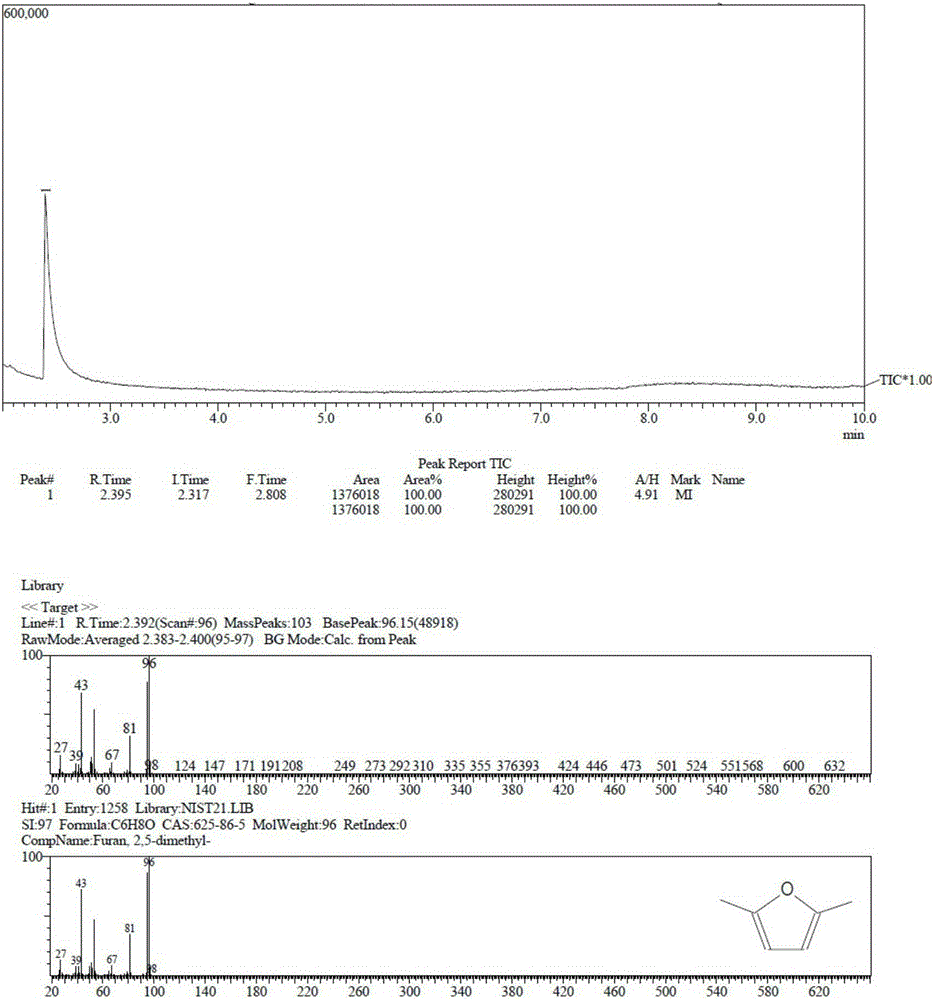

Catalyst for preparing 2,5-dimethylfuran through selective hydrogenolysis of 5-hydroxymethylfurfural and preparation method of catalyst

A technology of hydroxymethylfurfural and dimethylfuran, which is applied in the field of 5-hydroxymethylfurfural liquid-phase hydrogenolysis catalysts, can solve the problems of poor selectivity and low activity, and achieves high activity and selectivity, excellent catalytic performance, Low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

