Patents

Literature

1641results about "Lubrication of auxillaries" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

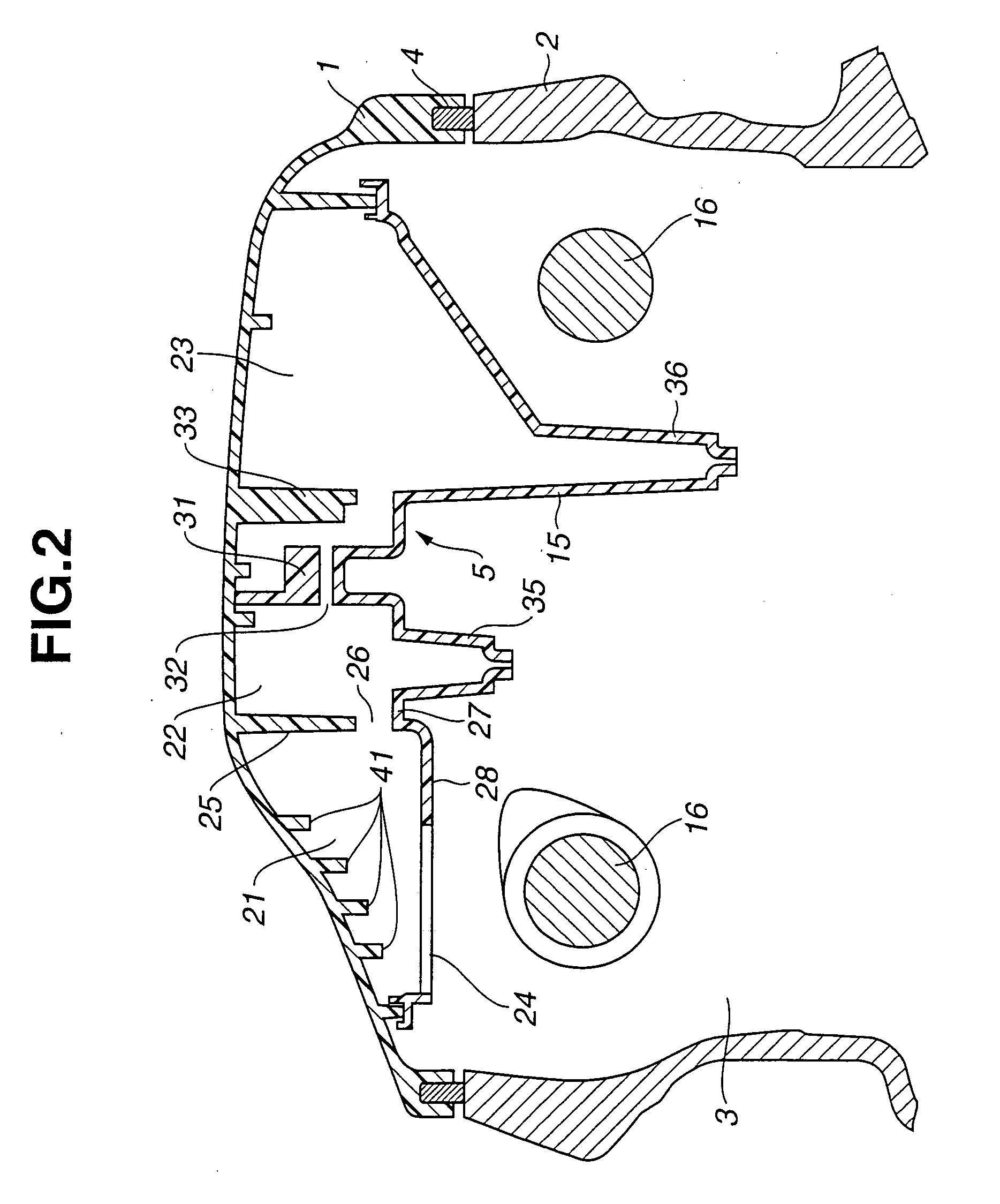

Separator for separating oil mist from the crankcase ventilation gas of an internal combustion engine, and functional module and internal combustion engine comprising a separator

ActiveUS20100180854A1Increase speedEasy to separateCombination devicesLubrication of auxillariesExternal combustion engineEngineering

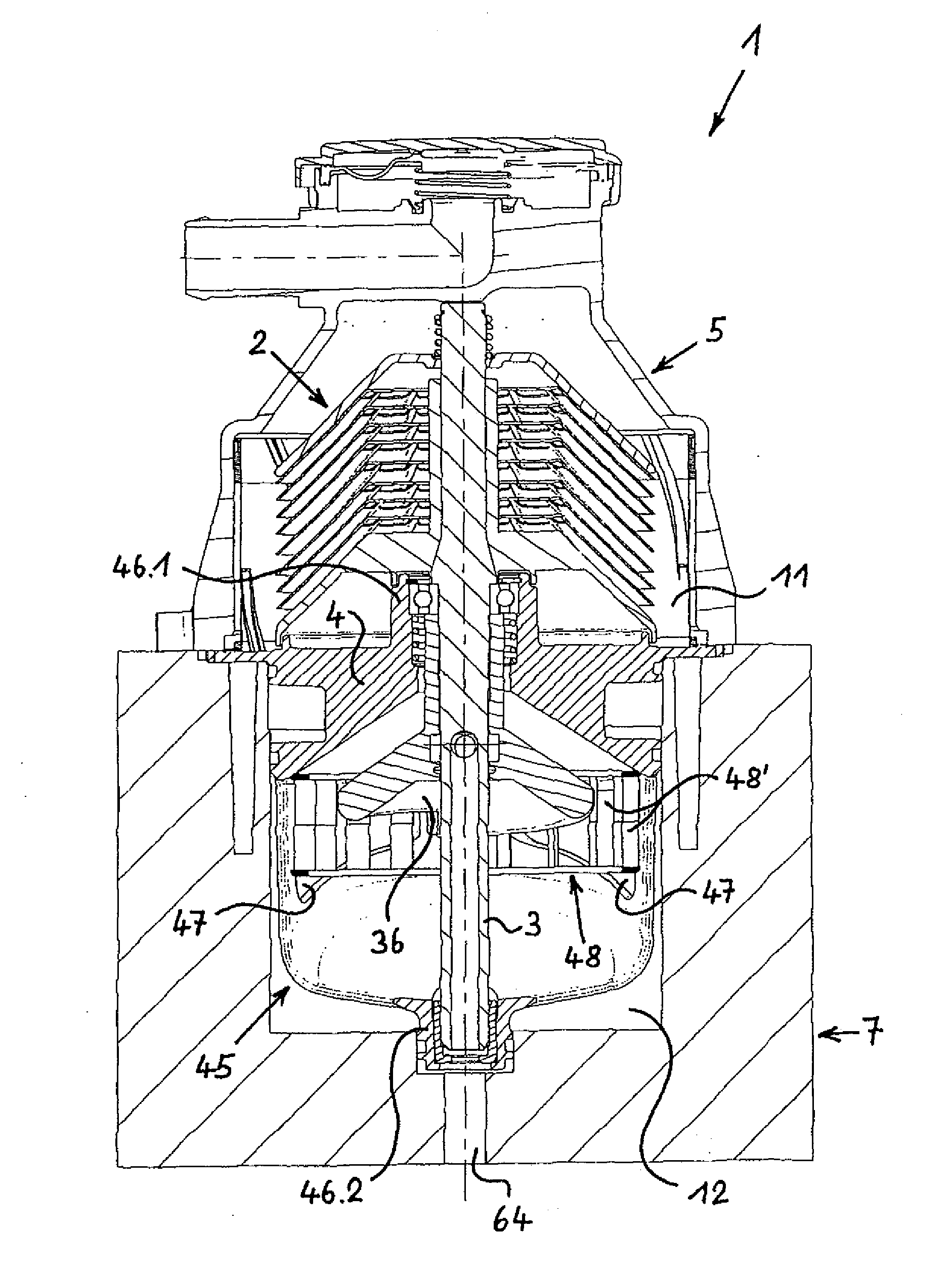

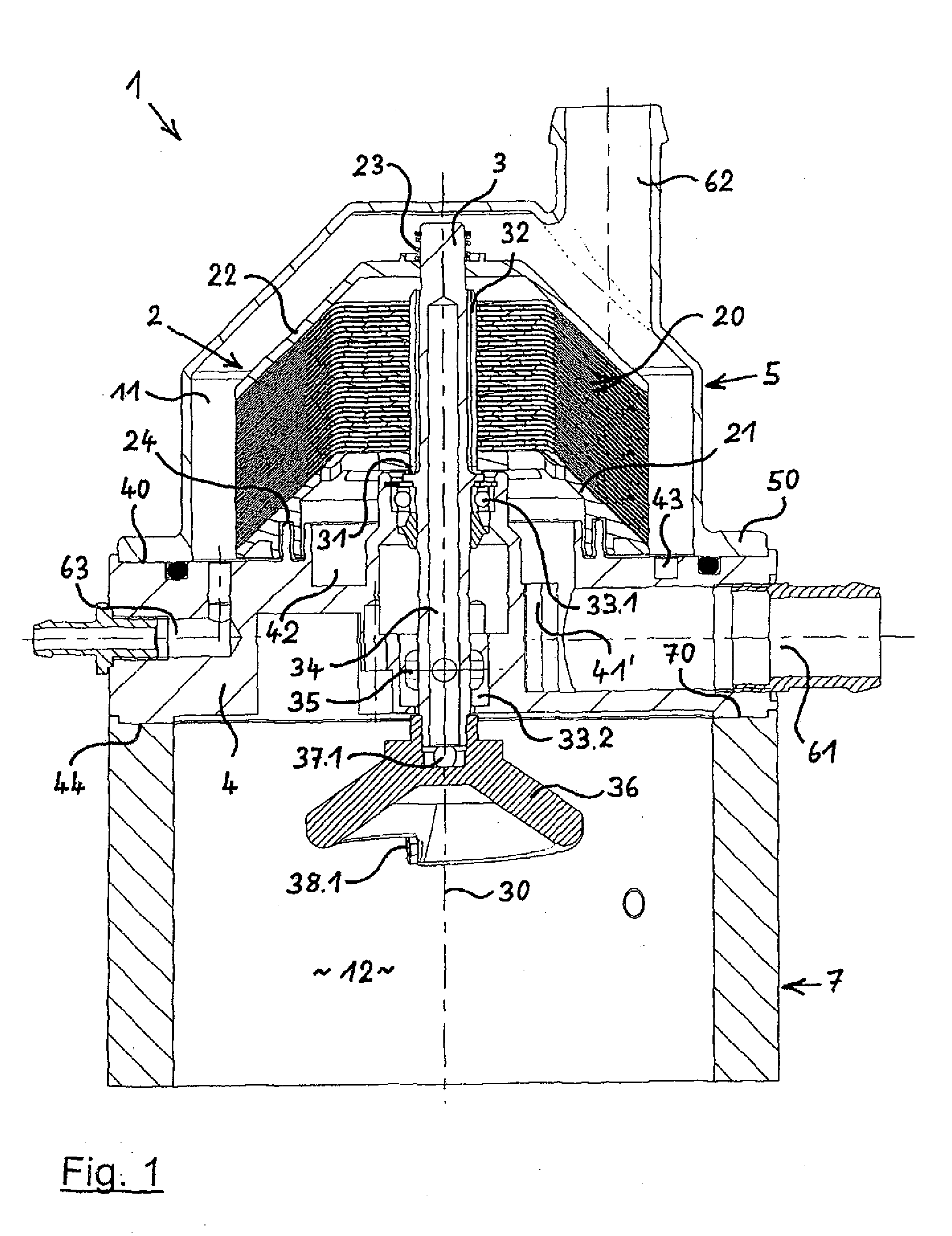

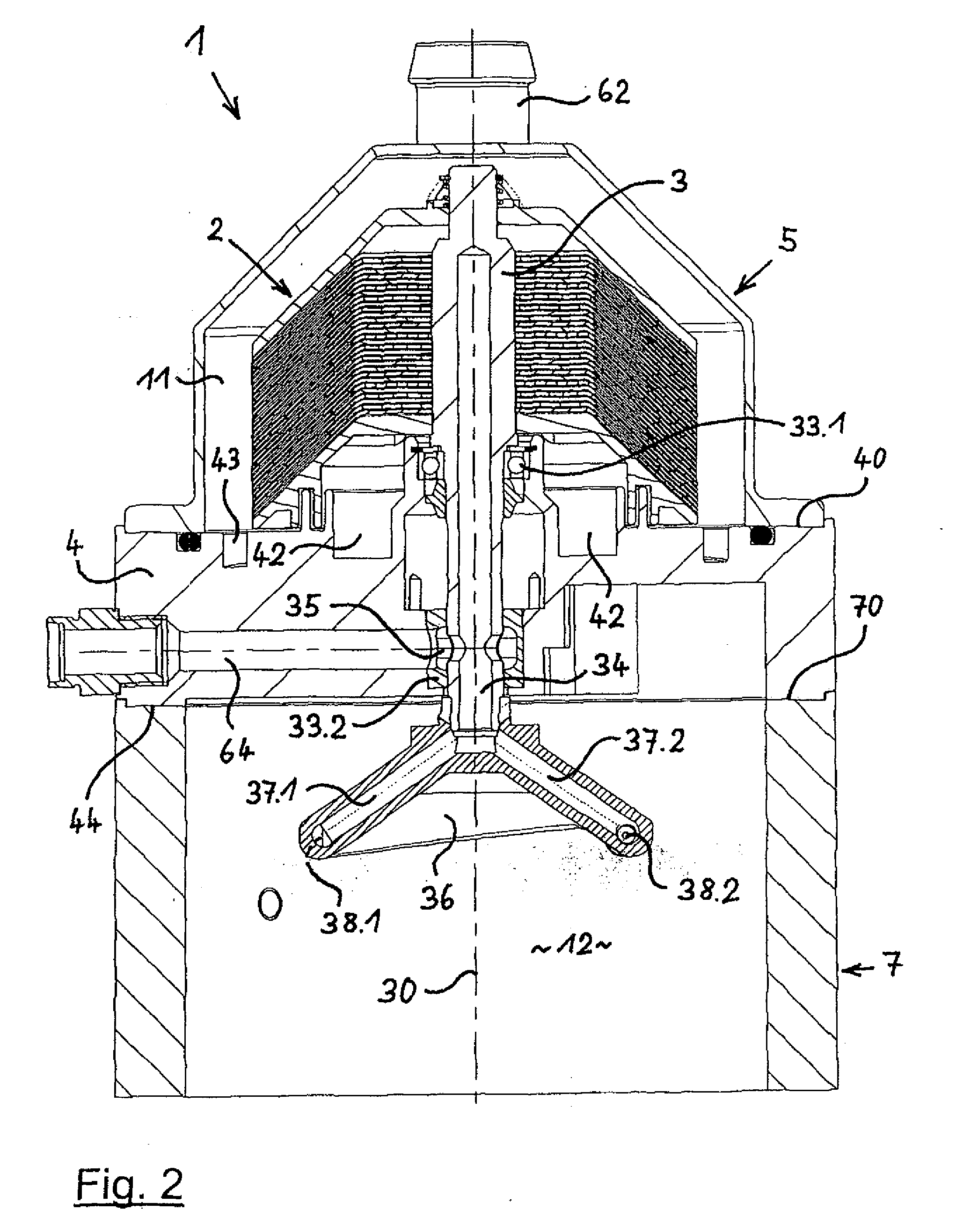

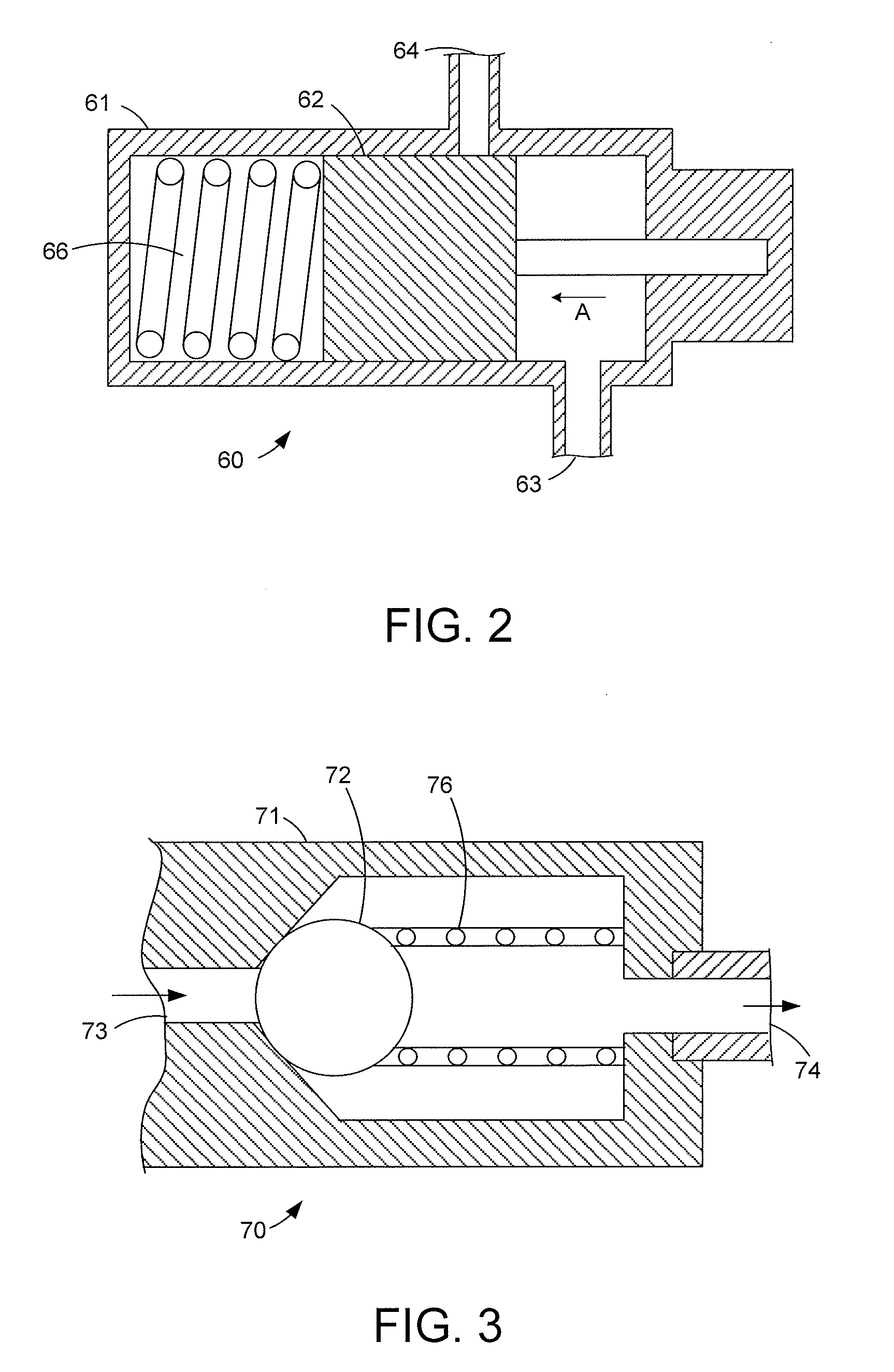

A separator for separating oil mist from the crankcase ventilation gas of an internal combustion engine, especially of a motor vehicle. The separator includes a gas purification chamber inside which a rotatably mounted centrifugal rotor is arranged. The gas purification chamber has a crude gas inlet, a pure gas outlet, and an oil outlet. The crankcase ventilation gas can be conducted into a radially internal zone of the centrifugal rotor via the crude gas inlet, while pure gas that is liberated from oil mist can be discharged from the gas purification chamber via the pure gas outlet, and oil separated from the gas can be discharged from the gas purification chamber via the oil outlet. The separator further includes a rotary drive for the centrifugal rotor. The rotary drive is disposed in a drive chamber of the separator, can be operated using pressurized lubrication oil of the internal combustion engine, and is connected to the centrifugal rotor by means of a shaft extending from the drive chamber into the gas purification chamber, from which the drive chamber is separated. The rotary drive is formed by at least one thrust nozzle which is connected to the shaft and to which the pressurized lubrication oil of the internal combustion engine can be fed. The separator includes at least one part of a base that forms the separation between the gas purification chamber and the drive chamber and extends into the drive chamber, the part of the base being fitted with a seat for a bearing of the shaft. The bearing is located at a distance from the centrifugal rotor.

Owner:HENGST WALTER

Modification of lubricant properties in an operating all loss lubricating system

Owner:EXXOMOBIL RES & EINGIEERING

Engine lubrication system

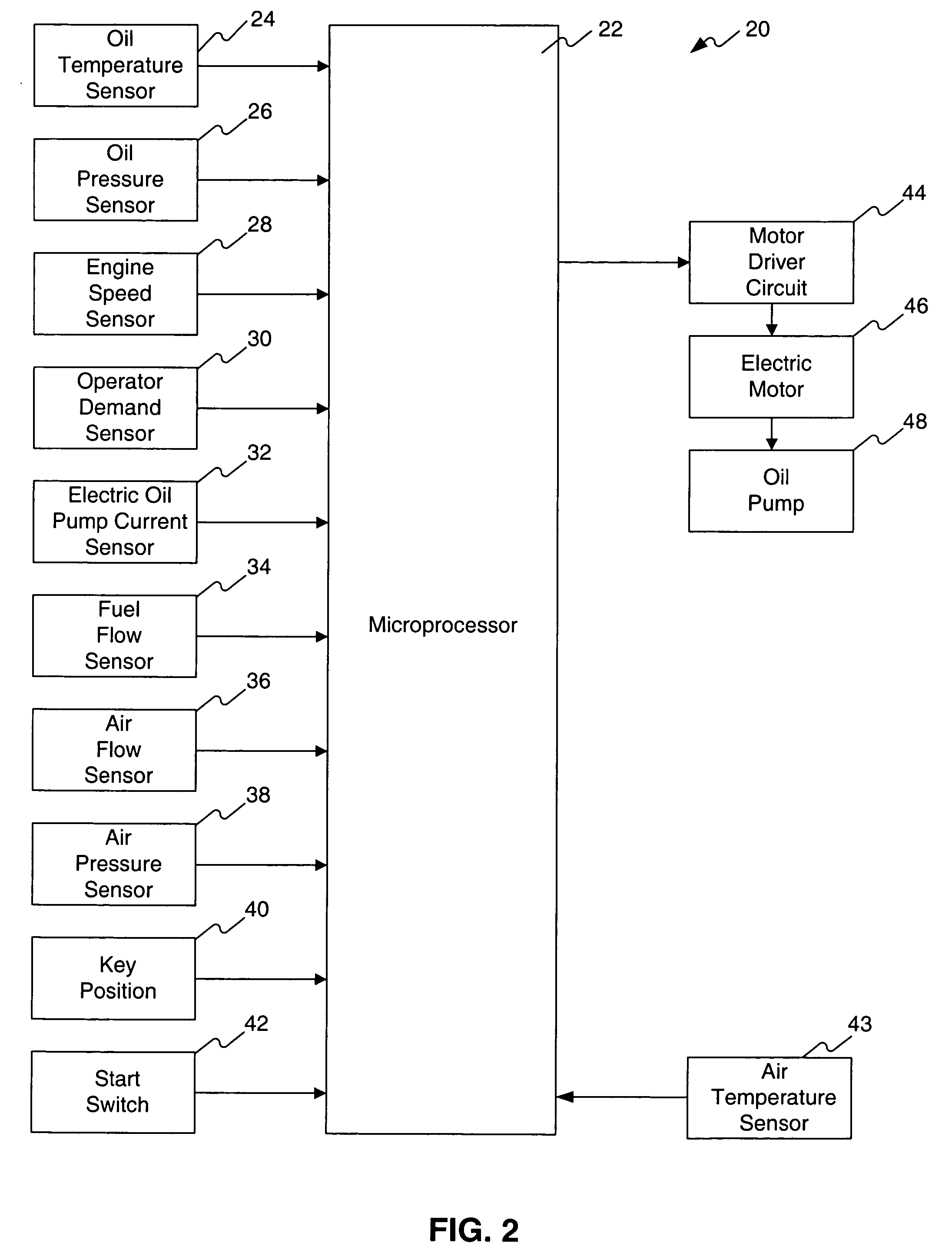

ActiveUS6941922B2Small sizeLubrication of auxillariesLubricant conduit arrangementsLine tubingEngineering

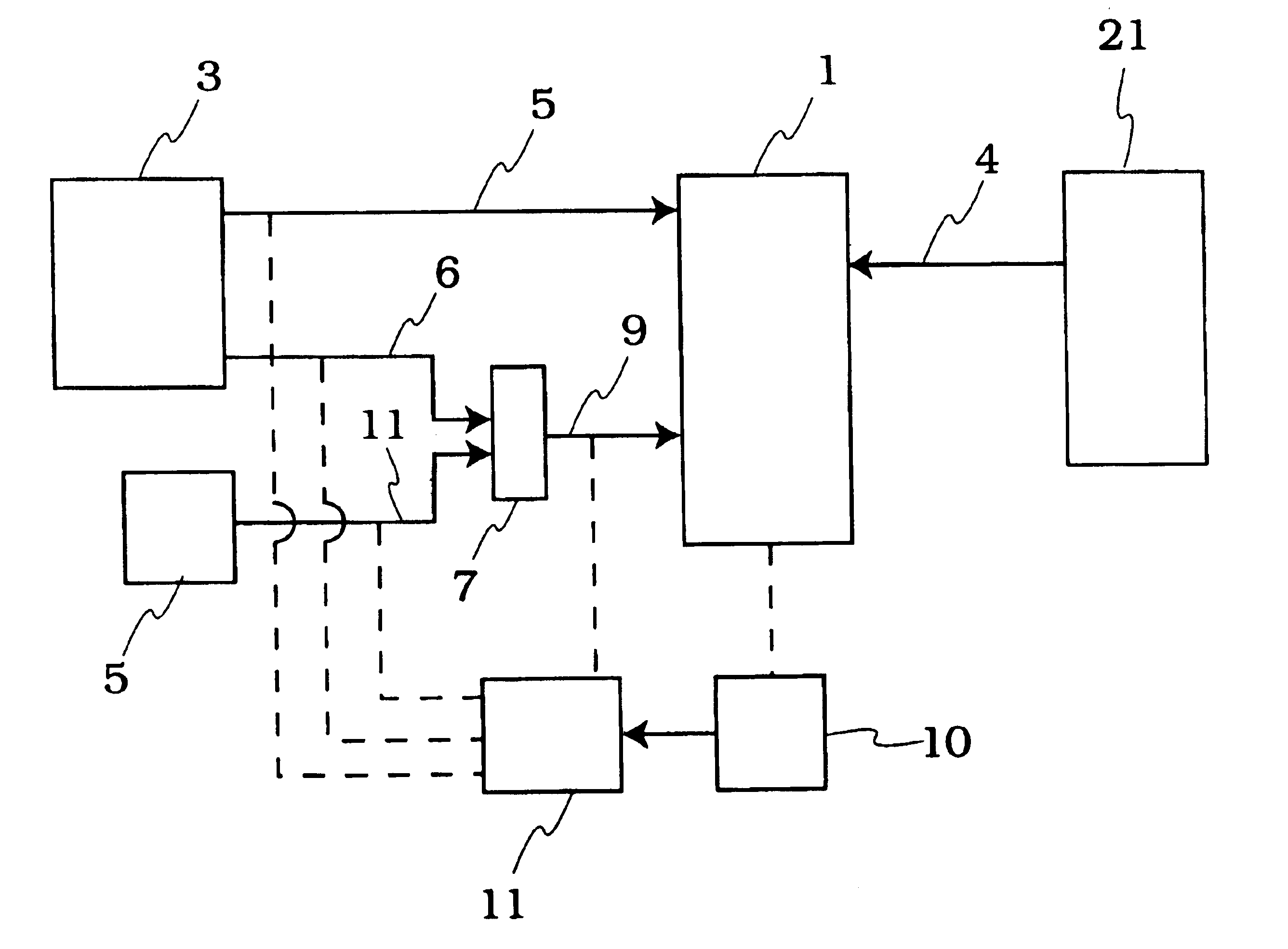

A lubrication system for an engine including a sump for lubricant, a main pump operable to pump lubricant to first lubrication positions within the engine, and an auxiliary lubricant pump also operable to pump lubricant to second lubrication positions within the engine and wherein the auxiliary pump is an electrically driven pump which is controlled by a system controller the output of the auxiliary pump being controlled according to engine operating conditions, the main pump in use, pumping lubricant to the first lubrication positions within the engine along a main lubricant feed line, and the auxiliary pump when operated pumping lubricant to the second lubrication positions within the engine along an auxiliary feed line, and wherein the main and auxiliary feed lines, are connected via a communication passage which includes a closeable communication valve, the communication valve when closed preventing the flow of lubricant from the auxiliary feed line to the first lubrication positions, and when open permitting the flow of lubricant from the auxiliary feed line to the first lubrication positions.

