Patents

Literature

1728results about How to "Variety of colors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foreign matter invading detecting method and foreign matter invading detecting device

ActiveCN107253485AImprove clarityHigh alarm accuracyImage enhancementImage analysisVisibilityForeign matter

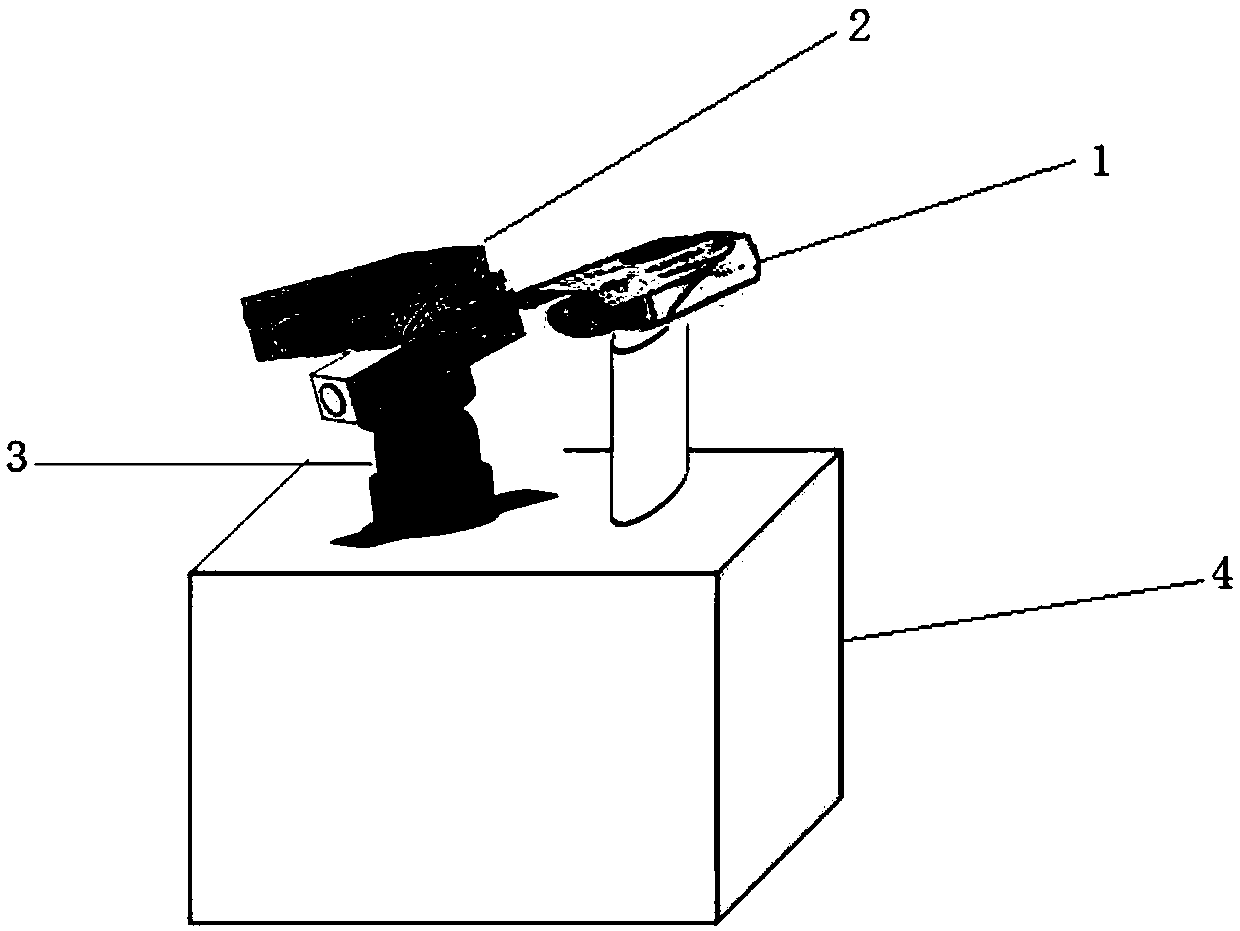

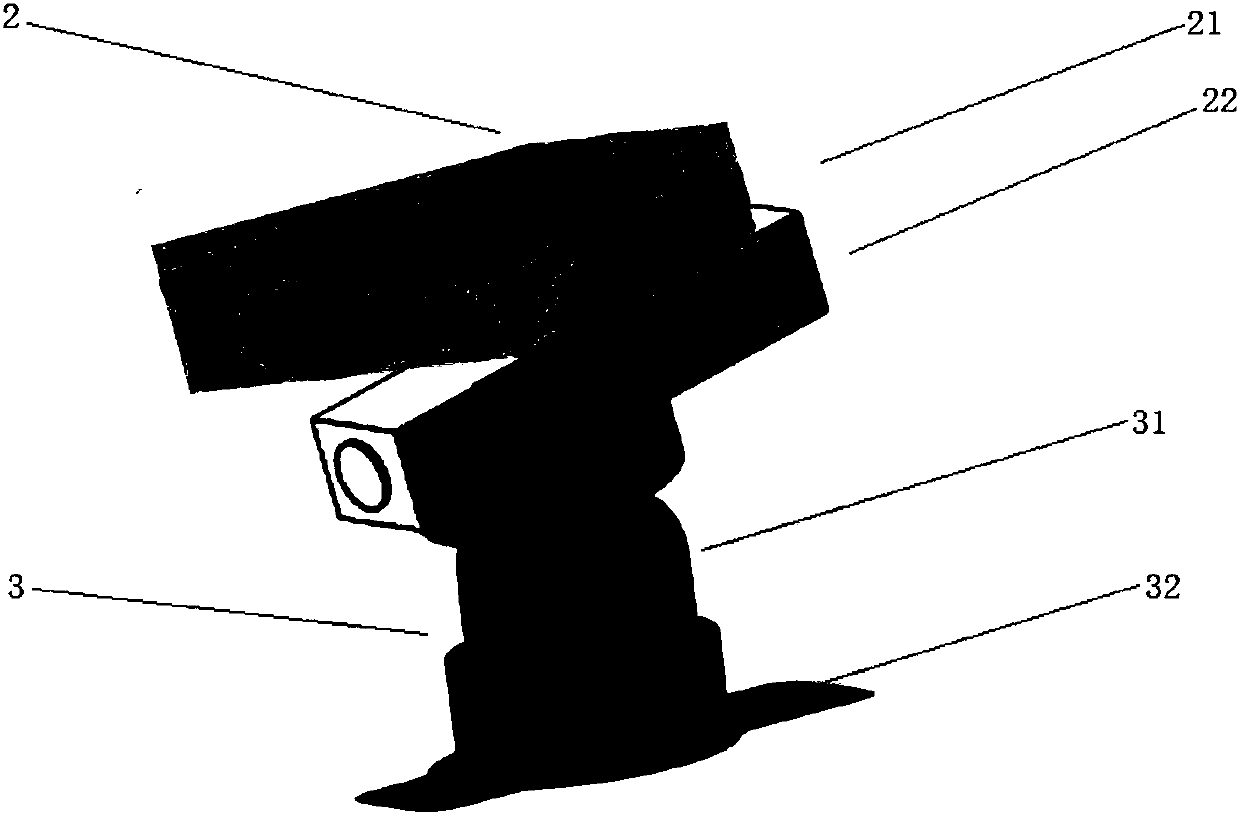

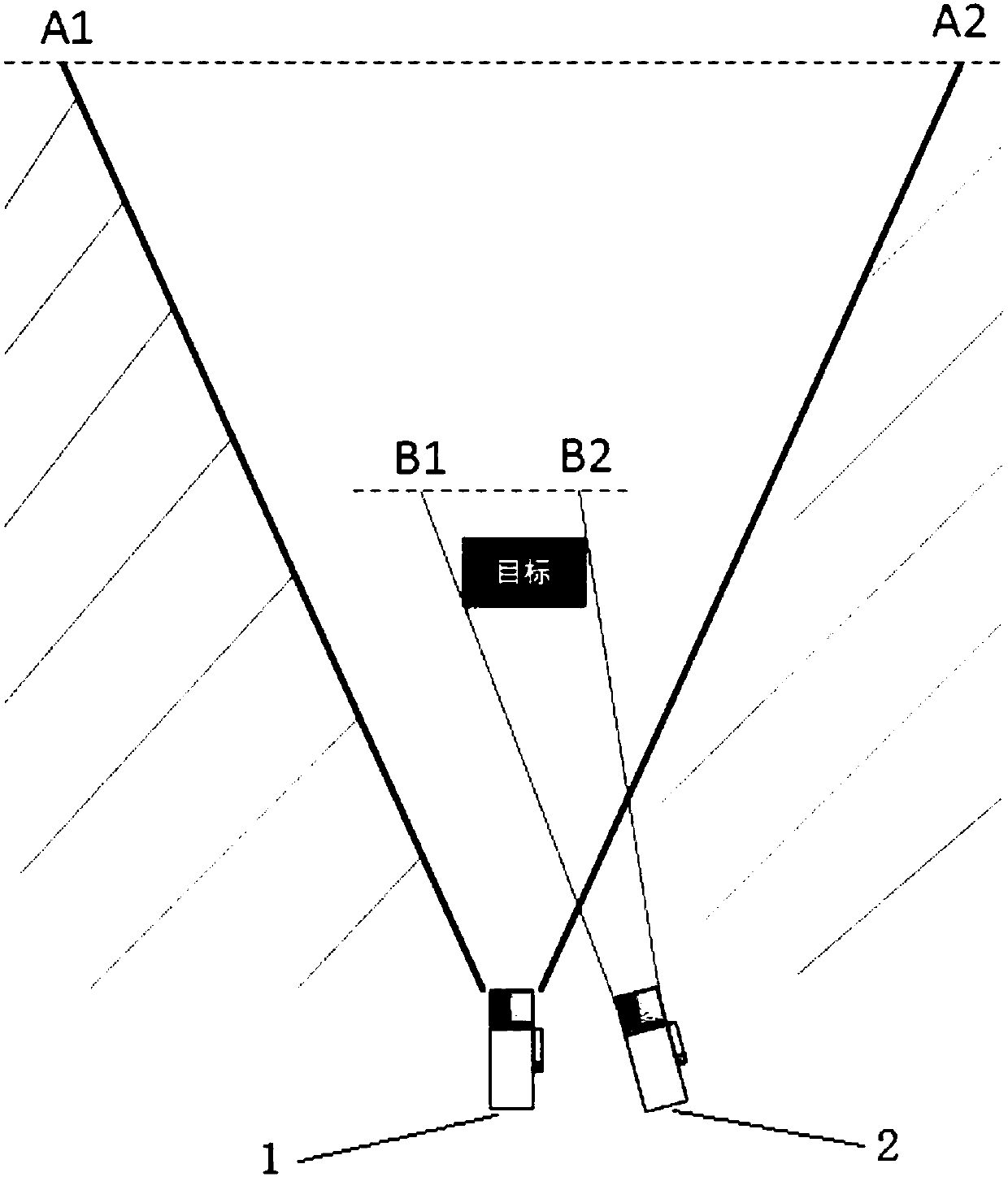

The invention provides a foreign matter invading detecting method and a foreign matter invading detecting device. The foreign matter invading detecting method comprises the following steps that infrared images within the monitoring scope are acquired by utilizing an infrared camera and are transmitted to an image collecting and processing system; whether a suspected foreign matter appears in the monitoring scope or not is determined by the image collecting and processing system according to the infrared images; when the suspected foreign matter appears, the laser light source and a visible light camera are focused on the suspected foreign matter within the monitoring scope, and filling light of laser light is conducted on the suspected foreign matter by utilizing the laser light resource; visible light images of the suspected foreign matter are acquired and transmitted to the image collecting and processing system; image registration and image fusion are conducted on the visible light images and images of the suspected foreign matter area in the infrared images by the image collecting and processing system; and information of the suspected foreign matter is provided by utilizing the fused images, and feature extraction and classification are conducted on the suspected foreign matter by utilizing the information of the suspected foreign matter, automatic identification and alarming for the suspected foreign matter are realized, and abundant and complete image information can be acquired in the time of dark light, dark skies and low visibility.

Owner:BEIJING JIAOTONG UNIV

Method for manufacturing high-breathability non-woven wallpaper body paper and product

The invention discloses a method for manufacturing high-breathability non-woven wallpaper body paper and a product. The existing non-woven wallpaper has the disadvantages that the hand feel thereof is not soft enough, the principal plane stereoscopic impression is not strong and the opacity degree is low. The method of the invention comprises the following steps: beating plant fiber containing chemical wood pulp until the beating degree is 20-30OSR, and mixing with non-plant fiber containing chemical fiber; adding chemical addition agent into the mixed fiber; manufacturing the mixed fiber containing the chemical addition agent into body paper semi-finished products by utilizing a fourdrinier wire or inclined wire paper machine; mixing pigment, chemical addition agent and adhesive to form coating liquor, carrying out dip coating on the body paper semi-finished products inside or outside the machine; and drying and finishing the body paper subject to dip coating, and rolling the body paper to form finished paper of body paper, thus obtaining non-woven wallpaper which contains continuous fiber, has high breathability, and can be directly printed. The principal plane has natural lines; and the finished paper has the advantages of soft hand feel, good processability, excellent shape stability, rich color, distinct image and strong stereoscopic impression.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

Natural-like multifunctional color batch and use thereof

The present invention features that the color concentrate is prepared with main carrier resin A, matched carrier resin X, compatizer, pigment, inorganic stuffing, antistatic agent, light stabilizer, antioxidant and pigment lubricating dispersant. The main carrier resin an and the matched carrier resin X, which has obviously different compatibility and smelting behavior from that of the basic resin B in the product, may constitute alloy carrier resin. The said materials may be altered to result in various decoration effects.

Owner:GUANGDONG SHENGHENGCHANG CHEM IND

Exterior wall color surface decoration mortar and preparation method thereof

The invention relates to a building material, and in particular relates to an exterior wall color surface decoration mortar and a preparation method thereof. The exterior wall color surface decoration mortar comprises the following raw materials by weight: 20%-30% of white cement, 50%-60% of quartz sand, 0.1%-0.5% of chopped fiber, 10%-20% of heavy calcium carbonate, 0.2%-1% of latex powder, 0.3%-0.5% of cellulose ether, 1%-5% of an inorganic pigment, 0.2%-0.4% of a water repellent, 5%-10% of coal powder ash, 0.1%-0.15% of a defoaming agent, 1%-3% of metakaolin, 0.2%-0.5% of a thixotropic lubricant and 1%-2% of a water reducing agent. The exterior wall color surface decoration mortar has the advantages of crack resistance, weather resistance, good ultraviolet resistance, permanent and uniform color, good whiskering resistance, and the like, can be well combined with various inorganic base layer materials, is good in coating density, and can be widely used in the building fields such as exterior wall decoration and the like.

Owner:KUNSHAN JIANGUO CONCRETE PROD CO LTD

Surface processing method of mobile phone plastic appearance piece and mobile phone plastic appearance piece

