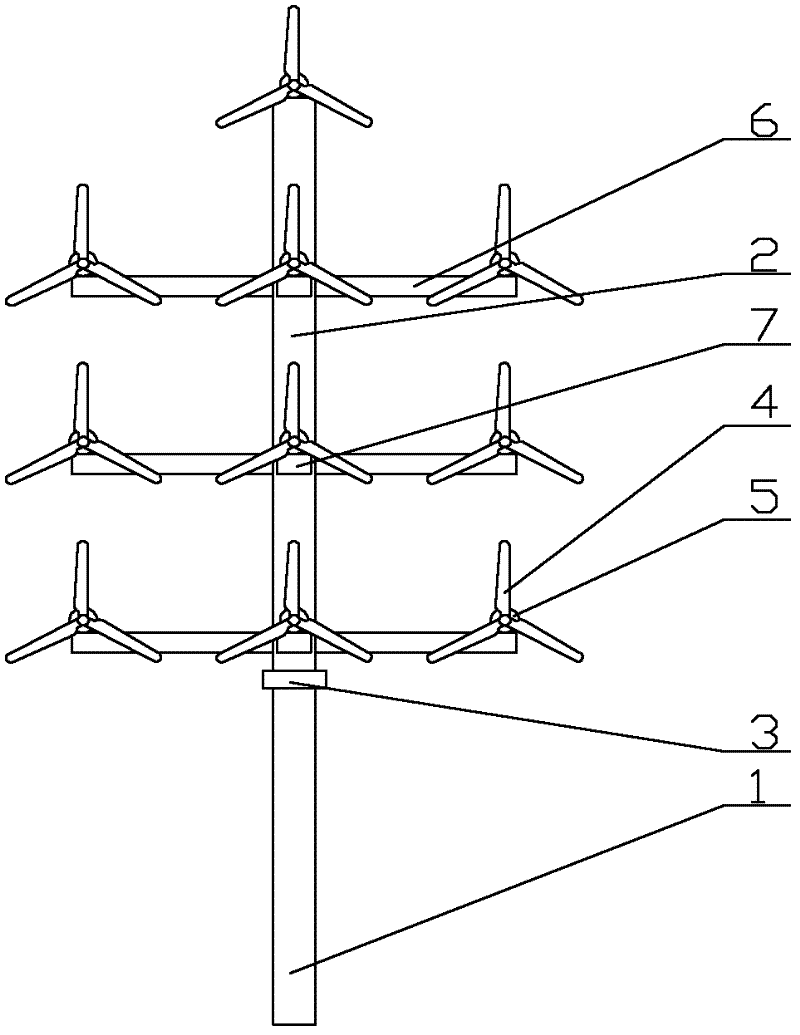

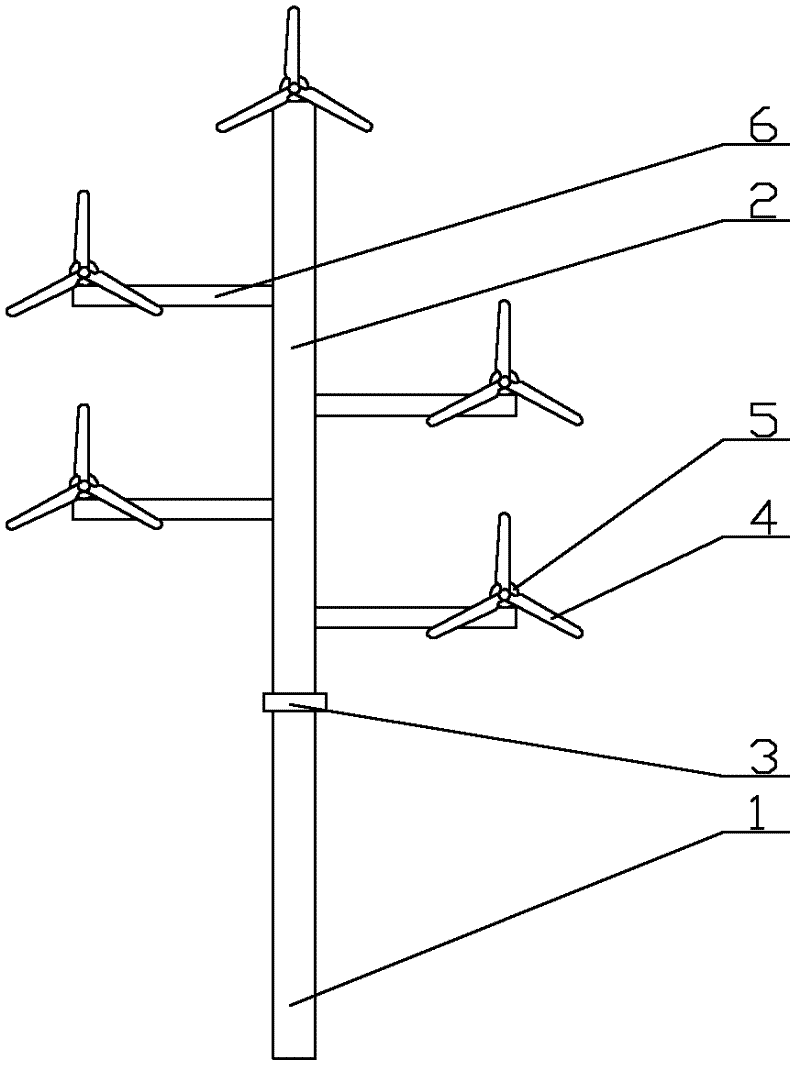

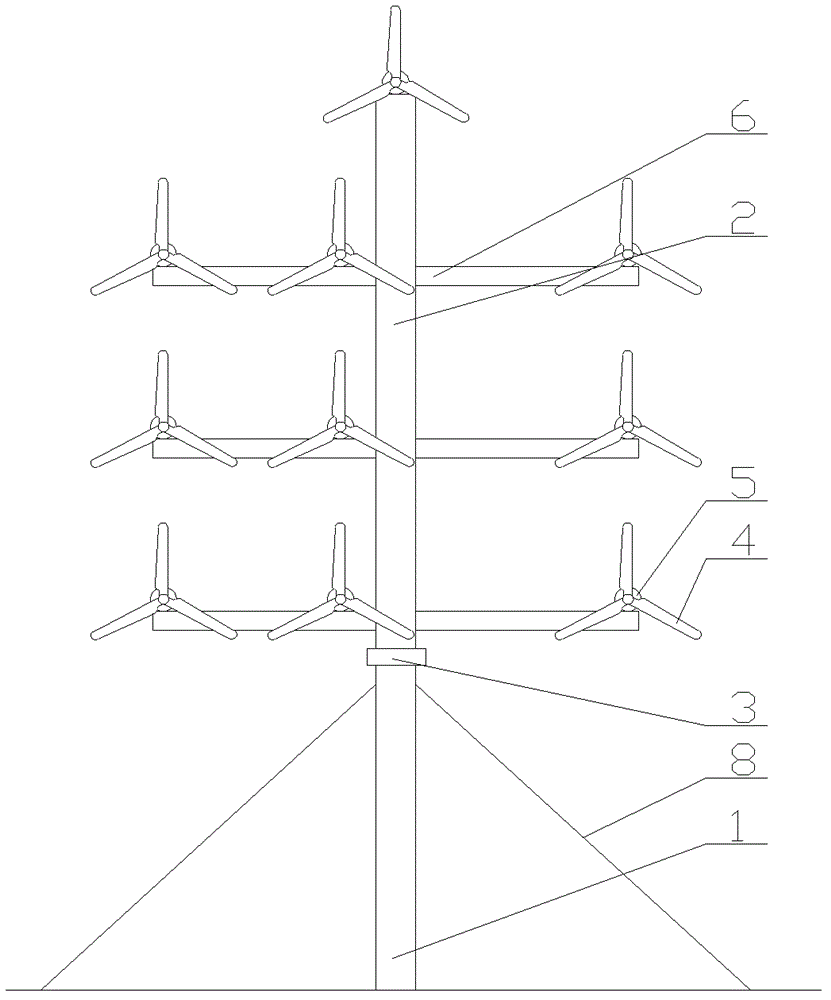

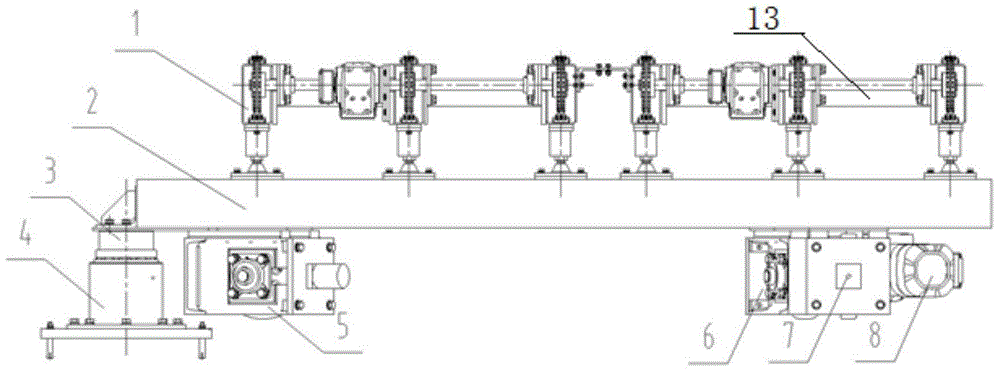

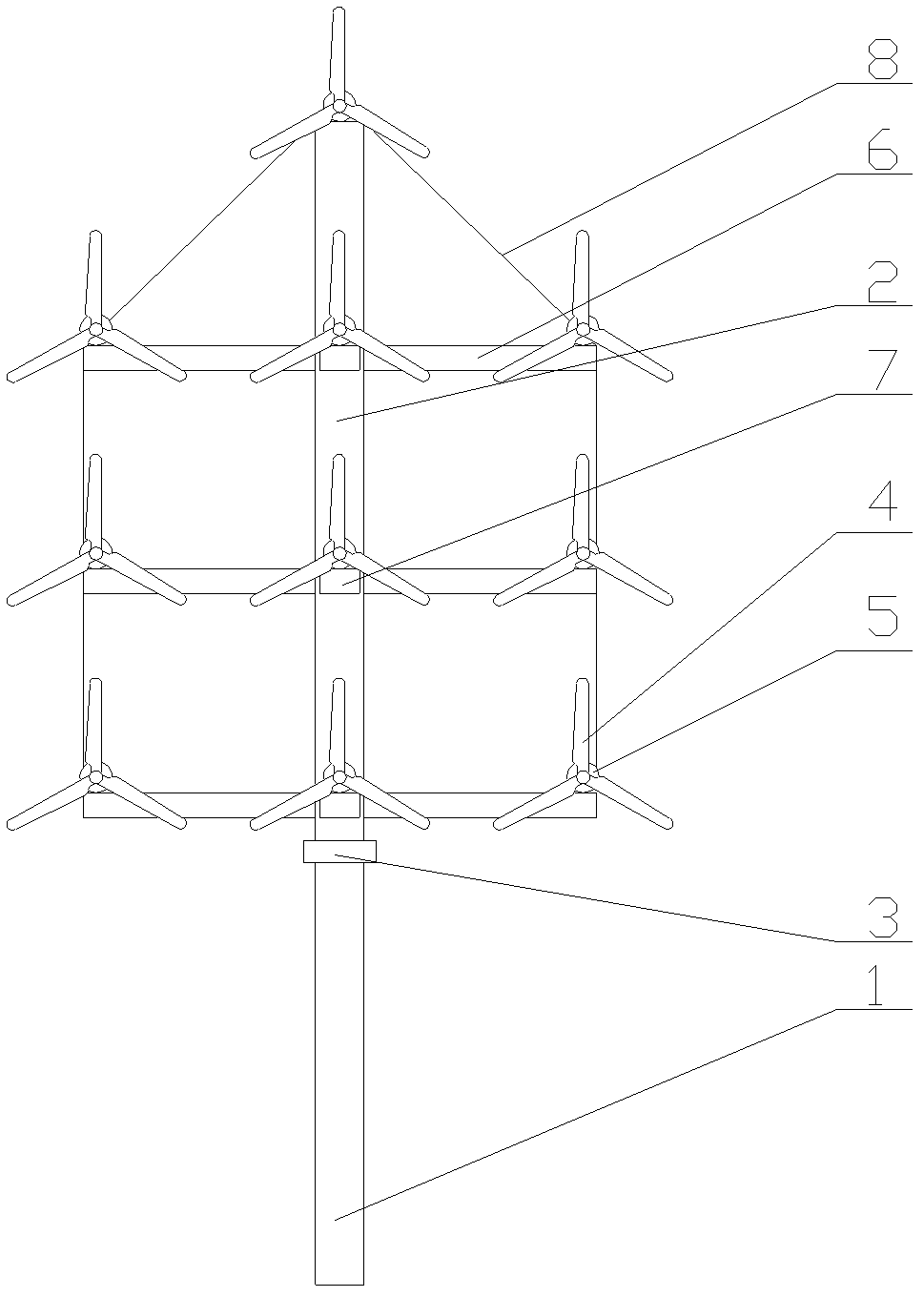

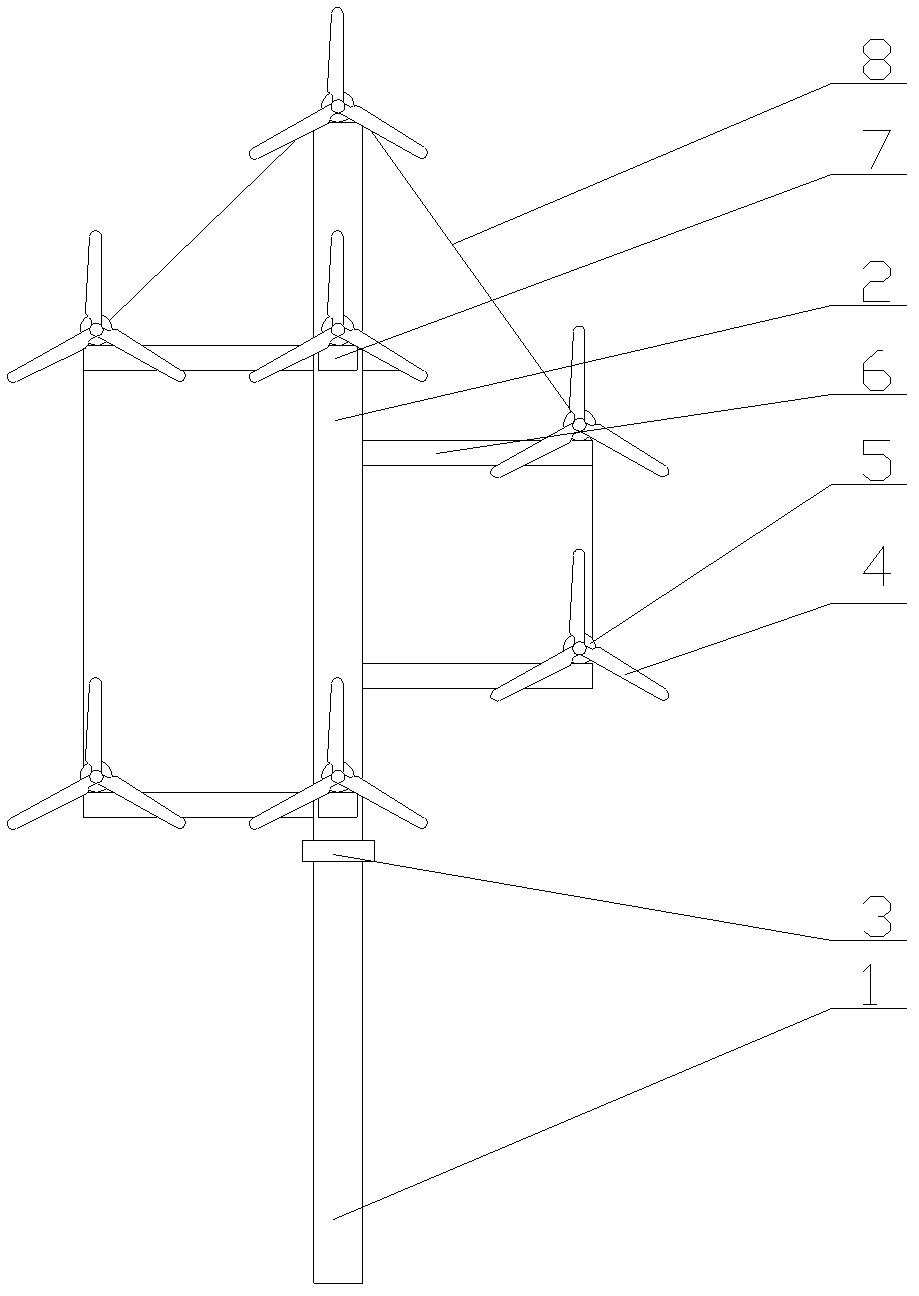

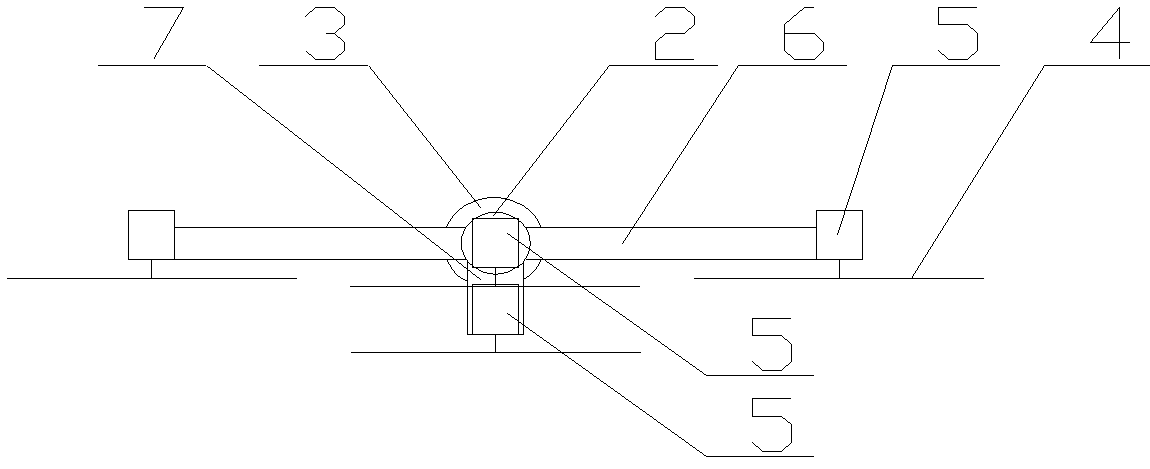

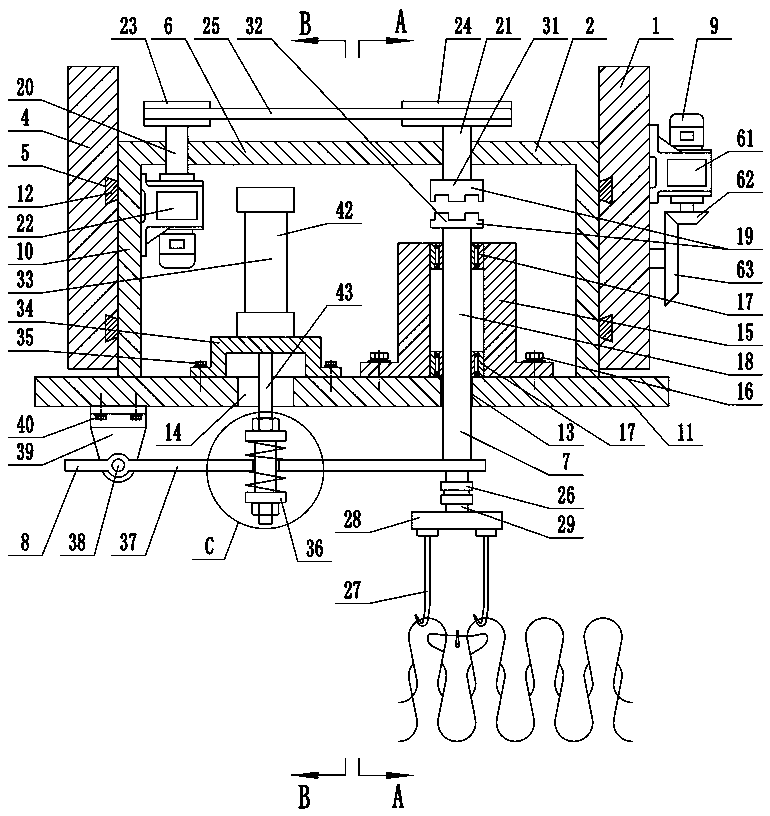

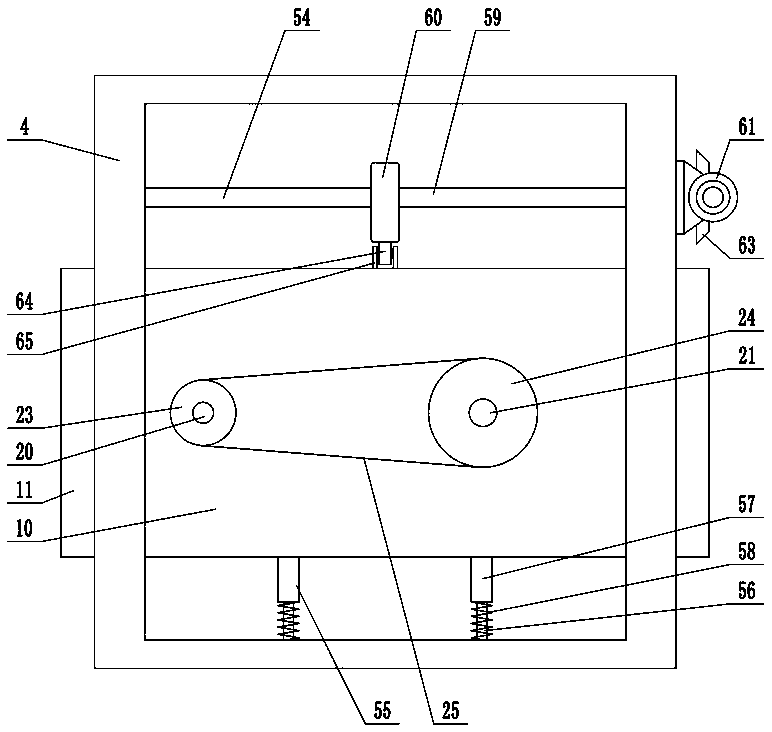

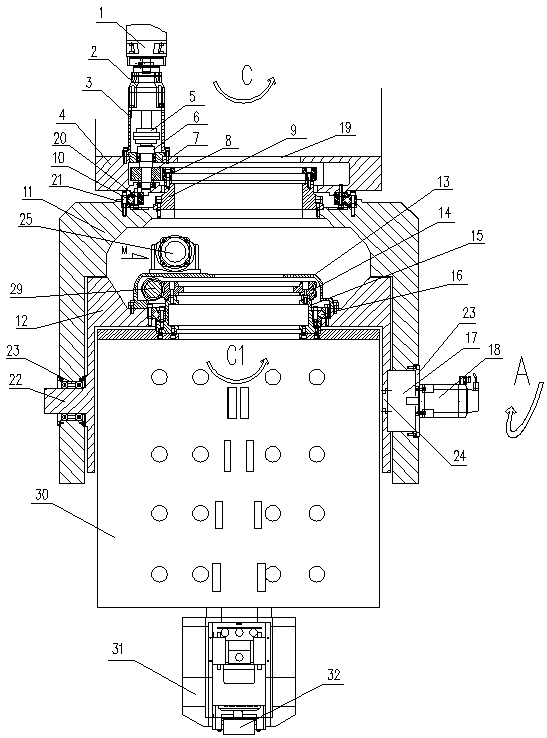

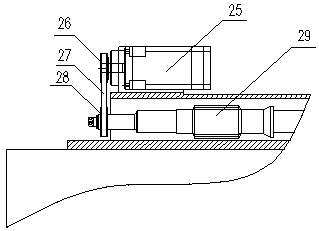

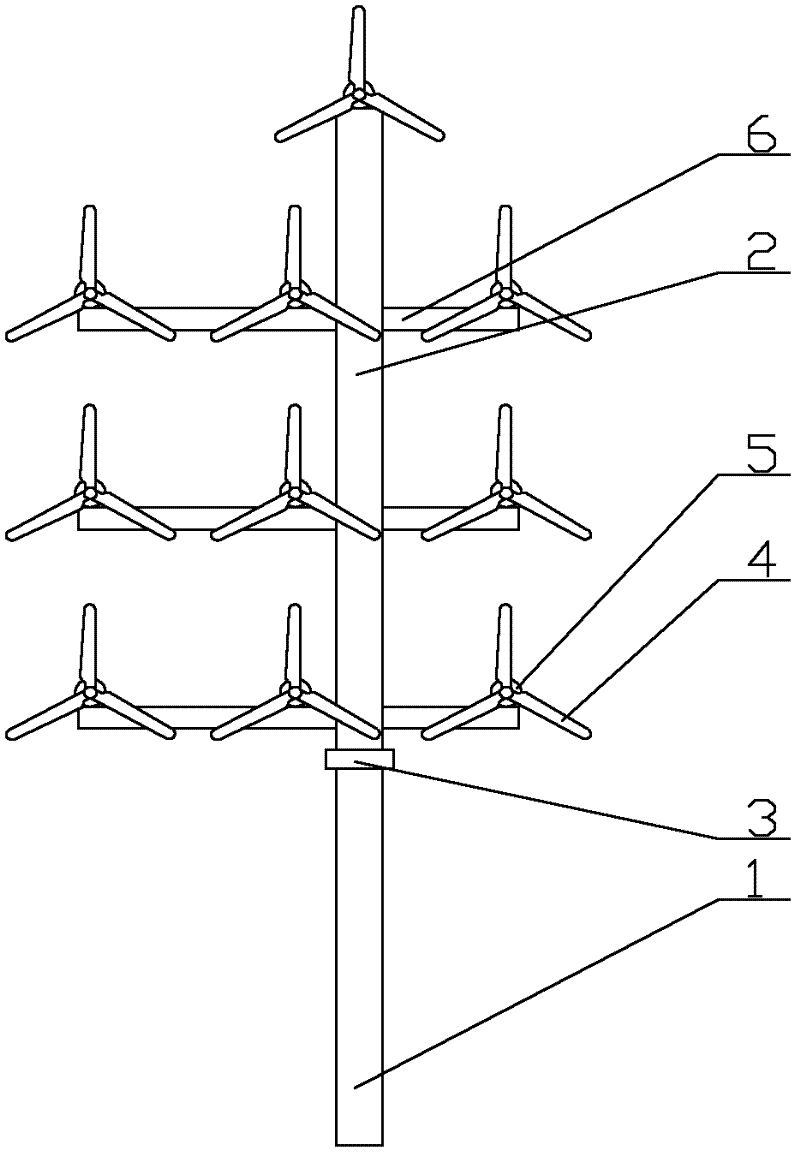

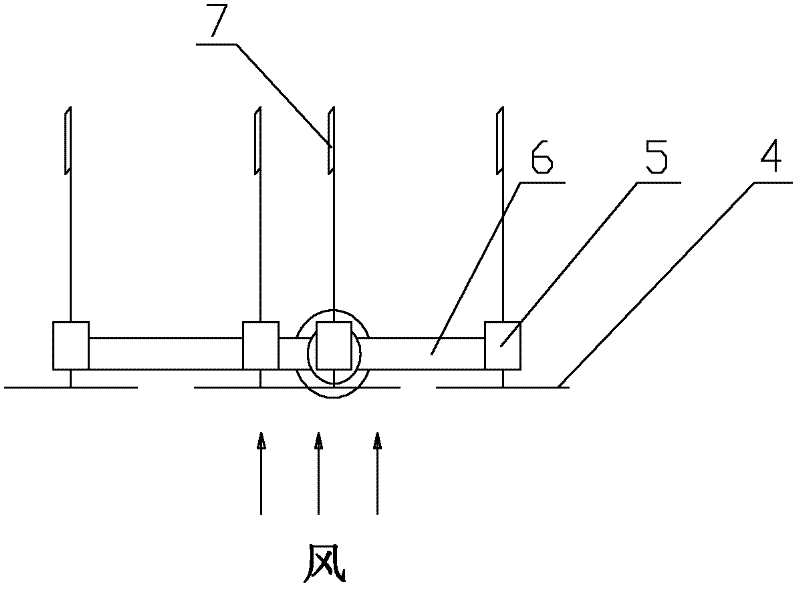

Multi-rotor wind generating system with connecting rods

InactiveCN102305171AExtend your lifeReduce fatigue loadMachines/enginesWind energy generationNacelleWind force

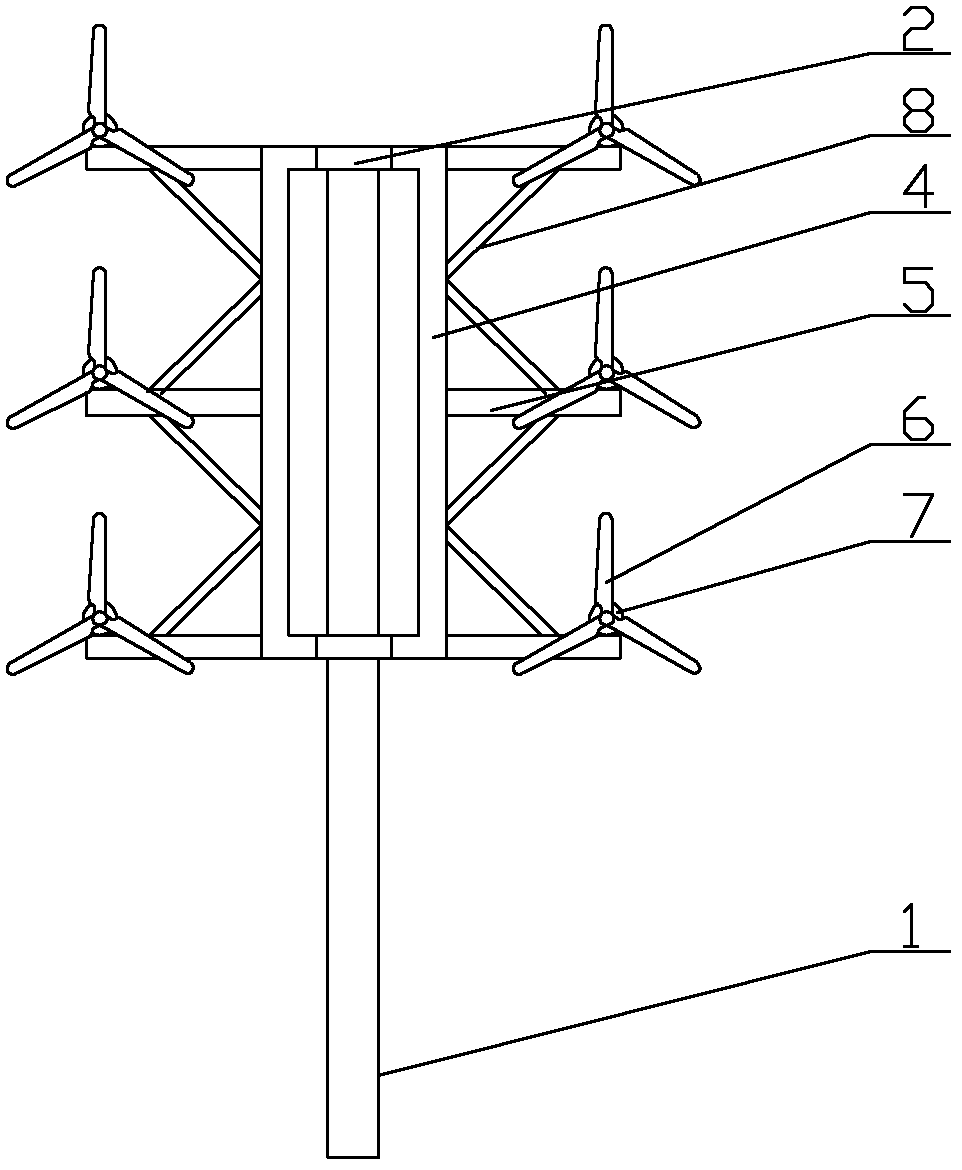

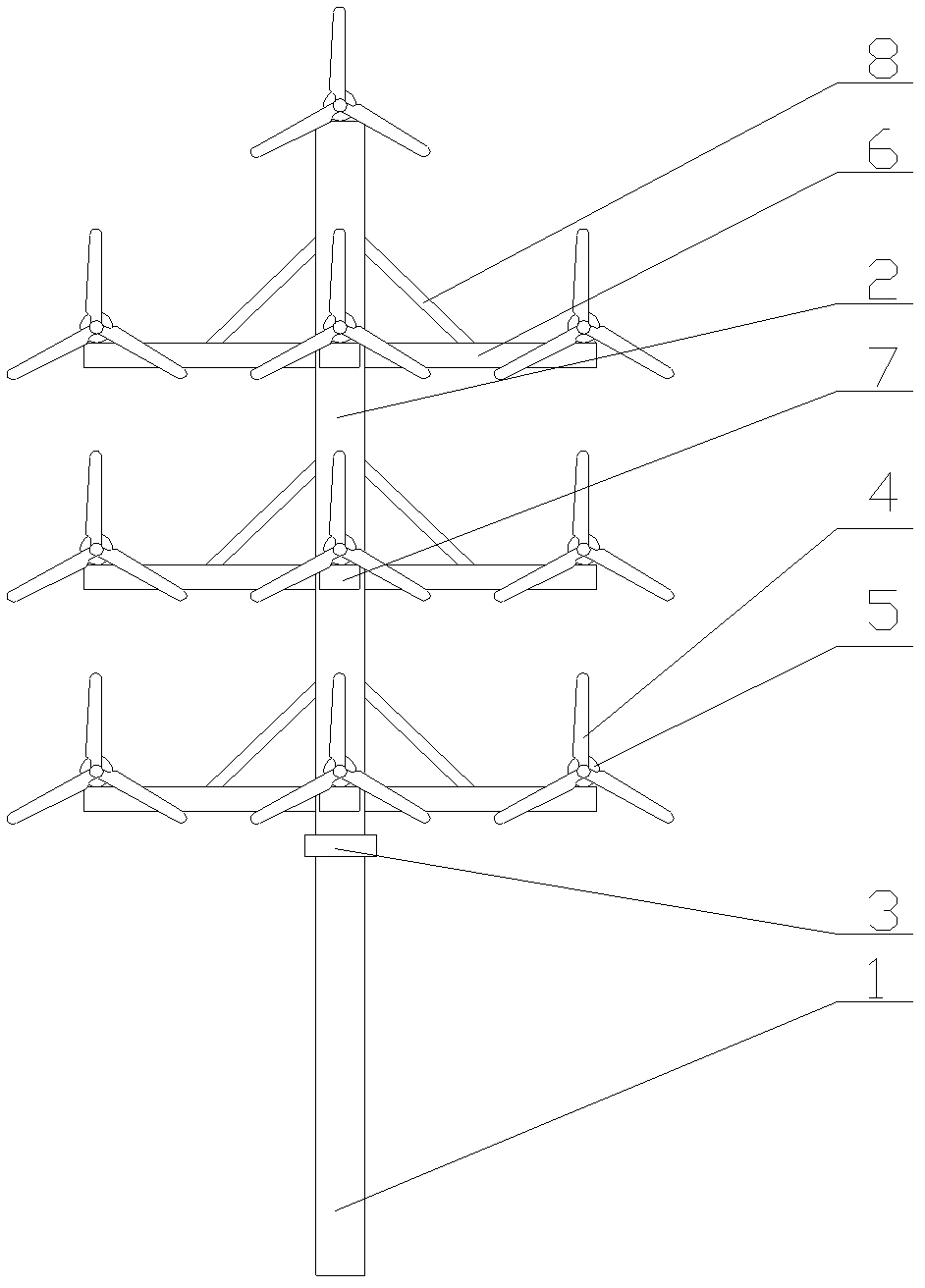

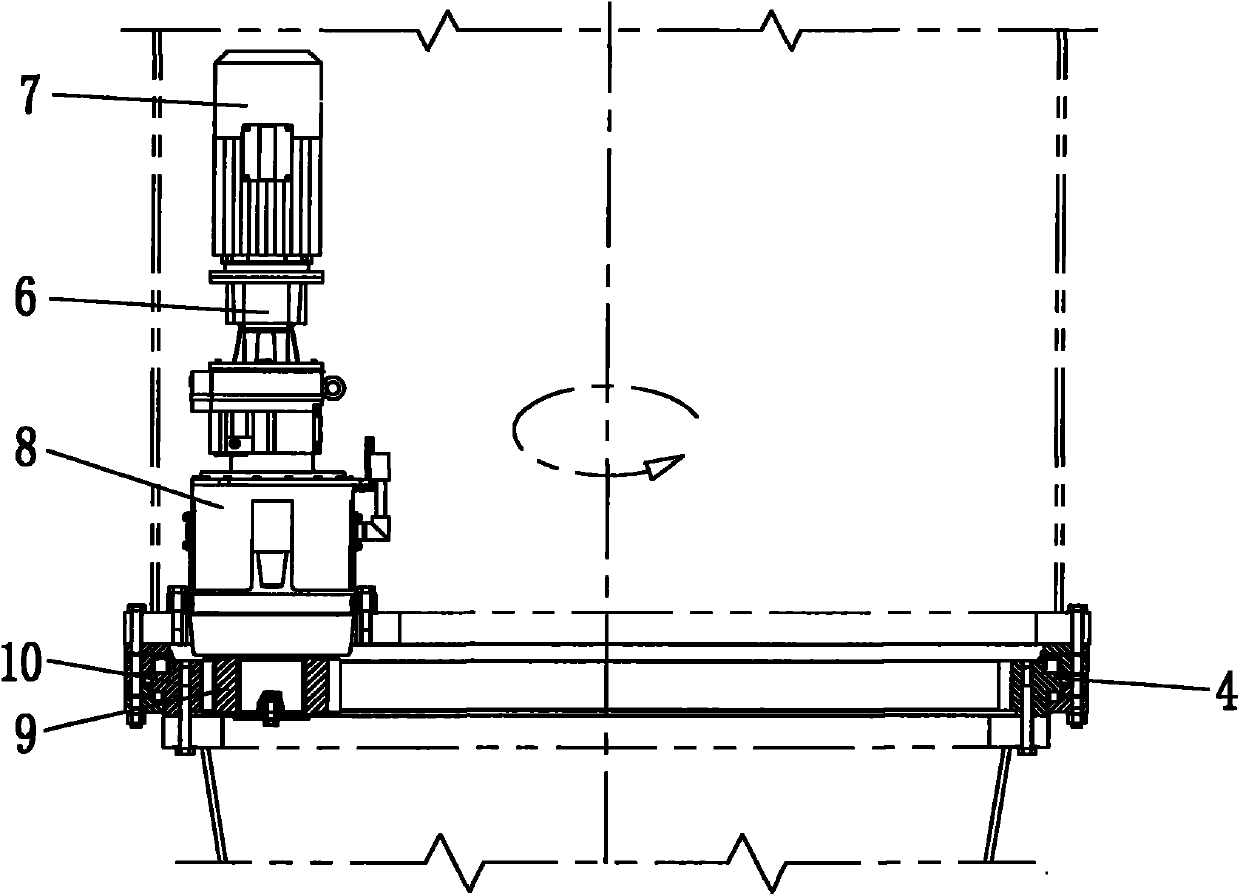

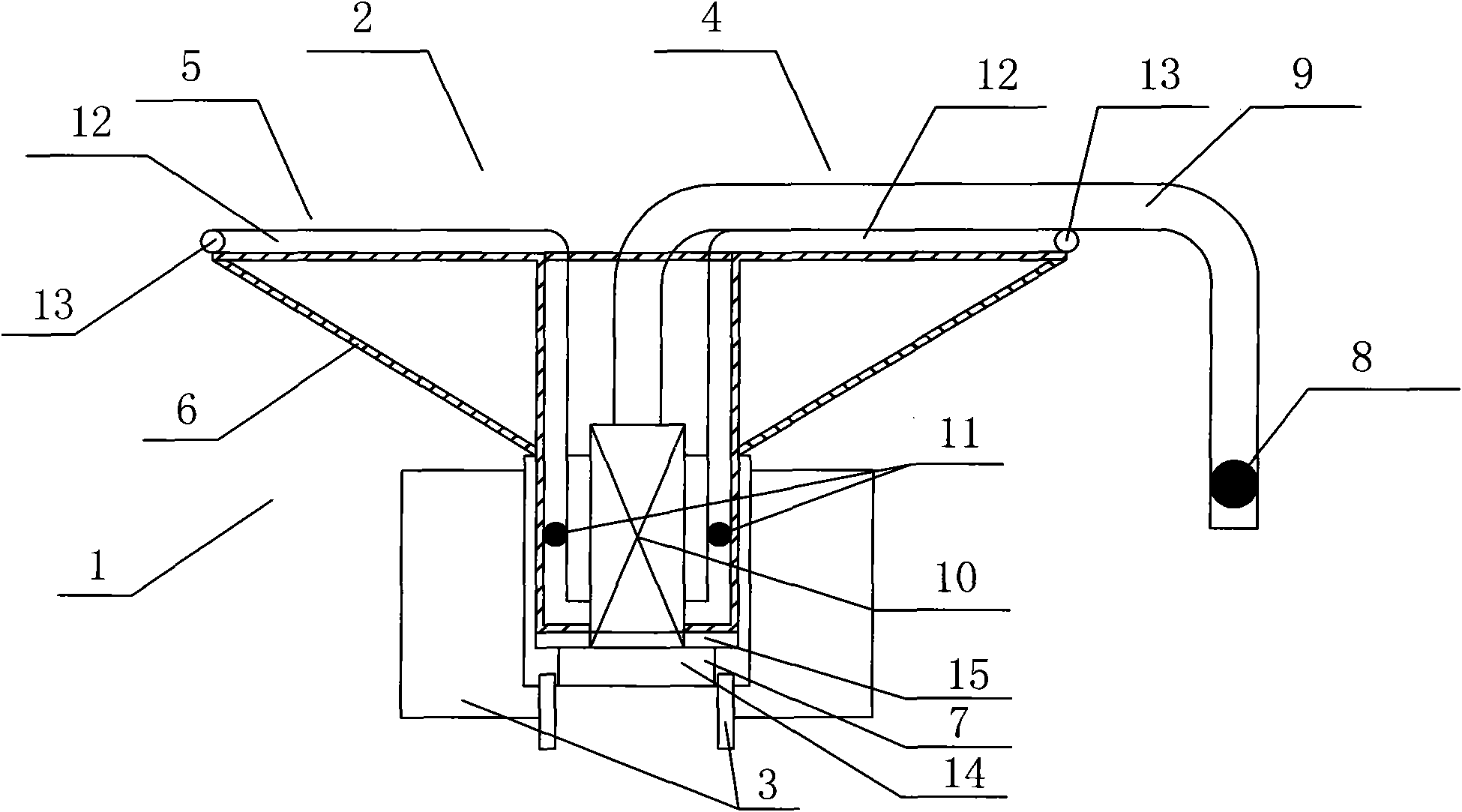

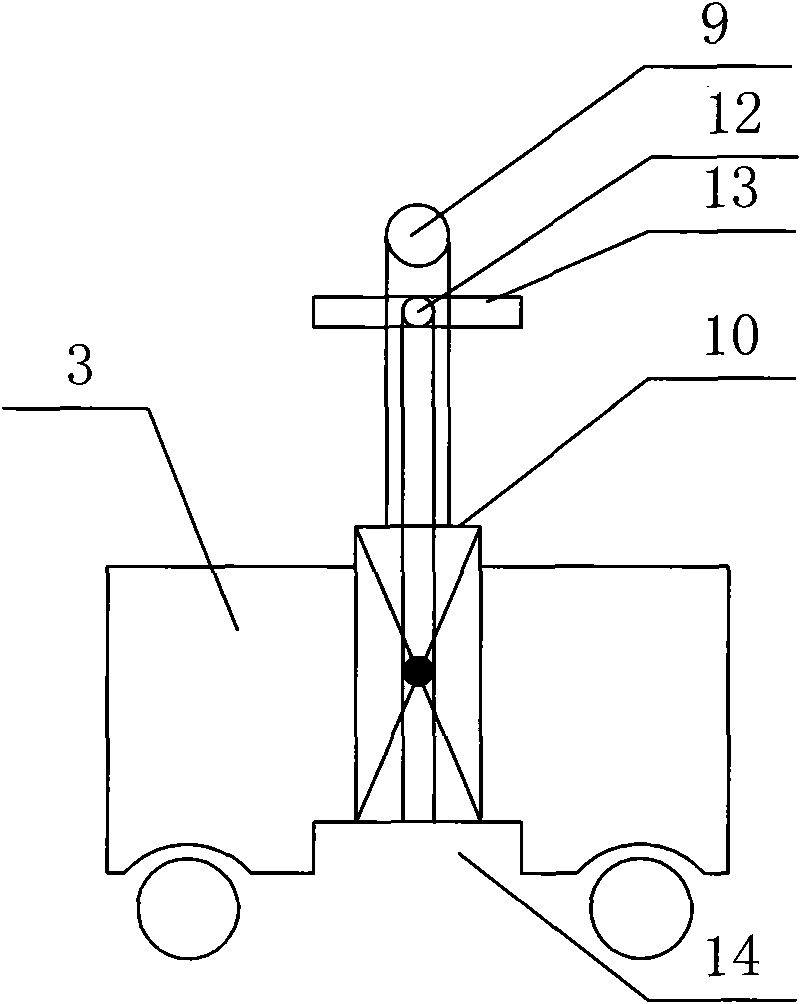

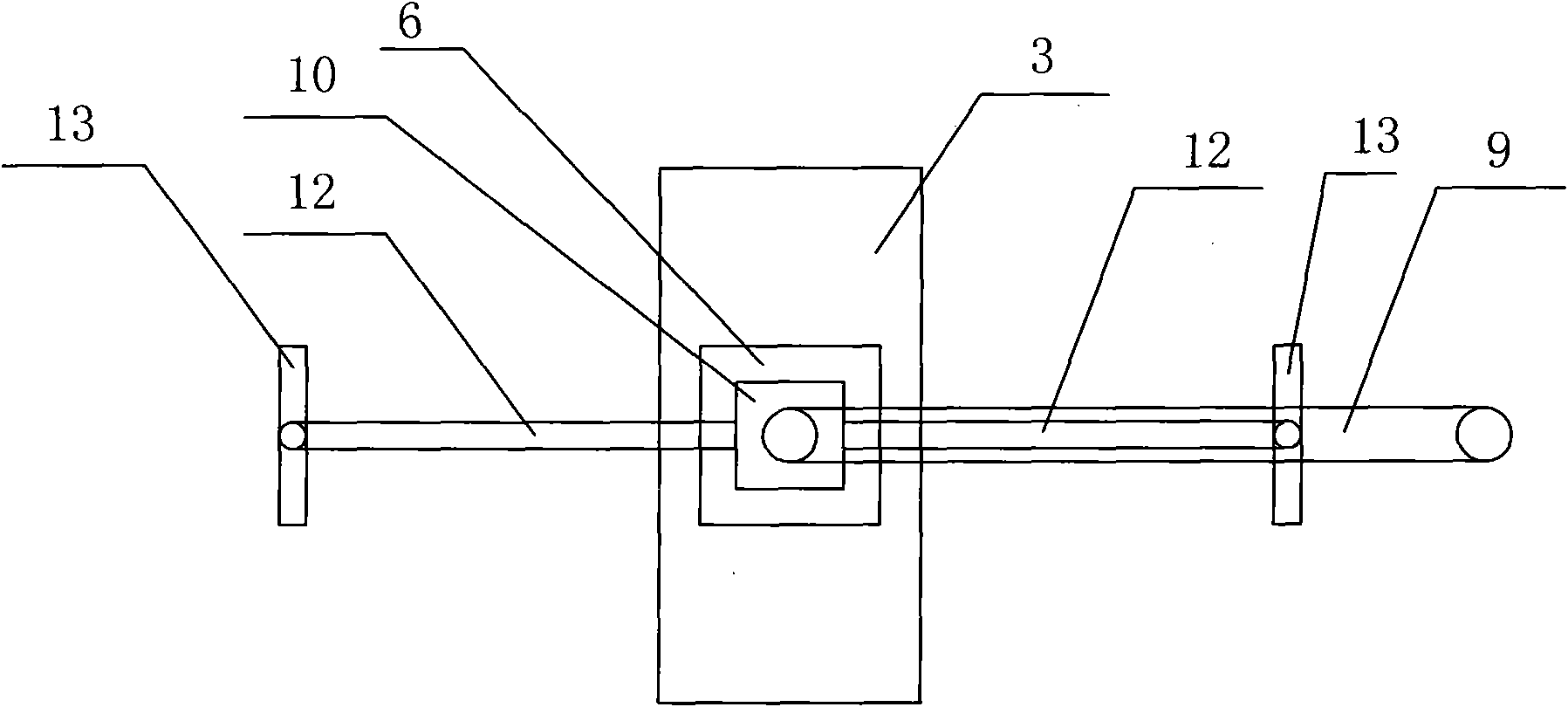

The invention discloses a multi-rotor wind generating system with connecting rods, which comprises a tower 1, wind turbines, two slewing bearings 2, a framework 4, beams 5 and the connecting rods 8. A rotary driving device A is arranged on the top of the tower; a rotary driving device B is arranged in the middle of the tower; inner rings of the slewing bearings of the rotary driving device A and the rotary driving device B are fixed on the tower; the framework is fixedly connected to the outer rings of the slewing bearings of the rotary driving device A and the rotary driving device B; one end of each beam is connected with the framework; one end of each connecting rod is connected with the middle part of each beam, and the other end of each connecting rod is connected with the framework; wind turbines are fixedly connected with the beams; each wind turbine comprises a wind wheel 6 and a cabin 7; and the power of each wind turbine is 0.5-500kW. The multi-rotor wind generating system has the advantages that: blades have long service life, the occupied area is small, installation and maintenance cost is low, the reliability is high, the application range is wide, a slewing bearing or a rotary driving device in the cabin is eliminated, the bearings bear small force, and the beams bear small force.

