Patents

Literature

6741 results about "Sand blasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for providing a grinding surface on glass implements used in personal care

ActiveUS8790749B2Increase variabilityEasy to manufacturePretreated surfacesManicure/pedicurePersonal careFlat glass

Manufacturing method of grinding surface on glass cosmetics, in particular the nail and skin file, from flat glass of FLOAT type, is carried out by marking at least one abrasive surface on one or two sides of a glass pane or intermediate product. This surface is then coated with fusing glue, powdered with clean quartz sand with grain size between 1 and 500 μm using a sieve, and the surplus sand is knocked-down. The intermediate product with fixed sand is inserted into the fusing furnace where it is baked at the temperature of up to 900° C. The abrasive surface may be roughened by sand blasting before the fusing glue application; the intermediate product coated with fusing glue can be decorated with glass fritte.

Owner:HACEK OVER SKUTCHANOVA ZUZANA

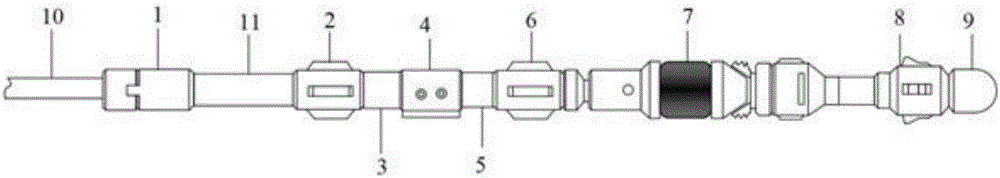

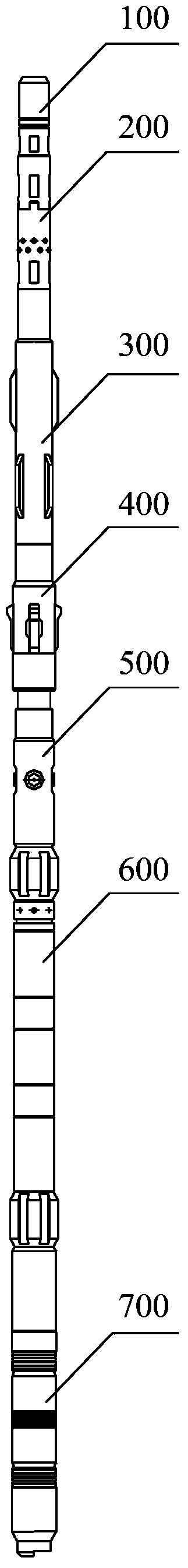

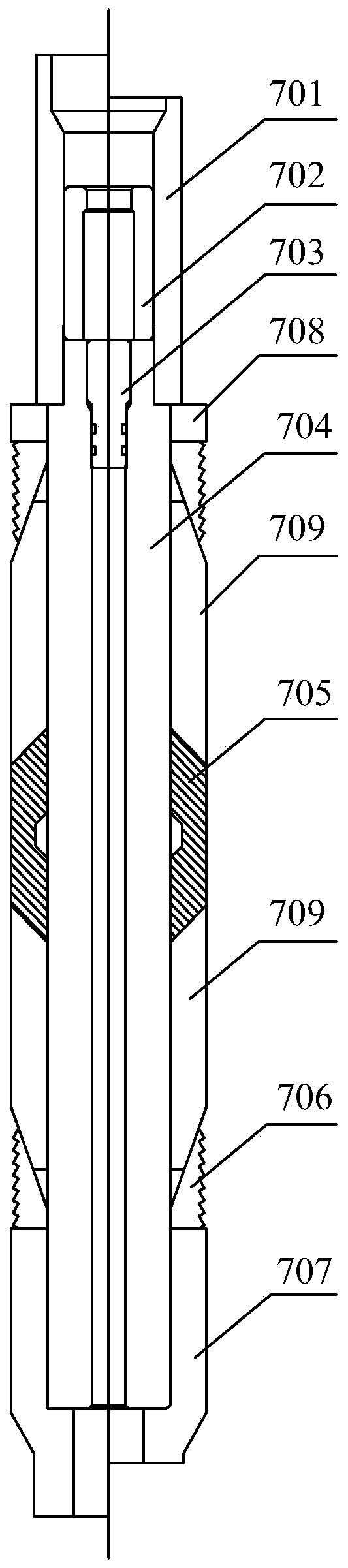

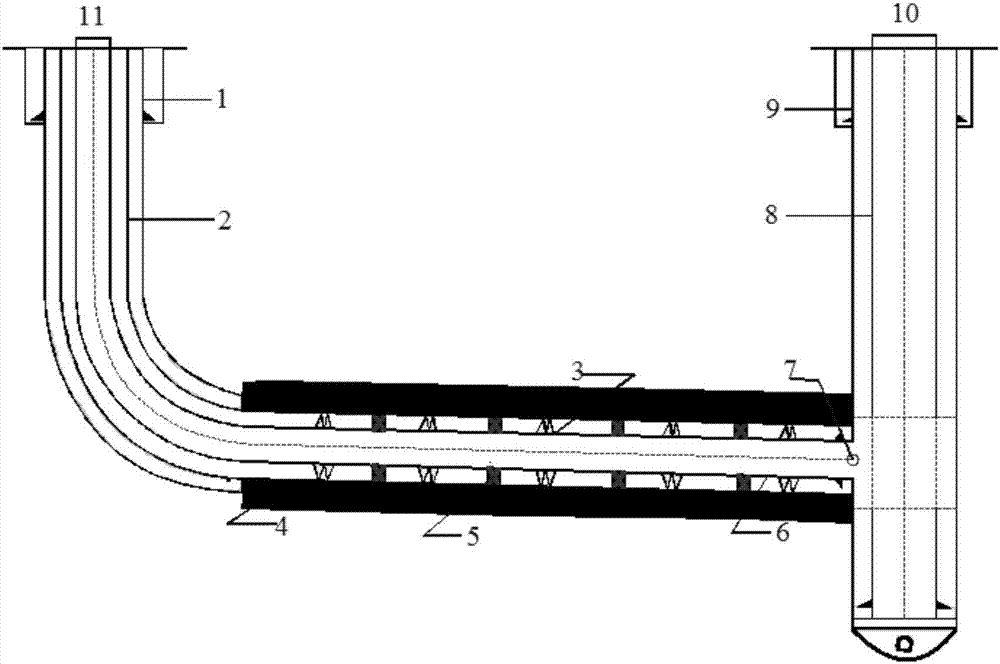

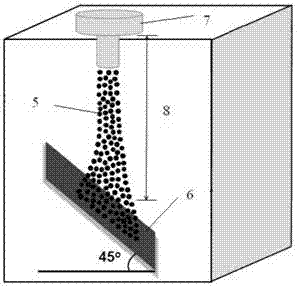

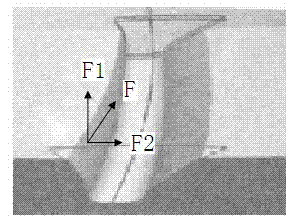

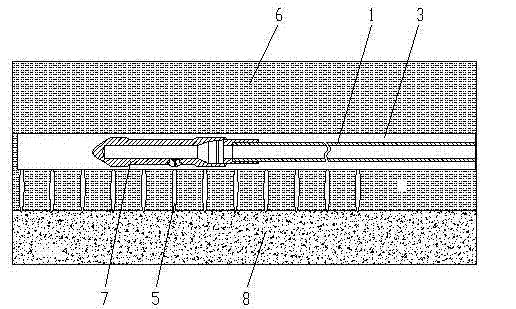

Horizontal well directional sand blasting perforation and fracturing integral tool pipe column and construction method thereof

ActiveCN106321045AAchieve dropReliable and reliableDrilling rodsFluid removalSand blastingMaterial Perforation

The invention relates to a horizontal well directional sand blasting perforation and fracturing integral tool pipe column and a construction method thereof. The tool pipe column comprises a safe joint, a first centralizer, a first rotating joint, a hydraulic sand blasting device, a second rotating joint, a second centralizer, a packer, a coupling positioning device and a guiding shoe, wherein the safe joint is arranged at the left end of the tool pipe column; the guiding shoe is arranged at the right end of the tool pipe column; the left end of the safe joint is connected with an oil pipe; the first centralizer, the first rotating joint, the hydraulic sand blasting device, the second rotating joint, the second centralizer, the packer and the coupling positioning device are sequentially arranged between the right end of the safe joint and the guiding shoe from left to right. The horizontal well directional sand blasting perforation and fracturing integral tool pipe column and the construction method provided by the invention have the advantages that the structure of the tool pipe column is simple; the directional san blasting perforation can be realized; the stratum energy is released to the greatest degree; the problem of shot hole compression zone of gunpowder perforation can be solved.

Owner:JEREH ENERGY SERVICES

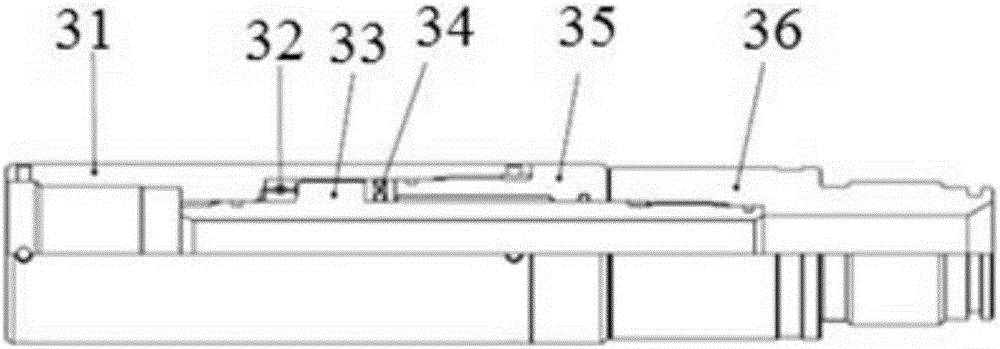

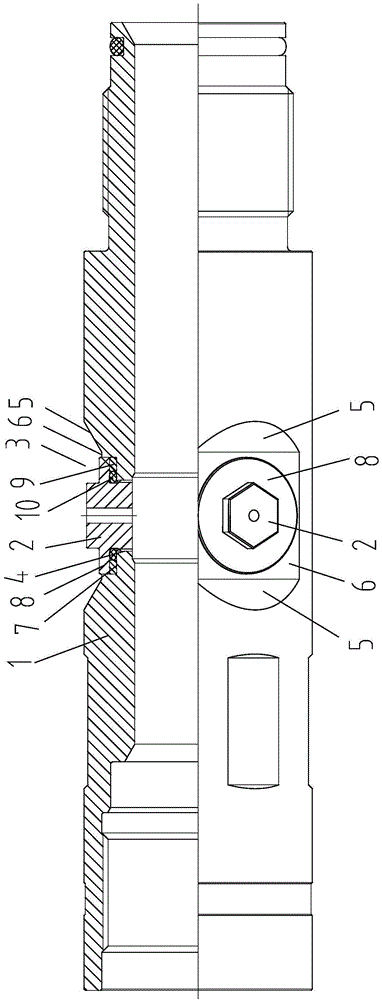

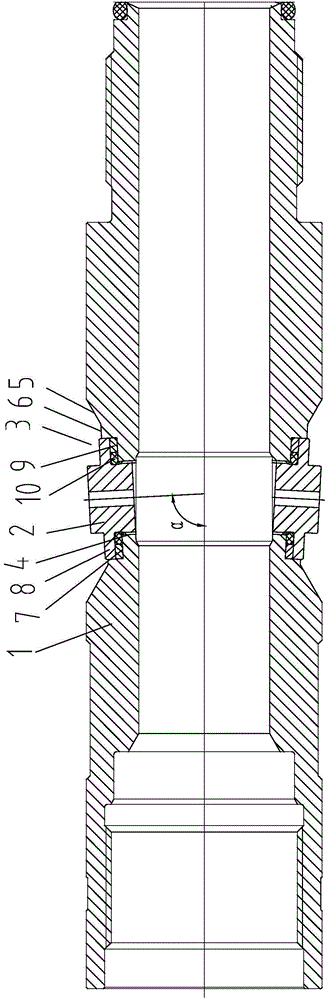

Tubular column string and bridge plug setting and sand blasting perforation combining method

The embodiment of the invention discloses a tubular column string. The tubular column string at least comprises a coiled tubing connector, a mechanical releasing tool, a centering device, a collar locator, a sand blasting perforation sliding sleeve, a hydraulic setting tool and a bridge plug. The sand blasting perforation sliding sleeve, the hydraulic setting tool and the bridge plug are sequentially connected in series in the direction from one end to the other end of the coiled tubing connector of the tubular column string, and the coiled tubing connector is used for being connected with coiled tubing. The whole operation of bridge plug tripping and setting can be completed through coiled tubing equipment, so that less equipment is used in construction, working procedures are few, and manual work is less; pyrotechnics equipment can be avoided, safety performance is high, the coiled tubing equipment is high in adaptability to well conditions, and large-discharge-capacity staged fracturing of a casing horizontal well can be achieved due to the full bore after the bridge plug is removed through drilling. The invention further discloses a bridge plug setting and sand blasting perforation combining method.

Owner:JEREH ENERGY SERVICES

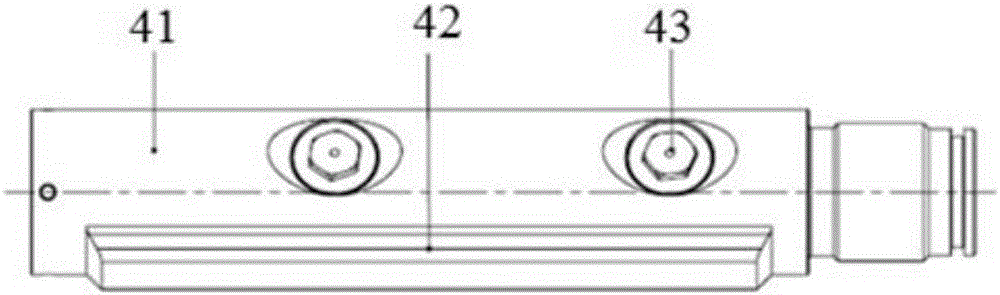

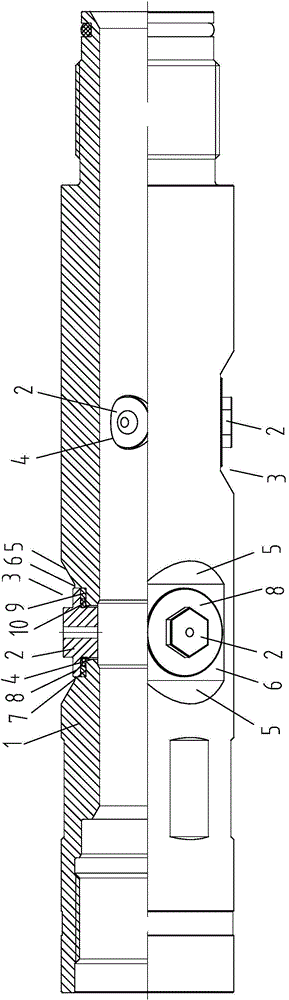

Anti-back-splash sand blasting perforator

The invention relates to an anti-back-splash sand blasting perforator, which comprises a body and a nozzle, wherein a groove is formed in the outer wall of the body; an installation hole is formed in the middle of the groove; the side wall of the groove is inclined; the nozzle is installed in the installation hole; the outer end of the nozzle stretches out from the bottom surface of the groove. The anti-back-splash sand blasting perforator is simple in structure, less in parts, and easy to process and assemble; through the arranged groove and a bulge on the outer end of the nozzle, a flow guide structure is formed around the nozzle, so that back-splash liquid can be timely and uniformly flown when back splashing on the perforator, can be prevented from forming vortex in the groove, and can be prevented from flowing in the groove for a long time; the erosion of the back-splash liquid on the perforator is reduced, and the service life of the perforator is improved.

