Patents

Literature

111 results about "Total Base Number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Total Base Number (TBN) is a measurement of basicity that is expressed in terms of the equivalent number of milligrams of potassium hydroxide per gram of oil sample (mg KOH/g). TBN is an important measurement in petroleum products, and the value varies depending on its application. TBN generally ranges from 6–8 mg KOH/g in modern lubricants, 7–10 mg KOH/g for general internal combustion engine use and 10–15 mg KOH/g for diesel engine operations. TBN is typically higher for marine grade lubricants, approximately 15-80 mg KOH/g, as the higher TBN values are designed to increase the operating period under harsh operating conditions, before the lubricant requires replacement.

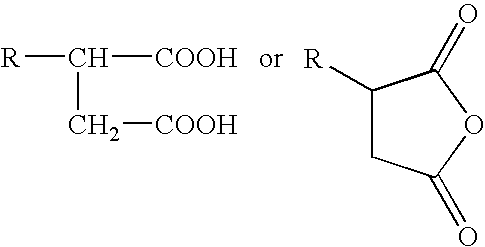

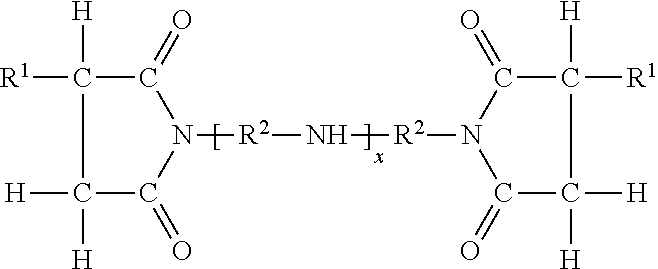

Low-chlorine, polyolefin-substituted, with amine reacted, alpha-beta unsaturated carboxylic compounds

A composition of matter comprising an amine acylated with a hydrocarbyl group substituted carboxylic acylating agent containing an average of from 1.3 to 1.6 groups derived from α,β-unsaturated carboxylic compounds per Mn of the hydrocarbyl group, wherein the hydrocarbyl group has Mn determined by GPC ranging from 1500 to 3000, the amine comprises polyamine bottoms and said acylated amine has total base number (TBN) ranging from 17 to 35. A method for preparing the composition, lubricating oils containing the composition and, in another embodiment, lubricating oil compositions of this invention further comprising a metal overbased sulfonate detergent.

Owner:THE LUBRIZOL CORP

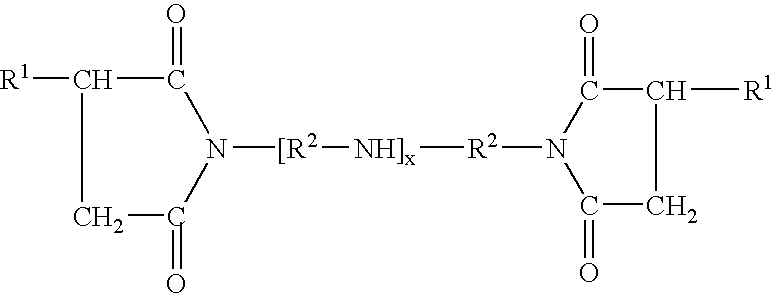

Nitrogen-containing Dispersant as an Ashless TBN Booster for Lubricants

Lubricant compositions comprising (a) an oil of lubricating viscosity; and (b) at least one non-metal-containing additive, comprising a nitrogen-containing dispersant having a total base number of at least about 90 are useful for lubricating an internal combustion engine. The lubricants have less than 1.0% sulfated ash and a total base number of at least about 8.5, and at least 30% of the total base number of the composition is provided by non-metal-containing additives. The lubricants exhibit a high TBN without deterioration of elastomeric seals.

Owner:THE LUBRIZOL CORP

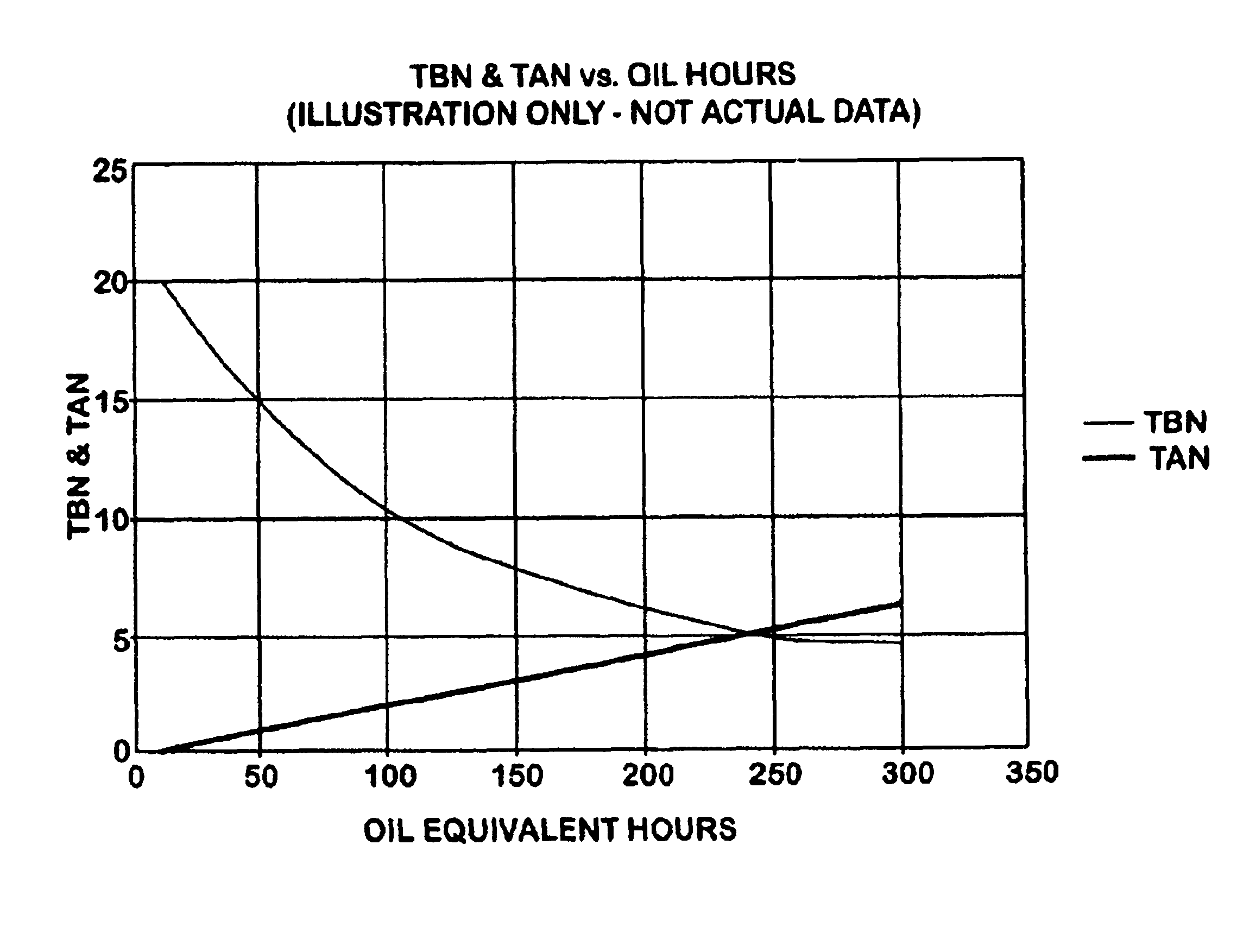

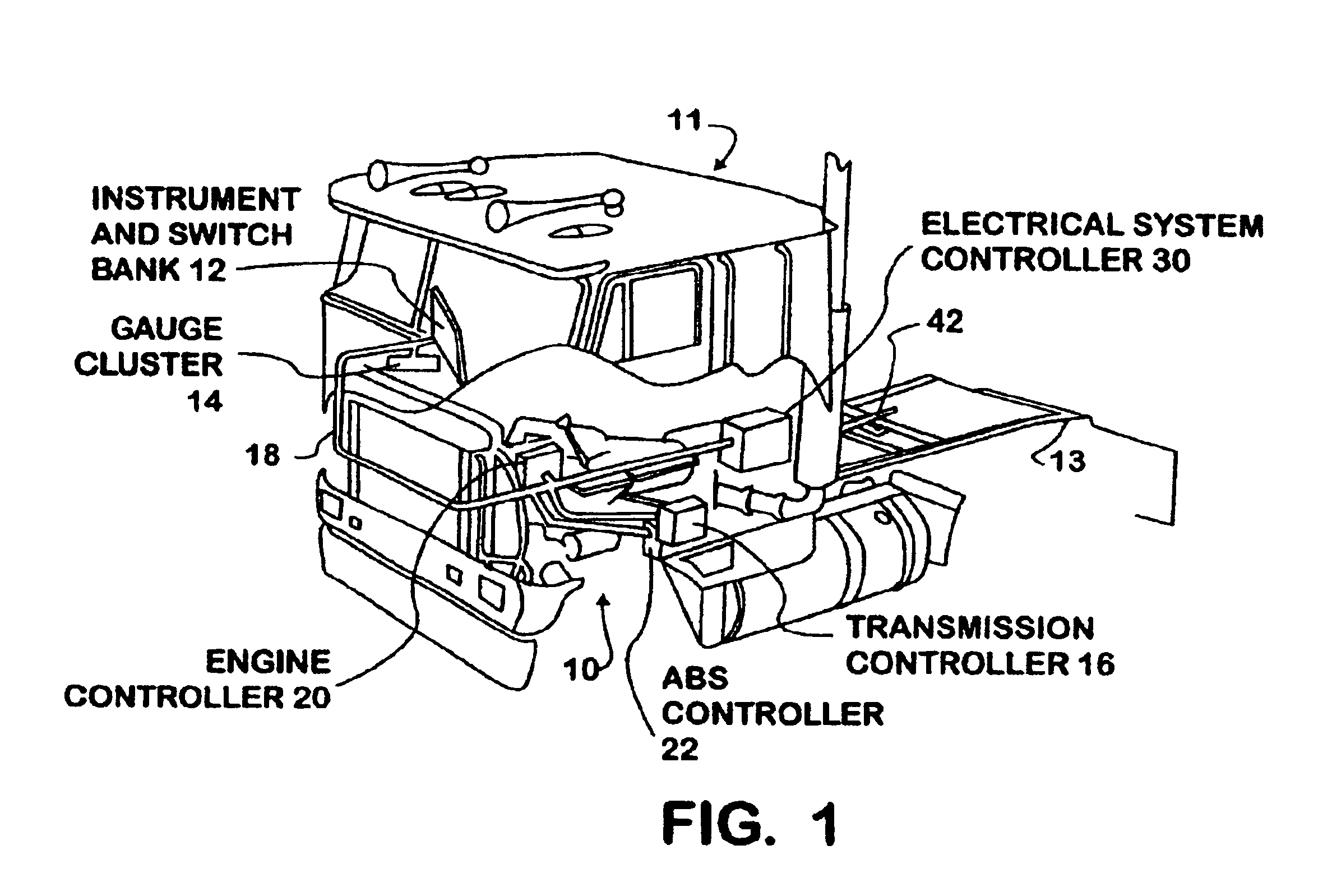

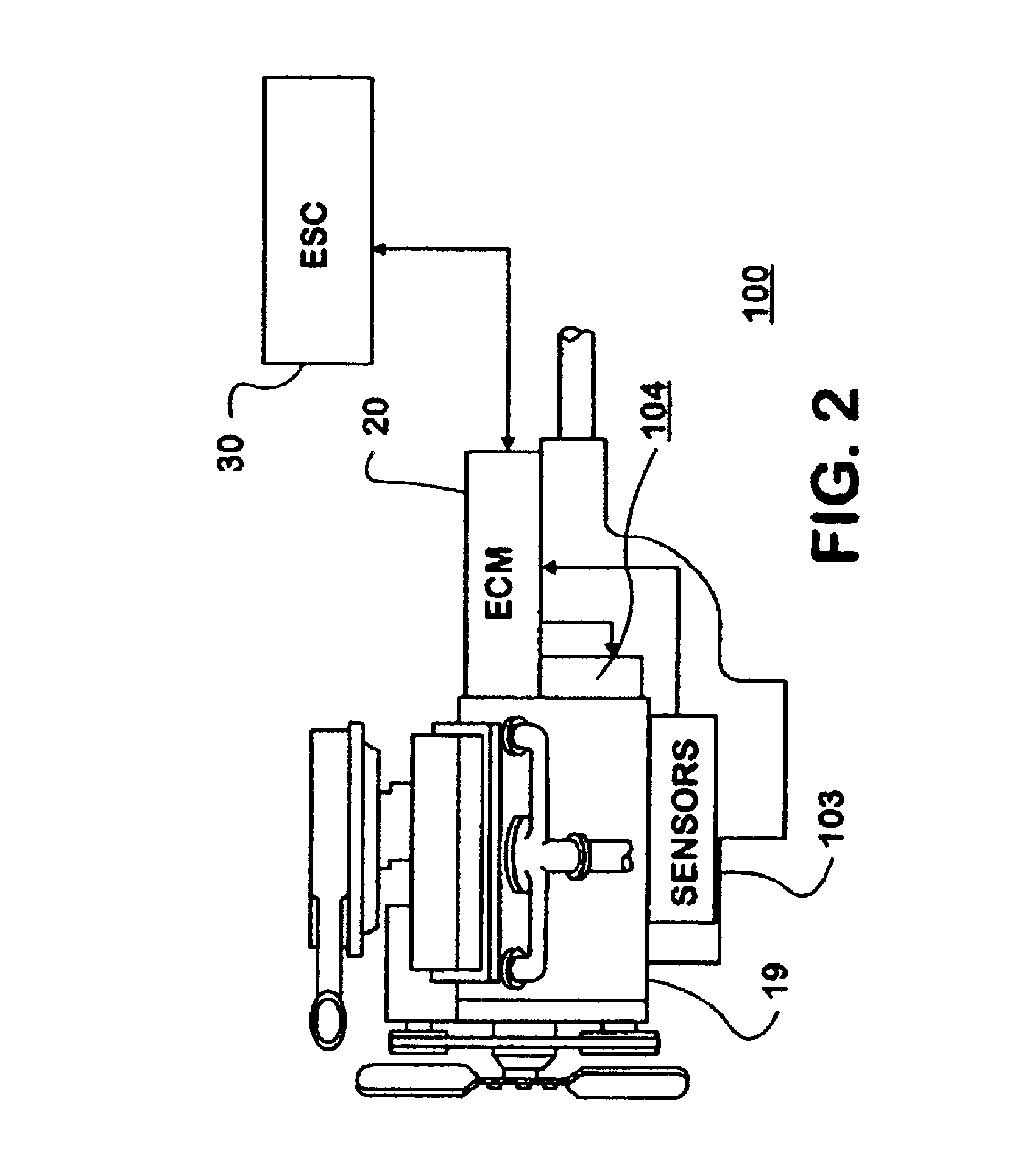

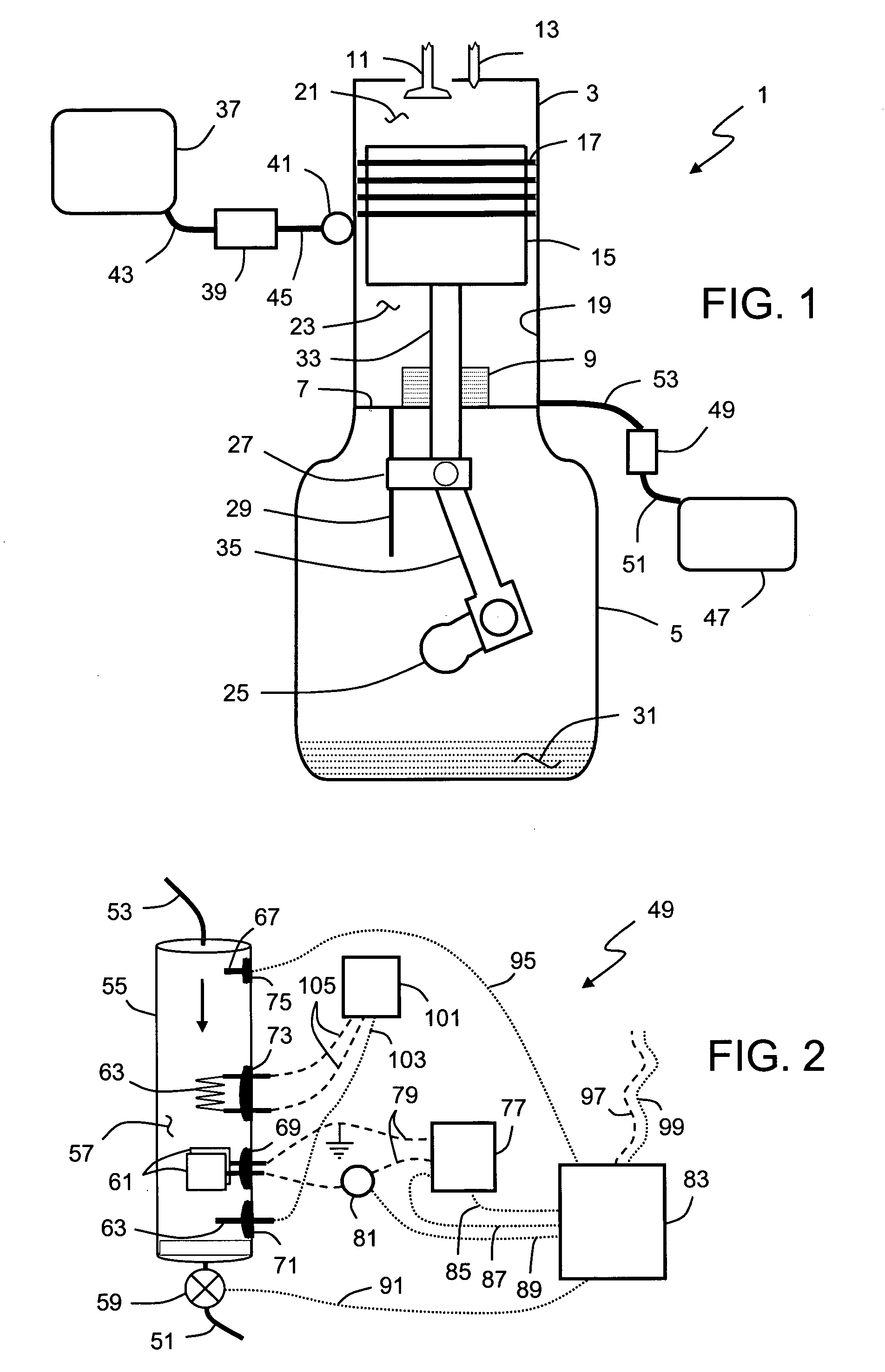

Method of estimating engine lubricant condition

A motor vehicle having an internal combustion engine and a lubricating oil circulation system provides estimates of the distance remaining before an oil change becomes imperative. An indirect estimate of the depletion of various additives and the deterioration of oil operating characteristics is based on engine operating variables including oil temperature, ignition timing and engine load. The limit of depletion of total base number is dynamic, since it is set against total acid number and the two figures are independently calculated.

