Patents

Literature

113 results about "Wire gauge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wire gauge is a measurement of wire diameter. This determines the amount of electric current a wire can safely carry, as well as its electrical resistance and weight.

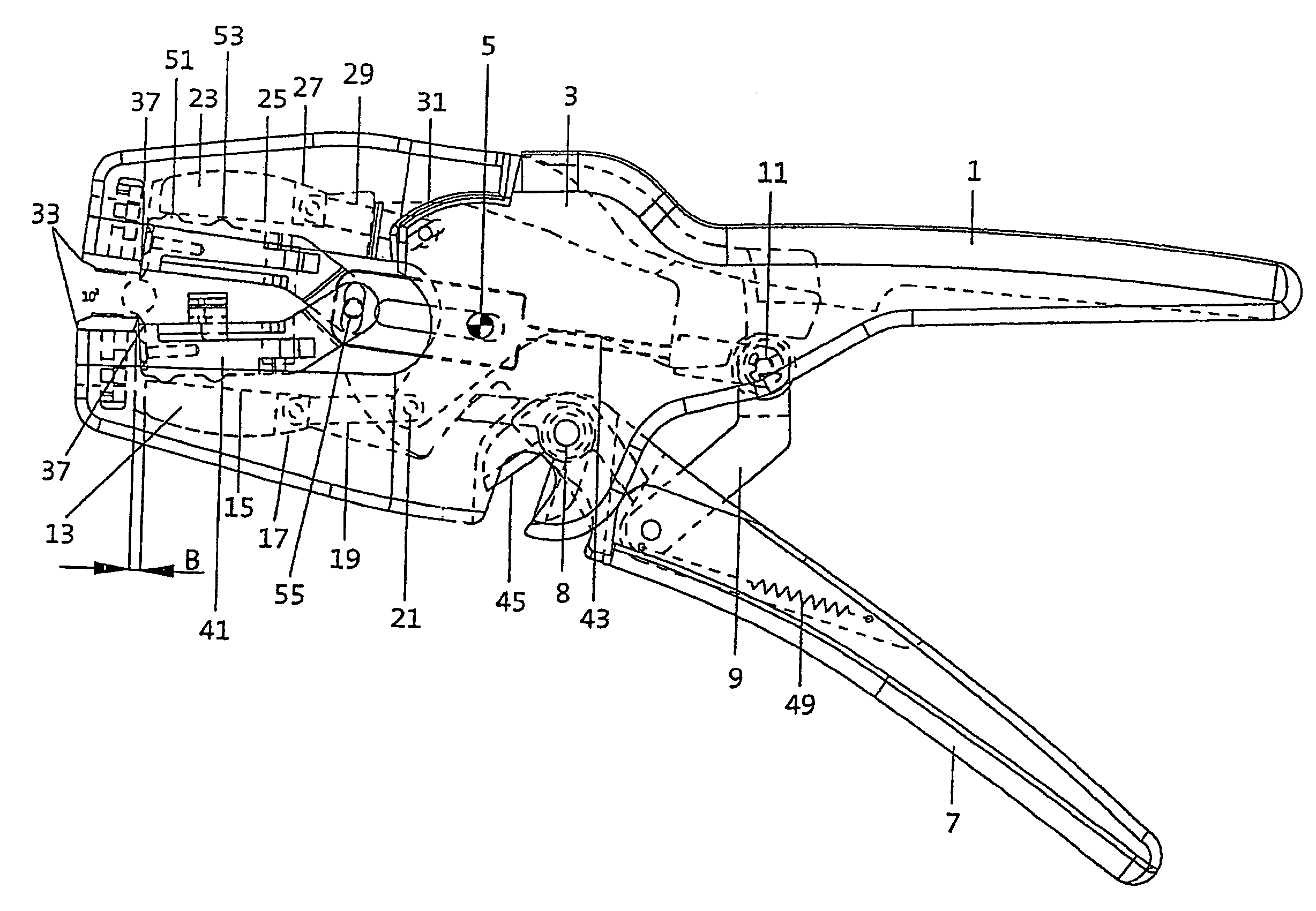

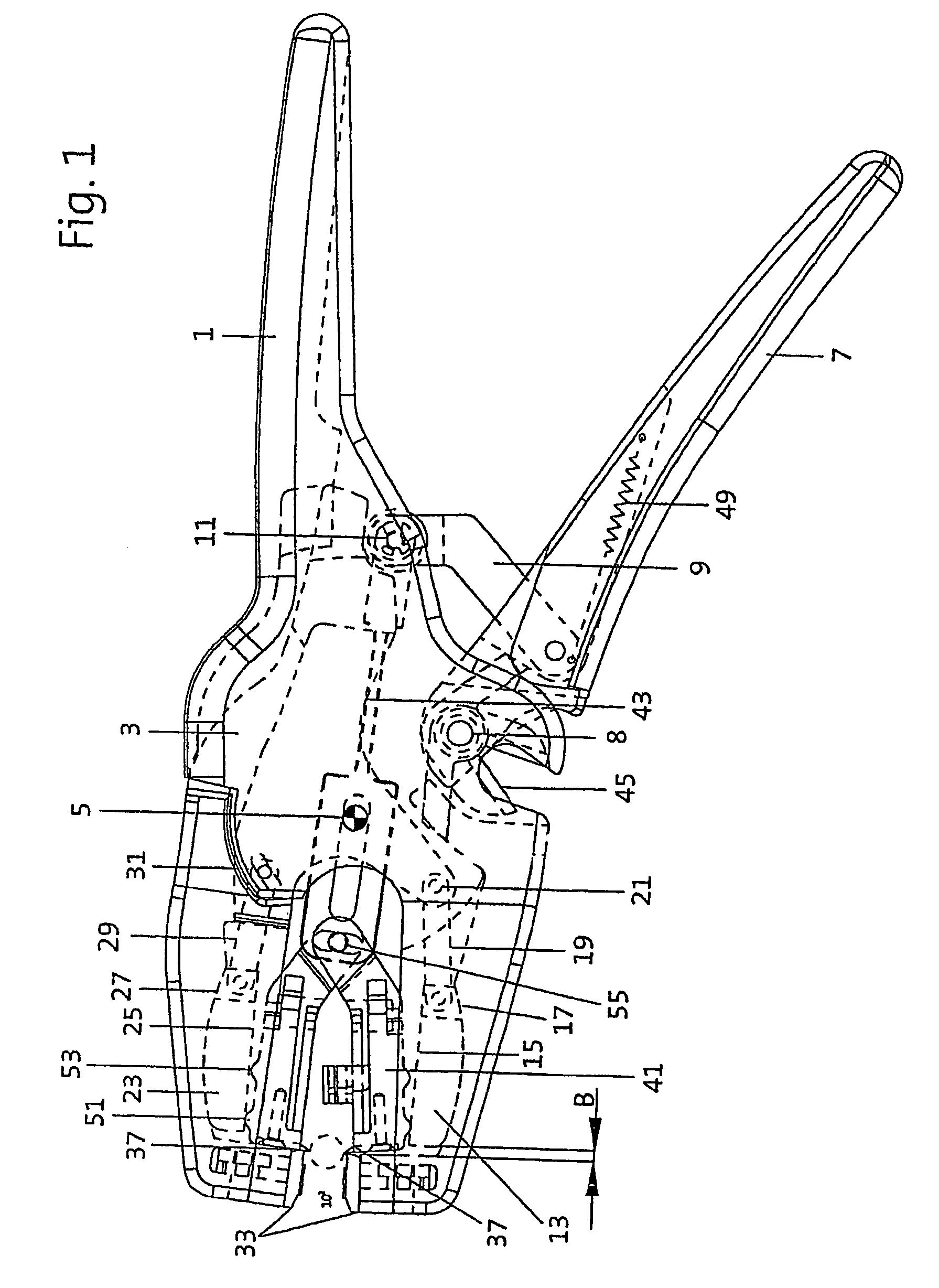

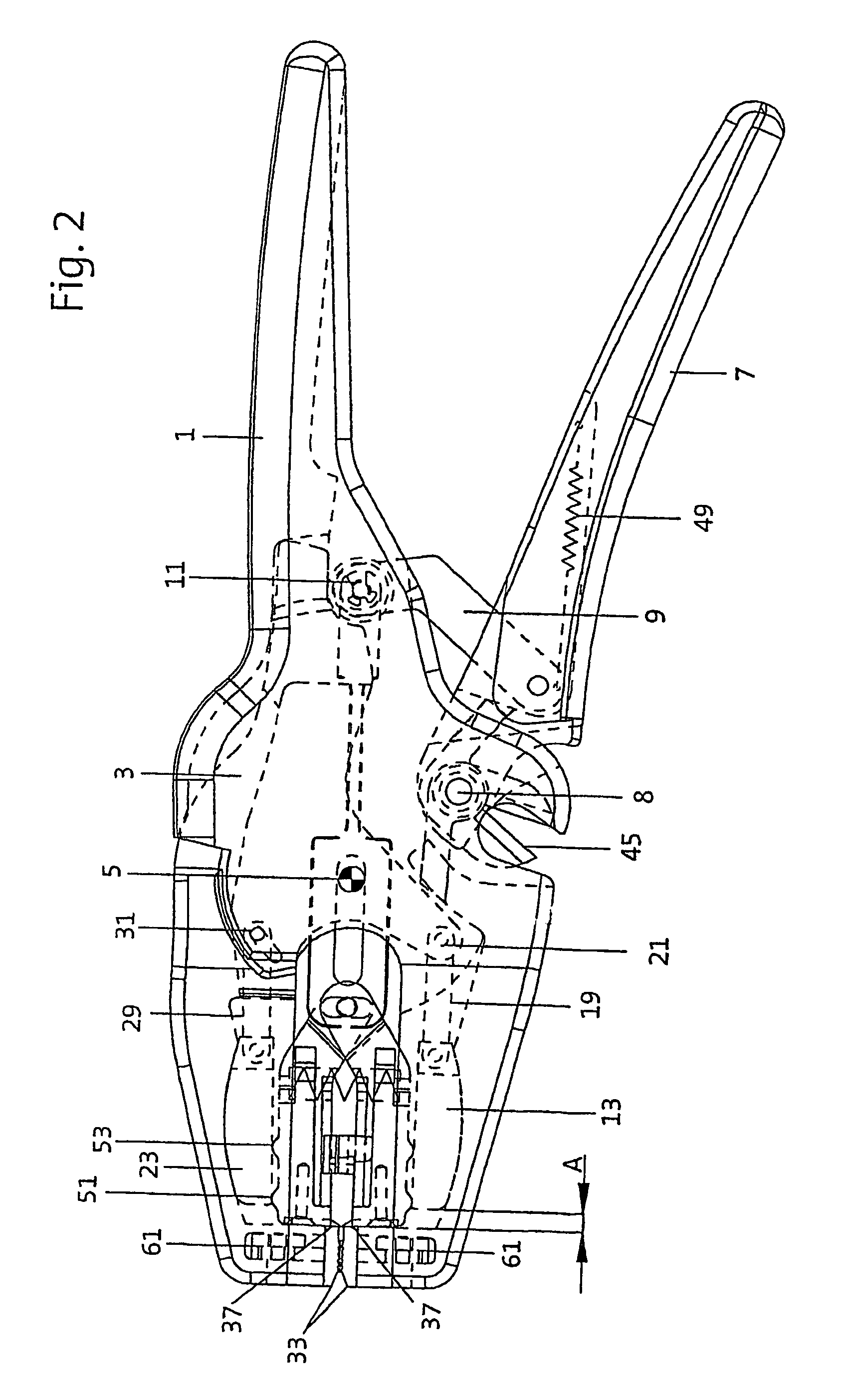

Wire stripper which can be automatically adapted to different conductor cross sections

ActiveUS7513177B2Avoid damageEasy to replaceApparatus for removing/armouring cablesWire gaugeElectrical conductor

Owner:RENNSTEIG WERKZEUGE

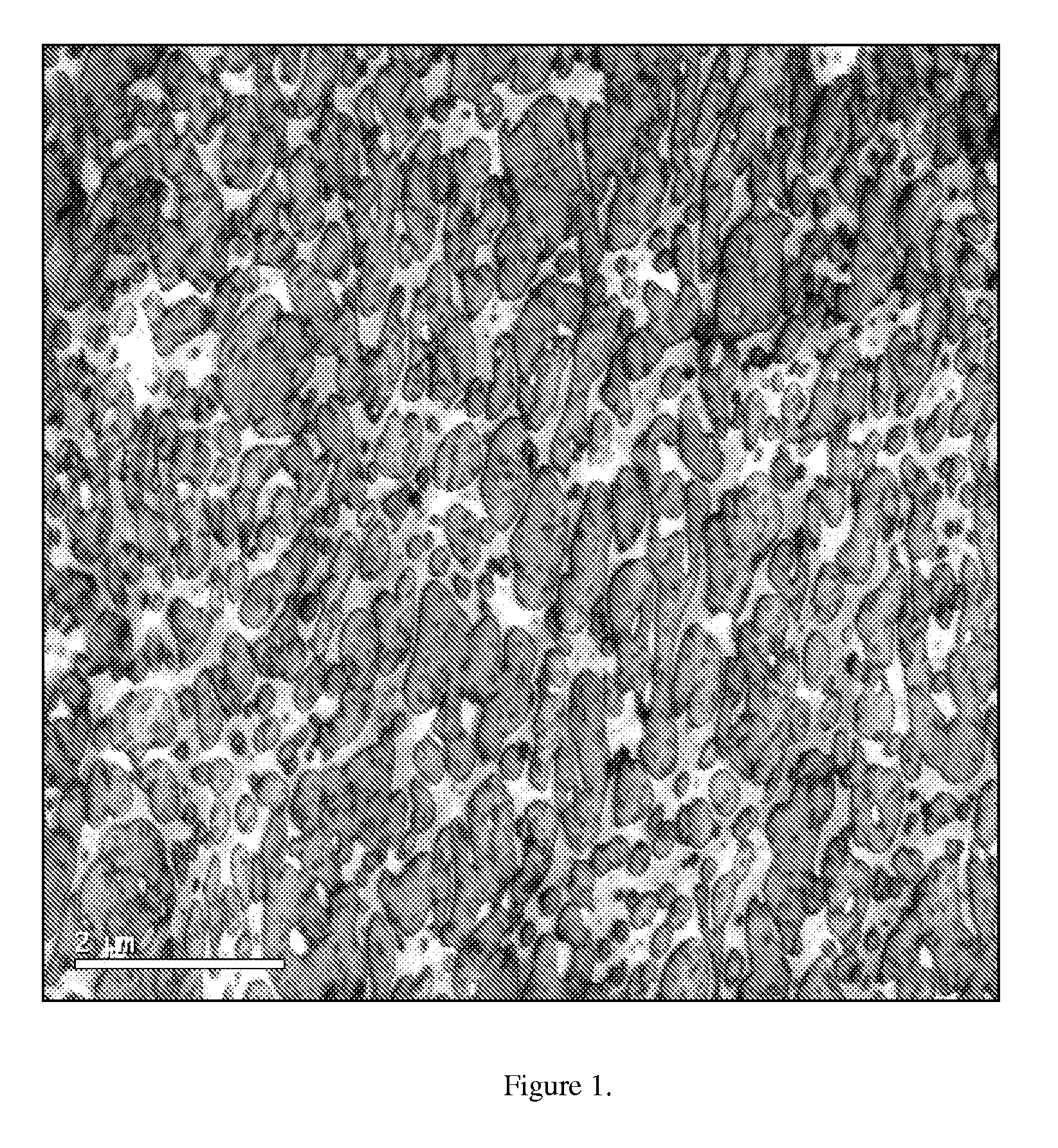

Poly(arylene ether) composition and a covered conductor with thin wall and small size conductor

A covered conductor comprising: a conductor; and a covering comprising a thermoplastic composition and the thermoplastic composition comprises: a poly(arylene ether) having an intrinsic viscosity greater than 0.25 dl / g as measured in chloroform at 25° C., a poly(alkenyl aromatic)polymer, a polyolefin resin and optionally a flame retardant and a compatibilizer, wherein the covered conductor essentially meets the performance requirement of ISO 6722, wherein the covering is disposed over the conductor, wherein the conductor has a cross section that meets as least one of following: (i) American Wire Gauge (AWG) from AWG 56 to AWG 26, (ii) a cross-section area from 0.000122 to 0.128 mm2 (corresponding to AWG 56 to AWG 26 according to ASTM B256-02); (iii) a nominal diameter from 0.0124 to 0.404 mm (corresponding to AWG 56 to AWG 26 according to UL 1581, 4th edition, Table 20.1). The covering of the covered conductor has a thickness from about 0.010 to about 0.85 mm. An automotive wire harness assembly comprises the covered conductor. An “end use equipment” comprises the wire assembly.