Owner:PIERBURG PUMP TECH UK

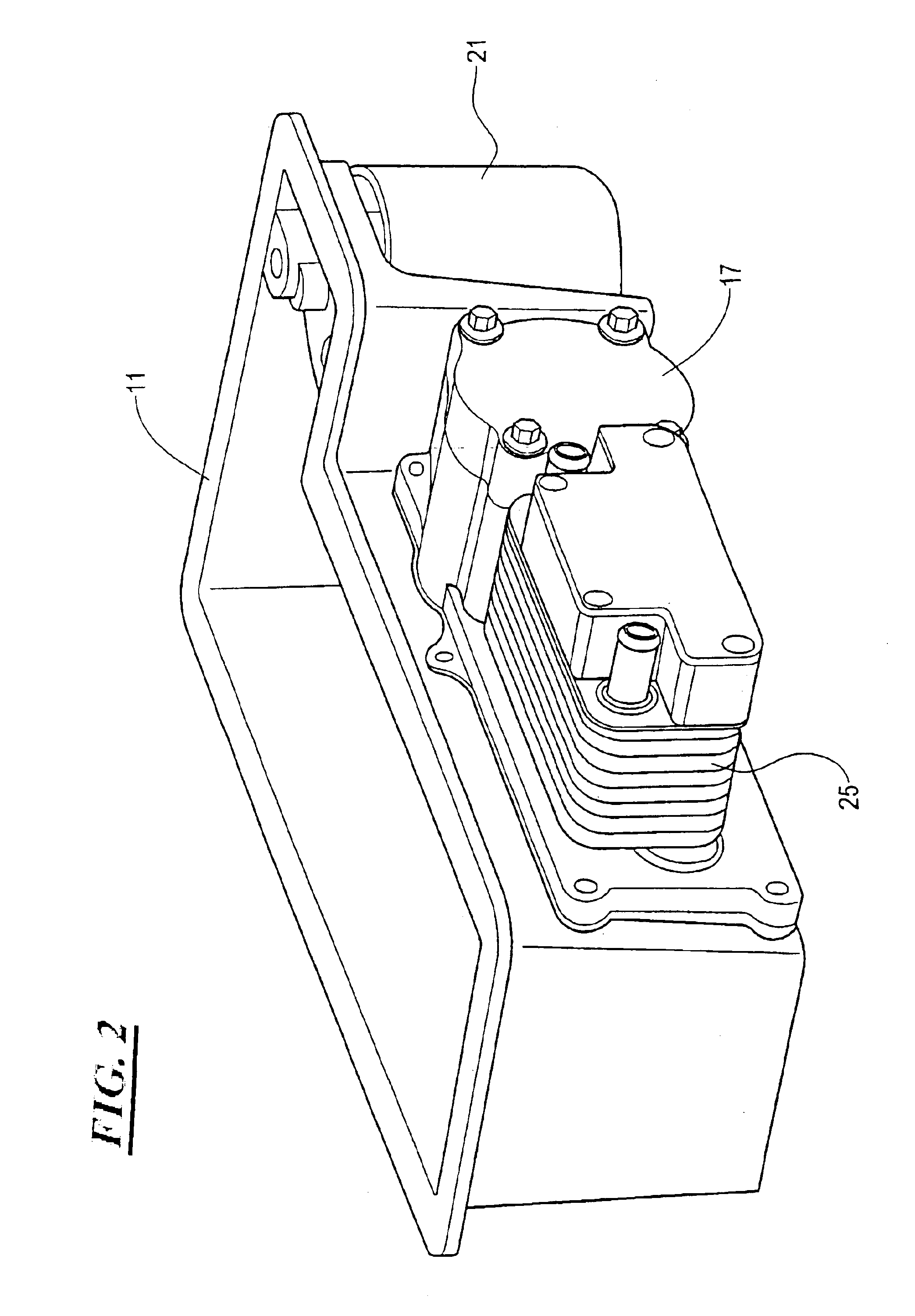

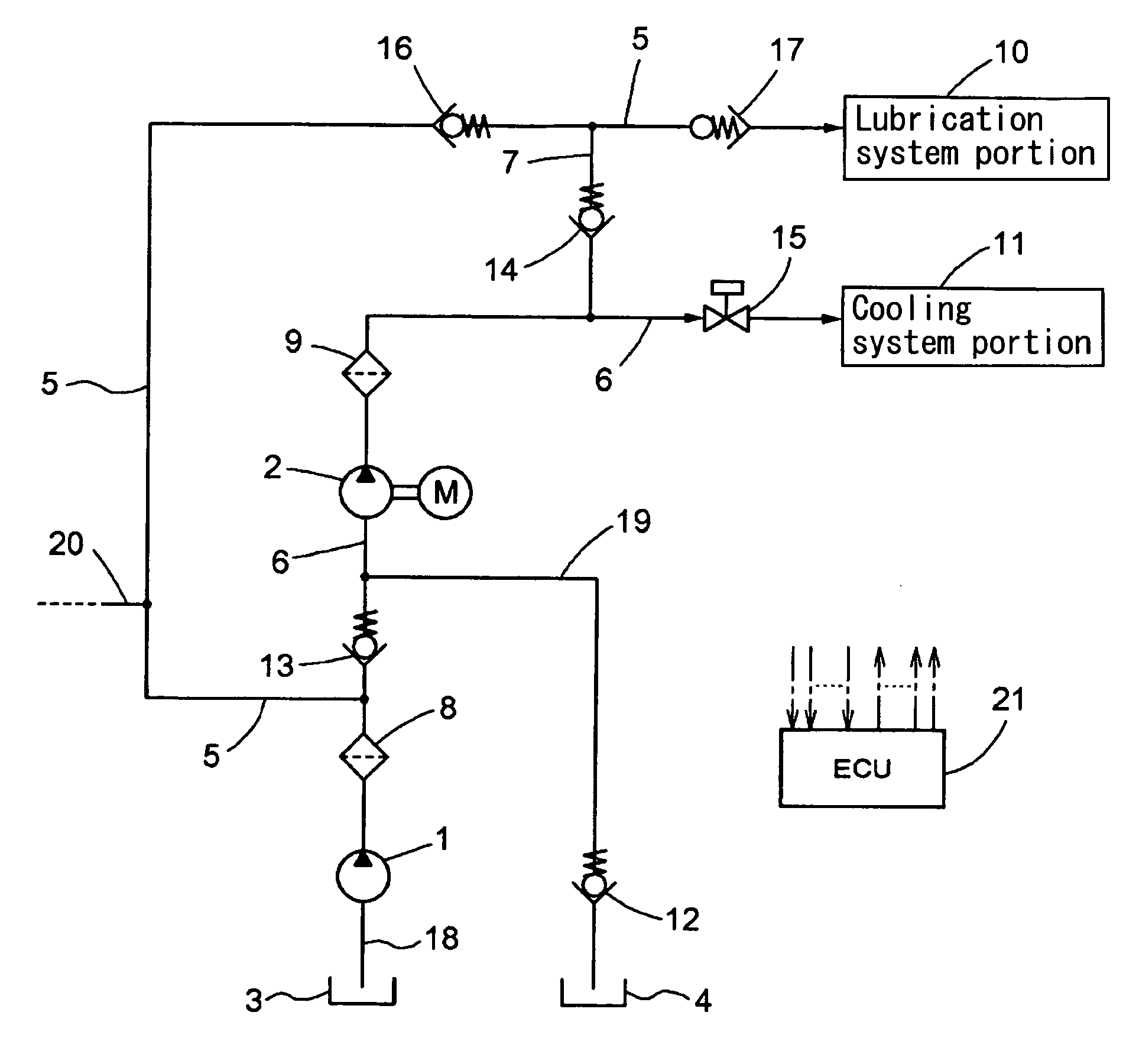

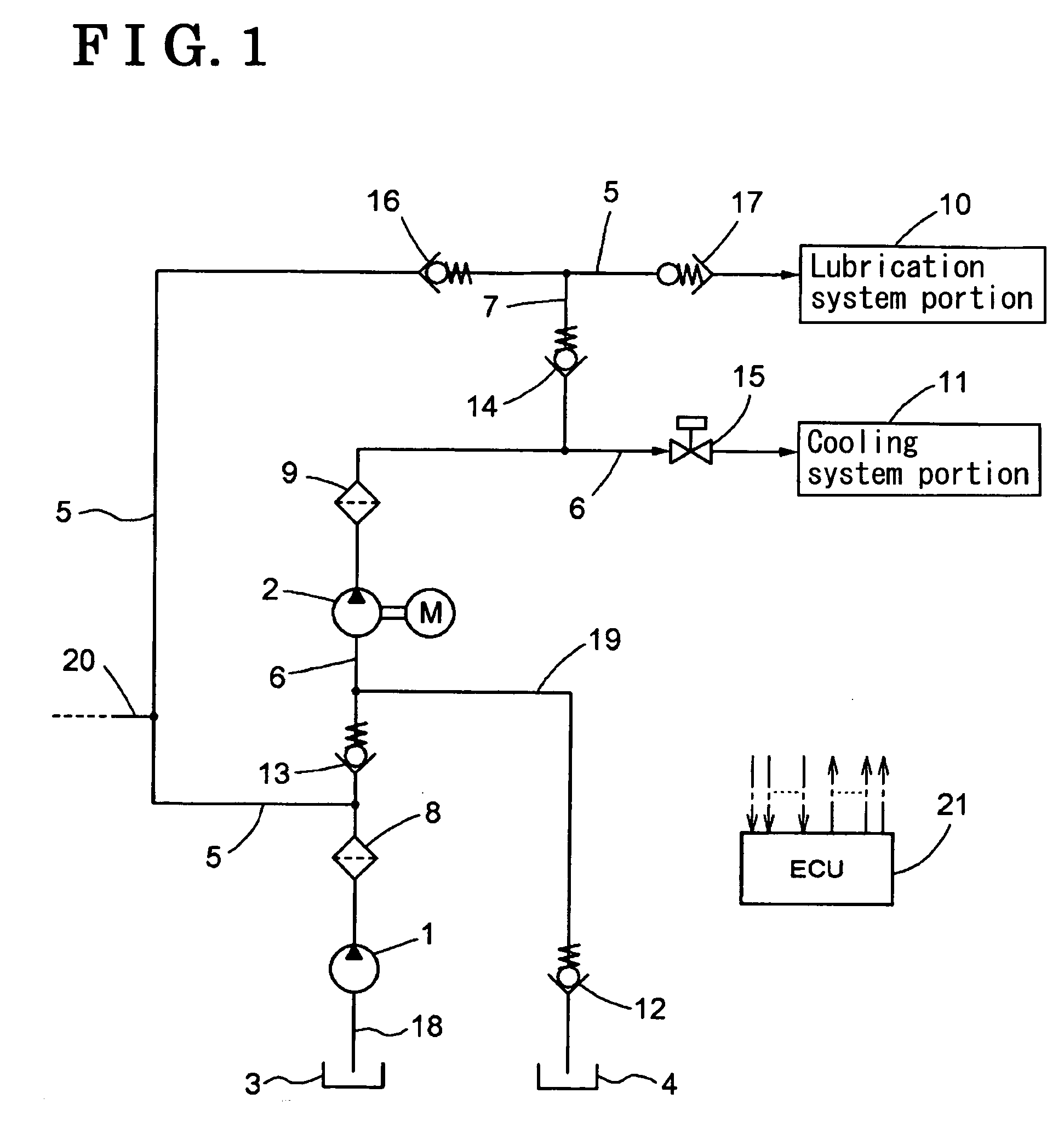

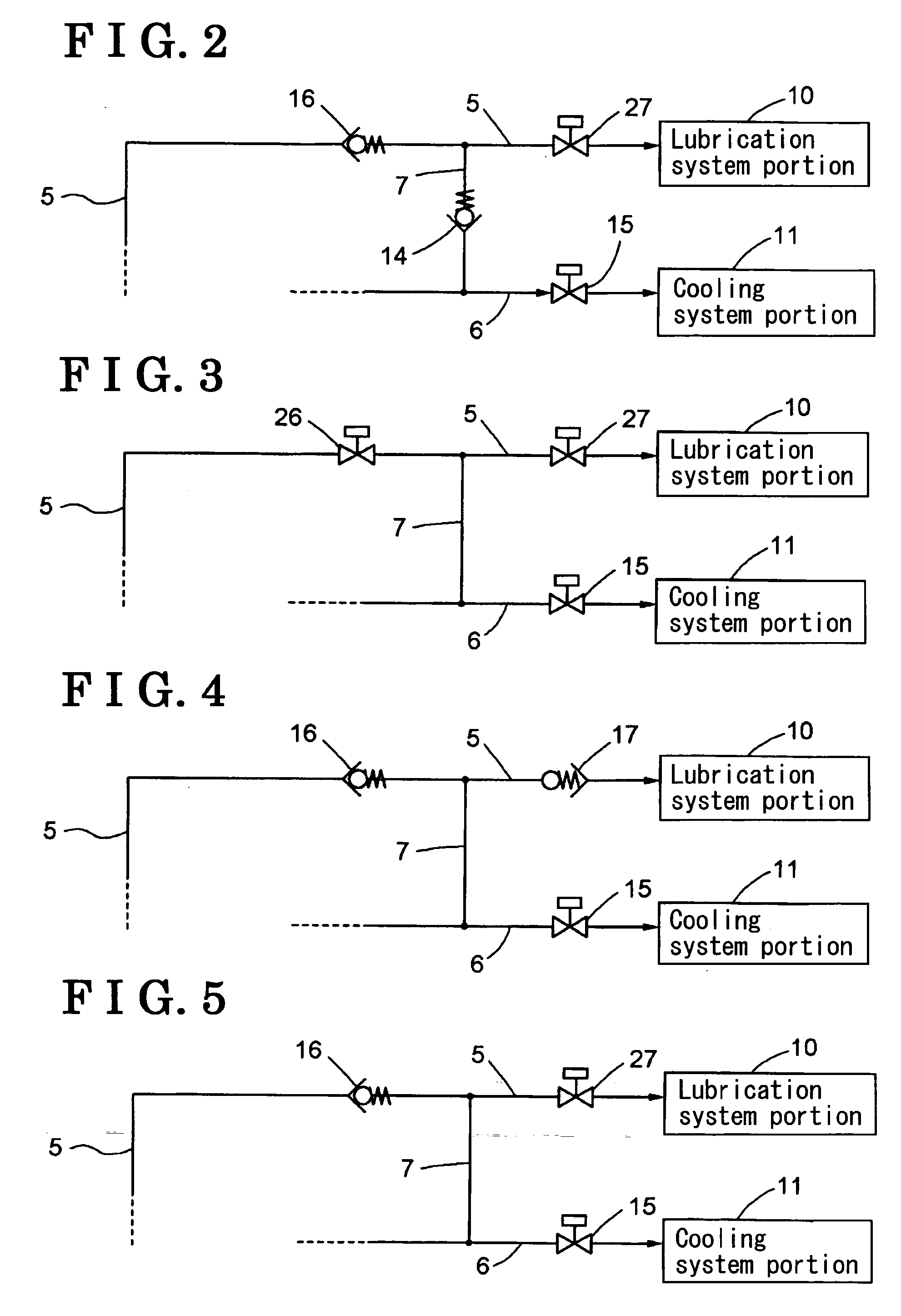

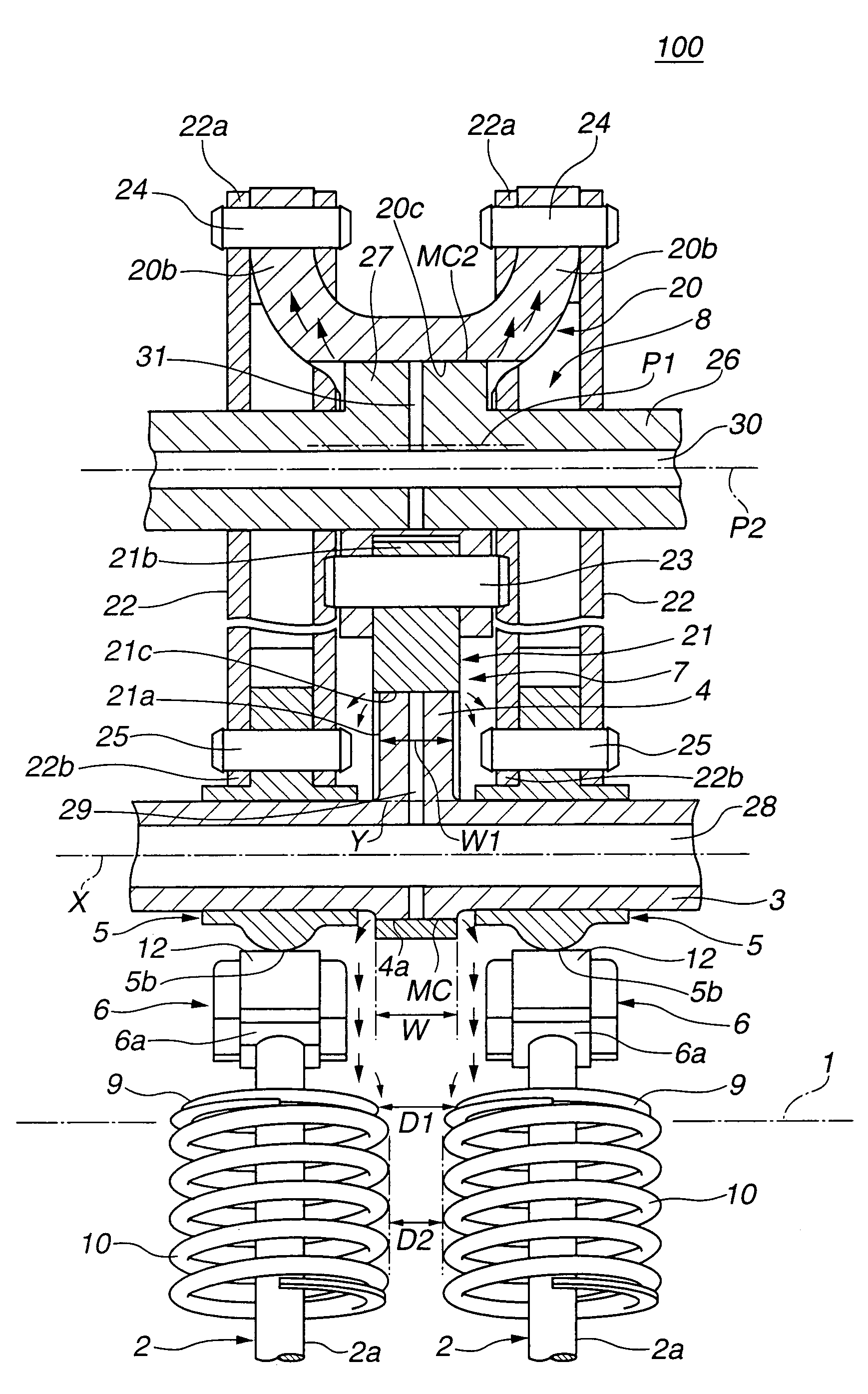

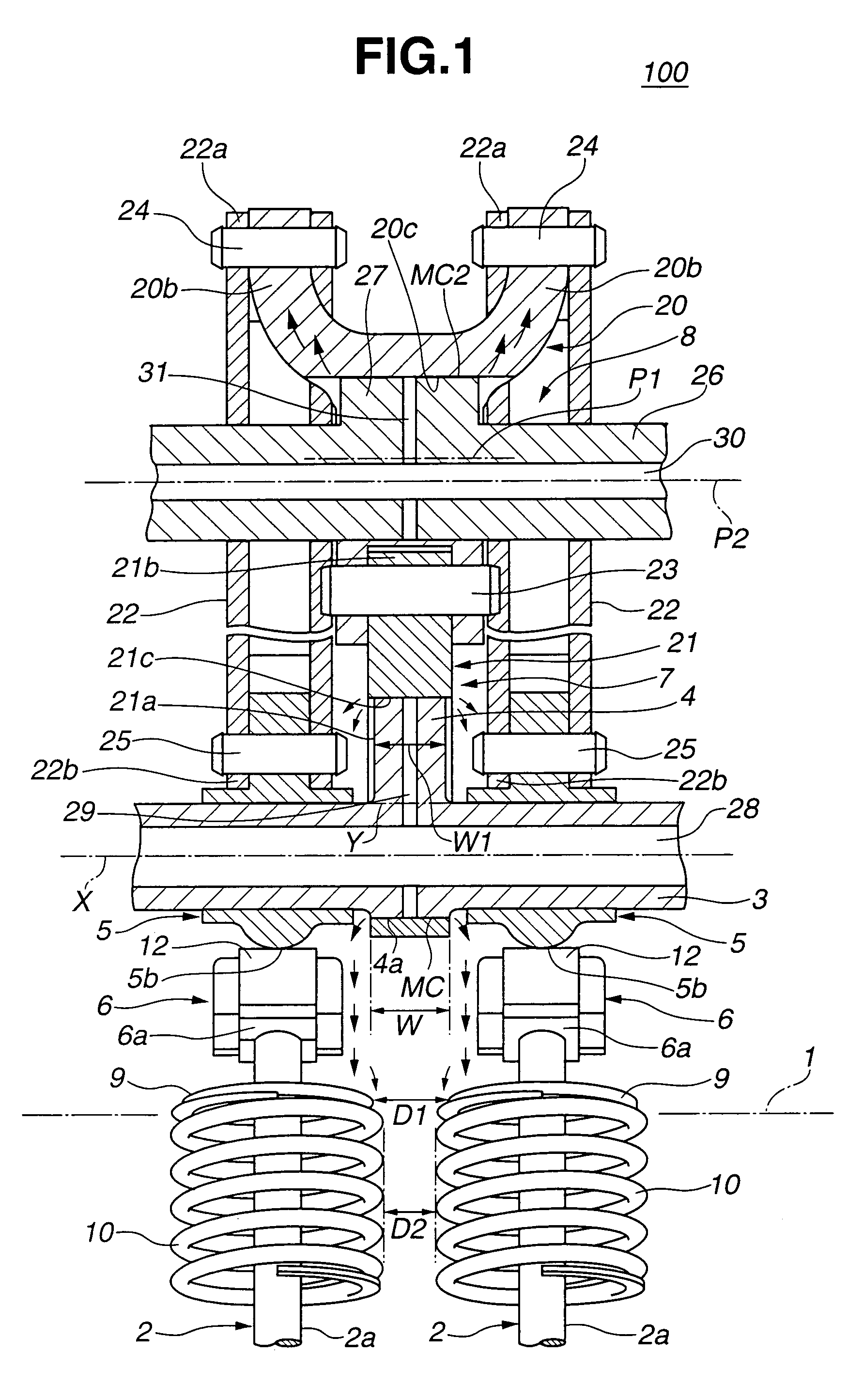

Oil supply device for engine

An oil supply device for an engine includes a first oil suction passage, a second oil suction passage, a first pump for sucking and discharging oil from the first oil suction passage, a second pump arranged in series with the first pump, the second pump for sucking and discharging oil from at least one of the first pump and the second oil suction passage, a check valve for blocking oil circulation, a first oil passage, a second oil passage, a third oil passage for establishing communication between the first oil passage and the second oil passage, and a supply volume control device for varying oil supply volume to a lubrication system portion, to a cooling system portion, or to the lubrication system portion and the cooling system portion in accordance with a change in at least one of an engine oil temperature, an engine rotation speed, and an engine load.

Owner:AISIN SEIKI KK

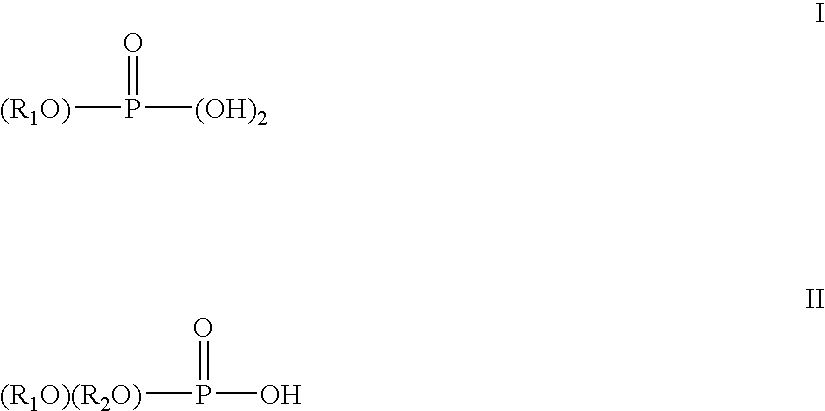

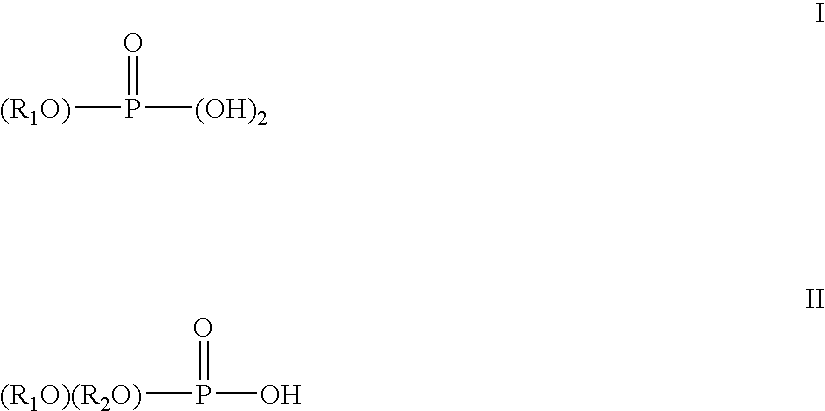

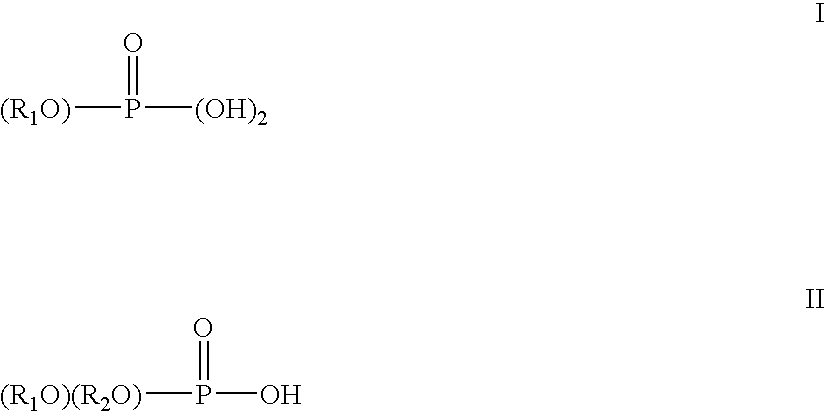

Modification of lubricant properties in an operating all loss lubricating system

ActiveUS20040144355A1Lubrication of auxillariesLubricant conduit arrangementsSulfonateAlkylphosphate

A marine diesel engine system includes a diesel engine having a plurality of cylinders. The system also includes, proximate the engine, a primary engine lubricant and an additive selected from certain alkylamine-alkylphosphates, 500 TBN calcium sulfonate and mixtures thereof. A means for blending the lubricant and additives into a mixture for introduction into a cylinder is provided. Thus lubricant properties may be modified depending upon engine conditions.

Owner:EXXOMOBIL RES & EINGIEERING

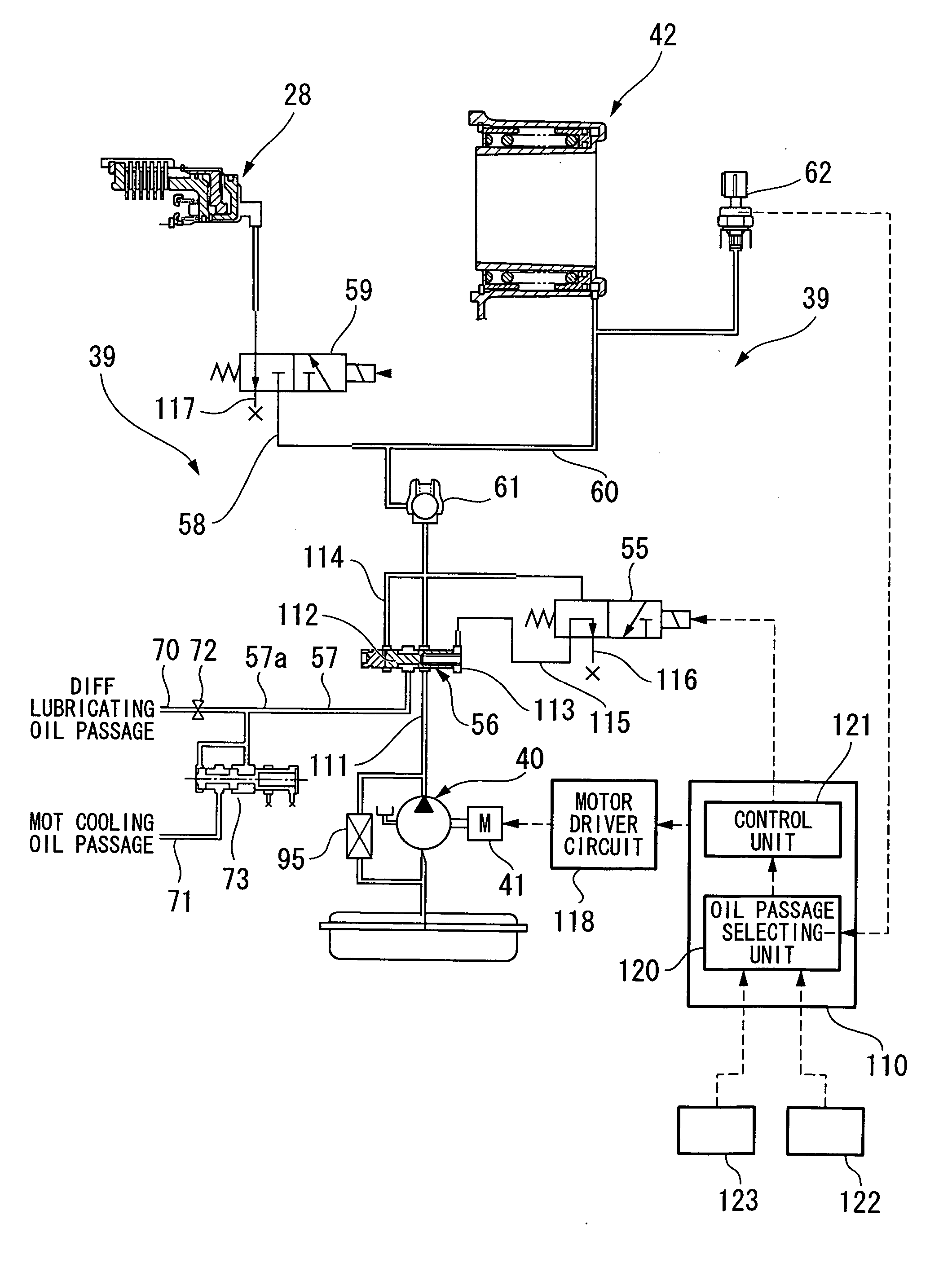

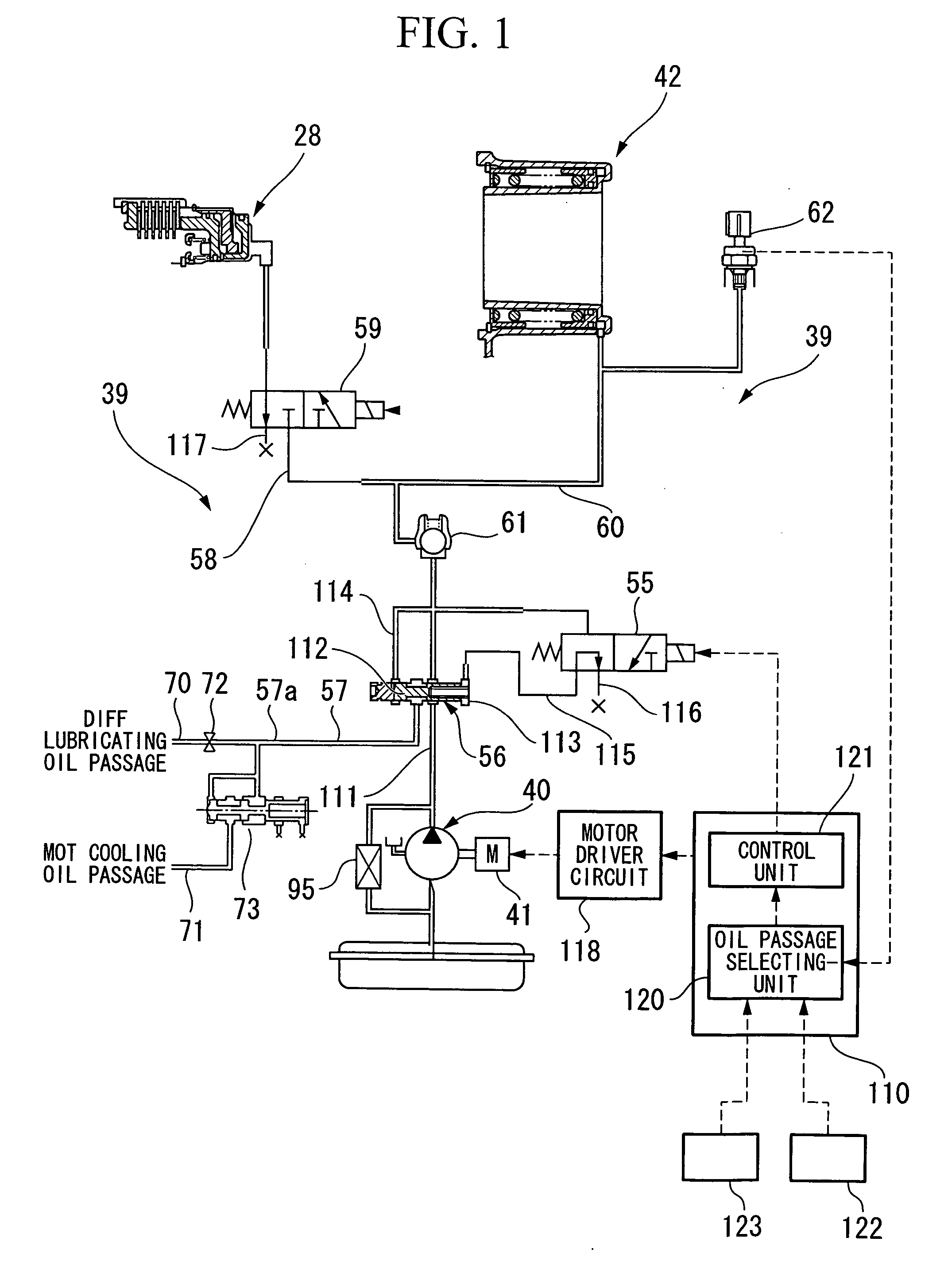

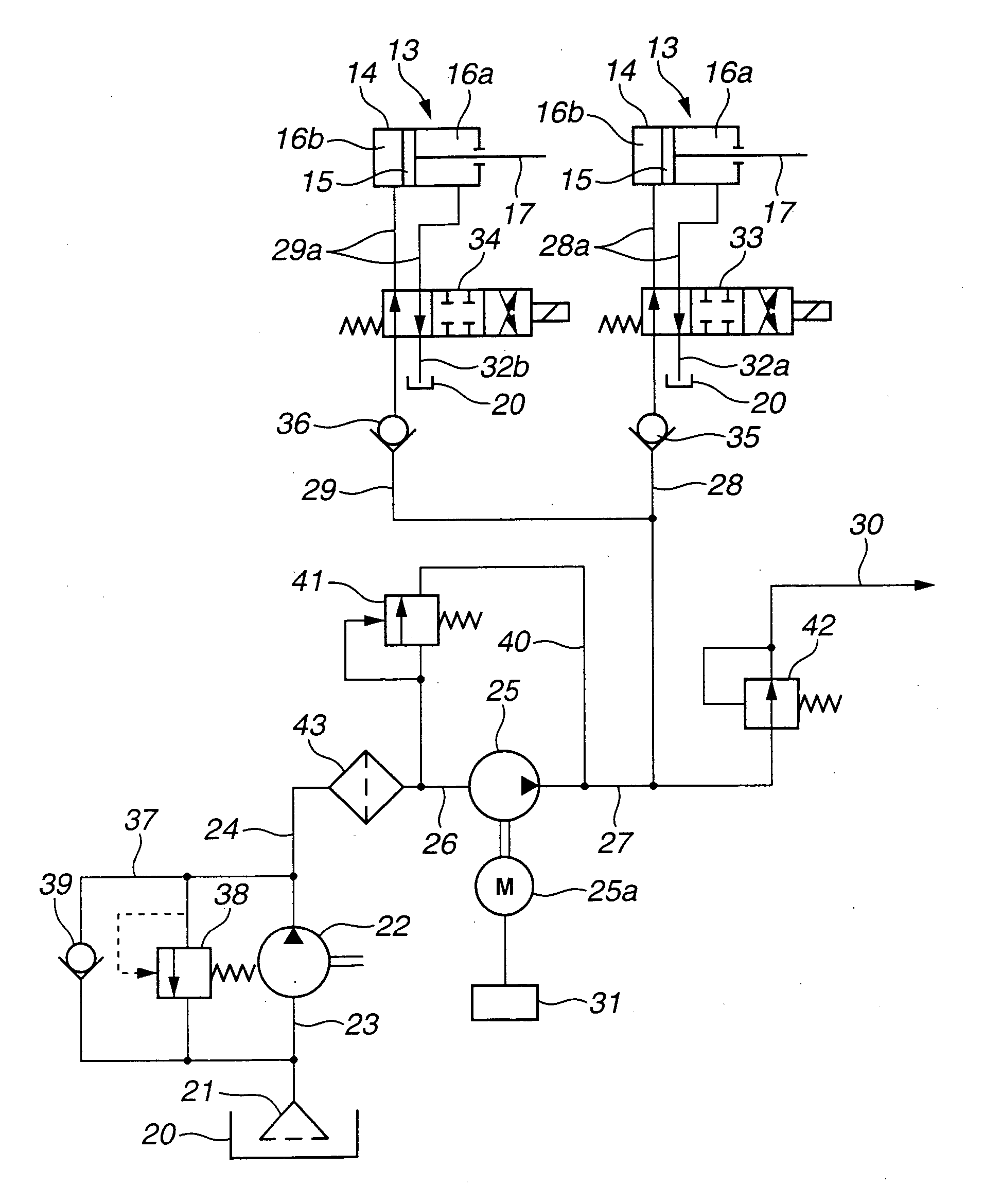

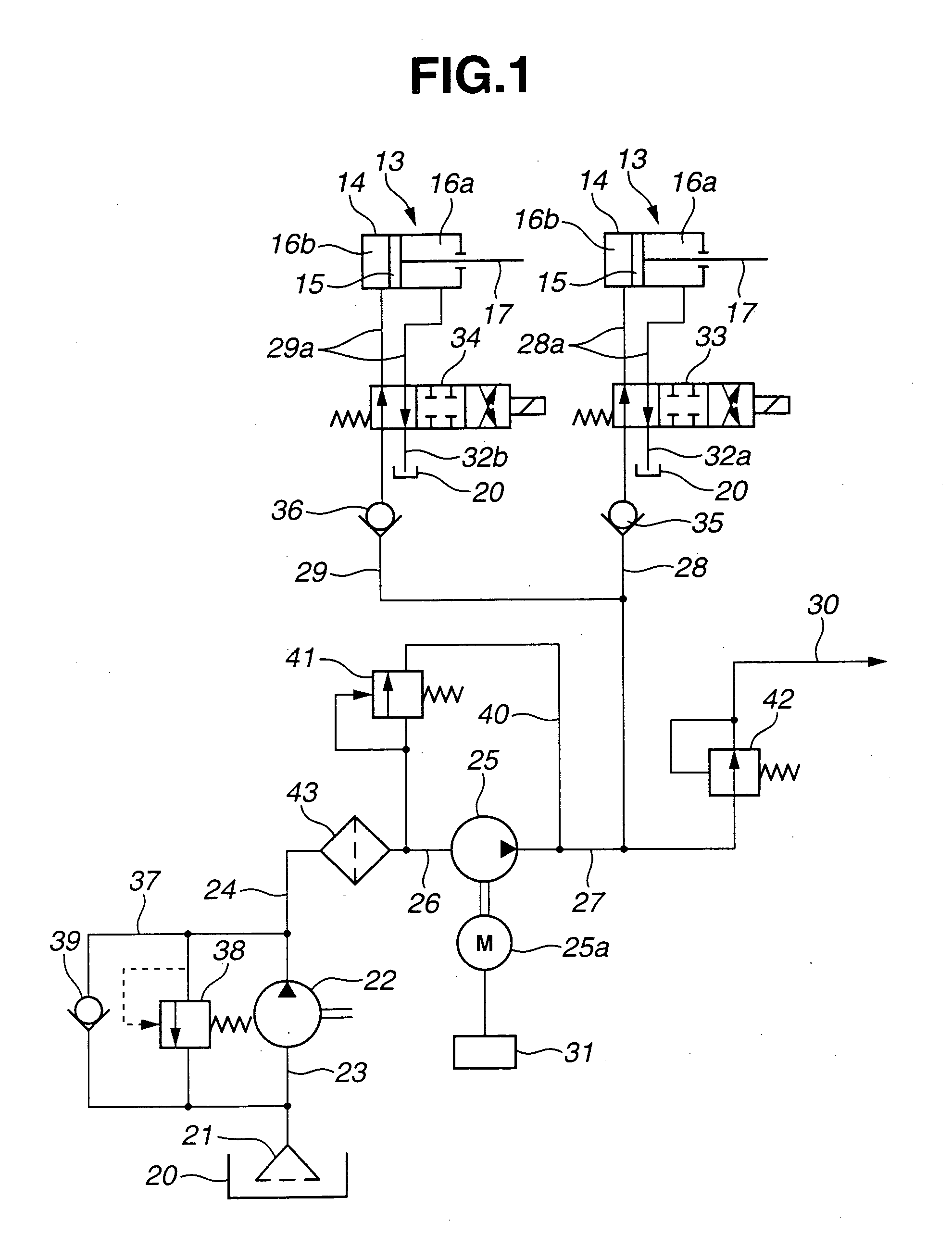

Hydraulic circuit control device

InactiveUS20060223670A1Reduce stressIncrease heightServomotorsGear lubrication/coolingHydraulic circuitControl mode

A hydraulic circuit control device that selectively supplies oil to a first oil passage and a second oil passage by an oil pump, the control device includes: an oil passage switching unit adapted to connect the oil pump to either the first oil passage or the second oil passage; a control mode switching unit adapted to switch the control mode of the electric motor to either a torque control mode or a speed control mode; an oil passage selecting unit adapted to select whether to connect the oil pump to the first oil passage or the second oil passage; and a control unit adapted to perform control so that the control mode switching unit switches the control mode to the torque control mode when the first oil passage has been selected, and perform control so that the control mode switching unit switches the control mode to the speed control mode when the second oil passage has been selected.

Owner:HONDA MOTOR CO LTD

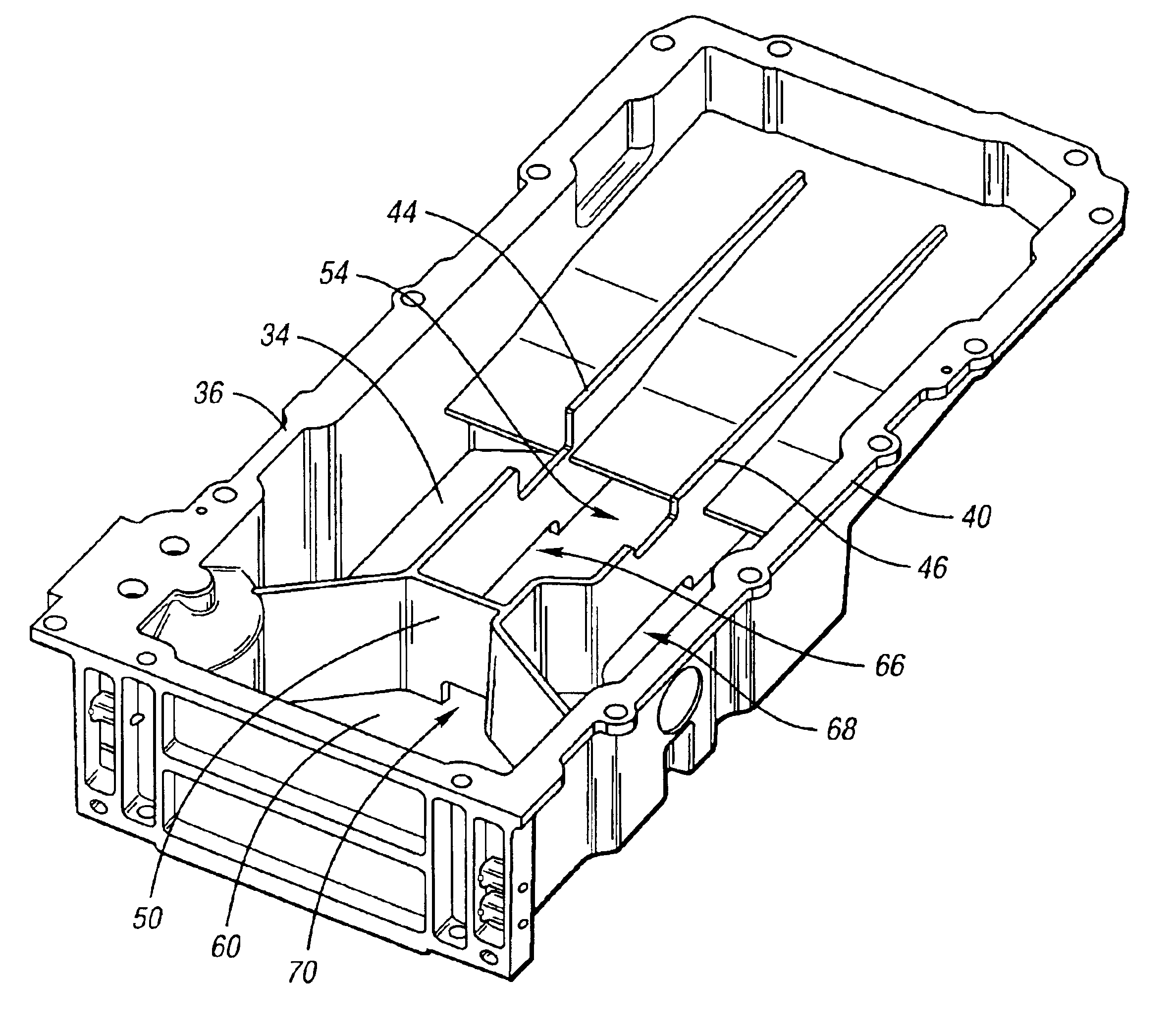

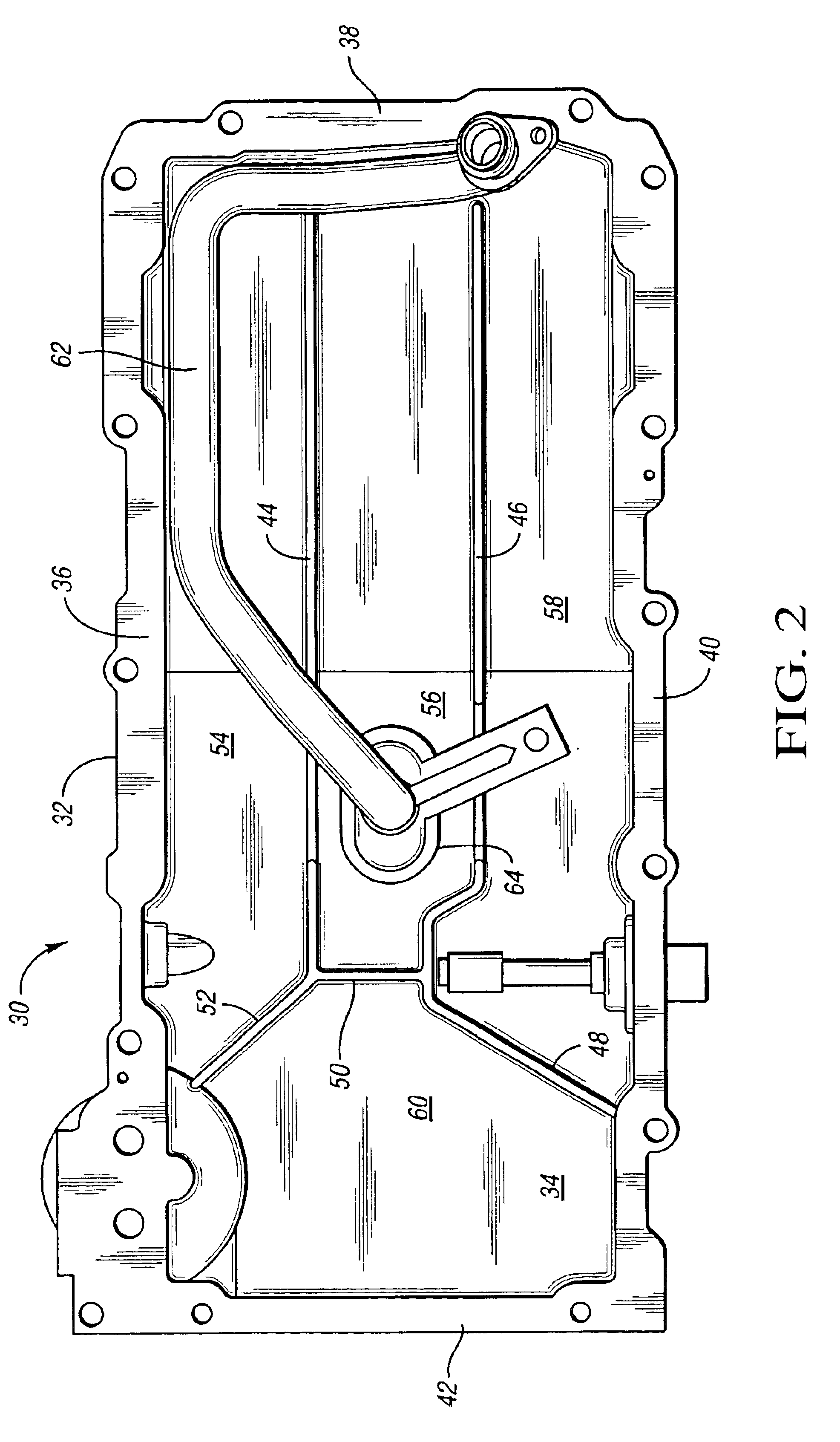

Oil pan with vertical baffles for oil flow control

ActiveUS6845743B1Low costReducing of oil quantity of oilCasingsLubrication of auxillariesWaste management