Owner:TIANJIN UNIV

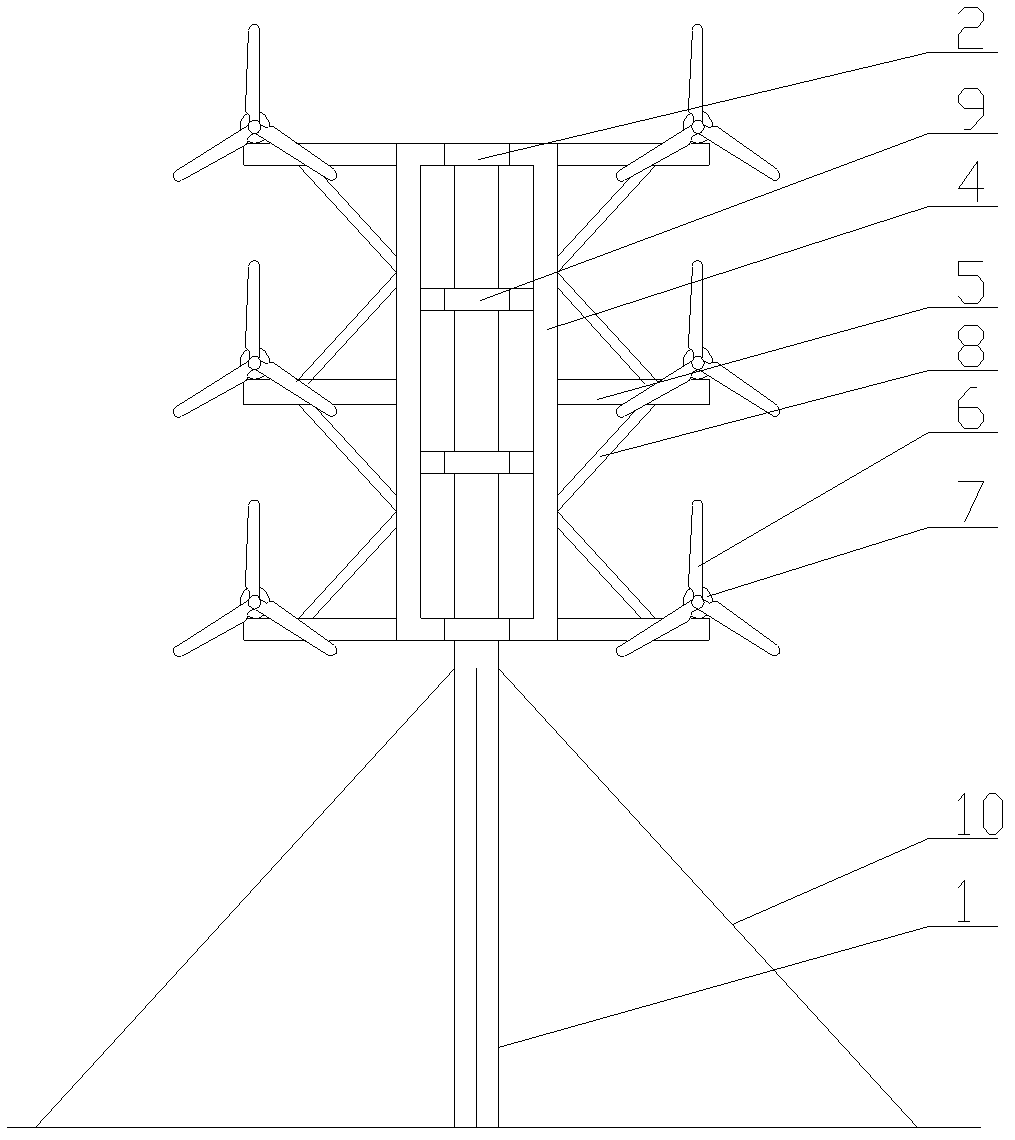

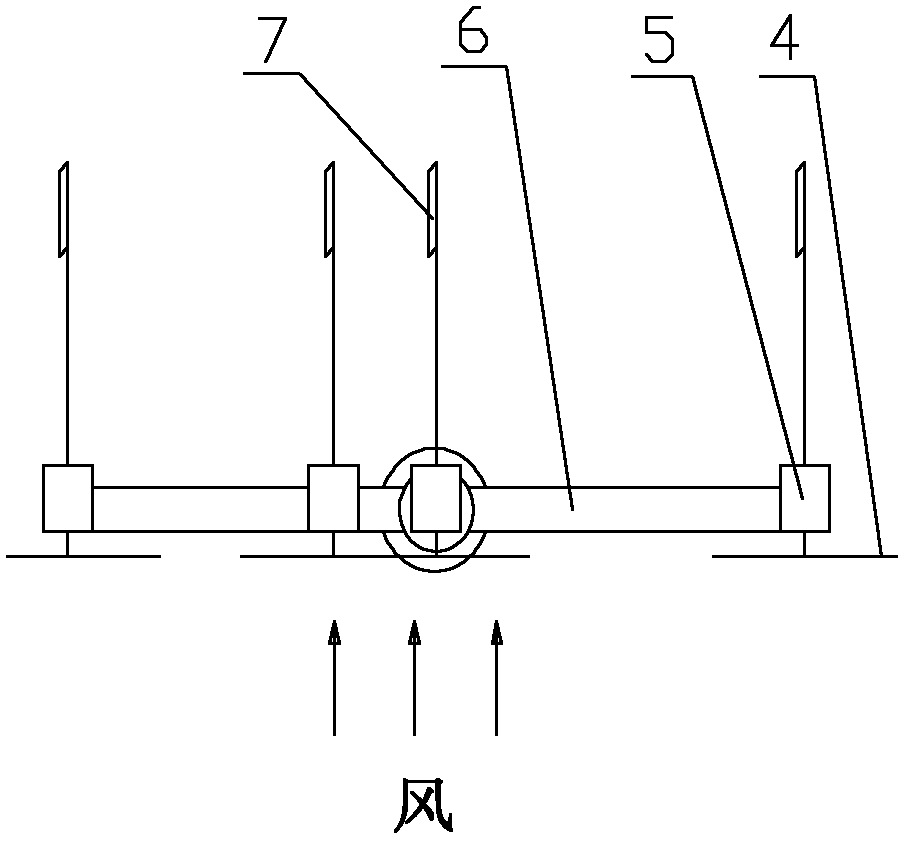

Multi-rotor wind power generation system with equal beam length

InactiveCN102322397ASolution to short lifeMature manufacturing technologyMachines/enginesWind motor combinationsEngineeringSmall footprint

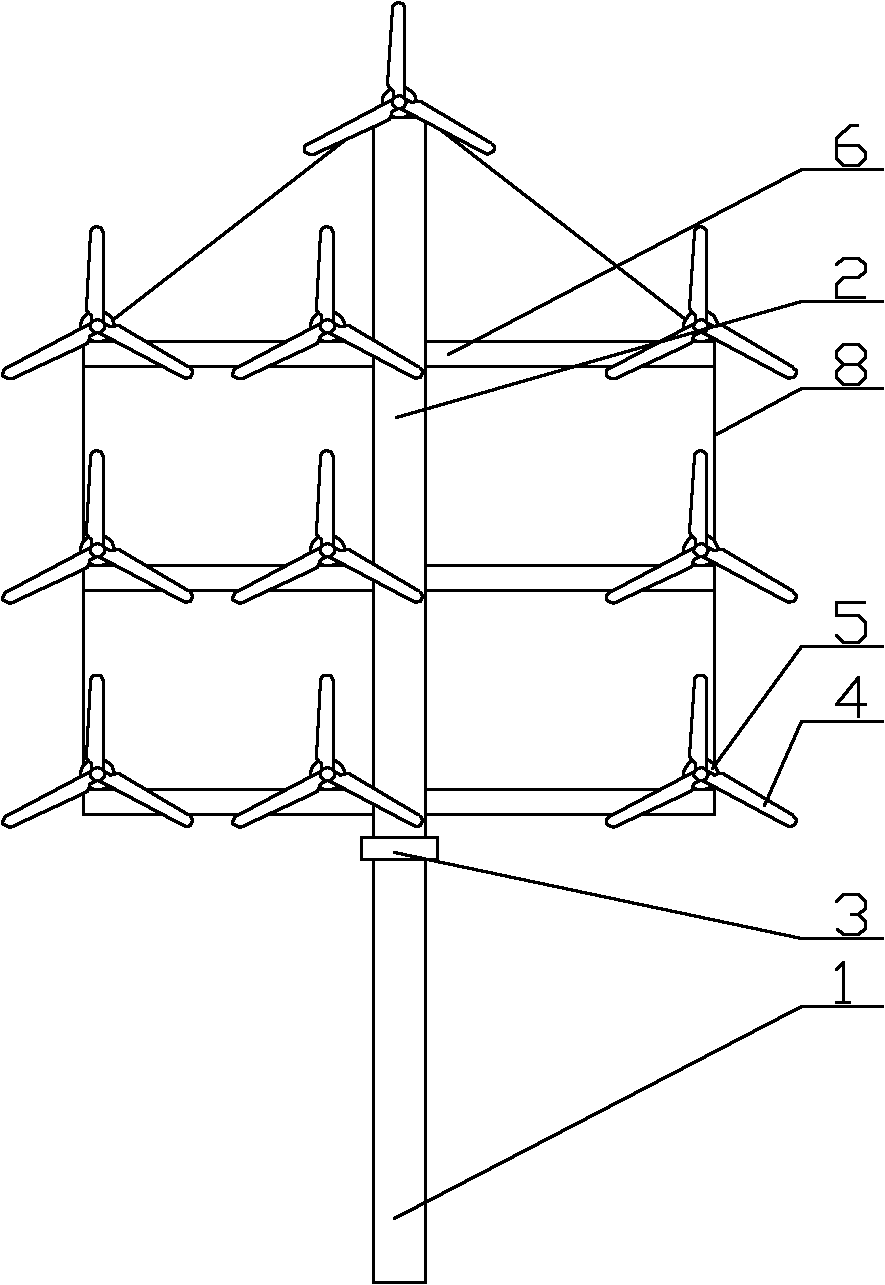

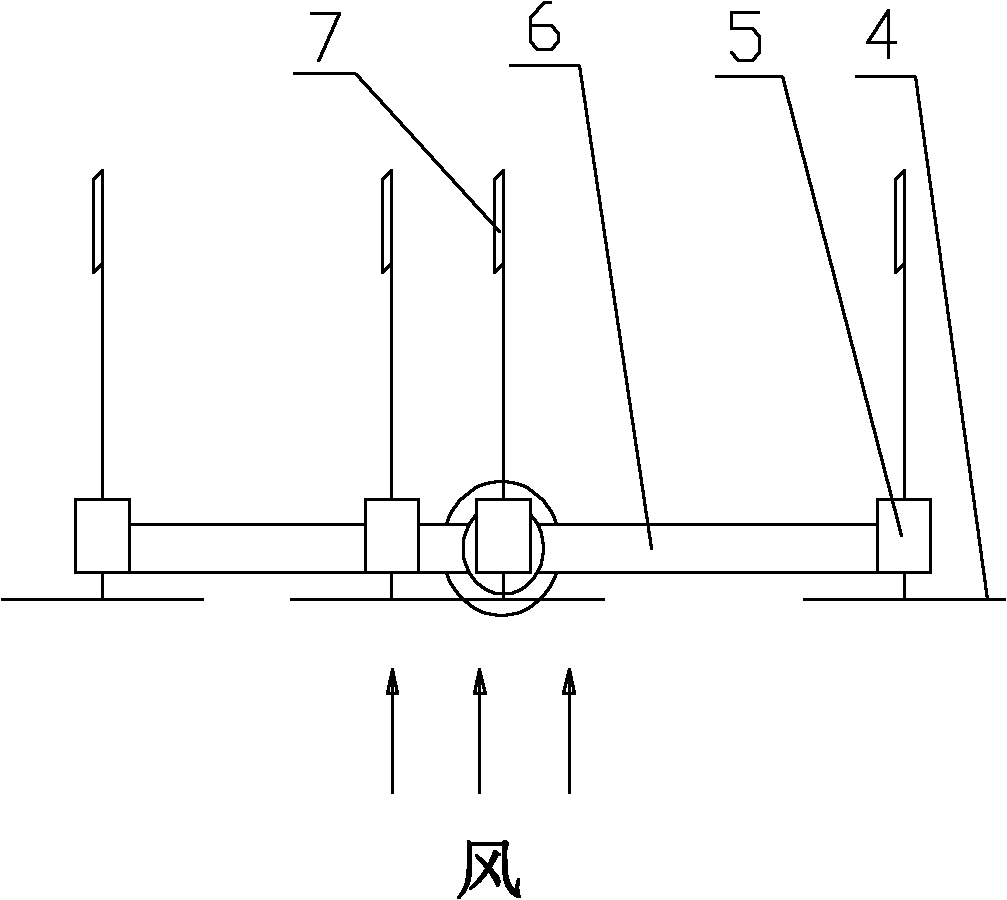

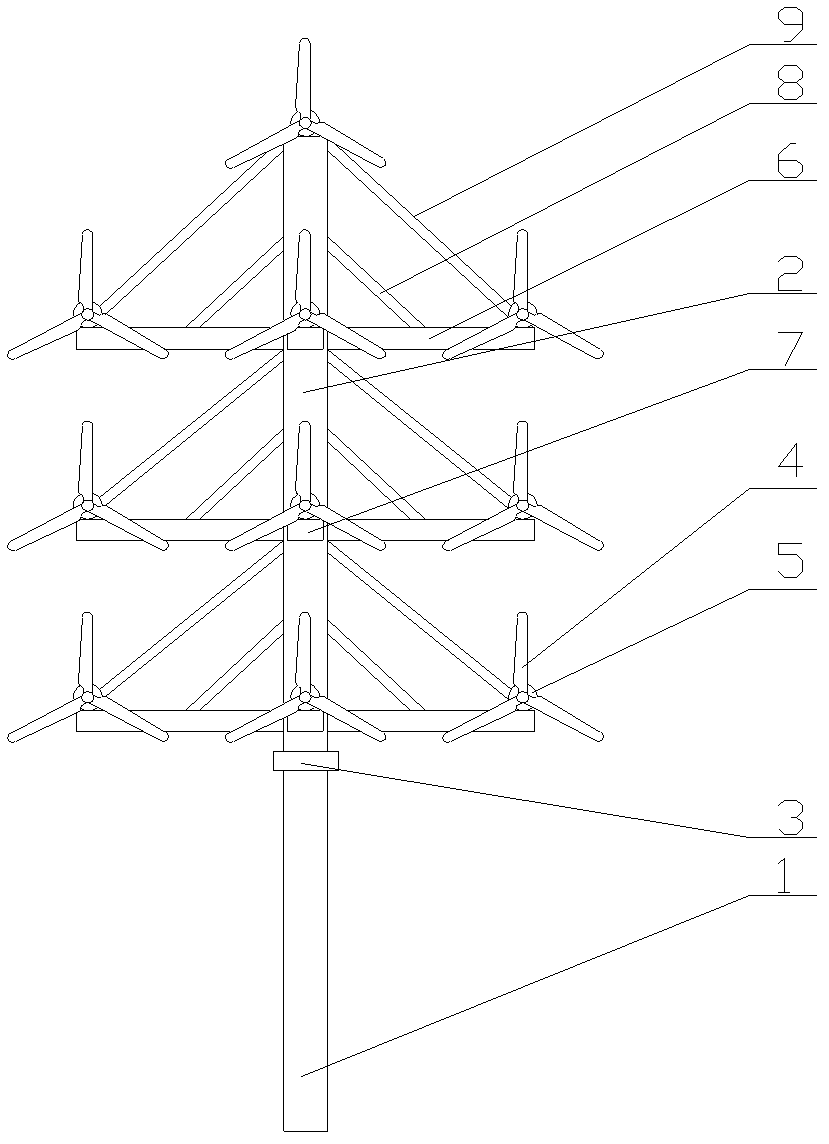

The invention discloses a multi-rotor wind power generation system with equal beam length, which comprises a lower pylon 1, a rotary bearing 3, windmills, an upper pylon 2, a rope and / or a rod 8, beams 6 and a tail vane 7, wherein the rotary bearing is arranged between the upper pylon and the lower pylon; two sides of the upper pylon are respectively connected with one ends of the beams; the outer end of the uppermost beam is connected with the top end of the upper pylon through the rope and / or the rod; the outer ends of adjacent beams are connected through the rope and / or the rod; the lengths of the beams at two sides of the upper pylon are equal; the windmills are fixedly connected with the top of the upper pylon or / and the beams; the number of the windmills on the beams at one side is greater than that of the windmills on the beams at the other side; and the tail vane is connected with the upper pylon, the beams or / and an engine room through a pin roll. The multi-rotor wind power generation system has the advantages of long service life of the vane, small occupied area, low cost for installation and maintenance, favorable reliability, wide application range, low bearing stress, automatic wind resistance and yawing and small stress of the beams; and the rotary bearing or a rotary driving device in the engine room is omitted.

Owner:TIANJIN UNIV

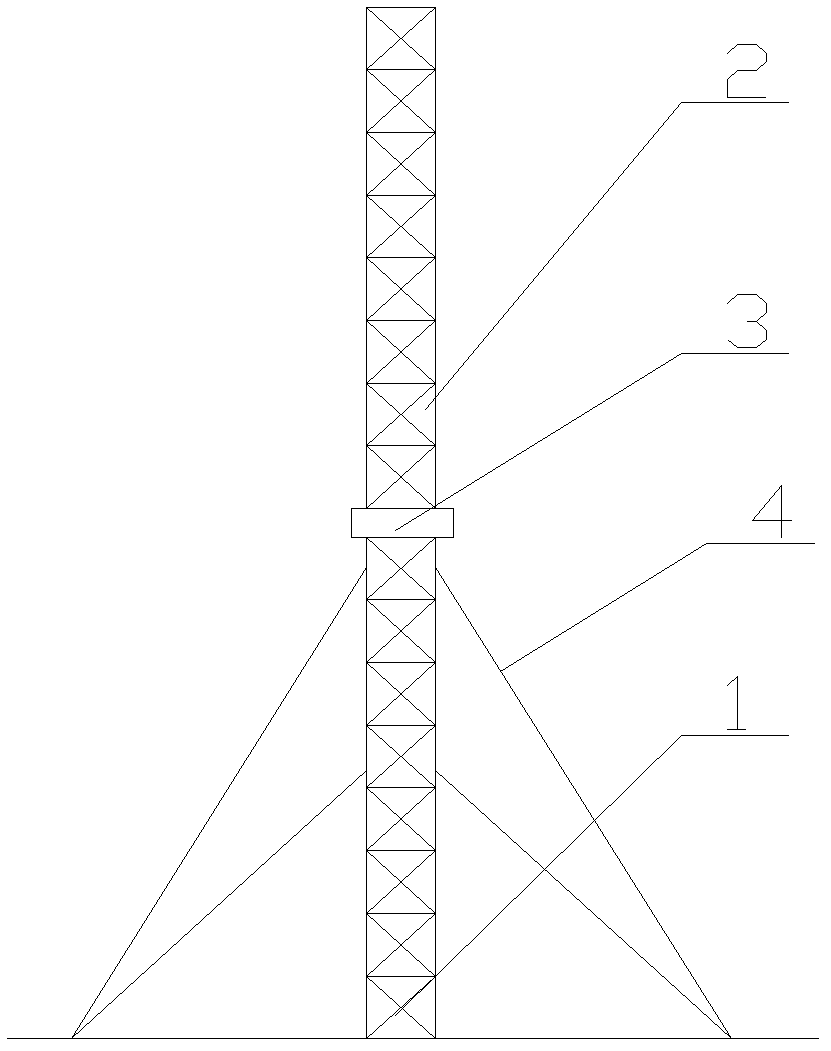

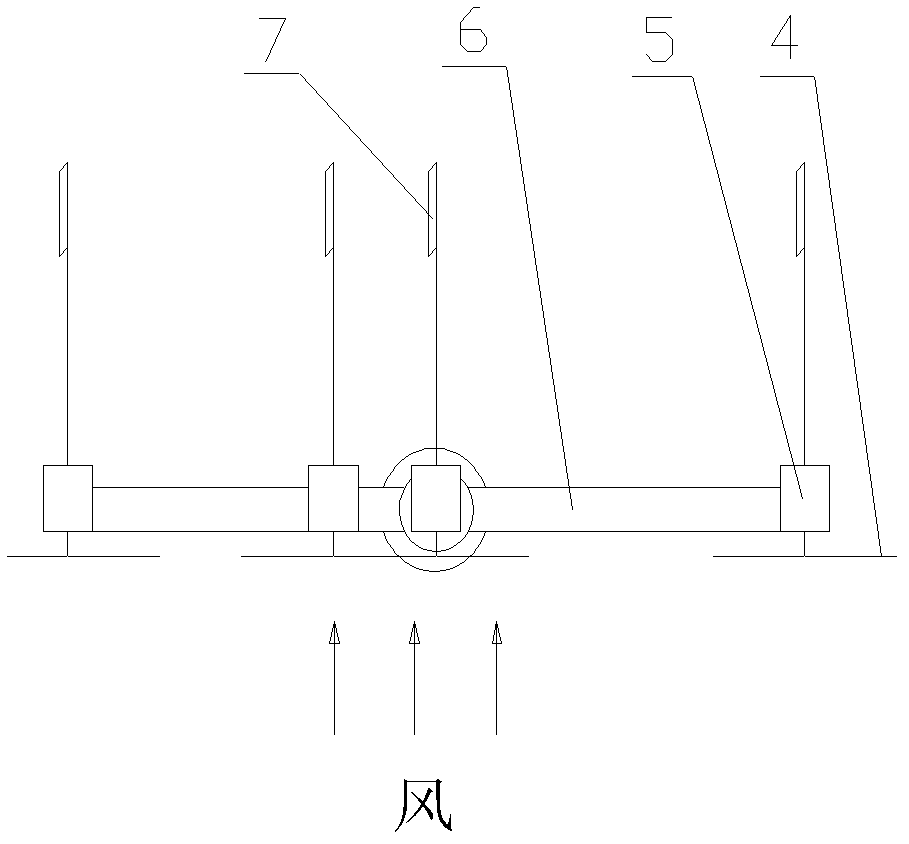

Multi-rotor wind generating system with fixing rods

InactiveCN102305172ASolution to short lifeMature manufacturing technologyMachines/enginesWind energy generationNacelleSmall footprint

The invention discloses a multi-rotor wind generating system with fixing rods. The multi-rotor wind generating system comprises a lower tower 1, a rotary driving device 3, wind turbines, an upper tower 2, beams 6, a cabin frame 7 and inner fixing rods 8; the rotary driving device is arranged between the upper tower and the lower tower; beams positioned on two sides of the upper tower are fixedly connected to the upper tower through one end of each beam; one end of each inner fixing rod is connected with the middle part of each beam, and the other end of each inner fixing rod is connected with the upper tower; the cabin frame is arranged on the upper tower; the wind turbines are arranged on the top of the upper tower, the beams or / and the cabin frame; each wind turbine comprises a wind wheel 4 and a cabin 5; and 2 to 100 wind turbines are arranged. The multi-rotor wind generating system with the fixing rods have the advantages that: blades have long service life, the occupied area is small, installation and maintenance cost is effectively reduced, the maintenance cost is low, the reliability of the system is high, the application range is wide, a slewing bearing or a rotary driving device in the cabin is eliminated, and the beams bear small force.