Owner:SABIC INNOVATIVE PLASTICS IP BV

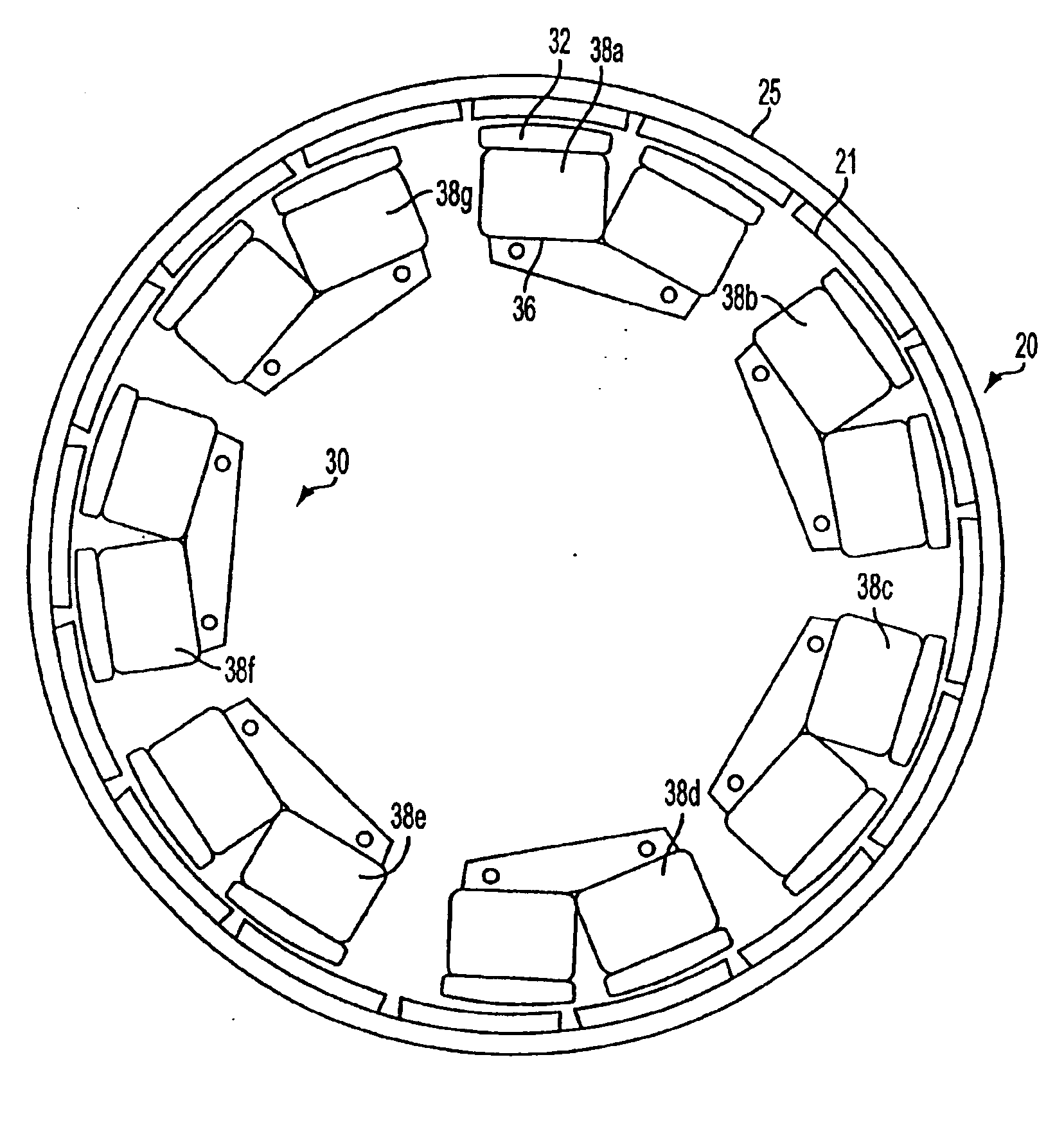

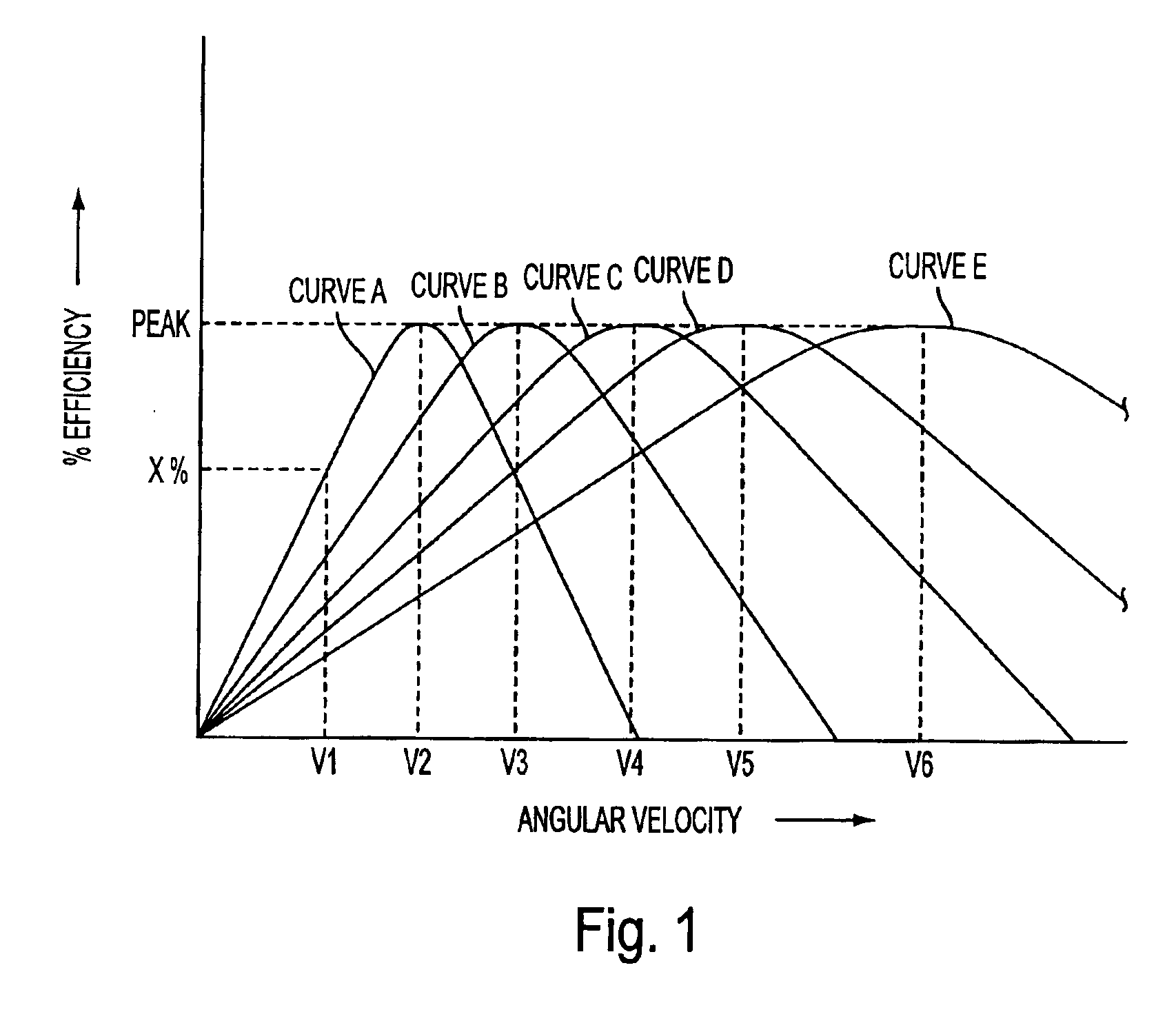

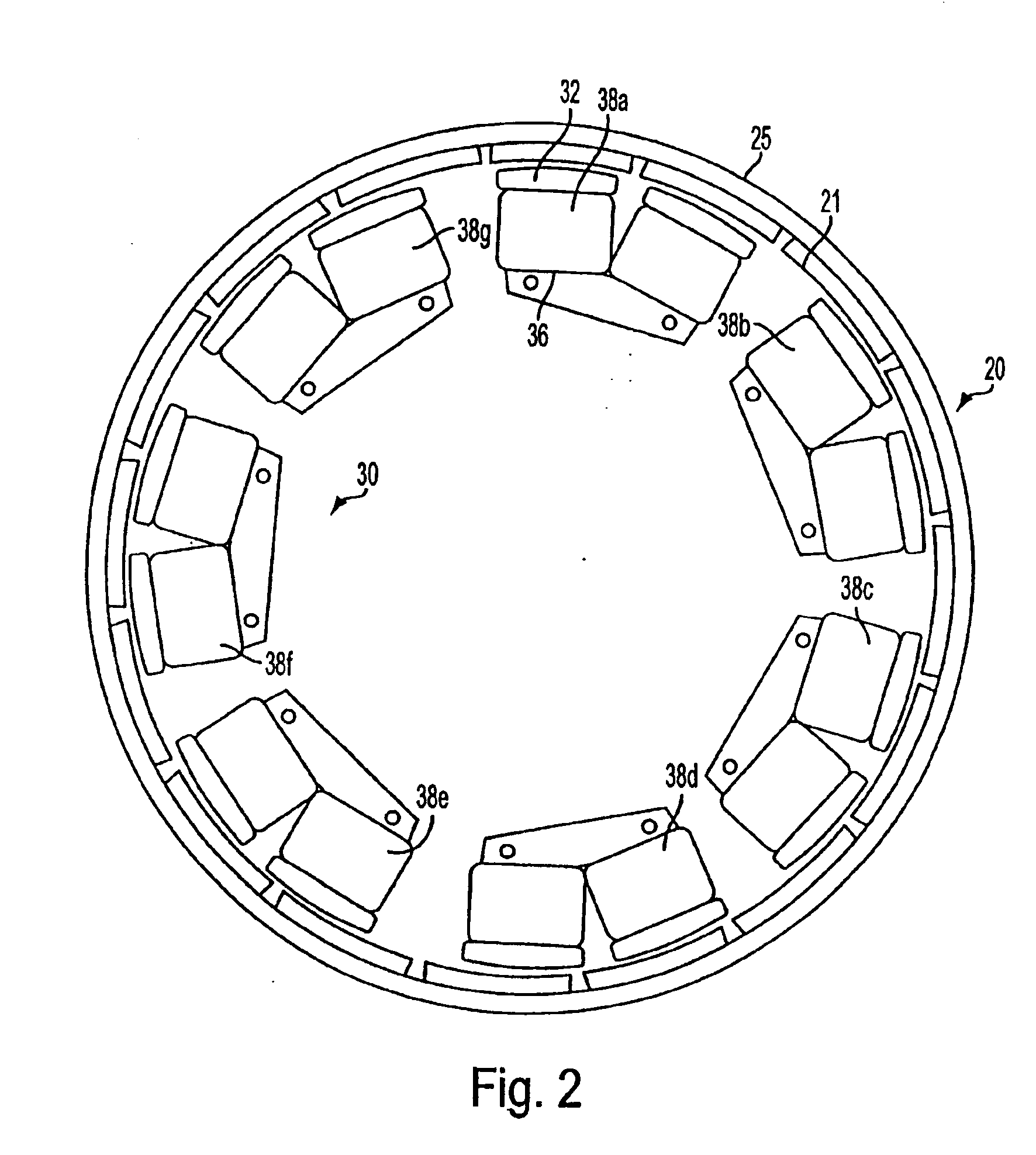

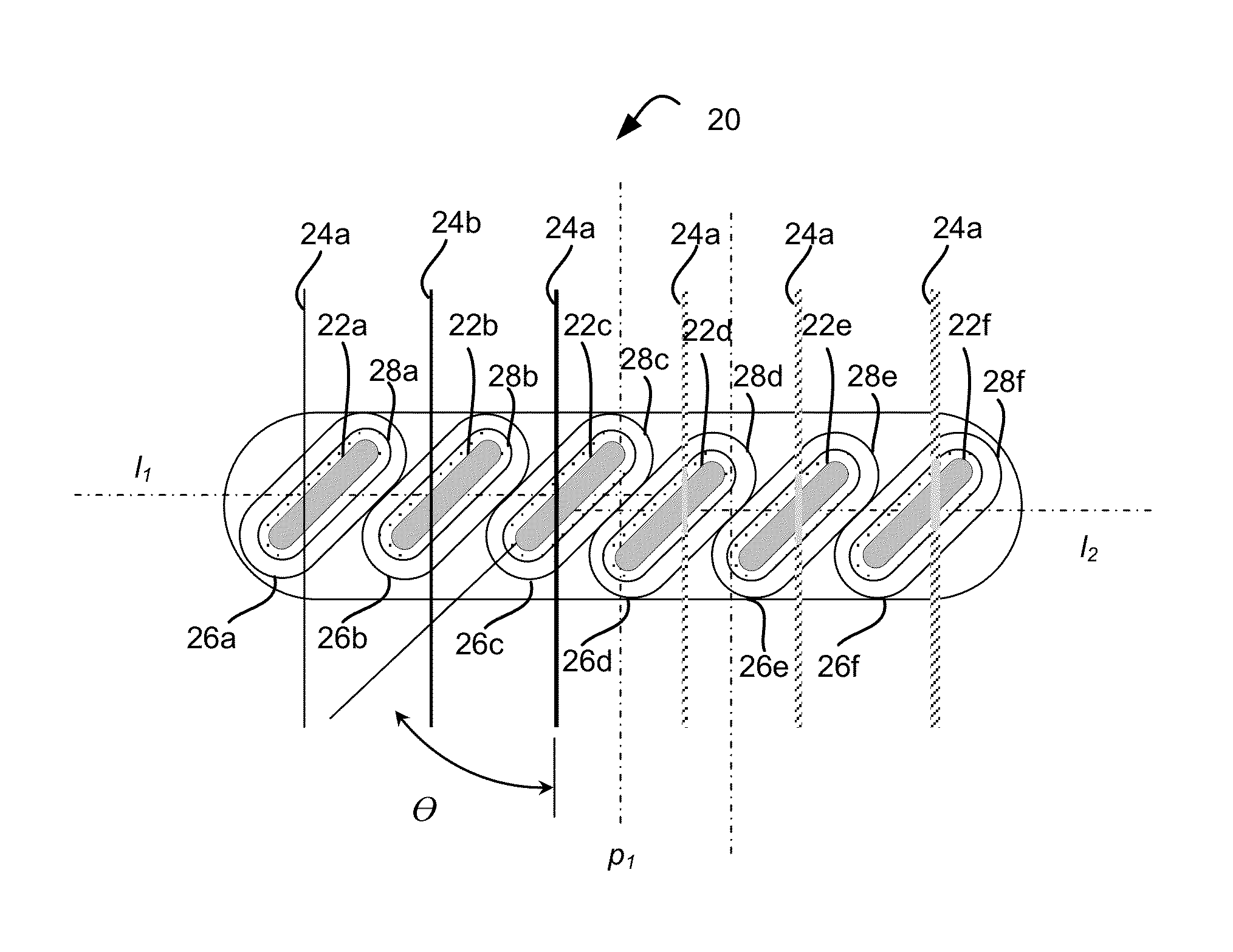

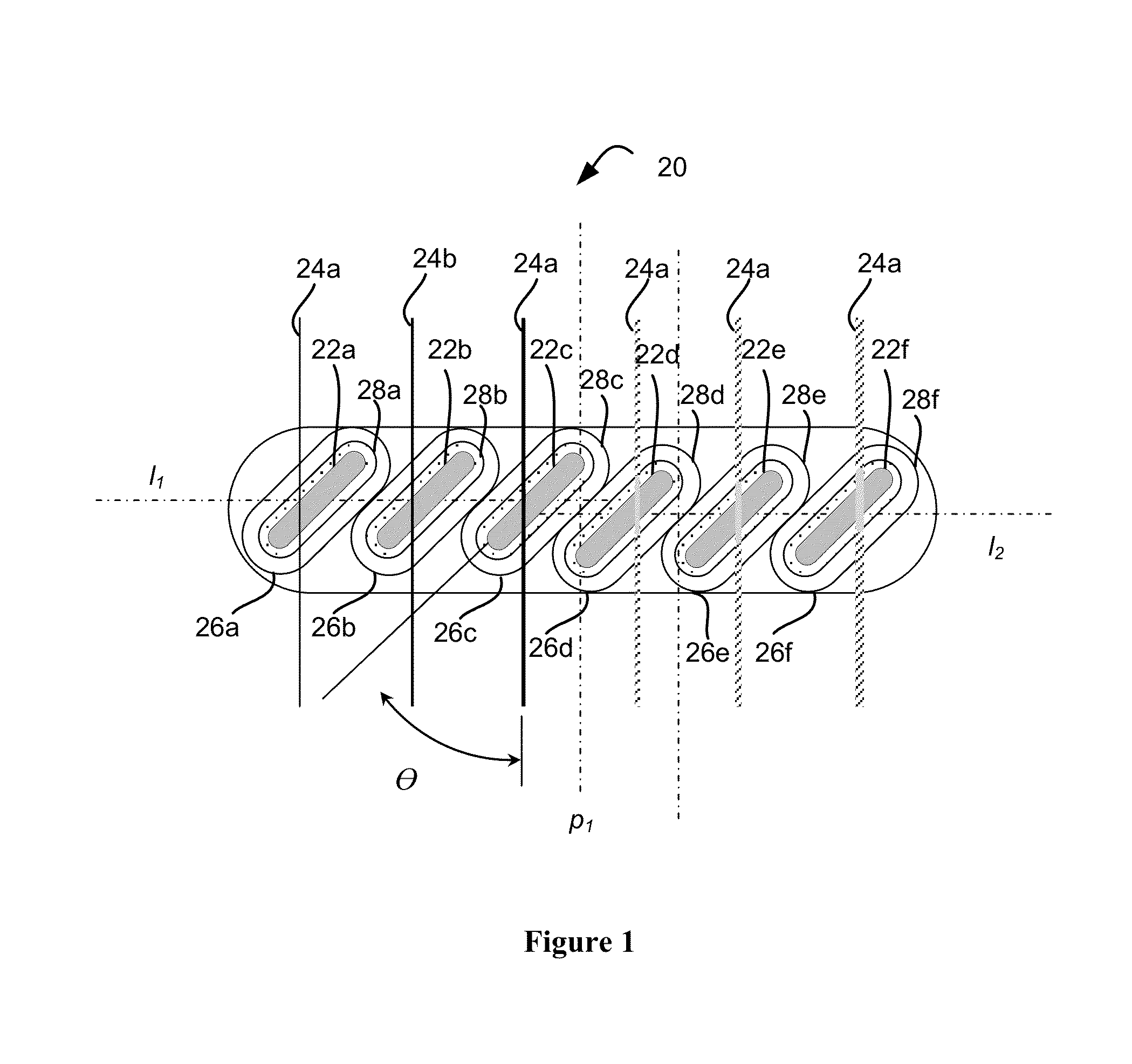

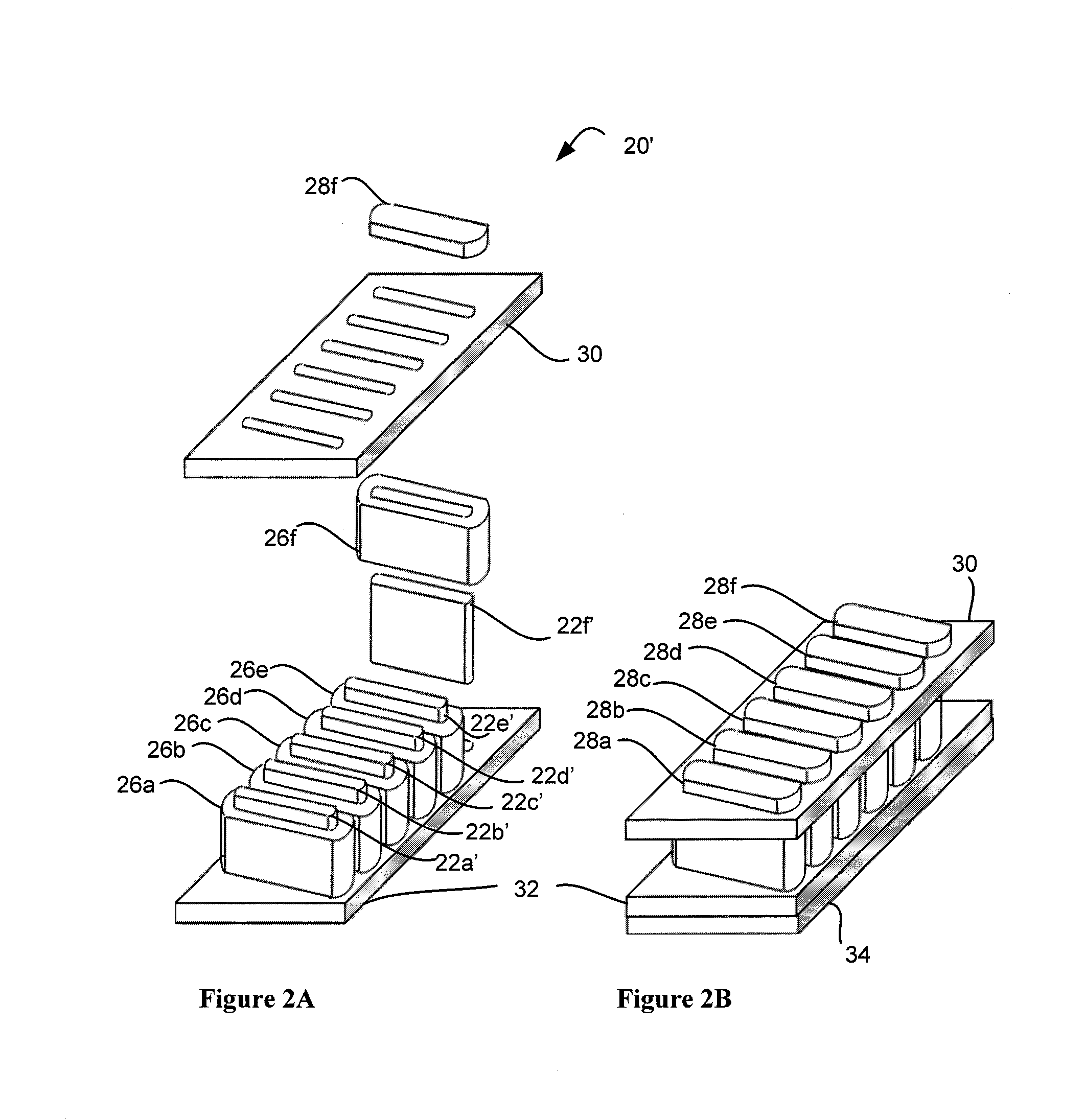

Dynamoelectric machine having windings that differ in wire gauge and number of winding turns

InactiveUS6847147B2Easy to manufactureEfficient and flexible characteristicSynchronous generatorsMagnetic circuitWire gaugeMagnetic poles

A multiphase motor comprises a plurality of ferromagnetic stator core segments, the core segments being substantially uniformly spaced around an axis of rotation and isolated from direct contact with each other. Each core segment forms at least one pair of poles having coils wound thereon to form a phase winding. Each stator phase winding is configured with a topology different from the topology of each of the other phase windings. Each phase winding has a different total number of coils from one or more of the other phase windings. Each phase winding comprises coils of a gauge different from the coil gauge of one or more of the other phase windings. Preferably, all of the phase windings have substantially the same total coil mass.

Owner:HANON SYST EFP BAD HOMBURG GMBH

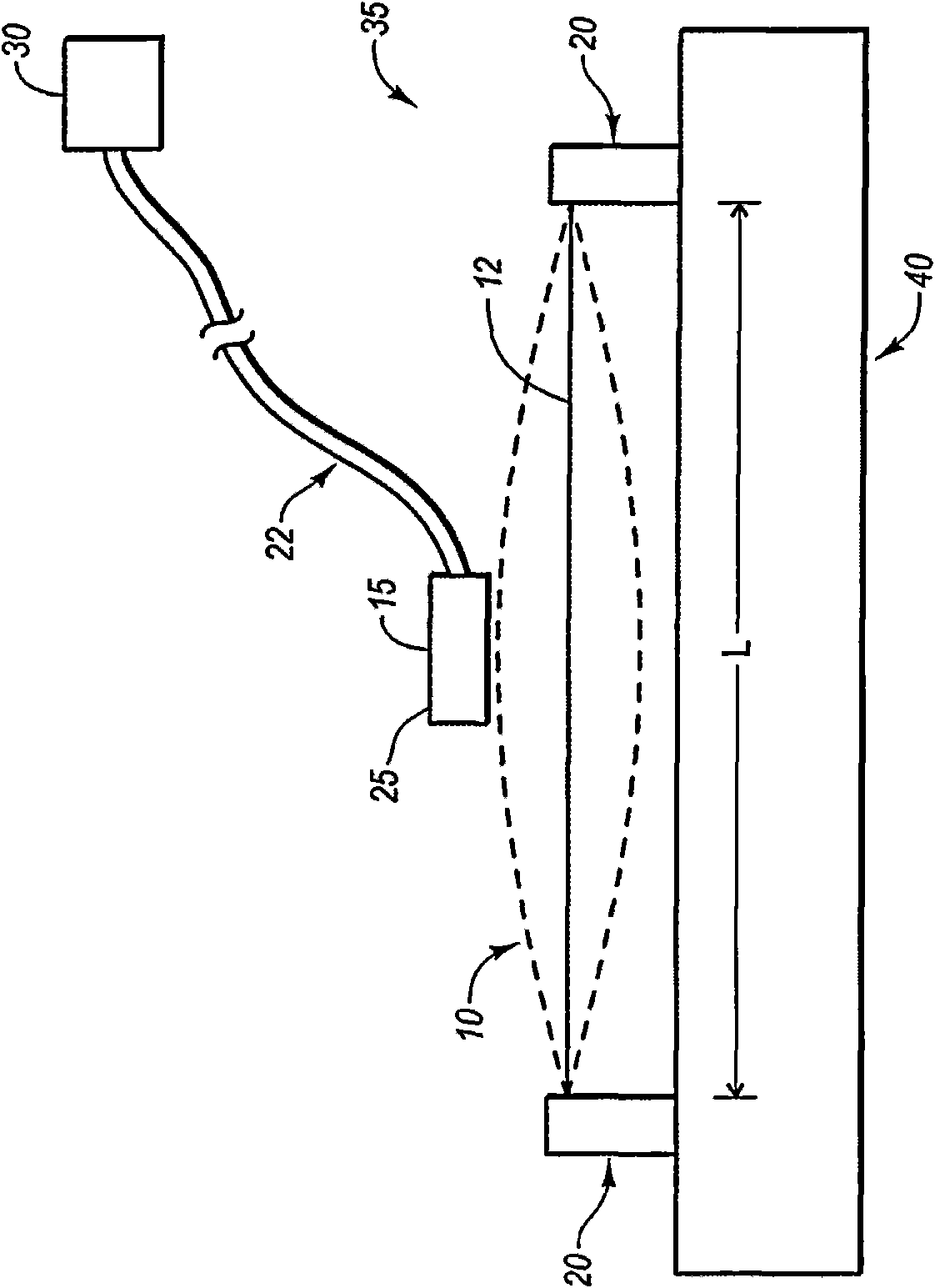

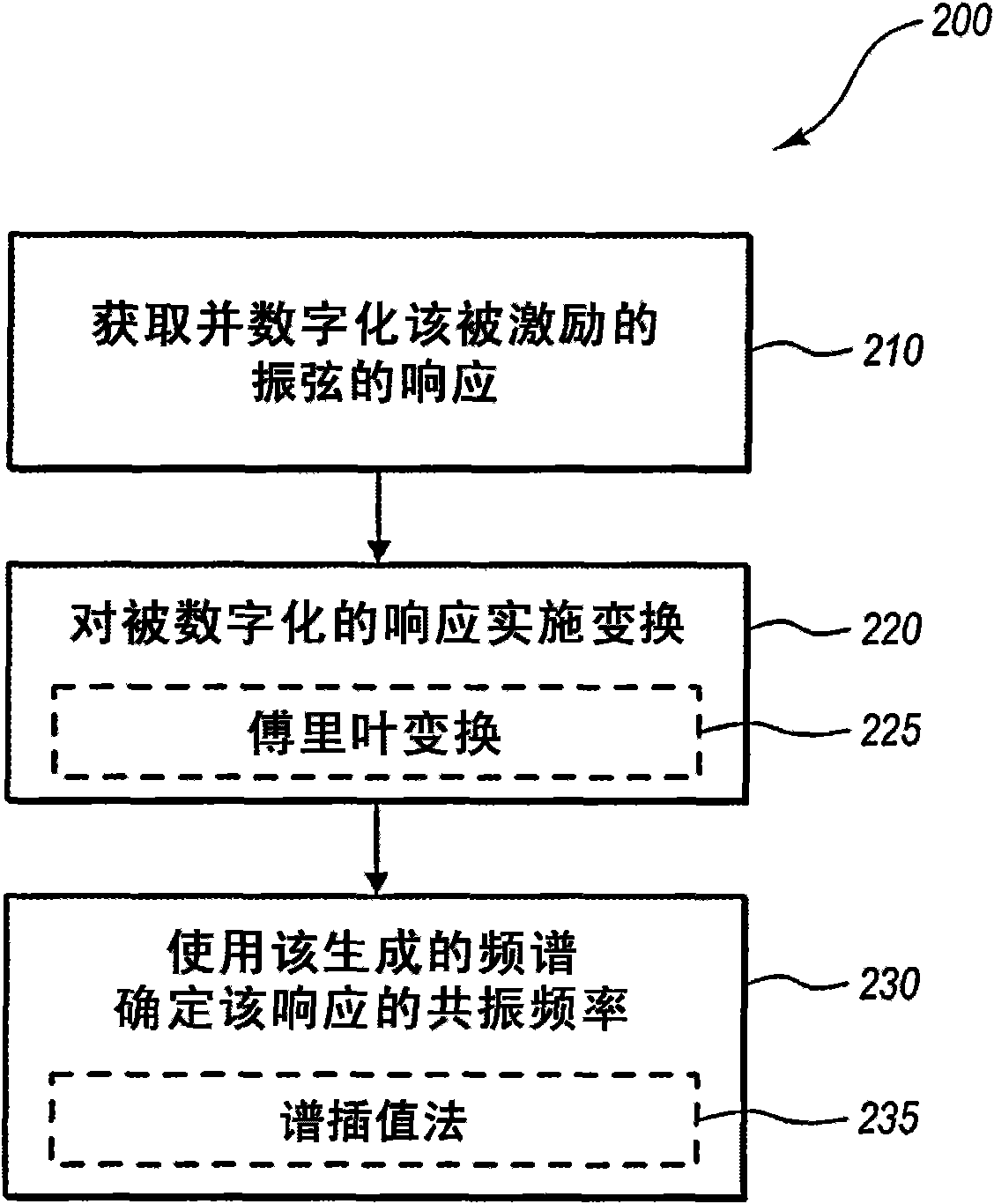

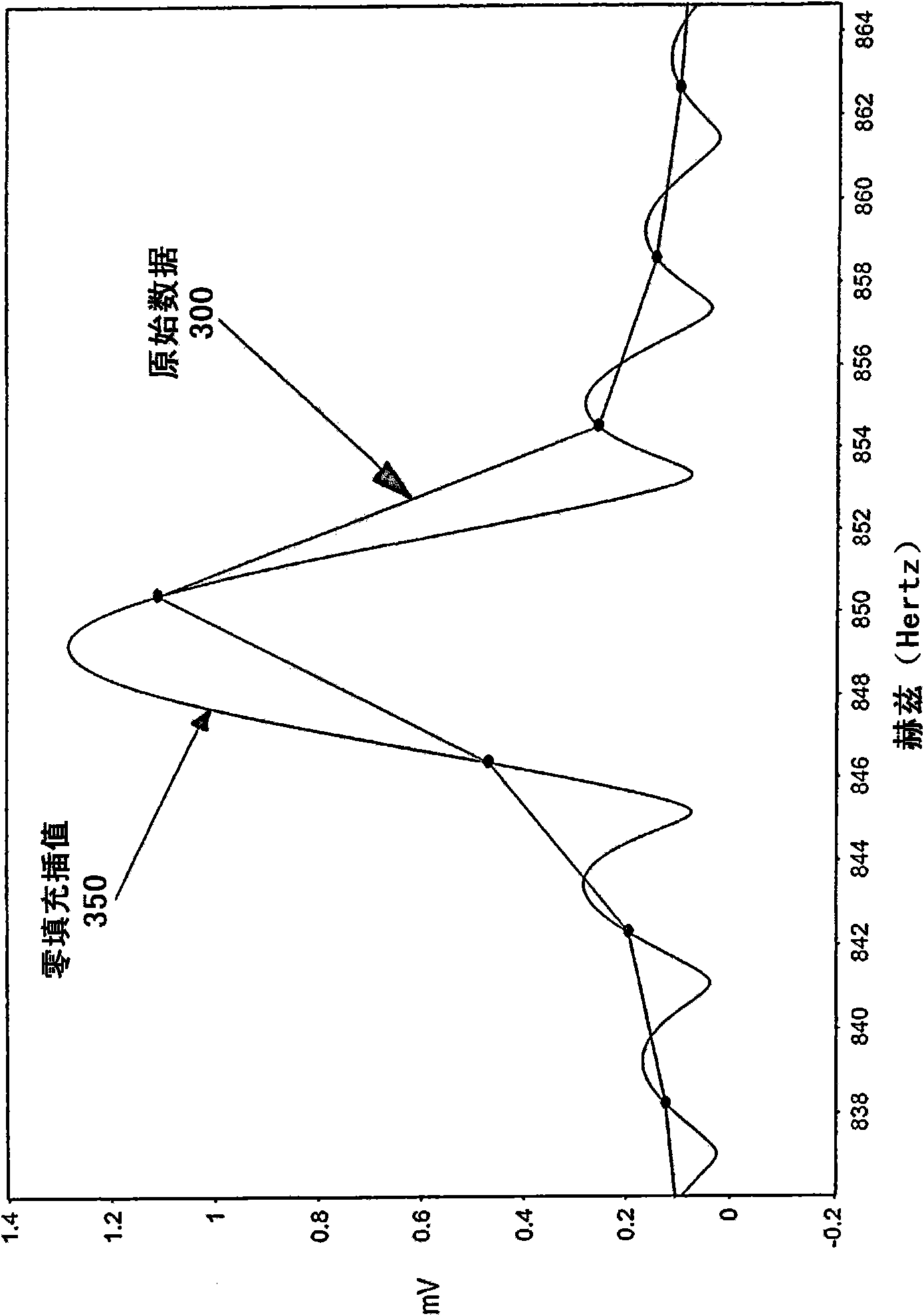

Vibrating wire sensor using spectral analysis

ActiveCN101641582AForce measurement by measuring frquency variationsResonant frequencyWire gaugeFrequency spectrum

Systems and methods for analyzing the resonant frequency of vibratory wires within vibratory wire gauges. The resonant frequency of the vibrating wire is determined by using an interface that digitizes the response of an excited wire in the gauge. A transform then converts the digitized data into a frequency spectrum. The resulting spectrum is used to estimate the resonant frequency of the vibrating wire. The resulting measurement or estimate of the resonant frequency can be used to measure or determine some physical characteristic of the device or structure or system connected to the gauge.

Owner:CAMPBELL SCI

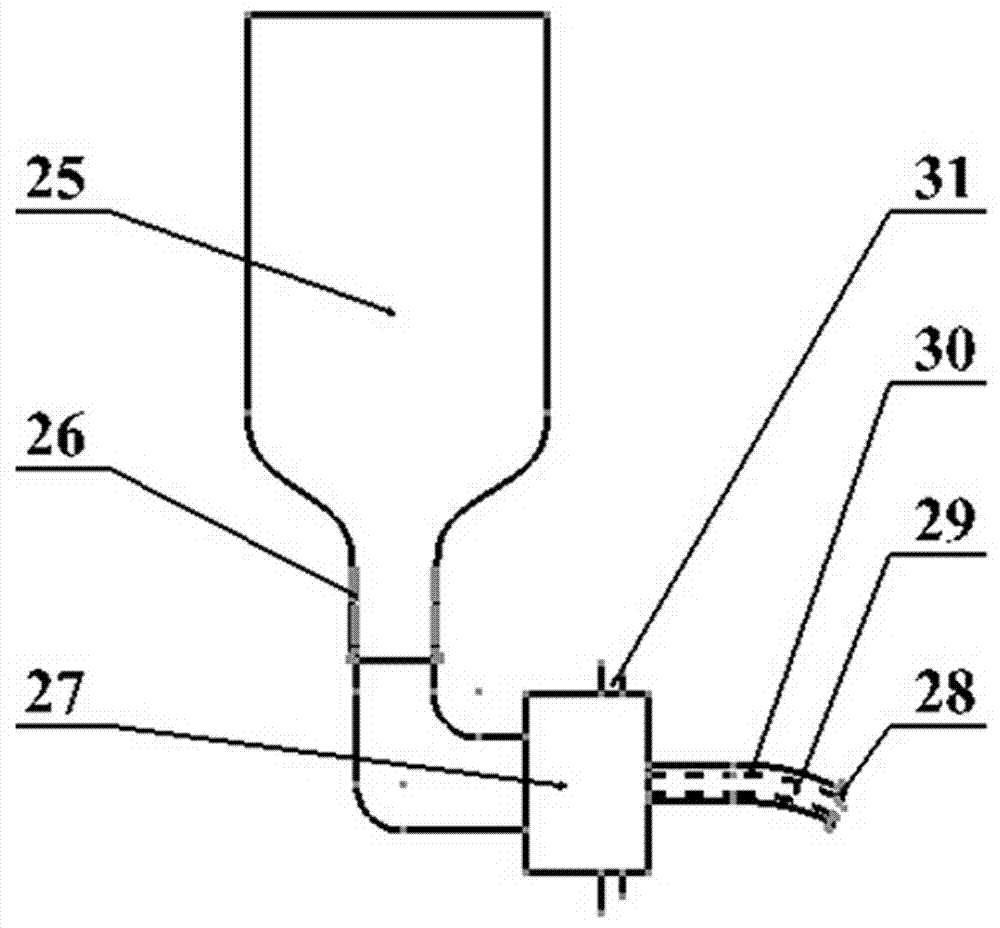

Cable length monitoring device

InactiveCN102374854AThe monitoring results are accurate and reliableThe monitoring process is simple and fastMeasurement devicesWire gaugeProximity sensor

The invention discloses a cable length monitoring device which comprises a guide wheel, a proximity sensor, a cable pressing wheel, more than two sections of steel wire gauge enclosures and a signal acquisition module, wherein the cable pressing wheel is in contact with a towing rope in a monitoring process, the towing rope is in a monitoring range of the proximity sensor; and the proximity sensor measures the quantity of the passes steel wire gauge enclosures through the proximity sensor, and the signal acquisition module is used for receiving and processing data monitored from the proximity sensor so that the length of the cable is figured out. By using the cable length monitoring device disclosed by the invention, the monitoring step of the cable length can be simplified, and the measurement precision of the cable length is improved.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

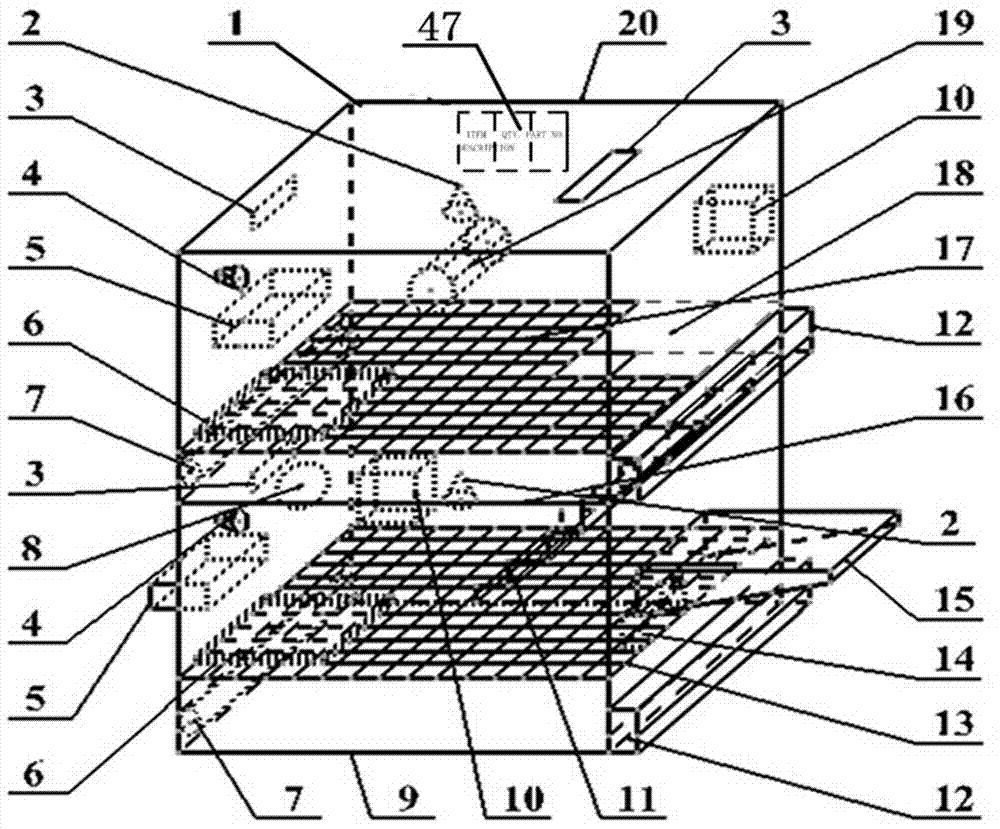

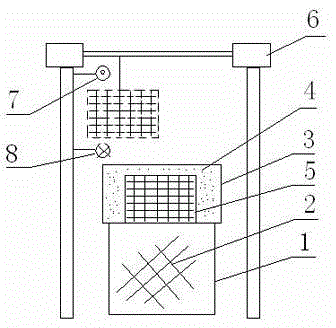

Test rat feeding box

The invention discloses a test rat feeding box. The test rat feeding box consists of a feeding box body, combined multifunctional lamps, a ventilation system assembly, multimedia speakers, humidity regulators, rat nest devices, driven drums, a drinking water bottle assembly, temperature regulators, a stair, drum active driving component assemblies, a lower wire gauze, a feed groove, a feeder assembly, an upper wire gauge, a stair outlet, a roller and a main assembly controller. The feeding box structure is partitioned into an upper layer and a lower layer which are isolated through a separating plate; the stair outlet is formed in the separating plate; a feeding box body upper cover is arranged on the upper part of the feeding box body; a foldable side door is arranged on one side wall of the lower layer of the box body. The functions of automatic disinfection, excrement cleaning, internal box temperature and humidity regulation, observation of the behaviors or health degrees of test rats, performance of noise test, ventilation and air exchange, creation of a proper illumination environment and the like are integrated, and the automation, safety and convenience of the test rat feeding box are superior to those of the conventional test rat feeding box. The test rat feeding box is convenient to maintain and manage, and has high cost performance and a high market value.