Owner:GM GLOBAL TECH OPERATIONS LLC

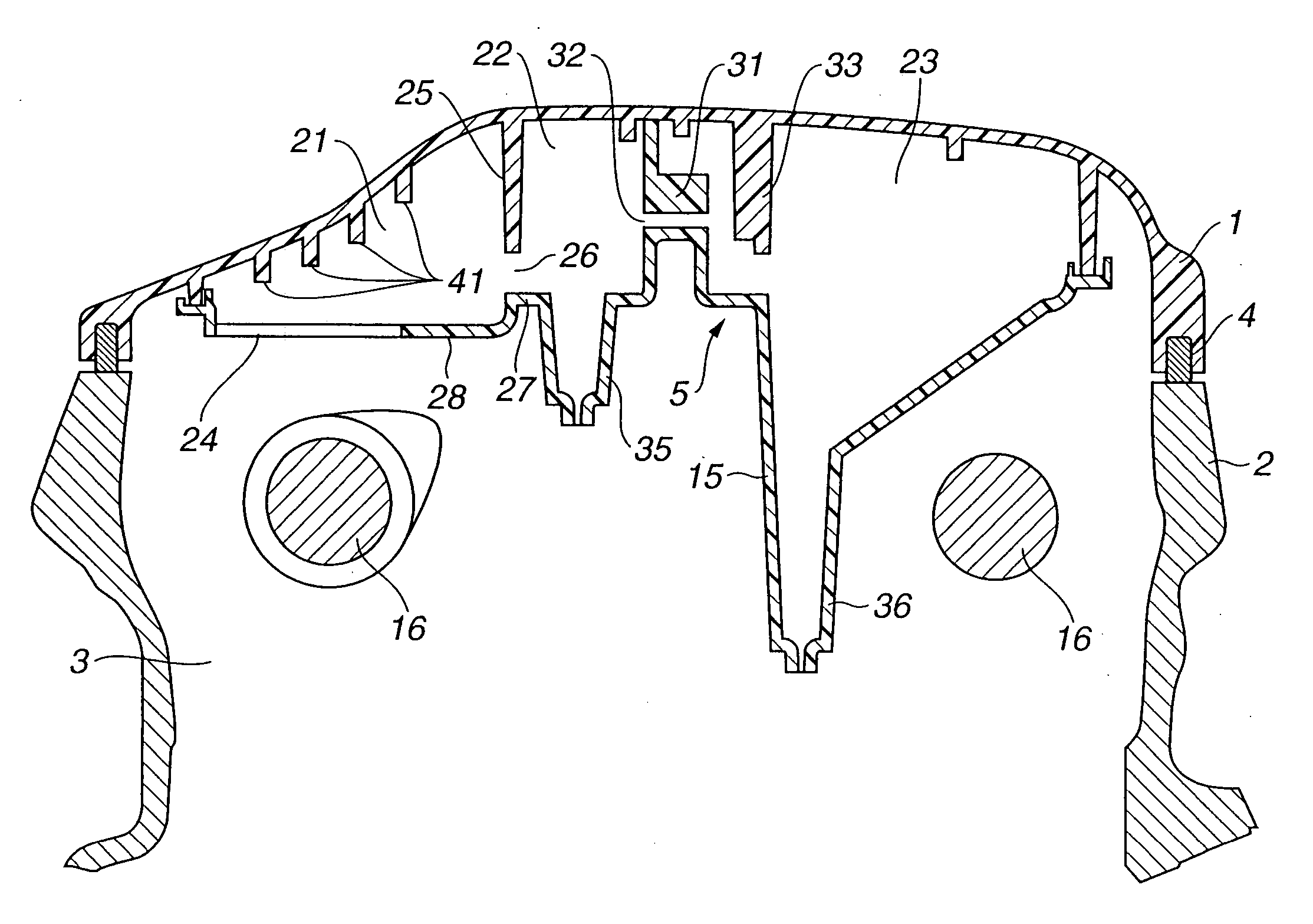

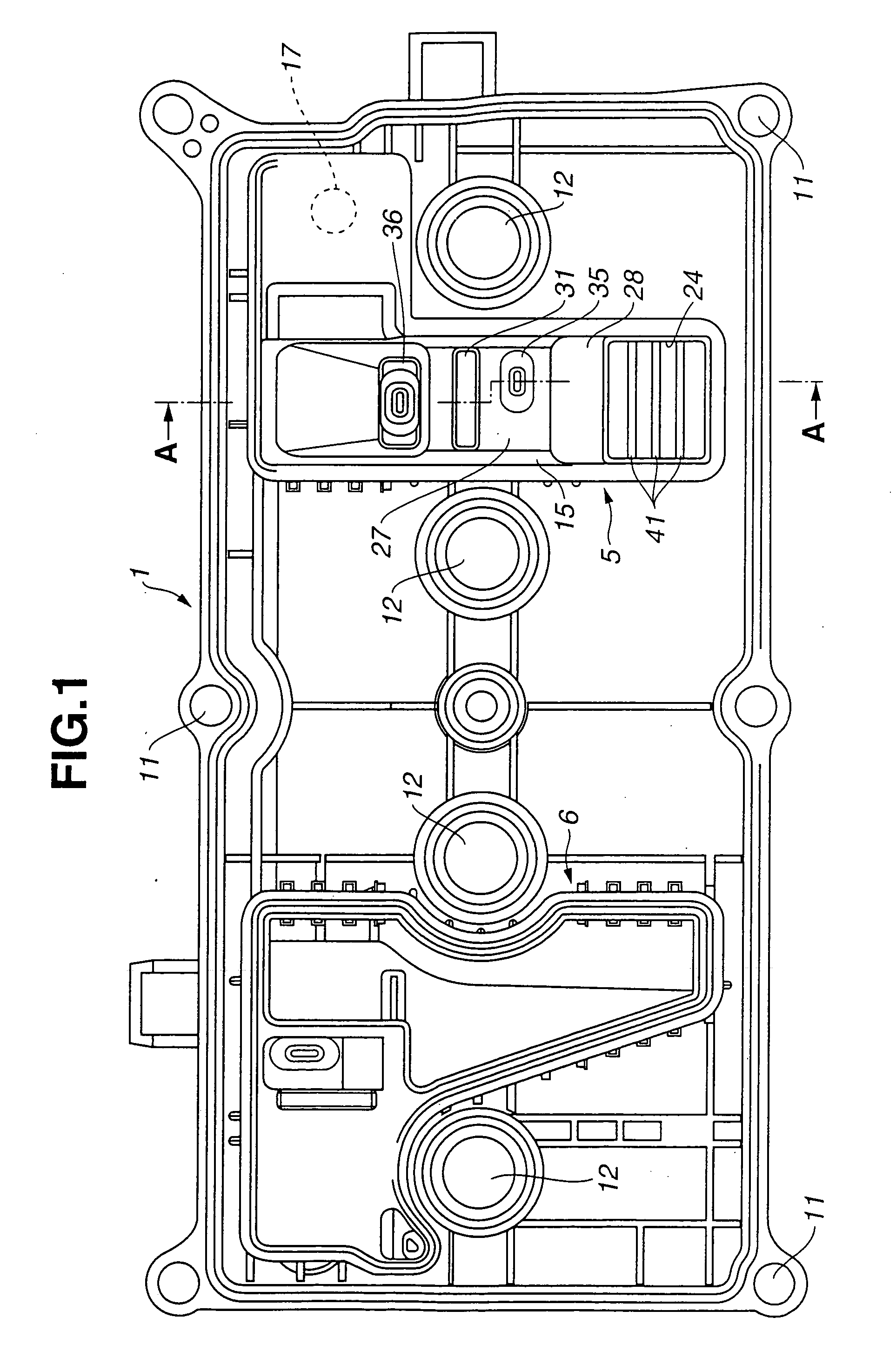

Oil separator combined with cylinder head cover

InactiveUS20050092267A1Effectively overcome drawbacksReduce the overall heightCasingsLubrication of auxillariesCylinder headEngineering

An oil separator provided in combination with a cylinder head cover of an internal combustion engine. The oil separator includes a separator cover fixed to an inner surface of the cylinder head cover defining a space extending in a first direction perpendicular to axis of a camshaft in plan, between the separator cover and the cylinder head cover. The separator cover has an opening through which the space is opened to a valve operating chamber. A partition wall is provided to define in the space an inlet-side separator chamber and an outlet-side separator. The partition wall extends in a second direction parallel with the axis of the camshaft and being formed with a plurality of fine passages. Additionally, a plurality of projection walls project from a part of the inner surface of the cylinder head cover which faces the valve operating chamber through the opening.

Owner:MAHLE FILTER SYST JAPAN CORP

Valve cover assembly for a vehicle engine and method for producing same

The present invention relates to a valve cover assembly adapted to be secured to a cylinder head of a vehicle engine. The valve cover assembly includes a valve cover body formed from a first material and an attachment member formed from a second material and attached to the valve cover body.

Owner:HARVEY HLDG

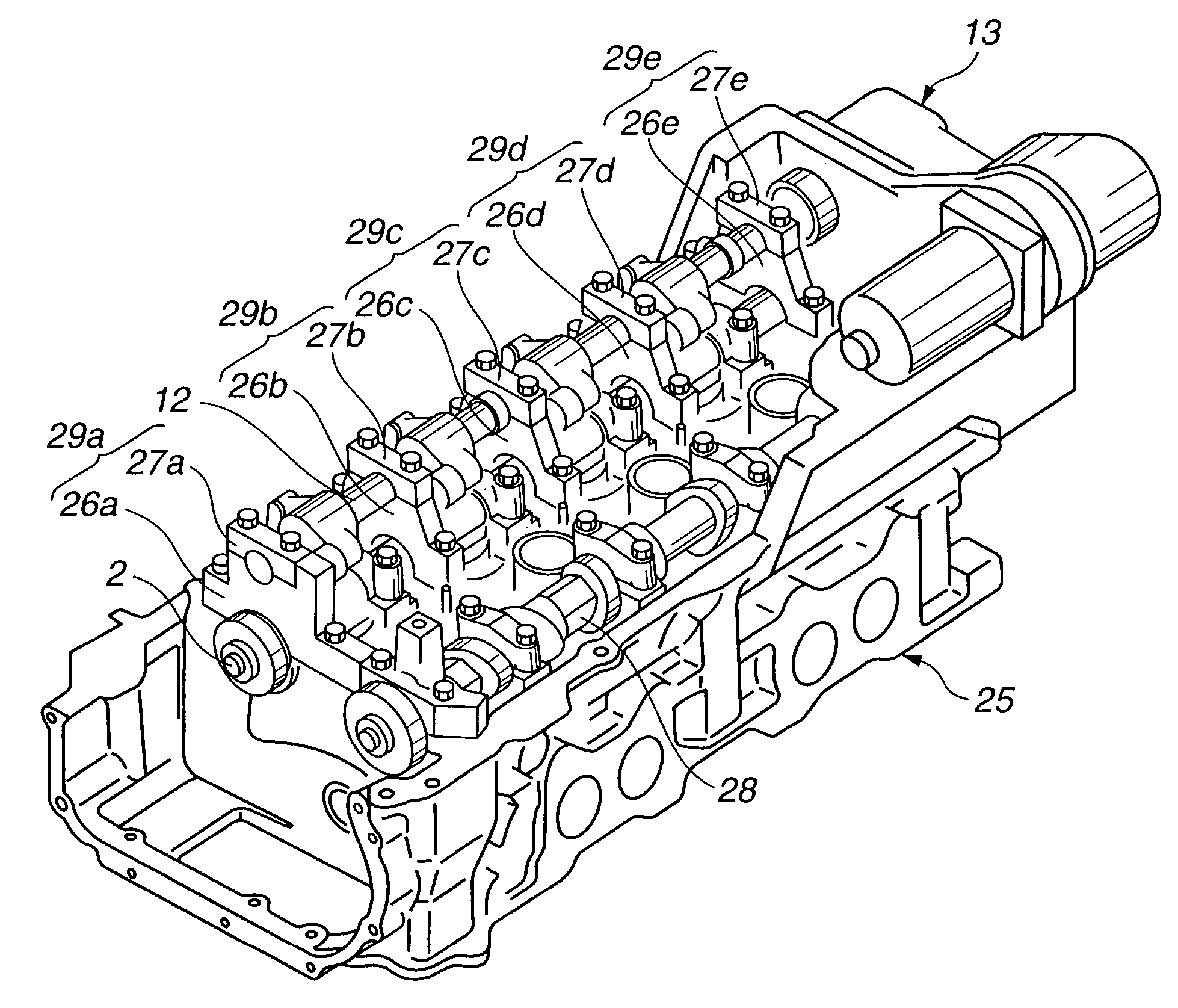

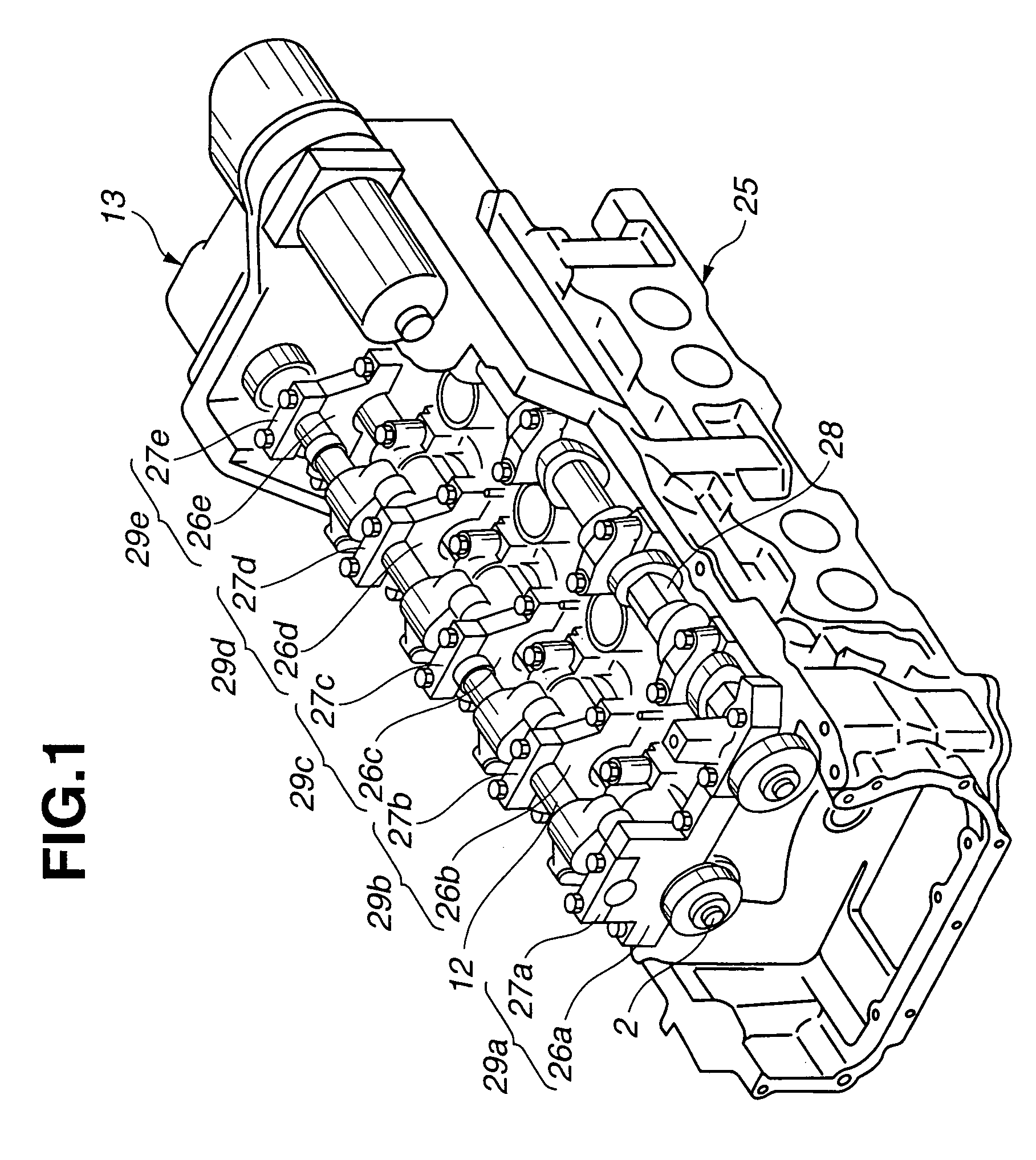

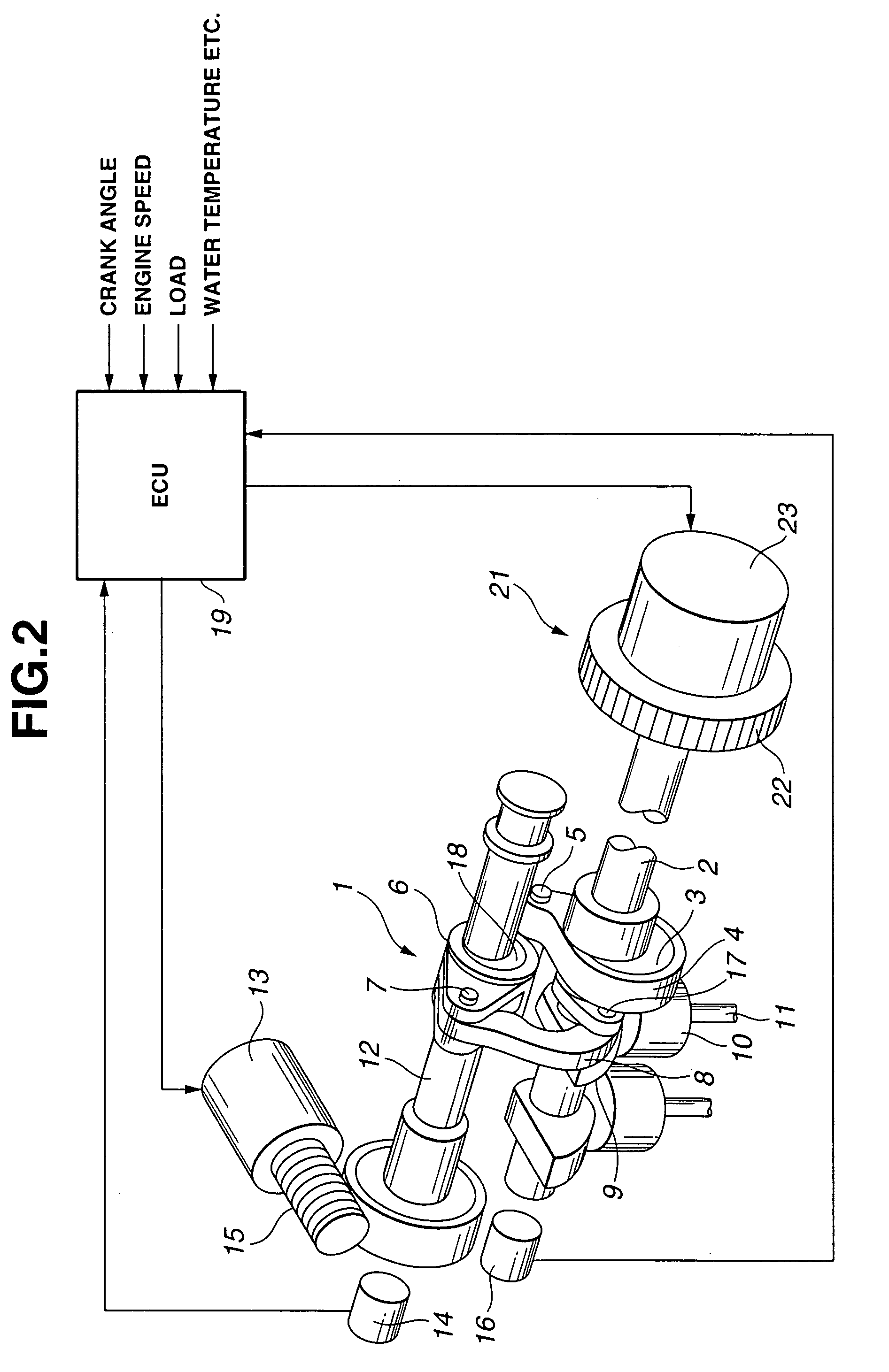

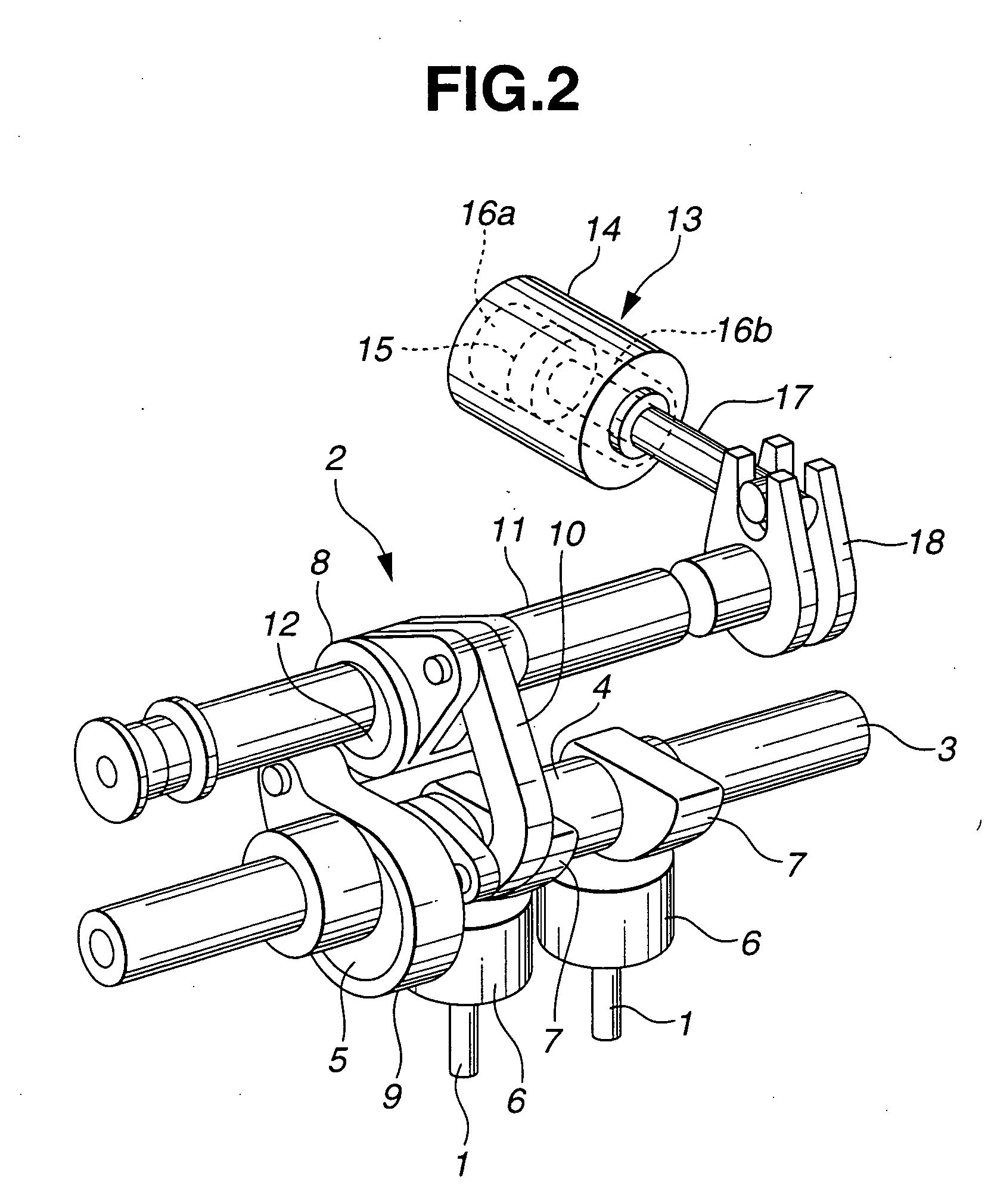

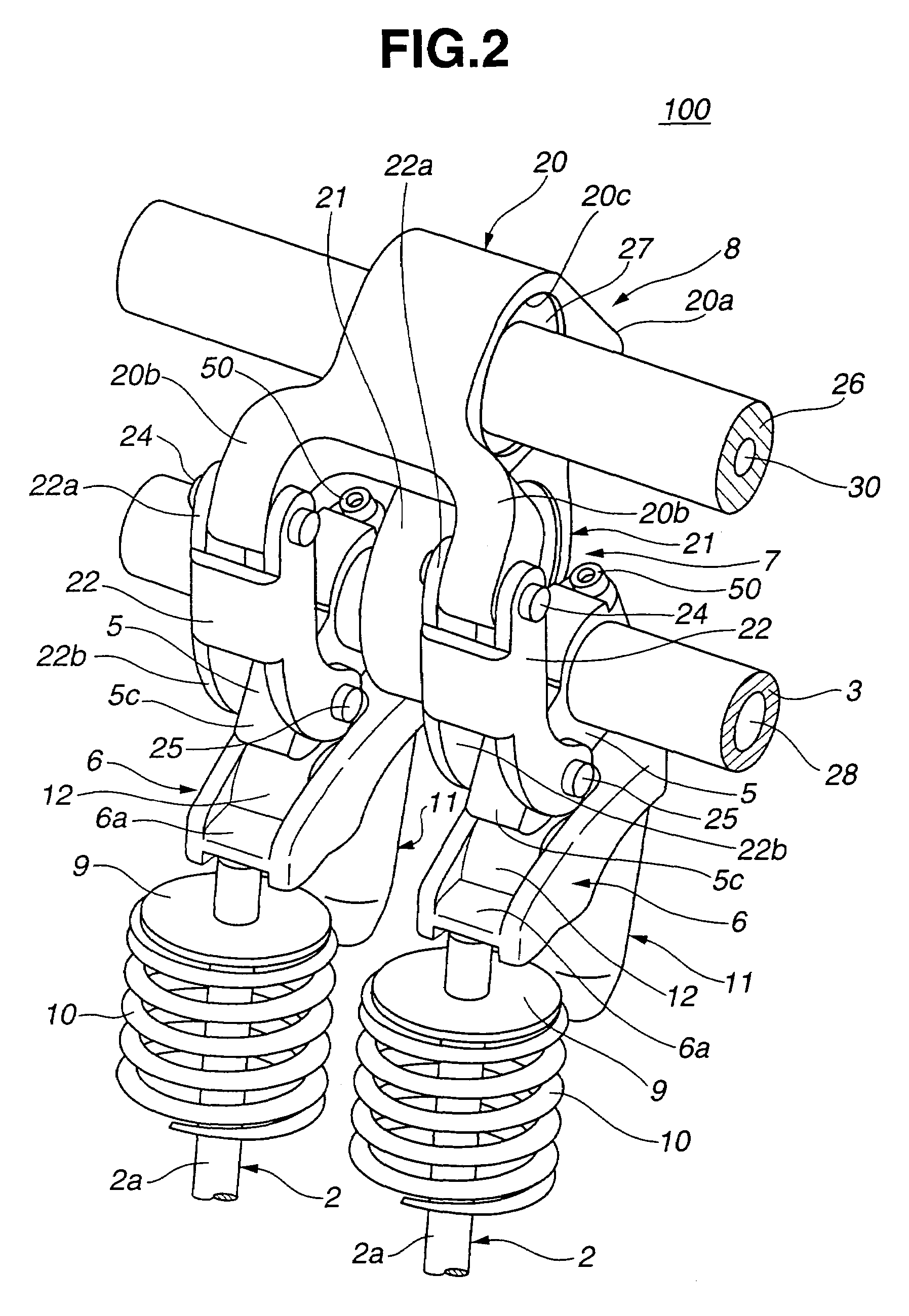

Variable valve actuating mechanism for internal combustion engine

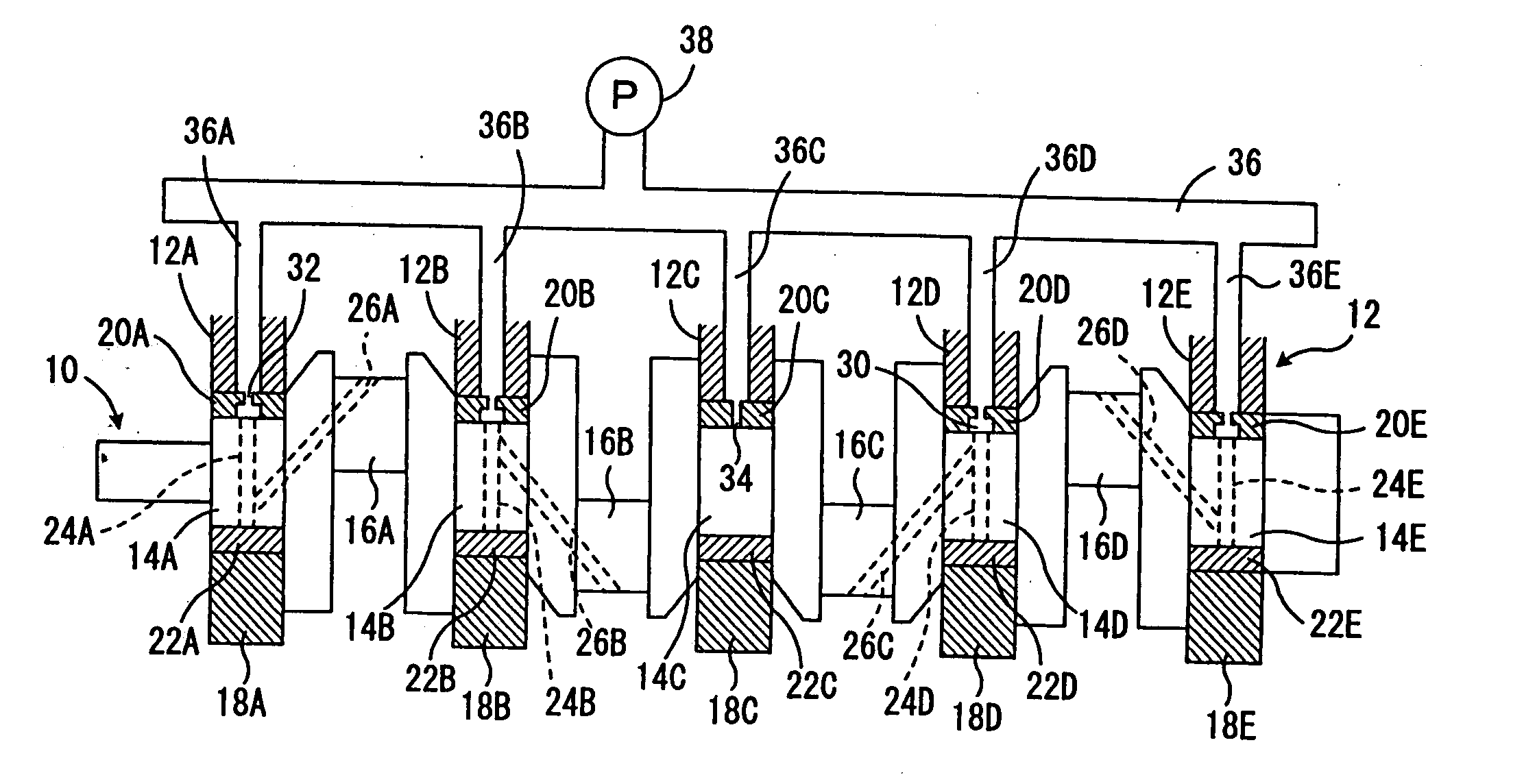

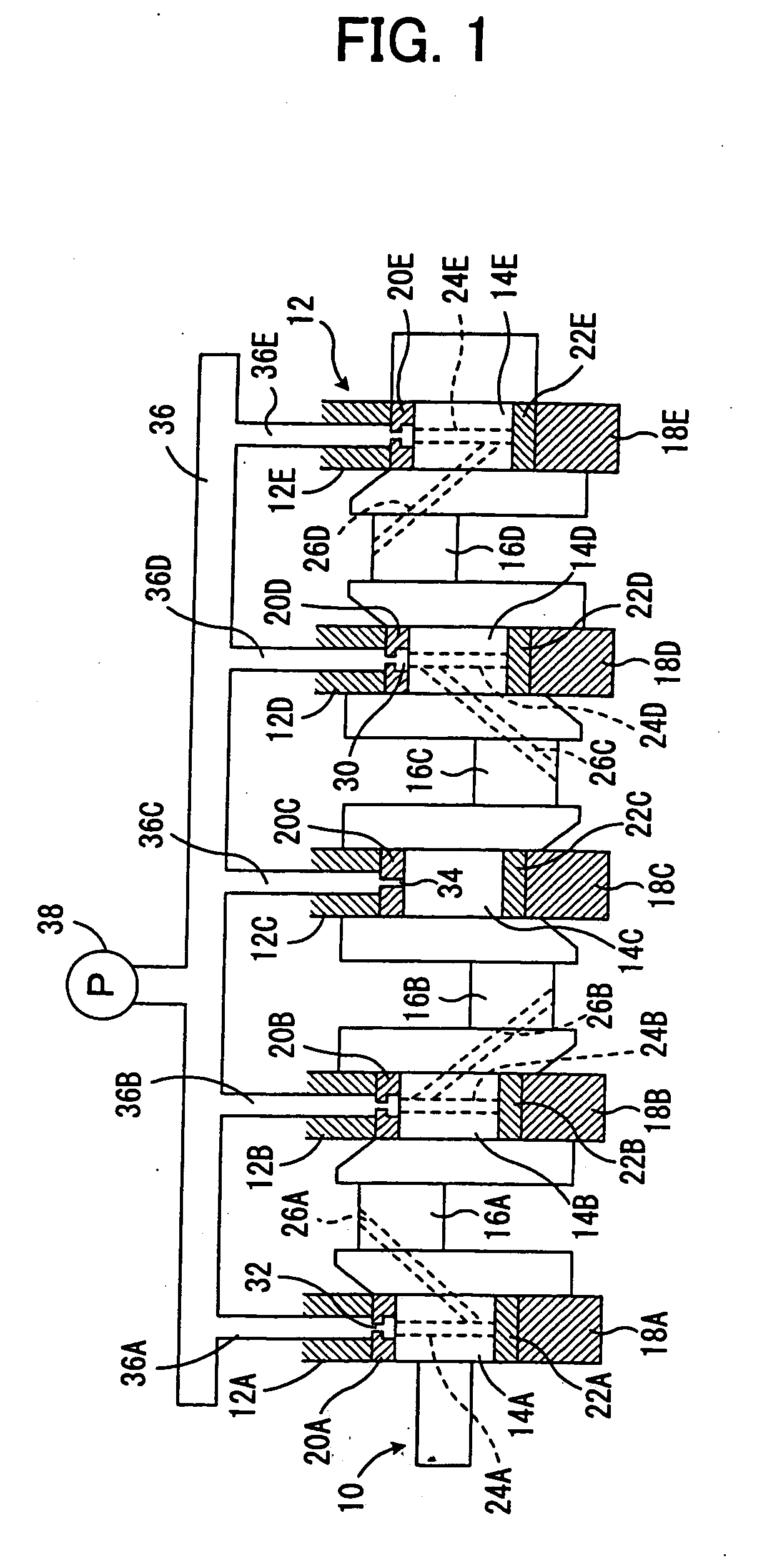

ActiveUS7107950B2Reduce temperature non-uniformityReduce unevennessClutchesCrankshaftsExternal combustion engineInlet valve

A lift and operating angle varying mechanism is arranged to vary an intake valve operation angle and an intake valve lift of the engine continuously by rotating a control shaft with an actuator disposed at an end of the control shaft which is rotatably supported by a plurality of bearings. A lubricating oil is supplied to the bearings so as to reduce nonuniformity in temperature distribution of the control shaft in the longitudinal direction.

Owner:NISSAN MOTOR CO LTD

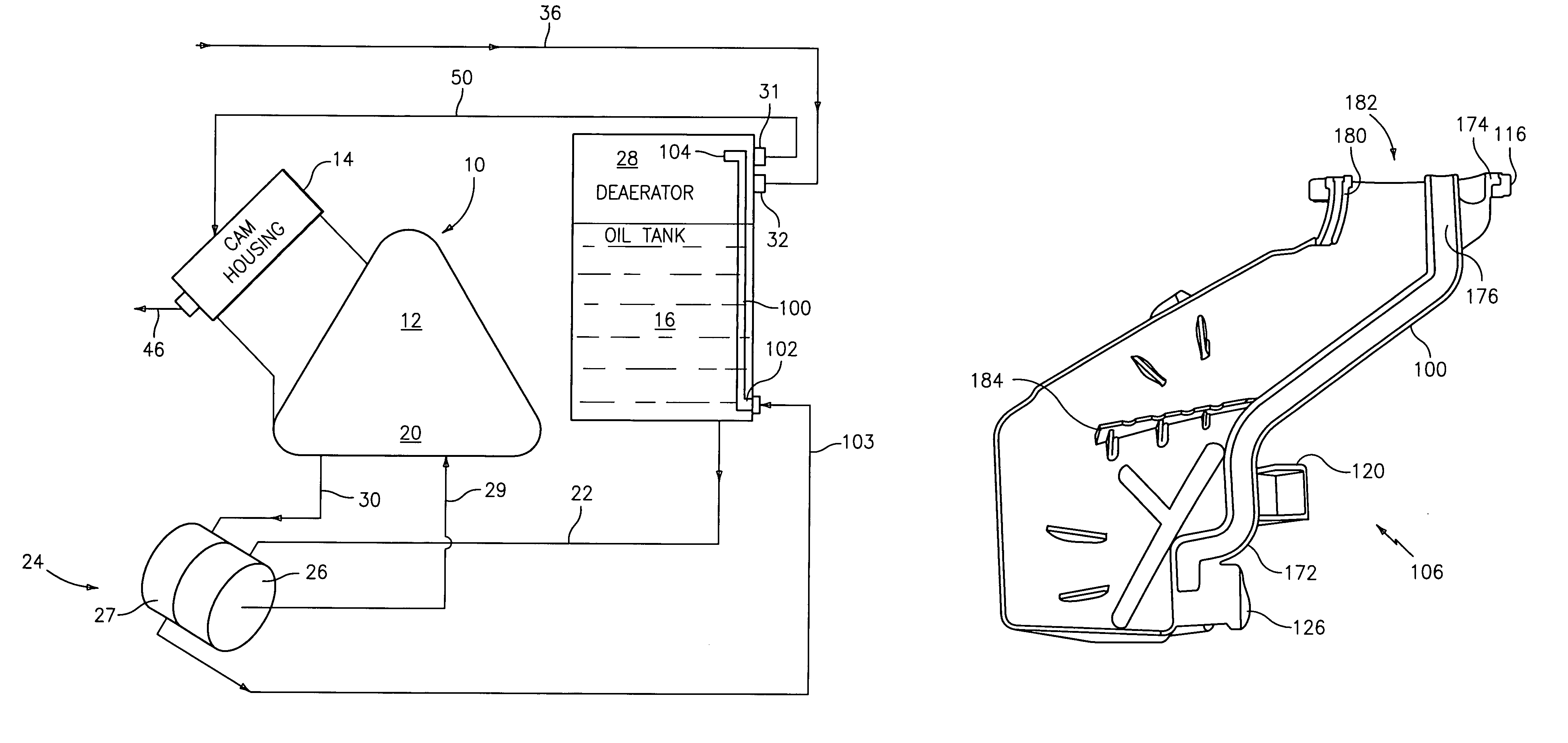

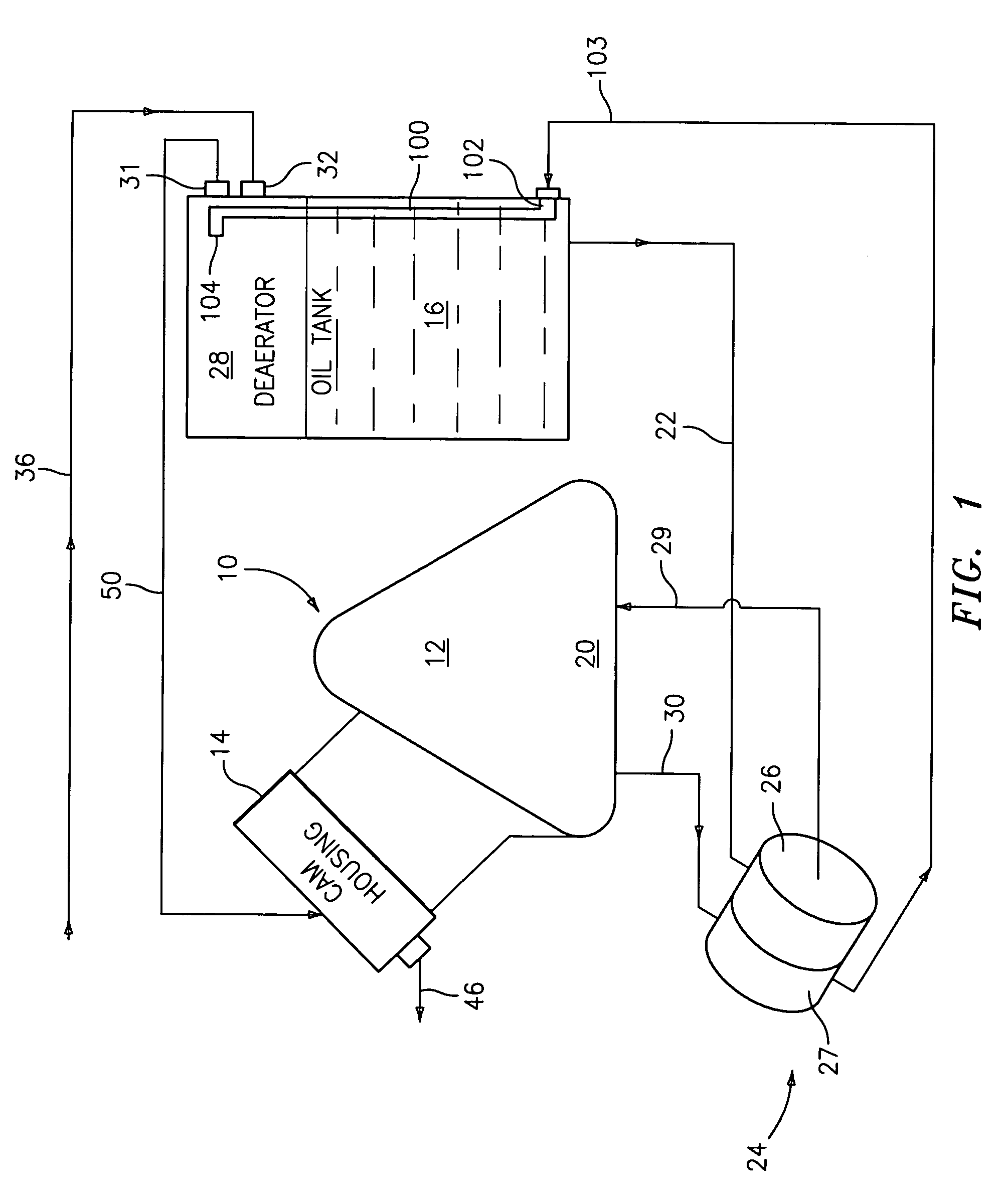

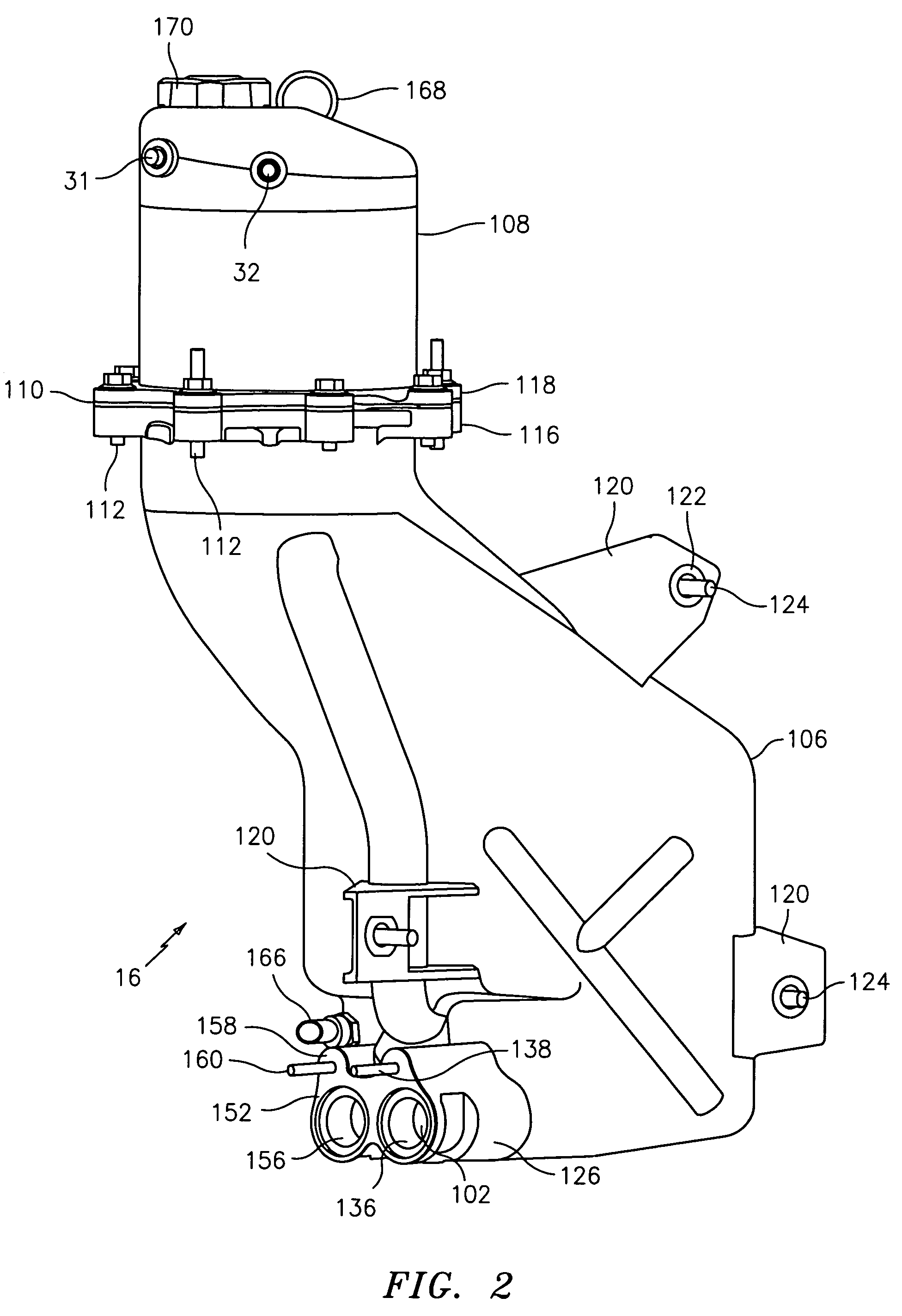

Dry sump oil tank assembly

A tank assembly for a dry sump lubrication system for an internal combustion engine is disclosed. The tank assembly includes a tank having an upper tank portion and a lower tank portion. An interface assembly is disposed at the lower tank portion and is configured to operably deliver and receive a lubricant to and from the engine. A first end of a return tube in fluid communication with a second end is configured to receive lubricant from the engine at the interface assembly. The second end opposite the first end is in fluid communication with the upper tank portion. In this manner, a return hose and a feed hose may be connected to a same portion of the tank assembly.

