Radial synchronous-adjusting mechanism for roller of pipe mill

A technology of synchronous adjustment and rolling mill, applied in the direction of metal rolling mill stands, metal rolling stands, metal rolling, etc., can solve the problems of low adjustment accuracy, complicated operation, and long time consumption, and achieve accurate radial positioning , Guaranteed pass rate and high control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

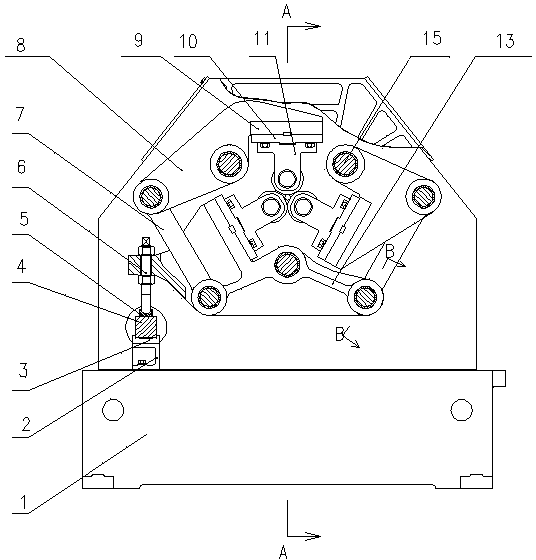

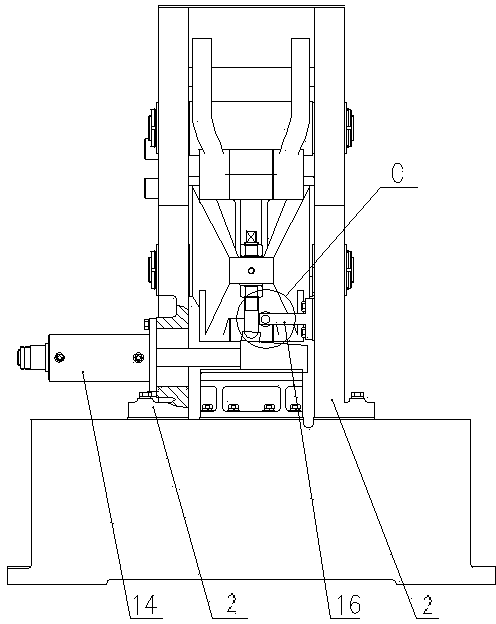

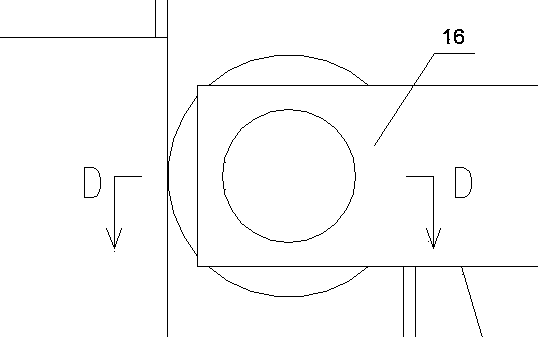

[0026] see figure 1 , an installation frame is fixed on the upper surface of the machine base 1, a wedge mechanism is fixed on the lower part of the installation frame, a five-bar mechanism is arranged above the wedge mechanism, the five-bar mechanism is fixed in the middle of the installation frame, and the inside of the arc surrounded by the five-bar mechanism There are also three roller mechanisms installed;

[0027] The above-mentioned installation frame includes two parallel vertical plates 2 vertically installed on the machine base; the wedge mechanism includes a slide seat 3, and a wedge block 4 is installed on the upper surface of the slide seat, and the ejector rod seat is fixed on the upper surface of the wedge block 5. The ejector rod 6 is set above the ejector rod seat; the five-bar mechanism is composed of a V-shaped lever 13 with an obtuse V-shaped included angle, two connecting rods 7 and two driven levers 8, and the central axis of the five-bar mechanism 20 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com