Patents

Literature

300results about "Electrographic processes using photoelectrophoresis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrophoretic medium and process for the production thereof

InactiveUS7411719B2Static indicating devicesElectrographic processes using photoelectrophoresisElectrophoresisElectric field

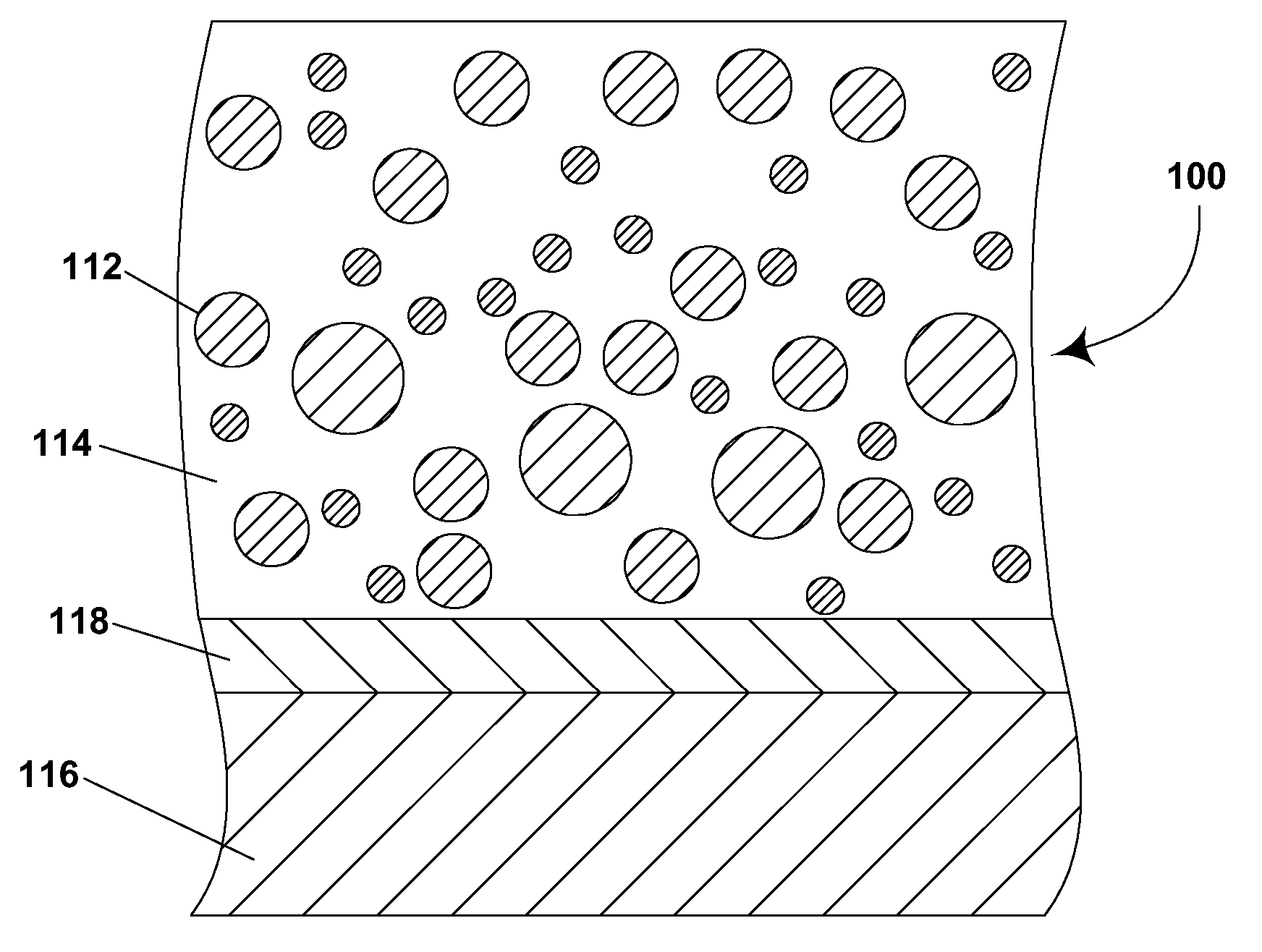

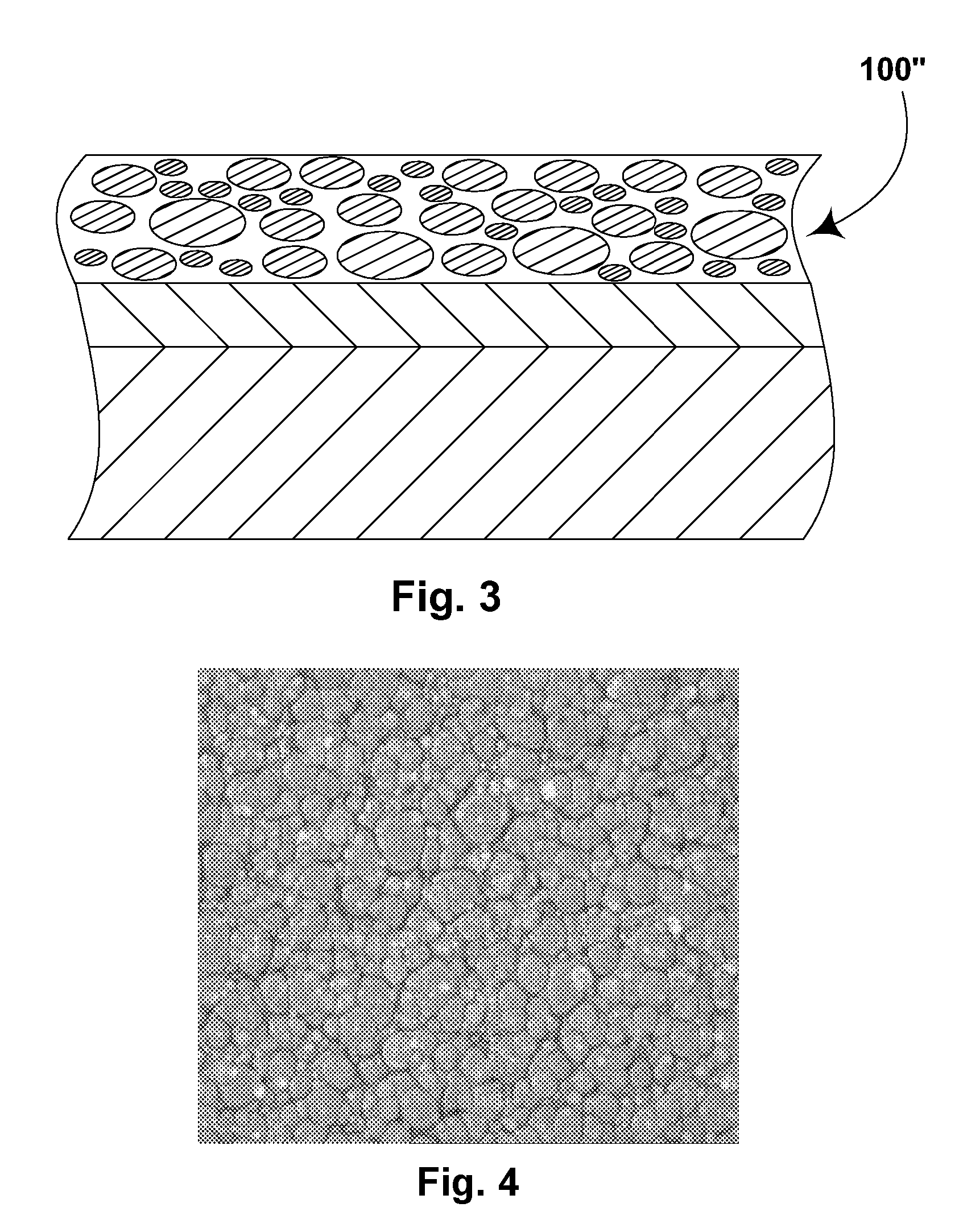

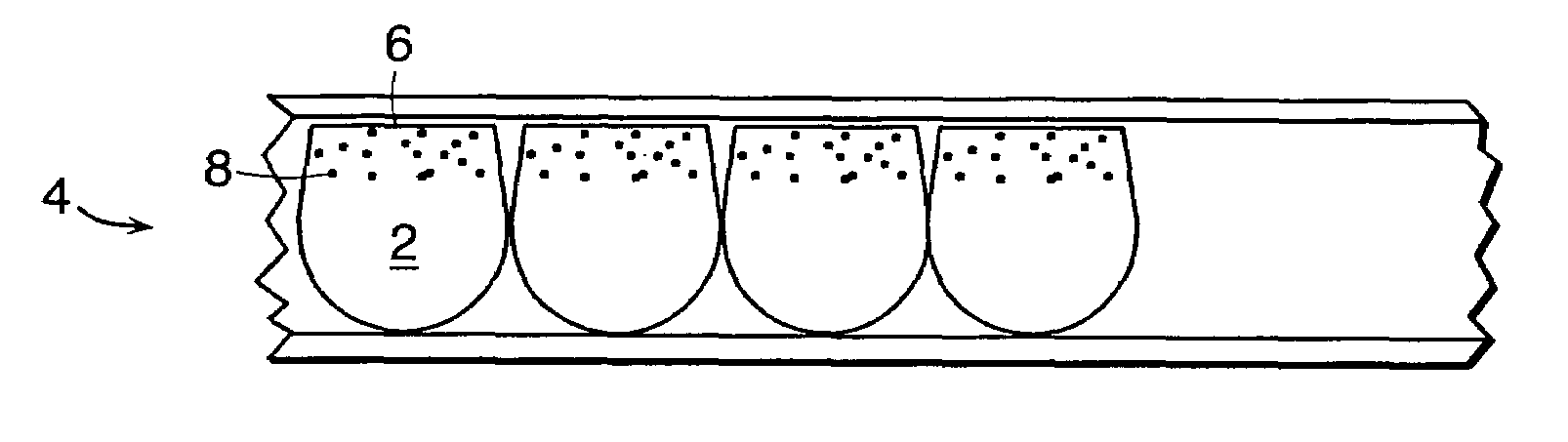

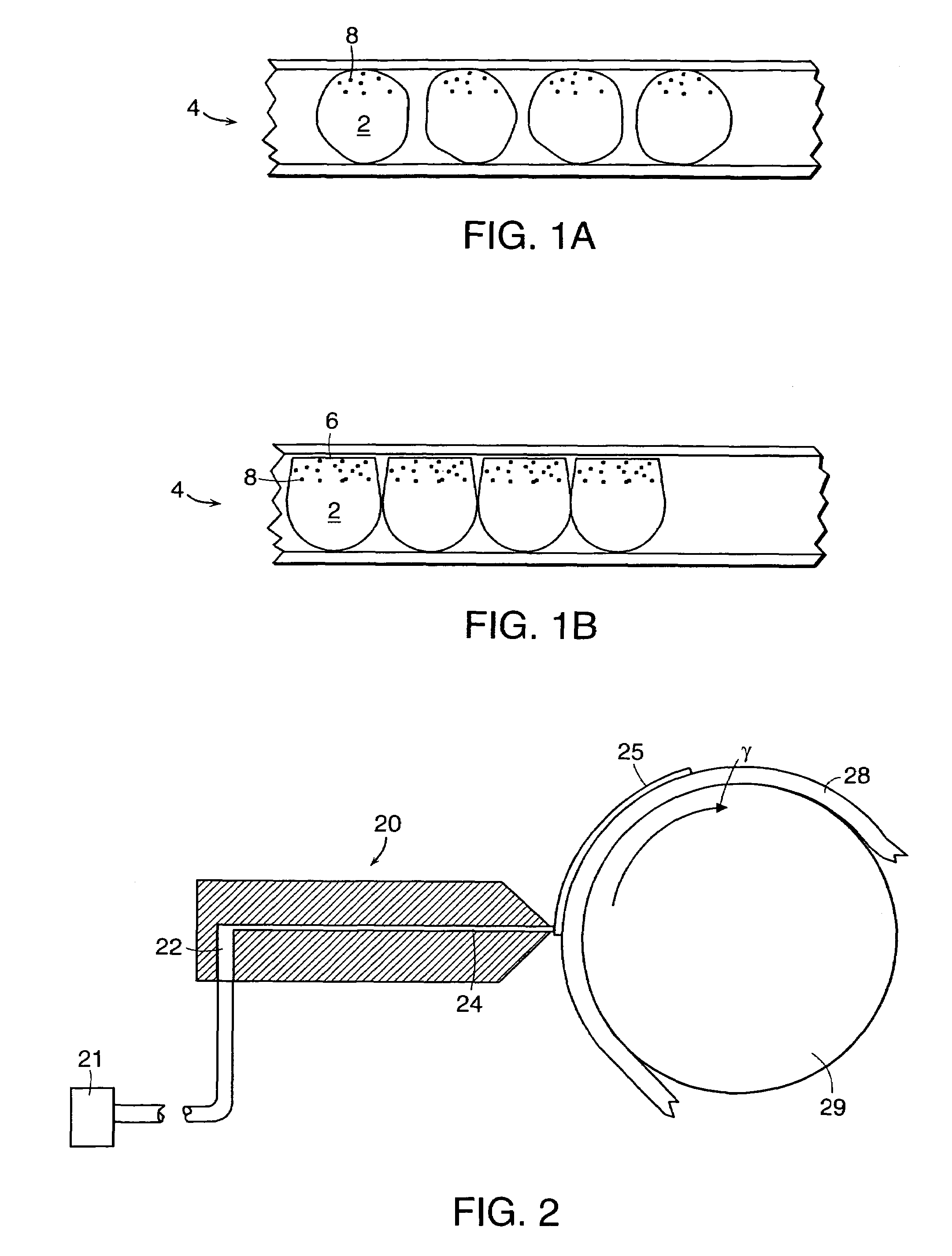

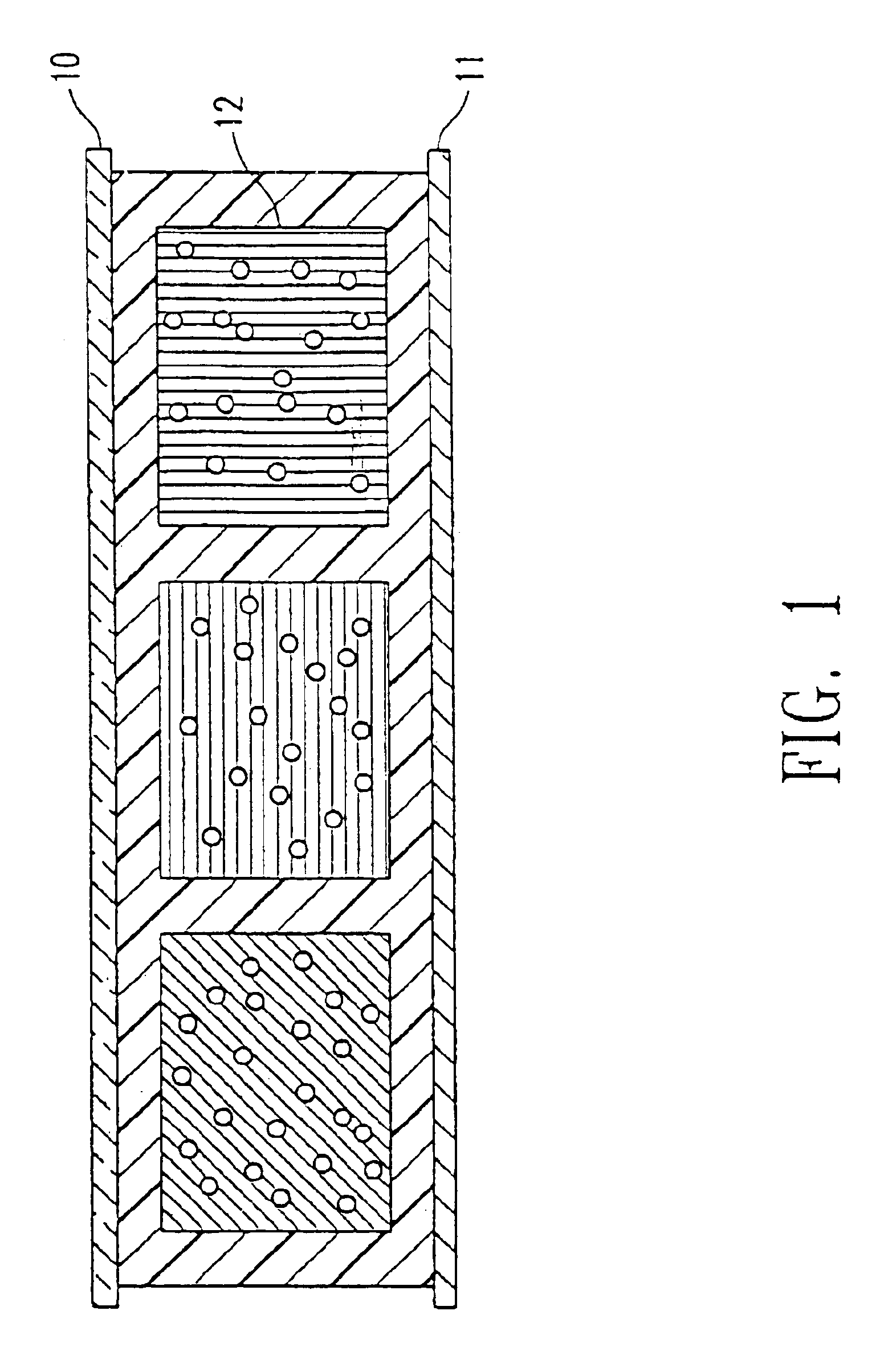

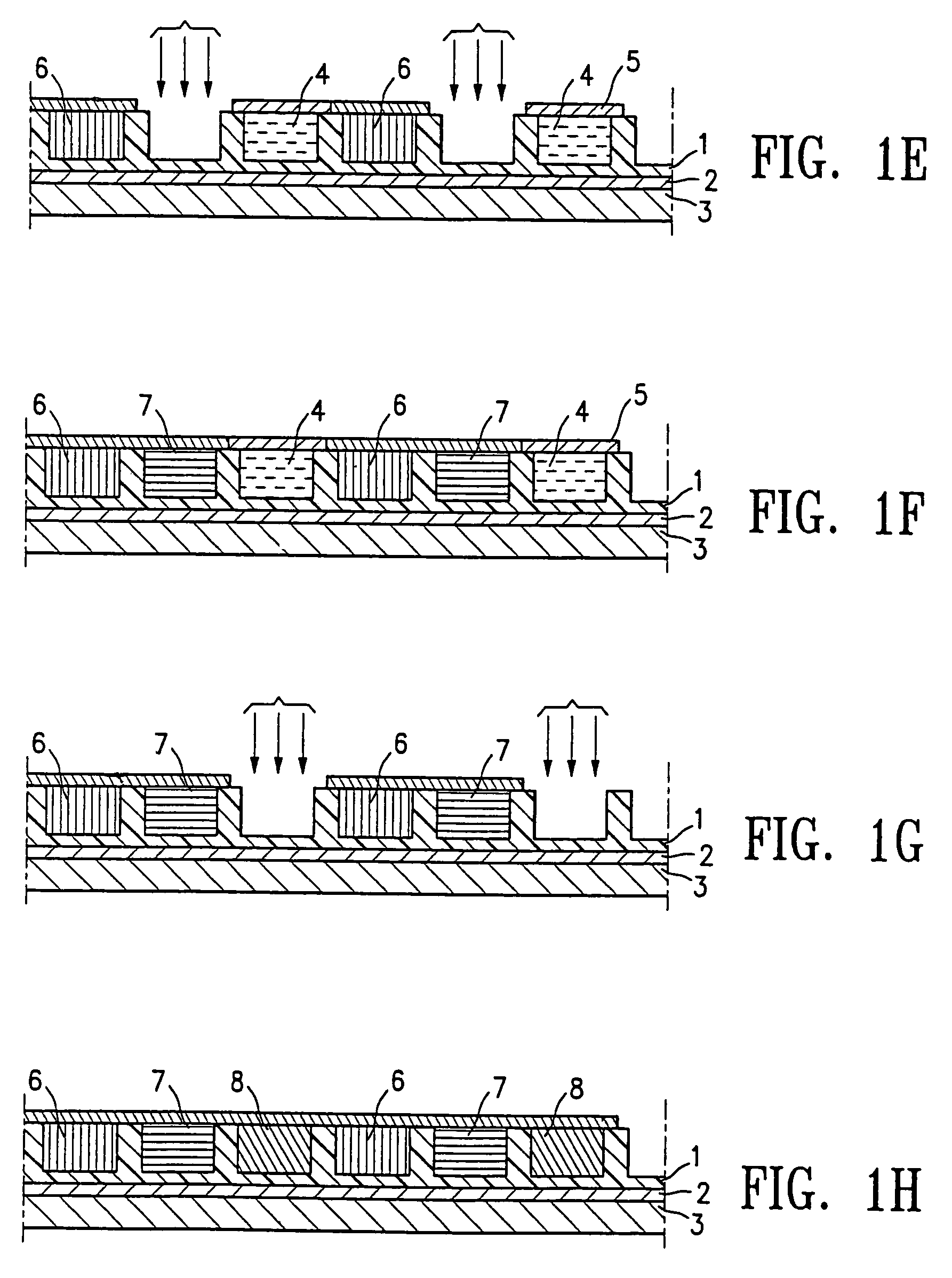

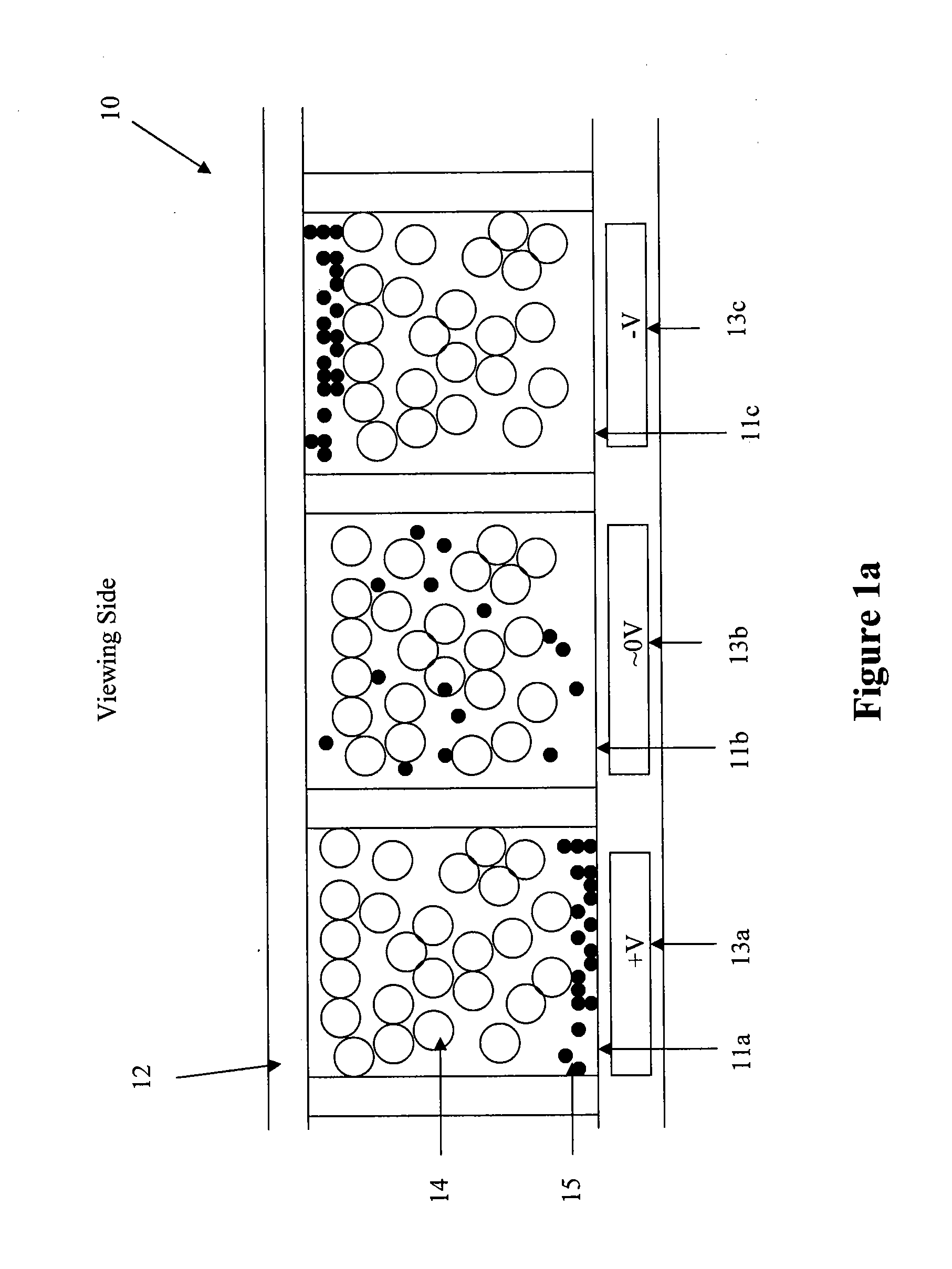

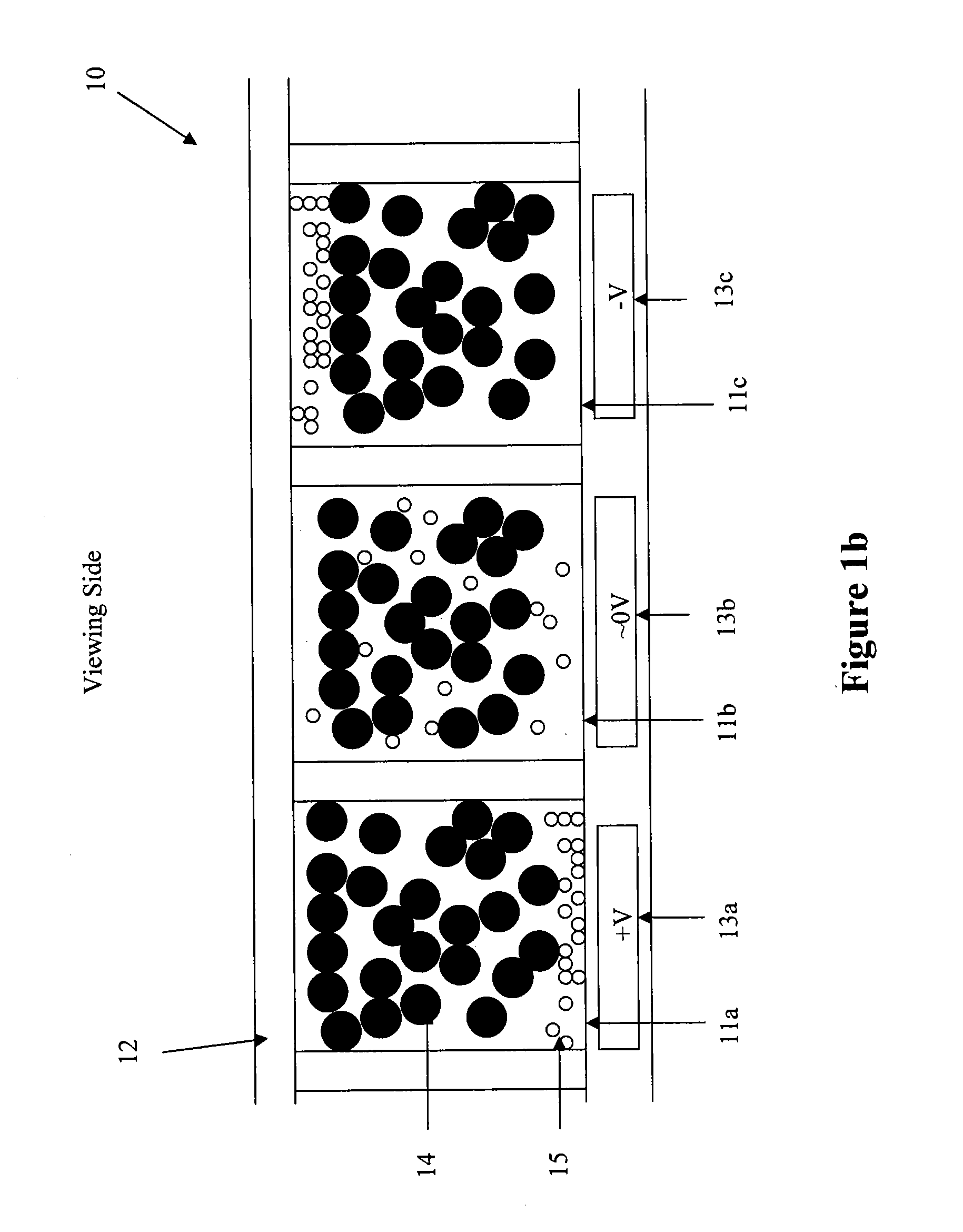

A two-phase electrophoretic medium comprises a continuous phase and a discontinuous phase. The discontinuous phase comprises a plurality of droplets, each of which comprises a suspending fluid and at least one particle disposed within the suspending fluid and capable of moving through the fluid upon application of an electric field to the electrophoretic medium. The continuous phase surrounds and encapsulates the discontinuous phase. To reduce the humidity sensitivity of the medium, a non-ionizable or crystalline polymer may be used as the continuous phase.

Owner:E INK CORPORATION

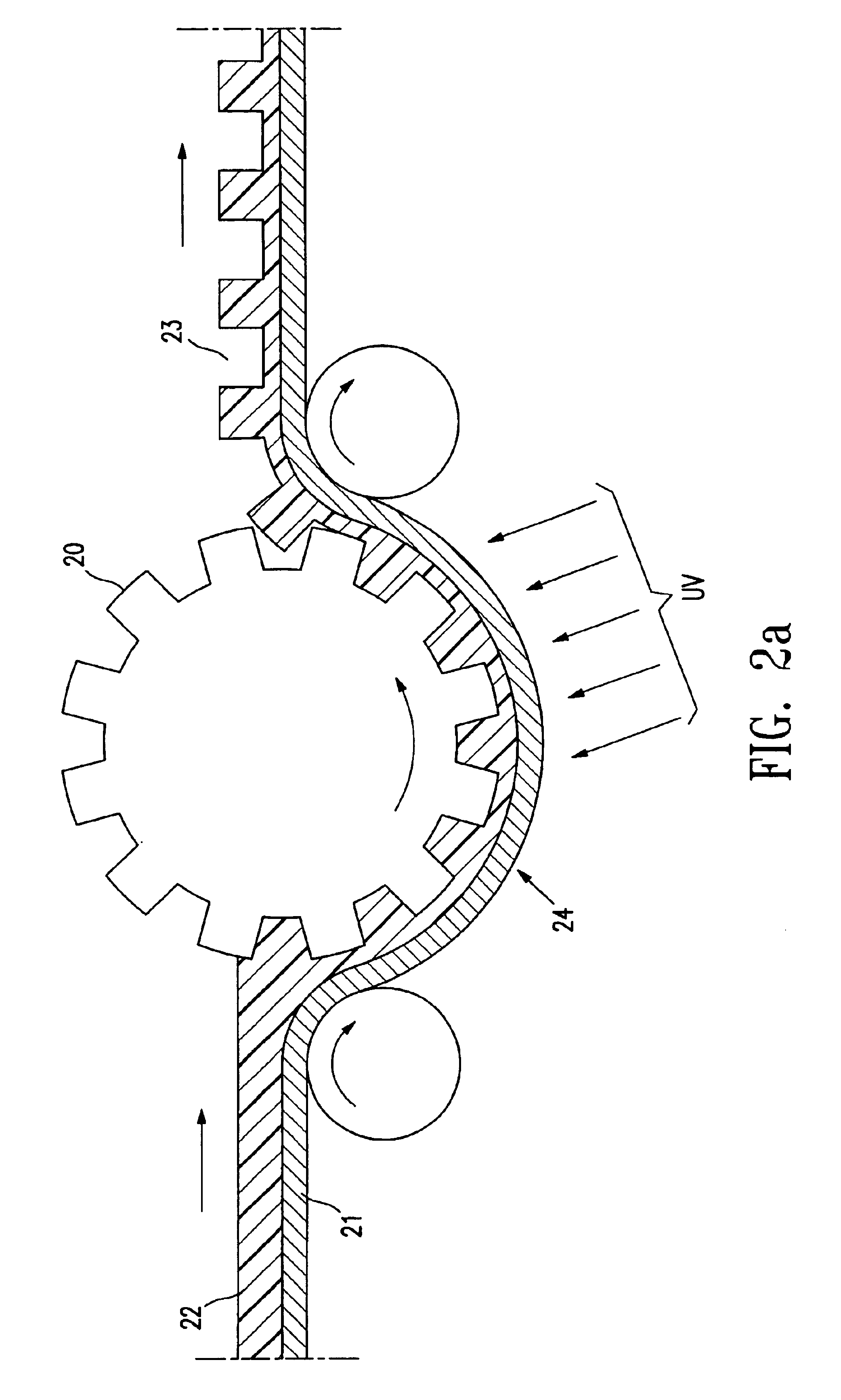

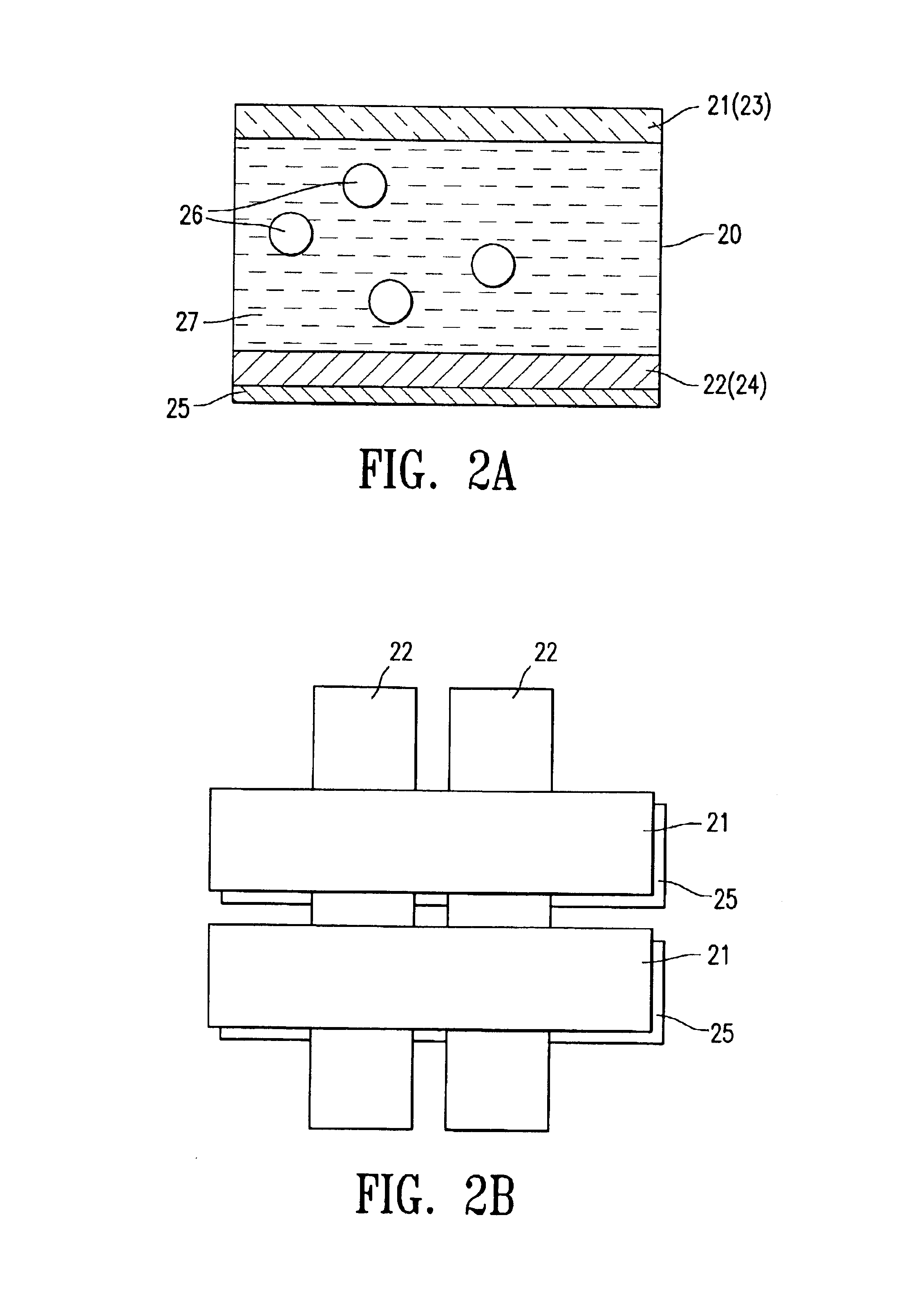

Electrophoretic display and novel process for its manufacture

InactiveUS6930818B1Excellent color addressabilityIncrease contrastStatic indicating devicesMaterial analysis by electric/magnetic meansElectrophoresesDisplay device

