Patents

Literature

35results about How to "Accurate radial positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hammer

InactiveUS6913089B2Reduce in quantityEfficient designConstructionsReciprocating drilling machinesCirclipMechanical engineering

Owner:BLACK & DECKER INC

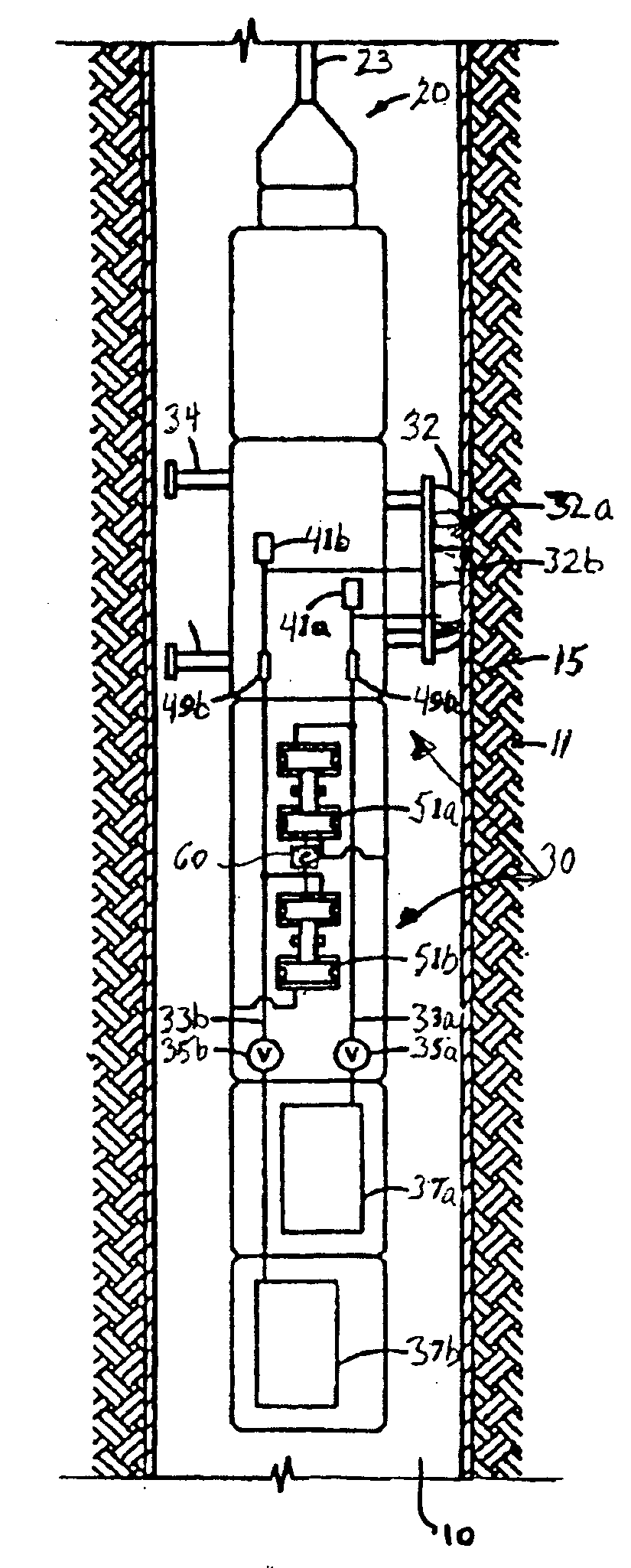

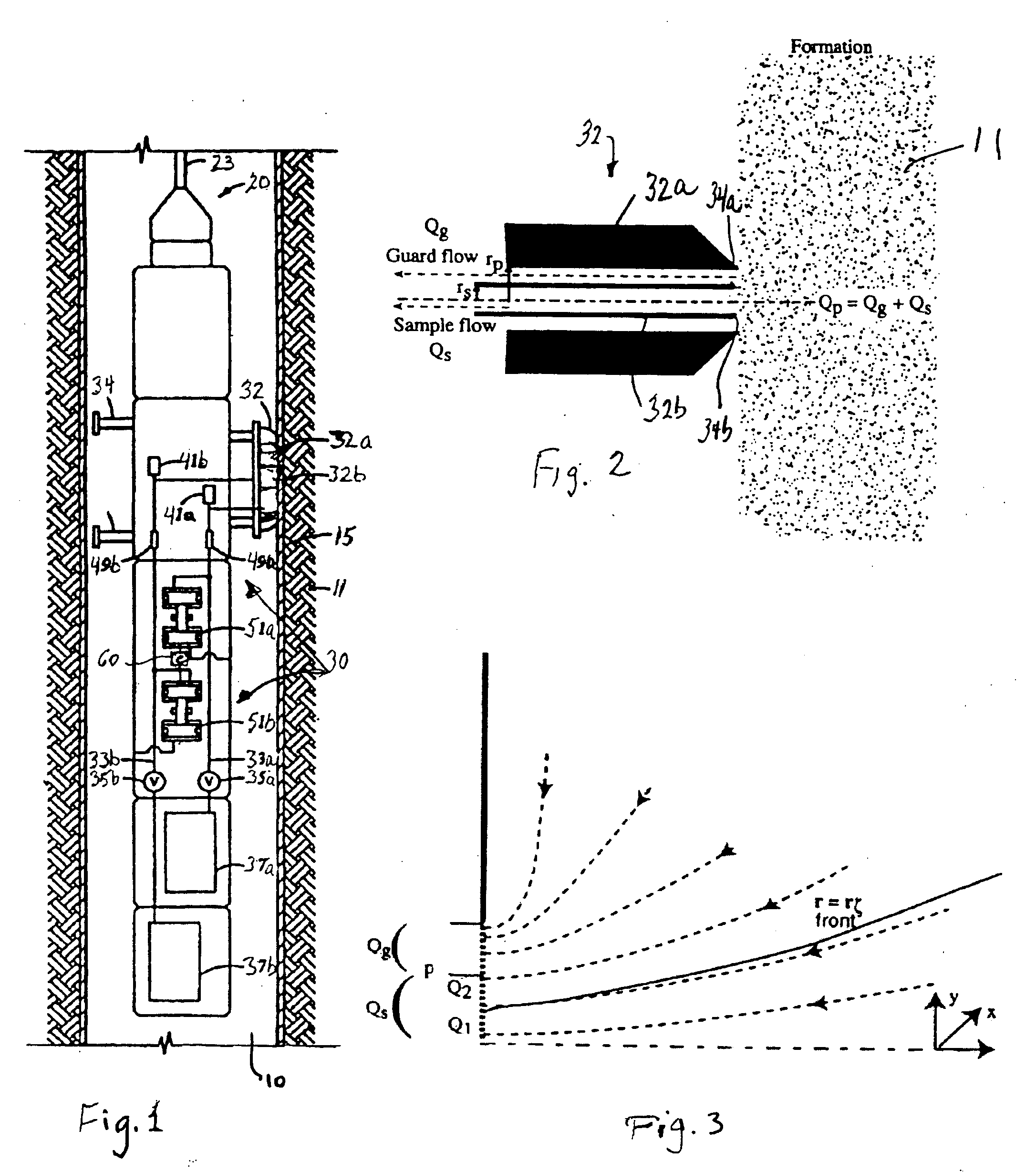

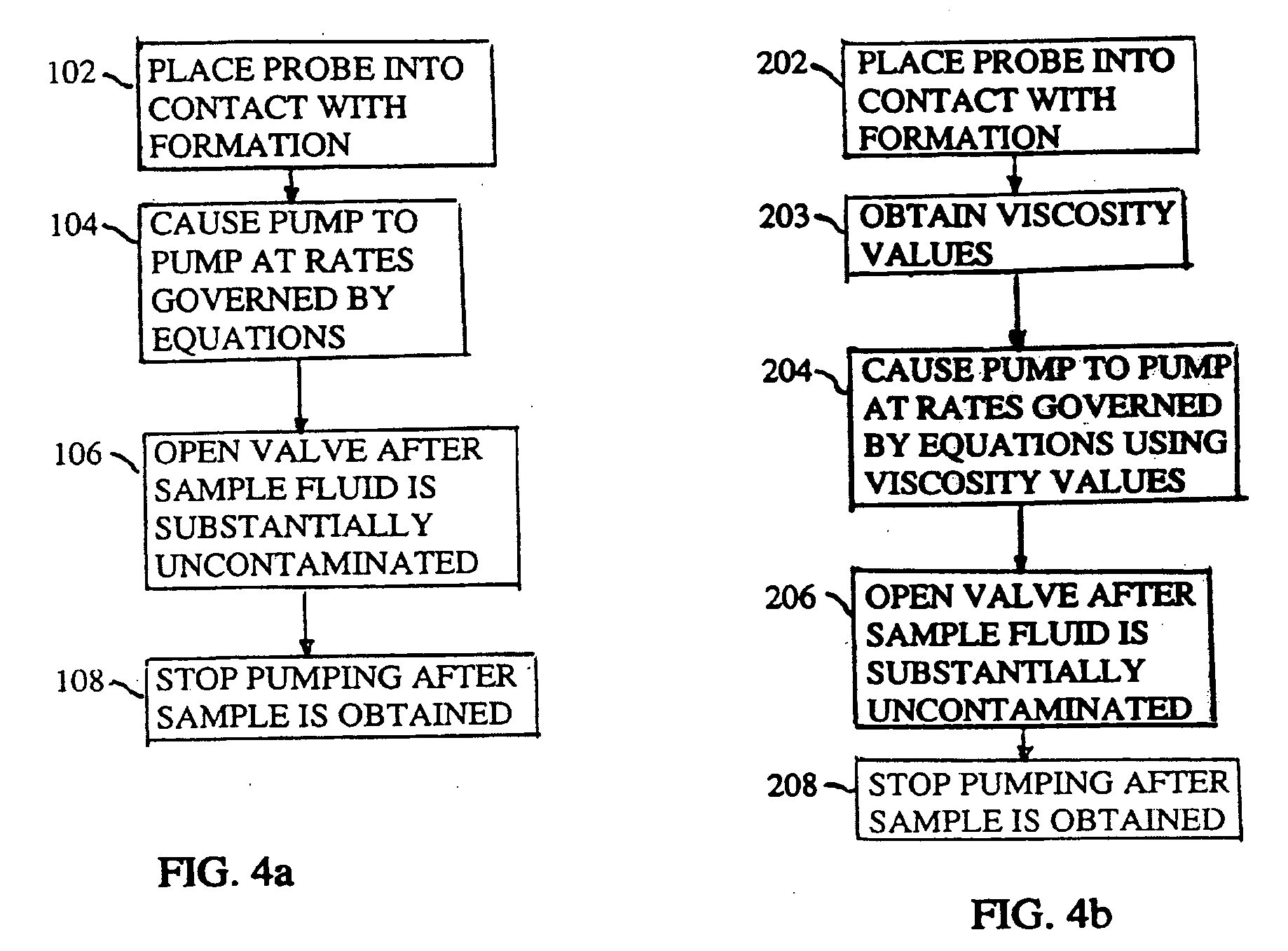

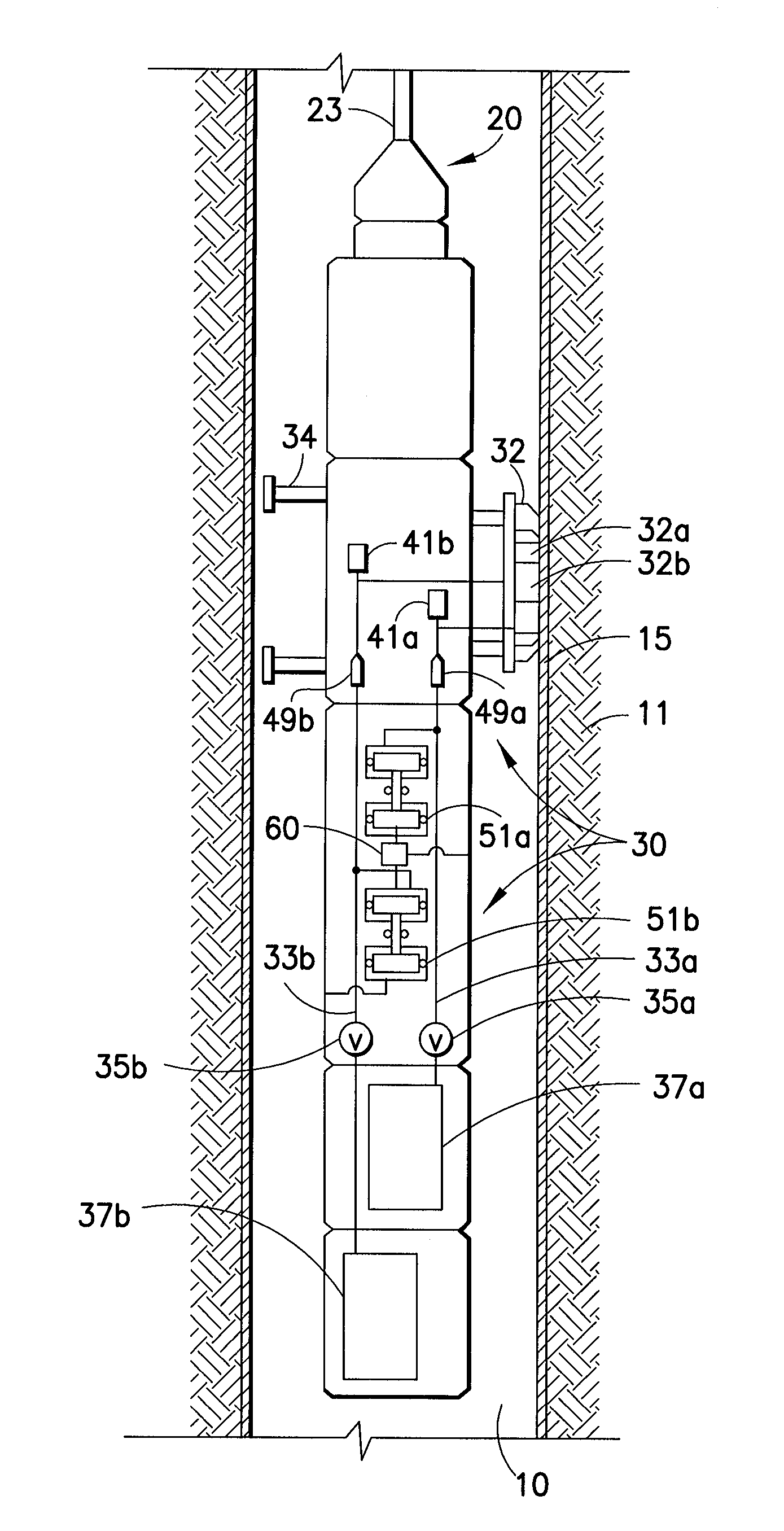

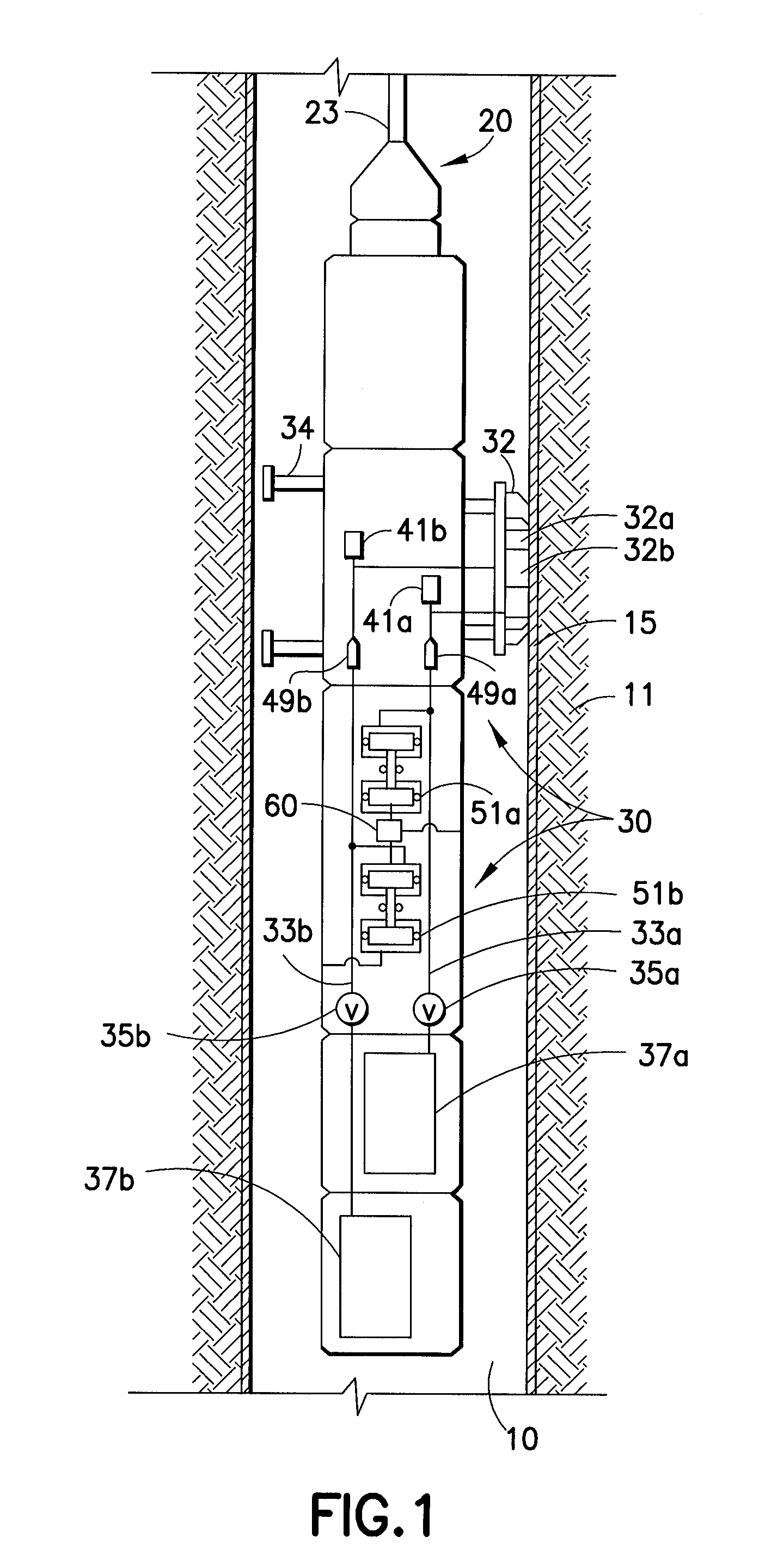

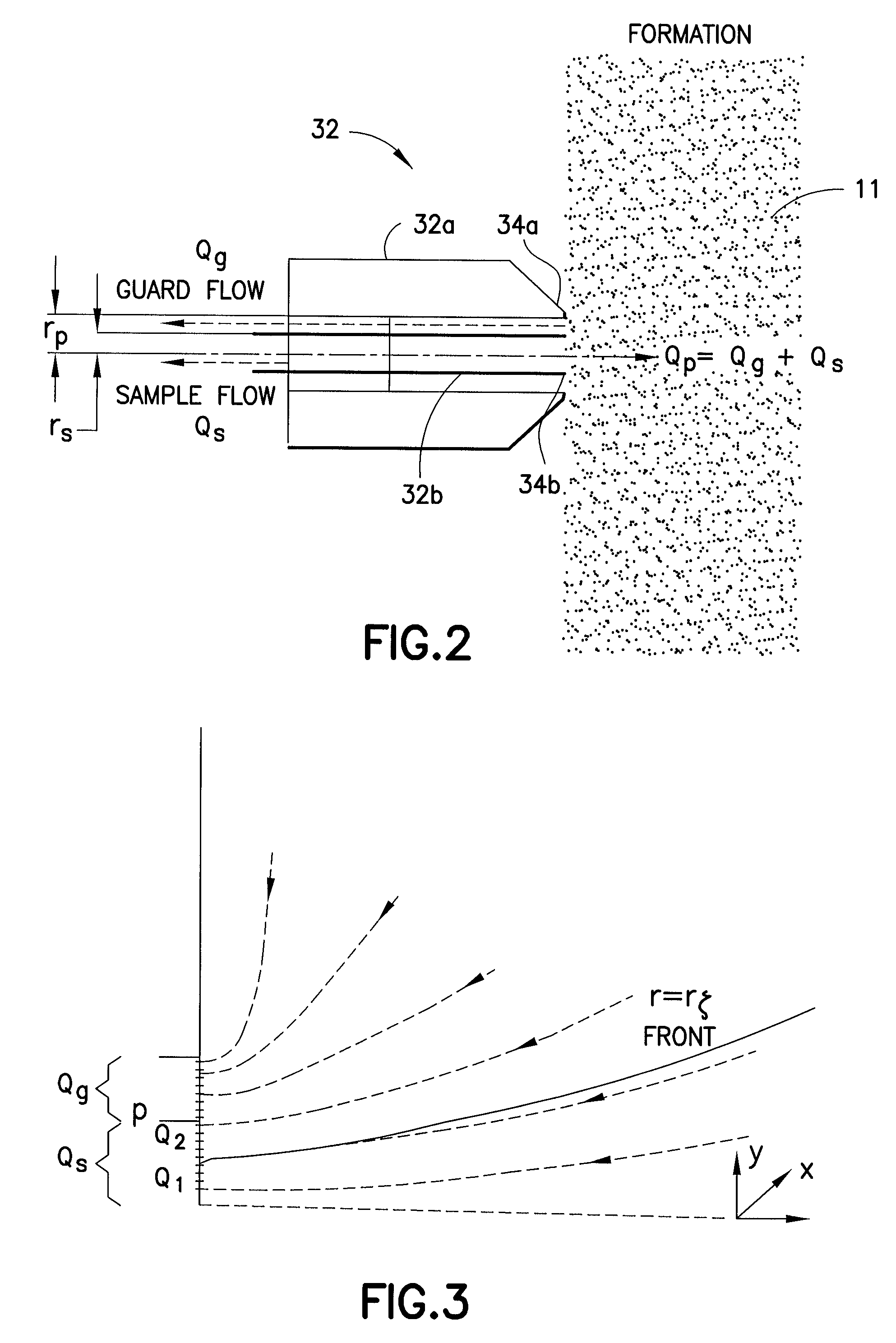

Single probe downhole sampling apparatus and method

A single probe system is utilized to quickly obtain uncontaminated formation fluid samples. The single probe includes an outer guard tube and an inner sampling tube which is slightly recessed relative to the outer tube such that the pressure at the front face of the probe is substantially uniform. Each tube is coupled to its own pump which controls the flow rate of the fluid moving through that tube. Knowing the size of the sampling tube relative to the size of the outer probe tube, and optionally based on relative viscosities of formation fluids and filtrates, the pumps are caused to generate a particular flow rate ratio through the tubes such that an appropriate pressure is maintained at the front face of the probe and such that the fluid flowing through the sampling tube is substantially uncontaminated.

