Patents

Literature

92results about How to "Steady braking force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

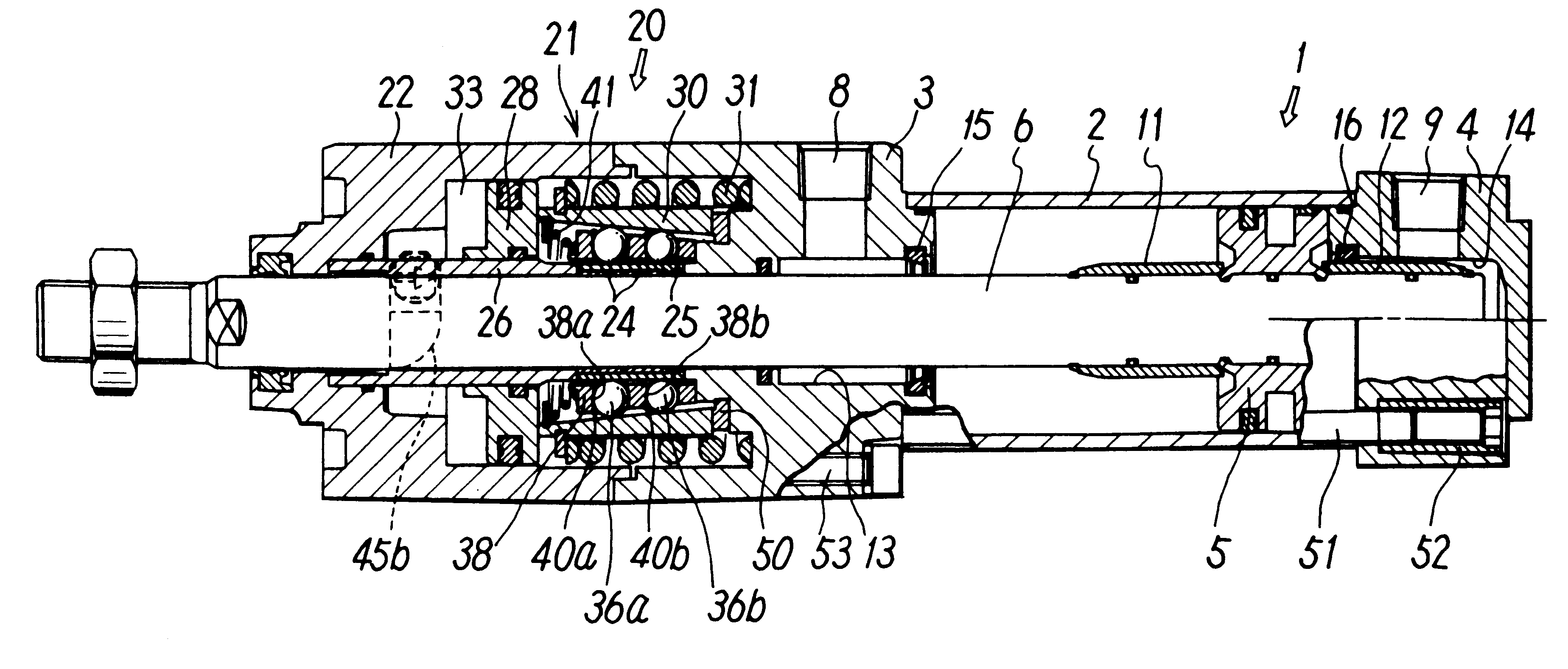

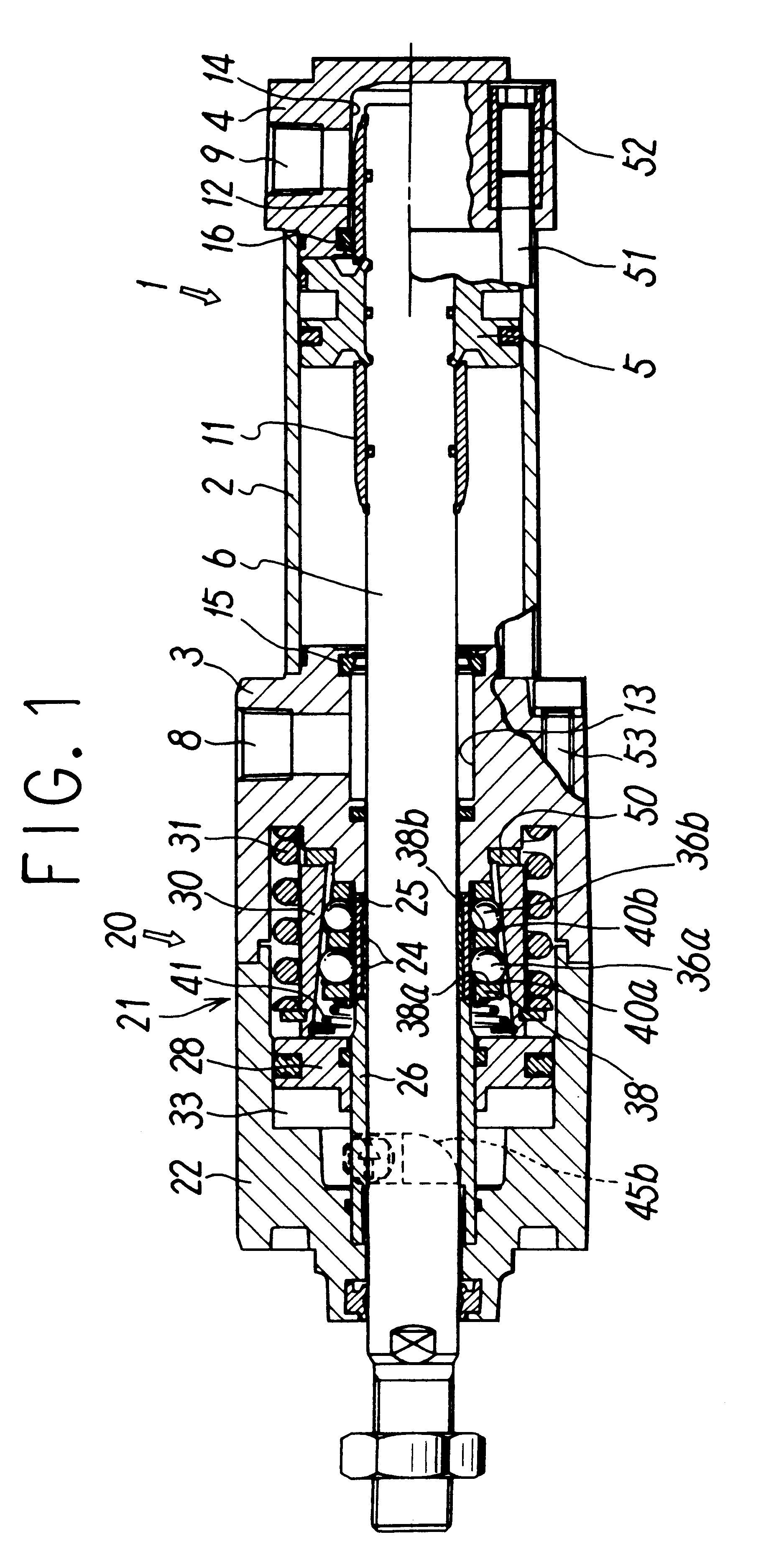

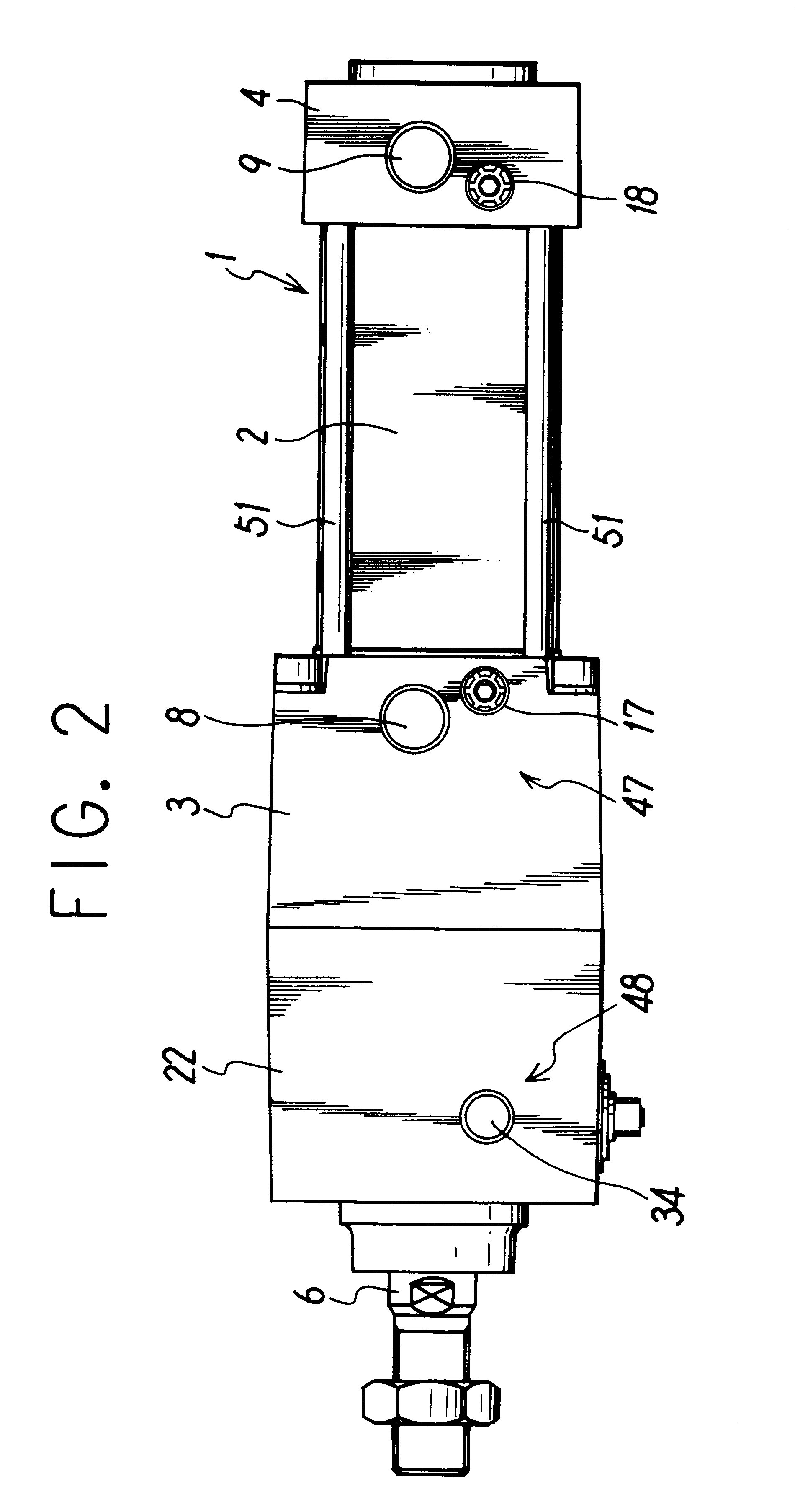

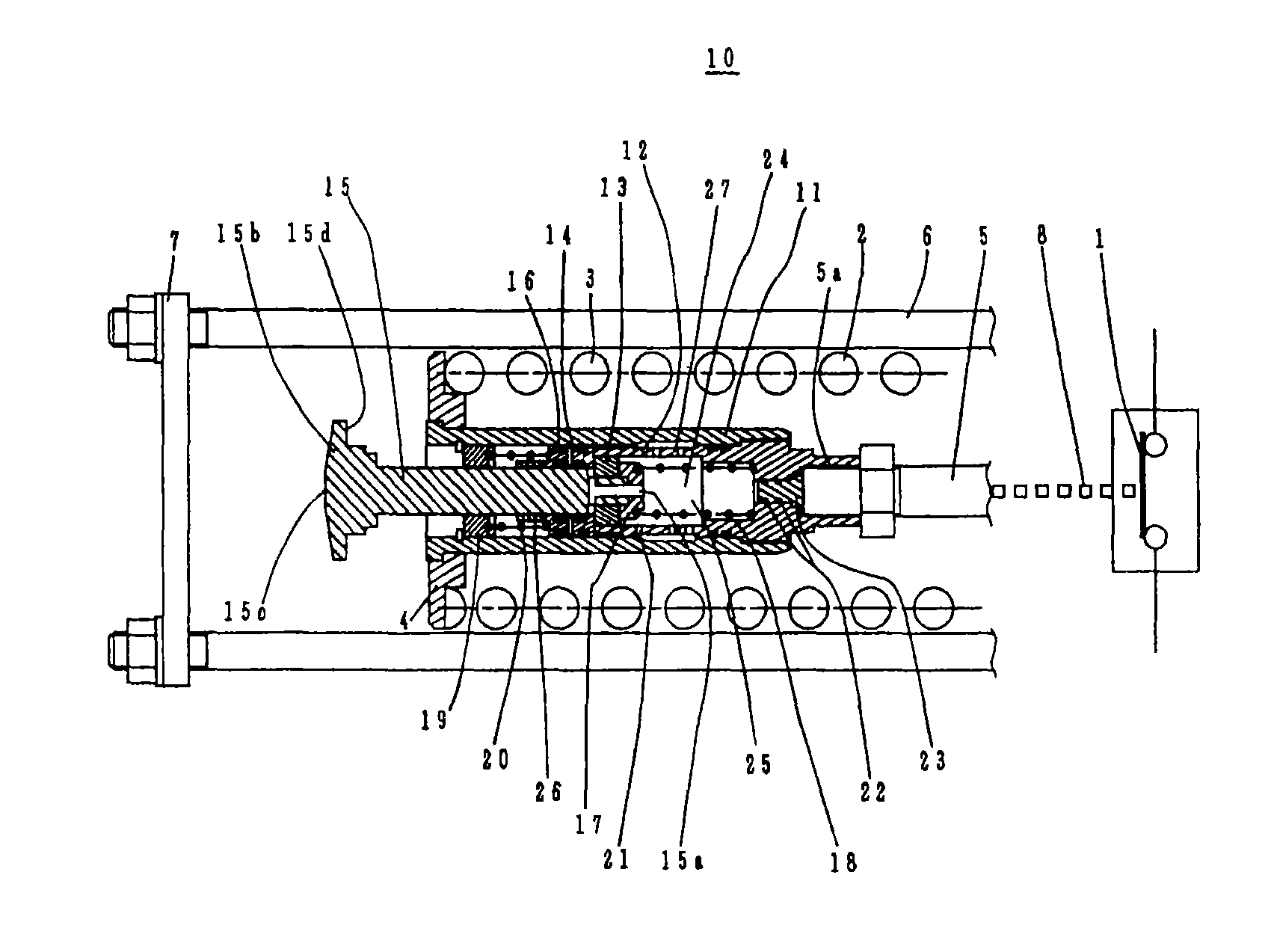

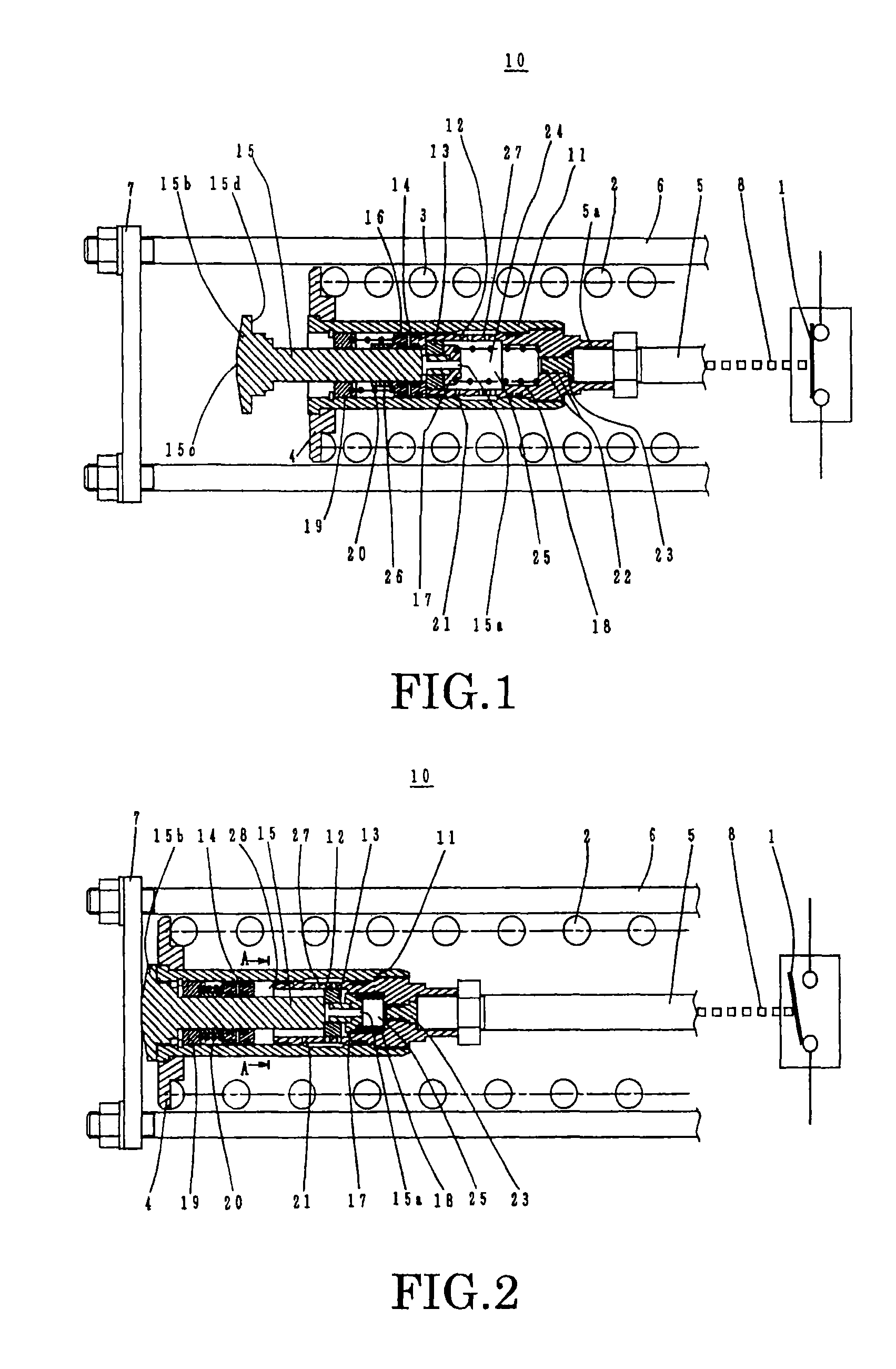

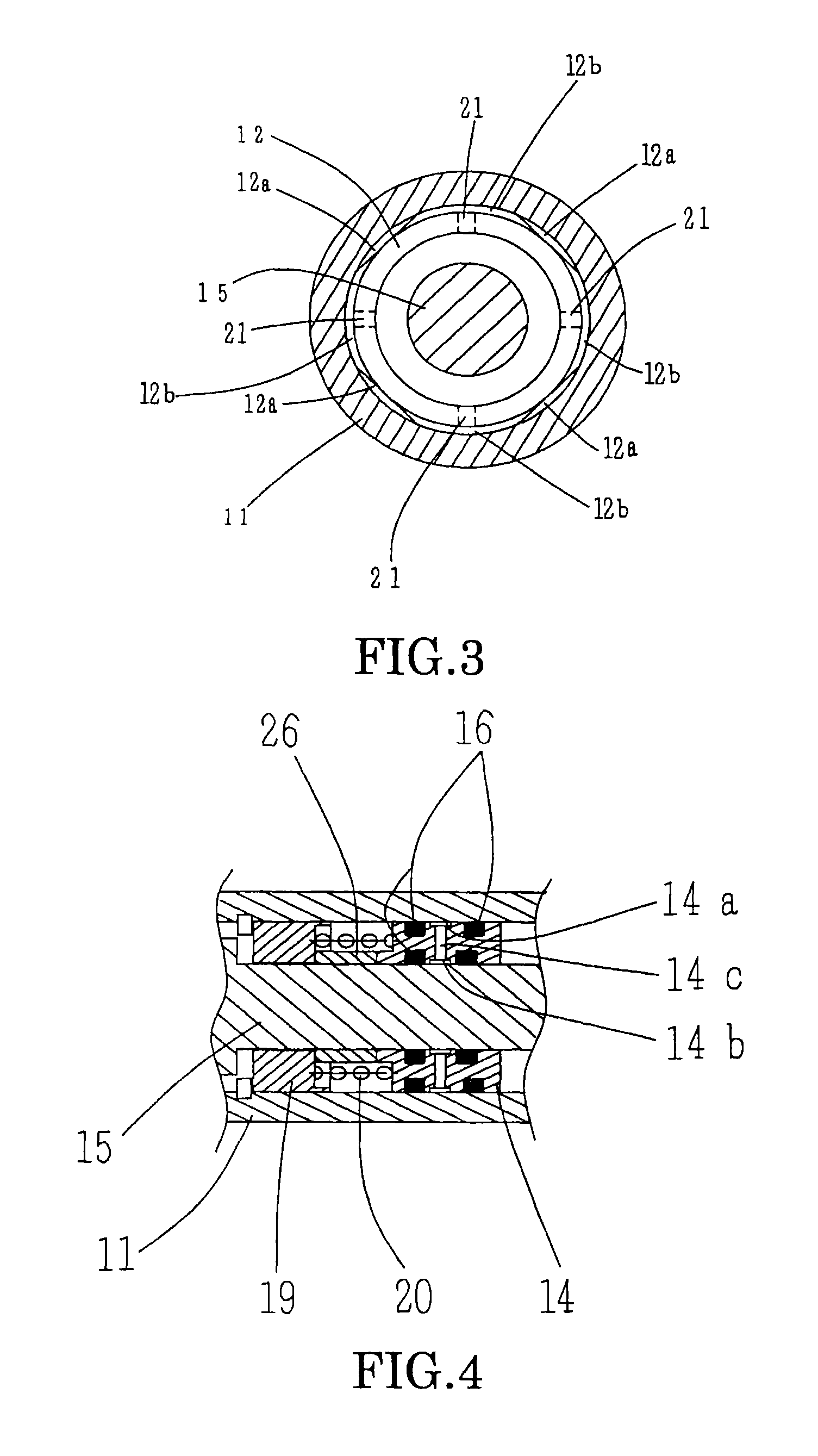

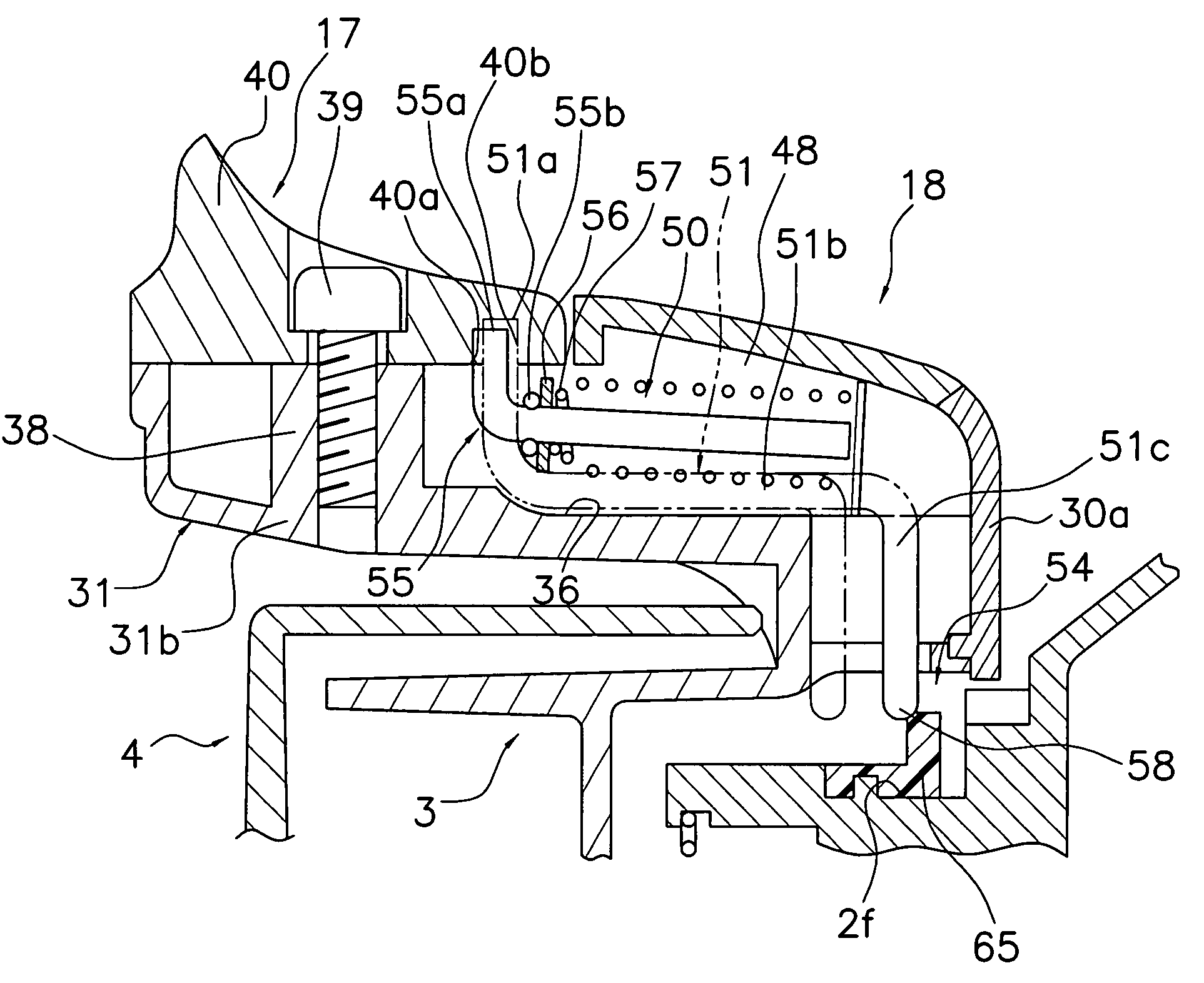

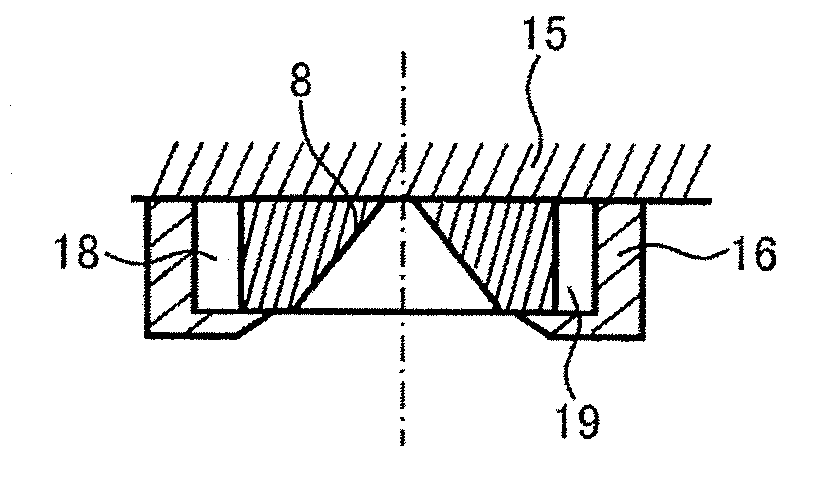

Fluid pressure cylinder with a lock mechanism

InactiveUS6178870B1Improve responseSteady braking forceFluid-pressure actuatorsLocking mechanismEngineering

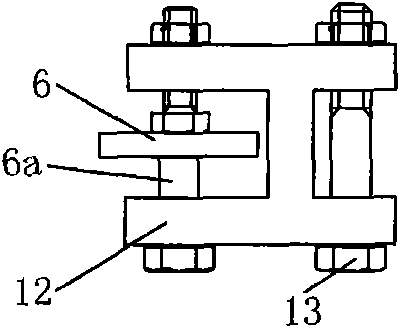

This fluid pressure cylinder with a lock mechanism is adapted to provide, on the lock mechanism cover, an area where valves for controlling the cylinder and lock mechanism can be installed. In the cylinder, a brake shoe grips a piston rod 6 via balls held by a retainer inside a lock mechanism cover 21 using a tapered ring which is driven by a brake spring and returned to its original position by a release piston. A cylinder port 8 that supplies or discharges compressed air to drive the piston is provided on the side of a cylinder 1 inside the lock mechanism cover 21. On the opposite side an unlocking port 34 which leads to a pressure chamber driving a release piston is disposed and a manual opening actuator 45 is provided. This arrangement is intended to ensure a flat area 48 where valves can be installed to control compressed air fed through the ports.

Owner:SMC CORP

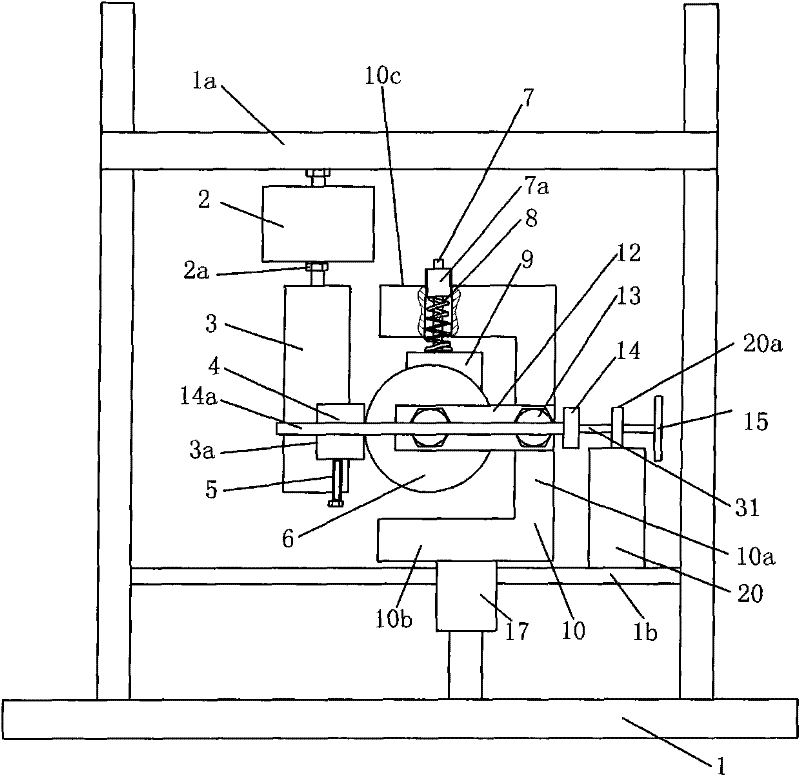

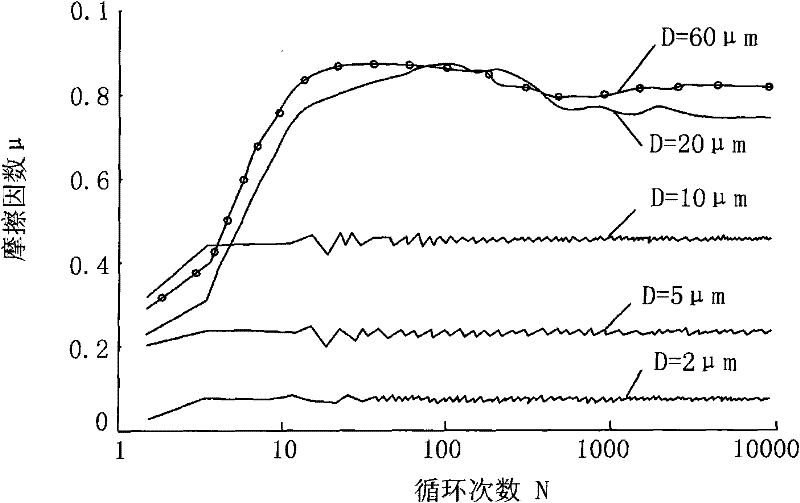

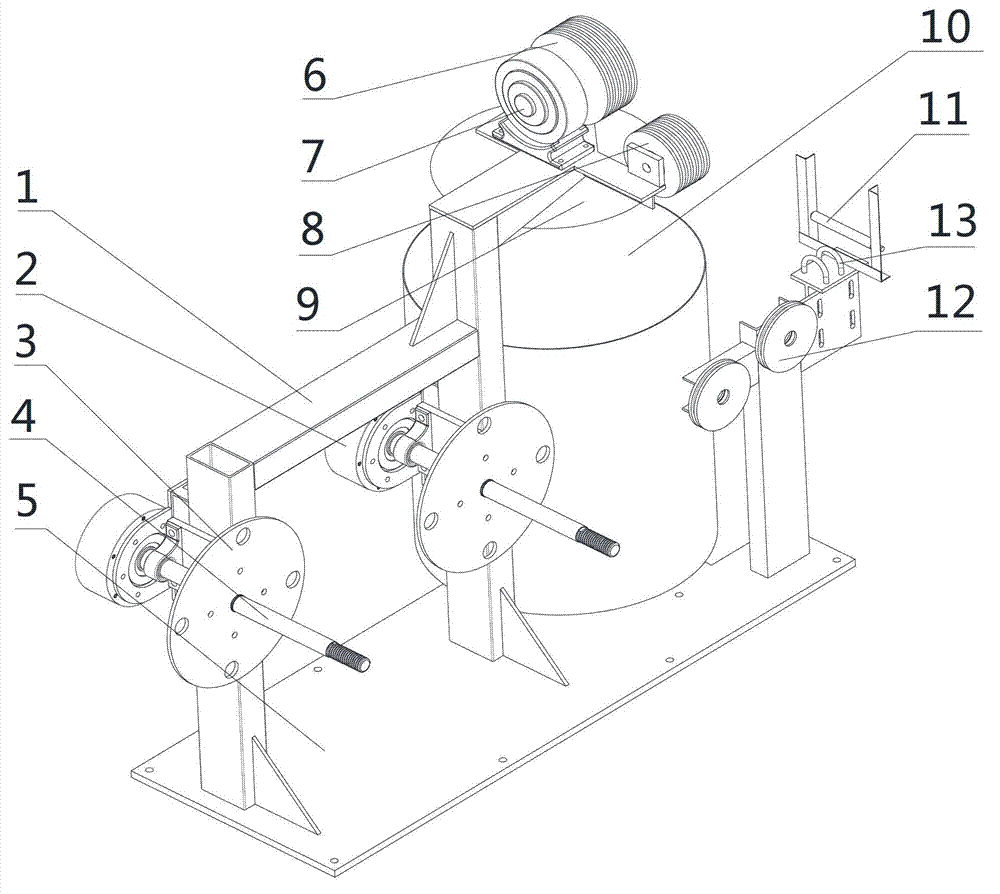

Small-displacement reciprocating rolling friction abrasion test device

InactiveCN101750259AAuthentic, reliable and effective simulationAuthentic, reliable and effective analysisInvestigating abrasion/wear resistanceRolling resistanceTangential force

The invention relates to a small-displacement reciprocating rolling friction abrasion test device. A plane sample clamp is fixedly connected below a cross beam of a hydraulic friction test machine by a tangential force sensor; a rolling sample clamp is positioned at the right side of the plane sample clamp and is fixed on a vertical column of a support frame; a bottom plate of the clamp support frame is connected on a hydraulic piston of the hydraulic friction test machine; the right side of the clamp support frame is provided with a normal force; a screw at the right side of the normal force sensor is connected on a support nut by threads, and the end part of the screw is connected with a rotating disc; the support nut is fixed on a work platform surface of the hydraulic friction test machine by a support seat; and a U-shaped connecting piece at the left side of the normal force sensor is sheathed on the vertical column of the clamp support frame. The small-displacement reciprocating rolling friction abrasion test device can simulate the friction abrasion between a plane sample and a rolling body more really and reliably, is convenient to microscopically analyze the test result, and has high degree of automation, simple and convenient operation, high accuracy of control and test and good repeatability of test data.

