Patents

Literature

370 results about "Line edge roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

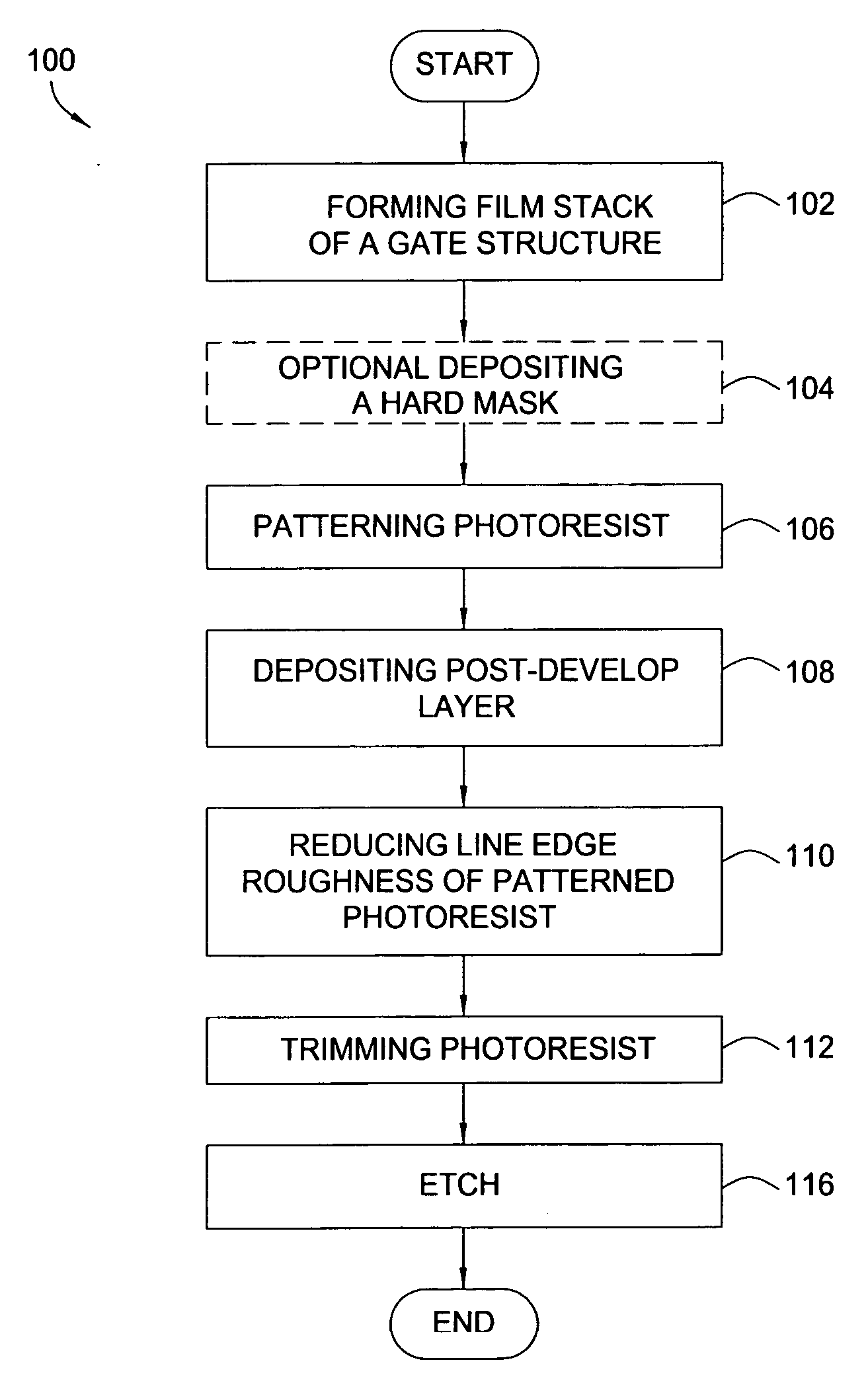

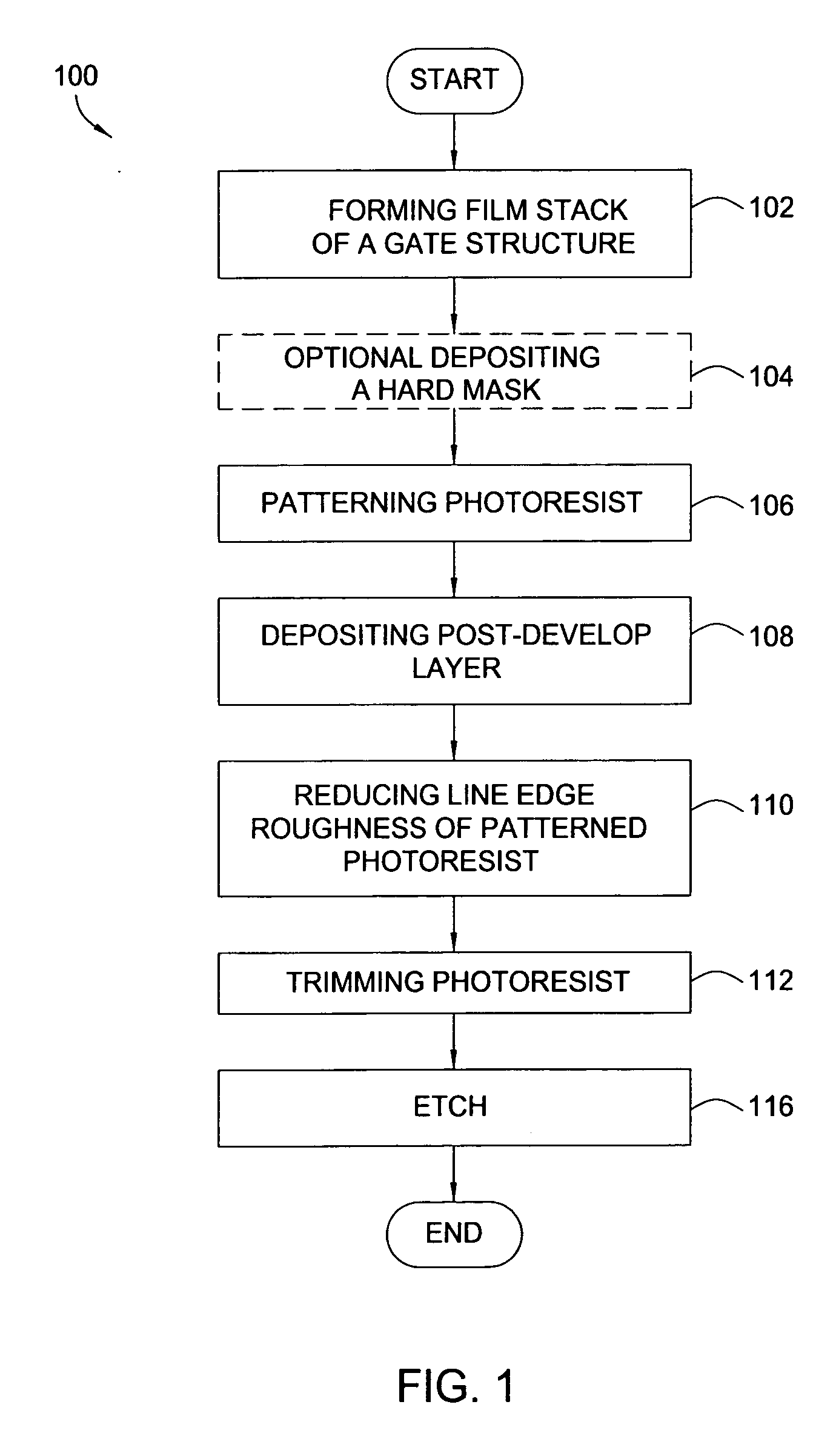

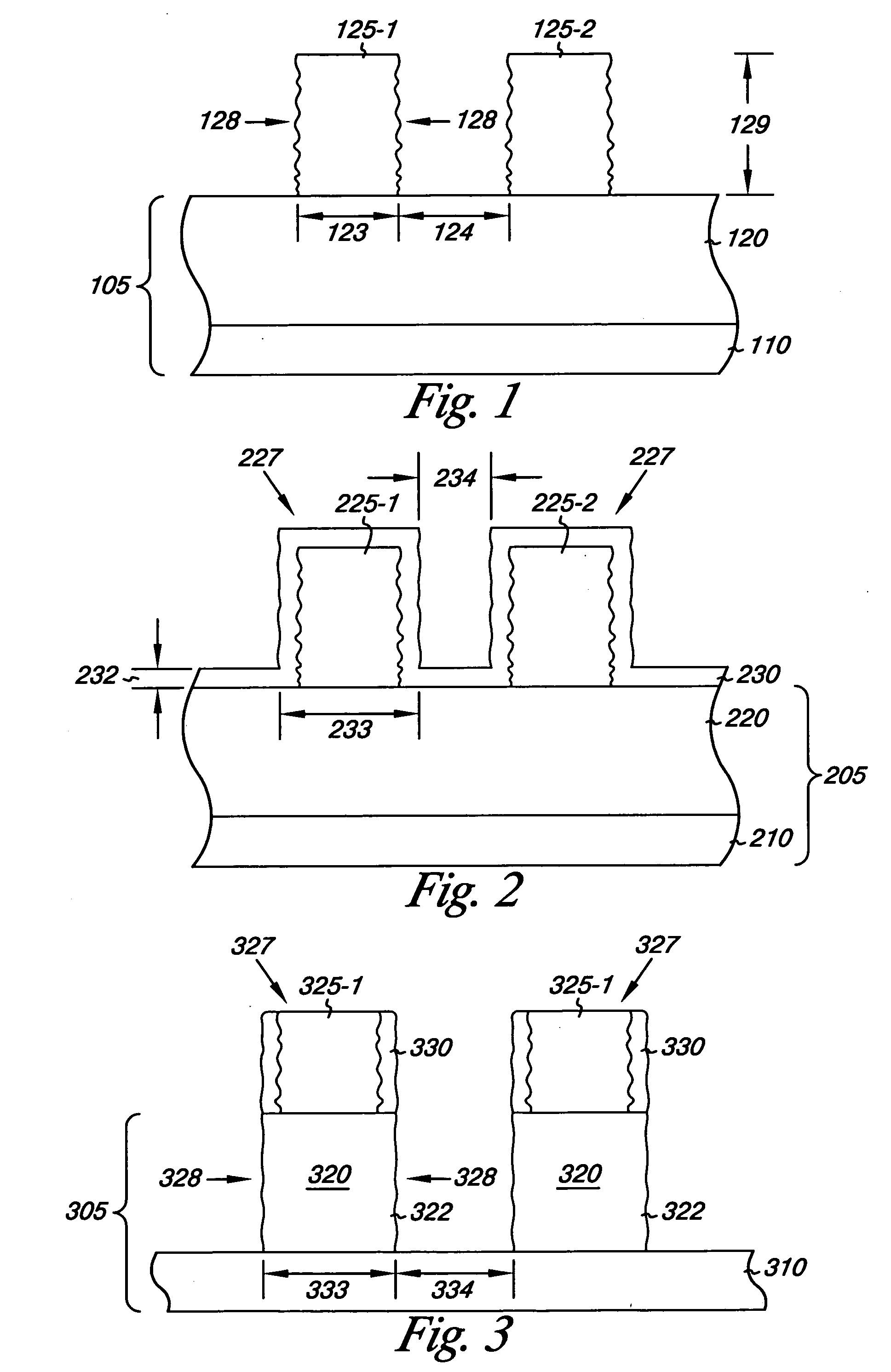

Line edge roughness reduction compatible with trimming

InactiveUS20060205223A1Semiconductor/solid-state device manufacturingPhotosensitive material processingEngineeringPhotoresist

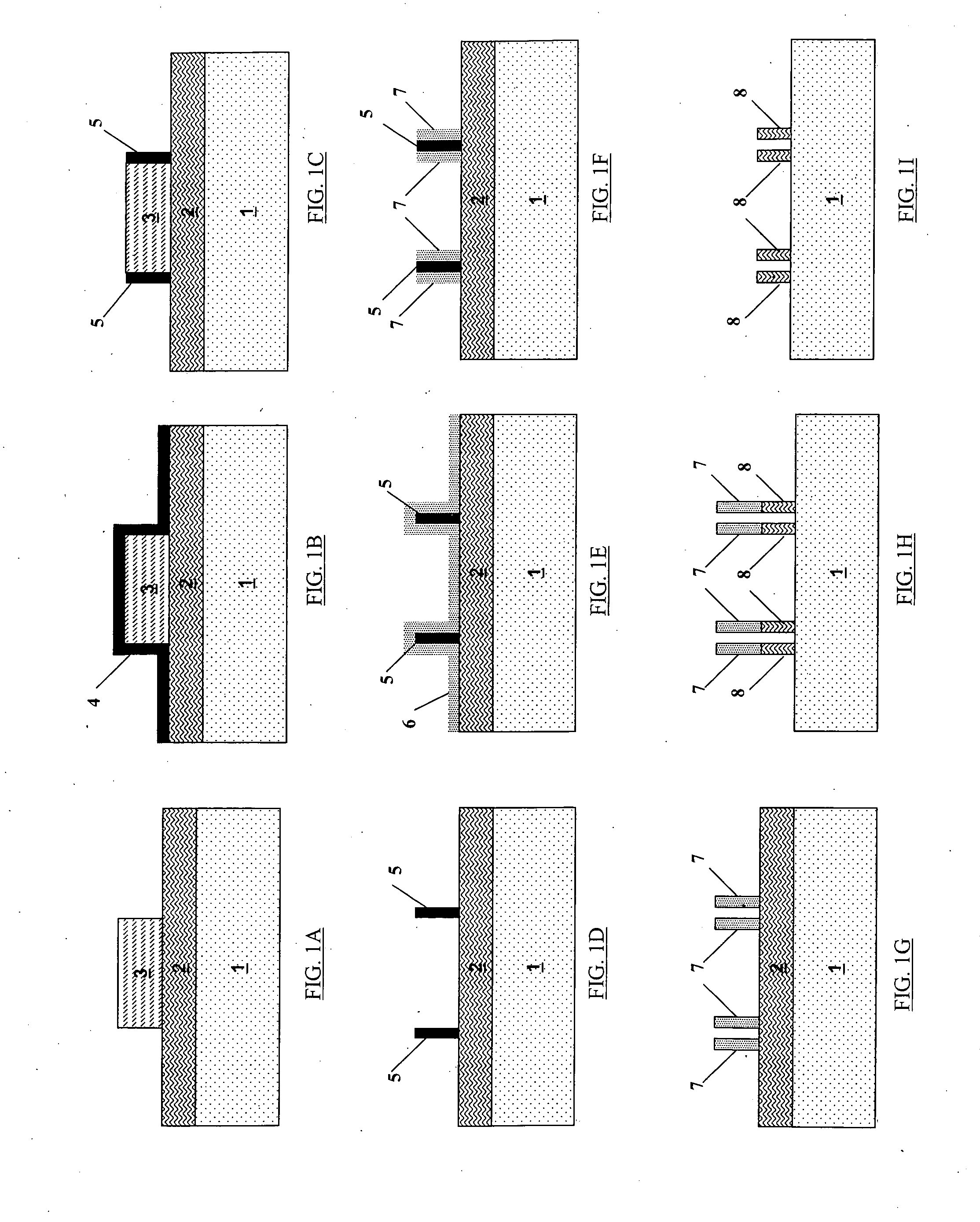

A method and apparatus for reducing line edge roughness, comprising patterning a photoresist to define lines for etching an underlying layer, depositing a post development material between the lines, curing and removing the post development material to reduce line edge roughness, trimming the lines in the underlying layer, and then etching the underlying layer.

Owner:APPLIED MATERIALS INC

Photoresist monomers, polymers and photoresist compositions for preventing acid diffusion

Photoresist monomers, polymers thereof, photoresist compositions containing the same for preventing acid generated in the exposed area during the course of a photolithography process from being diffused to the unexposed area. The line edge roughness and slope pattern are improved when an ultrafine photoresist pattern is formed using photoresist copolymer having a multi-oxygen-containing compound as a repeating unit such as an ethyleneoxy moiety represented by Formula 1 with at least one polymerizable carbon-carbon double bond. In addition, the shape of pattern is improved by eliminating top loss and the adhesion of pattern to the substrate is improved. wherein n is an integer ranging from 1 to 5.

Owner:SK HYNIX INC +1

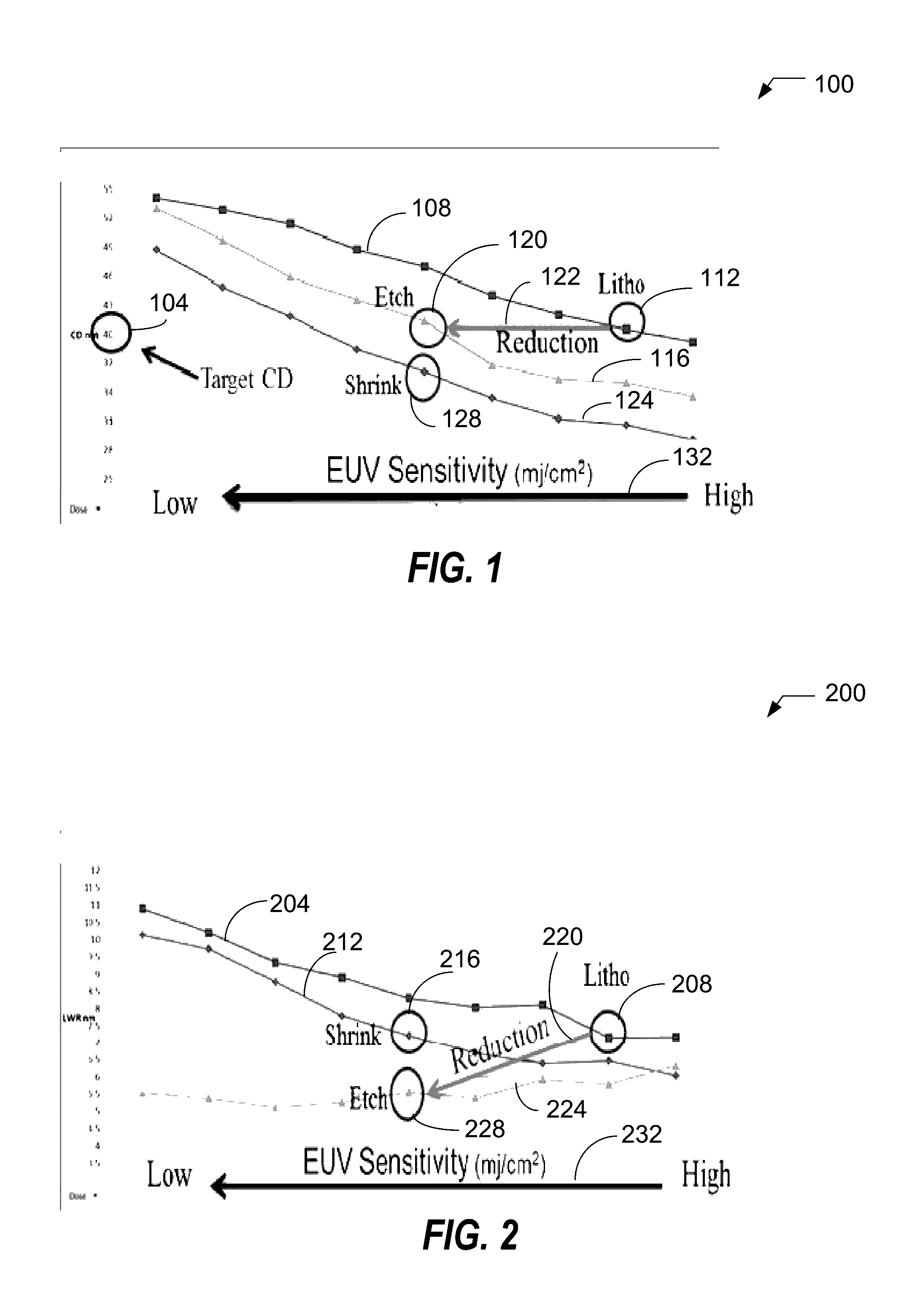

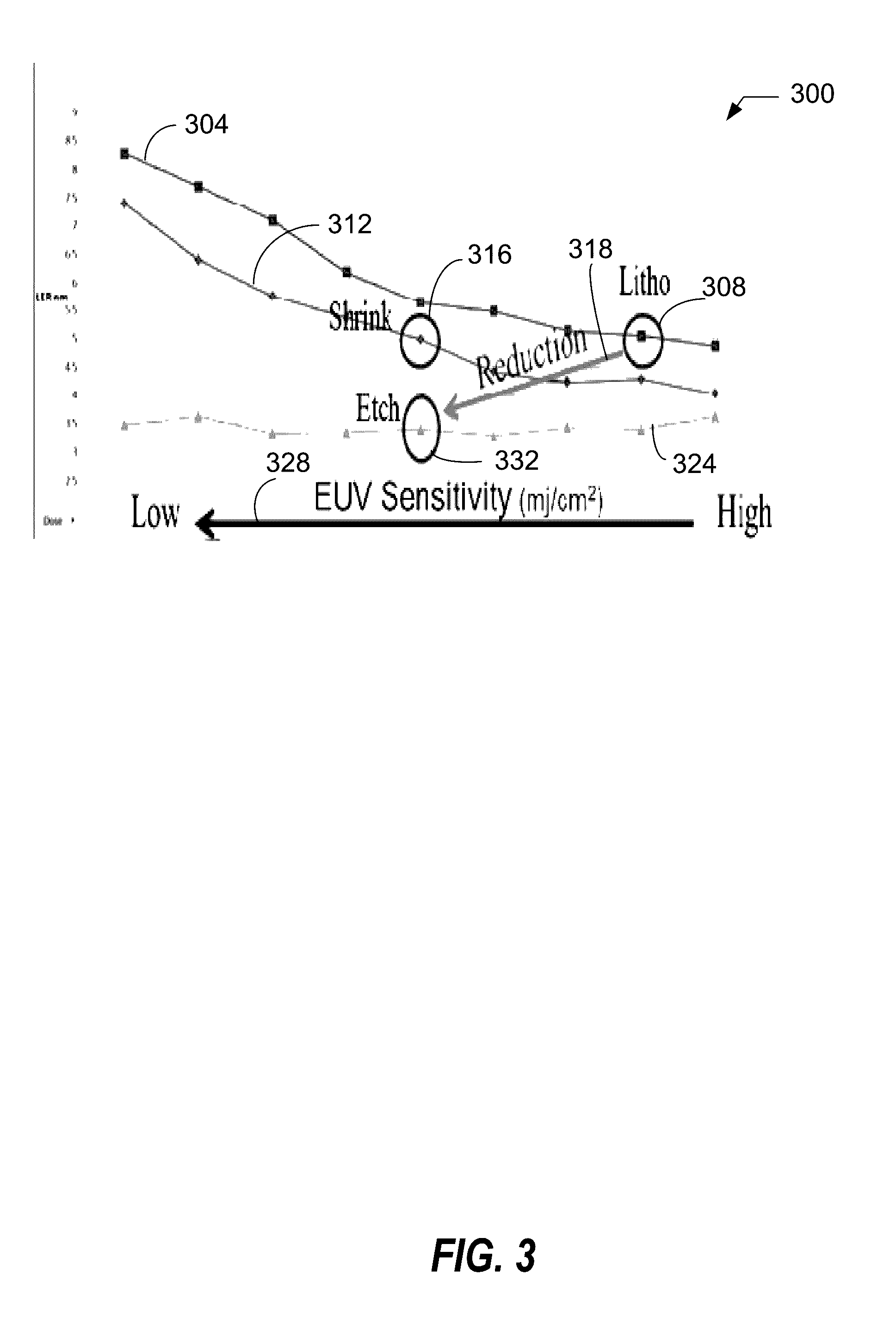

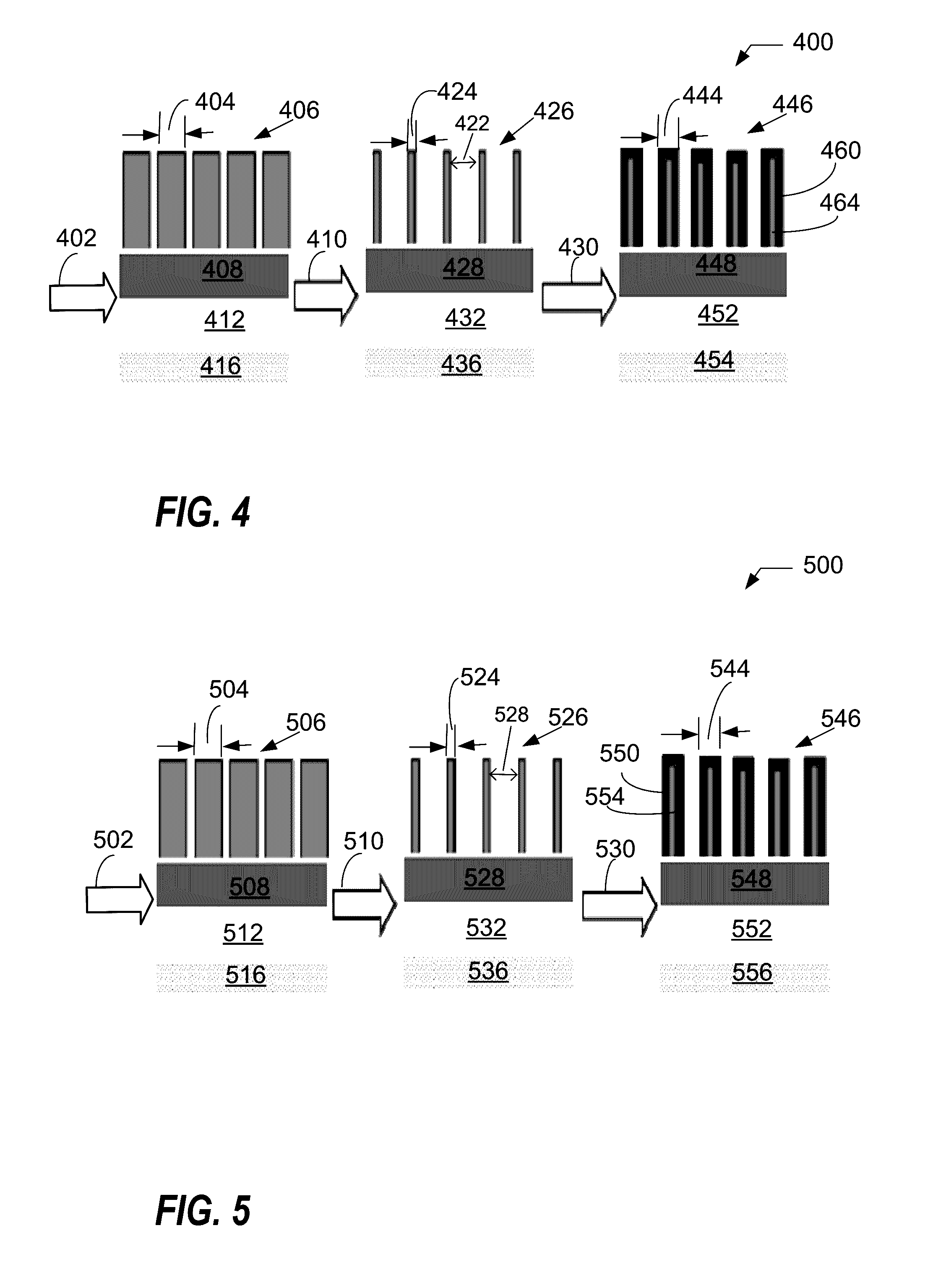

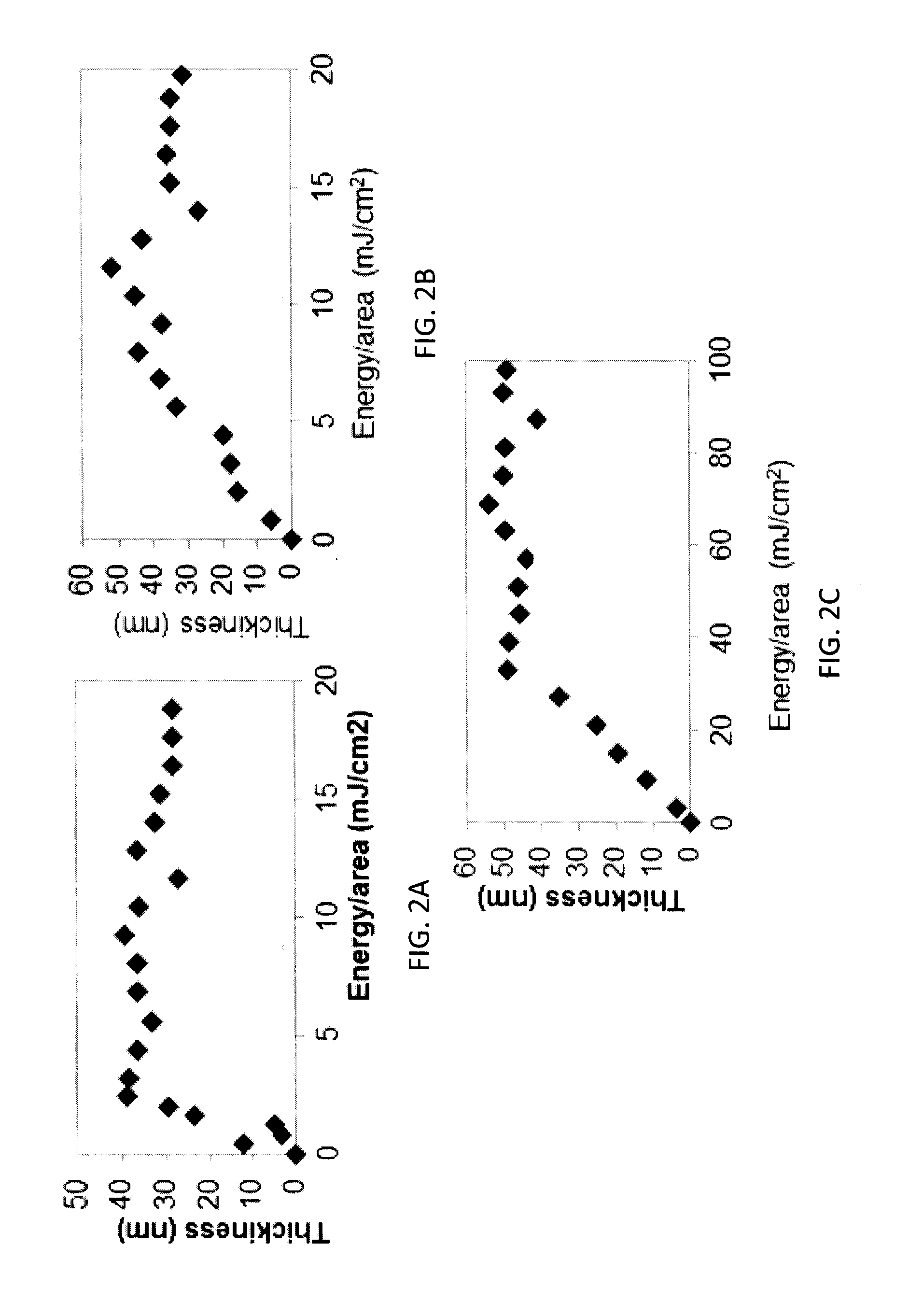

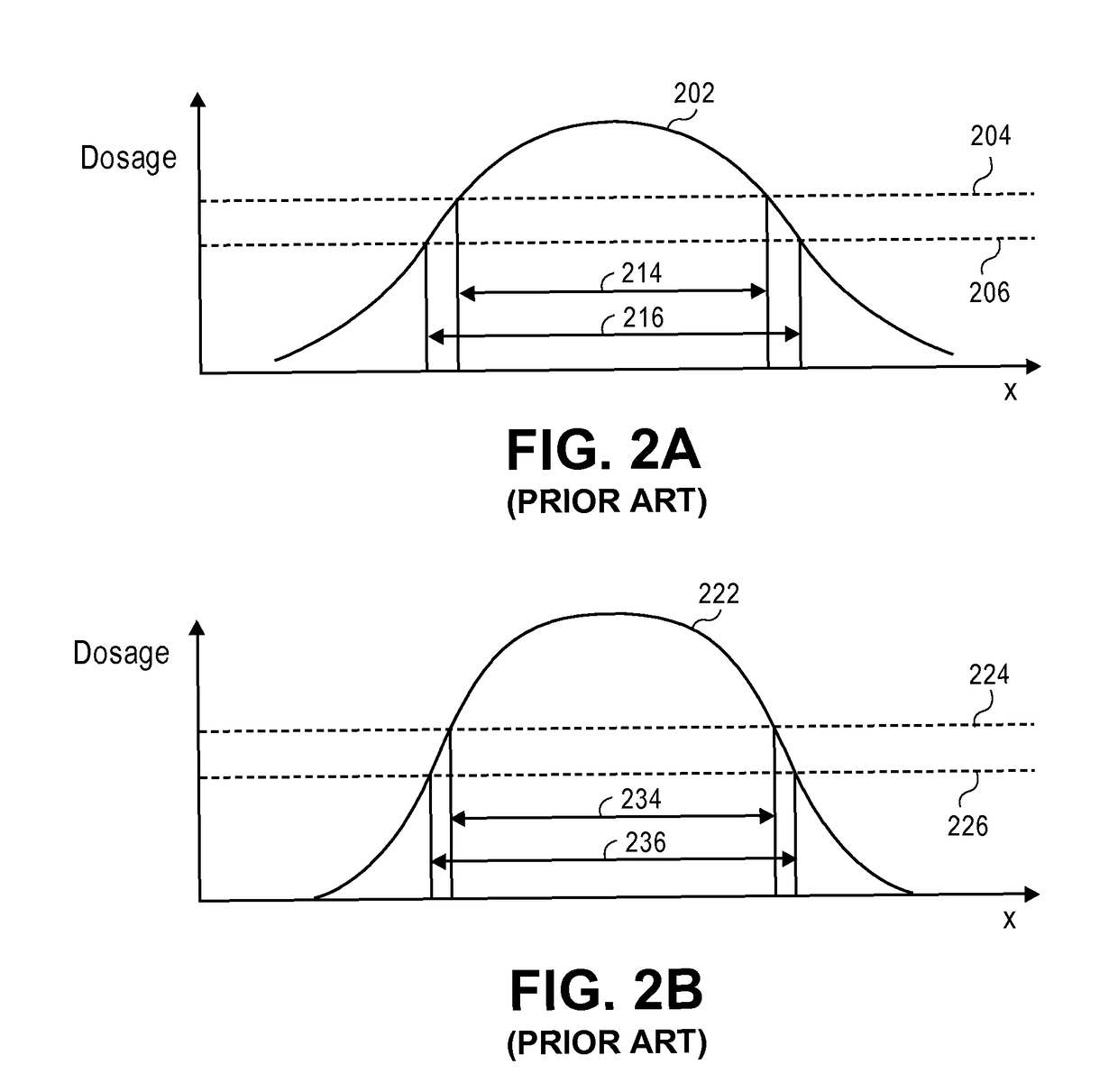

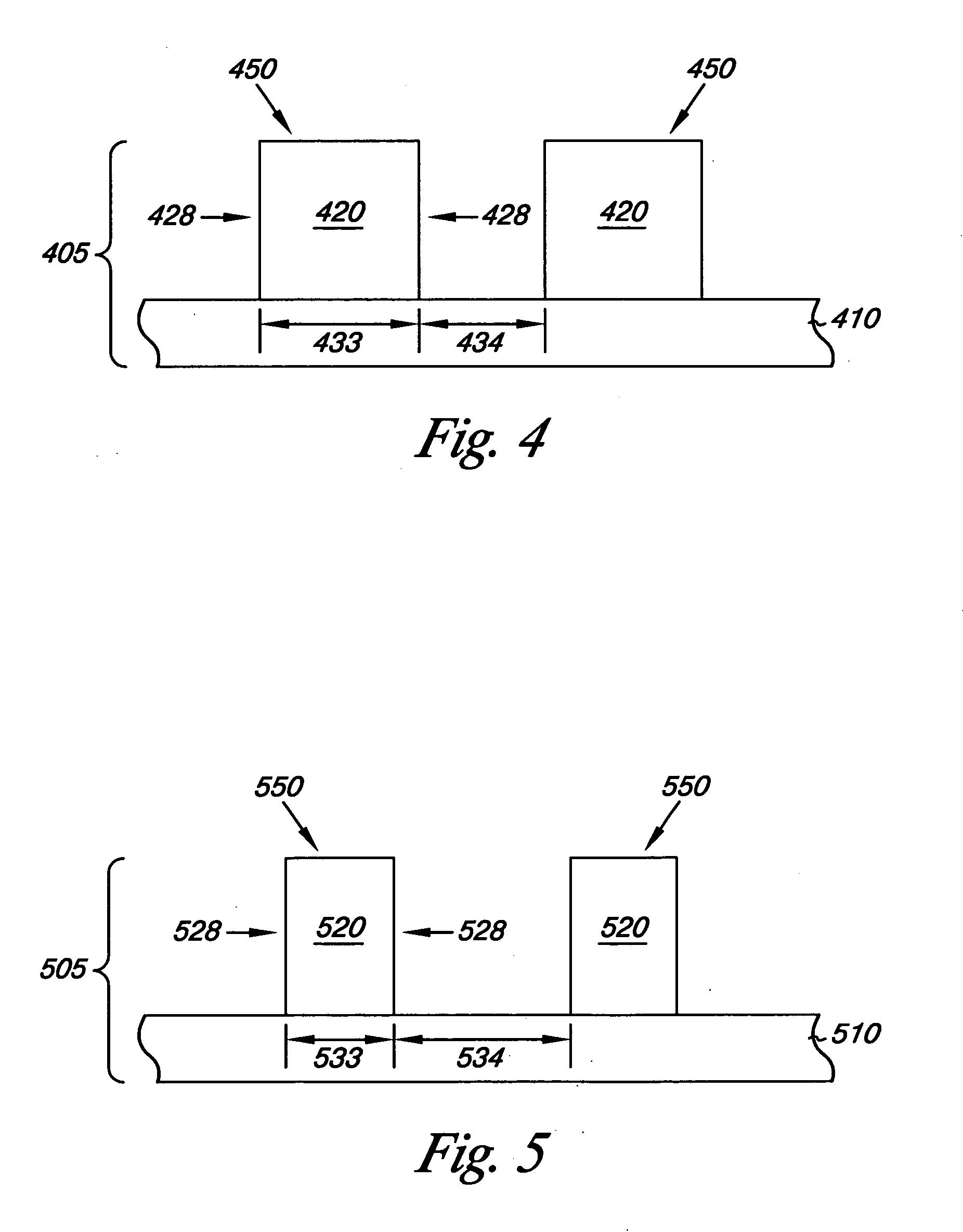

Extreme ultra-violet sensitivity reduction using shrink and growth method

ActiveUS20160334709A1Substrate throughput can be increasedImprove throughputPhotomechanical exposure apparatusPhotosensitive material processingCooking & bakingLine width

Provided is a method for patterning a substrate, comprising: forming a layer of radiation-sensitive material on a substrate; preparing a pattern in the layer of radiation-sensitive material using a lithographic process, the pattern being characterized by a critical dimension (CD) and a roughness; following the preparing the pattern, performing a CD shrink process to reduce the CD to a reduced CD; and performing a growth process to grow the reduced CD to a target CD. Roughness includes a line edge roughness (LER), a line width roughness (LWR), or both LER and LWR. Performing the CD shrink process comprises: coating the pattern with a hard mask, the coating generating a hard mask coated resist; baking the hard mask coated resist in a temperature range for a time period, the baking generating a baked coated resist; and developing the baked coated resist in deionized water.