Owner:JEREH ENERGY SERVICES

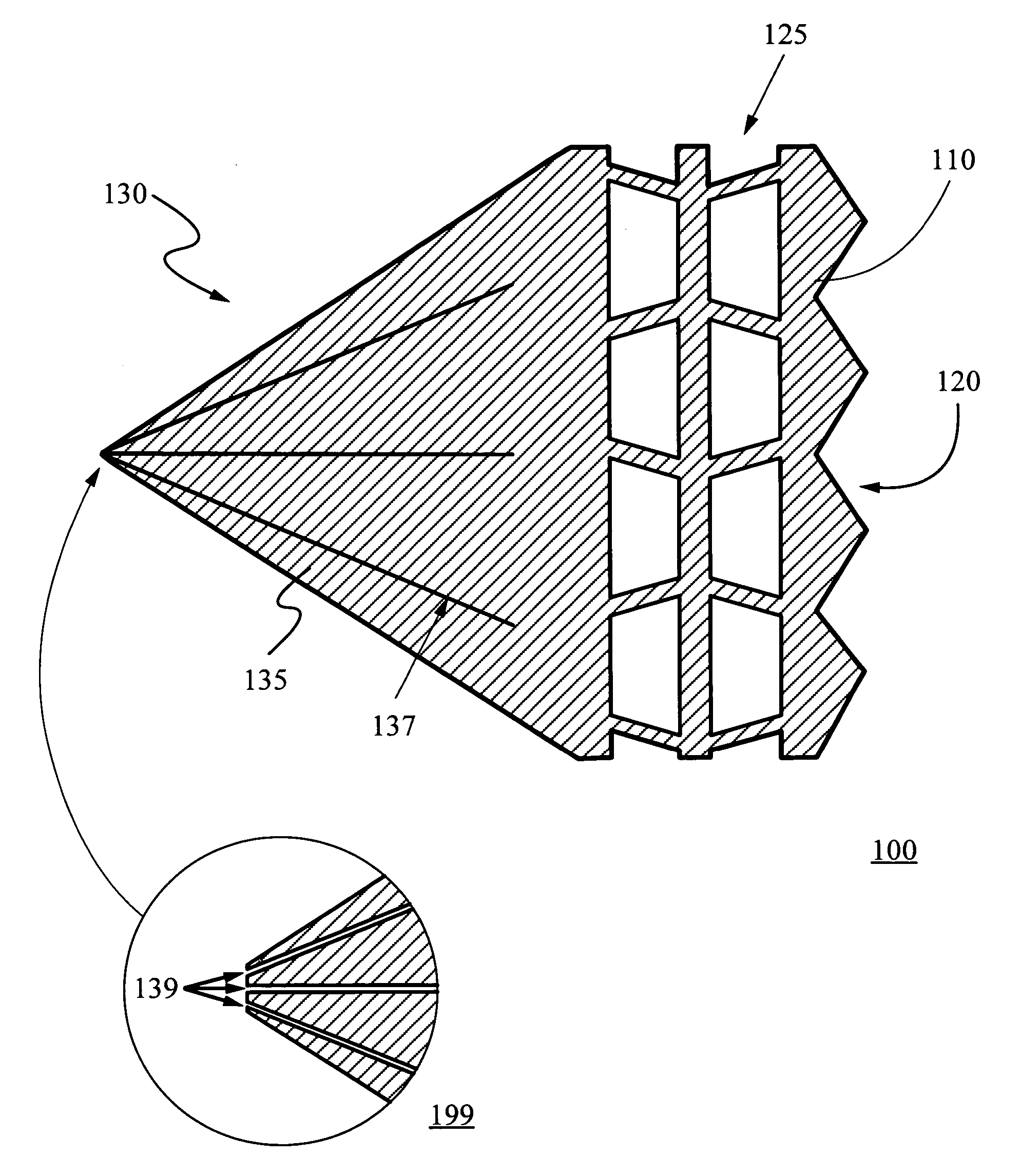

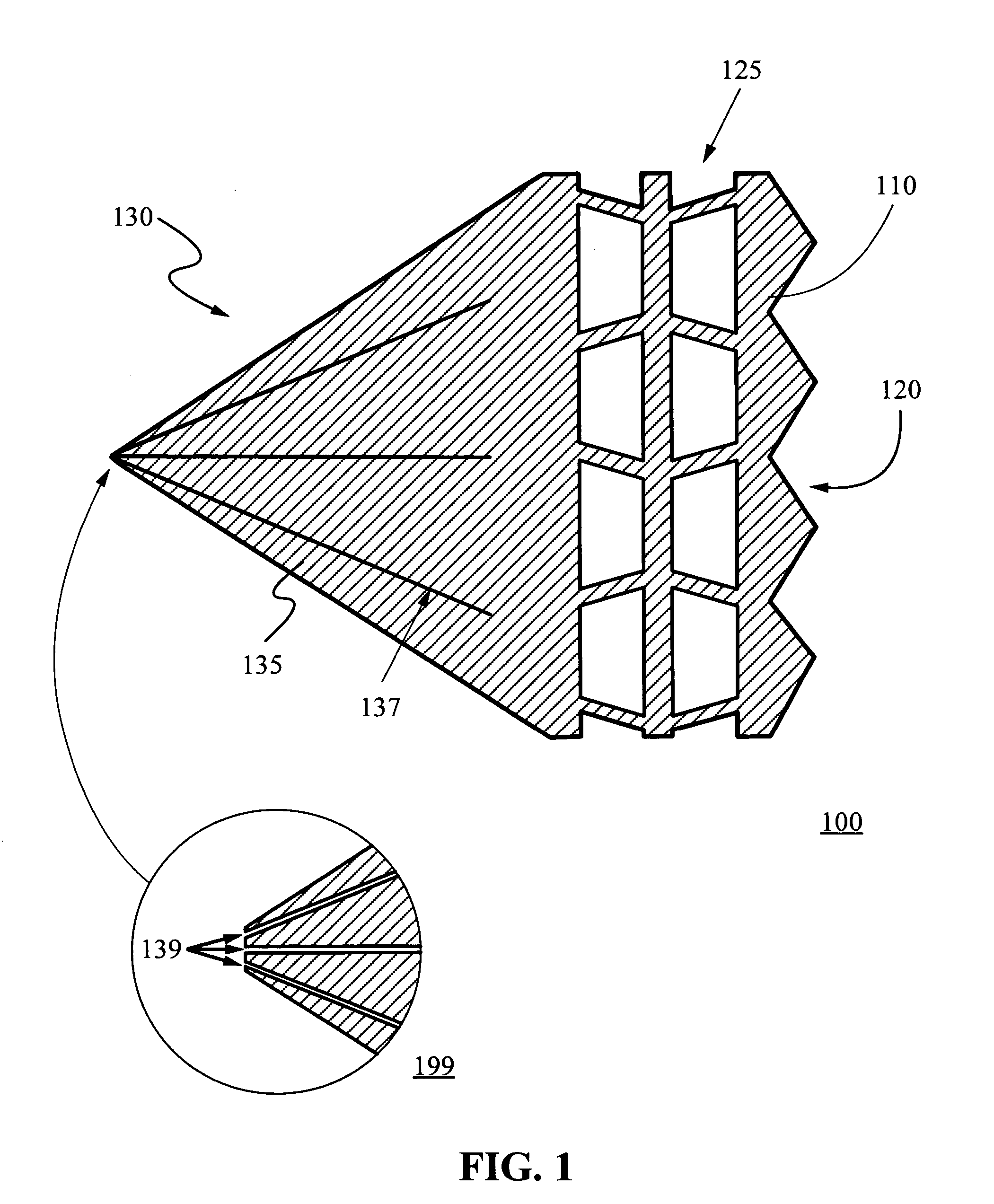

Implantable valves and methods of making the same

InactiveUS20060064174A1Enhance and strengthen bondingMore efficientVenous valvesBlood vesselsSand blastingBiocompatible coating

An implantable valve composed of a frame structure monolithically formed and covered with a biocompatible coating or soft structure. The implantable valve can have various shapes, openings, anchoring sites, attachment sites and is flexible, expendable, and easy to attach to body tissue. In some embodiments, the implantable valve is made by first determining a two or three dimensional configuration of the frame structure, which has an open end and a tapered end. The configuration may be scaled to obtain a desired size, e.g., length and diameter. One or more frame structure may be cut, stamped, etched, or machined from a single material, which could be metal or plastic with various thickness profiles and may have superelasticity and / or shape memory. The biocompatible coating selectively seals the valve to control / prevent fluid passage. To enhance bonding, the frame structure surface is treated with etching, polishing, sand blasting, plating, nanotechnology surface modification, etc.

Owner:ZADNO REZA

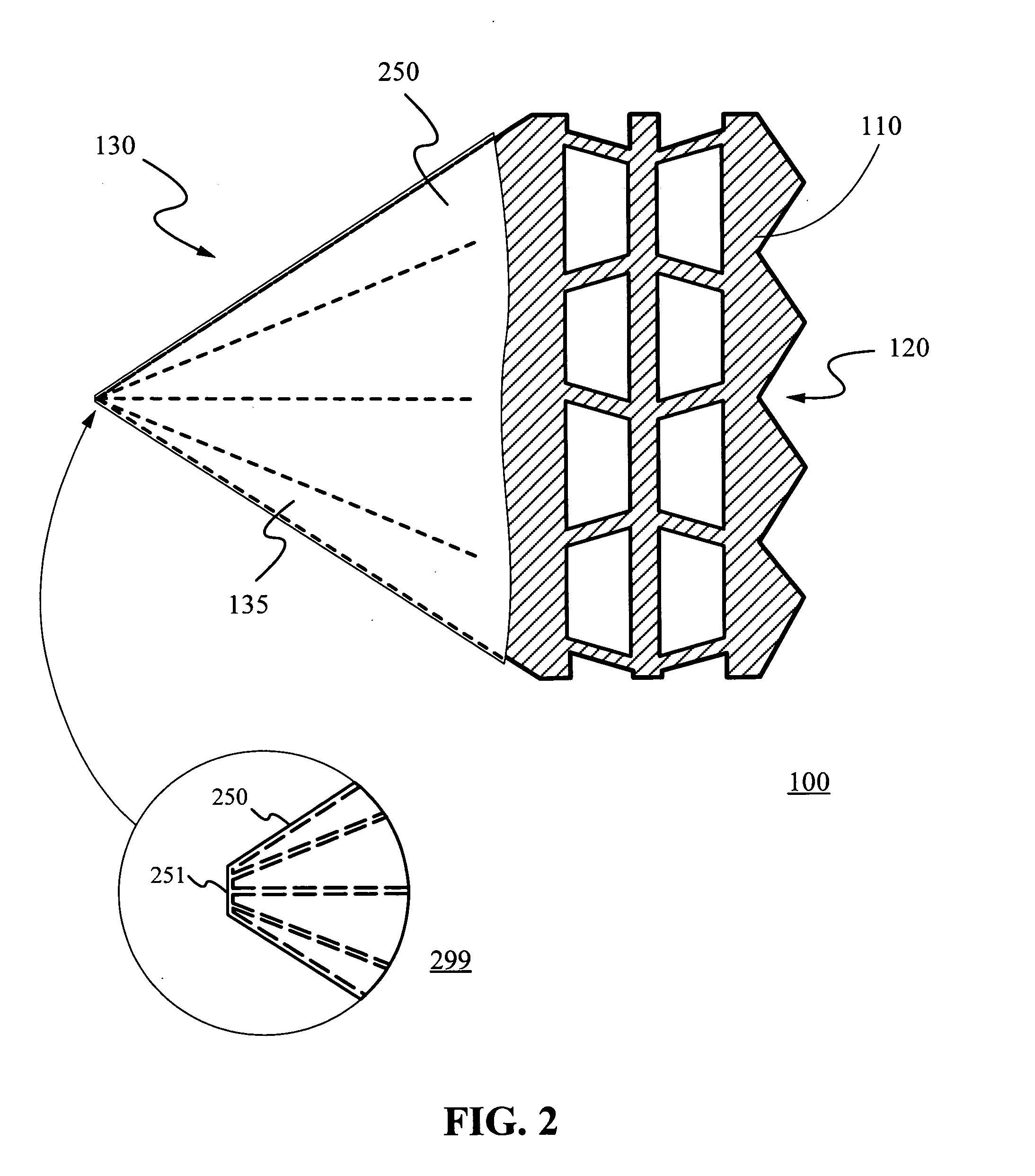

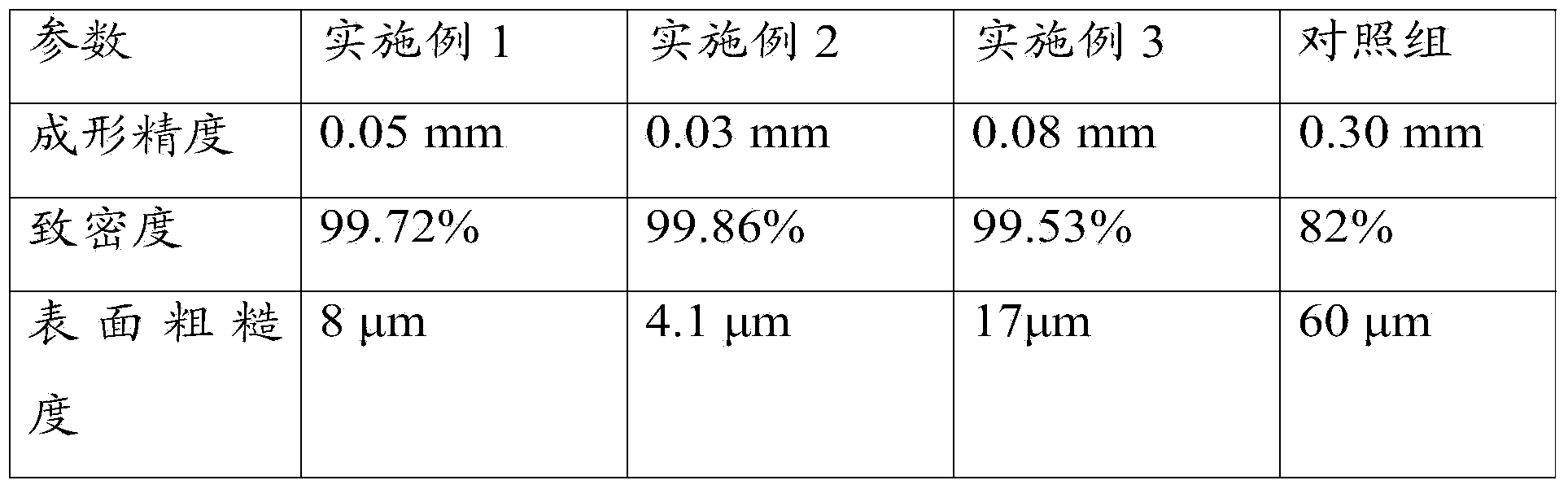

Method for producing titanium alloy artware by adopting selective laser melting

ActiveCN104259459AHigh precisionImprove forming qualityIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention relates to the field of material preparation, in particular to a method for producing titanium alloy artware by adopting selective laser melting. The method includes the steps: creating two-dimensional slicing data of a part structure to be produced and importing the two-dimensional slicing data into a metal powder laser melting system; setting processing technological parameters of the metal powder laser melting system; taking titanium alloy powder and spreading the titanium alloy powder on the metal powder laser melting system, and sequentially performing laser melting, powder sieving, heat treatment, wire cutting, cleaning, sand blasting, polishing and the like under the protection of inert gas to obtain the titanium alloy artware. According to the method, specific titanium alloy types and specification parameters are selected, and the processing technological parameters of the metal powder laser melting system are optimized for multiple times, so that the produced titanium alloy artware is high in precision, stable in shaping quality, small in distortion, excellent in mechanical property and good in surface smoothness through follow-up processing and has great artistic value.

