Ternary magnetic composite photocatalytic nanomaterial and preparation method and use thereof

A technology of composite photocatalysis and nanomaterials, which is applied in the field of ternary magnetic composite photocatalysis nanomaterials and their preparation, can solve the problems of expensive recycling of Ag-based materials, and improve the separation efficiency of electrons and holes and the absorption and utilization of light. rate, improve the photocatalytic degradation effect, and the effect of simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

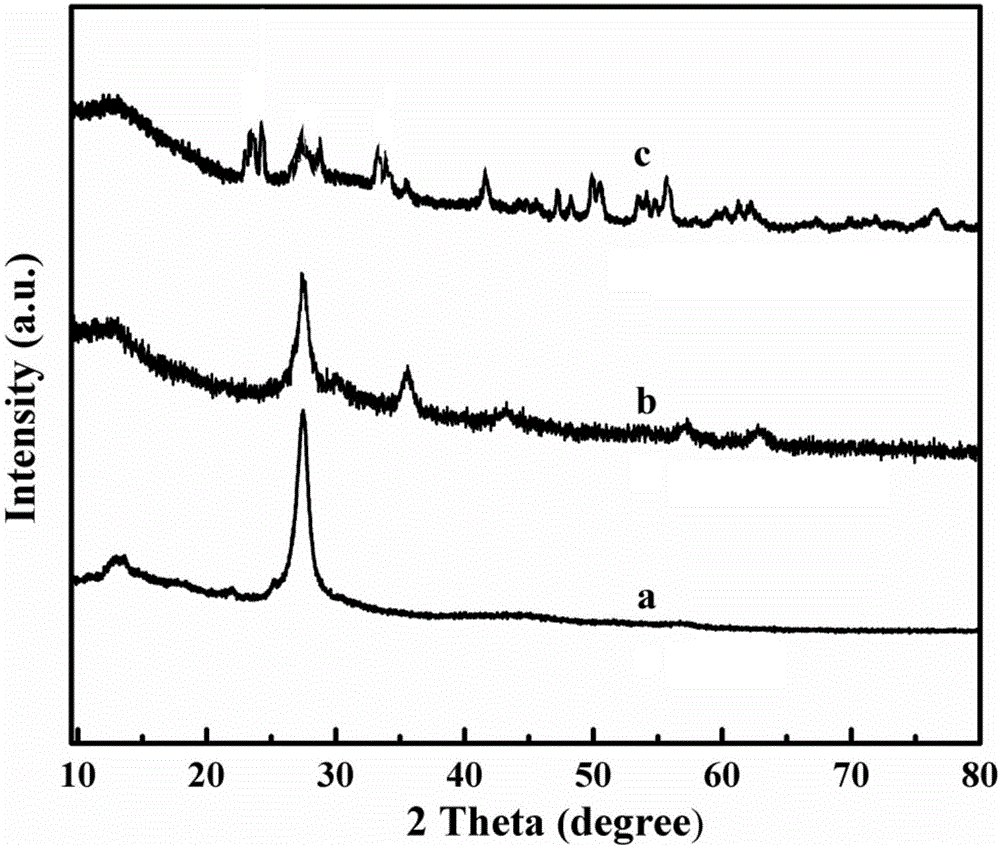

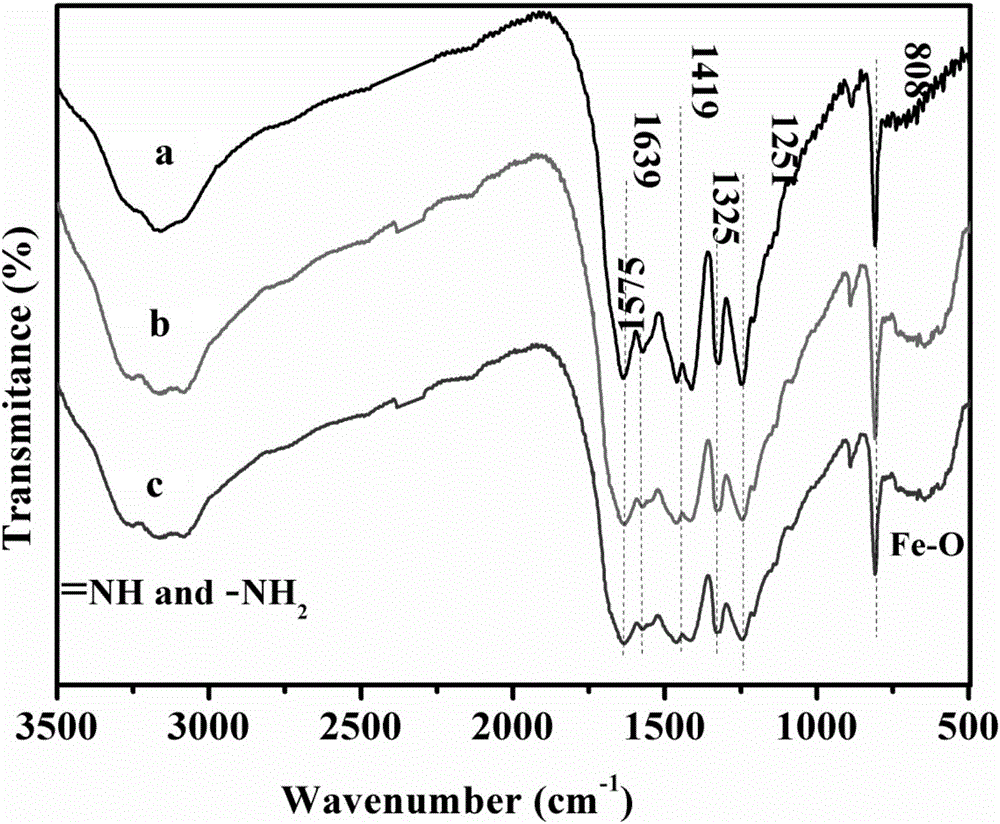

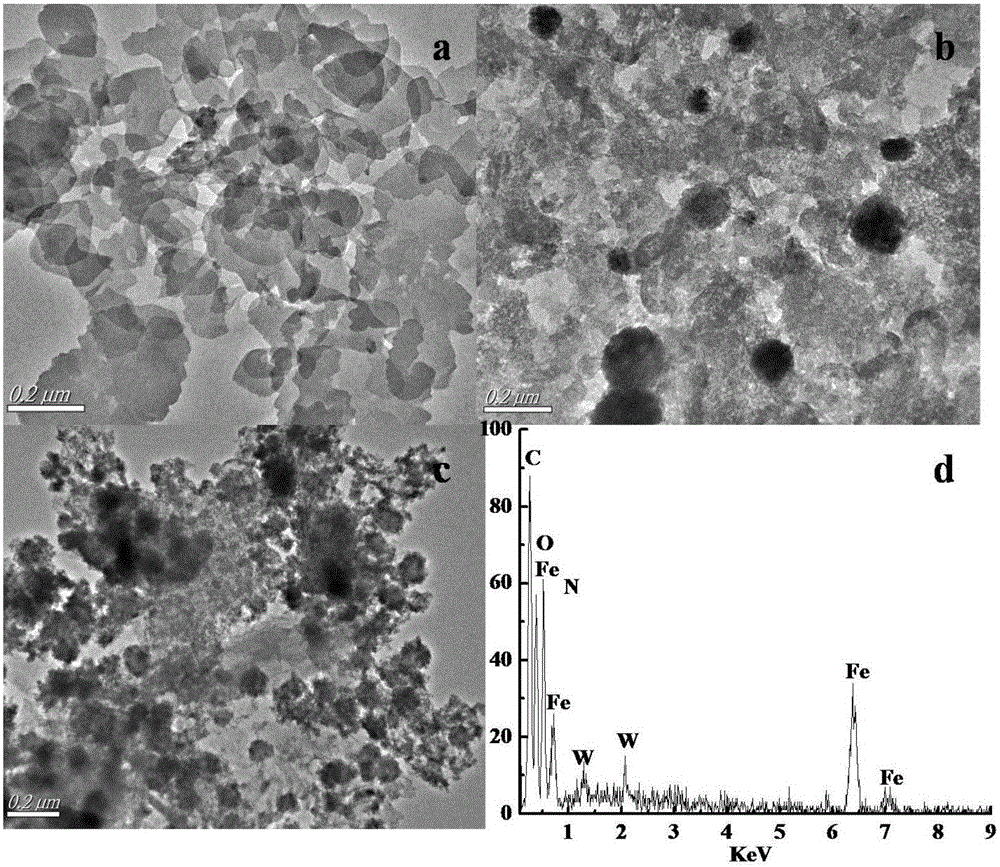

[0034] Step 1. Preparation of g-C 3 N 4 Photocatalyst: Take 6g of purchased melamine and place it in a crucible, place it in a muffle furnace, and calcine it in an air atmosphere, raise the temperature to 550°C at a heating rate of 3°C / min, and keep it at a constant temperature for 2 hours. Continue to raise the temperature to 620°C, keep at constant temperature for 2h, cool down to room temperature naturally and grind finely to obtain g-C 3 N 4 Photocatalyst, save for future use.

