Production method of large-scale paste chili powder

A production method and a technology for pasting chili noodles are applied in the field of large-scale production of chili noodles paste, which can solve the problems of low production efficiency, difficult preservation of fresh peppers, bad taste and the like, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

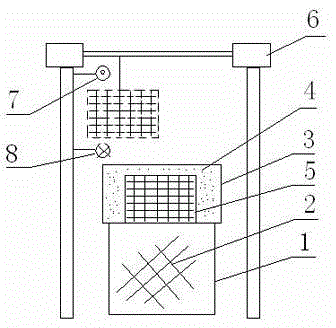

[0018] Below in conjunction with the accompanying drawings and examples, the specific implementation, features and effects of a production method for a large-scale pasted pepper noodle proposed by the present invention will be described in detail below.

[0019] see figure 1 , a kind of production method of large-scale paste chili noodles, comprises the following steps:

[0020] (1) Put a square flat-bottomed iron pot 3 on the square stove 1, fill the flat-bottomed iron pot 3 with 1 / 2-2 / 3 firewood ash 4, use firewood 2 as fuel in the square stove 1, put the flat-bottomed iron pot 3 Firewood ash 4 combustion; Combustion temperature 140-160 ° C;

[0021] (2) Use a square barbed wire frame 5 with a size of 1 / 2-2 / 3 of a flat iron pan, and fill it with selected and cleaned peppers;

[0022] (3) Remove the burnt firewood ashes 4 in the pan 3, put the wire mesh frame 5 filled with peppers, and then cover the peppers with the burning firewood ashes 4 until the peppers are cooked; ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com