Patents

Literature

365 results about "Operating variables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Operating Variables: Operating variables deal with the customer technologies, user and no user or heavy user status, and the customer capabilities. Purchasing Approaches: Some companies have centralized purchasing while others have decentralized purchasing. Industrial marketing often involves competitive tendering.

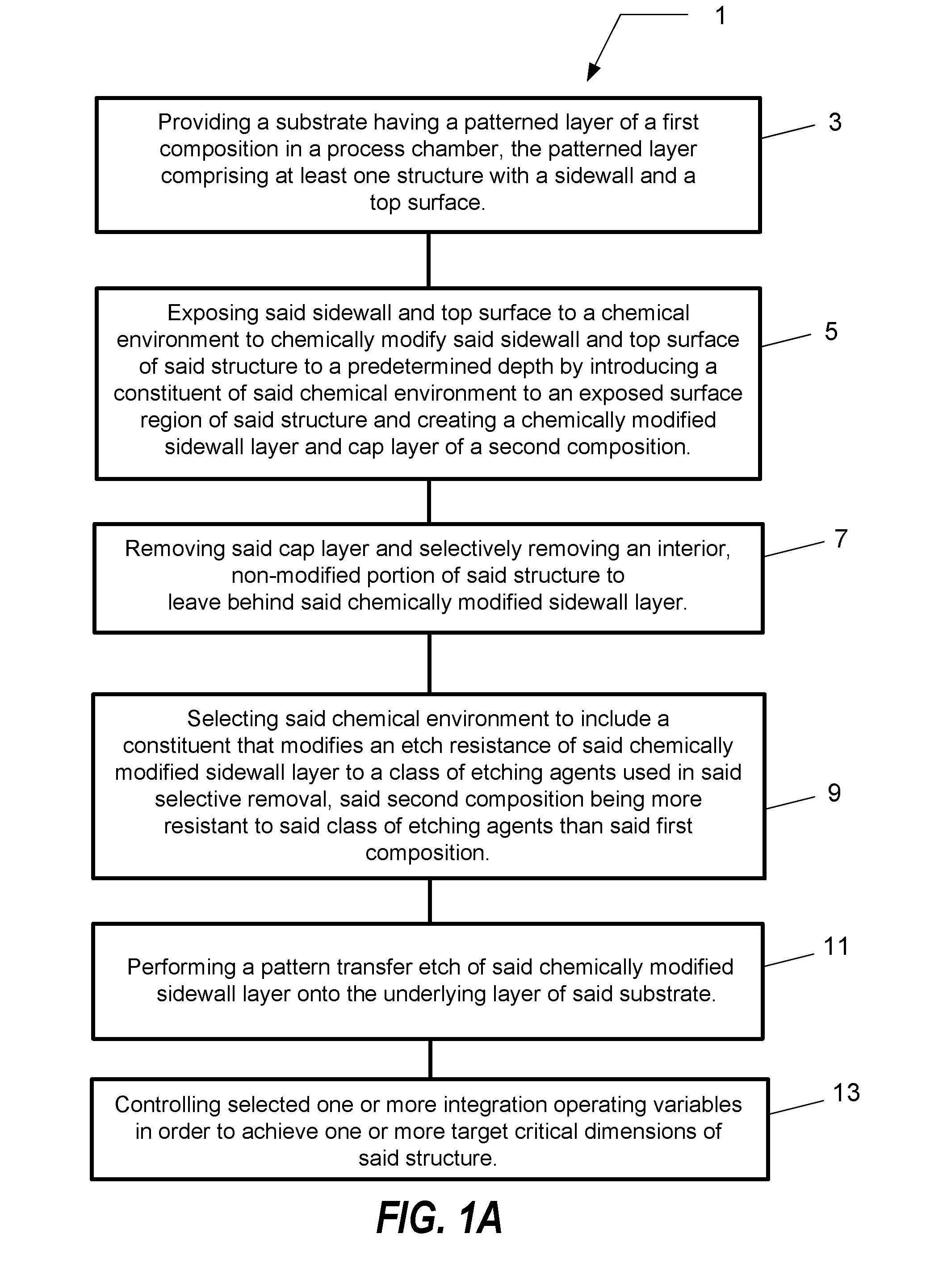

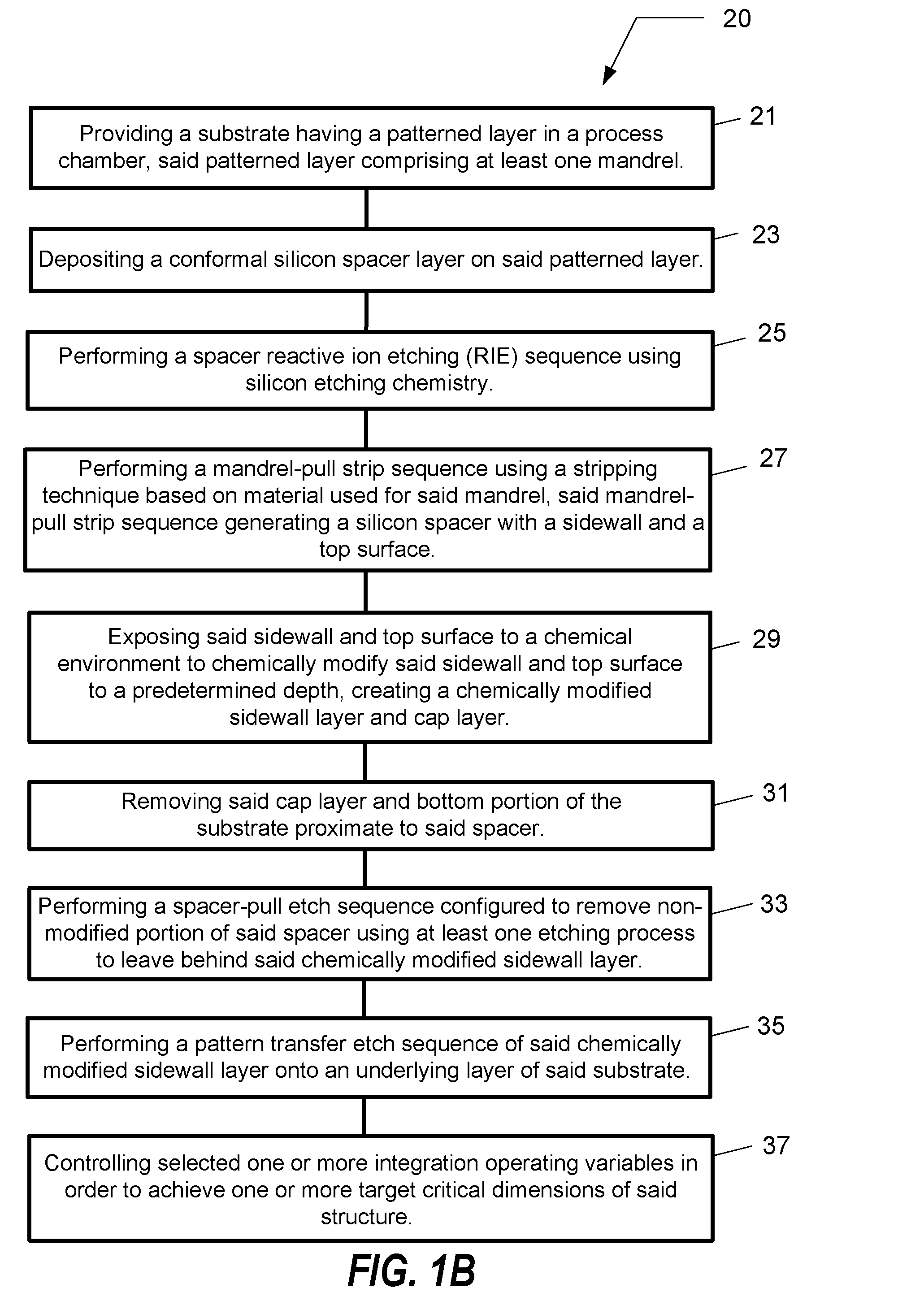

Organic mandrel protection process

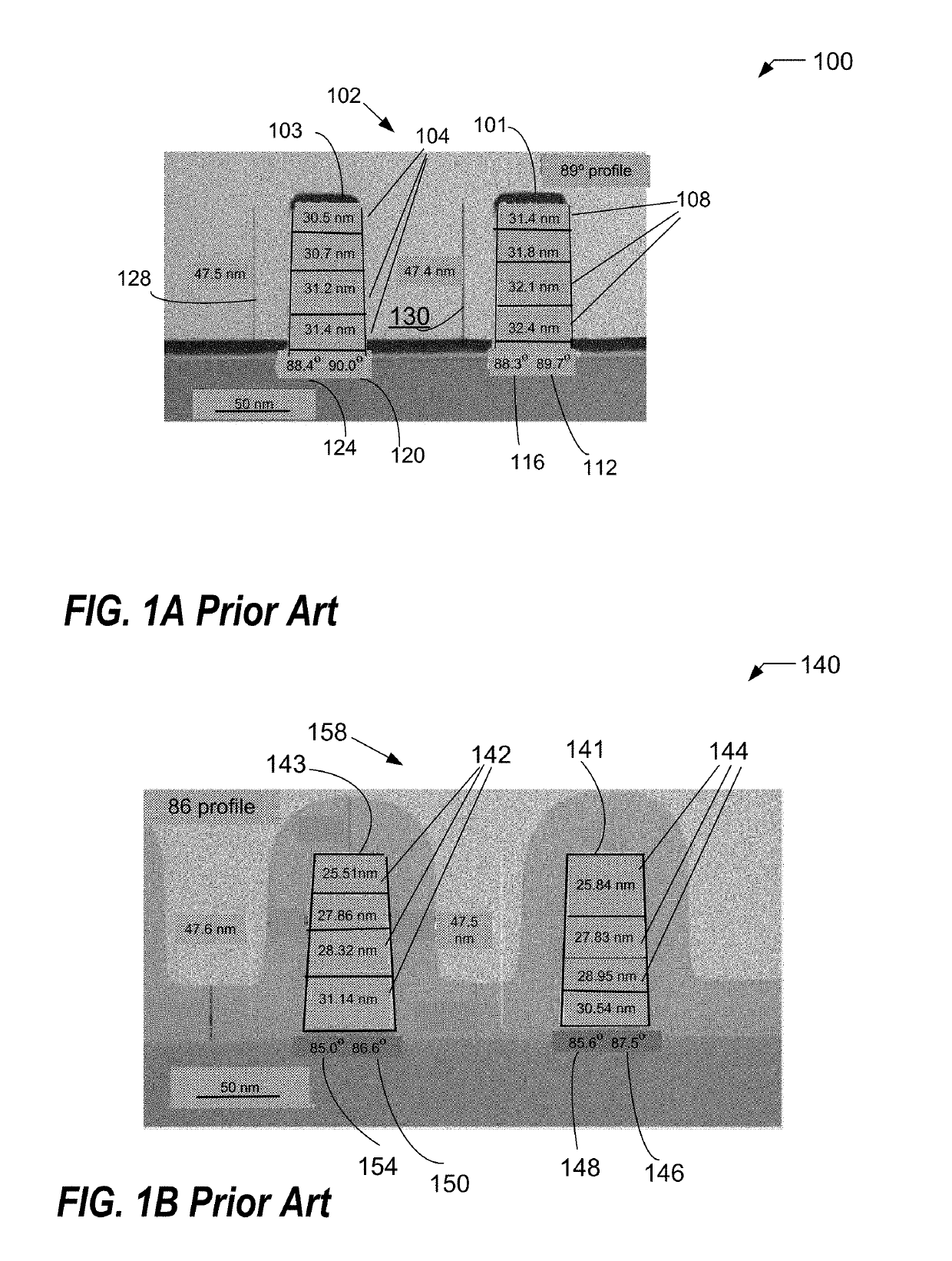

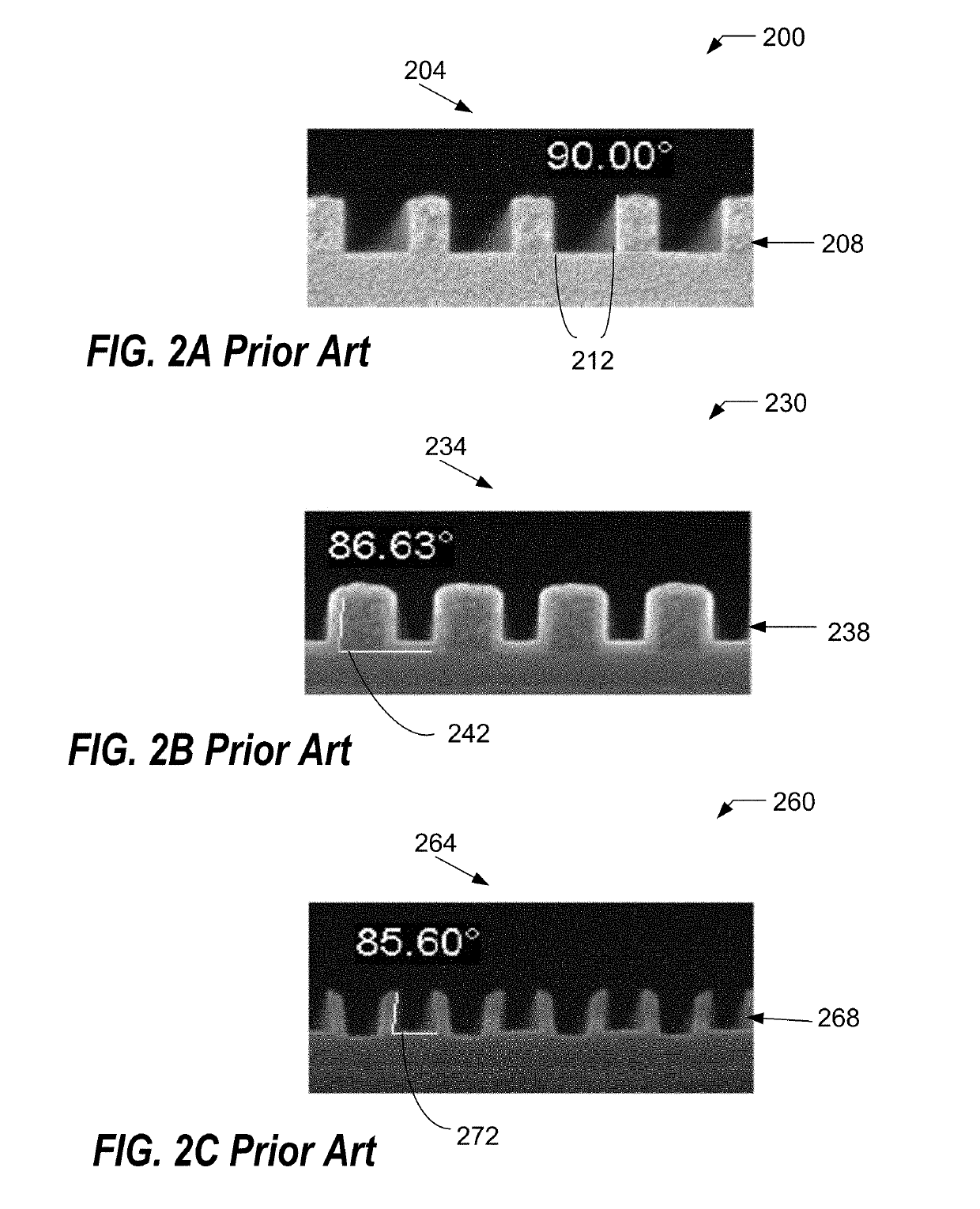

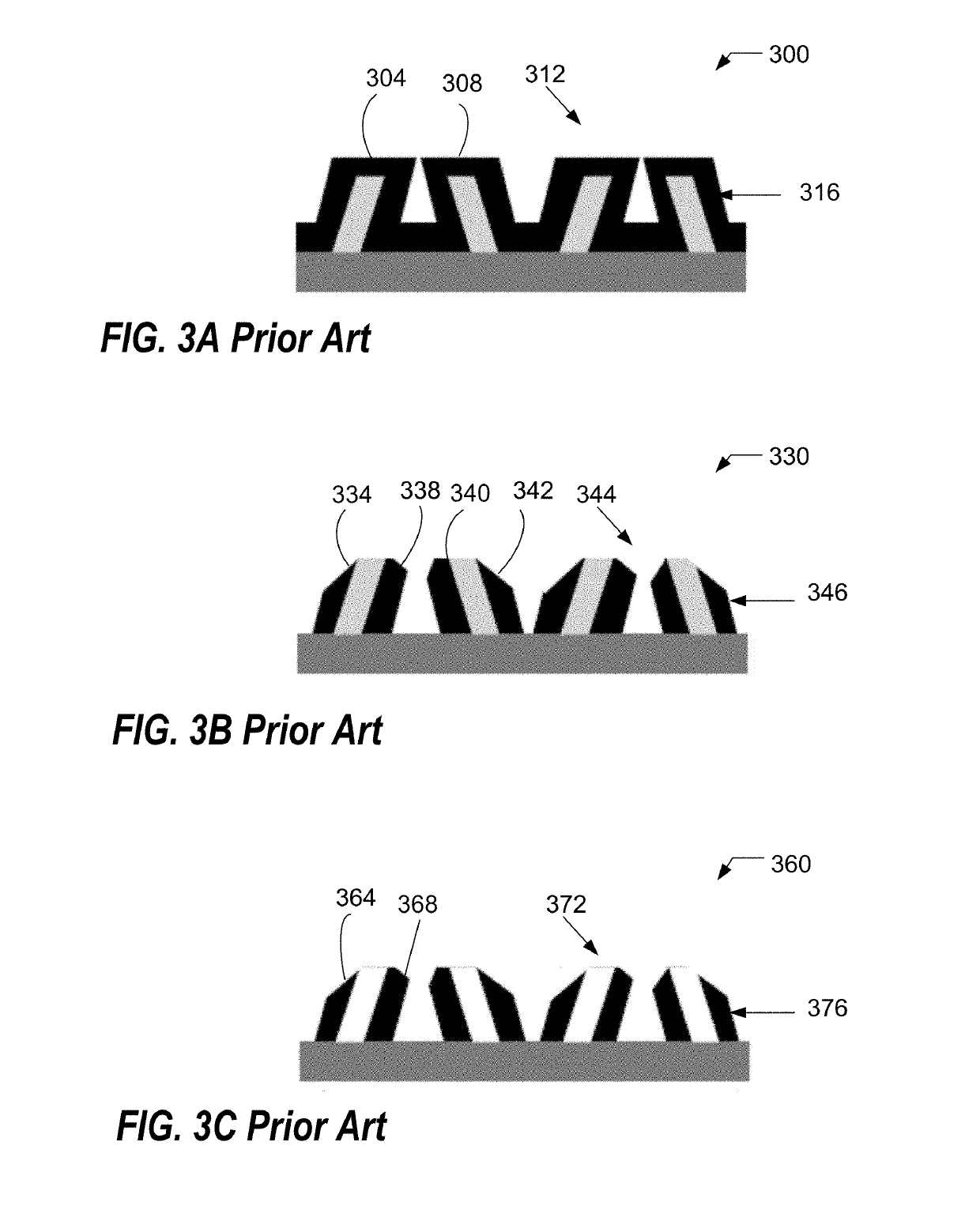

ActiveUS10354873B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingDeposition processOperating variables

Provided is a method of patterning spacers, the method comprising: providing an initial patterned structure in a substrate in a processing chamber, the initial patterned structure comprising an organic mandrel and an underlying layer; exposing the patterned structure in a direct current superposition (DCS) plasma treatment process, the process depositing a layer of a first material on the initial patterned structure; performing an atomic layer conformal deposition process using a second material, the first material providing protection to the organic mandrel at the beginning of the atomic layer conformal deposition process; performing a spacer etch mandrel pull process, the process creating a final patterned structure with a target final sidewall angle; concurrently controlling integration operating variables in the DCS plasma treatment process, the atomic layer conformal deposition process, and the spacer etch mandrel pull process in order to meet the target final sidewall angle and other integration objectives.

Owner:TOKYO ELECTRON LTD

Strategic planning and optimization system

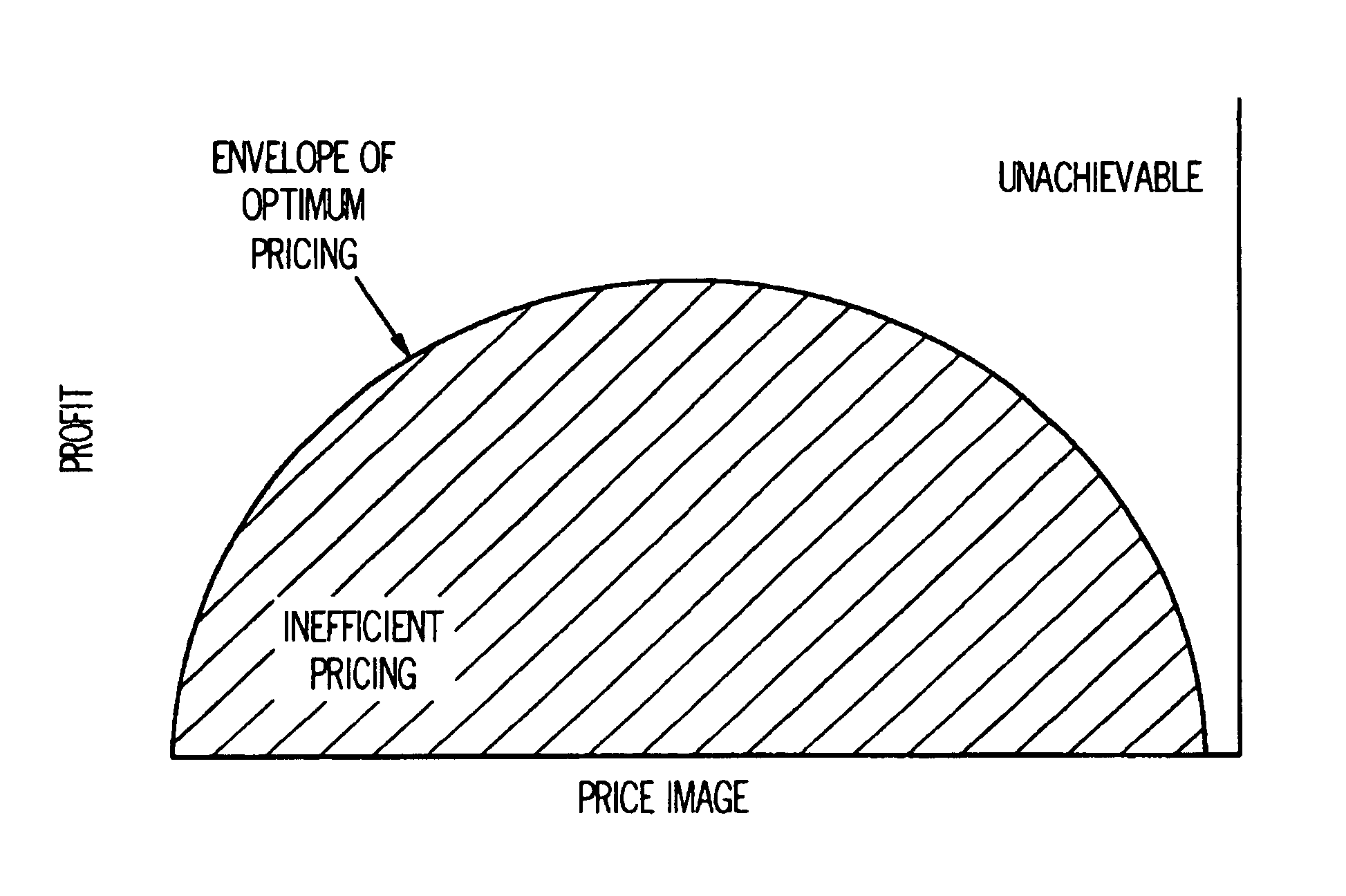

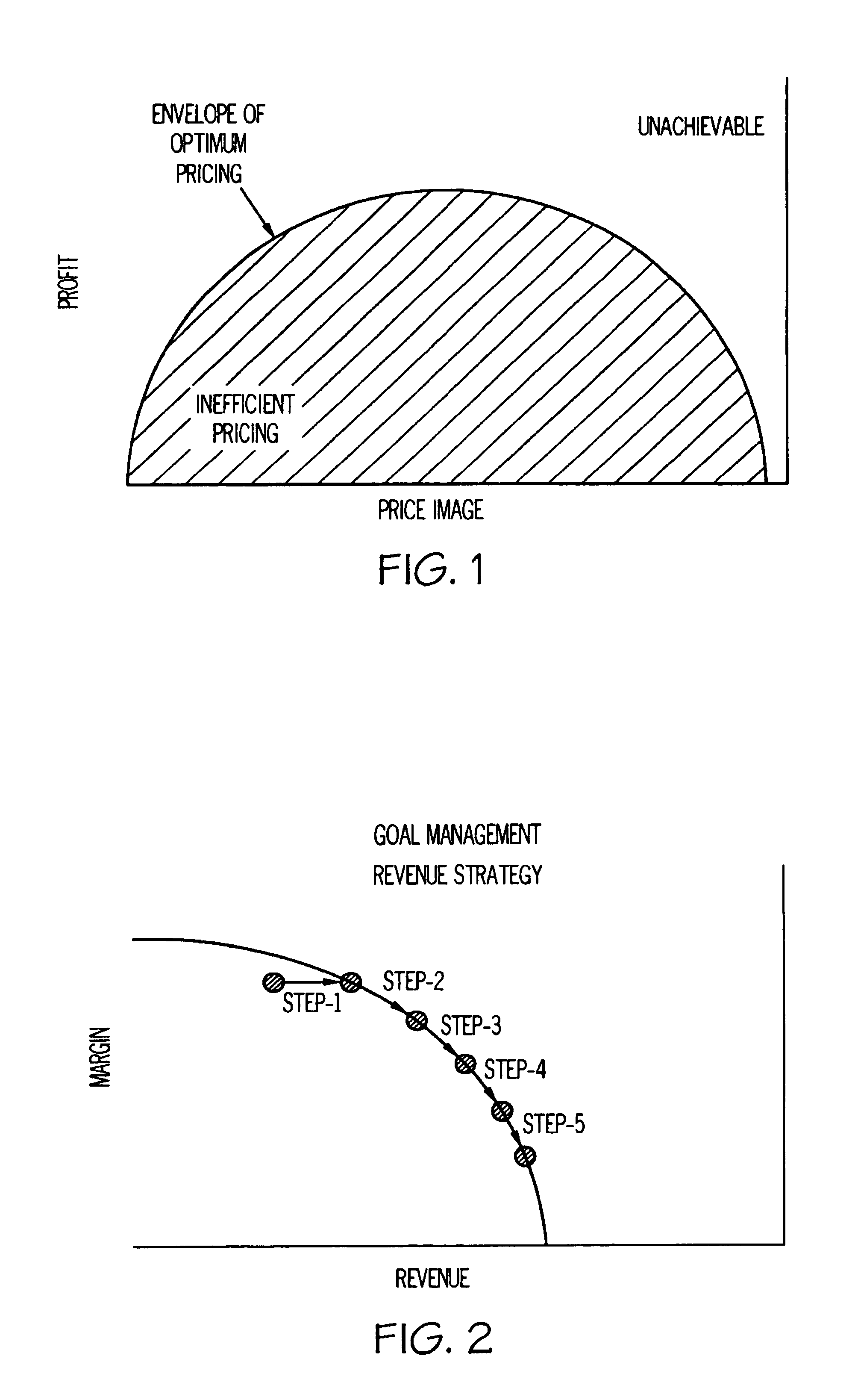

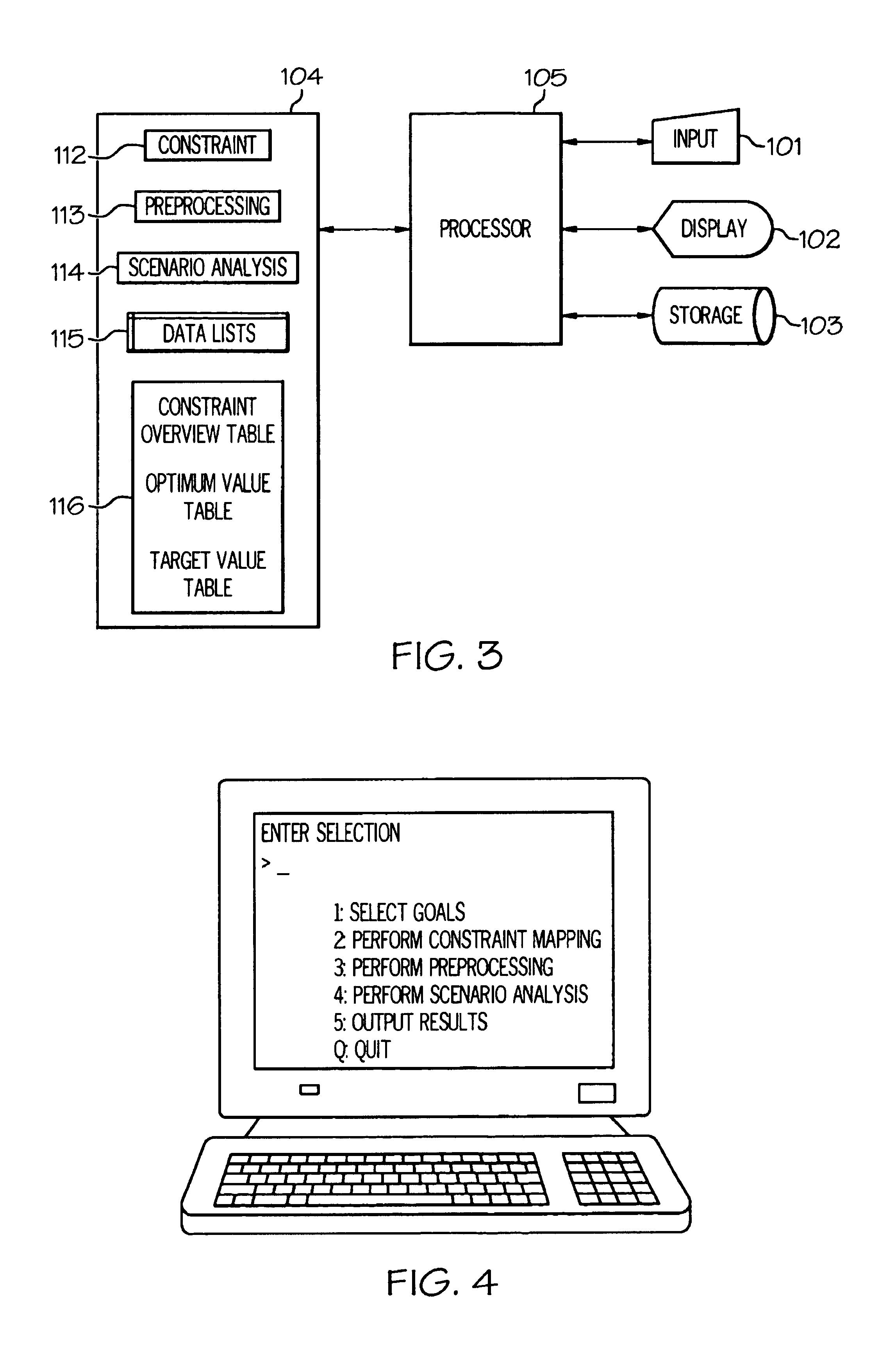

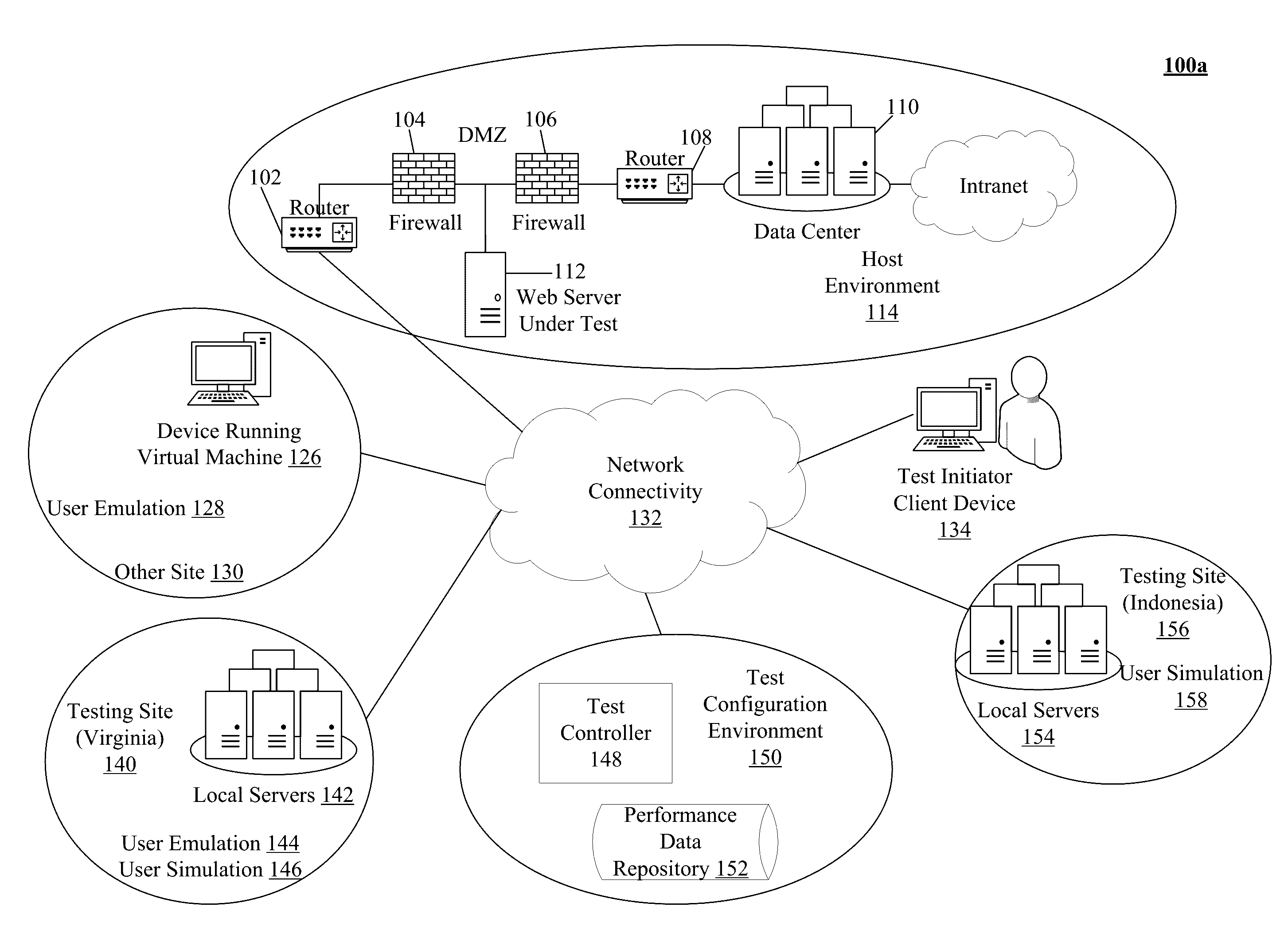

InactiveUS6988076B2Improve usabilityLow costReservationsForecastingEnterprise modellingObject function

A software method for strategic planning and optimization allows a user to model an enterprise to visualize an effect of an auxiliary goal, such as price image, on a primary goal of the enterprise. A primary goal of the enterprise is selected, and is represented by a primary objective function which, in turn, depends upon a set of operational variables. The auxiliary goal is represented by a constraint function that depends upon a subset of the operational variables. An effective objective function is constructed by combining the primary objective function and the constraint function, and the effective objective function is optimized to yield a set of operational decisions that optimize the primary objective function while concurrently satisfying the constraint function. The set of operational decisions are provided to a user, the operational decisions enabling the enterprise to achieve the primary goal and satisfy the auxiliary goal.

Owner:SAP AG

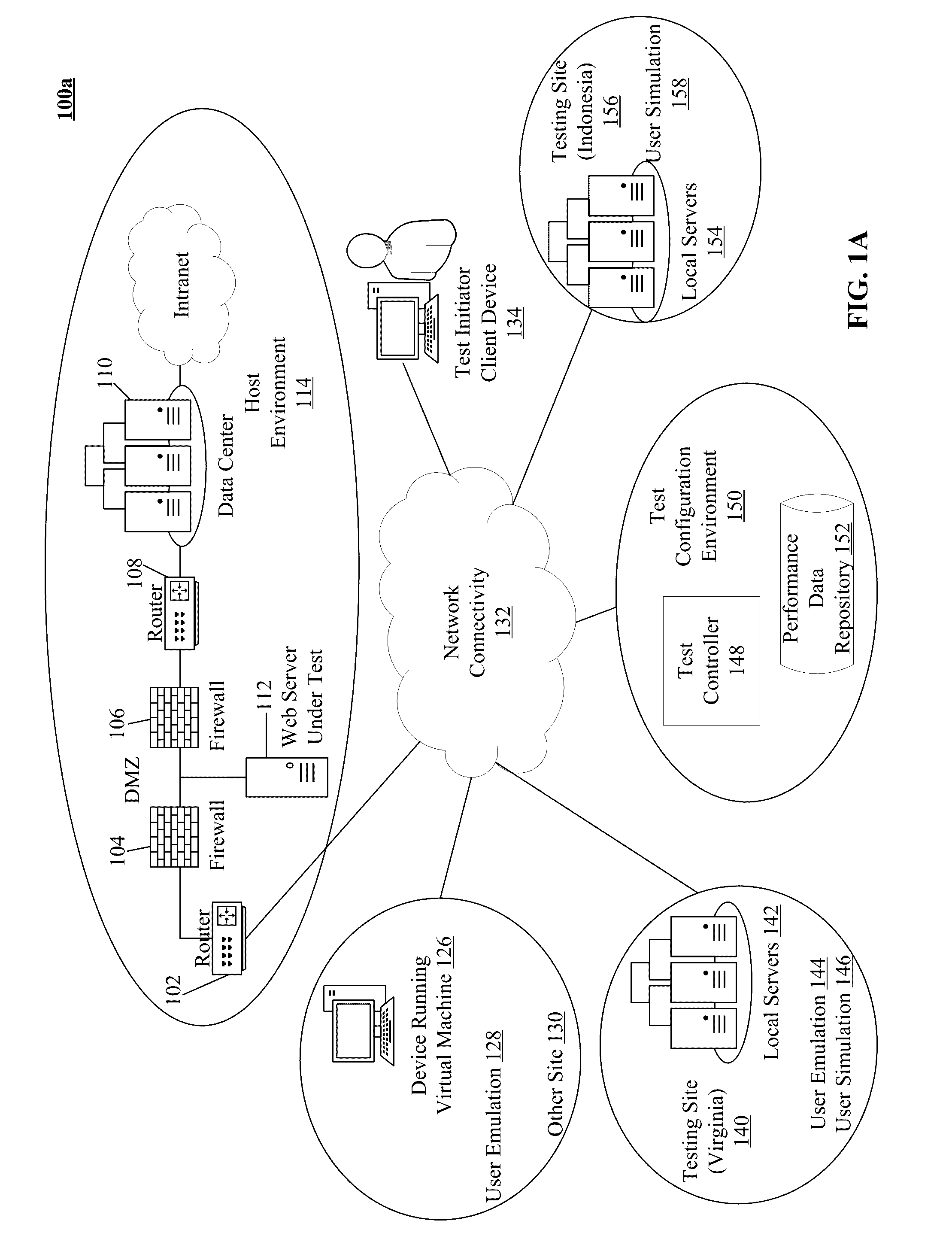

Method to configure monitoring thresholds using output of load or resource loadings

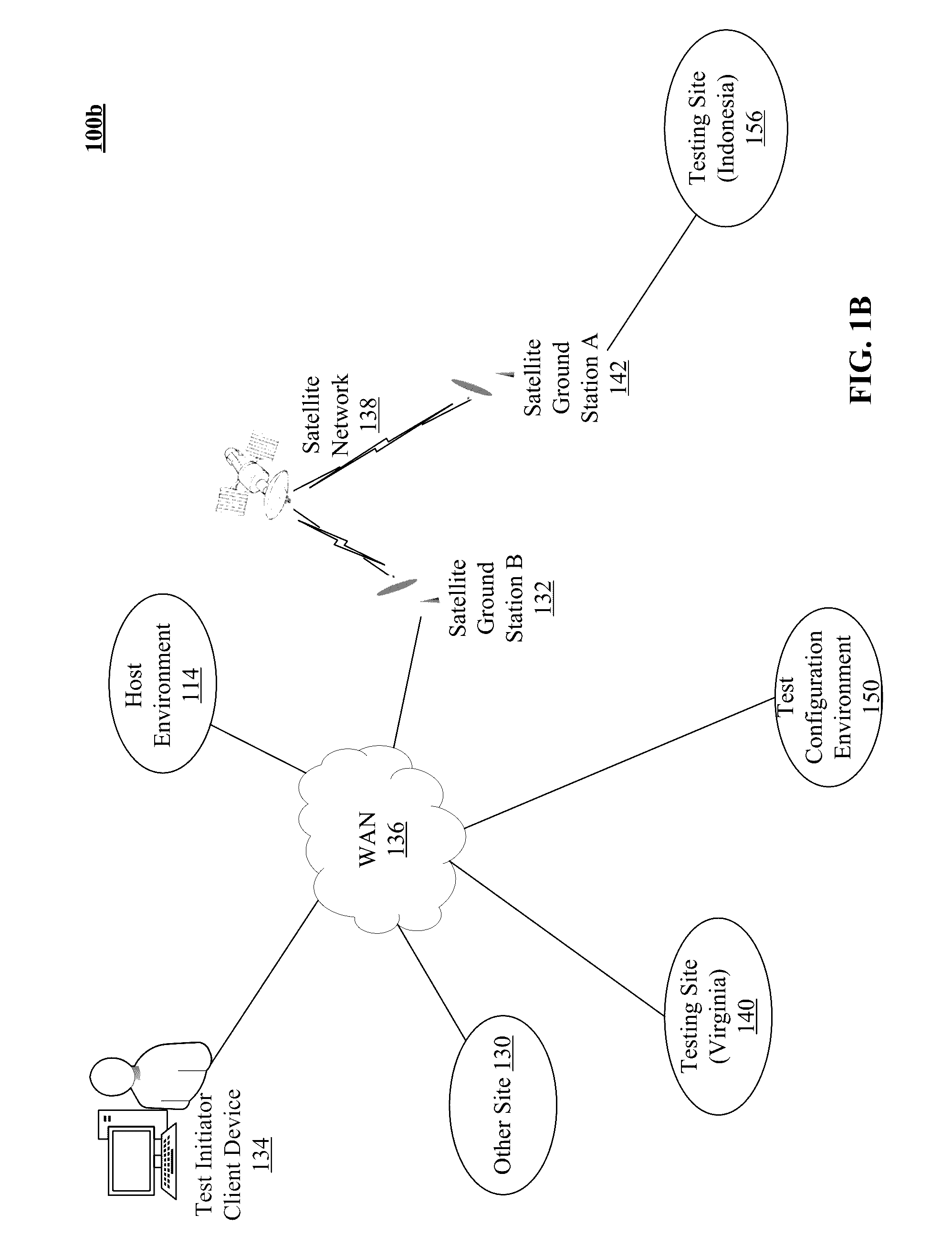

The technology disclosed enables the automatic definition of monitoring alerts for a web page across a plurality of variables such as server response time, server CPU load, network bandwidth utilization, response time from a measured client, network latency, server memory utilization, and the number of simultaneous sessions, amongst others. This is accomplished through the combination of load or resource loading and performance snapshots, where performance correlations allow for the alignment of operating variables. Performance data such as response time for the objects retrieved, number of hits per second, number of timeouts per sec, and errors per second can be recorded and reported. This allows for the automated ranking of tens of thousands of web pages, with an analysis of the web page assets that affect performance, and the automatic alignment of performance alerts by resource participation.

