Preparation method of magnetic iron-based heterogeneous Fenton catalyst taking graphene as carrier and application

A graphene and heterogeneous technology, applied in the fields of nanomaterials and environmental science, can solve the problems of difficult recycling of Fenton catalysts and chemical sludge, and achieve the effect of promoting COD removal, promoting decomposition, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

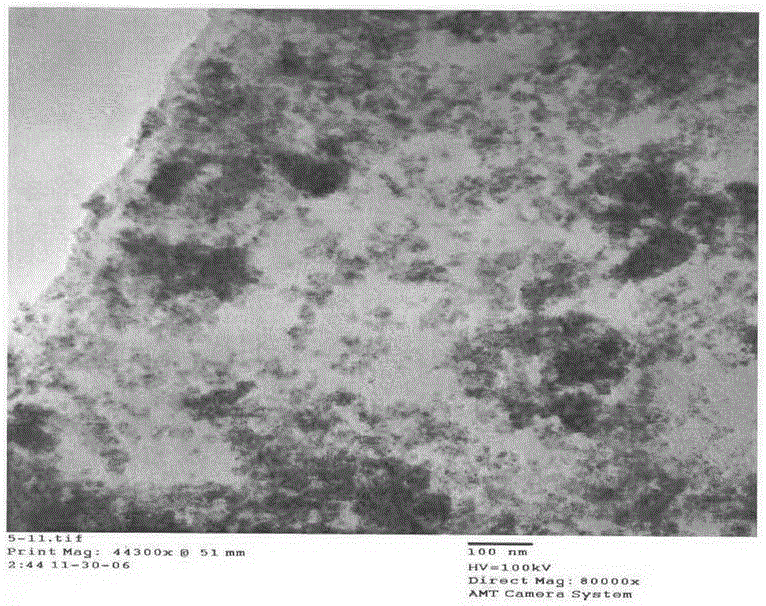

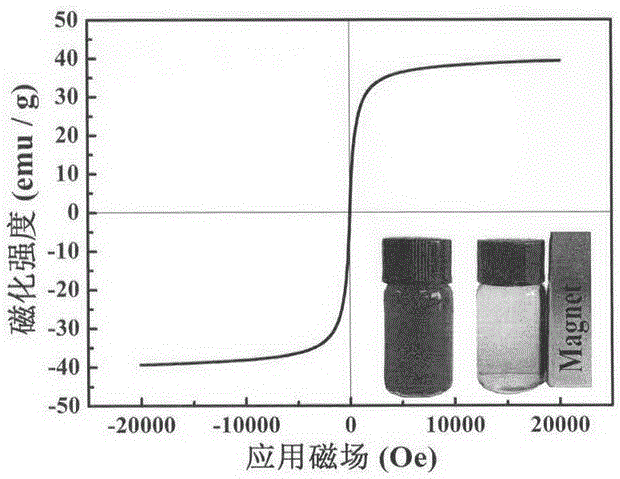

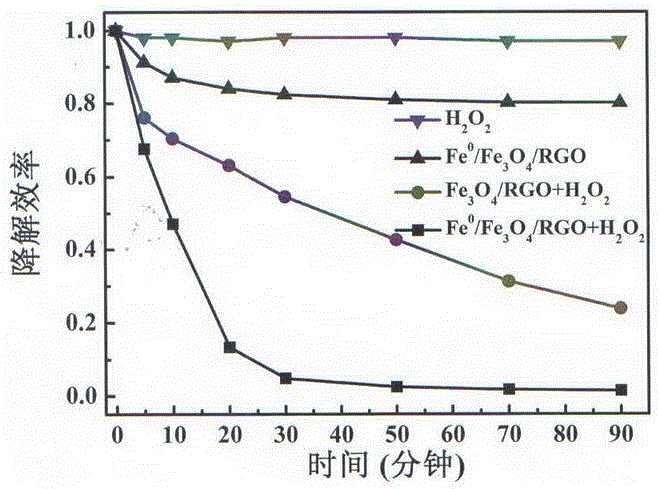

Image

Examples

Embodiment 1

[0057] a. Weigh 1.0 g of graphene oxide and add it to 200 mL of a mixture of ethylene glycol and diethylene glycol with a volume ratio of 19:1, ultrasonically disperse for 1 hour, then add 10 g of sodium acrylate, 15 g of sodium acetate, and 5.4 g of FeCl 3 ·6H 2 0, stirred at room temperature for 30min, fully dissolved to obtain a mixed solution;

[0058] b. Transfer the mixed solution obtained in a to a polytetrafluoro reactor at a temperature of 200° C., keep it warm for 10 hours, and then cool to room temperature. The product obtained is washed repeatedly with ethanol and water with a volume ratio of 1:1, and the cleaned The product was dispersed in 600ml of deoxygenated deionized water to obtain Fe 3 o 4 - an aqueous dispersion of graphene;

[0059] c. Weigh 1.5g FeSO 4 ·7H 2 O was dissolved in 50ml of deoxygenated deionized water;

[0060] d. Use 1mol / L NaOH solution to adjust the pH value of 50ml of deoxygenated deionized water in step c to 9, then add 1.36g NaBH ...

Embodiment 2

[0068] a. Weigh 1.5g of graphene oxide and add it to 200mL of a mixture of ethylene glycol and diethylene glycol with a volume ratio of 19:1, ultrasonically disperse for 1 hour, and then add 7.5g of FeCl 3 ·6H 2 0. 15g sodium acetate and 10g sodium acrylate were stirred at room temperature for 30min to fully dissolve to obtain a mixed solution;

[0069] b. Transfer the mixed solution obtained in a to a 100ml polytetrafluoro reactor, keep the temperature at 200°C for 10 hours, then cool to room temperature, and wash the obtained product repeatedly with ethanol and water with a volume ratio of 1:1. The final product was dispersed in 600ml of deoxygenated deionized water to obtain Fe 3 o 4 - an aqueous dispersion of graphene;

[0070] c. Weigh 2.0g FeSO 4 ·7H 2 O was dissolved in 50ml of deoxygenated deionized water;

[0071] d. Use 1mol / L NaOH solution to adjust the pH value of 50ml of deoxygenated deionized water in step c to 9, then add 2.0g NaBH 4 dissolve;

[0072] e...

Embodiment 3

[0077] a. Weigh 1.5g of graphene oxide, add it to 200ml of a mixture of ethylene glycol and diethylene glycol with a volume ratio of 19:1, ultrasonically disperse for 1h, and then add 5.4g of FeCl 3 ·6H 2 0. 15g sodium acetate and 10g sodium acrylate were stirred at room temperature to fully dissolve to obtain a mixed solution;

[0078] b. Transfer the mixed solution obtained in a to a 100ml polytetrafluoro reactor, keep the temperature at 200°C for 12 hours, then cool to room temperature, and wash the obtained product repeatedly with ethanol and water with a volume ratio of 1:1. The final product was dispersed in 600ml of deoxygenated deionized water to obtain Fe 3 o 4 - an aqueous dispersion of graphene;

[0079] c. Weigh 1.8g FeSO 4 ·7H 2 O was dissolved in 50ml of deoxygenated deionized water;

[0080] d. Use 1mol / L NaOH solution to adjust the pH value of 50ml of deoxygenated deionized water in step c to 9, then add 2.0g NaBH4 dissolve;

[0081] e. FeSO 4 ·7H 2 O ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com