Owner:TIANJIN UNIV

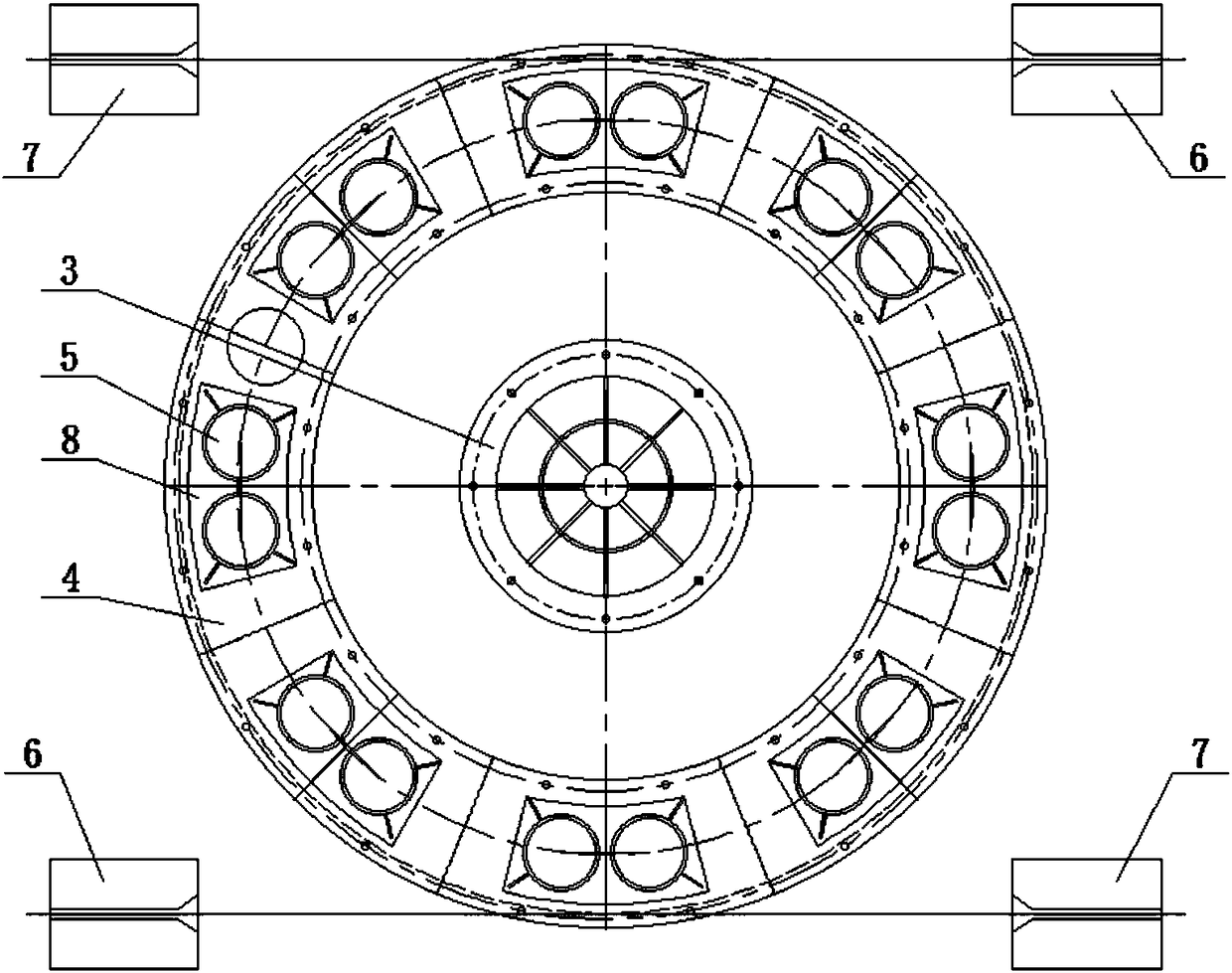

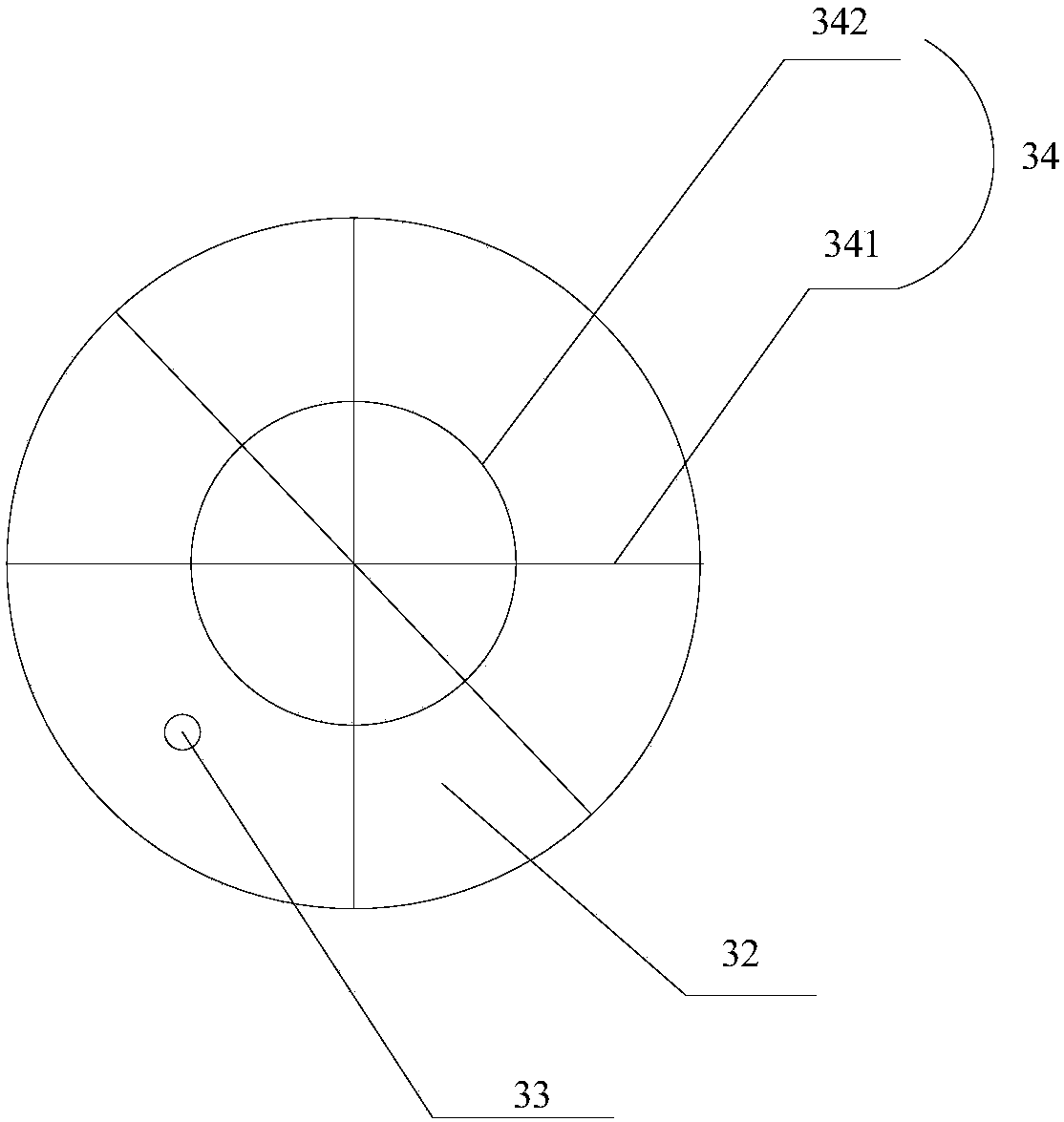

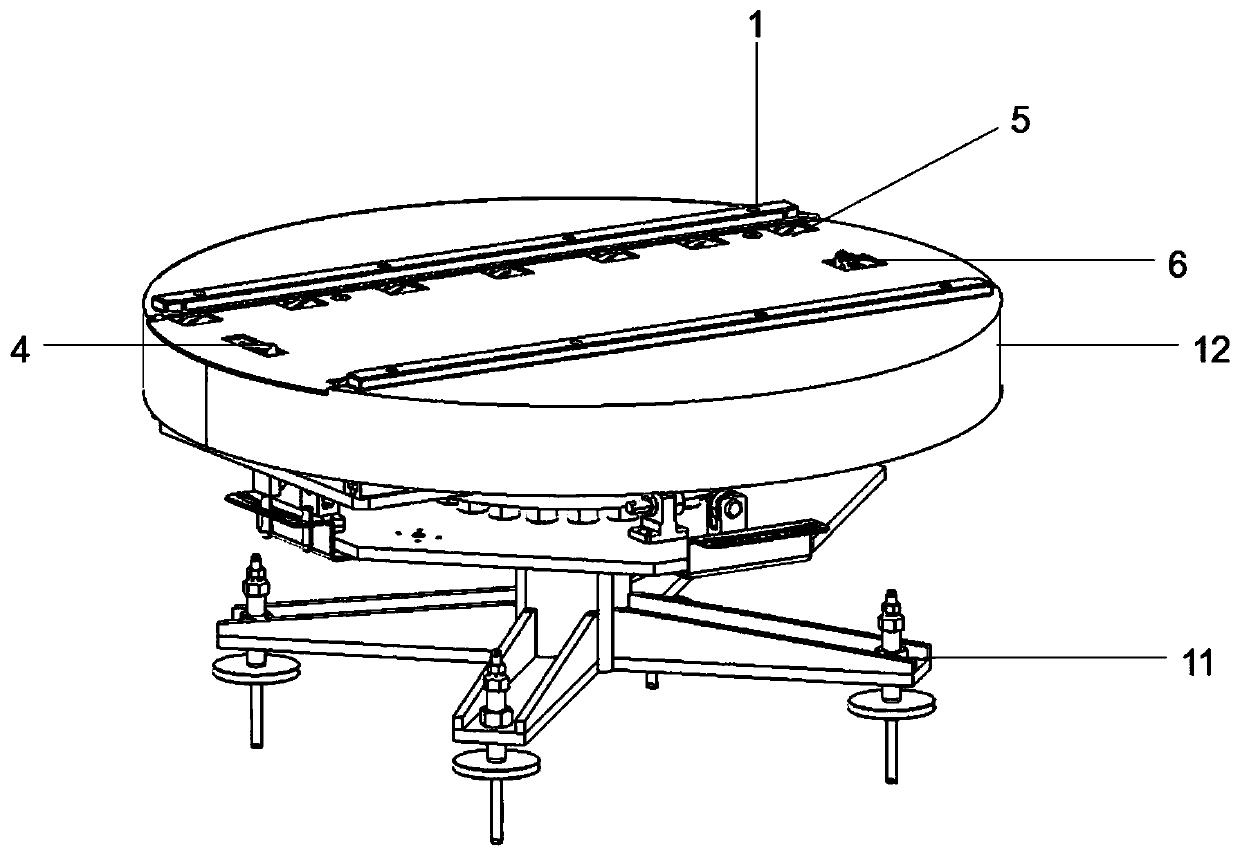

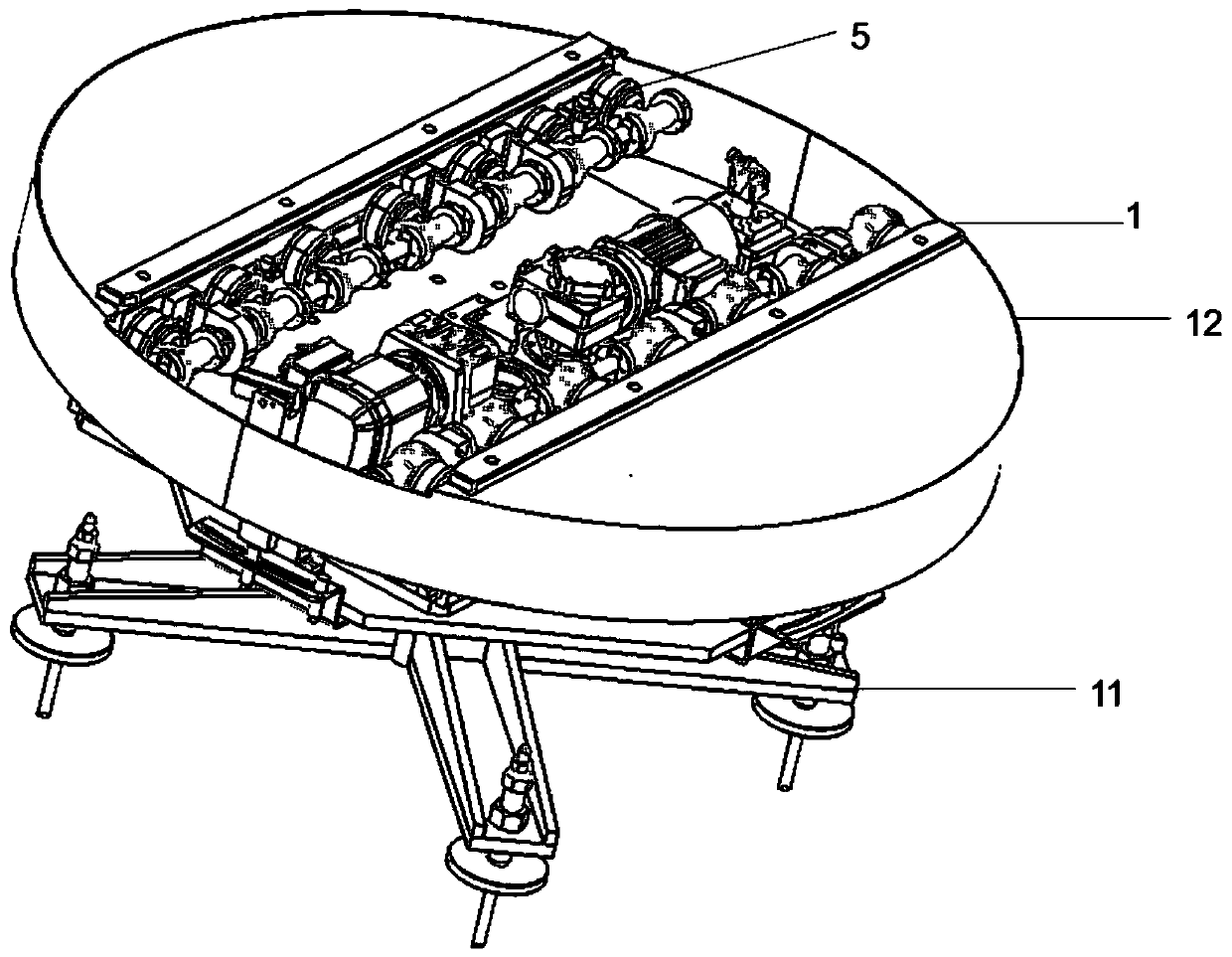

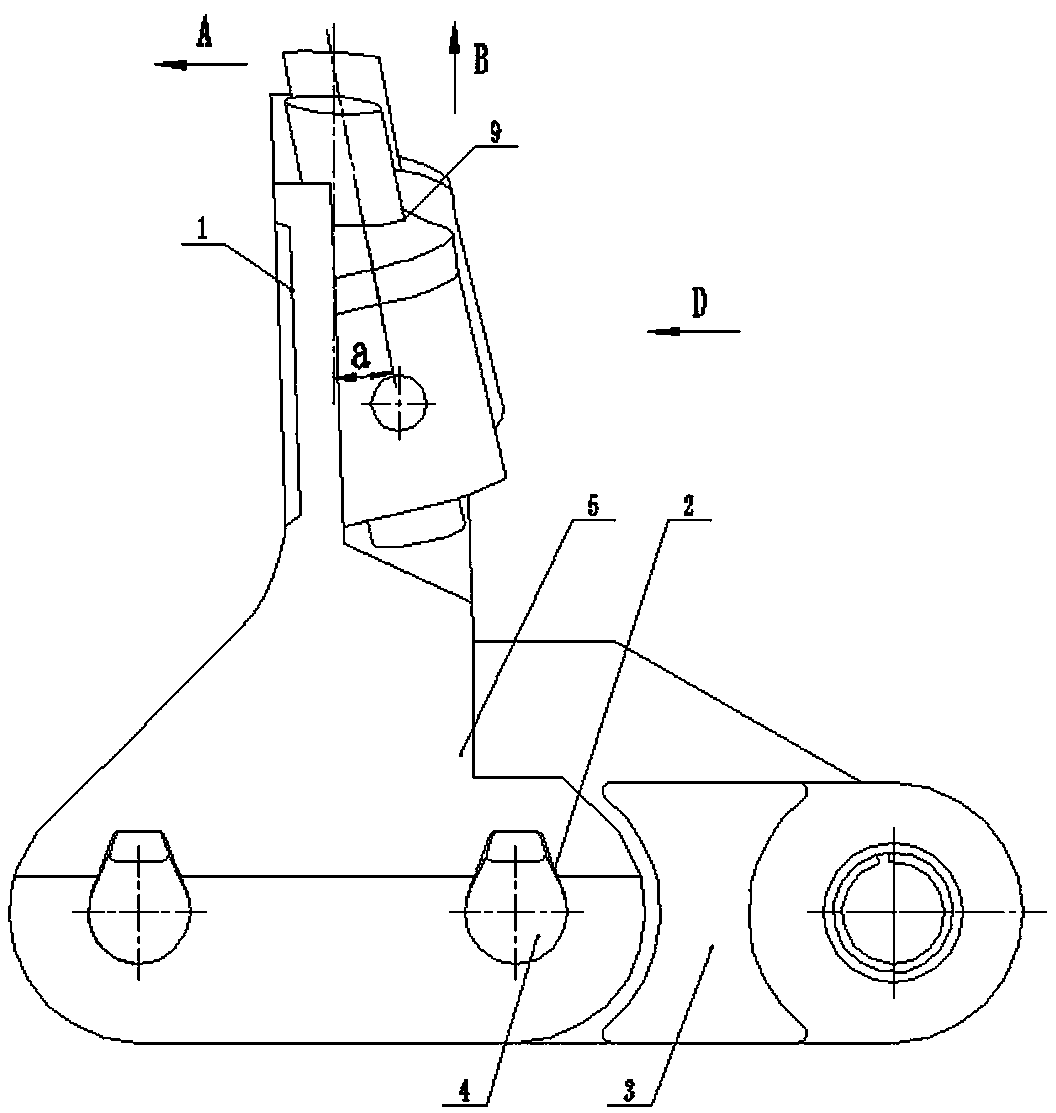

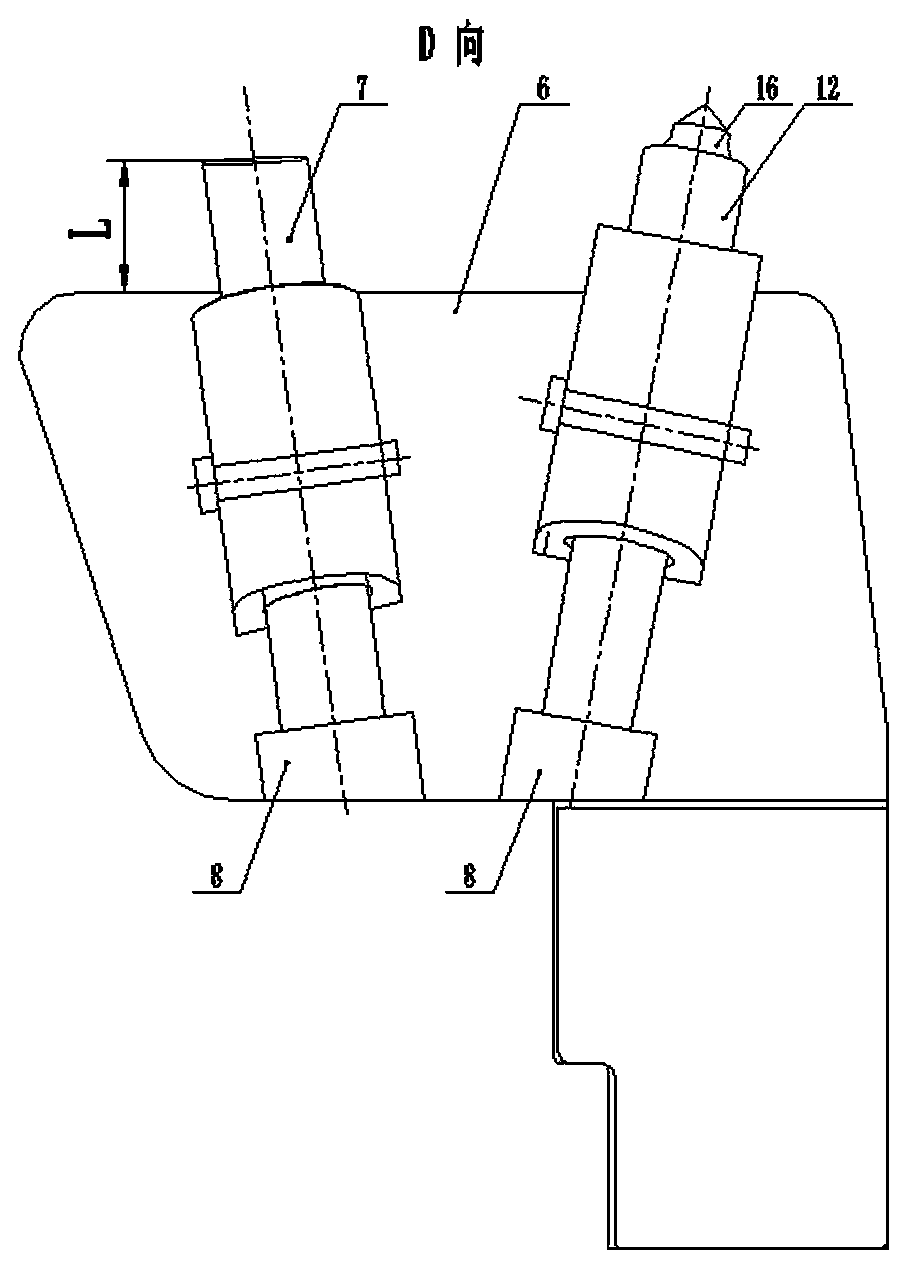

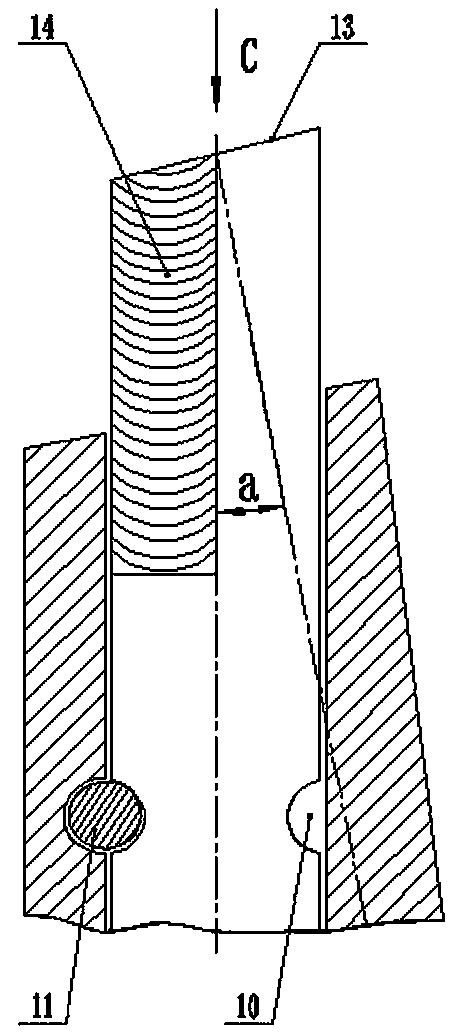

Pivoted bridge pivot body device

PendingCN108166401AAvoid influenceShorten the closing timeBridge erection/assemblySpherical pendulumWork site

Provided is a pivoted bridge swivel body device. The device comprises a pivot body support base, an annular slide track, multiple support feet, a first traction unit and a second traction unit; the pivot body support base comprises a lower spherical pendulum and an upper spherical pendulum which are fixed to a fixed part of a pivot body bridge and a rotary part of the pivot body bridge respectively; the annular slide track is fixed to the upper surface of the fixed part; the support feet are fixed to the lower portions of the rotary part and can slide on the annular slide track; the first traction unit drives the rotary part to rotate clockwise by exerting action force which can make the rotary part capable of sliding on the annular slide track clockwise on the rotary part through a traction cable; the second traction unit drives the rotary part to rotate anticlockwise by exerting action force which can make the rotary part capable of sliding on the annular slide track anticlockwise onthe rotary part through a traction cable. The pivoted bridge swivel body device can make the pivot body bridge capable of not only pivoting from a construction site to a work site but also pivoting back to the construction site from the work site, and thus the maintenance of the pivot body bridge is facilitated.