Owner:SPIRENT COMM

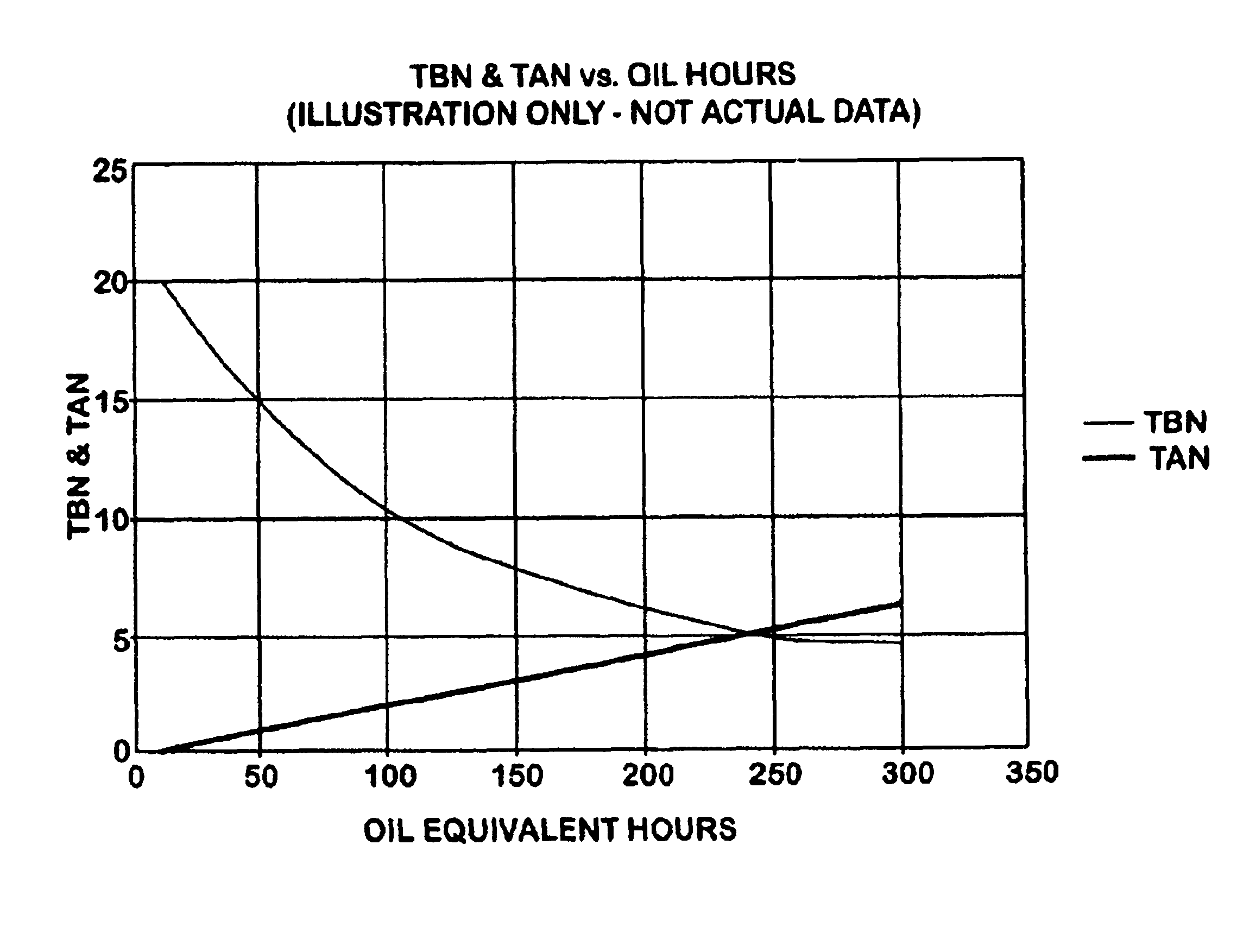

Method of estimating engine lubricant condition

A motor vehicle having an internal combustion engine and a lubricating oil circulation system provides estimates of the distance remaining before an oil change becomes imperative. An indirect estimate of the depletion of various additives and the deterioration of oil operating characteristics is based on engine operating variables including oil temperature, ignition timing and engine load. The limit of depletion of total base number is dynamic, since it is set against total acid number and the two figures are independently calculated.

Owner:INT TRUCK INTPROP LLC

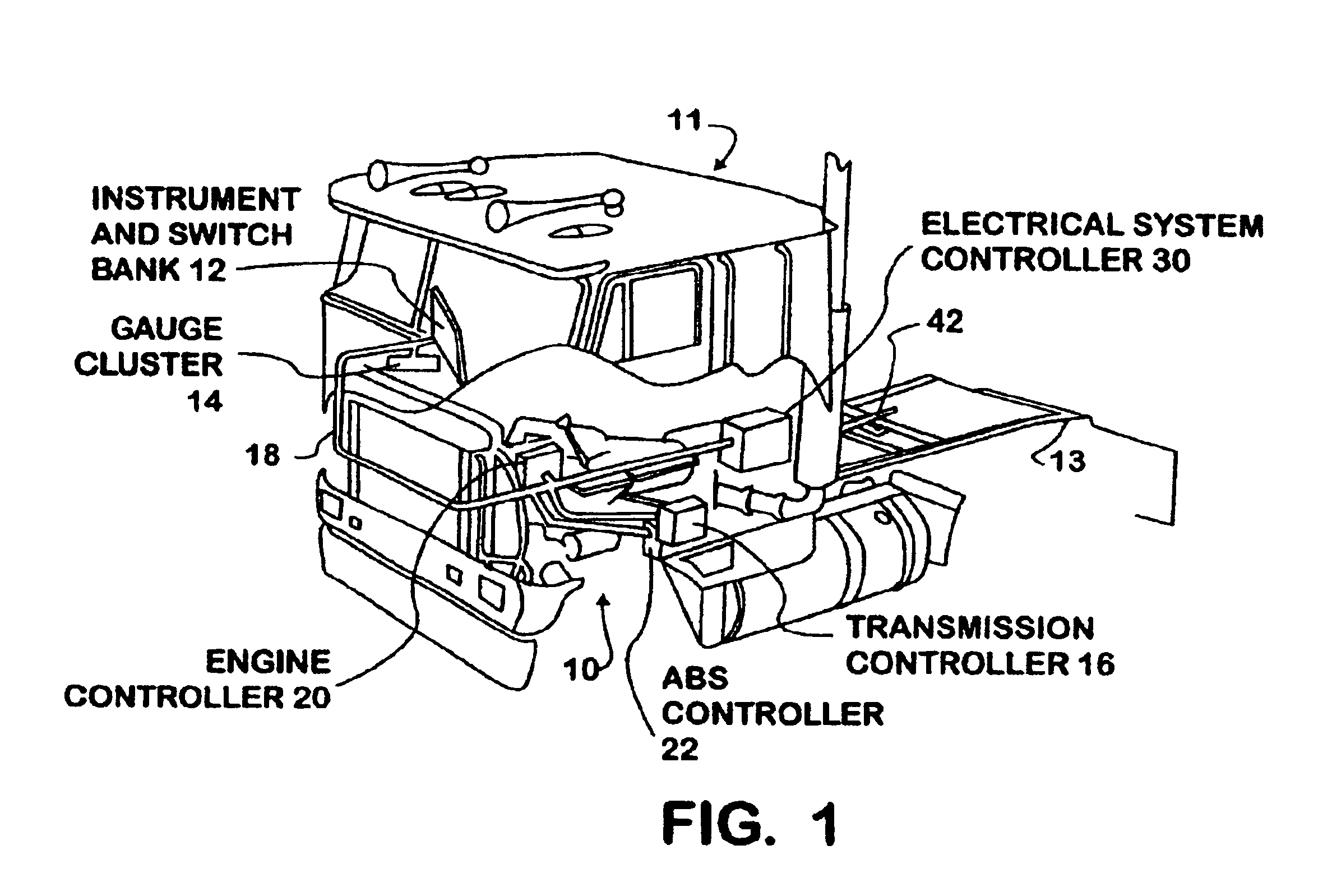

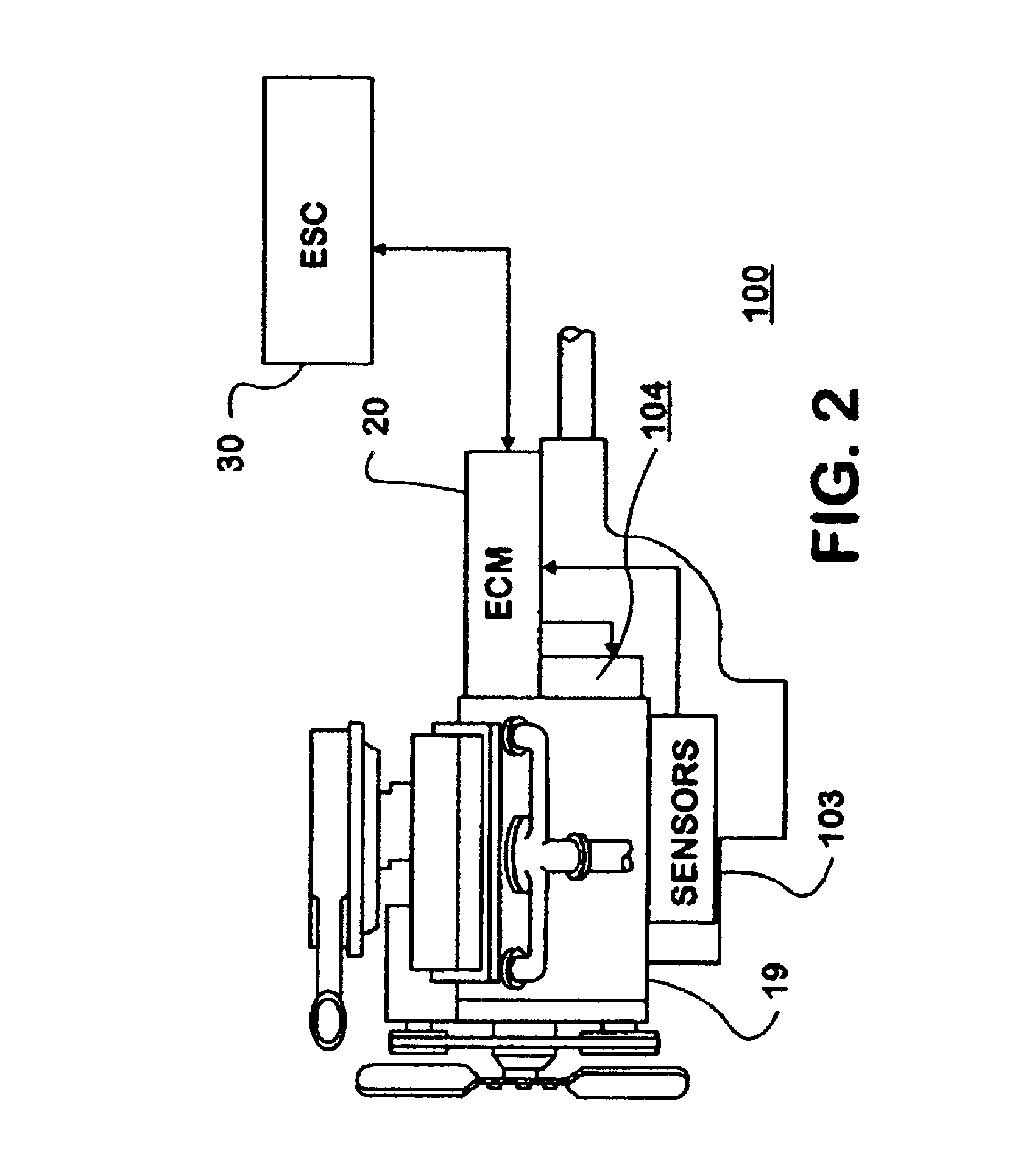

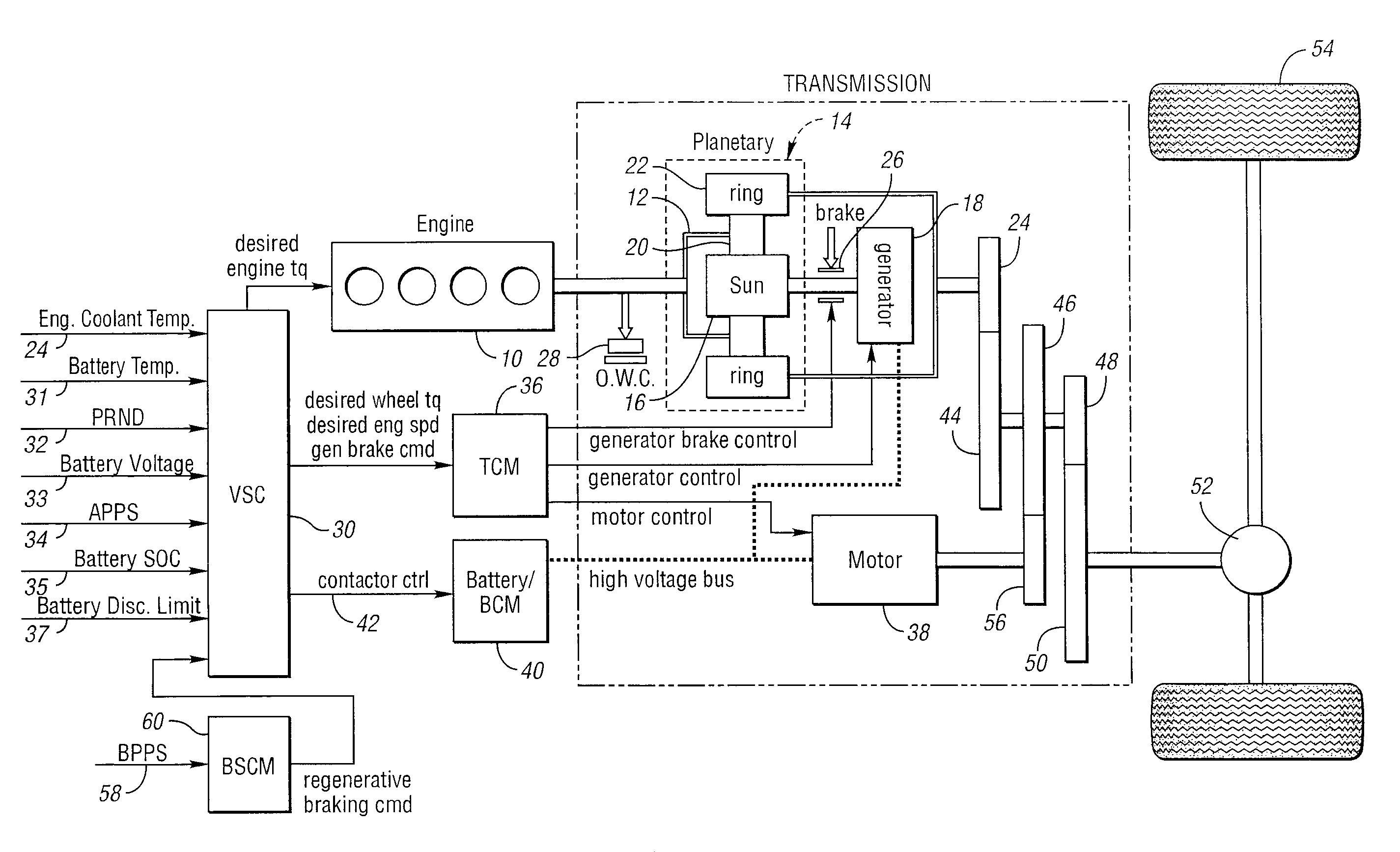

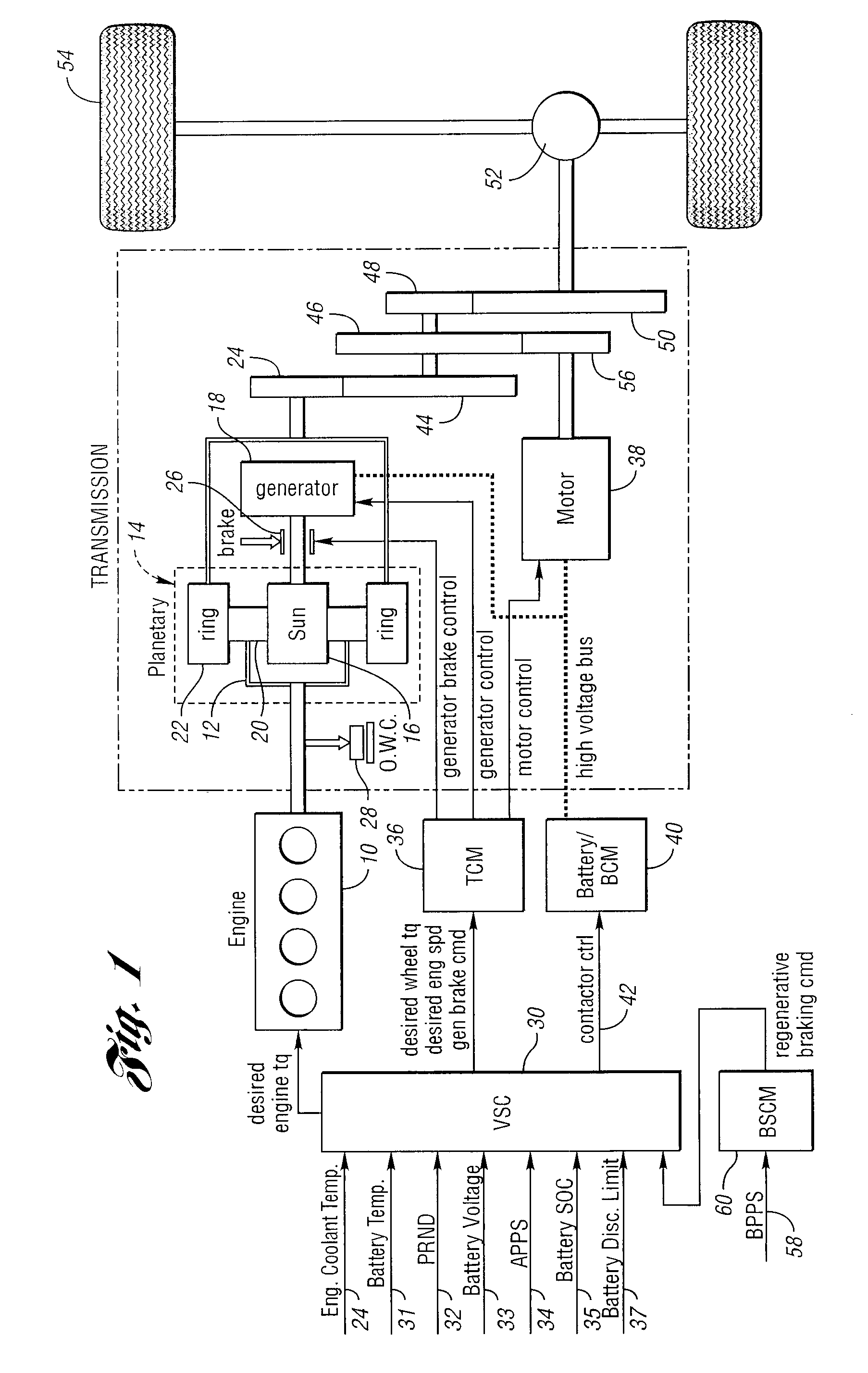

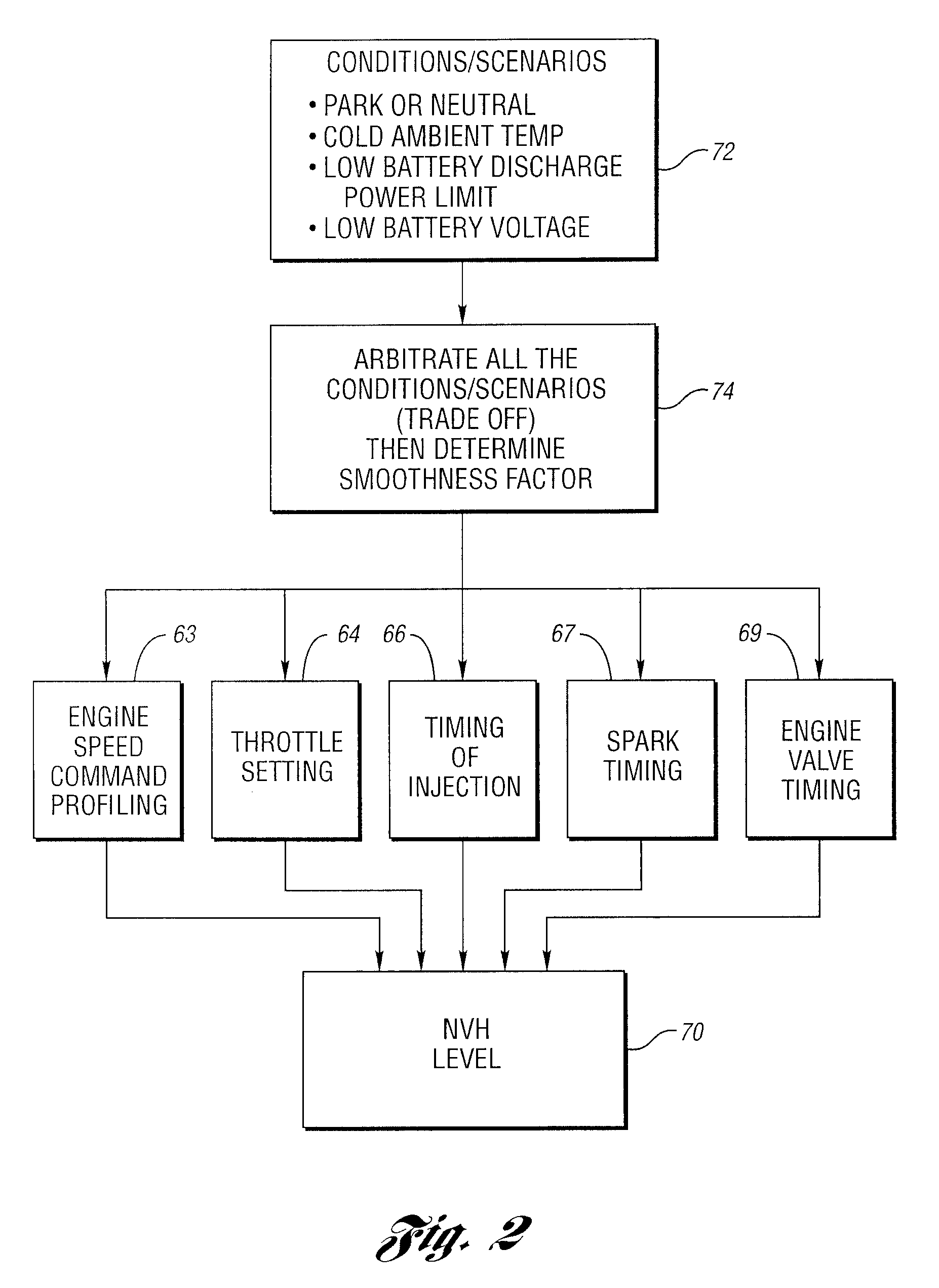

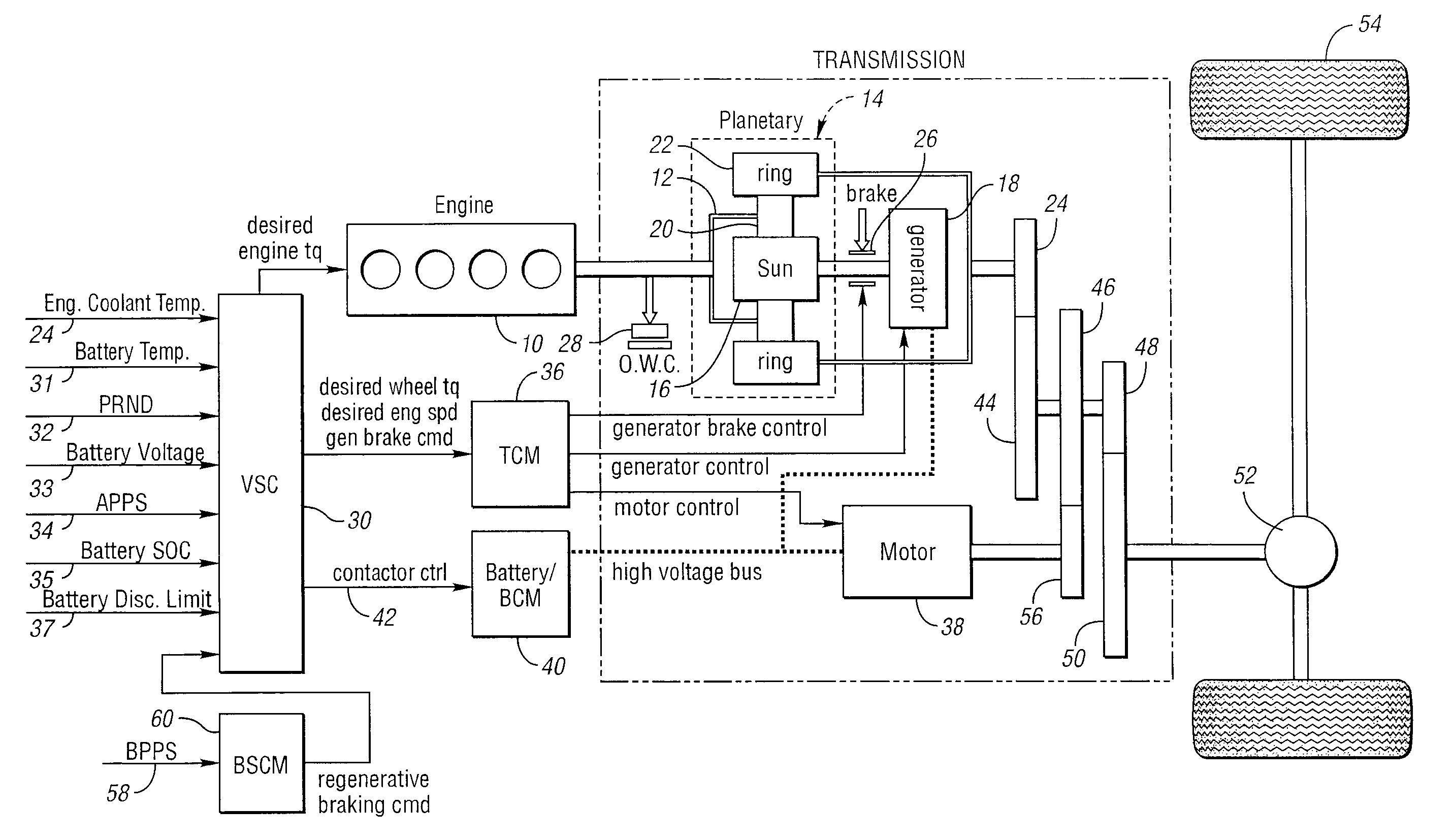

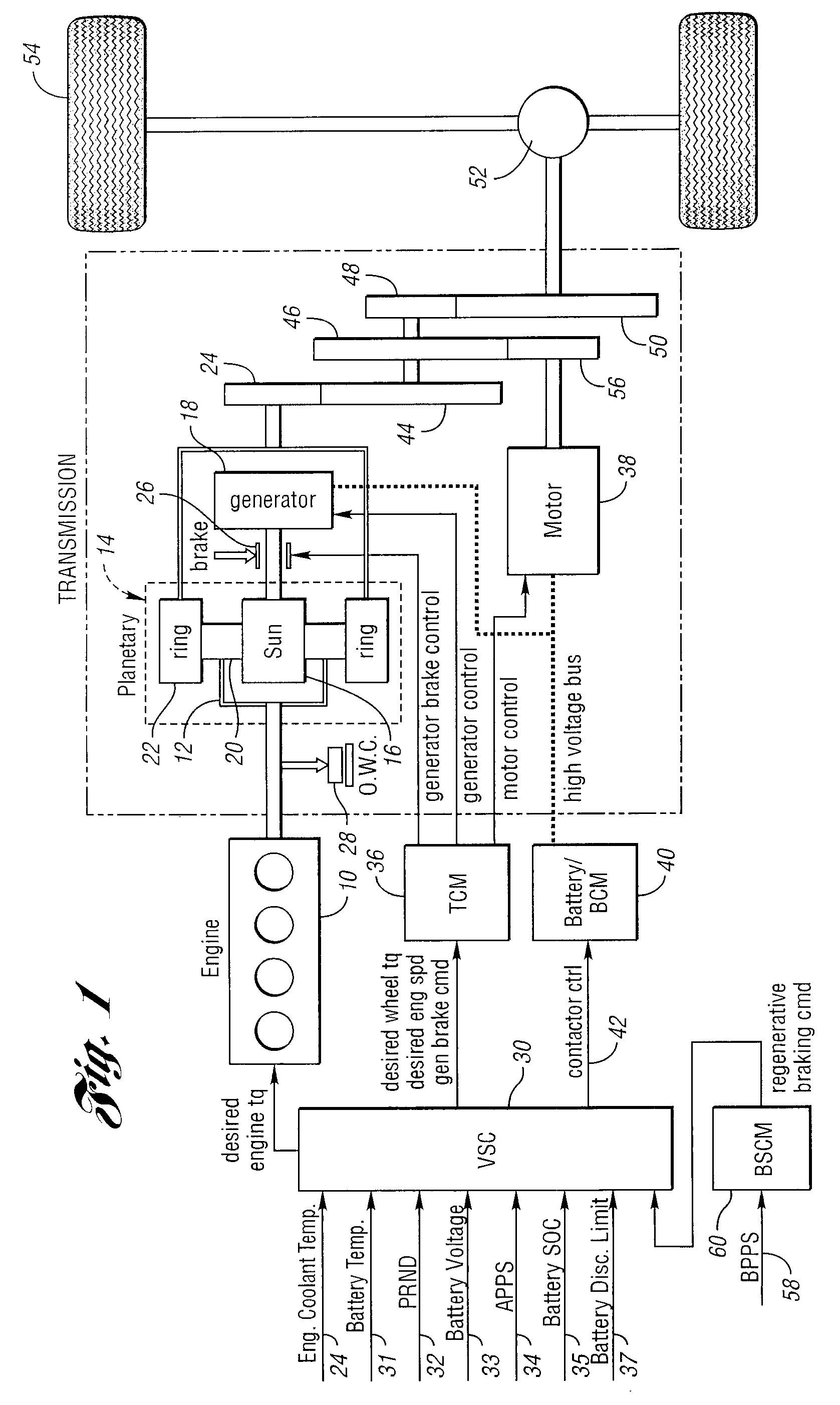

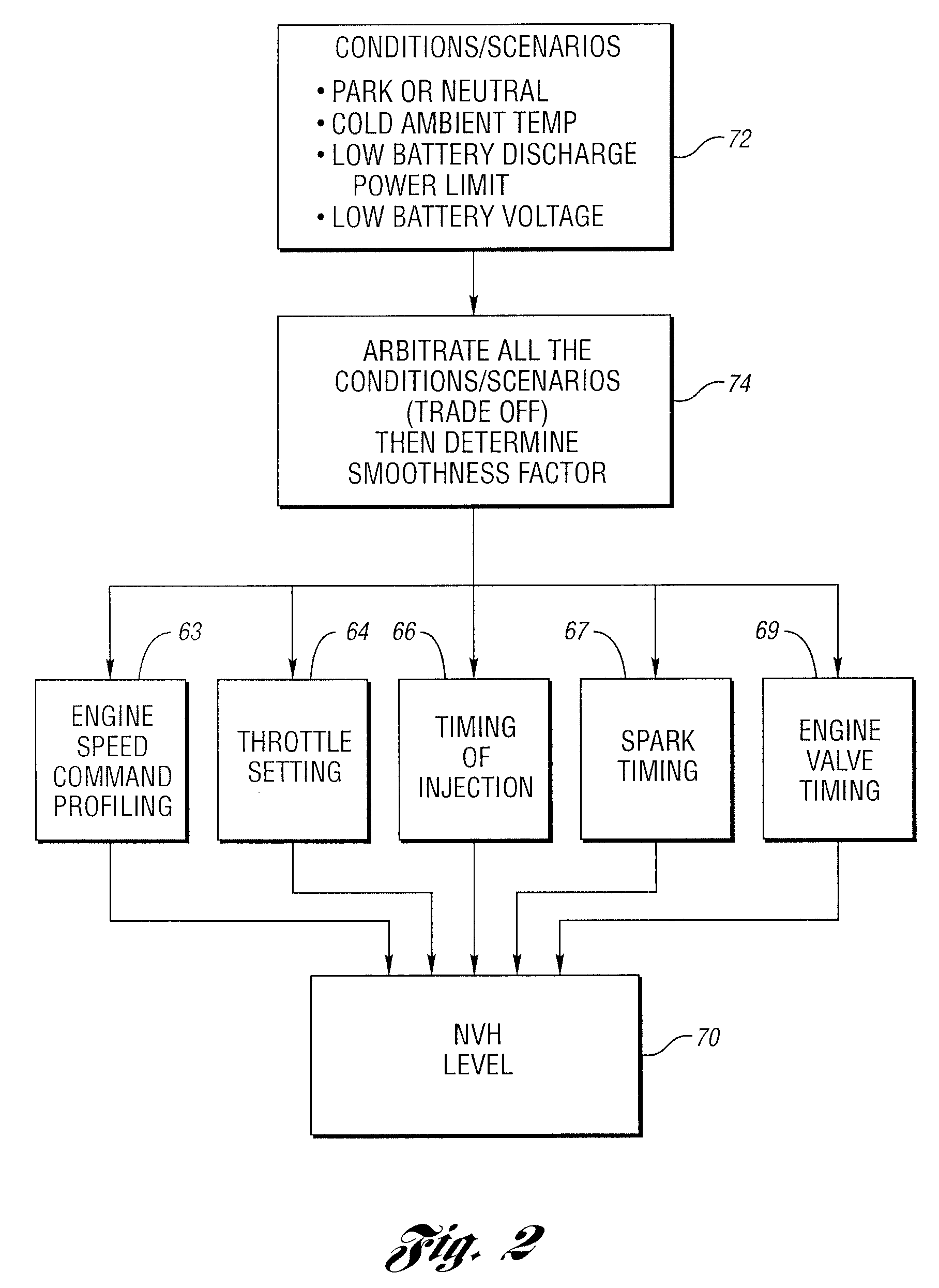

Method for controlling starting of an engine in a hybrid electric vehicle powertrain

ActiveUS7013213B2Regulate smoothnessEasy to implementHybrid vehiclesAnalogue computers for vehiclesPower flowInternal combustion engine

A method for controlling starting of an internal combustion engine in a hybrid electric vehicle powertrain having multiple power flow paths to vehicle traction wheels from the engine and from an electric motor. A smoothness factor is calculated to determine how smooth an engine start should be. Engine operating variables regulate engine smoothness during engine start events as determined by the calculated smoothness factor appropriate for selected vehicle operating conditions.

