Chain rotary type conveying line

A conveyor line, rotary technology, applied in the direction of conveyor, transportation and packaging, can solve the problem that the transfer pallet cannot be rotated by the chain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

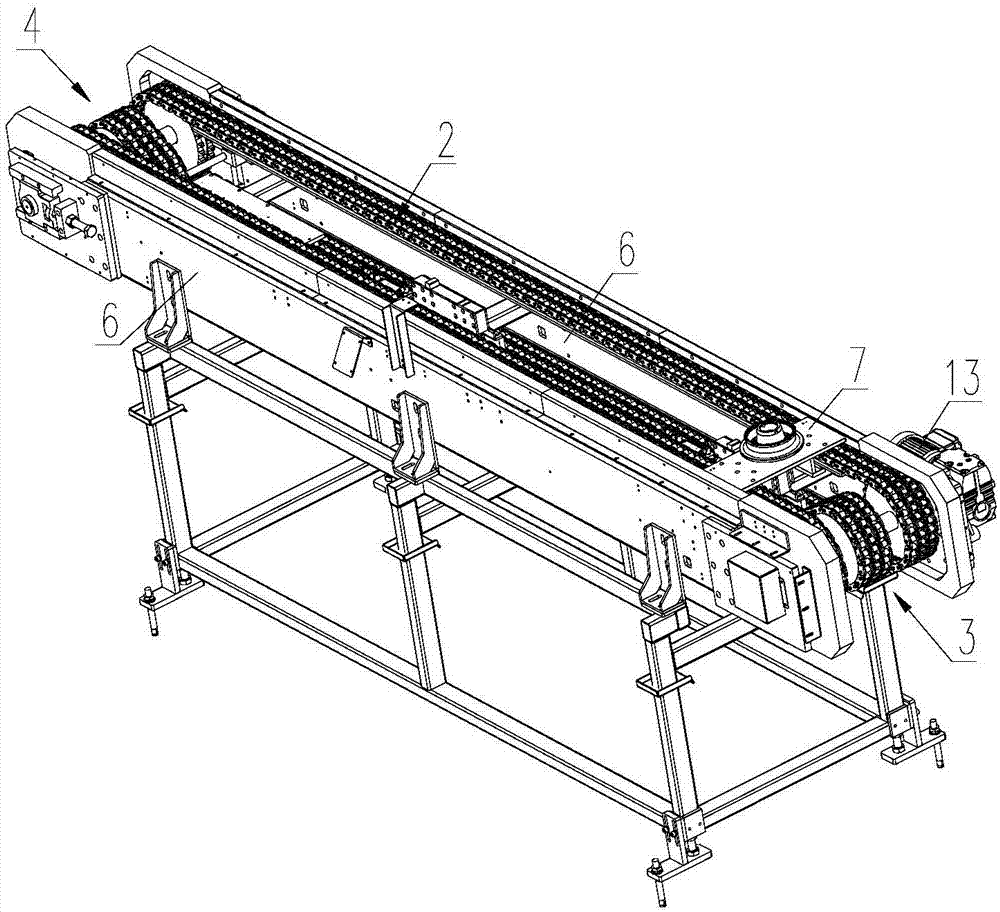

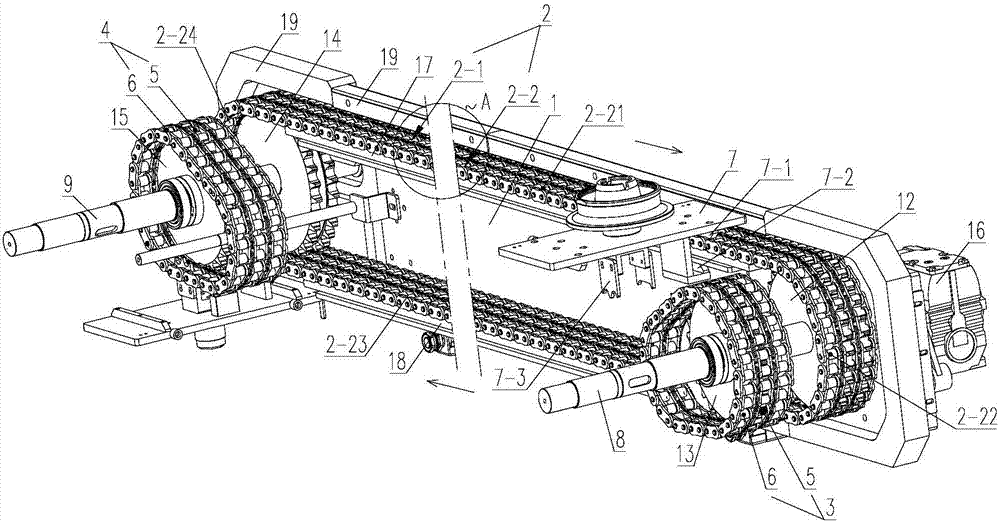

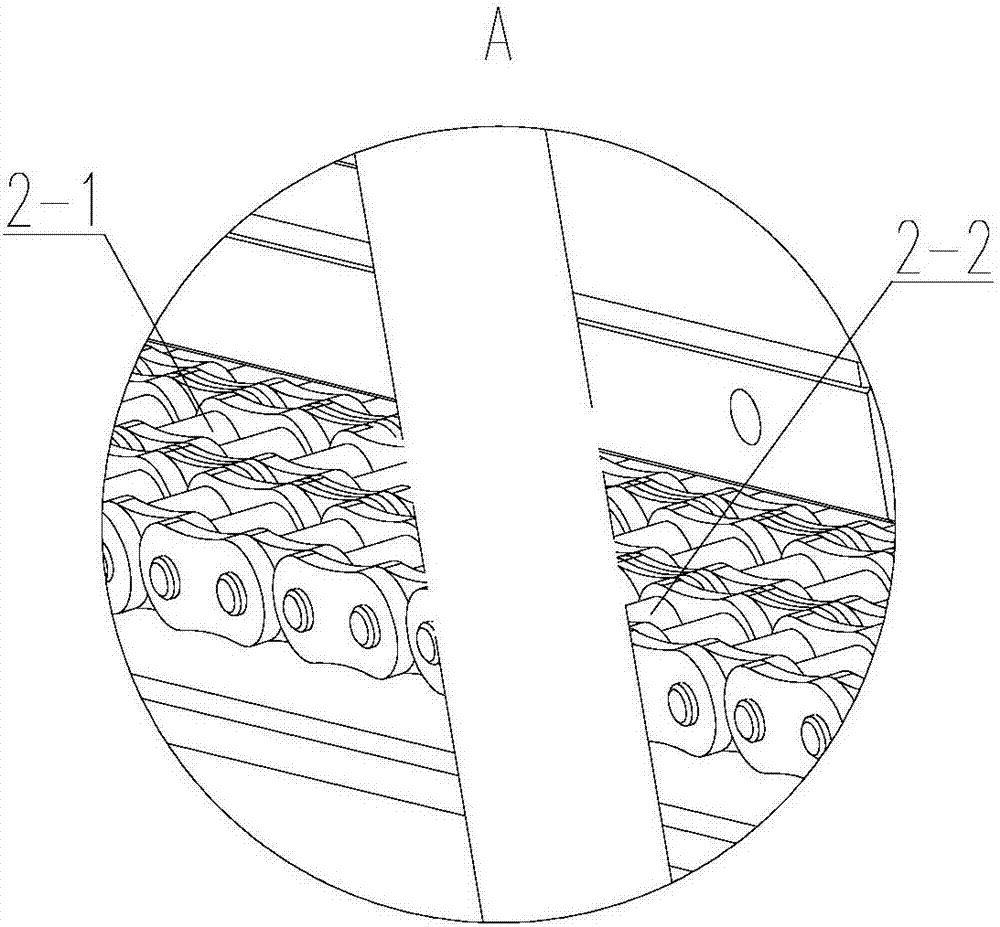

[0027] Such as Figure 1-9 As shown, a chain rotary conveyor line includes a closed conveyor chain group 2, a head-end drive chain group 3 and a tail-end drive chain group 4, and the conveyor chain group 2 includes parallel conveyor transmission chains 2-1 and conveyor The support chain 2-2, the head-end drive chain group 3 and the tail-end drive chain group 4 all include a parallel steering drive chain 5 and a steering drive chain 6, and the conveying support chain 2-2 includes conveying sections 2-21 connected end to end in sequence , the downward steering section 2-22, the feeding section 2-23 and the upward steering section 2-24, the steering transmission chain 5 and the conveying transmission chain 2-1 are all driven by external force, and the conveying section 2-21 and the feeding section 2 -23 all extend along the horizontal direction and are parallel to each other. The conveying section 2-21, the downward diversion section 2-22, the return section 2-23 and the upward d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com