Owner:SOUTHWEST JIAOTONG UNIV

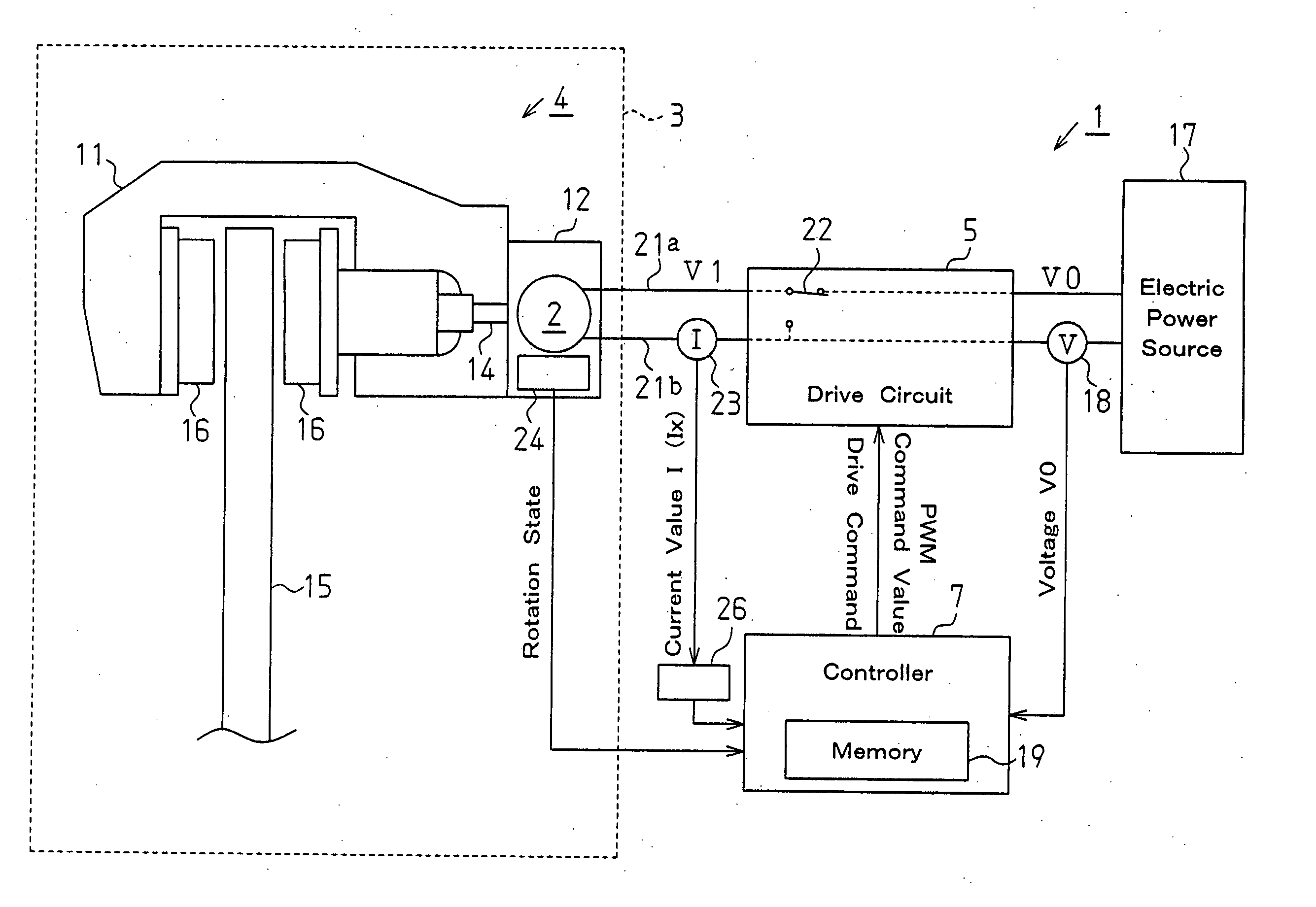

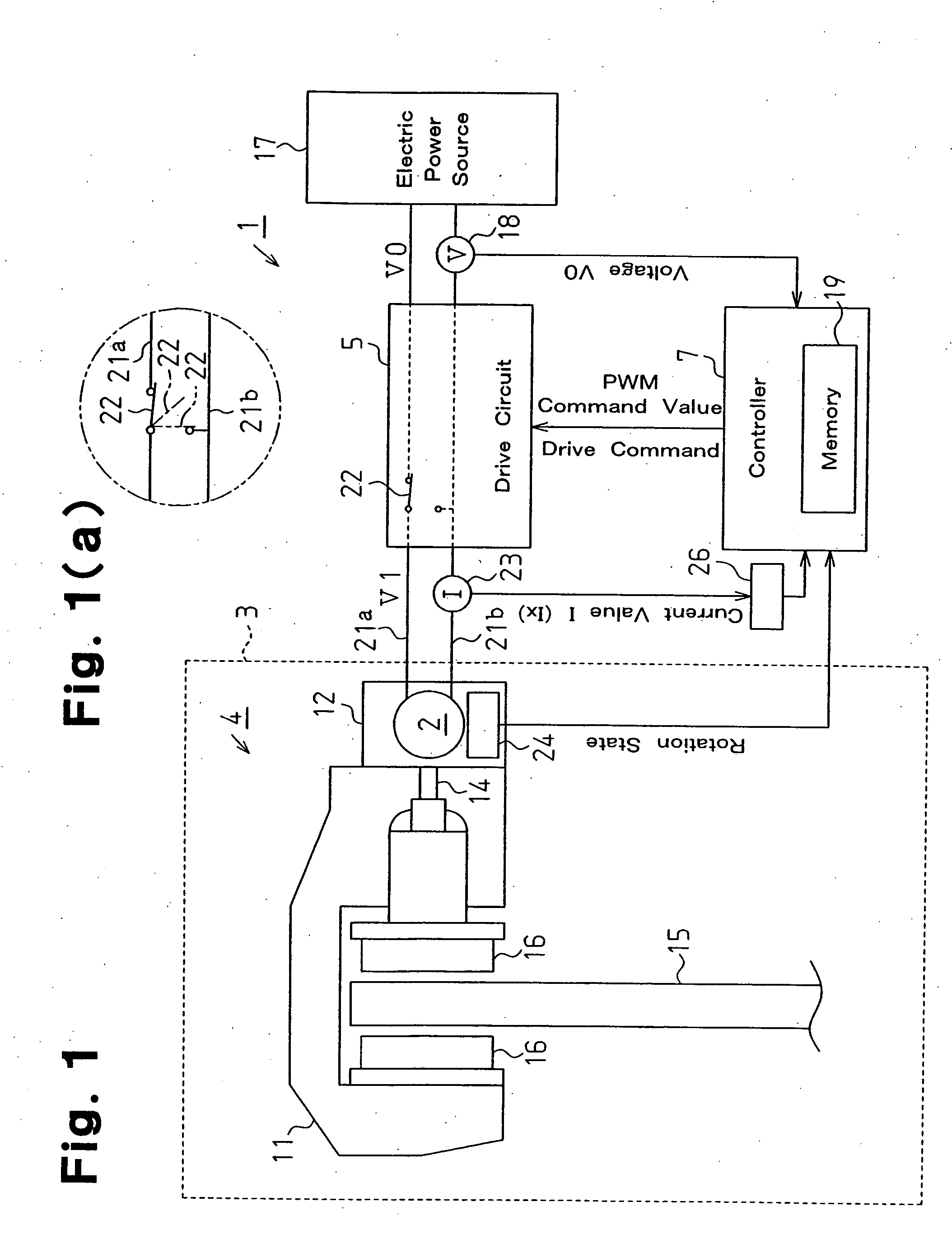

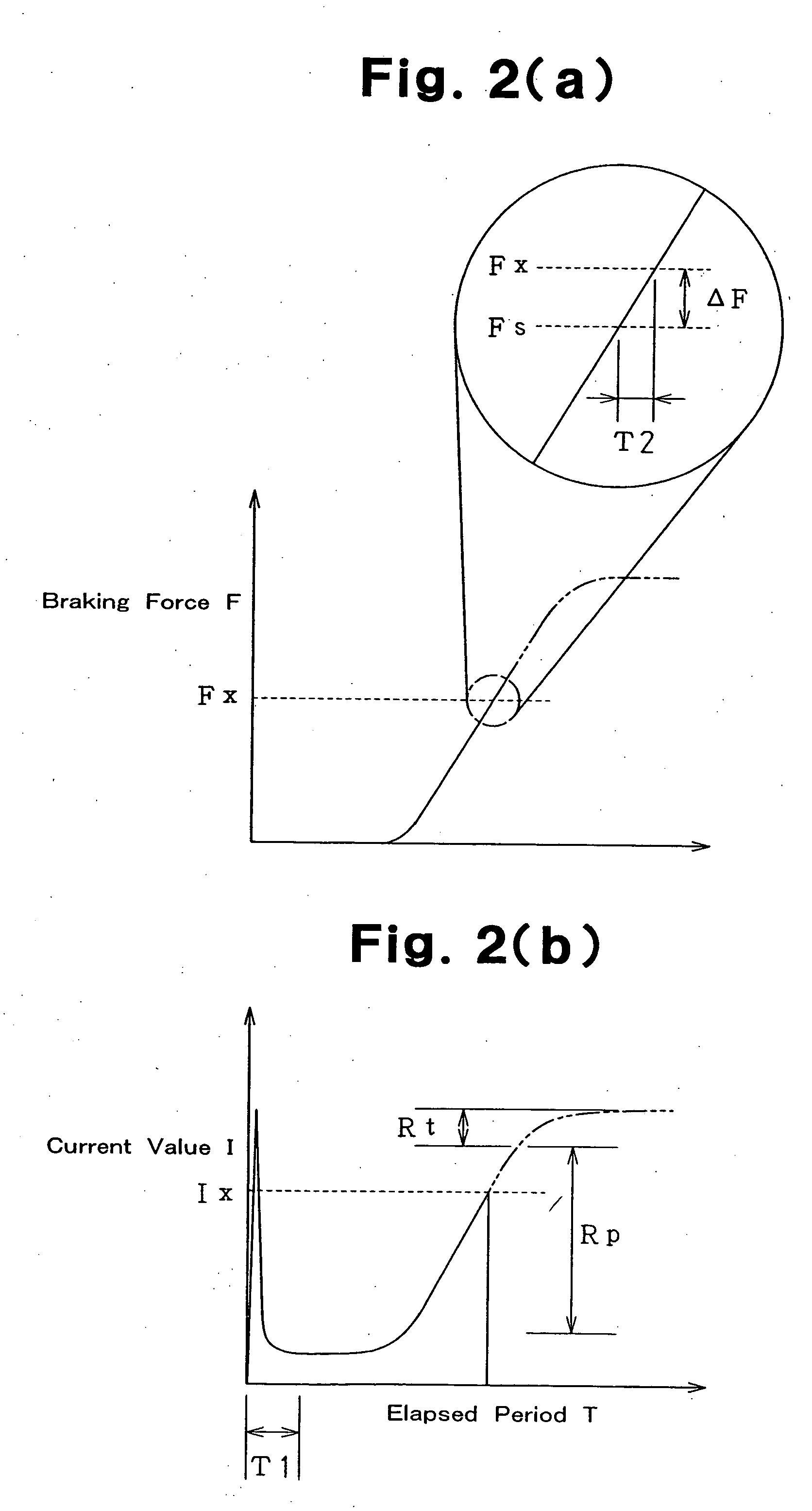

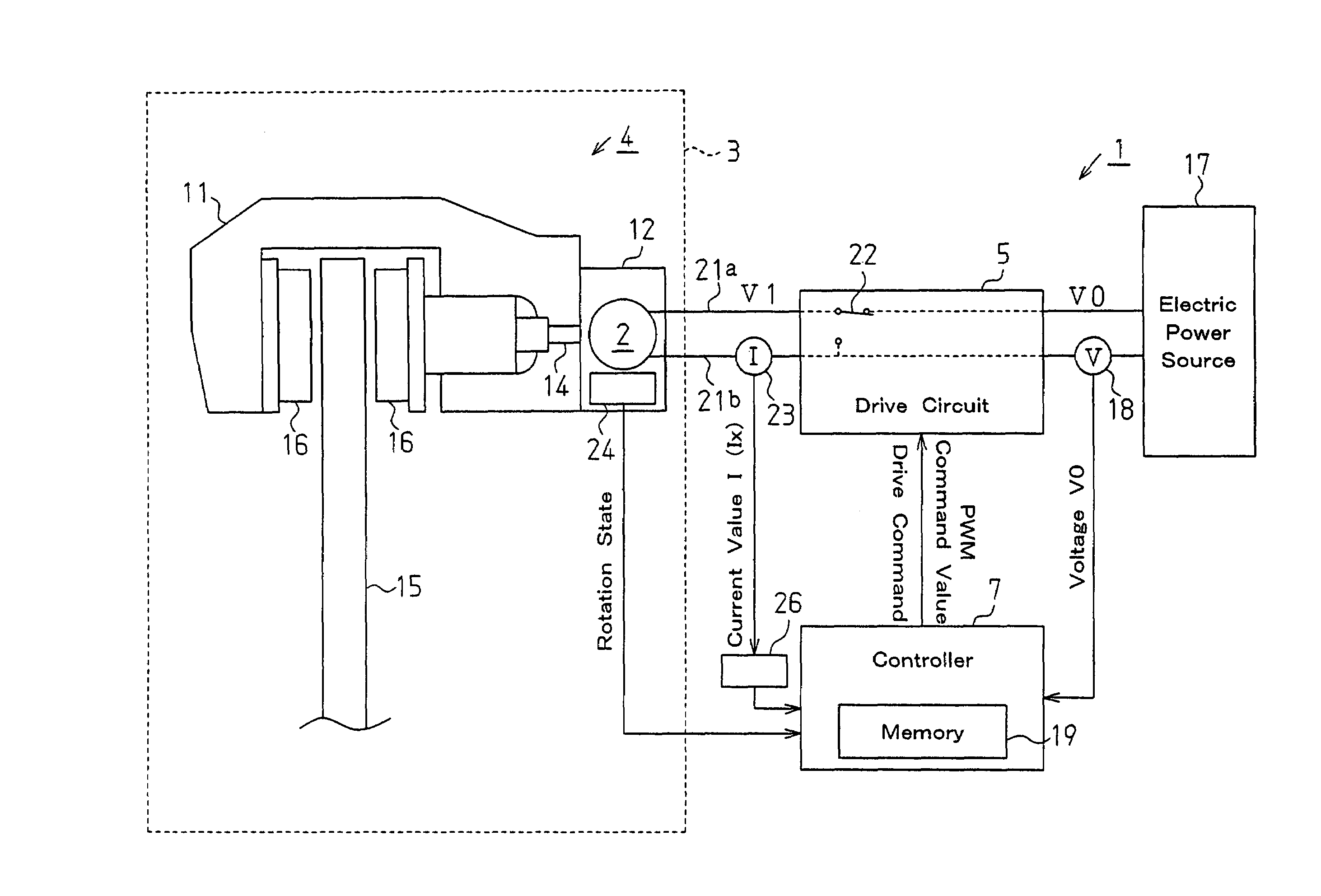

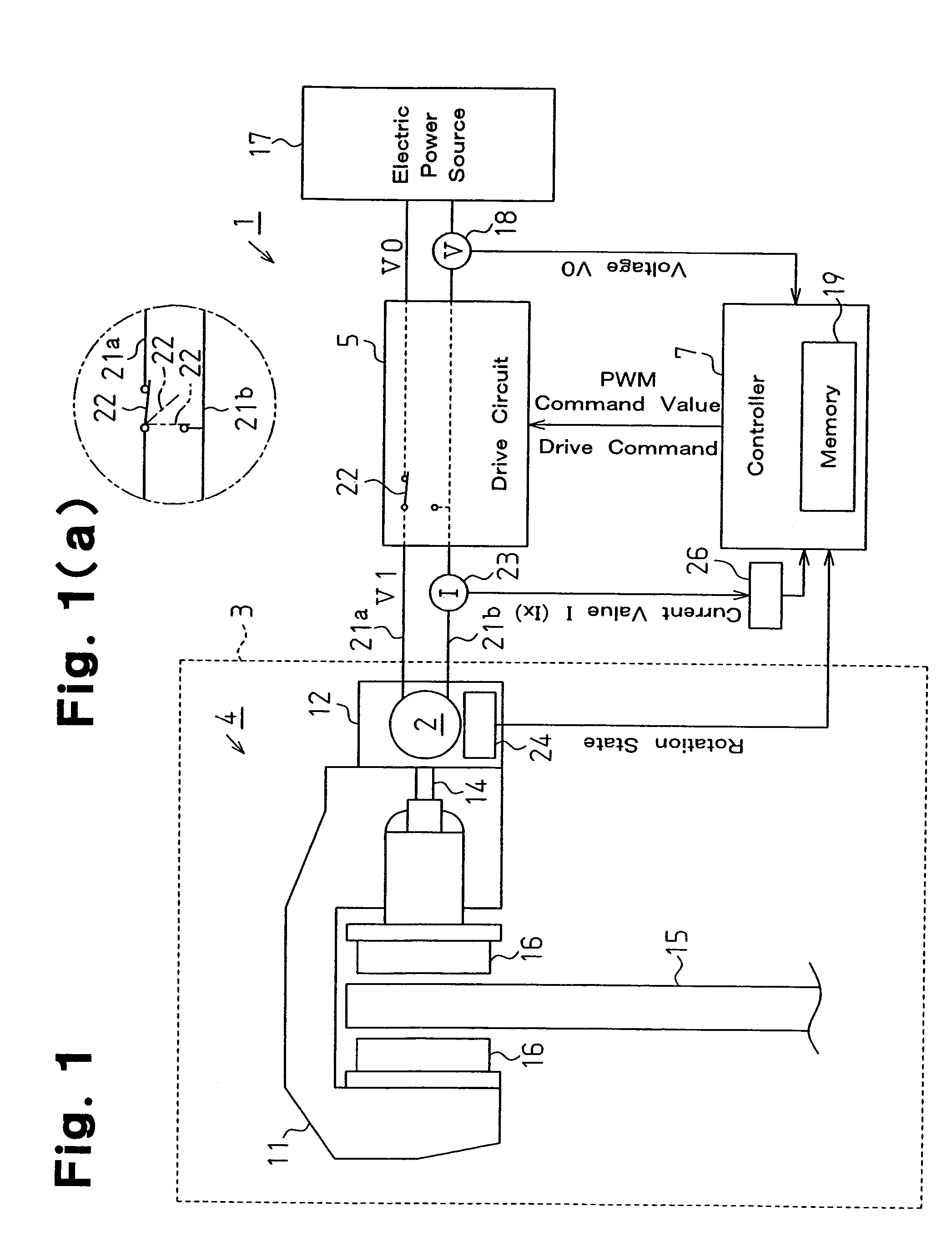

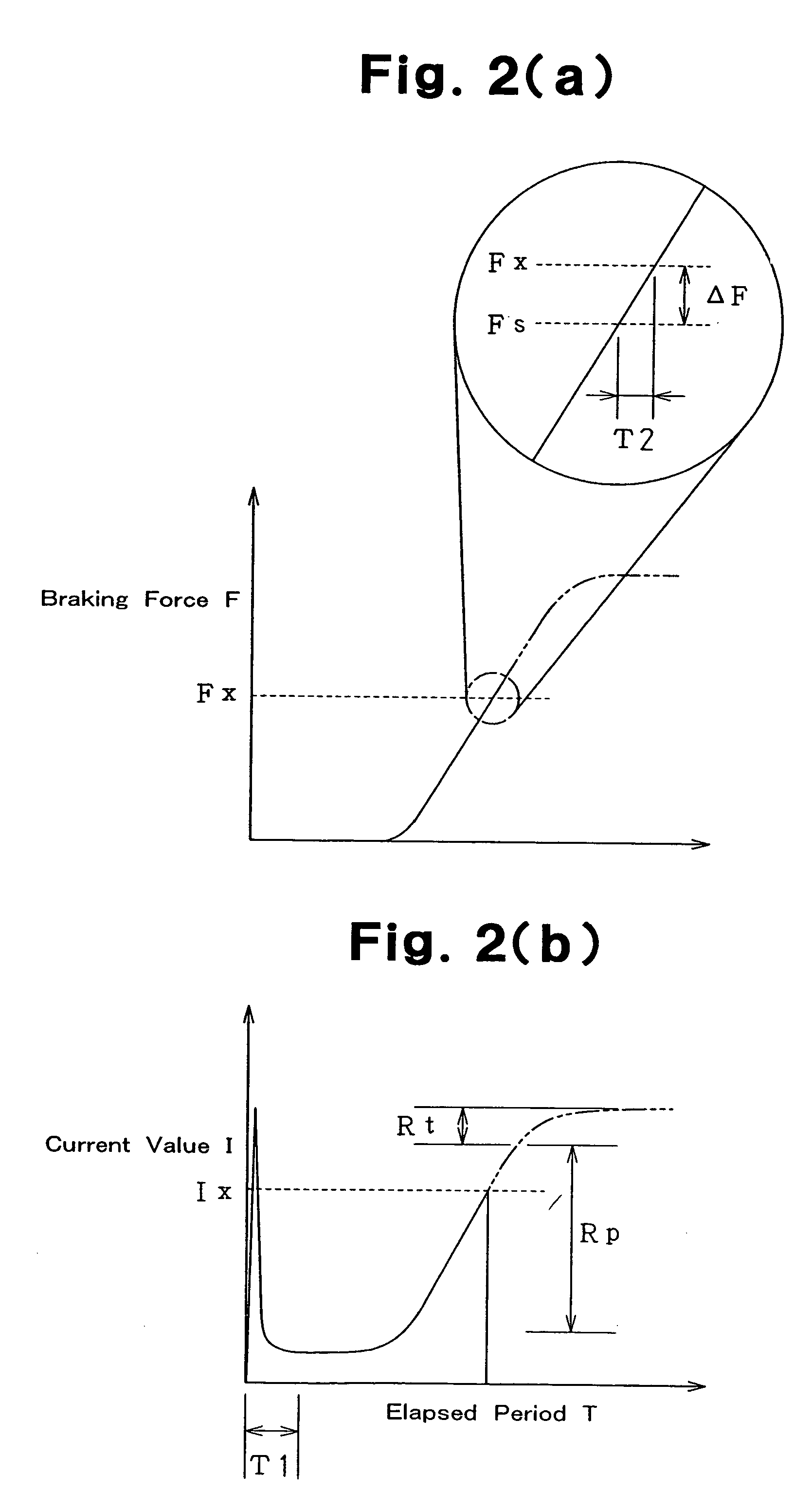

Electric parking brake system and method for controlling the same

InactiveUS20050046271A1Simple structureSteady braking forceBraking action transmissionElectrodynamic brake systemsElectricityElectric parking brake

An electric parking brake system includes motors, parking brakes, current a detection portion, a drive circuit, and a controller. The parking brakes are driven by the motors to apply braking force to wheels. The current detection portion detects the amount of current supplied to the motors. The drive circuit supplies a constant predetermined voltage to the motors. The controller controls supply of electricity to the motors. The drive circuit is controlled by the controller. When a detected current value exceeds a predetermined value, the controller stop supplying electricity to the motors.

Owner:ASMO CO LTD

Electric parking brake system and method for controlling the same

InactiveUS7052093B2Simple structureSteady braking forceBraking action transmissionElectrodynamic brake systemsElectricityElectric parking brake

An electric parking brake system includes motors, parking brakes, current a detection portion, a drive circuit, and a controller. The parking brakes are driven by the motors to apply braking force to wheels. The current detection portion detects the amount of current supplied to the motors. The drive circuit supplies a constant predetermined voltage to the motors. The controller controls supply of electricity to the motors. The drive circuit is controlled by the controller. When a detected current value exceeds a predetermined value, the controller stop supplying electricity to the motors.

Owner:ASMO CO LTD

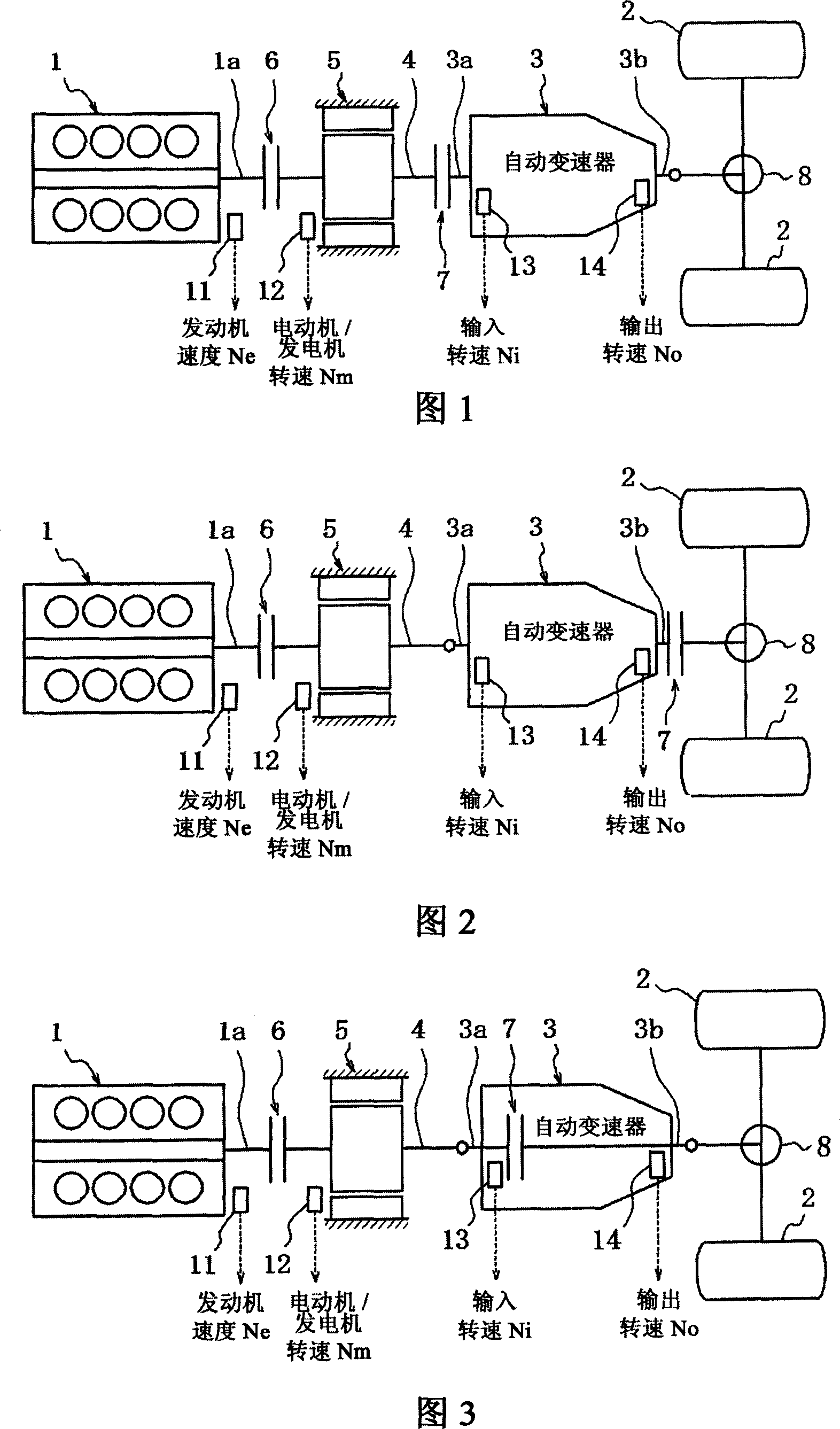

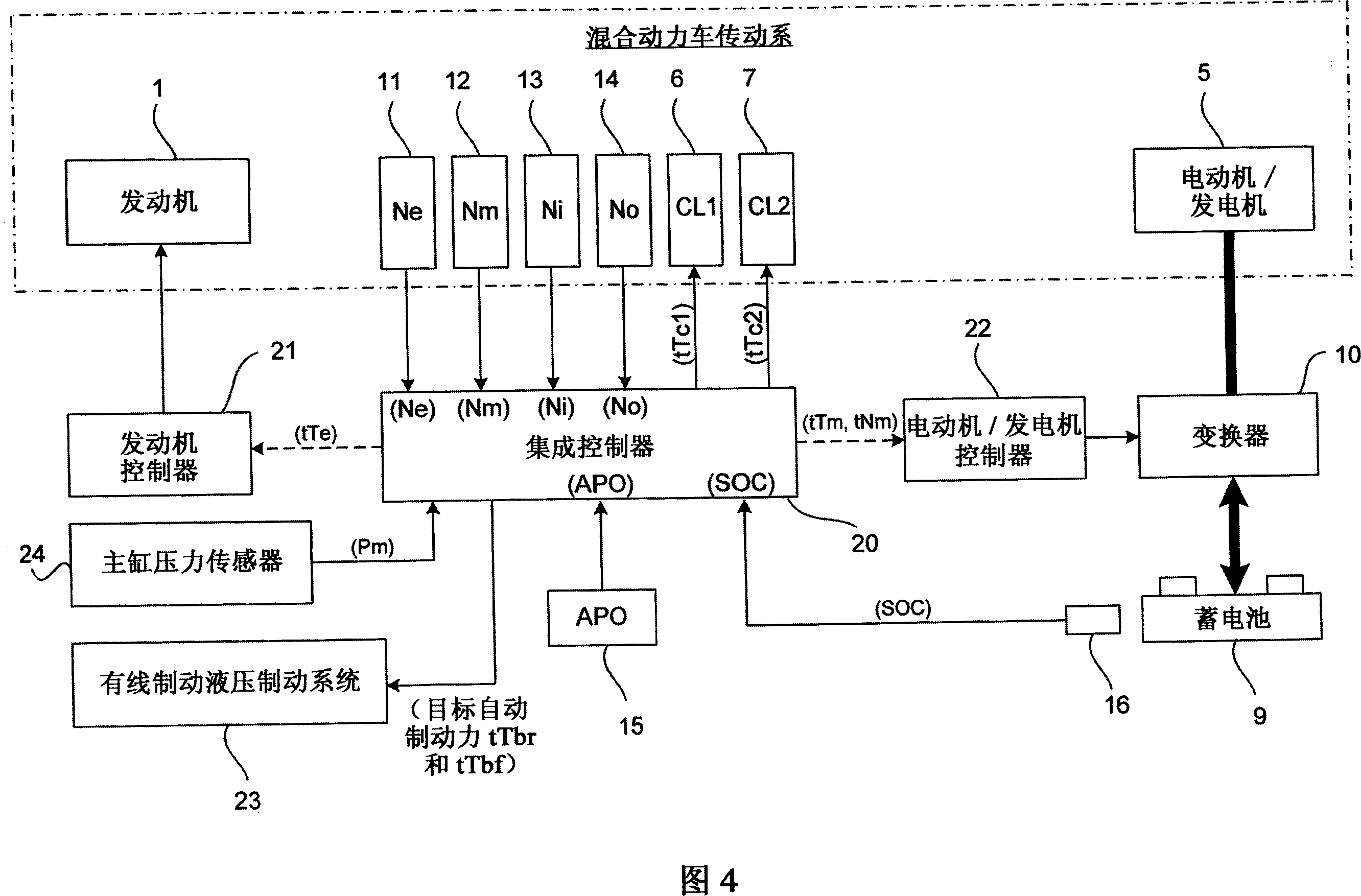

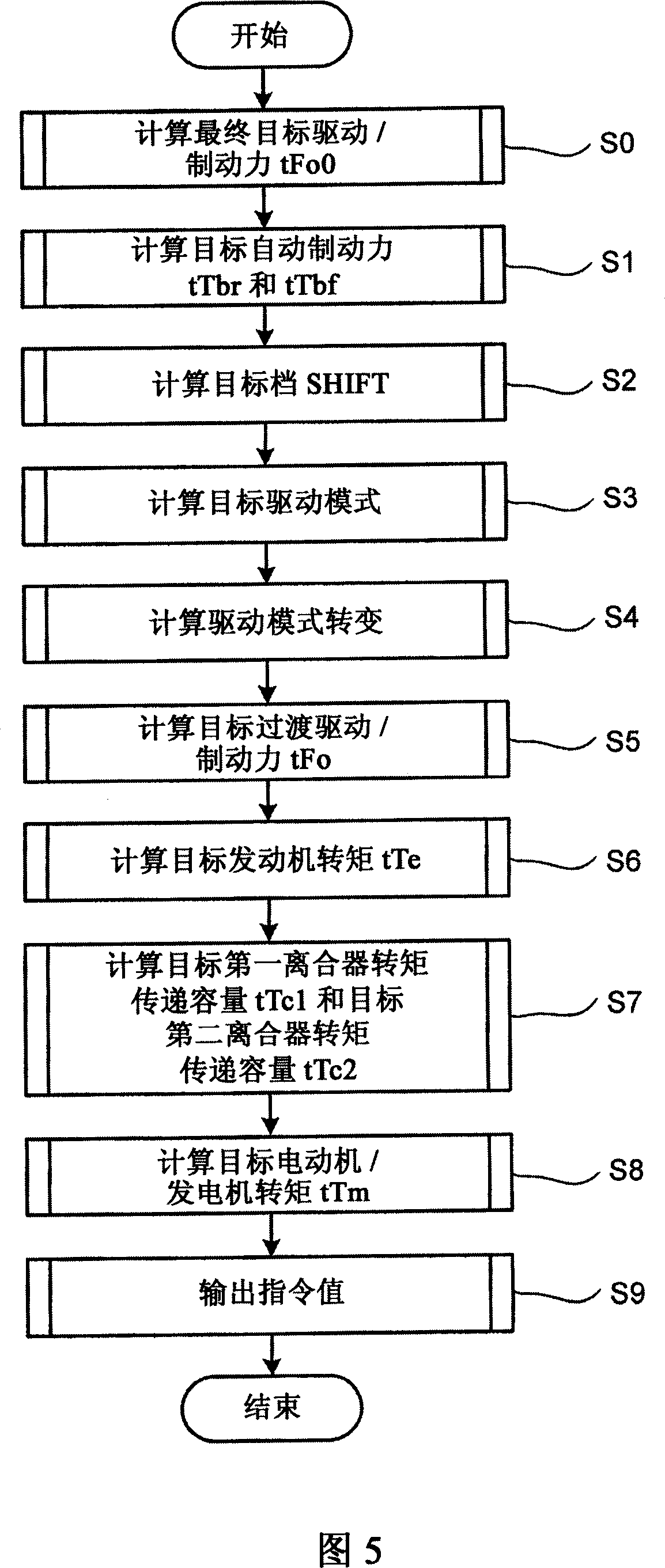

Hybrid vehicle control

InactiveCN1962332ASteady braking forceElectrodynamic brake systemsPropulsion using engine-driven generatorsControl systemAutomatic braking

A hybrid vehicle control system is configured to use automatic braking to compensate for an excess or deficiency of a braking force available from the power train of a hybrid vehicle that occurs when the hybrid vehicle switches from an electric drive (EV) mode to a hybrid drive (HEV) mode when the accelerator pedal depressing amount is detected as being substantially zero. In particular, hybrid vehicle control system determines whether a power train braking force from the power train is sufficient to achieve a target braking force. If the power train braking force is sufficient to achieve the target braking force when an accelerator pedal depressing amount is detected as being substantially zero, then a wheel brake is activated to apply a wheel braking force against a wheel of the vehicle to maintain the target braking force.