Owner:SCHLUMBERGER TECH CORP

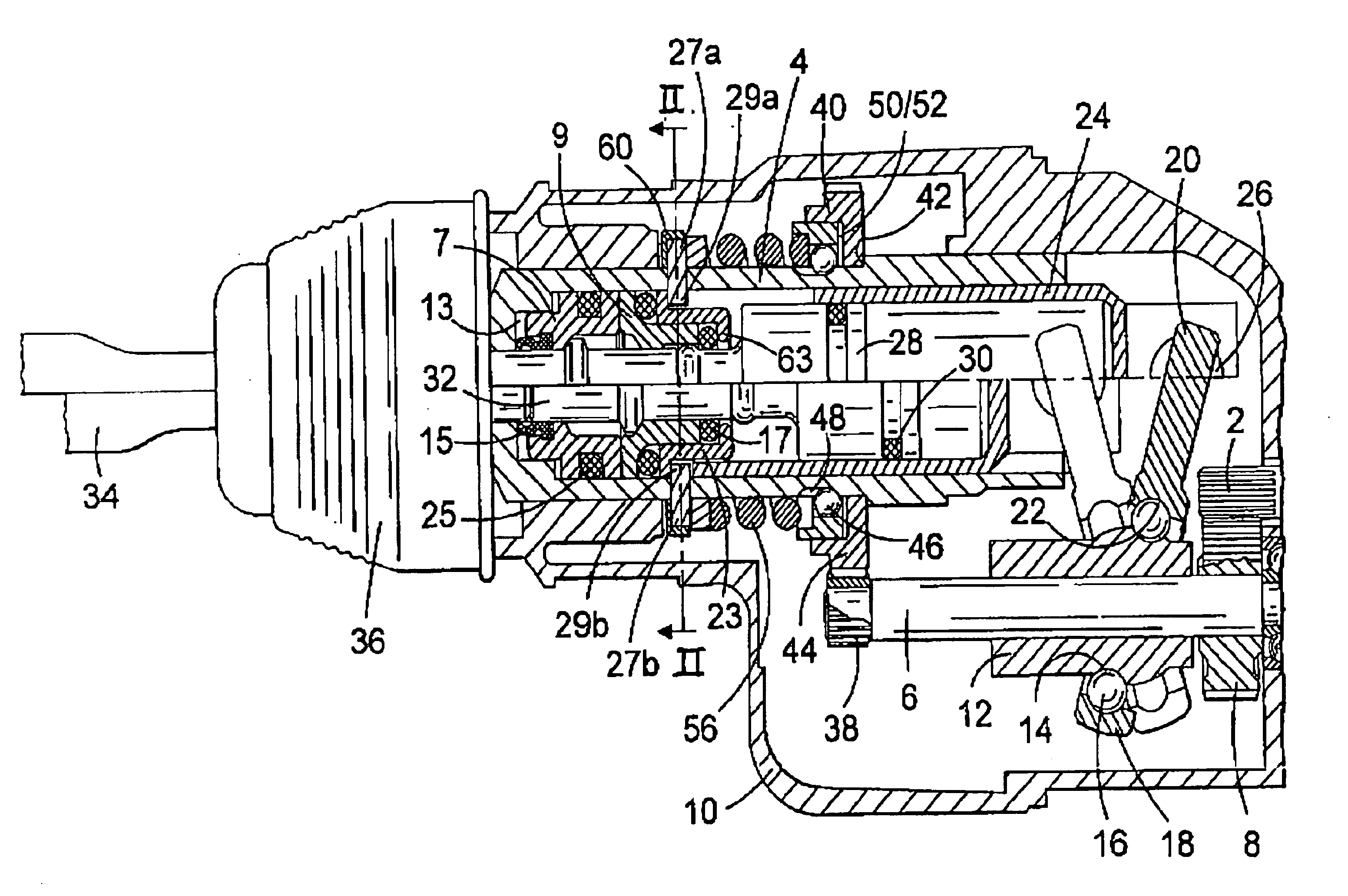

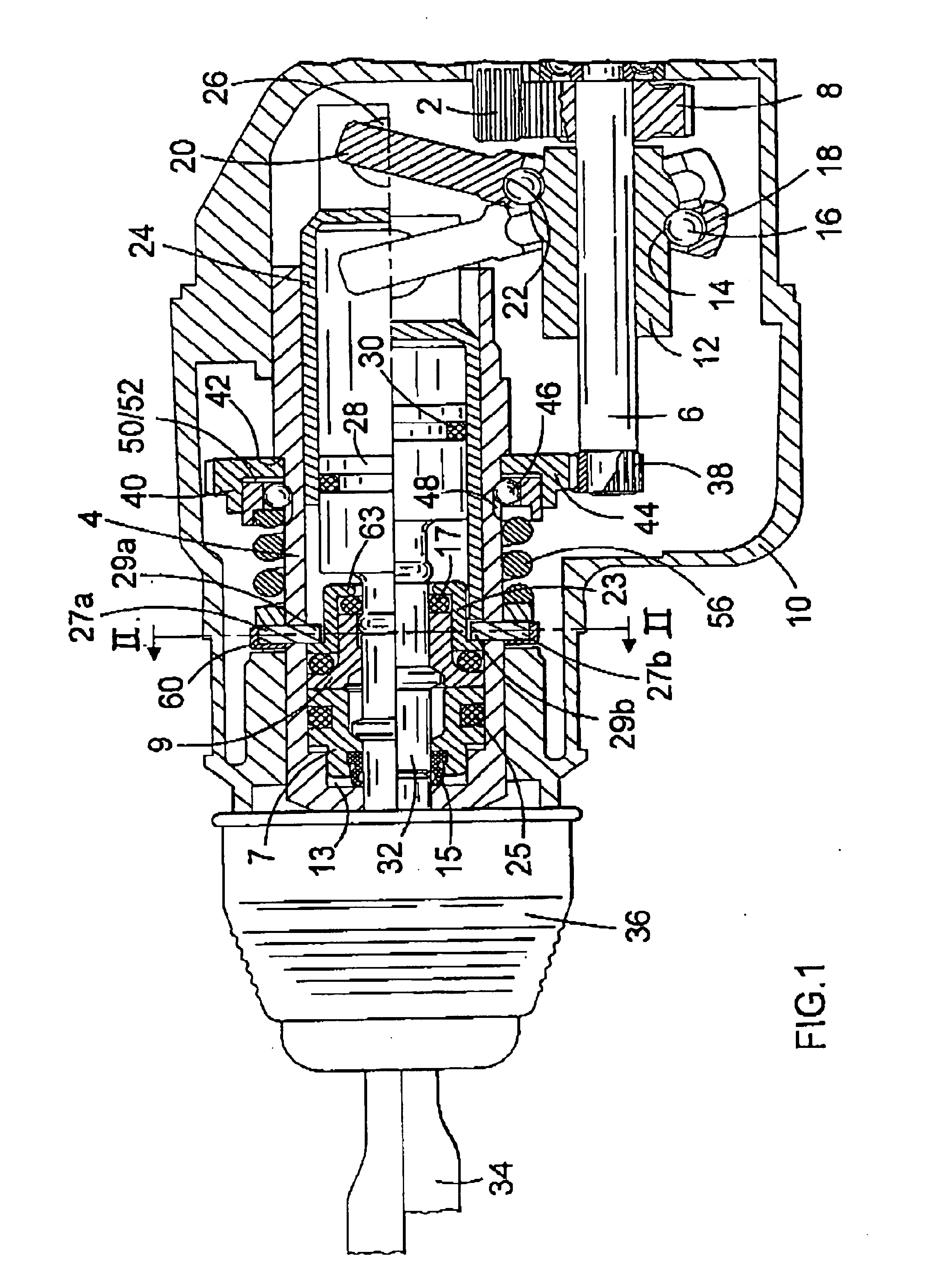

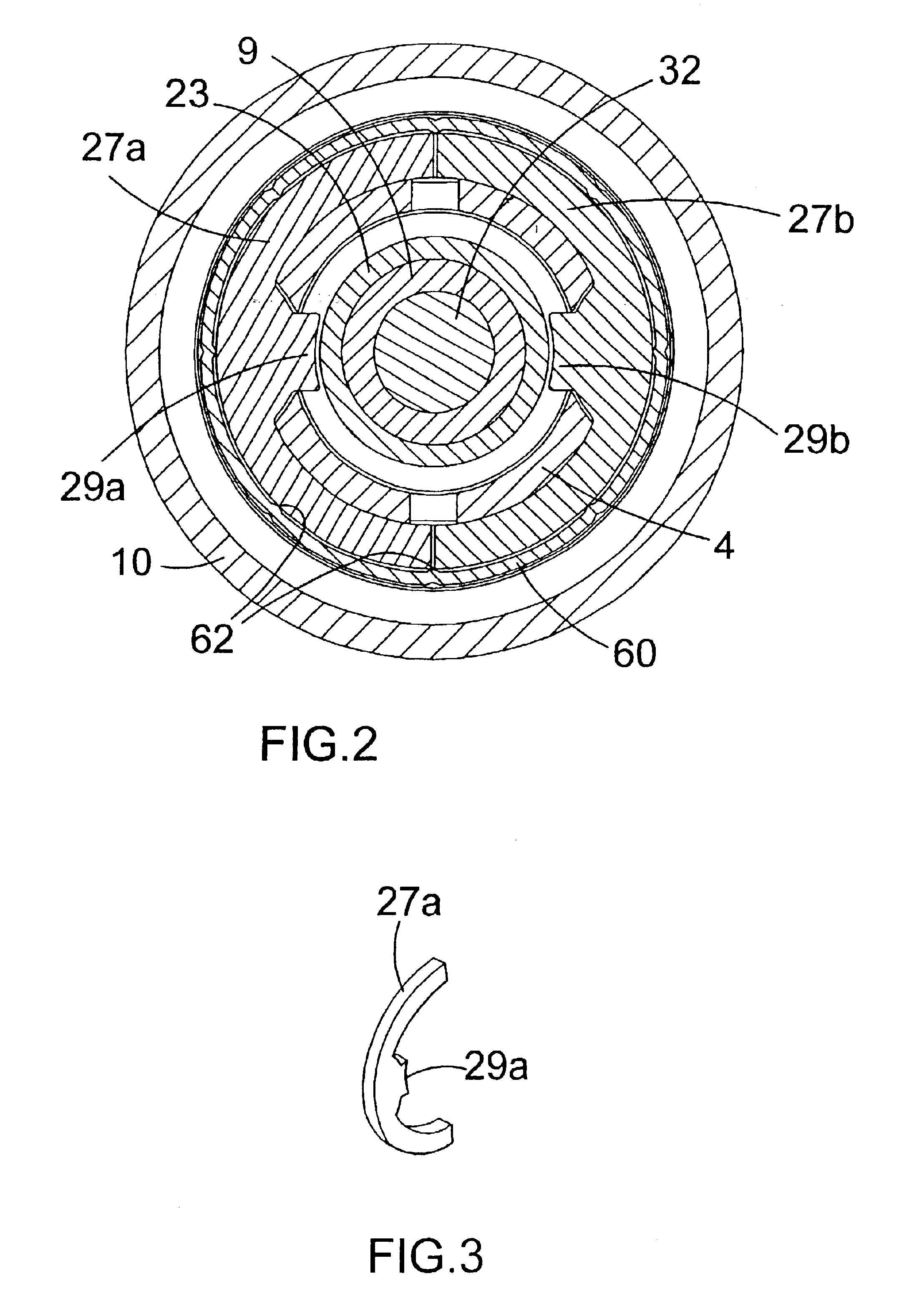

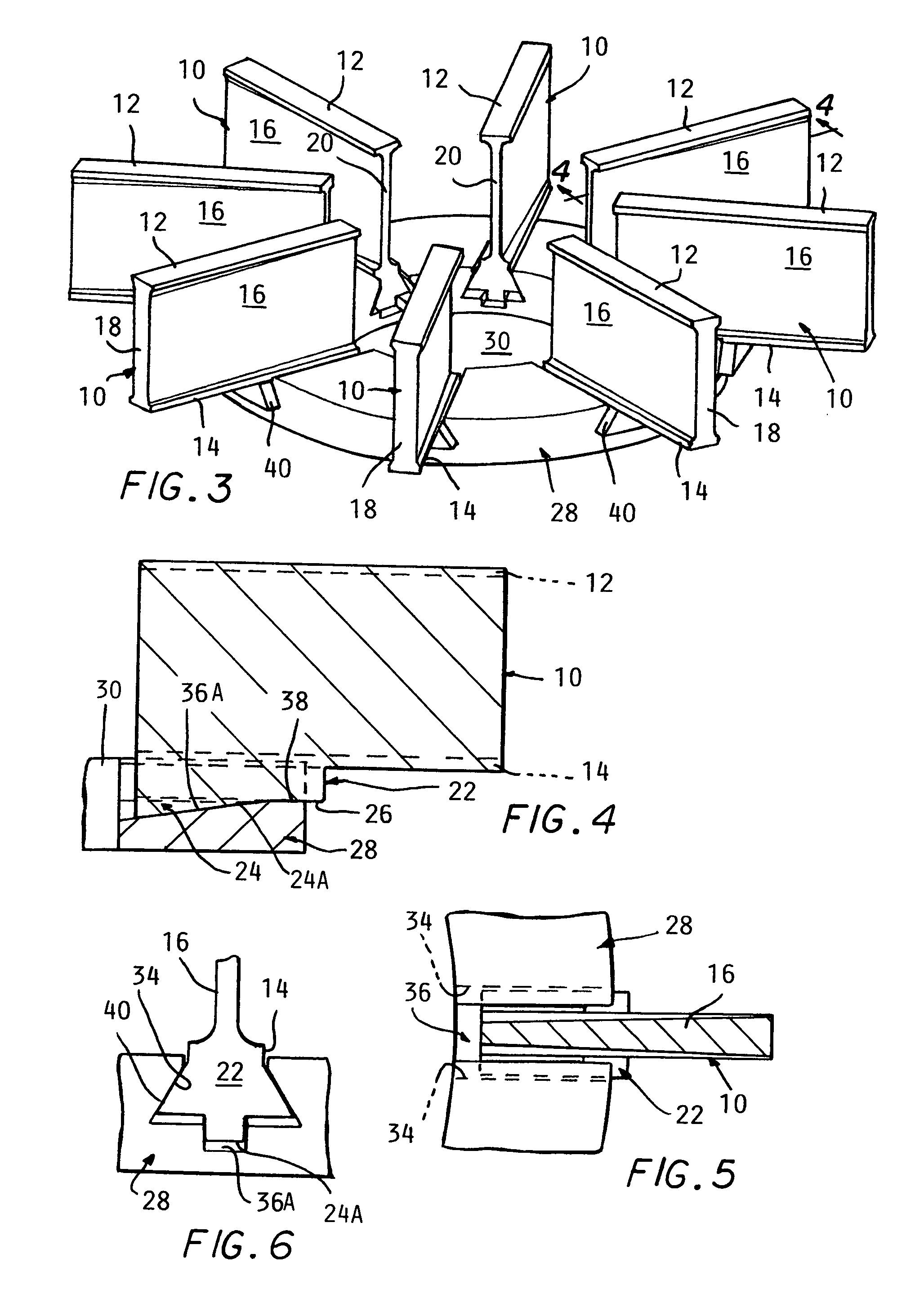

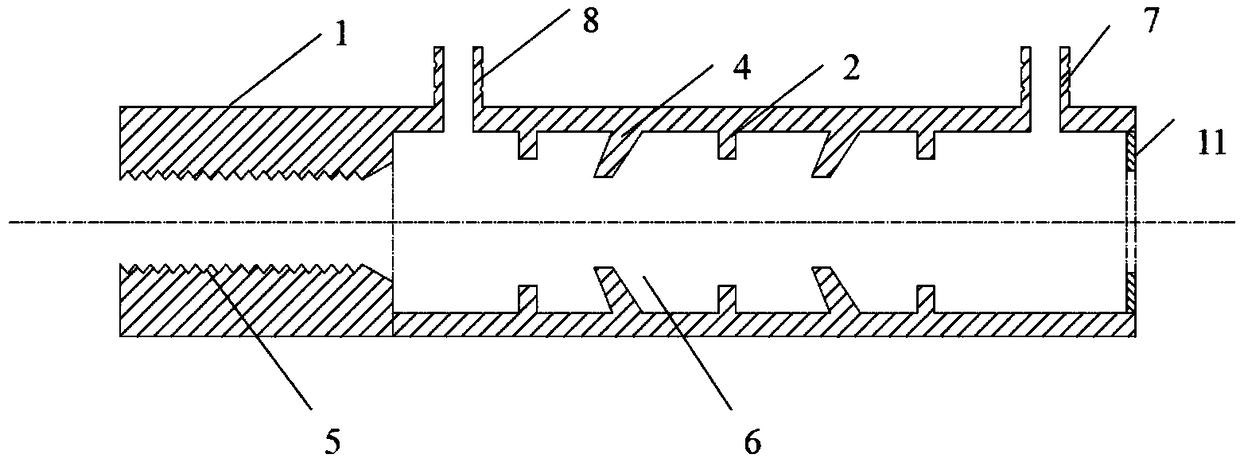

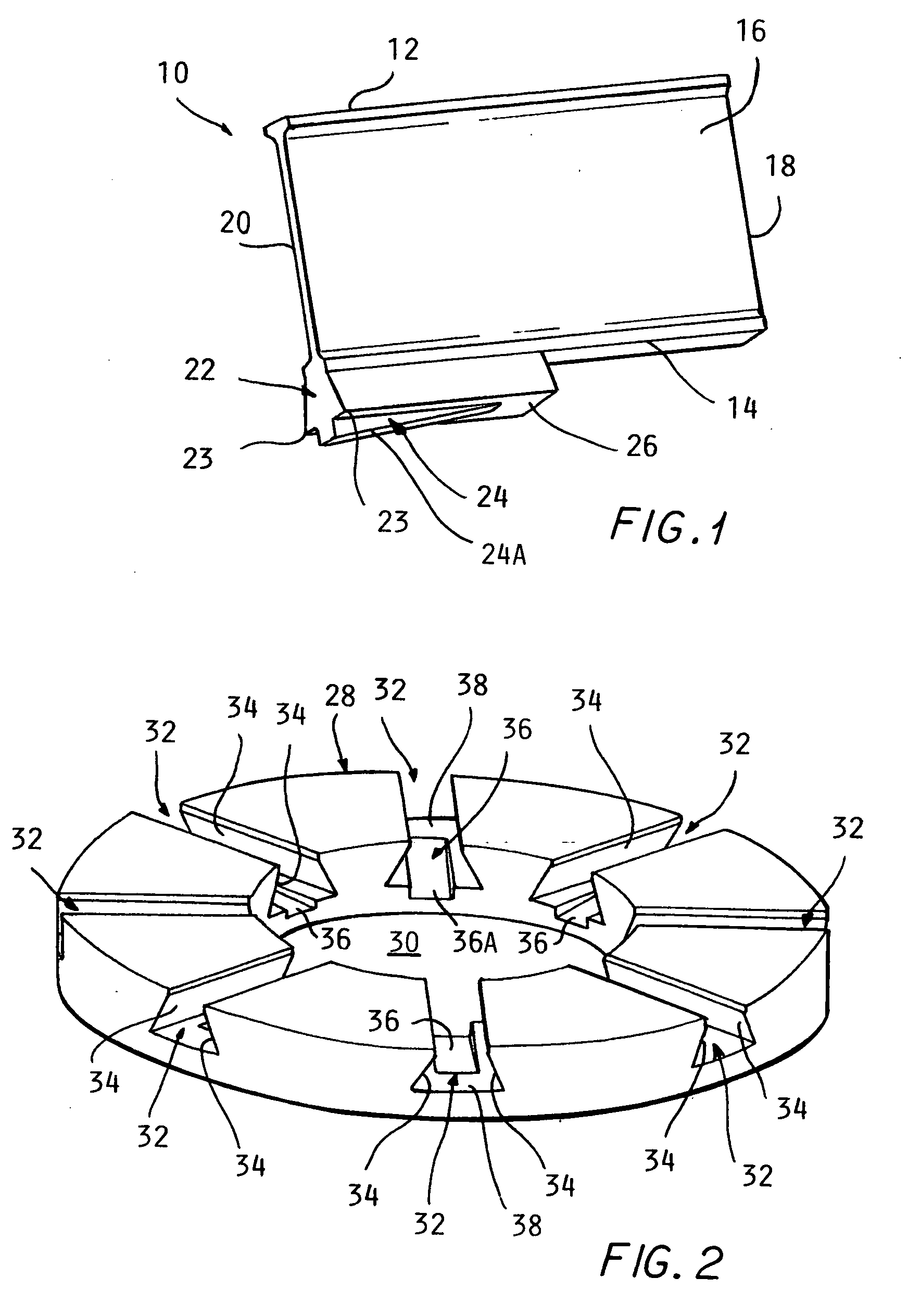

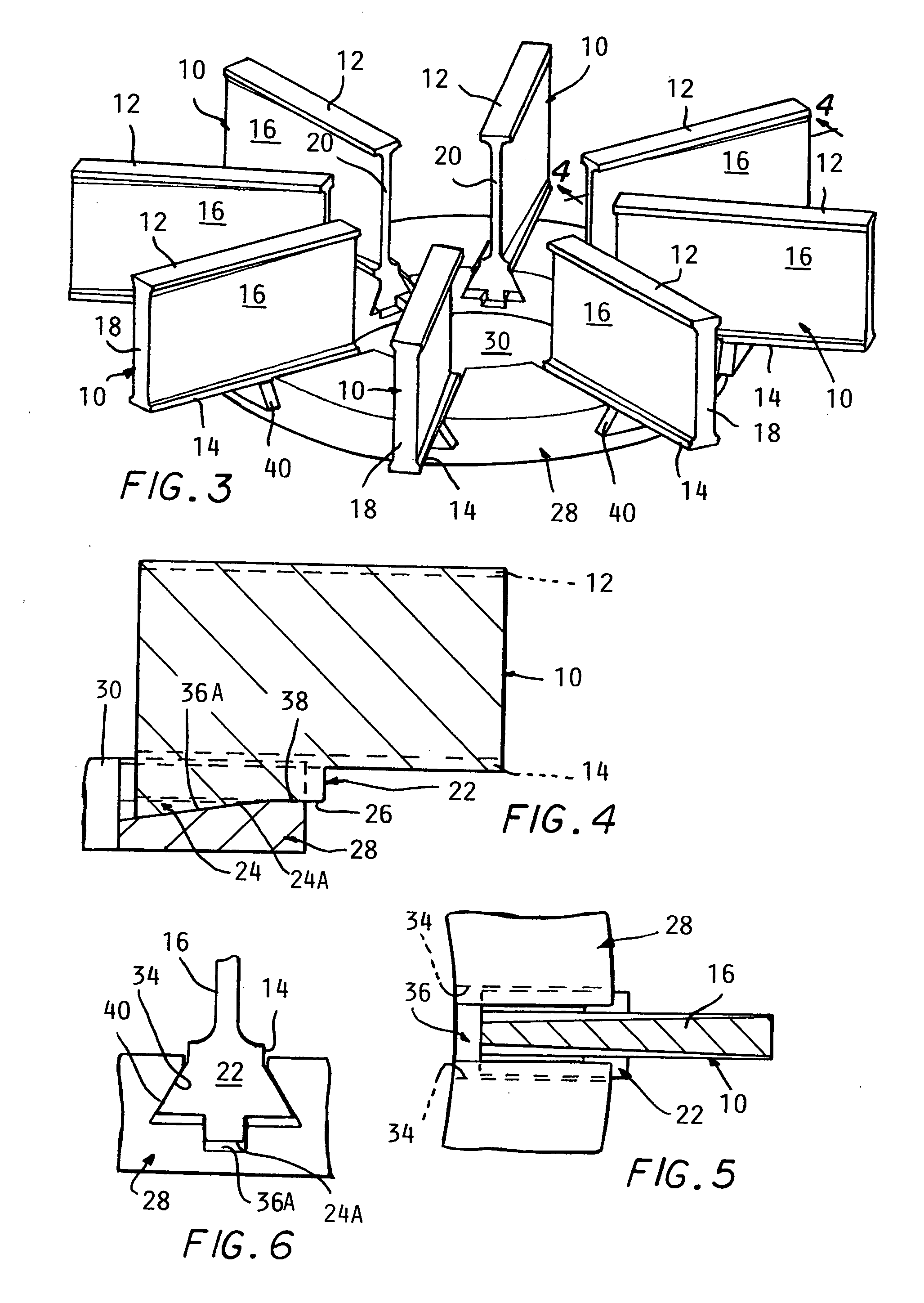

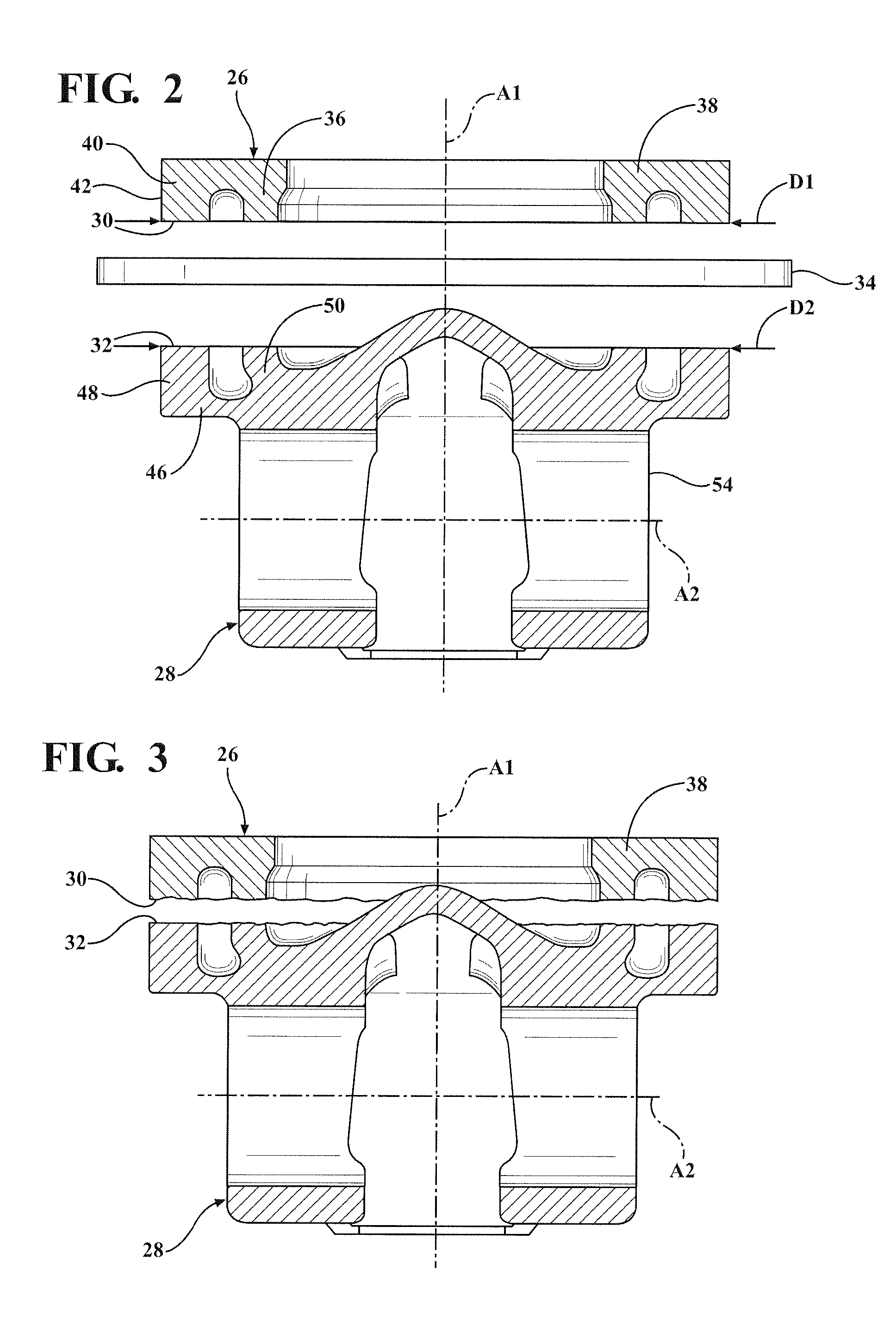

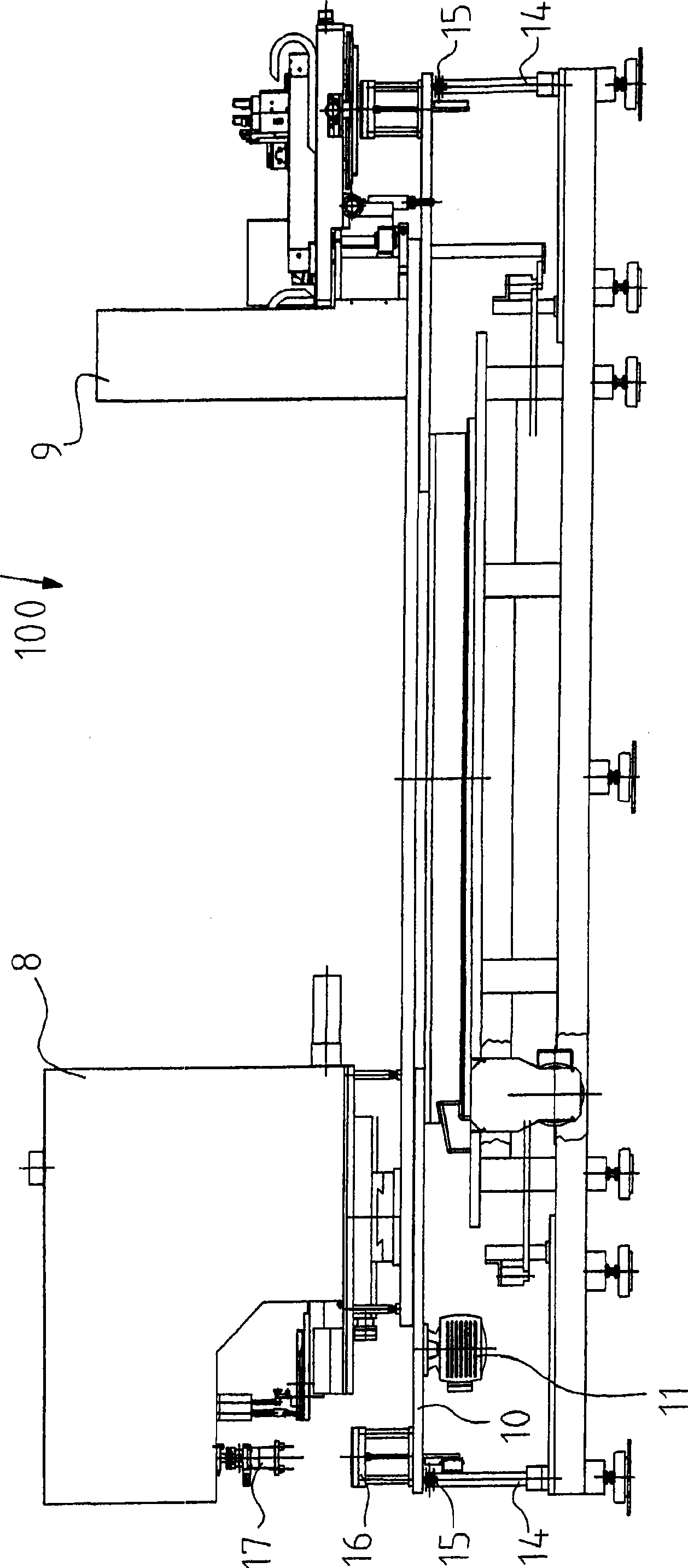

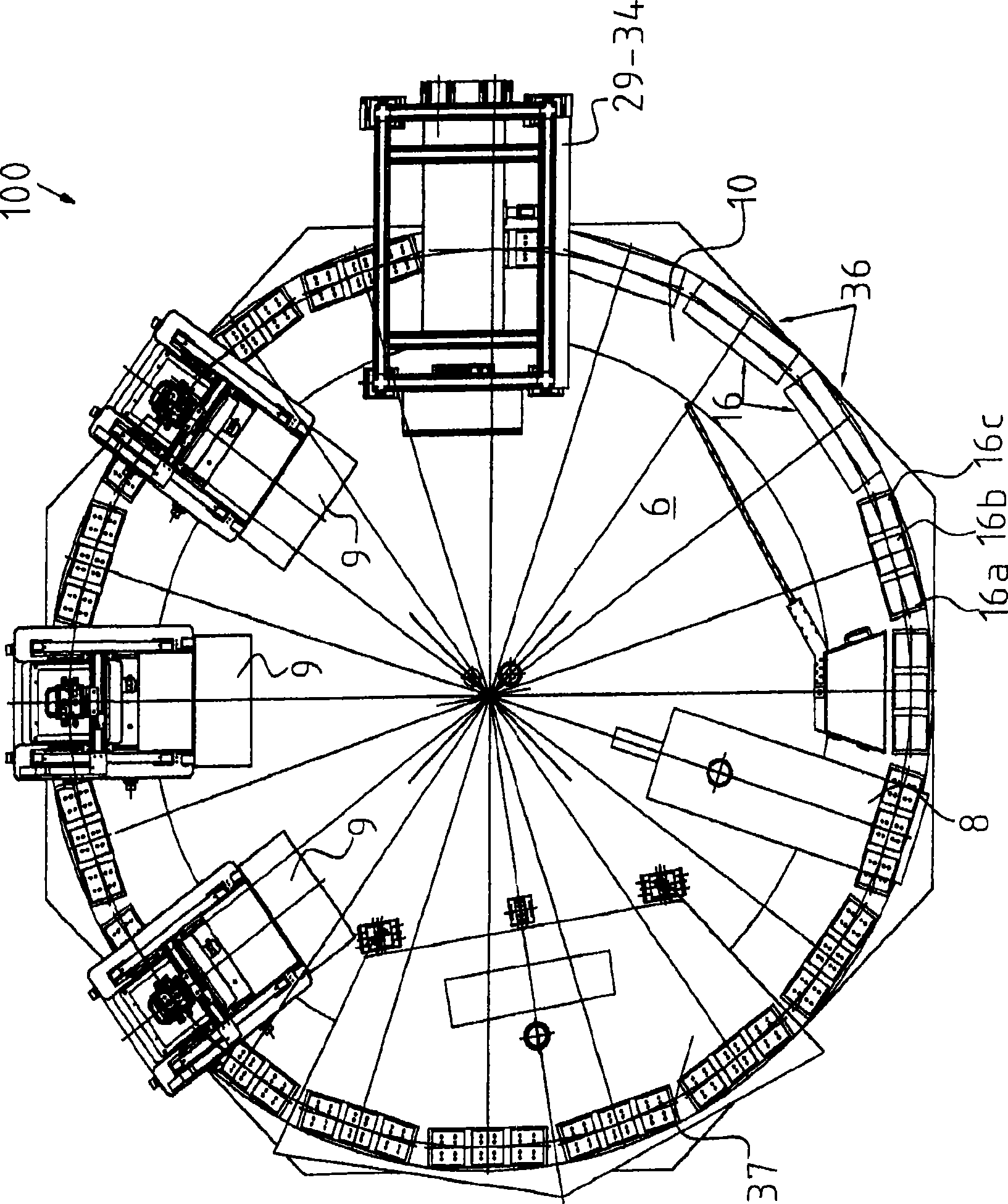

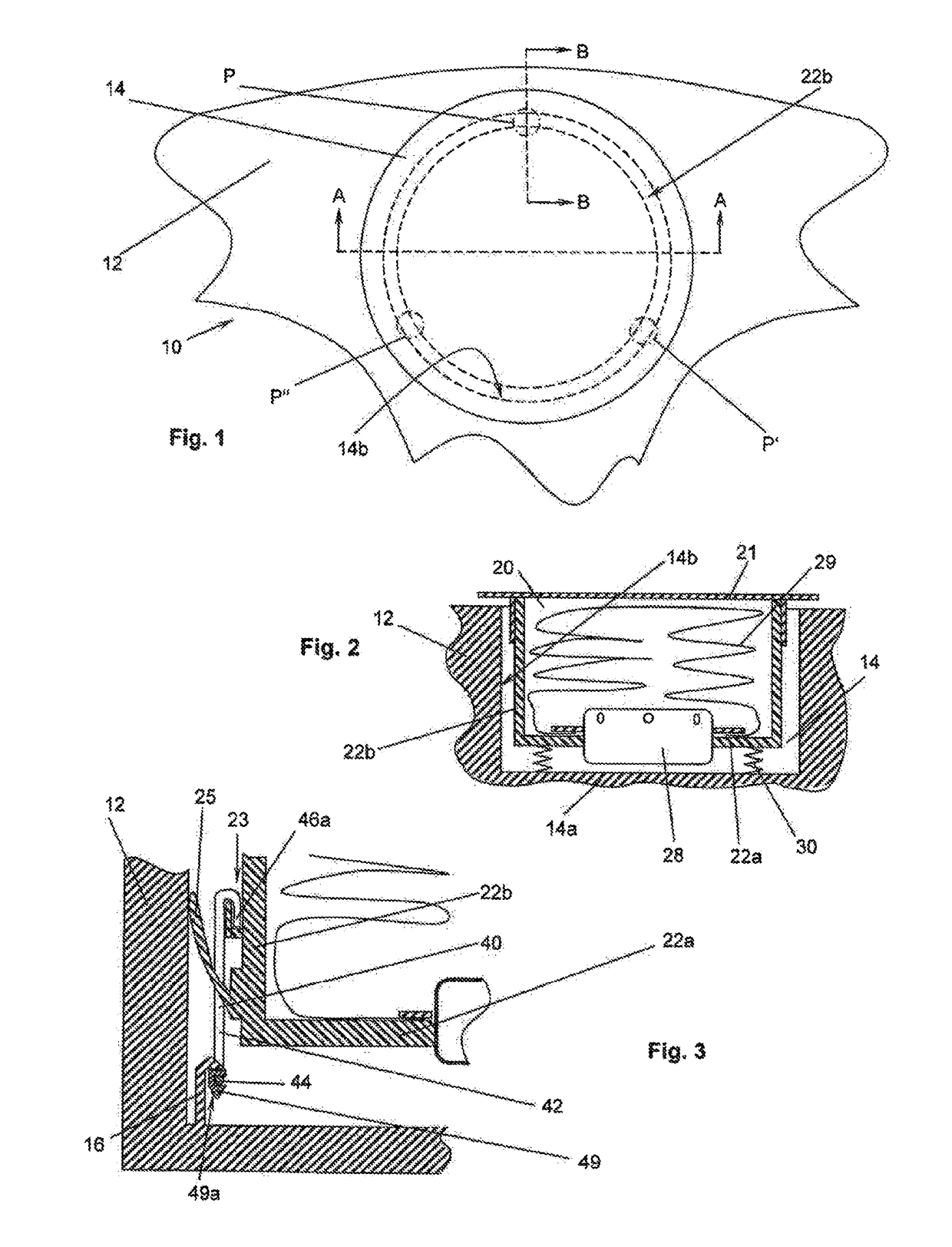

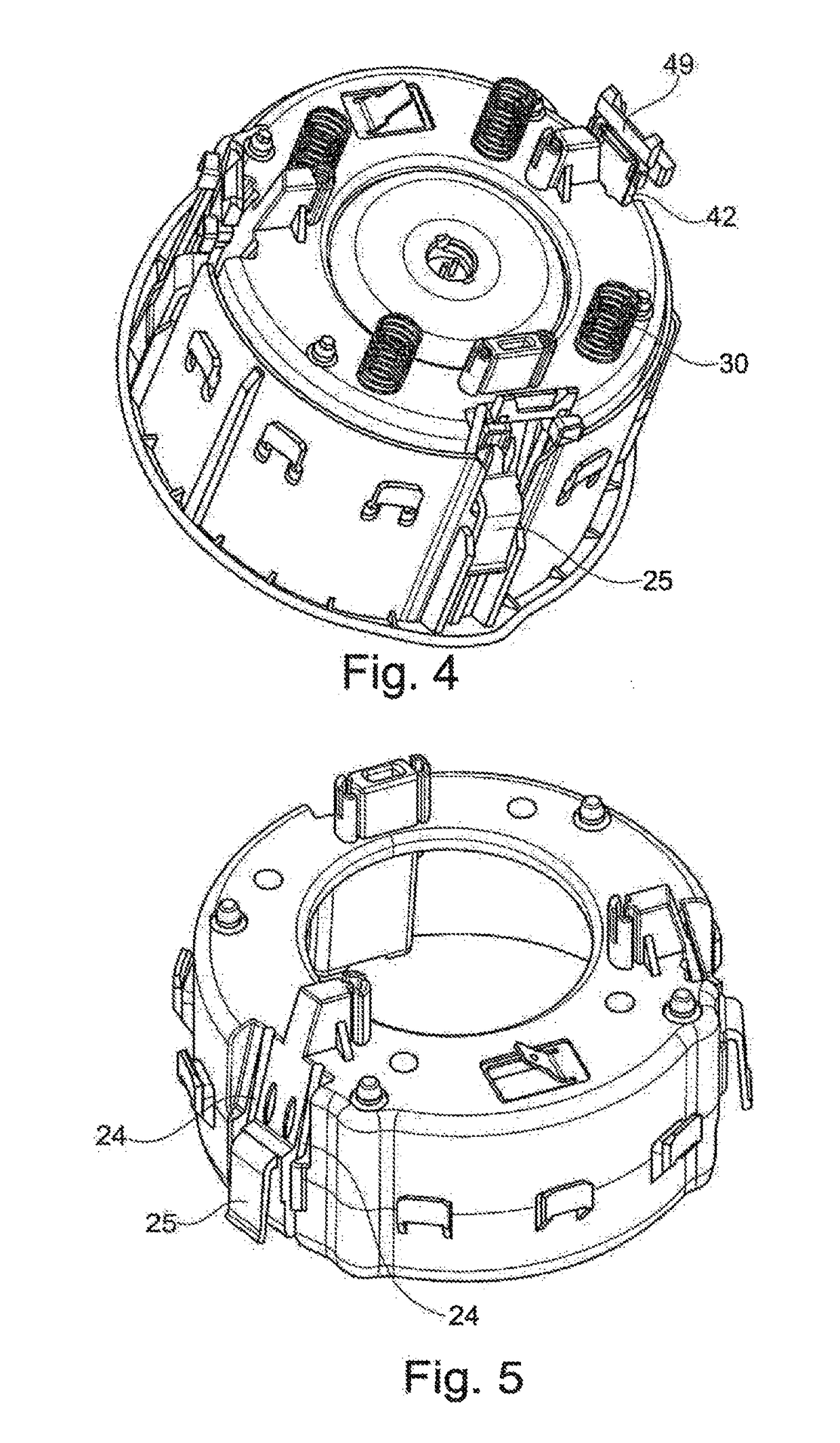

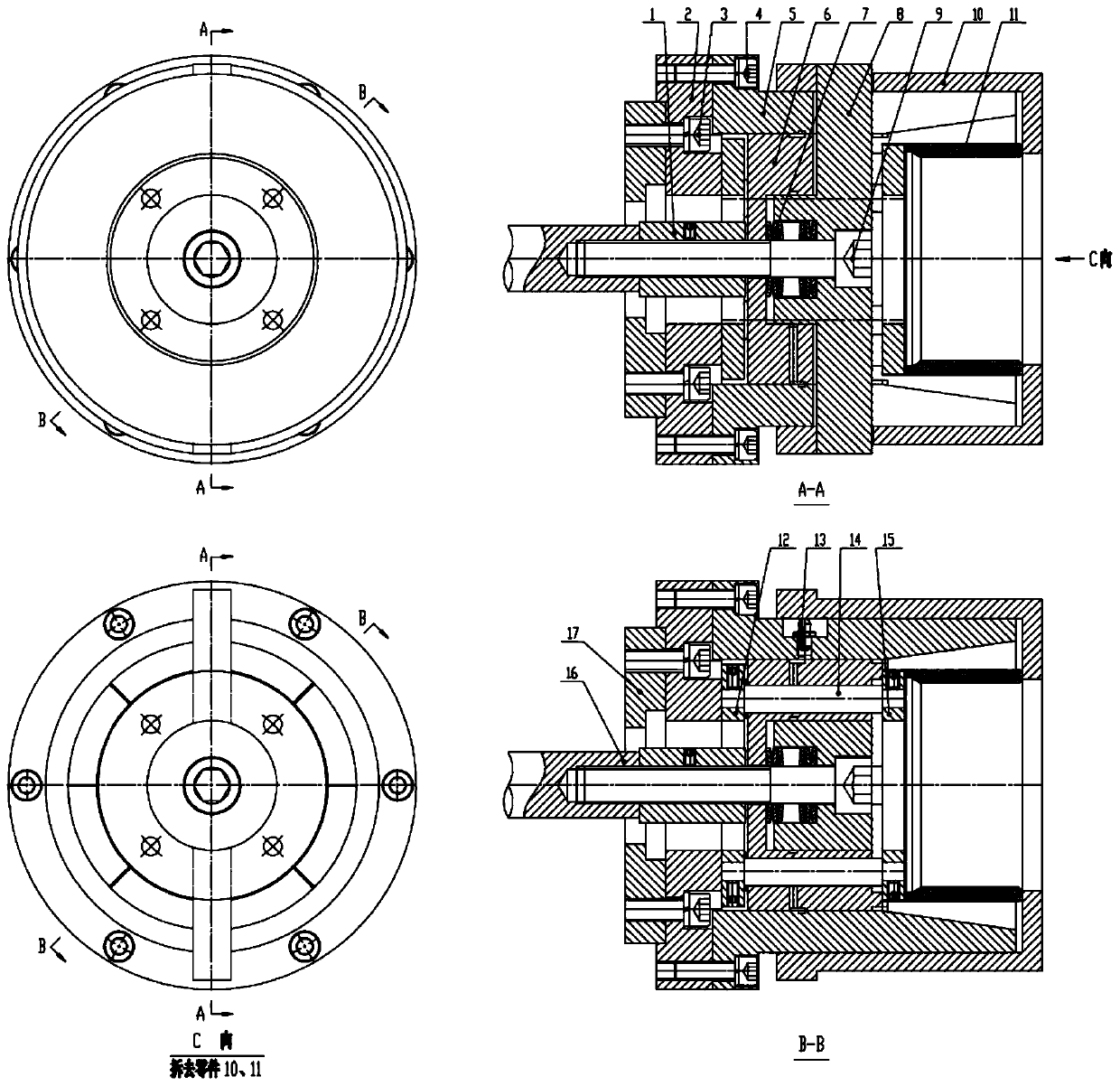

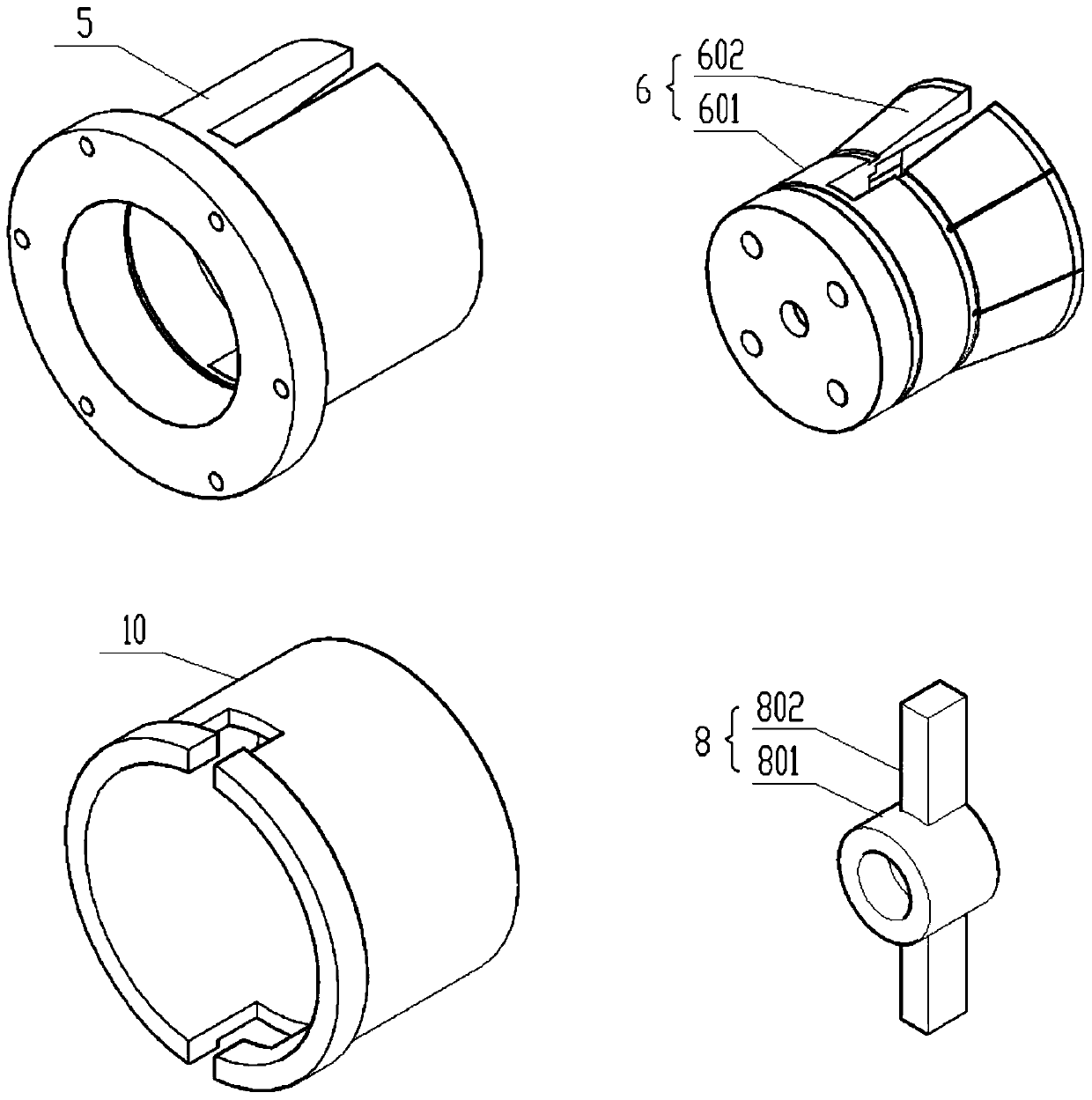

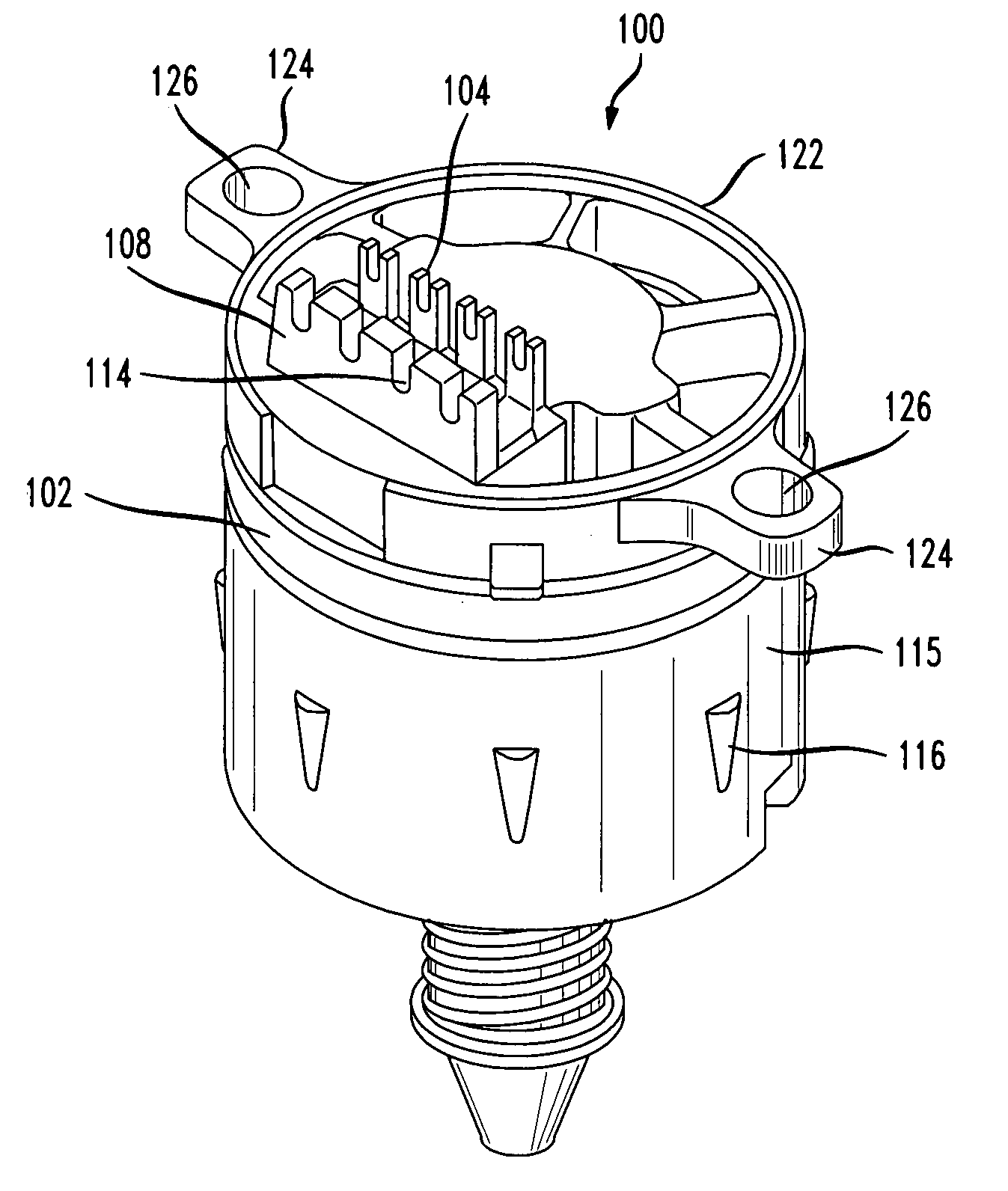

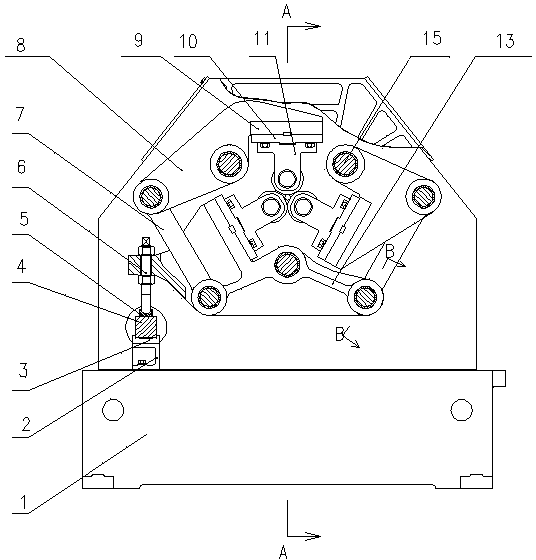

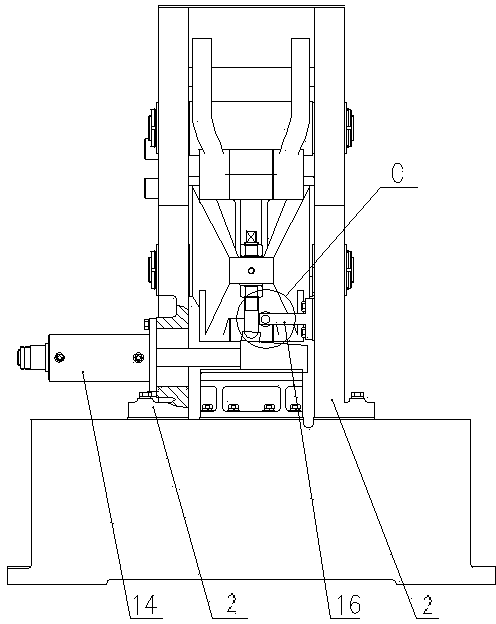

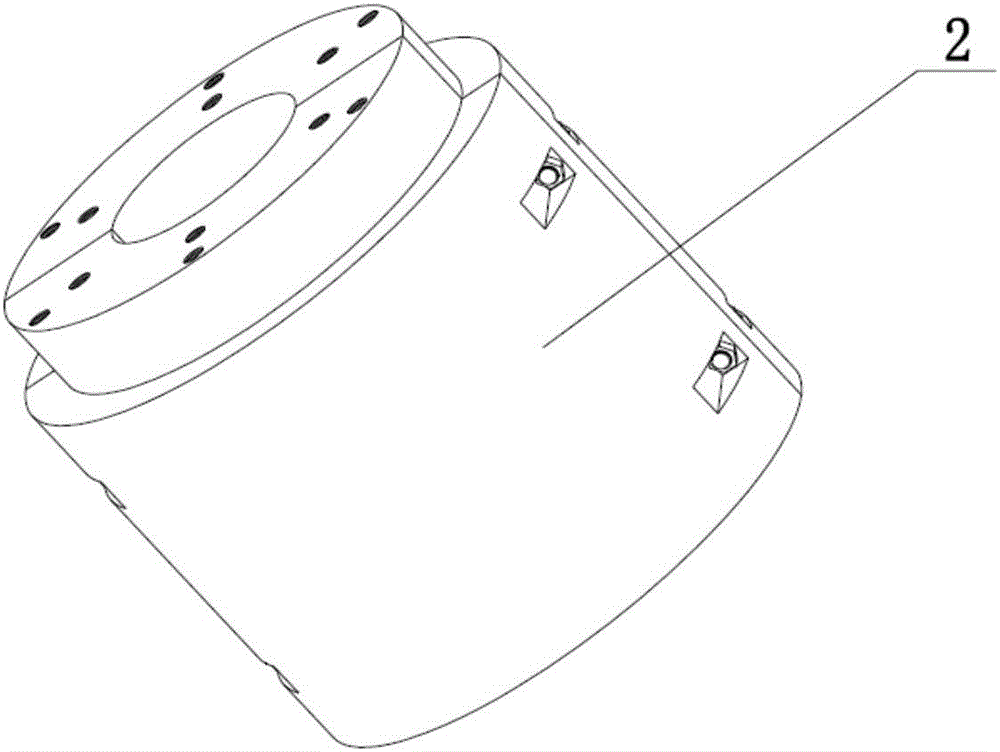

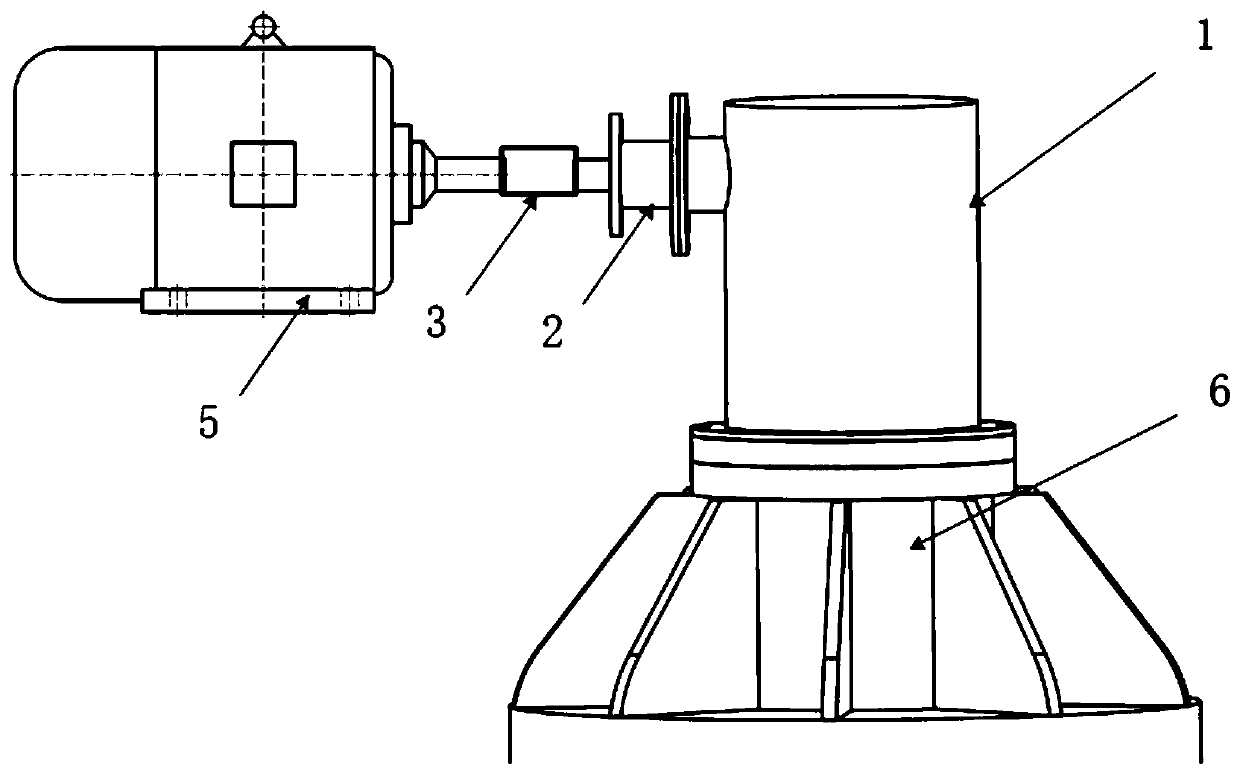

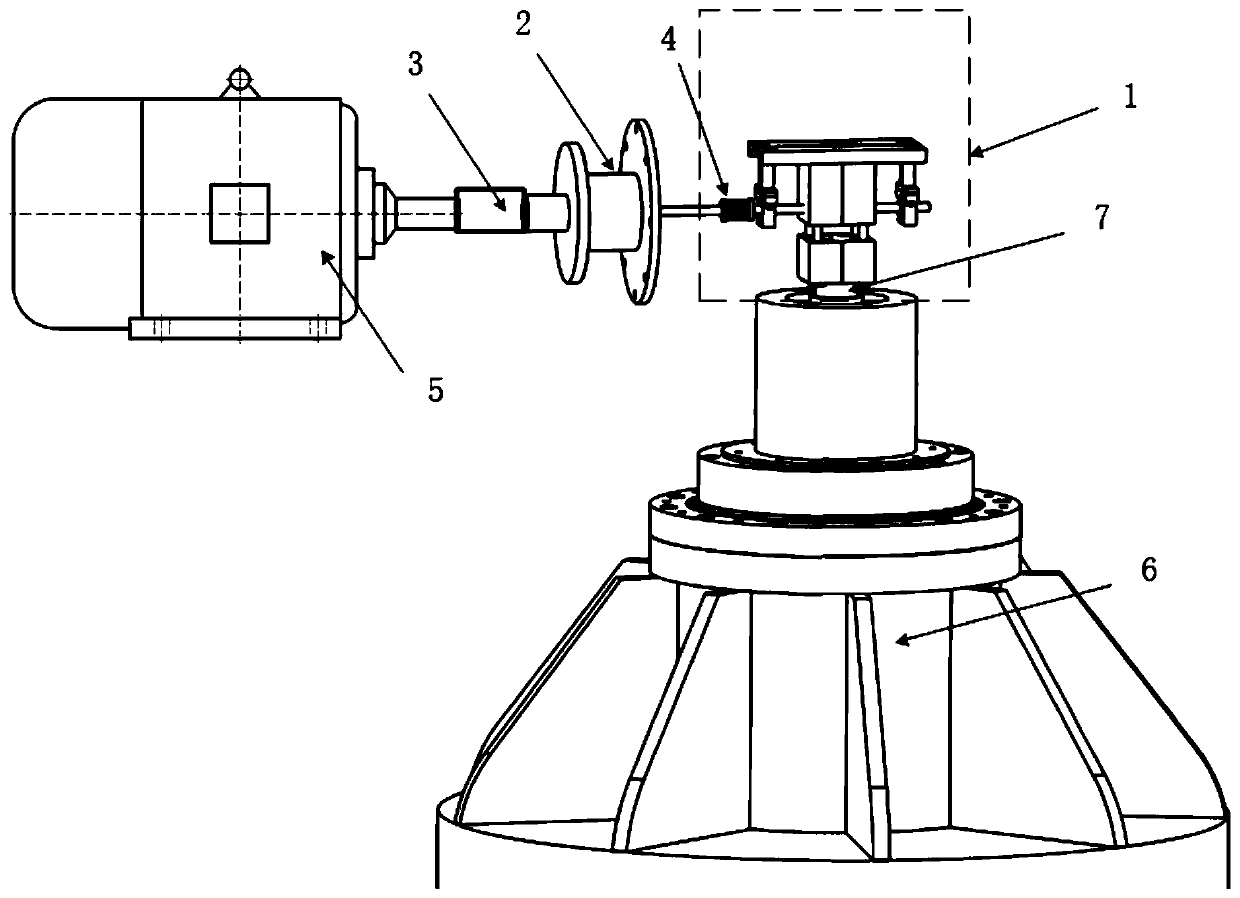

Throwing wheel assembly

InactiveUS7585207B2Accurate radial positioningLock tightlyImpeller wheelsRotor bladesEngineeringMechanical engineering

Owner:ROBERTS SINTO A MICHIGAN

Single probe downhole sampling apparatus and method

A single probe system is utilized to quickly obtain uncontaminated formation fluid samples. The single probe includes an outer guard tube and an inner sampling tube which is slightly recessed relative to the outer tube such that the pressure at the front face of the probe is substantially uniform. Each tube is coupled to its own pump which controls the flow rate of the fluid moving through that tube. Knowing the size of the sampling tube relative to the size of the outer probe tube, and optionally based on relative viscosities of formation fluids and filtrates, the pumps are caused to generate a particular flow rate ratio through the tubes such that an appropriate pressure is maintained at the front face of the probe and such that the fluid flowing through the sampling tube is substantially uncontaminated.

Owner:SCHLUMBERGER TECH CORP

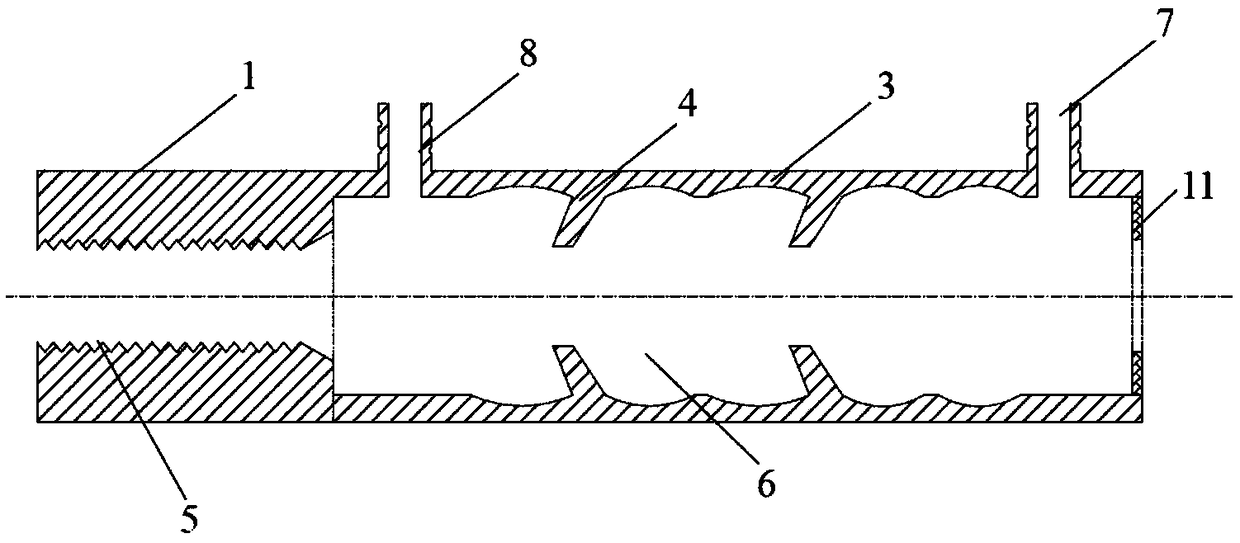

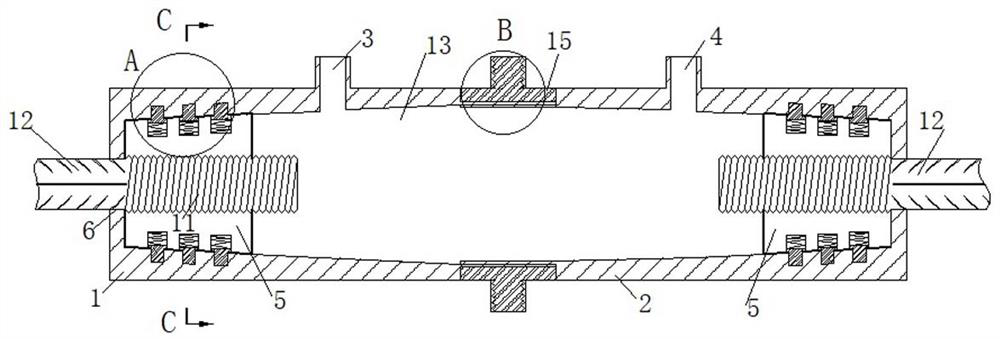

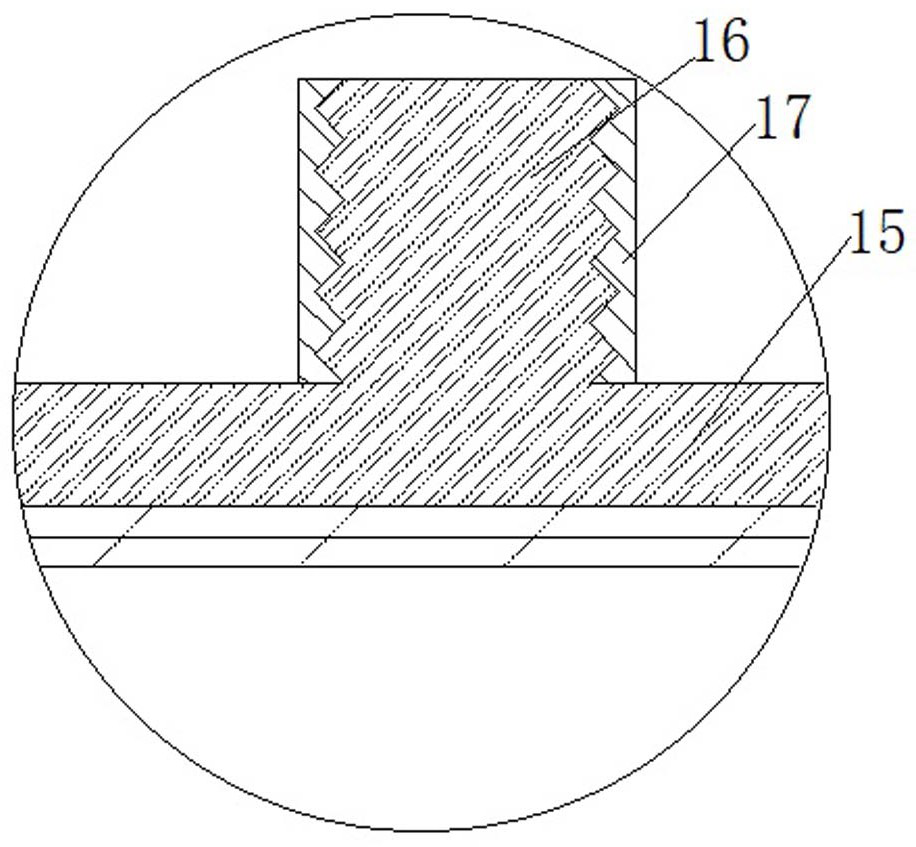

Self-locking steel bar connecting grouting sleeve

The invention discloses a self-locking steel bar connecting grouting sleeve which comprises a sleeve body. The sleeve body is provided with a grouting hole and a grout outlet hole, a grouting cavity communicated with the grouting hole and the grout outlet hole is formed in the sleeve body, the inner wall of the grouting cavity is provided with ribs or corrugations, and the inner wall of the grouting cavity is also provided with multiple clamping tongues. On one hand, when steel bars are inserted into the self-locking steel bar connecting grouting sleeve, a mechanical anchoring force can be effectively