Patents

Literature

9520results about "Fluid-pressure actuators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

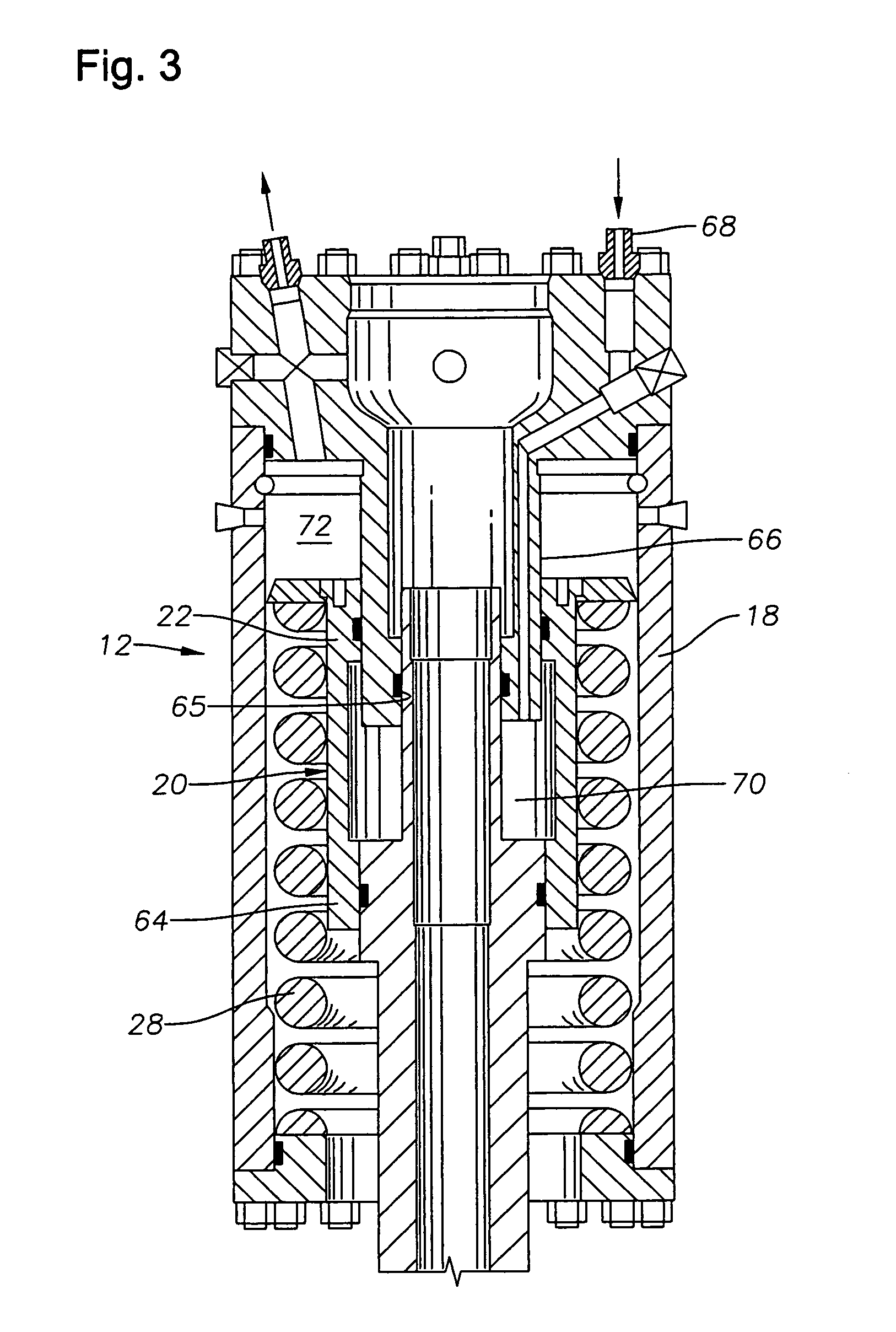

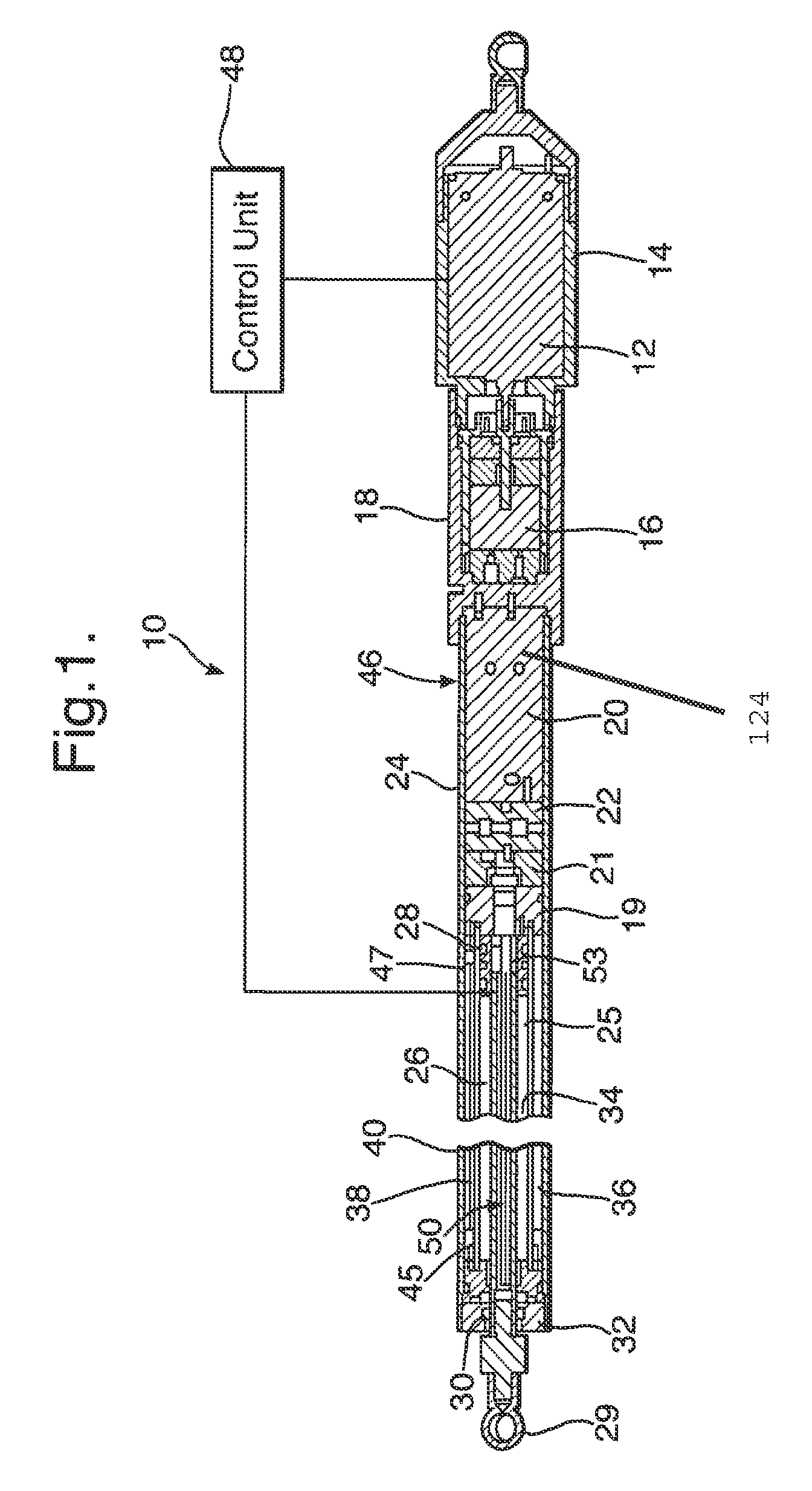

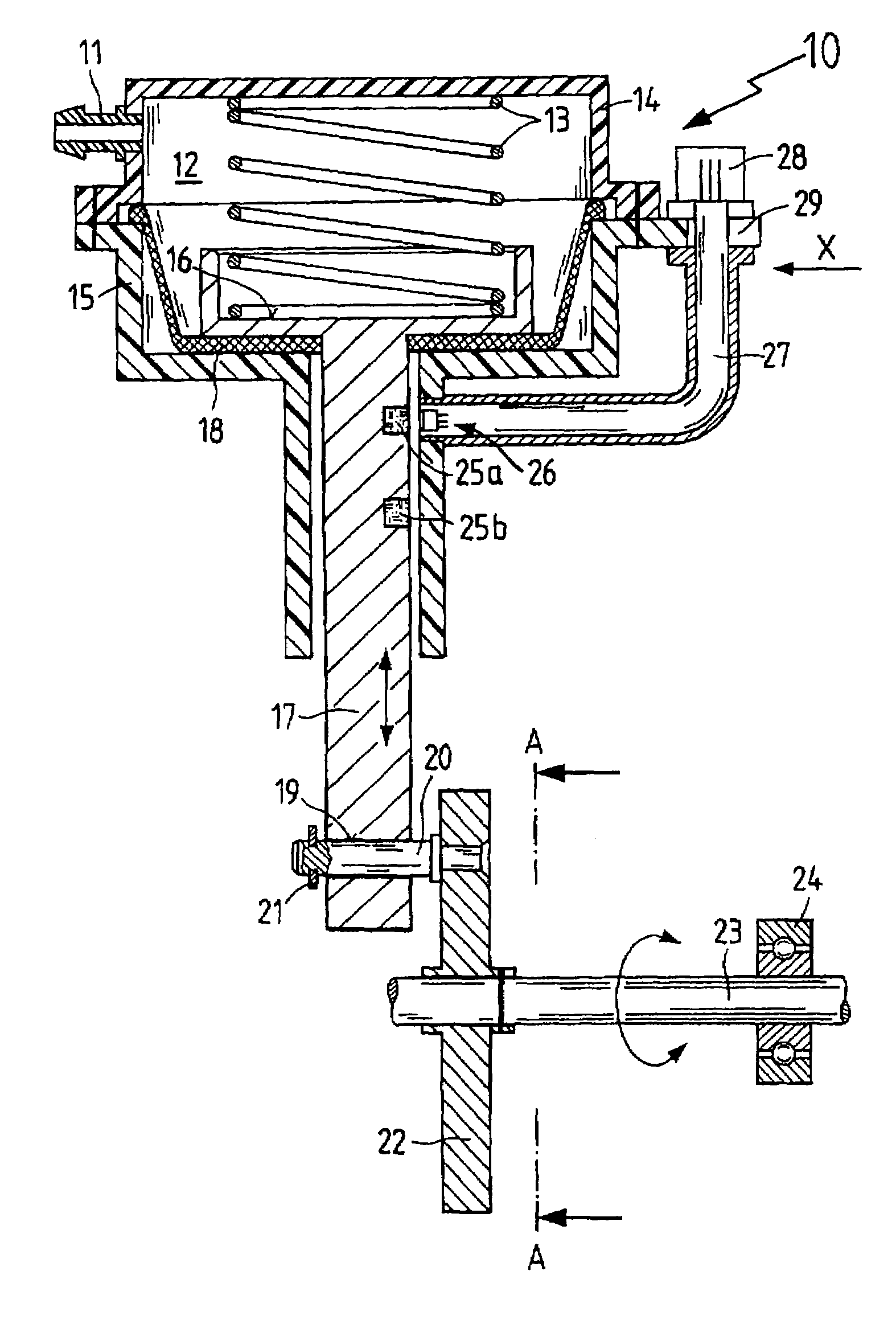

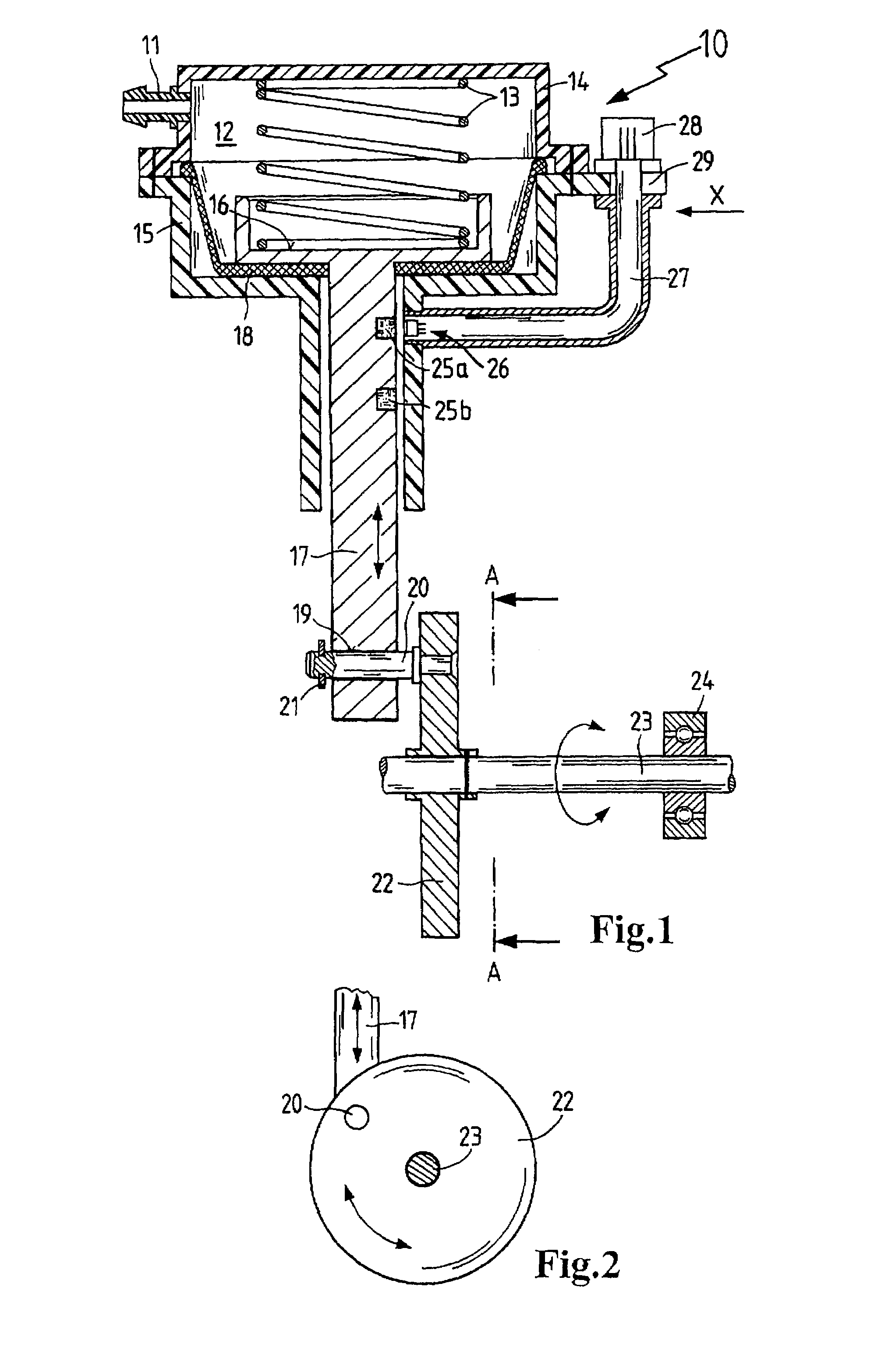

Surgical robotic system

ActiveUS7988215B2Simple and compact designReduce rateWaterborne vesselsDiagnosticsHydraulic cylinderRobotic arm

A surgical robotic system includes a robotic arm, an end effector movably connected thereto and provided with a movable end effector element driven by an actuator, and a force sensor arranged between the robotic arm and the end effector. The actuator is formed by a hydraulic cylinder. The robotic arm is provided with a hydraulic line connected to said hydraulic cylinder of the end effector.