Owner:NISSAN MOTOR CO LTD

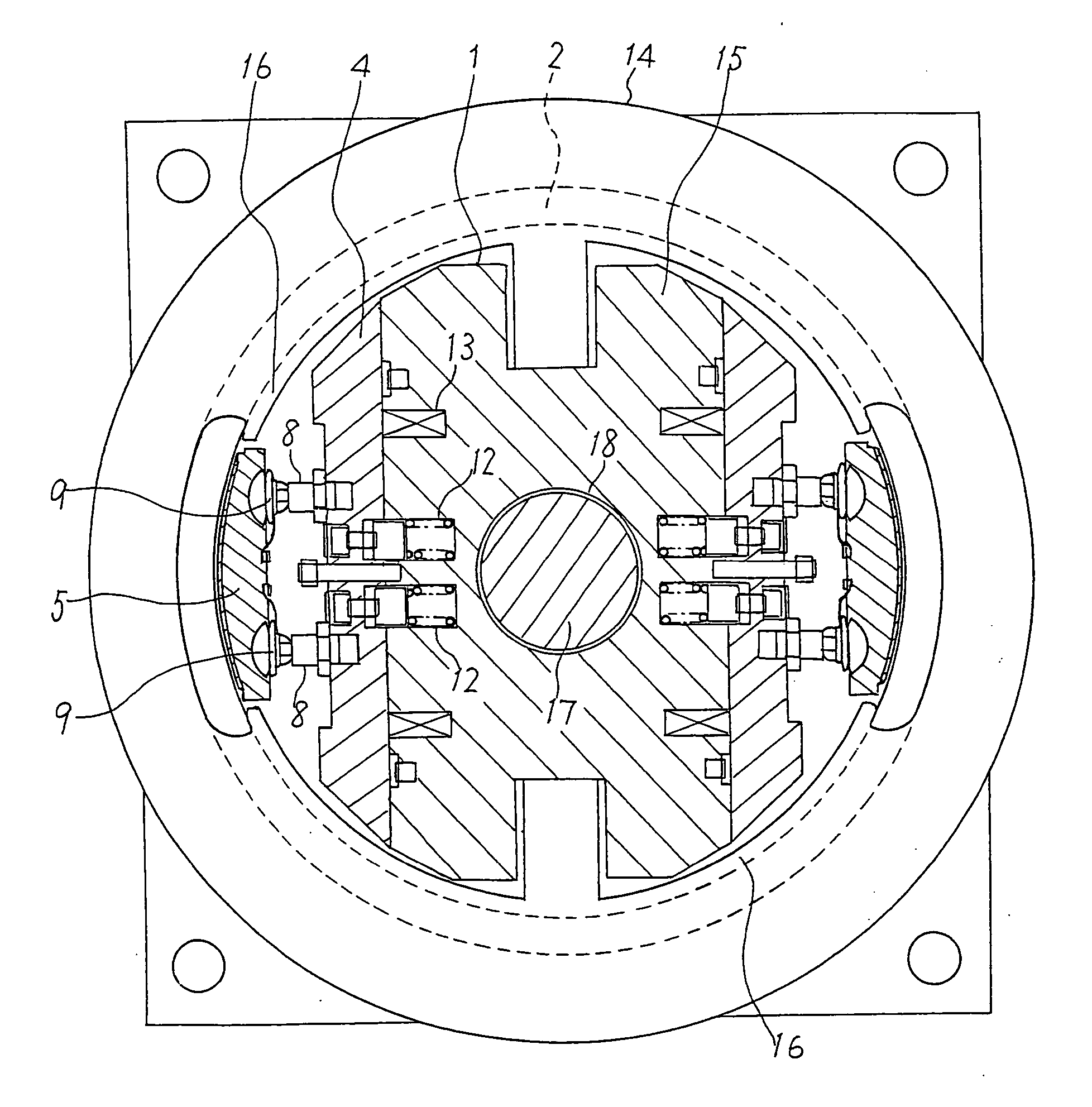

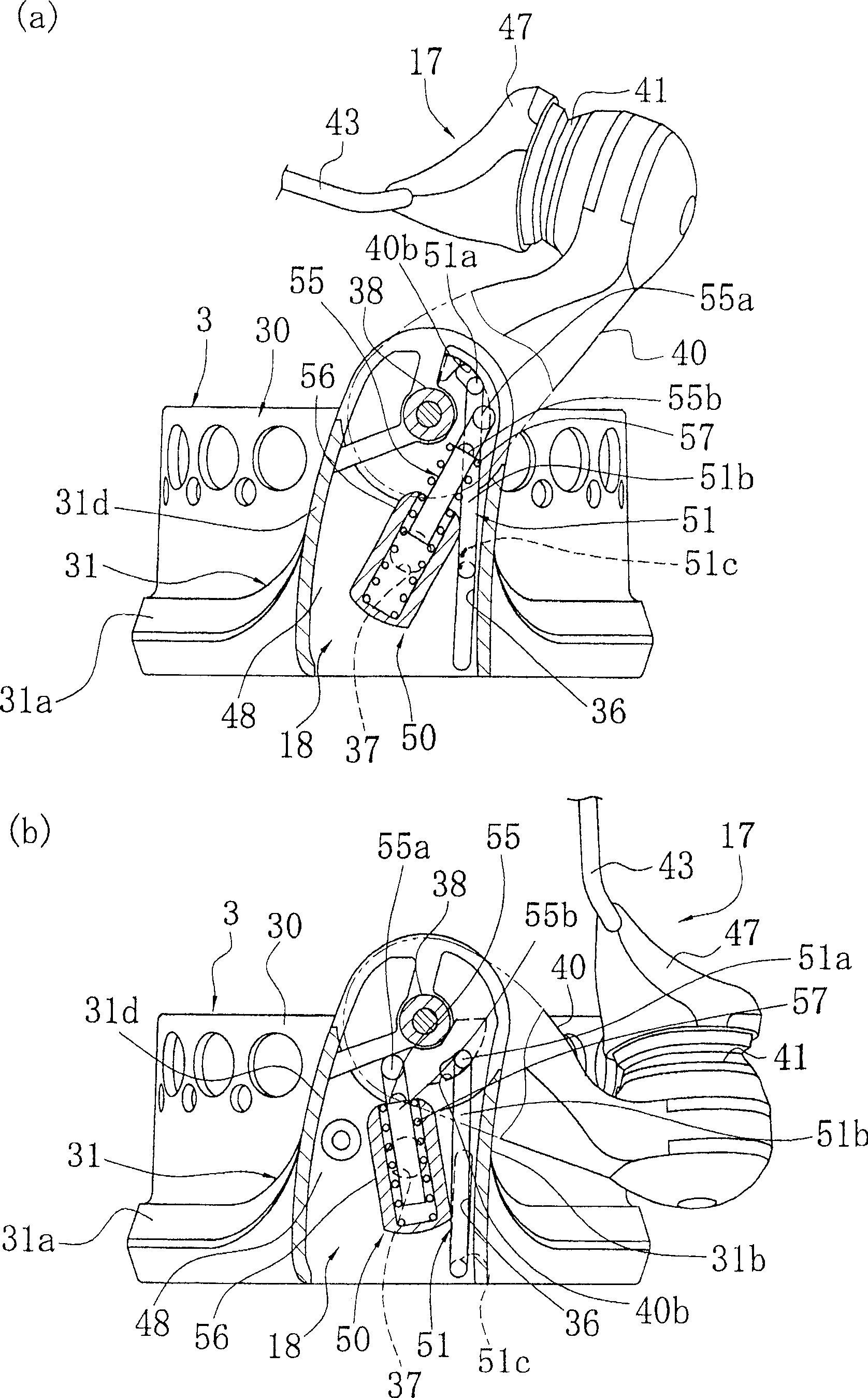

Brake structure of traction machine

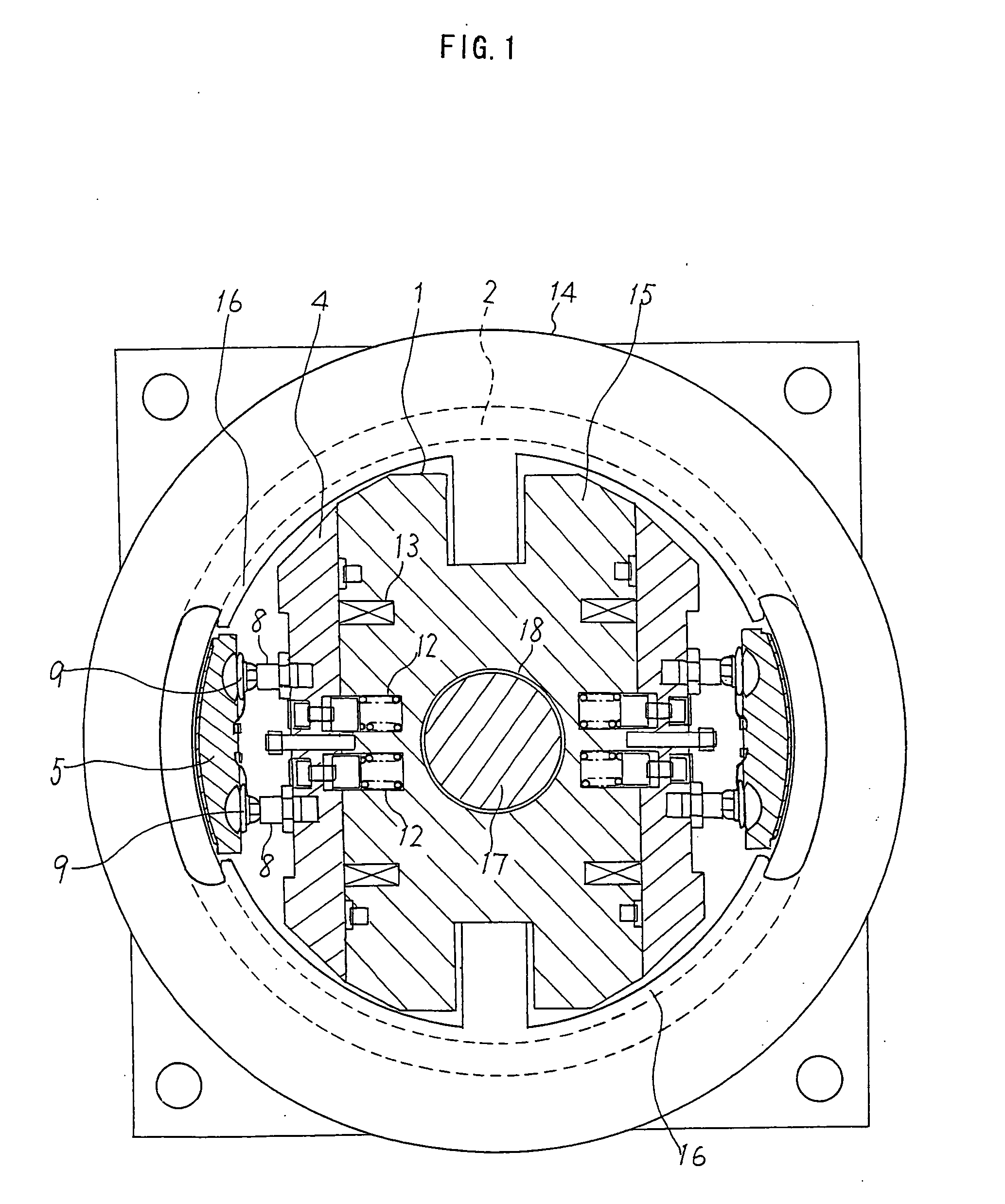

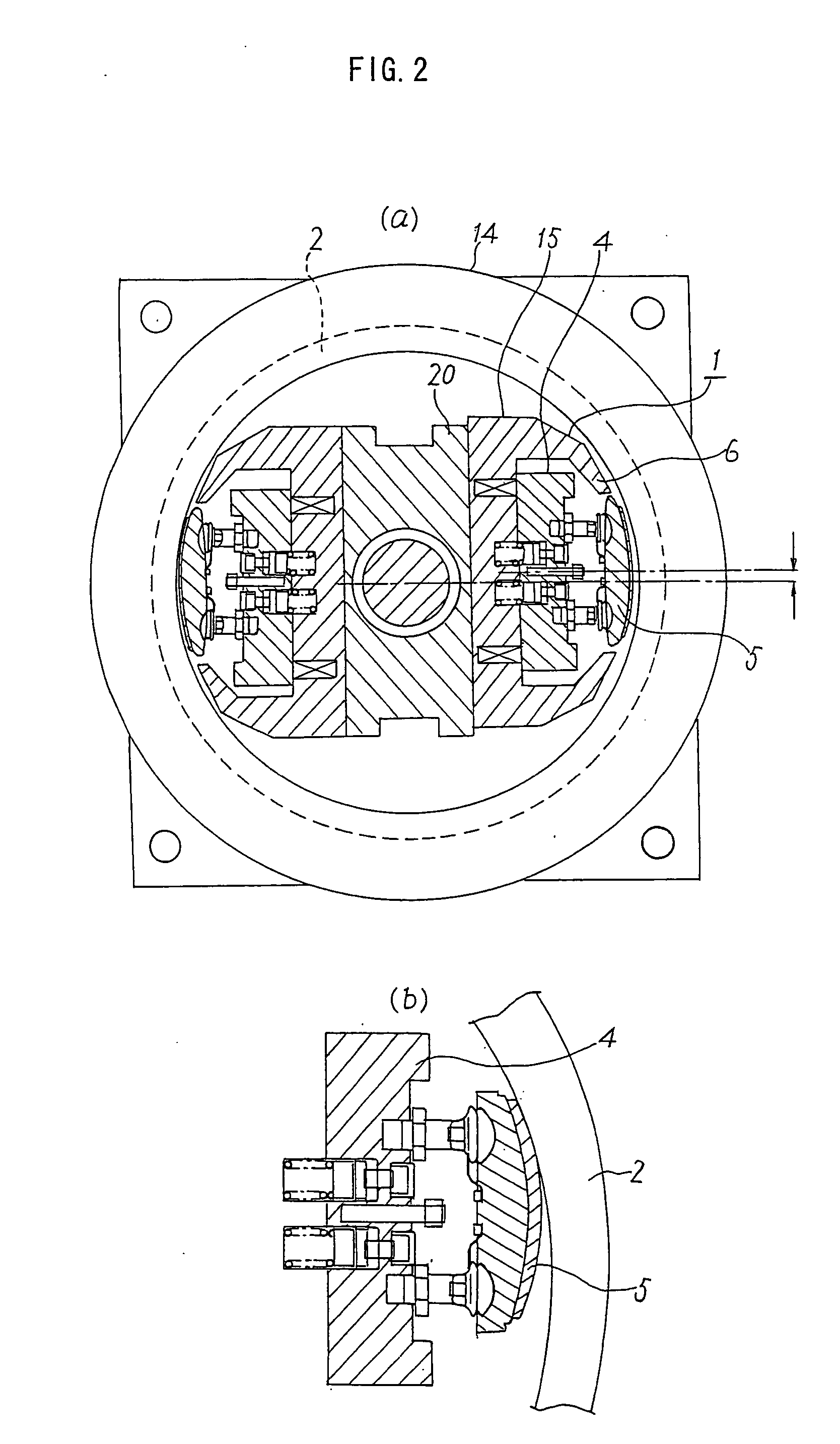

InactiveUS20040262102A1Steady braking forceStable ON/OFF action of brakeBraking action transmissionElectrodynamic brake systemsEngineeringBrake shoe

A brake structure of a traction machine includes a brake drum which is made rotatable about a shaft disposed on a rotary axis of the traction machine, and an electromagnetic brake unit built in an inner space of the brake drum. The electromagnetic brake unit includes a plurality of movable iron cores, a plurality of brake shoes located on the outside of the individual movable iron cores and joined thereto by connecting members, the brake shoes having curved outer surfaces facing a curved inner surface of the brake drum, and a one-piece formed stationary iron core block. The one-piece formed stationary iron core block has a plurality of stationary iron core portions joined to the individual movable iron cores via compression springs for forcing the individual brake shoes against the curved inner surface of the brake drum via the movable iron cores and the connecting members.

Owner:MITSUBISHI ELECTRIC CORP

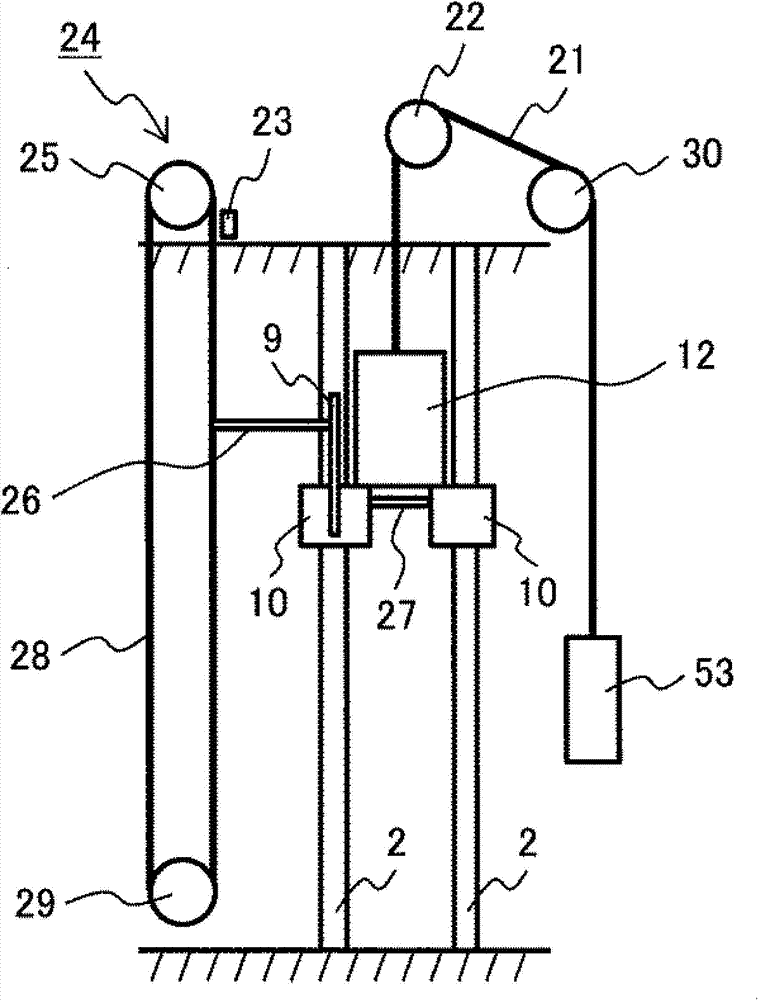

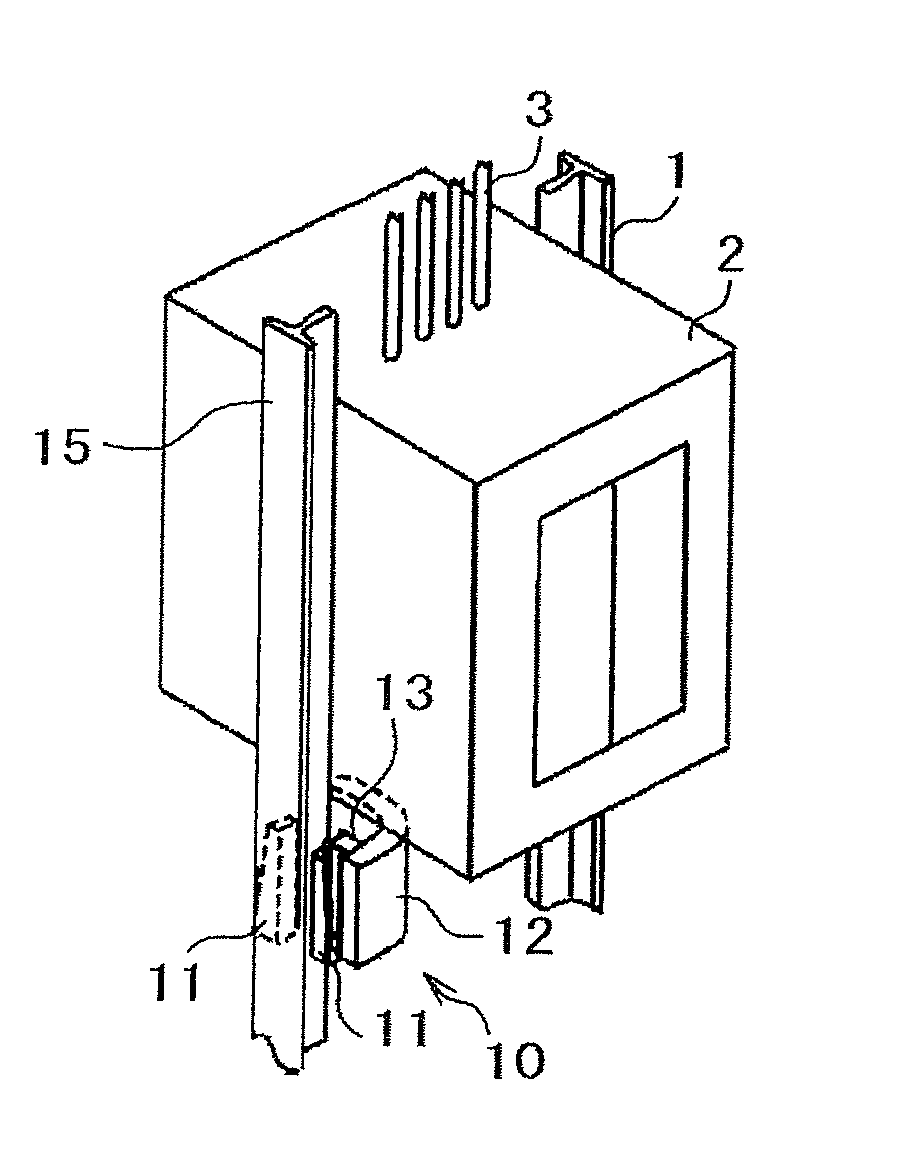

Emergency braking device of elevator

InactiveCN103771213ASteady braking forceInhibition heightElevatorsArresting gearAutomotive engineering

The invention provides an emergency braking device of an elevator. The device restrains position variation of brake components in a braking initial period and generates stable braking forces, so as to effectively stop the elevator by a specified deceleration. In the elevator with the emergency braking device, in order to stop the elevator car, the emergency braking device makes the brake components slidably press guiding rails in an elevating channel, so as to generate braking forces. The elevator is provided with a maintaining mechanism. The maintaining mechanism maintains a lifting component on the elevator car when the brake components are lifted, and when the brake components are reset, the lifting component of the brake components is separated from the elevator car through lifting operation of the elevator car.

Owner:HITACHI LTD

Disc brake

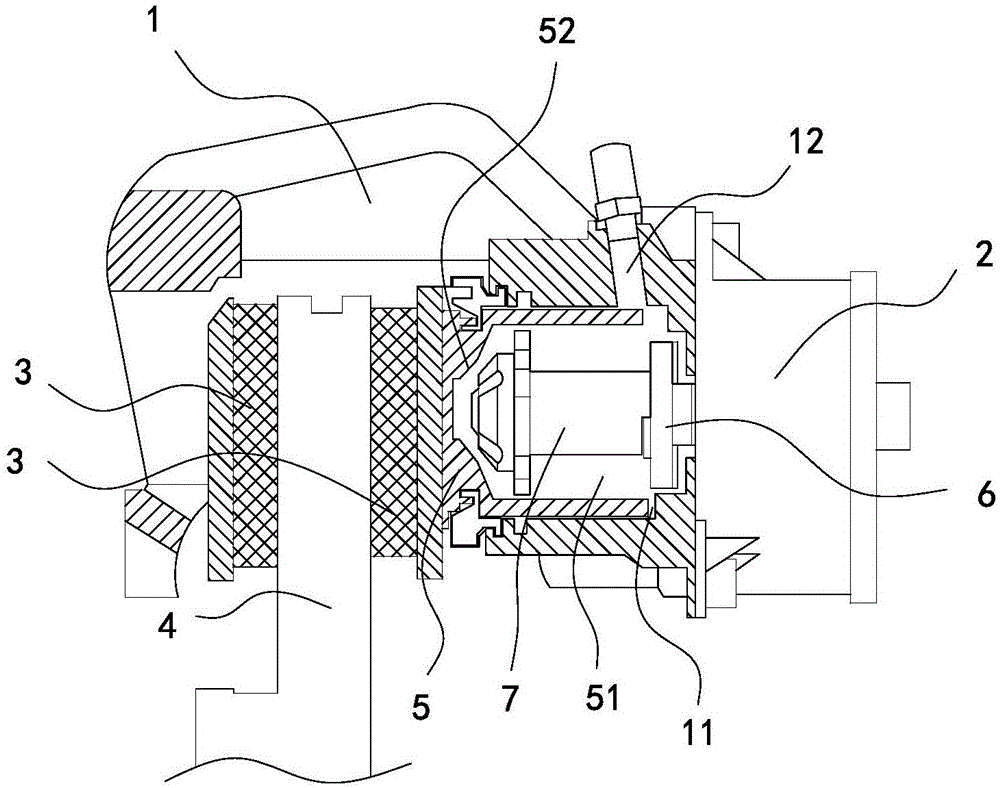

ActiveUS20150053511A1Avoid draggingReduce frictionAxially engaging brakesSlack adjustersEngineeringCalipers

Disclosed is a disc brake including a carrier on which a pair of pad plates are movably installed and a caliper housing, which is slidably installed on the carrier and is provided with a cylinder having a piston mounted so as to move forward and backward by a hydraulic braking pressure, the disc brake including: an adjuster installed in the piston to prevent the pad plates from moving away from a disc and to maintain the pad plates at a constant distance from the disc; a push rod installed in the cylinder, a front portion thereof being screw-coupled to the adjuster and a rear portion thereof being provided with a flange extending toward an inner circumferential surface of the cylinder; a ramp unit into which the rear portion of the push rod is inserted and which is installed in the cylinder and compresses the push rod toward the piston in cooperation with a parking cable to prevent rotation of the push rod; a spring case having an end portion of one side thereof fixed to the cylinder and forming a predetermined accommodation space between the inner circumferential surface of the cylinder and the push rod; a first elastic member and a second elastic member arranged in series with each other in the accommodation space of the spring case to provide elastic force to the push rod; and a support plate supported by an end portion of the ramp unit and interposed between the first elastic member and the second elastic member.