Owner:CHINA RAILWAY DESIGN GRP CO LTD +1

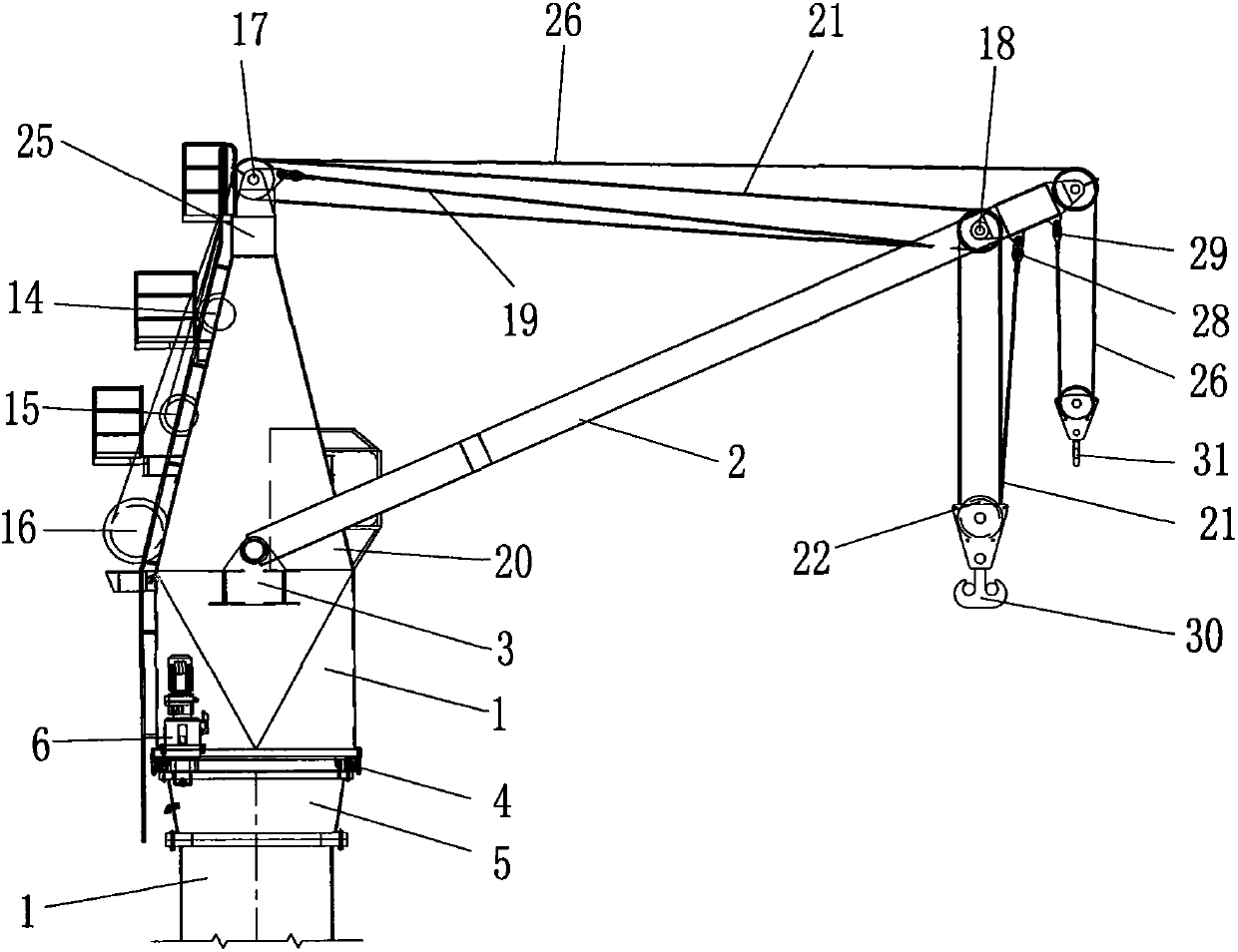

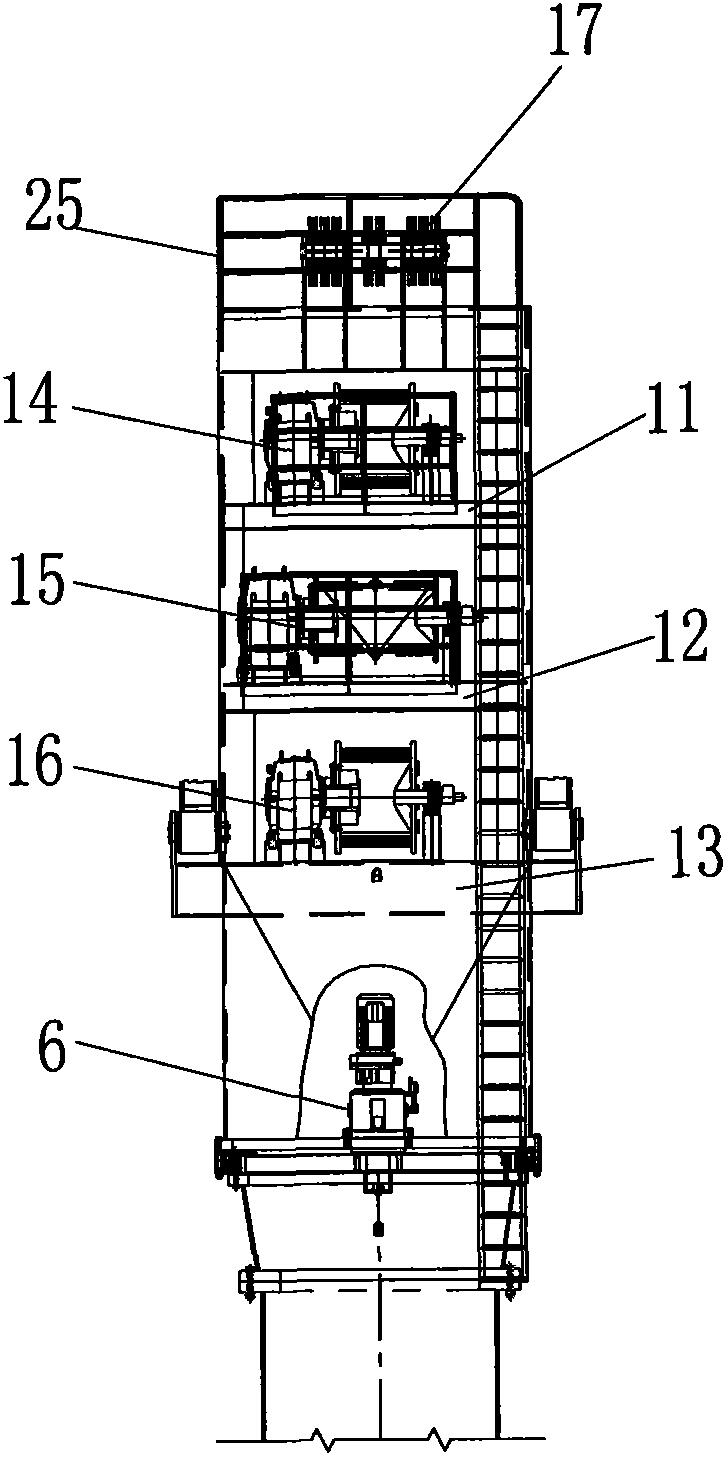

Maintenance crane for electric full-variable frequency rock crushing station

InactiveCN102887438AAvoid damageAchieve energy saving effectLoad-engaging elementsCranesEngineeringWinch

The invention relates to a maintenance crane for an electric full-variable speed rock crushing station. The maintenance crane comprises an upper rotary column, the bottom end of an arm frame is hinged on a rotating shaft seat, and the maintenance crane is characterized in that the upper rotary column and a connecting flange are connected together through a rotary support, and a slewing mechanism is fixedly arranged in the bottom of the upper rotary column. The slewing mechanism comprises a motor, a speed redactor and a small gear, wherein the small gear is meshed with a big gear of the rotary support. A platform is arranged at the middle part of the upper rotary column, and a winch is arranged on the platform. Pulley blocks are arranged at the top end of the upper rotary column and the top end of the arm frame, one end of a variable-amplitude steel wire rope is wound on a variable-amplitude winch, and the other end of the variable-amplitude steel wire rope is fixed at the top end of the upper rotary column. One end of a main hook steel wire rope is wound on a main lifting winch, and the other end of the main hook steel wire rope is fixed at the top end of the arm frame. One end of an auxiliary hook steel wire rope is wound on an auxiliary lifting winch, and the other end of the auxiliary hook steel wire rope is fixed at the top end of the arm frame. A main hook is hung on the main hook steel wire rope, and an auxiliary hook is hung on the auxiliary hook steel wire rope. The maintenance crane for the rock crushing station can save energy consumption and reduce cost.

Owner:ELEPHANT KING HEAVY IND

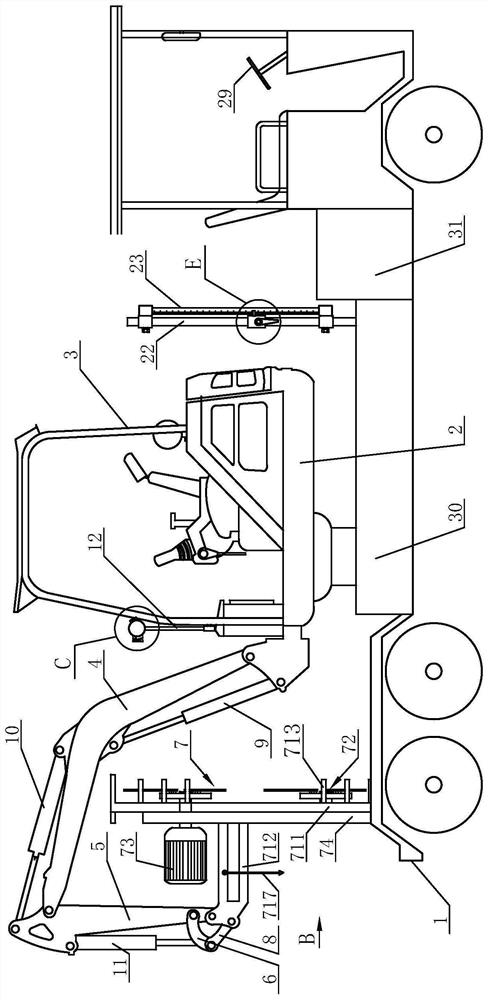

Movable water station for rock-fill dam materials

ActiveCN101775837AAdd water and move flexiblyEasy to swing operationWater closetsEarth-fill damsRoad surfaceEngineering

The invention relates to a movable water station, in particular to a water station for providinga watering procedure for rock-fill dam materials. The movable water station for rock-fill dam materials comprises a water-adding system and a driving system, wherein the water-adding system is mounted in the driving system which drives the water station to move, the water-adding system comprises a water-feeding device, a water-adding device, a supporting device and a rotary device, and the water-feeding device and the water-adding device are communicated and mounted on the supporting device which is mounted on the rotary device. The movable water station for rock-fill dam materials can movably add a great amount of water, effectively ensures the water-adding quality to dam materials, avoids polluting roads and is beneficial to the driving safety guarantee of a transport vehicle.