provided through the self-locking effect between the steel bars and threaded steel bar ribs; on the other hand, when connected steel bars inserted into prefabricated members have deviations,and when the steel bars are inserted into the grouting sleeve, the situation of wall attachment or eccentricity occurring during connection of the self-locking steel bar connecting grouting sleeve canbe effectively avoided through appropriate position correction of the steel bars due to the vertical radial effect of the clamping tongues.

Owner:SOUTHEAST UNIV

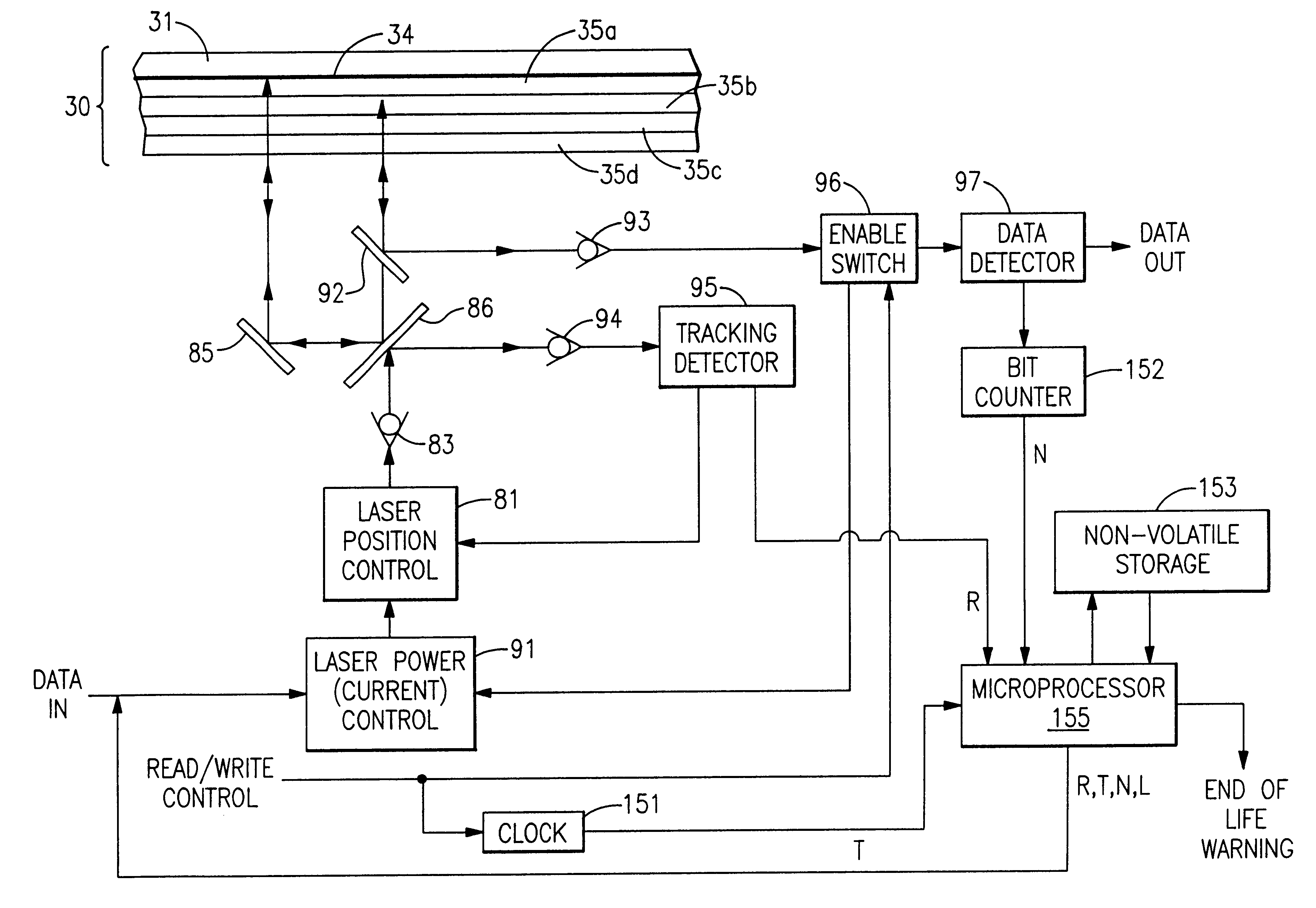

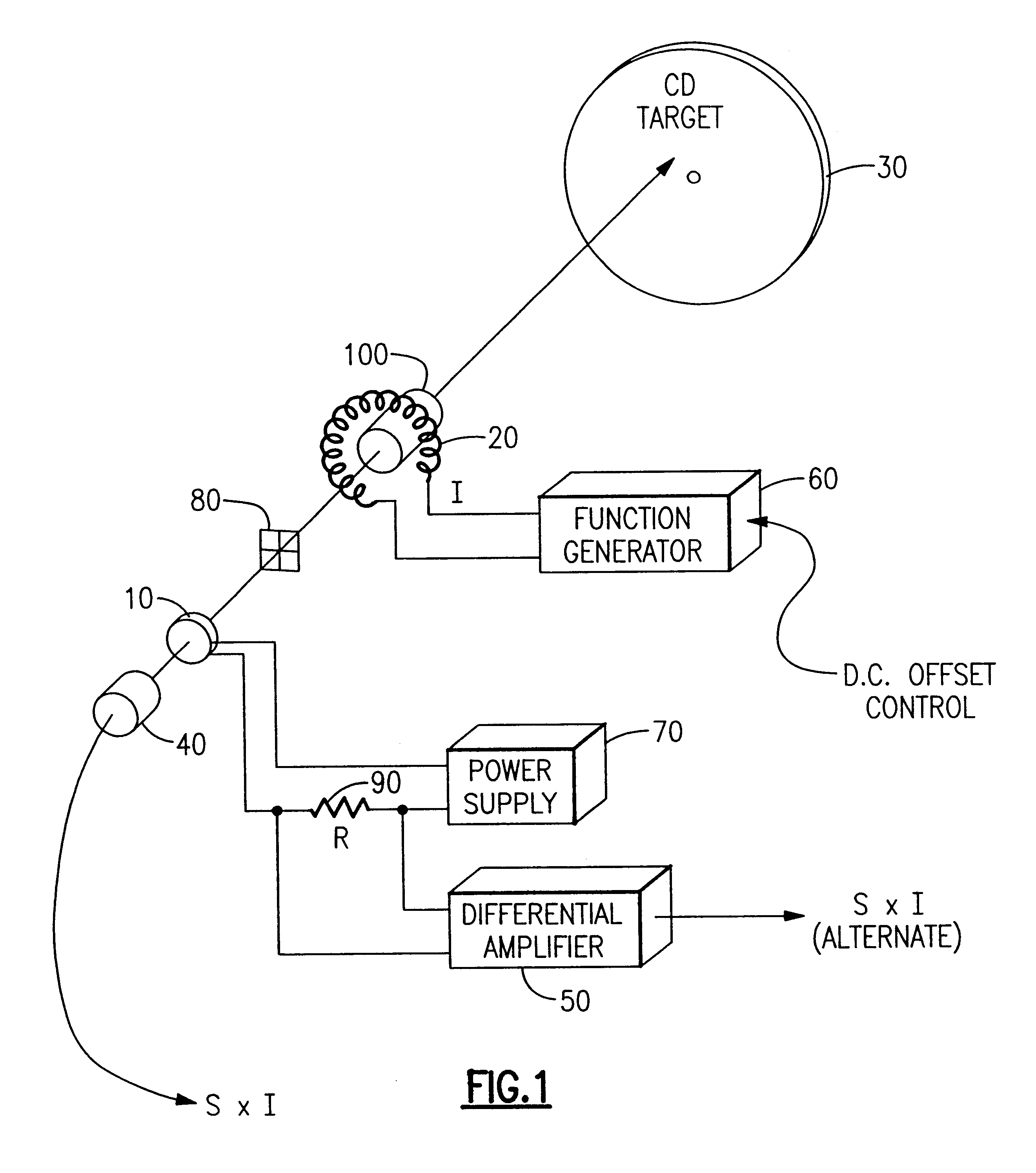

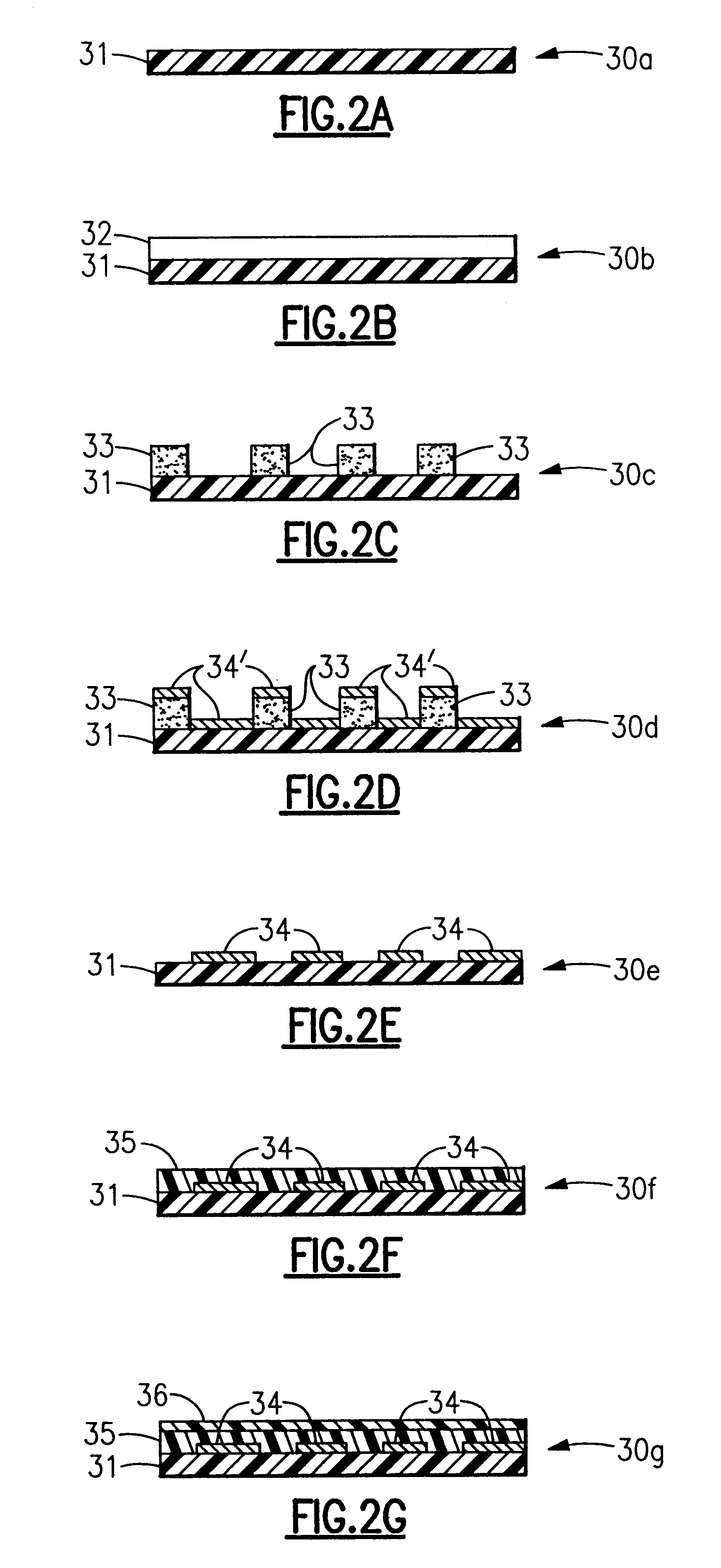

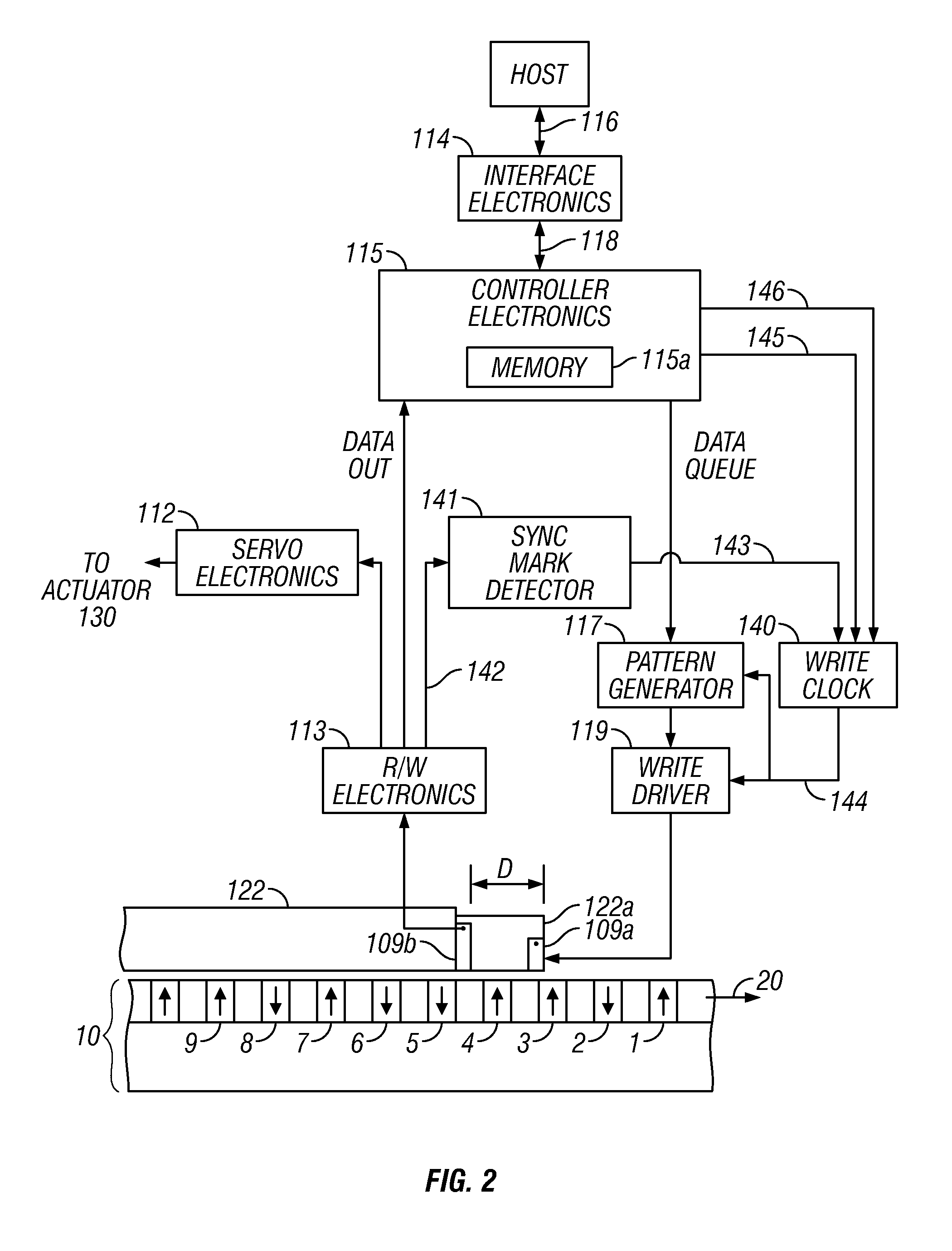

System for creating, reading and writing on rotatable information storage media, a method for customizing said media with timing information

InactiveUS6269064B1Easy to measureAccurate radial positioningMultilayered discsTelevision system detailsRadial positionComputer science

In a system for writing a plurality of information tracks between adjacent portions of a reference track on a rotatable medium, advantage is taken of the fact that laser beam dithering a cross an edge of a reference track produces signals which are analyzable to determine much more exact radial positions. A pattern of bits is written on the medium with a known spacing between bits. This may be at the time of disk manufacture or later. As these bits are being read, a clock is started along with a bit counter. At this time, a precise determination is made of the radial position at which the read bits are present. From these values, angular and / or linear velocities are computed and stored on the medium. Collected over time, this information is useful for determining aging characteristics of the drive mechanism for the medium. Also, even one-time collection of this speed information is useful for determining the speed at which data was written so that the drive speed can be accurately controlled for read operations, for example.

Owner:IBM CORP

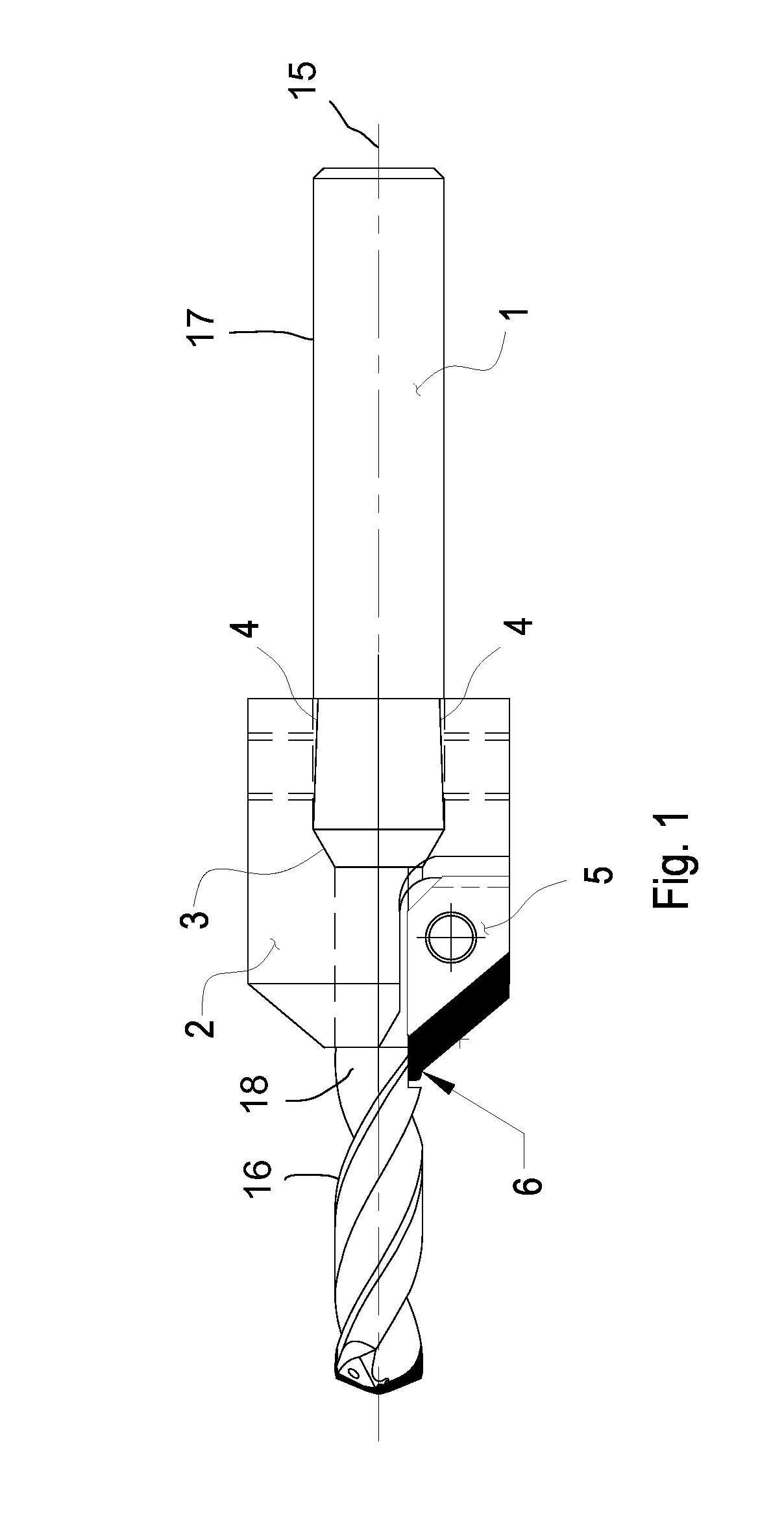

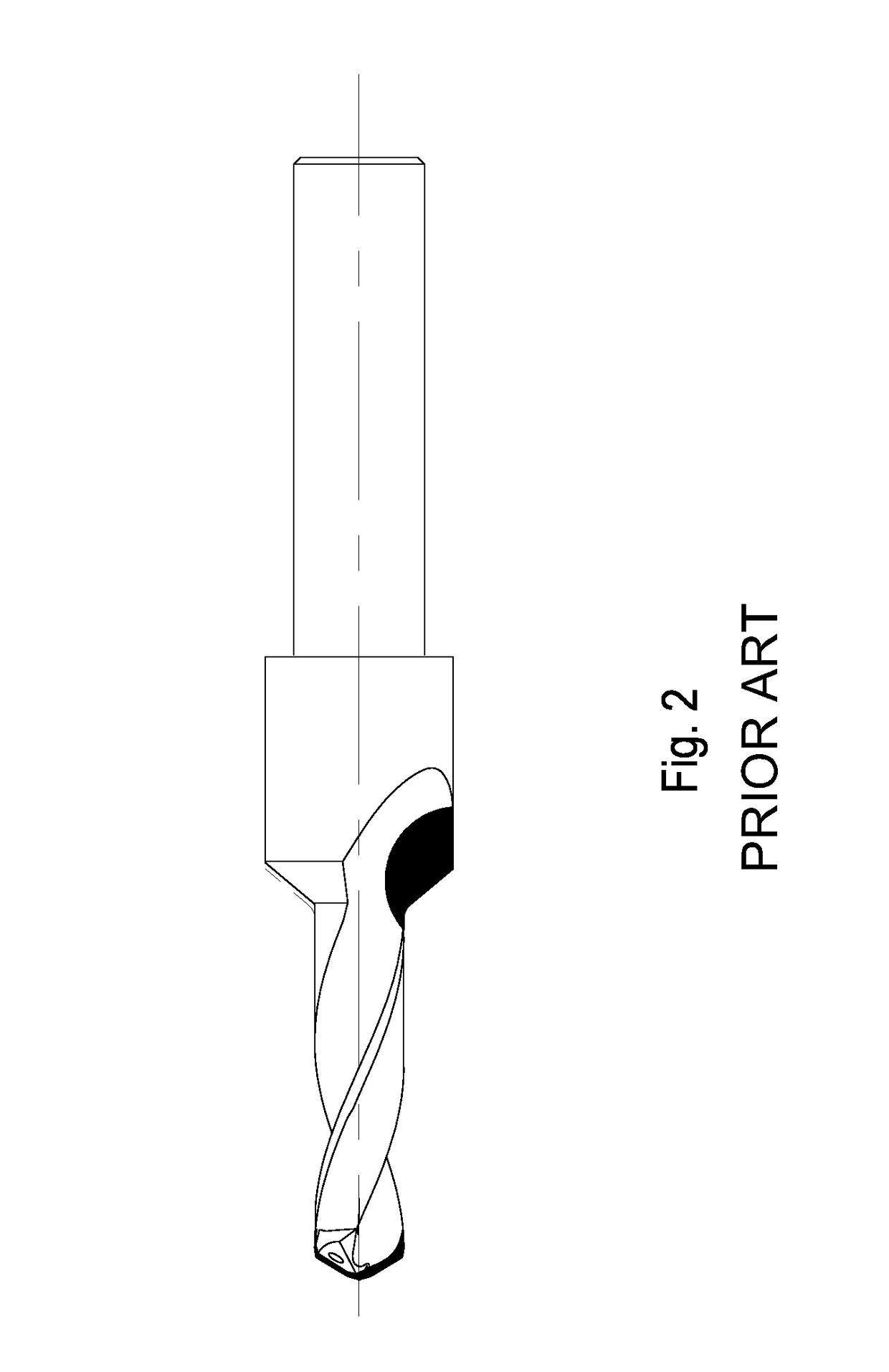

Modular precision drill countersink assembly

ActiveUS8469642B1Good precisionImprove matchThread cutting toolsWood turning toolsEngineeringDrill bit

A modular countersink assembly, comprising a drill having an exterior tapered surface, a countersink body having an interior tapered surface for mating with the exterior tapered surface of the drill, and an insert removably secured to the countersink body enables an operator to replace either the drill and / or the insert if one or the other or both become worn. The insert is positioned both axially and radially and may have a PCD cutting edge.