Owner:HL MANDO CORP

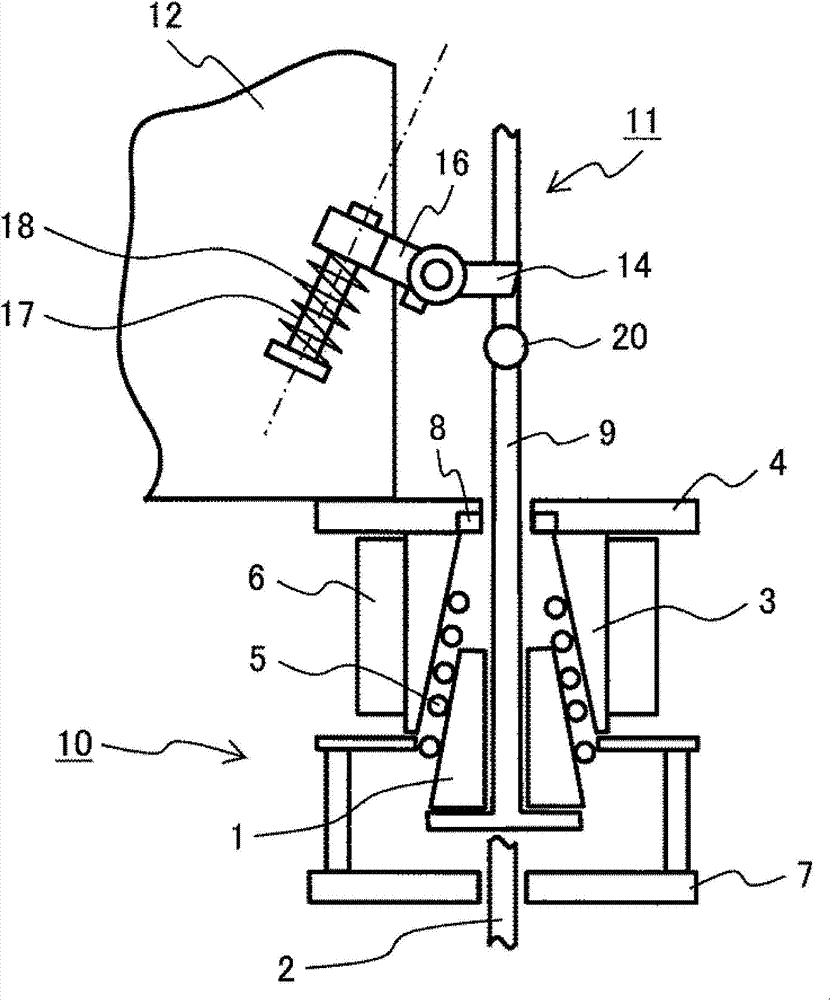

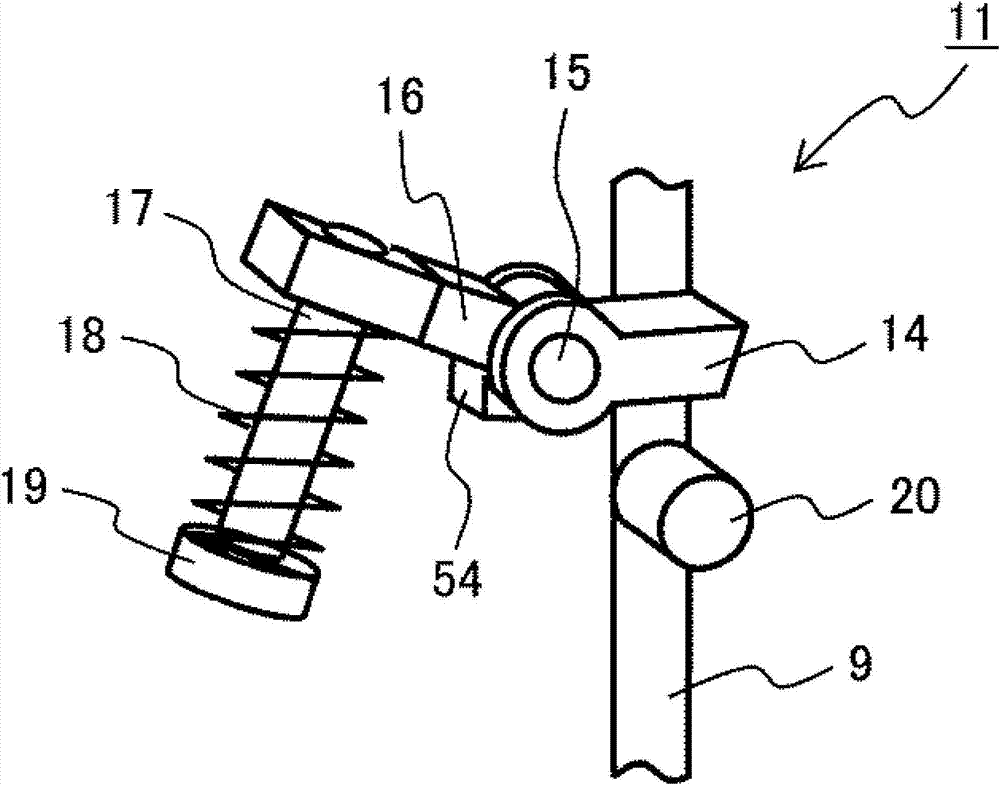

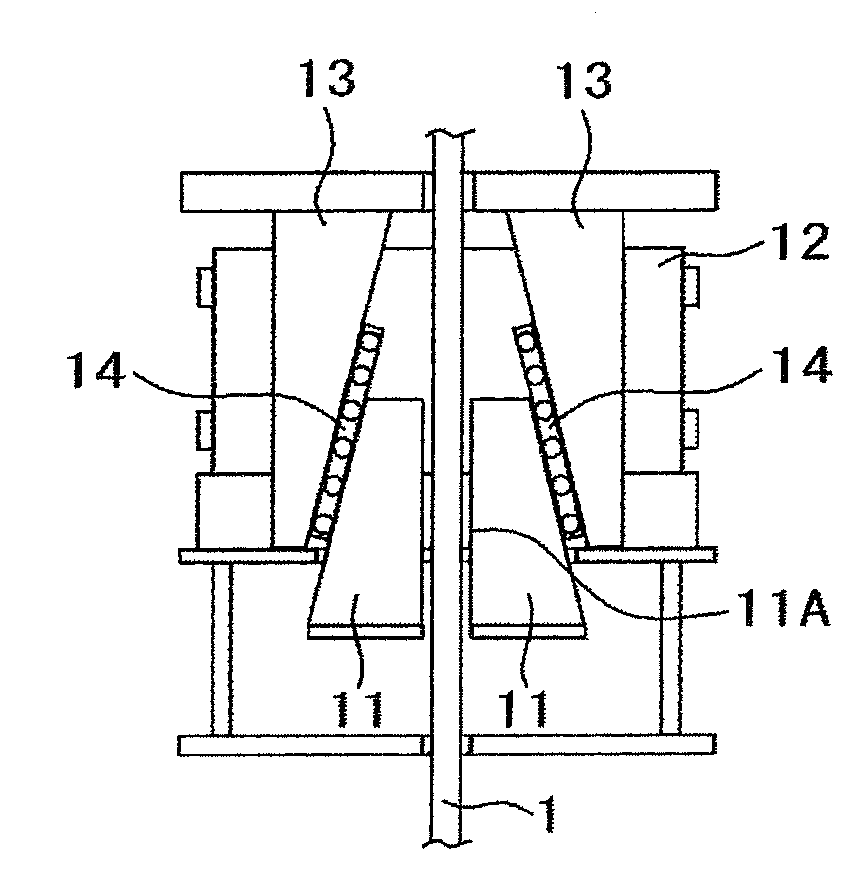

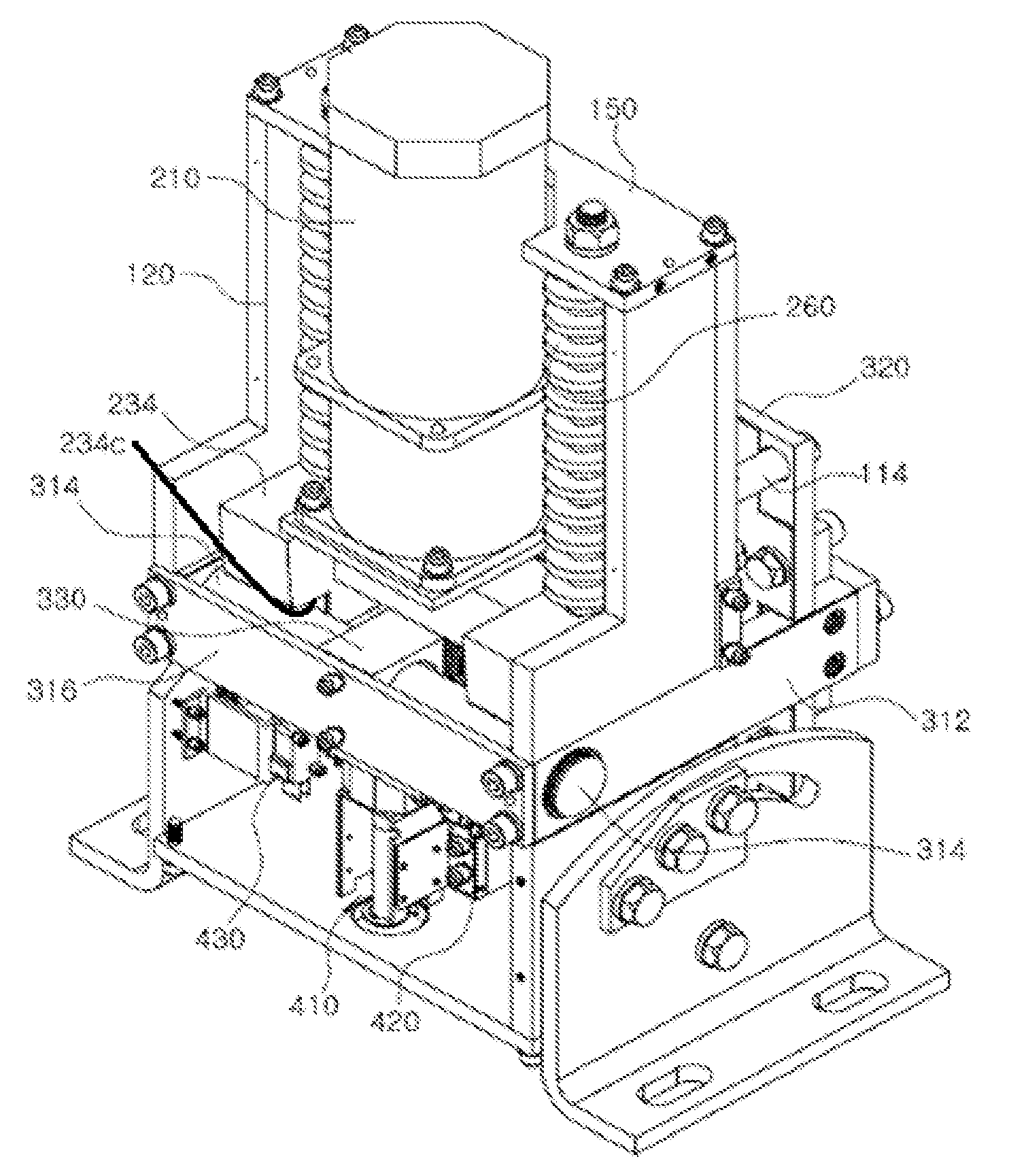

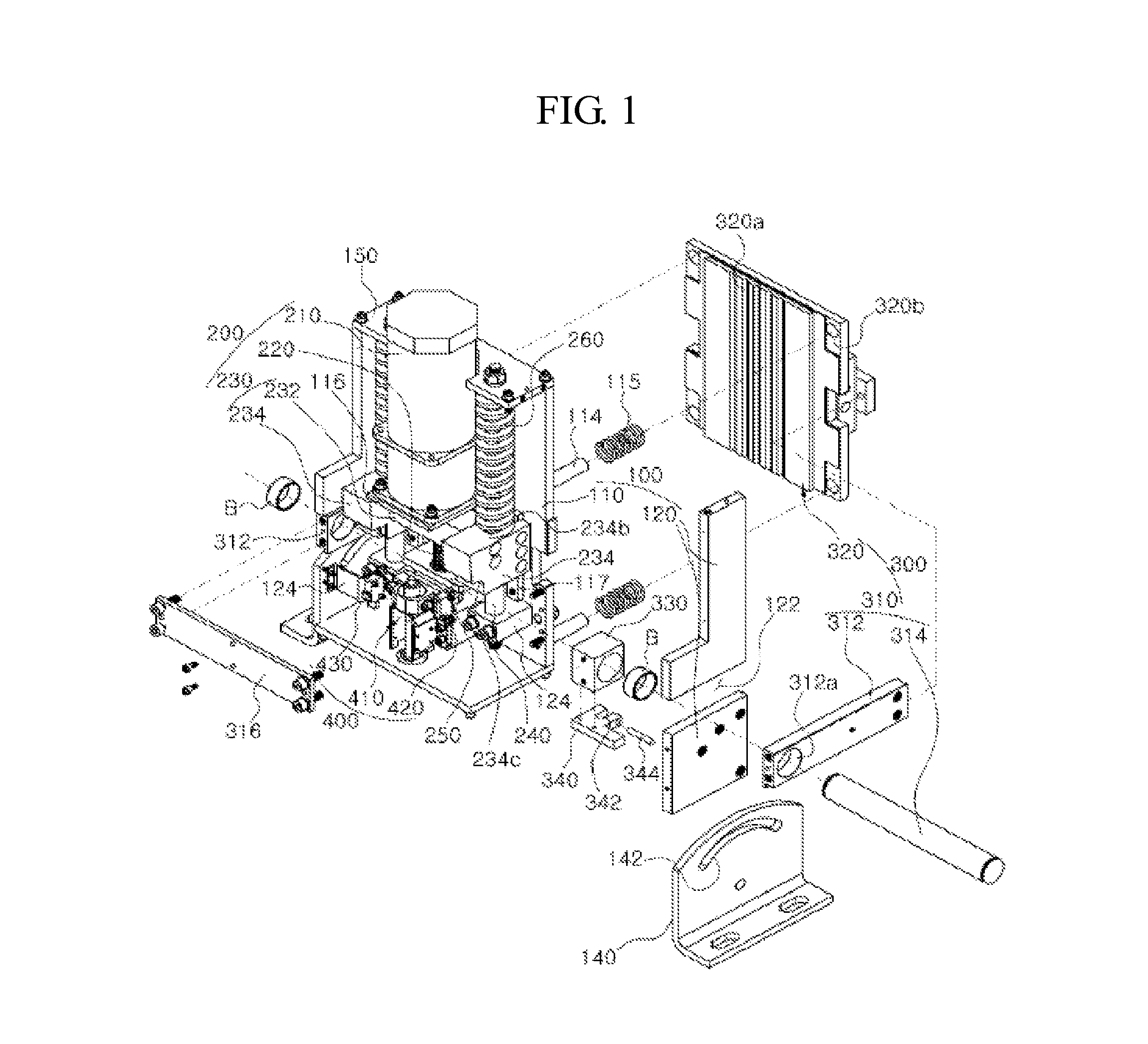

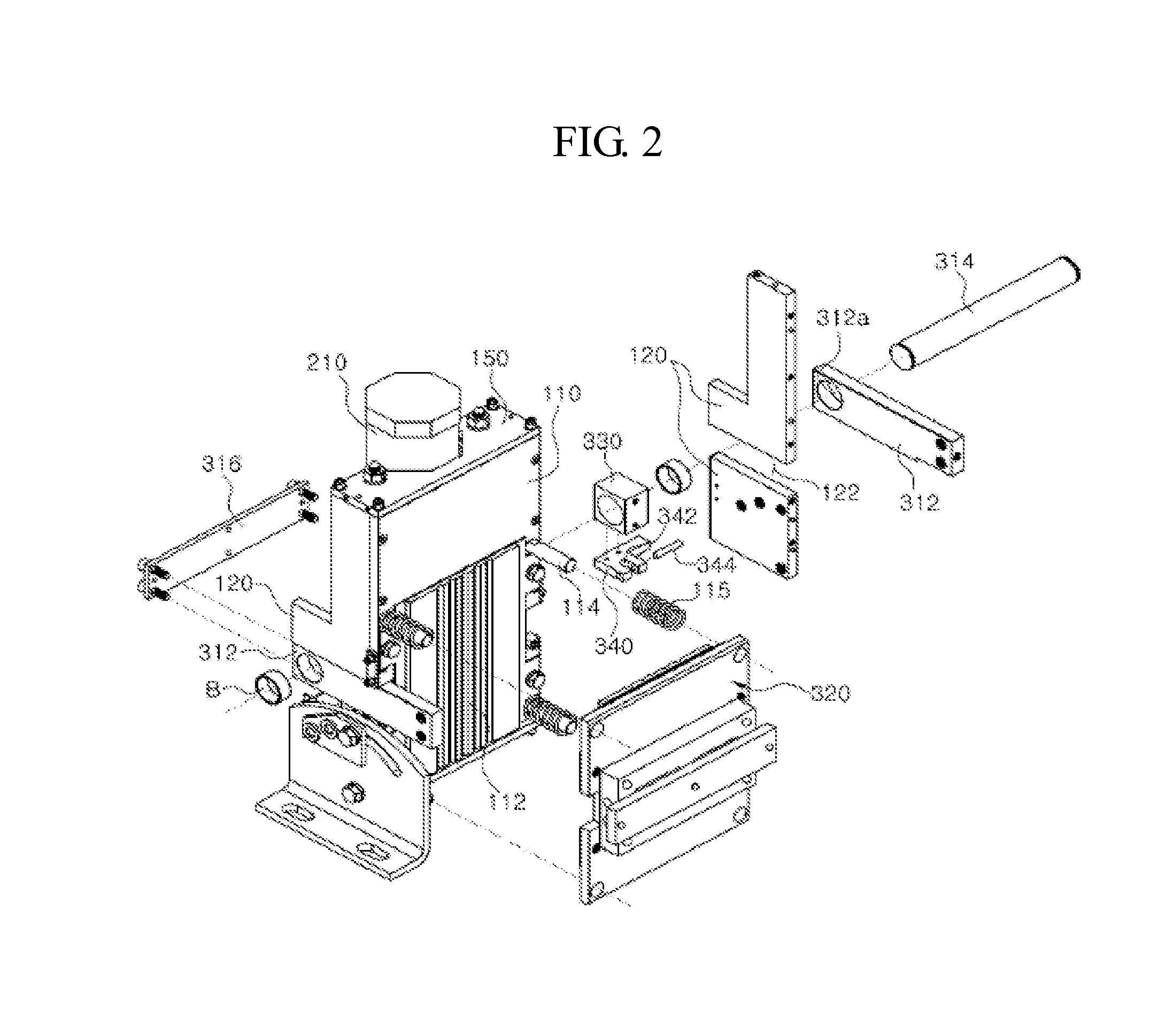

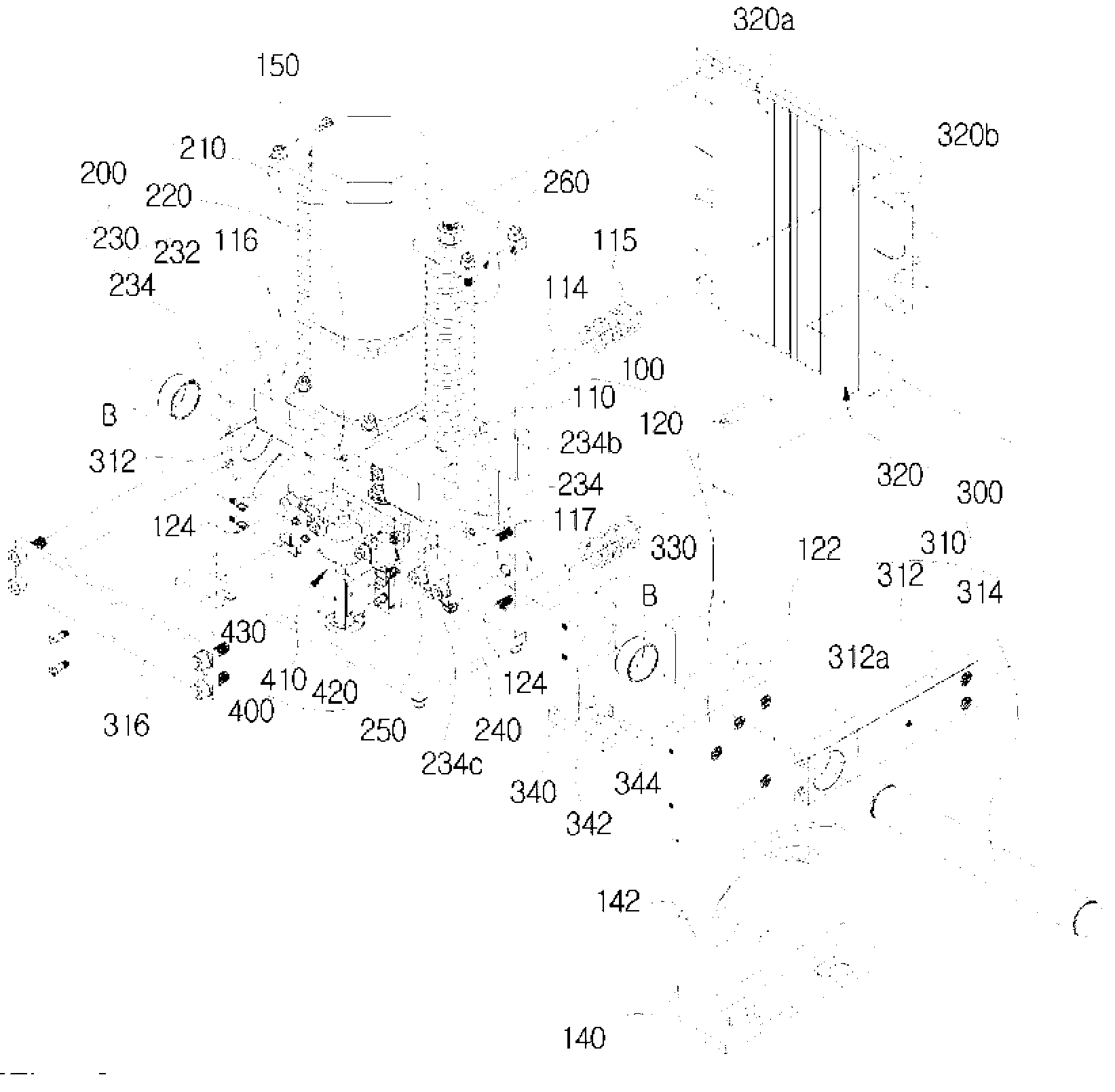

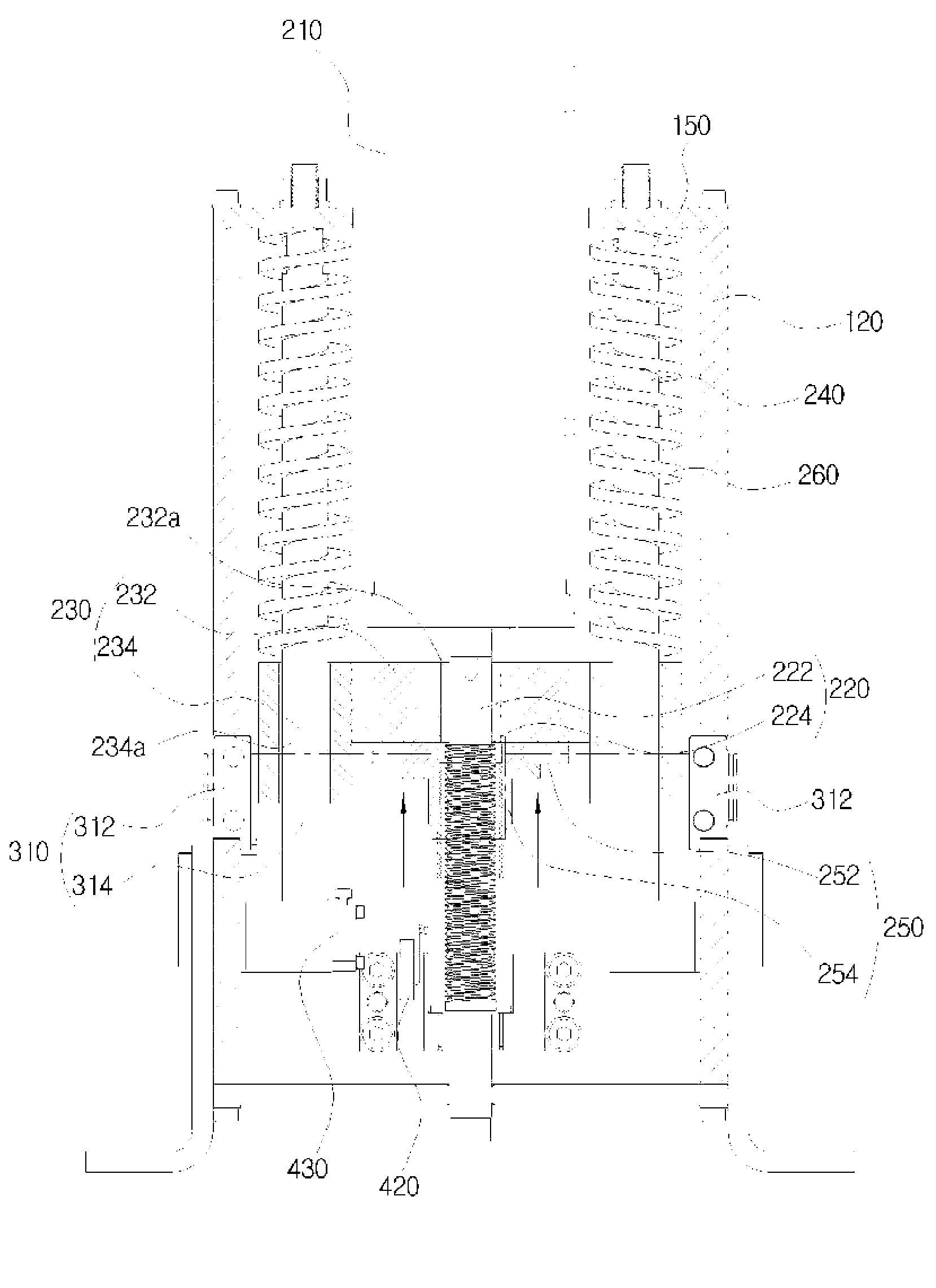

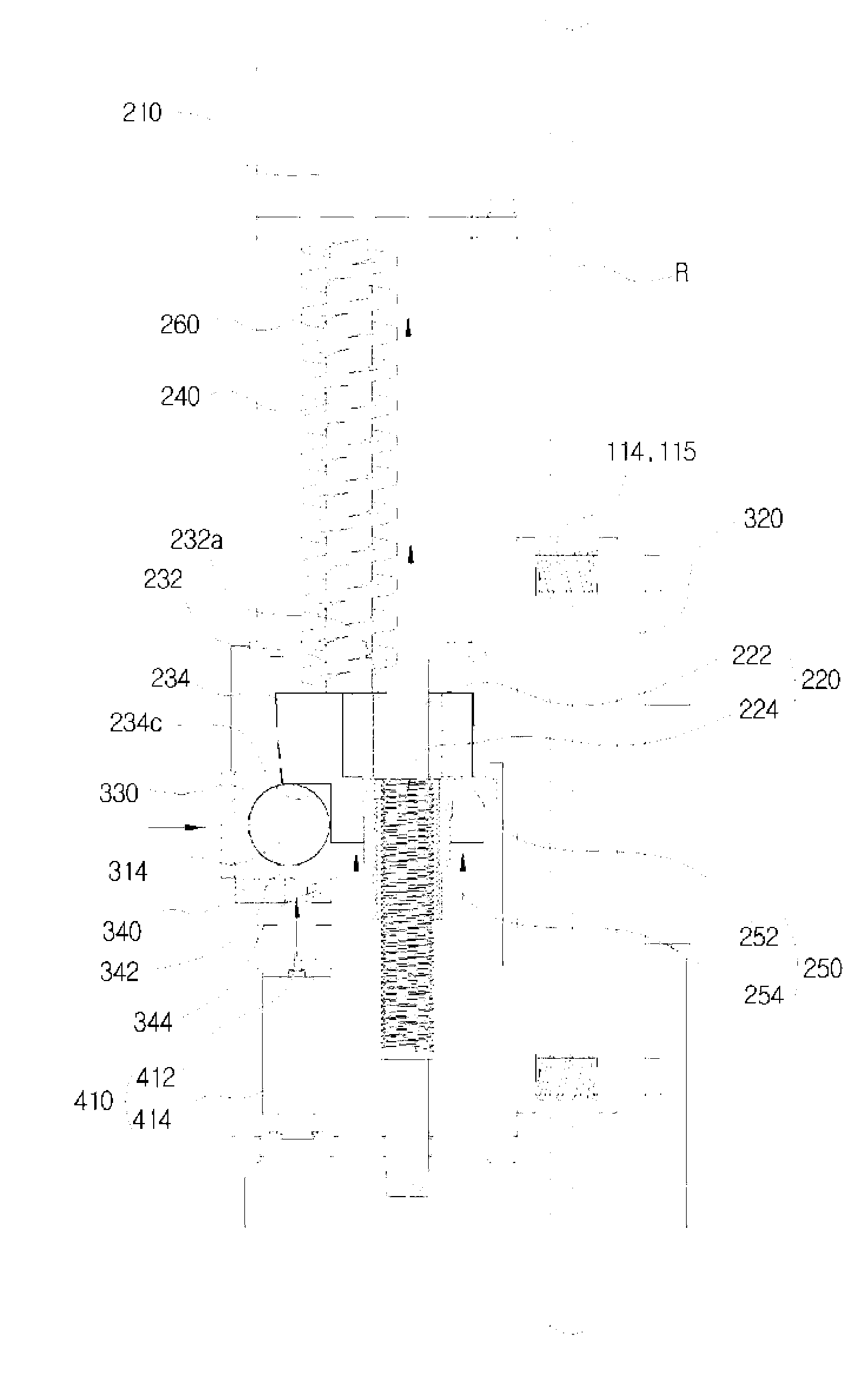

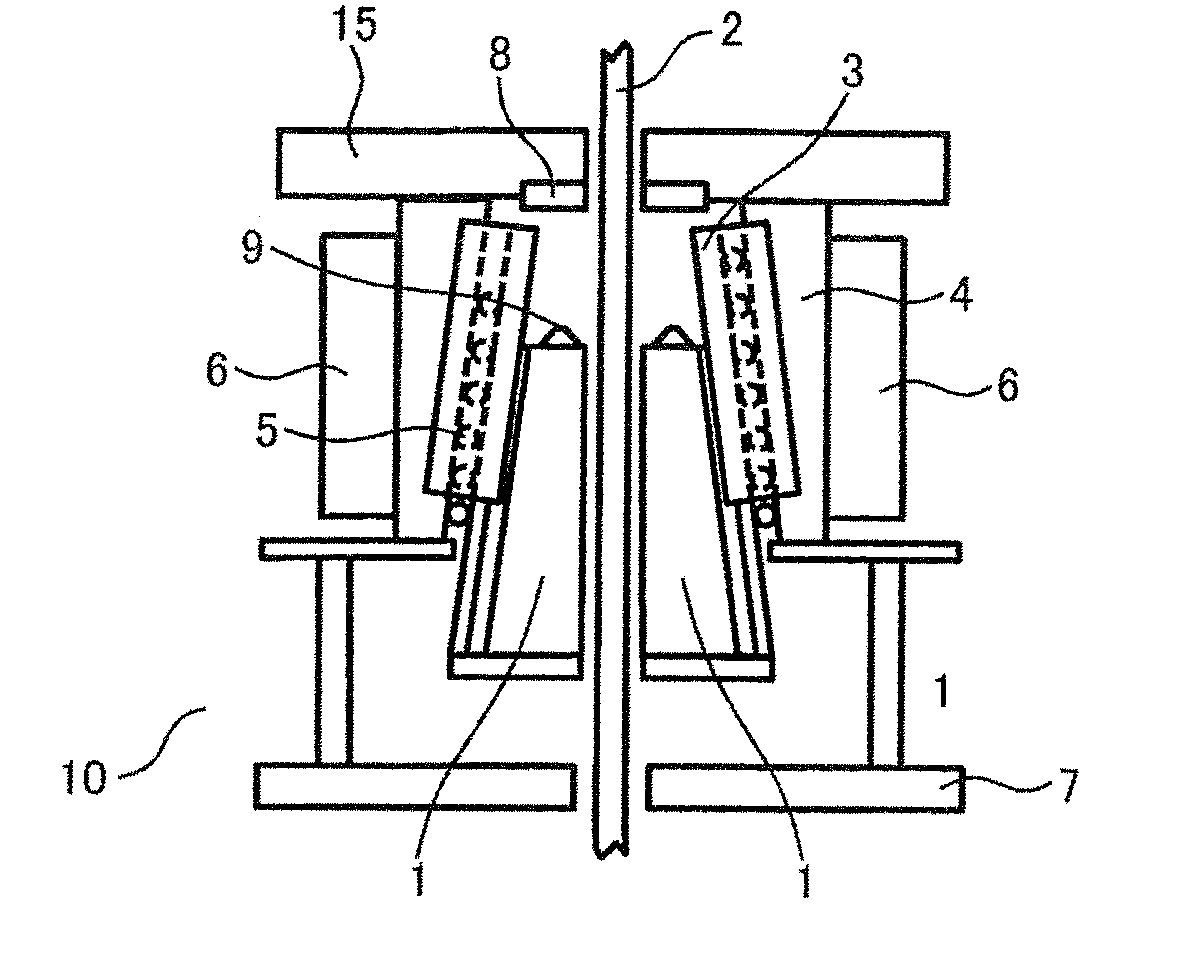

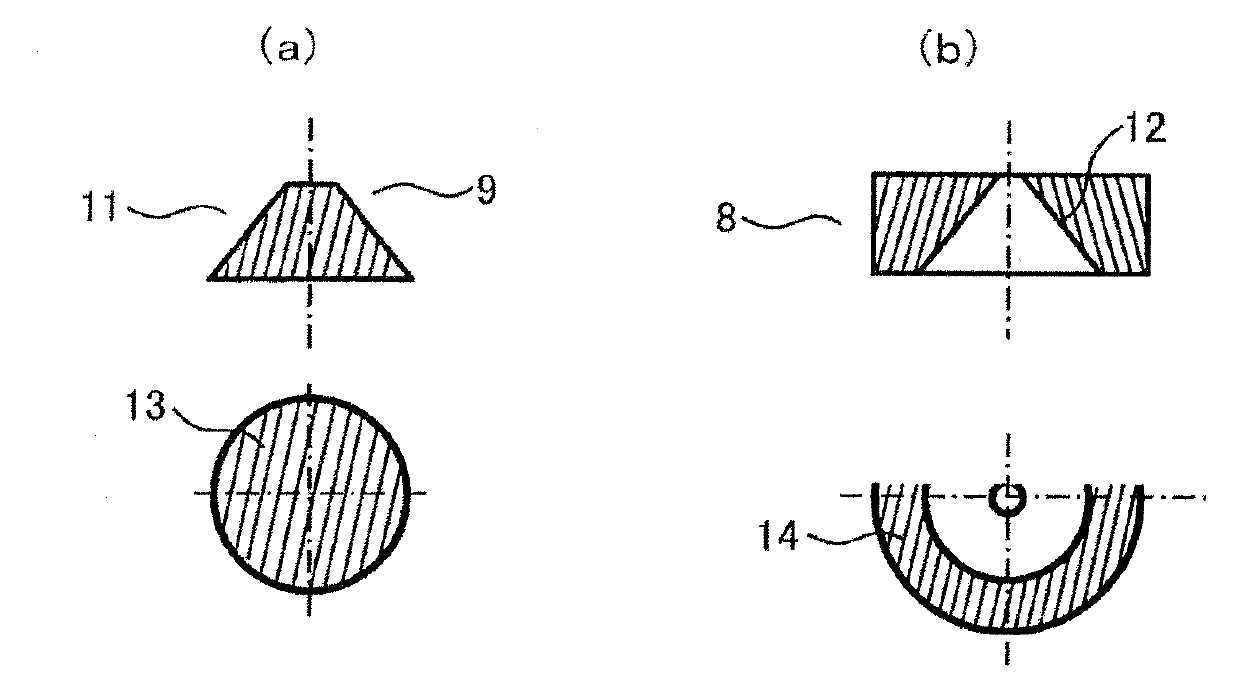

Rope braking apparatus

InactiveUS20130140113A1Steady braking forceAvoid uneven wearFilament handlingBrake typesEngineeringMechanical construction

The present invention relates to an elevator wire rope braking apparatus, and more particularly, to a rope braking apparatus which prevents partial abrasion of the wire rope while increasing braking efficiency by preventing a deviation in the pressure applied to the wire rope by a pressure plate moving in a straight line to apply pressure to the wire rope. Since the pressure application is based not on a hydraulic method but on a purely mechanical structure using only a spring elastic force, environmental pollution caused by hydraulic oil may be prevented and product cost may be reduced.