Owner:THE FIRST HOSPITAL OF CHINA MEDICIAL UNIV

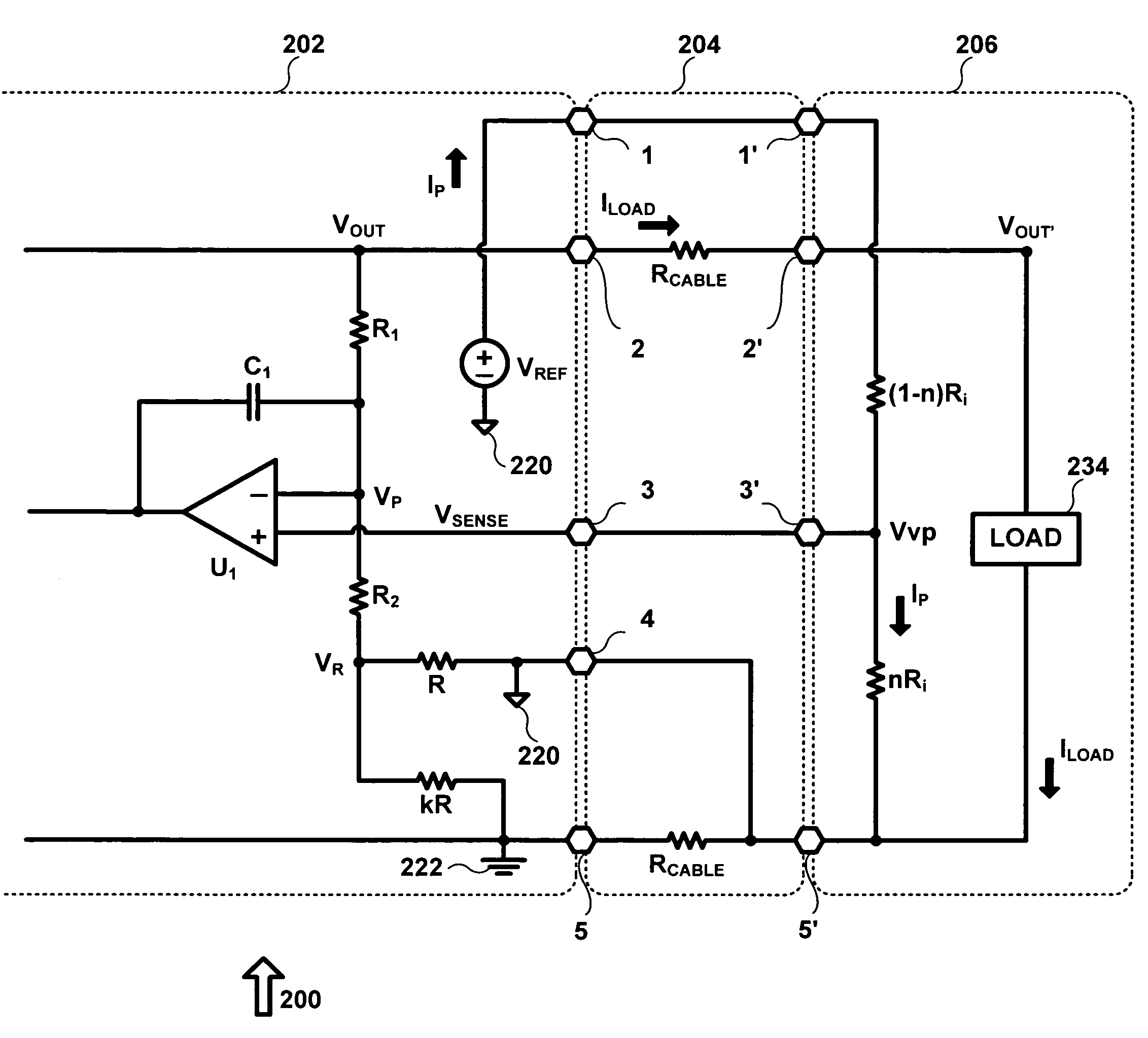

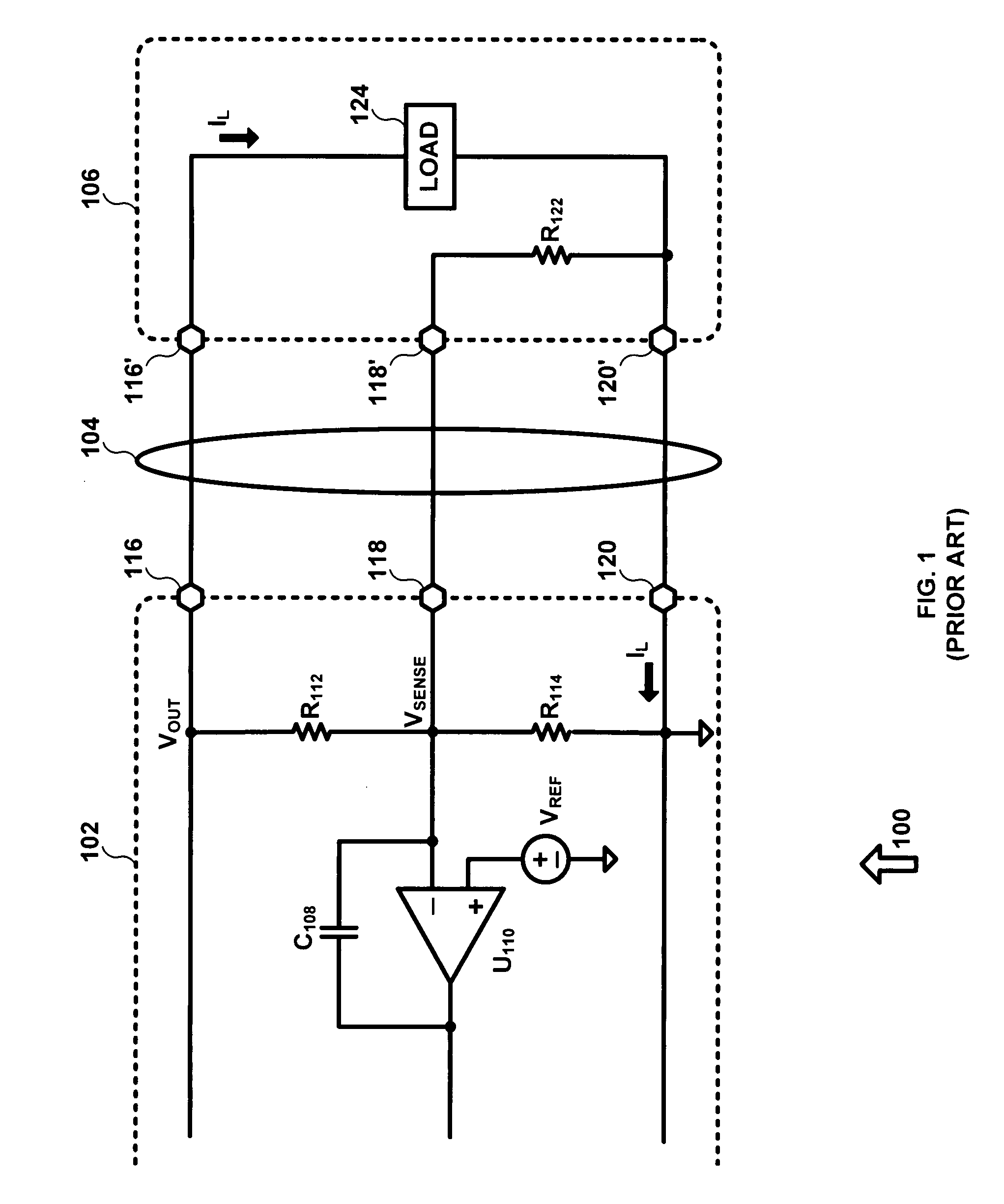

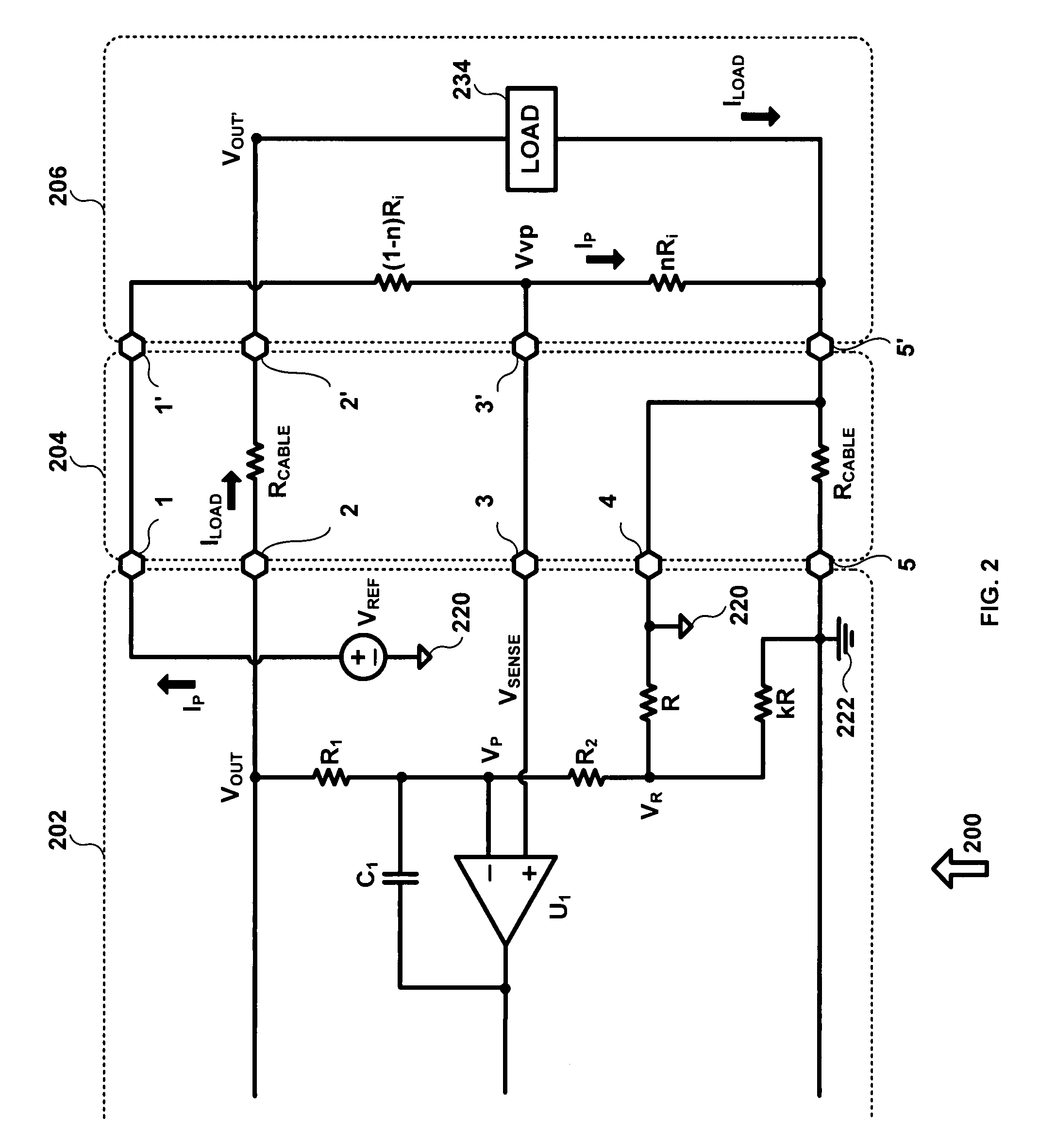

System and method for cable resistance cancellation

InactiveUS8093875B2Tight output accuracyReduce the required powerThree-or-more-wire dc circuitsElectric variable regulationWire gaugeElectrical resistance and conductance

A method for cable resistance cancellation. A single remote sense line and a simple cable resistance cancellation network are leveraged in a power supply unit to compensate for the total cable voltage drop, while maintaining tight output accuracy. By completely compensating for the voltage drops, the wire gauge for the main power wires can be reduced, thereby allowing the use of smaller diameter cables.

Owner:IGO INC

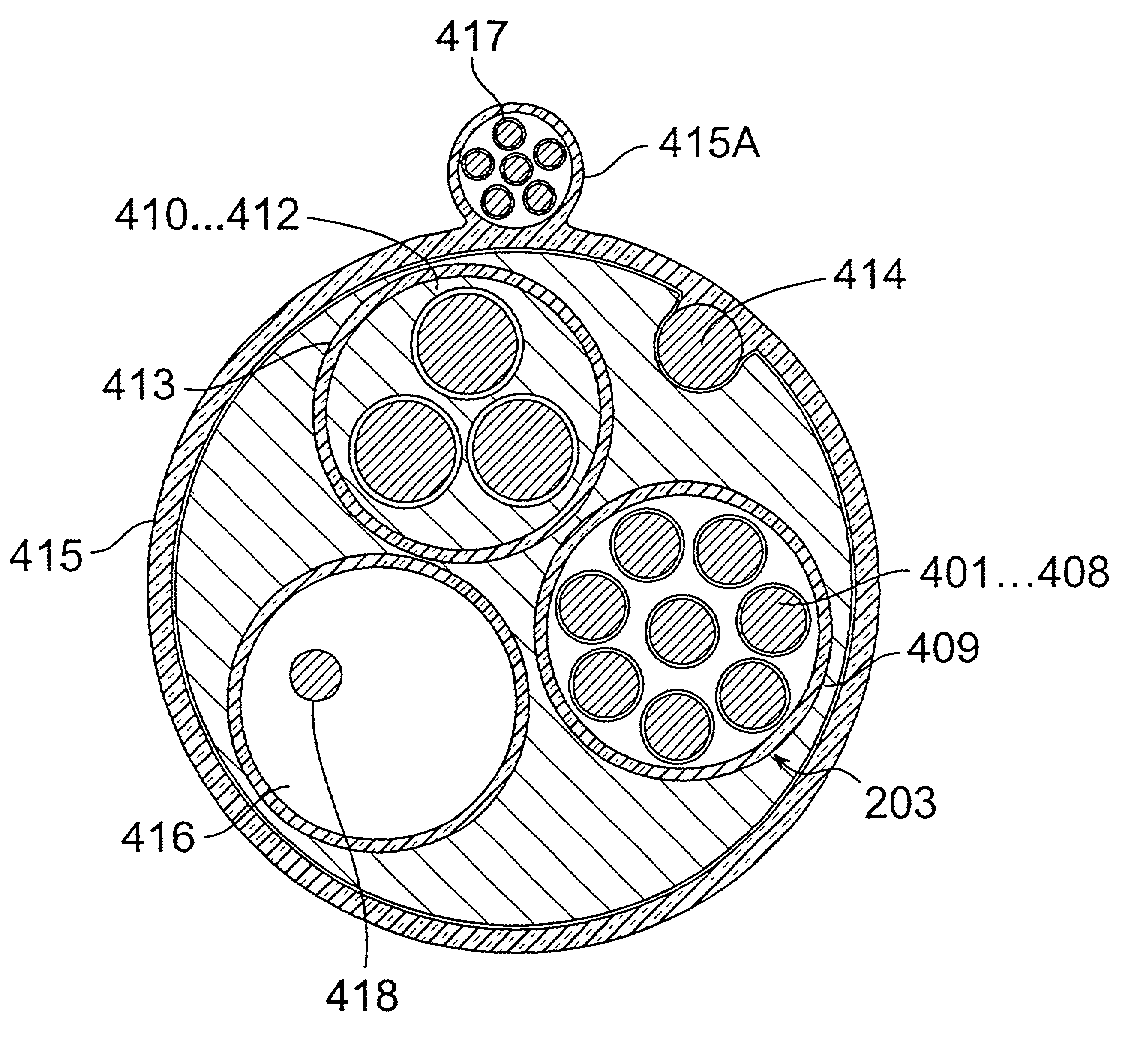

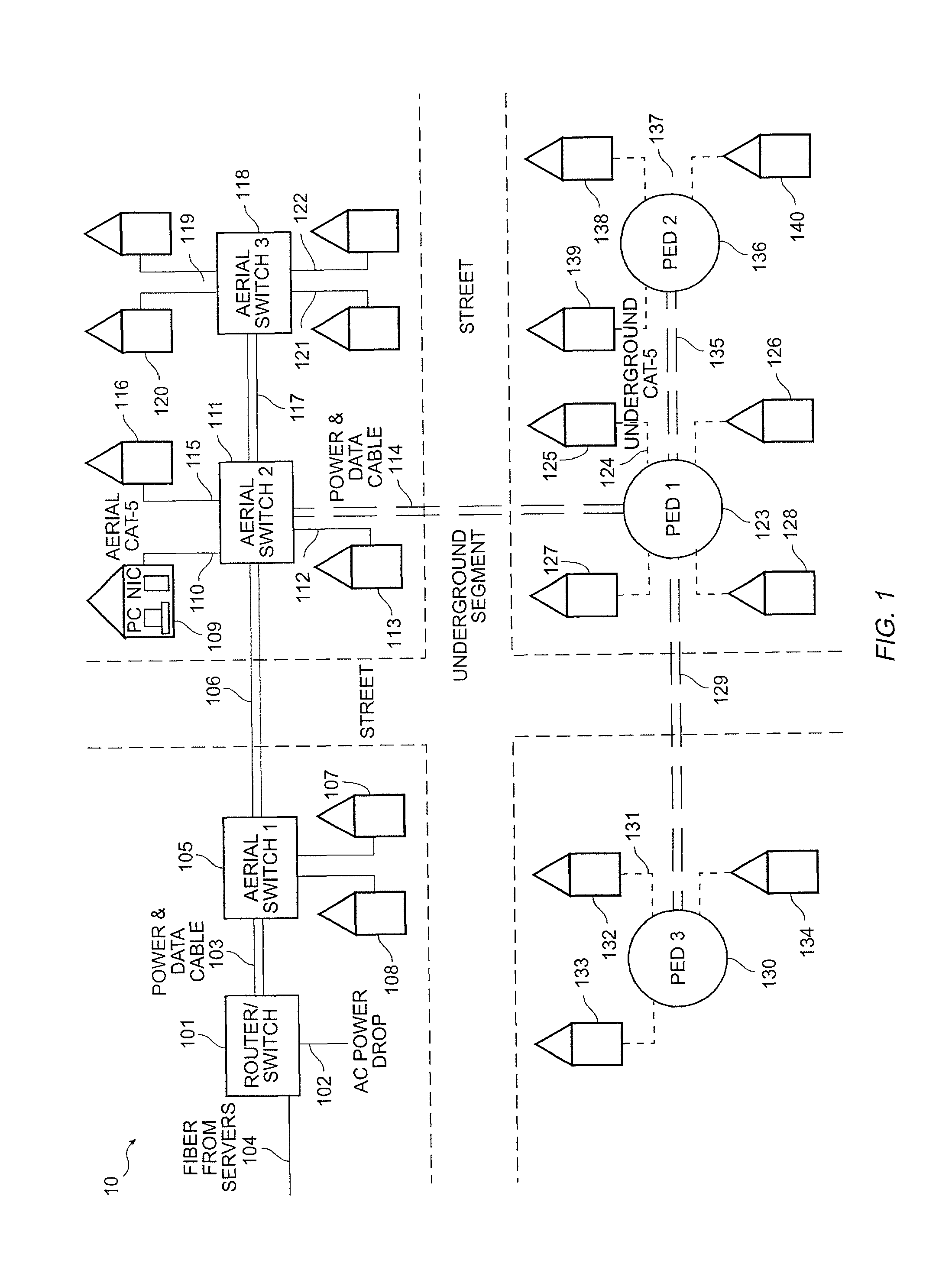

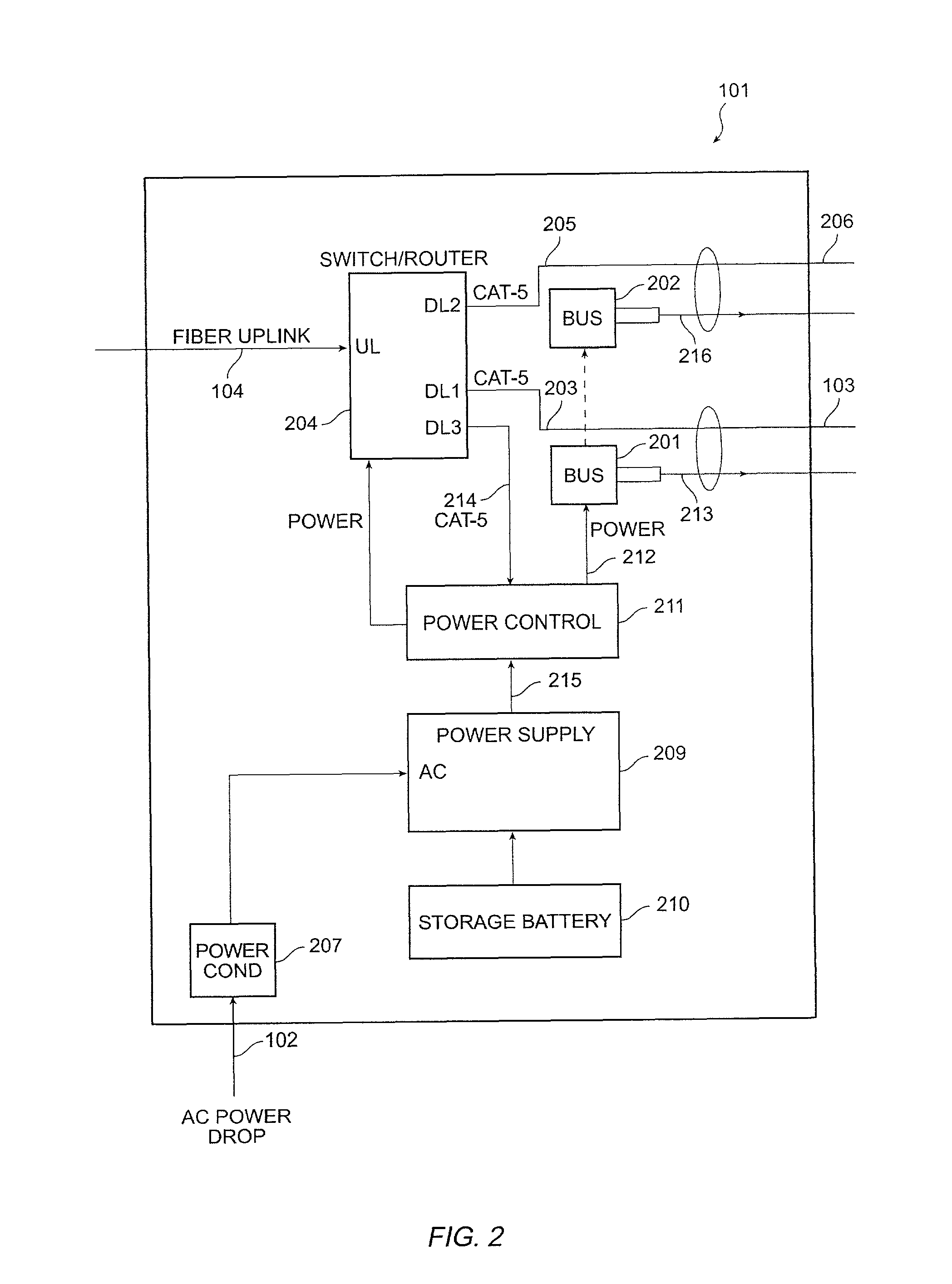

Method and apparatus for an environmentally hardened ethernet network system

ActiveUS8045565B1Fully contactedIncrease rangeCable installations on groundCable installations in surface ductsElectric power transmissionWire gauge

In an environmentally hardened network, a data and power distribution cable is employed in connection with reliable end connectors, high performance physical layer transceivers clocked at a lower rate than is specified and full duplex switched packet transmission techniques between switched nodes in order to extend operational distance between network elements. In a specific embodiment, the data and power distribution cable comprises a data distribution element, a power distribution element, an optional strain distribution element, an optional hollow conduit, and an extra shield and outdoor sheath. The cable may incorporate: 1) a Gel filled outdoor UTP (CAT-5) cable; 2) end connectors of type DB-9 [D-Sub] for connection of the UTP to network equipment; 3) power transmission cable of wire gauge sufficient to carry the power required by network equipment (switches, etc) for the specific segment of the network; and optionally 4) a hollow conduit that permits installation of optical fiber before or after installation of the cable.