Owner:INT TRUCK INTPROP LLC

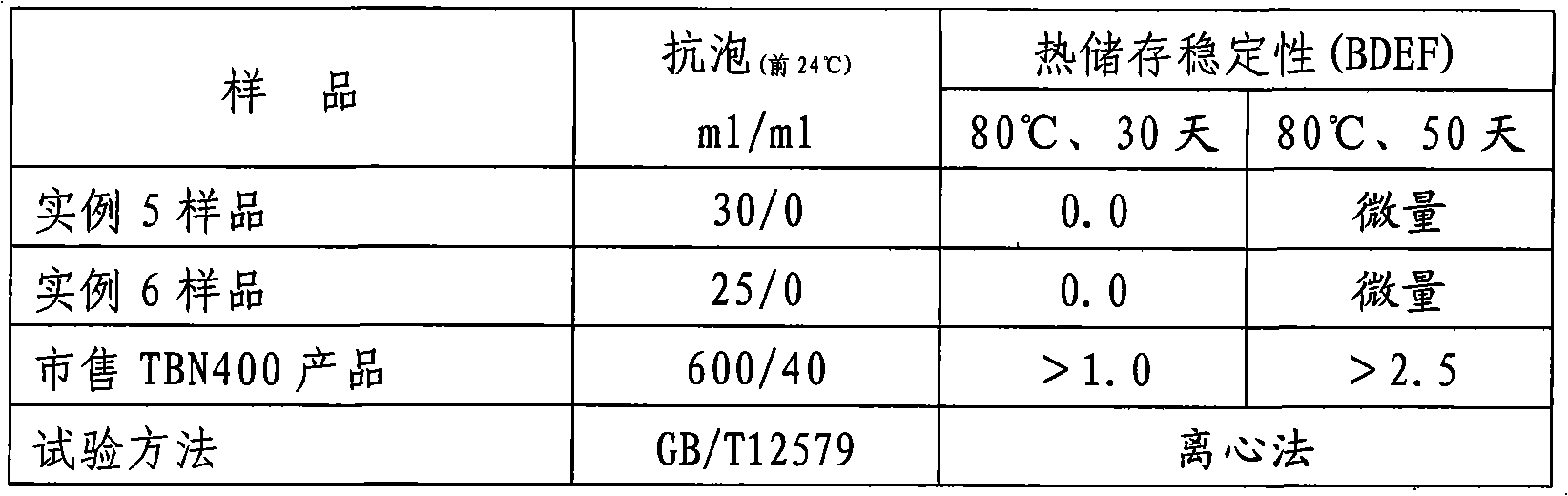

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

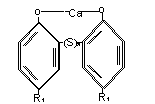

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

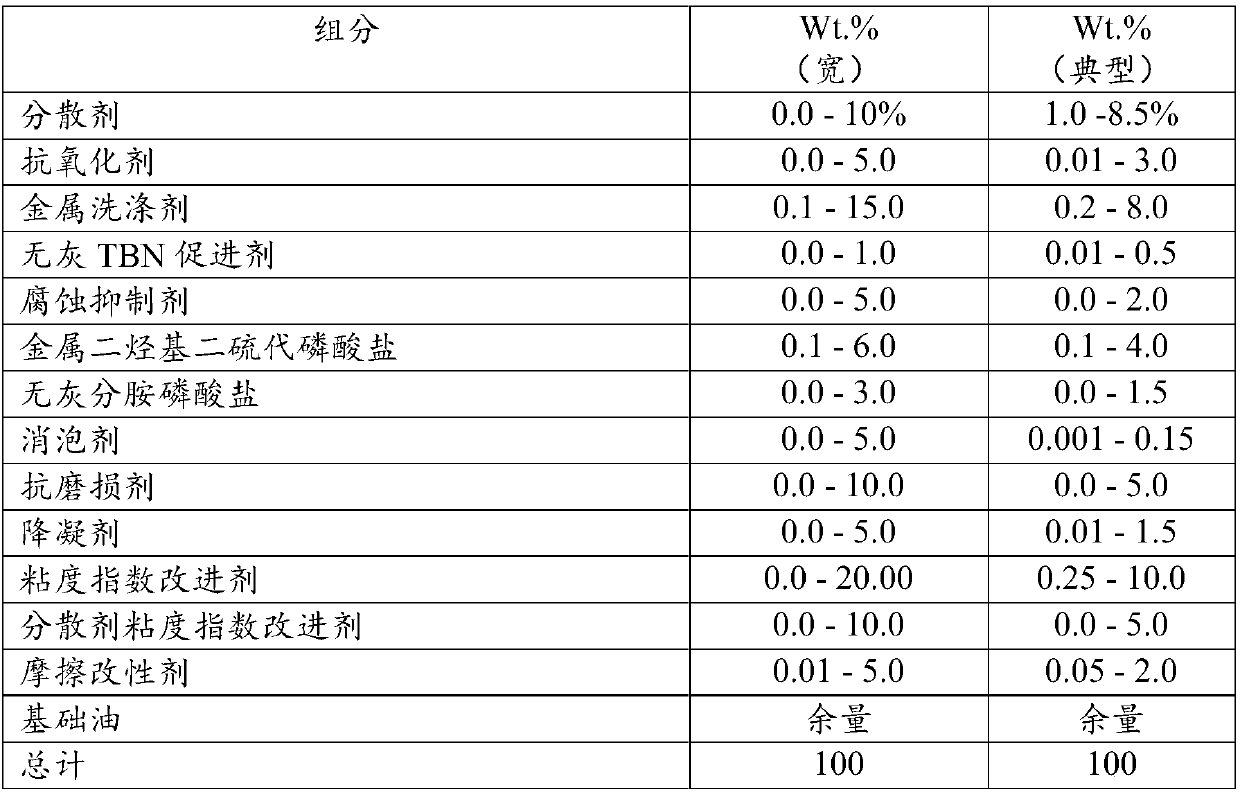

Lubricating oil composition for internal combustion engines

ActiveUS20060025313A1Improve fuel economyLow in phosphorusGroup 3/13 element organic compoundsAdditivesTotal Base NumberAlkaline earth metal

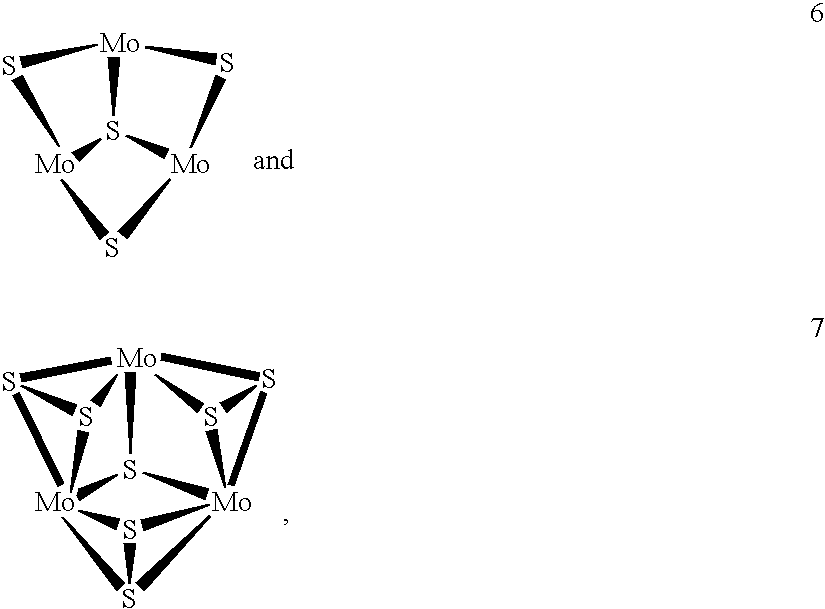

The present invention relates to a low phosphorus lubricating oil composition for internal combustion engines which demonstrates fuel economy benefits while also providing high temperature oxidation, piston deposits, and wear. The lubricating oil composition of the present invention comprises: a) major amount of a base oil of lubricating viscosity; b) from about 0.1 to 10 wt % of an overbased alkaline earth metal alkyl aryl sulfonate detergent having a total base number (TBN) of about 25 to 500; c) from about 0.02 to 10 wt % of a oxymolybdenum-containing complex; d) from about 0.1 to 5 wt % of a friction modifier; and e) from about 0.2 to 10 wt % of an antioxidant selected from the group consisting of a diphenylamine type, a sulfurized ester-containing compound and mixtures thereof; wherein the total concentration of the oxymolybdenum-containing complex and antioxidant must be at least 1.3 wt %, based on the total weight of the lubricating oil composition and wherein the phosphorus content of the total lubricating oil composition is 0.08 wt % or less, based on the total weight of the lubricating oil composition.

Owner:CHEVRON ORONITE CO LLC

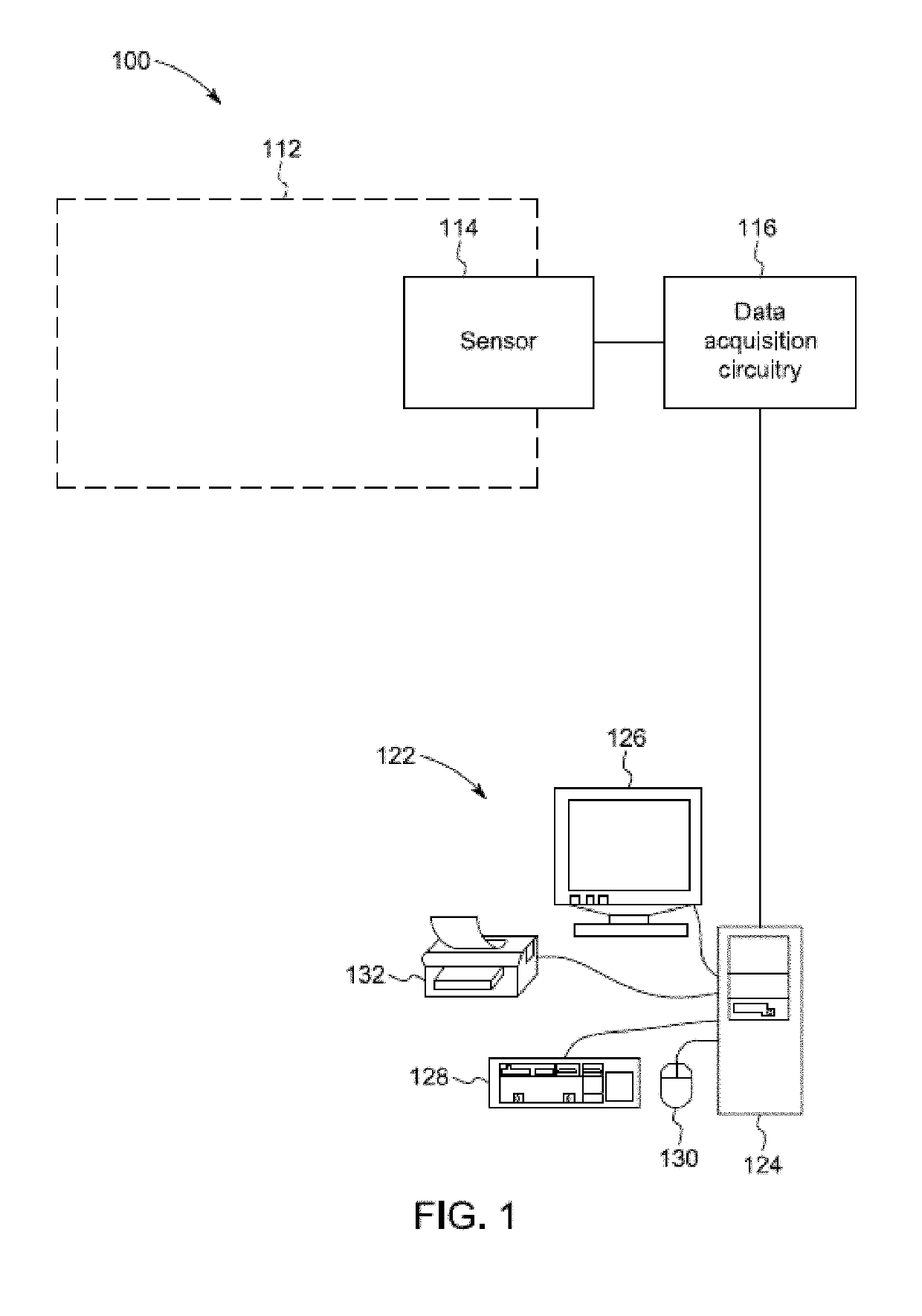

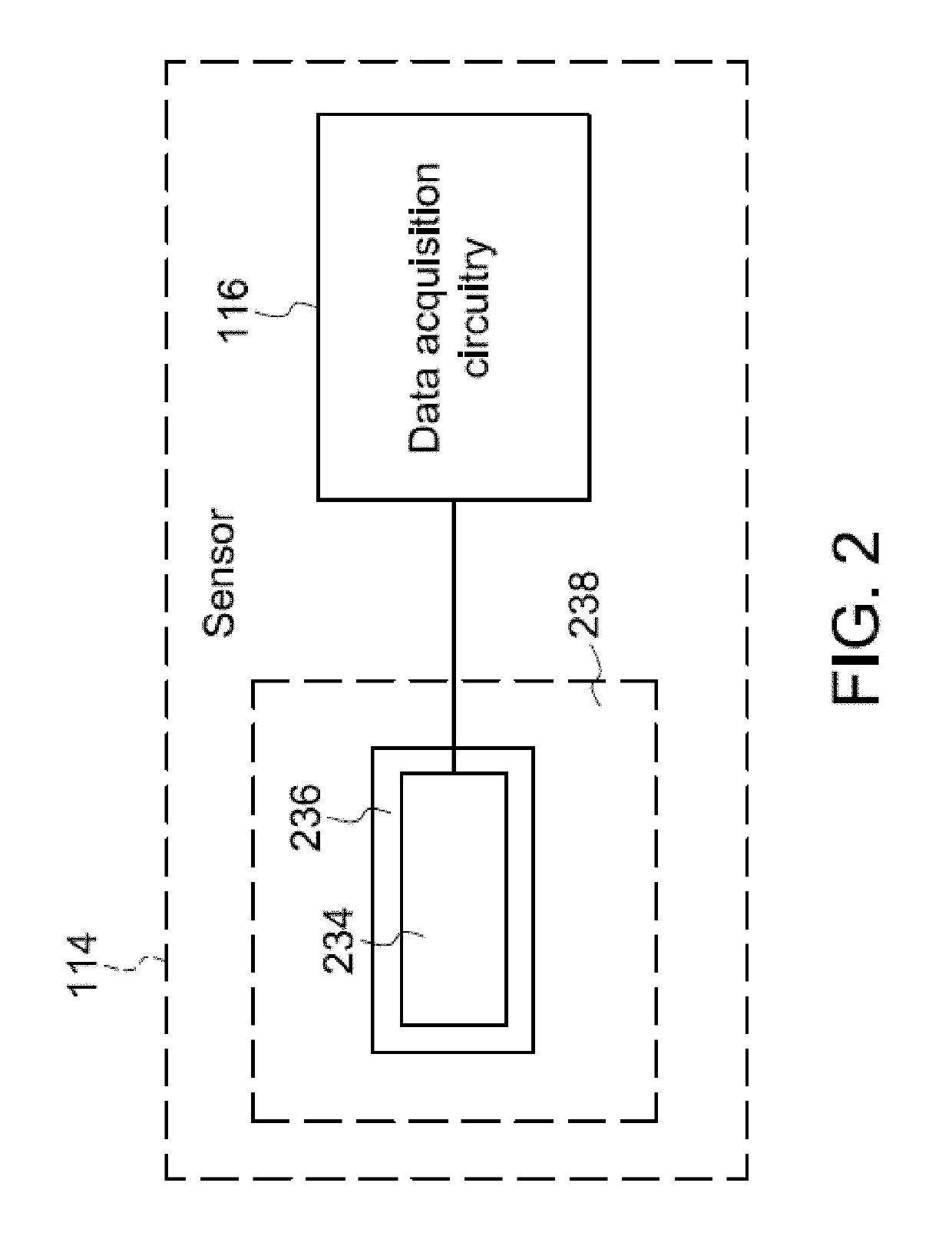

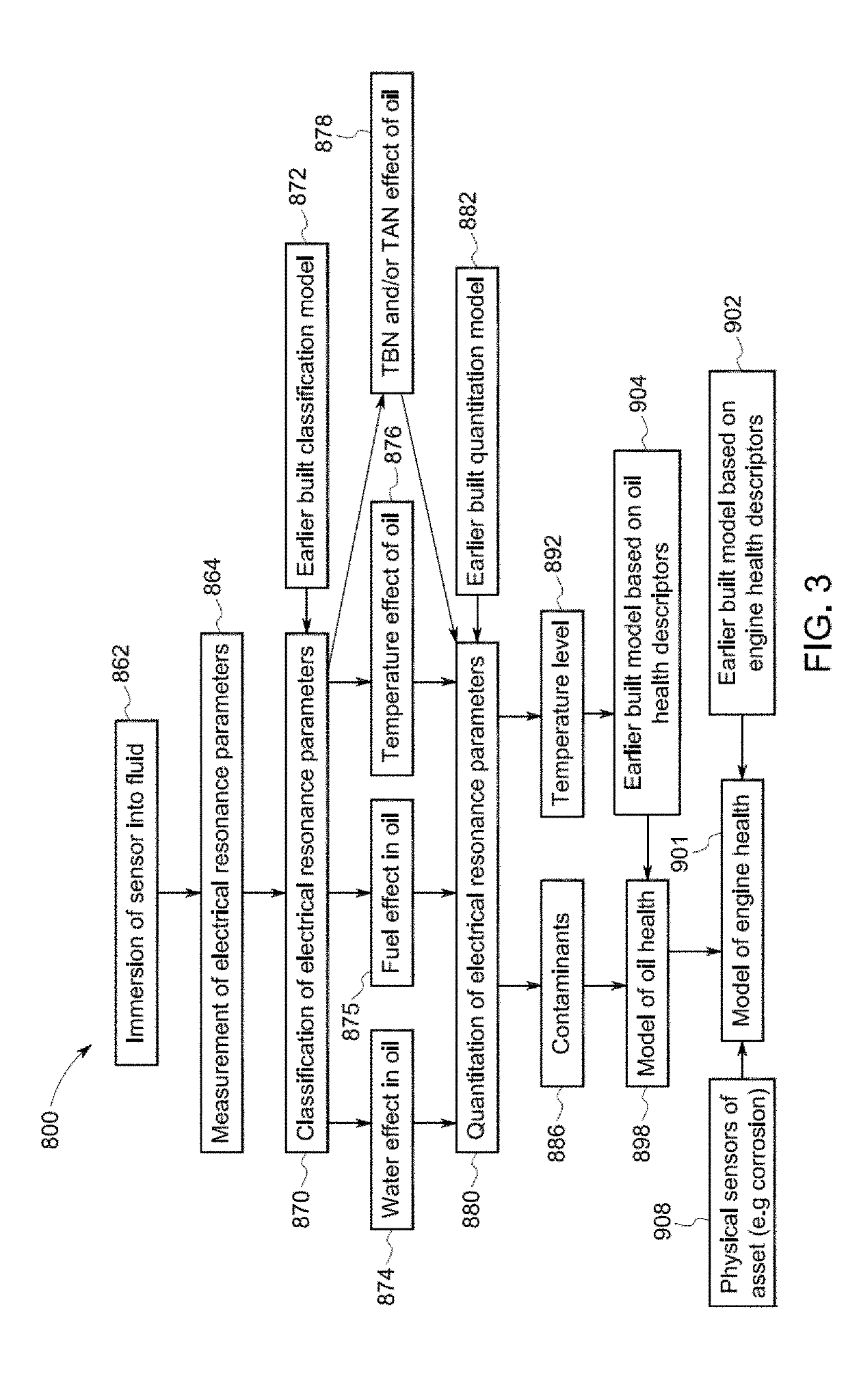

Locomotive sensor system for monitoring engine and lubricant health

PendingUS20190156600A1Registering/indicating working of vehiclesRailway transportTotal Base NumberEngineering

A locomotive sensor system includes a sensor configured to be in contact with lubricant within an engine of a locomotive. The sensor includes a sensing region circuit that is configured to generate stimuli at different times during an operational life of the engine. The system also includes one or more processors configured to receive signals from the sensor. The signals are representative of responses of the lubricant to the stimuli. The one or more processors are configured to analyze the responses and determine a characteristic of the lubricant that represents one or more of a total base number (TBN) or a total acid number (TAN) of the lubricant. The are configured to determine an unhealthy state of one or more of the engine or the lubricant based on the characteristic of the lubricant that is determined.

Owner:GE GLOBAL SOURCING LLC

Lubricating oil compositions

InactiveUS7018958B2Non-fuel substance addition to fuelCombustion enginesTotal Base NumberChemical composition

A lubricating oil composition having a total base number of at least about 8, comprising a major amount of oil of lubricating viscosity; an amount of one or more dihydrocarbyl dithiophosphate metal salt introducing into the lubricating oil composition no more than 0.06 wt. % of phosphorus; at least 1.2 wt. % of hindered phenol antioxidant; and boron, and / or a boron-containing compound or compounds in an amount providing the lubricating oil composition with at least 200 ppm by weight of boron, all weight percentages being based on the total weight of the lubricating oil composition.

Owner:INFINEUM INT LTD

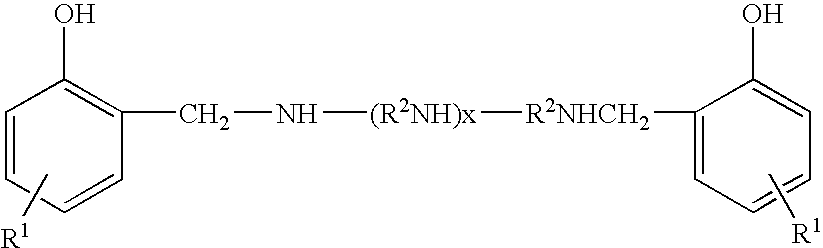

Carboxylated detergent-dispersant-containing compositions having improved properties in lubricating oils

A lubricant additive composition comprising (a) a carboxylated detergent-dispersant obtained by (i) neutralizing alkylphenols using an alkaline earth base in the presence of at least one carboxylic acid that contains from one to four carbon atoms but in the absence of alkali base, dialcohol, and monoalcohol, forming an intermediate product, then (ii) carboxylating the intermediate product using carbon dioxide so that at least 20 mole percent of the original alkylphenol starting material has been converted to single aromatic-ring hydrocarbyl salicylate; and (b) an overbased, non-sulfonate-containing detergent such as, for instance, a hydrocarbyl phenate-carboxylate; a medium overbased salicylate having a total base number of about 50 to 170; a high overbased salicylate having a total base number greater than 170; or an overbased sulfurized hydrocarbyl phenate of alkaline earth metals; and combinations and mixtures thereof. Also provided for are additive packages and finished lubricating oil compositions comprising the same. The compositions of this invention reduce sludge and contaminant formation, especially in low and medium speed diesel engines and in marine diesel engines.