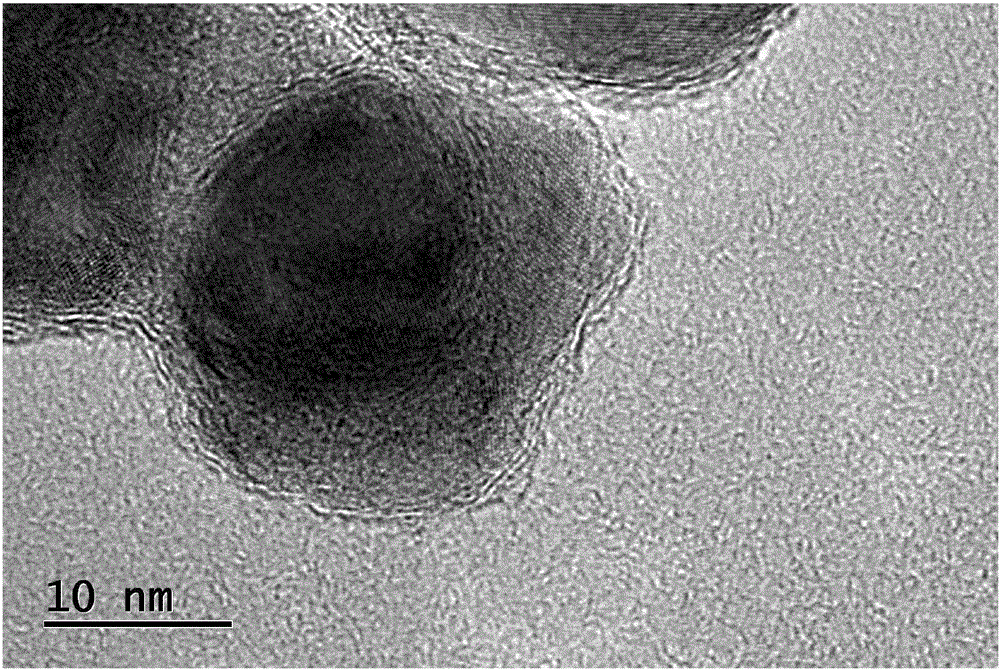

Embodiment 1

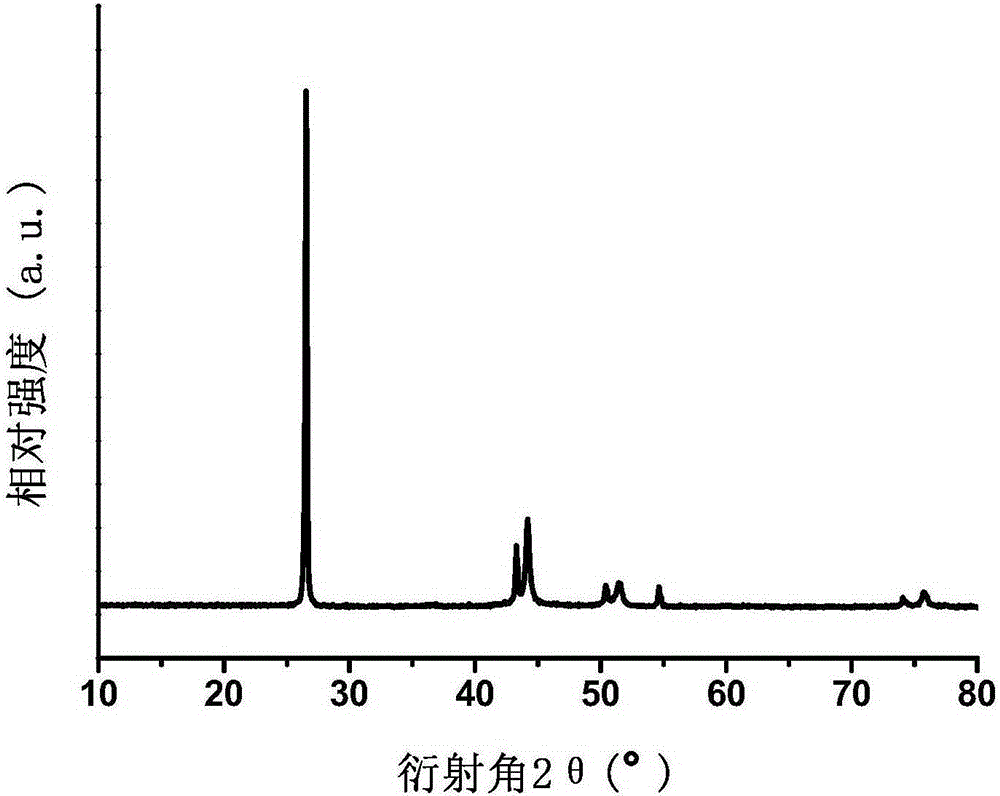

[0047] Take 20ml of distilled water, add 2.52g of tartaric acid under stirring, then add 1.819g of Co(NO 3 ) 2 ·6H 2 O and 0.53gCu(NO 3 ) 2 ·3H 2 0, then add 60ml glycerin aqueous solution (glycerin:water=4:1, volume ratio) and 5.0g polyethylene glycol PEG6000, then add 0.5g nano-graphite carbon, after stirring evenly, place in the hydrothermal kettle 150 ℃ and keep warm for 13h, After the obtained solid was dried, it was transferred to a tube furnace and calcined at 800° C. for 2.0 h under argon to obtain a catalyst marked as Cu-Co / C, wherein the content of Co was 30.7 wt%, and the content of Cu was 12.0 wt%.

[0048] figure 2 The powder diffraction pattern of the Cu-Co / C catalyst shown shows that the active metals cobalt and copper are both in reduced state.

Embodiment 2

[0050] Take 20ml of distilled water, add 2.50g of tartaric acid under stirring, then add 1.819g of Co(NO 3 ) 2 ·6H 2 O and 0.606gNi(NO 3 ) 2 ·6H 2 0, then add 60ml glycerin aqueous solution (glycerin: water = 4:1, volume ratio) and 5.0g polyethylene glycol PEG6000, then add 0.5g nano-graphite carbon, after stirring evenly, place in a hydrothermal kettle at 150°C for 13h, After the obtained solid was dried, it was transferred to a tube furnace and calcined at 800° C. for 2.0 h under argon to obtain a catalyst marked as Ni-Co / C, wherein the content of Co was 29.7 wt%, and the content of Zn was 11.9 wt%.

Embodiment 3

[0052] Take 20ml of distilled water, add 2.50g of tartaric acid under stirring, then add 1.819g of Co(NO 3 ) 2 ·6H 2 O and 0.284g ZnCl 2 , then add 60ml of glycerin aqueous solution (glycerin: water = 4:1, volume ratio) and 5.0g of polyethylene glycol PEG6000, then add 0.5g of nano-graphite carbon, stir evenly, place in a hydrothermal kettle at 150°C for 13h, and obtain After the solid was dried, it was transferred to a tube furnace and calcined at 800° C. for 2.0 h under argon to obtain a catalyst marked as Zn-Co / C, wherein the content of Co was 30.5 wt%, and the content of Zn was 11.7 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com