Owner:GM GLOBAL TECH OPERATIONS LLC

Lubricant composition for bio-diesel fuel engine applications

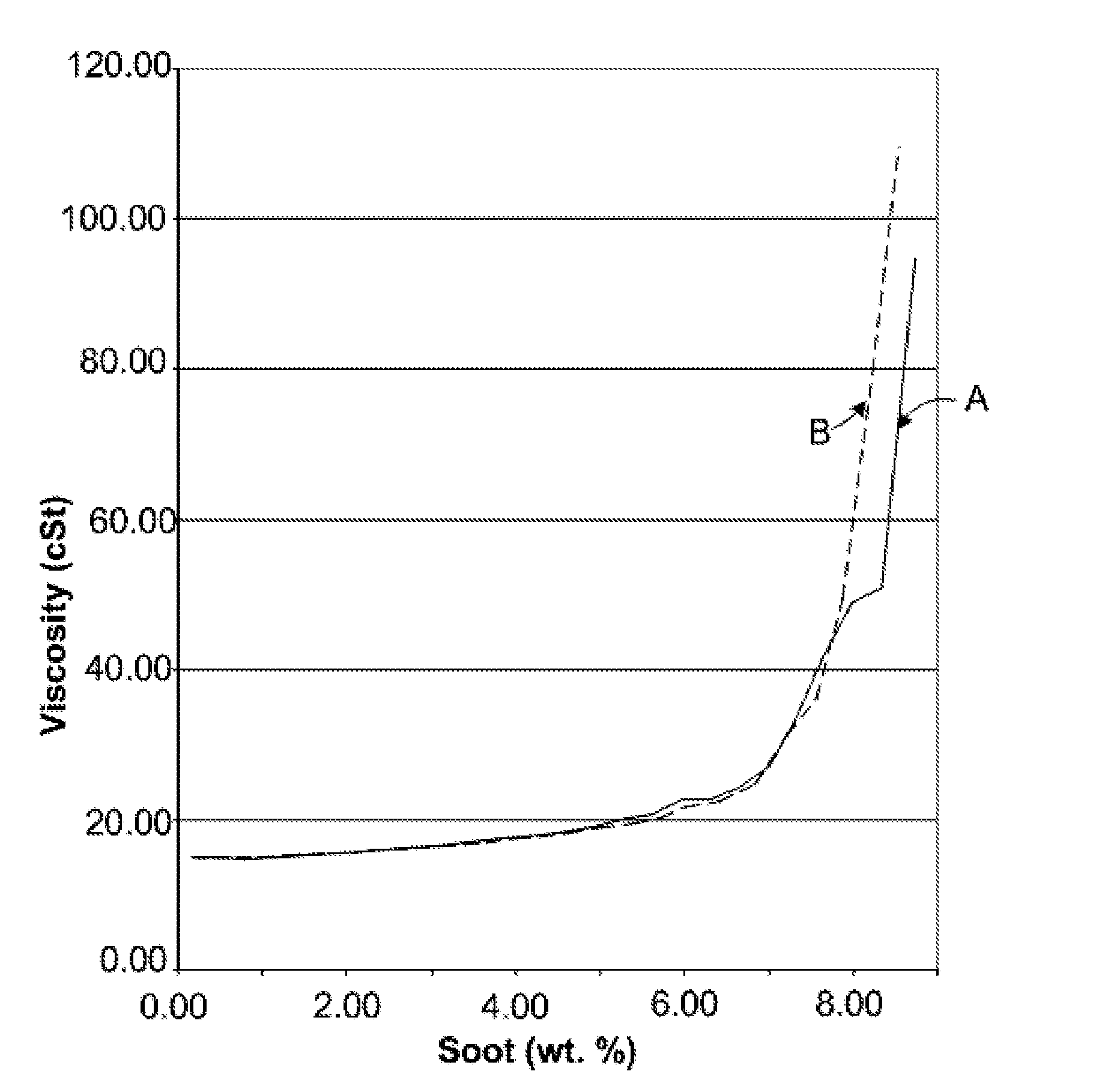

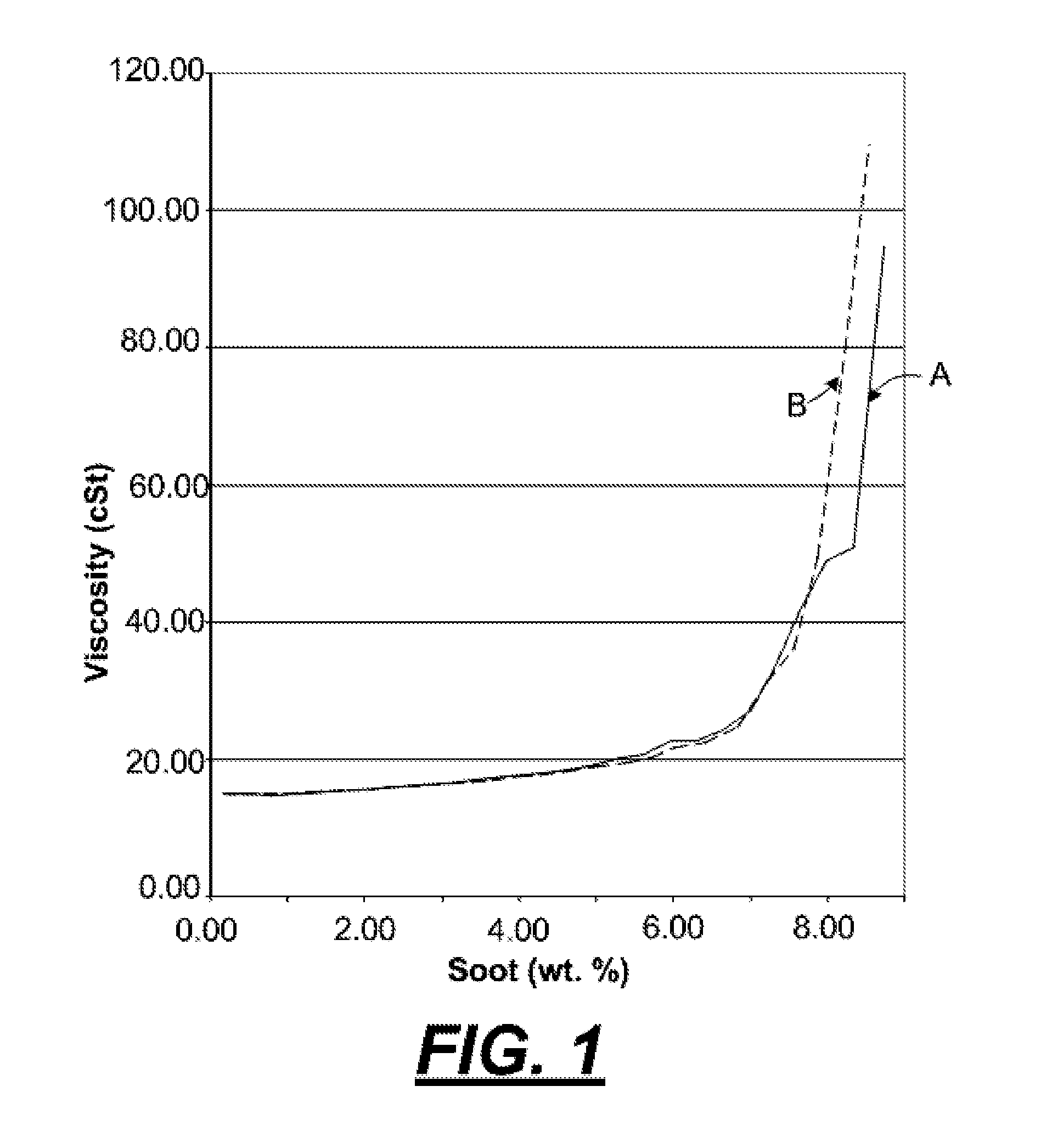

InactiveUS20080182768A1Reduce viscosity increaseHigh viscosityLubrication of auxillariesLubricant conduit arrangementsBiodieselAlkene

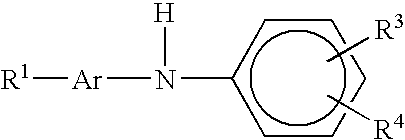

A diesel engine operating on a fuel containing from about 5 to about 100 wt. % bio-diesel components and being lubricated with a lubricating oil composition including a major amount of oil of lubricating viscosity, and a minor amount of at least one highly grafted, multi-functional olefin copolymer. The olefin copolymer is made by reacting an acylating agent with an olefin copolymer having a number average molecular weight greater than about 1,000 in the present of a free radical initiator to provide an acylated olefin copolymer having a degree of grafting (DOG) of the acylating agent on the olefin copolymer of at least 0.5 wt. %, and reacting the acylated olefin copolymer with an amine to provide the highly grafted, multi-functional olefin copolymer. As used, the highly grafted, multi-functional olefin copolymer is effective to reduce a viscosity increase in the lubricating oil composition for the engine.

Owner:AFTON CHEMICAL

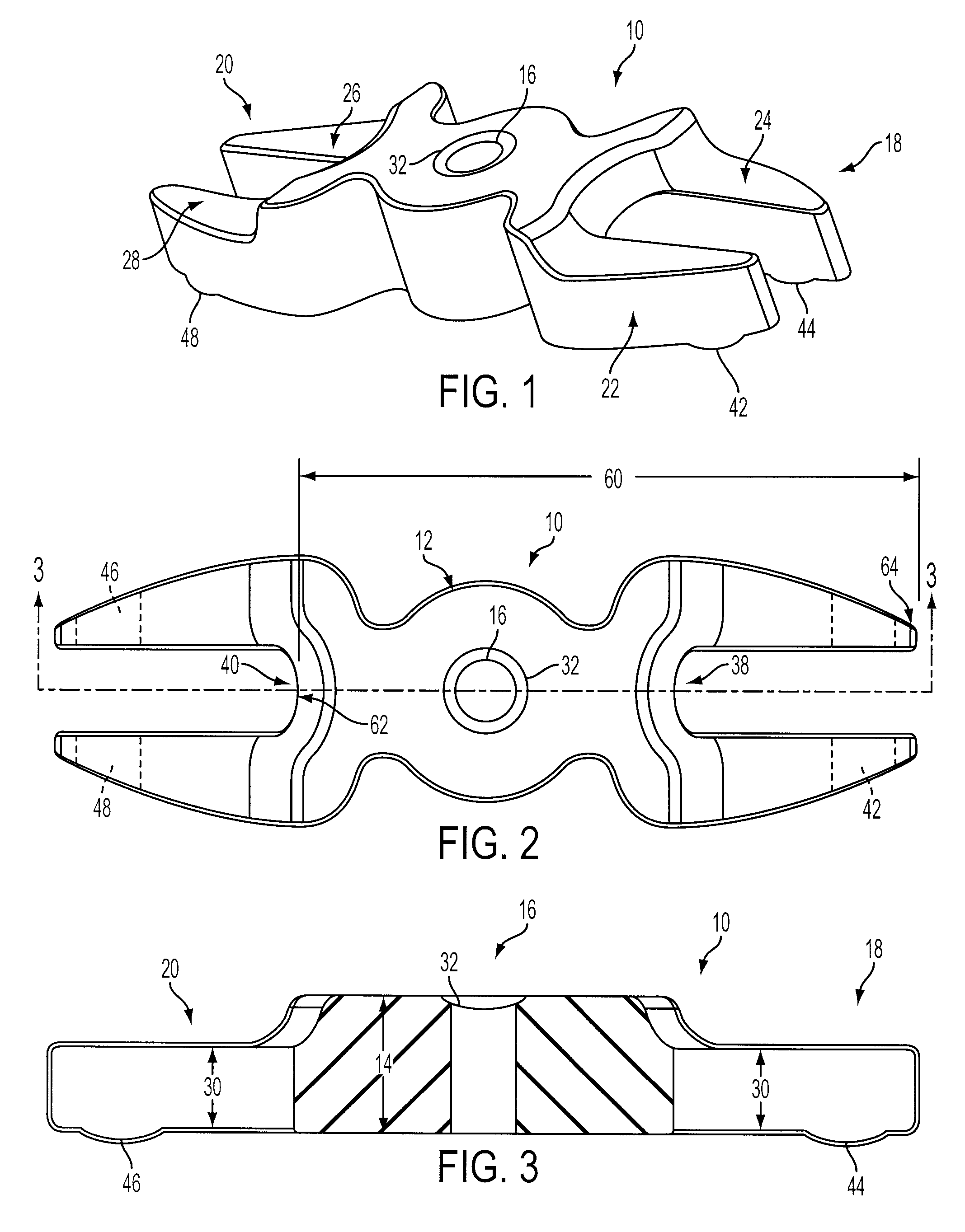

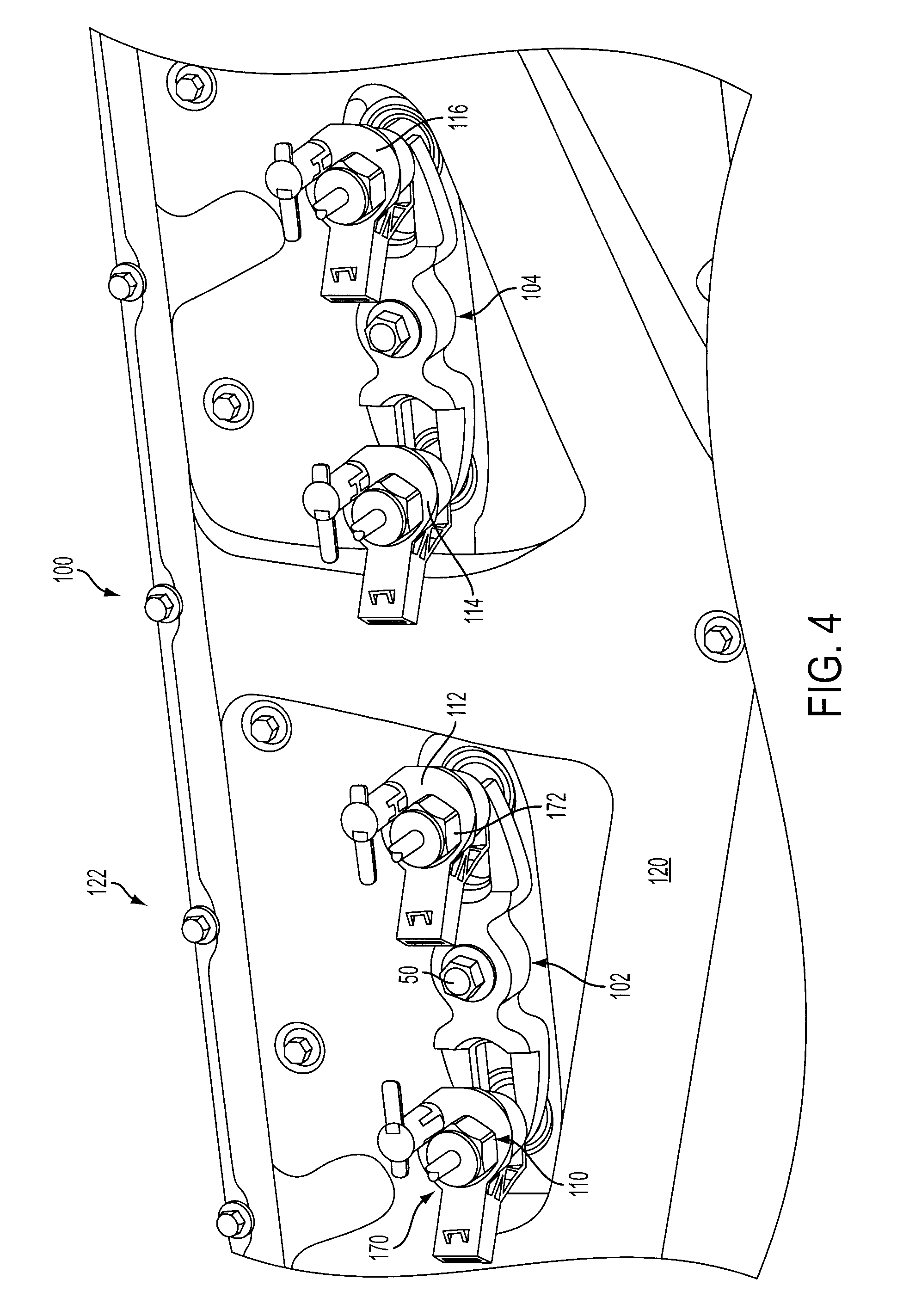

System and method for securing fuel injectors

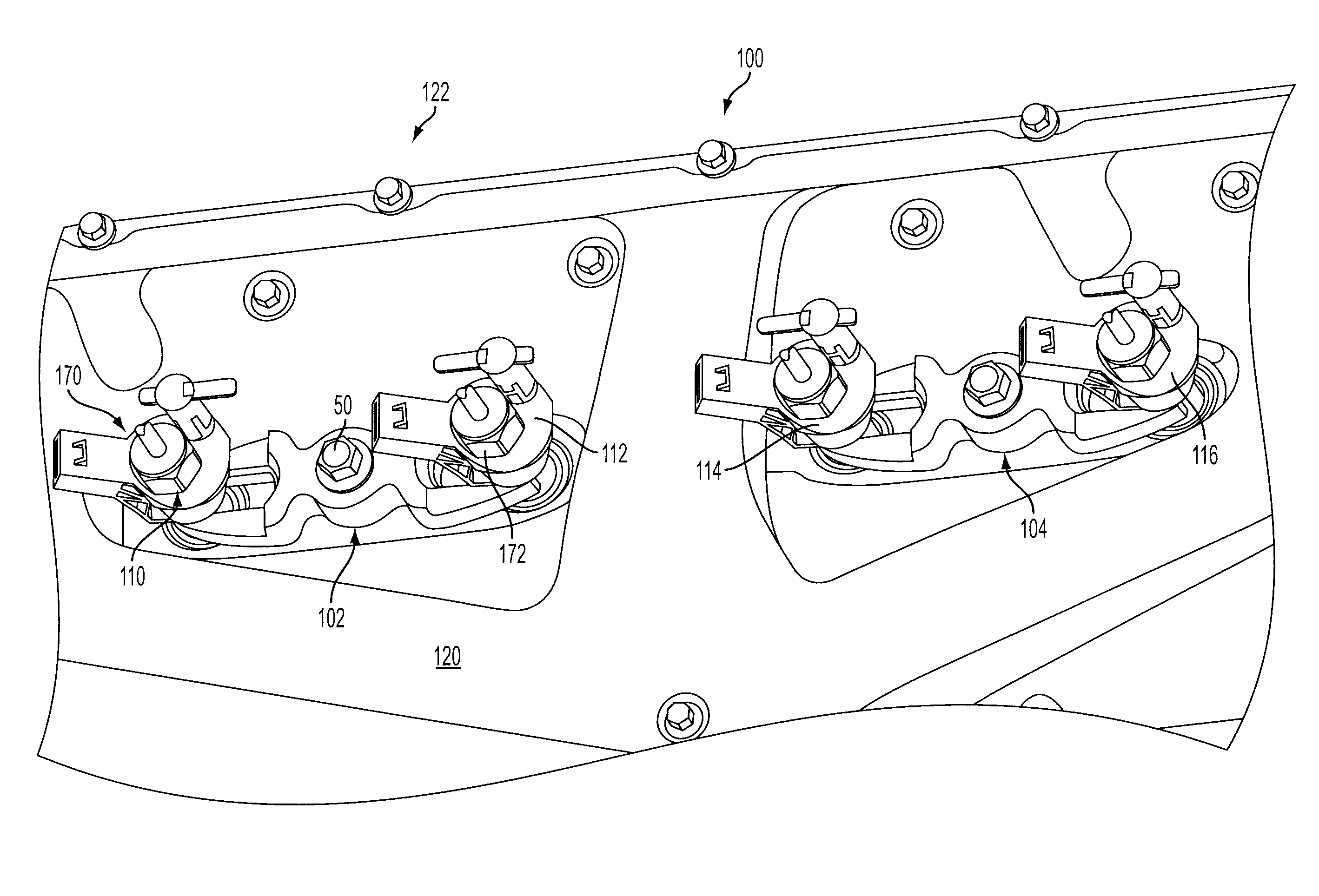

InactiveUS7334572B1Accurate radial positioningAccurate rotation positioningCasingsLubrication of auxillariesCylinder headEngineering

A system and method for securing a fuel injector in an internal combustion engine include a clamp for securing adjacent injectors to a cylinder head. The clamp includes a central portion with a hole for receiving a fastener to secure the clamp to the cylinder head, and a pair of symmetrical crescent-shaped clamping forks forming a U-shaped opening to facilitate lateral sliding engagement with diametrically opposed flatted portions of corresponding fuel injectors. Each arm includes an arcuate pad that engages a corresponding shoulder of the fuel injector to provide an axial clamping force to the fuel injector. The distance between the distal ends of one fork and the semicircular portion of the opposite fork is selected to allow lateral sliding disengagement of the clamp from one of the adjacent injectors without rotation or removal of the other injector to facilitate servicing of individual injectors.

Owner:FORD GLOBAL TECH LLC

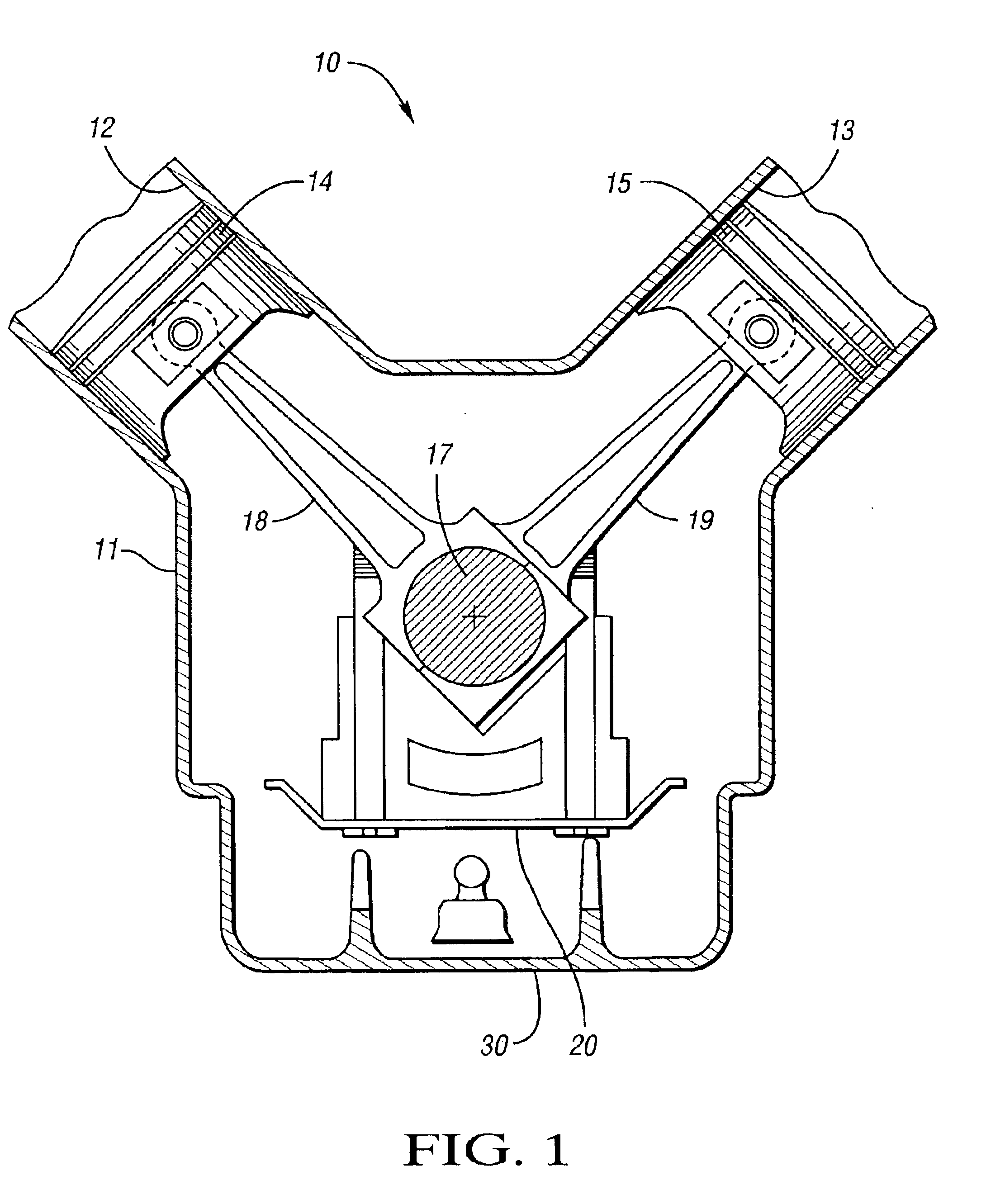

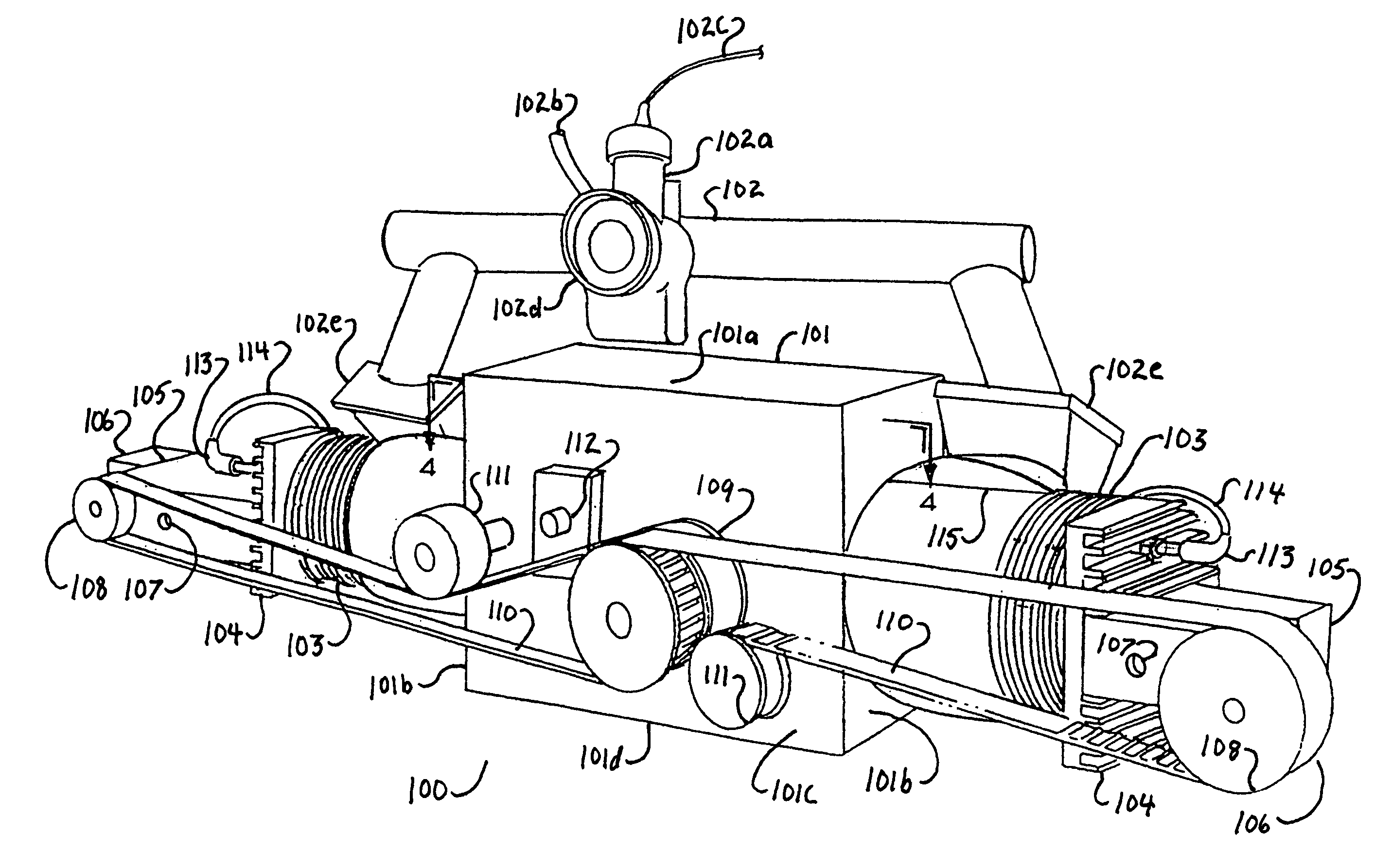

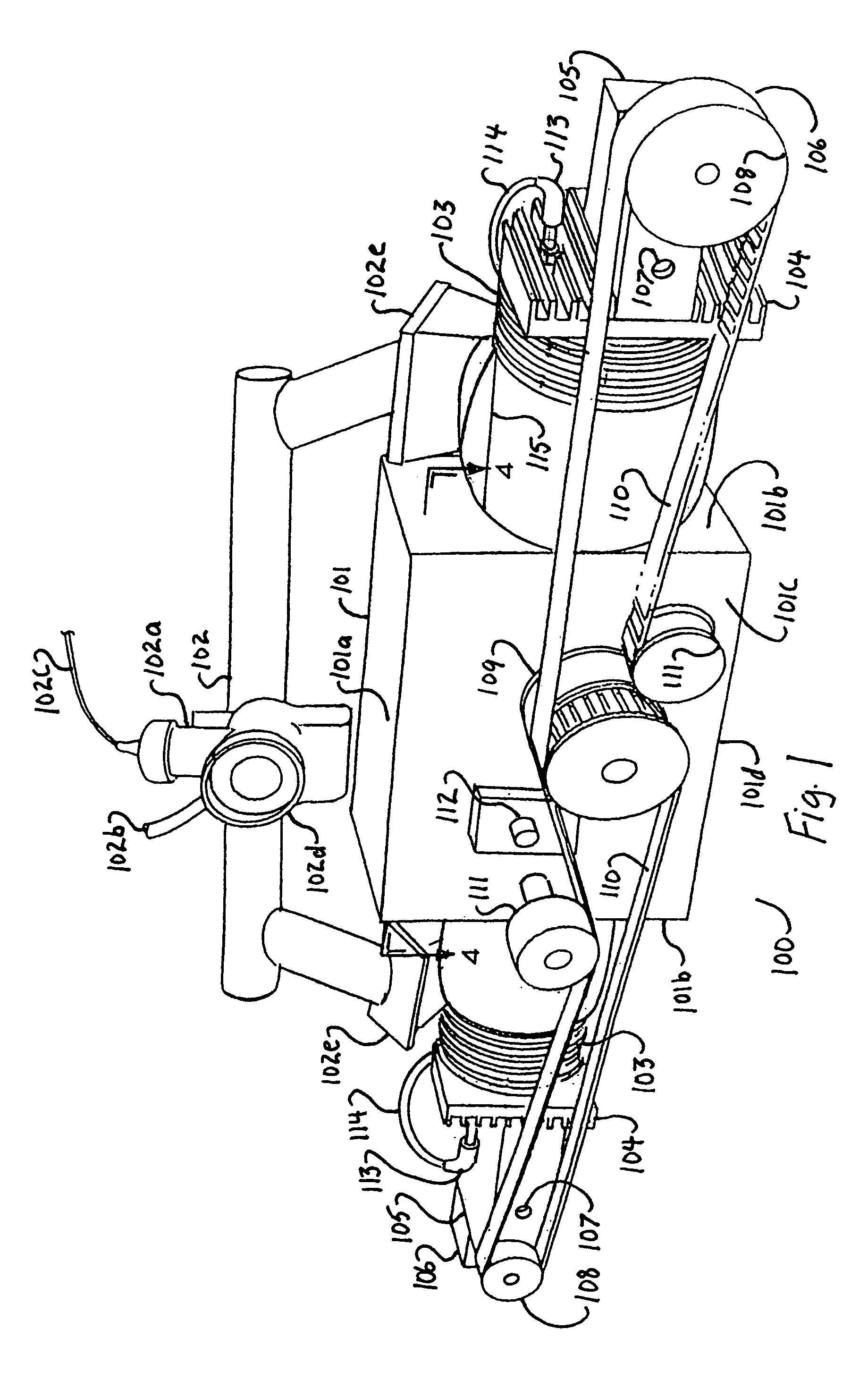

Internal combustion engine machine incorporating significant improvements in power, efficiency and emissions control

InactiveUS7104227B2Increase powerImprove efficiencyValve arrangementsLubrication of auxillariesExternal combustion engineFour-stroke engine

A two stroke cycle internal combustion engine machine that does not require lubricating oil to be mixed with its fuel, producing greater efficiency, higher power to weight ratio, cooler operating temperatures, a wider speed range, greater simplicity, and lower toxic emissions, many of the improvements also transferable to four stroke engines.

