Patents

Literature

748results about How to "Magnetic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

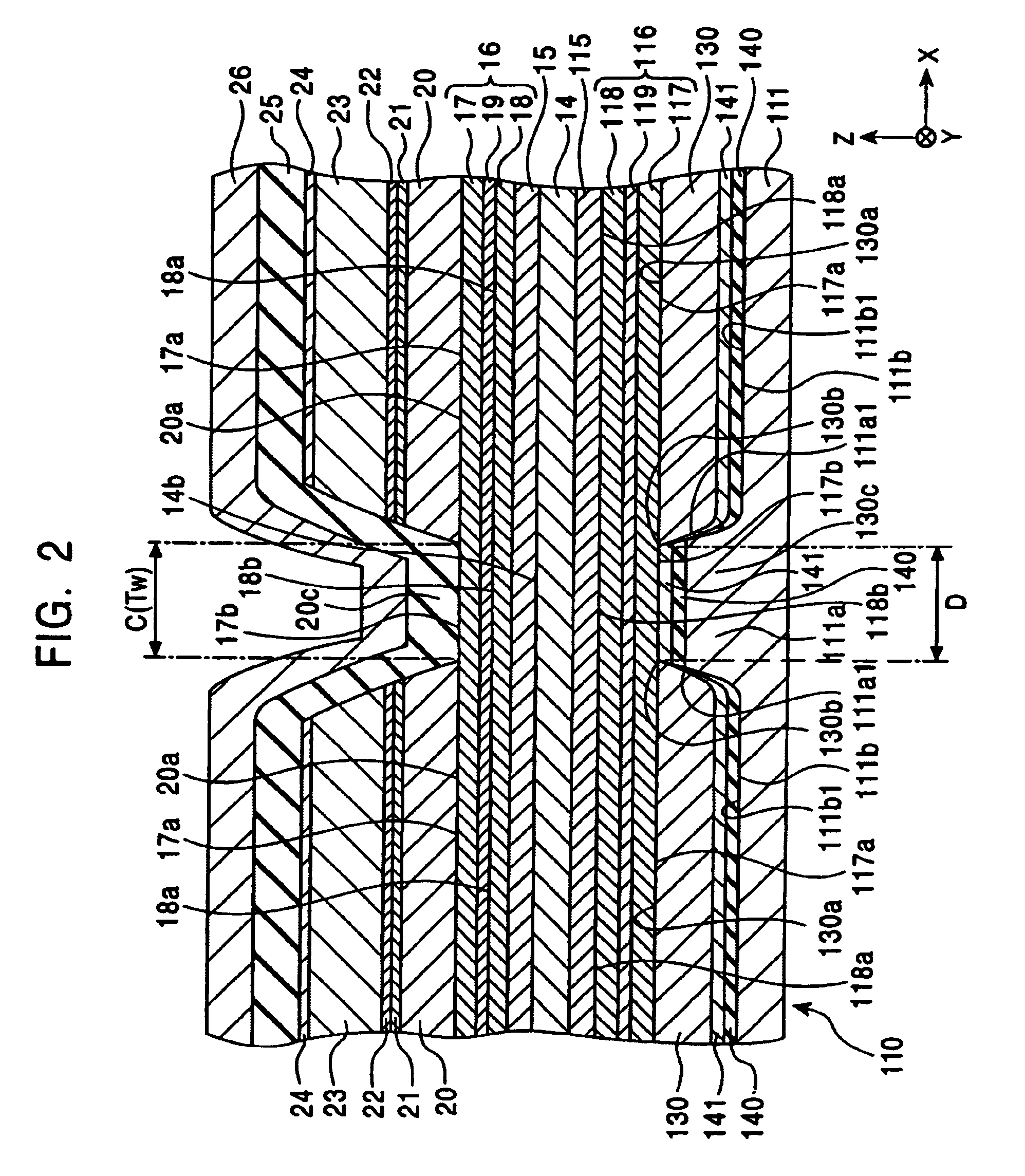

Magnetic recording medium, method of manufacturing the same, and magnetic recording apparatus

InactiveUS20070217071A1Improve film qualitySuppression of Leakage FluxRecord information storageDisk carriersRecording layerNon magnetic

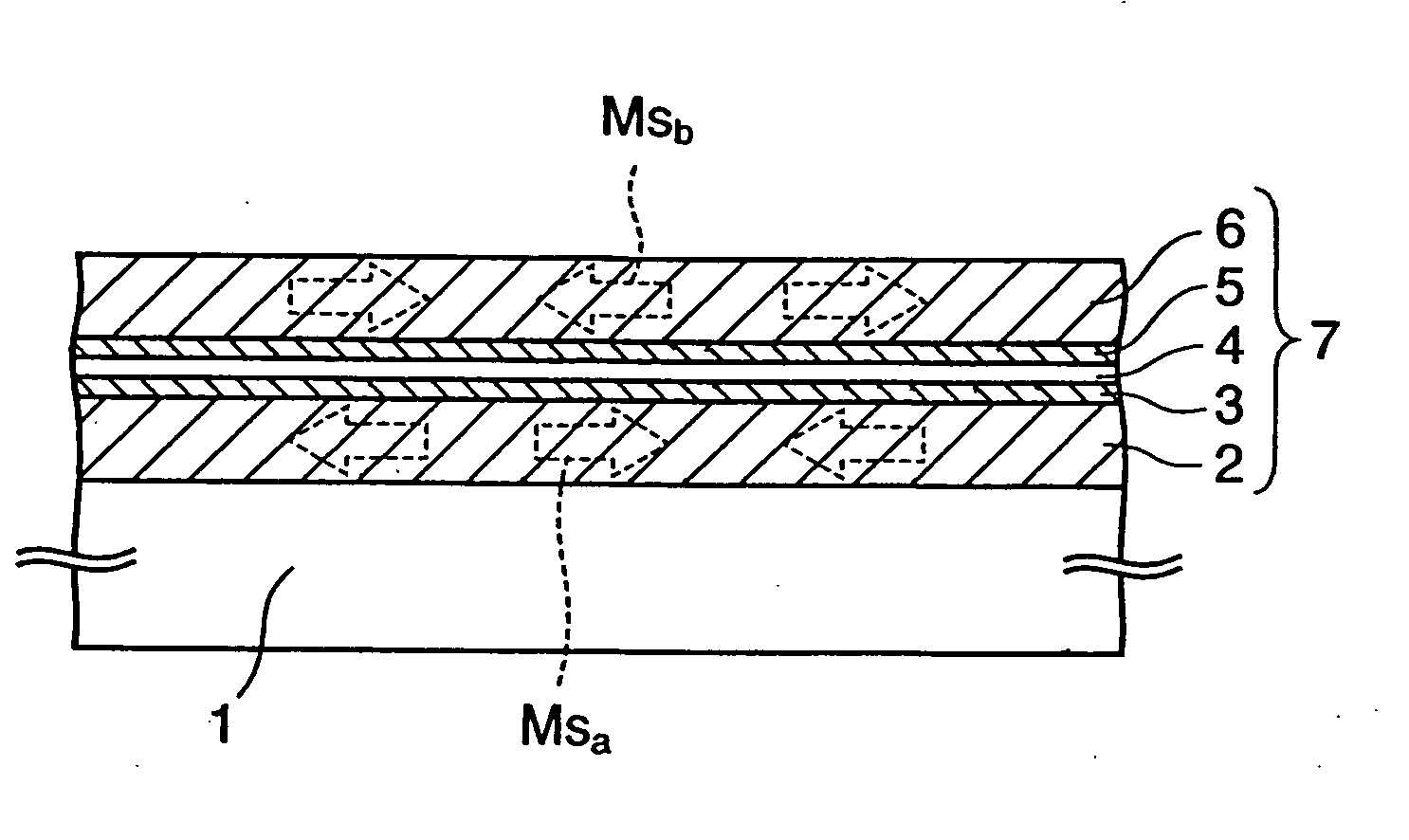

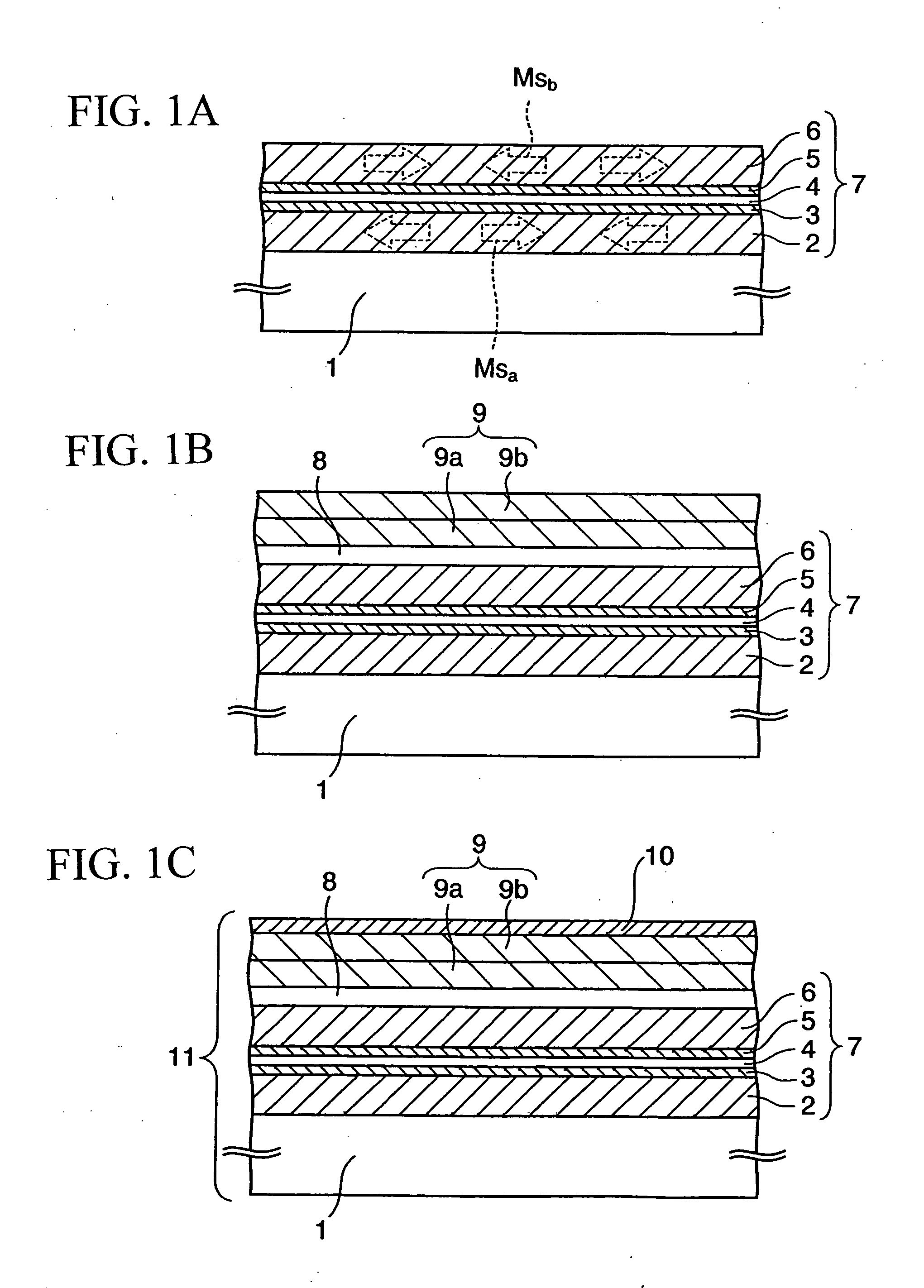

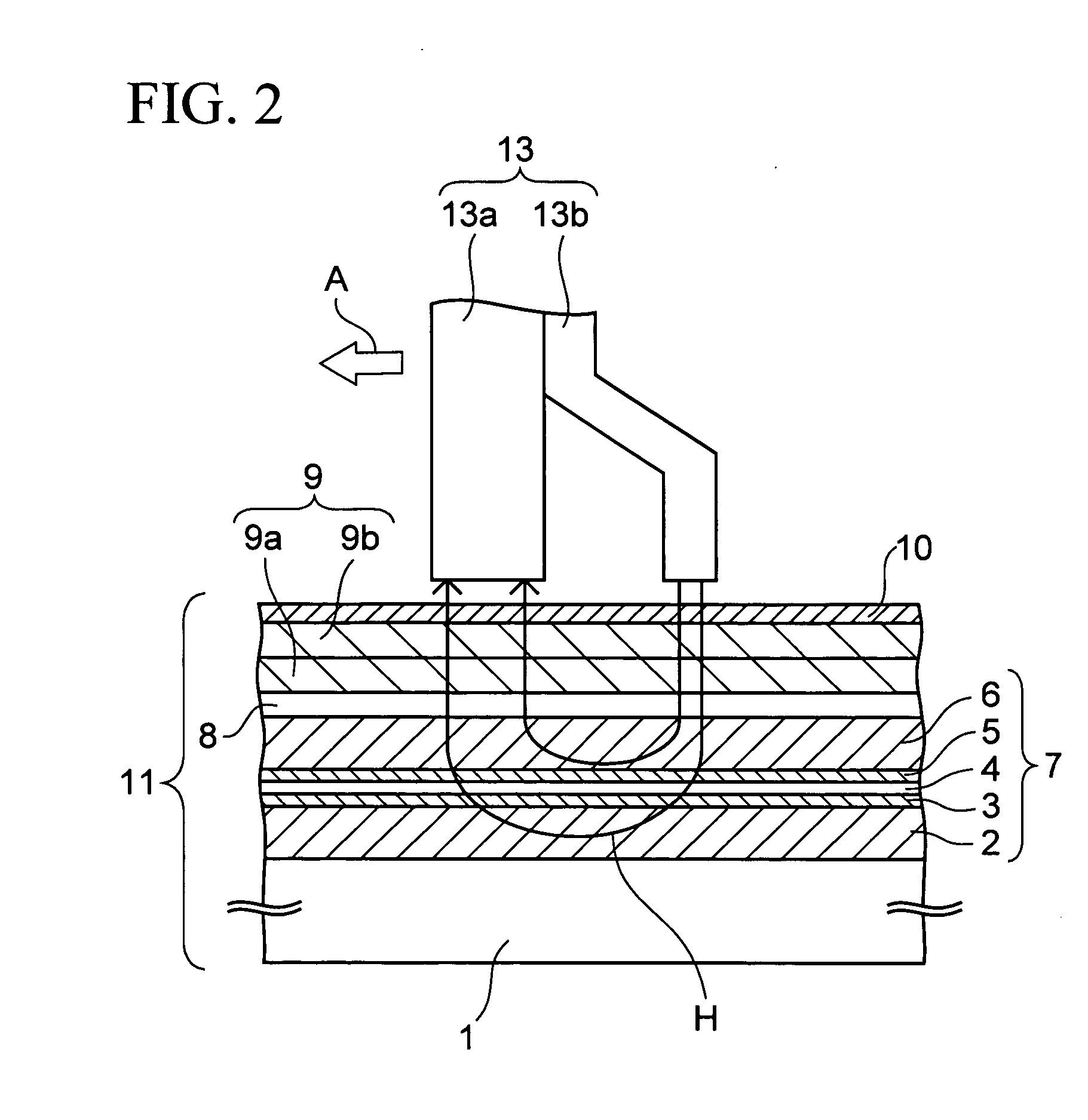

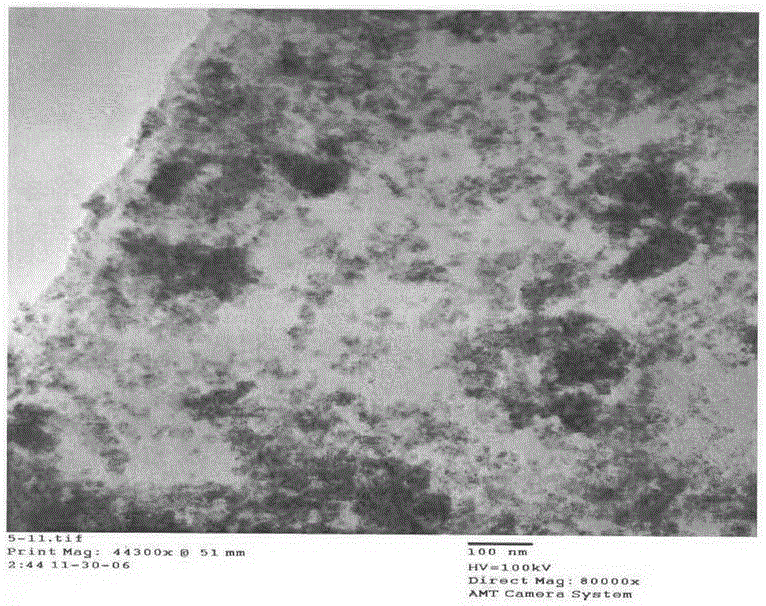

According to the present invention, provided is a magnetic recording medium 11 comprising: a non-magnetism base member 1; a lower soft magnetic underlying layer 2 formed on the non-magnetism base member 1; a non-magnetic layer 4 formed on the lower soft magnetic underlying layer 2; an upper soft magnetic underlying layer 6 formed on the non-magnetic layer 4; and a recording layer 9 having a perpendicular magnetic anisotropy, the recording layer 9 being formed on the upper soft magnetic underlying layer 6, wherein crystalline magnetic layers 3 and 5 are formed between the lower soft magnetic underlying layer 2 and the non-magnetic layer 4 or between this non-magnetic layer 4 and the upper soft magnetic underlying layer 6.

Owner:SHOWA DENKO KK

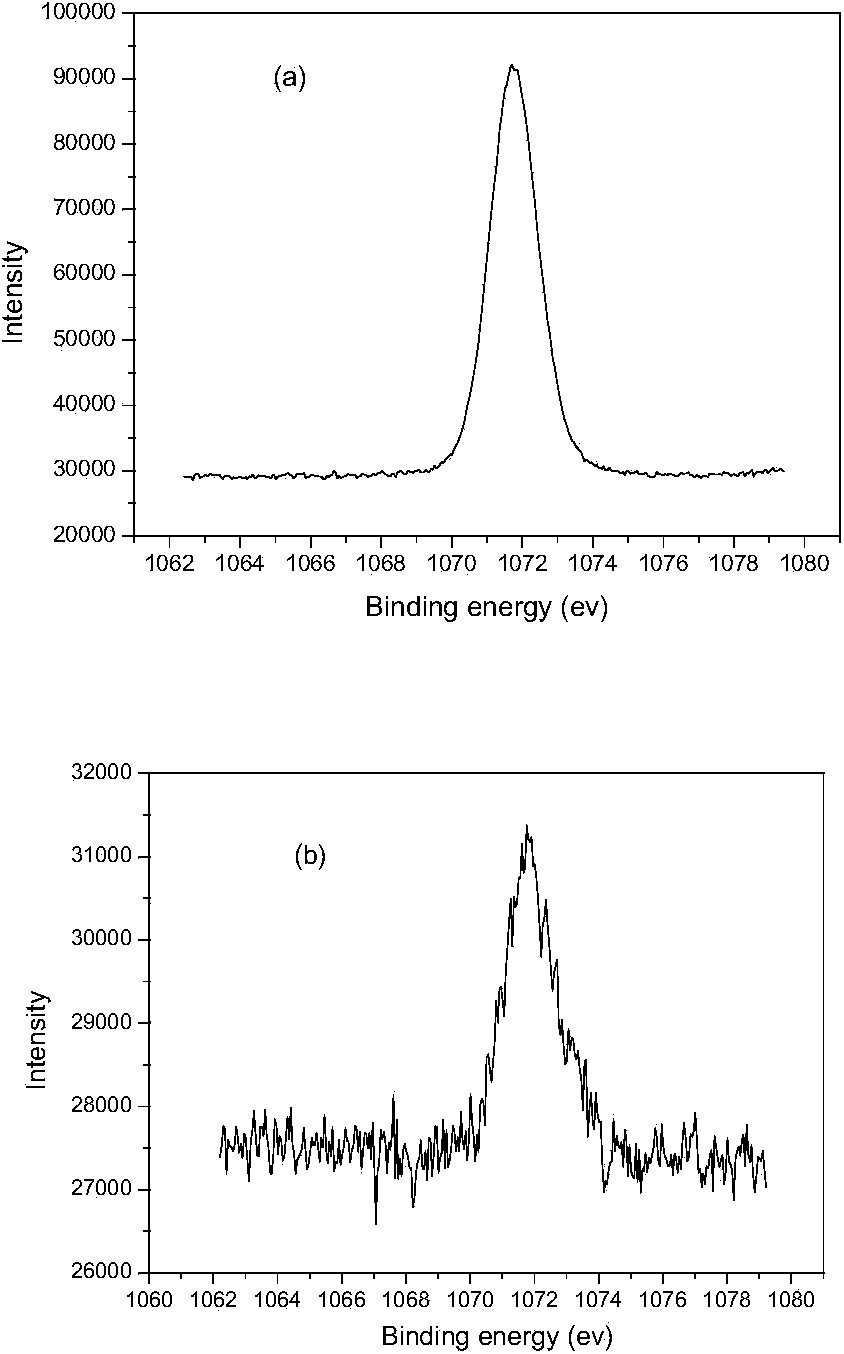

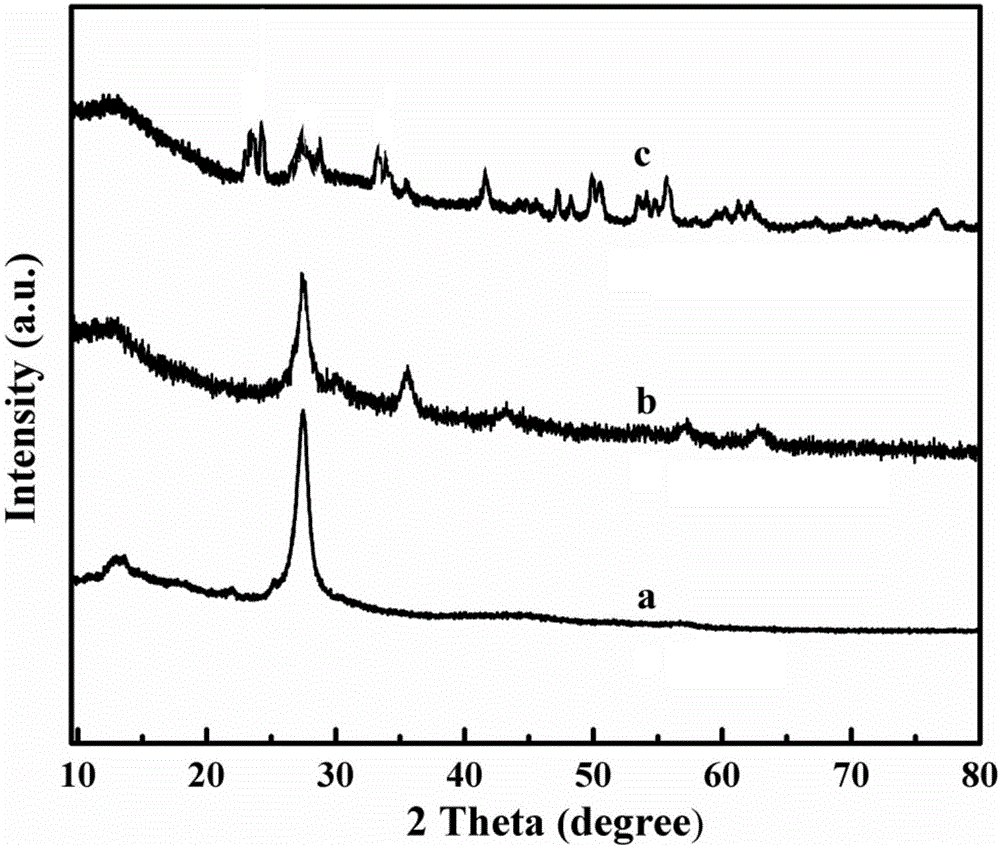

Preparation method of magnetic iron-based heterogeneous Fenton catalyst taking graphene as carrier and application

InactiveCN106669677APromote decompositionGood removal effectWater treatment compoundsWater contaminantsPtru catalystGraphene