Owner:TOKYO ELECTRON LTD

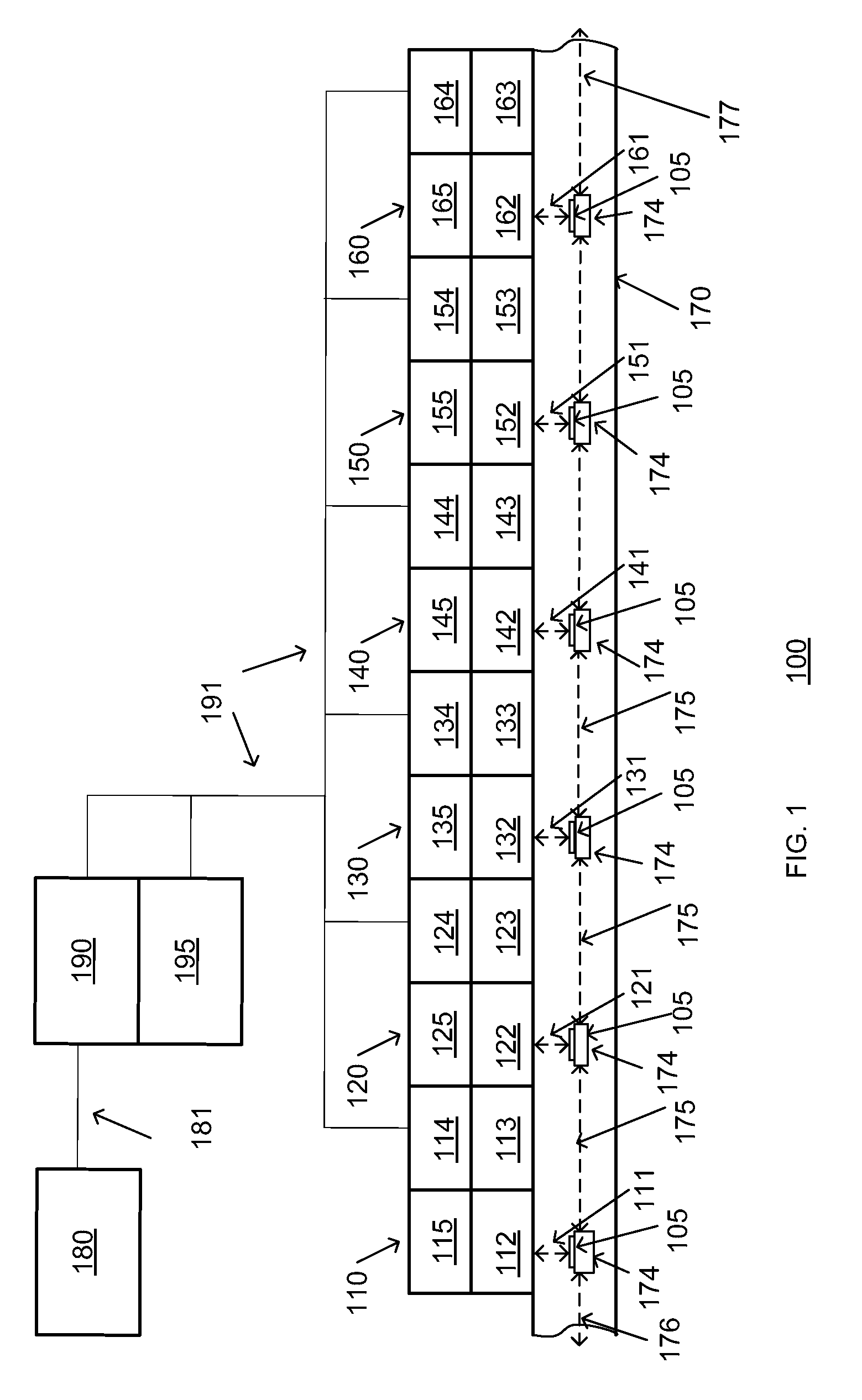

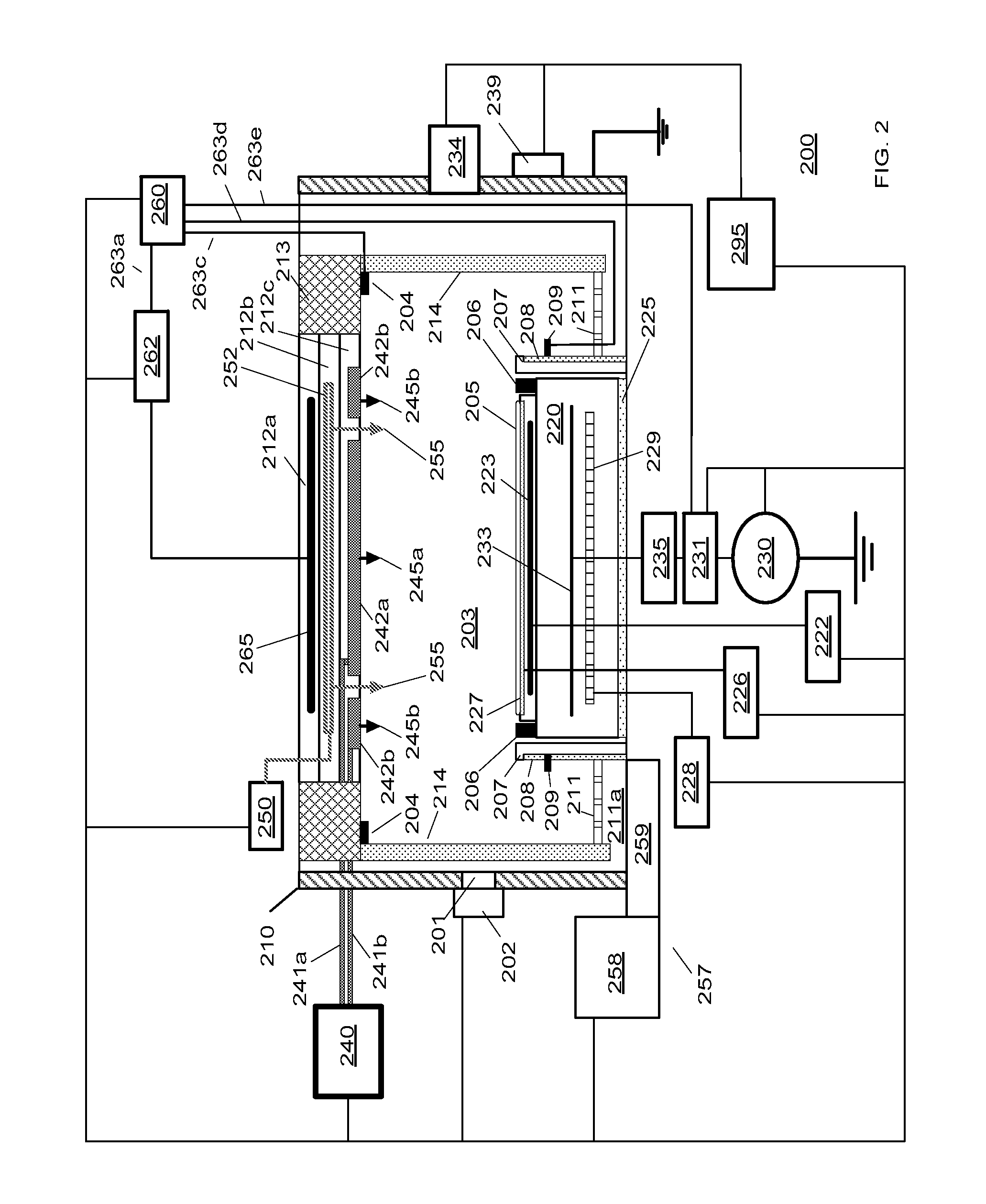

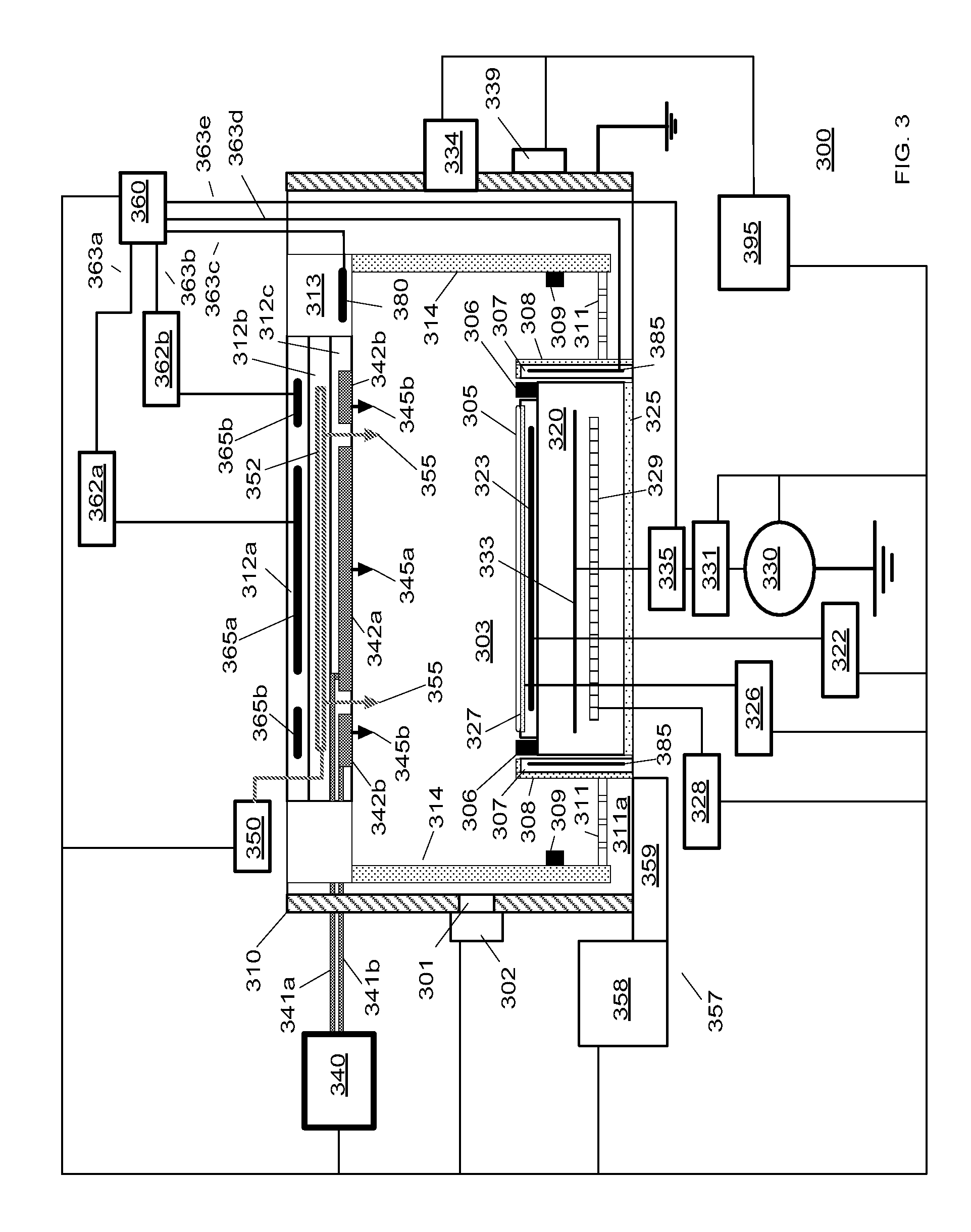

Apparatus and Method for Improving Photoresist Properties

InactiveUS20100081285A1Harden radiation-sensitive materialsRemove roughnessSemiconductor/solid-state device manufacturingPhotosensitive material processingLine widthEngineering

The invention can provide apparatus and methods of processing a substrate in real-time using subsystems and processing sequences created to improve the etch resistance of photoresist materials. In addition, the improved photoresist layer can be used to more accurately control gate and / or spacer critical dimensions (CDs), to control gate and / or spacer CD uniformity, and to eliminate line edge roughness (LER) and line width roughness (LWR).

Owner:TOKYO ELECTRON LTD

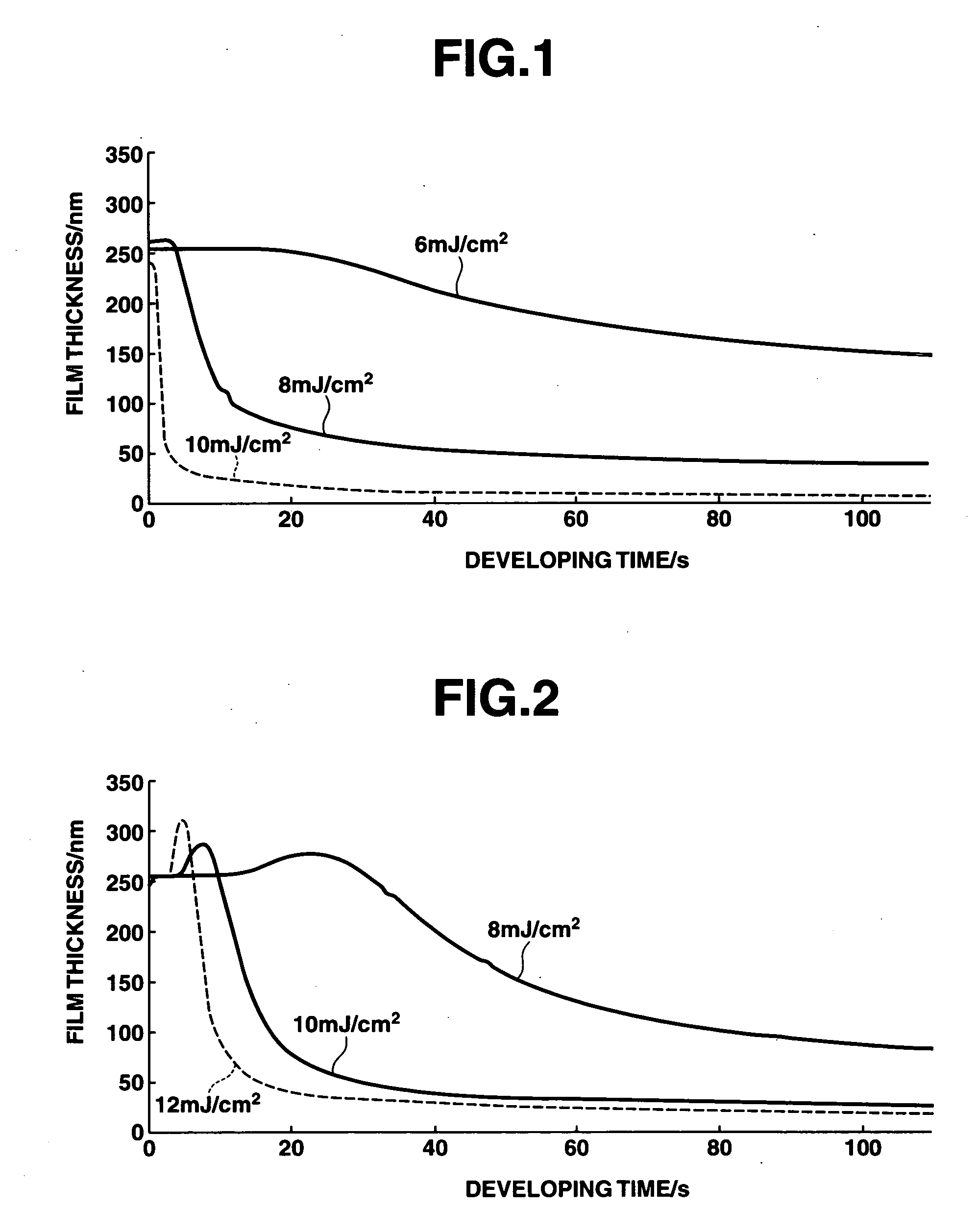

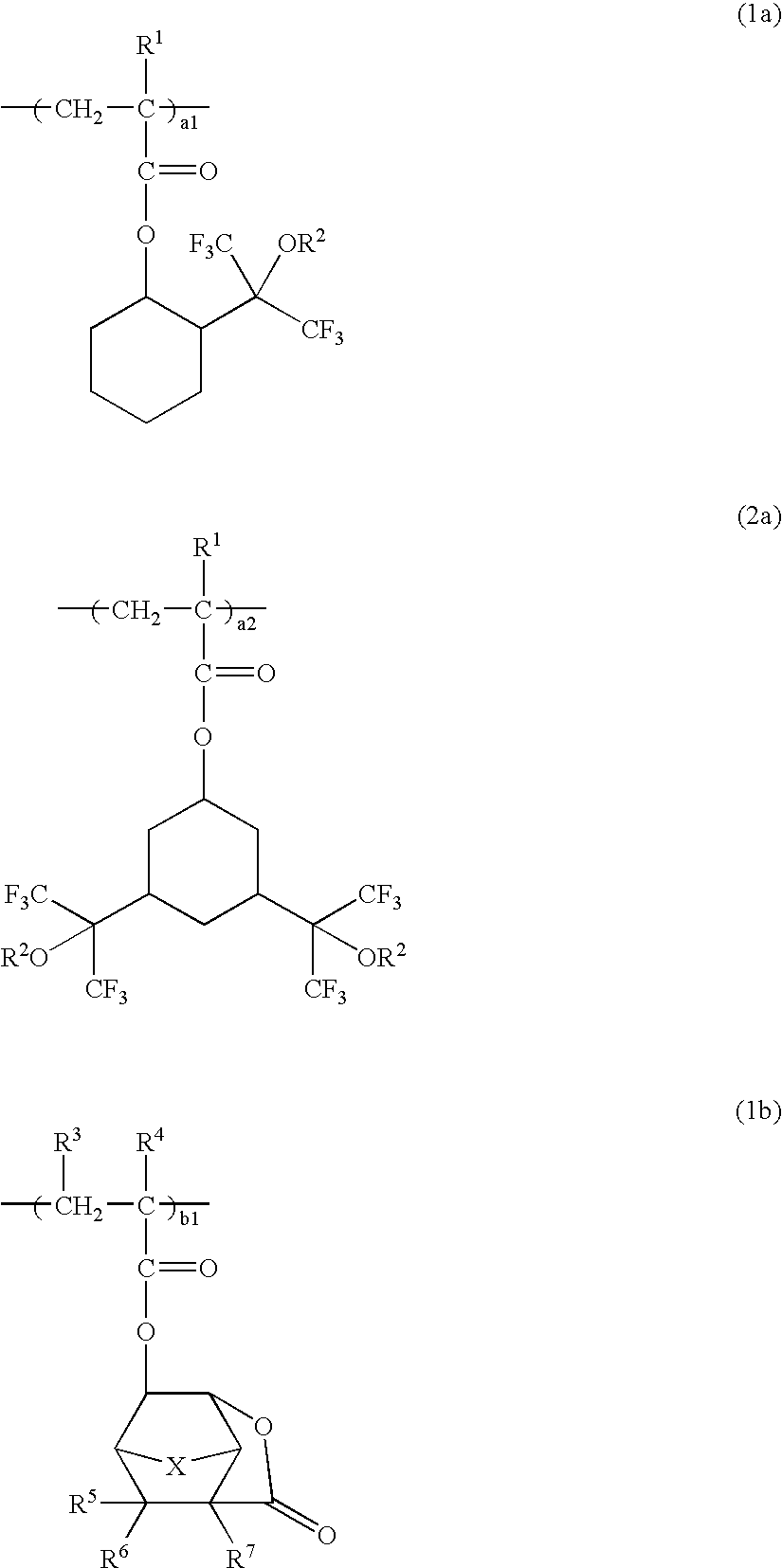

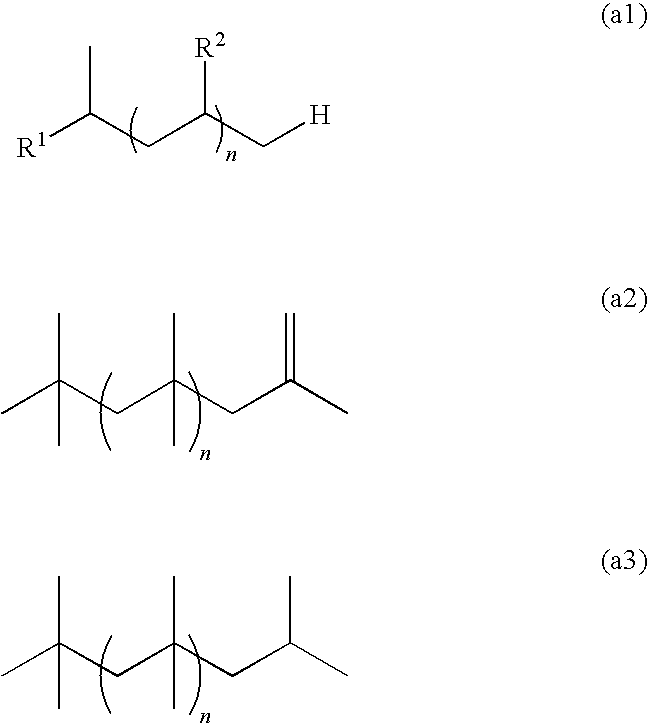

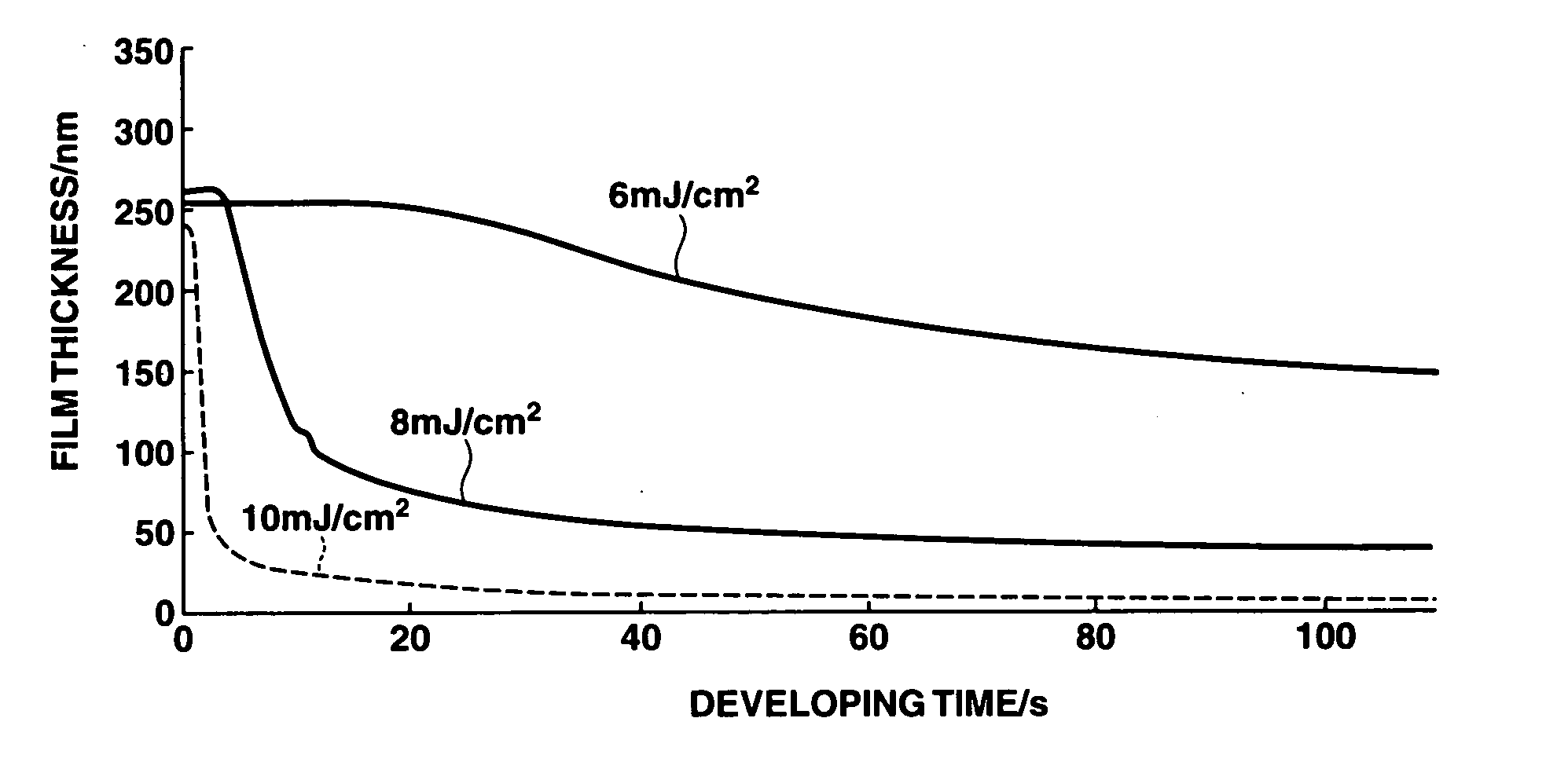

Positive resist composition and method of forming resist pattern from the same

InactiveUS20040110085A1Small line edge roughnessHigh resolutionRadiation applicationsSemiconductor/solid-state device manufacturingSolubilityMethacrylate

There is provided a positive type resin composition comprising (A) a resin component comprising within the principal chain a structural unit derived from a (meth)acrylate ester and incorporating an acid dissociable, dissolution inhibiting group containing a polycyclic group on an ester side chain section, for which the solubility in alkali increases under the action of acid, (B) an acid generator component which generates acid on exposure, and (C) an organic solvent, wherein the component (A) comprises both a structural unit derived from a methacrylate ester and a structural unit derived from an acrylate ester. According to such a resist composition, a resist pattern can be formed which displays little surface roughness and line edge roughness on etching, and also offers excellent resolution and a wide depth of focus range.