Owner:CHEVROU USA INC

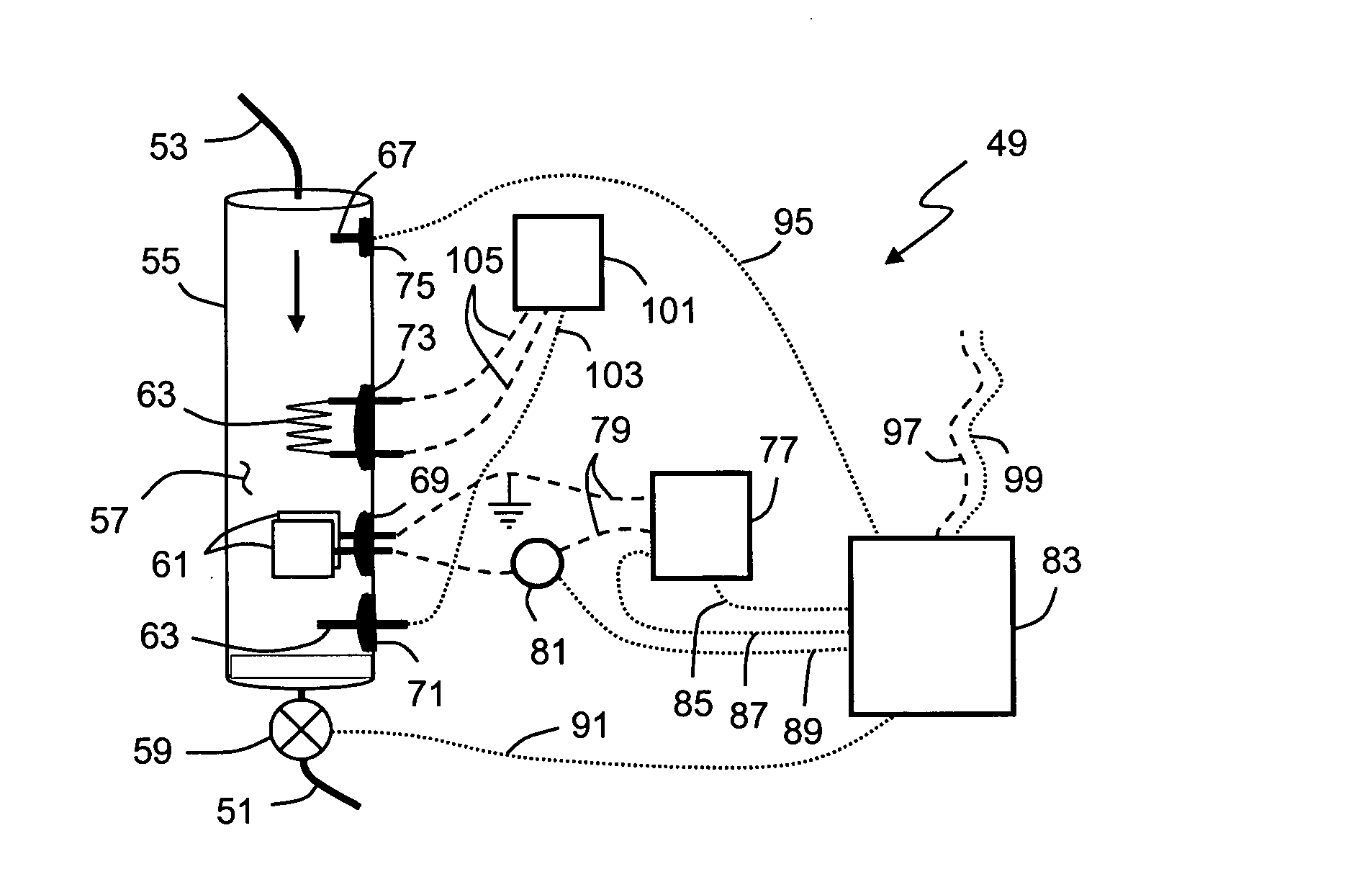

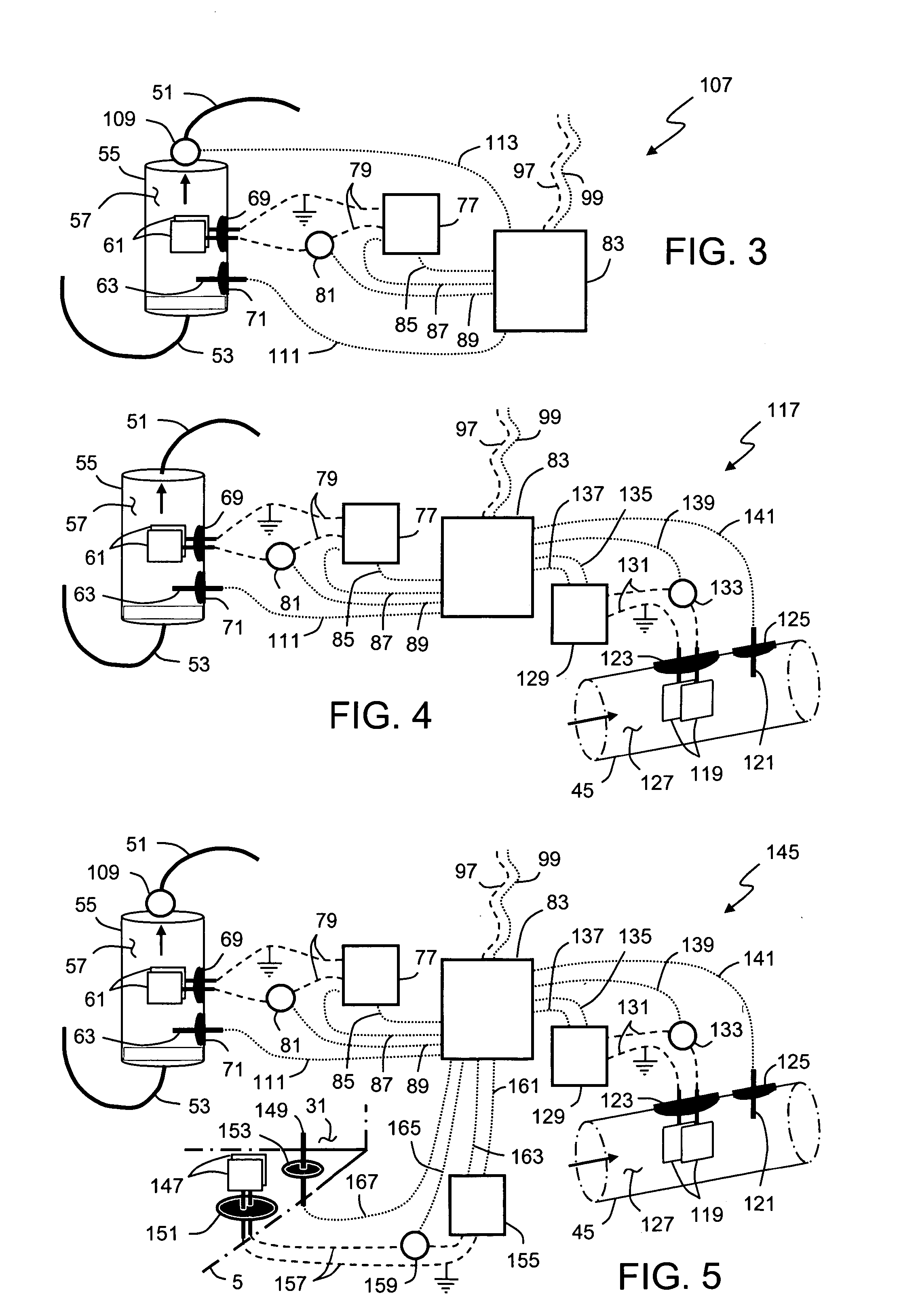

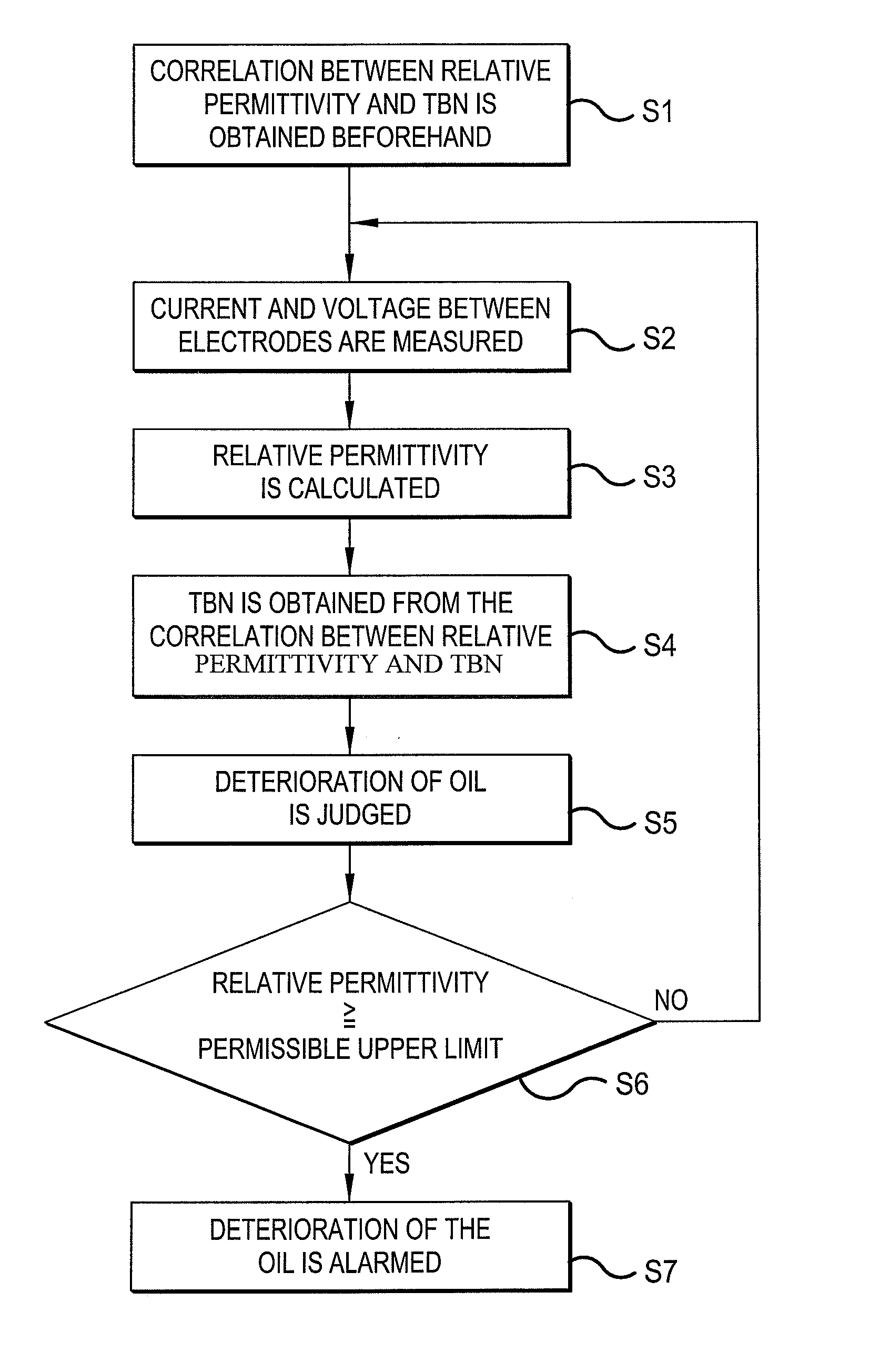

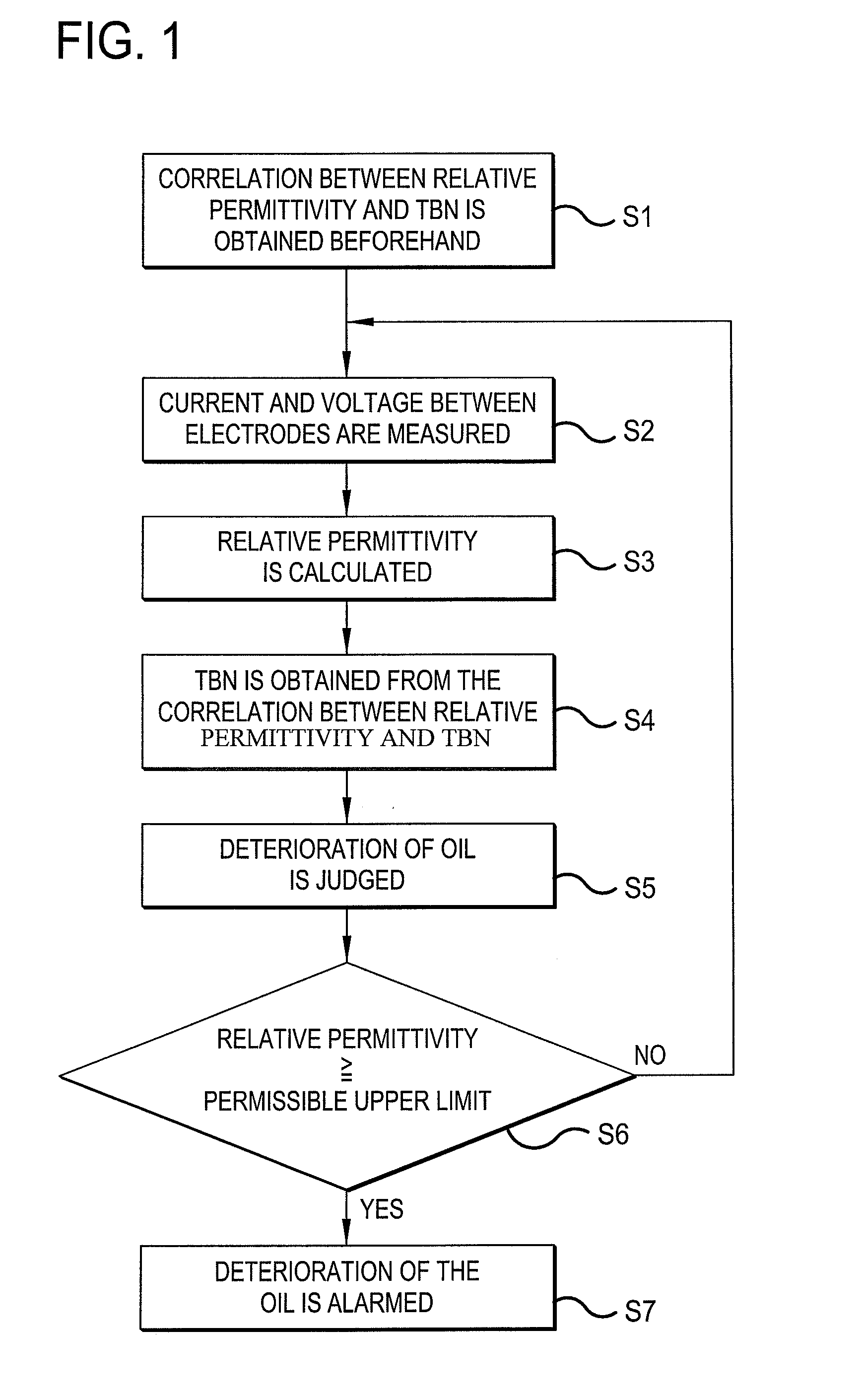

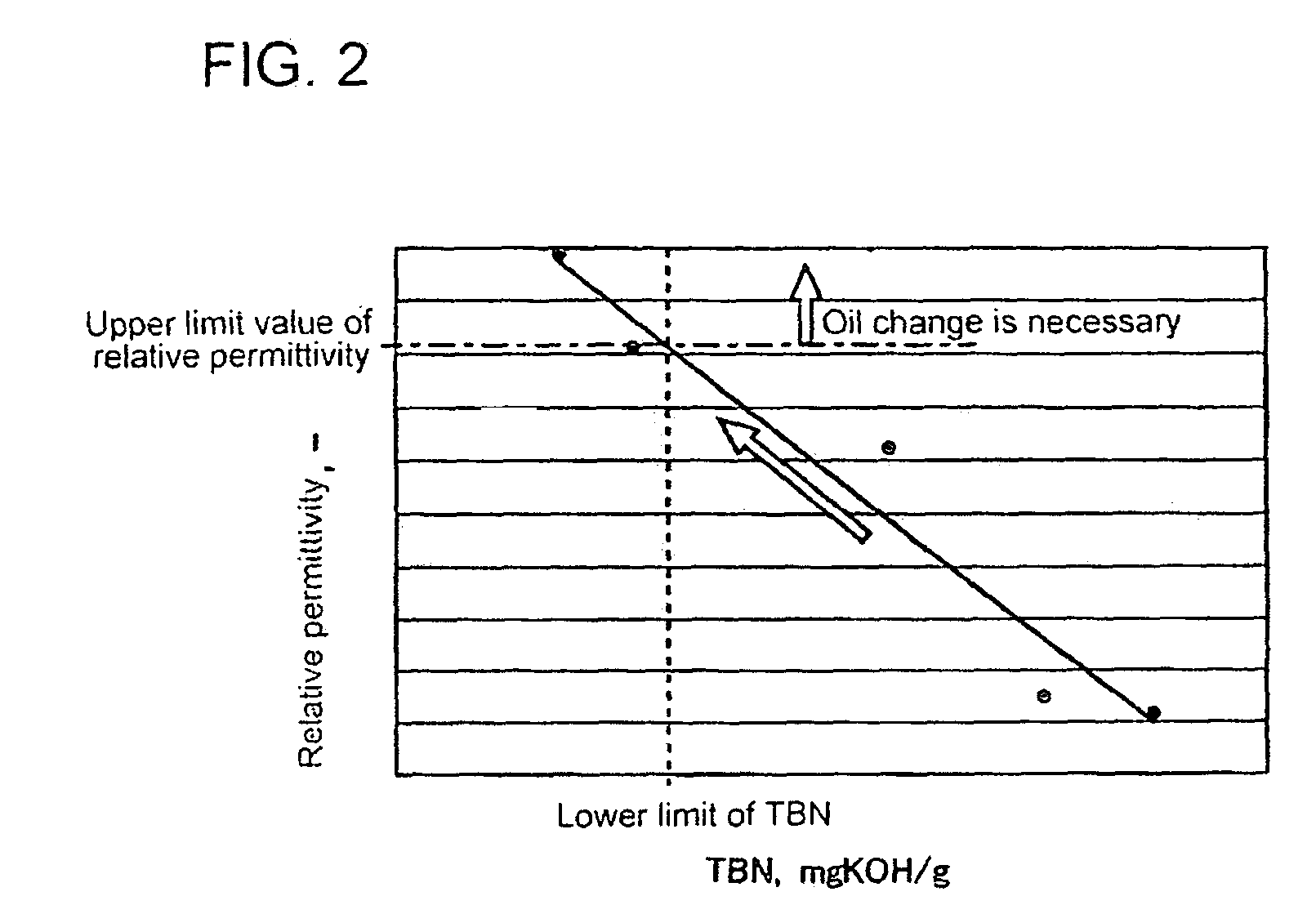

Method of monitoring deterioration of lubricating oil and device therefore

InactiveUS20090216471A1Stable measurement of permittivityUnnecessary changing of oil can be evadedResistance/reactance/impedenceVoltage-current phase angleTotal Base NumberForeign matter