Owner:WARREN III C MADISON

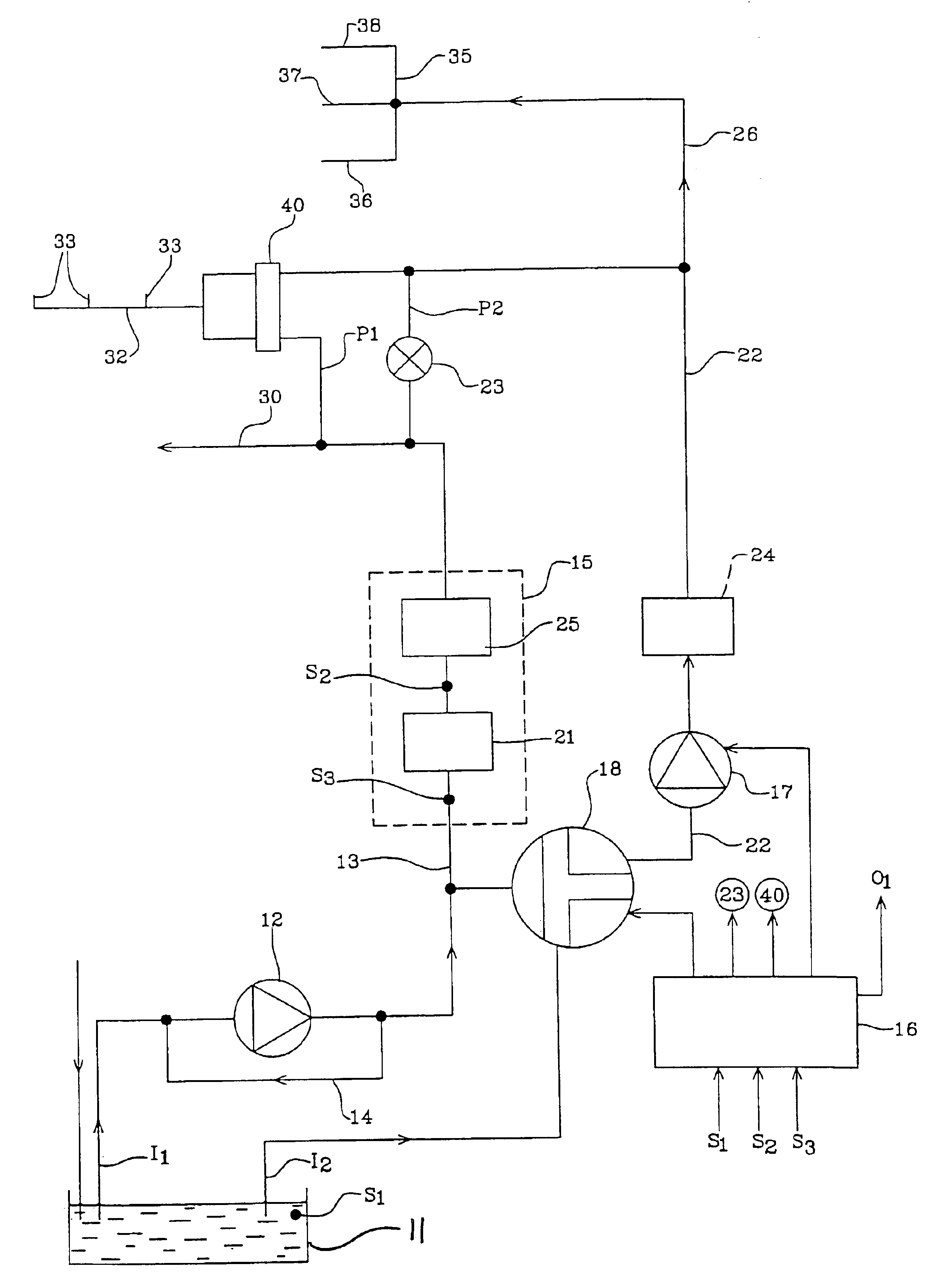

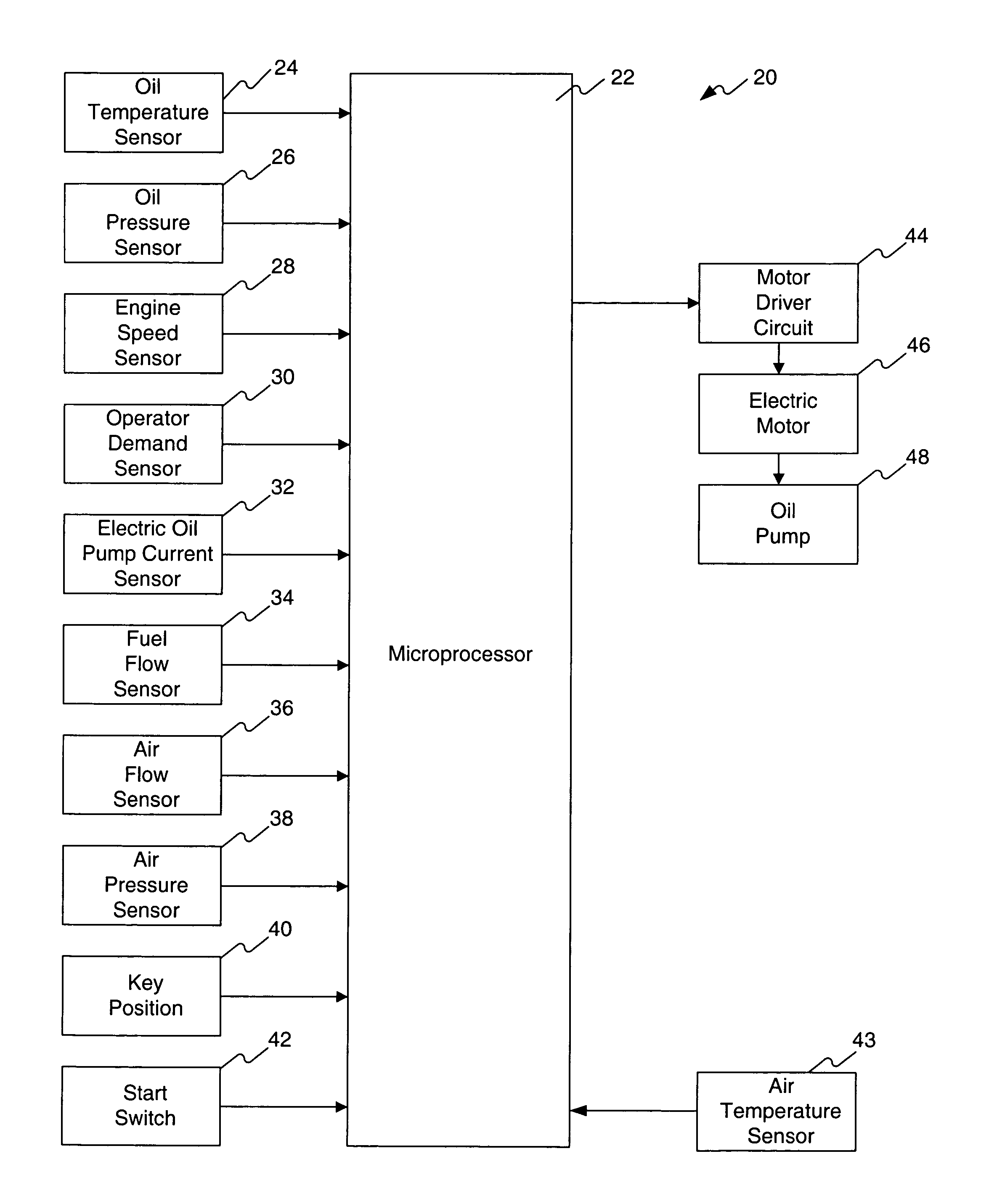

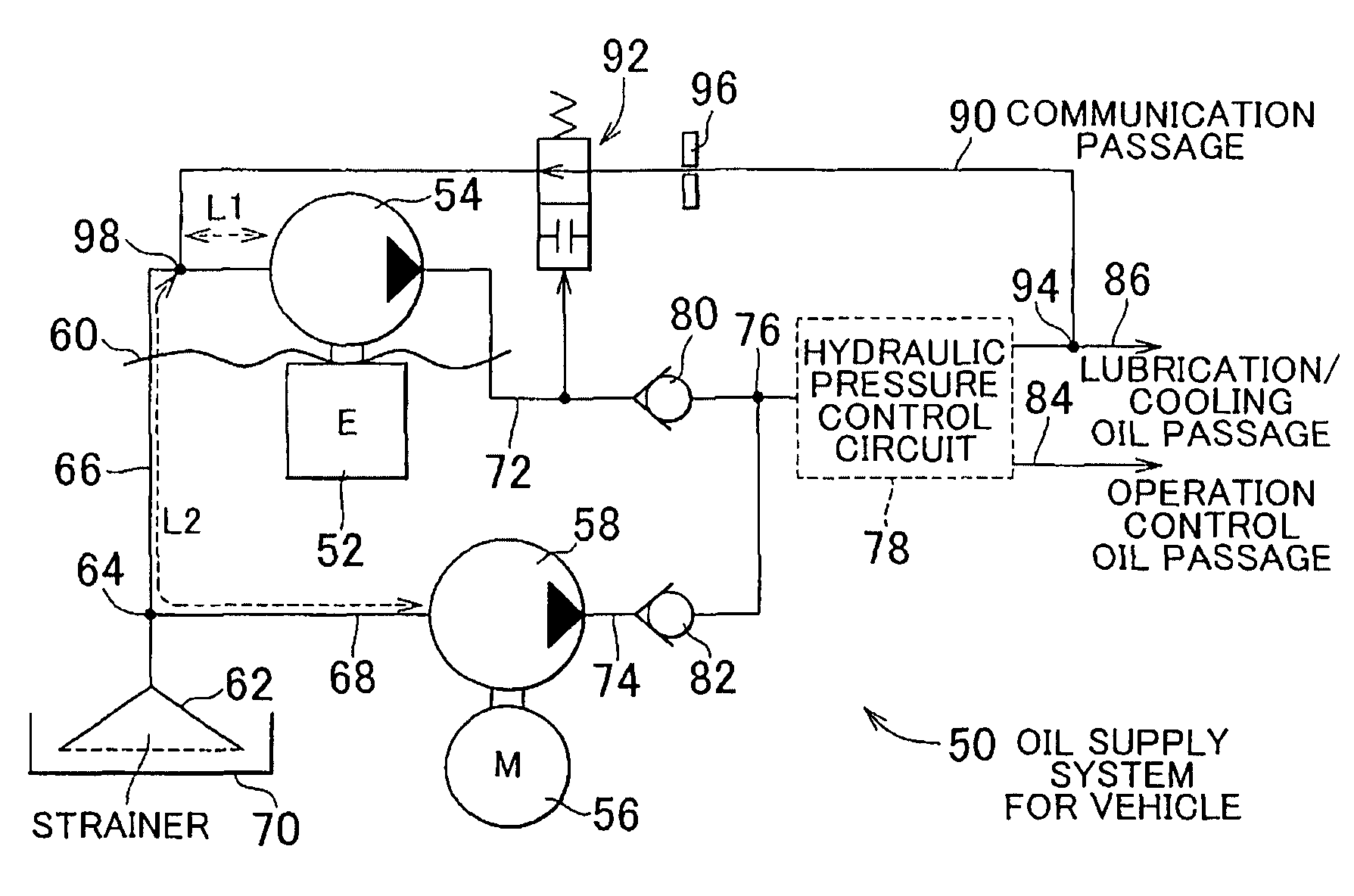

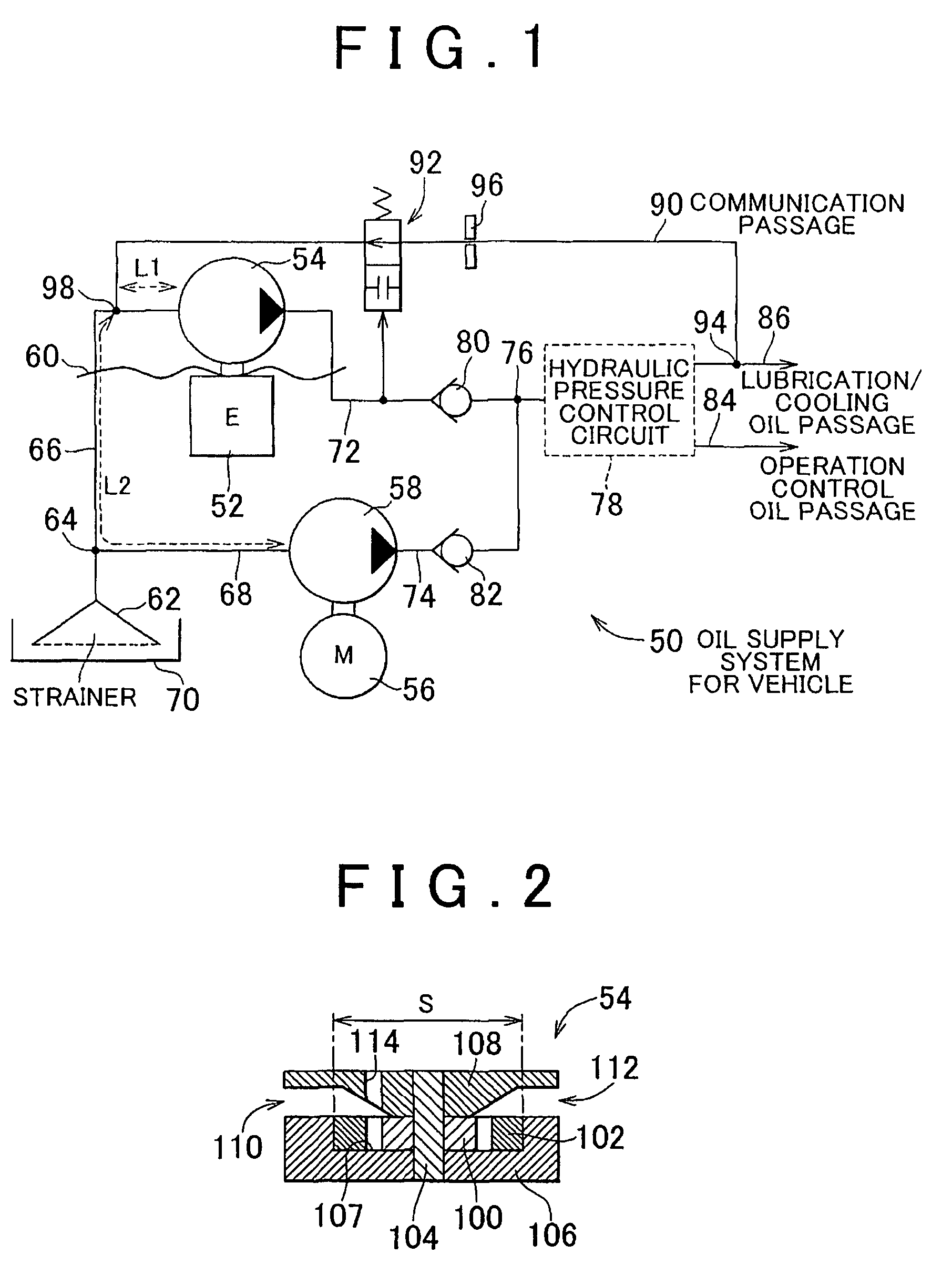

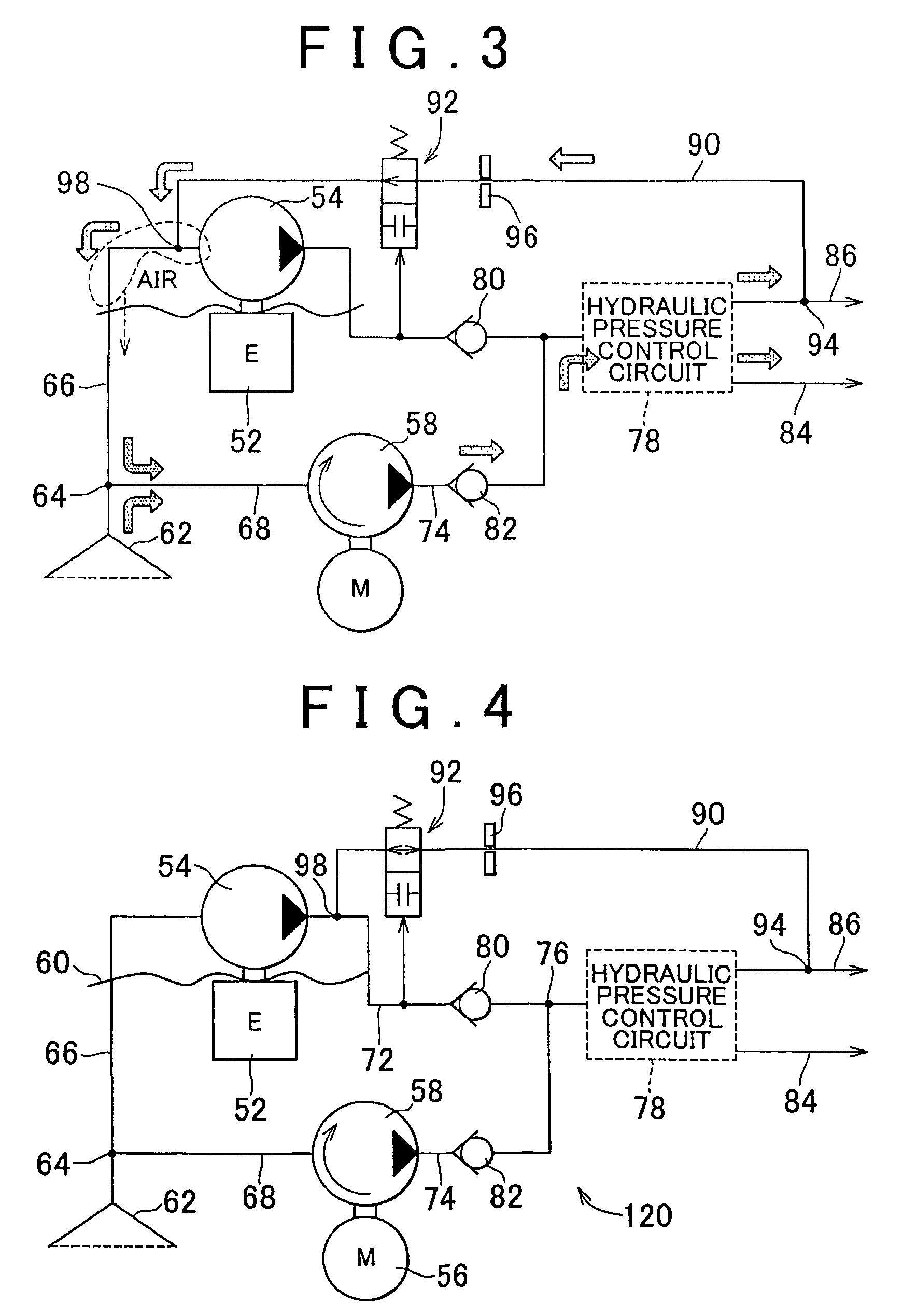

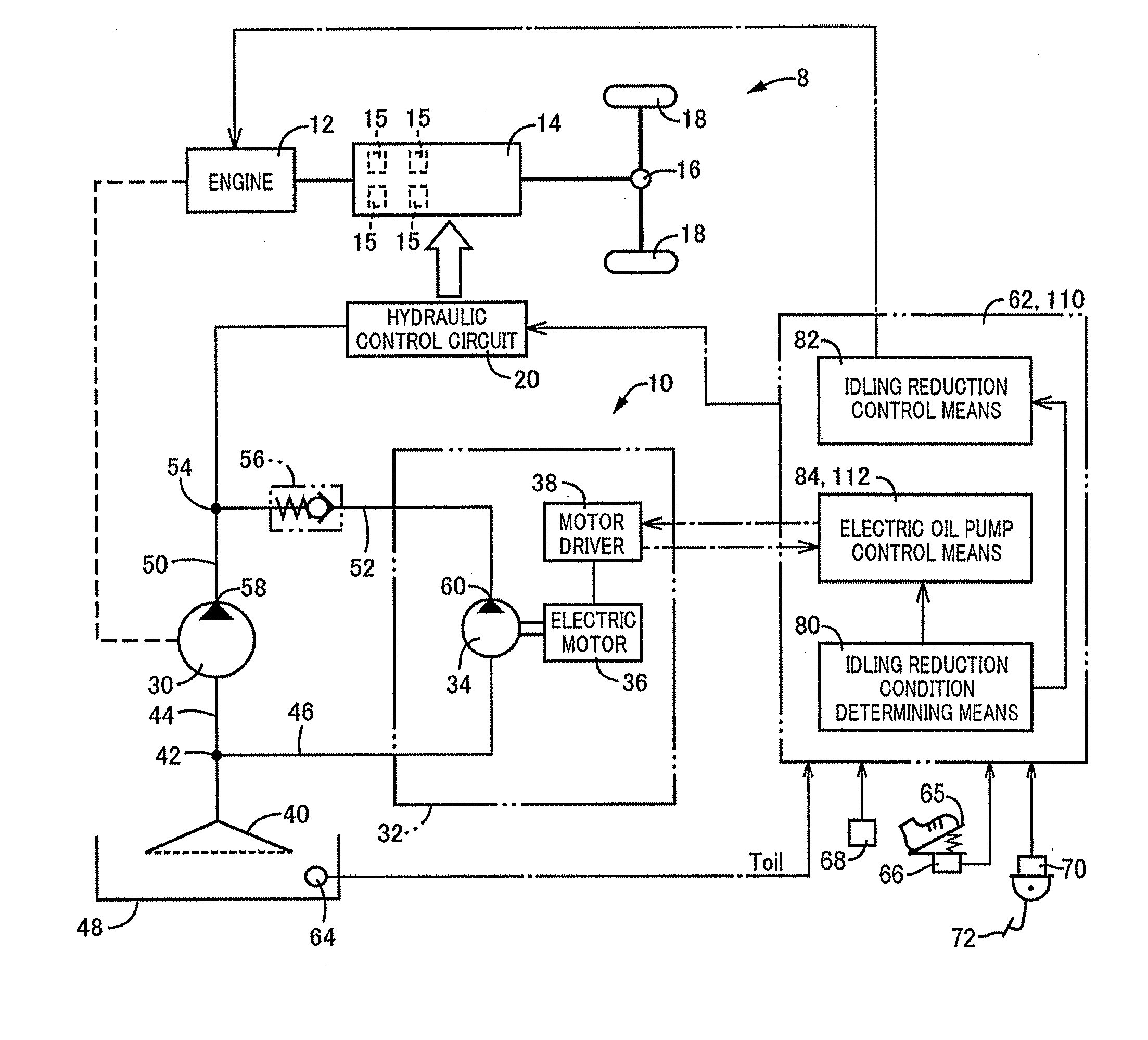

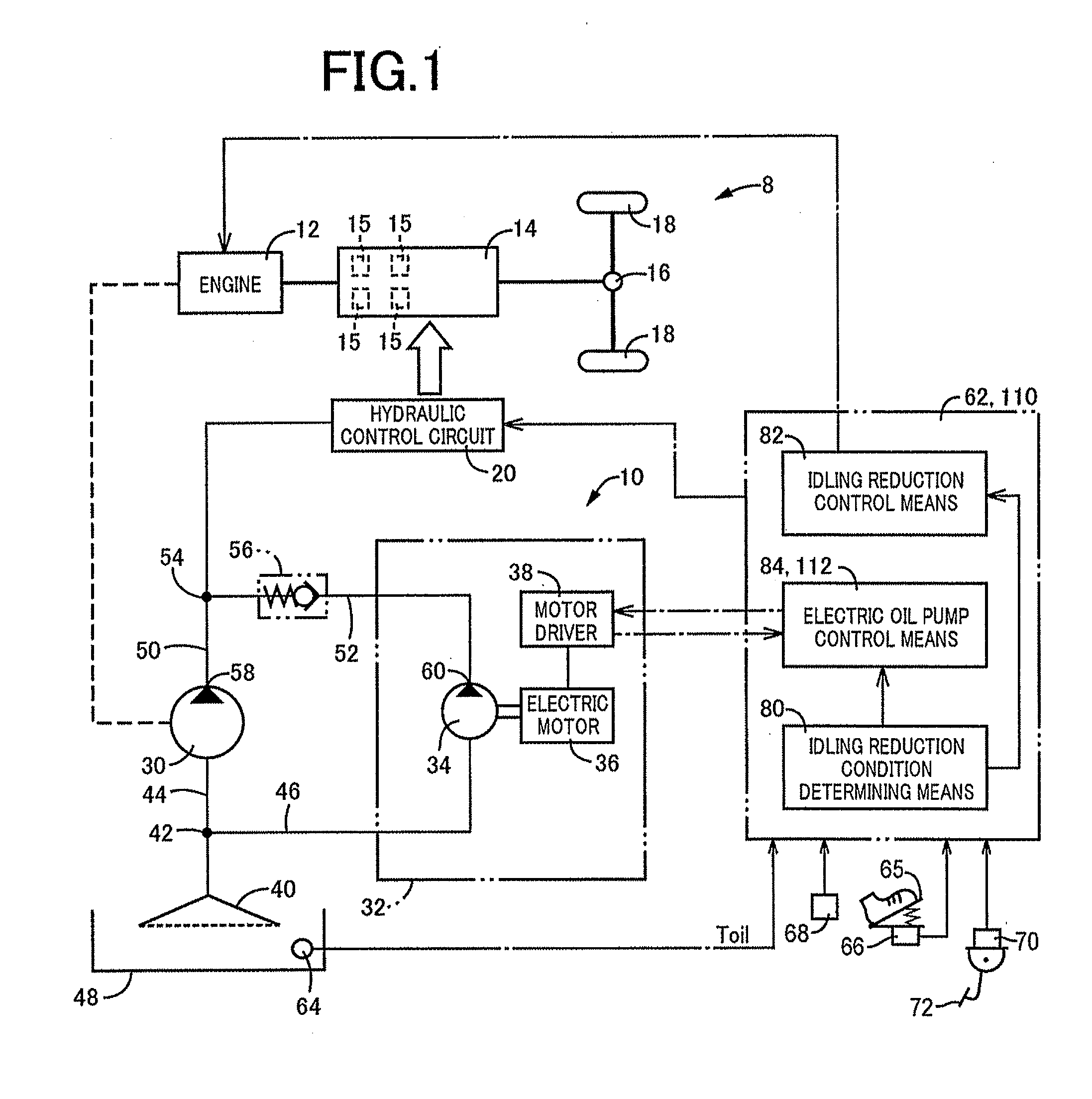

Oil supply system for vehicle

InactiveUS7946389B2Avoid airEasy to disassembleLubrication of auxillariesGearboxesControl circuitLubrication

An oil supply system for a vehicle includes: a mechanical oil pump driven by an engine; an electric oil pump driven by an electric motor; a hydraulic pressure control circuit supplied with oil from the mechanical oil pump and the electric oil pump through an oil discharge passage for the mechanical oil pump and an oil discharge passage for the electric oil pump, which are connected to each other; a lubrication / cooling oil passage that is supplied with the oil from the hydraulic pressure control circuit; and a communication passage that provides communication between the lubrication / cooling oil passage and the mechanical oil pump. With this oil supply system, it is possible to prevent the electric oil pump from causing air-sucking noise, for example, in the motor-power cruise mode, and to improve the rising characteristics of the hydraulic pressure produced by the mechanical oil pump during startup of the engine.

Owner:TOYOTA JIDOSHA KK +1

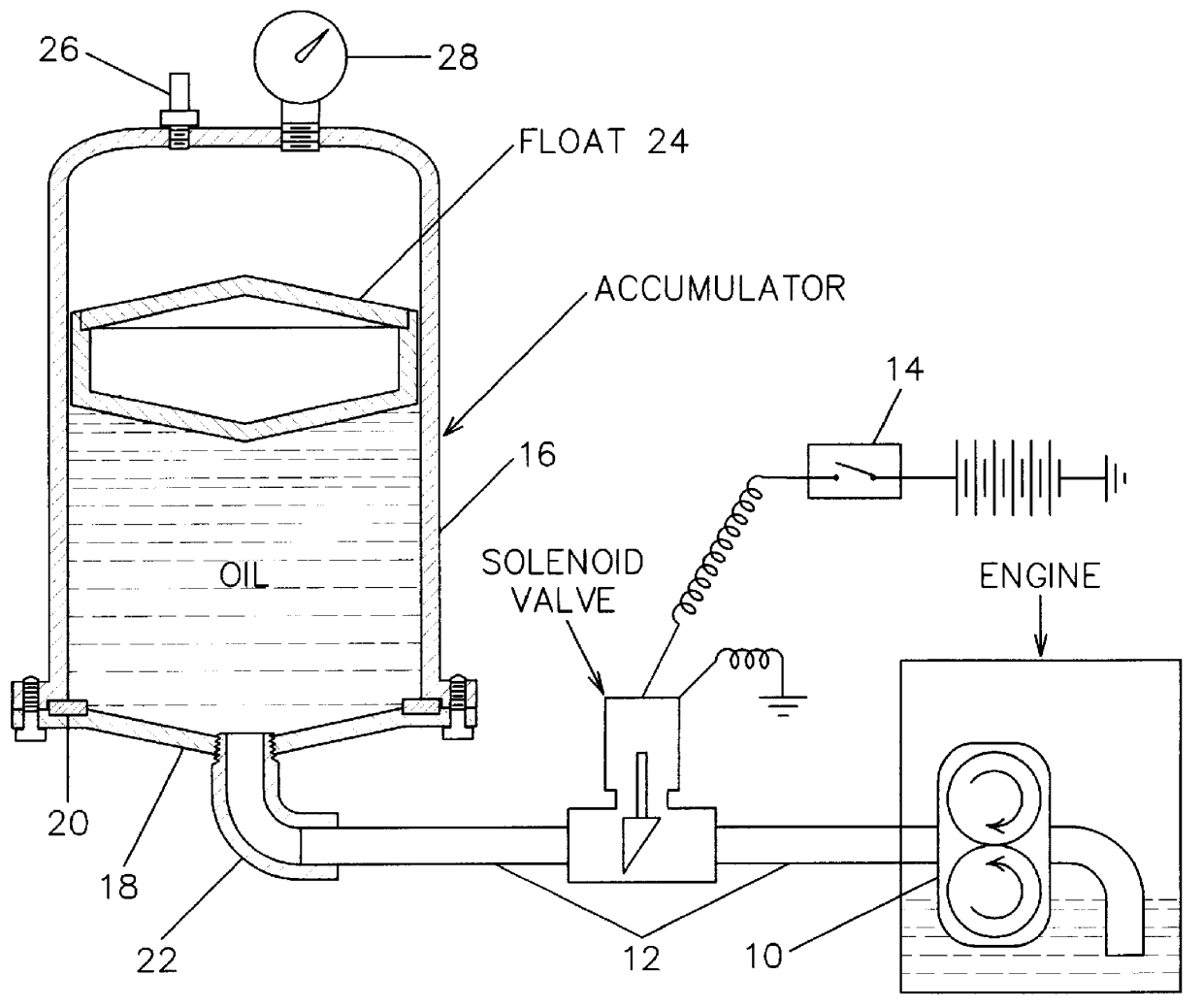

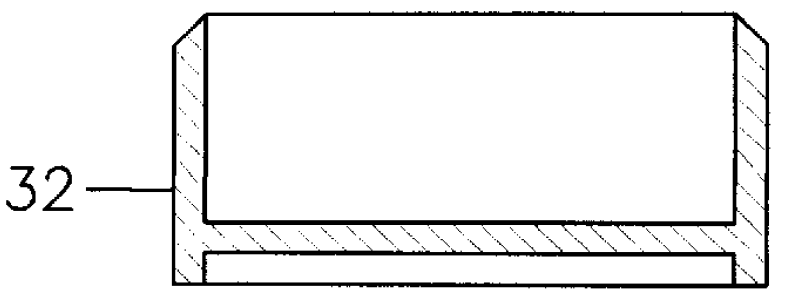

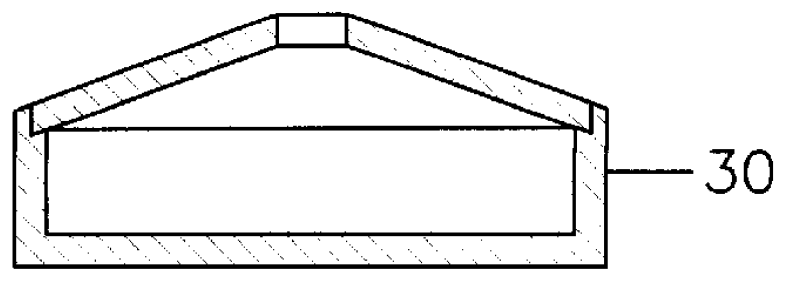

Engine-pressurized prestart oiler

InactiveUS6148789AEasy to modifyMinimal modificationLubrication of auxillariesLubricant conduit arrangementsAutomatic controlSolenoid valve

An engine-pressurized prestart oiler for an engine having pressure lubrication is provided, which rapidly lubricates critical engine bearing surfaces prior to the starting sequence. An accumulator for storing oil and pressurized air contains an air-oil separation float, which essentially fills the internal cross-sectional area and prevents absorption of the air. Discharge and recharge of the accumulator is preferably implemented by a normally closed solenoid valve. Discharge is controlled either manually by a switch or automatically by circuitry containing ignition-off time and accumulator pressure comparators, a starter interrupter, and a prestart oiling timer. Recharge is automatic, as the solenoid valve allows oil flow whenever the engine oil pressure sufficiently exceeds the accumulator pressure. A conduit connects the accumulator, solenoid valve, and engine, connecting to the engine either at the oil pressure sensor port or through an adaptor installed between the oil filter and the oil filter mount.

Owner:JOHNS RALPH HOWARD

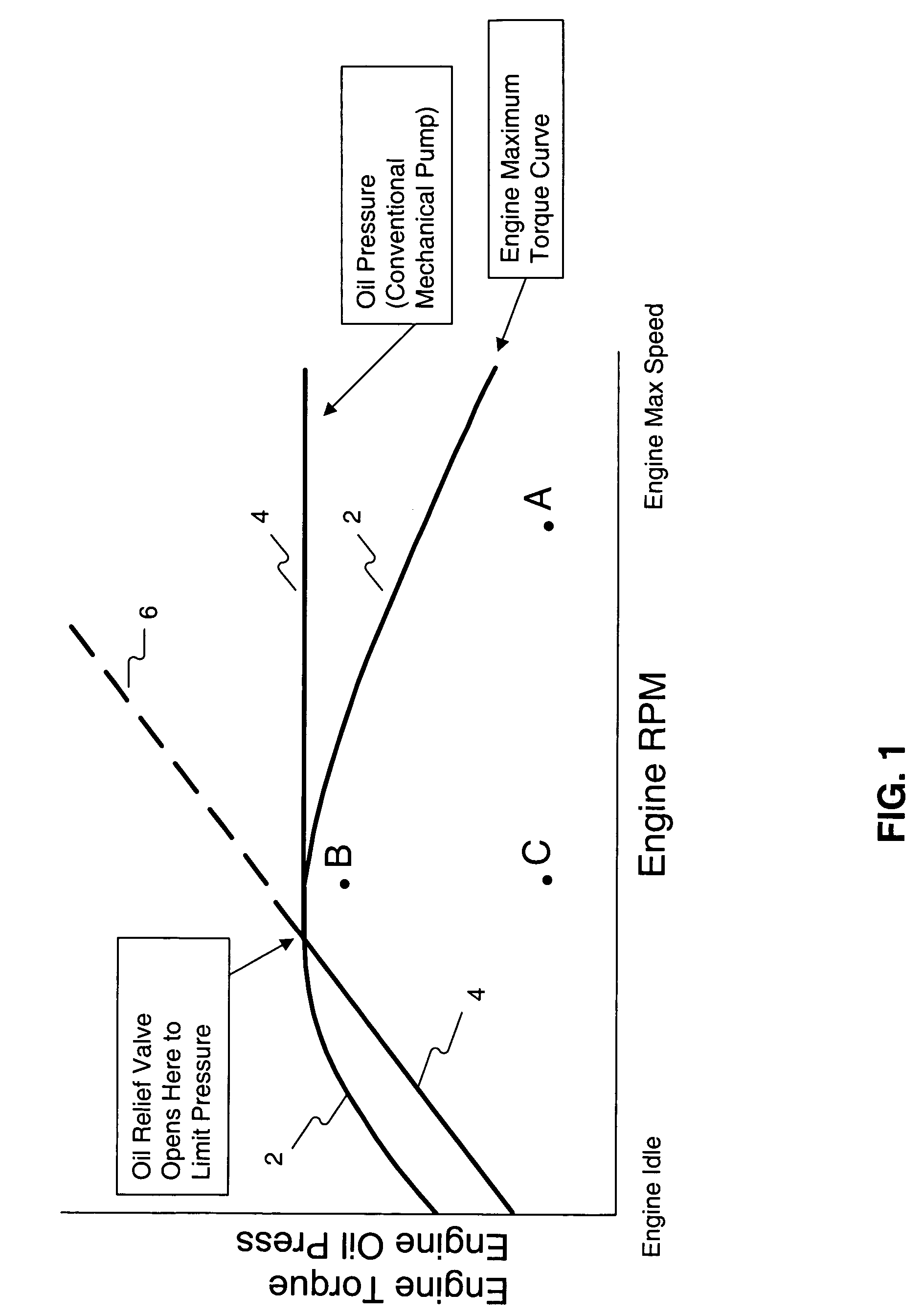

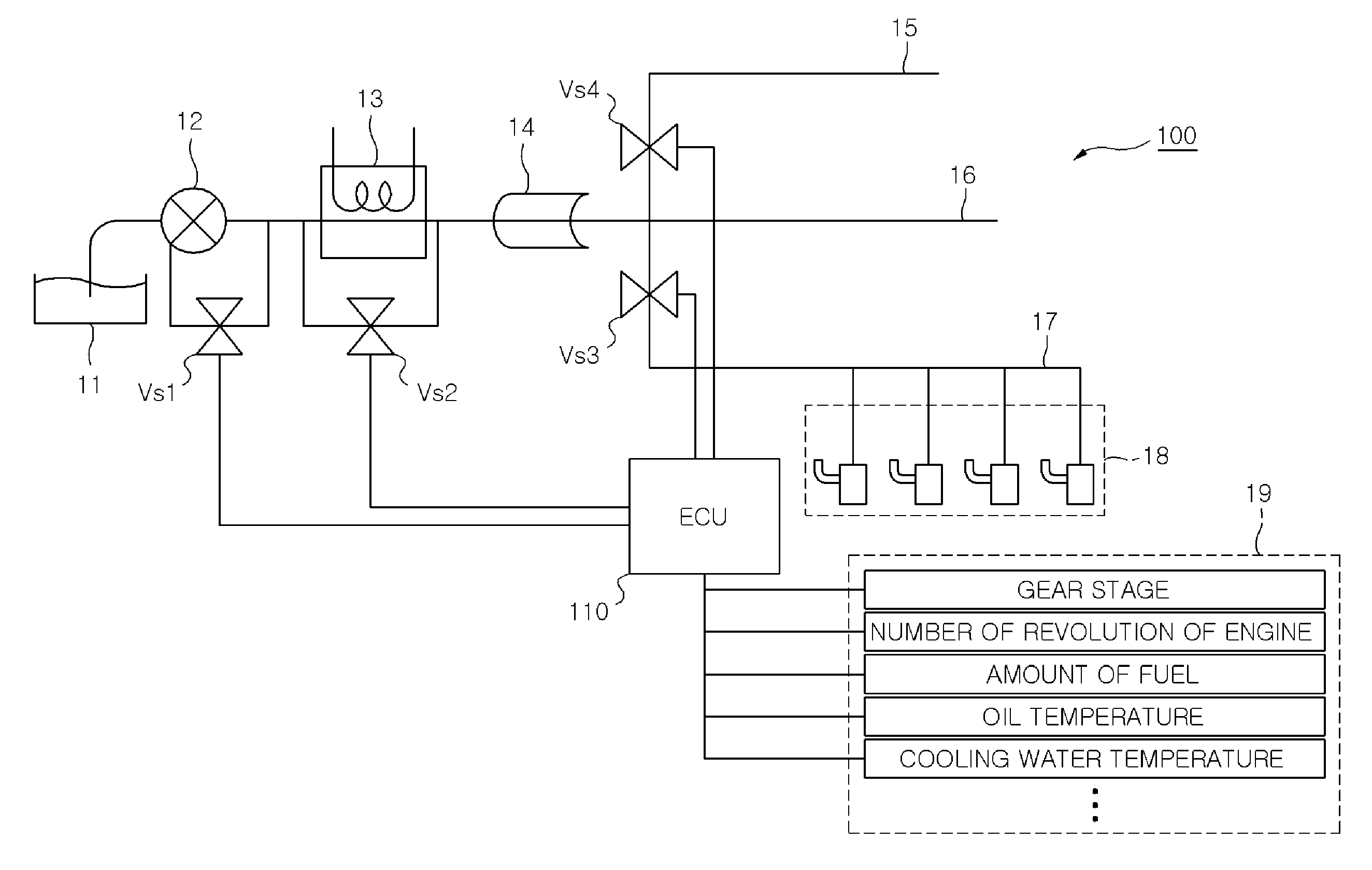

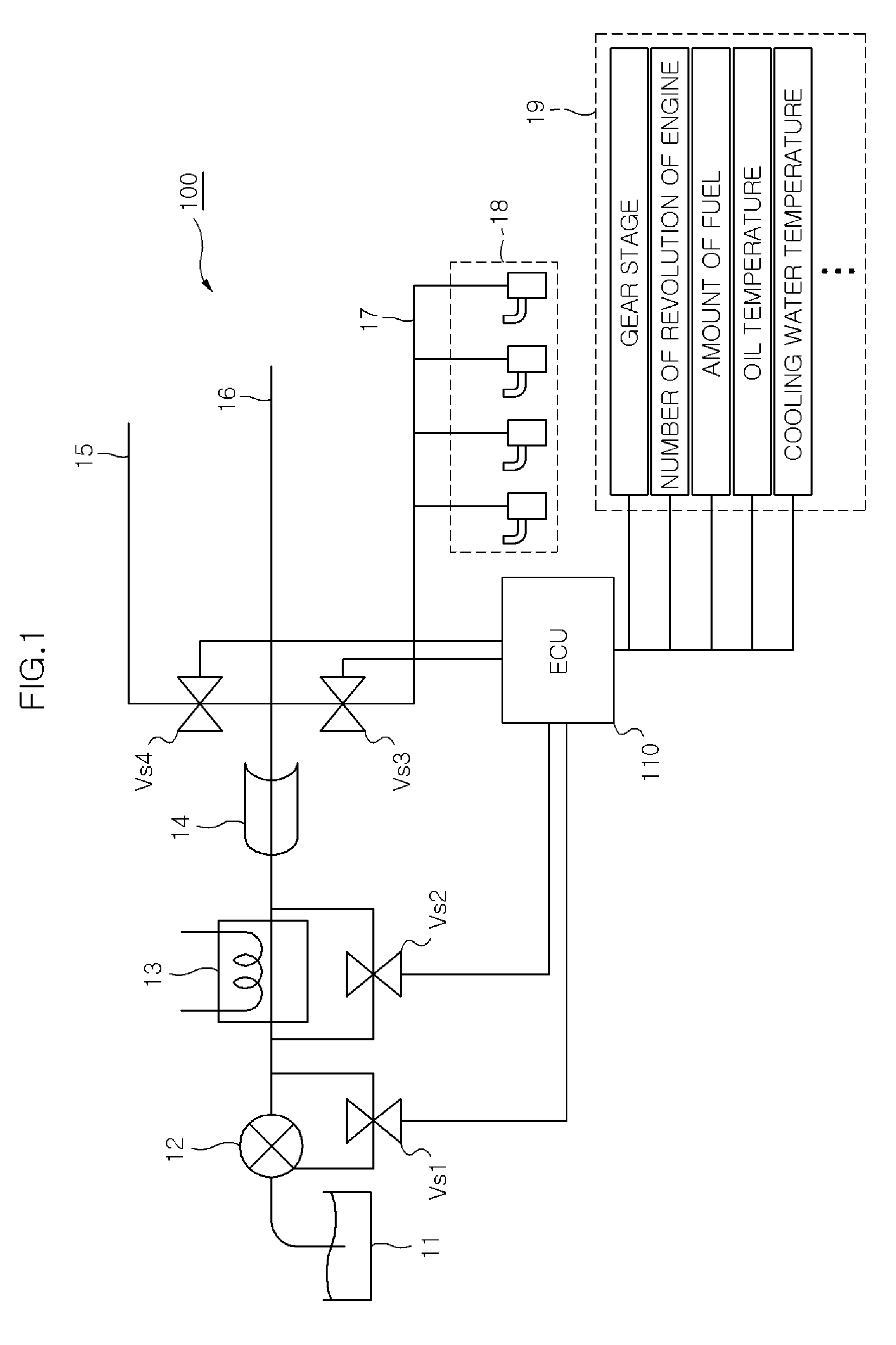

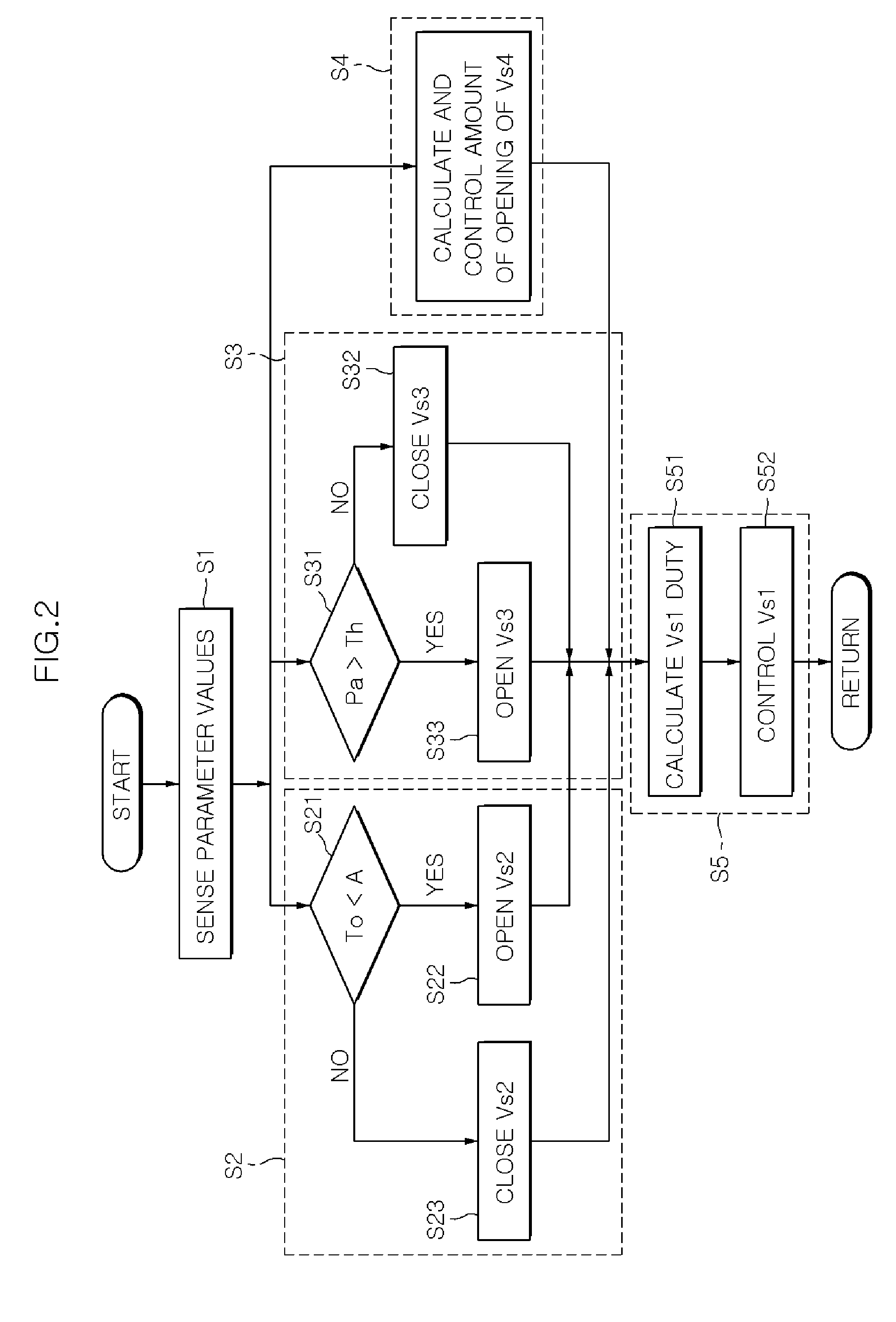

System for controlling hydraulic pressure and flow rate of oil in engine and control method thereof

InactiveUS20120048228A1Avoid friction lossLubrication of auxillariesLubricant conduit arrangementsElectronic controllerSolenoid valve

A system for controlling hydraulic pressure and flow rate of oil in an engine, may include a first solenoid valve disposed in a channel connecting an inlet and an outlet of an oil pump supplying oil from an oil pan to the engine, and an electronic controller controlling the first solenoid valve on the basis of number of revolution of the engine, load of the engine, and temperature of the oil.