Owner:飞而康快速制造科技有限责任公司

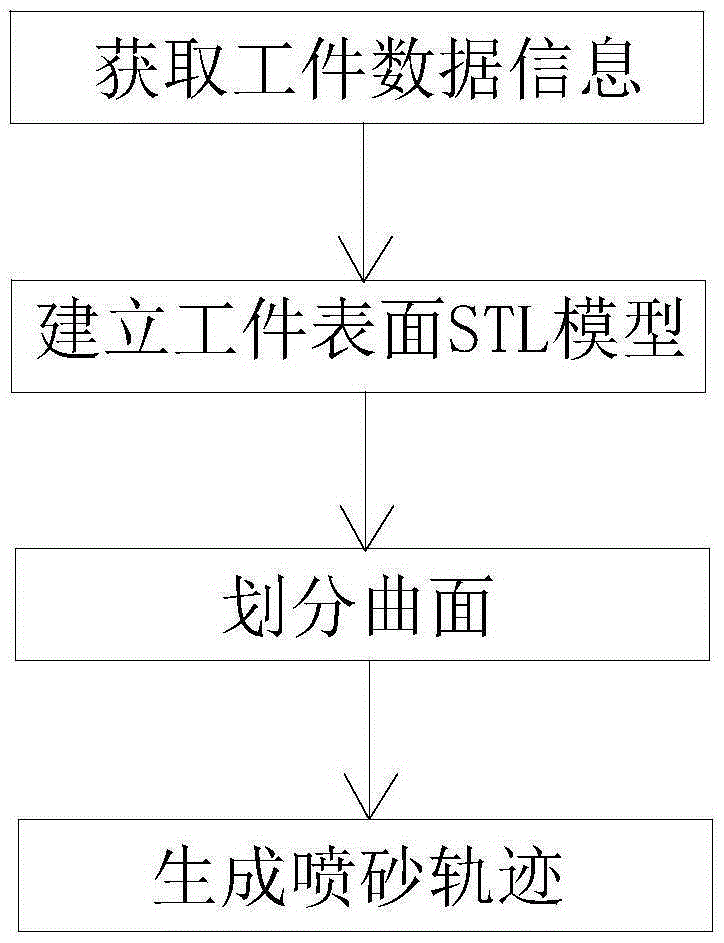

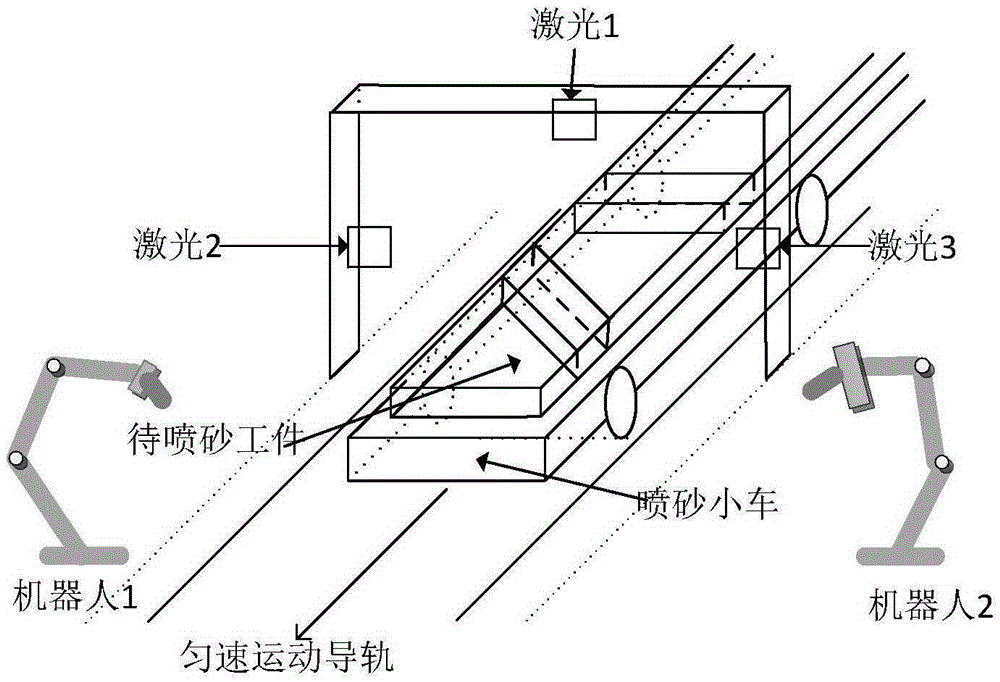

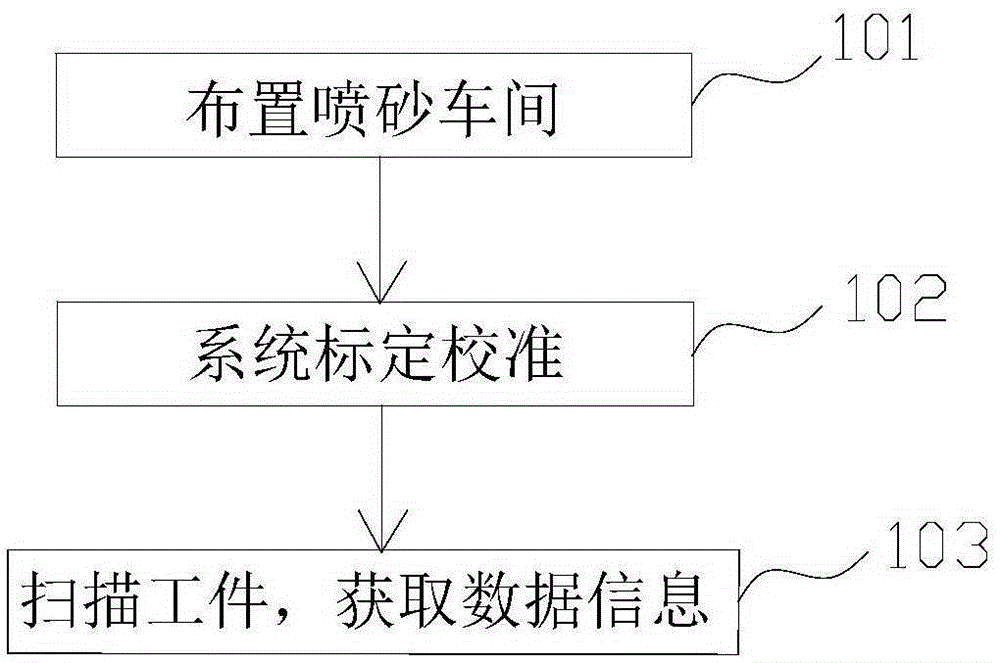

Line laser scanning-based sand blasting robot automatic path generation method

The invention discloses a line laser scanning-based sand blasting robot automatic path generation method. The method comprises the following steps: 1, workpiece data information obtaining: obtaining data information of scanning sampling points on the surface of a workpiece to be sand blasted by adopting a 2D laser scanning manner; 2, workpiece surface STL model establishment: establishing a to-be-sand blasted workpiece surface STL model through point cloud pre-processing; 3, curved surface division: extracting and utilizing the geometrical characteristics and topological characteristics of the workpiece surface STL model so as to divide the curved surface of the workpiece into a plurality of planes without cavities; and 4, sand blasting track generation: constructing a characteristic frame according to the workpiece surface STL model and generating sand blasting tracks by adopting a cut plane projection method.

Owner:SOUTHEAST UNIV

Method for preparing durable super-amphiphobic coatings capable of being sprayed

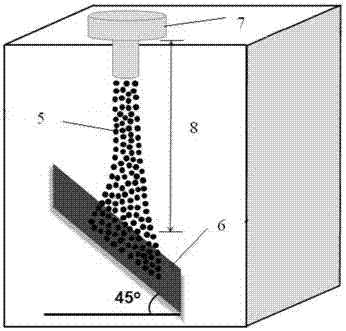

ActiveCN106893454AIncrease roughnessHigh bonding strengthAnti-corrosive paintsPolyurea/polyurethane coatingsAnti freezingSand blasting

The invention belongs to the field of super-hydrophobic or super-amphiphobic coating preparation, and particularly relates to a method for preparing durable super-amphiphobic coatings capable of being sprayed. The method particularly includes steps of 1, carrying out cleaning and sand blasting roughening treatment on the surfaces of base materials; 2, preparing resin solution; 3, preparing particle composite suspension; 4, spraying the resin solution obtained at the step 2 on the surfaces, treated at the step 1, of the base materials, drying the base materials and carrying out semi-solidification on resin adhesive; 5, spraying the particle composite suspension obtained at the step 3 on the surfaces of the base materials obtained at the step 4, and drying the base materials to completely solidify the base materials; 6, washing the surfaces of the base materials obtained at the step 5 to obtain the durable super-amphiphobic coatings capable of being sprayed. The method has the advantage that the durable super-amphiphobic coatings with excellent durability and firmness can be prepared on the surfaces of the various base materials by the aid of spraying technologies and have persistent anti-freezing performance.

Owner:哈尔滨毓干科技有限公司

Composite reinforced wear-resistant part of metal-ceramic prefabricated member and manufacturing method of composite reinforced wear-resistant part

The invention discloses a composite reinforced wear-resistant part of a metal-ceramic prefabricated member and a manufacturing method of the composite reinforced wear-resistant part. The manufacturing method comprises the steps as follows: uniformly mixing ceramic particles with self-fluxing alloy powder to obtain a mixture; filling a mould cavity of a pressing machine with the mixture, pressing by pressure, forming and demoulding, and placing biscuits and gaskets into a drying box for drying; placing the dried biscuits and gaskets into a vacuum furnace for sintering, cooling and discharging to obtain the metal-ceramic composite prefabricated member; carrying out sand blasting on the prefabricated member, and spraying a layer of nickel-based self-fluxing alloy powder onto the surface of the prefabricated member; and placing the processed fabricated member onto the end surface of a cast cavity, and pouring metal liquid formed by smelting metal matrix materials into the bottom of the cast cavity to obtain the composite reinforced wear-resistant part of the metal-ceramic prefabricated member. According to the manufacturing method, the wear resistance and the impact resistance of the composite wear-resistant part are improved.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

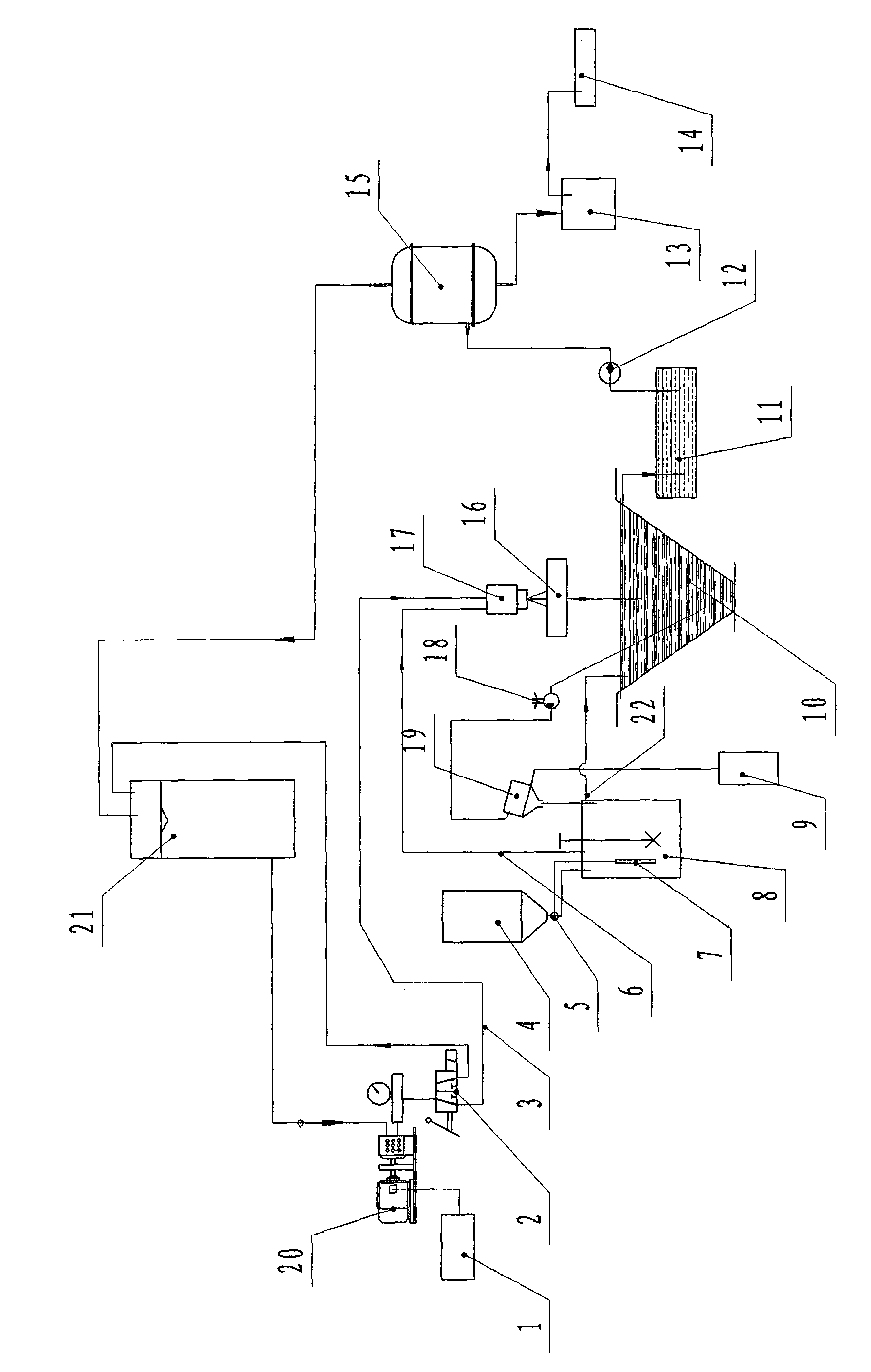

Online high-pressure water-jet blasting surface cleaning system

ActiveCN101633154AUniform supplyGuaranteed uptimeAbrasive feedersAbrasive machine appurtenancesSlagSurface cleaning