Owner:FORD GLOBAL TECH LLC

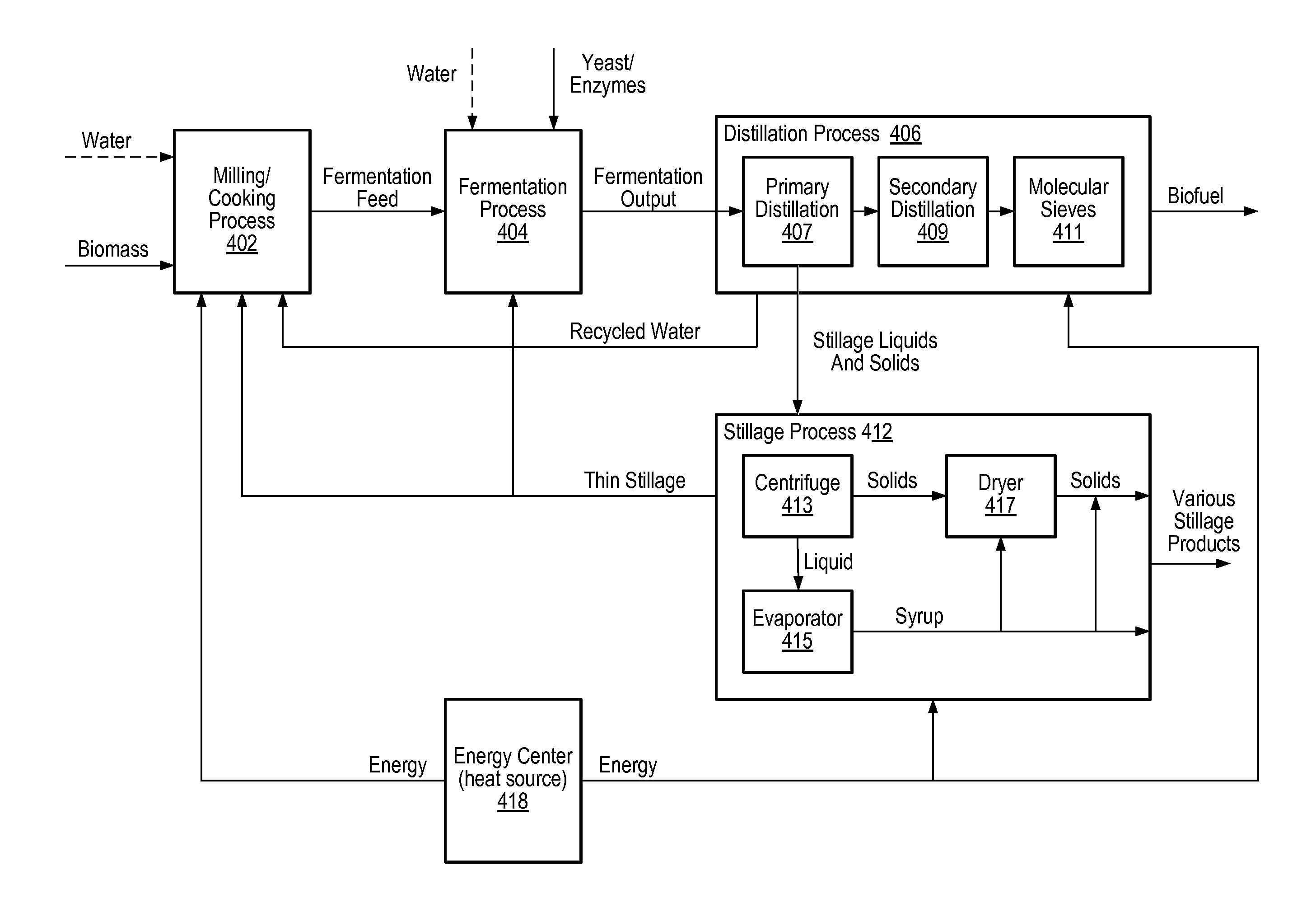

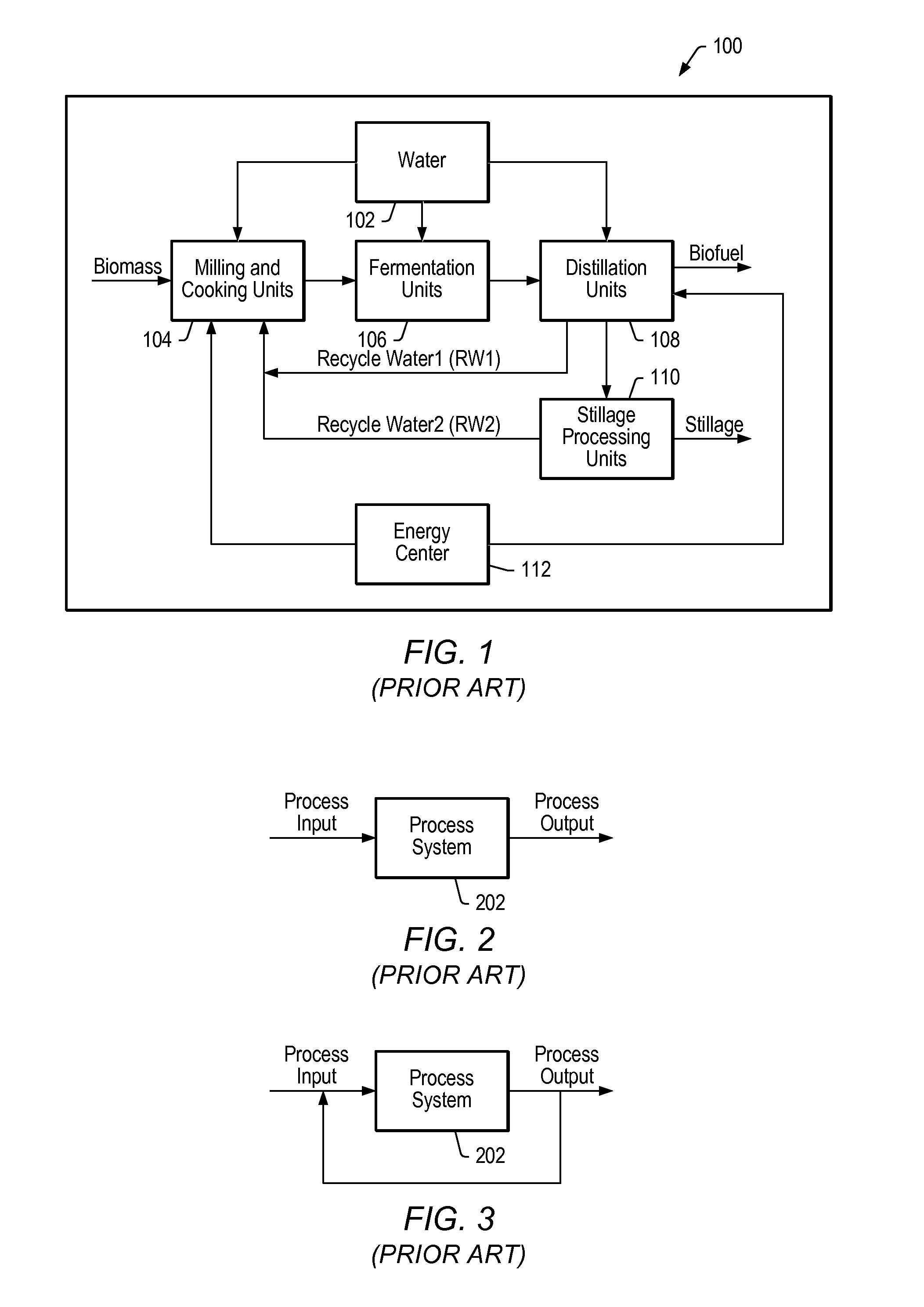

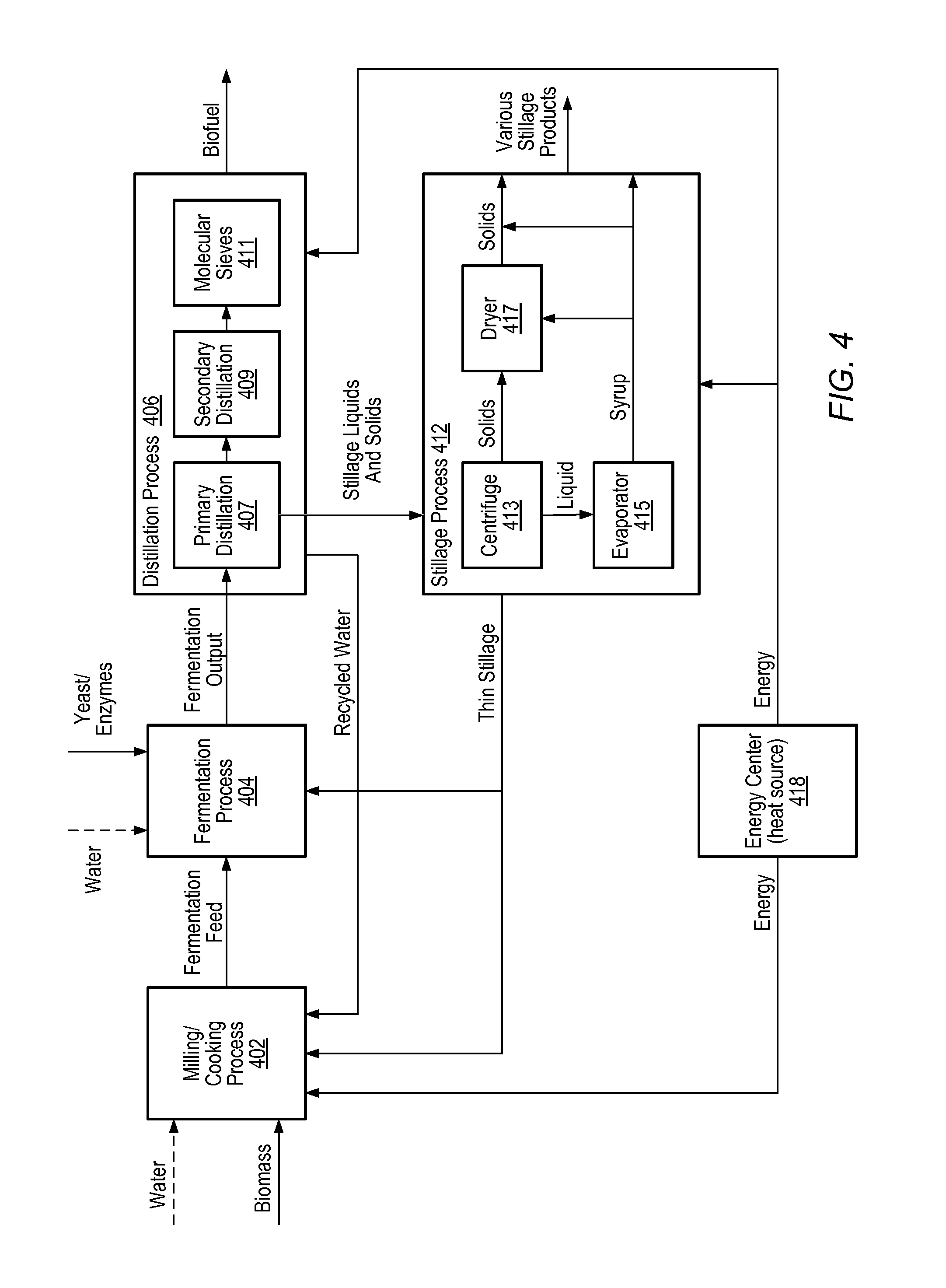

Integrated model predictive control of distillation and dehydration sub-processes in a biofuel production process

ActiveUS20080103748A1Efficiently manipulatedBioreactor/fermenter combinationsAnalogue computers for chemical processesProcess systemsProduction rate

System and method for integrated management of a biofuel distillation process and a biofuel dehydration process of a biofuel production process, comprising a dynamic multivariate model-based controller coupled to a dynamic multivariate predictive model. The model is executable to: receive distillation and dehydration process information including biofuel compositions, receive an objective for biofuel production output from the distillation and dehydration processes, e.g., target product composition, production rate, and / or feed rate, and generate model output comprising target values for a plurality of manipulated variables related to the distillation and dehydration processes in accordance with the objective. The controller is operable to dynamically control the biofuel production process by adjusting the plurality of manipulated variables to the model-determined target values in accordance with the objective for biofuel production.

Owner:ROCKWELL AUTOMATION TECH

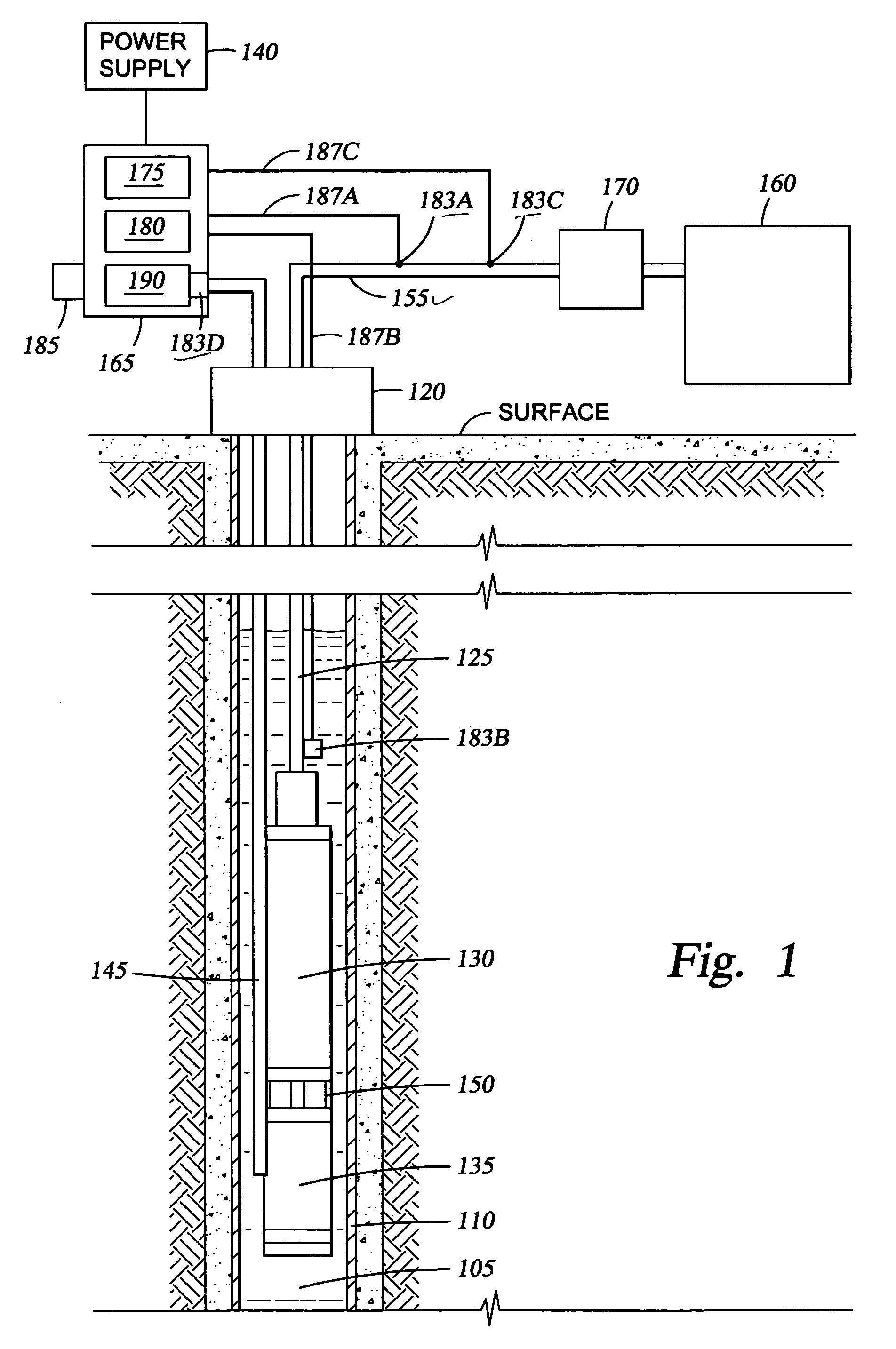

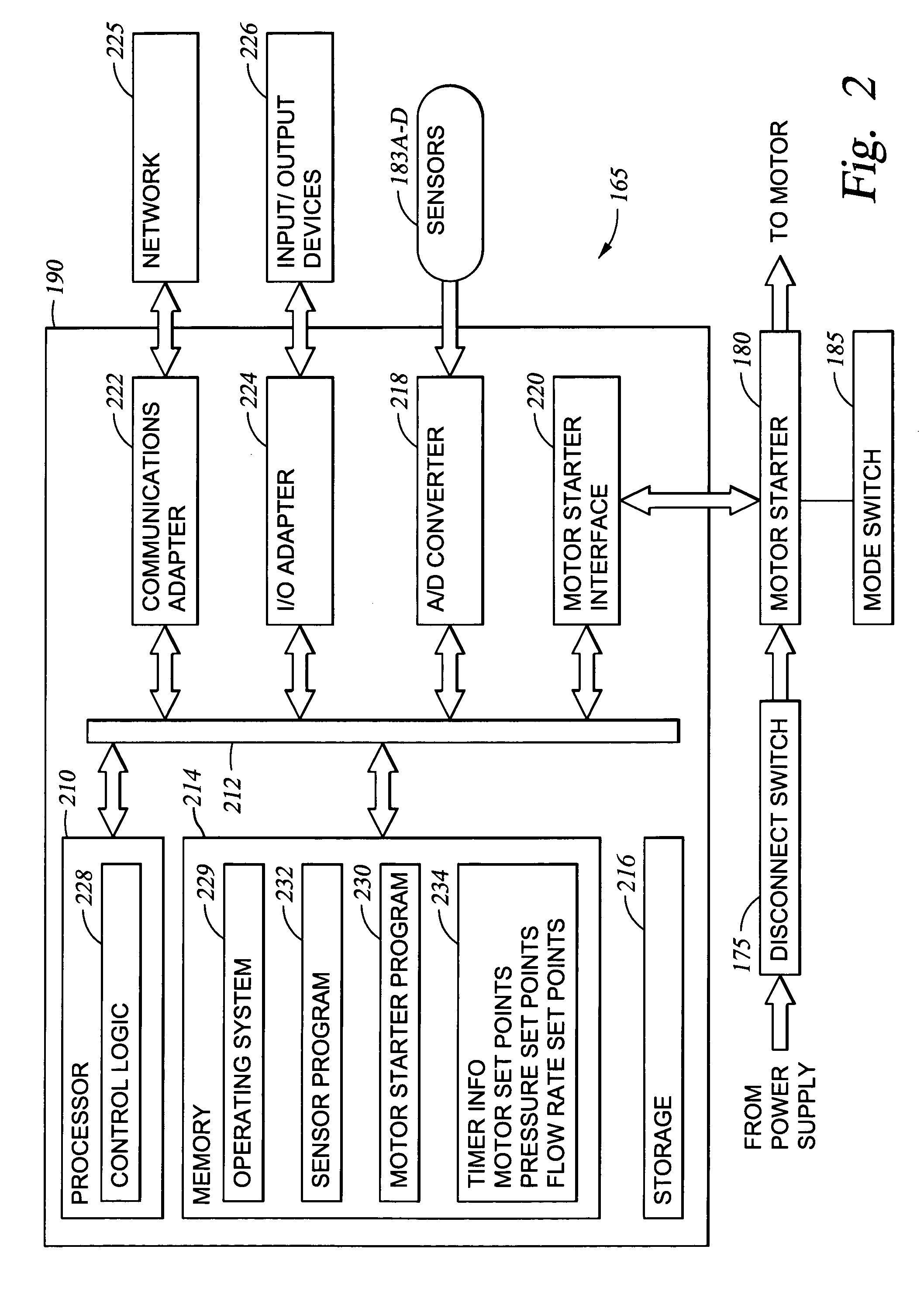

Controller system for downhole applications

Owner:OILFIELD EQUIP DEVMENT CENT

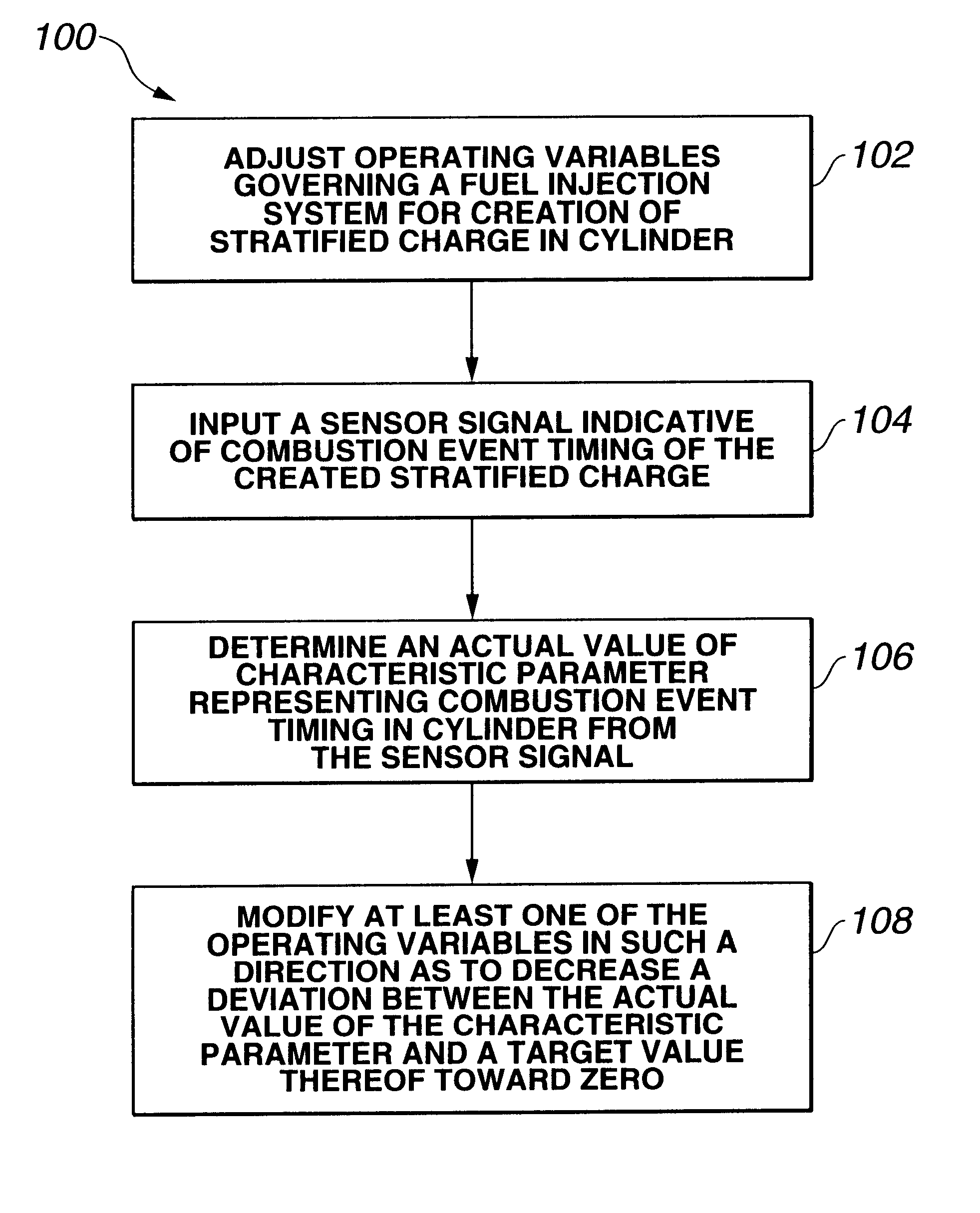

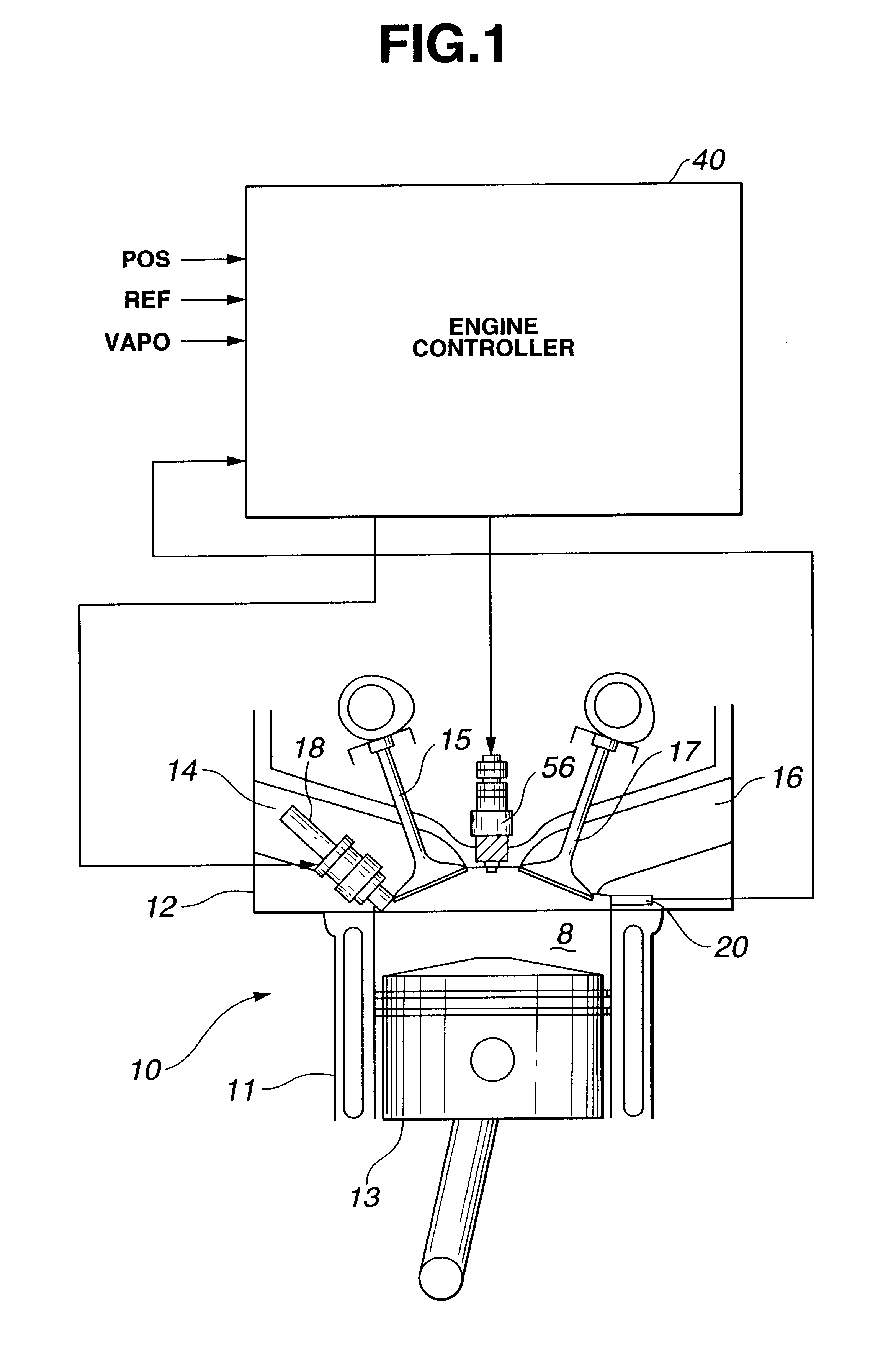

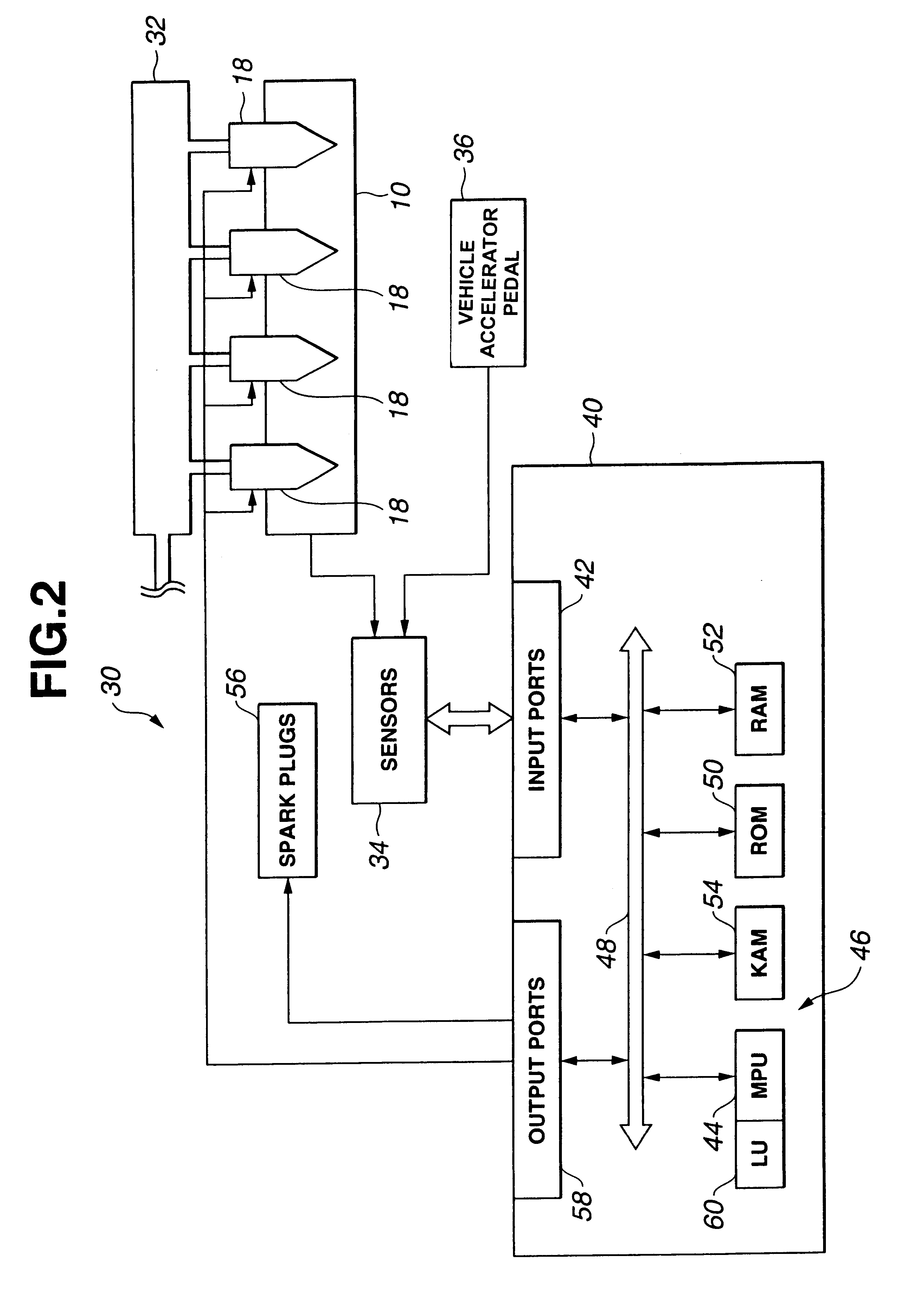

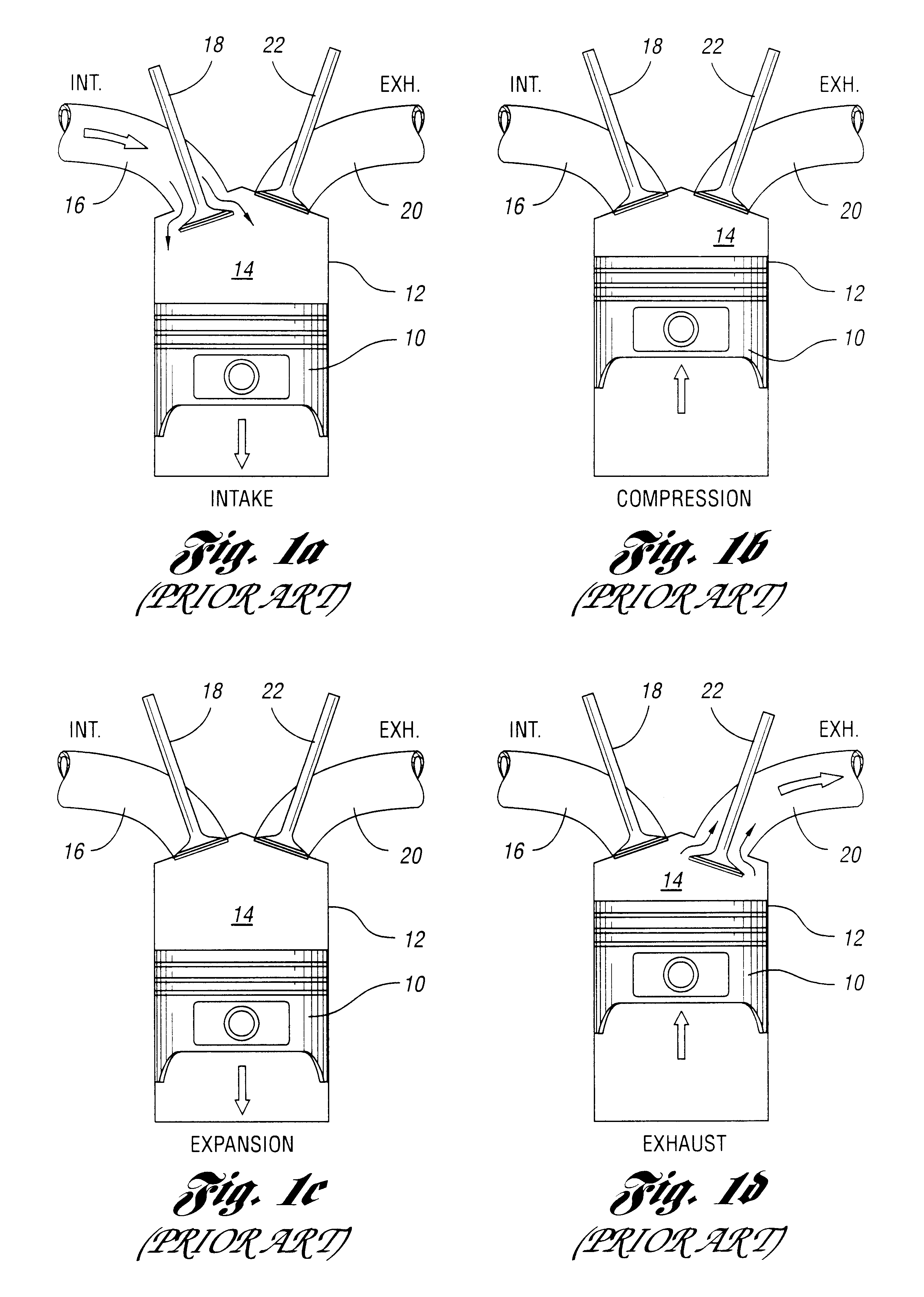

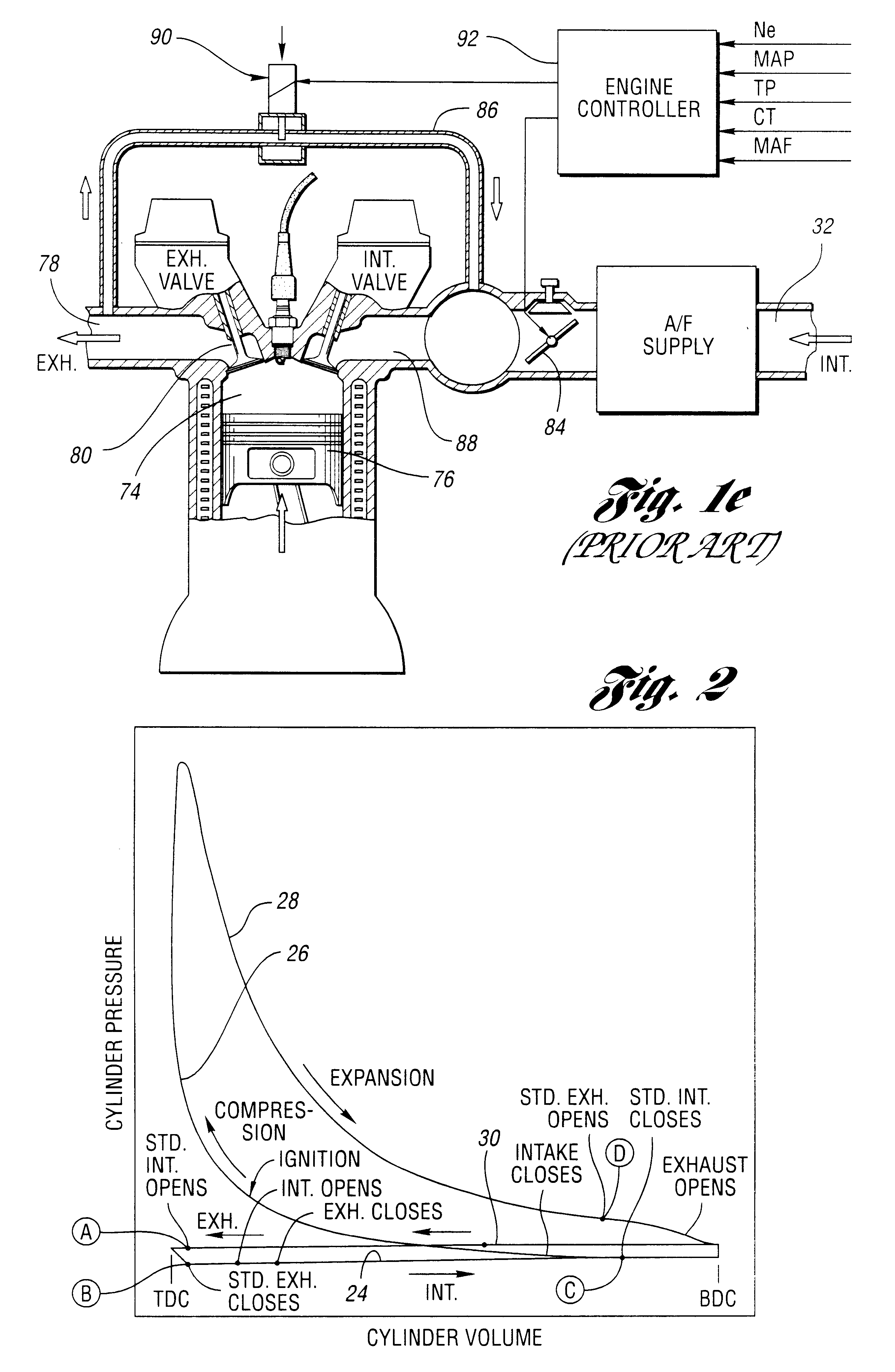

Feedback control for auto-ignition two-stage combustion of gasoline in engine cylinder

A split injection of gasoline produces stratified charge in at least one cylinder. A sensor measures cylinder pressure or knock and generates a sensor signal indicative of combustion event timing of stratified charge. From the sensor signal, a controller determines an actual value of a characteristic parameter representing combustion event timing in the cylinder. The controller modifies at least one of operating variables governing a split injection for the subsequent cycle in such a direction as to decrease a deviation between the actual value of the characteristic parameter and a target value thereof toward zero.

Owner:NISSAN MOTOR CO LTD

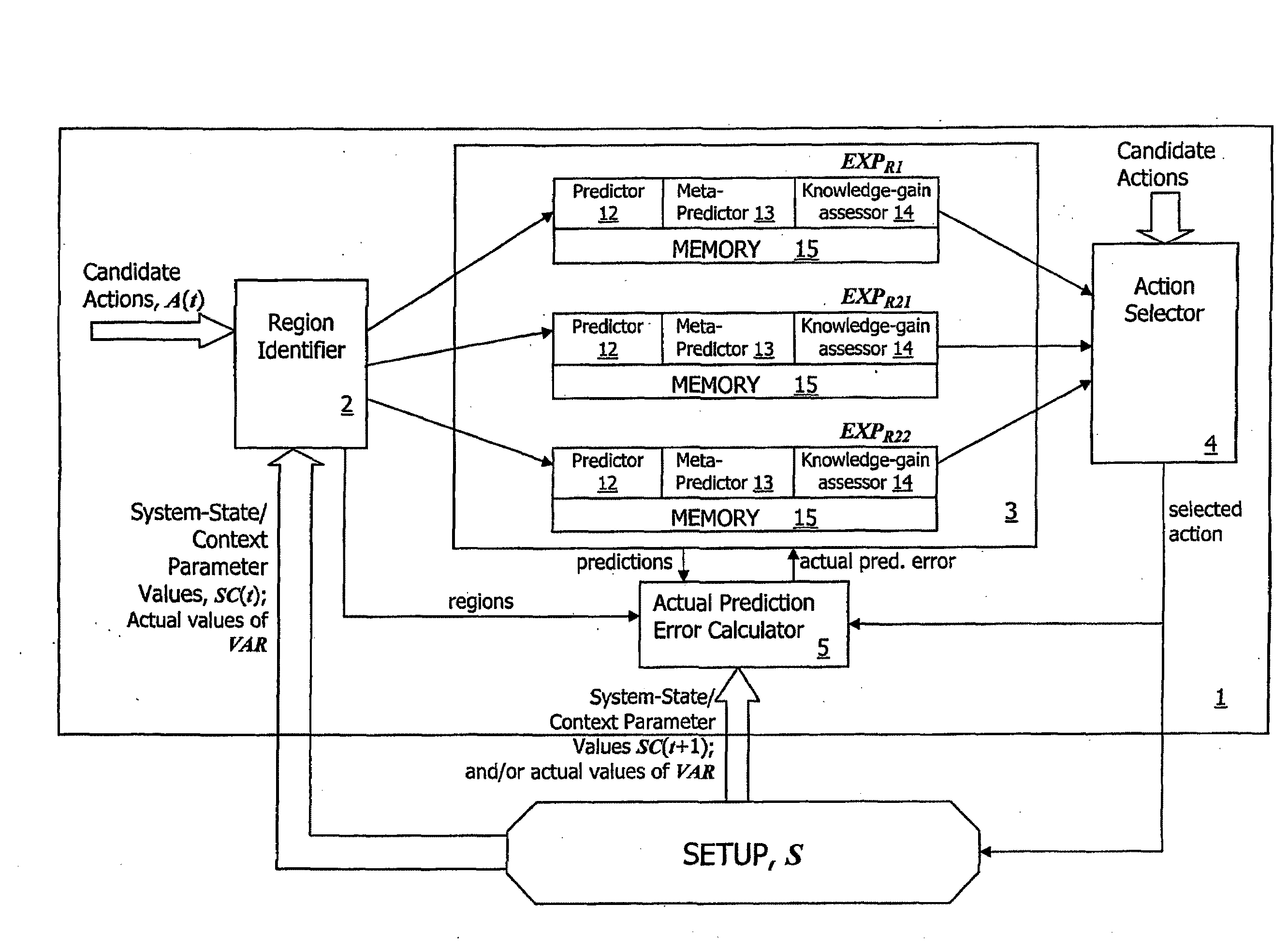

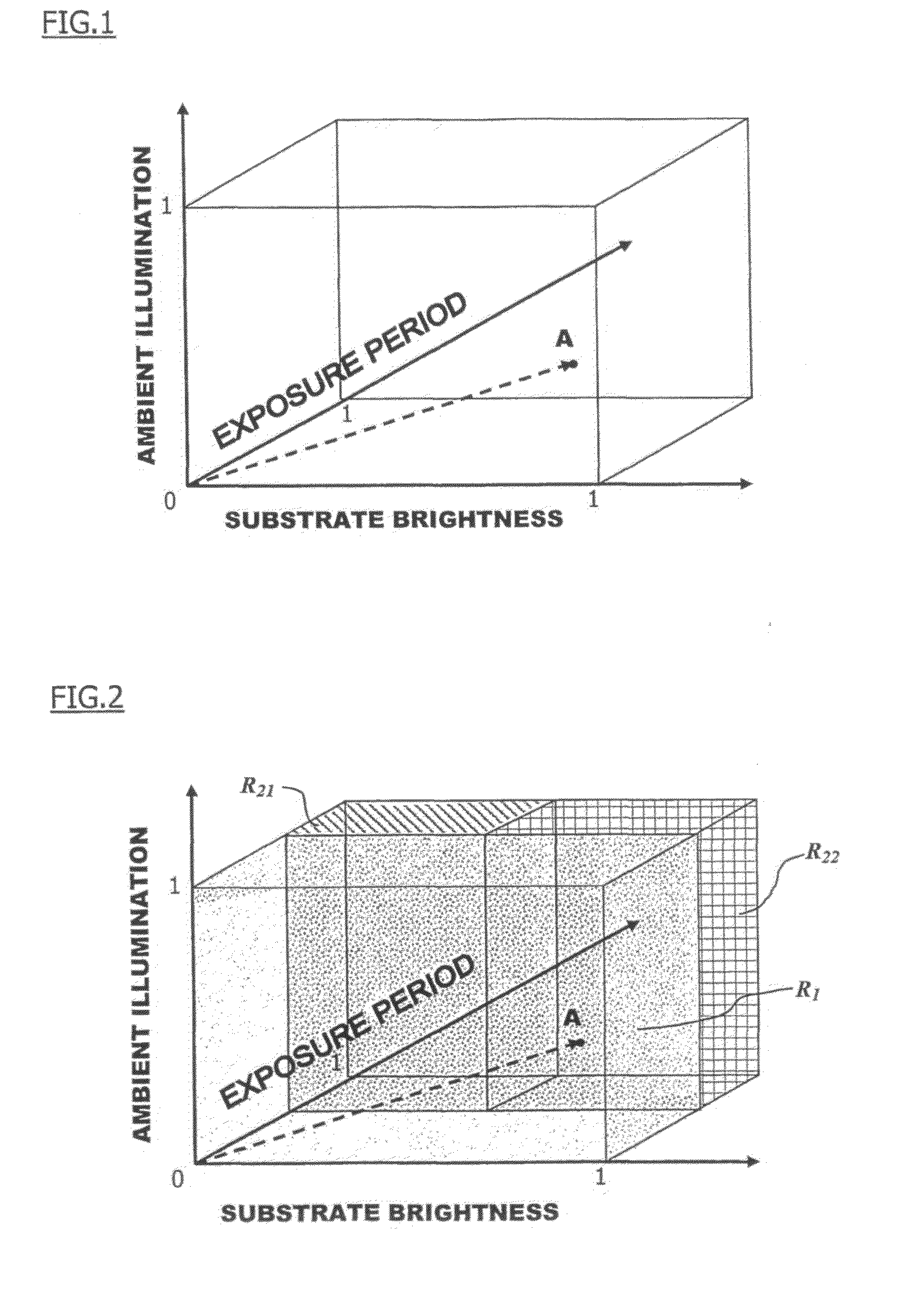

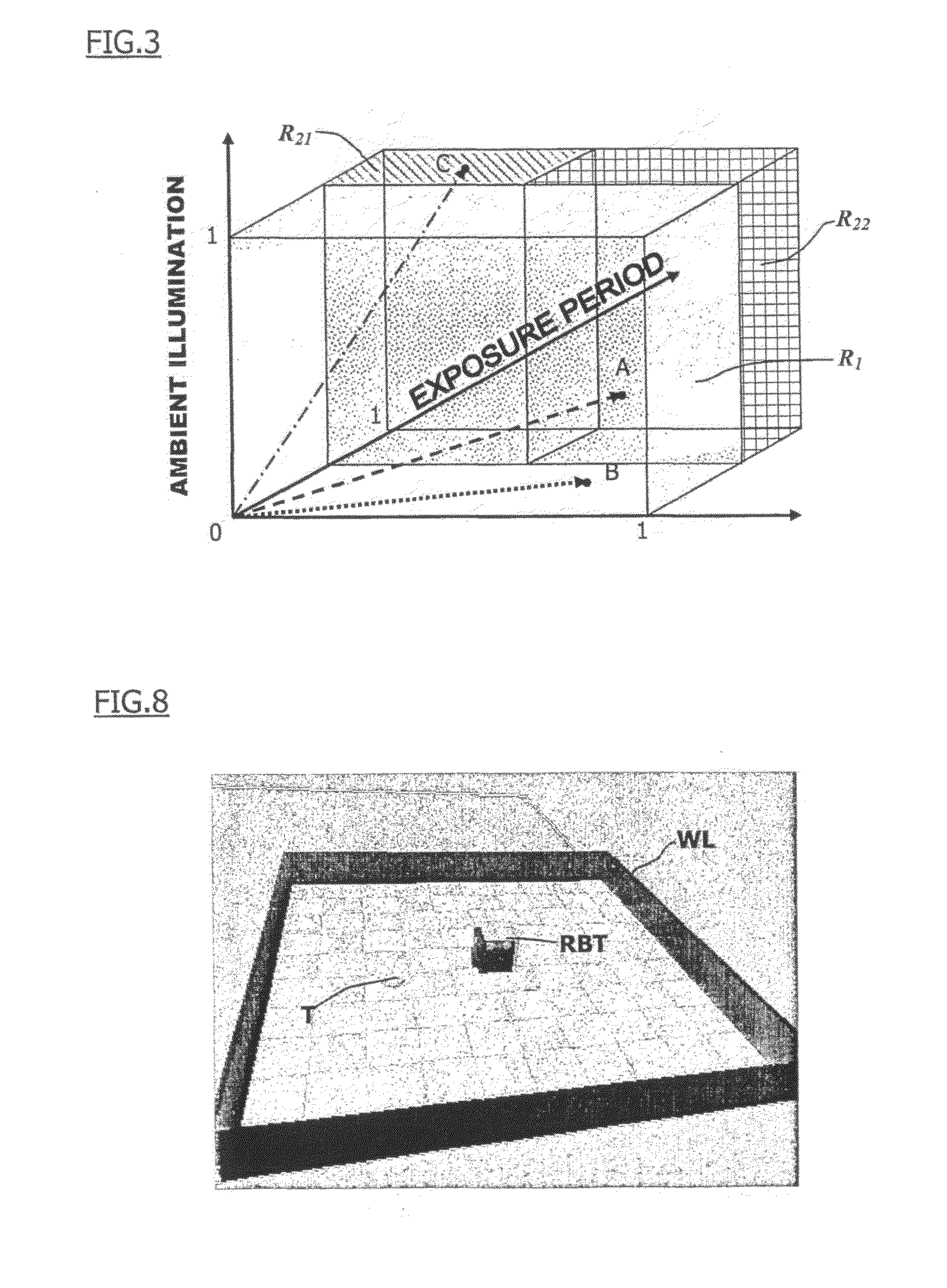

Automated Action-Selection System and Method , and Application Thereof to Training Prediction Machines and Driving the Development of Self-Developing Devices

ActiveUS20080319929A1Simple weighting of the different drivesDigital computer detailsArtificial lifeKnowledge gainSelection system

In order to promote efficient learning of relationships inherent in a system or setup S described by system-state and context parameters, the next action to take, affecting the setup, is determined based on the knowledge gain expected to result from this action. Knowledge-gain is assessed “locally” by comparing the value of a knowledge-indicator parameter after the action with the value of this indicator on one or more previous occasions when the system-state / context parameter(s) and action variable(s)=had similar values to the current ones. Preferably the “level of knowledge” is assessed based on the accuracy of predictions made by a prediction module. This technique can be applied to train a prediction machine by causing it to participate in the selection of a sequence of actions. This technique can also be applied for managing development of a self-developing device or system, the self-developing device or system performing a sequence of actions selected according to the action-selection technique.