Owner:HYUNDAI MOTOR CO LTD +1

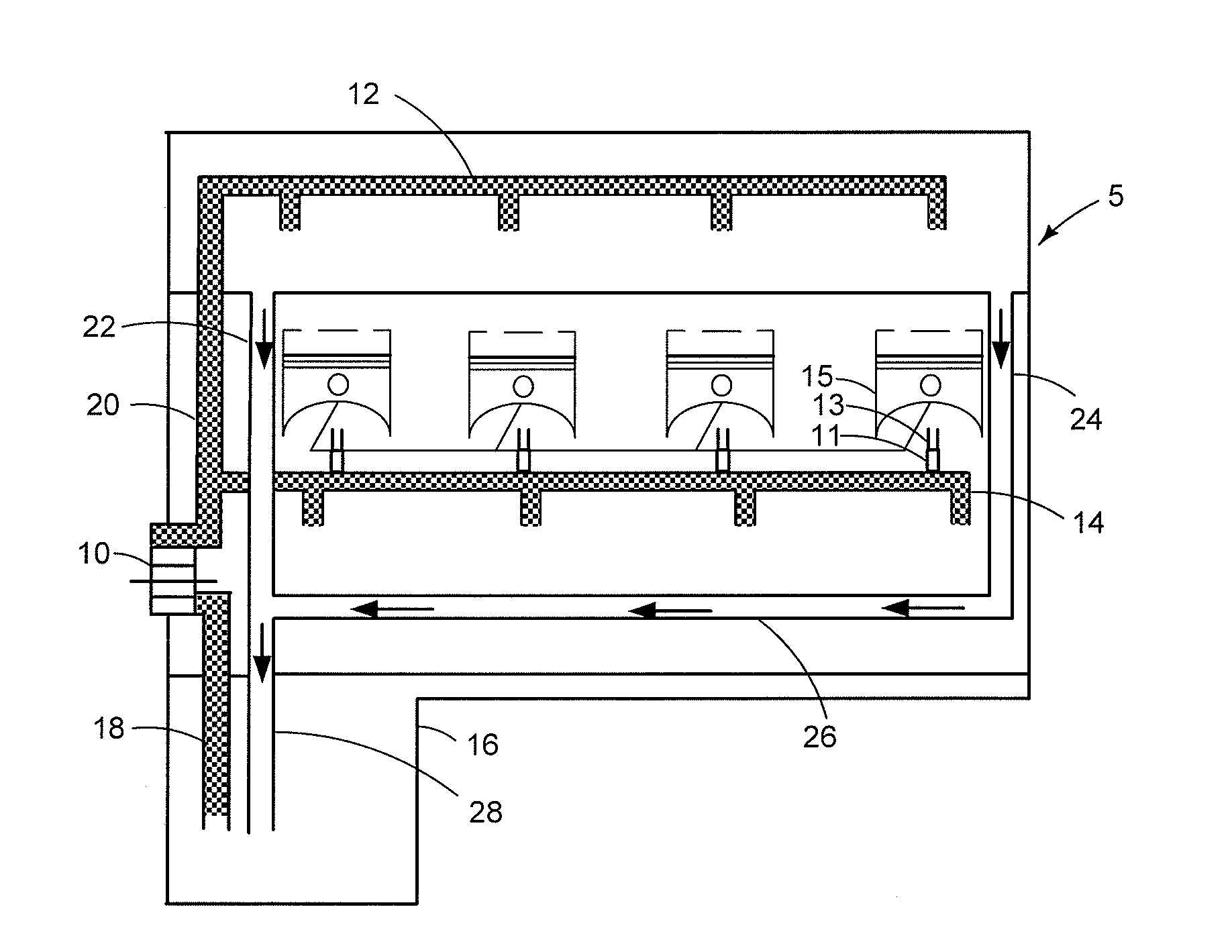

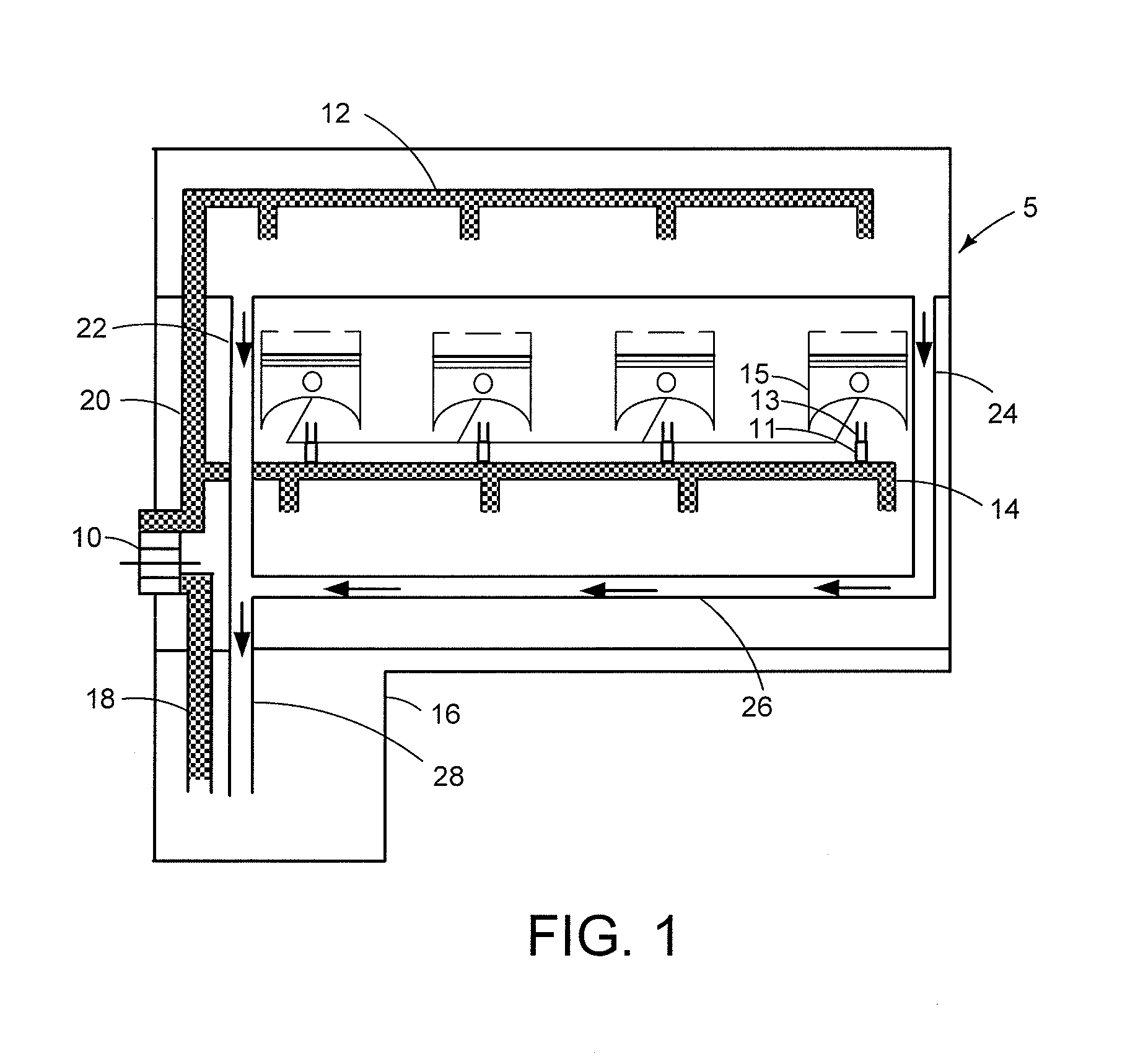

Oil supply system for an engine

ActiveUS20110283968A1Reduce fuel usageLiquid coolingLubrication of auxillariesInternal combustion enginePiston

An oil supply system for a reciprocating piston internal combustion engine is disclosed in which the supply of oil to piston cooling jets is controlled by pressure operated valves designed to open at a pre-defined valve opening pressure. The pressure of oil supplied by a pump is controlled to be below this pre-defined valve opening pressure during operation of the engine in which piston cooling is not required, and the pressure of oil is controlled to above the pre-defined valve opening pressure when piston cooling is required. The control of the pump is by an electronic control unit based upon a combination of engine speed and engine load.

Owner:FORD GLOBAL TECH LLC

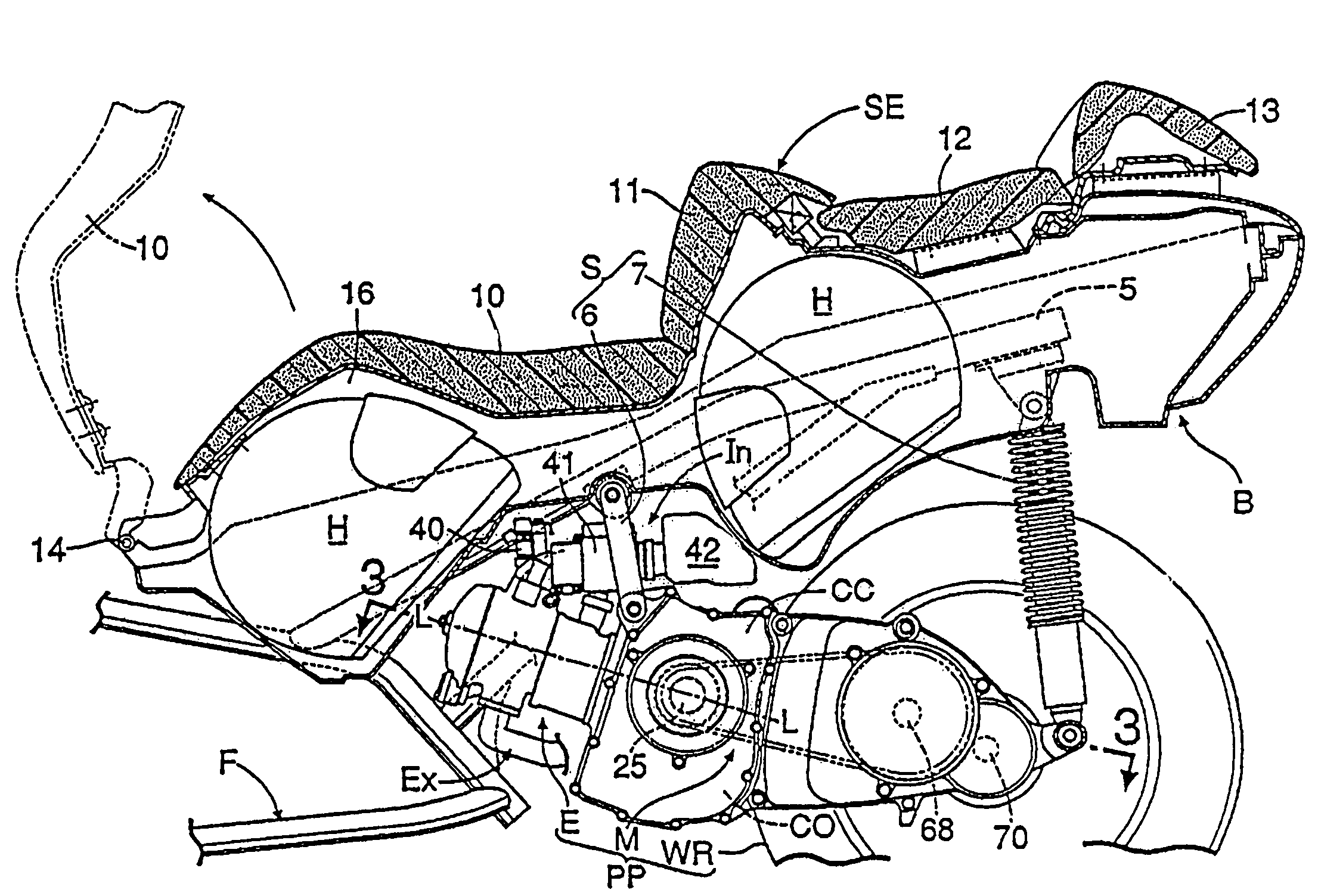

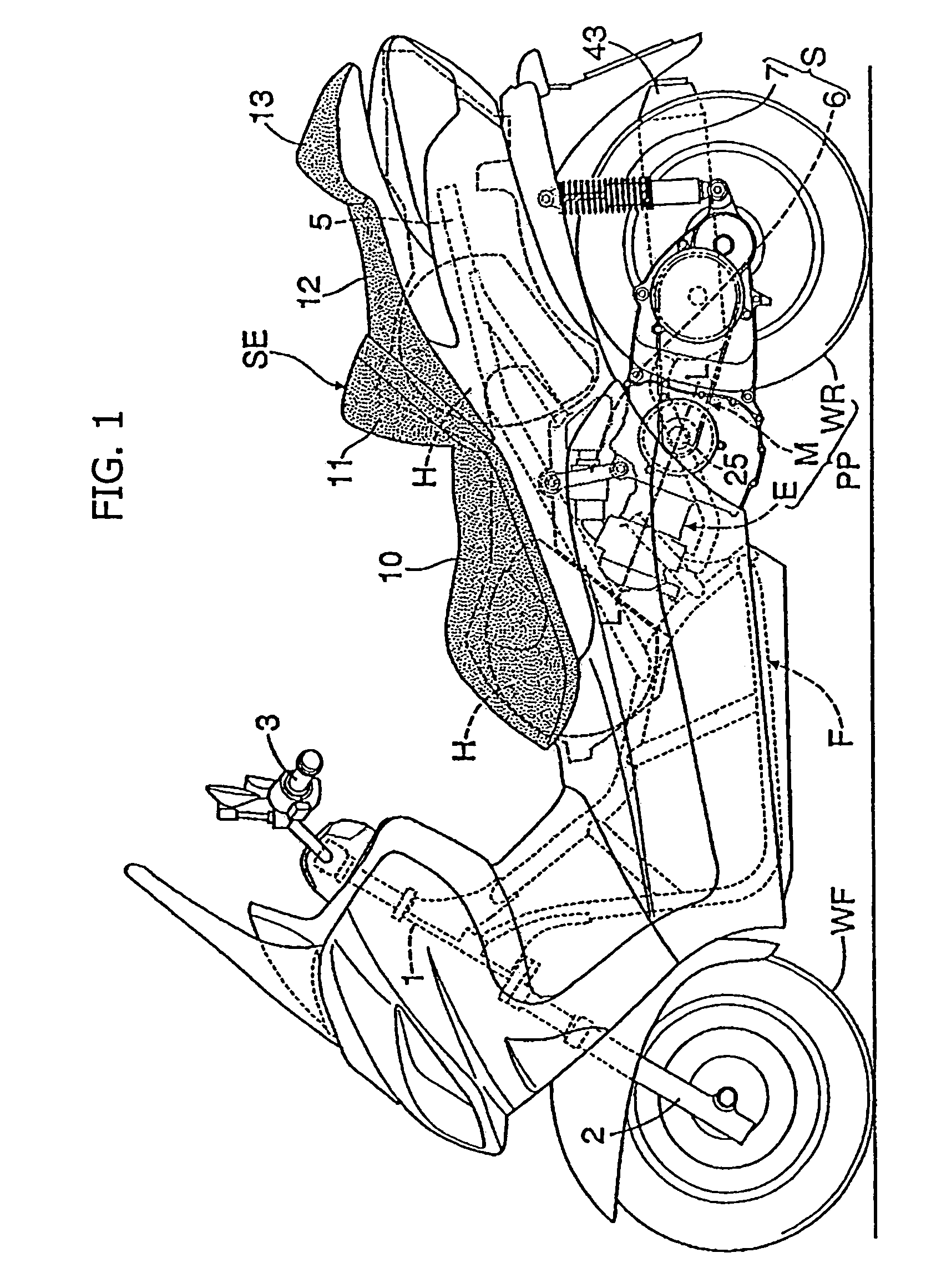

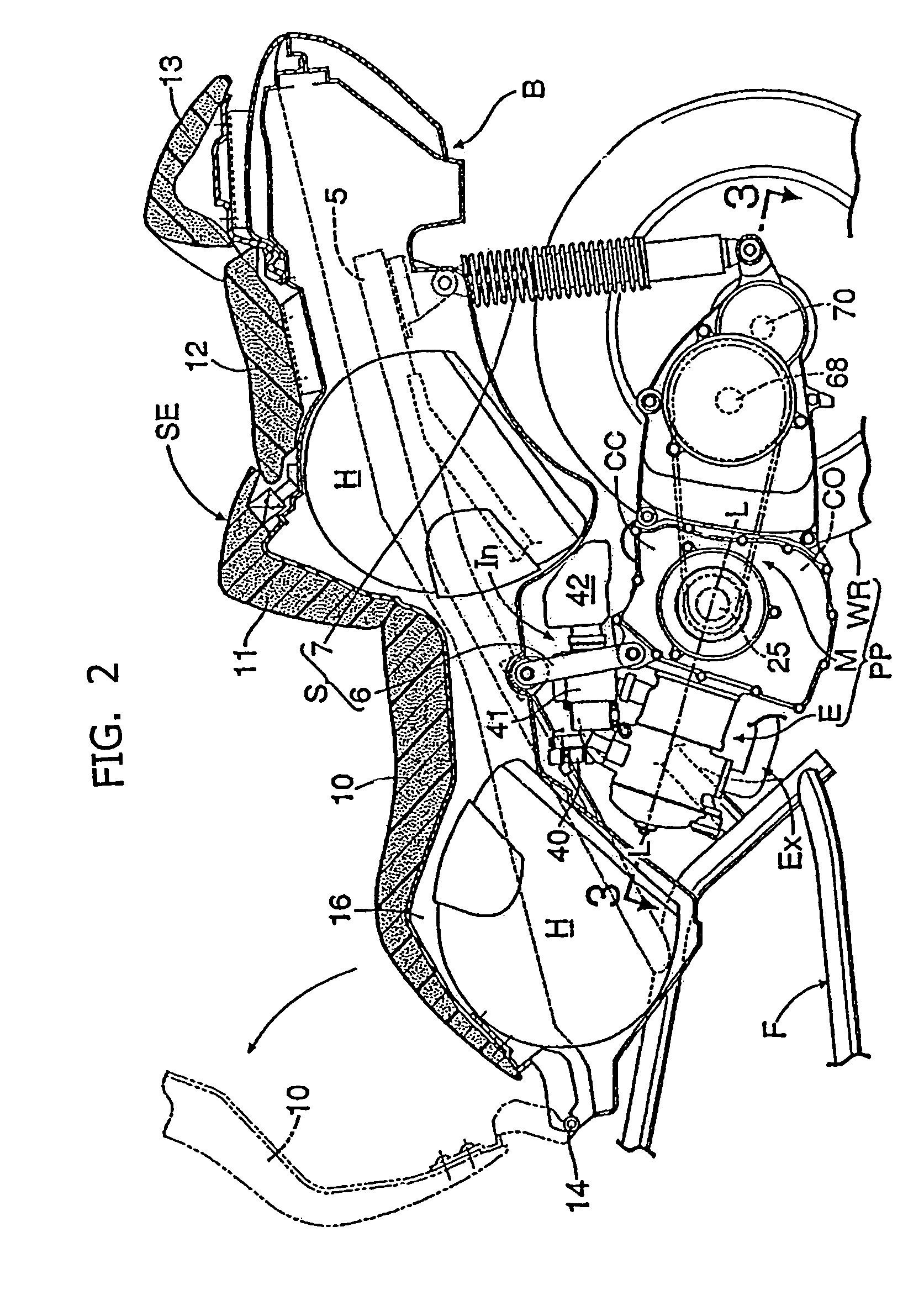

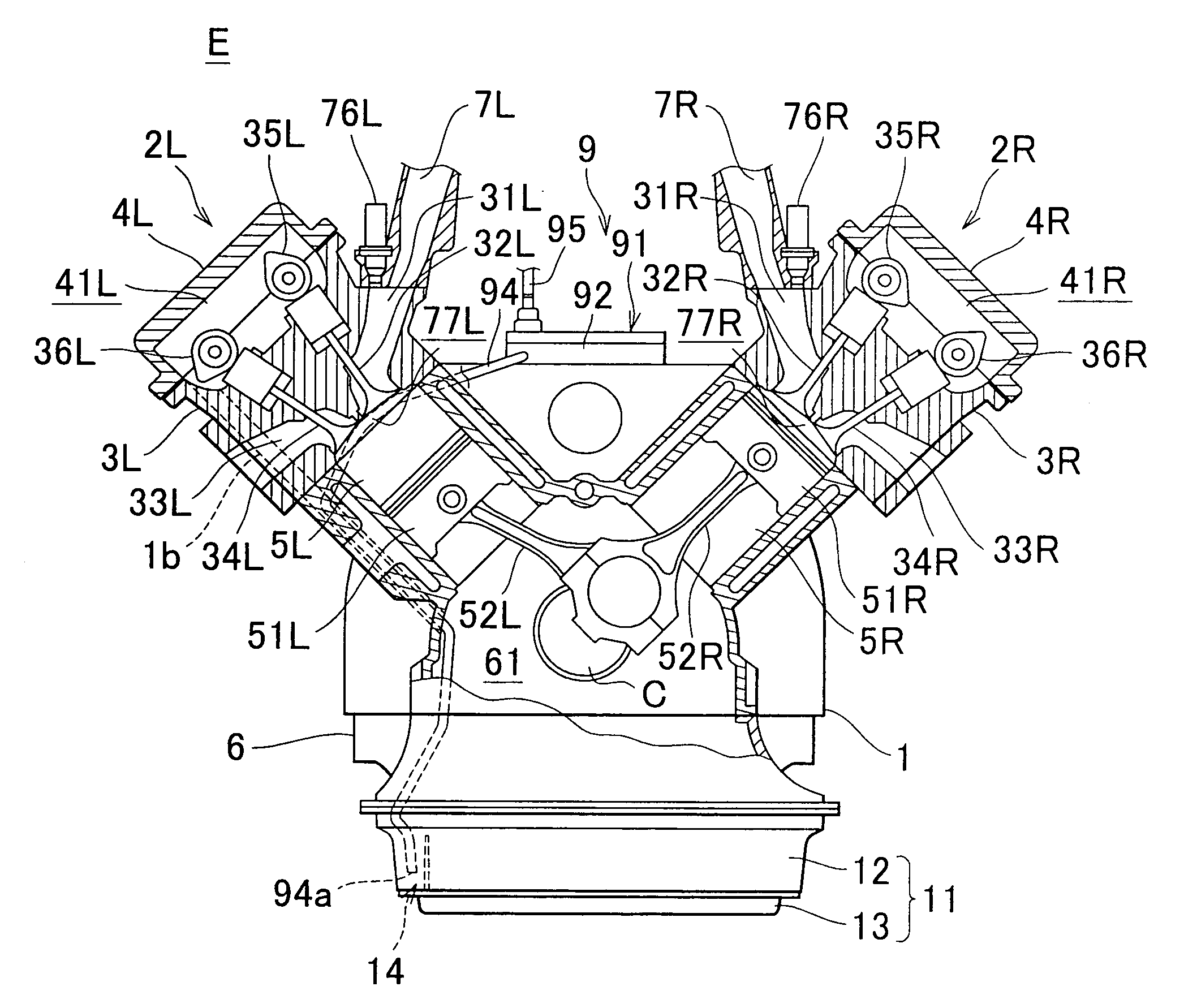

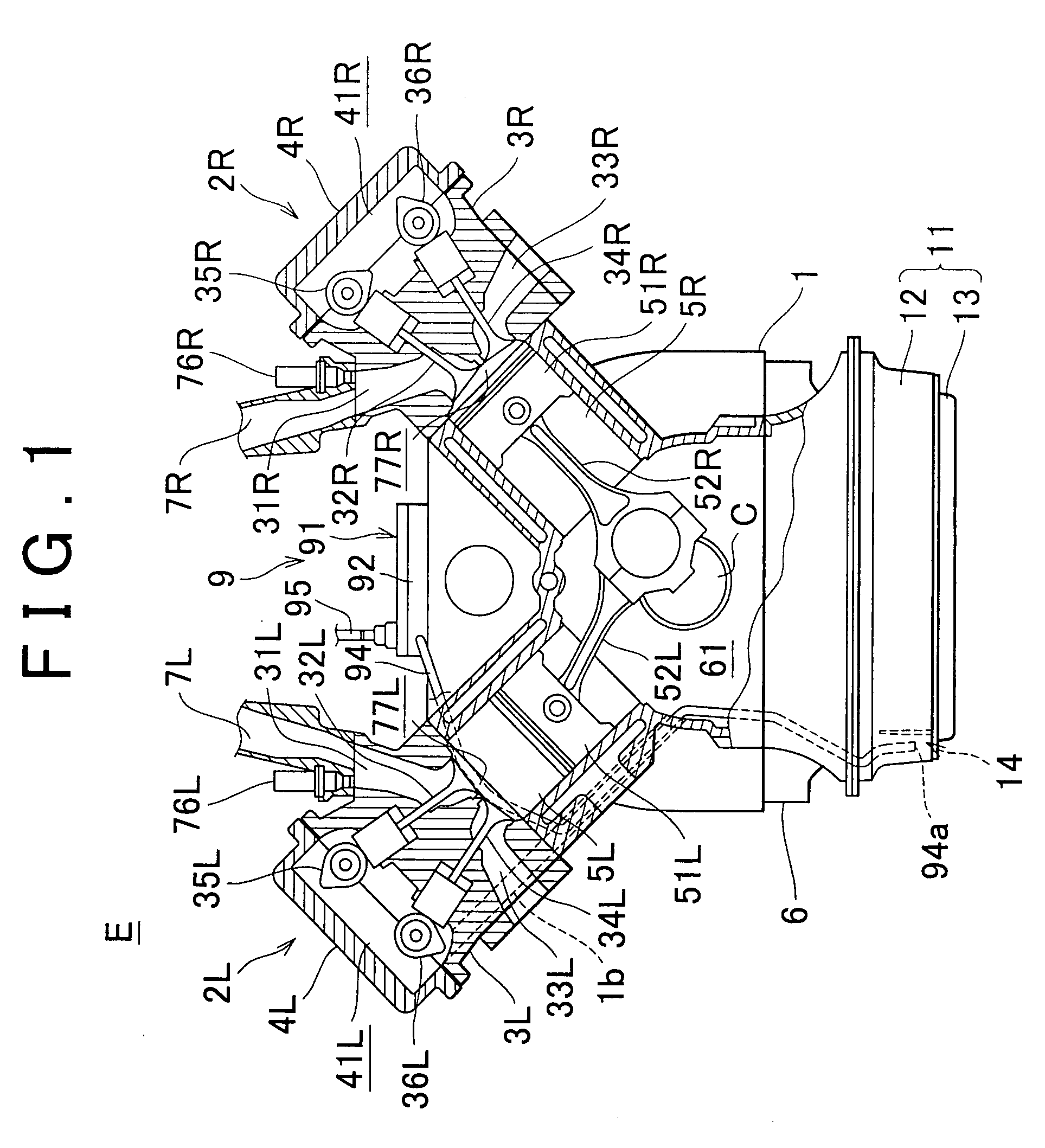

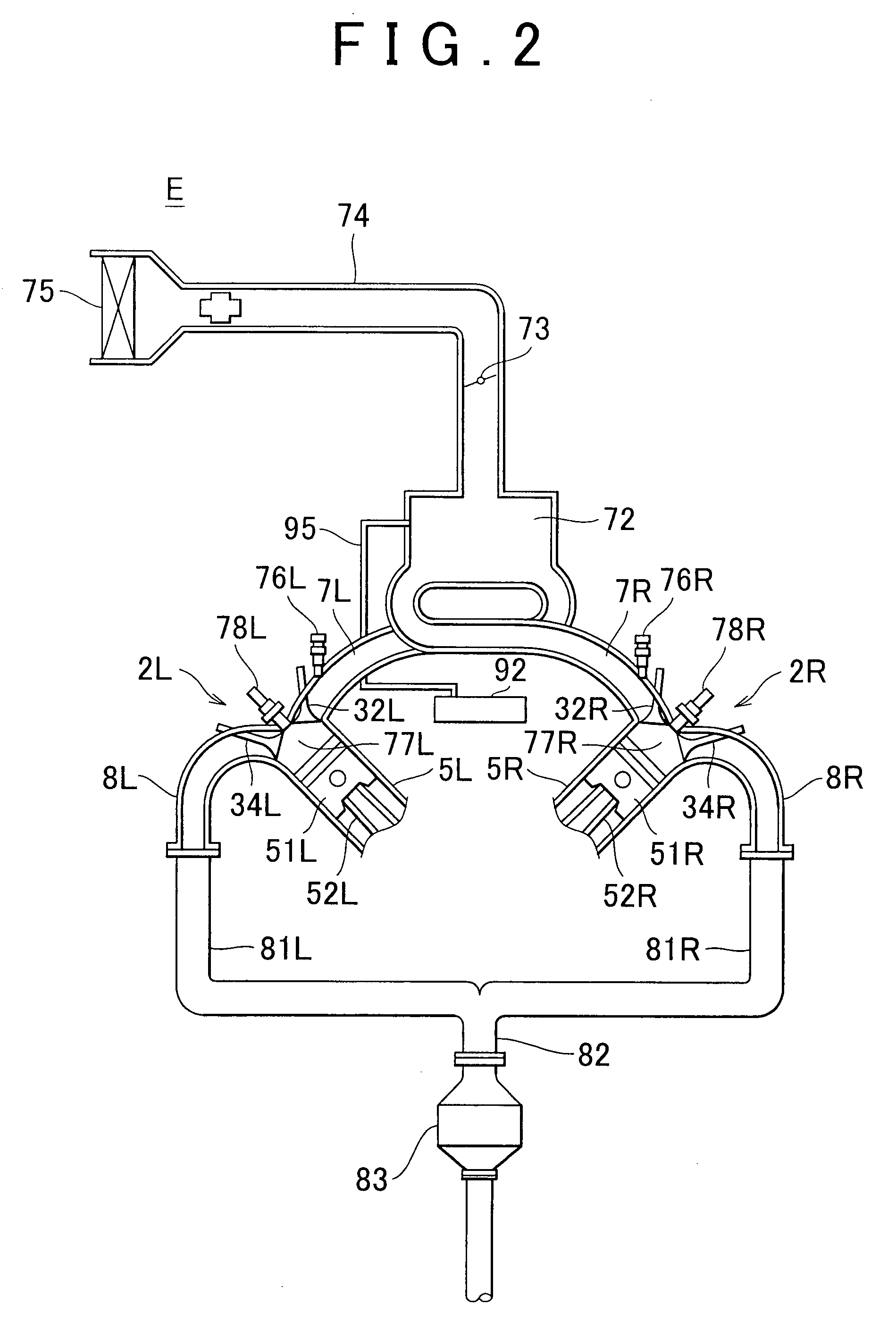

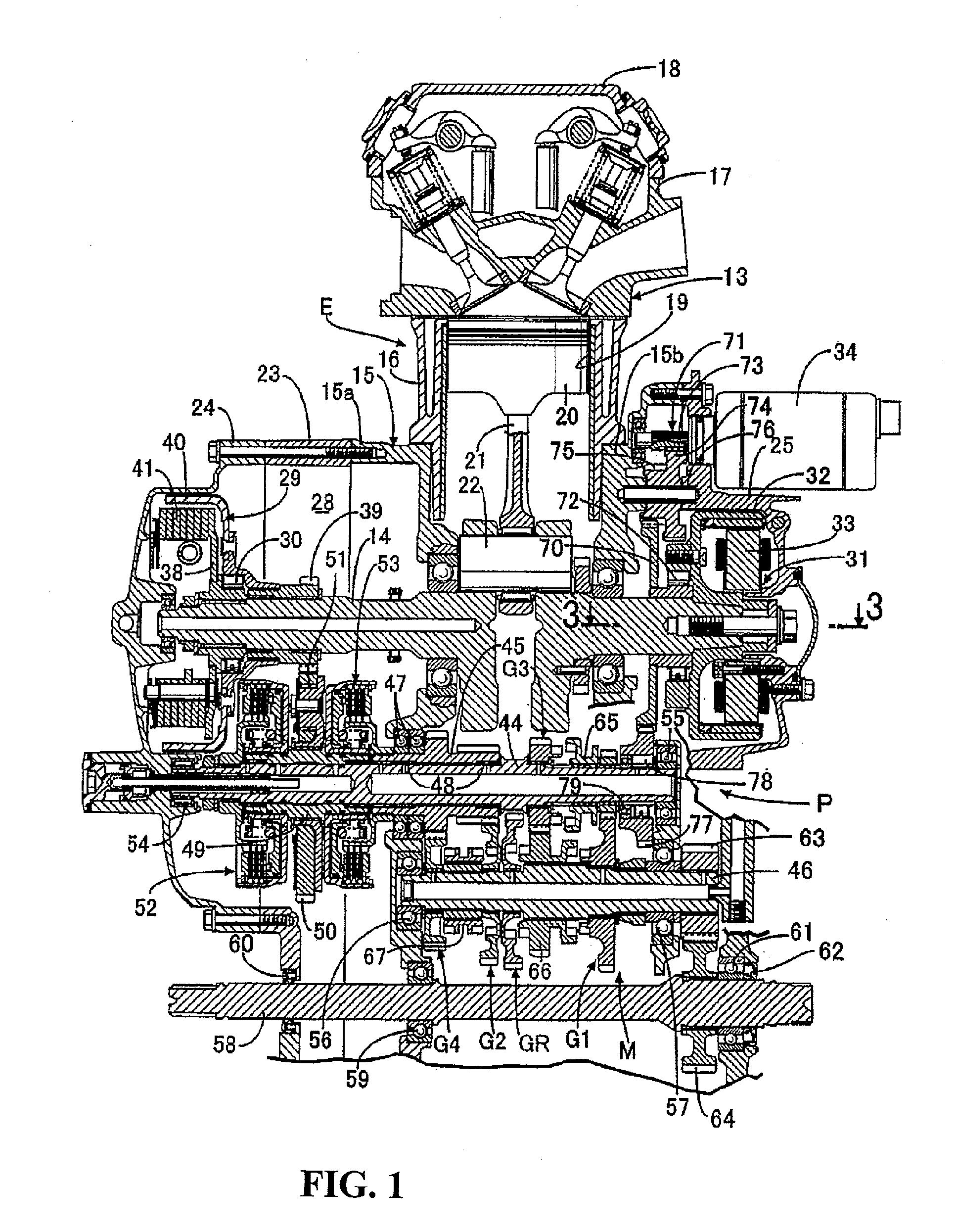

Engine configuration for a motorcycle

ActiveUS7334556B2Prevention of entrance of the lubricating oilEasy to processCasingsLubrication of auxillariesCrankcaseLubrication

A motorcycle is provided in which a seat and a storage box are arranged so as to be vertically stacked on each other in a rear portion of a body frame, and a pivotally mounted powertrain unit is suspended from the body frame under the storage box. The powertrain unit extends in the fore-and-aft direction of the body frame, and the engine has a crank chamber and a lubricant oil chamber provided separately from each other. A lubrication-oil passage structure for the engine is provided between each of a pair of journal bearing portions of a crankcase. The crankcase has an enclosed crank chamber and a crankshaft which is freely rotatably supported by the journal bearing portions with plain bearings. The journal bearing portions are provided with protrusion bosses for resisting entry of lubricating oil into the crank chamber from outside of the crankcase.

Owner:HONDA MOTOR CO LTD

Oil-feeding device for engine crankshaft

InactiveUS20050263125A1Reduce the amount requiredIncrease frictionCrankshaftsCasingsEngineeringCylinder block

An oil-feeding device for a crankshaft where the amount of lubricant oil leaking from supporting areas of main journal portions is reduced without increasing friction of bearing members against the main journal portions. The oil-feeding device for a crankshaft includes upper bearing members and lower bearing members. The upper and lower bearing members have a half hollow cylindrical shape, are provided with crush relief portions at both ends, and jointly encompass main journal portions of a crank shaft. The upper bearing members have circumferentially extending oil grooves provided in the faces opposite the main journal portions, the grooves penetrating through oil passages of a cylinder block. The lower bearing members do not have oil grooves. The oil grooves do not extend in the crush relief portions, and therefore the leakage of lubricant oil, fed to the oil grooves, to the areas of the crush relief portions is suppressed.