Owner:BAE HOO GEUN

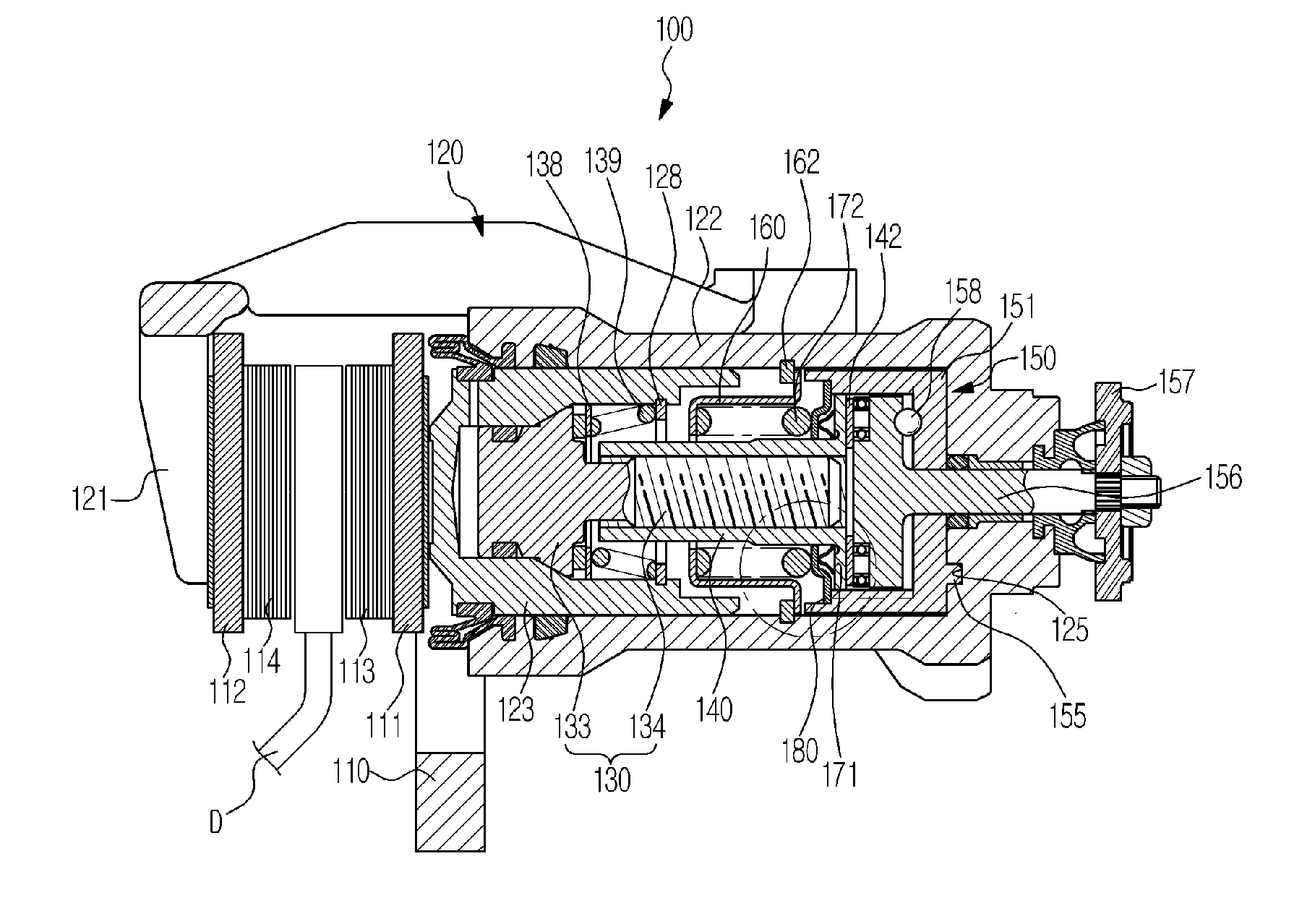

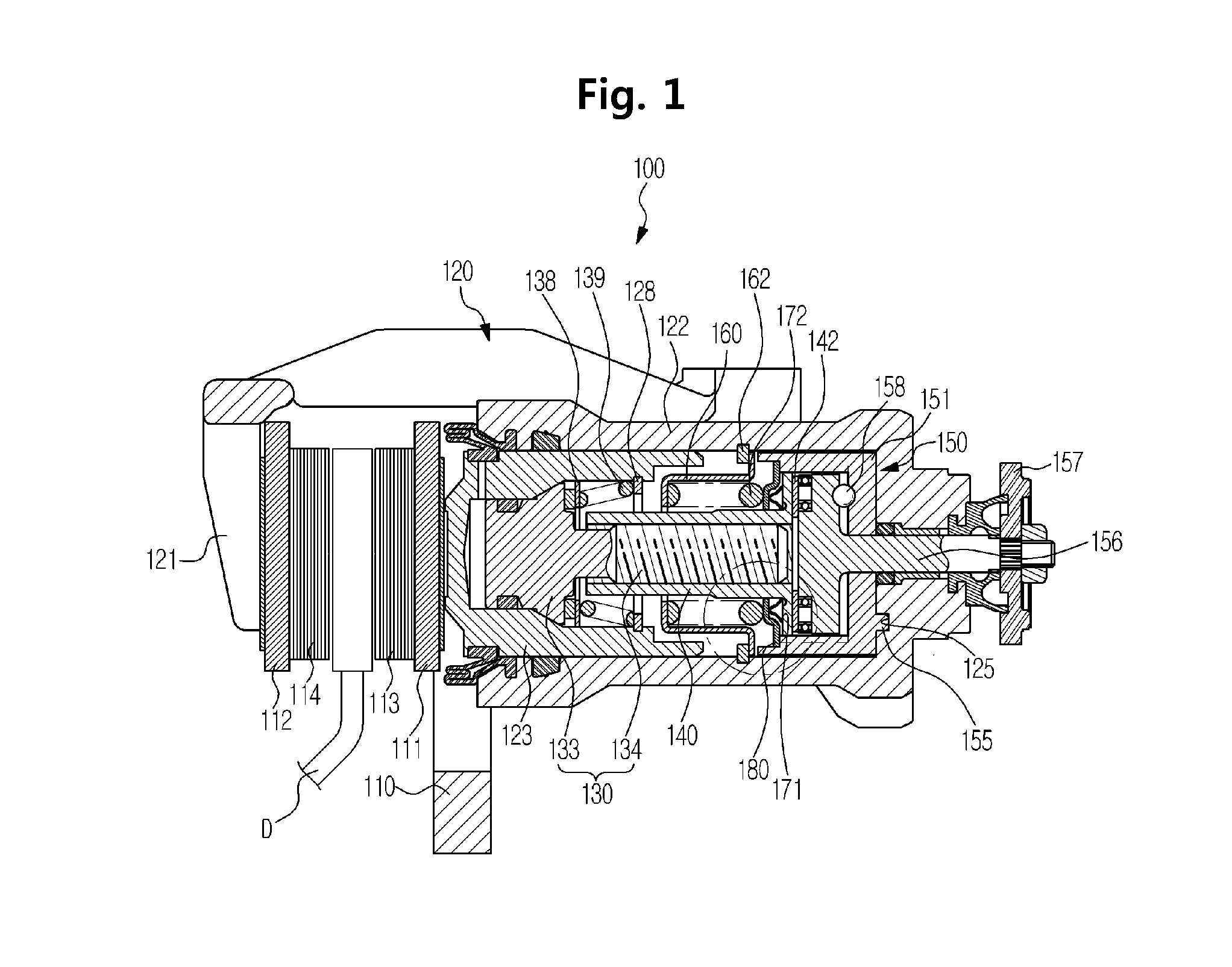

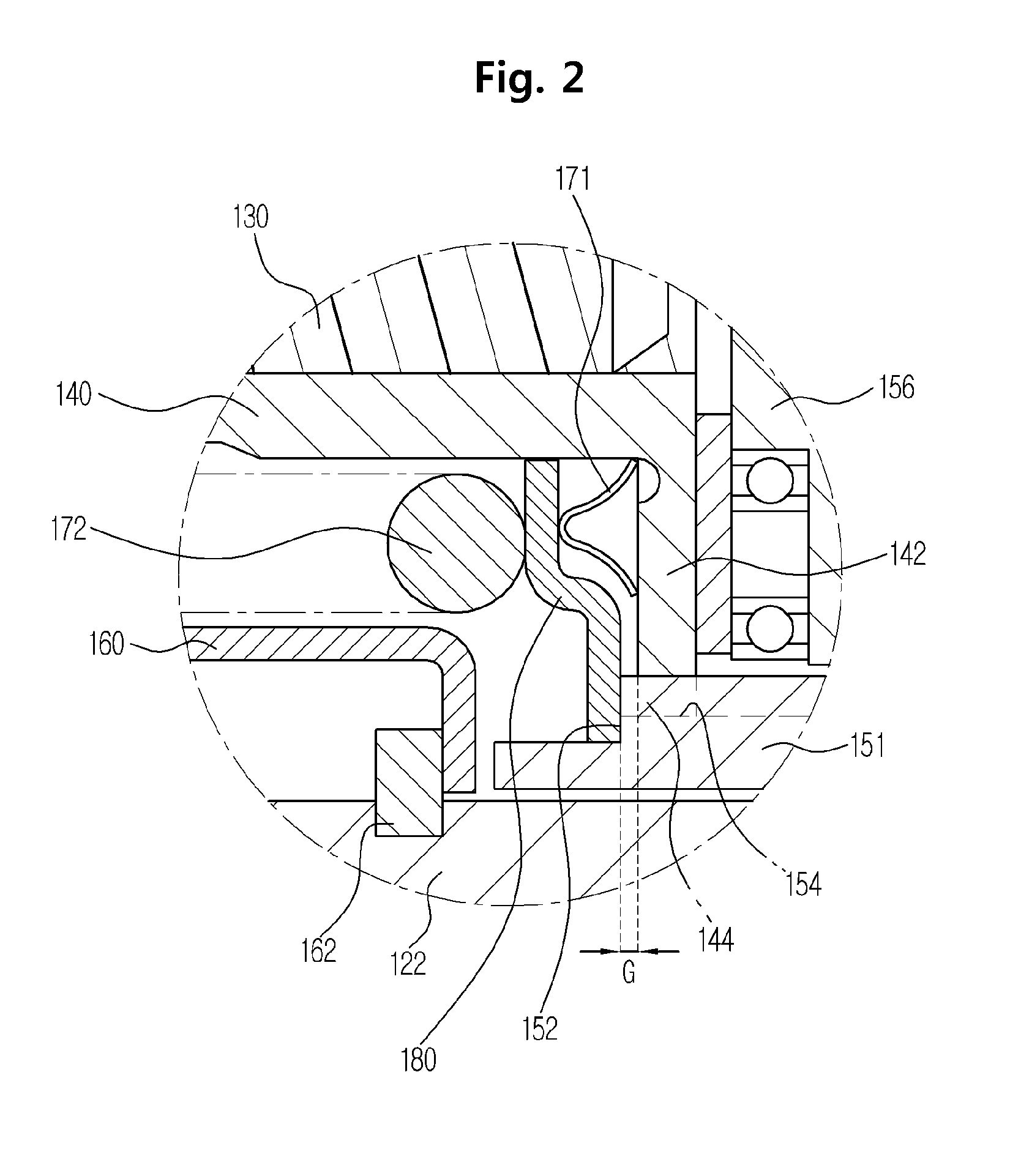

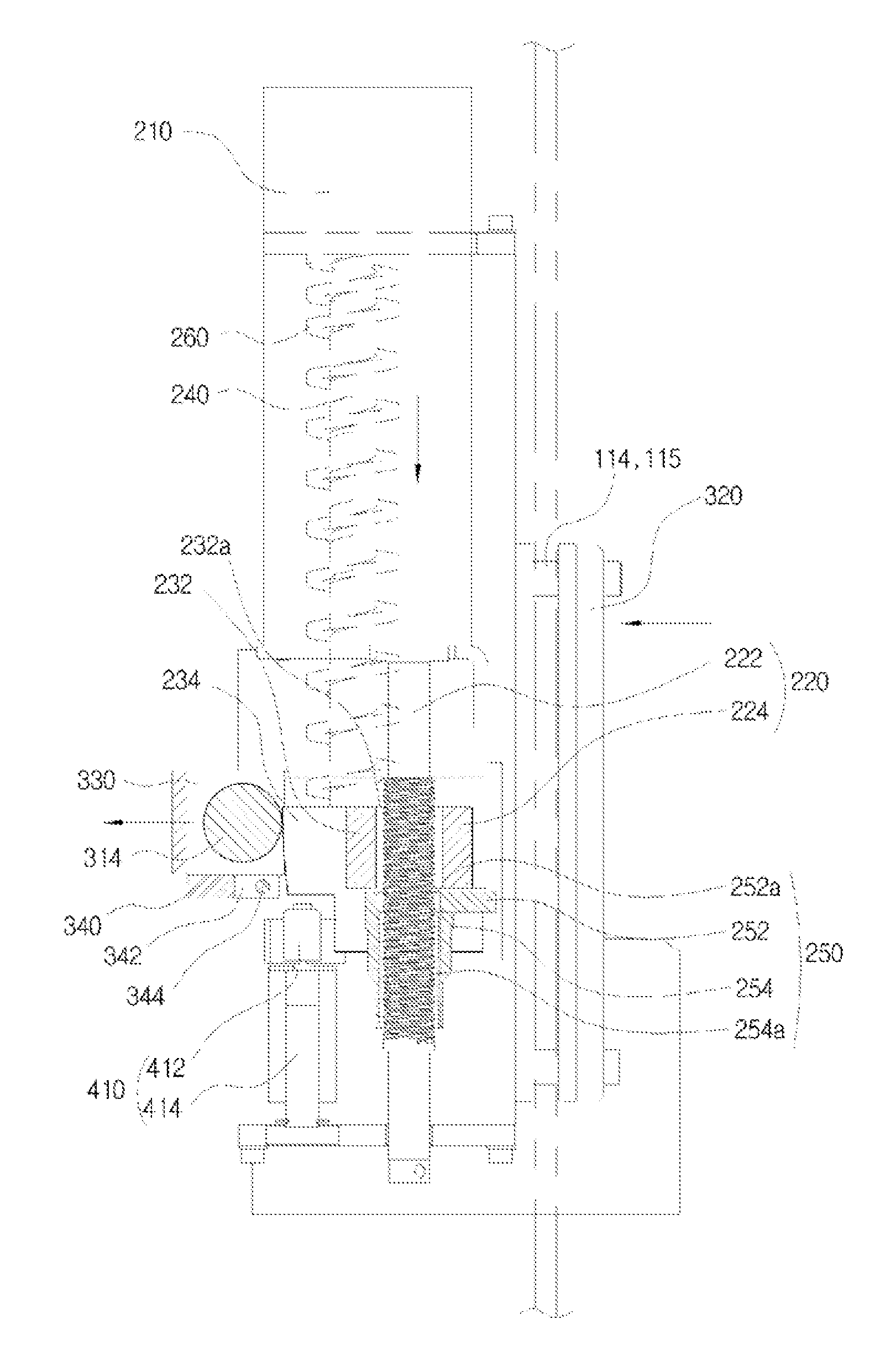

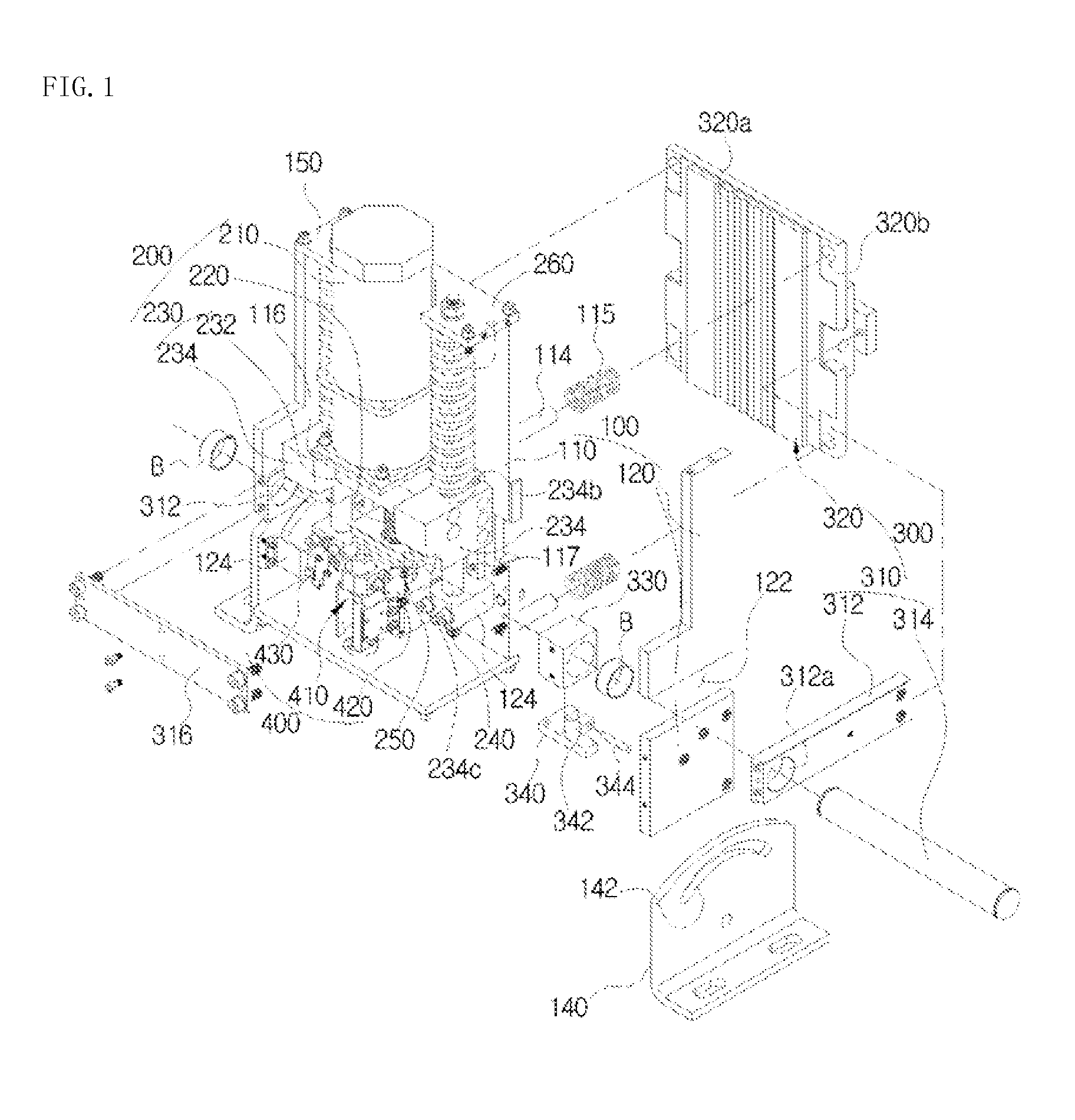

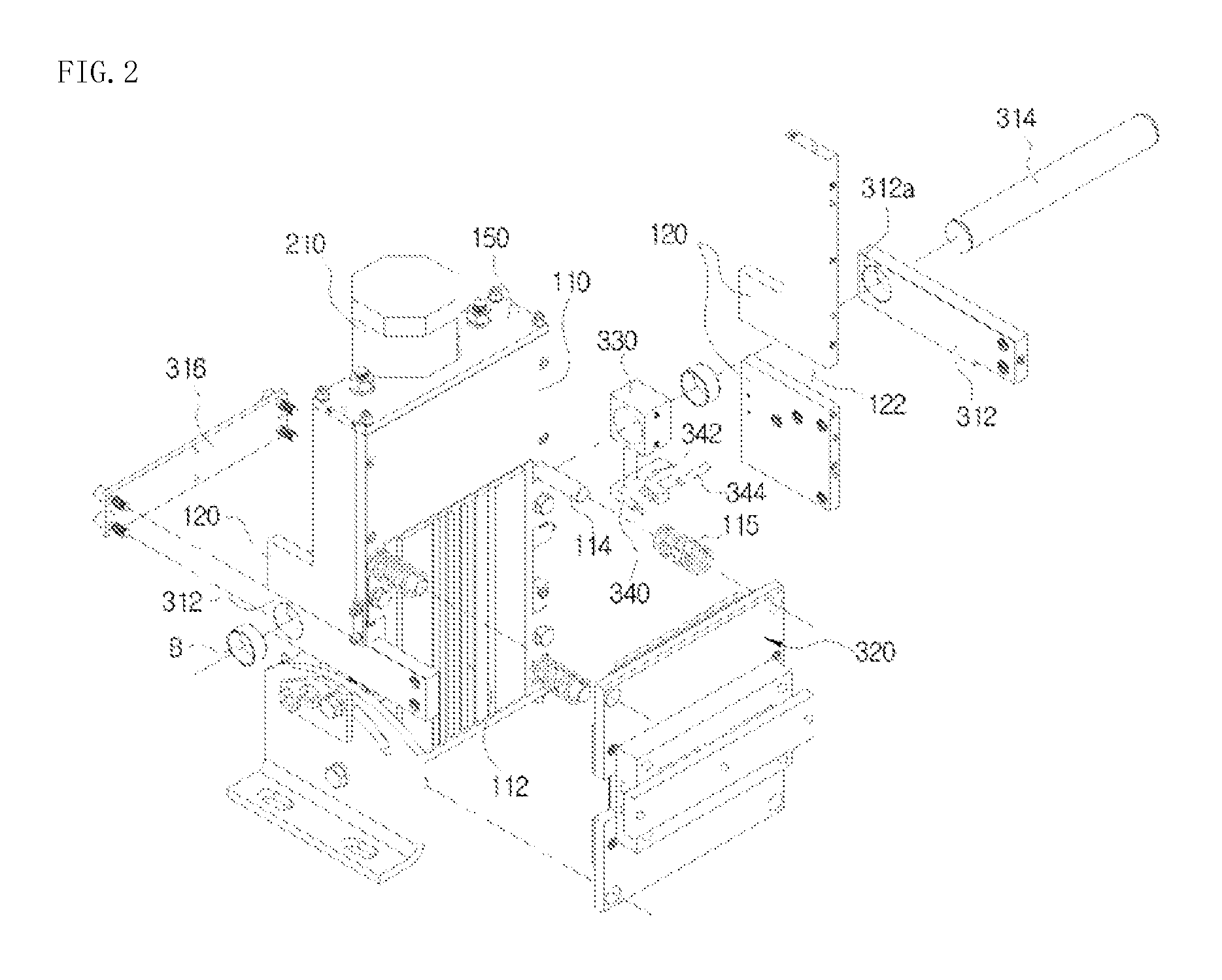

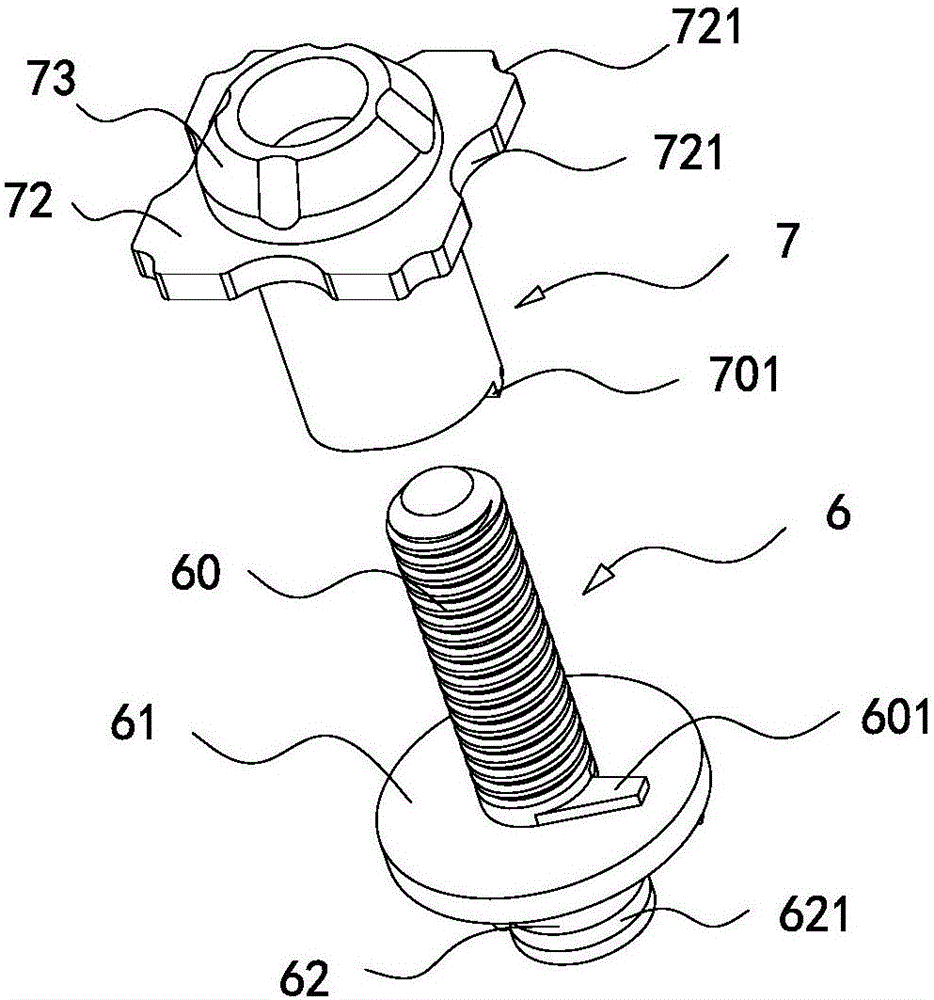

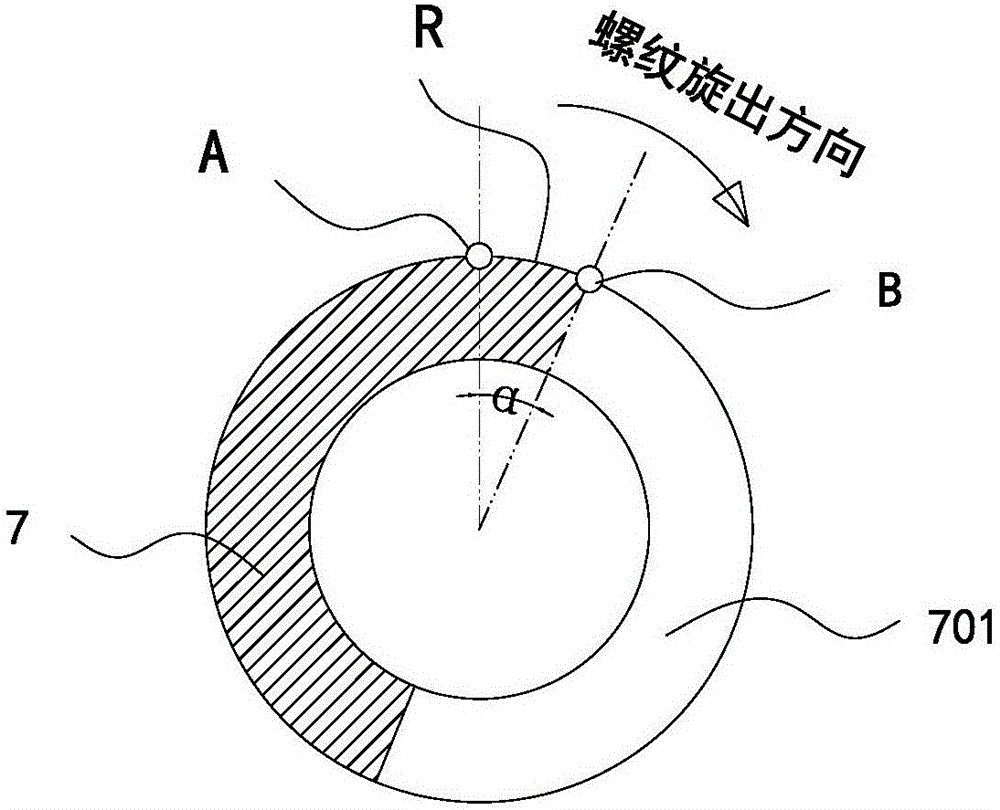

Driving assembly for parking braking calipers and manufacturing method for manufacturing driving assembly

The invention discloses a driving assembly for parking braking calipers. The driving assembly comprises a piston and further comprises threaded rods and nut sleeves, wherein the threaded rods are used for being connected with a motor, and the nut sleeves are in threaded connection with the threaded rods. The motor drives the threaded rods to rotate. The threaded rods drive the nut sleeves to be displaced during rotating. The nut sleeves push the piston to make contact with a braking pad in a jacking mode during being displaced. A limiting structure for preventing thread engagement is arranged between each threaded rod and the corresponding nut sleeve and comprises a circular truncated cone arranged on the threaded rod and a limiting protrusion arranged on the end surface of the circular truncated cone. The end surface of each nut sleeve is provided with a limiting notch abutting against the corresponding limiting protrusion. The problems that existing parking braking calipers are unstable in braking force and prone to being self-locked are solved. The invention further discloses a manufacturing method for manufacturing the driving assembly. Mass production can be ensured, and meanwhile, the matching precision of the limiting protrusions and the limiting notches is ensured, so that the matching and interchangeable effect between each nut sleeve and the corresponding threaded rod is achieved, the production efficiency is high, the production cost is low, and the product market competitiveness is improved.

Owner:杭州南宇派科技有限公司

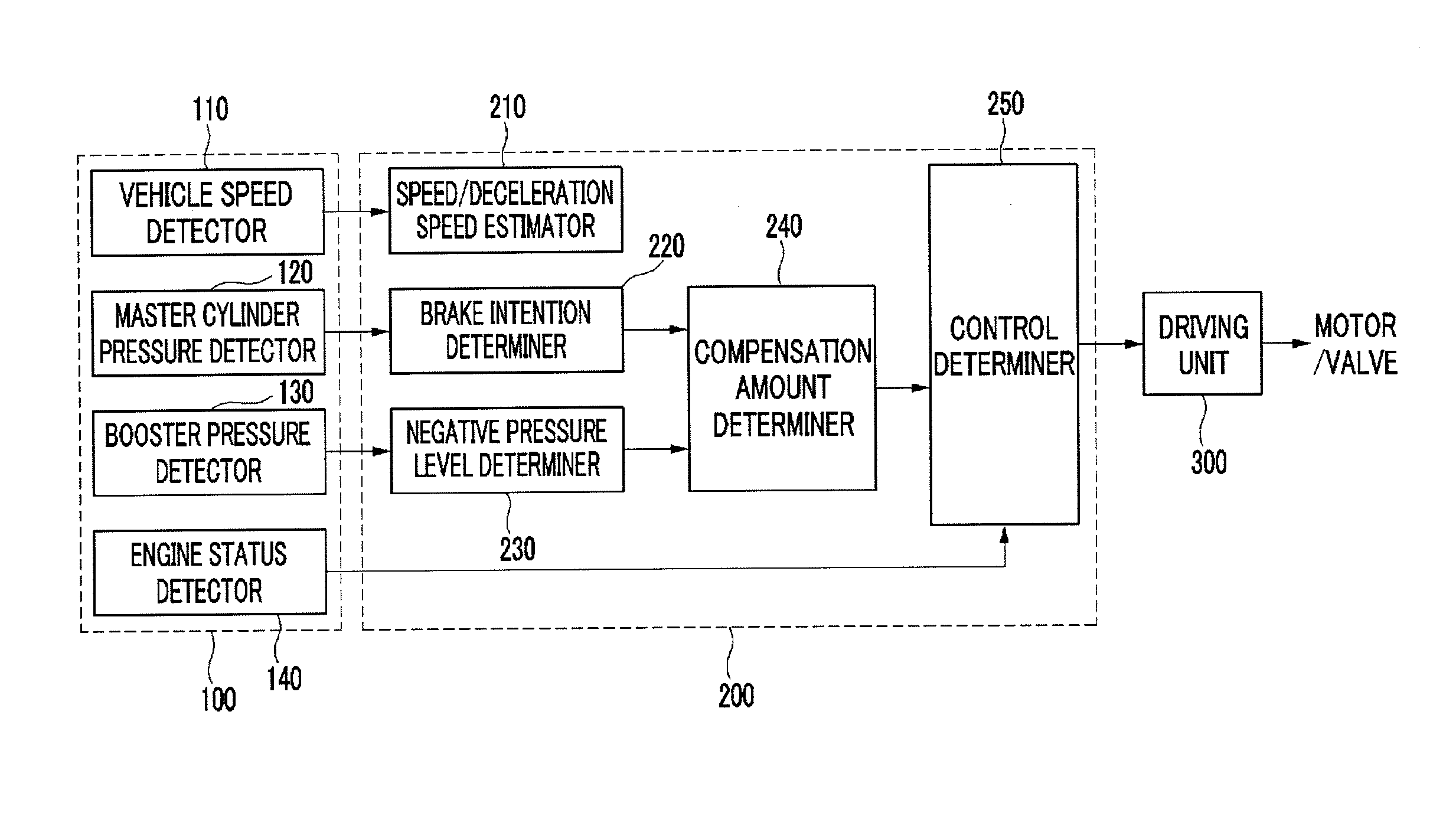

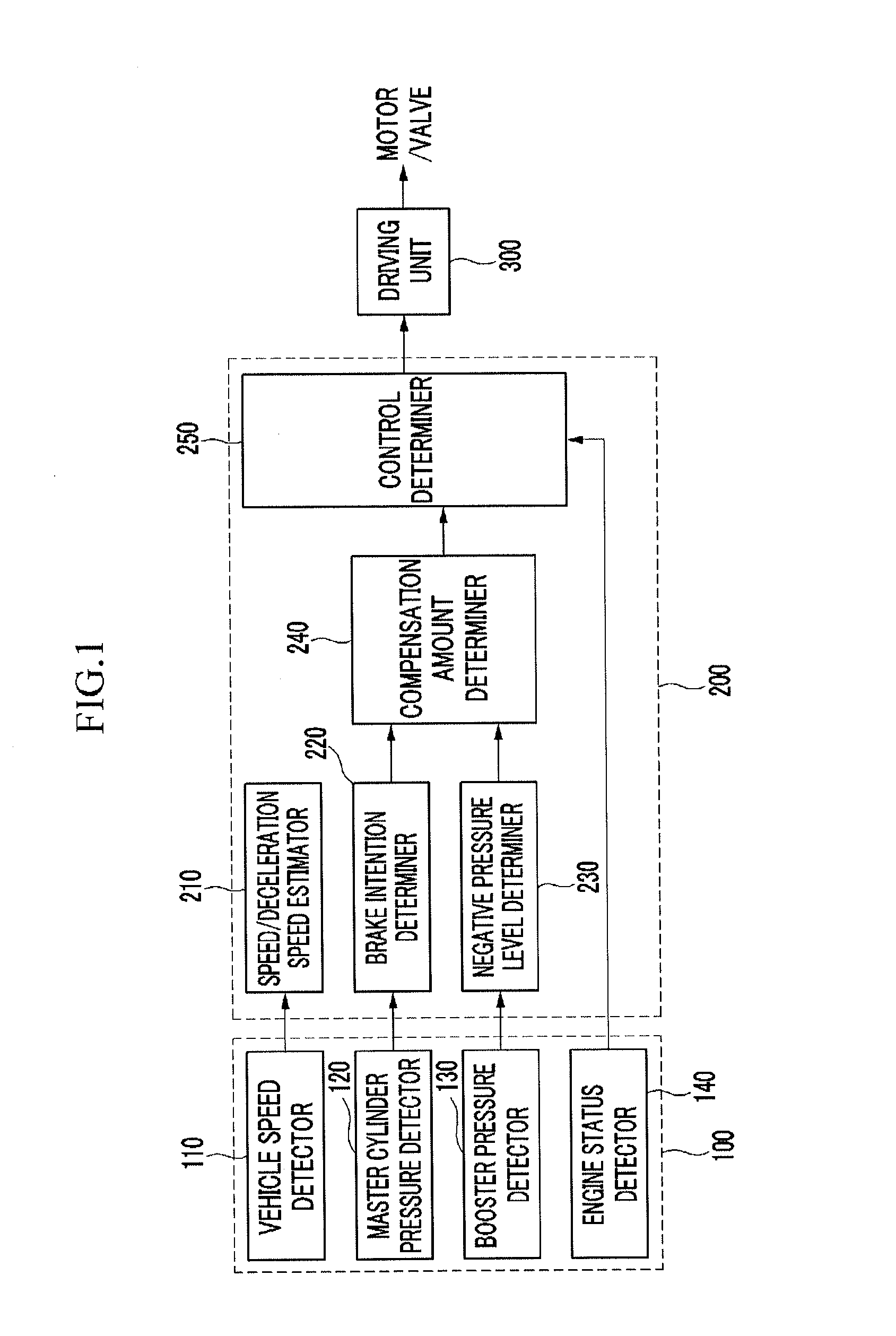

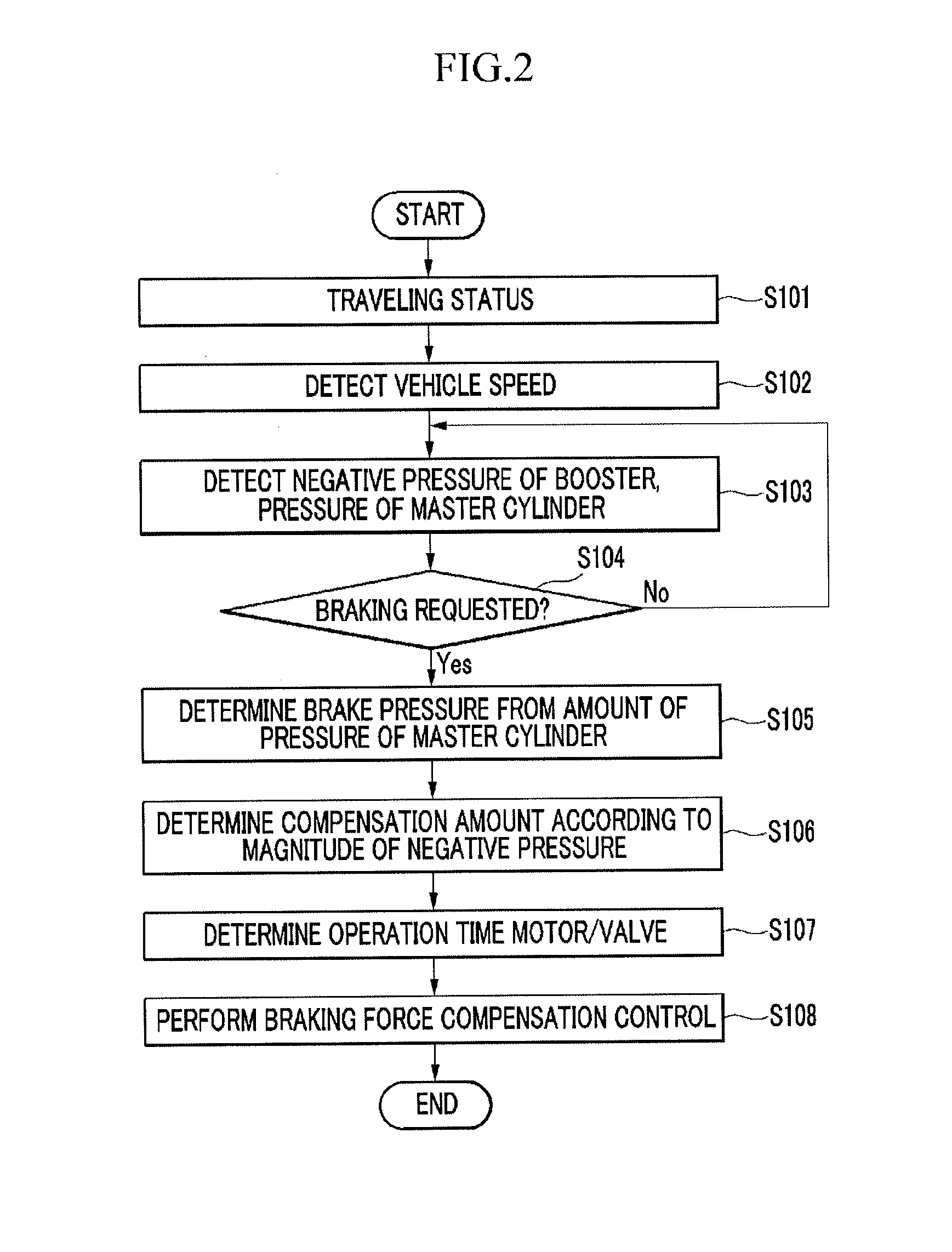

Brake pressure compensation system and method thereof

InactiveUS20130332041A1Steady braking forceAnalogue computers for trafficComputations using stochastic pulse trainsMaster cylinderHydraulic brake

A brake pressure compensation method may include determining a vehicle speed, the magnitude of a negative pressure, and the pressure of a master cylinder, determining brake intention from a change in pressure of the master cylinder, and deciding a brake pressure from the amount of pressure of the master cylinder, determining the compensation amount of the brake pressure by applying the magnitude of a negative pressure of a booster, and performing brake control by compensating for a hydraulic brake pressure through an ESC module.

Owner:HYUNDAI MOTOR CO LTD +2

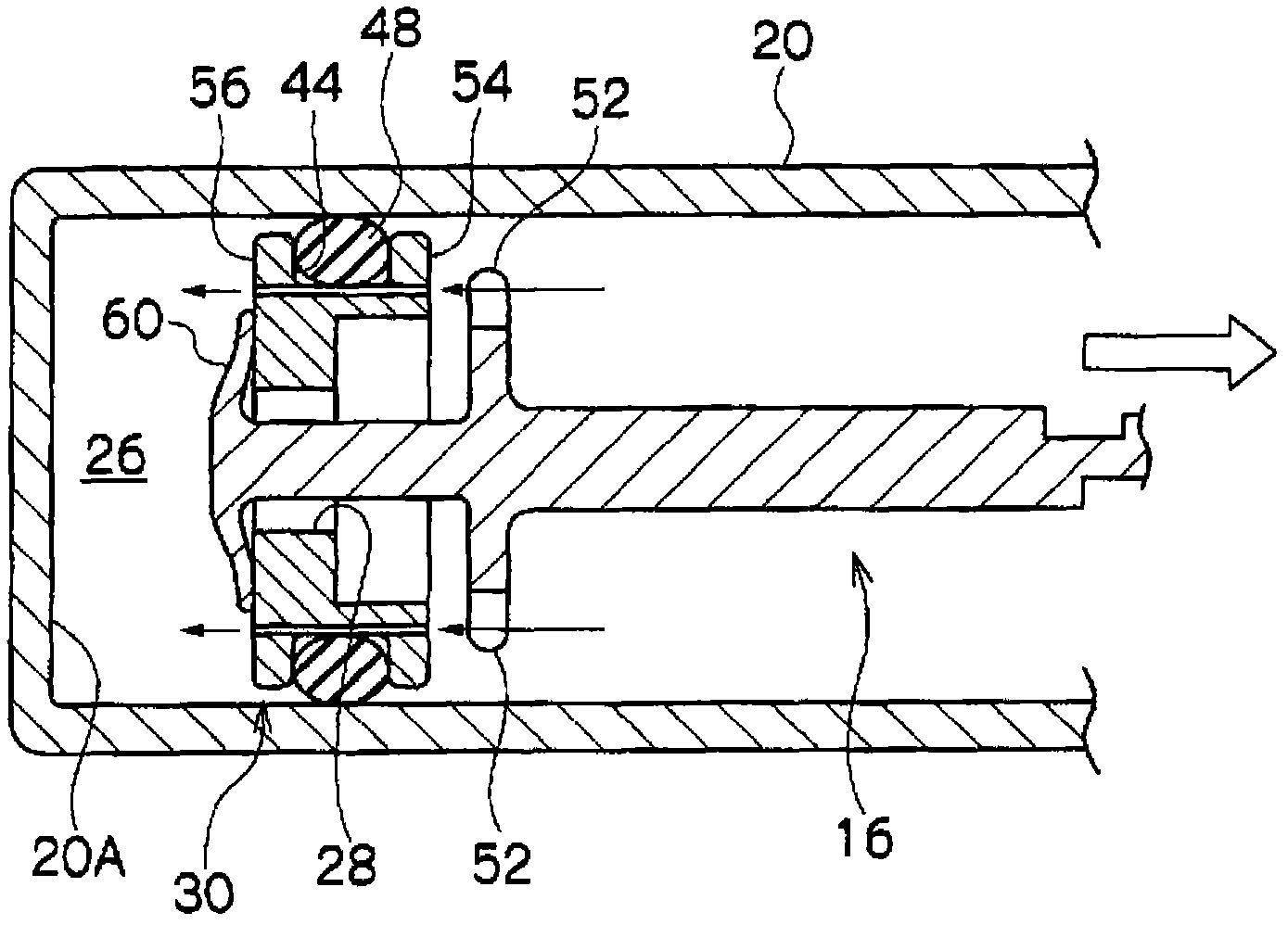

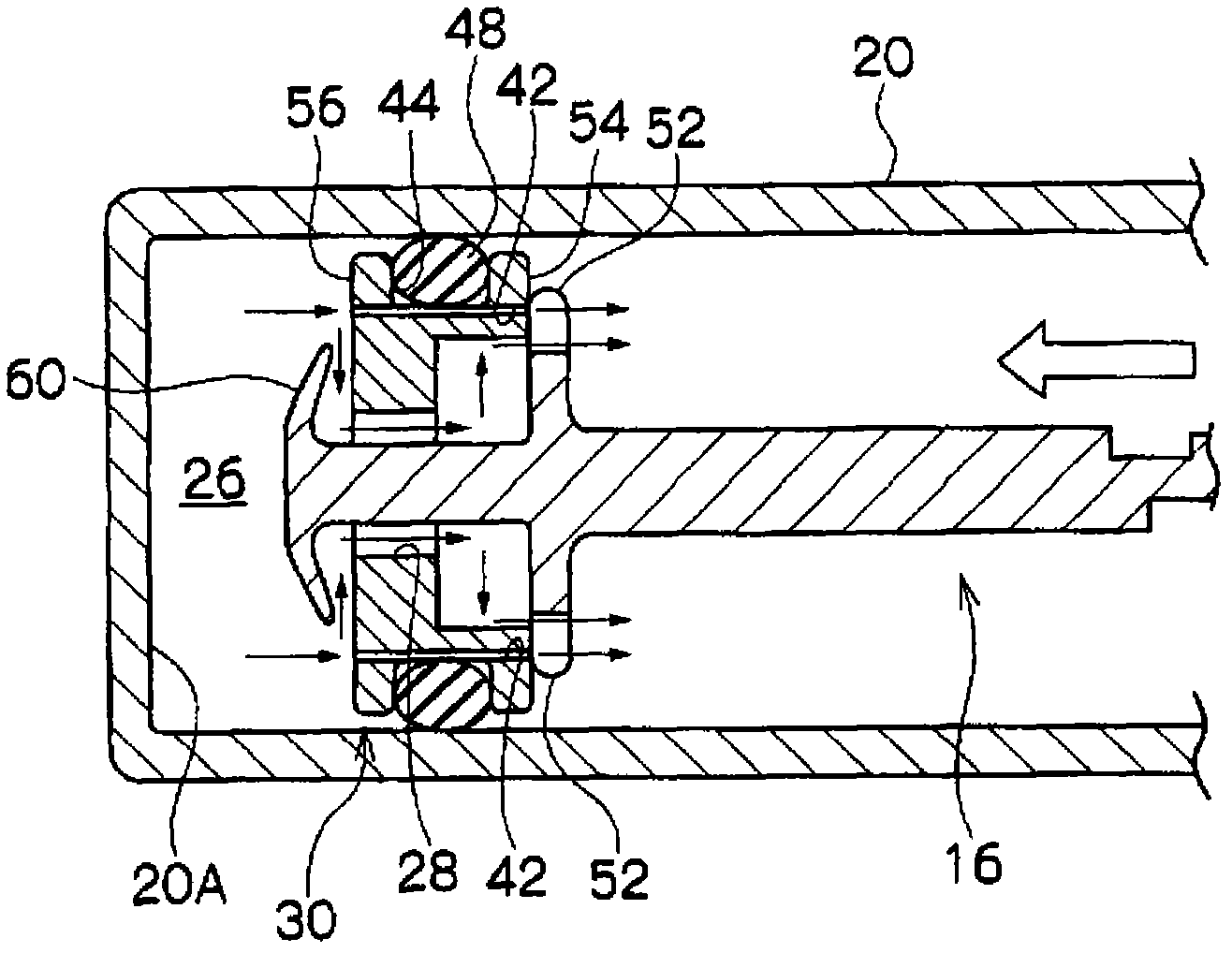

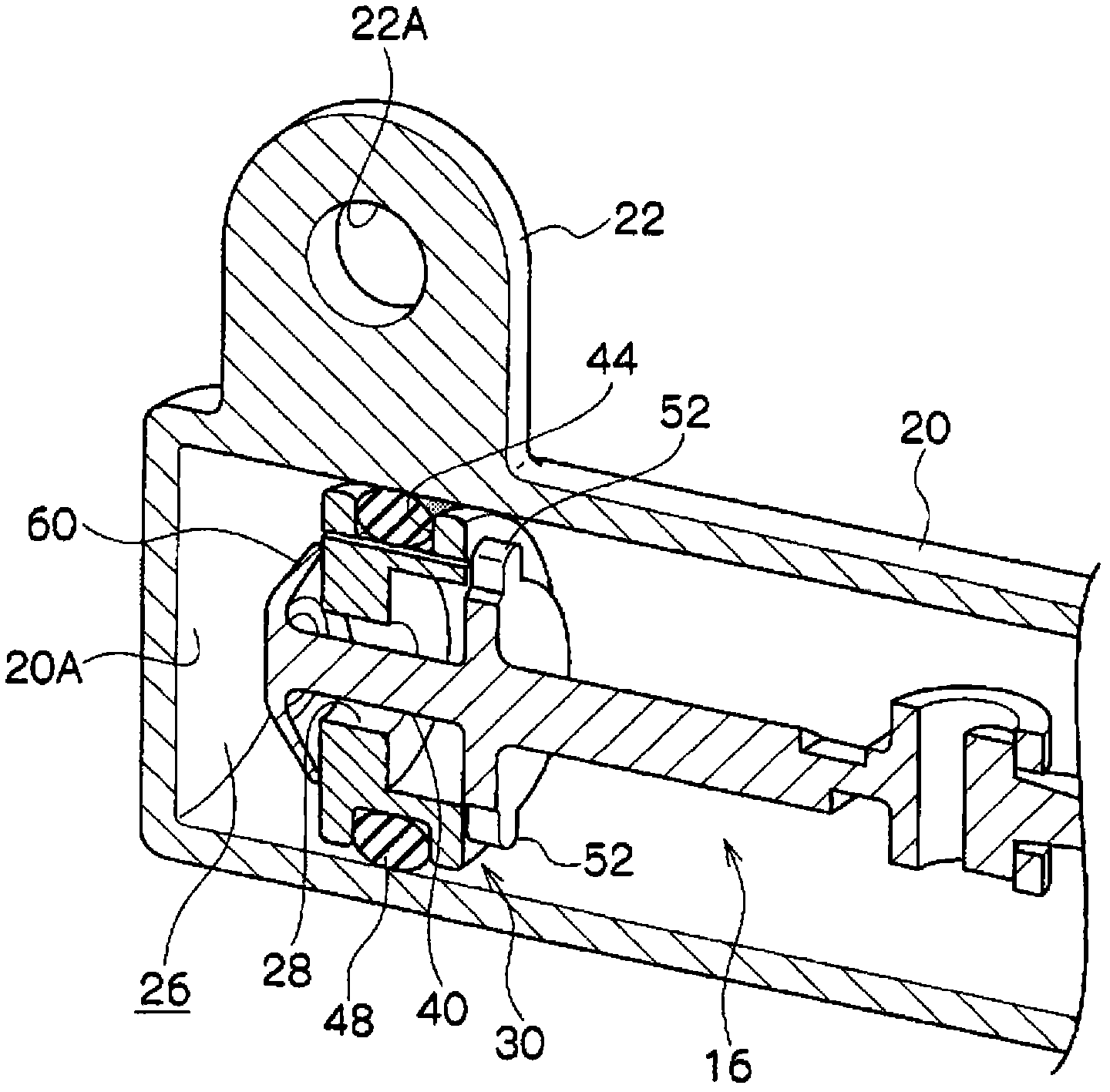

Air damper

Provided is an air damper wherein the damping force can be stabilized. When a rod member (16) is extended outwards from a cylinder member (20), a suction plate member (60) comes into abutment with an opposite surface (56) of a piston member (30), closing an air passage (28), and the air passage which provides communication between an air chamber (26) and the outside is reduced to an orifice part (42). On the other hand, when the rod member (16) is pushed into the cylinder member (20), the suction plate member (60) moves away from the opposite surface (56) of the piston member (30), opening the air passage (28). As a result, the air passage (28) can be opened and closed in the intended fashion, and the damping force can be stabilized to a greater extent than a conventional structure in which an O-ring rolls under the friction force with the inner peripheral surface of the cylinder in order to open / close the air passage.