Owner:SONY EUROPE BV

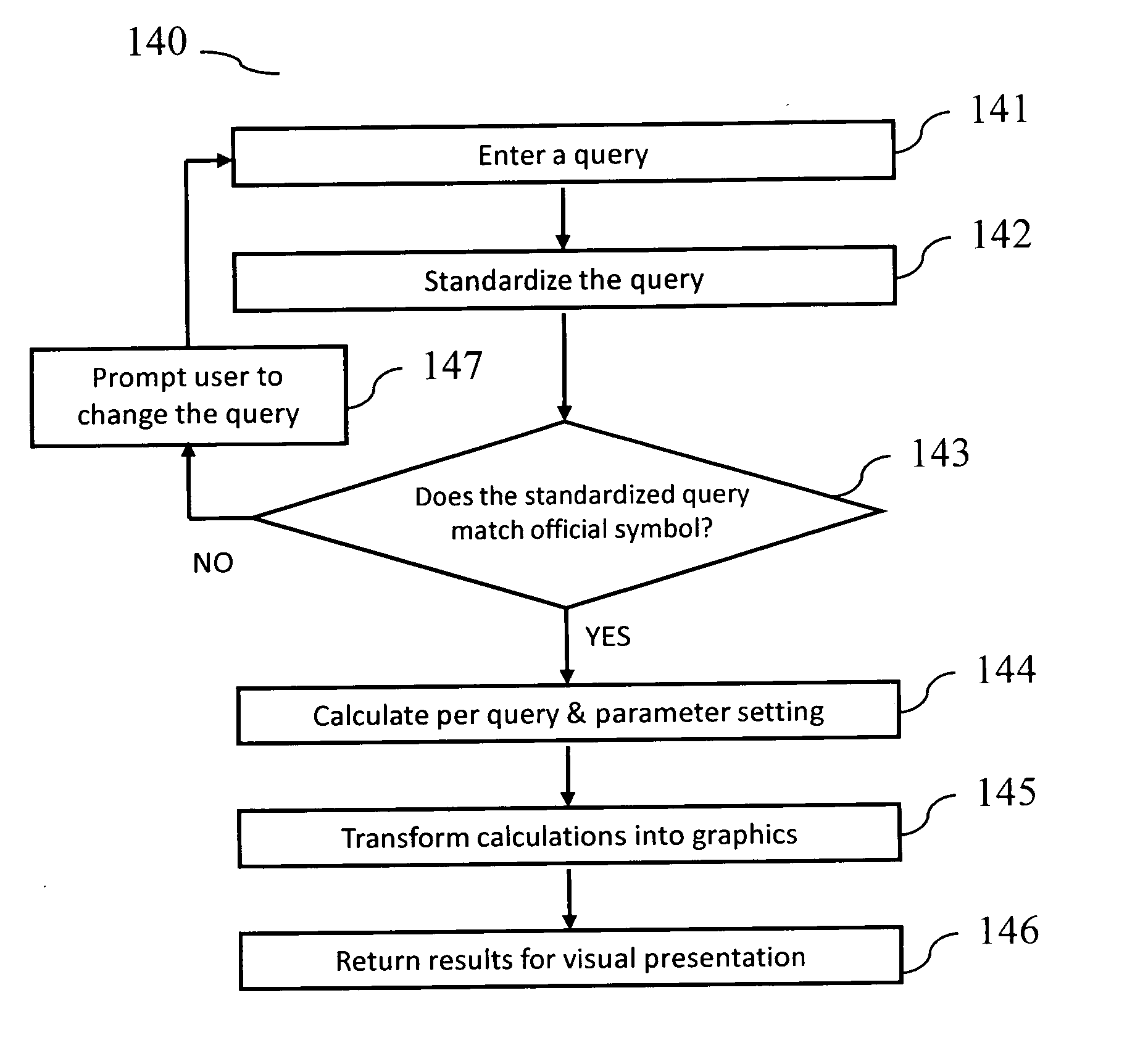

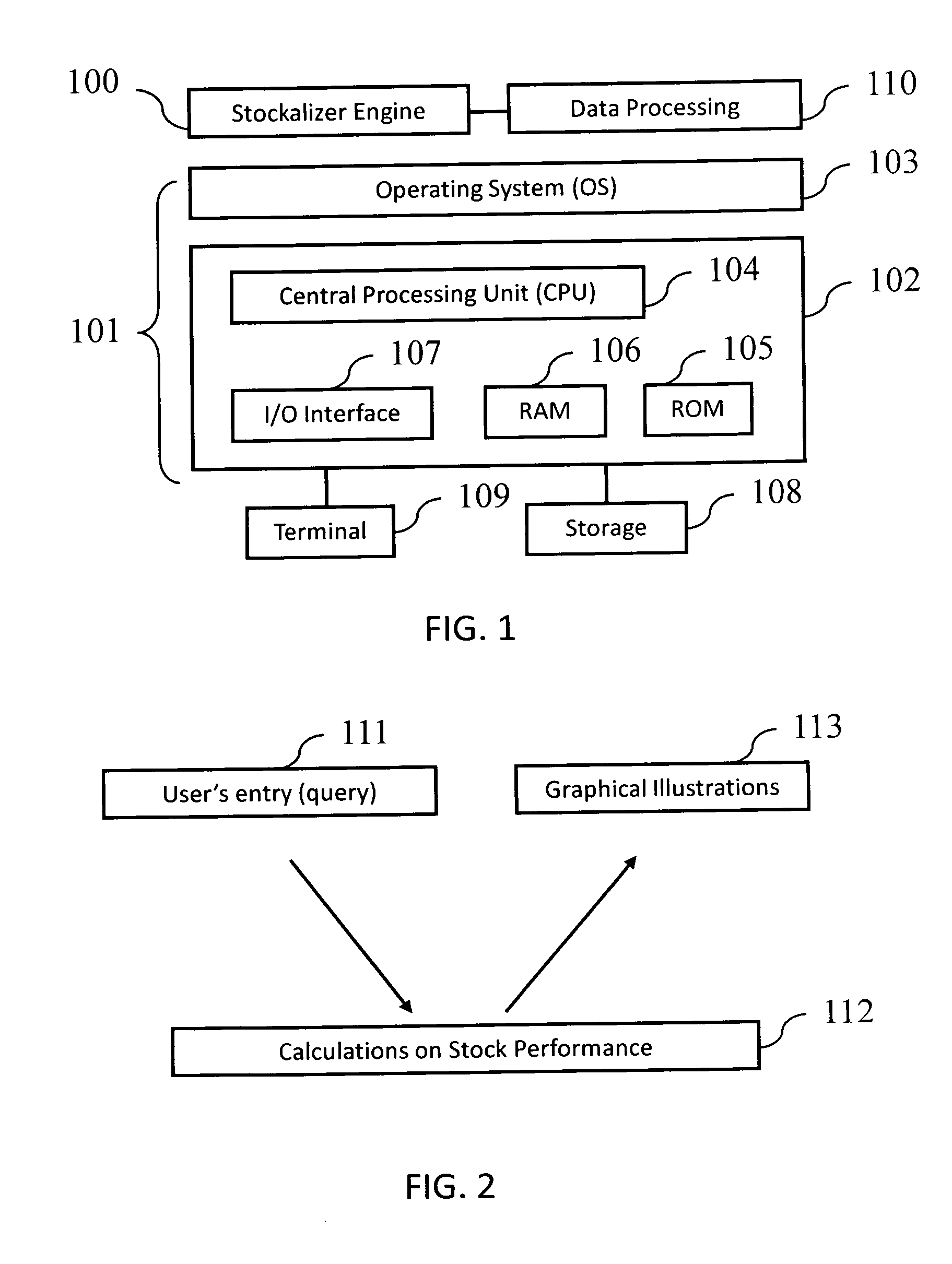

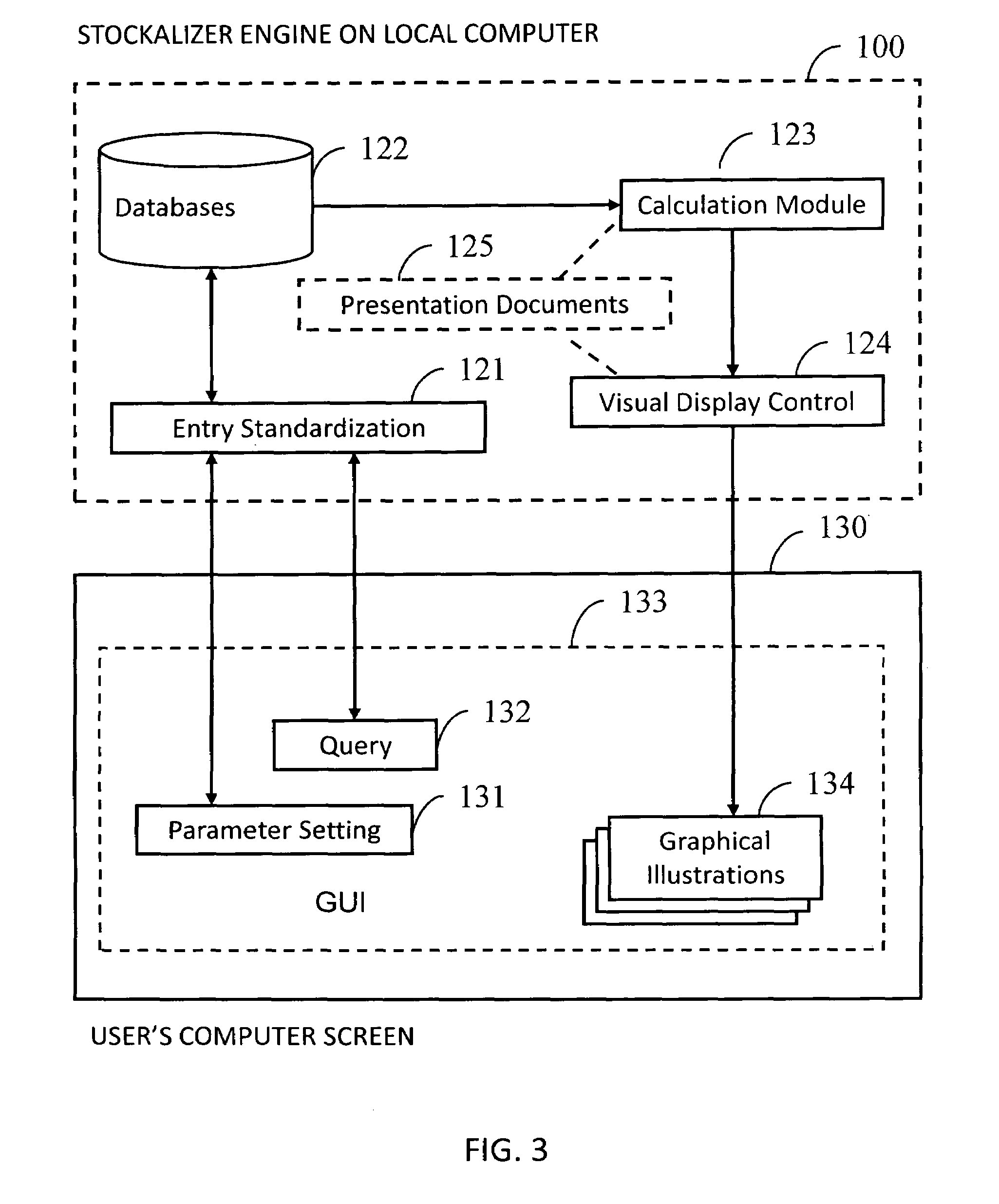

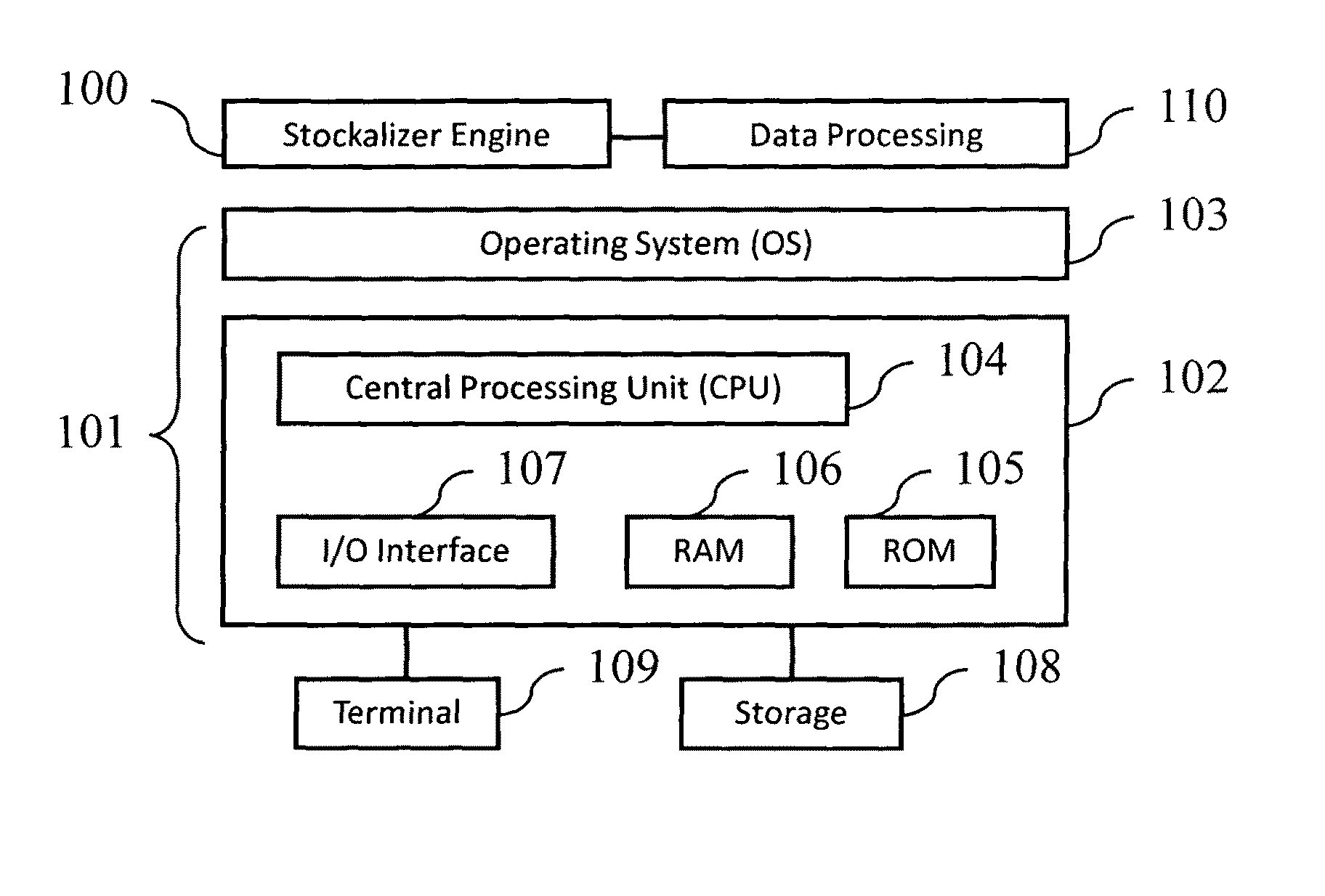

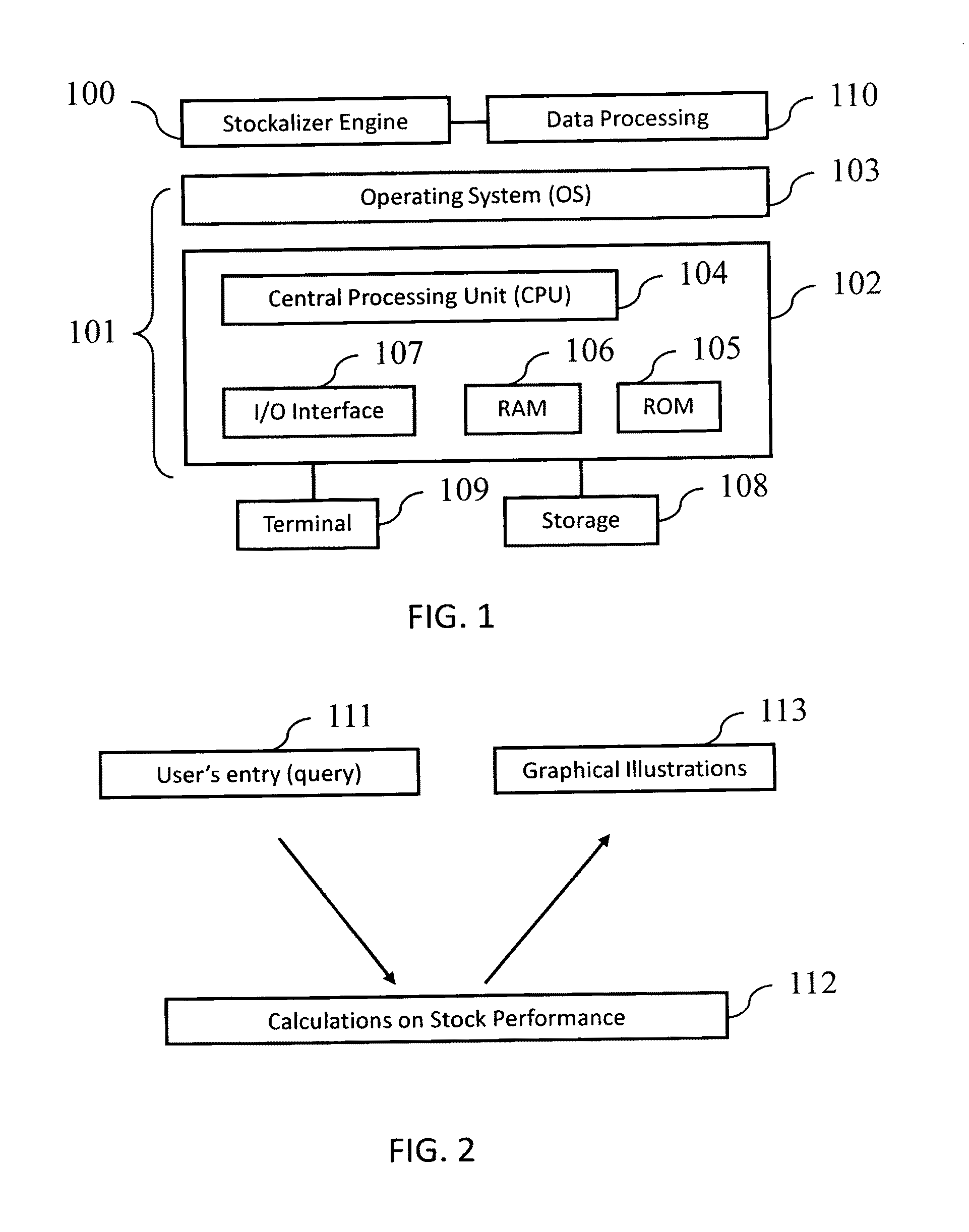

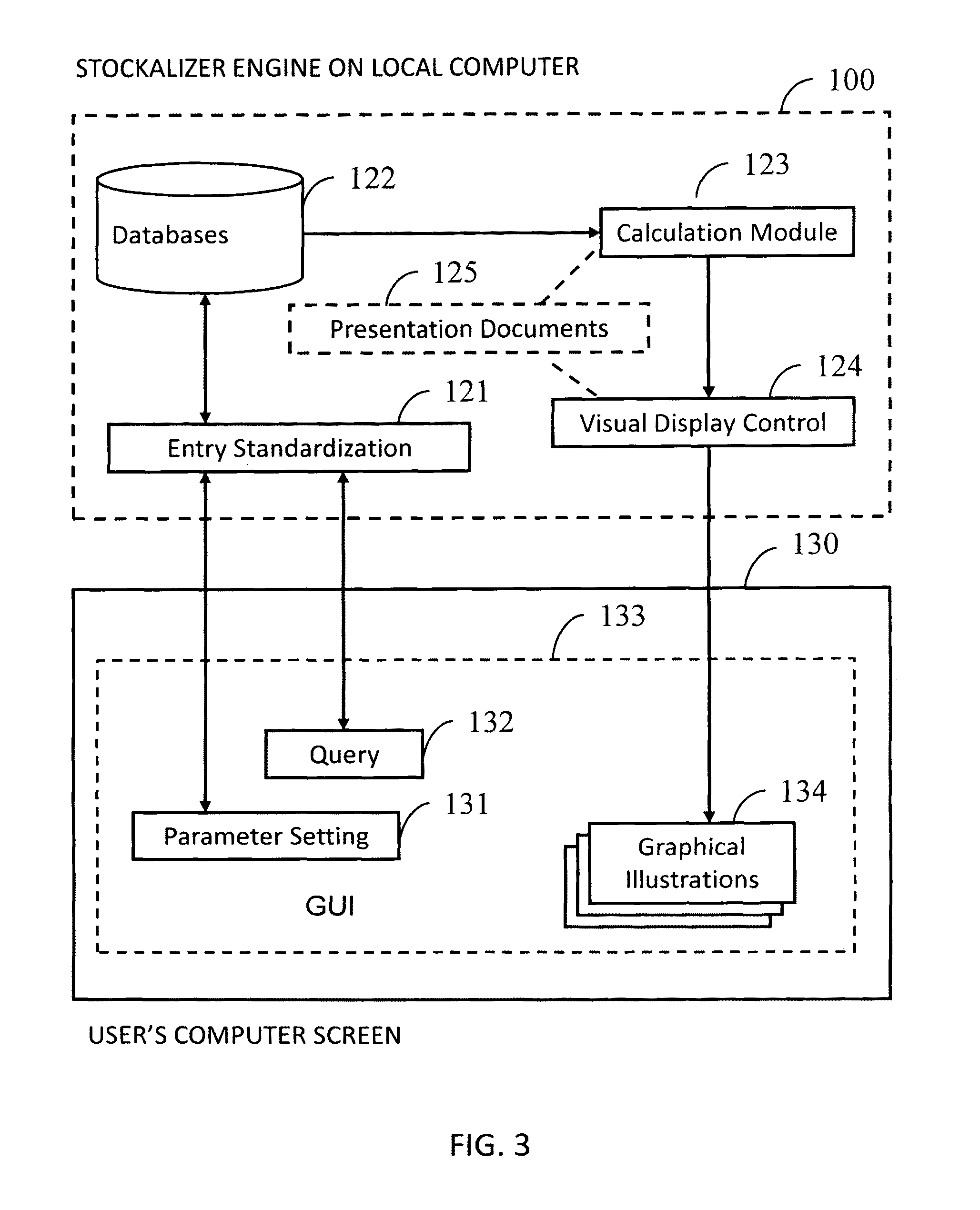

System and method of visual illustration of stock market performance

The present invention provides a system and method for calculating and arraying an entirely universe of publicly traded stock performance data, technical and dynamic range of movement stock price data, underlying operating corporate balance sheet plus income statement fundamental data and ratios, and derived corporate operating and stock analysis data in such a manner as to enable the data for any selected single company to be phased, combined and superimposed within a series of graphical illustrations, which enable investors to easily visualize and compare the relationship of stock price movement and the underlying progression of fundamental operating variables of companies listed on exchanges around the world. The system includes a server computer, one or more client computer coupled to the server computer via the Internet, a database for storing, identifying and extrapolating stocks data, one module for calculating a set of selected performance parameters pursuant to a set of preset standards, a module for transforming calculation results of said calculation module into graphical illustrations; and a graphical user interface from which a user may send an inquiry to the server computer and be returned with a set of graphical illustrations on the inquired stock performance.

Owner:CHANGE POINT ANALYTICS

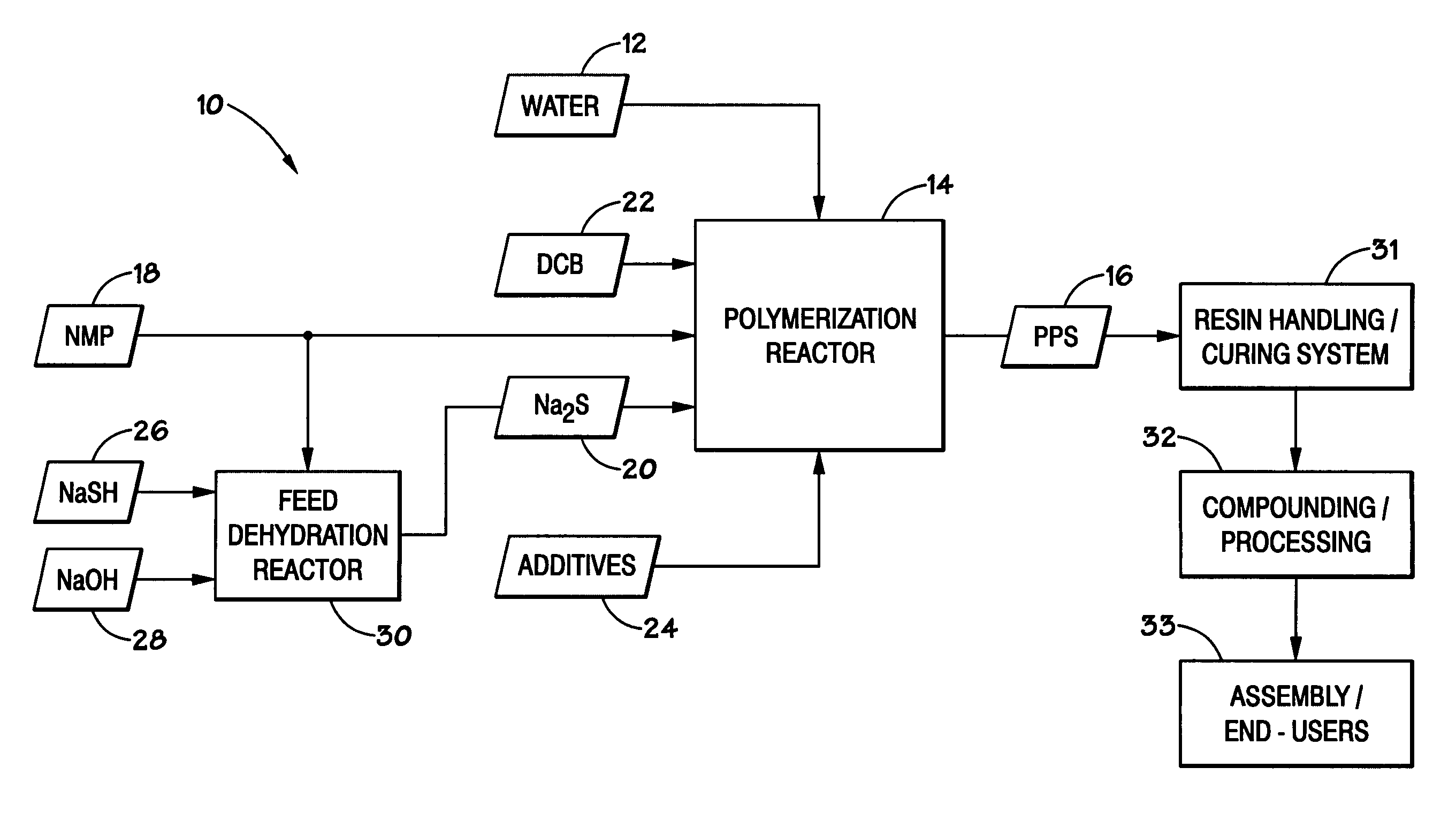

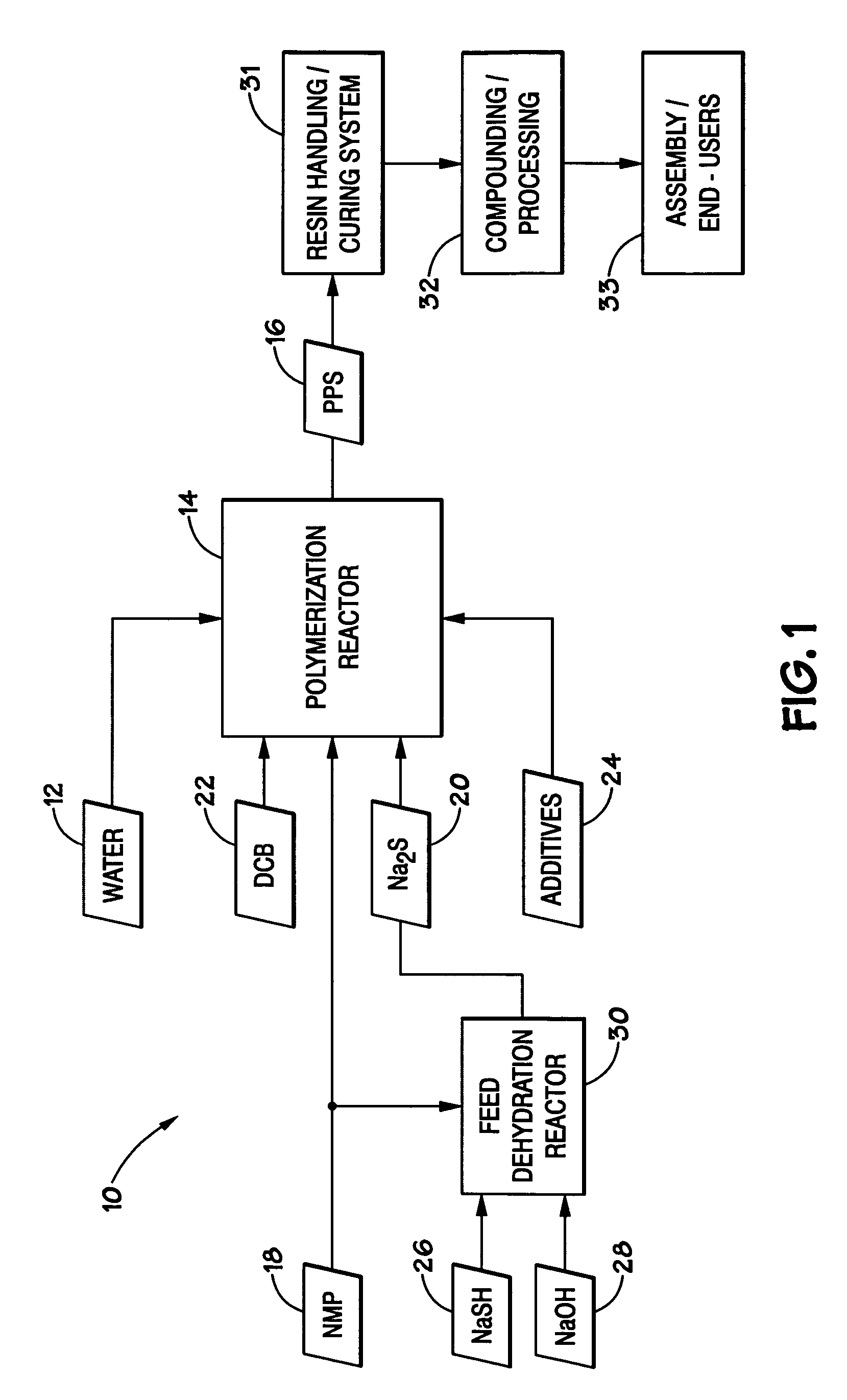

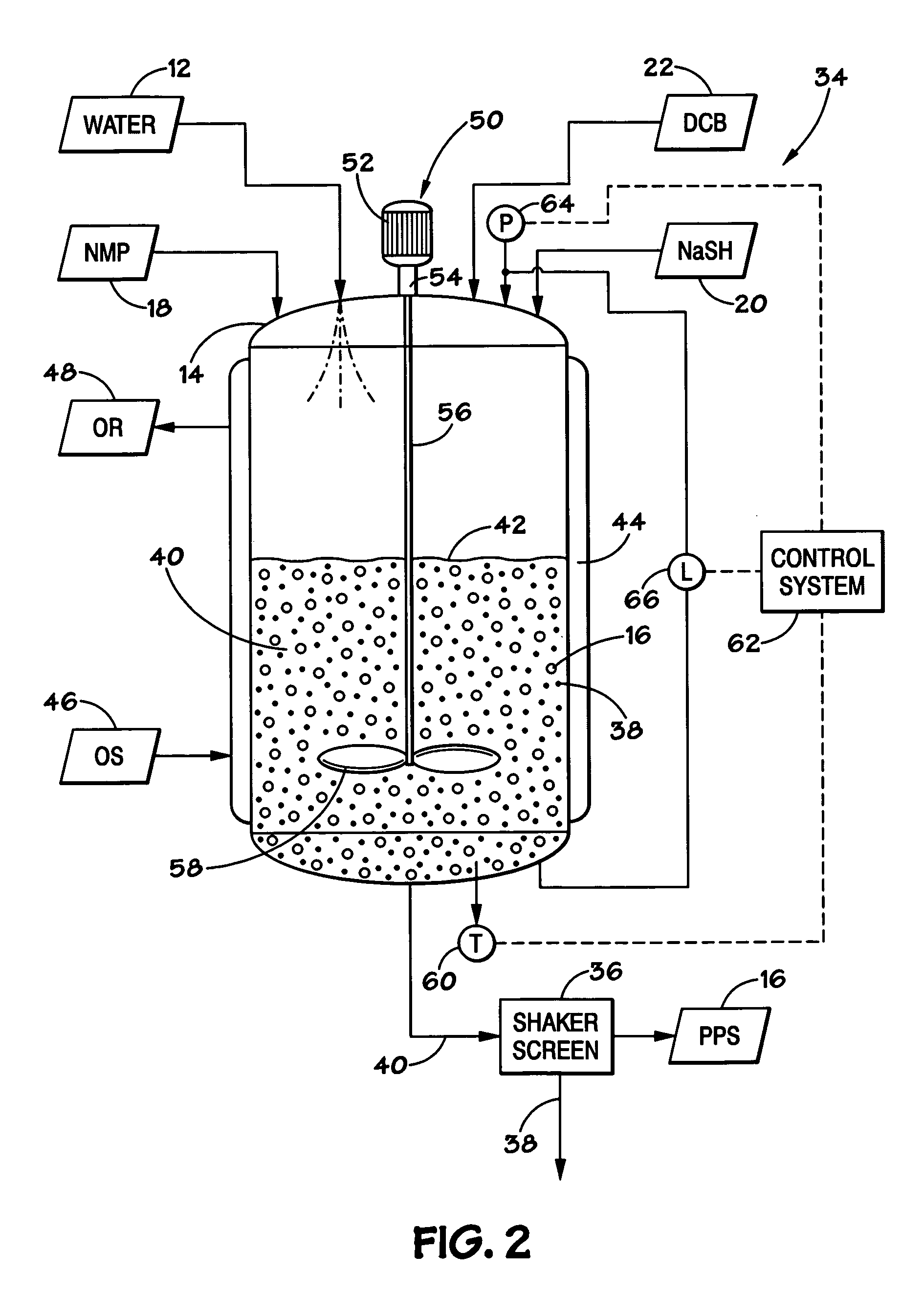

Inferred water analysis in polyphenylene sulfide production

A method for producing polyphenylene sulfide (PPS) polymer, including polymerizing reactants in a reaction mixture in a vessel to form PPS polymer in the vessel, measuring values of operating variables of the vessel and / or PPS process, and determining the amount of quench fluid to add to the vessel based on the values of the operating variables. The technique may rely on the vapor liquid equilibrium (VLE) of the mixture to calculate the concentration of water existing in the reactor prior to quench, and accounts for the effectiveness of the upstream dehydration process and in the amount of water produced during the polymerization. The technique is a striking improvement over the trial-and-error estimation of the amount of quench water based on human operating experience, and avoids direct measurements of the existing water concentration in the reactor. The result is improved control of PPS particle size and other properties.