Owner:中国安能集团第一工程局有限公司

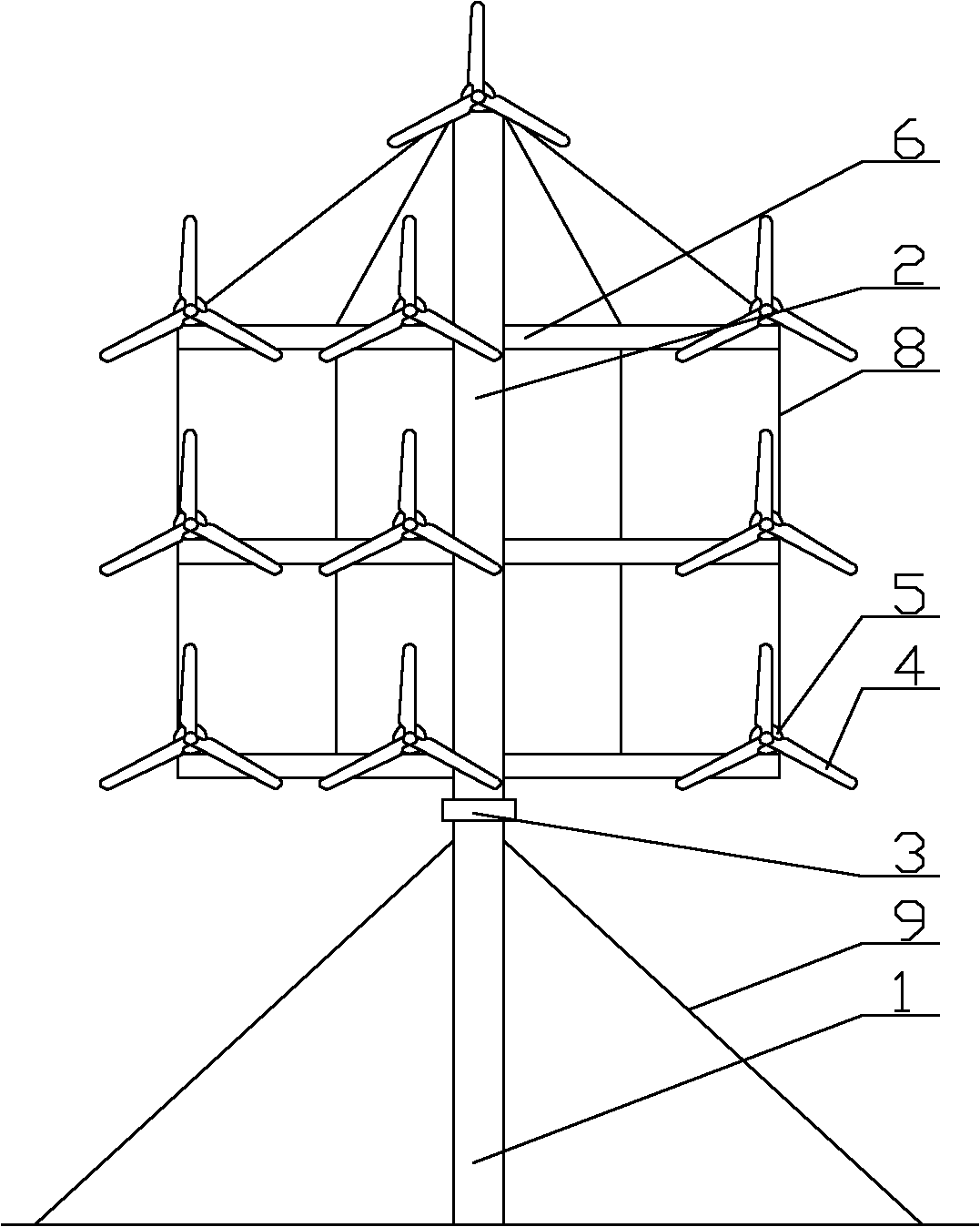

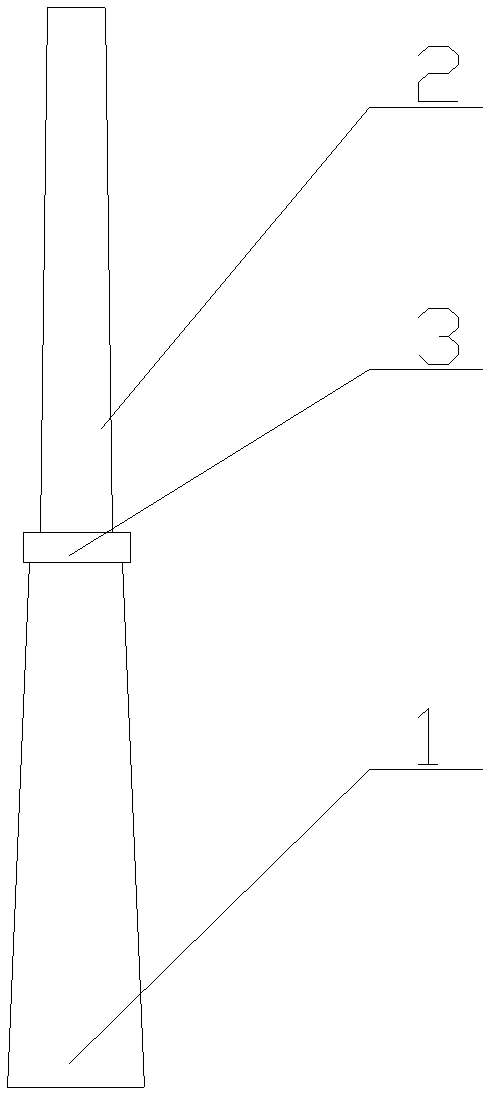

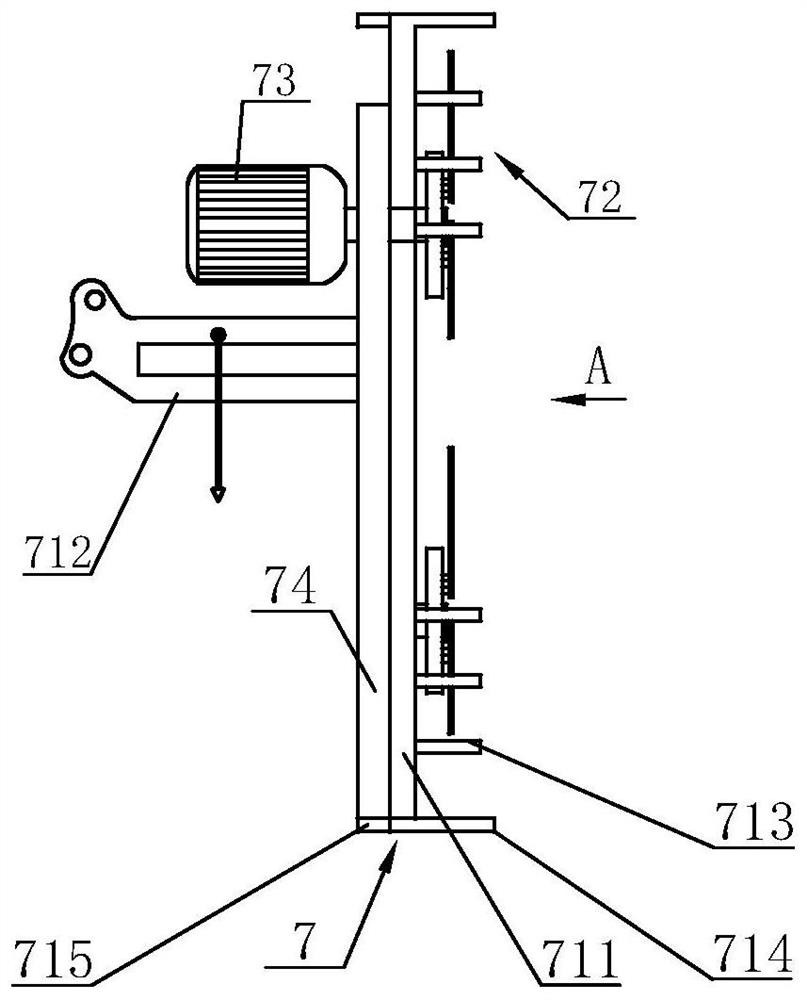

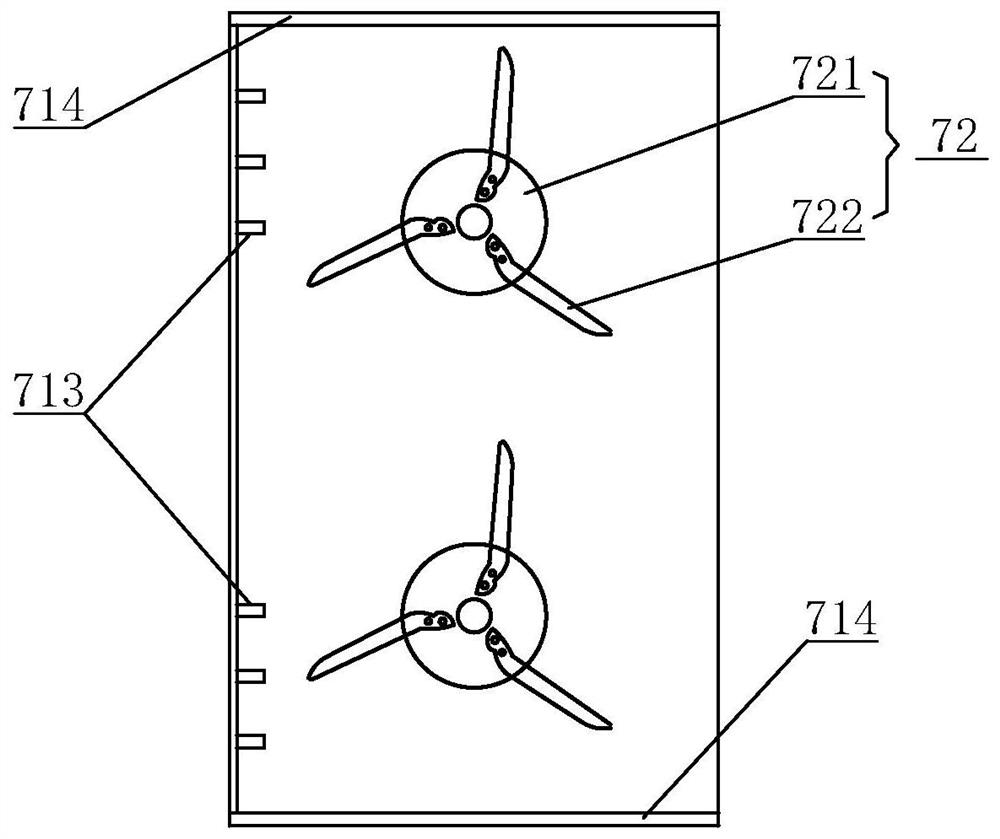

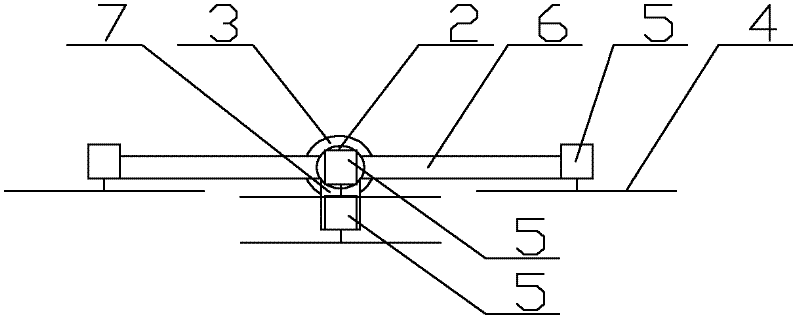

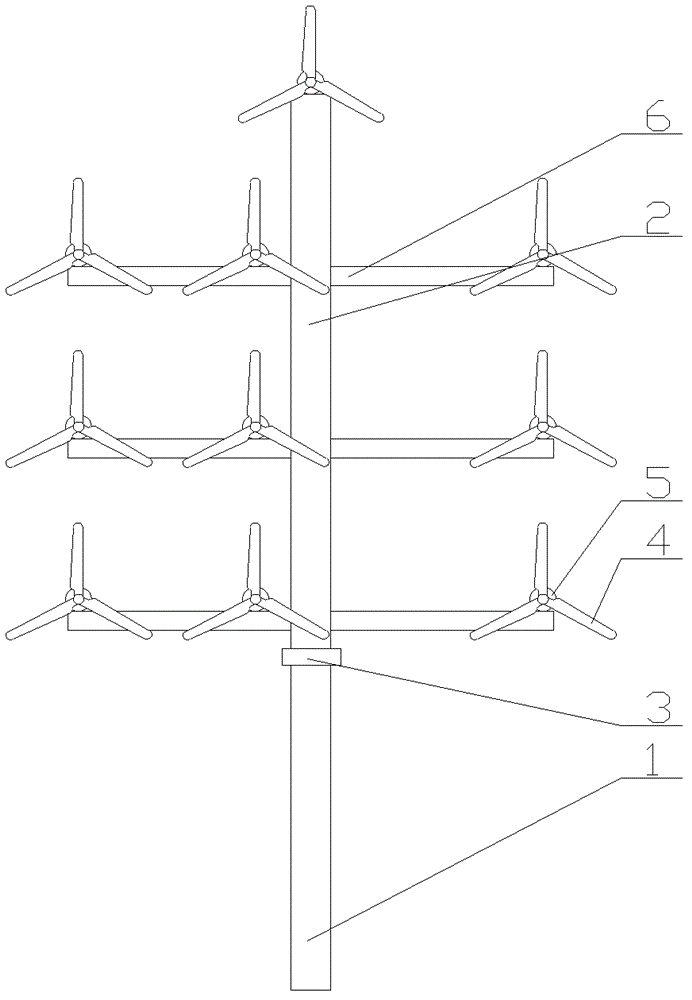

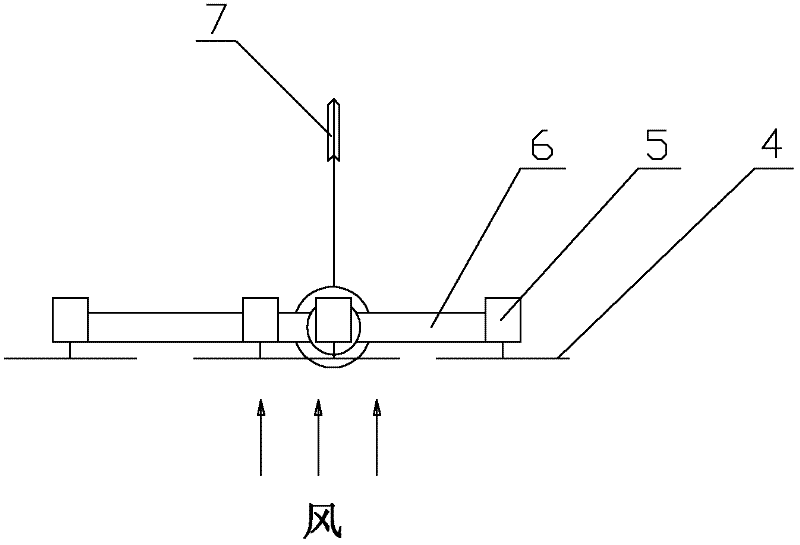

Tower for multi-rotor wind generating system

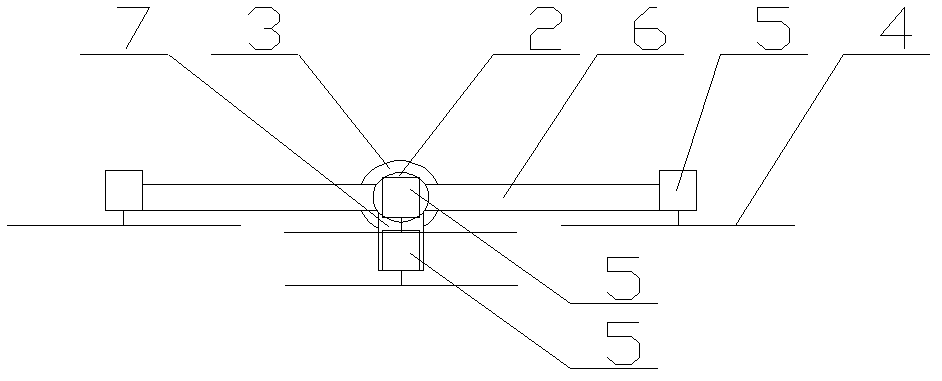

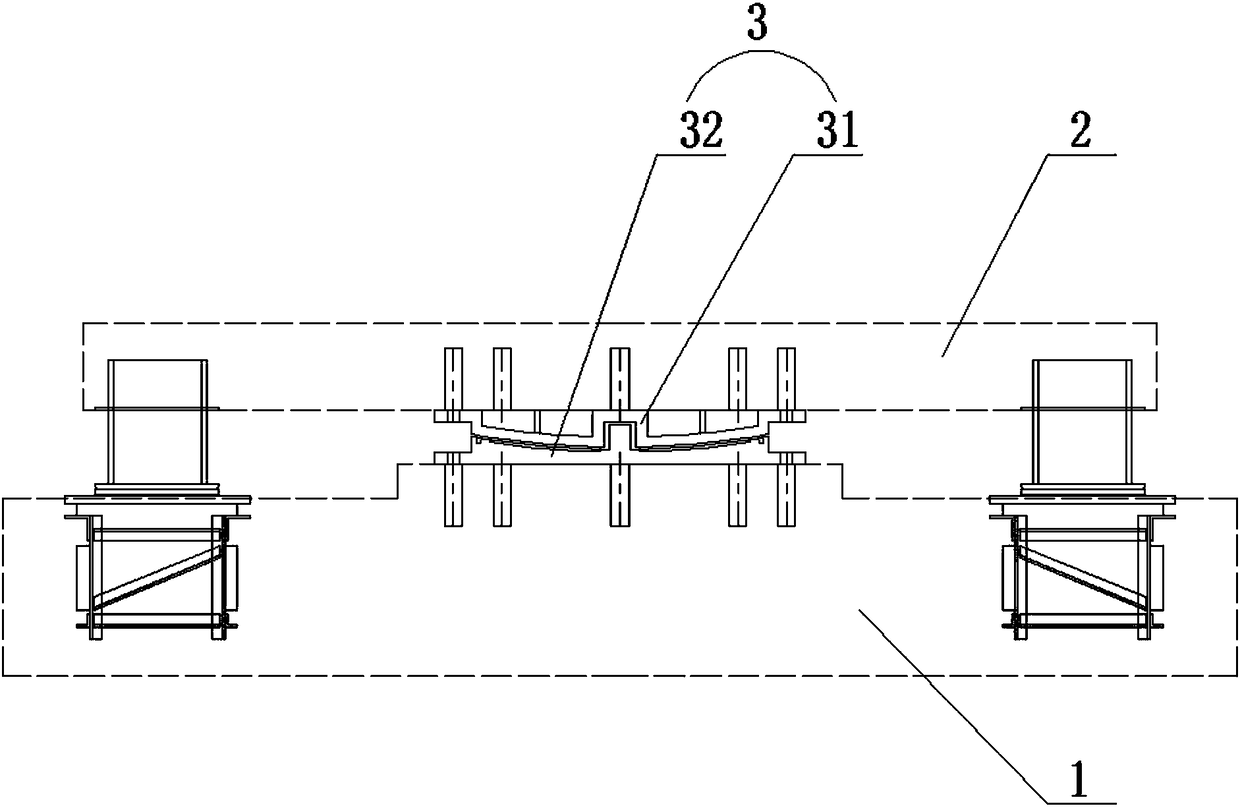

InactiveCN102305196ARotary realizationUntwistingWind motor controlFinal product manufactureNacelleEngineering

The invention discloses a tower for a multi-rotor wind generating system. The tower comprises a lower tower (1), an upper tower (2) and a rotary driving device (3), wherein the rotary driving device is arranged between the upper tower and the lower tower. The tower has the advantages that: (1) the rotary driving device arranged in the middle of the towers can integrally rotate a plurality of wind turbines arranged to fulfill the aims of wind facing, casting off and safe protection and ensure that the plurality of wind turbines cannot influence one another in the wind direction and partial wind turbines cannot be positioned in wake flow areas of other wind turbines, or towers or beams so as to furthest utilize wind energy; (2) a slewing bearing or a rotary driving device in a cabin in the prior art is eliminated; because the rotary driving device is arranged between the upper tower and the lower tower realizes wind facing, yawing and safe protection functions, the slewing bearing or the rotary driving system is not required to be arranged in a cabin of a single wind turbine; and (3) the cost of the tower is reduced.

Owner:TIANJIN UNIV

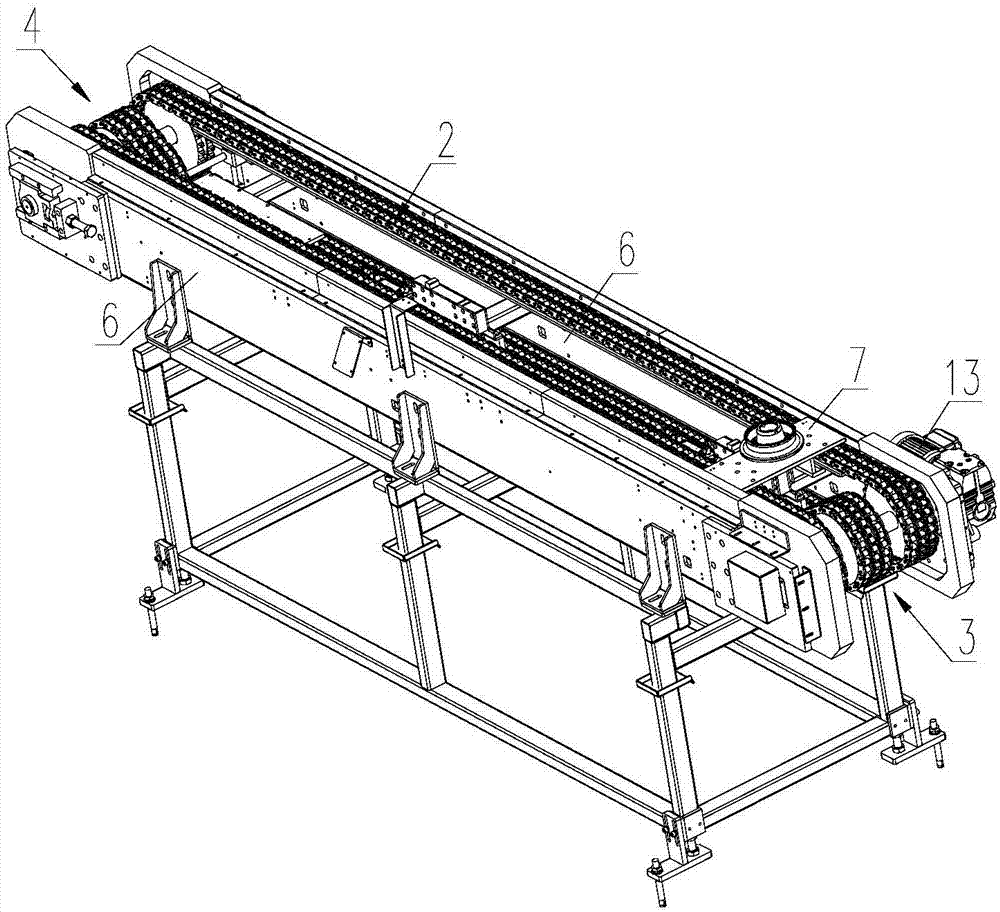

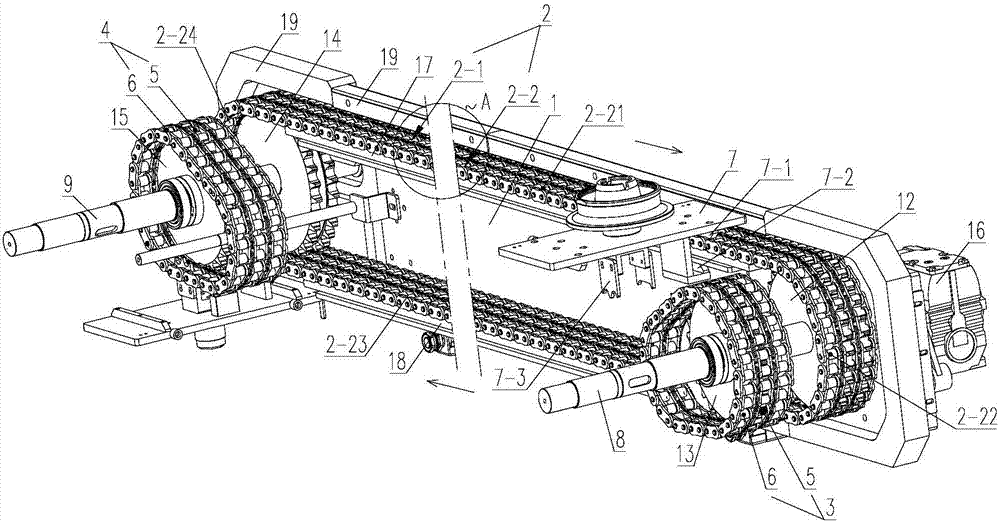

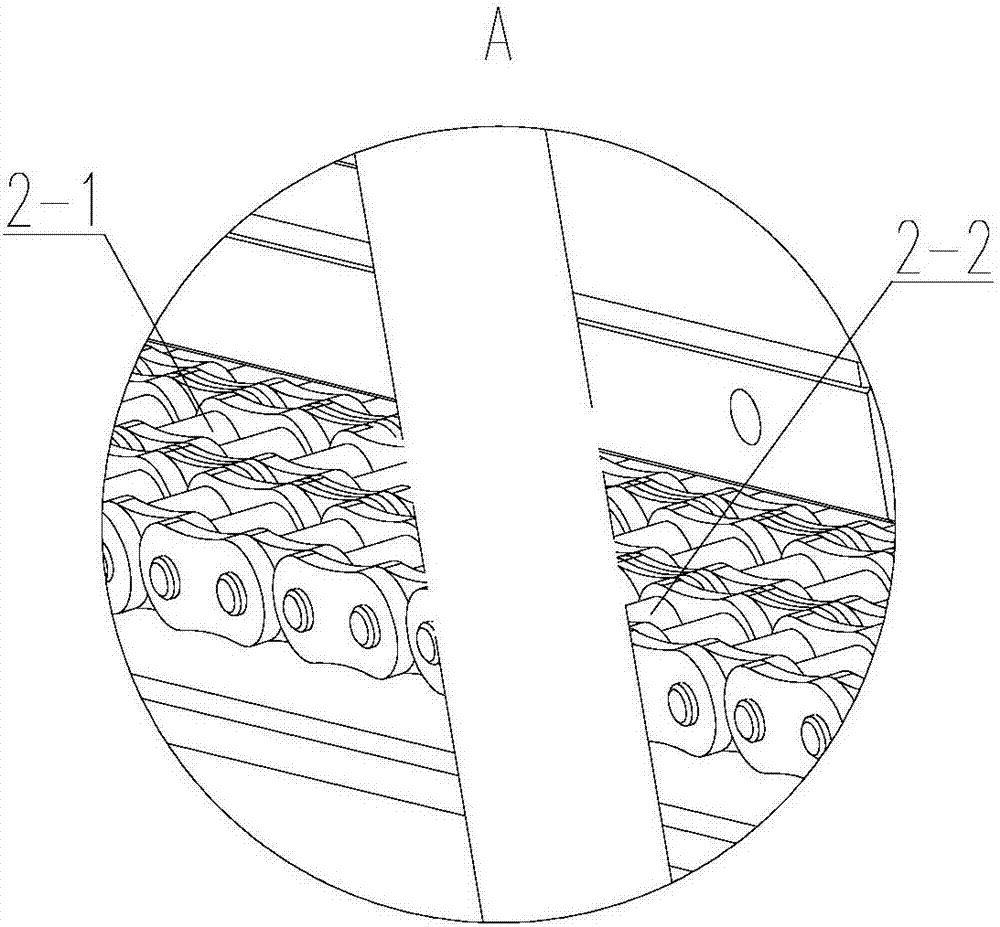

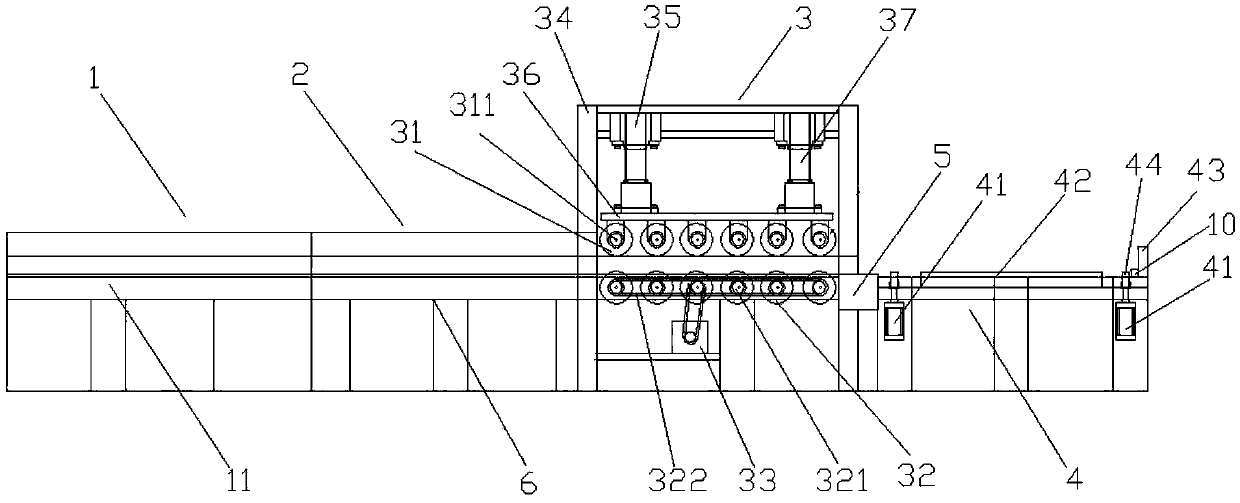

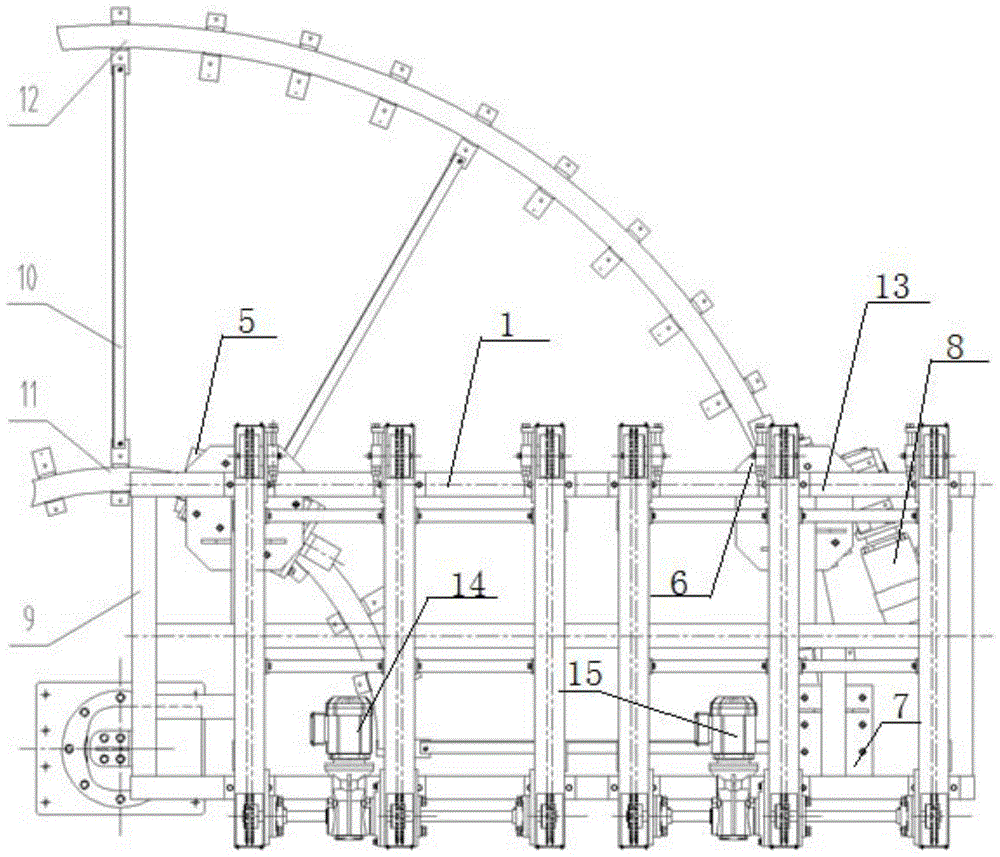

Chain rotary type conveying line

The invention relates to the technical field of rotary conveying devices, in particular to a chain rotary type conveying line. The chain rotary type conveying line comprises conveying chain sets, a head end driving chain set and a tail end driving chain set, wherein the conveying chain sets, the head end driving chain set and the tail end driving chain set are all closed; each conveying chain set comprises a conveying transmission chain and a conveying supporting chain which are connected in parallel; the head end driving chain set and the tail end driving chain set each comprise a steering transmission chain and a steering driving chain which are connected in parallel; and each conveying supporting chain comprises a conveying section, a descending steering section, a return section and an ascending steering section which are connected end to end in sequence. According to the chain rotary type conveying line, when a transferring supporting plate passes through the descending steering sections and the ascending steering sections, a drive tooth at the lower part of the transferring supporting plate meshes with the corresponding steering driving chain so as to provide forward movement power for the transferring supporting plate, a second guiding strip abuts against the inner side of the conveying supporting chains so as to enable the transferring supporting plate to smoothly pass through the ascending steering sections and the descending steering sections, and therefore rotation of the transferring supporting plate on the conveying line can be realized.

Owner:STON ROBOT CHANGZHOU

Multi-rotor wind power generation system with tail vane

ActiveCN102322400ASolution to short lifeMature manufacturing technologyWind motor controlWind motor supports/mountsSmall footprintSlewing bearing

The invention discloses a multi-rotor wind power generation system with a tail vane, which comprises a lower pylon 1, a rotary bearing 3, windmills, an upper pylon 2, beams 6 and the tail vane 7, wherein the rotary bearing is arranged between the upper pylon and the lower pylon; one end of each beam is fixedly connected with the upper pylon; the windmills are fixedly connected with the top of theupper pylon or / and the beams; each windmill comprises a wind wheel 4 and an engine room 5; the number of the windmills is 2 to 100; the lengths of the beams at two sides of the upper pylon are unequal; the number of the windmills on the beams at one side of the upper pylon is 1 to 20 more than that of the windmills on the beams at the other side of the upper pylon; and the tail vane is connected with the upper pylon, the beams or / and the engine room through a pin roll. The multi-rotor wind power generation system has the advantages of long service life of the vane, small occupied area, low cost for installation and maintenance, favorable reliability, wide application range, automatic wind resistance and yawing and safe protection; and the rotary bearing or a rotary driving device in the engine room is omitted.