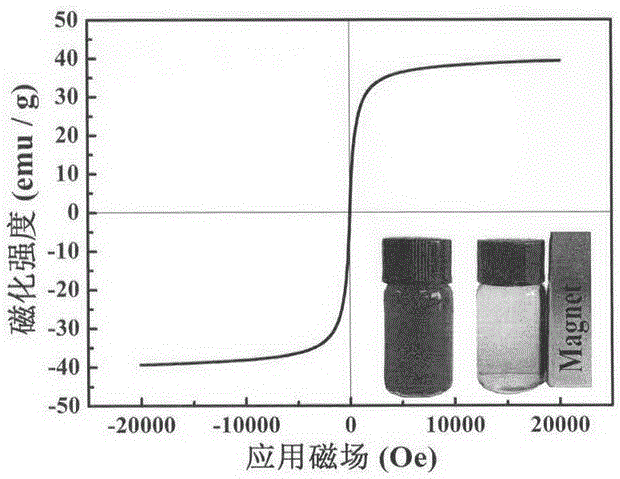

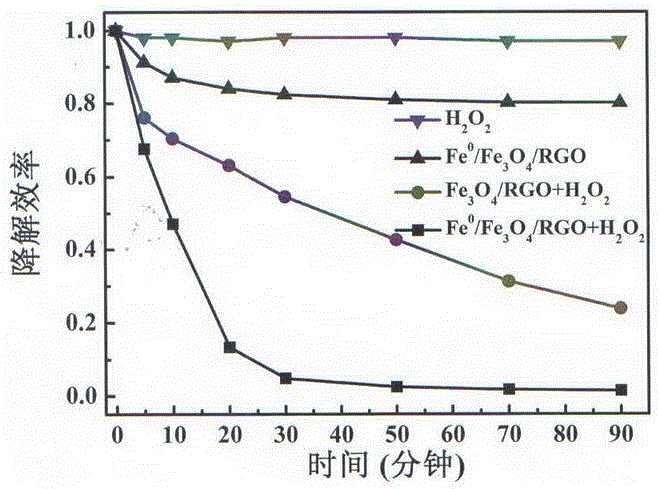

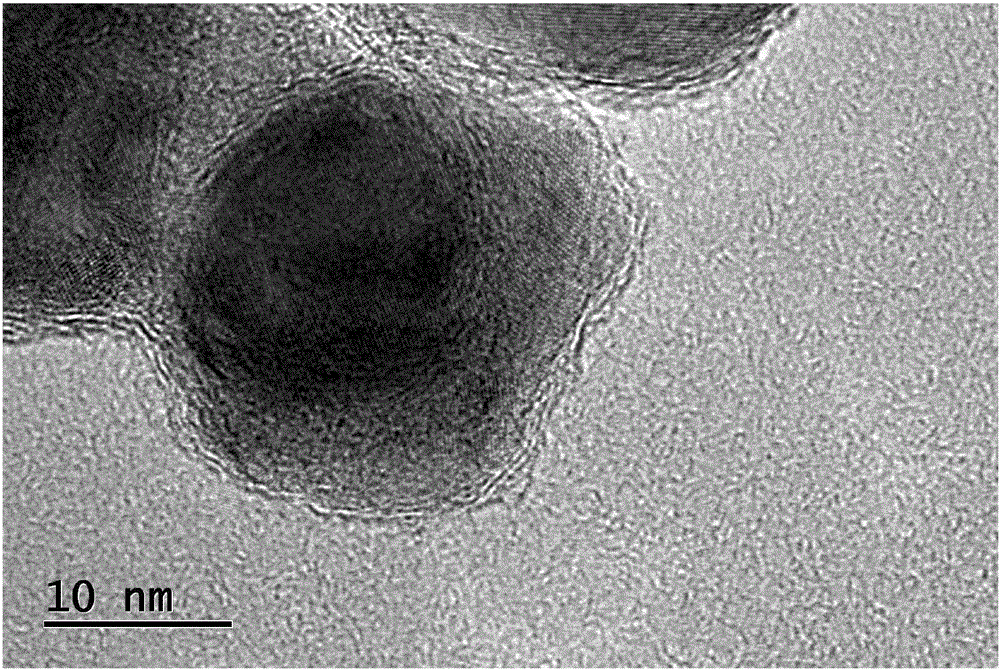

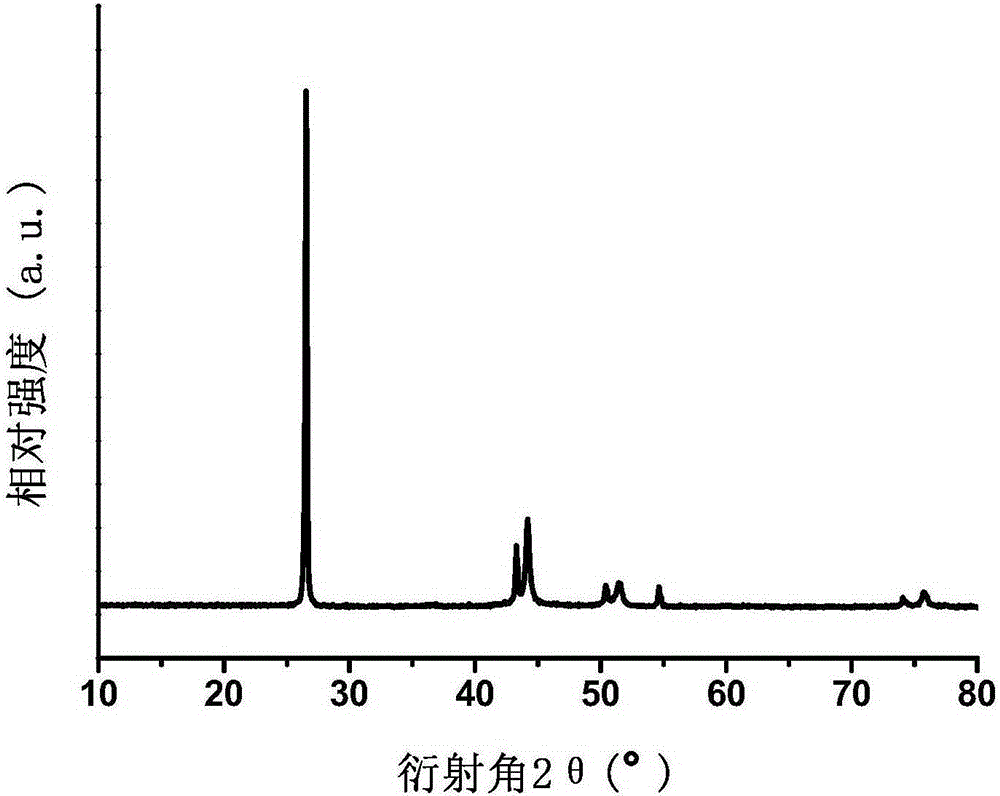

The invention relates to a preparation method of a magnetic iron-based heterogeneous Fenton catalyst taking graphene as a carrier and an application. According to the method, the graphene serves as the carrier, magnetic nano-scale ferroferric oxide and nano-scale zero-valent iron (Fe0) are compounded to the surface of the graphene to serve as the heterogeneous Fenton catalyst in an in-situ growth mode, aggregation of catalytic active nano-particles can be effectively prevented by the graphene serving as the carrier, and more active sites are exposed. Besides, the graphene has high electron transfer capability, Fe0 easily transfers electrons to Fe3+ by taking the graphene as the carrier, Fe3+ is promoted to be transformed into Fe2+, so that catalytic activity of the catalyst is improved, the catalyst is easily recovered and reusable, pollutant removal efficiency is improved, phenol removal efficiency reaches 99% or more, and the used catalyst is recovered by an external magnetic field. The preparation method solves the problems that traditional Fenton catalysts are difficultly recycled and generate a lot of chemical sludge, and the preparation method has a certain economic value and practical value.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

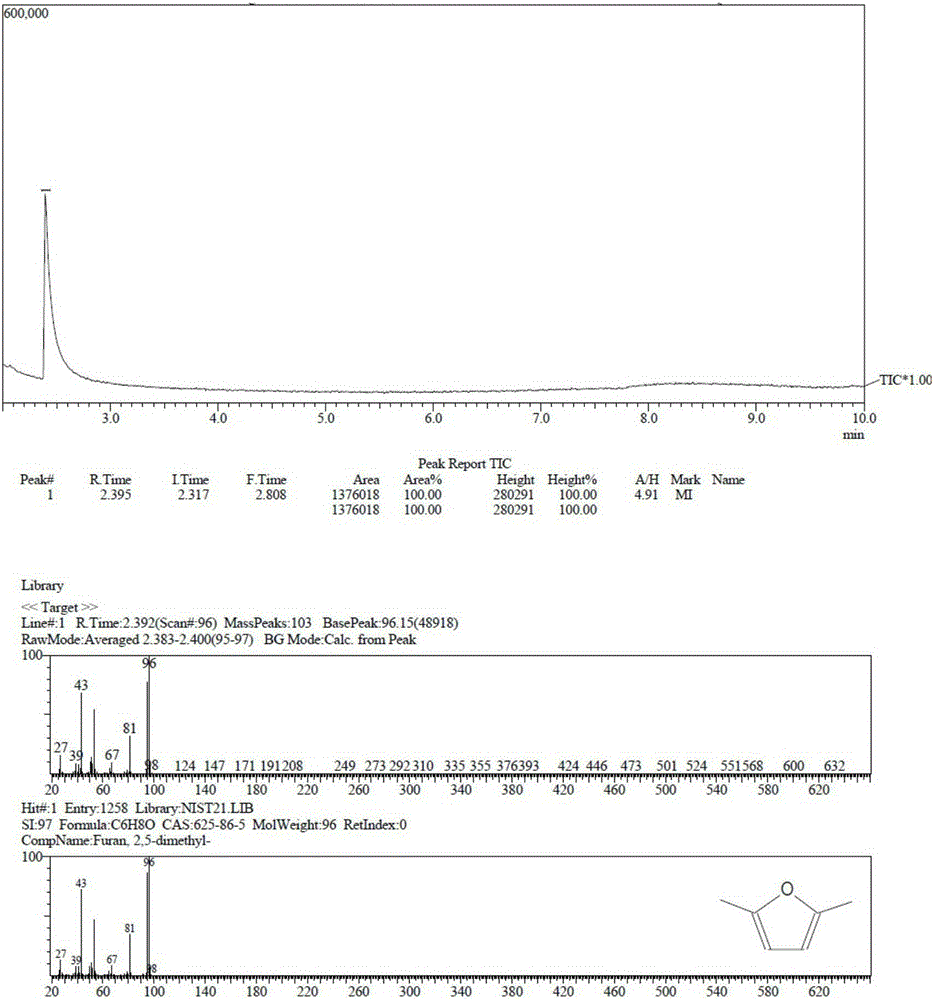

Catalyst for preparing 2,5-dimethylfuran through selective hydrogenolysis of 5-hydroxymethylfurfural and preparation method of catalyst

ActiveCN105251491ALow costPlay a protective roleOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsCarbon layerHydroxymethylfurfural

The invention discloses a catalyst for preparing 2,5-dimethylfuran through selective hydrogenolysis of 5-hydroxymethylfurfural and a preparation method of the catalyst. The catalyst consists of a catalyst carrier and carbon layer coated reactive metals, wherein the catalyst carrier comprises a carbon-based carrier, SiO2, TiO2 or Al2O3 and the like; and the reactive metals are selected from Co, Fe, Ni, Cu or Zn and other base metals. Compared with the conventional catalyst system, the catalyst disclosed by the invention has the advantages that (1) the reactive metal of the catalyst refers to a first transition metal, and the raw materials are cheap and readily available; (2) compared with a noble metal catalyst, the catalyst disclosed by the invention has extremely high activity and selectivity; and (3) the catalyst has magnetism and is easy to recycle.

Owner:INST OF CHEM CHINESE ACAD OF SCI

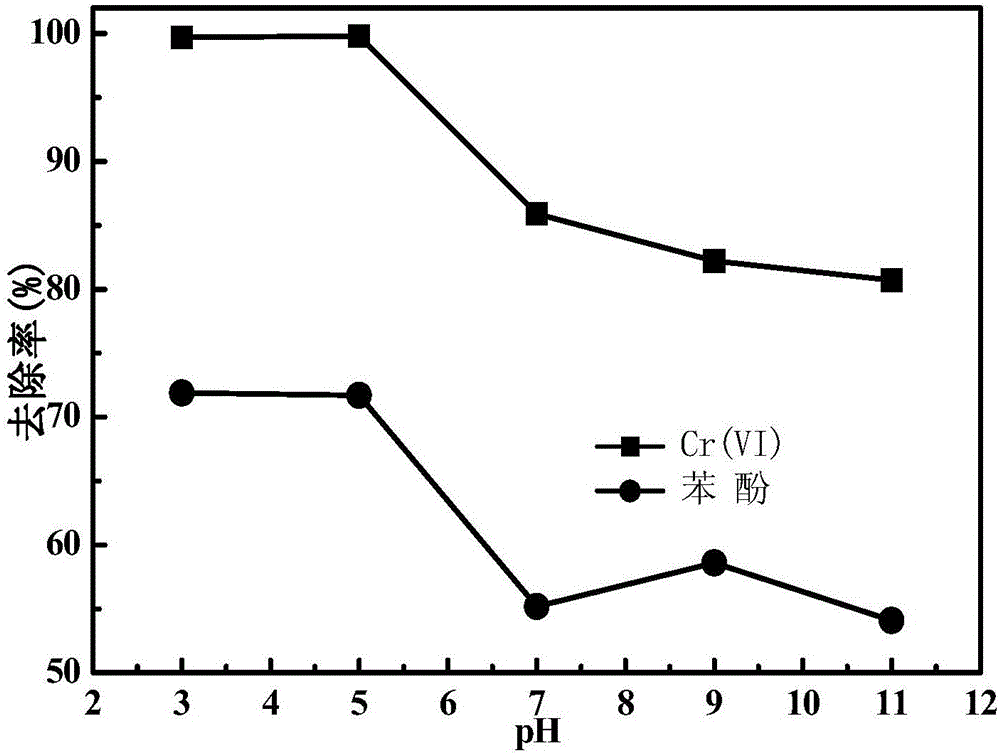

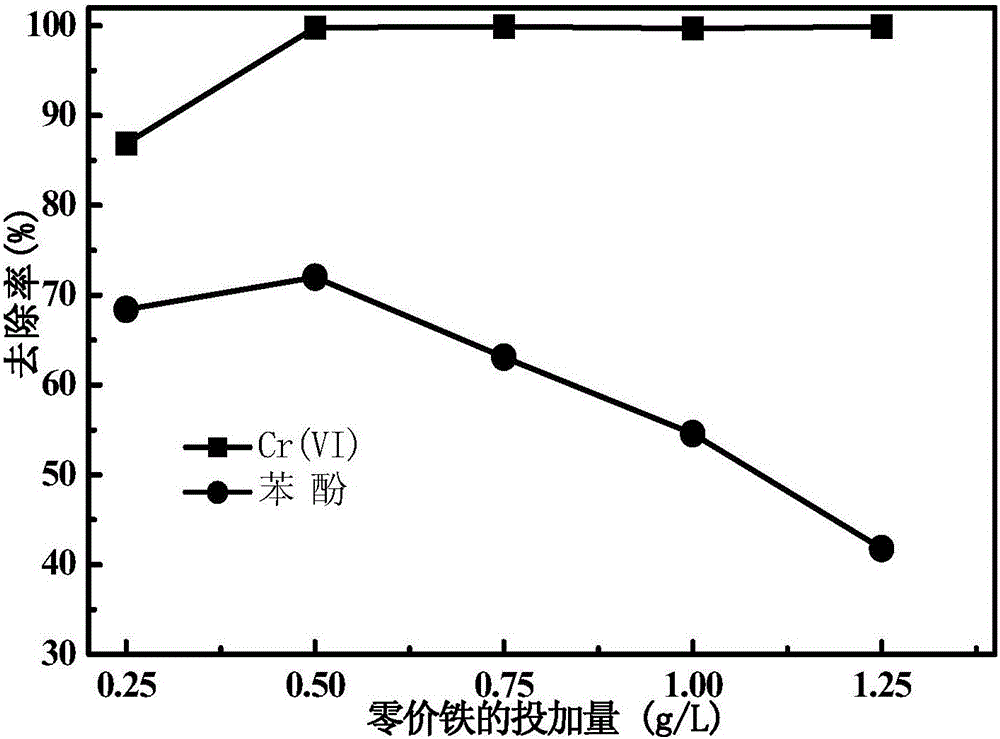

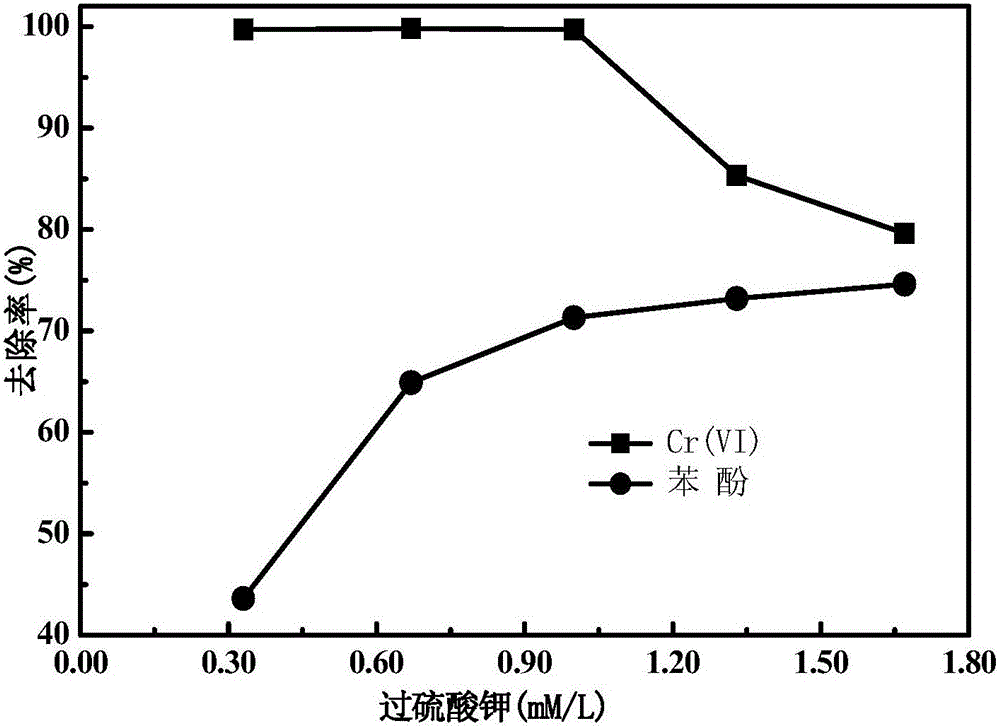

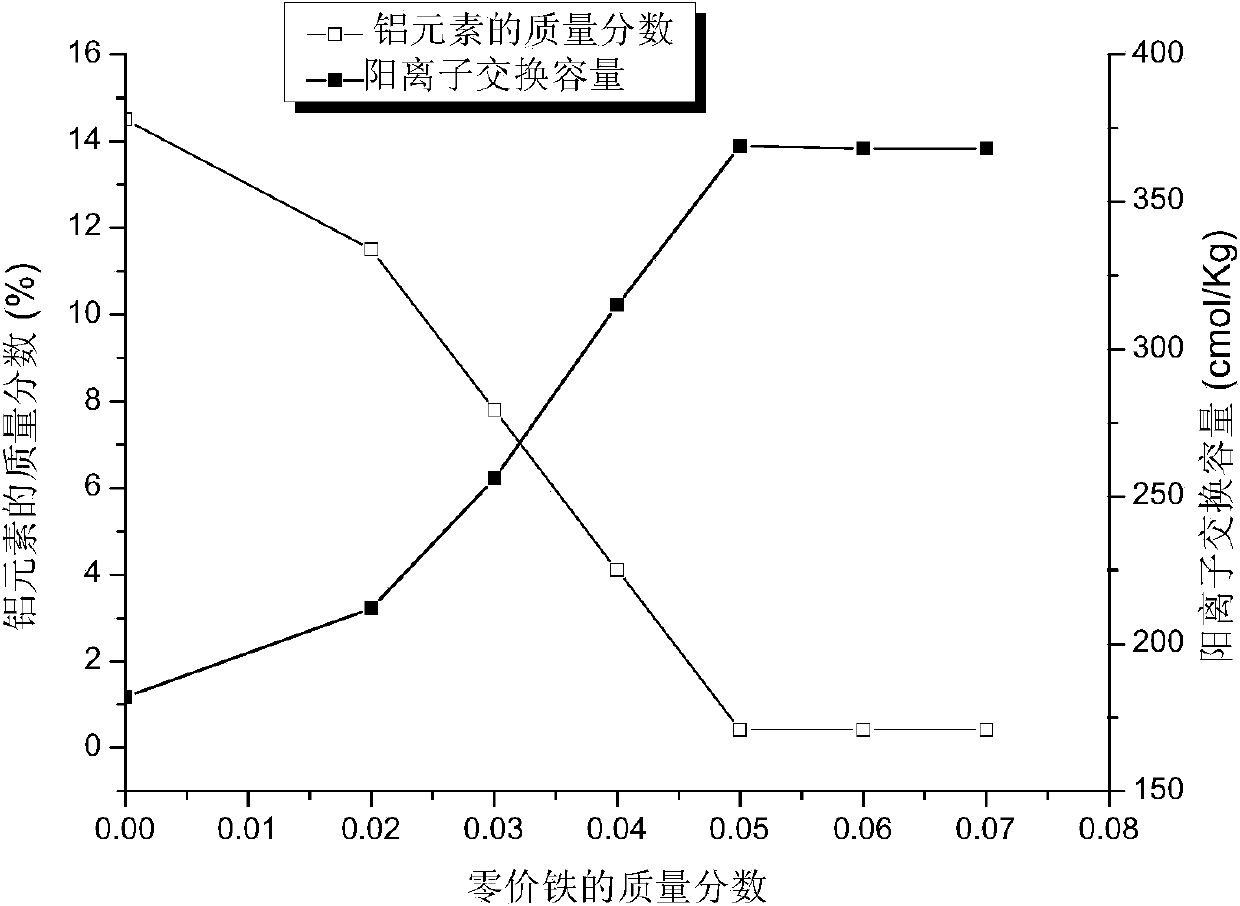

Method for removing heavy metal and organic matter composite pollutants in water body by means of zero-valent iron and persulfate

ActiveCN105110448ALarge specific surface areaSimple preparation processWater contaminantsWater/sewage treatment by reductionPotassium persulfateSodium Bentonite

The invention discloses a method for removing heavy metal and organic matter composite pollutants in a water body by means of zero-valent iron and persulfate. According to the method, bentonite-supported nanoscale zero-valent iron and persulfate are added to the water body containing heavy metal and organic matters, a multi-phase coexistent system is formed, and the heavy metal and the organic matters are removed. Cr(VI) and phenol contained in the water body can be removed simultaneously with the bentonite-supported nanoscale zero-valent iron and potassium persulfate combined method, the heavy metal Cr(VI) is removed through the strong reduction performance of the nanosacle zero-valent iron, Fe2+ generated by the nanoscale zero-valent iron in the reaction process is fully used to activate potassium persulfate, so that SO4<->* is continuously generated to oxidize and degrade phenol, and the heavy metal and organic matter composite pollutants in the water body are removed synergistically.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