Owner:SOLVAY SA

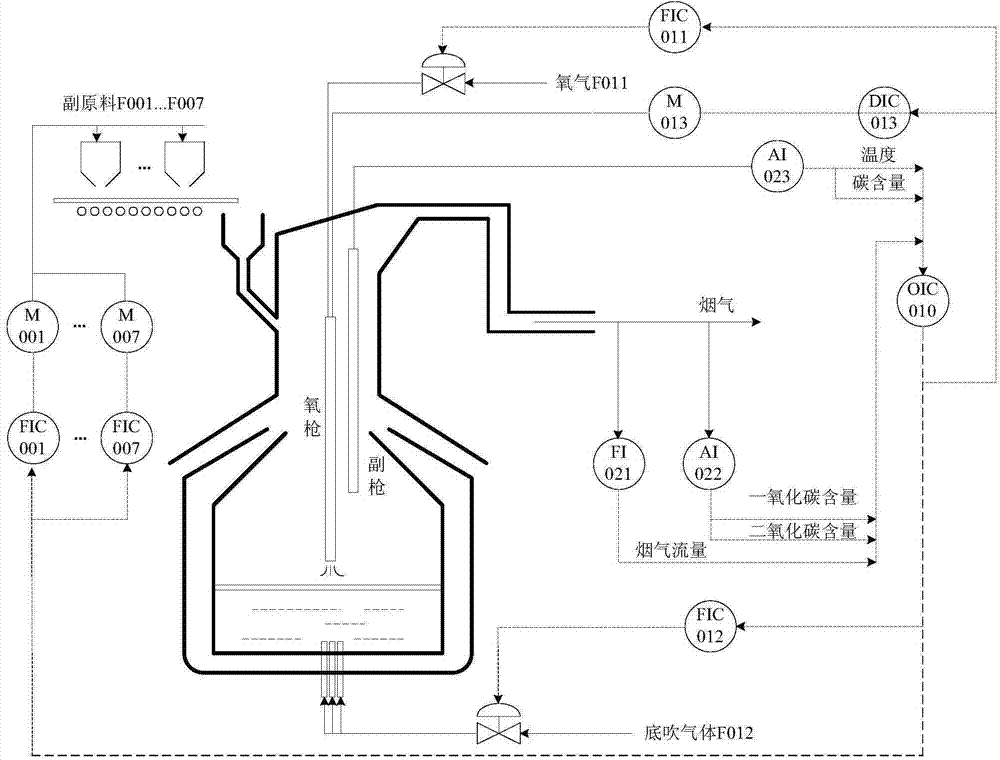

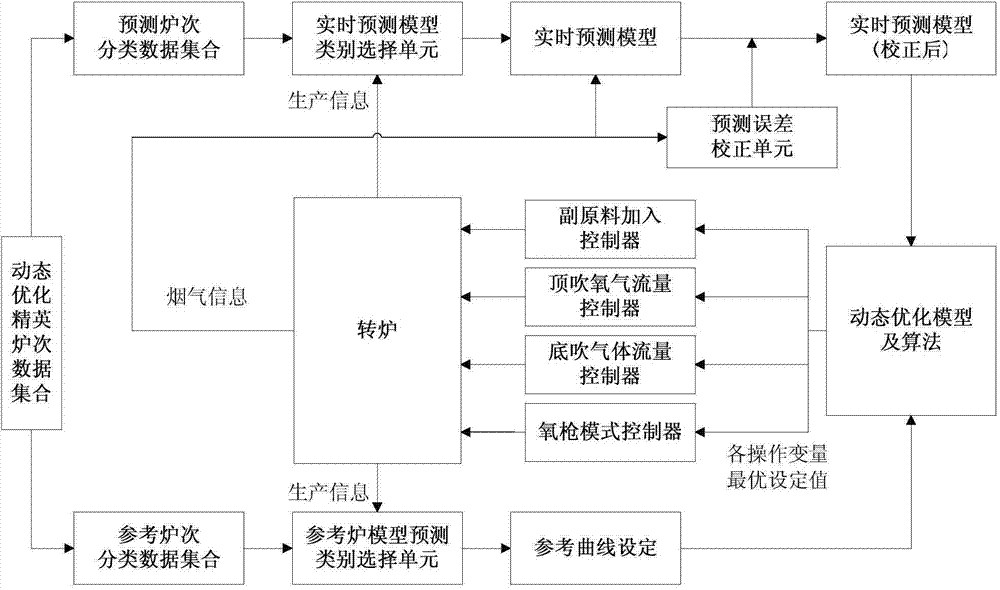

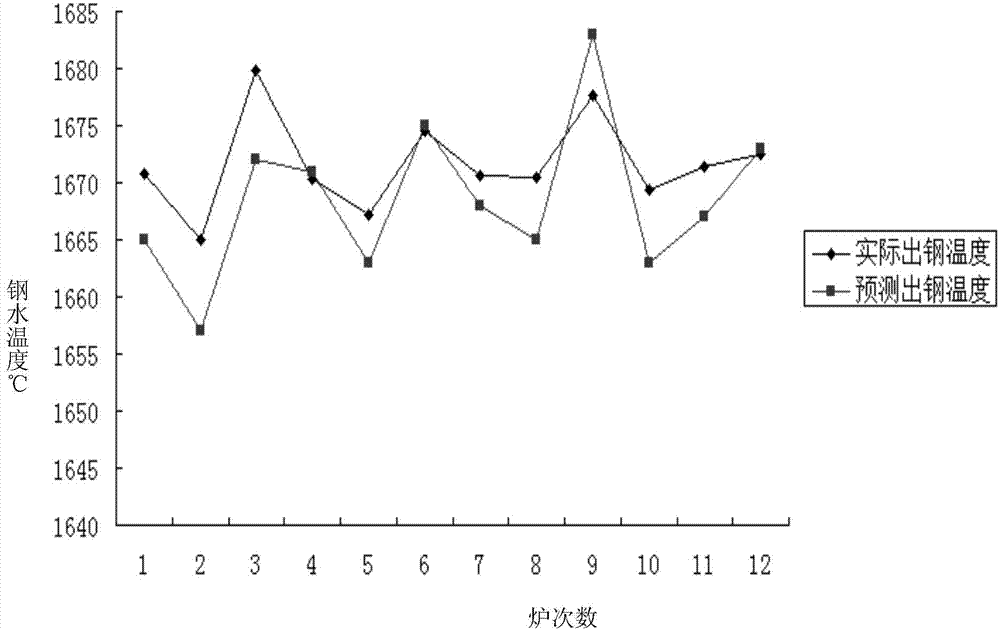

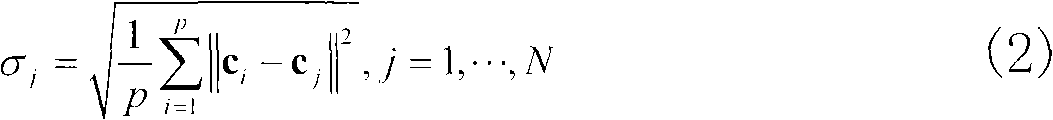

On-line dynamic optimization control method for converter steelmaking process based on data driving

ActiveCN103882176AImprove hit rateIncrease productivityManufacturing convertersSteelmakingDynamical optimization

The invention discloses an on-line dynamic optimization control method for a converter steelmaking process based on data driving. The method comprises the following steps: building an off-line prediction model database; building a liquid steel temperature prediction model and a carbon content prediction model by use of a data driving method to obtain a corresponding relationship between operating variables and the temperature and carbon content of liquid steel in the converter steelmaking process; selecting a melt data unit matched with the information of the current converter steelmaking production process and determining a control reference curve of the liquid steel temperature and carbon element content; building a real-time dynamic optimization model of the converter steelmaking process and determining an optimized set value unit of each operating variable; and selecting the set value of each operating variable from the optimized set value unit so as to carry out control operation. The method disclosed by the invention can be used for realizing real-time on-line control over the converter steelmaking process and providing convenience for an operator to set selection conditions according to actual working conditions, thus the production efficiency of a steelmaking plant is improved.

Owner:NORTHEASTERN UNIV

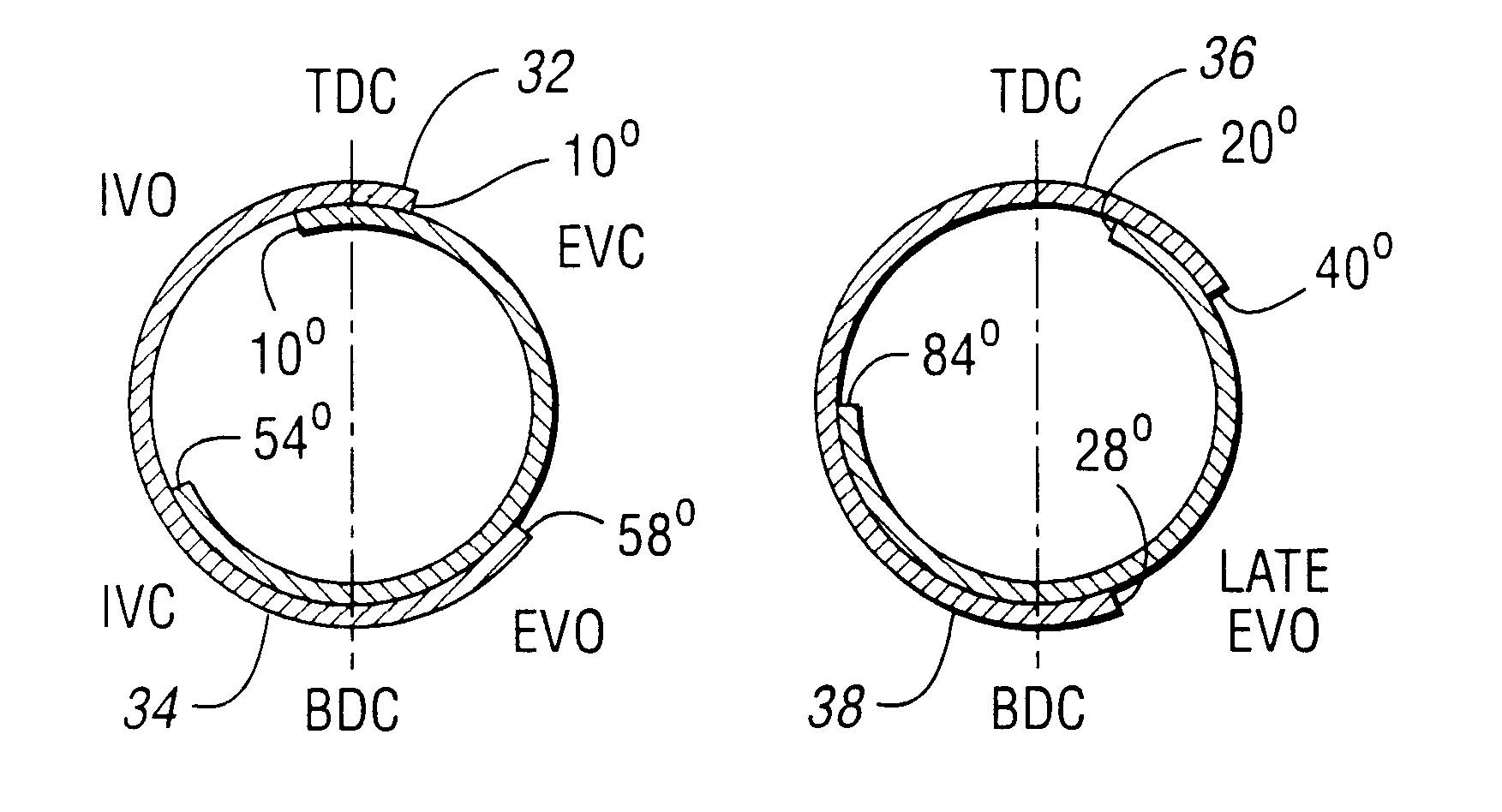

Engine control strategy using dual equal cam phasing combined with exhaust gas recirculation

InactiveUS6321731B1Improve thermal efficiencyReduction nitrous oxide gasInternal combustion piston enginesNon-fuel substance addition to fuelExhaust valveInlet valve

The invention comprises a strategy and method for phase shifting intake and exhaust valve timing relative to crankshaft position as a function of engine operating variables, whereby valve overlap is delayed to obtain improved fuel economy resulting from a late intake valve closing to reduce pumping work during the intake stroke. The exhaust gases are drawn into the combustion cylinder of the engine during the intake stroke, which reduces oxides of nitrogen in the exhaust gas and reduces unburned hydrocarbons. Improved thermal efficiency and reductions in oxides of nitrogen are achieved as the combustion charge is diluted at higher loads by an external exhaust gas recirculation system, thereby combining the effects of exhaust gas recirculation and dual equal variable camshaft timing to obtain fuel economy benefits that cannot be achieved with either a conventional EGR system acting alone or dual equal variable camshaft timing acting alone.

Owner:FORD MOTOR CO

System and method of visual illustration of stock market performance

The present invention provides a system and method for calculating and arraying an entirely universe of publicly traded stock performance data, technical and dynamic range of movement stock price data, underlying operating corporate balance sheet plus income statement fundamental data and ratios, and derived corporate operating and stock analysis data in such a manner as to enable the data for any selected single company to be phased, combined and superimposed within a series of graphical illustrations, which enable investors to easily visualize and compare the relationship of stock price movement and the underlying progression of fundamental operating variables of companies listed on exchanges around the world. The system includes a server computer, one or more client computer coupled to the server computer via the Internet, a database for storing, identifying and extrapolating stocks data, one module for calculating a set of selected performance parameters pursuant to a set of preset standards, a module for transforming calculation results of said calculation module into graphical illustrations; and a graphical user interface from which a user may send an inquiry to the server computer and be returned with a set of graphical illustrations on the inquired stock performance.

Owner:CHANGE POINT ANALYTICS

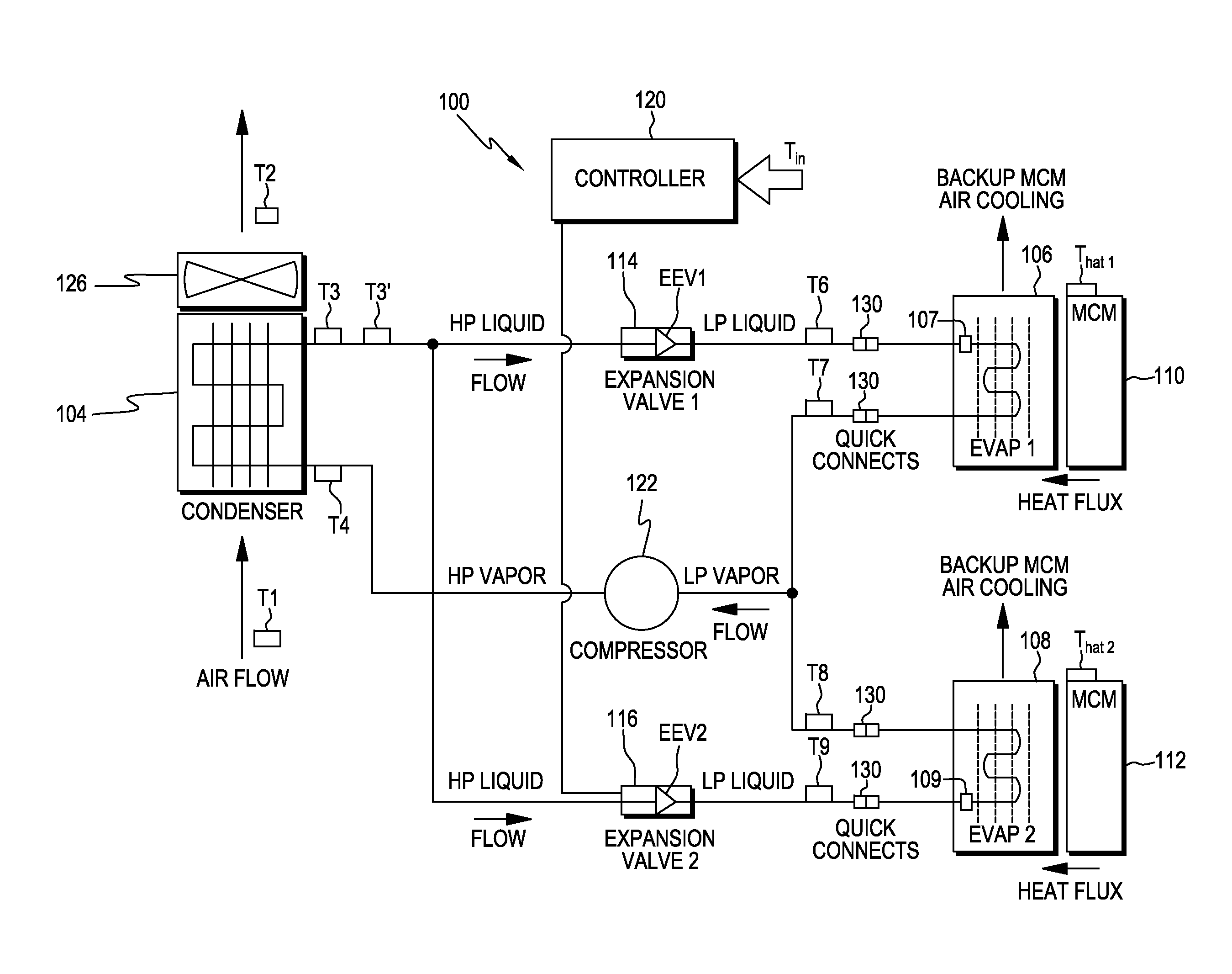

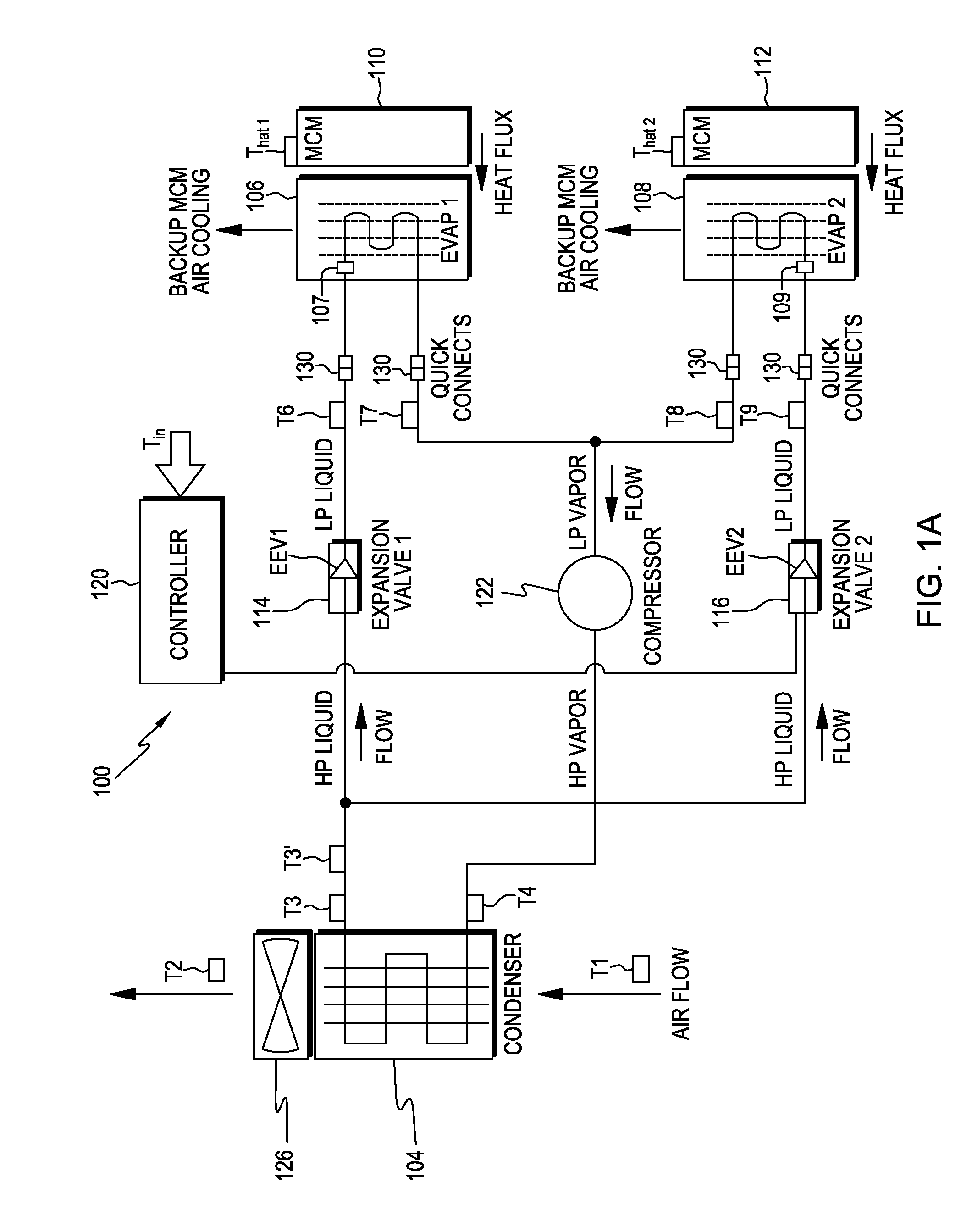

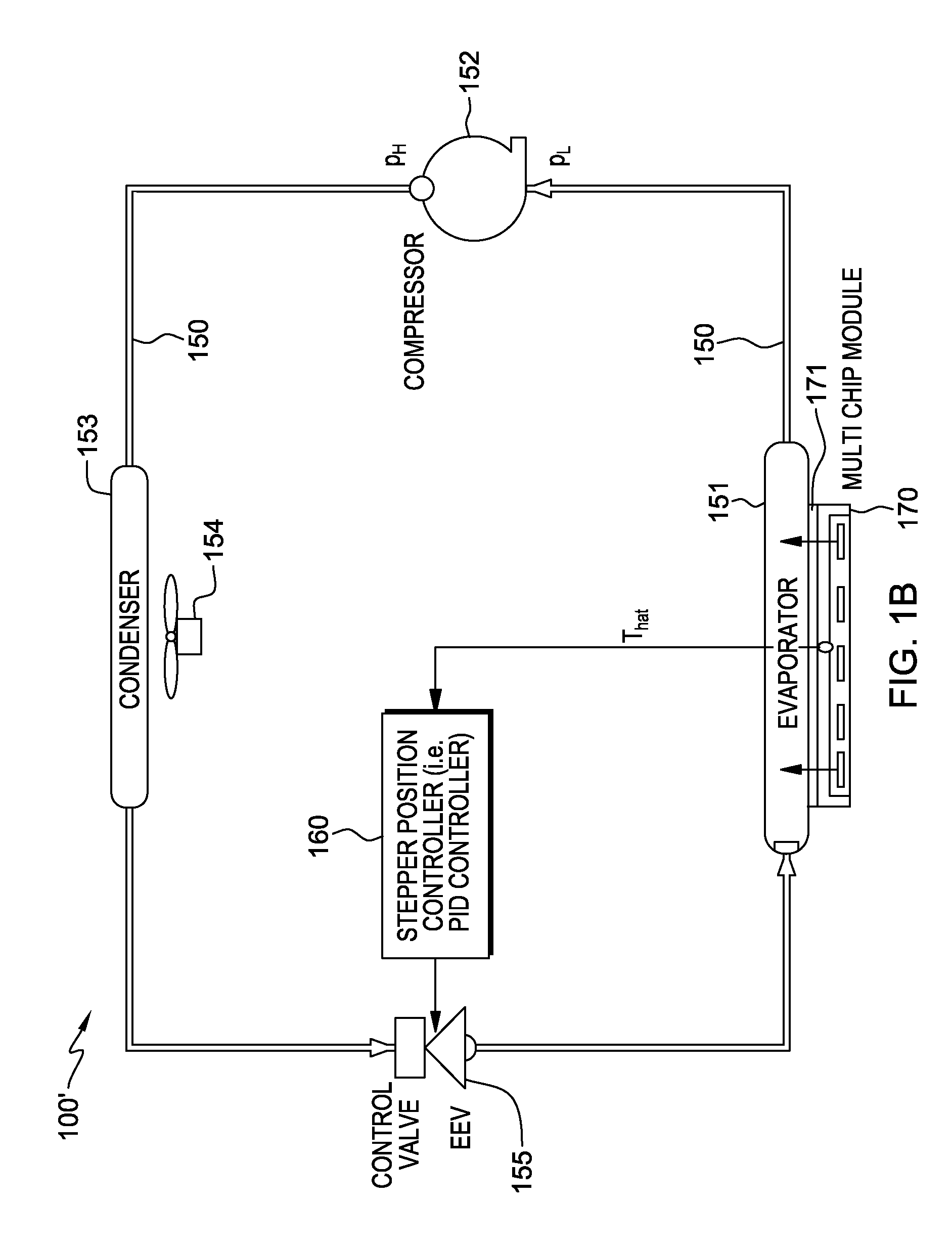

Cooling system control and servicing based on time-based variation of an operational variable

ActiveUS20130263611A1Overcomes shortcomingEnhanced advantageSampled-variable control systemsDomestic cooling apparatusAutomatic controlLife time

Automated control of a cooling system cooling at least one electronic component is provided. The control includes monitoring over a period of time variation of an operational variable of the cooling system or of the at least one electronic component, and based, at least in part, on variation of the operational variable over the period of time, automatically determining whether to adjust control of the cooling system to limit variation of the operational variable. In one implementation, depending on the variation of the operational variable, and whether control of the cooling system has been previously adjusted, the method may further include automatically determining a probability of fail or an expected residual life of the cooling system, and responsive to the predicted probability of fail exceeding a first acceptable threshold or the expected residual life being below a second acceptable threshold, automatically scheduling for a cooling system repair or replacement.

Owner:IBM CORP

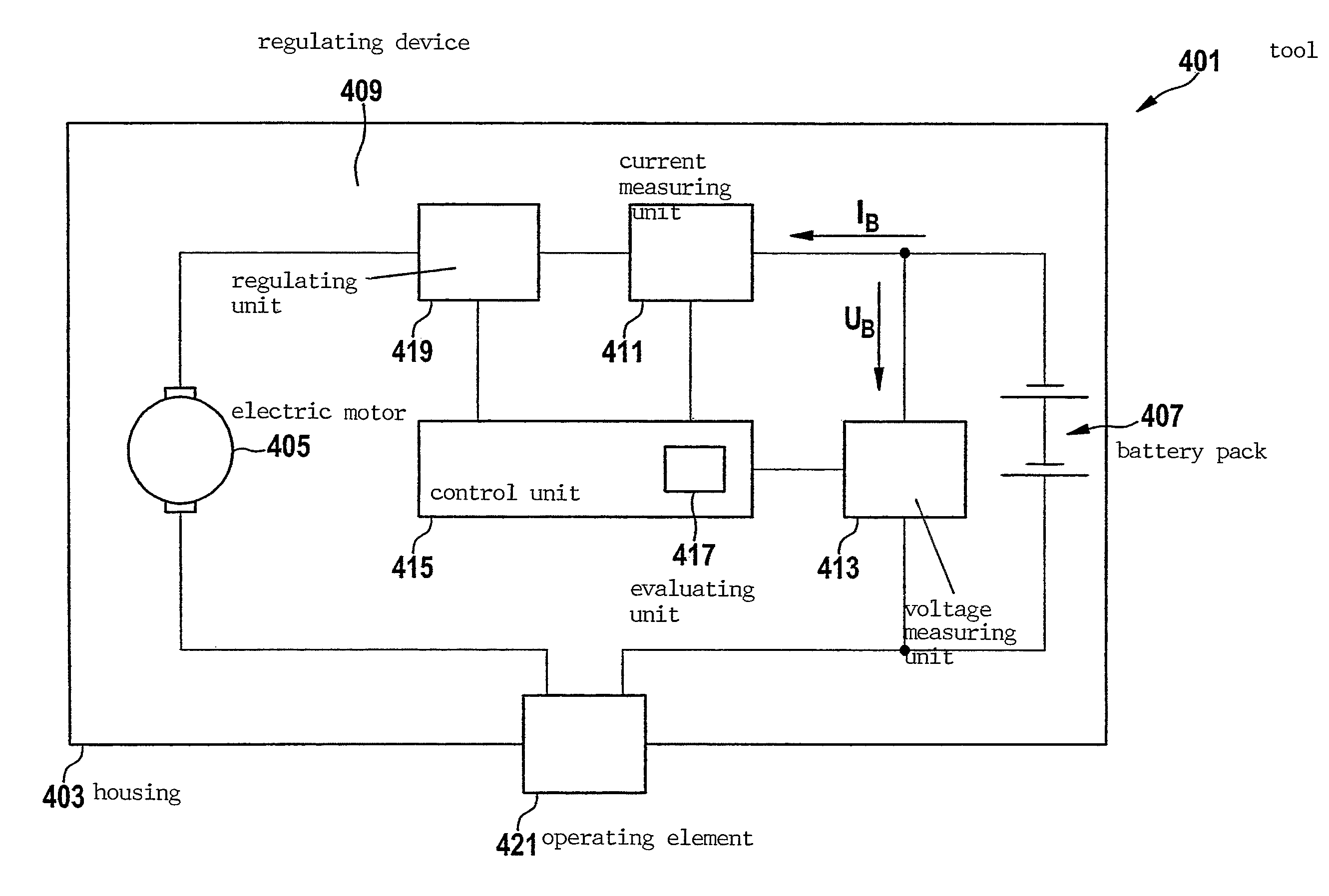

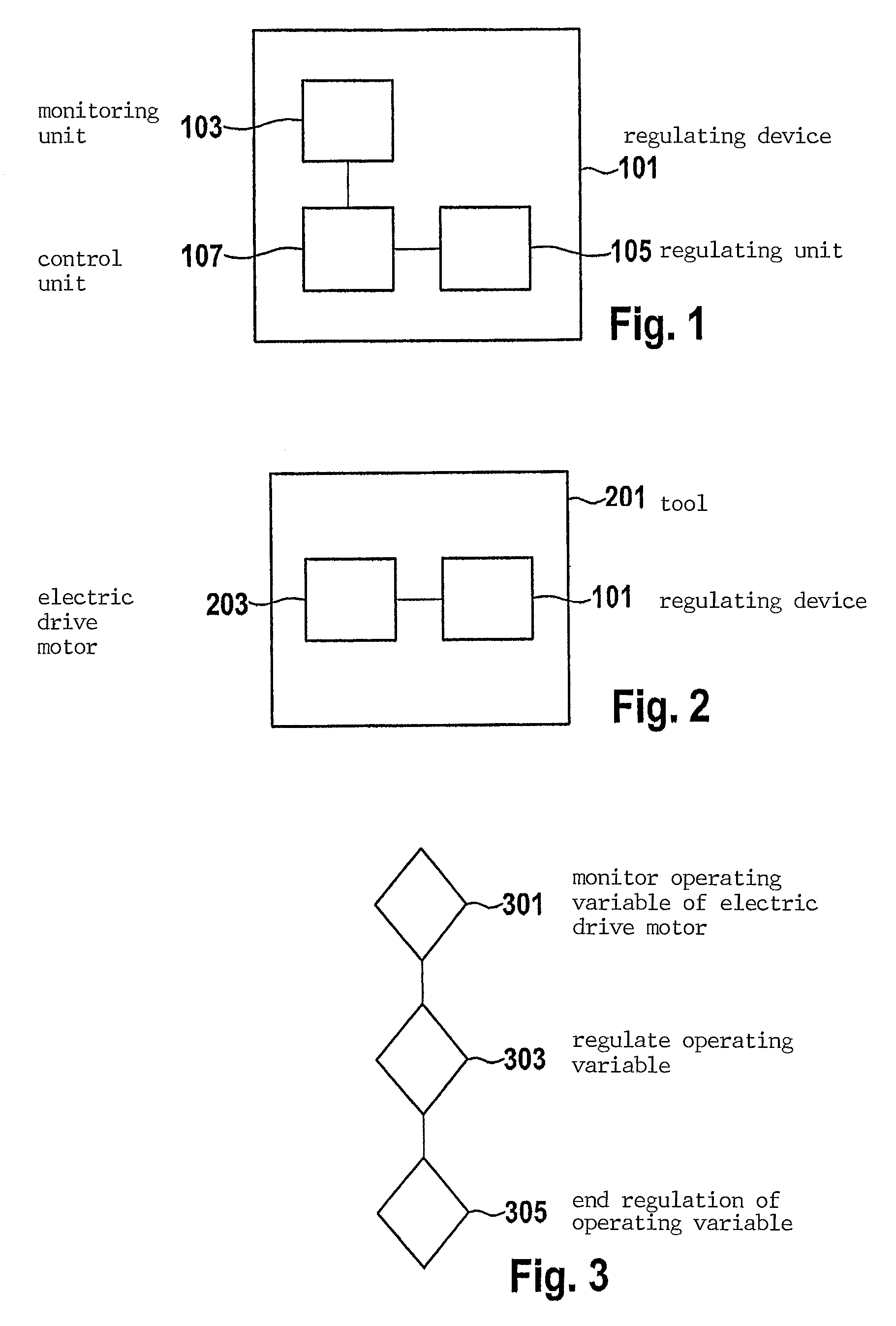

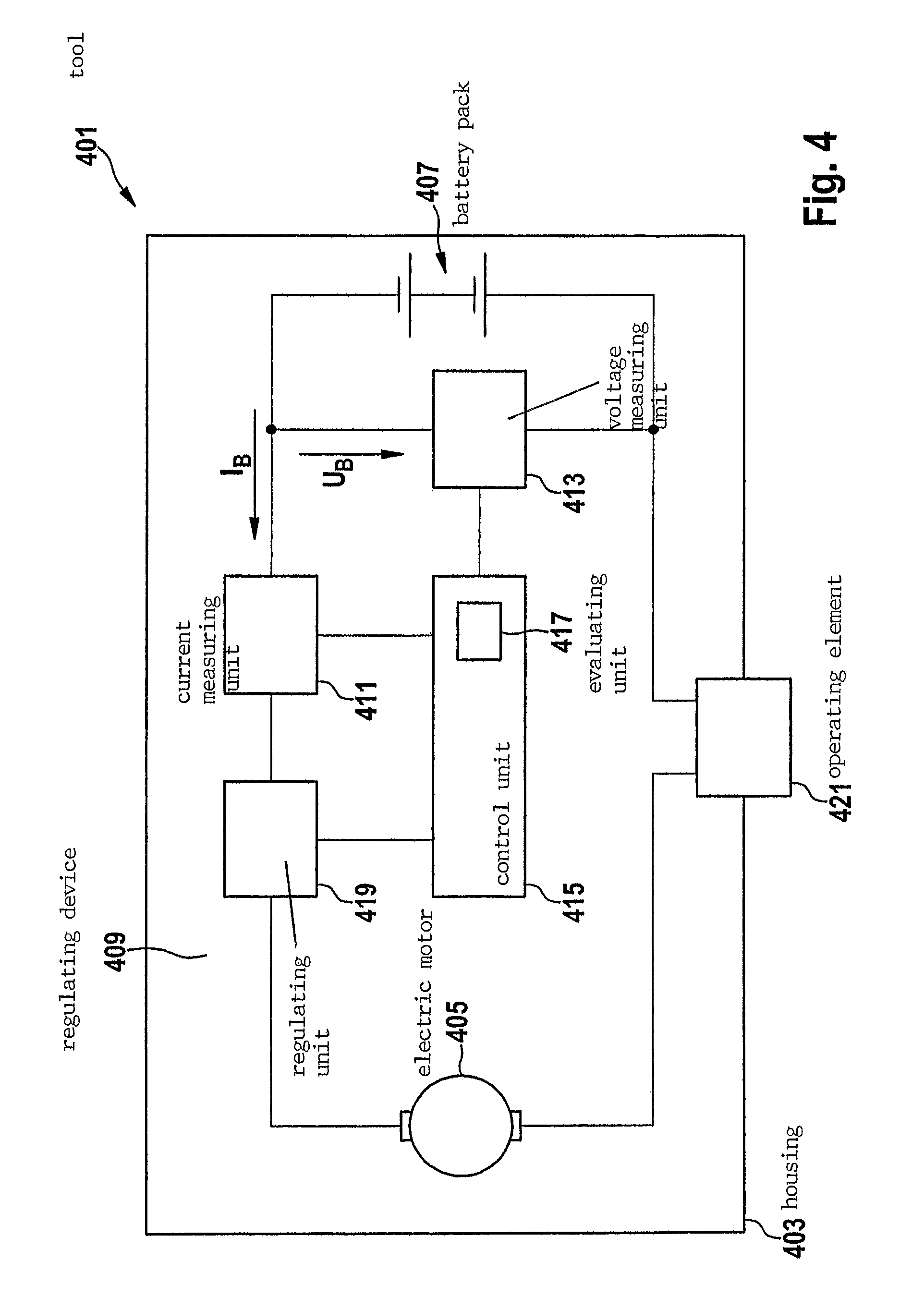

Device and method for regulating an increase in the output torque over time of an electric drive motor

ActiveUS9030145B2Increase output torqueCarry-out quicklyVector control systemsDerricks/mastsElectricityElectric drive

A device for regulating an increase in the output torque over time of an electric drive motor, including a monitoring unit for monitoring an operating variable of the electric drive motor, a regulating unit for regulating the operating variable for regulating the increase in output torque over time, a control unit for activating the regulating unit as a function of a time derivation of the monitored operating variable, the regulating unit being designed to be deactivated after a predetermined period of time. A method for regulating an increase in the output torque over time of an electric drive motor is also described. A corresponding tool and a computer program having program code for carrying out the method are also described.