Owner:TIANJIN UNIV

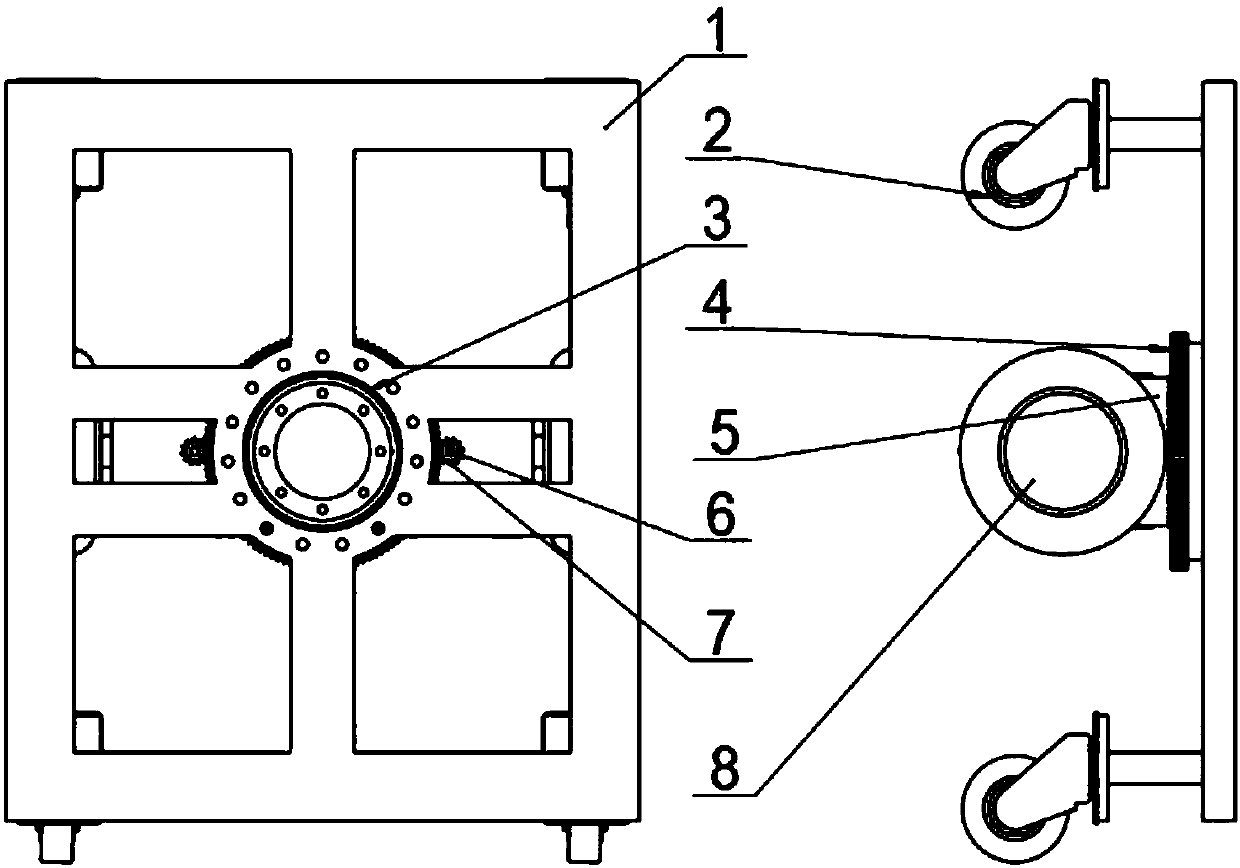

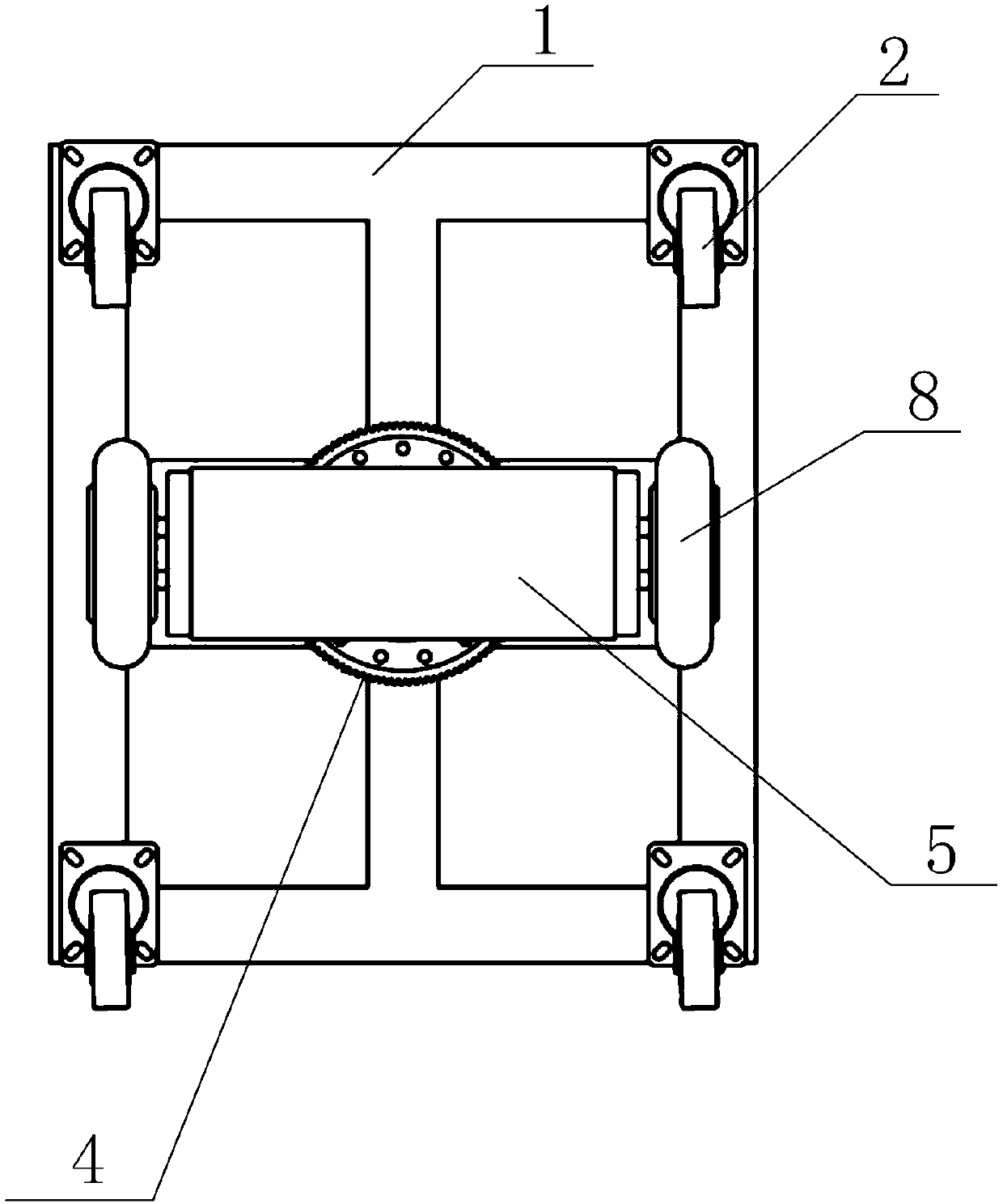

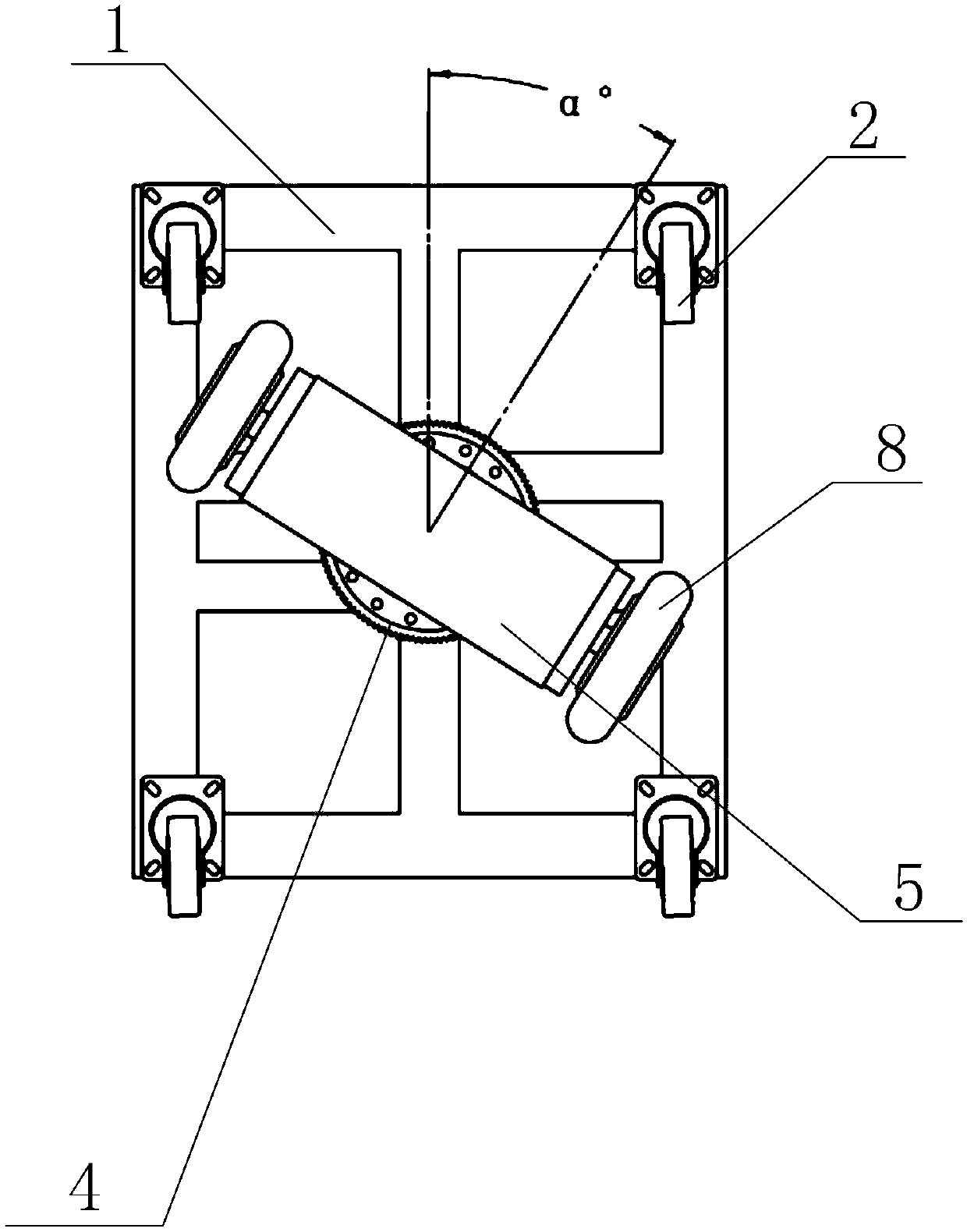

Workpiece horizontal rotary device

PendingCN110817291ALower quality requirementsGuaranteed stabilityControl devices for conveyorsRotary conveyorsDrive shaftGear wheel

Owner:上海天永智能装备股份有限公司

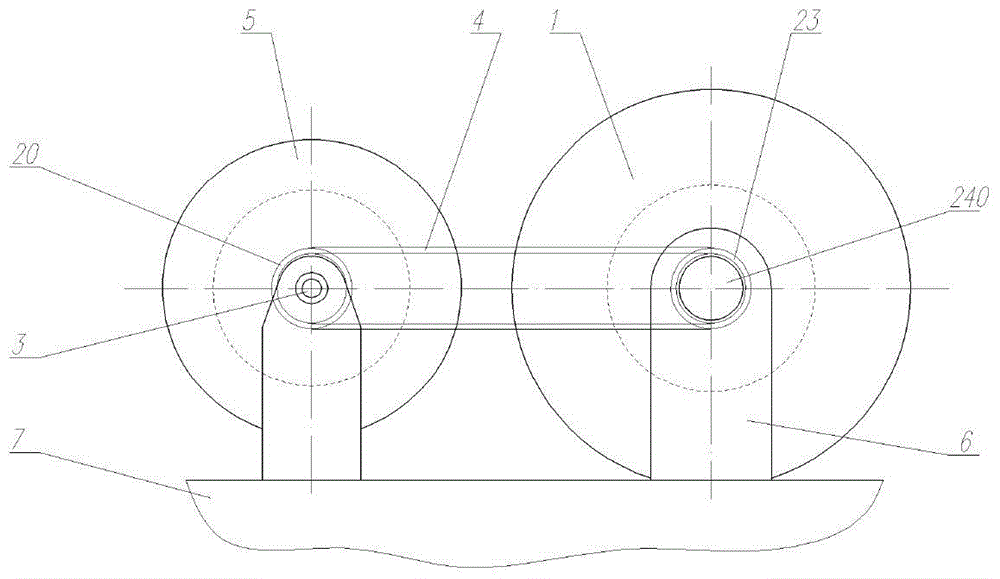

Walking chassis mechanism and robot

InactiveCN109968311ARealize turning in placeRotary realizationProgramme-controlled manipulatorDrive wheelControl theory

The invention discloses a walking chassis mechanism. When a rotary motor is braked, forward or backward walking of the chassis mechanism is realized by respectively controlling two driving wheels to run at the same speed and in the same direction; when the rotary motor is braked, the turning of the chassis mechanism is realized by controlling the two driving wheels run at differential speeds and in the same direction; when the rotary motor is braked, in-situ rotation of the chassis mechanism is realized by controlling the two driving wheels to run at the same speed and in opposite directions;and when the rotary motor is in a driving state, the two driving wheels are controlled to run at the same speed and in the opposite directions, so that the forward direction of a driving wheel frame and the forward direction of a chassis form a certain deflection angle, and then the two driving wheels are forced to run at the same speed and in the same direction to achieve the purpose of translating in any direction. The front-back walking and the front-back turning walking of the walking chassis mechanism can be realized, and the translation in any direction and the in-situ rotation can alsobe realized. The invention also provides a robot with the walking chassis mechanism.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Movable automatic pruning machine and pruning method thereof

PendingCN112790027AEasy to adjustReduce workloadHedge trimming apparatusCuttersTool bitVertical plane

Owner:山东绿美生态环境工程集团有限公司

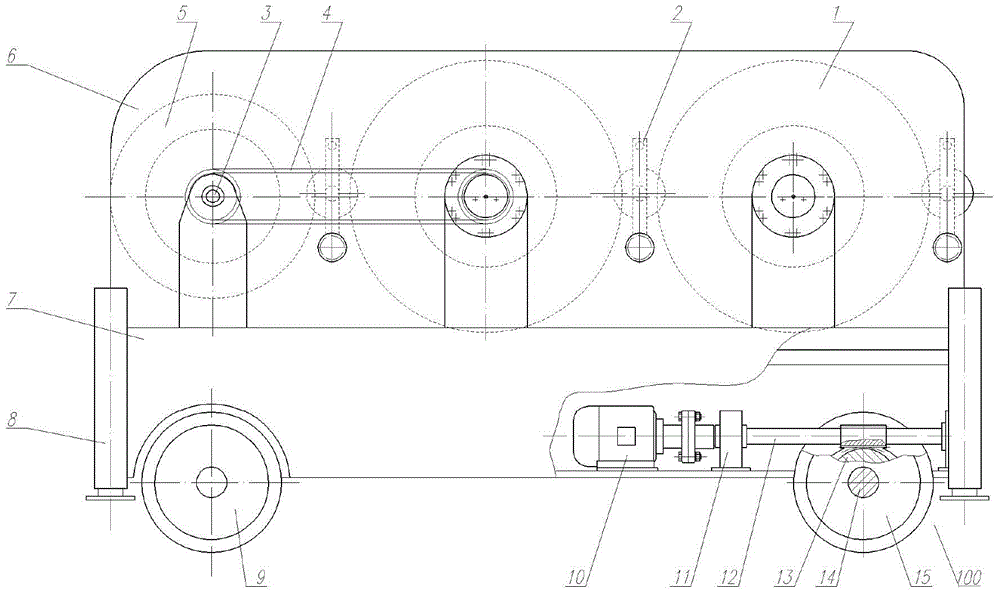

Automatic warehouse-in and warehouse-out tractor truck for oil tanks

InactiveCN104627258AAchieve windingGreat tractionTractorsTowing devicesHydraulic cylinderHydraulic motor

The invention discloses an automatic warehouse-in and warehouse-out tractor truck for oil tanks. The automatic warehouse-in and warehouse-out tractor truck comprises a traveling mechanism, a traction mechanism, rope arrangers and supports. The traveling mechanism is of a four-wheel train structure, and power can be provided for the traveling mechanism by storage batteries. The traction mechanism comprises steel cable drum mechanisms, an electric cable drum mechanism, chain transmission mechanisms, the rope arrangers and the like. Driving force can be provided for the steel cable drum mechanisms by hydraulic motors, and the steel cable drum mechanisms can rotate at identical speeds or differential speeds under the control of the hydraulic motors, so that steel cables can be driven to be wound, and oil tank traction and dragging warehouse-in and warehouse-out operation can be completed. Power of the intermediate hydraulic motor can be transmitted to electric cable drums by means of chain transmission, so that the electric cable drums can synchronously rotate, and electric cables can be wound. Driving force can be provided for the rope arrangers by stepper motors, reciprocating frames can be driven by means of spiral transmission to horizontally move, and accordingly ropes can be arranged in an ordered manner. The supports can be extended and retracted by the aid of hydraulic cylinders, can be extended and supported on the ground during traction operation and can be retracted during traveling. The automatic warehouse-in and warehouse-out tractor truck has the advantages that the automatic warehouse-in and warehouse-out tractor truck is good in movement flexibility, the oil tank warehouse-in and warehouse-out operation intensity can be reduced, and the work efficiency can be improved.

Owner:周庆忠

Underground self-moving device of coal mine

The invention discloses an underground self-moving device of a coal mine. The underground self-moving device comprises a supporting frame and a track frame, wherein supporting legs are arranged at four corners of the supporting frame; a revolving plate is arranged at the middle part of the supporting frame; a bolt hole is formed in the revolving plate; the supporting legs and the supporting frame are bolted through fixing plates; hydraulic connectors and telescopic claws are respectively arranged on the upper ends and the lower ends of the supporting legs; hydraulic cylinders are arranged in the supporting legs. According to the underground self-moving device disclosed by the invention, the supporting frame and the track frame are directly connected through bolts, disassembling is convenient, and transportation and installation are facilitated; the design of the supporting frame is simple and practical, and other fixing devices used for transporting various underground devices can be conveniently arranged on the supporting frame; by arranging a propelling device and a rotation device, the underground self-moving device can realize moving actions in the longitudinal direction and the transverse direction, and rotation in narrow space and can realize load-bearing walking.

Owner:徐州市苏文机械设备制造有限公司

Scrabbling plate device

The invention relates to the technical field of railway maintenance equipment, in particular to a scrabbling plate device for loosening and excavating the railway ballast. The scrabbling plate devicecomprises scrabbling plates, link holes are arranged in the lower positions of the scrabbling plates, the scrabbling plates can be linked through an intermediate link board and link pins, the scrabbling palm surfaces of the scrabbling plates are each of a concave structure, scrabbling tooth mounting holes are arranged in the backs of the scrabbling palm surfaces, and scrabbling teeth are arrangedin the scrabbling tooth mounting holes. The scrabbling plate device has the advantages of simple structure, low processing cost and long service life, and the concave structure design of the scrapingpalm parts of the scrabbling plates is more conducive to the retention and movement of the ballast in the scrabbling plates.

Owner:孙艳东

Multi-rotor wind power generation system with cantilever beam

InactiveCN102269111ASolution to short lifeMature manufacturing technologyMachines/enginesWind energy generationCantilevered beamNacelle

The invention discloses a multi-rotor wind power generation system with a cantilever beam, comprising a lower tower (1), a slewing drive device (3) and a wind turbine, and an upper tower (2), a cantilever beam (6) and a nacelle frame (7), the slewing drive device is arranged between the upper tower and the lower tower, one end of the cantilever beam is fixedly connected with the upper tower, and the cabin frame is arranged on the upper tower above, the wind turbine is arranged on the top of the upper tower, the cantilever beam or / and the nacelle frame, the wind turbine includes a wind wheel (4) and a nacelle (5), and the number of the wind turbines is 2-100 . The advantages and positive effects of the present invention are: (1) long blade life; (2) small footprint; (3) low installation cost; (4) low maintenance cost; (5) good reliability of the system; (6) Wide range of applications; (7) The slewing bearing or slewing drive system in the nacelle is eliminated.

Owner:TIANJIN UNIV

A steel pipe rolling device

ActiveCN107042237BTurn aroundEven by forceRoll mill control devicesMetal rolling arrangementsEngineeringMechanical engineering

The invention relates to a steel tube rolling device, and mainly solves the problem that an existing steel tube rolling device cannot operate automatically and is low in working efficiency. According to the technical scheme, the steel tube rolling device comprises a support, wherein an automatic feeding mechanism, a rotation feeding mechanism, a tube blank rolling mechanism, an automatic discharging mechanism and a controller which are successively connected are arranged on the support; and the controller is used for controlling the automatic feeding mechanism, the rotation feeding mechanism, the tube blank rolling mechanism and the automatic discharging mechanism to work. The problem is solved well. The steel tube rolling device is easily used industrially.

Owner:张家港市宏大钢管有限公司

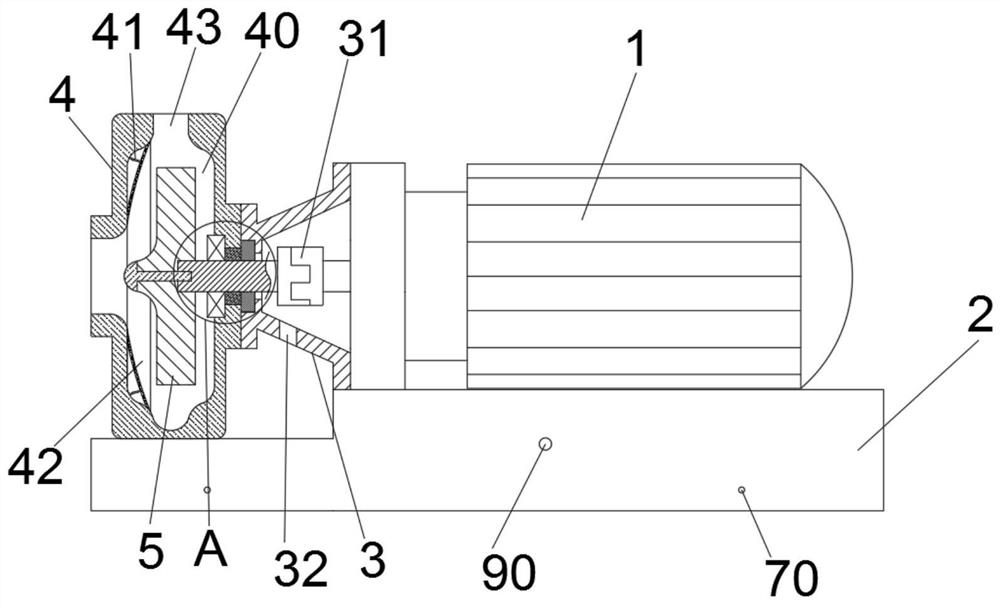

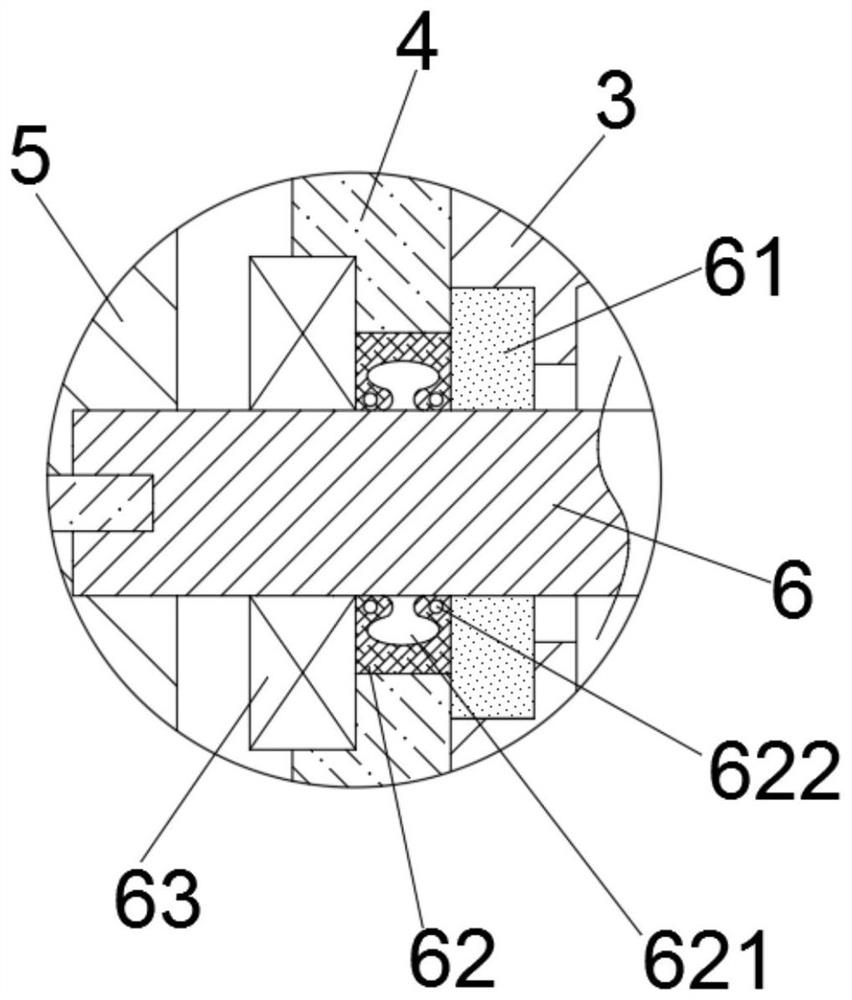

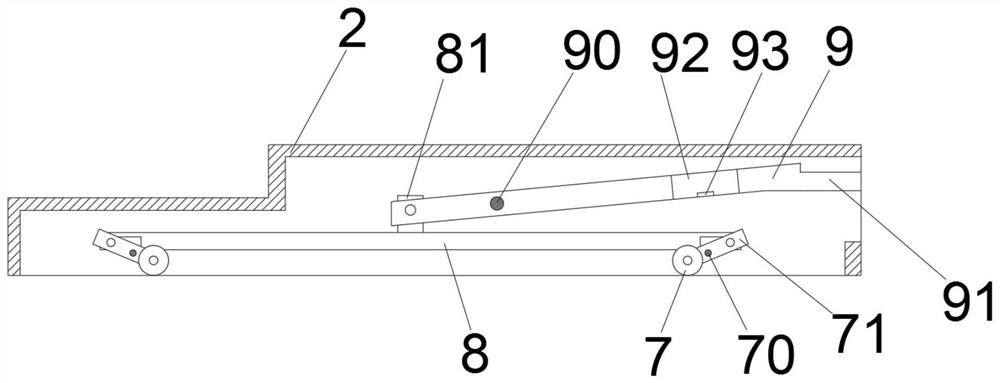

Self-adjusting chemical pump

PendingCN113757130AImprove sealingAvoid fragilePortable framesSpecific fluid pumpsImpellerRubber ring

The invention discloses a self-adjusting chemical pump which comprises a motor. A connecting base and a pump shell are installed on the motor, an impeller is arranged in the pump shell and connected with a rotating shaft of the motor through a connecting shaft, the connecting shaft is connected with the rotating shaft through a coupler, the coupler is arranged in the connecting base, the connecting shaft is connected with the pump shell through a sealing piece, the sealing piece comprises a sealing bearing, a rubber ring and a secondary sealing ring, the sealing bearing is arranged on the portion, on one side of the impeller, of the pump shell, the rubber ring is arranged between the sealing bearing and the secondary sealing ring, the secondary sealing ring is arranged at the connecting position of the connecting base and the pump shell, and an overflow opening is formed in the lower part of the connecting base. According to the self-adjusting chemical pump, the defects in the prior art are overcome, the service life of the chemical pump is prolonged, the maintenance cost is low, and the application range is wide.

