Method and system for treating load type palladium-contained dead catalyst

A waste catalyst and supported technology, which is applied in the chemical industry, can solve the problems of difficult filtration, palladium entry, and inapplicability of waste catalysts, so as to improve the use efficiency, reduce the treatment cost, and achieve the effect of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

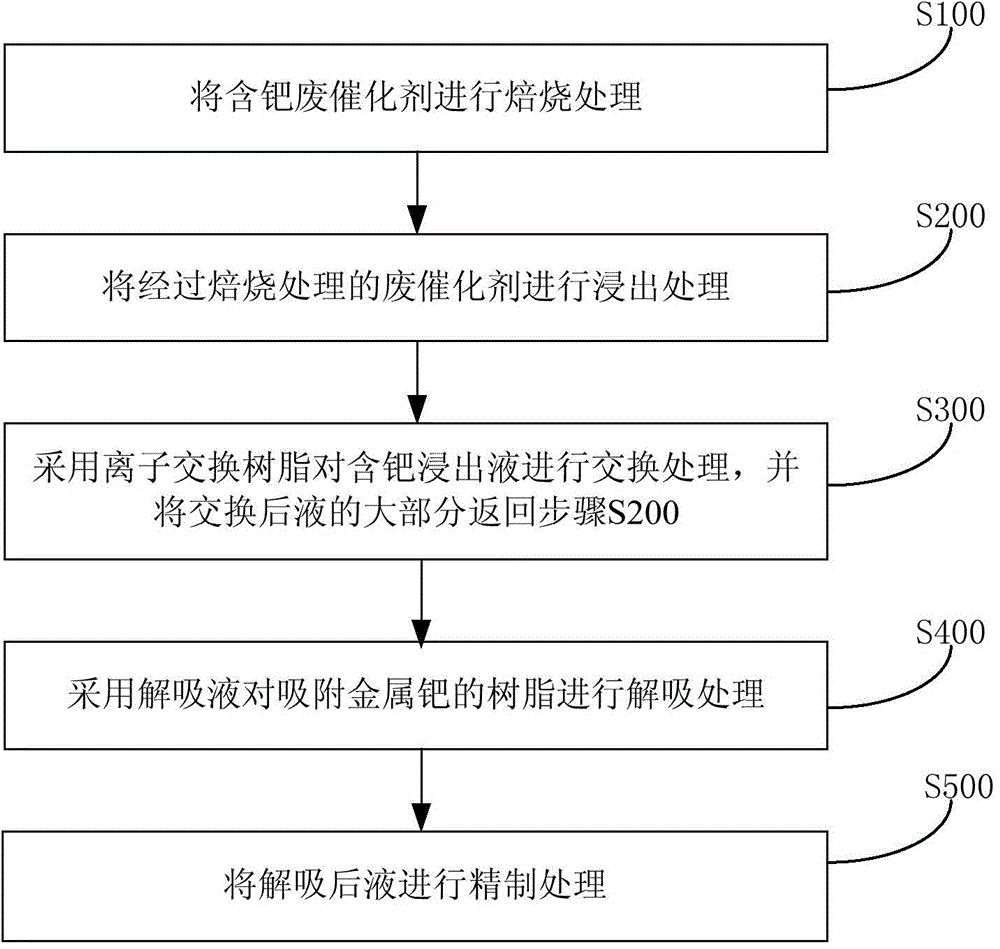

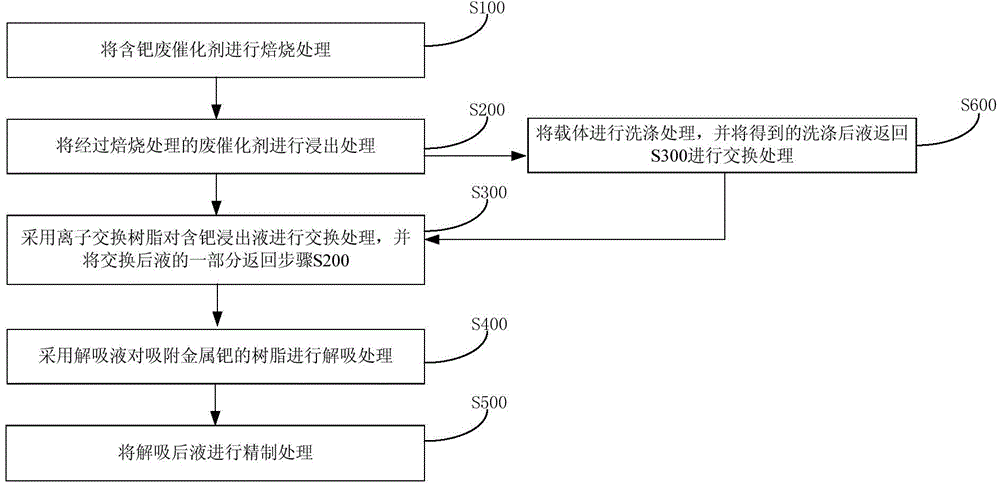

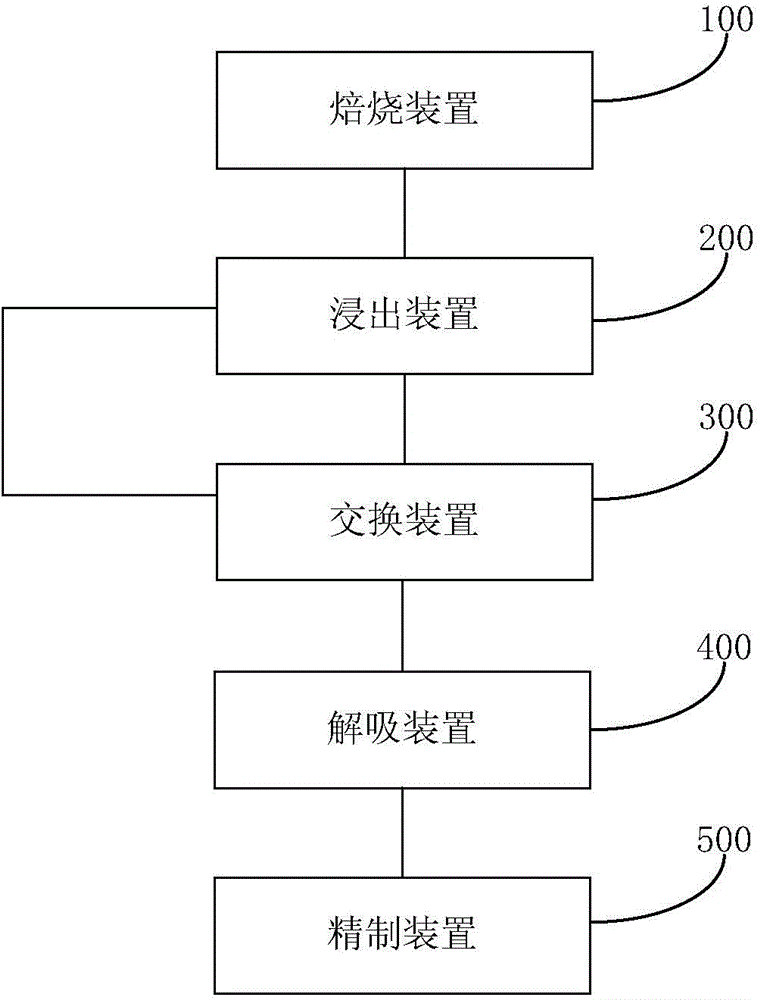

[0049] In one aspect of the present invention, the present invention provides a method for treating supported palladium-containing spent catalyst. According to an embodiment of the present invention, the carrier of the supported spent catalyst can be α-Al 2 o 3 or SiO 2 -α-Al 2 o 3 , it should be noted that SiO 2 -α-Al 2 o 3 Can be understood as containing SiO 2 and α-Al 2 o 3 mixture. Refer below Figure 1-2 The method for treating the supported palladium-containing spent catalyst according to the embodiment of the present invention is described in detail. According to a specific embodiment of the invention, the method includes:

[0050] S100: Roasting the spent palladium-containing catalyst

[0051] According to the embodiment of the present invention, the spent catalyst containing palladium is roasted, so that the carbon deposits and organic matter in the spent catalyst can be effectively removed.

[0052] According to the embodiment of the present invention, ...

Embodiment 1

