Method for producing fermented bean curd through multi-strain mixed fermentation

A mixed fermentation, multi-strain technology, applied in dairy products, cheese substitutes, applications, etc., can solve the problems of not meeting the technical requirements of dietary requirements, insufficient flavor of fermented bean curd products, low enzyme activity, etc., and is suitable for large-scale production. , the effect of rich flavor and high protease activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

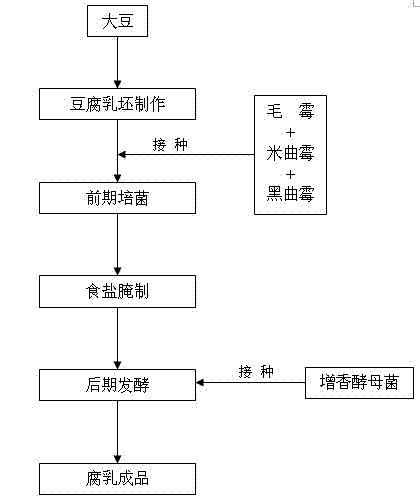

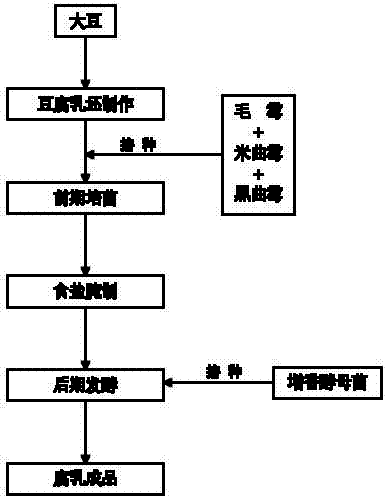

[0036] (1) Production of bean curd base: take soybeans to make bean curd base according to conventional methods.

[0037] (2) Pre-culture: Take Mucor, Aspergillus oryzae and Aspergillus niger and mix them according to the spore ratio of 5:2:1 to obtain mixed strains, dilute with distilled water to a concentration of 1.0×10 5 The number of spores / ml is then inoculated into the bean curd base by weight ratio of 1% inoculation amount, and the pre-culture is carried out. The cultivation temperature is 32°C, the humidity is 95%, and the cultivation time is 30h.

[0038] (3) Salt pickling: put the tofu milk blank obtained in step (2) into a plastic box, sprinkle salt layer by layer, follow the principle of less lower layers and gradually increase the upper layer, and marinate for 8 hours according to the conventional method, and the salt content of the tofu milk is controlled at 14%.

[0039] (4) Post-fermentation: After bottling the pickled fermented bean curd and salty base, pour...

Embodiment 2

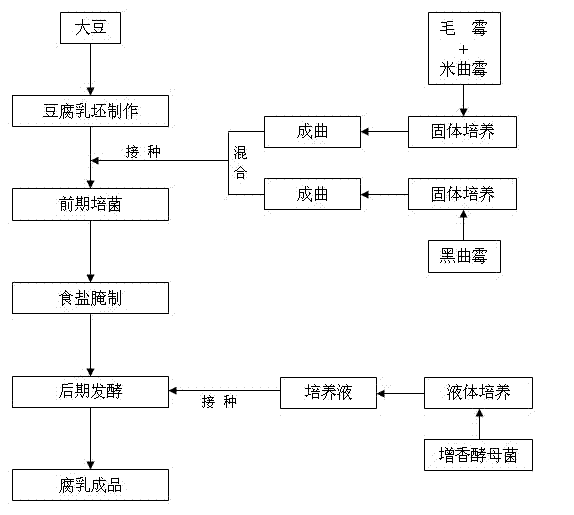

[0042] (1) Music making:

[0043] a) Preparation of slant strains: After activating the slant strains of Mucor, Aspergillus oryzae, Aspergillus niger, Saccharomyces rouxii and Torulopsis sphaeroides preserved in cold storage, dip a ring into the corresponding slant medium respectively and cultured at 30°C for 48 hours until the slant medium was overgrown.

[0044] Among them, the formula of Mucor slant culture medium is: 200g potatoes, 20g glucose, 5g peptone, 25g agar, 1000mL distilled water, natural pH;

[0045] Both Aspergillus oryzae and Aspergillus niger slant medium: soybean juice 5°Bé, glucose 20g / L, agar 20g / L, KH 2 PO 4 1g / L, MgSO 4 ·7H 2 O 0.5g / L, (NH 4 ) 2 SO 4 0.25g / L, natural pH;

[0046] The slant culture medium for Saccharomyces rouxii and Torulopsis globosa was: 200g potatoes, 20g sucrose, 25g agar, 1000mL distilled water, natural pH.

[0047] b) Preparation of bacterial strains in the triangular flask: get the bacterial strains of Mucor and Aspergillu...

Embodiment 3

[0058] (1) Music making:

[0059] a) Preparation of slant strains: After activating the slant strains of Mucor, Aspergillus oryzae, Aspergillus niger, Saccharomyces rouxii and Torulopsis sphaeroides preserved in cold storage, dip a ring into the corresponding slant medium respectively and cultured at 31°C for 45 hours until the slant medium was overgrown.

[0060] Among them, the formula of Mucor slant culture medium is: 300g potatoes, 25g glucose, 10g peptone, 25g agar, 1000mL distilled water, natural pH;

[0061] Both Aspergillus oryzae and Aspergillus niger slant medium: soybean juice 4°Bé, glucose 25g / L, agar 25g / L, KH 2 PO 4 1.5g / L, MgSO 4 ·7H 2 O 0.5g / L, (NH 4 ) 2 SO 4 0.2g / L, natural pH;

[0062] The slant culture medium for Saccharomyces rouxii and Torulopsis sphaeroides is: 200g potatoes, 25g sucrose, 25g agar, 1000mL distilled water, natural pH.

[0063] b) Preparation of strains in the triangular flask: get Mucor and Aspergillus oryzae strains and mix them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com