Owner:NIFCO INC

An emergency braking device used for an elevator and an elevator

InactiveCN103224176ARoughly even pressure distributionSteady braking forceElevatorsElastomerEngineering

In order to maintain uniform pressing force of a brake shoe, multiple plate springs are superposed in the up and down direction. The pressing force applied to the brake shoe is maintained uniform by adjusting the pressing force of each plate spring with adjusting plates and adjusting screws. Because multiple plate springs and adjusting plates and adjusting screws which correspond to the plate springs, problems of complex structure and increased amount of components are provided. The invention provides an emergency braking device used for an elevator and an elevator. The brake shoe is configured in manner in which a contact plate is mounted on the back surface part of the brake shoe, wherein the back surface part is opposite to a guiding member. A pressure adjusting plate is detachably disposed between the back surface part and the contact plate. Therefore, the pressing force borne by brake shoe from the guiding member can be adjusted. The pressure adjusting plate is disposed between brake shoe and the contact plate, and the displacement of the elastic body of the part equipped with the press adjusting plate of the contact plate is adjusted. therefore, the pressing force distribution of the brake shoe in the up and down direction can be adjusted.

Owner:HITACHI LTD

Buffering device for the operating mechanism of a switchgear, and method of lubrication thereof

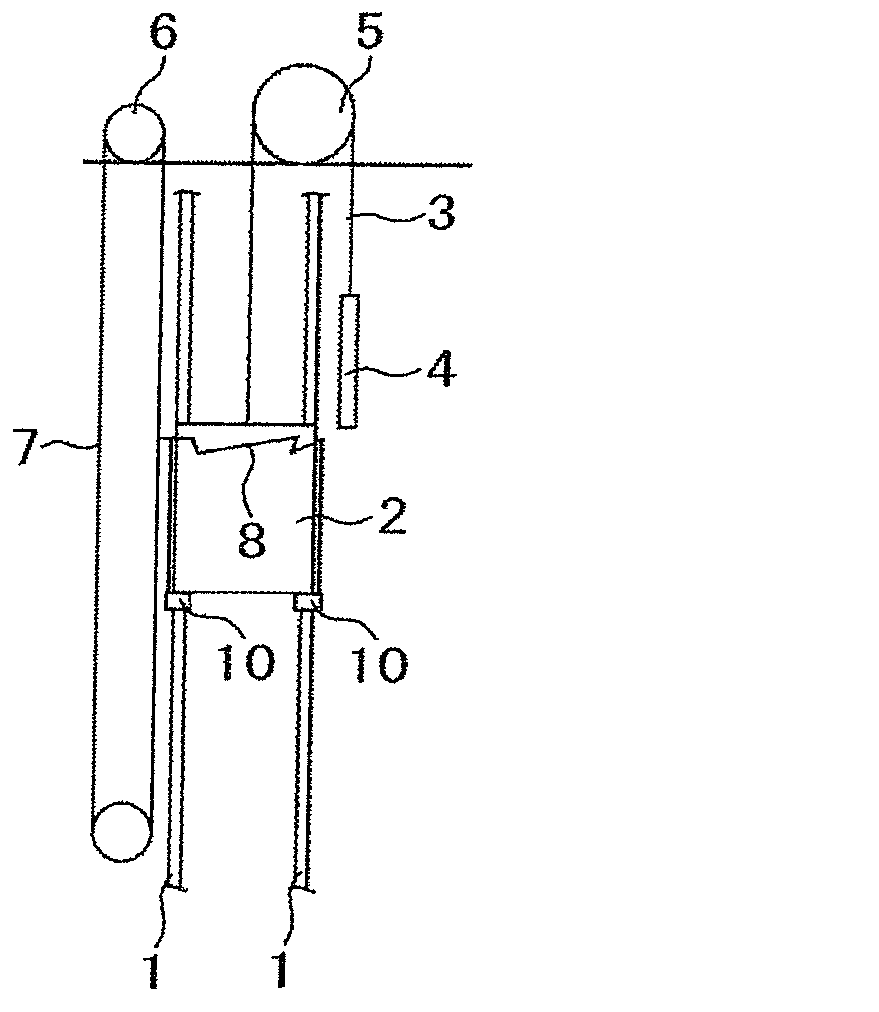

ActiveUS8844913B2Large braking forceSmall sizeSwitchgear arrangementsStands/trestlesEngineeringSwitchgear

A piston rod (15) and a first piston (13) are arranged in the interior of an external cylinder (11) and internal cylinder (12); a second piston for absorbing the change of volume of operating fluid (24) is also arranged therein. Also, a first return spring (18) for returning the piston rod (15) to the interruption position is provided and a second return spring (20) for returning the operating fluid 24 into the high-pressure chamber (25) by pressurizing the second piston (14) is provided. In addition, the air in the interior of the buffering device (10) is withdrawn by a vacuum pump (38), and operating fluid (24) is thus introduced in a degassed condition.

Owner:KK TOSHIBA

Rope braking apparatus

InactiveUS8973717B2Avoid uneven wearSteady braking forceFilament handlingBrake typesEngineeringArresting gear

The present invention relates to an elevator wire rope braking apparatus, and more particularly, to a rope braking apparatus which prevents partial abrasion of the wire rope while increasing braking efficiency by preventing a deviation in the pressure applied to the wire rope by a pressure plate moving in a straight line to apply pressure to the wire rope. Since the pressure application is based not on a hydraulic method but on a purely mechanical structure using only a spring elastic force, environmental pollution caused by hydraulic oil may be prevented and product cost may be reduced.

Owner:BAE HOO GEUN

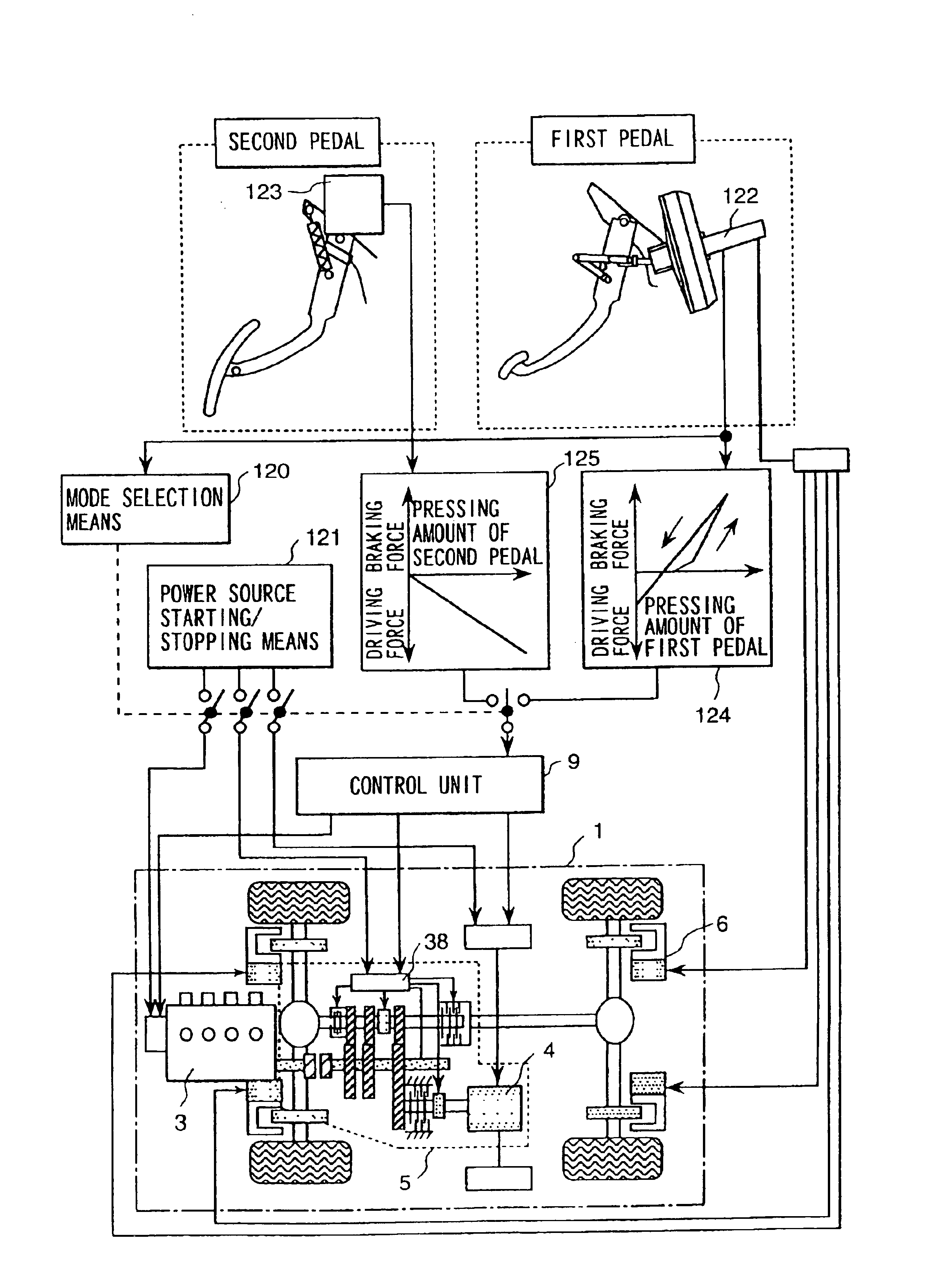

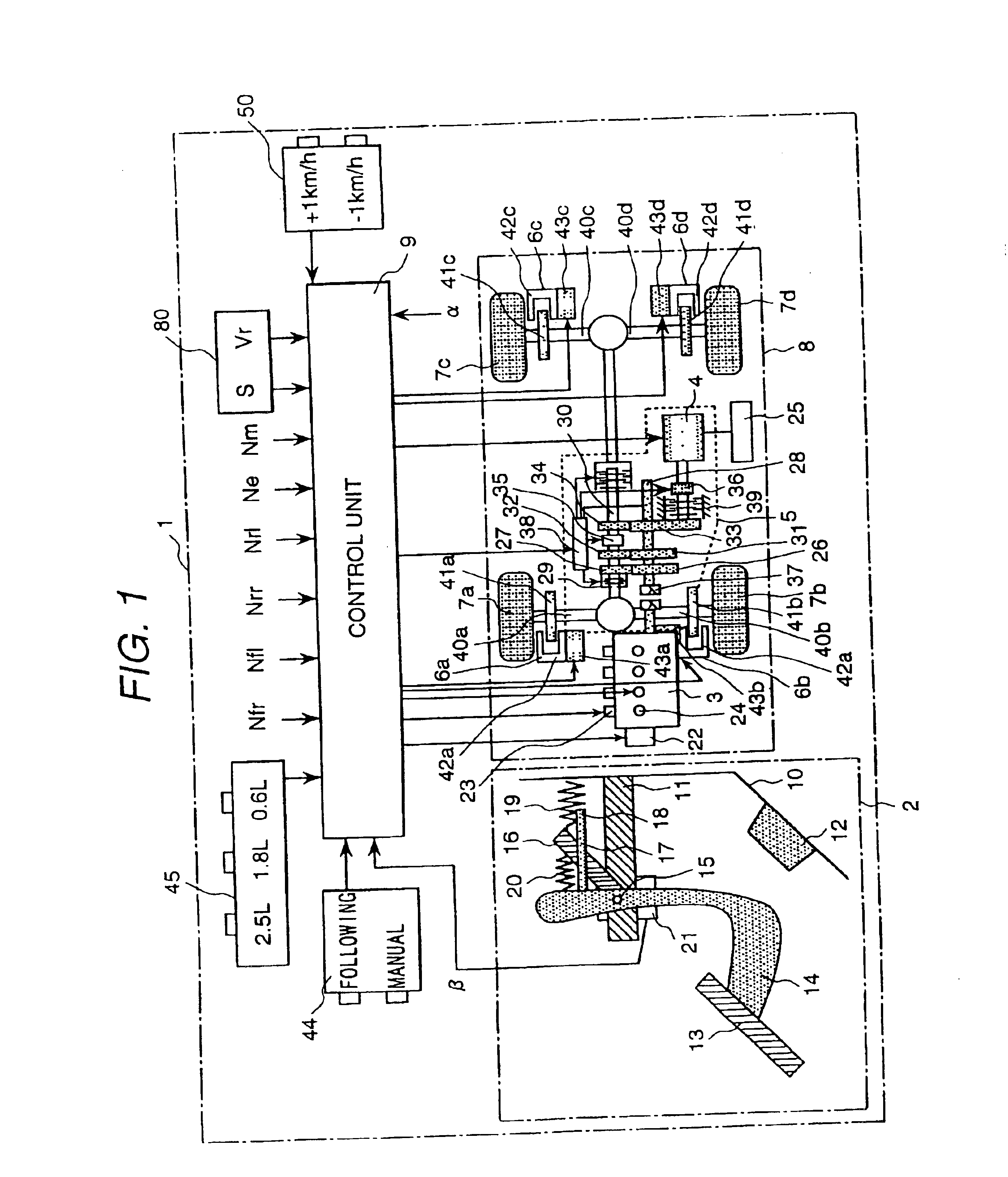

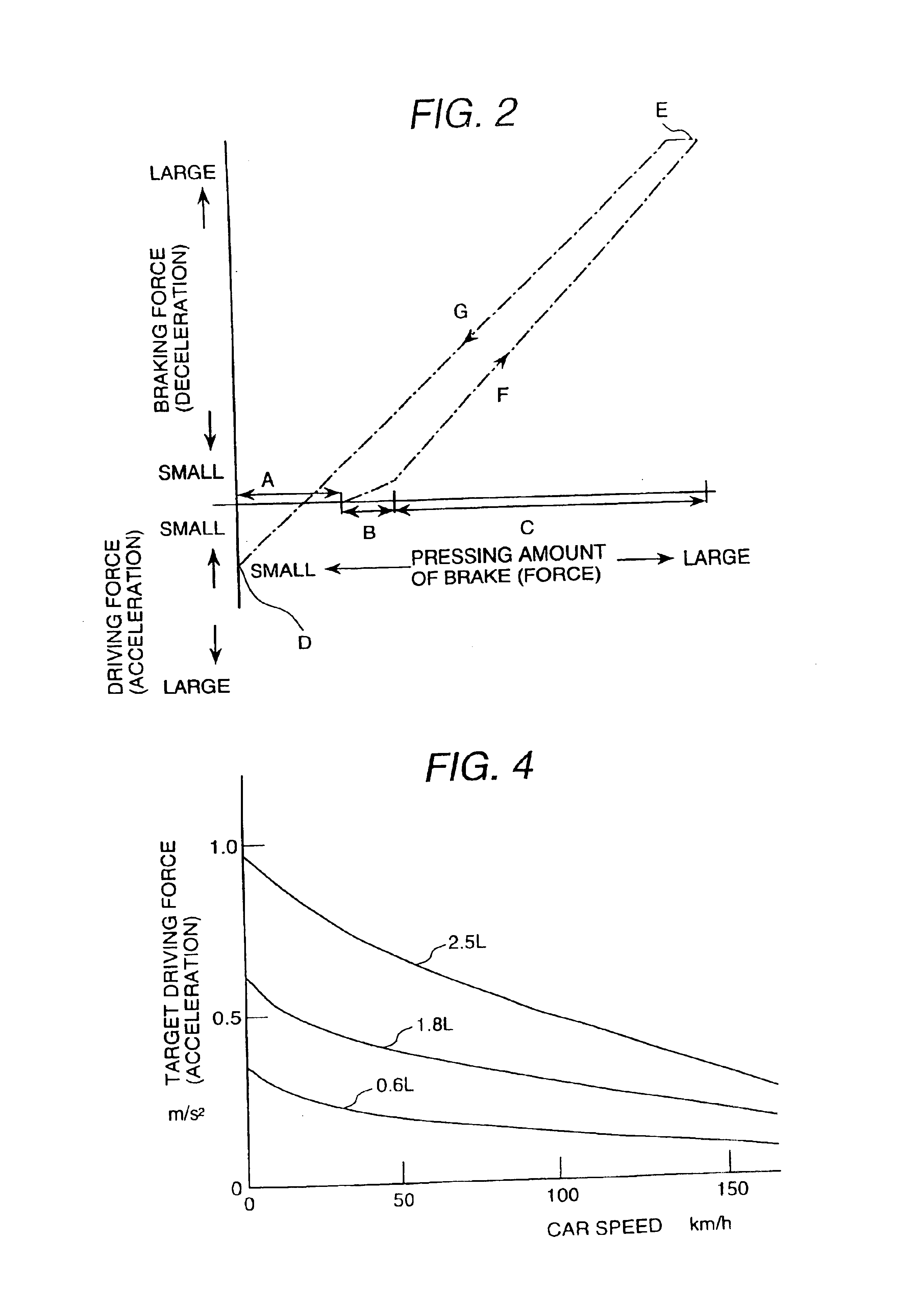

Apparatus for controlling run of a car, and car using the apparatus

InactiveUS6980899B2Simple structureSteady braking forceVehicle fittingsAnalogue computers for trafficDriver/operatorBrake force

In a system of accelerating a car using a brake operating mechanism, the driver is required to be ready to step on the brake operating mechanism so as to rapidly decelerate the car in order to avoid danger, if necessary, while he is releasing his foot from the brake operating mechanism, which is a burden for the driver. Therefore, a footrest function range and a braking force increasing function range are provided to an operating amount or an operating force of a pedal 13.

Owner:HITACHI LTD

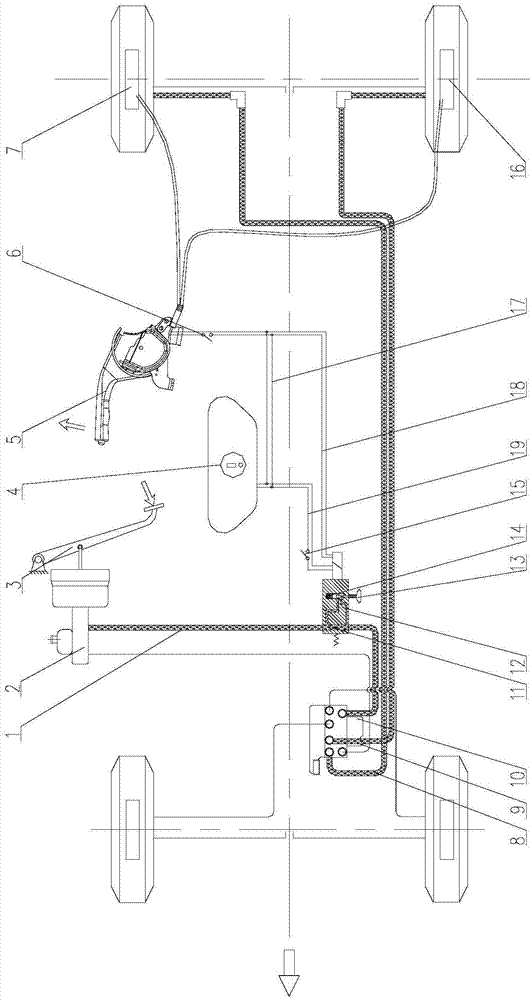

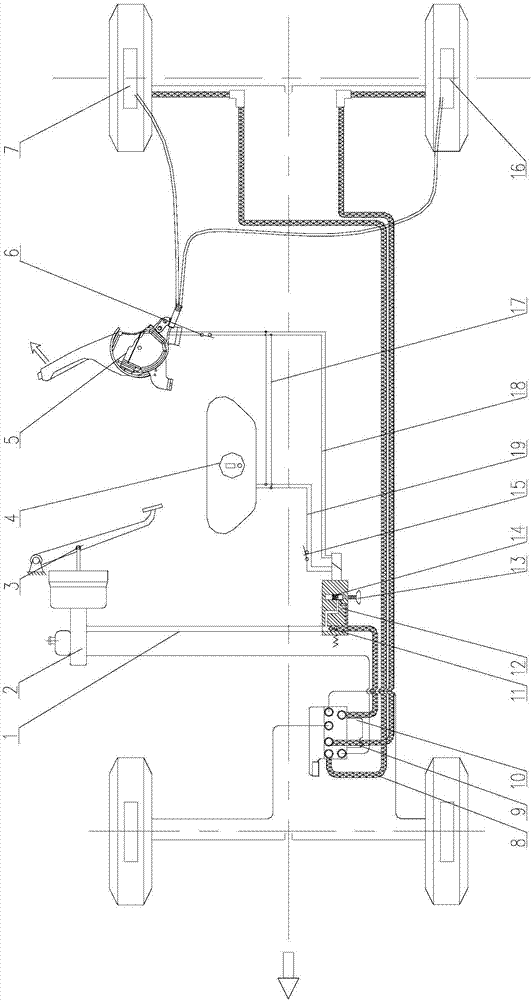

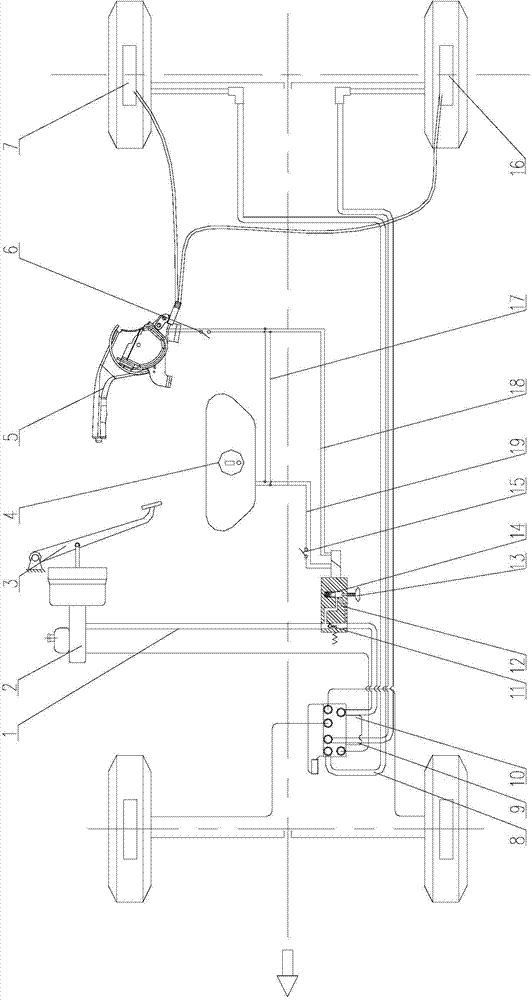

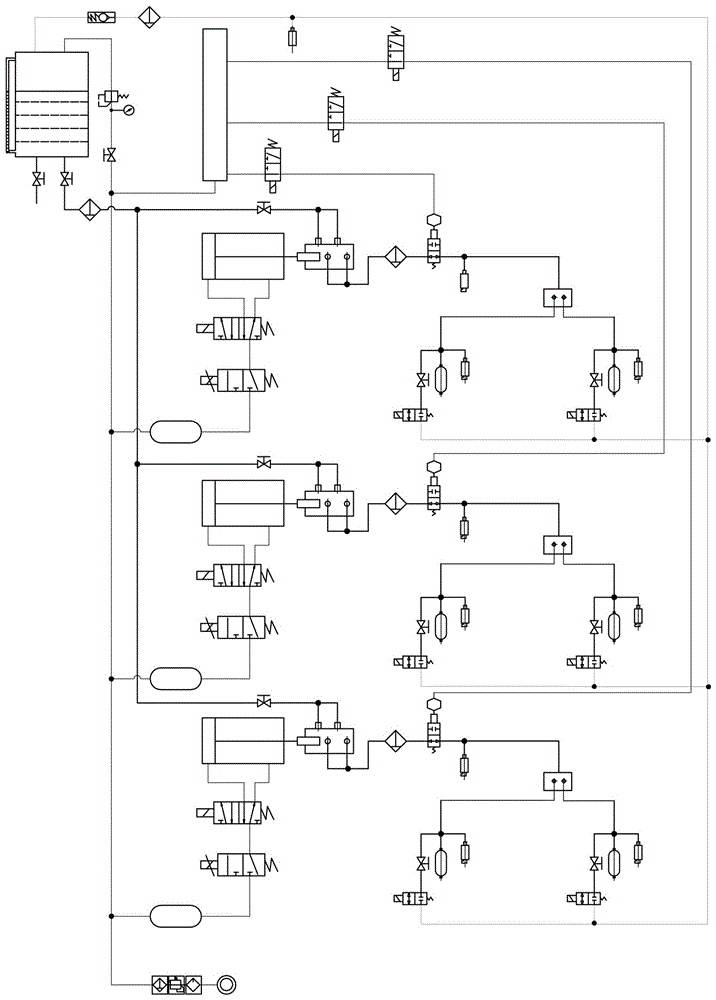

Parking assisting device, vehicle braking system and vehicle

ActiveCN104842978ASteady braking forceReliable parking performanceHand actuated initiationsFluid braking transmissionElectricityElectric control

The invention discloses a parking assisting device, a vehicle braking system and a vehicle. The parking assisting device comprises an electric control valve (12) arranged on a brake oil-supply pipeline connected to a position between a brake master pump (2) and a wheel brake, a first current loop (18) which is connected to the electric control valve (12) so as to supply electricity to the electric control valve (12), and a first switch (6) arranged on the first current loop (18); when a parking control handle (5) is pulled up, the first switch (6) is driven to be switched on, so that the electric control valve (12) obtains electricity, and the brake oil-supply pipeline is closed; when the parking control handle (5) is pressed down, the first switch (6) is driven to be switched off, so that the electric control valve (12) loses electricity, and the brake oil-supply pipeline is opened. According to the parking assisting device disclosed by the invention, the control force of the parking control handle does not need to be too large, so that the parking property of the vehicle brake system is more reliable, and the handling comfort can be improved.