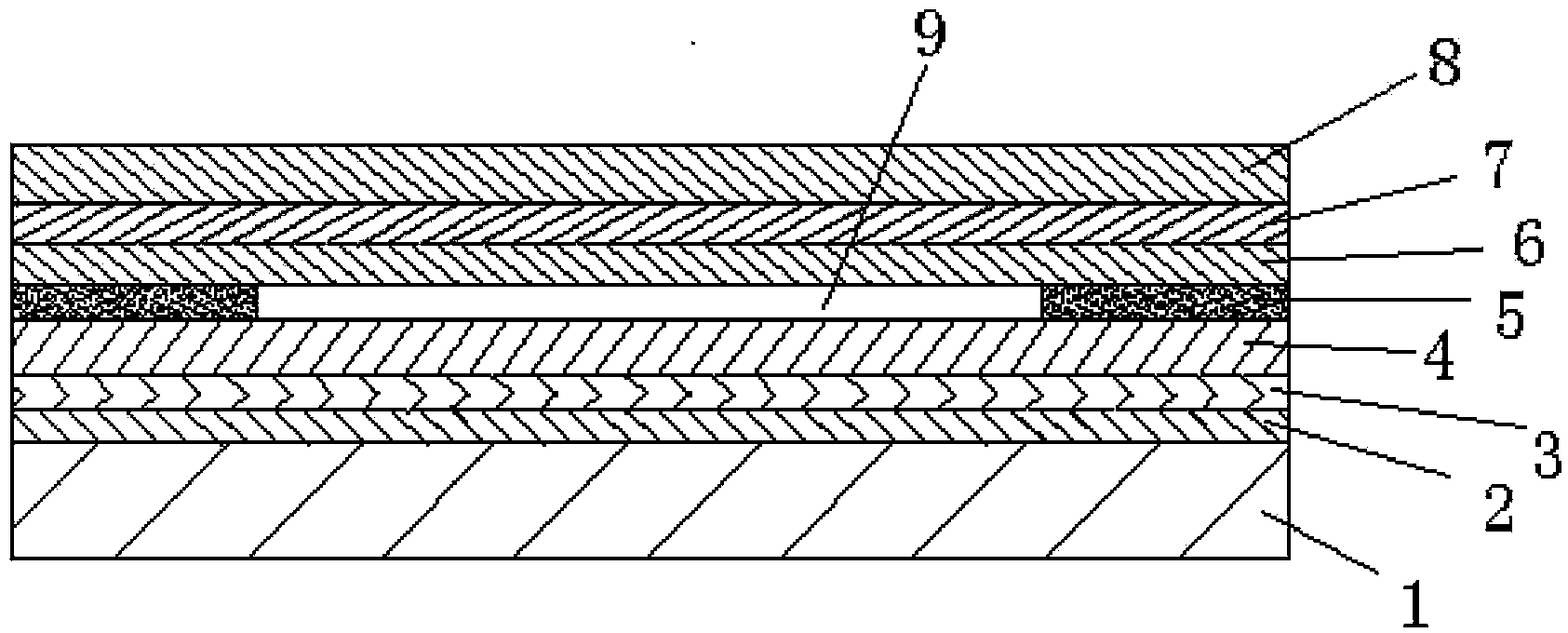

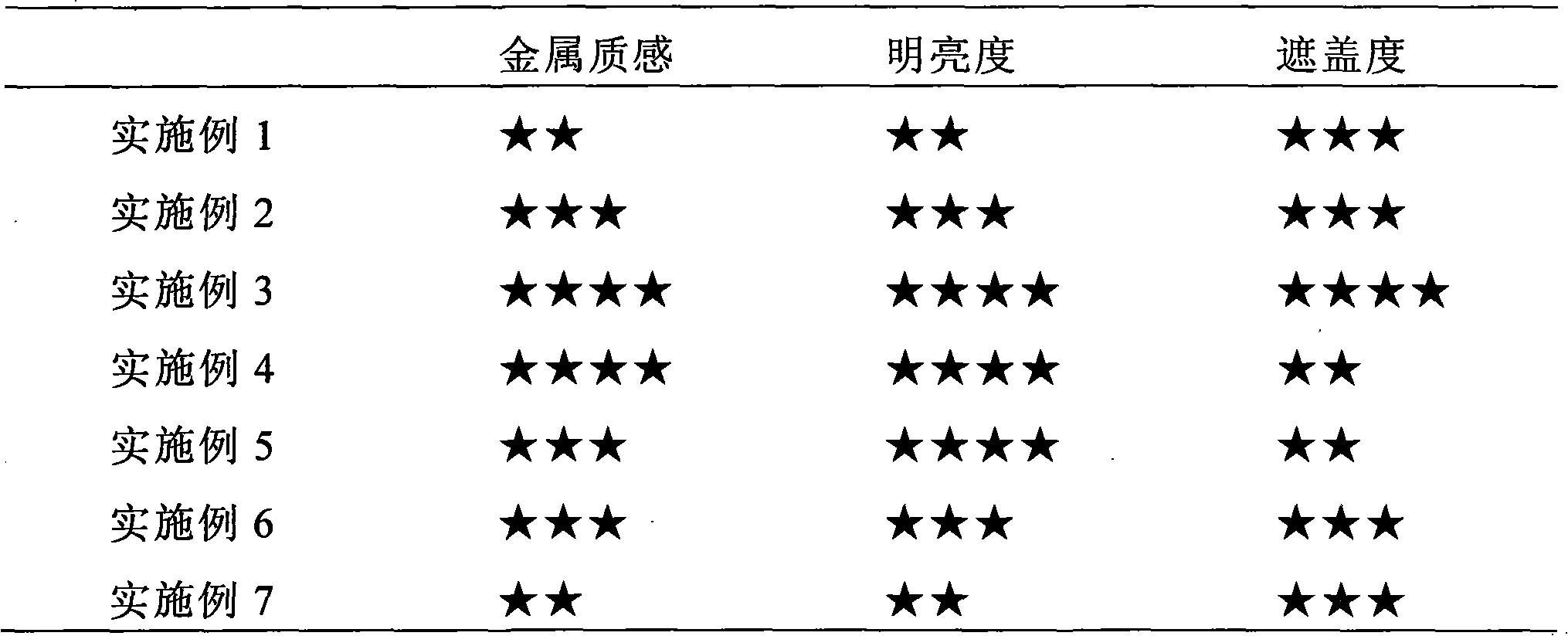

ActiveCN103516843ARich colors and texture effectsLow costVacuum evaporation coatingSputtering coatingLacquerSurface finishing

The invention discloses a surface processing method of a mobile phone plastic appearance piece and the mobile phone plastic appearance piece. The method comprises the steps that plastic base materials are provided; a first base coating layer is formed on the surface of the plastic base materials; a color coating layer is formed on the surface of the first base coating layer. A transparent second base coating layer is formed on the surface of the color coating layer. A vacuum film coating layer is formed on the surface of the second base coating layer. A transparent first middle coating layer is formed on the surface of the vacuum film coating layer. Vacuum coated films on the zone where the color coating layer needs to be displayed on the vacuum film coating layer are removed through laser radium carving. A transparent second middle coating layer is formed on the surface of the first middle coating layer. A transparent UV face coating layer is formed on the surface of the second middle coating layer. The effect that different textures and colors are matched with vacuum plating colors, namely the effect that different textures and colors are matched with high brightness edges can be achieved, for example, a fake metal dull polishing and high brightness edge effect, a fake ceramic white and high brightness edge effect and the like, and the appearance visual effect can meet the individuation requirements of people.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Extrusion grade aesthetical resin possessing metal color effect and its preparation method

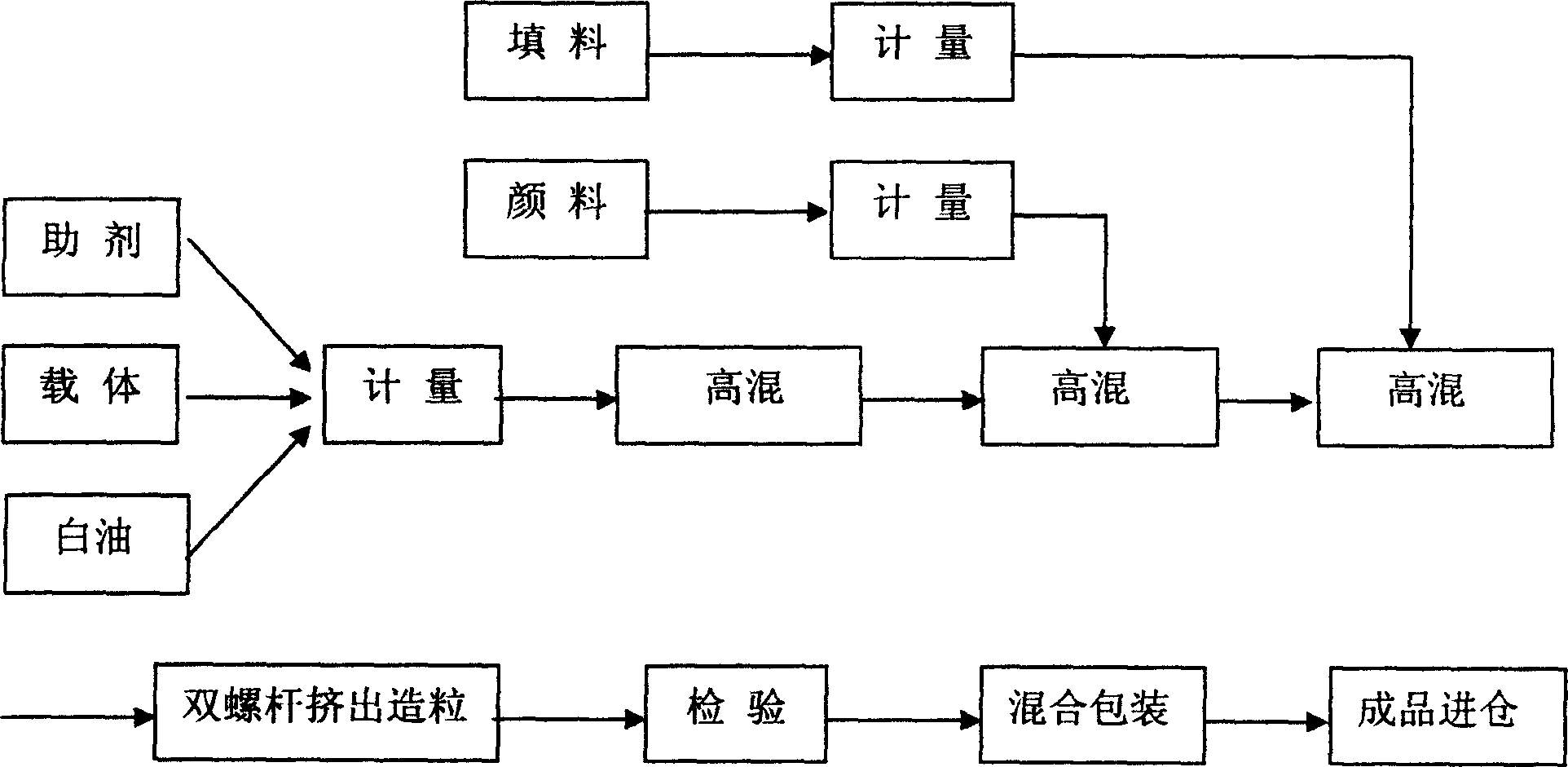

The invention relates to an extrusion grade aesthetical resin possessing metal color effect and its preparation method, which comprises the following ingredients by weight content: 100 parts of matrix resin, 0.1-3.0 parts of metal pigment, 0.1-3.0 parts of pearlescent pigment, 0.1-3.0 parts of molecular sieve adsorbent, 0.1-3.0 parts of lubricant and 0.1-1.0 parts of anti-oxidant. The method comprises the following steps: stirring and mixing the above raw materials in a high speed mixer, sending in a double screw extruder, under the conveying, shearing and mixing of a screw, fusing the raw materials, compositing, extruding, bracing, cooling, cutting into granule to obtain the extrusion grade aesthetical resin possessing the metal color effect. Compared with prior art, the extrusion surface effect of the extrusion grade aesthetical resin possessing metal color effect is close to metal spray paint effect, thereby the energy saving and environmental protection scheme without spraying can be realized, the aesthetical resin possessing metal color effect enables large market potential in the fields of automobile, household electrical appliance, consumer electronics and the like which possess high appearance requirement.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Weatherproof color shape bars in aluminium alloy, and manufacturing method

InactiveCN1760497AColorfulModerate costPattern printingSolid state diffusion coatingPolyesterSolid wood

The present invention relates to a superweathering color aluminum alloy section material and its production method. The composition of its base material is AlMg Si0.5-F22 alloy, according to Mg / Si=1.73, in which Mg (0.50-0.75%), Si (0.35-0.50%), Fe (less than 0.3%), Cu(less than 0.1%), Mn (less than 0.1%), Cr (less than 0.1%), Zn (less than 0.1%) and Ti (less than 0.1%); said base material is covered with chromized film whose thickness is 300-1000 mg / sq.m, and the chromized film also is covered with polyester powder coating layer which has imitation woodgrain pattern and whose thickness is 40-120 microns. Its production method includes the following steps: preparing aluminum alloy section base material, making pretreatment and chromizing process, spray-coating super weathering antistatic powder and heat transfer printing imitation woodgrain pattern.

Owner:SHANGHAI ZHENXING ALUMINUM IND

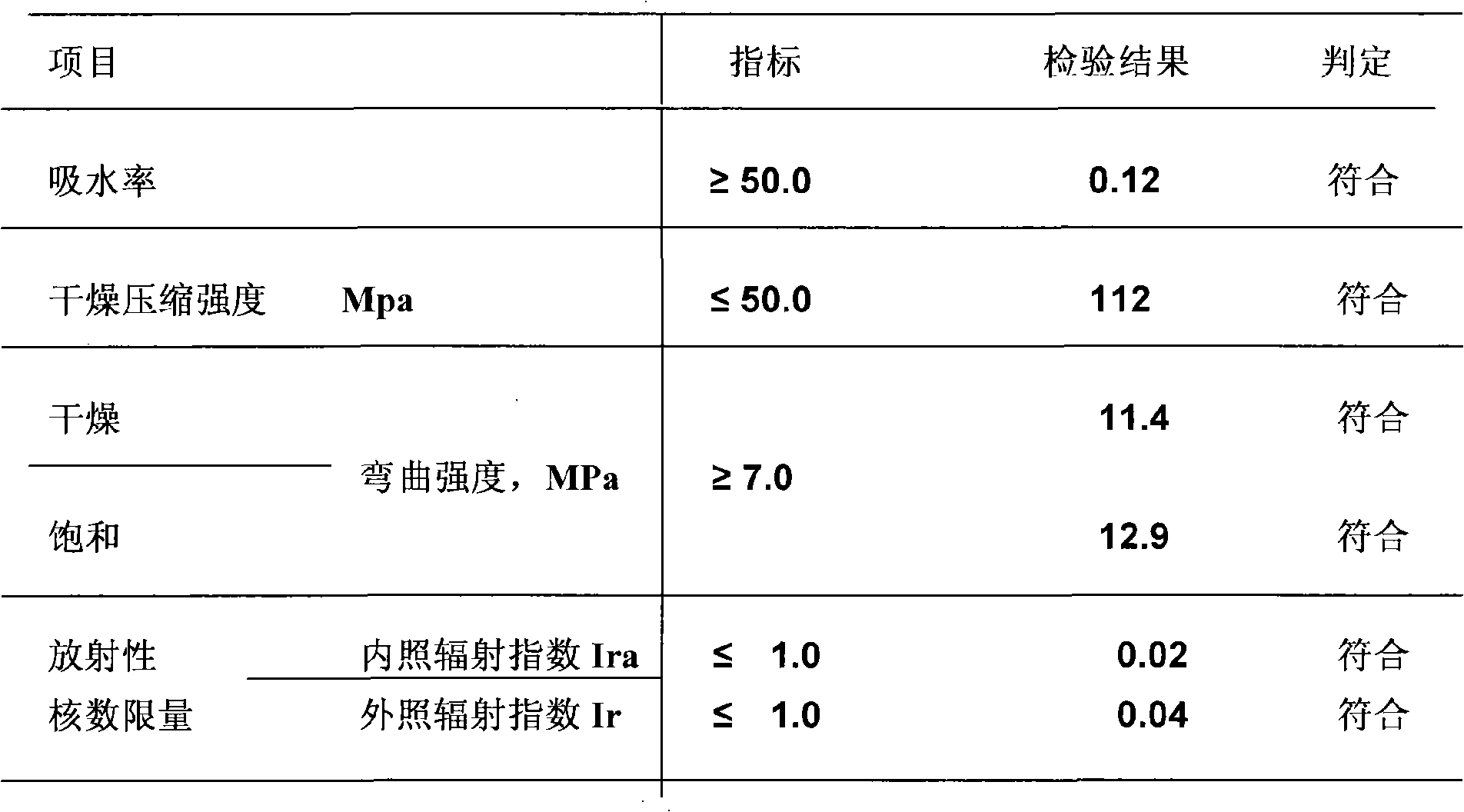

Light glazed ceramic tile with anion function and low water absorption and production method thereof

The invention discloses a light glazed ceramic tile with anion function and low water absorption and a production method thereof. The formula of the glazed ceramic tile is as follows: fancy glaze containing 0.1-90 portions of stamp powder, 0.0-190 portions of pigments, 100-200 portions of stamp-pad ink and 0.01-15 portions of anion material; a green body containing 10-45 portions of ceramic shraff, 15-20 portions of clay, 10-20 portions of feldspar, 30-50 portions of sandstone, 30-50 portions of water, 0.0-0.3 portion of lignin, and 0.0-1.0 portion of sodium tripolyphosphate; and conventionalcover glaze. The production method comprises the following steps: stirring and screening the fancy glaze materials to obtain the fancy glaze; conducting ball-milling, screening and pelleting after materials of the green body are mixed, and then conducting compression moulding and drying, glazing, embossing, and sintering for 50-55 minutes at the temperature of 1195-1205 DEG C, thus obtaining the product. The ceramic tile has the characteristics of being light, low in water absorption, high in mechanical strength, small in coefficient of thermal conductivity, strong in antifouling capability and the like, can continuously release anions with the number of more than 500 / cm3 in space, and can be widely applied to decoration of building outer walls and home furnishing spaces.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

