A rotary device for automatic silk laying equipment

A rotary device and automatic wire laying technology, applied in the field of rotary devices, can solve the problems of low laying operation efficiency, poor laying accuracy, and difficulty in processing fiber reinforced materials, and achieve high laying operation efficiency and stable laying quality. , The effect of laying high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

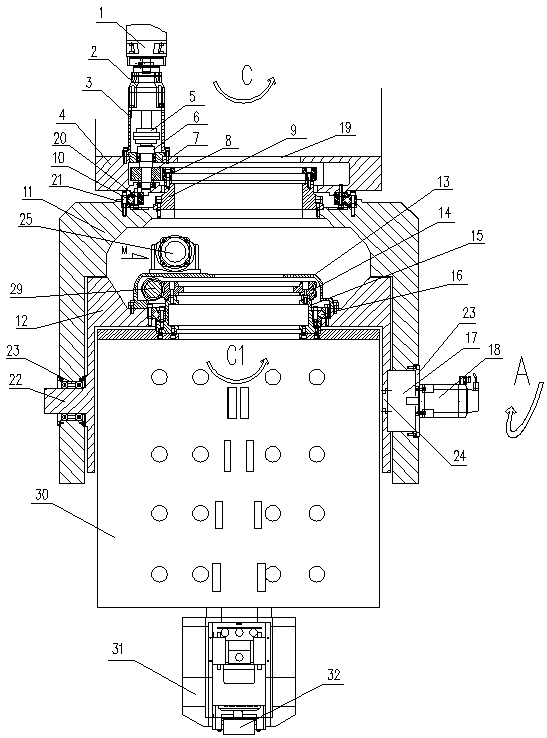

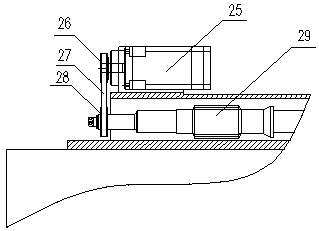

[0012] Such as figure 1 and figure 2 As shown, the present embodiment includes a fixed body 4, a C-axis rotary body 11, a C-axis rotary mechanism, a swing body 12, a C1-axis rotary mechanism, an A-axis rotary mechanism, and a control system. The inner ring 20 of the bearing 10 is fixed on the fixed ear A protruding from the lower end of the fixed body 4 , and its outer ring 21 is fixed on the fixed ear B protruded from the upper end of the C-axis rotating body 11 . The C-axis rotating mechanism fixed on the fixed body 4 drives the C-axis rotating body 11 to rotate along the central axis C of the C-axis rotating body. Further preferably, the C-axis turning mechanism includes a servo motor I 1 with a reducer I 2, an anti-backlash pinion gear set 7 with an anti-backlash mechanism, an anti-backlash bull gear 8 and a shaft coupling 5; the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com