Owner:BEIQI FOTON MOTOR CO LTD

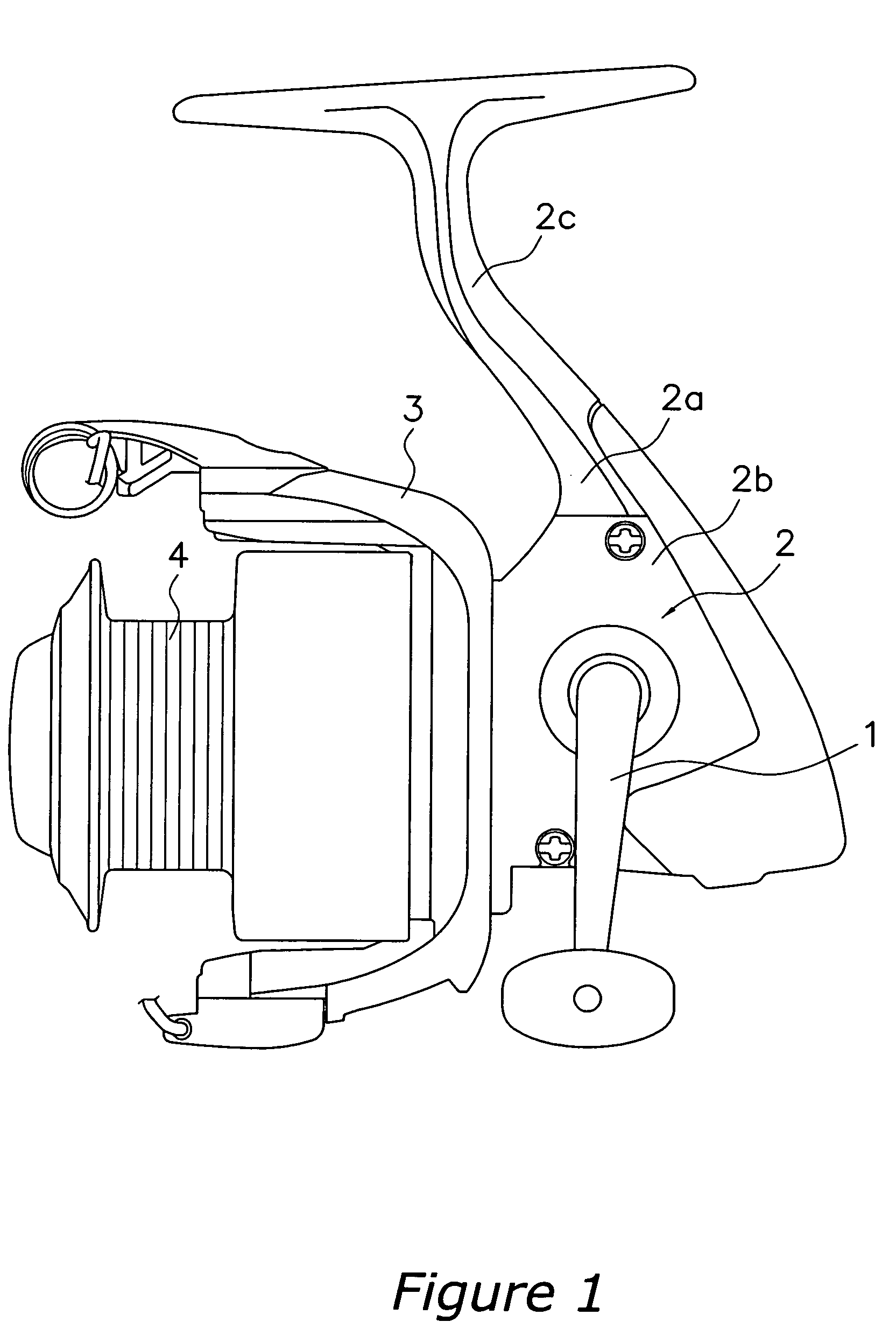

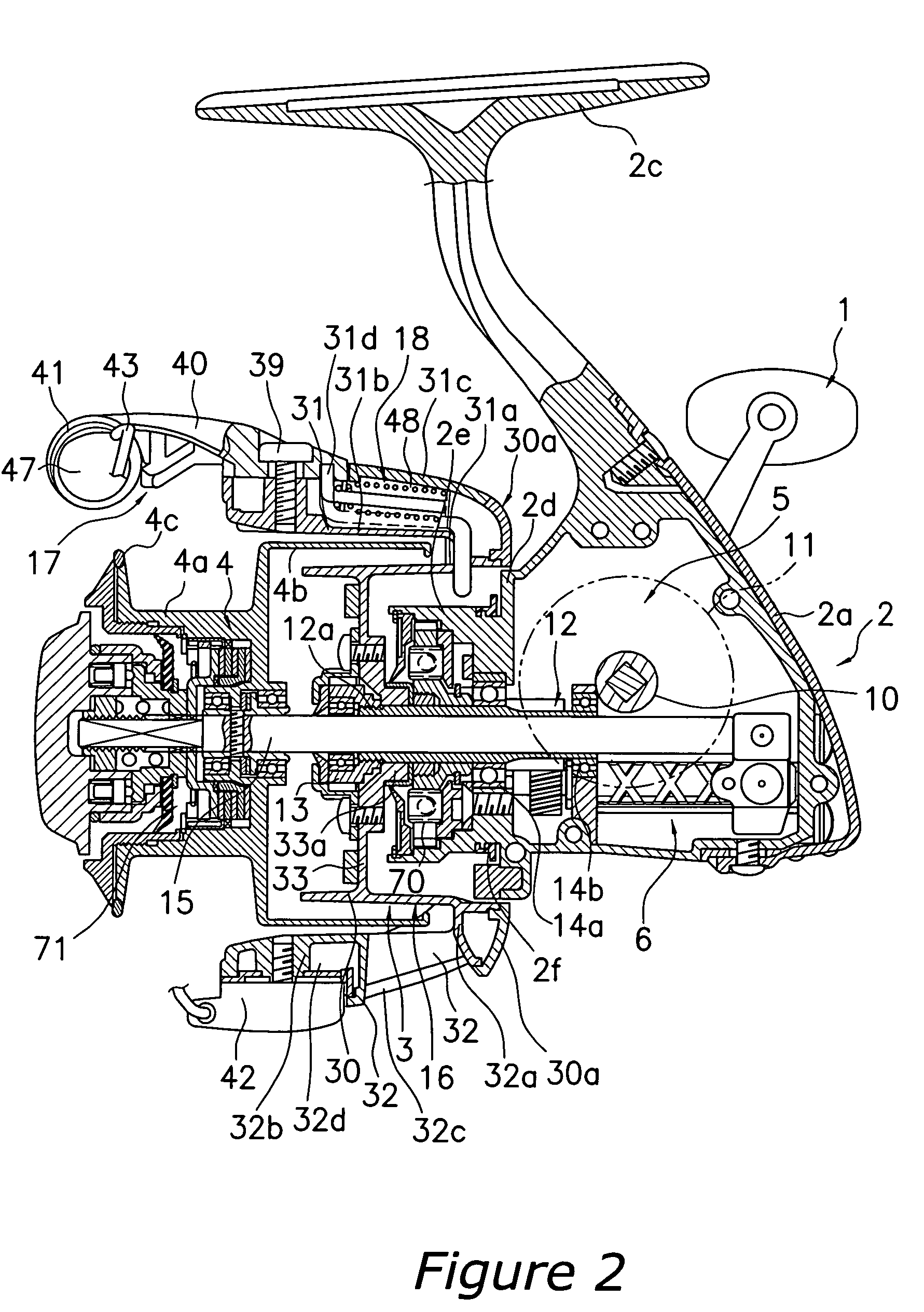

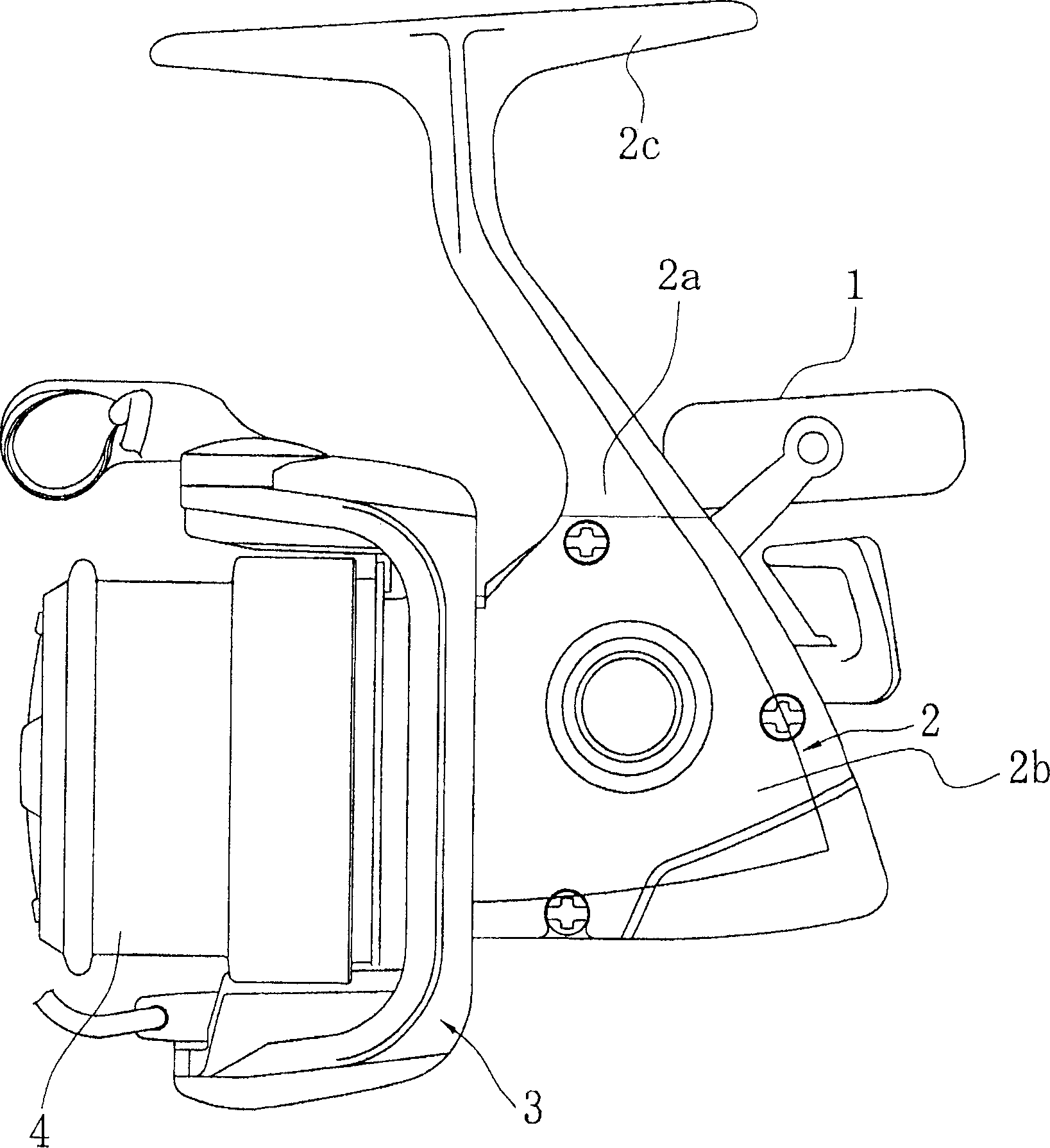

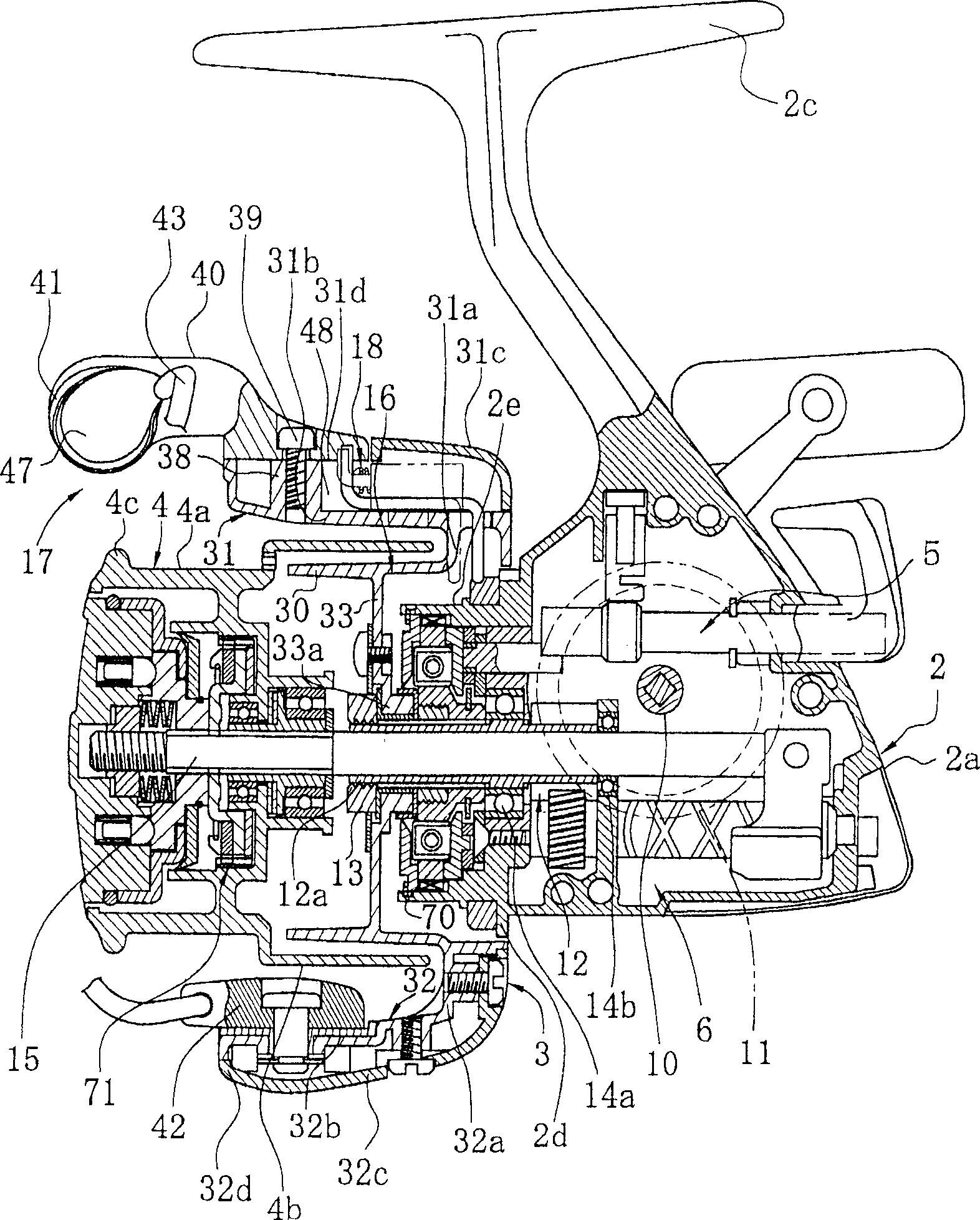

Spinning reel rotor braking device

A spinning reel rotor braking device has a moving member, a braking member, and a restriction mechanism. The moving member is provided on the rotor and movable between a first position and a second position as the bail arm moves. The braking member is mounted on the mounting groove of the reel unit, and has a drag portion that generates a braking force by frictionally sliding against the moving member when the moving member is in the second position. The restriction mechanism is formed on an inner periphery of the braking member and on an outer periphery of the mounting groove, and restricts backward movement of the braking member relative to the reel unit so that the braking member does not come into contact with a rear end portion of the mounting groove. With the present invention, the braking force of the rotor braking device can be stabilized.

Owner:SHIMANO INC

Brake drum for vehicle and method of manufacturing the same

InactiveUS20090277731A1Improve wear resistanceSteady braking forceBraking drumsBraking discsSulfurManganese

Disclosed herein is a composition for a vehicle brake drum, including 3.2˜4.2 wt % of carbon, 1.5˜2.8 wt % of silicon, 0.6˜0.9 wt % of manganese, 0.1 wt % or less of sulfur, 0.1˜0.3 wt % of chromium, 0.2˜0.5 wt % of molybdenum, 5˜10 wt % of carbon nanotubes, and a balance of cast iron. The vehicle brake drum is thermally coated with carbon nanotubes. The vehicle brake drum has excellent wear resistance and provides stable braking force.

Owner:HYUNDAI MOTOR CO LTD +1

Rotor brake of rotating reel

Rotor braking device(54)-which is for braking the rotor (3), fitted rotatively to a spinning-reel reel unit (2), in response to pivoting of the bail arm (17) that pivots between line-winding and line-releasing postures-includes a braking member (65) and a shifting member (51). The elastic braking member (65) is provided on front of the reel unit facing the rotor, and includes, in at least a portion of its contour, a braking surface (65a) and a conducting surface (65b) arranged in continuation with the braking surface, extending frontward from the braking surface and gradually receding from the braking surface. The shifting member is disposed on the rotor and can be shifted in a direction perpendicular to a pressure direction of the braking member, such that when the bail arm pivots from the line-winding posture to the line-releasing posture, the shifting member contacts first the conducting surface and then the braking surface.

Owner:SHIMANO INC

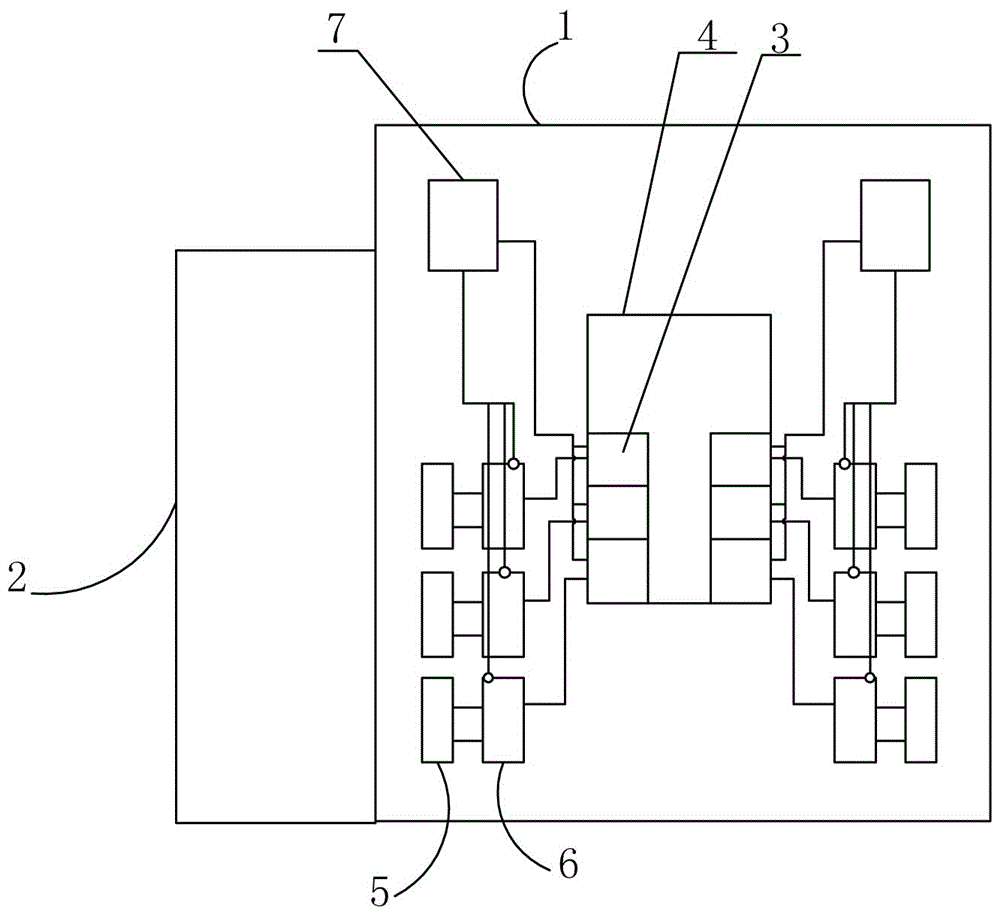

Motorcycle anti-lock braking system endurance testing experiment table

ActiveCN105938054APressure change monitoringReduce labor intensityVehicle testingWheel cylinderTest fixture

The invention discloses a motorcycle anti-lock braking system endurance testing experiment table which comprises an experiment table frame, an electronic control cabinet and a hydraulic loading device. The experiment table frame is provided with multiple motorcycle anti-lock braking system endurance testing devices. Each motorcycle anti-lock braking system endurance testing device comprises a power loading mechanism, a motorcycle simulation main cylinder, a motorcycle simulation wheel cylinder and a clamp, wherein a first pressure sensor is arranged on a pipeline, communicated with a motorcycle anti-lock braking system to be tested, of the motorcycle simulation main cylinder, a second pressure sensor is arranged on a pipeline, communicated with the motorcycle simulation wheel cylinder, of the motorcycle anti-lock braking system to be tested, and the first pressure sensor and the second pressure sensor are electrically connected with a control circuit of the electronic control cabinet. The motorcycle anti-lock braking system endurance testing experiment table can automatically test durability of the motorcycle braking anti-lock braking system, and is small in labor intensity and high in efficiency.

Owner:宁波赛福汽车制动有限公司

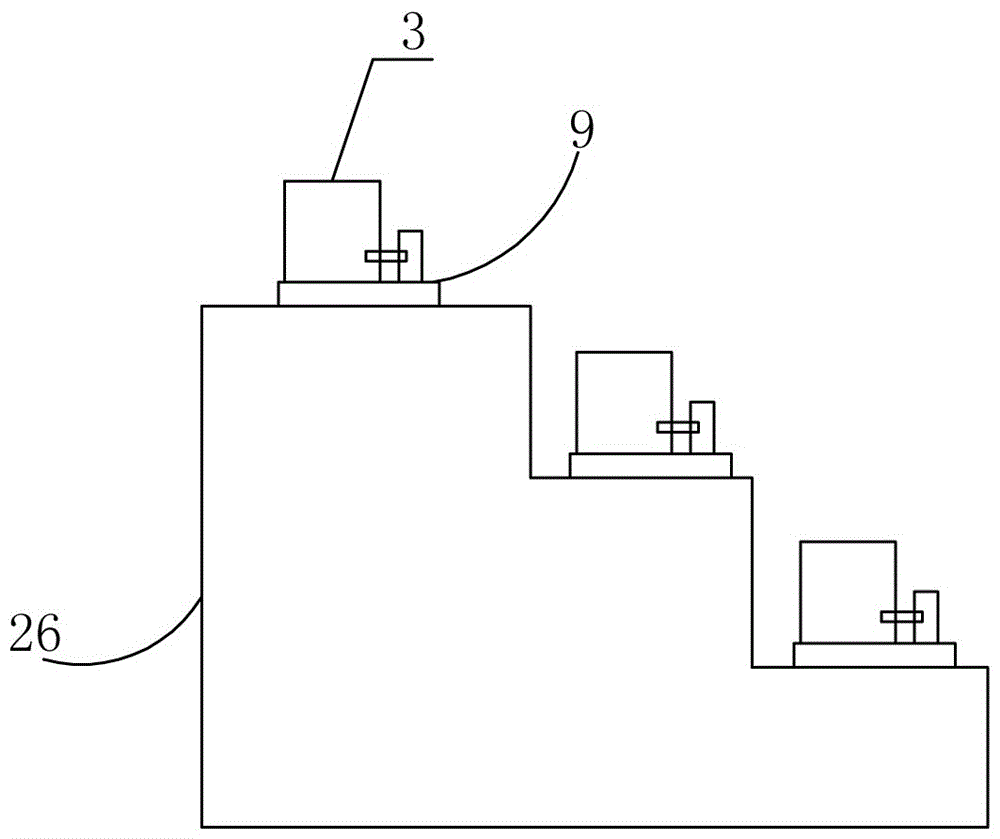

Numerical control electromagnetic brake winding tension device for distribution transformer

InactiveCN103050274AOvercome the disadvantage of unstable tensionTense to meetFilament handlingCoils manufactureWire gaugeDistribution transformer

The invention discloses a numerical control electromagnetic brake winding tension device for a distribution transformer. The numerical control electromagnetic brake winding tension device comprises a controller, an enameled round wire tension mechanism, a paper-covered flat wire tension mechanism, an enameled wire guide mechanism, an enameled wire buffering mechanism and an outlet guide anti-twist scratch-resistant mechanism. The numerical control electromagnetic brake winding tension device for the distribution transformer is in high-low voltage integrated design, electromagnetic force is used for braking, brake force can be remotely regulated and controlled by a numerical control system, wires are tensioned by electromagnetic brake, enameled wires and paper-covered wires can be wound and tensioned by various wire gauges, tensile force can be remotely regulated and controlled, the brake force is stable, and the tension device has anti-damage, anti-loose and anti-twist functions for the wires. The tension device is convenient and simple to operate and safe to use, and overcomes the shortcomings that a pneumatic tension device is affected by an air source, and tensile force applied to the wires in unstable. The tension device is applicable to products such as S11 and S13 oil-immersed distribution transformers, an SH15 amorphous alloy distribution transformer, a dry transformer, a prefabricated substation and a combined transformer.

Owner:HAINAN WEITE ELECTRIC GRP CO LTD

Rope braking apparatus

InactiveCN103052584AAvoid partial wearSteady braking forceBrake typesElevatorsEngineeringArresting gear

Owner:裴厚根

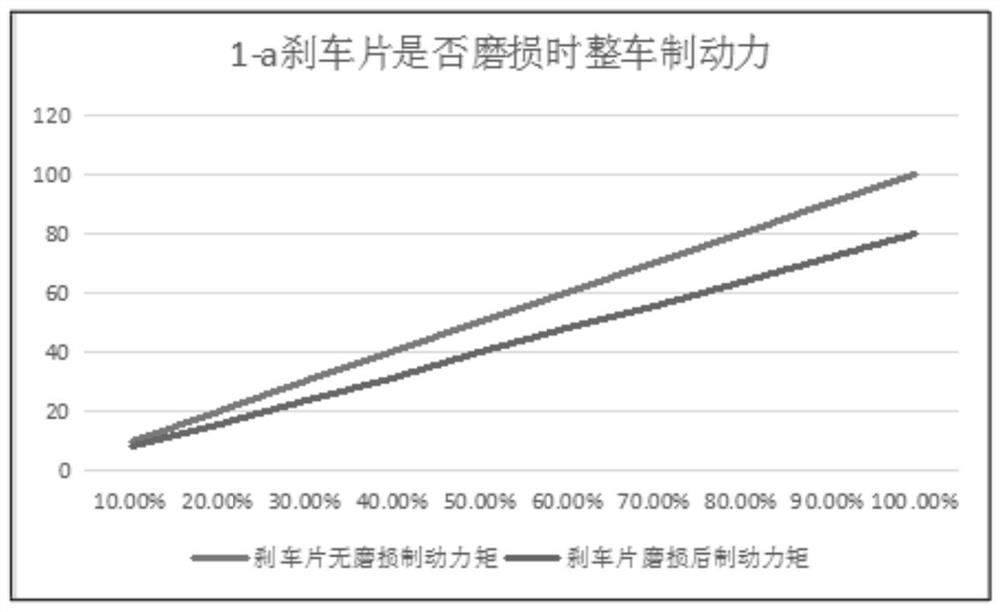

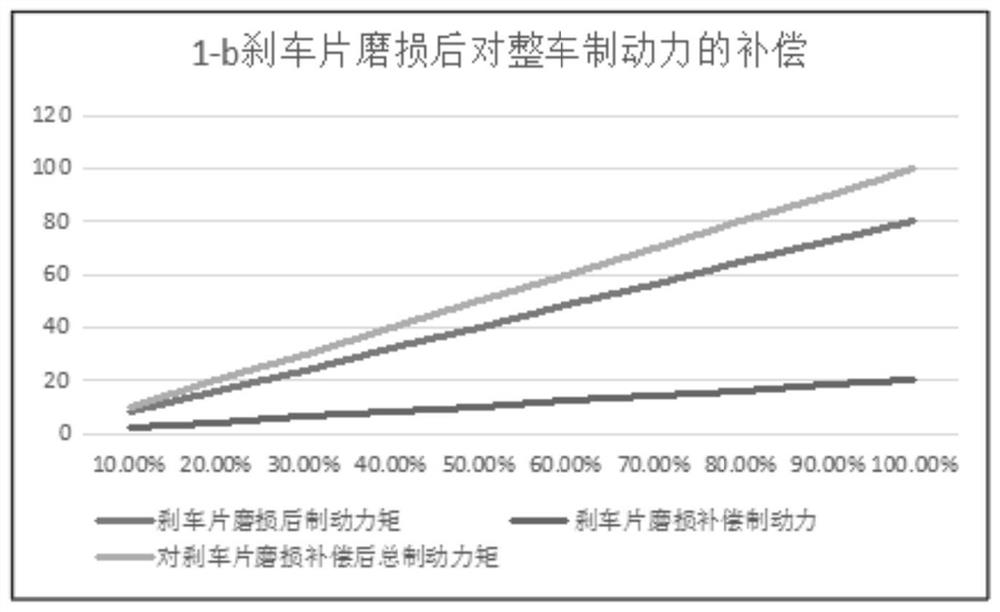

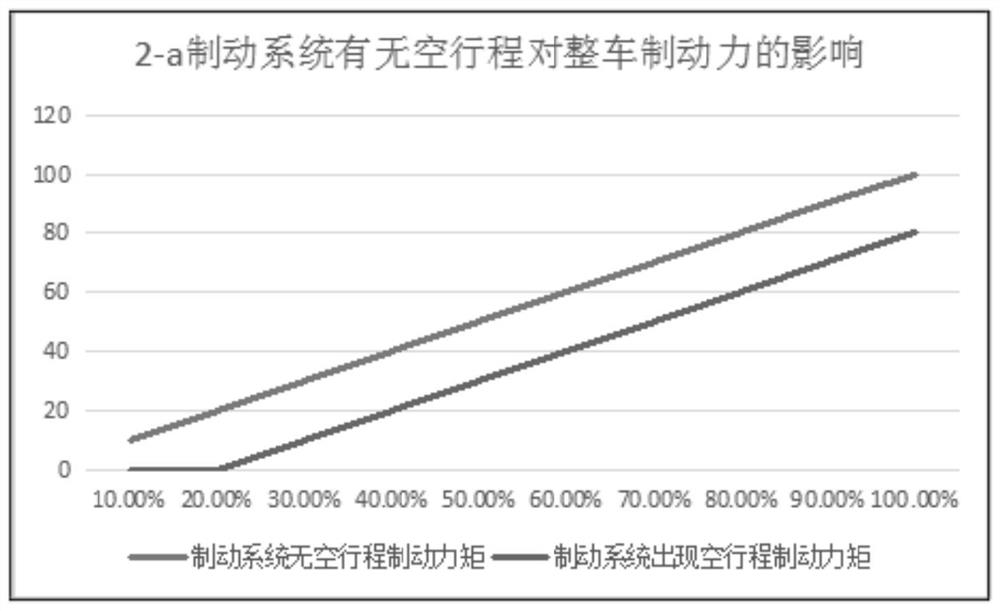

Automobile braking force compensation scheme and control method thereof

PendingCN112078556ADriving safetyContinuous braking forceBrake safety systemsElectric machineryControl theory

The invention discloses an automobile braking force compensation scheme and a control method thereof, and relates to the technical field of automobile control. A braking force compensation module is additionally arranged in software, when it is detected that a brake pad is abraded, if a driver steps on a brake pedal, the braking force needing to be compensated for in the current braking can be calculated according to the braking force compensation module and the compensated total braking force is output through a motor, and the risk during driving can be effectively reduced. The automobile braking force compensation scheme and the control method thereof are a set of schemes for compensating the lost braking force of an automobile through software according to the current abrasion degree ofthe brake pad and the state of a braking system after it is detected that the brake pad is abraded and the braking system has a fault / idle stroke. The scheme is realized by the whole vehicle controlunit and the motor, the safety problem in the driving process caused by the abrasion of the brake pad and the fault / idle stroke of the brake system at present is solved, and a mechanical device is notrequired to be additionally arranged.

Owner:天津中科华誉科技有限公司

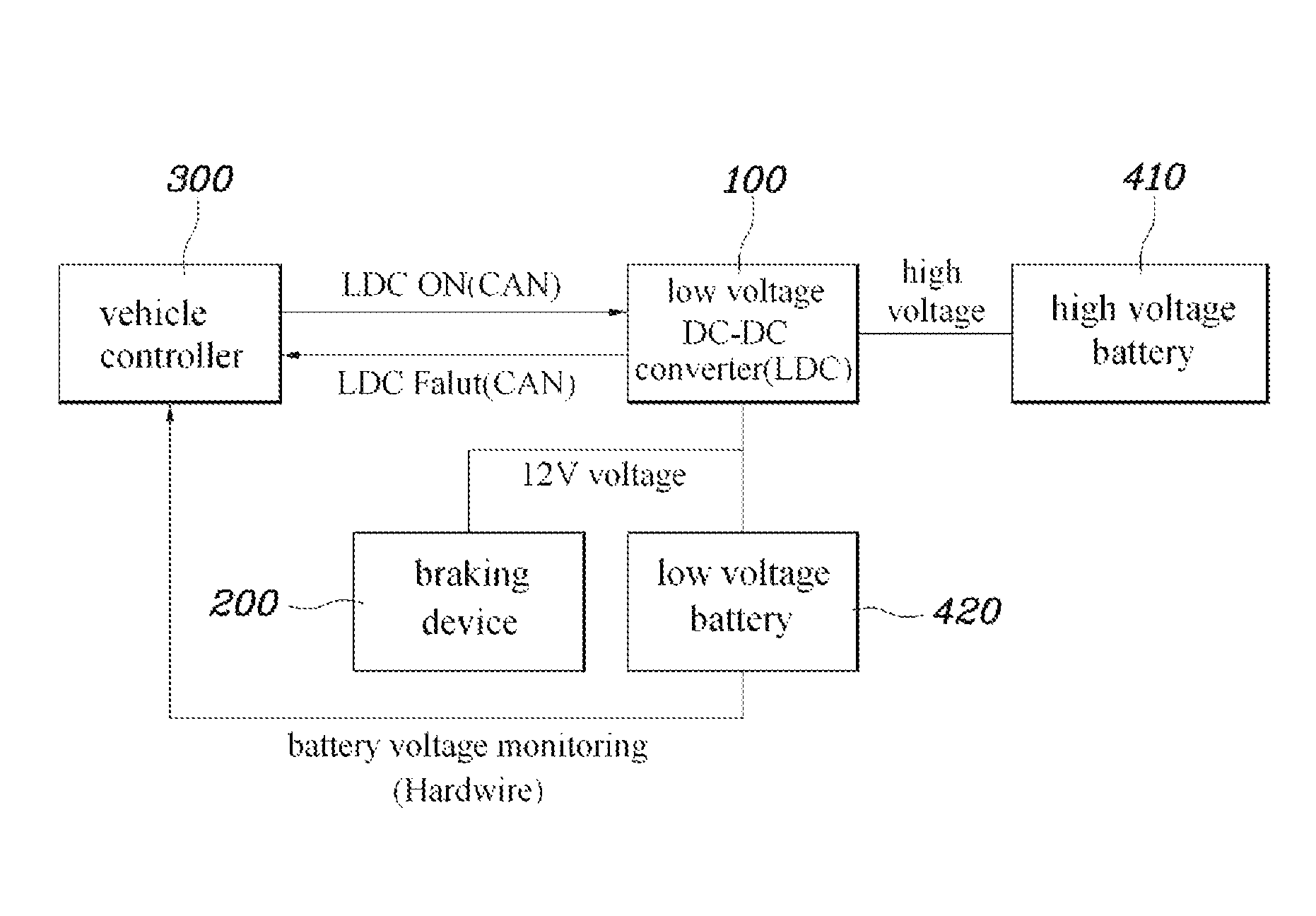

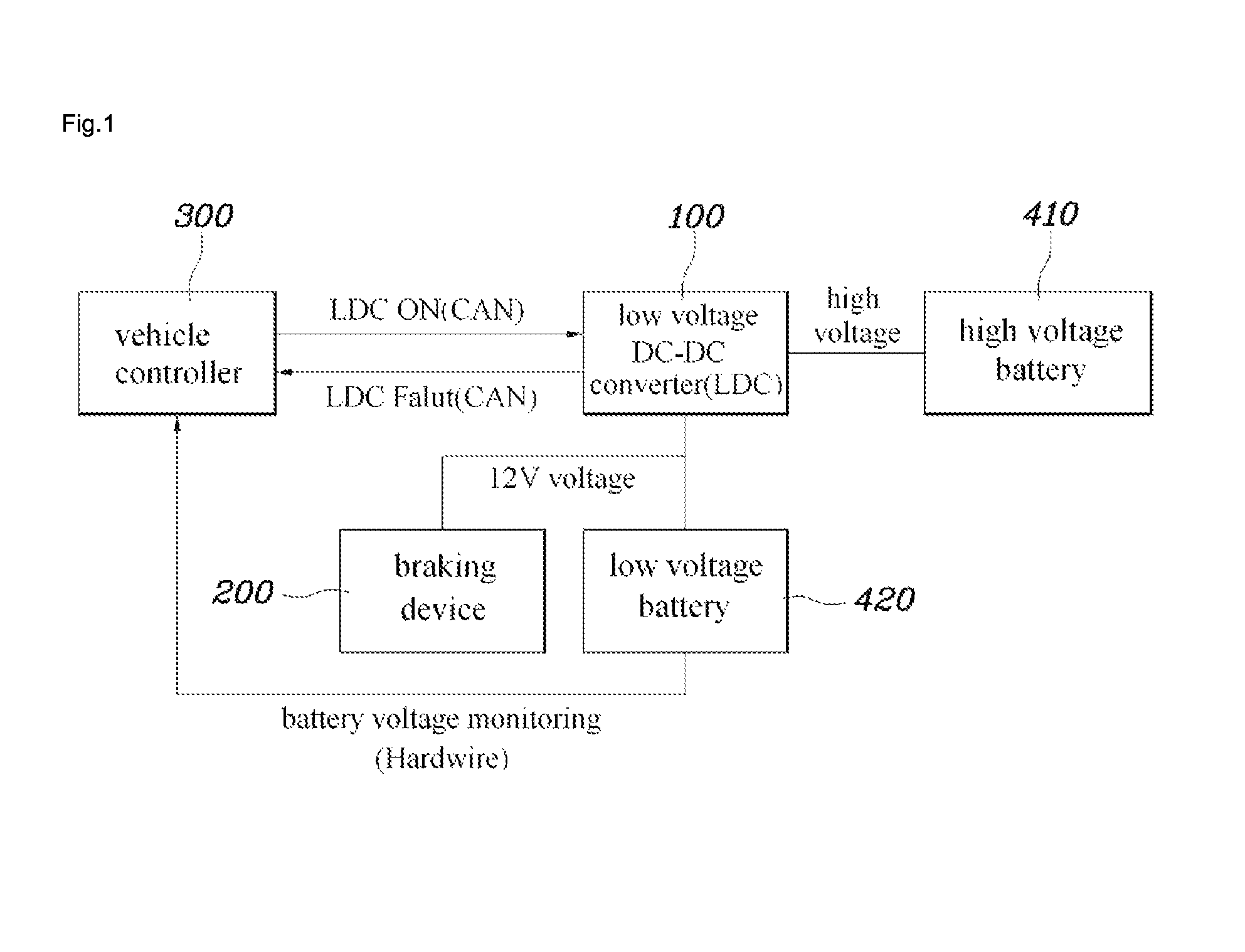

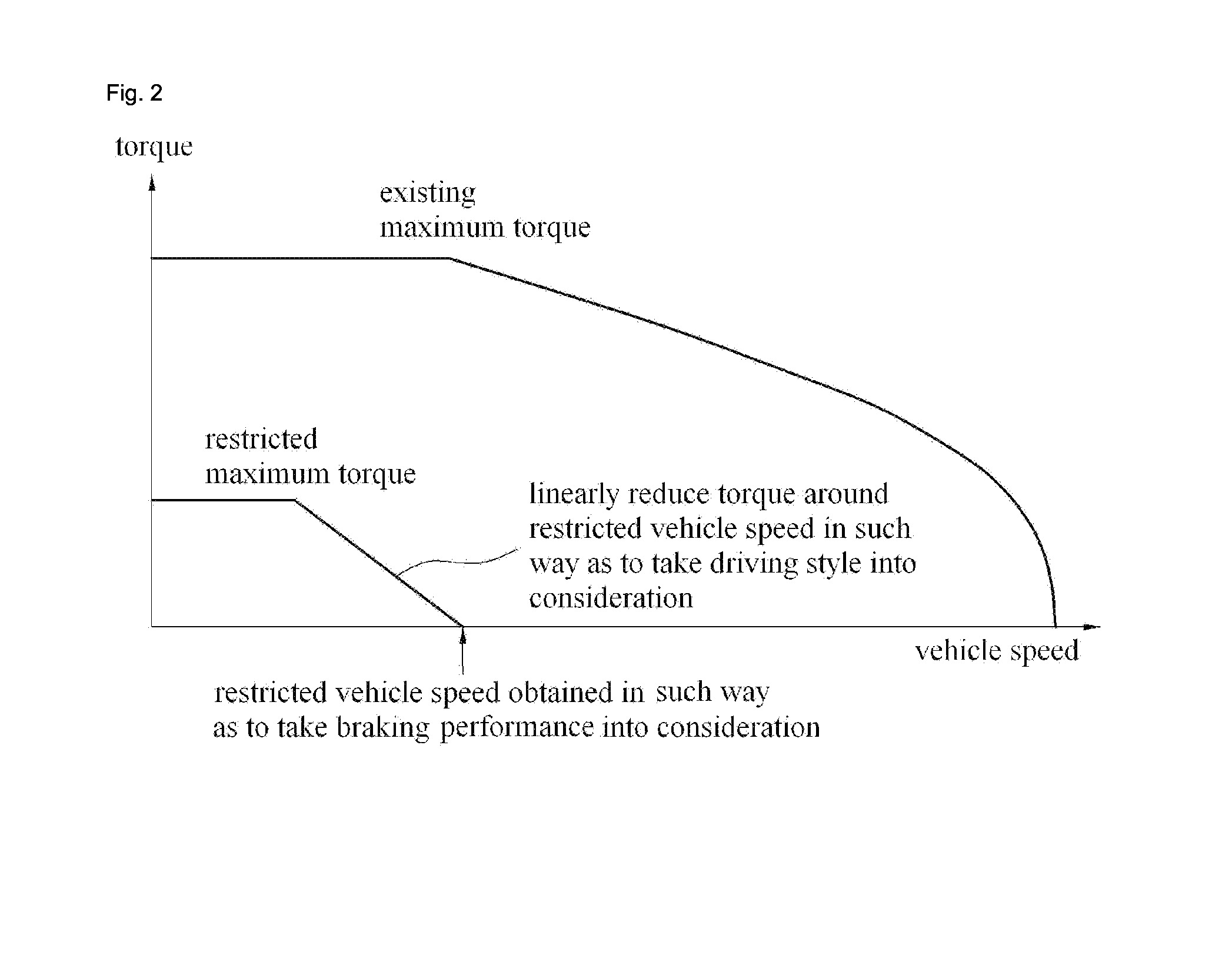

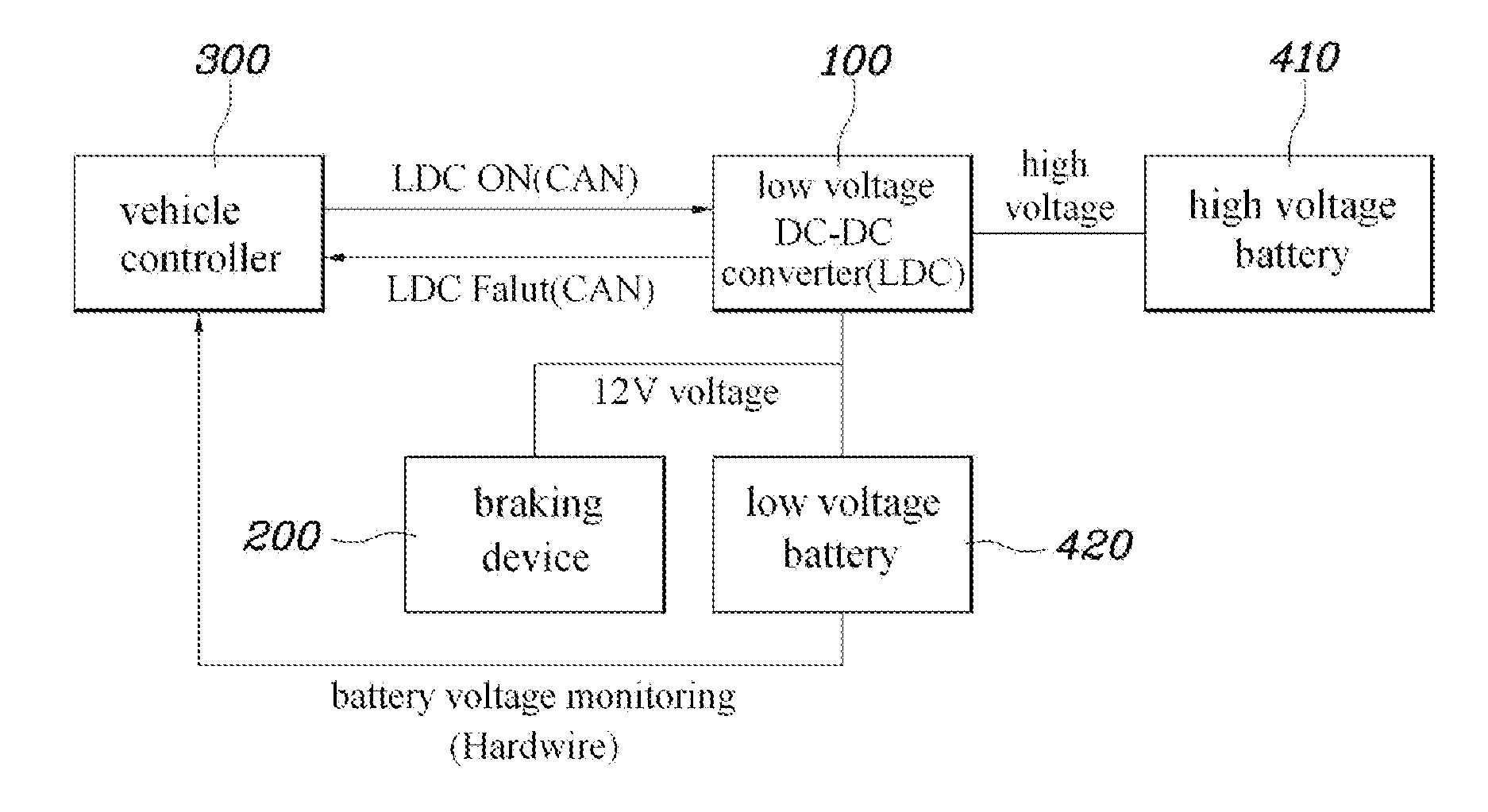

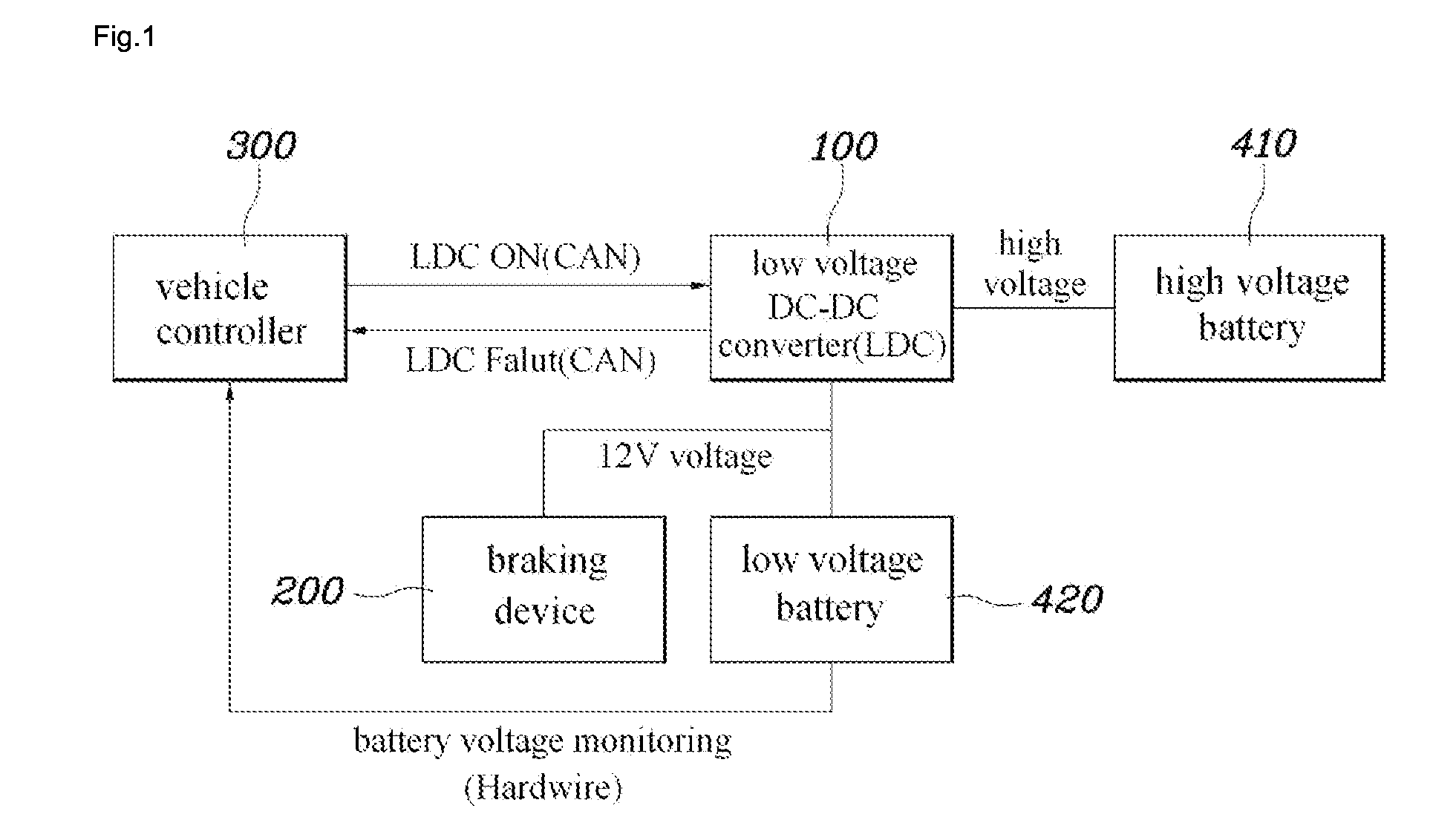

System and method for controlling travel of hybrid electric vehicle in an emergency

Disclosed herein is a method of controlling the travel of a hybrid electric vehicle in an emergency. It is determined whether an abnormality has occurred in a low voltage Direct Current-Direct Current (DC-DC) converter. When it is determined that an abnormality has occurred in the low voltage DC-DC converter, it is determined whether the voltage of a low voltage battery has deviated from the operational voltage range of a braking device. When the voltage of the low voltage battery has deviated from the operational voltage range of the braking device, a restricted vehicle speed is set to take into account mechanical braking power. A maximum torque used to restrict the torque of a driving motor is set based on the set restricted vehicle speed.