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV

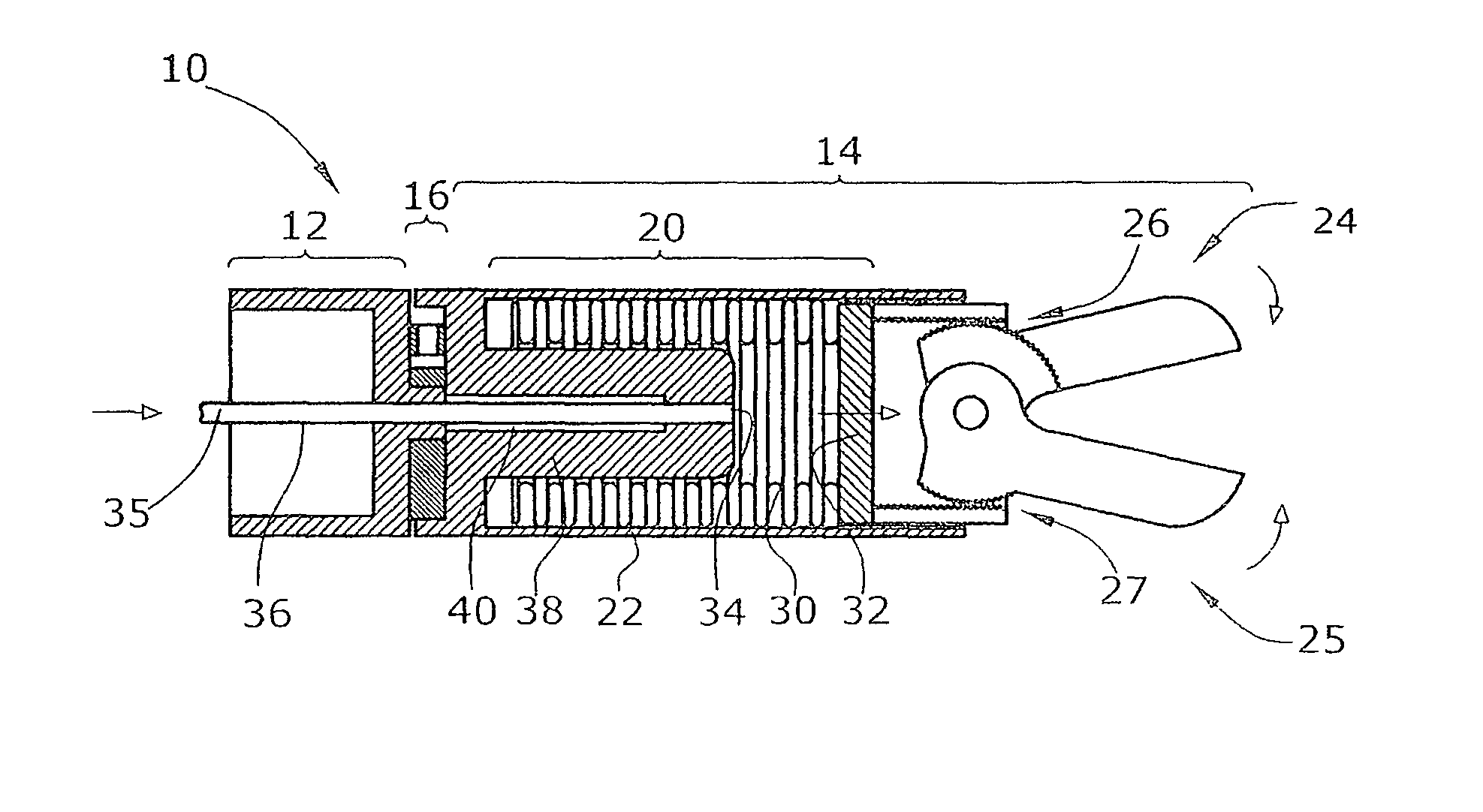

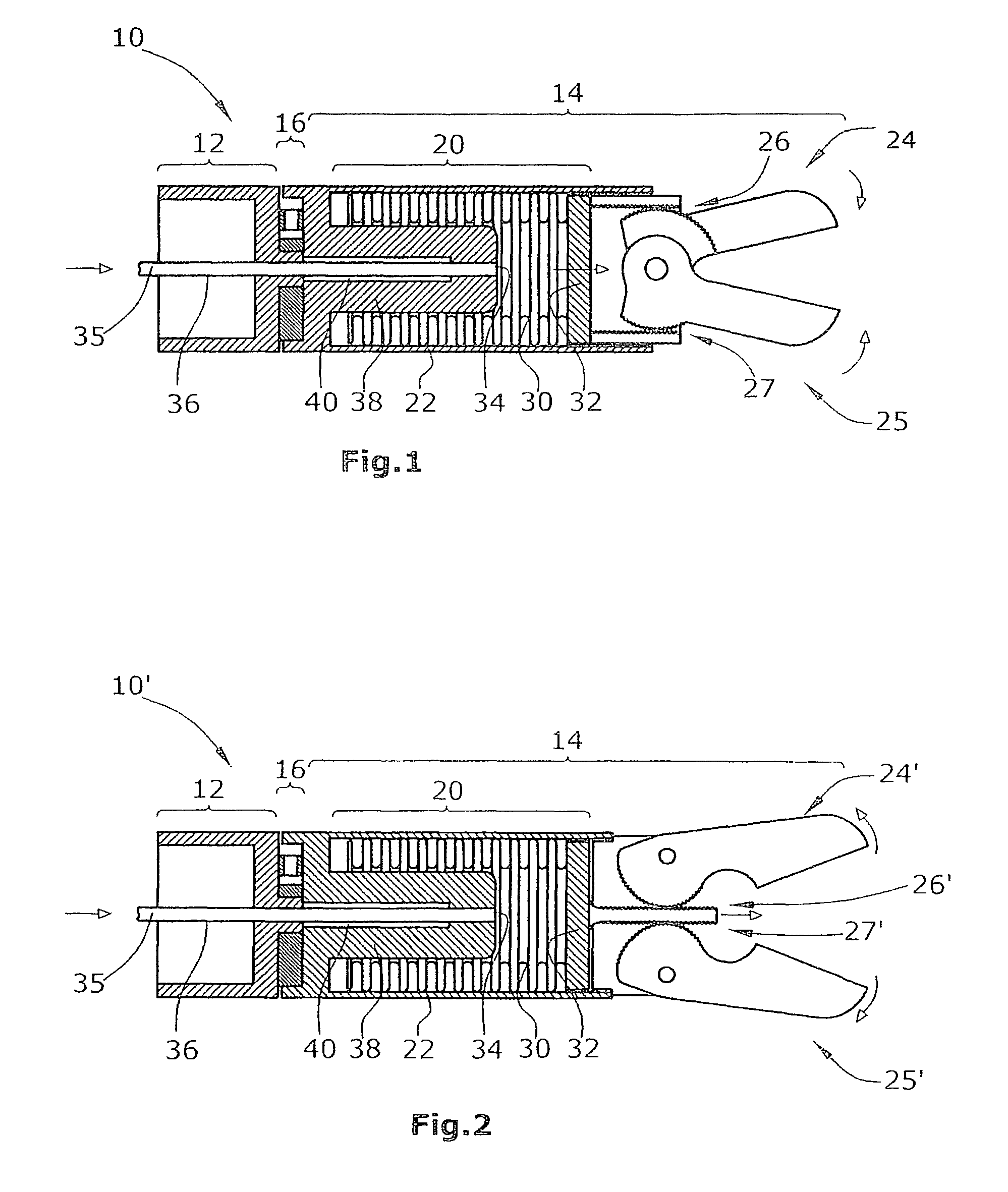

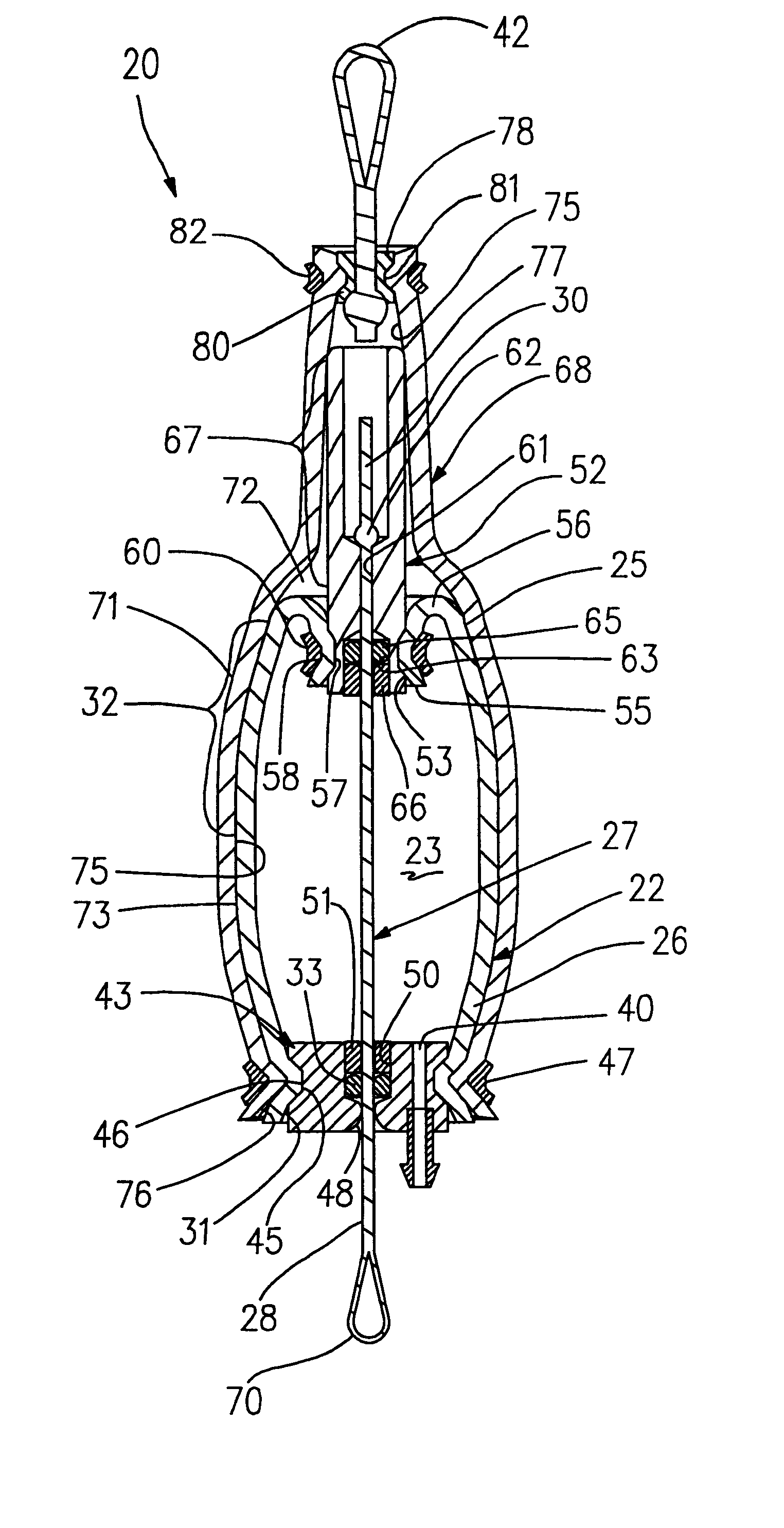

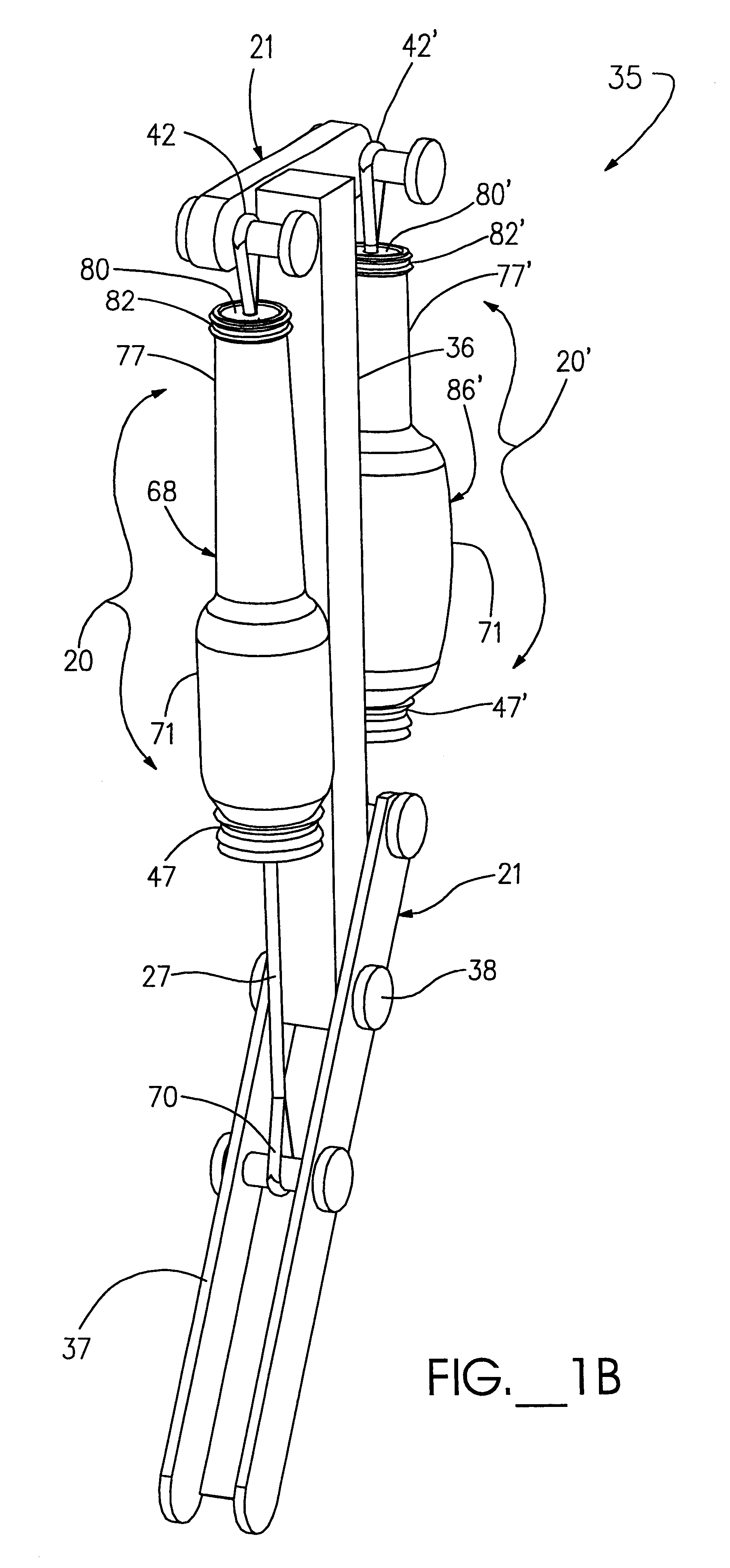

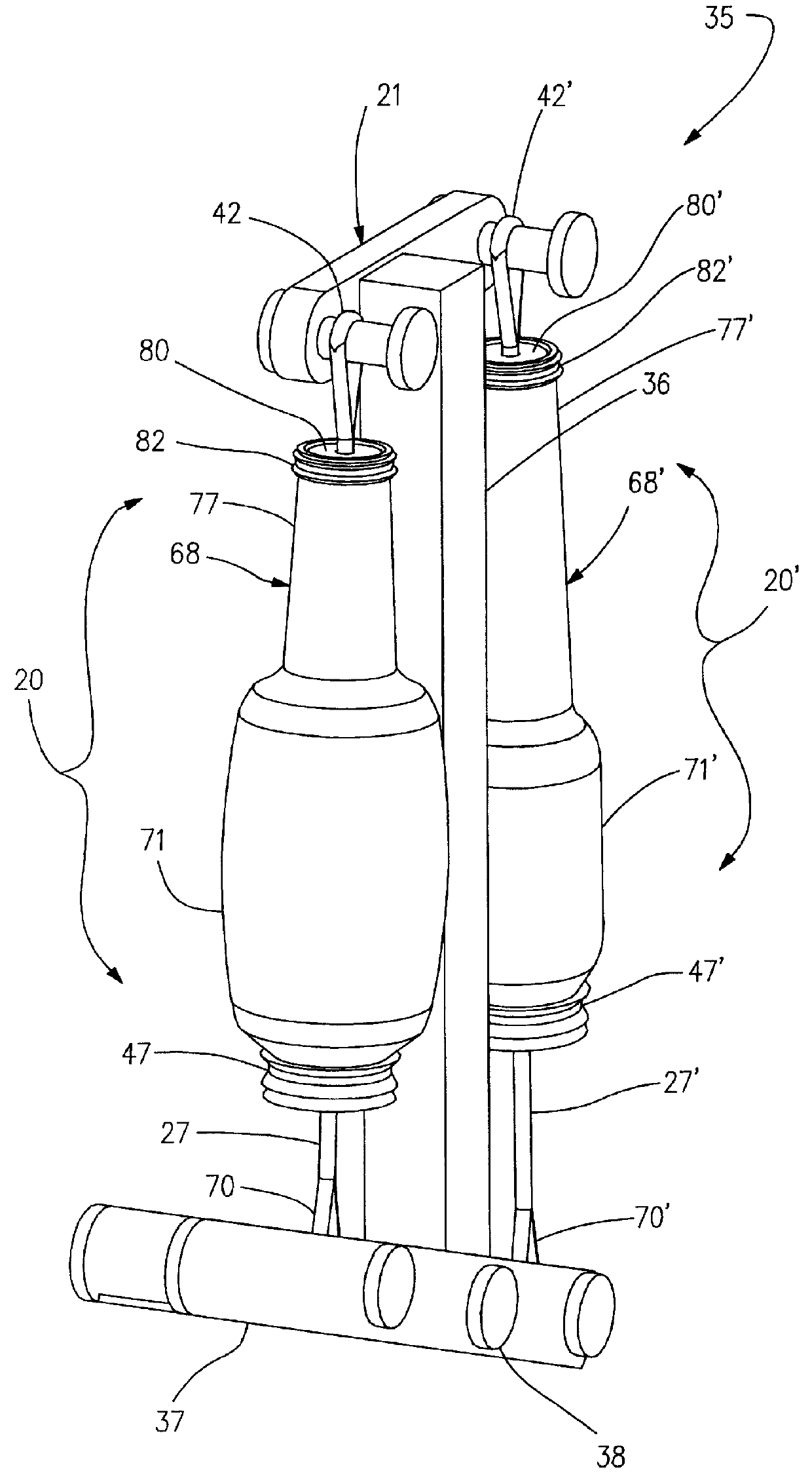

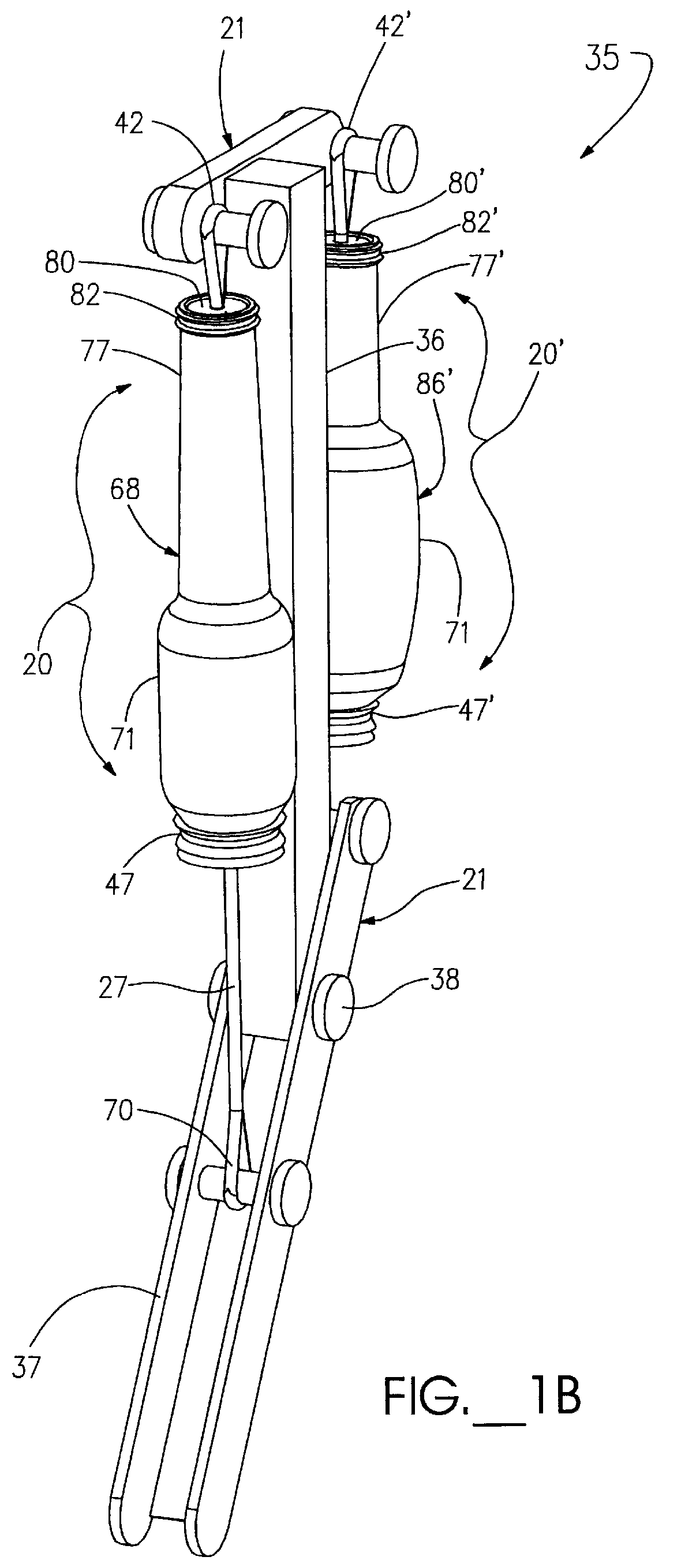

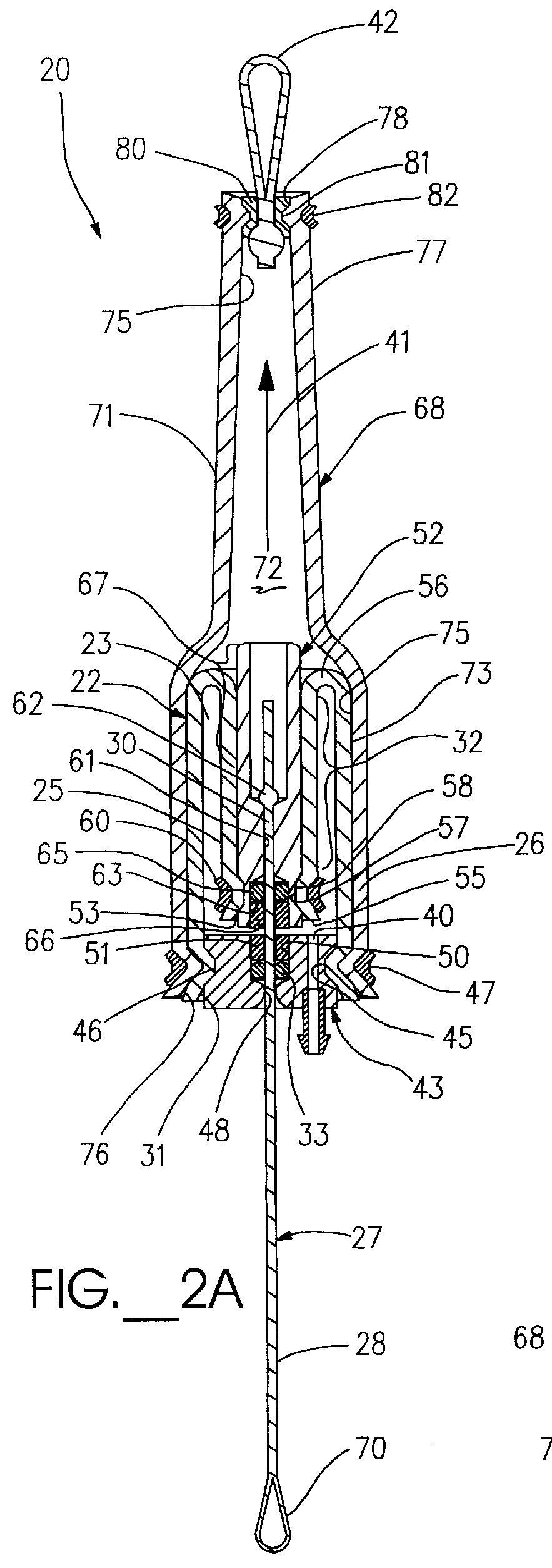

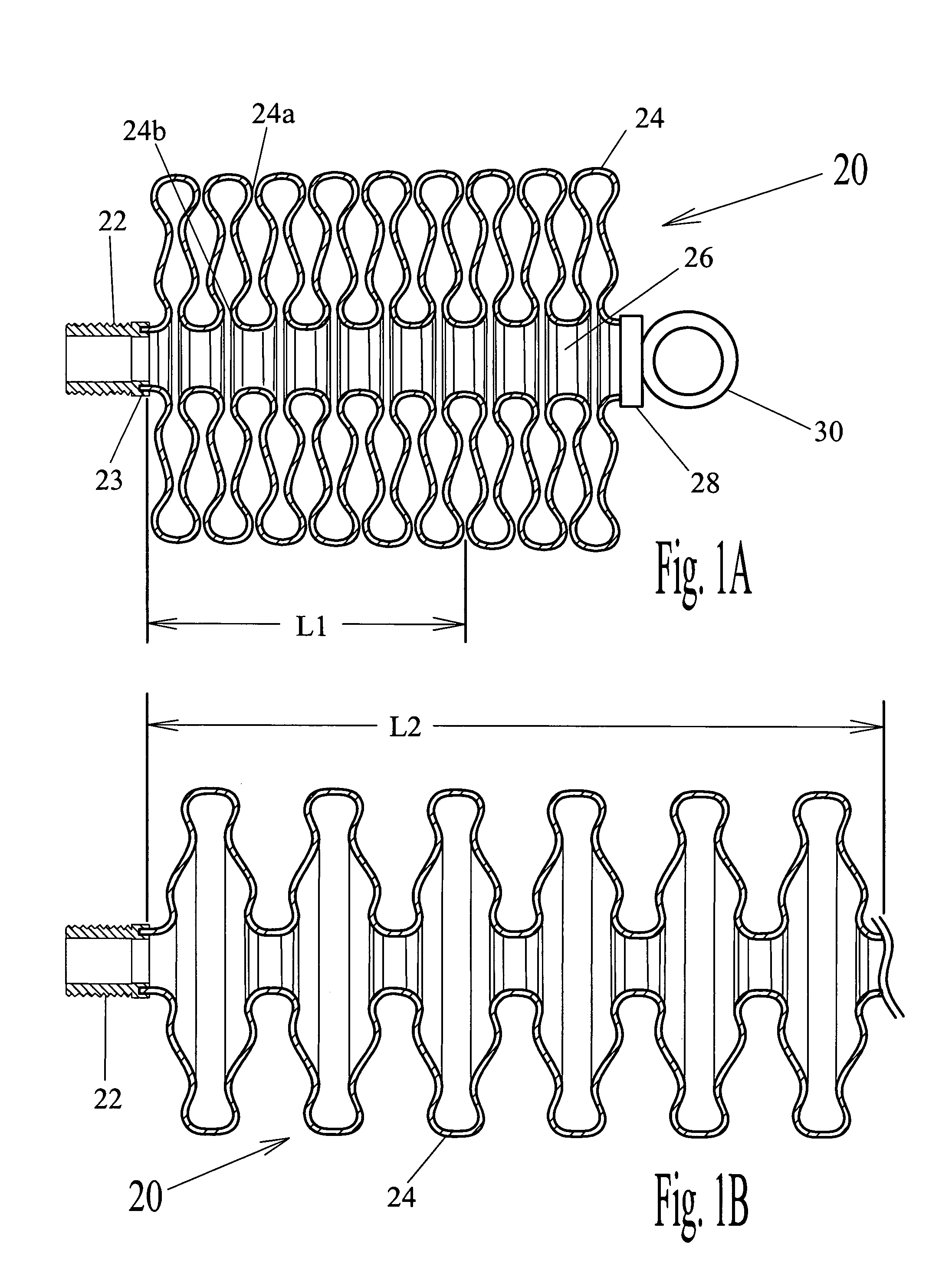

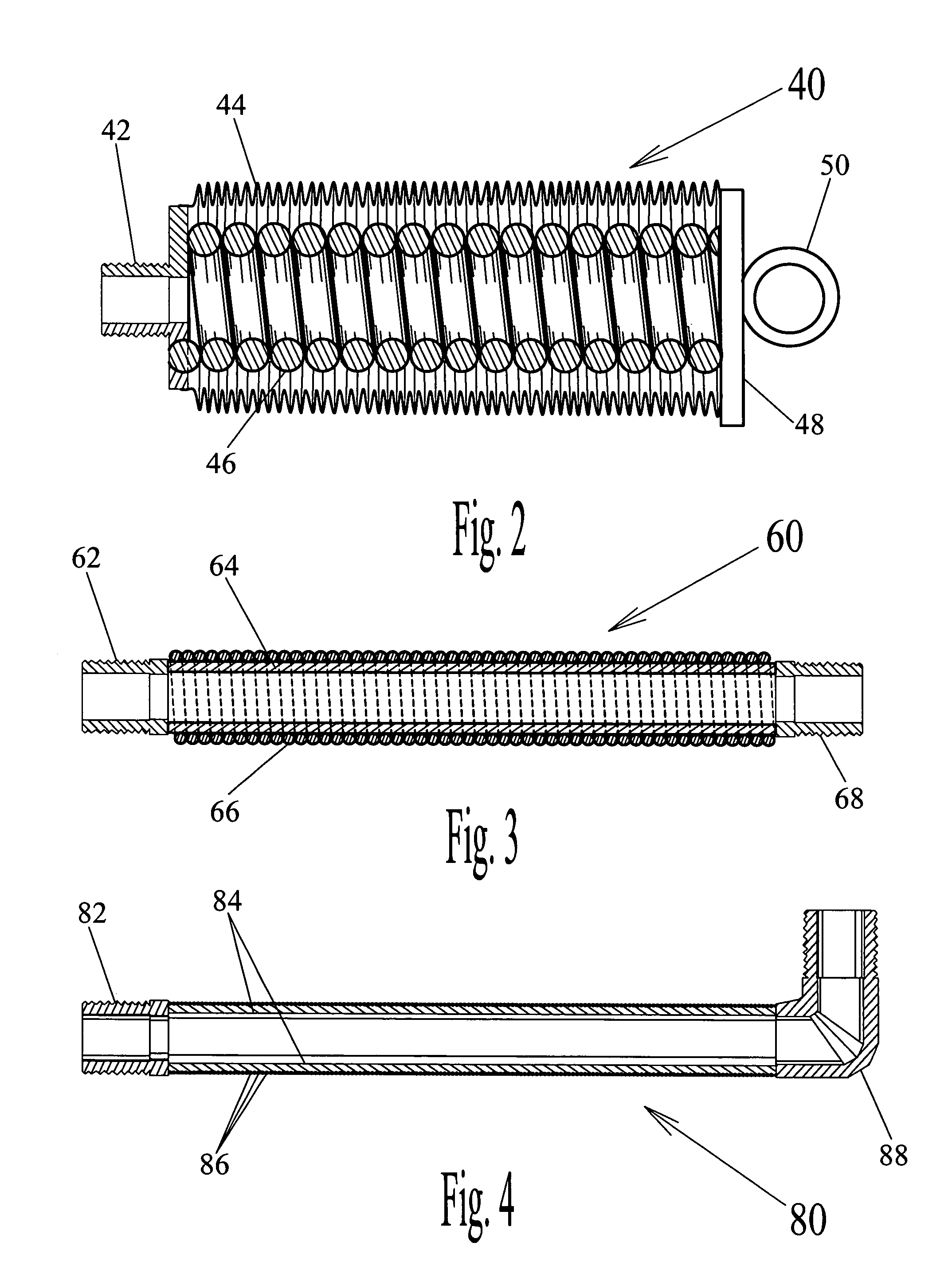

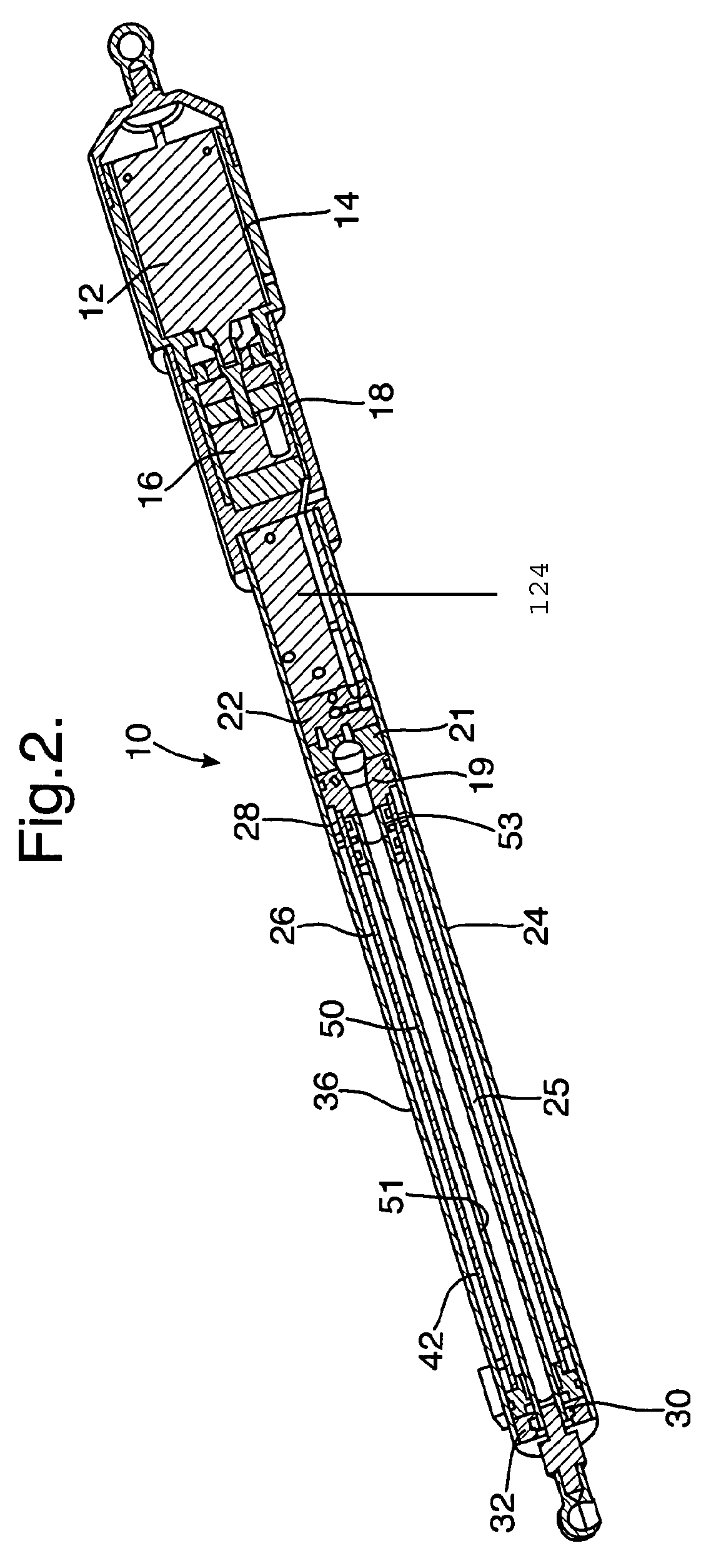

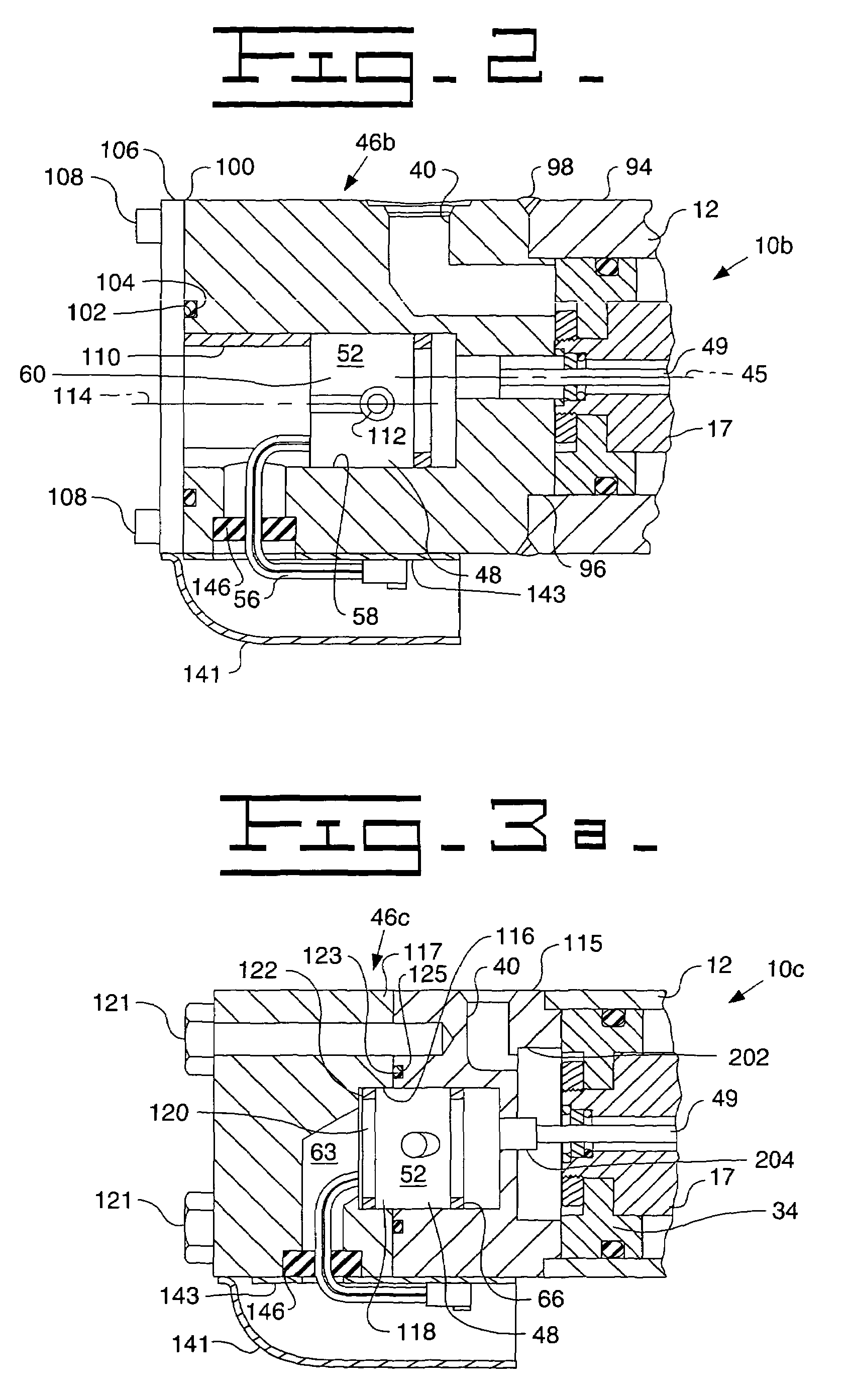

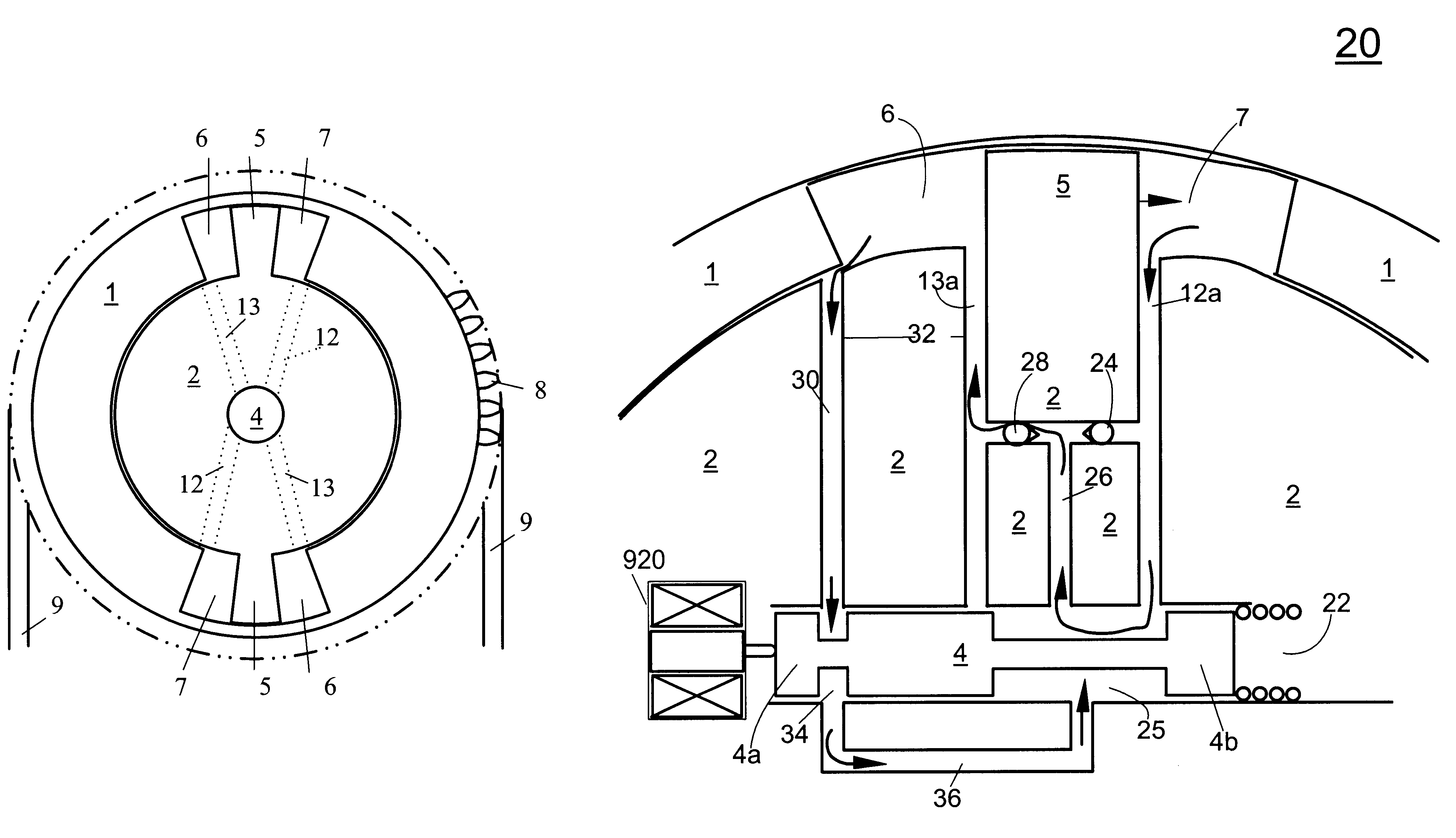

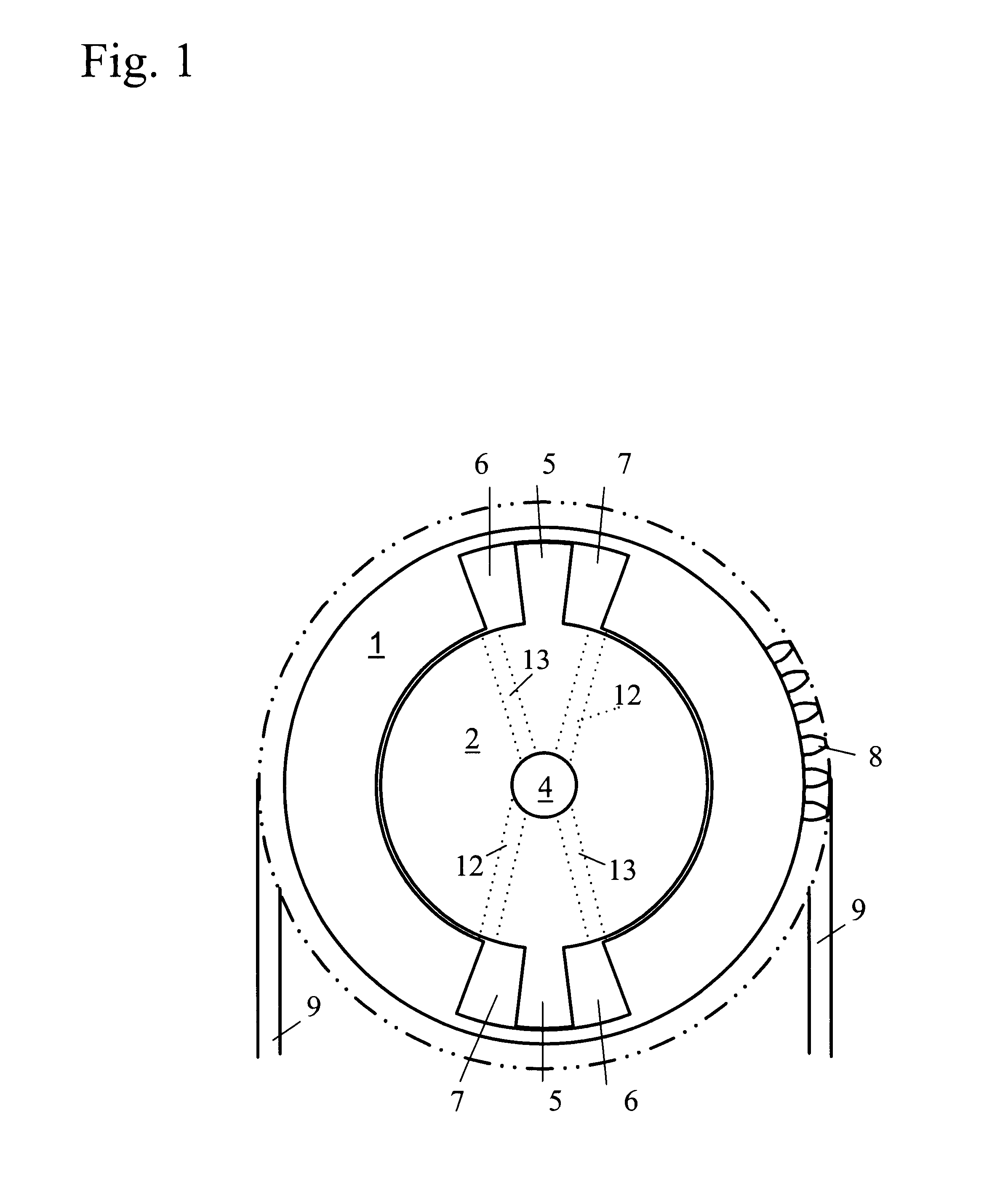

Artificial muscle actuator assembly

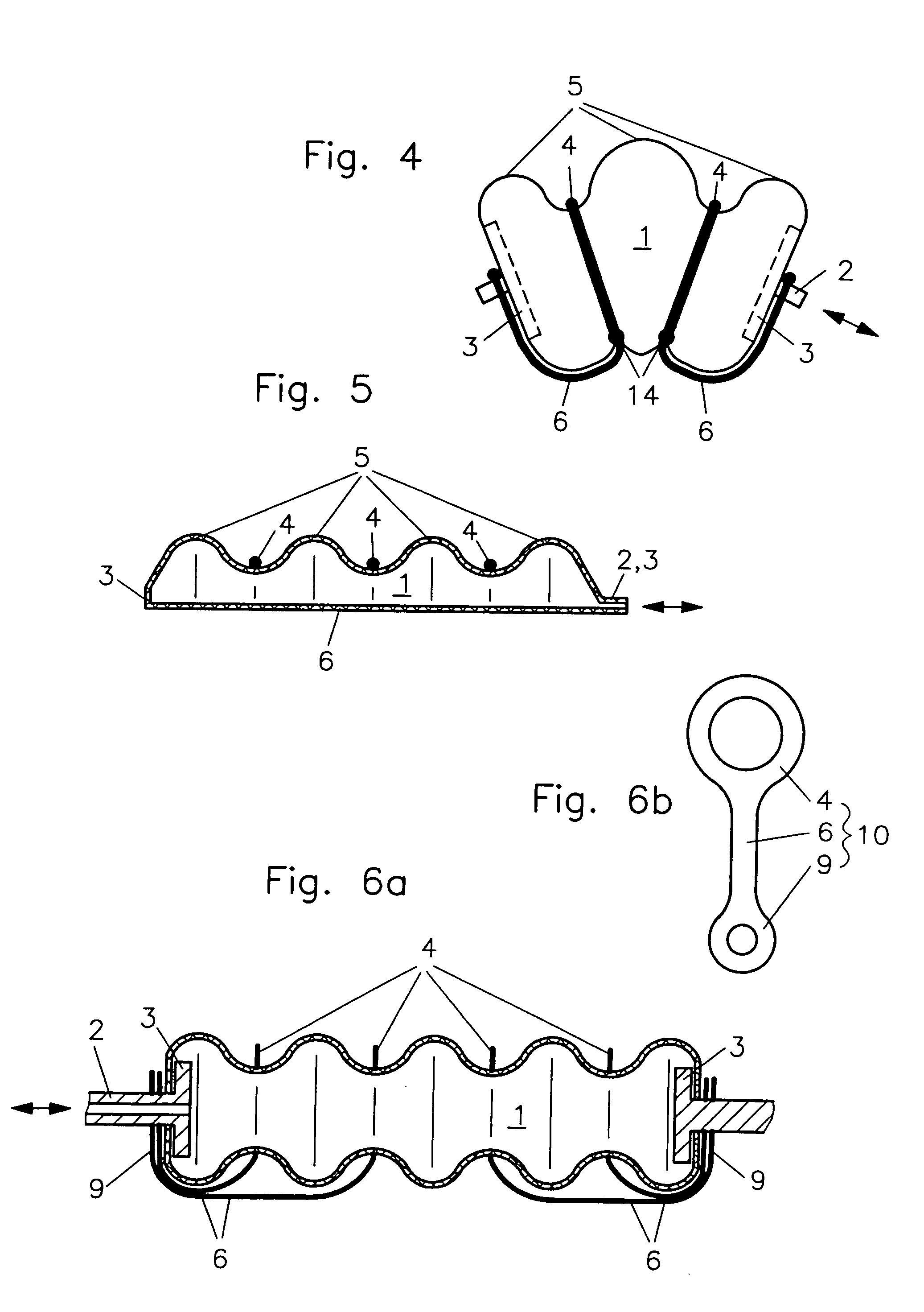

InactiveUS6223648B1Substantially flexibleAvoid formingFlexible wall reciprocating enginesFluid-pressure actuatorsDistal portionEngineering

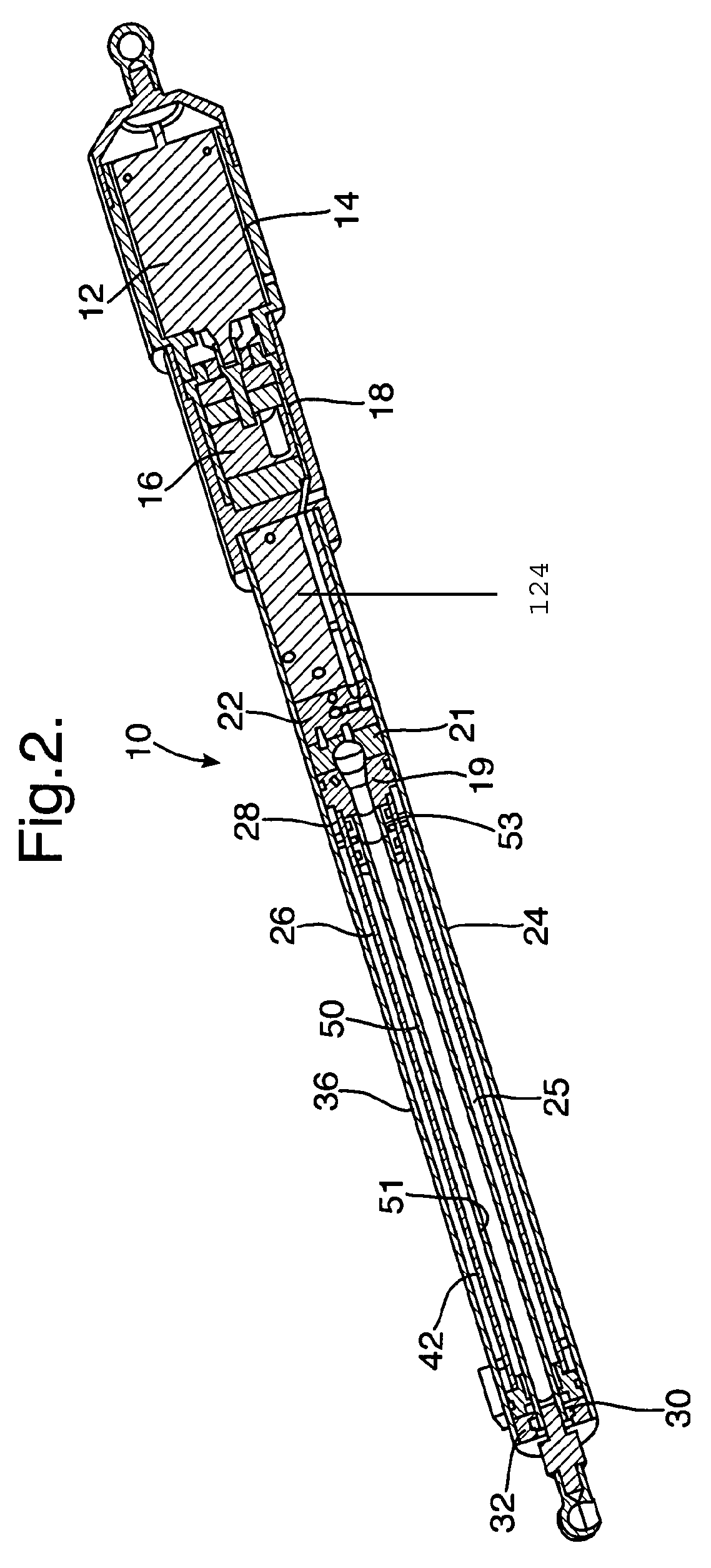

A flexible actuator assembly (20) including a flexible bladder device (22) having an expandable sealed chamber (23) adapted to substantially directionally displace between a deflated condition and an inflated condition, displacing a proximal portion (25) of the bladder device (22) away from a distal portion (26) thereof. An elongated tendon member (27) includes a distal portion (28) oriented outside the chamber (23), while an anchor portion (30) extends into the chamber (23) through a distal opening (31) in the bladder device (22). The tendon anchor portion (30) is further coupled proximate to the bladder proximal portion (25) in a manner adapted to: selectively invert displaceable portions (32) of the bladder device (22) when urged toward the deflated condition to position the anchor portion (30) and the bladder proximal portion (25) relatively closer to the bladder distal portion (26); and selectively evert the inverted displaceable portions (32) of the bladder device (22) when displaced toward the inflated condition which positions the anchor portion (30) and the bladder proximal portion (25) relatively farther away from the bladder distal portion (26) for selective movement of the tendon distal portion (28) between an extended condition and a retracted condition, respectively.

Owner:ERICKSON JOEL R

Artificial muscle actuator assembly

InactiveUS6067892ASubstantially flexibleAvoid formingFlexible wall reciprocating enginesFluid-pressure actuatorsDistal portionEngineering

A flexible actuator assembly (20) including a flexible bladder device (22) having an expandable sealed chamber (23) adapted to substantially directionally displace between a deflated condition and an inflated condition, displacing a proximal portion (25) of the bladder device (22) away from a distal portion (26) thereof. An elongated tendon member (27) includes a distal portion (28) oriented outside the chamber (23), while an anchor portion (30) extends into the chamber (23) through a distal opening (31) in the bladder device (22). The tendon anchor portion (30) is further coupled proximate to the bladder proximal portion (25) in a manner adapted to: selectively invert displaceable portions (32) of the bladder device (22) when urged toward the deflated condition to position the anchor portion (30) and the bladder proximal portion (25) relatively closer to the bladder distal portion (26); and selectively evert the inverted displaceable portions (32) of the bladder device (22) when displaced toward the inflated condition which positions the anchor portion (30) and the bladder proximal portion (25) relatively farther away from the bladder distal portion (26) for selective movement of the tendon distal portion (28) between an extended condition and a retracted condition, respectively.