Owner:TAIHO INDUSTRIES CO LTD

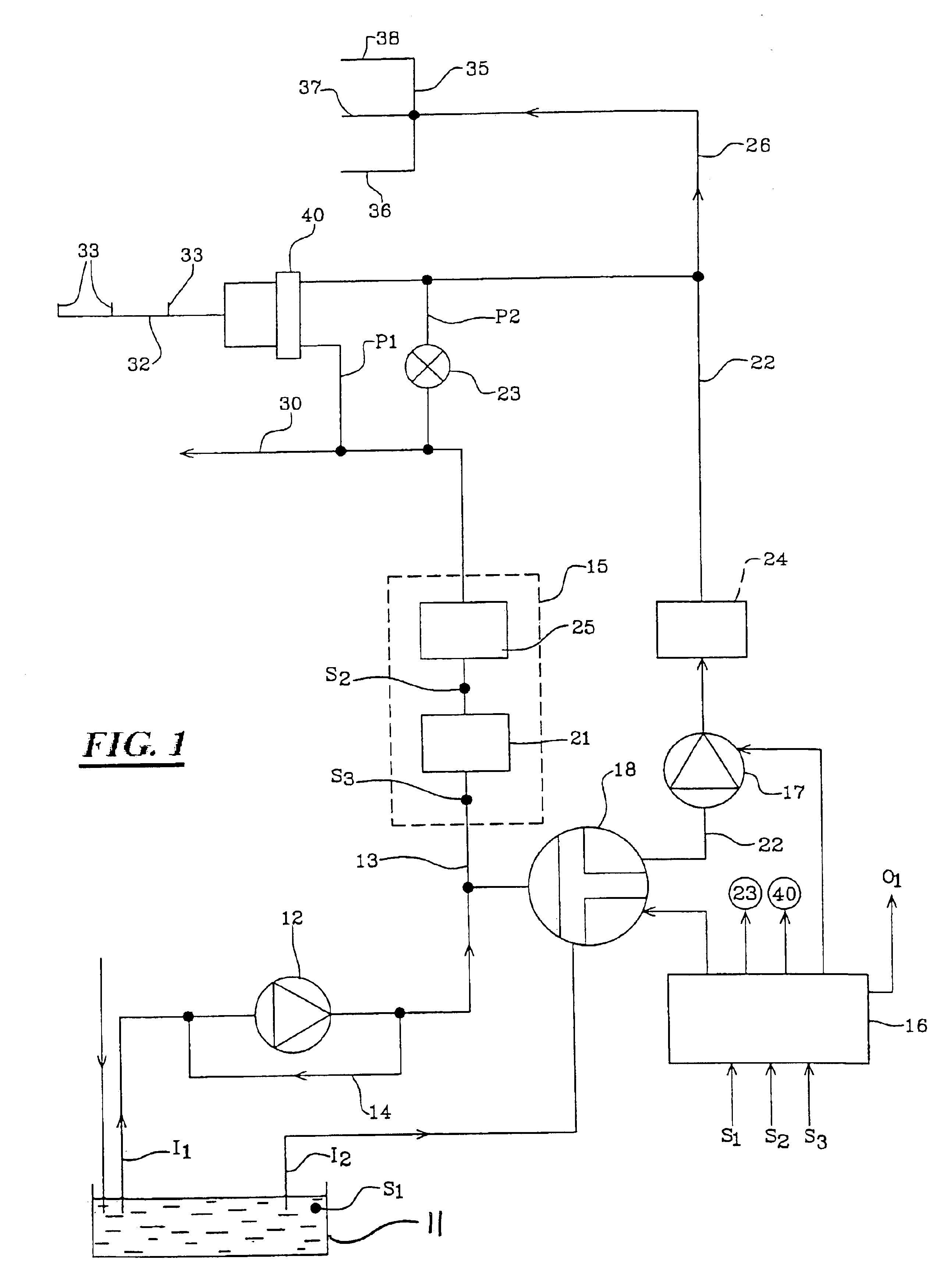

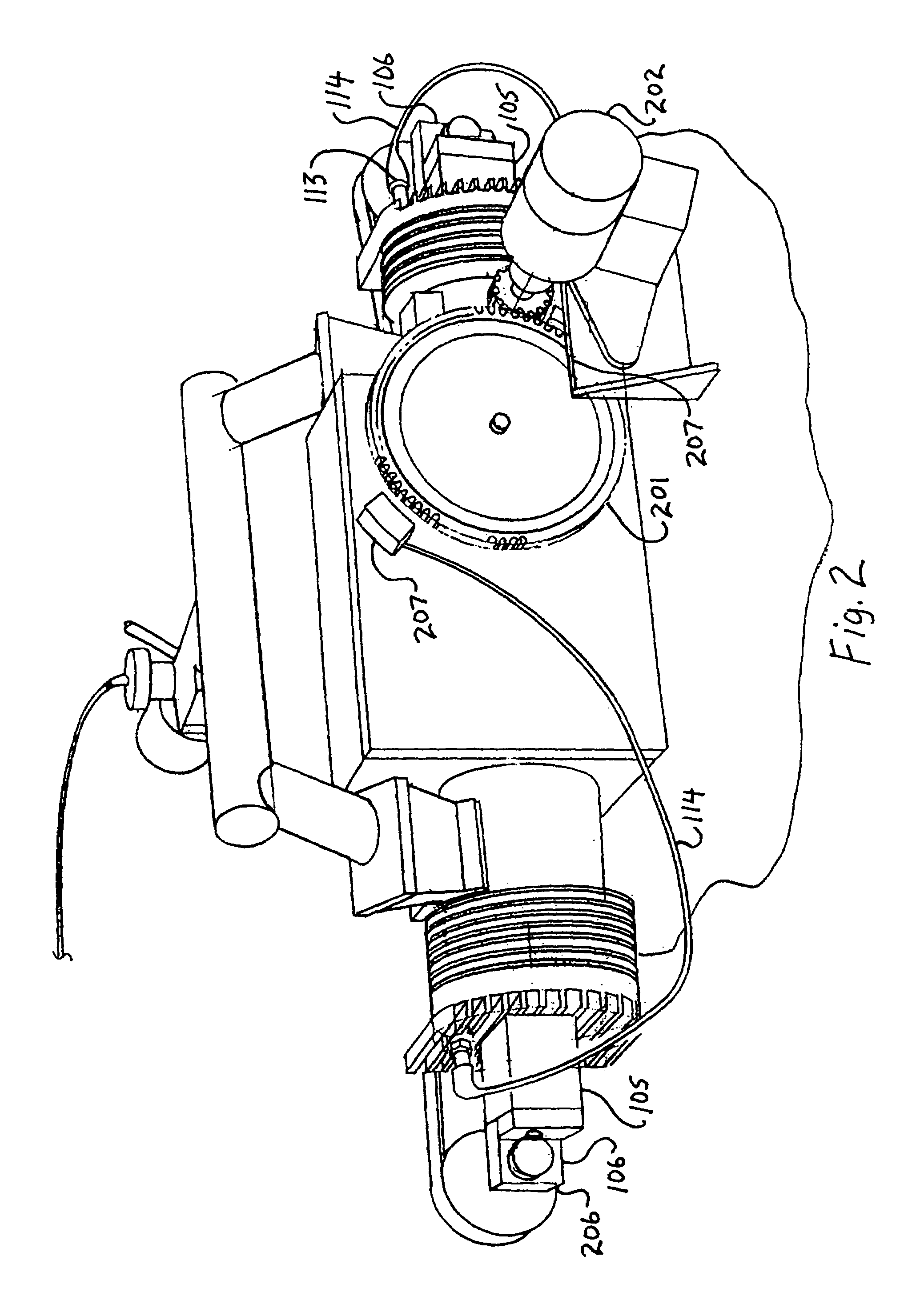

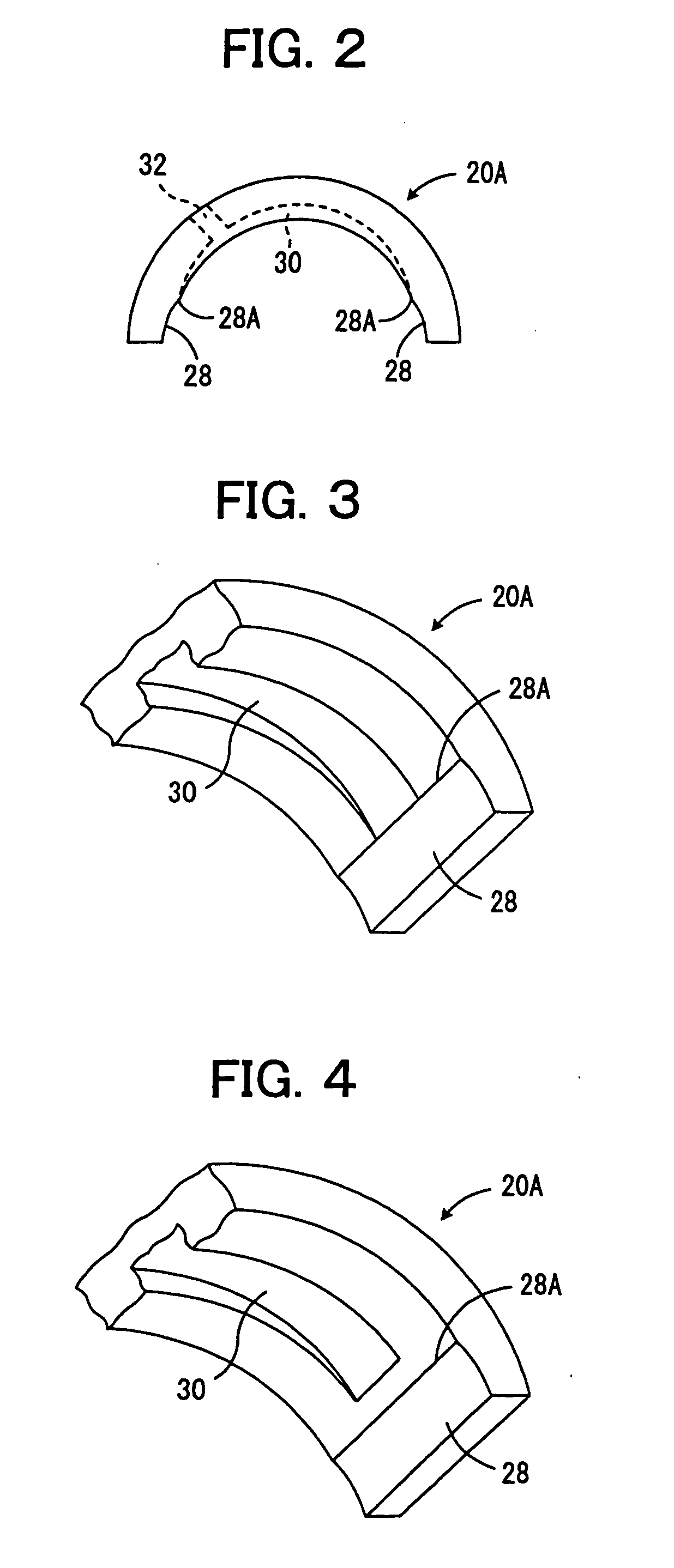

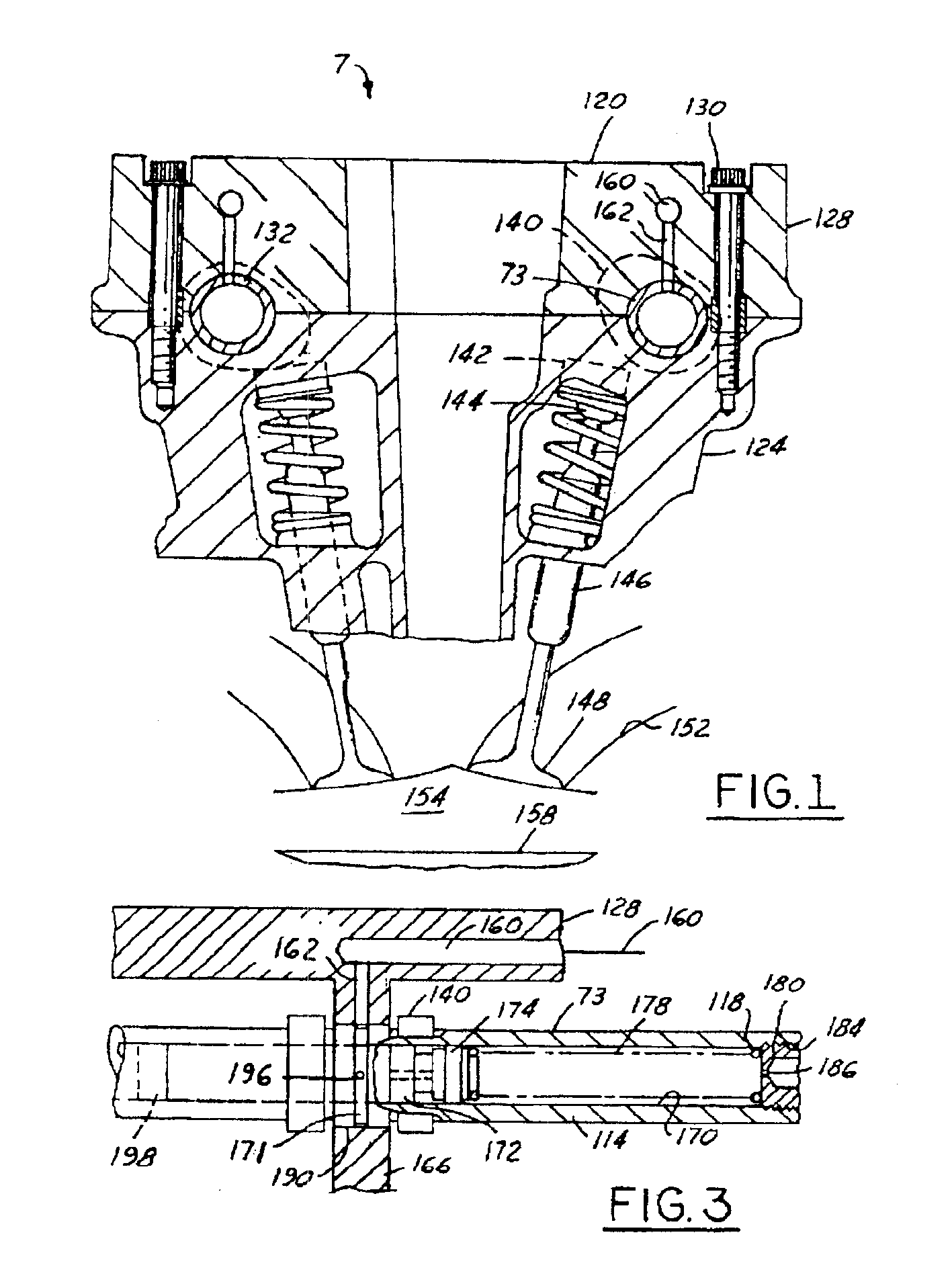

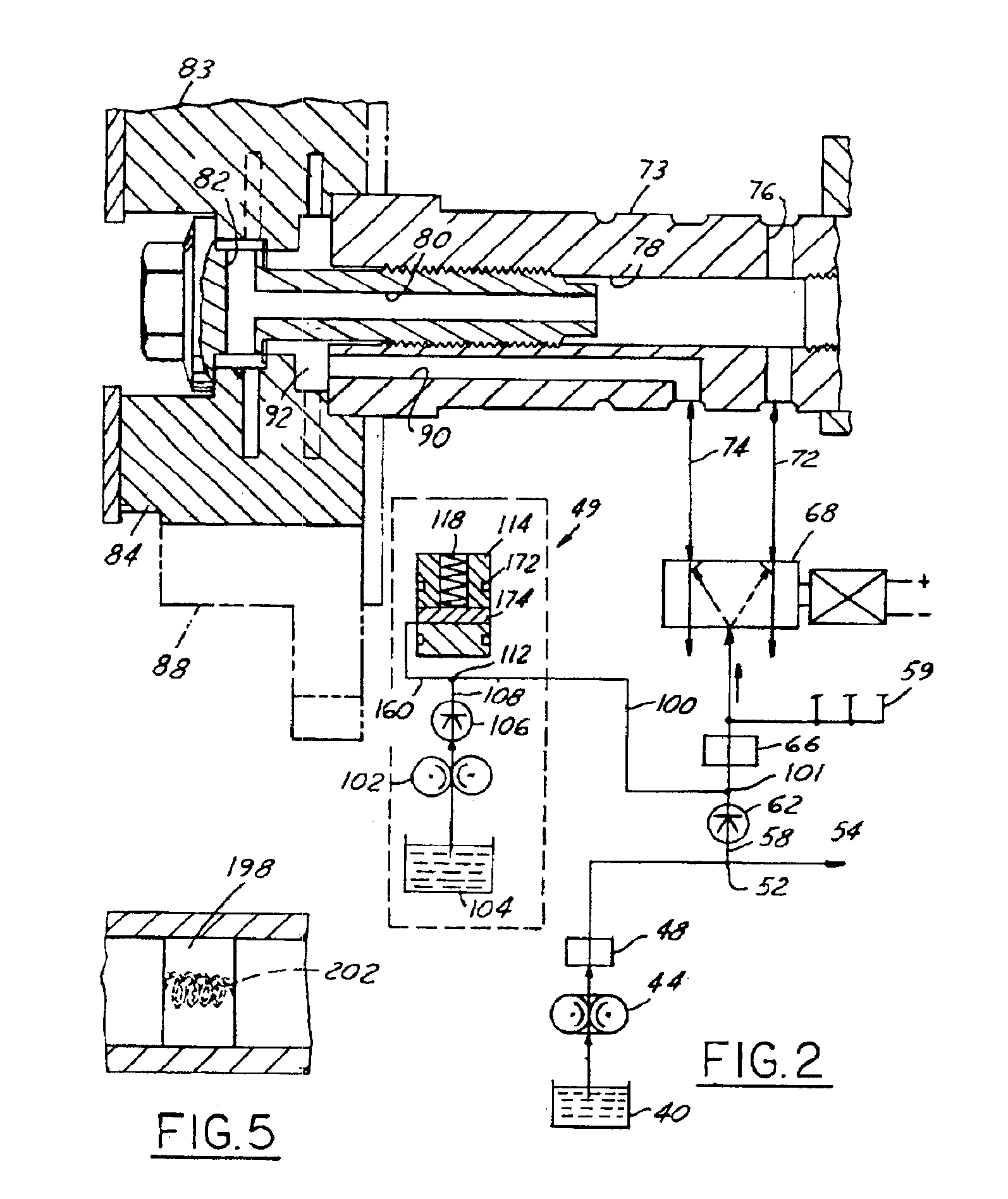

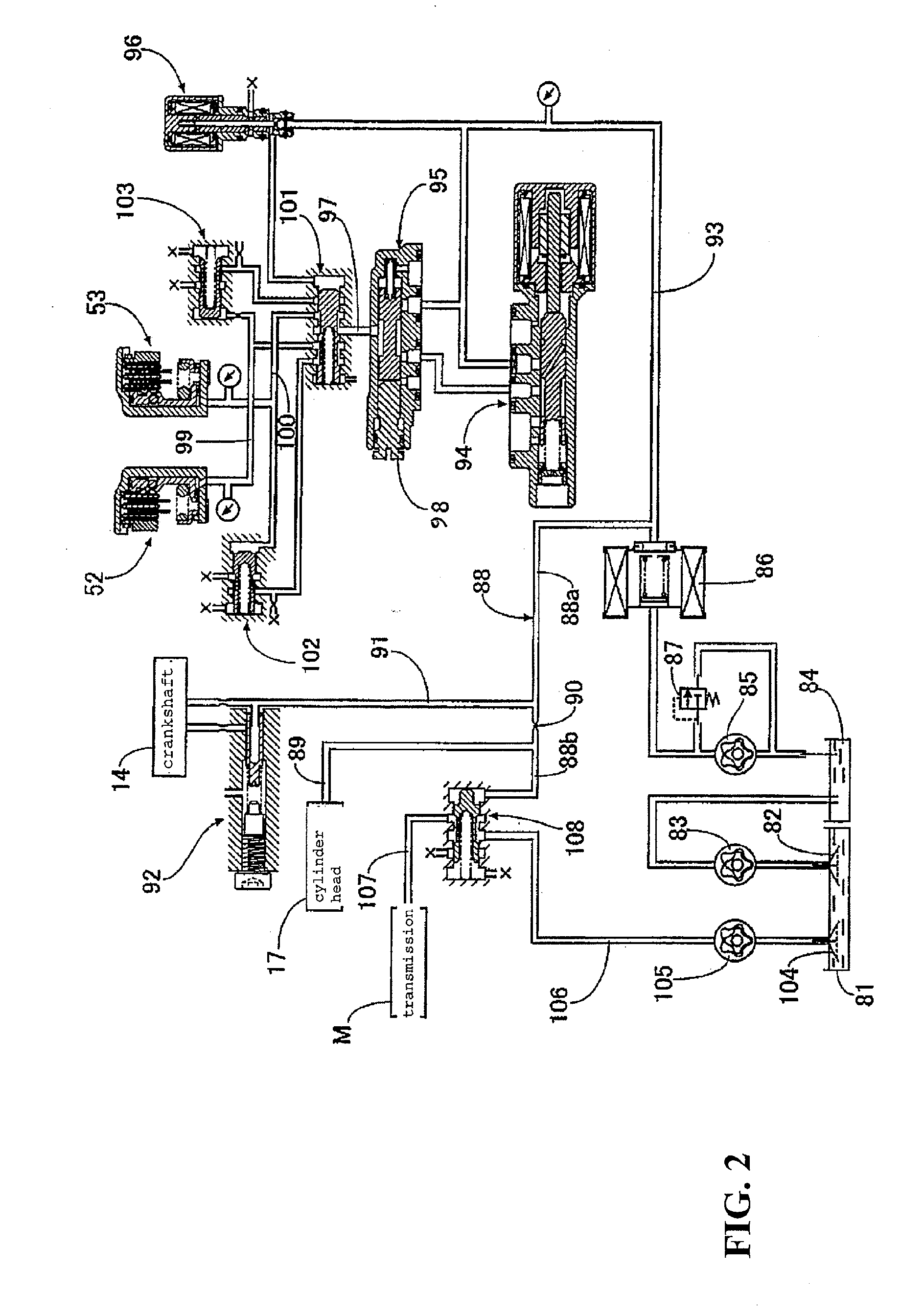

Variable cam timing unit oil supply arrangement

InactiveUS6871620B2High oil pressureIncrease flow rateValve arrangementsLubrication of auxillariesInternal combustion engineCheck valve

An internal combustion engine arrangement 7 with a variable cam timing unit pressurized oil supply arrangement 49 is provided. A first pump 44 delivers oil through a first check valve 62 to a VCT unit 83 and additionally provides oil to the engine lubrication system. A second oil pump 104 provides pressurized oil to the VCT unit 83 through a second check valve 106. An accumulator 114 is connected between the first 62 and second 106 check valves to pressurize oil delivered to the variable cam timing unit 83.

Owner:FORD GLOBAL TECH LLC

Lubricating oil supplying system for internal combustion engine

InactiveUS20060070600A1Simple processReduce stressLubrication of auxillariesEqualizing valvesControl signalExternal combustion engine

A lubricating oil supplying system for an internal combustion engine includes a lubricating oil storage section for storing lubricating oil. A driven pump is driven by the internal combustion engine to suck the lubricating oil from the lubricating oil storage section and discharge the lubricating oil to a discharge passage. An electric pump is provided for sucking the lubricating oil discharged from the driven pump to the discharge passage and discharge the lubricating oil to a lubricating oil requiring section in the internal combustion engine. A controlling mechanism is provided for drivingly controlling the electric pump in accordance with a control signal. A bypass passage is provided for bypassing the driven pump. A check valve is disposed in the bypass passage to allow the lubricating oil in the lubricating oil storage section to flow only through a path bypassing said driven pump and toward side of the discharge passage.

Owner:HITACHI LTD

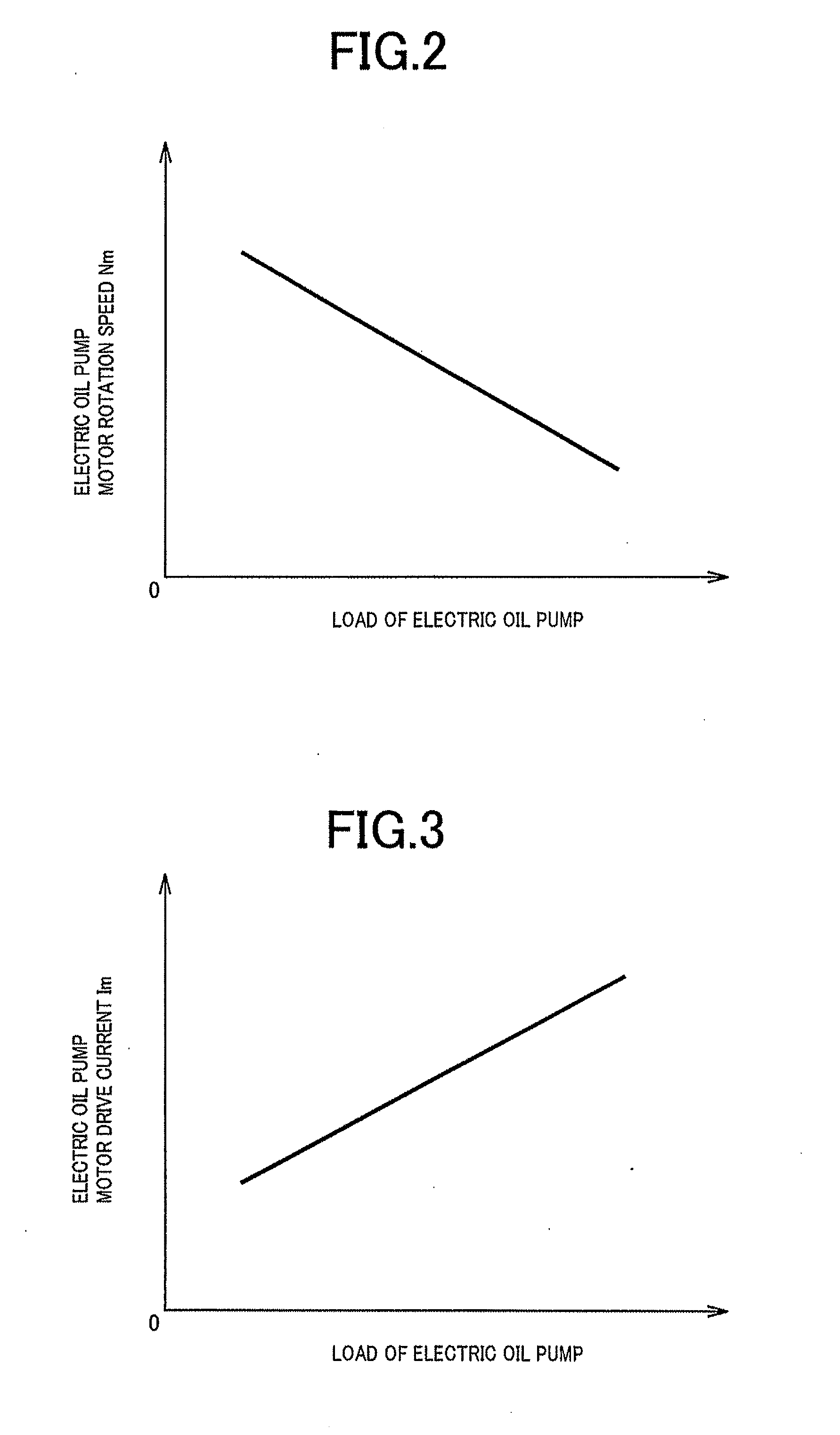

Control device of vehicle oil supply device

InactiveUS20130319366A1Improve fuel efficiencyWasteful operation of the electric oil pump is reducedLubrication of auxillariesGearing controlCheck valveOil pressure

A control device has a mechanical oil pump driven by an engine and an electric oil pump supplying oil via a check valve in an oil passage connecting the mechanical oil pump and the electric oil pump, the check valve allowing a flow of the oil from the electric oil pump side to the mechanical oil pump side while blocking a flow in an opposite direction, regardless of the pressure of the electric oil pump. When the check valve is closed under an oil pressure condition in which the electric oil pump outputs a maximum output oil pressure while the mechanical oil pump is driven by the engine at idle, the control device is configured to drive the electric oil pump during stop of the mechanical oil pump, and to stop the electric oil pump based on a load increase after start of the mechanical oil pump.

Owner:TOYOTA JIDOSHA KK

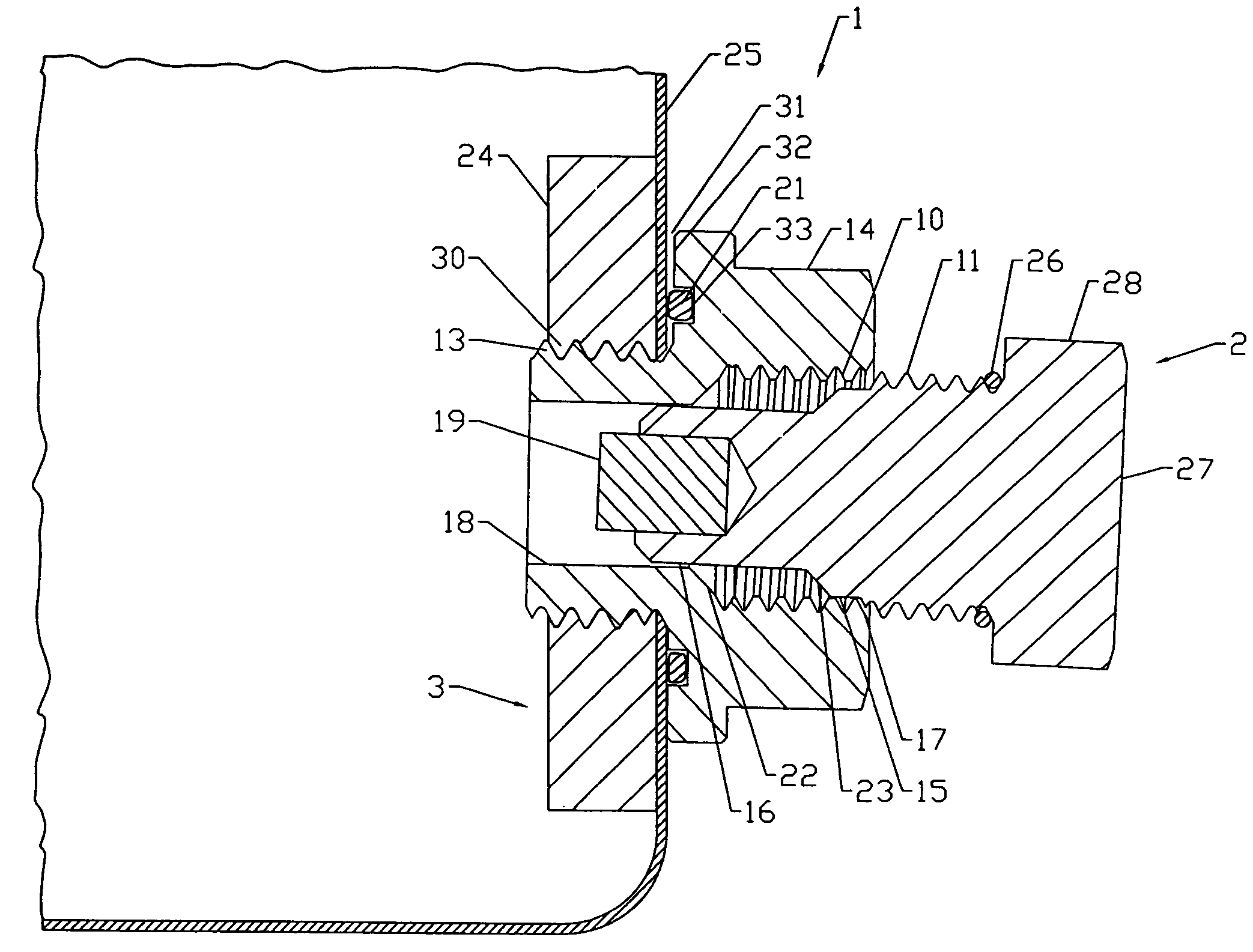

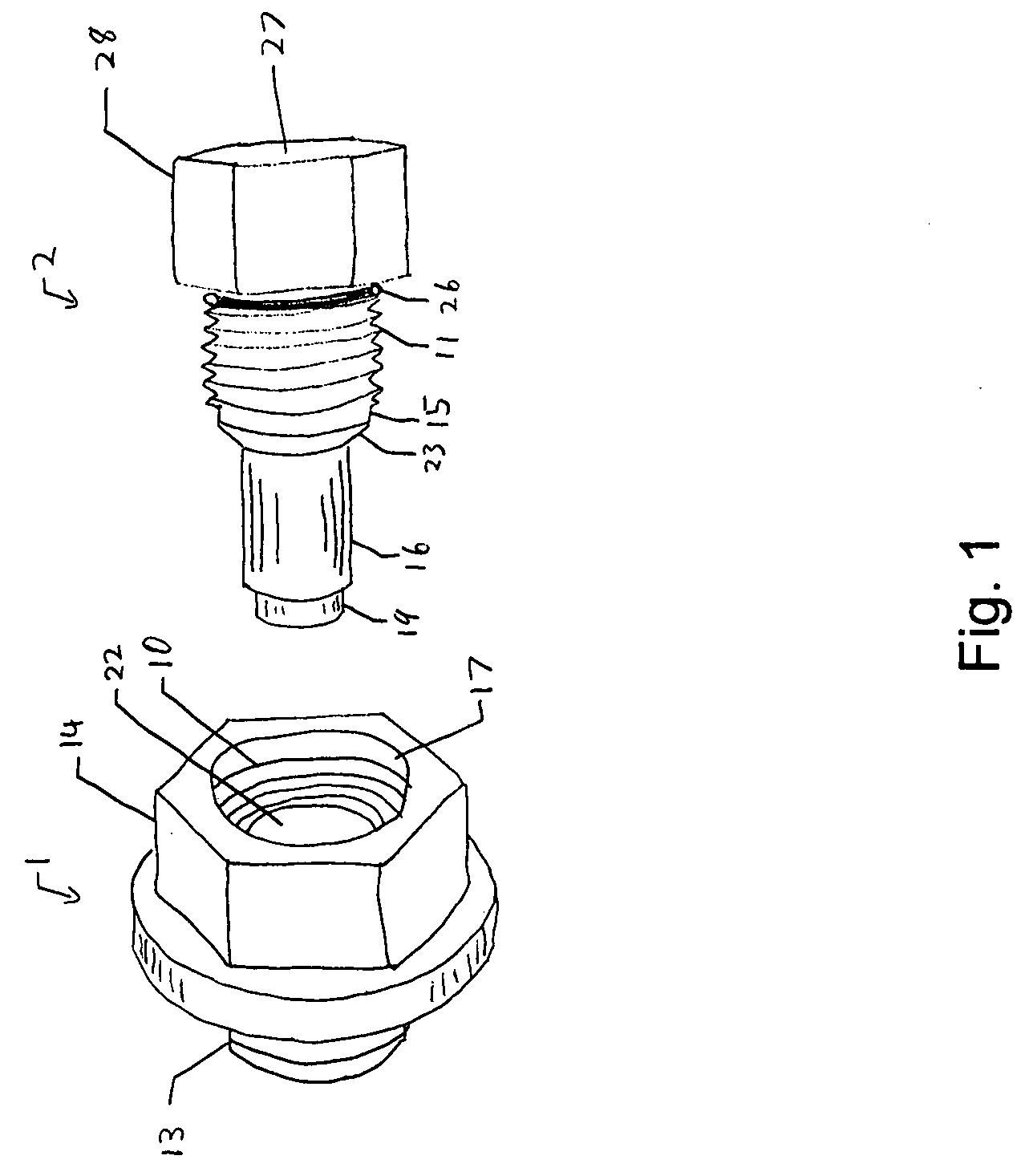

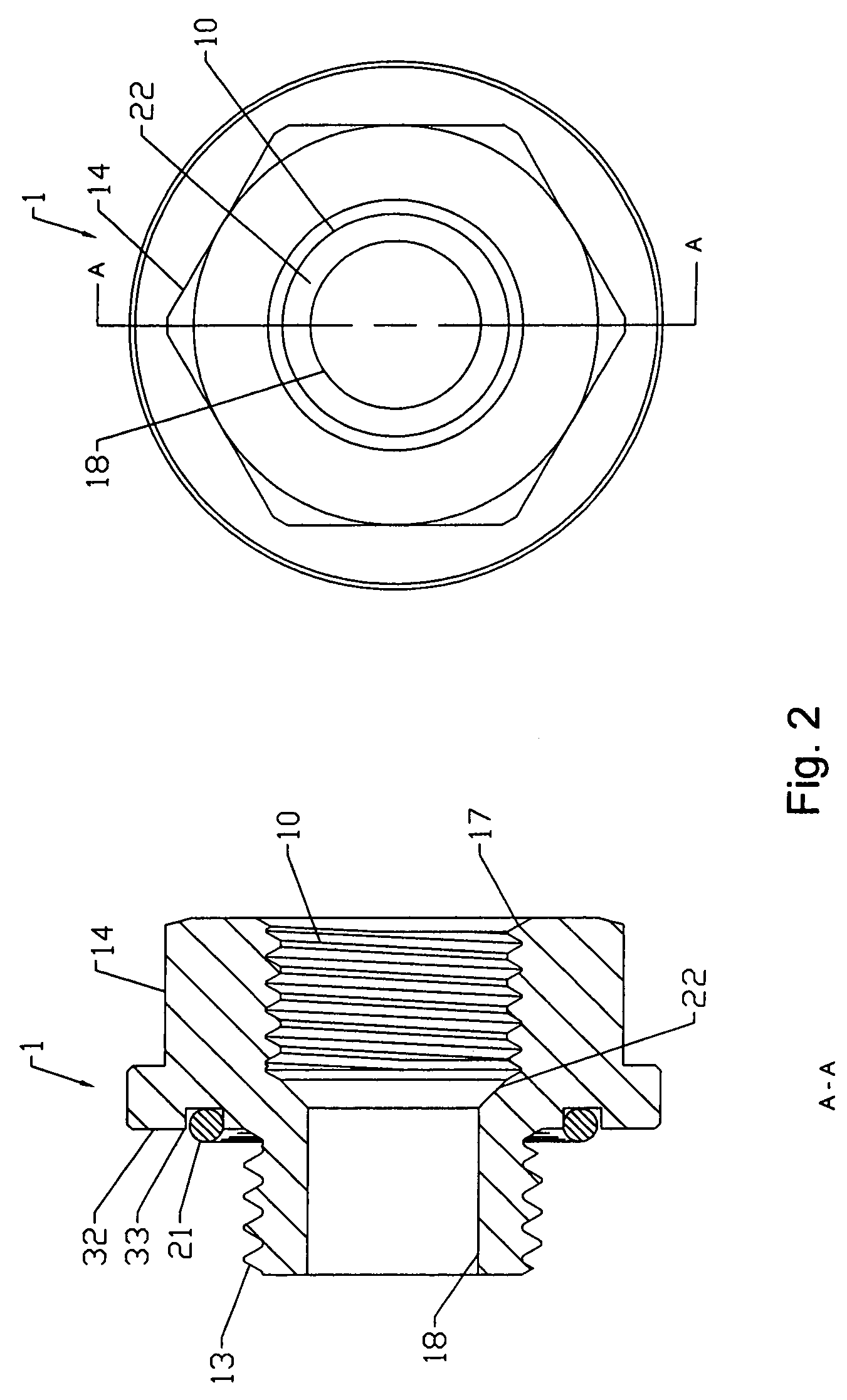

Two part oil or fluid drain plug with magnet

A two part oil drain plug assembly facilitates the draining of oil or fluid from a sump, and its use prevents the threads of the sump, which may be an automotive oil pan, from becoming stripped or damaged. Further, the device aids in the determination of the physical condition (wear) of the engine, transmission or the like to which the sump is attached, by attracting metal particles to an isolated magnet on the drain plug.