Owner:TOKYO OHKA KOGYO CO LTD

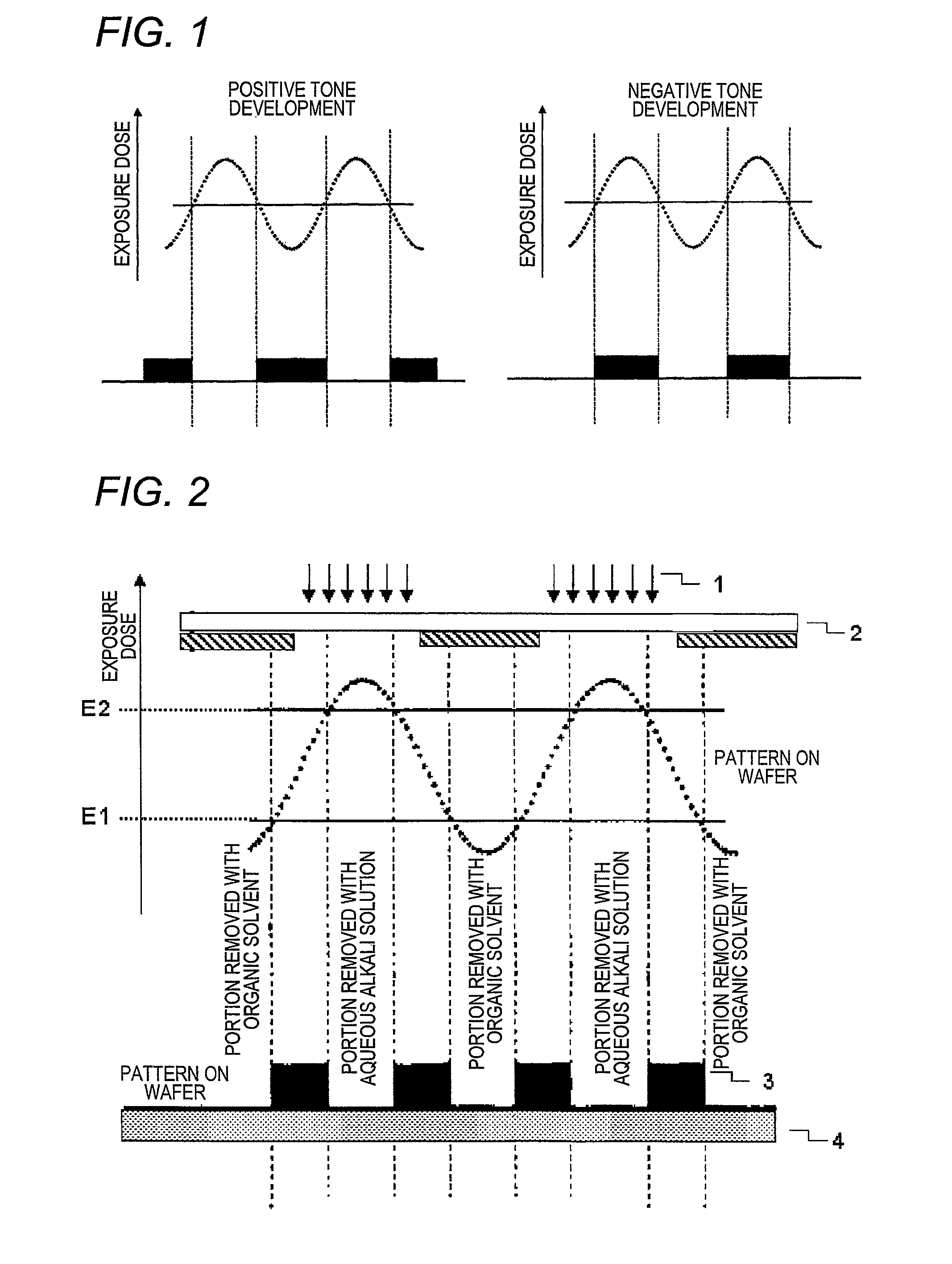

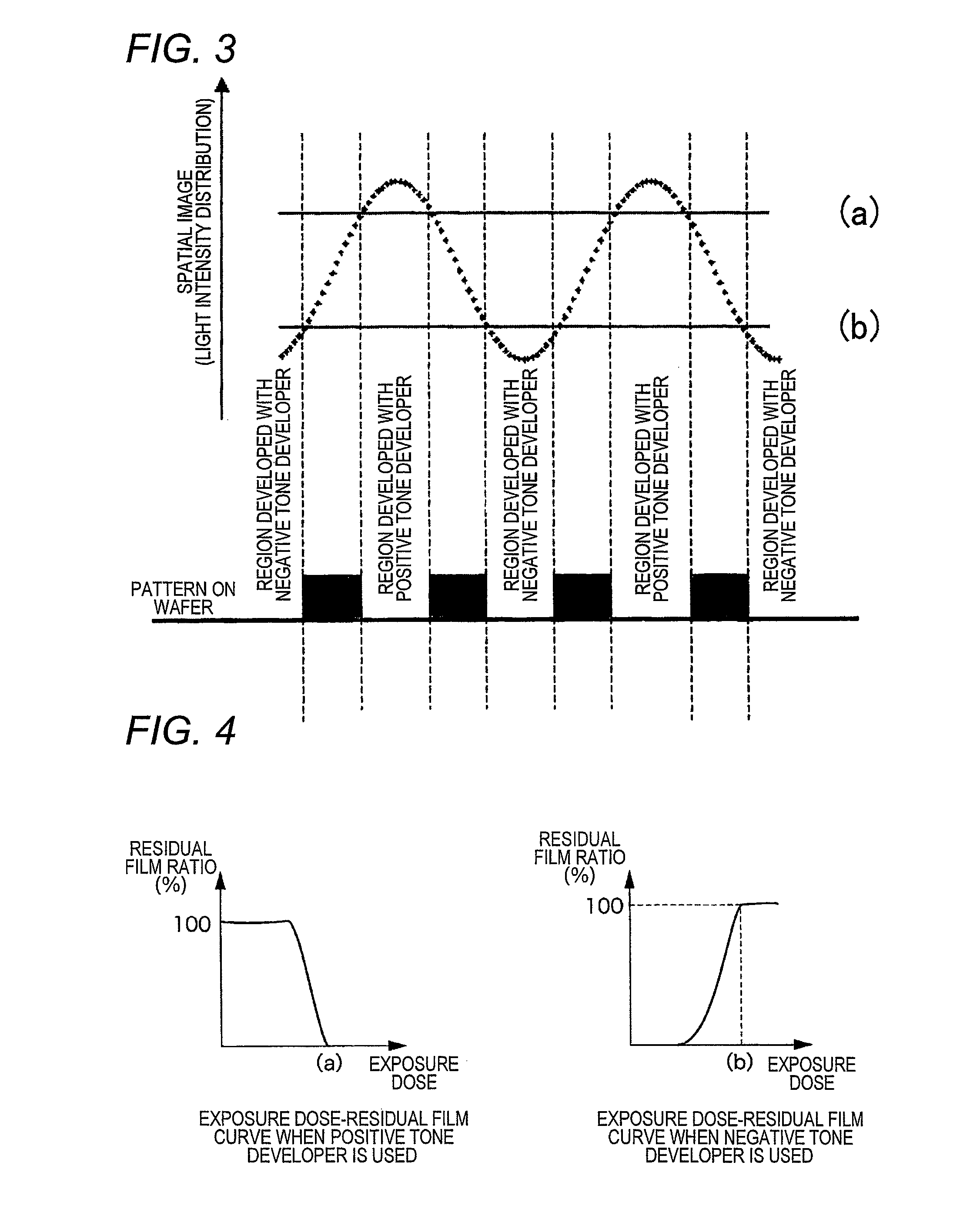

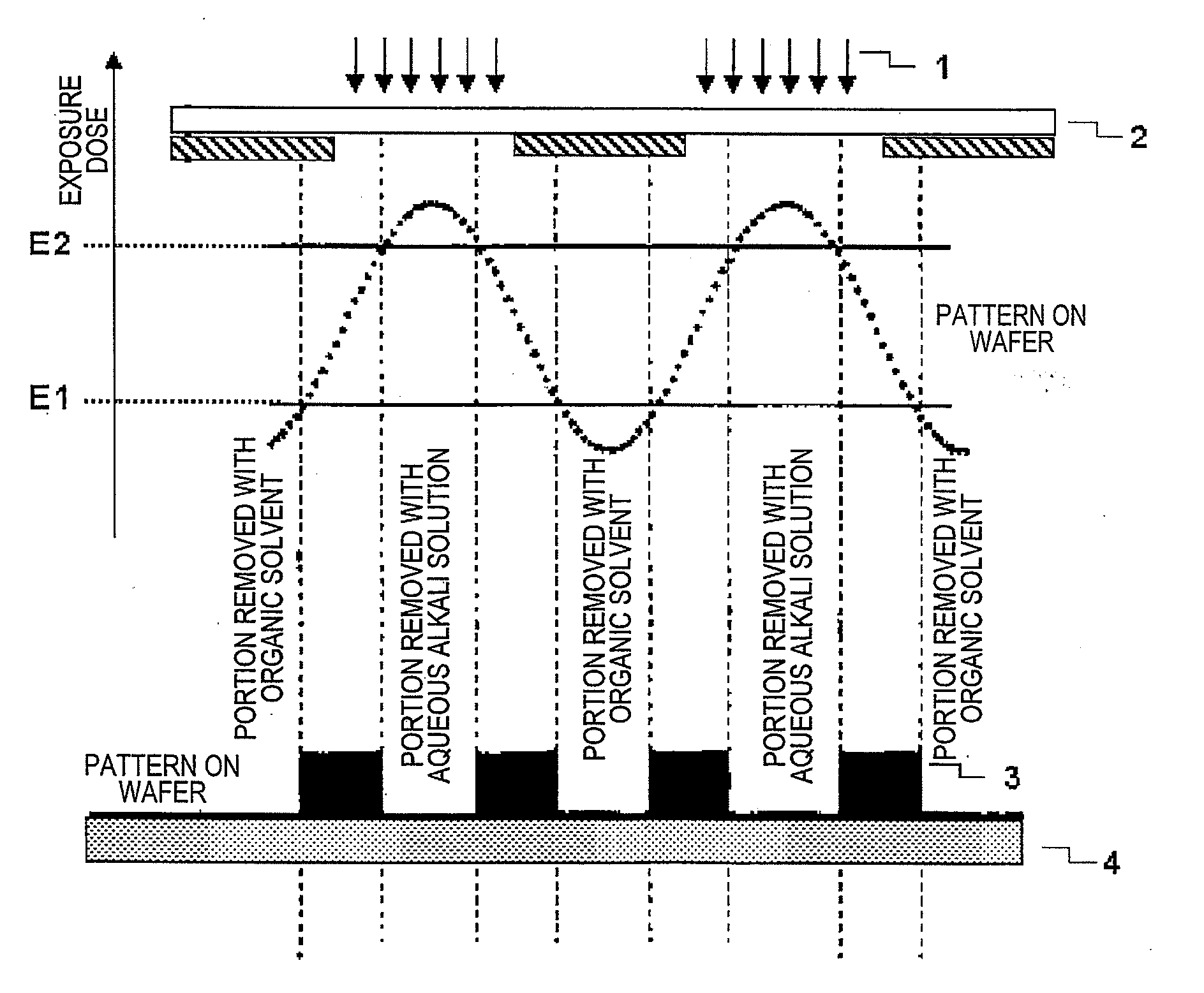

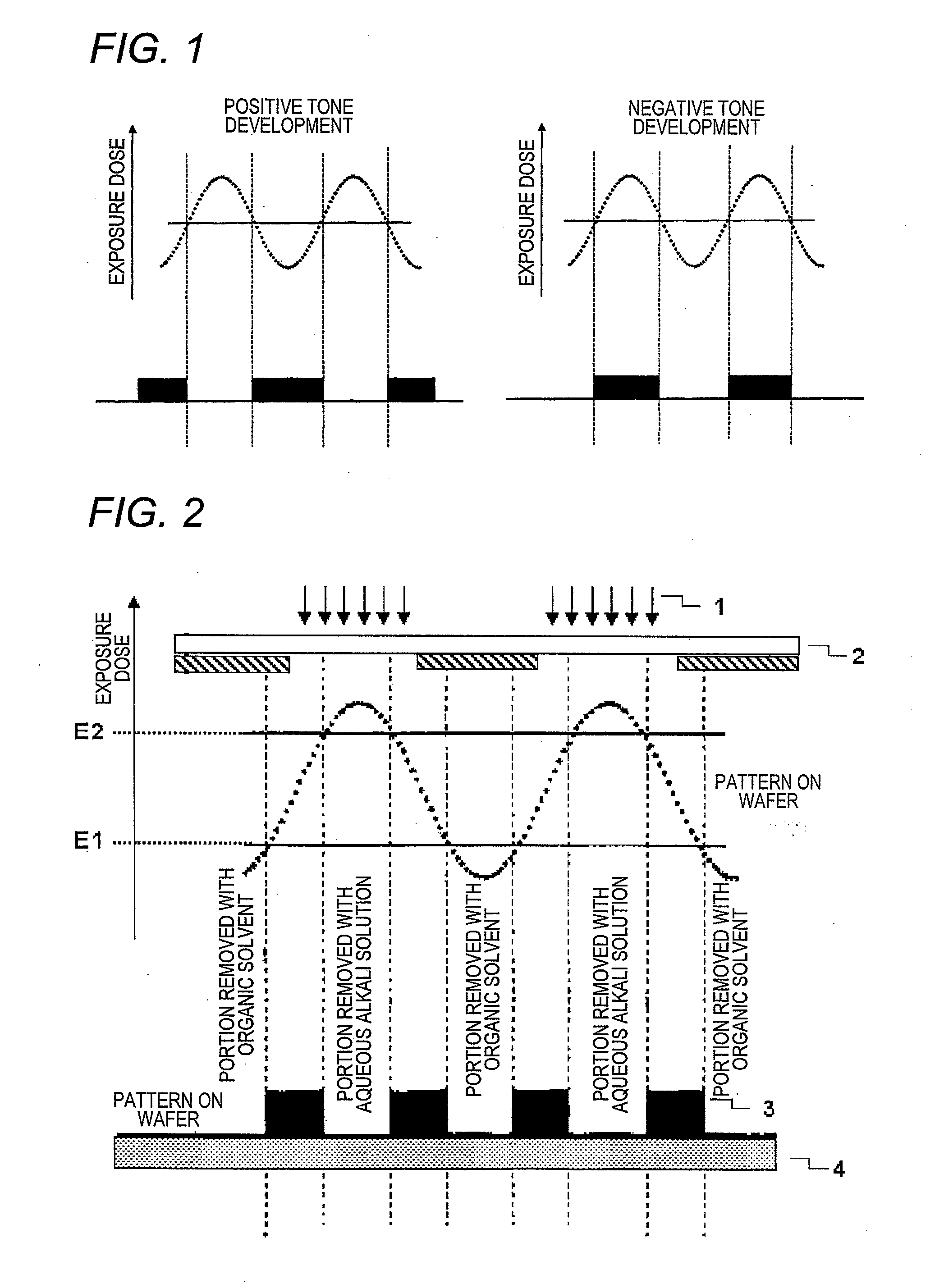

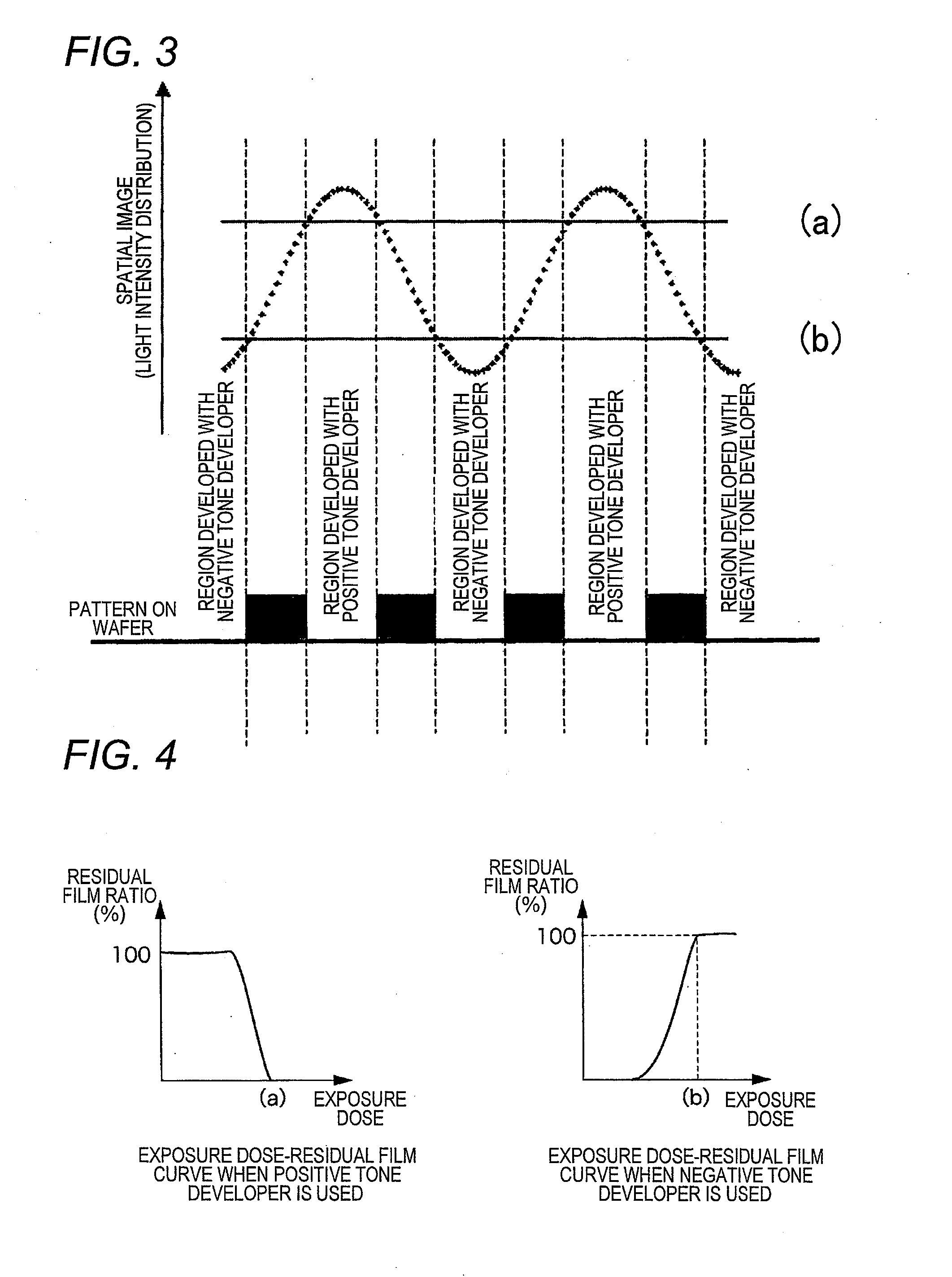

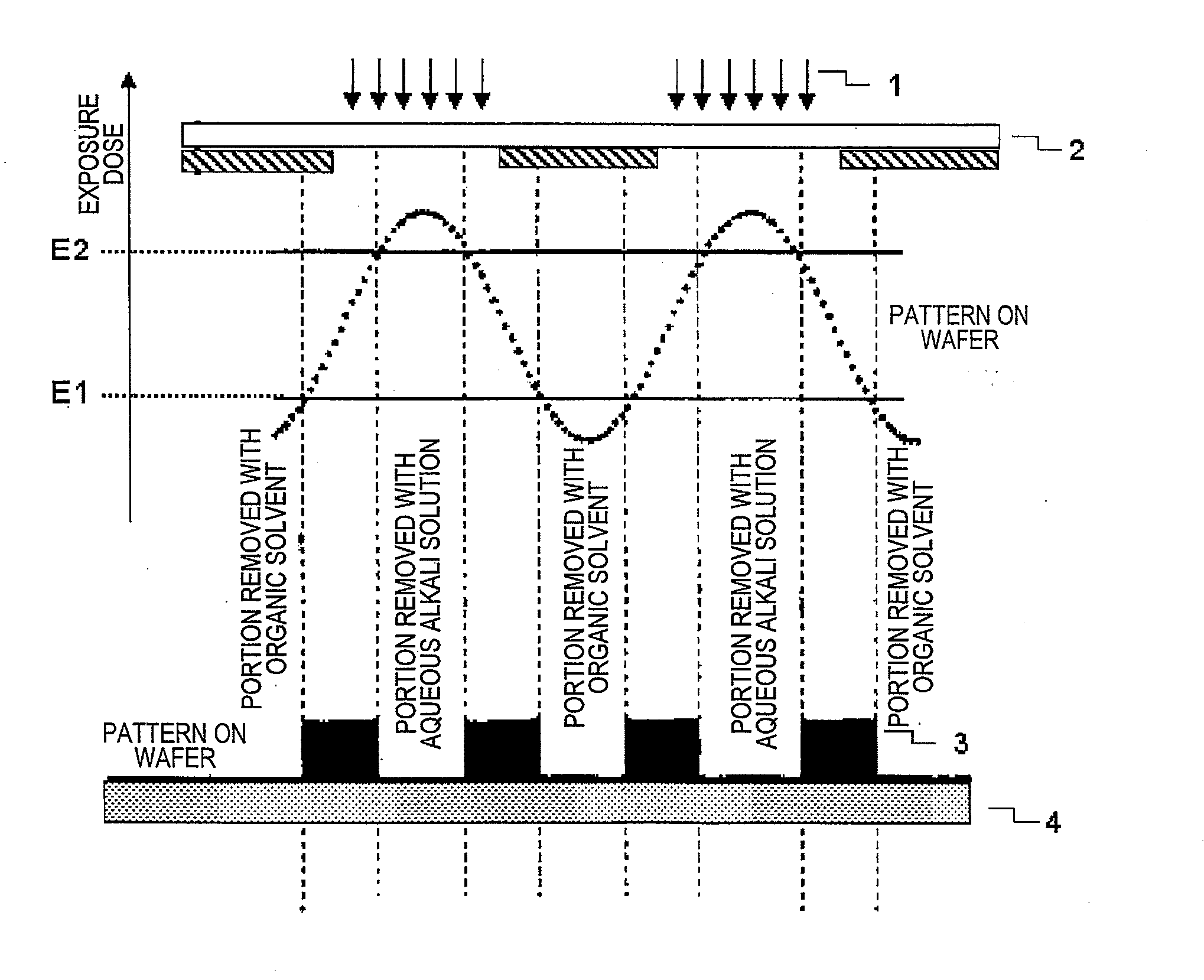

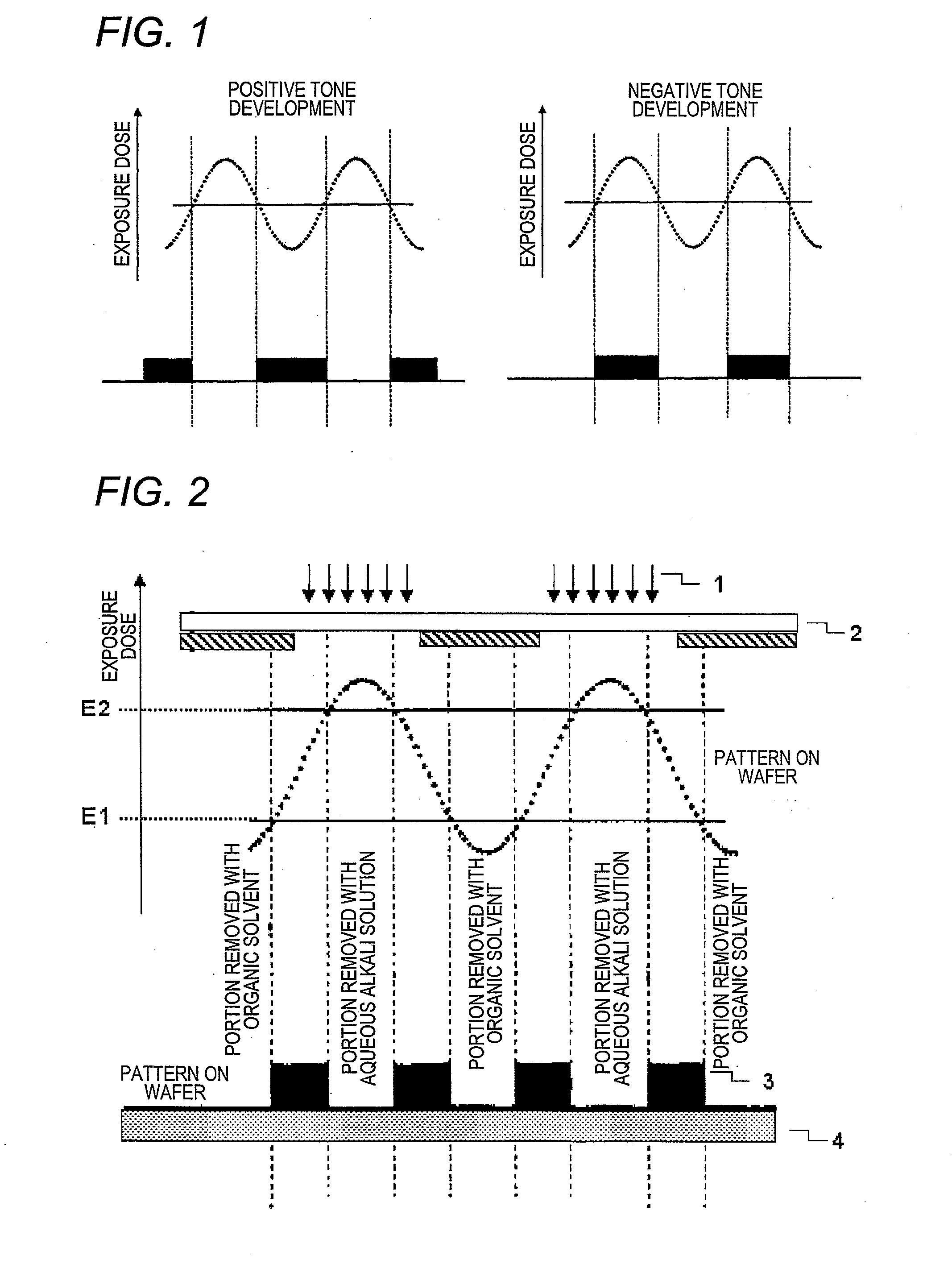

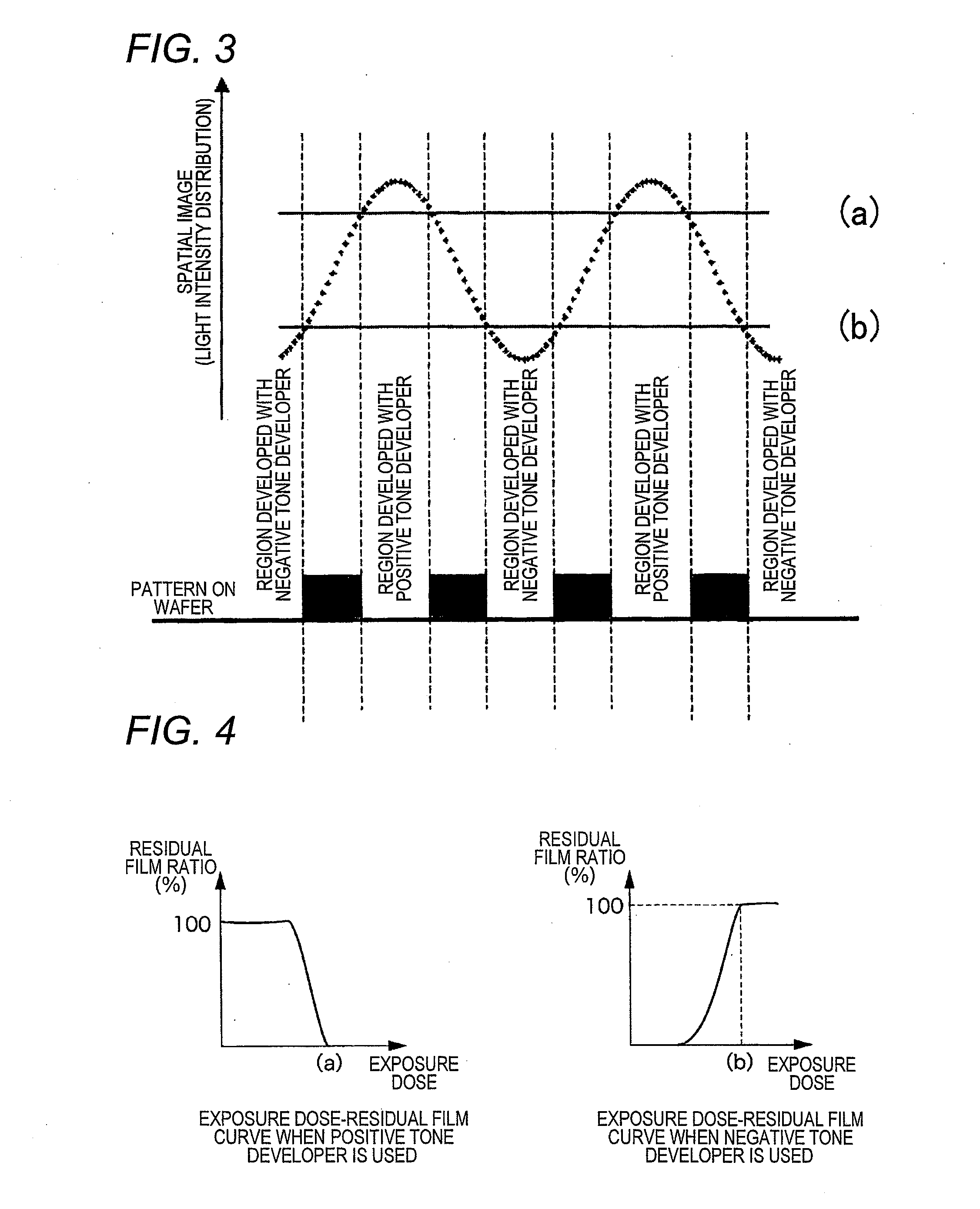

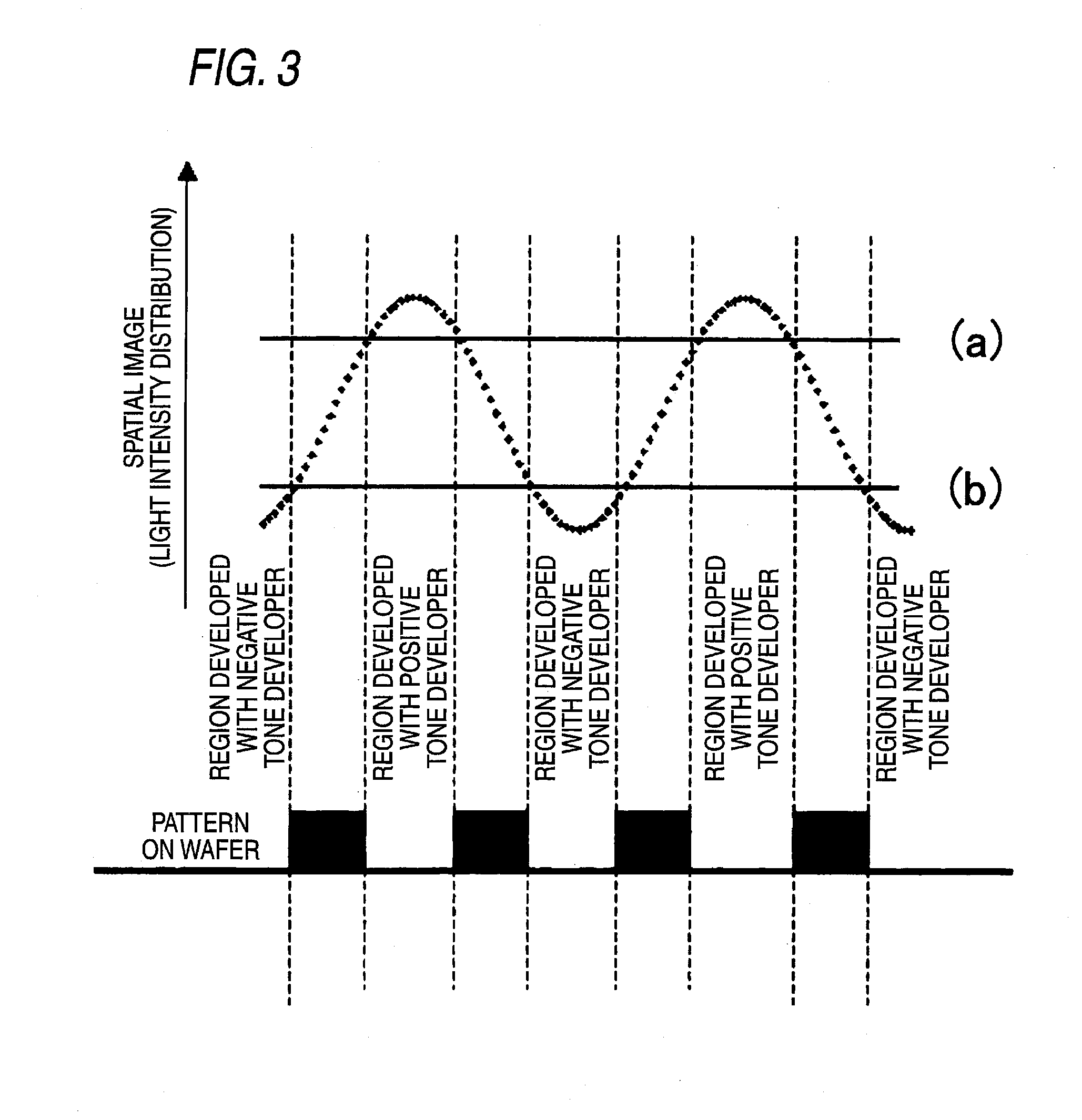

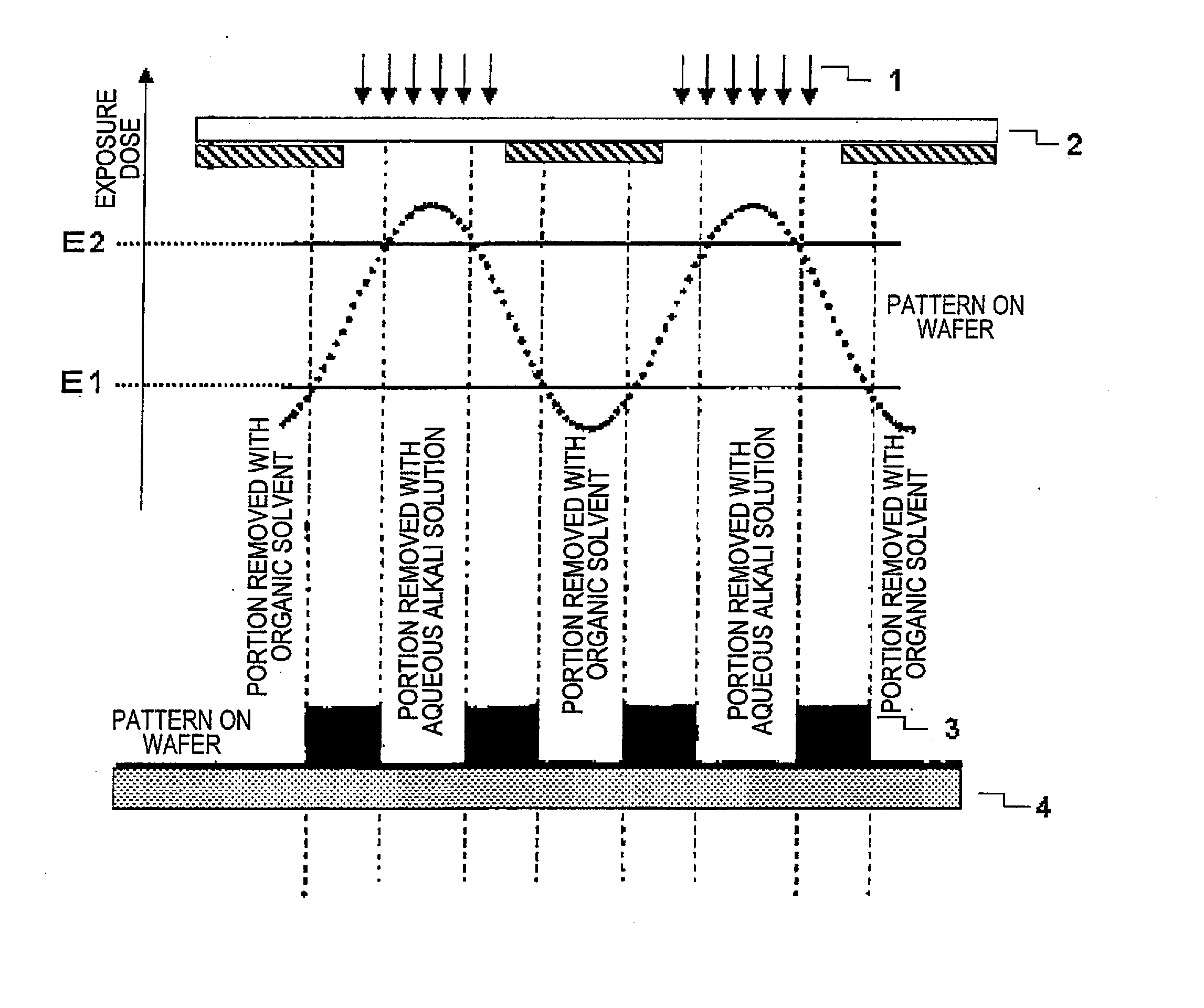

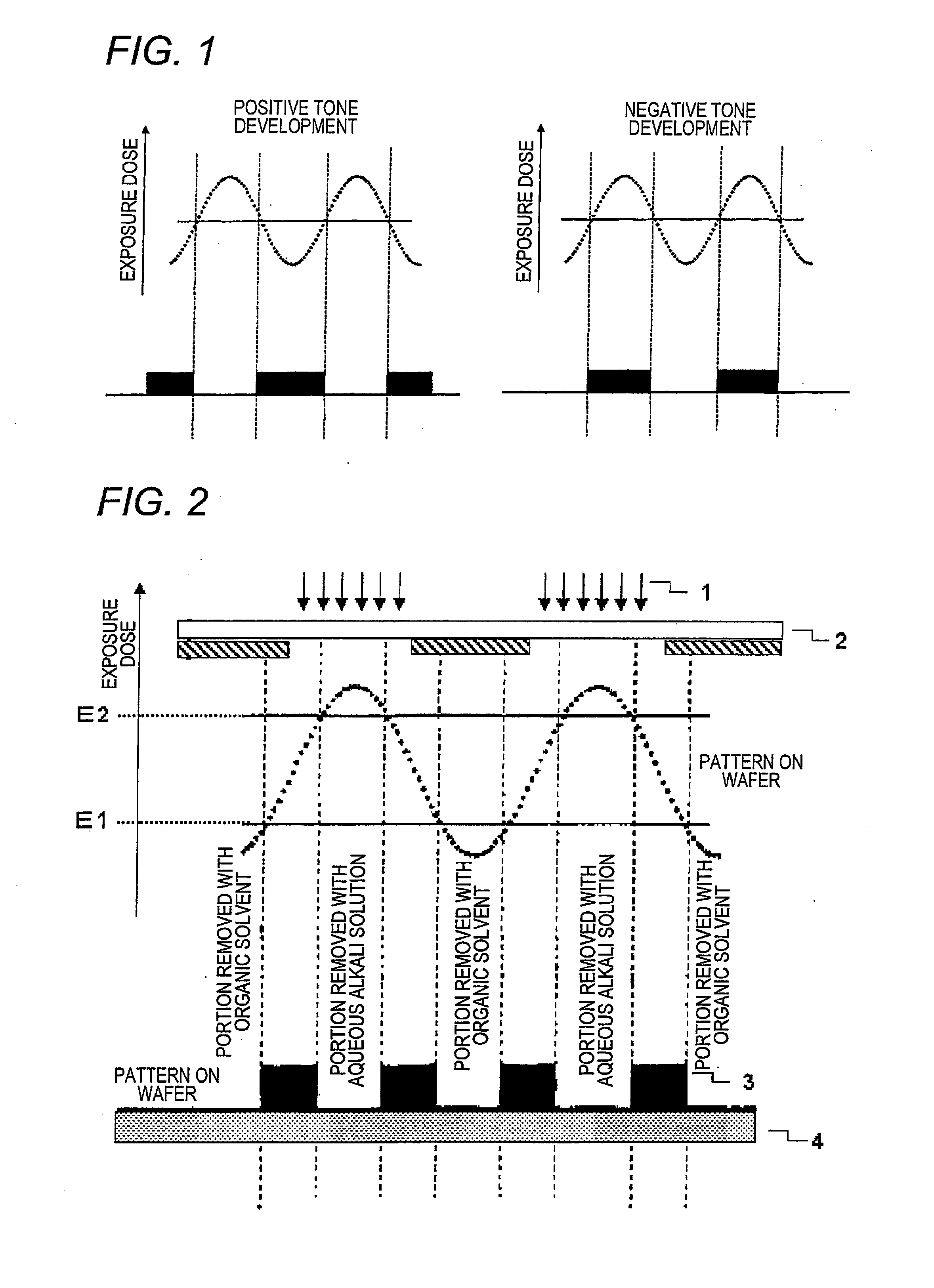

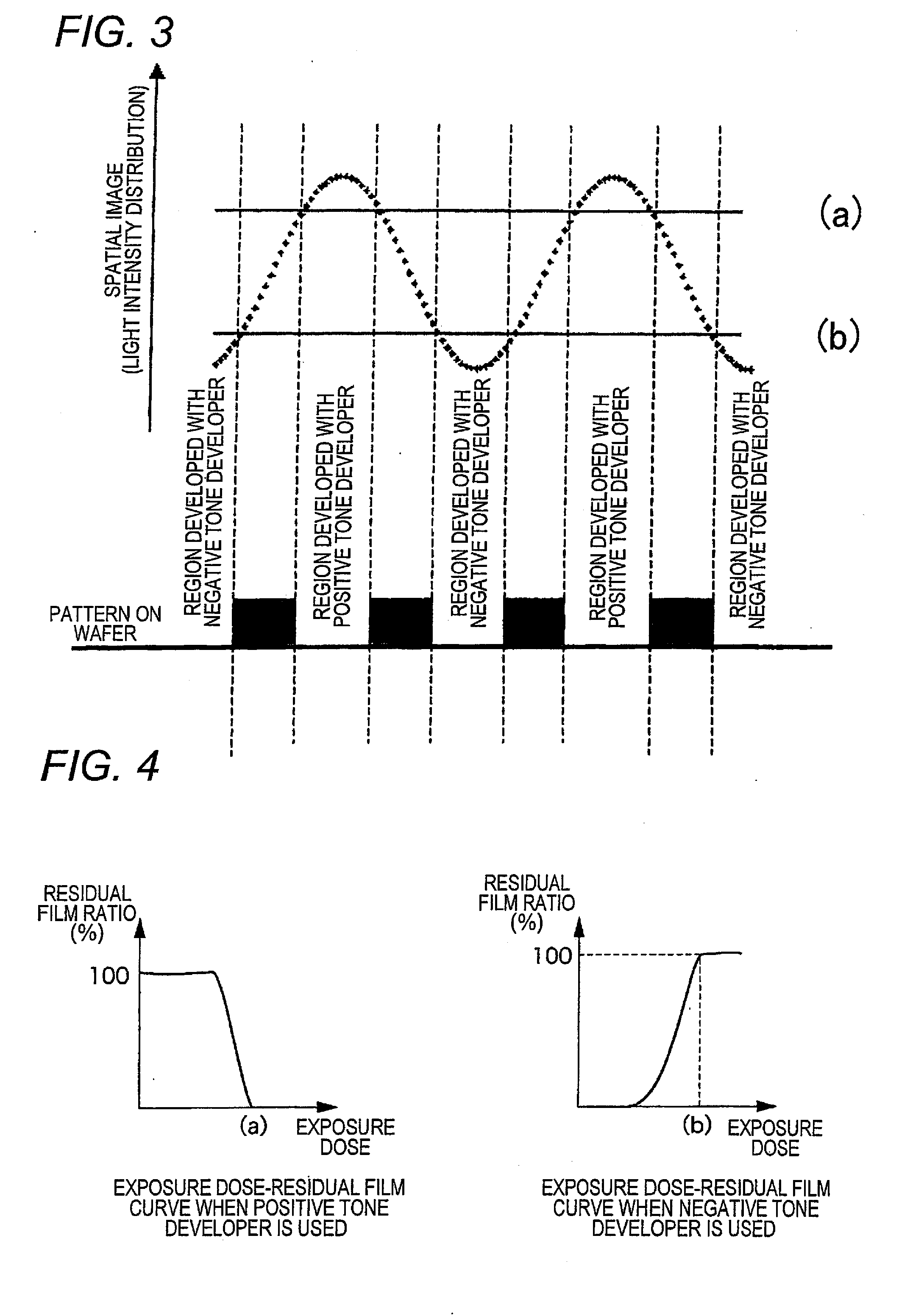

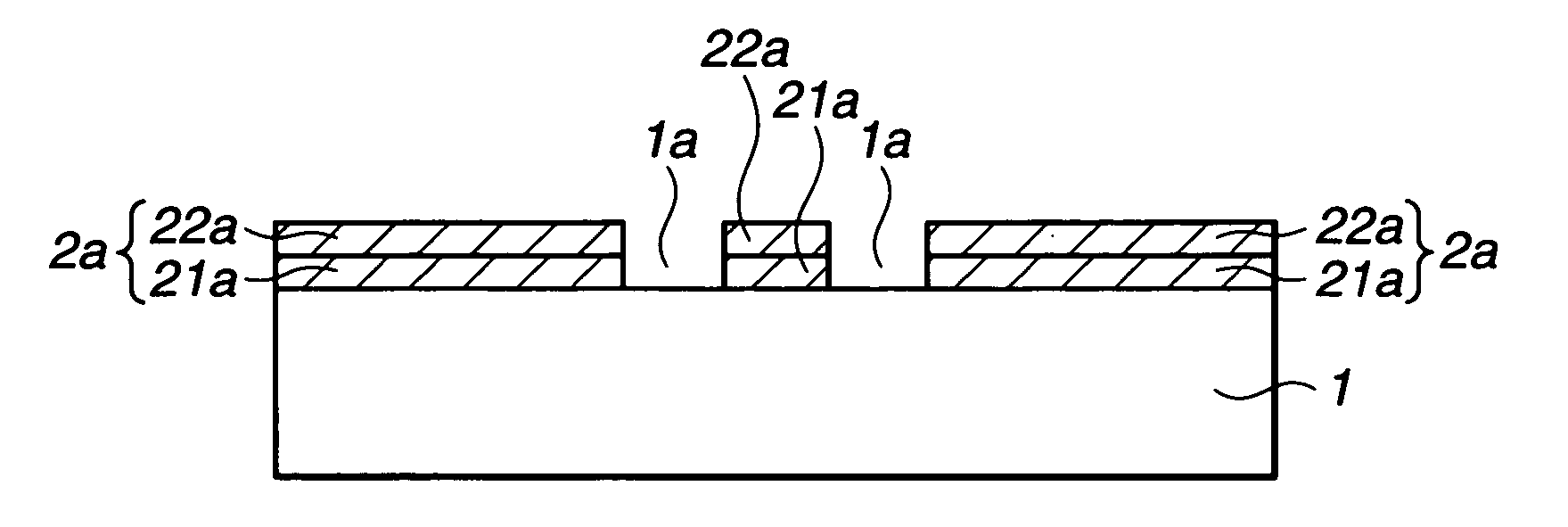

Pattern forming method, and resist composition, developer and rinsing solution used in the pattern forming method

ActiveUS8017304B2Molding stabilityReduce roughnessPhotosensitive materialsPhotoprinting processesDispersityActinic Rays

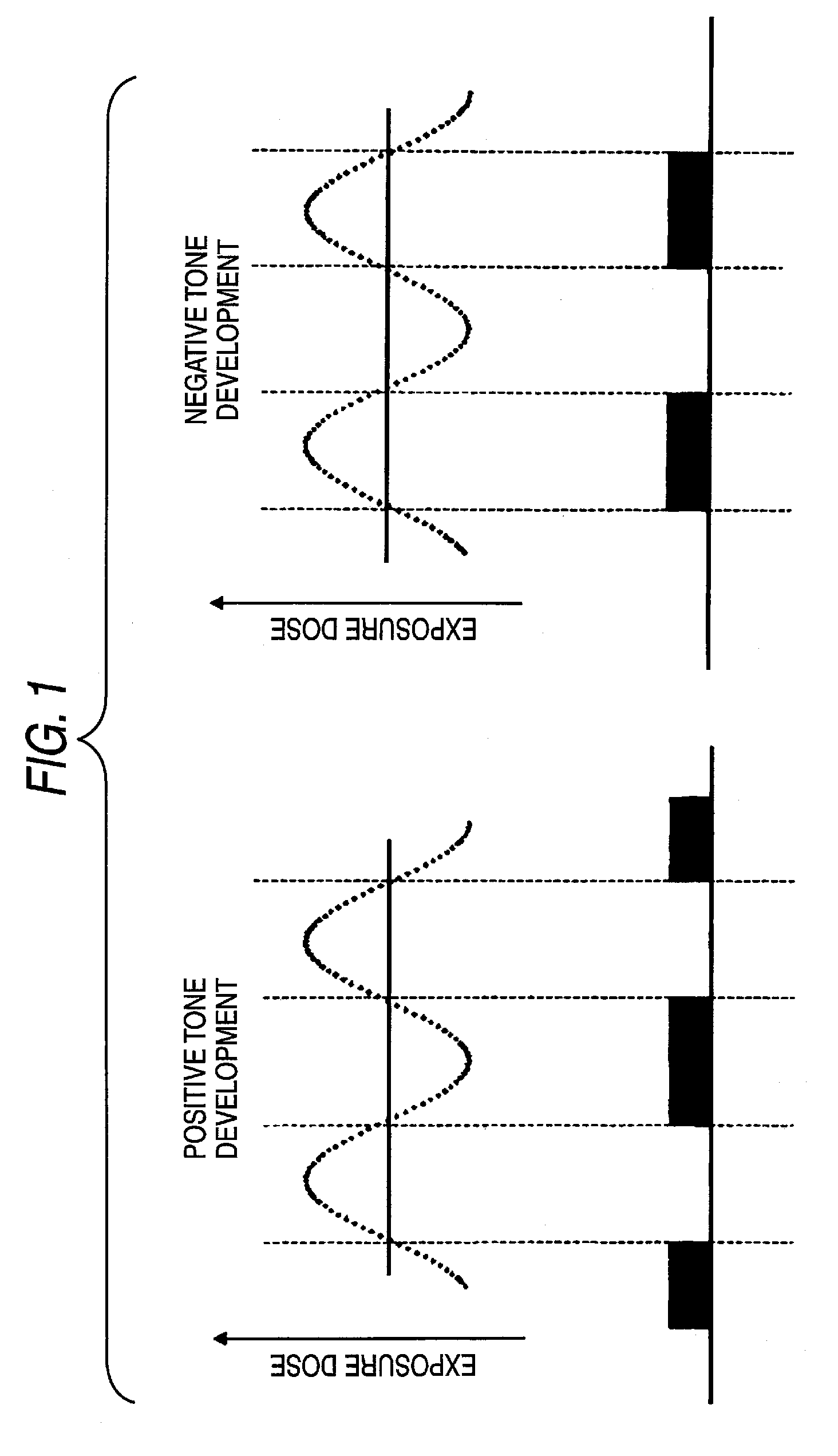

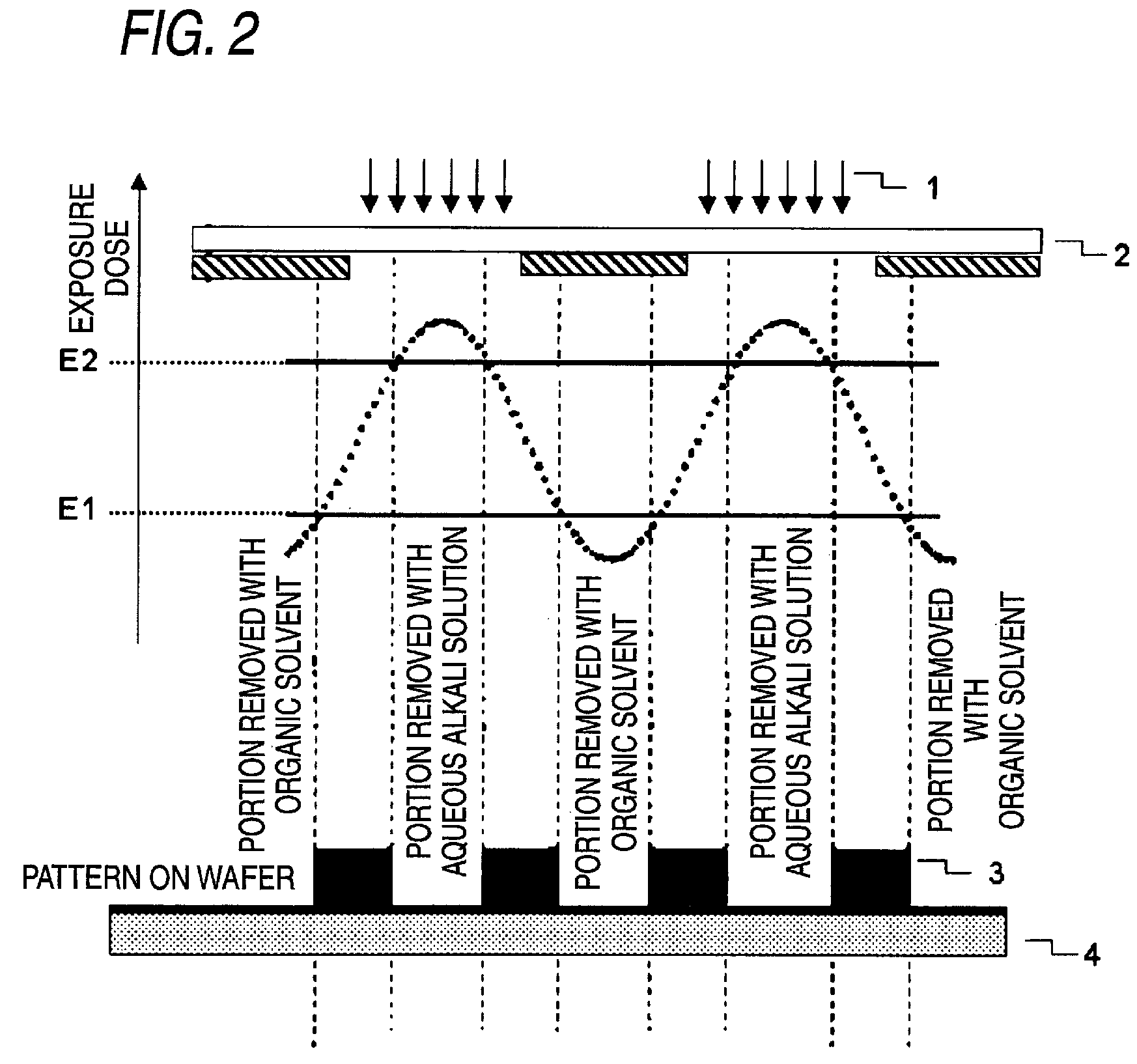