Owner:ERICKSON JOEL R

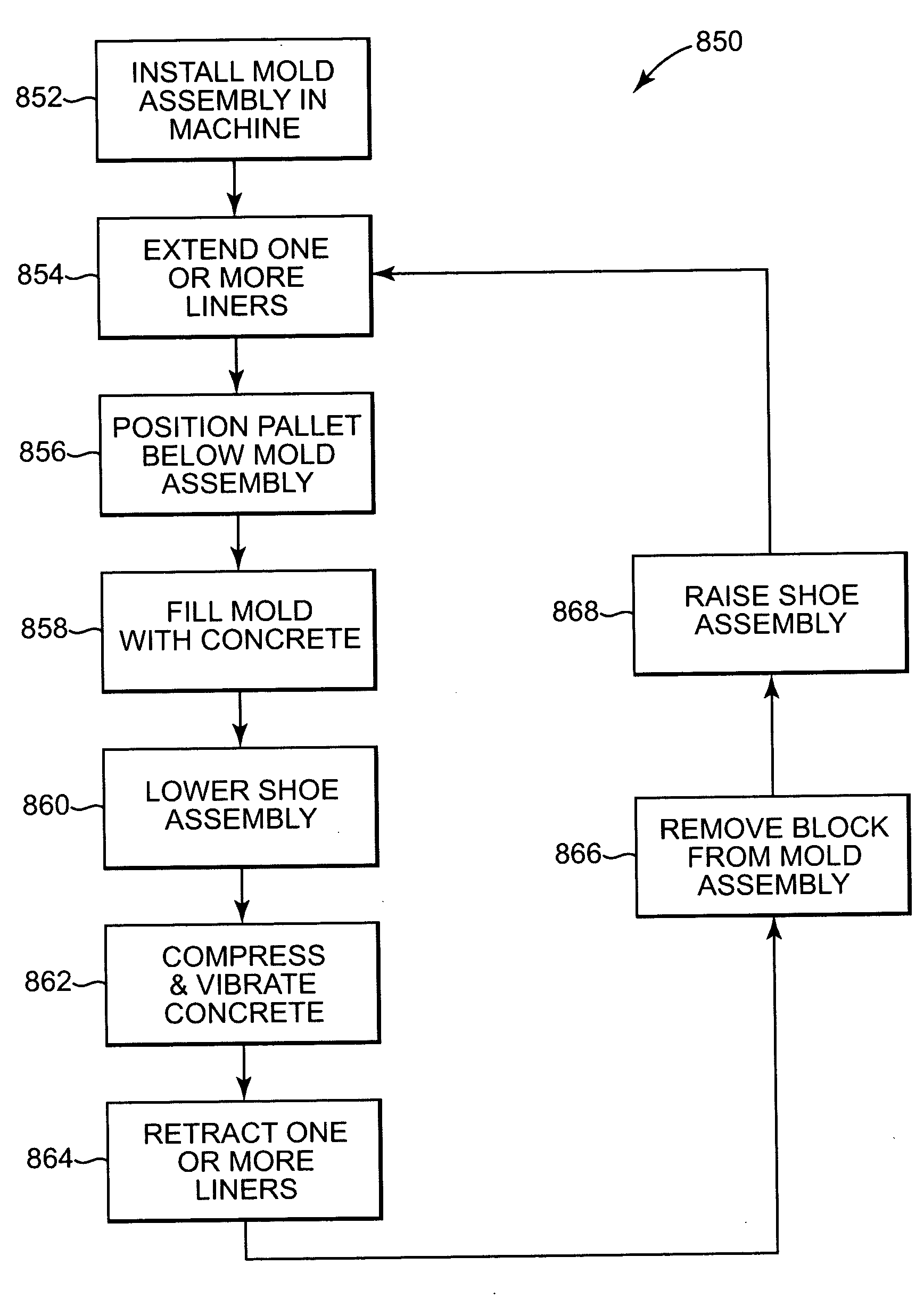

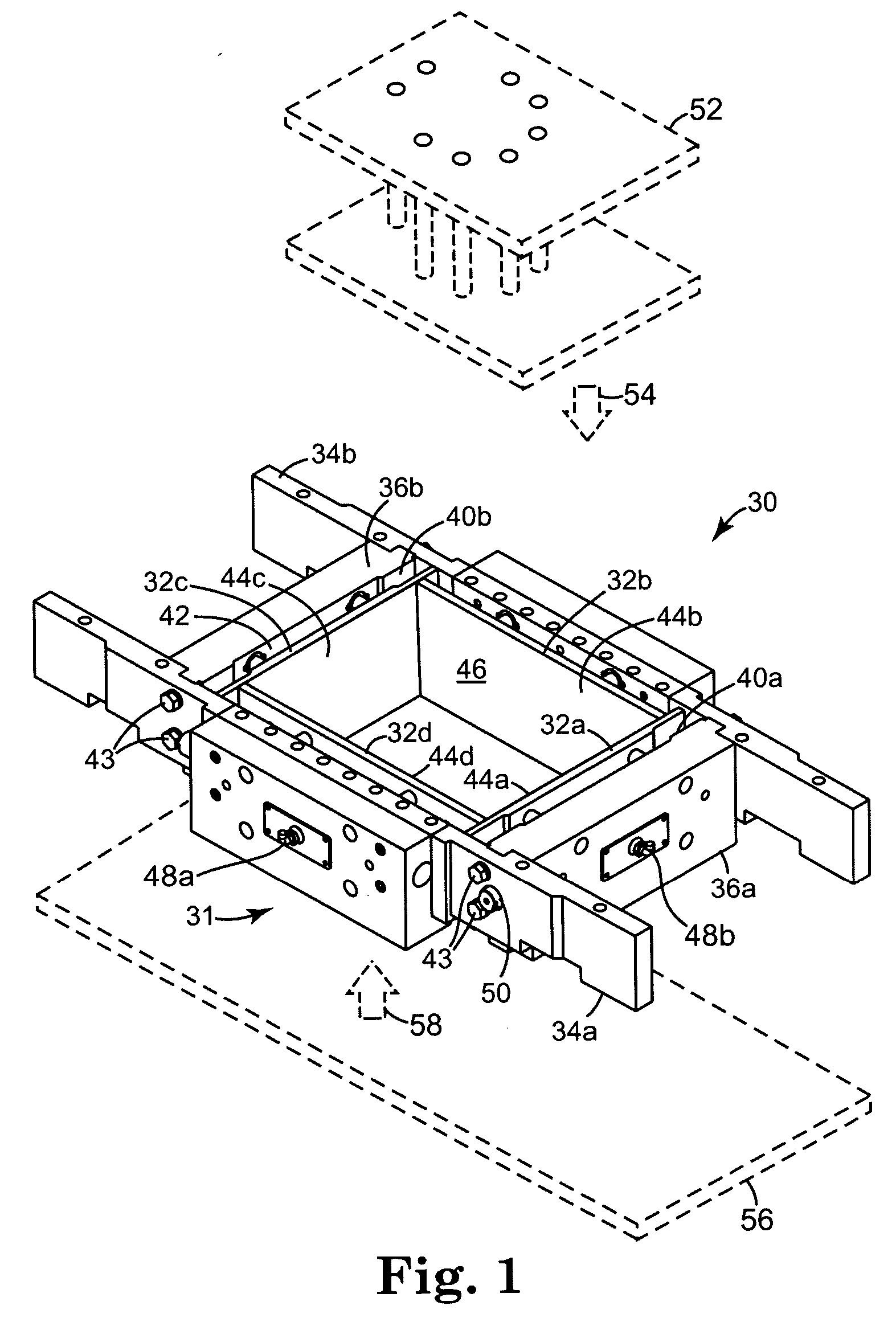

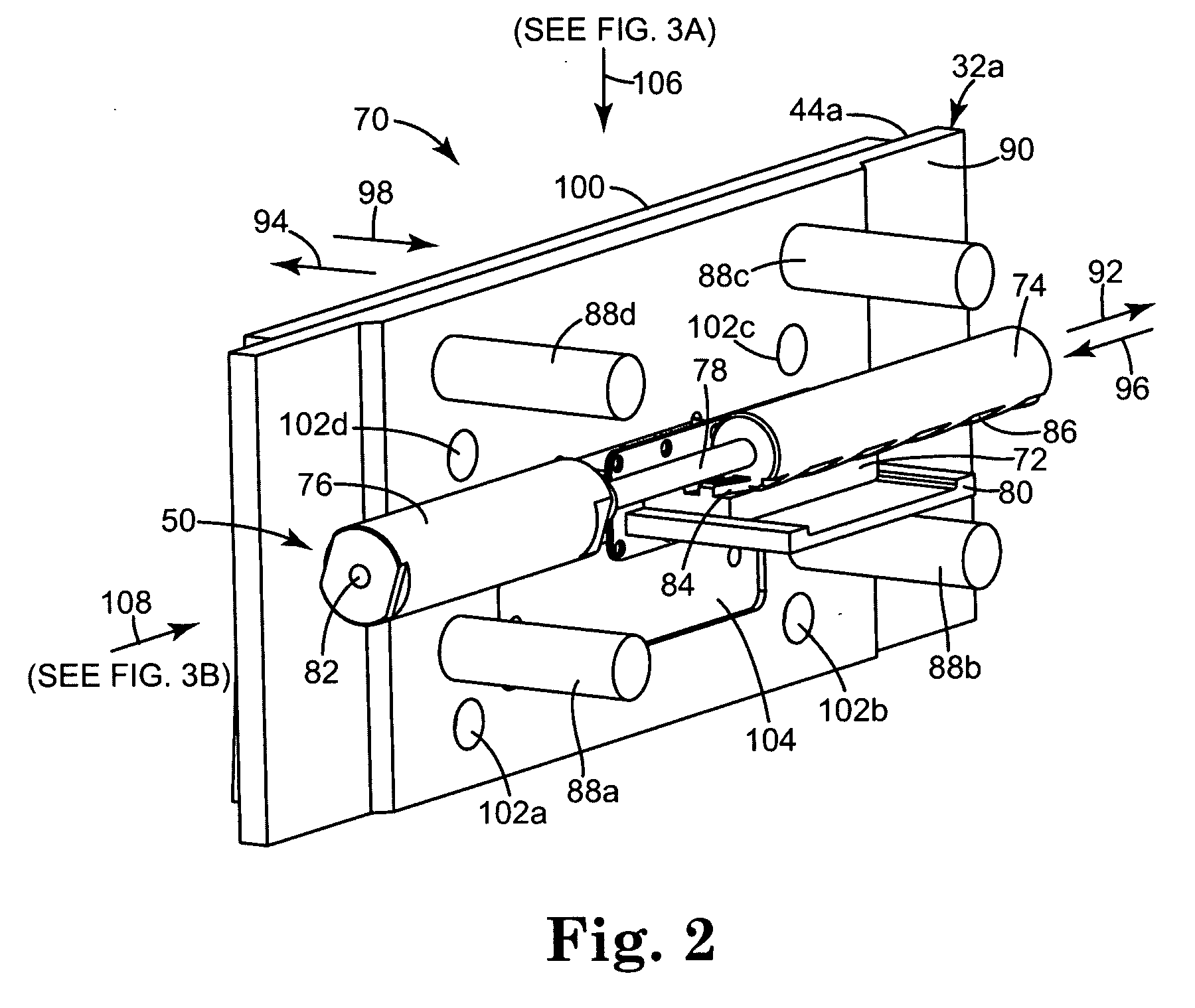

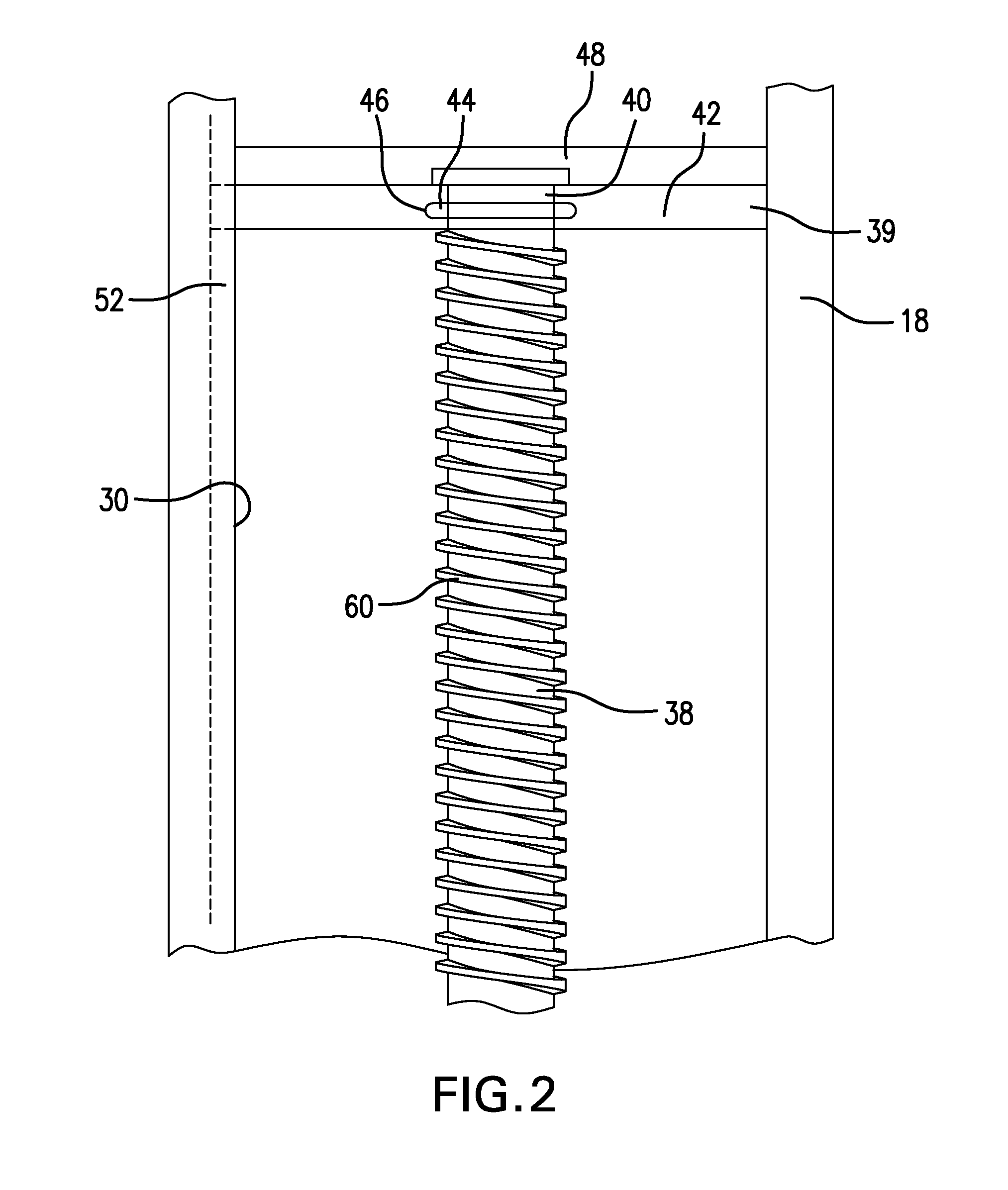

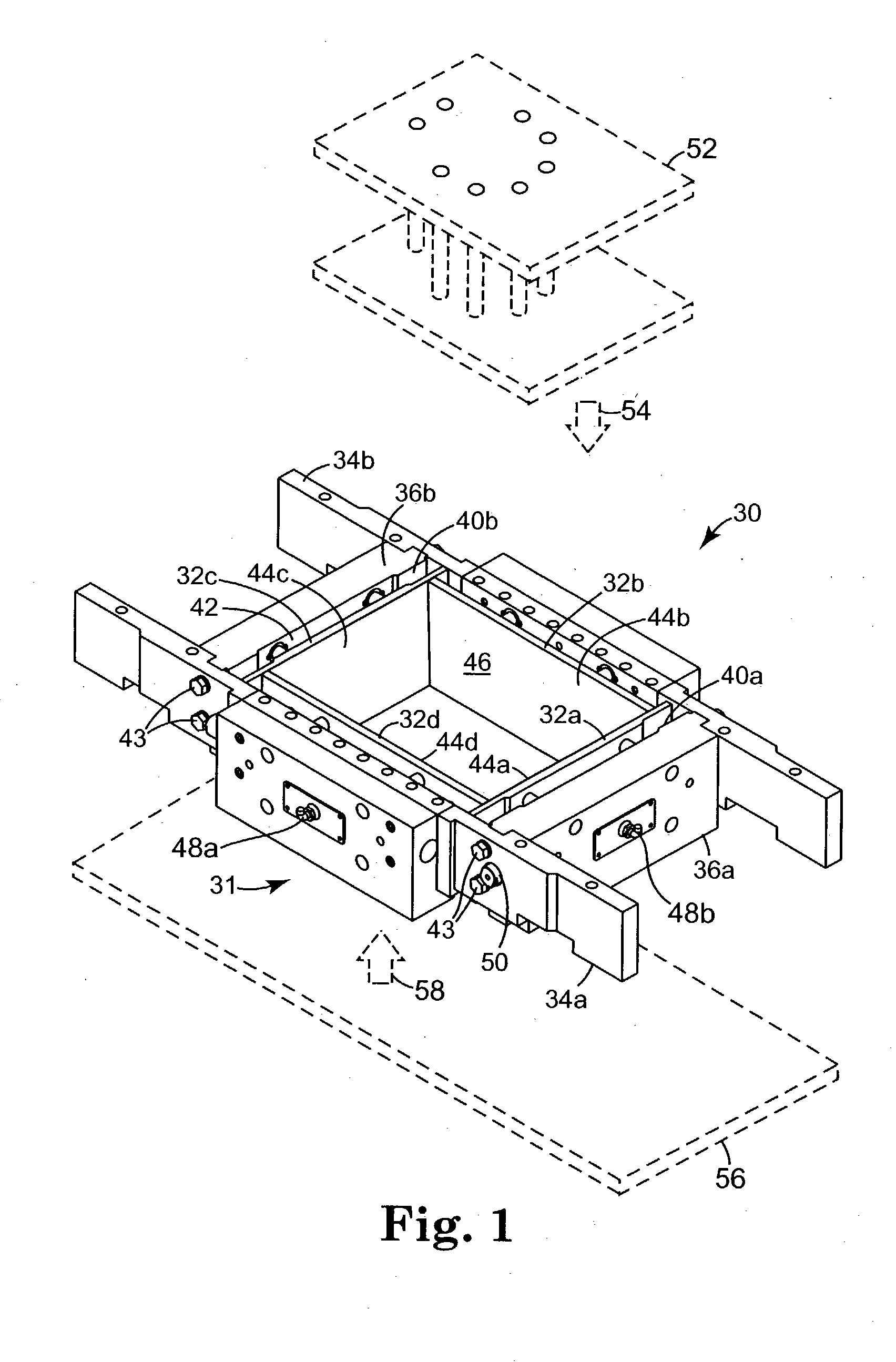

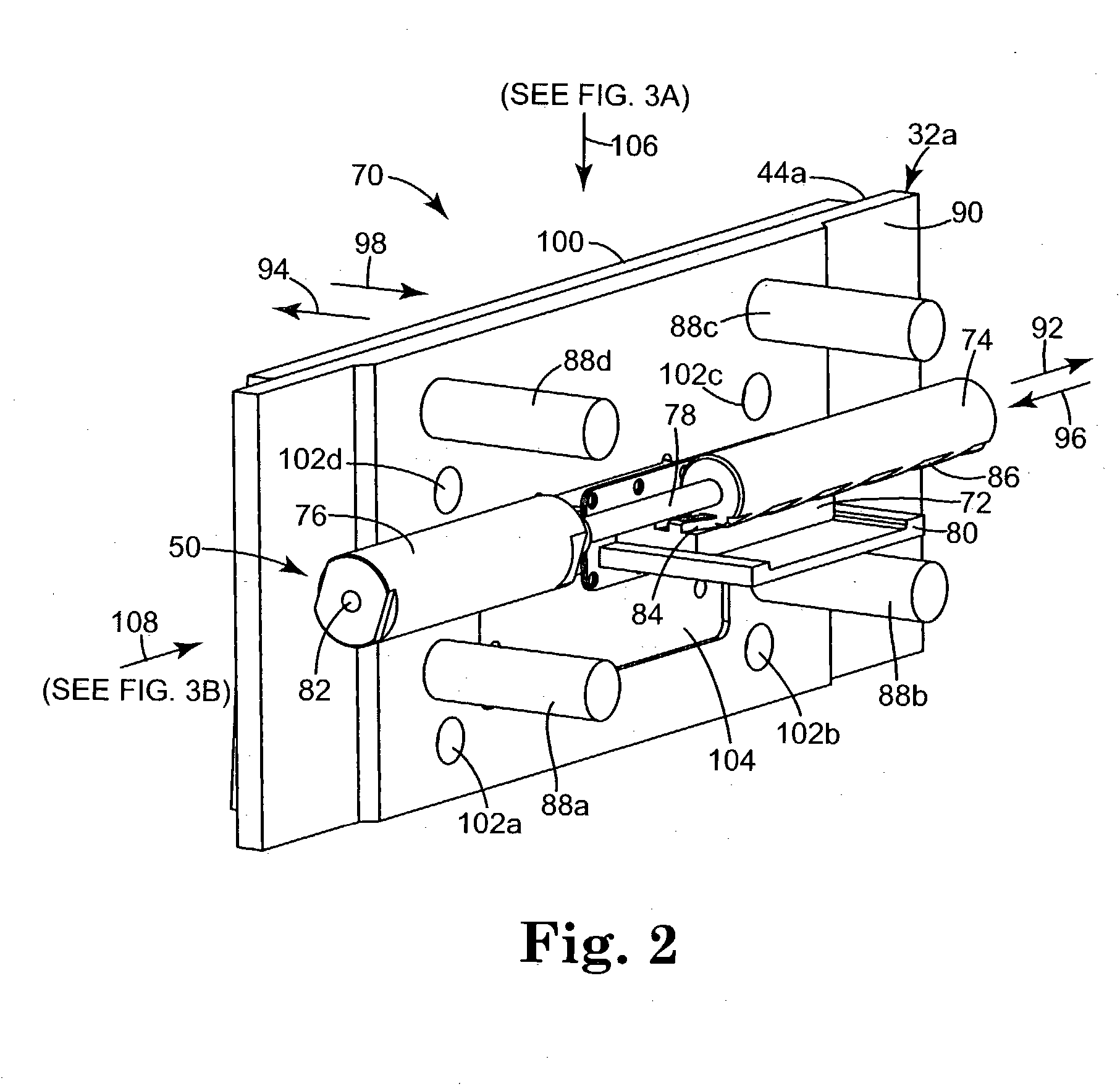

Masonry blocks and method and system of making masonry blocks

A method of producing a masonry block including providing a mold assembly having a plurality of liner plates that together form a mold cavity having an open top and an open bottom, wherein at least one of the liner plates is moveable between a retracted position and a desired extend position relative to an interior of the mold cavity with a gear drive assembly. The at least one moveable liner plate is moved to the desired extended position, the bottom of the mold cavity is closed with a pallet, dry cast concrete is placed in the mold cavity via the open top, the top of the mold cavity is closed with a moveable head shoe assembly, and the dry cast concrete is compacted to form a pre-cured masonry block. The at least one moveable liner plate is moved to the retracted position, the pre-cured masonry block is expelled from the mold cavity and cured.

Owner:NESS INVENTIONS

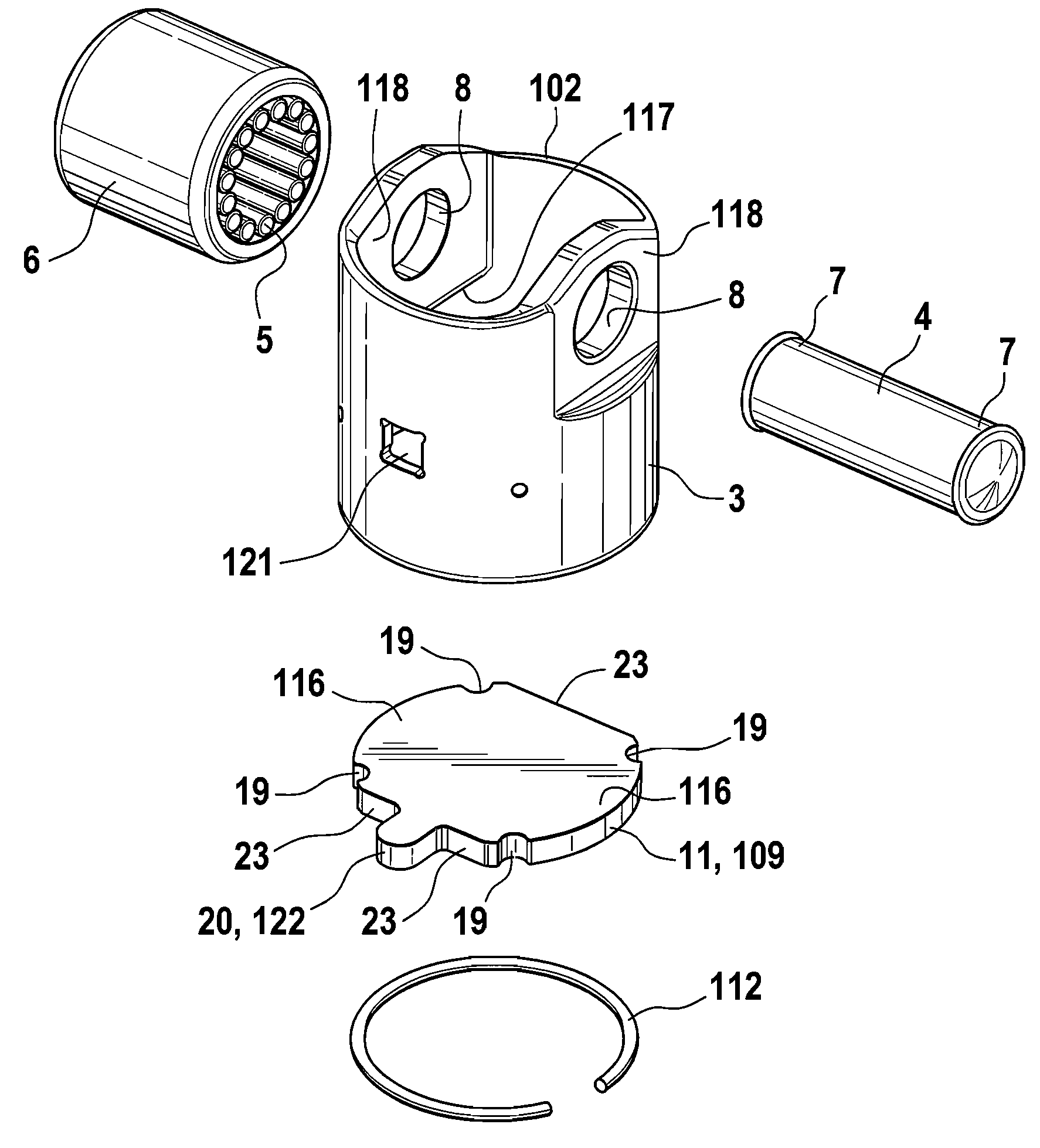

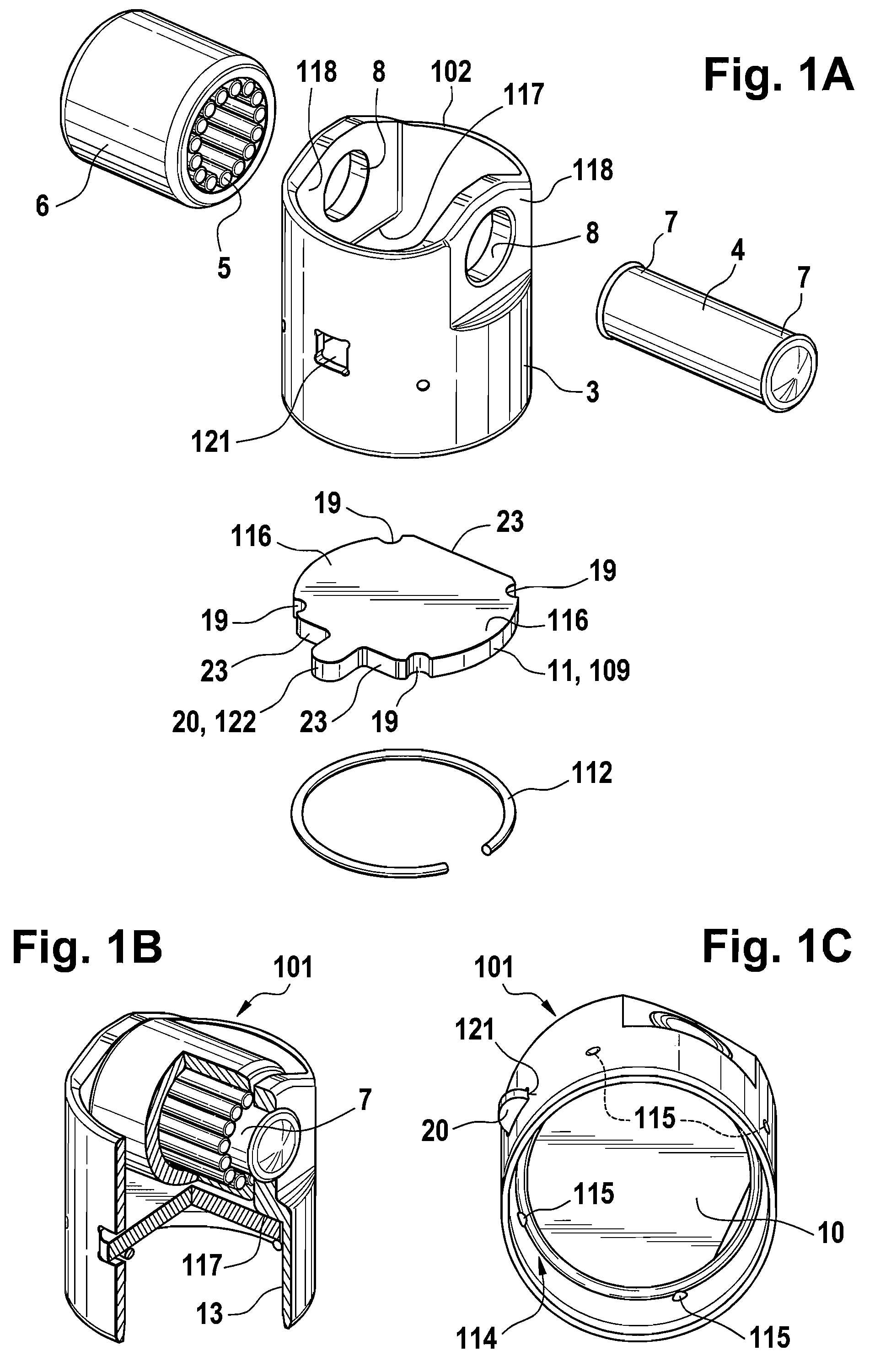

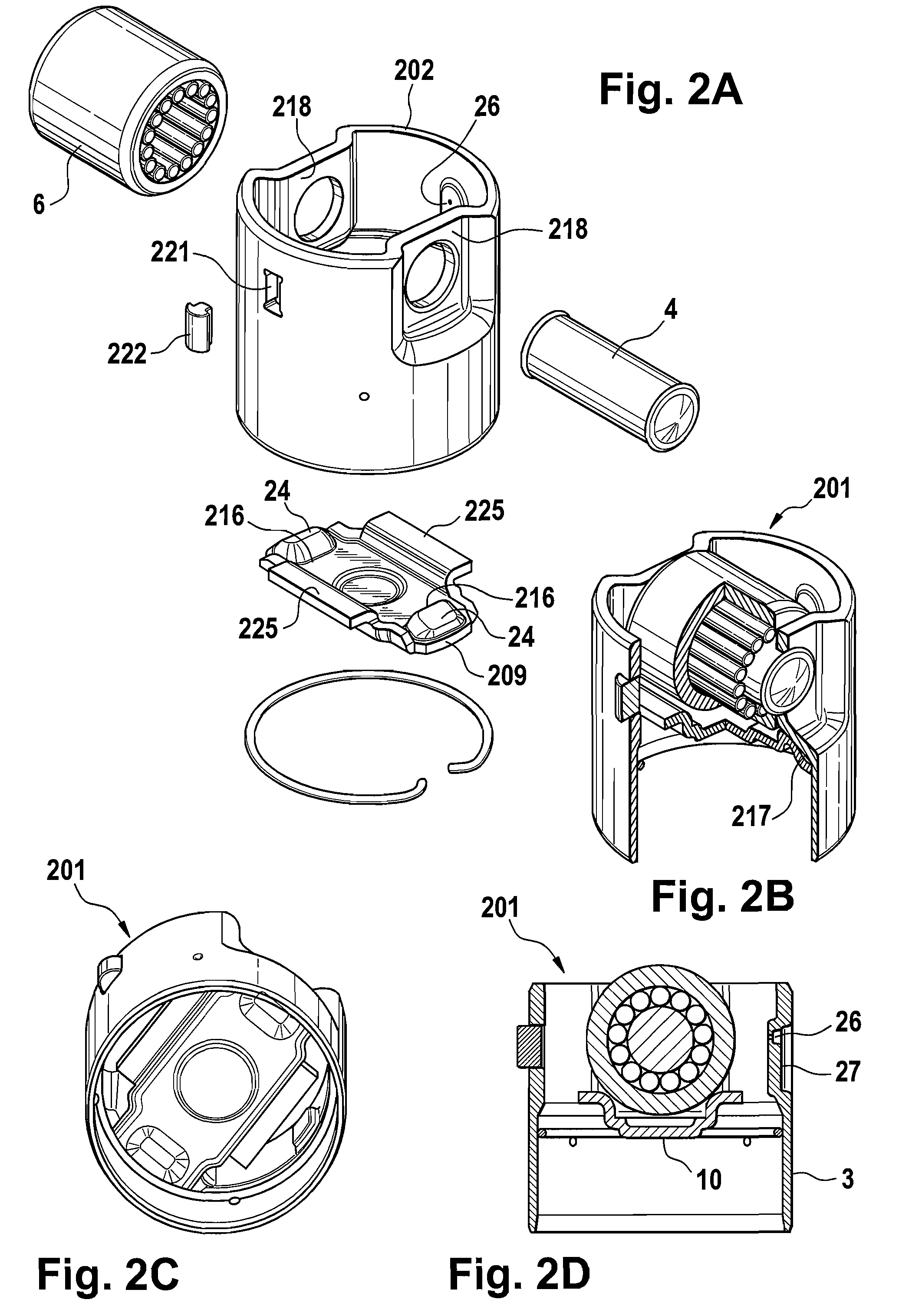

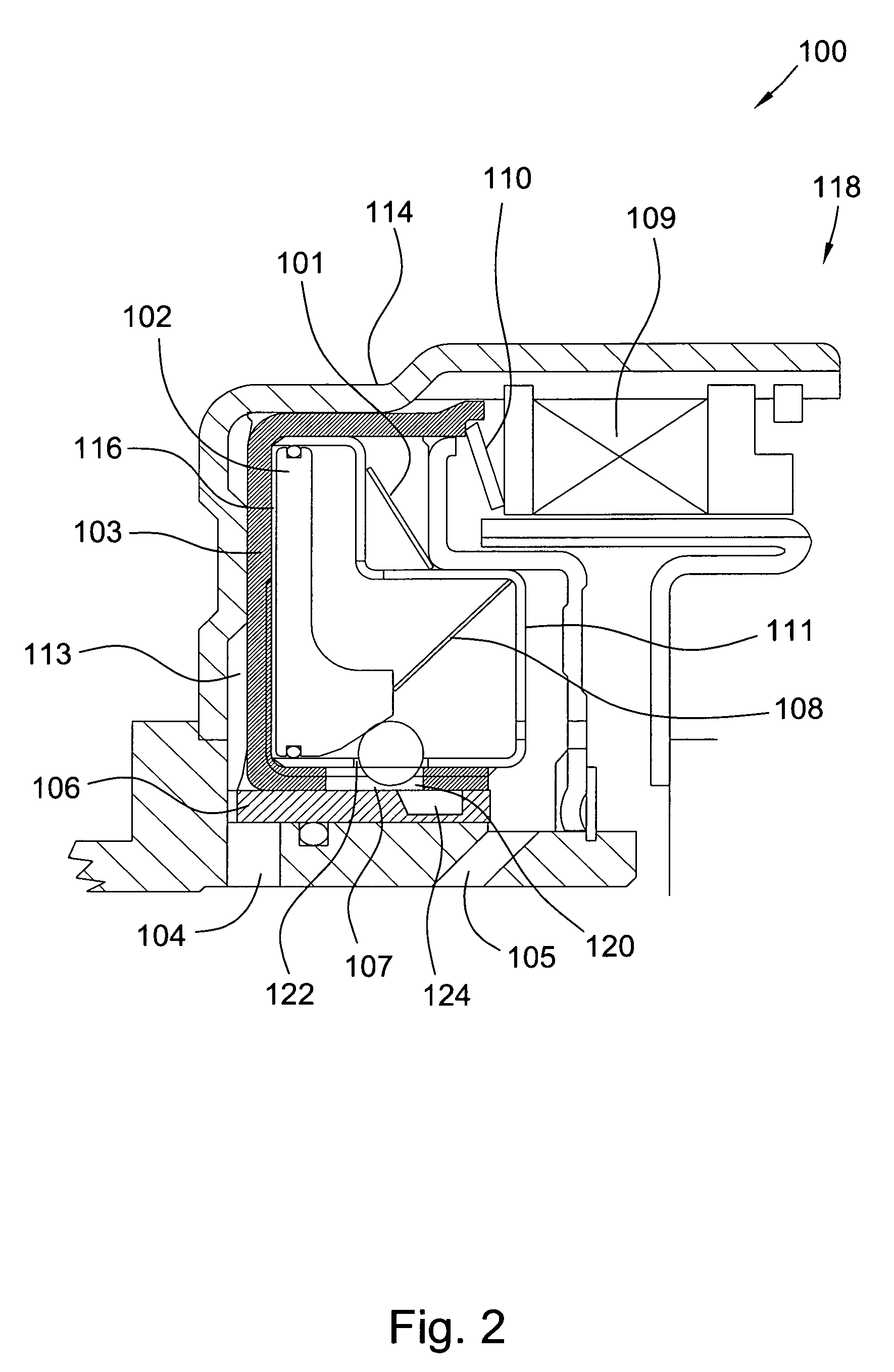

Mechanical tappet in particular for a fuel pump of an internal combustion engine

InactiveUS7793583B2High potential lightweight constructionSave on high costsValve arrangementsEngine sealsInternal combustion engineTappet

A mechanical tappet (101, 201, 301, 401, 501, 601, 701, 801, 901, 1001) is provided, in particular for actuating the lifting of a pump piston (39) of a fuel pump of an internal combustion engine, with a sleeve-shaped tappet housing (102, 202, 302, 402, 502, 602, 702, 902, 1002) constructed as a shaped sheet-metal part and with a driving roller (6) supported so that it can rotate. Here, a bolt (4) supports the driving roller so that it is centered, and end sections (7) of the bolt projecting from the driving roller are supported in bolt eyes (8) of the tappet housing.

Owner:SCHAEFFLER TECH AG & CO KG

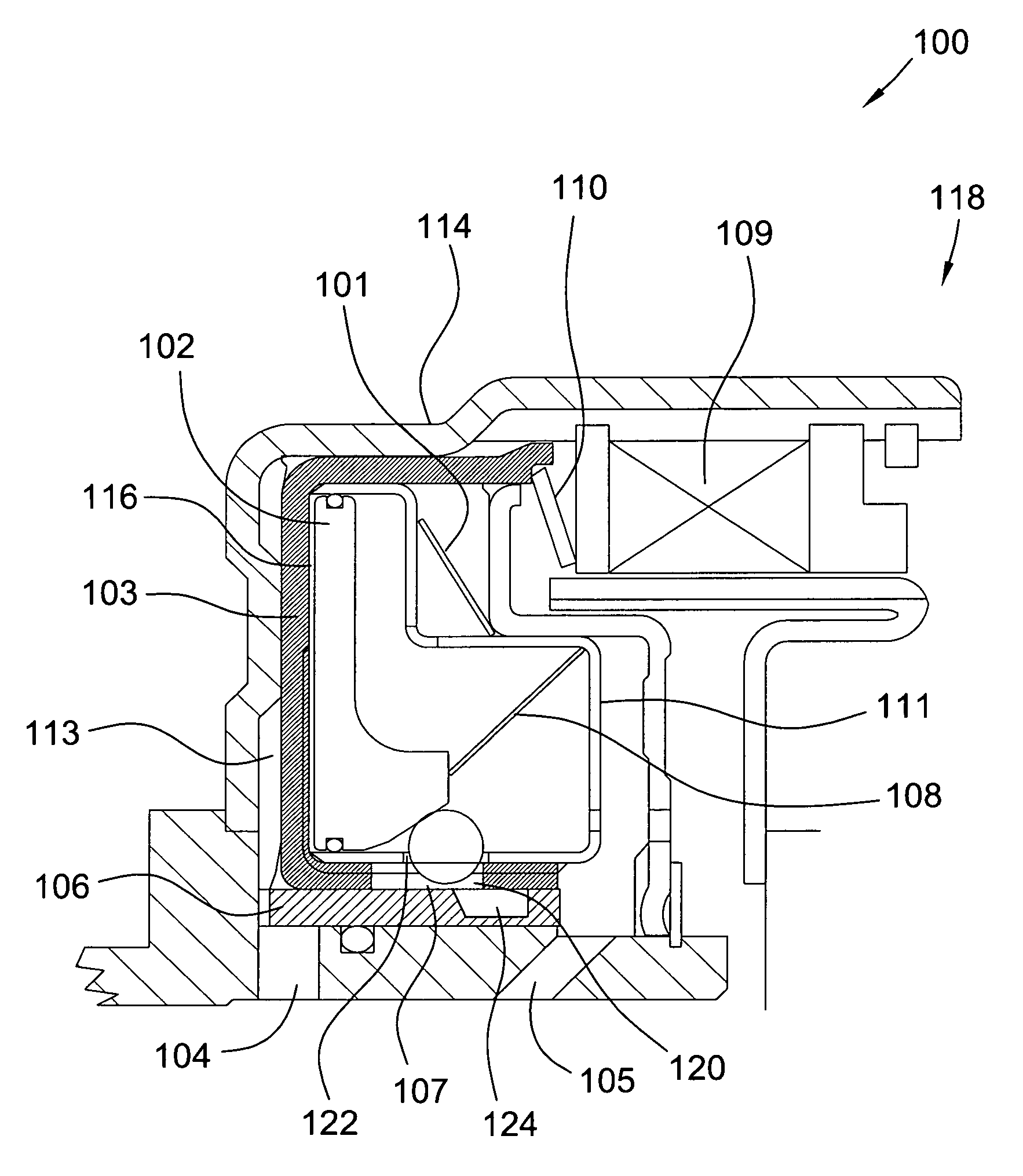

Clutch and brake latch mechanism

A clutch including: a first piston displaceable to operate a clutch pack; a second piston; a first fluid chamber partially formed by the pistons, wherein the second piston is displaceable by fluid pressure in the first fluid chamber; and a locking means fixable by the second piston to hold the pack closed. In a preferred embodiment, the locking means includes at least one displaceable ball. In another preferred embodiment, in response to a loss of fluid pressure in the first chamber, the second piston is displaceable to enable displacement of the locking means to open the pack. In a further preferred embodiment, the clutch includes a second chamber, separate from the first chamber and partially formed by the first piston. The first piston is displaceable in response to fluid pressure in the second chamber. The pack remains closed after a loss or reduction of fluid pressure in the second chamber.

Owner:SCHAEFFLER TECH AG & CO KG

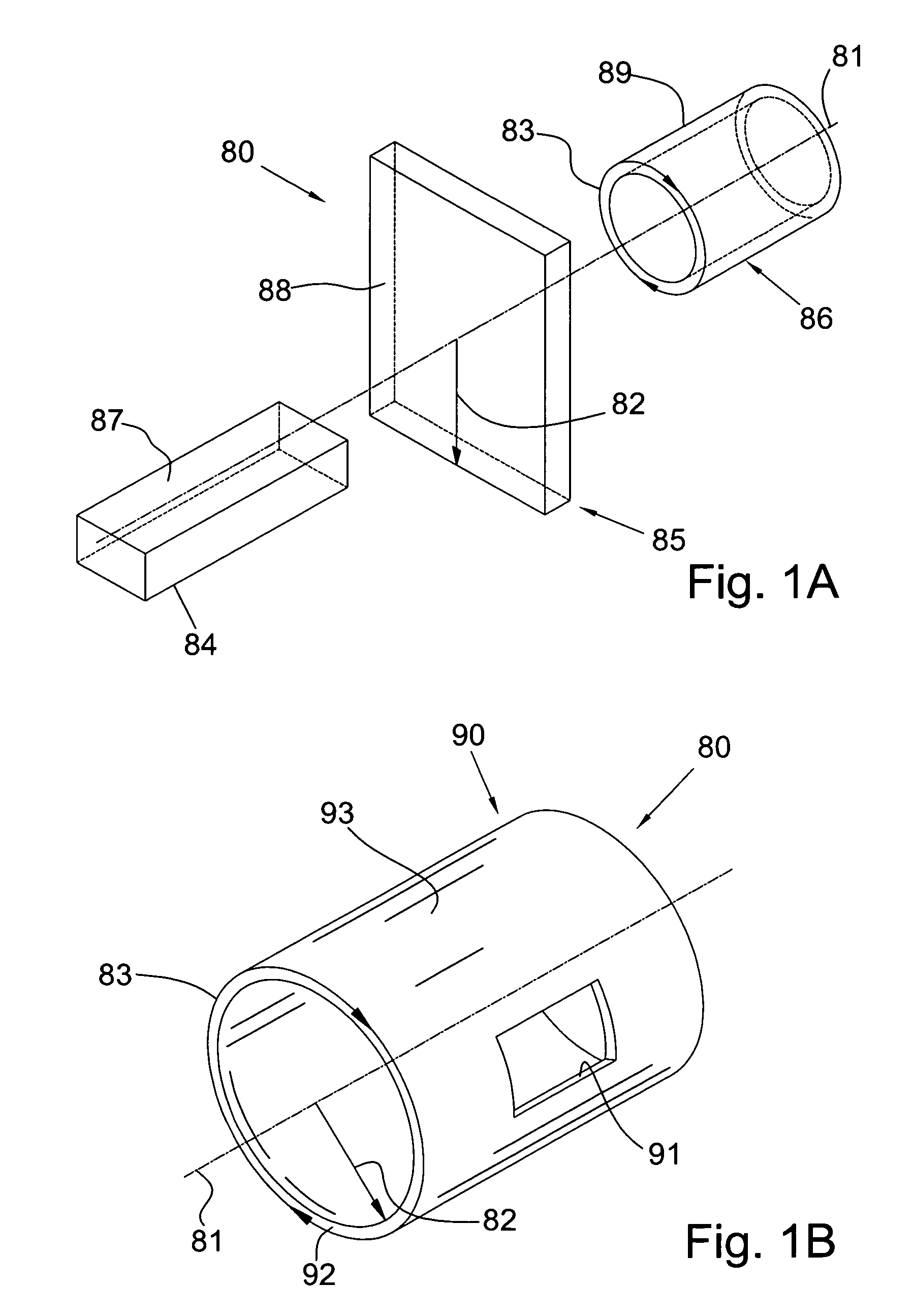

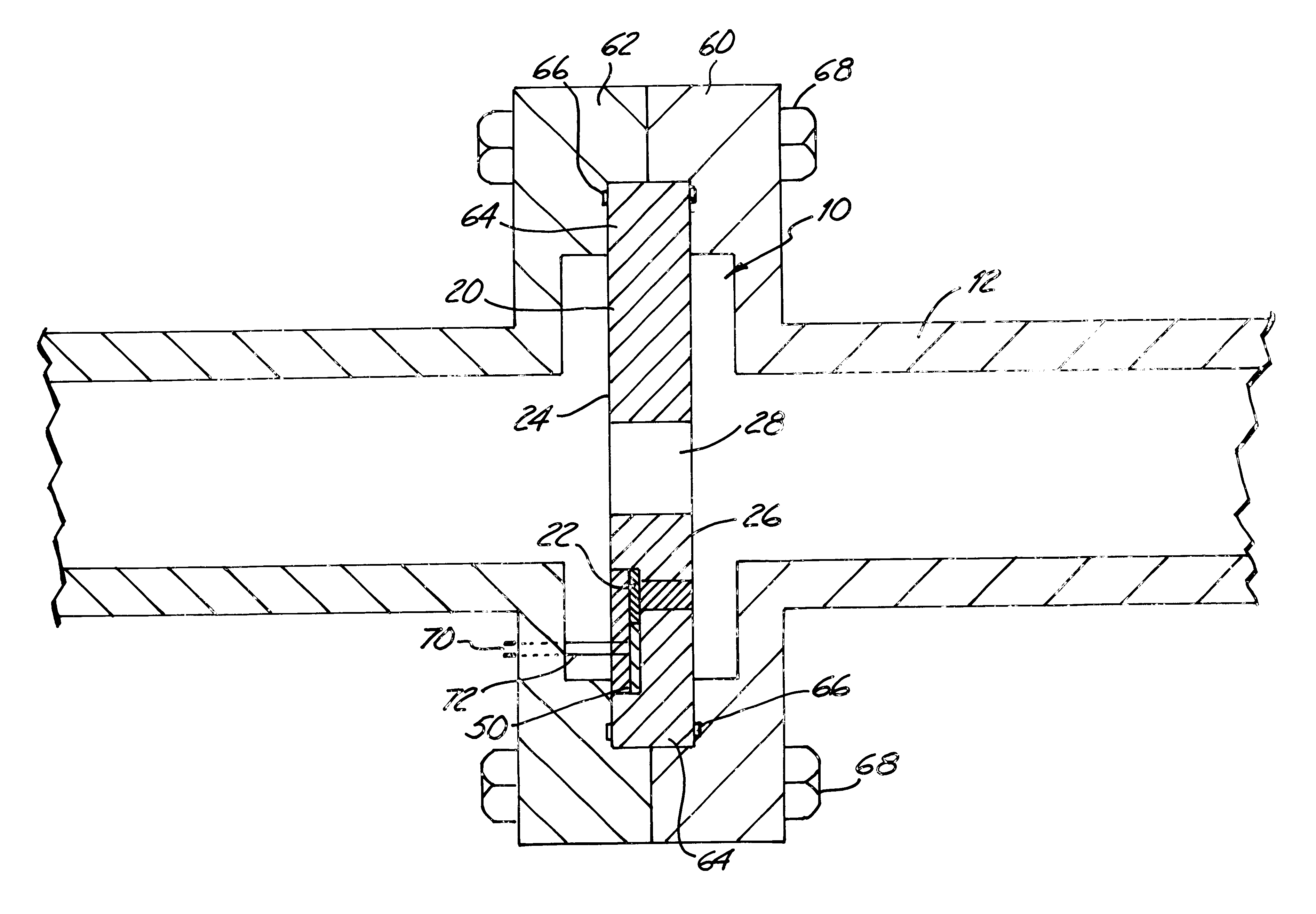

Bi-directional differential pressure flow sensor

InactiveUS6725731B2Volume variation compensation/correction apparatusFluid-pressure actuatorsDifferential pressureEngineering

Disclosed is a bi-directional differential pressure flow sensor that is configured to establish a direction and flow rate of a fluid flow. The flow sensor includes a flow restriction member, a differential pressure sensor, and processing electronics. The flow restriction member is configured to produce a pressure drop when placed inline with the fluid flow. The differential pressure sensor is embedded or integral with the flow restriction member and produces a differential pressure signal that is indicative of the pressure drop. The processing electronics produces a flow rate signal that is indicative of the direction and flow rate of the fluid flow as a function of the differential pressure signal.