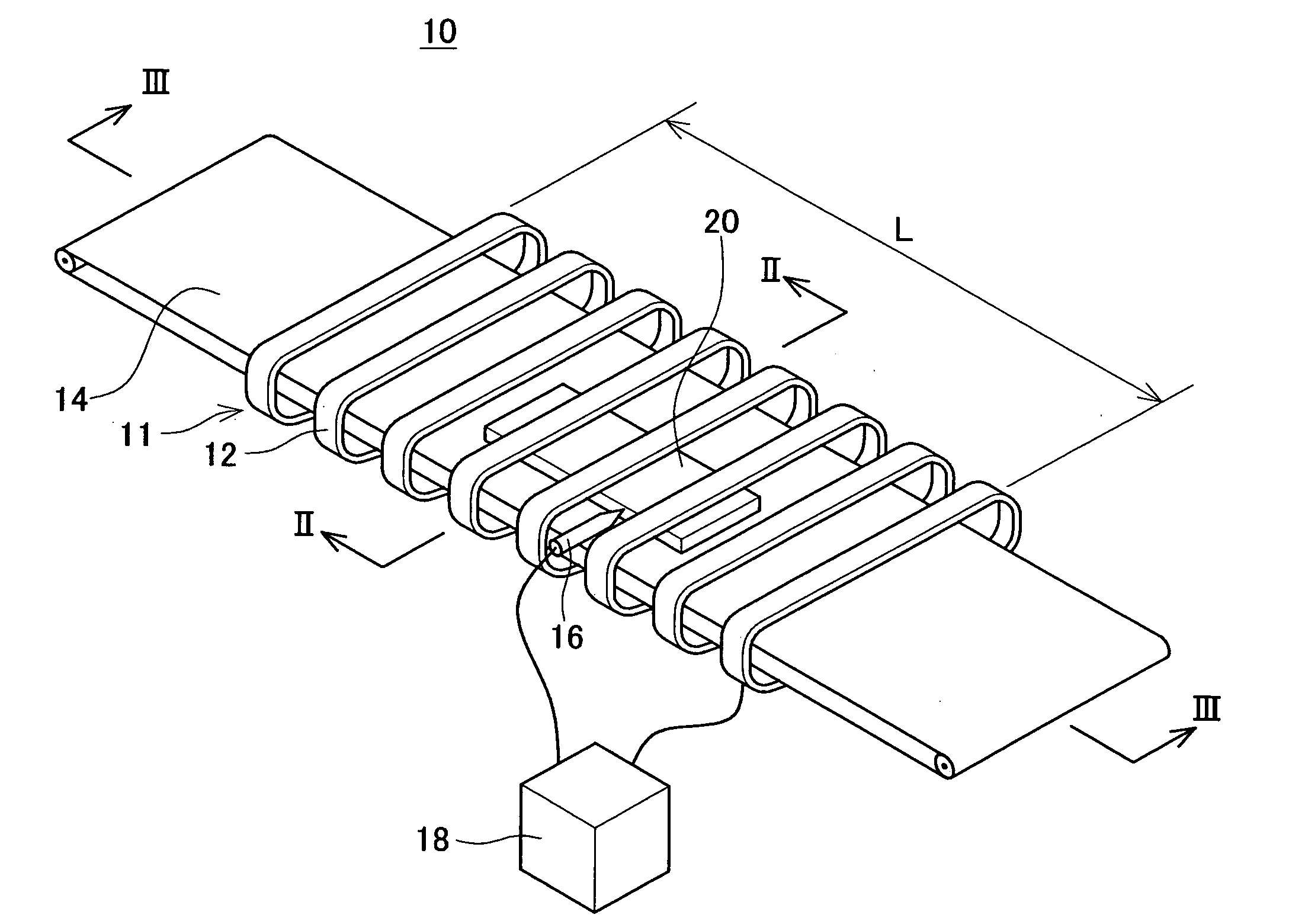

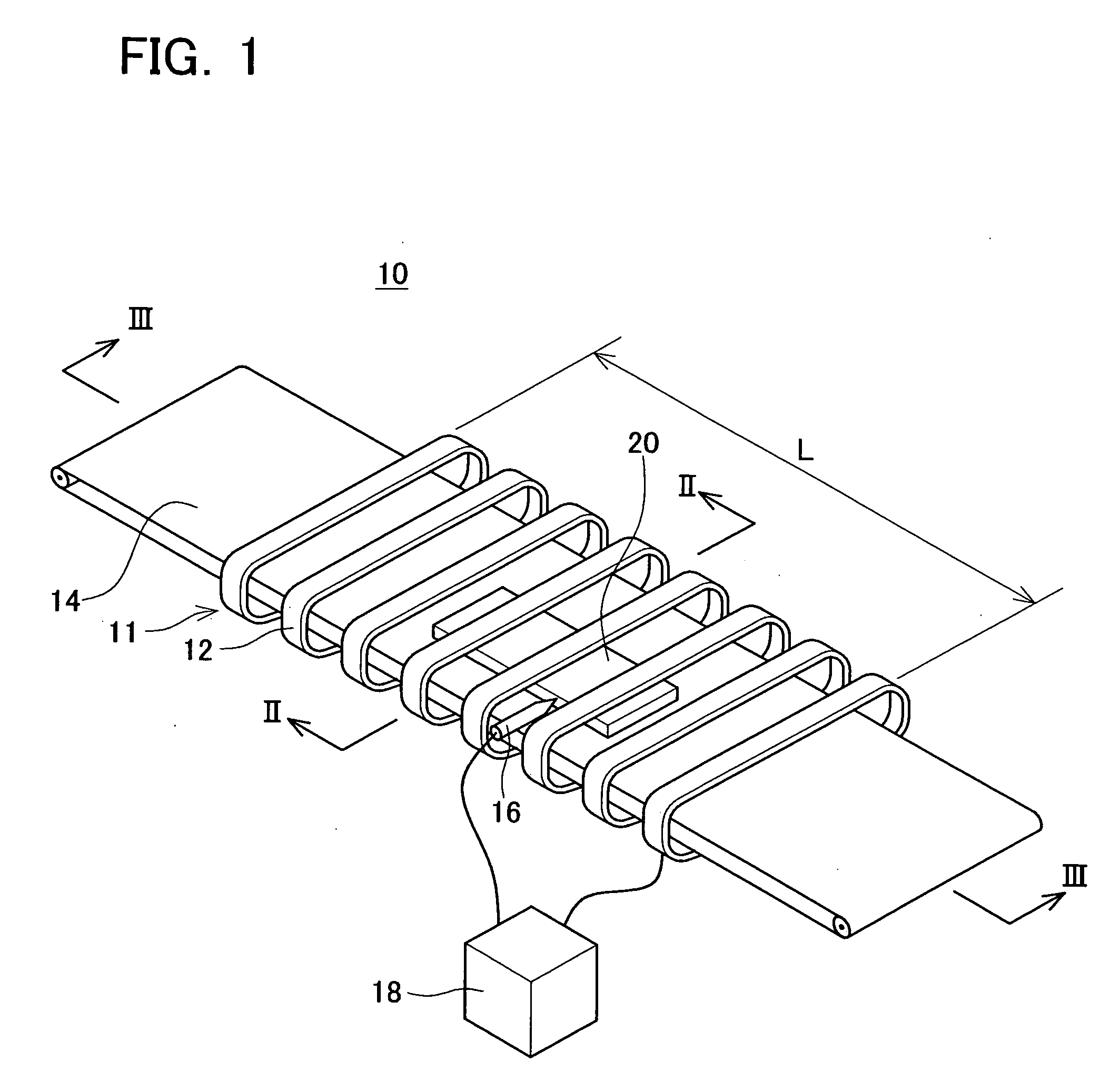

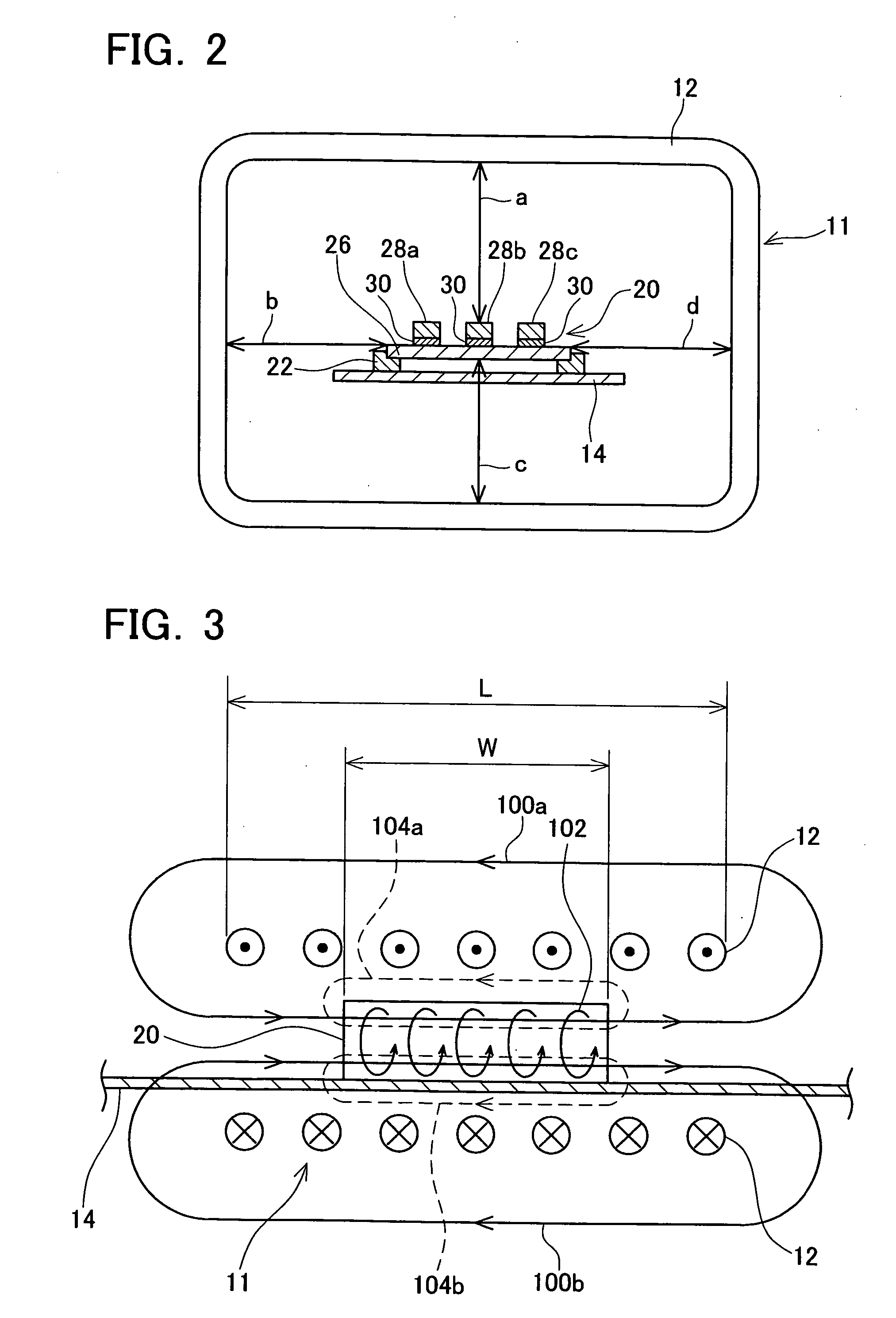

Apparatus and a method of soldering a part to a board

ActiveUS20070023486A1Heating evenlyEvenly distributedAutomatic control devicesPrecision positioning equipmentEngineeringAlternating current

The present invention provides technology that uniformly heats and melts a plurality of solder material arranged in a plurality of locations on a board, and uniformly solders a plurality of parts to the board that are arranged in a plurality of locations on the board. A soldering apparatus includes an induction coil having a length in the longitudinal direction that is longer than the length of the board. An inner space having a size sufficient to arrange the board therein is maintained inside the induction coil. The board supporting the parts and the solder material will be positioned in the approximate center of the inner space of the induction coil. An alternating current will flow through the induction coil in this state. An alternating magnetic field will be generated in the inner space of the induction coil. Magnetic fluxes will substantially uniformly pass through the inner space of the induction coil along the longitudinal direction of the induction coil. In this way, the plurality of solder material arranged on a plurality of locations on the board may be uniformly heated and melted. The plurality of parts arranged on a plurality of locations on the board may be uniformly soldered to the board because the plurality of solder material may be uniformly heated and melted due to magnetic fluxes that uniformly passing through the board.

Owner:SENSBY +2

Composite hydroxyapatite/carbon nanotube material and its prepn process

InactiveCN1440948AImprove mechanical propertiesGood biocompatibilitySurgeryProsthesisApatiteCarbon nanotube

The present invention relates to a kind of composite hydroxyapatite / carbon nanotube material and its preparation process. The composite material consists of mainly two components including hydroxyapatite and carbon nanotube. The technological process includes chemical preciptiation to synthesize hydroxyapatite, and compounding directly with carbon nanotube to prepare compoiste hydroxapatite / carbon nanotube material. The composite material possesses excellent mechanical performance and biocompatibility and certain magnetism and wave absorbing performance, so that the composite material may be used in repairing and replacement of body bone and extracorporeal physical treatment of bone diseases, and may have latent application as body's bearing bone, magnetic and wave-absorbing material.

Owner:SHANDONG UNIV

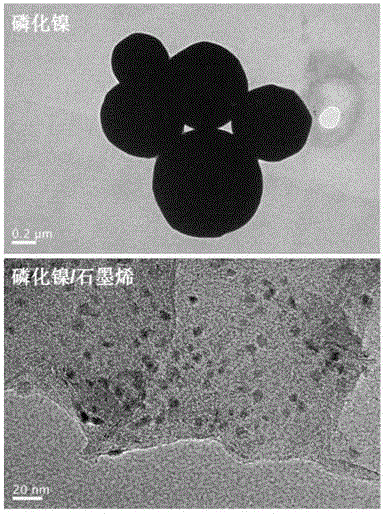

Preparation method of graphene-loaded nano nickel phosphate hydrogenation catalyst

ActiveCN104437572AGood dispersionSolve bottlenecksPhysical/chemical process catalystsHydrocarbon by hydrogenationNickel phosphateReusability

The invention relates to a preparation method of a graphene-loaded nano nickel phosphate hydrogenation catalyst. According to the method, graphene oxide capable of being stably dispersed in water is used as a carrier precursor and loaded nano nickel phosphate is prepared by a static hydrothermal synthesis method. The graphene oxide can be uniformly and stably dispersed into a water solution due to a unique two-dimensional structure and abundant oxyl radicals of the graphene oxide; and furthermore, the graphene oxide has a strong adsorption capability on metal cations, and a nickel source can be highly dispersed. The catalyst provided by the invention is used for hydrogenation of olefin and has relatively high catalytic activity and good reusability. According to the catalyst, preparation conditions are moderate, the process is simple and the cost is low; and industrial production is easy to realize.

Owner:CHANGZHOU UNIV

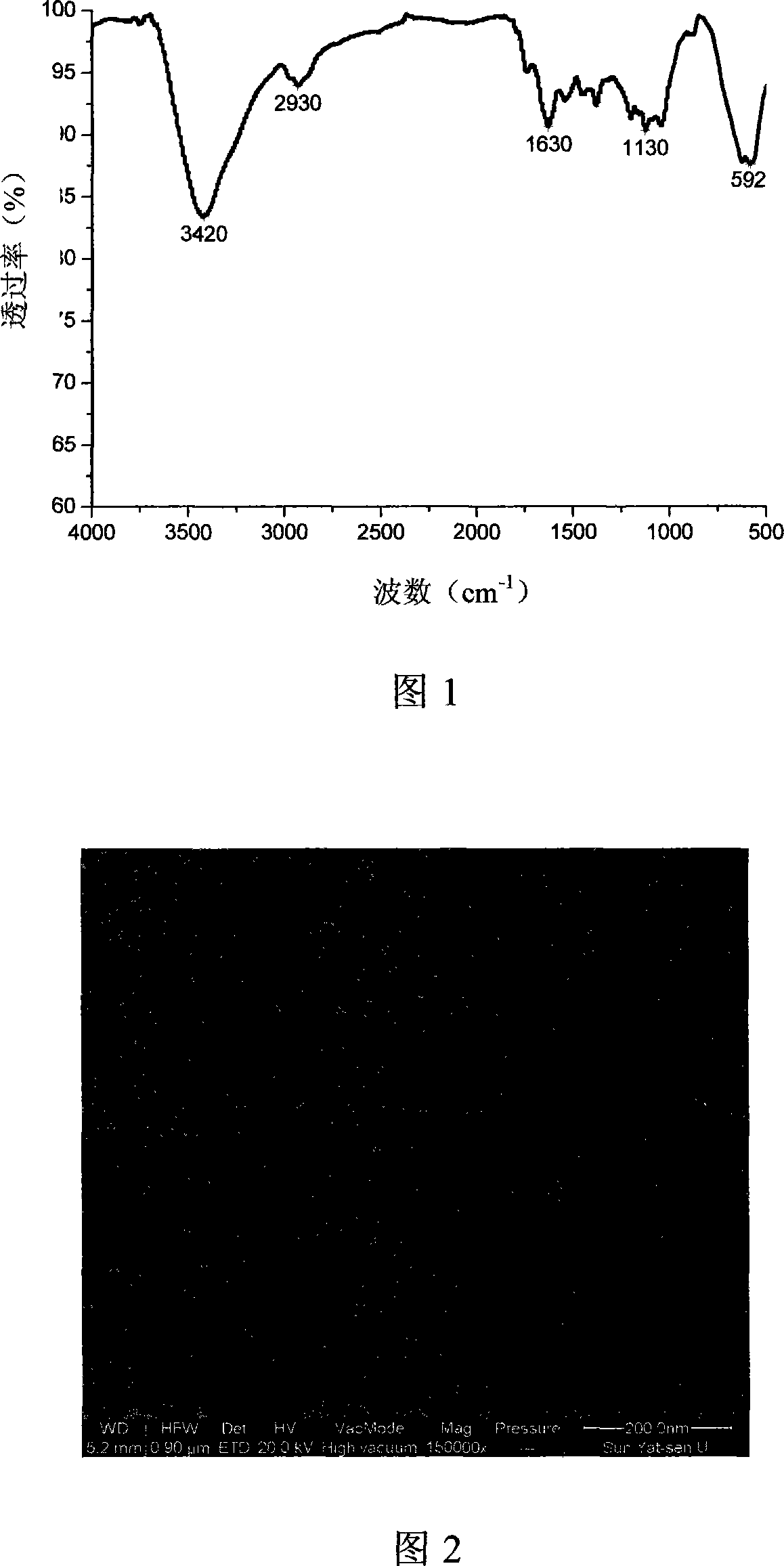

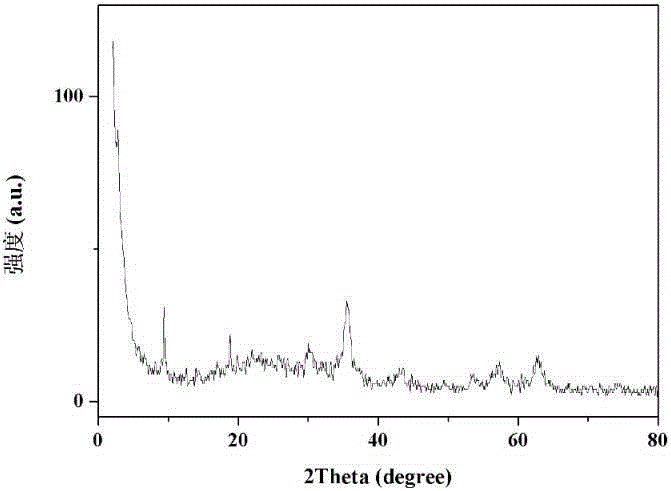

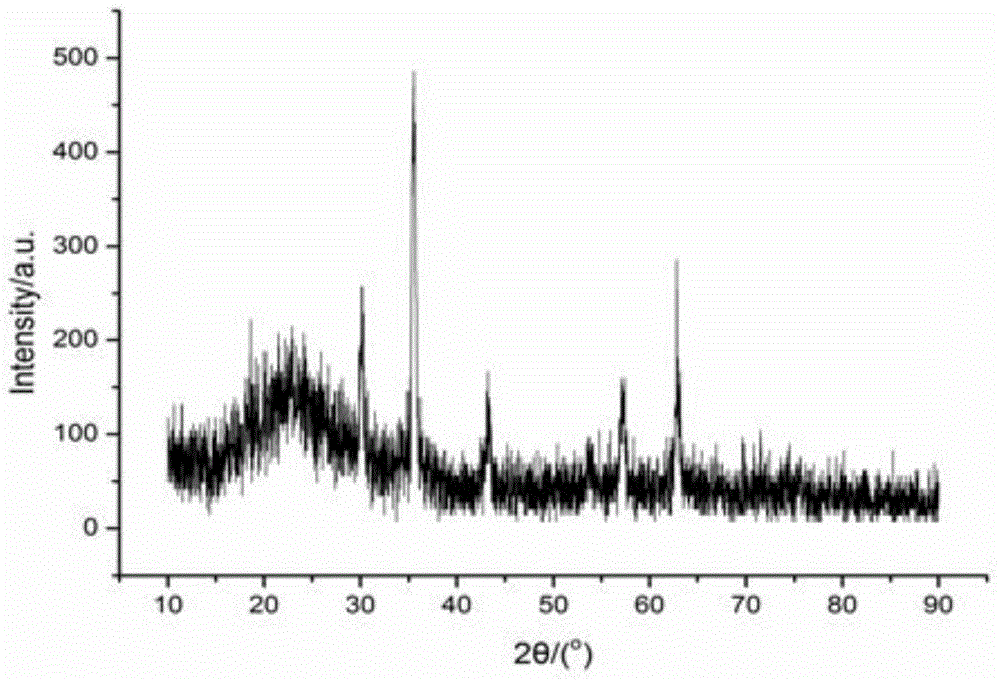

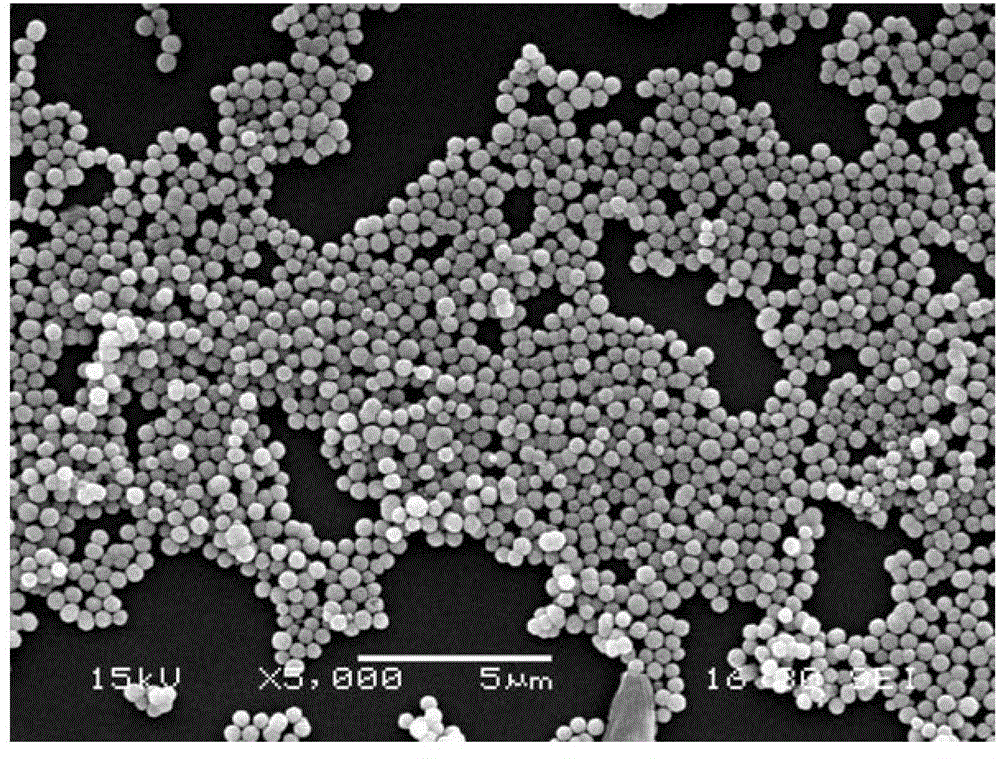

Magnetic temperature sensing nano-particle with bioavailability and synthesizing method thereof

InactiveCN101173025ABiocompatibleMagneticOrganic/organic-metallic materials magnetismBiocompatibility TestingDrug release

The invention relates to a magnetic thermometer nm particle with biocompatibility, which has biocompatibility, and double response properties of magnetism and thermometer property, and the particle diameter thereof is 20 to 60 nm, and the magnetic responsibility is strong, and magnetic saturation intensity is 10.0 to 27.0 emu / g. The synthetic method of the magnetic thermometer nm particle with biocompatibility comprises: firstly, adopting chemical coprecipitation method to prepare magnetic Fe3O4 nm particle, and using silane coupler to hold surface modification, and then using the modified magnetic Fe3O4 nm particle as a seed, and having polyreaction with dextran, N-isopropyl acrylamide, finally obtaining the magnetic thermometer nm particle with biocompatibility. The magnetic thermometer nm particle with biocompatibility synchronously has double responses of magnetism and thermometer property, and has wide application prospect in the fields of drug release, protein and enzyme separation.

Owner:SUN YAT SEN UNIV

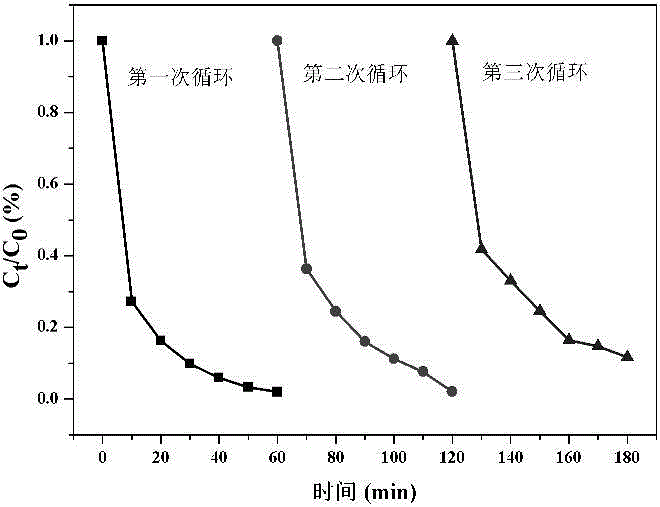

Preparing method and application of core-shell structure Fe3O4@MIL(Fe) composite material

InactiveCN105214613AGood dispersionImprove catalytic performanceMaterial nanotechnologyOther chemical processesPtru catalystGlycol synthesis

The invention discloses a preparing method and application of a core-shell structure Fe3O4@MIL(Fe) composite material. According to the method, MIL(Fe) is prepared firstly with the solvothermal method, then FeCl3 ethylene glycol solution is transferred into a pore canal of MIL(Fe), nanometer Fe3O4 is obtained in the pore canal with the solvothermal method through in situ formation, and then the core-shell structure Fe3O4@MIL(Fe) composite material is obtained. A catalyst is high in catalytic activity, environmentally friendly, easy to recover and capable of being used repeatedly. Furthermore, equipment adopted in the method is simple, operation is convenient, organic pollutants in water can be degraded efficiently within a wide pH range, and application prospects are great.