Owner:PRECORP INC

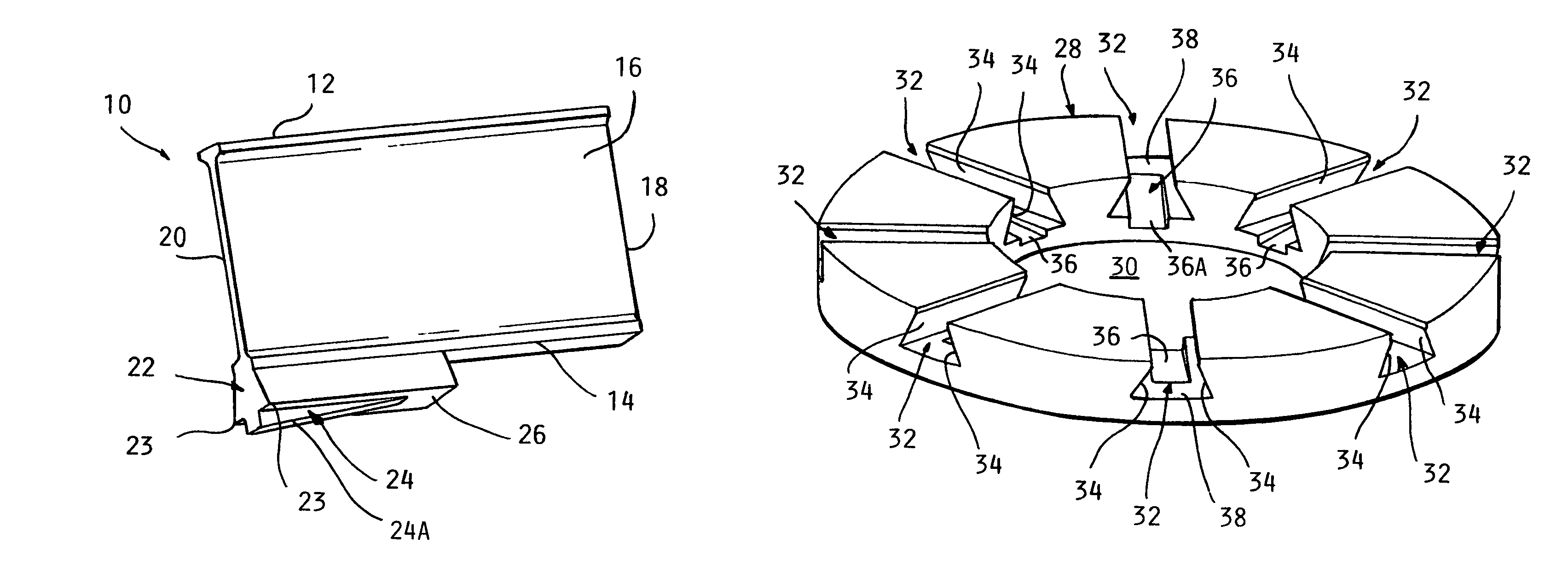

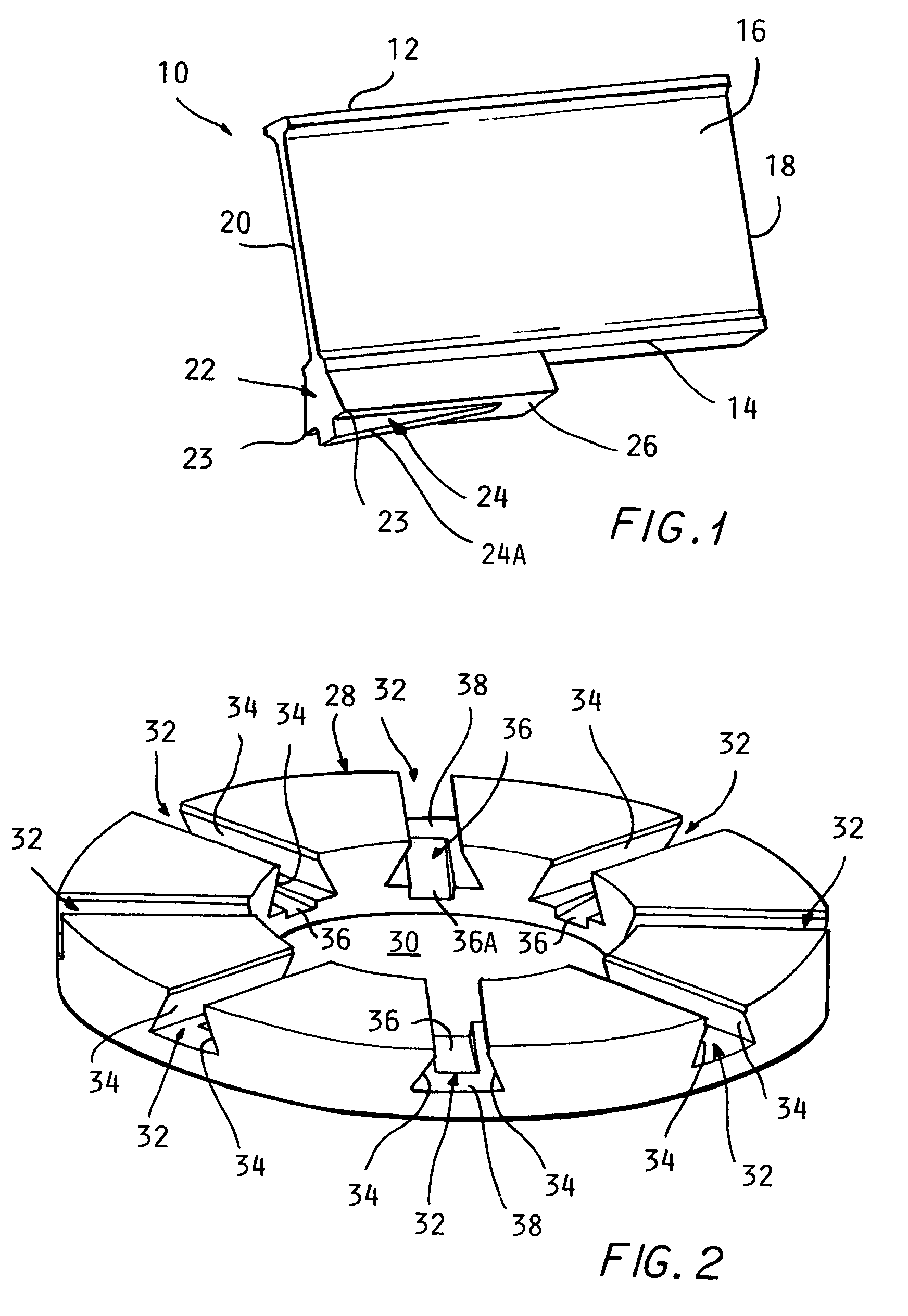

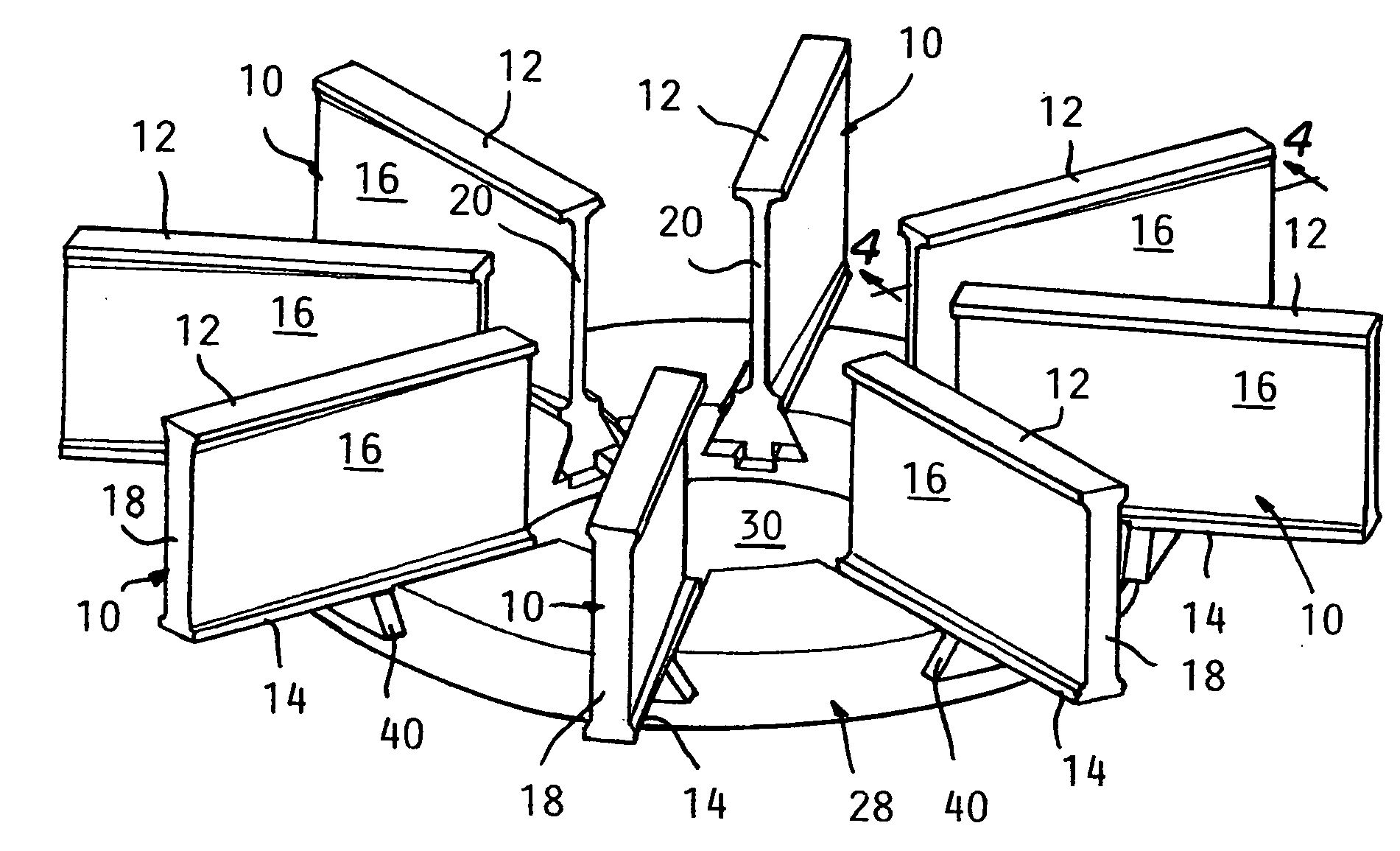

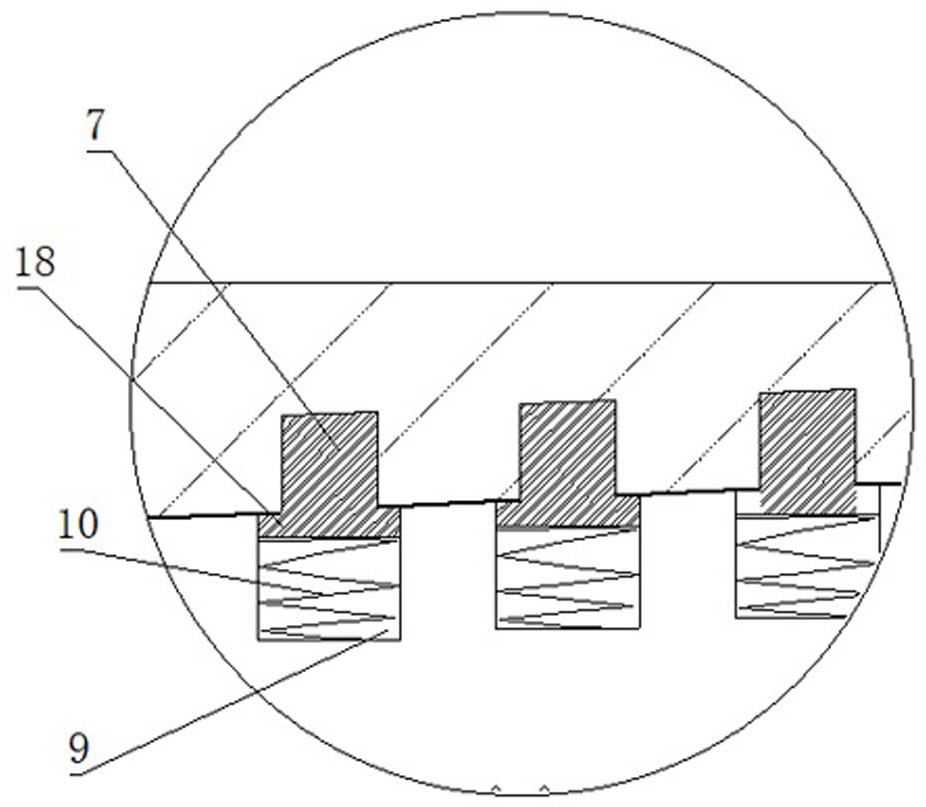

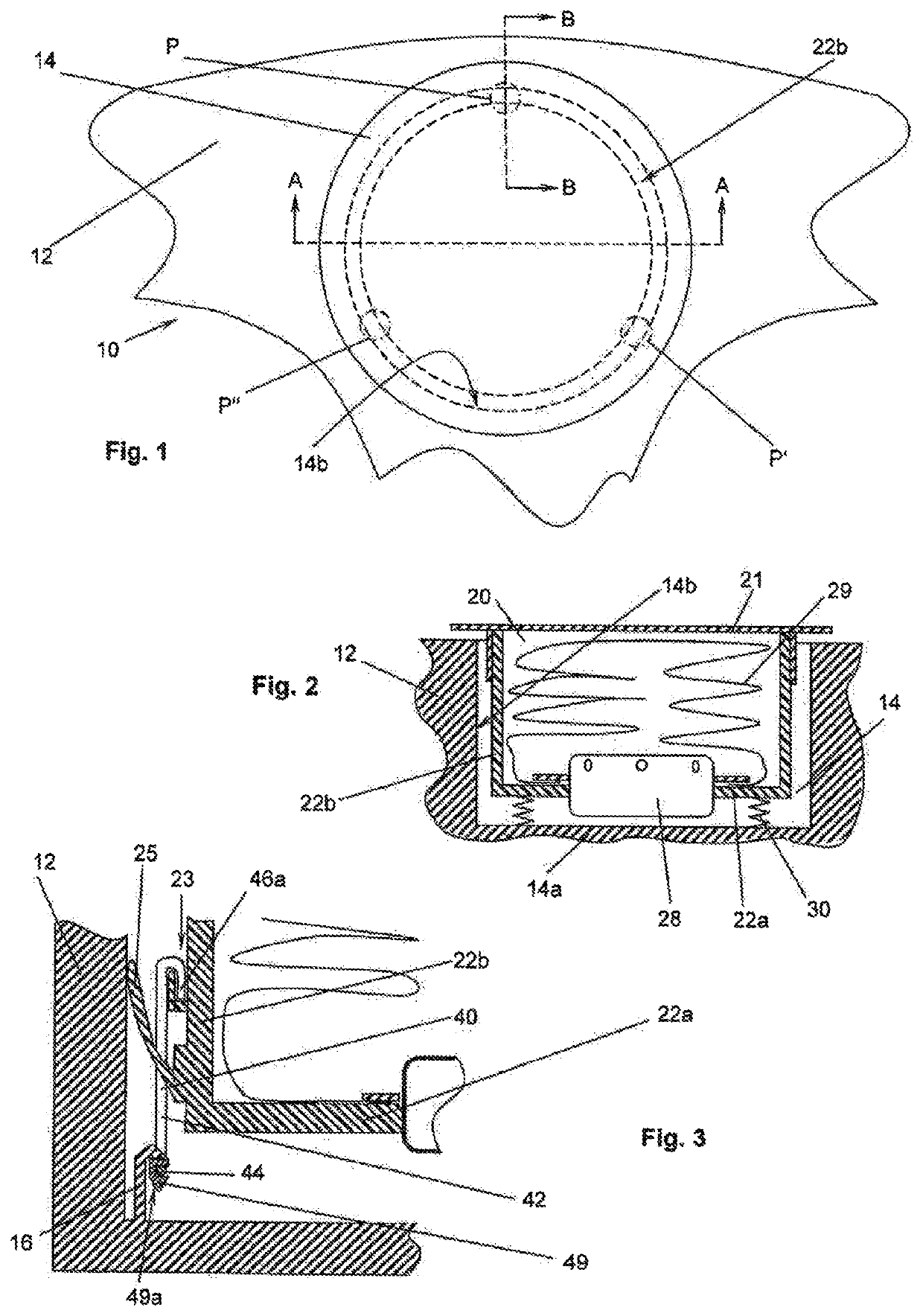

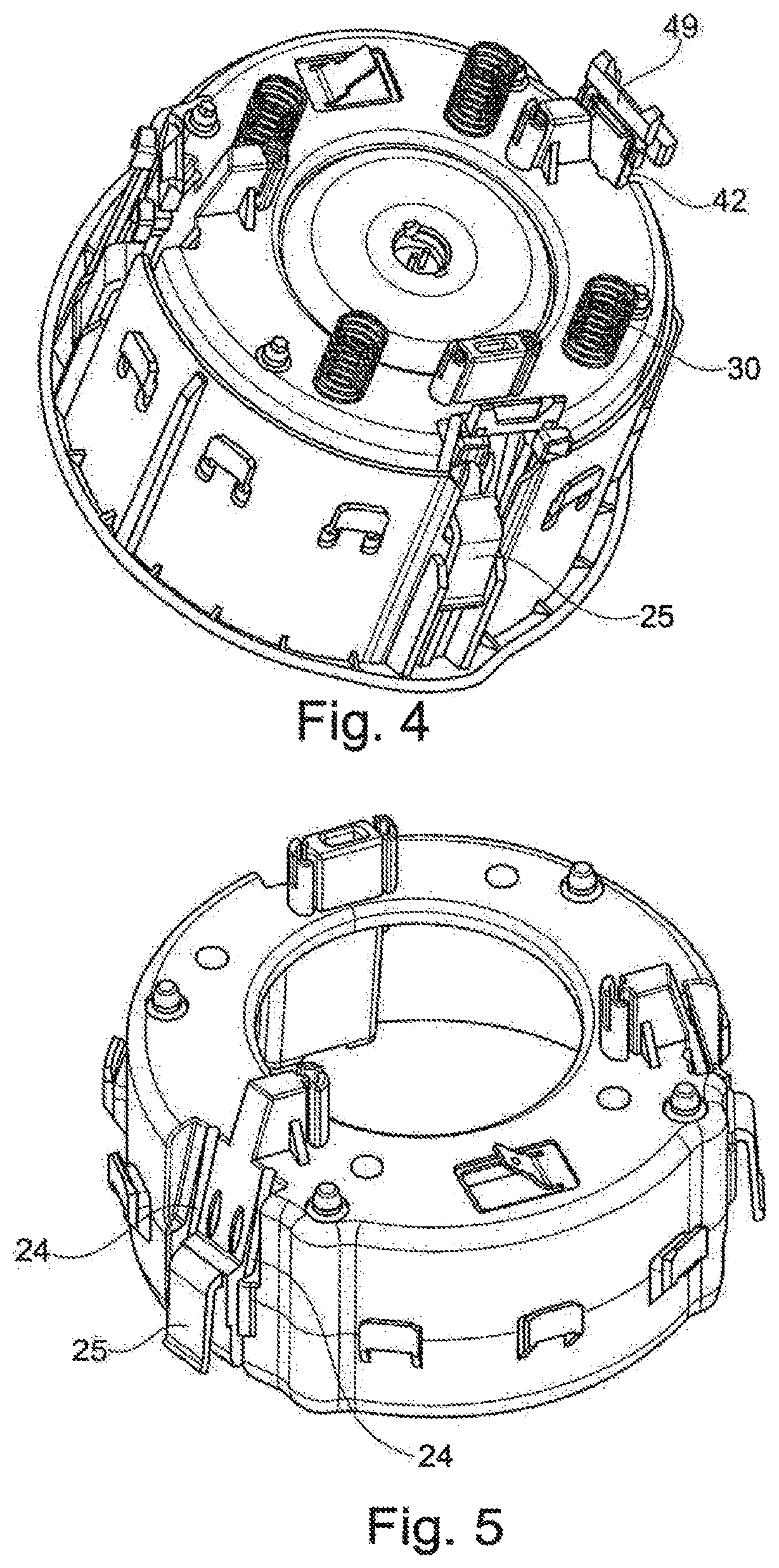

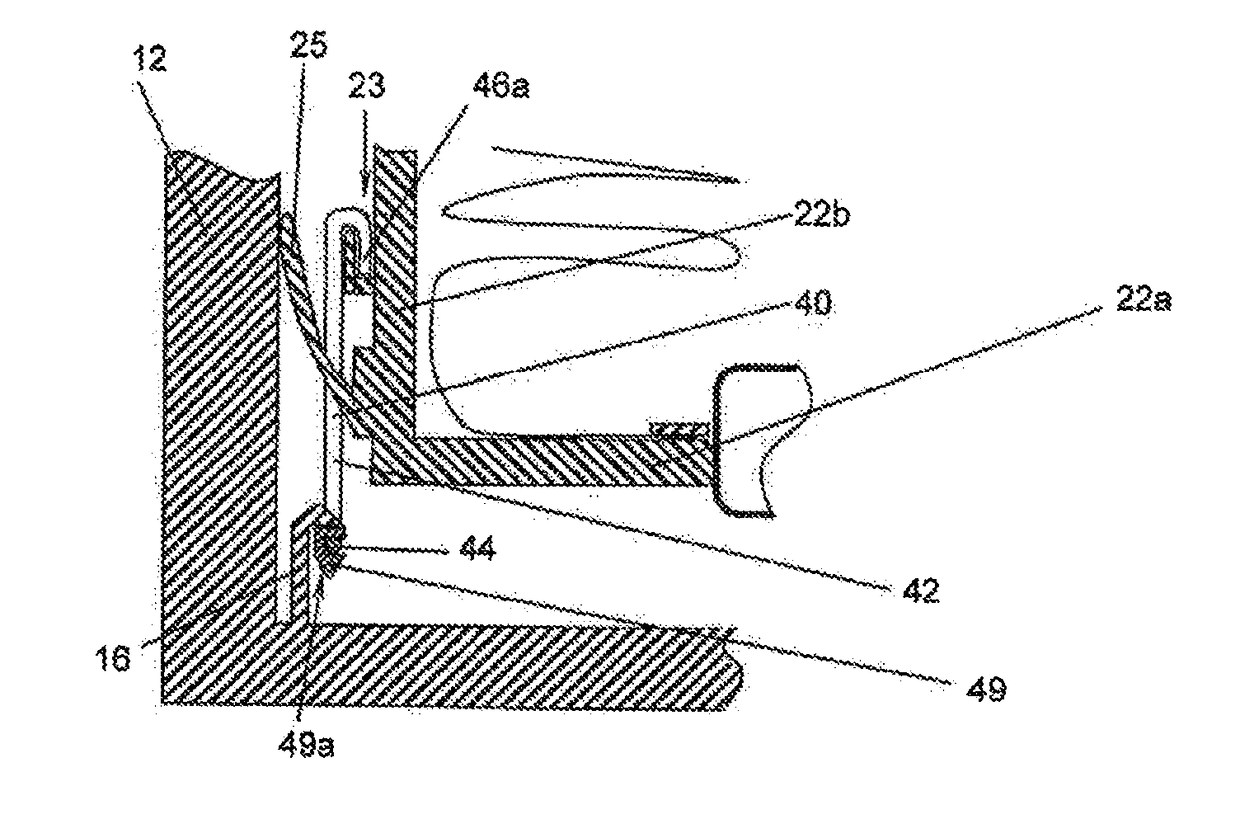

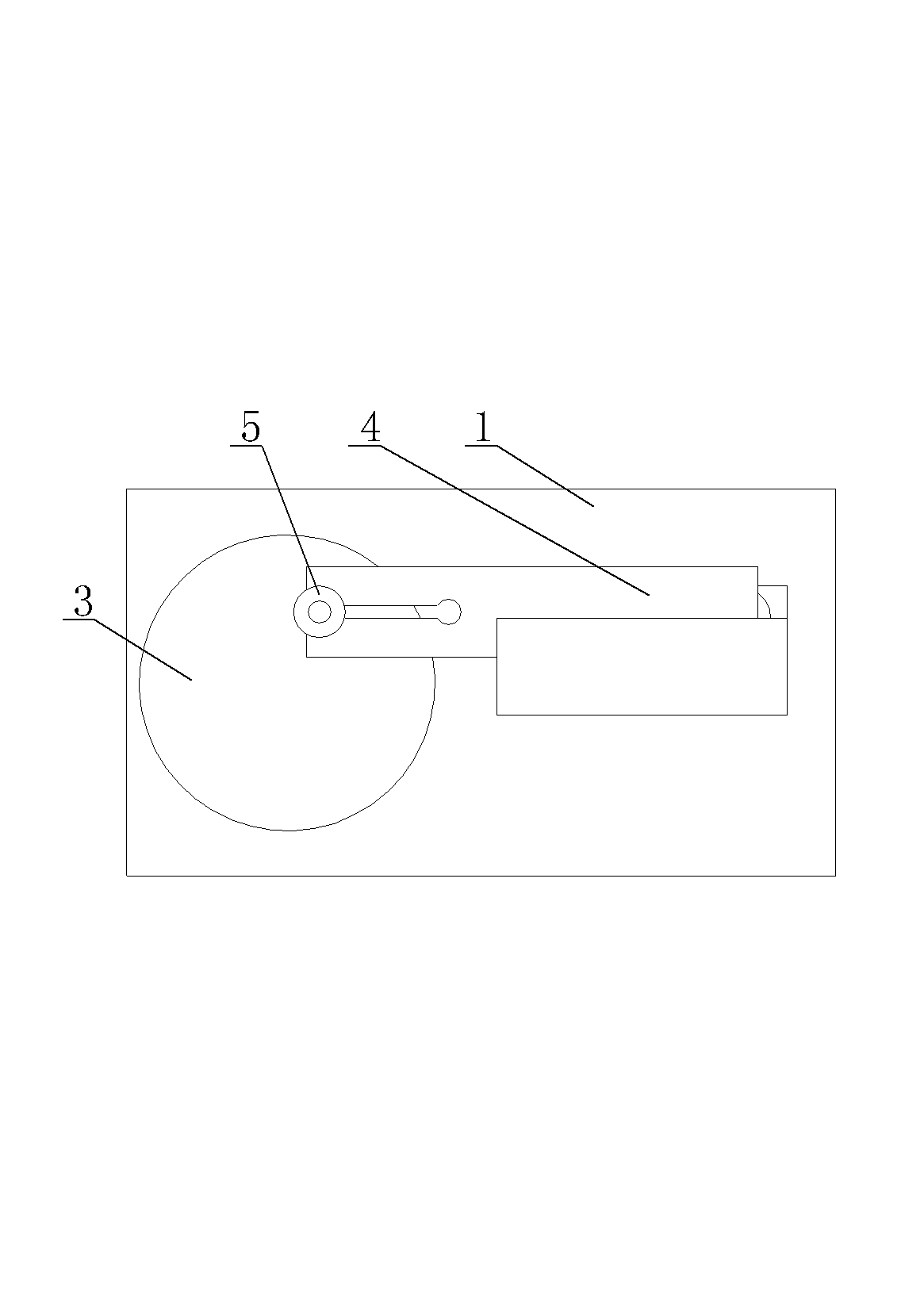

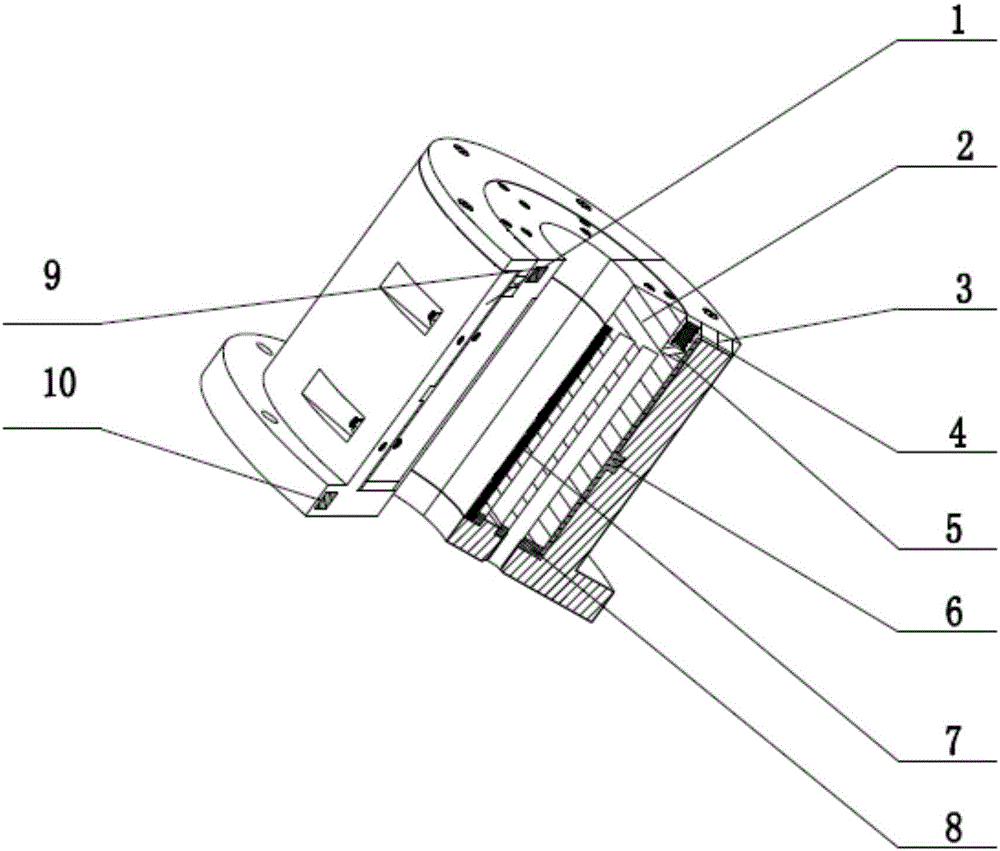

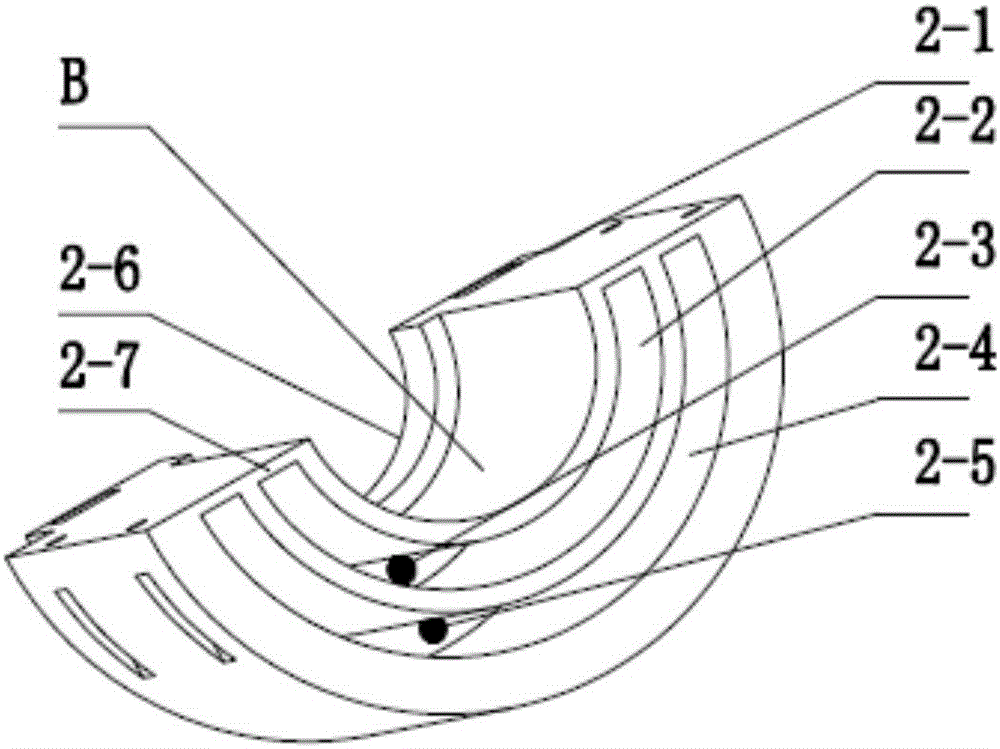

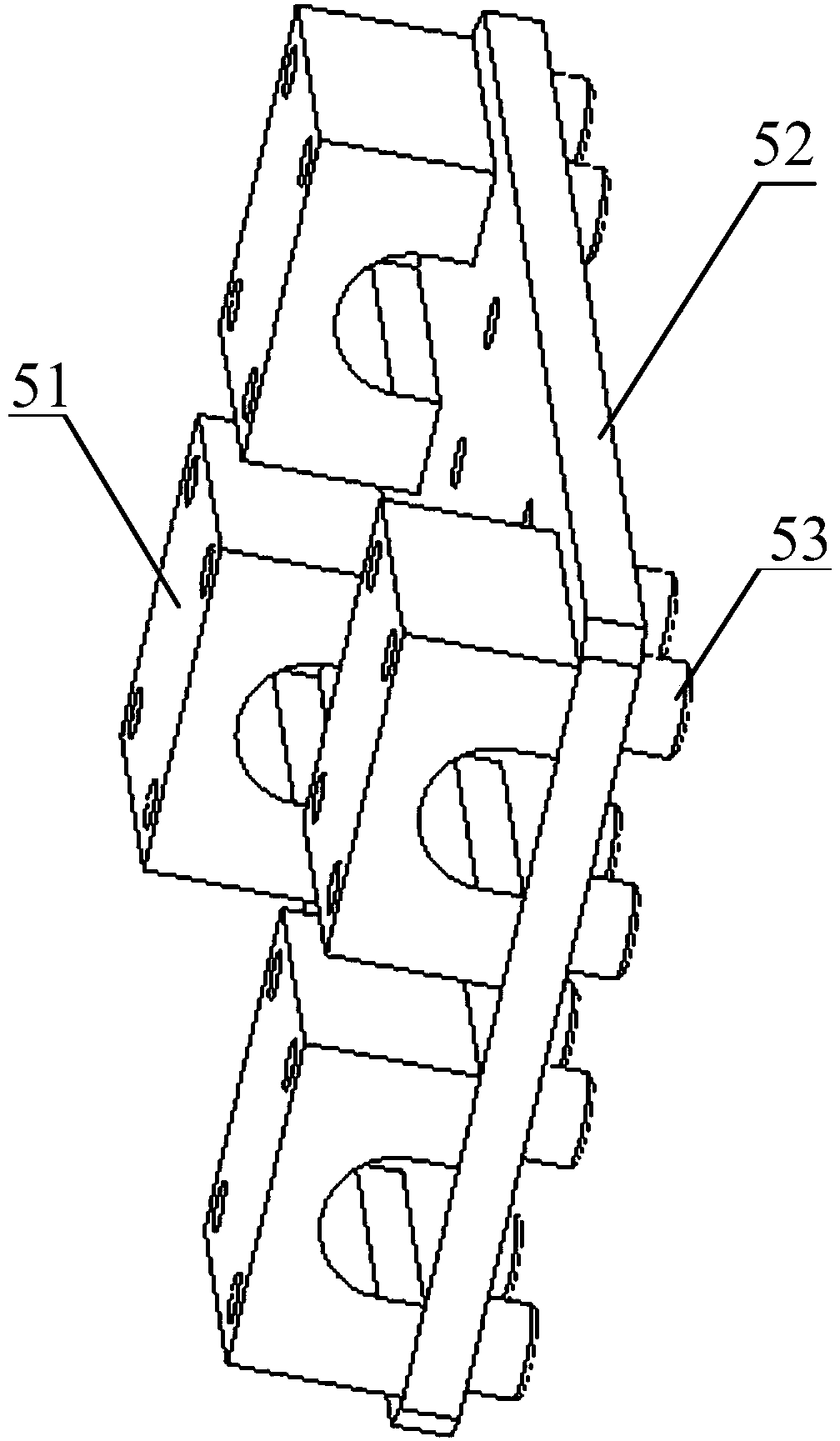

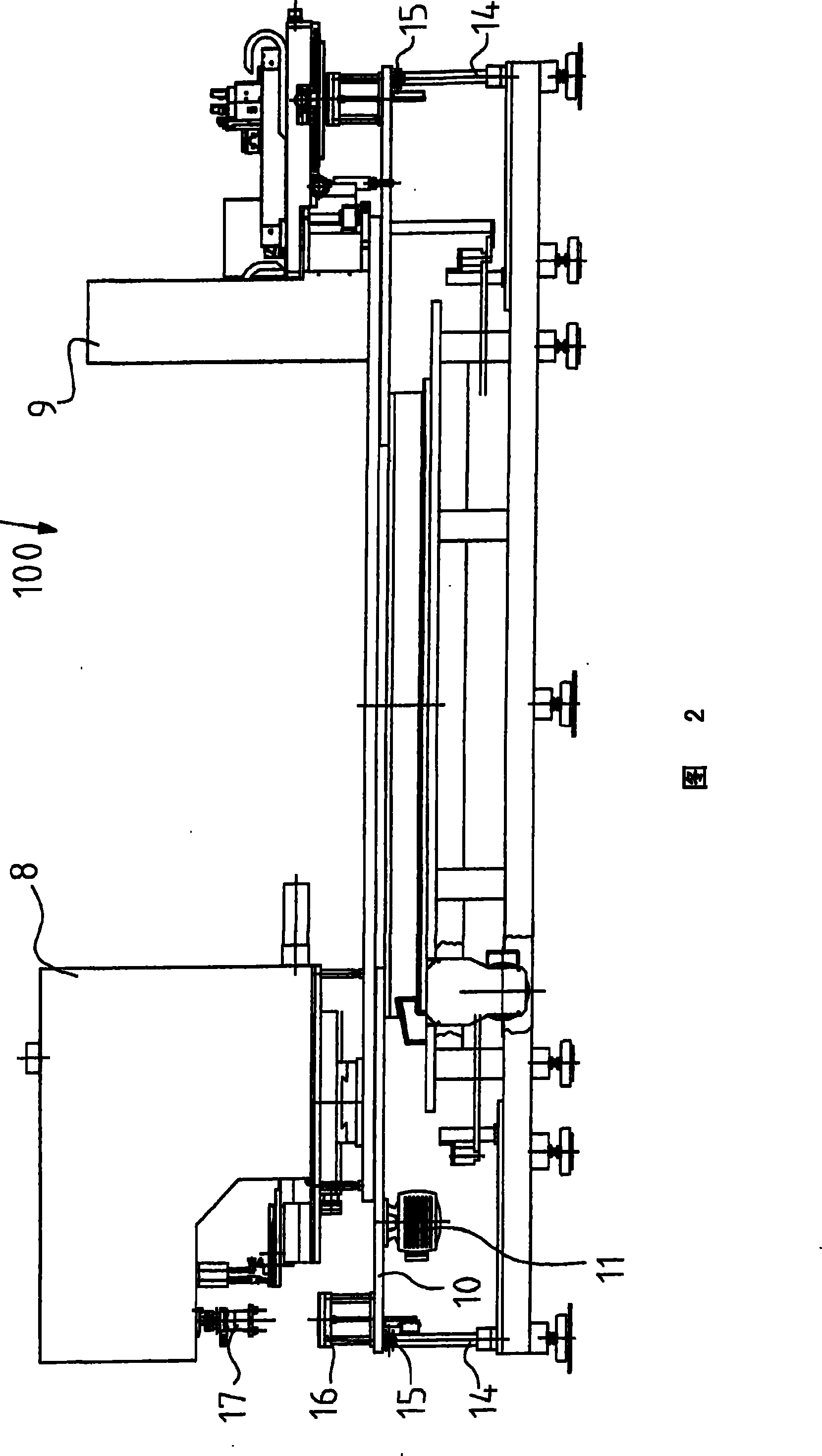

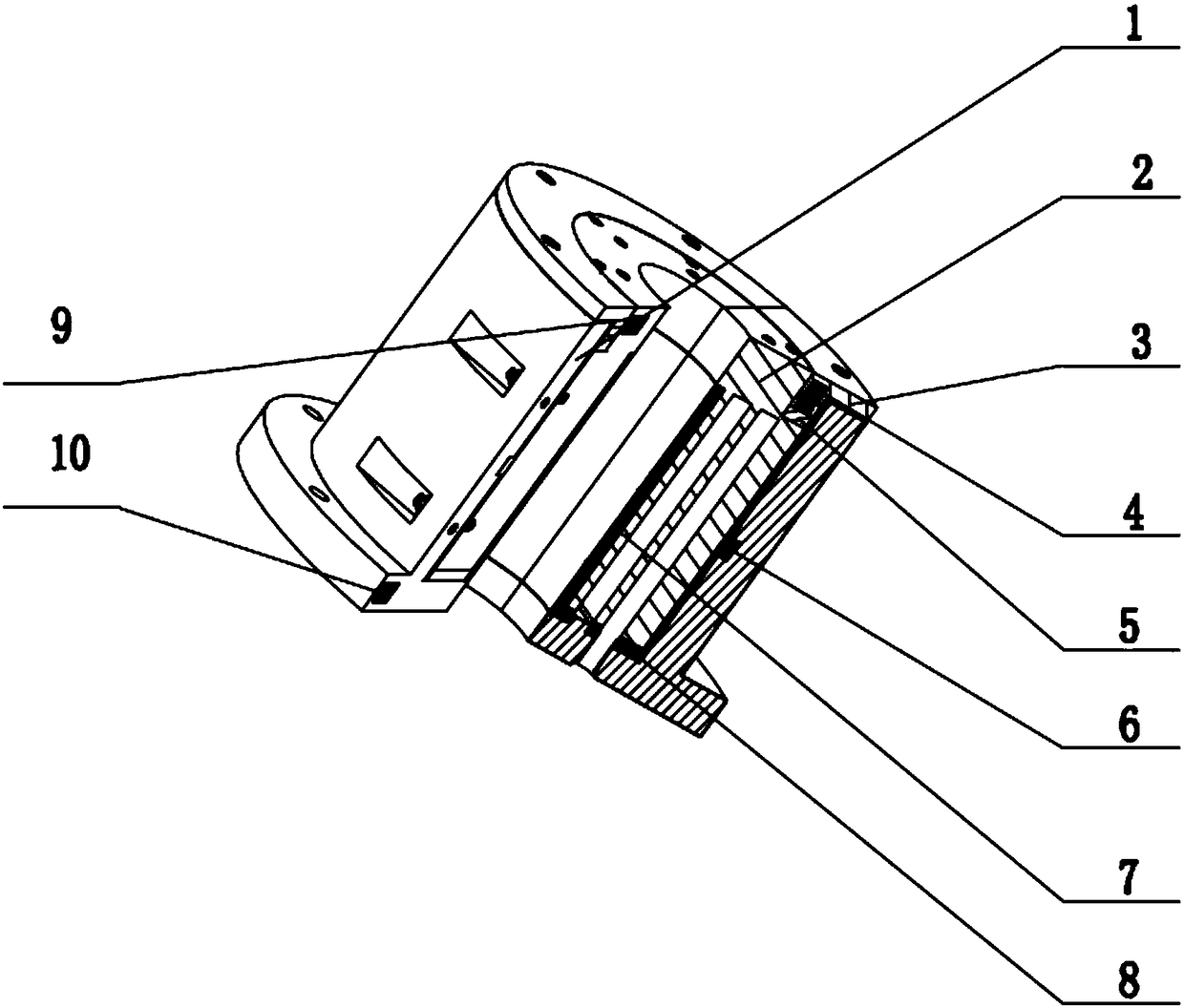

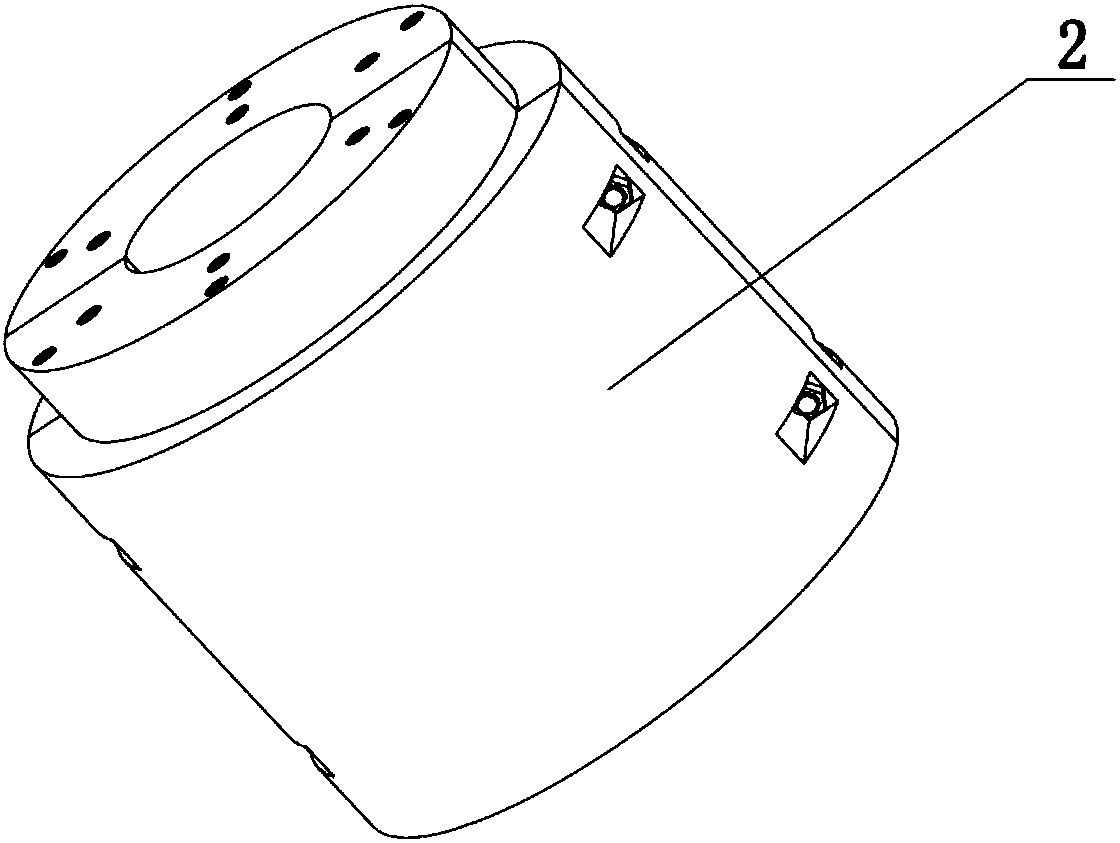

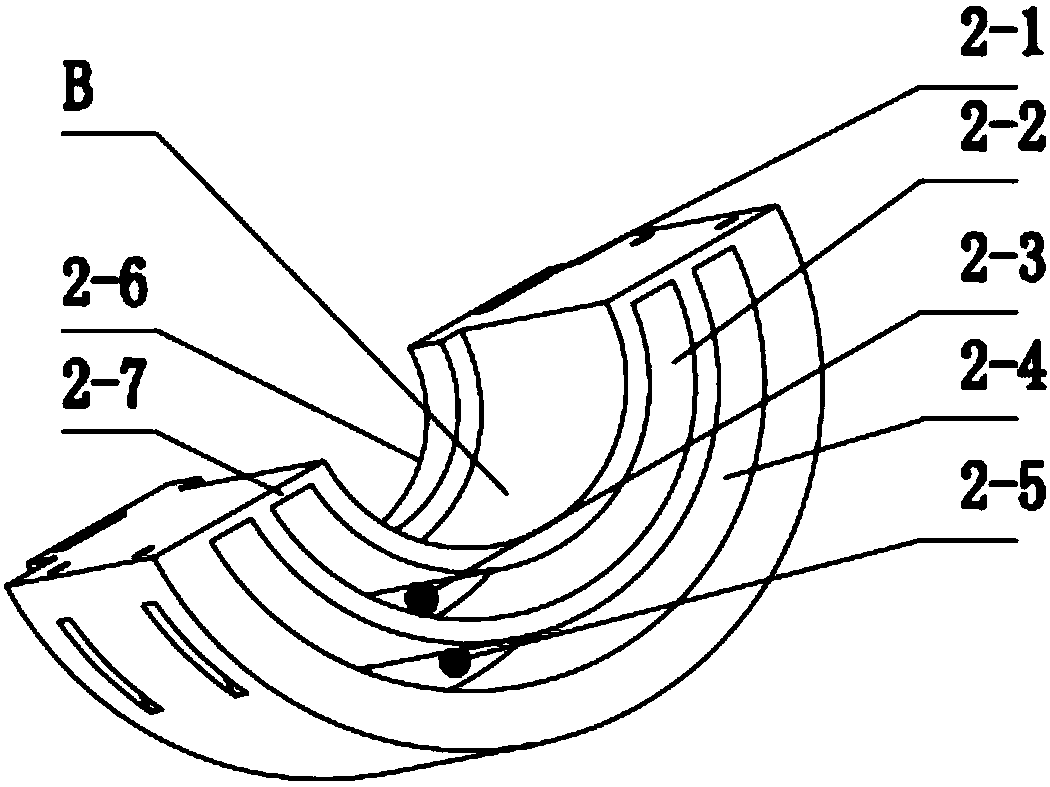

Throwing wheel assembly

InactiveUS20090149117A1Accurate radial positioningImpeller wheelsRotor bladesEngineeringMechanical engineering

A throwing wheel assembly including a wheel and a series of throwing blades mounted in radial channels in the wheel formed with mating dovetail wing portions on the slot sides and a projecting at the base of the blade. A sloping grove in the bottom of each channel engages a projecting ramp feature on the base of the mating blade received therein to cam the blade outwardly and thereby create a tight fit of the dovetail portions and to lock the blades in position.

Owner:ROBERTS SINTO A MICHIGAN

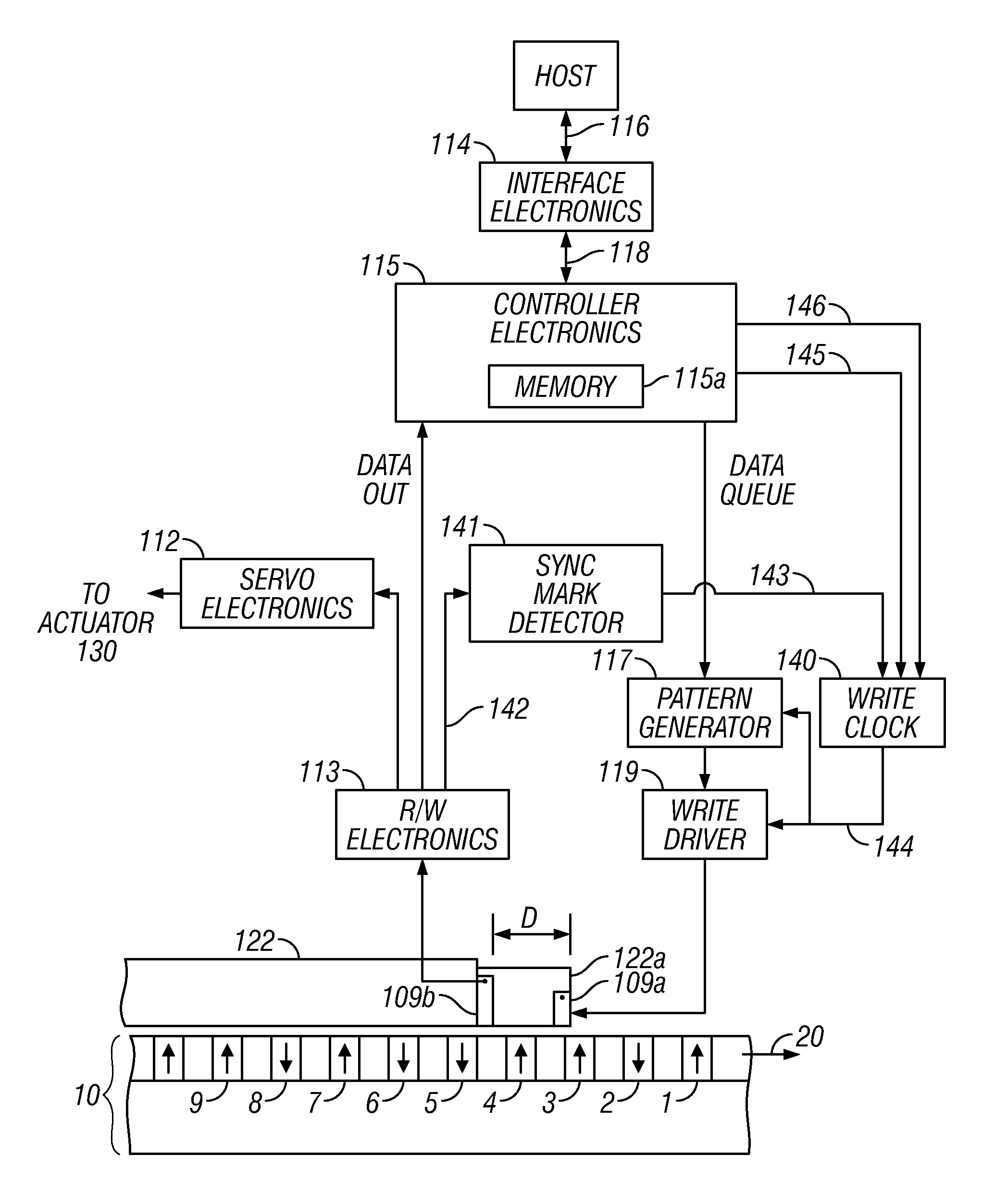

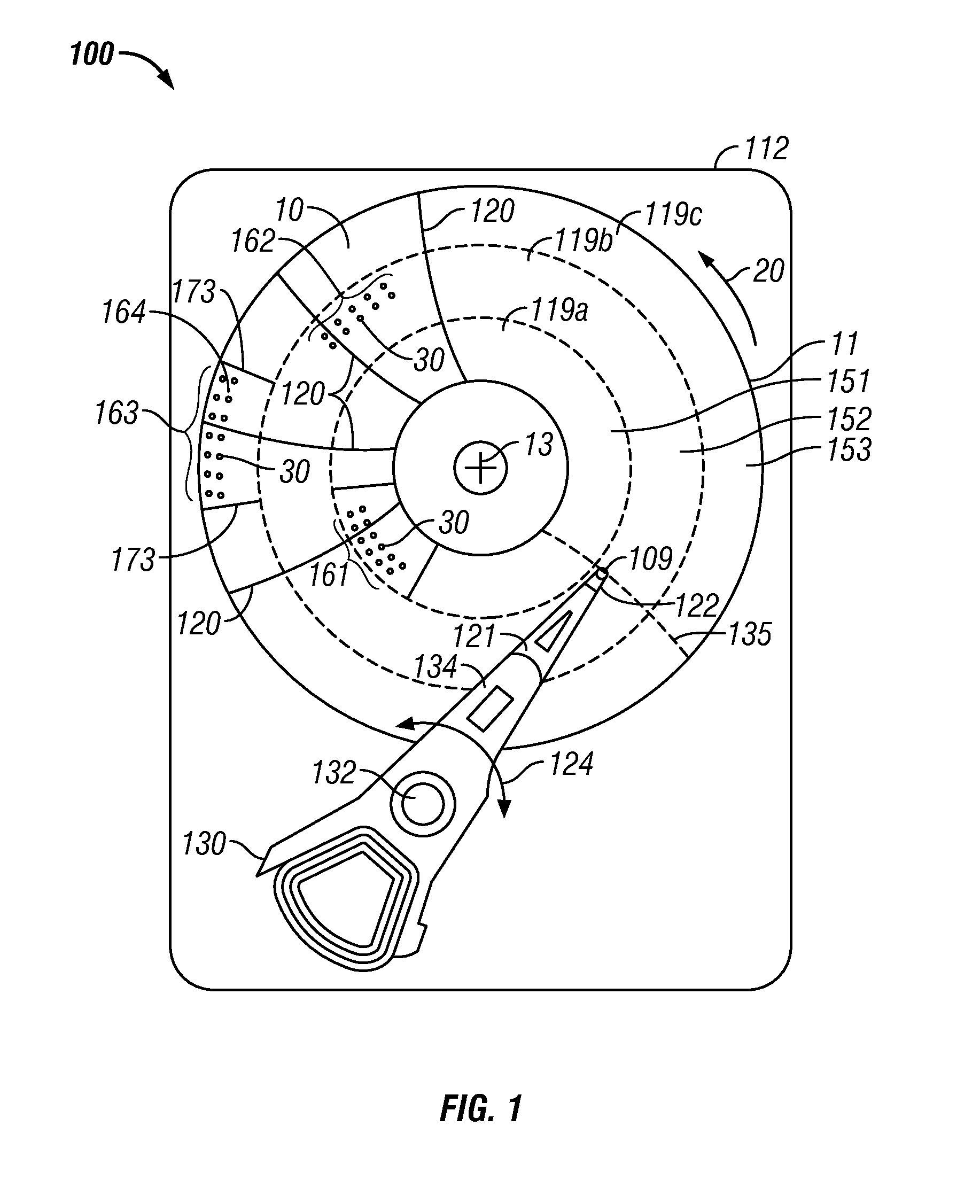

Patterned-media magnetic recording disk drive with data island misplacement information in the servo sectors

ActiveUS20110286125A1Accurate radial positioningModification of read/write signalsDriving/moving recording headsRadial positionComputer science

A disk drive with patterned-media disks has information recorded in the servo sectors that identifies misplacement of the data islands in the data regions between the servo sectors. This misplacement information is read from the servo sectors prior to writing to correct either or both the radial position of the write head and the timing of the write pulses to the data islands. The misplacement information may include radial deviation of the data tracks, circumferential or along-the-track misplacement of the data islands, or the location of defective data islands.

Owner:WESTERN DIGITAL TECH INC

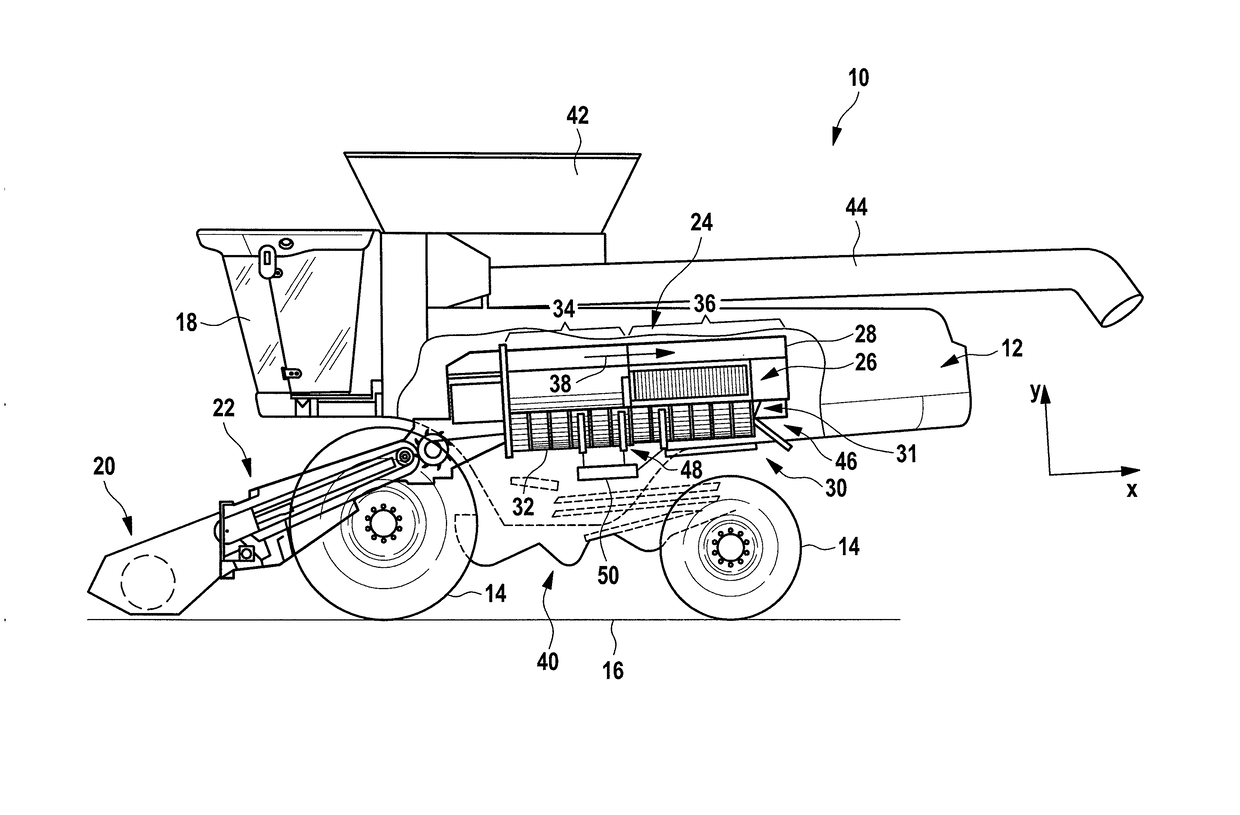

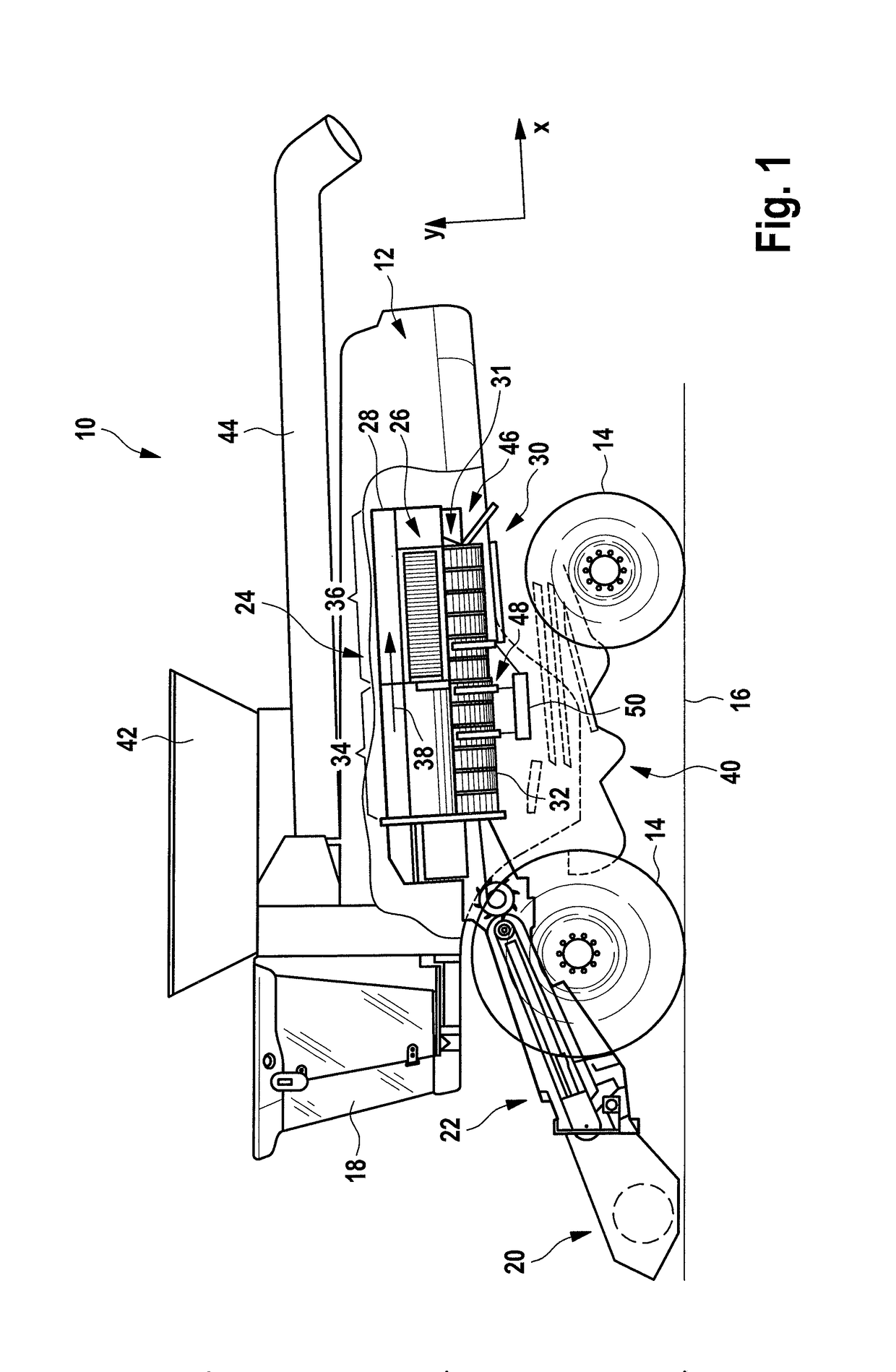