Owner:DORIAN GEORGE P

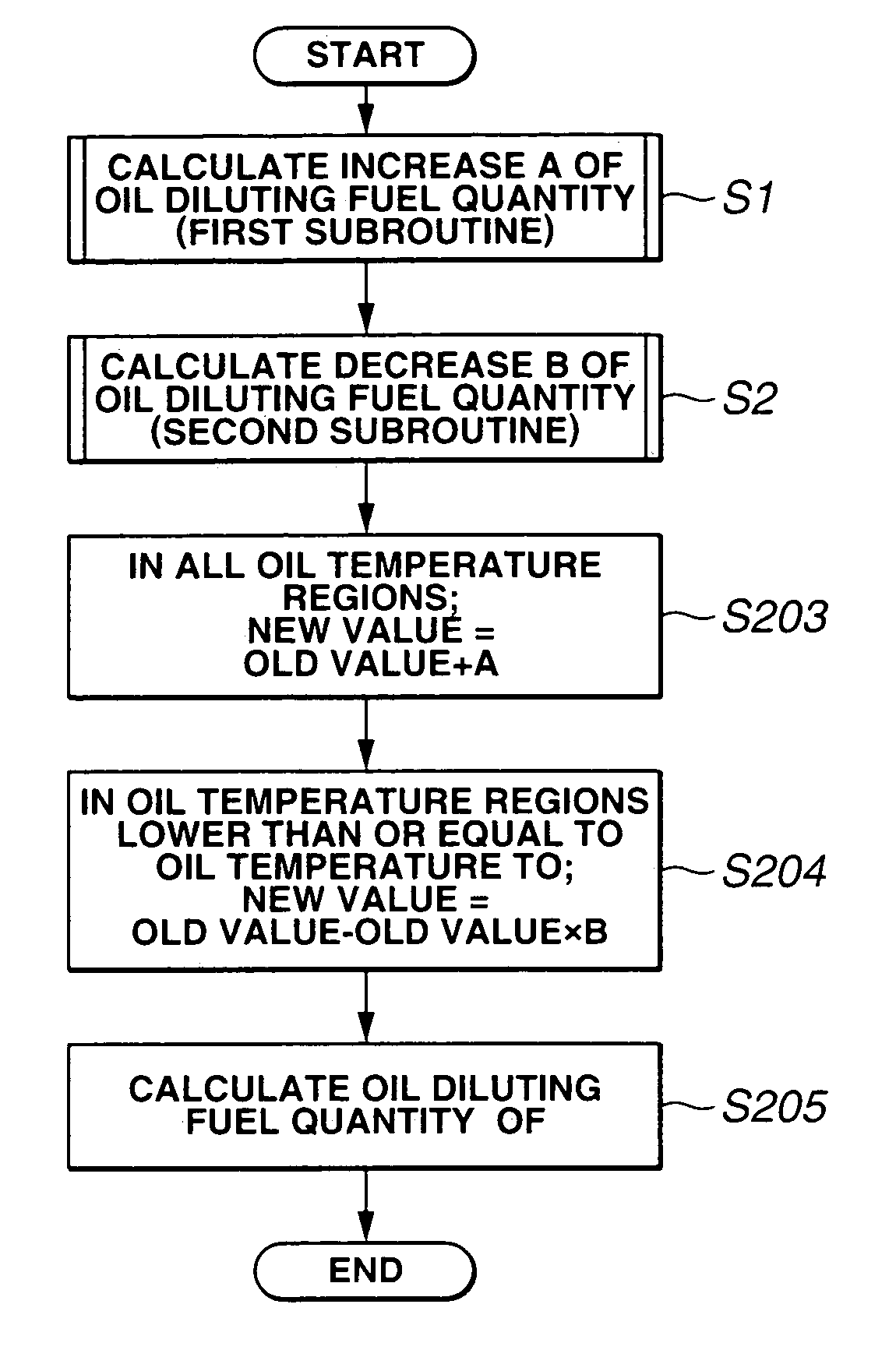

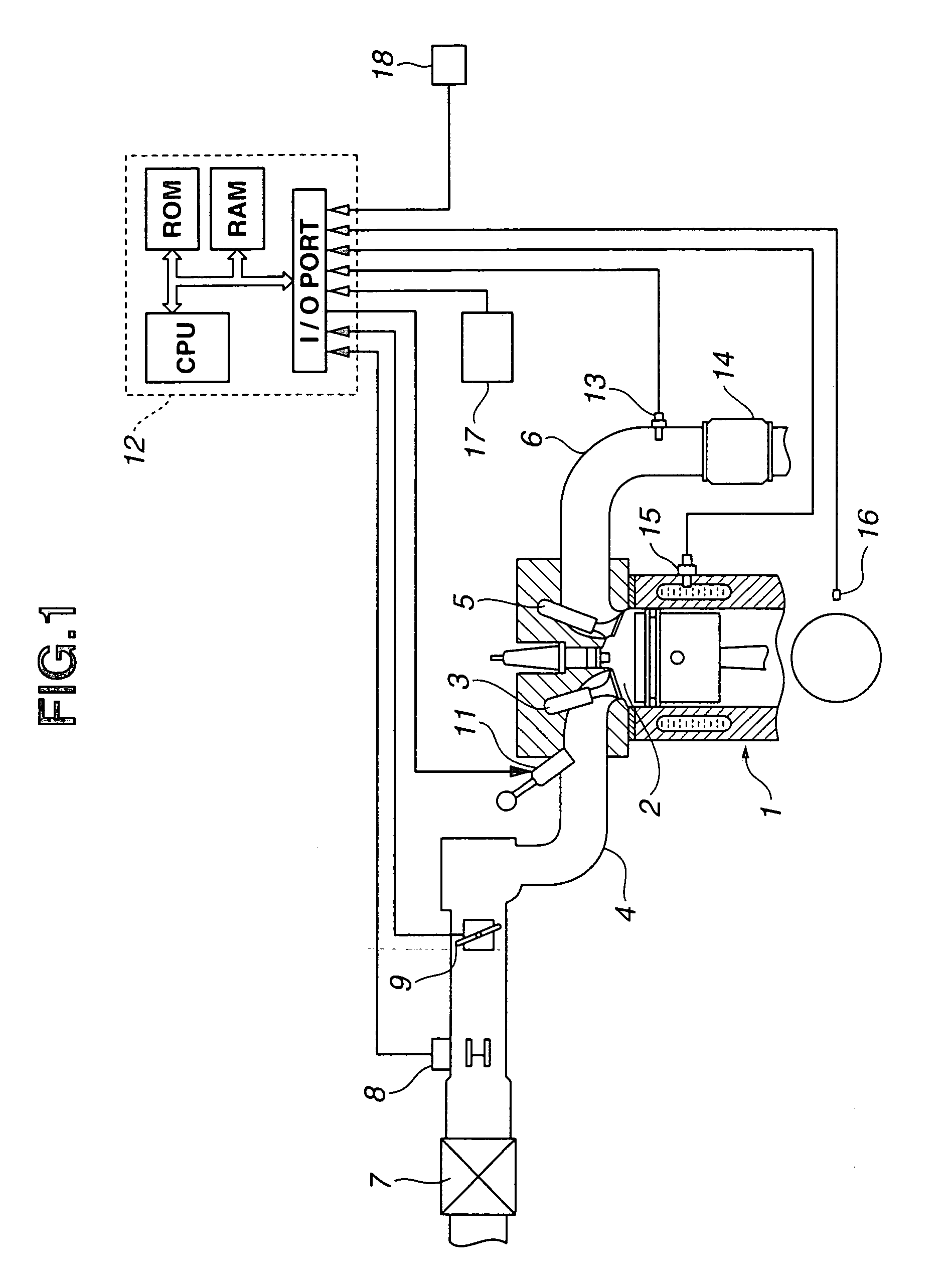

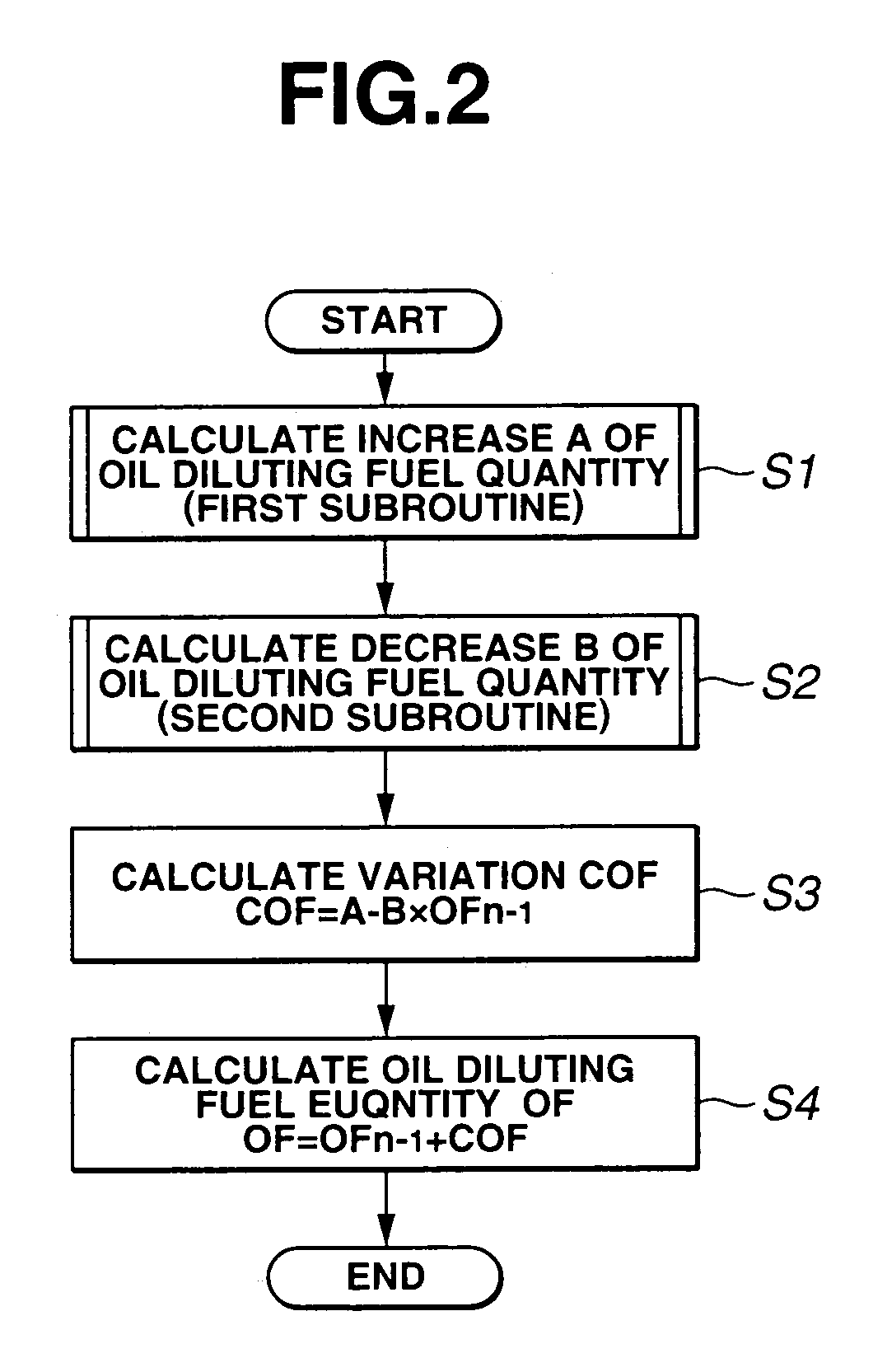

Estimation of oil-diluting fuel quantity of engine

ActiveUS6966304B2Accurate estimateElectrical controlLubrication of auxillariesEngineeringInternal combustion engine

Apparatus for an internal combustion engine includes an estimating or controlling unit to determine an oil-diluting fuel quantity of an engine oil-diluting fuel which is fuel leaking out through a clearance between a piston and a cylinder of the engine and diluting an engine oil. The unit calculates a variation of the engine oil-diluting fuel quantity, and determines the oil-diluting fuel quantity in accordance with the variation.

Owner:NISSAN MOTOR CO LTD

Valve operating mechanism of internal combustion engine

Owner:HITACHI LTD

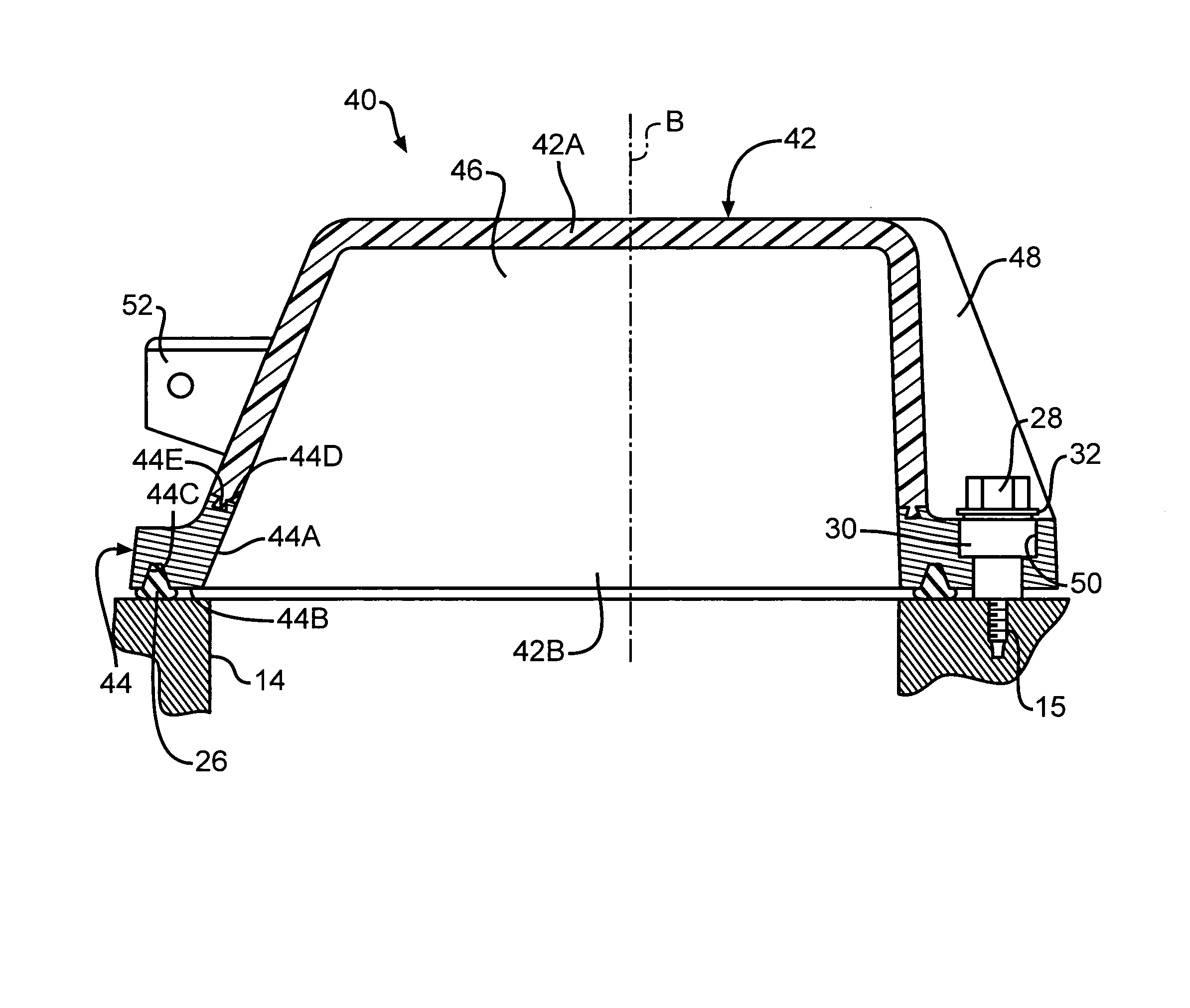

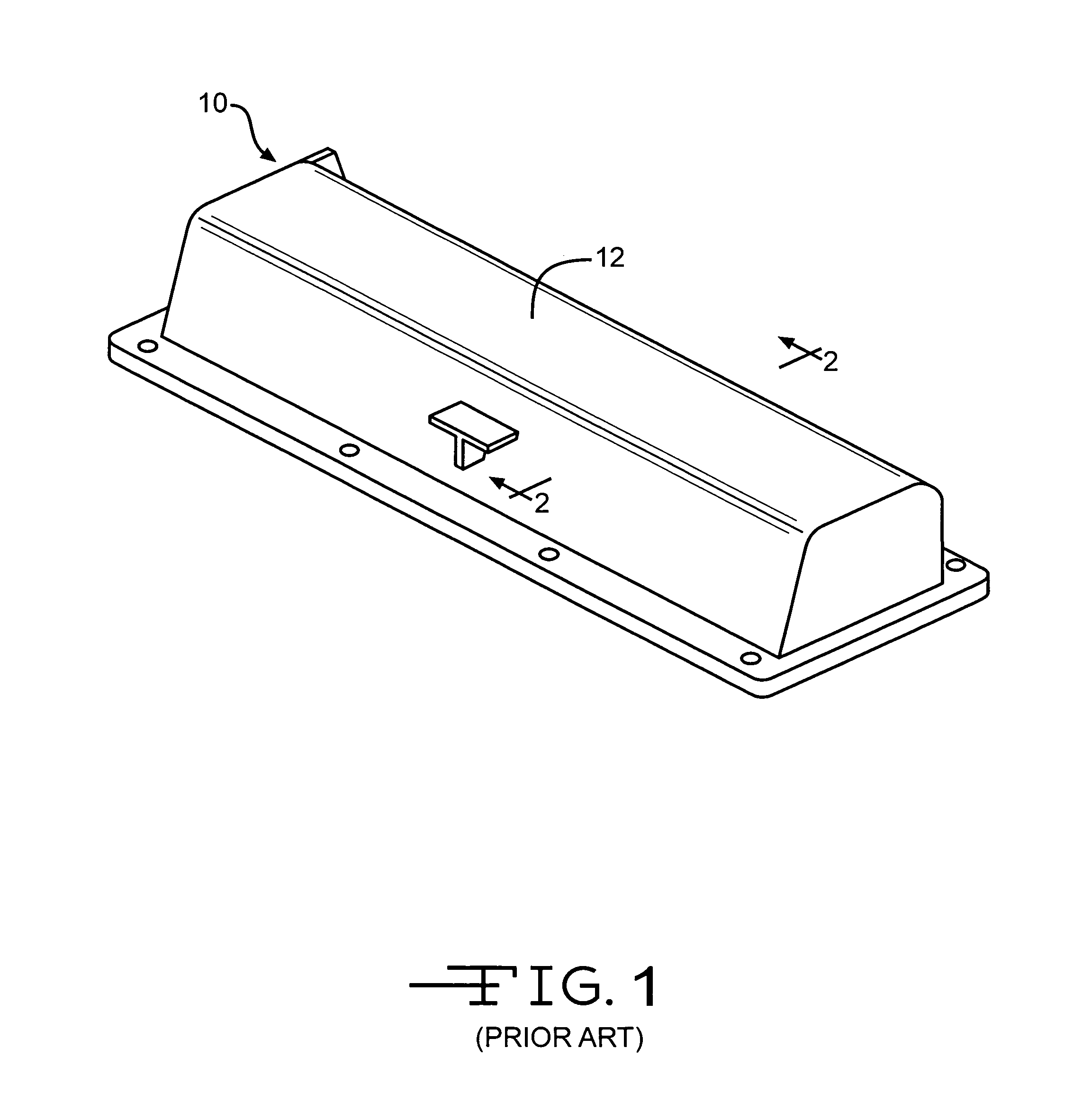

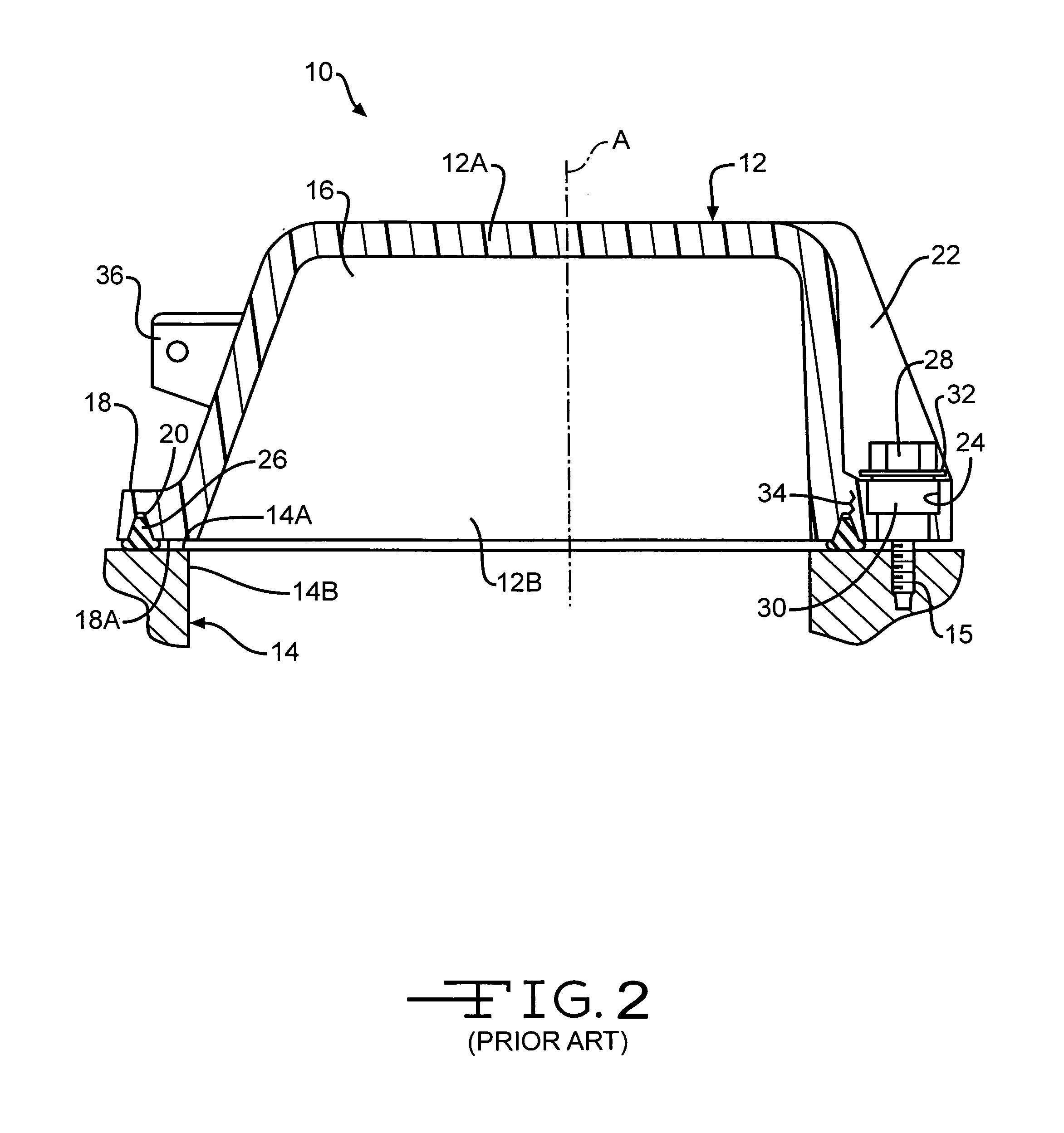

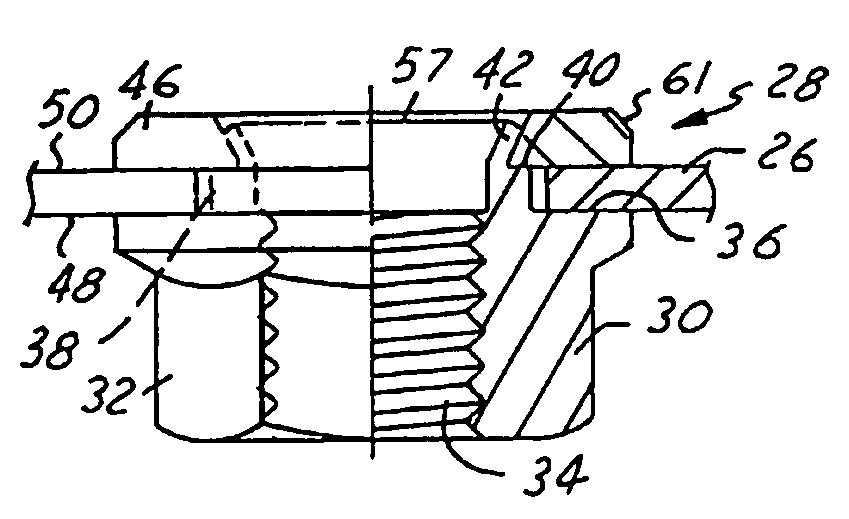

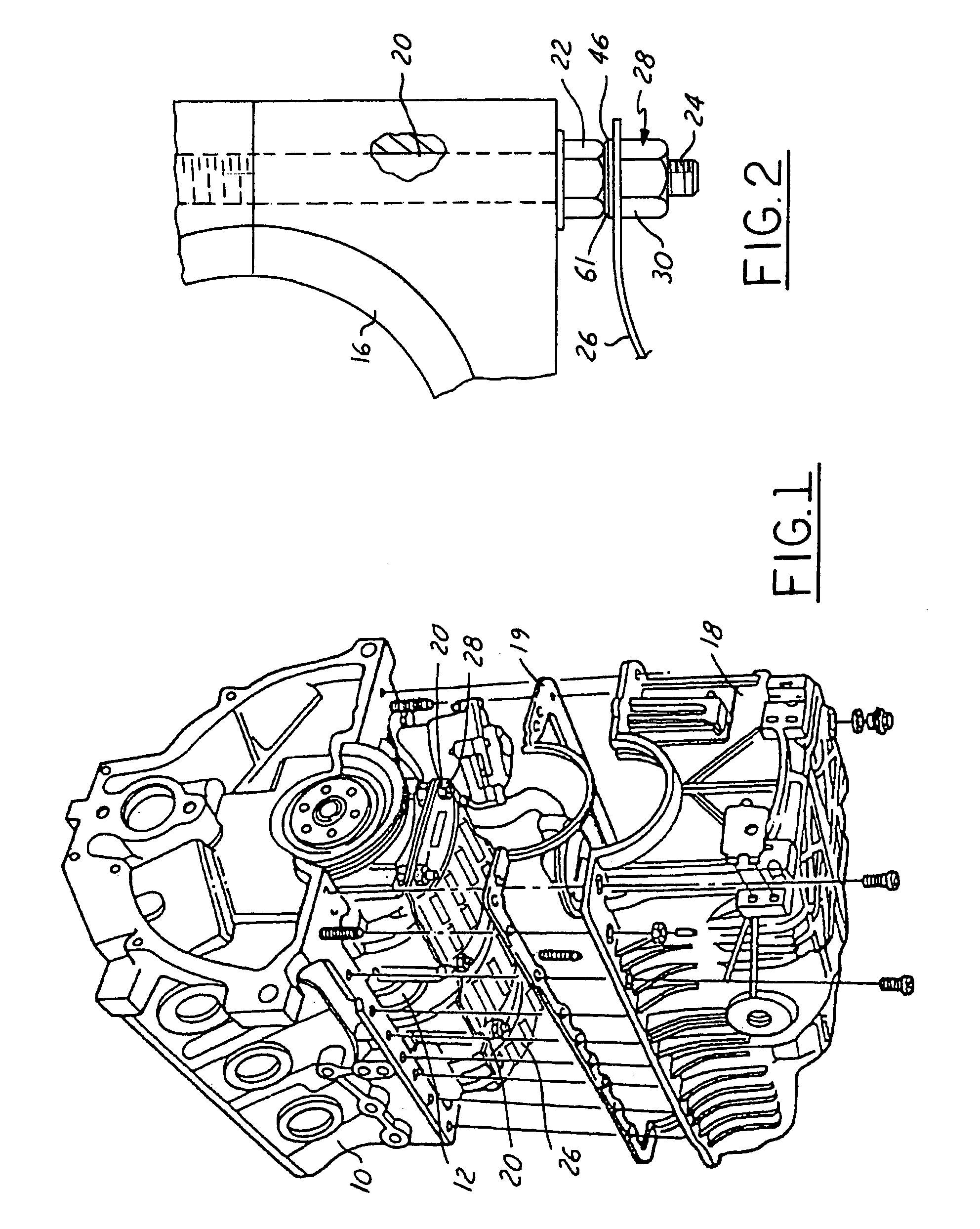

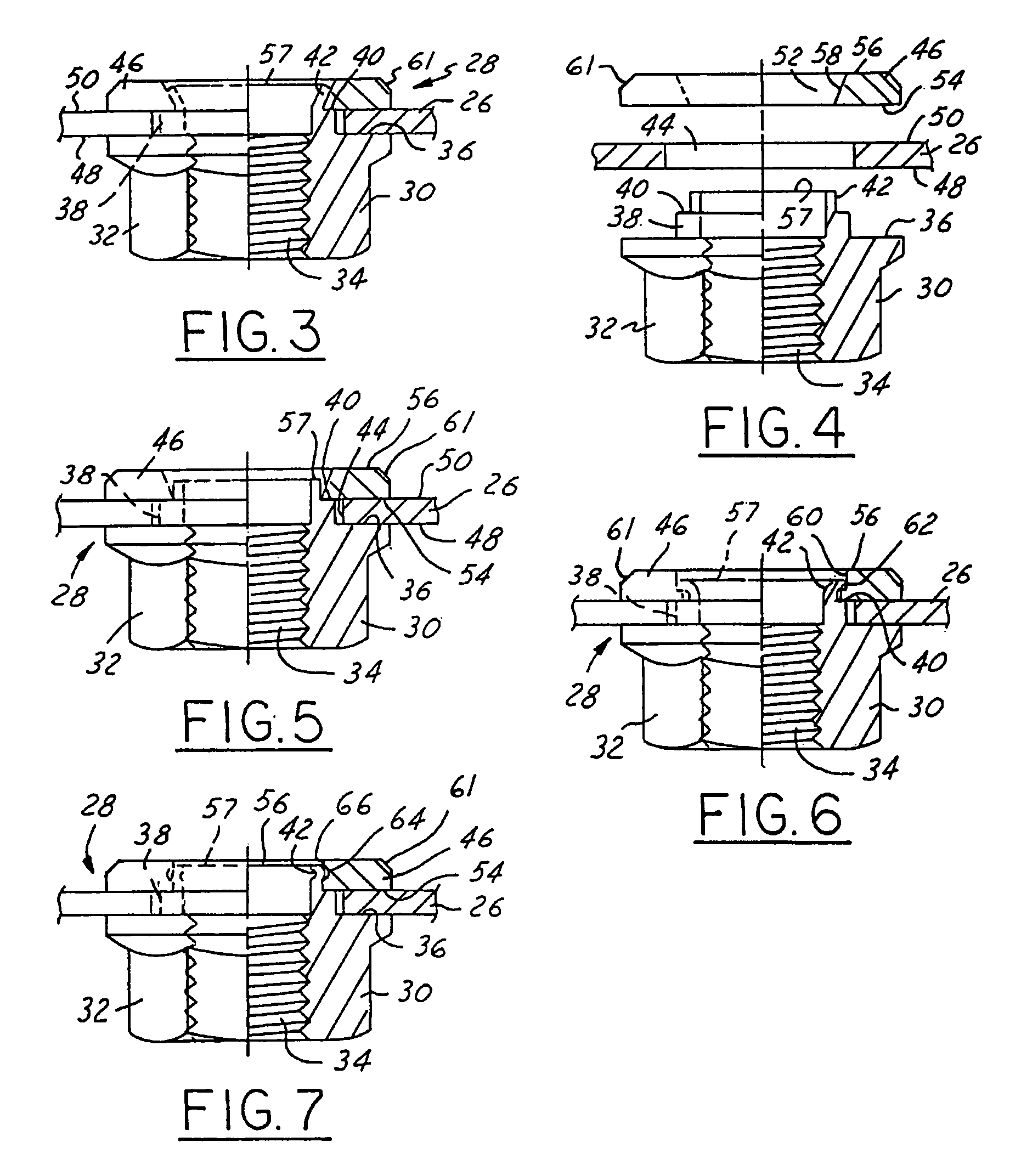

Windage tray with improved captured nut

InactiveUS6932044B1Accurately obtainedAccurately retainingCasingsLubrication of auxillariesEngineeringInternal combustion engine

A windage tray (26) has a captured nut (30) mounted to a retaining washer (46) through a central aperture (52) that has a tapered interior wall (58) which wholly retains a collar (42) of the captured nut for mounting the tray onto an internal combustion engine (10).

Owner:GENERAL FASTENERS

Oil return structure for internal combustion engine

InactiveUS20080011264A1Prevent buildupAvoid sludgeLubrication of auxillariesCombustion enginesFuel tankCrankcase

An oil pan is provided below a crankcase of an engine. The oil pan has an oil reservoir in its upper case. An oil discharge pipe is located within the oil reservoir, the oil discharge pipe extending from an oil separator of a PCV system. The oil reservoir protrudes inward of an inner wall surface of a lower case. The oil reservoir has an oil drain hole on a bottom surface at its inwardly protruding portion. The oil reservoir communicates with a lower chamber through the oil drain hole.

Owner:TOYOTA JIDOSHA KK

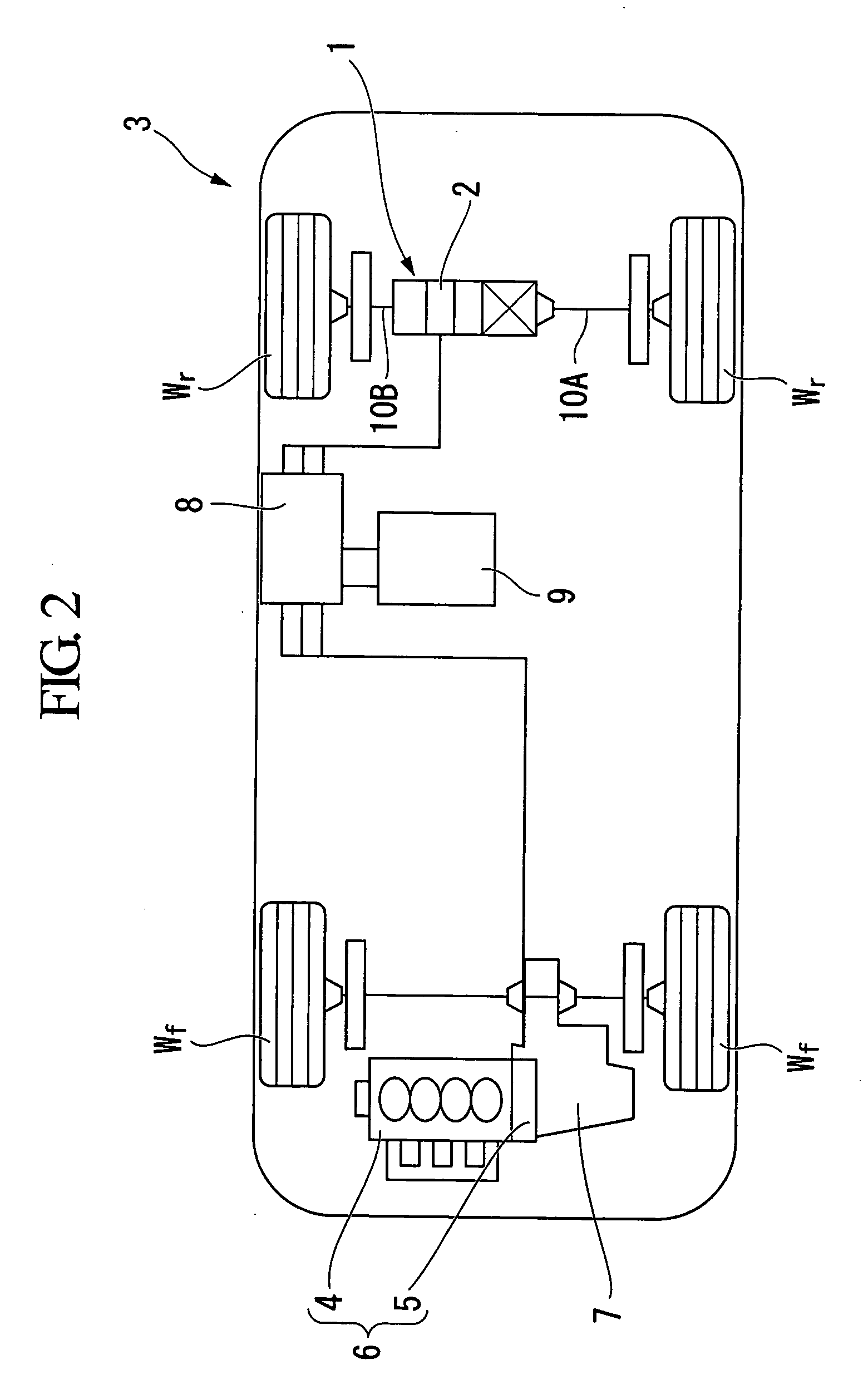

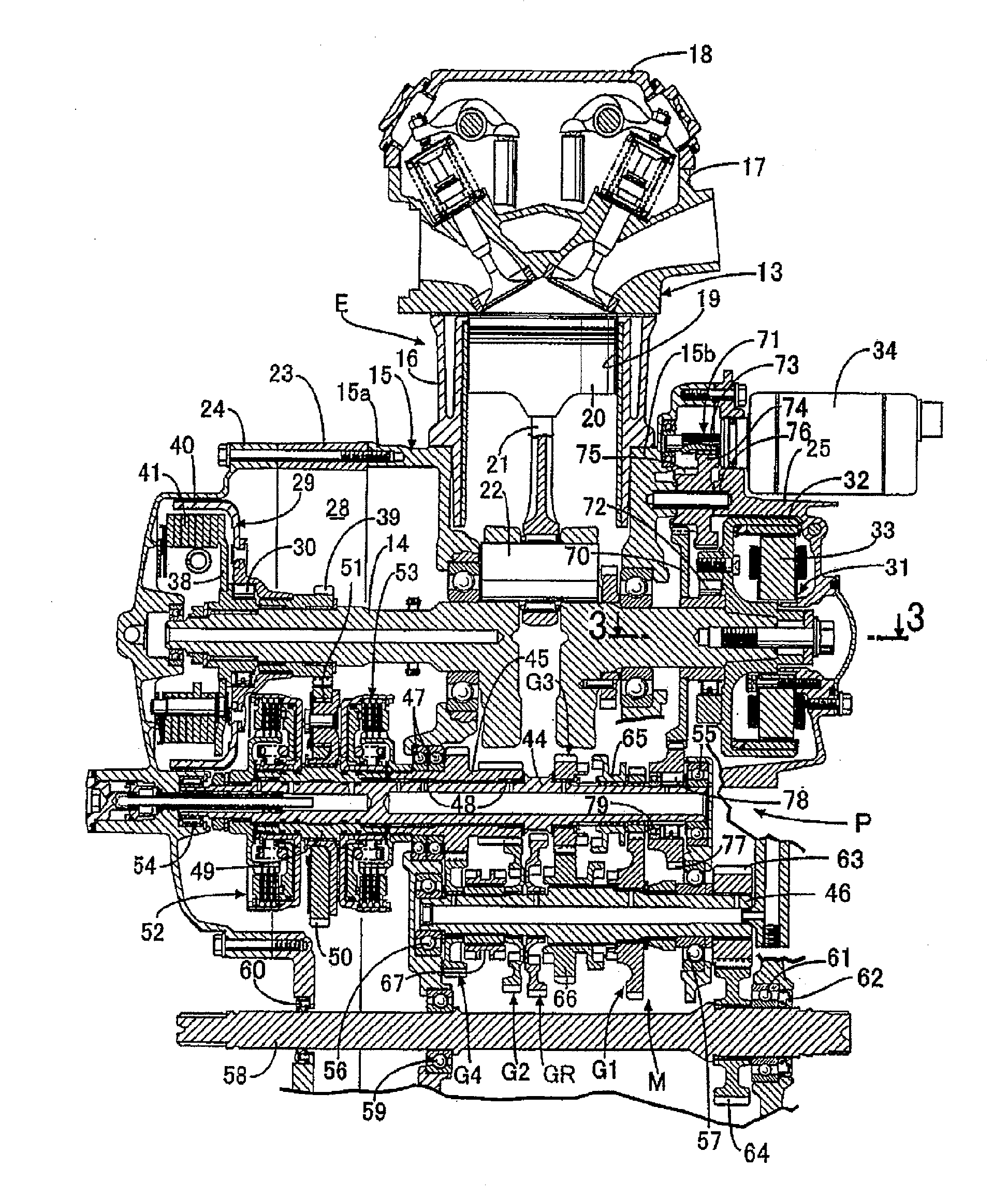

Lubrication structure for hybrid type vehicle power unit

InactiveUS20100229824A1Reduce the number of partsLow costHybrid vehiclesPower operated startersHybrid typeTorque transmission

In a hybrid type vehicle power unit including a first oil pump interlockingly connected to a crankshaft so as to supply at least a lubricating oil to an engine and a transmission, and a second oil pump for supplying the lubricating oil to the transmission, it is not necessary for an electric motor to be exclusively used for the second oil pump. Thus, a reduction in the number of component parts and a reduction in the cost of manufacturing are achieved. The second oil pump is interlockingly connected to an electric motor capable of transmitting a driving torque to an output shaft through the transmission.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com