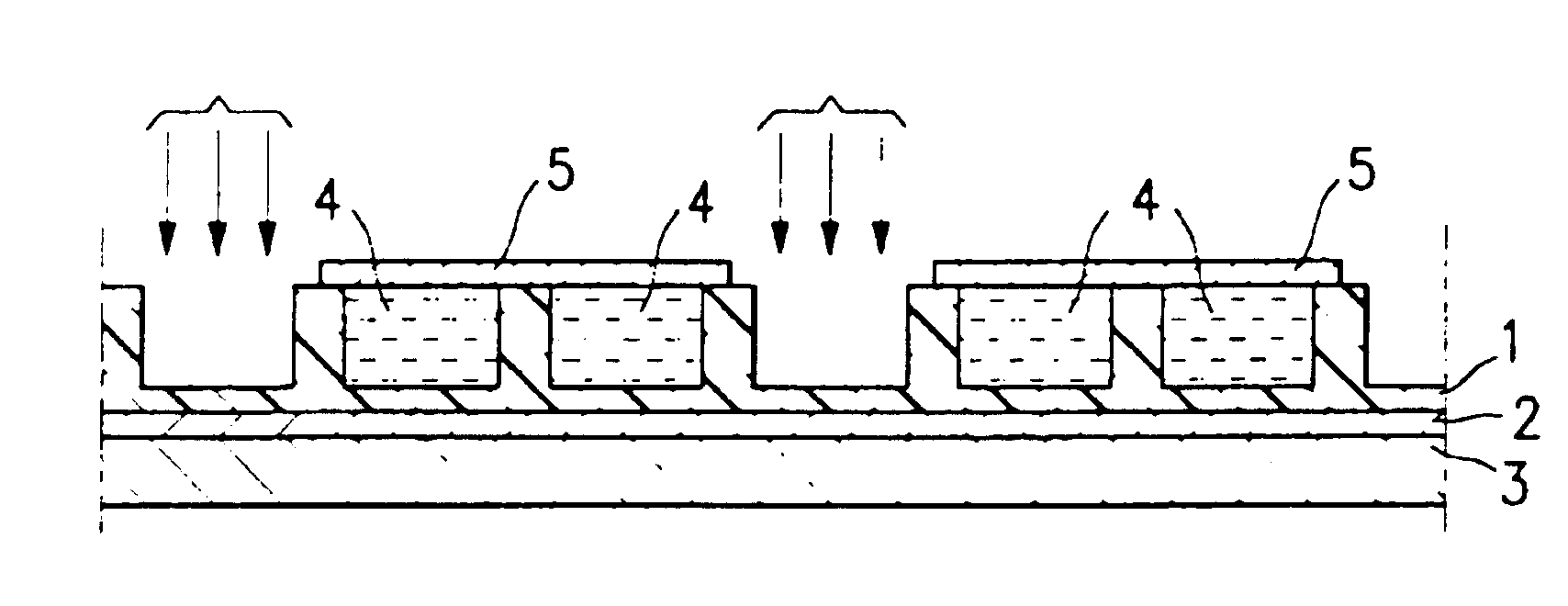

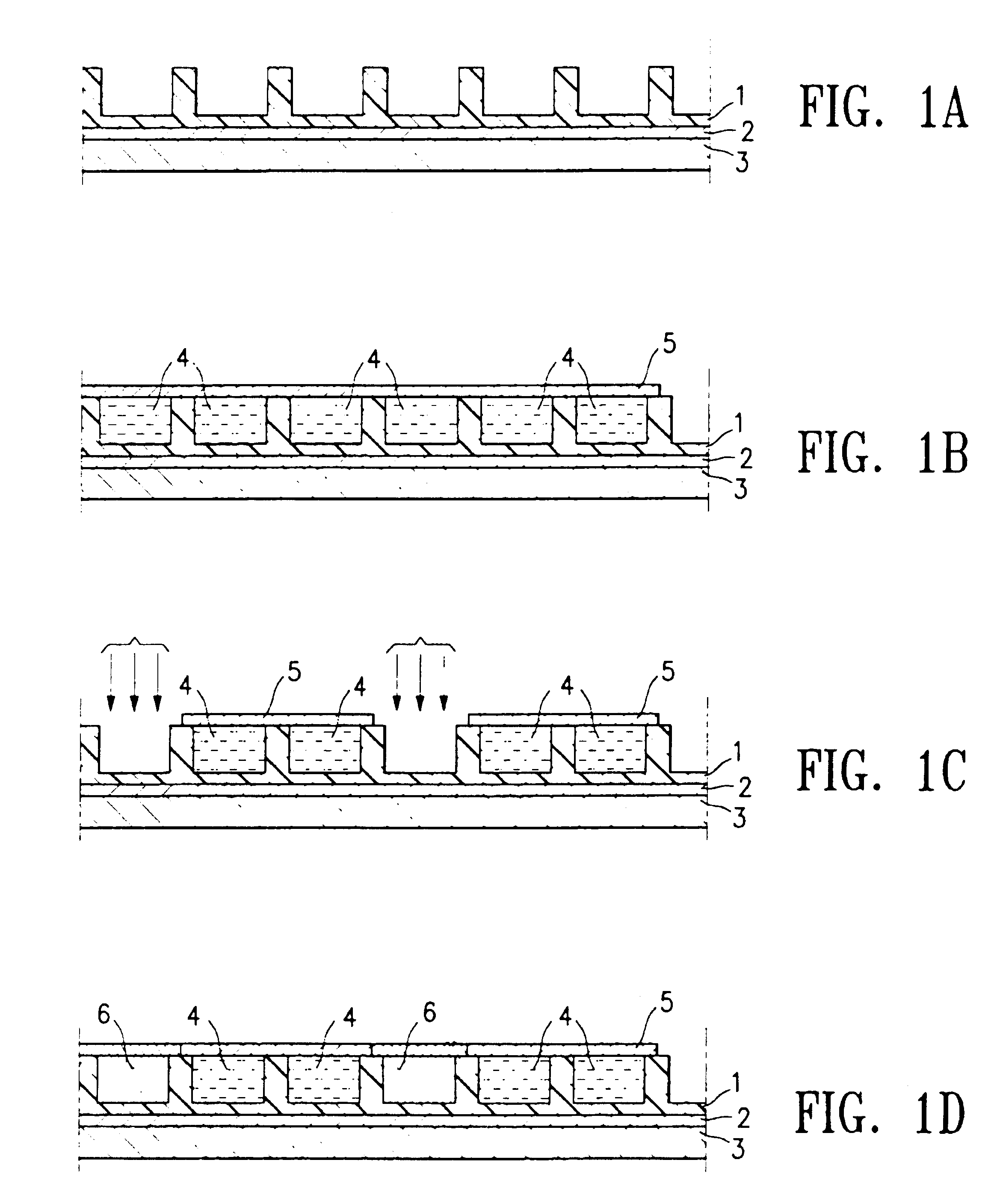

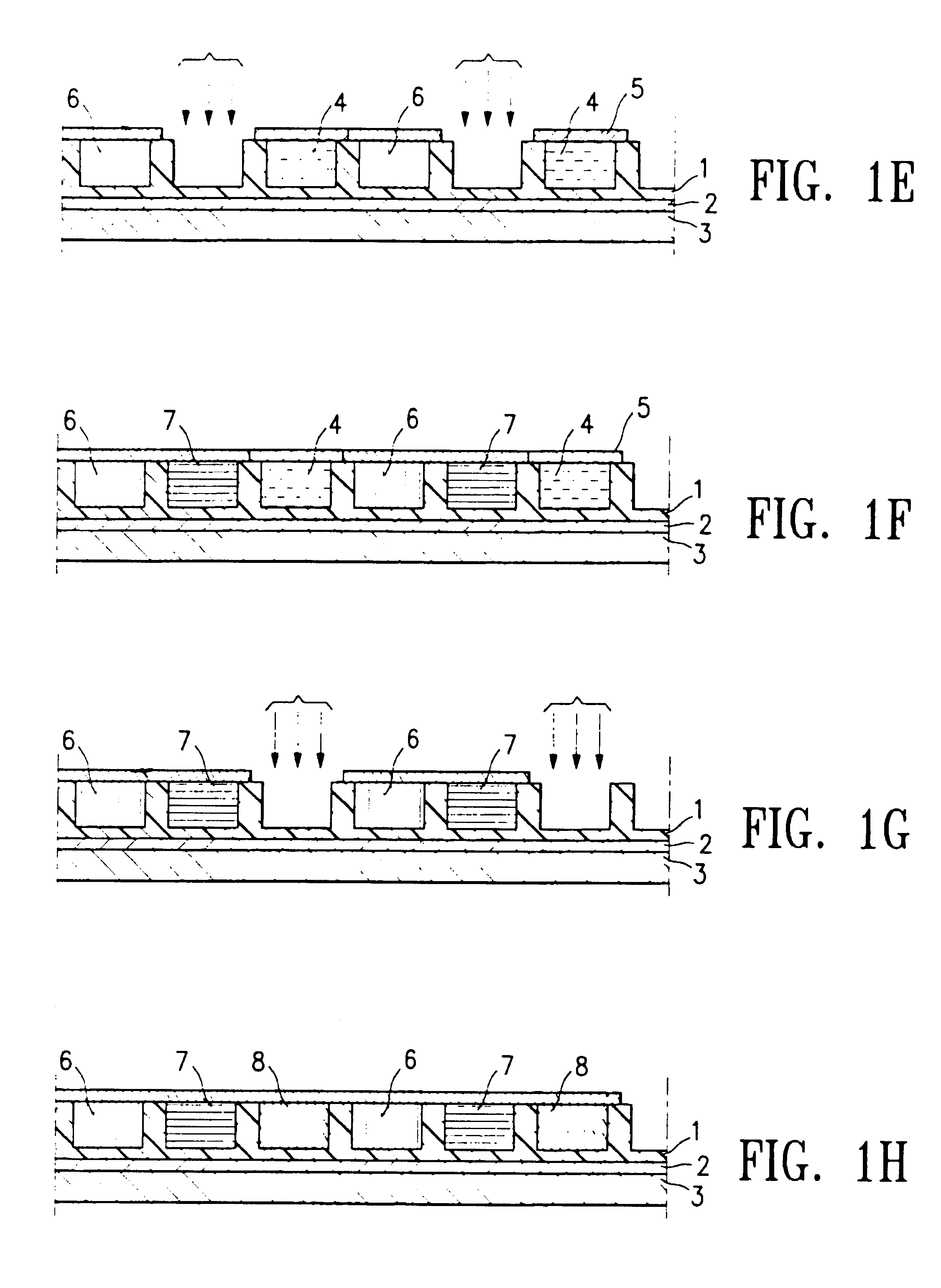

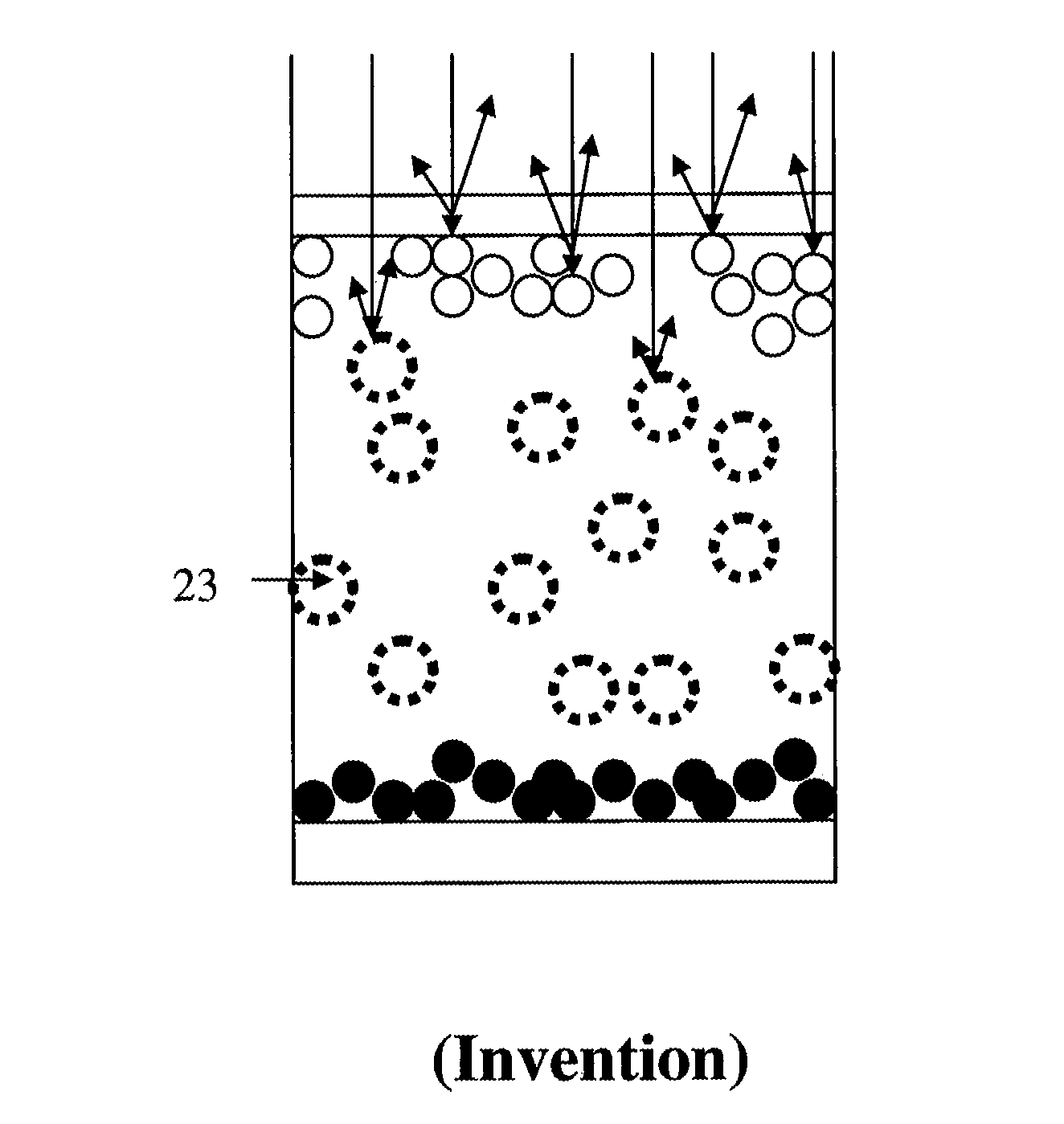

This invention relates to an electrophoretic display comprising cells of well-defined shape, size and aspect ratio which cells are filled with charged pigment particles dispersed in a solvent, and novel processes for its manufacture.