Owner:RATEZE REMOTE MGMT LLC

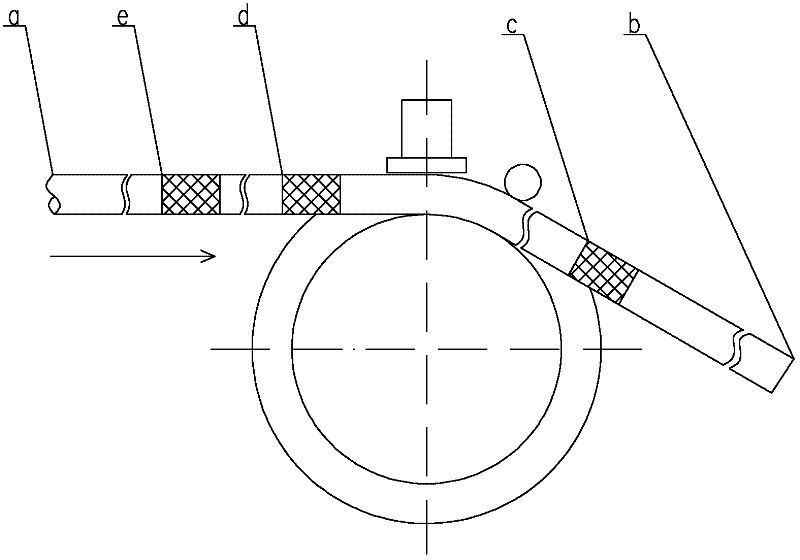

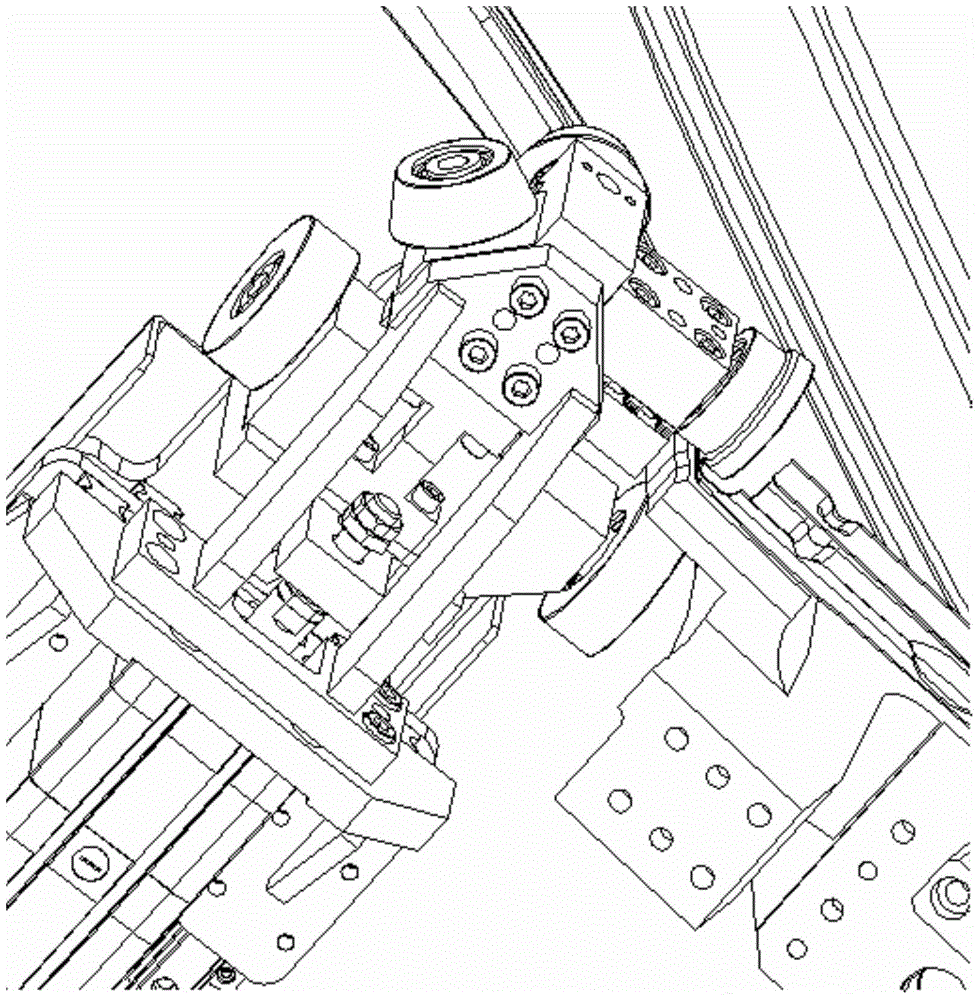

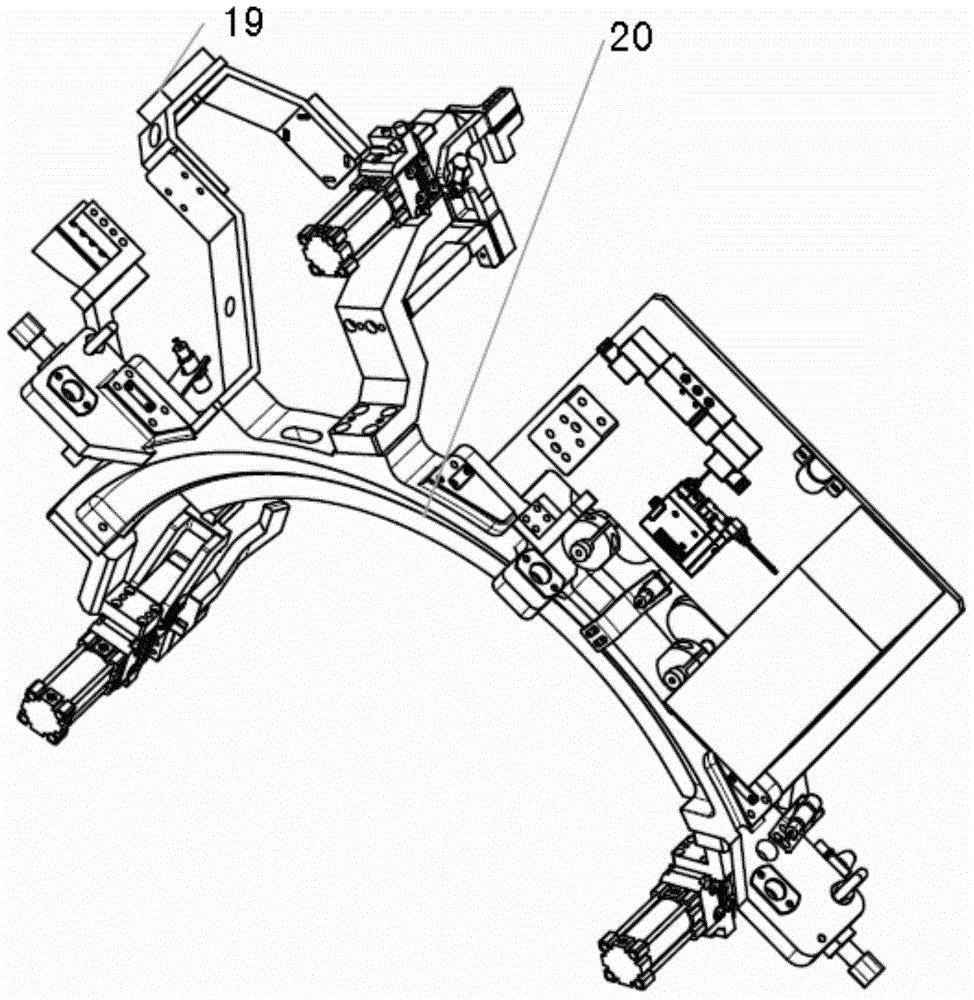

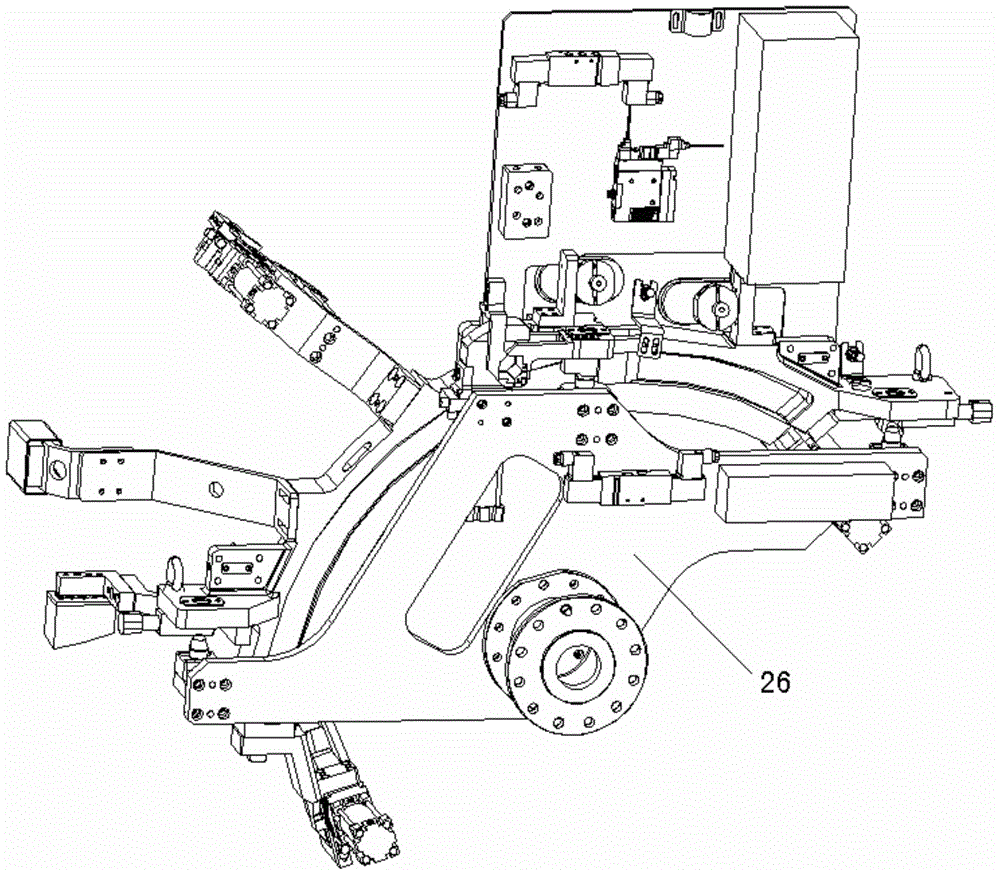

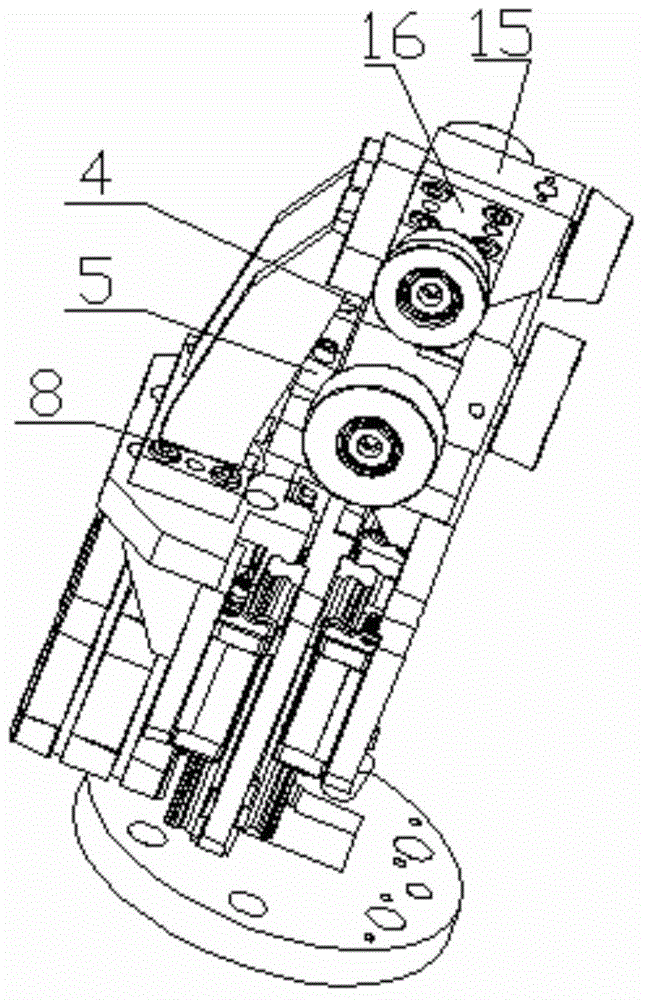

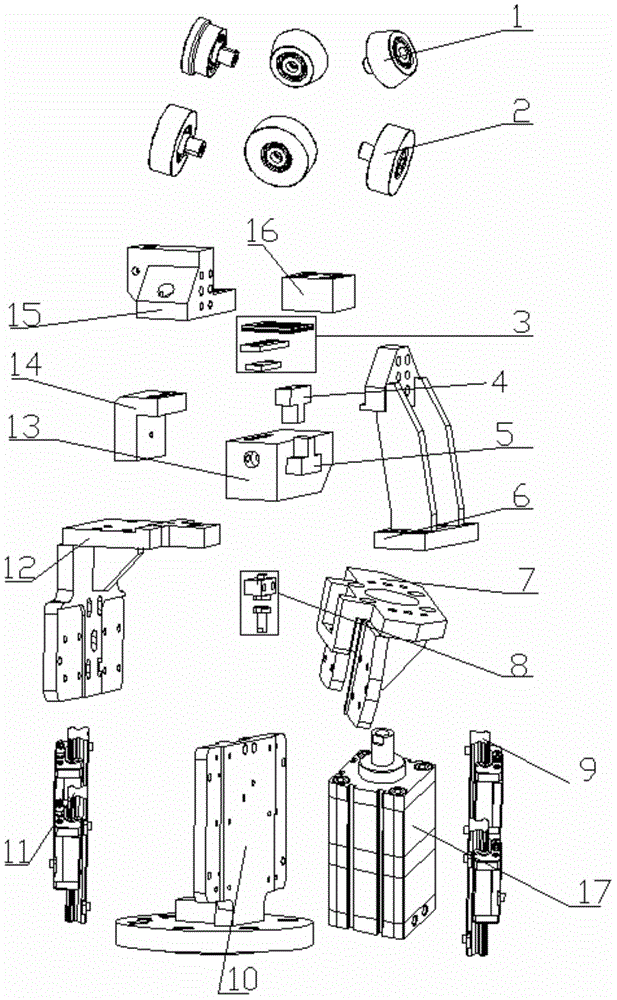

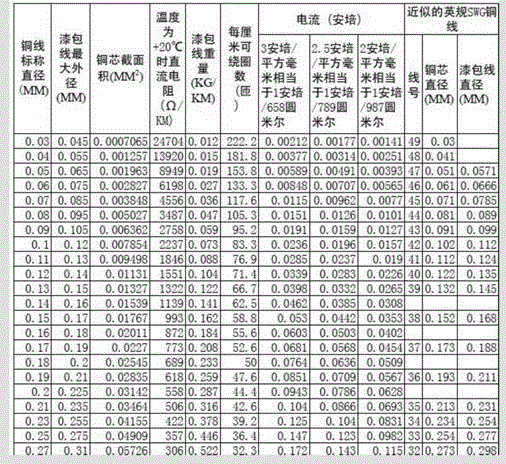

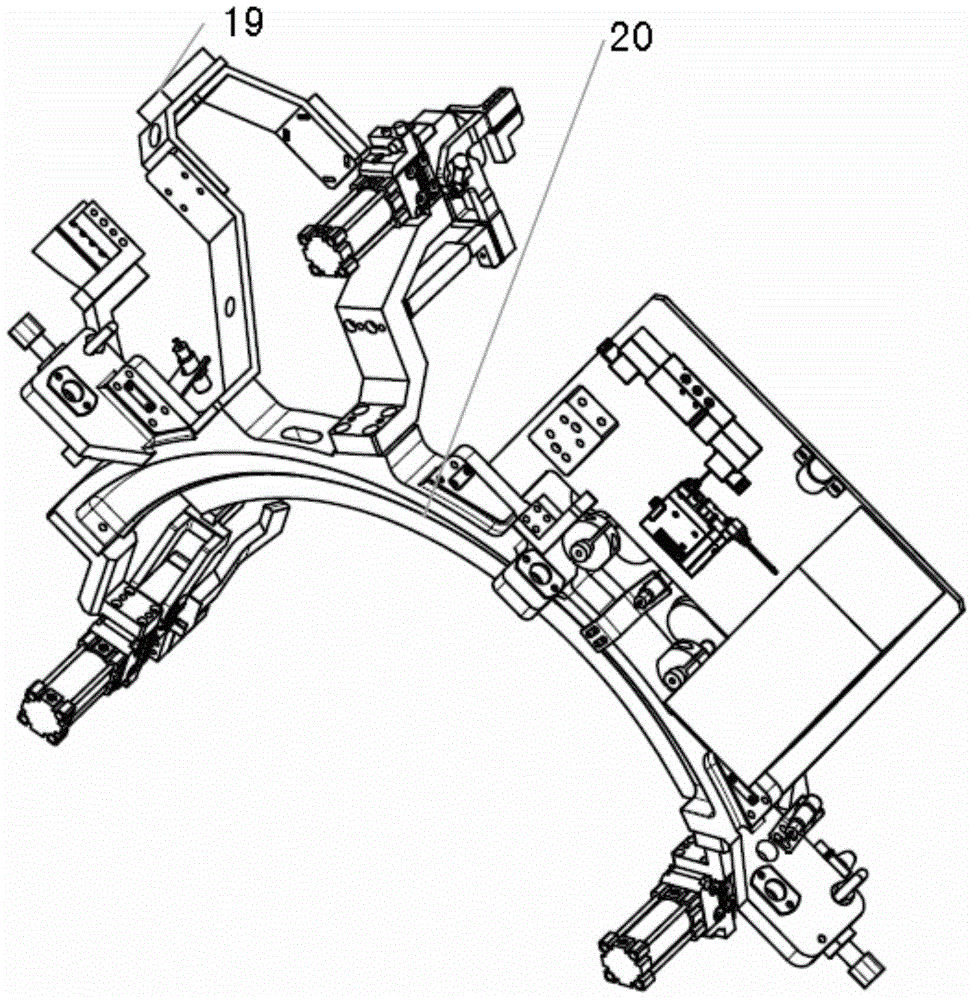

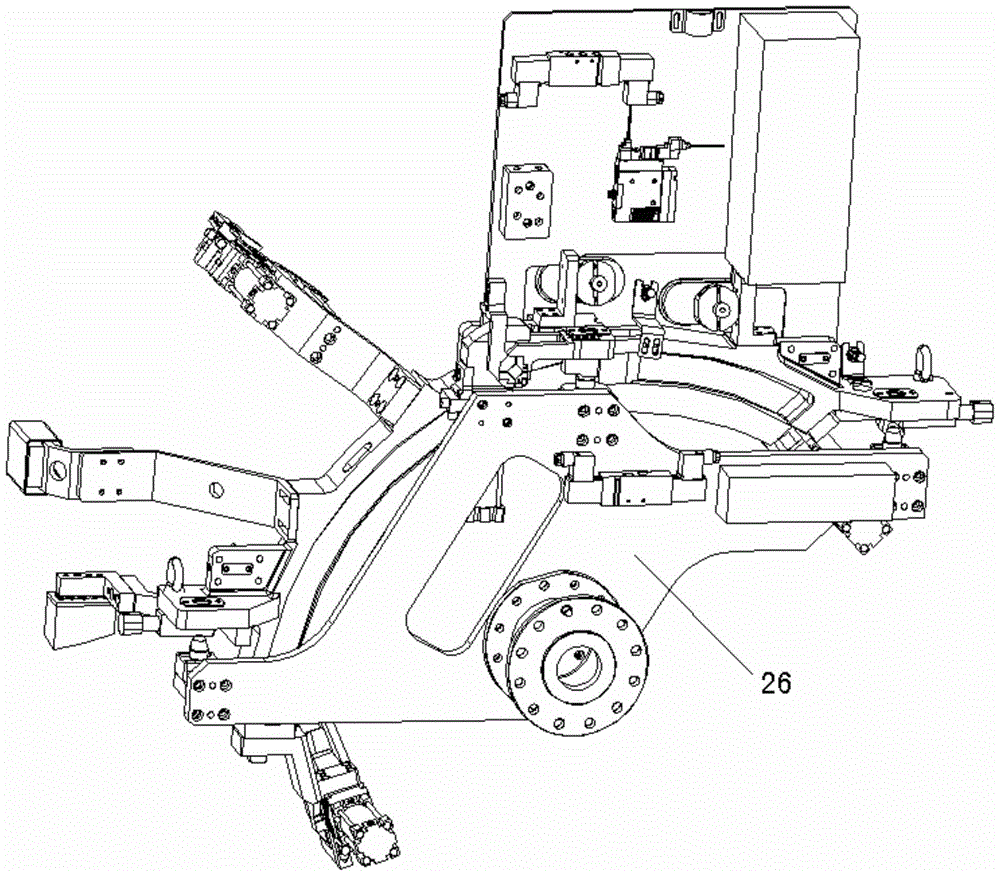

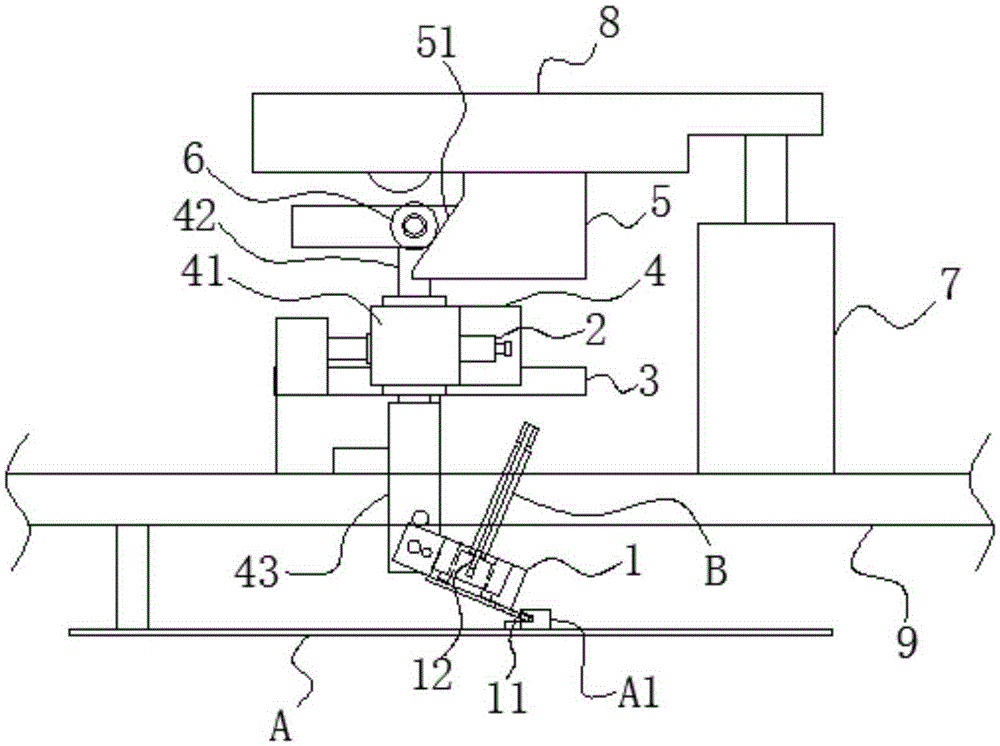

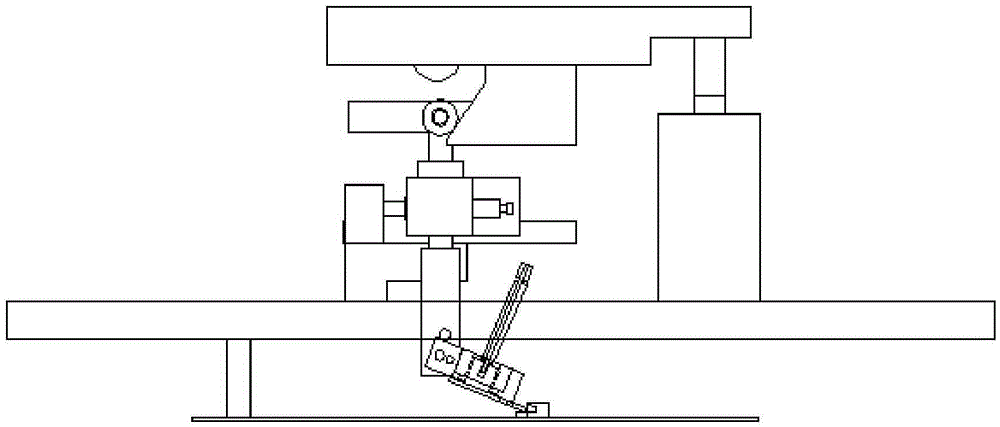

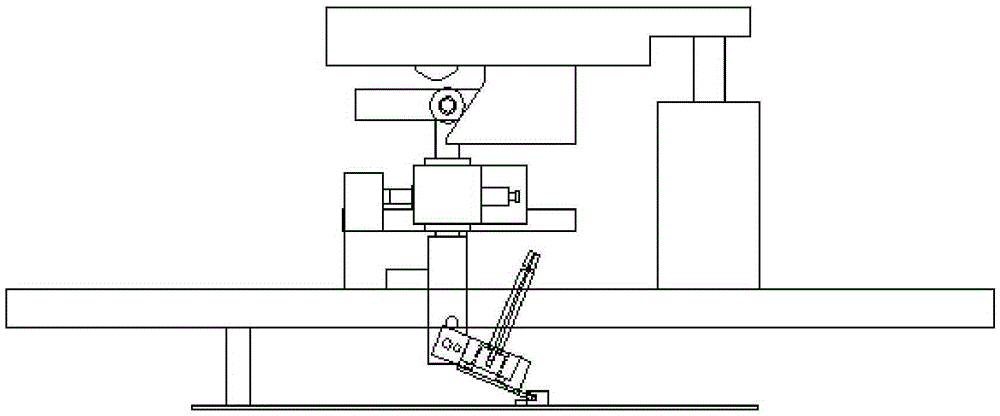

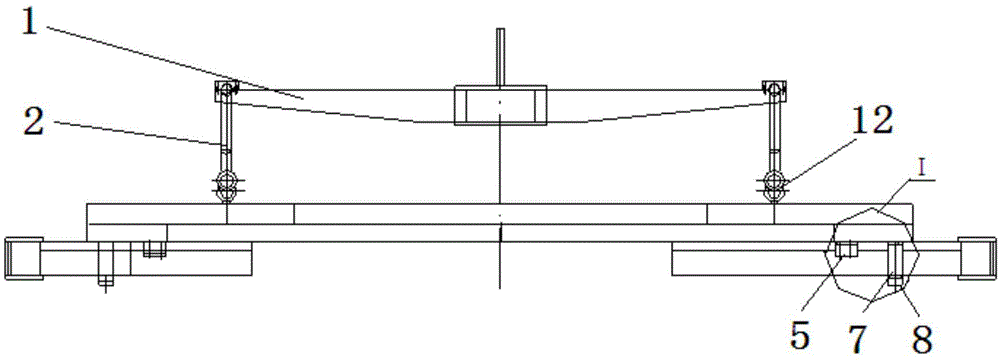

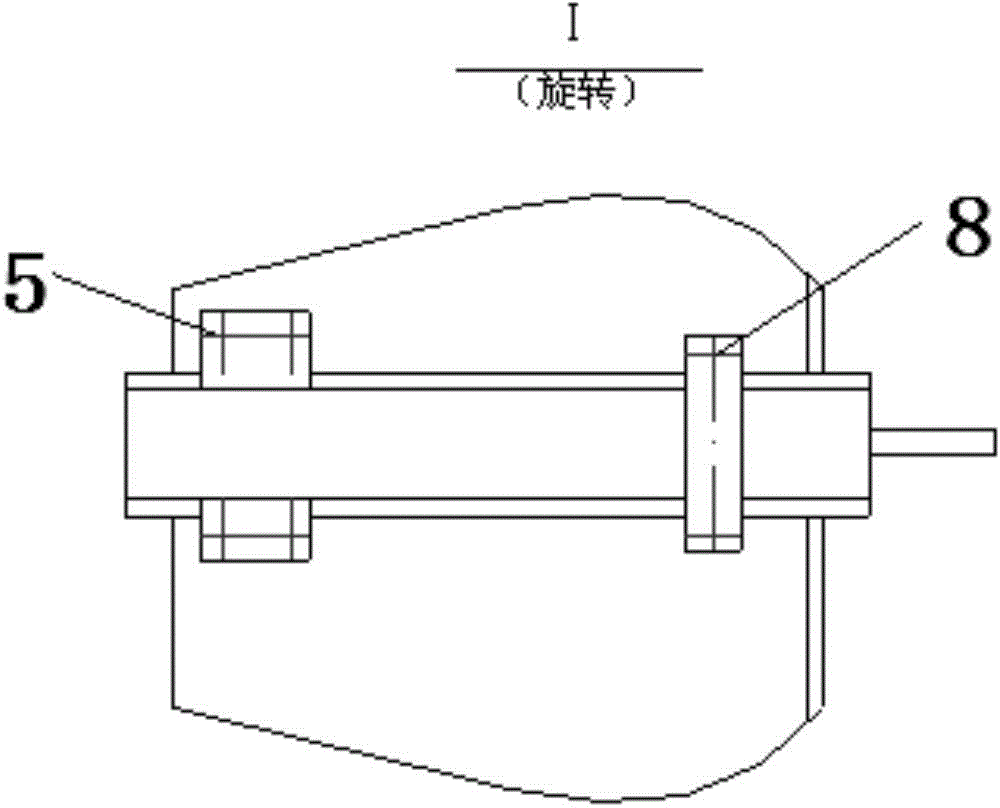

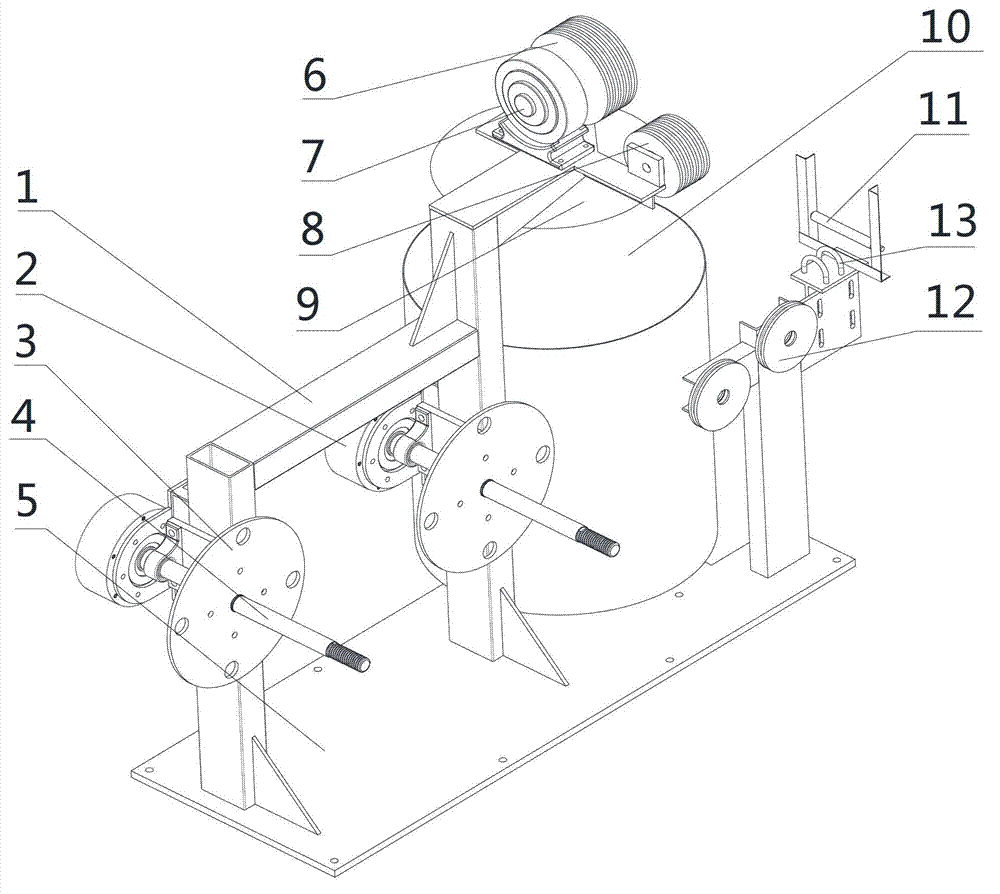

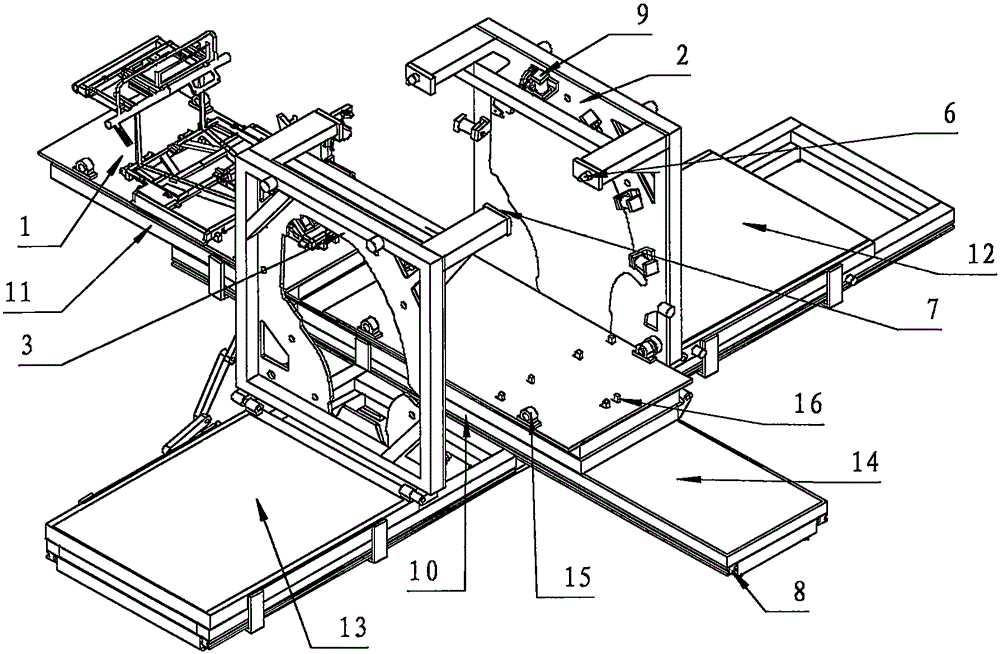

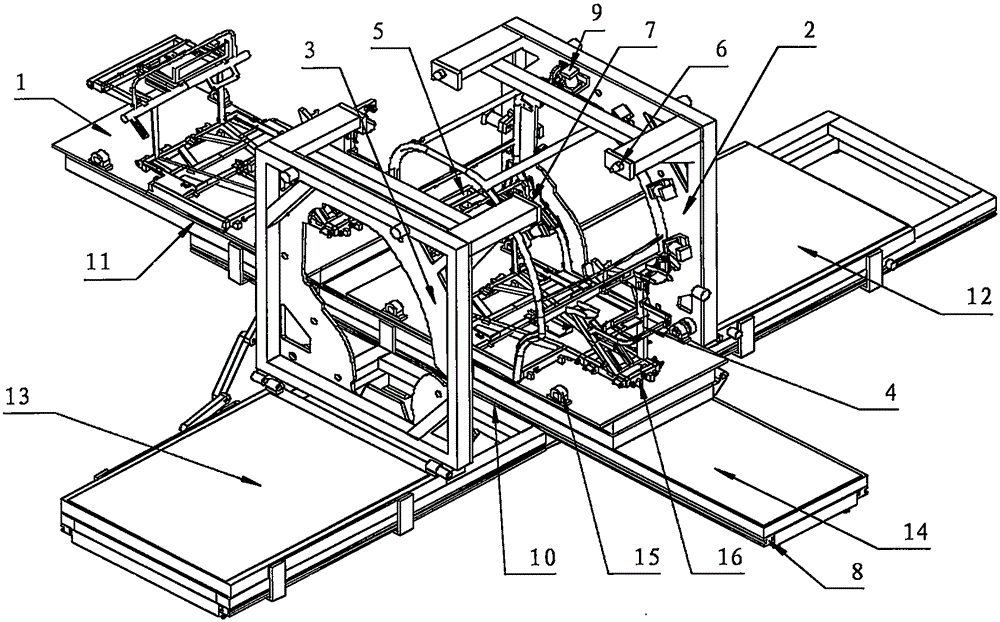

Automobile wheel casing trimming system and using method thereof

The invention relates to an automobile wheel casing trimming system and a using method thereof. The automobile wheel casing trimming system comprises a mechanical grip, a tire mould clamp and a rolling assembly. The tire mould clamp is matched with an automobile wheel casing to be trimmed in an arc mode. The middle and the positions close to two ends of the tire mould clamp are each provided with a clamping point. The tire mould clamp is provided with a visual system. The rolling assembly comprises a body, an upper pressure wheel set and a lower pressure wheel set, wherein the body comprises a base and an installation board; the two surfaces of the installation board are each provided with a wire gauge set; the two wire gauge sets are provided with two connection blocks; the first connection block is provided with an air cylinder connected with an upper roller set through the first connection block; the second connection block is provided with a lower pressure wheel set, and connected with a piston of the air cylinder. In the using process, the mechanical grip grips the tire mould clamp to be installed to the automobile wheel casing, and the rolling assembly rolls the automobile wheel casing through a robot. According to the shapes of a board and a tire mould, the rolling assembly can adjust the interval automatically based on the balance principle so as to maintain the trimming force uniform. The structure is simple. The trimming effect is good.