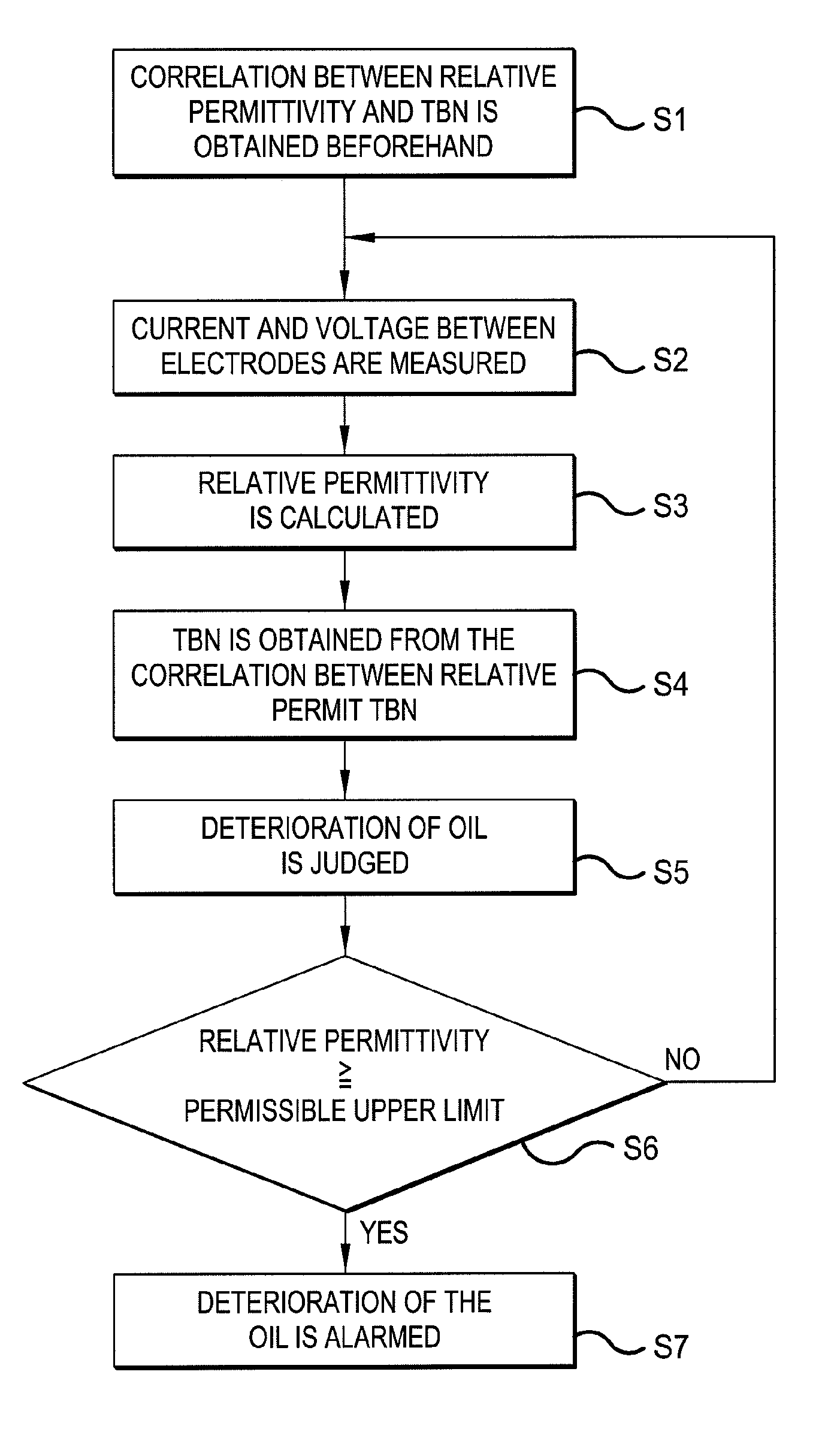

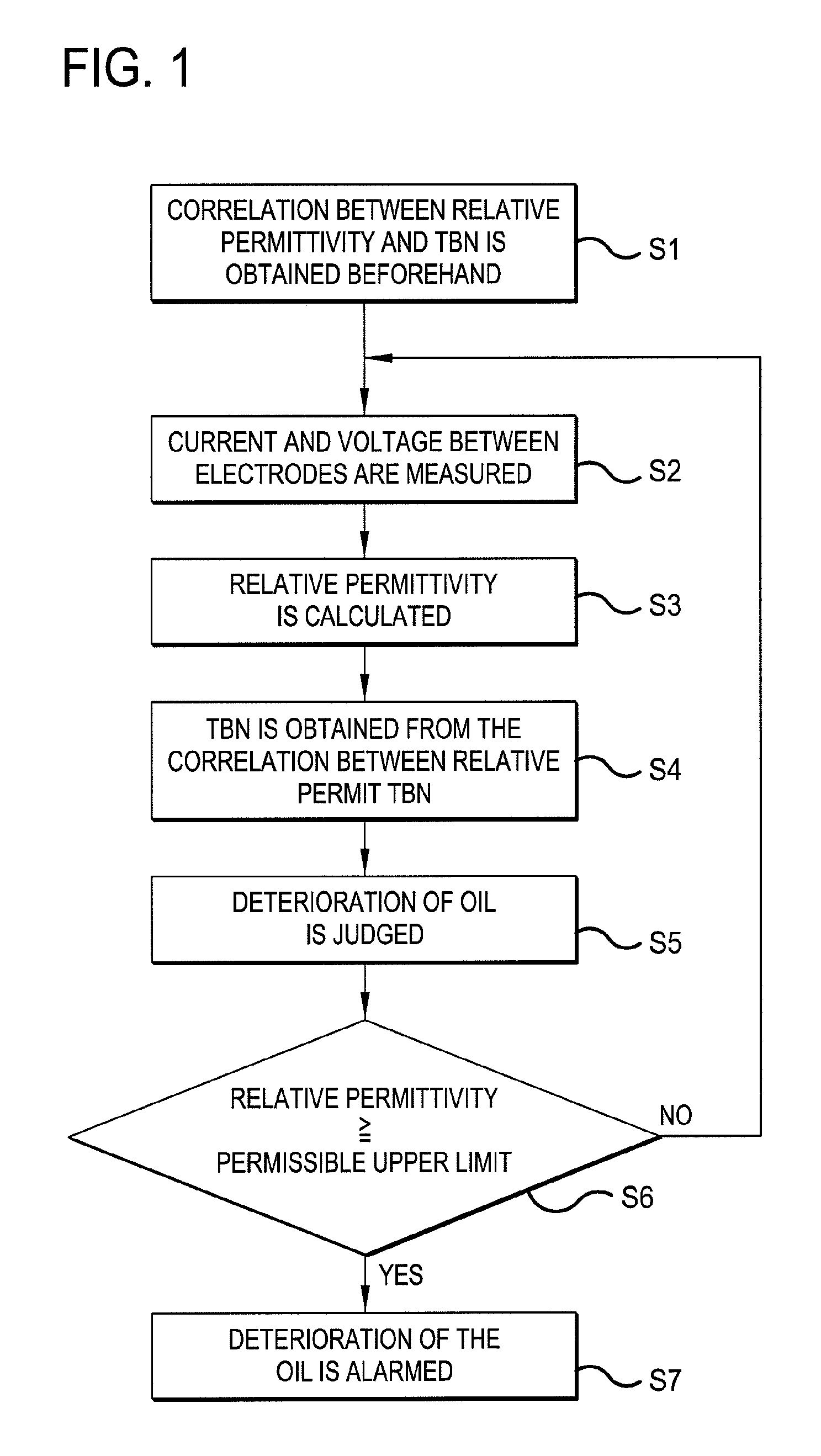

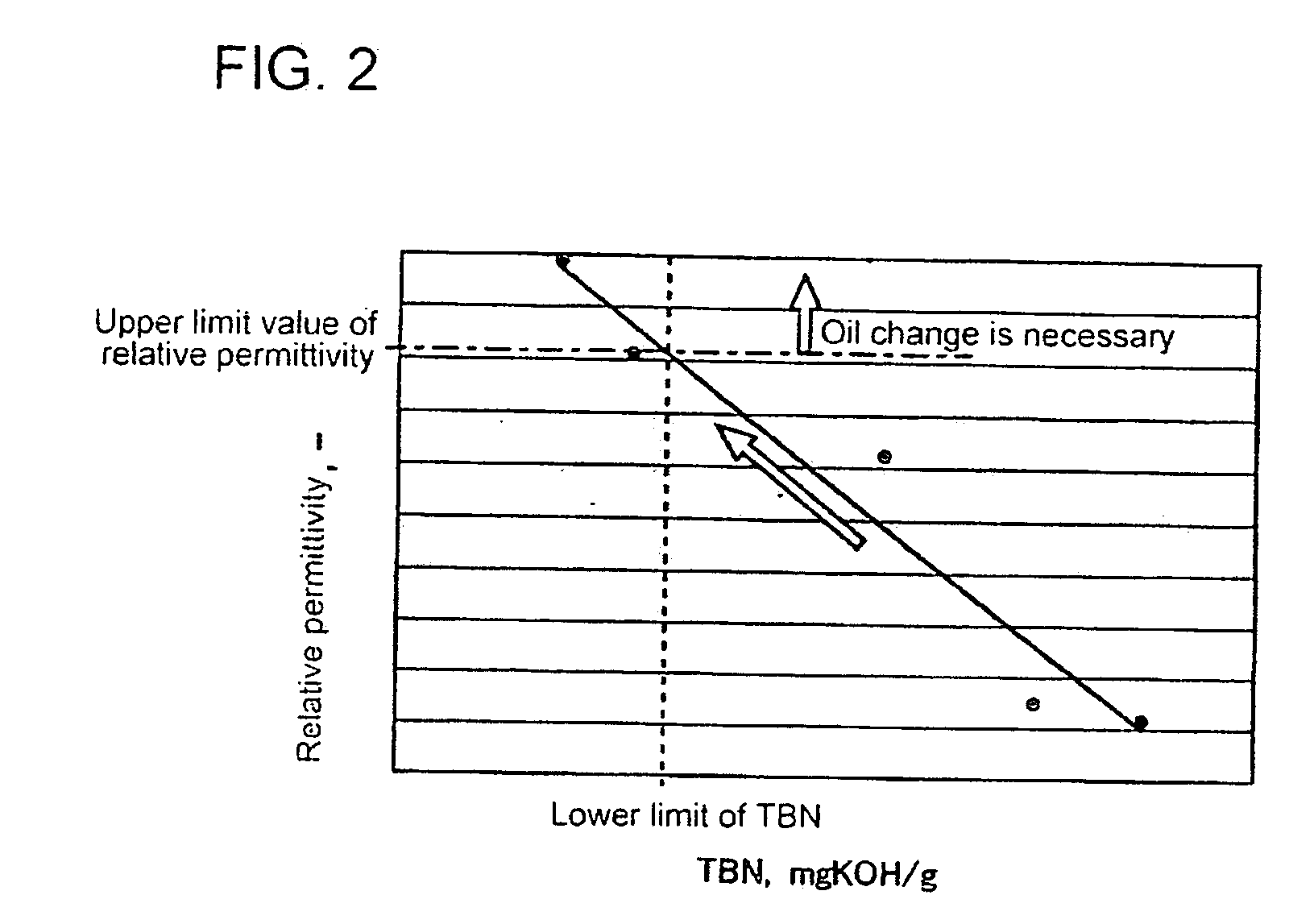

A method of monitoring deterioration of lubricating oil and a device therefore capable of judging deterioration of the oil with high accuracy suppressing measurement error due to mixing of foreign matter in the oil. Correlation between relative permittivity and TBN (total base number) of the lubricating oil is obtained beforehand (step S1), electric current and voltage are measured (step S2) when high-frequency voltage is applied between a pair of electrodes located in an oil path in a gas engine, permittivity of the oil is detected (step S3) based on the measurement of current and voltage, TBN of the oil is obtained (step S4) from the correlation between relative permittivity and TBN, and deterioration of the oil is judged by the obtained value of TBN.

Owner:MITSUBISHI HEAVY IND LTD

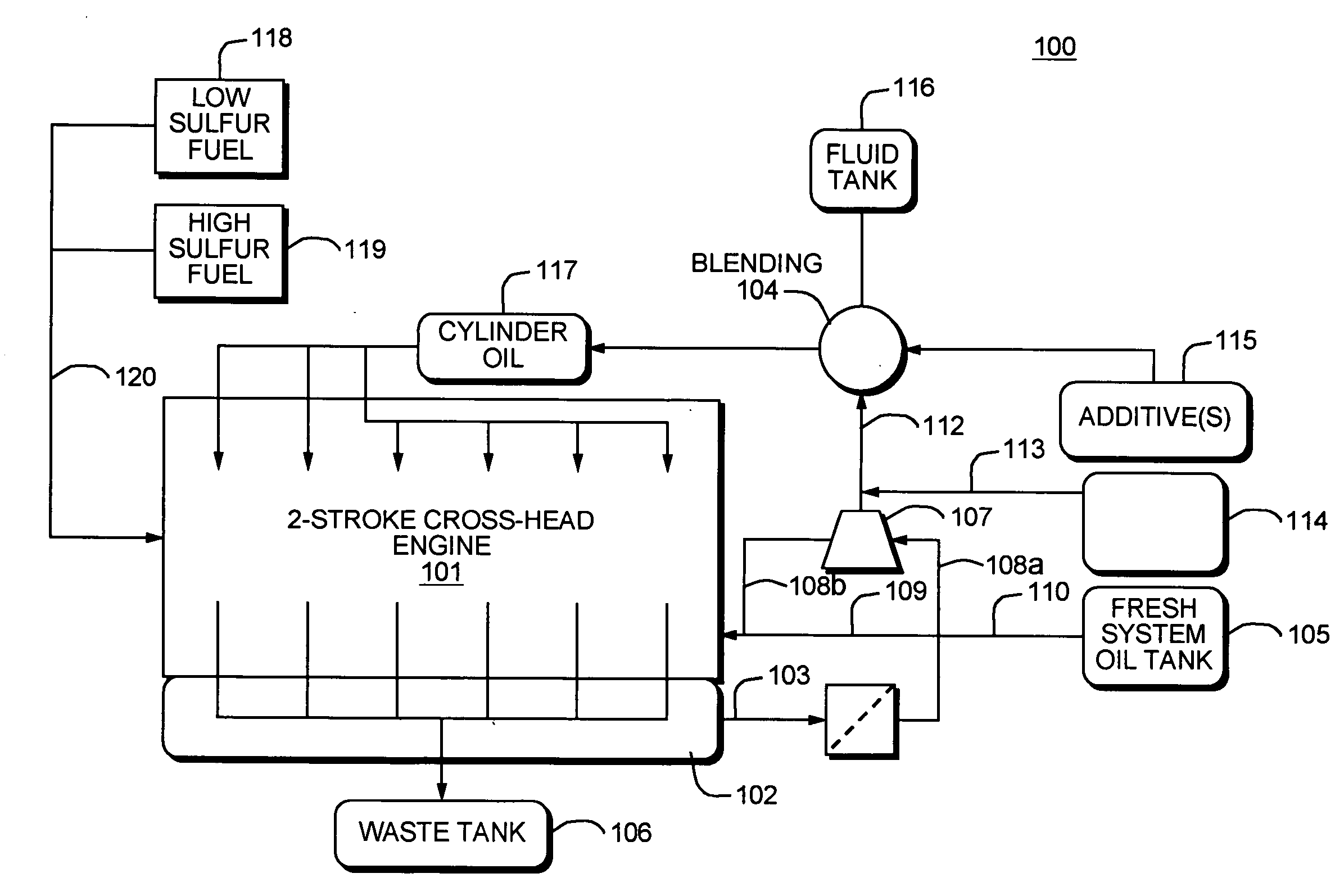

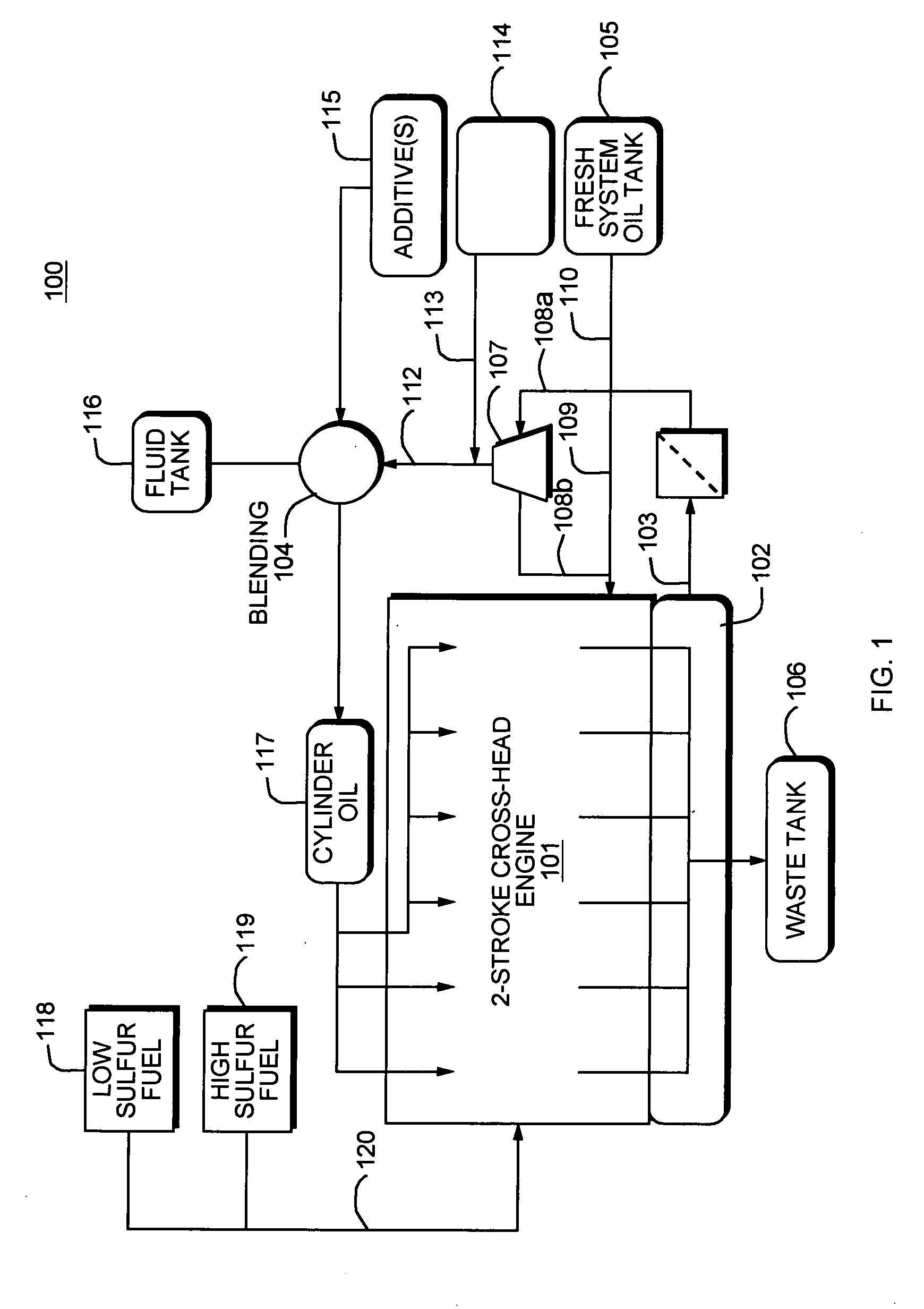

Method and system for operating two-and four-stroke engines using low sulfur fuels

InactiveUS20080153726A1Non-fuel substance addition to fuelInternal combustion piston enginesTotal Base NumberSulfur

A method for operating a two-stroke engine using low sulfur fuels. Blended cylinder oil is produced by blending base oil and at least one additive where the total base number (“TBN”) of the blended cylinder oil ranges from 1 TBN to 20 TBN. The engine is operated by supplying the blended cylinder oil and a fuel having less than 1.0% sulfur to the engine cylinders. The additive includes a low TBN calcium salts at a weight ratio ranging from 90:10 to 10:90; or any combination thereof.A method for operating a 4-stroke engine using low and high sulfur fuels. Blended oil, having a TBN that is greater than 20 TBN, is produced by blending base oil and at least one additive. The engine is operated by exchanging a low sulfur fuel having less than 1.0% sulfur with a high sulfur fuel. The engine lubricating system is switched to the blended cylinder oil in accordance with switching the fuel from a low sulfur fuel to a high sulfur fuel.

Owner:A P MOLLER AS

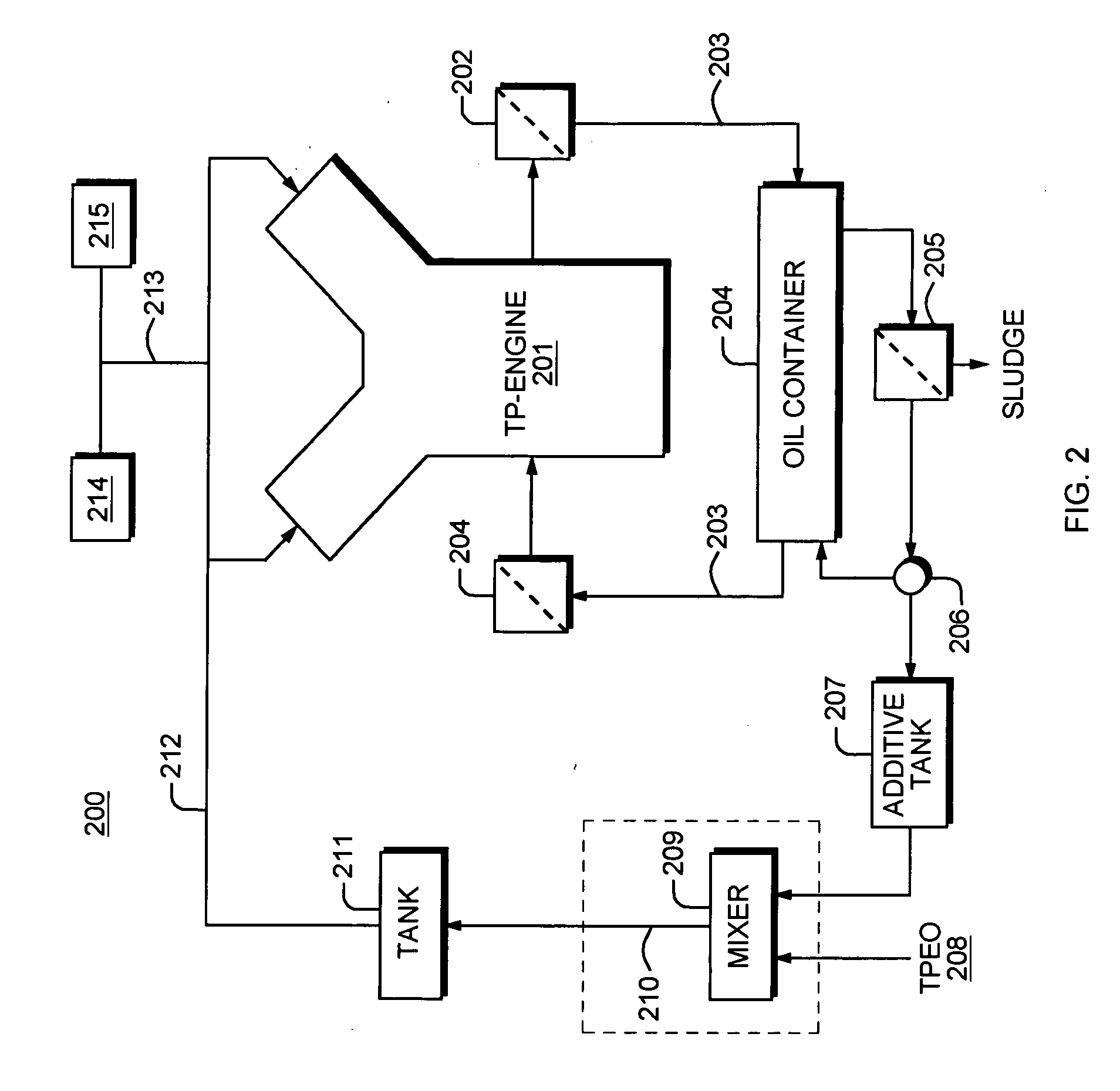

Method and apparatus for estimating basicity of a used, all-loss cylinder lubricant

InactiveUS20070084271A1Readily apparentResistance/reactance/impedenceMaterial testing goodsTotal Base NumberAC - Alternating current

A method and apparatus for determining the total base number of a used lubricant from an open, all loss, lubricating system. An AC voltage signal is applied between electrodes immersed in the used lubricant and a used-lubricant dependent response to the applied signal measured. The used lubricant base number is determined from the response. To allow for changes in the fresh lubricant inputted to the open lubricating system, the method and apparatus can have means for determining properties of the fresh lubricant needed to determine the total base number of used lubricant. To allow for possible contamination of the used lubricant, the method and apparatus can have means for determining the concentration of contamination and for determining properties of the contaminant needed to determine the total base number of used lubricant.