Owner:ROSEMOUNT INC

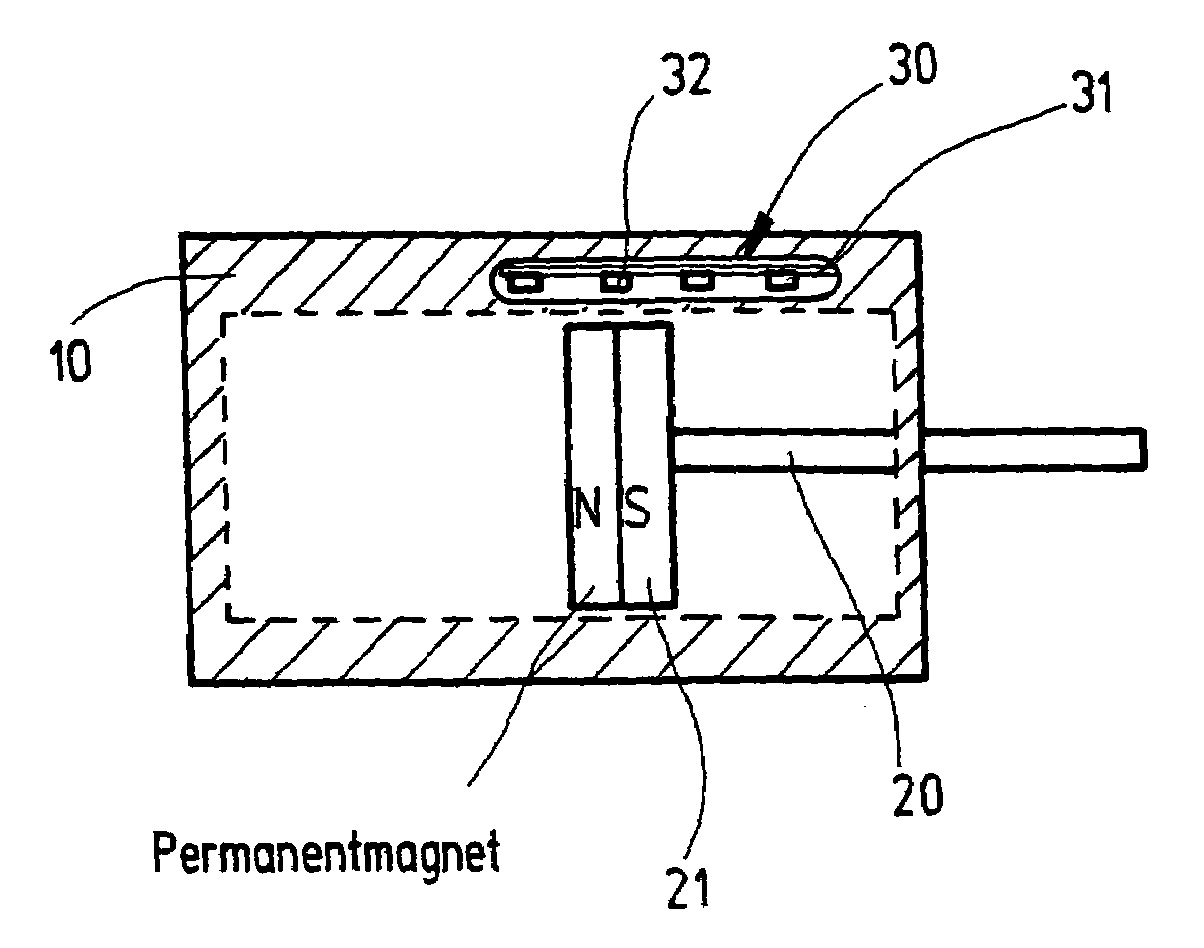

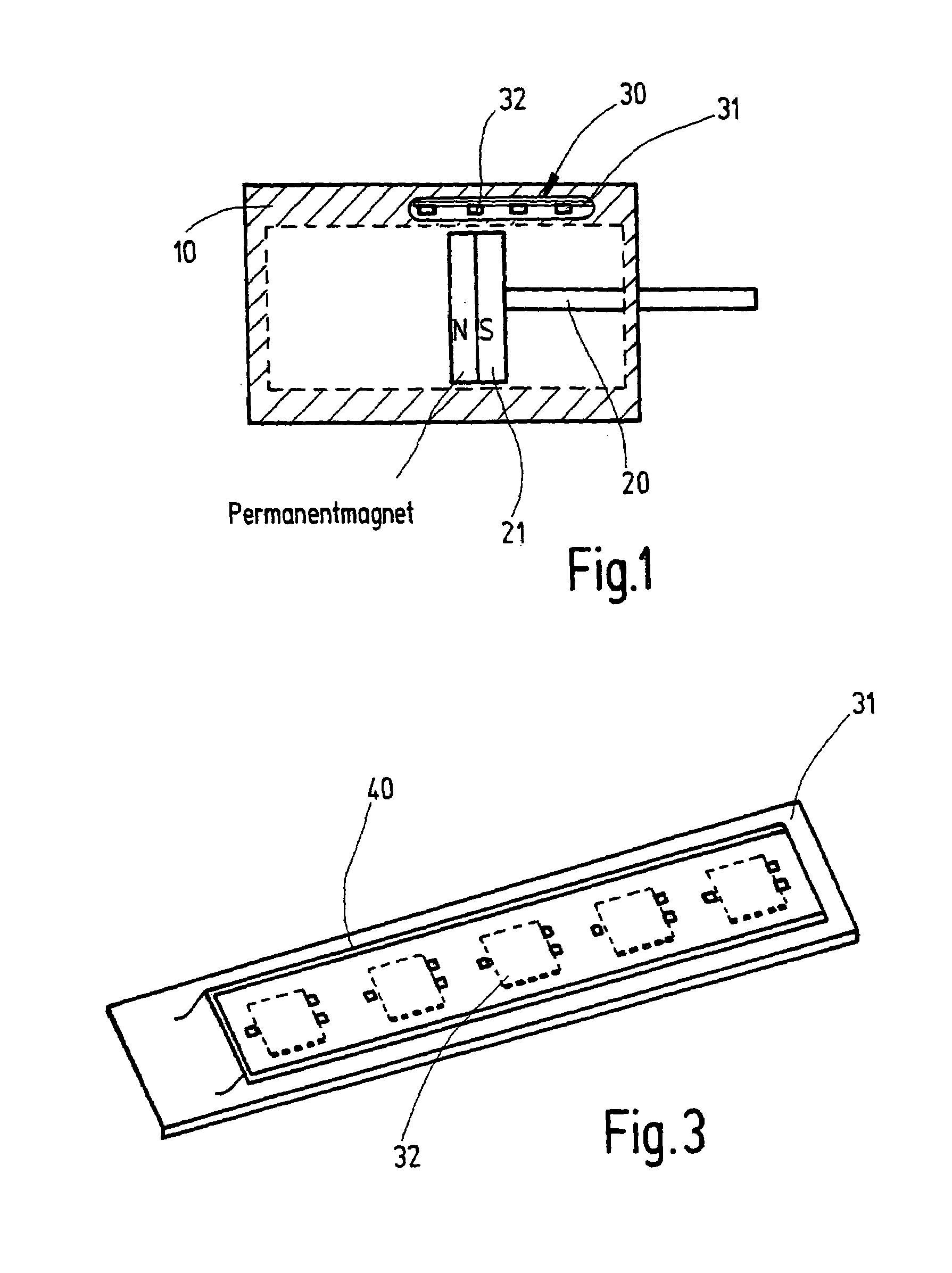

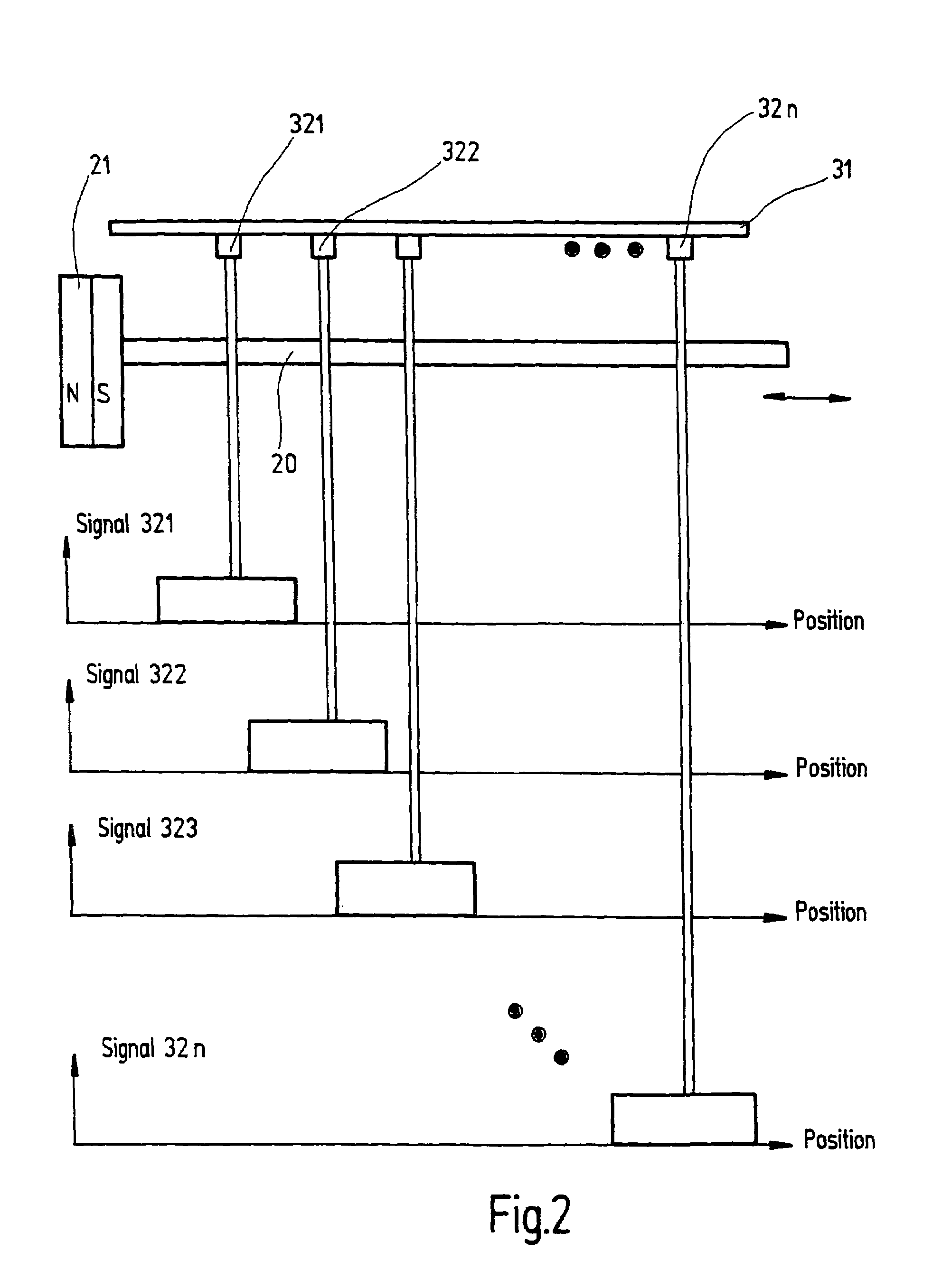

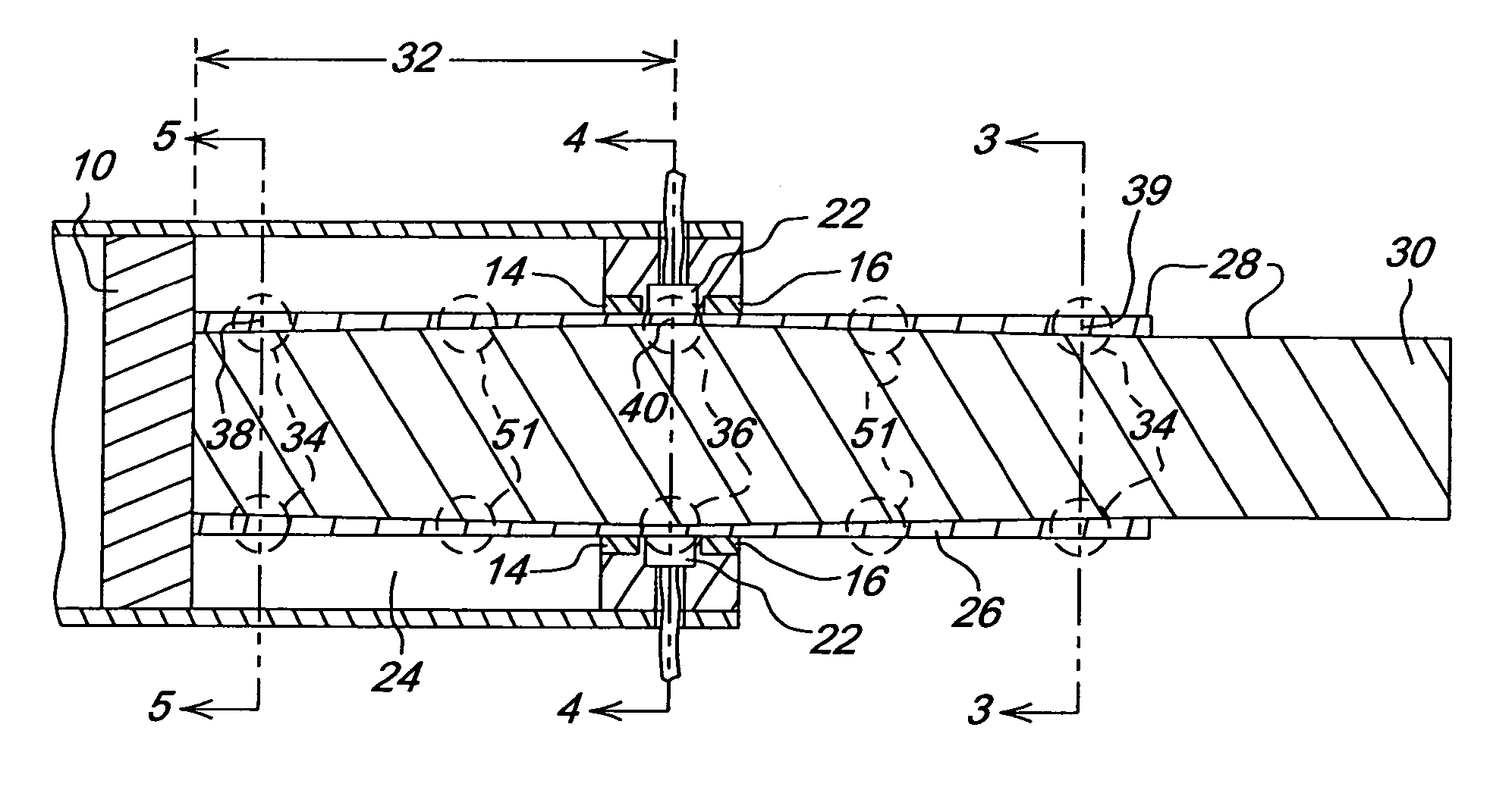

Position-measuring device for fluidic cylinder-and-piston arrangements

InactiveUS7263781B2Easily integrated into cylinder profileEasy to adjustWalking sticksUsing electrical meansSensor arrayPiston

A position-measuring device for fluidic cylinder-and-piston arrangements having at least one Hall sensor, preferably arranged in the area of the cylinder wall, especially in a cylinder wall, and a magnetic region, arranged in the piston. At least one Hall sensor array has at least two Hall sensors spaced one from the other in the direction of movement of the piston. One coil is provided whose magnetic field permits the switching points of the Hall sensors to be adjusted in response to the coil current.

Owner:NORGREN GMBH

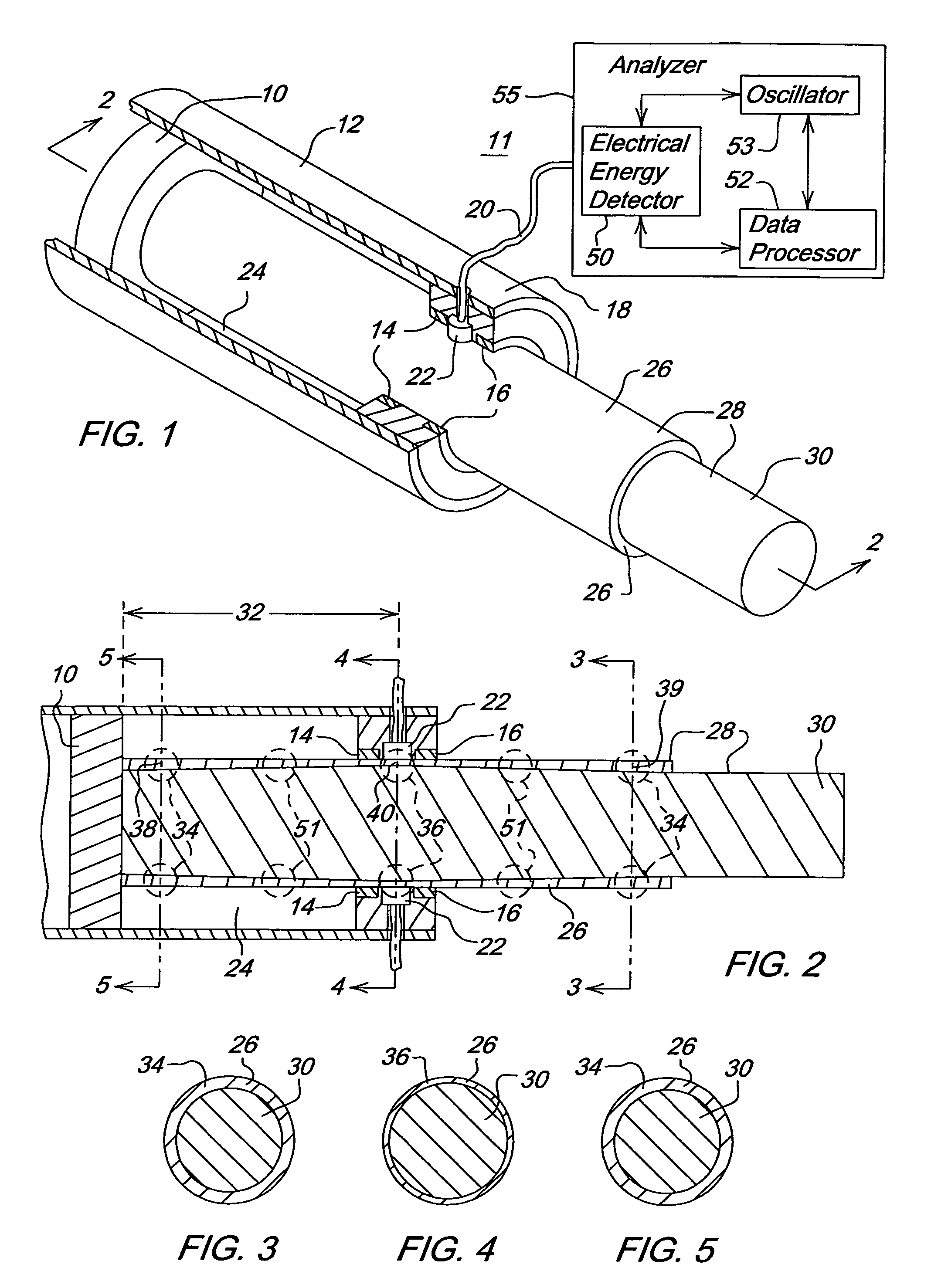

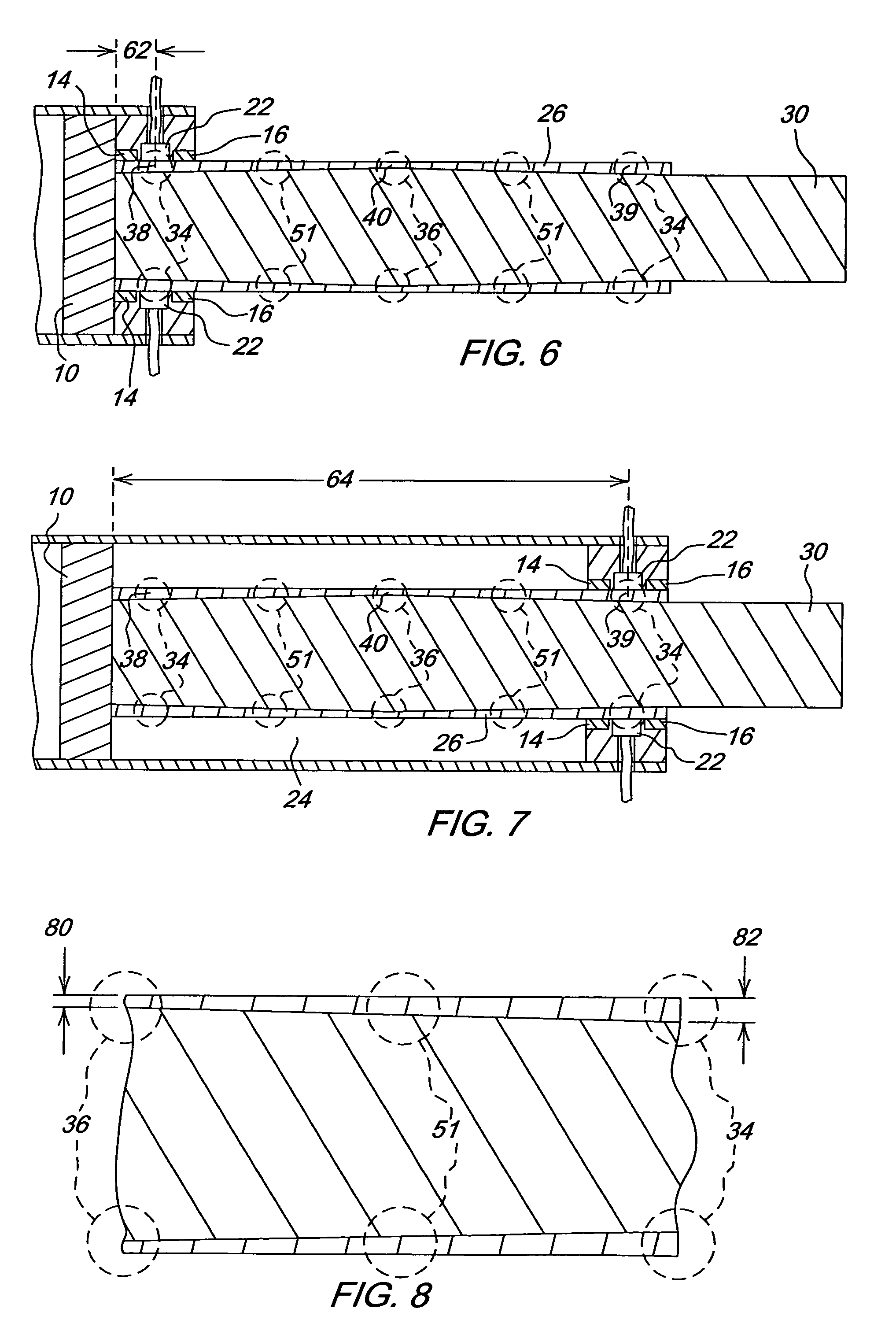

System and method for detecting the axial position of a shaft or a member attached thereto

In accordance with one embodiment of the invention, a method and system for detecting the position of a shaft comprises providing a shaft with defined hardened metallic regions. The shaft has a first hardened metallic region from a surface of the shaft to a first radial depth from the surface at a first longitudinal position. The shaft has a second hardened metallic region from the surface of the shaft to a second radial depth at a second longitudinal position. The second radial depth is different from the first radial depth. A sensor senses an eddy current to detect an alignment of at least one of the first hardened metallic region and the second hardened metallic region with a fixed sensing region at a respective time. A data processor determines a longitudinal position of the shaft with respect to a cylinder at the respective time based on the sensed eddy current.

Owner:DEERE & CO

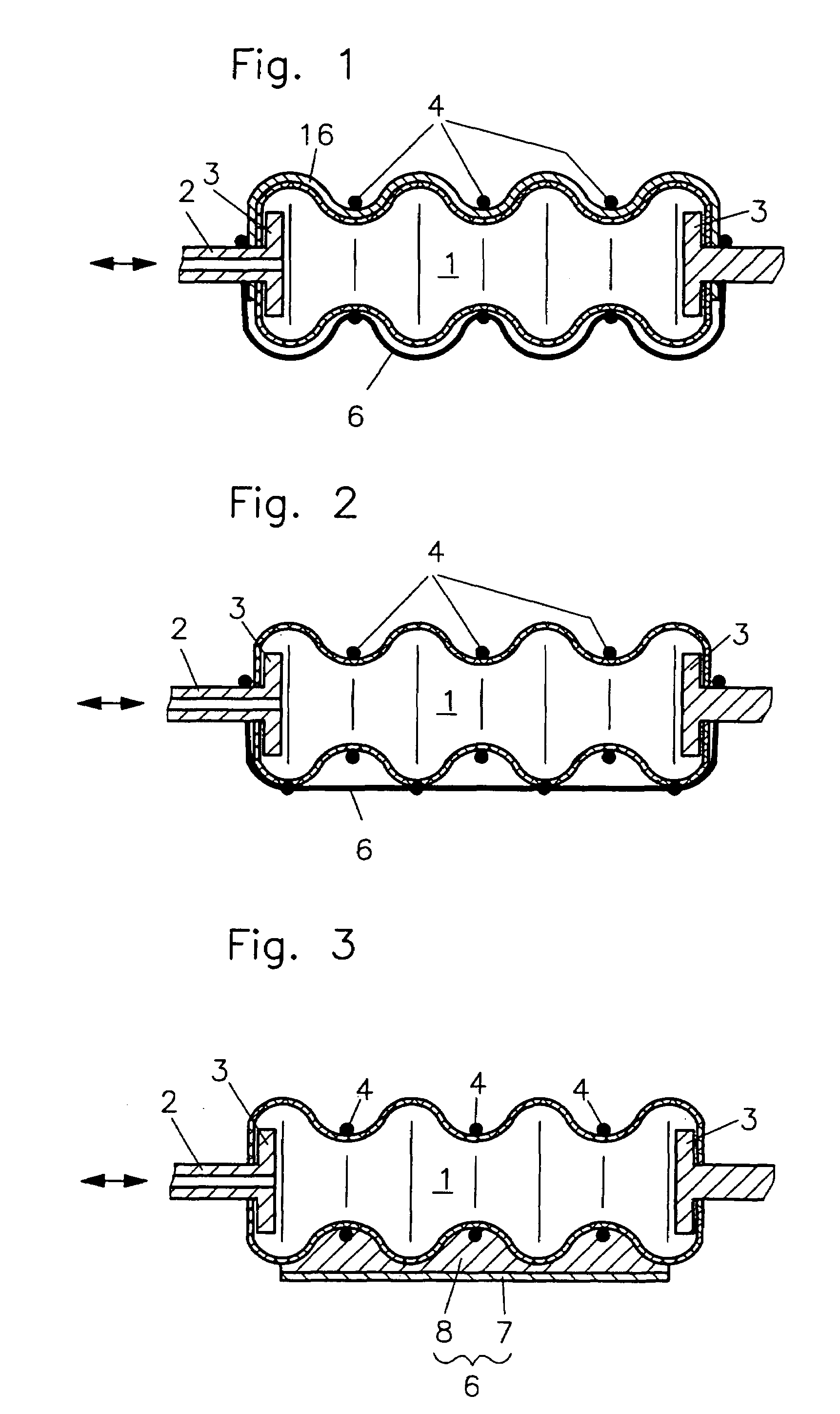

Fluidic device

InactiveUS7086322B2Easy to controlAccurate doseFlexible wall reciprocating enginesFluid-pressure actuatorsEngineeringRing element

In a fluidic drive for disposition between two components which are movable relative to each other comprising a hollow body with a duct for supplying fluid to, and discharging it from, the hollow body wherein the hollow body consists at least partially of a bellows structure, non-resilient ring elements extend around the hollow body in each of its pleats and a connecting structure extends at least at one side of the hollow body and interconnects the non-resilient ring elements.

Owner:GSI HELMHOLTZZENT FUR SCHWERIONENFORSCHUNG

Subsea actuator assemblies and methods for extending the water depth capabilities of subsea actuator assemblies

InactiveUS7108006B2Improved hydraulic pressure compensation systemIncrease fluid pressureOutboard propulsion unitsEqualizing valvesOcean bottomPressure transmission

A hydraulic pressure compensation system for valve actuator assemblies is described having particular application for subsea wellhead installations. The compensation system includes at least one valve actuator assembly having a housing that retains a reciprocable piston therewithin. The piston is spring biased into its fail safe configuration. The valve actuator assembly is hydraulically associated with an accumulator reservoir that defines a closed fluid reservoir and an open fluid reservoir that is exposed to ambient pressures. The two chambers are separated by a membrane. The valve actuator assembly is also operationally associated with a fluid pressure intensifier that boosts the ambient pressure of the accumulator so that an increased fluid pressure may be transmitted to the actuator assembly to bias the actuated valve toward its fail safe configuration. In a described embodiment, the fluid pressure intensifier comprises a housing that defines a chamber having a fluid inlet and fluid outlet. A dual-headed piston is moveably retained within the housing. The piston has an enlarged piston face and a reduced size piston face. Fluid pressure entering the fluid inlet is exerted upon the enlarged piston face, and due to the difference of piston face sizes, an increased pressure is transmitted out of the fluid outlet.