Owner:E INK CALIFORNIA

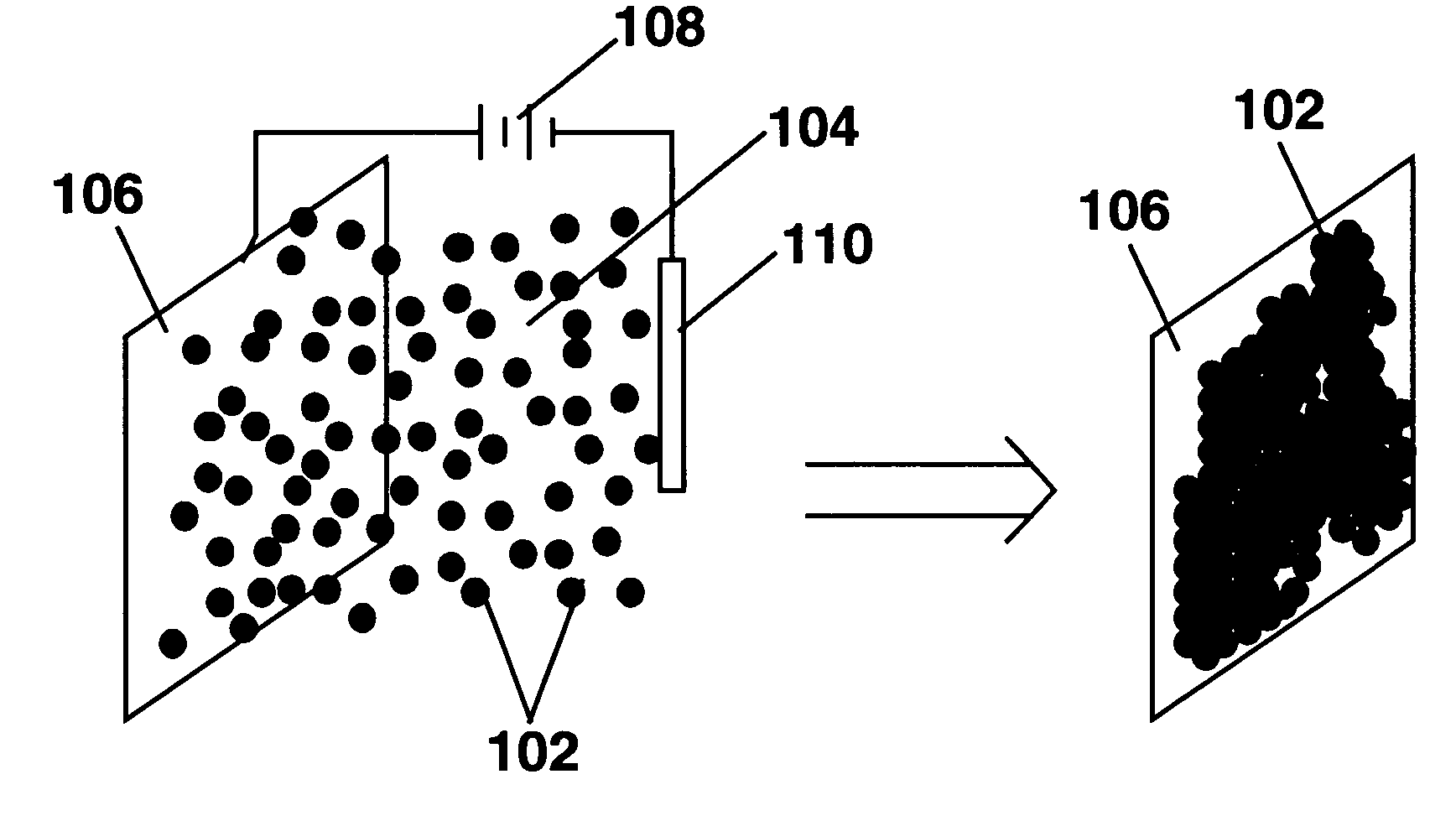

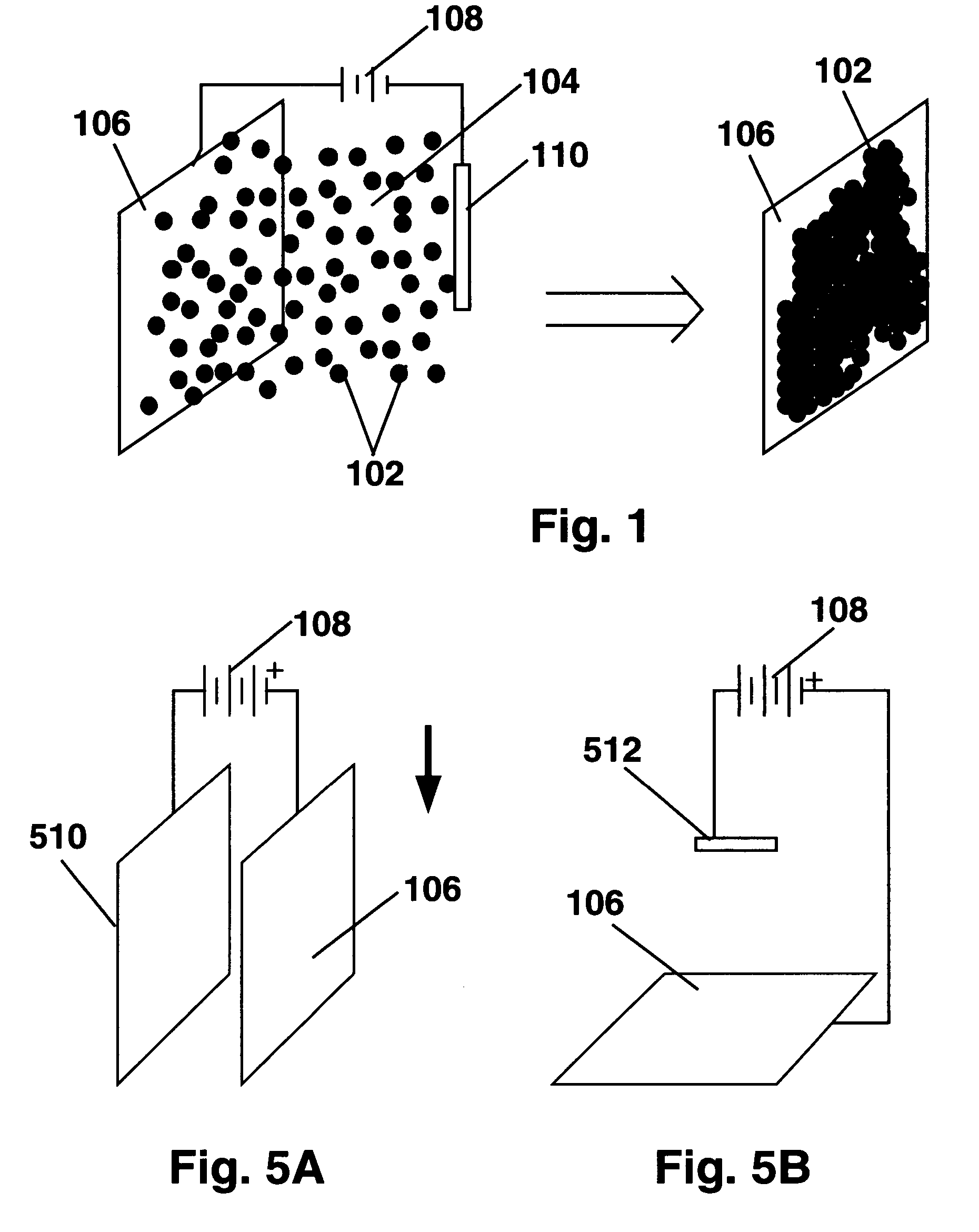

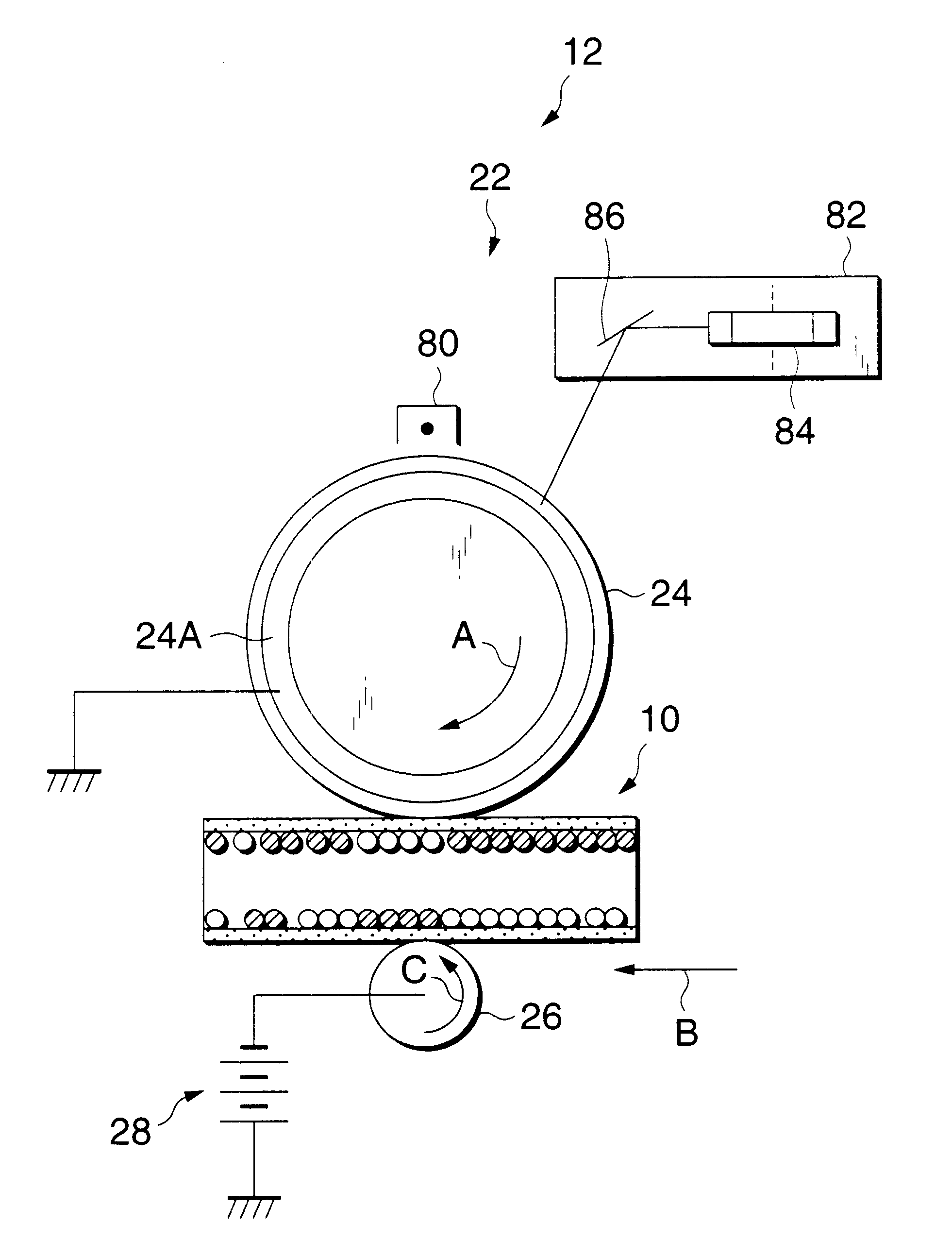

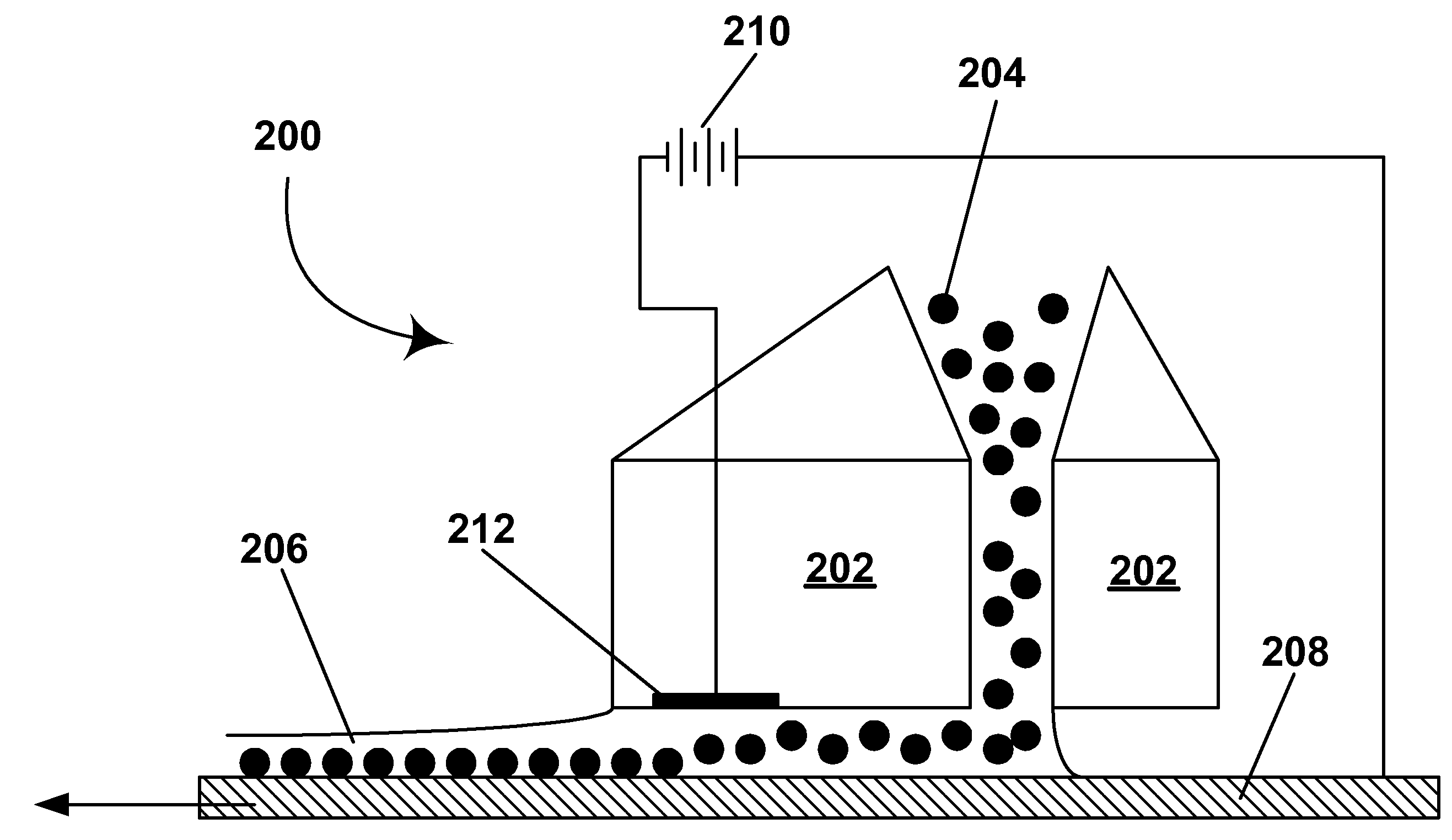

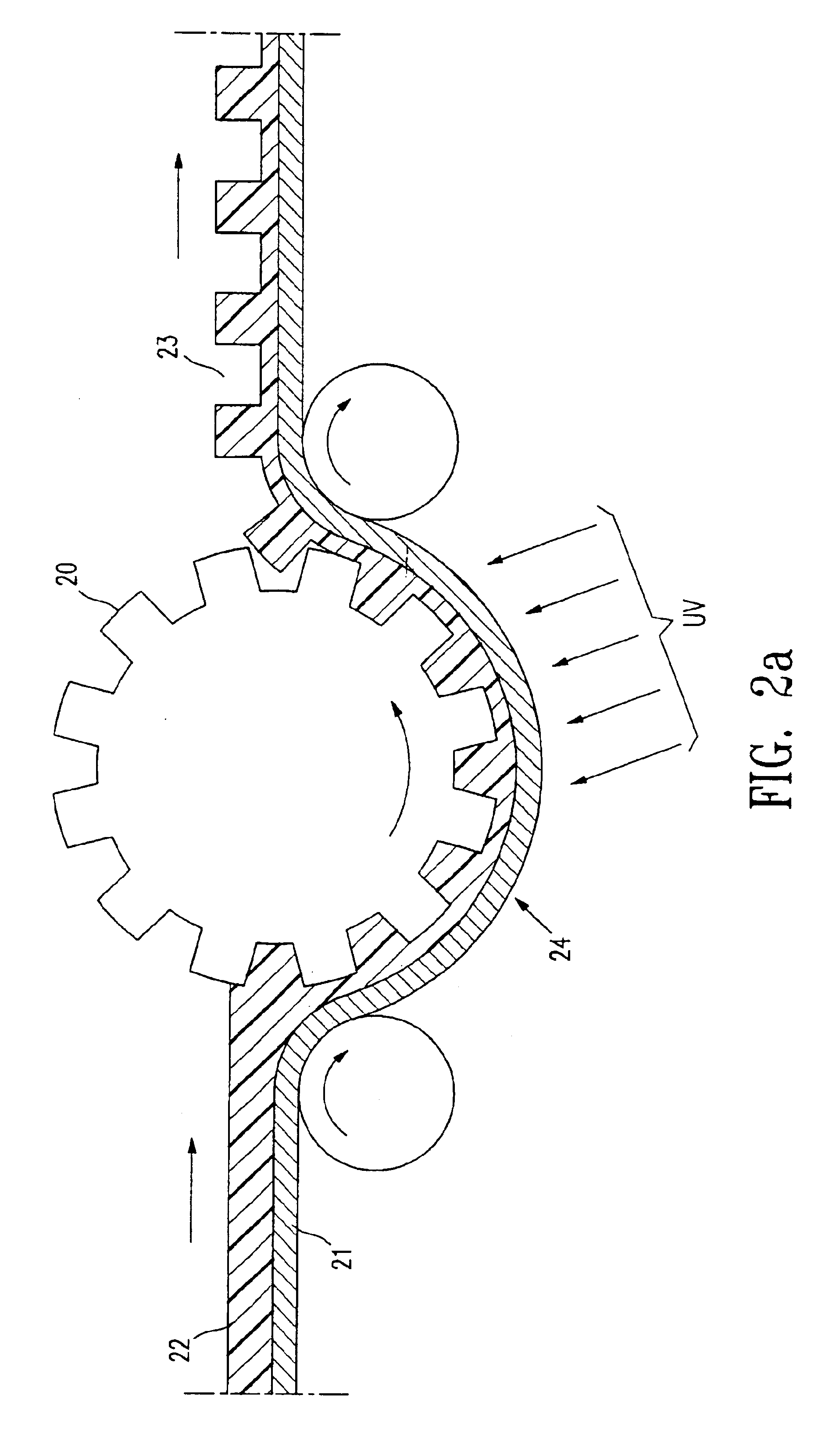

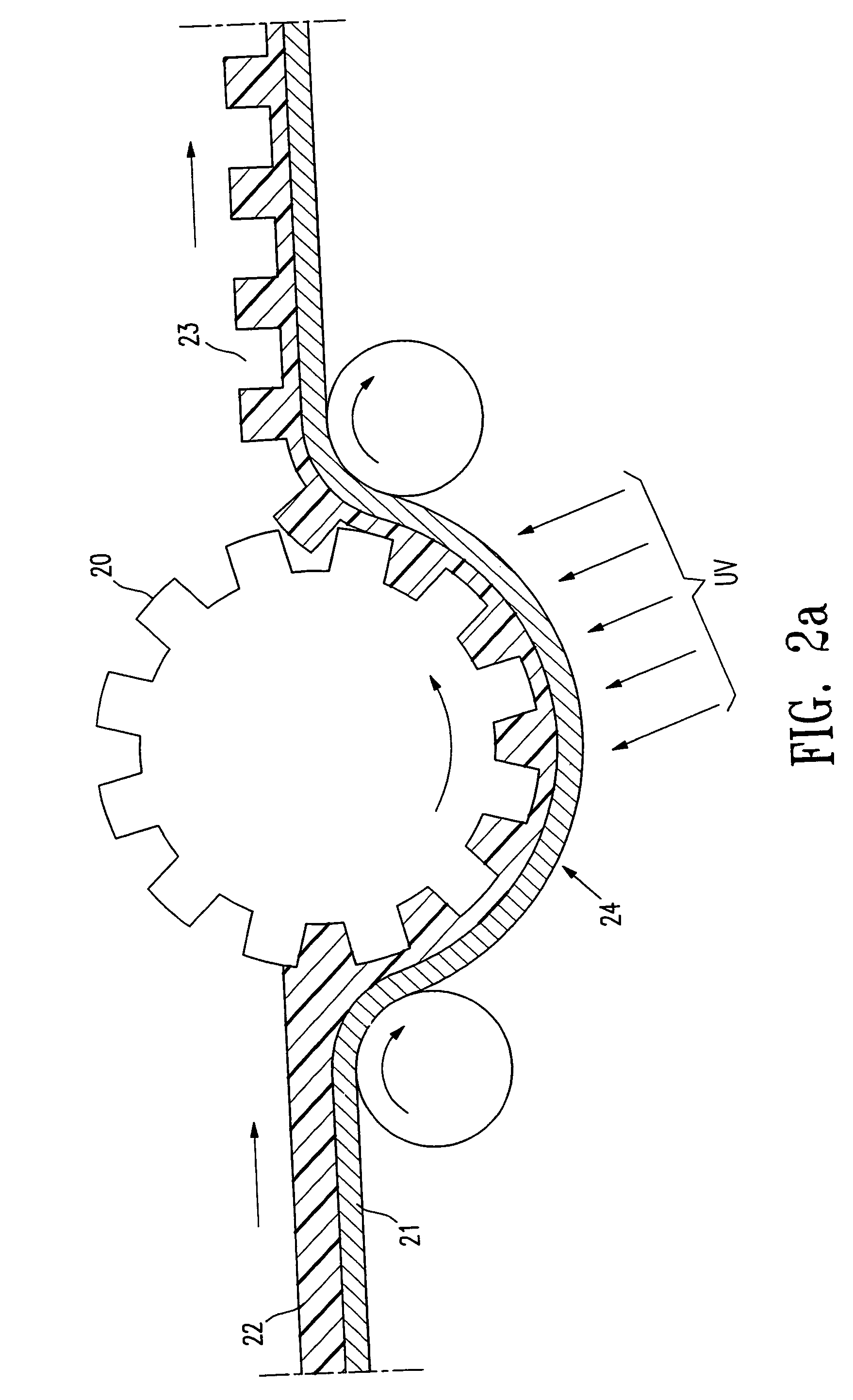

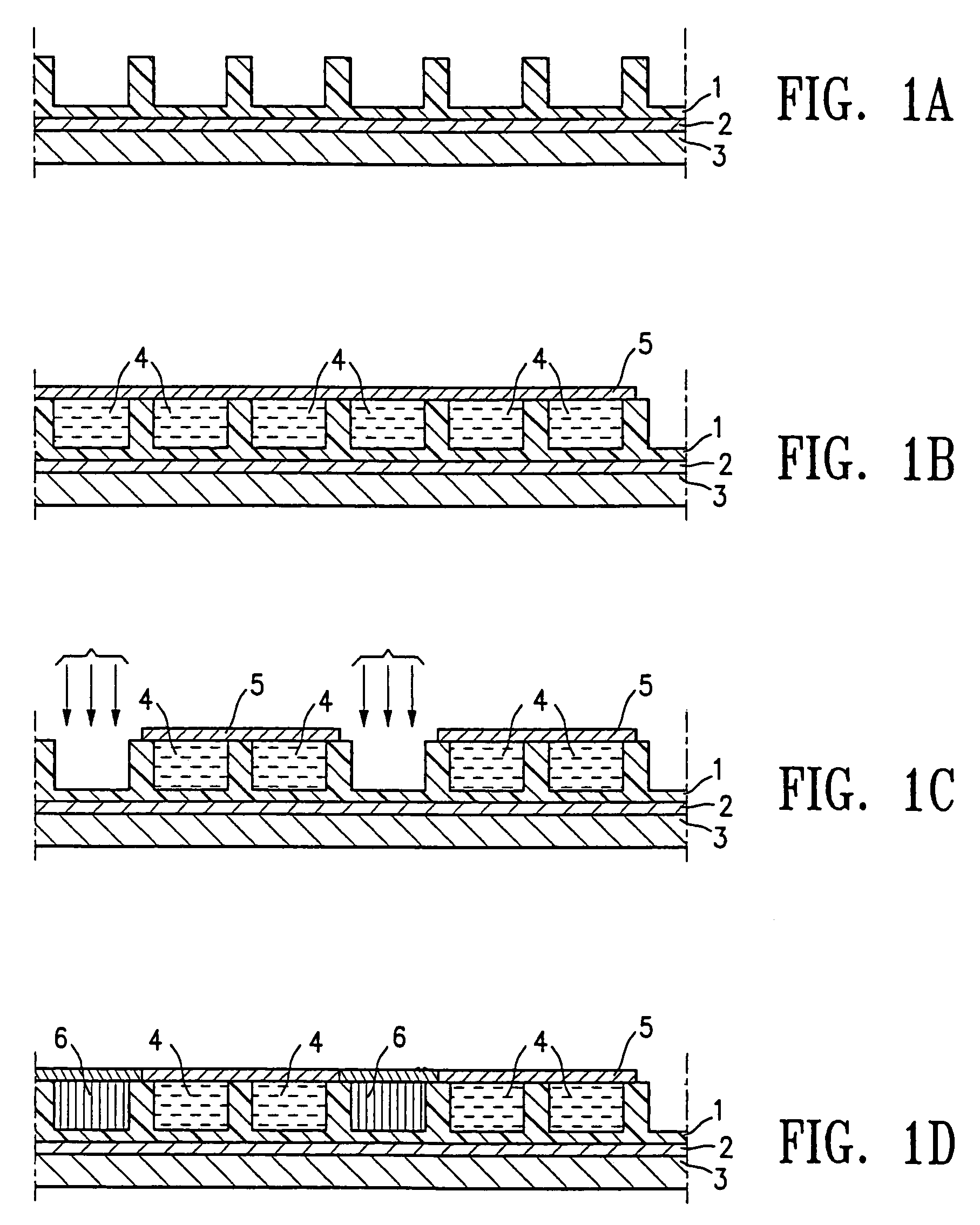

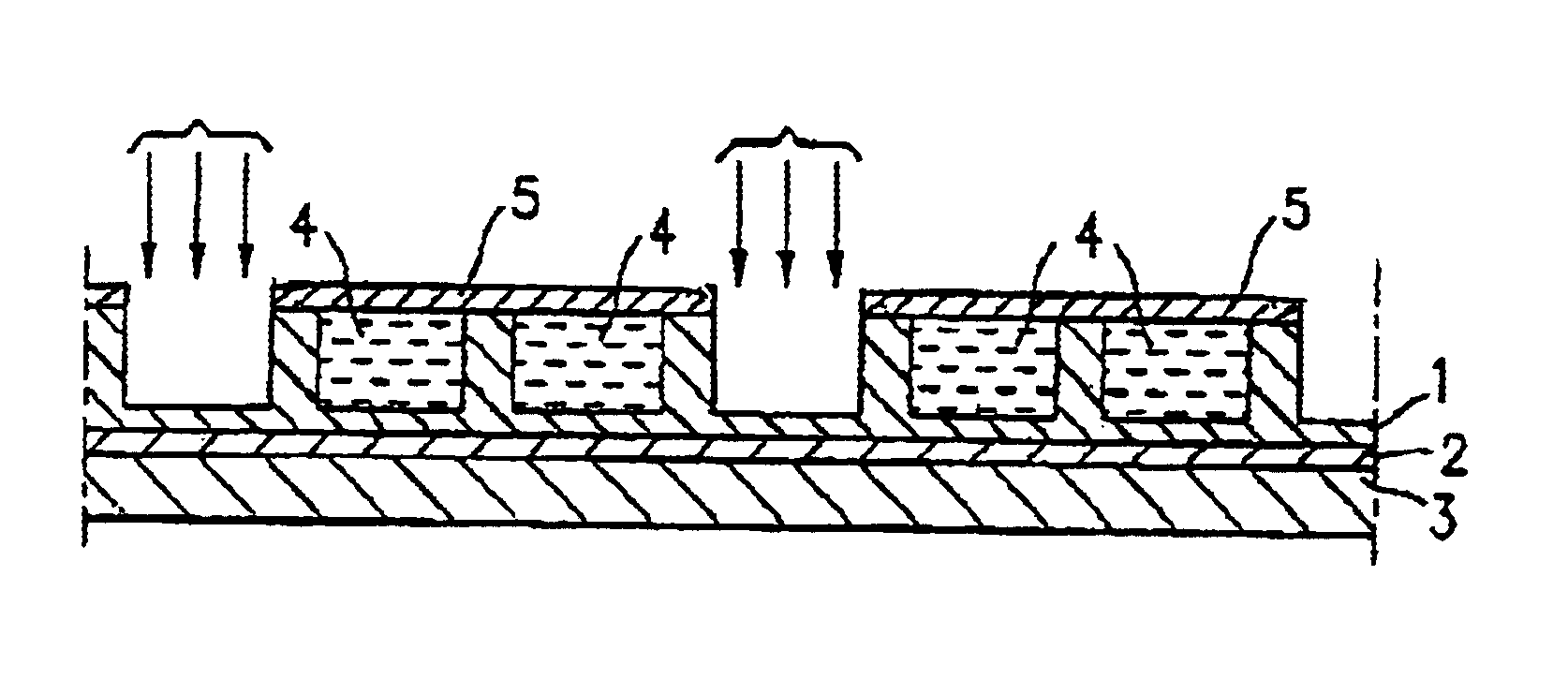

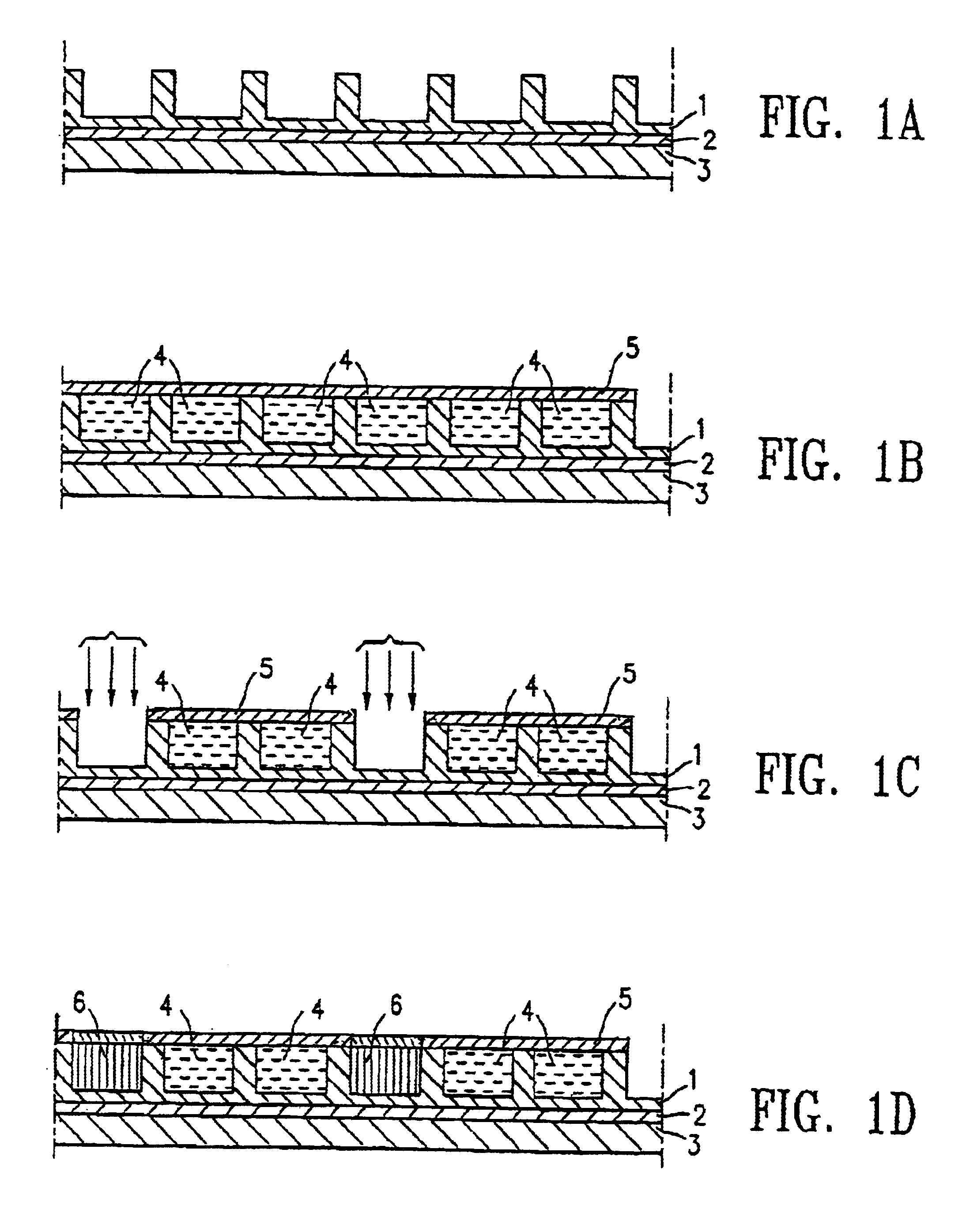

Processes for the production of electrophoretic displays

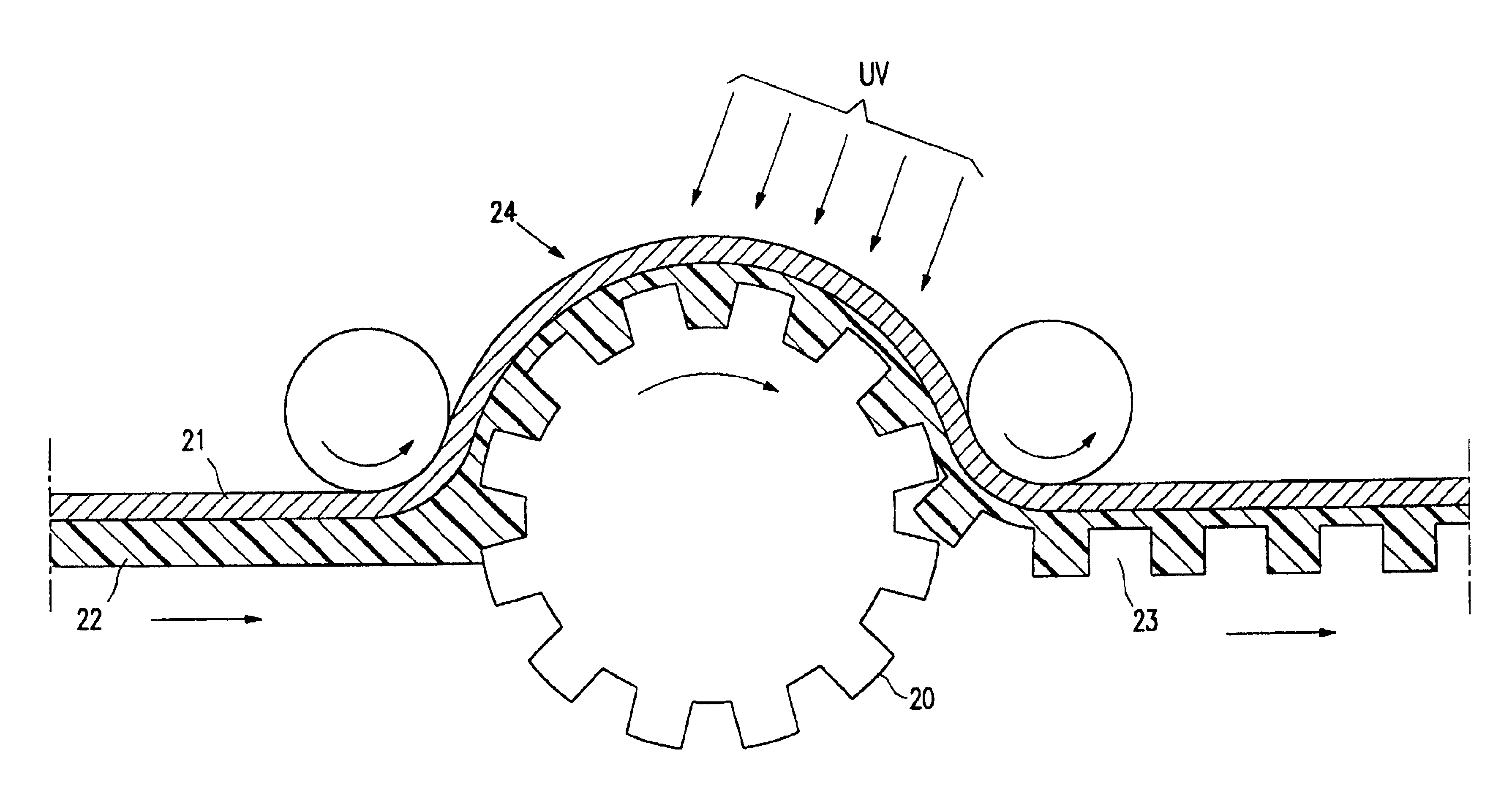

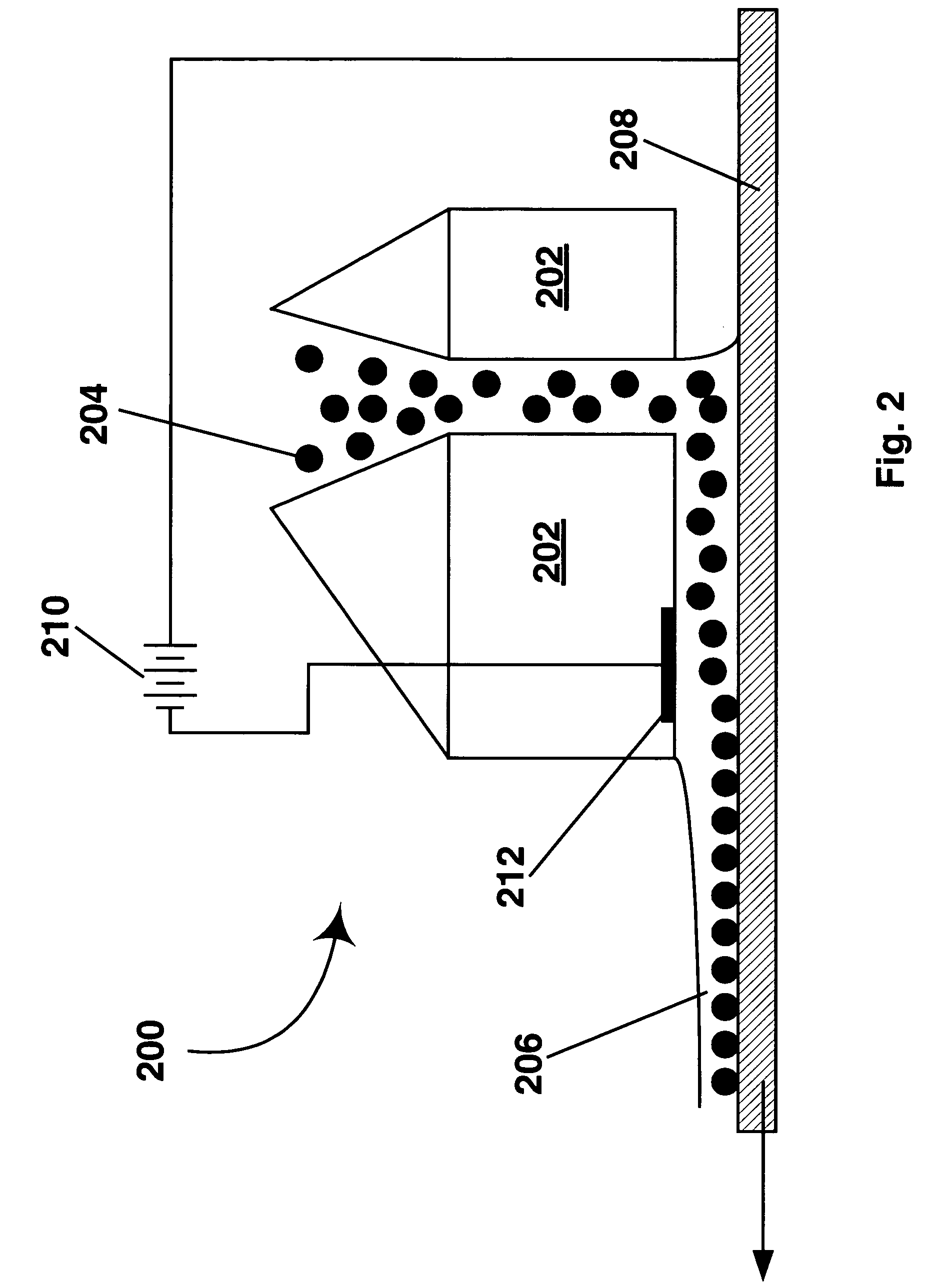

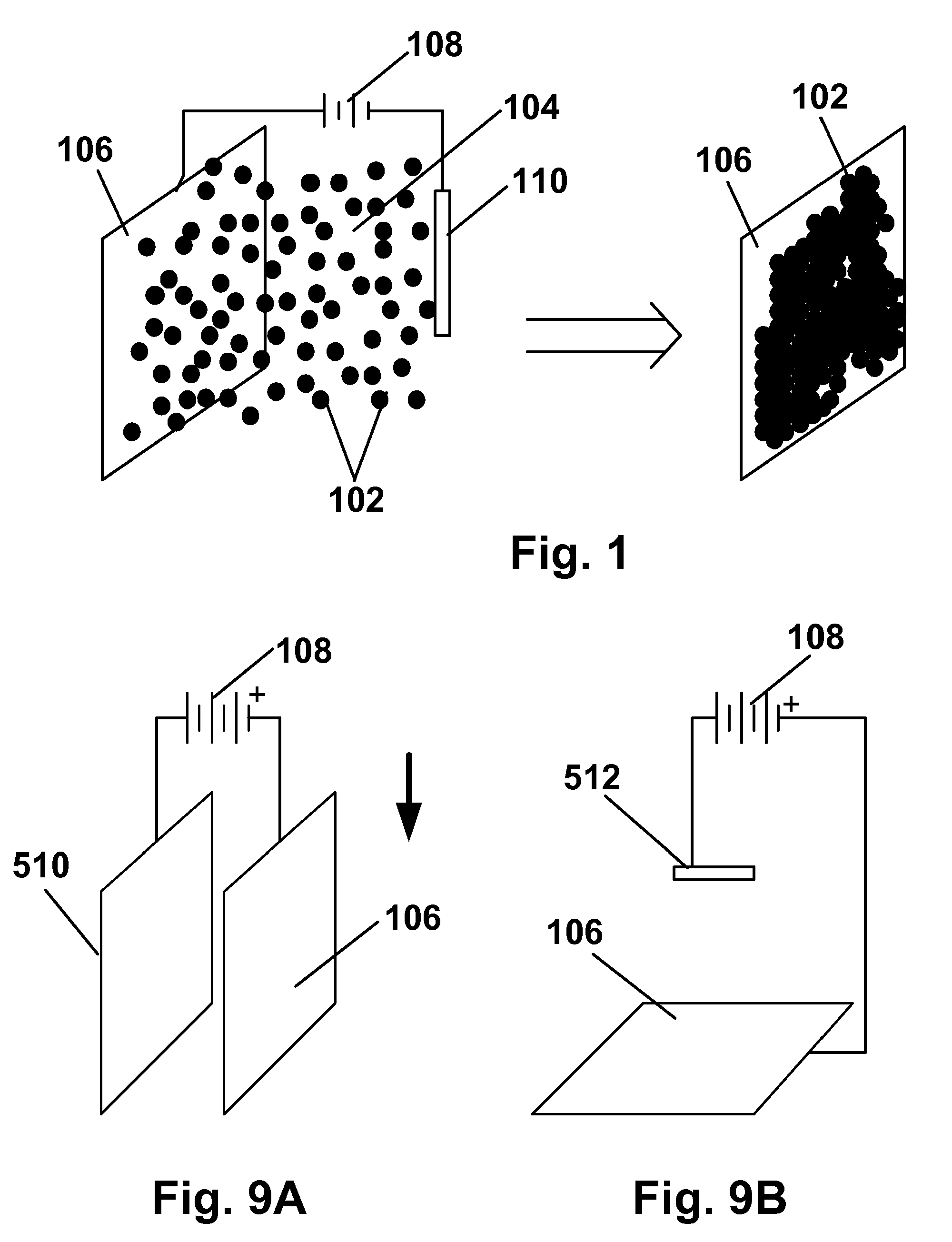

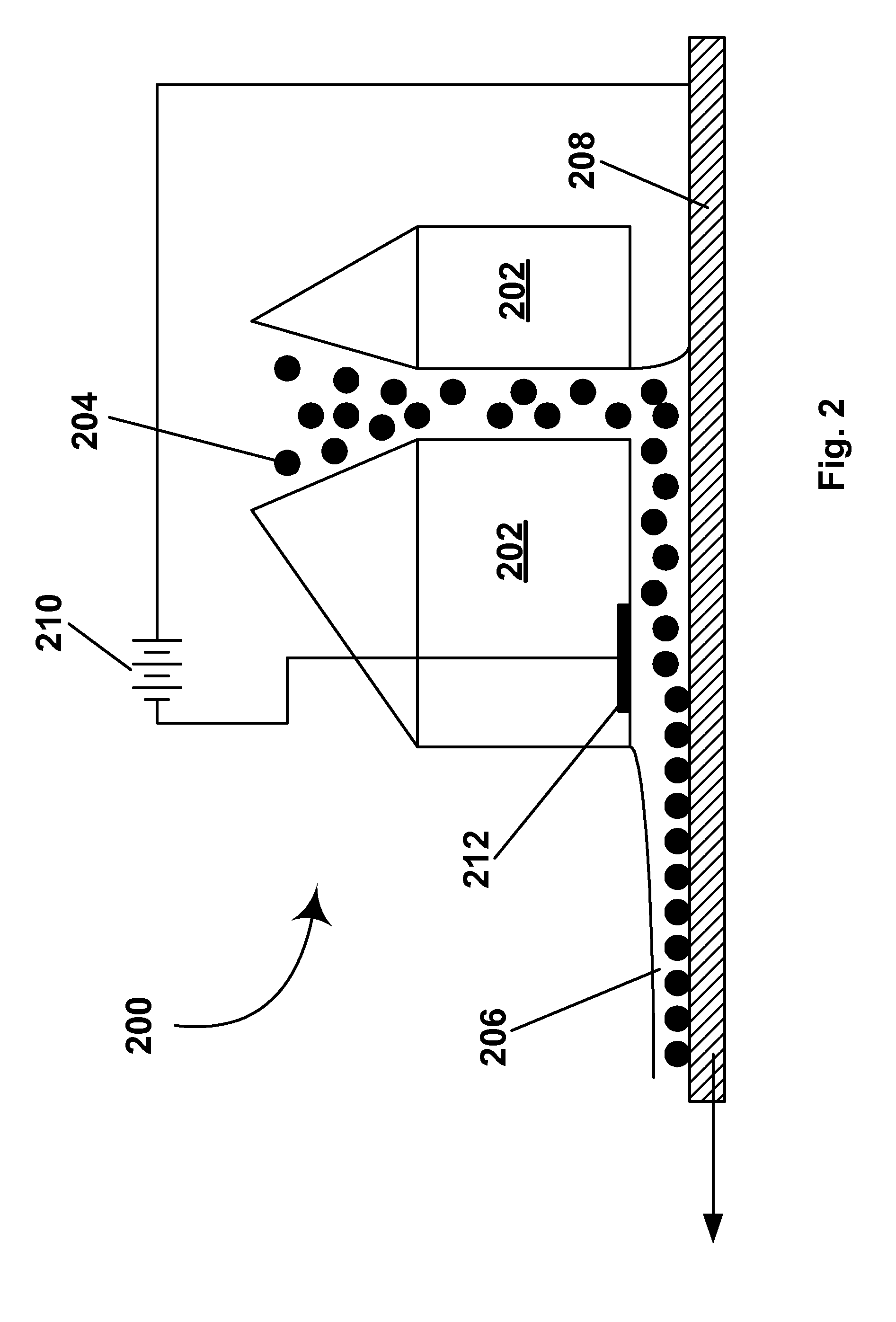

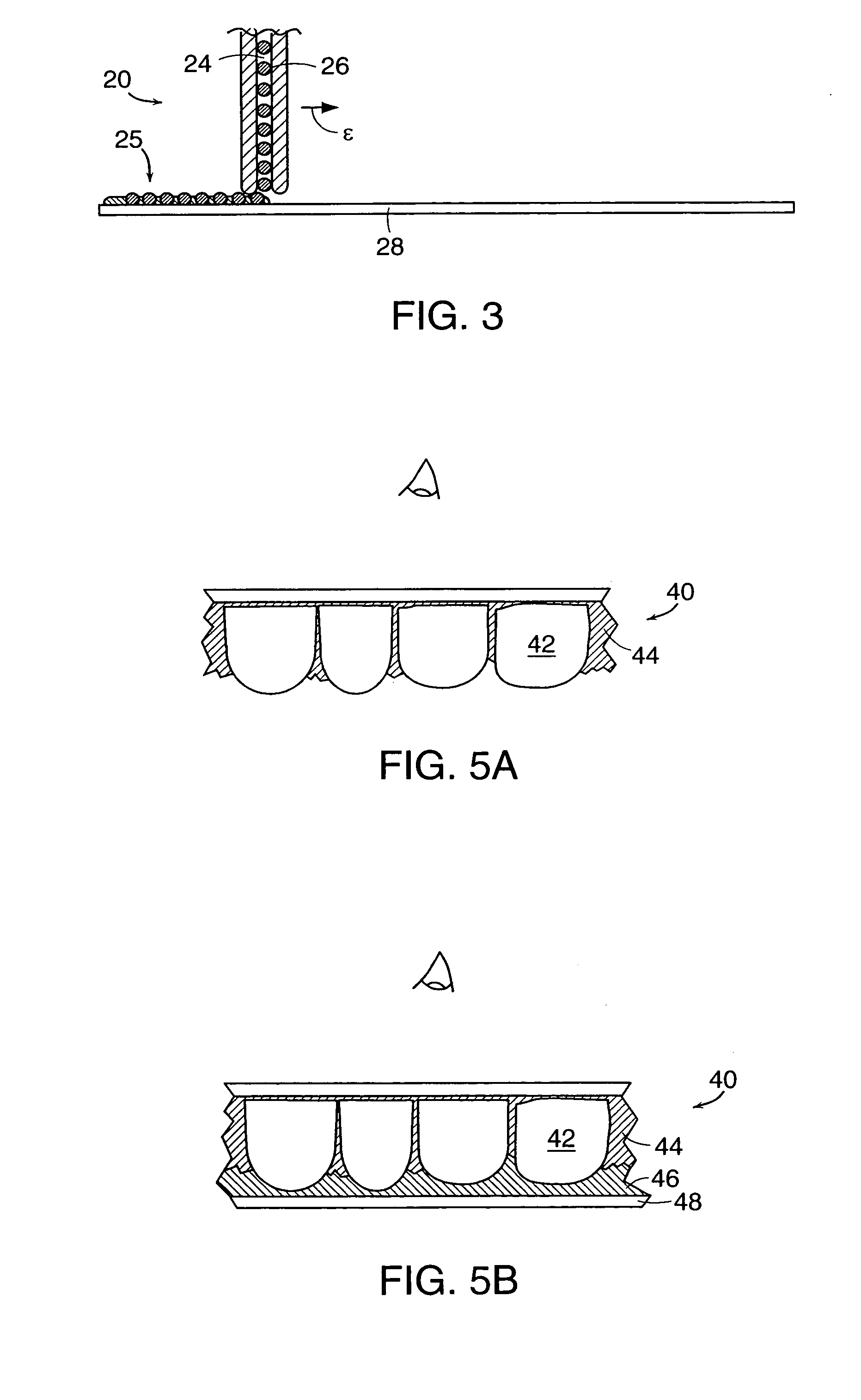

ActiveUS7339715B2Electric shock equipmentsElectrophoretic coatingsElectrophoresisPotential difference