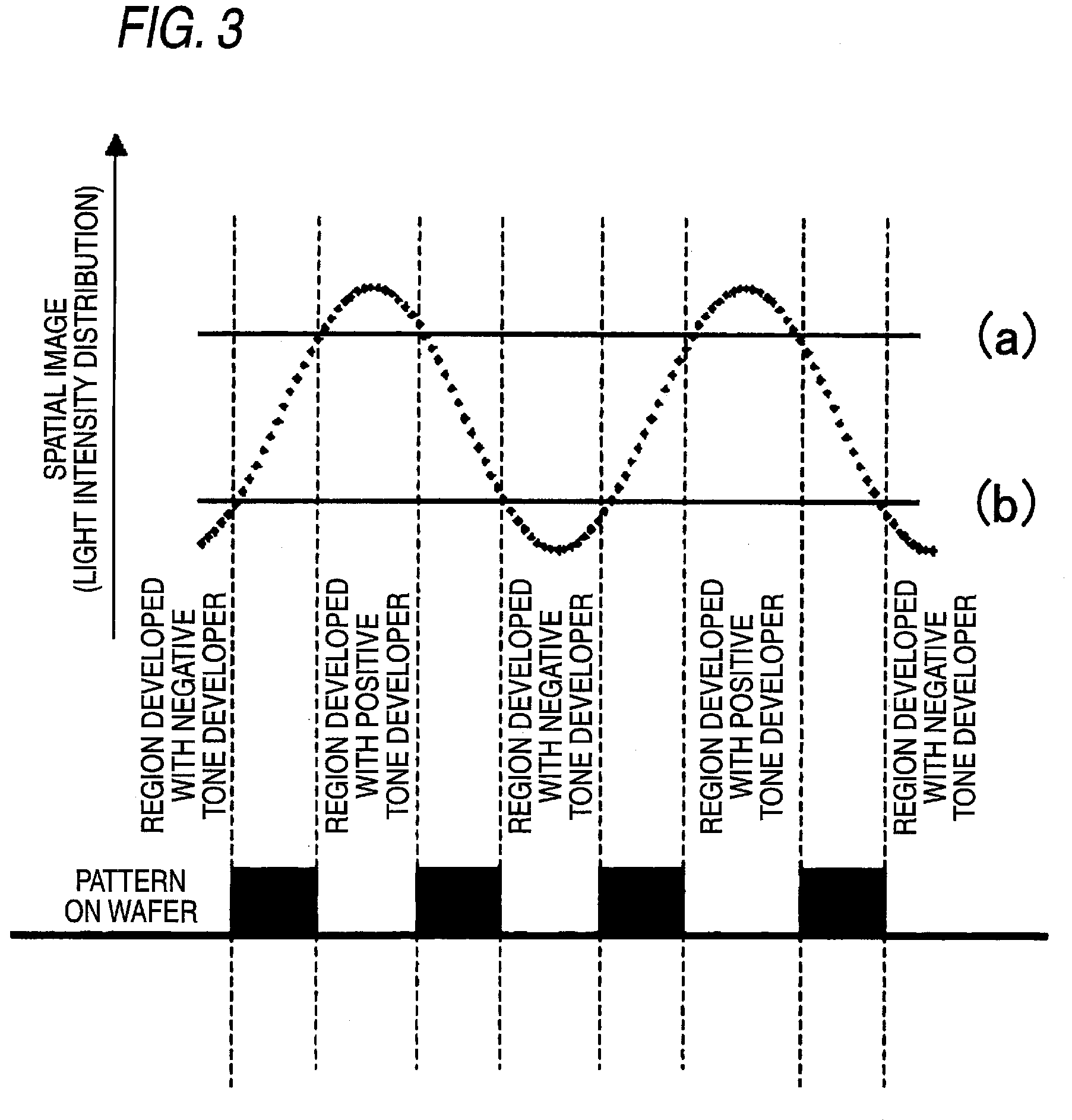

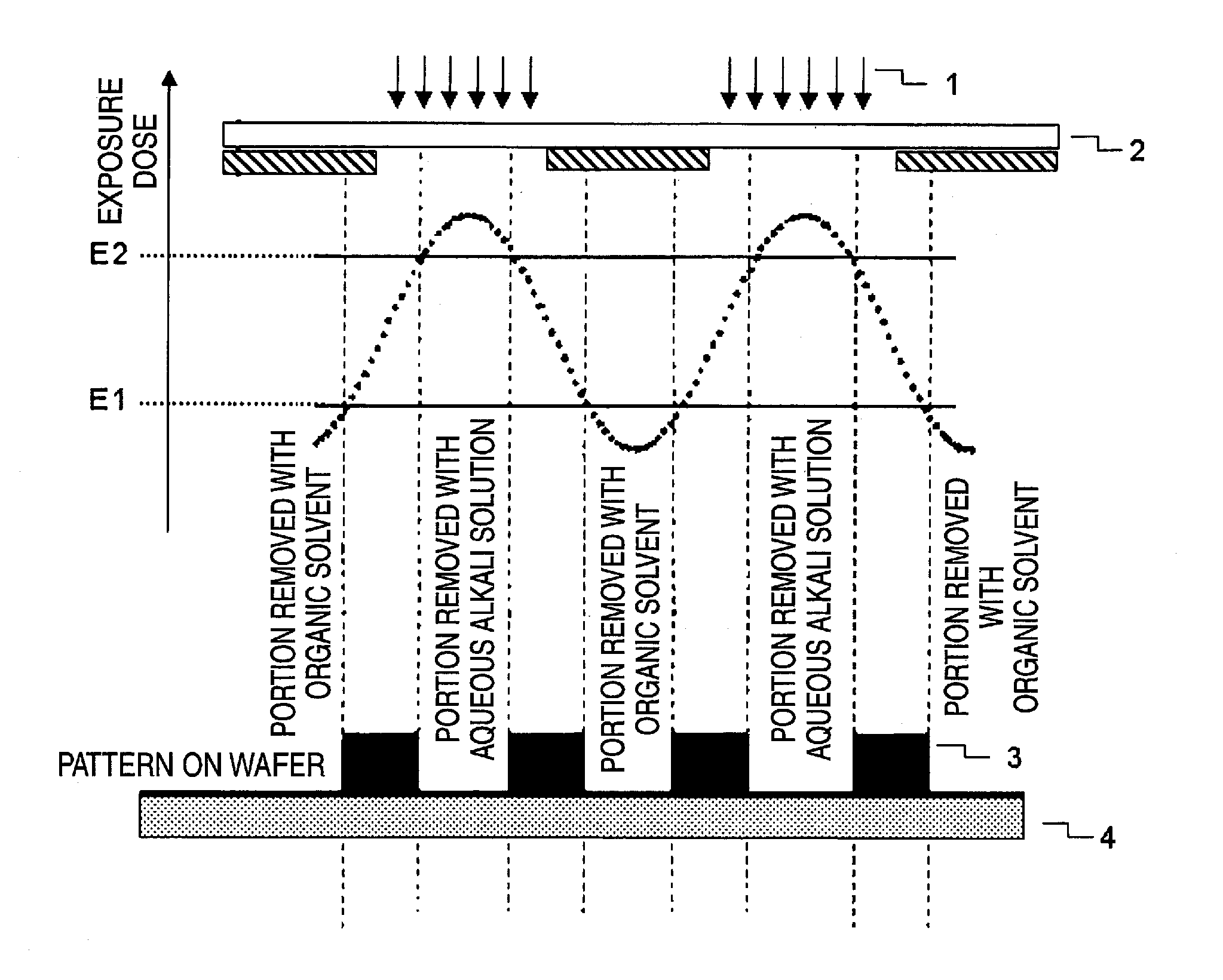

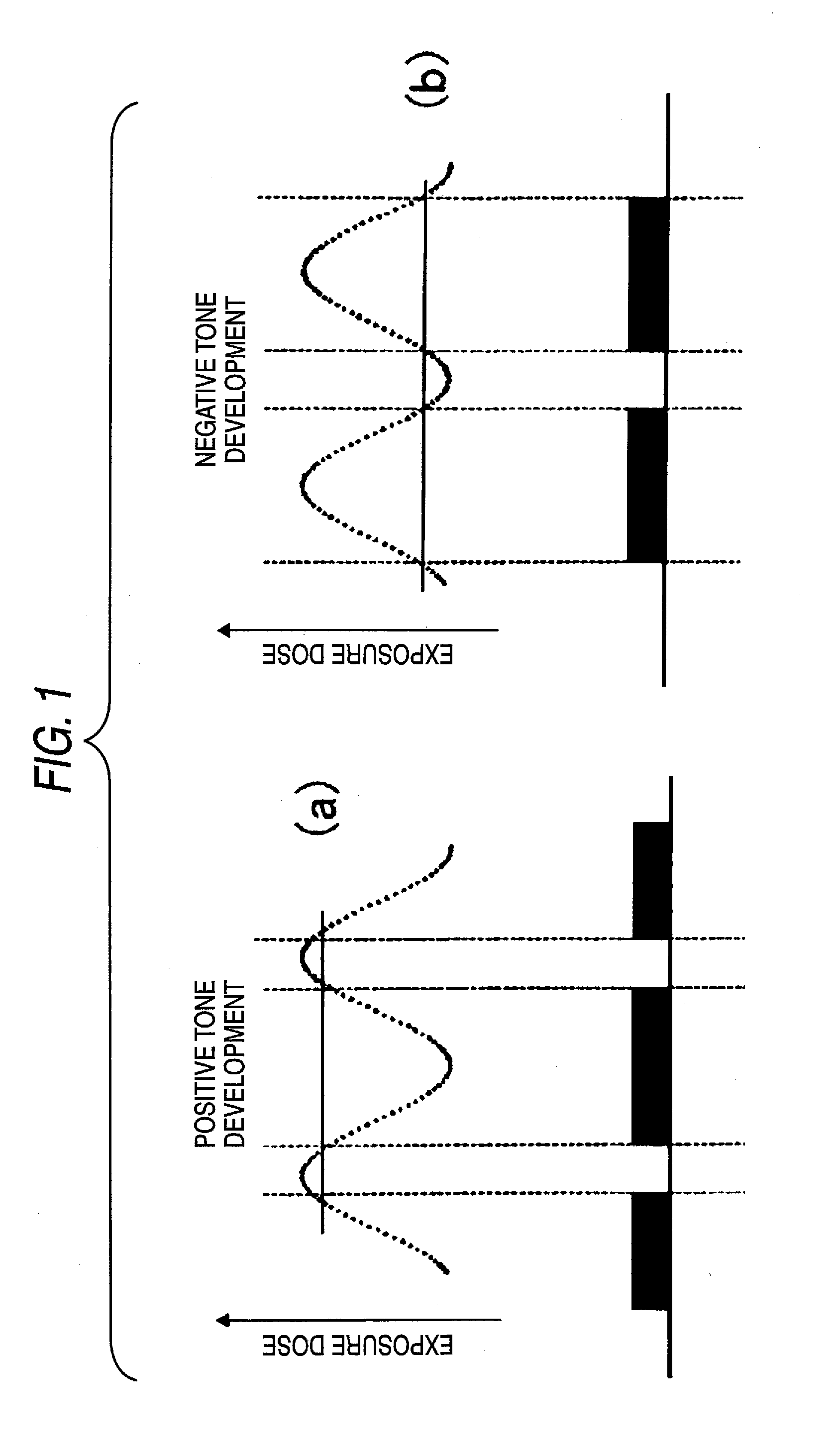

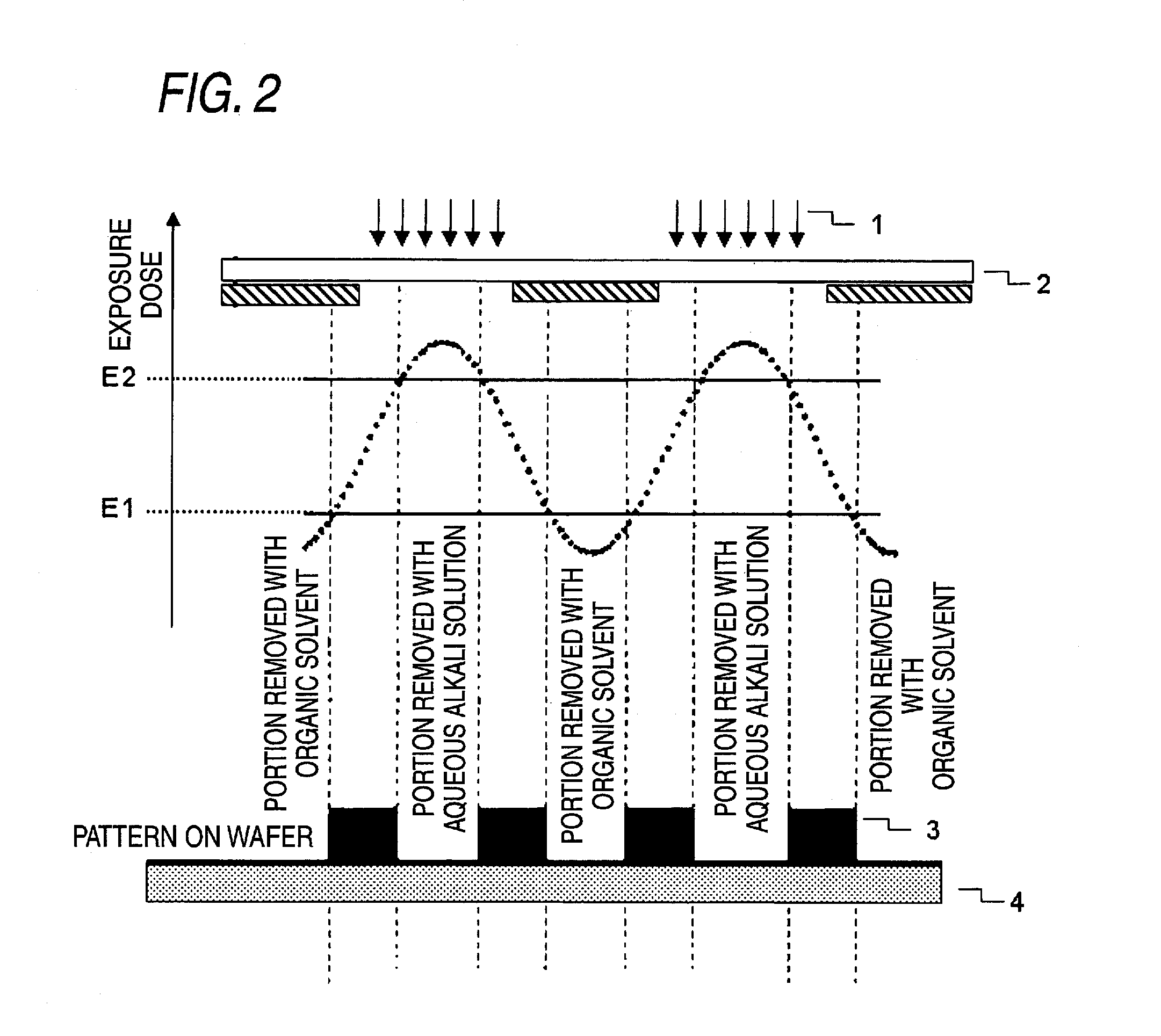

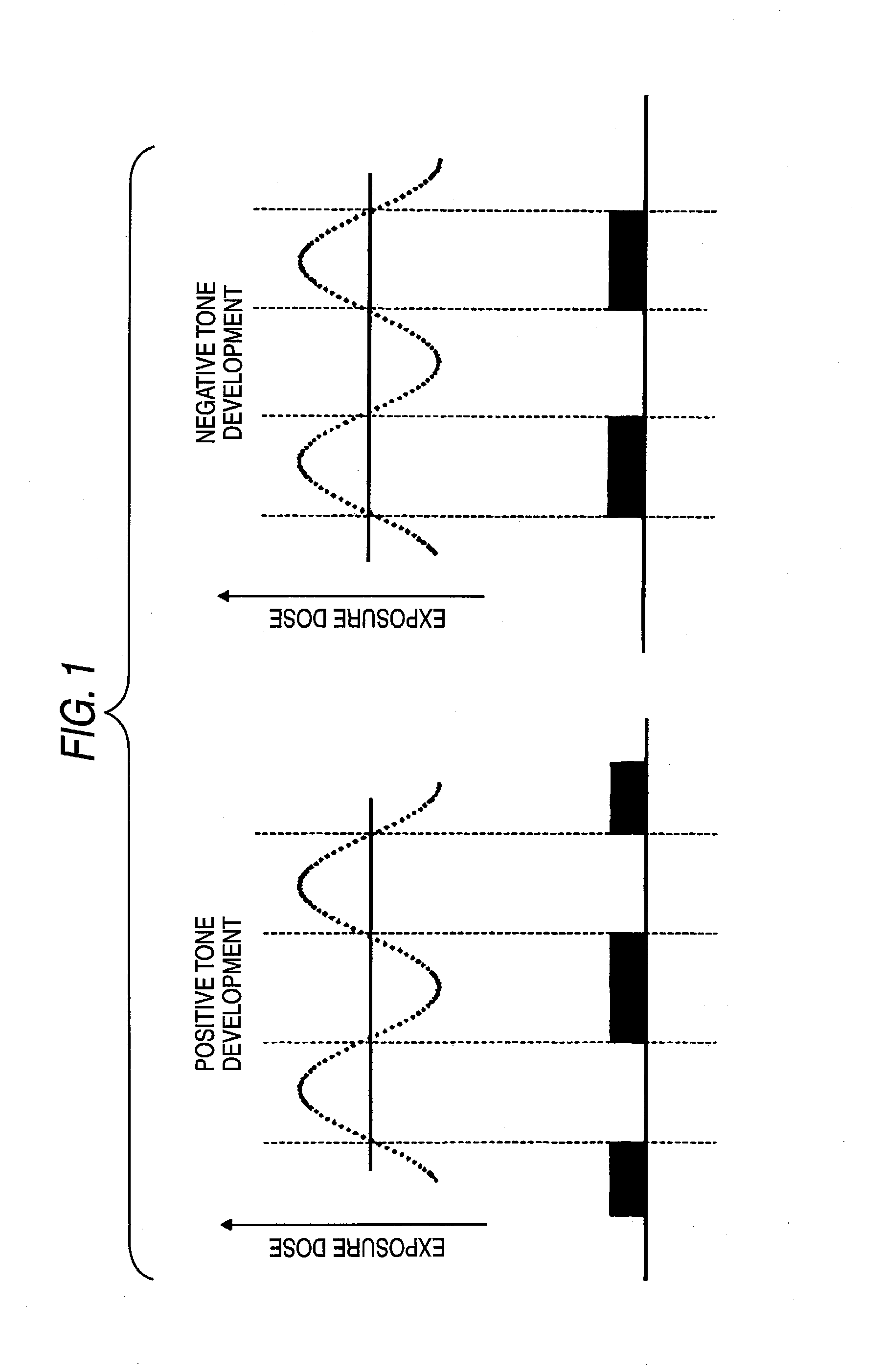

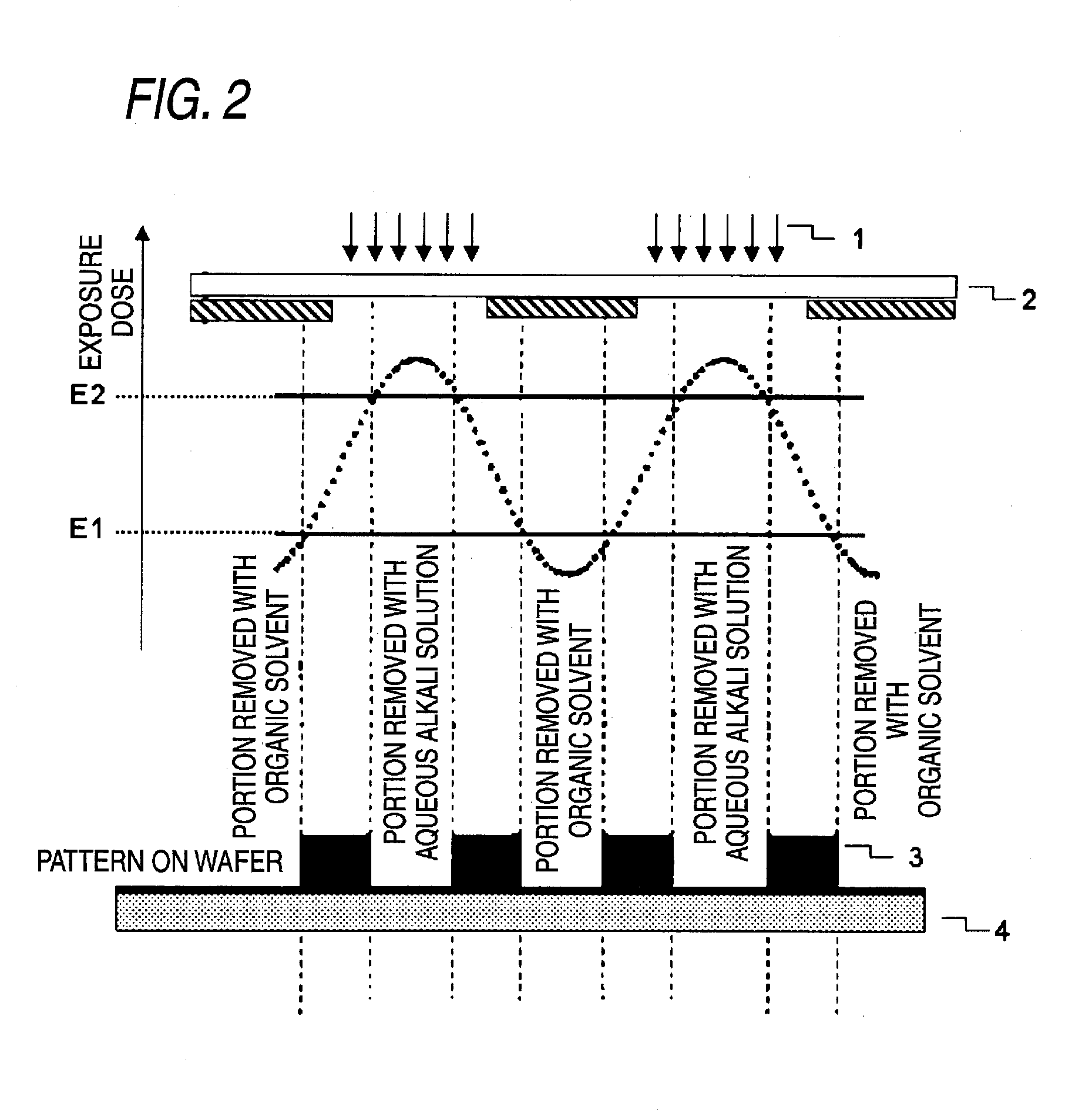

A pattern forming method comprising a step of applying a resist composition whose solubility in a negative tone developer decreases upon irradiation with an actinic ray or radiation and which contains a resin having an alicyclic hydrocarbon structure and a dispersity of 1.7 or less and being capable of increasing the polarity by the action of an acid, an exposure step, and a development step using a negative tone developer; a resist composition for use in the method; and a developer and a rinsing solution for use in the method, are provided, whereby a pattern with reduced line edge roughness and high dimensional uniformity can be formed.