Owner:UNIV OF JINAN

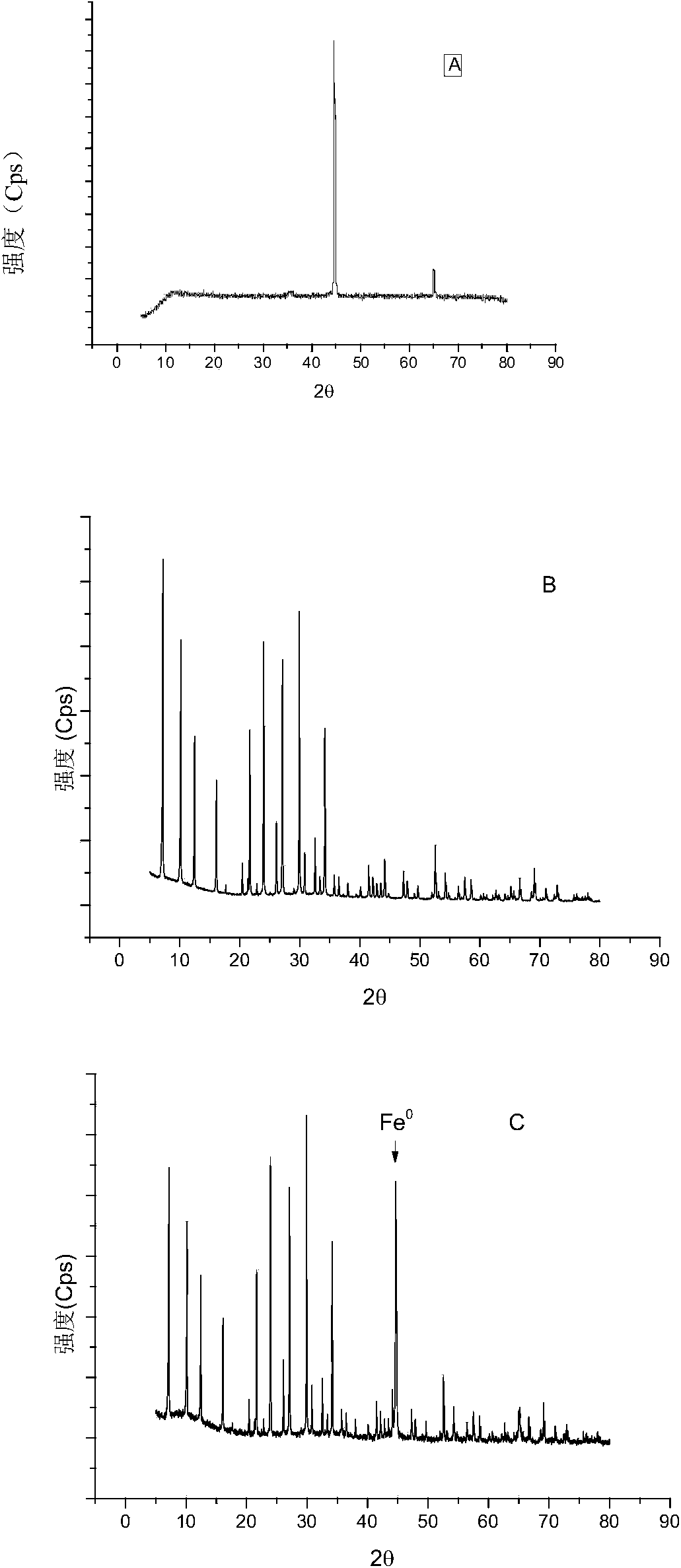

Preparation method of nano-iron modified zeolite

InactiveCN103464094AMagneticAmmonia nitrogen adsorption capacity increasesOther chemical processesAlkali metal oxides/hydroxidesSewage treatmentAmmonia nitrogen

The invention relates to a preparation method of nano-iron modified zeolite, which comprises the steps of firstly mixing natural zeolite or artificially synthesized zeolite with an alkali solution so as to obtain hydrogel, or mixing natural zeolite or artificially synthesized zeolite with an alkali solution in a certain proportion through a silicon source and an aluminum source so as to obtain hydrogel; uniformly mixing the hydrogel with nano iron so as to obtain a modified zeolite synthesized material; crystallizing the modified zeolite synthesized material under appropriate conditions so as to obtain a nano-iron modified zeolite product. Compared with the existing zeolite, in the aspect of ammonia nitrogen adsorption, the adsorption capacity of the synthesized modified zeolite is greatly increased. The synthesized modified zeolite also can be applied to the technical field of catalytic cracking, sewage treatment, and the like.

Owner:TONGJI UNIV

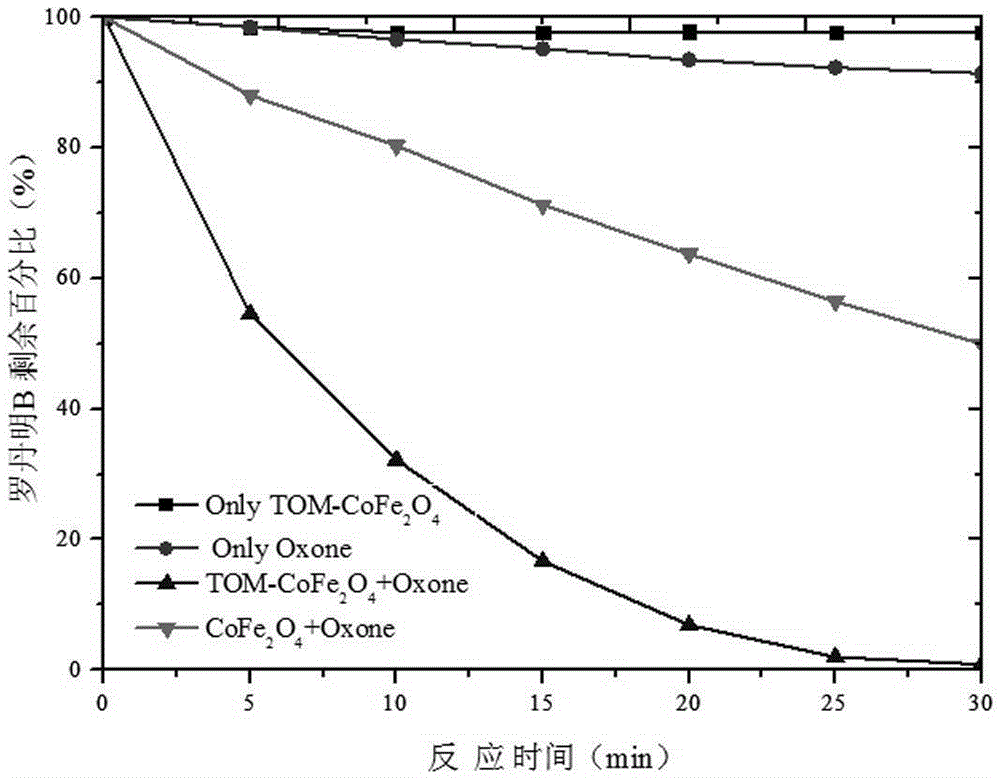

Method for processing dye waste water based on activation of peroxymonosufate by three-dimensional ordered mesoporous CoFe2O4

ActiveCN105399197ASustained high-efficiency catalytic performanceEfficient degradationPhysical/chemical process catalystsWater contaminantsWater basedBiological activation

The invention discloses a method for processing dye waste water based on activation of peroxymonosufate by three-dimensional ordered mesoporous CoFe2O4 and aims to solve the problem of low catalysis efficiency of present spinel CoFe2O4 to peroxymonosufate. The method is implemented through the following steps: firstly, three-dimensional ordered mesoporous CoFe2O4 is prepared; secondly, dye waste water with an appointed concentration is prepared, and the prepared solution is placed in a brown shake flask; thirdly, peroxymonosufate is added; fourthly, the three-dimensional ordered mesoporous CoFe2O4 is added; fifthly, the three-dimensional ordered mesoporous CoFe2O4 is separated by utilization of an applied magnetic field, and processing of dye in waste water based on activation of peroxymonosufate by three-dimensional ordered mesoporous CoFe2O4 can be completed. High-efficiency processing of dye waste water can be achieved by utilization of three-dimensional ordered mesoporous CoFe2O4 in cooperation with the peroxymonosufate technology, and the removal rate exceeds 90%. The cobalt ion leaching rate is low during the usage process, and environment pollution is reduced. The catalyst can be separated rapidly through an applied magnetic field and can be recycled, and the operation cost is lowered.

Owner:湖州智清环保科技有限公司

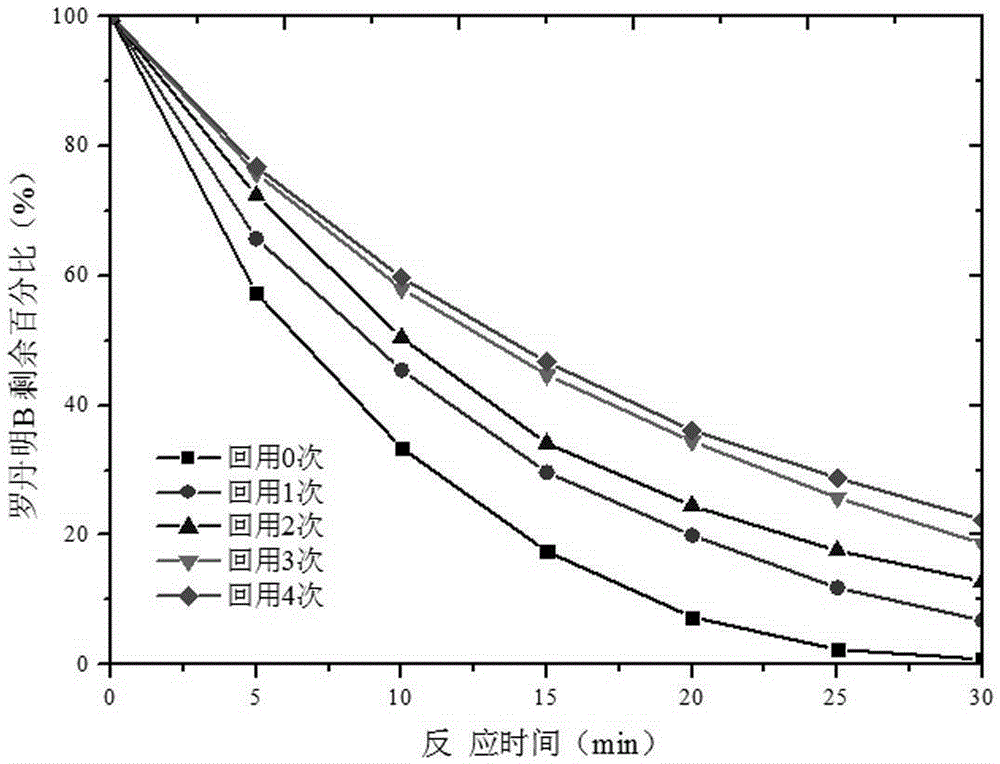

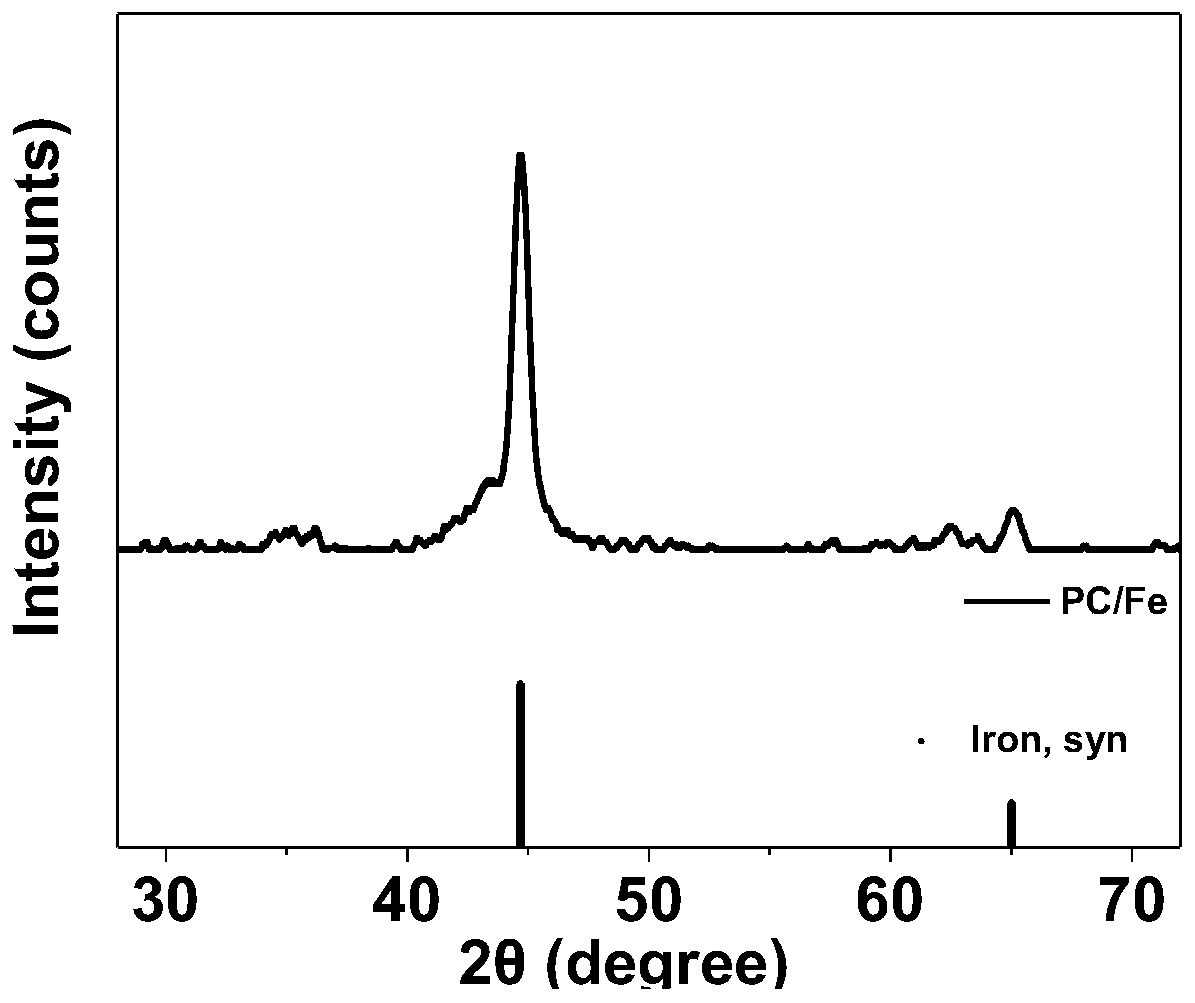

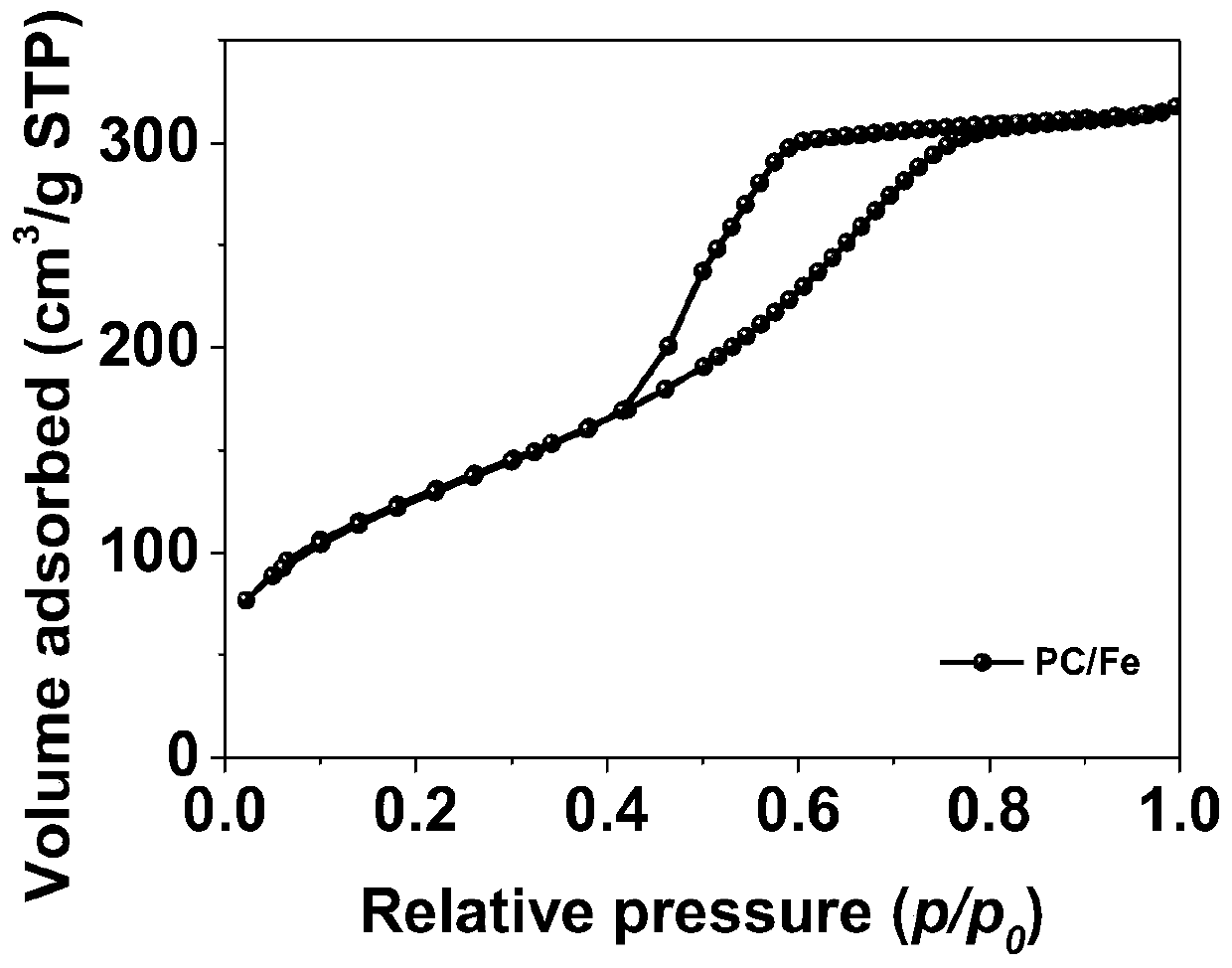

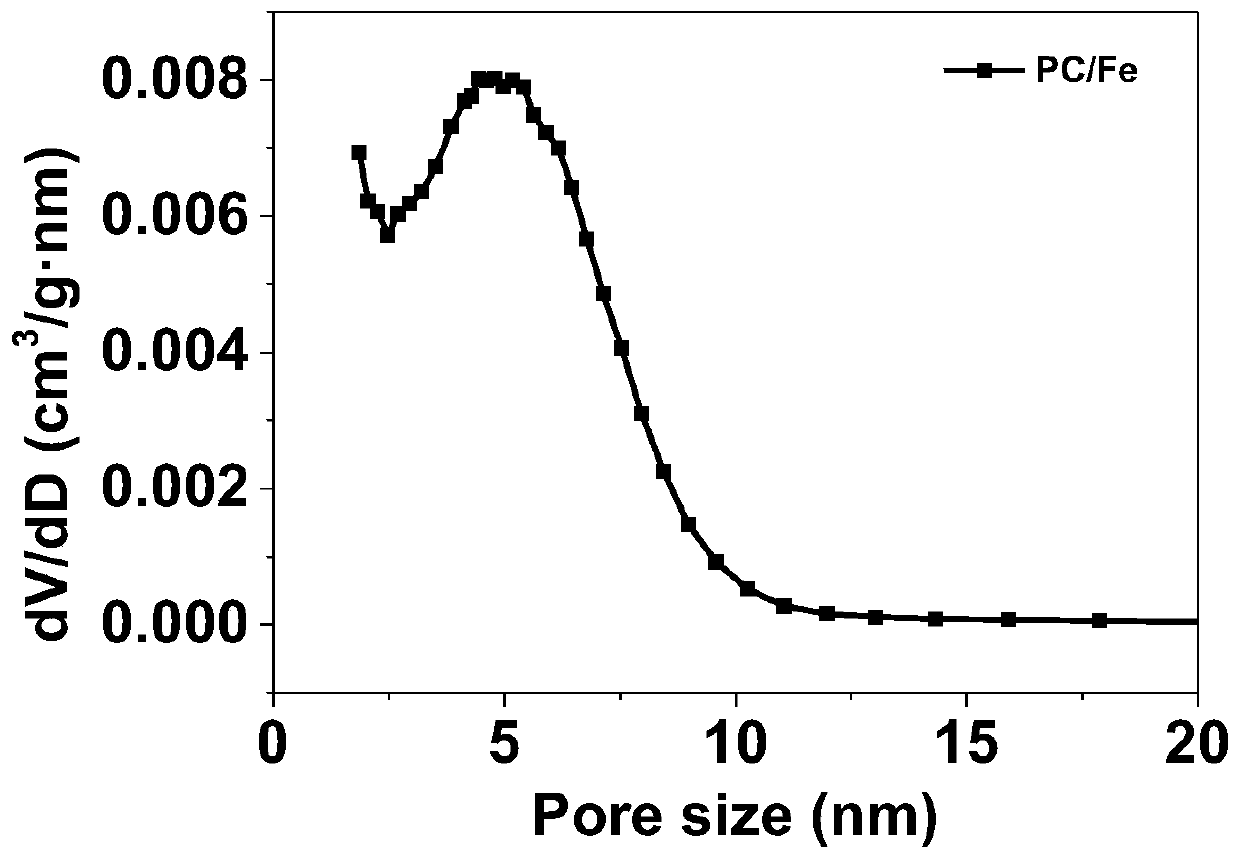

High-adsorption porous carbon supported zero-valent iron catalyst as well as preparation method and application thereof

ActiveCN109999753ALarge specific surface areaStable physical and chemical propertiesOther chemical processesWater treatment compoundsIron saltsPorous carbon

The invention discloses a high-adsorption porous carbon supported zero-valent iron catalyst as well as a preparation method and an application thereof and provides a new catalyst for an adsorbing andactivating oxidizing agent to decompose organic pollutants in soil and water. With high polymer and biomass as carbon sources, a compound catalyst with zero-valent iron supported in a porous carbon framework in a high-dispersion manner is prepared with a carbon thermal reduction one-step method. According to the prepared porous carbon supported zero-valent iron catalyst, nano zero-valent iron particles are uniformly distributed in the porous carbon framework, and the catalyst has a high specific surface area (500-1,000 m<2> / g) and large pore volume (0.3-0.7 cm<3> / g) and is magnetic. The preparation method of the catalyst can be used for batch production. The prepared catalyst can rapidly and massively adsorb organic pollutants, activate persulfate, hydrogen peroxide and other strong oxidizers, has the reaction activity higher than that of bivalent iron salt and imported commercial zero-valent iron and has broad application prospects in decomposing persistent organic pollutants in waterand soil.