Owner:VETCO GRAY

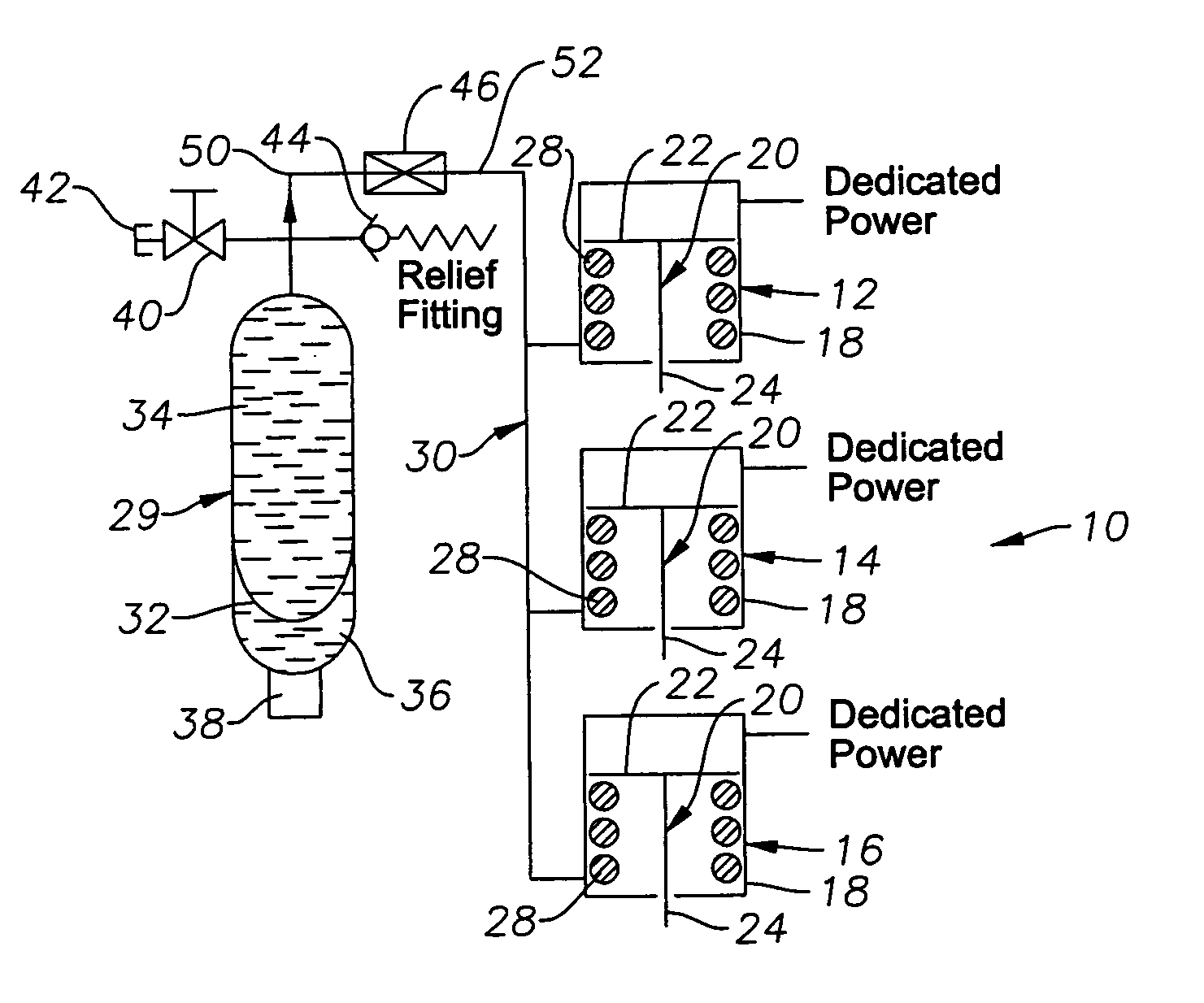

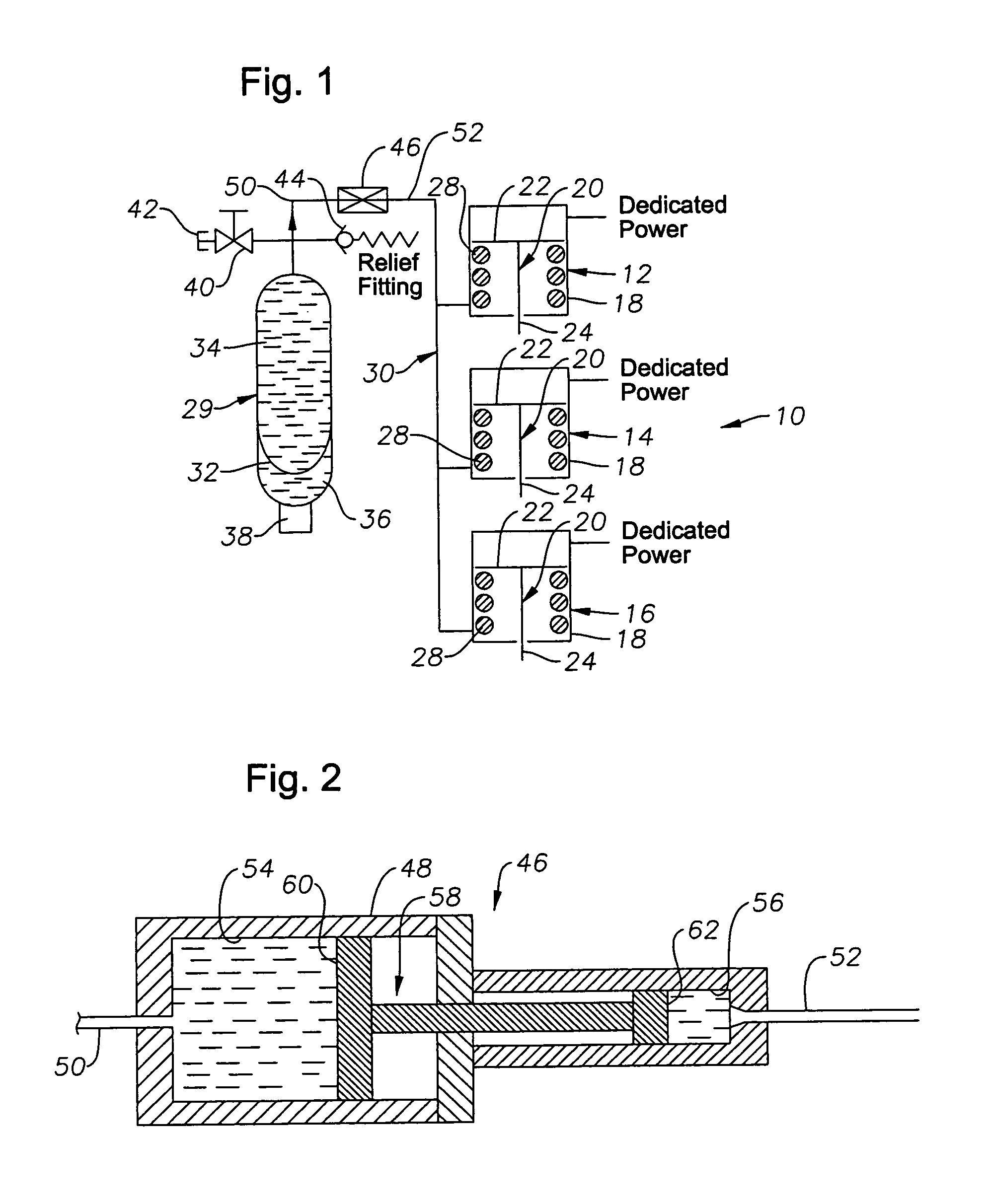

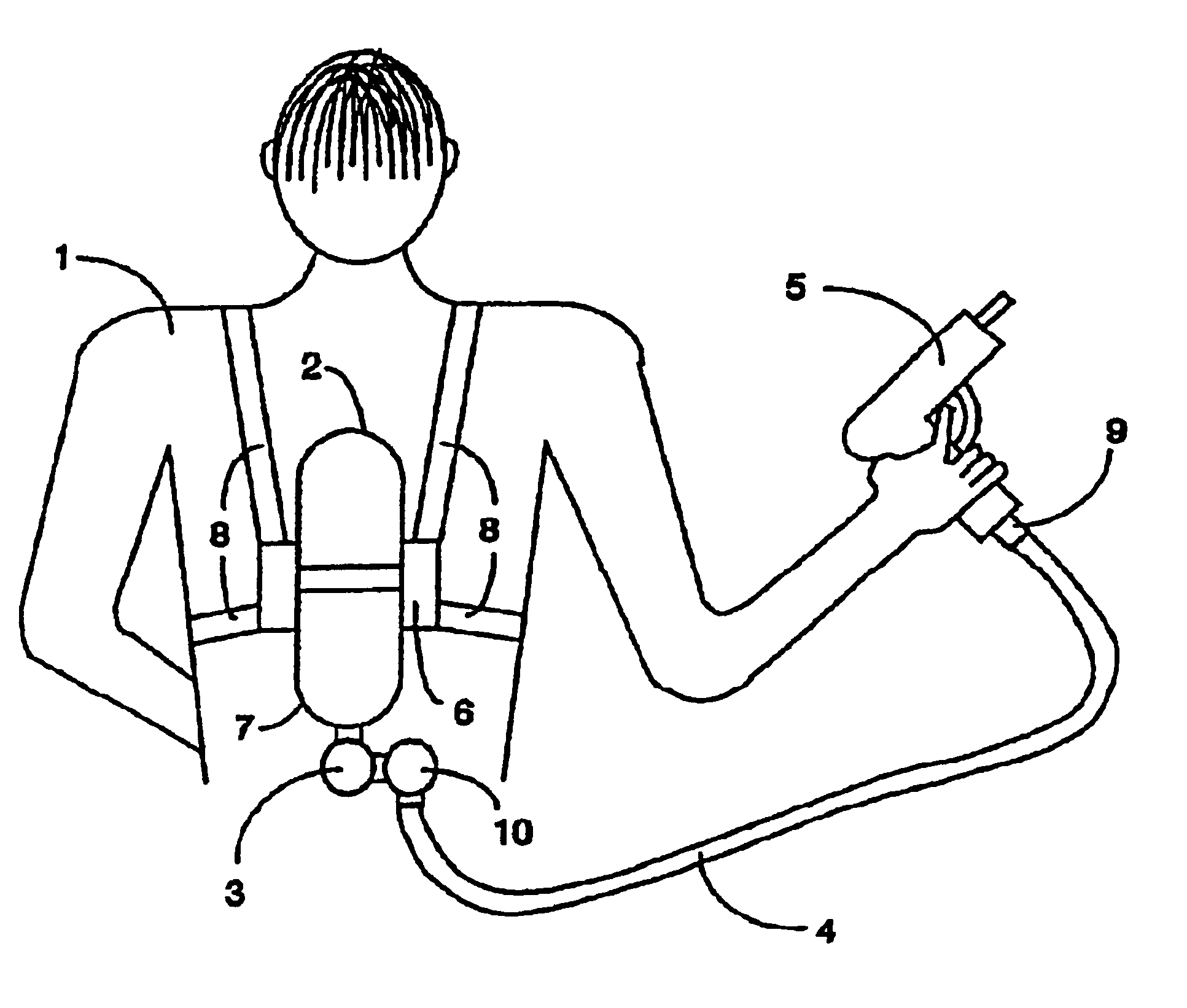

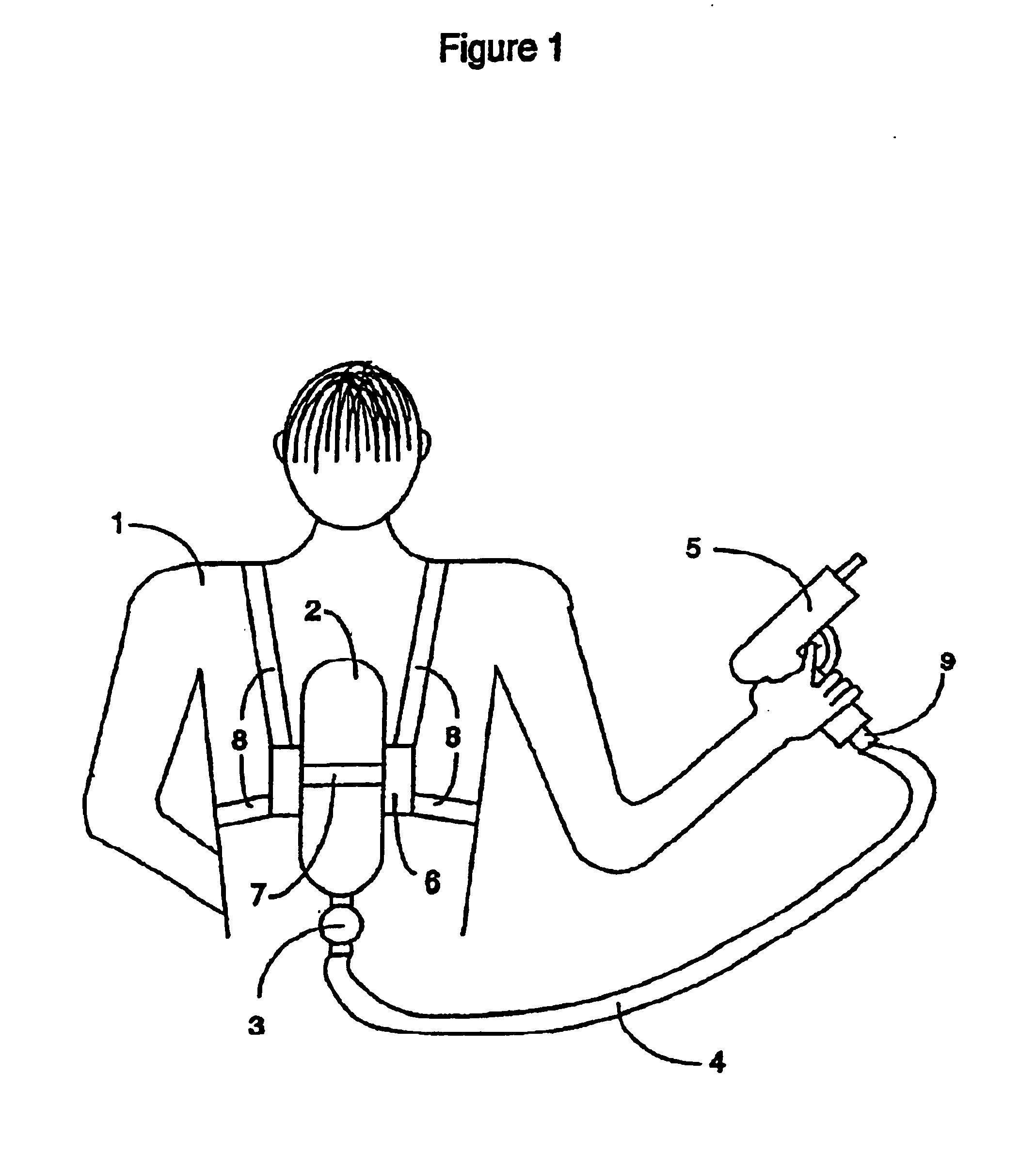

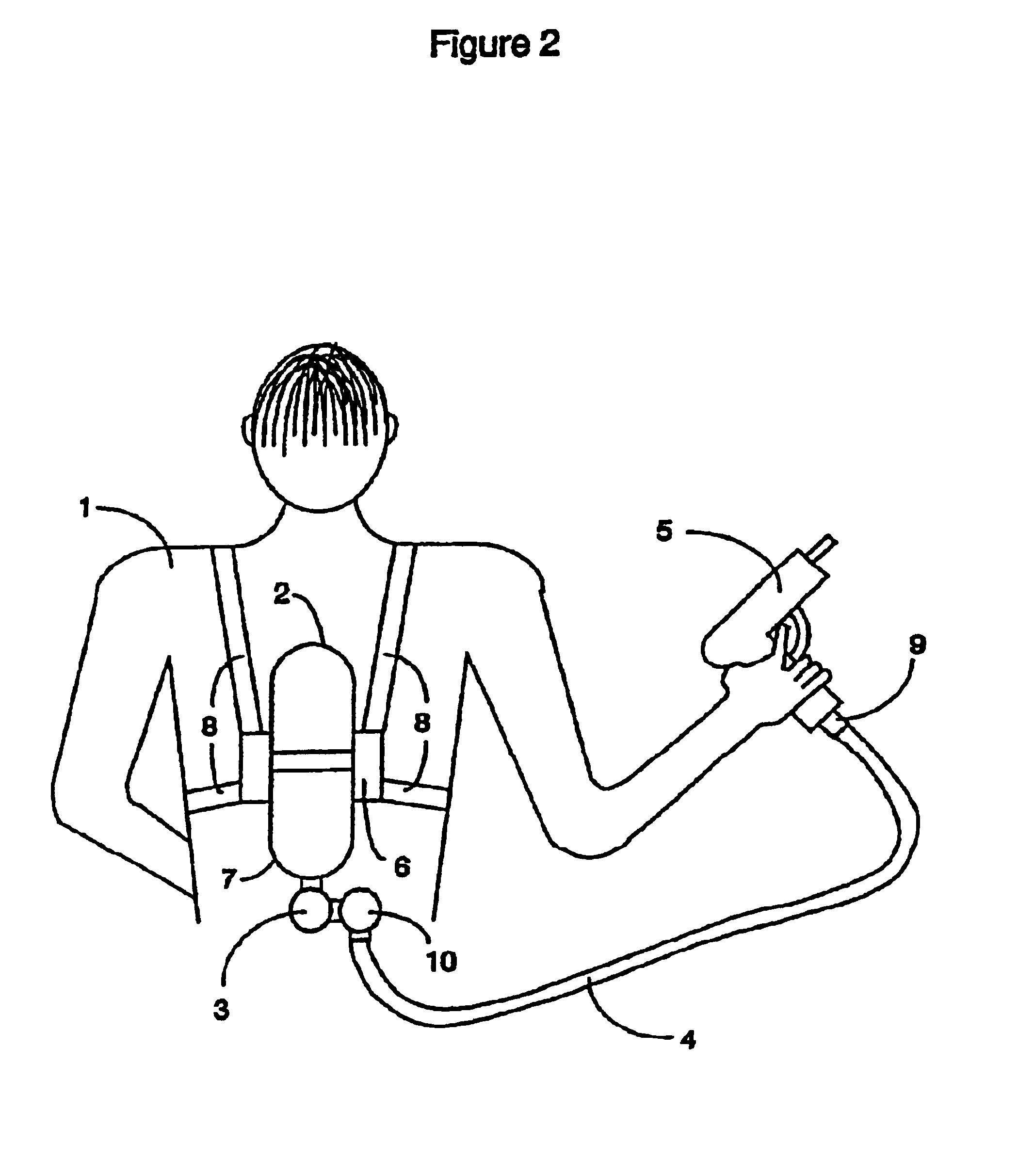

Apparatus and method for using a lightweight portable air/gas power supply

ActiveUS6932128B2Easily and quickly refilledHigh pressure levelTravelling sacksLiquid fillingFiberMulti-valve

A lightweight carbon fiber air / gas supply vessel storing high pressure air / gas. The air / gas supply vessel output is controlled by an adjustable pressure reduction valve which varies output pressure from very high to low pressure levels. An alternative multi-valve system uses a first pressure reduction valve to reduce output pressure from the very high levels in the air / gas supply vessel to an intermediate pressure level, and a second pressure reduction valve that reduces the air / gas pressure from the intermediate level to a fine tunable low pressure level. In both embodiments, the output of the last pressure reduction valve used is connected to a high pressure cable which in turn uses a standard universal fitting which can be coupled to most pneumatically powered equipment. Additional high pressure reservoir vessels can be used to replenish the lightweight air / gas supply vessel when its supply of air / gas is depleted.

Owner:SPEED AIR SYST

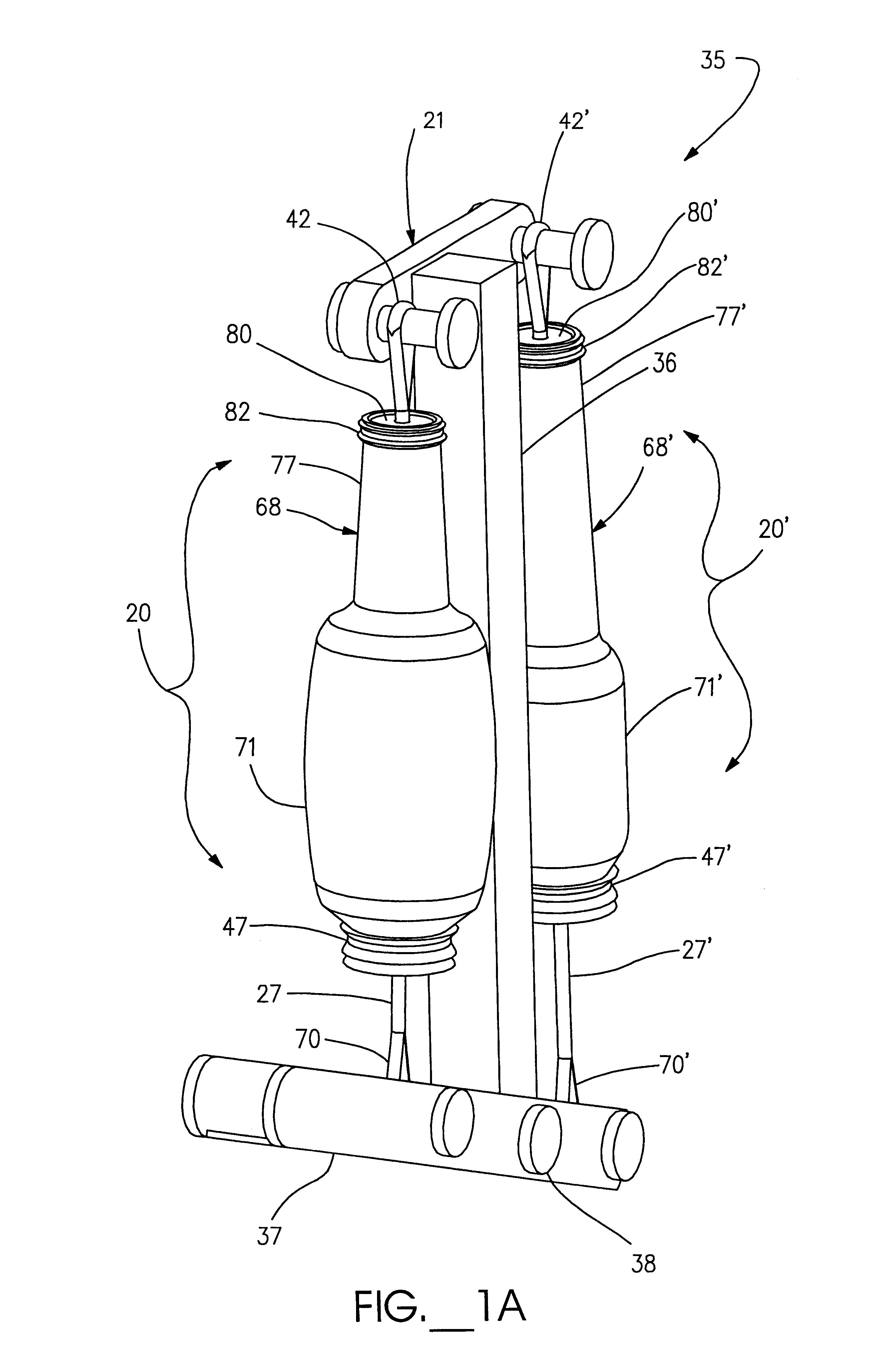

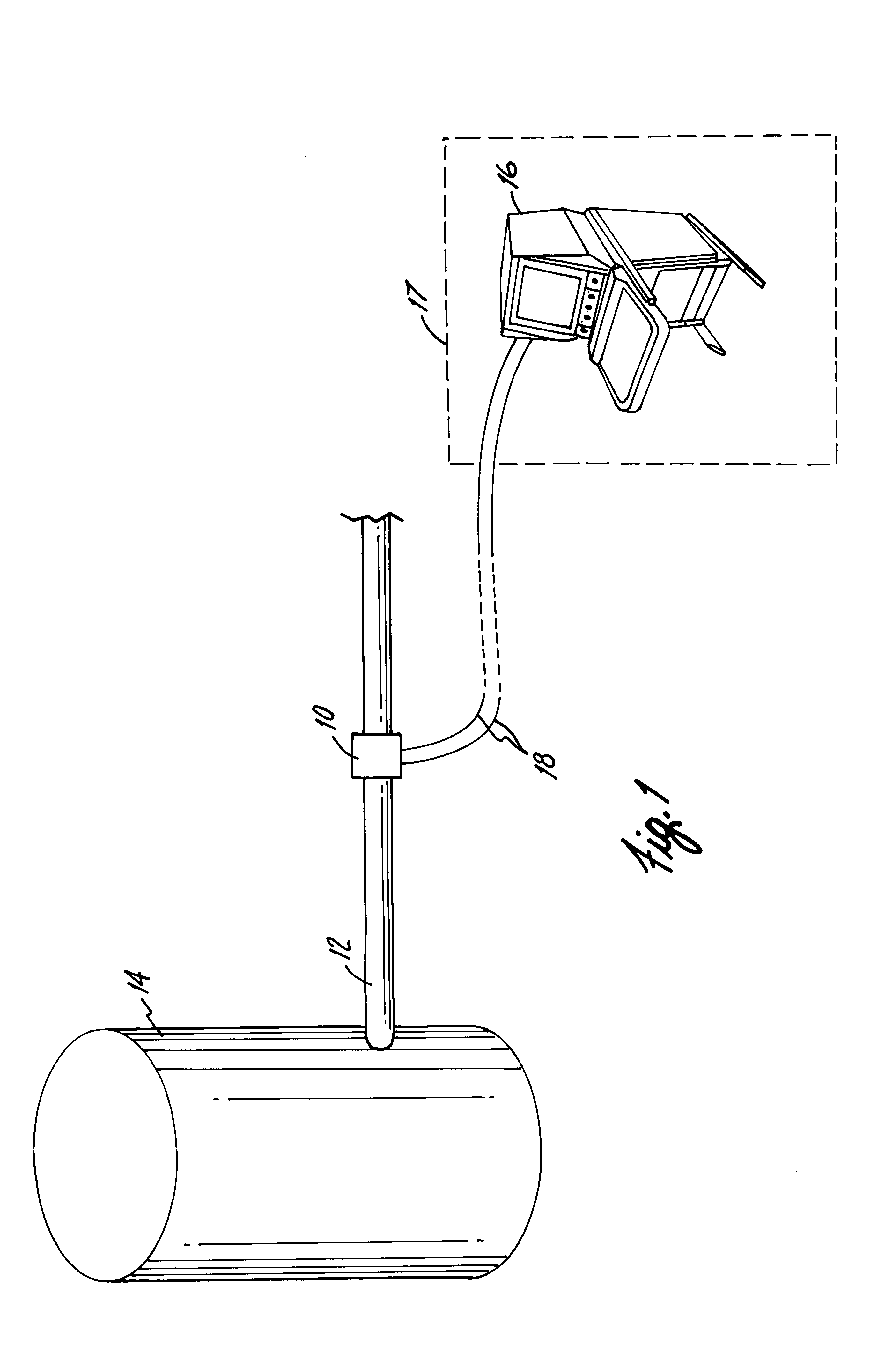

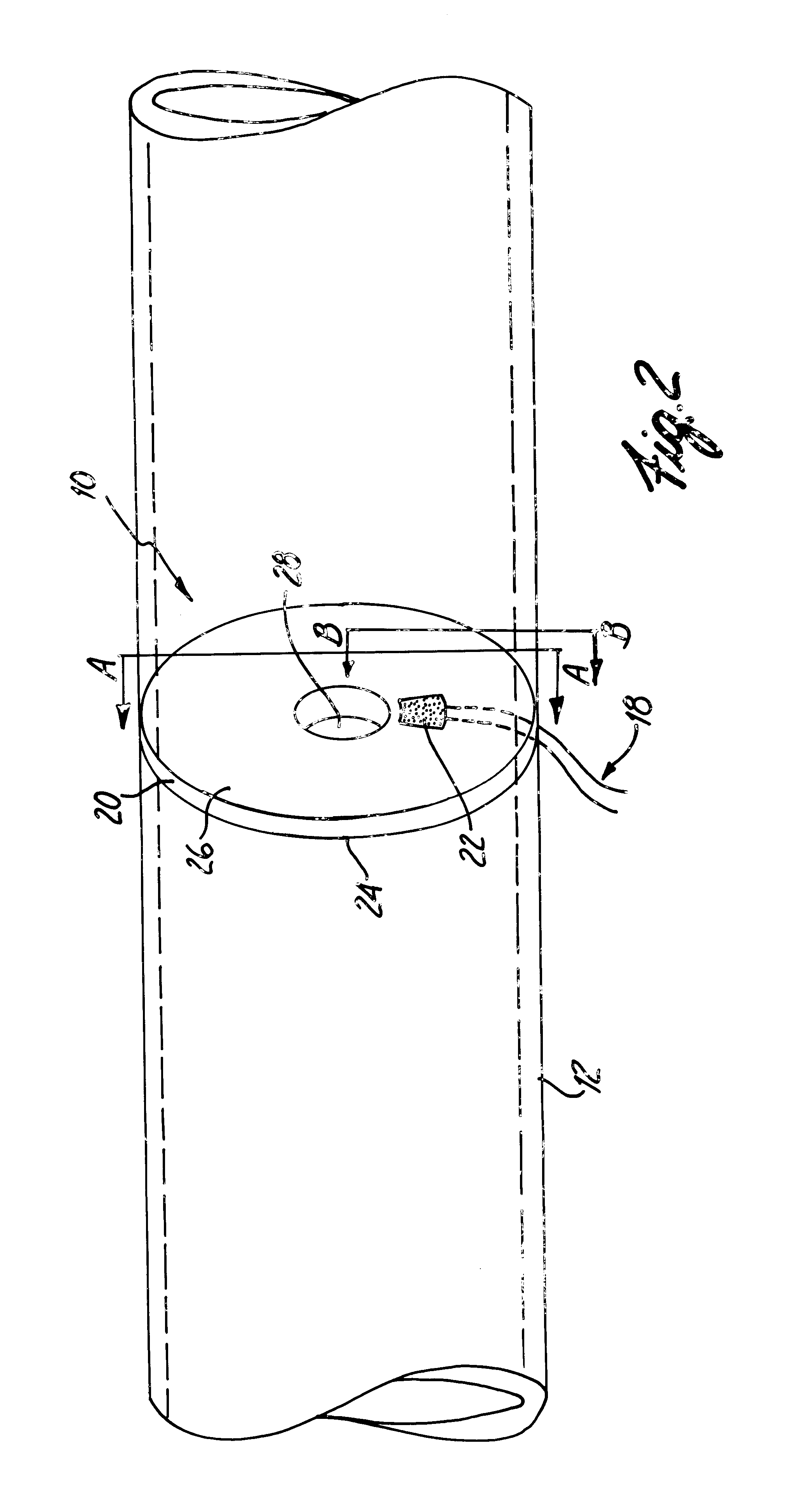

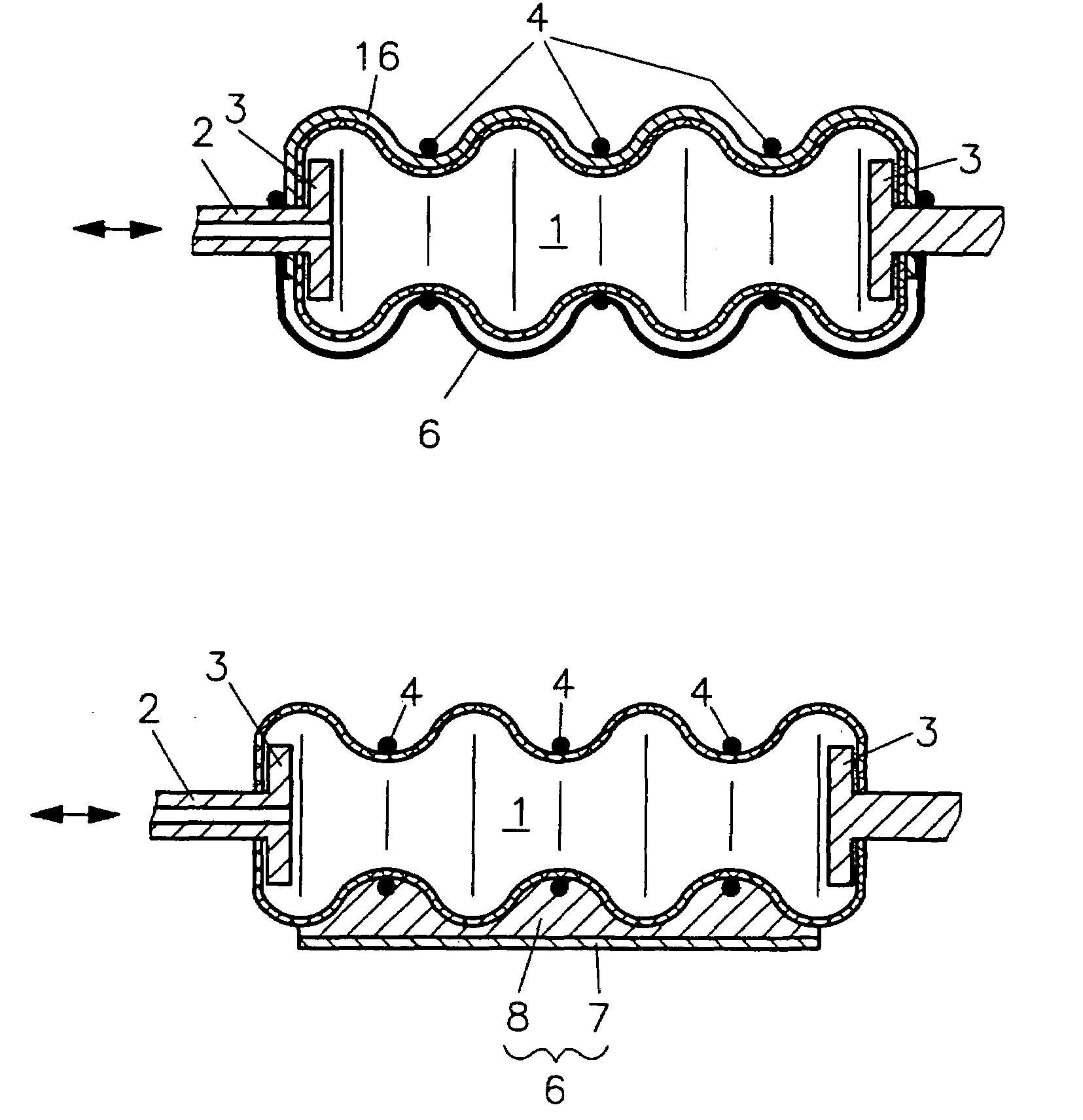

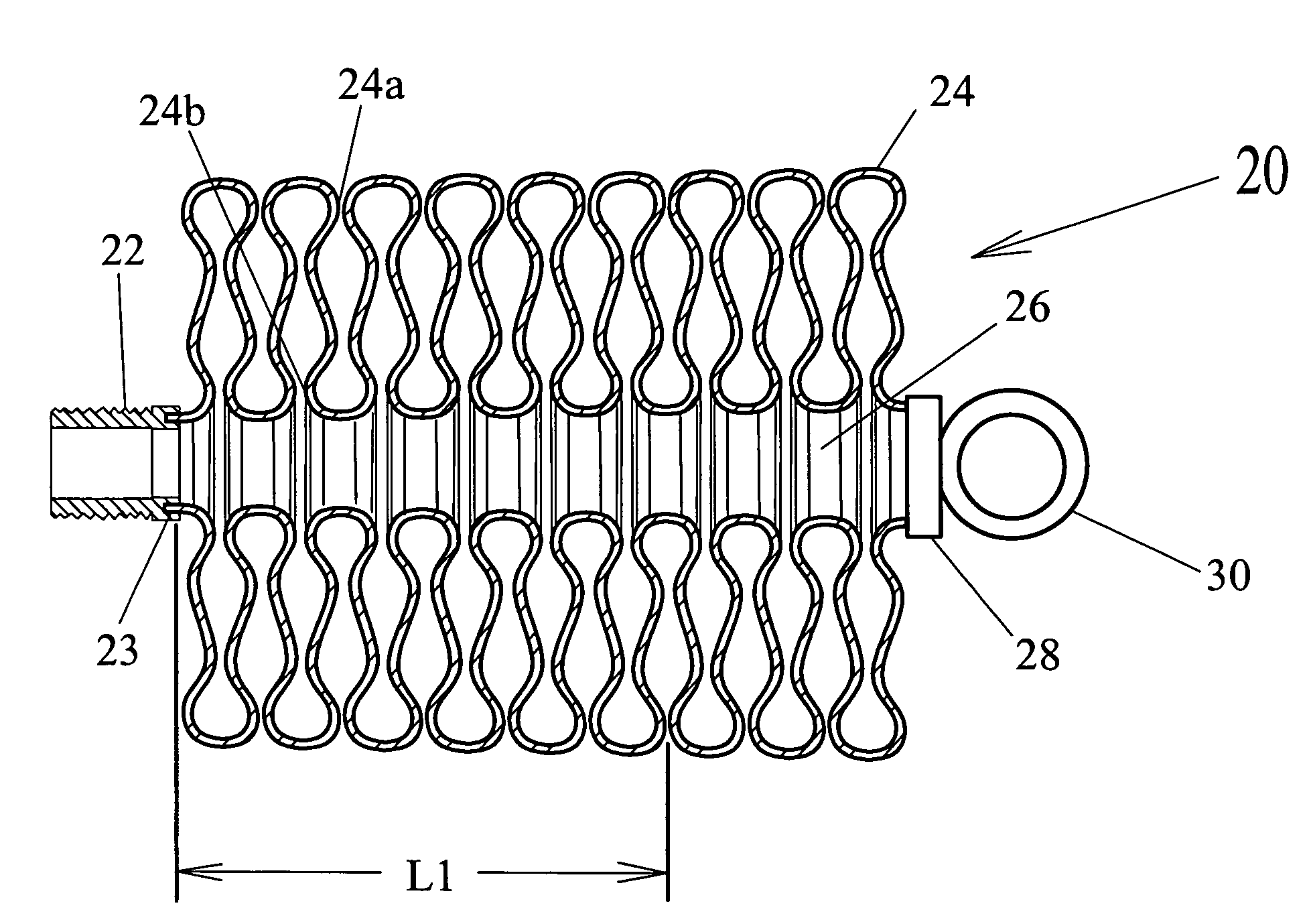

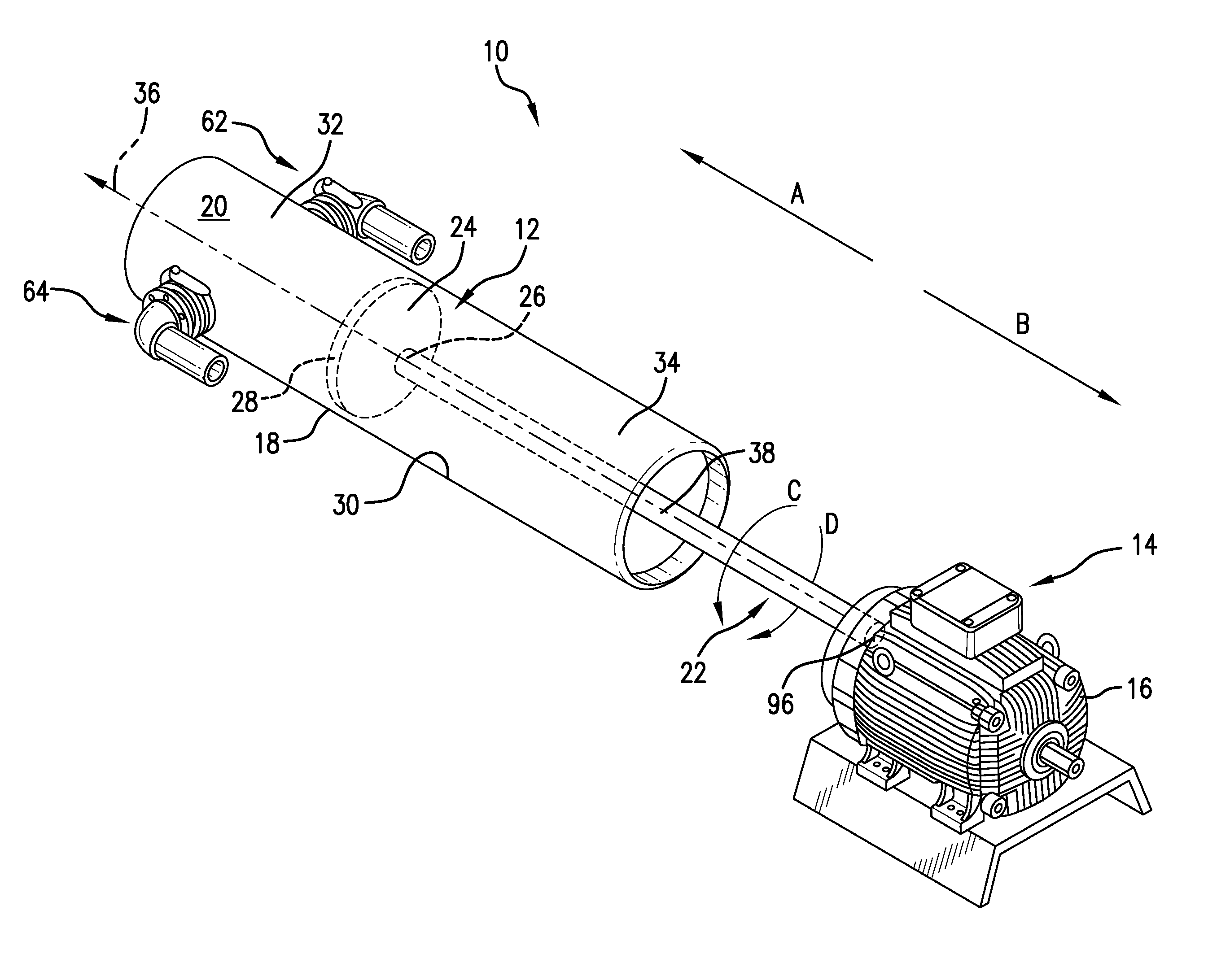

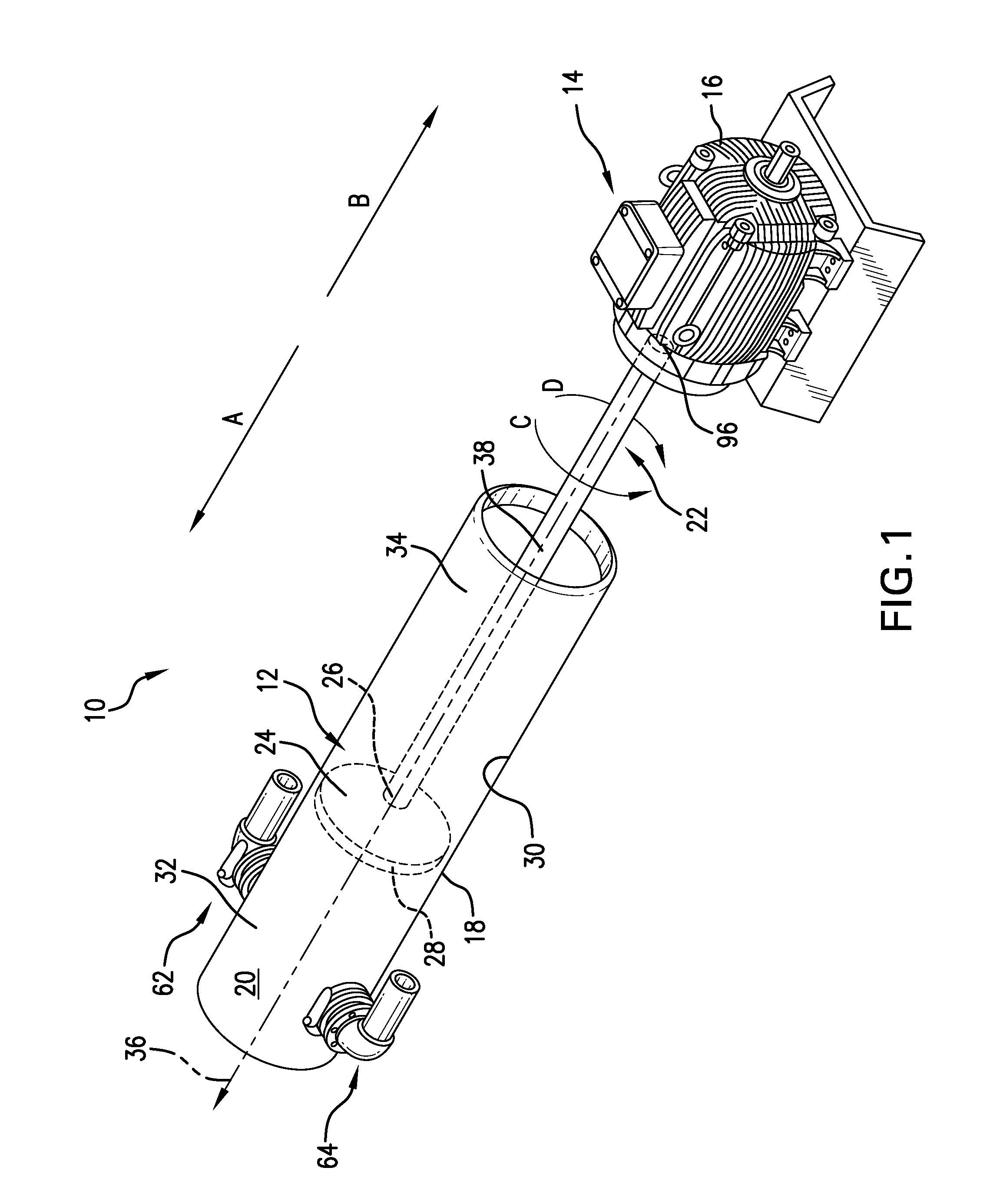

Flexible hydraulic muscle

A flexible hydraulic muscle (20) comprising a fluid port (22), bellow (24), end seal (28) and attachment ring (30). Bellow (24) also defines a retracting spring bias for generating contracting forces within muscle (20). Fluid port (22) is designed to provide an anchor point for the muscle, while at the same time, providing a means to introduce and remove hydraulic fluid from bellow (24). End seal (28) and attachment ring (30) provide the second connecting point for the muscle. These two anchor points on each end of bellow (24) provide connection points to communicate contracting force from bellow (24) into useful work. End seal (28) is securely attached or bonded to the end of bellow (24) to provide a fluid tight seal, and designed to resist longitudinal forces on the connection.