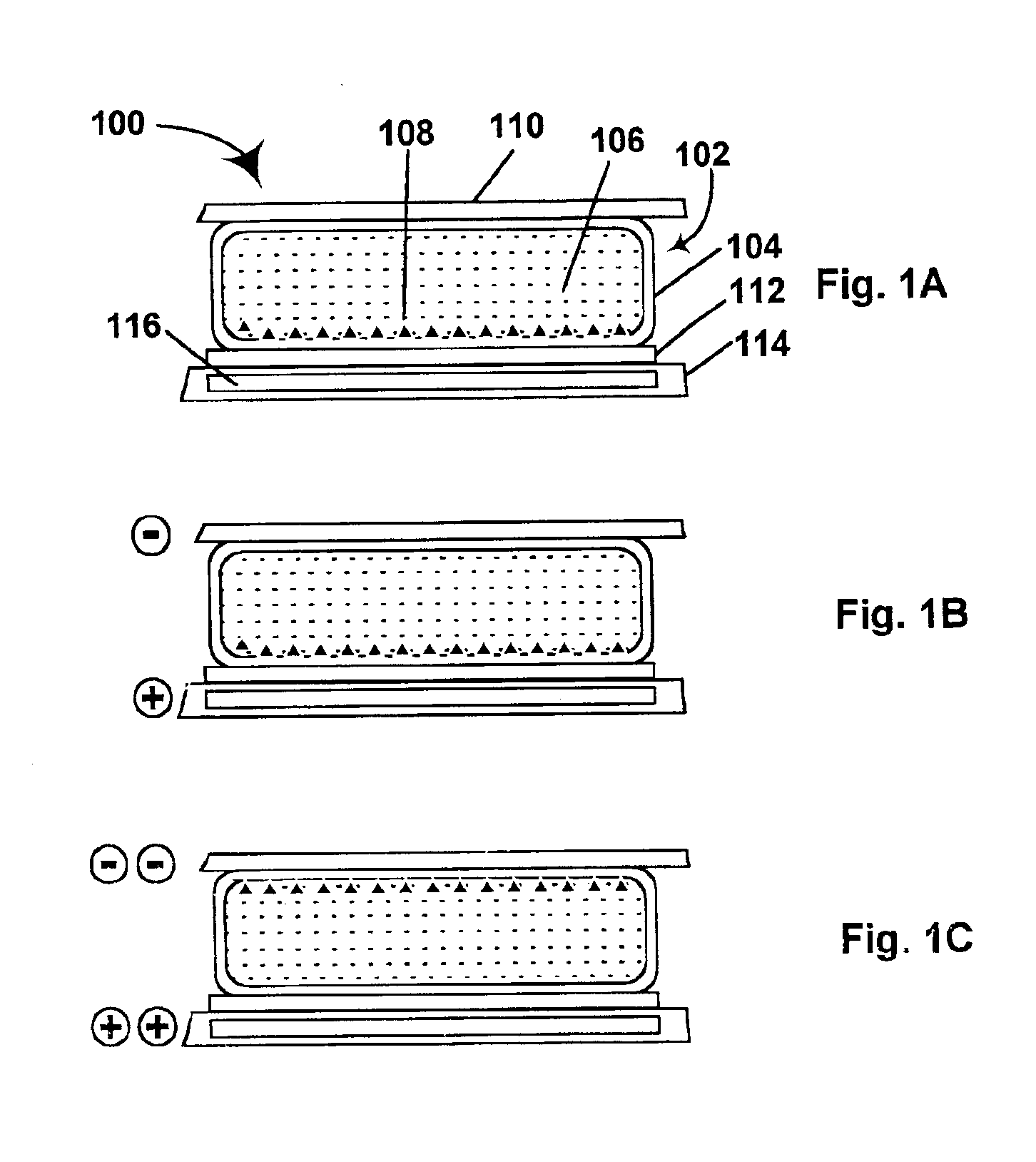

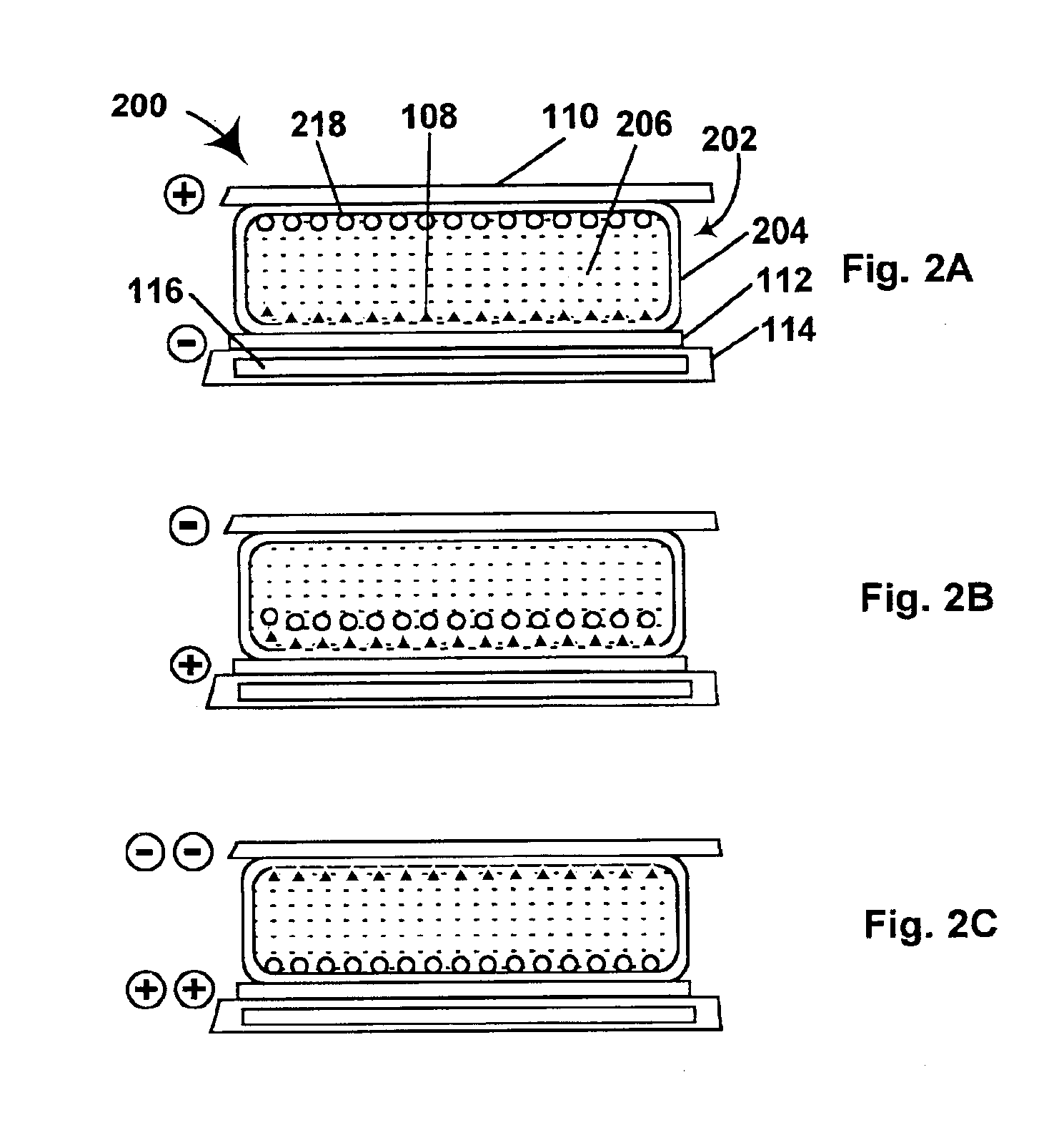

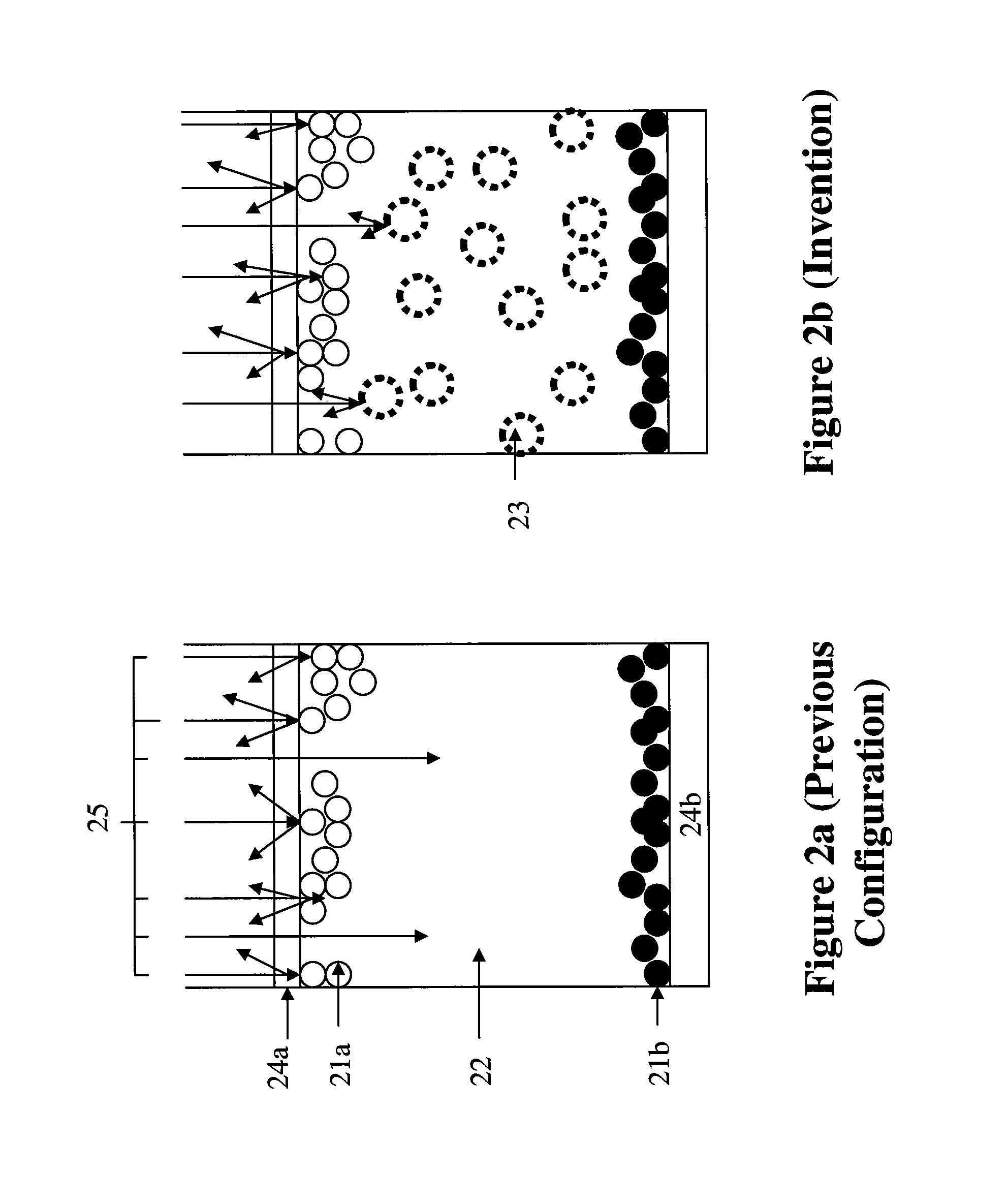

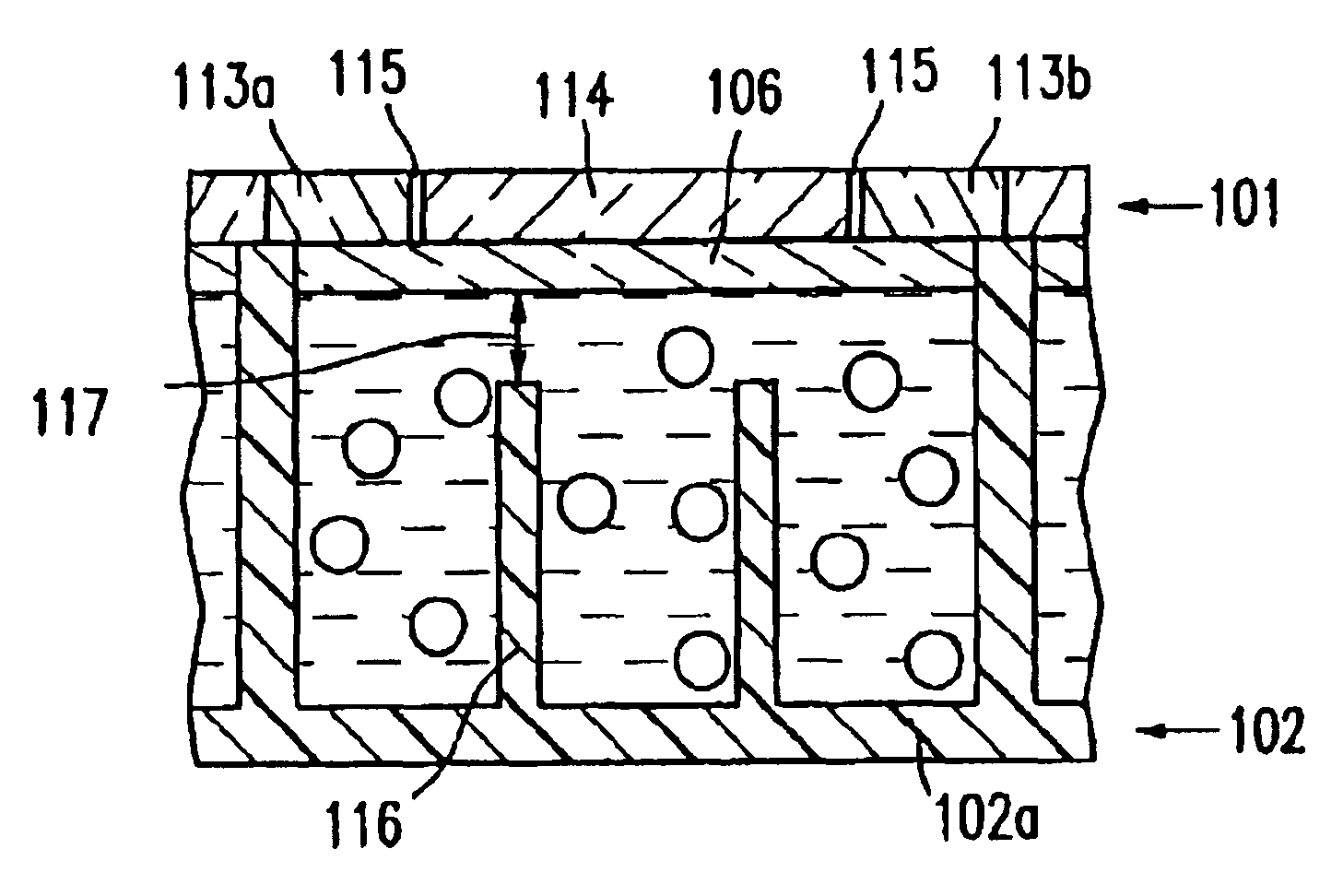

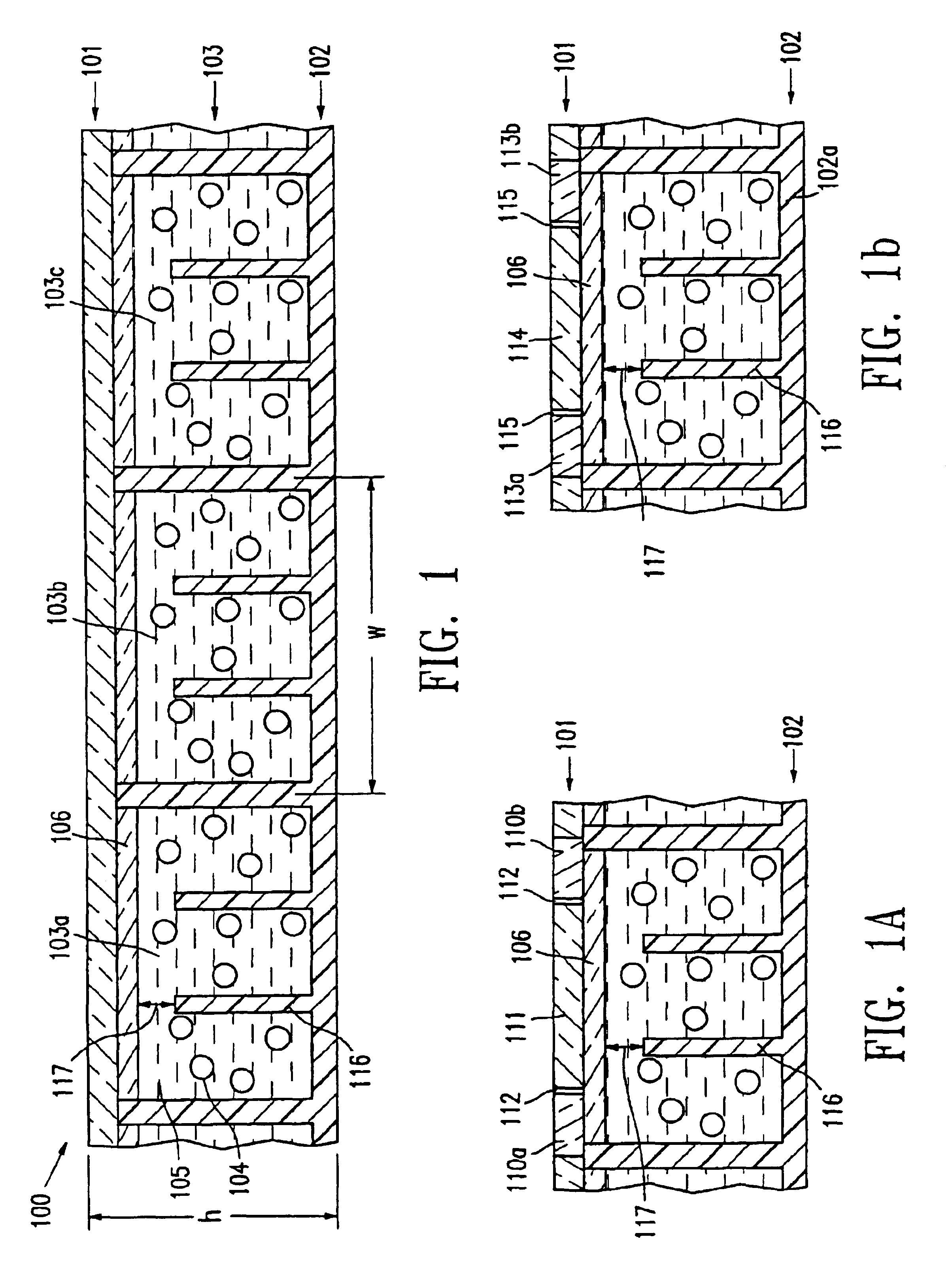

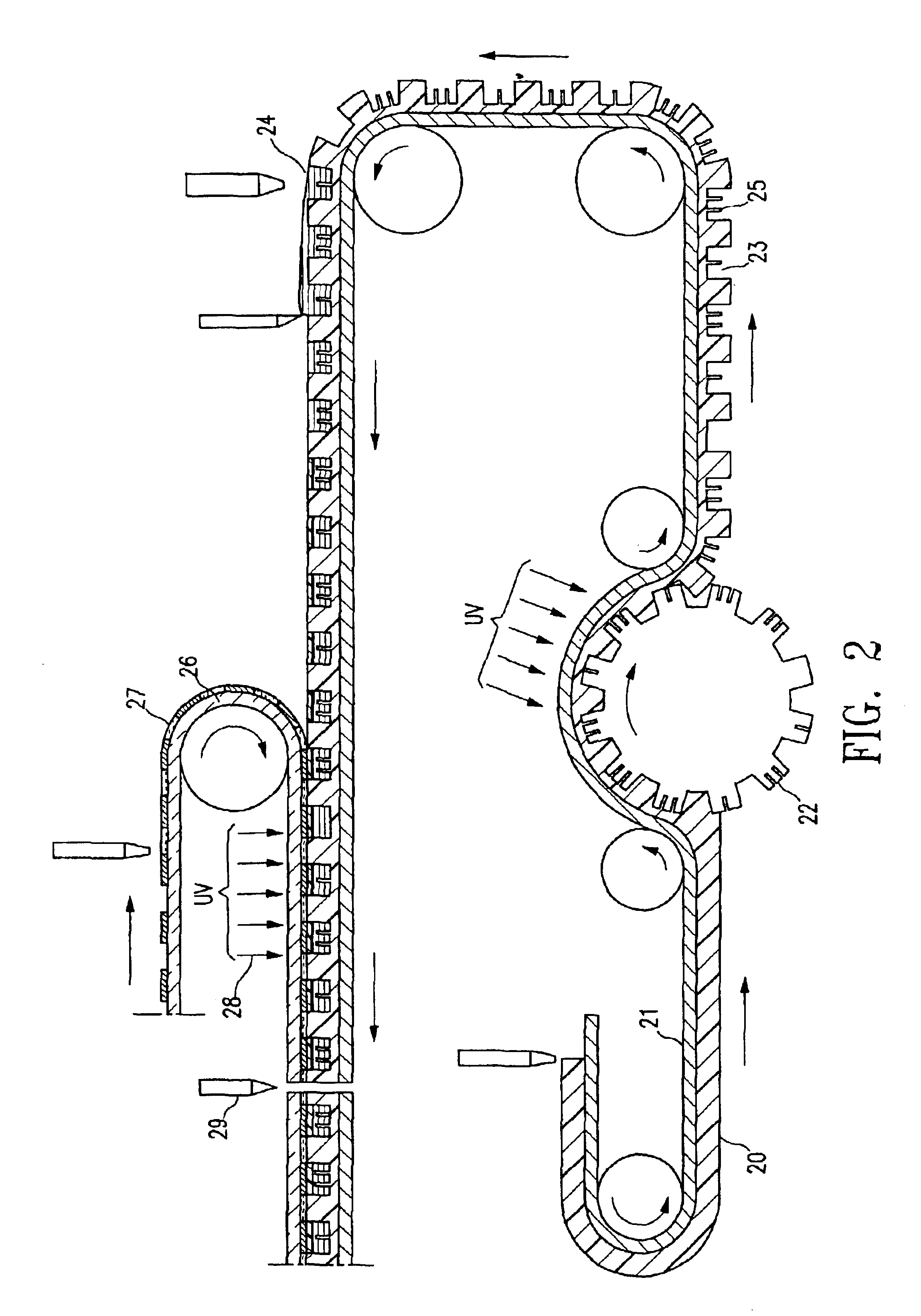

A coating of an encapsulated electrophoretic medium is formed on a substrate (106) by dispersing in a fluid (104) a plurality of electrophoretic capsules (102), contacting at least a portion of a substrate (106) with the fluid (104); and applying a potential difference between at least a part of the portion of the substrate (106) contacting the fluid (104) and a counter-electrode (110) in electrical contact with the fluid (104), thereby causing capsules (102) to be deposited upon at least part of the portion of the substrate (106) contacting the fluid (102). Patterned coatings of capsules containing different colors may be deposited in registration with electrodes using multiple capsule deposition steps. Alternatively, a patterned coating may be deposited upon a substrate containing a conductive layer by varying the conductivity of the conductive layer by radiation exposure or by coating portions of the conductive layer with an insulating layer, typically a photoresist.

Owner:E INK CORPORATION

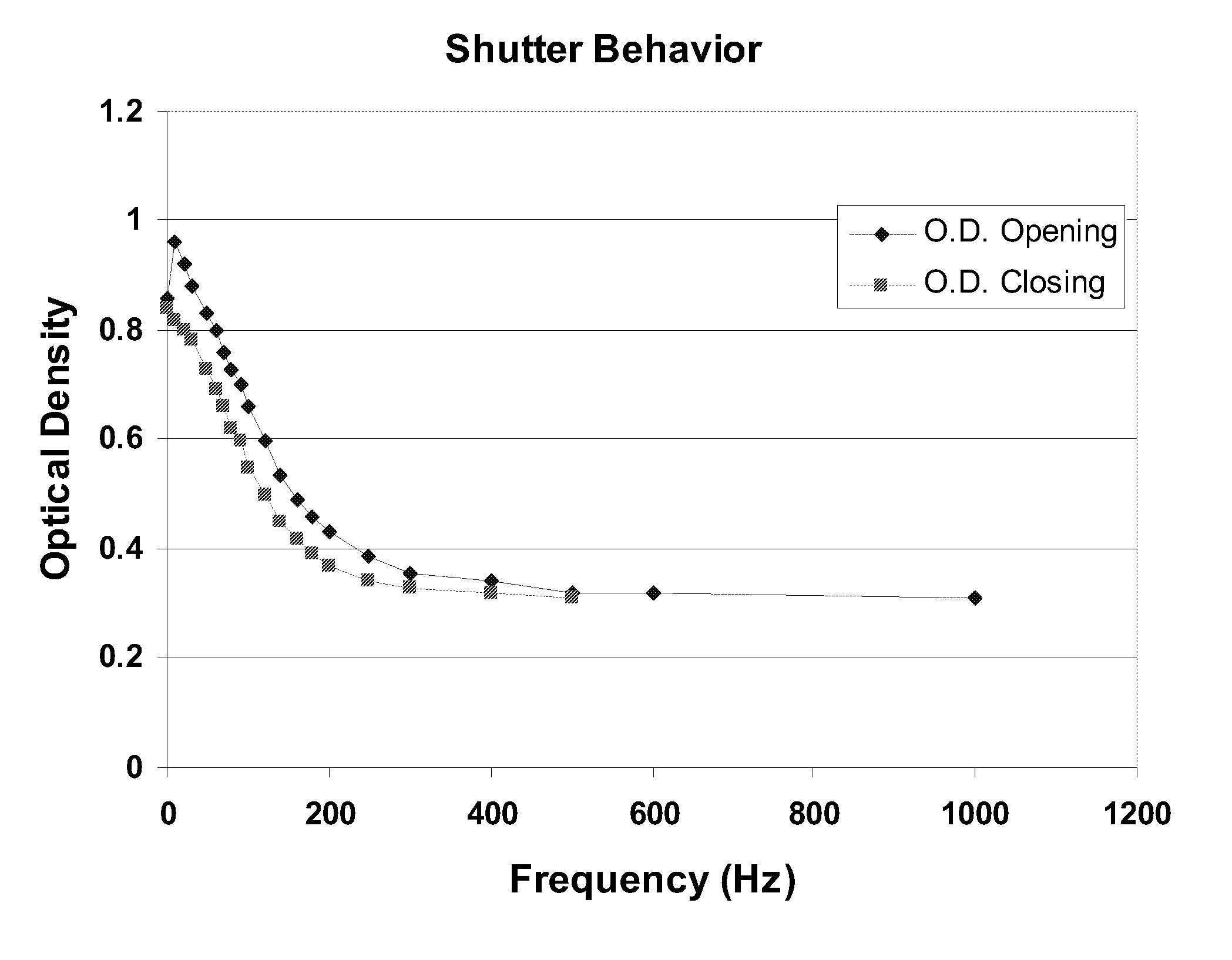

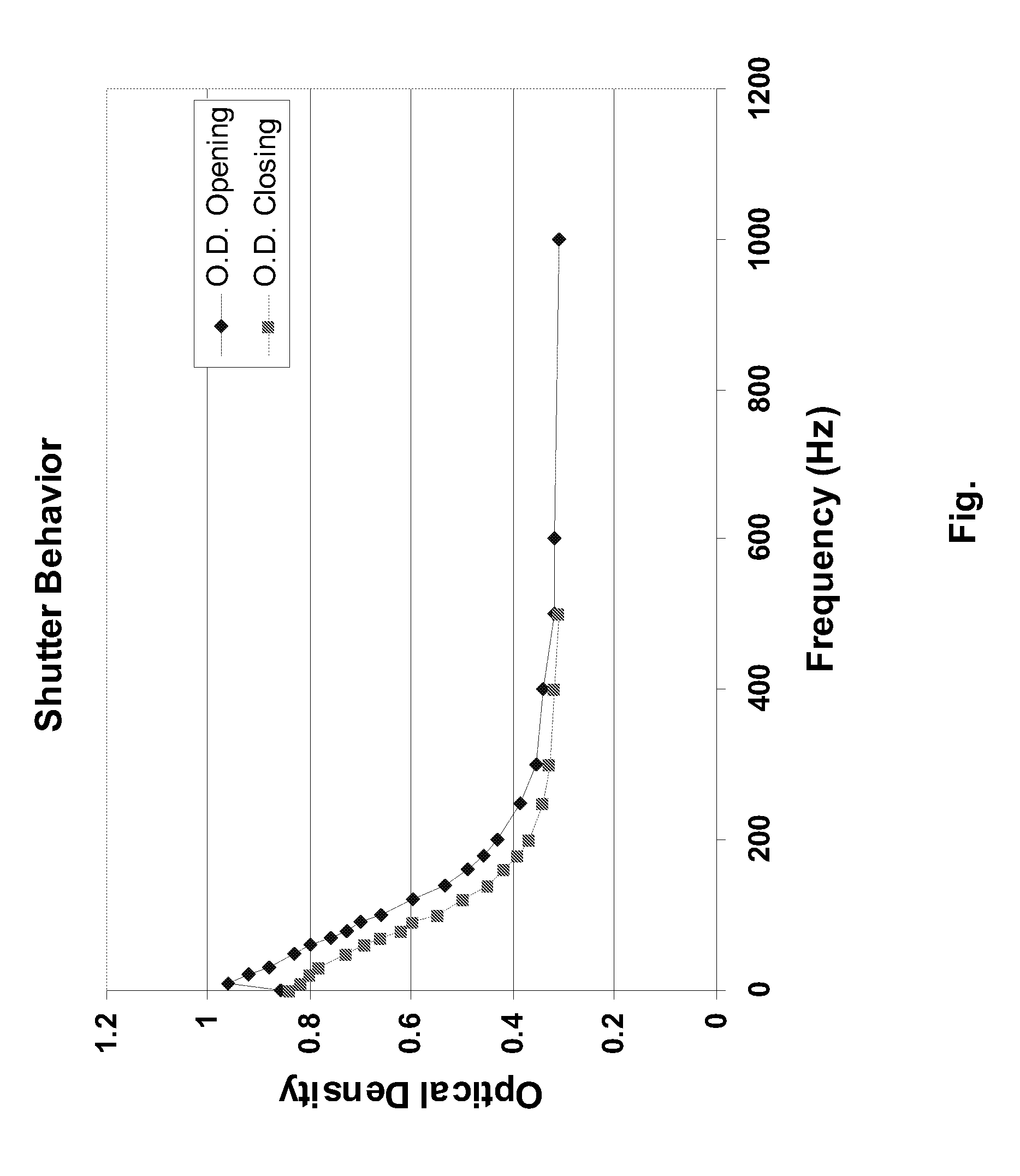

Light modulators

ActiveUS7327511B2Door/window protective devicesStatic indicating devicesElectrophoresisDisplay device

Various improvements in electrophoretic media and displays intended for use in light modulators are described. These improvements include index matching of the suspending fluid to a continuous phase surrounding the fluid, index matching of a capsule wall to a binder, planarization of a layer containing electrophoretic capsules before application of adhesive thereto, methods for concentrating electrophoretic particles into limited areas of sidewalls of electrophoretic capsules or microcells in the light-transmissive state of the display, and, in the case of light modulators comprising an electrophoretic layer sandwiched between two transparent plates, forming at least one of the plates so as to absorb electromagnetic radiation which adversely affects the electrophoretic layer.

Owner:E INK CORPORATION

Electrophoretic displays containing magnetic particles

InactiveUS6870661B2Easy to fallImprove stabilitySludge treatmentStatic indicating devicesElectrophoresisDisplay device

An electrophoretic medium comprises a plurality of one or more types of particles suspended in a suspending fluid. The particles include at least one electrically charged, electrophoretically mobile particle capable of translating through the suspending fluid upon application of an electric field to the medium and at least one magnetic particle. A magnet is disposed adjacent the electrophoretic medium to introduce a threshold resistance to magnetic particle movement.

Owner:E INK CORPORATION

Electrophoretic display and novel process for its manufacture

ActiveUS7072095B2Improve contrast ratioImprove switching performanceStatic indicating devicesElectrographic processes using photoelectrophoresisElectrophoresisDisplay device

This invention relates to an electrophoretic display with improved contrast ratio, switching performance, reflectivity at the Dmin state and structural integrity, and methods for its manufacture.

Owner:E INK CALIFORNIA

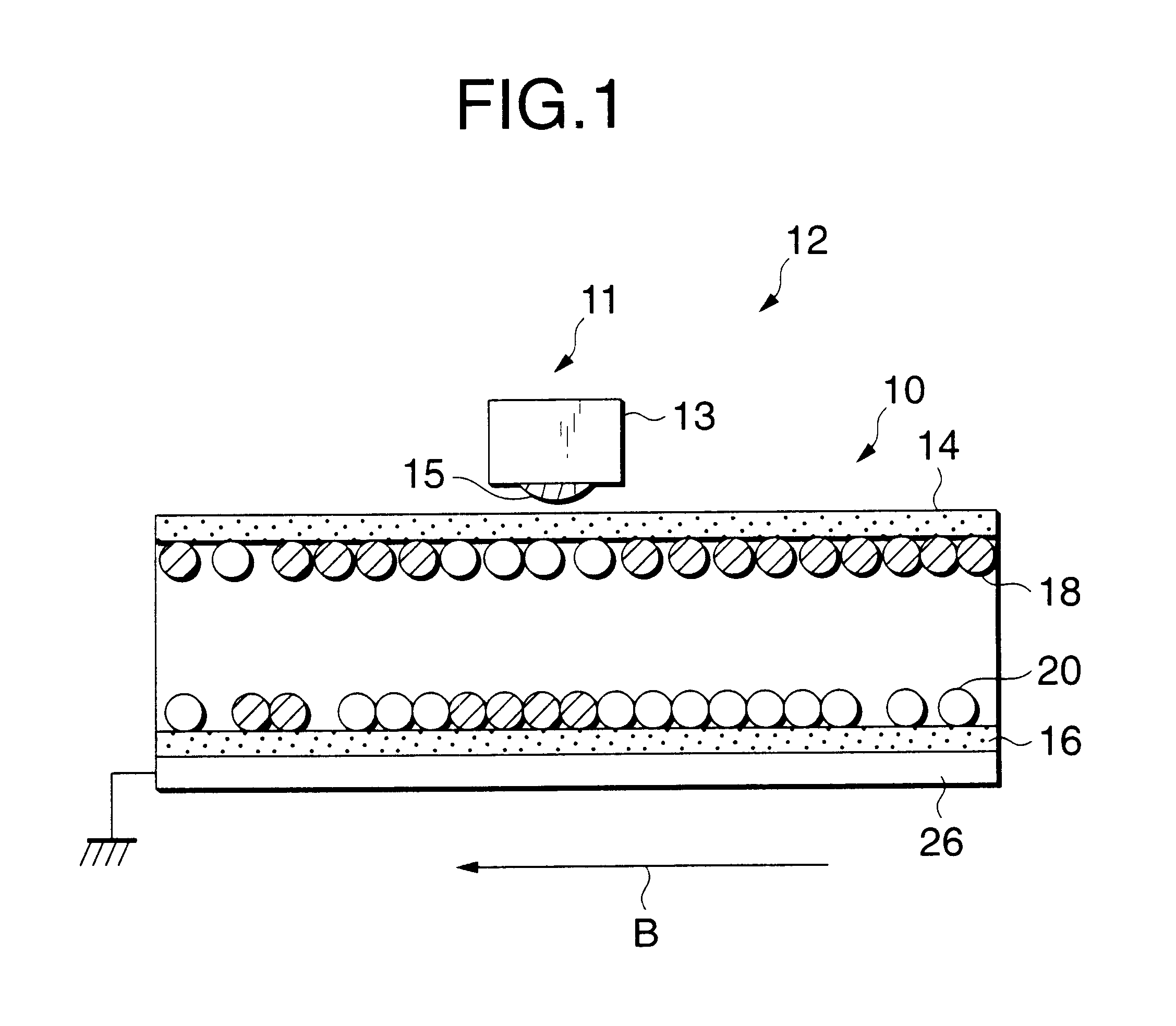

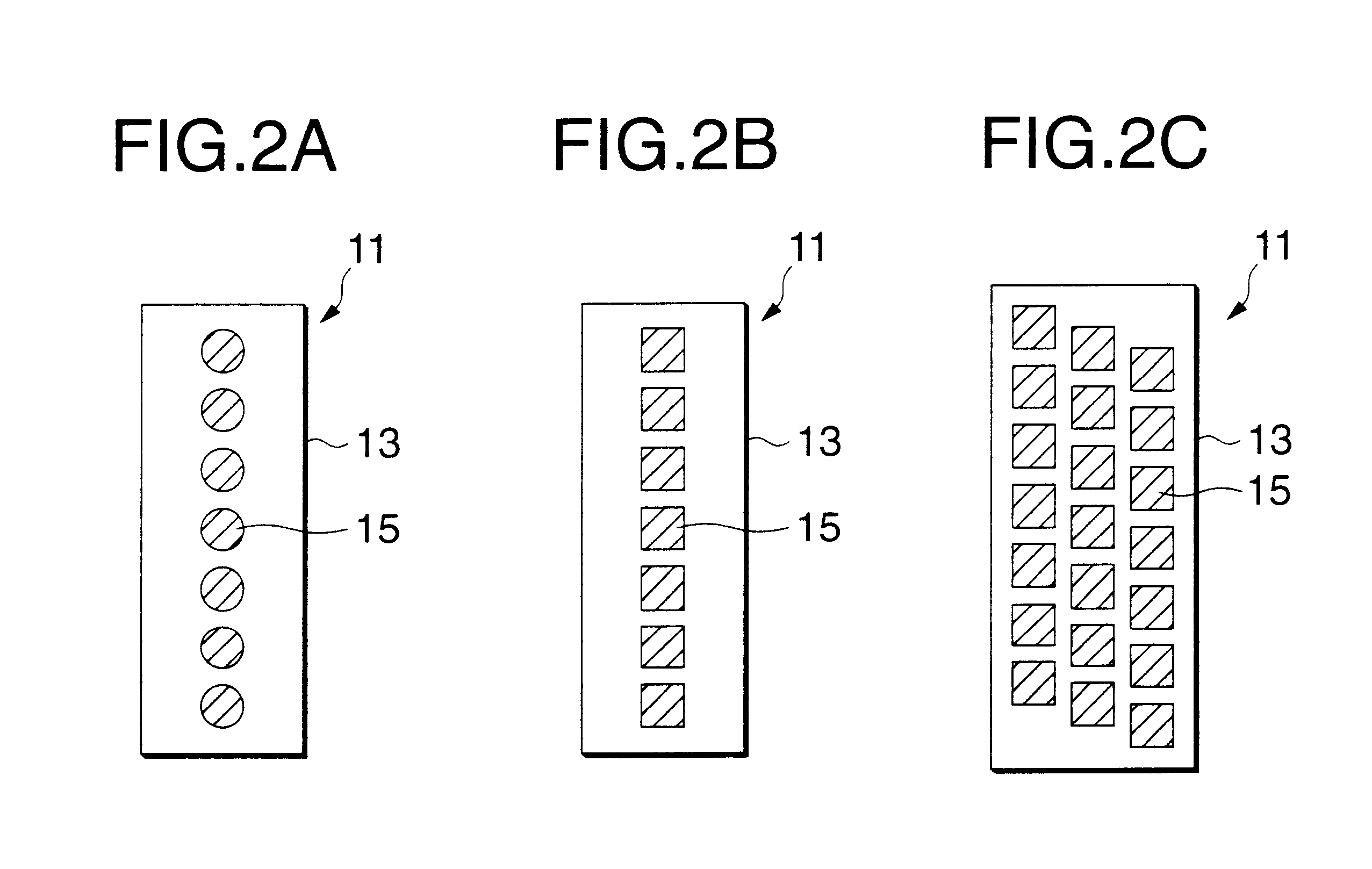

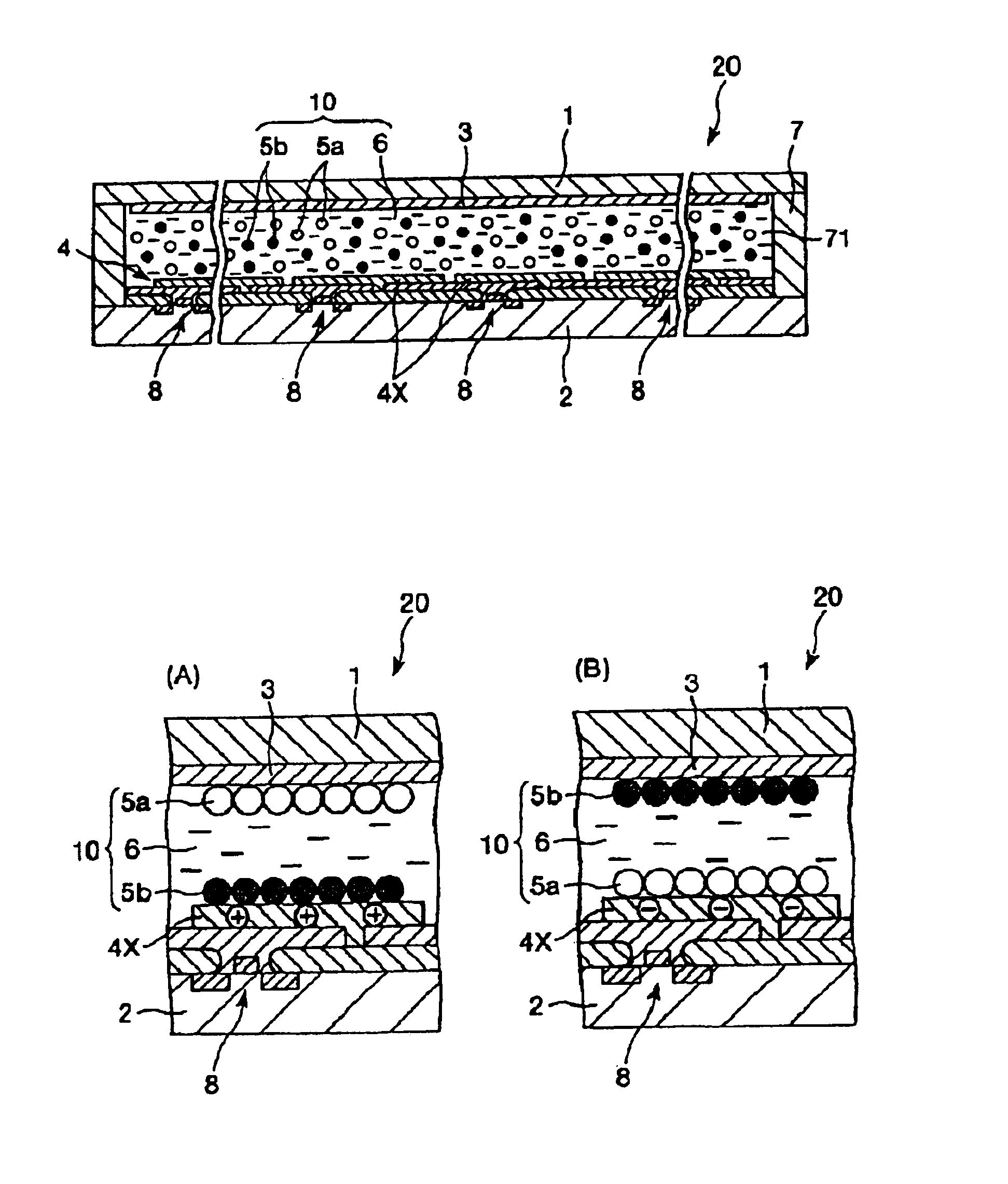

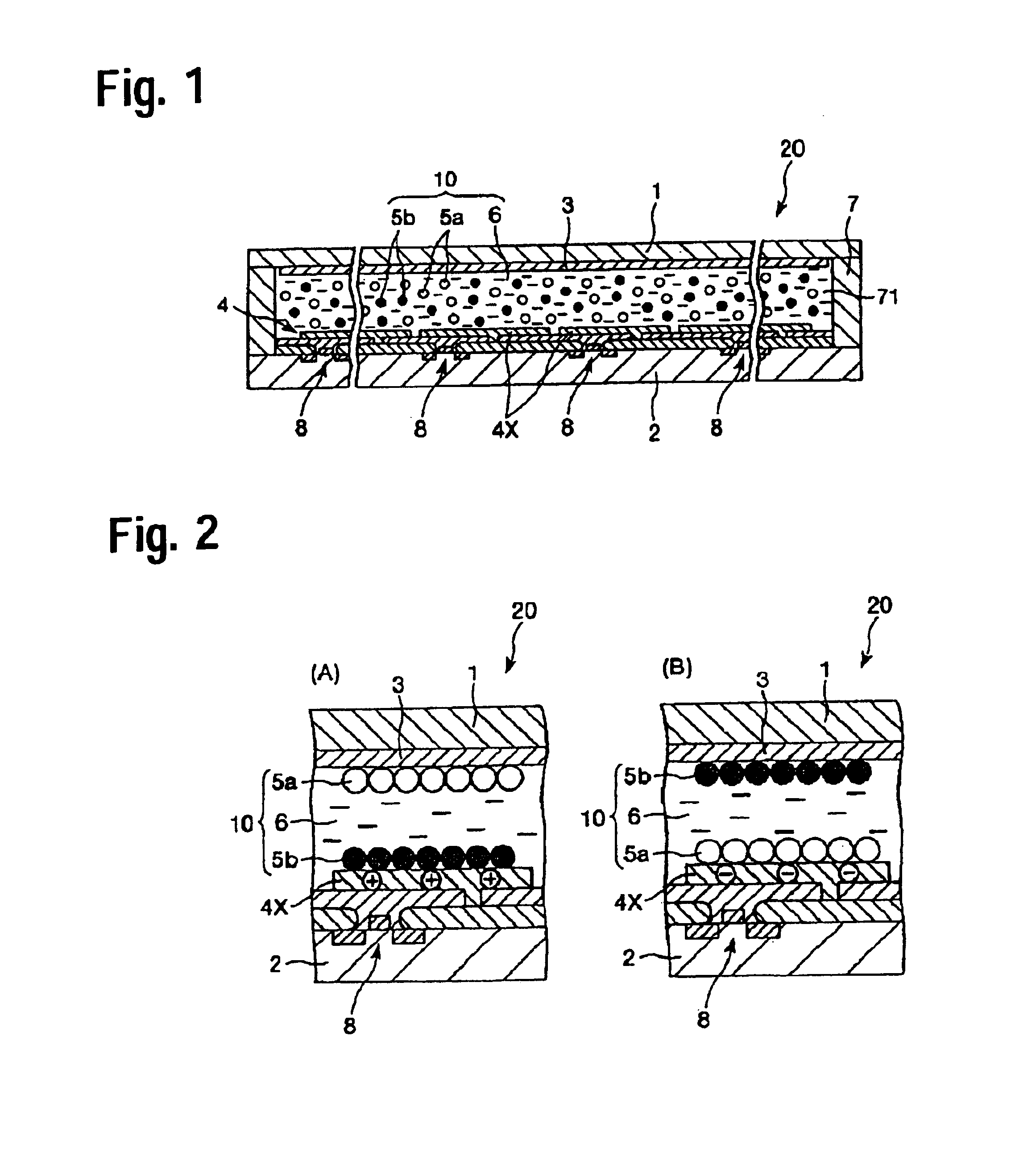

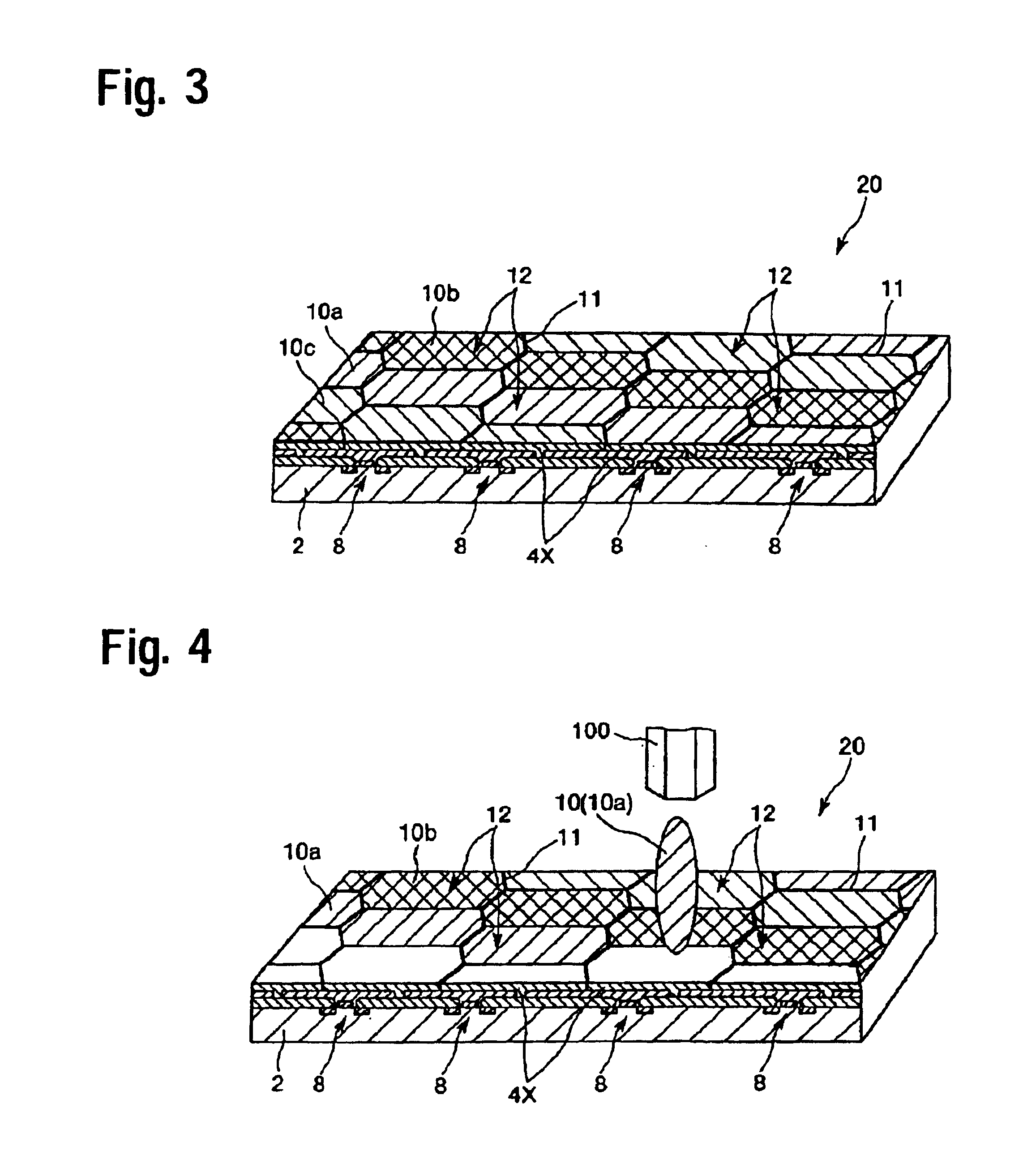

Image display medium, image-forming method and image-forming apparatus capable of repetitive writing on the image display medium

Provided are an image display medium which satisfies, a safety and a high-speed response and which is capable of repetitive rewriting, an image-forming method in which an image can be formed on the image display medium, and an image-forming apparatus. An image display medium is formed by interposing black particles and white particles between a display substrate and a non-display substrate made of a dielectric. A printing electrode first applies an AC voltage to frictionally charge the black and white particles, and then applies a DC voltage adapted to an image between the substrates. The black particles adhered to a portion (non-image portion) to which the voltage of the display substrate is applied are moved to the non-display substrate.