Owner:FUJIFILM CORP

Pattern forming method, and resist composition, developer and rinsing solution used in the pattern forming method

InactiveUS20100040971A1Reduced line edge roughnessGood size uniformityPhotosensitive materialsPhotomechanical exposure apparatusDispersityActinic Rays

A pattern forming method comprising a step of applying a resist composition whose solubility in a negative tone developer decreases upon irradiation with an actinic ray or radiation and which contains a resin having an alicyclic hydrocarbon structure and a dispersity of 1.7 or less and being capable of increasing the polarity by the action of an acid, an exposure step, and a development step using a negative tone developer; a resist composition for use in the method; and a developer and a rinsing solution for use in the method, are provided, whereby a pattern with reduced line edge roughness and high dimensional uniformity can be formed.

Owner:FUJIFILM CORP

Pattern forming method, and resist composition, developer and rinsing solution used in the pattern forming method

ActiveUS20100040972A1Reduced line edge roughnessGood size uniformityPhotosensitive materialsPhotoprinting processesDispersityActinic Rays

A pattern forming method comprising a step of applying a resist composition whose solubility in a negative tone developer decreases upon irradiation with an actinic ray or radiation and which contains a resin having an alicyclic hydrocarbon structure and a dispersity of 1.7 or less and being capable of increasing the polarity by the action of an acid, an exposure step, and a development step using a negative tone developer; a resist composition for use in the method; and a developer and a rinsing solution for use in the method, are provided, whereby a pattern with reduced line edge roughness and high dimensional uniformity can be formed.

Owner:FUJIFILM CORP

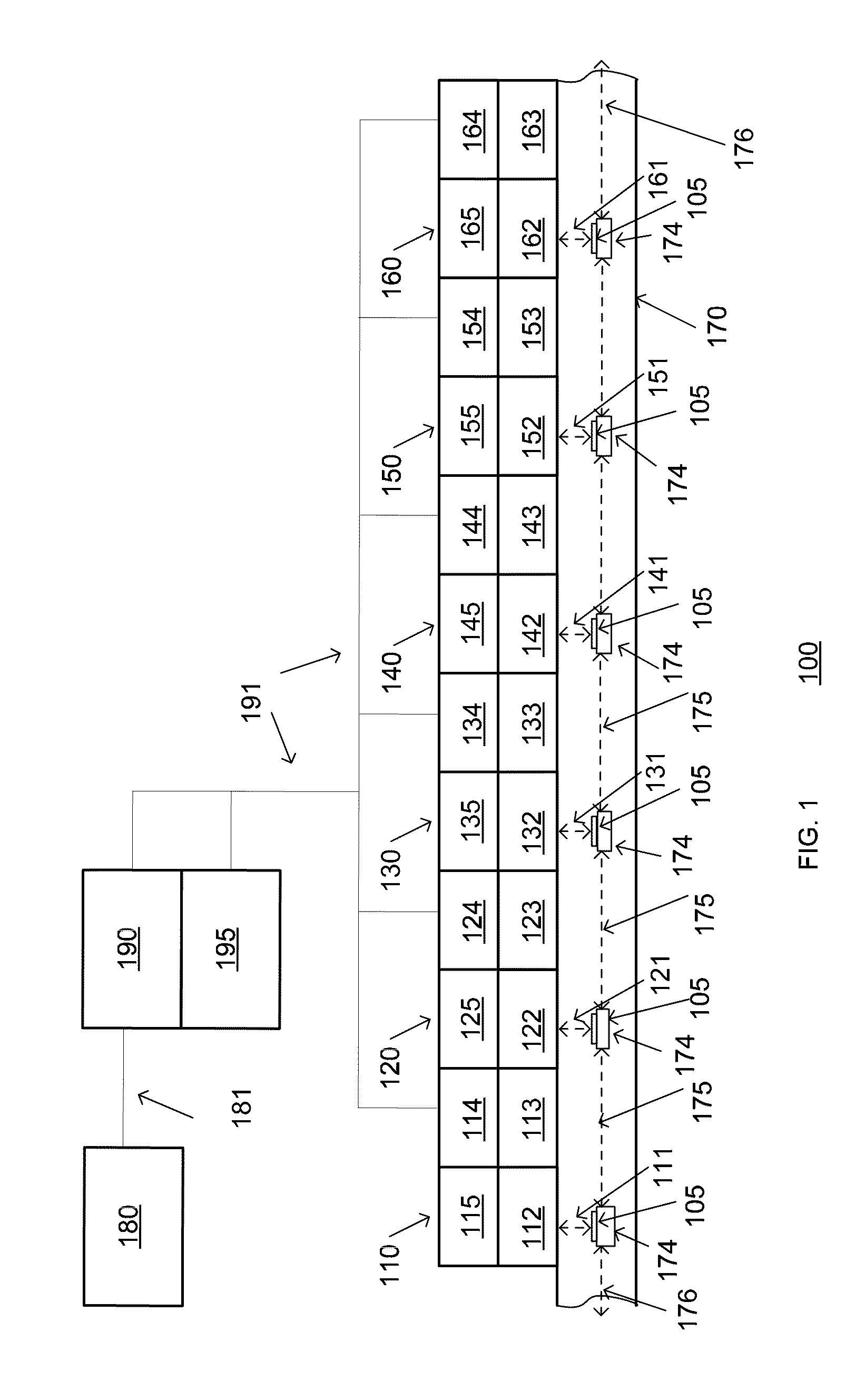

Circuits and methods for characterizing random variations in device characteristics in semiconductor integrated circuits

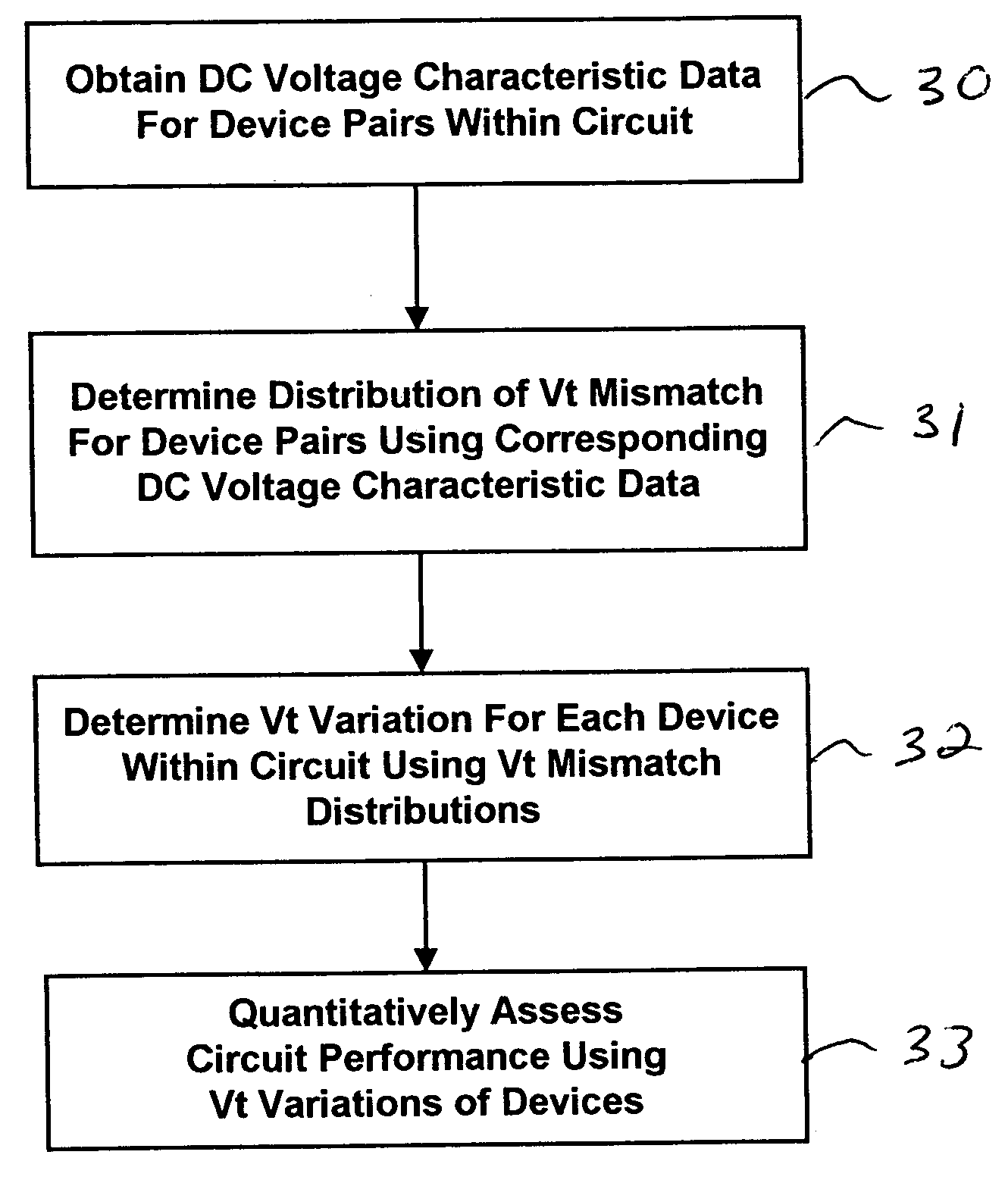

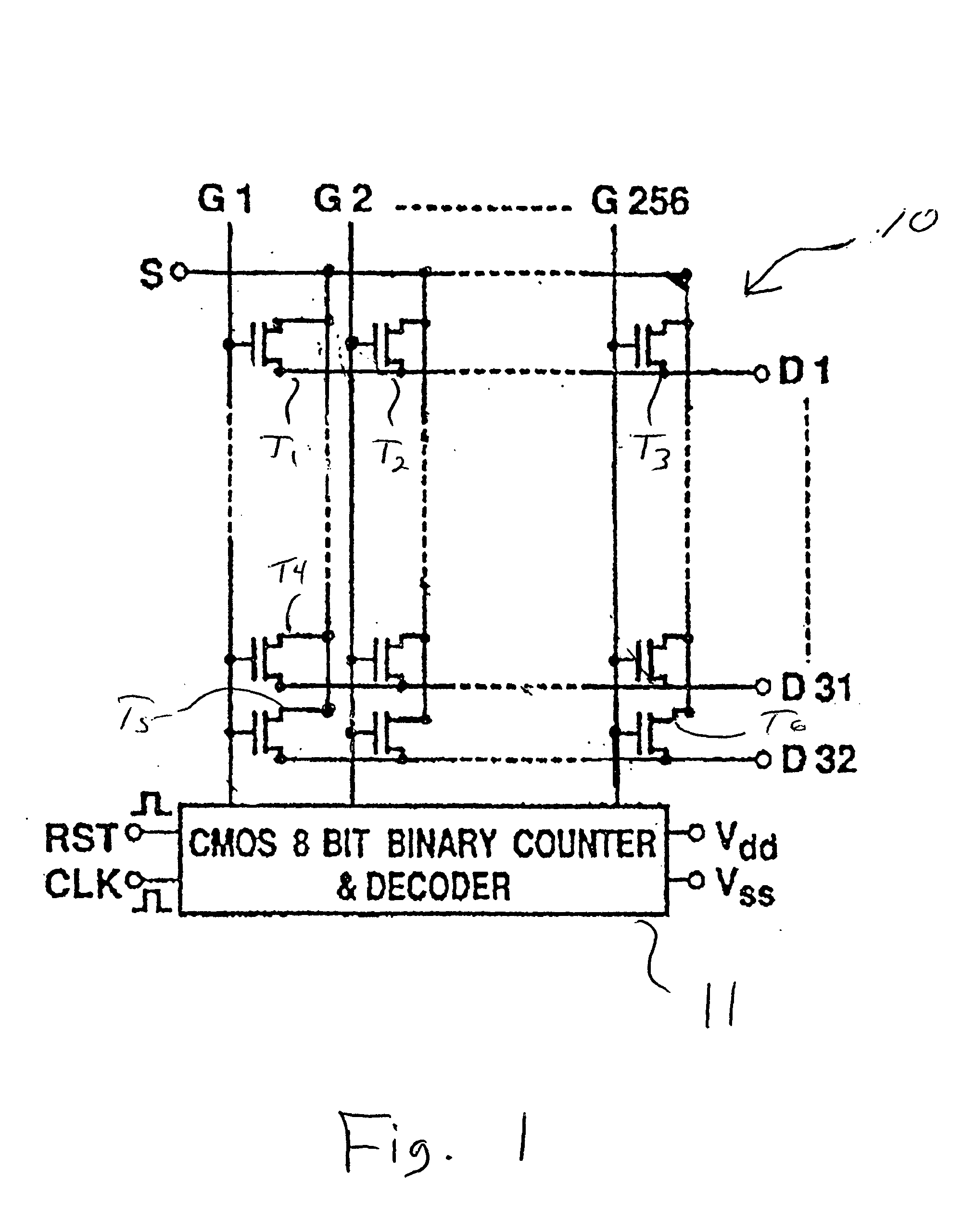

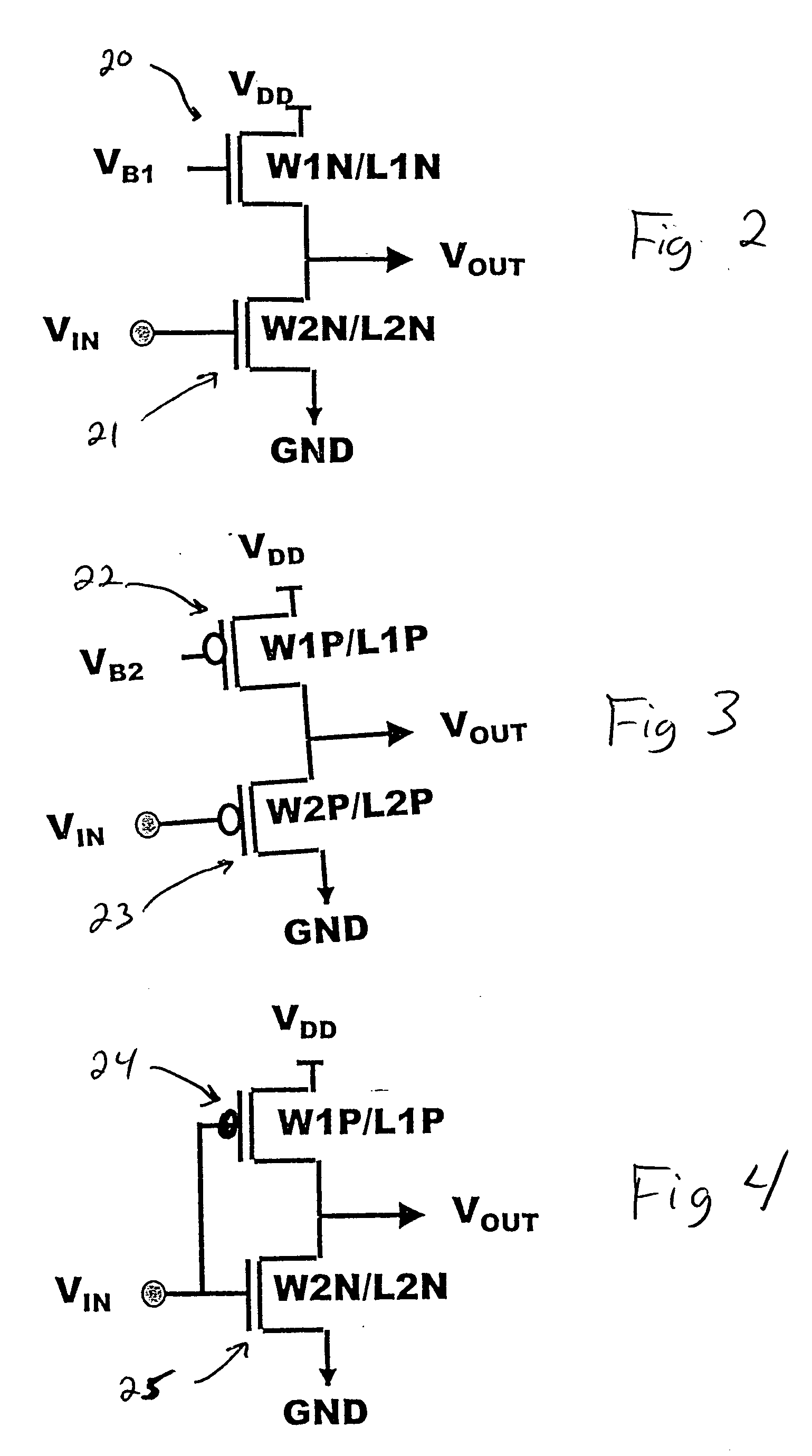

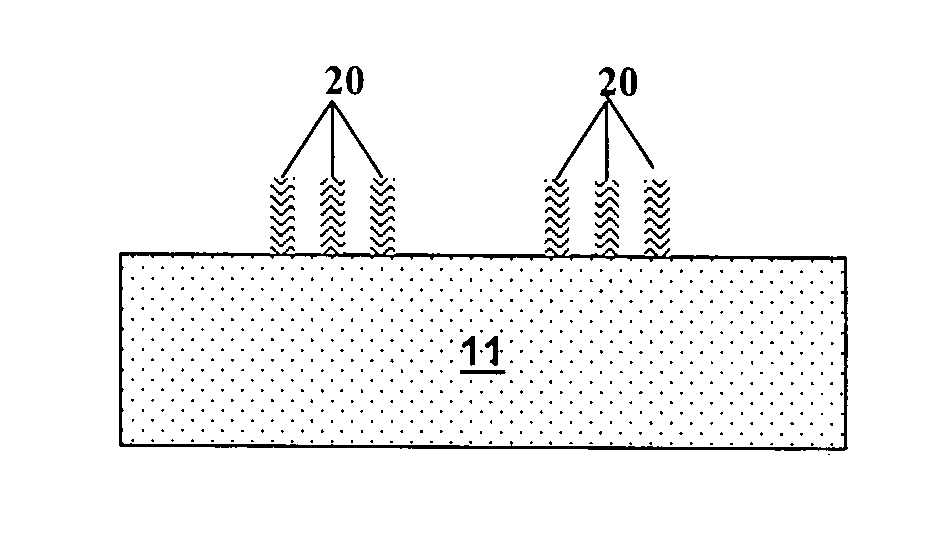

ActiveUS20050043908A1Accurate measurementAccurately characterizeDigital circuit testingCurrent/voltage measurementDopantDc voltage

Circuits and methods for measuring and characterizing random variations in device characteristics of semiconductor integrated circuit devices, which enable circuit designers to accurately measure and characterize random variations in device characteristics (such as transistor threshold voltage) between neighboring devices resulting from random sources such as dopant fluctuations and line edge roughness, for purposes of integrated circuit design and analysis. In one aspect, a method for characterizing random variations in device mismatch (e.g., threshold voltage mismatch) between a pair of device (e.g., transistors) is performed by obtaining subthreshold DC voltage characteristic data for the device pair, and then determining a distribution in voltage threshold mismatch for the device pair directly from the corresponding subthreshold DC voltage characteristic data. The voltage threshold mismatch distributions of different device pairs of a given circuit design can then be used to determine voltage threshold variations of the constituent circuit devices. The voltage threshold variation of the devices can be used to characterize the random variations of the given circuit.

Owner:GLOBALFOUNDRIES US INC

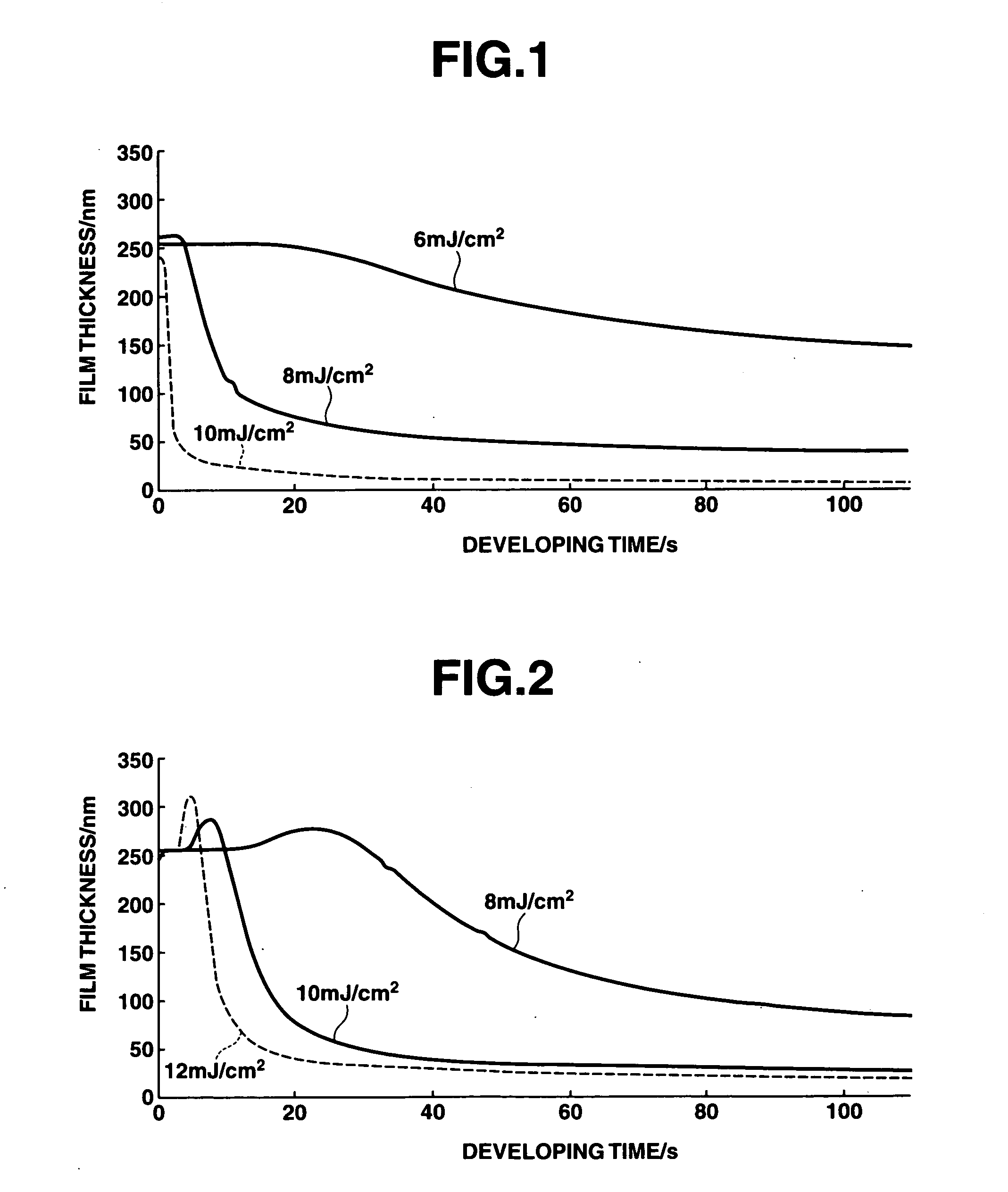

Recursive spacer defined patterning

InactiveUS20070065990A1Increases fin densityImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesHigh densityEngineering

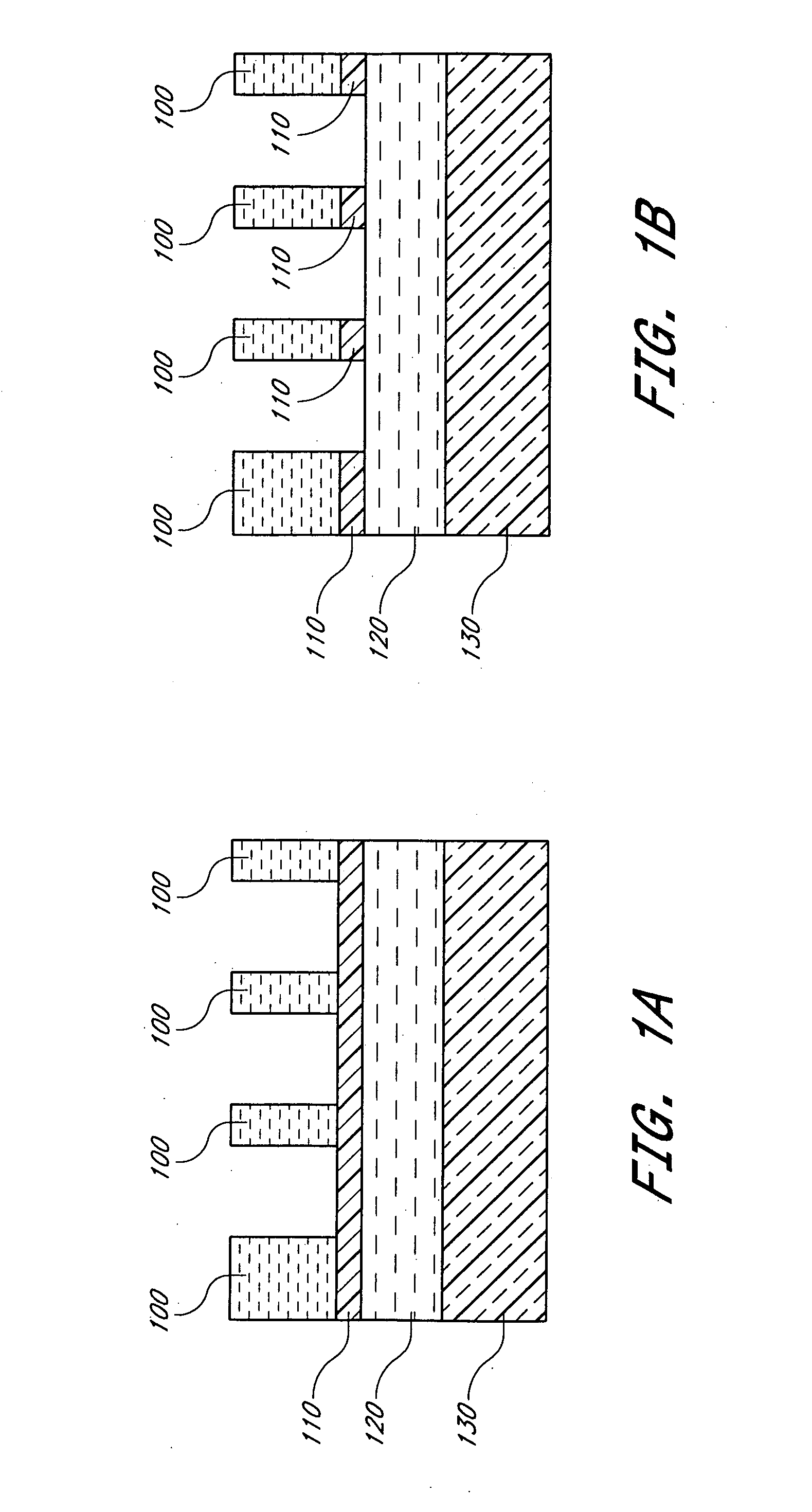

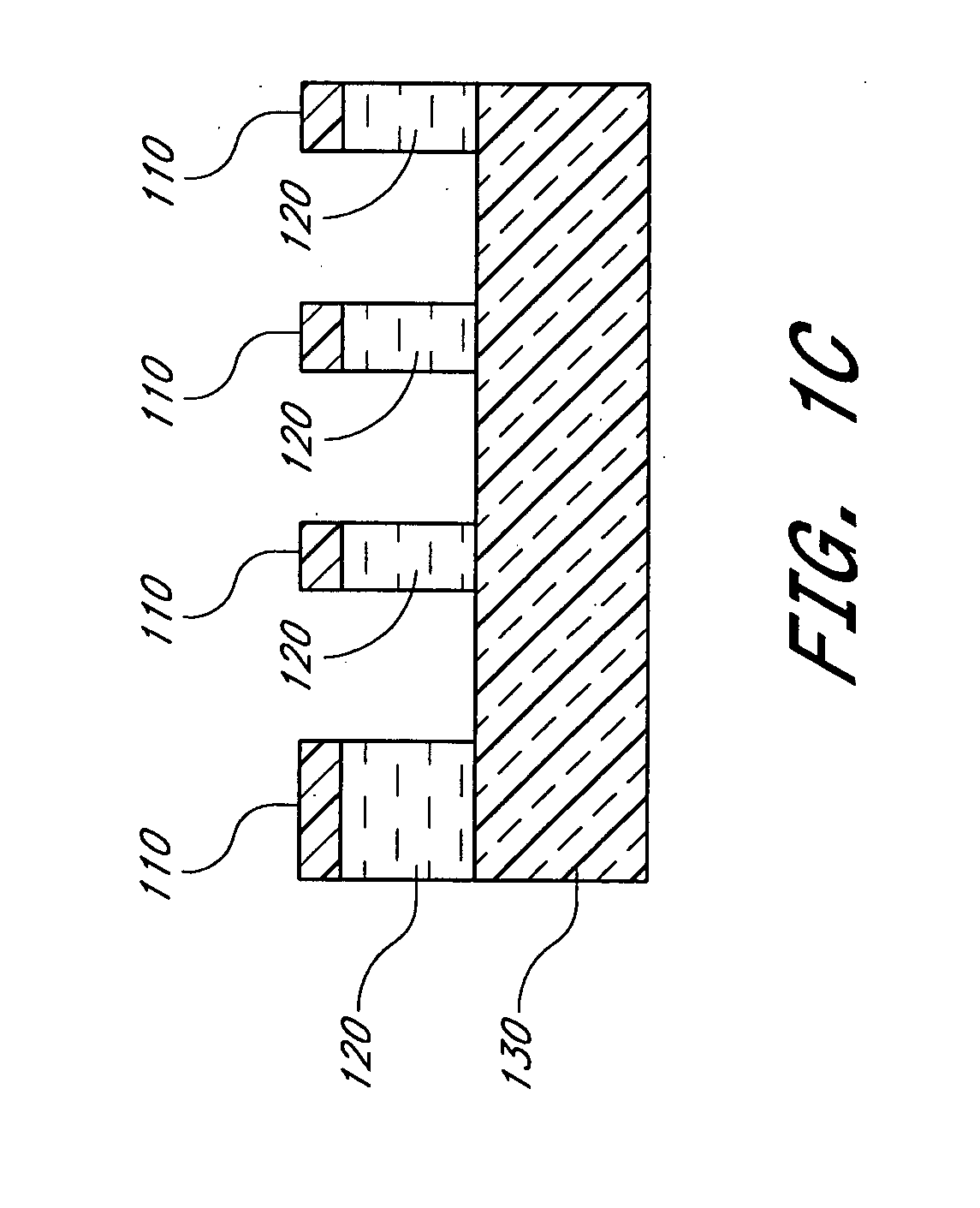

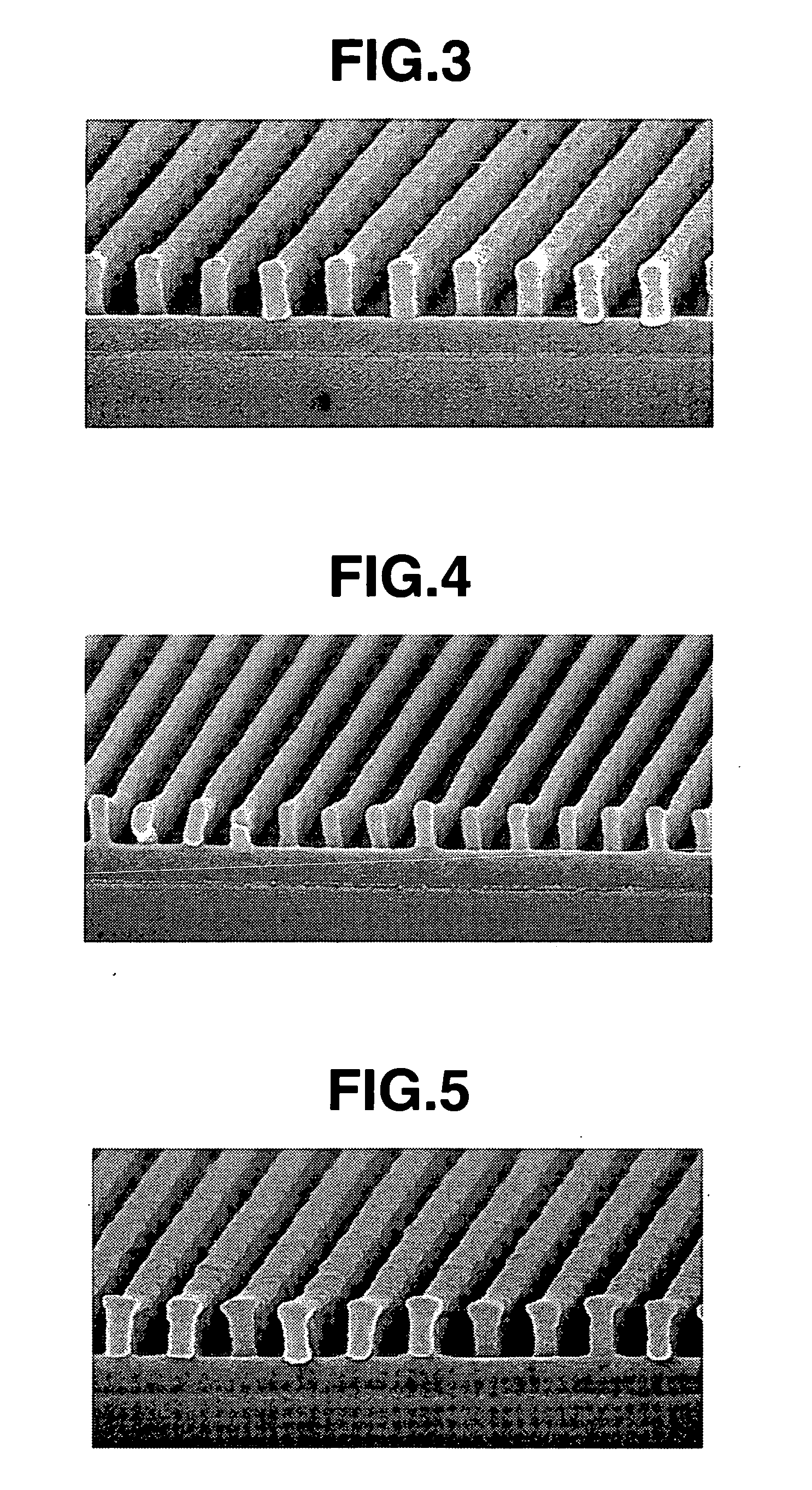

A method for the patterning of a plurality of fins in a MugFET device is provided. The method involves depositing at least one temporary pattern using photolithography. Further processing steps include a combination of depositing a conformal layer and spacer defined patterning of the conformal layer such that a very high density of fins can be achieved. The distance between the fins is no longer determined by photolithography, which is only used to define the temporary pattern which is removed in further processing, but instead by the thickness of the conformal layer, with all fins defined by spacers. Additionally an improved line edge roughness is achieved for the fins using the method.