An online high-pressure water-jet blasting surface cleaning system comprises a high pressure water feed mechanism, an abrasive material feed mechanism and a spray nozzle. The high pressure water feed mechanism and the abrasive material feed mechanism are communicated with an input end of the spray nozzle, an abrasive material collecting pit is arranged below the spray nozzle, an output end of the abrasive material collecting pit is divided into two paths, one path is connected with an input end of an abrasive material sorting device by an abrasive material cyclical feeding device and a pipeline, and the other path is connected with an input end of a waste water treatment circulating mechanism by a pipeline, an output end of the waste water treatment circulating mechanism is connected with the high pressure water feed mechanism by a pipeline, an output end of the abrasive material sorting device is divided into two paths, one path is connected with the abrasive material feed mechanism, and the other path is connected with a slag collection barrel by a pipeline. The online high-pressure water-jet blasting surface cleaning system has the advantages of simple and compact structure, low energy consumption, good environmental protection, good operational reliability and stability, and recycled water and abrasive materials.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

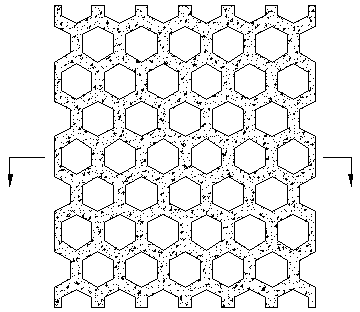

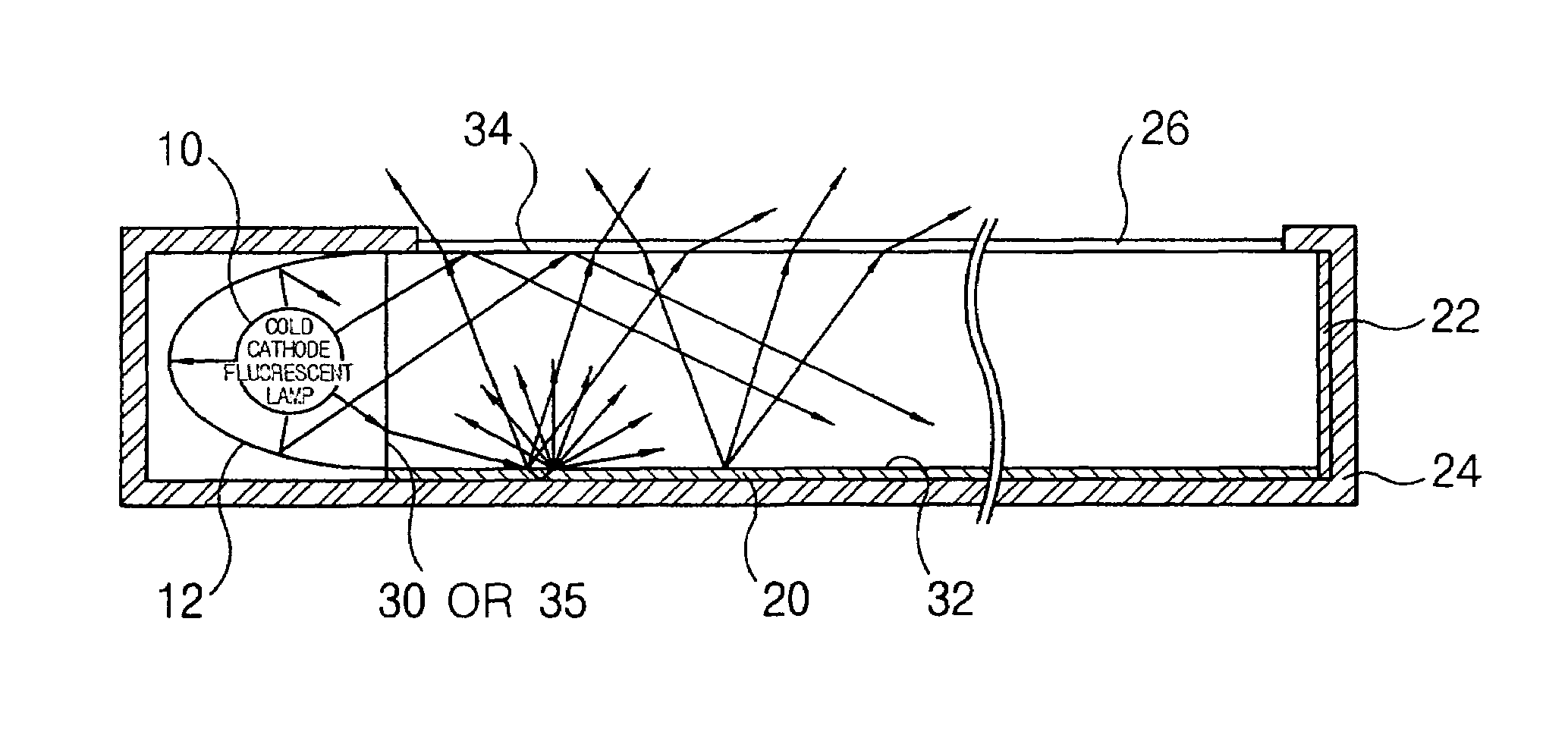

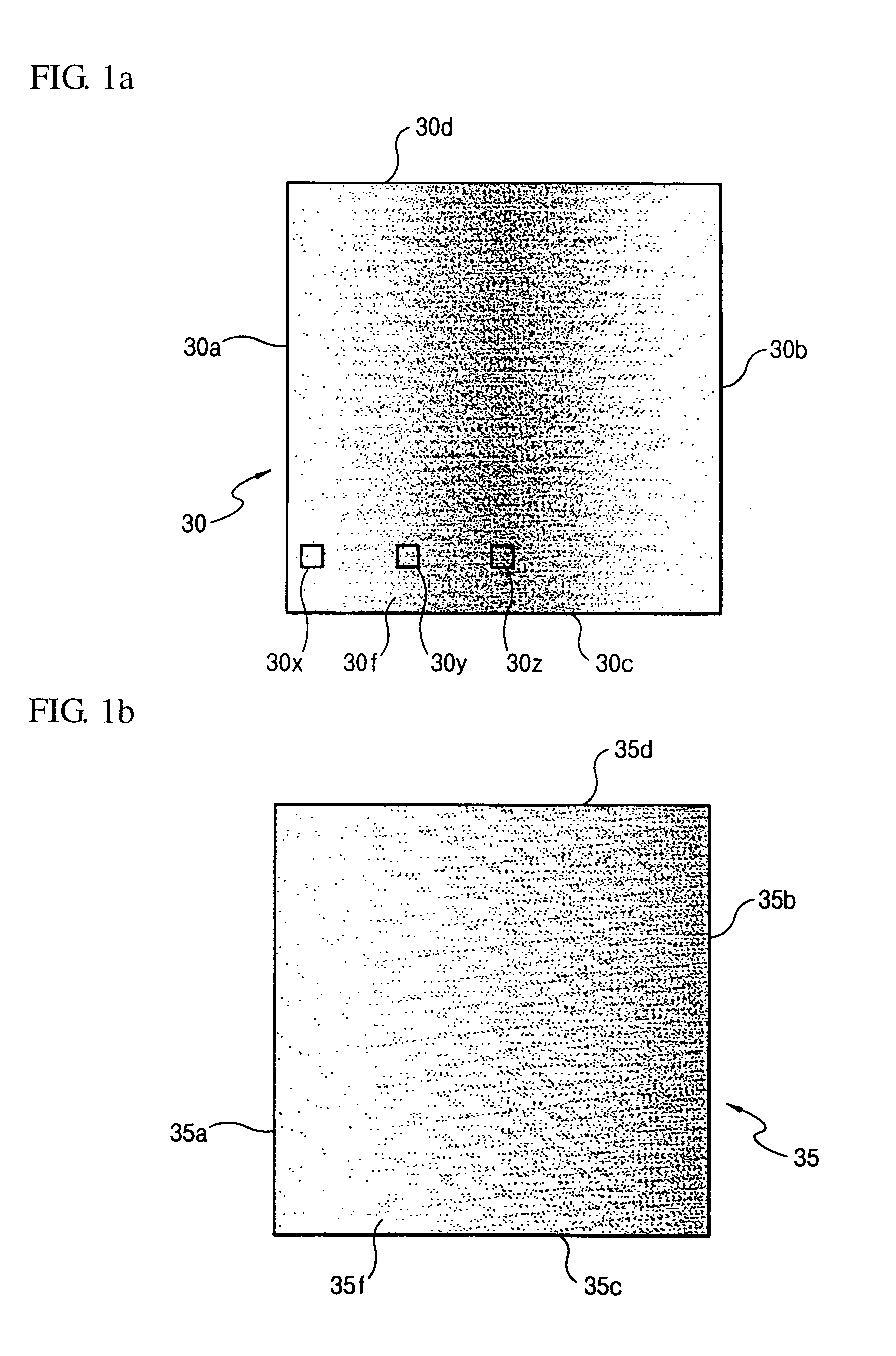

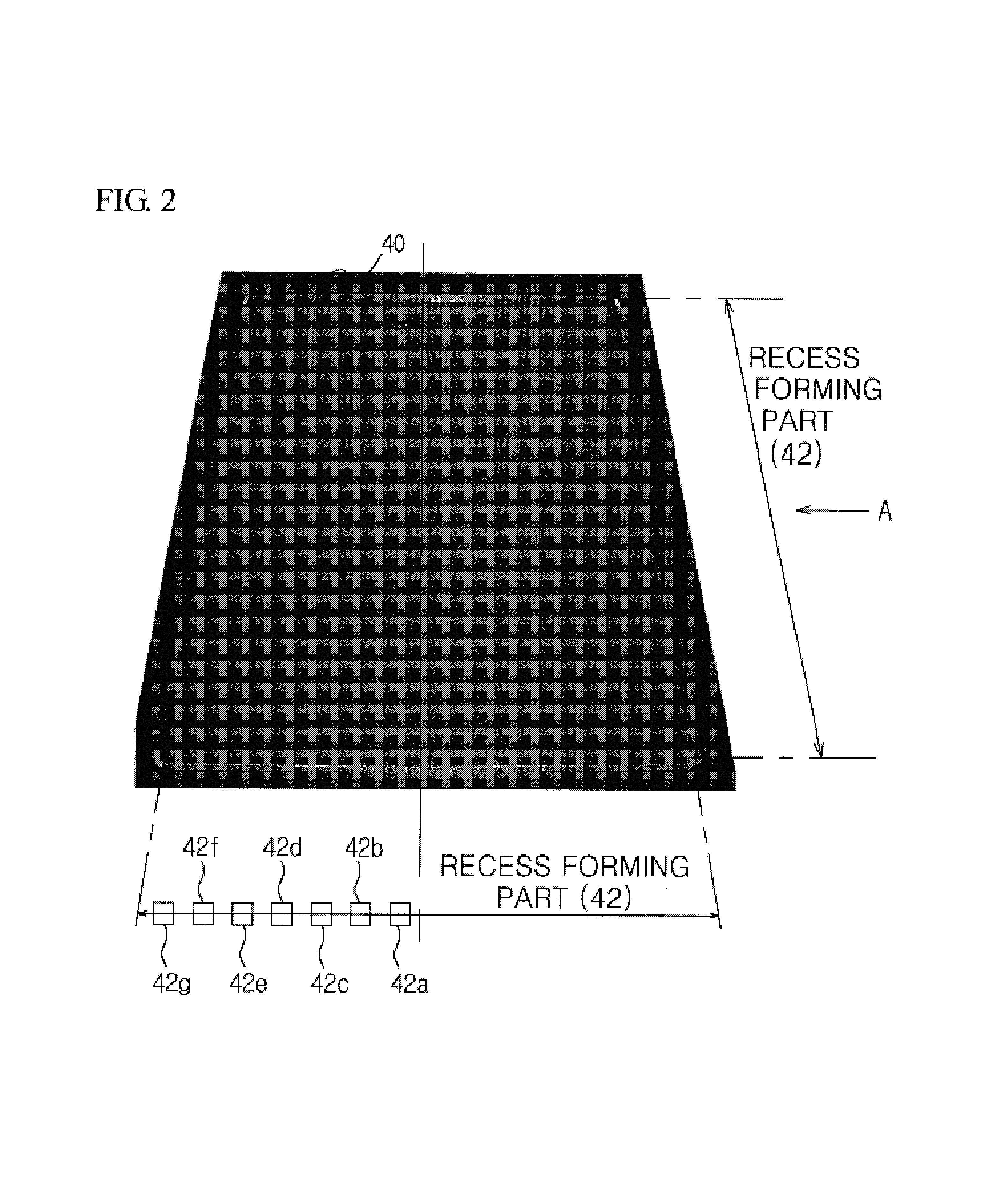

Light guiding panel formed with minute recesses by a sand blasting process and a backlight unit using the same

InactiveUS7192174B2Improve brightness uniformityImprove optical efficiencyShow cabinetsMechanical apparatusDiffusionSand blasting

Disclosed is a light guiding plate formed with fine recesses and a backlight unit utilizing the same. There are formed on a bottom surface of a transparent acryl resin substrate a number of fine recesses, which are unable to be distinguished with the naked eye, in order to reflect on front surface of the plate a source light introduced through at least one side surface. The fine recesses are formed by means of a sandblasting process. The amount of the fine recesses jetted per unit hour is uniformly maintained. The number of sands collided into unit area per unit hour and impact energy of the sands are higher the further away from the side through the source light is introduced. Accordingly, density, average depth and average size of the recesses are gradually higher the further away from the light introduced side. Also, area, average complexity of the contour of the recesses and average complexity of the surface profile of the recesses are increased. Therefore, as a light getting out of the front surface of the plate is uniformly diffused, a diffusion sheet is not needed in composing a backlight unit for an advertising film or a LCD panel by utilizing the plate.