Owner:RAGNER GARY DEAN

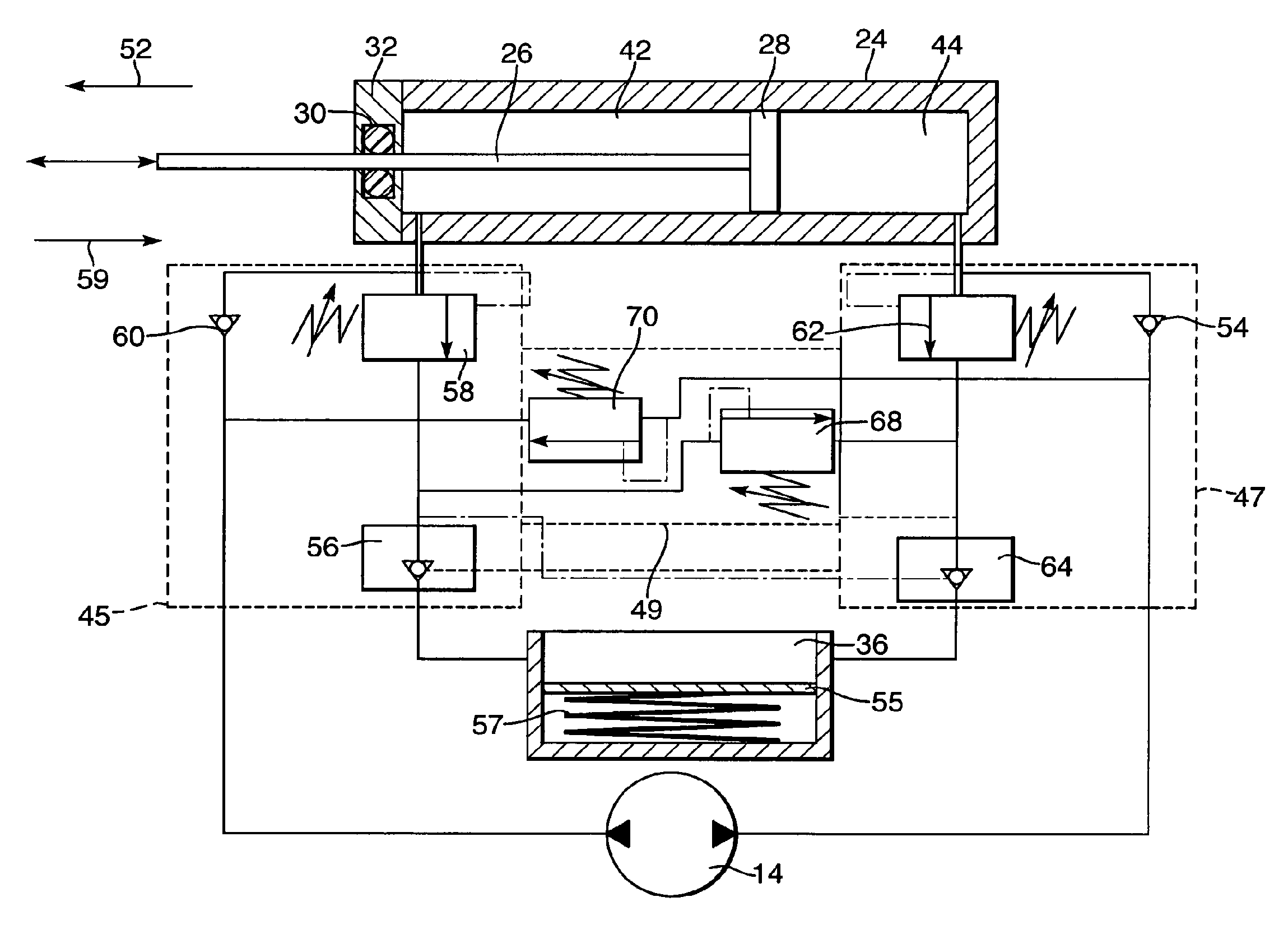

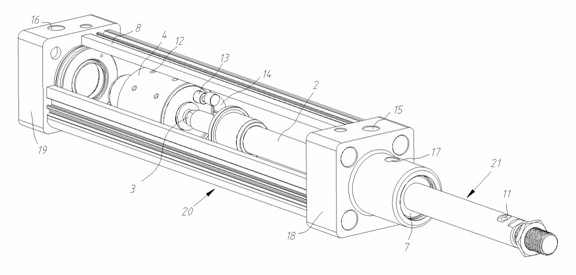

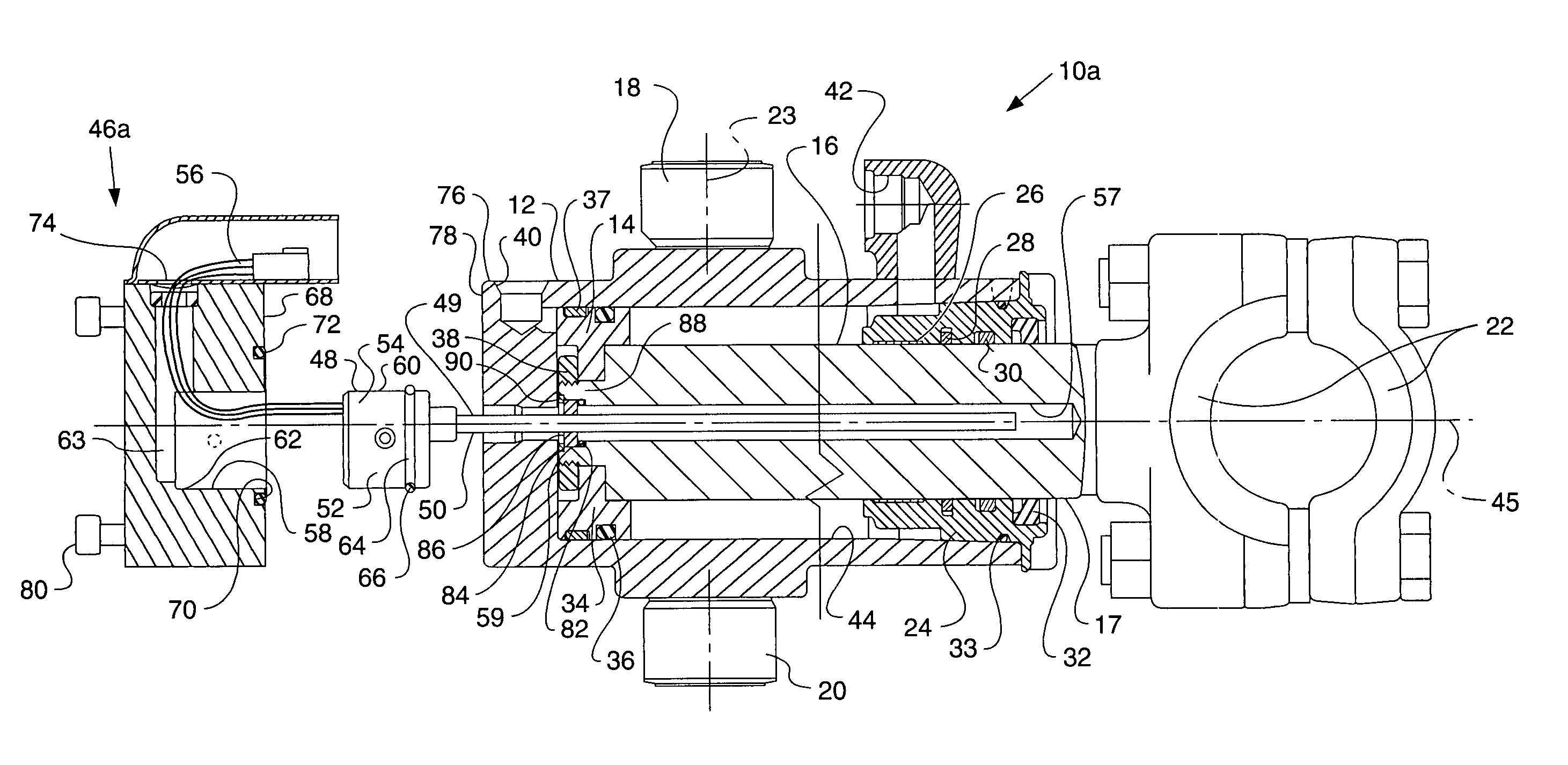

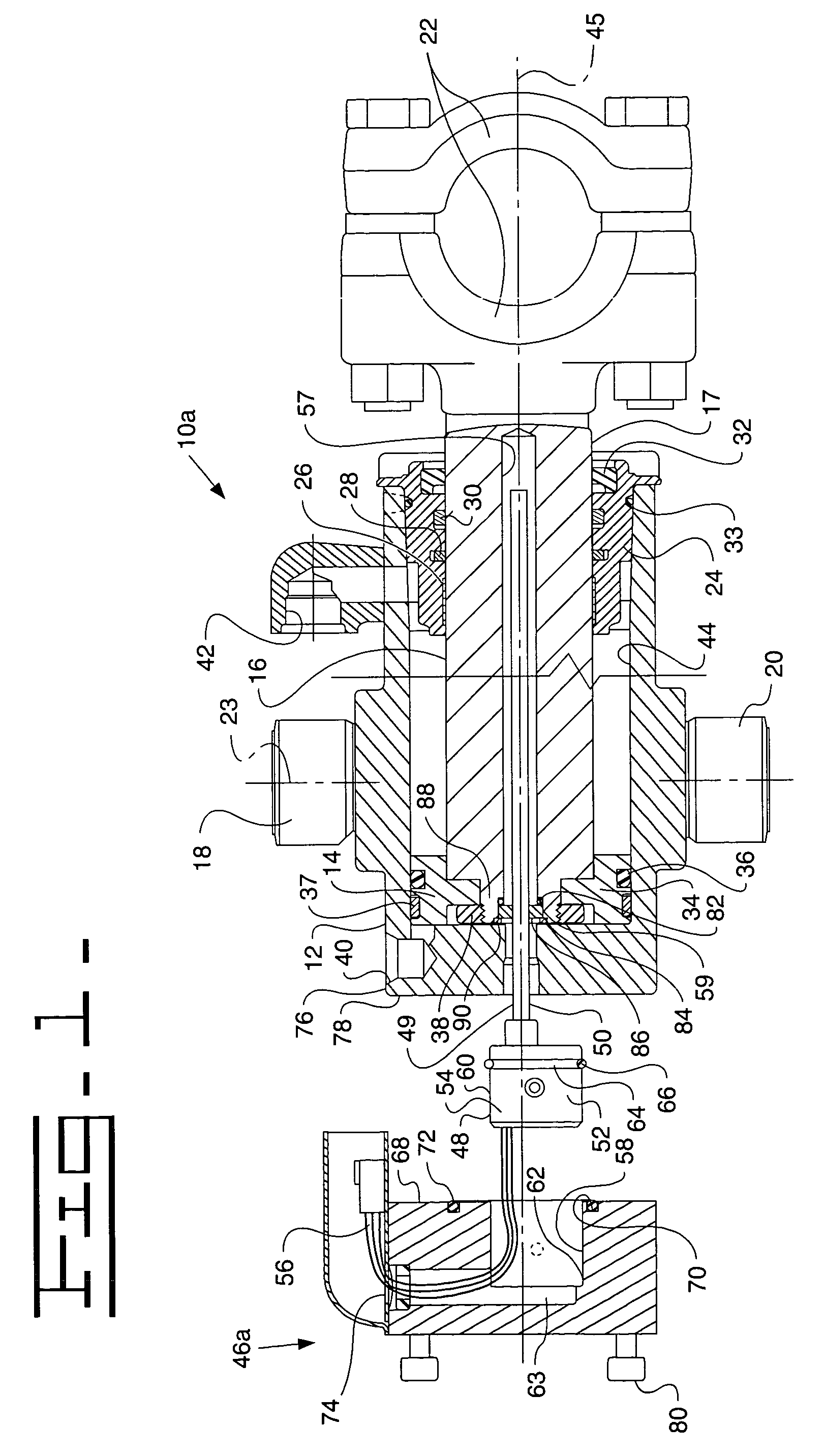

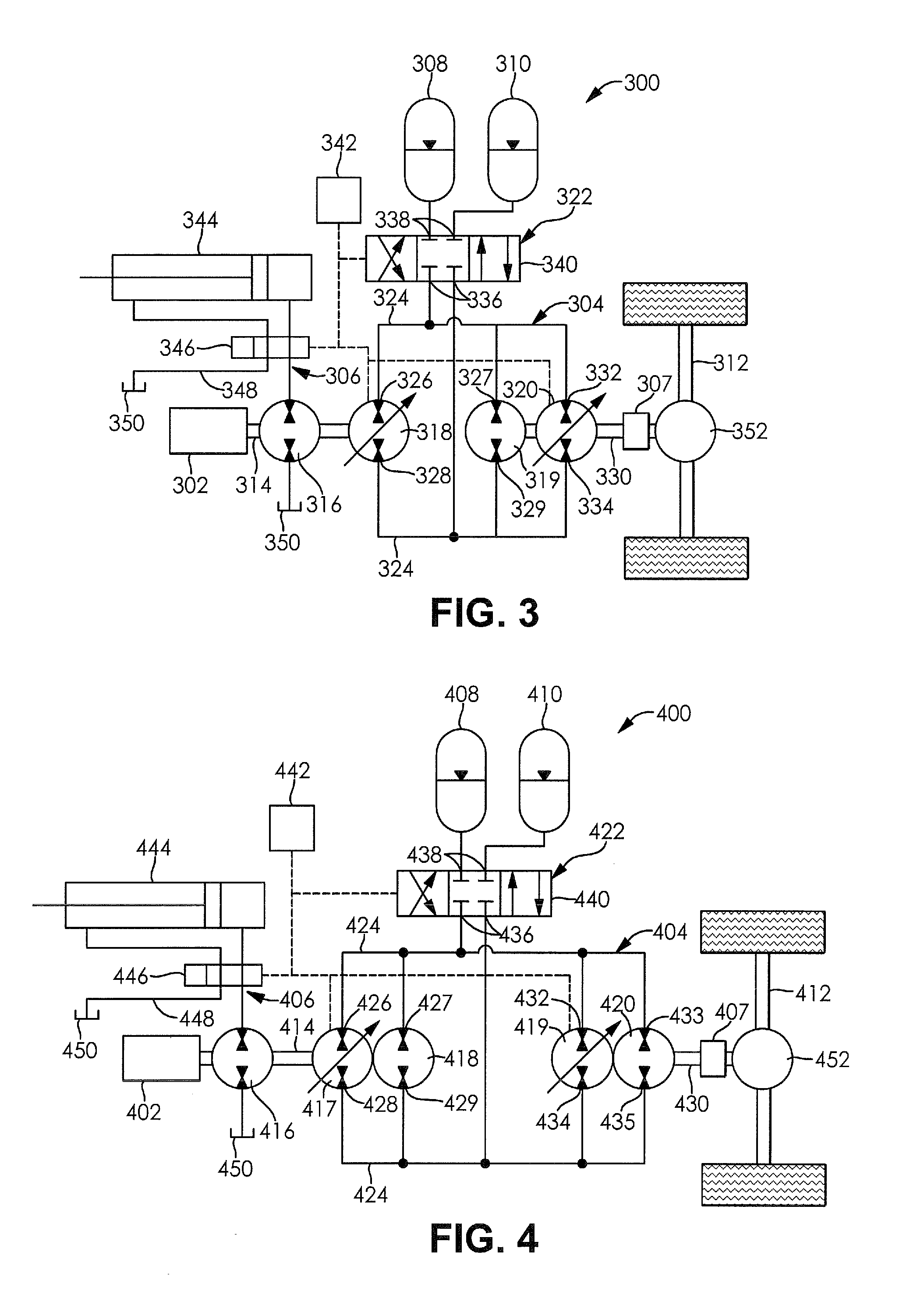

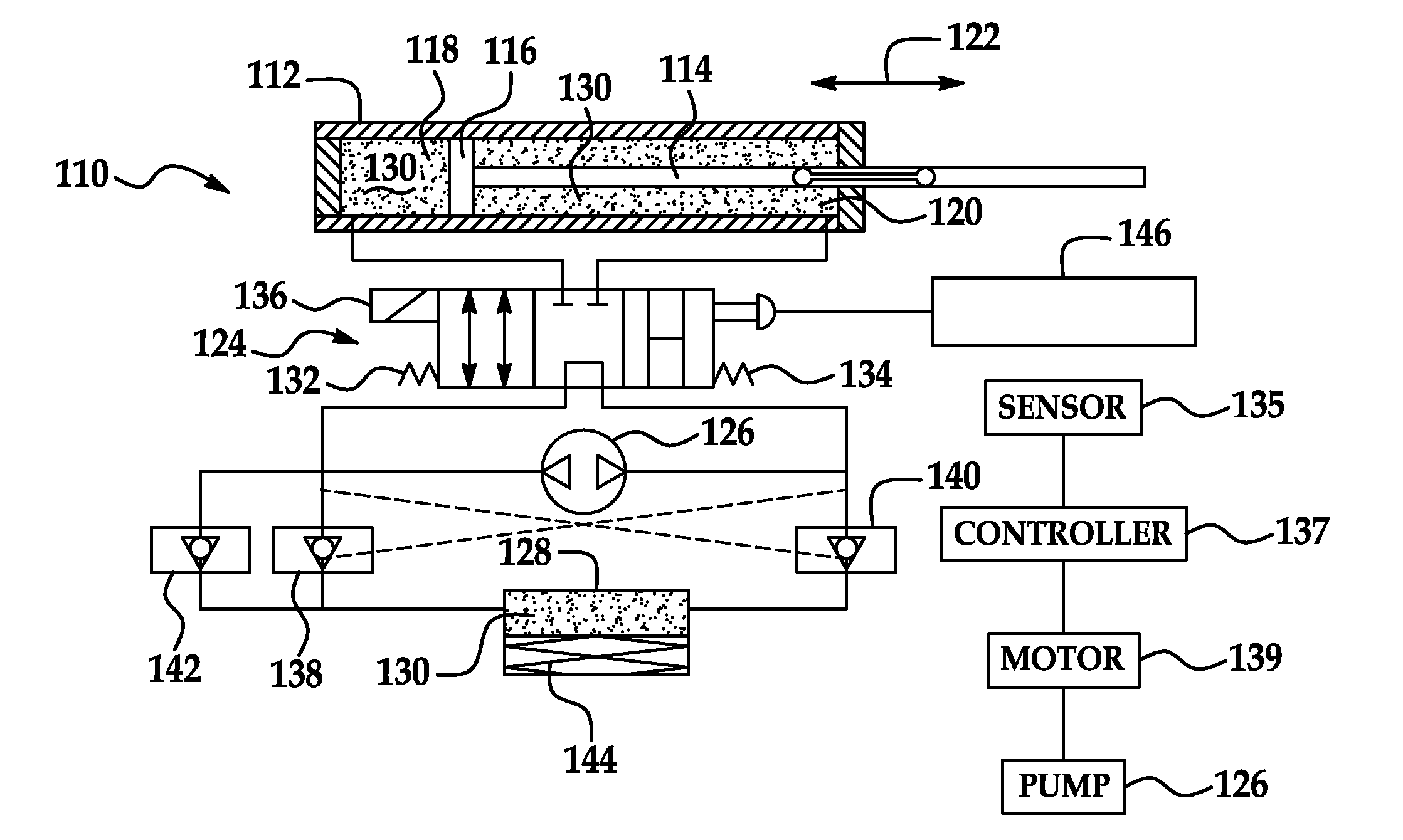

Apparatus and method for dual mode compact hydraulic system

InactiveUS20080022672A1Preventing fluid communicationFluid couplingsAccumulator installationsMode controlDual mode

A dual mode hydraulic actuator, comprising: a housing; a rod secured to a piston, the rod and piston being slidably received within the housing; a first chamber positioned on one side of the piston; a second chamber positioned on another side of the piston; a sealed reservoir; a fluid disposed in the first chamber, the second chamber and the reservoir; a bidirectional pump for moving the fluid between the first chamber, the second chamber and the sealed reservoir; a bi-mode control valve for providing selective fluid communication between the first chamber, the second chamber and the sealed reservoir, wherein the bi-mode control valve is spring biased into a neutral position wherein fluid communication between the first chamber, the second chamber and the sealed reservoir is prevented; and wherein the bi-mode control valve is capable of being manually manipulated into a manual mode position wherein fluid flow from the first chamber to the second chamber is provided and fluid flow from or to the sealed reservoir is also provided, the fluid flow from or to the sealed reservoir being dependant upon a volume of fluid in the first chamber and the second chamber.

Owner:STRATTEC POWER ACCESS

Zero-friction air cylinder with air bearing

InactiveCN102155465AReduce frictionIncrease the itineraryFluid-pressure actuatorsAir bearingEngineering

The invention discloses a zero-friction air cylinder with an air bearing. The zero-friction air cylinder comprises the air bearing and a piston, wherein the air bearing is matched with the piston rod; the piston is designed according to an air-float principle; and the zero-friction support of a moving part and a fixed part of the air cylinder can be realized by the air-float bearing and the piston, namely a high-pressure air film is formed at a contact surface to isolate two surfaces which are supported mutually. Air is provided for the piston in the inner part of the air cylinder by the zero-friction air cylinder through the hollow piston rod and a soft pipe, and spherical hinge connection is applied, thus the zero-friction air cylinder can bear certain radial loading, and the piston is not stuck in the air cylinder; by the zero-friction air cylinder provided by the invention, the friction of the air cylinder is reduced greatly, greater stroke can be realized without lubrication and sealing, the radial force in a certain range can be borne, and the structure is simple and is convenient to maintain.

Owner:ZHEJIANG UNIV

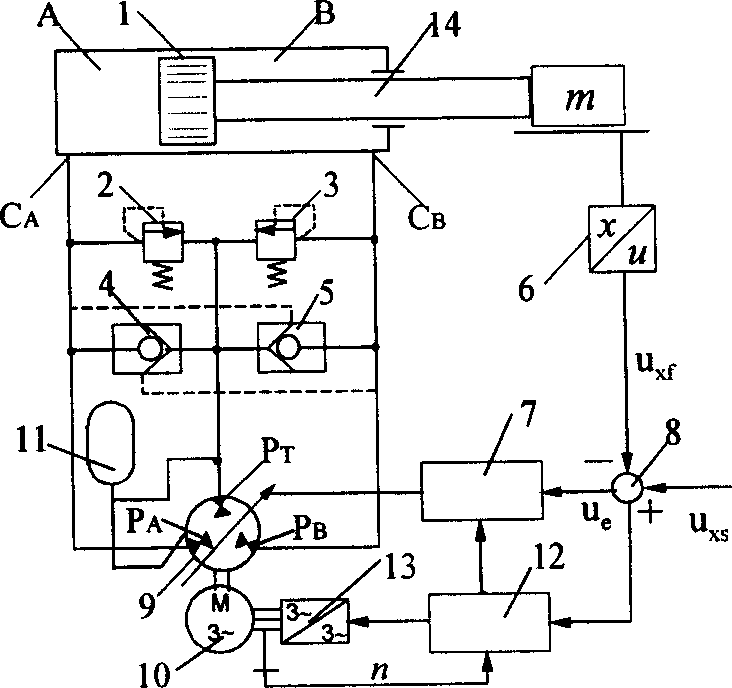

Closed electrohydraulic controlling system

InactiveCN1818382AControl movementPromote sportsFluid-pressure actuatorsPump controlHydraulic cylinderControl system

A closed electro-hydraulic control system comprised a differential hydraulic cylinder, two safety valves, a small path fluid one-way valve, a displacement transducer, a subtractor, two controllers, a hydraulic pump, a prime motor, a low-pressure oil-supply system and a rotational speed governor. The hydraulic pump has three oil ports connected with a rod-free cavity, a rod cavity of the differential hydraulic cylinder and the low-pressure oil-supply system separately.

Owner:TAIYUAN UNIV OF TECH

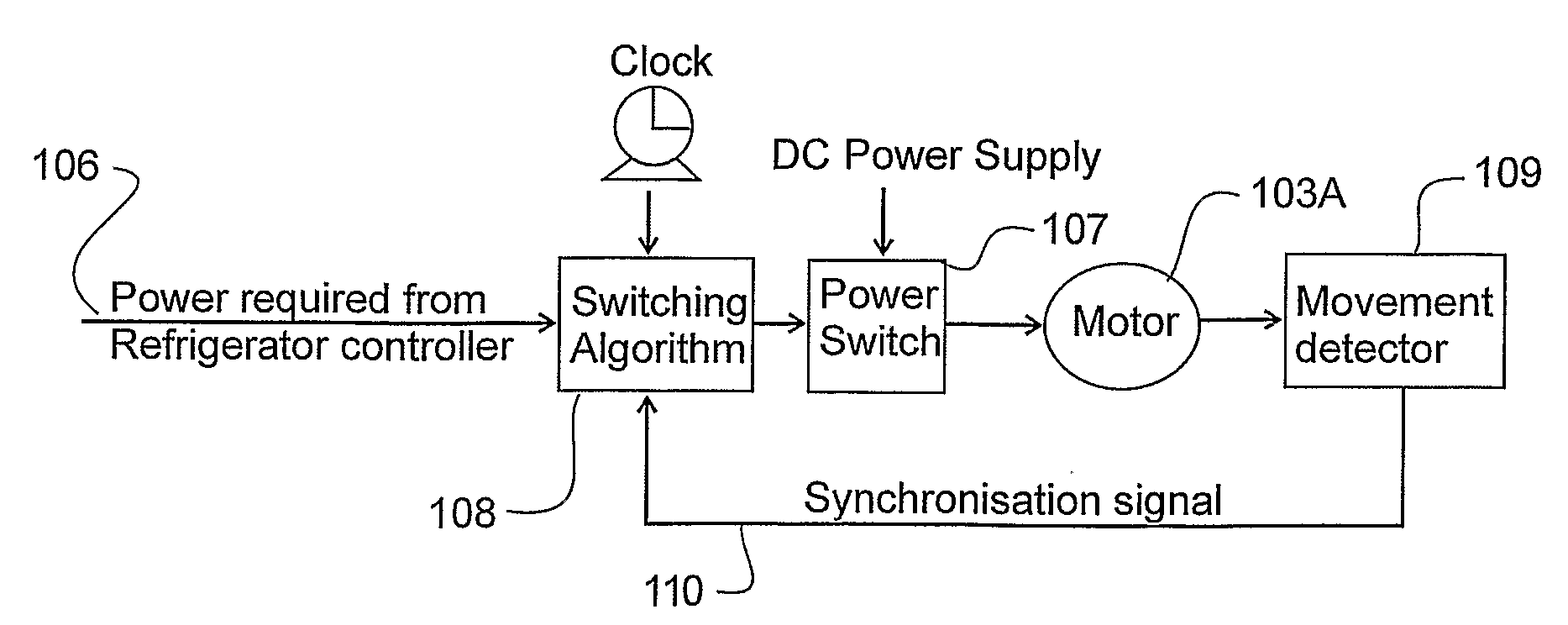

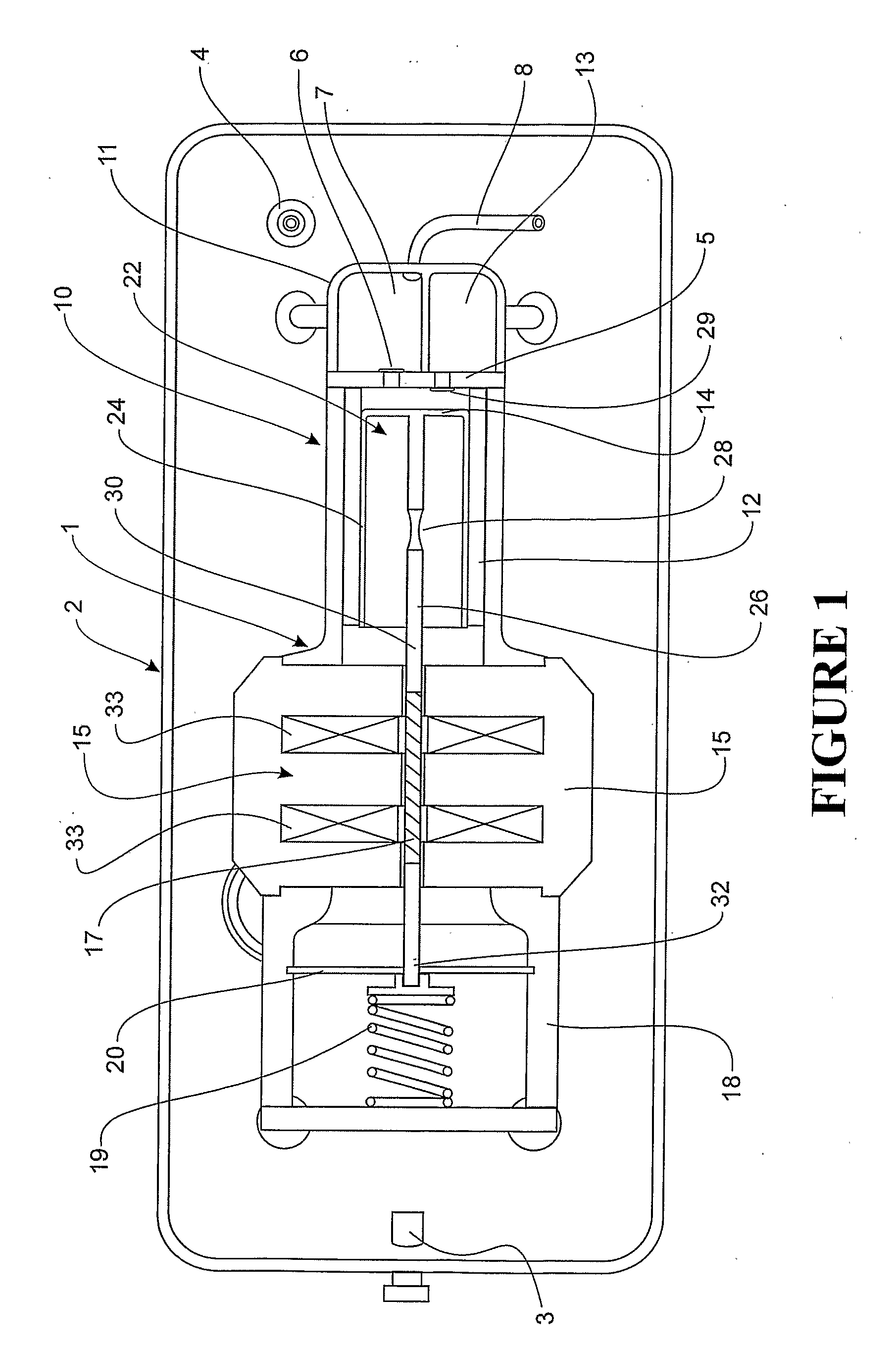

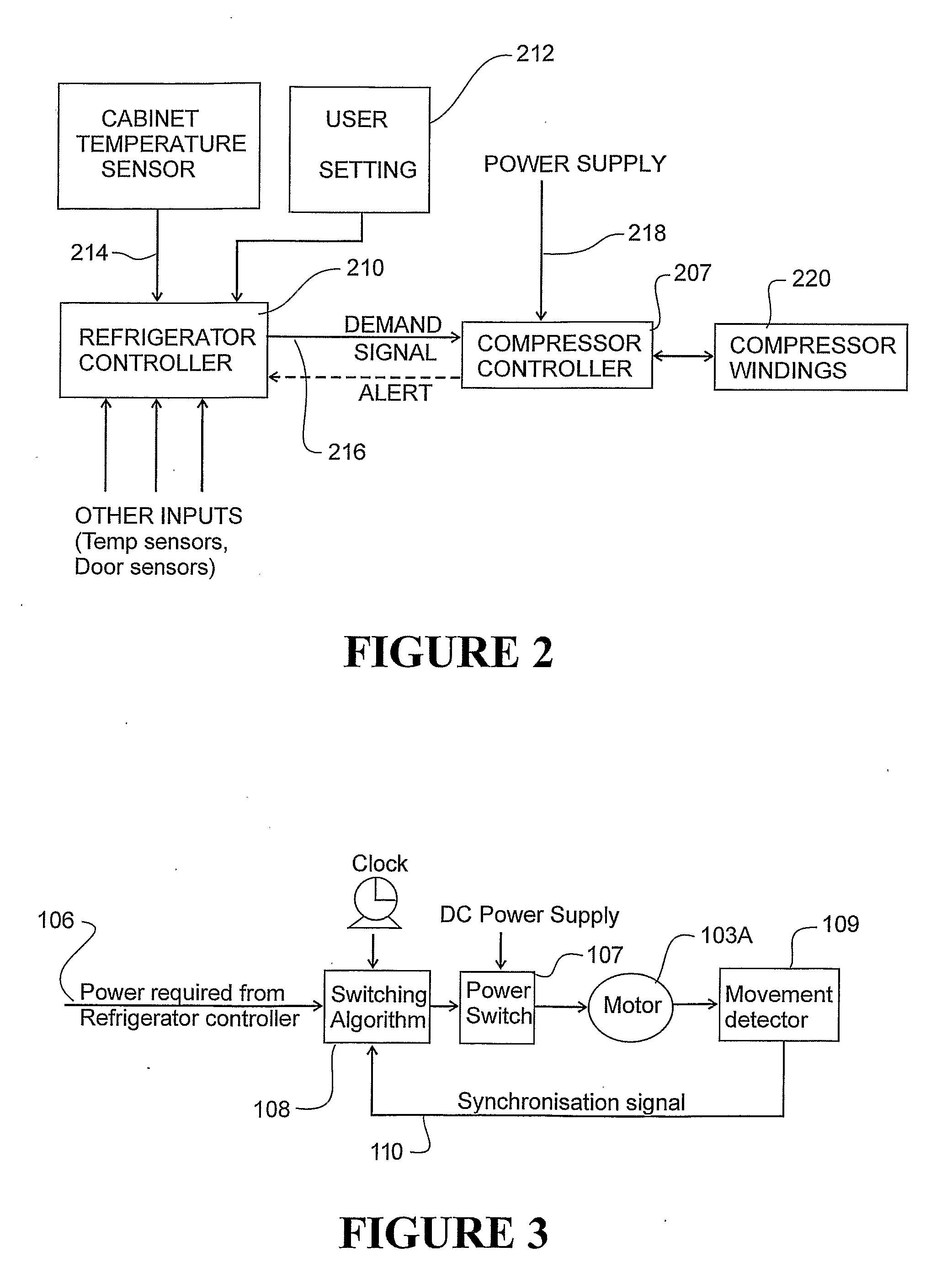

Linear compressor controller

ActiveUS20090081049A1Reduce stepsReduce total powerExternal parameterFluid-pressure actuatorsLower limitLinear compressor

A control for a linear compressor energises the linear motor in harmony with the present natural frequency of the compressor. The controller monitors the present operating frequency and compares the frequency with one or more outer limit thresholds. The control may remove power from the linear motor if the running frequency drops below a lower threshold. The control may reduce power to the linear motor if the running frequency rises above an upper threshold. The control uses compressor running frequency to operate the comperssor within safe operating limits.

Owner:FISHER & PAYKEL APPLIANCES LTD

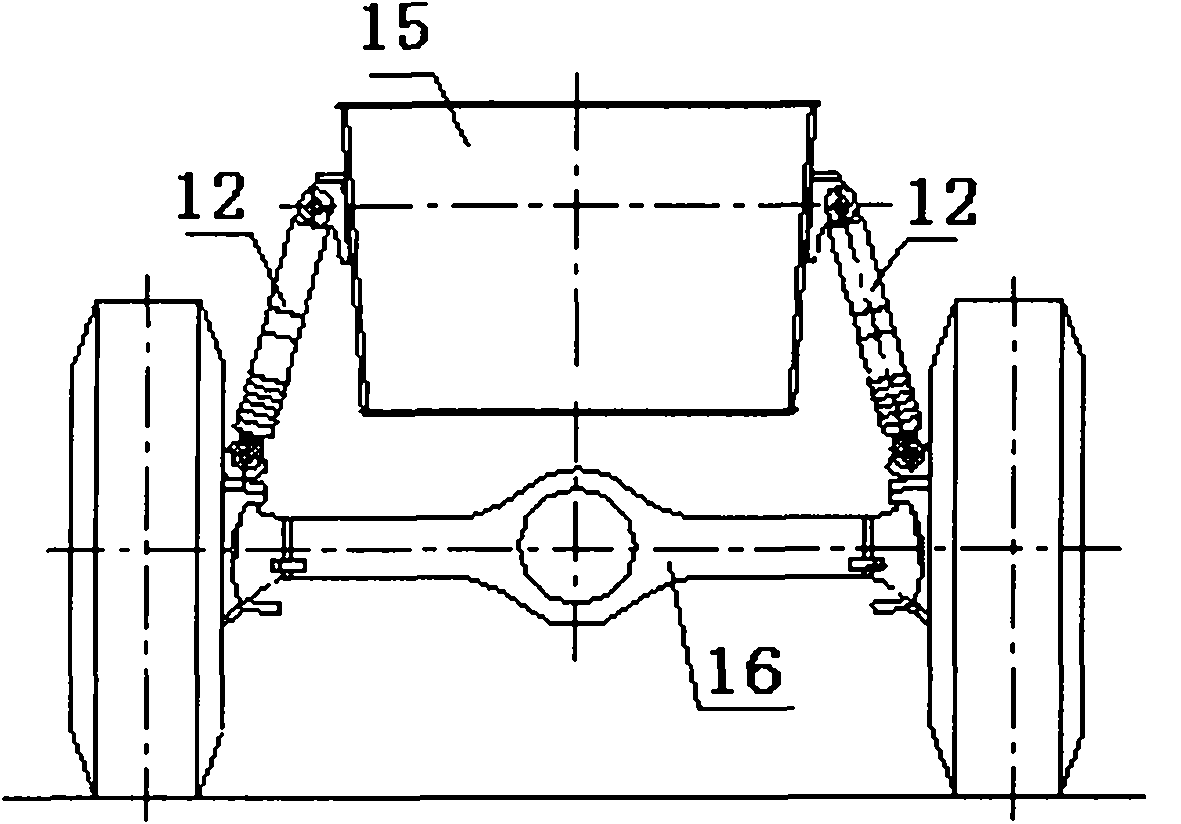

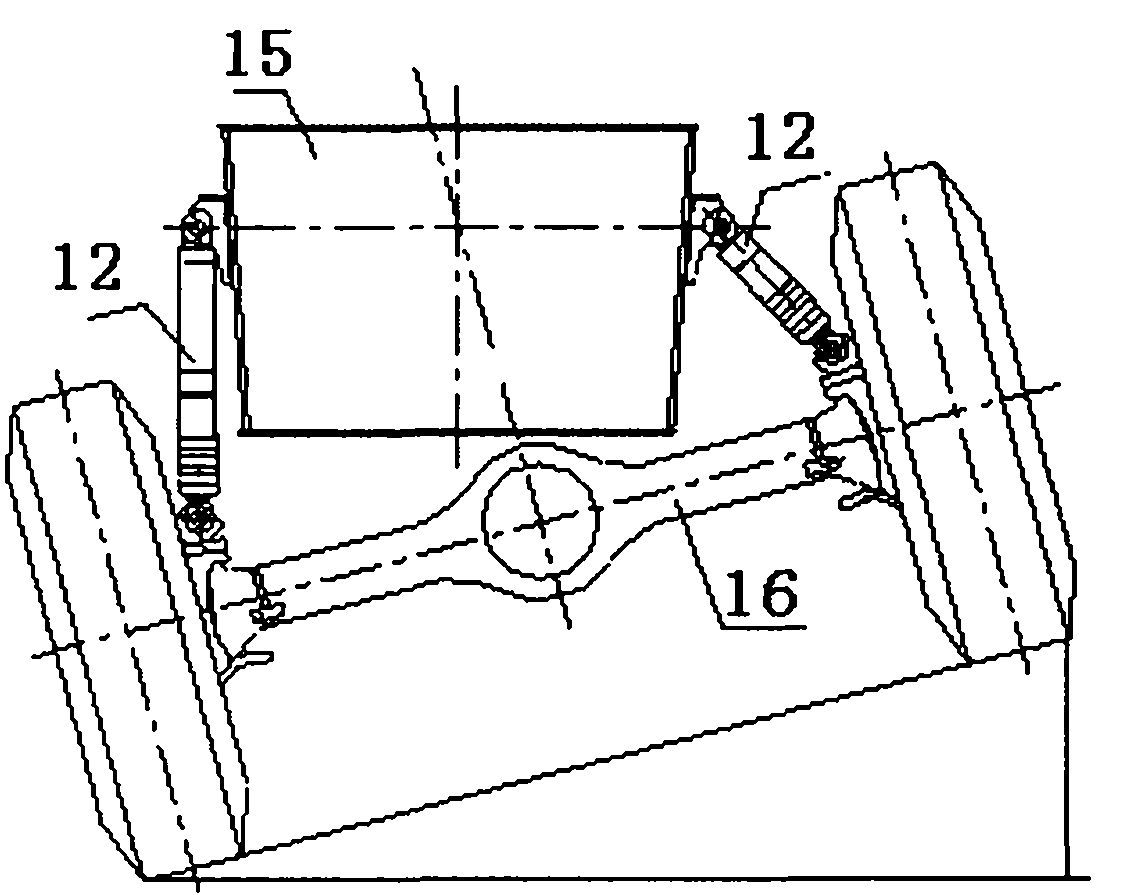

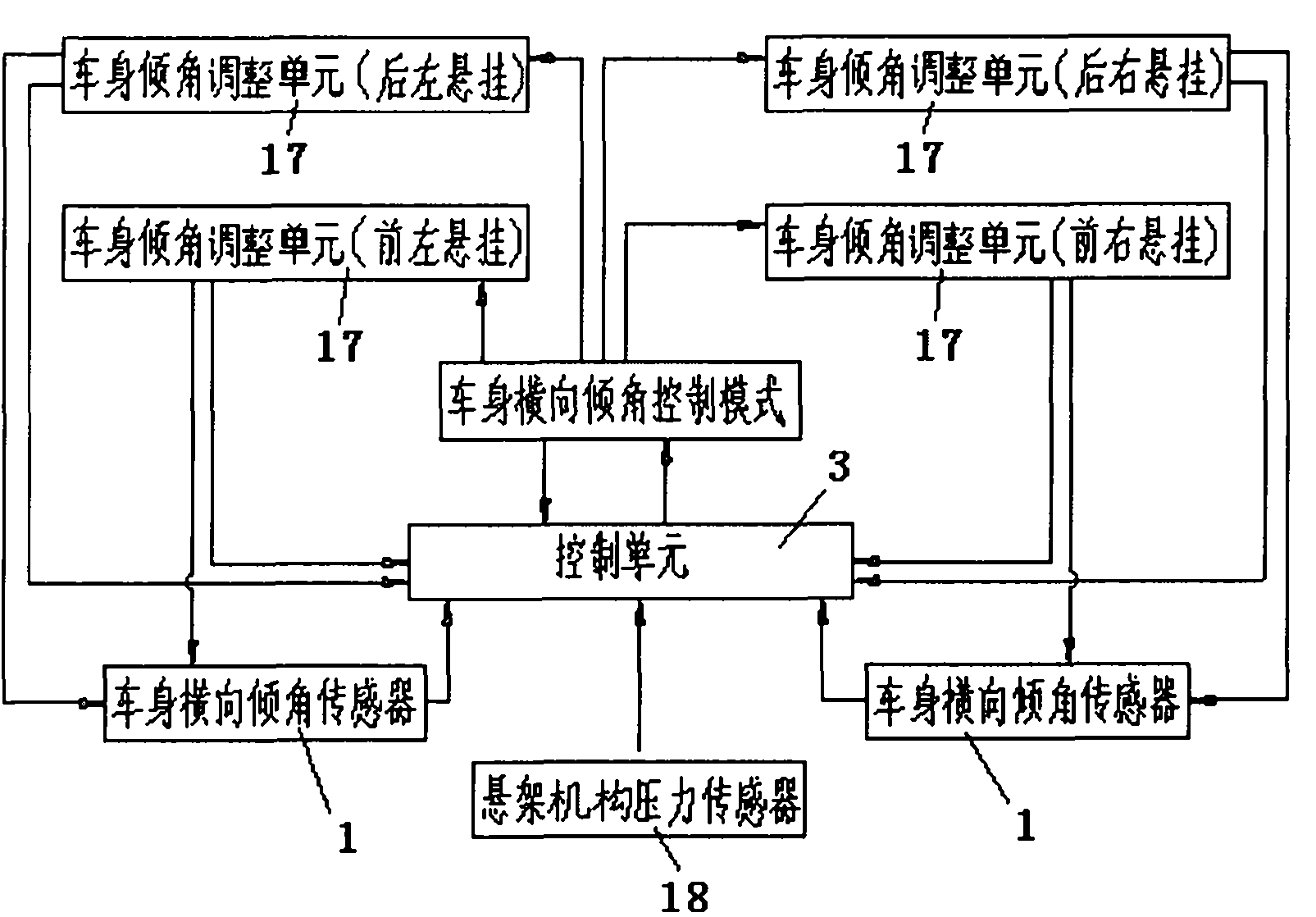

Vehicle body dip angle adjusting unit, oil gas suspension mechanism and mobile crane

ActiveCN102039791AEasy to operateLogicalFluid-pressure actuatorsInterconnection systemsHydropneumatic suspensionFuel tank

The invention relates to an automatic leveling oil gas suspension mechanism, which comprises at least two pairs of suspension oil cylinders (12), a vehicle body dip angle adjusting unit (17), a vehicle body traverse dip angle sensor and a control unit, wherein each suspension oil cylinder is provided with a vehicle body dip angle adjusting unit with a balanced oil cylinder (10) correspondingly; and one cavity of the balanced oil cylinder is connected to an oil tank (5) and a leveling operating oil source by a first one-way damper valve (8) and an electronic control switching valve (14), and the other cavity of the balanced oil cylinder (10) is connected to a rodless cavity of each suspension oil cylinder by an electronic control lockup valve (14) and a second one-way damper valve (9). In addition, the invention also provides a mobile crane with an automatic leveling oil gas suspension mechanism. The automatic leveling oil gas suspension mechanism realizes the function of dynamic leveling of various roads, particularly traverse rampways, of the mobile crane effectively, and is simple in operation and high in logicality; and the operation is completed automatically by the control unit, so the running safety is improved obviously, and accidents such as overturn and the like are prevented from occurring.

