Furnace transmutation decoration glazed brick and production technology

A production process and decorative glaze technology, applied in the direction of clay products, other household appliances, household utensils, etc., can solve the problem of impossible application of the production process of wall and floor tiles, deterioration of glaze wear resistance, chemical corrosion resistance, and limited use range and other problems, to achieve the effect of increasing decorative technical means, strengthening decorative effect, and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] The present invention will be described in further detail below in conjunction with embodiment and accompanying drawing:

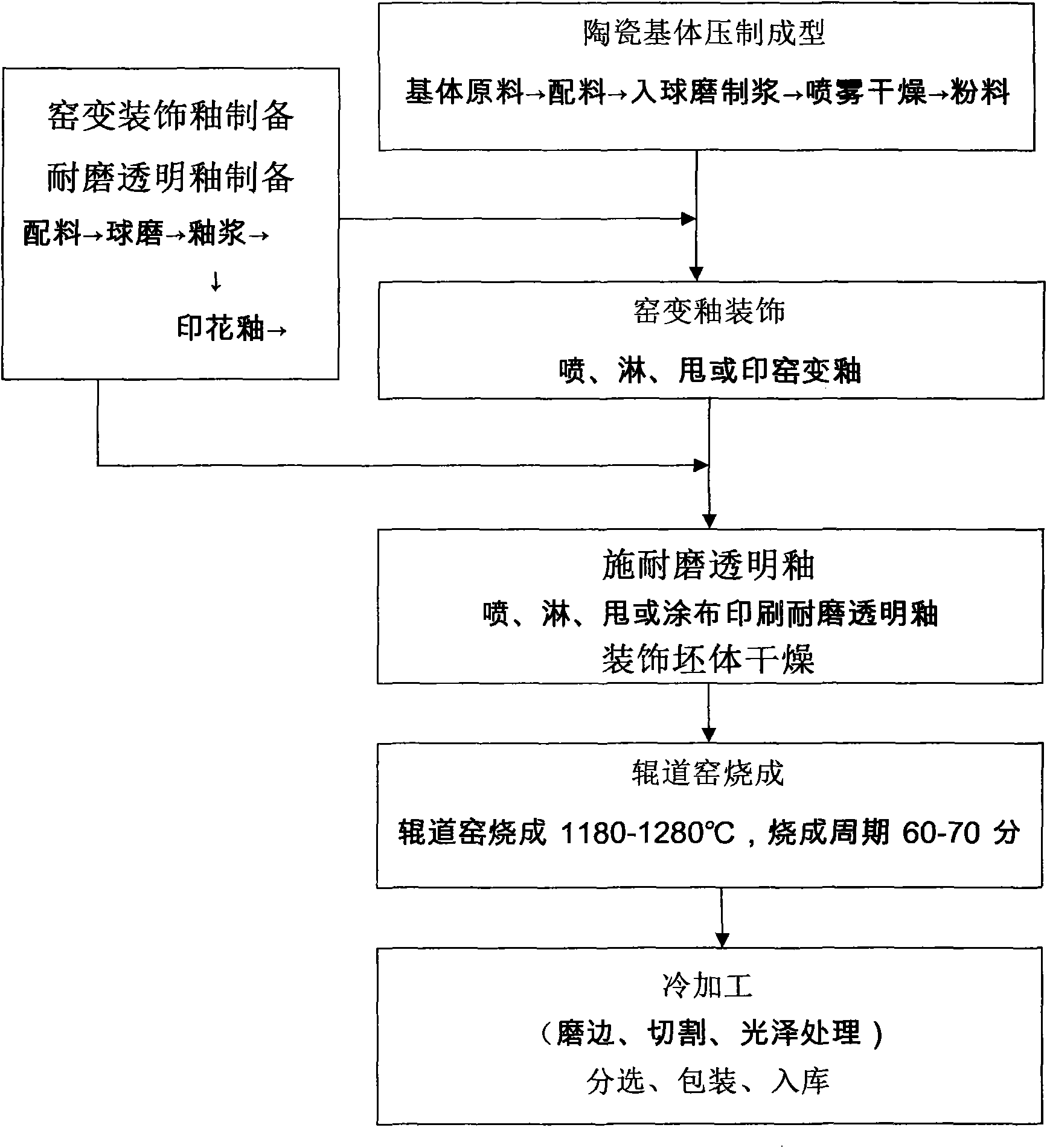

[0082] see figure 1 Shown, the manufacturing process of kiln variable decorative glazed wall and floor tile of the present invention comprises:

[0083] (1) The ceramic tile matrix is pressed and formed, and its matrix is composed of the following components:

[0084] Porcelain sand 59%~80%

[0085] Black and white clay 15%~40%

[0086] Additive 0.5%~5%

[0087] (1.1) Put various raw materials into a ball mill and add water to wet grind into mud;

[0088] (1.2) The slurry is dried in a spray tower to prepare powder;

[0089] (1.3) The powder is pressed and formed into the matrix of kiln-variable decorative glazed wall and floor tiles;

[0090] (1.4) Dry the base brick adobe.

[0091] (2) the preparation of described kiln-changing decorative glaze and wear-resistant transparent glaze, its kiln-changing glaze and wear-resistant transparent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com