Owner:MYOUNG BUM YOUNG

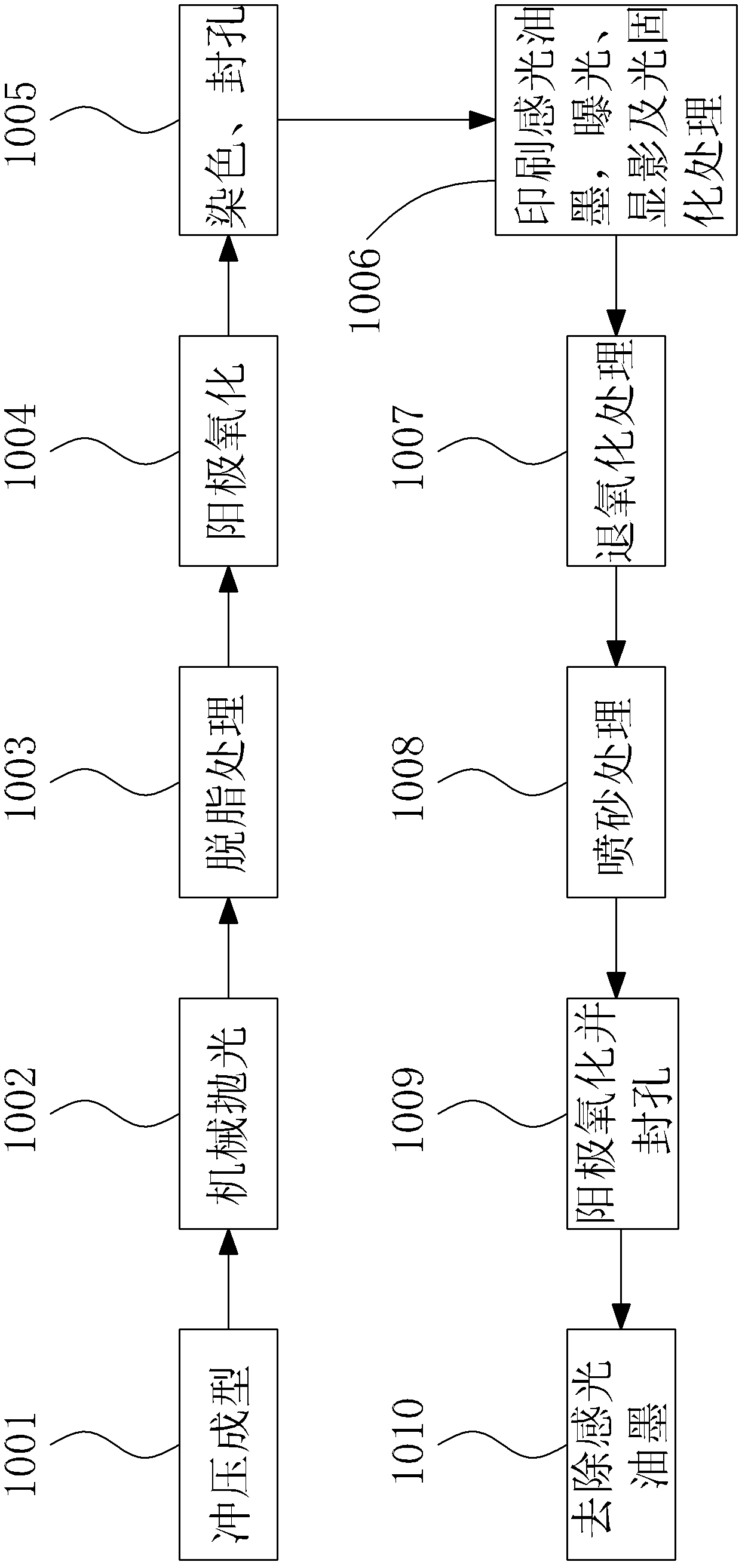

Method for surface treatment of aluminium alloy and product of aluminium alloy

ActiveCN103253072AImprove reflectivityImprove sandblasting resistanceAnodisationDuplicating/marking methodsScreen printingMetallurgy

The invention discloses a method for surface treatment of an aluminium alloy and a product of the aluminium alloy. The method comprises the steps of punching the aluminium alloy into a required shape; conducting mechanical polishing on the aluminium alloy which is subjected to punch forming; conducting degreasing treatment on the aluminium alloy which is subjected to mechanical polishing in a degreasing agent; placing the aluminium alloy which is subjected to degreasing treatment into an acid liquor tank for first-time anodic oxidation; placing the aluminium alloy which is subjected to first-time anodic oxidation into dye for dying, and conducting hole sealing treatment after dying; conducting screen printing on the surface of the aluminium alloy which is subjected to dying and hole sealing treatment with photosensitive ink, and conducting exposure, developing and photocuring treatment; conducting oxidation film removing treatment on the printed aluminium alloy in an alkaline solution; conducting sand blasting treatment on the treated product of the aluminium alloy; conducting second-time anodic oxidation on the product of the aluminium alloy, which is subjected to sand blasting treatment, and conducting hole sealing treatment on the product which is subjected to second-time anodic oxidation; and removing the photosensitive ink from the surface of the product of the aluminium alloy. The product of the aluminium alloy is processed by the method.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

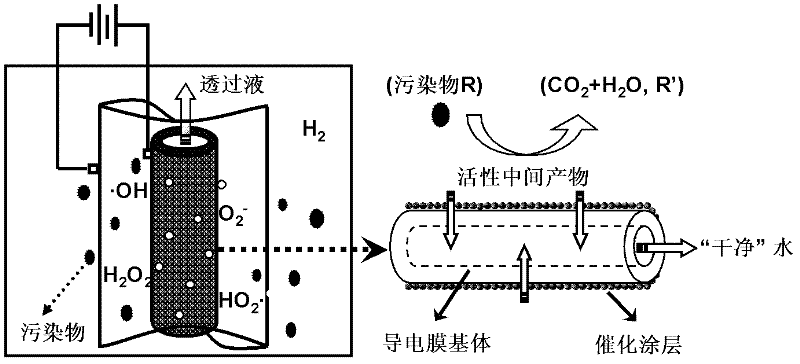

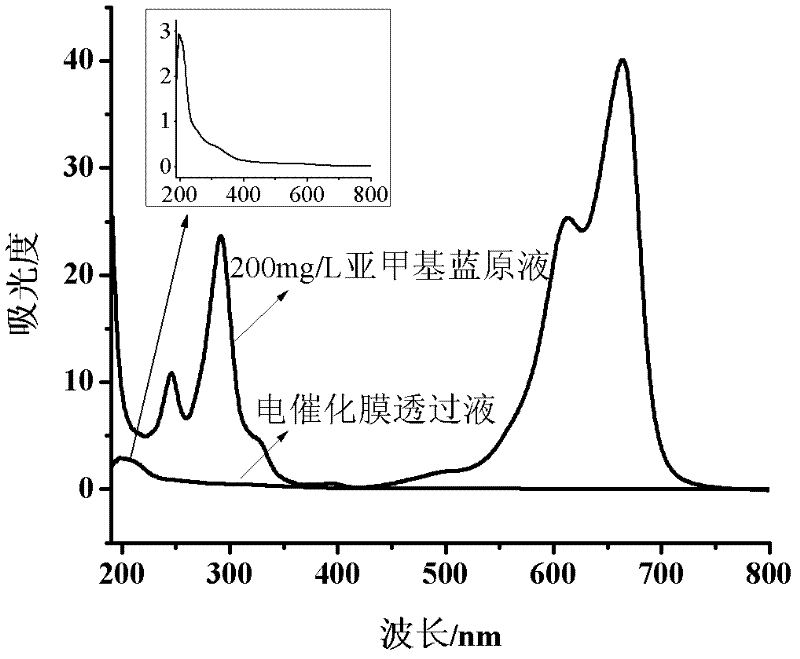

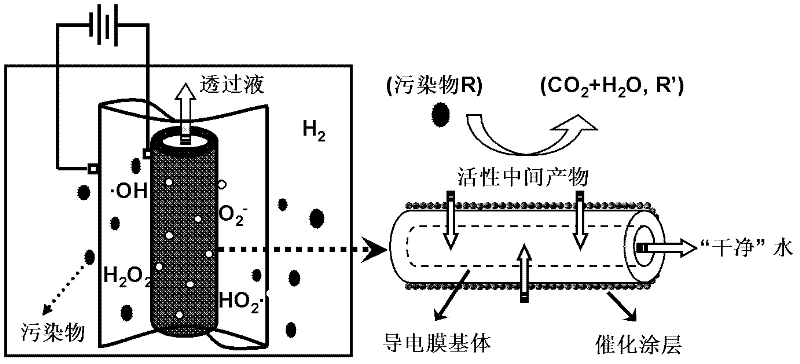

Nano loaded titanium-based electric catalytic film and preparation method thereof

InactiveCN102350228AImprove degradation efficiencyHigh electrode strengthSemi-permeable membranesDispersed particle separationAcid etchingCatalytic oxidation

The invention discloses a nano loaded titanium-based electric catalytic film comprising a conductive microporous separating titanium film matrix and a catalytic coating. Furthermore, the invention also discloses a preparation method of the nano loaded titanium-based electric catalytic film, which comprises the following steps of: (1) preprocessing the titanium film matrix by sand blasting, alkali washing, and acid etching: soaking the matrix after sand blasting in an NaOH solution for 0.5 to 2h, then processing for 1 to 2h in an oxalic acid solution with the mass percent concentration of 10 percent after washing to a neutral state, washing with water and drying at 100 to 120 DEG C; and (2) preparing and loading a catalytic coating: preparing the catalytic coating by adopting a sol-gel method, a thermal decomposition method, an electrodeposition method or a chemical vapor deposition method and loading at the surface of the titanium film matrix and in a hole. Furthermore, the invention also discloses a film reactor comprising the nano loaded titanium-based electric catalytic film. According to the nano loaded titanium-based electric catalytic film, the defects on material strength, range limitation of working voltage, catalytic oxidation efficacy and the like in the prior art are solved.

Owner:SHANGHAI CAS ADVANCED RES INST

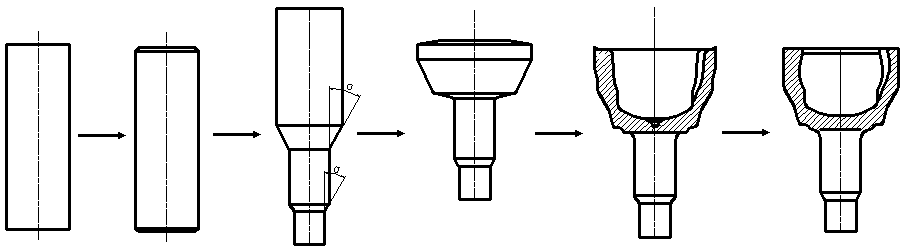

Precision-forging plastic molding technology of bell shell of ball-cage type universal joint

InactiveCN102861861AReduce workloadImprove product qualityRailway componentsForging/hammering/pressing machinesSand blastingUniversal joint

The invention discloses a precision-forging plastic molding technology of a bell shell of a ball-cage type universal joint, comprising steps of warm-forging plastic molding and cold-forging plastic molding. The warm-forging plastic molding technology comprises the following steps: a. blanking; b. manufacturing a blank; c. coating; d. heating; e. directly extruding; f. upsetting; g. extruding reversely; h. normalizing, shaping, sand blasting, parkerising, and treating the surface by a manner of saponification; and adopting the forging plastic molding technology of combining the warm-forging plastic molding technology with the cold-forging plastic molding technology, firstly upsetting to obtain the pre-molding blanking material, secondly, extruding reversely in the chamber of the molding mold to form a ball channel and finally forming the inner spherical surface by using the cold-forging plastic molding technology. The product quality is steady, the production efficiency is improved, the production period is short, the method for adopting the machine tool after the hot-forging is replaced, the workload of the machine tool process is reduced, the precision requirements are met, the manufacturing cost and the period are reduced, and the development trend of the manufacturing field in the world is met.

Owner:张太良

Composite metal carbide wear-resistant coating and preparation process thereof

The invention relates to a composite metal carbide wear-resistant coating and a preparation process thereof, and belongs to a wear-resistant coating and a preparation process thereof. The composite metal carbide wear-resistant coating consists of adhesive coated tungsten carbide and other carbides, wherein the adhesive coated tungsten carbide has the grain size of WC-Co or WC-Ni; and the other carbides comprise chromium carbide, vanadium carbide, iron carbide, titanium carbide and the like. The preparation process comprises the following steps of: mixing the adhesive coated tungsten carbide and one or more kinds of the carbide powder; and performing spray coating (welding) or plasma spray coating (welding) on the surface of a medium-carbon steel part through supersonic flame to form the wear-resistant coating, wherein the carbon content of the medium-carbon steel is 0.35 to 0.55 weight percent (wt); the medium-carbon steel is subjected to the thermal refining state of quenching and high-temperature tempering; and the supersonic flame spray coating (welding) or plasma spray coating (welding) process sequentially comprises steps of performing sand blasting and rust removal on the surface of the medium-carbon steel, spraying a Ni-5 percent Al alloy adhesive coating and spraying a composite carbide wear-resistant coating. The composite carbide wear-resistant coating has Vickers hardness (HV) of 1,200 to 1,800, bonding force of more than 60 Mpa, and high mechanical property, wear resistance and corrosion resistance.

Owner:CHINA UNIV OF MINING & TECH +1

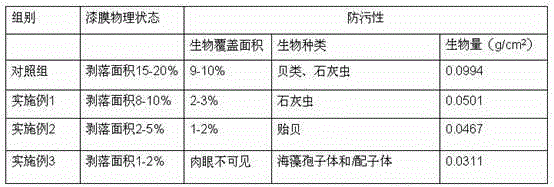

Ship anti-pollution method

InactiveCN104549961ANo toxic effectsNot volatileAntifouling/underwater paintsPretreated surfacesAdhesion forceDefect repair

The invention discloses a ship anti-pollution method. The ship anti-pollution method comprises the following steps of surface pretreatment of a steel plate, sanding treatment of a substrate, defect repair and sand blasting of welding seams and other structures, spraying of a primer, spraying of a reinforced paint, and subsequent servicing. Before coating, the surface of the steel plate is pretreated; during integral coating, the bottom part of a ship is sprayed with bionic marine anti-pollution coating, the coating contains a pure natural biological anti-pollution agent, the aversion function on marine organisms is realized, the adhesion force of the marine organisms is damaged, the pollution preventing purpose is realized, any poisonous influence on the marine environment is avoided, any damage on the marine organisms is avoided, and the coating is pure natural and is free from public nuisance; the adhesion force, anti-corrosive and strain-proof properties are excellent, the requirements of semi-gloss and matte of an anti-rust paint of a ship cabin are met, the spraying for multiple times is easy, the easiness in volatizing of moisture is avoided, the adhesion capability is higher, and the flash rust is avoided; the process flow is short, and the produced ship has excellent anti-pollution, anti-corrosive and anti-rust properties.