Owner:E INK CORPORATION

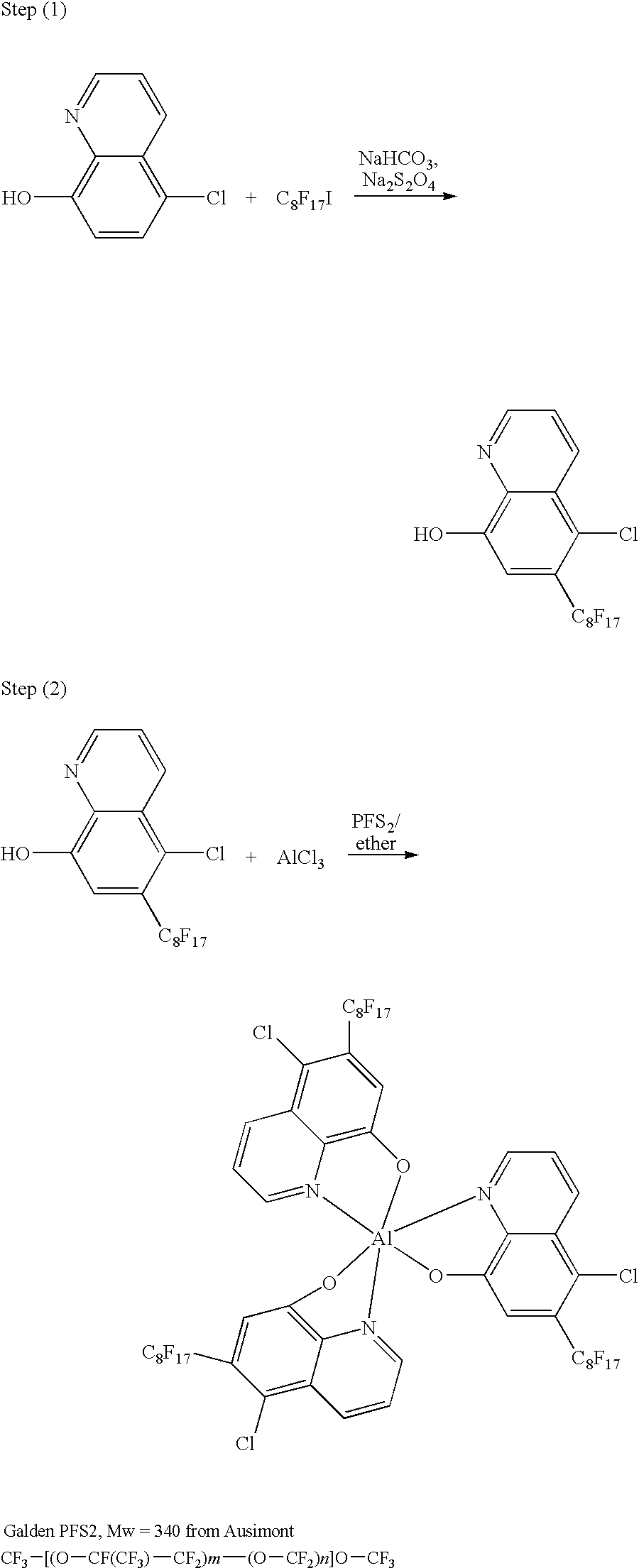

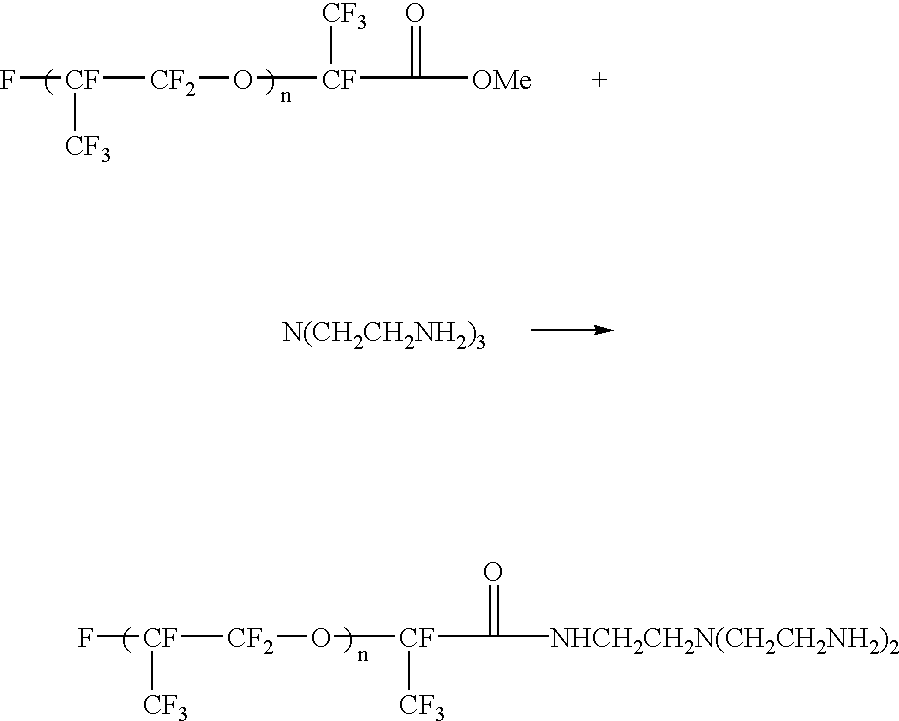

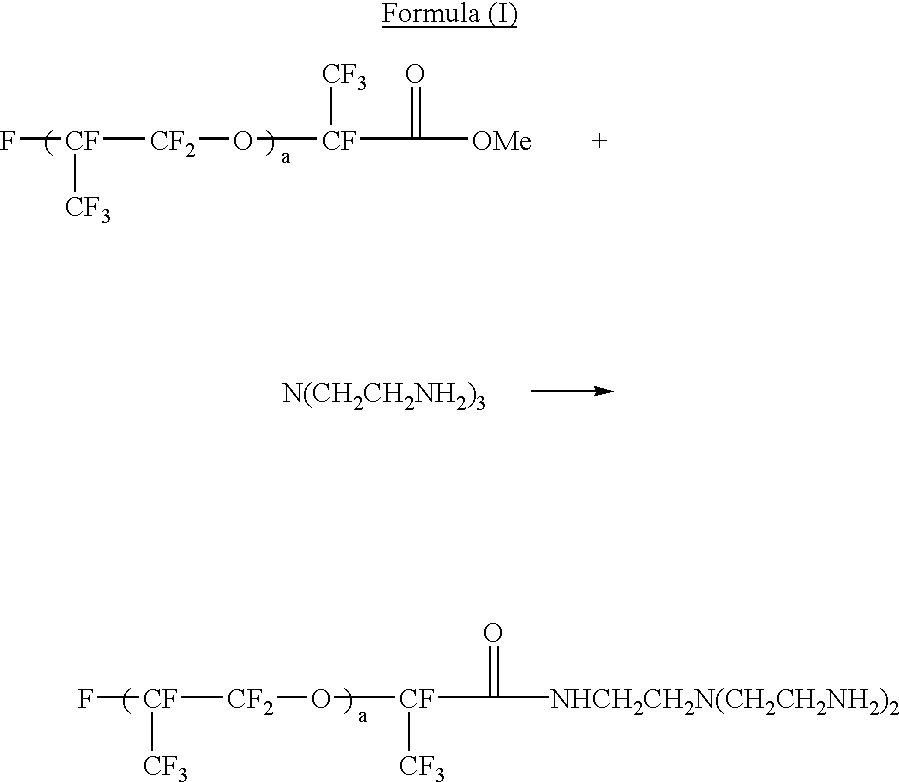

Electrophoretic dispersion with a fluorinated solvent and a charge controlling agent

ActiveUS7110162B2Improve adsorption capacityImprove surface activityStatic indicating devicesAzo dyesElectrophoresisCharge control

The invention relates to a novel electrophoretic dispersion comprising a fluorinated solvent as the continuous phase, charged pigment particles or pigment containing microcapsules as the dispersed phase, and the charge of the pigment particles is provided by a charge controlling agent comprising:(i) a soluble fluorinated electron accepting or proton donating compound or polymer in the continuous phase and an electron donating or proton accepting compound or polymer in the dispersed phase; or(ii) a soluble fluorinated electron donating or proton accepting compound or polymer in the continuous phase and an electron accepting or proton donating compound or polymer in the dispersed phase.

Owner:E INK CALIFORNIA

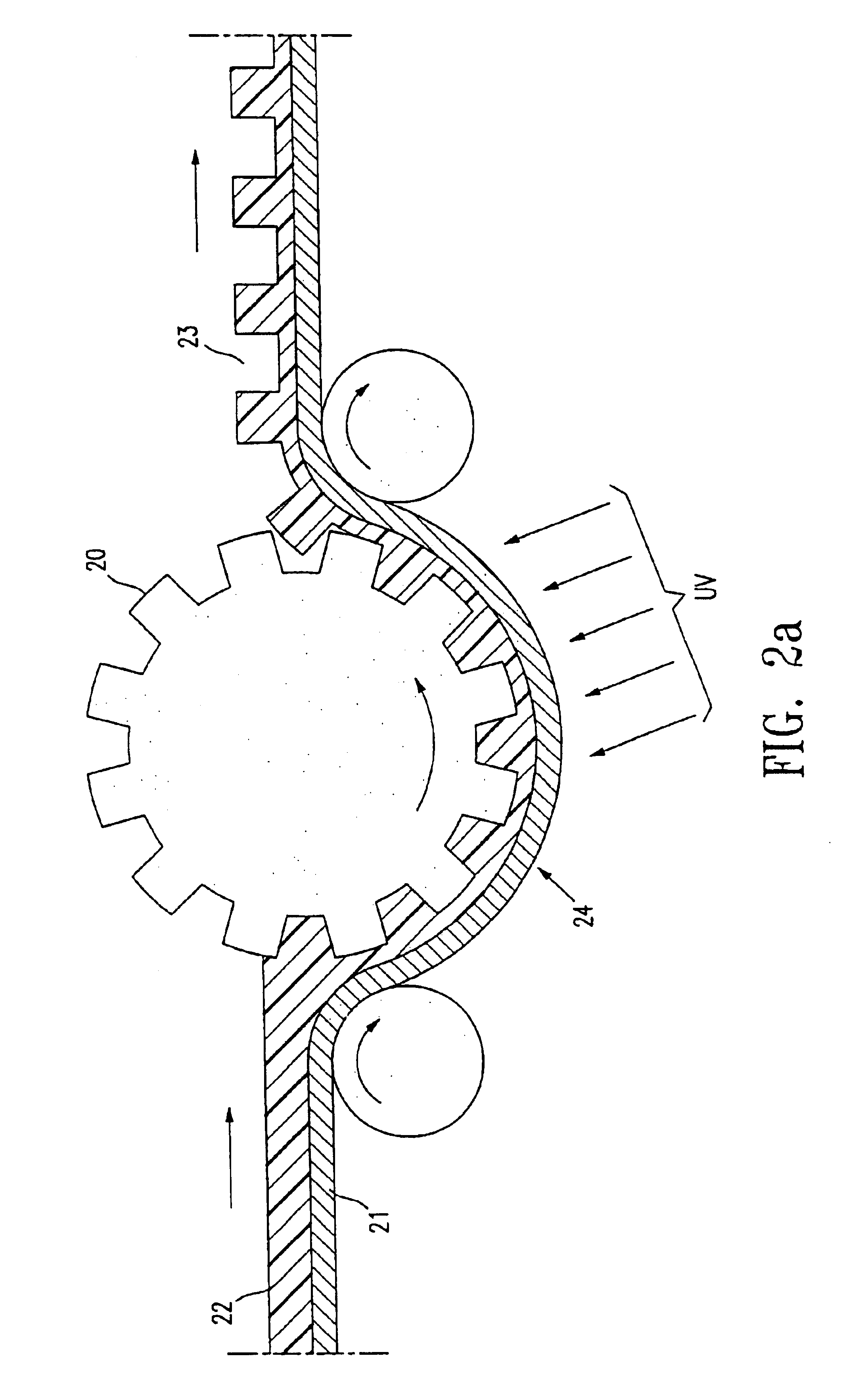

Processes for the production of electrophoretic displays

ActiveUS7910175B2Electric shock equipmentsElectrophoretic coatingsPotential differenceElectrophoresis

A coating of an encapsulated electrophoretic medium is formed on a substrate (106) by dispersing in a fluid (104) a plurality of electrophoretic capsules (102), contacting at least a portion of a substrate (106) with the fluid (104); and applying a potential difference between at least a part of the portion of the substrate (106) contacting the fluid (104) and a counter-electrode (110) in electrical contact with the fluid (104), thereby causing capsules (102) to be deposited upon at least part of the portion of the substrate (106) contacting the fluid (102). Patterned coatings of capsules containing different colors may be deposited in registration with electrodes using multiple capsule deposition steps. Alternatively, patterned coatings of capsules may be formed by applying a fluid form of an electrophoretic medium to a substrate, and applying a temporally varying voltage between an electrode and the substrate. The process may be repeated to allow for deposition of full color displays.

Owner:E INK CORPORATION

Encapsulated electrophoretic displays having a monolayer of capsules and materials and methods for making the same