Owner:SHANGHAI JUNYI IND AUTOMATION CO LTD

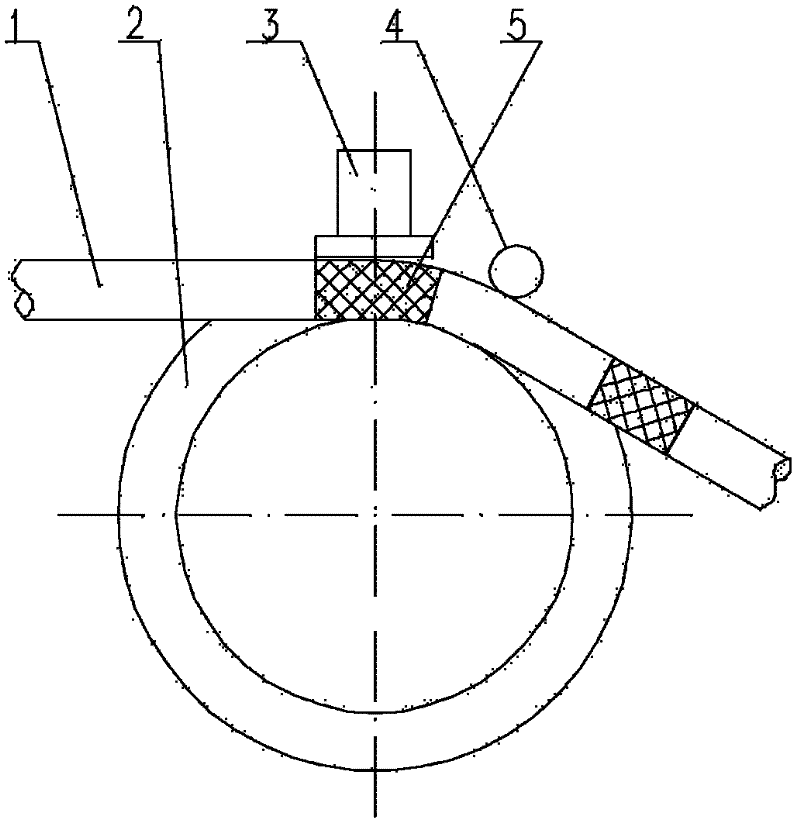

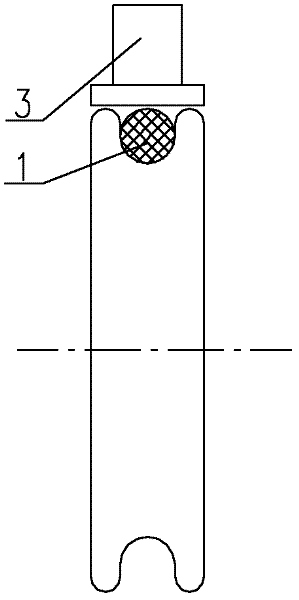

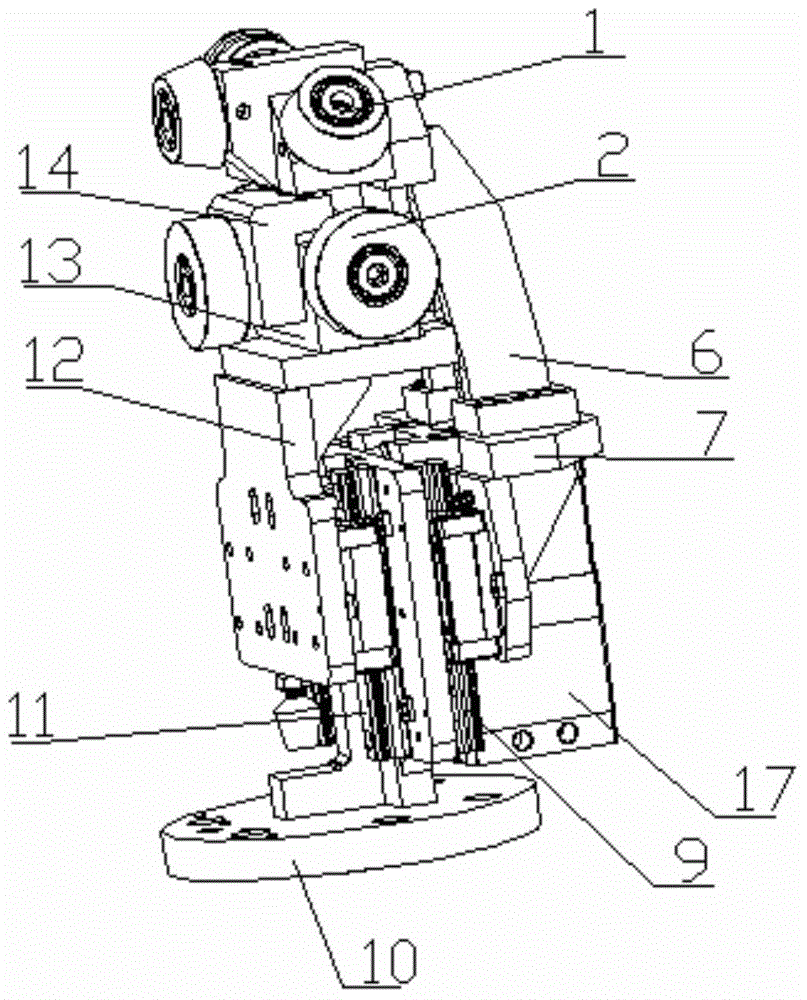

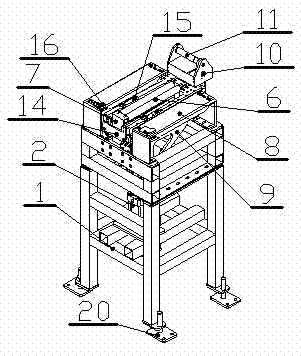

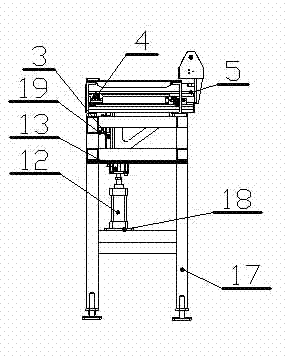

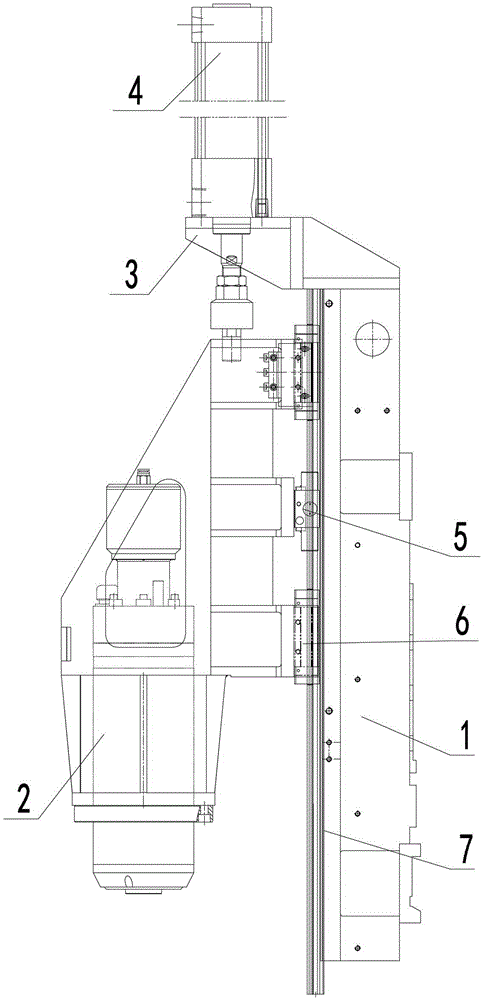

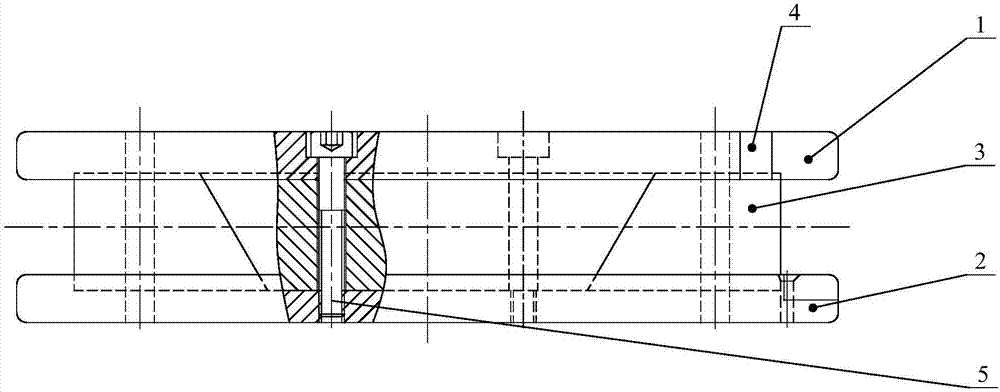

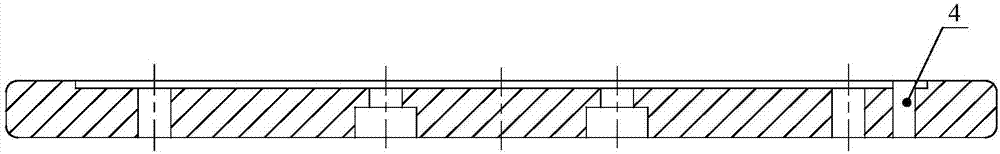

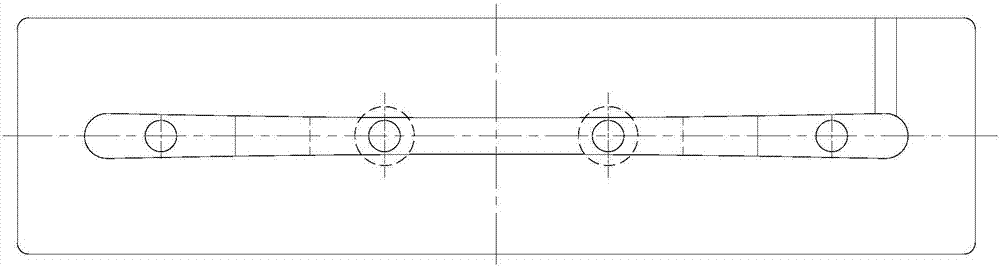

Automobile wheel cover edge rolling device

The invention relates to an automobile wheel cover edge rolling device. The automobile wheel cover edge rolling device comprises a body (10), an upper pressing wheel set (1) and a lower pressing wheel set (2). The body (10) comprises a circular base and a mounting plate perpendicular to the base. The two surfaces of the mounting plate are provided with a wire gauge set (9) and a wire gauge set (11) respectively. The wire gauge set (9) is provided with a connecting block (7). The wire gauge set (11) is provided with a connecting block (12). The first connecting block (7) is provided with an air cylinder (17). The second connecting block (12) is provided with the lower pressing wheel set (2). A piston of the air cylinder (17) is connected with the second connecting block (12). The connecting block (7) is connected with a supporting block (6). The upper pressing wheel set (1) is mounted on the supporting block (6). The automobile wheel cover edge rolling device conducts edge rolling according to the shape of a plate and the shape of a tire mold; a roller head can automatically adjust the space according to the force balance principle so that the edge rolling force can keep uniform; the automobile wheel cover edge rolling device is simple in structure and good in edge rolling effect.

Owner:SHANGHAI JUNYI IND AUTOMATION CO LTD

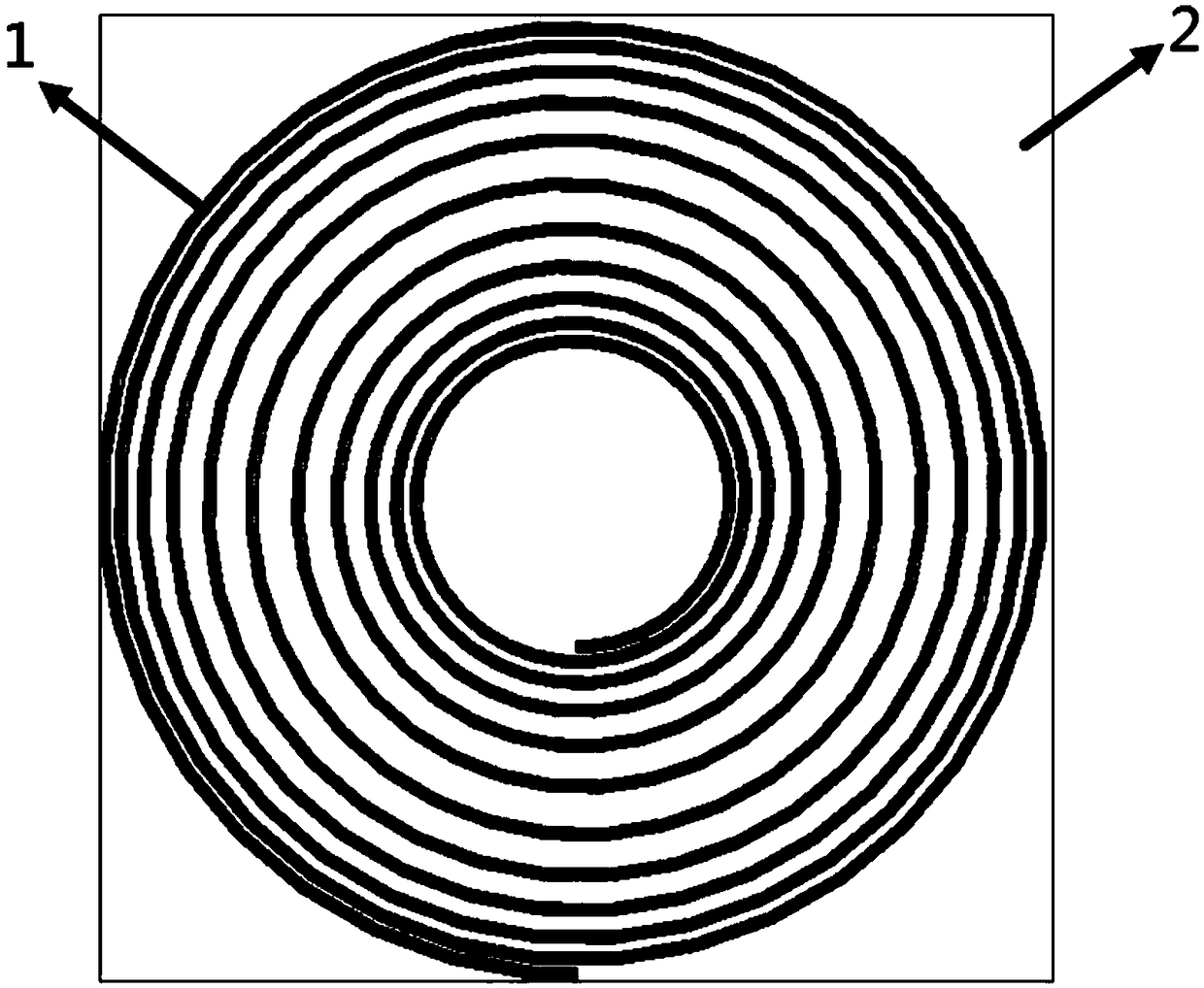

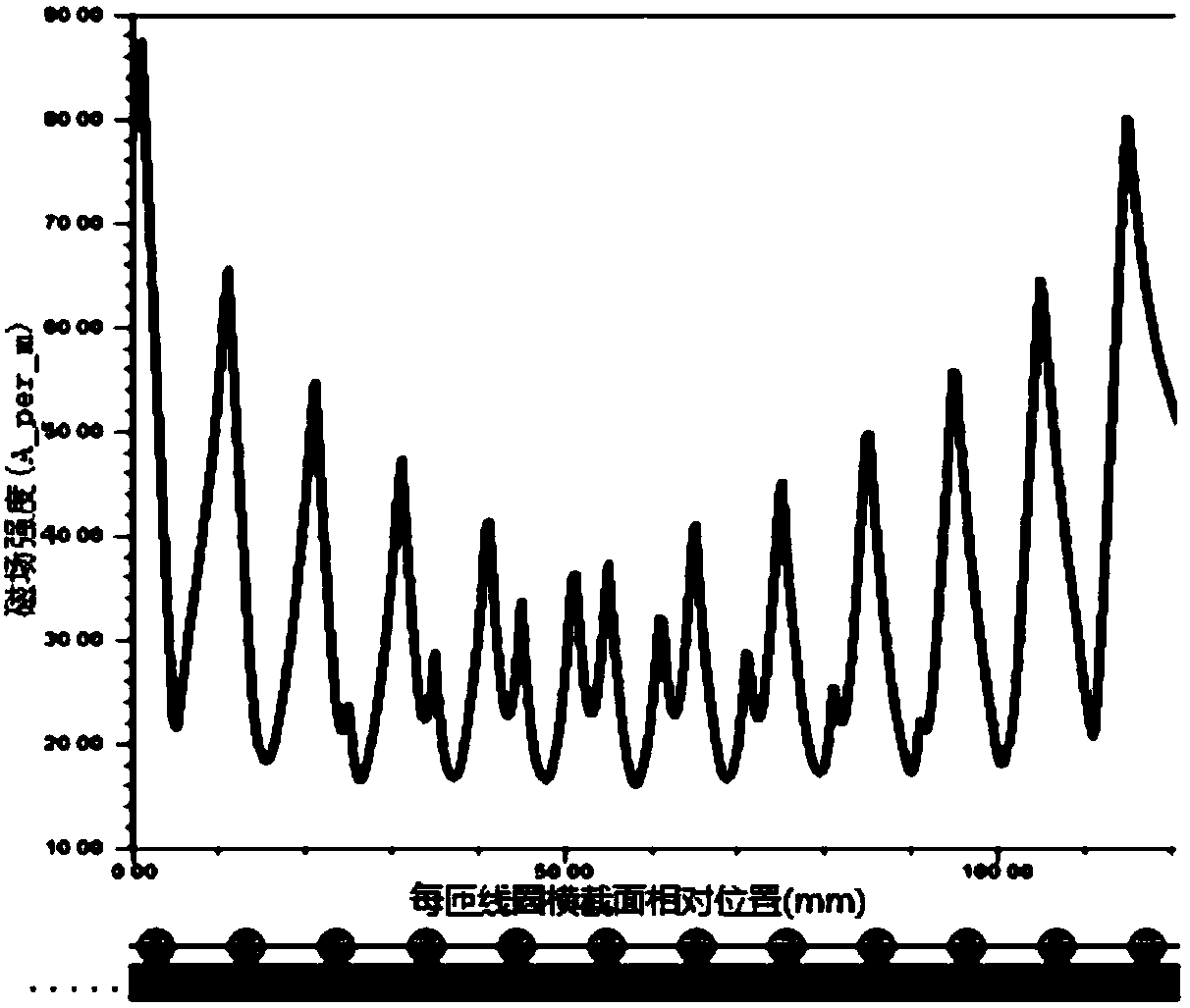

A variable turn pitch planar helical coil

ActiveCN109166708AMitigate copper loss problemsEvenly distributedTransformersCircuit arrangementsWire gaugeCoupling

The invention provides a variable turn pitch planar helical coil, comprising a magnetic core and a planar helical coil arranged above the magnetic core and coiled by an insulated conductor in a clockwise or counterclockwise direction by turns; The turn spacing of the coil is arranged from close to sparse and then from sparse to close in radial direction from the center of the coil to the outside.As that inner diameter of the plane helical coil does not change the equal turn pitch, outer diameter, On the premise of wire gauge, according to the magnetic field distribution on the coil to changethe dense arrangement of the coil into a planar helical coil with variable turn pitch, the overall magnitude of the magnetic field strength on the coil is reduced, The loss of proximity effect of thecoil is reduced, and the increasing trend of AC internal resistance of the coil is finally alleviated so as to reduce the copper loss of the magnetic coupling structure. At the same time, the magneticfield distribution and offset tolerance characteristics of the spiral coil structure with equal turn pitch are not obviously inferior to those of the spiral coil structure with the same specification(inner diameter, outer diameter, turn number, wire gauge).

Owner:WUHAN UNIV OF TECH

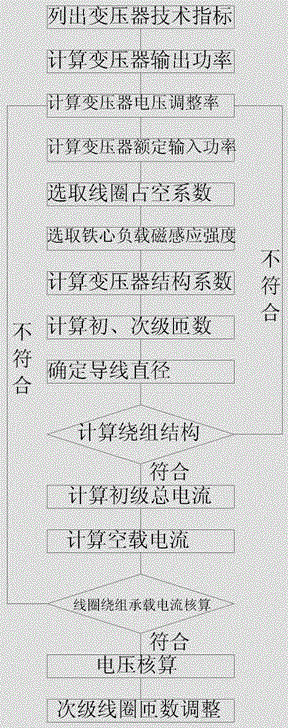

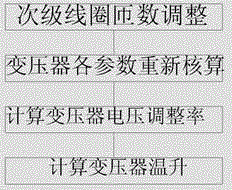

Designing method for single-phase intelligent ammeter power transformer

ActiveCN104538166AReduce volumeReduce temperature riseInductances/transformers/magnets manufactureWire gaugeCarrying capacity

The invention discloses a designing method for a single-phase intelligent ammeter power transformer based on an EI type insert iron core. According to the designing method for the single-phase intelligent ammeter power transformer, output voltage and current meet index requirements, besides, the size is small, and temperature rise is low. The designing method is based on references New electronic transformer handbook, written by Quanbao Wang, Liaoning science and technology press, June 2007; from the step S1 to the step S13, an integrated round copper wire gage list is added, so that the current carrying capacity of copper wires of the selected sizes and specifications is judged, and wire selection errors are avoided. In addition, the number of turns of a secondary coil of a transformed designed for the first time may not meet the voltage output index requirements, and output voltage cannot meet the index requirements unless the number of the turns of the secondary coil is adjusted properly; a method for adjusting the number of the turns of the secondary coil is put forward in the step S14 and the step S15, and in terms of the selection principle of decreasing or increasing the number of the turns, the number of the turns is decreased or increased according to the average value of all secondary floating voltage and load voltage errors; finally, from the step S16 to the step S18, recalculation is performed on the transformer. Accordingly, the output voltage and current of the intelligent ammeter power transformer can meet the index requirements, and meanwhile the intelligent ammeter power transformer is small in size and low in temperature rise.

Owner:TAIZHOU XINYI ELECTRIC APPLIANCE +1

A kind of automobile wheel cover hemming system and using method thereof

Owner:SHANGHAI JUNYI IND AUTOMATION CO LTD

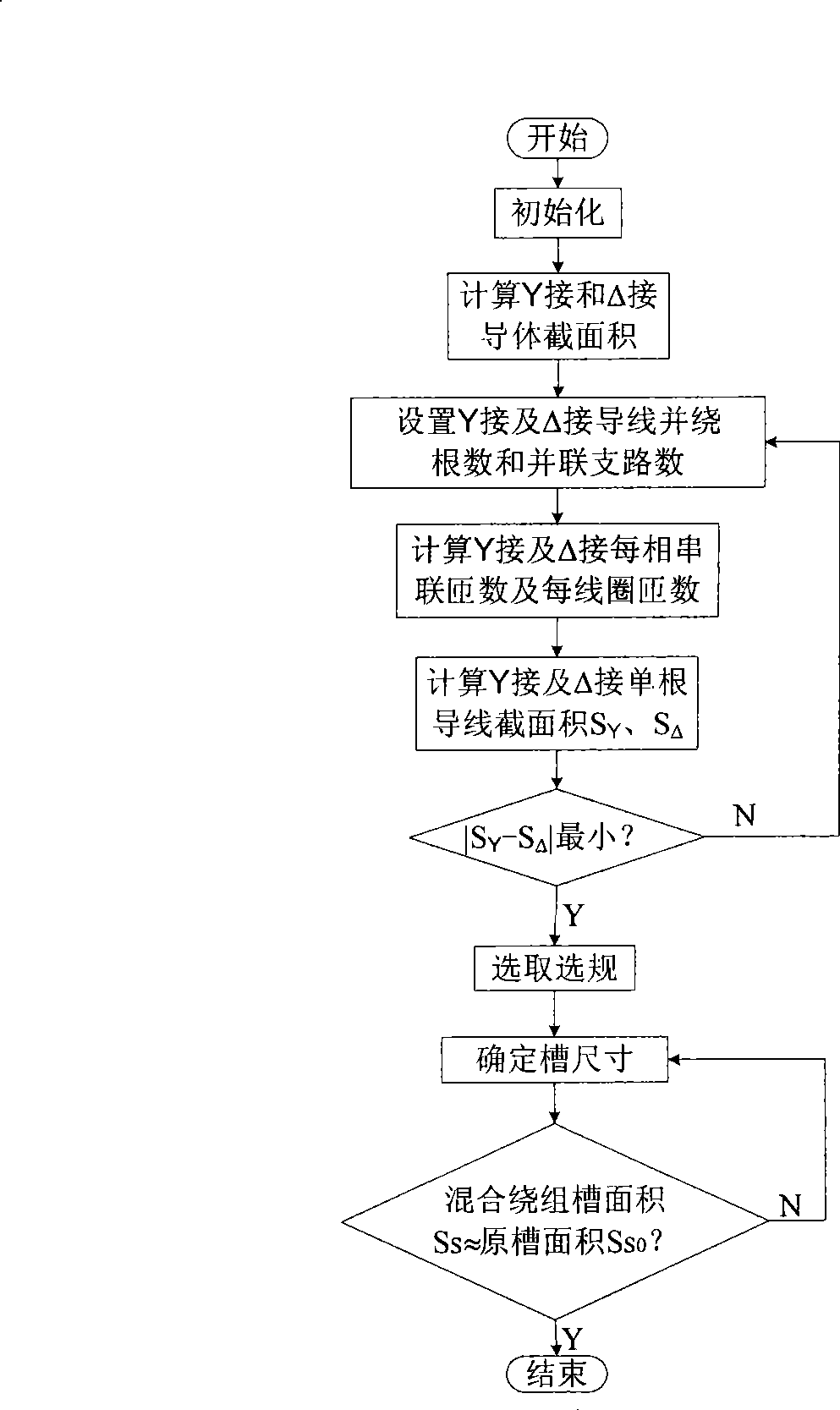

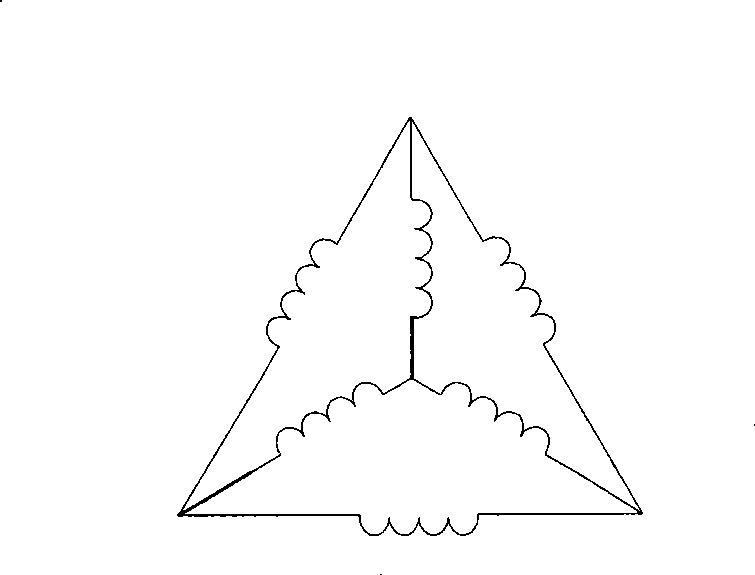

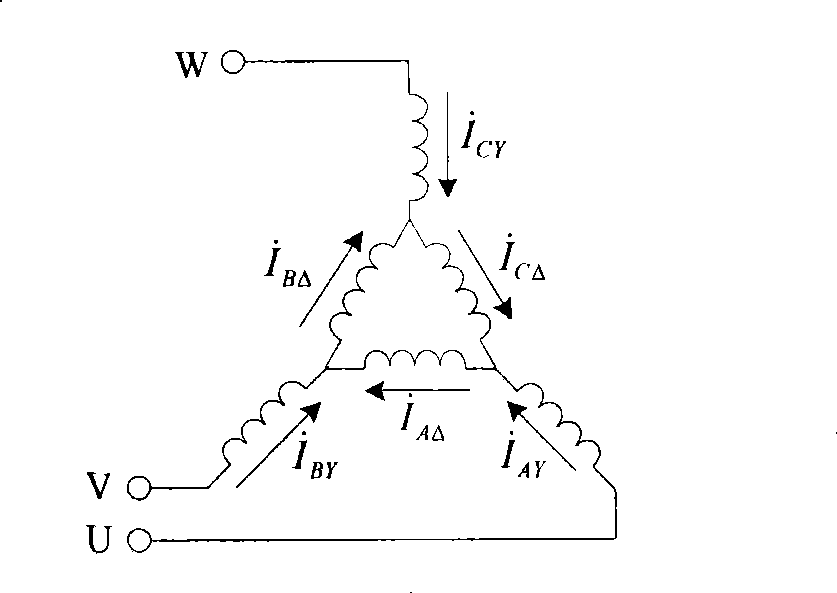

Method for modifying double layer winded performing winding into Y-Delta mixed performed winding

ActiveCN101364751AManufacturing dynamo-electric machinesWindings conductor shape/form/constructionWire gaugeElectrical conductor

The invention relates to a method for changing a double-layer lap-winding winding to Y-delt connection mixed winding. The method is characterized in that the method comprises the steps of calculating the section areas of a Y-connection winding conductor and a delt-connection winging conductor, and determining the number of branches connected with each other in parallel, the number of turns of the coil and the width and the thickness of a wire on the basis of the prior double-layer lap-winding windings. In consideration of the manufacture cost of the motor, other parameters and the size of the motor are kept original values when changing to the Y-delt connection mixed winding, but the size of a stator groove needs to be adjusted correspondingly according to the wire gauge and the number of turns of the coil without changing the groove area. The winding has improved winding coefficient and can weaken harmonic waves with higher harmonic contents such as the fifth and the seventh harmonic waves, thereby increasing the wire gauge, reducing the number of turns, lowering the motor loss, and improving the motor efficiency and the power coefficient. Additionally, the Y-connection and delt-connection coils are arranged in a non-alternate manner so as to reduce the process difficulty. The method suits the alteration of common double-layer lap-winding winding of high-voltage large and medium asynchronous motor with a power lower than 2,000 kW.