Owner:HYUNDAI MOTOR CO LTD +1

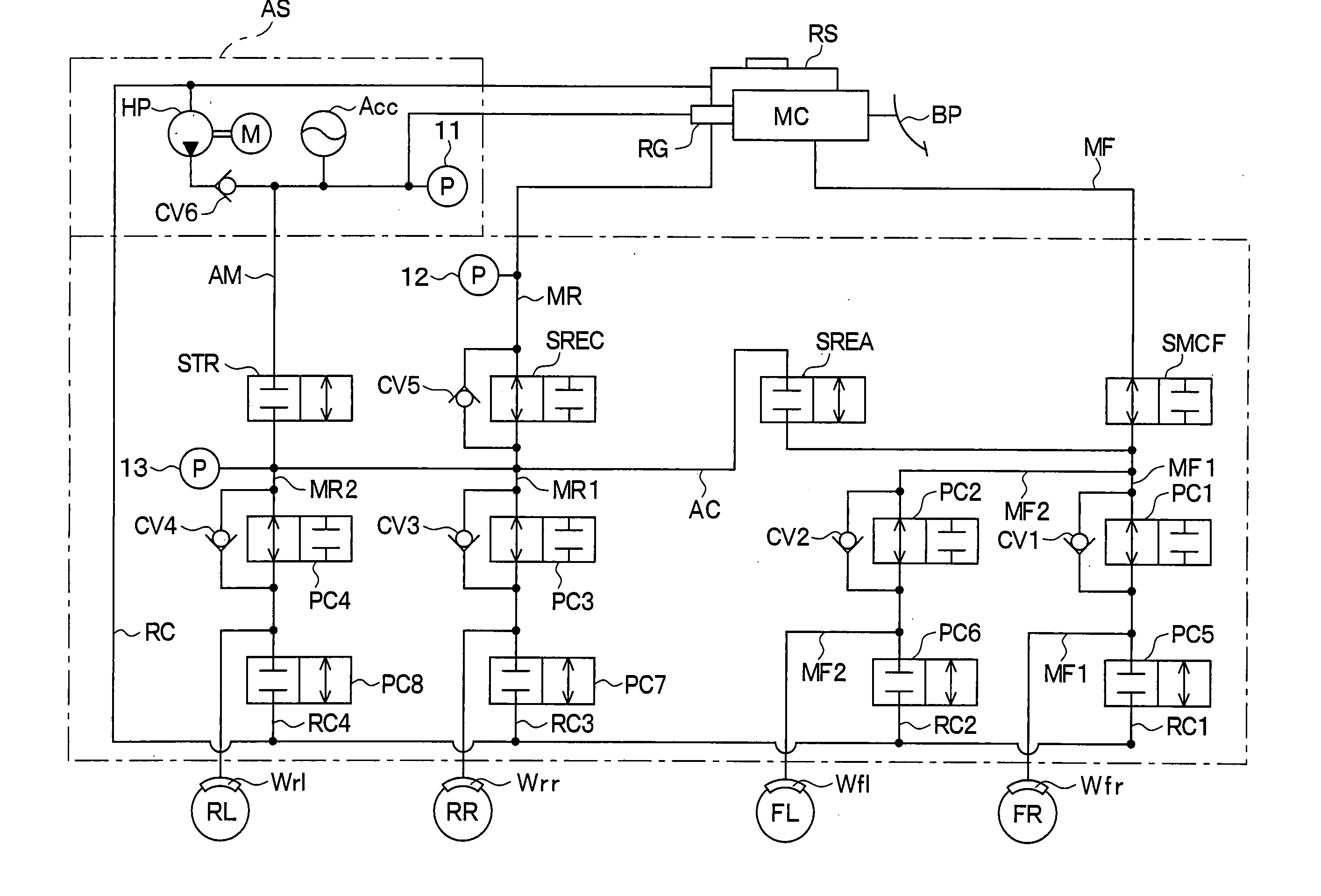

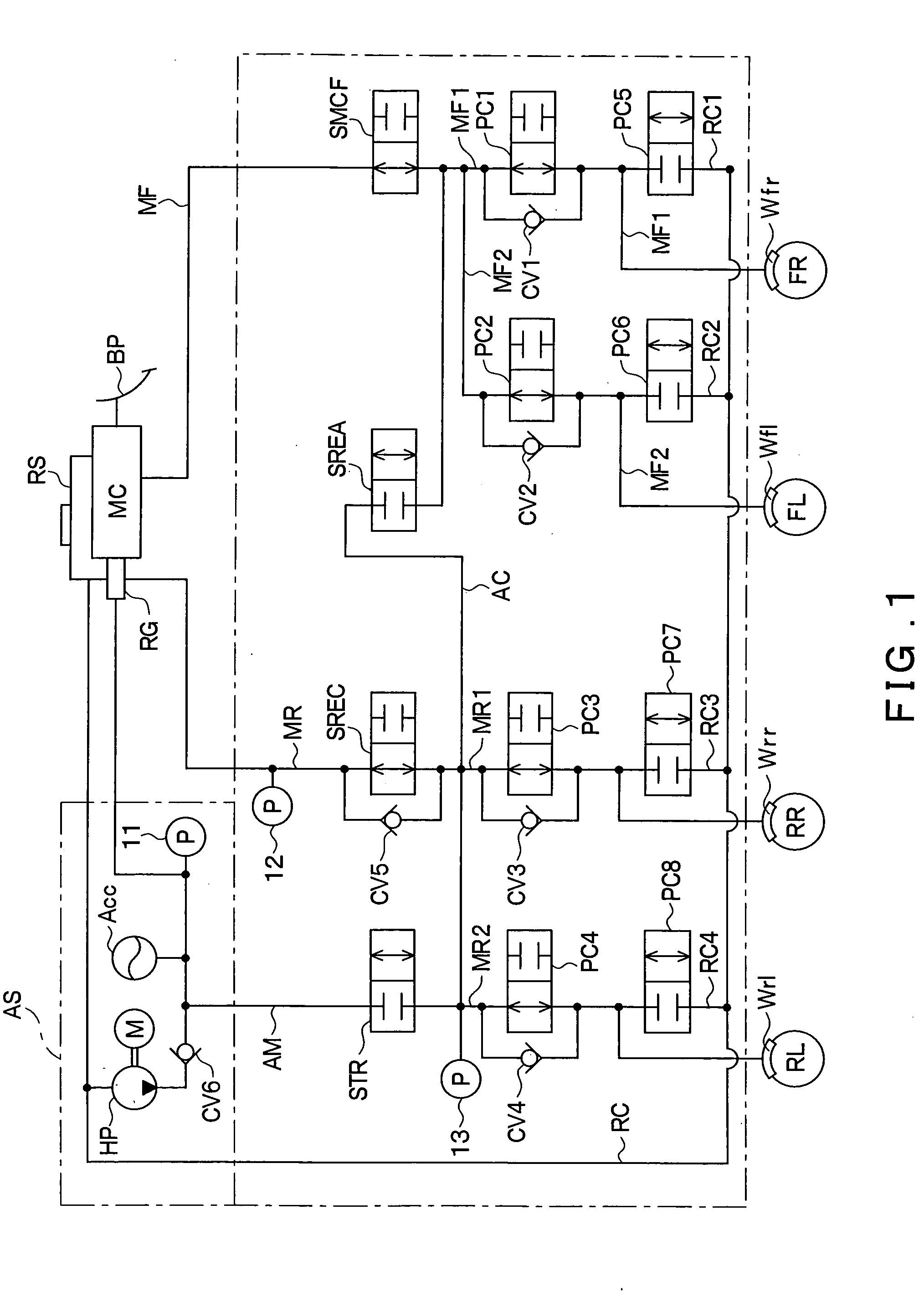

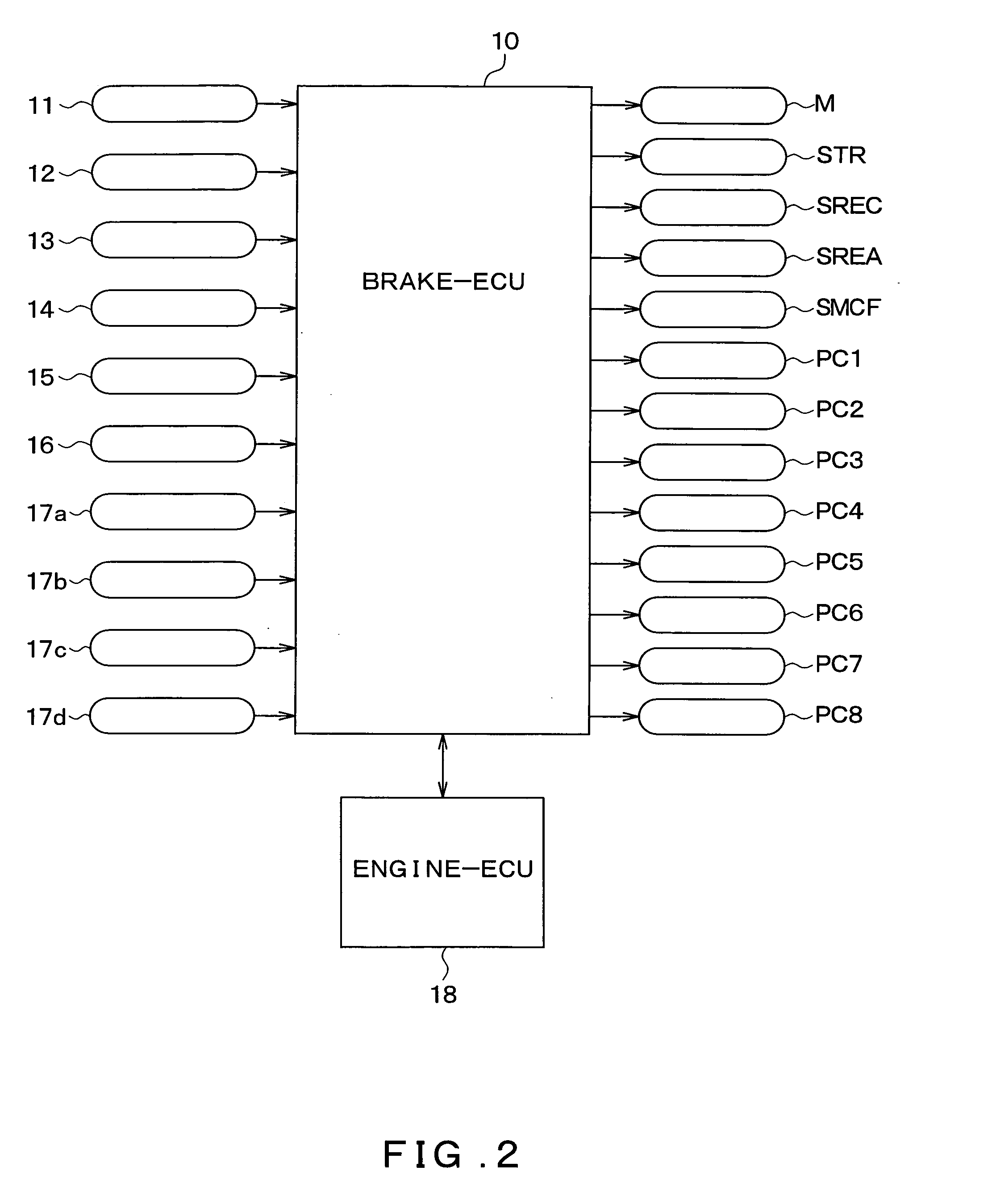

Vehicular brake control device

InactiveUS20060017322A1Increase or decrease pressureSimple configurationBraking systemsAutomatic brakingEngineering

A master cylinder MC is connected to wheel cylinders via brake conduits, and electromagnetic opening / closing valves configured as two-position valves with two ports are provided in the brake conduits, respectively. A brake conduit connects an area among a brake conduit between an electromagnetic opening / closing valve and pressure increase control valves with an area among another brake conduit between another electromagnetic opening / closing valve and pressure increase control valves. The brake conduit therebetween is provided with an electromagnetic opening / closing valve formed from a two-position valve with two ports. By using such a configuration, various controls can be executed as required in the event of an emergency, in addition to normal braking including automatic braking.

Owner:ADVICS CO LTD

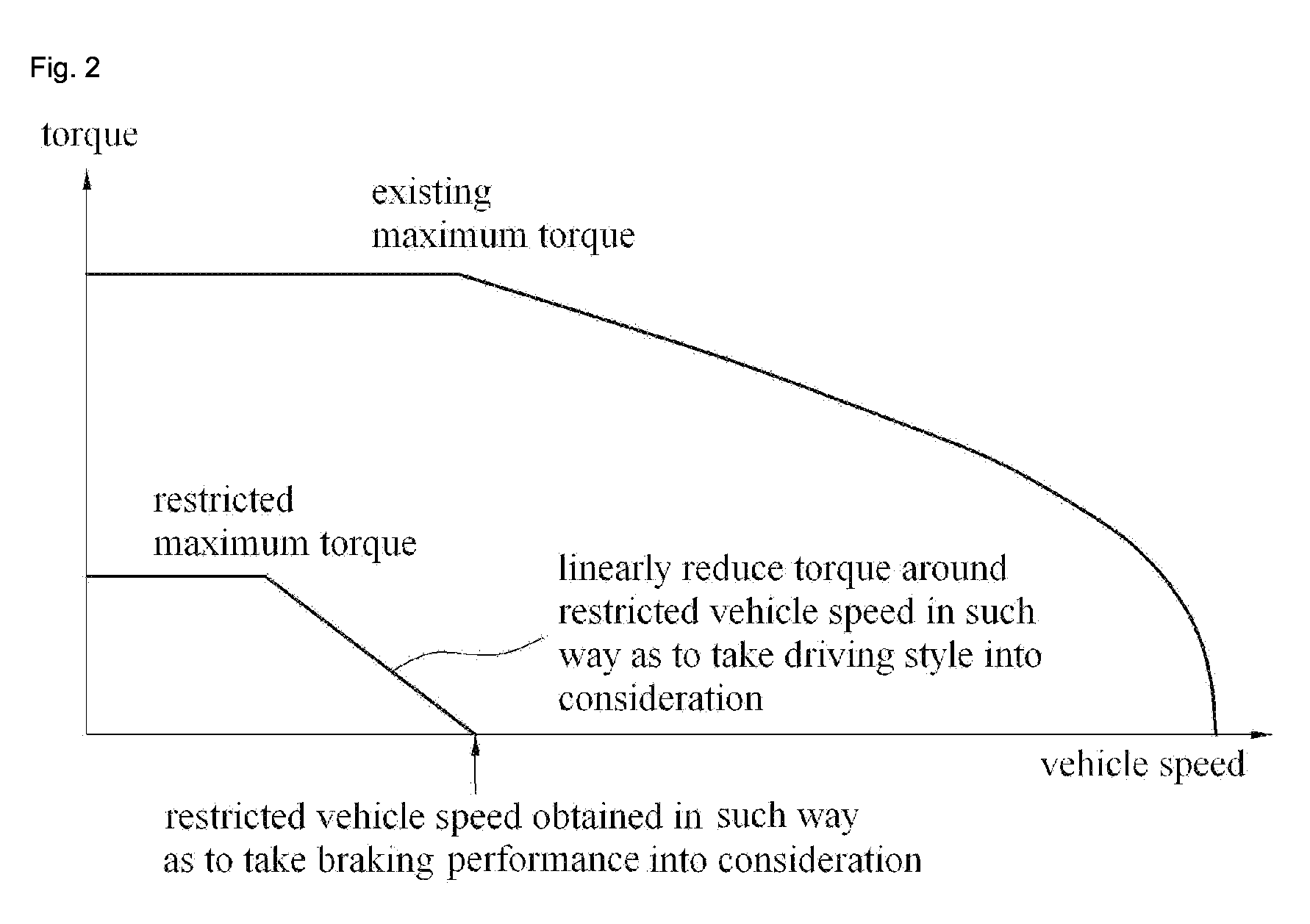

System and method for controlling travel of hybrid electric vehicle in an emergency

ActiveUS20120303192A1Secure stable braking powerSteady braking forceHybrid vehiclesSpeed controllerMaximum torqueDc dc converter

Disclosed herein is a method of controlling the travel of a hybrid electric vehicle in an emergency. It is determined whether an abnormality has occurred in a low voltage Direct Current-Direct Current (DC-DC) converter. When it is determined that an abnormality has occurred in the low voltage DC-DC converter, it is determined whether the voltage of a low voltage battery has deviated from the operational voltage range of a braking device. When the voltage of the low voltage battery has deviated from the operational voltage range of the braking device, a restricted vehicle speed is set to take into account mechanical braking power. A maximum torque used to restrict the torque of a driving motor is set based on the set restricted vehicle speed.

Owner:HYUNDAI MOTOR CO LTD +1

Elevator brake releasing device

ActiveCN105000491AAvoid the problem of electrical fault failureImprove synchronicityElevatorsHoisting equipmentsBiochemical engineeringSynchronism

The invention relates to an elevator brake releasing device. The elevator brake releasing device comprises a first brake, a second brake, a first support and a second support, wherein the first brake and the second brake are symmetrically arranged on an elevator host. The elevator brake releasing device further comprises a control rope, an outside well releasing operating mechanism used for tensioning or releasing the control rope, a first pull rod and a second pull rod, wherein the first pull rod and the second pull rod are arranged in a crossed mode. One end of the first pull rod is rotationally connected with the first support, and a pulley is connected to the other end of the first pull rod. The first pull rod is provided with a movable groove. One end of the second pull rod is movably connected with the second support. The other end of the second pull rod penetrates through the movable groove and is connected with one end of the control rope. The other end of the control rope winds around the pulley to be connected with the outside well releasing operating mechanism. The first brake and the second brake are connected with the first pull rod and the second pull rod respectively. According to the elevator brake releasing device, releasing is carried out in a mechanical mode, the problem of failure of the releasing device due to electric failure can be solved, and safety and reliability are achieved. The first pull rod and the second pull rod are arranged in the crossed mode, the synchronism of releasing of the first brake and the second brake is high, and brake force is stable.

Owner:HITACHI ELEVATOR CHINA

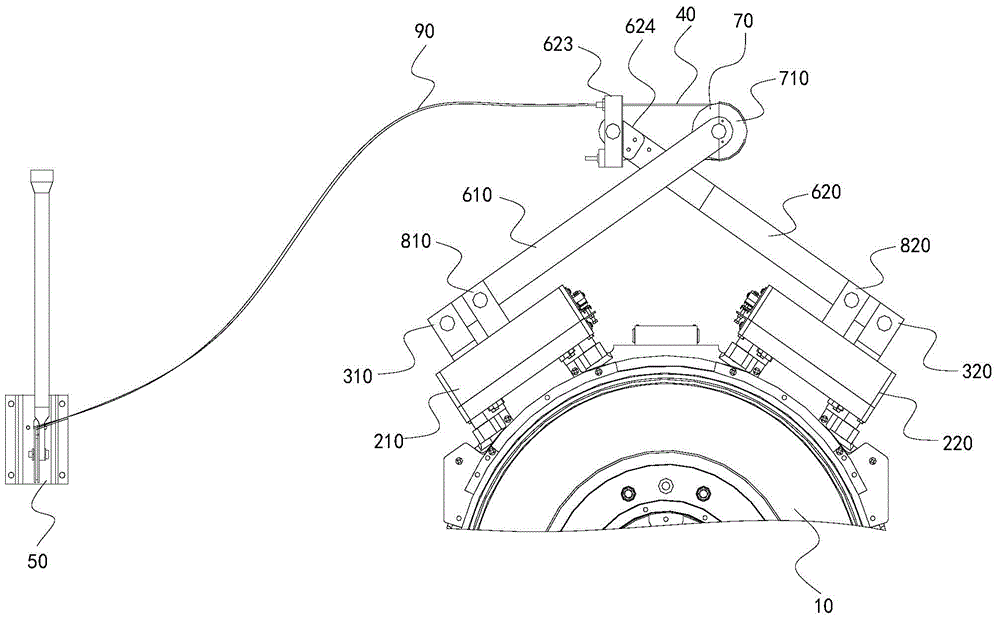

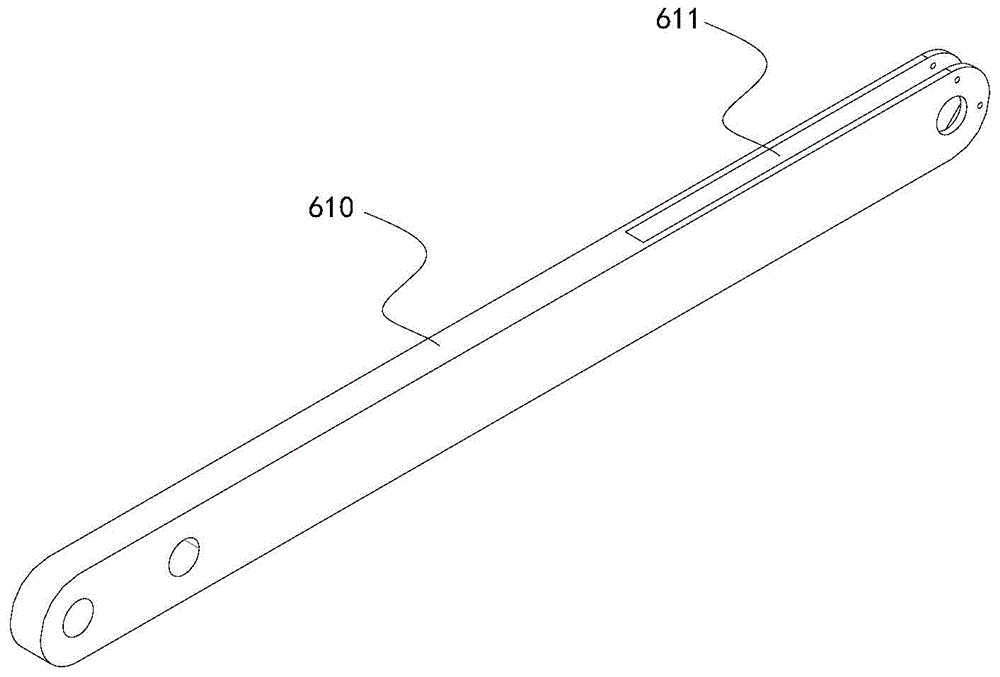

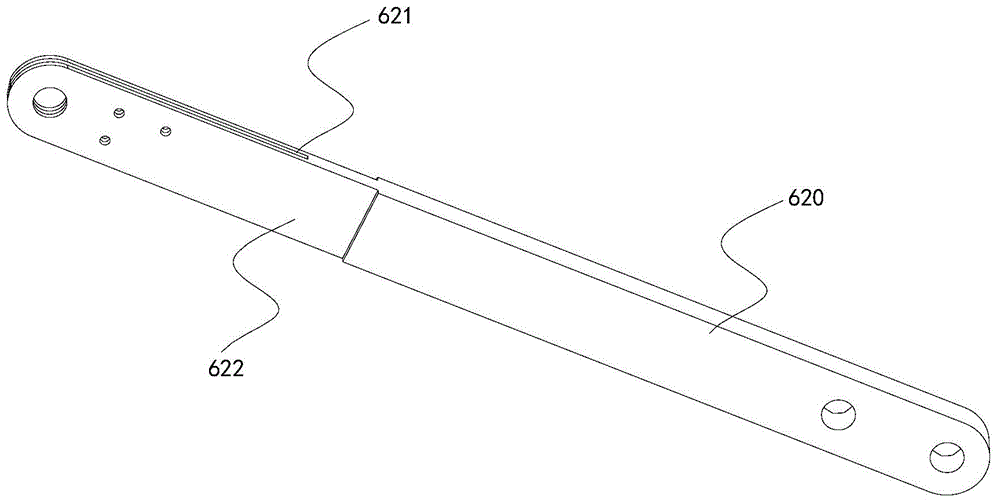

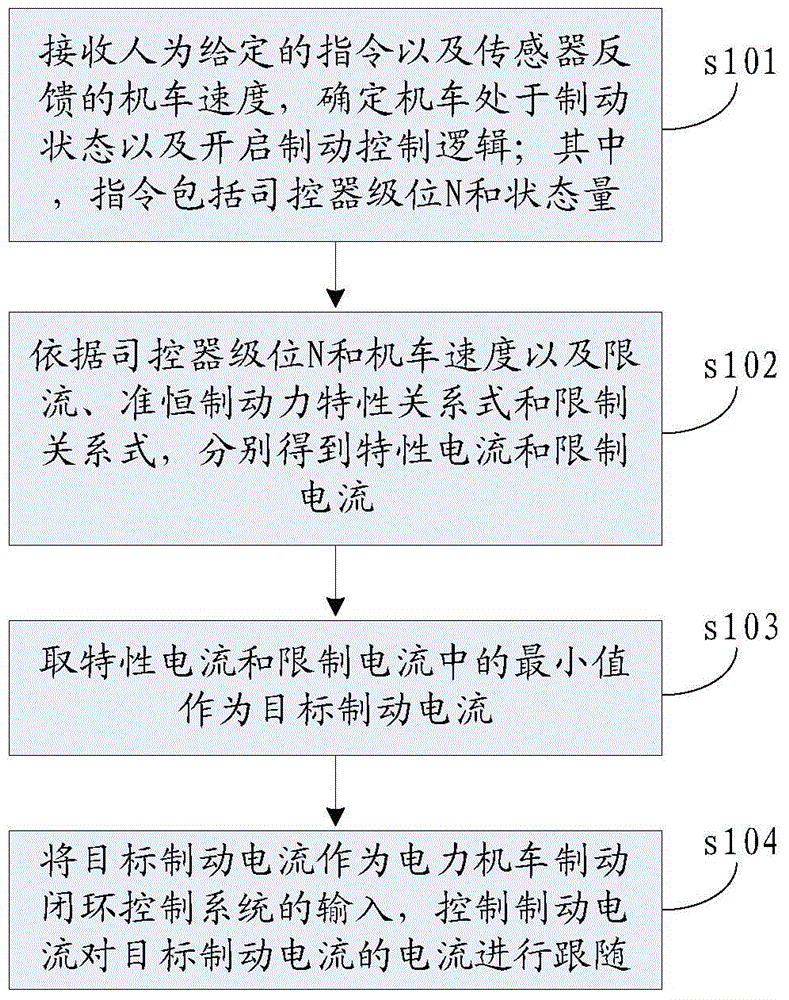

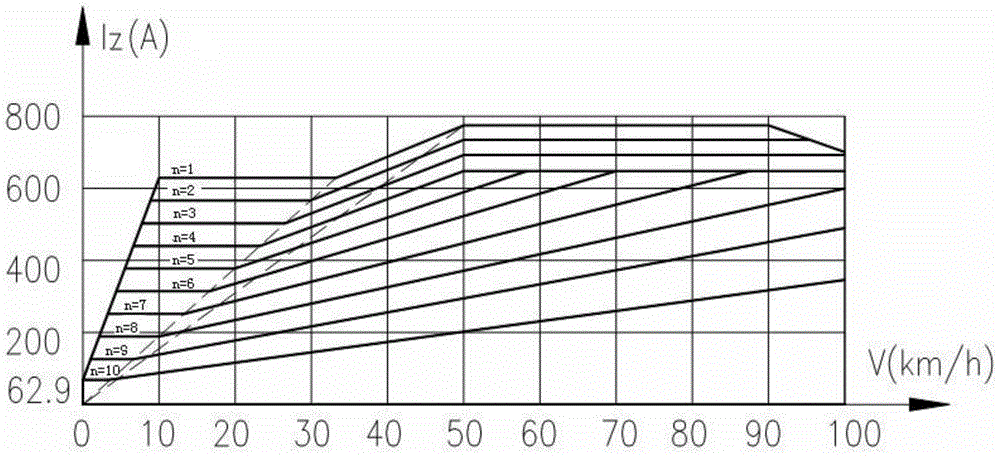

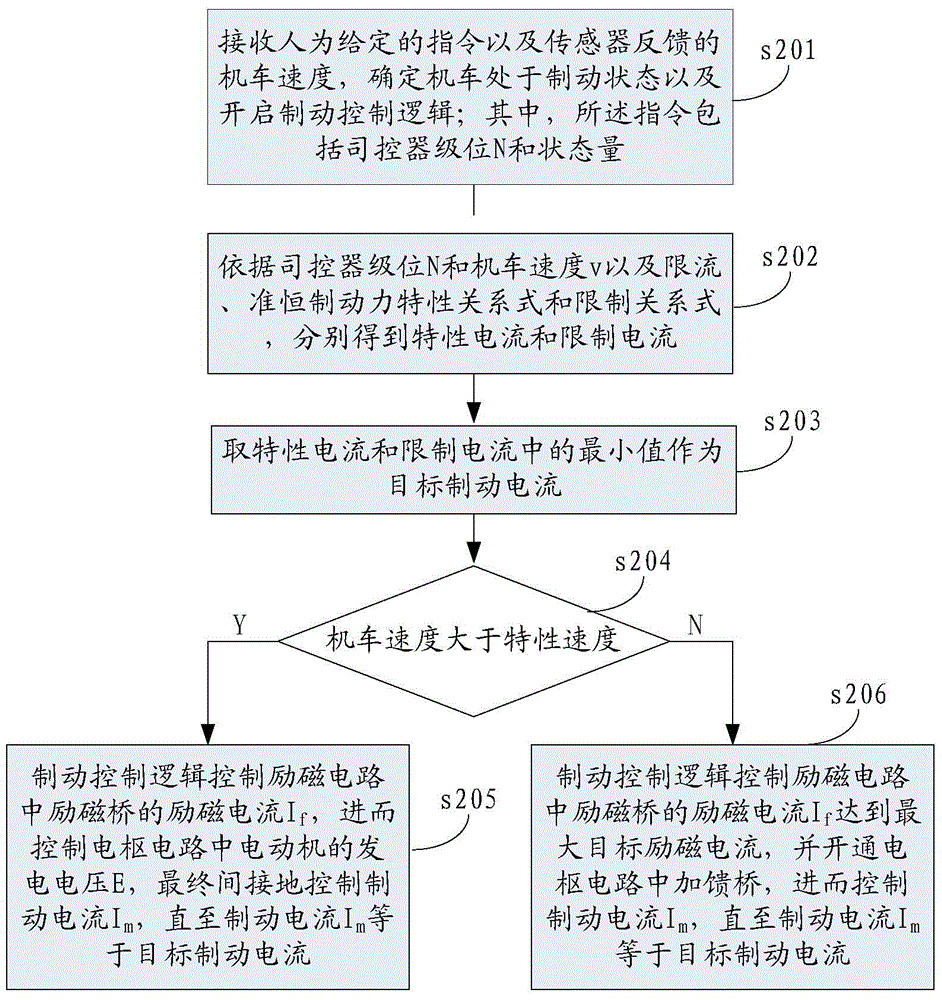

Electric locomotive braking control method and system

ActiveCN104590038ASteady braking forceSmooth changeElectrodynamic brake systemsClosed loopElectric power

The invention discloses an electric locomotive braking control method. The method includes the steps of receiving a manually-given instruction and the locomotive speed v fed back by a sensor, determining that a locomotive is in the braked state, and starting the braking control logic, wherein the instruction includes the motorman controller level N and the state amount; obtaining the characteristic current I1 and the limiting current I2 according to the motorman controller level N, the locomotive speed v and the characteristic relational expression and the limiting relational expression of the current-limiting and quasi-constant braking force, and selecting the minimum value in the characteristic current I1 and the limiting current I2 to serve as the target braking current IZ; using the target braking current IZ as the input of an electric locomotive braking closed-loop control system, and controlling the braking current Im to follow the current of the target braking current IZ. The invention further discloses an electric locomotive braking control system. By means of the method and the system, under the periodic locomotive speed sudden change working condition of the electric locomotive, the braking electricity generation voltage and the braking current changes are smoother, the influences of electric impact on an electric motor are effectively eliminated, and meanwhile the reversing performance is optimized and the reverser working environment is improved.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Elevator provided with emergency braking device

In order to prevent the bounce of a brake shoe during the initial braking, produce the braking force stably, and stop at the predetermined speed, the invention provides an elevator provided with an emergency braking device. In order to stop the cabin of the elevator, the brake shoe is slidably disposed on a guide rail in an elevating channel in a pressed manner by using the emergency brake device, and therefore the brake force can be generated. The elevator provided with the emergency brake device is further provided with a collision force direction converting part, which can be used to convert the collision force generated by the collision between the brake shoe being lifted upward and a top plate of the emergency braking device into the movement resistance in the horizontal direction. The collision force direction converting part is constituted by a pin used as a protruding member and a gap filling sheet used as a concave member. The pin is disposed on an upper part of the brake shoe, and the gap filling sheet is disposed on the top plate of the emergency braking device by the housing part in a supported manner, and can be embedded with the pin. The movement of the gap filling sheet in the horizontal direction can be used to prevent the bounce of the brake shoe.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com