Owner:QINGDAO WUWEI THERMAL INSULATION MATERIAL

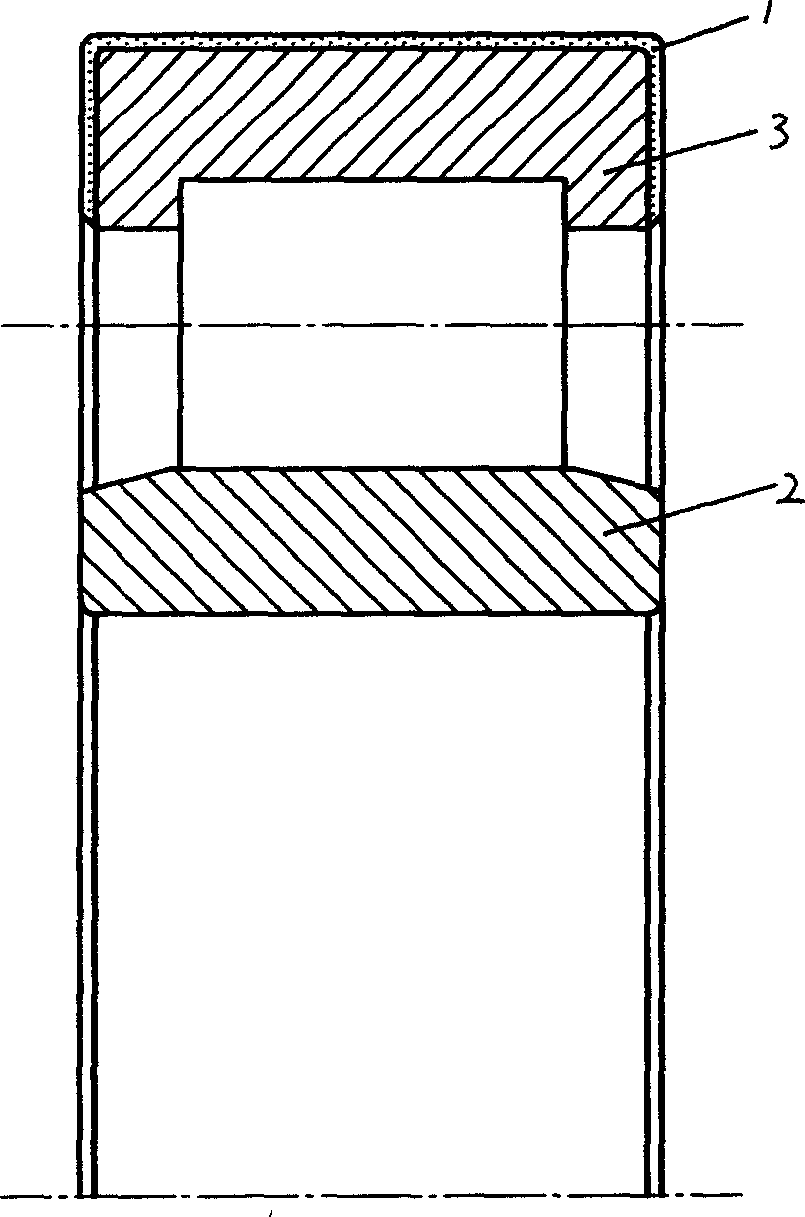

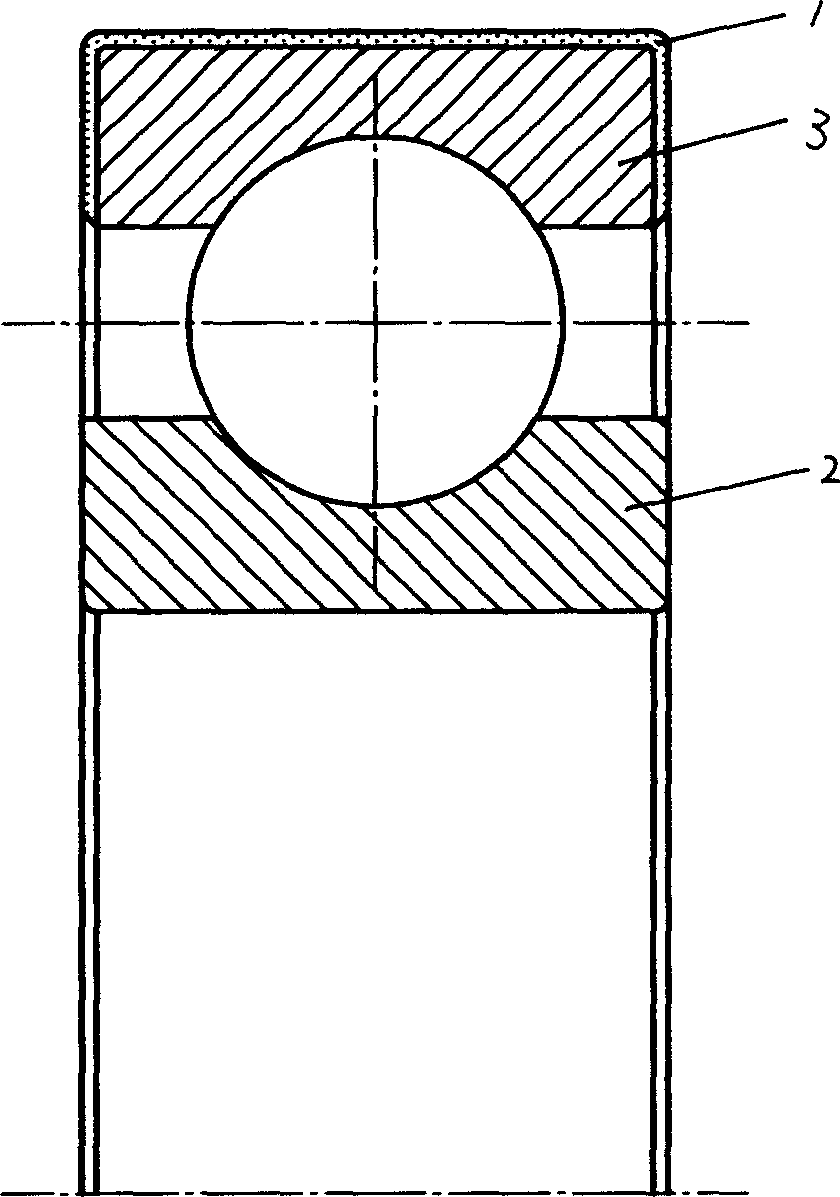

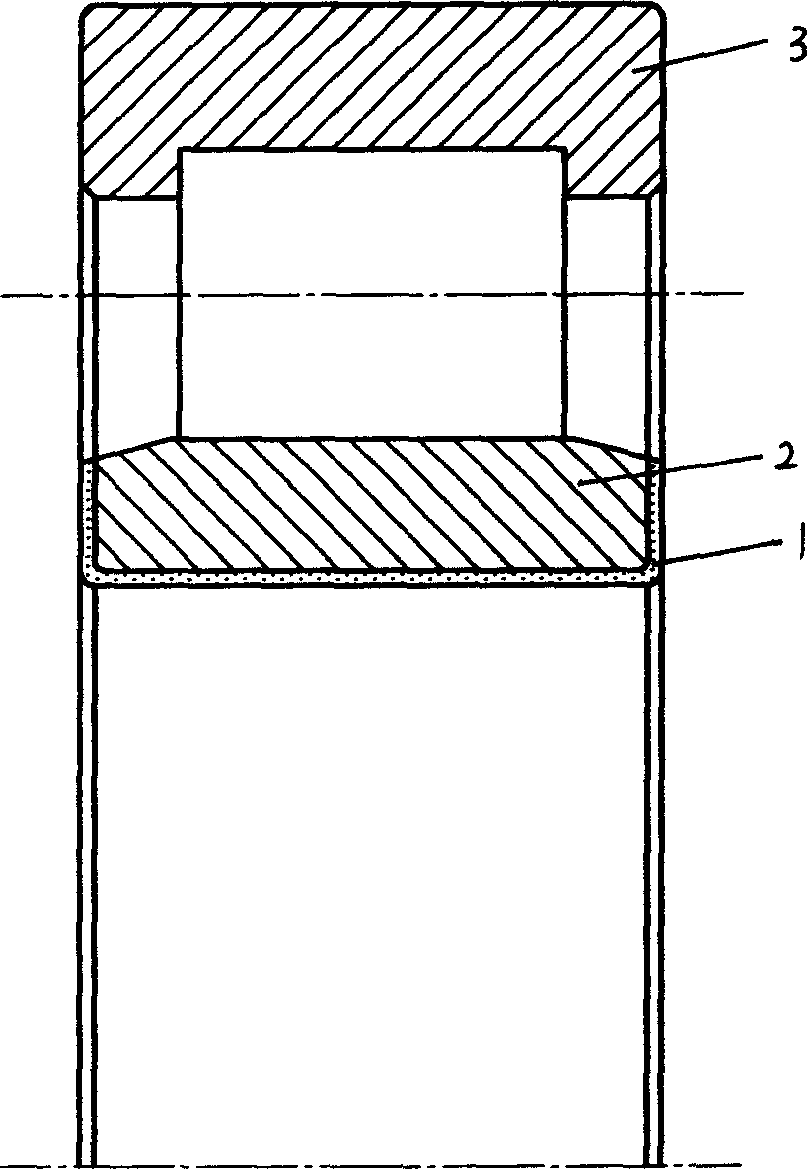

Surface insulating layer treating process for roller bearing

InactiveCN1706980AImprove thermal stabilityHigh failure voltageMolten spray coatingBearing componentsSand blastingAlloy

The surface insulating layer preparing process for roller bearing is to form homogeneous and firm non-metal coating to the surface of bearing through plasma hot spraying process. The preparation process includes the following steps: degreasing the steel base of bearing; shielding the parts needing no surface treatment with steel or copper belt; sand blasting pre-treatment of the base with Ni-Al alloy powder; preparing coating material of alumina-titania alloy with alumina content of 3-13 wt% and size 200-360 / micron; spraying the coating material; sealing holes in coating; and final finishing treatment of the coating. The insulated roller bearing is used in motor mainly.

Owner:LUOYANG BEARING GROUP

Drainage method of non-cell-cementation cased-hole-completion coal bed gas horizontal well

ActiveCN107387034AAvoid pollutionImprove fracturing effectFluid removalSand blastingProduction effect

The invention discloses a drainage method of a non-cell-cementation cased-hole-completion coal bed gas horizontal well. The method includes: a U-shaped butted well is used, the horizontal section of the horizontal well is deployed along the declination direction of a coal bed and a direction parallel to the minimum main stress of the coal bed, and well completion is performed by using casing running and an external self-expansion casing packer in a non-cell-cementation manner; the setting section, perforation and fracturing section of the external casing packer of the horizontal well are optimized; perforation is performed in a large-displacement and fixed-direction hydraulic abrasive perforation manner, and slug insertion type sand-carrying fracturing is performed on the horizontal well section by section in a large-displacement, large-scale, high-prepad-fluid-ratio and medium-sand-ratio manner; draining is performed at the wellhead of a drainage vertical well, and gas production is performed at the wellhead of the horizontal well. The drainage method has the advantages that pollution of a coal reservoir and production and operation costs can be lowered, the fracturing transformation effect and draining and gas production effect of the non-cell-cementation cased-hole-completion horizontal well are improved, the drainage efficiency and effect of the horizontal well are increased, the coal bed gas content of soft, broken and low-permeability coal beds can be lowered in a large-range and fast manner, and intensified coal bed gas drainage is achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Preparation method of persistent icing-resistant superhydrophobic coating

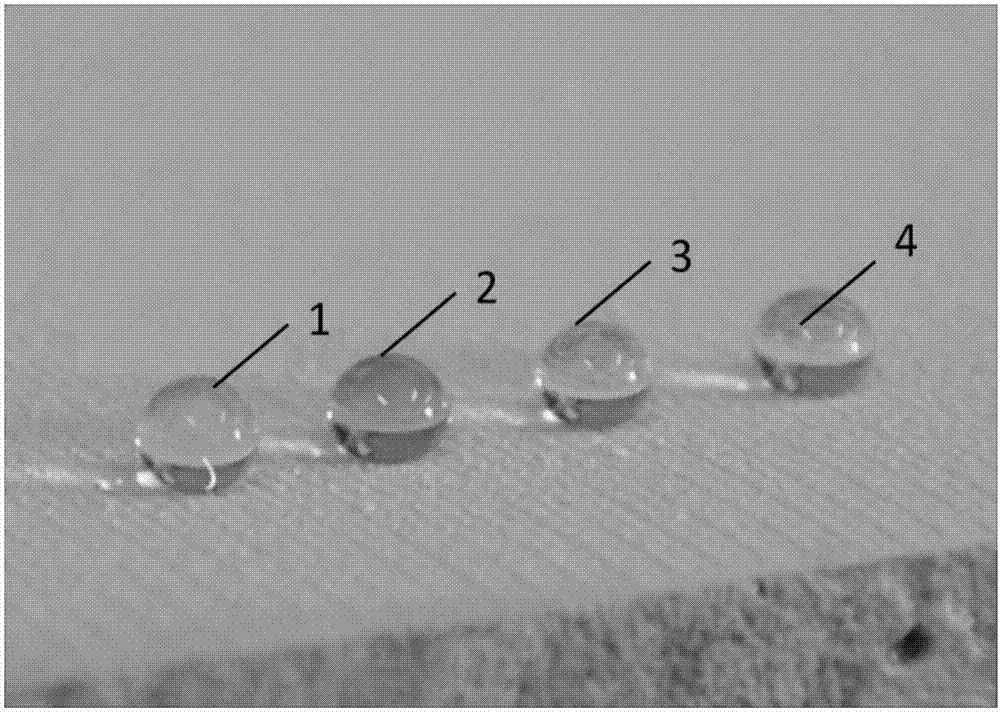

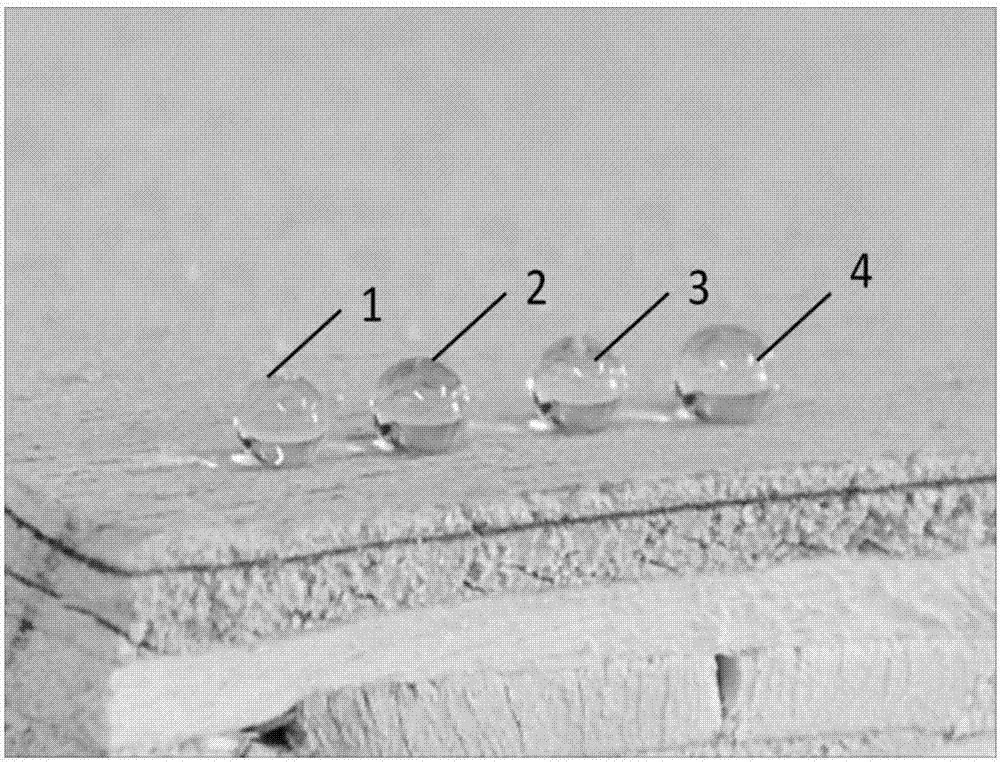

ActiveCN106883650AImproved long-lasting anti-icing performanceLong-lasting anti-icing performanceAntifouling/underwater paintsPaper coatingSuperhydrophobePolymer science

The invention relates to the field of preparation of superhydrophobic coatings, in particular to a preparation method of a persistent icing-resistant superhydrophobic coating. The preparation method comprises the following steps: firstly, carrying out cleaning and sand-blasting roughen treatment on the surface of a substrate; secondly, blending epoxy resin, a curing agent and a first solvent to obtain an epoxy resin solution; thirdly, dispersing submicron particles and nanoparticles into a second solvent, and then adding a silane coupling agent to obtain particle composite suspension; fourthly, spraying the epoxy resin solution obtained in the second step on the surface of the substrate treated in the first step, and partially curing epoxy resin adhesive; fifthly, spraying the particle composite suspension obtained in the third step on the surface of the substrate obtained in the fourth step and completely curing; sixthly, obtaining the persistent icing-resistant superhydrophobic coating. The persistent icing-resistant superhydrophobic coating disclosed by the invention has the beneficial effects that the superhydrophobic coatings prepared on the surfaces of all the substrates have good durability and firmness and persistent icing-resistant property.