Owner:TSINGHUA UNIV +1

Automatic inserting-drawing mechanism for memory chip of mainboard function testing device

The invention discloses an automatic inserting-drawing mechanism for a memory chip of a mainboard function testing device. The mechanism comprises an adapter plate, a spring PIN, a guide wire gauge, a connecting block, a guide block, a guide rolling shaft and a power device, wherein the spring PIN and the guide wire gauge are transversely fixed; the connecting block, which can move forwards and backwards along the guide wire gauge, is fixed to the spring PIN; the upper end of the connecting block is connected with a rolling bearing while the lower end of the connecting block is connected with the adapter plate; the rolling bearing is in contact with an inclined surface of the guide block; the power device can downwards press the guide block; one end of the adapter plate is in rotating connection with the connecting block while the other end of the adapter plate is an inserting part which is in match with a memory chip slot of a mainboard; the memory chip can be inserted into an inserting slot in the adapter plate; the memory chip slot communicates with the memory chip through the adapter plate. With the adoption of the mechanism, the memory chip can be mounted in a time and can be automatically inserted and drawn out; the automation degree is high, and the testing efficiency can be effectively improved.

Owner:昆山凯耀电子科技有限公司

Manual feed mechanism for processing automobile engine cylinder

ActiveCN102814691AUnique structureSolve the problem of low efficiency of manual upper and lower fixturesMetal working apparatusWire gaugeSprocket

The invention relates to a device which is suitable for the assembly line work of engine cylinders and other parts in the automobile industry, and in particular to a manual feed mechanism for processing an automobile engine cylinder, which is characterized by comprising a support frame, wherein the lower part of the support frame is provided with an air cylinder, vertical wire gauge and a chain wheel are sequentially matched with the upper part of the air cylinder, a rack is matched with the lower part of the chain wheel, a roller is matched with the upper part of the chain wheel, vertical support plates are fixed on the support frame at the periphery of the chain wheel, one sides of the upper parts of the vertical support plates are fixed with a fork support, pneumatic control boxes are respectively fixed on the fork supports, push-in handles are respectively arranged at the upper parts of the pneumatic control boxes, and the vertical support plates at the left side and the right side of the fork support are respectively fixed with a horizontal guide support plate. The manual feed mechanism has a unique structure, can be used for solving the problem of low manual efficiency when materials are loaded and unloaded on a fixture during the processing of engine cylinders and other parts, is reliable and stable, and has high efficiency.

Owner:NINGXIA KOCEL MOLD

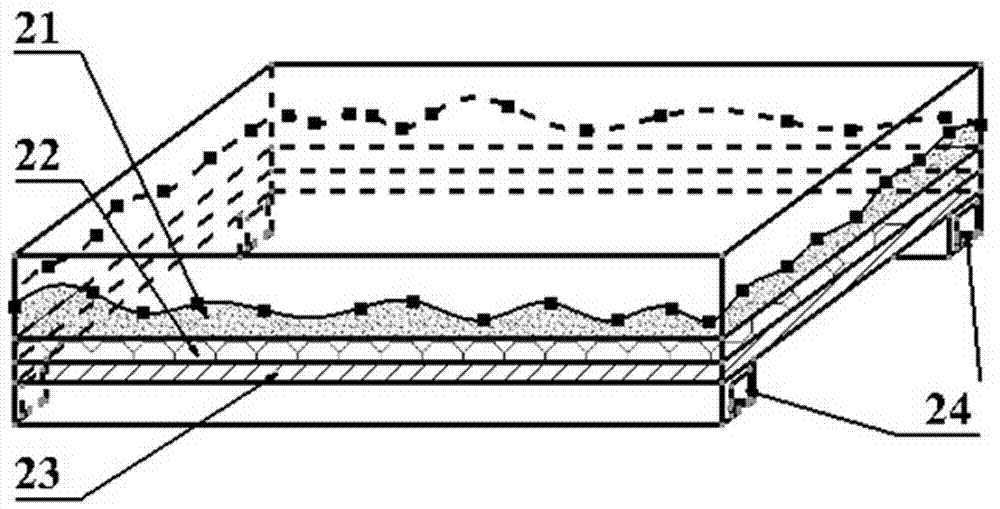

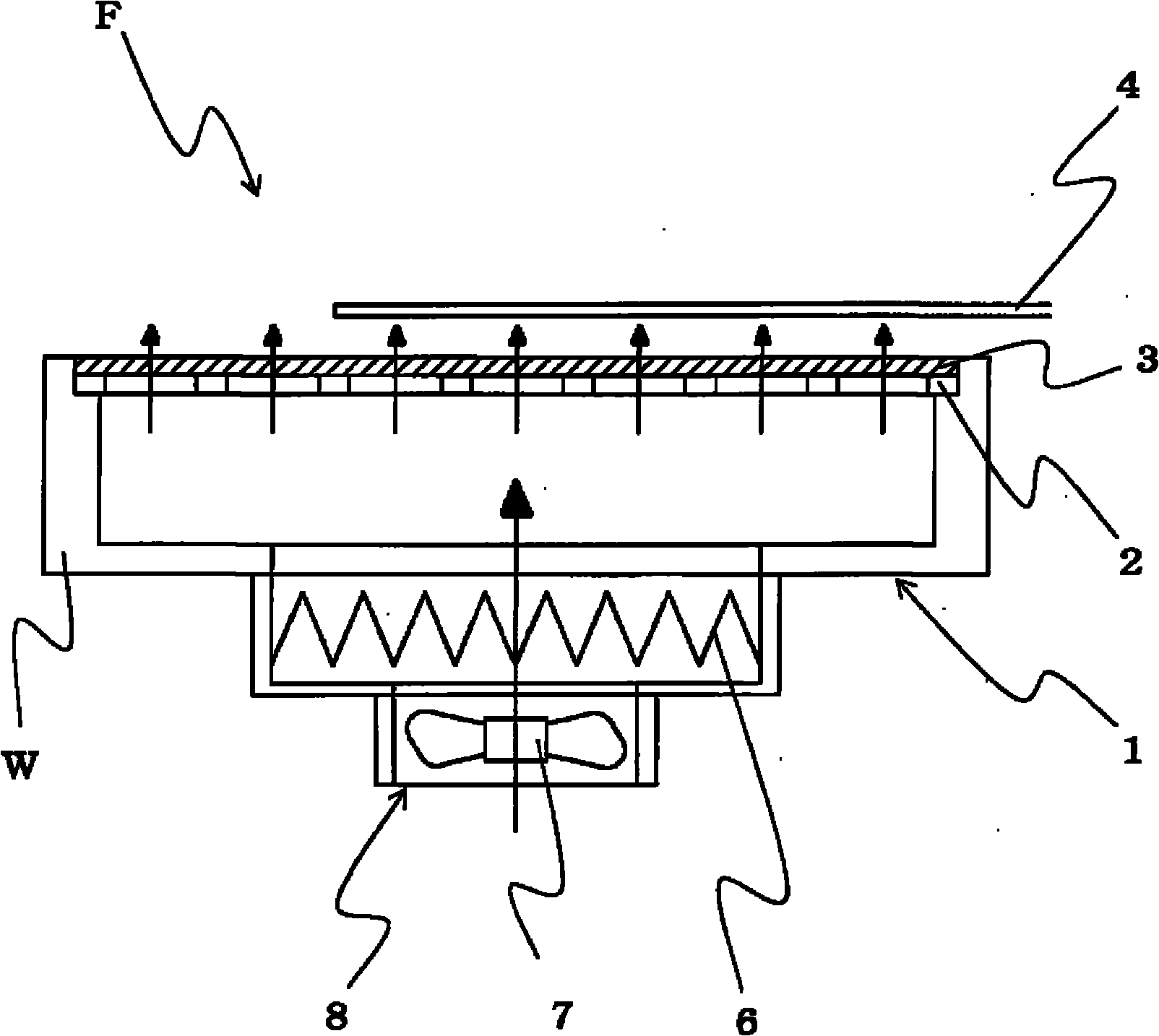

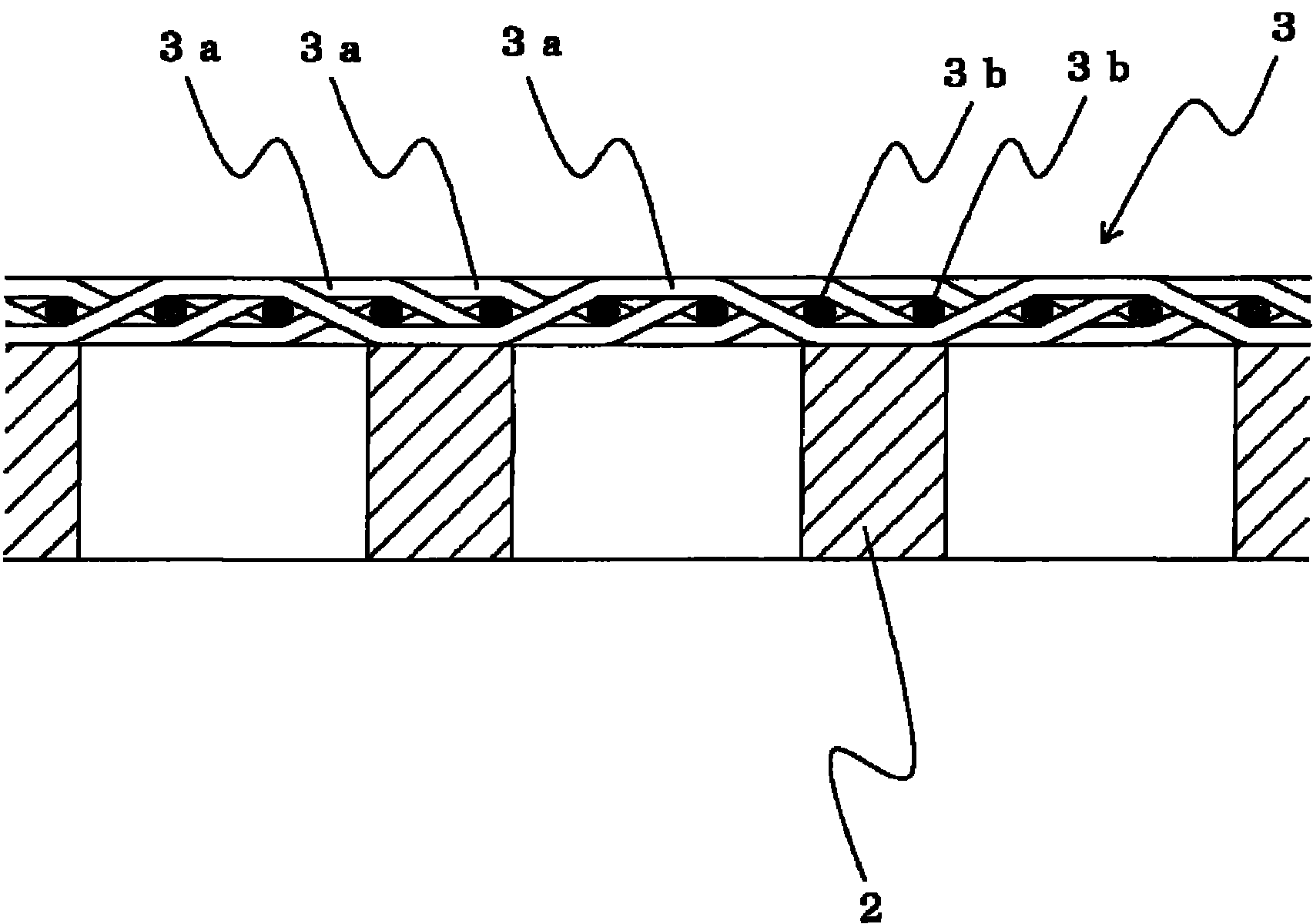

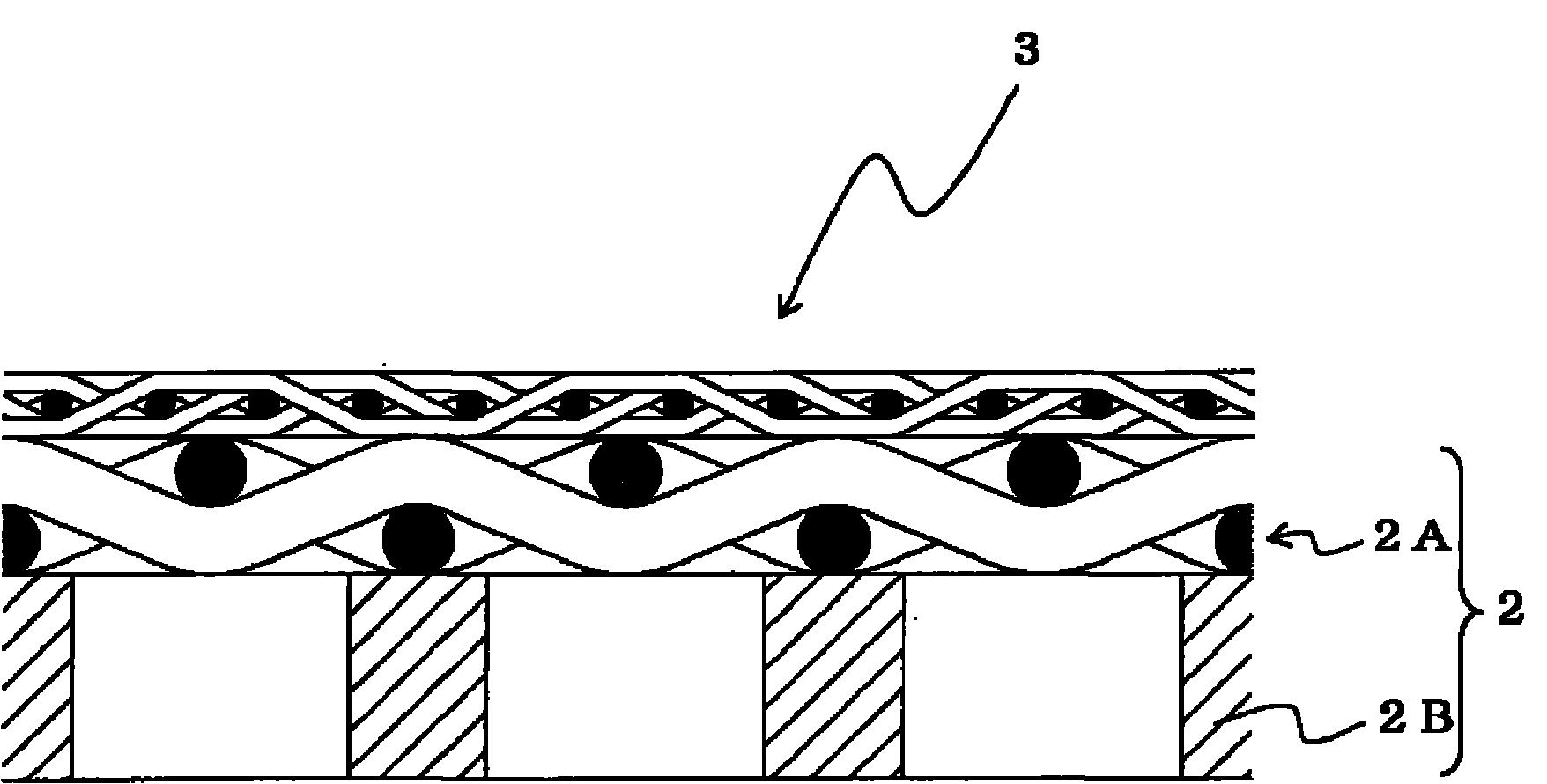

Air blowout structure and air blowout unit for air-floating conveyor apparatus, and air-floating conveyor apparatus having the same

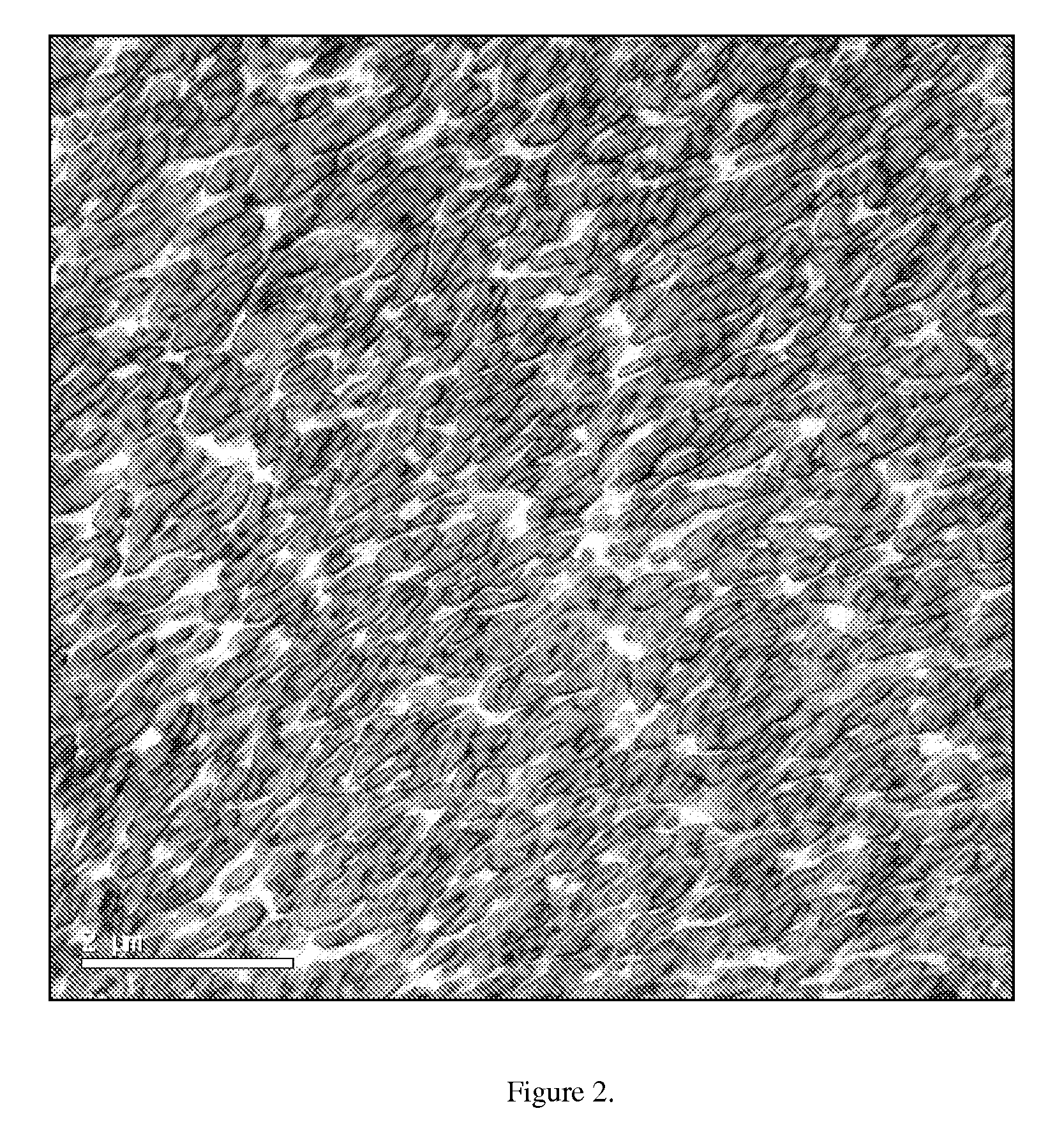

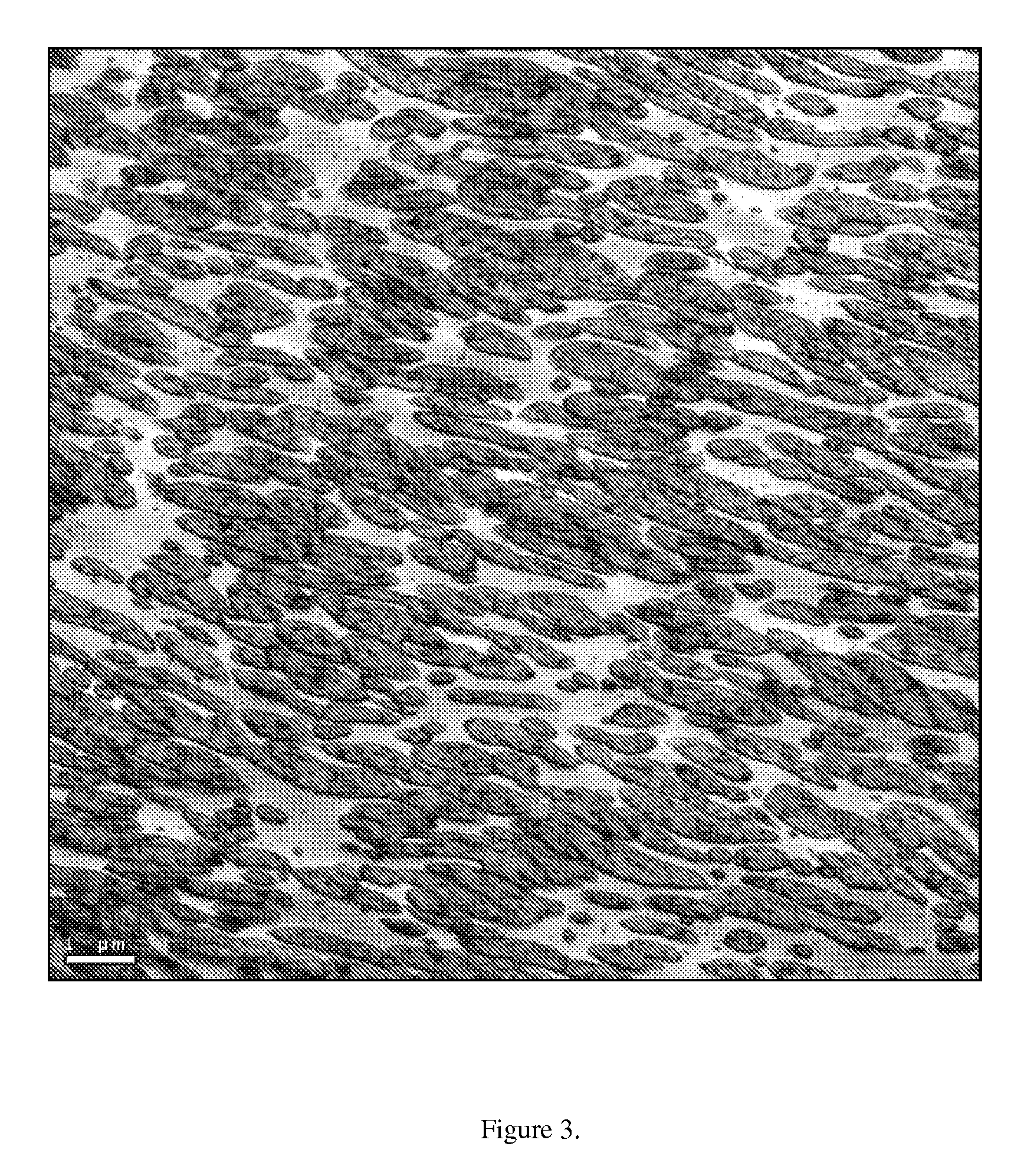

InactiveCN101778787AEasy maintenanceEasy to manufactureConveyorsCharge manipulationWire gaugePorosity

Provided is an air blowout structure for an air-floating conveyor apparatus, which can be easily maintained. The air blowout structure for the air-floating conveyor apparatus conveys a glass substrate (4) as a thin plate by floating it pneumatically. The air blowout structure comprises a woven wire gauge (3) arranged in the highest portion of the structure, and a reinforcing member (2) having a porosity and arranged below the woven wire gauge (3). This woven wire gauge (3) can be exemplified by a plain-woven wire gauge, a twilled wire gauge, a plain-woven mat wire gauge or a twilled mat wire gauge. Moreover, the reinforcing member (2) has a single- or multi-layer structure.