Owner:DEGROOTE BART +1

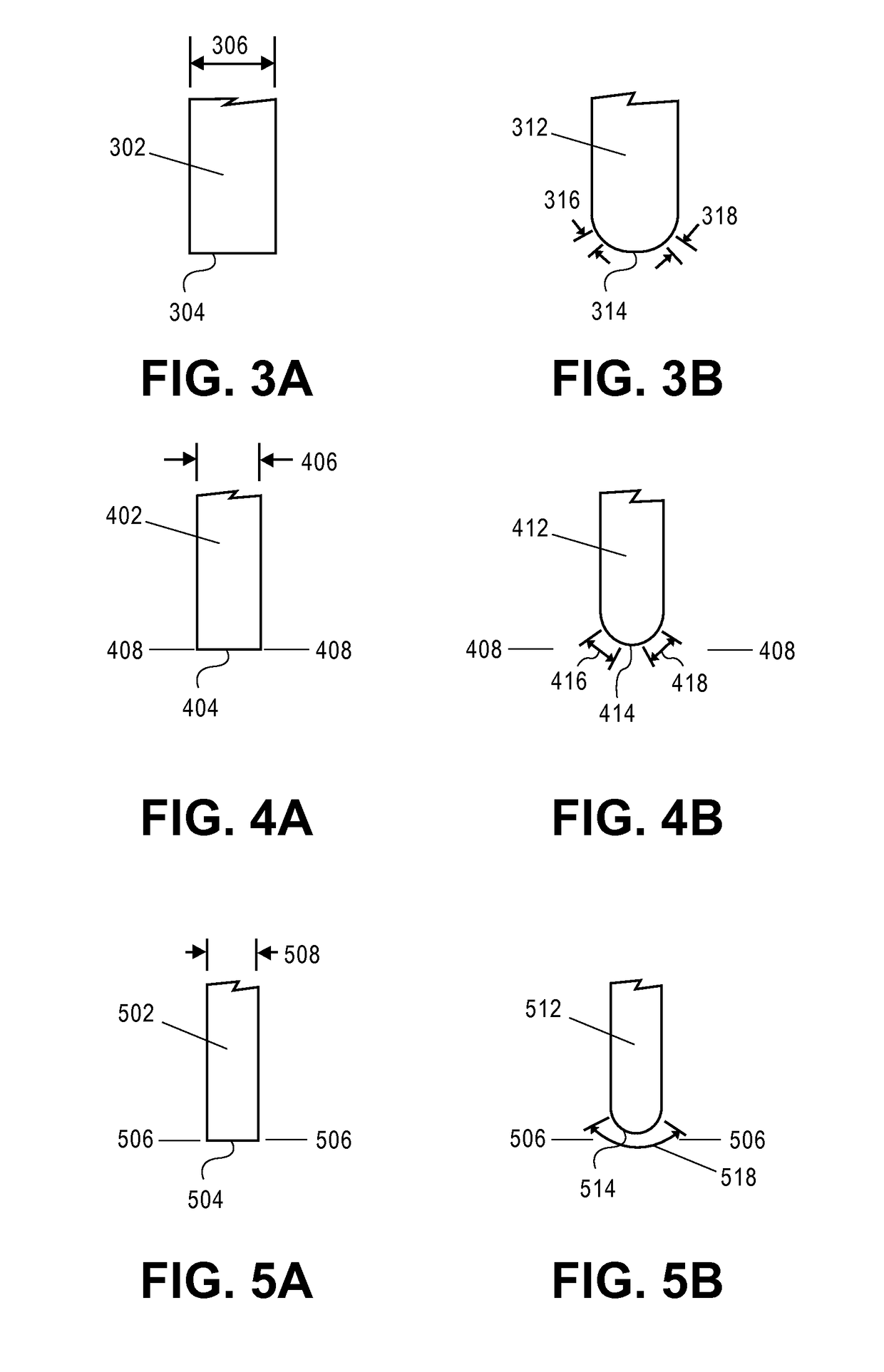

Critical dimension control for integrated circuits

ActiveUS20060046483A1Decorative surface effectsPhotomechanical apparatusCritical dimensionMaterials science

Methods of etching substrates with small critical dimensions and altering the critical dimensions are disclosed. In one embodiment, a sulfur oxide based plasma is used to etch an amorphous carbon hard mask layer. The features of a pattern can be shrunk using a plasma etch to reduce the resist elements on the surface of the masking structure. Features in the pattern can also be enlarged by depositing polymer on the resist elements or by sloping an underlying layer. In one preferred embodiment, features of the pattern are shrunk before being enlarged in order to reduce line edge roughness.

Owner:MICRON TECH INC

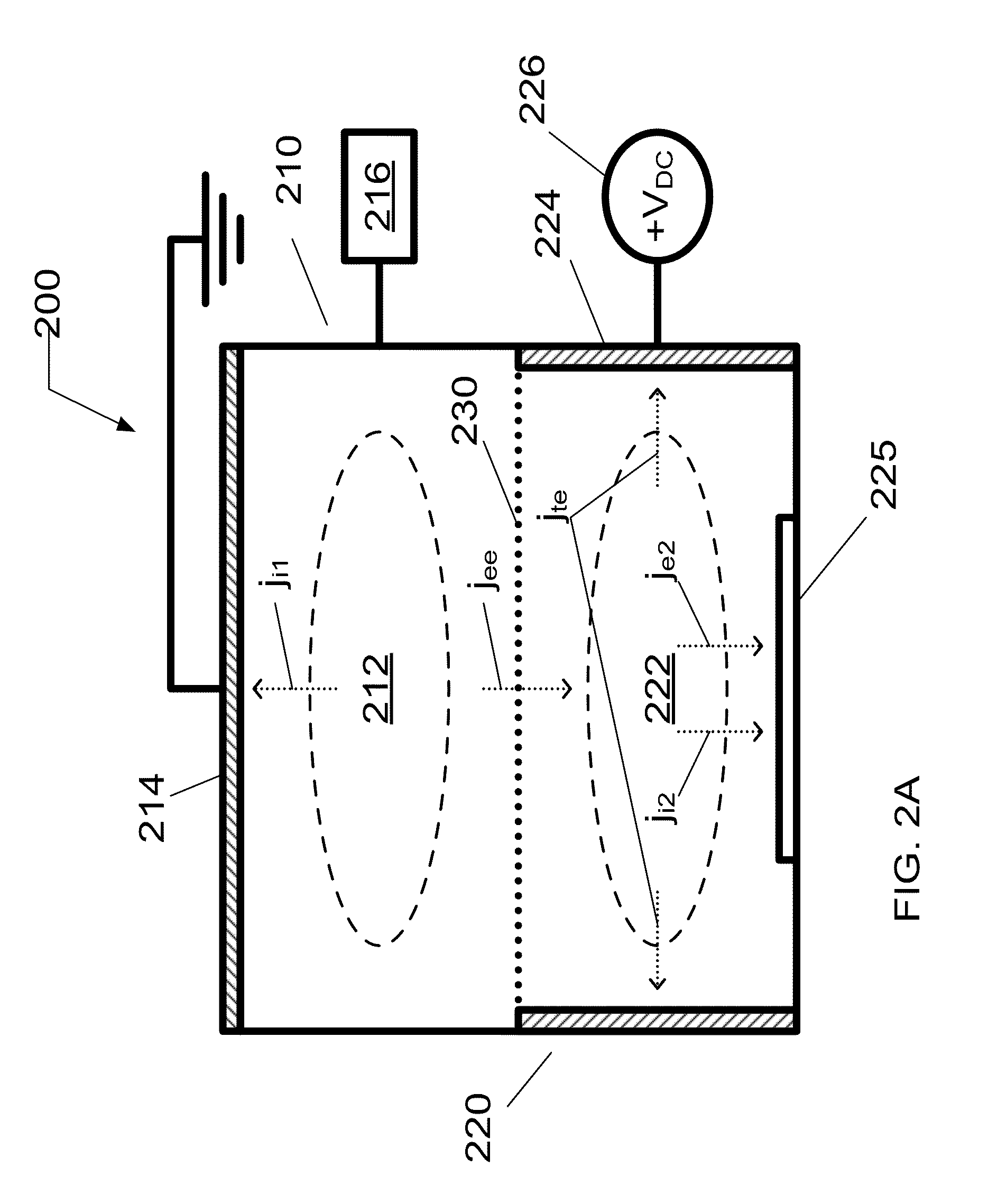

Switchable Neutral Beam Source

InactiveUS20110177694A1Easy to controlRemove roughnessElectric discharge tubesPhotomechanical apparatusBeam sourceLine width

The invention can provide apparatus and methods of processing a substrate in real-time using a switchable quasi-neutral beam system to improve the etch resistance of photoresist layer. In addition, the improved photoresist layer can be used in an etch procedure to more accurately control gate and / or spacer critical dimensions (CDs), to control gate and / or spacer CD uniformity, and to eliminate line edge roughness (LER) and line width roughness (LWR).

Owner:TOKYO ELECTRON LTD

Resist composition for negative tone development and pattern forming method using the same

InactiveUS7851140B2Enhance the imageImprove in-plane uniformityPhotosensitive materialsRadiation applicationsIn planeActinic Rays

Owner:FUJIFILM CORP

Resist composition for negative tone development and pattern forming method using the same

ActiveUS20100190106A1Improve accuracySmall line edge roughnessPhotosensitive materialsPhotomechanical exposure apparatusIn planeActinic Rays

For stably forming a high-precision fine pattern and thereby producing a highly integrated electronic device with high precision, a resist composition for negative tone development, which can reduce the line edge roughness and enhance the in-plane uniformity of the pattern dimension and furthermore, can ensure excellent bridge margin, and a pattern forming method using the same are provided.A resist composition for negative tone development, comprising (A) a resin capable of increasing the polarity by the action of an acid to increase the solubility in a positive tone developer and decrease the solubility in a negative tone developer, (B) a compound capable of generating an acid upon irradiation with an actinic ray or radiation, and (C) a solvent, wherein the logP value of the acid generated from the (B) compound capable of generating an acid upon irradiation with an actinic ray or radiation is from 1.5 to 12.0; and a pattern forming method using the same.

Owner:FUJIFILM CORP

Resist composition for negative tone development and pattern forming method using the same

InactiveUS20100167201A1Reduced line edge roughnessImprove in-plane uniformityPhotosensitive materialsRadiation applicationsIn planeActinic Rays

To provide a resist composition for negative tone development, which can form a pattern having a good profile improved in the pattern undercut and moreover, can reduce the line edge roughness and enhance the in-plane uniformity of the pattern dimension, and a pattern forming method using the same.A resist composition for negative tone development, comprising (A) a resin capable of increasing the polarity by the action of an acid to increase the solubility in a positive tone developer and decrease the solubility in a negative tone developer, (B) a compound capable of generating an acid having an acid dissociation index pKa of −4.0 or less upon irradiation with an actinic ray or radiation, and (C) a solvent; and a pattern forming method using the same.

Owner:FUJIFILM CORP

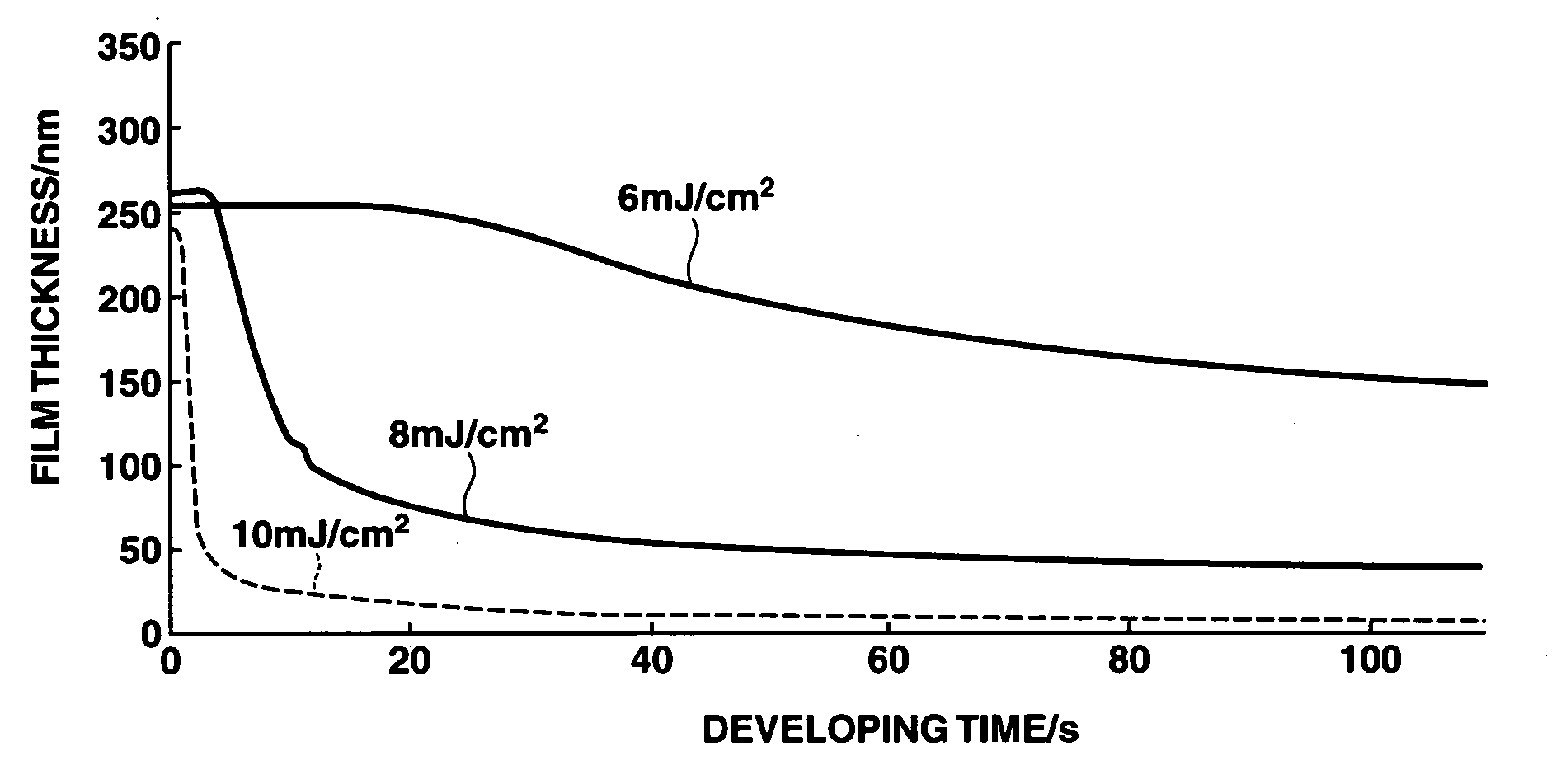

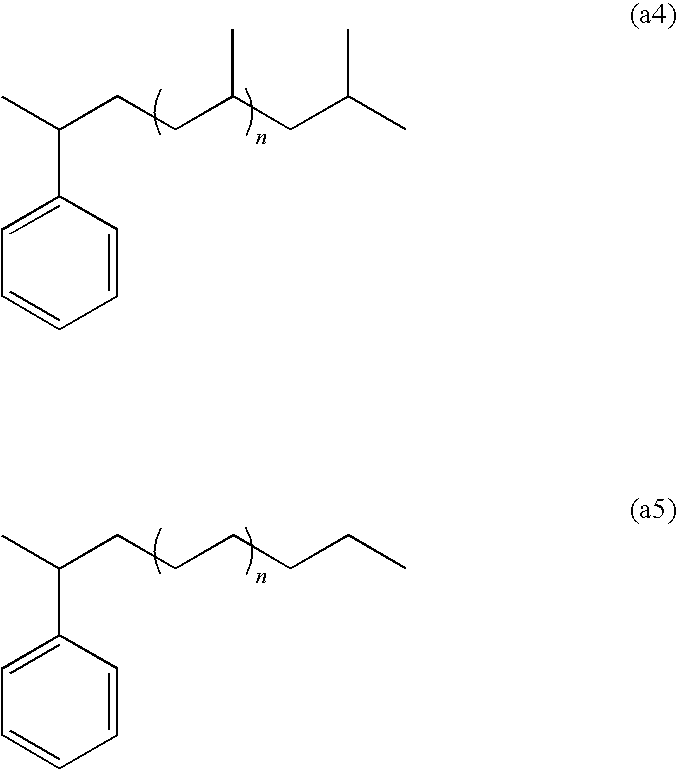

Positive resist compositions and patterning process

ActiveUS20050227174A1Minimal line edge roughnessHigh sensitivityAgricultural machinesRadiation applicationsMeth-Leaving group

A polymer which is obtained from a combination of (meth)acrylate having a bridged ring lactone group and (meth)acrylate having an acid leaving group with a hexafluoroalcohol group is used as a base resin to formulate a positive resist composition which when exposed to high-energy radiation and developed, exhibits a high sensitivity, a high resolution, and a minimal line edge roughness due to controlled swell during development. The composition also has excellent dry etching resistance.

Owner:SHIN ETSU CHEM IND CO LTD

Resist composition and patterning process using the same

ActiveUS20070111140A1High sensitivityHigh resolutionPhotosensitive materialsRadiation applicationsPolymer chemistryHigh energy beam

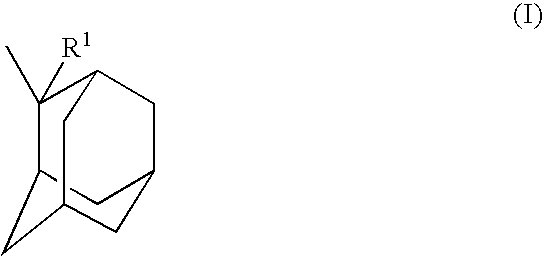

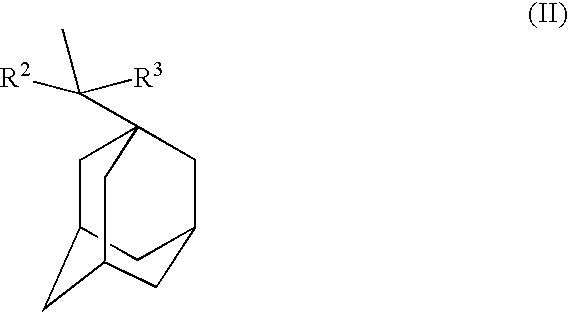

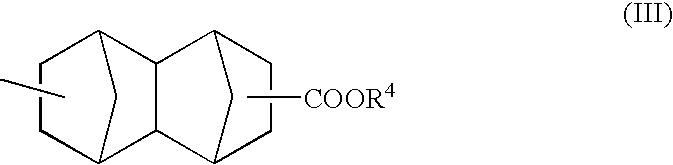

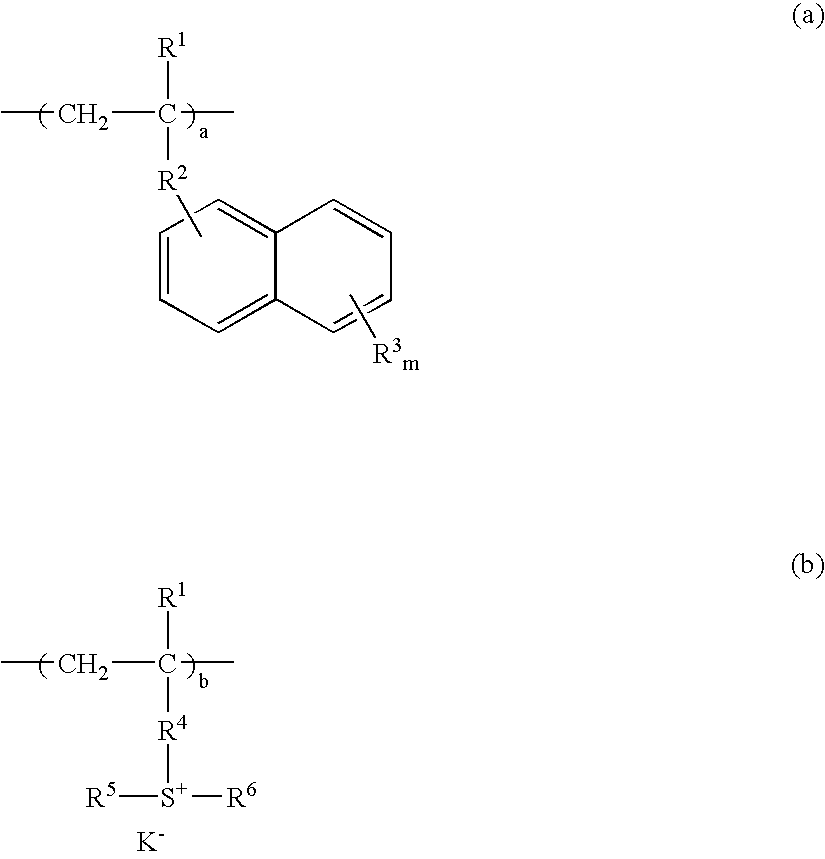

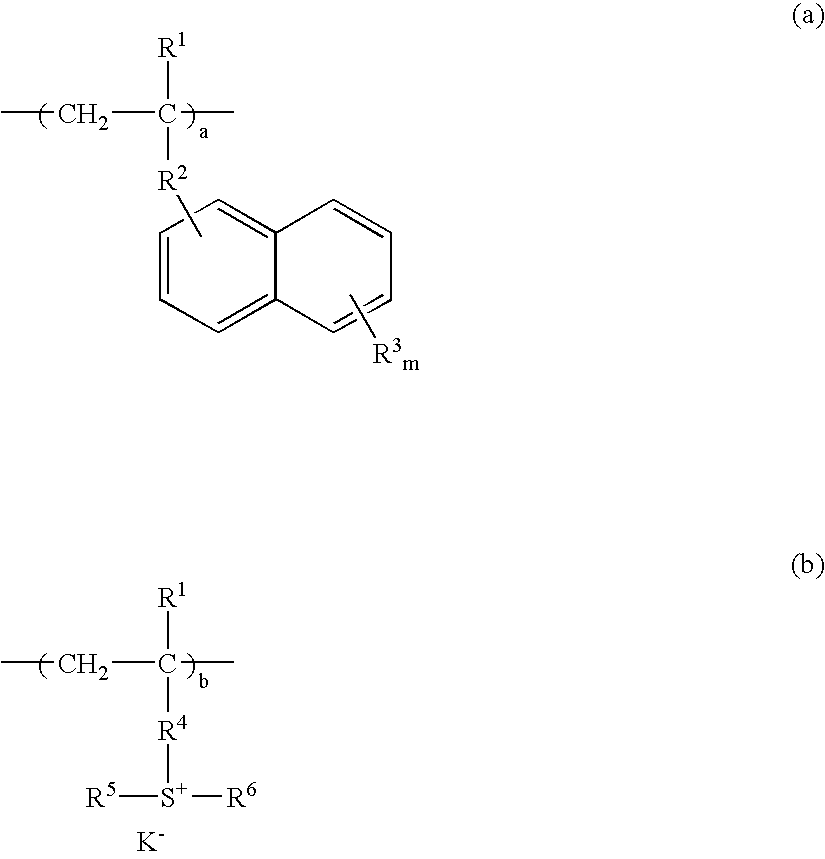

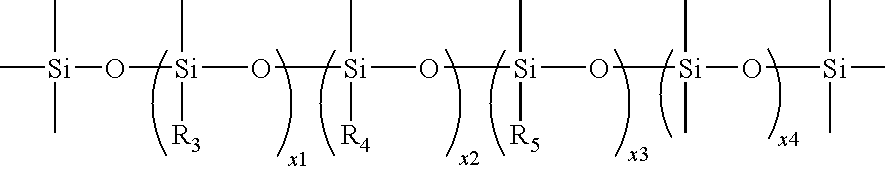

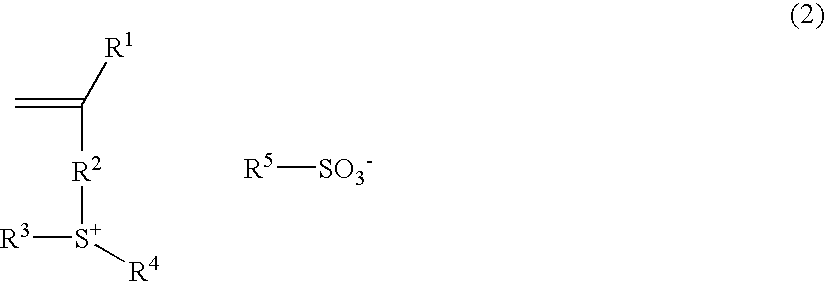

There is disclosed a resist composition which shows high sensitivity and high resolution on exposure to high energy beam, provides reduced Line Edge Roughness because swelling at the time of development is reduced, provides minor amounts of residue after development, has excellent dry etching resistance, and can also be used suitably for the liquid immersion lithography; and a patterning process using the resist composition. There can be provided a resist composition which comprises, at least, a polymer including repeating units represented by the following general formulae (a) and (b).

Owner:SHIN ETSU CHEM IND CO LTD

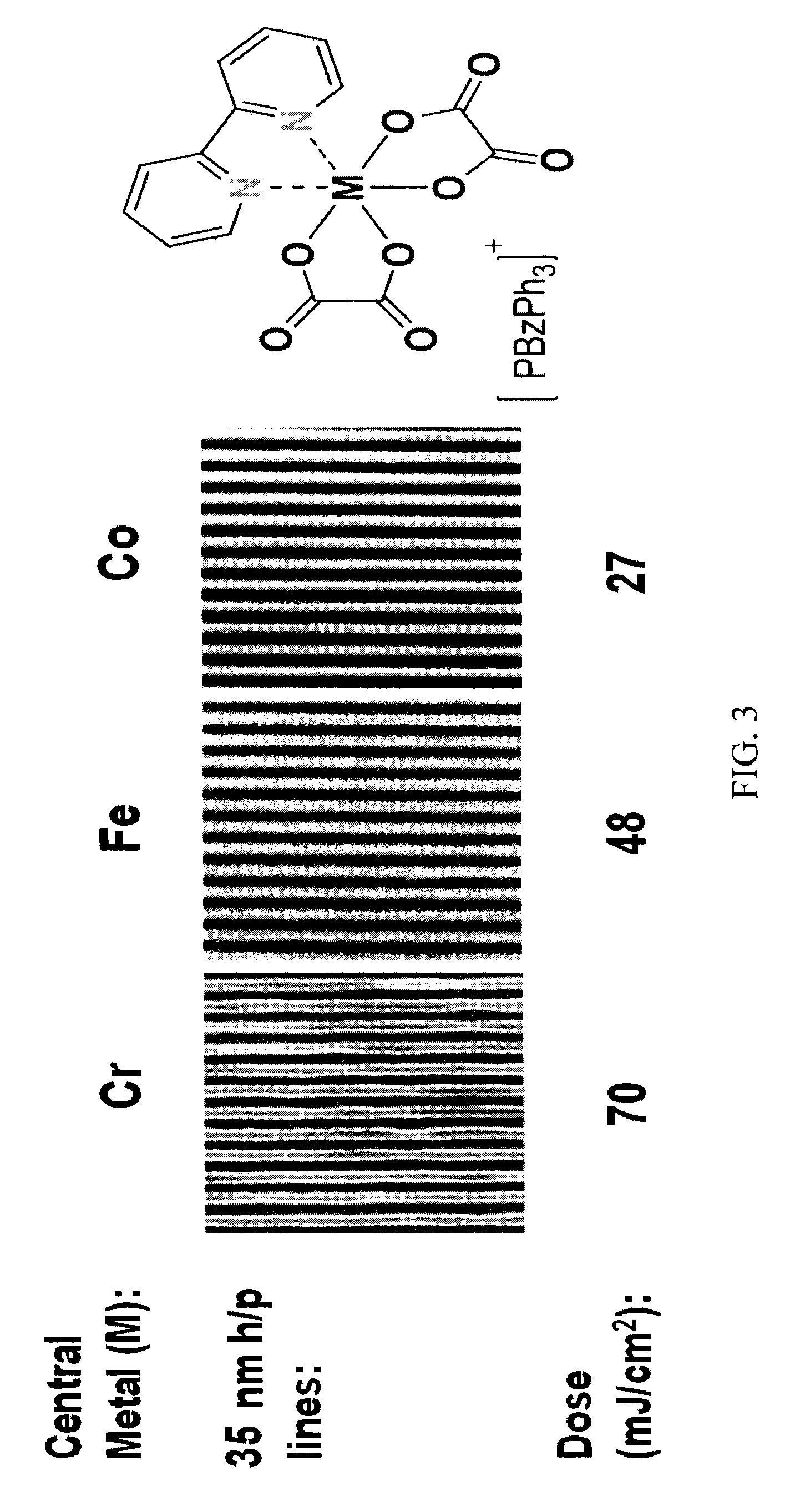

Molecular Organometallic Resists for EUV

ActiveUS20150079393A1Synthetic resin layered productsNickel organic compoundsNanoparticleOptical density

Described herein are organometallic or inorganic complexes with high extreme ultraviolet (EUV) optical density (OD) and high mass density for use in thin films. These thin films are used as high resolution, low line edge roughness (LER) EUV photoresists. The complexes may also be included in nanoparticle form for use in photoresists.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Composition for imprints, pattern and patterning method

InactiveUS20100009137A1Hardly worsening mold transferabilitySolve the real problemDecorative surface effectsLayered productsMonomerLubricant

A lubricant-containing composition for imprints comprising a polymerizable monomer and a photopolymerization initiator in combination or a resin component is excellent in patternability and mold releasability. The composition can form a pattern having a small line edge roughness after etching.