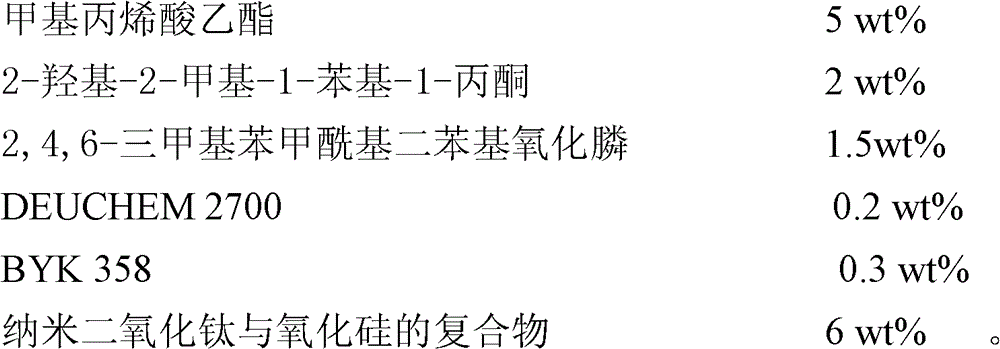

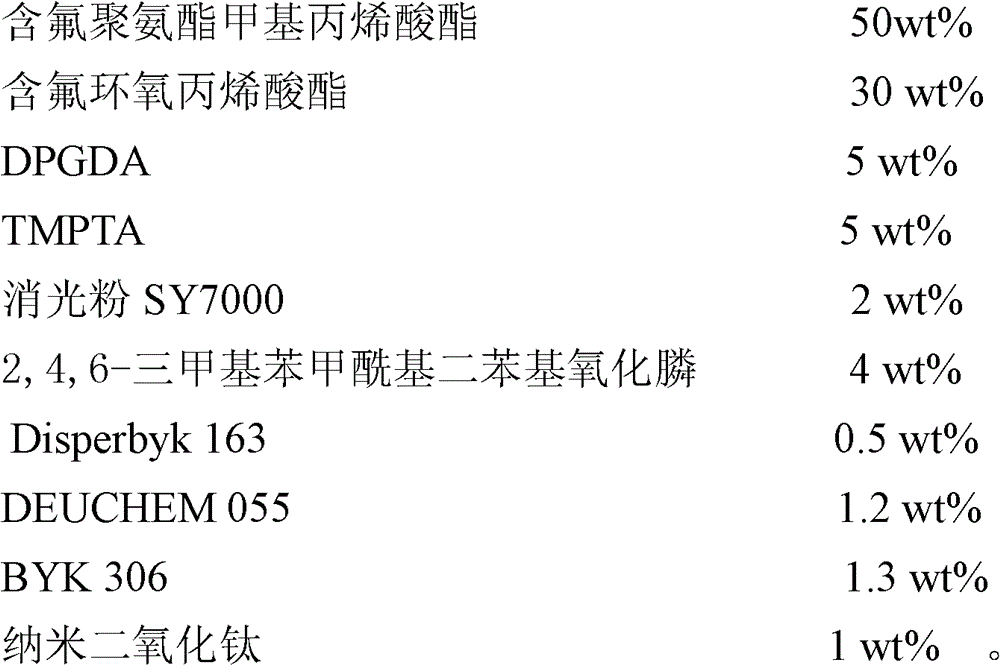

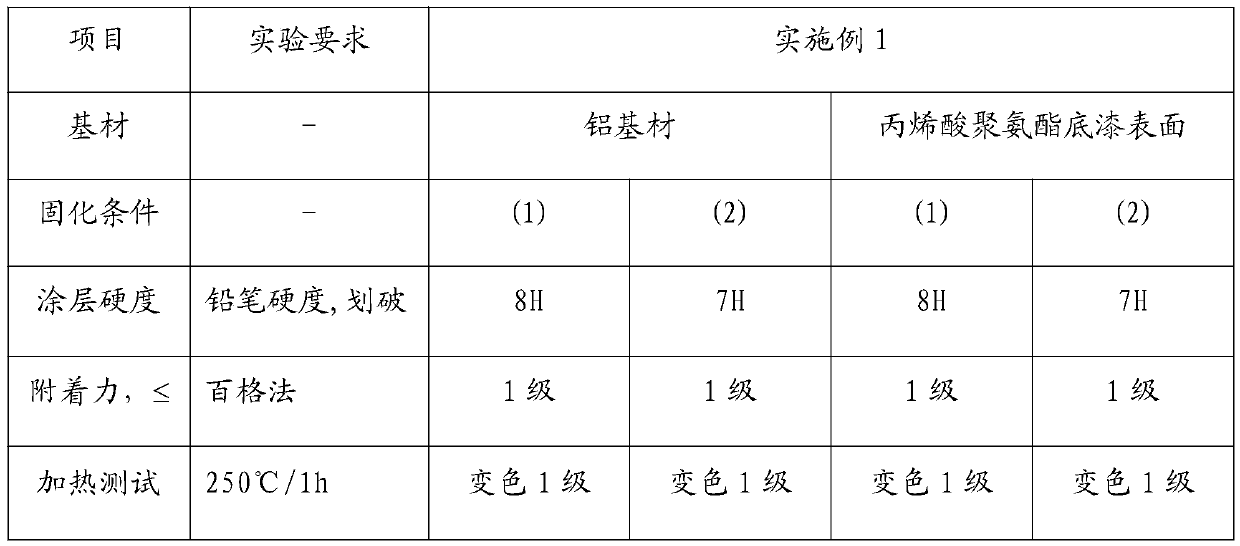

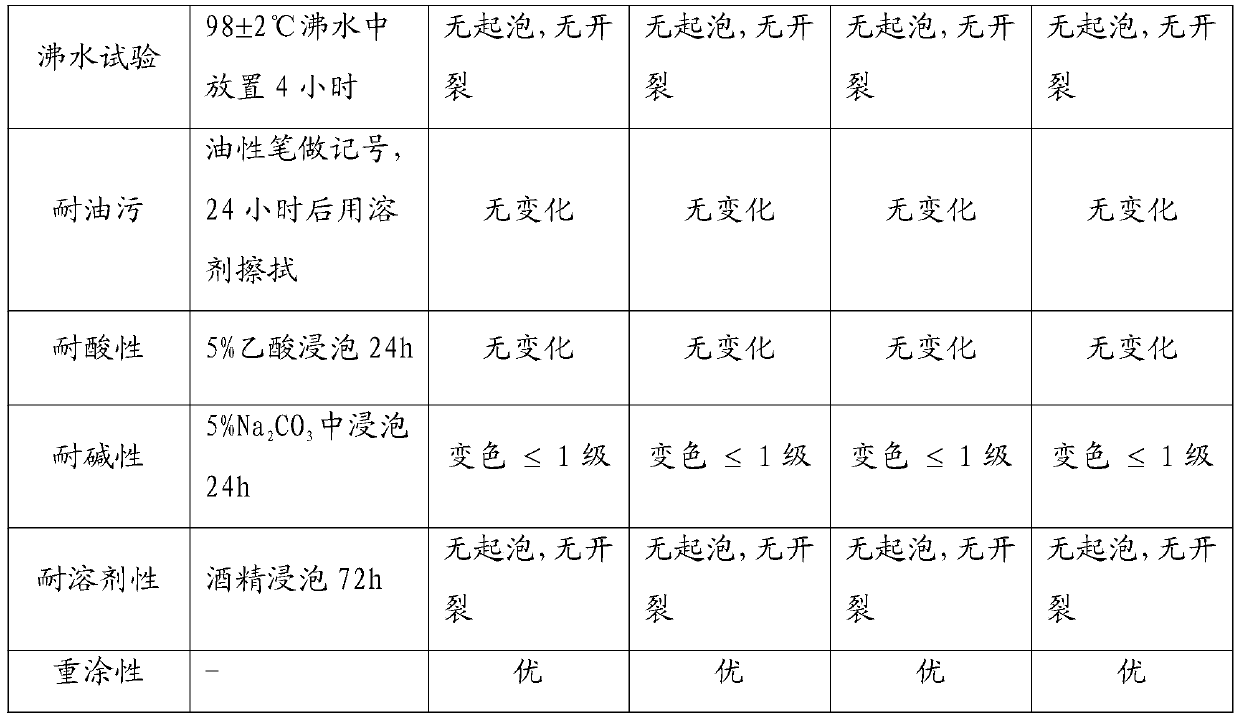

Ultraviolet light-cured self-cleaning coating, and preparation method and application thereof

InactiveCN103059713AWith self-cleaning functionVariety of colorsPolyurea/polyurethane coatingsEpoxy resin coatingsUltraviolet lightsPolymer chemistry

The invention belongs to the field of coatings, and relates to an ultraviolet light-cured self-cleaning coating, and a preparation method and an application thereof. The self-cleaning coating is obtained by mixing 30-80 wt% of a reactive fluorine-containing acrylic ester prepolymer, a acrylic ester prepolymer or a mixture of the above two 10-60 wt% of reactive fluorine-containing acrylic ester monomers, acrylic ester monomers or a mixture of the above two, 2-10 wt% of a photoinitiator, 0-40 wt% of a pigment, 0-30 wt% of an auxiliary agent and 1-30 wt% of a photocatalytic material, based on the total amount of the ultraviolet light-cured self-cleaning coating, grinding and stirring uniformly. The coating is coated on the surface of a substrate. The coated film can produce a photochemical polymerization and is cured under the irradiation of ultraviolet light. The cured film has the advantages of plump film, abundant colors, high hardness, good scratch resistance, good weather resistance and stain resistance, good self-cleaning feature and the like.

Owner:ZHUHAI DONGCHENG UV MATERIALS

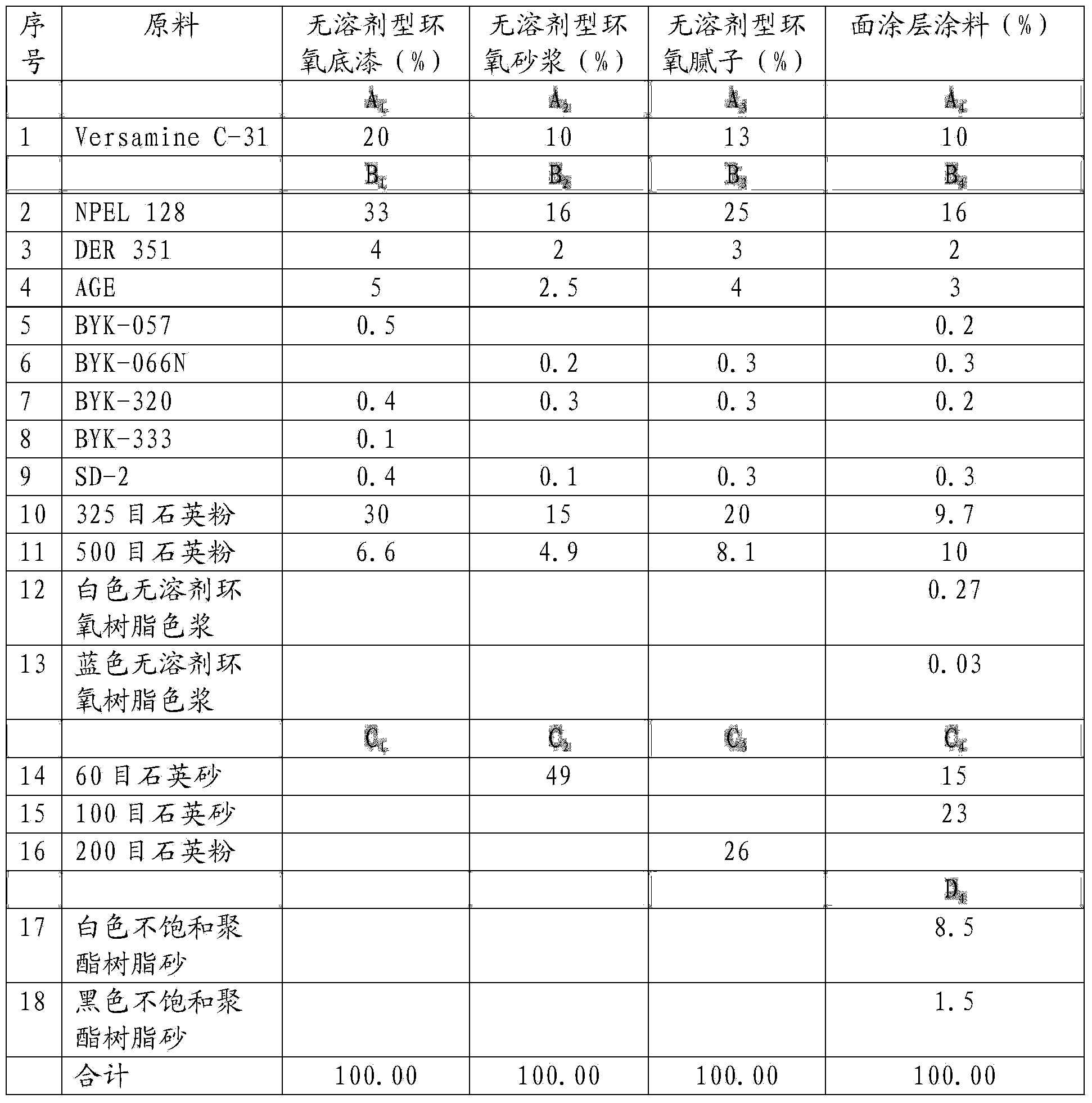

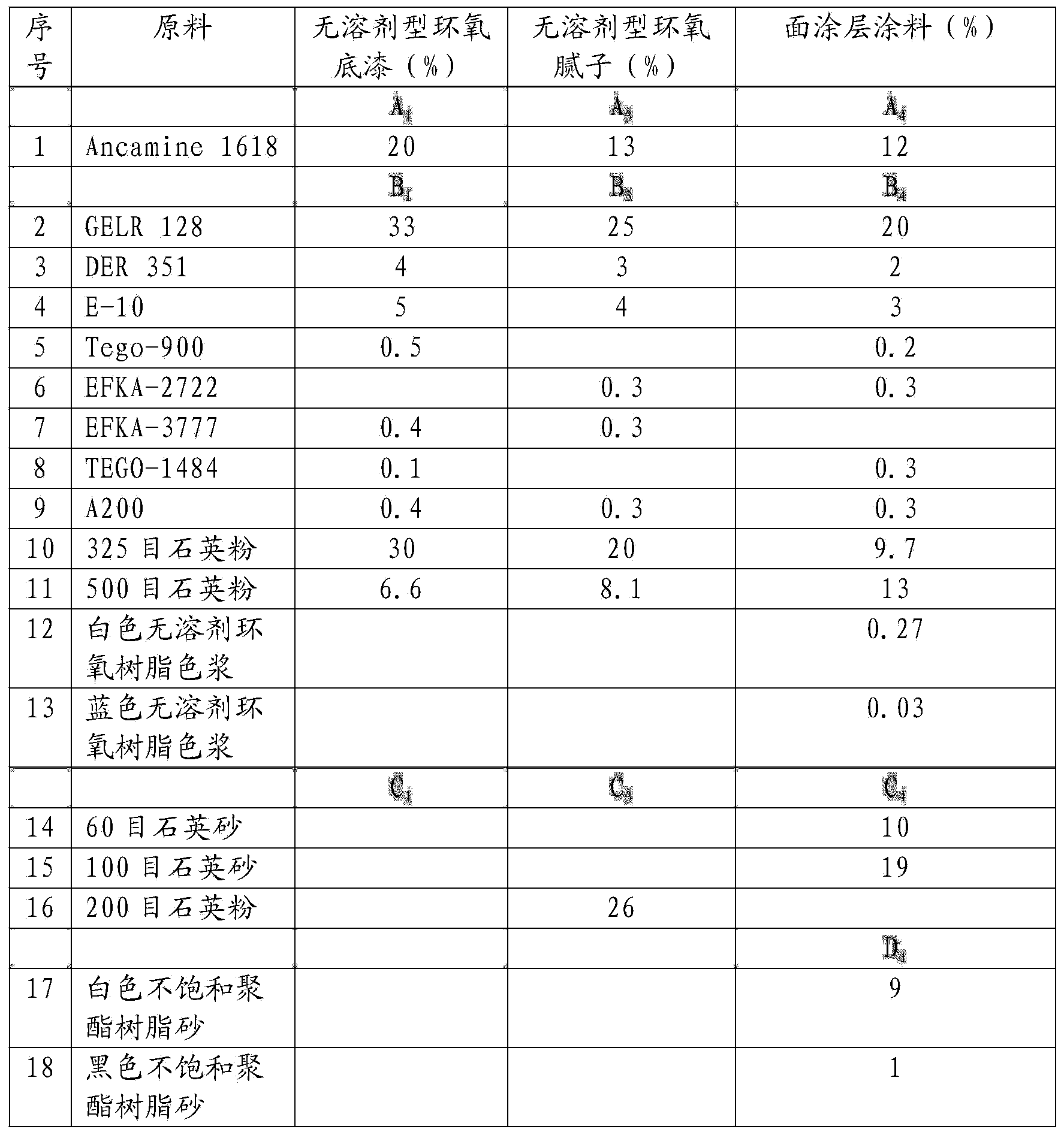

Solvent-free epoxy self-leveling floor paint, preparation method thereof and using method thereof

The invention belongs to the technical field of floor paint, and particularly relates to solvent-free epoxy self-leveling floor paint, a preparation method thereof and a using method thereof. The solvent-free epoxy self-leveling floor paint comprises a solvent-free epoxy primer, leveling blanket paint and surface coating paint. When construction is performed, components in the solvent-free epoxy primer, components in the leveling blanket paint and components in the surface coating paint are respectively mixed uniformly, and coated in order on a pretreated floor to form a priming coating, a leveling coating and a surface coating. The floor surface formed by the floor paint generates diffuse reflection to light with soft luster and high comfort. The floor formed is stereoscopic and highly decorative, and has good skid resistance and wear resistance. Highly-stereoscopic floors with various patterns and colors can be manufactured by the floor paint and the using method.

Owner:深圳市威尔地坪材料有限公司

Wooden wares surface archaizing treatment technology

InactiveCN1730255AEasy to produceVariety of colorsWood treatment detailsPretreated surfacesLacquerDiluent

The invention relates technology of surface treatment of wooden wares, comprising the following steps: drying the wood and blanking according to the requirement, processing and charring; brushing or spraying the archaized color priming paint which is compounded by diluent and mixture of yellow paint, red paint, black paint, and white paint in proper proportion, after drying, repairing the surface of the wood, then spraying the priming paint repeatedly twice or thrice, making it dry naturally; sanding the said wooden wares by fineness abrasive cloth, taking out the paint around 20%; spraying the press polish archaized paint to the surface of the wooden wares. The invention processes simple technology, good effect of imitation antique, convenience production, economy and utility.

Owner:DAKANG HLDG GROUP

Seashell-diatom ooze wall surface decoration wall material and production and construction method thereof

The invention discloses a seashell-diatom ooze wall surface decoration wall material and a production and construction method thereof. The decoration wall material comprises: 20 to 98 parts of shell powder, 8 to 30 parts of silica, 4 to 100 parts of kieselguhr, 2 to 20 parts of medical stone, 3.8 to 48 parts of mica powder, 2 to 10 parts of magnesium-rich silicate, 6 to 26 parts of scolecite, 1.5to 36 parts of hydrosilicate, 0 to 50 parts of titanium dioxide powder, 2 to 50 parts of calcium carbonate, 0.1 to 0.3 part of vegetable fiber, 1 to 30 parts of pigment, 4.8 to 40 parts of kelp powder, 1 to 30 parts of cold soluble polyvinyl alcohol powder and 1 to 20 parts of hydroxypropyl methyl cellulose. The production and construction method comprises: placing the raw material components into a stirrer for uniform stirring; filling the mixture in bags, packing the bags in boxes, sealing the boxes and storing the boxes in a storehouse; adding water into the mixture and stirring the mixture uniformly; and pasting the mixture on a wall surface to be decorated to make various texture patterns. The seashell-diatom ooze wall surface decoration wall material has the advantages of: (1) soft texture and no toxicity, fading nor stripping; (2), characteristics of eliminating indoor pollution, regulating indoor humidity, eliminating odor, isolating noises and offering high skin texture feel; (3) fire proofing and flame retarding; and (4) rich color.