Owner:SINTOKOGIO LTD +1

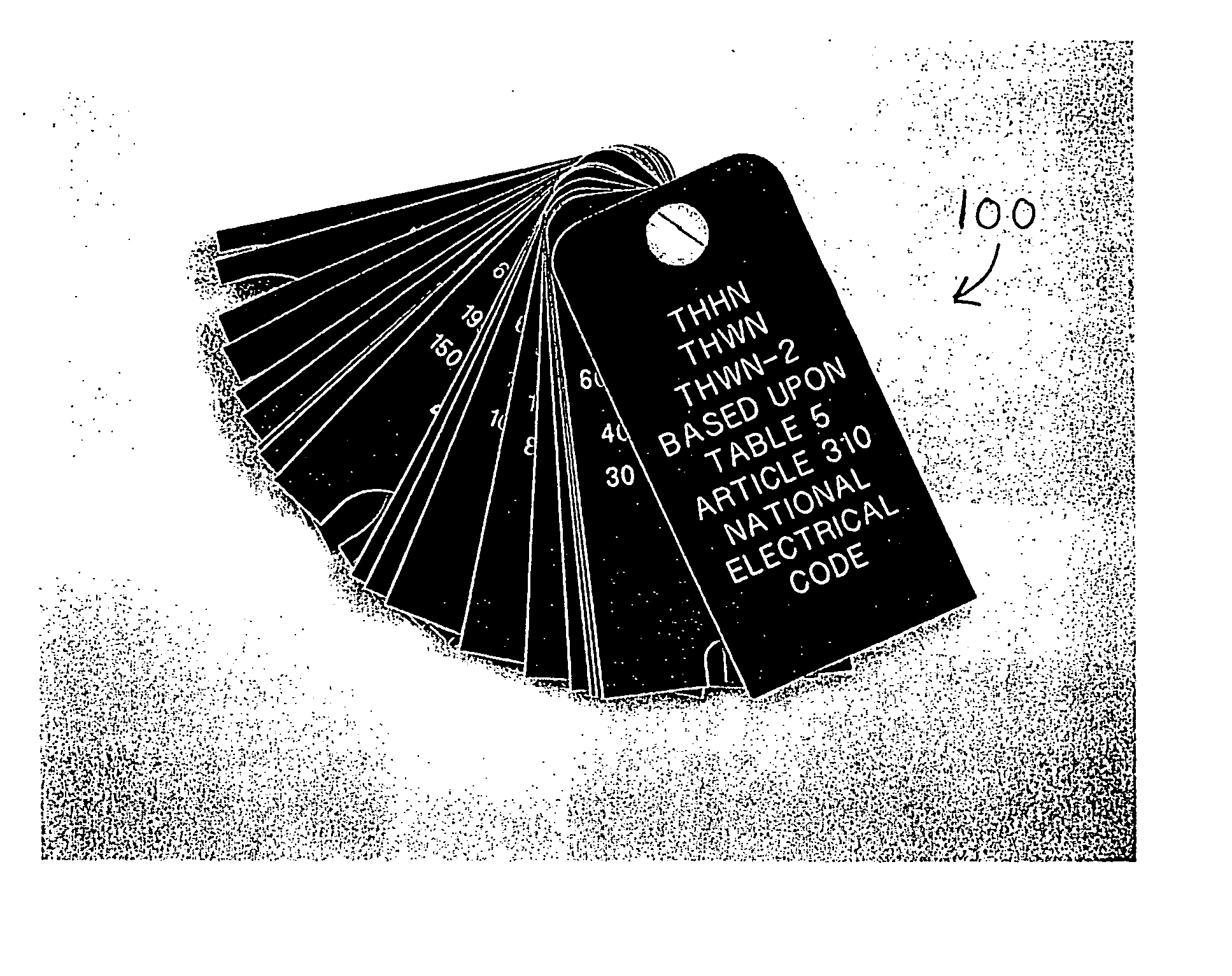

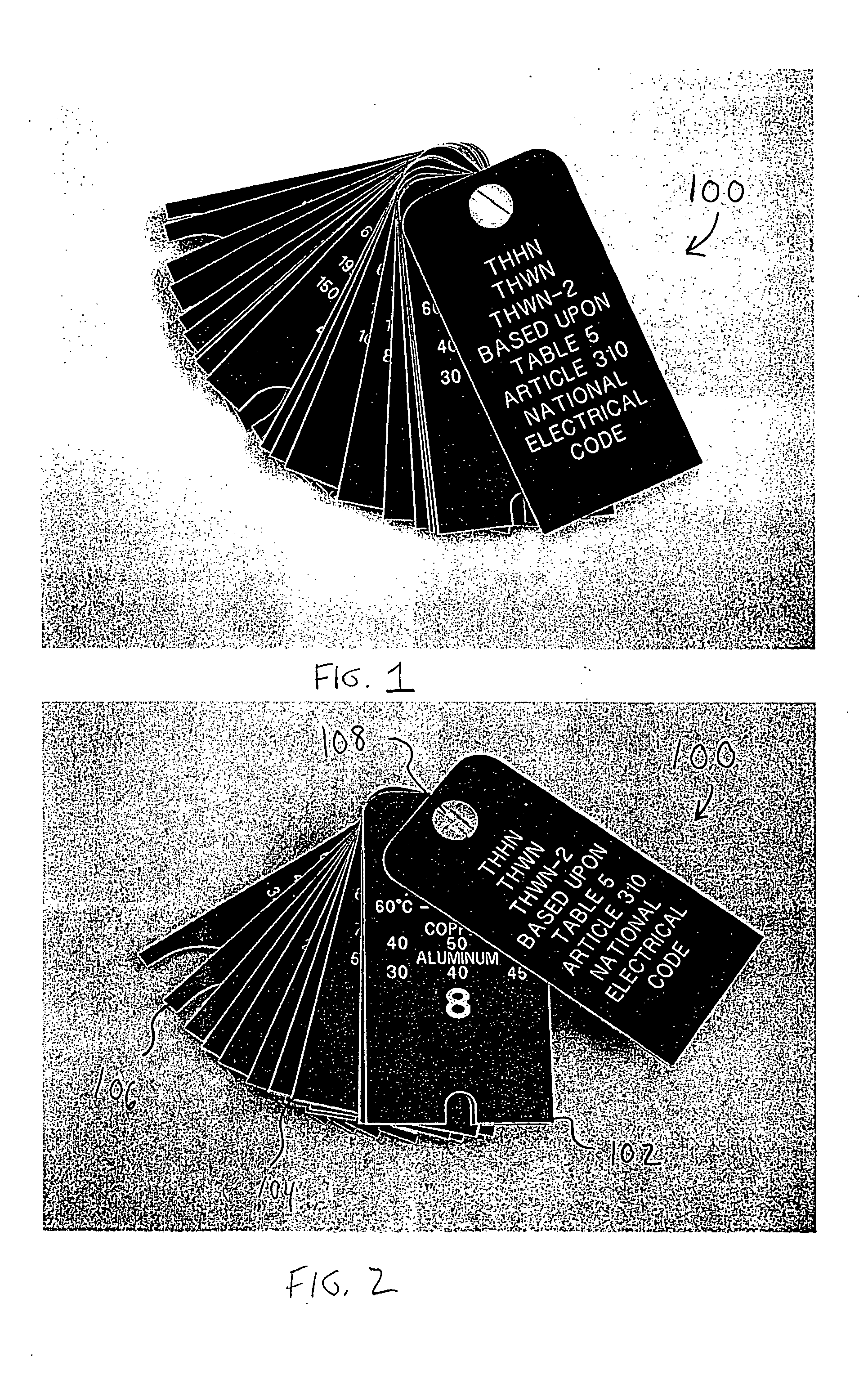

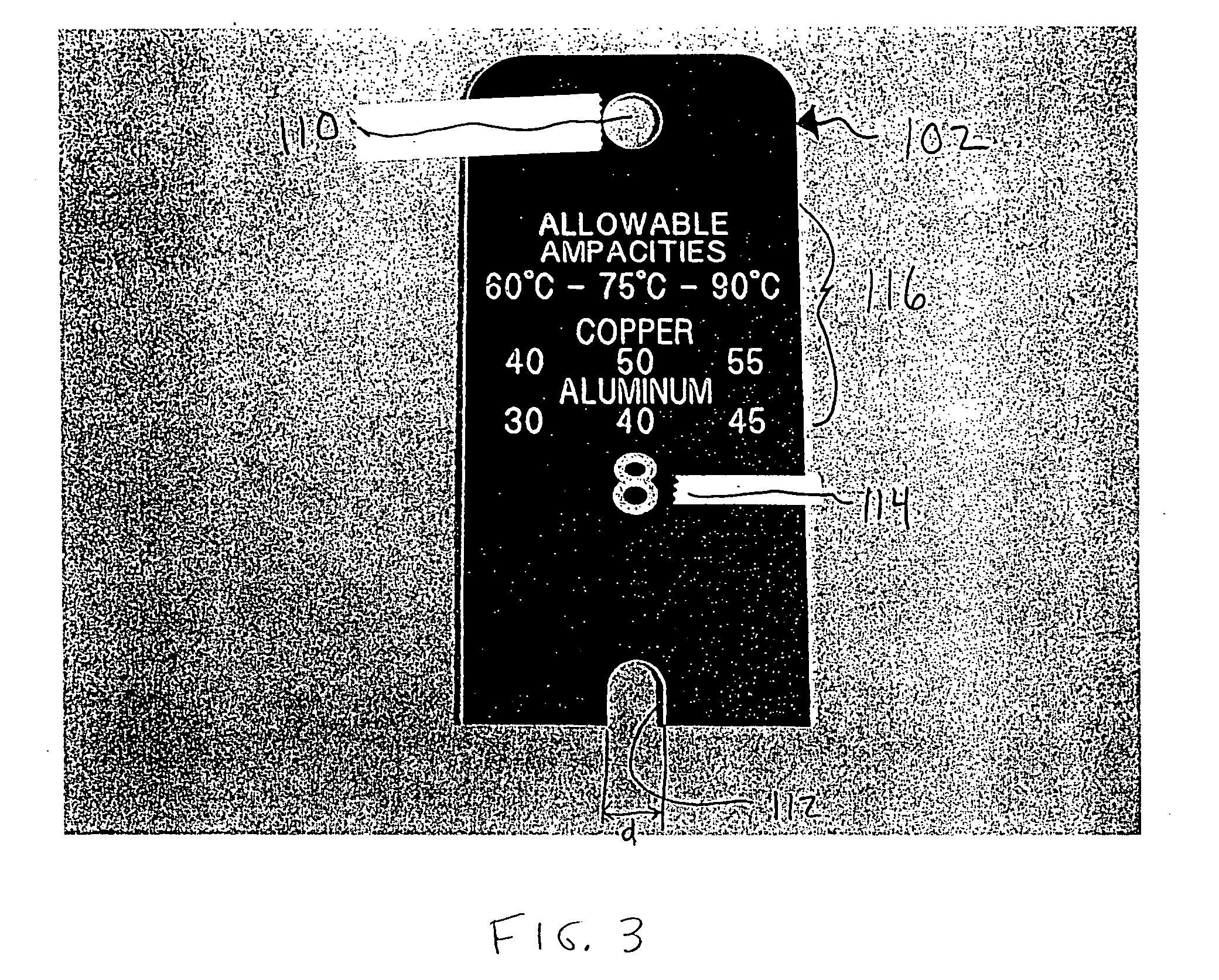

Wire gauging tool

A tool for measuring the outside insulation of electrical conductors (wire) in the electrical trade. The tool includes a set of leaves which are cut to match the various conductor insulations in the trade. The tools have leaves at each end or both ends. The tool is held together by means of a post and screw or other acceptable means that will allow the leaves to swing out to fit over the insulated conductors. The tool has engraved or printed text that has the amperage stated for copper and aluminum conductors a various ambient temperatures as well as the size measured in (kcmil) which is stated in circular mil area of the insulated conductor which will vary with the types of insulation used on the conductors.

Owner:NAVE GERALD ADAM

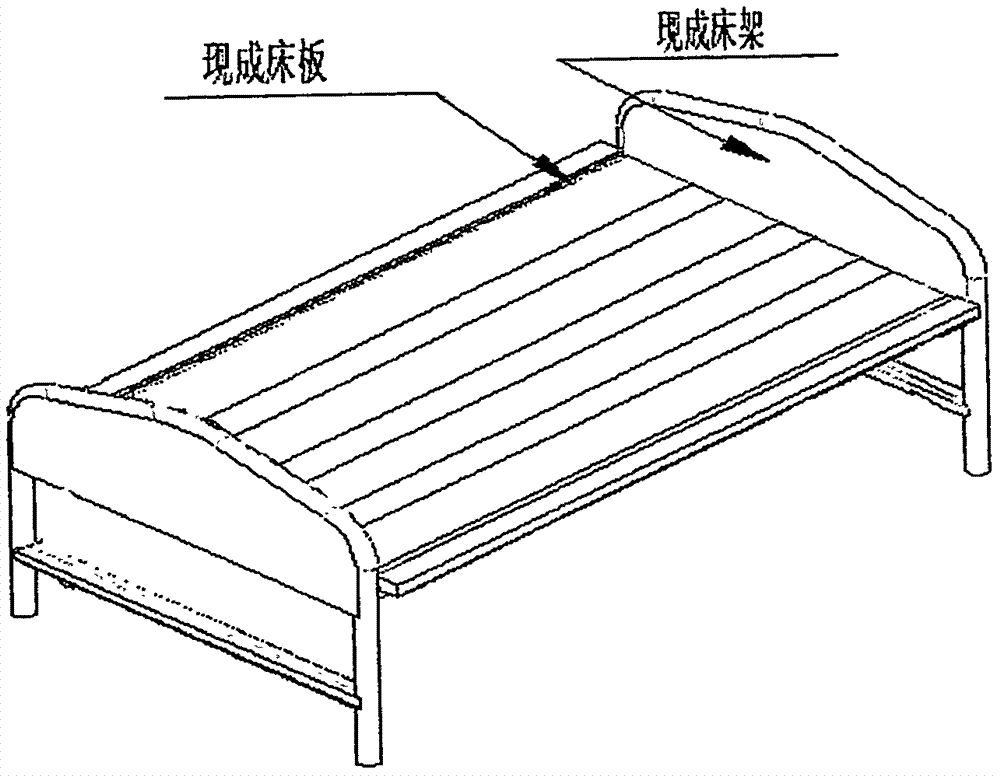

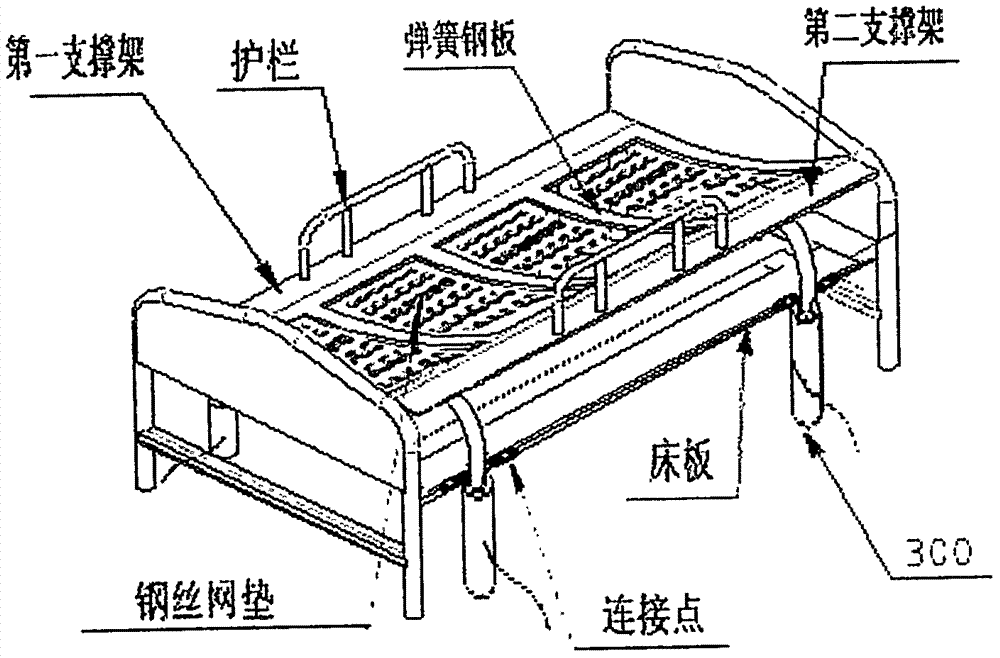

Overturning device for bed-ridden patients

InactiveCN107456338AIngenious designLeft and right side turning interlocking guaranteeNursing bedsMedical transportBed-riddenEngineering

The invention discloses an overturning device for bed-ridden patients. The overturning device for bed-ridden patients comprises a first support frame and a second support frame which are respectively arranged on the left and right bed edges, wherein each support frame comprises a front support electric cylinder and a rear support electric cylinder, and each front support electric cylinder and each rear support electric cylinder operate synchronously; a steel wire mattress is a steel wire gauge mattress adopting a scaffold composed of five spring steel plates and stainless steel square tubes; the first support frame and the second support frame are respectively connected with electric screw rods of a front support and a rear support, and four electric cylinder top bracket are connected with the edge of a ready-made panel bed; upper and lower stroke parts of the electric screw rods are flexible spring steel plates, and body protecting guide rails are mounted on the left and right sides of the steel wire mattress; an electric control unit adopts the mains supply, and a safe mode of switched-mode power supply DC 24V driving is adopted; the first support frame and the second support frame of left and right bed boards are in interlocking lifting, and thus the left and right gap overturning effect is achieved. The invention provides the overturning device for bed-ridden patients which is ingenious in design, the structure of the ready-made panel bed is sufficiently utilized, the overturning device is suitable for a standard single bed, and also suitable for various non-standard beds, the steel wire gauge mattress has strong breathability, the operation and use are convenient, thus the workload of rehabilitation nursing is reduced, and the risk that bed sores are bred and the body is stiff existing in the bed-ridden patients is eliminated.

Owner:上海杨浦区吉祥敬老院

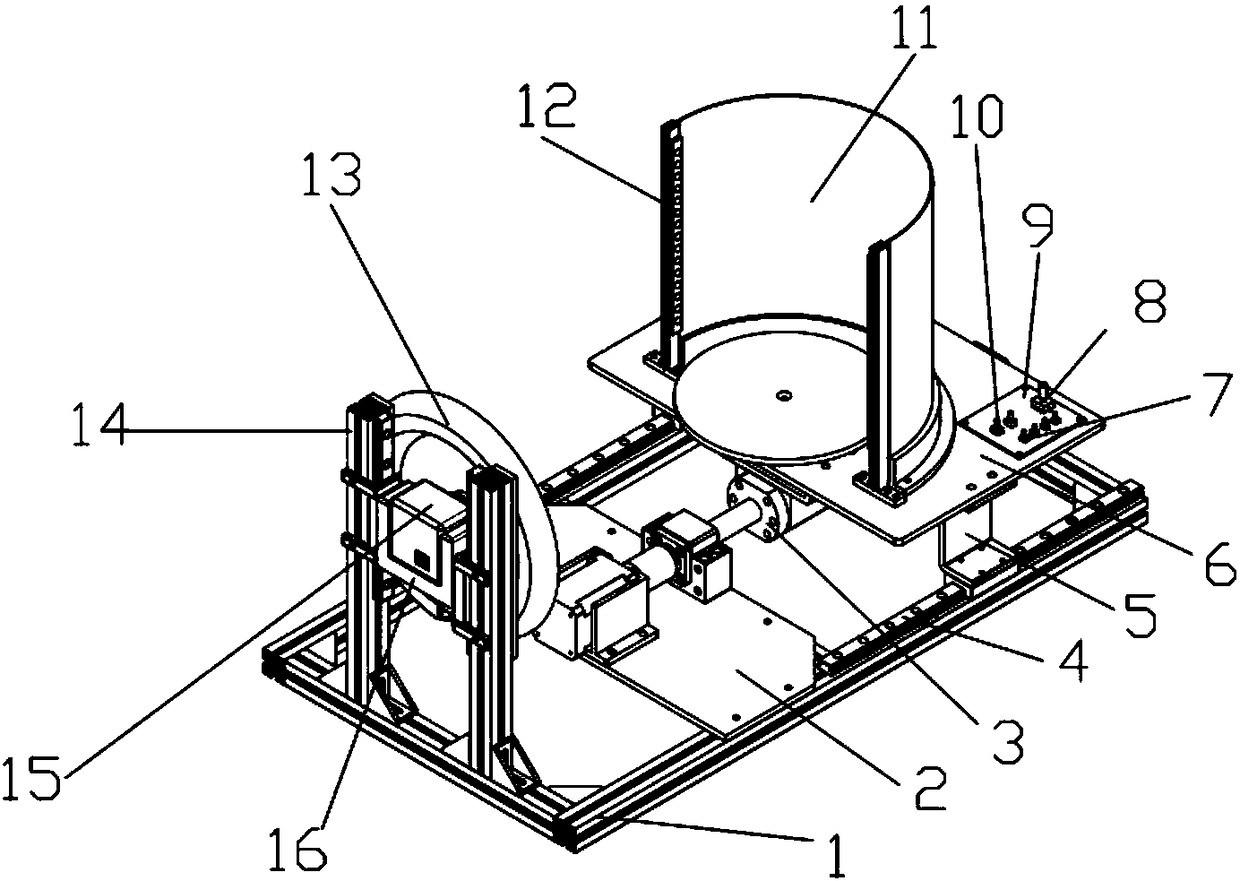

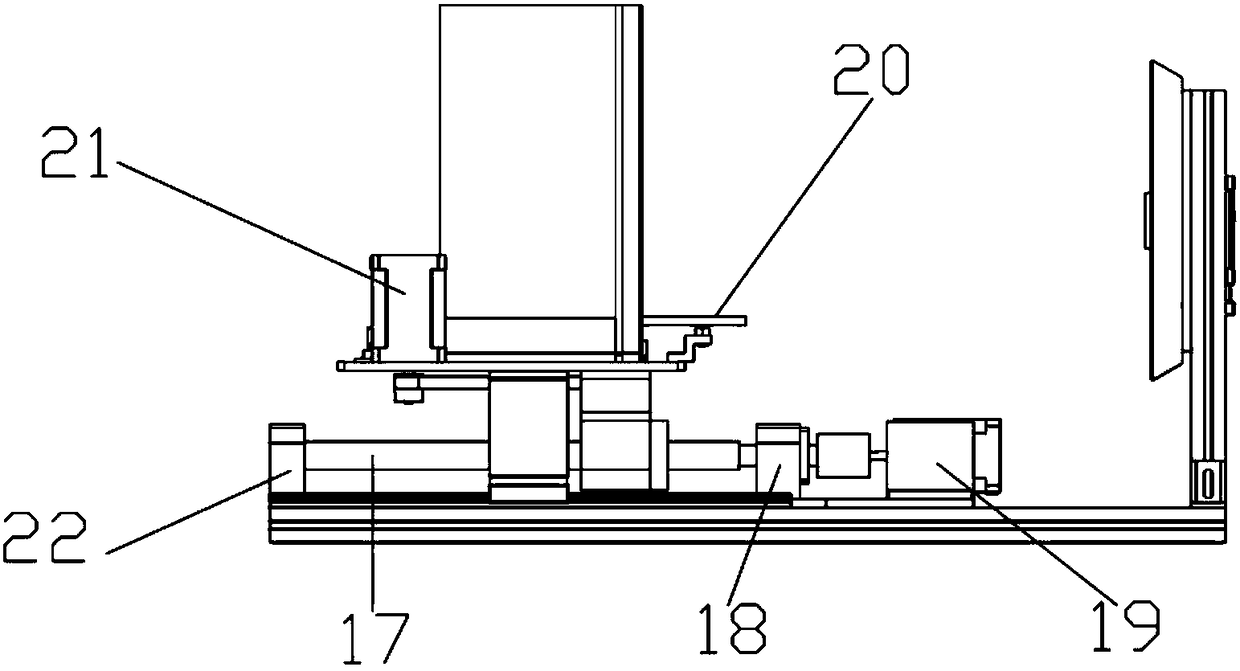

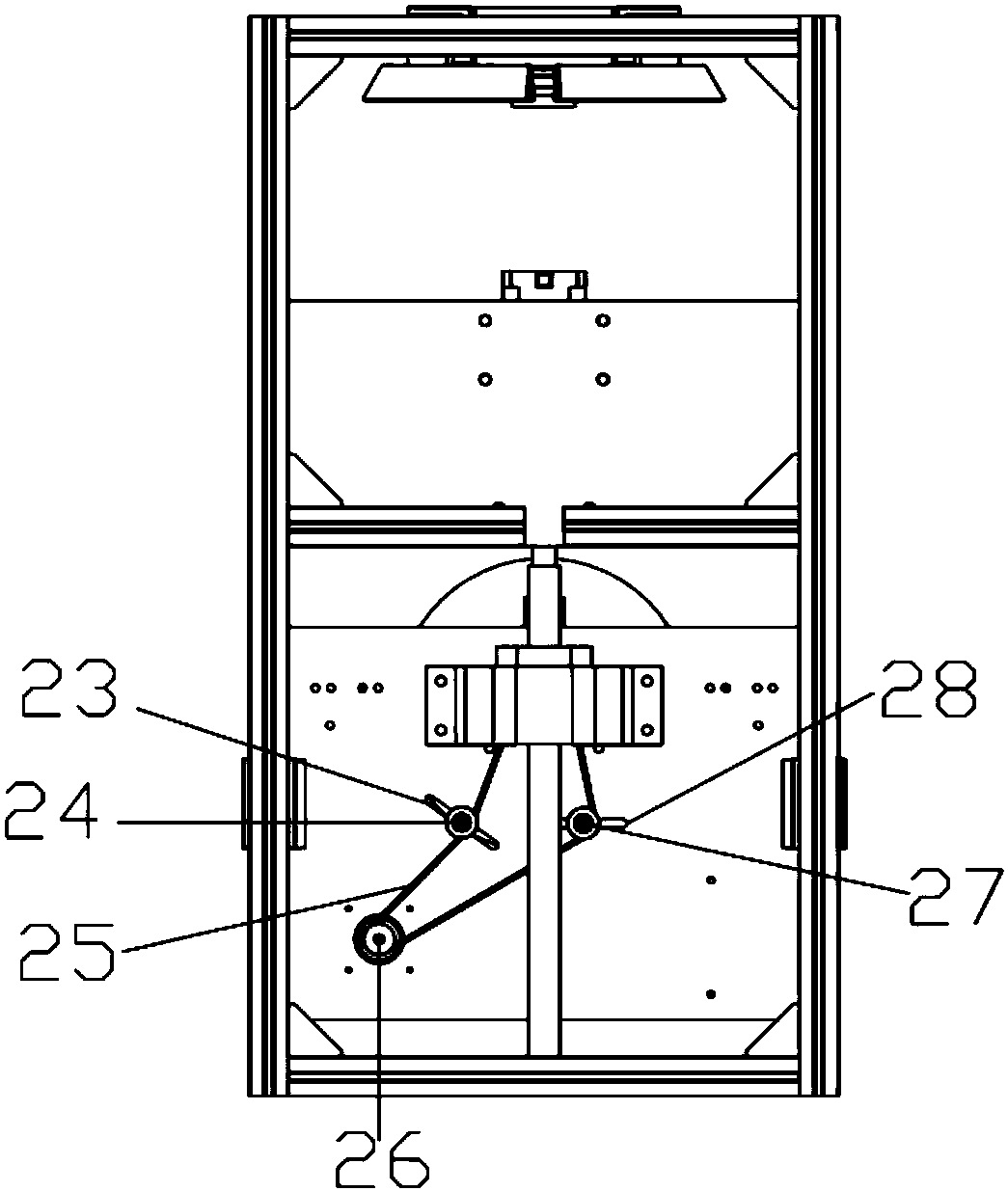

Rotatable multi-angle visual inspection device and method

PendingCN108426595ARealize multi-angle detectionHigh precisionMeasurement apparatus componentsControl using feedbackWire gaugeMachine vision

The invention discloses a rotatable multi-angle visual inspection device and method. The inspection device comprises a rack, and a camera support frame, a horizontal displacement mechanism and wire gauges are arranged on the upper portion of the rack; a camera fixing block is arranged on the camera support frame, and used for fixing a camera, and a ring light is arranged around the camera; the wire gauges are arranged on the two side edges of the rack, support sliding blocks sliding along the wire gauges are arranged on the wire gauges, a bottom plate is arranged on the upper portions of the support sliding blocks, and a second stepping motor, an electric control module and a rotating platform are arranged on the bottom plate; a semicircular light is arranged around the rotating platform,and strip-shaped lights are arranged on the two sides of the semicircular light; the second stepping motor controls the rotating platform to rotate. The device is simple in structure, the stepping motor controls the rotating platform to rotate stably, products can be shot in multiple angles, and then the multi-angle machine visual inspection is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Musical instrument pickup and methods

Musical instrument pickups and methods of constructing same to achieve a user-desired signal output level and a user-desired tonal characteristic from a stringed instrument are disclosed. The method may include steps for selecting a coil geometry, selecting a number of coils, selecting a coil wire gauge and number of turns for each coil and selecting a pole piece. In selecting the pole piece consideration may be given to pole piece composition, pole piece thickness, height and width, and pole piece response in terms of relative inductive and relative resonant frequency characteristics and / or the shape of the frequency response in the vicinity of resonance.

Owner:LAWING ANDREW SCOTT

Production method of large-scale paste chili powder

InactiveCN104605305AGuaranteed not to be brokenIncrease productivityFood preparationWire gaugeFirewood

The invention discloses a production method of large-scale paste chili powder. The production method comprises the following steps: (1) putting a square flat-bottom iron pot on a square hearth, filling firewood ash in the pot, and combusting the firewood ash in the flat-bottom iron pot by taking firewood in the square hearth as fuels; (2) filling selected and cleaned chili by the square iron wire gauge frame with the size of 1 / 2-2 / 3 of the flat-bottom iron pot; (3) pushing the combusted firewood ash in the flat-bottom iron pot aside, putting in the iron wire gauze frame filled with the chili, and then covering the chili with the combusted firewood ash until baking the chili to be done; (4) suspending the iron wire gauze frame by a traveling vehicle, and purifying the firewood ash by a draught fan above and an exhaust fan below; (5) putting in a smudging frame, and combusting by chypre branches for 30-40 minutes; and (6) grinding into chili powder by use of a grinding bowl. According to the production method disclosed by the invention, a traditional technology is combined with modern equipment for treating chili powder products on a large scale, not only are active substances in the chili not damaged, but also all products have natural flavor of paste chili, and the production efficiency is improved.

Owner:吴正洪

Pneumatically-balanced automatic brake device combined with calliper brake

InactiveCN105345588AAvoid displacementImprove machining accuracyLarge fixed membersMetal working apparatusNumerical controlEngineering

The invention relates to a pneumatically-balanced automatic brake device combined with a calliper brake, which is applied to a vertical moving component of a numerically-controlled machine tool. The technical scheme adopted in the invention is as follows: the pneumatically-balanced automatic brake device combined with the calliper brake comprises the calliper brake, wherein the calliper brake and a wire gauge slide plate are fixed on a machine tool spindle box, the calliper brake and the wire gauge slide plate are installed on a wire gauge, and the wire gauge is fixed on a slide plate; a balance cylinder support is arranged on the upper end part of the slide plate and installed on the slide plate, a balance cylinder is arranged on the balance cylinder support, and a piston end of the balance cylinder is connected with the machine tool spindle box. The pneumatically-balanced automatic brake device combined with the calliper brake, which is disclosed by the invention, has the following advantages and effects: due to the structure, a displacement of the vertical moving component of the numerically-controlled machine tool with a linear motor due to dead weight and inertia in case of sudden power loss can be avoided; the machining accuracy of the machine tool is improved (vibration is prevented), and in particular, brake can be carried out in an emergency, so that the safety and the controllability of the machine tool are improved; and moreover, the quality for machining components can be better improved.

Owner:SHANDONG WEIDA HEAVY INDS

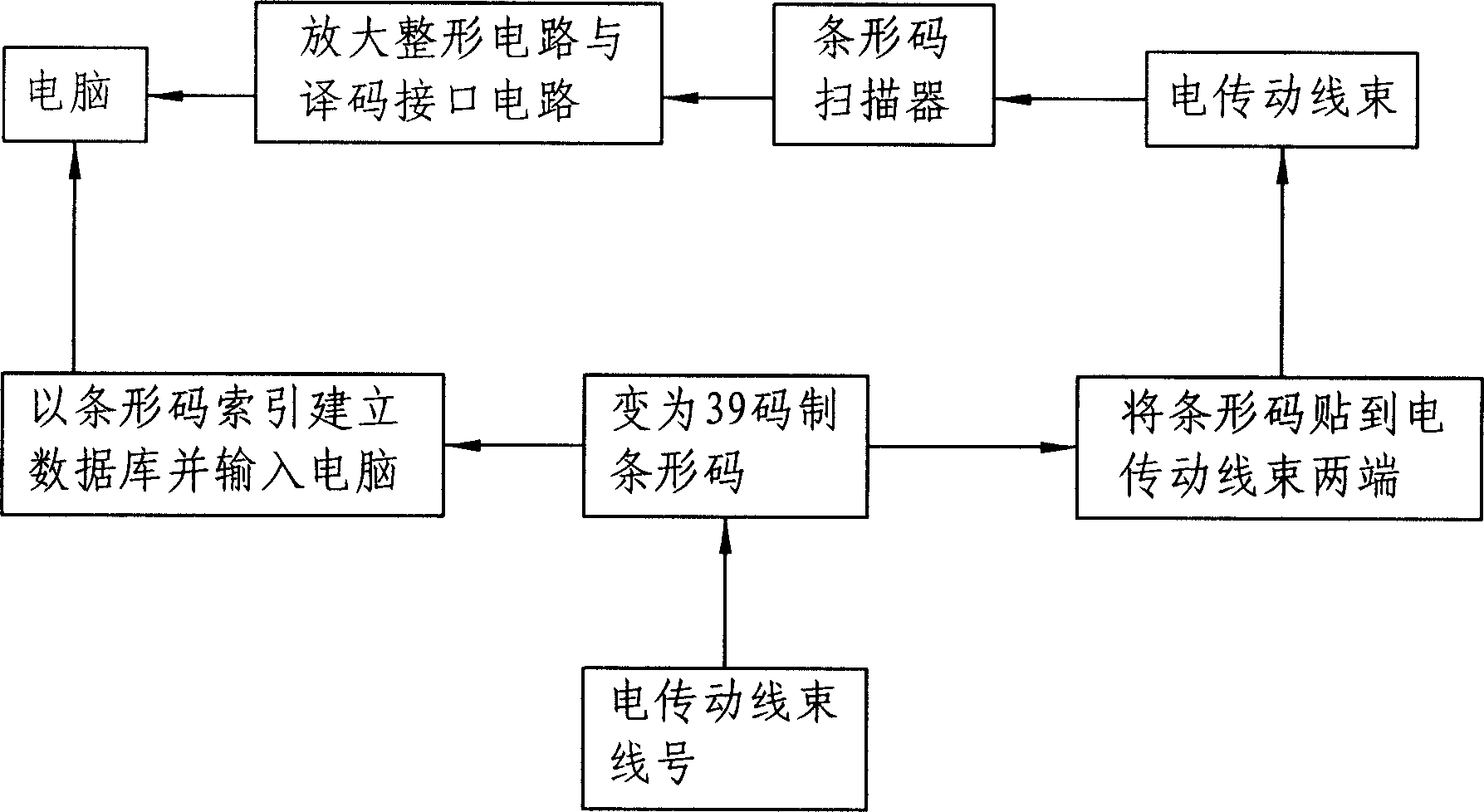

Method for quick identifying electrical transmission wires, and system

InactiveCN1917098AFast recognitionIncrease productivityDigitally marking record carriersInsulated cablesElectricityWire gauge

The method includes steps: wire gauges of electrical transmission wires are converted to bar codes of system of 39 codes, and there is one-to-one correspondence between bar code and wire gauge; printing bar code on paster, and sticking the paster with bar code being printed on to two ends of corresponding wire; building information database of the said wire gauges and technical qualification in computer by using bar code as index; being connected to computer, bar code scanner scans bar codes on transmission wires, then computer displays wire gauges and technical qualification so as to realize identifying electrical transmission wires quickly. Advantages are: raising speed for identifying electrical transmission wires so as to increase production efficiency.