Owner:FUJIFILM CORP

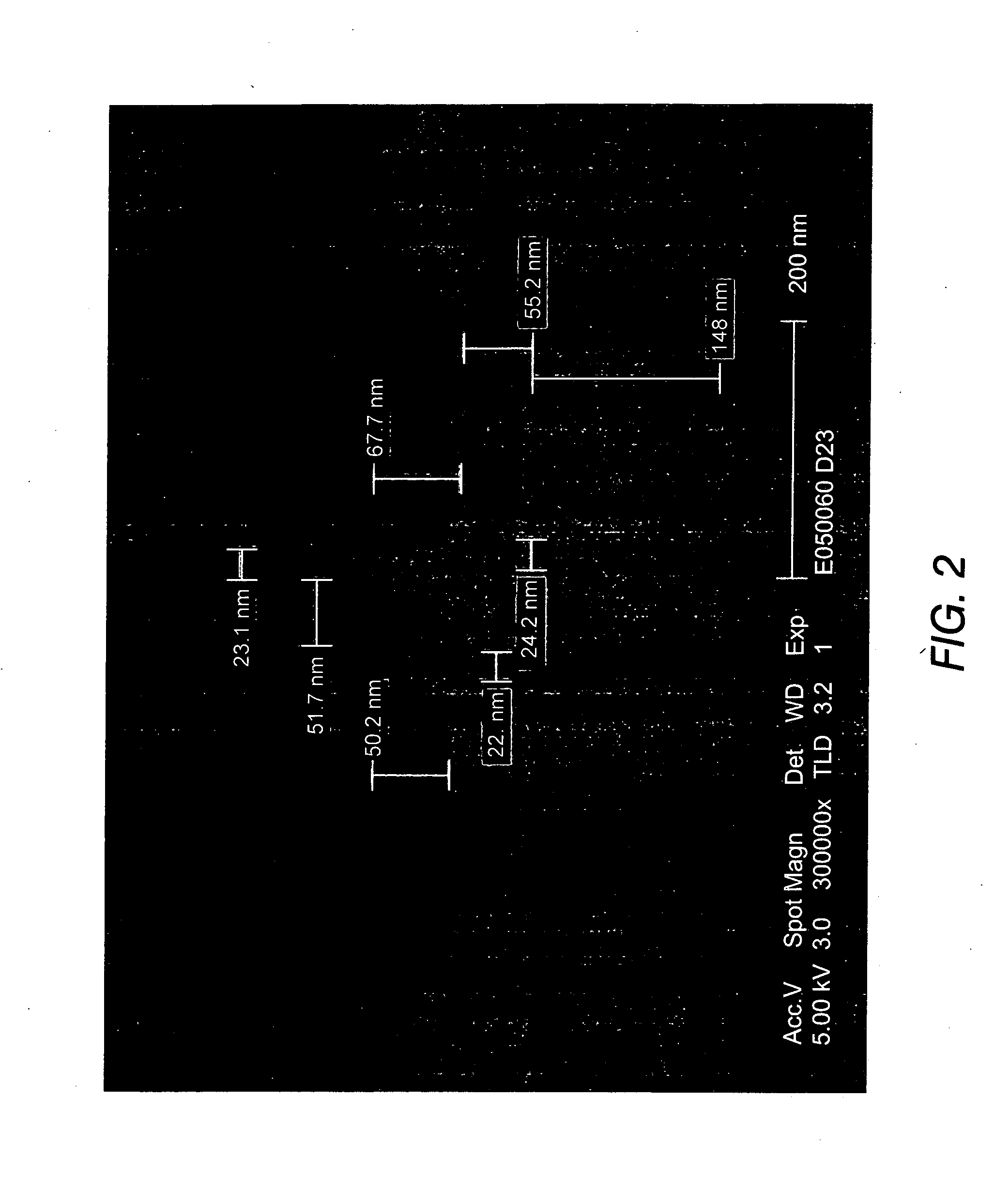

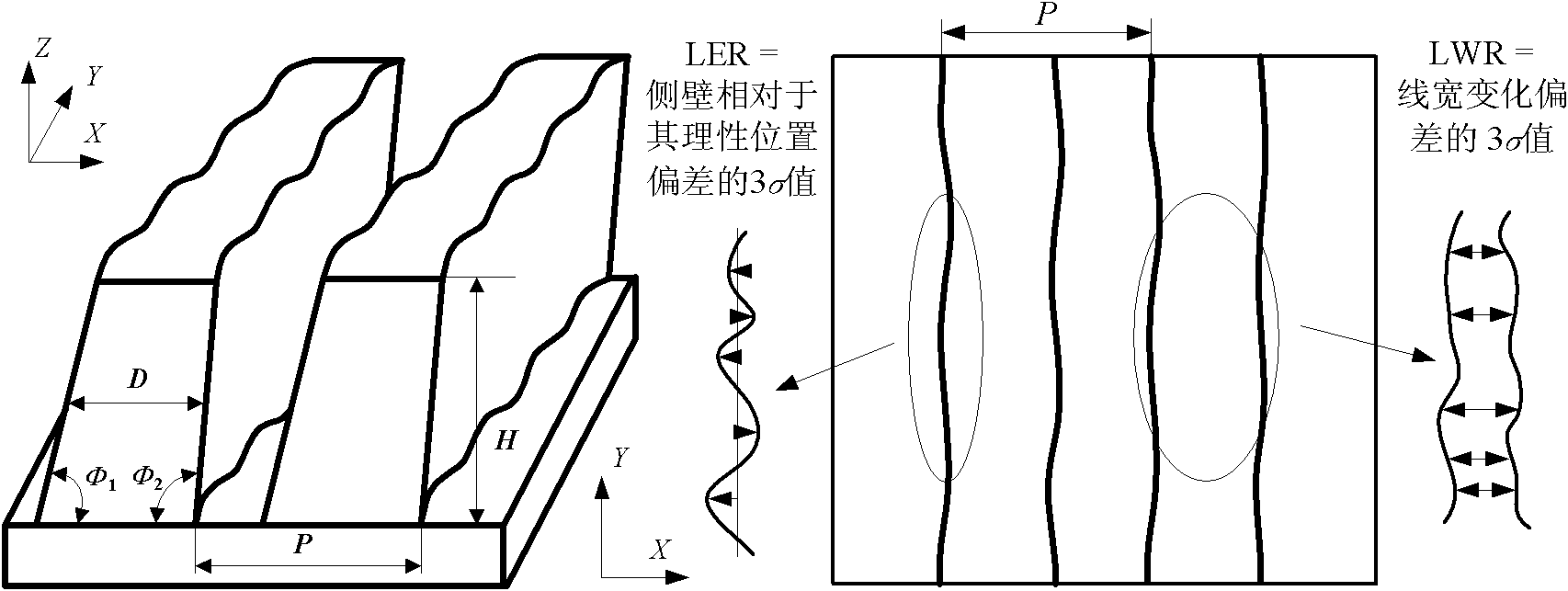

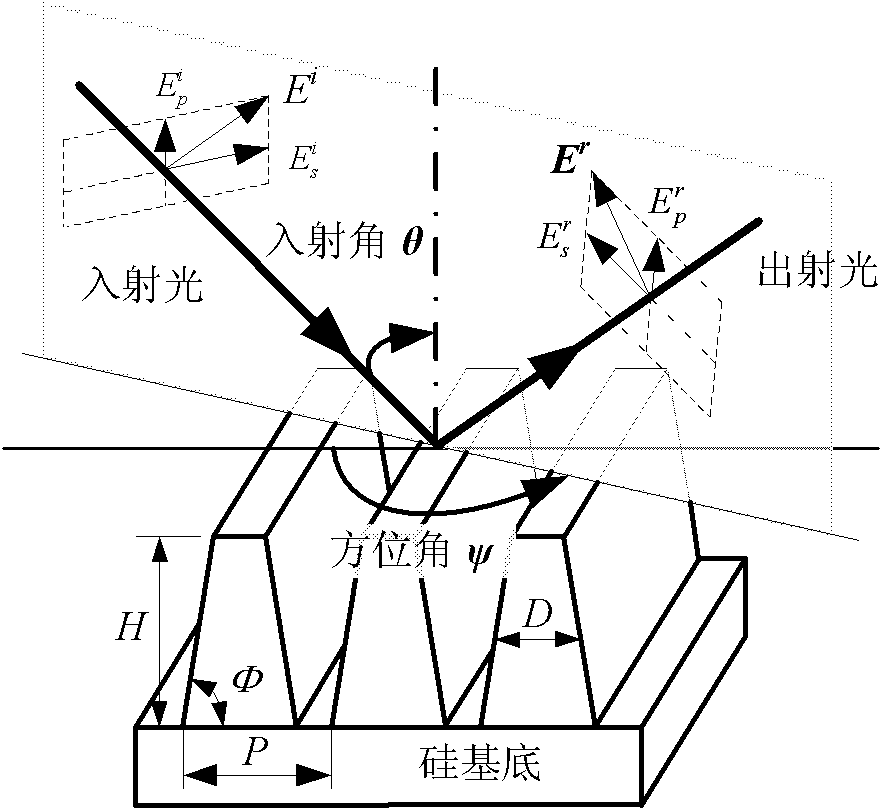

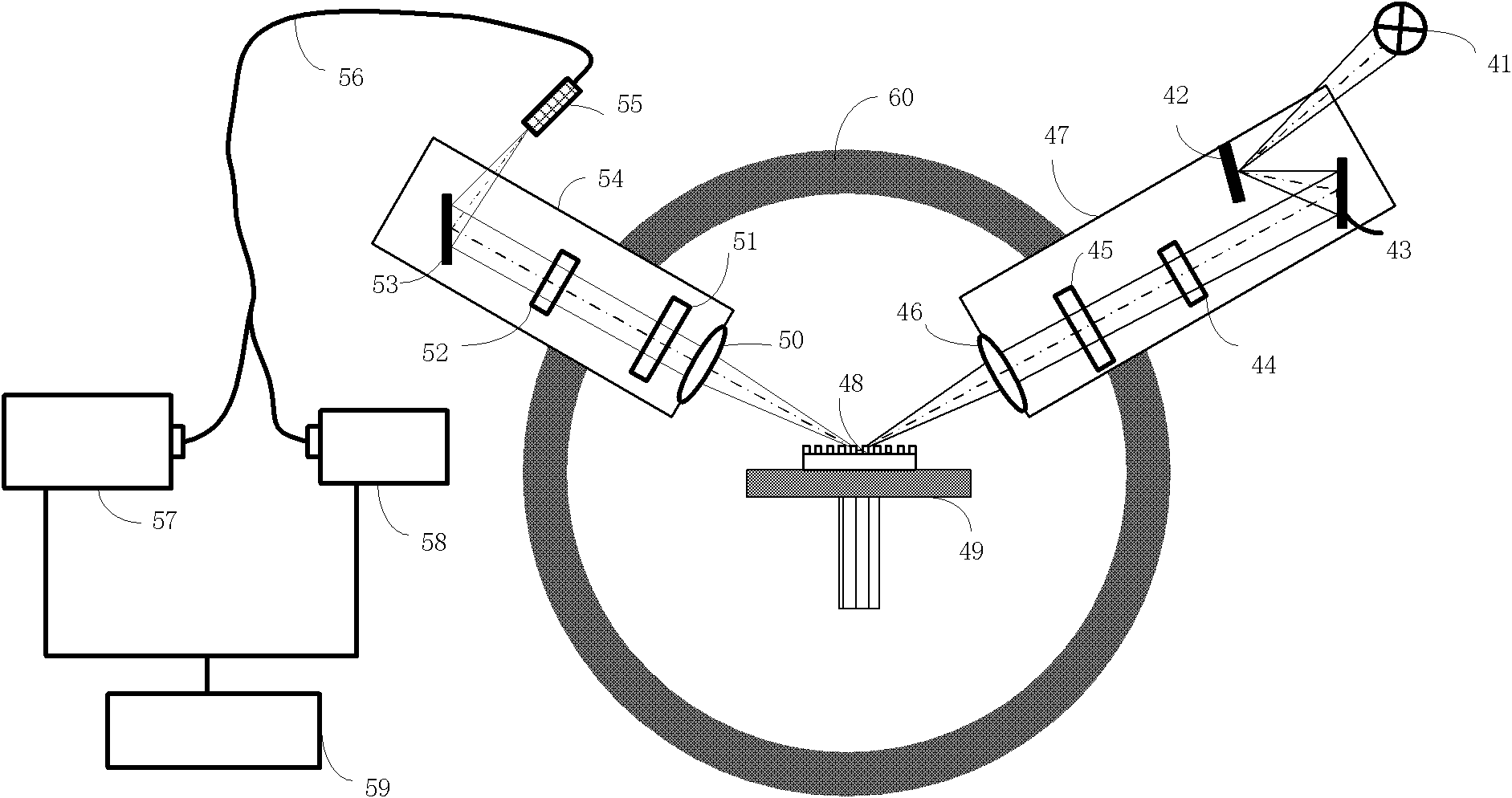

Method and device for measuring three-dimensional topography of nano structure

ActiveCN101881599AMeet measurement needsHigh spectral sensitivityUsing optical meansEtchingImage transfer

The invention discloses a method and a device thereof for measuring three-dimensional topography of a nano structure, which can simultaneously measure three-dimensional topography parameters such as line width, depth, side corner, line edge roughness, line width roughness and the like of the nano structure. The method comprises the following steps of: performing splitting, polarization and front and back phase compensation on light beams with wavelengths in ultraviolet to near-infrared wave band to obtain elliptical polarized light and projecting the elliptical polarized light for later measurement; acquiring surface reflected zero-level diffraction signals of the to-be-measured structure, and obtaining a measurement Mueller matrix of the nano structure by calculation; and matching the measurement Mueller matrix and a theoretical Mueller matrix, and obtaining a three-dimensional topography parameter value of the to-be-measured nano-scale structure. The device provided by the invention for measuring the three-dimensional topography parameter of the nano structure can provide a non-contact, nondestructive, low-cost and quick measurement means for one-dimensional and two-dimensional sub-wavelength periodic structures in processes of photo-etching, nano impressing and the like of an image transfer-based batch manufacturing method.

Owner:WUHAN EOPTICS TECH CO LTD

Pattern forming method, and resist composition, developer and rinsing solution used in the pattern forming method

ActiveUS20110305992A1Reduced line edge roughnessGood size uniformityPhotosensitive materialsPhotoprinting processesDispersityActinic Rays

Owner:FUJIFILM CORP

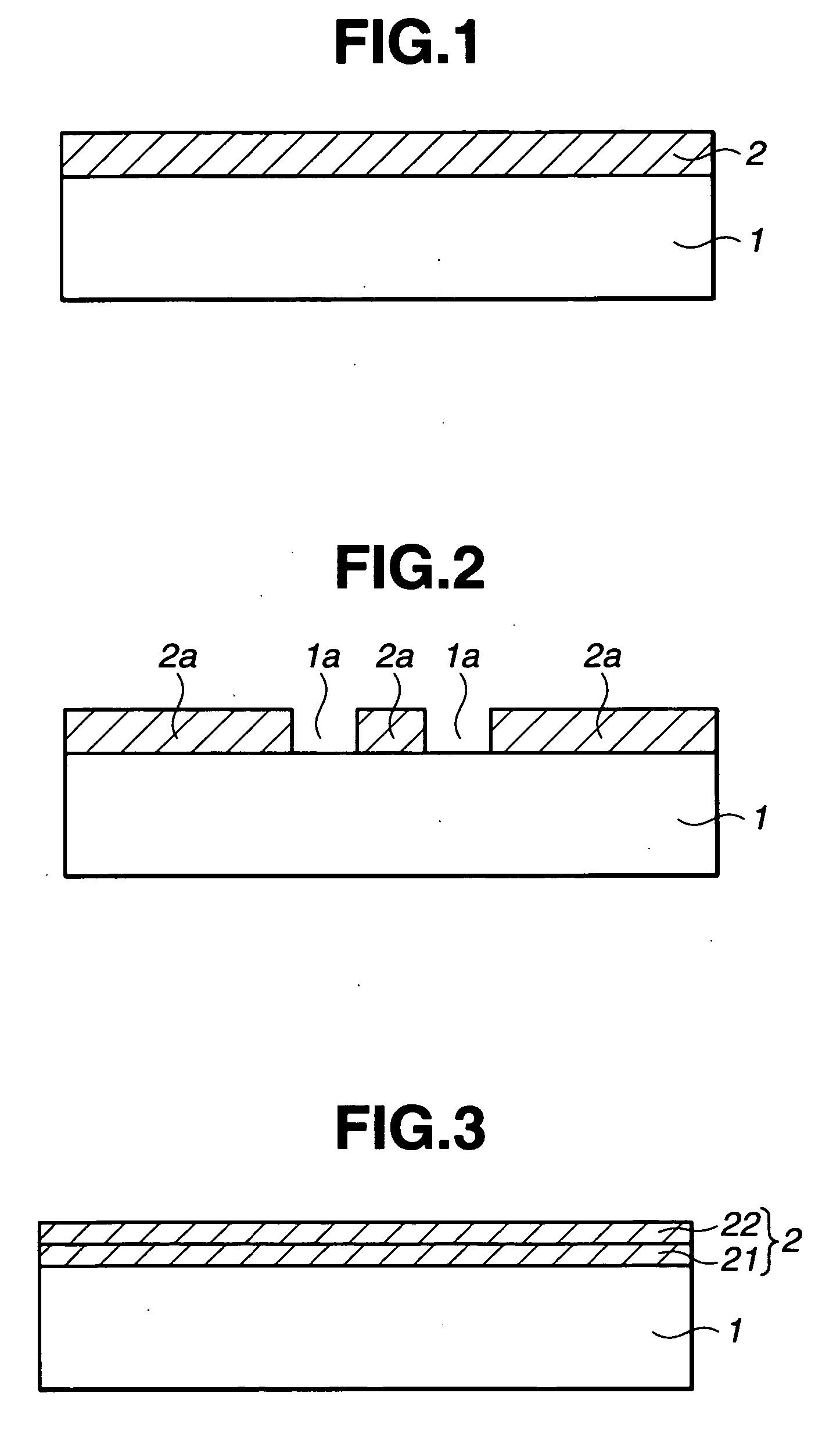

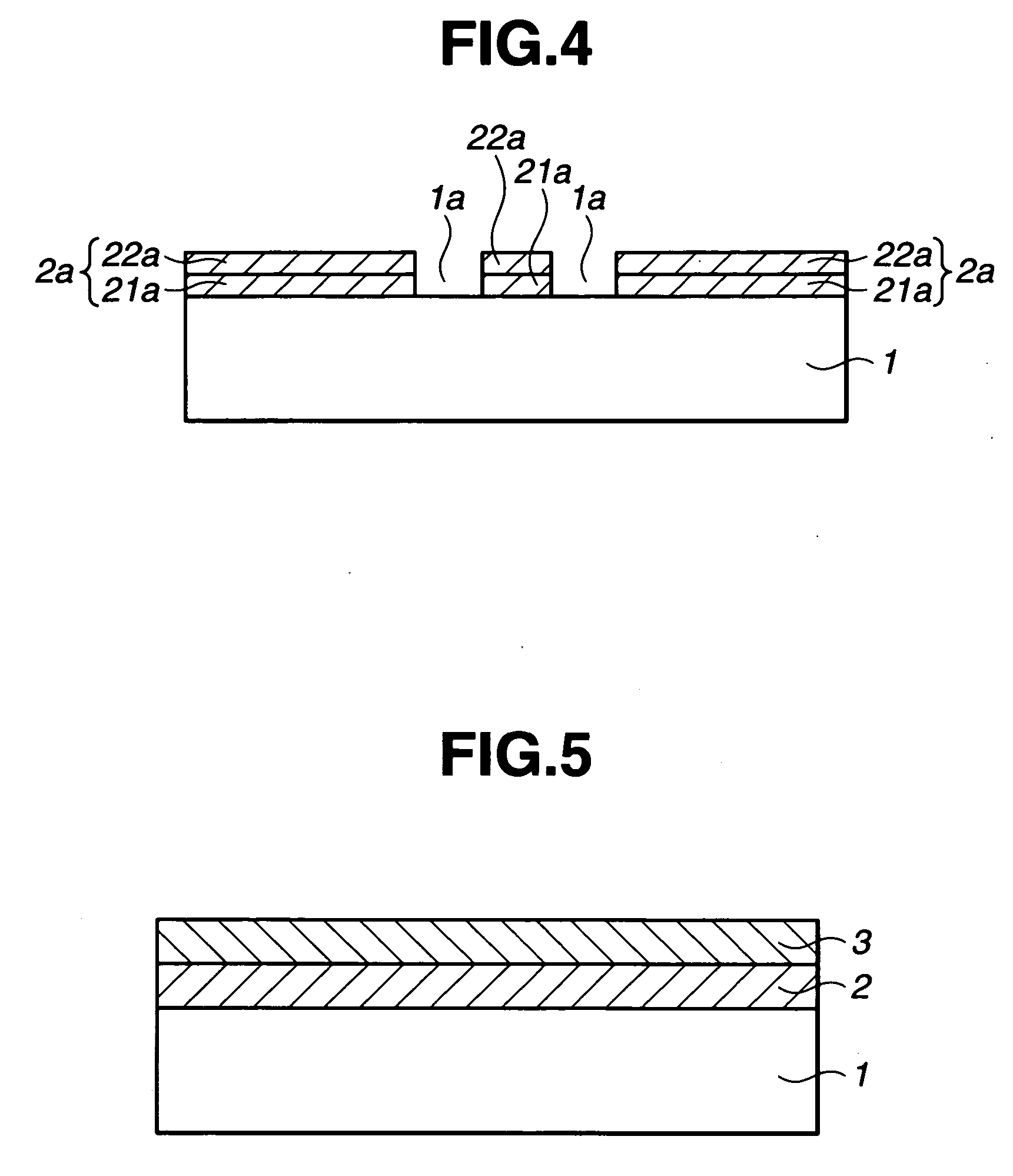

Photomask blank, photomask, and method of manufacture

A photomask blank comprising a multilayer film including at least four layers of different compositions, wherein the interface between the layers is moderately graded in composition; a phase shift mask blank comprising a phase shift film of at least two layers including a surface layer of a composition based on a zirconium silicide compound and a substrate adjacent layer of a composition based on a molybdenum silicide compound, and a further layer between one layer and another layer of a different composition, the further layer having a composition moderately graded from that of the one layer to that of the other layer; a phase shift mask blank comprising a phase shift film including a plurality of layers containing a metal and silicon in different compositional ratios which are stacked in such order that a layer having a higher etching rate is on the substrate side and a layer having a lower etching rate is on the surface side. The invention provides a photomask blank, typically a phase shift mask blank, which satisfies optical properties such as transmittance, reflectance and refractive index at an exposure wavelength of interest, and has an etched pattern with a minimal line edge roughness, and a photomask, typically a phase shift mask obtained therefrom.

Owner:SHIN ETSU CHEM IND CO LTD

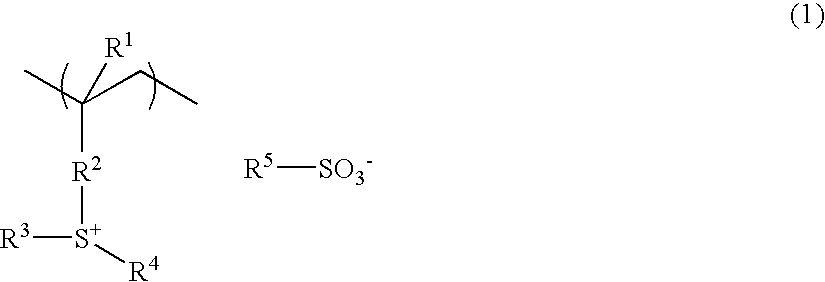

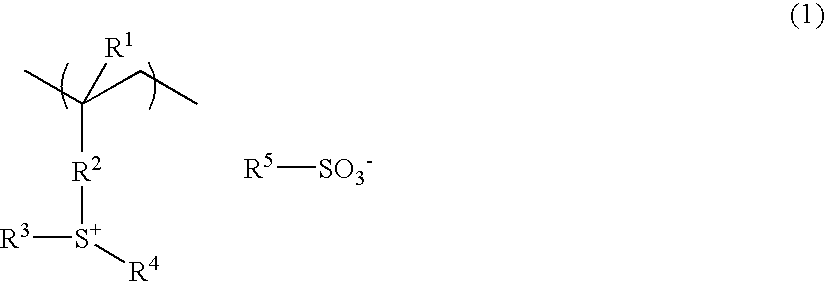

Resist composition and patterning process using the same

ActiveUS7459261B2High resolutionHigh sensitivityPhotosensitive materialsRadiation applicationsMeth-X-ray

There is disclosed a resist composition which comprises, at least, a polymer in which a sulfonium salt having a polymerizable unsaturated bond, a (meth)acrylate having a lactone or a hydroxyl group as an adhesion group, and a (meth)acrylate having an ester substituted with an acid labile group are copolymerized. There can be provided a resist composition with high resolution which has high sensitivity and high resolution to high energy beam, especially to ArF excimer laser, F2 excimer laser, EUV, X-ray, EB, etc., has reduced line edge roughness, and comprises a polymeric acid generator which has insolubility in water, and sufficient thermal stability and preservation stability.

Owner:SHIN ETSU CHEM IND CO LTD

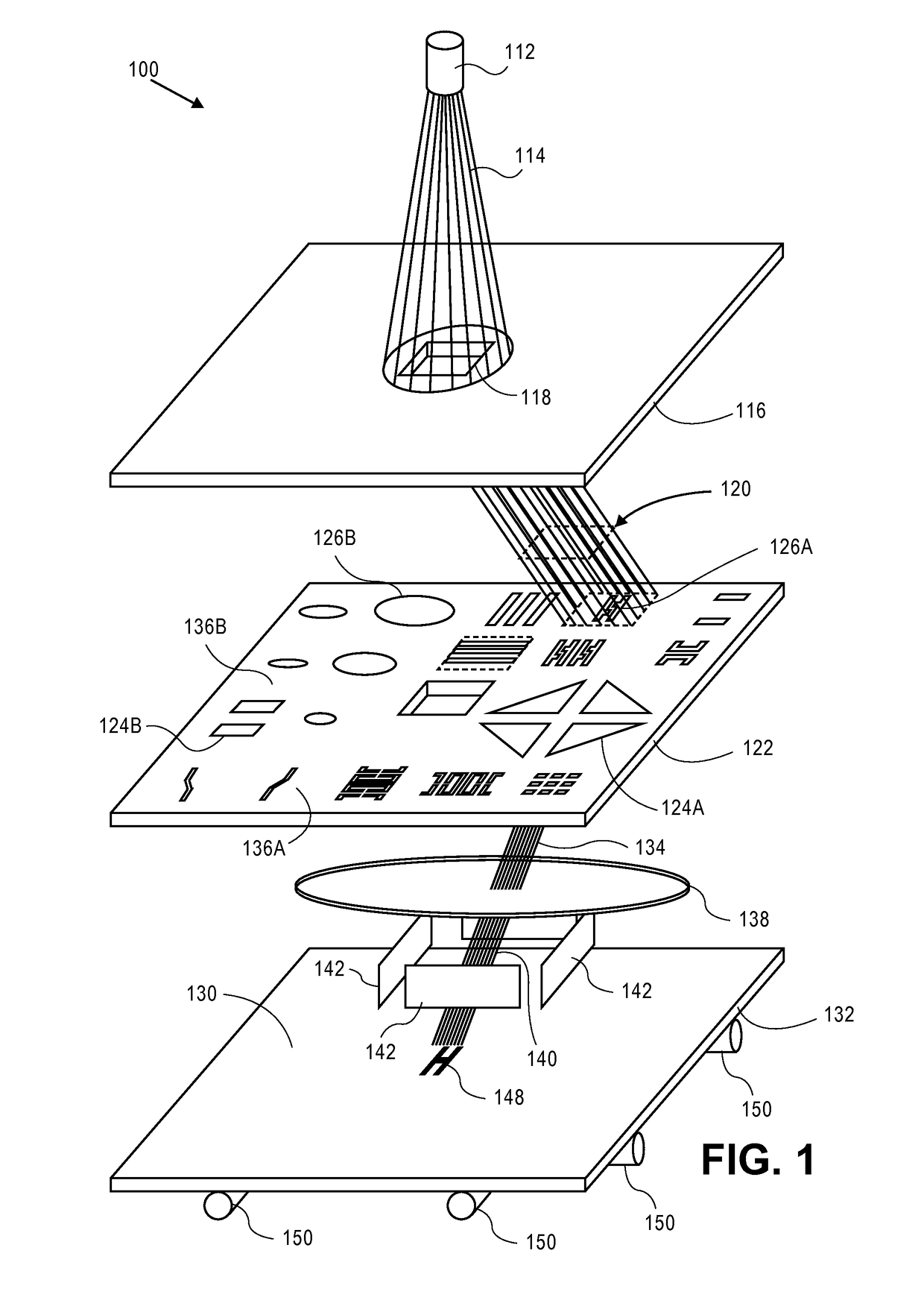

Method and system for forming high accuracy patterns using charged particle beam lithography

ActiveUS8473875B2Increase roughnessImprove variationPhotomechanical apparatusComputer aided designMask data preparationLithographic artist