Owner:青岛泉佳美硅藻泥科技有限公司

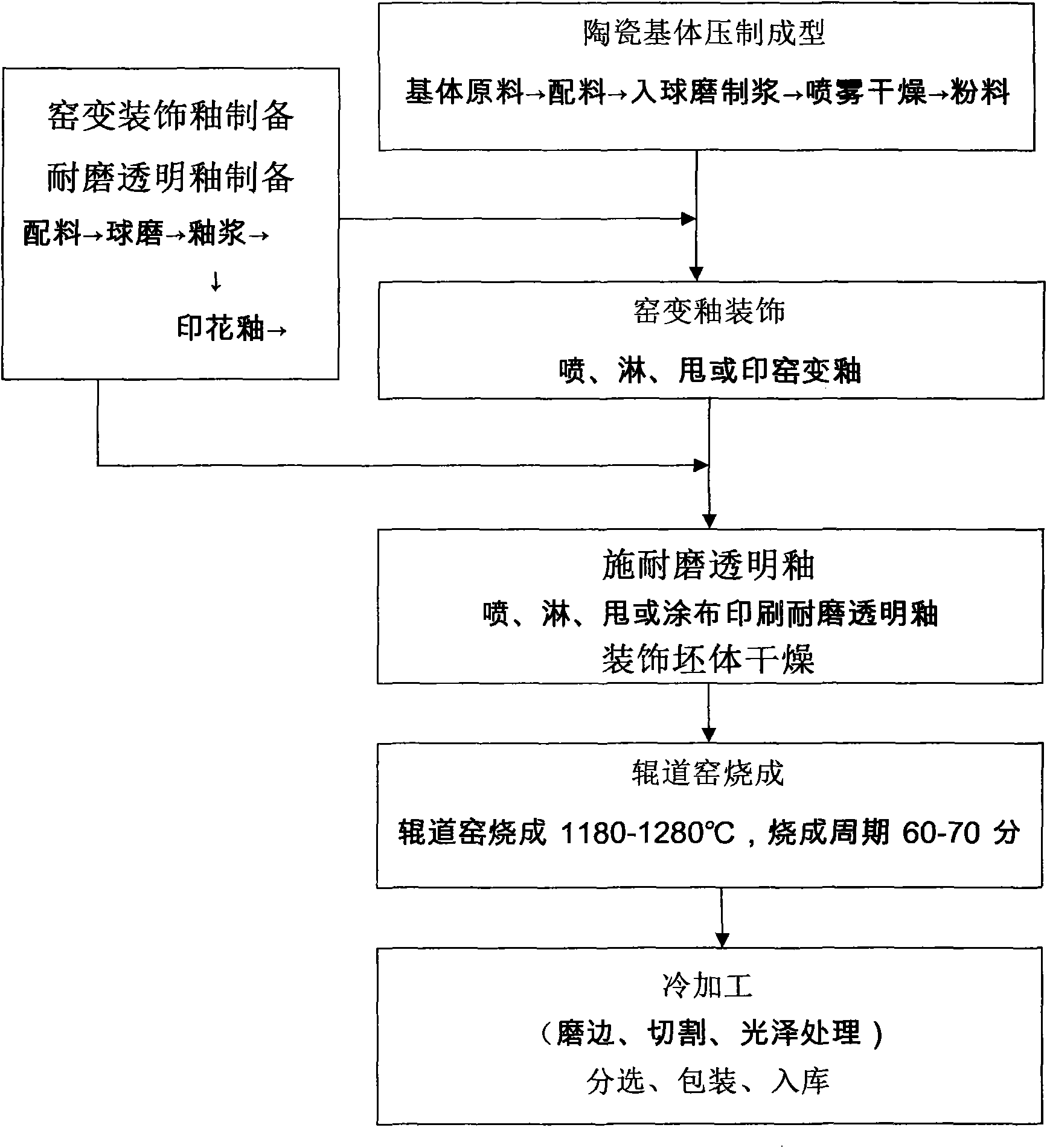

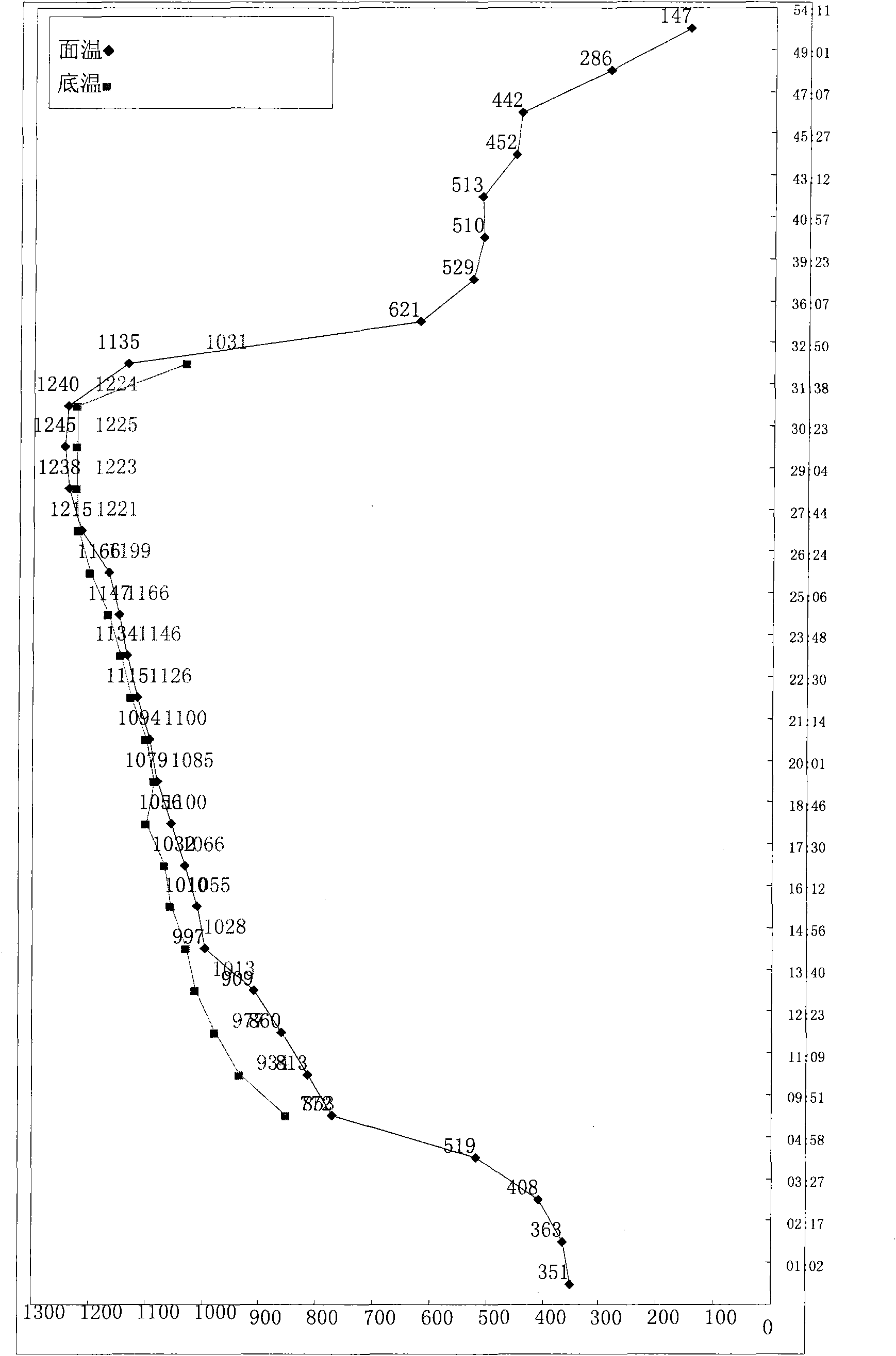

Furnace transmutation decoration glazed brick and production technology

The invention relates to a furnace transmutation decoration glazed brick and a production technique thereof. The furnace transmutation decoration glazed brick is prepared from the following componentsin percentage by weight: 10-30% of albite, 3-10% of spodumene, 5-10% of kaoline Al2O3.2SiO2.2H2O, 8-30% of zinc oxide ZnO, 3-10% of talc 3MgO.4SiO2.H2O, 0-20% of titanium TiO2, 3-10% of zirconite ZrSiO, and 1-10% of coloring metallic oxide MnO2, V2O5, Fe2O3 and CoO2. The production technique of the furnace transmutation decoration glazed brick comprises the following steps: (1) shaping the substrate of the furnace transmutation decoration glazed wall and floor bricks; (2) decorating the wall and floor brick substrate surface or anti-abrasion transparent glaze layers and drying; and (3) sintering the furnace transmutation decoration glazed wall and floor bricks once in a high-temperature roller kiln.

Owner:黄建平

Inorganic powder texture coating, and its applying method

ActiveCN1757688AEasy constructionUnique texturePowdery paintsCement coatingsInorganic pigmentsMaterials science

A inorganic dry powder paint with good mass sensation is prepared proportionally from cement, color sand, re-dispersed emulsoid powder, hydrophobic agent, inorganic pigment and filler. Its advantages are high adhesion to concrete, high weatherability, good air permeability, and no pollution. Its application method is also disclosed.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

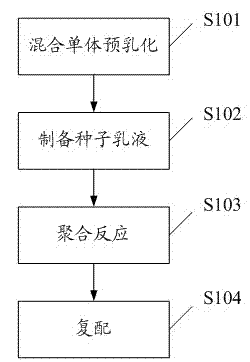

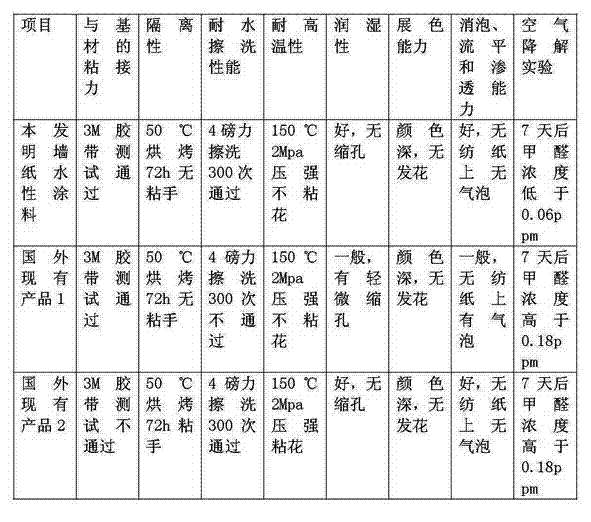

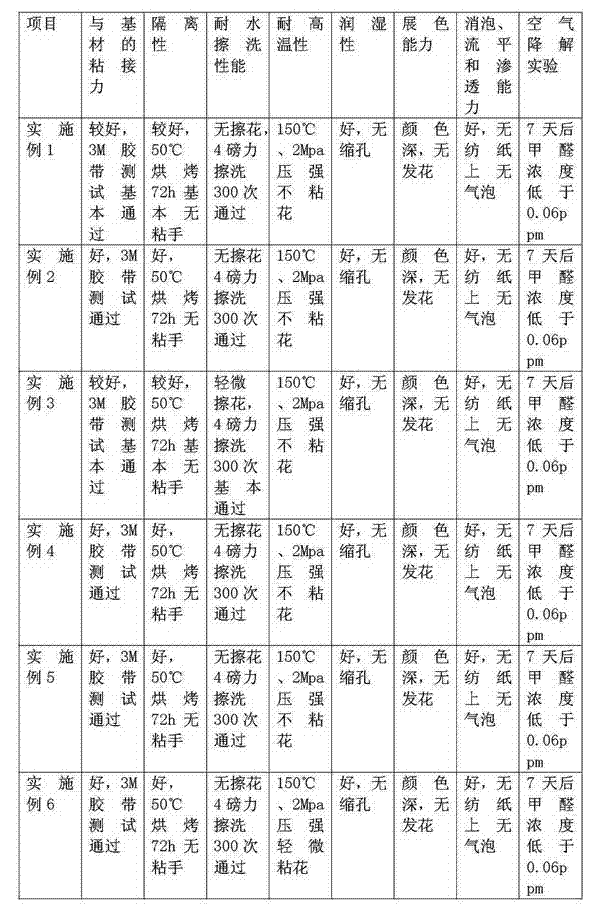

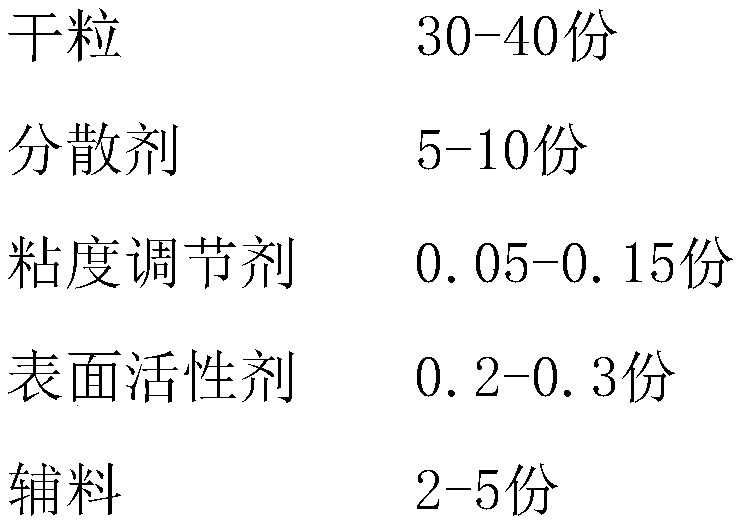

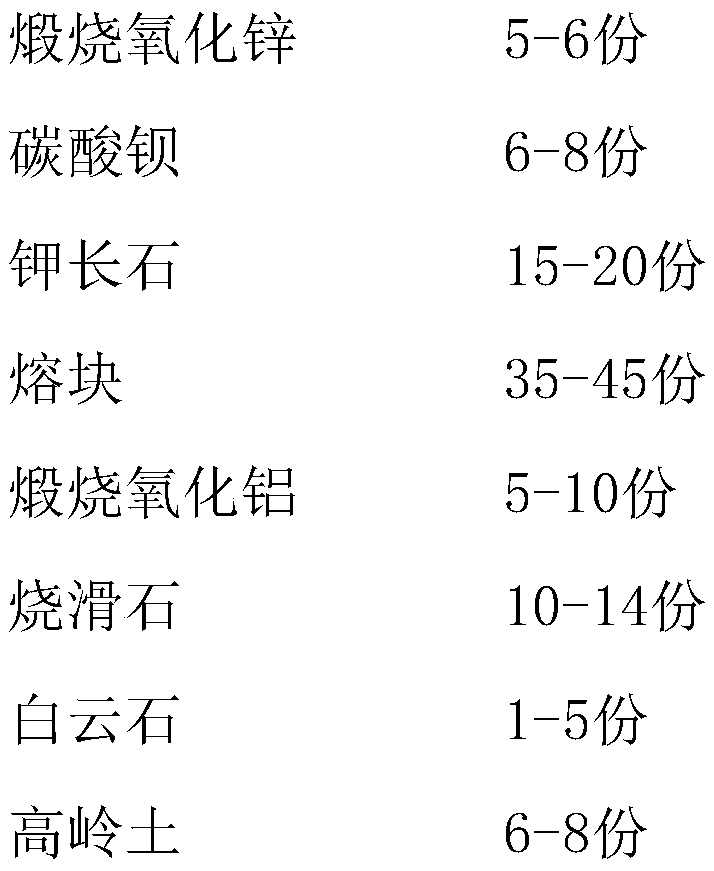

Wallpaper water-based paint, preparation method thereof and wallpaper

The invention discloses wallpaper water-based paint. The wallpaper water-based pain is water-based acrylate emulsion with solid content being 20-40% and the water-based acrylate emulsion is mainly made from a (methyl) acrylate monomer, a functional polymerizable monomer, an emulsifier, a photocatalyst, an initiator and deionized water through an emulsion polymerization method and a sol-gel method. Accordingly, the invention also discloses a method for preparing the wallpaper water-based paint and wallpaper made by adopting the wallpaper water-based paint. The wallpaper water-based paint is obviously improved in wallpaper substrate adaptability, the wallpaper water-based paint has good adhesive force, isolation, wettability and colour developing capability and is resistant to scrubbing and high temperature, defoaming is realized and the hole shrinkage phenomenon of a substrate is avoided; meanwhile, the wallpaper water-based paint also has light degradation property and can purify indoor air.

Owner:佛山市三水灏诚合成树脂有限公司

Ink-jet dry granular decorative ceramic tile and manufacturing method thereof

The invention relates to the technical field of ceramic tiles, in particular to an ink-jet dry granular decorative ceramic tile and a manufacturing method thereof. The manufacturing method includes the following steps: A. bottom glaze decoration; B. pattern decoration; C. drying for the first time; D. dry granular decoration; E. spraying a protective glaze; and F. calcining to obtain the product.The method for preparing the dry granular decorative ceramic tile has the advantages of simple operation steps, convenient control, simplified process flow, improved production efficiency, reduced production difficulty and production cost, so that the method is suitable for industrial large-scale production; by spraying with dry granular ink, spray printing can be carried out on a designated position on the surface of a blank body, so as to enable a spray printed texture to be accurately correspond to a pattern decorative texture, and thus the distribution uniformity and adhesion of dry granules on the surface of the blank body are improved, and the prepared ceramic tile product has clear and distinct patterns, low glaze gloss, good anti-skid effect, obvious dry granular feeling, strong stereoscopic impression, rich colors, stable physicochemical properties and wide temperature adaptation range.