Owner:THE LUBRIZOL CORP

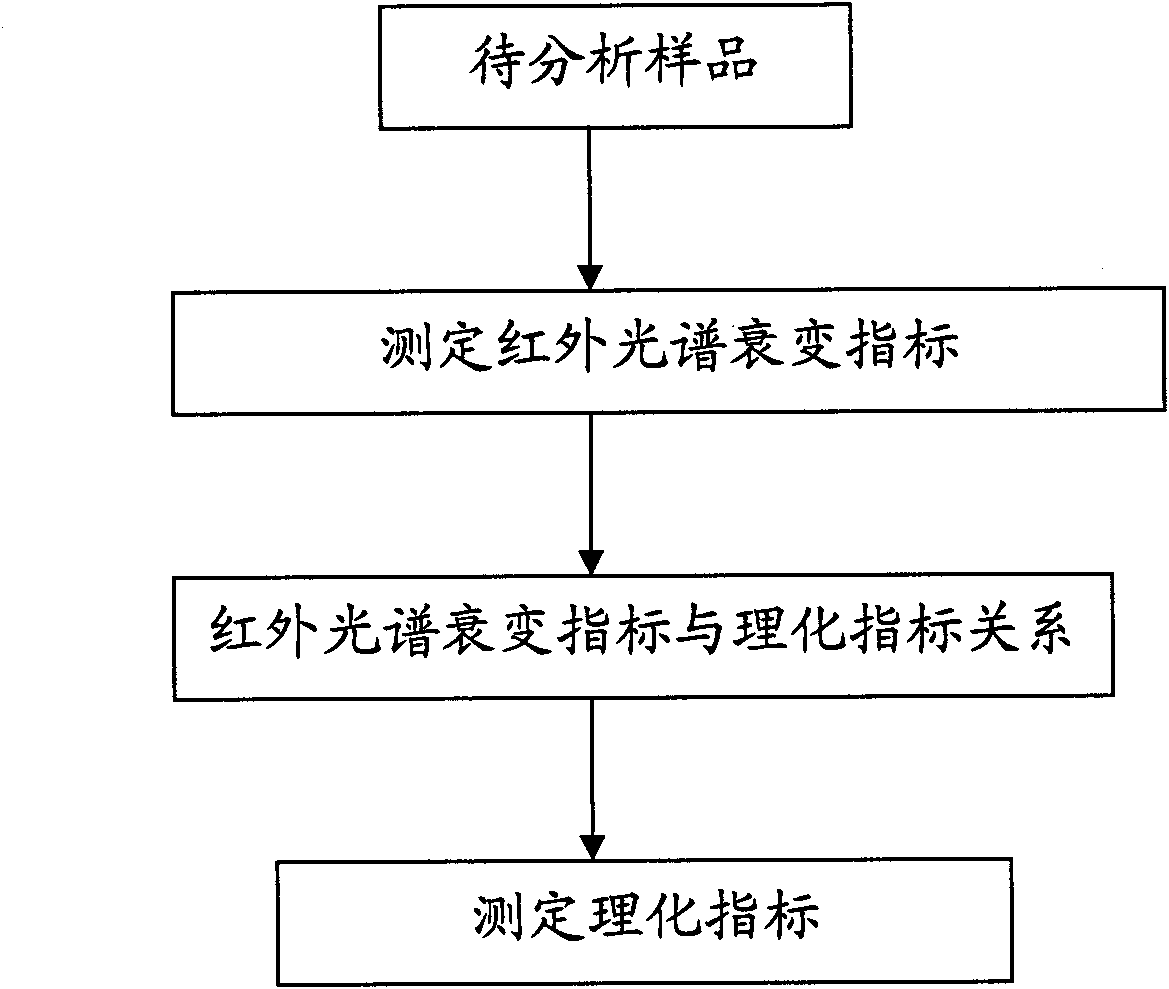

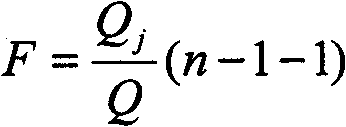

Method for rapidly measuring physical and chemical quality indexes of in-use lubricating oil

InactiveCN101782512AAccurate measurementSave human effortColor/spectral properties measurementsTotal Base NumberChemical quality

The invention discloses a method for rapidly measuring physical and chemical quality indexes of in-use lubricating oil, which comprises the following steps: in a first step, collecting representative samples as a training set; in a second step, measuring an infrared spectrum decay index of the in-use lubricating oil; in a third step, measuring in-use oil physical and chemical quality indexes; in a fourth step, adopting a gradual linear regression method to carry out optimization on the infrared spectrum decay index and establishing a multiple linear regression equation of the physical and chemical indexes and the infrared spectrum decay index; and in a fifth step, for an in-use oil sample, firstly measuring the infrared spectrum decay index and then utilizing the regression equation established in the fourth step to calculate the physical and chemical quality indexes. The method of the invention can rapidly measure seven physical and chemical quality indexes of the in-use lubricating oil, i.e. a kinematic viscosity at the temperature of 40 DEG C, a kinematic viscosity at the temperature of 100 DEG C, water content, a total acid number (TAN), a total base number (TBN), a flash point and a pour point, monitor the quality decay of the lubricating oil, guide to change the oil and guarantee the normal operation of the engine.

Owner:PETRO OIL & LUBRICANT RES INST OF THE GENERAL LOGISITIC DEPT OF PLA

Quick detection method of oil quality spectrum for lubricating oil

InactiveCN101799411AMonitor qualityImprove quality monitoring capabilitiesColor/spectral properties measurementsTotal Base NumberEngineering

The invention discloses a quick detection method of oil quality spectrum for lubricating oil, comprising the following steps: 1, collecting a lubricating oil sample with representativeness as a training set; 2, measuring the infrared spectrum of the training set sample; 3, measuring the quality index of the training set sample; 4, selecting a proper variable preference technology, preferably selecting a proper characteristic wavelength, taking the absorbance of the characteristic wavelength as a variable, and building the linear regression equation of each quality index and absorbance; 5, forthe quality detection of unknown lubricating oil samples, firstly measuring the infrared spectrum thereof, selecting the absorbance of wavelength with the same characteristic, and measuring each quality index of lubricating oil by the built liner regression equation. The invention quickly measures seven quality parameters, such as oil water content, total acid number, total base number, 40 DEG C viscosity, 100 DEG C viscosity, flash point, pour point and the like of lubricating oil and monitors lubricating oil quality. The quick detection method has high analysis speed and simple operation and greatly improves lubricating oil quality monitoring capability.