Owner:SHANGHAI JIAO TONG UNIV

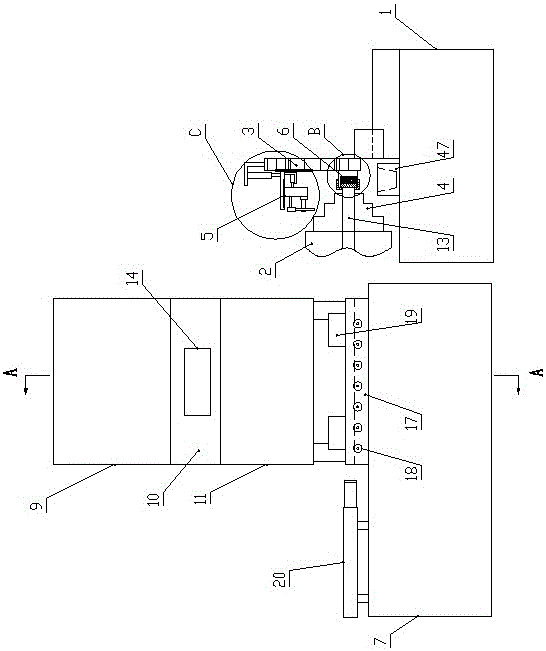

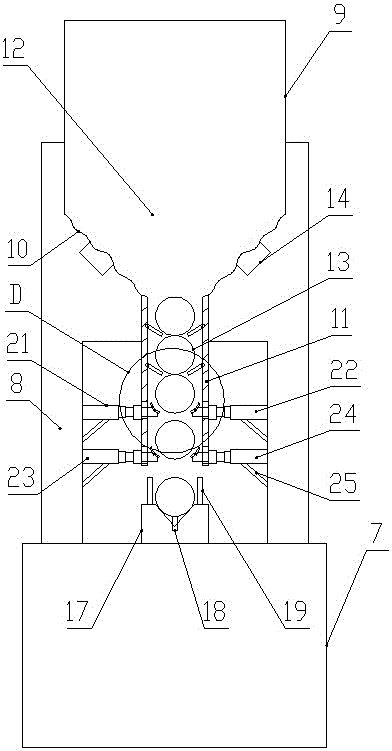

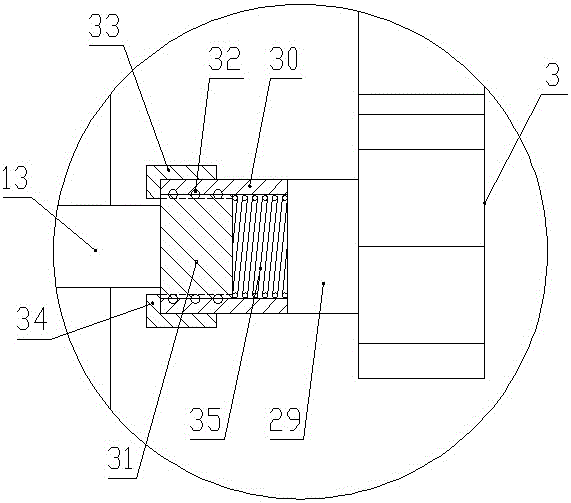

Automatic feeding numerical control lathe

InactiveCN105798332AAvoid shockPrevent flying outMetal working apparatusNumerical controlMaterial storage

The invention discloses an automatic feeding numerical control lathe. The automatic feeding numerical control lathe comprises a lathe body, wherein a hollow spindle is arranged on the lathe body; a sliding rail is arranged on the lathe body along the front and back horizontal direction; a knife rest is slidably arranged on the sliding rail; a hollow chuck is axially and fixedly connected to the front end of the hollow spindle; a cutting mechanism and an electromagnetic adsorption mechanism are arranged on the knife rest; an automatic feeding device is arranged behind the lathe body; the automatic feeding device comprises a material box base; a material box support is fixedly connected onto the material box base; a material storage box, a corrugated pipe elastic joint and a discharging box are sequentially arranged on the material box support from top to bottom in a fixed manner; a vibration motor is arranged on the outer wall of each of the left and right sides of the corrugated pipe elastic joint; a material baffle mechanism is arranged on the lower part of the discharging box; and a material pushing base which is right blow the discharging box is fixedly connected onto the upper surface of the material box base. The automatic feeding numerical control lathe is simple and convenient for operation, high in automatic degree and stable in work; automatic feeding can be realized; non-cutting time is effectively shortened; cutting can be performed rapidly; and the working efficiency is improved.

Owner:HUANGHE S & T COLLEGE

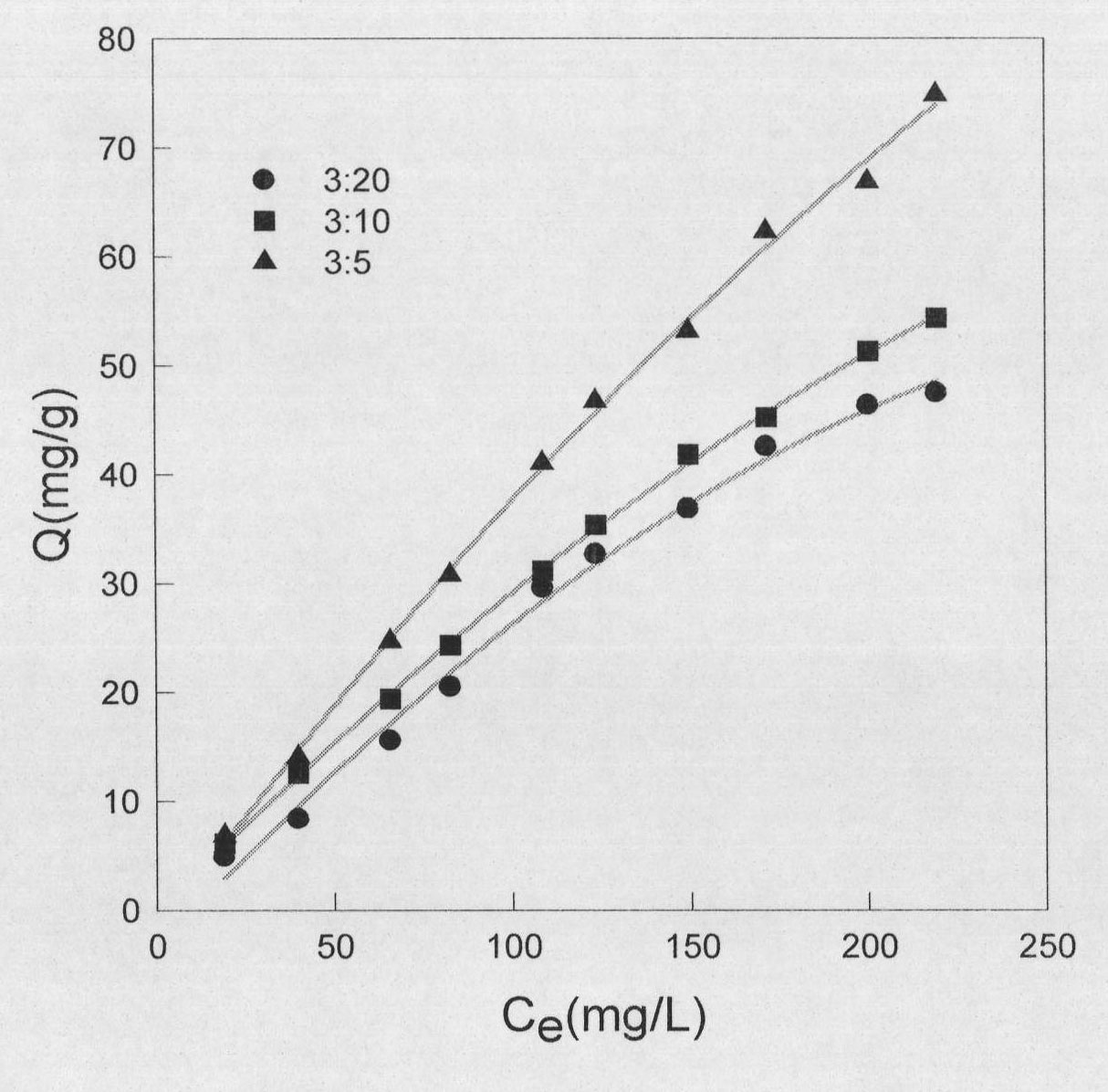

Method for preparing magnetic adsorbents on basis of iron-based metal-organic framework materials and application of magnetic adsorbents

ActiveCN105688825AGood dispersionImprove adsorption capacityOther chemical processesWater contaminantsPhosphateSorbent

The invention discloses a method for preparing magnetic adsorbents on the basis of iron-based metal-organic framework materials and application of the magnetic adsorbents. The method includes preparing La-doped nanometer Fe3O4(La-Fe3O4) by the aid of solvent-thermal processes and then wrapping the surfaces of the nanometer Fe3O4(La-Fe3O4) with metal-organic framework materials MIL(Fe) to obtain magnetic composite materials La-Fe3O4@MIL(Fe); applying the magnetic composite materials La-Fe3O4@MIL(Fe) to absorbing and removing phosphate in water. The method and the application have the advantages that phosphate radicals in the water can be efficiently adsorbed and removed by the magnetic adsorbents, the magnetic adsorbents are environmentally friendly, are easy to recycle and are reusable, equipment for implementing the method is simple and is convenient to operate, and accordingly the method has an excellent application prospect.