Owner:ROBERT BOSCH GMBH

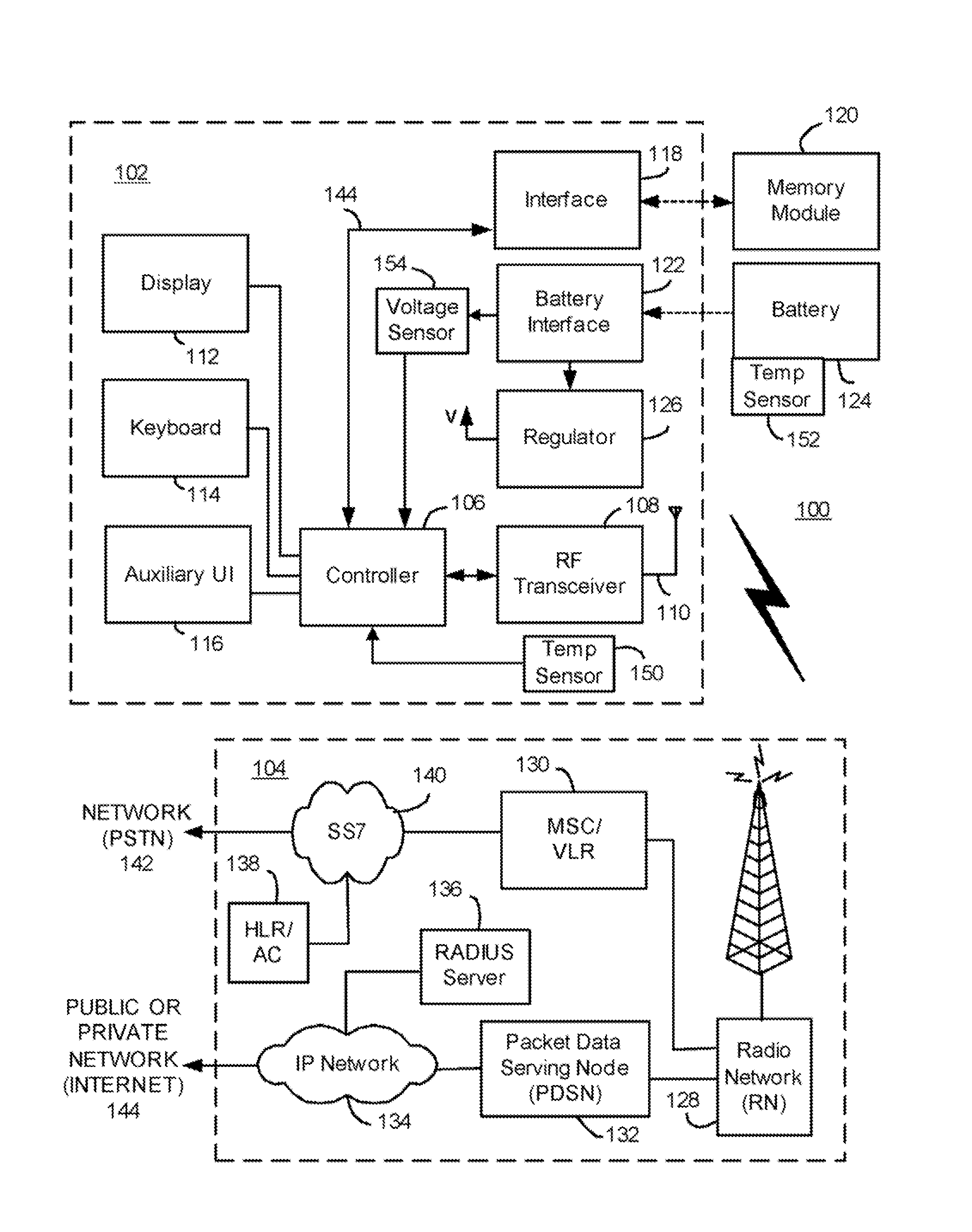

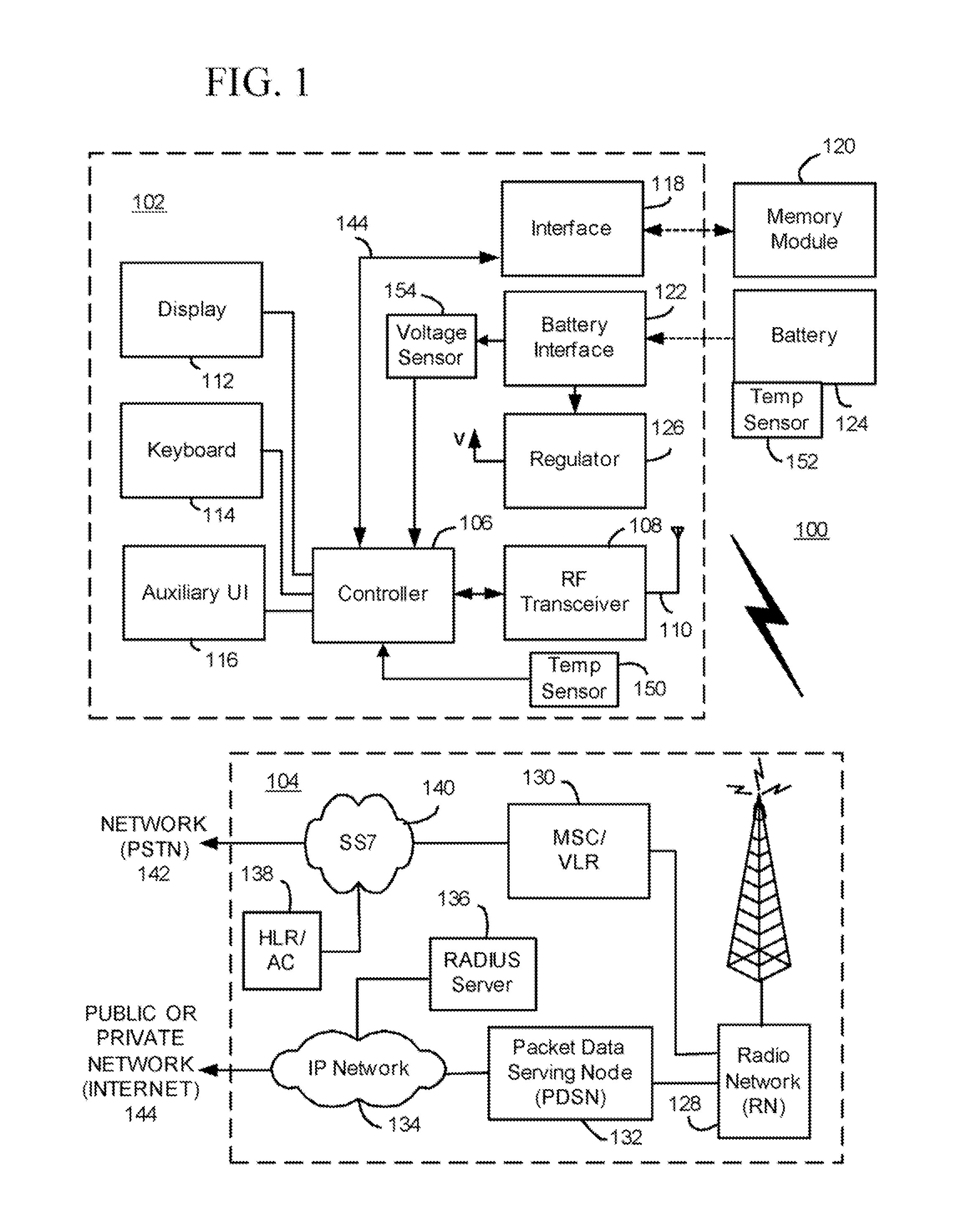

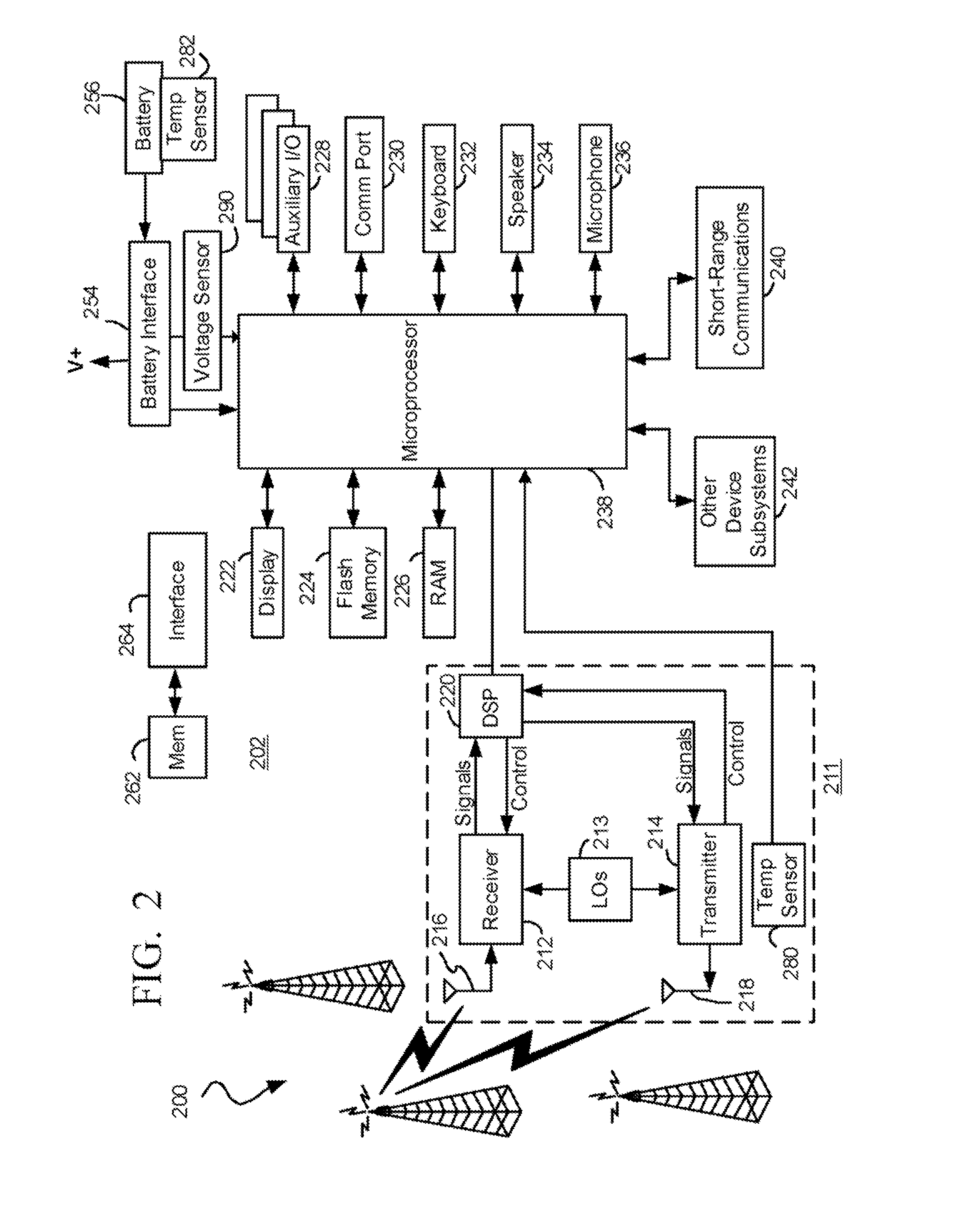

Methods And Apparatus For Limiting Communication Capabilities In Mobile Communication Devices

Methods and apparatus for limiting communication capabilities in mobile communication devices are disclosed. In one illustrative example, an operating variable of a mobile communication device is detected to be within one of a first range of values, a second range of values, and a third range of values. The mobile device operates in a full communication state if the operating variable is detected to be within the first range of values, a first limited communication state if the operating variable is detected to be within the second range of values, or a second limited communication state if the operating variable is detected to be within the third range of values. When receiving a communication request for establishment of a voice call or for communication of a user data message, the mobile device permits or prohibits the communication depending on the communication state, and preferably depending on whether the communication request is for a non-emergency or emergency communication. In one preferred embodiment, the operating variable is a temperature of the mobile device.

Owner:OT PATENT ESCROW LLC

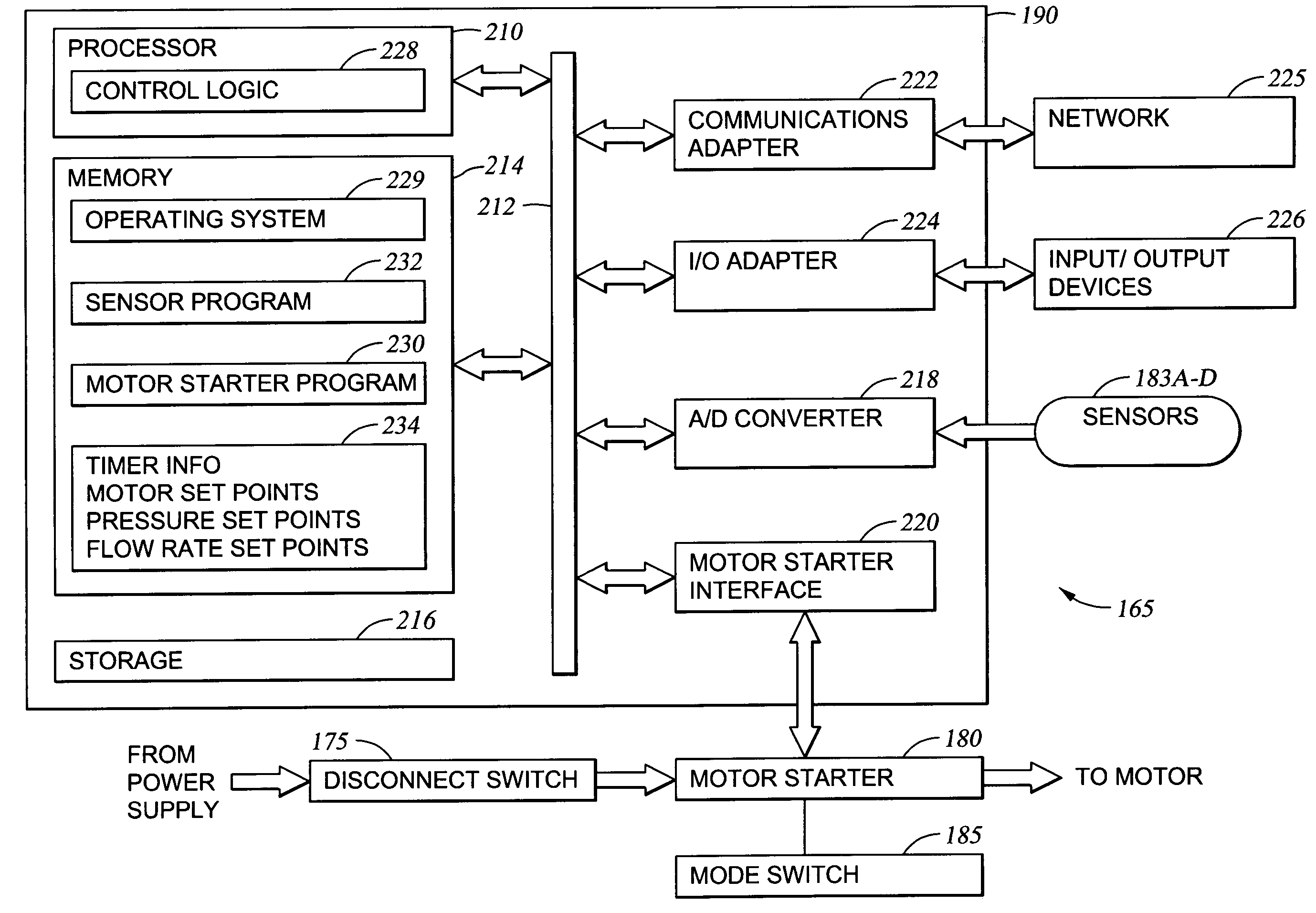

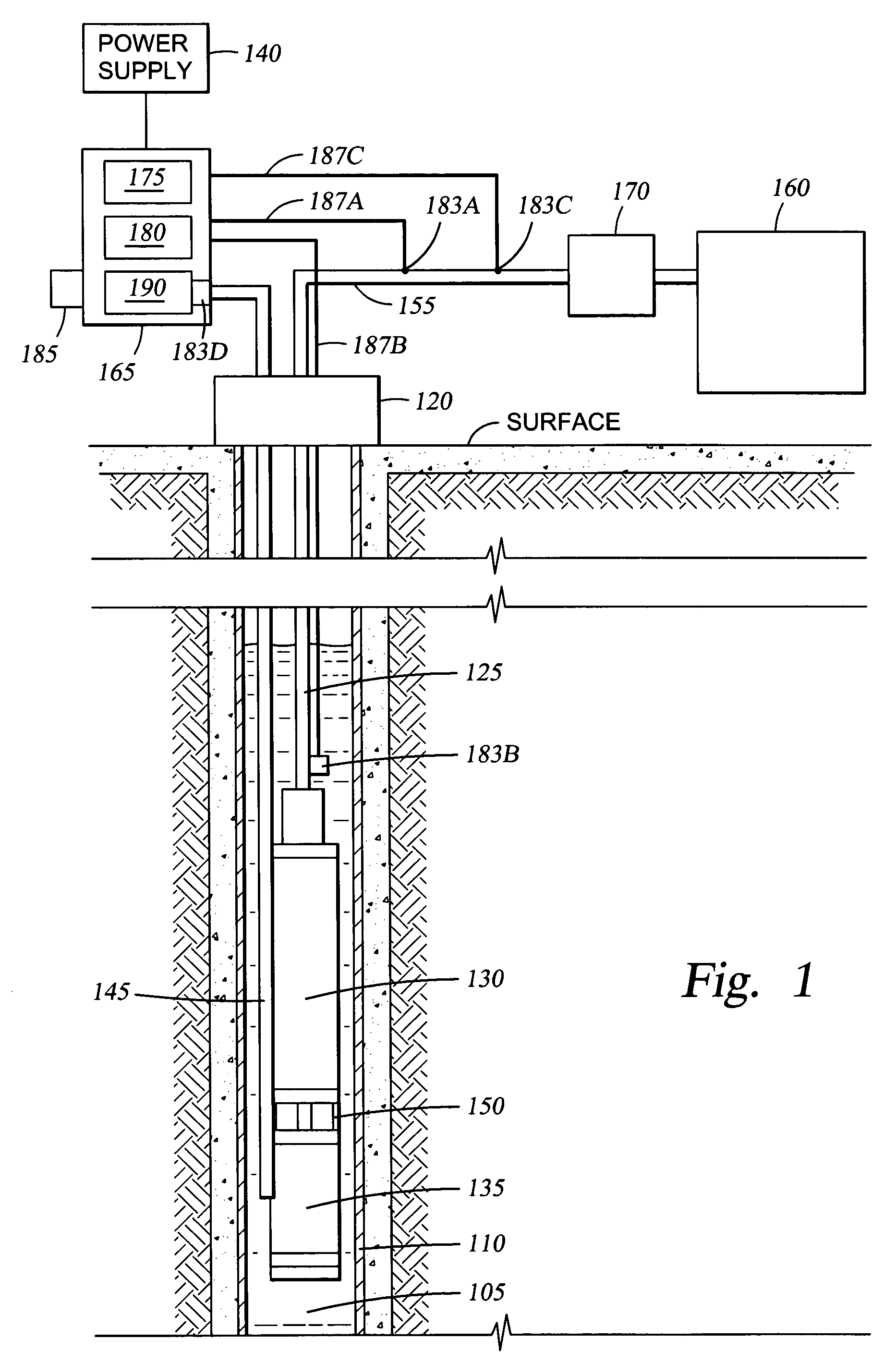

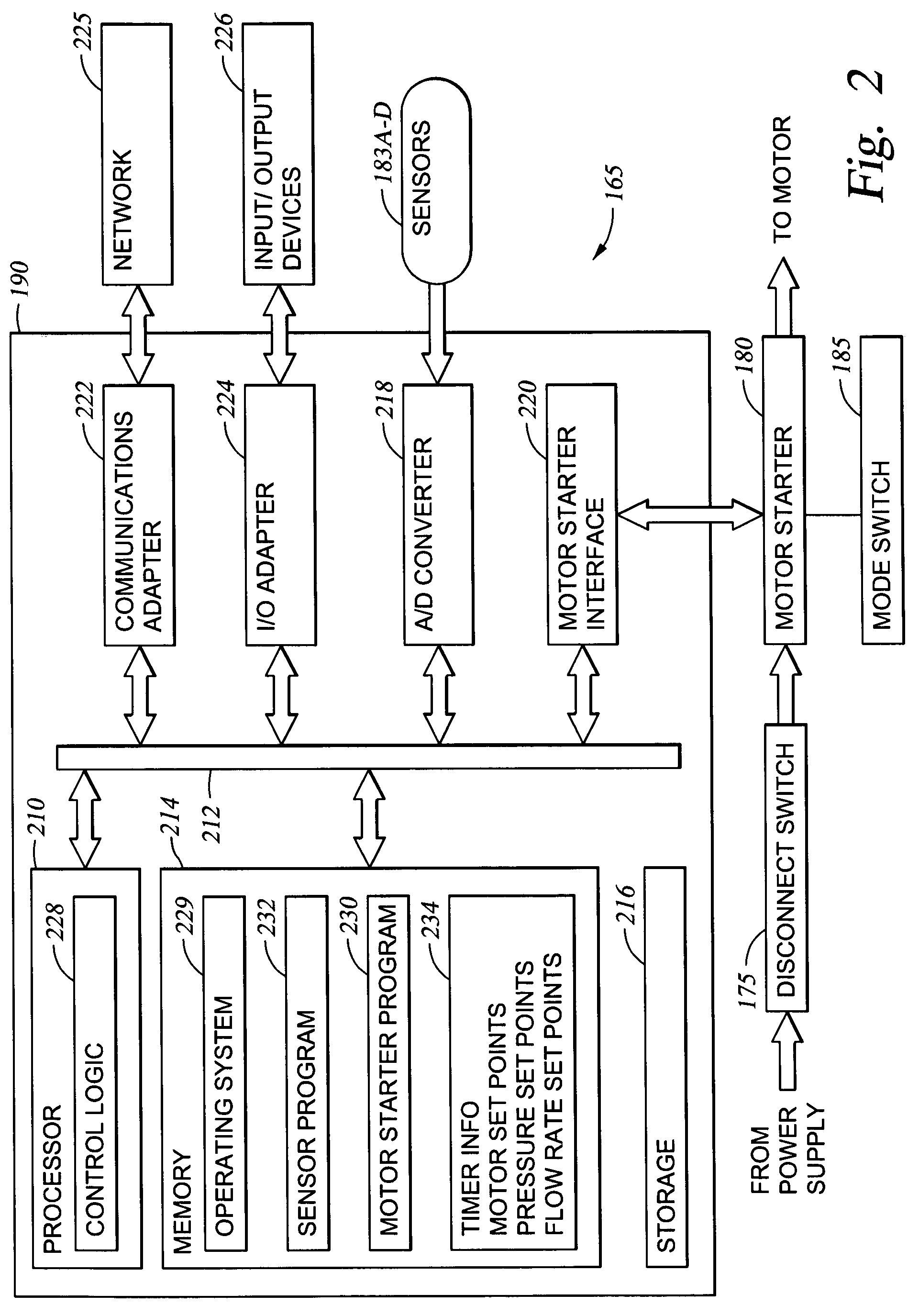

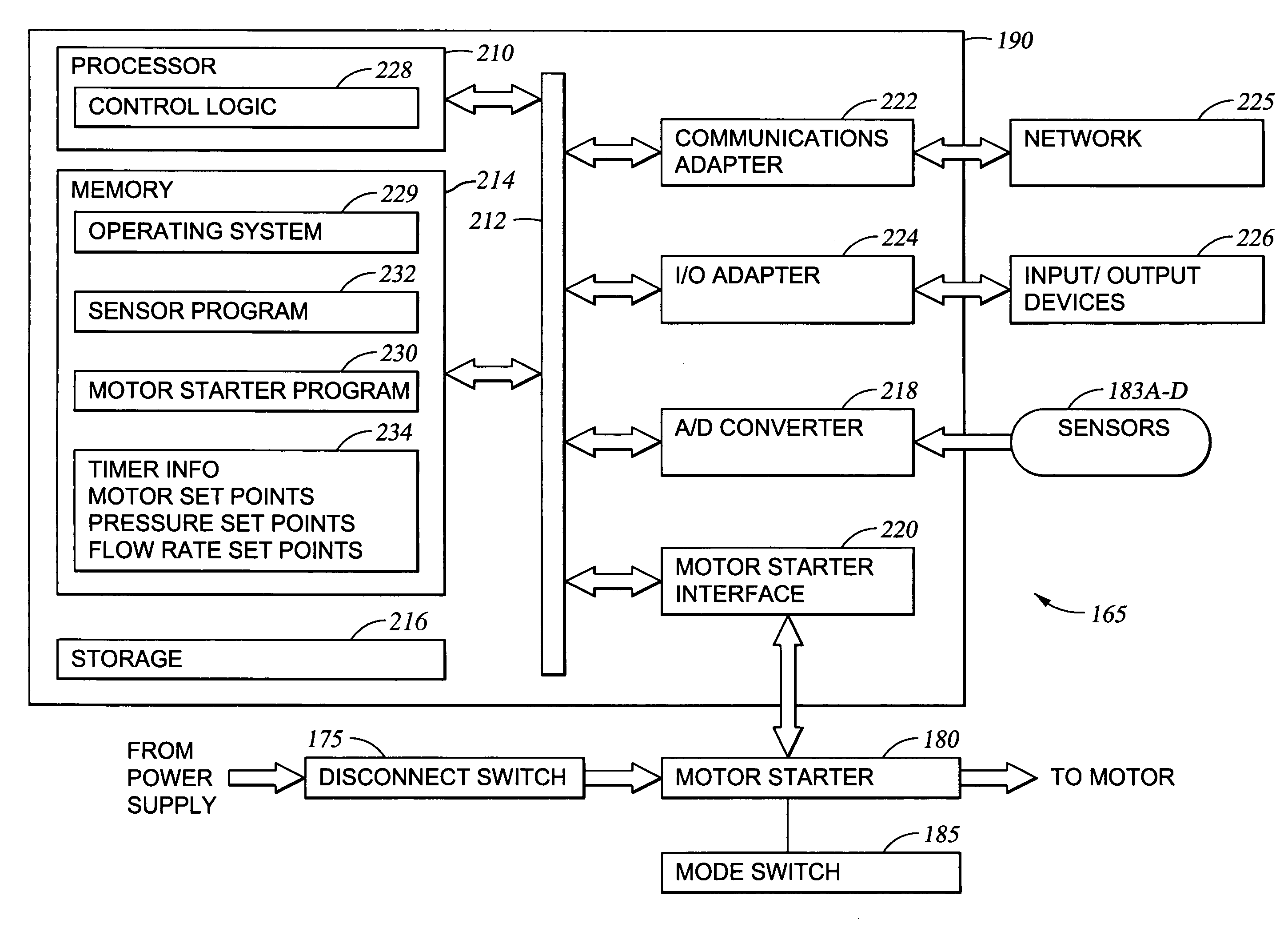

Controller system for downhole applications

The present invention generally provides a closed feedback system for operating peripheral devices in response to environmental conditions. Illustrative environmental conditions include well bore pressure, line pressure, fluid levels, flow rates and the like. In one embodiment, a flow controller disposed in a fluid line is operated in response to operating variable readings (e.g., pressure and / or flow rate) taken in the flow line and / or a well bore. The variable measurements are then compared to target values. If necessary, the flow controller is closed or opened to control the rate of fluid flow through the flow line and thereby achieve the desired target values. In another embodiment, the operation of a pump motor is monitored. Operating variables, such as voltage, current and load, are measured and compared to target values. In the event of a difference between the actual values of the variables and the target values, the flow controller is adjusted to affect the head pressure on a pump being driven by the motor. In some cases, the motor operation may be halted or otherwise adjusted.

Owner:OILFIELD EQUIP DEVMENT CENT

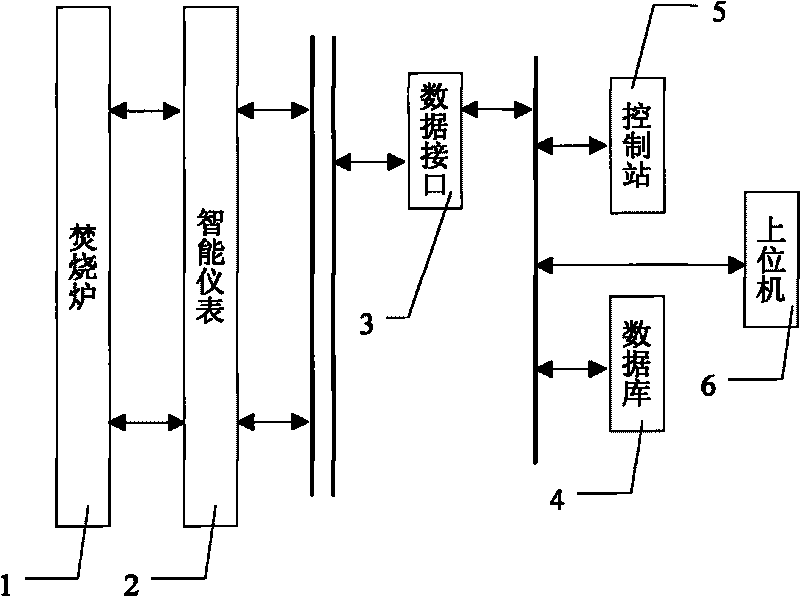

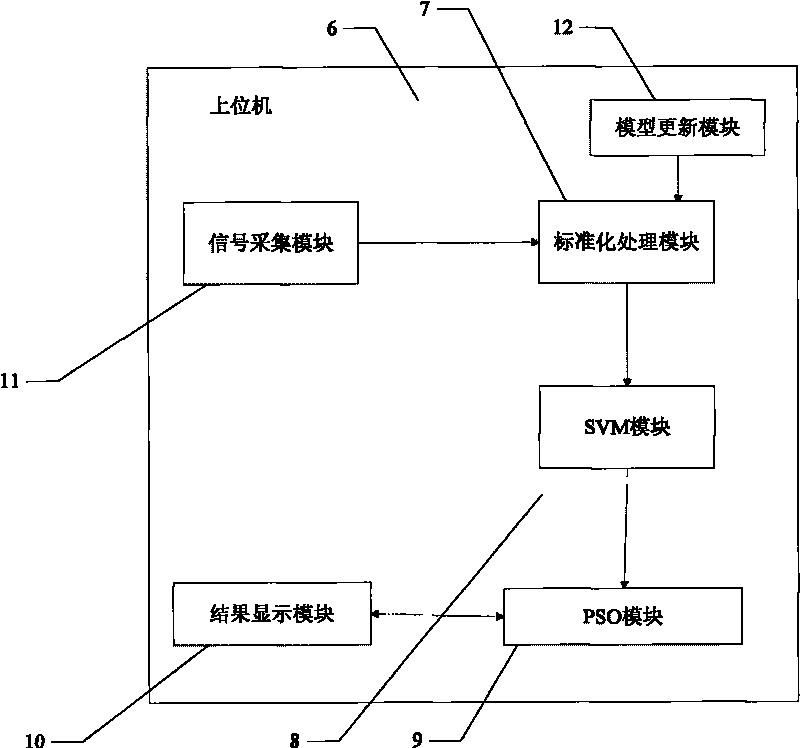

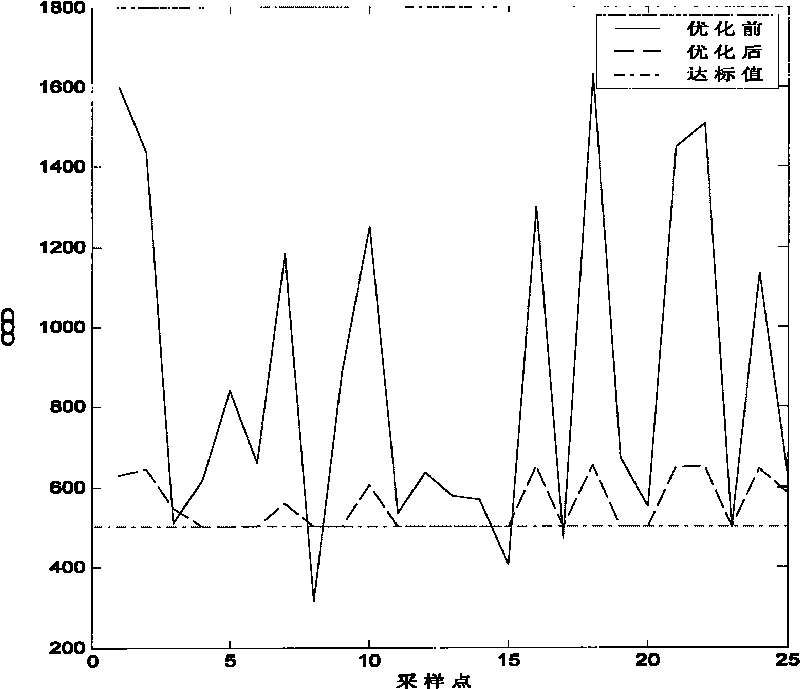

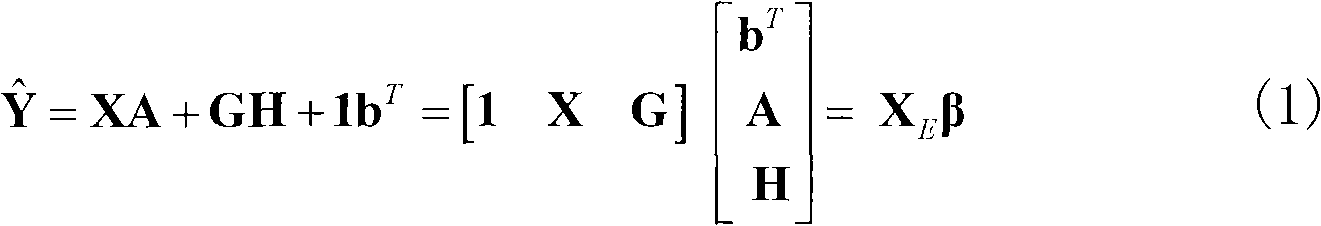

System and method for minimizing chemical oxygen demand (COD) discharge of pesticide production waste liquid incinerator

InactiveCN101763084ASmall operand variable valueTotal factory controlProgramme total factory controlLiquid wasteEnvironmental engineering

The invention discloses a system for minimizing chemical oxygen demand (COD) discharge of a pesticide production waste liquid incinerator, comprising a field intelligent instrument connected with the pesticide production waste liquid incinerator, a DCS system and a host computer. The host computer comprises a standardized processing module for collecting training samples TX of key system variables from a database and the chemical oxygen demand data Y corresponding to the training samples TX and standardized processing the training samples TX, a support vector machine (SVM) module for soft-sensor modeling and a particle swarm algorithm module for solving the following minimum problem with the pgK obtained when iteration is ended being the operating variable with minimum chemical oxygen demand. The invention also discloses a method for minimizing the chemical oxygen demand (COD) discharge of the pesticide production waste liquid incinerator. The invention provides a system and a method for minimizing the chemical oxygen demand (COD) discharge of the pesticide production waste liquid incinerator, which can measure the COD online and effectively monitor whether the COD exceeds standard.

Owner:ZHEJIANG UNIV

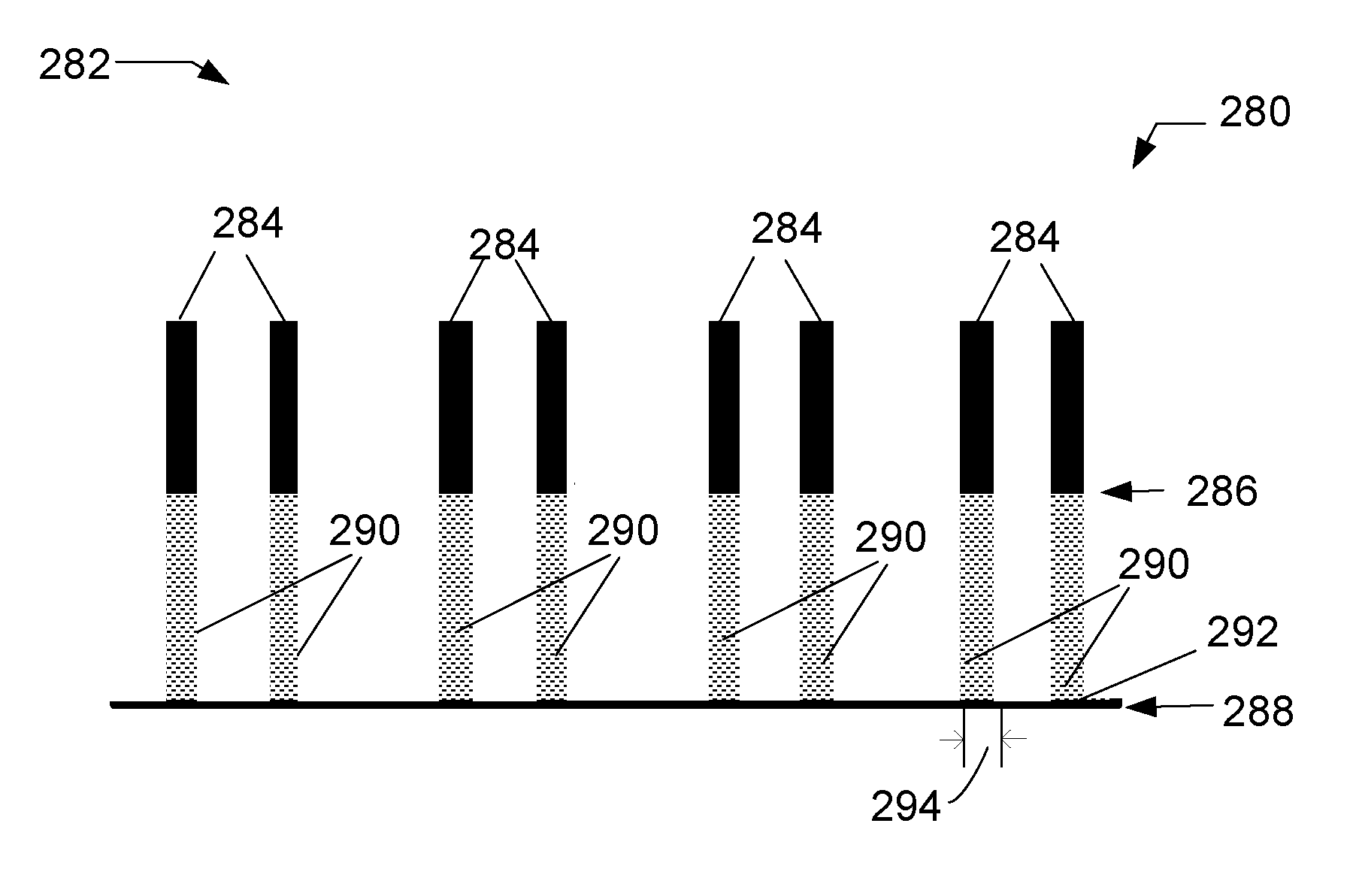

Material processing to achieve sub-10nm patterning

ActiveUS20160247680A1Electric discharge tubesSemiconductor/solid-state device manufacturingLine widthCompound (substance)

Provided is a method for increasing pattern density on a substrate comprising a structure with a patterned layer with a first composition and a sidewall and a cap layer of a second composition formed atop said structure. The sidewall is exposed to a chemical environment and creates a chemically modified sidewall layer of a third composition. The cap layer and an interior, non-modified portion of said structure is removed using an etching process to leave behind said chemically modified sidewall layer. A pattern transfer etch of said sidewall chemically modified layer onto the underlying layer of said substrate is performed. One or more integration operating variables are controlled to achieve target critical dimensions comprising width, height, sidewall angle, line width roughness, and / or line edge roughness of said structure.

Owner:TOKYO ELECTRON LTD

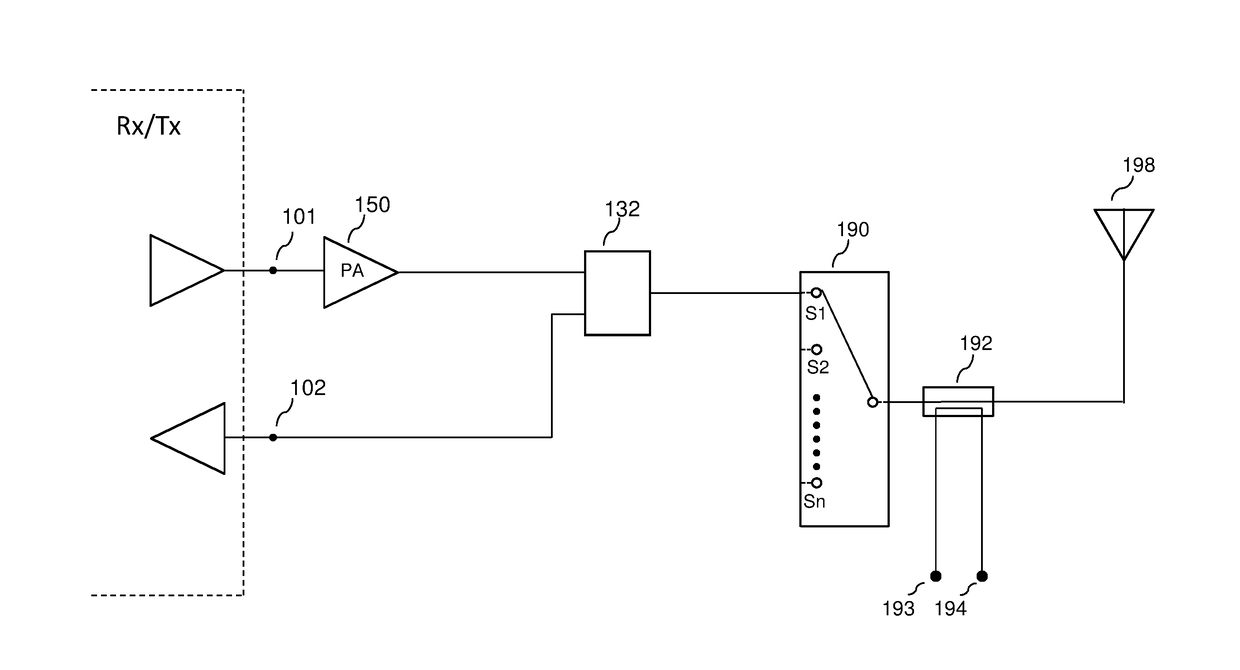

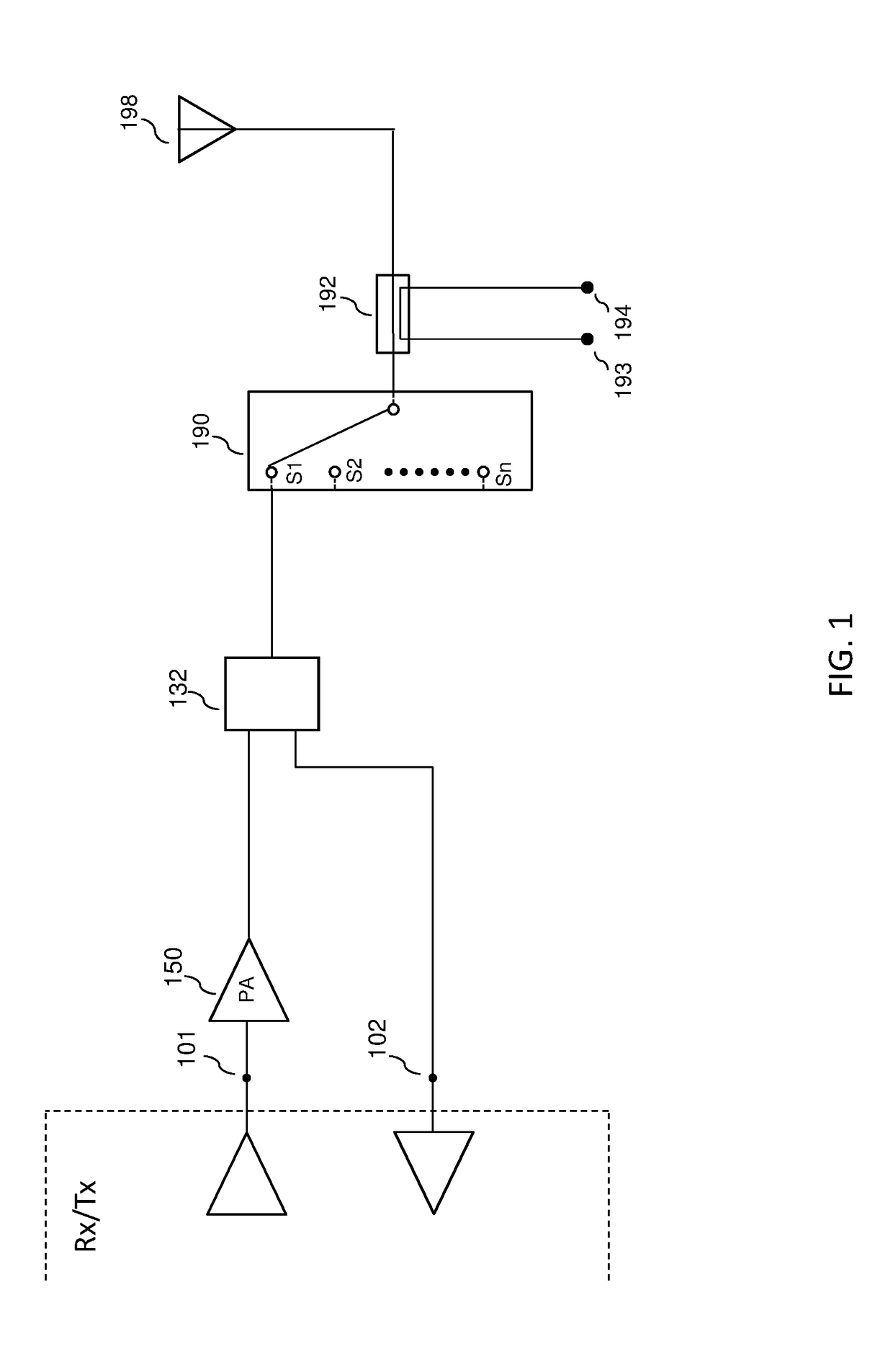

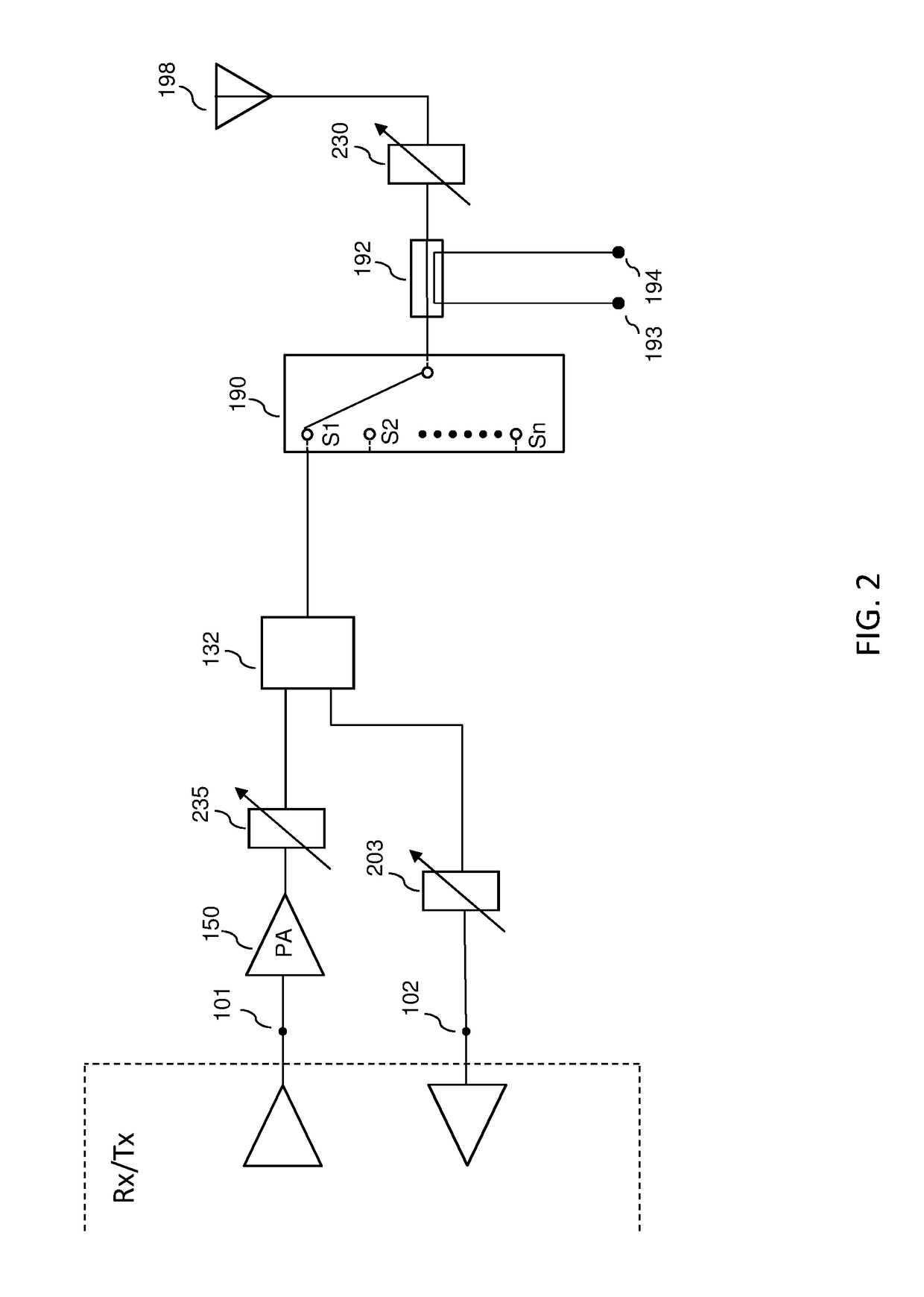

Mismatch Detection Using Replica Circuit

ActiveUS20170146591A1Relieve pressureReducing HCI effectTransmitters monitoringMultiple-port networksOperating variablesEngineering

An apparatus for detecting difference in operating characteristics of a main circuit by using a replica circuit is presented. In one exemplary case, a sensed difference in operating characteristics of the two circuits is used to drive a tuning control loop to minimize the sensed difference. In another exemplary case, several replica circuits of the main circuit are used, where each is isolated from one or more operating variables that affect the operating characteristic of the main circuit. Each replica circuit can be used for sensing a different operating characteristic, or, two replica circuits can be combined to sense a same operating characteristic.