Owner:安徽凯特泵业有限公司

Multi-rotor wind power generation system with tail vane

ActiveCN102322400BSolution to short lifeMature manufacturing technologyWind motor controlWind motor supports/mountsSmall footprintSlewing bearing

Owner:TIANJIN UNIV

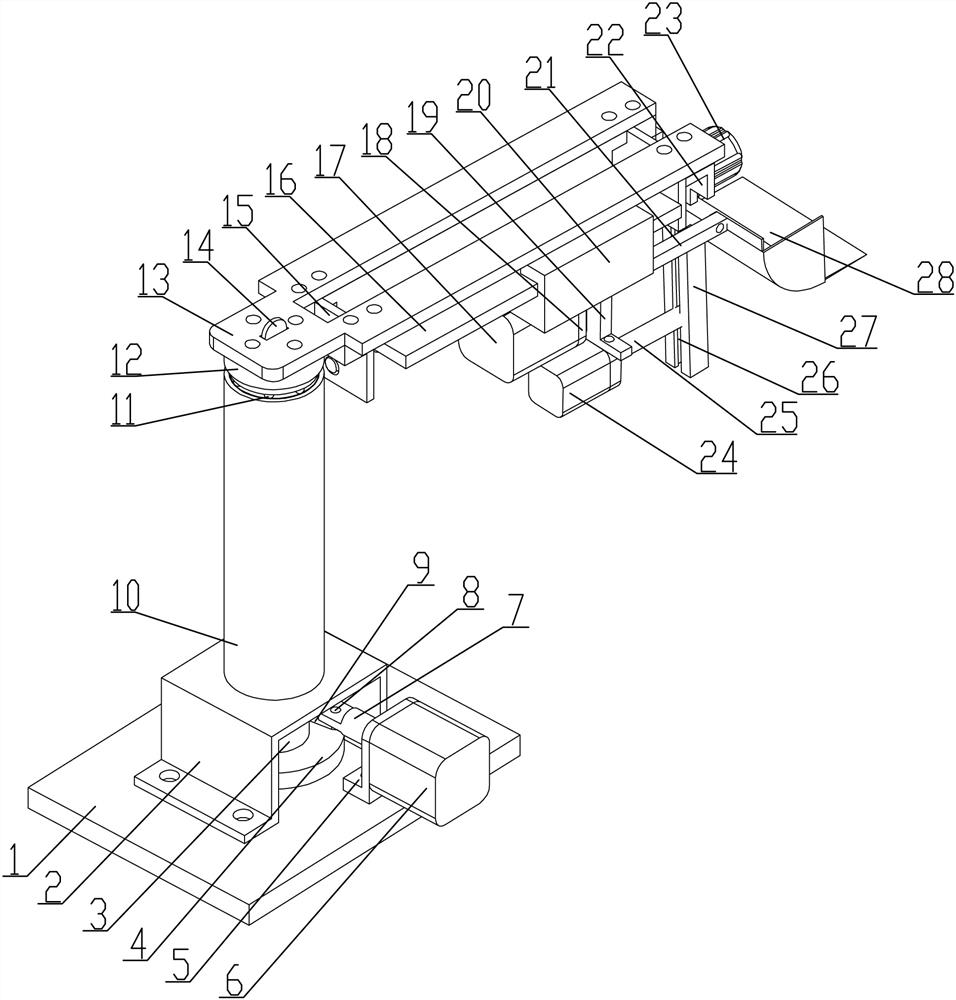

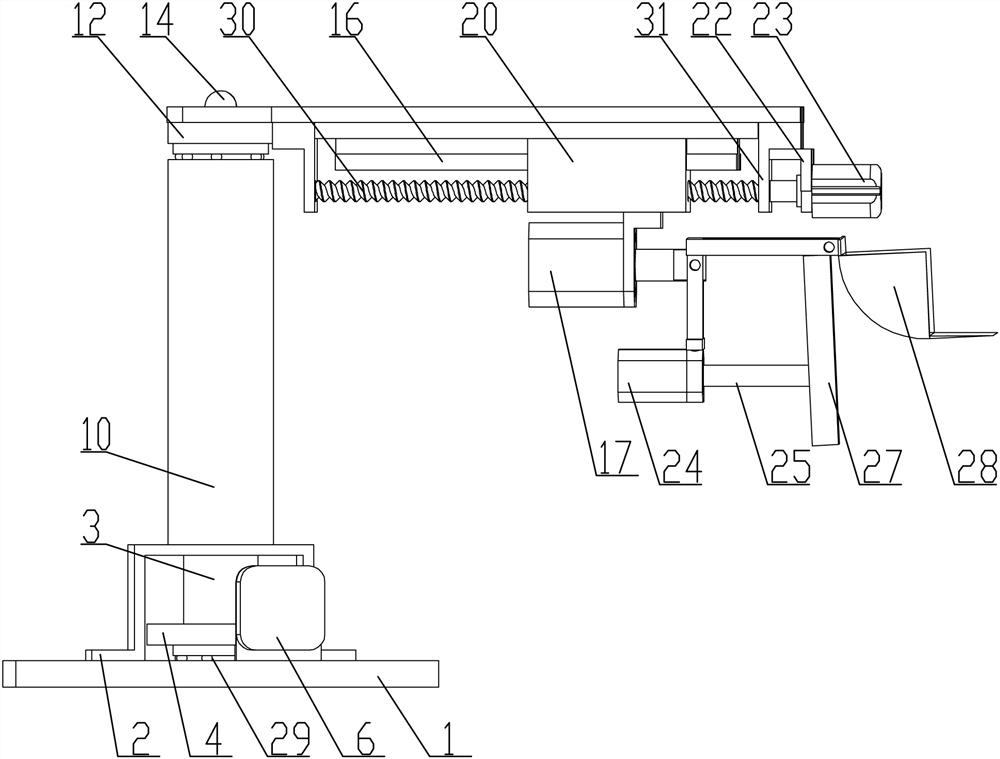

Transfer manipulator and usage method for underground coal mining

ActiveCN110863827BReduce labor intensityImprove work efficiencySlitting machinesRobot handMining engineering

The invention provides an underground coal mining transferring mechanical arm and an application method. The underground coal mining transferring mechanical arm comprises a bottom plate, a supportingbase is fixed to the top of the bottom plate, a sleeve stand column is fixed to the top of the supporting base, the interior of the sleeve stand column supports a rotation shaft through rotation fit,the bottom end of the rotation shaft is provided with a power device for driving the rotation shaft to rotate, and a top flange plate is fixed to the top of the rotation shaft. A top beam plate is fixedly arranged on the top flange plate, and the bottom end of the top beam plate is provided with a sliding block through a lead screw transmission mechanism. The bottom end of the sliding block is fixedly provided with a pushing cylinder through an L-shaped connecting plate. A bucket mechanism for coal shoveling and coal overturning and unloading is arranged at the tail end of a piston rod of thepushing cylinder. The underground coal mining transferring mechanical arm can be applicable to the underground severe operation environment in the coal mining process and is used for coal transferring, the mined coal is transferred to a conveying belt, accordingly automatic coal transferring is achieved, the work efficiency is improved, and the labor intensity of workers is lowered.

Owner:CHINA THREE GORGES UNIV

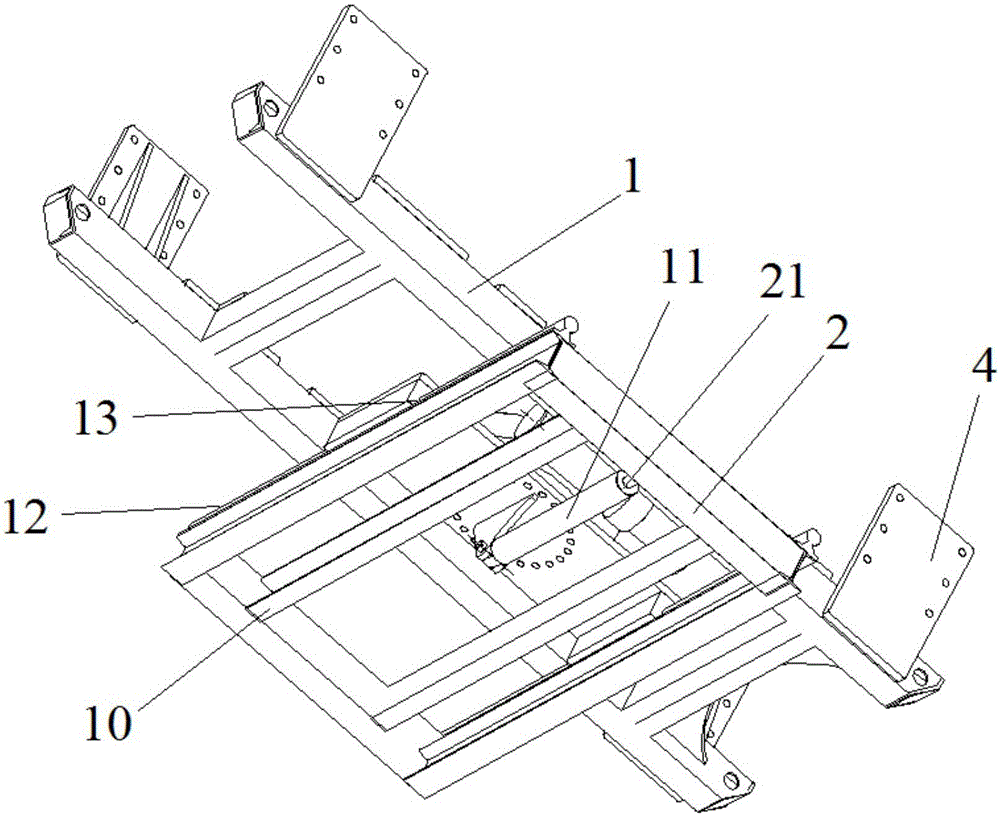

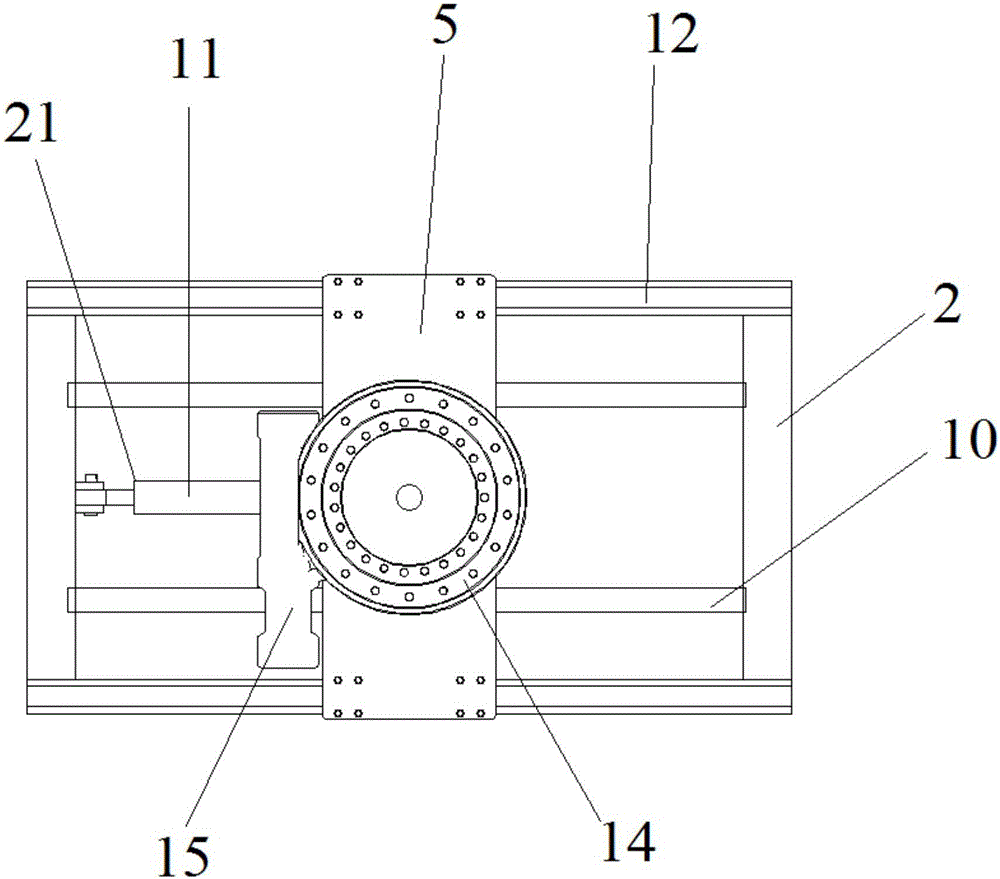

An electric pressure cooker with a cover that is convenient to open

The invention provides an electric pressure cooker capable of facilitating cover opening. The electric pressure cooker comprises a pot body, a pot cover and a clamping buckling component; the pot cover comprises a liner and a lock cover located below the liner; the clamping buckling component comprises a movable clamping component arranged on the liner and a buckling component located on the pot body; the pot cover is buckled to the pot body through the clamping buckling component; the liner is provided with a cover opening assembly; the cover opening assembly drives the lock cover to rotate; the rotation of the lock cover enables the locking and unlocking of the lock cover and the pot body; the lock cover is provided with an unbuckling component; a distance from the unbuckling component to the center of the lock cover is 1 / 5 to 4 / 5 of the radius of the lock cover; a collision avoidance groove is arranged on the liner; the unbuckling component passes through the collision avoidance groove and extends to the upper surface of the liner; and the cover opening assembly drives the lock cover to rotate for unlocking, and the unbuckling component acts, so that the movable clamping component is separated from the buckling component. According to the electric pressure cooker of the invention, the pot cover can be opened just through rotation, and therefore, the electric pressure cooker is convenient for a user to use.

Owner:JOYOUNG CO LTD

A kind of double cargo position rotary conveyor

The invention relates to the technical field of material storage and transportation equipment, in particular to a double-goods-allocation rotary conveyer. The double-goods-allocation rotary conveyer comprises two chain conveyer sets, a rotary table and an arc-shaped rail. First chain conveyers and second chain conveyers are arranged on the rotary table in parallel. The rotary table is rotationally arranged on the arc-shaped rail. The rotary table drives the first chain conveyers and the second chain conveyers to rotate around the arc center of the arc-shaped rail. The double-goods-allocation rotary conveyor is usually installed at the warehouse in-out position, the double-tray warehouse in-out purpose is achieved, and rotation without the altitude difference is achieved. The first chain conveyers and the second chain conveyers are in butt joint at two angled conveying lines respectively, goods steering, diversion and integration are achieved, and conveying efficiency is greatly improved.

Owner:BEIJING MATERIALS HANDLING TECH INST CO LTD

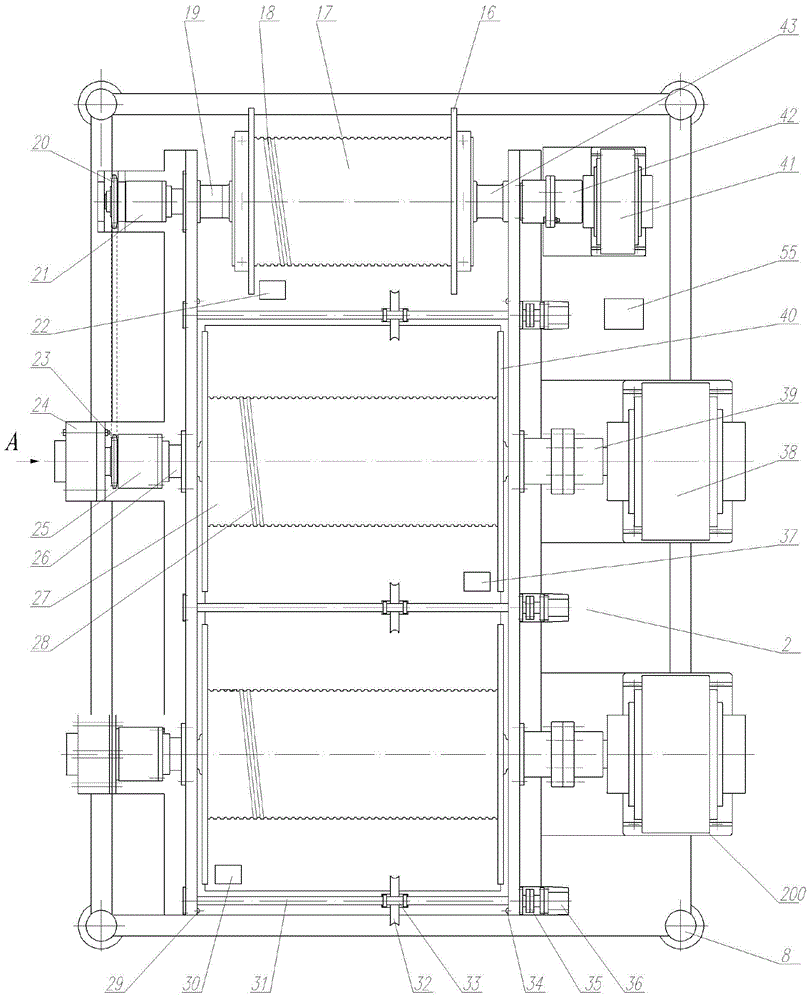

Multi-rotor wind generating system

InactiveCN102305186ASolution to short lifeMature manufacturing technologyFinal product manufactureWind motor combinationsNacelleSmall footprint

The invention discloses a multi-rotor wind generating system, which comprises a lower tower 1, a rotary driving device 3, wind turbines, an upper tower 2, beams 6 and a cabin frame 7, wherein the rotary driving device is arranged between the upper tower and the lower tower; 2 to 50 beams are arranged; beams positioned on two sides of the upper tower are connected to the upper tower through one end of each beam in a symmetrical or staggered manner, and the other end of each beam is connected with the top end of the upper tower through a rope and / or a rod 8, or connected with other beams first and then connected with the top end of the upper tower; the cabin frame is arranged on the upper tower; the wind turbines are arranged on the top of the upper tower, the beams or / and the cabin frame; each wind turbine comprises a wind wheel 4 and a cabin 5; and 2 to 100 wind turbines are arranged. The multi-rotor wind generating system has the advantages that: blades have long service life, the occupied area is small, the installation and maintenance cost is effectively reduced, the maintenance cost is low, the reliability of the system is high, the application range is wide, a slewing bearing or a rotary driving device in the cabin is eliminated, and the bearing capacity of the beams is high.

Owner:TIANJIN UNIV

An electric pressure cooker with a cover that is convenient to open

The invention provides an electric pressure cooker with a cover being conveniently opened. The cooker comprises a cooker body, a cooker cover and a buckling part. The buckling part comprises a movable clamping part arranged on the cooker cover and a fastener located on the cooker body. The cooker cover is buckled with the cooker body through the buckling part. The cooker cover comprises a lining and a lock cover located below the lining. The lock cover rotates so that the lock cover and the cooker body are locked and unlocked. The cooker cover is further provided with a cover-opening assembly which drives the locking cover to rotate. The lock cover is provided with an unlocking part. When the cover-opening assembly drives the lock cover to rotate at the first set position, the lock cover and the cooker body are unlocked. When the cover-opening assembly drives the lock cover to continuously rotate at the second set position, the fastener is acted upon the movable clamping part. The movable clamping part is separated from the fastener such that the cooker cover is opened. The rotation angle at which the lock cover rotates from the first set position to the second set position is Alfa. The cooker cover is provided with an elastic device driving the lock cover to rotate. After the cooker cover is opened, the elastic device drives the lock cover to rotate at the angle of Beta which is less than Afla. The electric pressure cooker with the cover being conveniently opened facilitates opening the cover.

Owner:JOYOUNG CO LTD

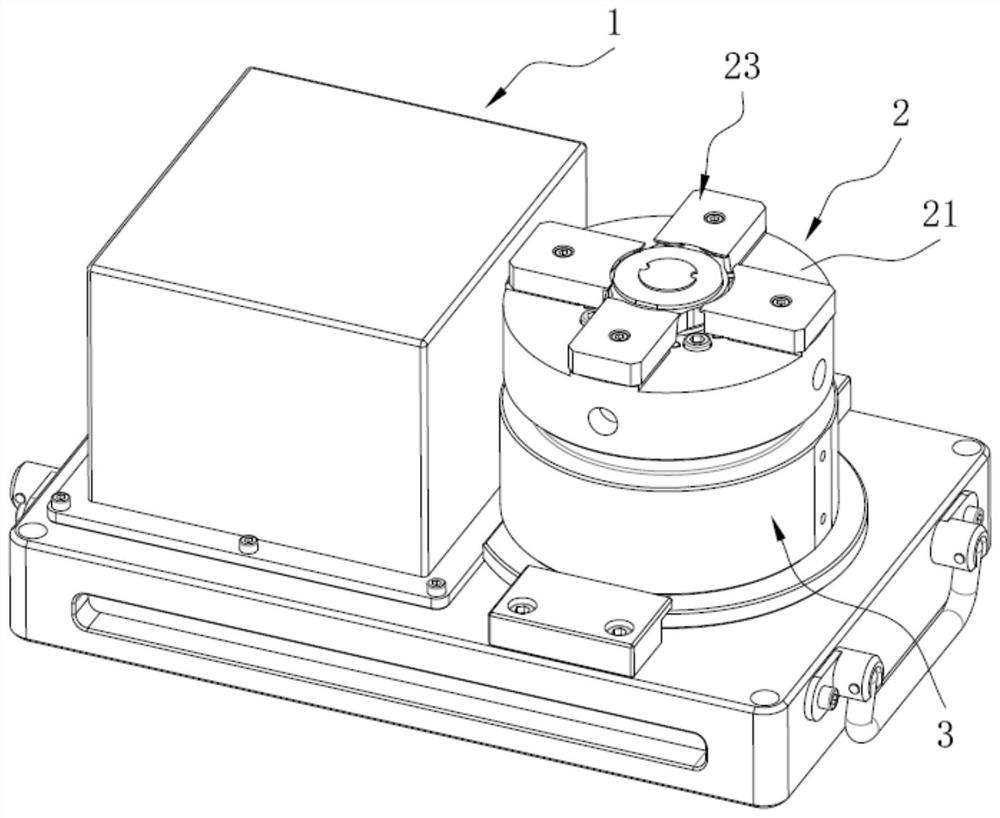

Rotary table

PendingCN111894932ARotary realizationImprove processing efficiencyFluid-pressure actuatorsEngineeringMechanical engineering

The invention relates to the technical field of machining centers, in particular to a rotary table. The rotary table comprises a rotary driving device, a clamp, and an annular air cylinder. The rotarydriving device comprises a rotating shaft. The clamp comprises a chuck, an elastic piece and at least two sets of clamping pieces, the clamping pieces are arranged on the chuck and can move in the radial direction of the chuck, and the elastic piece abuts against the clamping pieces. The annular air cylinder comprises an annular piston, and the rotating shaft penetrates through the inner side ofthe annular piston in the radial direction. The output end of the rotating shaft is fixedly connected with the chuck, the elastic piece pushes the at least two sets of clamping pieces to move inwardsin the radial direction of the chuck so as to lock a workpiece, and the annular piston moves in the axial direction so that the clamping pieces can be pushed to move outwards in the radial direction of the chuck so as to unlock the workpiece. Firstly, the machining efficiency of a product capable of being rotationally machined is greatly improved; secondly, the reliability and stability of the clamp clamping the workpiece are improved, and the production cost is reduced; and thirdly, the structure of the rotary table is more compact.

Owner:KEYIZHAN INTELLIGENT EQUIP CO LTD +1

Yarn hooking device special for weaving cool milk silk modified antistatic knitted fabric

The invention provides a yarn hooking device special for weaving a cool milk silk modified antistatic knitted fabric, and belongs to the technical field of weaving equipment. The device comprises a longitudinal yarn hooking rotary circling mechanism and a transverse yarn hooking mechanism. The longitudinal yarn hooking rotary circling mechanism comprises a rotary circling assembly, a longitudinalyarn hooking driving assembly and a yarn withdrawing driving assembly, a rotary circling main shaft of the rotary circling assembly can rotate through a rolling needle supporting bearing and is arranged on a rotary circling supporting table in a vertical sliding mode, the left end of a longitudinal lifting platen of the longitudinal yarn hooking driving assembly is hinged to a longitudinal liftingplaten supporting seat through a longitudinal lifting platen supporting pin shaft, the lower end of a longitudinal yarn hooking driving piston rod is connected with the middle end of the longitudinallifting platen through a longitudinal flexible connector, and the right end of the longitudinal lifting platen is connected with a lifting supporting step at the lower end of rotary circling main shaft through the rotary connector. The device can realize yarn hooking of cool yarns, milk silk yarns and antistatic yarns, and has reasonable structure and good reliability.

Owner:浙江正辉针织科技股份有限公司

A rotary device for automatic silk laying equipment

Owner:BAODING BIAOZHENG MACHINE TOOL

Multi-rotor wind power generation system with tail rudder

InactiveCN102269115AExtend your lifeReduce fatigue loadWind motor controlMachines/enginesNacelleWind force

The invention discloses a multi-rotor wind power generation system with a tail rudder, which includes a lower tower 1, a slewing bearing 3 and a wind turbine, and also includes an upper tower 2, a beam 6 and a tail rudder 7, and the slewing bearing is arranged on the upper tower and the wind turbine. Between the lower towers, the lengths of the beams arranged on both sides of the upper towers are unequal, and are fixedly connected to the upper towers through one end of the beams respectively, and the wind turbine is fixedly connected to the top of the upper tower or / and the beams, and the wind turbine Including the wind wheel 4 and the nacelle 5, the number of wind turbines arranged on the longer beam is 0-10 more than the number of wind turbines on the shorter beam, and the tail rudder is connected with the upper tower, beam or / and nacelle through pin shafts. connect. The blade of the invention has long service life, small occupied area, low installation cost, low maintenance cost, good reliability, wide application range, cancels the slewing bearing or slewing driving device in the nacelle, and has automatic wind control, yaw and safety protection.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com