Owner:JIANGXI HEMEI CERAMICS +3

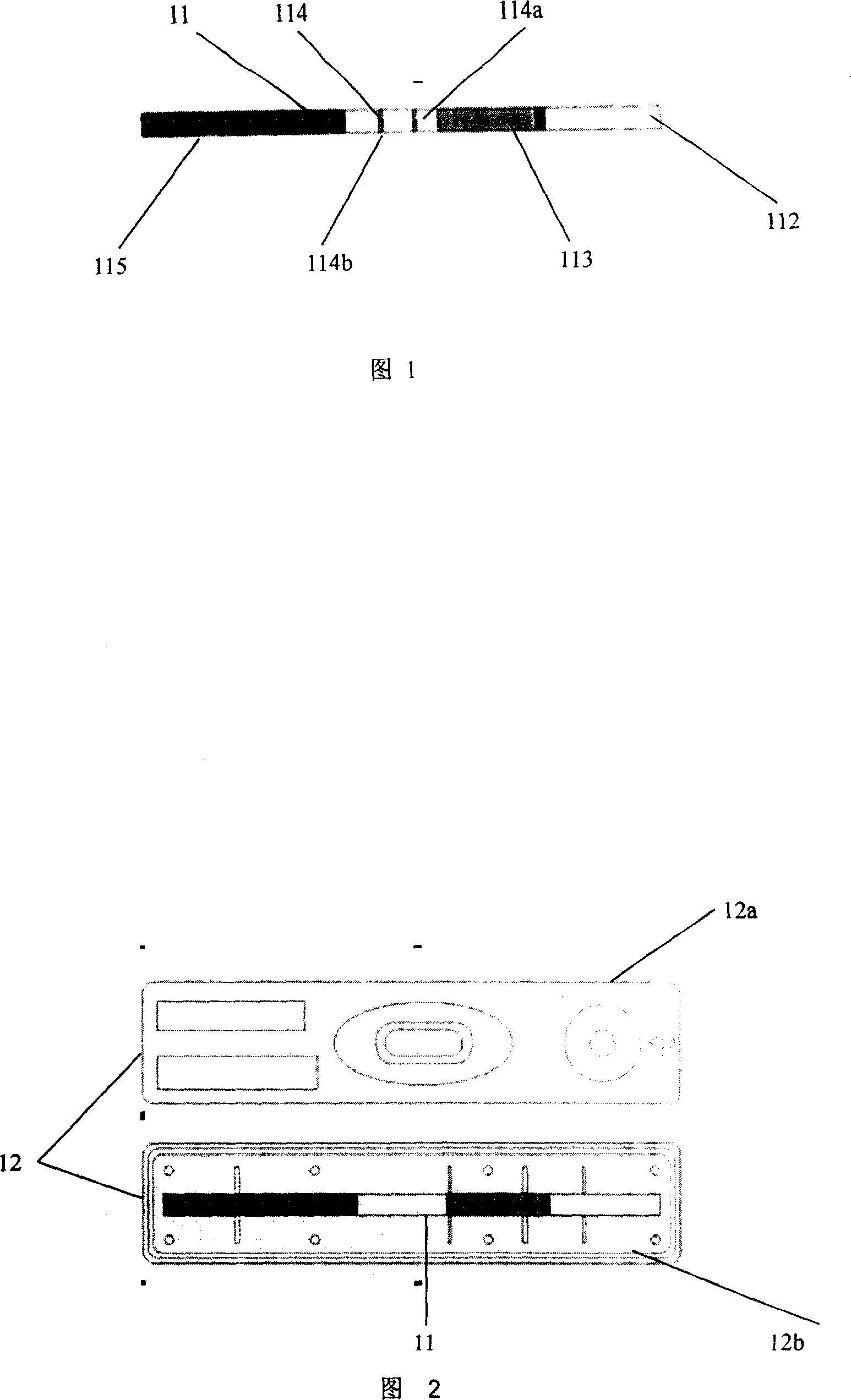

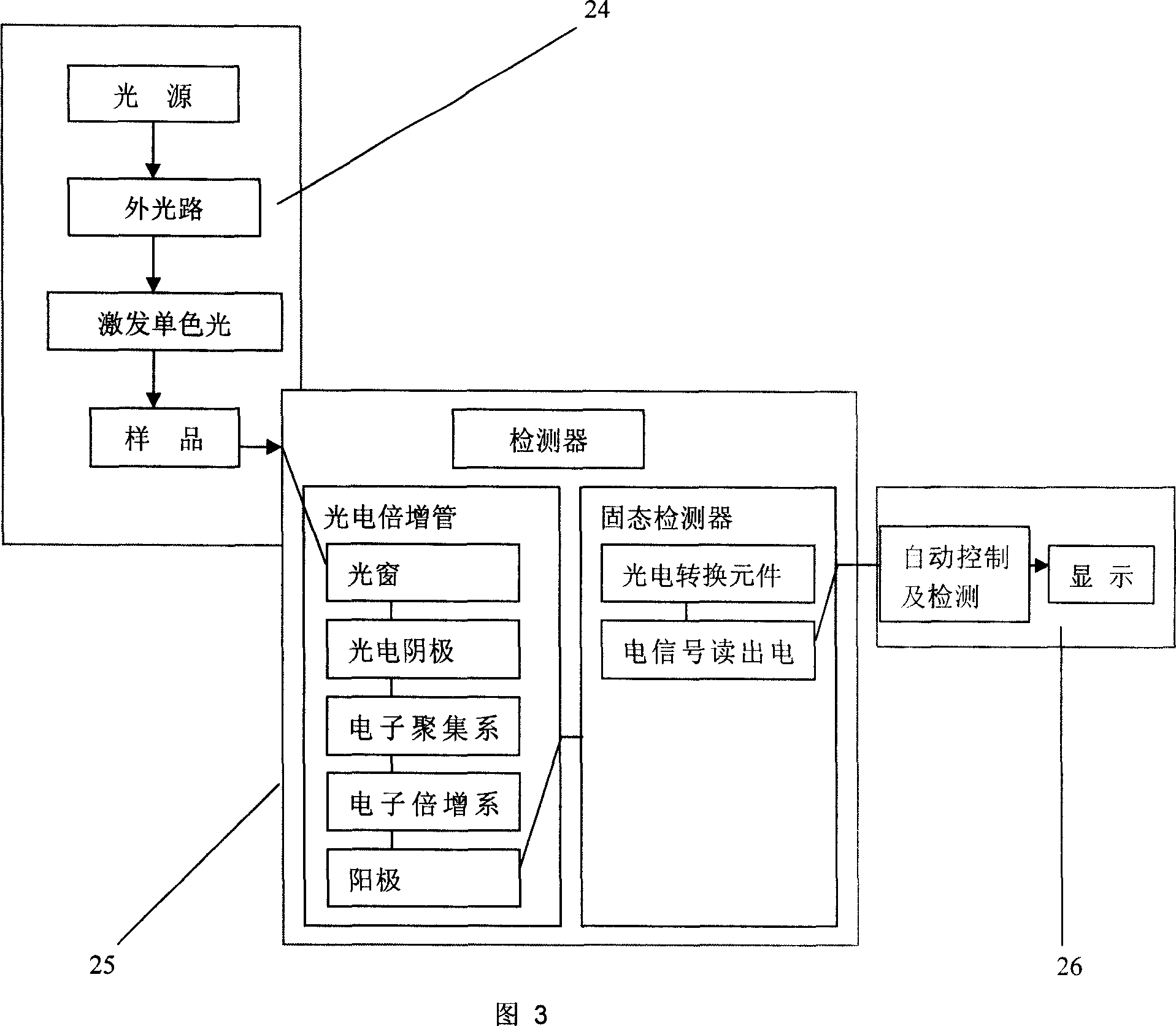

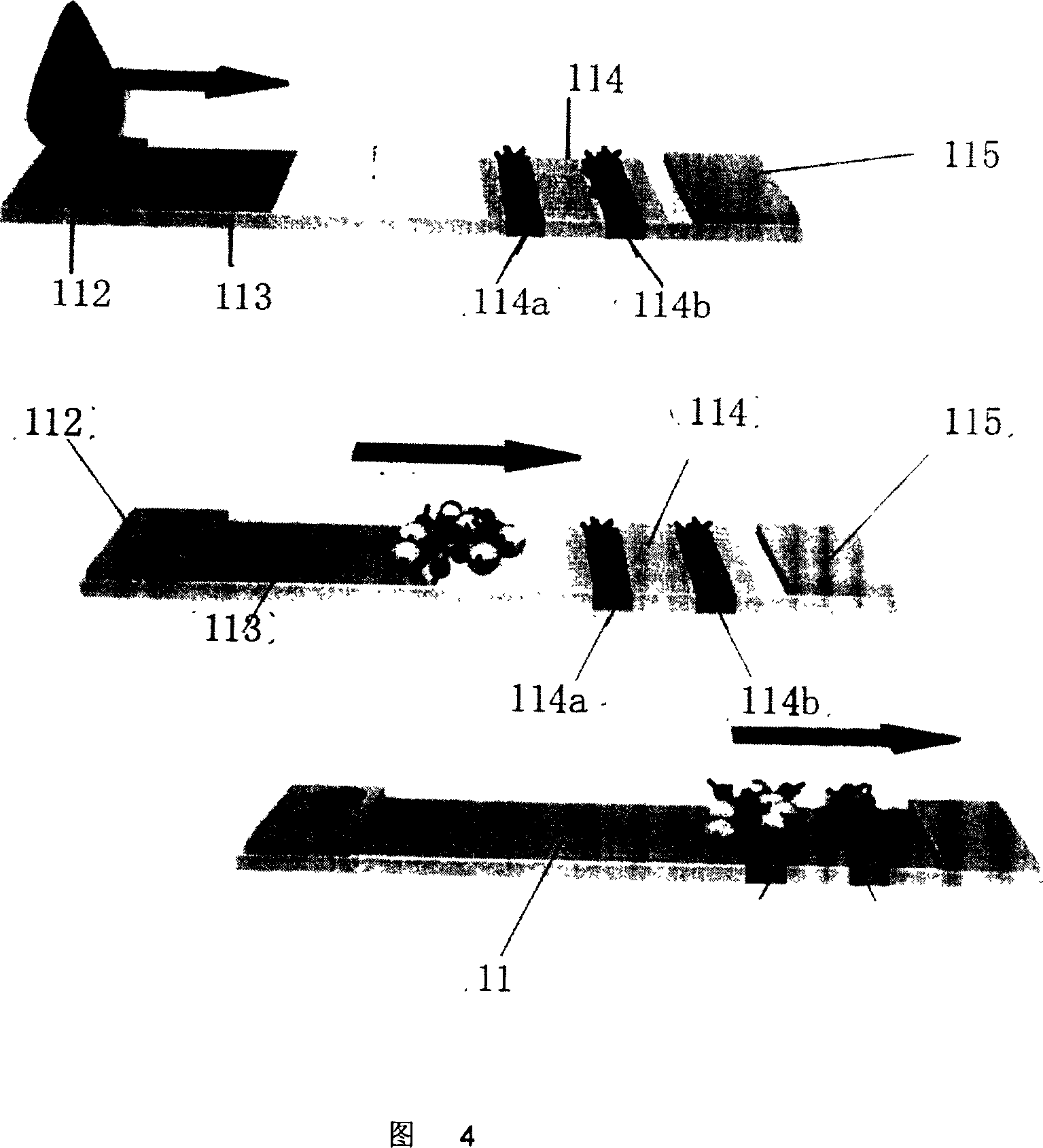

Fluorescence rubber latex quantitative chromatography indicator paper and manufacture method thereof

ActiveCN101017168AVariety of colorsWide range of applicationsFluorescence/phosphorescenceChemistryEmulsion

This invention discloses one fluorescent emulsion quantitative diagnostic apparatus bar and its process method, wherein, the test bar comprises orderly on the underlay earth connection sample pad, glass fiber film, cover film and water absorptive water, wherein, the cover film is set with cover antibody or antigen test area and anti-mouse control area; the said glass fiber film is coated with label protein. the process method comprises the following steps: emulsion covalence activating; fluorescence emulsion micro particle label protein processing; antigen or antibody covering onto aqua fortis fiber film and its enclosing; on underlay orderly connecting sample pad, glass fiber film of the protein, cover film and water absorptive paper to get the test board.

Owner:GUANGZHOU WONDFO BIOTECH

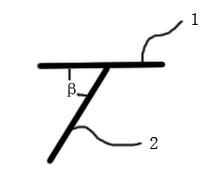

Light-free T-shaped stitch for embroidery and embroidering method

ActiveCN102182023APreserve the characteristics of line lightThere will be no color deviationEmbroidering machines apparatusHand embroideringBiomedical engineeringTextile

The invention discloses a light-free T-shaped stitch for embroidery and an embroidering method. At least three layers of embroidering stitches are embroidered from top to bottom on the front face of an embroidered cloth through an embroidering needle and an embroidering thread, wherein each layer of embroidering stitches is formed by adjacently arranging a group of T-shaped embroidering stitch units with stitches having approximately the same length on the front face of the embroidered cloth; when any T-shaped embroidering stitch unit serves as a standard, the tightly adjacent T-shaped embroidering stitch units around the T-shaped embroidering stitch unit are arranged at angles; the lengths of needle feet of the T-shaped embroidering stitch units in each layer of embroidering stitches aregradually reduced from top to bottom; the stitch of the T-shaped embroidering stitch units consists of first needle feet and second needle feet; the first needle feet and the second needle feet are arranged in a shape of 'T' on the front face of the embroidered cloth; an included angle between the first needle feet and the second needle feet is in a range of between 60 and 90 degrees in the shapeof 'T'; and the ratio of the length of the first needle feet to the length of the second needle feet is in a range of between 1:0.7 and 1:1.3. The problem that faces and limbs of characters reflect light because of inherent thread light and thread textures of silk threads is solved through the T-shaped stitch and the embroidering method, so breakthrough and innovation are made in Suzhou (a province in China) embroidery in the embroidering method for portraits.

Owner:顾金珍

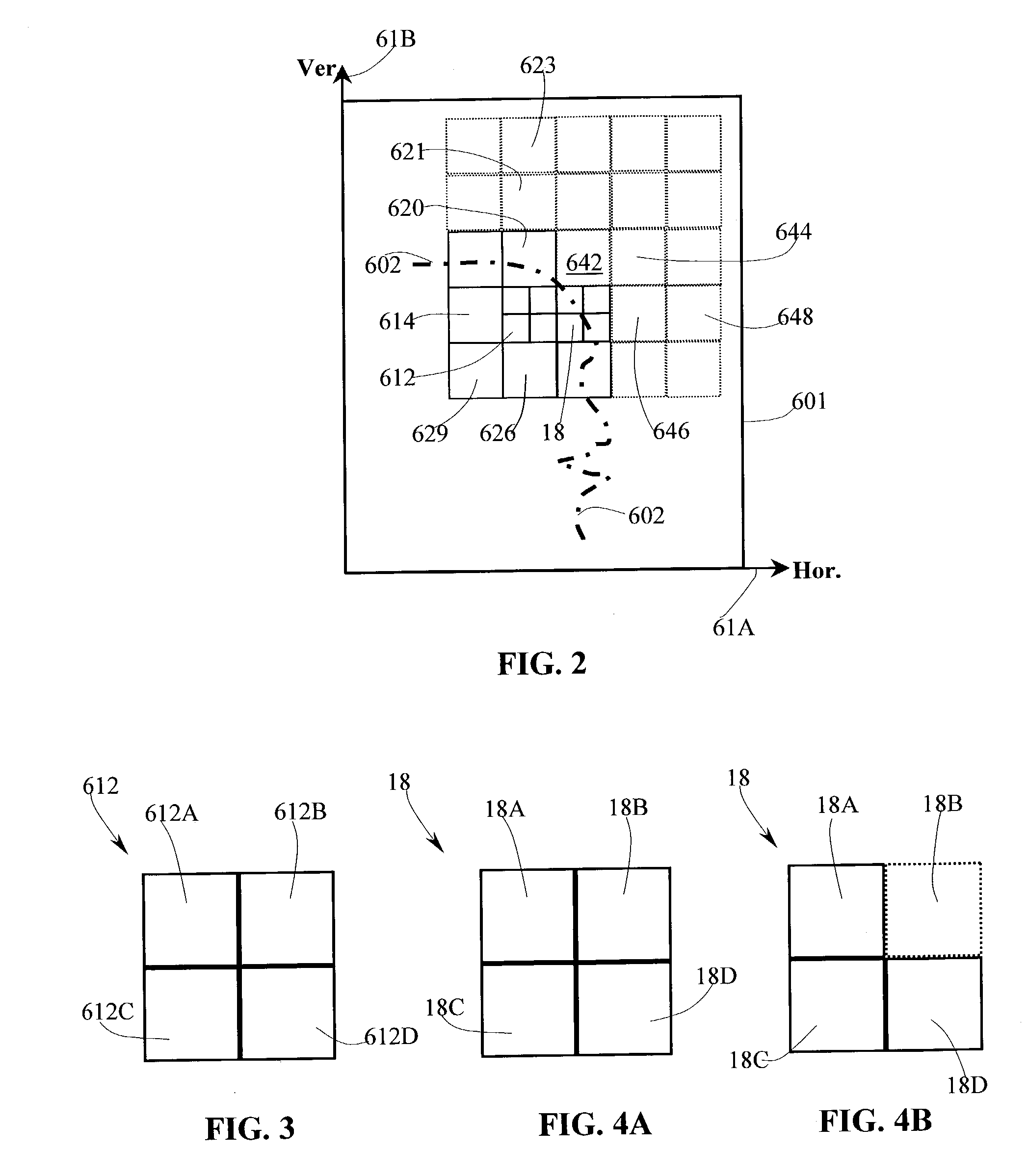

Digital enhancement of streaming video and multimedia system

InactiveUS7030845B2Improve image qualitySimilarTelevision system detailsCharacter and pattern recognitionDigital videoImaging quality