Owner:D2S

Material processing to achieve sub-10nm patterning

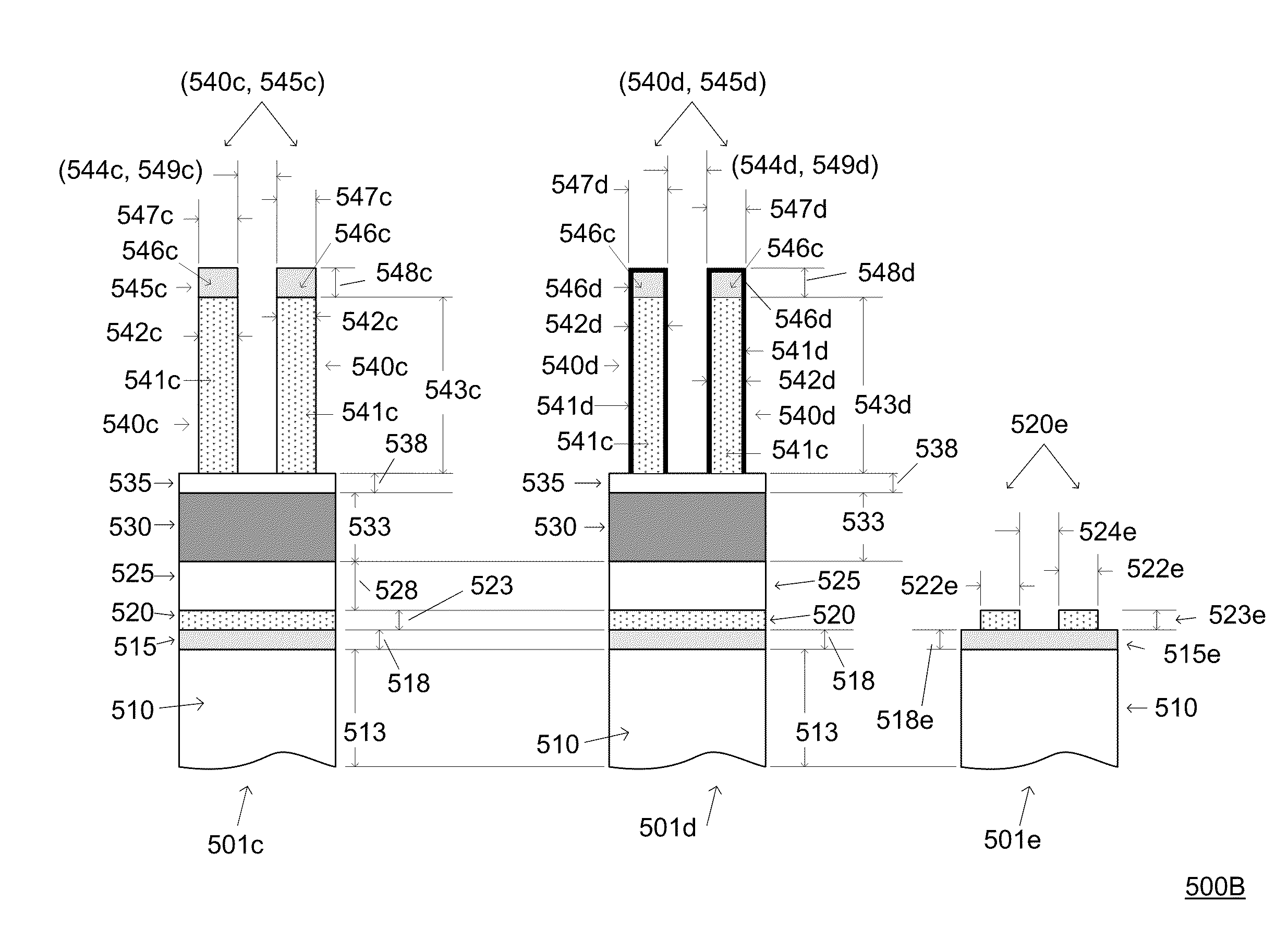

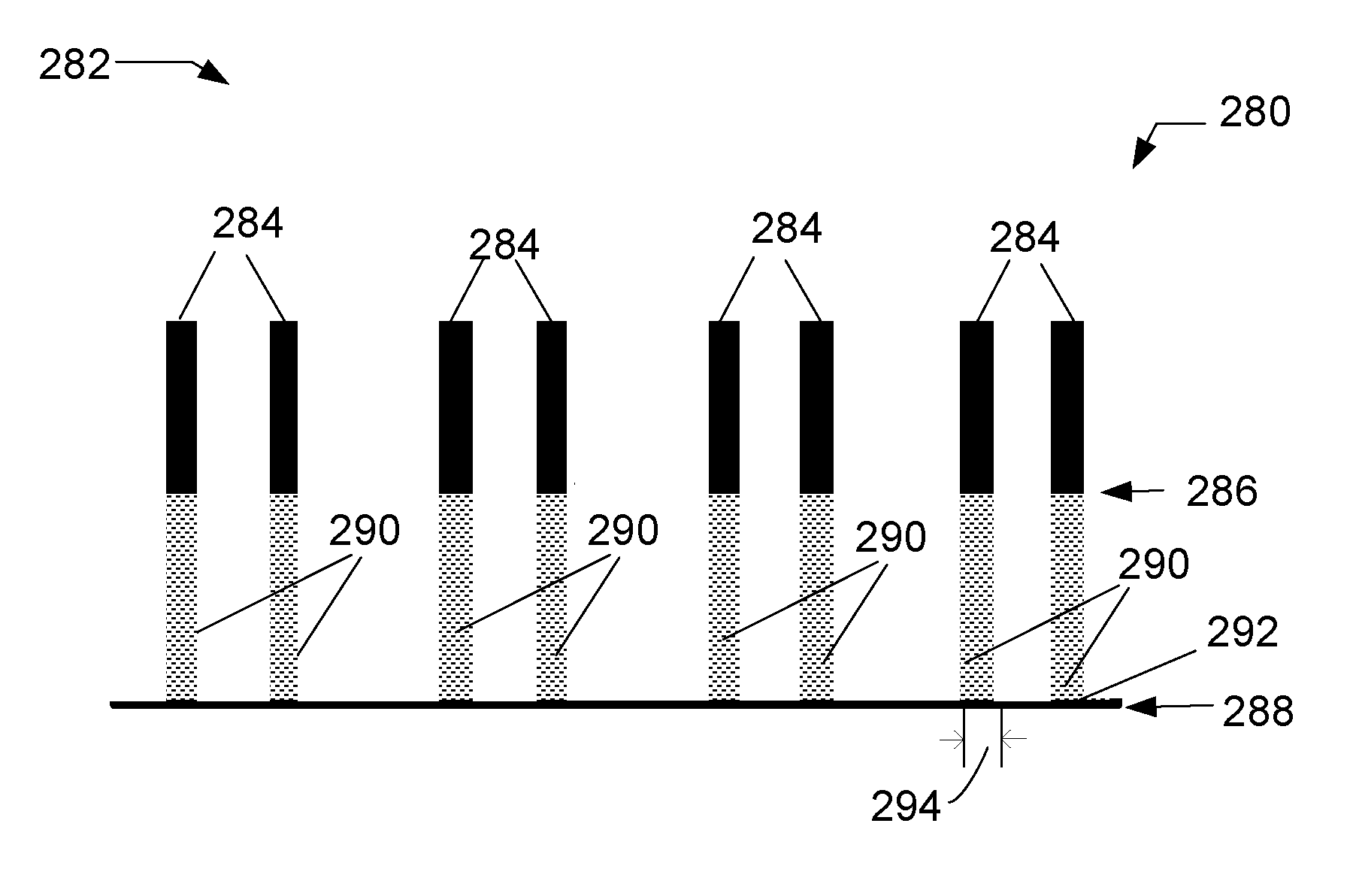

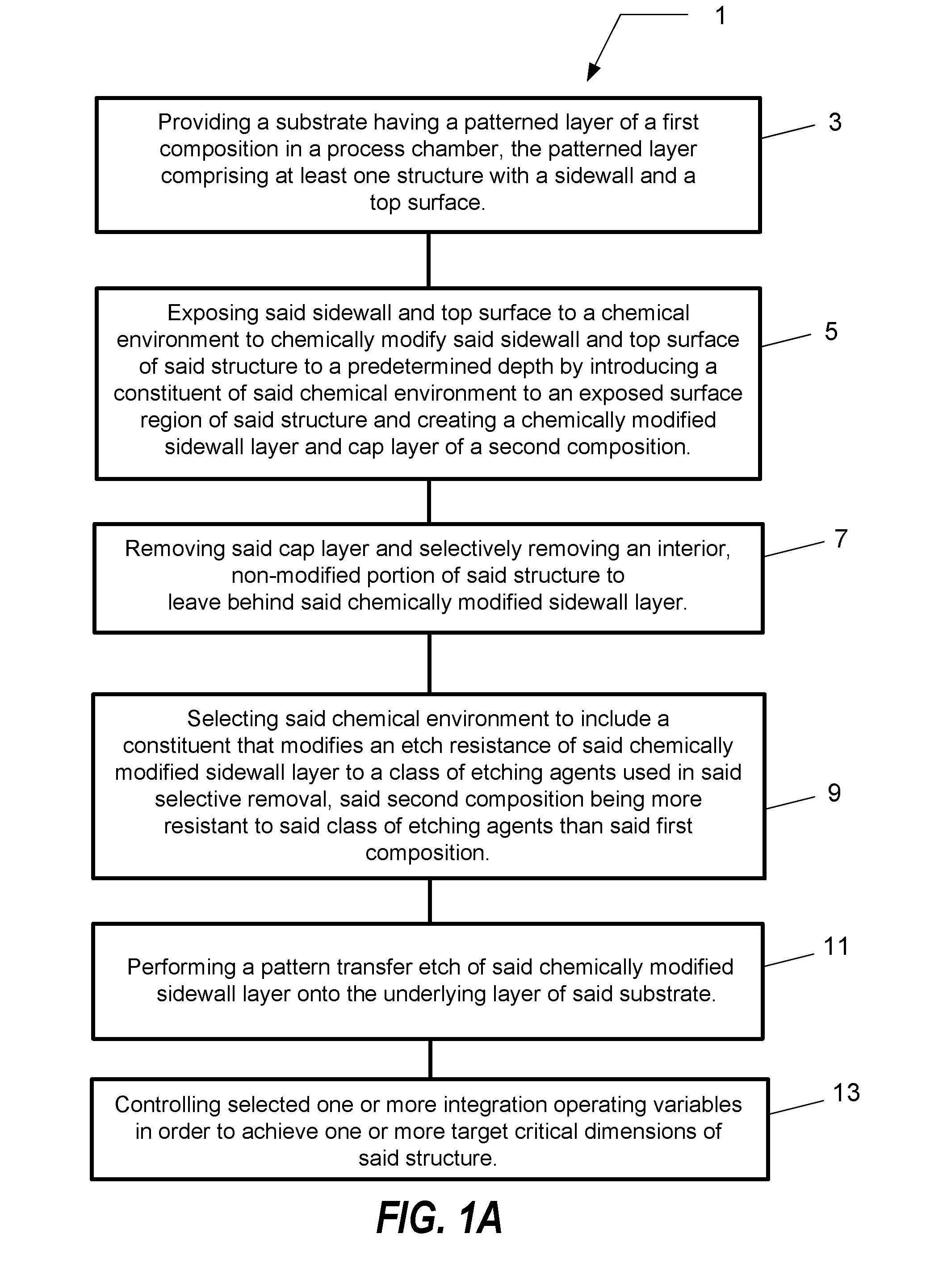

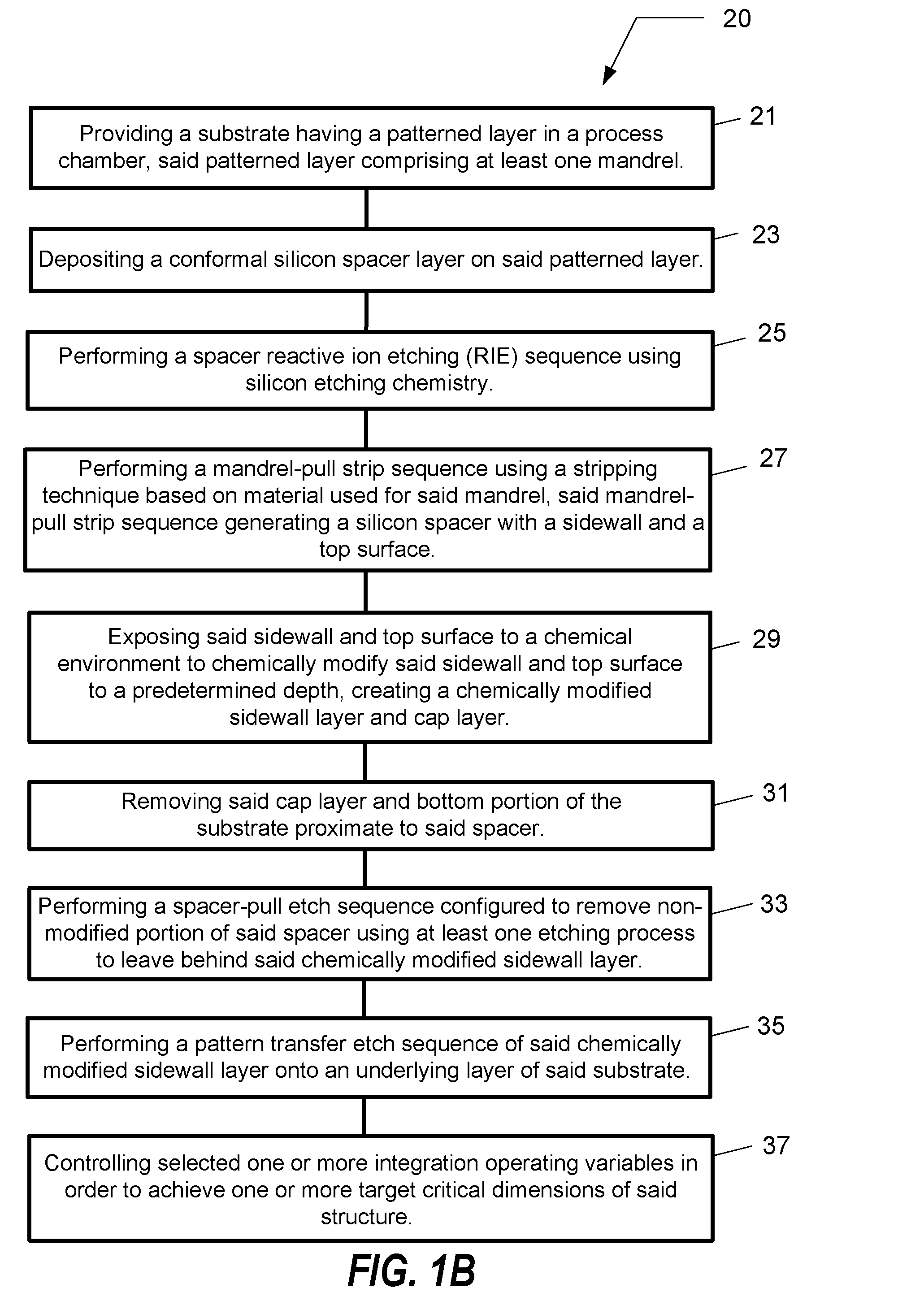

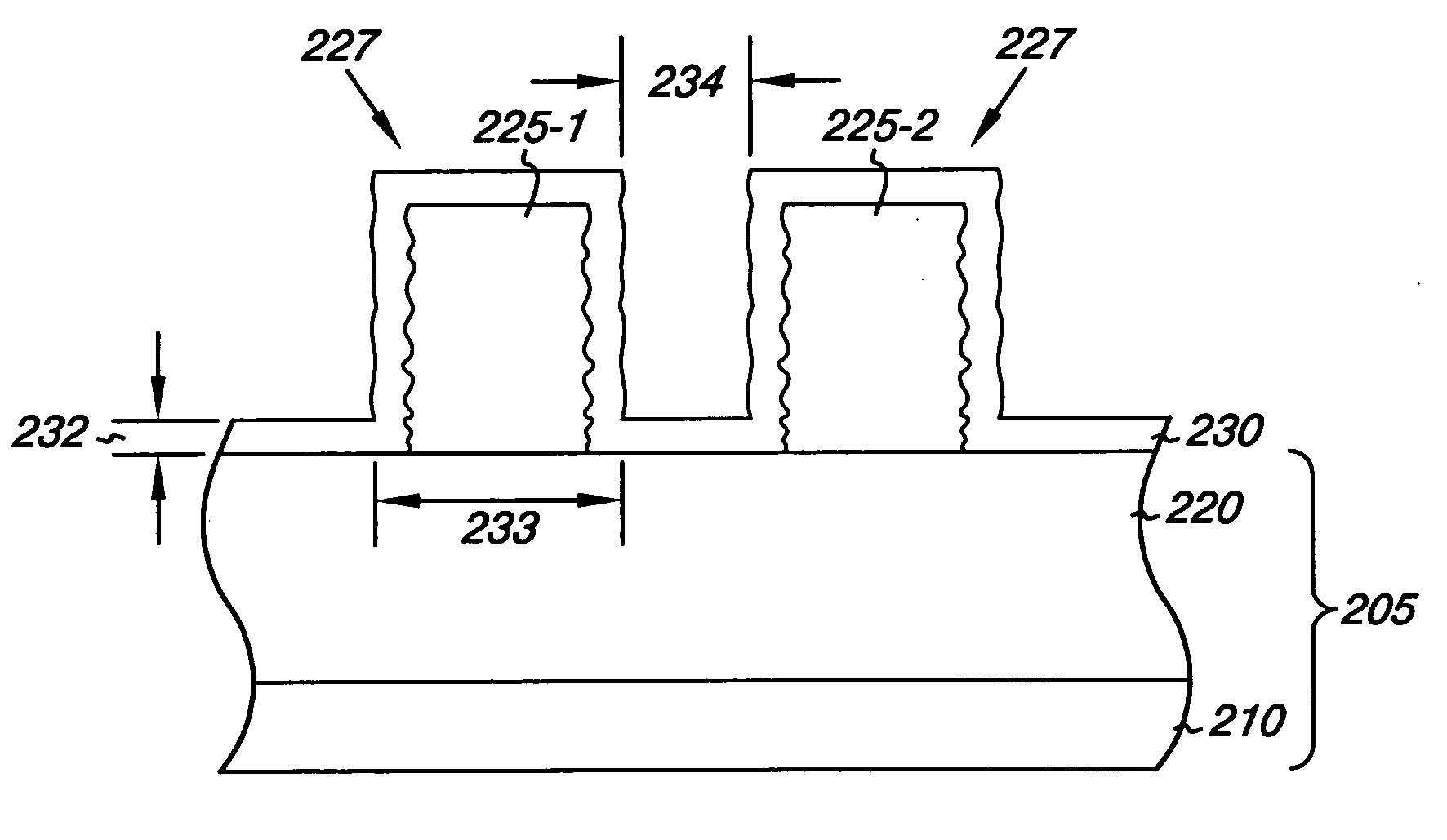

ActiveUS20160247680A1Electric discharge tubesSemiconductor/solid-state device manufacturingLine widthCompound (substance)

Provided is a method for increasing pattern density on a substrate comprising a structure with a patterned layer with a first composition and a sidewall and a cap layer of a second composition formed atop said structure. The sidewall is exposed to a chemical environment and creates a chemically modified sidewall layer of a third composition. The cap layer and an interior, non-modified portion of said structure is removed using an etching process to leave behind said chemically modified sidewall layer. A pattern transfer etch of said sidewall chemically modified layer onto the underlying layer of said substrate is performed. One or more integration operating variables are controlled to achieve target critical dimensions comprising width, height, sidewall angle, line width roughness, and / or line edge roughness of said structure.

Owner:TOKYO ELECTRON LTD

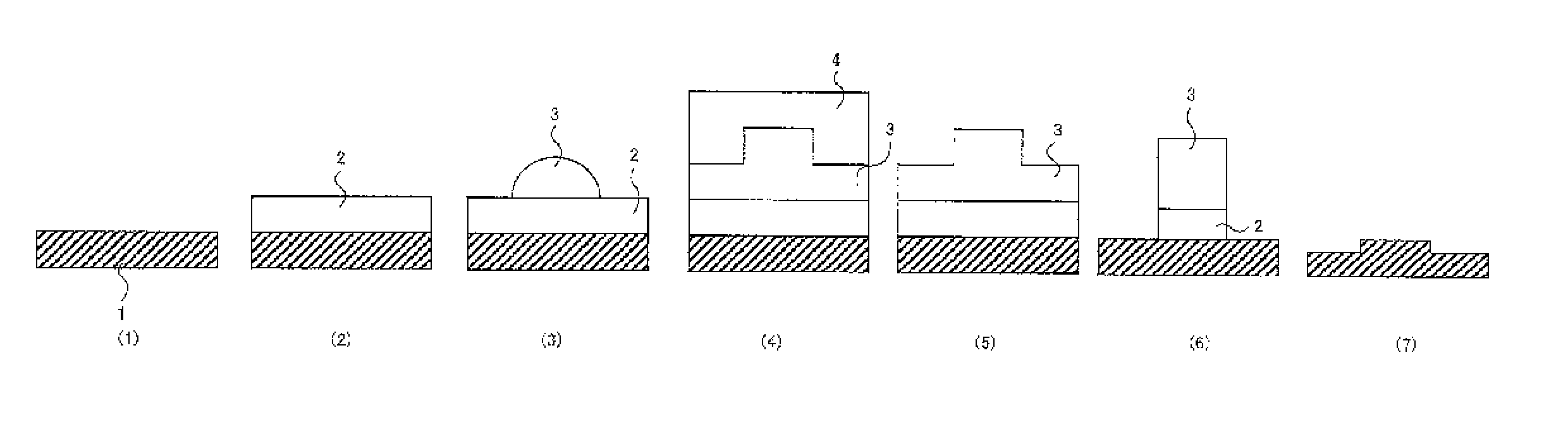

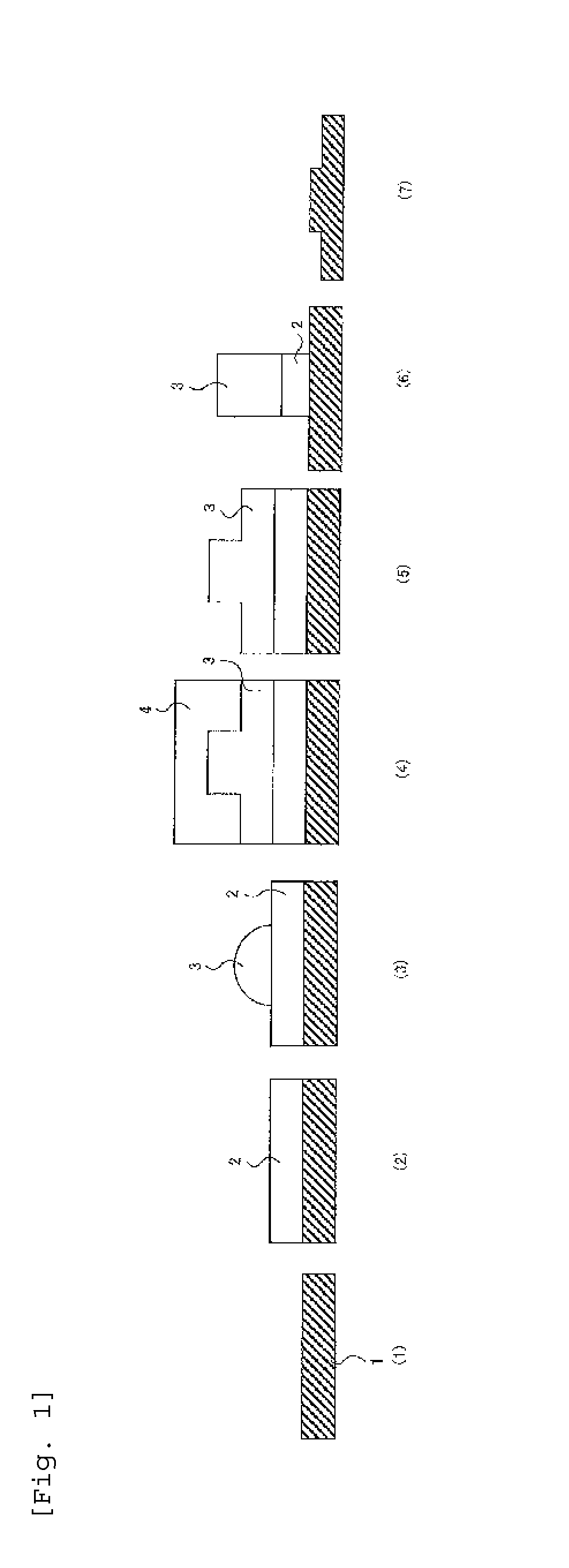

Line edge roughness reduction

InactiveUS20070196980A1Reduce roughnessSemiconductor/solid-state device manufacturingPhotosensitive material processingEngineeringLine edge roughness

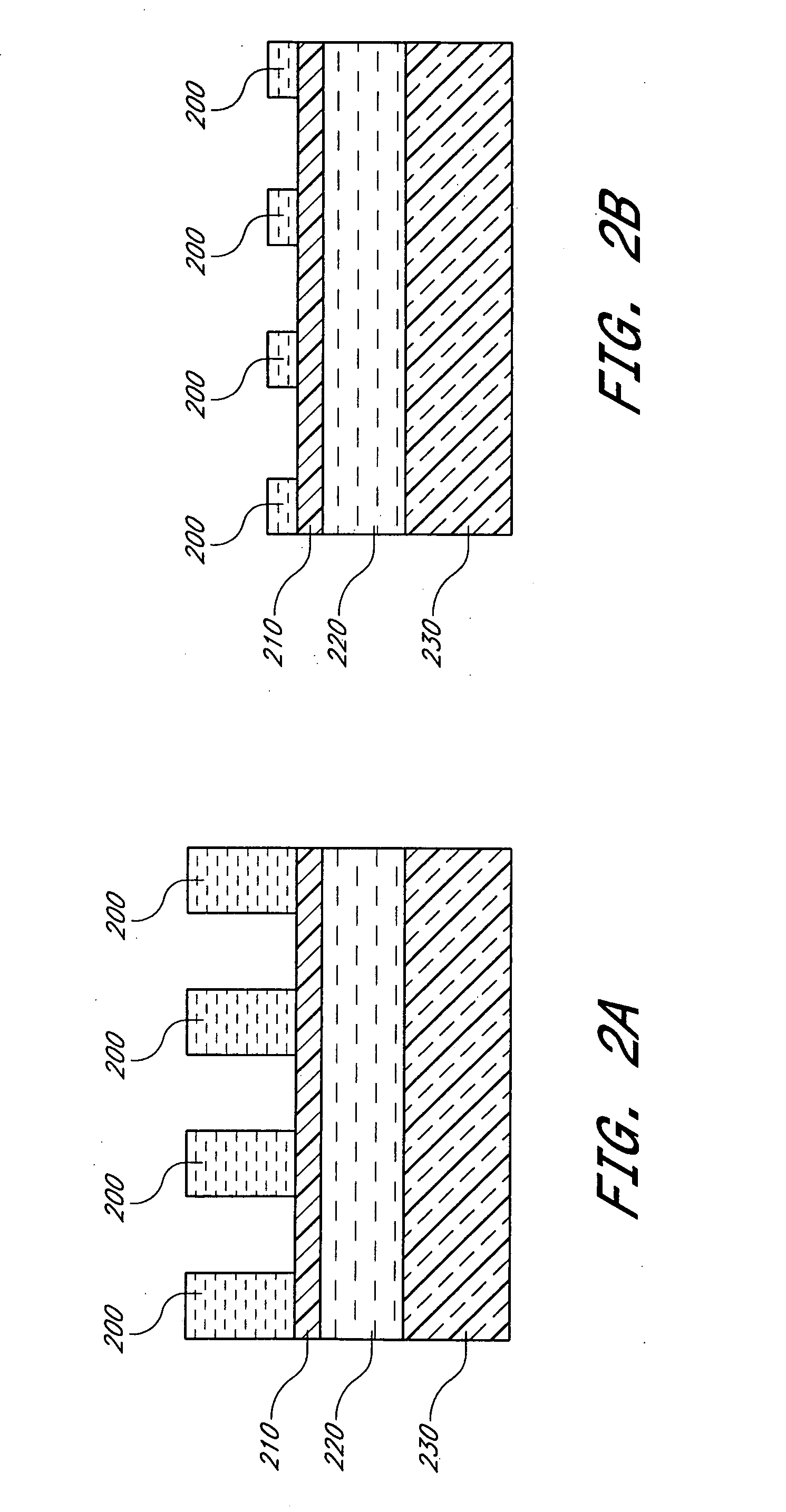

A method for reducing line edge roughness comprises forming a masking structure on a substrate assembly, wherein the substrate assembly includes a number of layers. The method includes forming a layered masking structure by depositing a layer of material on the masking structure in order to reduce a line edge roughness (LER) of the masking structure, and etching a pattern of the layered masking structure into one or more of the number of layers of the substrate assembly before trimming the layered masking structure.

Owner:MICRON TECH INC

Positive resist compositions and patterning process

ActiveUS20050227173A1Minimized line edge roughnessIncrease contrastPattern makingRadiation applicationsPolymer sciencePolymer chemistry

A polymer comprising units derived from an exo-form ester and units derived from an ester having two hexafluoroisopropanol groups is used as a base resin to formulate a positive resist composition which, when exposed and developed by photolithography, is minimized in line edge roughness by swelling during development and residue after development, and improved in adhesion.

Owner:SHIN ETSU CHEM IND CO LTD

Underlay film composition for imprints and method of forming pattern and pattern formation method using the same

ActiveUS20140220353A1Improve adhesionGood formabilityLayered productsDecorative surface effectsCovalent modifierOxygen atom

Provided is the pattern formability and line edge roughness of the resultant substrate.An underlay film composition for imprints comprising a compound (A) and a solvent (B), the compound (A) having at least either one of a group (Ka) capable of covalently bonding and / or interacting with a substrate, and, a group (Kb) capable of covalently bonding and / or interacting with a curable composition for imprints, an Ohnishi parameter (Z) calculated from (equation 1) of 3.8 or larger, and a molecular weight of 400 or larger:the Ohnishi parameter=(total number of atoms) / (number of carbon atoms−number of oxygen atoms) (Equation 1)

Owner:FUJIFILM CORP

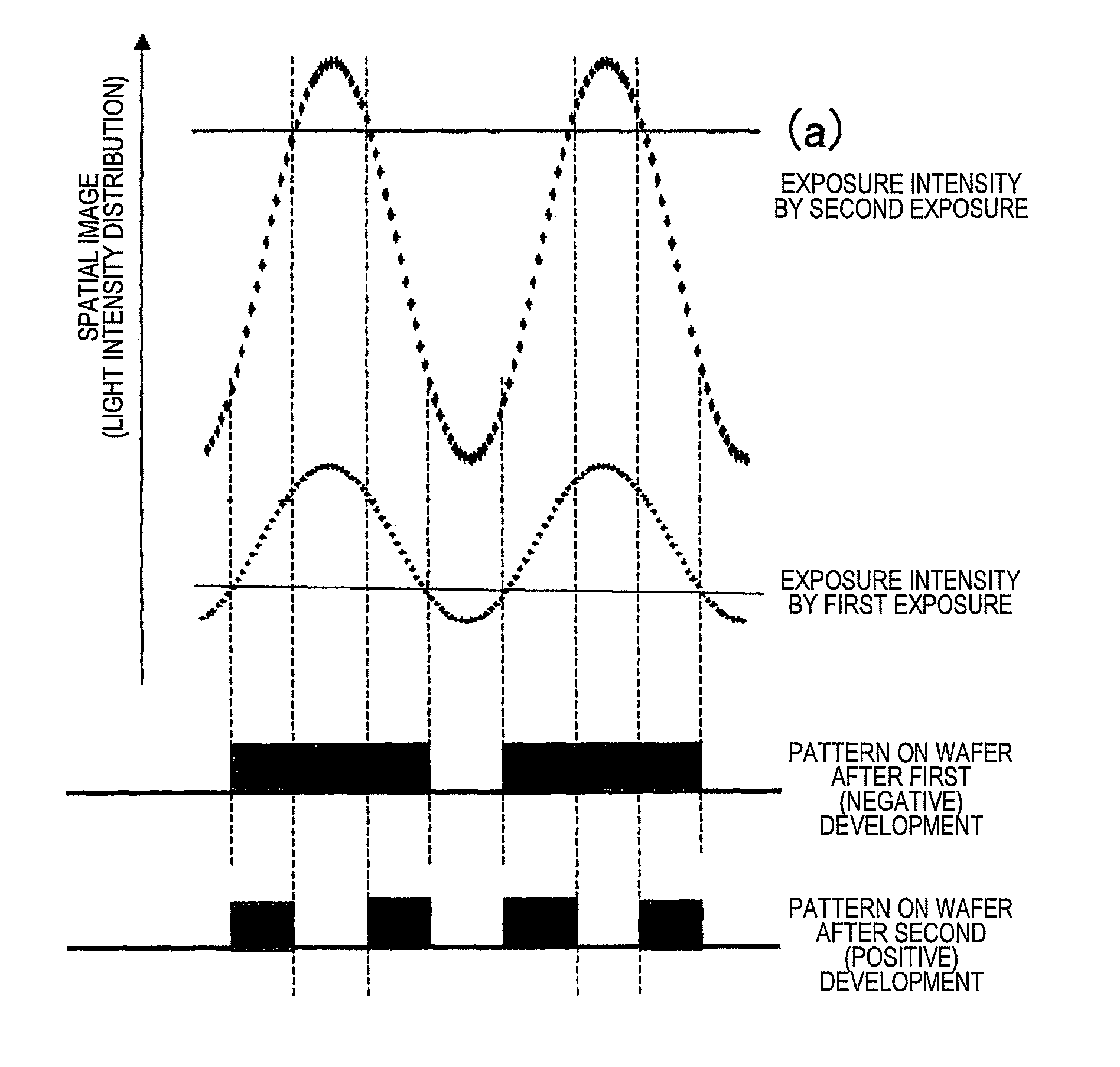

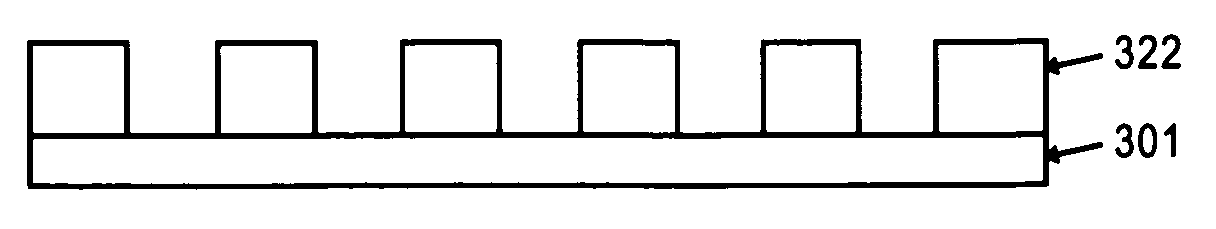

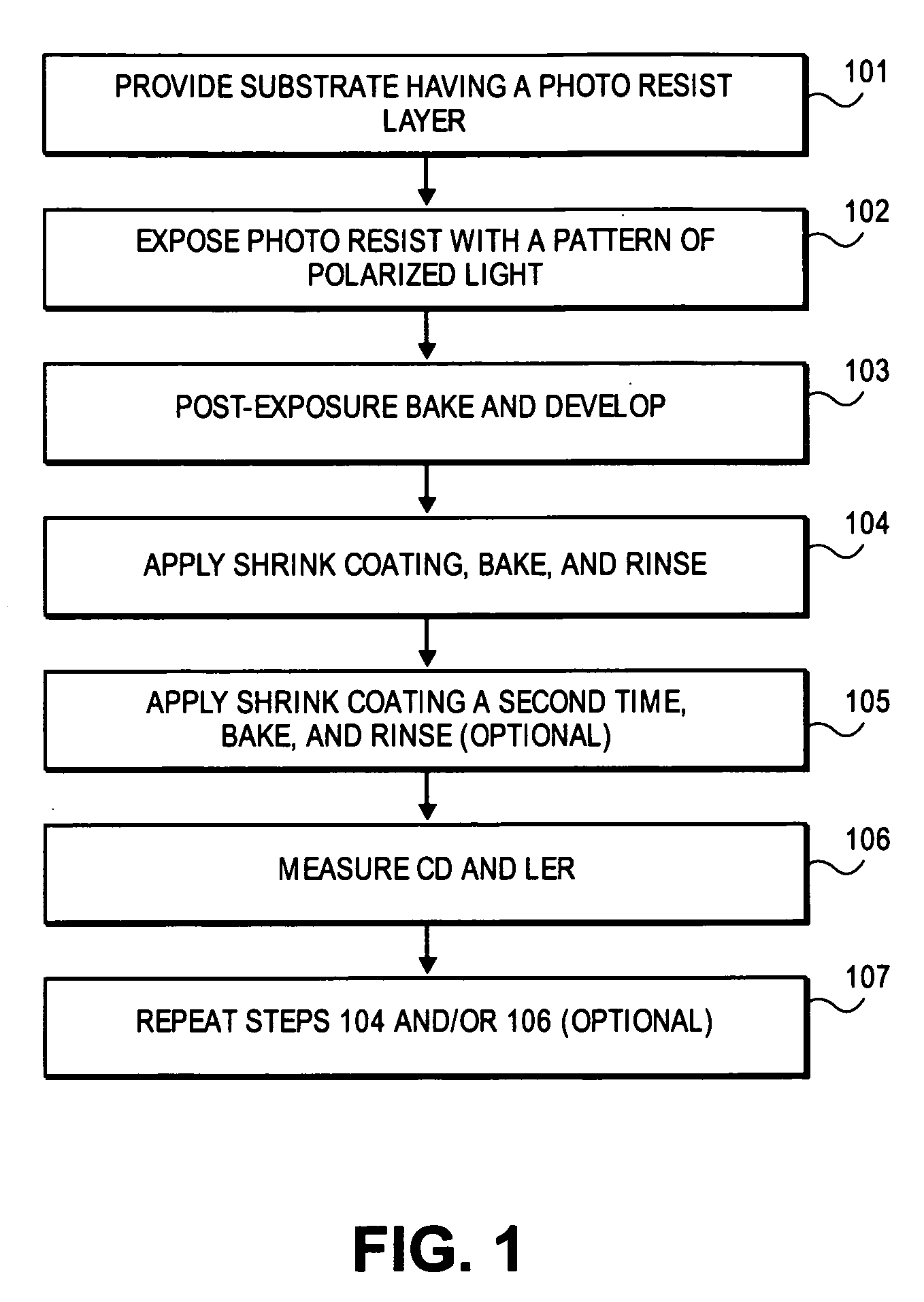

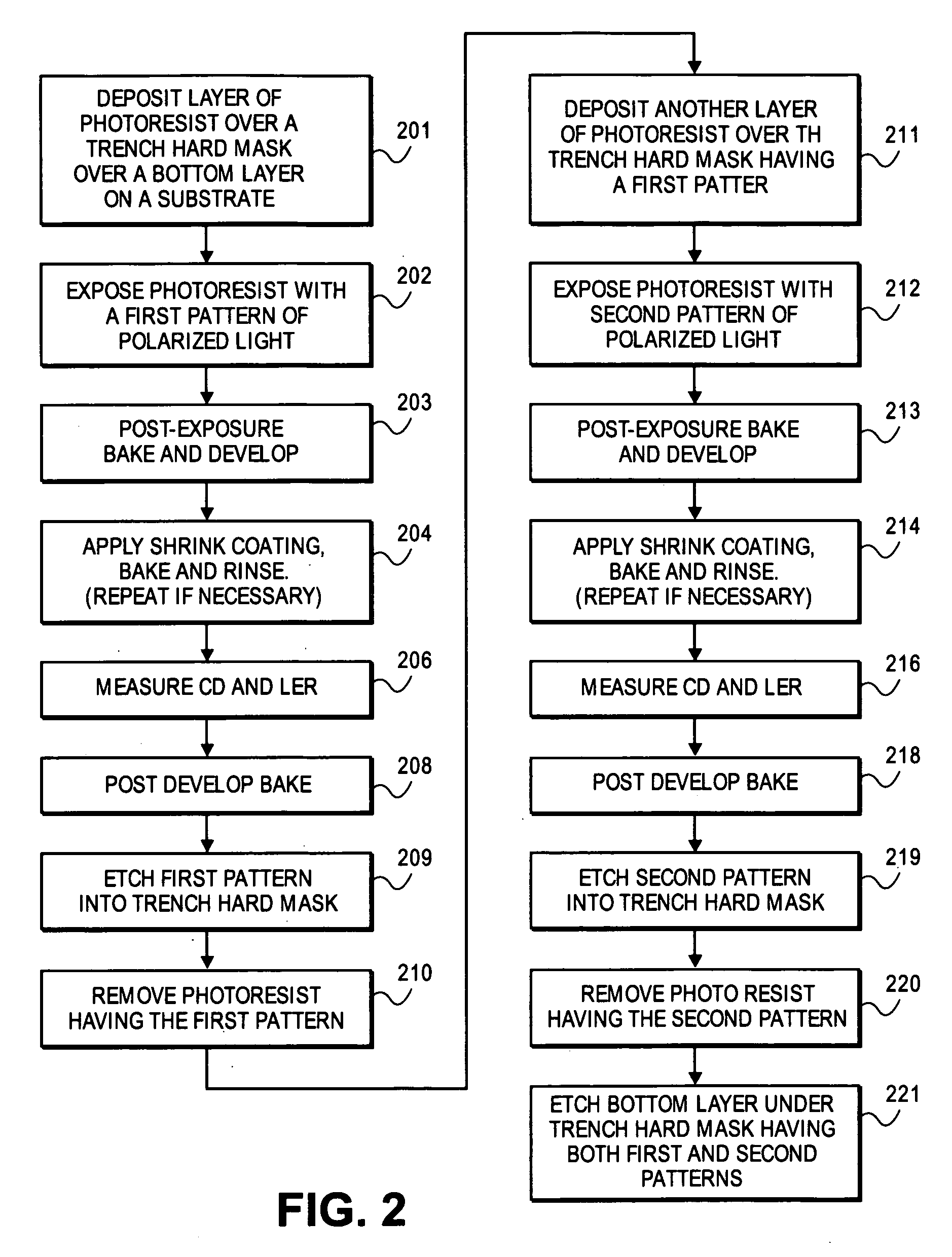

Line edge roughness reduction and double patterning

InactiveUS20090142926A1Small sizeSemiconductor/solid-state device manufacturingPhotosensitive material processingLithographic artistImage resolution

Embodiments of the present invention relate to lithographic processes used in integrated circuit fabrication for improving line edge roughness (LER) and reduced critical dimensions (CD) for lines and / or trenches. Embodiments use the combinations of polarized light lithography, shrink coating processes, and double exposure processes to produce synergetic effects in the formation of trench structures having good resolution, reduced CDs, reduced pitch, and reduced LER in the lines and / or trenches of the patterned interconnect structures.

Owner:APPLIED MATERIALS INC

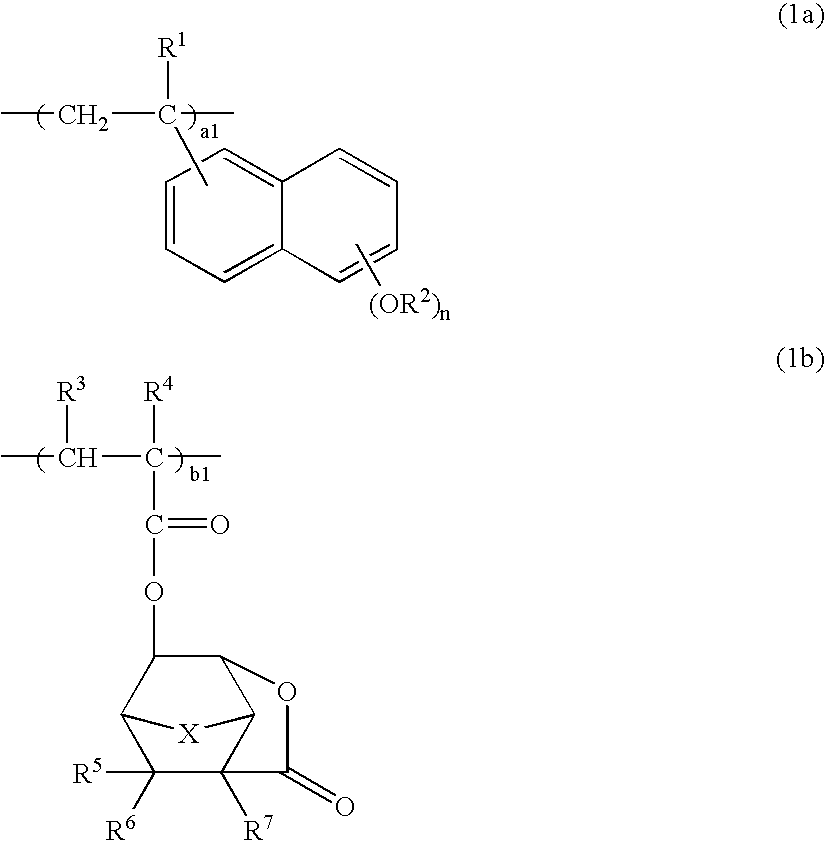

Polymers, positive resist compositions and patterning process

ActiveUS20070207408A1High sensitivityHigh resolutionPhotosensitive materialsRadiation applicationsPolymer scienceMeth-

A polymer is composed of recurring units of hydroxyvinylnaphthalene, (meth)acrylic units having a lactone ring fused to a bridged ring, and (meth)acrylic units having acid labile groups. A positive resist composition comprising the polymer as a base resin, when exposed to high-energy radiation and developed, exhibits a high sensitivity, a high resolution, and a minimal line edge roughness due to controlled swell during development.

Owner:SHIN ETSU CHEM IND CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com