Owner:ZOOMLION HEAVY IND CO LTD

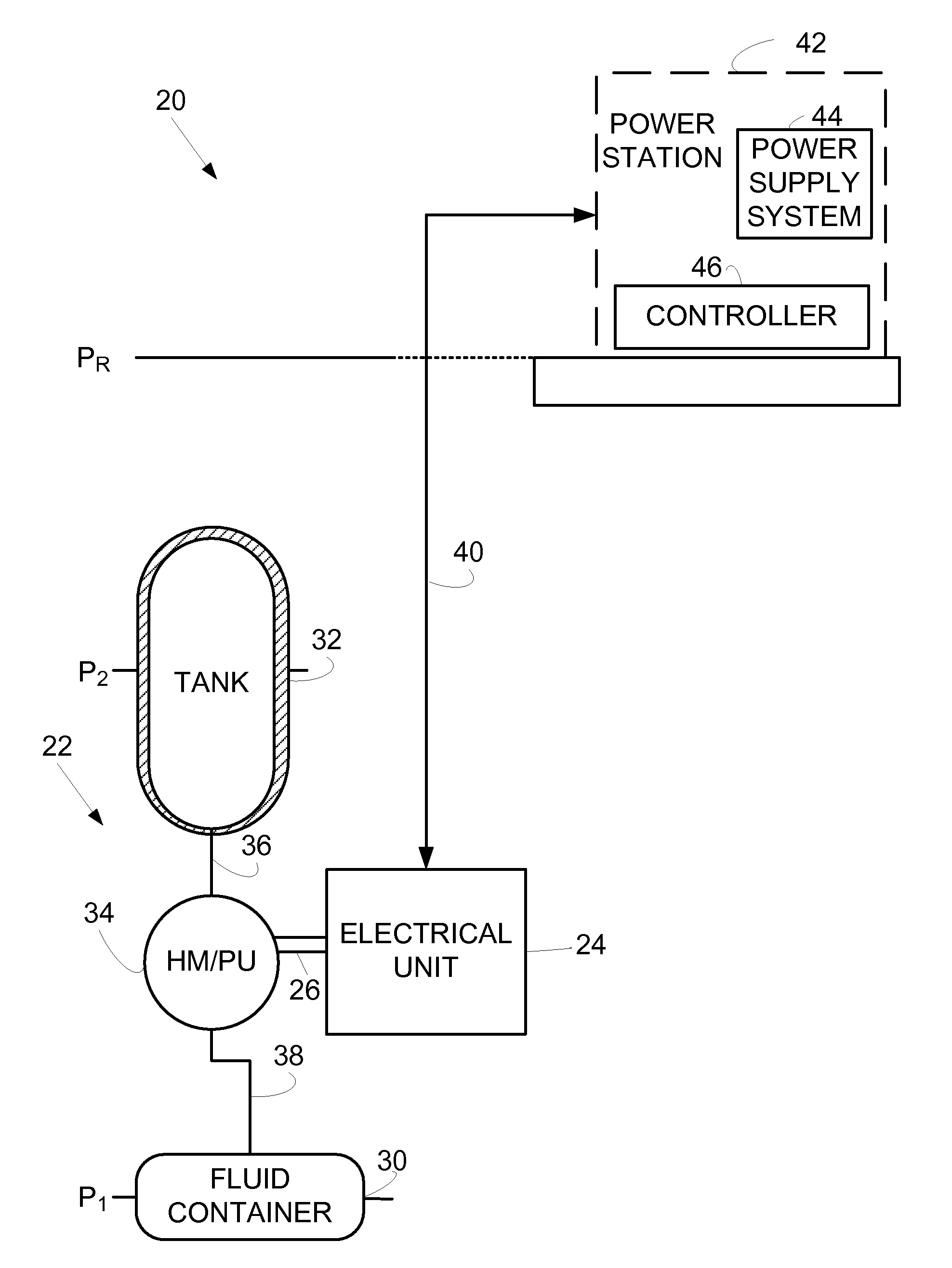

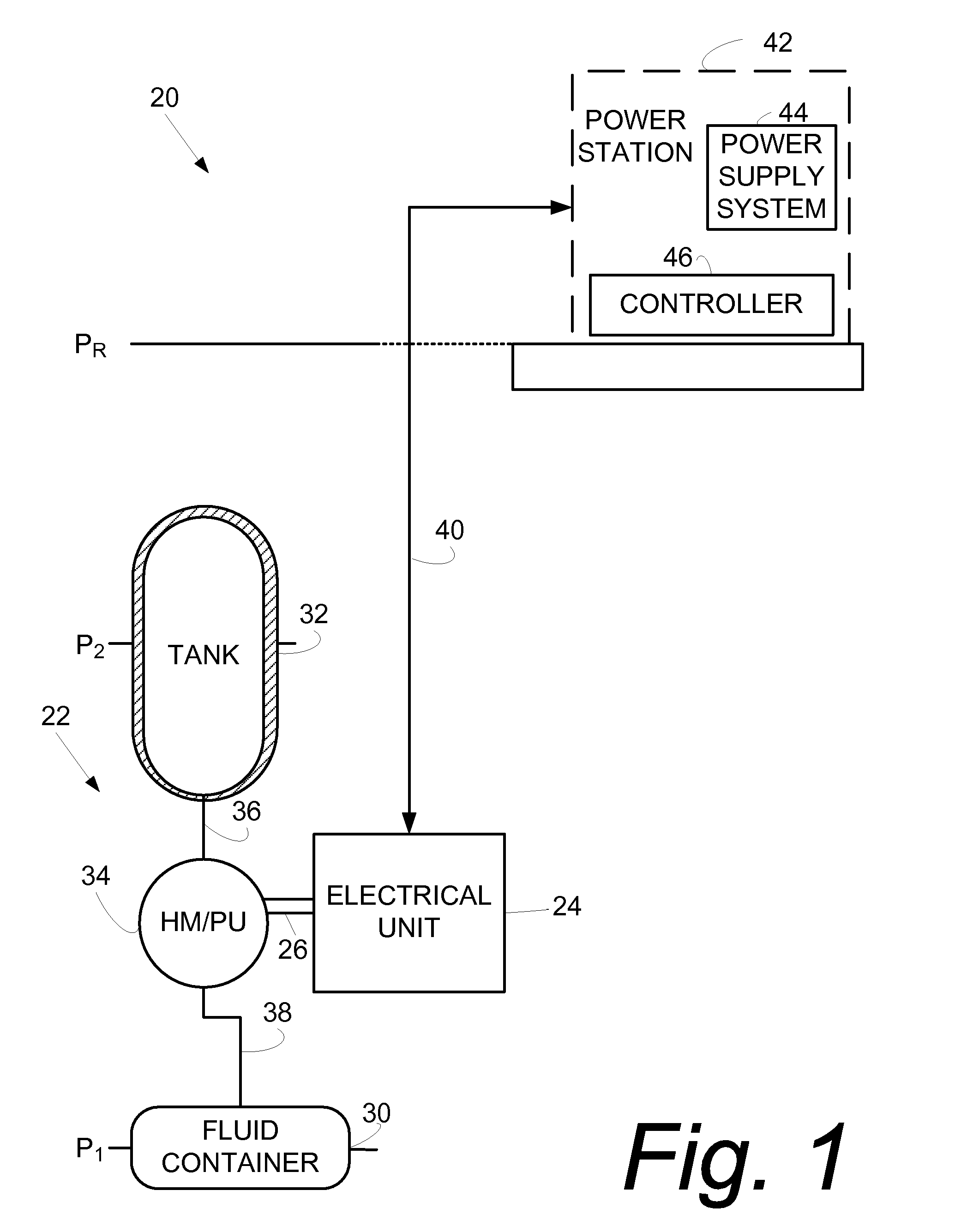

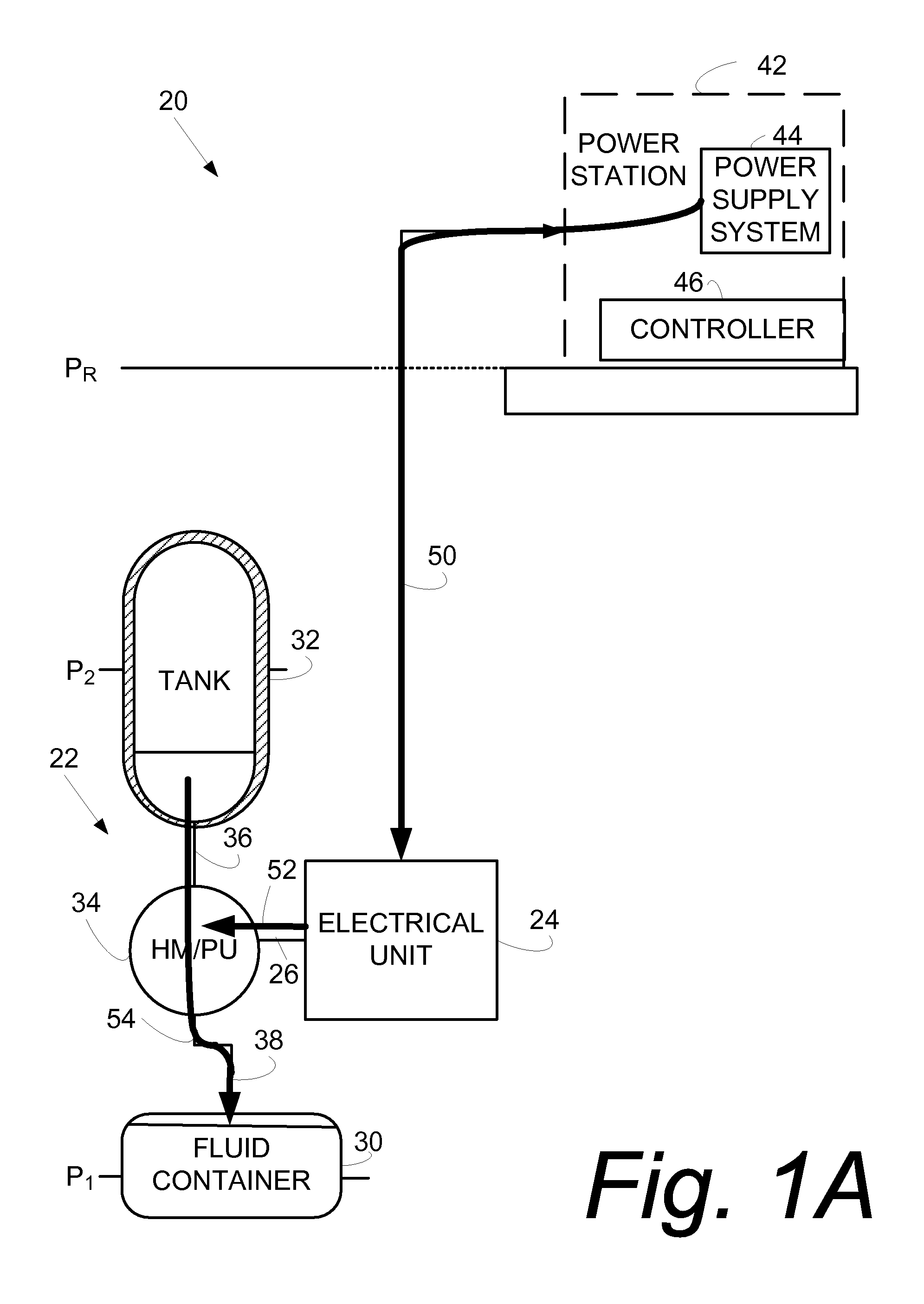

Hydraulic energy accumulator

Example energy storage systems (20, 20′, 20″) comprises a fluid circuit (22, 22′, 22″) and an electrical unit (24, 24′, 24″) configured to operate as a motor in a first phase of operation and to operate as a generator in a second phase of operation. The fluid circuit (22, 22′, 22″) comprises a first fluid container (30, 30′, 30″) situated so content of the first fluid container experiences a first pressure level; a tank (32, 32′, 32″) having its content at a second pressure level (the second pressure level being less than the first pressure level): and, a first hydraulic motor / pump unit (34, 134, 34″connected to communicate a first working fluid between the tank and the first fluid container. In the first phase of operation electricity is supplied to the first hydraulic / motor unit (34, 134, 34″) whereby the first hydraulic / motor unit transmits the first working fluid from the tank into the first fluid container (30, 30′, 30″). In the second phase of operation pressurized first working fluid in the first fluid container (30, 30′, 30″) is transmitted from the first fluid container through the first hydraulic / motor unit 34, 134, 34″) to the tank (32, 32′, 32″), thereby causing the electrical unit (24, 24′, 24″) to generate electricity.

Owner:YSHAPE

Position sensing cylinder cap for ease of service and assembly

An actuator arrangement includes a body and at least one of a piston assembly and a rod assembly slideably disposed in the body. A sensor arrangement includes a sensor, a sensor electronics module, and an interactive element. The interactive element is moveable relative to the sensor, wherein a position of the interactive element indicative of a position of the at least one of a piston assembly and a rod assembly is communicated to the sensor electronics module through the sensor. A housing assembly is attached to an end of the body and includes a sensor pilot portion. The sensor pilot portion in the housing assembly is structured and arranged to sealably receive the sensor electronics module therein, wherein the sensor electronics module is encased within the housing.

Owner:CATERPILLAR INC

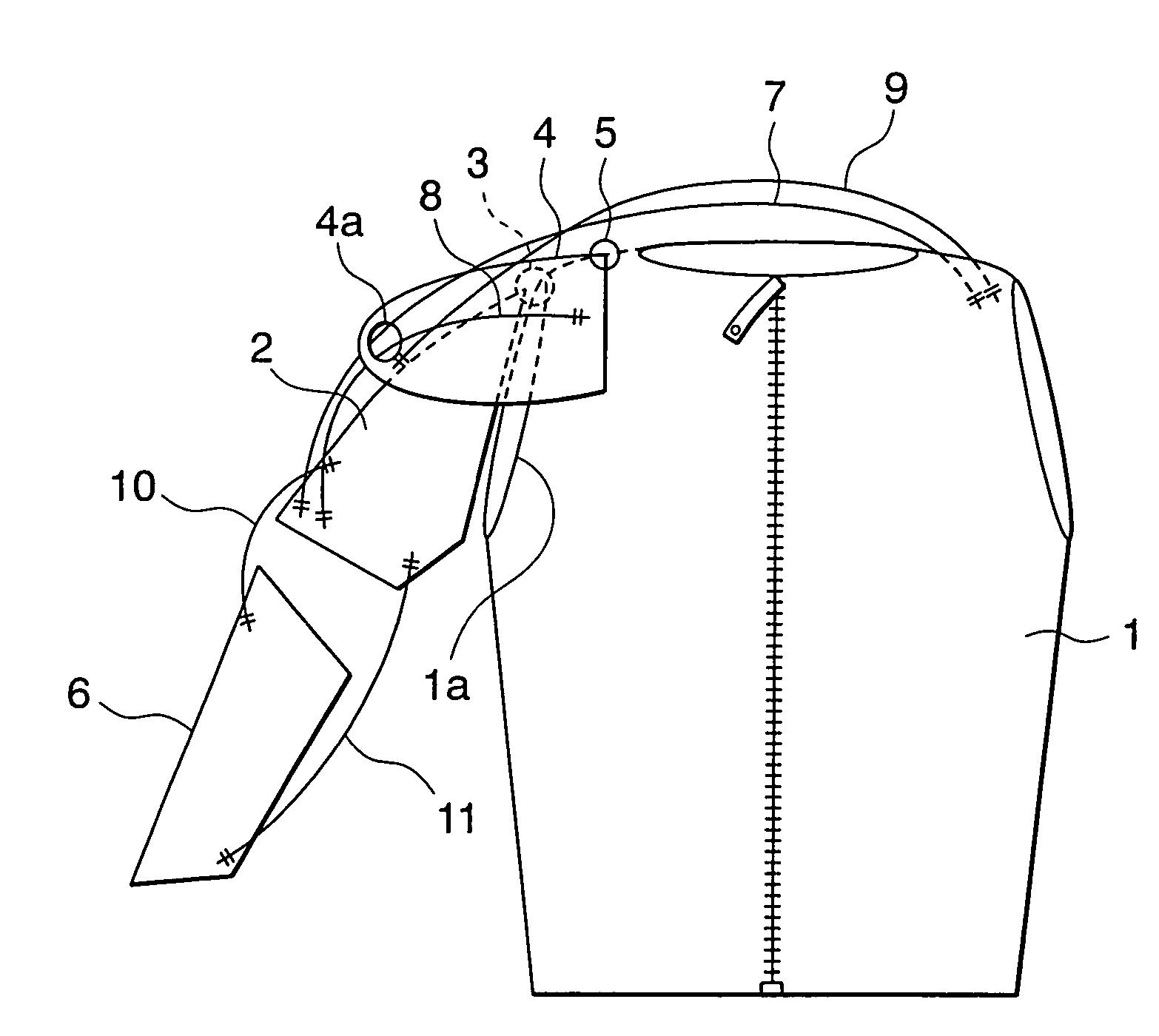

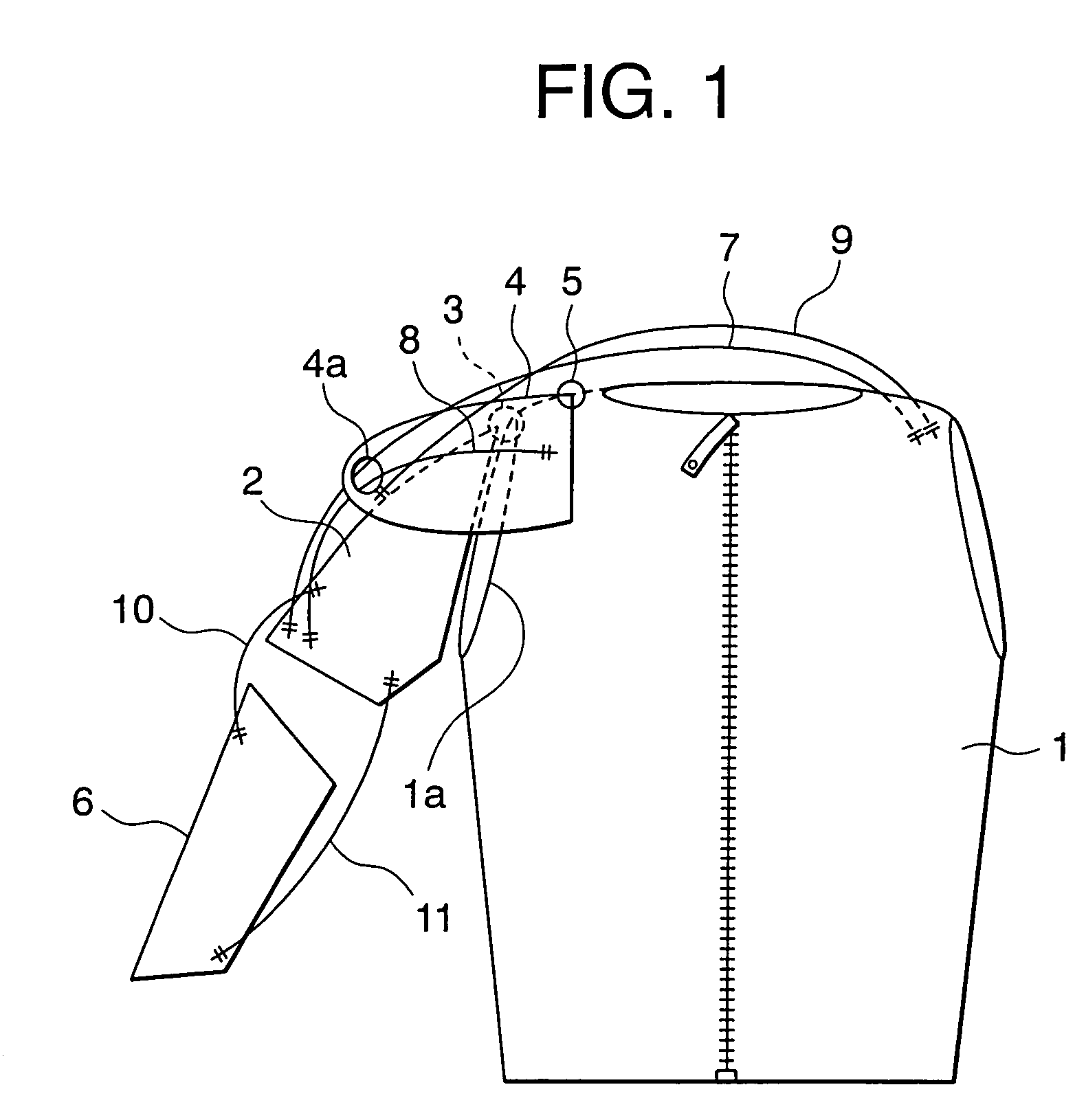

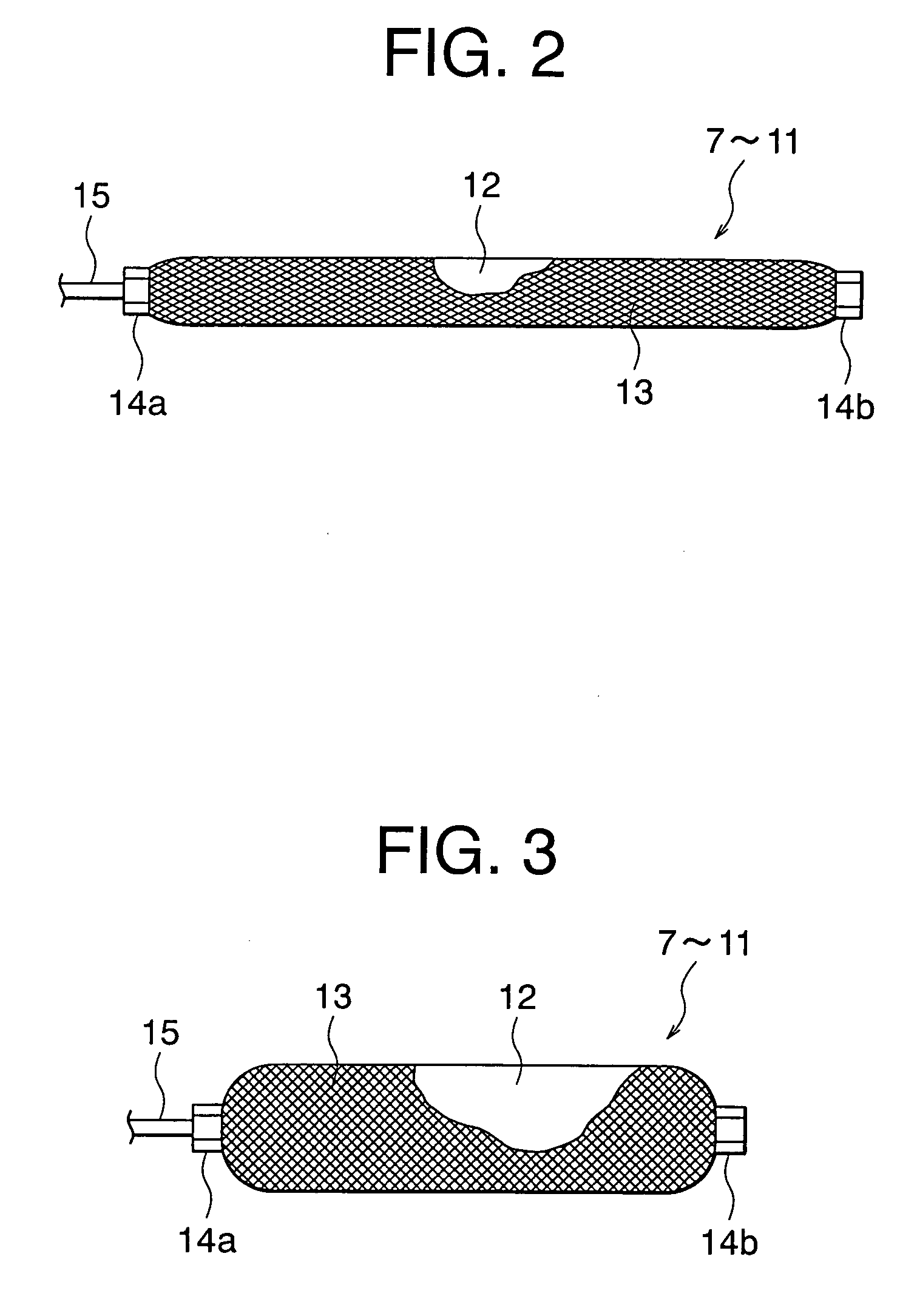

Wearable joint driving device

InactiveUS7413554B2Improvement in driving force transmission efficiencyReduce the amount of solutionProgramme-controlled manipulatorElectrotherapyActuatorSacroiliac joint

Owner:TOKYO UNIVERSITY OF SCIENCE

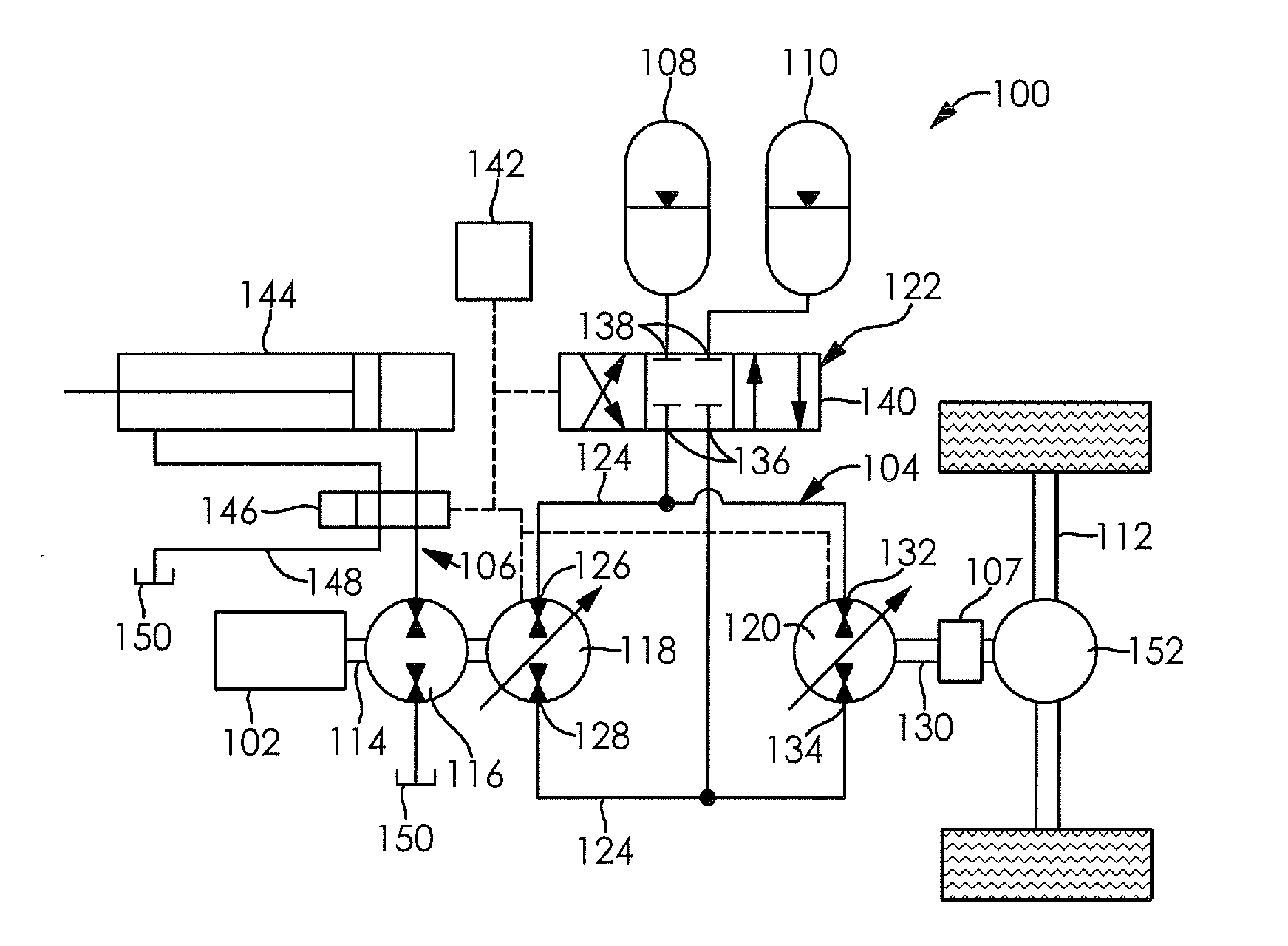

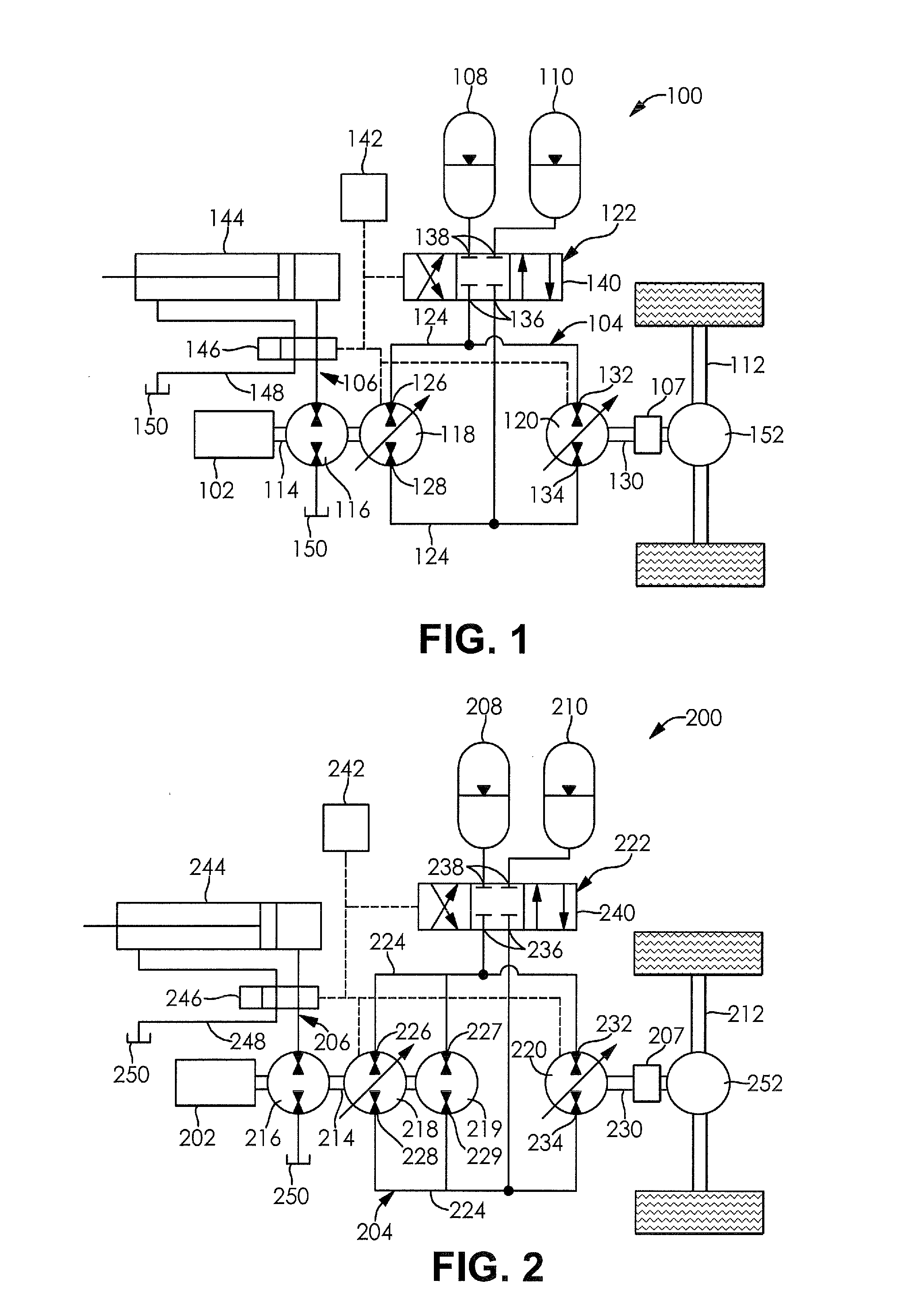

Accumulator assisted hydrostatic driveline and optimization method thereof

InactiveUS20120240564A1Easily procuredEasily servicedRotary clutchesAccumulator installationsState of chargeEngineering

A hydrostatic driveline for a vehicle, a method for minimizing a fuel consumption rate of the vehicle, and a method for tracking an optimal state of charge function for a hydrostatic accumulator are provided. The driveline includes a power source, a drive axle, a first fluid accumulator, a second fluid accumulator, an auxiliary circuit including a first pump drivingly engaged with the power source, and a drive circuit including a second pump drivingly engaged with the power source, a motor drivingly engaged with the drive axle, and a directional valve. The second pump is in fluid communication with the directional valve and the directional valve in fluid communication with the first fluid accumulator and the second fluid accumulator. The directional valve may be selectively controlled to direct fluid from the second pump and the motor to the first fluid accumulator and the second fluid accumulator.

Owner:DANA BELGIUM

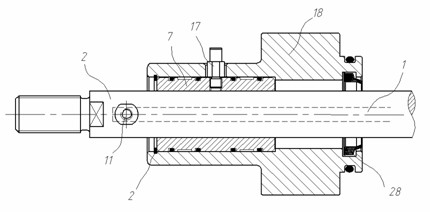

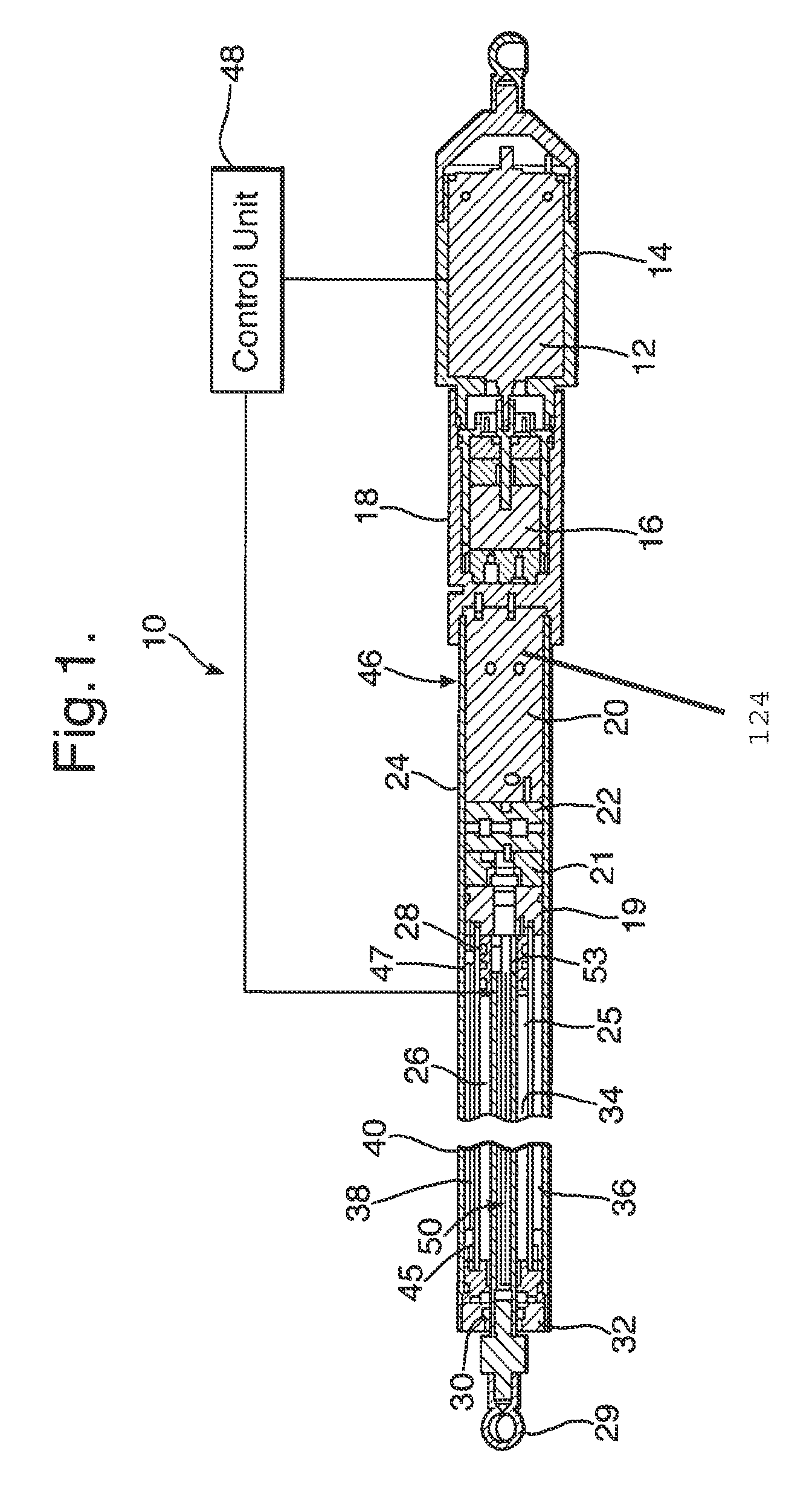

Actuator element with position detection

InactiveUS7044444B2Simple designEasy to detectOperating means/releasing devices for valvesPipeline systemsFlap valveActuator

An actuator element suitable, for example, for actuating a rotatable disk or a flap valve shaft. The actuator includes a housing, a drive situated in the housing, and at least one position detector, in which a movably mounted piston rod in the housing is operatively connected to the drive for exerting a force effect, and in which the position detector includes at least one stationary Hall sensor and at least one magnet movable relative to the Hall sensor such that the magnet produces a magnetic field for generating a magnetic flux.