Owner:ZHONGTONG BUS HLDG

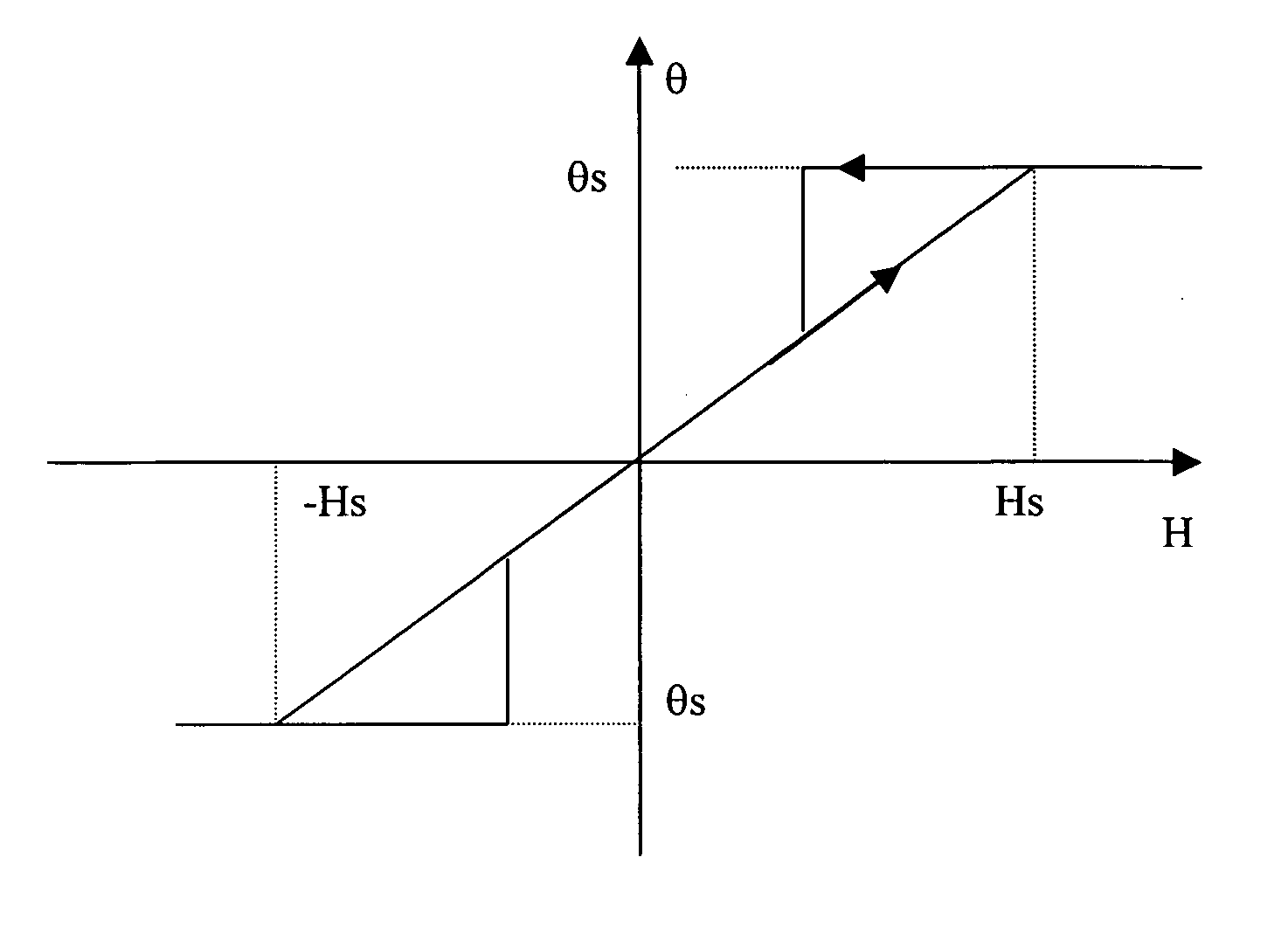

Switchable latching-type faraday rotator

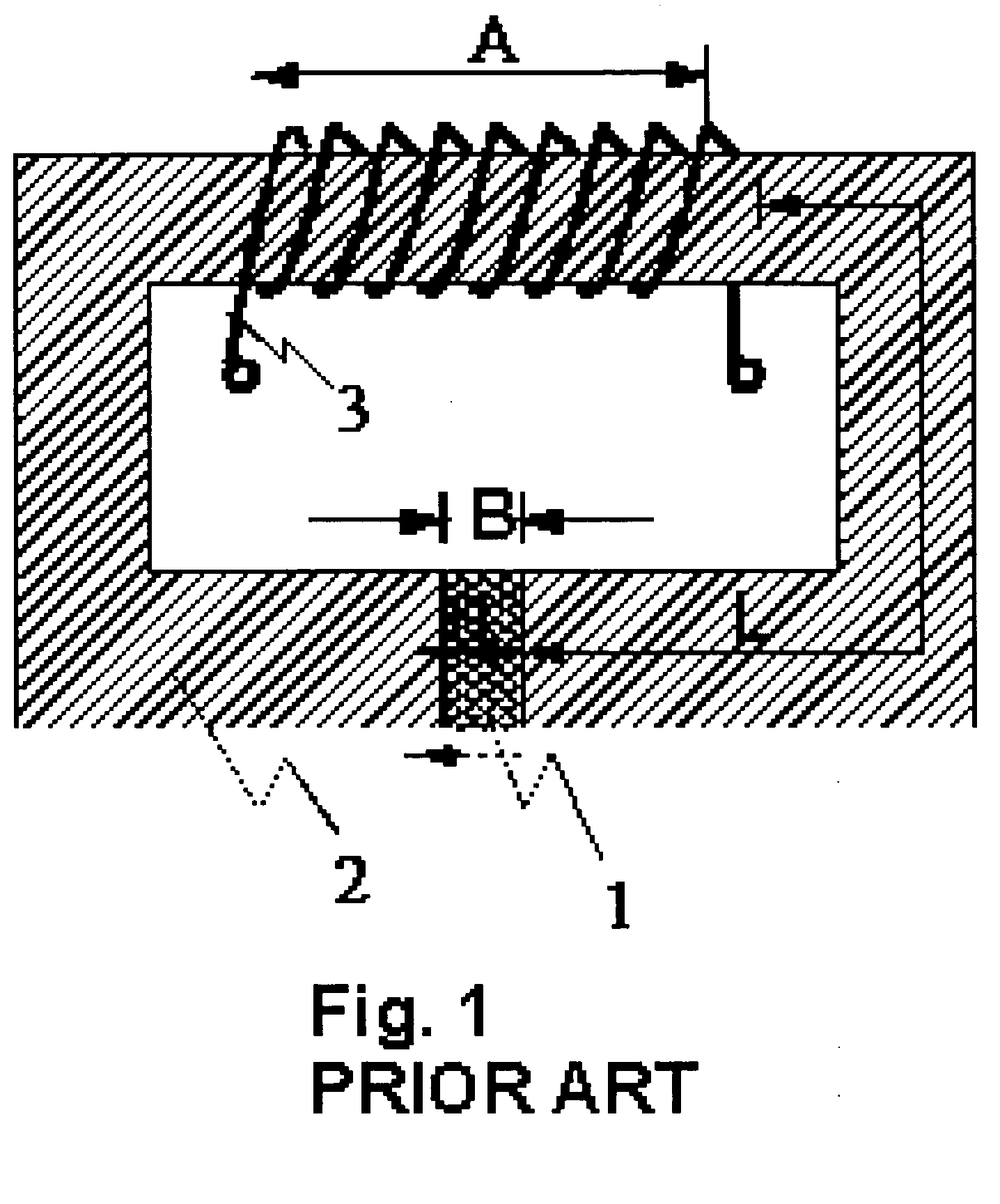

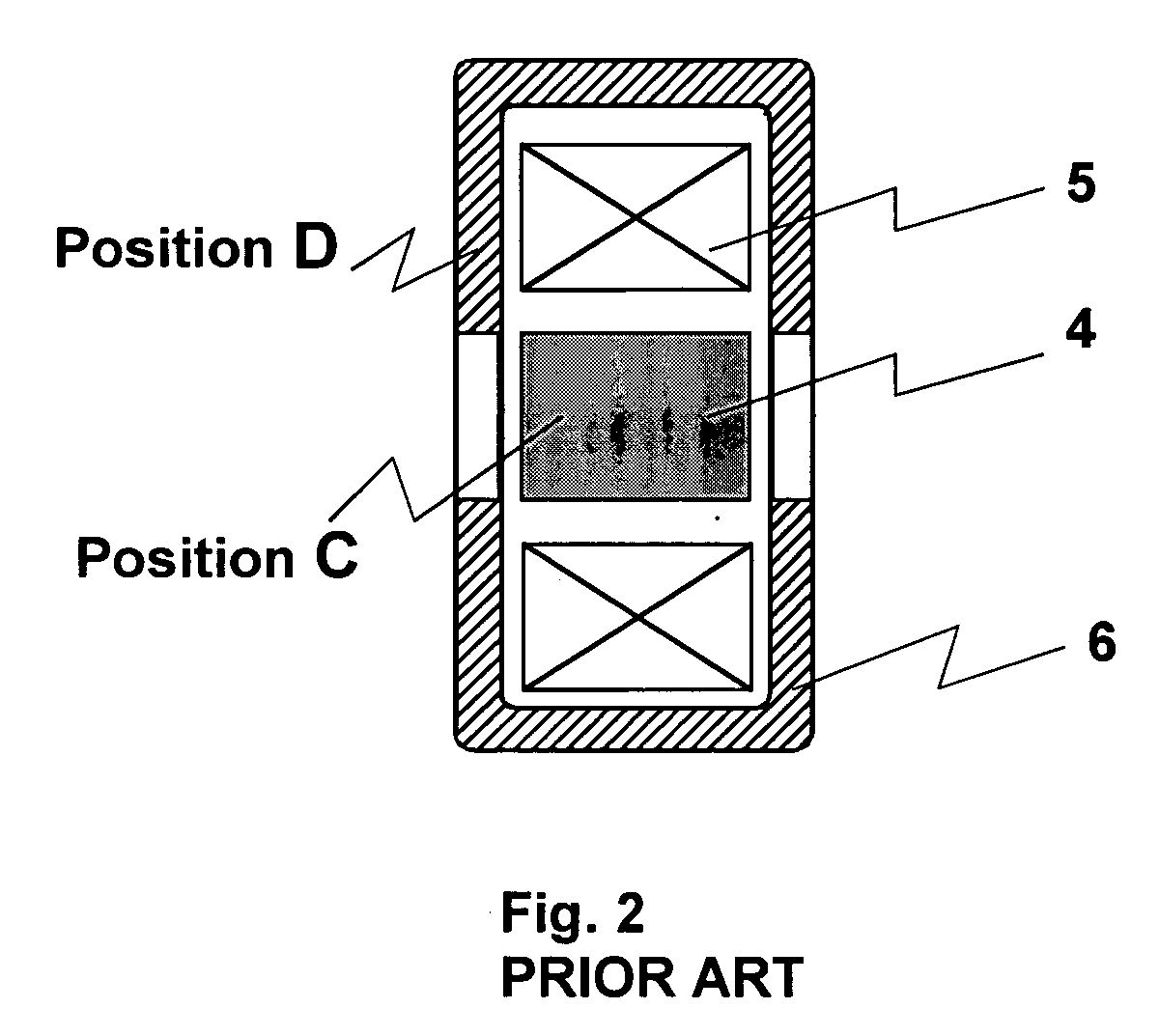

InactiveUS20050117218A1Reduce power consumptionSmall profileElectromagnets without armaturesPolarising elementsEnergy transferWire gauge

The present invention relates to the. use of optimized magnet design, magnetic circuit design and wire coil design to improve latching reliability and reduce driving current for the switchable Faraday rotator devices. The geometrical parameters of semi-hard magnet are optimized to produce maximal magnetic field at the location of magneto-optic crystal and hence improve latching reliability and reduce driving current. The wire coil is optimized in coil length, wire gauge, and number of turns to produce most efficient energy transfer and hence reduce driving current and driving voltage. To reduce magnetic energy loss, soft magnetic material is included to form a magnetic conductive close loop and further reduces driving current requirements.

Owner:SHANGHAI PRIMANEX PHOTOELECTRIC TECH +1

Annular axial pressing device and annular axial pressing method for transformer coil

ActiveCN105679526ASolve the problem that the winding is not tightSolve the preload problemCoils manufactureWire gaugeTransformer

The invention relates to an annular axial pressing device and an annular axial pressing method for a transformer coil. The annular axial pressing device is provided with a pressure plate and an upper hanger plate which are connected through a chain; and the lower part of the pressure plate is provided with a plurality of position adjustable pressure beams along the radial direction of the pressure plate. The method comprises the following steps: according to the inner diameter of a coil to be pre-pressed, adjusting the adjustable pressure beams of the annular axial pressing device; using a hoist to hoist the annular axial pressing device, and directly putting the annular axial pressing device on the section of the coil to be pre-pressed; controlling the pre-pressing time to be 10-20 minutes; and after the pre-pressing of the section of the coil is finished, hoisting and moving away the annular axial pressing device, so that the one-time pre-pressing process is finished. According to the annular axial pressing device and the annular axial pressing method, the pre-pressing process is realized in the coil winding process as well as after completion of winding and before demolding, so that the problem that the winding of the coil with a larger wire gauge or a special structure is not compact is solved.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD

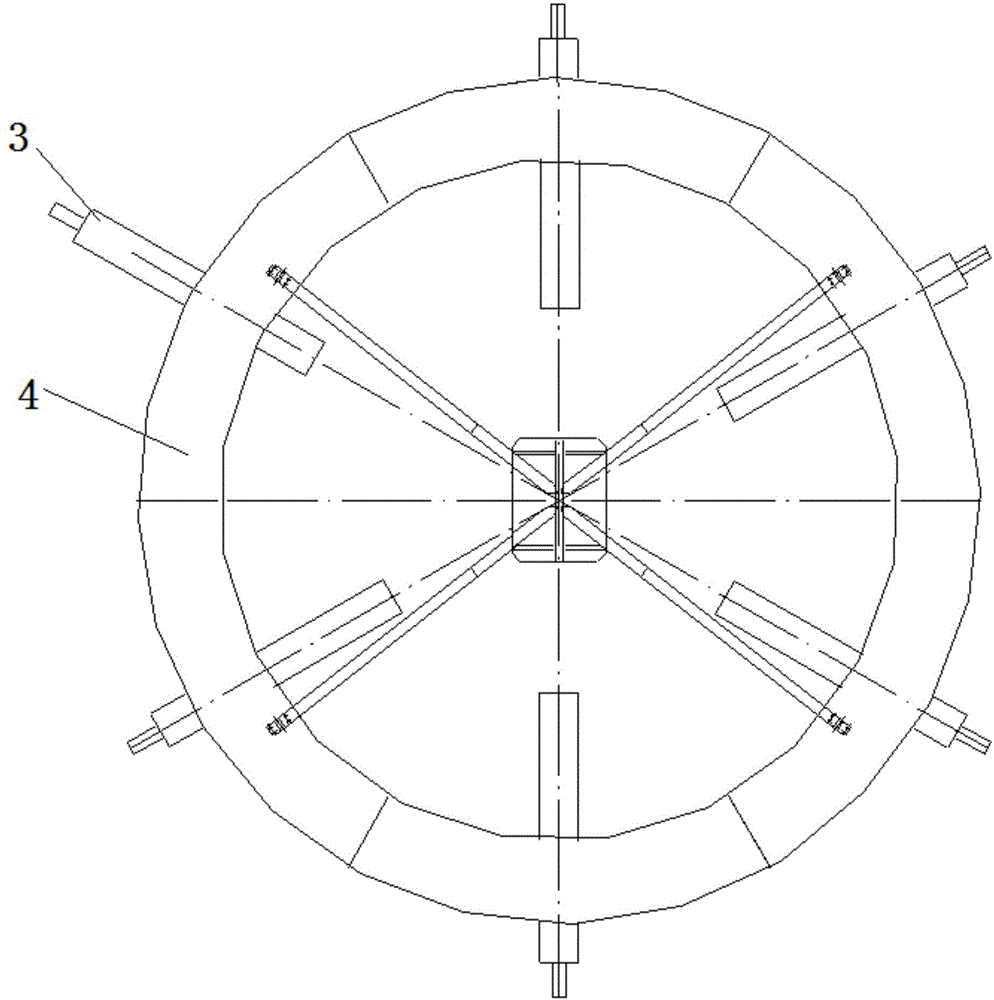

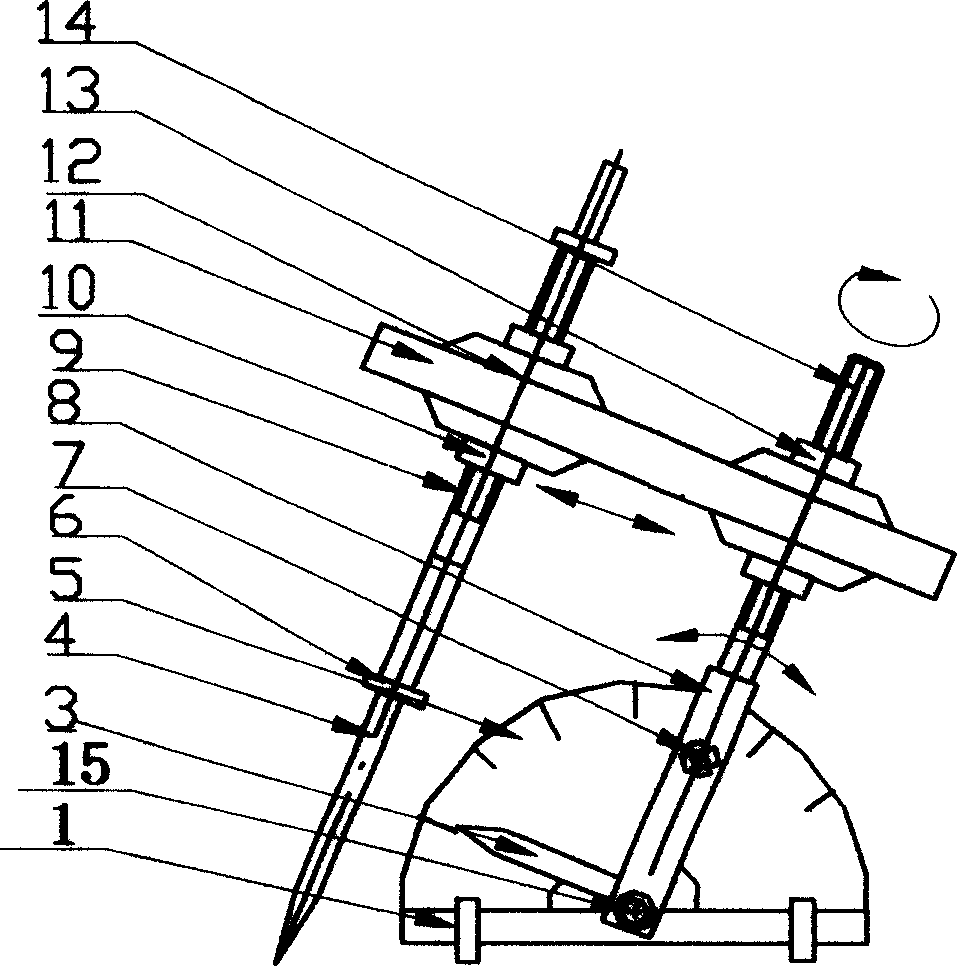

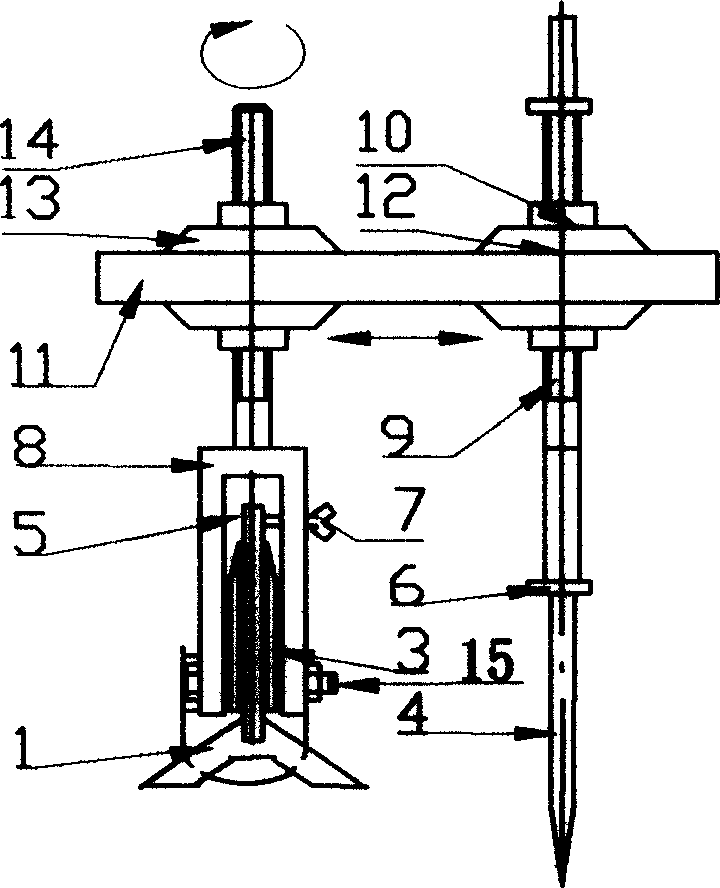

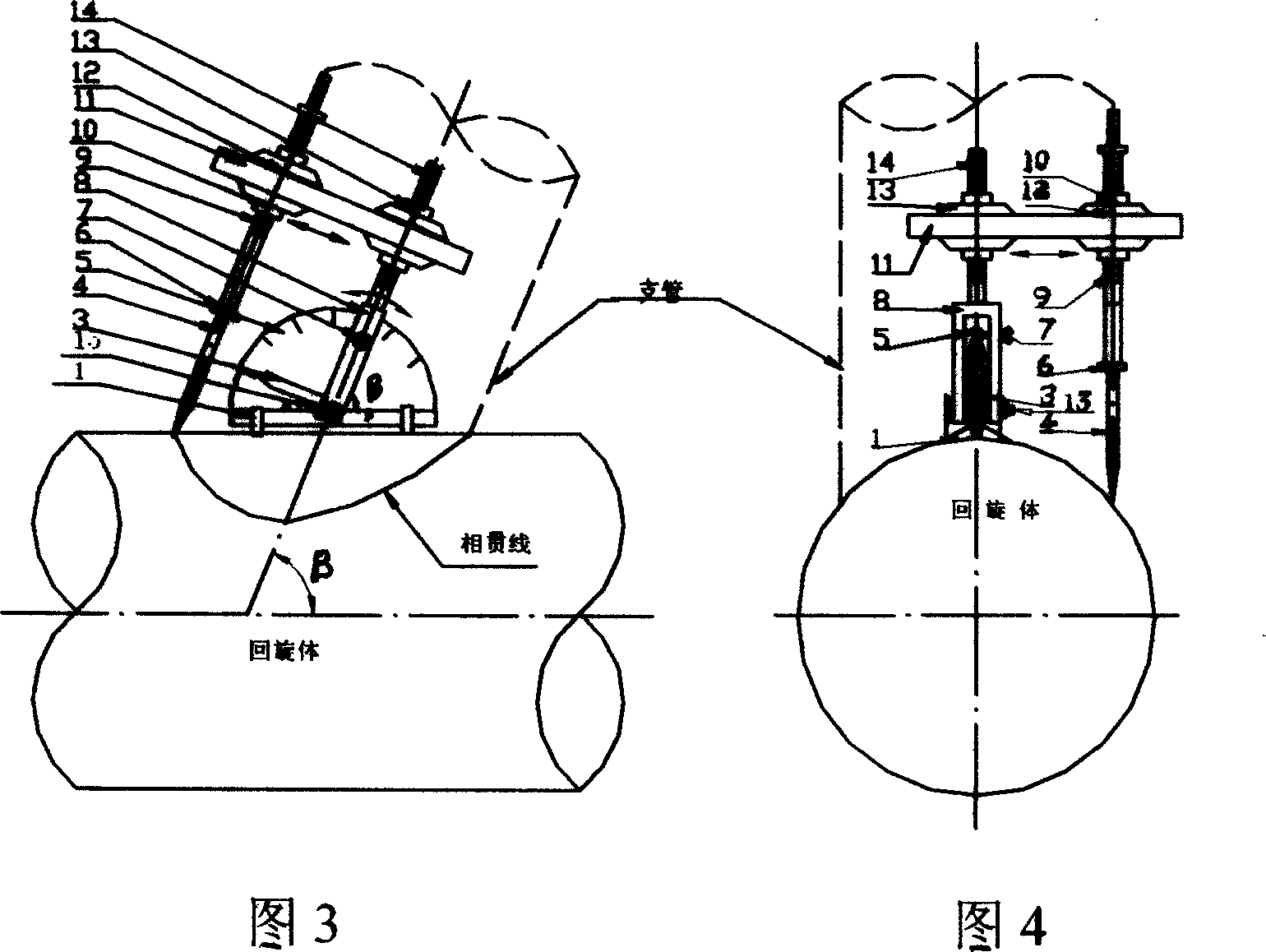

Metal plate developed intersecting line marking-gauge

The present invention relates to a sheet-metal work developed intersecting line marking gauge, and it is sued for marking out intersecting line on the surface of recovling body. Said invention is composed of the components of indicator, marking awl, scale disk, centering bush, positioning bolt, fork bar, sleeve, positioning nut, adjustable rotary frame, sizing pointer, regulating nut, adjustable screw bolt and connecting bolt. It can raise marking accuracy and efficiency, and can save sample sheet material.

Owner:ANYANG IRON & STEEL GRP

Winding mold for producing formed winding by using large-wire-gauge circular copper wires

InactiveCN107222071AGuaranteed plastic operation spaceGuaranteed sizeManufacturing dynamo-electric machinesWire gaugeCopper wire

The invention discloses a winding mold for producing a formed winding by using large-wire-gauge circular copper wires. On the basis of ensuring the cross-sectional dimension of the linear side of a coil, and an end portion layer replacement shaping groove is specially designed on an original closed pressure plate so that a shaping tool (such as shaping bar) can pass through the end portion layer replacement shaping groove, thereby greatly increasing the shaping operation space of the end portion of the coil, reducing the operational difficulty at the coil winding layer replacement position, and ensuring a coil size.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Numerical control electromagnetic brake winding tension device for distribution transformer

InactiveCN103050274AOvercome the disadvantage of unstable tensionTense to meetFilament handlingCoils manufactureWire gaugeDistribution transformer

The invention discloses a numerical control electromagnetic brake winding tension device for a distribution transformer. The numerical control electromagnetic brake winding tension device comprises a controller, an enameled round wire tension mechanism, a paper-covered flat wire tension mechanism, an enameled wire guide mechanism, an enameled wire buffering mechanism and an outlet guide anti-twist scratch-resistant mechanism. The numerical control electromagnetic brake winding tension device for the distribution transformer is in high-low voltage integrated design, electromagnetic force is used for braking, brake force can be remotely regulated and controlled by a numerical control system, wires are tensioned by electromagnetic brake, enameled wires and paper-covered wires can be wound and tensioned by various wire gauges, tensile force can be remotely regulated and controlled, the brake force is stable, and the tension device has anti-damage, anti-loose and anti-twist functions for the wires. The tension device is convenient and simple to operate and safe to use, and overcomes the shortcomings that a pneumatic tension device is affected by an air source, and tensile force applied to the wires in unstable. The tension device is applicable to products such as S11 and S13 oil-immersed distribution transformers, an SH15 amorphous alloy distribution transformer, a dry transformer, a prefabricated substation and a combined transformer.

Owner:HAINAN WEITE ELECTRIC GRP CO LTD

Using method for semi-automatic frame combined welding tool

InactiveCN105081649AReduce distortionEasy to moldWelding/cutting auxillary devicesAuxillary welding devicesWire gaugeSemi automatic

The invention discloses a using method for a semi-automatic frame assembly welding tool. The using method comprises: arranging a wire gauge below a frame combined welding tool, respectively arranging three sections of mobile stations on the wire gauge, and arranging at least one movable chassis tool assembly platform above the wire gauge; arranging a chassis assembly welding station in front of a central assembly welding station, arranging an assembly replacing station behind the central assembly welding station, and symmetrically arranging symmetrical lines of a left door frame assembly welding station and a right door frame assembly welding station at the two sides of the central assembly welding station; and during working, placing the chassis tool assembly platform into a chassis tool assembly, moving the chassis tool assembly platform to a central assembly welding station by virtue of the wire gauge and stopping the chassis tool assembly platform after assembly welding is completed, then, turning over a left door frame and a right door frame to correspond to each other respectively by virtue of a left door frame tool assembly locating rack and a right door frame tool assembly locating rack, pushing a left door frame and a right door frame to clamp by virtue of a hydraulic device, and locating a locating pin and a locating pin base of a beam to carry out assembly welding. According to the using method, the structure is simple, the welding construction surface is concentrated, the frame is precisely located and the welding is automatic.

Owner:LUOYANG JINUO ELECTRIC VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com