Owner:PETRO OIL & LUBRICANT RES INST OF THE GENERAL LOGISITIC DEPT OF PLA

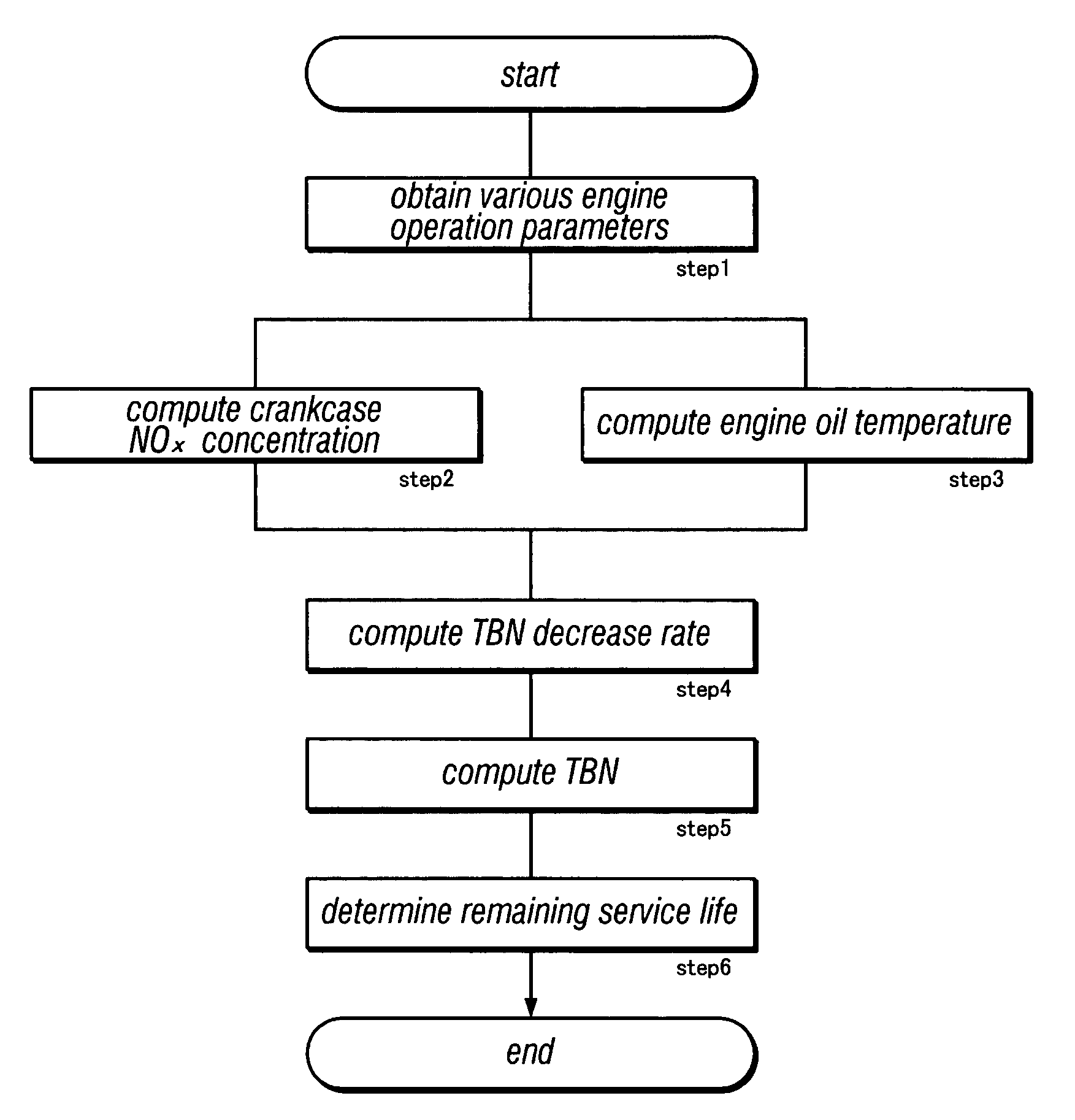

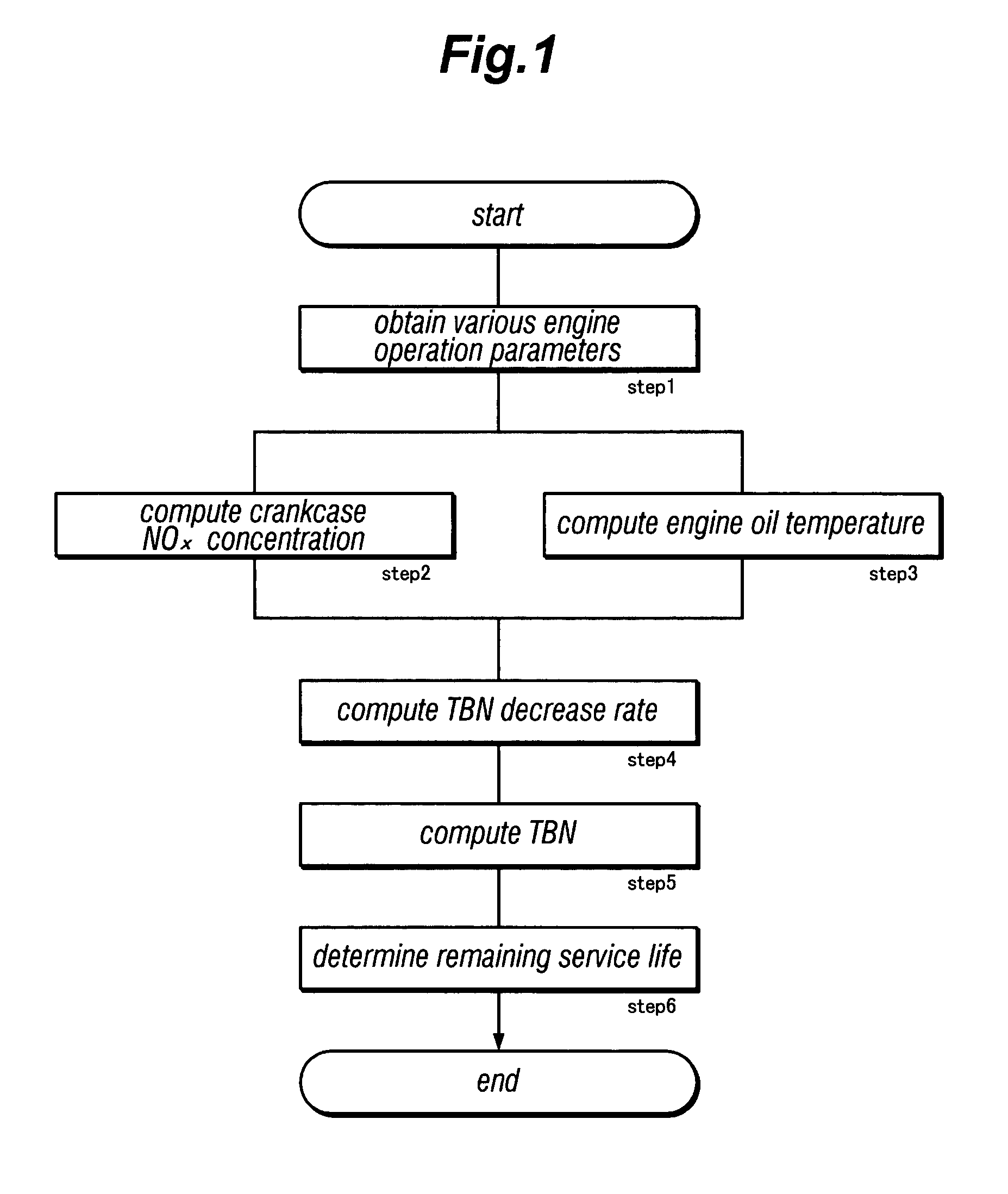

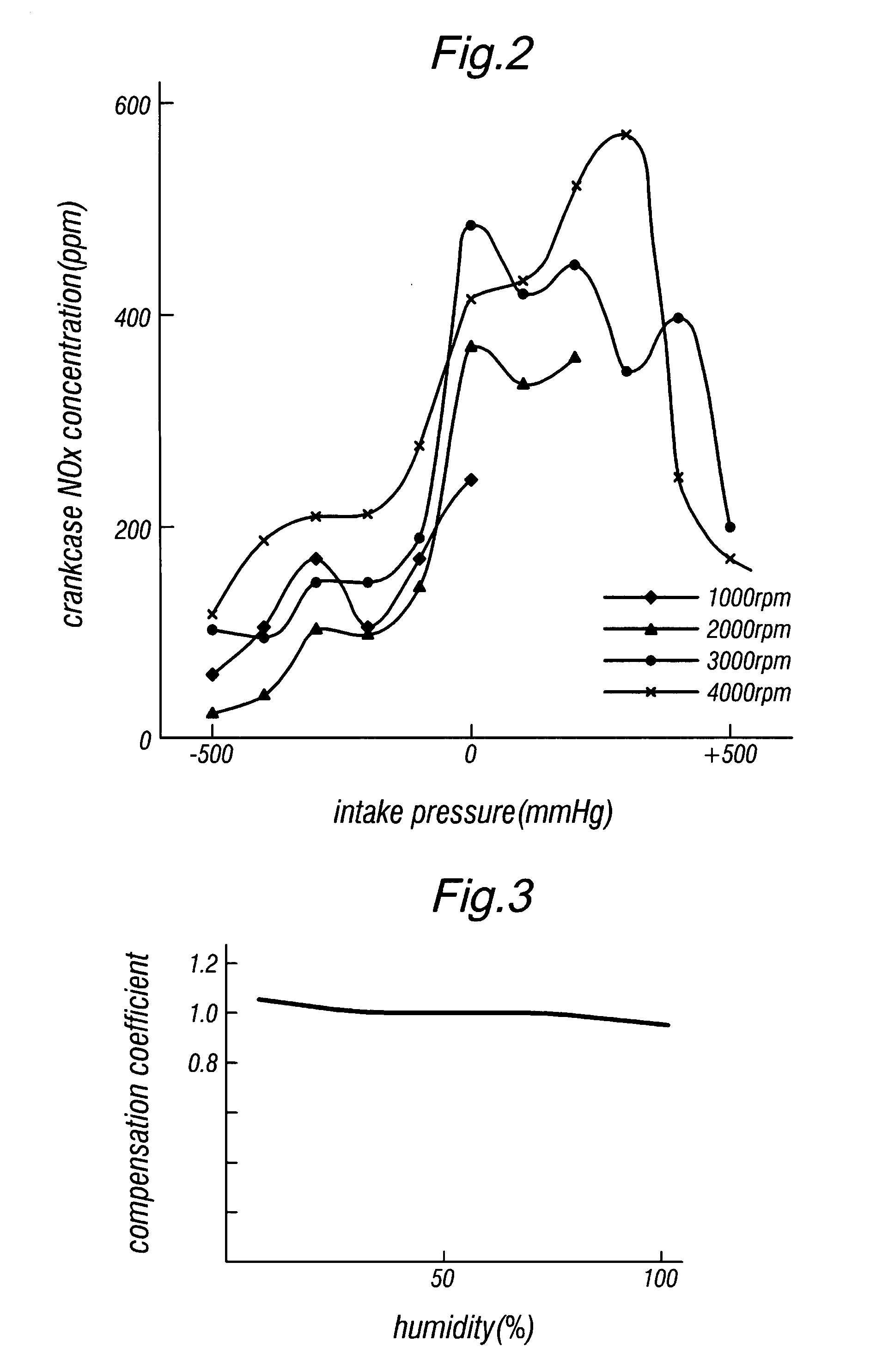

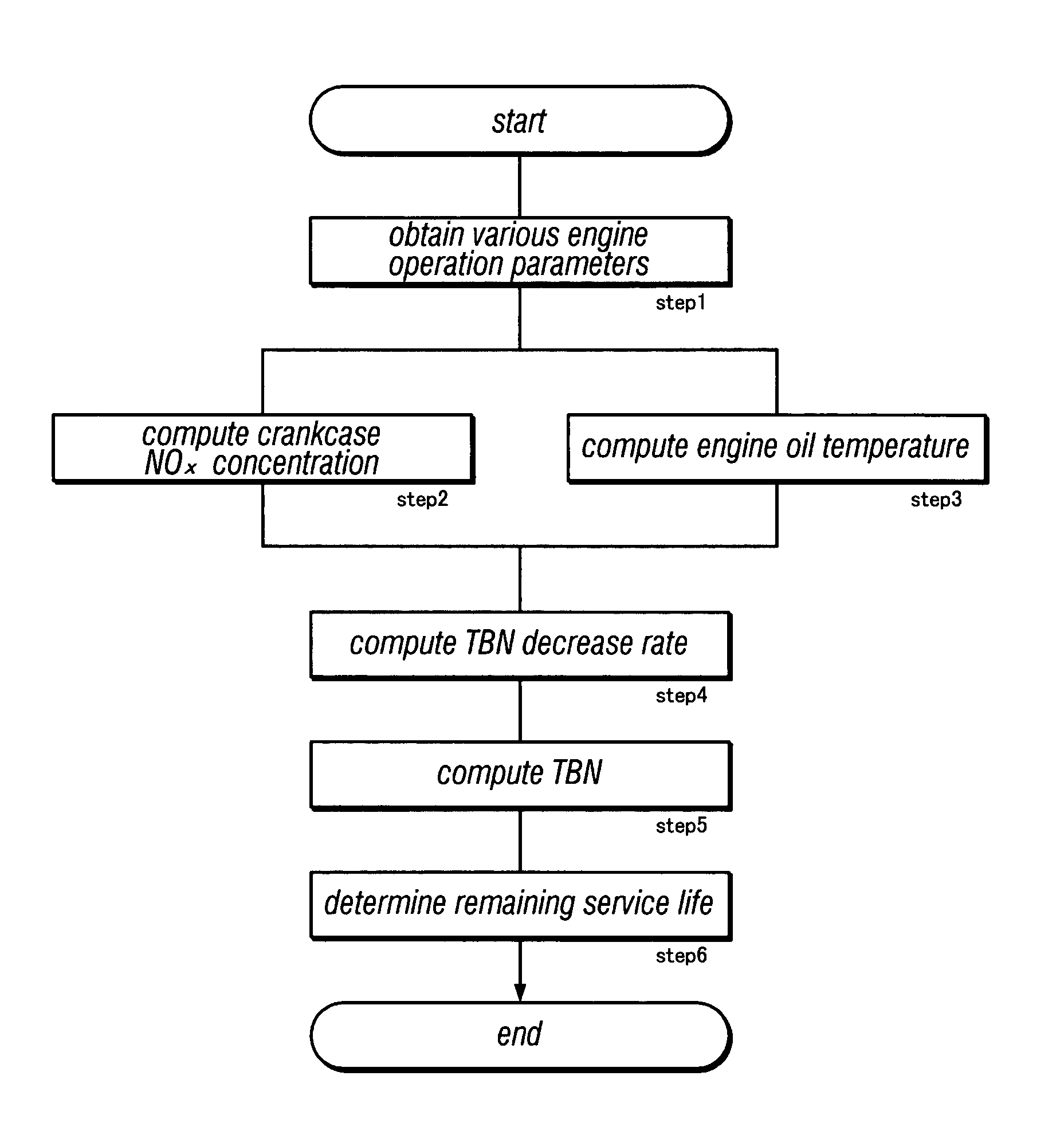

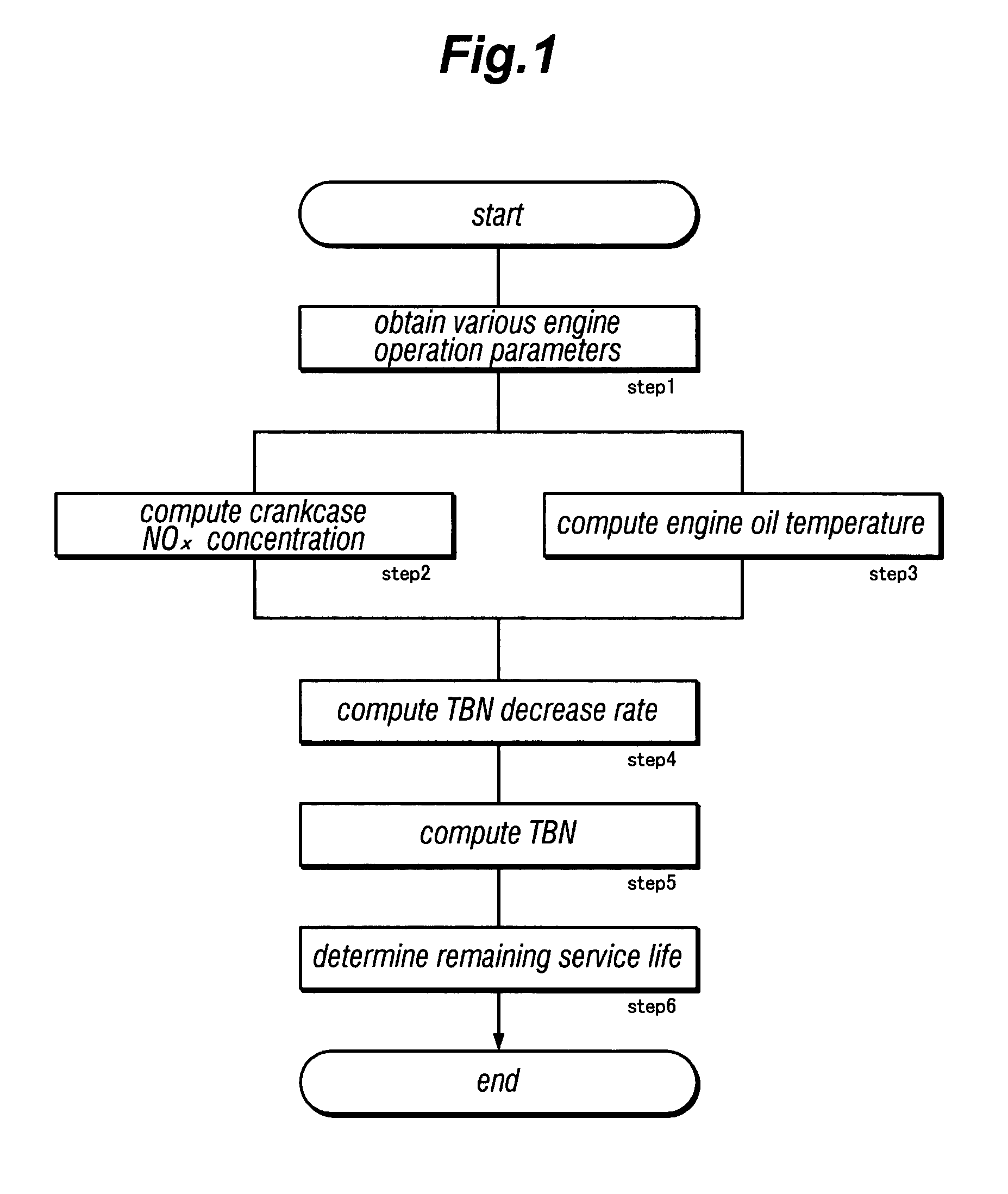

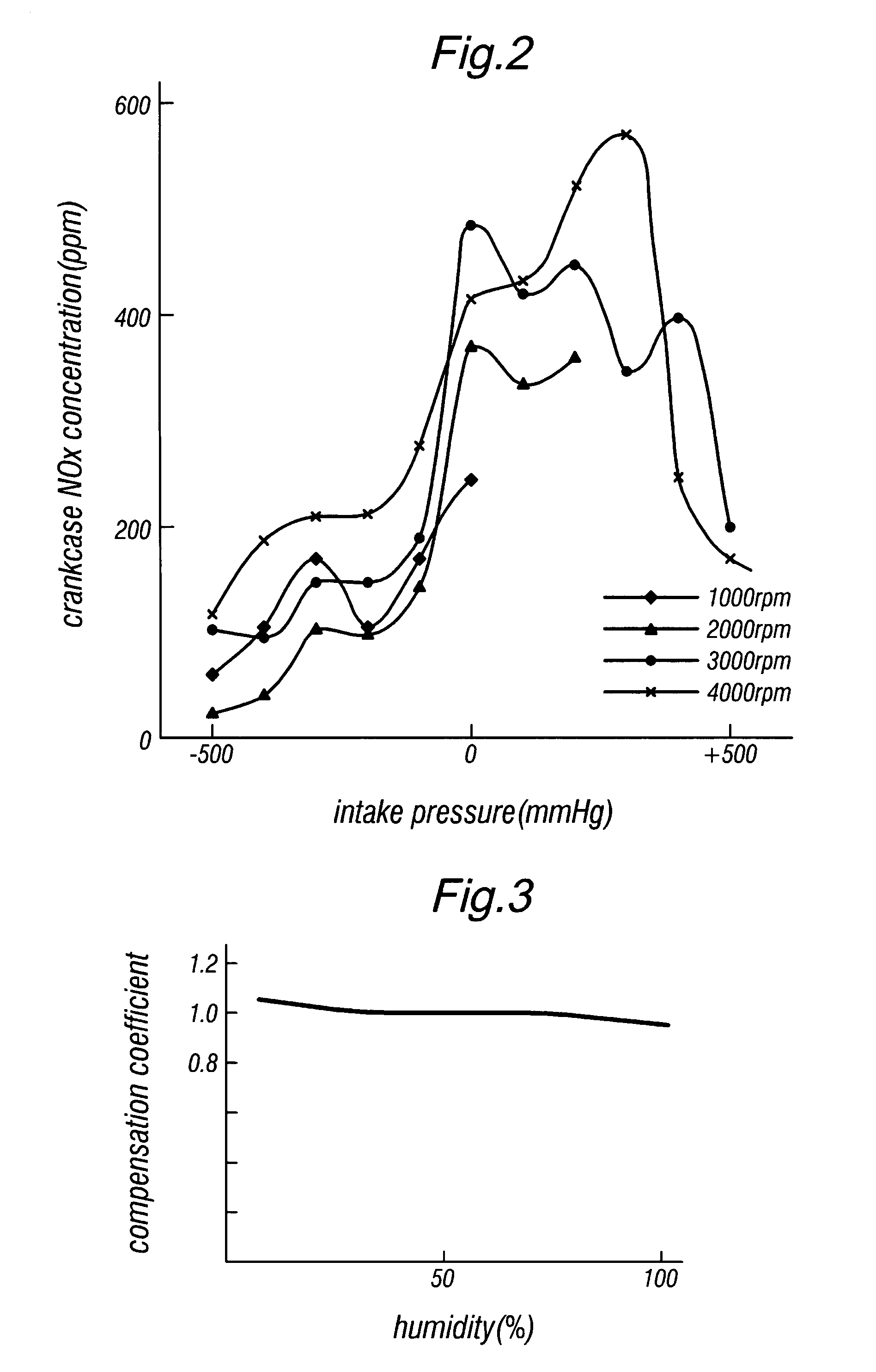

Method for detecting a condition of engine oil

ActiveUS20080027661A1Accurately determineImprove accuracyEngine testingFlow propertiesTotal Base NumberCrankcase

Provided is a method for detecting a condition of engine oil that allows the progress of degradation of engine oil to be more accurately determined without incurring any significant cost. In a method for detecting a state of engine oil by defining a degradation index that changes with a progress in degradation of the engine oil that lubricates an internal combustion engine and determining a progress of the degradation of the engine oil according to the degradation index, a value related to a concentration of blow-by gas that flows into a crankcase of the engine is computed, and the degradation index is computed according to the computed value related to a concentration of blow-by gas that flows into a crankcase of the engine. The degradation index may consist of a total base number of the engine oil, and the concentration of blow-by gas that flows into a crankcase of the engine may consist of a NOx concentration.

Owner:HONDA MOTOR CO LTD

Lubricant compositions comprising epoxide compounds

A lubricant composition including an epoxide compound is disclosed. An additive package including the epoxide compound is also disclosed. The epoxide compound of the lubricant composition acts to improve compatibility of the lubricant composition with a fluoropolymer seal and improve the total base number of the lubricant composition.

Owner:BASF AG

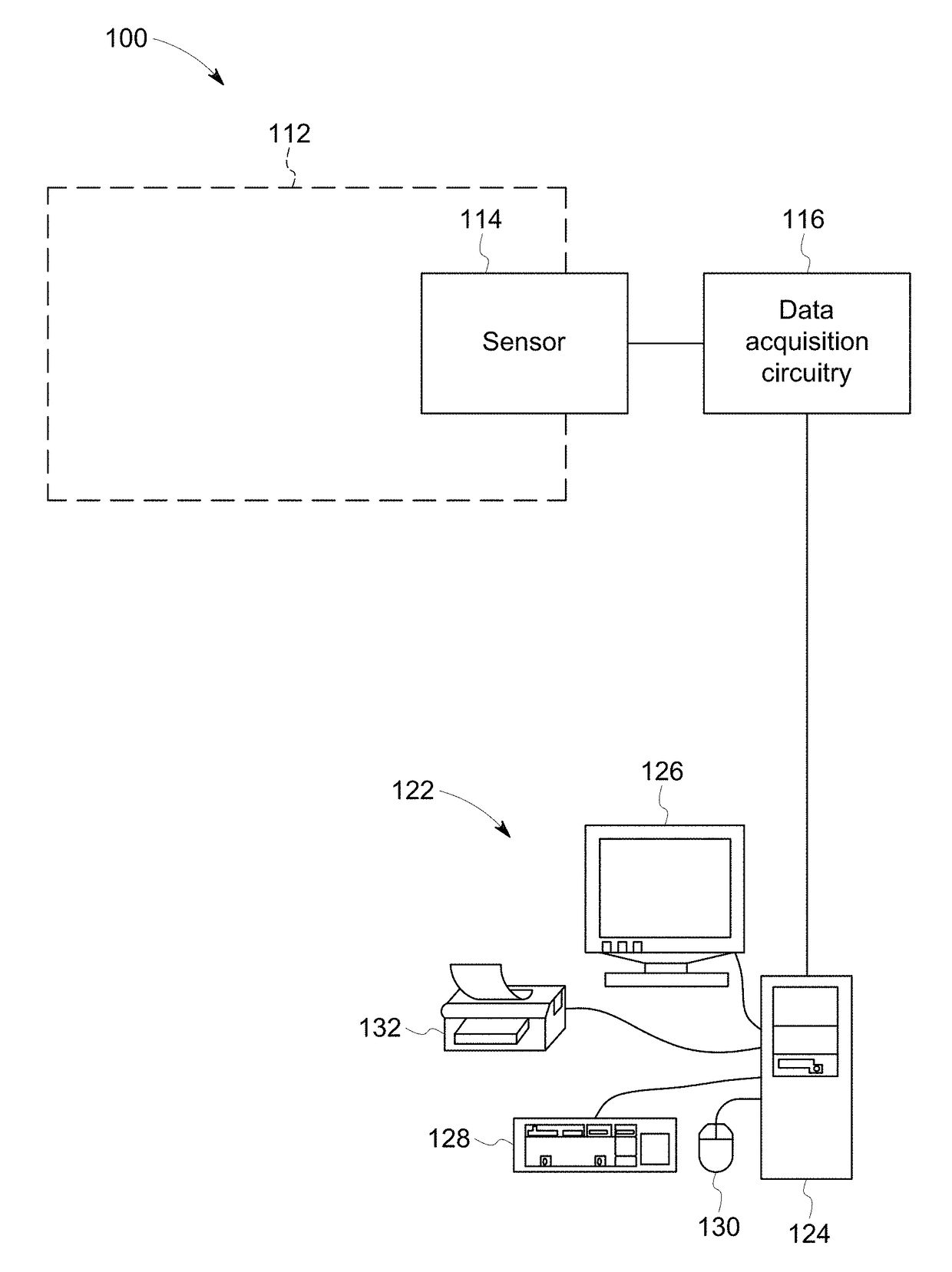

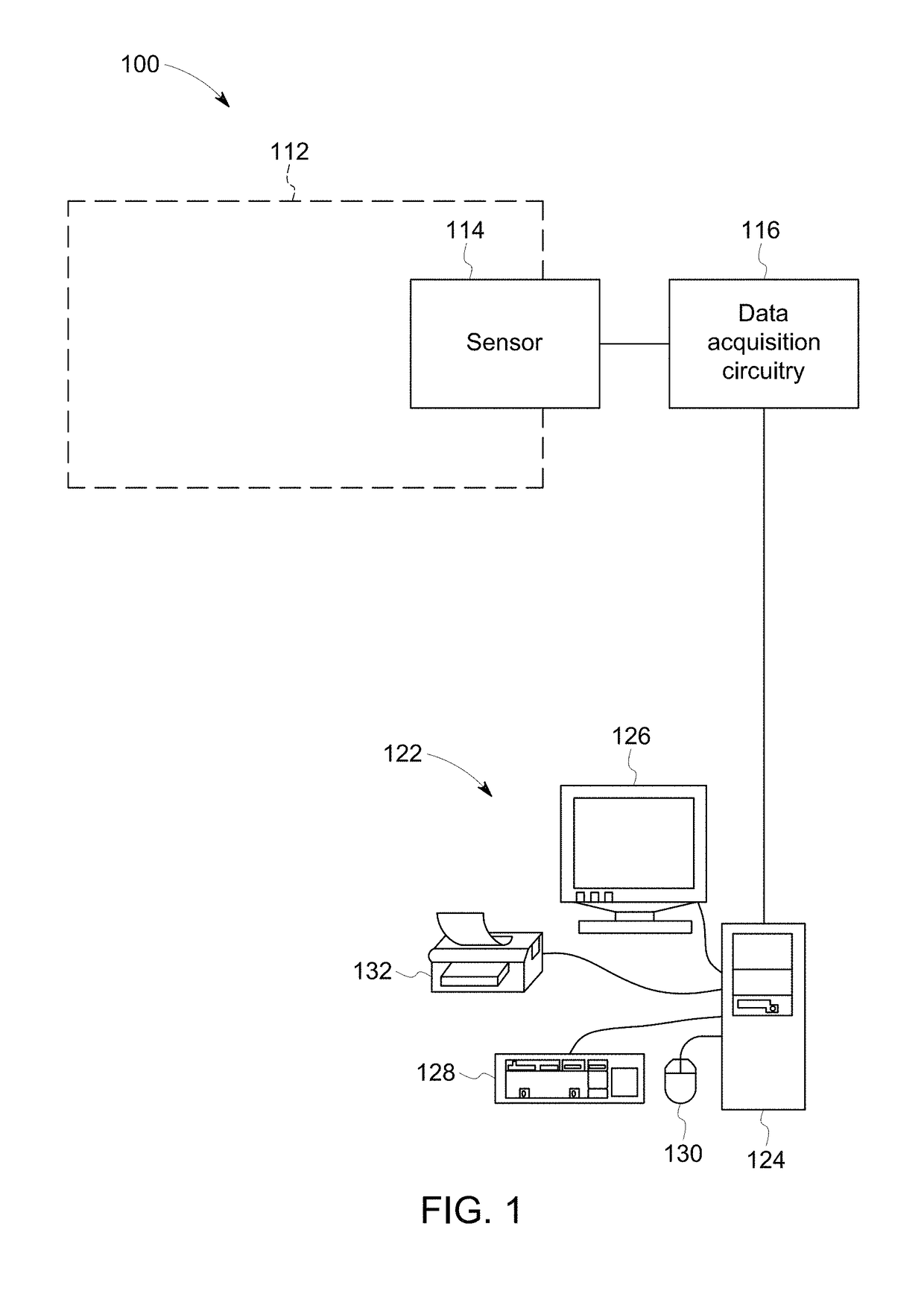

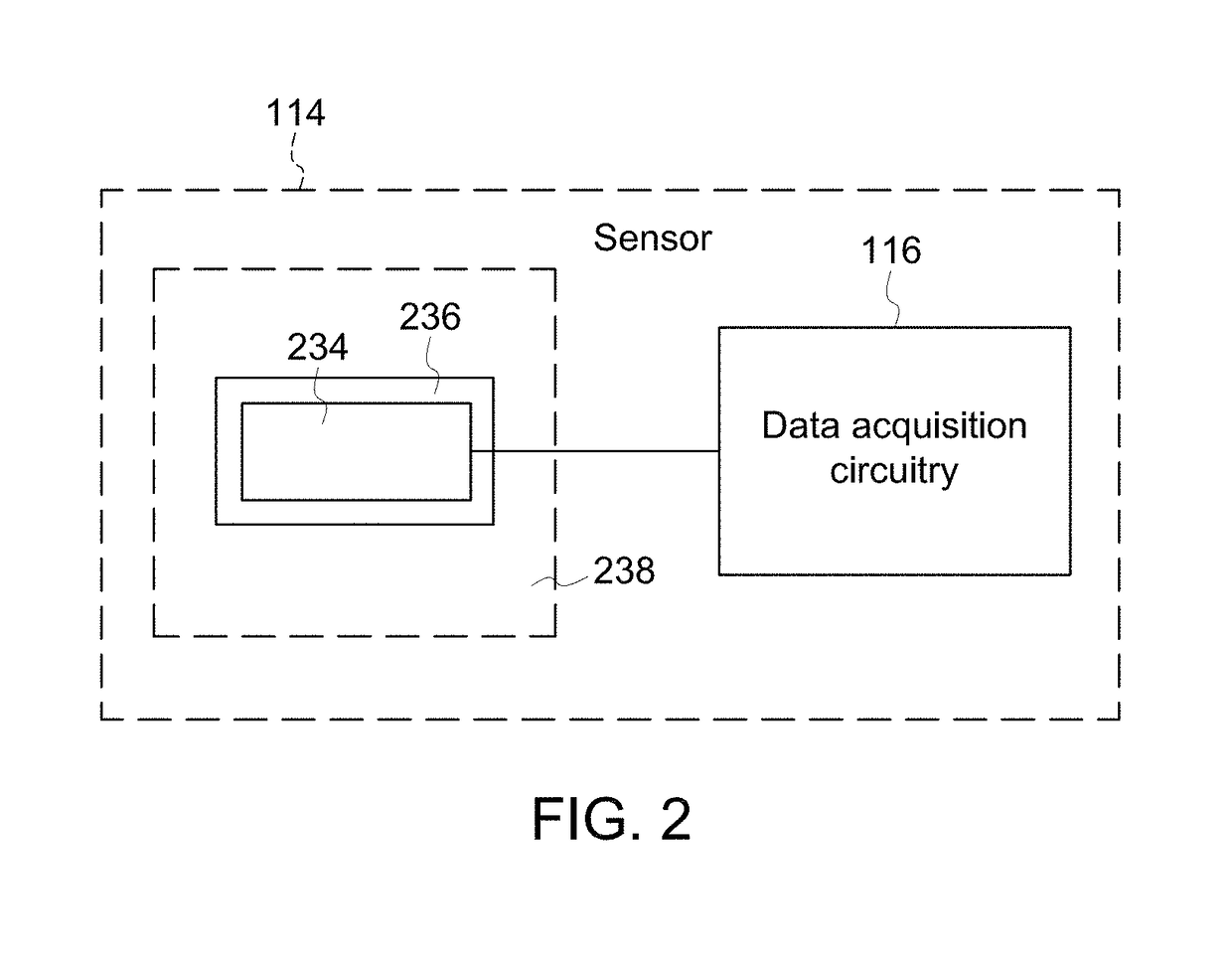

System and method for sensing lubricant and engine health

PendingUS20180158261A1Guaranteed safe operationIncrease elasticityRegistering/indicating working of vehiclesVehicle componentsTotal Base NumberEngineering

A system includes a sensor configured to be in contact with lubricant within an engine of a vehicle system. The sensor includes a sensing region circuit that is configured to generate stimuli at different times during an operational life of the engine. The system also includes one or more processors configured to receive signals from the sensor. The signals are representative of responses of the lubricant to the stimuli. The one or more processors are configured to analyze the responses and determine a characteristic of the lubricant that represents one or more of a total base number (TBN) or a total acid number (TAN) of the lubricant. The one or more processors are configured to determine an unhealthy state of one or more of the engine or the lubricant based on the characteristic of the lubricant that is determined.

Owner:GE GLOBAL SOURCING LLC

Composite calcium-sulfonate-base lubricating grease and preparation method thereof

ActiveCN103122266ASimple processing methodEasy to operateLubricant compositionTotal Base NumberHazardous substance

The invention relates to the technical field of a composite calcium-sulfonate-base grease and preparation thereof, particularly a composite calcium-sulfonate-base lubricating grease and a preparation method thereof. The preparation method of the composite calcium-sulfonate-base lubricating grease comprises the following step: 1. respectively weighing 20-30 parts by weight of high-base-number petroleum calcium sulfonate with the total base number of 200-400 mg KOH / g, and 44-55 parts by weight of high-viscosity-index base oil with the viscosity index of 90-120. The invention has the advantages of simple technique, accessible raw materials and safe working environment, is convenient for operation, and effectively lowers the energy consumption; the product obtained by the method provided by the invention has excellent properties, and can satisfy the product index requirements without adding any additive, and thus, the production input cost of the product is lower than that of any other high temperature grease; no harmful substance is generated in the product production and use process, so the composite calcium-sulfonate-base grease is harmless to the human body; and the composite calcium-sulfonate-base grease can be recycled and reutilized to maximize the use of energy sources, thereby completely satisfying the requirements of energy saving and environmental protection.