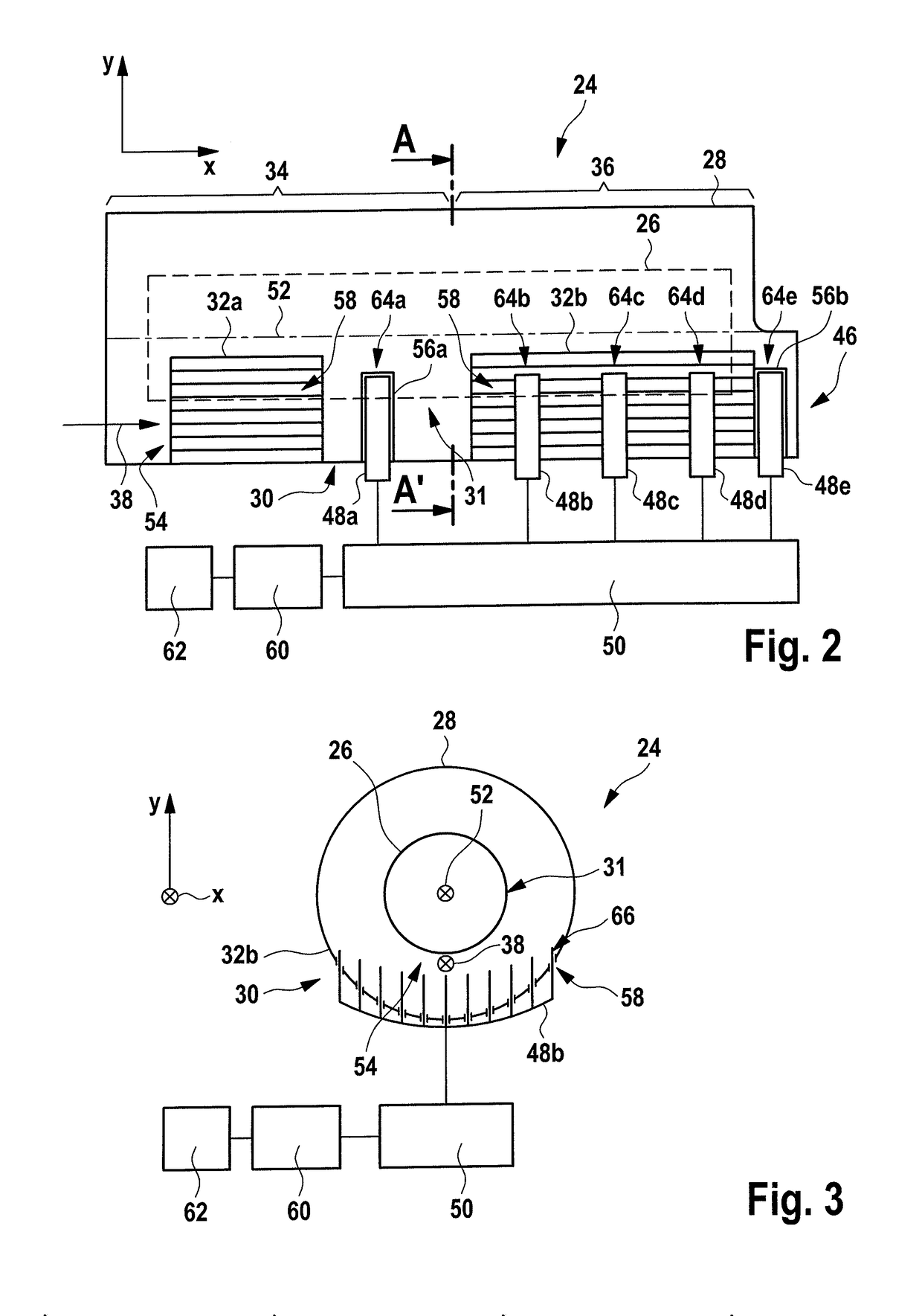

Device for Processing Harvested Crops and Method for Controlling the Flow of a Harvested Crop in the Device

An apparatus for processing harvested crops, in particular a threshing and / or separating apparatus, comprising a rotor which is mounted rotatably about its longitudinal axis, a separating device with a separating device region which at least partially surrounds a lower circumferential region of the rotor, the circumferential region being arranged below the longitudinal axis in an operationally ready state of the apparatus, and is arranged radially spaced apart from the rotor. A passage region for the harvested crop is formed between the separating device regions and the lower circumferential region of the rotor, wherein the separating device region extends along the longitudinal axis, and comprises at least one control element. The control element is movable into the passage region and / or into an axial projection of the passage, in order to control the flow of harvested crop.

Owner:KEMMNER HARTMUT

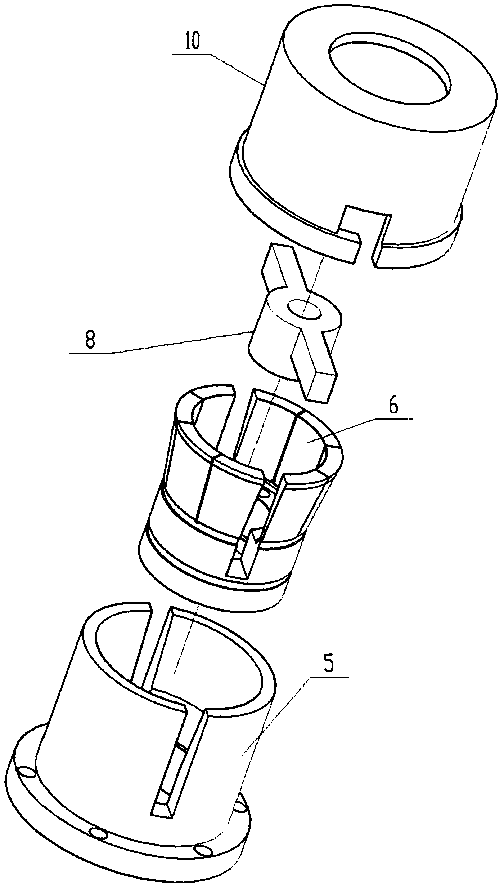

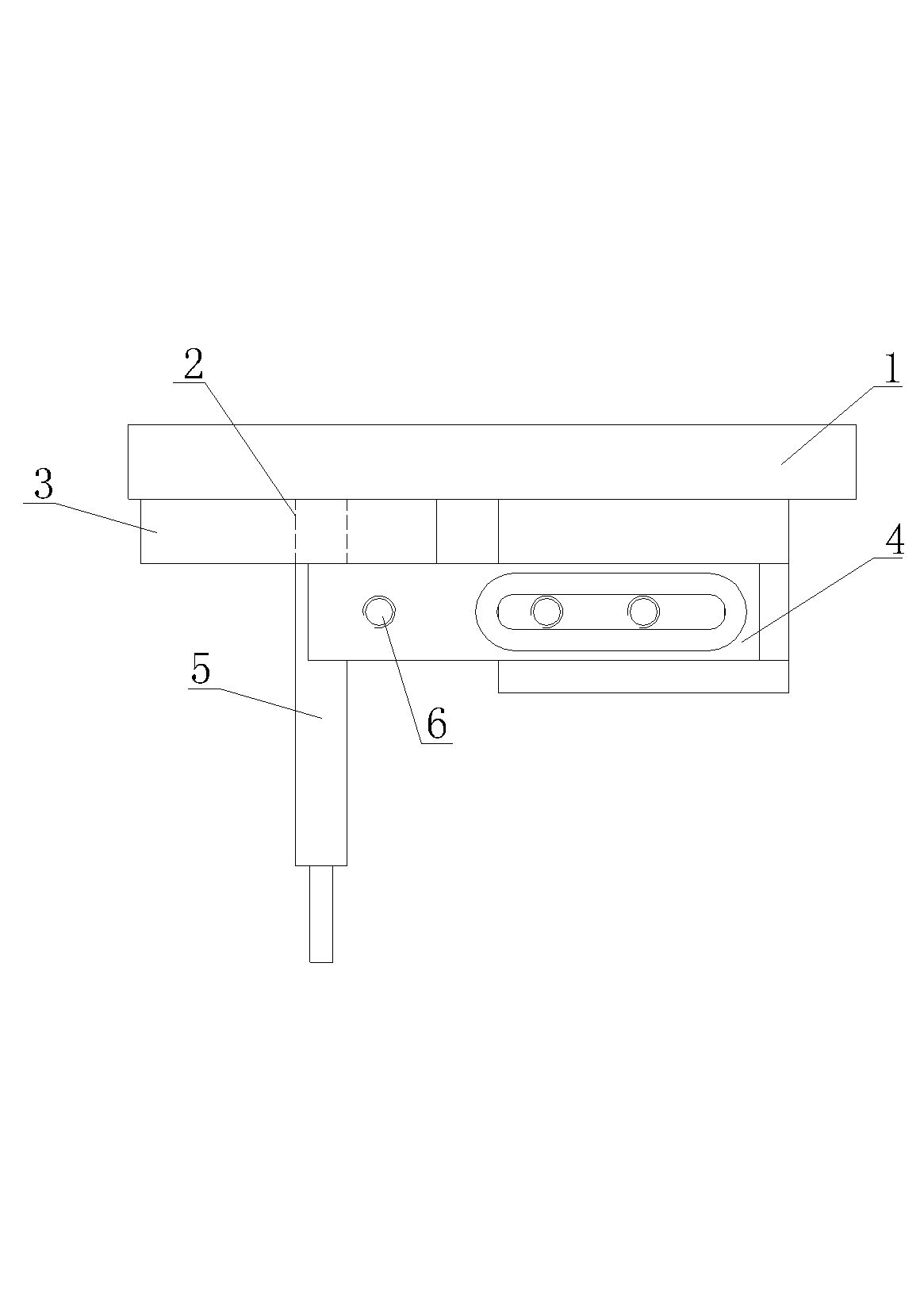

Buckle type reinforcing steel bar connection grouting sleeve and construction process

ActiveCN112900752AAccurate radial positioningImprove installation efficiencyBuilding reinforcementsArchitectural engineeringRebar

The invention discloses a buckle type reinforcing steel bar connection grouting sleeve which is simple and reliable in field construction operation and does not need a sealing ring and a construction process. The grouting sleeve comprises a sleeve connecting part; a first sleeve assembly and a second sleeve assembly which are connected in an inserted mode are arranged in the sleeve connecting part in a sleeved mode; each sleeve assembly comprises a sleeve; the inner wall of each sleeve is sleeved with a steel bar connecting block in a clamped mode; and threaded holes are formed in the ends, away from each other, of the two steel bar connecting blocks. Two prefabricated elements needing to be connected in a structure can be prepared separately, so that the installation efficiency of the prefabricated elements is improved, connection is more convenient and faster through the connection mode of the sleeve, and the working performance of the grouting sleeve is guaranteed.