[0104] The spent supported palladium-containing spent catalyst (the carrier is SiO 2 -α-Al 2 o 3 ) was roasted at 600° C. for 3 hours under the condition of dust collection and tail gas absorption, then got 1500 grams of spent catalyst (containing palladium 0.27wt%) after roasting, and divided into 3 parts, each part of 500 grams, numbered respectively as 1#, 2#, 3#, under the condition of negative pressure and tail gas absorption, add 2L of 4.0mol / L hydrochloric acid solution to 1#, heat to 75°C, and slowly add 5-15mL of 10wt% sodium chlorate solution dropwise, After reacting for 1 hour, most of the palladium was transferred into the solution to obtain a palladium-containing leaching solution, and an ion exchange resin was used to exchange the obtained palladium-containing leaching solution to obtain the exchanged solution and the resin for adsorbing metal palladium, and return the exchanged solution to 1# for further processing. For the second leaching treatment, repeat th...

Embodiment 2

[0106] The spent supported palladium-containing spent catalyst (the carrier is SiO 2 -α-Al 2 o 3 ) was roasted at 600°C for 3 hours under the condition of dust collection and tail gas absorption, and then 18000 grams of spent catalyst (containing palladium 0.27wt%) was taken after roasting, divided into 36 parts, each 500 grams, divided into three groups of numbers, a total of 12 groups, that is, numbered 1-1, 1-2, 1-3, 2-1, 2-2, 2-3, and so on, under the condition of negative pressure and exhaust gas absorption, add to 1-1 2L of 4.0mol / L hydrochloric acid solution was heated to 75°C, and 5-15mL of 10wt% sodium chlorate solution was slowly added dropwise, reacted for 1 hour, and most of the palladium was transferred into the solution to obtain a palladium-containing leaching solution. Repeat the above operations. 1-1 Carry out two more leachings, add an appropriate amount of water to the process ratio in the process, and so on, so that the total palladium-containing leaching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com