Owner:PSEMI CORP

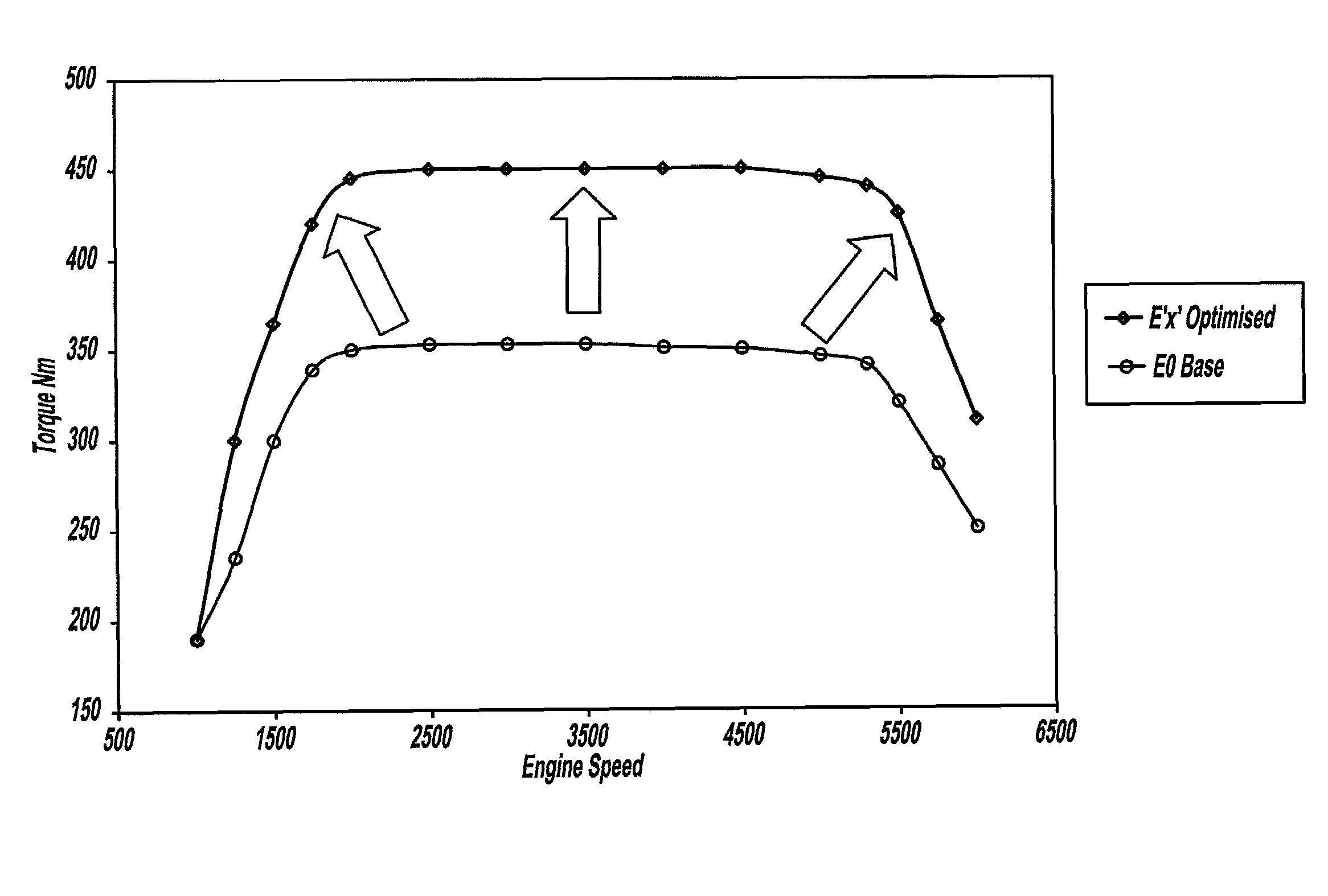

Optimized flex fuel powertrain

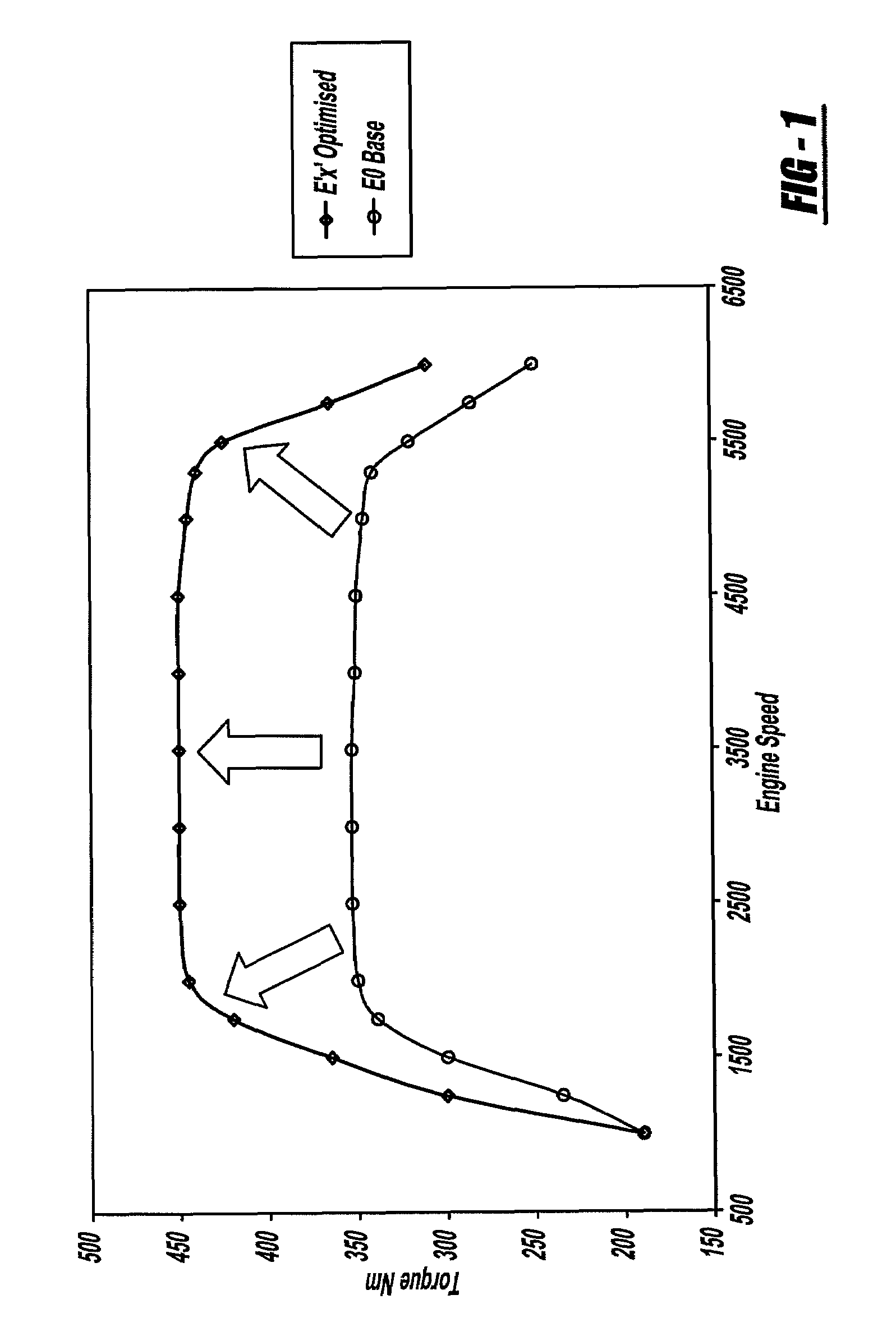

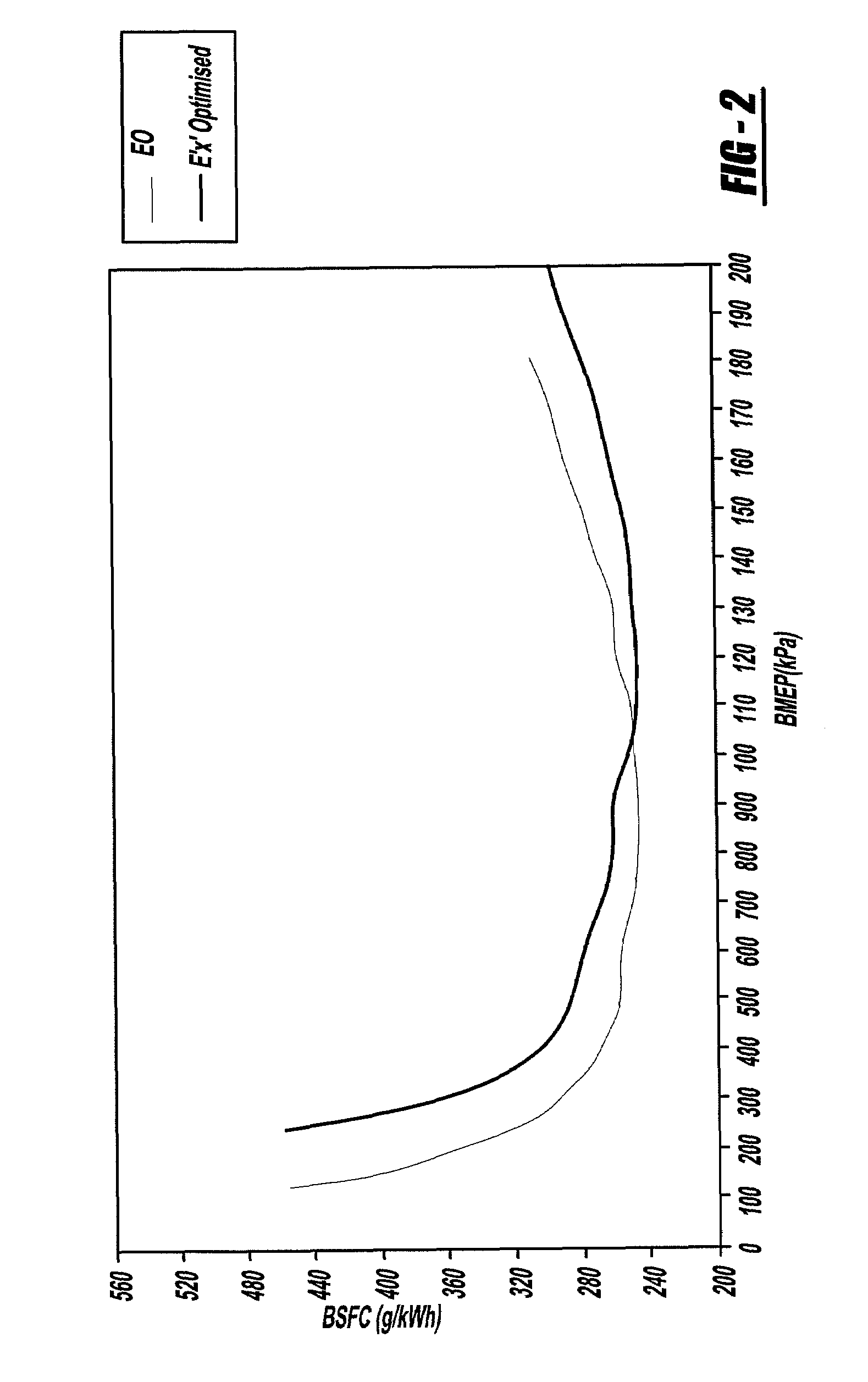

InactiveUS7454285B2Minimize fuel economyImproved wide open throttle performanceAnalogue computers for vehiclesElectrical controlGasolinePowertrain

A fuel system and powertrain for a flexible fuel system vehicle utilizes a controller system to control variables in an engine and the final drive optimize operating efficiency of the vehicle while using an alcohol-gasoline blend. The controller system regulates engine operating variables such as fuel pressure, fuel flow, air-fuel flow, air-fuel temperature, and valve timing. The controller system regulates engine operating variables such as transmission gear selection and gear changing as well as differential ratio changes.

Owner:RICARDO INC

Method for controlling starting of an engine in a hybrid electric vehicle powertrain

ActiveUS20050256632A1Regulate smoothnessEasy to implementHybrid vehiclesAnalogue computers for vehiclesPower flowInternal combustion engine

A method for controlling starting of an internal combustion engine in a hybrid electric vehicle powertrain having multiple power flow paths to vehicle traction wheels from the engine and from an electric motor. A smoothness factor is calculated to determine how smooth an engine start should be. Engine operating variables regulate engine smoothness during engine start events as determined by the calculated smoothness factor appropriate for selected vehicle operating conditions.

Owner:FORD GLOBAL TECH LLC

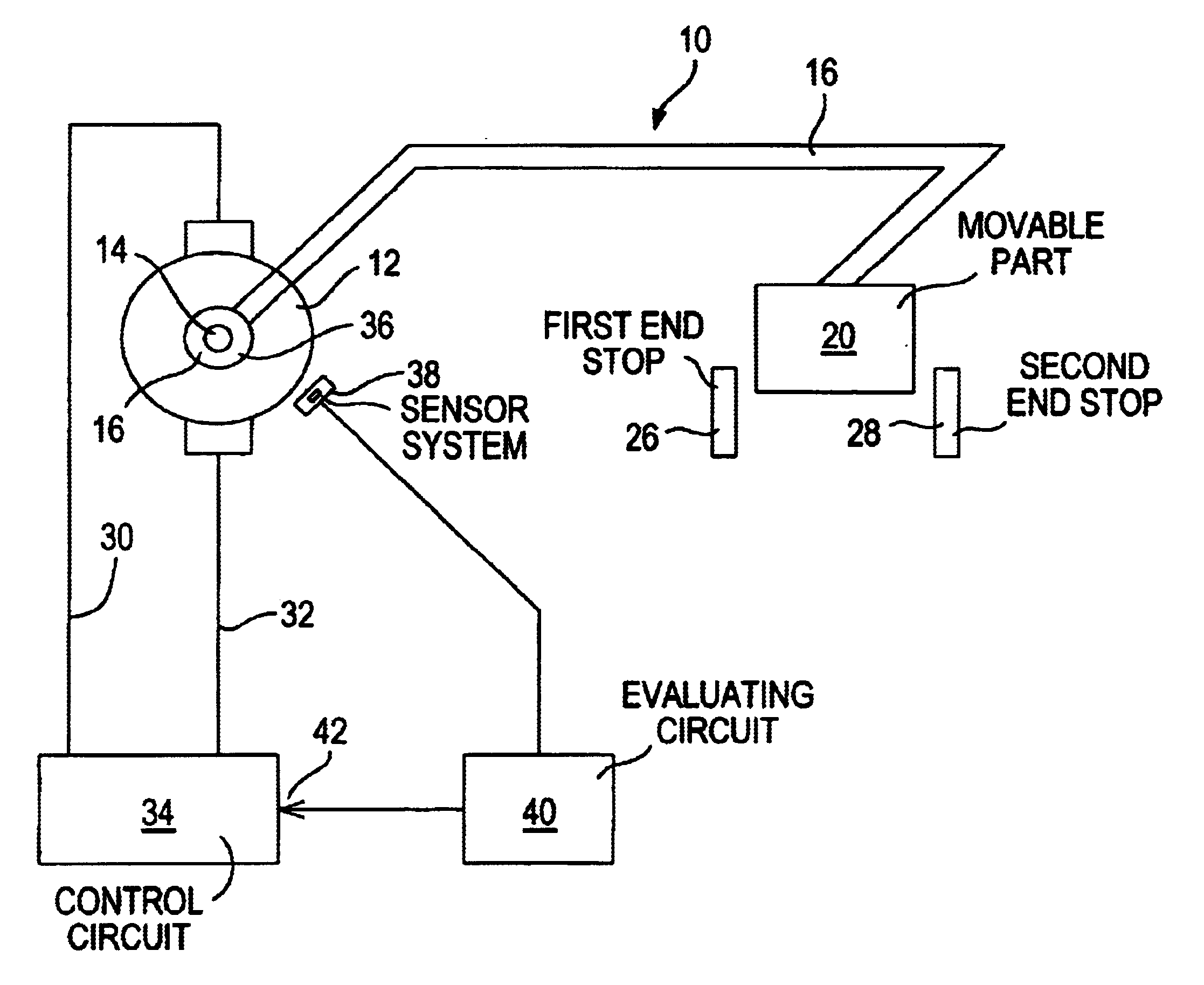

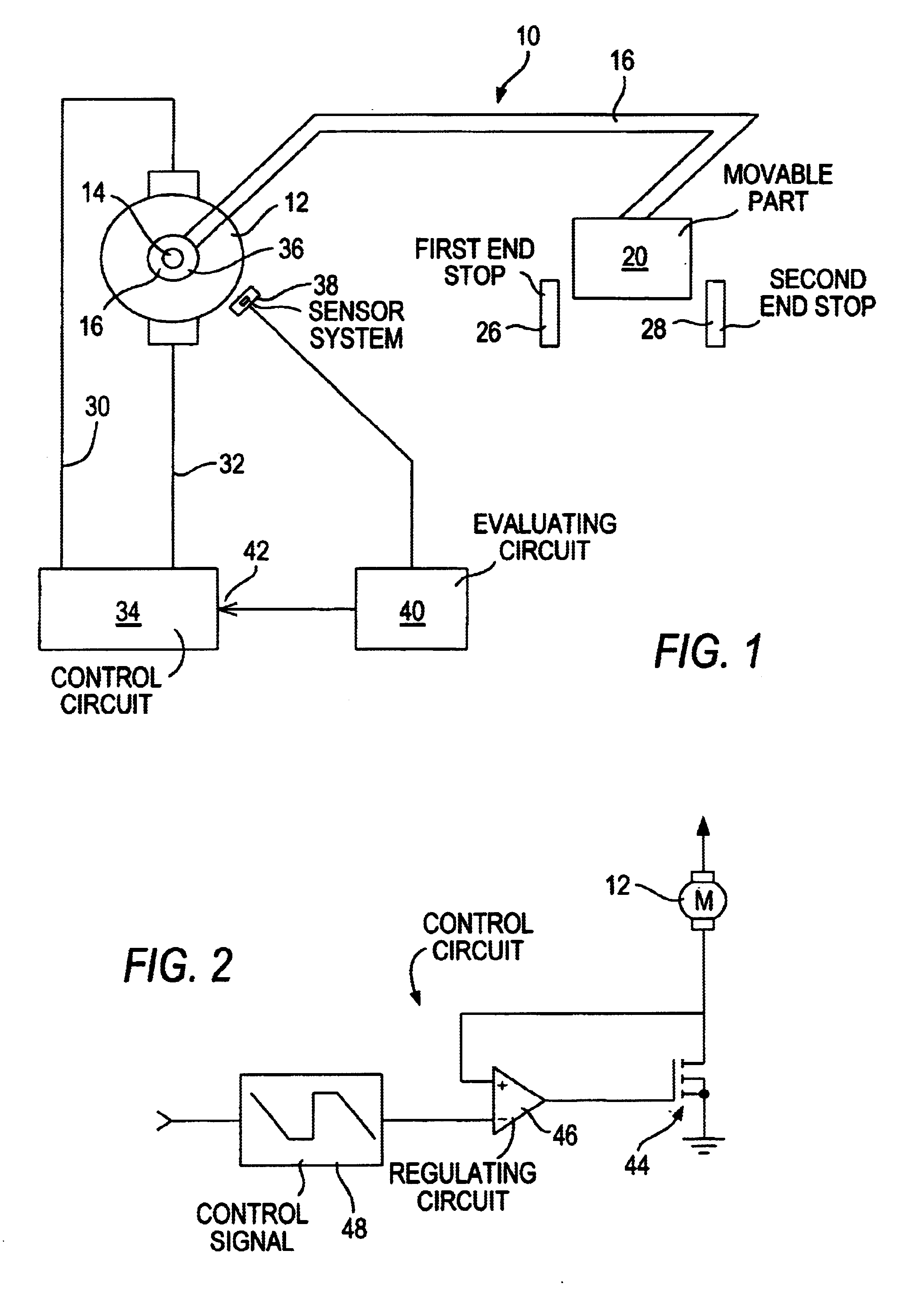

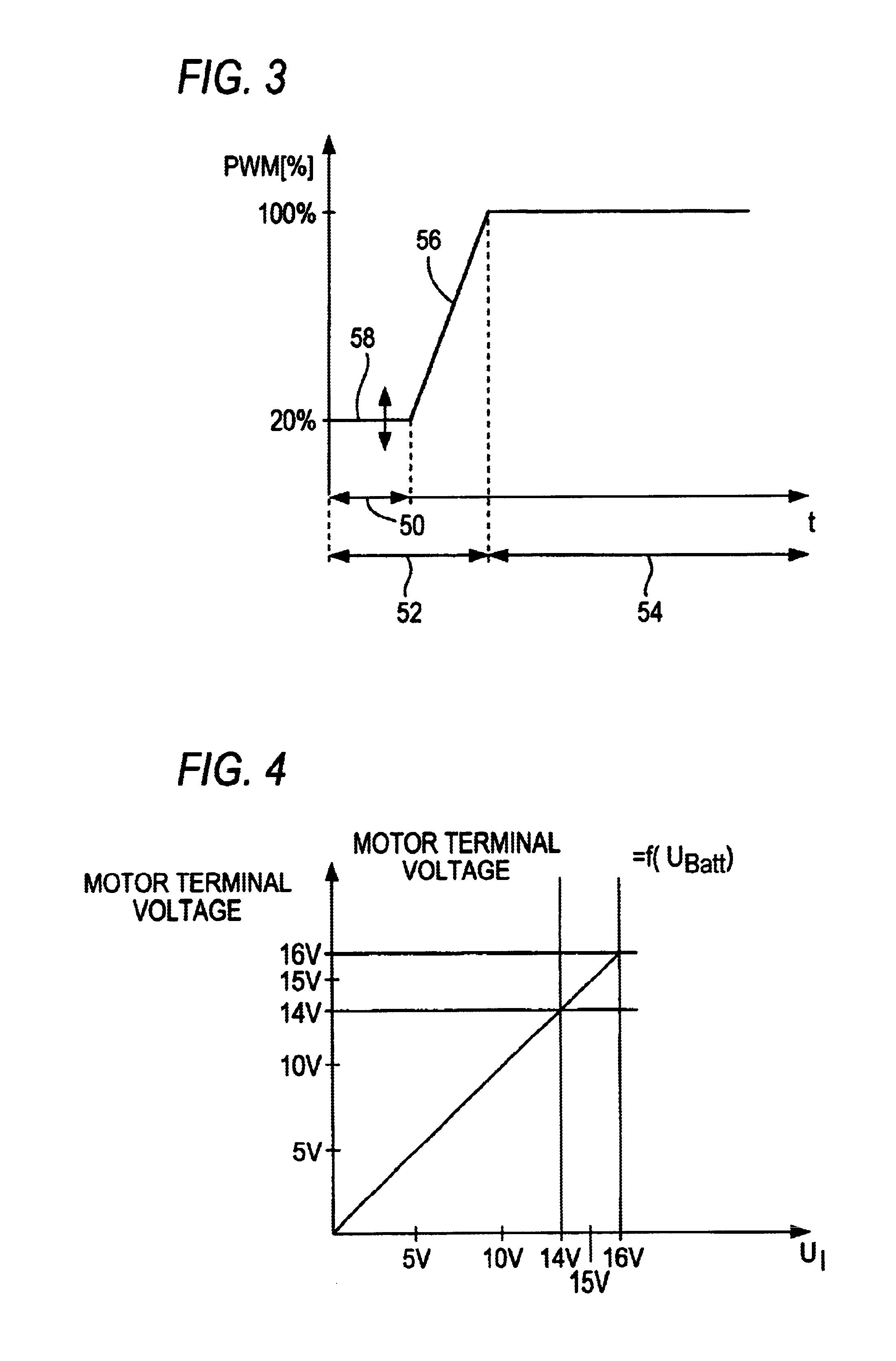

Method for controlling an adjustment process of a part

InactiveUS6952087B2DC motor speed/torque controlAsynchronous induction motorsEnd stagesField-effect transistor

In the method of controlling a process for moving a part (20) by an electric motor (12) against an end stop, pinching events are detected by monitoring a motor operating variable, such as a motor rpm, and if pinching is detected the motor (12) is stopped and / or reversed. The electric power triggering the motor (12) at the start of and during a startup phase while system slack is taken up is controlled so that it is constant and lower than the power triggering the motor in an ensuing operating phase (54) in which the part (20) moves. Preferably power during the startup phase is reduced to power values that are just barely enough to move the motor while system slack is taken up. In a preferred embodiment the applied motor voltage is reduced and controlled by a power end stage that includes a bipolar transistor or a field effect transistor.

Owner:ROBERT BOSCH GMBH

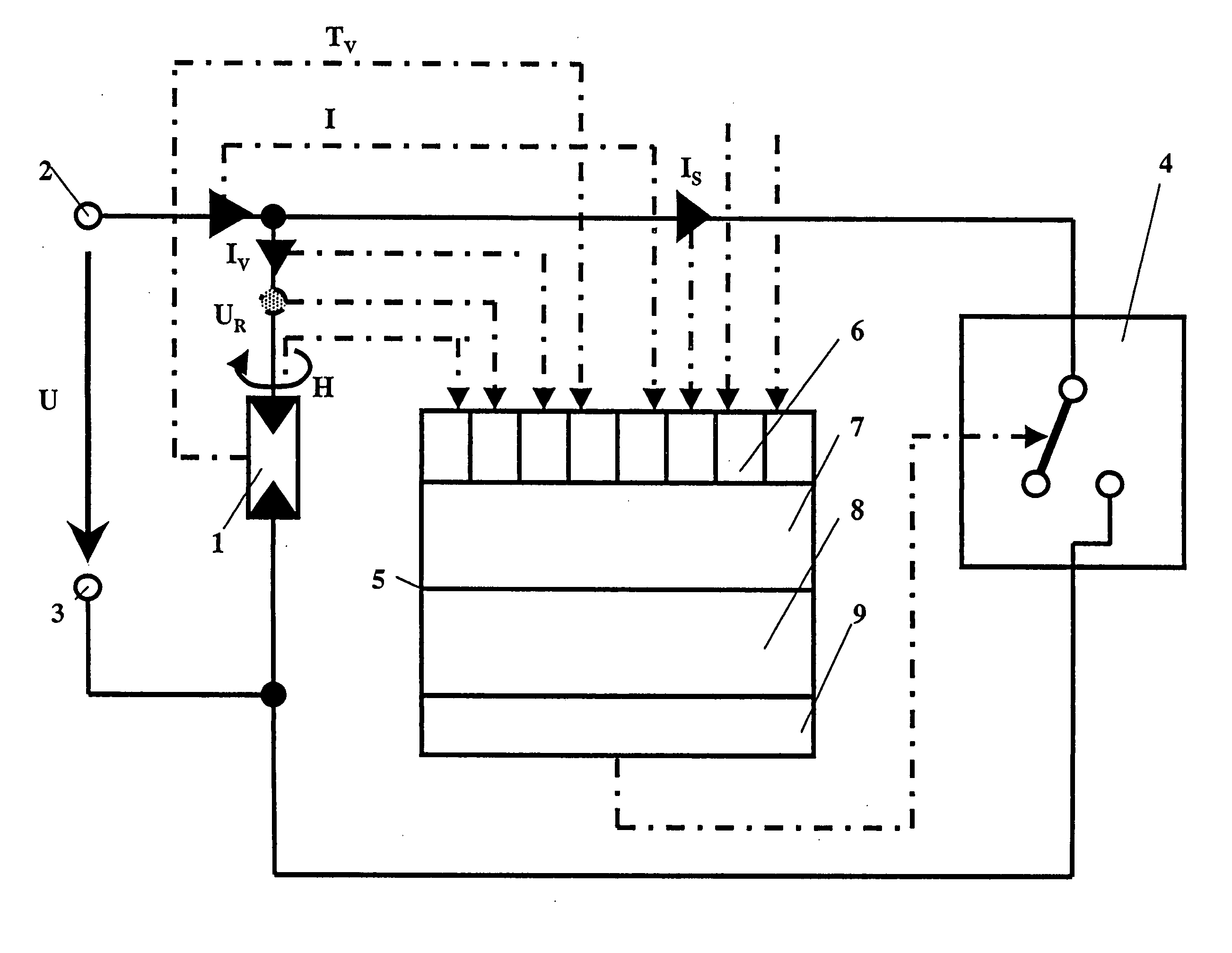

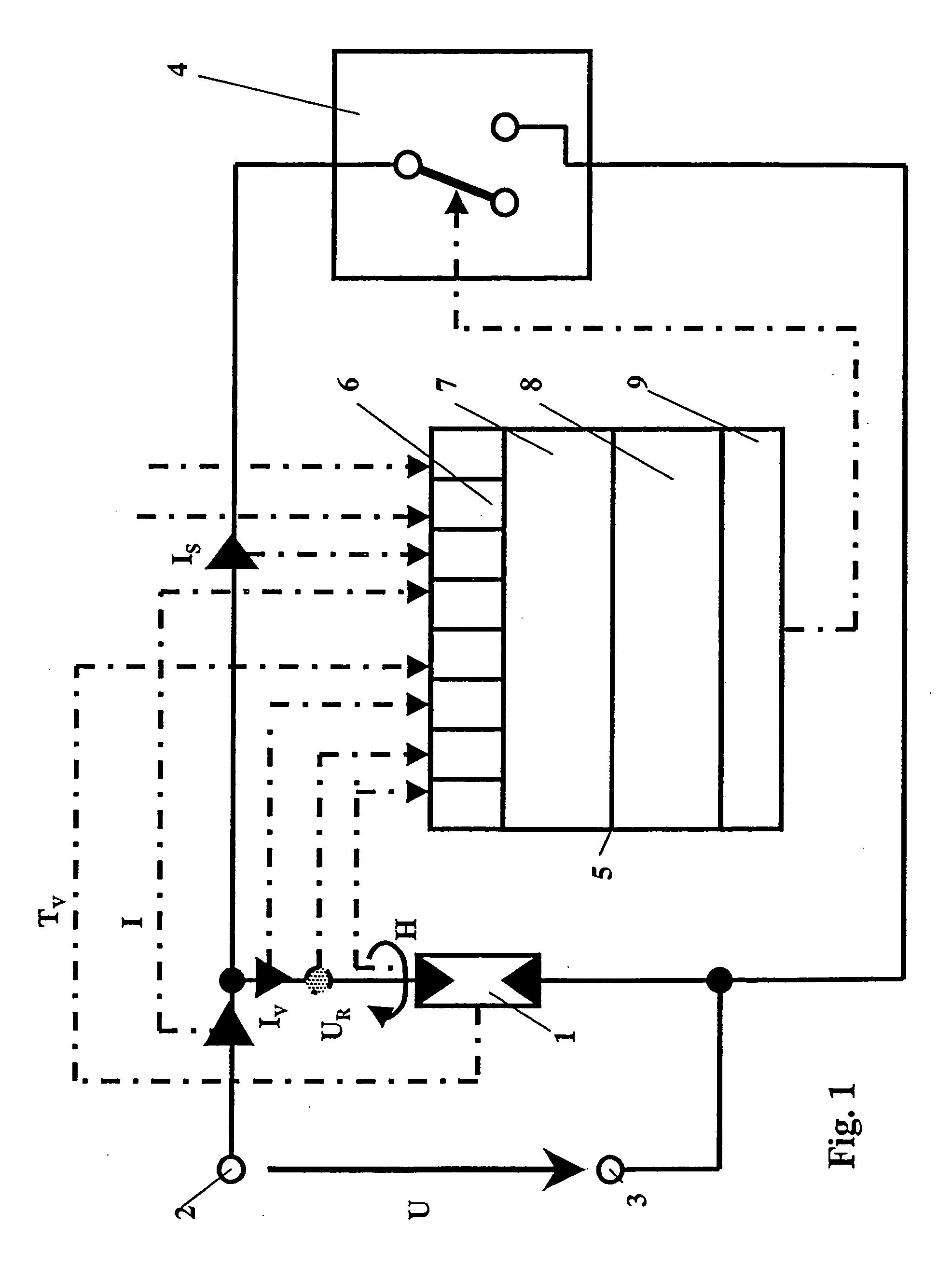

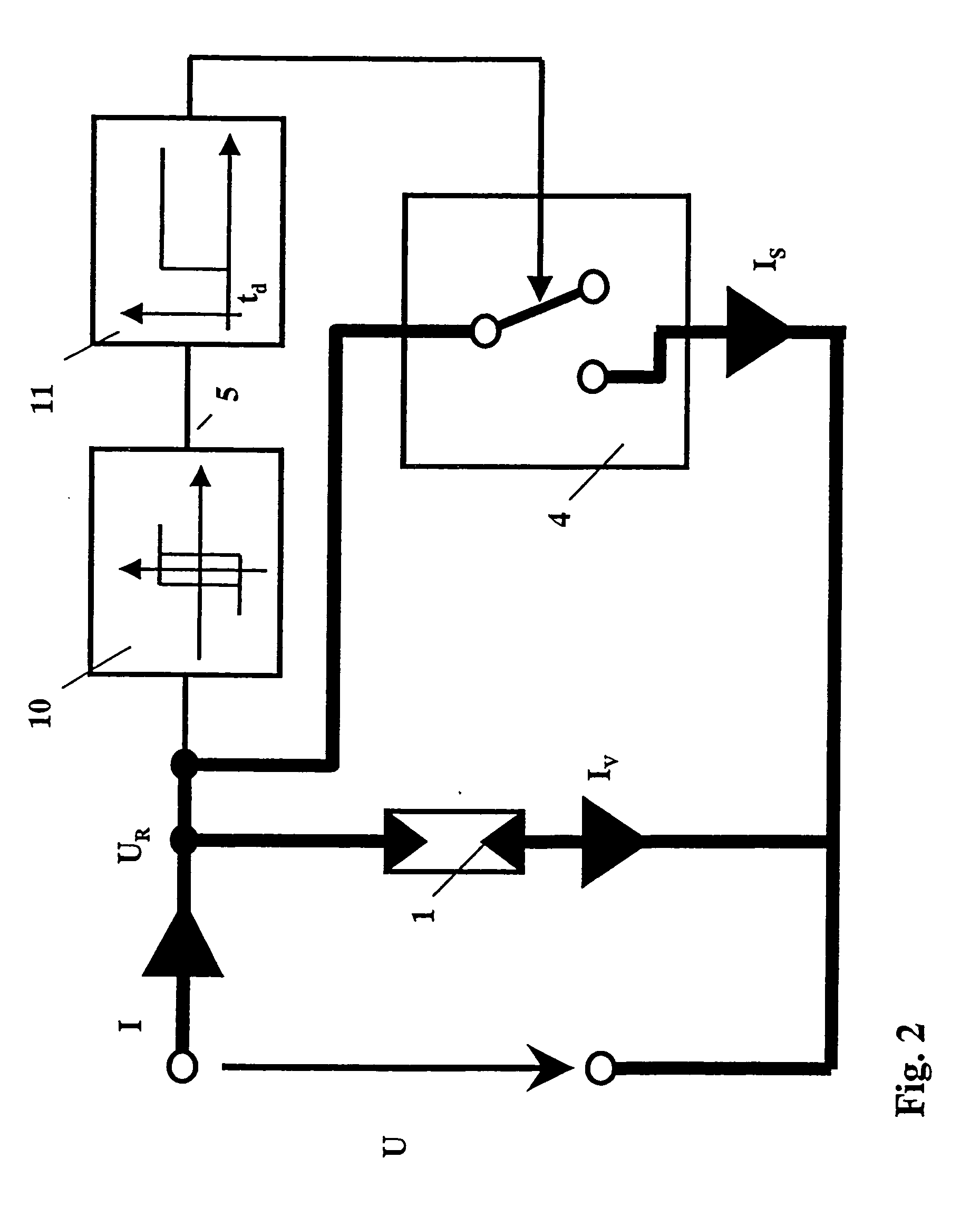

Voltage limiter

InactiveUS20040257742A1Improve electromagnetic compatibilitySwitch accuratelyMagnetic/electric field screeningResistor electrostatic/electromagnetic shieldingOperating variablesVaristor

The voltage limiter is used to effectively limit short-term and long-term overvoltages. Said voltage limiter has a varistor (1) and a discharge path which can be connected in parallel with the varistor. The discharge path contains a switching point (4), which is preferably in the form of a semiconductor switch and can be loaded with an uninterrupted current, and which can be closed above a limit value of a signal which is dependent on an operating variable of the varistor (1). The varistor (1) is arranged in a first area (24) and the switching point (4) is arranged in a second area (26) of two areas (24, 26, 28) which are at an axial distance from one another in the direction of an axis of symmetry (20). Means (5) for operating the switching point (4) are accommodated in a third area (28), which is at a defined potential. The arrangement of the components (1, 4, 5) of the voltage limiter in separate areas (24, 26, 28) results in a compact, modular construction, and those components of the voltage limiter which are subject to power loading, namely the varistor (1) and the switching point (5), are physically separated from one another, so that they can be cooled independently of one another. Since the operating means (5), which generally operate electronically, are accommodated in an electromagnetically shielded area (28), the operational reliability of the voltage limiter is at the same time improved, and, in particular, undesirable high-energy electromagnetic interference is kept away from this area (28).