Owner:哈尔滨毓干科技有限公司

Method for paving resin filling type asphalt concrete steel box-beam bridge deck combined structure

ActiveCN101200873AHigh strengthChemically stableBridge structural detailsBuilding insulationsSheet steelSurface layer

The present invention relates to a paving method of the paving layer of the bridge deck of a steel box girder bridge. A resin infusion type paving method of the composite structure of the asphalt concrete steel box girder bridge deck includes three steps: (1) the sand blasting and the derusting of the steel plates of the steel box girder bridge deck; (2) the preparation of materials: (a) the preparation of high-viscosity modified asphalt; (b) mineral aggregate gradation; (c) the preparation of large pored asphalt concrete; (d) the preparation of thermoset resin grouting material; (3) The pavement of the paving layer of the bridge deck: (a) The large pored asphalt concrete is paved on the steel plates of the steel box girder bridge deck, the pavement thickness is 2cm to 4cm, and after final pressure, a large pored asphalt concrete skeleton layer is formed; (b) While the large pored asphalt concrete skeleton layer is still in a hot state, the thermoset resin grouting material is grouted into the large pored asphalt concrete skeleton layer; (c) After the maintenance of three days, a layer of bonding oil is sprinkled, and an asphalt abrasion surface layer with the thickness of 4cm is paved. The paving method is characterized in good interface cohesive property and simple and convenient construction process.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Biomedical porous pure-titanium implant material and preparation method thereof

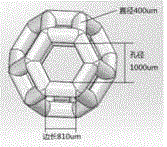

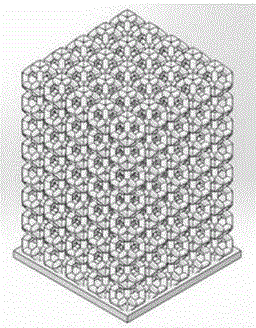

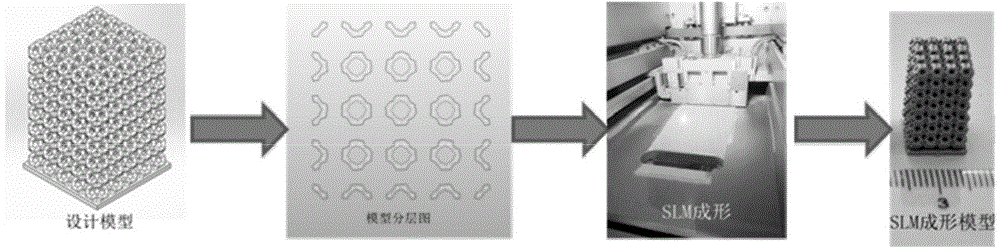

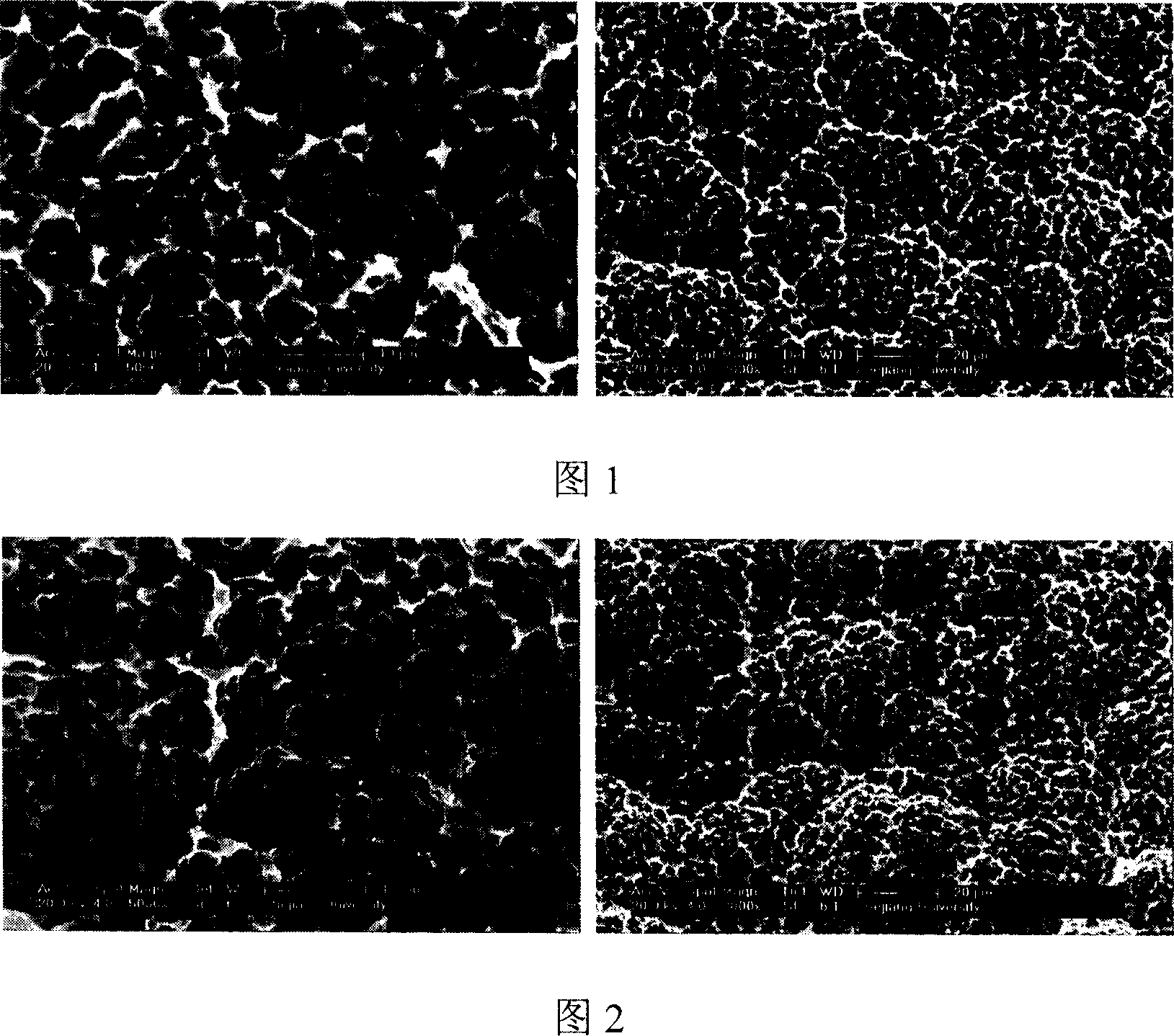

InactiveCN104646669AImprove compactnessImprove mechanical propertiesSelective laser meltingDot matrix

The invention discloses a preparation method of a biomedical porous pure-titanium implant material. The method comprises the steps of S1, constructing a three-dimensional model of the implant material through drawing software, slicing through layering software, conveying the obtained two-dimensional section information to a computer control system of an SLM former, and providing a laser scanning route; S2, paving a layer of titanium powder being 30 to 70 microns in thickness on a workbench of the SLM former through a powder paving layer; S3, performing selective laser meting for the titanium powder through a laser beam under the conditions that the power is 90 to 100W, the scanning spacing is 0.10 to 0.20mm, and the scanning speed is 275 to 540mm / s to obtain a layer of sections of the implant material, and synchronously lowering down the worktable in a distance equal to the height of a layer of powder; S4, repeating the steps 2 and 3 until the three-dimensional model of the implant material is formed; S5, automatically stopping working by the SLM former, cooling the three-dimensional model to reach room temperature, then performing sand blasting to obtain the porous pure-titanium implant material; the three-dimensional model is a porous structural mode using a tetrakaidecahedron unit as a dot matrix and formed by repeatedly accumulating the tetrakaidecahedron units.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Process of forming fluoric stepped hole structure on the surface of pure titanium dental implant

InactiveCN1985774AImprove long-term clinical successGood compatibilityDental implantsArtificial teethClinical successSurface modified

The process of forming fluoric stepped hole structure on the surface of pure titanium dental implant includes sand blasting the pure titanium implant, etching in mixed solution of sulfuric acid and hydrochloric acid, etching in mixed solution of hydrofluoric acid and nitric acid, soaking in sodium fluoride solution and other steps. The pure titanium dental implant with stepped hole surface structure has excellent bone tissue compatibility, capacity of raising the combination strength of the implant to the bone tissue and raised long term clinical success rate of dental implant.

Owner:ZHEJIANG UNIV

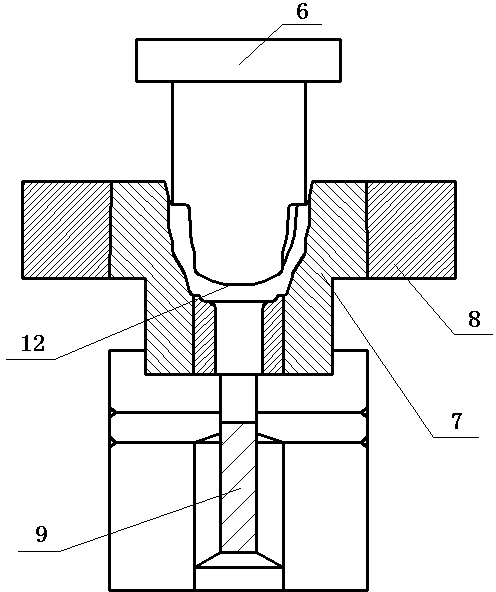

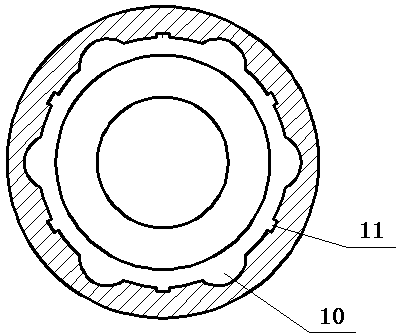

Fine forging forming method of spiral bevel gears

InactiveCN102240774AReduce radial flowAvoid destructionForging/hammering/pressing machinesWheelsSand blastingTechnical design

The invention discloses a fine forging forming method of spiral bevel gears, comprising the steps of: preparing for a material bar satisfying technical design requirements; heating the material bar to 1150-1180 DEG C; upsetting and punching as well as ring-enlarging the material bar on a press; pre-forging and forming in a pre-forging die on a multistage hot die forging press to obtain a pre-forging blank with pre-forging teeth, wherein the curved tooth spiral angle beta of the pre-forging die is 8-12 degrees smaller than that of a finish forging die; arranging the pre-forging blank on the multistage hot die forging press, and finish-forging and forming in the finish forging die; after a spheroidizing annealing treatment, cleaning the surface by sand-blasting, and phosphating and saponifying the surface; and finishing tooth profiles at normal temperature in a hydraulic machine. The method provided by the invention adopts a gradually forming manner consisting of pre-forging first and finish forging at last, therefore, the radial flow of the blank is greatly reduced, the side pressure of the blank to the tooth profile die cavity is reduced, the tooth profiles of the curved teeth of the forging die are prevented from being damaged, the service life of the forging die is prolonged, the production efficiency is improved, and the production cost can be efficiently reduced.

Owner:CHONGQING CHUANGJING WARM FORGING FORMING

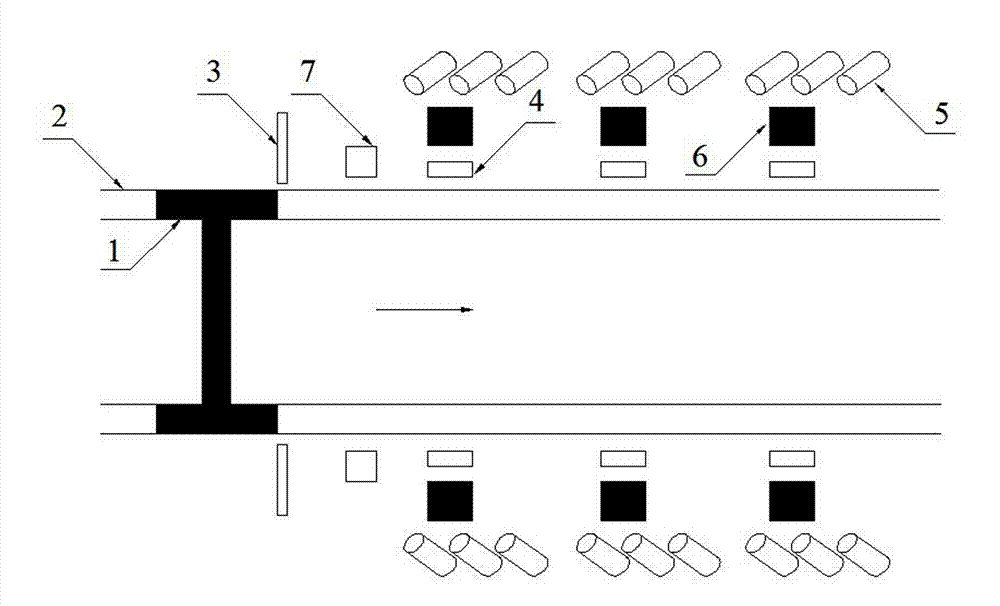

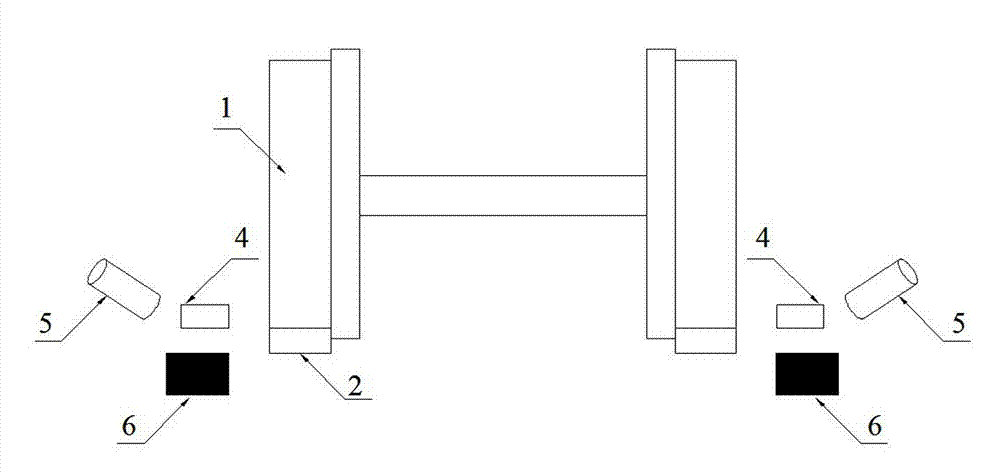

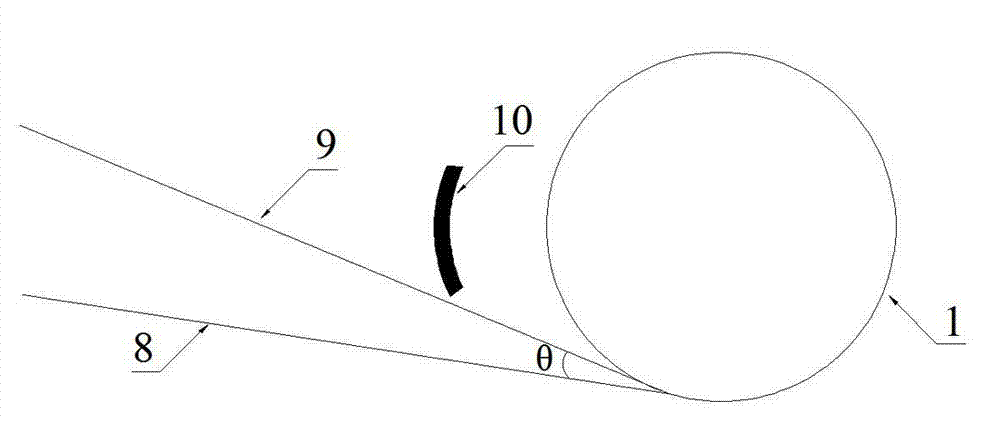

On-line high-speed detection system of train wheel set tread and wheel rim and detection method thereof