Owner:E INK CORPORATION

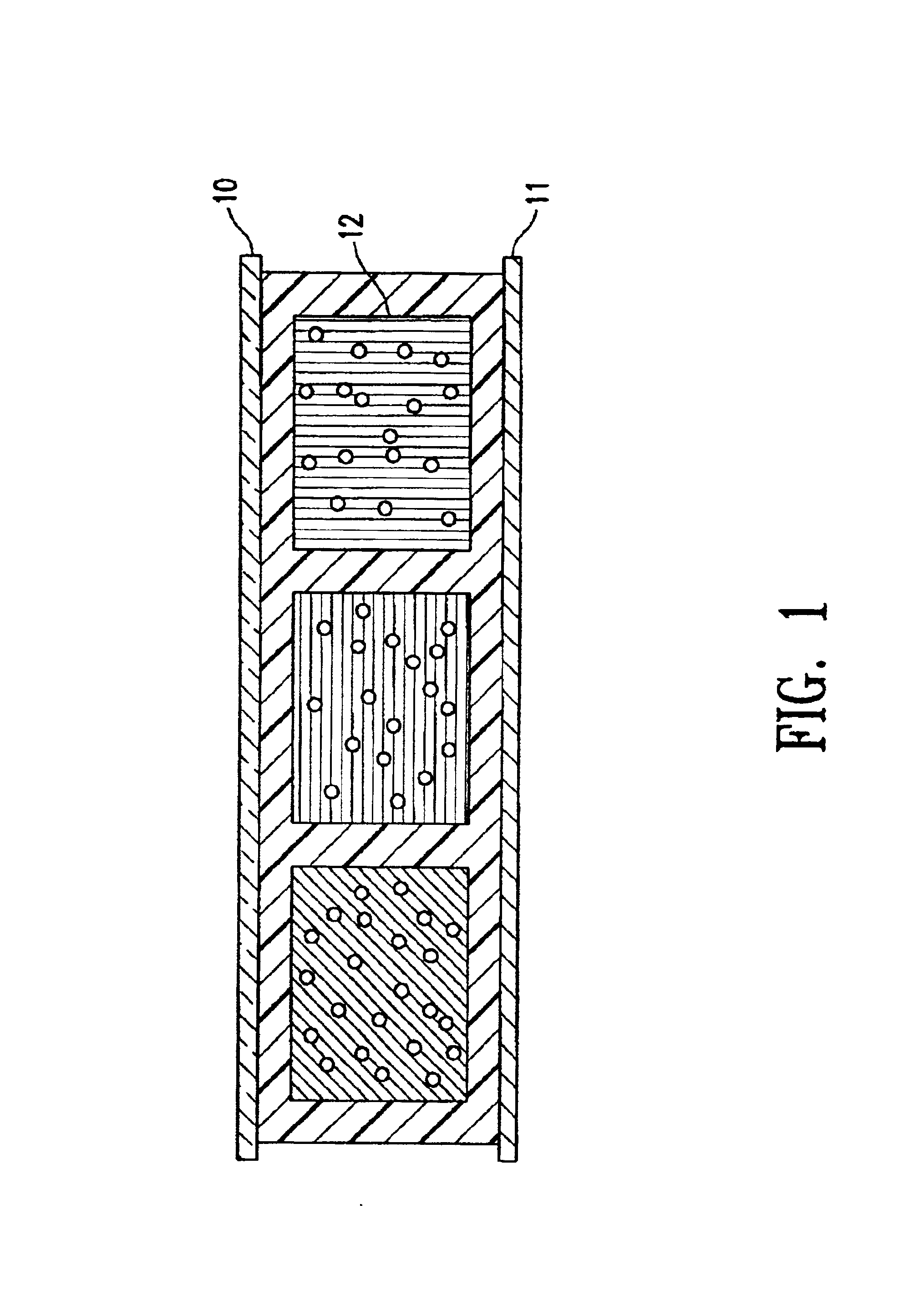

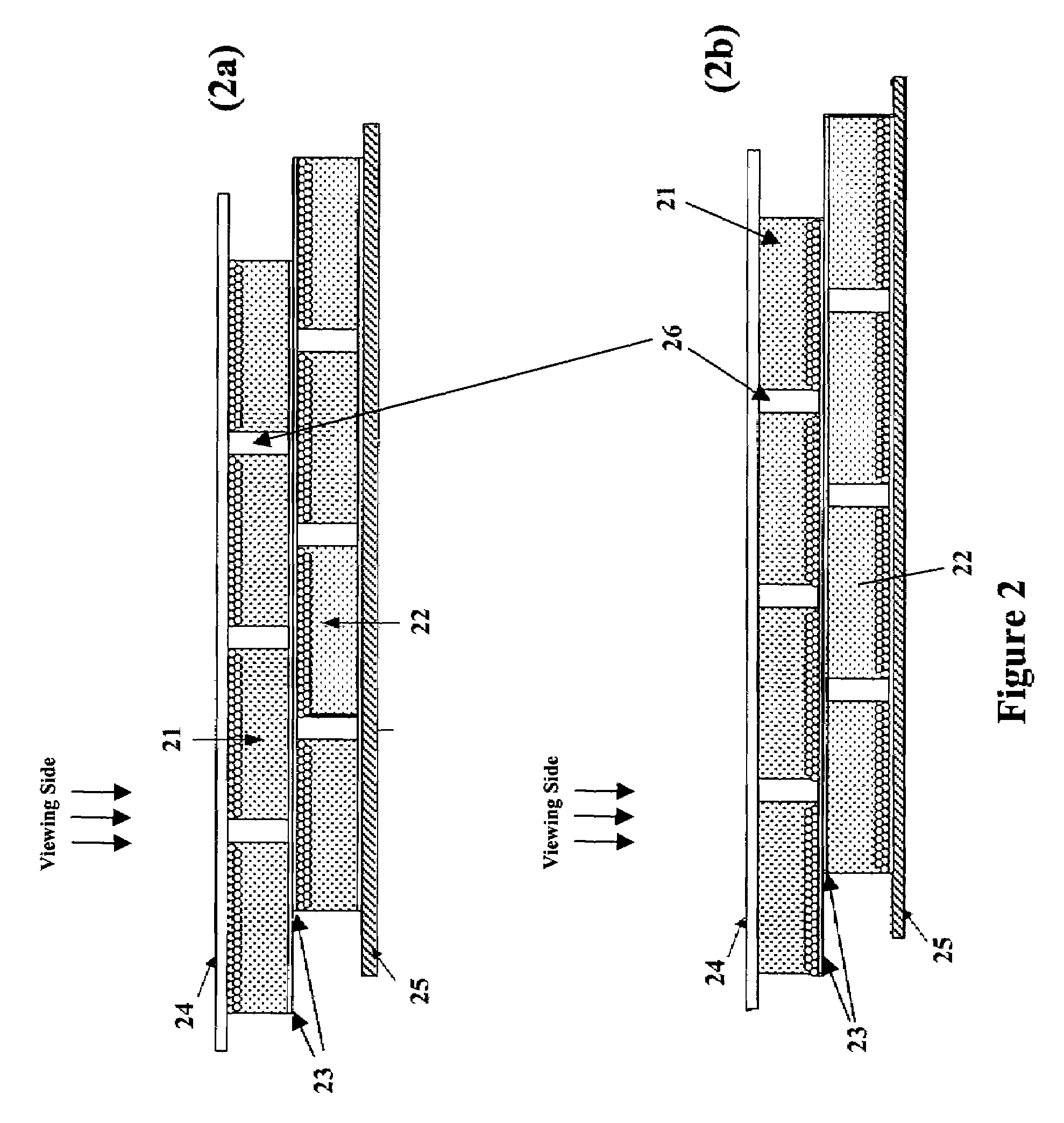

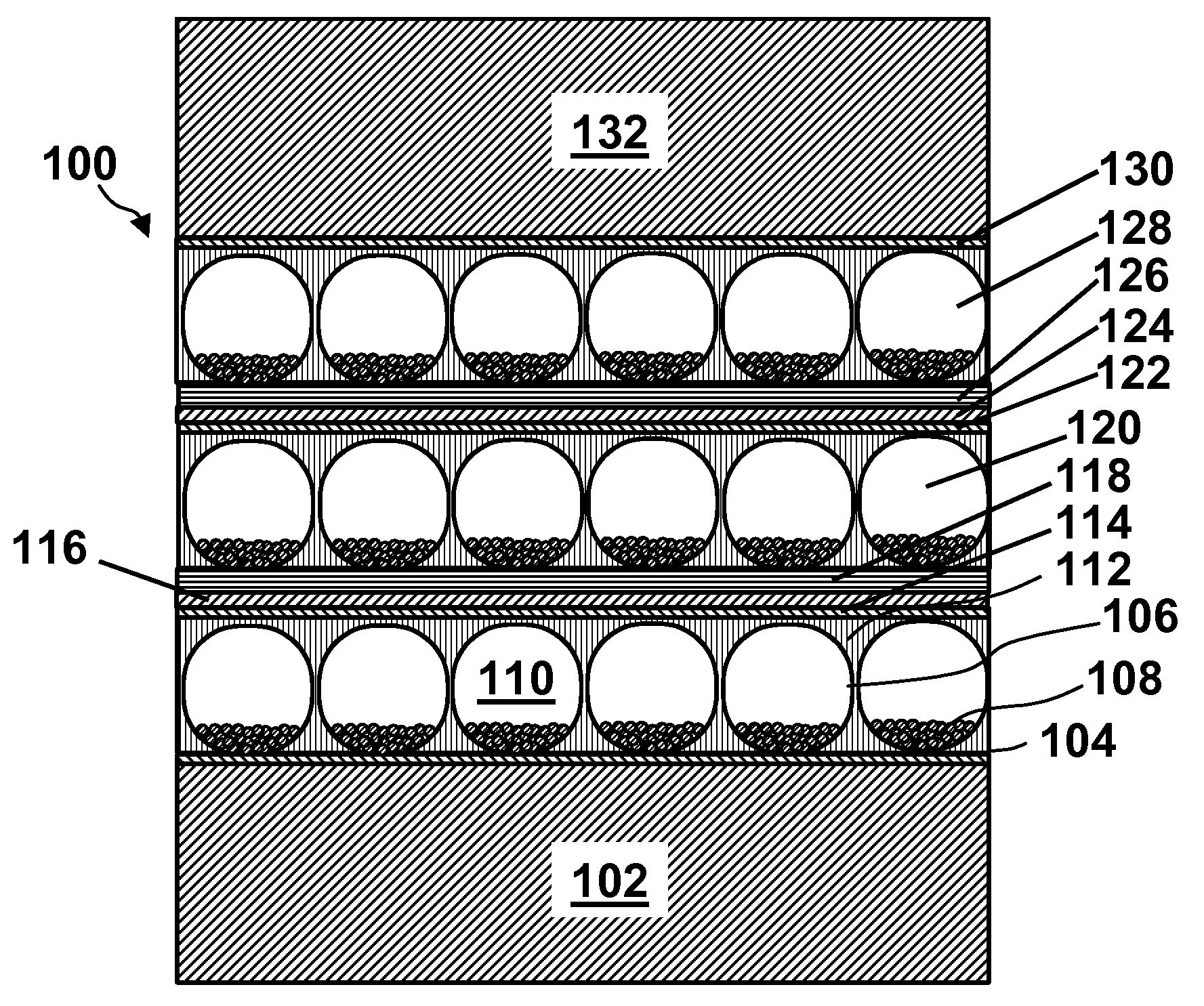

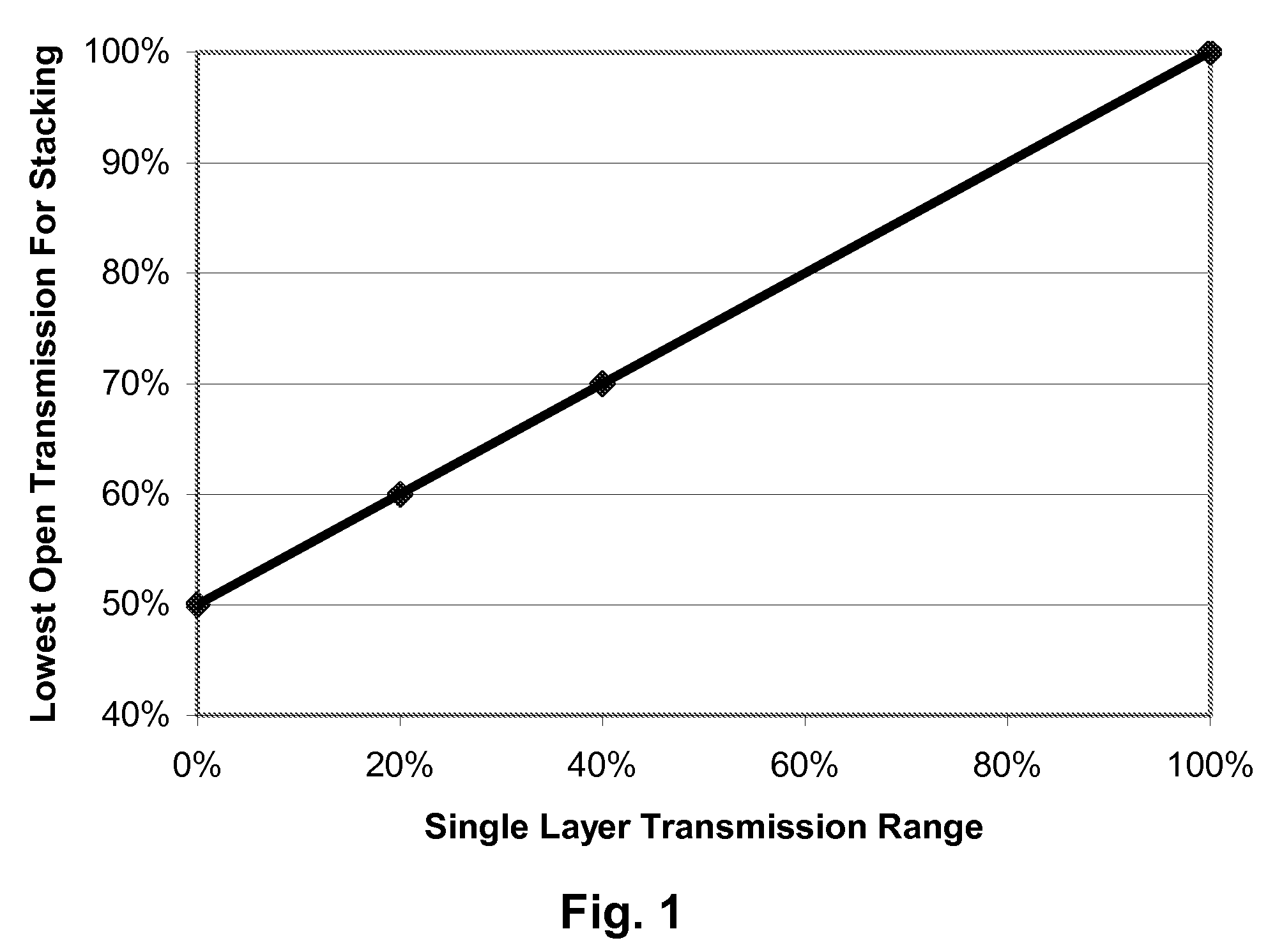

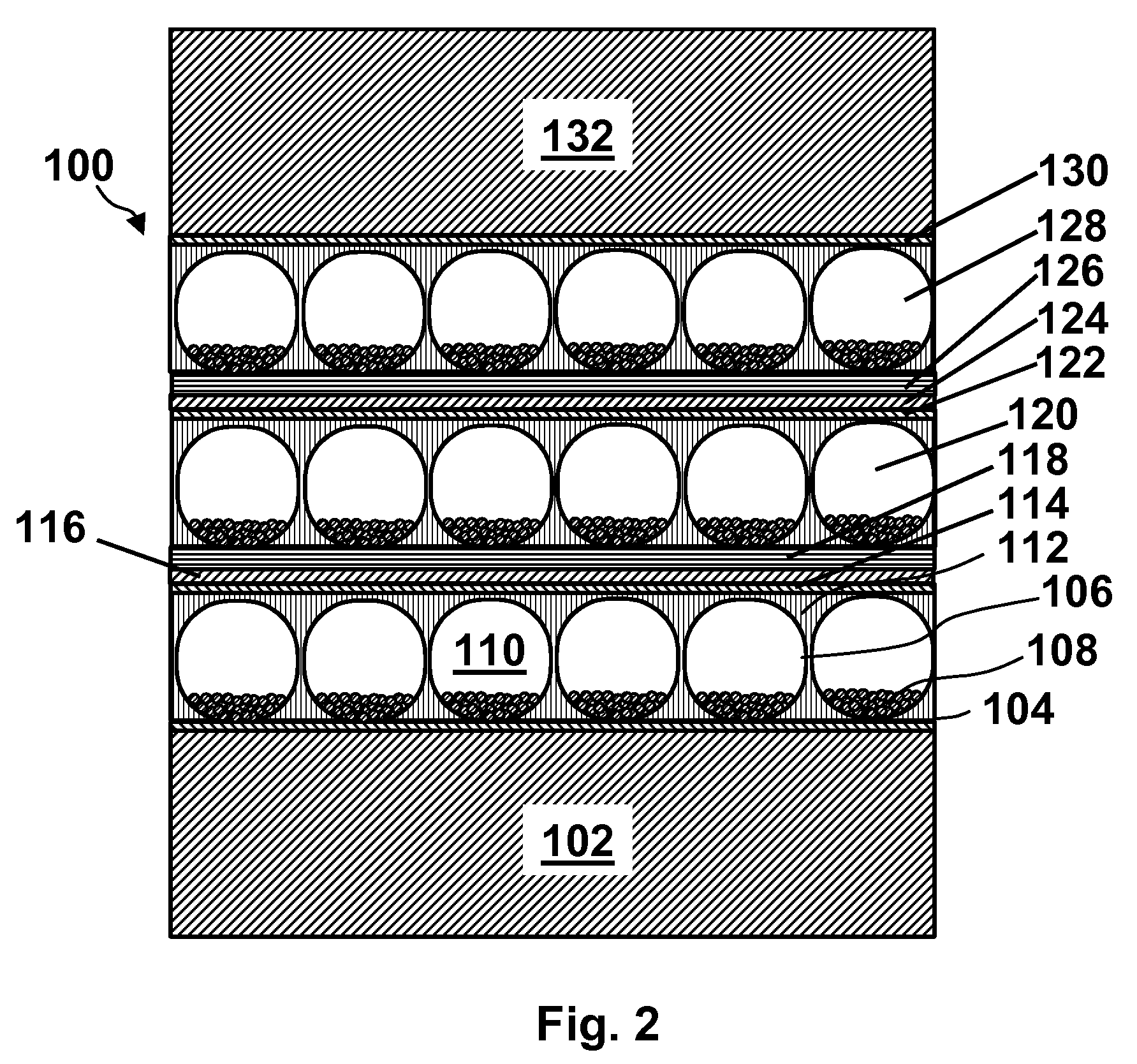

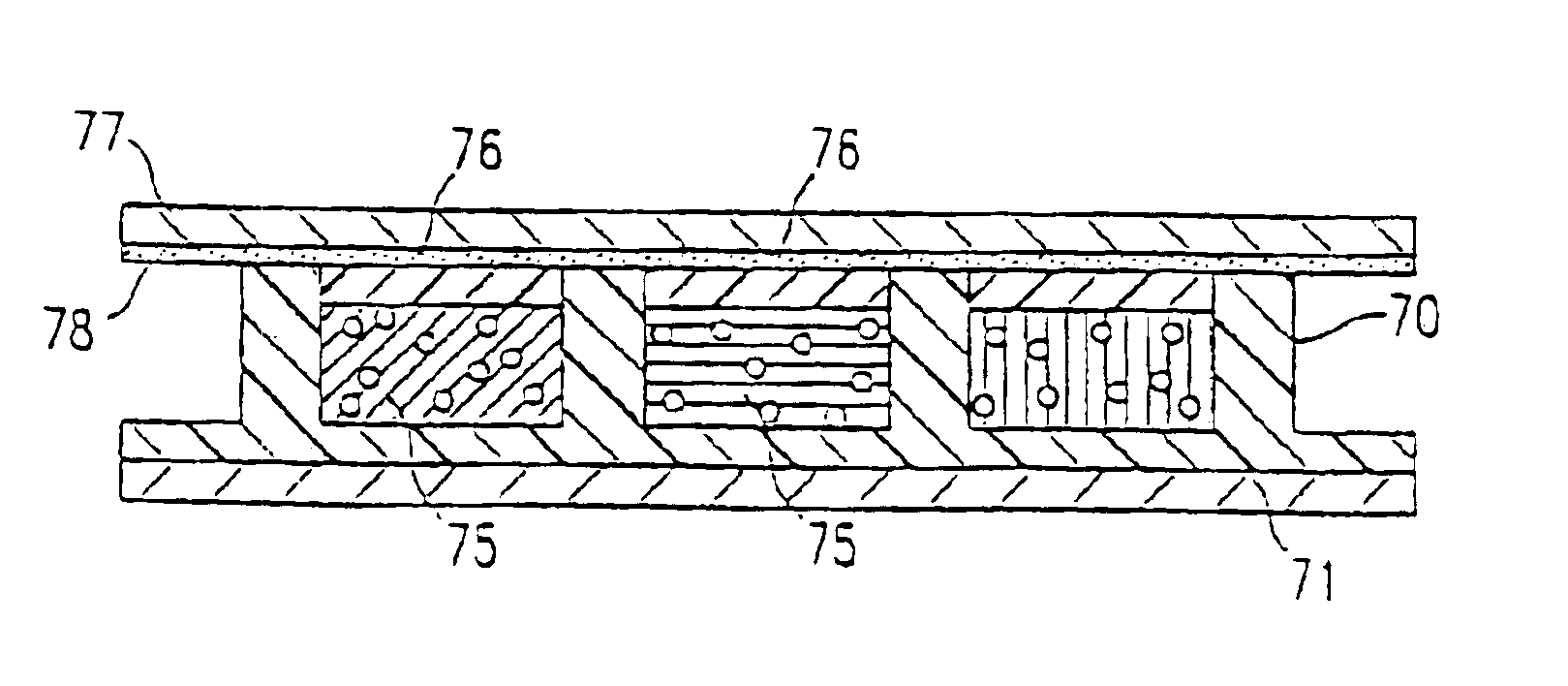

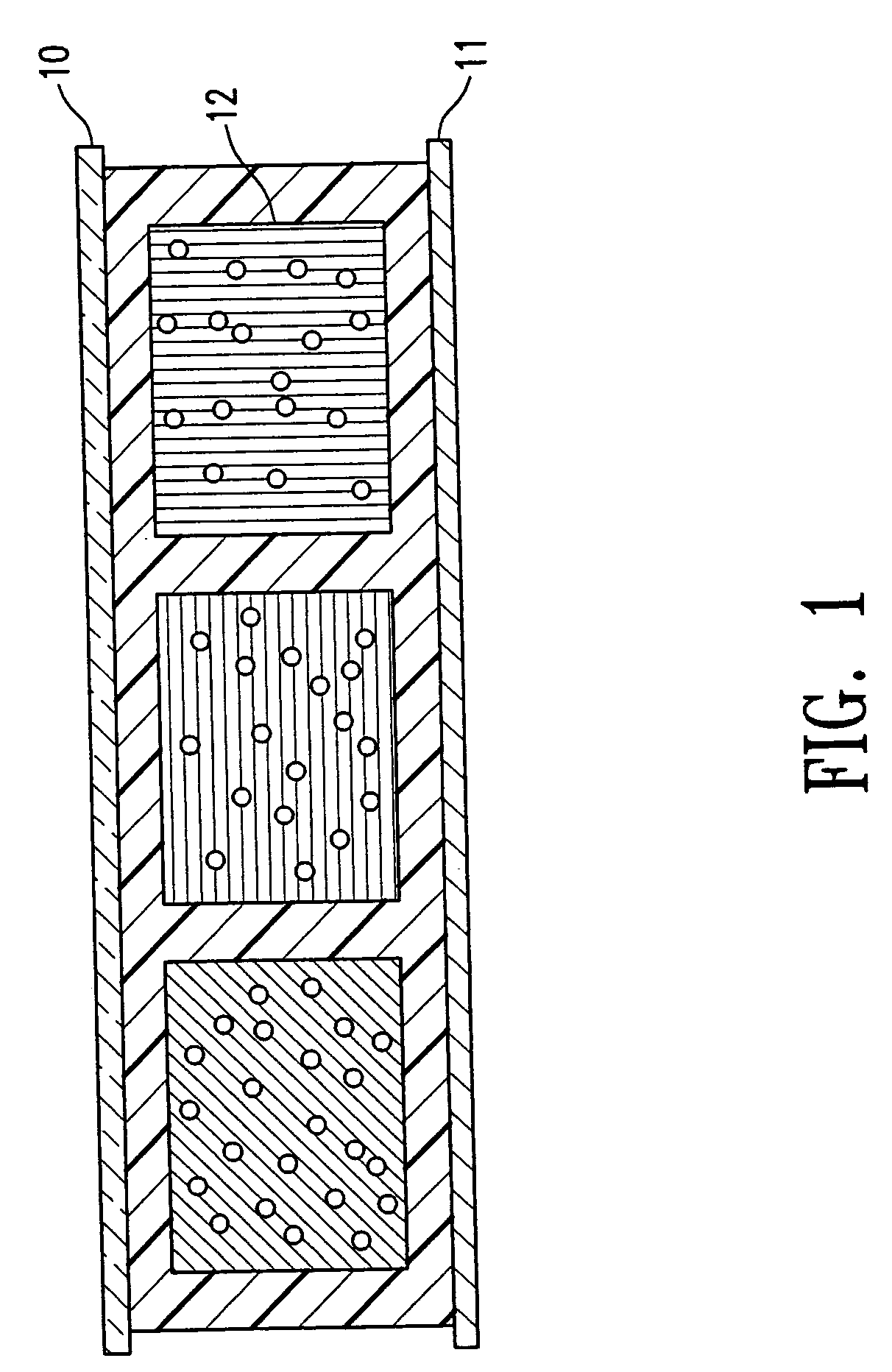

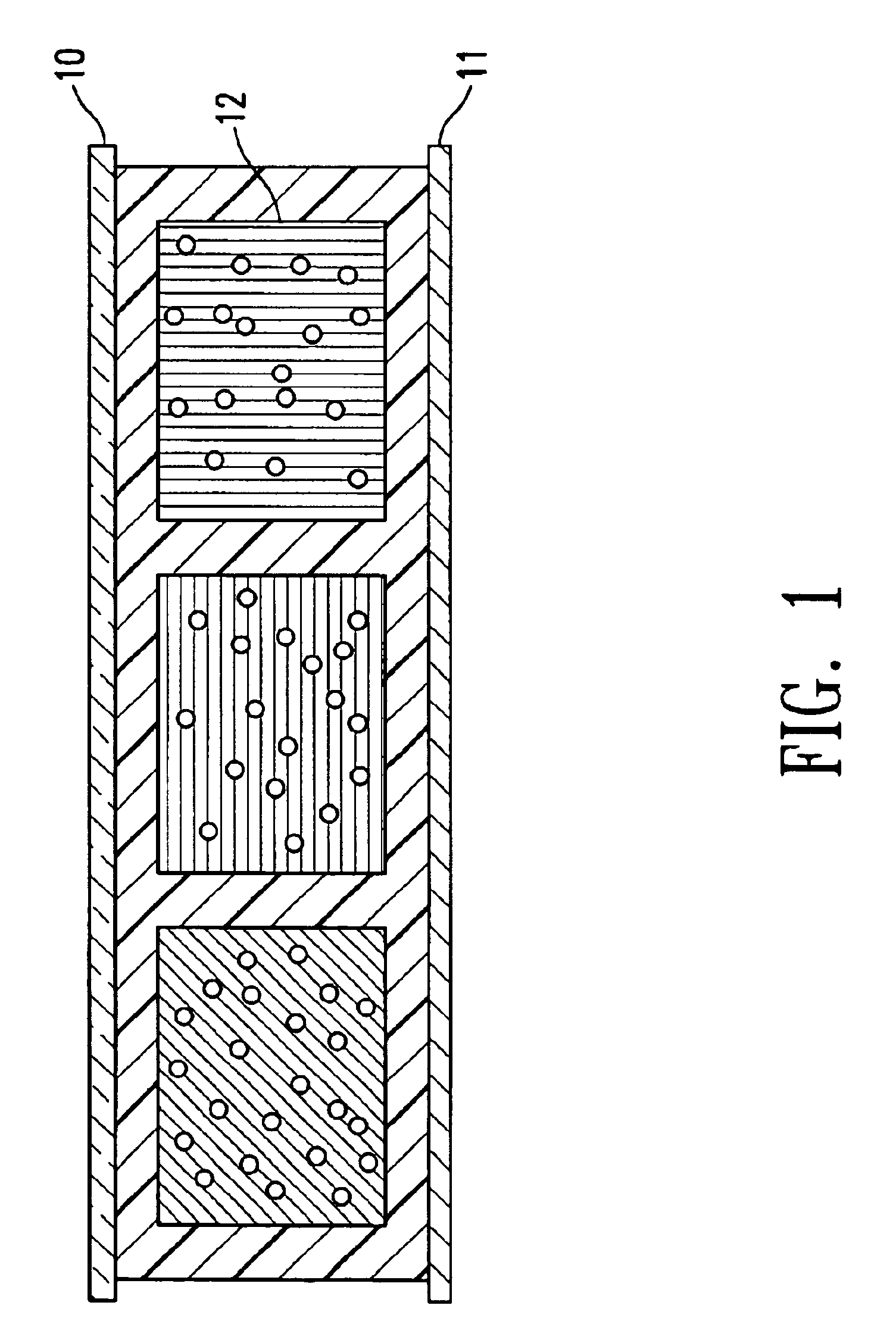

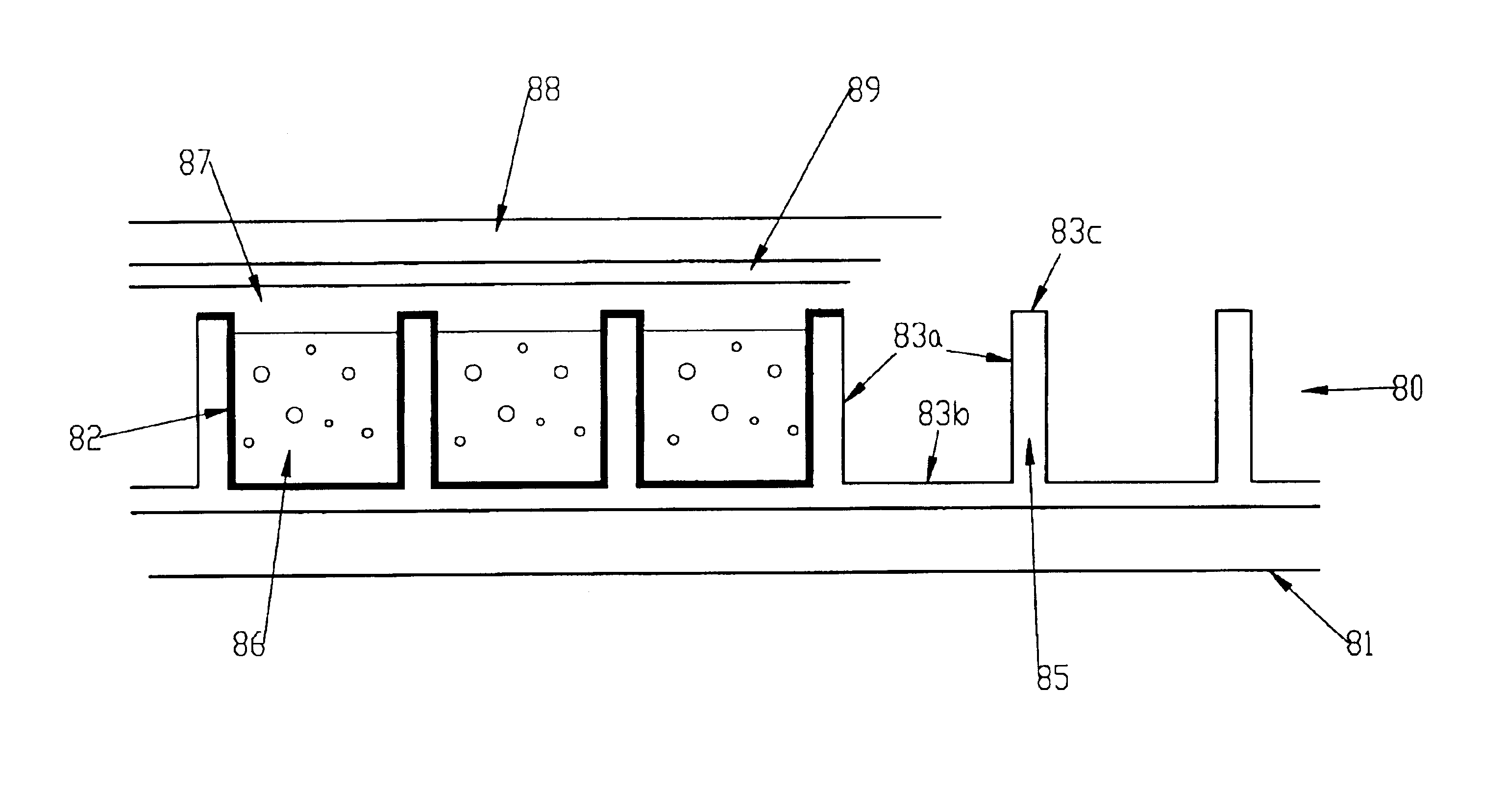

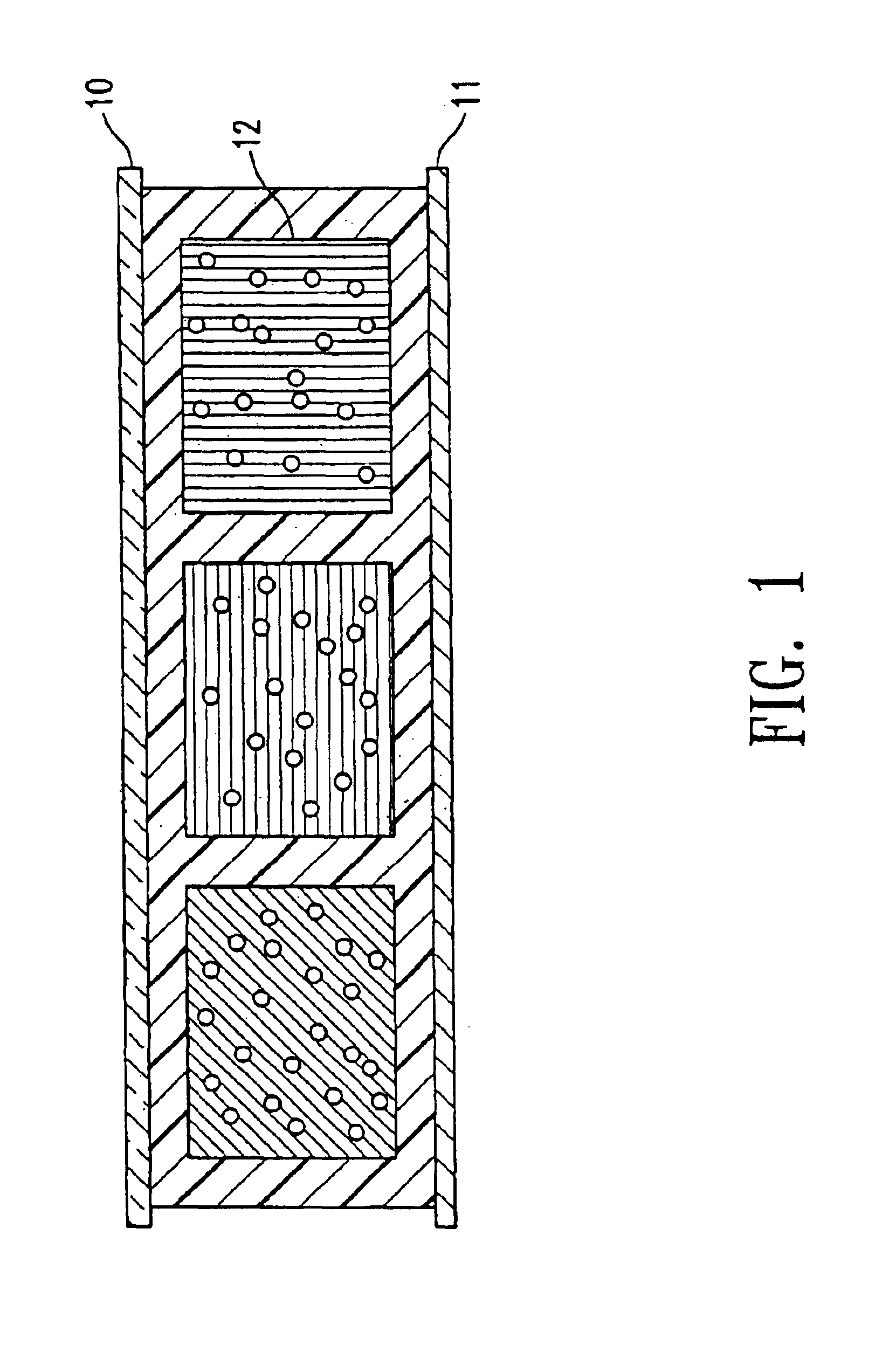

Multi-layer light modulator

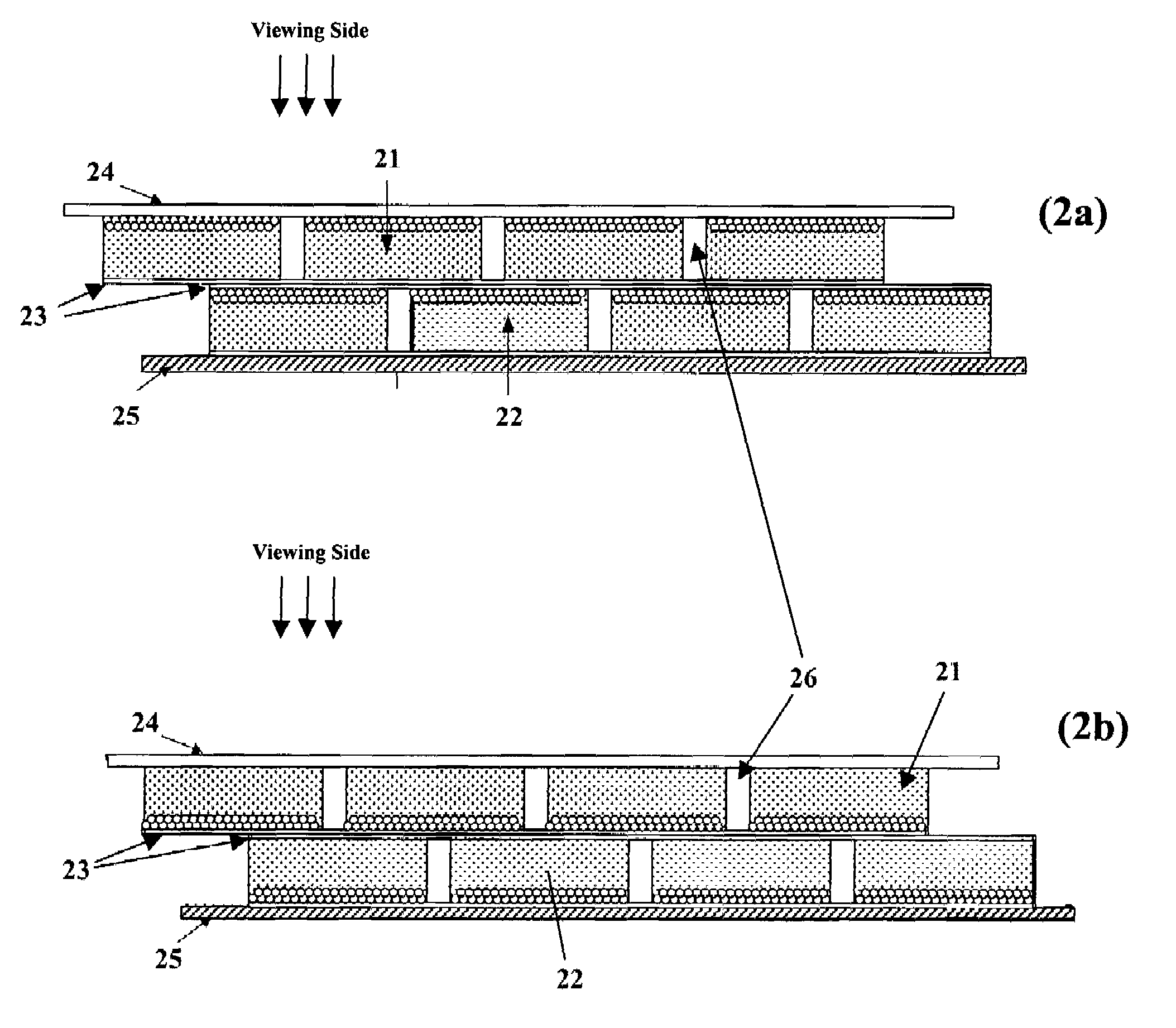

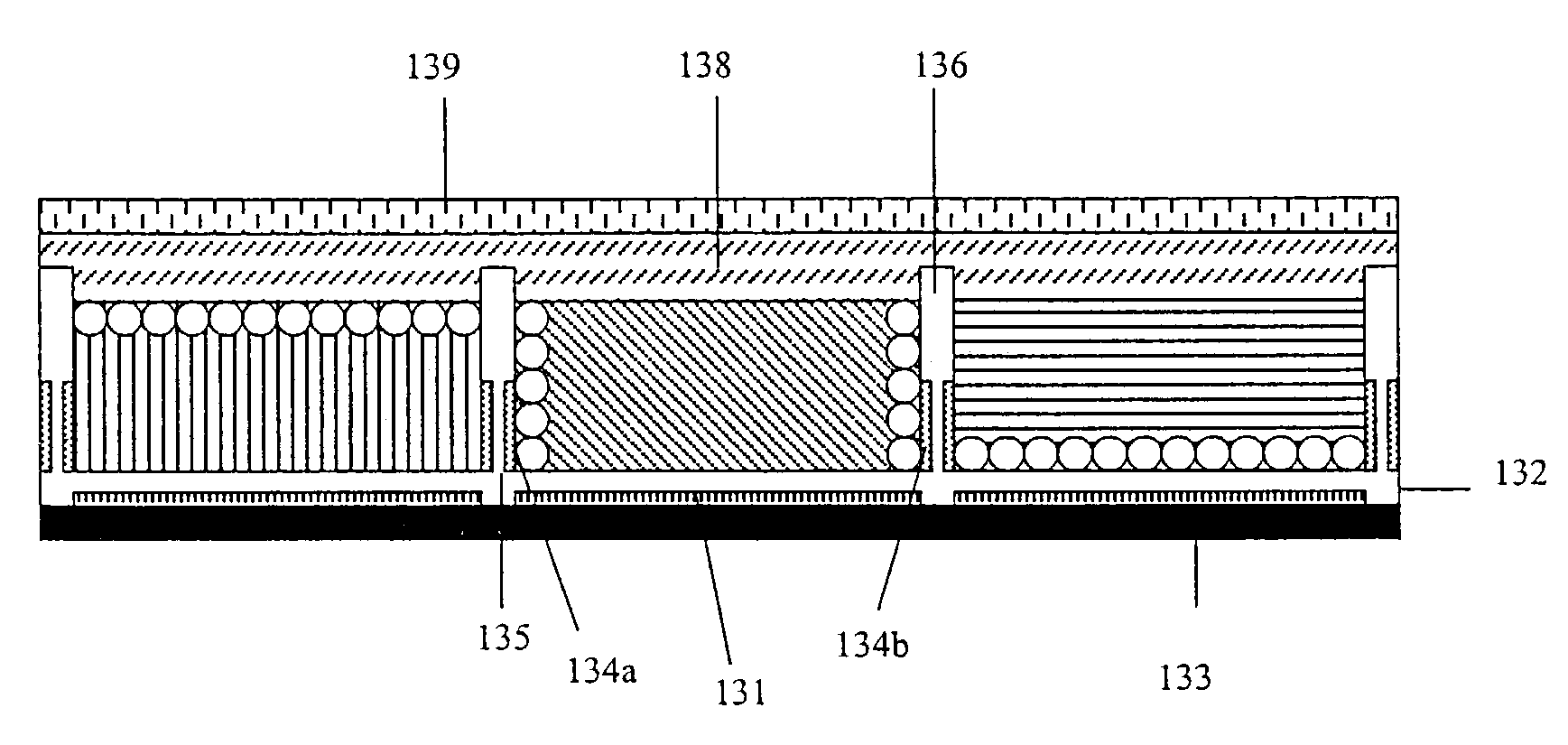

ActiveUS7492497B2Reduce light lossRecording apparatusStatic indicating devicesOptic layerHigh transmission

A light modulator comprises a plurality of discrete variable transmission electro-optic layers arranged so that light will pass successively through the plurality of layers; the light modulator has a higher transmission range than any of the individual electro-optic layers separately.

Owner:E INK CORPORATION

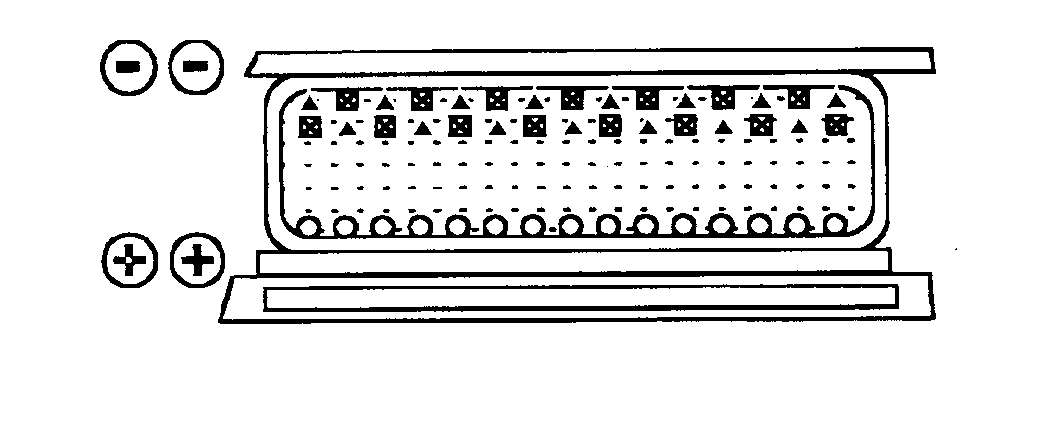

Electrophoretic dispersion, electrophoretic display device, method of manufacturing electrophoretic display device, and electronic system

ActiveUS6947203B2Reduces and prevents aggregationImprove the display effectElectrolysis componentsStatic indicating devicesInorganic particleElectronic systems

To provide an electrophoretic dispersion capable of reducing or preventing the aggregation of electrophoretic particles, an electrophoretic display device using the electrophoretic dispersion, a method of manufacturing the electrophoretic display device, and an electronic system superior in display performance; an electrophoretic display device (electrophoretic display unit) has: a first substrate with a first electrode; a second substrate with a second electrode opposite the first electrode; and an electrophoretic dispersion provided between the first substrate and second substrate. The electrophoretic dispersion (dispersion for electrophoretic display units) includes a liquid phase insulative dispersion medium and electrophoretic particles dispersed in the dispersion medium, the particles electrophoretically migrated under an influence of an electric field. Also included as the electrophoretic particles, inorganic particles and resin particles dyed a color different from that of the inorganic particles and having an electrical polarity opposite to that of the inorganic particles.

Owner:E INK CORPORATION

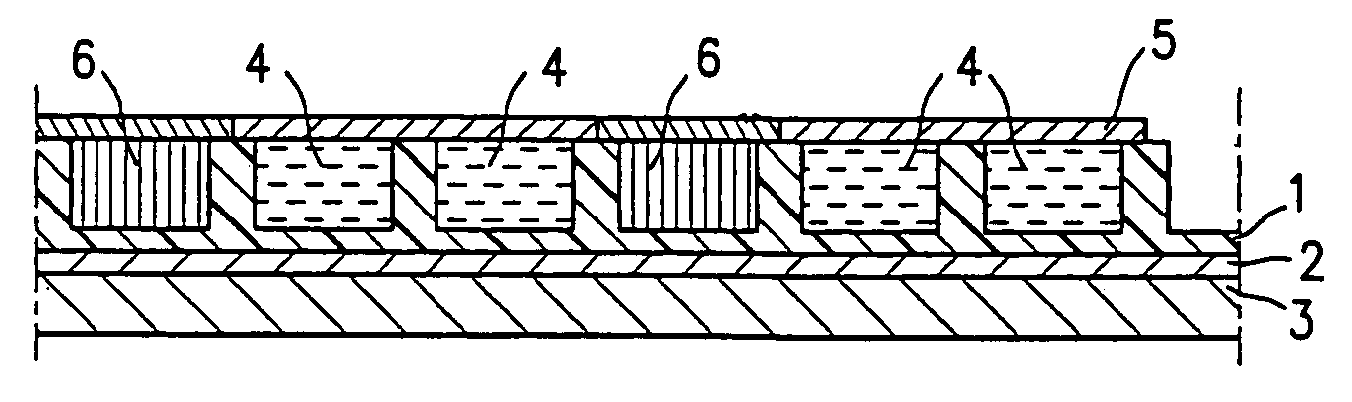

Process for imagewise opening and filling color display components and color displays manufactured thereof

InactiveUS6972893B2Maintain structural integrityWider materialStatic indicating devicesElectrographic processes using photoelectrophoresisDisplay deviceEngineering

Owner:E INK CALIFORNIA

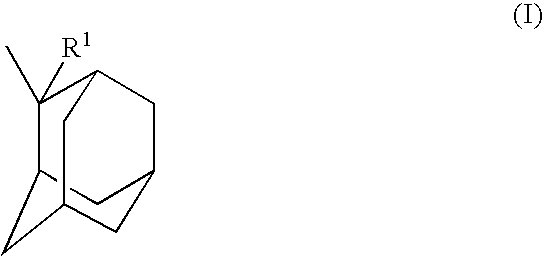

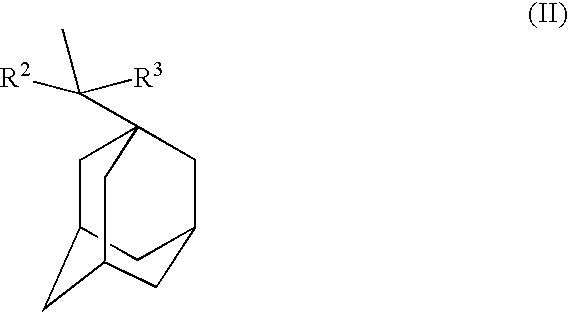

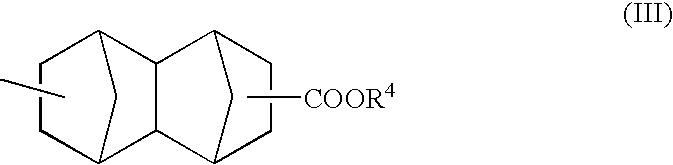

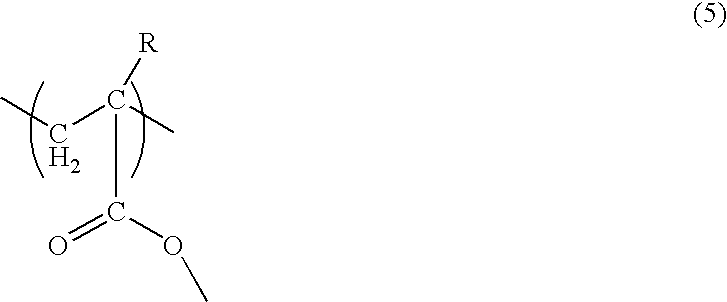

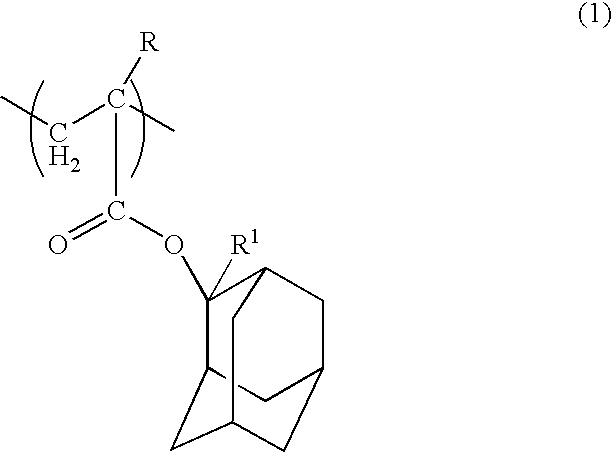

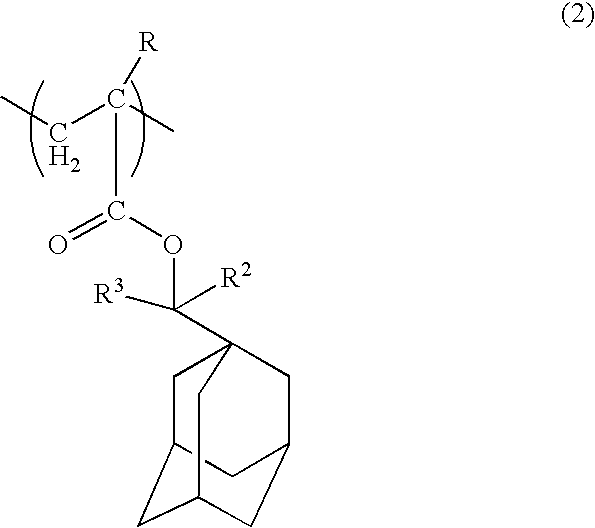

Positive resist composition and method of forming resist pattern from the same

InactiveUS20040110085A1Small line edge roughnessHigh resolutionRadiation applicationsSemiconductor/solid-state device manufacturingSolubilityMethacrylate

There is provided a positive type resin composition comprising (A) a resin component comprising within the principal chain a structural unit derived from a (meth)acrylate ester and incorporating an acid dissociable, dissolution inhibiting group containing a polycyclic group on an ester side chain section, for which the solubility in alkali increases under the action of acid, (B) an acid generator component which generates acid on exposure, and (C) an organic solvent, wherein the component (A) comprises both a structural unit derived from a methacrylate ester and a structural unit derived from an acrylate ester. According to such a resist composition, a resist pattern can be formed which displays little surface roughness and line edge roughness on etching, and also offers excellent resolution and a wide depth of focus range.

Owner:TOKYO OHKA KOGYO CO LTD

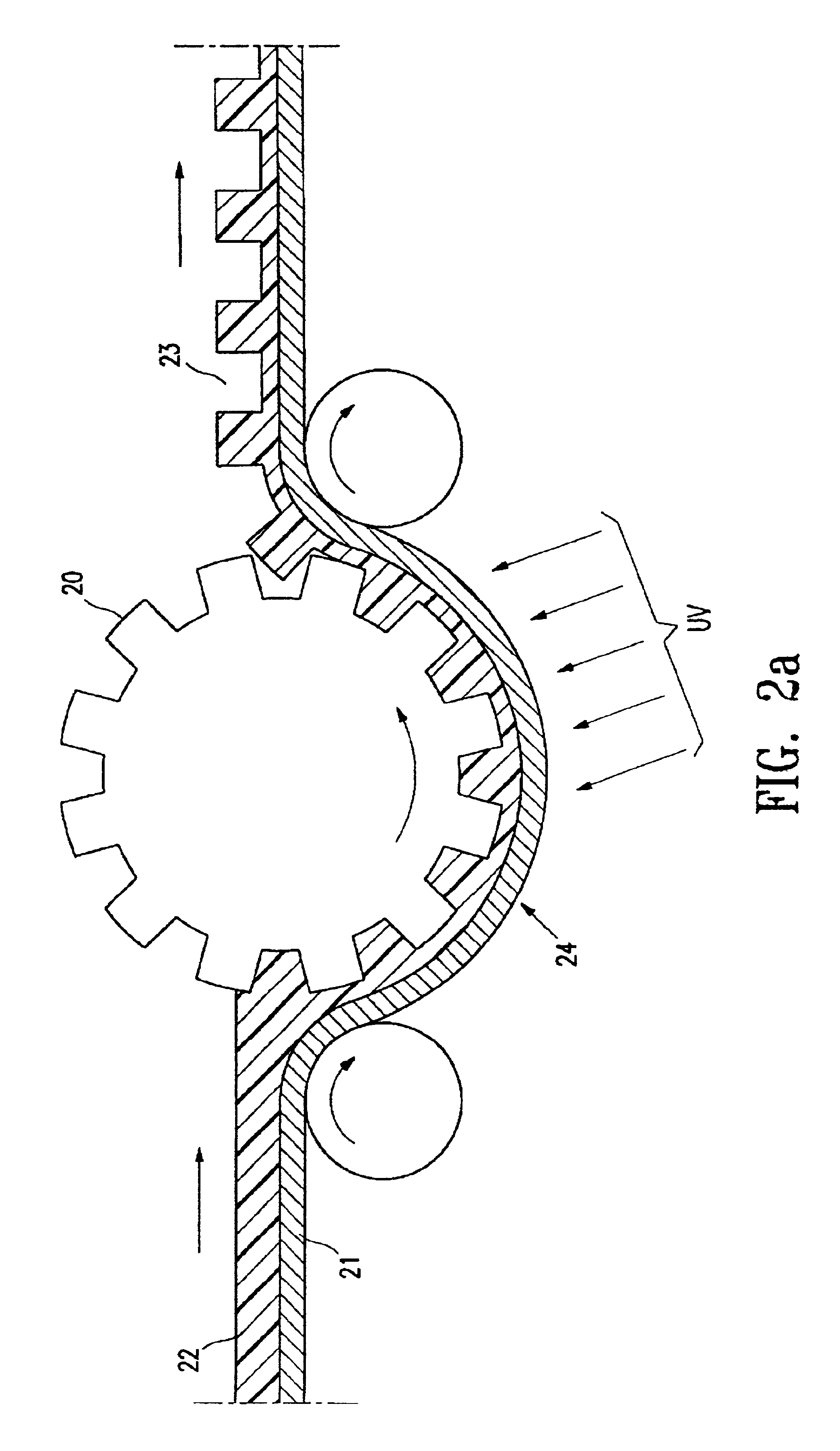

Electrophoretic display and novel process for its manufacture

InactiveUS6859302B2Excellent color addressabilityIncrease volumeSludge treatmentStatic indicating devicesElectrical batteryElectrophoresis

This invention relates to an electrophoretic display comprising cells of well-defined shape, size and aspect ratio which cells are filled with charged pigment particles dispersed in a solvent, and novel processes for its manufacture.