Owner:UNIV OF JINAN

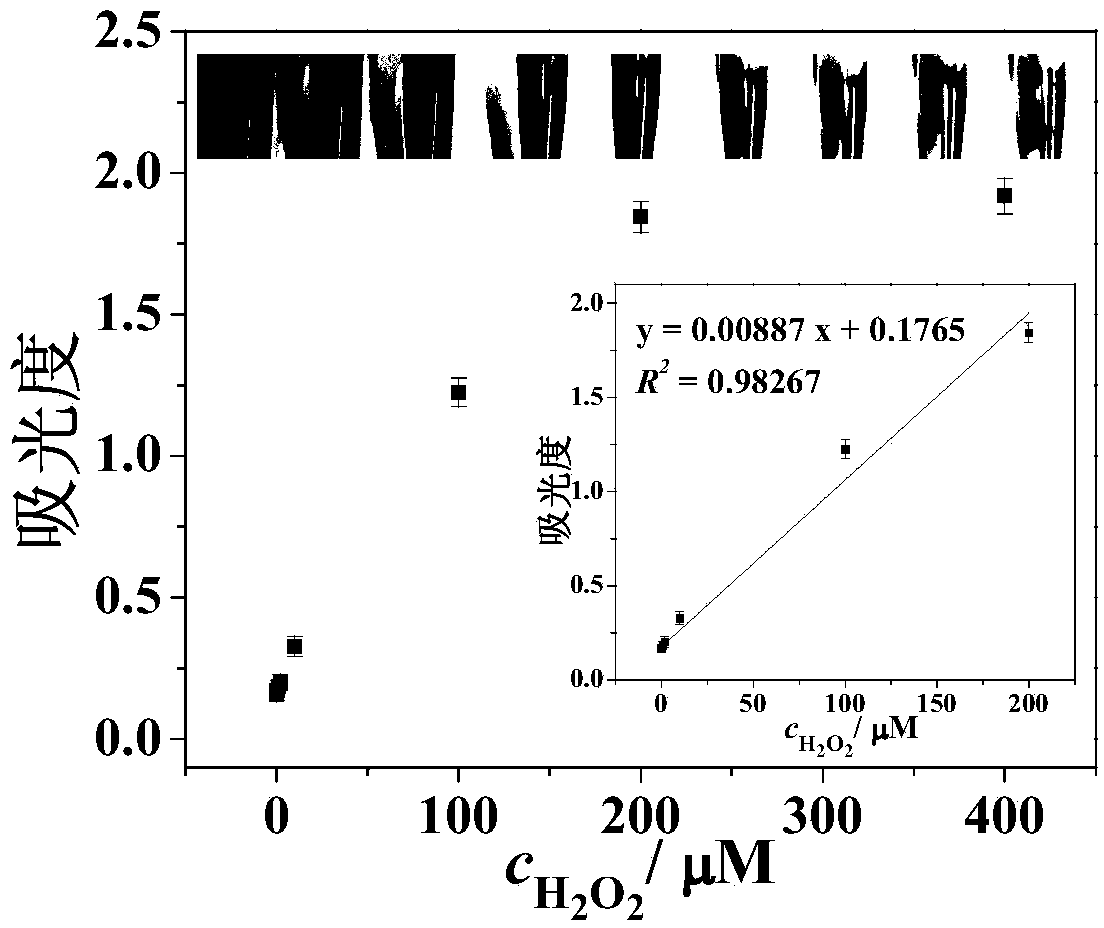

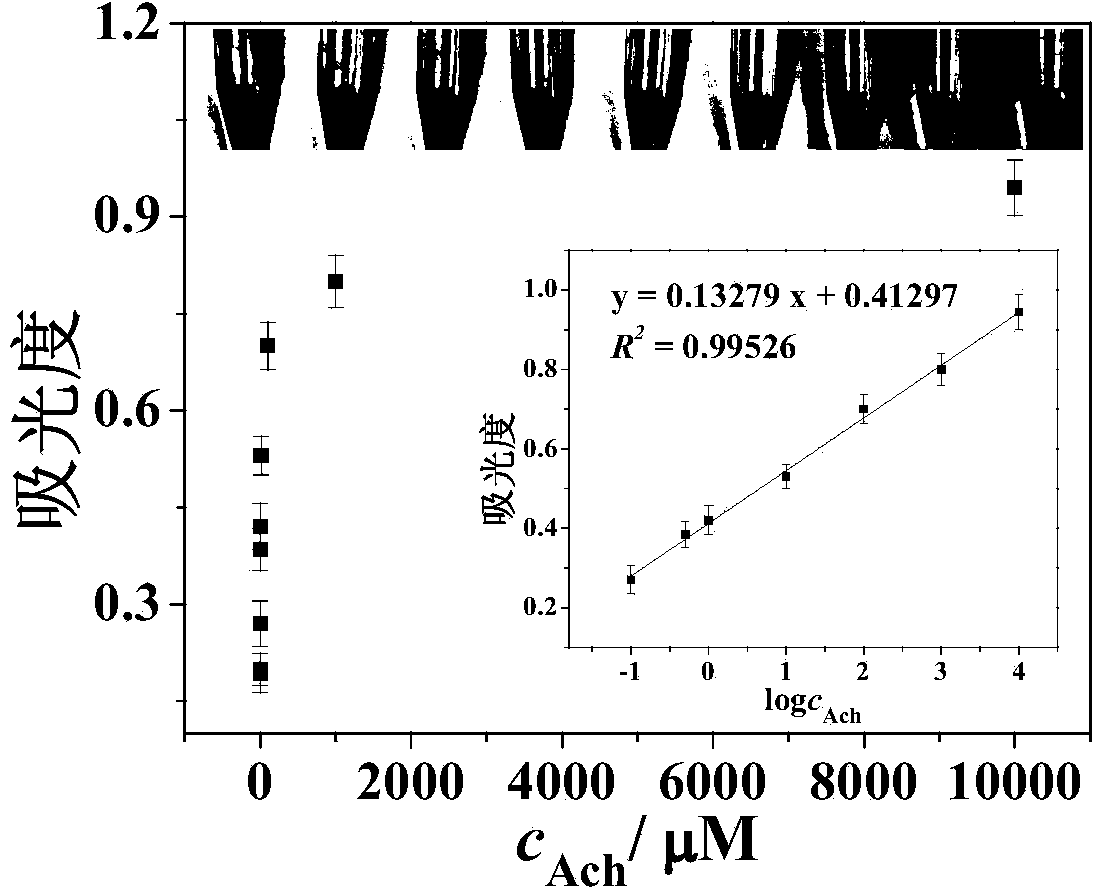

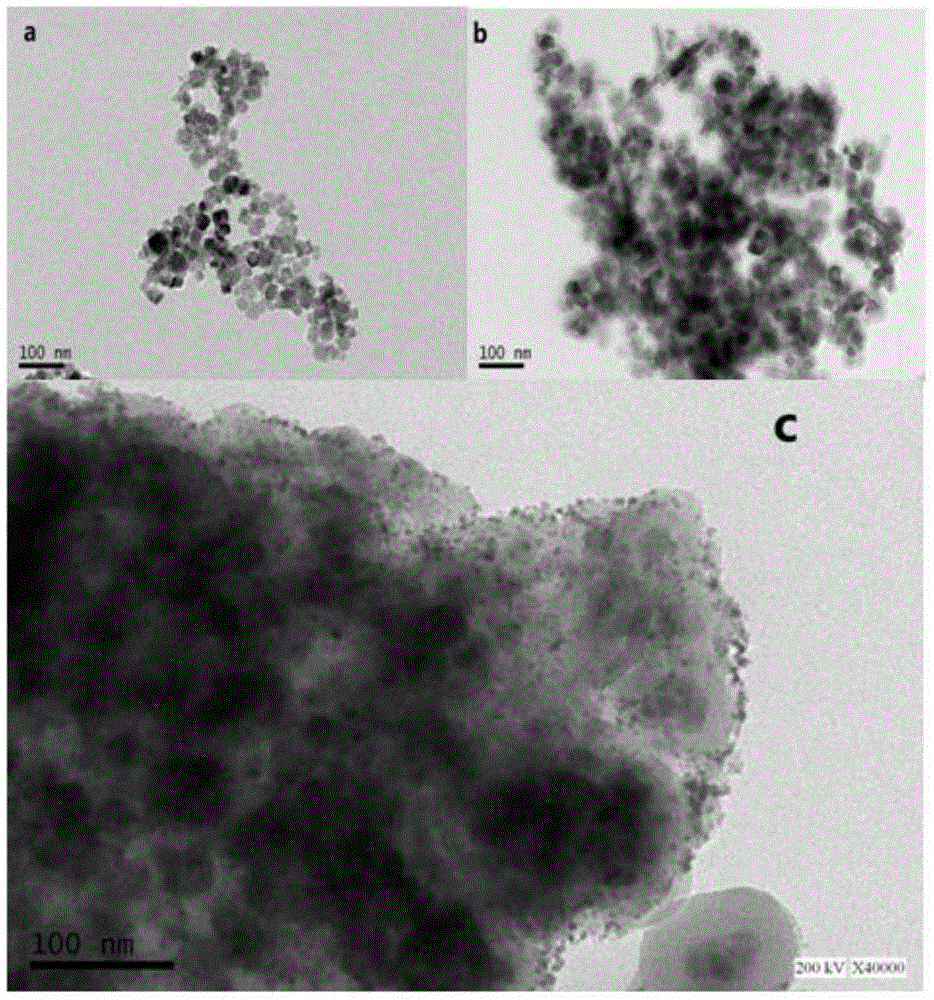

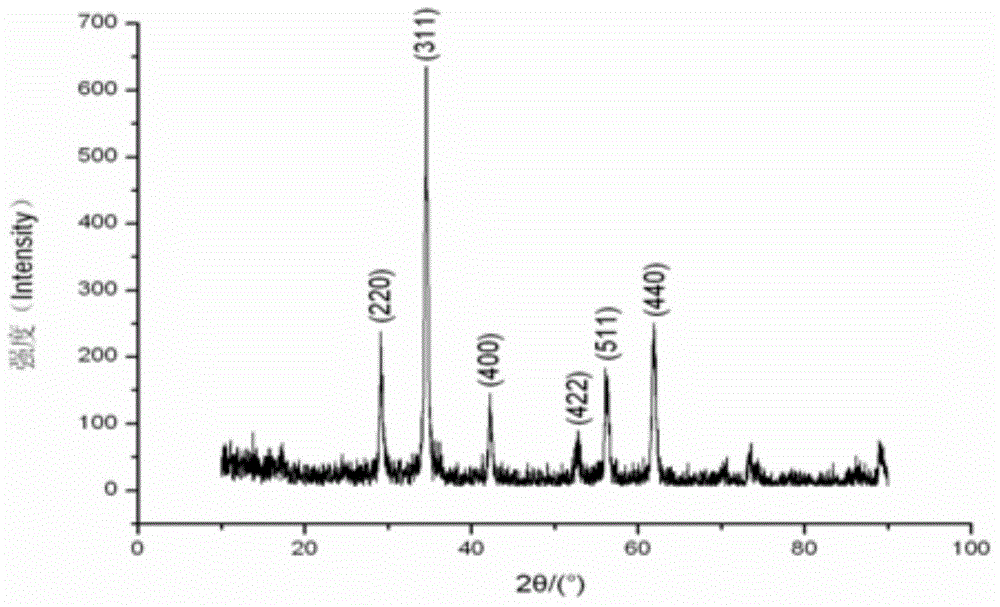

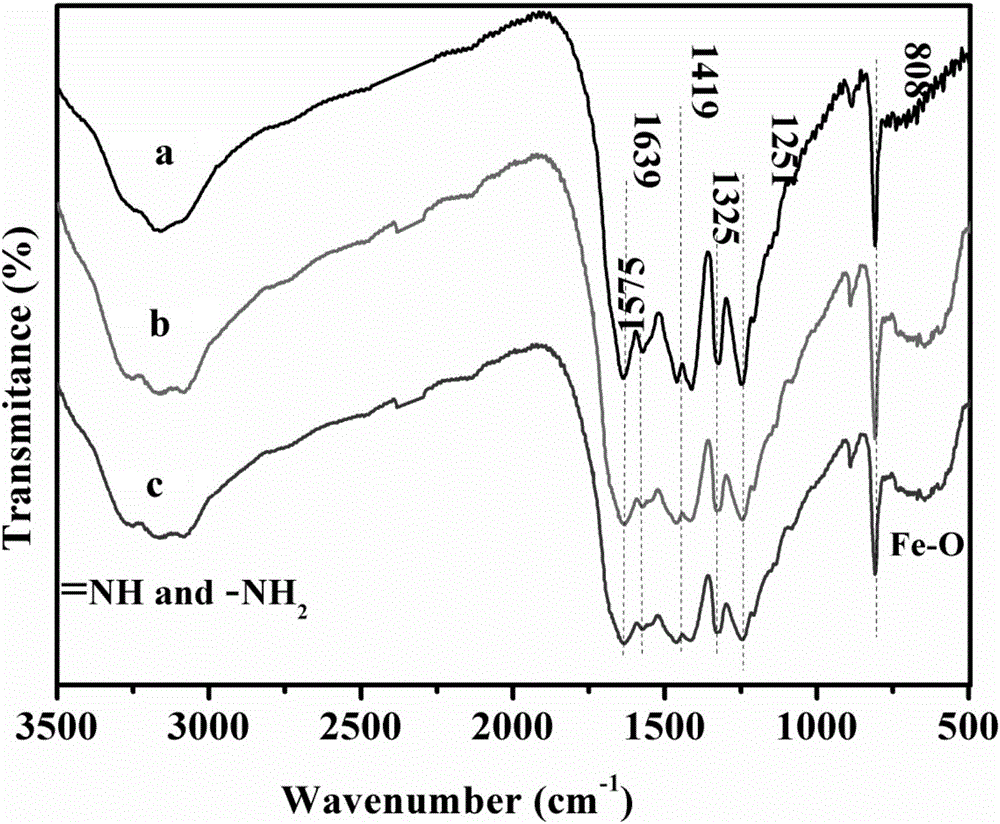

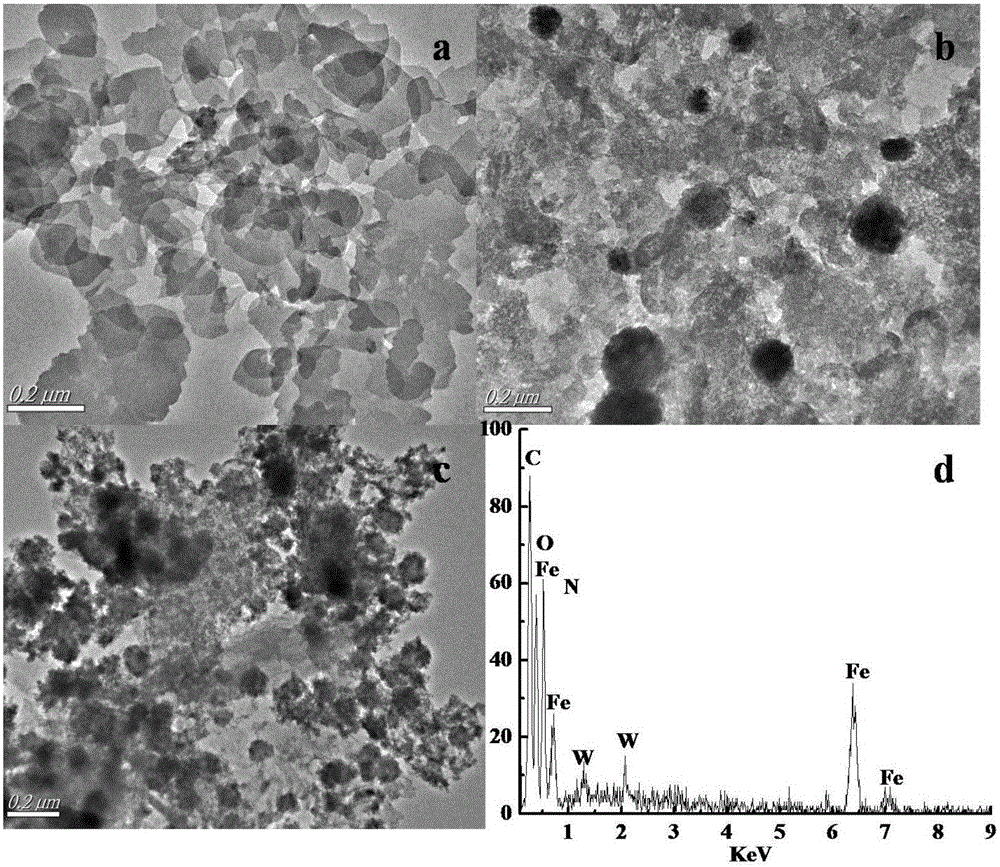

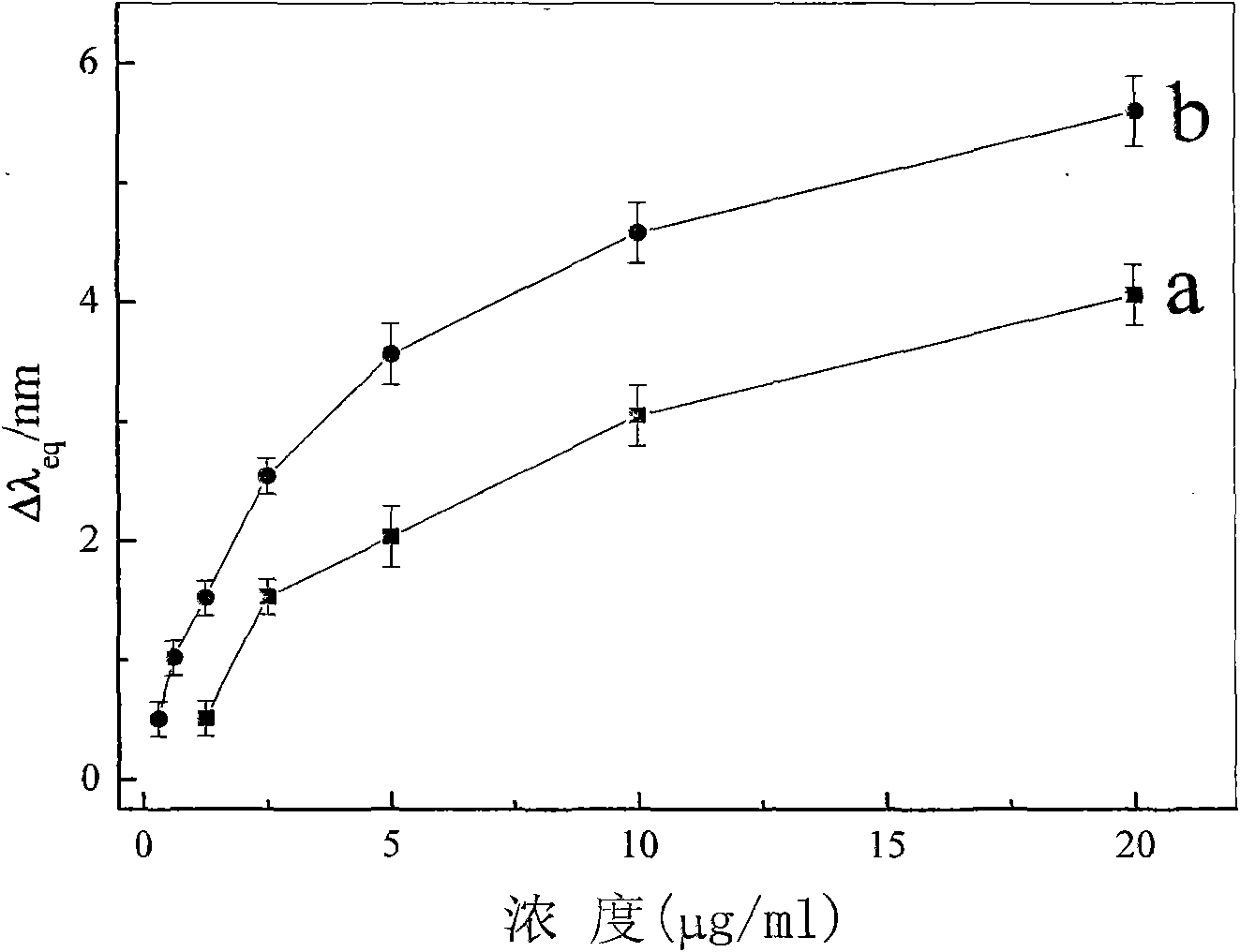

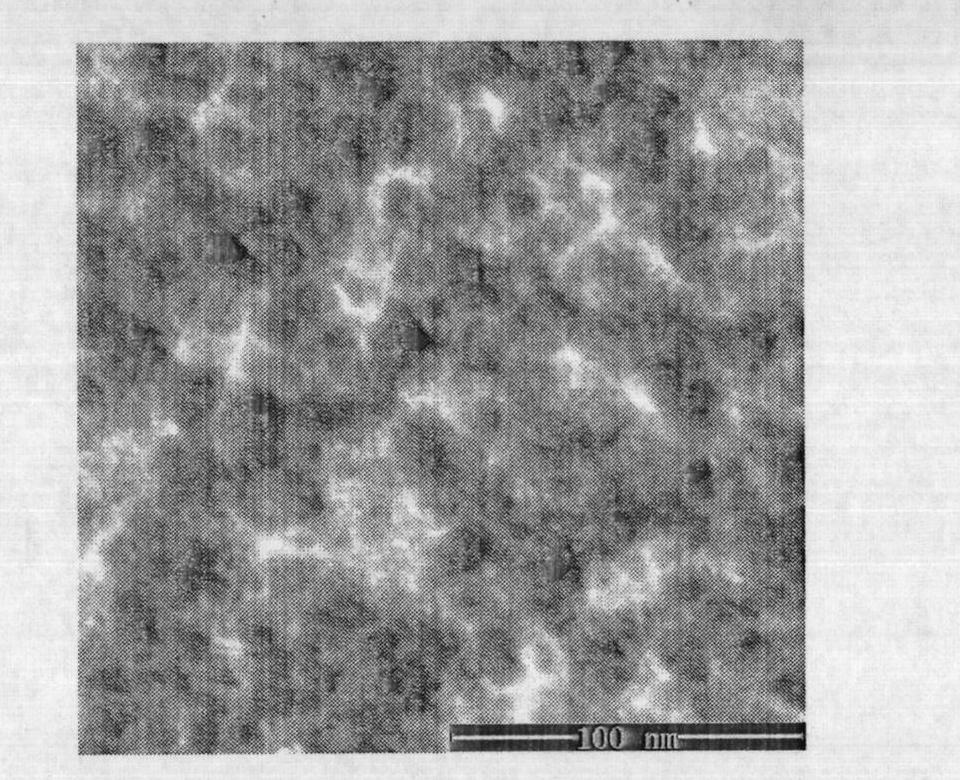

Magnetic graphene enzyme-mimicking property-based acetylcholine visual-detection method

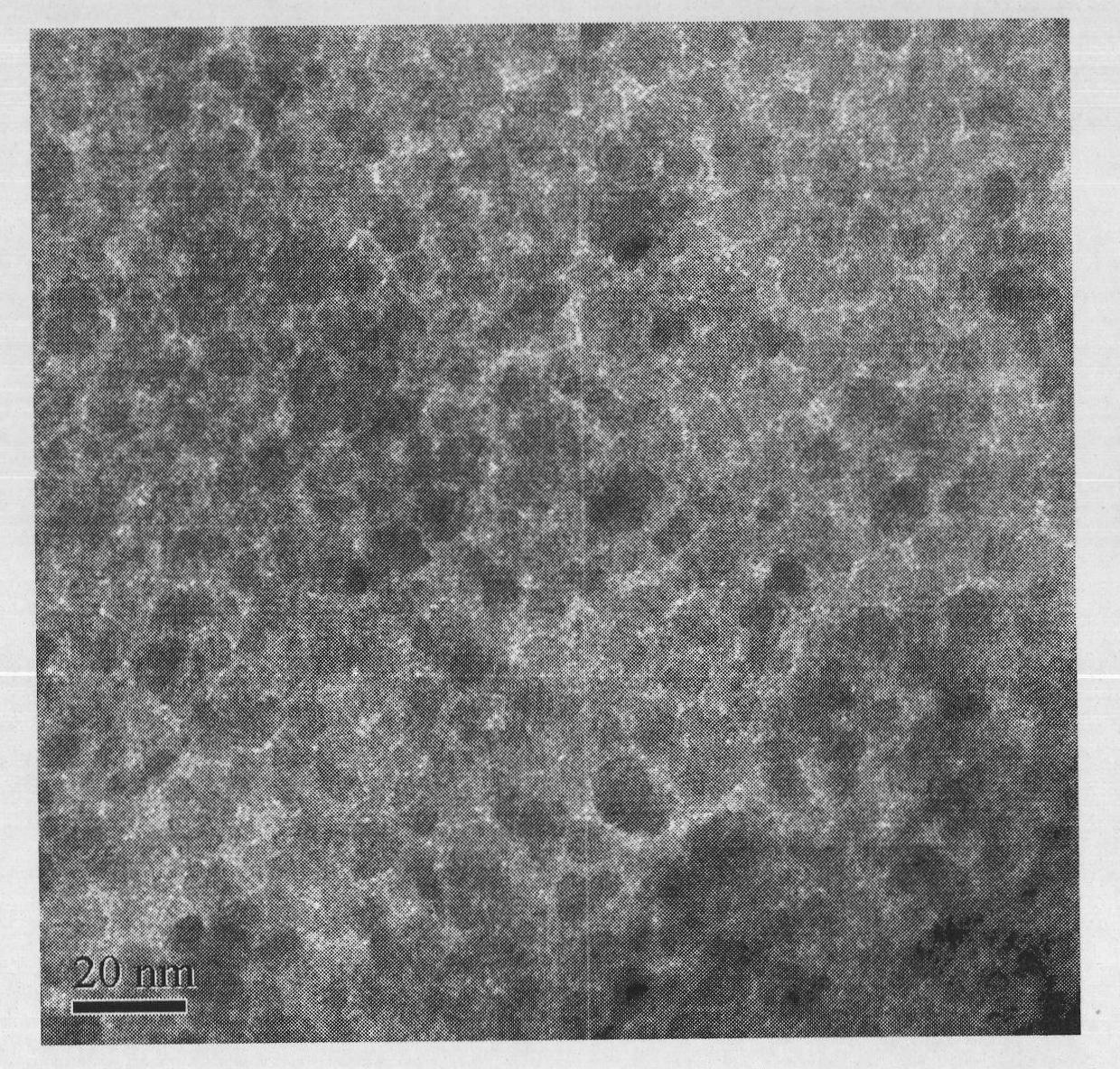

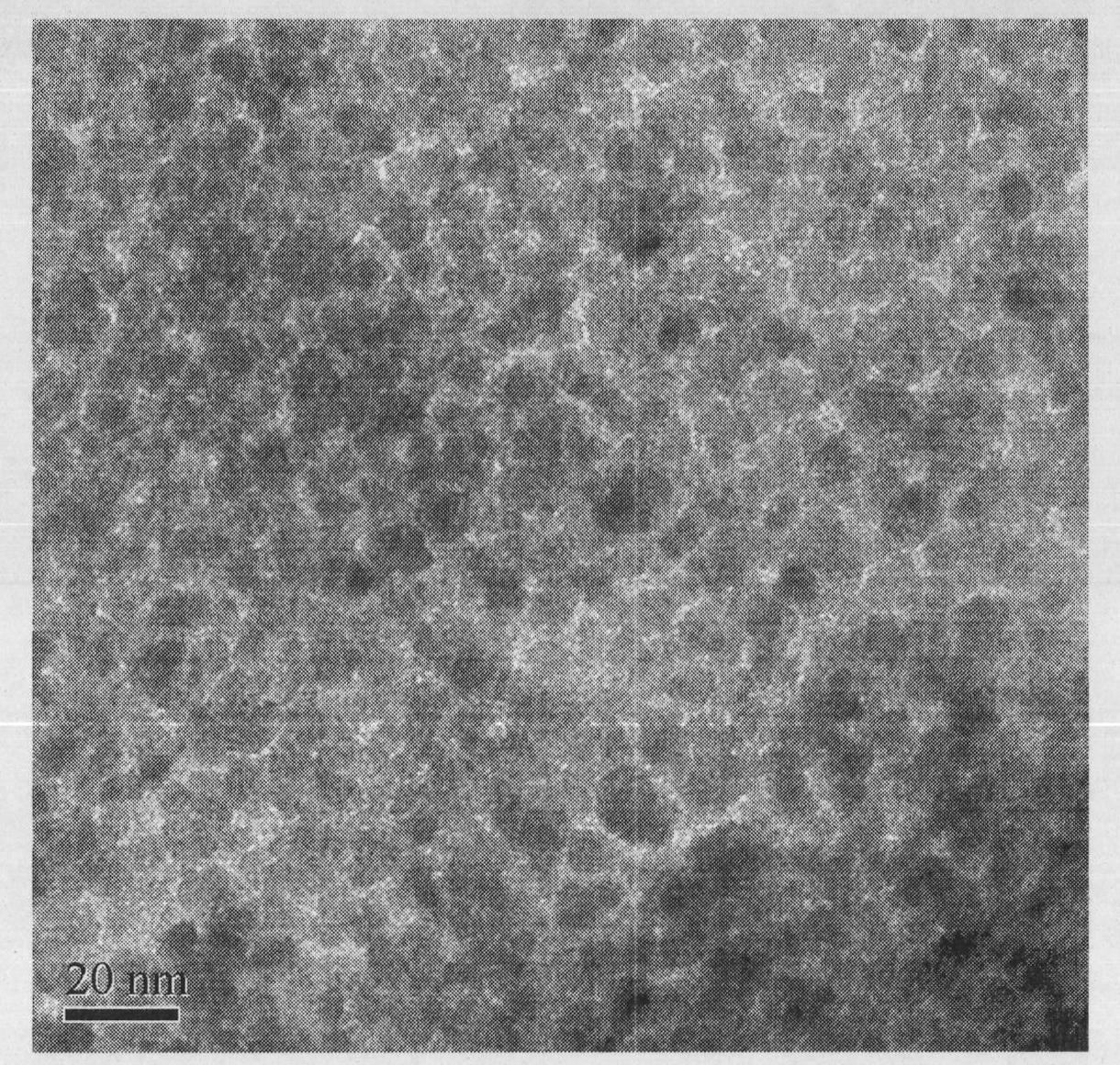

InactiveCN103712983ASmall particle sizeEvenly distributedMaterial analysis by observing effect on chemical indicatorPeroxidaseAcetylhomocholine

The invention relates to a magnetic graphene enzyme-mimicking property-based acetylcholine visual-detection method, belonging to the technical field of biosensing. A hydrothermal method is used for synthesizing Fe3O4 / rGO by one step, H2O2 (hydrogen peroxide) is catalyzed to oxidize a substrate TMB (tetramethylabenzidine) to generate blue by utilizing the peroxidase-like property of the Fe3O4 / rGO, and the characteristic absorption intensity of an oxidation product of the TMB at the wavelength of 652nm is detected to realize the detection of hydrogen peroxide; furthermore, the H2O2 can be catalyzed to oxidize and convert the colorless TMB into a corresponding blue product based on the Fe3O4 / rGO, and the blue product is combined with acetyl choline to decompose H2O2 in the presence of both acetylcholinesterase and choline oxidase, and a novel acetylcholine visual-sensing method is established. The invention aims to provide an acetylcholine colorimetric detection method, and according to the method, the operation is convenient and flexible, the detection cost is low, the sensitivity is high, and instruments and equipment are simple.

Owner:JIANGSU UNIV

Preparation of supported palladium catalyst Fe3O4/SiO2/Pd and application of supported palladium catalyst Fe3O4/SiO2/Pd in Suzuki reaction

InactiveCN104667945AImprove magnetic propertiesEasy to useOrganic chemistry methodsMetal/metal-oxides/metal-hydroxide catalystsThiobacillus ferrooxidansPtru catalyst

The invention discloses a supported palladium catalyst Fe3O4 / SiO2 / Pd for Suzuki reaction, and a preparation method of the supported palladium catalyst Fe3O4 / SiO2 / Pd. The compound is a supported palladium catalyst material containing Fe3O4 / SiO2 / Pd, obtained by composite reaction of a precursor-based Fe3O4 / SiO2 composite particles and Pd; the supported palladium catalyst Fe3O4 / SiO2 / Pd has the molecular characteristics that the compound structure contains a magnetic nanometer material Fe3O4 and porous absorption materials SiO2 and Pd; the supported palladium catalyst has relatively good magnetism, is easy to recover and reuse, and is a relatively ideal material as the supported palladium catalyst. The supported palladium catalyst is simple in synthesis route, mild in reaction condition, relatively high in yield and convenient to apply; post-treatment is simple; meanwhile, a secondary resource generated in biological mineral separation preparation and simulation and coal biological desulphurization by adopting thiobacillus ferrooxidans as a raw material; and a reference is provided for a comprehensive utilization technology of developing a metallurgical tail liquid or a desulphurization waste solution.

Owner:ANHUI UNIVERSITY

Composite conducting microball and its preparing method

InactiveCN1936078AMagneticConductiveLiquid/solution decomposition chemical coatingMicroballoon preparationAnisotropic conductive filmMicrosphere

The invention relates to a new type composite conductive micro-balloon and the manufacturing method that is made up of high polymer micro-balloon core material and external conductive metal carcass material that is achieved by chemical coating method. It has the advantages of strong designability, good conductivity and wonderful sensitivity to temperature and pressure, and it is simple technology and low cost.

Owner:YANTAI SHUODE NEW MATERIAL

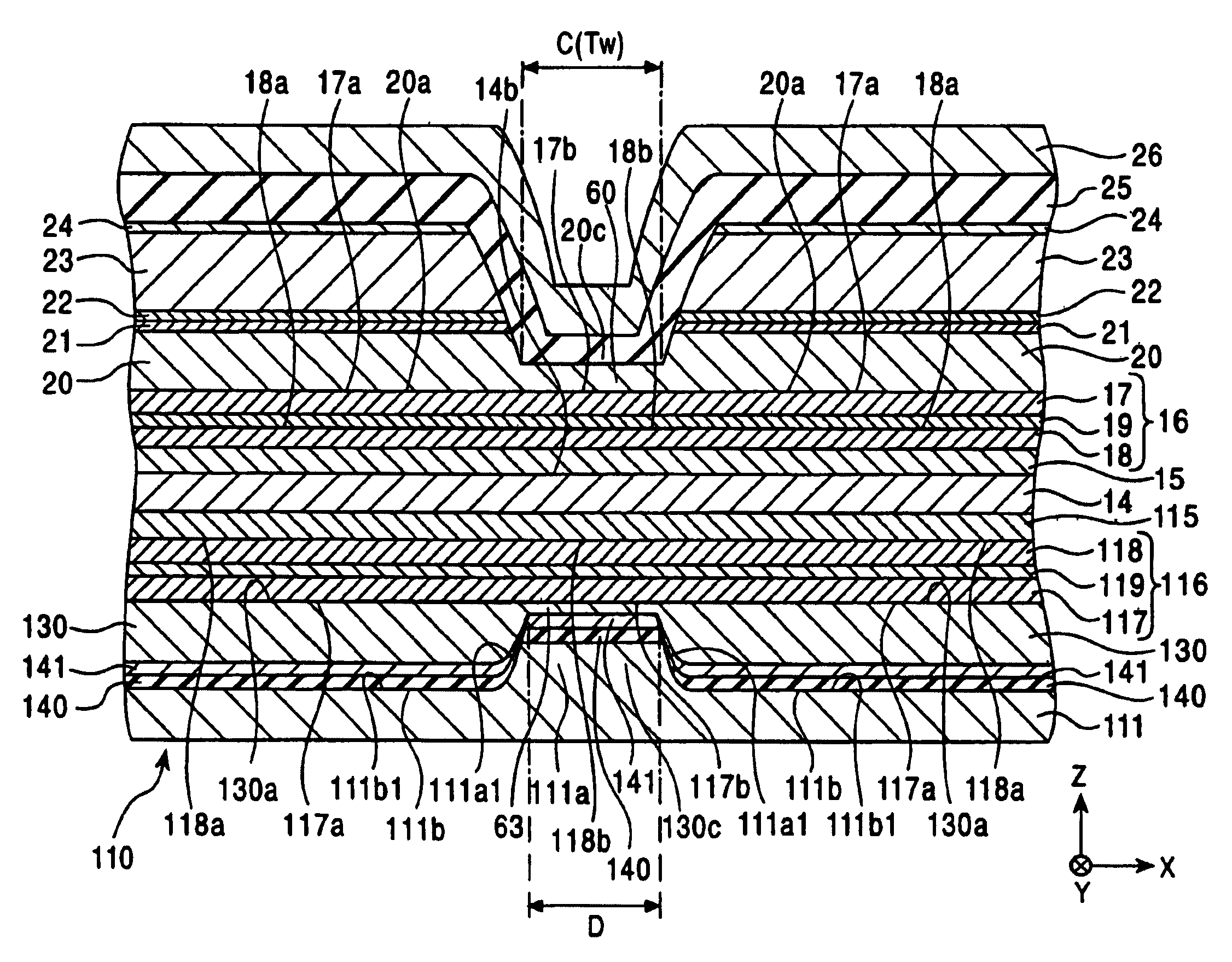

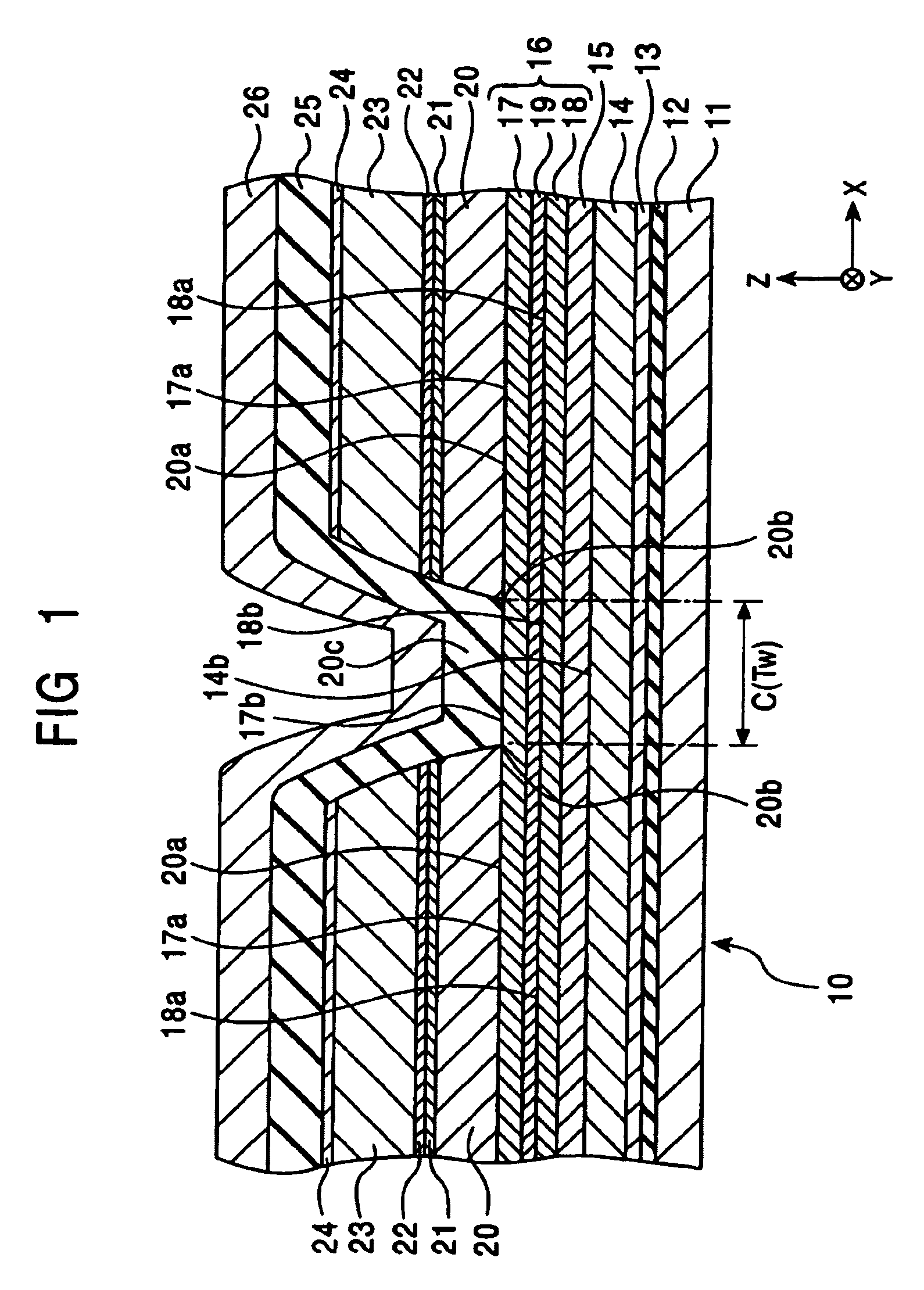

Magnetic sensor having free layer additionally provided with magnetic anisotropy by shape anisotropy

InactiveUS7029771B2Small thicknessSimple structureNanomagnetismMagnetic measurementsMagnetic anisotropyUltimate tensile strength

An intermediate region is formed at a central portion of an element in a track width direction, and an antiferromagnetic layer is not provided at the intermediate region. Accordingly, a sense current can be prevented from being shunted to the intermediate region, and as a result, improvement in reproduction output and strength against magnetic electrostatic damage can be realized. In addition, since the thickness of the central portion of the element is decreased, trend toward narrower gap can be realized. Furthermore, since the direction of magnetization of a free magnetic layer is oriented in the track width direction by shape anisotropy, means for orienting the magnetization is not necessary, and hence the structure and manufacturing method of the element can be simplified.