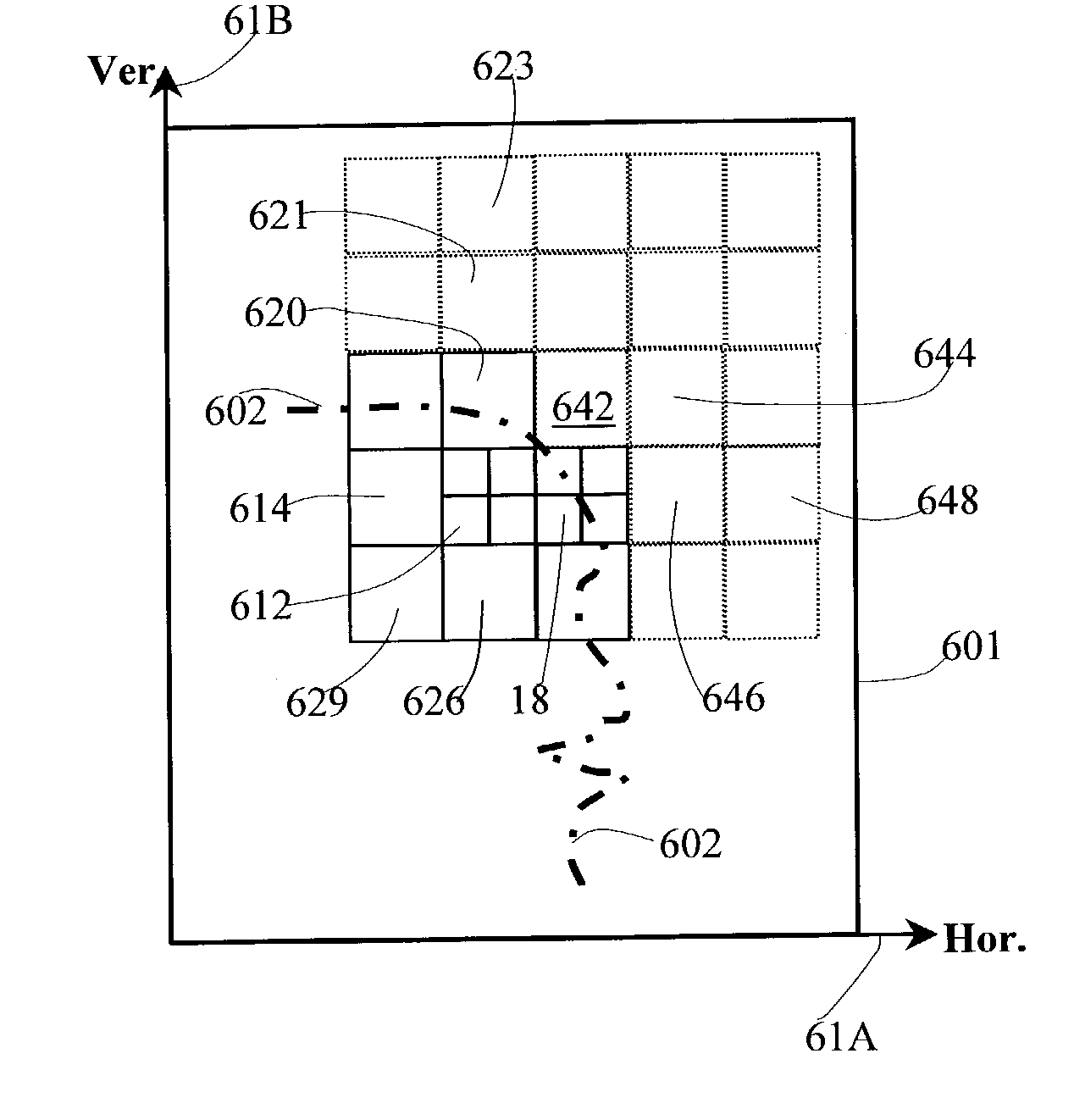

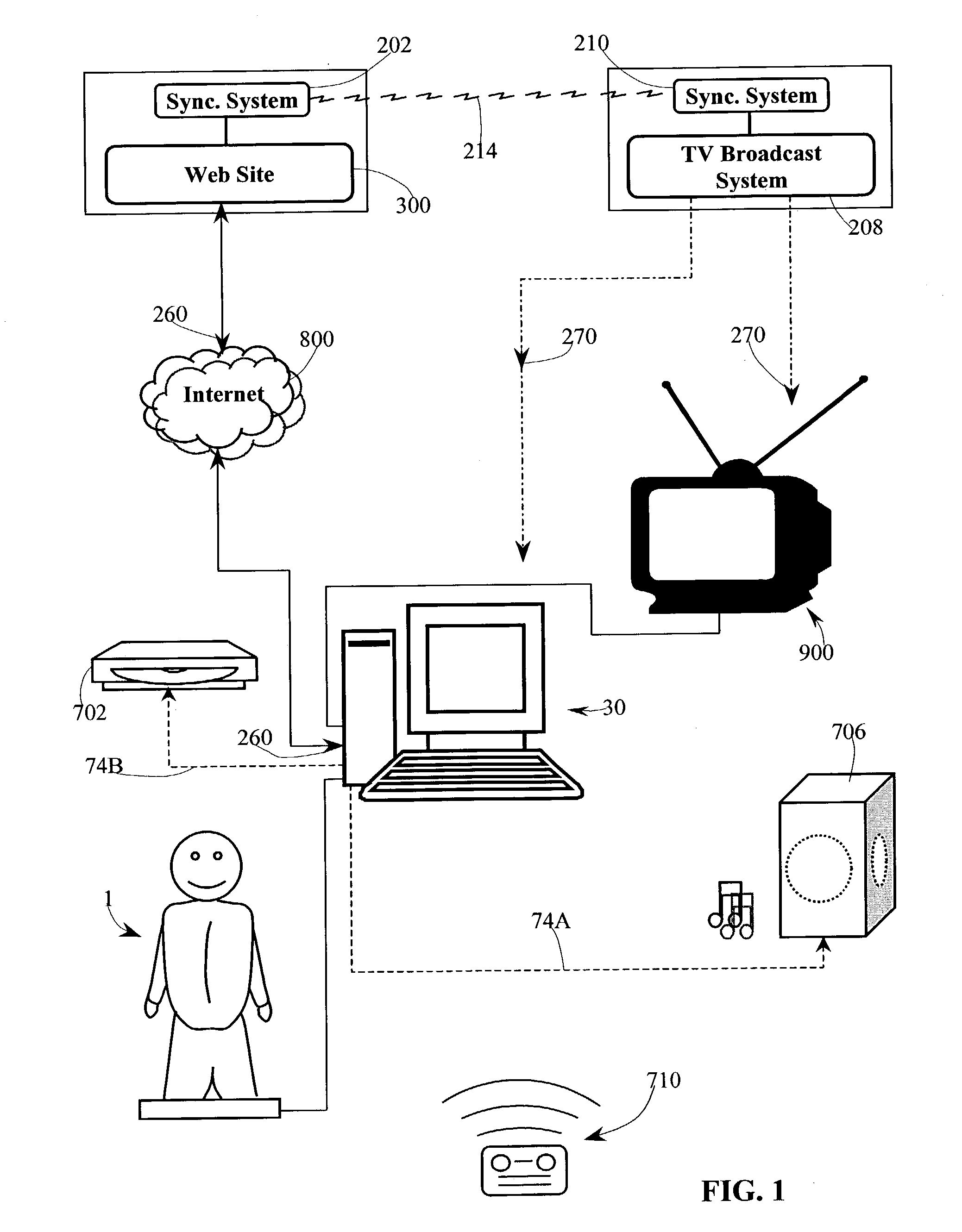

Disclosed herein are methods and systems for enhancing digital streaming video. According to the present invention, the pixel resolution of the image frame of a digital streaming video, i.e., the numbers of pixels within said image frame, are artificially amplified by increasing the number of columns and rows of pixels therein. The color characters, such for examples as the color, contrast, brightness, saturation, hue, and / or luminescence, etc., of each newly created pixel or cell are obtained according to the color characters of those original neighboring pixels. The boundary or border of an image-element within said image frame may be improved by adjusting the color characters of those newly created or child pixels that are situated at or close to said image-element boundary. As a result, a small-frame digital video can be displayed as a large-frame high-resolution video having similar or even better image quality.

Owner:MAA SHALONG

Method for dyeing cotton fabrics through color matching of natural vegetable dyes

The invention provides a method for dyeing cotton fabrics through color matching of natural vegetable dyes. The method comprises the following steps: preparing a dyeing solution from two different vegetable raw materials according to different extraction methods, and reasonably blending a mixed dyeing solution for dyeing the cotton fabrics according to the dyeing performance of the dyeing solution so as to obtain different colors. The defect that the vegetable dyes are single in colors and types is overcome, the colors and types of the vegetable dyes on the cotton fabrics are enriched, and the dyed cotton fabrics are uniform in color, soft and natural in luster, high in color fastness and difficult to fade and discolor.

Owner:李振新

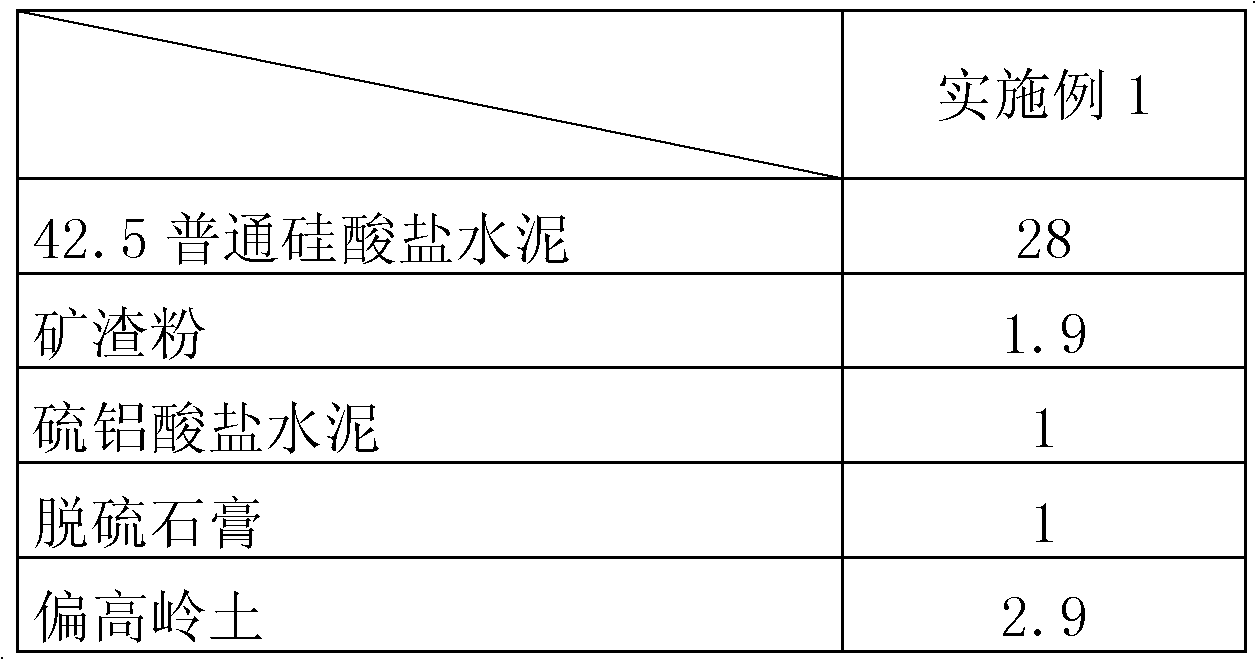

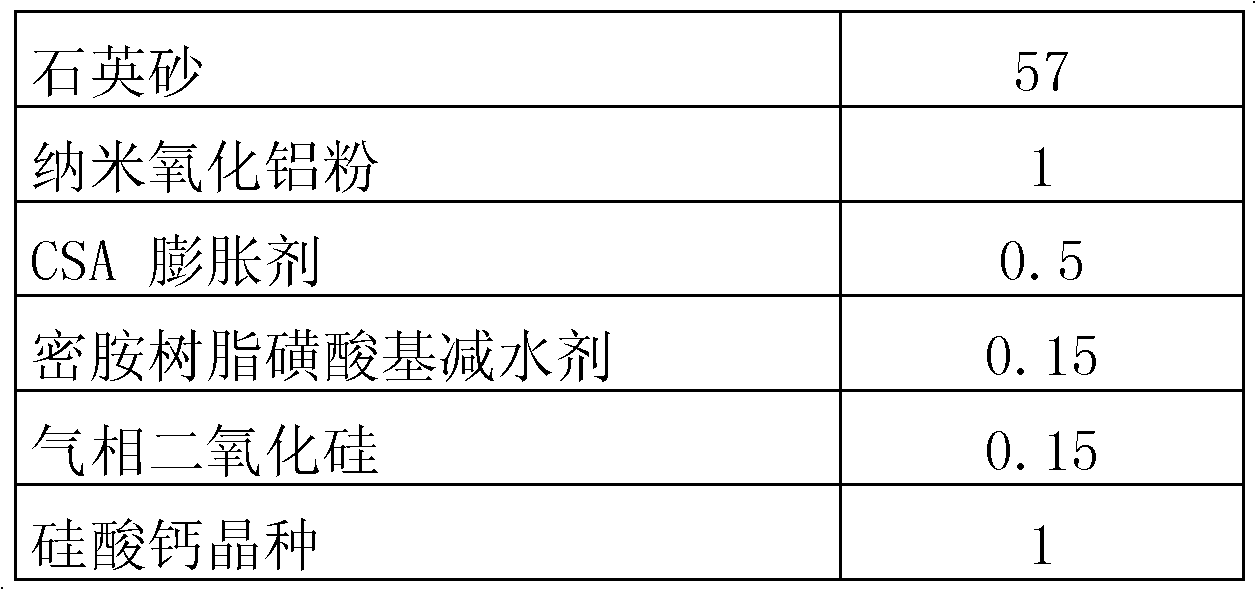

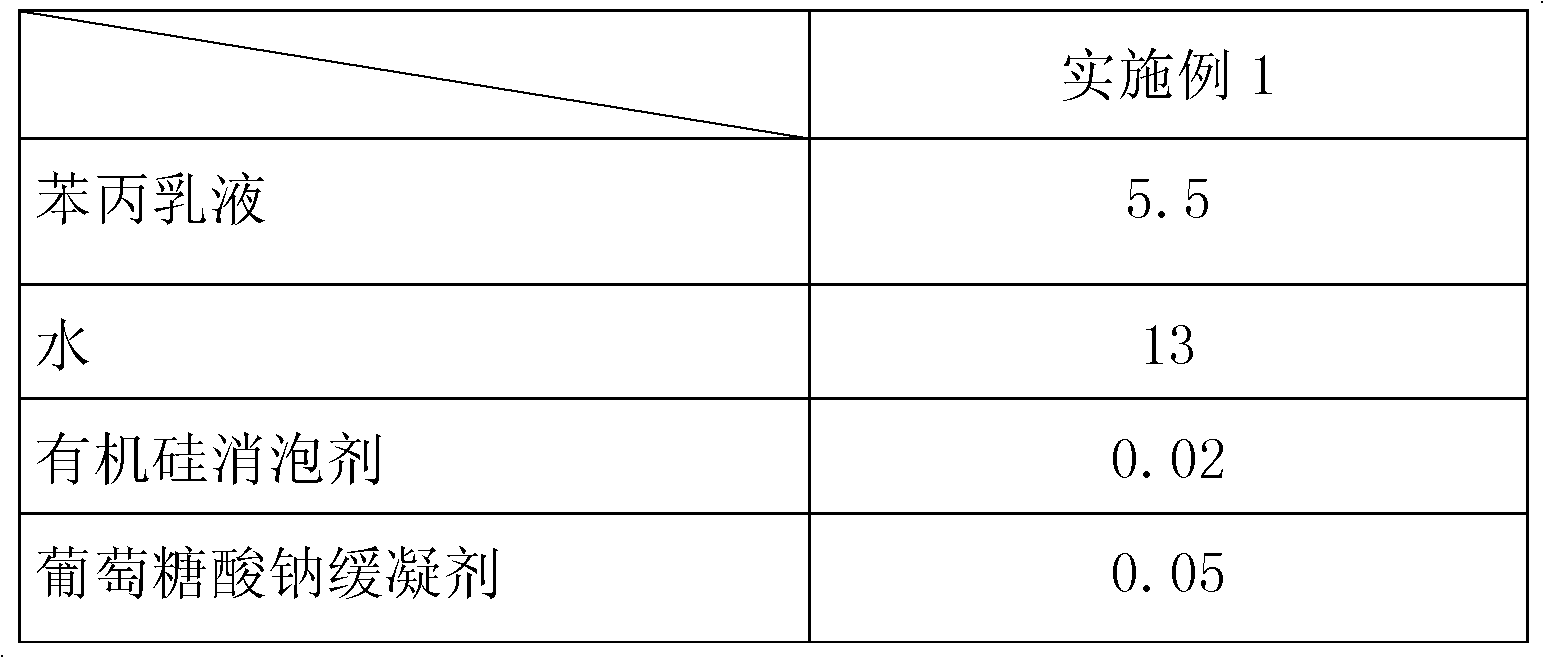

Wear-resistant cement mortar, wear-resistant floor and preparation method thereof

InactiveCN102910885AHas high strengthNon-shrinkableIn situ pavingsFlooringCalcium silicateWear resistant

The invention discloses wear-resistant cement mortar, a wear-resistant floor and a preparation method thereof, wherein the wear-resistant cement mortar is composed by mixing the following components according to a normal method, by weight, 22-40 parts of ordinary portland cement, 1.9-7.5 parts of slag powder, 1-5 parts of special cement, 1-5 parts of metakaolin, 1-5 parts of gypsum, 40-60 parts of quartz sand, 1-3 parts of calcium silicate seed crystal; 1-7 parts of nano alumina powder and 0.1-0.3 part of a water reducing agent, wherein the special cement is sulphoaluminate cement or aluminate cement. The wear-resistant cement mortar has the advantages of excellent hardness and strength. The wear-resistant floor prepared by the wear-resistant cement mortar has no micro-cracks on the surface after being grinded; good smoothness and various fresh brilliant colors can be obtained; color ordonnance can be realized on the surface with extremely high compactness; and aesthetic patterns with paint effects can be obtained.