Owner:E INK CALIFORNIA

Electrophoretic display and process for its manufacture

InactiveUS7052571B2Excellent color addressabilityIncrease contrastFurnace componentsLamination ancillary operationsElectrophoresisDisplay device

This invention relates to an electrophoretic display comprising cells of well-defined shape, size and aspect ratio, which cells are filled with charged pigment particles dispersed in a solvent, and novel processes for its manufacture.

Owner:E INK CORPORATION

Process for imagewise opening and filling color display components and color displays manufactured thereof

InactiveUS7385751B2Wider materialWider processElectrographic processes using photoelectrophoresisElectrographic process apparatusDisplay deviceEngineering

Owner:E INK CALIFORNIA

Additive for improving optical performance of an electrophoretic display

ActiveUS8902491B2Static indicating devicesElectrographic processes using photoelectrophoresisElectrophoresisDisplay device

The present invention is directed to an electrophoretic fluid comprising uncharged or lightly charged neutral buoyancy particles. The resulting fluid can improve not only image stability but also contrast ratio of a display device, without significantly affecting the switching speed. The present invention is also directed to an electrophoretic display comprising display cells filled with the electrophoretic fluid.

Owner:E INK CORPORATION

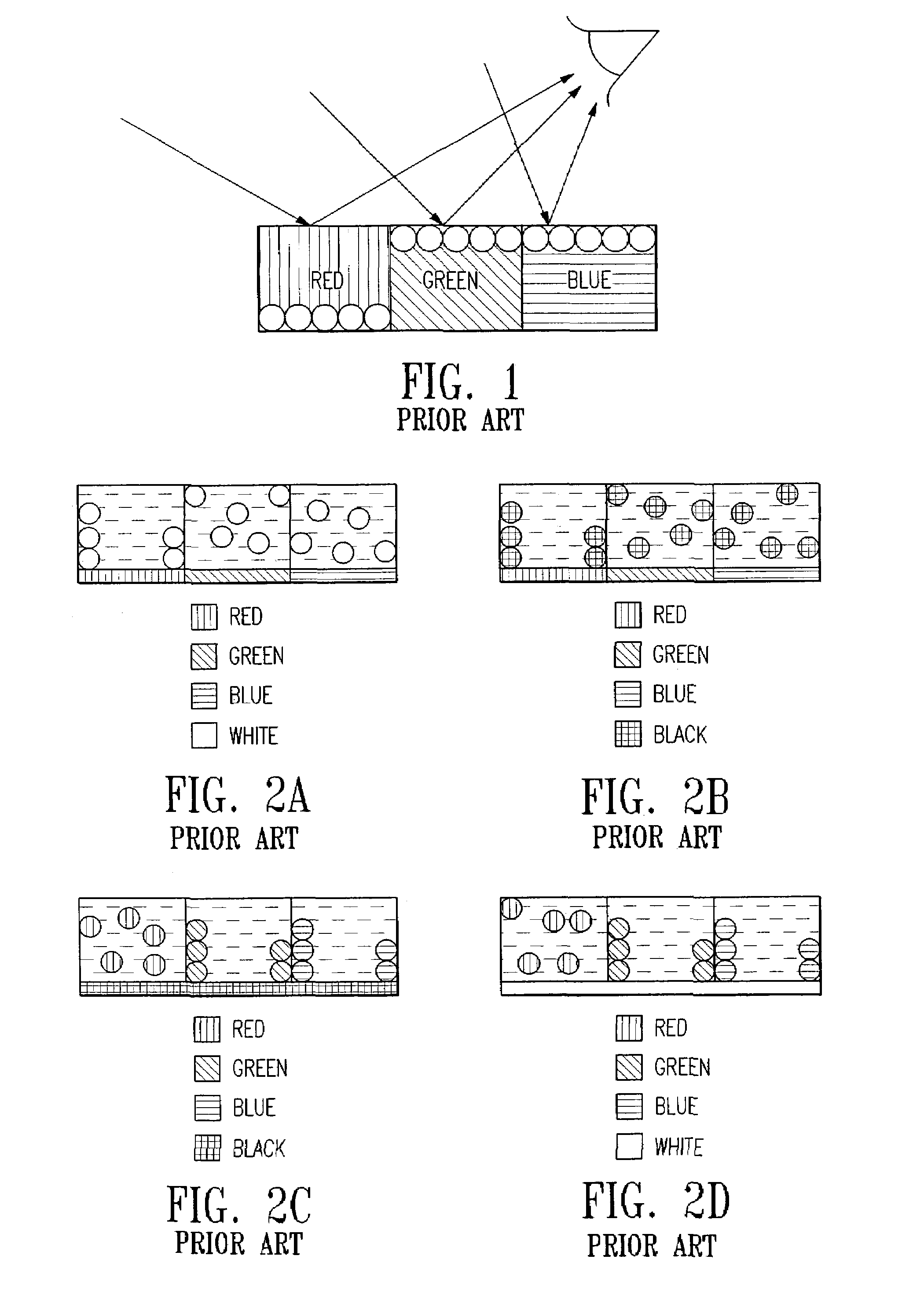

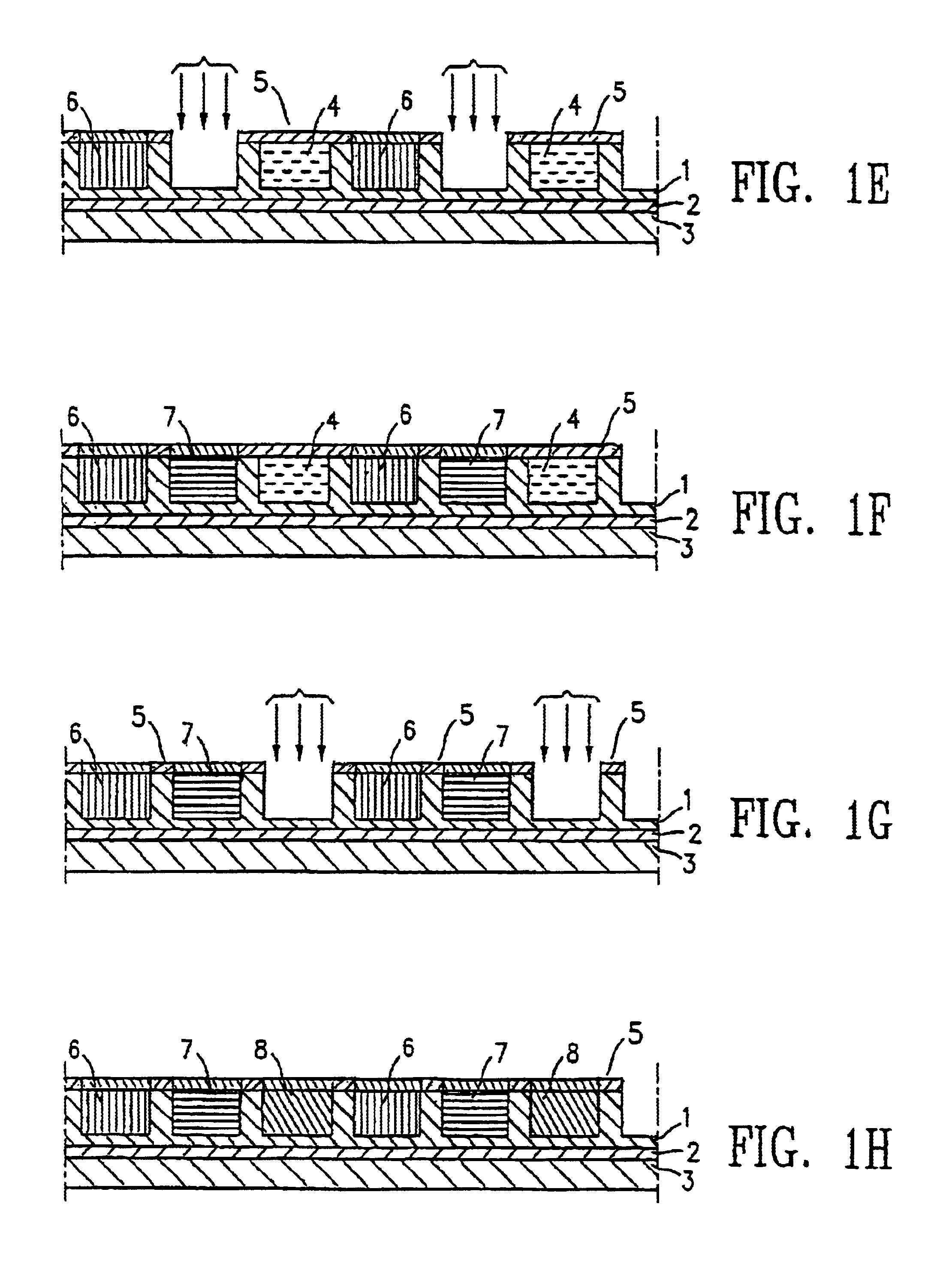

Multi-color electro-optic displays

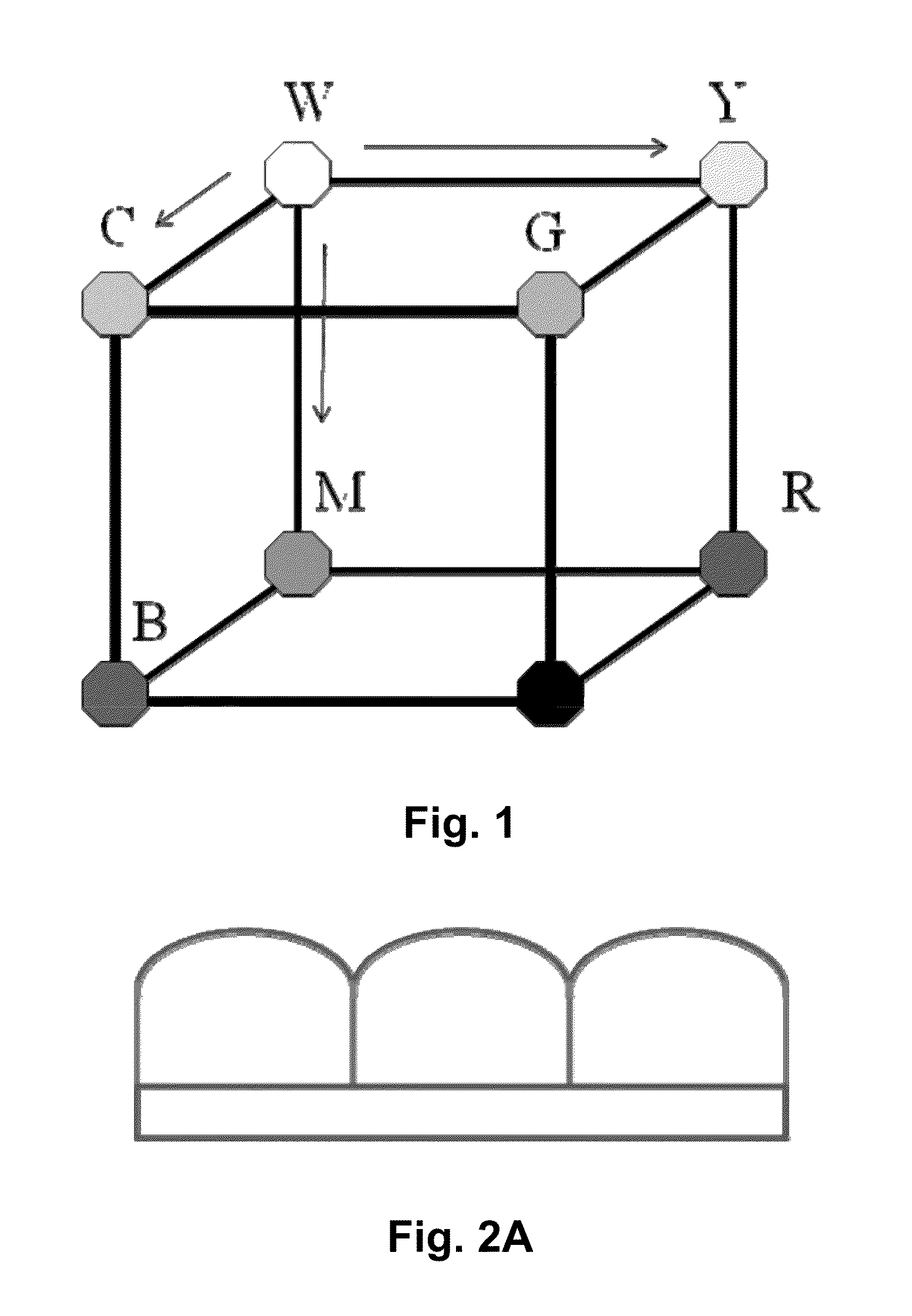

ActiveUS8576476B2Low viscosityLow dispersionStatic indicating devicesElectrographic processes using photoelectrophoresisDisplay deviceComputer science

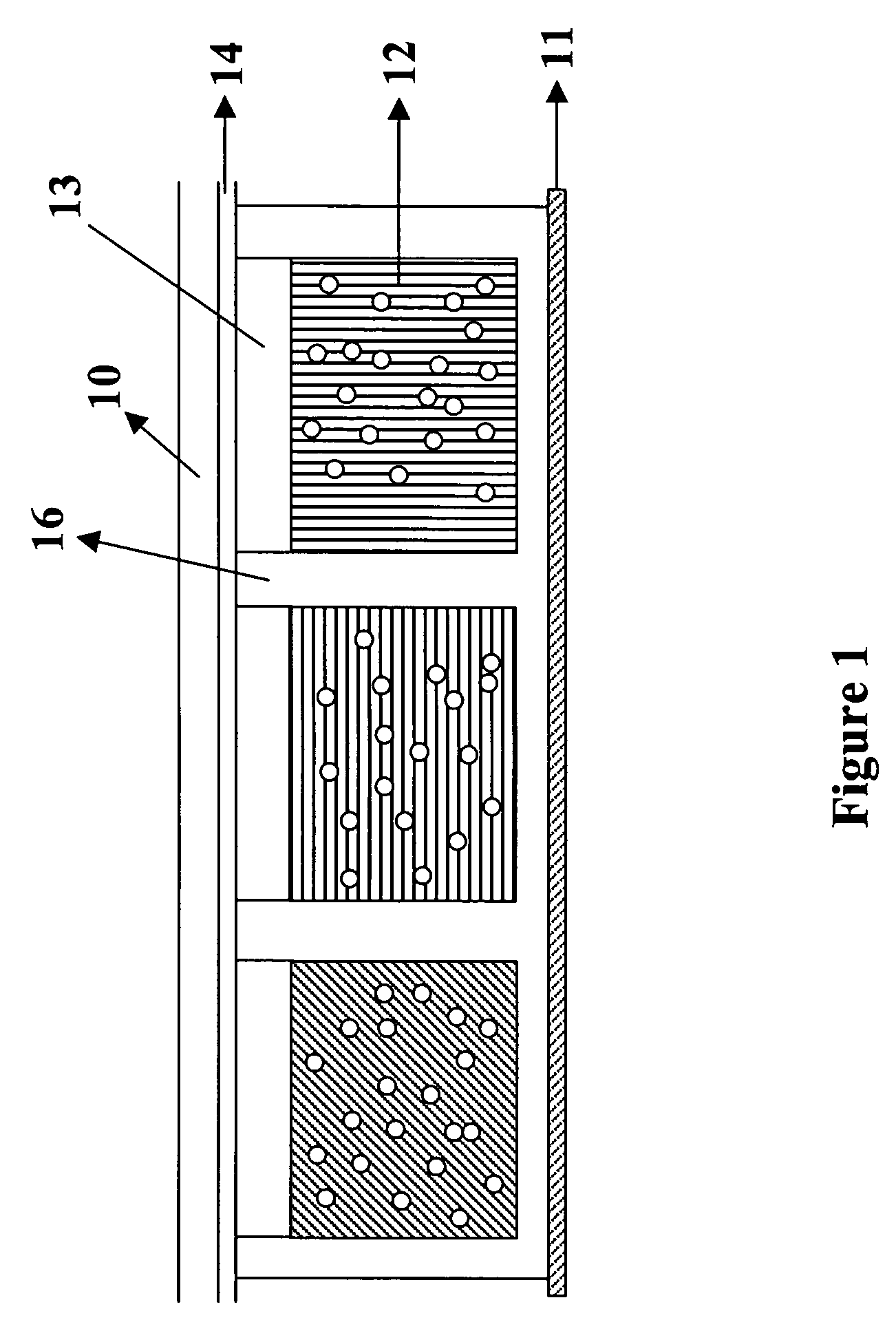

An electro-optic display comprising at least two separate layers of electro-optic material, with one of these layers being capable of displaying at least one optical state which cannot be displayed by the other layer. The display is driven by a single set of electrodes between which both layers are sandwiched, the two layers being controllable at least partially independently of one another. Another form of the invention uses three different types of particles within a single electrophoretic layer, with the three types of particles being arranged to shutter independently of one another.

Owner:E INK CORPORATION

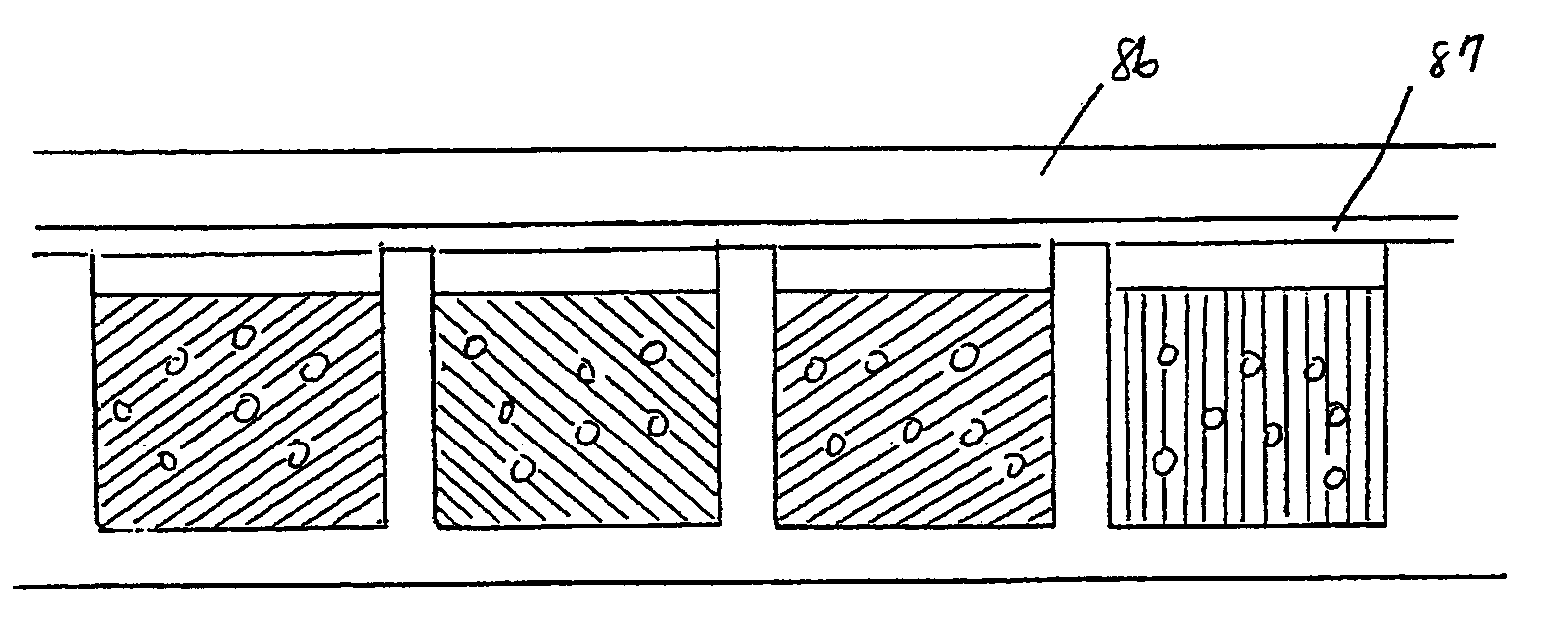

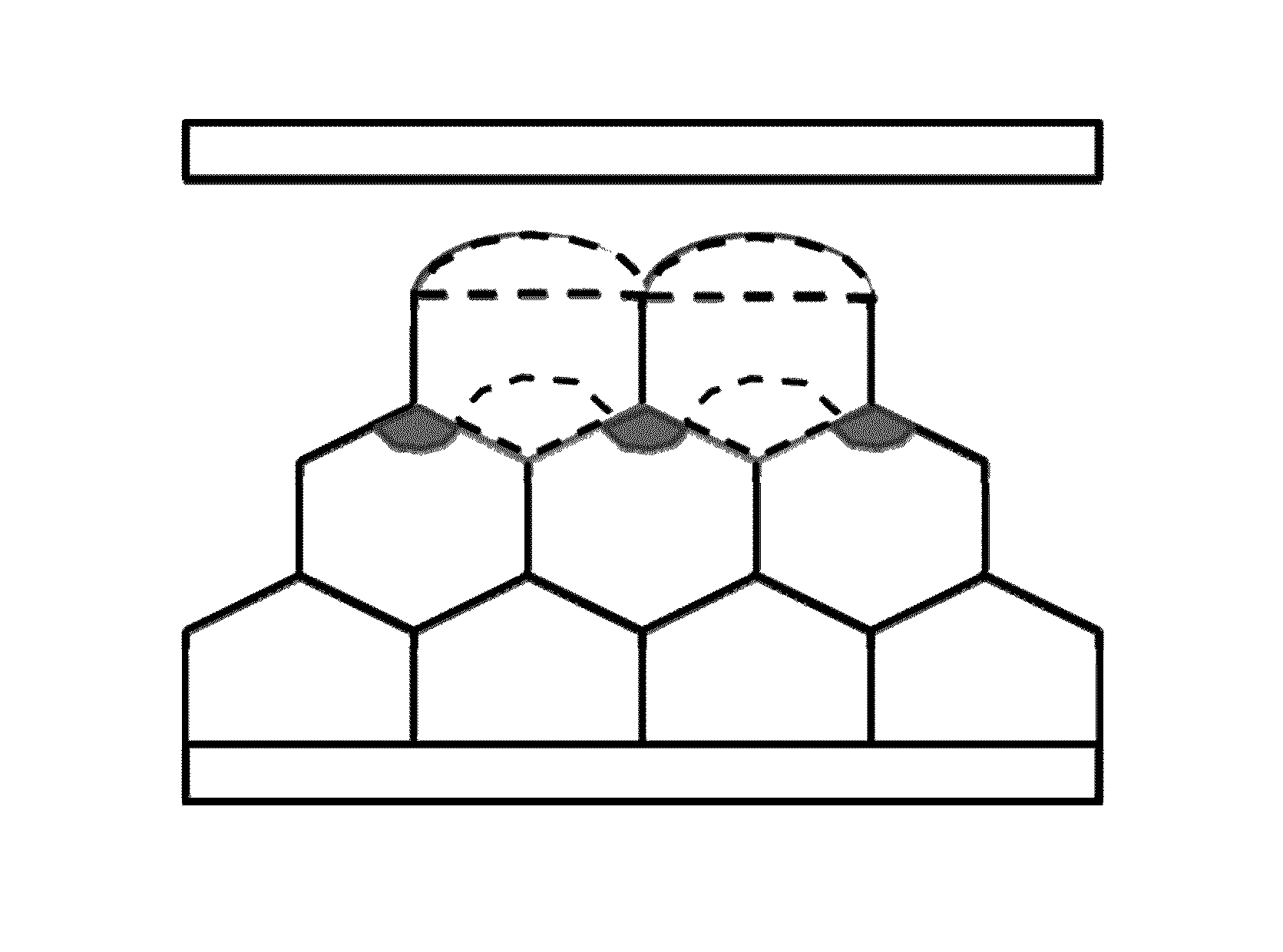

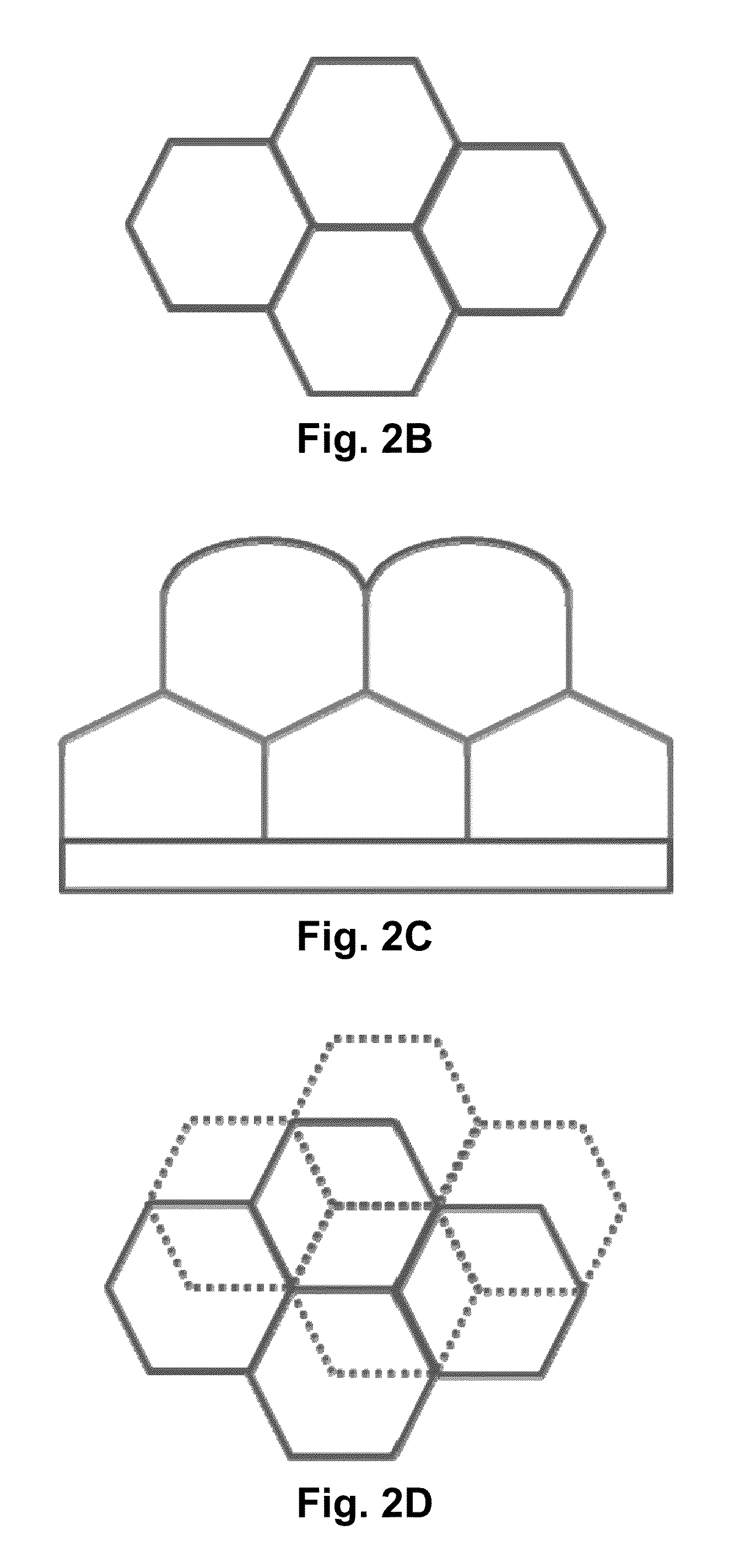

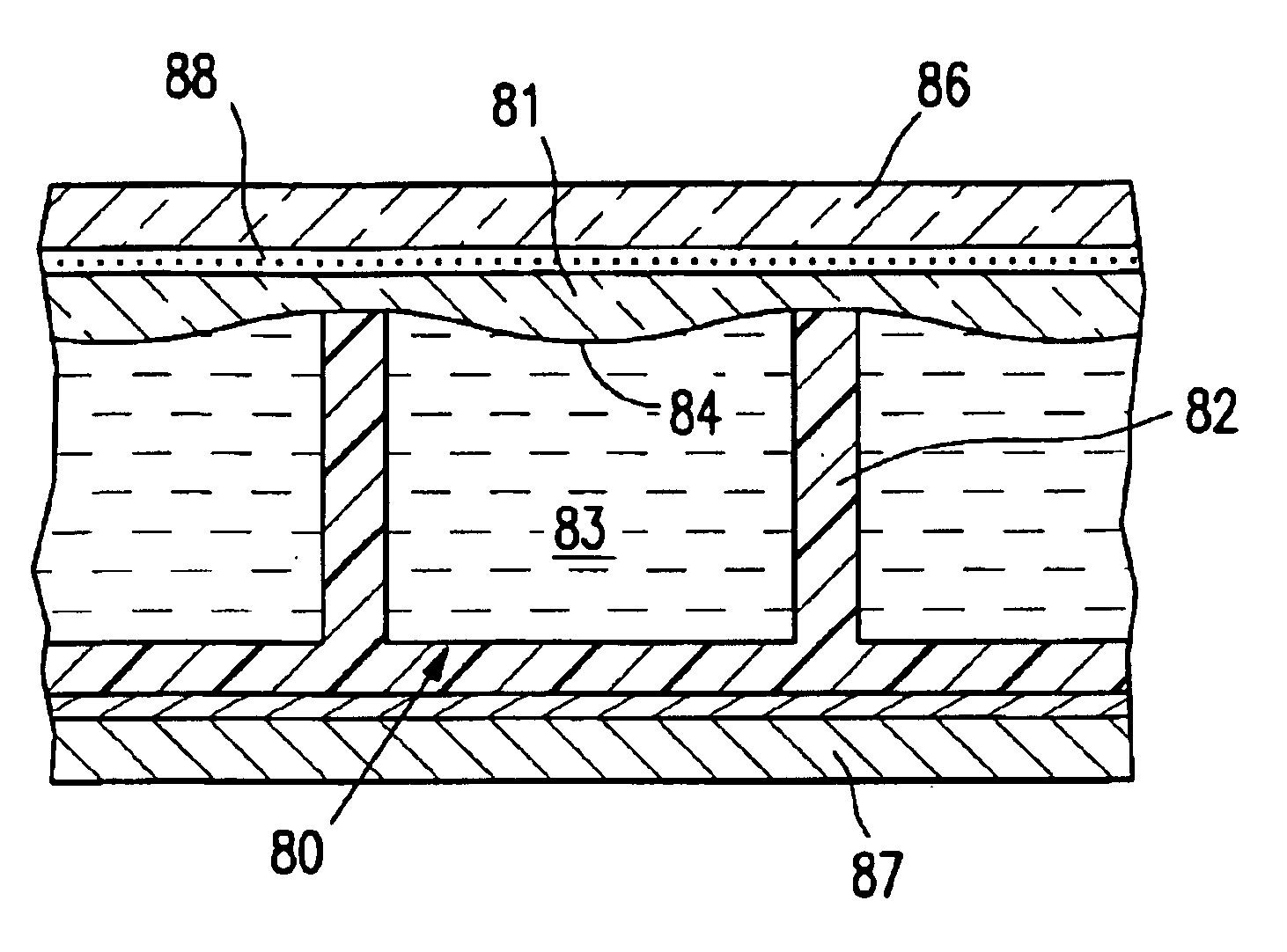

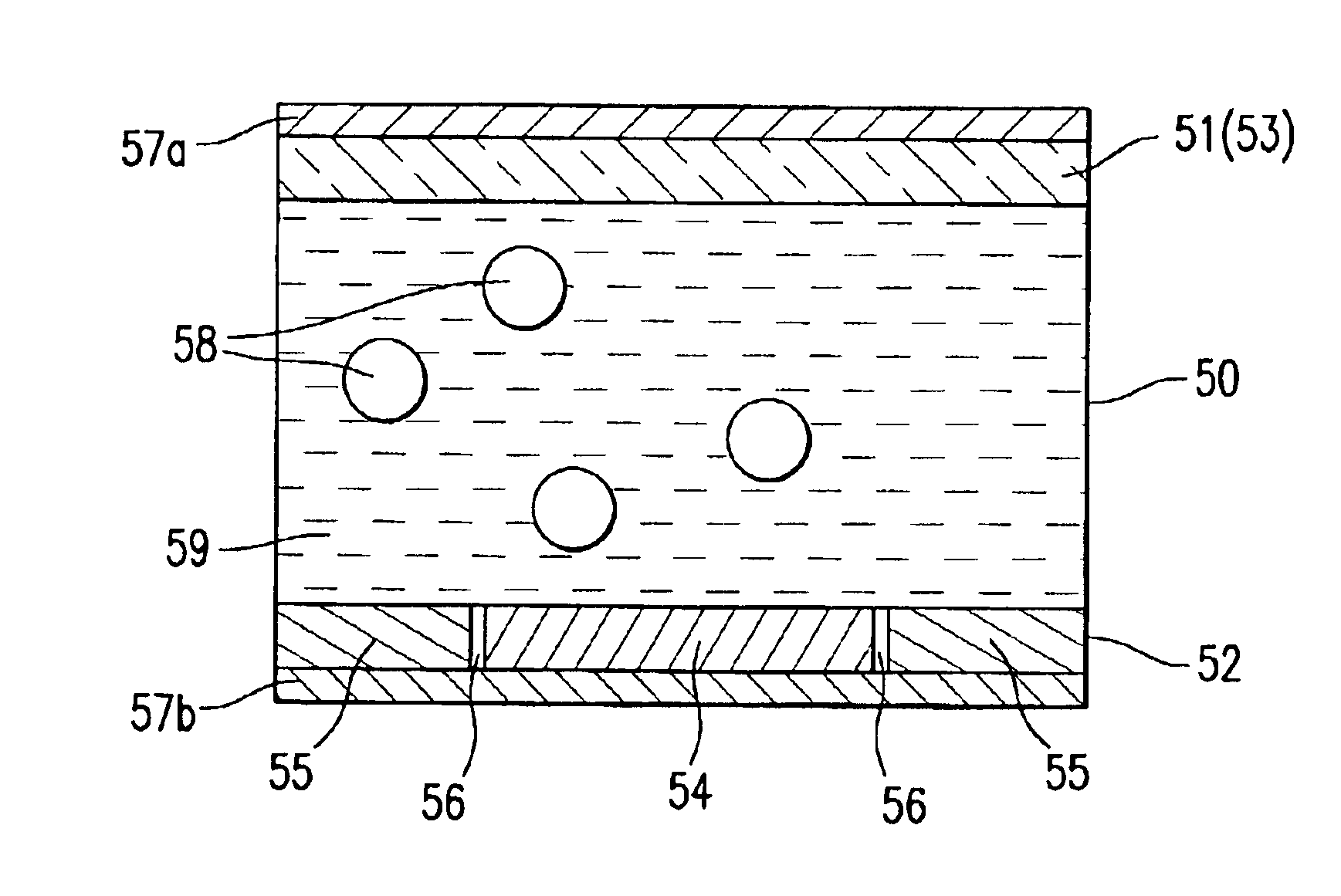

Electrophoretic display with sub relief structure for high contrast ratio and improved shear and/or compression resistance

This invention relates to an electrophoretic display comprising isolated cells of well-defined shape, size and aspect ratio which cells have internal sub relief structures and are filled with charged pigment particles dispersed in a dielectric solvent. The display shows an improved contrast ratio and resistance against shear and compression pressures. The display may have the traditional up / down switching mode, an in-plane switching mode or a dual switching mode.