Owner:TDK CORPARATION

Method of preparing magnetic nano composite fibre

The present invention discloses a method for preparing magnetic nano-composite fiber. The steps are: dissolving the cellulose in NaOH / urea water solution completely and getting the cellulose solution, debubbling in vacuum and preparing fiber through spinning machine, then soaking the cellulose fiber into 0. 01 mol / L - 2mol / L ferric salt or ferrous salt solution, passing the 0. 1 mol / L - 4mol / L NaOH solution, then producing the magnetic nano-composite fiber. The method is simple to operating, raw materials are cheap, the prepared products have good mechanical and magnetic properties. The nano-magnetic fiber can be made protective clothing, health care supplies and so on, and it also has certain prospect in daily health care, military and other areas.

Owner:WUHAN UNIV

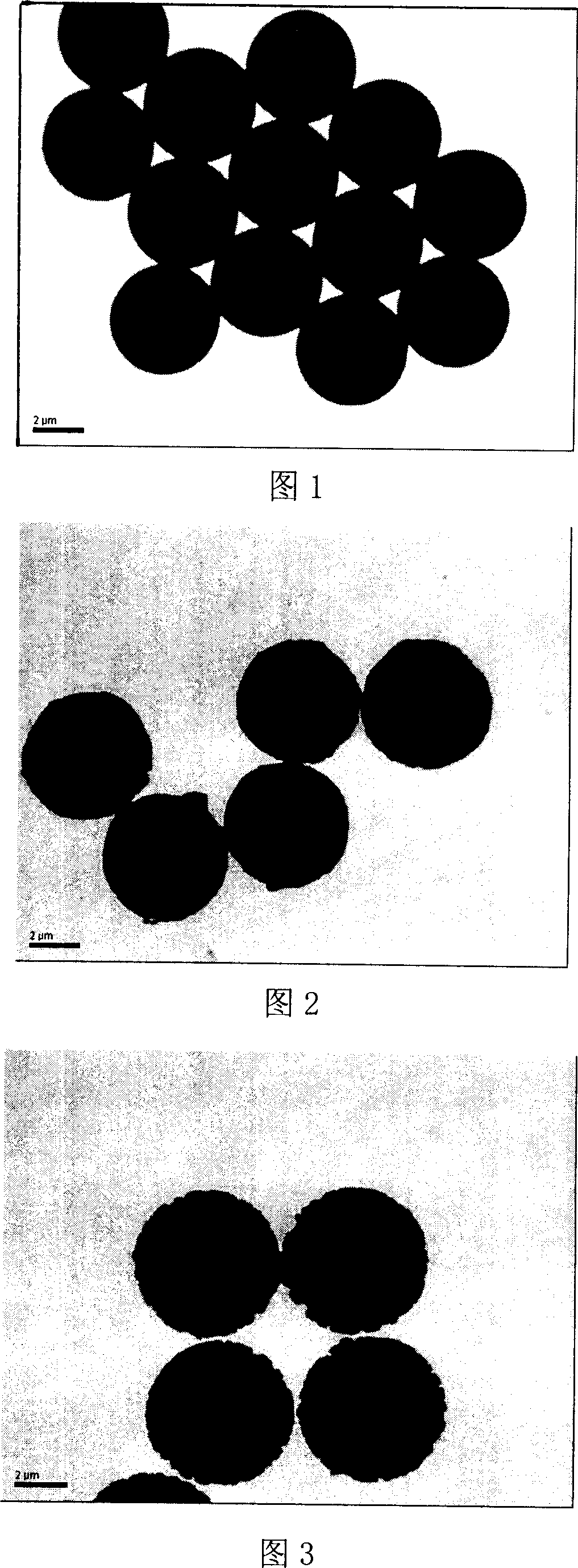

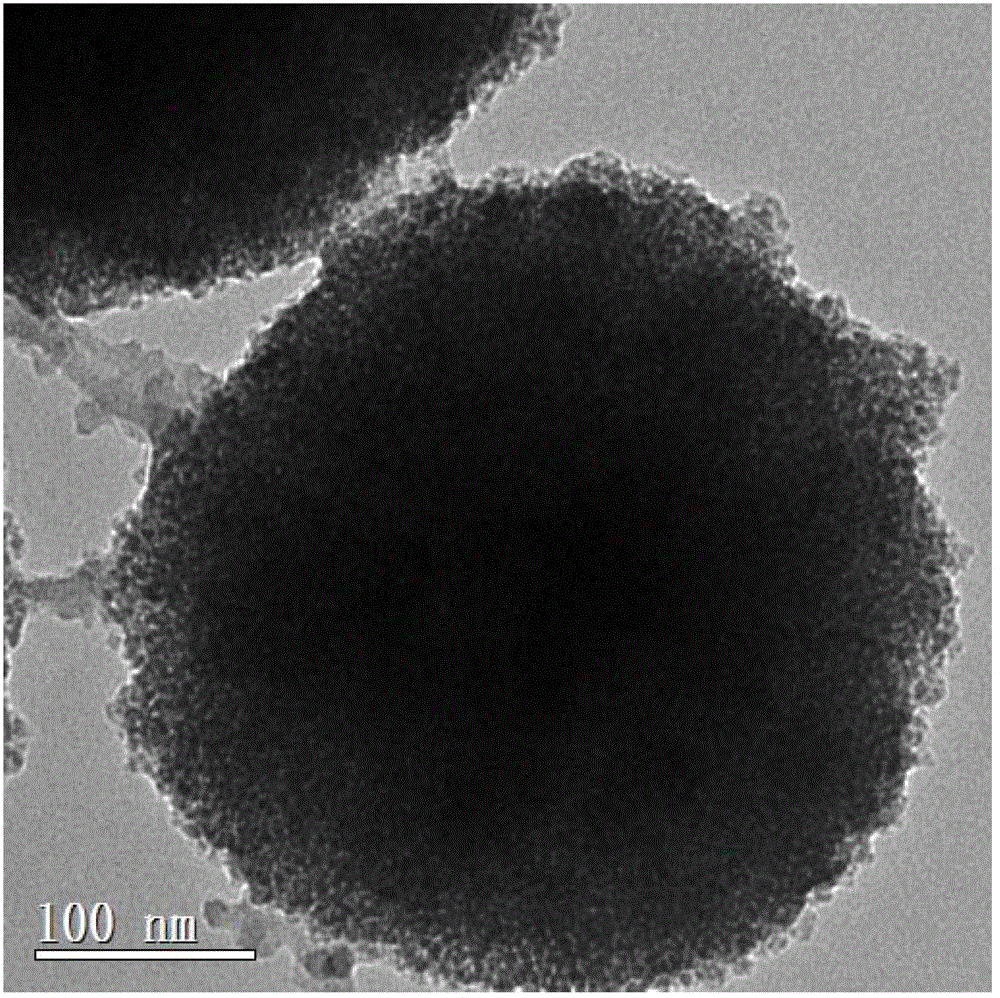

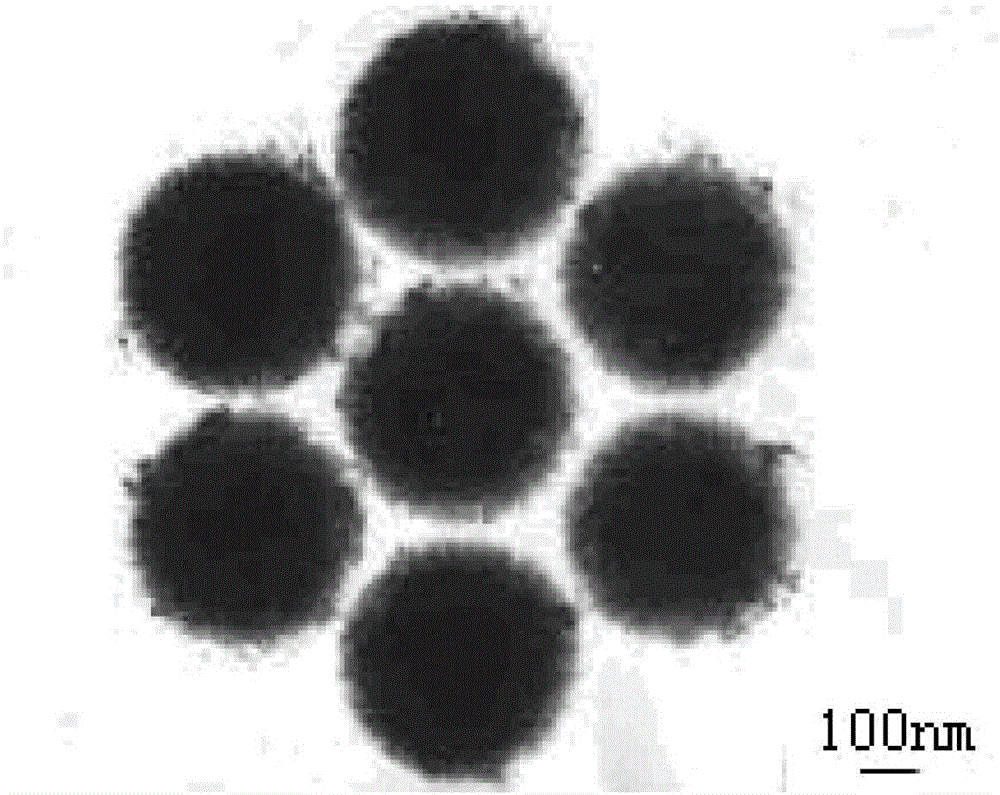

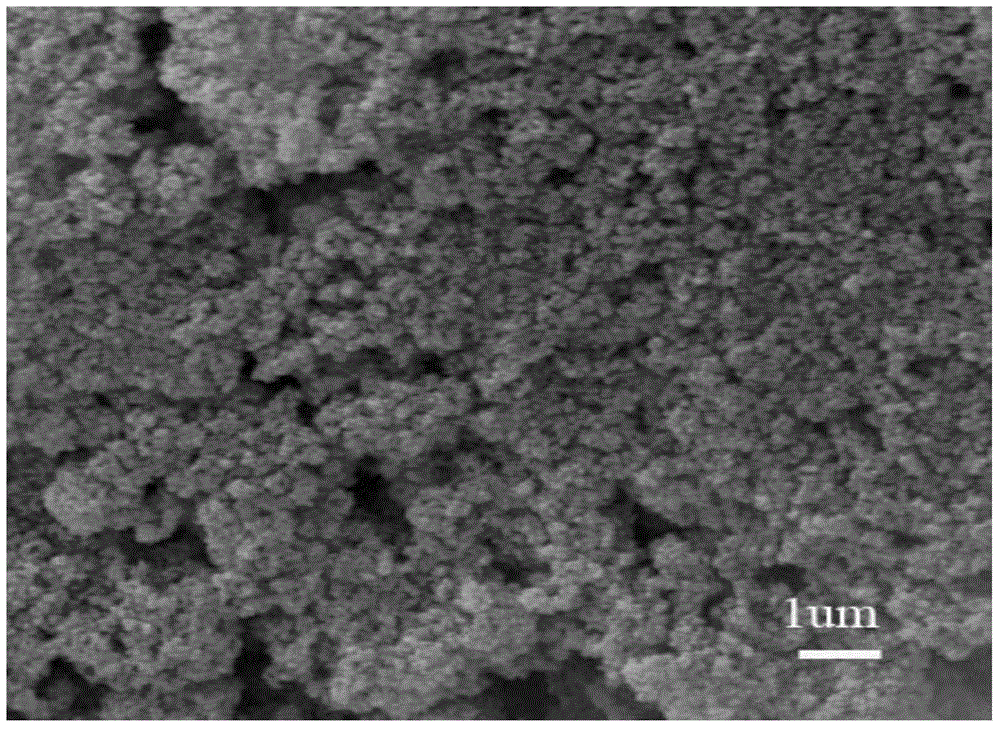

Magnetic core-shell Fenton-type catalyst, and preparation method and application of catalyst

InactiveCN103331181AMagneticEasy to recycleOrganic-compounds/hydrides/coordination-complexes catalystsWater/sewage treatment by oxidationMicrosphereCationic polyelectrolytes

The invention discloses a magnetic core-shell Fenton-type catalyst, and a preparation method and an application of the catalyst. An inner core of the core-shell Fenton-type catalyst is an Fe3O4 microsphere accumulated by nano Fe3O4 particles; a shell layer is an alternate adsorption sequence layer formed by a cationic polyelectrolyte and nano SiO2 particles; and an outermost layer of the alternate adsorption sequence layer is an SiO2 nano particle layer such as -ABABAB, wherein A is the cationic polyelectrolyte, and B is SiO2. The preparation method of the catalyst comprises the steps of preparing the Fe3O4 microsphere by a hydrothermal method, preparing the nano SiO2 particles by a sol-gel method, and assembling the cationic polyelectrolyte with positive charges and the nano SiO2 particles with negative charges on the Fe3O4 microsphere by a layer-by-layer electrostatic self-assembly method. The core-shell Fenton-type catalyst is high in catalysis efficiency and easy to recover, can be used repeatedly, can be coupled with H2O2 to form an inhomogeneous phase Fenton-type system, and can conduct catalytic oxidation on phenolic wastewater.

Owner:SHANGHAI WINNER ENVIRONMENTAL TECH +2

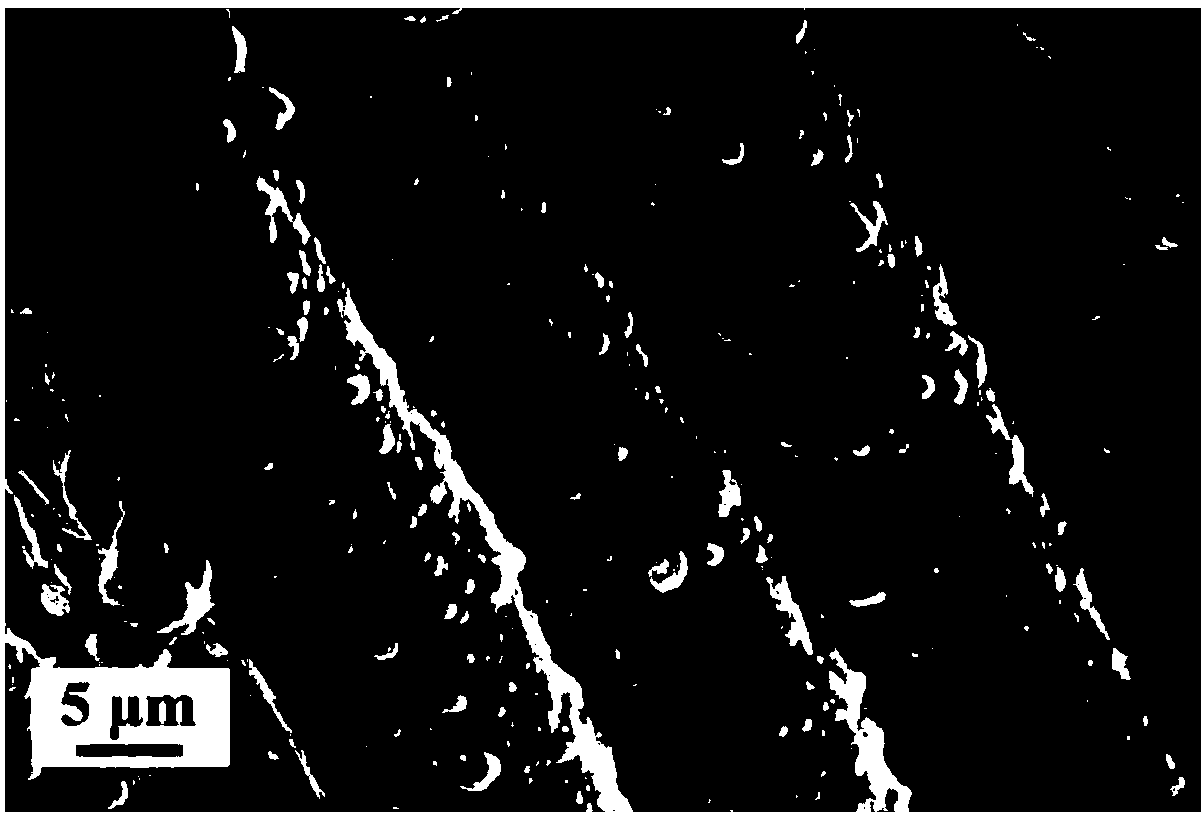

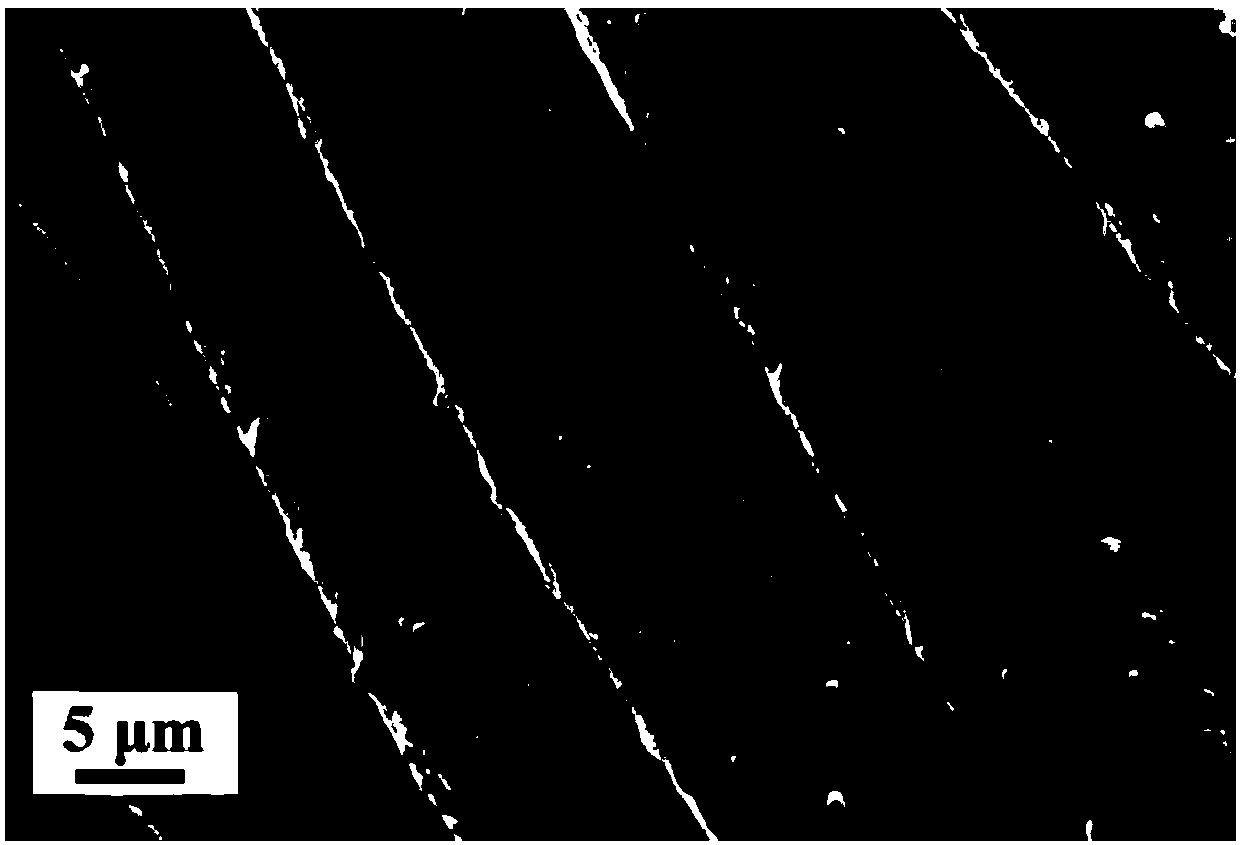

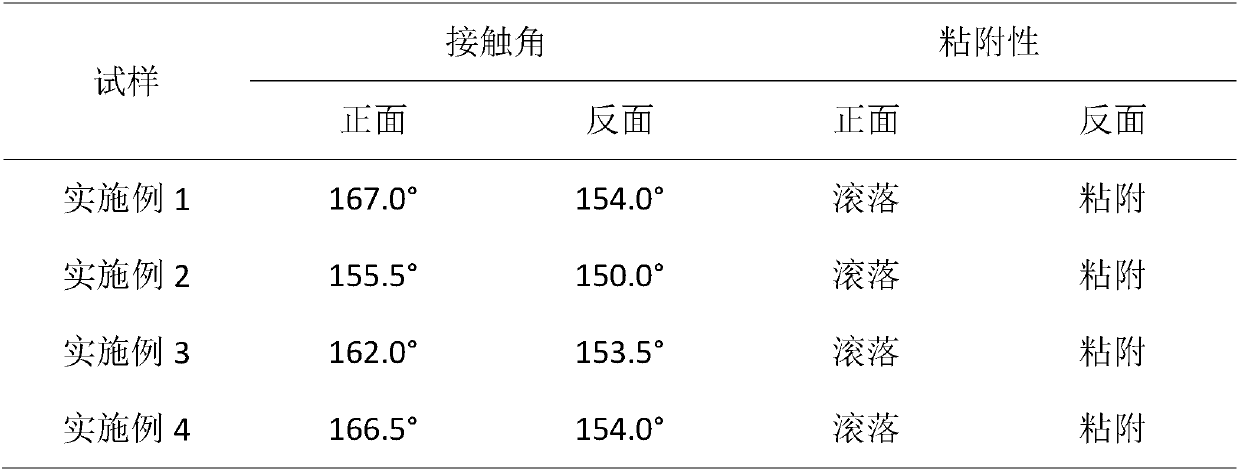

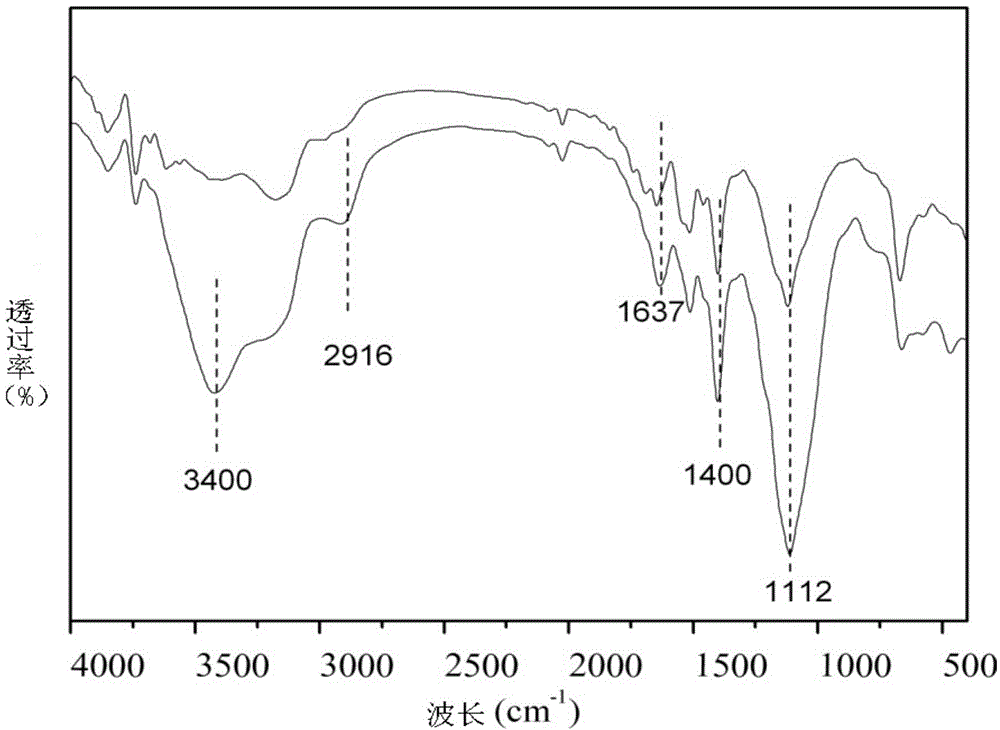

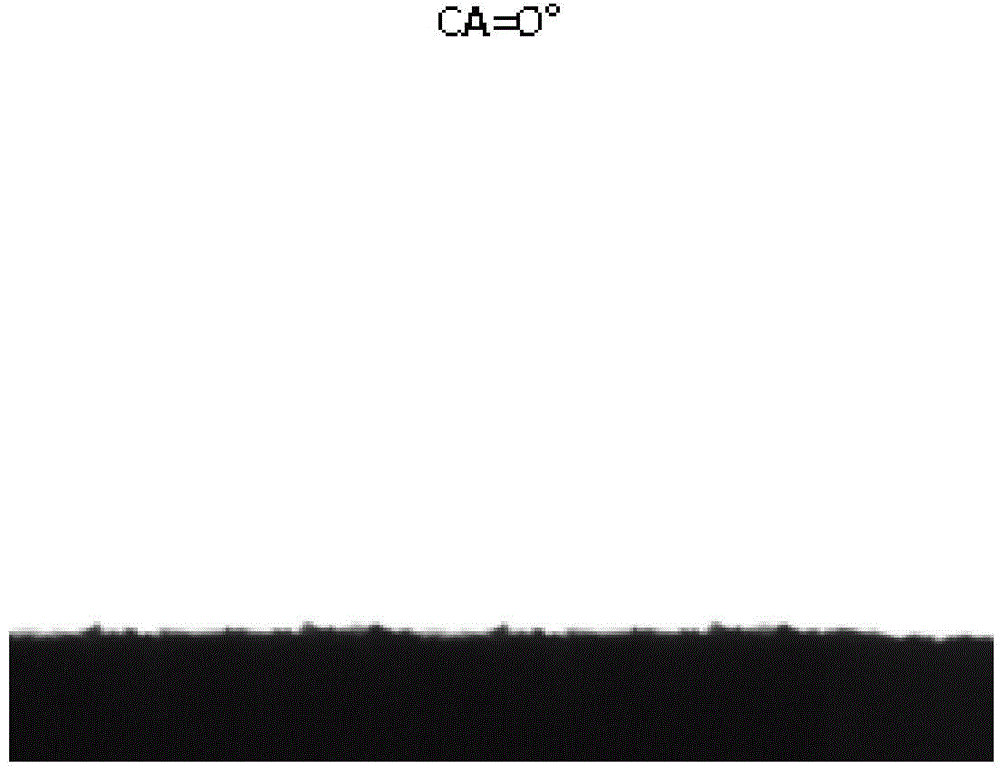

Magnetic super-hydrophobic fabric and preparation method thereof

The invention discloses a magnetic super-hydrophobic fabric and a preparation method thereof. The preparation method comprises the following steps: immersing an ordinary fabric into a mixed solution of polydimethylsiloxane-containing ferric oxide particles modified by a silane coupling agent and an organic solvent to be stirred; taking out the fabric, placing the fabric at a position which is 1-5mm away from the lower side of a magnet, maintaining at a room temperature for 10-60 minutes, and granularly migrating the ferric oxide particles to the polydimethylsiloxane surface layer on the fabricdue to the magnetic field action during solvent evaporation; and finally, placing the fabric at a temperature of 80-130 DEG C, and performing heat curing on the polydimethylsiloxane to form a cross-linked structure, thereby obtaining the magnetic super-hydrophobic fabric with a micro-nano rough structure on the surface. According to the invention, the process is simple, and for the prepared magnetic super-hydrophobic fabric, a front water contact angle is 167 degrees, and water drops easily roll; and an opposite water contact angle is 154 degrees, and the water drops are easily adhered. In addition, the fabric has excellent magnetism and saturation magnetization reaching 1.285emu / g.