Owner:新疆金雪驰科技股份有限公司 +1

Lubricating Composition With Improved TBN Retention

ActiveUS20140187458A1Reduce probabilityImproving TBN retentionLiquid carbonaceous fuelsAdditivesTotal Base NumberProcess engineering

The invention provides a lubricating composition containing a diarylamine, an aminobenzene and an oil of lubricating viscosity. The invention further relates to the use of the lubricating composition in an internal combustion engine. The invention further relates to the use of the lubricating composition to improve TBN retention.

Owner:THE LUBRIZOL CORP

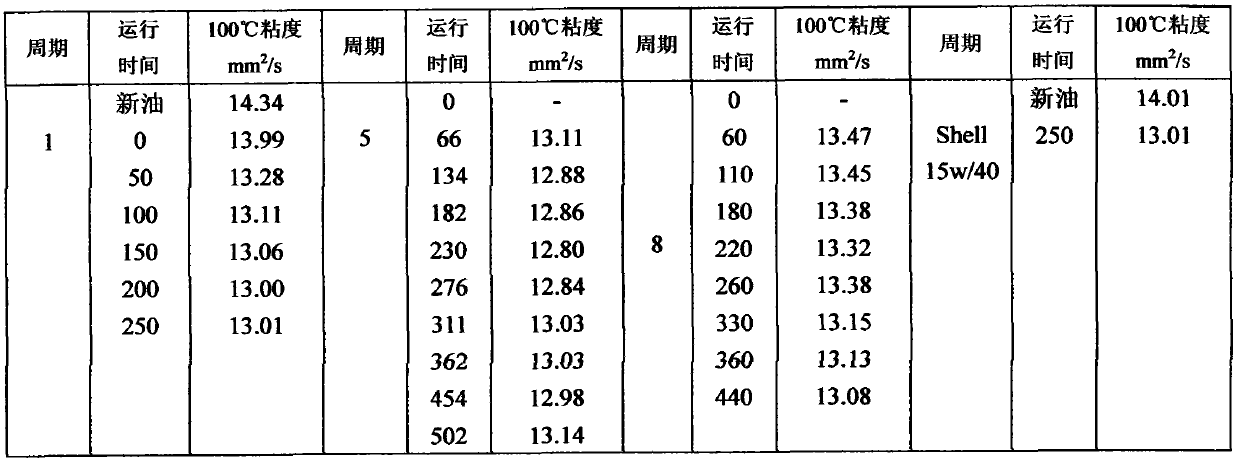

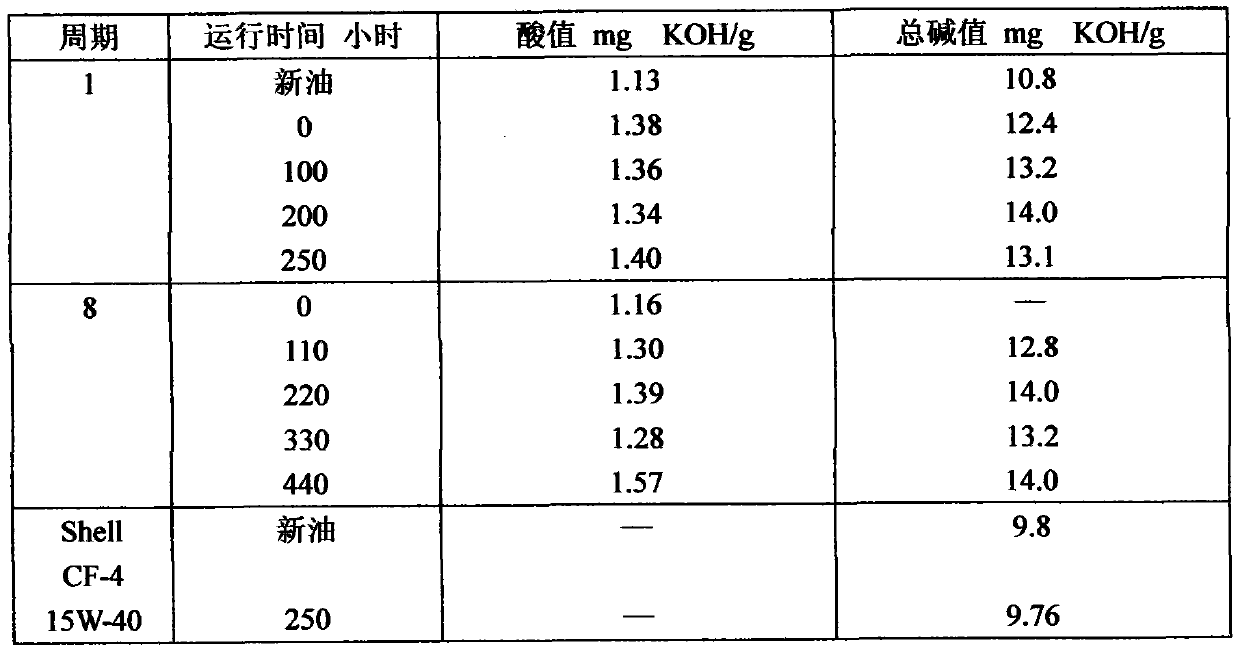

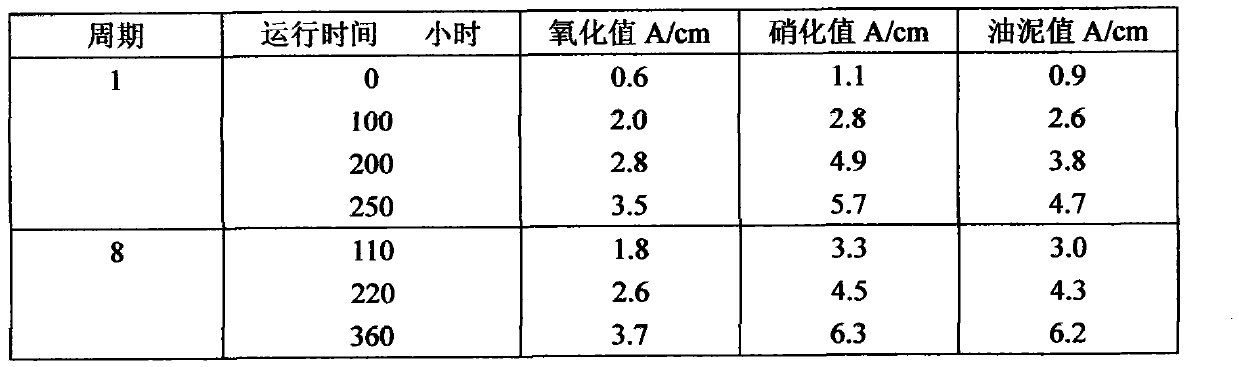

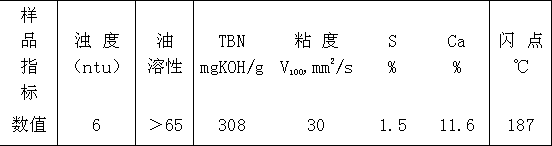

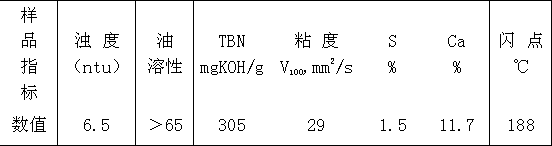

Performance analysis experiment of internal combustion engine oil

InactiveCN103471963AExtended maintenance timeExtended run timeFlow propertiesColor/spectral properties measurementsTotal Base NumberEngineering

The invention provides a performance analysis experiment of internal combustion engine oil, and relates to the field of internal combustion engine oil technology. The performance analysis is as follows: (1) viscosity change; (2) changes of acid value and total base number; (3) differential infrared spectroscopic analysis result; (4) spot dispersibility test; (5) metal content, which can prolong vehicle maintenance time for durability, thereby the vehicle has long operation time and strong practicality.

Owner:JINING HTP PETROCHEM

Detergent for synthetic calcium alkyl benzene sulfonate type lubricating oil and production technology

The invention relates to a detergent for synthetic calcium alkyl benzene sulfonate type lubricating oil and a production technology. A technological process for producing a lubricating oil additive with TBN (total base number) being from 20 to 300mgKOH / g comprises the steps of reacting the following components with the lower temperature of 0 to 70 DEG.C: a component (A): synthetic alkyl benzene sulfonic acid; a component (B): alkaline earth alkali can be added or added more than once in the reaction process in a disposable manner; a component (C): an aromatic hydrocarbon solvent; a component (D): neutral oil; a component (E): water; a component (F): sulfurized calcium alkyl phenolate; a component (I): methane solution; a component (J): carbon dioxide (CO2), CO2 is fed to perform alkalization after the neutral reaction and then is filtered, the filter cakes and the component (C) are filtered after being uniformly mixed, and a filtrate is served as a solvent instead of the component (C).

Owner:JINZHOU DPF TH CHEM CO LTD

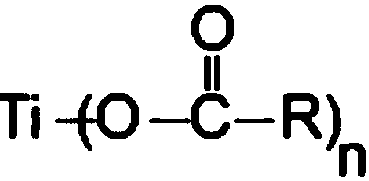

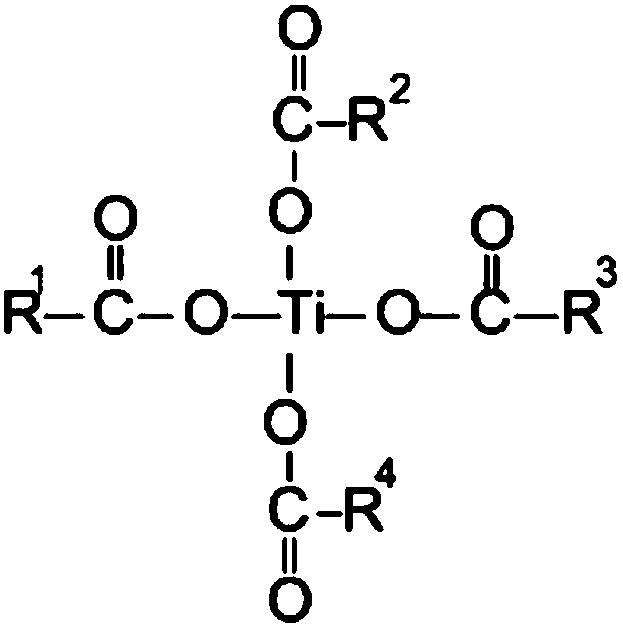

Lubricants with titanium and/or tungsten and their use for improving low speed pre-ignition

A lubricating oil composition and method of operating a boosted internal combustion engine. The lubricating oil composition includes a major amount of a base oil, one or more overbased calcium-containing detergents having a total base number of greater than (225) mg KOH / gram, to provide greater than (900) ppm by weight to less than (2400) ppm by weight of calcium to the lubricating oil composition, and a low speed pre-ignition reducing amount of one or more titanium-containing compounds to provide from (10) ppm to (3000) ppm titanium and / or one or more tungsten-containing compounds to providefrom (125) ppm to (3000) ppm tungsten, all based on the total weight of the lubricating composition. The low speed pre-ignition events in the boosted internal combustion engine may be reduced relativeto a number of low speed pre-ignition events in the same engine lubricated with the same lubricating oil without the titanium- and / or tungsten-containing additive.

Owner:AFTON CHEMICAL

Method for detecting a condition of engine oil

ActiveUS7826987B2Accurately determineImprove accuracyLubrication of auxillariesFlow propertiesTotal Base NumberCrankcase

Provided is a method for detecting a condition of engine oil that allows the progress of degradation of engine oil to be more accurately determined without incurring any significant cost. In a method for detecting a state of engine oil by defining a degradation index that changes with a progress in degradation of the engine oil that lubricates an internal combustion engine and determining a progress of the degradation of the engine oil according to the degradation index, a value related to a concentration of blow-by gas that flows into a crankcase of the engine is computed, and the degradation index is computed according to the computed value related to a concentration of blow-by gas that flows into a crankcase of the engine. The degradation index may consist of a total base number of the engine oil, and the concentration of blow-by gas that flows into a crankcase of the engine may consist of a NOx concentration.

Owner:HONDA MOTOR CO LTD

Nitrogen-containing dispersant as an ashless TBN booster for lubricants

Lubricant compositions comprising (a) an oil of lubricating viscosity; and (b) at least one non-metal-containing additive, comprising a nitrogen-containing dispersant having a total base number of at least about 90 are useful for lubricating an internal combustion engine. The lubricants have less than 1.0% sulfated ash and a total base number of at least about 8.5, and at least 30% of the total base number of the composition is provided by non-metal-containing additives. The lubricants exhibit a high TBN without deterioration of elastomeric seals.

Owner:THE LUBRIZOL CORP

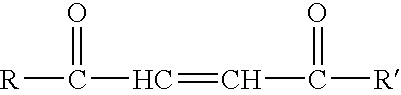

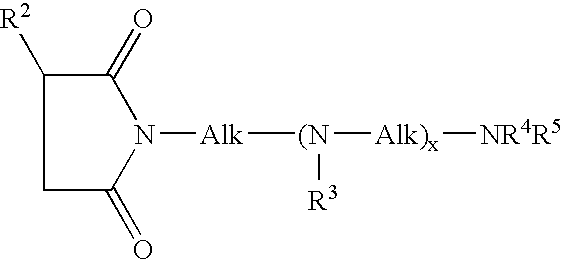

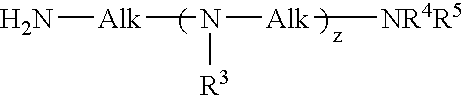

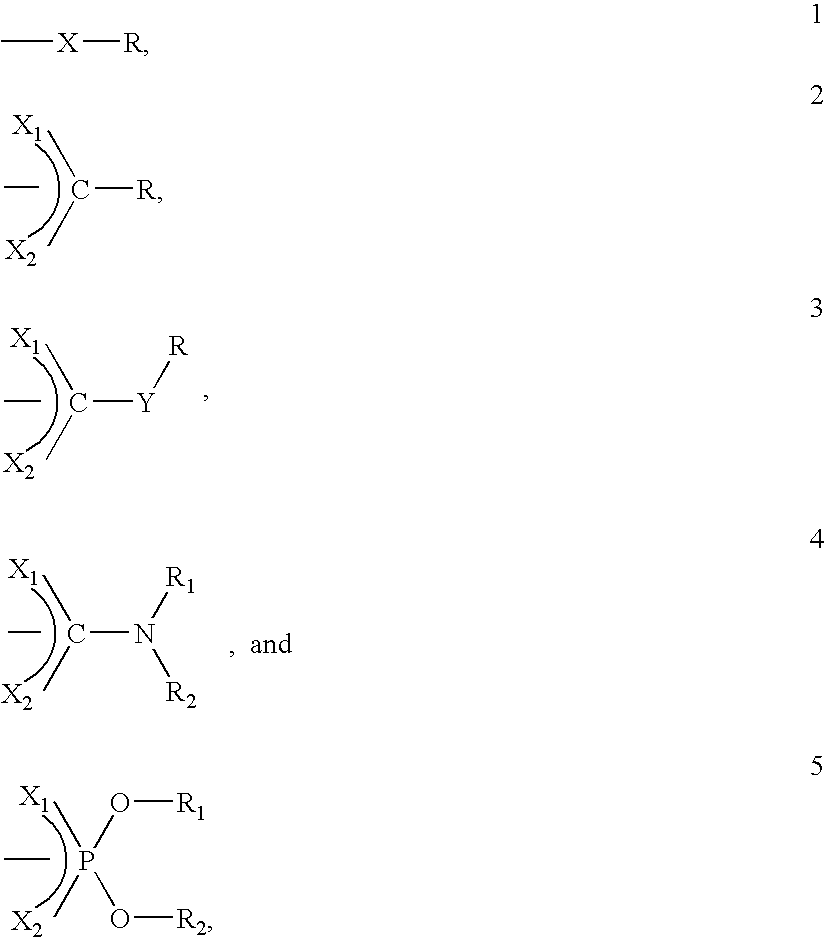

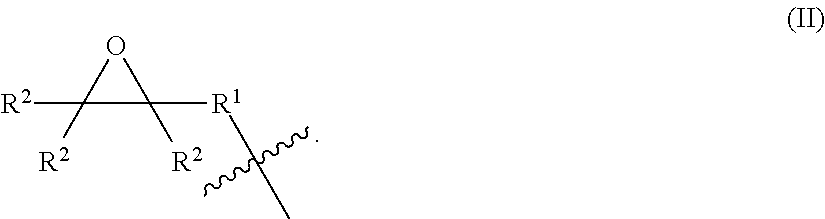

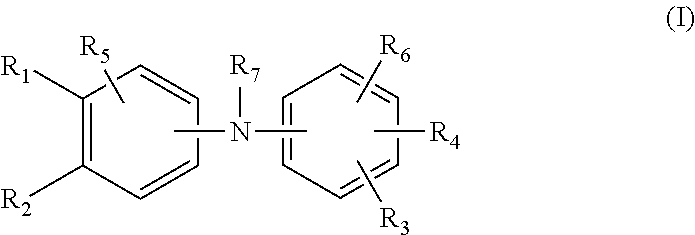

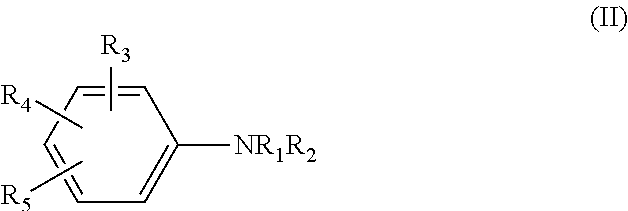

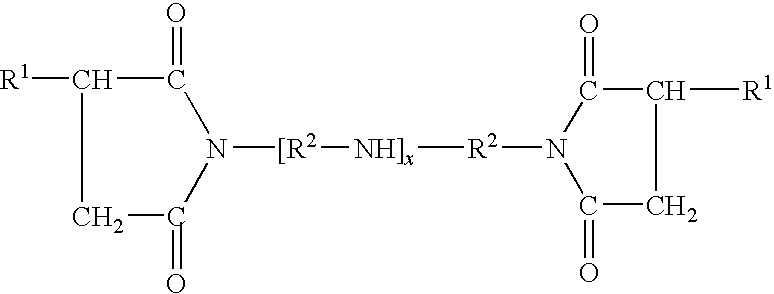

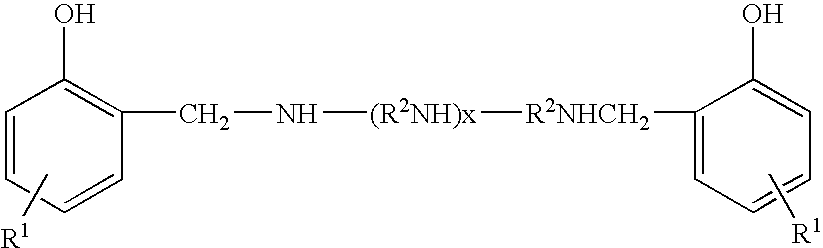

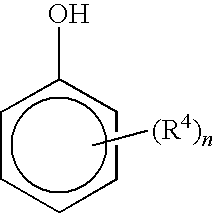

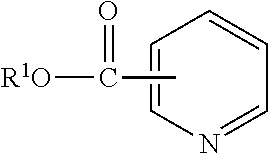

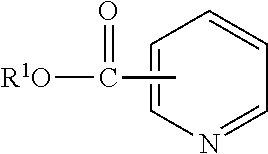

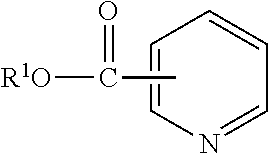

Lubricant compositions containing a heteroaromatic compound

ActiveUS20120291737A1Maintaining seal compatibilityBoosting total base numberOrganic chemistryNon-fuel substance addition to fuelTotal Base NumberAlcohol

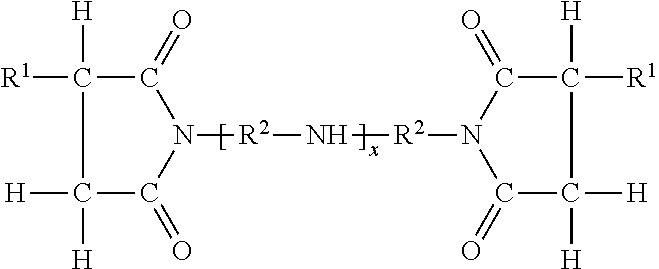

An ashless additive for lubricating oil compositions, lubricating oil compositions and methods for lubricating that are effective to improve the total base number (TBN) of a lubricant composition. The additive is a reaction product of a compound of the formula:with NH3, an alcohol, an amine, or a hydrocarbyl amine, wherein R1 is selected from H, a hydrocarbyl group, the alcohol or amine contains from 1 to about 24 carbon atoms, and the hydrocarbyl amine has a number average molecular weight ranging from about 100 to about 6000

Owner:AFTON CHEMICAL

Process for preparing an overbased salt of a sulfurized alkyl-substituted hydroxyaromatic composition

ActiveUS9062271B2Improve stabilityExtended service lifeAdditivesSulfide preparationTotal Base NumberAlkyl

Disclosed herein is an overbased salt of a sulfurized alkyl-substituted hydroxyaromatic composition, which is prepared by the process comprising (a) providing an overbased salt of a sulfurized alkyl-substituted hydroxyaromatic composition having a total base number (TBN) greater than about 250; and (b) sparging the overbased salt of a sulfurized alkyl-substituted hydroxyaromatic composition with air at a temperature ranging from about 190° C. to about 250° C.