InactiveCN102788803AResolve detectionAddress the sphere of influenceWheel-rims surveying/measuringOptically investigating flaws/contaminationImaging processingSand blasting

The invention discloses an on-line high-speed detection system of train wheel set treads and wheel rims and a detection method thereof. The detection system comprises a target detection unit, a speed measurement unit, a location determination unit and an image acquisition unit which are arranged at the outside of tracks in order, and an image processing unit and a control unit, wherein the image acquisition unit comprises multi-group line structure-light sources and a high-speed planar array camera, an intersecting line formed by intersecting the light plane with the wheel set is arranged between a train sand blasting pipe / braking unit and the track, and the imaging filed of the planar array camera covers and is slightly larger than the intersecting area. The detection method comprises: 1, judging whether the wheel set is defective by canny edge detection; 2, calculating the depth of the defects to obtain the size of the defects; and 3, splicing the light band portion of each image in order into an image. According to the invention, the influence of the train sand blasting pipe and braking unit on the detection is avoided, and the detection speed is fast; the system is suitable for 20-300km / h train on-line detection, the precision is high, the detection of the defects which are less than 1mm can be realized; the detection result is displayed in an image, thus the observation is convenient.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for preparing novel aluminum-based composite lead dioxide-manganese dioxide anode for zinc electrodeposition

InactiveCN101736369ASolution to short lifeStrong acid resistancePhotography auxillary processesElectrolytic inorganic material coatingLead dioxideSand blasting

The invention discloses a method for preparing a novel aluminum-based composite lead dioxide-manganese dioxide anode for zinc electrodeposition, which is characterized by sequentially plating conductive coating, an alpha-PbO2-CeO2-TiO2 layer and a beta-PbO2-MnO2-WC-ZrO2 layer outside an aluminum matrix of a composite lead dioxide-manganese dioxide anode from inside to outside. The method comprises the following steps of: carrying out quenching, oil removal and sand blasting processing on the aluminum matrix; spraying the conductive coating on a matrix material; then carrying out alkaline composite plating on the alpha-PbO2-CeO2-TiO2 layer and carrying out acidic composite plating on the beta-PbO2-MnO2-WC-ZrO2 layer to obtain the composite lead dioxide-manganese dioxide anode. The aluminum-based composite lead dioxide-manganese dioxide anode manufactured by the process and method of the invention can obviously reduce the voltage of an electrode bath and energy consumption; and meanwhile, a plating layer and a matrix have strong binding force and small internal stress, and the service life of an electrode is long.

Owner:KUNMING UNIV OF SCI & TECH

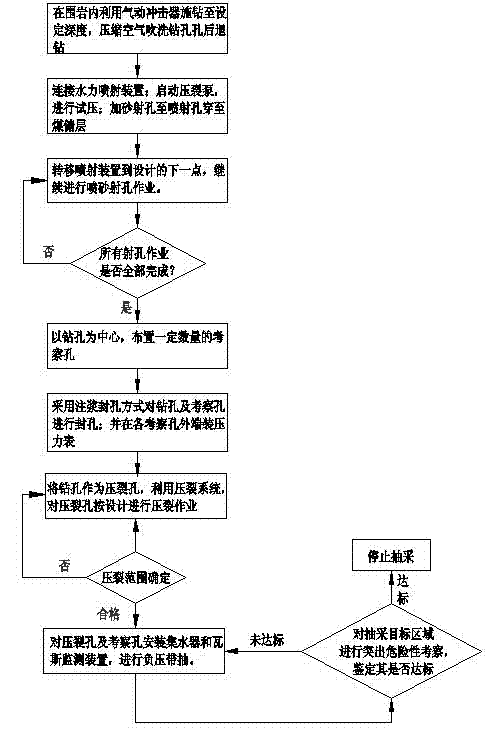

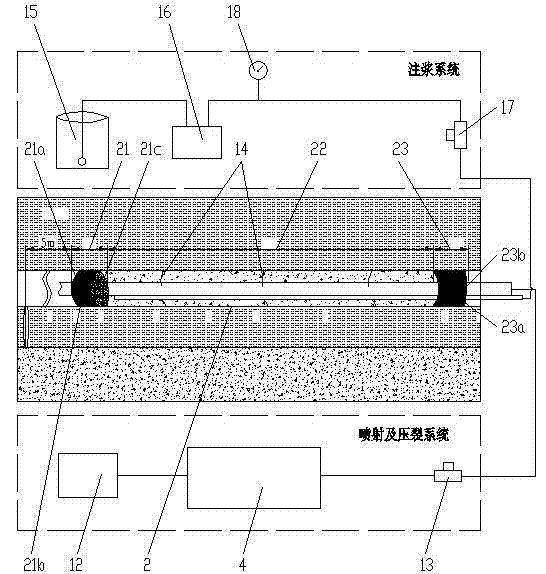

System process for conducting efficient strengthened extraction in surrounding rock

InactiveCN103195468AIncrease the exposed areaImprove mining efficiencyConstructionsReciprocating drilling machinesGeomorphologySand blasting

The invention discloses system process for conducting efficient strengthened extraction in a surrounding rock. The system process includes that a common drilling machine is used for forming a drill hole through a pneumatic impacter in the surrounding rock, namely a top plate or a base plate, of a coal reservoir, wherein strengthened extraction is planned to be implemented on the coal reservoir, a plurality of spray holes for communicating a coal rock stratum and the drill hole are sprayed through a hydraulic sand blasting perforation method, a plurality of observing holes are distributed with the drill hole as a center, and hole sealing processing is conducted on the drill hole and the observing holes; and fracture is conducted through the drill hole, a fracture affecting range is determined through monitoring pressure change conditions of the observing holes, and operation of draining while extracting with negative pressure through the drill hole and the observing holes is conducted. Preferentially, hole sealing operation is conducted through a grouting hole sealing method. The system process has the advantage that a problem of hole collapsing, drilling machine blocking and the like during hole drilling in a minge layer can be solved; exposing area of a coal mass is increased due to branch holes formed by high-pressure spraying; and hydraulic fracture presses coal and rock mass among cracks, original cracks in a coal layer are fully opened, extend and are communicated with one another, large-range of pressure relief of the coal mass is achieved, and gas extraction rate is improved.

Owner:重庆市能源投资集团科技有限责任公司

Process for forging hydrogenated titanium alloy forging blade

ActiveCN101648254AGood molding effectHigh dimensional accuracyMetal-working apparatusEngine componentsHydrogenSand blasting

The invention discloses a process for forging a hydrogenated titanium alloy forging blade, which relates to a blade forging process. The invention aims to solve the problems of high forging temperature and material performance requirement of a die and low blade size precision of a titanium alloy blade on the prior aeroengine in the forging production. The process comprises the following steps: 1.filling hydrogen in a titanium alloy blade blank; 2. processing the hydrogenated titanium alloy blade blank into a hydrogenated titanium alloy blade prefabricated blank; 3. carrying out first sand blasting processing; 4.spraying a lubricating agent; 5. placing the hydrogenated titanium alloy blade prefabricated blank in a preheated die; 6. forging to obtain the hydrogenated titanium alloy blade forging blank; 7. removing furs; 8. carrying out second sand blasting processing; 9. washing; and 10. dehydrogenizing to obtain the hydrogenated titanium alloy forging blade. In the method, a hydrogen element is filled in the titanium alloy blade blank; when the hydrogenated titanium alloy blade is forged, the forging temperature can be reduced, thereby reducing the deformation and the abrasion degree of the die and further improving the size precision of the titanium alloy blade.

Owner:HARBIN INST OF TECH

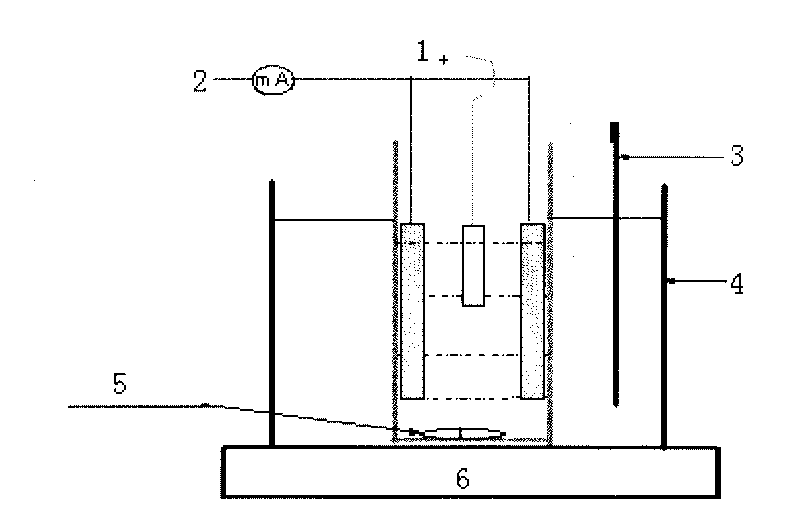

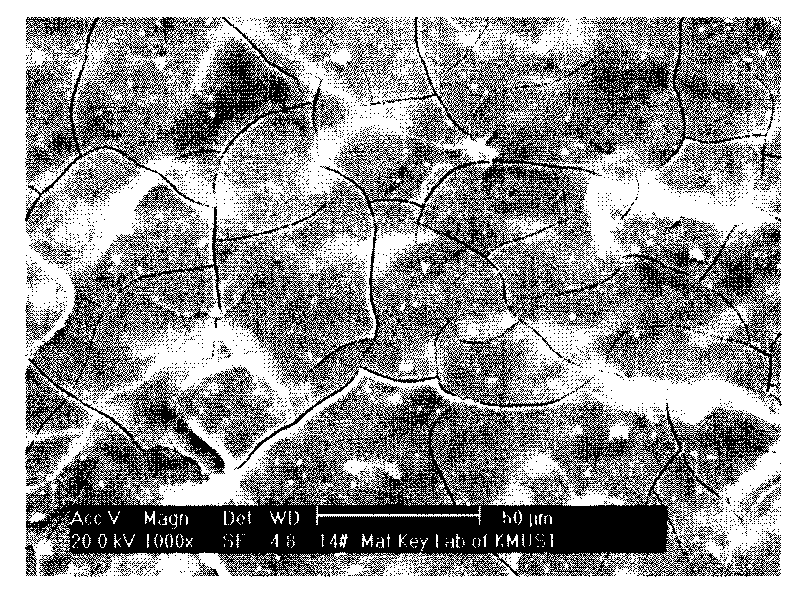

Bioactive film on titanium metal surface and its sand blasting-micro arc oxidizing compounding process

InactiveCN1974876ASolve for bond strengthAddressing Binding StabilitySurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

The present invention relates to film on the surface of medical titanium-base metal material and its sand blasting-micro arc oxidizing compounding process. Through the first surface sand blasting treatment of titanium or titanium alloy material and the subsequent micro arc oxidizing in electrolyte solution containing phosphate radical ion and calcium ion and with the titanium or titanium alloy material as anode, stainless steel or titanium as cathode and DC power source or DC pulse power source, one bioactive film is in-situ formed on the surface of the titanium or titanium alloy material. The bioactive film of rough porous hydroxyapatite has surface roughness Ra of 2-4.5 micron, no interface with the substrate, elastic modulus reaching that of bone and excellent bioactivity, and may be used as the substitute for femur, hip joint, tooth root, etc. The bioactive film has optimized combination strength, stability and bioactivity.

Owner:SOUTH CHINA UNIV OF TECH

Gear thermal precision forging machining process adopting carburizing steel 20CrMnTi as material

InactiveCN102764838AOvercome concentrated stressOvercome the defect of easily broken teethMetal-working apparatusWheelsSand blastingMachining process

The invention discloses a gear thermal precision forging machining process adopting carburizing steel 20CrMnTi as a material. The process especially comprises the following steps of: upsetting prolonging, blank manufacturing, die forging, burring, forging aftert-reatment (including quenching, tempering thermal treatment; accomplishing the gear thermal treatment through nitriding, surface quenching and normalizing; and finally carrying out sand blasting to remove a scale cinder and the surface acid treatment), and tooth profile cold-finish. By utilizing the process, the fogging process is simplified, the procedures are reduced; the processed product is good in quality; the production in scale can be realized so as to achieve the purposes of good quality, material conservation, energy conservation and time saving; and meanwhile the service life of a mold can be improved greatly, so that the wear resistance of the manufactured gear is enhanced greatly; the gear point-corrosion spalling is overcome; the strength is improved greatly; the service life is prolonged; and the cost is reduced.

Owner:无锡市钻通工程机械有限公司

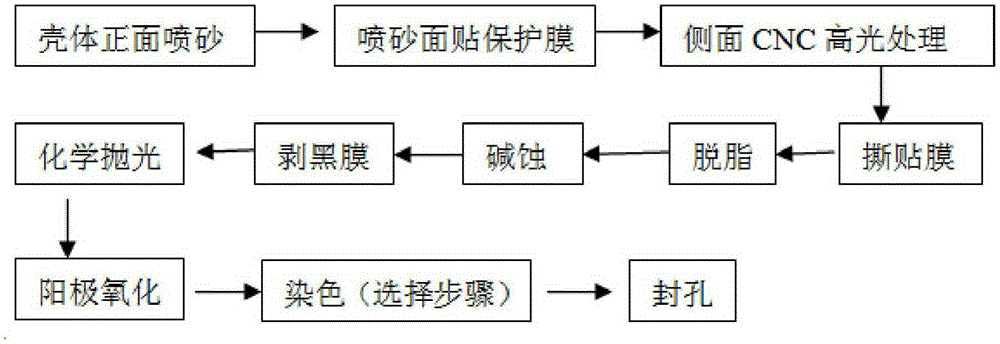

Surface treatment method for aluminum alloy shell

InactiveCN105177669AVariety of colorsVarious appearance effectsSurface reaction electrolytic coatingSand blastingMachining

The invention provides a surface treatment method for an aluminum alloy shell. The surface treatment method includes the following steps that S1, sand blasting is conducted on the front face of the aluminum alloy shell, and the aluminum alloy shell with the front face being the sand blasting face is obtained; S2, CNC machining is conducted on the side face of the aluminum alloy shell to achieve the highlight effect; S3, anodizing treatment is conducted on the whole aluminum alloy shell obtained after sand blasting and CNC treatment are conducted, and an oxidation film layer is formed; and S4, hole sealing treatment is conducted on the aluminum alloy shell obtained after anodizing treatment is conducted, and the aluminum alloy shell with the sand blasting front face and the highlight side face is obtained. By means of the surface treatment method for the aluminum alloy shell, the appearance effect of the aluminum alloy shell is more diverse.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com