Owner:SHANDONG JIANZHU UNIV

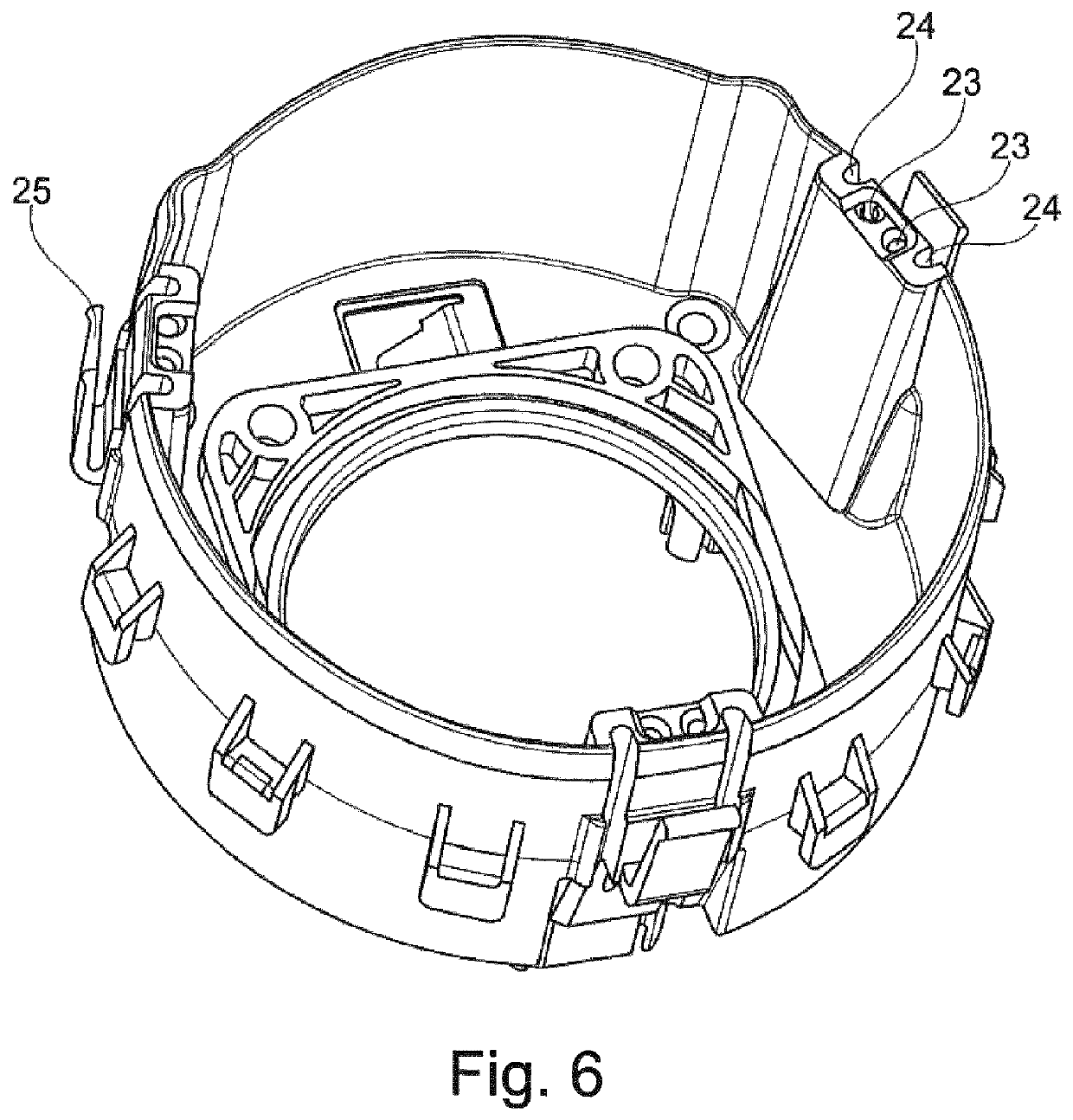

Steering wheel unit, airbag module, and steering wheel body

ActiveUS10532715B2Reduce weightEasy to producePedestrian/occupant safety arrangementPassengers carsSteering wheelAirbag

Owner:AUTOLIV DEV AB

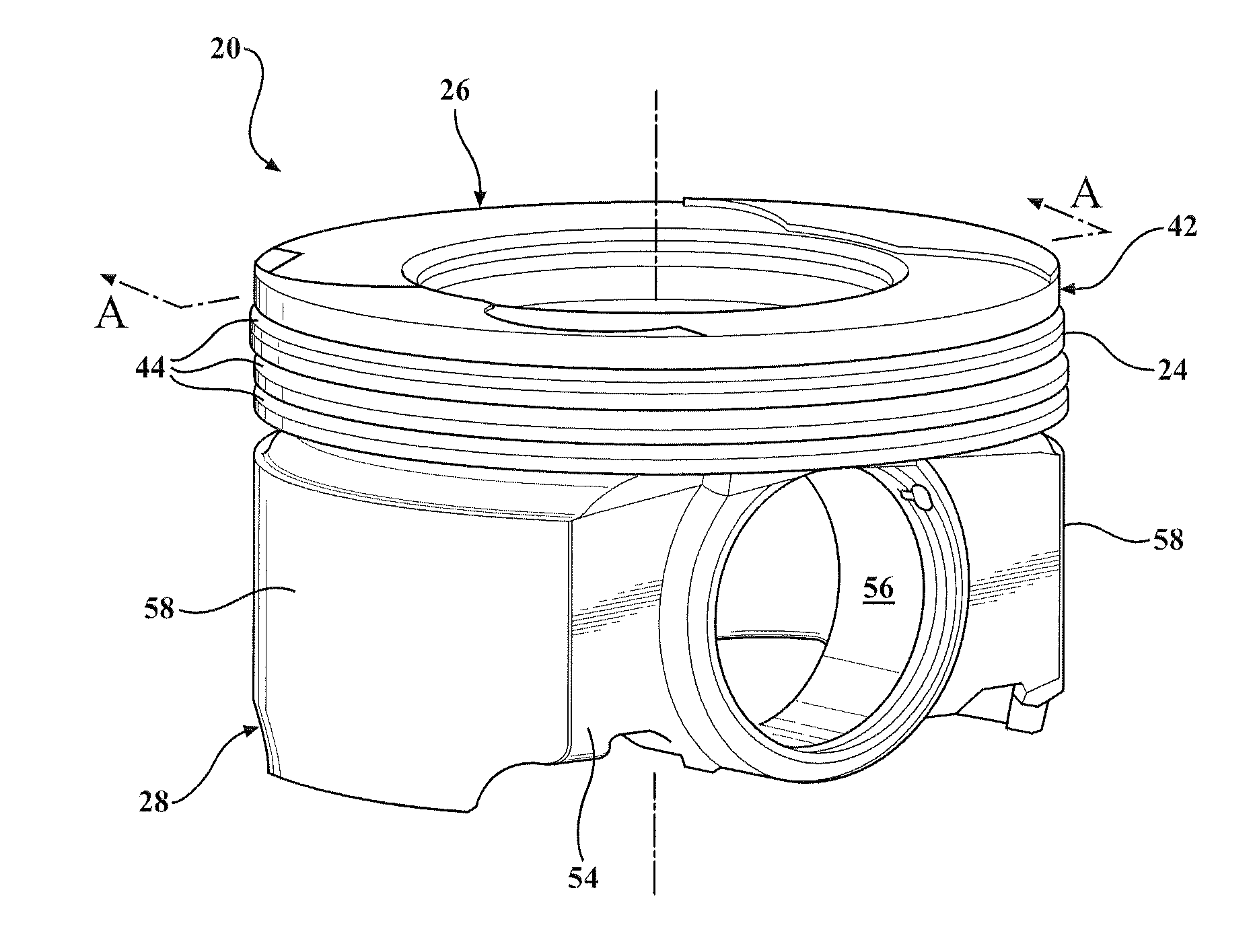

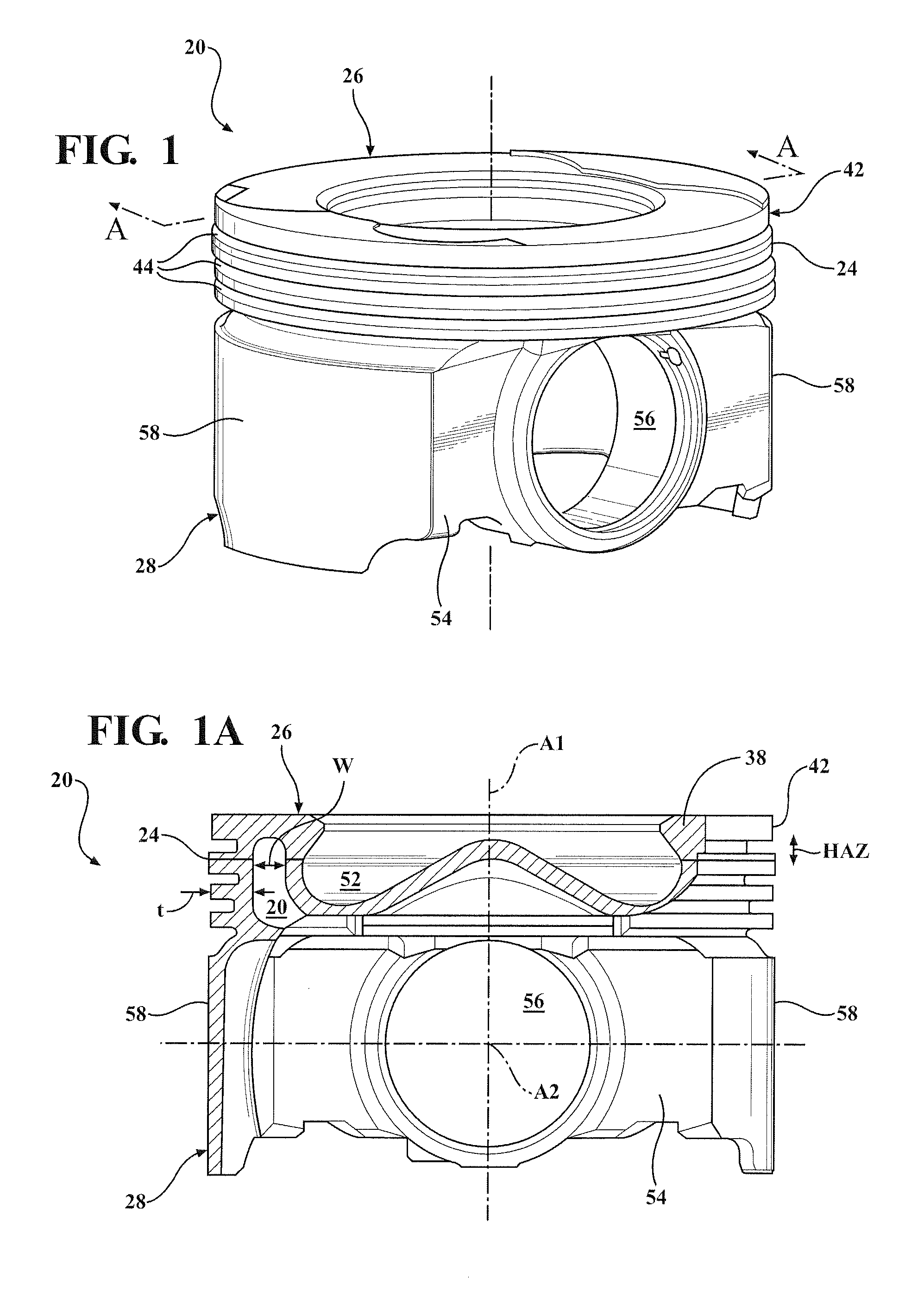

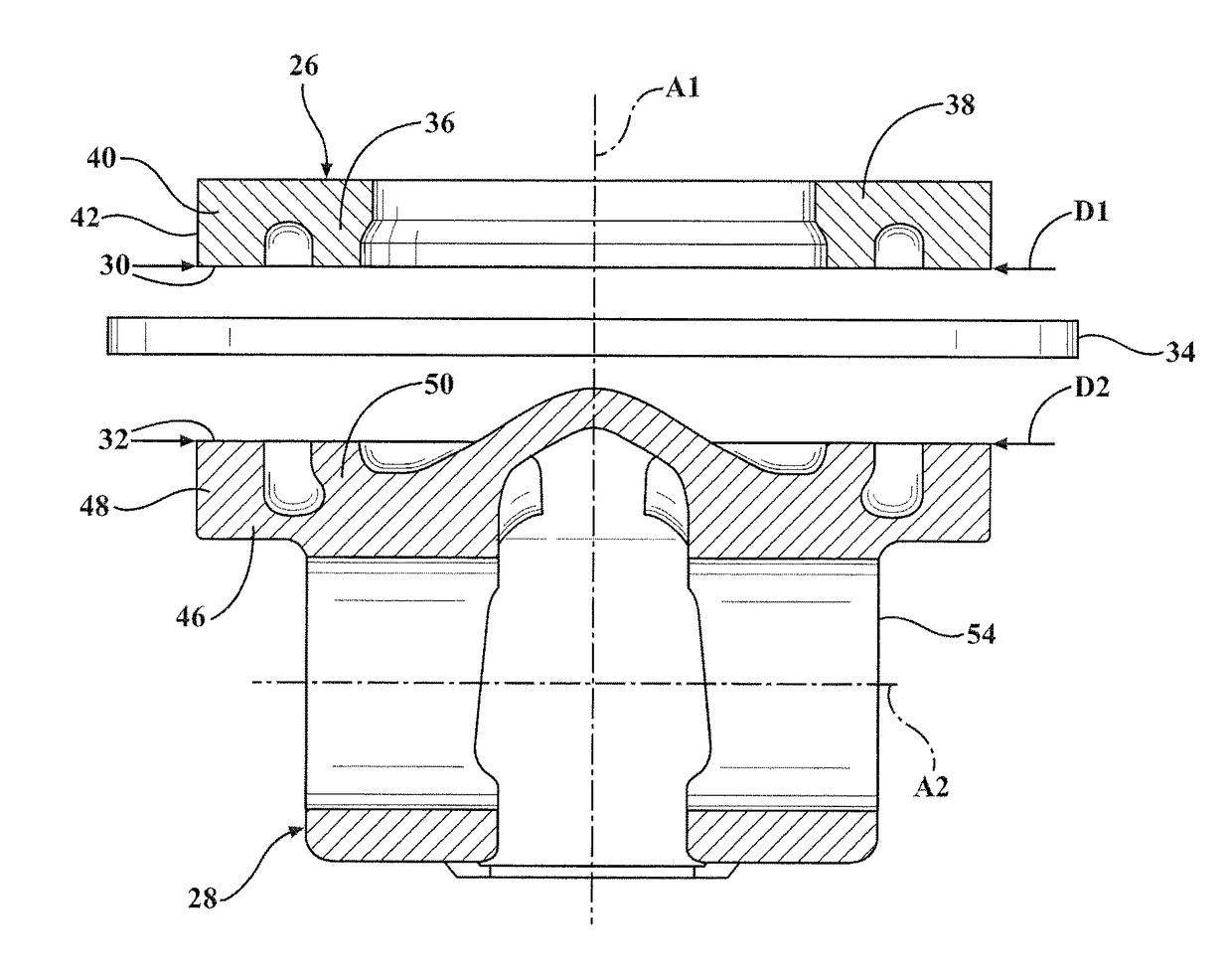

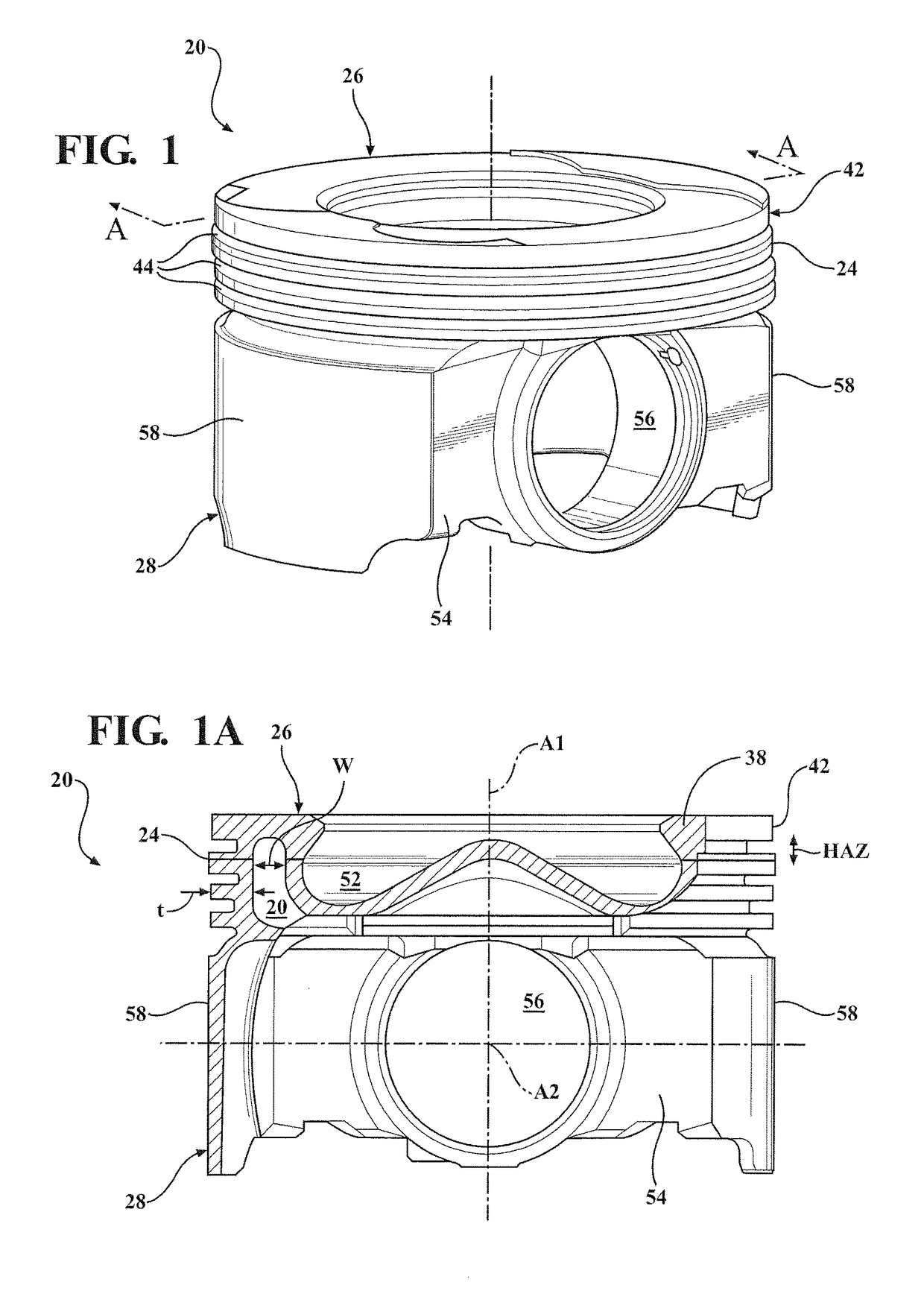

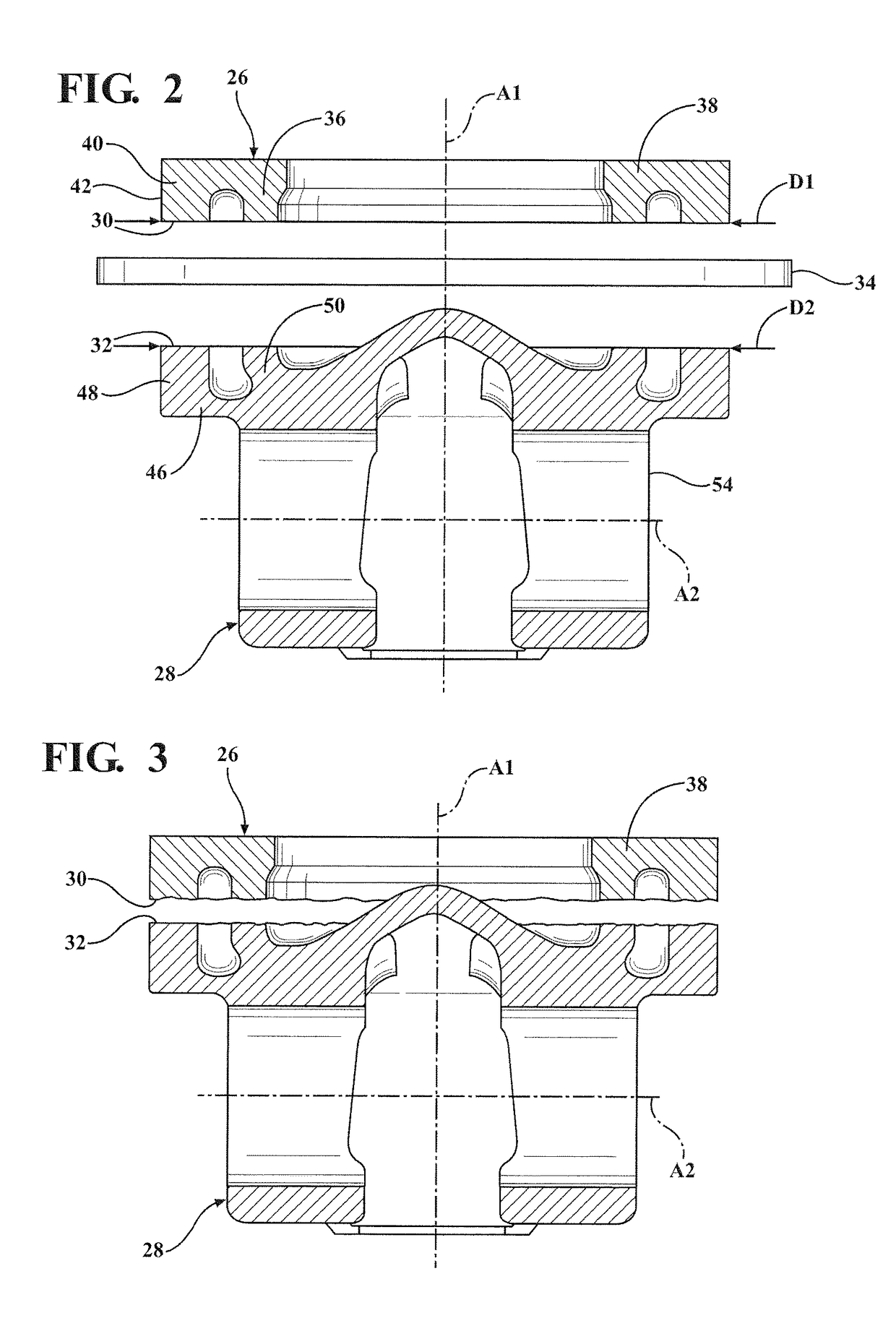

Hybrid induction welding process applied to piston manufacturing

ActiveUS20160061142A1Increase pressureIncrease volumePlungersMachines/enginesMaximum levelCooling chamber

A hybrid induction welded piston including an upper piston part welded to a lower piston part is provided. The piston is produced by induction heating the upper piston part and the lower piston part, and bringing the parts together to a part growth compensated position. The method then includes rotating the upper piston part 17 to 34 degrees clockwise and then 17 to 34 degrees counterclockwise. In addition to controlling the axial position and degree of rotation, the force applied to the piston parts is controlled so that preferably no flash is formed in a narrow cooling chamber of the piston. During the rotating steps, the pressure gradually increases to a maximum level which occurs while the upper piston part is rotating in the second direction. The piston includes a homogenous metallurgical bond across the weld and no indentation on the outer surface at the weld prior to machining.

Owner:TENNECO

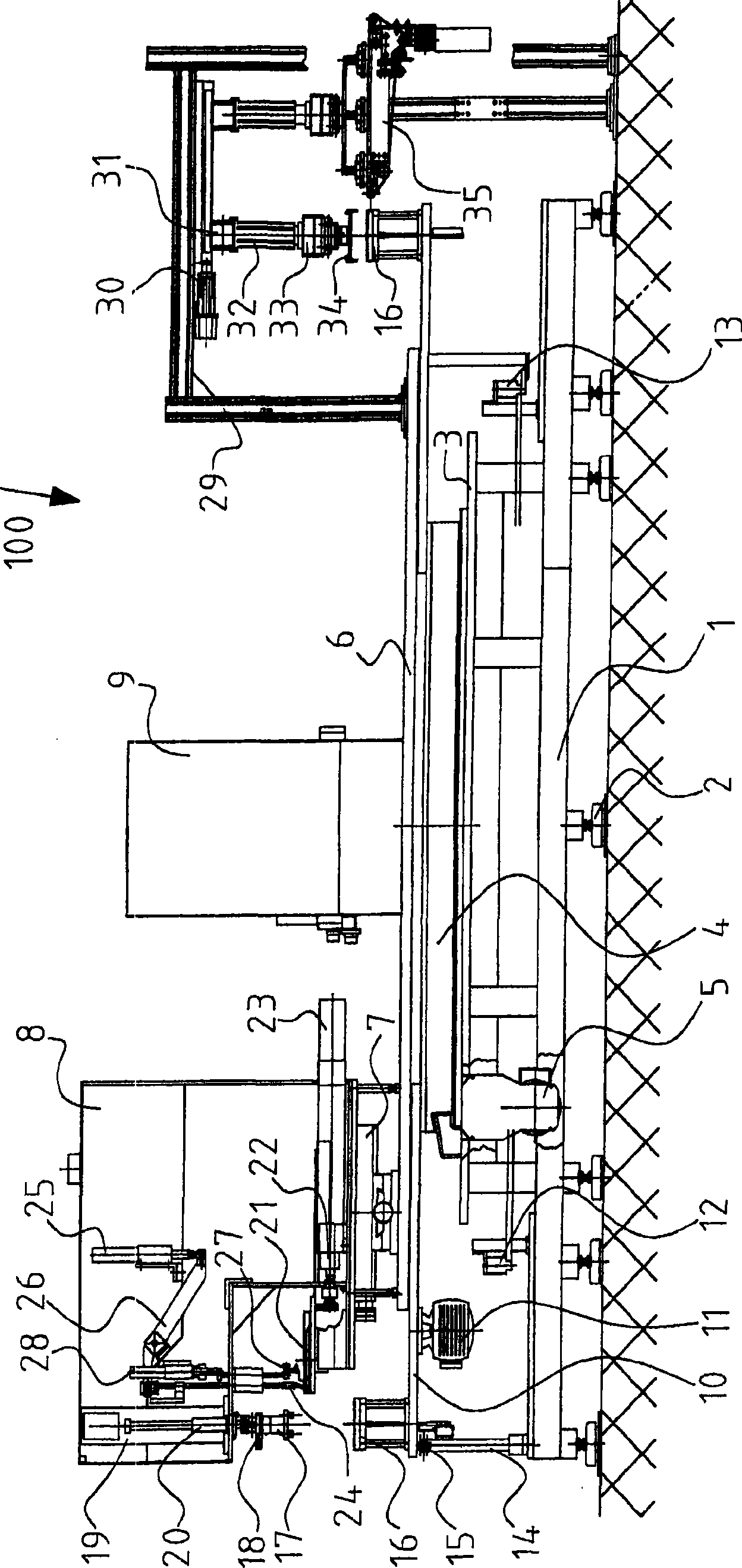

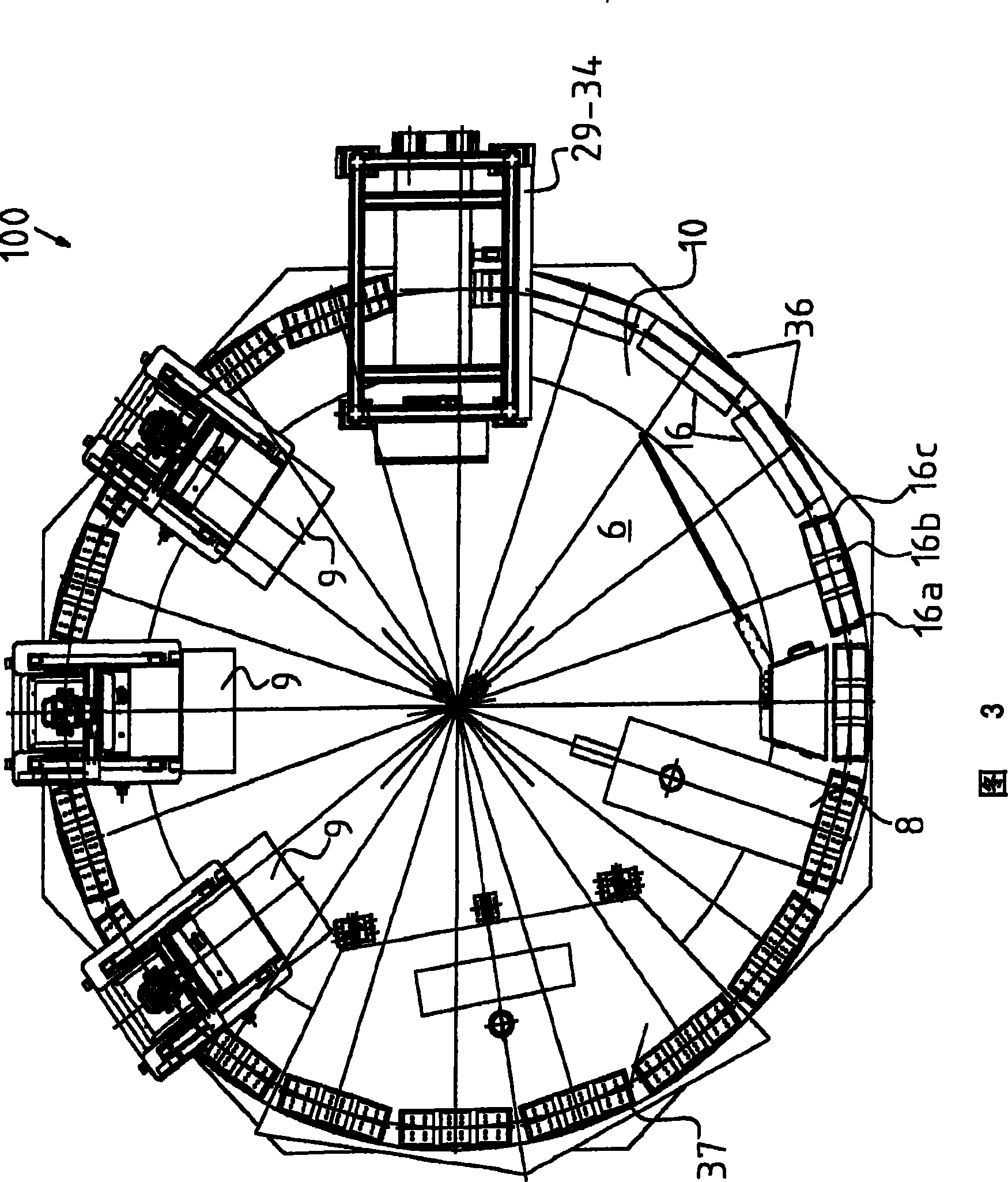

Device to coat metallic coating onto wafer

InactiveCN101533759AIncrease freedomAvoid mechanical stressSemiconductor/solid-state device manufacturingMetal coatingMechanical engineering

The present invention discloses a device (100) that used to coat a metal coating onto a wafer, wherein the device is provided with at least one printing apparatus (8, 9) and at least one work piece plug socket (16). The device is made for improving productivity and therefore is designed as arranging the work piece plug socket (16) on a rotary display stand (10) which could rotate relative to a foundation bed (6) and arranging the printing apparatus (8, 9) on the foundation bed.

Owner:COLORFUL TC PRINTING MACHINES

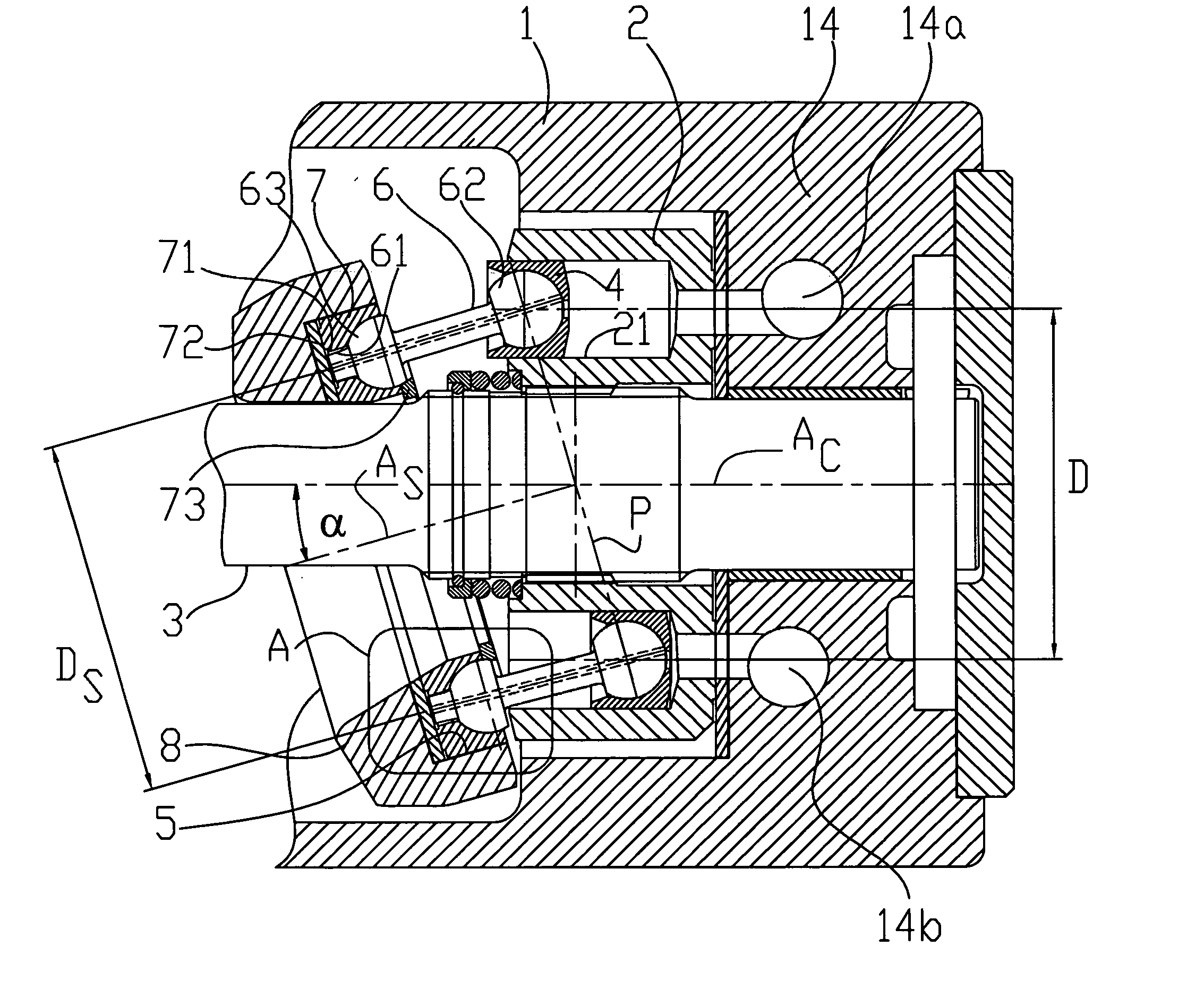

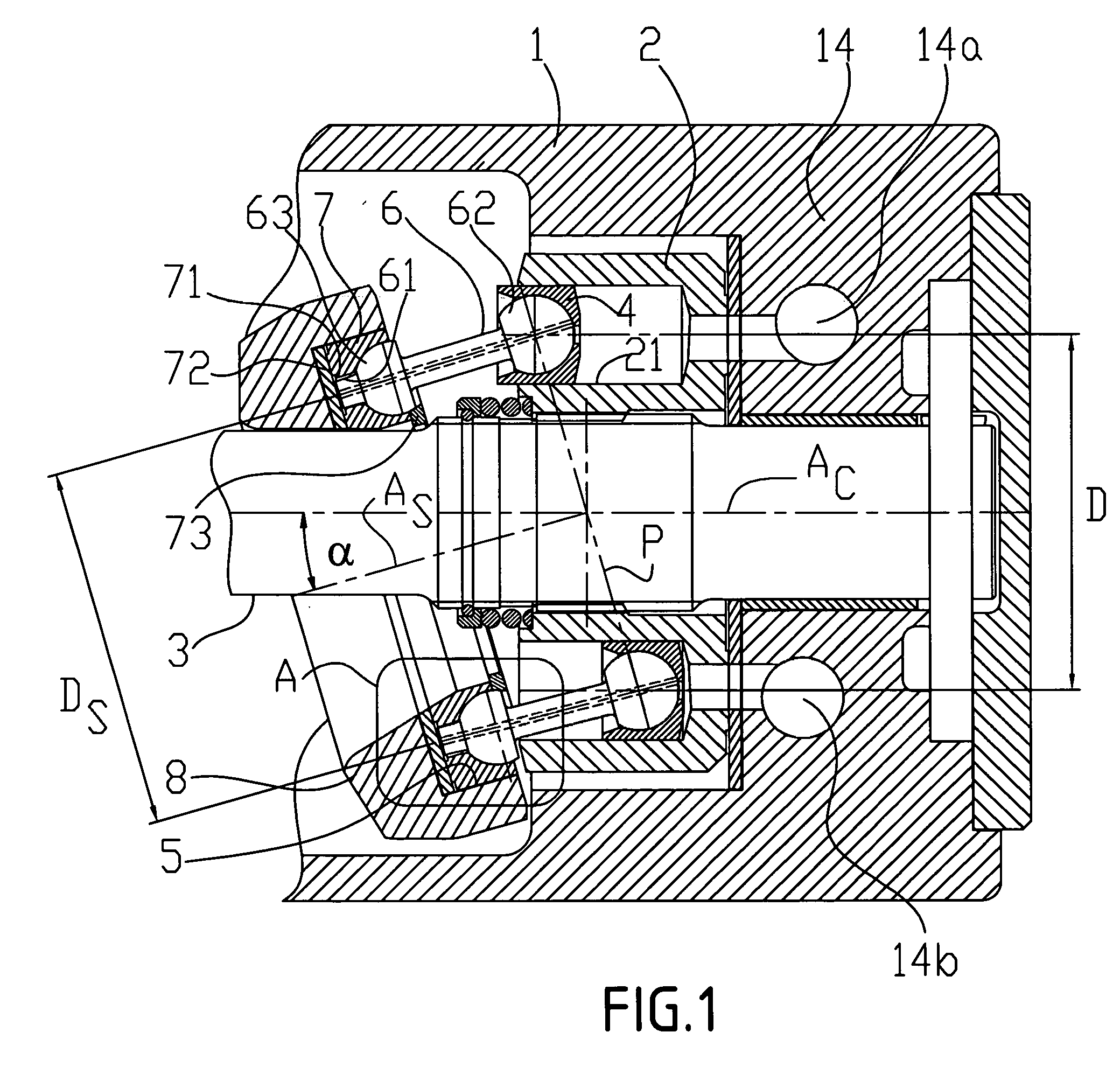

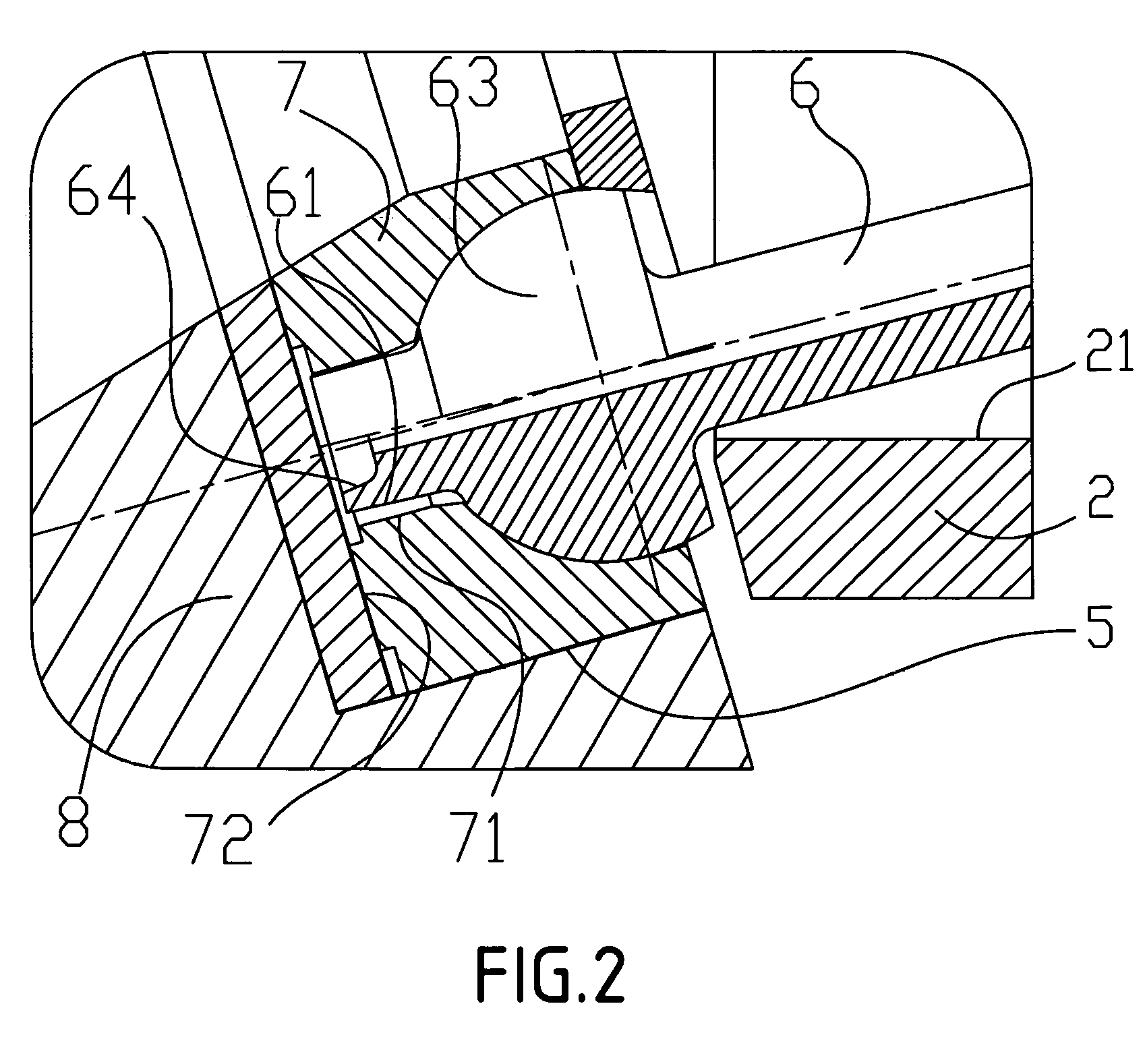

Axial piston machine with a swash plate

ActiveUS7013791B2Avoid shockAvoid irregularitiesPump componentsMulti-stage pumpsSlide plateSpherical joint

The axial piston machine comprises a case, a shaft and a cylinder block (2), arranged so as to rotate in the case and having a plurality of cylinders (21) with pistons, adapted to slide in said cylinders and connected to piston rods (6) by means of first spherical joints, the piston rods being connected to a sliding plate (7) by means of second spherical joints (63), said sliding plate (7) being supported by a swash plate (8) via a bearing (72). For the connection between a piston rod (6) and the sliding plate (7), the machine further comprises a first driving rotational surface (61) linked to the piston rod (6) and a corresponding second driving rotational surface (71) linked to the sliding plate (7), a clearance being left between said first driving rotational surface (61) and said second driving rotational surface (71) and said surfaces being adjacent.