Owner:CHEVRON ORONITE CO LLC

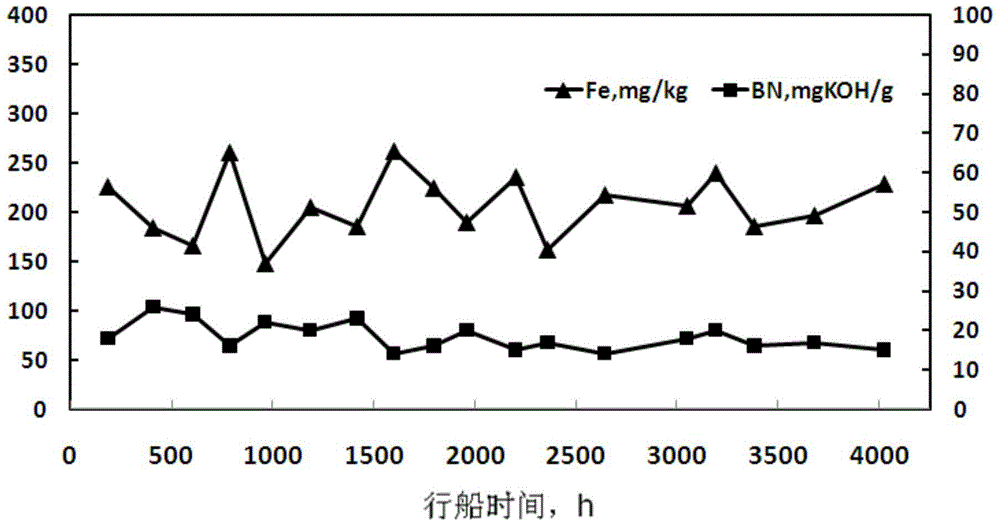

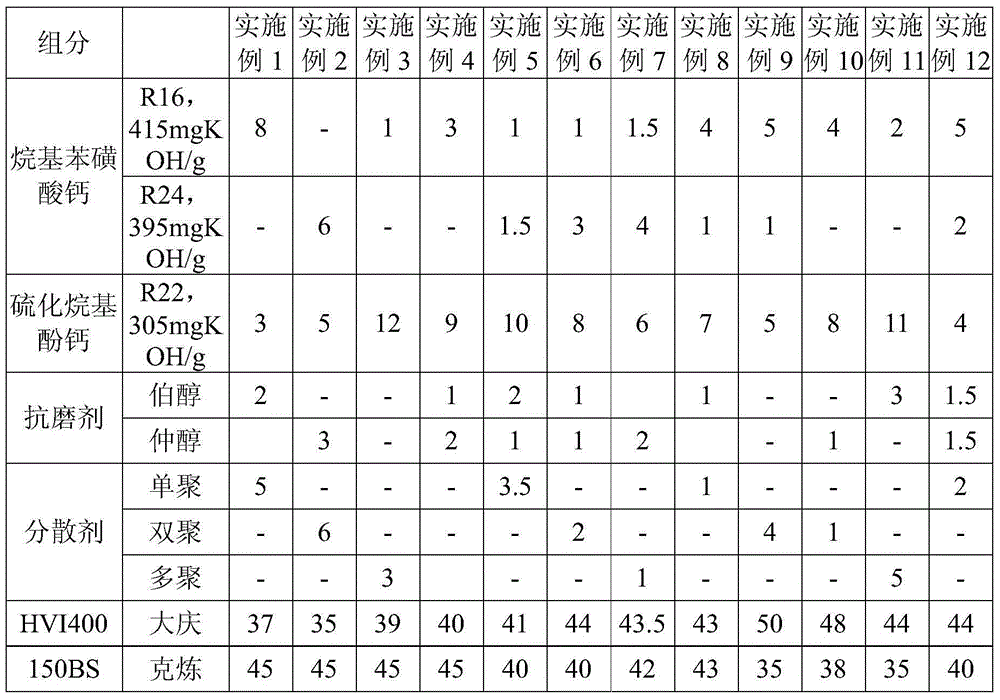

Marine cylinder oil composition as well as preparation method and application thereof

InactiveCN104450091AImprove detergencyGood dispersionLubricant compositionTotal Base NumberSulfonate

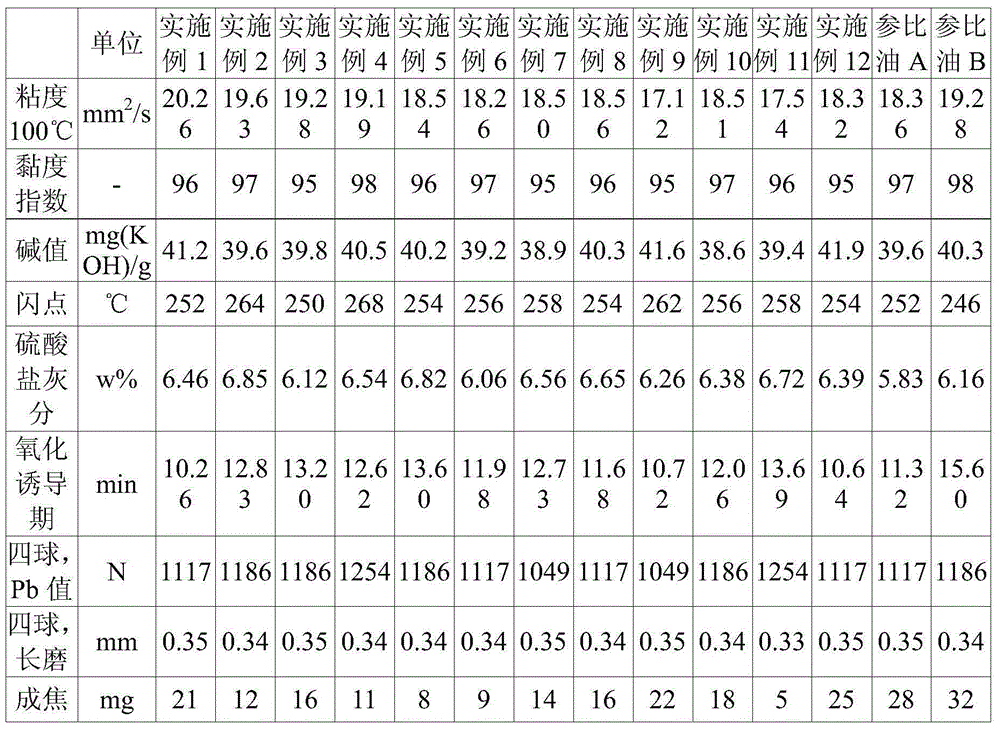

The invention relates to a marine cylinder oil composition as well as a preparation method and application thereof. The cylinder oil composition comprises the following components in percentage by mass: 1-8% of calcium alkylbenzene sulfonate, 3-12% of calcium alkylphenol sulfide, 0-6% of a dispersant, 0-3% of an anti-wear agent and the balance of base oil, wherein the total base number of the cylinder oil composition is 38.6-41.9mgKOH / g. The invention also provides the preparation method of the composition and the application of the composition in marine fuel in which the content of sulfur is 0.5-2.5%. The cylinder oil composition meets the application requirement of the marine fuel in which the content of sulfur is 0.5-2.5% and has excellent cleaning and dispersing properties, antioxidant and anti-wear properties and the like; by a service test of a low-speed crosshead marine engine, the comprehensive property of the cylinder oil composition can meet technical requirements of OEM.

Owner:PETROCHINA CO LTD

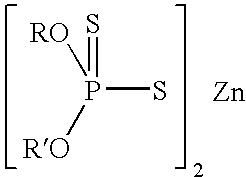

Diesel engine lubricating oil composition for large-bore two-stroke cross-head diesel engines

ActiveUS20070149421A1Improve high temperature wear resistanceImprove thermal stabilityAdditivesTotal Base NumberChemical composition

A lubricating oil composition comprising a base oil of lubricating viscosity having a kinematic viscosity of 22 to 300 mm2 / s at 40° C. and dissolved or dispersed therein the following additives in the following amounts based on a total amount of the lubricating oil composition: (1) an overbased sulfurized alkylphenol calcium salt detergent in an amount of 0.1 to 1.6 wt. % in terms of calcium content, (2) an overbased calcium alkylbenzenesulfonate detergent in an amount of 0.6 to 2.1 wt. % in terms of calcium content, (3) a nitrogen-containing ashless dispersant in an amount of 0.005 to 0.1 wt. % in terms of nitrogen content, and (4) a zinc dihydrocarbyldithiophosphate in an amount of 0.01 to 0.1 wt. % in terms of phosphorus content, wherein the weight ratio of the overbased sulfurized alkylphenol calcium salt detergent to the overbased calcium alkylbenzenesulfonate detergent is in the range of 10:90 to 40:60 in terms of calcium content and wherein the lubricating oil composition has a total base number of 30 to 60 mg·KOH / g.

Owner:CHEVRON JAPAN

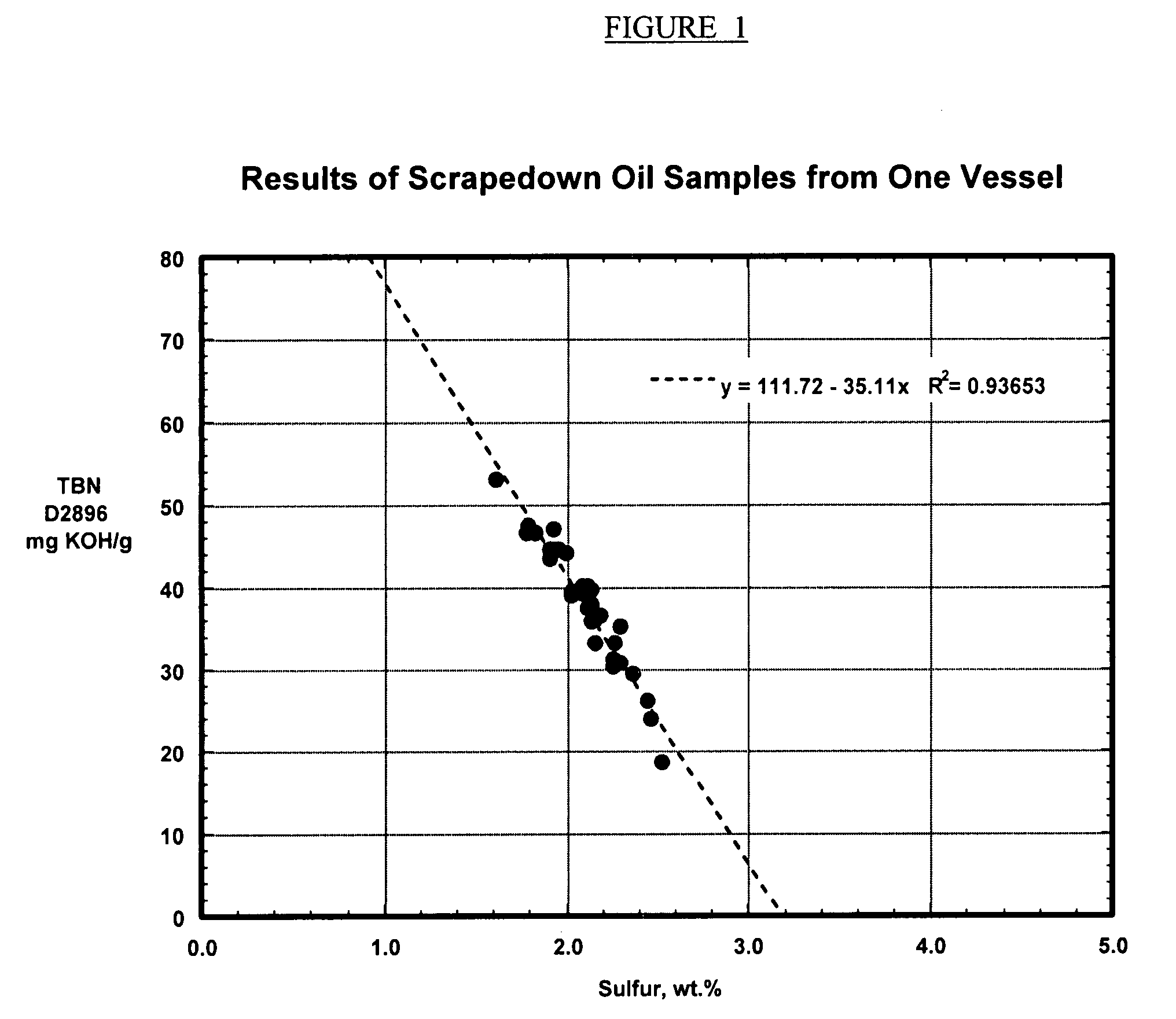

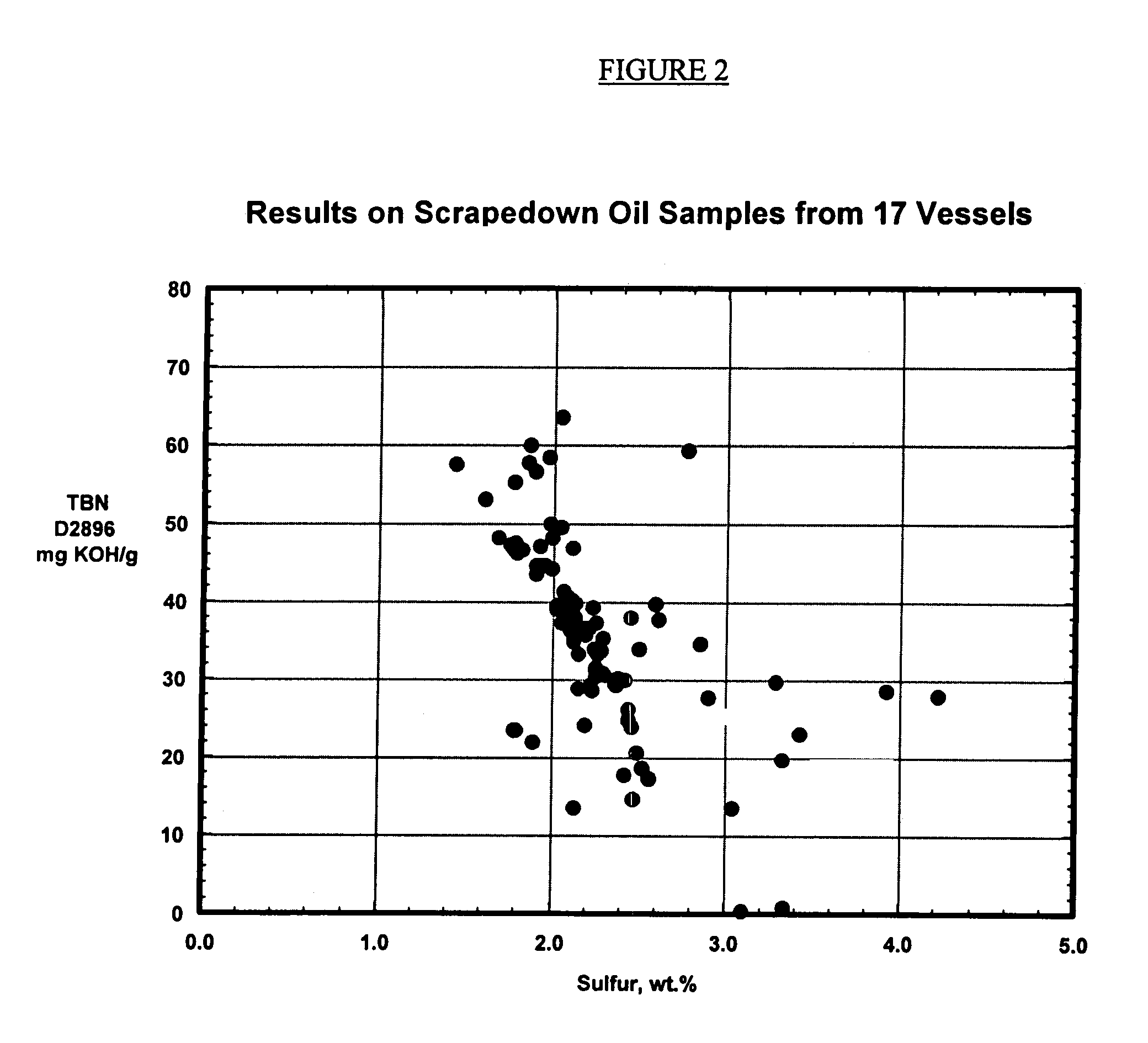

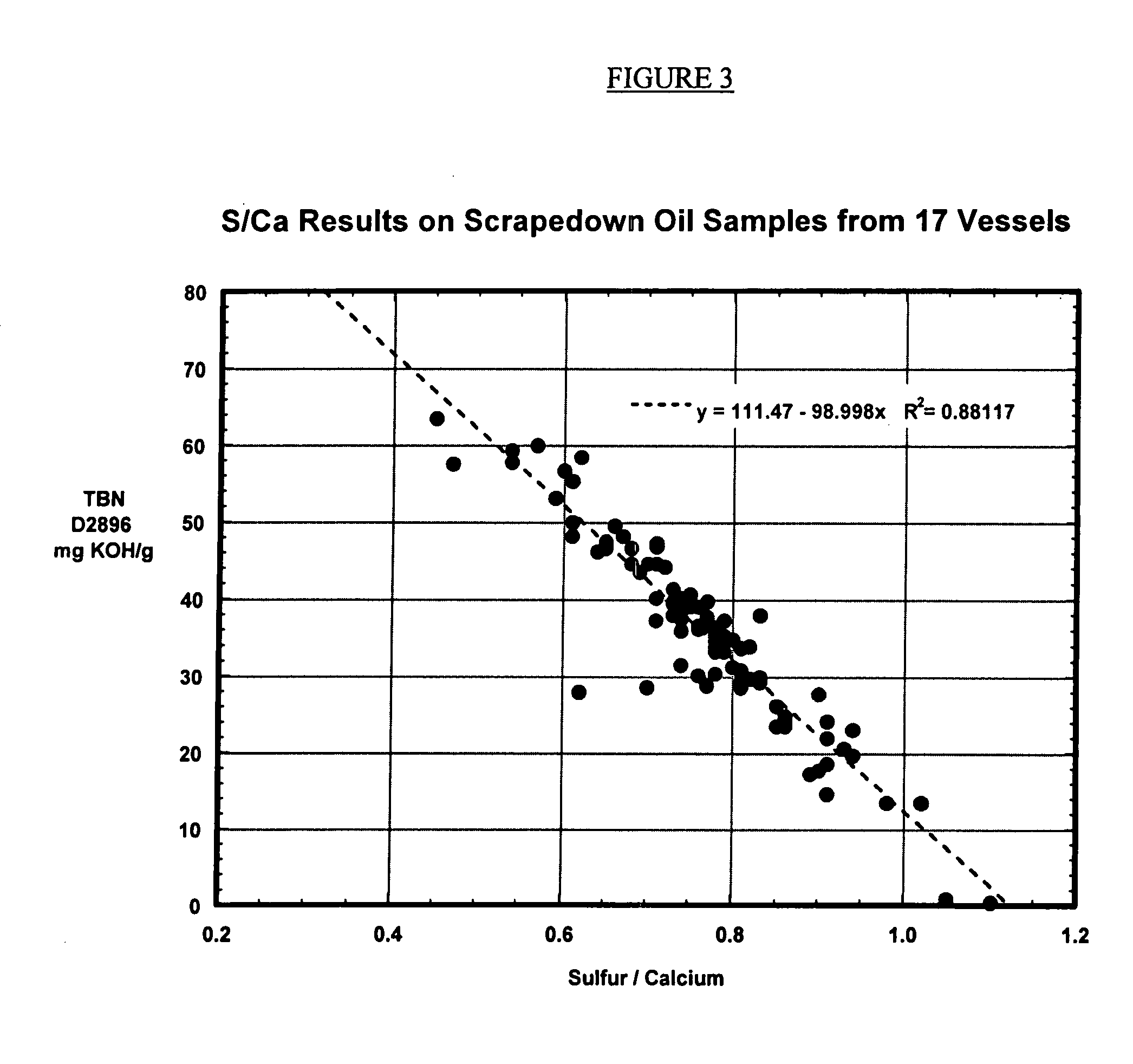

Determination of total base number in marine engine lubricants by elements

The present invention provides a method for determining the TBN of a used lubricating oil by measuring with a single device at least one element, such as sulfur, and correlating the measured amount to the oil's TBN. Preferably, a spectroscopic device is used to make the measurement.

Owner:EXXON RES & ENG CO

Low viscosity marine cylinder lubricating oil compositions

InactiveUS8702968B2Maintain wear resistanceMaintain performanceAdditivesBase-materialsTotal Base NumberChemical composition

Disclosed herein are marine cylinder lubricants which comprise a major amount of basestock selected from the group consisting of a Group II basestock, a Group III basestock and mixtures thereof, wherein the marine cylinder lubricant has a kinematic viscosity at 100° C. of from 13 to about 16.2 cSt; and contains less than about 10 wt. % bright stock. Also disclosed are marine cylinder lubricants which comprise a major amount of basestock selected from the group consisting of a Group II basestock, a Group III basestock and mixtures thereof, wherein the marine cylinder lubricant has a kinematic viscosity at 100° C. of between about 13 and about 16.2 cSt; and a total base number of 5 to about 70, and further wherein the marine cylinder lubricant contains less than about 10 wt. % bright stock.

Owner:CHEVRON ORONITE TECH BV

Method of monitoring deterioration of lubricating oil and device therefore

InactiveUS8224600B2Suppresses measurement errorsJudging deterioration of oilResistance/reactance/impedenceMaterial analysis by electric/magnetic meansTotal Base NumberForeign matter

A method of monitoring deterioration of lubricating oil and a device therefore capable of judging deterioration of the oil with high accuracy suppressing measurement error due to mixing of foreign matter in the oil. Correlation between relative permittivity and TBN (total base number) of the lubricating oil is obtained beforehand (step S1), electric current and voltage are measured (step S2) when high-frequency voltage is applied between a pair of electrodes located in an oil path in a gas engine, permittivity of the oil is detected (step S3) based on the measurement of current and voltage, TBN of the oil is obtained (step S4) from the correlation between relative permittivity and TBN, and deterioration of the oil is judged by the obtained value of TBN.

Owner:MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com