Owner:MINGLUN BUILDING MATERIALS IND SUZHOU CO LTD

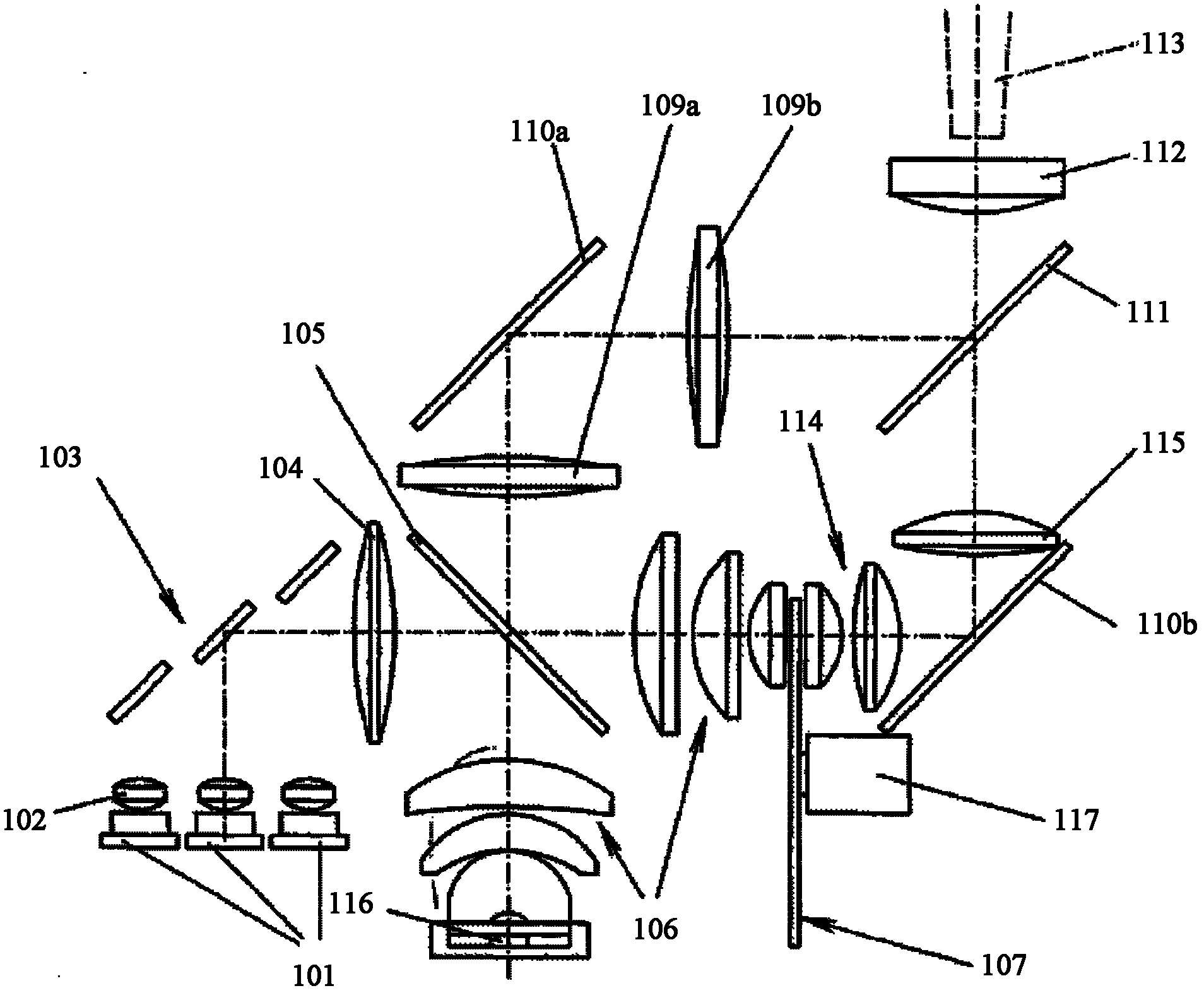

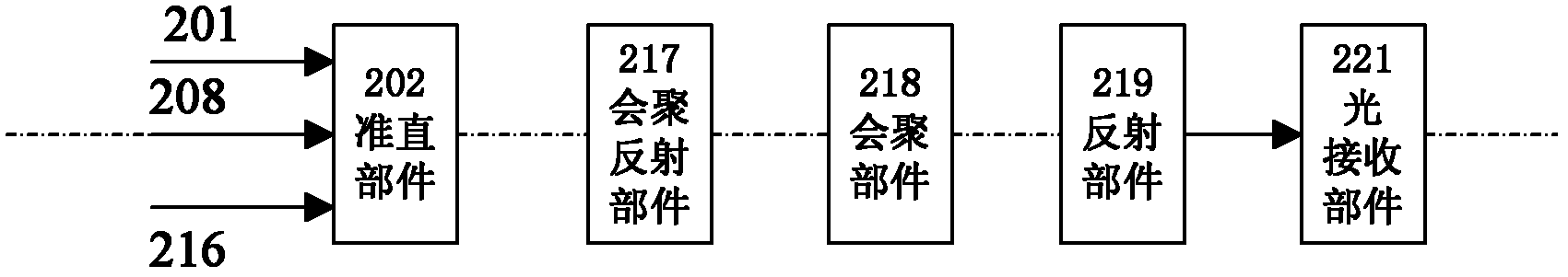

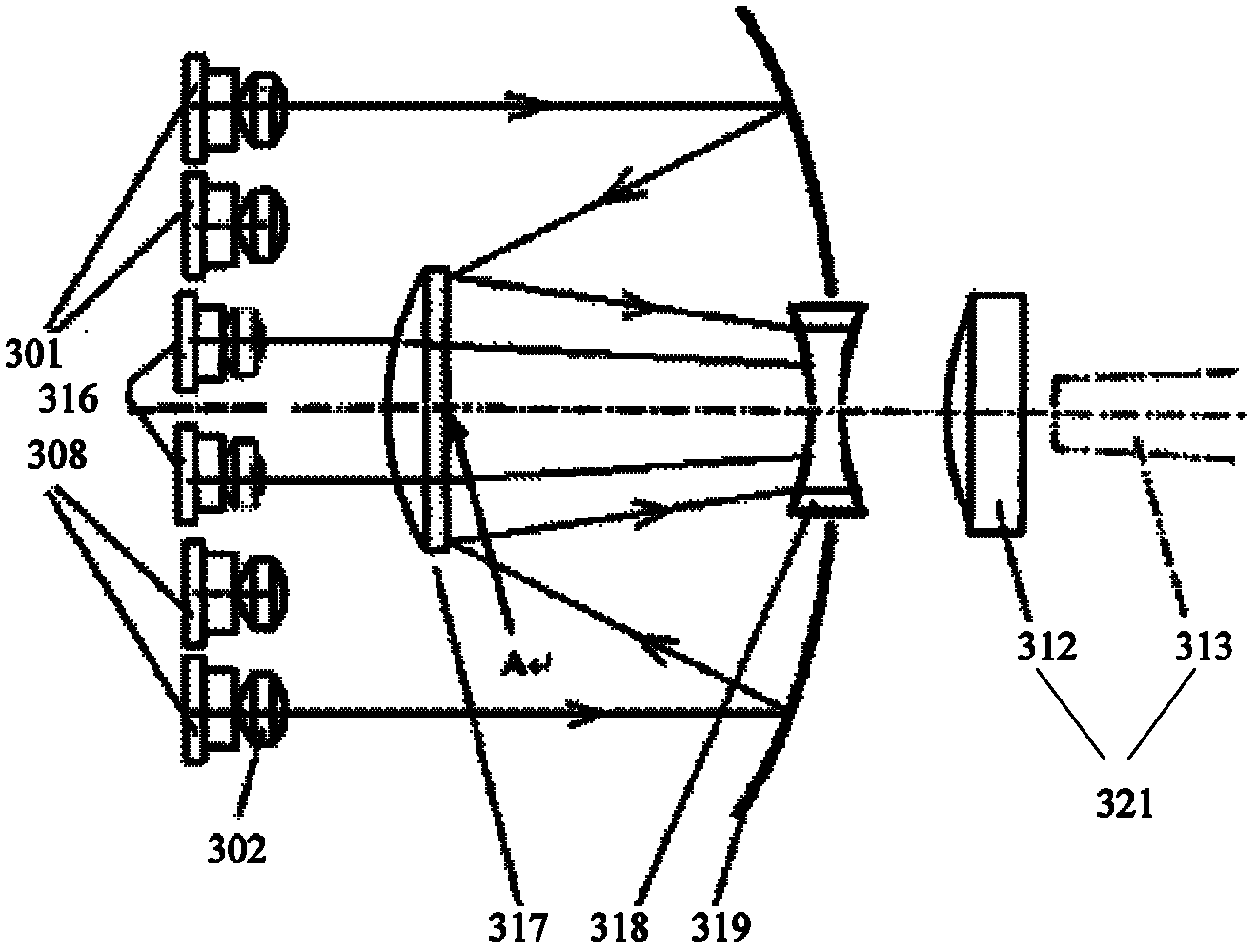

Light source device, light source generation method and laser projection machine comprising light source device

ActiveCN102591120AReduce in quantityReduce lossProjectorsLighting device detailsLength waveLaser projection

The invention discloses a light source device, a light source generation method and a laser projection machine comprising the light source device. The light source device comprises light sources, wherein the light sources comprise a first light source, a second light source and a third light source with different wavelengths; the light source device further comprises a collimating part, a reflecting part, a converging and reflecting part and a converging part, wherein the collimating part is positioned at the ejection side of the first light source, the second light source and the third light source and is used for carrying out collimation processing on the received light sources; the reflecting part is used for reflecting the first light source and the second light source to the converging and reflecting part; the converging and reflecting part is used for carrying out reflection processing on the first light source and the second light source reflected by the reflecting part and carrying out convergence processing on the third light source after collimation processing; and the converging part is used for carrying out convergence processing on the first light source, the second light source and the third light source received so as to enable the first light source, the second light source and the third light source to enter to a light receiving part along the same direction. According to the invention, the quantity of parts in the light source device can be effectively reduced, the light path is simplified, the energy utilization ratio is increased, and the installation and the maintenance are simple.

Owner:HISENSE

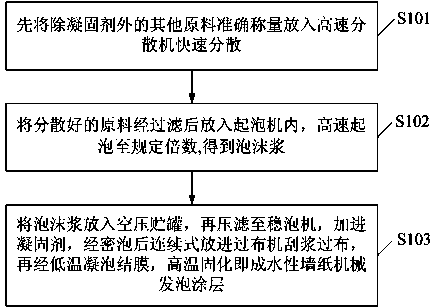

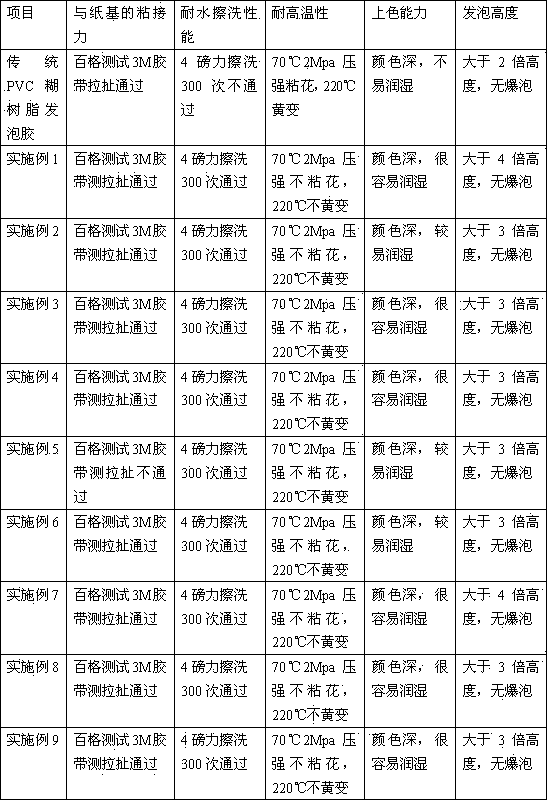

Foam coating glue of water-based wallpaper, preparation method thereof and wallpaper

InactiveCN104004473AImprove adhesionGood flexibilitySpecial visual effect coatingsSpecial paperWater basedPolymer science

The invention discloses a foam coating glue of water-based wallpaper. The foam coating glue includes 40-60% of a main body emulsion resin, 35-55% of a compounding agent and 1-10% of water. The main body emulsion resin is selected from one or more of neoprene latex, nitrile rubber latex, styrene-butadiene latex, water-based acrylate resin, water-based polyurethane resin and ethylene-vinyl acetate resin. The compounding agent includes a dispersing agent, an emulsifier, a thickening agent, a foam-starting agent, a foam-stabilizing agent, a foaming agent, a coagulating agent and a foam-densifying agent. Correspondingly, the invention discloses a preparation method of the foam coating glue of the water-based wallpaper and wallpaper prepared by using the foam coating glue of the water-based wallpaper. Through the preparation method, the foam coating glue of the water-based wallpaper is environmental-friendly and energy-saving, has an excellent foaming effect and can form an excellent-performance foam coating on the water-based wallpaper.

Owner:佛山市三水灏诚合成树脂有限公司

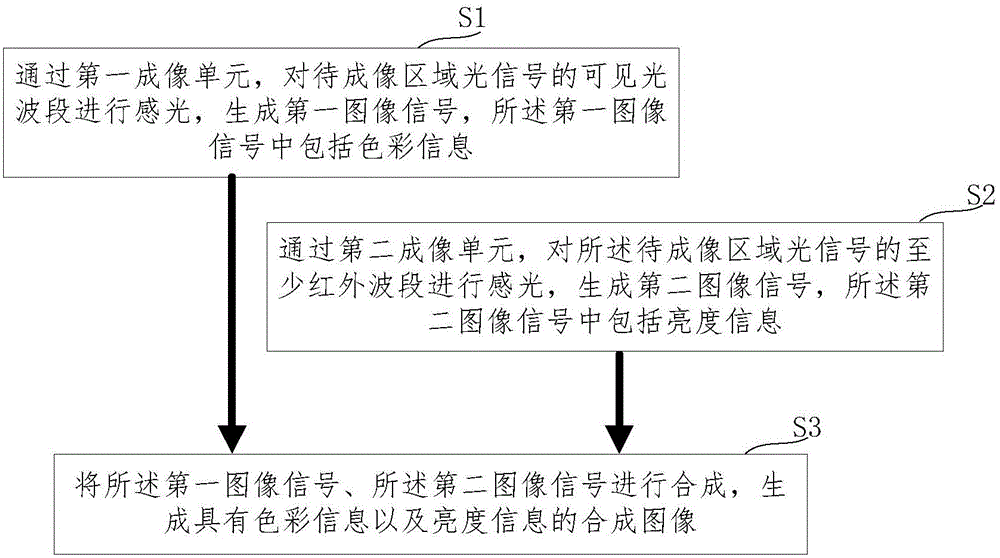

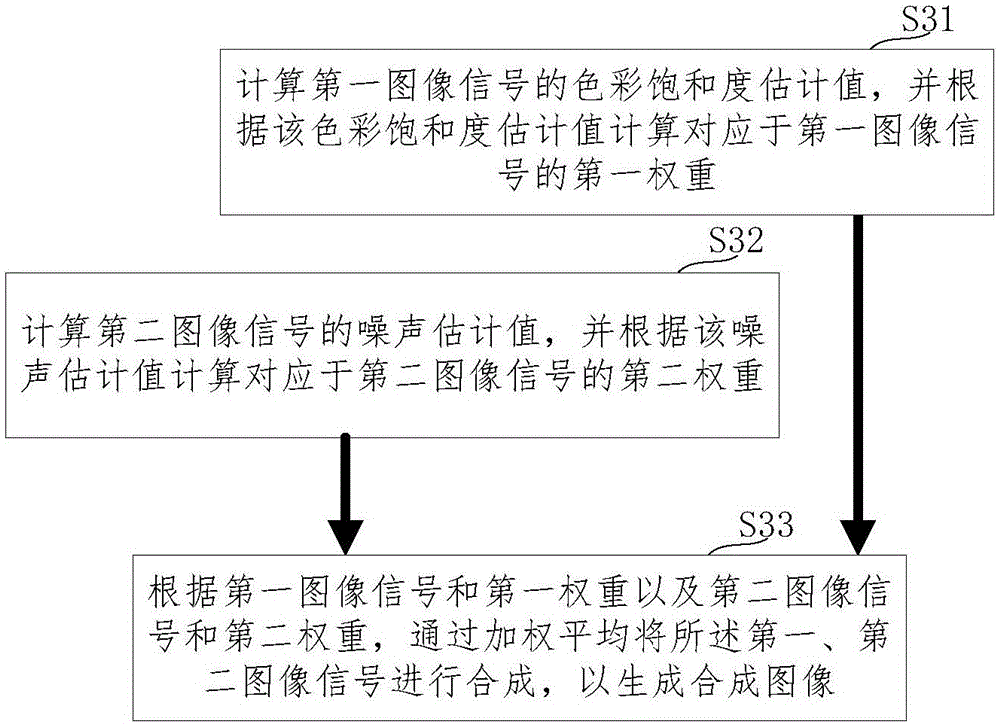

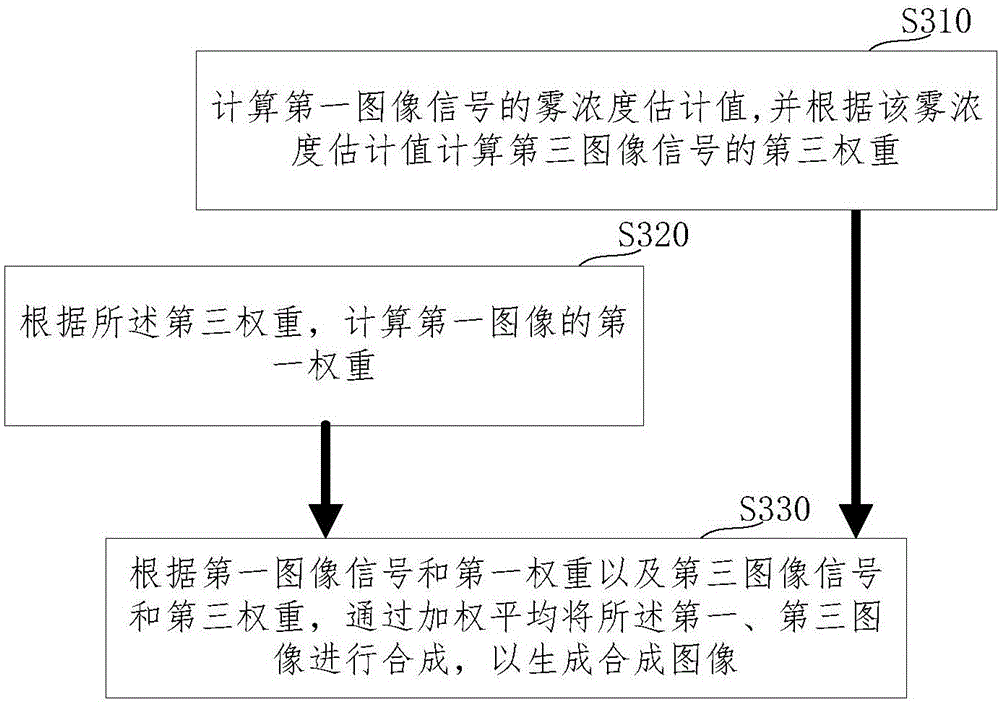

Image signal processing method and system

ActiveCN106488201AReduce noiseGood fog penetration effectImage enhancementTelevision system detailsIlluminanceLight signal

The invention discloses an image signal processing method and system. The method comprises the steps of carrying out light sensitization on a visible light waveband of a to-be-imaged region light signal via a first imaging unit to generate a first image signal, wherein the first image signal includes color information; carrying out the light sensitization on at least infrared waveband of the to-be-imaged region light signal via a second imaging unit to generate a second image signal, wherein the second image signal includes brightness information; and carrying out synthesis on the first image signal and the second image signal to generate a synthetic image having the color information and the brightness information. According to the image signal processing method and system disclosed by the invention, the synthetic image having multiple advantages can be generated, and the requirements on two monitoring environments of low illumination and through-frog relatively concerned in the guard field can be met.

