Automatically telescopic universal moving bearing device

A bearing device and automatic telescopic technology, which is applied in the direction of transportation and packaging, casters, wheels, etc., can solve the problems of lack of mobile sensitivity, convenient alignment and positioning, high maintenance cost of the plant, and impact on the production environment, so as to save maintenance costs, Protect the production environment and avoid damage to the workshop floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

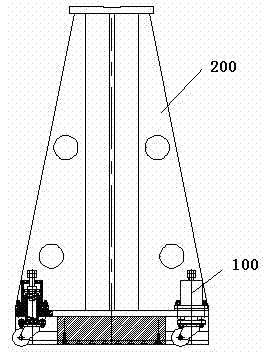

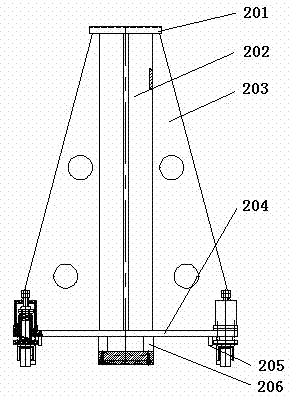

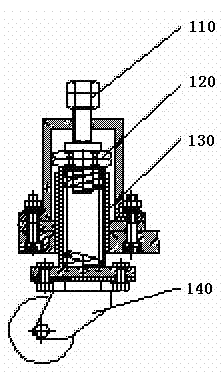

[0021] Referring to the accompanying drawings, this embodiment includes a car pier 200, and four sets of automatic telescopic universal moving mechanisms 100 are evenly distributed on the car pier 200, and the automatic telescopic universal moving mechanism 100 is composed of a spring force adjustment mechanism 110, a stop A fixed mechanism 120, a telescopic mechanism 130 and a universal wheel assembly 140; the spring force adjustment mechanism 110 includes an outer cover 111, an adjustment screw 112, a lock nut 113, a spring washer 114 and a telescopic spring 115, and the outer cover 111 is fixed On the pier 200, the adjustment screw 112 is installed on the outer cover 111, and the telescopic spring 115 is fastened by the spring washer 114. The telescopic spring 115 is installed in the telescopic mechanism 130, and the lock nut 113 is installed on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com