Multi-degree-of-freedom regulation device and spraying system

A technology of adjusting device and degree of freedom, applied in the field of pipeline patching, can solve the problems of inability to quickly and accurately adjust the relative position of the pipeline, and inability to ensure the uniformity of the FBE coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

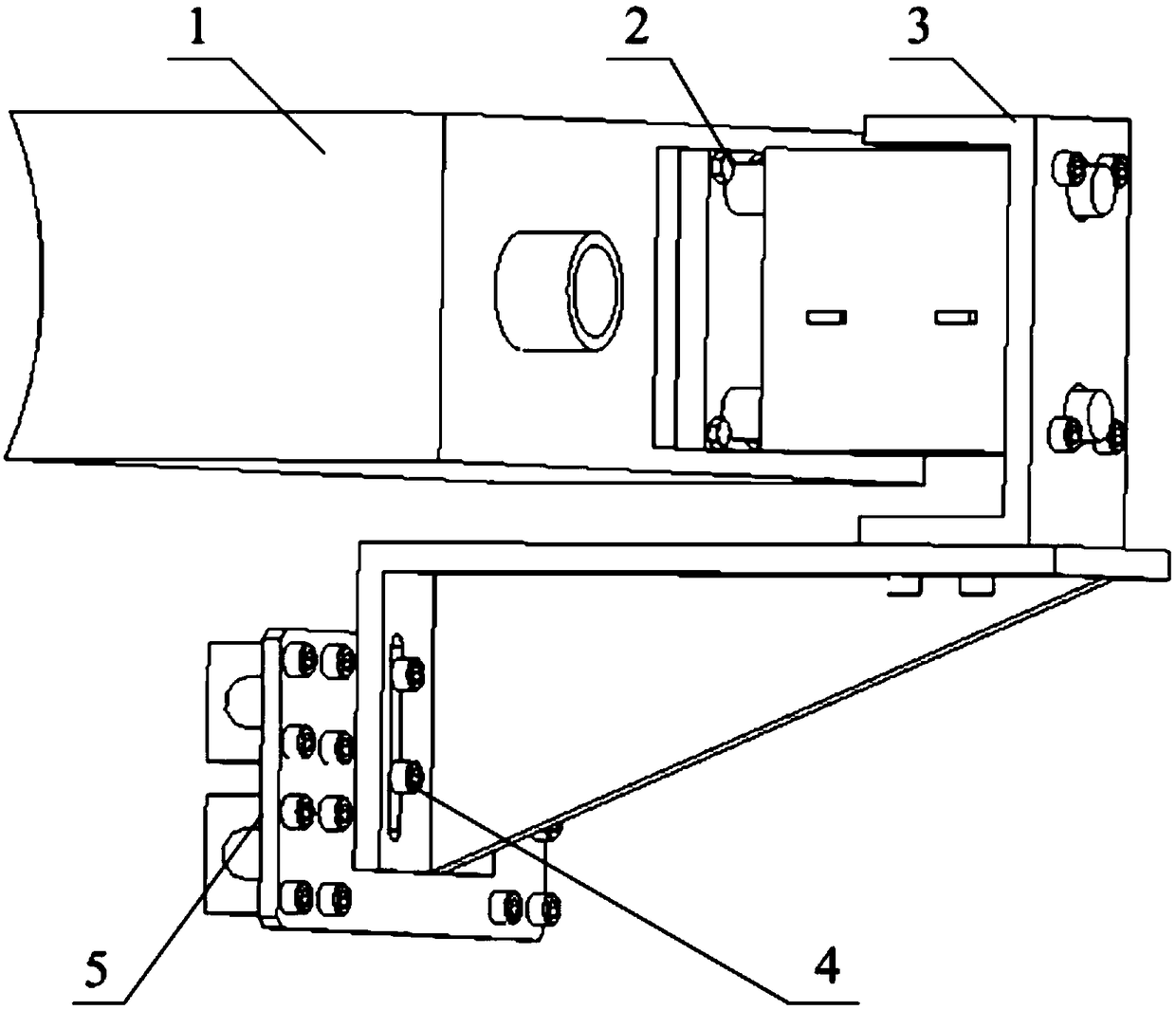

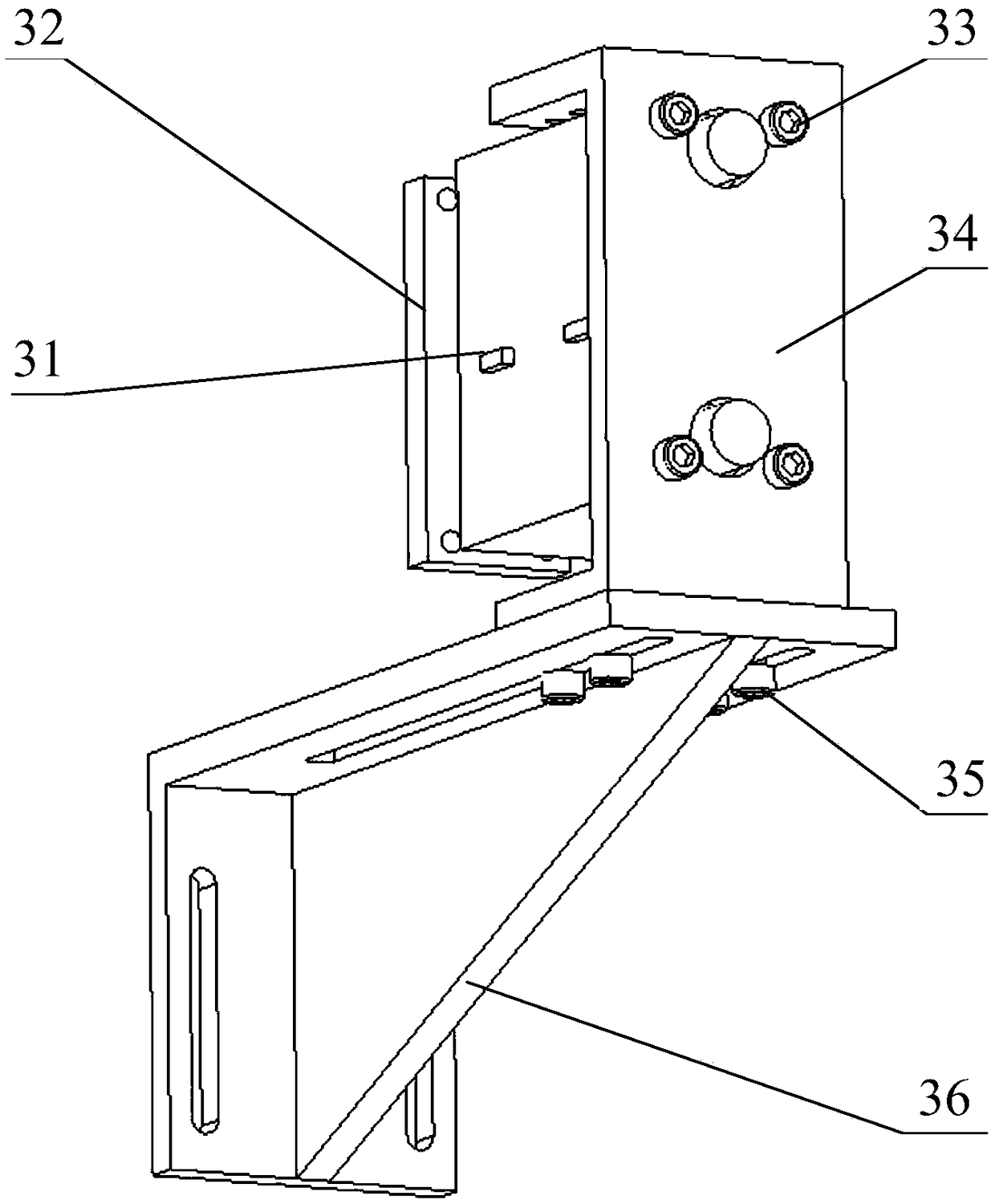

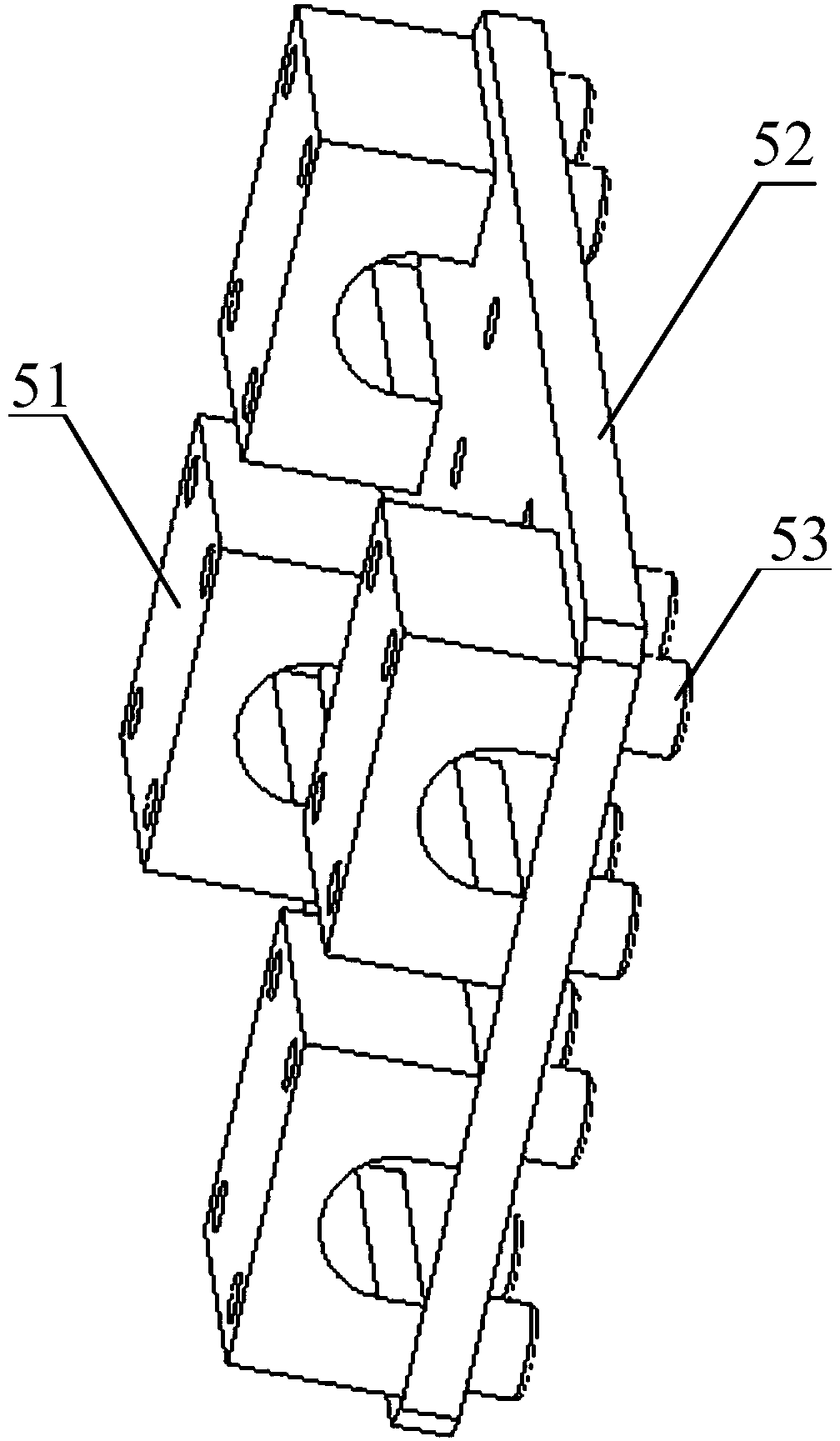

[0034] The embodiment of the application provides a multi-degree-of-freedom adjustment device and a spraying system, which solves or partially solves the inability of the automatic coating equipment in the prior art to quickly and accurately adjust the relative position with the pipeline, and then cannot ensure the FBE during the pipeline anticorrosion patch construction. For the technical problem of the uniformity of the coating, by providing a spraying system consisting of a powder spraying room, spraying equipment and a multi-degree-of-freedom adjustment device, the multi-degree-of-freedom adjustment device is composed of an installation mechanism and a rotating frame mounting seat. The installation mechanism includes: a drive cylinder , Positioning control valve, driving cylinder fixing seat and connecting parts; the end of the piston rod of the driving cylinder is fixedly connected to the powder spray chamber, the driving cylinder is provided with a slideway, the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com