Owner:HANGZHOU HIKVISION DIGITAL TECH

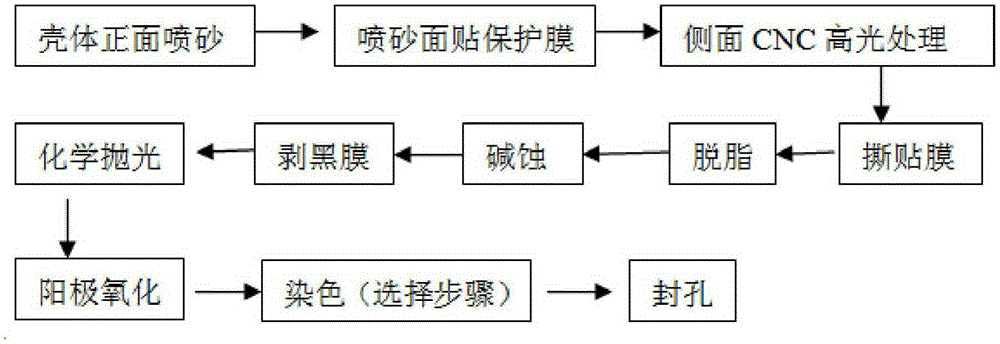

Surface treatment method for aluminum alloy shell

InactiveCN105177669AVariety of colorsVarious appearance effectsSurface reaction electrolytic coatingSand blastingMachining

The invention provides a surface treatment method for an aluminum alloy shell. The surface treatment method includes the following steps that S1, sand blasting is conducted on the front face of the aluminum alloy shell, and the aluminum alloy shell with the front face being the sand blasting face is obtained; S2, CNC machining is conducted on the side face of the aluminum alloy shell to achieve the highlight effect; S3, anodizing treatment is conducted on the whole aluminum alloy shell obtained after sand blasting and CNC treatment are conducted, and an oxidation film layer is formed; and S4, hole sealing treatment is conducted on the aluminum alloy shell obtained after anodizing treatment is conducted, and the aluminum alloy shell with the sand blasting front face and the highlight side face is obtained. By means of the surface treatment method for the aluminum alloy shell, the appearance effect of the aluminum alloy shell is more diverse.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Artificial stone panel and manufacturing method thereof

InactiveCN101328039AGood wear resistanceNoble and elegant decorative effectCalcium carbonateArtificial stone

The invention discloses a artificial stone plate prepared by adding cobalt naphthenate accelerator, methylethylketone, light stabilizer, paint and antioxidant into unsaturated polyester resin. The preparation method includes the following steps: firstly modifying the aluminium hydroxide and / or calcium carbonate to get surface modified aluminium hydroxide and / or calcium carbonate or pure aluminium hydroxide powder, then adding cobalt naphthenate accelerator, methylethylketone, light stabilizer, paint and antioxidant into unsaturated polyester resin, uniformly mixing and stirring the mixture in a high speed stirring reactor, adding surface modified aluminium hydroxide and / or calcium carbonate powder or pure aluminium hydroxide powder, stirring and casting the mixture into a mould after vacuum defoamtion, heating up to 60-80 DEG C and curing to get the artificial stone and marble panel.

Owner:覃庆峰

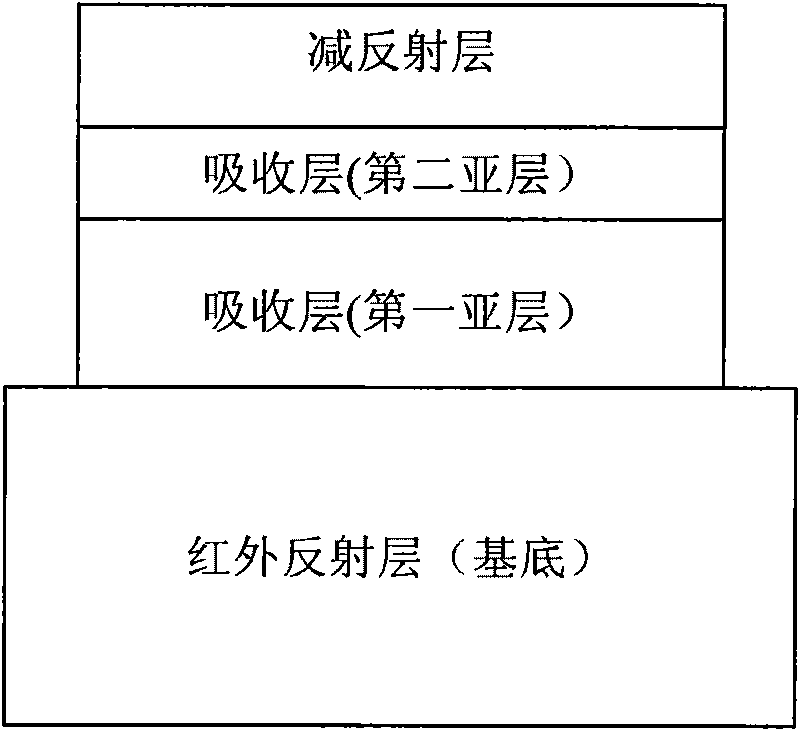

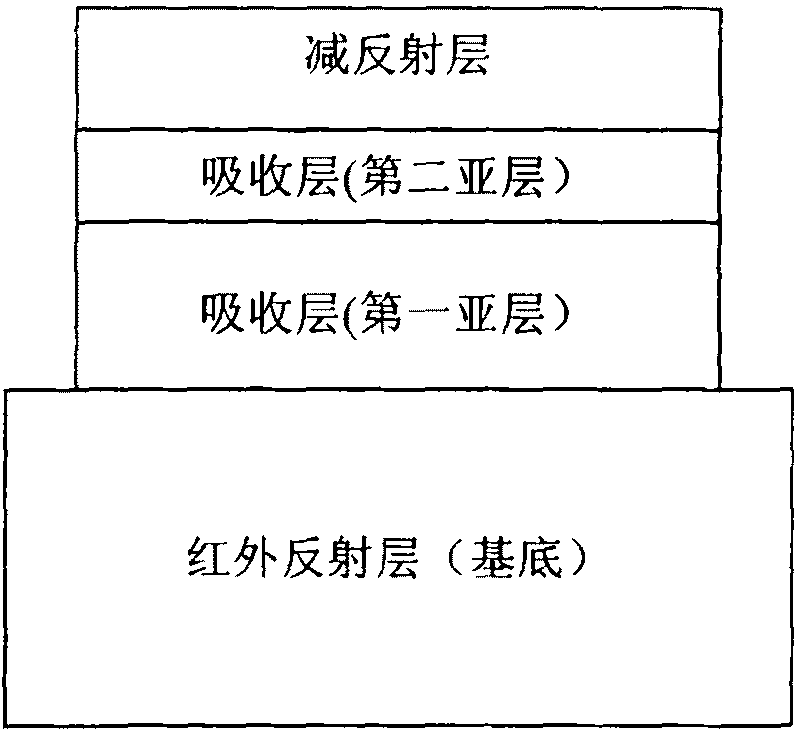

Solar spectrum selective absorbing coating and preparation method thereof

ActiveCN101737983AImprove thermal stabilityMeet the requirements of sustainable developmentSolar heat devicesLayered productsRefractive indexAlloy

The invention relates to a solar spectrum selective absorbing coating which is prepared by adopting magnetron sputtering technology. The absorber of the coating comprises the following three layers of films from substrate to top: a first layer adopts copper with infrared reflectivity or aluminium substrate as an infrared reflecting layer; a second layer uses a metalloid layer and a medium type layer which have different refractive indexes and thicknesses; and a third layer uses SiON film as an antireflection layer. The preparation method comprises the following steps: the first layer (infrared reflecting layer): cleaning copper or aluminium sheets with ultrasonic wave or polishing the copper or aluminium sheets; the metalloid layer of second layer: using two metals as alloy target, argon gas as sputtering gas and nitrogen gas as reaction gas and adopting DC electrical source to perform reactive sputtering; the medium type layer of the second layer: using two metals as alloy target, argon gas as sputtering gas and nitrogen and oxygen gas as reaction gas and adopting DC electrical source to perform reactive sputtering; the third layer (antireflection layer): uses SiN as target, argon gas as sputtering gas and nitrogen and oxygen gas as reaction gas and adopting radio frequency power source to perform reactive sputtering; and finally obtaining the absorber.

Owner:安徽科鑫光热技术有限公司

PVC foaming architectural decoration material and preparation technique thereof

The invention relates to a PVC foaming construction decorative material and a preparation technique thereof. The preparation technique comprises the following steps: PVC plastics which are waste and are screened and ground, calcium carbonate, a stabilizer, an antioxidant, a lubricant, a foaming agent, a modifier, a foaming modifier, a dispersing agent, a colorant and the like are added into a high mixing machine according to the weight in sequence, mixed for 5 to 10 minutes, then placed into a low-temperature mixing machine for 5 to 10 minutes when being heated to be 120 to 125 DEG C; discharging is carried out when the temperature is 35 to 45 DEG C; the obtained materials are extruded by a parallel conical twin-screw extruder, molded, cooled in vacuum, pulled, film-stuck, cut and inspected and then the finished product of foaming plastic product is obtained. The invention is applicable to families, hotels, offices and entertainments, is the most ideal home decorative material with environment protection and is also the most practical home floor material.

Owner:胡大忠

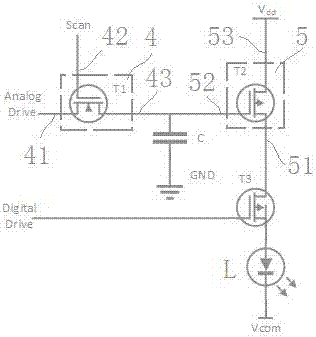

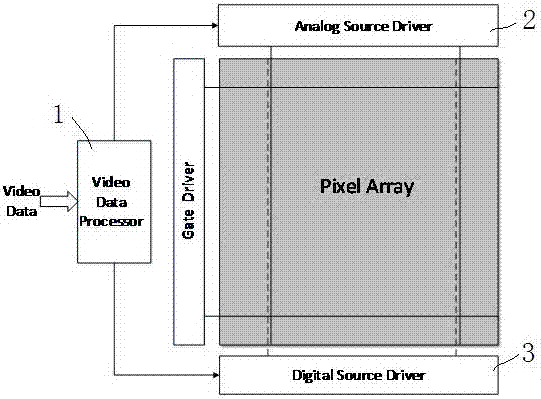

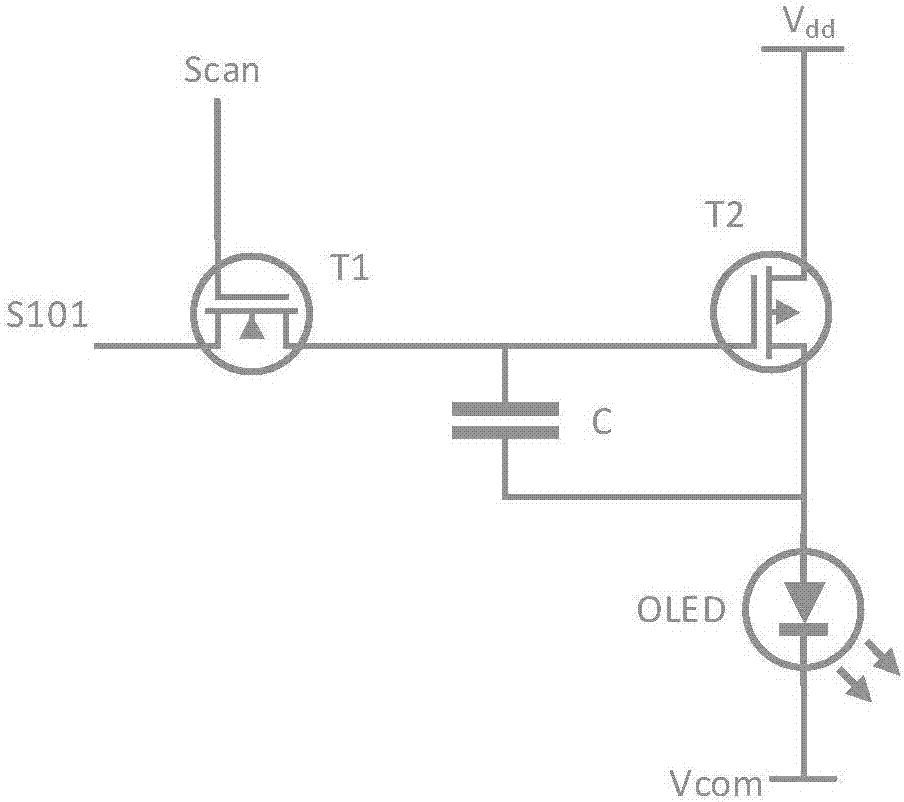

Method and system for driving displaying of display unit through analog and digital hybrid drive and drive circuit

InactiveCN107993609AImprove the performance of color scaleEnhanced gradation performance and high contrastStatic indicating devicesComputer hardwareHemt circuits

The invention discloses a method for driving displaying of a display unit through analog and digital hybrid drive. The method comprises the following steps that analog drive quantity controls the illumination brightness of the display unit; under the illumination brightness, digital drive quantity controls the illumination time of the display unit. The combination of the illumination brightness and the illumination time controls the illumination of the display unit, the rich gray scale and color are realized, the gray scale and color gradation expression ability of an image is obviously improved, the display of high contrast and high dynamic range is realized, and meanwhile, the system power dissipation and design requirements of a drive chip are reduced. The invention further discloses asystem for driving displaying of the display unit through analog and digital hybrid drive, and a drive circuit adopting analog and digital hybrid drive.

Owner:CHENGDU JINGSHA TECH

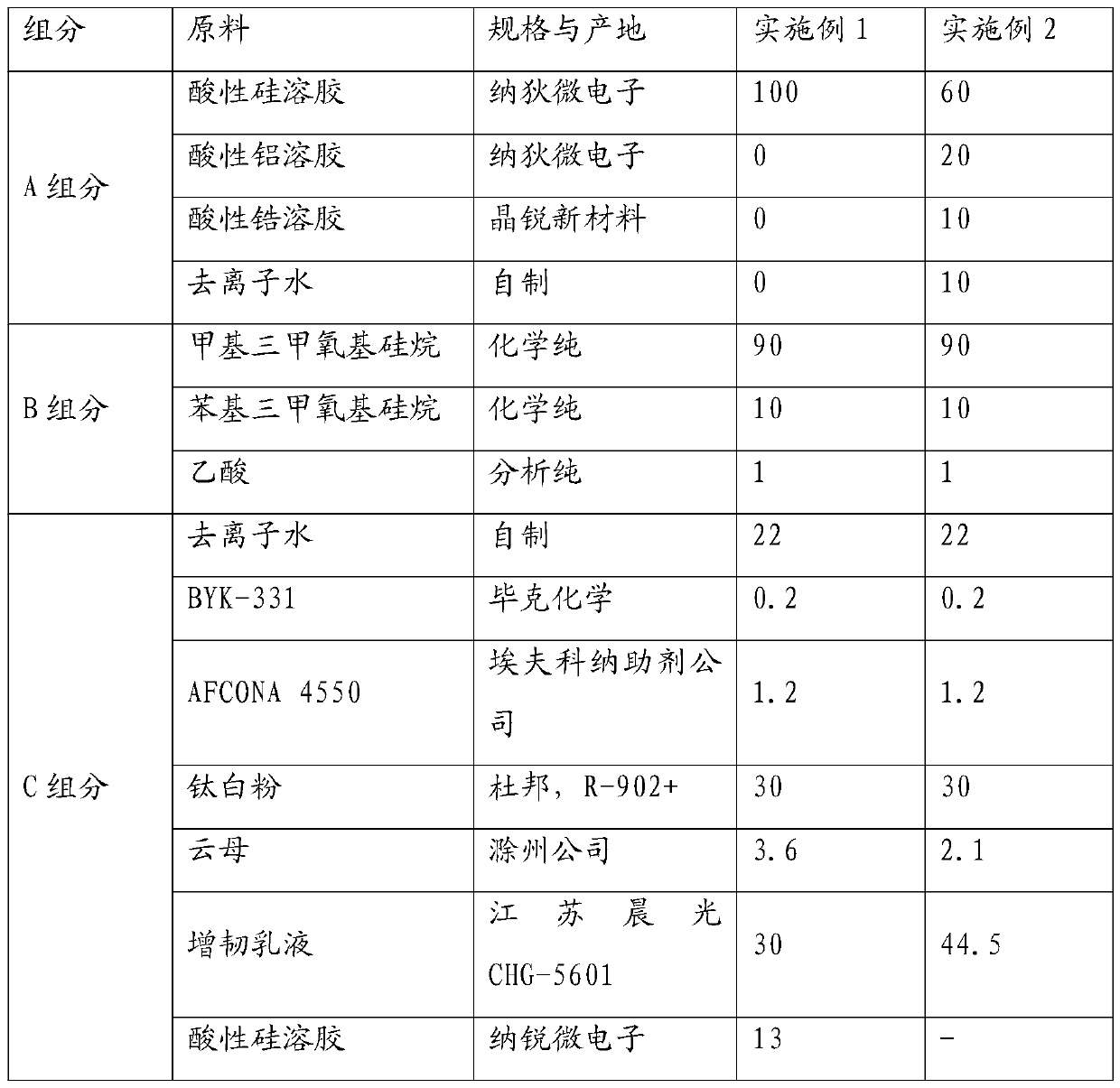

No-curing high-performance ceramic water-based paint and preparation method thereof

InactiveCN109867991AVariety of colorsComprehensive effectFireproof paintsAnti-corrosive paintsWater basedSolvent

The invention relates to no-curing high-performance ceramic water-based paint and a preparation method thereof. The coating has is composed of an A component, a B component and a C component; the A component is prepared by mixing the following raw materials, in parts by weight: an acidic silica sol, an acidic aluminum sol, an acidic zirconium sol or a mixture of the acidic silica sol, the acidic aluminum sol and the acidic zirconium sol in any ratio, deionized water and an alcohol solvent, and performing dispersion; the B component is composed of the following materials: methyltrialkoxysilane,phenyltrialkoxysilane, tetraalkoxysilane, dimethyldialkoxysilane, diphenyldialkoxysilane, a silane coupling agent, an non-sticking auxiliary agent and a catalyst; and the C component is prepared by mixing the following raw materials: deionized water, isopropanol or ethanol, an acidic silica sol, a neutral silica sol or a mixture of the acidic silica sol and the neutral silica sol in any ratio, aninorganic filler, a coloring pigment, a toughening emulsion, a dispersant and other auxiliary agents, and performing dispersion. The paint provided by the invention does not need curing, has simple and convenient construction, excellent performance and good environmentally-friendly performance, and is easy to produce in a large scale, thereby being a novel high-performance water-based coating.

Owner:常州穗时新材料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com