[0035] Step 2, disperse 0.25g sodium tungstate and 0.15g oxalic acid in 40ml deionized water and stir, then use HCl (hydrochloric acid concentration is 2.0mol L -1 ) to adjust the pH of the above solution to 1, stir for 40 minutes, and finally transfer it to a 50ml stainless steel high-temperature reactor, raise the temperature to 120°C for 10h, dry it, and then transfer it to a muffle furnace for calcination at 500°C for 2h.

[0036] Step 3, add 1.0g g-C 3 N 4 ,0.2g Fe(NO) 3 9H 2 O, 0.15g ...

Embodiment 2

[0038] Step 1. Preparation of g-C 3 N 4 Photocatalyst: Take 3g of melamine in a crucible, place it in a muffle furnace, and calcine it in an air atmosphere, raise the temperature to 500°C at a heating rate of 1°C / min, and keep it at a constant temperature for 2 hours, and continue at the same heating rate Raise the temperature to 600°C, keep it at a constant temperature for 2 hours, cool down to room temperature naturally and grind it finely to obtain g-C 3 N 4 Photocatalyst, save for future use.

[0039] Step 2, disperse 0.1g sodium tungstate and 0.1g oxalic acid in 30ml deionized water and stir, then use HCl (hydrochloric acid concentration is 2.0mol L -1 ) Adjust the pH of the above solution to 1, stir for 30 minutes, and finally transfer it to a 50ml stainless steel high-temperature reactor, raise the temperature to 120° C. for 10 hours, and then calcine in a muffle furnace at 400° C. for 2 hours after drying after the reaction.

[0040] Step 3, 0.5g C 3 N 4 ,0.1g Fe...

Embodiment 3

[0042] Step 1. Preparation of g-C 3 N 4 Photocatalyst: Take 10g of melamine in a crucible, then place it in the muffle furnace for calcination in the air atmosphere, raise the temperature to 550°C at a constant temperature of 5°C / min for 2 hours, then continue to heat up to a constant temperature of 650°C at the same heating rate 2h, naturally cool to room temperature after the completion of the reaction, the obtained g-C 3 N 4 Grind the powder finely and save it for later use.

[0043] Step 2, disperse 0.3g sodium tungstate and 0.2g oxalic acid in 50ml deionized water and stir, then use HCl (hydrochloric acid concentration is 2.0mol L -1 ) Adjust the pH of the above solution to 1, stir for 50 minutes, and finally transfer it to a 50ml stainless steel high-temperature reaction kettle, raise the temperature to 120°C for 10 hours, and then calcine in a muffle furnace at 600°C for 2 hours after drying after the reaction.

[0044] Step 3, 1.5g C 3 N 4 ,0.3g Fe(NO) 3 9H 2 O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com