Owner:ABB (SCHWEIZ) AG

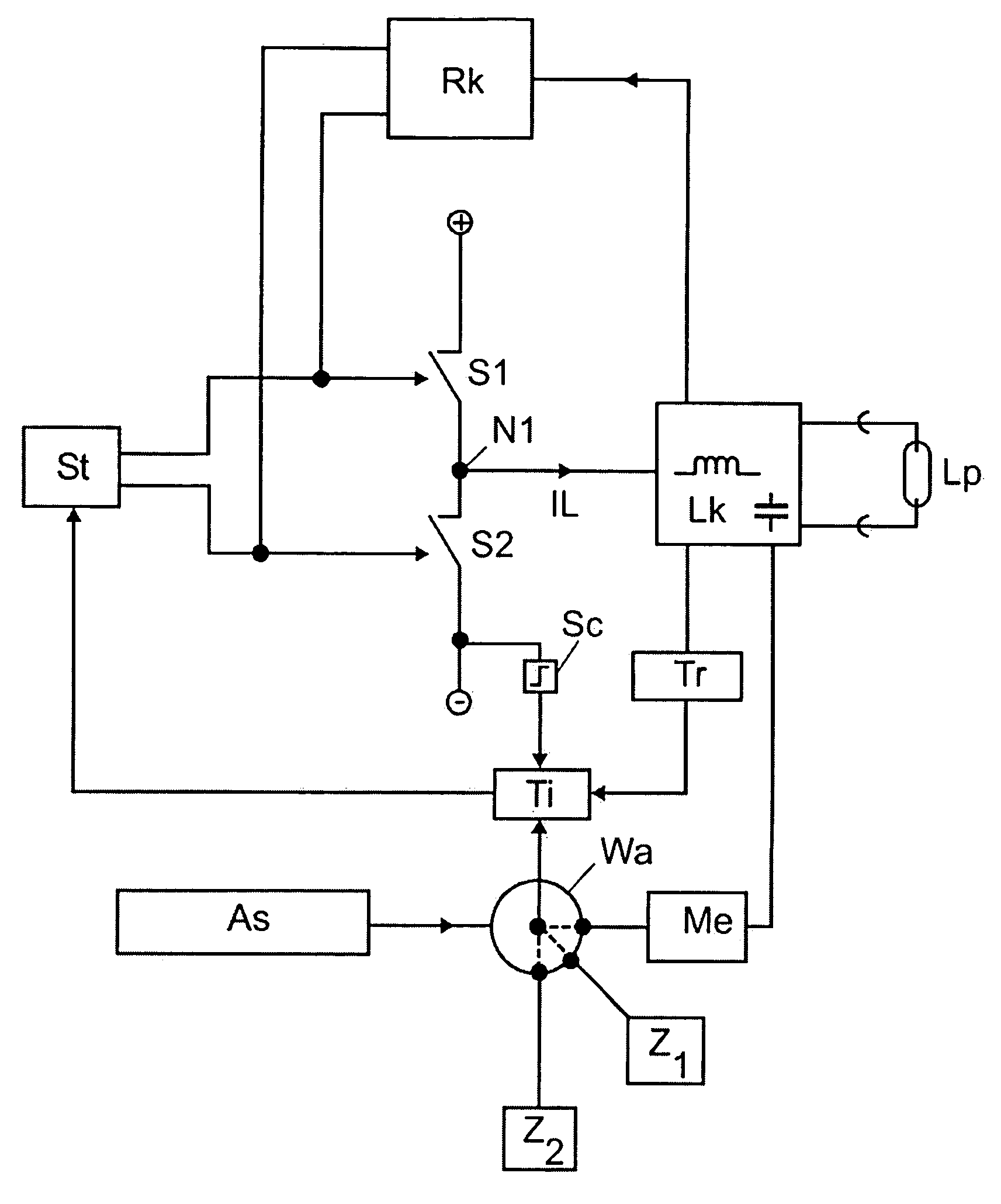

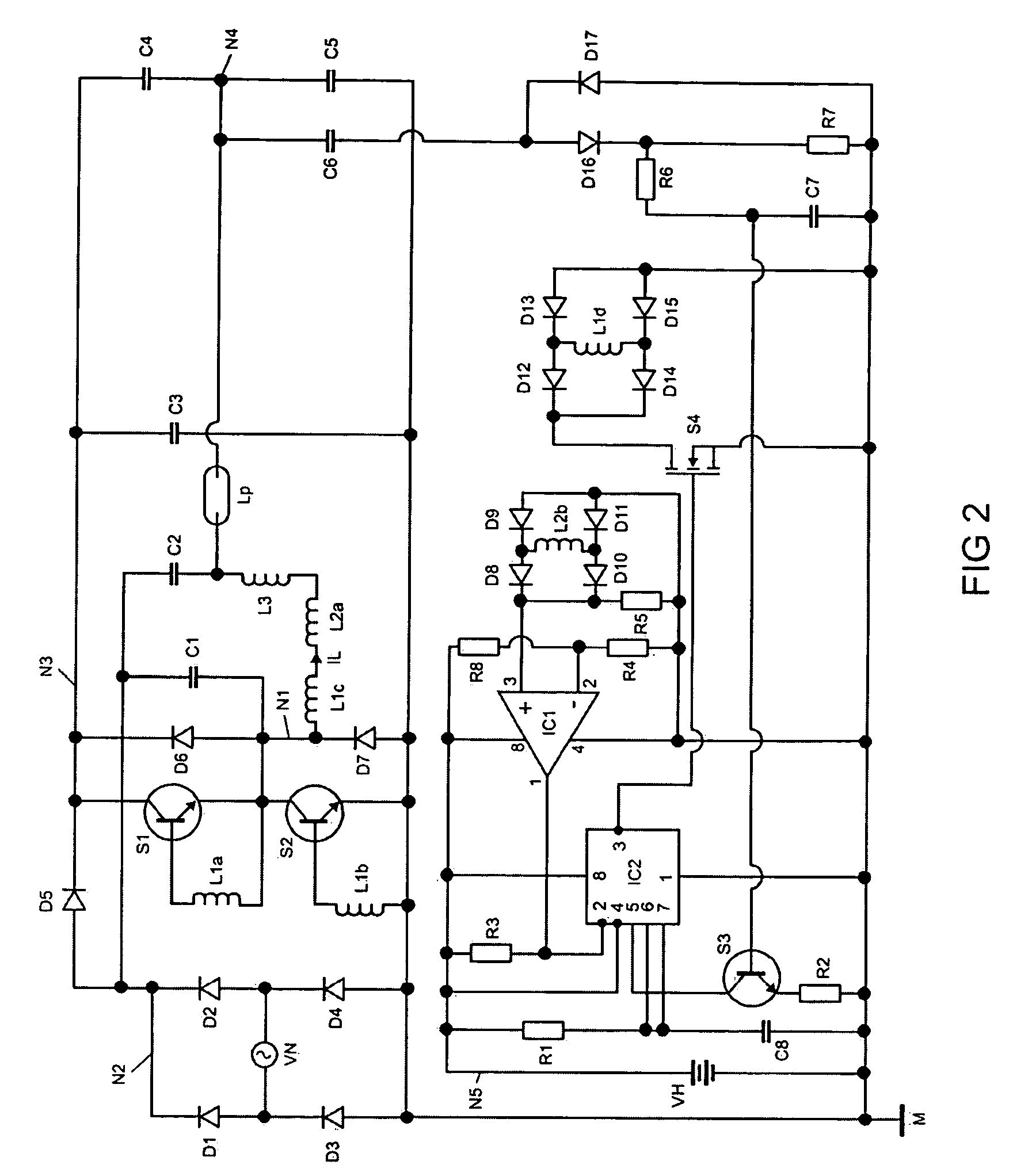

Circuit arrangement and method for operation of lamps

InactiveUS7242154B2Reliable adjustmentAvoid drivingElectrical apparatusElectroluminescent light sourcesGas-discharge lampStops device

Circuit arrangement having a free-running half-bridge inverter for operation of gas discharge lamps. A stop device is used to enable the drive to the half-bridge switches only during an on time. The oscillation frequency of the half-bridge inverter can be adjusted by the duration of the on time. This allows control of the lamp operating variables.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

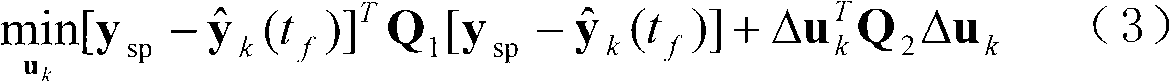

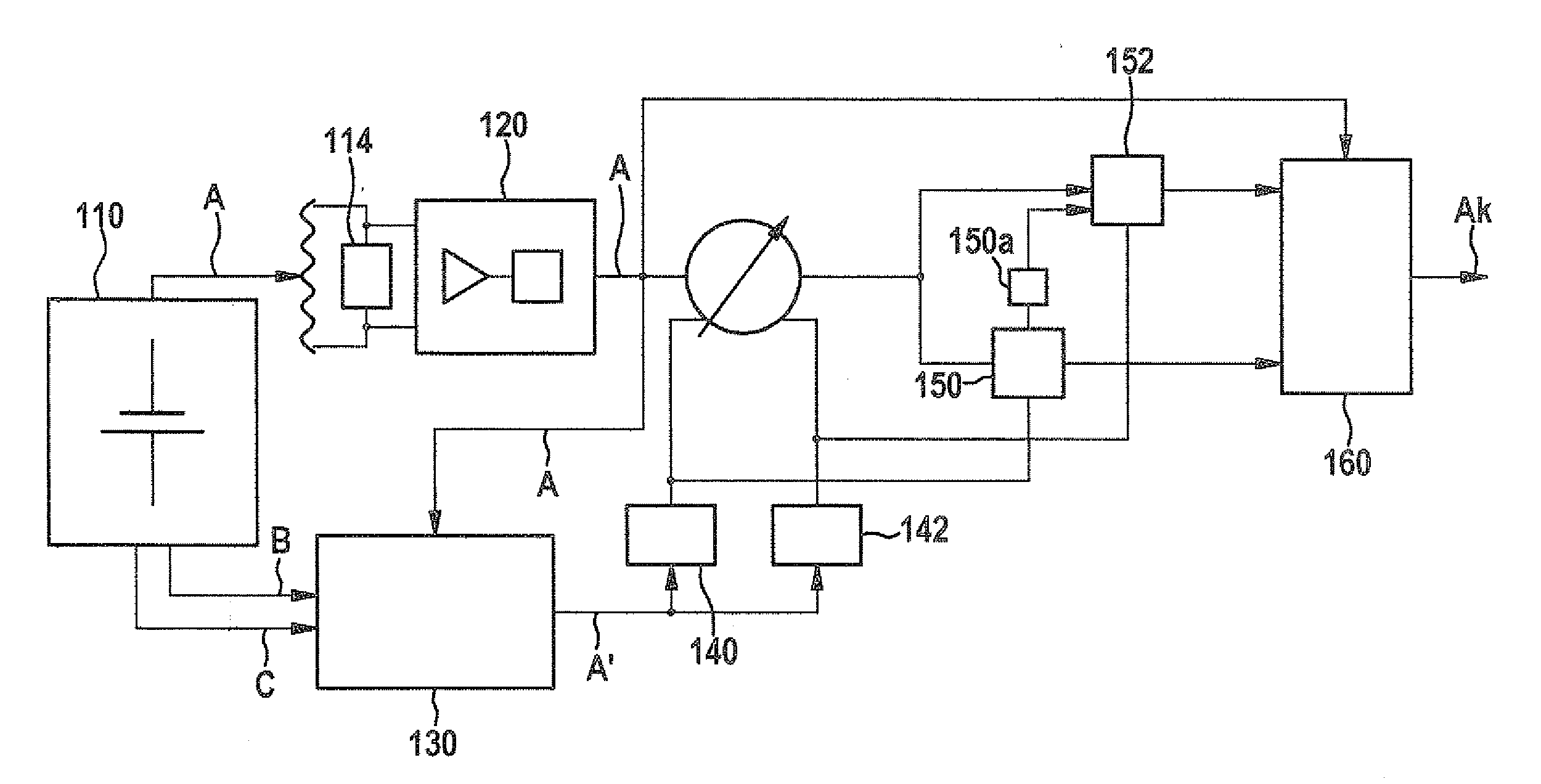

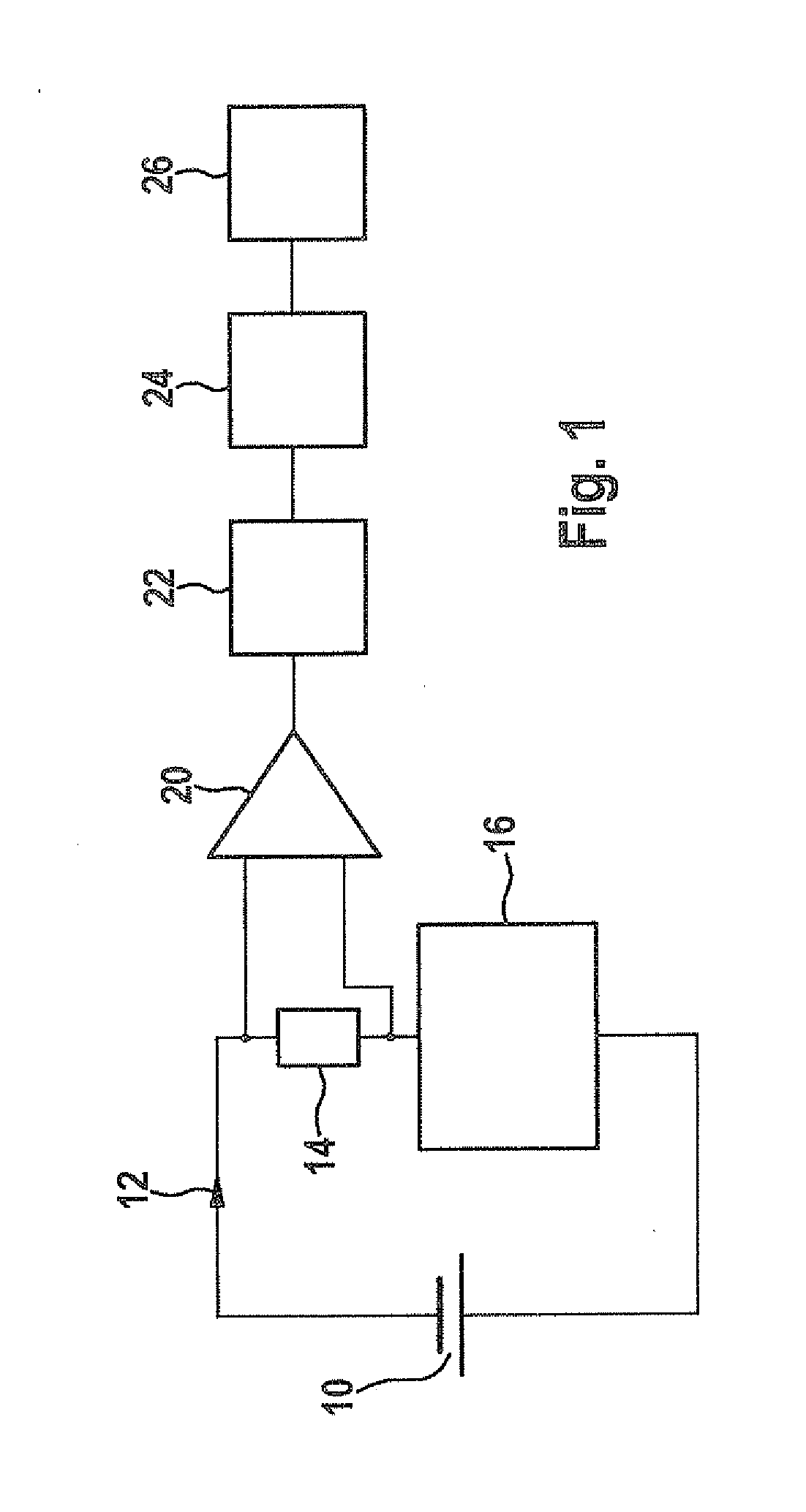

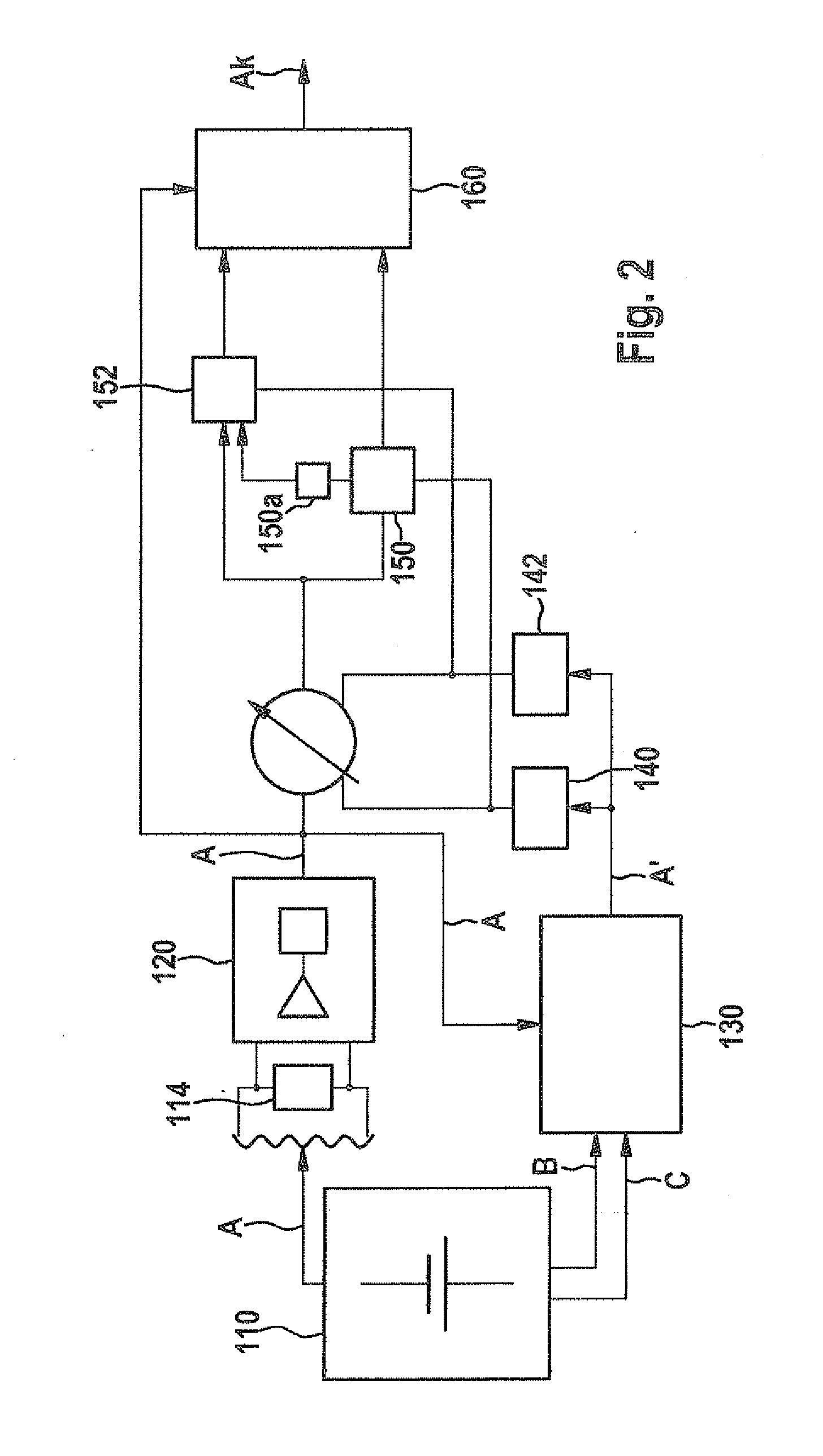

Batch-to-batch optimization method of batch process by combining medium-term correction strategy

The invention relates to a batch-to-batch optimization method of a batch process by combining a medium-term correction strategy. The method comprises the following steps: firstly establishing a quality variable predictive model of an NLPLS, and carrying out prediction on final product quality according to control operation variables of the process; on the basis of the model, calculating an optimal control strategy and implementing the optimal control strategy on a practical device; adopting a recurrence algorithm to carry out updating on the original NLPLS model according the newly-obtained data and old model parameters after each batch is finished; then solving the optimal control strategy again and implementing the optimal control strategy on an object; generally, after several batches, leading the control strategy to converge a satisfactory solution; and simultaneously, in order to process the interference in batches, adopting the medium-term correction strategy, utilizing new information obtained by the current batch to carry out correction on the latter control strategy. The method combines the batch-to-batch optimization and the medium-term correction strategy, makes up the insufficiency that the traditional batch-to-batch optimization method can not process the interference in batches and improves the control performance.

Owner:杭州坤天自动化系统有限公司

Method and device for error-compensated current measurement of an electrical accumulator

InactiveUS20120283970A1Improve Manufacturing TolerancesImprove accuracyElectrical testingCurrent measurements onlyEngineeringRelative maximum

A method for error-compensated current measurement of an electrical accumulator, including: providing a time window-related estimated charge ascertained by a model-based estimator from operating variables of the accumulator and reflecting the estimated charge that has been withdrawn from the accumulator and supplied to the accumulator within the time window; and detecting the accumulator current supplied to the accumulator and withdrawn from the accumulator during the time window, with a current detection sensor. A zero crossing point in time (estimated charge is essentially zero) and a maximum point in time (the absolute value of the estimated charge essentially has a relative maximum or has a value which is greater than a minimum charge difference) are detected. A current measurement offset error is ascertained at the zero crossing point in time by comparing the estimated charge to the detected accumulator current. The accumulator current is ascertained according to the current measurement offset error, and a current measurement scaling error is ascertained at the maximum point in time by comparing the estimated charge to the detected accumulator current. The ascertained current measurement offset error is subtracted from the comparison result thus obtained, and the accumulator current is compensated for based on the current measurement scaling error. A related device for error-compensated current measurement is also described.

Owner:ROBERT BOSCH GMBH

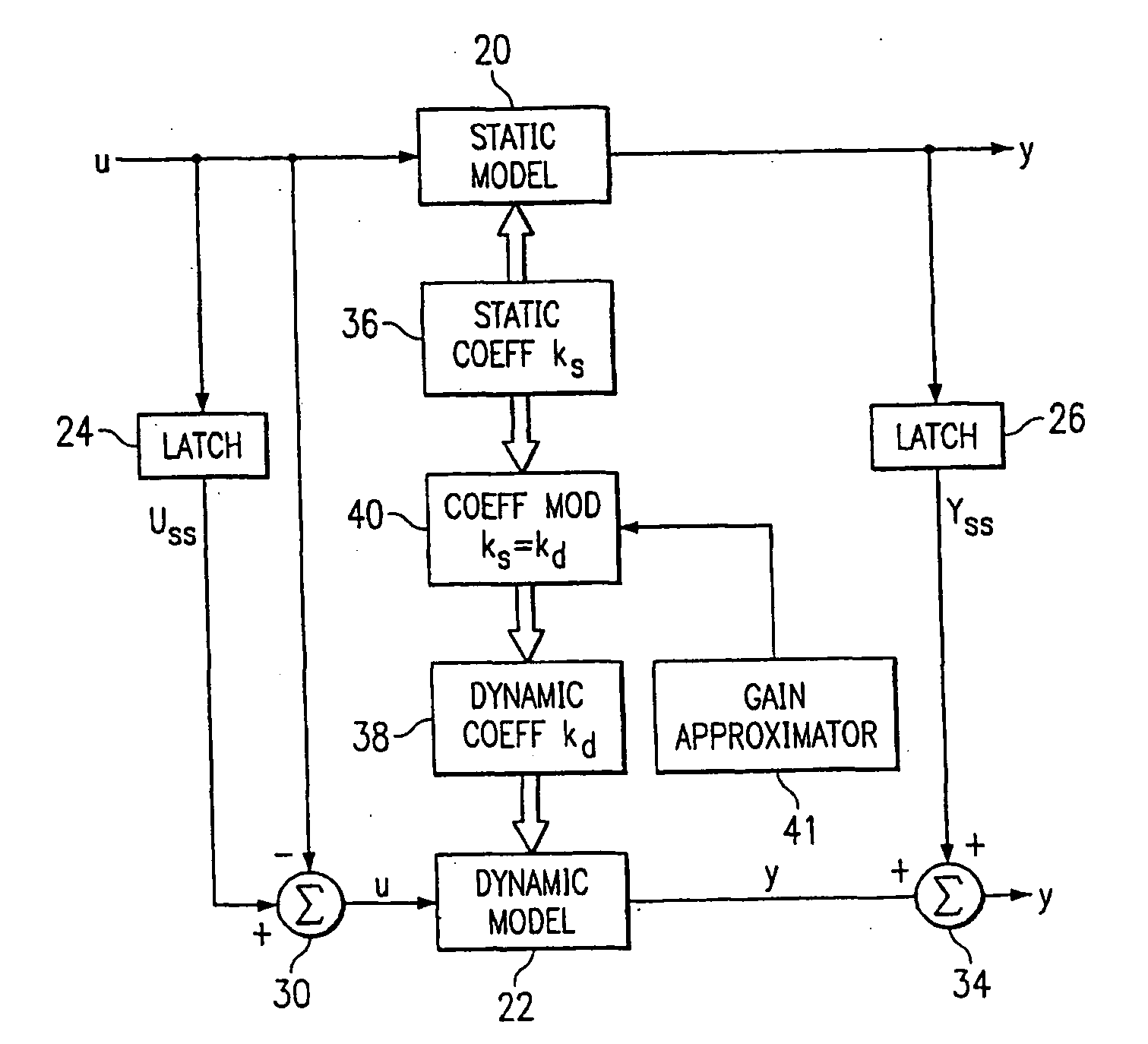

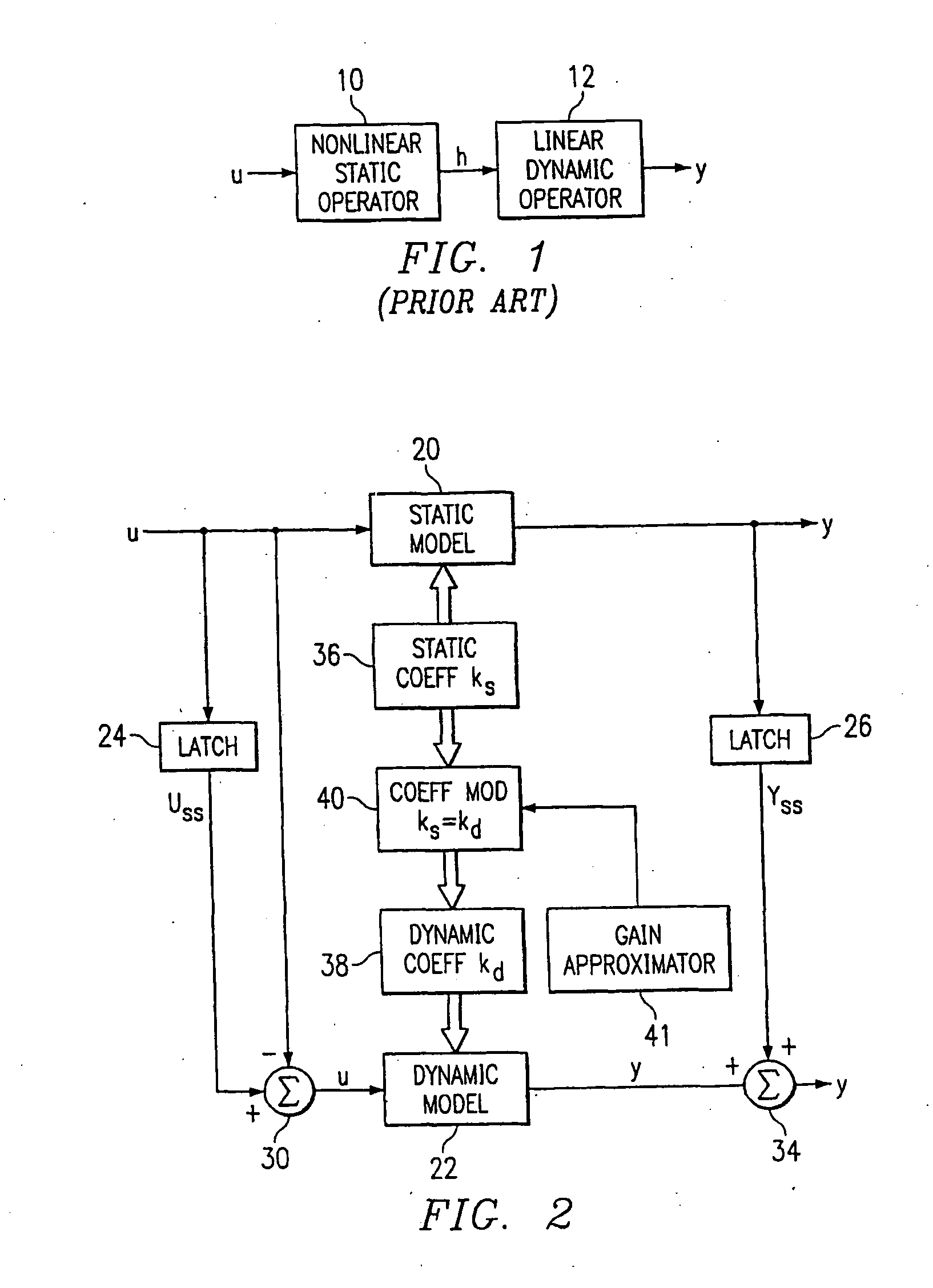

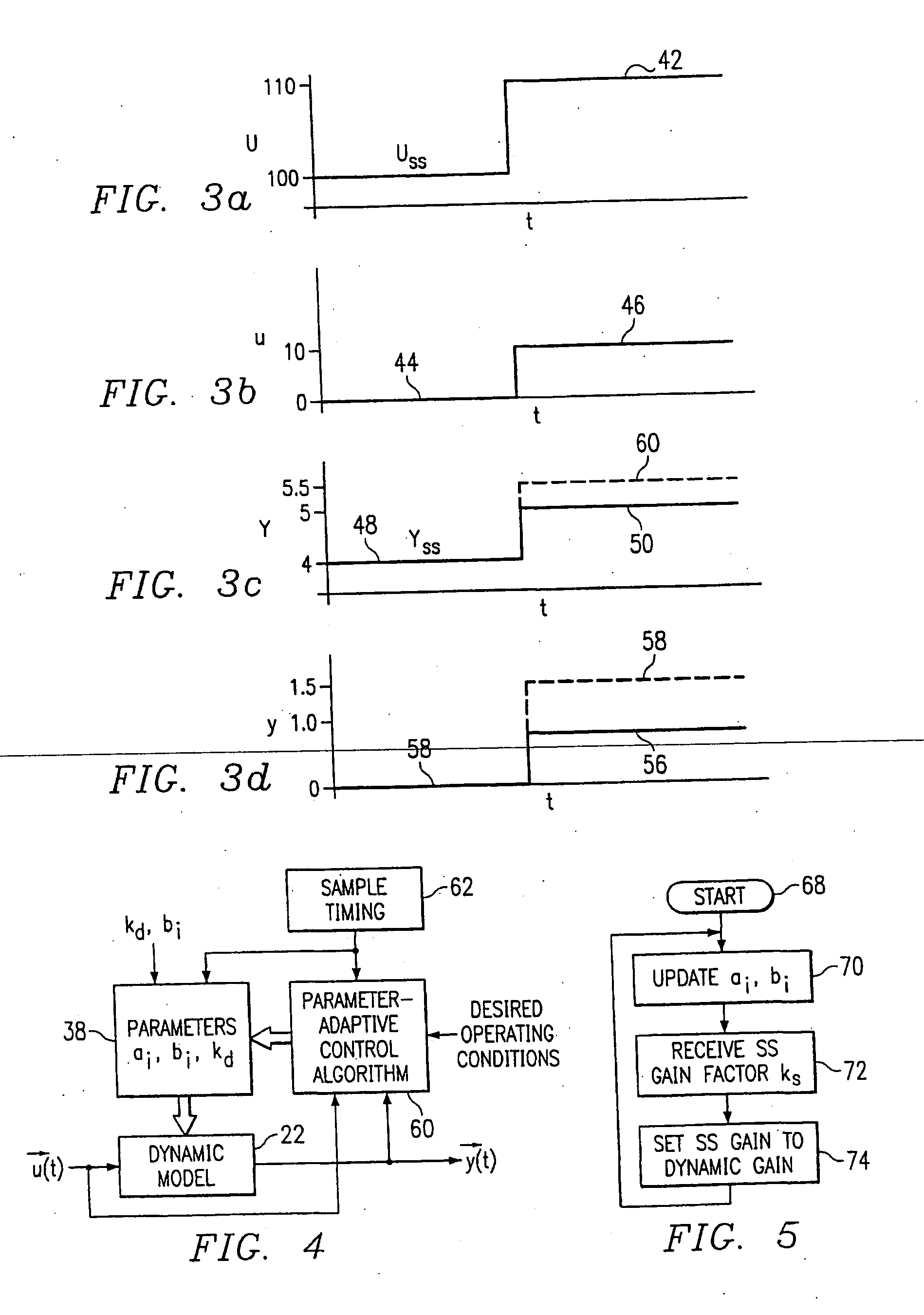

Method and apparatus for approximating gains in dynamic and steady-state processes for prediction, control, and optimization

A method and apparatus for controlling a non-linear mill. A linear controller is provided having a linear gain k that is operable to receive inputs representing measured variables of the plant and predict on an output of the linear controller predicted control values for manipulatible variables that control the plant. A non-linear model of the plant is provided for storing a representation of the plant over a trained region of the operating input space and having a steady-state gain K associated therewith. The gain k of the linear model is adjusted with the gain K of the non-linear model in accordance with a predetermined relationship as the measured variables change the operating region of the input space at which the linear controller is predicting the values for the manipulatible variables. The predicted manipulatible variables are then output after the step of adjusting the gain k.

Owner:ROCKWELL AUTOMATION TECH

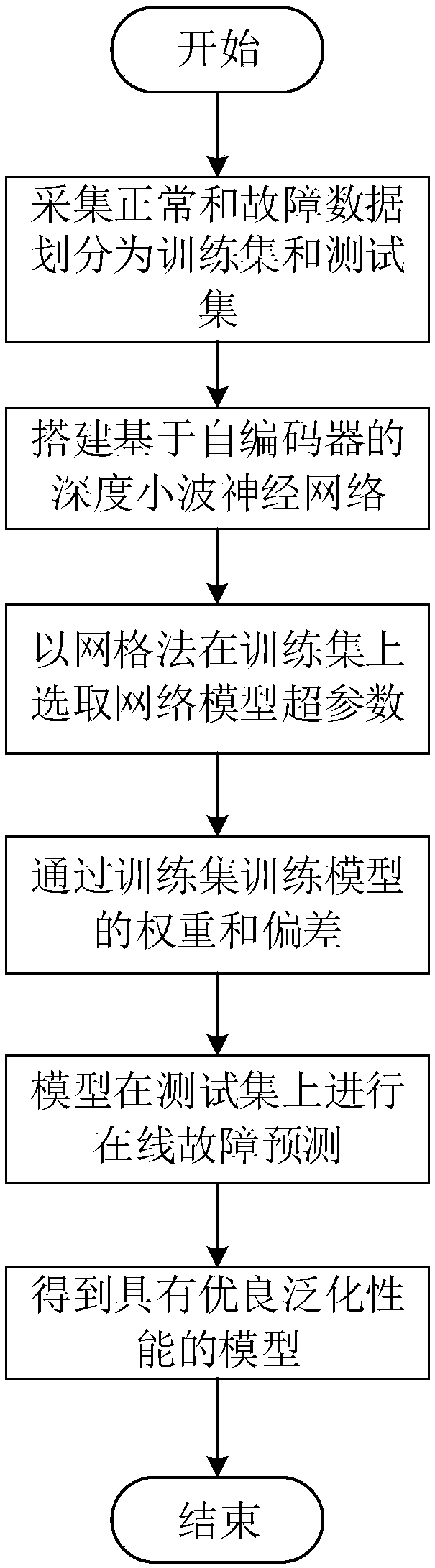

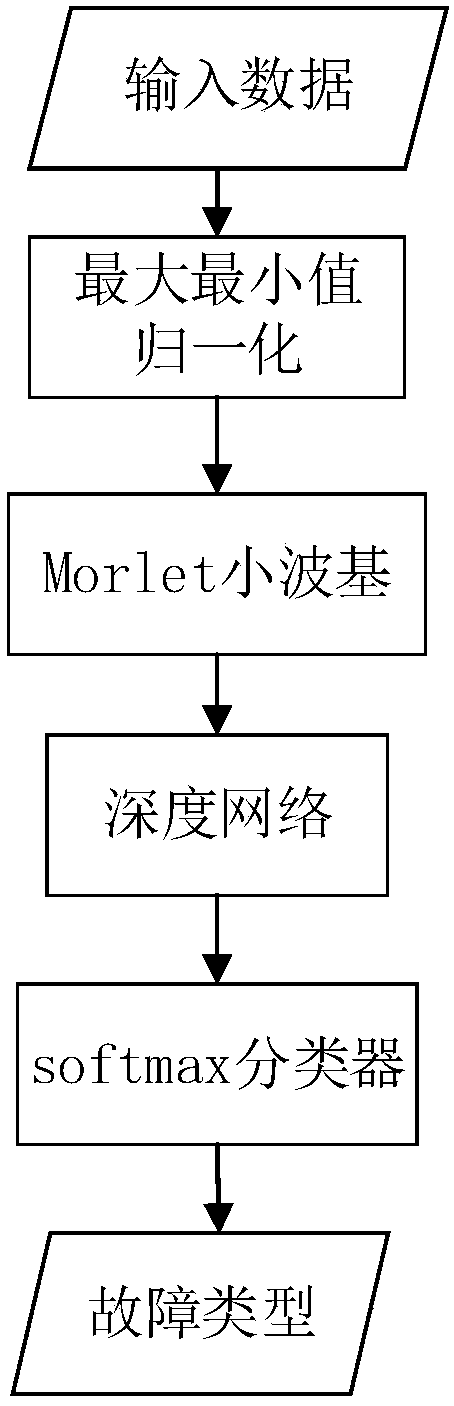

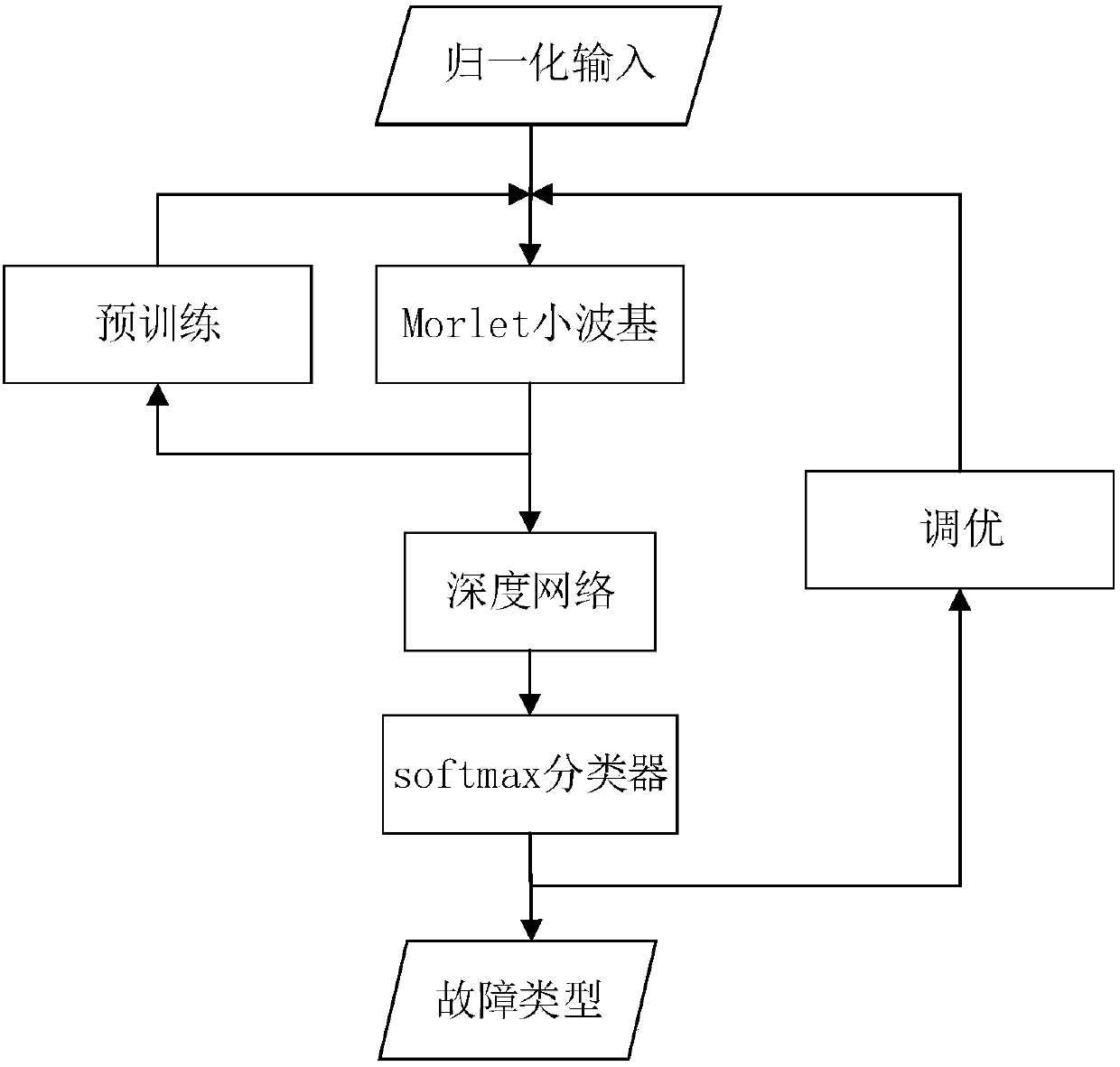

Fault diagnosis method based on deep learning and signal analysis

InactiveCN108519768AEase of overcoming variabilityEasy to overcome complexityElectric testing/monitoringPerformance indexProcess measurement

The invention discloses a fault diagnosis method based on deep learning and signal analysis. The method includes: acquiring data in normal and faulty states of an industrial process in advance, and dividing the data into a training set and a test set; and training model parameters offline based on the training set, detecting a model through the test set, wherein a performance index refers to the precision of fault diagnosis, and a value thereof represents the generalization performance of the model, namely the online diagnosis capability of faults. According to the method, as a variant of a neural network, physical information of a process operation variable in a time domain can be obtained, and frequency domain information of a process measurement variable can be obtained through introduction of a wavelet analysis method; besides, a depth structure adopted by the method adapts to big, fast, various, and uncertain characteristics of industrial big data, the physical information of theprocess operation variable and frequency characteristics of the process measurement variable are combined, a complex mode of a deep grade of the faults is learned, fault diagnosis can be effectively realized, and excellent generalization capability is displayed in an online diagnosis test.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com