Owner:E INK CALIFORNIA

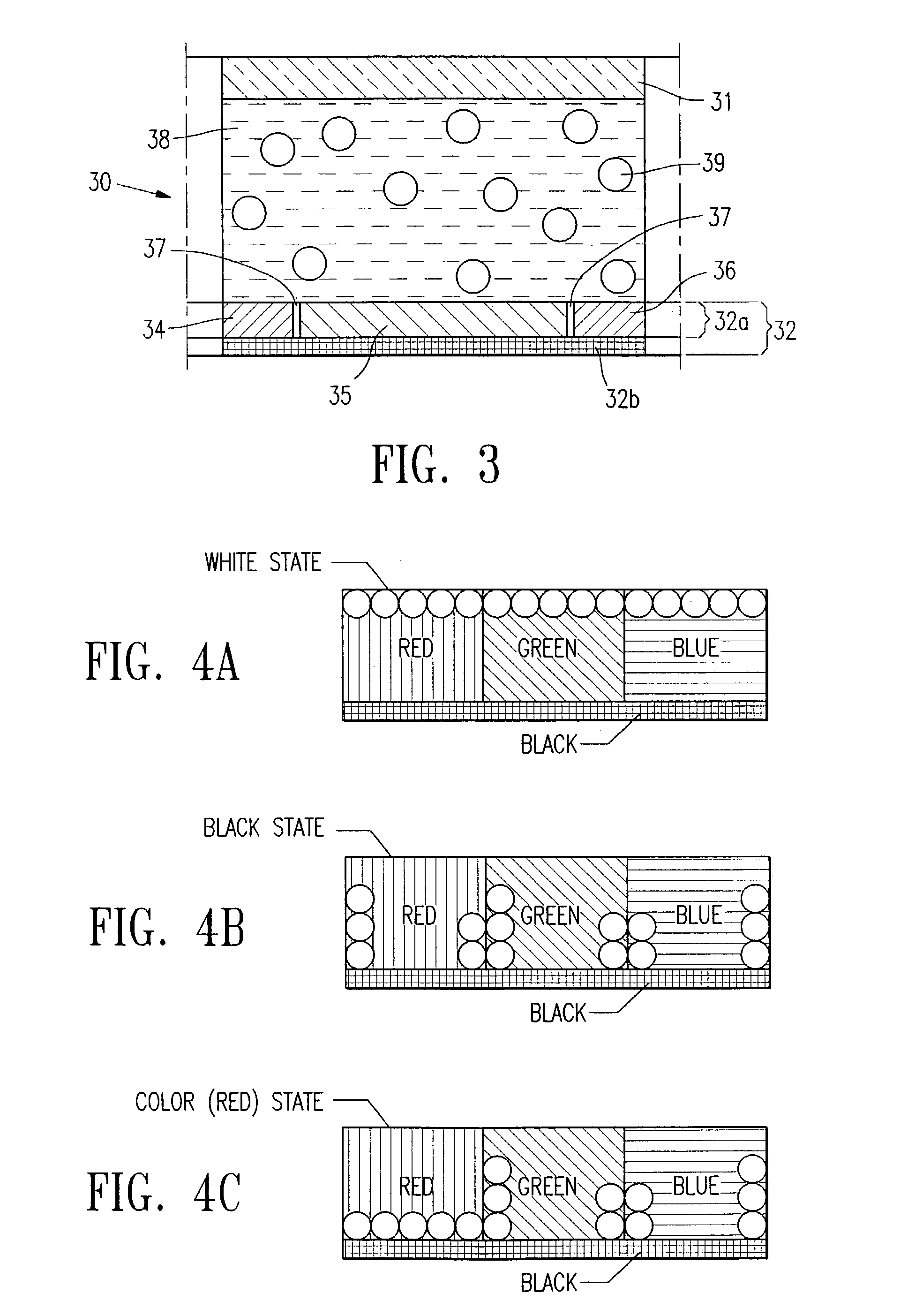

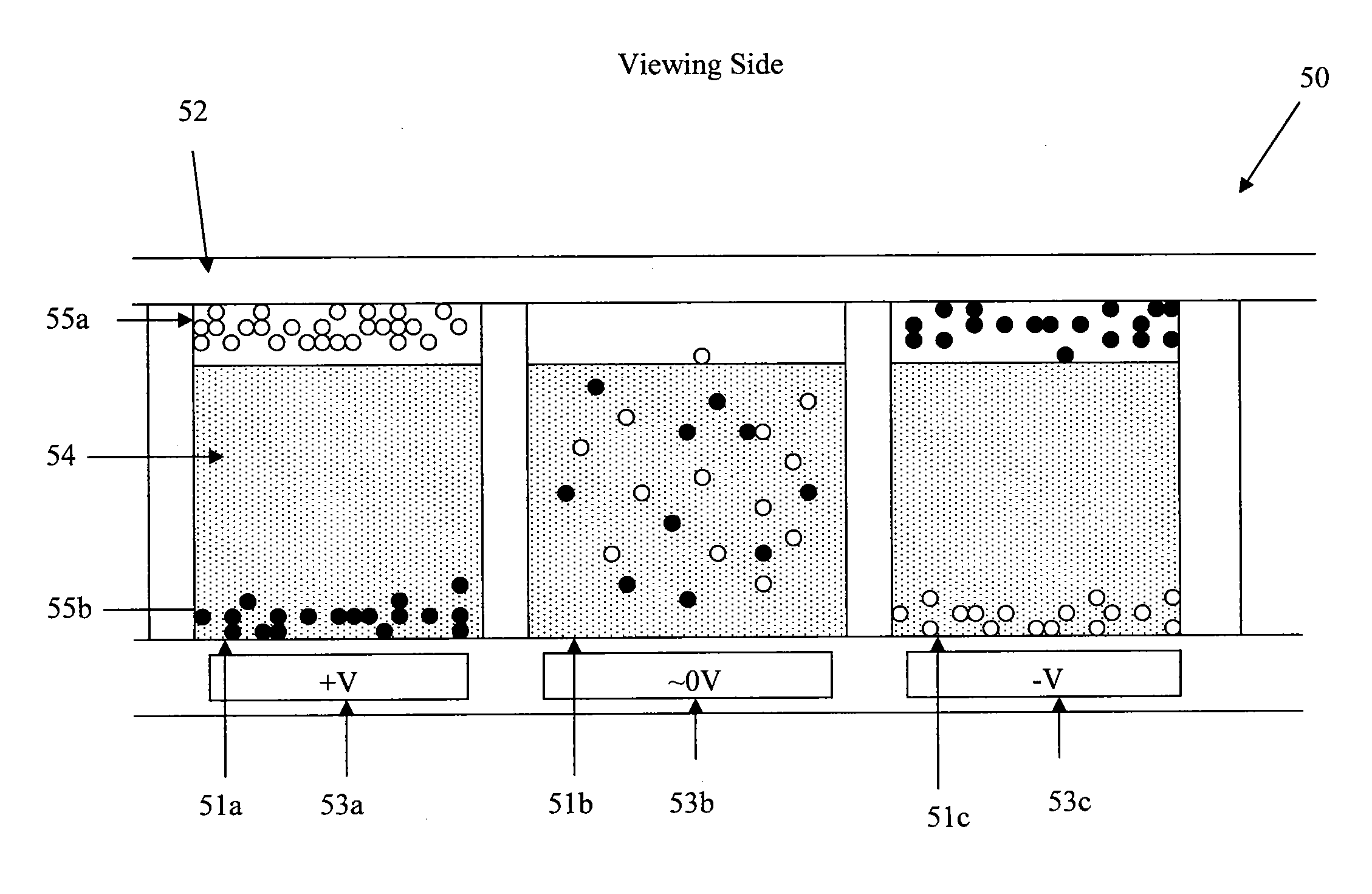

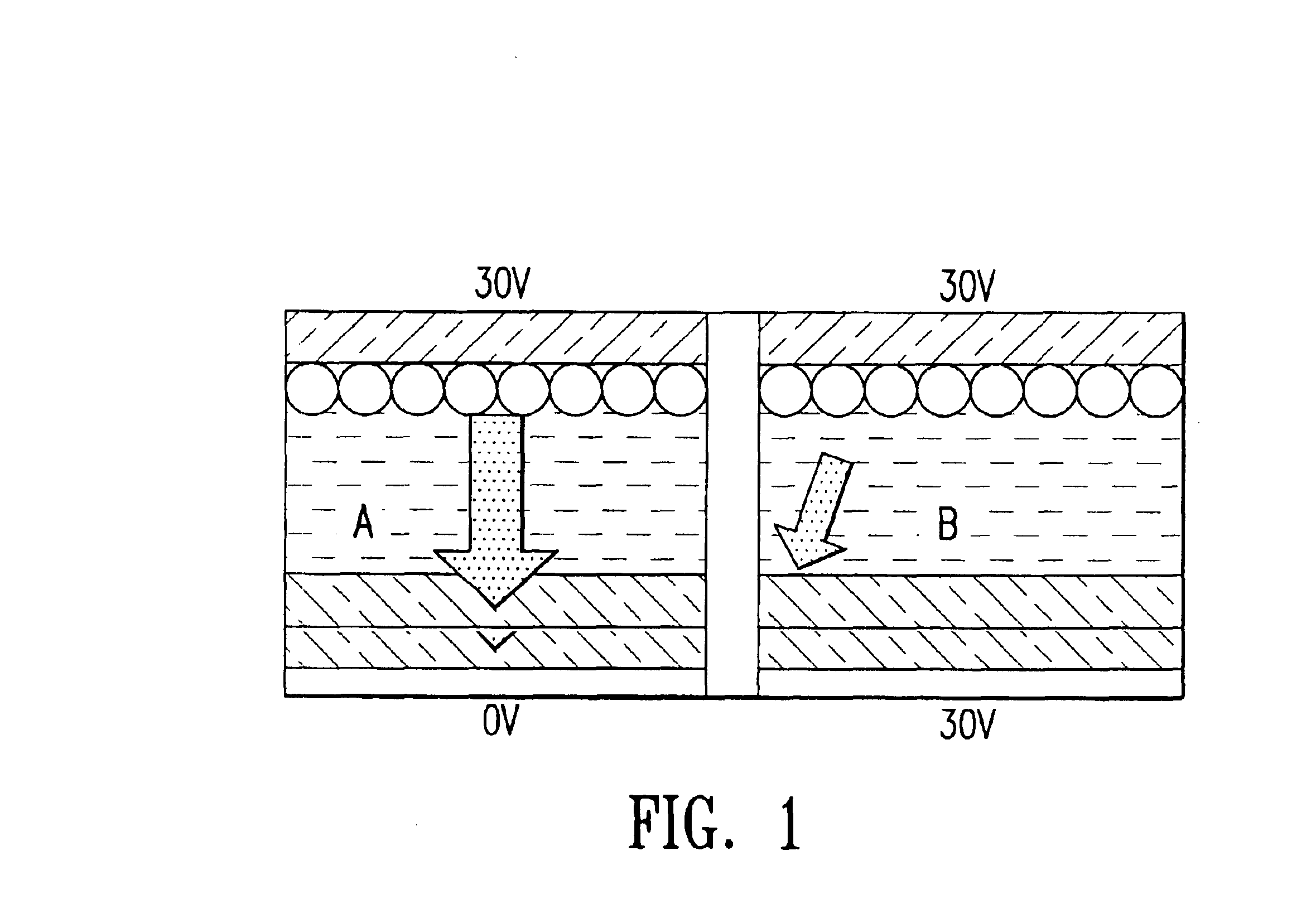

Electrophoretic display with dual-mode switching

InactiveUS7271947B2Increase contrastHigh saturationTransistorStatic indicating devicesIn planeDual mode

The present invention relates to an improved EPD which comprises both the traditional up / down switching and the in-plane switching modes. The monochrome EPDs of the present invention are capable of displaying highlight color of choice which is different from the text. Furthermore, the full color EPDs of the present invention are capable of displaying high contrast images of high color saturation. Both high quality black and white states are possible in the full color displays of the present invention. The EPDs of the present invention do not need complex circuitry design, and are compatible with low cost and high yield roll-to-roll manufacturing processes.

Owner:E INK CALIFORNIA

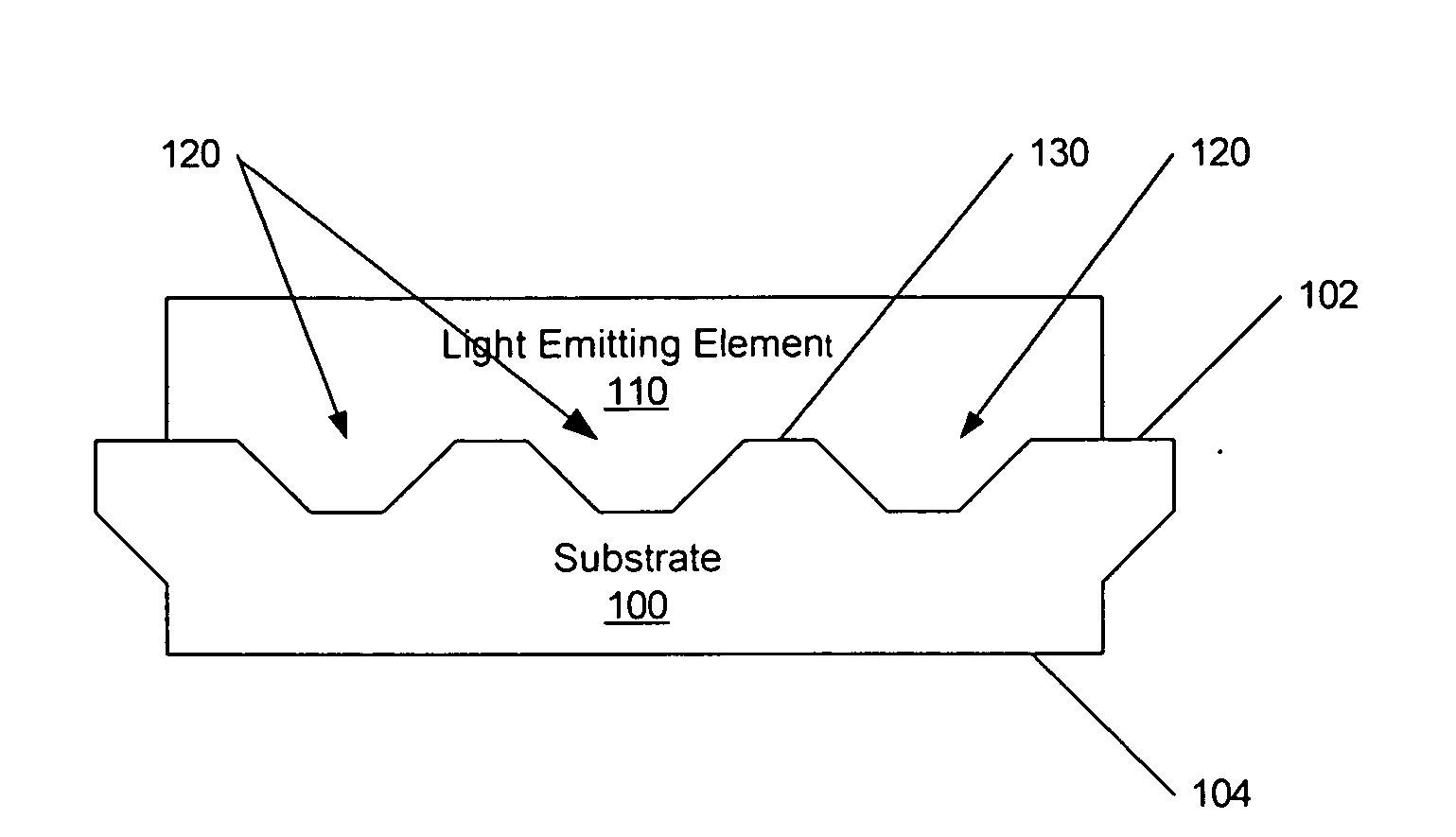

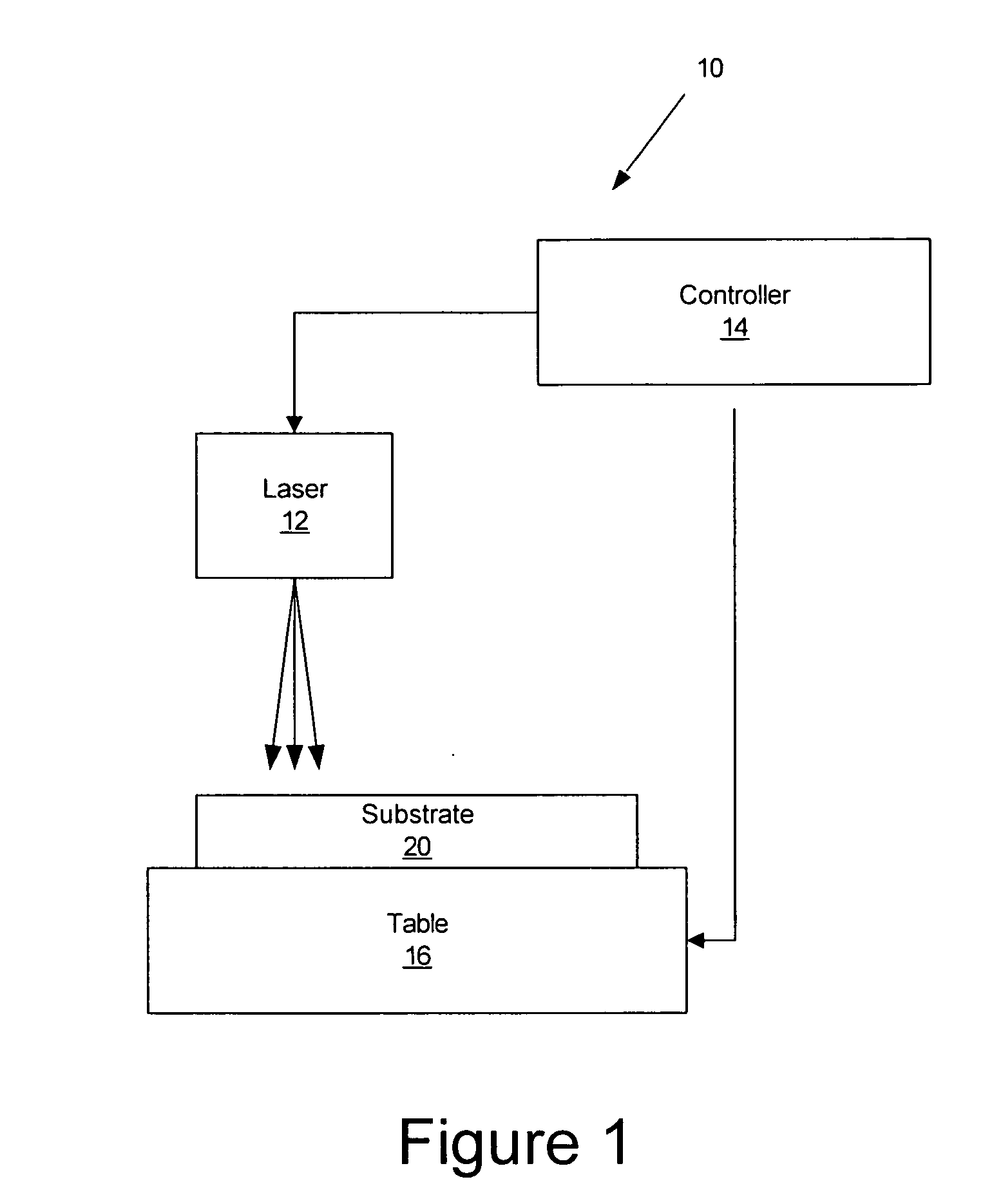

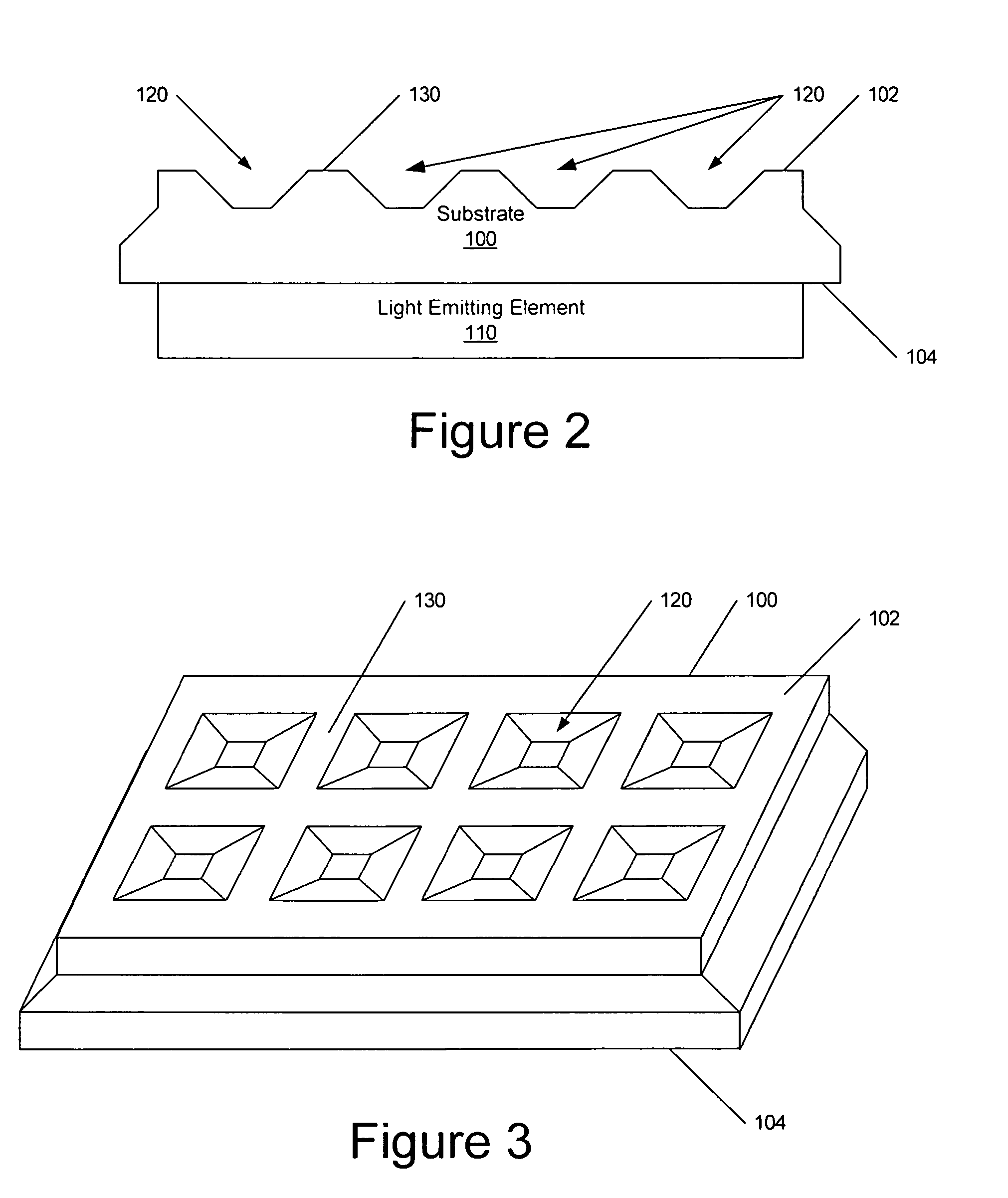

Laser patterning of light emitting devices and patterned light emitting devices

ActiveUS20050227379A1Fully removedDecorative surface effectsSemiconductor/solid-state device manufacturingSemiconductor materialsLaser patterning

Light extraction features are provided for a light emitting device having a substrate and a semiconductor light emitting element on the substrate by shaping a surface of a layer of semiconductor material utilizing a laser to define three dimensional patterns in the layer of semiconductor material. The layer of semiconductor material may be the substrate. In particular embodiments of the present invention, the surface of the layer of semiconductor material is shaped by applying laser light to the layer of semiconductor material at an energy sufficient to remove material from the layer of semiconductor material. The laser light may also by applied in a blanket manner at a level below the ablation threshold. The application of laser light to the layer of semiconductor material may be followed by etching the substrate. The layer of semiconductor material may be anisotropically etched. A mask could also be patterned utilizing laser light and the layer of semiconductor material etched using the mask. Light emitting devices have three dimensional patterns in a layer of semiconductor material of the device are also provided.

Owner:CREE INC

Electrophoretic display and novel process for its manufacture

InactiveUS6833943B2Improve the display effectCost effectiveStatic indicating devicesMaterial analysis by electric/magnetic meansElectrophoresisElectrical battery

This invention relates to an electrophoretic display comprising cells which are filled with charged particles dispersed in a solvent and are individually sealed with a polymeric sealing layer which is an integral part of the display and is curved.

Owner:E INK CALIFORNIA

Developer/rinse formulation to prevent image collapse in resist

An apparatus and method are provided for developing photoresist patterns on electronic component substrates such as semiconductor wafers. The method and apparatus use a specially defined developer composition in sequence with a specially defined rinse composition to develop an exposed photoresist pattern and then to rinse the developed pattern. Both the developer composition and rinse composition contain an anionic surfactant and, when the solutions are used in sequence, have been found to provide a resist pattern which avoids pattern collapse even when small features such as line widths less than 150 nm with aspect ratios of greater than about 3 are formed. It is preferred to use a puddle developing and puddle rinsing process to develop and rinse the exposed wafer. Preferred anionic surfactants are ammonium perfluoroalkyl sulfonate and ammonium perfluoroalkyl carboxylate.

Owner:IBM CORP

Process for imagewise opening and filling color display components and color displays manufactured thereof

InactiveUS6914714B2Easy and efficient to prepareReduce processing costsStatic indicating devicesElectrographic processes using photoelectrophoresisEngineeringDisplay device

Owner:E INK CALIFORNIA

Electrophoretic display fluid

InactiveUS20110217639A1Increase contrastElectrographic processes using photoelectrophoresisElectrographic process apparatusElectrophoresisContrast ratio

The present invention is directed to an electrophoretic fluid which comprises a non-mobile or semi-mobile phase and charged pigment particles. The fluid has many advantages, such as increased contrast without affecting the switching speed.

Owner:SIPIX IMAGING INC

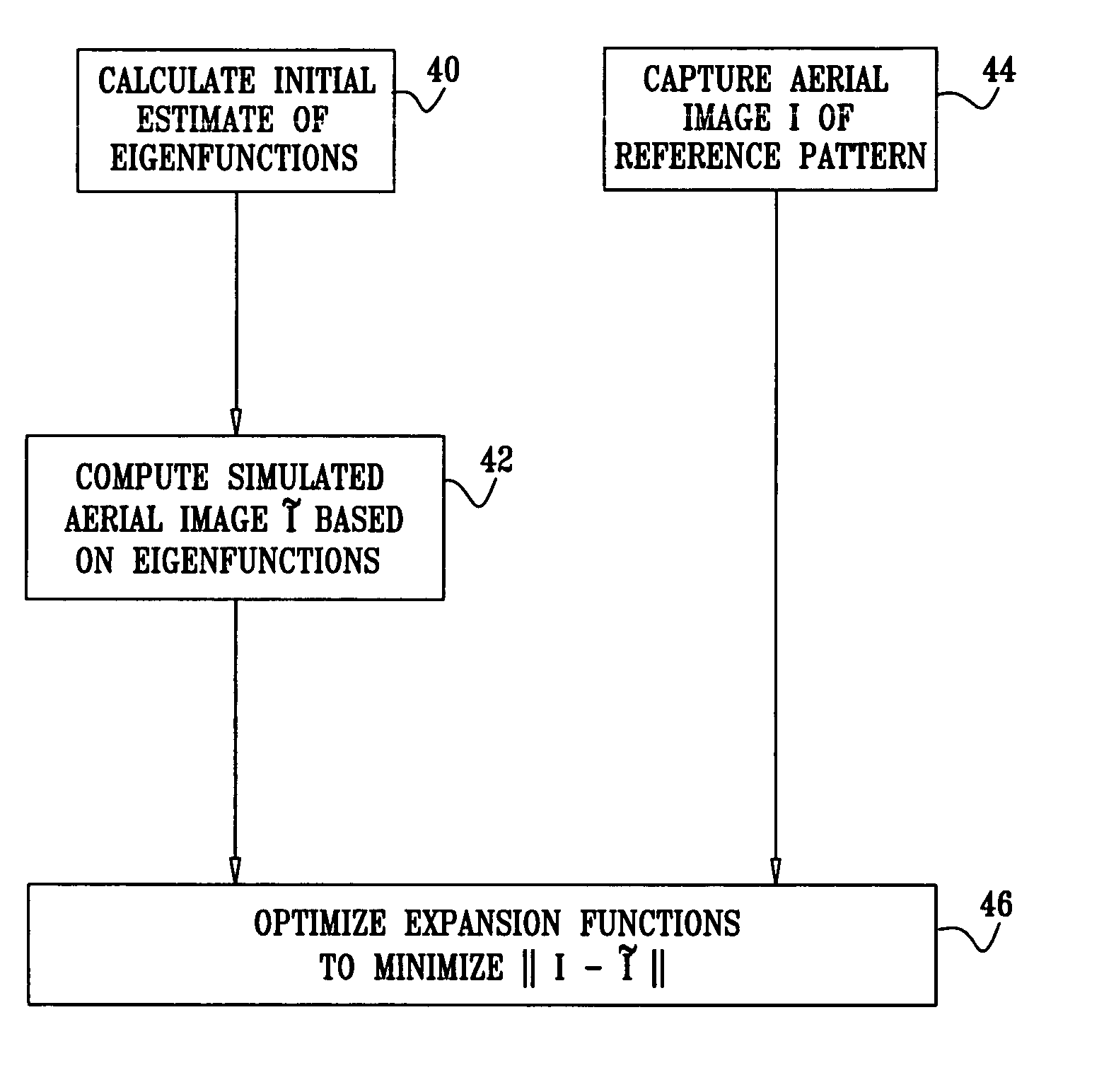

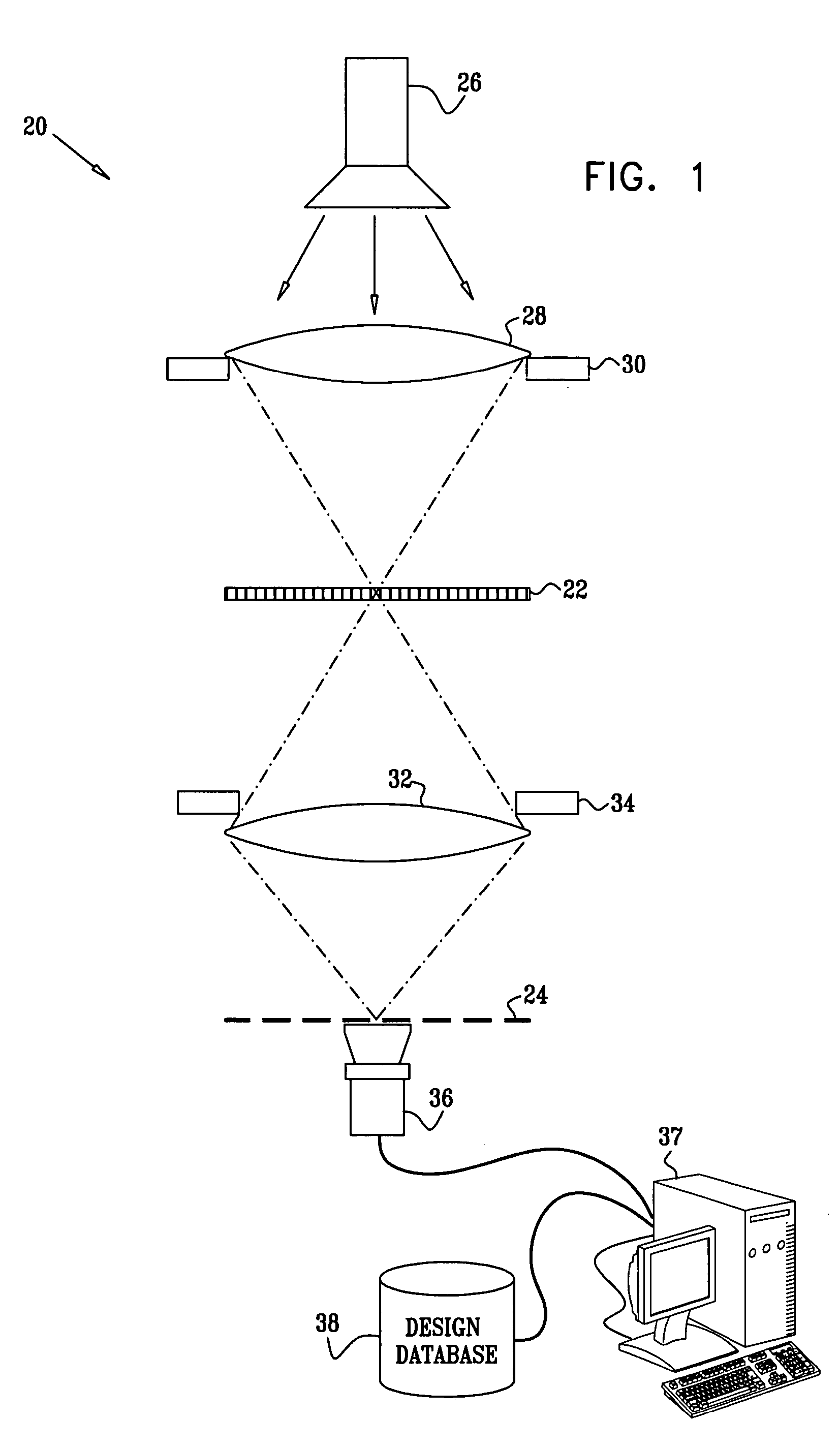

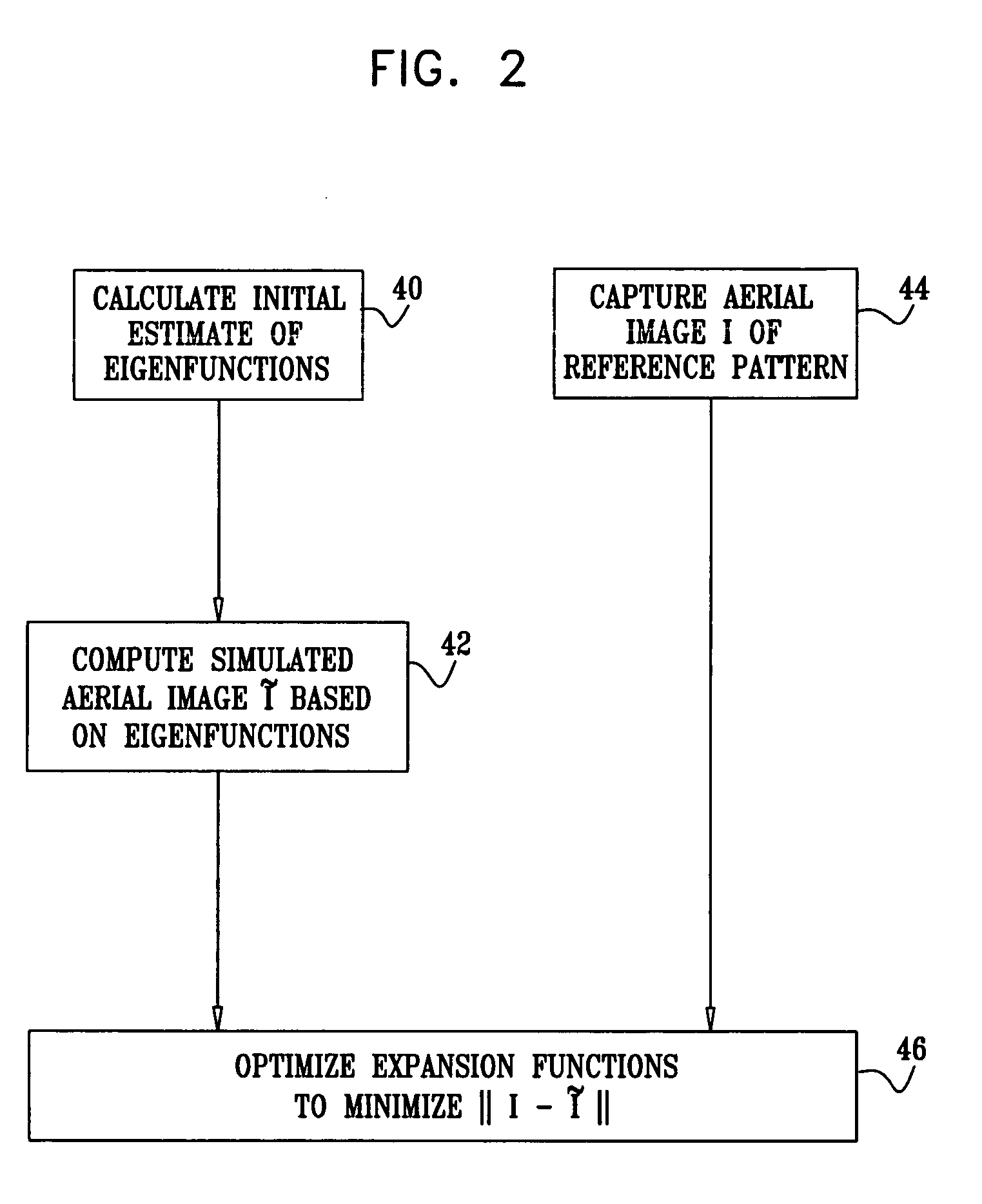

System and method for simulating an aerial image

ActiveUS20060048089A1Minimize the differenceEnsure correct executionPhotomechanical apparatusCharacter and pattern recognitionReference spaceSpatial image

A method for generating a simulated aerial image includes forming a reference aerial image of a first mask using an optical system, and capturing and processing the reference aerial image so as to generate a set of expansion functions representative of the optical system. The simulated aerial image of a second mask is then computed by applying the expansion functions to a design of the second mask.

Owner:APPL MATERIALS ISRAEL LTD

Positive resist composition and method of forming resist pattern

InactiveUS20040058269A1High resolutionIncreased focus rangePhotosensitive materialsRadiation applicationsSolubilityResist

There is provided a positive type resist composition formed by dissolving (A) a resin component with a unit derived from a (meth)acrylate ester in the principal chain, for which the solubility in alkali increases under the action of acid, and (B) an acid generator component which generates acid on exposure, in an organic solvent component (C), wherein the resin component (A) is a copolymer comprising (a1) a unit derived from a (meth)acrylate ester comprising an acid dissociable, dissolution inhibiting group containing a polycyclic group, (a2) a unit derived from a (meth)acrylate ester comprising a lactone containing monocyclic group or polycyclic group, (a3) a unit derived from a (meth)acrylate ester comprising a hydroxyl group containing polycyclic group, and (a4) a unit derived from a (meth)acrylate ester comprising a polycyclic group which is different from the unit (a1), the unit (a2) and the unit (a3). This composition provides a chemically amplified positive type resist composition which displays excellent resolution, enables the depth of focus range of an isolated resist pattern to be improved, and enables the proximity effect to be suppressed.

Owner:TOKYO OHKA KOGYO CO LTD

Electro-magnetophoresis display

ActiveUS6914713B2Avoid accidental movementInhibition effectStatic indicating devicesElectrographic processes using photoelectrophoresisMagnetic tension forceElectrical battery

The present invention is directed to an electro-magnetophoresis display having either the traditional up / down or dual switching mode. The display cells are filled with an electro-magnetophoretic dispersion comprising particles suspended in a solvent and the particles are both charged and magnetized.The display of the invention prevents undesired movement of the particles in the cells. The magnetic force generated by the magnetic layer(s) eliminates the need to provide cells with a threshold voltage high enough to avoid the cross talk and / or cross bias effects. In addition, the dual switching mode allows the particles to move in the up / down direction as well as the planar direction, thus providing a multicolor display of high color quality at very low cost.

Owner:E INK CALIFORNIA

Electrophoretic display and novel process for its manufacture

InactiveUS6865012B2Increase volumeLow cost productionStatic indicating devicesElectrographic processes using photoelectrophoresisElectrophoresisDisplay device

This invention relates to an electrophoretic display comprising cells of well-defined shape, size and aspect ratio which cells are filled with charged pigment particles dispersed in a solvent, and novel processes for its manufacture.

Owner:E INK CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com