Owner:SA POCLAIN HYDRAULICS B P

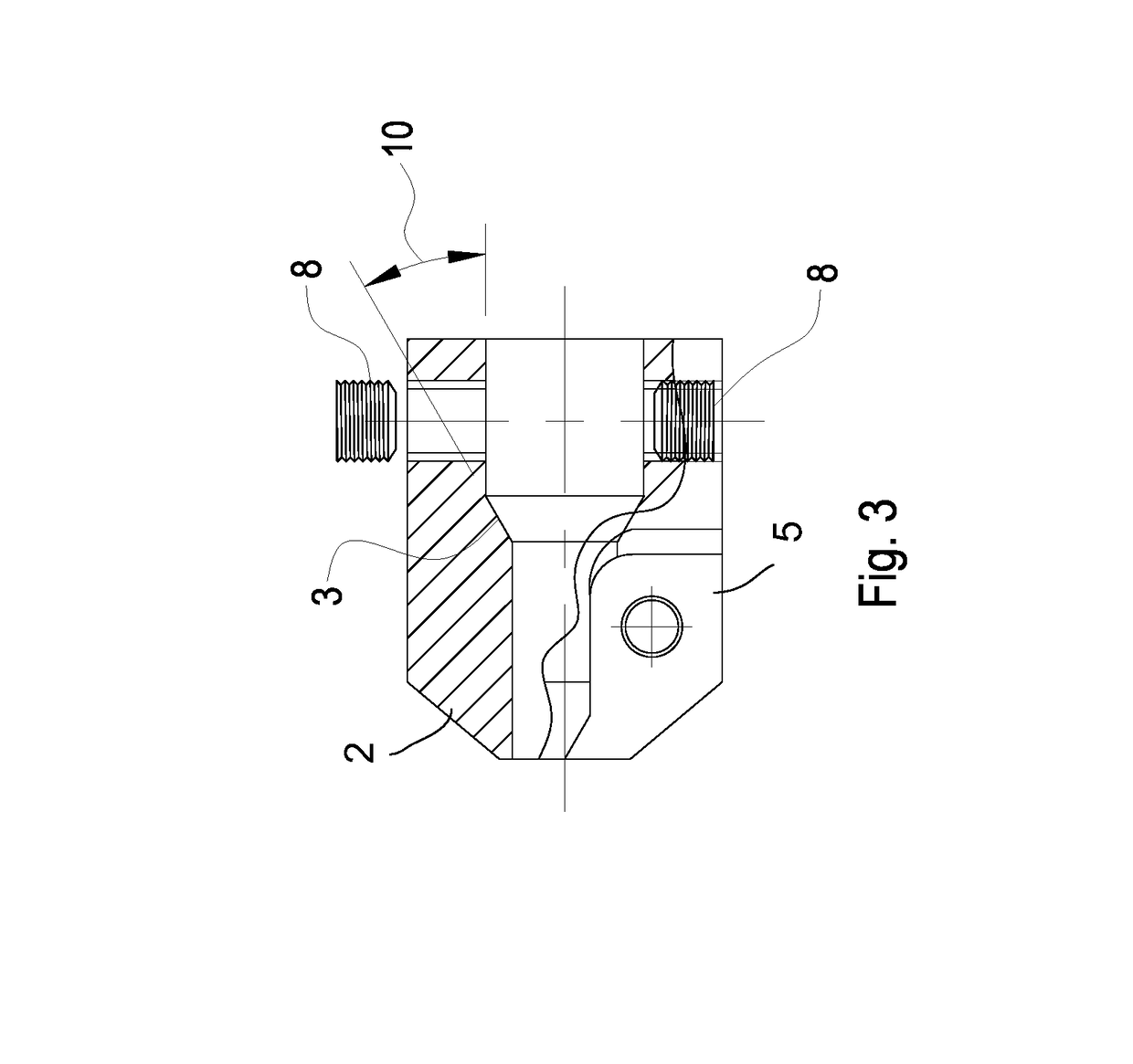

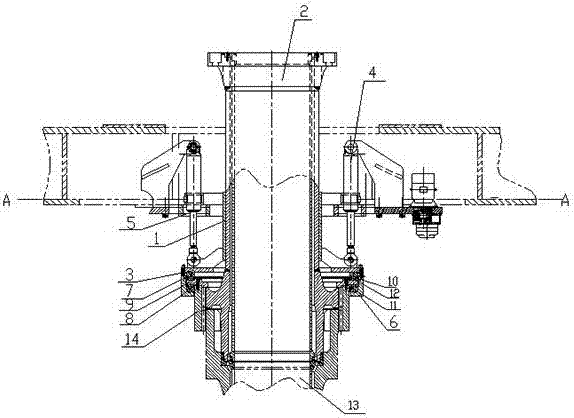

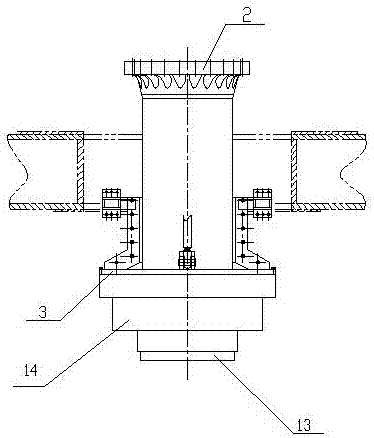

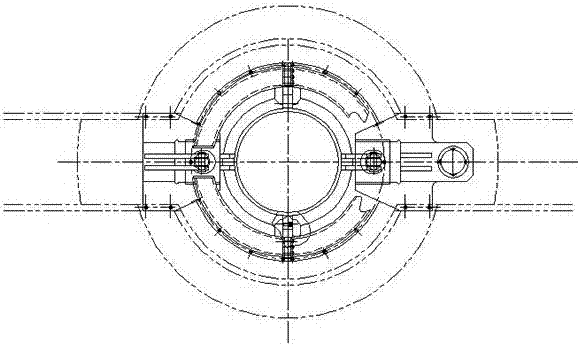

Quick mounting and dismounting device for drill rod

PendingCN107975348AEasy to operateReduce labor intensityDrilling rodsDrilling casingsSteel ballUltimate tensile strength

The invention provides a quick mounting and dismounting device for a drill rod. The quick mounting and dismounting device is used for inner tooth embedded outer gear type drill rods of an engineeringdriller and mainly composed of a protection cylinder mechanism, a driving mechanism and an executing mechanism. A cylinder capable of moving up and down long a short connection drill rod is arranged on the upper portion of the protection cylinder mechanism, the outer surface of the short connection drill rod is sleeved with the cylinder, and an annular steel plate is arranged on the lower portionof the protection cylinder mechanism and connected with the driving mechanism and the executing mechanism. The driving mechanism adopts hydraulic oil cylinders, operation is convenient and quick, andthe labor intensity is relieved. The executing mechanism is provided with roller ways and a steel ball, the problem that the short connection drill rod drives the dismounting device to rotate is solved, and quick dismounting and mounting between the short connection drill rod and the drill rod can be achieved.

Owner:PINGMEI JIANGONG GRP SPECIAL DRILLING ENG CO LTD

Steering wheel unit, airbag module, and steering wheel body

ActiveUS20180126939A1Reduce weightEasy to producePedestrian/occupant safety arrangementPassengers carsSteering wheelEngineering

A steering wheel unit (10) for a motor vehicle having, a steering wheel body (12), an airbag module (20) accommodated in a hub region of the steering wheel body (12), which includes a housing (22), an inflator connected to the housing (22), and an airbag (29) folded into the housing (22), and at least three axial positioning units which define the axial position of the housing (22) when not pressed down with respect to the steering wheel body (12). Each of the three axial positioning units include an axial positioning element (40) connected on the module side to the housing (22), or an axial positioning element connected to the steering wheel body on the steering wheel body side, wherein the positioning element features a metal support unit (42). The at least three support units (42) are elements separate from each other.

Owner:AUTOLIV DEV AB

Automatic clamp for external holding positioning and end face pressing for thin-wall sleeve

PendingCN110640521AAchieve clampingDifficulties in realizing clamping deformationExpansion mandrelsPositioning apparatusStructural engineeringLever pressing

The invention provides an automatic clamp for external holding positioning and end face pressing for a thin-wall sleeve, and belongs to the field of machining. According to the automatic clamp, a clamp body is arranged on a transition flange, the left end of the clamp body is provided with a circular hole, and the right end of the clamp body is provided with a conical hole; an external holding elastic sleeve is concentrically arranged in the clamp body, the left end of the external holding elastic sleeve is matched with the circular hole of the clamp body, and the right end of the external holding elastic sleeve and the conical hole of the clamp body form a conical surface holding-tightly structure; a column body of a pressing rod is matched with an inner hole at the left end of the external holding elastic sleeve, a disc spring is arranged between the column body of the pressing rod and the inner hole at the left end of the external holding elastic sleeve, a rod body of the pressing rod extends out of the clamp body through a through rectangular groove in the external holding elastic sleeve and the clamp body, and the pressing rod is connected with a machine tool pull rod throughusing a screw; an end face pressing sleeve concentrically sleeves on the clamp body, and L-shaped through grooves on the pressing sleeve is buckled with the rod body of the pressing rod; an internal supporting ring, an external supporting ring and supporting rods form a frame to sleeve on the two sides of the external holding elastic sleeve and the pressing rod; and the thin-wall sleeve is placedin an inner hole of the right end of the external holding elastic sleeve, and is axially positioned by the external supporting ring, the external holding elastic sleeve holds the thin-wall sleeve by the pressing rod through the disc spring, the end face of the thin-wall sleeve is pressed by the end face pressing sleeve at the same time, and the problem of clamping deformation of the thin-wall sleeve is solved.

Owner:合肥波林新材料股份有限公司

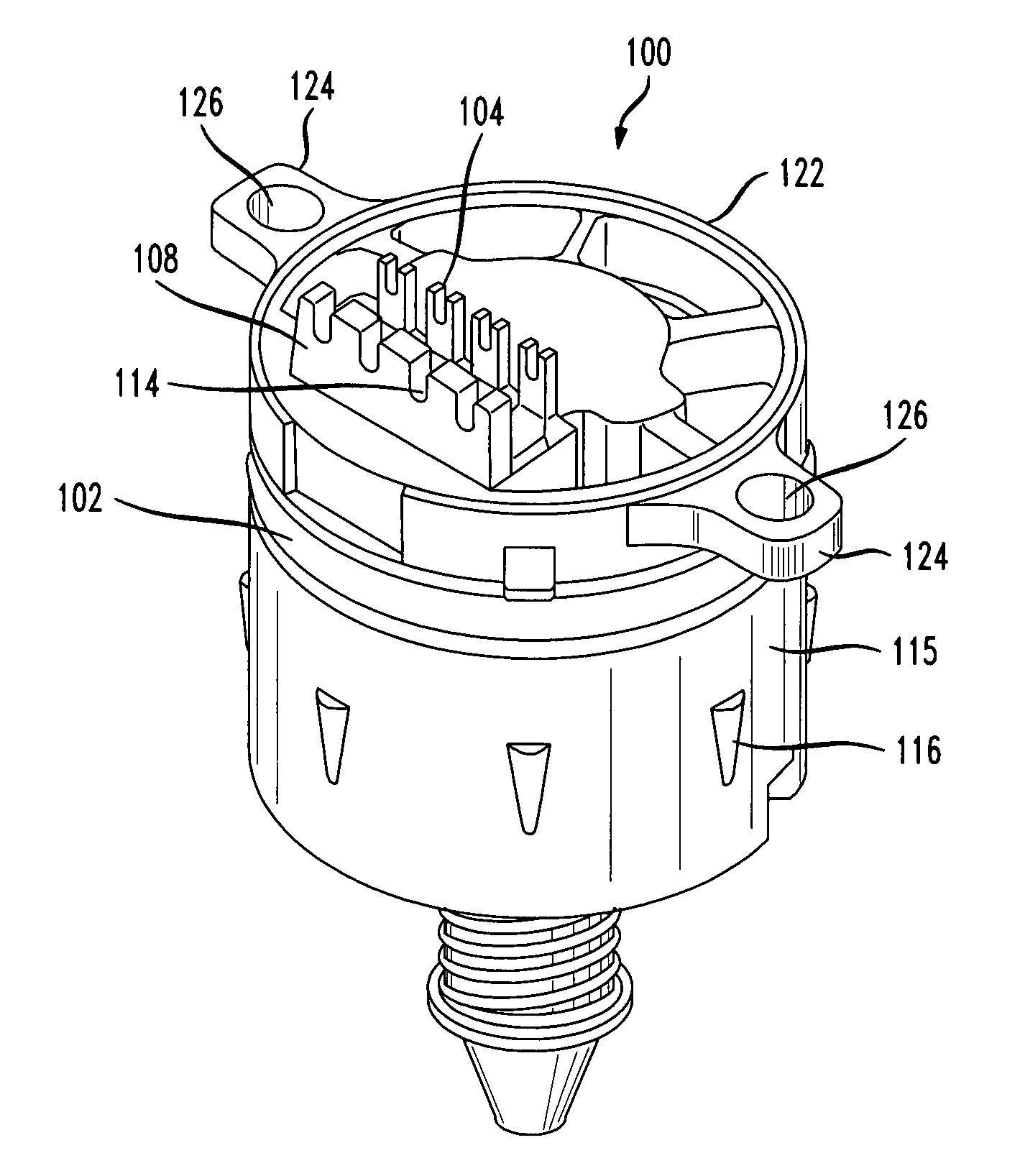

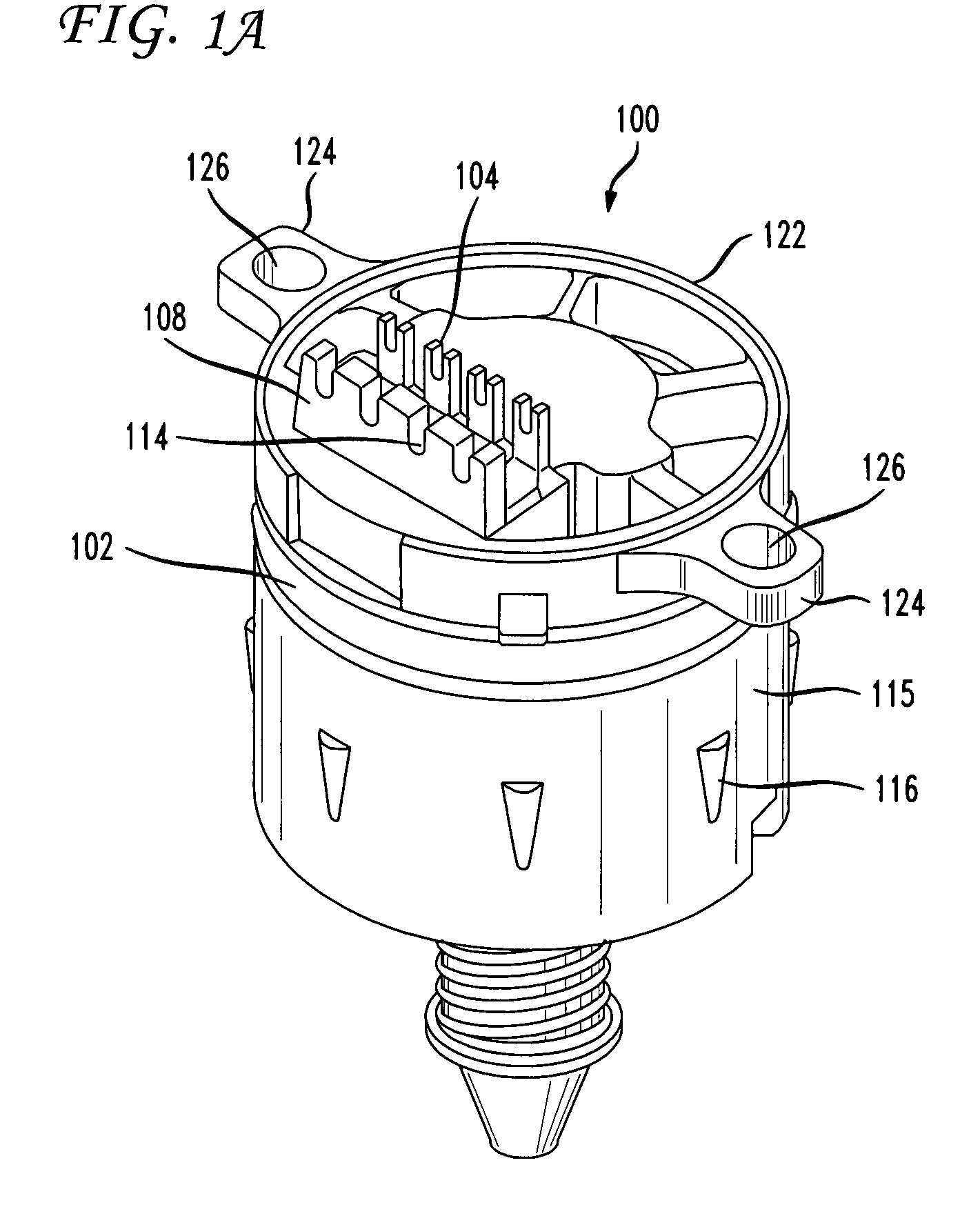

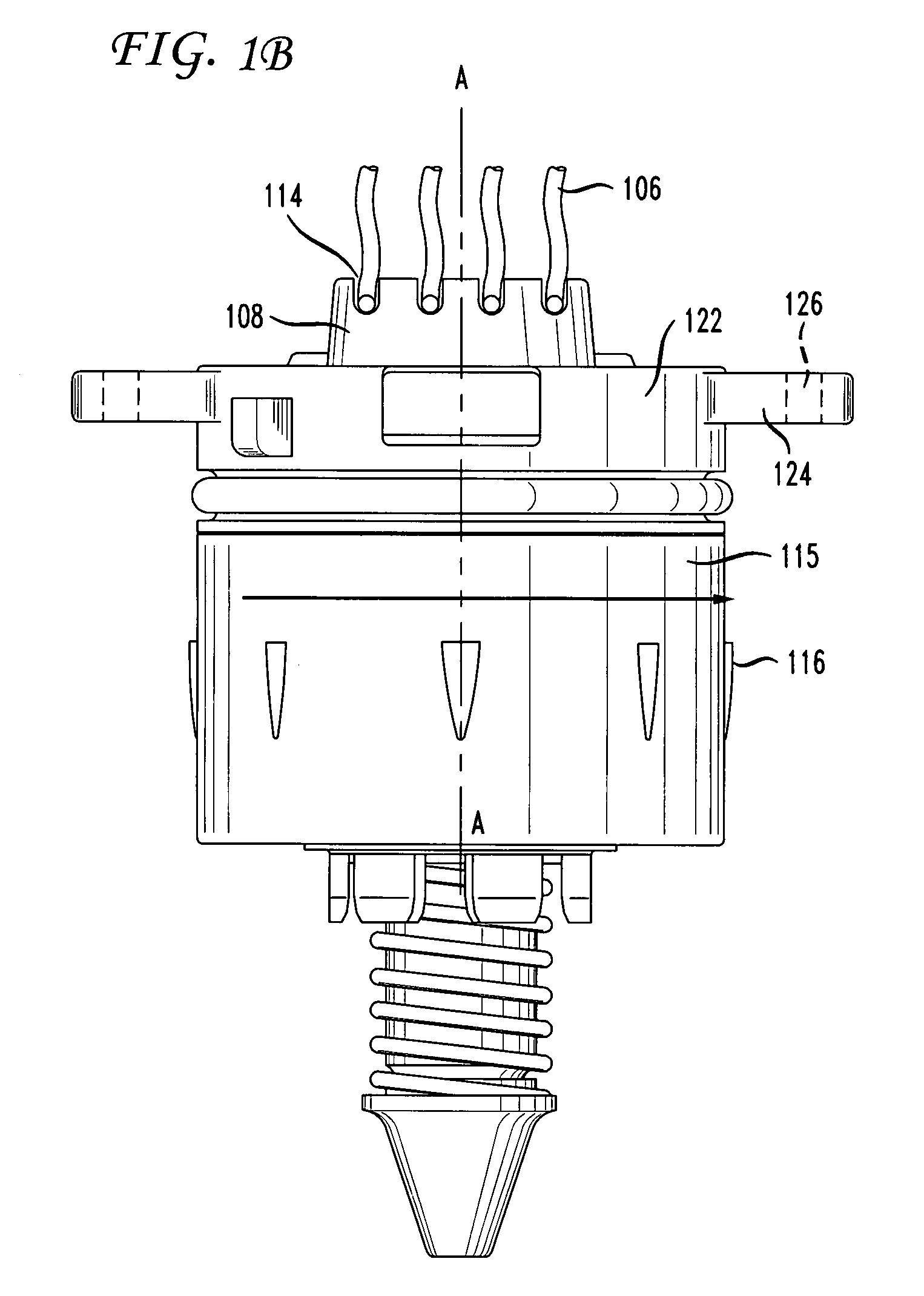

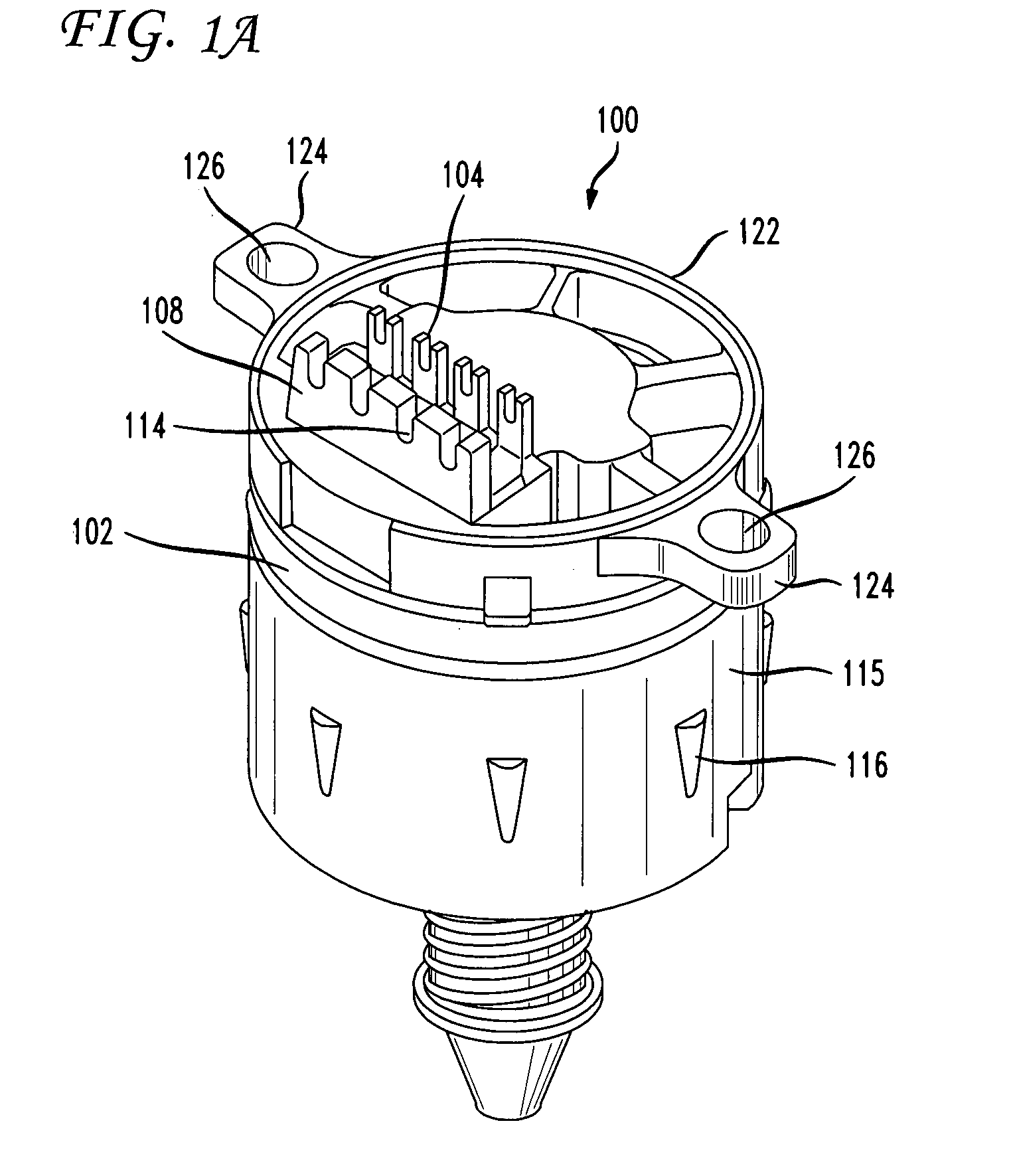

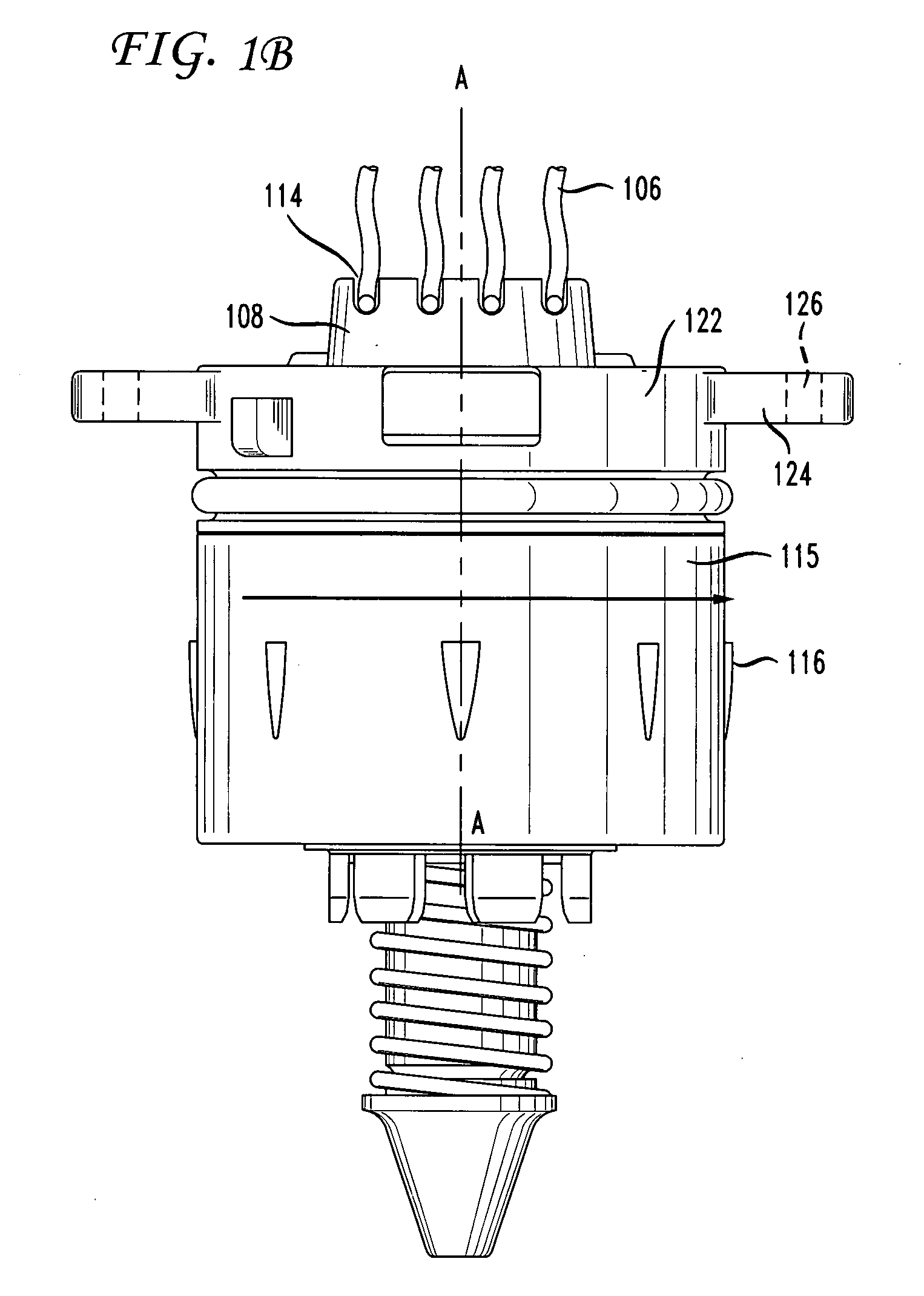

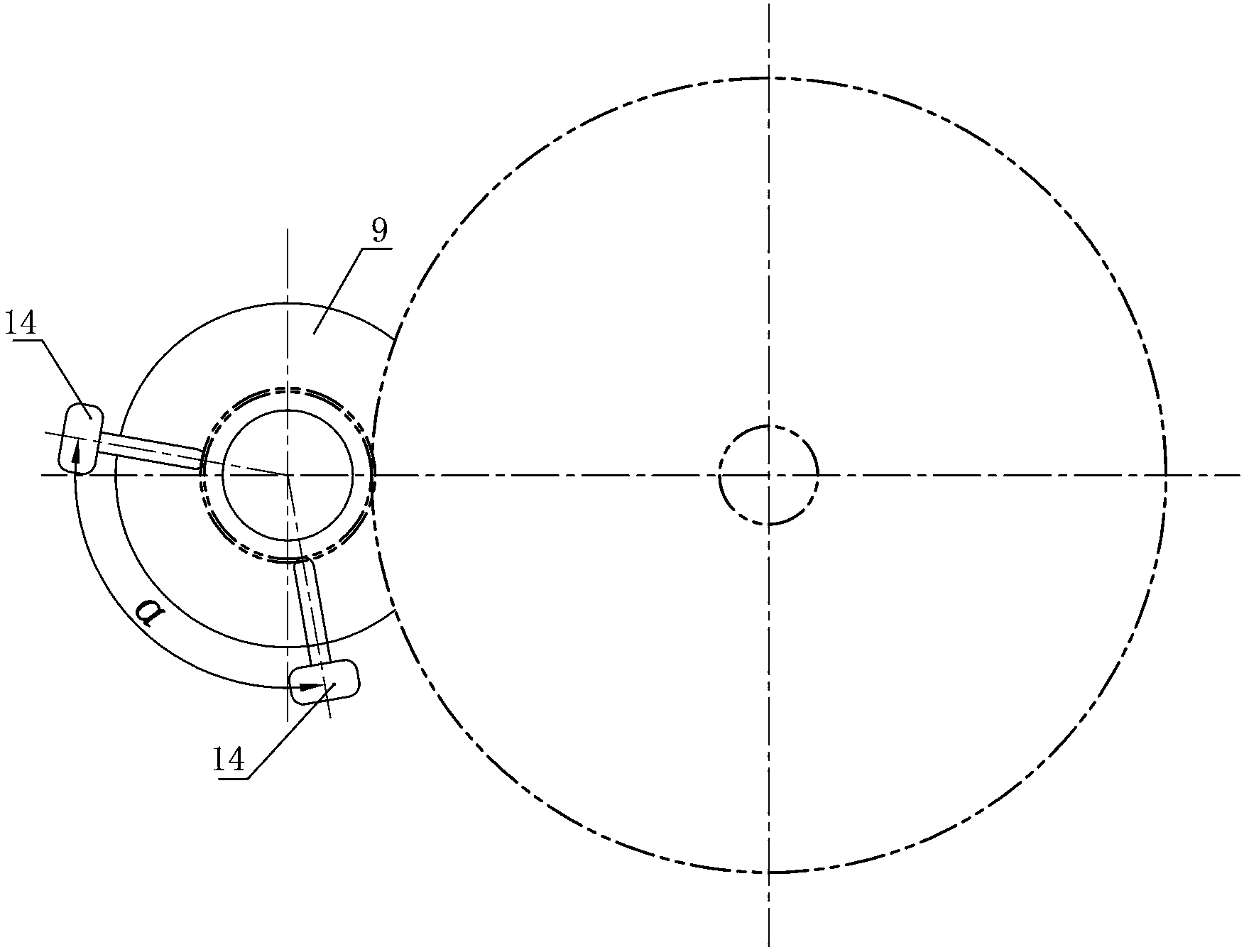

Idle air control valve wire stress relief feature and assembly aids

InactiveUS7472683B2Relieve stressUnwanted stressRelieving strain on wire connectionElectrical controlExternal combustion engineStress relief

An idle air control valve assembly including a strain relief feature for a plurality of wire terminals that couple the control valve to a remote source. The strain relief feature prevents damage to solder joints attaching the wire leads to the valve assembly. Additional improvements in the idle air control valve assembly include a plurality of axially and radially extending protrusions on a peripheral surface of a valve body that assist in the alignment and retention of the valve body in a throttle body manifold of an internal combustion engine. The protrusions are operable in combination with a plurality of bolt flange tabs to ensure proper radial positioning of the valve body when inserted into the throttle body manifold.