Owner:SOUTH CHINA UNIV OF TECH

Ternary magnetic composite photocatalytic nanomaterial and preparation method and use thereof

InactiveCN106732713AInhibitory complexExtend your lifePhysical/chemical process catalystsWater/sewage treatment by irradiationPhotocatalytic degradationSemiconductor

The invention provides a ternary magnetic composite photocatalytic nanomaterial and a preparation method and use thereof. The preparation method comprises the following steps: step 1, preparing a g-C3N4 photocatalyst; step 2, preparing WO3; and step 3, preparing the ternary magnetic composite photocatalytic nanomaterial. In the ternary magnetic composite photocatalytic nanomaterial prepared in the invention, the g-C3N4 photocatalyst is a novel organic visible-light-activated photocatalyst, and the Fe3O4 nanoparticles have excellent magnetism and electric conductivity. In addition, the WO3 as an inorganic semiconductor with good visible-light response has a band gap structure matching the g-C3N4. Therefore, according to the valence band theory and as reported in literatures, the WO3 can form a Z-type heterojunction photocatalyst having high photocatalytic activity with the g-C3N4. The composite material of such a special structure has improved photocatalytic effect such that the ternary magnetic composite photocatalytic nanomaterial prepared in the invention has excellent stability and photocatalytic degradation effect.

Owner:JIANGSU UNIV

Target of high-purity nickel or nickel alloy and its producing method

ActiveUS20060137782A1High purityGood film uniformityVacuum evaporation coatingSputtering coatingSputteringThin membrane

Provided is high purity nickel or nickel alloy target for Magnetron sputtering having superior sputtering film uniformity and in which the magnetic permeability of the target is 100 or more, and this high purity nickel or a nickel alloy target for magnetron sputtering capable of achieving a favorable film uniformity (evenness of film thickness) and superior plasma ignition (firing) even during the manufacturing process employing a 300 mm wafer. The present invention also provides the manufacturing method of such high purity nickel or nickel alloy target.

Owner:JX NIPPON MINING & METALS CORP

Method for preparing magnetic solid acid catalyst for production of biodiesel

The invention discloses a method for preparing a magnetic solid acid catalyst for the production of biodiesel. The solid acid catalyst is prepared by performing sulfonic acid group modification on zirconia-based Fe3O4 / ZrO2 compound. The preparation method comprises the following steps: after mixing ferrous chloride and ferric chloride, adding ammonia water or solution of sodium hydroxide to adjust the pH value of the mixture to between 10 and 12; ageing the mixture for 2 hours; washing the mixture by distilled water to be neutral to obtain a magnetic substrate; mixing the magnetic substrate and zirconium oxychloride in proportion, adding a certain amount of water to fully dissolve the zirconium oxychloride, uniformly oscillating the mixed solution, adjusting the pH value of the mixed solution to between 10 and 12 by ammonia water or the solution of sodium hydroxide; filtering and precipitating after ageing for 2 hours; fully washing the precipitate by deionized water until no Cl- exists; fully soaking the precipitate for 4 hours by ammonium sulfate or solution of concentrated sulfuric acid or solution of ammonium persulphate; and leaching and roasting a filter cake in a muffle furnace at the temperature of 500 DEG for 3 hours to obtain the magnetic catalyst.

Owner:GUANGXI ACAD OF SCI

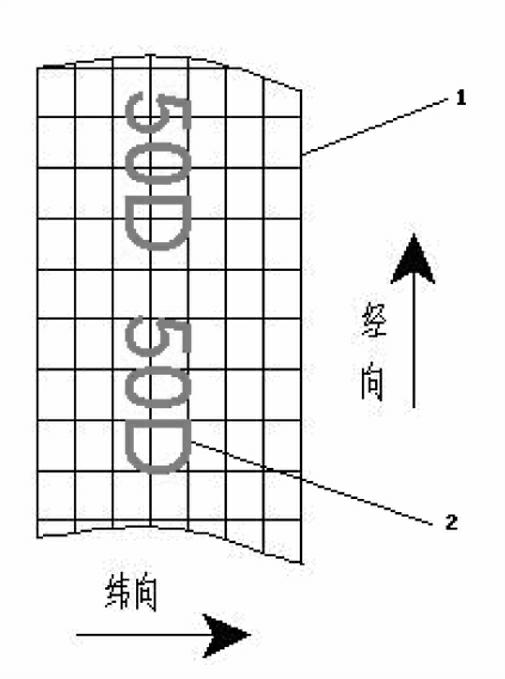

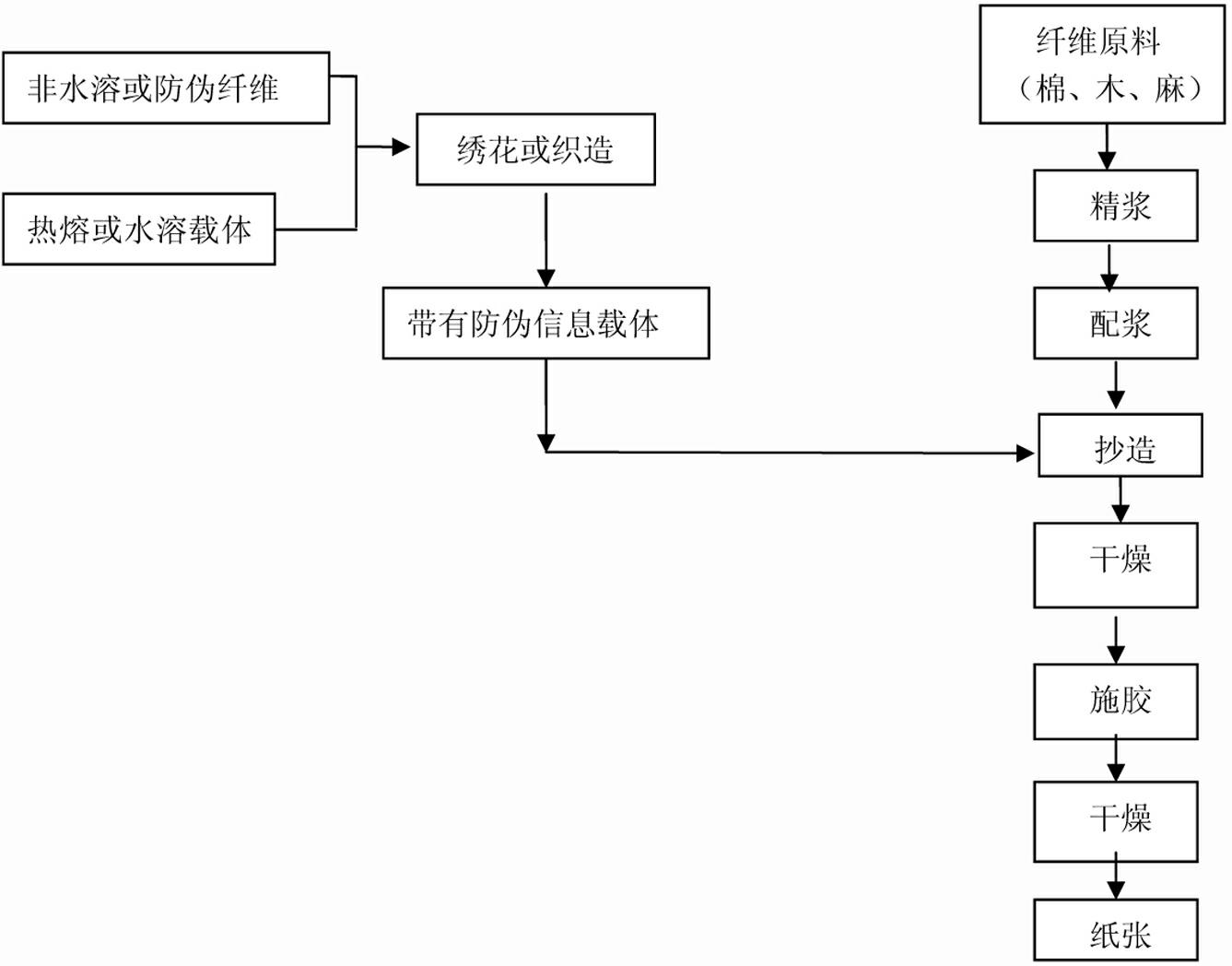

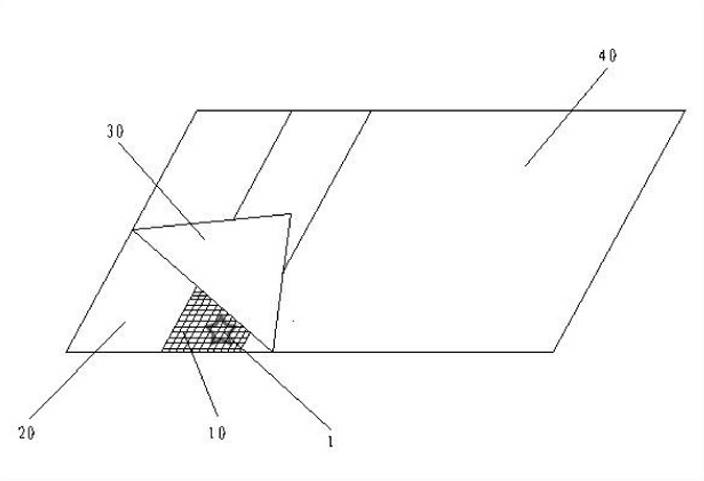

Multiple anti-counterfeit watermark paper and manufacturing method thereof

ActiveCN102191722ACompatible with and strengthen the concave-convex feelingDifficult to forgeNon-fibrous pulp additionFiberPhotoluminescence

The invention relates to multiple anti-counterfeit watermark paper and a manufacturing method thereof. The watermark paper is provided with patterns, figures or lines which are woven or embroidered by non-water-soluble fibers or anti-counterfeit fibers; and the paper has rich levels and a concavo-convex touch feel under transmission light. A film, non-woven fabric or woven fabric made from a water-soluble material or a hot-melting material is used as a carrier, so that the patterns, the figures or the lines are woven or embroidered on the carrier by using the non-water-soluble fibers or the anti-counterfeit fibers; and the carrier with the patterns, the figures or the lines is released in front of a paper machine net through a positioning and releasing device so that the carrier is combined with paper. Compared with the conventional watermark, the patterns, the figures or the lines of the watermark paper are more fine and smooth; meanwhile, during processing of the patterns, the anti-counterfeit fiber loaded with one or more pieces of anti-counterfeit information (such as fluorescence, color, temperature variation, photoluminescence, magnetism and the like) is adopted; therefore, the watermark is integrated with vision, touch and multiple anti-counterfeit effects of the anti-counterfeit material as well as combination of the vision, the touch and the multiple anti-counterfeit effects.

Owner:BAODING BANKNOTE PAPER CO LTD +1

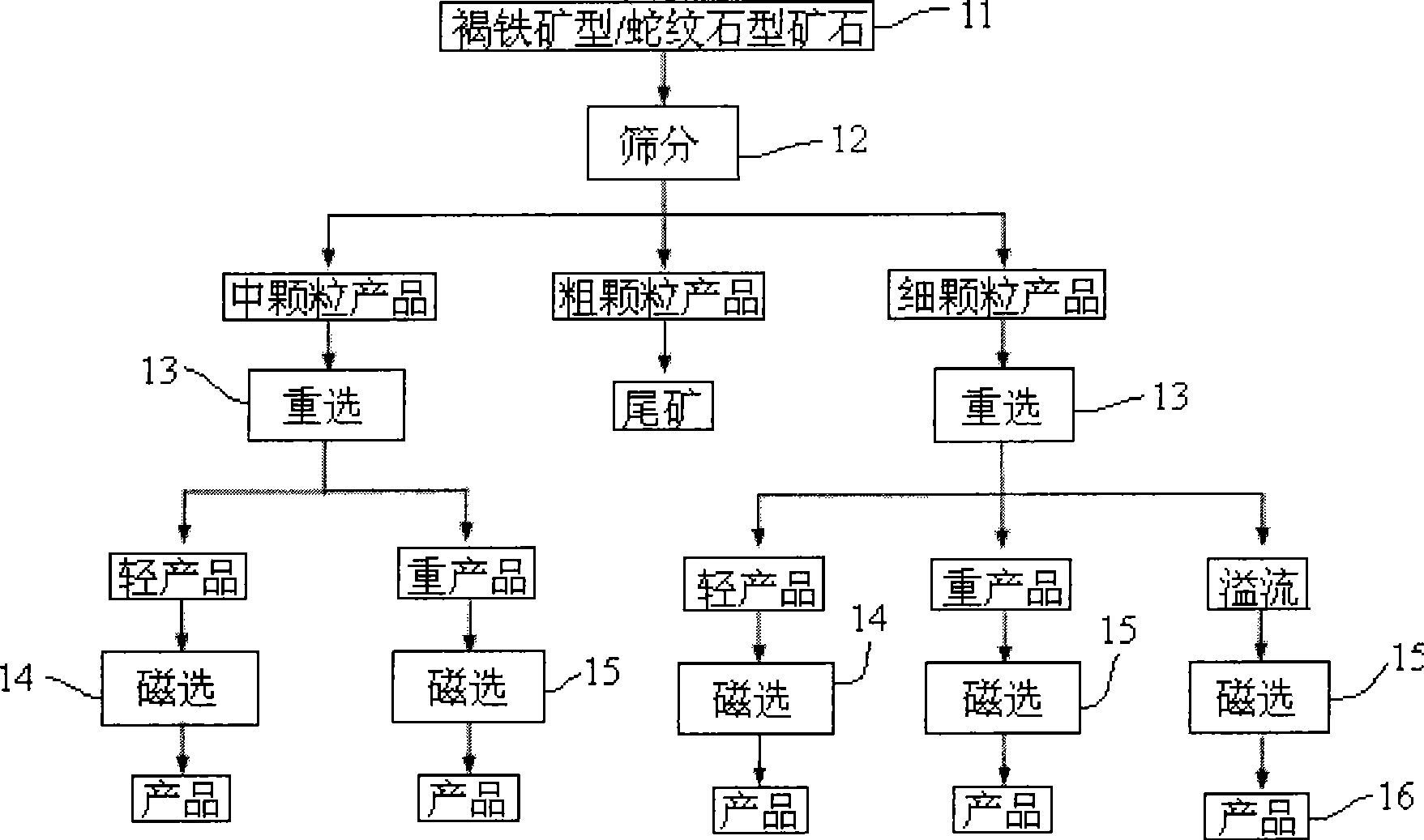

Ore concentration technique for laterite nickel ore rich in nickel and/or cobalt

A mineral dressing technique used for enriching nickel and / or cobalt is characterized in that limonite type ore and serpentine type ore are separated for mineral dressing, and adopt a sieve to be processed by classification for at least once after being processed by ore washing; mineral dressing is carried out on the products with granulometric classes, and the target concentrated ore is obtainedby the techniques of reelection and magnetic classification. According to the invention, after the limonite type ore and the serpentine type ore are treated by sieve classification, coarse fraction materials directly enter subsequent hydrometallurgy operation, so that the handling capacity of the selected crude ore is reduced, and the sorting conditions are improved; materials with medium fraction and fine fraction adopt a combined process flow of reelection and magnetic classification for sorting to obtain the target concentrated ore, so that the mineral quantity entering the process flow ofhydrometallurgy is reduced. Mineral dressing is respectively carried out on the limonite type ore and the serpentine type ore in lateritic nickel, thus obtaining the concentrated ore having higher quality, recovery rate and concentration ratio.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

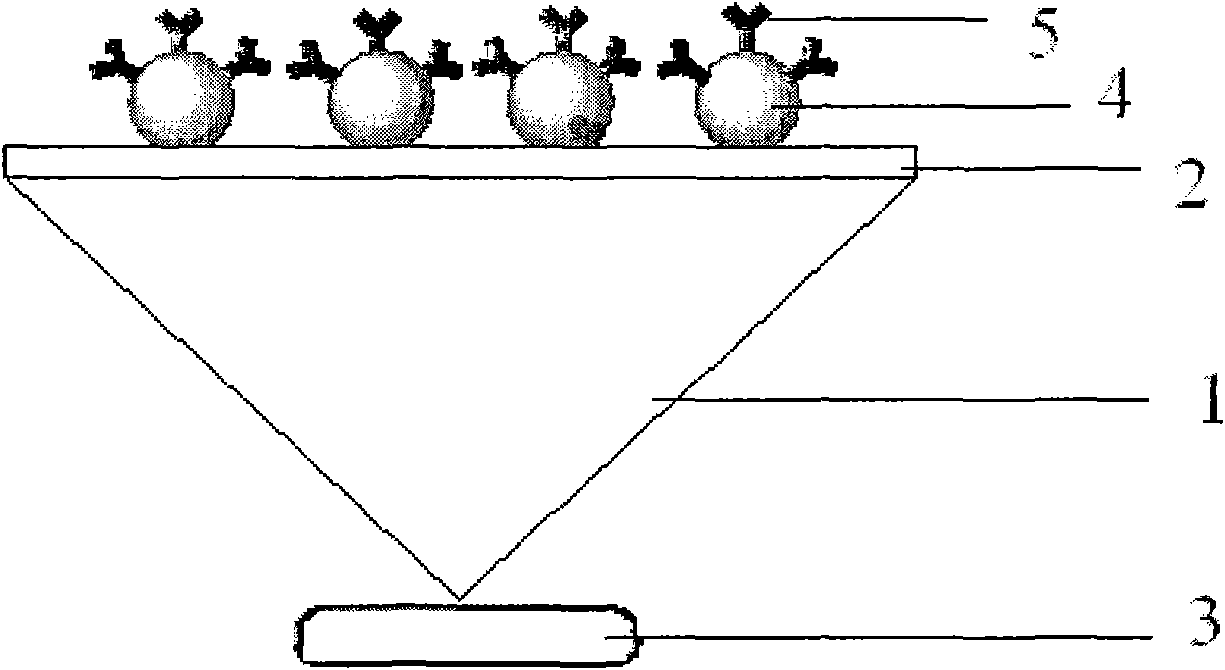

Surface plasmon resonance sensing element and manufacturing method thereof

InactiveCN101975765ALarge specific surface areaEasy to fixSilicaScattering properties measurementsAntigenBiocompatibility Testing

The invention provides a surface plasmon resonance sensing element and a manufacturing method thereof, belonging to the technical field of a sensor for biological system detection. The sensing element comprises a metallic membrane (2), a sensitive membrane and a magnet (3), wherein, the metallic membrane with a chromium membrane and a gold membrane as the sensing elements is plated on the bottom surface of a glass prism (1), the sensitive membrane composed of magnetic nanoparticles (4) subject to surface hydroformylation and an antibody (5) linked with an aldehyde group through a covalent bond is made on the metallic membrane, and the magnet is arranged under the glass prism. The manufacturing method of the sensing element comprises the following steps: preparation of the metallic membrane, preparation of Fe3O4 magnetic nanoparticles, preparation of ammoniated SiO2-coated magnetic nanoparticles, preparation of magnetic nanoparticles subject to surface hydroformylation and preparation of the sensitive membrane. The invention has the advantages of simple manufacturing process, high sensitivity, good biocompatibility and good selectivity and can be used in all antibody and antigen detection and protein and drug measurement.

Owner:JILIN UNIV

Nano compound with multilayer structure, and applications thereof

InactiveCN106944153ALower TiO2 bandgapBroaden the Absorbing BoundaryWater/sewage treatment by irradiationPhotodynamic therapyMagnetic coreNanometre

The invention provides a nano compound with a multilayer structure, and applications thereof. The multilayer structure is composed of an inner core layer, an insolating layer, a main functional layer, and a double modified layer from inside to outside; the general structure formula of the nano compound is FeO-SiO<2>-TiO<2>-(X+FA); the inner core layer FeO is magnetic Fe3O4 or magnetic Fe2O3 or a mixture of magnetic Fe3O4 and Fe2O3; the isolating layeris SiO2; the main functional layer is TiO2; X in the double modified layer (X+FA) is one element selected from Zn, La, and Ce; FA is used for representing folic acid. The nano compound possesses magnetism, visible light responsiveness, bio specificity, and enhanced photocatalytic activity, and can be used in the photocatalysis field; steps are simple; operation is simple; and practicality is high.

Owner:TAISHAN MEDICAL UNIV

Super-hydrophobic wood and preparation method thereof

ActiveCN104924379ASimple stepsReaction conditions are easy to achieveRadiation/waves wood treatmentWood treatment detailsSurface energyRolling angle

The invention discloses super-hydrophobic wood. The surface of the super-hydrophobic wood is covered with a composite film layer which is formed by settling silane coupling agents which are wrapped by nano particles after hydrolysis and polycondensation. Chemical bonding is generated between the composite film layer and the wood through the hydroxyl action, and the composite film layer contains uniform micron-size grooves and nano-size protrusions and is assembled with low-surface-energy materials. The water drop contact angle of the super-hydrophobic wood reaches 150-156 degrees, and the rolling angle is smaller than 4 degrees. The nano particles are one or more kinds of nano SiO2, nano TiO2, nano Al2O3, nano ZnO and nano Fe3O4. According to a preparation method, alkali treatment is carried out on the wood firstly, and then reaction liquid containing hydrophobic materials deposits on the surface of the wood subjected to alkali treatment through a gas-phase deposition reaction, so that the super-hydrophobic wood is obtained. The super-hydrophobic wood is high in hydrolytic resistance. The steps of the preparation method are simple, the reaction conditions are easy to realize, and the preparation period is short.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Method for preparing Fe3O4@ZrO(OH)2 magnetic nano-adsorbing material for high-efficient fluoride removal from drinking water

InactiveCN101811020AShort adsorption pathMagneticOther chemical processesWater contaminantsMicrosphereReaction temperature

The invention discloses a method for preparing an Fe3O4@ZrO(OH)2 magnetic nano-adsorbing material for high-efficient fluoride removal from drinking water. The method comprises the following steps: (1) preparing magnetic nano-Fe3O4 microspheres by using a coprecipitation method; and (2) adding the magnetic nano-Fe3O4 microspheres and deionized water into a reaction vessel; adding a certain amount of solution of zirconium salt dropwise into the reaction vessel under the condition of mechanical stirring; adding the solution of NaOH into the reaction vessel dropwise; and separating and washing by utilizing an externally-applied magnetic field after heating, refluxing and reacting for 1 to 3 hours so as to obtain the magnetic nano-Fe3O4@ZrO(OH)2 composite microspheres. The method has the following advantages that: 1, adsorption capacity is large, so the method is suitable for advanced treatment of large volume of drinking water; 2, the removal speed is high, and the adsorption paths of nano-particles are short; and 3, the preparation is simple because the overall preparation process has no need of complex reaction process, special reaction equipment or harsh reaction temperature, the operation is simple and easy to implement, and the reproducibility is high.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com