Owner:MANN HUMMEL GMBH

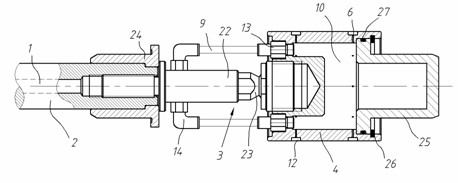

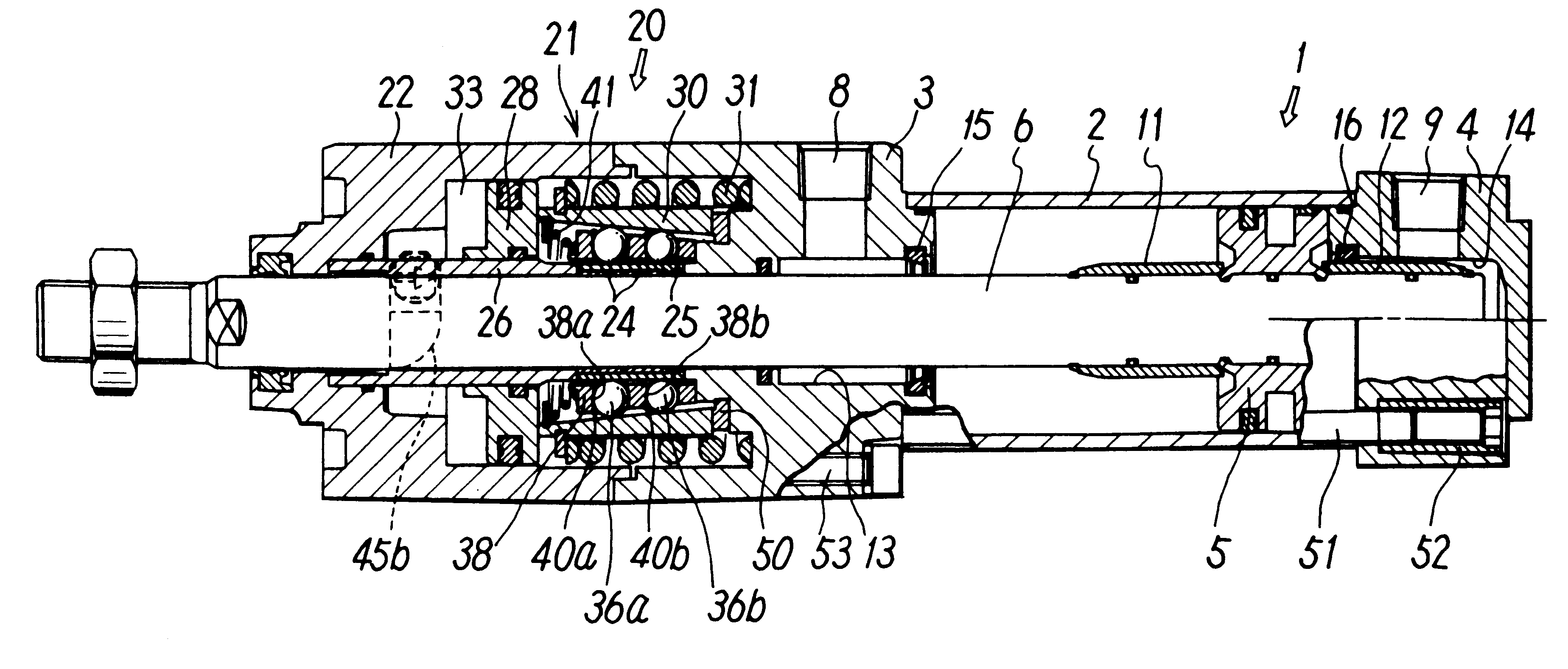

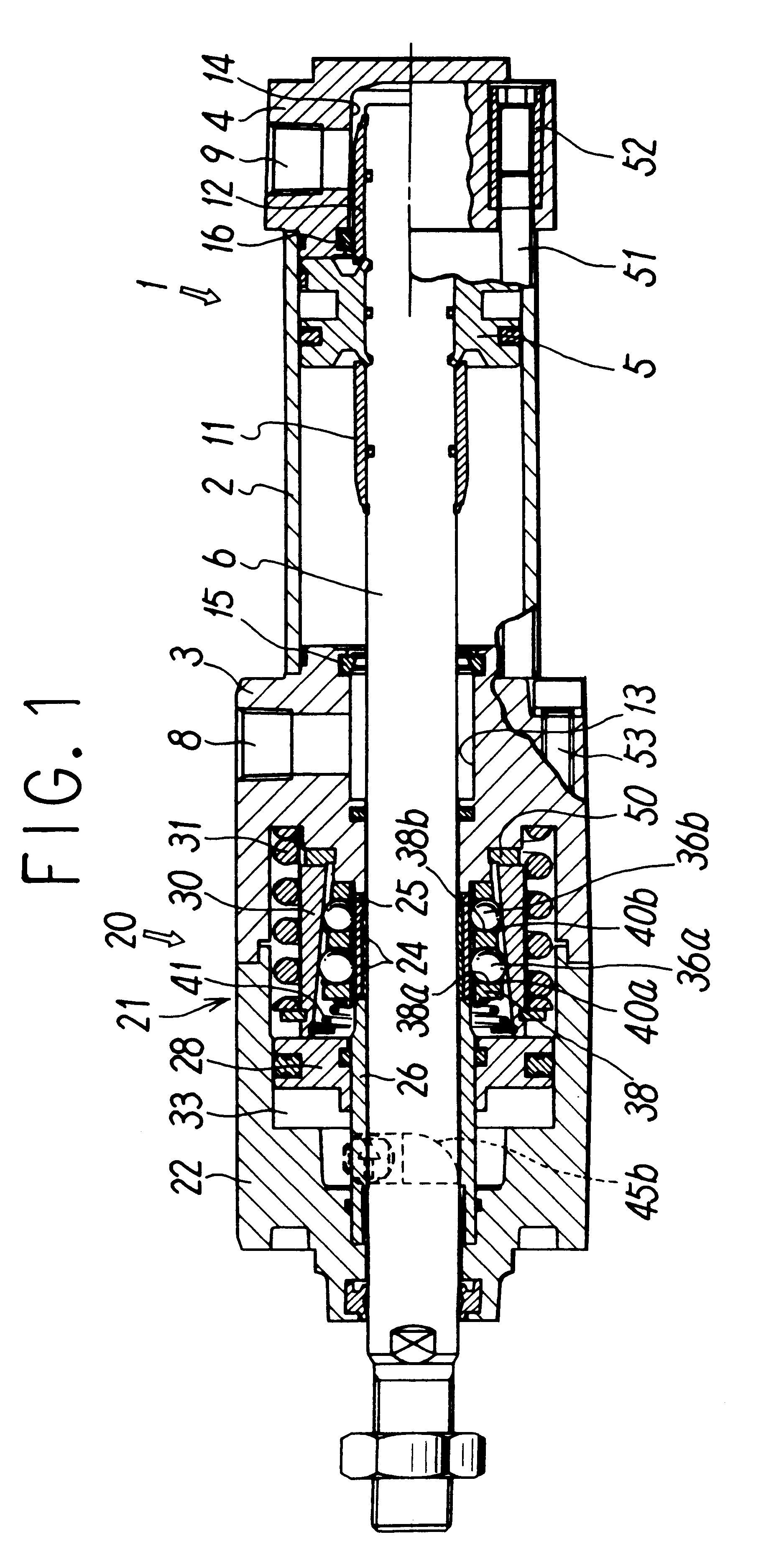

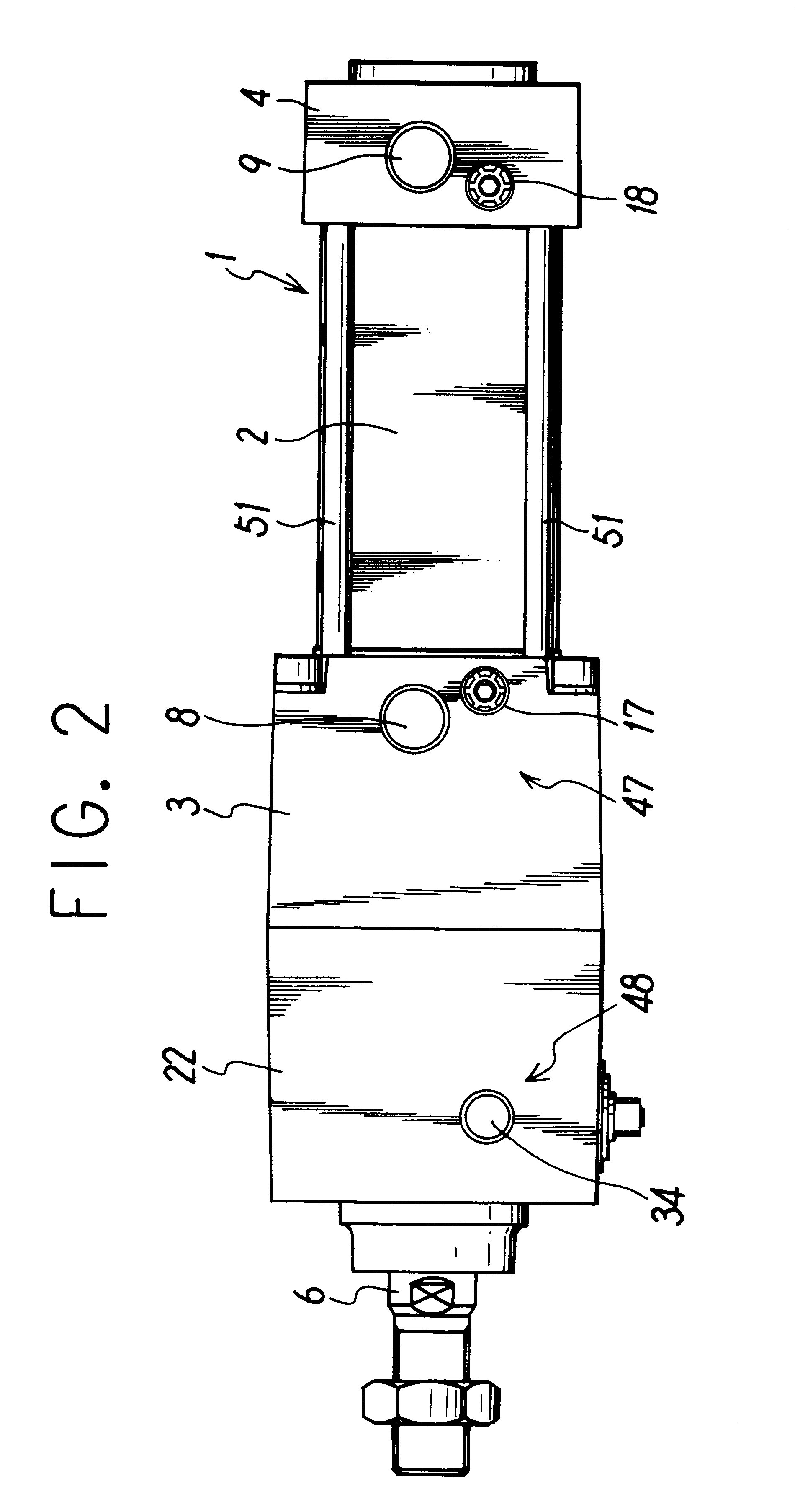

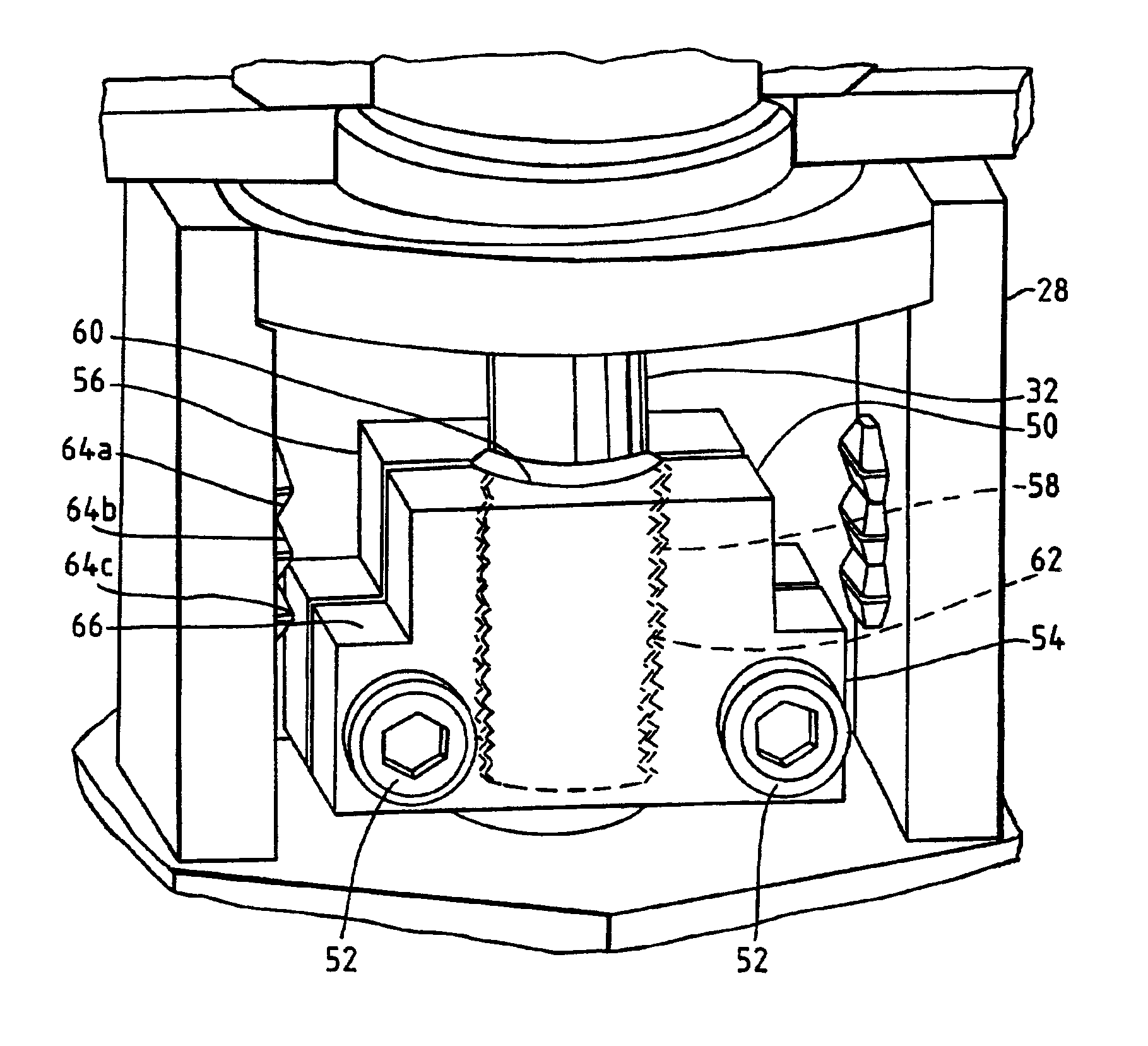

Fluid pressure cylinder with a lock mechanism

InactiveUS6178870B1Improve responseSteady braking forceFluid-pressure actuatorsLocking mechanismEngineering

This fluid pressure cylinder with a lock mechanism is adapted to provide, on the lock mechanism cover, an area where valves for controlling the cylinder and lock mechanism can be installed. In the cylinder, a brake shoe grips a piston rod 6 via balls held by a retainer inside a lock mechanism cover 21 using a tapered ring which is driven by a brake spring and returned to its original position by a release piston. A cylinder port 8 that supplies or discharges compressed air to drive the piston is provided on the side of a cylinder 1 inside the lock mechanism cover 21. On the opposite side an unlocking port 34 which leads to a pressure chamber driving a release piston is disposed and a manual opening actuator 45 is provided. This arrangement is intended to ensure a flat area 48 where valves can be installed to control compressed air fed through the ports.

Owner:SMC CORP

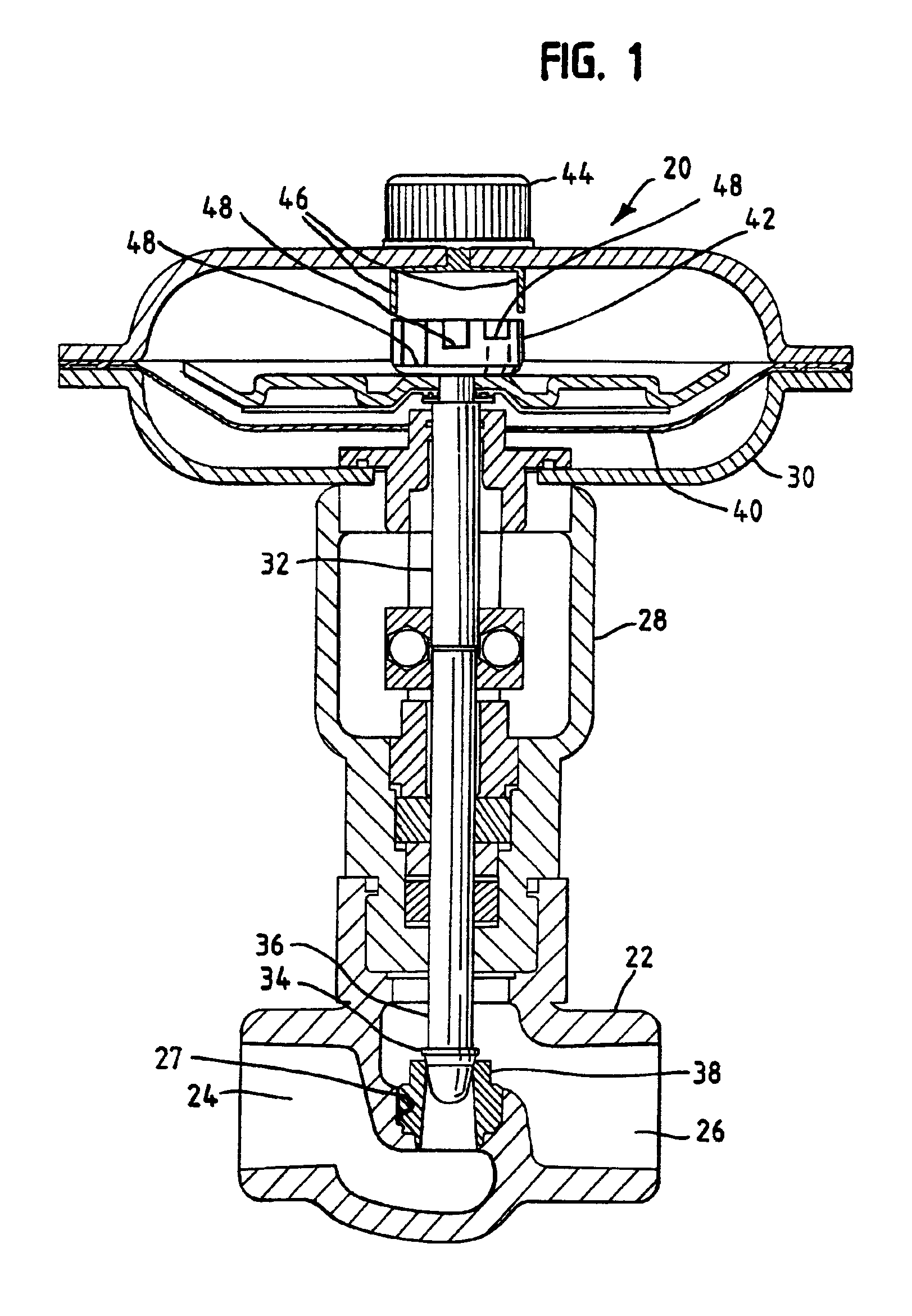

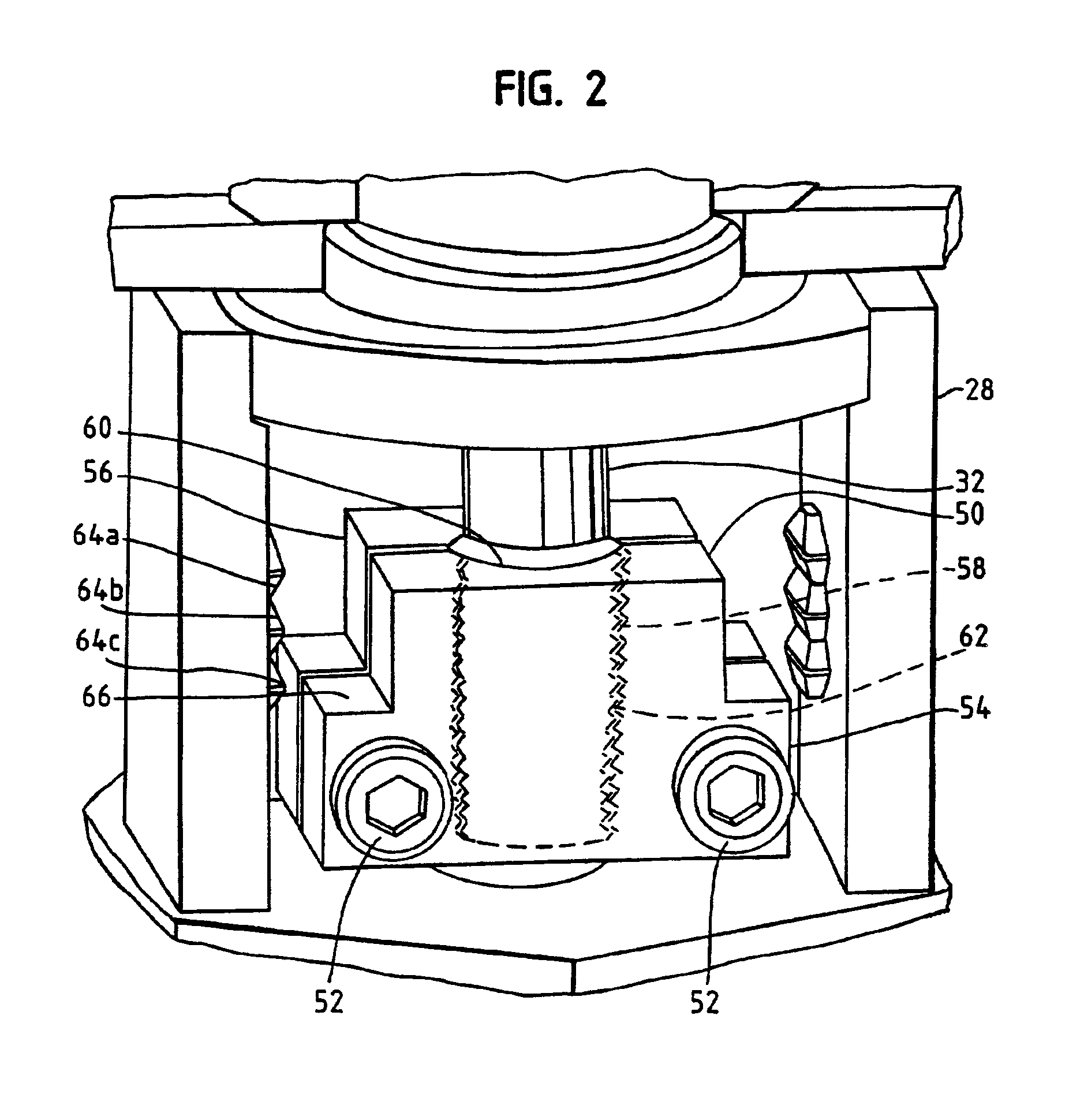

Control valve flow adjustment device

InactiveUS6905108B2Easy to controlTravel can be limitedOperating means/releasing devices for valvesFluid-pressure actuatorsEngineeringControl valves

A valve includes a fluid inlet passage having a fluid inlet, a fluid outlet passage, an orifice between the fluid inlet passage and the fluid outlet, and a moveable valve plug adapted to move with respect to the orifice to vary the flow of fluid between the fluid inlet passage and the fluid outlet passage. A movable valve stem is attached to the valve plug and a travel limiting device is attached to the valve stem. The travel limiting device permits the valve to be placed in one of a plurality of desired flow configurations.

Owner:FISHER CONTROLS INT LLC

Apparatus and method for dual mode compact hydraulic system

A dual mode hydraulic actuator, comprising: a housing; a rod secured to a piston, the rod and piston being slidably received within the housing; a first chamber positioned on one side of the piston; a second chamber positioned on another side of the piston; a sealed reservoir; a fluid disposed in the first chamber, the second chamber and the reservoir; a bidirectional pump for moving the fluid between the first chamber, the second chamber and the sealed reservoir; a bi-mode control valve for providing selective fluid communication between the first chamber, the second chamber and the sealed reservoir, wherein the bi-mode control valve is spring biased into a neutral position wherein fluid communication between the first chamber, the second chamber and the sealed reservoir is prevented; and wherein the bi-mode control valve is capable of being manually manipulated into a manual mode position wherein fluid flow from the first chamber to the second chamber is provided and fluid flow from or to the sealed reservoir is also provided, the fluid flow from or to the sealed reservoir being dependant upon a volume of fluid in the first chamber and the second chamber.

Owner:STRATTEC POWER ACCESS

Fracturing pump assembly and method thereof

A fracturing pump assembly includes an intensifier including a hydraulic cylinder, a compression member arranged within the hydraulic cylinder and a rotatable member, wherein the compression member is linearly actuated within the hydraulic cylinder by rotation of the rotatable member.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

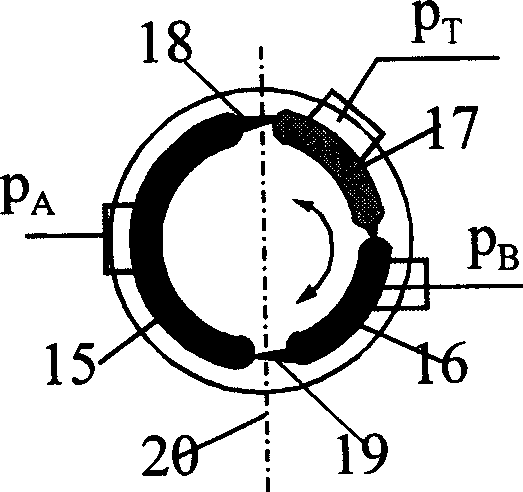

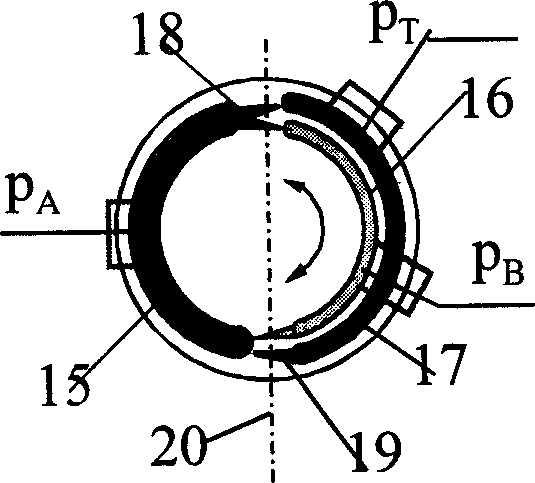

Hydraulic detent for a variable camshaft timing device

InactiveUS6666181B2Quickly reachImprove vibrationValve arrangementsOscillating piston enginesDetentEngineering

A phaser which includes a housing and a rotor disposed to rotate relative to each other is provided. The housing has at least one cavity disposed to be divided by a vane rigidly attached to the rotor. The vane divides the cavity into a first chamber and a second chamber. The phaser further includes passages connecting the first and the second chamber, thereby facilitating the oscillation of the vane within the cavity. The phaser includes: a) a valve disposed to form at least two openings for fluid flowing between the first chamber and the second chamber and being disposed to keep at least one opening closed; and b) at least one by-pass disposed to stop or slow down the rotation between the housing and the rotor, thereby allowing a locking mechanism to lock the housing and the rotor together independent of fluid flow.

Owner:BORGWARNER INC

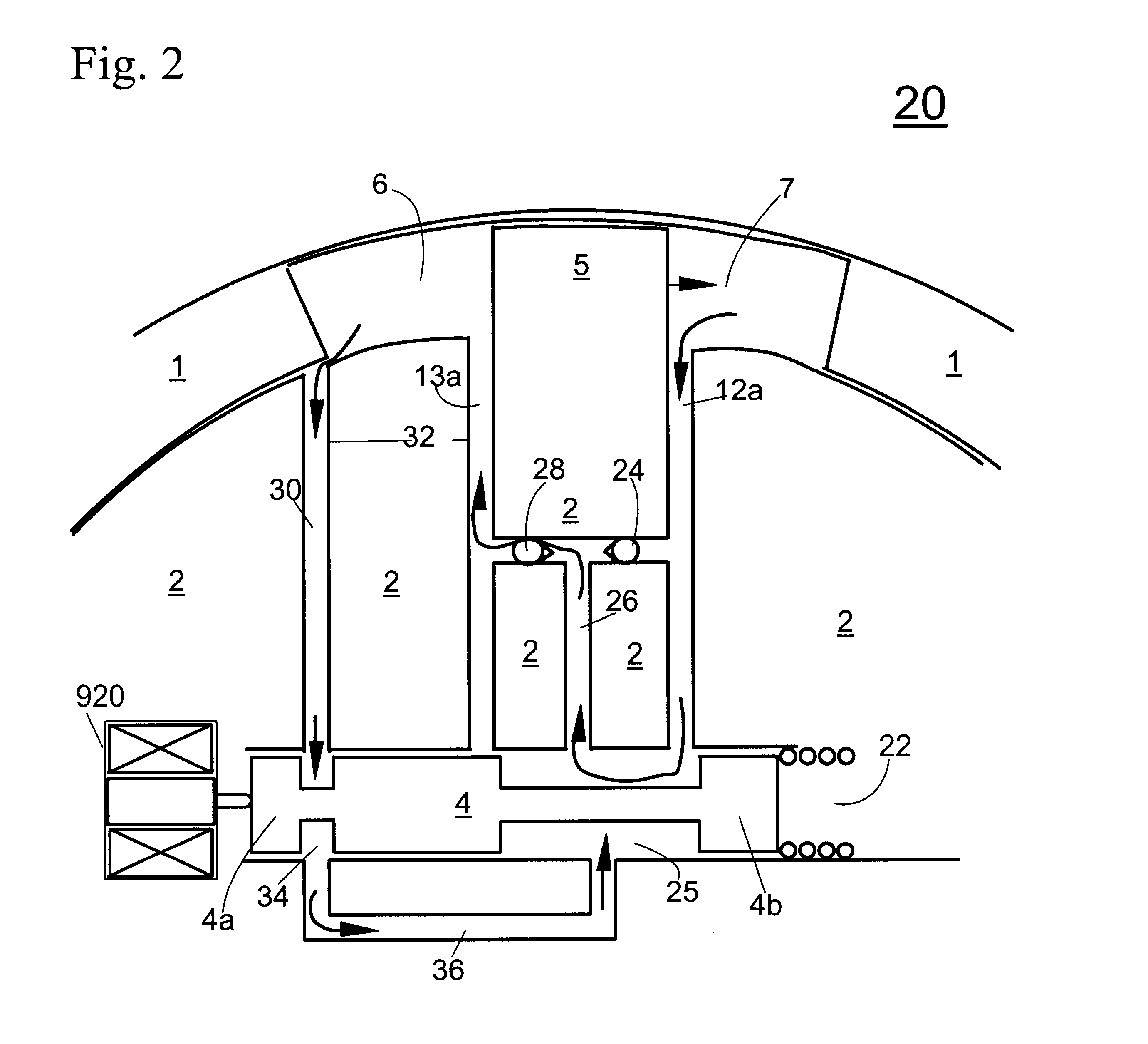

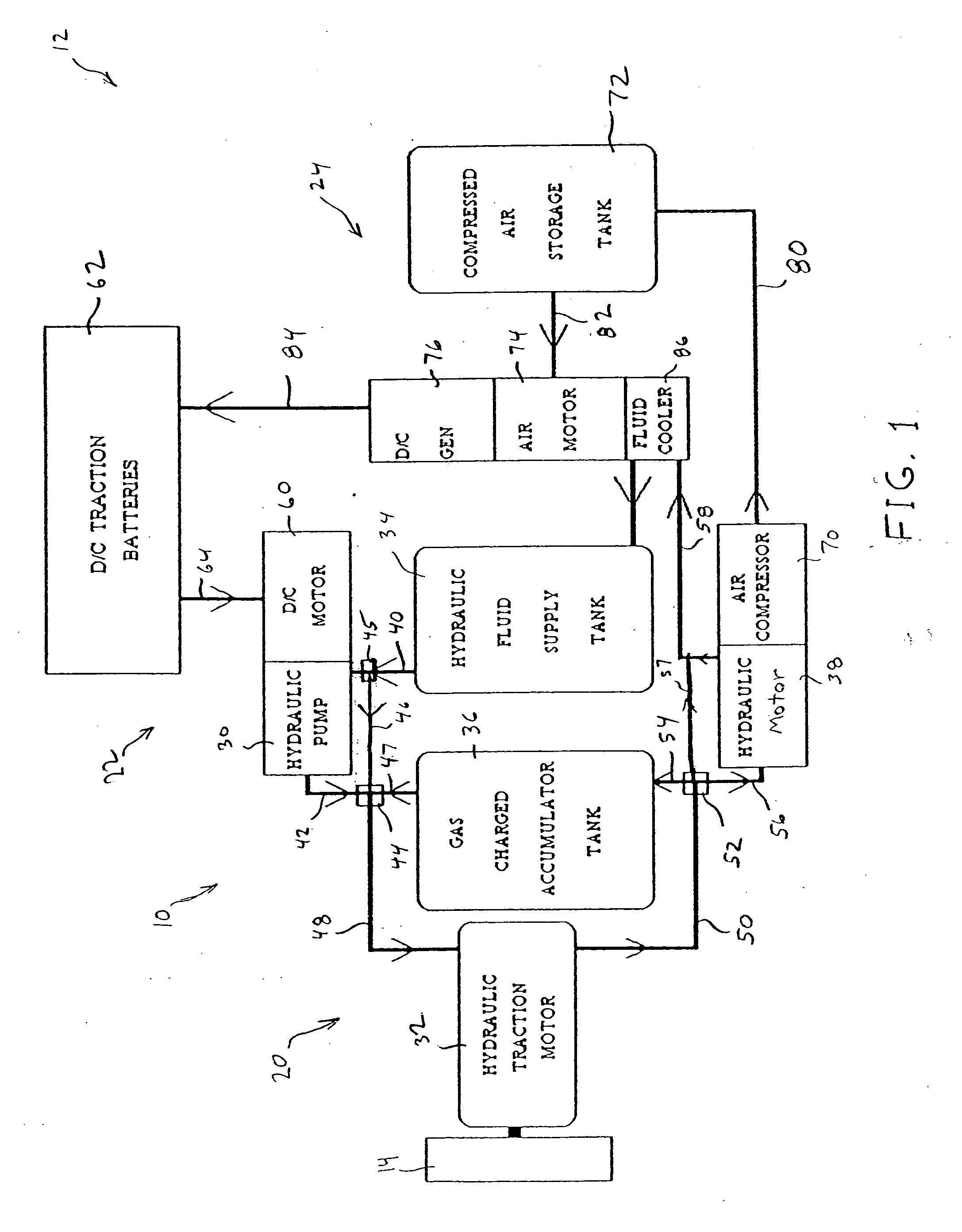

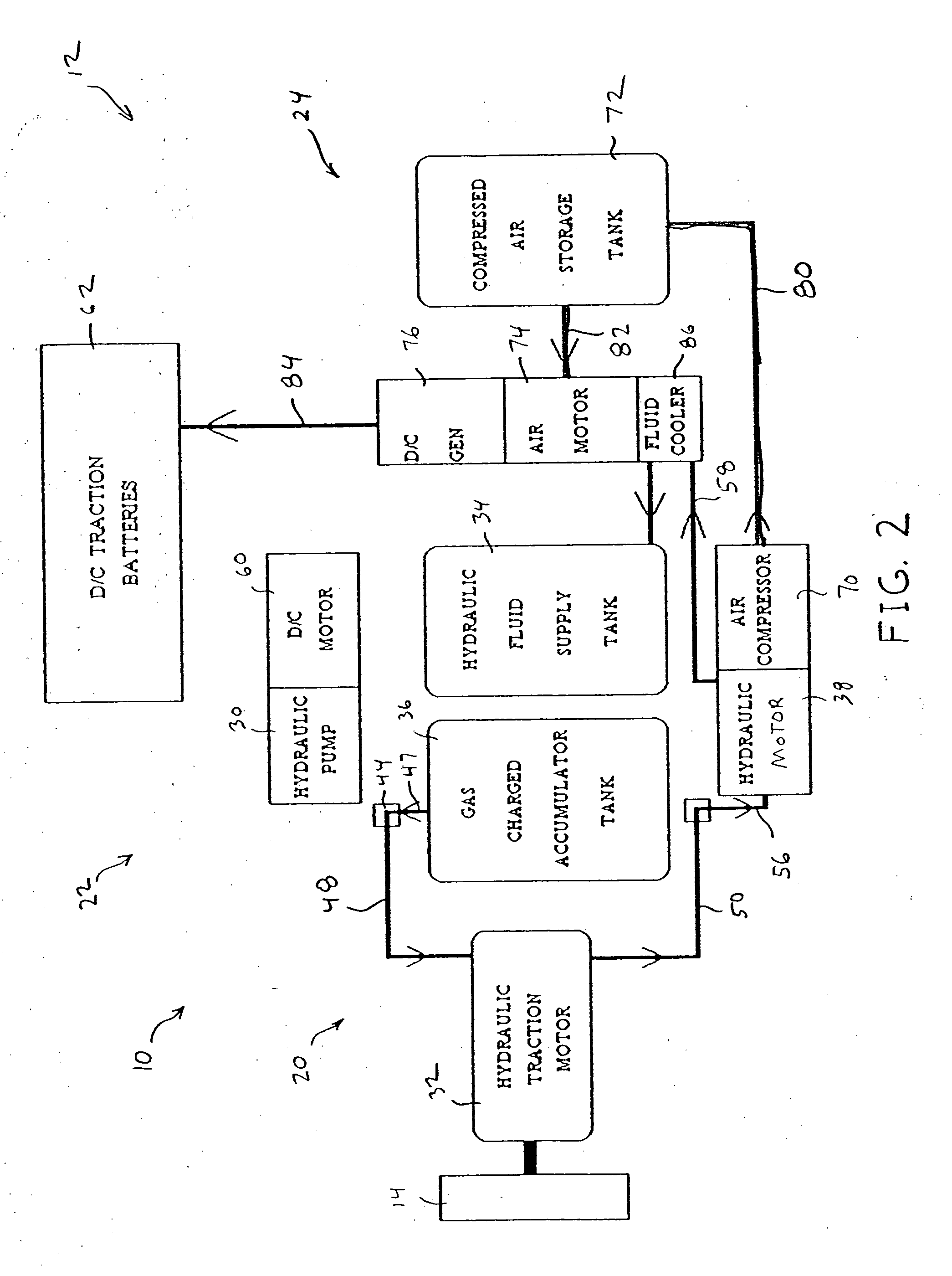

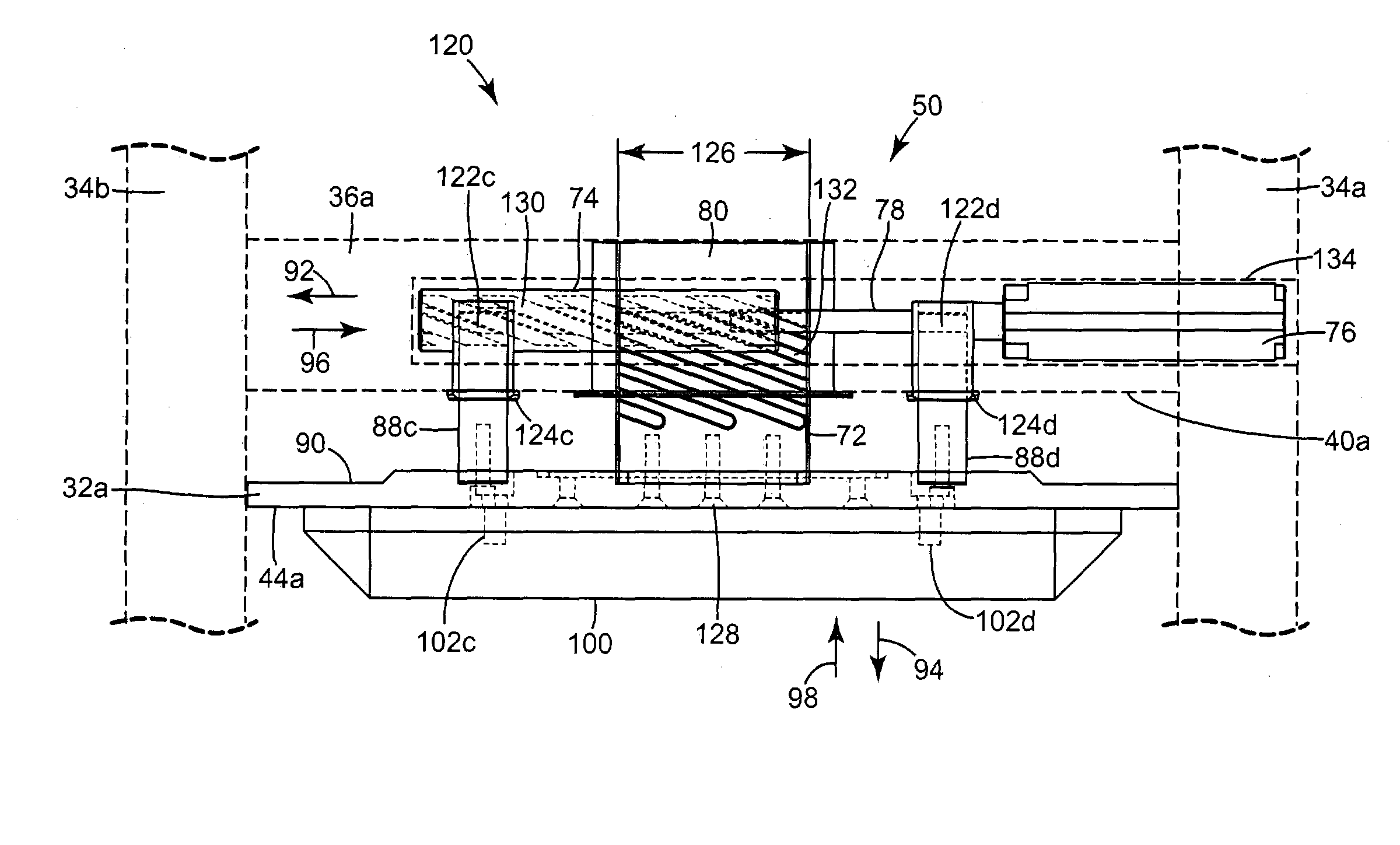

Vehicle system to recapture kinetic energy

ActiveUS20050178115A1Solve large capacityRailway vehiclesPlural diverse prime-mover propulsion mountingElectricityHydraulic motor

A fluid drive system that can be used to drive a vehicle and has energy regeneration and storage capabilities. The fluid drive system includes an electrical energy supply source mounted on the vehicle, at least one electrical motor electrically connected to the electrical supply source, and a hydraulic pump driven that may be of the variable displacement type by the electrical motor. The fluid drive system may also include a low pressure hydraulic fluid supply tank supplying fluid to the hydraulic pump, at least one pneumatically charged accumulator tank for storing pressurized hydraulic fluid, a combination hydraulic motor and pump that may also be of the variable displacement type being alternately driven by the hydraulic pump and the pneumatically charged accumulator tank; and an electrical regeneration system for regenerating the electrical energy supply. The electrical regeneration system may be powered by hydraulic fluid from the combination electrical motor and pump. The combination hydraulic motor and pump propels the vehicle during acceleration and speed maintaining operations and may also serves as a braking mechanism during deceleration of the vehicle. The combination hydraulic motor and pump may also pump hydraulic fluid into the pneumatically charged accumulator tank during at least a portion of the time that the vehicle is decelerating. The combination hydraulic motor and pump may further pump hydraulic fluid for powering the electrical regeneration system when the pneumatically charged accumulator tank is fully pressurized. The electrical regeneration system also has the ability to recharge the electrical energy supply while the vehicle is stopped using stored recovered kinetic energy.

Owner:PARKER I L L C +1

Concrete block mold with moveable liner

One aspect of the present invention provides a mold assembly for manufacturing concrete blocks that is adapted for use in a concrete block machine. The mold assembly comprises a plurality of liner plates and a gear drive assembly. Each liner plate has a major surface and the liner plates are configured such that the major surfaces form a mold cavity, wherein at least one of the liner plates is moveable. The gear drive assembly is selectively coupled to the at least one moveable liner plate and is configured to move the at least one moveable liner plate in a first direction toward an interior of the mold cavity by applying a force in a second direction different from the first direction, and to move the liner plate in a direction away from the interior of the mold cavity by applying a force in a direction opposite the second direction.

Owner:NESS INVENTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com