Owner:SIEMENS VDO AUTOMOTIVE INC

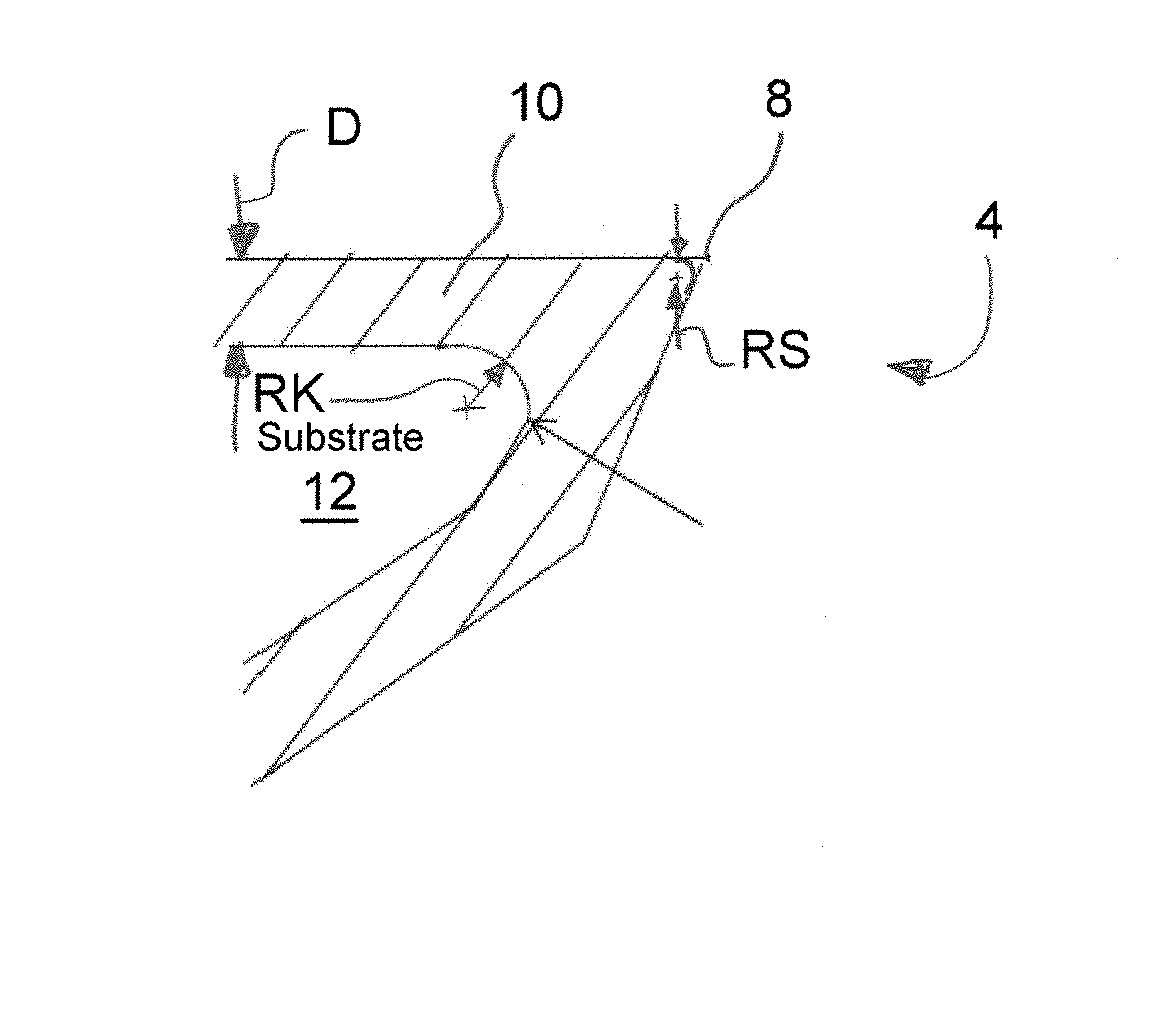

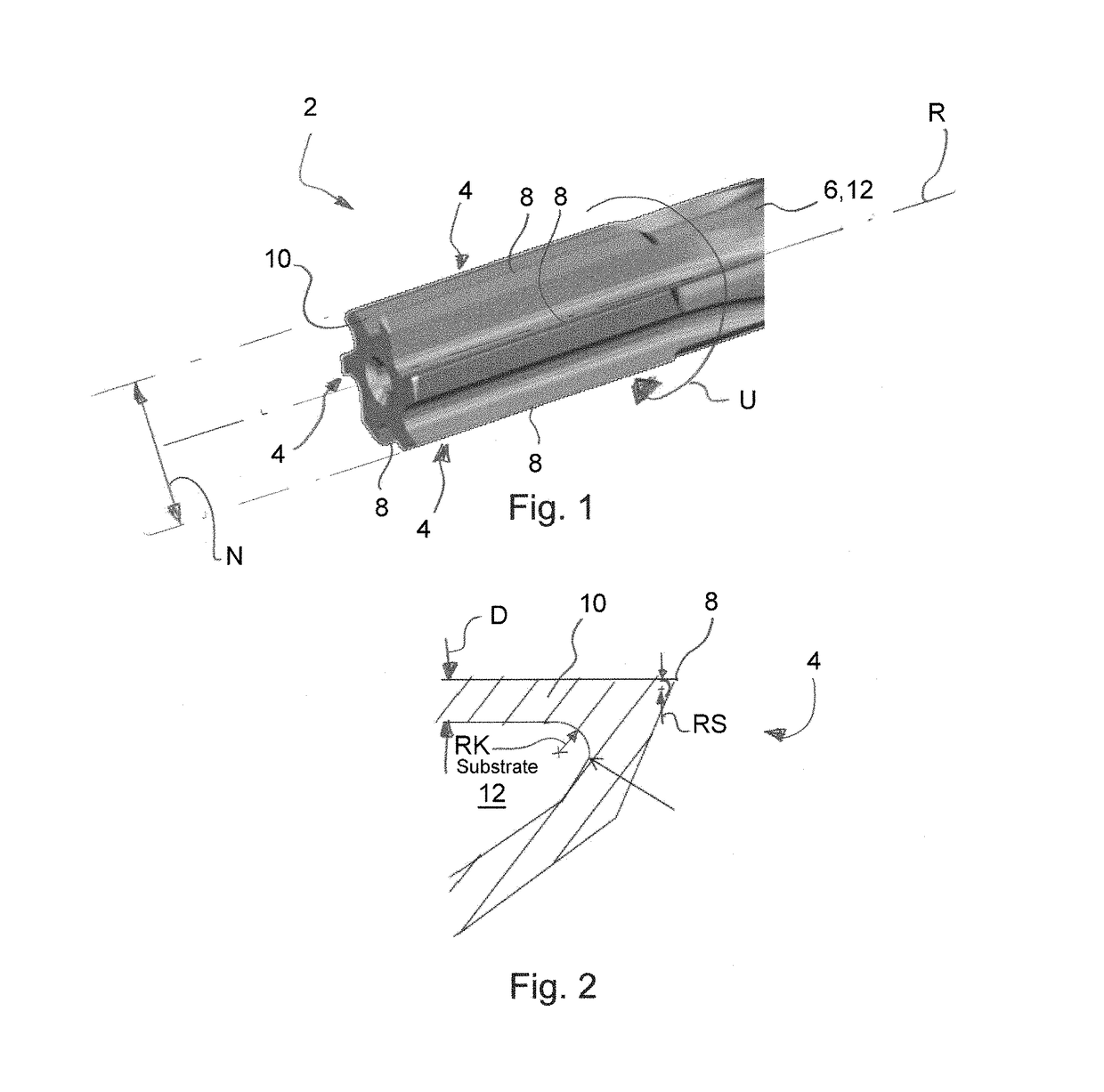

Cutting tool and method for its manufacture

ActiveUS10131007B2Accurate radial positioningEasy to adjustMilling cuttersVacuum evaporation coatingEngineeringSharpening

A cutting tool (2) is specified with a cutting region (4) that comprises a substrate (12) onto which a coating (10) is applied, which coating (10) is subsequently processed, whereby a sharp cutting edge (8) is formed. Furthermore, a corresponding method for the manufacture of the cutting tool (2) is specified. By means of the sharpening of the cutting edge (8) after the coating rather than before, a particularly sharp cutting edge (8) is formed, whereby the precision of the cutting tool (2) as well as its service life is improved.

Owner:KENNAMETAL INC

Idle air control valve wire stress relief feature and assembly aids

InactiveUS20080076294A1Relieve undue stressUnwanted stressElectrical controlRelieving strain on wire connectionEngineeringStress relief

An idle air control valve assembly including a strain relief feature for a plurality of wire terminals that couple the control valve to a remote source. The strain relief feature prevents damage to solder joints attaching the wire leads to the valve assembly. Additional improvements in the idle air control valve assembly include a plurality of axially and radially extending protrusions on a peripheral surface of a valve body that assist in the alignment and retention of the valve body in a throttle body manifold of an internal combustion engine. The protrusions are operable in combination with a plurality of bolt flange tabs to ensure proper radial positioning of the valve body when inserted into the throttle body manifold.

Owner:SIEMENS VDO AUTOMOTIVE INC

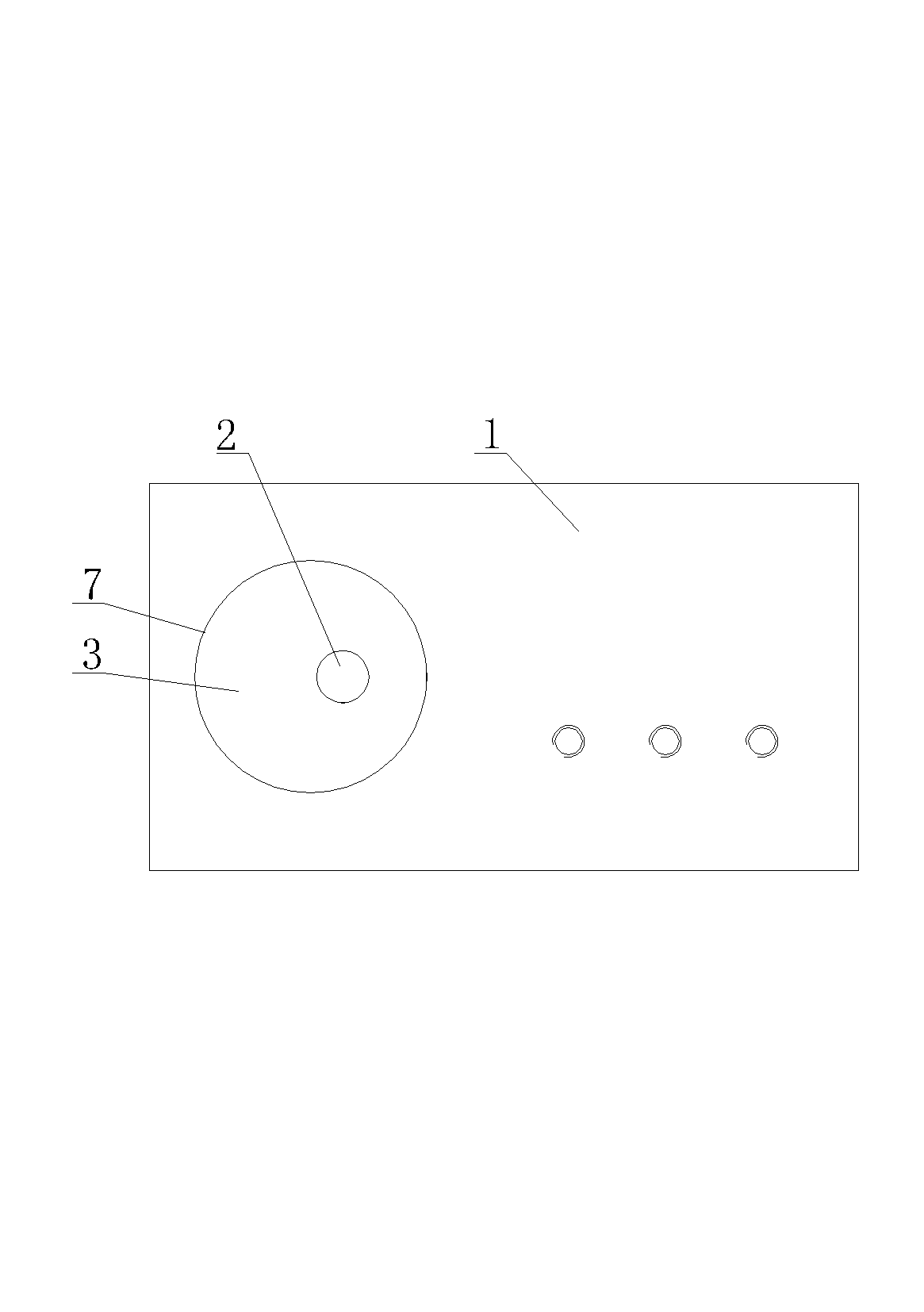

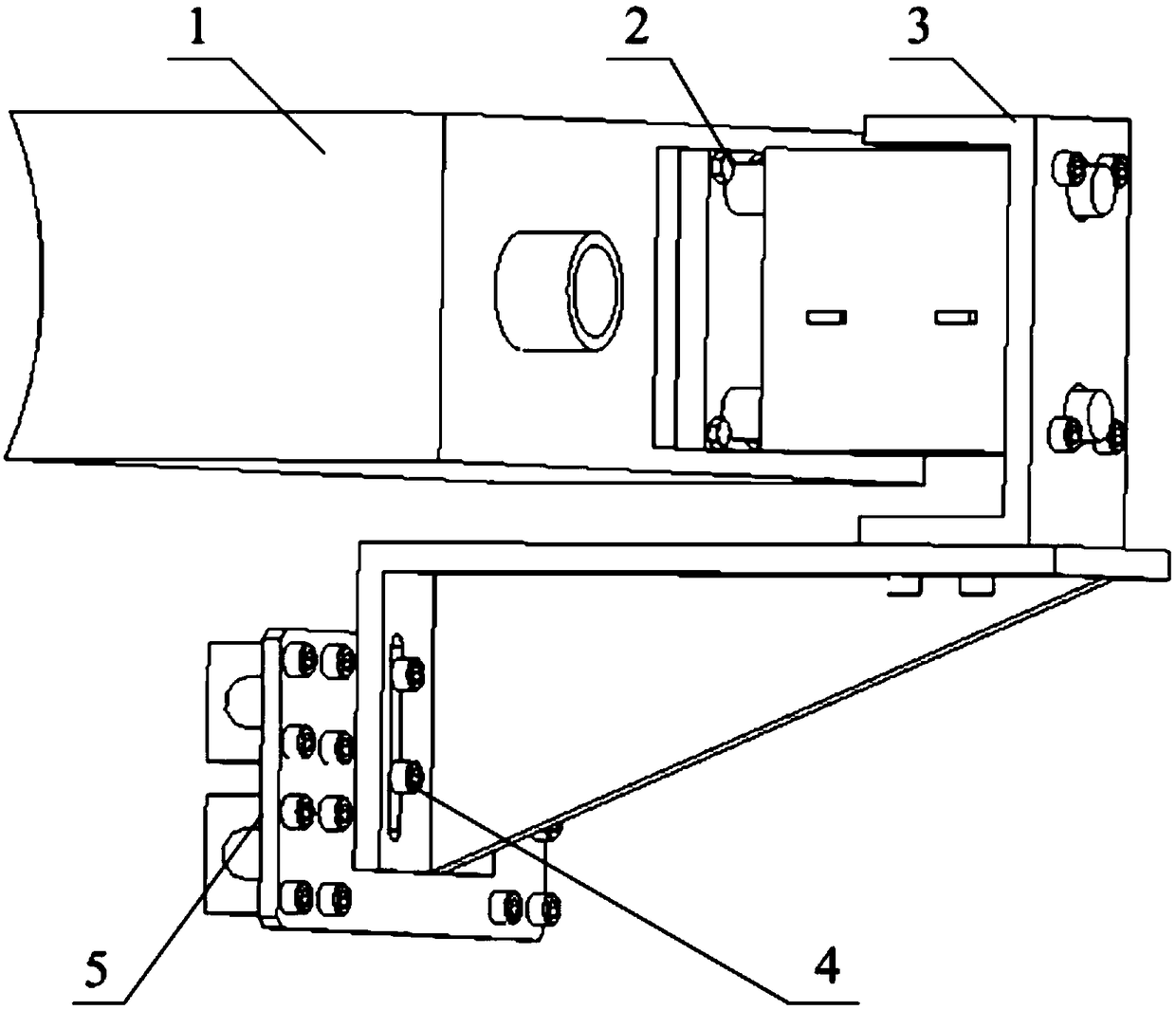

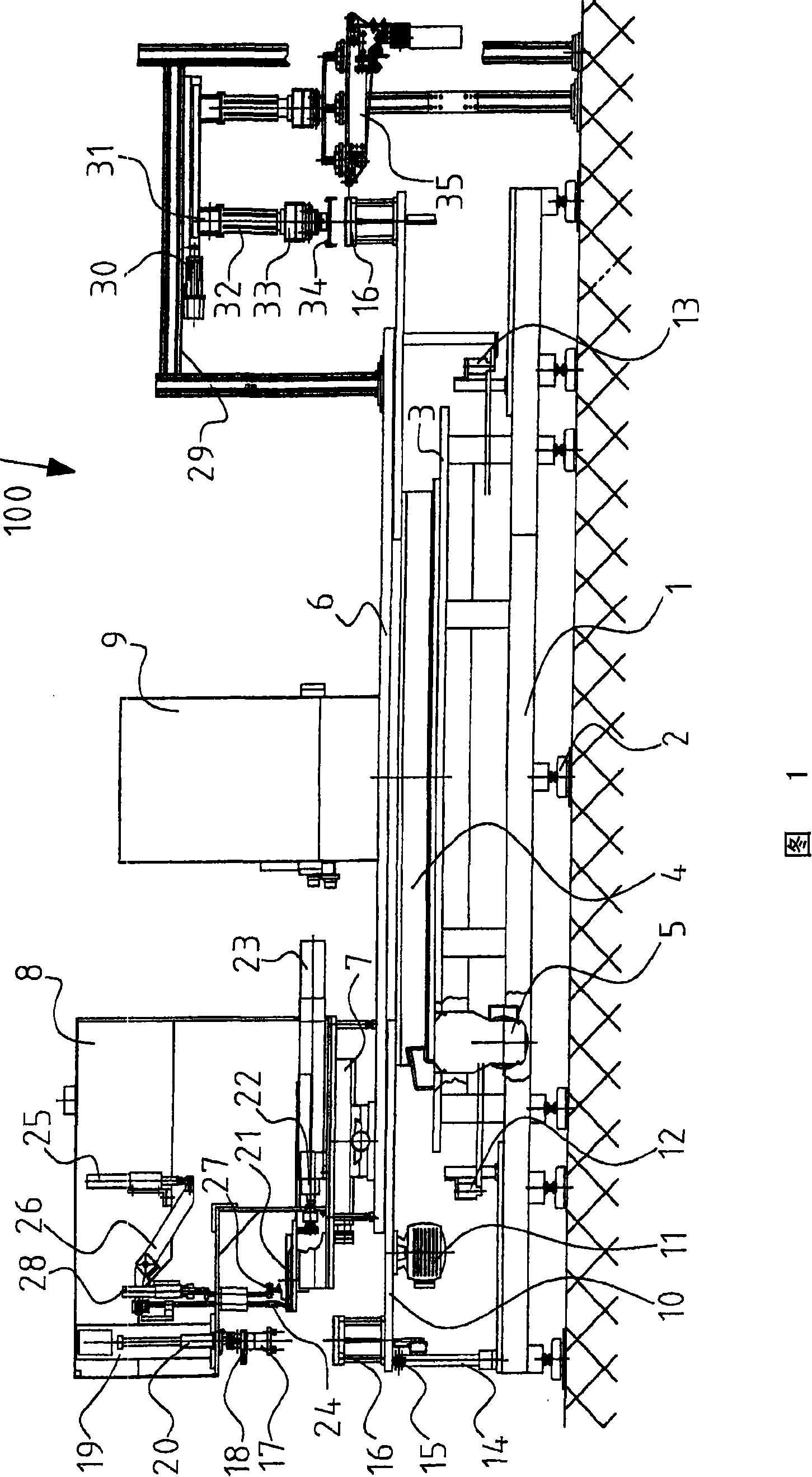

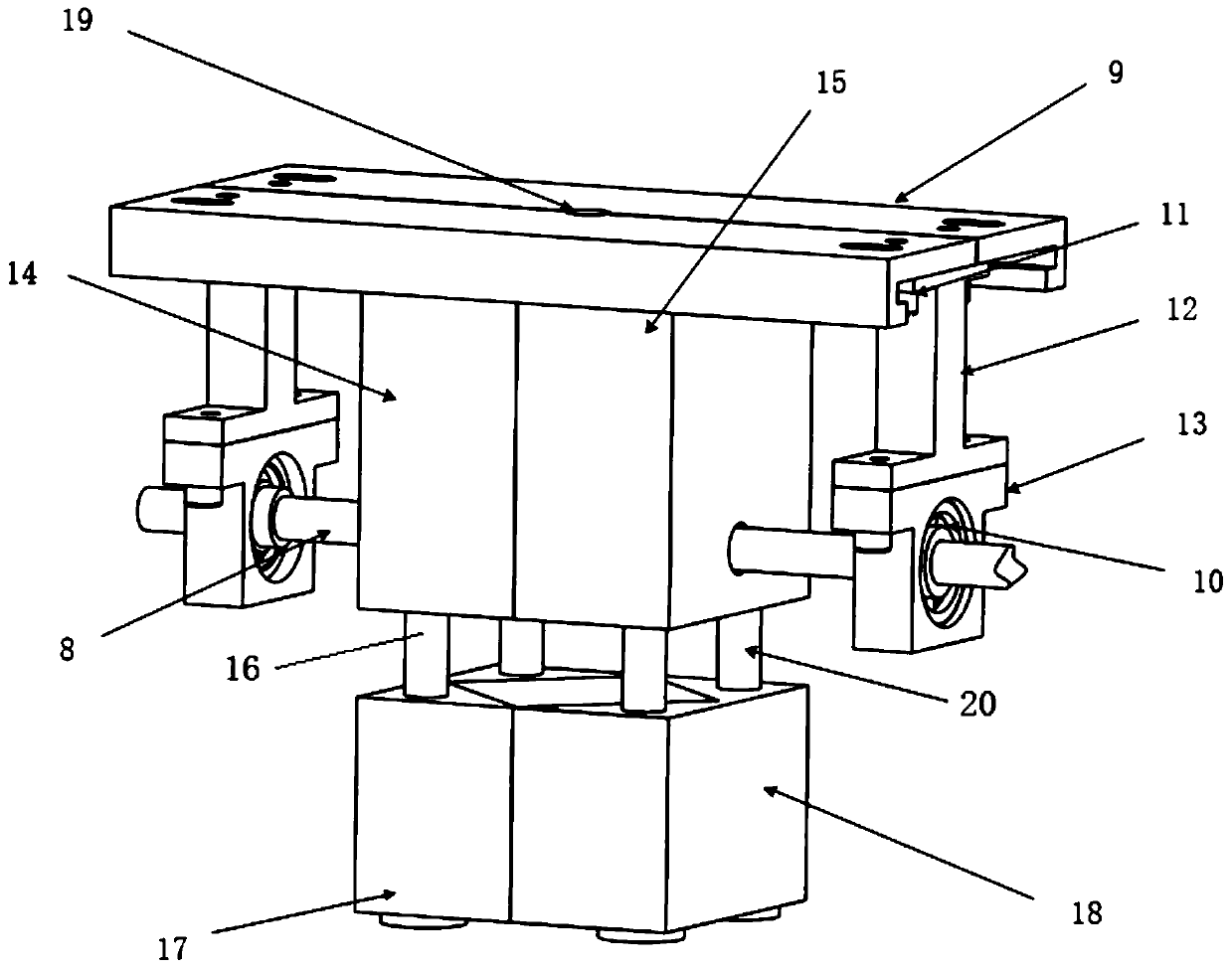

Radial synchronous-adjusting mechanism for roller of pipe mill

InactiveCN103447306AAccurate radial positioningGuaranteed pass rateMetal rolling stand detailsMetal rolling arrangementsRadial positionEngineering

The invention provides a radial synchronous-adjusting mechanism for the roller of a pipe mill, so as to solve the problems, in the prior art, that the effect of roller adjusting is bad, the product qualification rate is low during mass production of pipes, and a novel structural way is required for radial adjustment to rolling pipe diameter; the invention adopts the technical point that a mounting framework is fixed on the upper surface of a frame, an inclined wedge mechanism is fixed at the lower part of the mounting framework, a five-rod mechanism is arranged above the inclined wedge mechanism and fixed in the middle of the mounting framework, and three roller mechanisms are further mounted on an arc-shaped inner side formed by the surrounding of the five-rod mechanism; the radial synchronous-adjusting mechanism provided by the invention has the positive effects as follows: adjustment to radial positions of the rollers can be achieved according to needs, so as to meet the requirements of producing different products, the rollers can be contracted and released at the same time through the five-rod synchronous mechanism, radial positioning is accurate, and the product qualification rate is ensured; the invention further has the characteristics of high control degrees, low cost, stability, reliability and stronger practicability and the like.

Owner:沈阳汇博热能设备有限公司

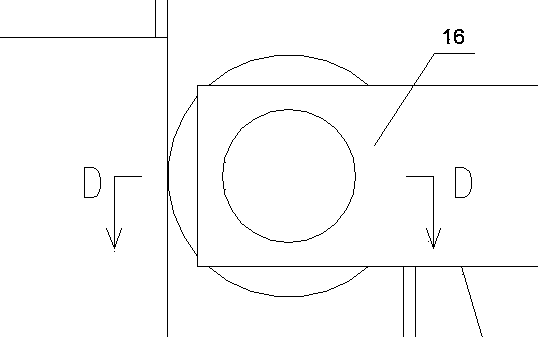

Positioning device of round table with eccentric hole

InactiveCN102430941AAccurate radial positioningGuarantee subsequent processingPositioning apparatusMetal-working holdersRound tableSoftware engineering

The invention provides a positioning device of round table with eccentric hole making radial positioning of the round table accurate and ensuring quality of subsequent processing. It comprises a table panel and a round table with eccentric hole. It is characterized in that the table panel is tightly connected with a core rod clamping head, the clamping head end of the core rod clamping head is installed with core rod and is fastened by an adjusting bolt, the core rod is pointed to the round table, the table panel is opened with a positioning hole with diameter identical to that of the round table, the round table is provided into the positioning hole, diameter of the core rod is the same with that of the eccentric hole, and the core rod penetrates through the eccentric hole.

Owner:WUXI SHUANGYI PRECISION MACHINERY

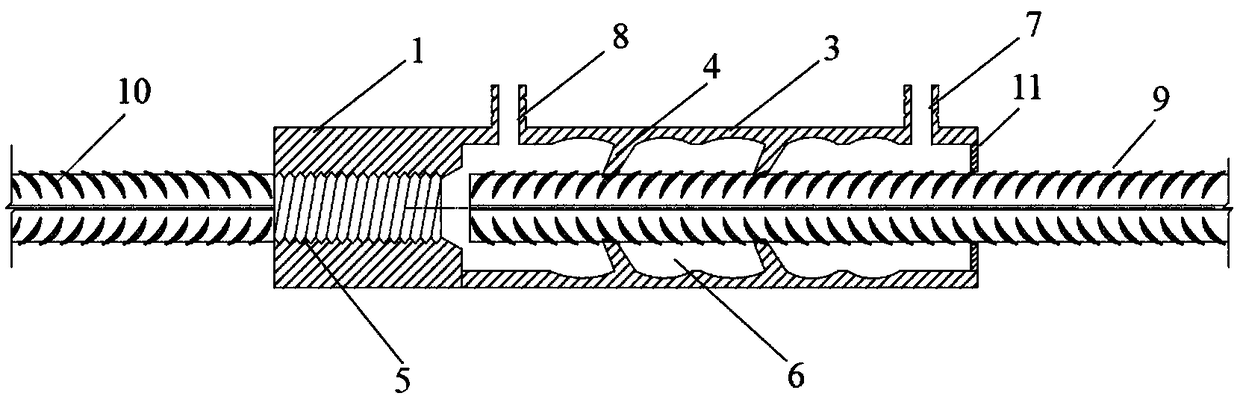

Flange sectioning connection type rotary connector

InactiveCN106641524ASimple structureAccurate radial positioningAdjustable jointsRotational axisEngineering

A flange sectioning connection type rotary connector consists of a shell, a moving ring, an end cover, a spring, a spring pad, a bearing bush, a sealing material and a semicircular sealing ring which are assembled together and is characterized in that the shell and the moving ring are both of an opposite-open sectioning structure, a positioning block is positioned by a positioning slot thereof, and a sectioning surface is fixedly connected into a whole by a bolt group. The end cover is fixed at the shaft end of the sectioning shell, the sectioning shell and the bearing bush are connected by a positioning annular slot and a positioning bugle, the shell and a rotary shaft fixing member are connected, and a static part is formed; the moving ring and a rotary shaft are fixedly connected to form a rotary part; the end cover, the spring and the spring pad form a pressing mechanism; the pressing mechanism tightly presses the moving ring on the semicircular sealing ring, such that the rotary connector is sealed for the first time, a rotary shaft hole of the moving ring, the rotary shaft and a rotary shaft hole of the shell are connected to form annular vacuum, a sealing material is filled, and the rotary connector is sealed for the second time. The flange sectioning connection type rotary connector is simple in structure, accurate in radial positioning, firm in sealing and simple and fast to detach, replace and mount.

Owner:BEIJING UNIV OF TECH

Hybrid induction welding process applied to piston manufacturing

A hybrid induction welded piston including an upper piston part welded to a lower piston part is provided. The piston is produced by induction heating the upper piston part and the lower piston part, and bringing the parts together to a part growth compensated position. The method then includes rotating the upper piston part 17 to 34 degrees clockwise and then 17 to 34 degrees counterclockwise. In addition to controlling the axial position and degree of rotation, the force applied to the piston parts is controlled so that preferably no flash is formed in a narrow cooling chamber of the piston. During the rotating steps, the pressure gradually increases to a maximum level which occurs while the upper piston part is rotating in the second direction. The piston includes a homogenous metallurgical bond across the weld and no indentation on the outer surface at the weld prior to machining.

Owner:TENNECO INC

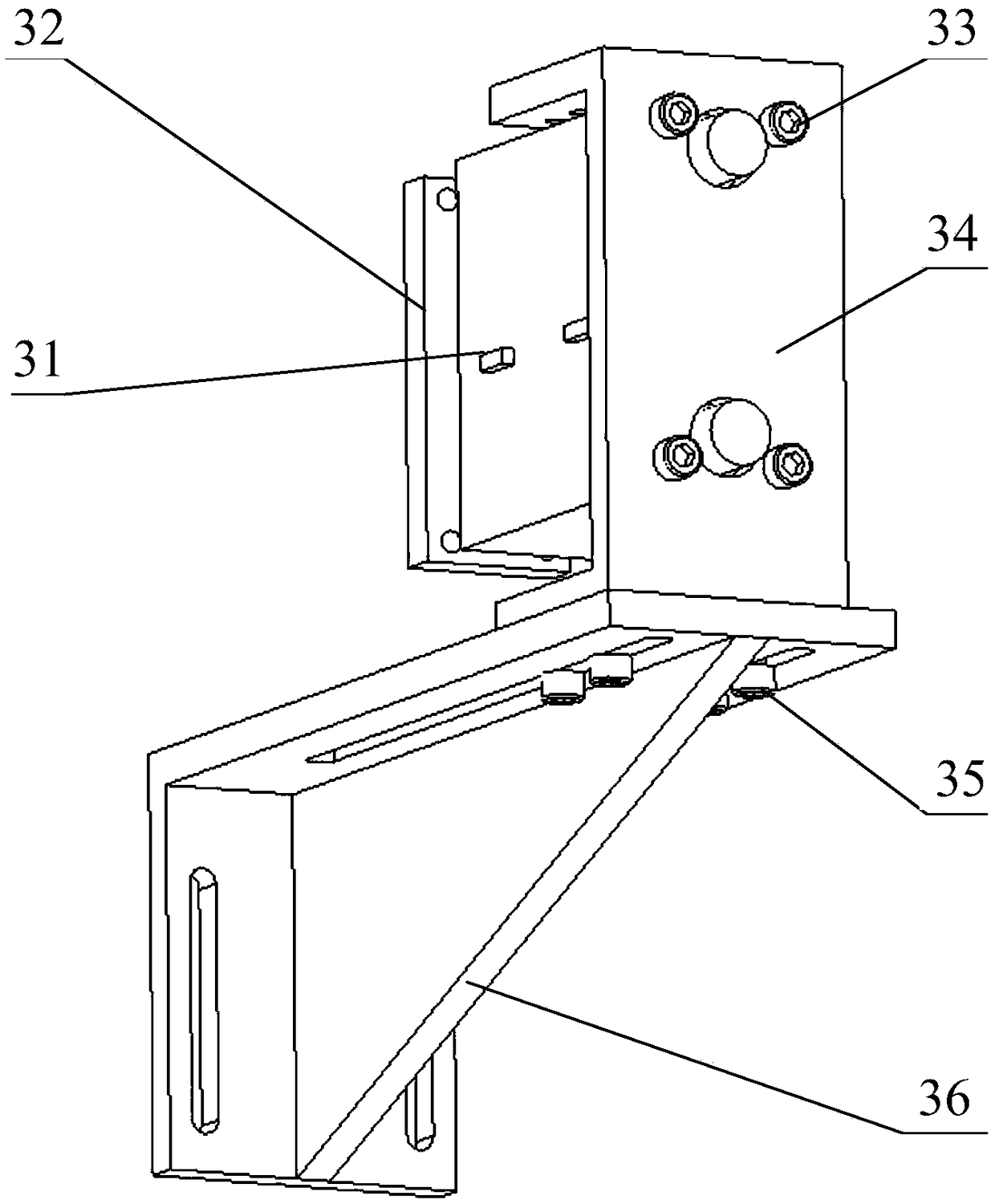

Multi-degree-of-freedom regulation device and spraying system

PendingCN108787298ASolve technical problems of uniformityEasy to adjustSpray boothsEngineeringMulti degree of freedom

The invention relates to a multi-degree-of-freedom regulation device and a spraying system. The multi-degree-of-freedom regulation device comprises a mounting mechanism and a rotary frame mounting seat; the mounting mechanism comprises a drive cylinder, a positioning control valve, a drive cylinder fixing seat and a connection component; the end part of a piston rod of the drive cylinder is fixedly connected with a component to be regulated; the drive cylinder fixing seat is arranged on the connection component in a sliding manner and can slip in a stretching or shortening direction of the piston rod relative to the connection component; the rotary frame mounting seat comprises a connection plate and a plurality of fixed blocks; the connection plate is connected with the connection component in the sliding manner and can slip relative to the connection component; and a plurality of fixed blocks are fixedly connected with the connection plate and are fixed on a mounting component. The spraying system comprises a powder spraying chamber, spraying equipment and the multi-degree-of-freedom regulation device. By adopting the spraying system, accurate positioning of a pipe wall distancebetween the powder spraying chamber and a pipeline is realized, and the uniformity of an FBE coating during pipeline anticorrosion and mending construction is guaranteed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

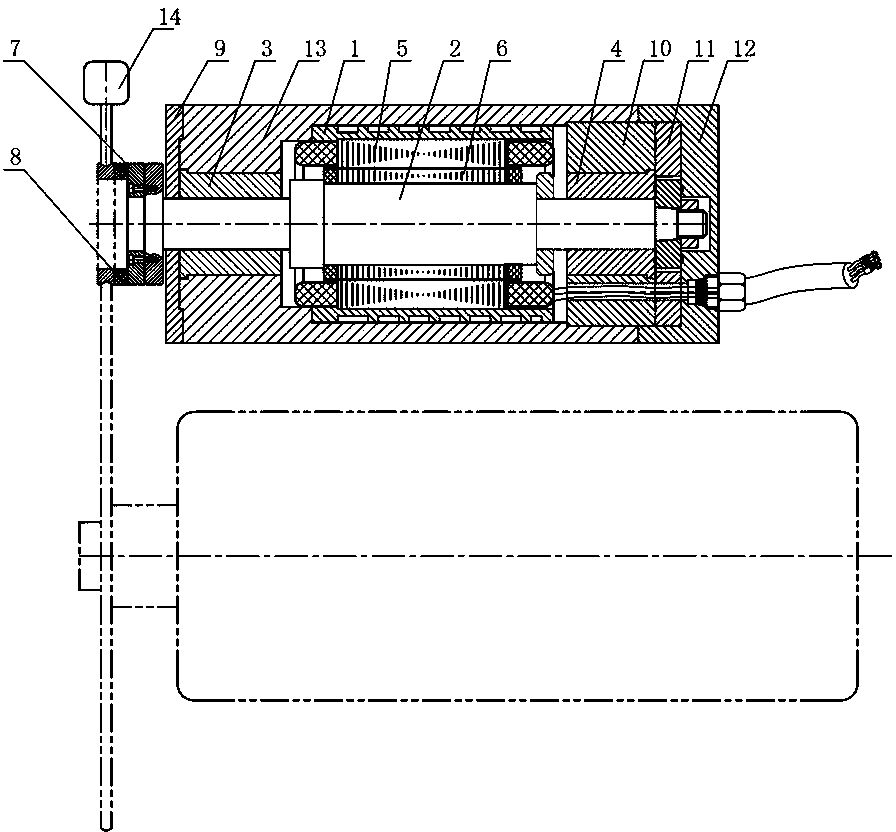

Static pressure electric spindle headstock clamping device for ultra precision ball bearing ring grinding

InactiveCN104070450AAccurate radial positioningStable Radial PositioningGrinding machinesSuperfinishing machinesBall bearingEngineering

The invention discloses a static pressure electric spindle headstock clamping device for ultra precision ball bearing ring grinding. The static pressure electric spindle headstock clamping device comprises a headstock machine base, a spindle, a front hydrostatic bearing, a rear hydrostatic bearing, a stator and a rotor, wherein the stator is fixed in the headstock machine base, the spindle is fixedly sleeved with the rotor, the headstock machine base is sleeved with the spindle, the front end of the spindle is supported through the front hydrostatic bearing, the rear end of the spindle is supported through the rear hydrostatic bearing, a rear bearing block is arranged between the rear hydrostatic bearing and the headstock machine base, a rear end cover is installed at the rear end of the rear hydrostatic bearing, an adjusting pad for adjusting thrust clearance is installed between the rear hydrostatic bearing and the rear end cover, the front end of the spindle extends out of the headstock machine base, a pole mounting base is installed at the front end of the spindle and provided with a pole plate for fixing an ultra precision ball bearing ring, and a support for positioning the ultra precision ball bearing ring in the radial direction is arranged on the periphery of the ultra precision ball bearing ring in front of the pole plate. The static pressure electric spindle headstock clamping device is high in rotation precision, small in end face runout, good in vibration reducing performance and high in processing precision.

Owner:HUNAN HYDRO SPINDLE TECH +1

Device to coat metallic coating onto wafer

InactiveCN101533759BIncrease freedomAvoid mechanical stressSemiconductor/solid-state device manufacturingMetal coatingEngineering

Owner:COLORFUL TC PRINTING MACHINES

Superconducting flywheel main shaft positioning device and using method thereof

PendingCN110176830AReliable radial positioningAccurate radial positioningMechanical energy handlingElectric machineEngineering

The invention relates to a superconducting flywheel main shaft positioning device and a using method thereof. The positioning device comprises a vacuum sealing cavity, a radial positioning mechanism and a motor, wherein the vacuum sealing cavity is arranged above a superconducting flywheel host, the radial positioning mechanism is arranged in the vacuum sealing cavity, and the motor is positionedon one side of the vacuum sealing cavity. The radial positioning mechanism comprises a sliding rail, a left sliding block and a right sliding block which are located below the sliding rail and are insliding fit with the sliding rail, a screw rod which penetrates through the left sliding block and the right sliding block in sequence and is in threaded fit with the left sliding block and the rightsliding block, a left guide rod and a right guide rod which are arranged at the bottoms of the left sliding block and the right sliding block respectively, a left clamping block which is arranged on the left guide rod in a sleeved mode and is in clearance fit with the left guide rod, and a right clamping block which is arranged on the right guide rod in a sleeved mode and is in clearance fit withthe right guide rod. The output shaft of the motor is connected with one end of the screw rod. The left clamping block and the right clamping block are provided with clamping grooves respectively. According to the positioning device, the main shaft of the superconducting flywheel can be subjected to reliable, accurate and rapid radial positioning, and the radial displacement caused by axial movement when the flywheel main shaft is in a non-working state is effectively reduced.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

A Split Flange Connection Rotary Joint

InactiveCN106641524BSimple structureAccurate radial positioningAdjustable jointsRotational axisConnection type

A flange sectioning connection type rotary connector consists of a shell, a moving ring, an end cover, a spring, a spring pad, a bearing bush, a sealing material and a semicircular sealing ring which are assembled together and is characterized in that the shell and the moving ring are both of an opposite-open sectioning structure, a positioning block is positioned by a positioning slot thereof, and a sectioning surface is fixedly connected into a whole by a bolt group. The end cover is fixed at the shaft end of the sectioning shell, the sectioning shell and the bearing bush are connected by a positioning annular slot and a positioning bugle, the shell and a rotary shaft fixing member are connected, and a static part is formed; the moving ring and a rotary shaft are fixedly connected to form a rotary part; the end cover, the spring and the spring pad form a pressing mechanism; the pressing mechanism tightly presses the moving ring on the semicircular sealing ring, such that the rotary connector is sealed for the first time, a rotary shaft hole of the moving ring, the rotary shaft and a rotary shaft hole of the shell are connected to form annular vacuum, a sealing material is filled, and the rotary connector is sealed for the second time. The flange sectioning connection type rotary connector is simple in structure, accurate in radial positioning, firm in sealing and simple and fast to detach, replace and mount.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com